Oxide thin film

Inactive Publication Date: 2001-09-25

TDK CORPARATION +1

View PDF4 Cites 4023 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, since prior art transparent conductive oxides are all of n type and no transparent conductive oxides of p type are available, it is difficult to form a p-n junction solely from transparent conductive oxides.

This suggests that even if a hole is successfully created by any suitable means in order to provide a p-type transparent conductive thin film, the hole is localized on the oxygen ion and has a deep level that cannot be ionized at room temperature, failing to prov

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to view more

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Energy | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Login to view more

Abstract

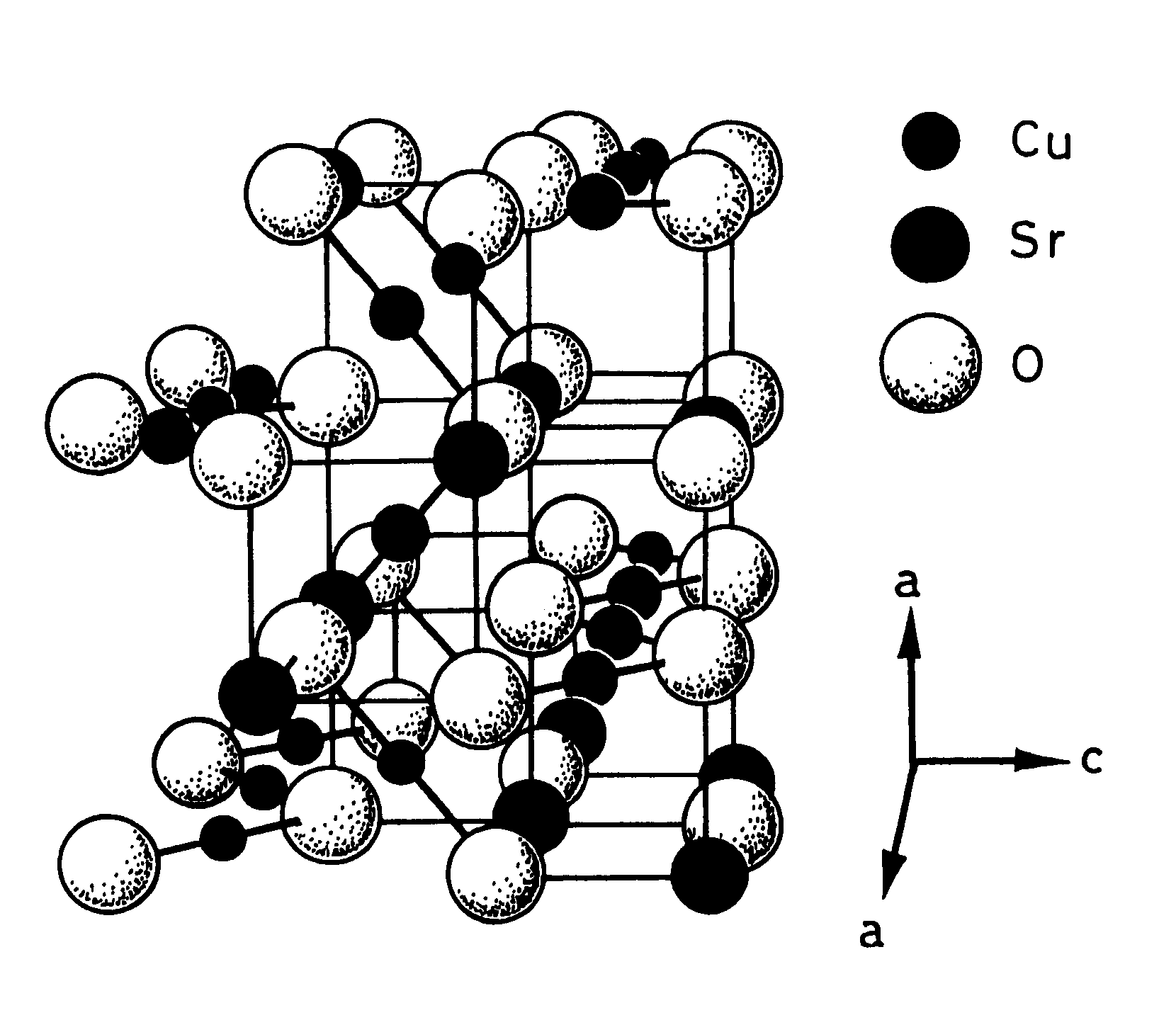

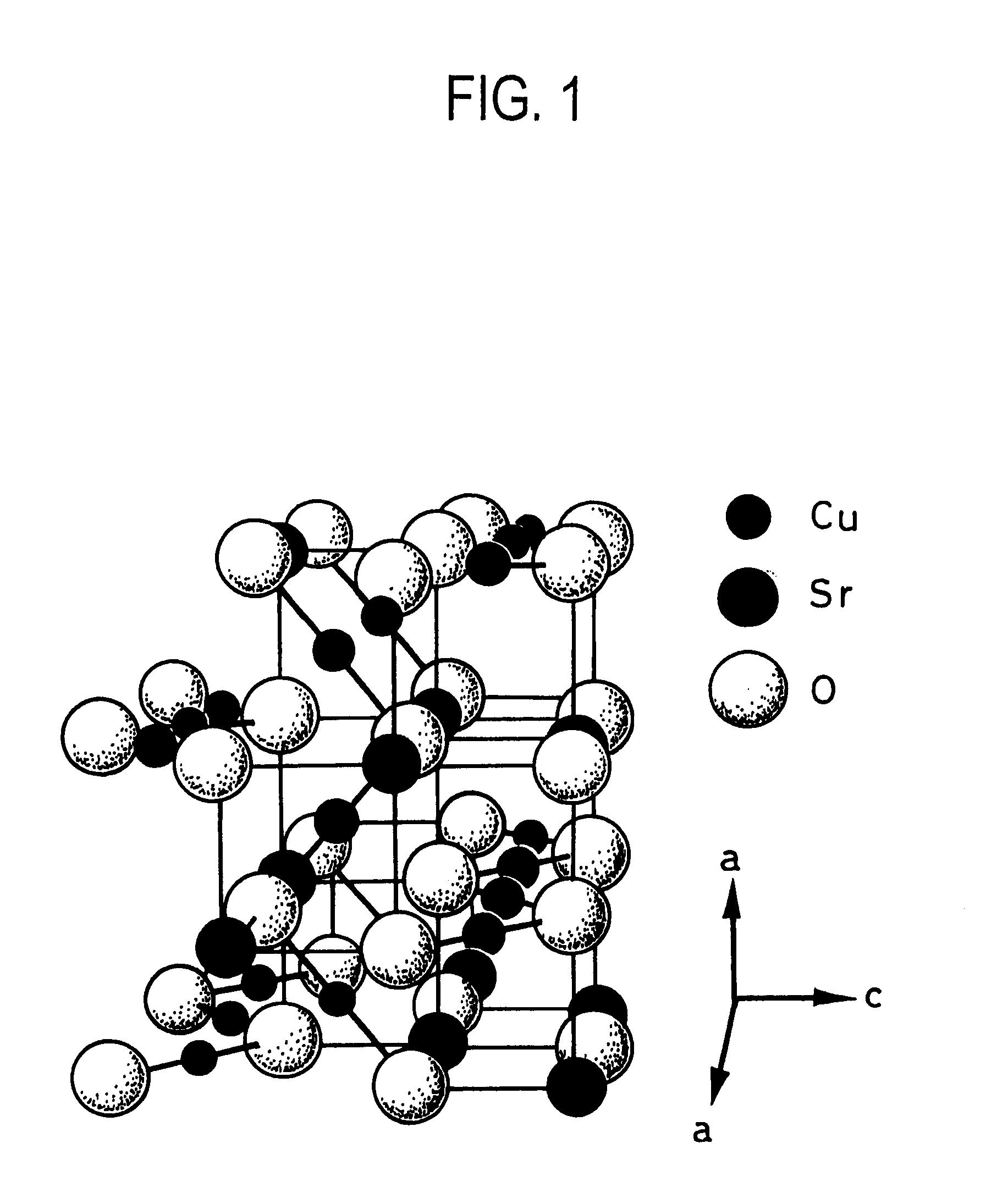

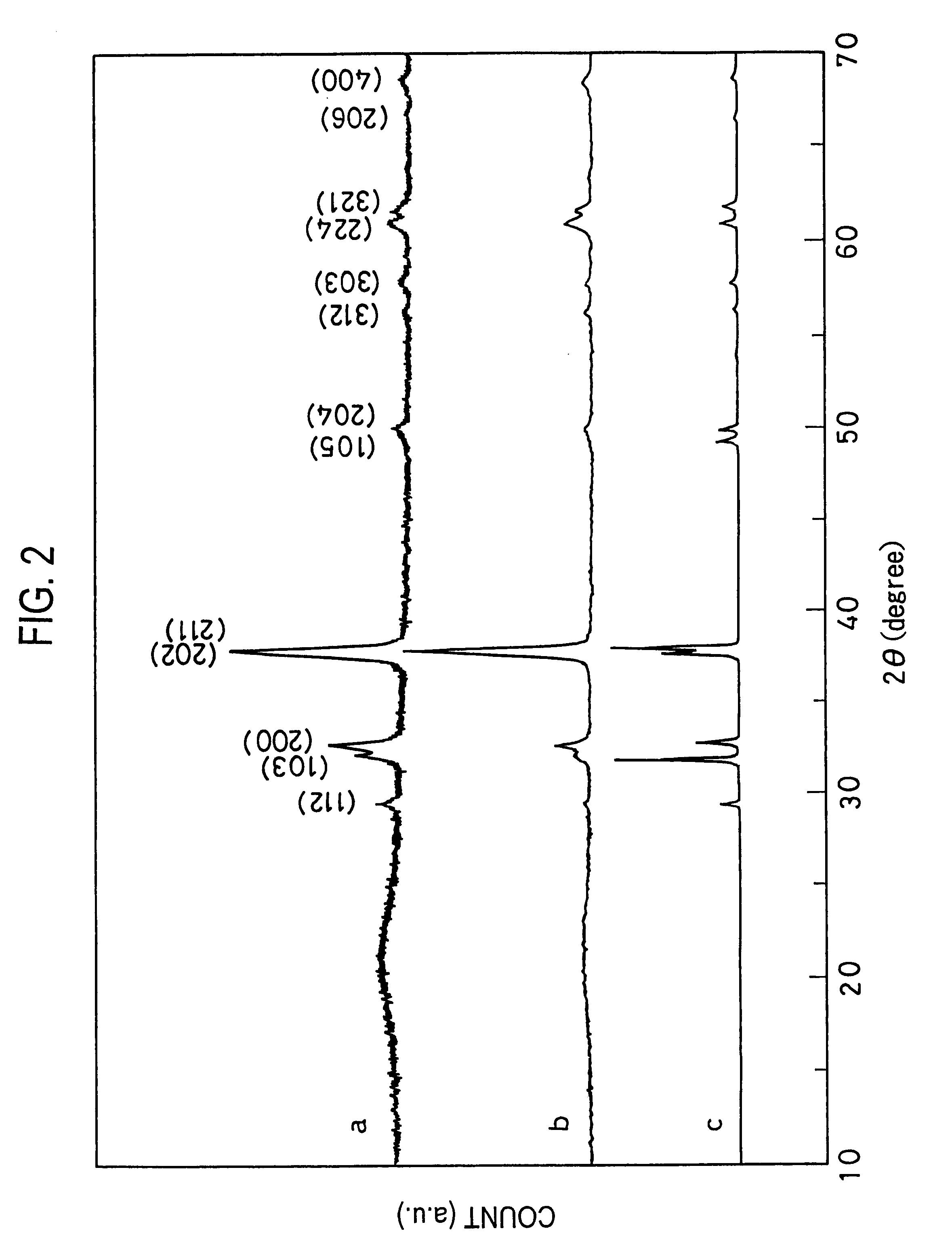

An object of the invention is to provide an oxide thin film which exhibits a widegap or transparency and p-type conductivity although it has heretofore been very difficult to form. The oxide thin film formed on a substrate contains copper oxide and strontium oxide as a main component and exhibits p-type conductivity at a bandgap of at least 2 eV.

Description

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Owner TDK CORPARATION

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap