Inverter and overload protection method

A power conversion device and electric power technology, which is applied in the direction of output power conversion device, emergency protection circuit device, electrical components, etc., can solve the problems of sudden stop of the motor, damage to production efficiency, etc., and achieve the effect of preventing sudden stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

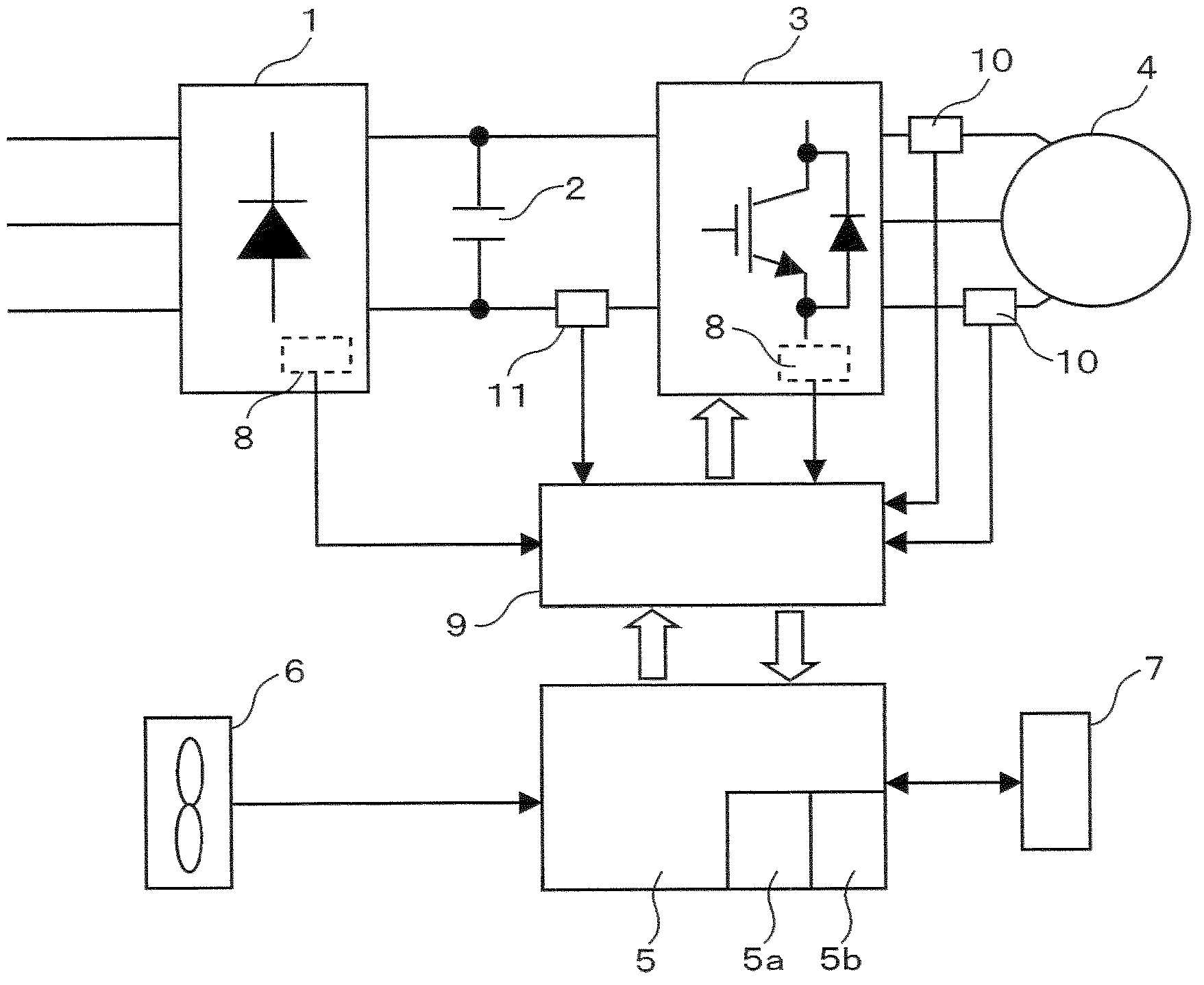

[0030] figure 1 is a configuration diagram of the main circuit of the power conversion device according to the embodiment of the present invention. 1 is a rectifier that rectifies commercial AC power and converts it to DC power; An AC motor that controls the speed of AC power at a given frequency. 6 is a cooling fan for cooling the power modules in the above-mentioned rectifier and inverter.

[0031] 7 is a digital control panel capable of setting, changing, abnormal state and monitoring and displaying various control data of the power conversion device. 8 is a temperature detector provided inside the power semiconductor modules of the rectifier 1 and the inverter 3 . 9 is a drive circuit for driving the switching elements of the inverter 3, 10 is a current detector, and 11 is a resistor for detecting current in the DC circuit. For example, the line current of the AC motor 4 is detected by the current detector 10, and the overload state of the AC motor can be determined from

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap