Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about "Claywares" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

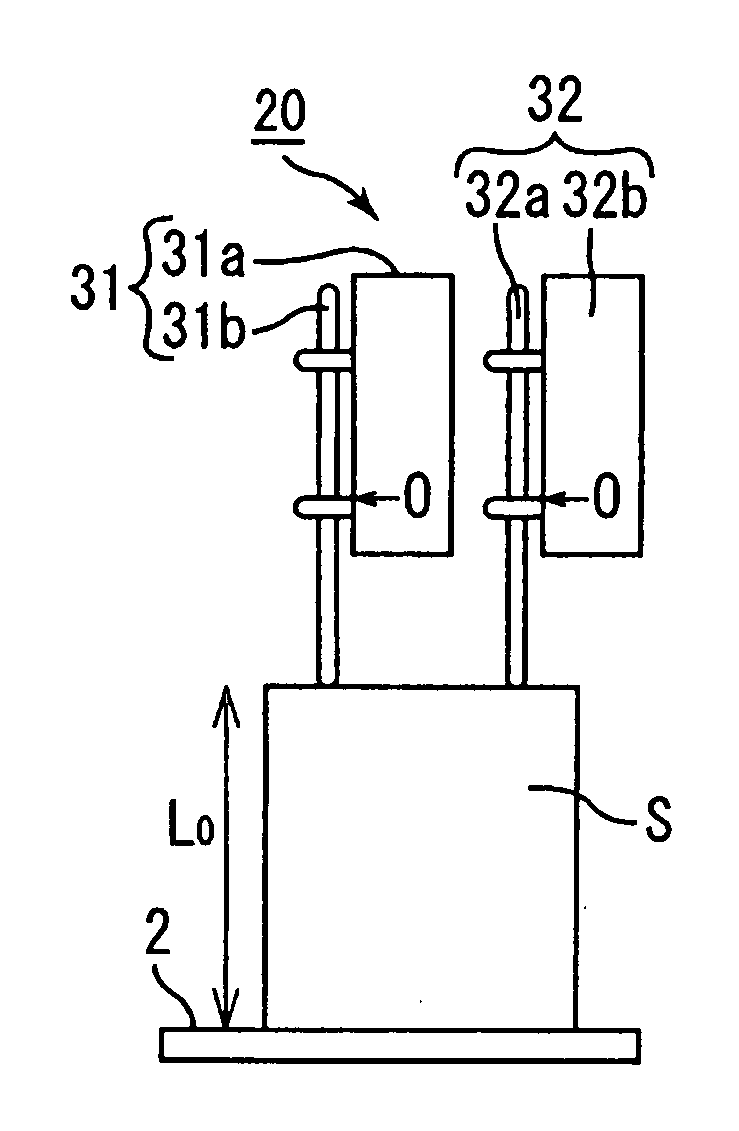

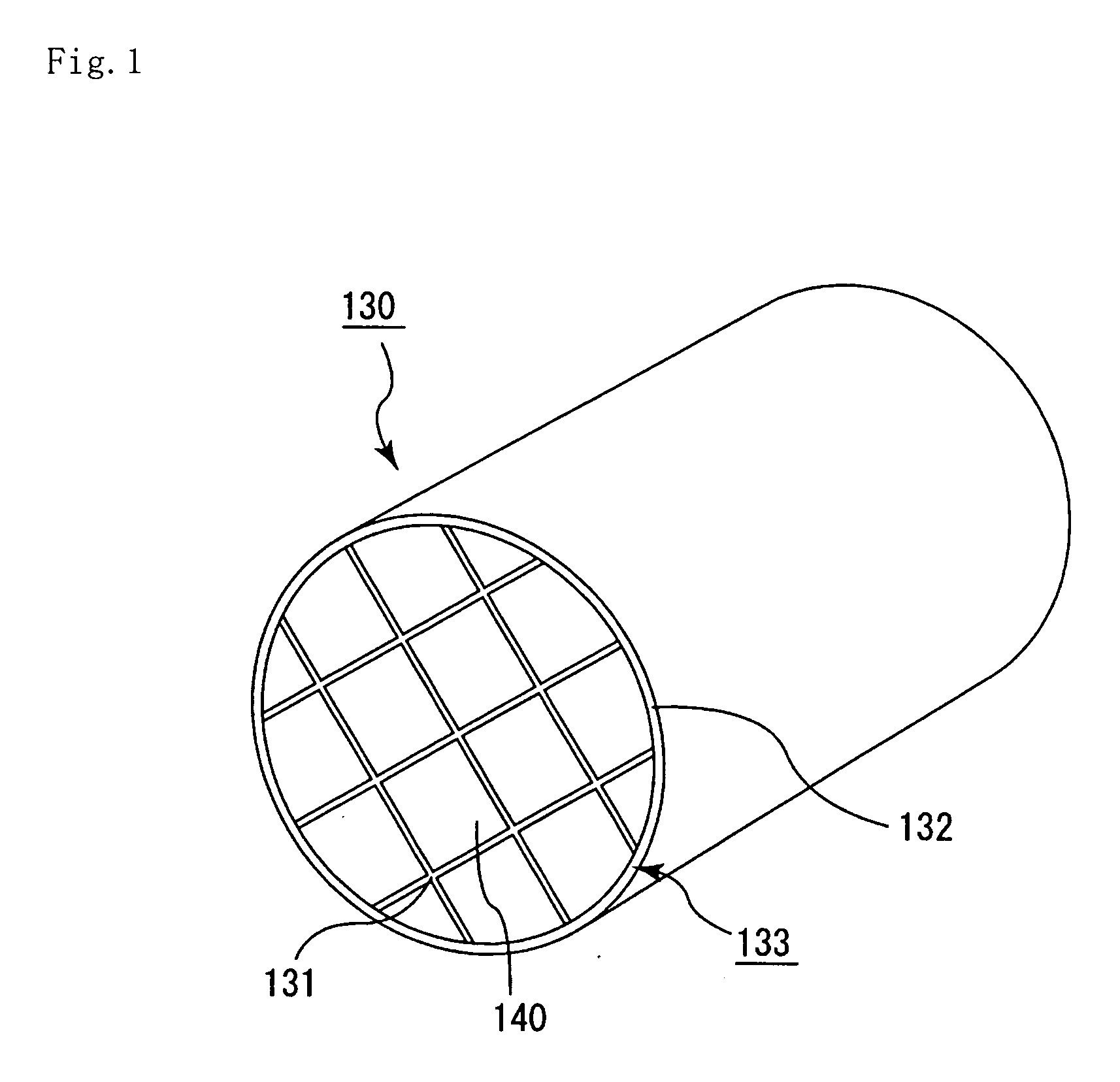

Method for inspecting honeycomb structured body and method for manufacturing honeycomb structured body

InactiveUS20070175060A1Good informationShort timeWalking sticksInternal combustion piston enginesEngineeringCell wall

Owner:IBIDEN CO LTD

Technique for producing energy-saving sintering brick by silt

InactiveCN101265077AHigh porosityImprove thermal insulationCeramic materials productionClaywaresPorosityBrick

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

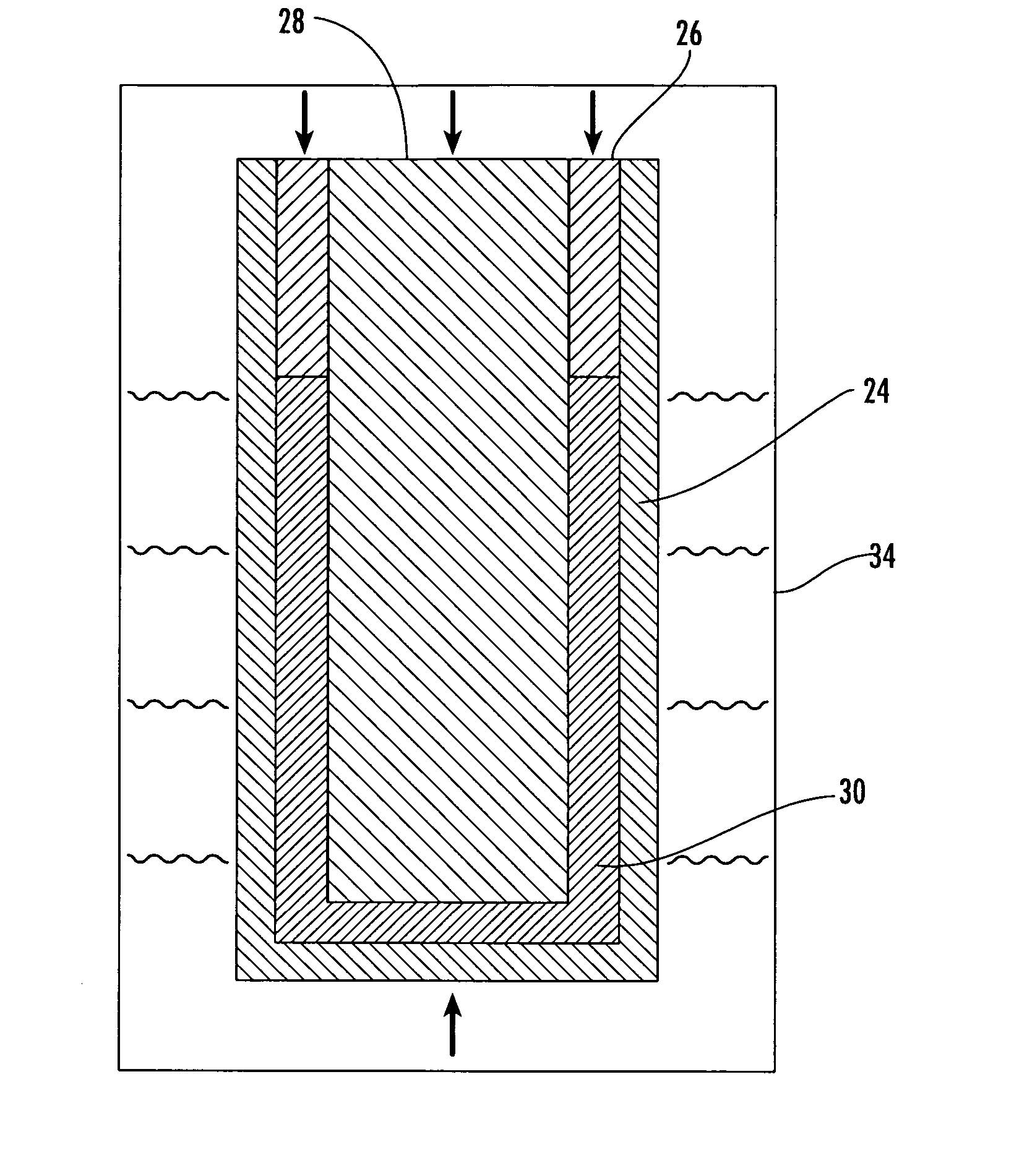

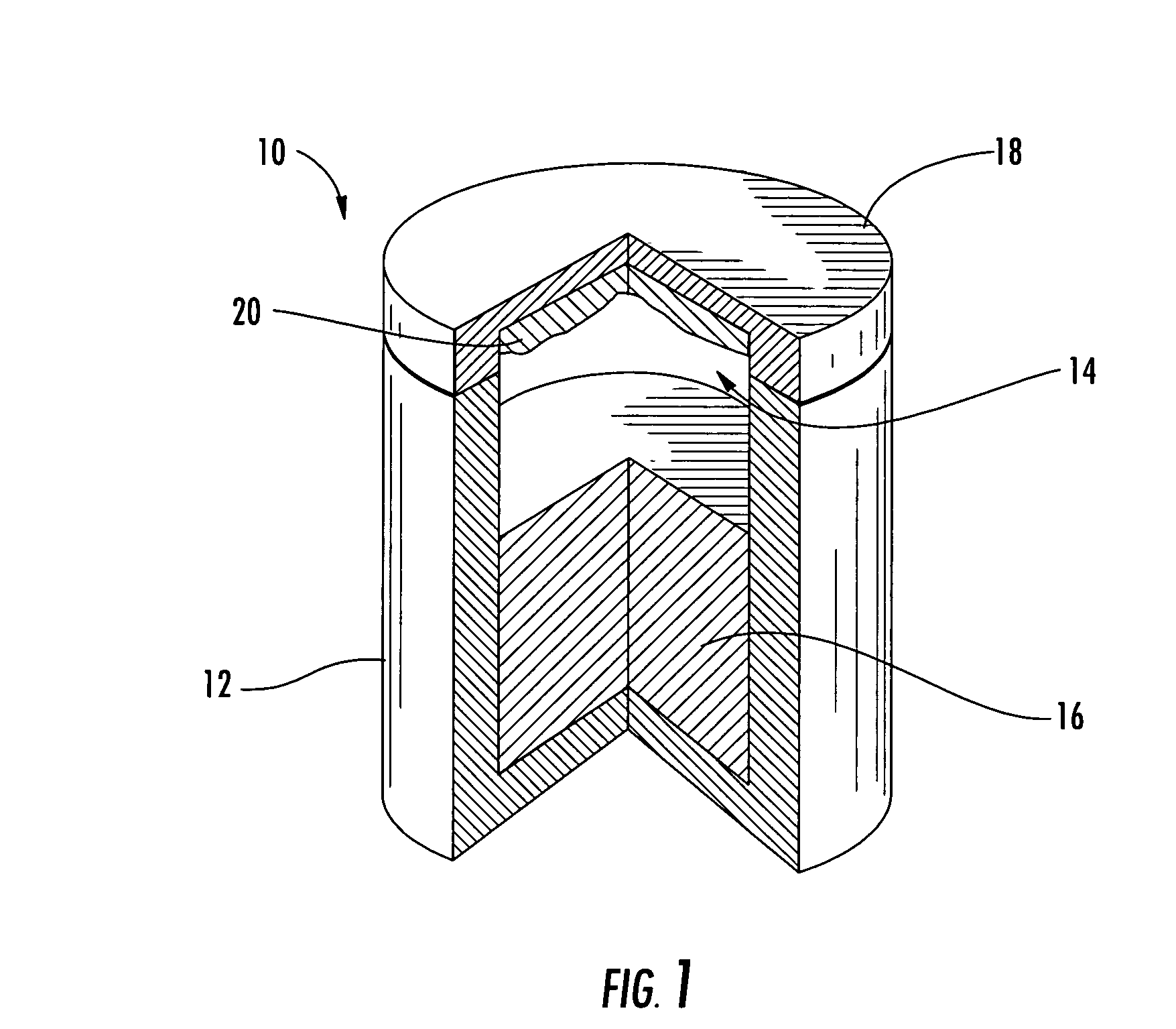

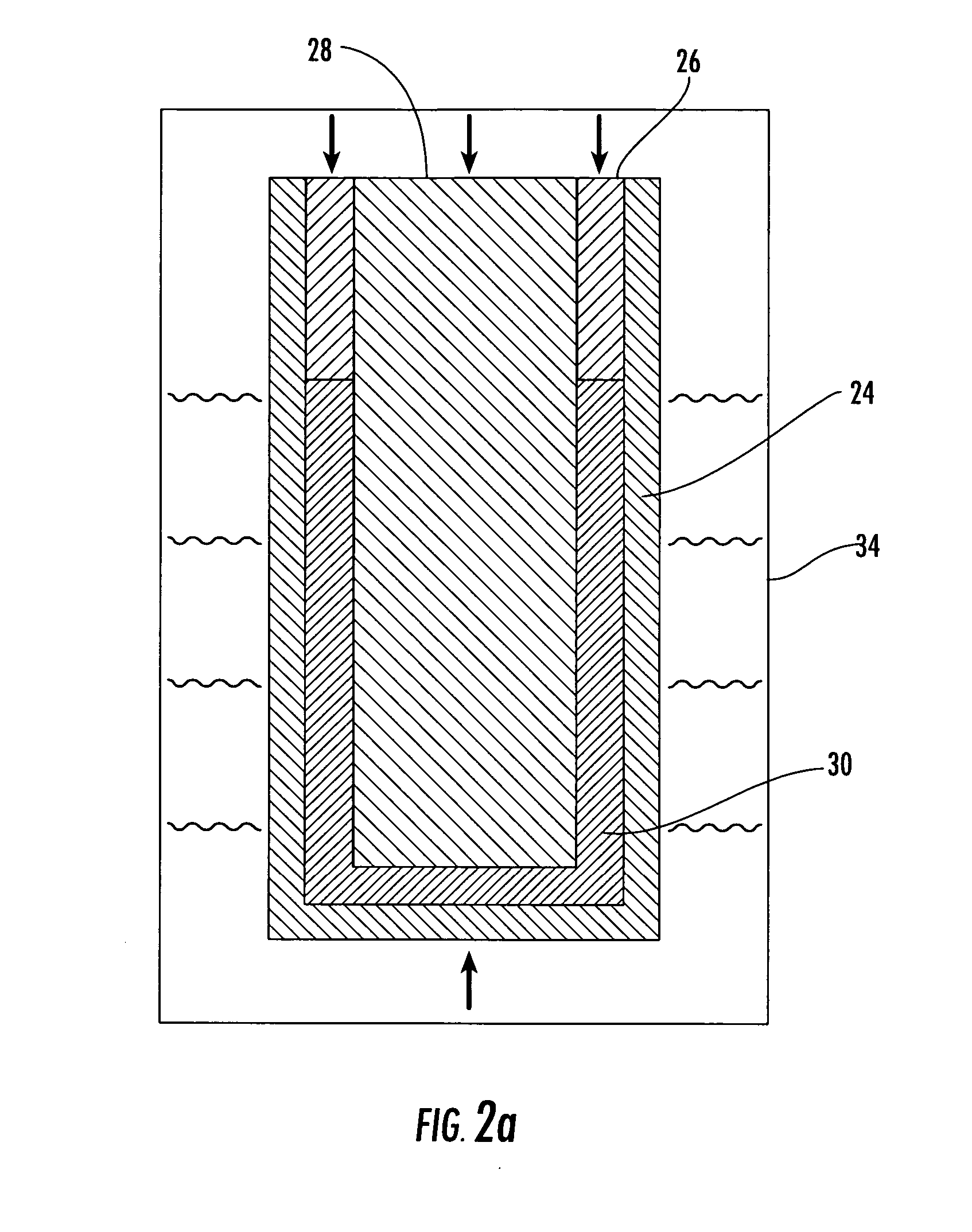

Dense, shaped articles constructed of a refractory material and methods of preparing such articles

ActiveUS20060280640A1High utilization yieldUniform material propertiesPolycrystalline material growthCeramic shaping apparatusPorosityCrucible

Owner:NORTH CAROLINA STATE UNIV +6

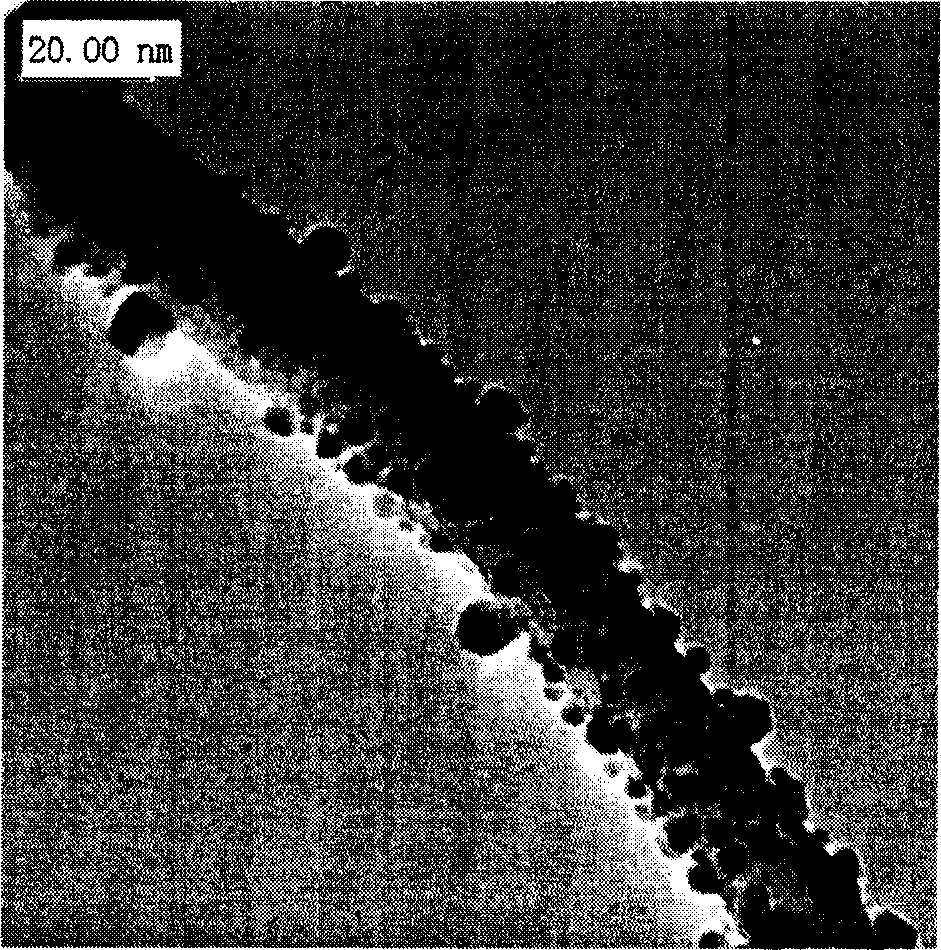

Magnetic granule and attapulgite nanometer composite material, and hydrolytic method for preparing its ferrous salts

InactiveCN1830884AWith characteristicsResolve separabilityWater/sewage treatment by sorptionClaywaresFerrous saltsMagnetite Nanoparticles

Owner:HEFEI UNIV OF TECH

Far infrared Nixing pottery product and preparation method thereof

The invention discloses a far infrared Nixing pottery product and a preparation method thereof. The far infrared Nixing pottery finished product, far infrared Nixing pottery powder and far infrared Nixing pottery slurry is prepared by adding the metal oxides Cr2O3, MgO, MnO2 and ZrO2 and other compounds serving as auxiliary raw materials into Nixing pottery which is made in Qinzhou, Guangxi, and has the advantages of more cheap chemical components, high content and high quality and serves as a main raw material and roasting the mixture at the temperature of between 1,000 and 1,200 DEG C in a high-temperature electric furnace or a high-temperature roasting furnace or a high-temperature burning kiln according to the pottery. The far infrared Nixing pottery product transmits a far infrared ray with the wavelength of 6 to 23 mu m at the normal temperature and can be applied to the industry, medical care and living goods in the fields such as medical care, energy conservation and environment protection, building materials, heat insulating materials, water quality improvement, paper making plastic, fiber weaving, food preservation, food roasting, wine making industry, pharmaceutical industry and the like. The preparation method has the advantages of simple process, low energy consumption, low cost, high benefit and good product quality.

Owner:李建洪

Ceramic floor tile with diatom mud and method for manufacturing ceramic floor tile

InactiveCN105298081AReduce processing difficultyNice appearanceCeramic shaping apparatusFlooringSurface layerEthylic acid

Owner:佛山市高明区生产力促进中心

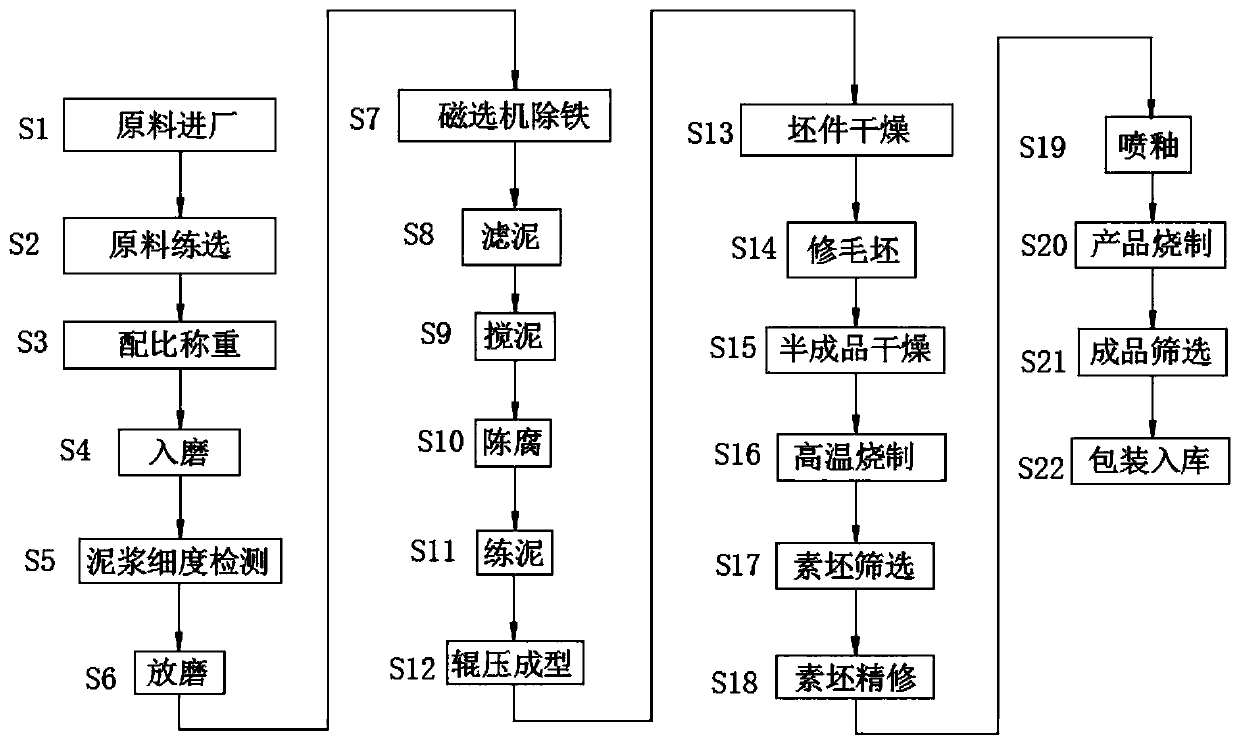

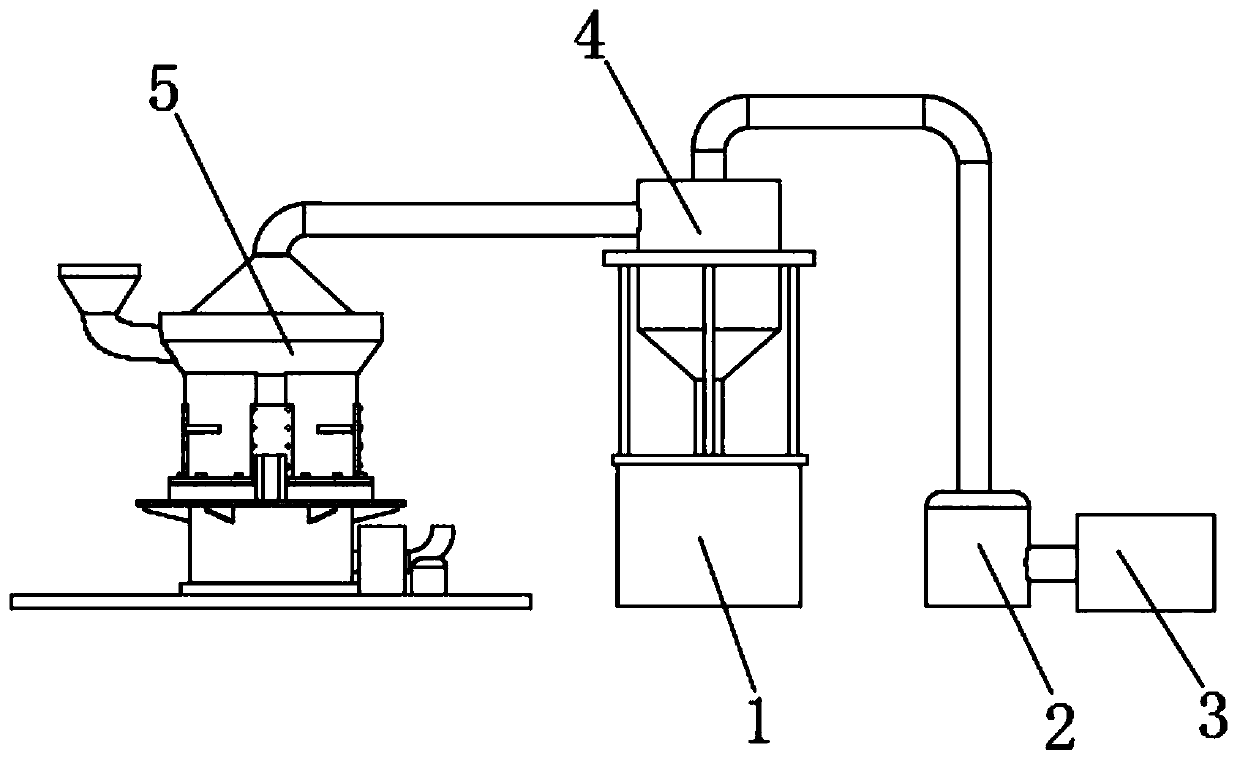

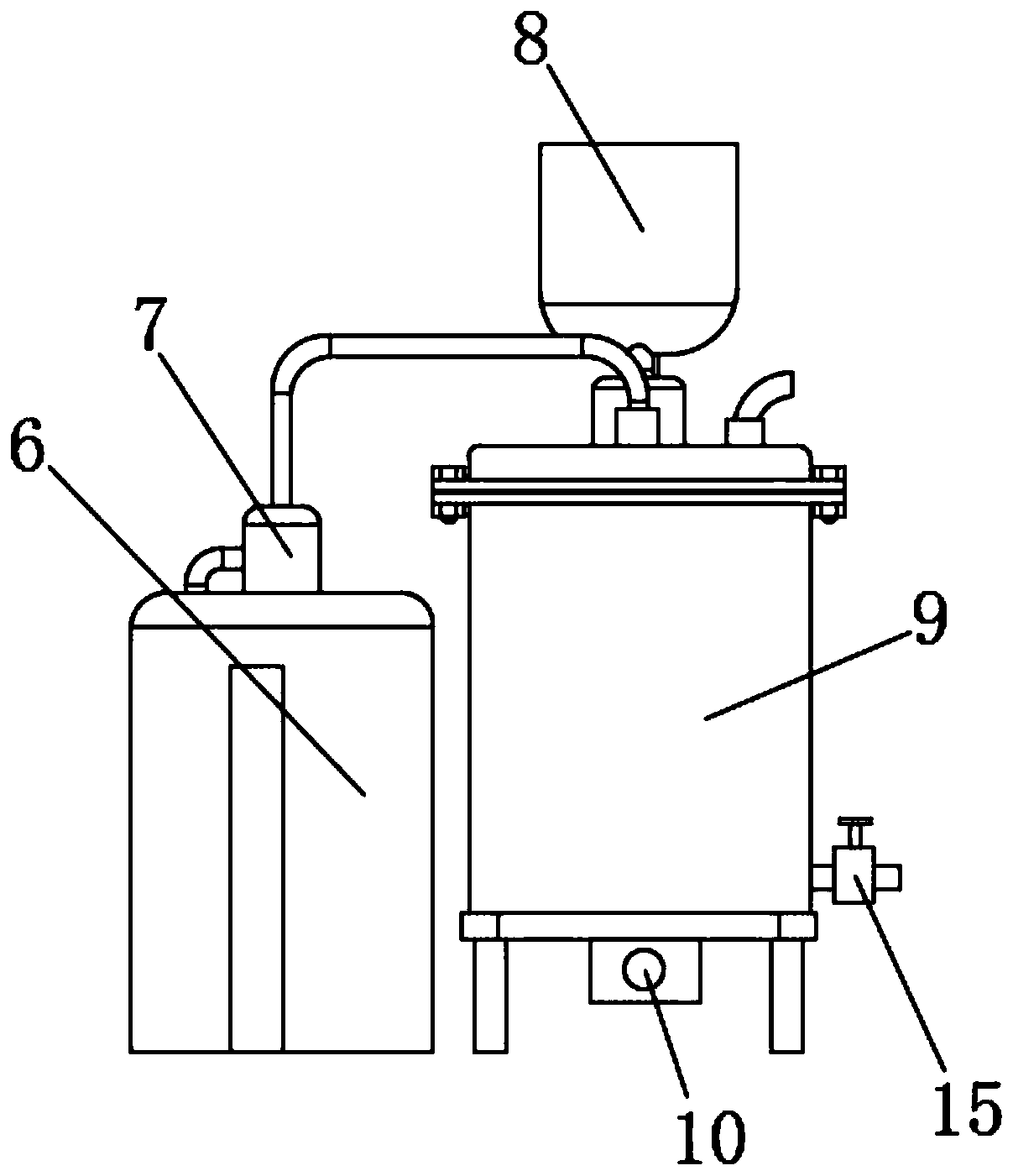

New process for preparing powder by dry method of ceramic tiles

InactiveCN101857421AReduce pollutionReduce energy consumptionClaywaresEnergy consumptionMaterials science

Owner:淄博新空间陶瓷有限公司

Shale-sintered hollow ganged brick

Owner:陈振杰

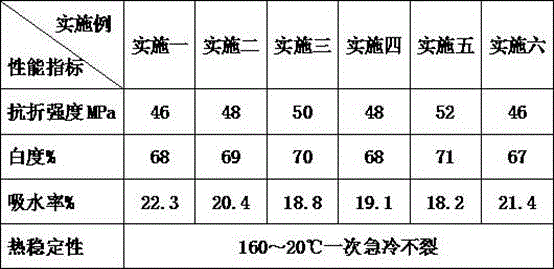

Low-cost high-strength dolomite earthen-ware green body and preparation method thereof

Owner:FUJIAN DEHUA FIVE CONTINENTS CERAMIC MFG CO LTD

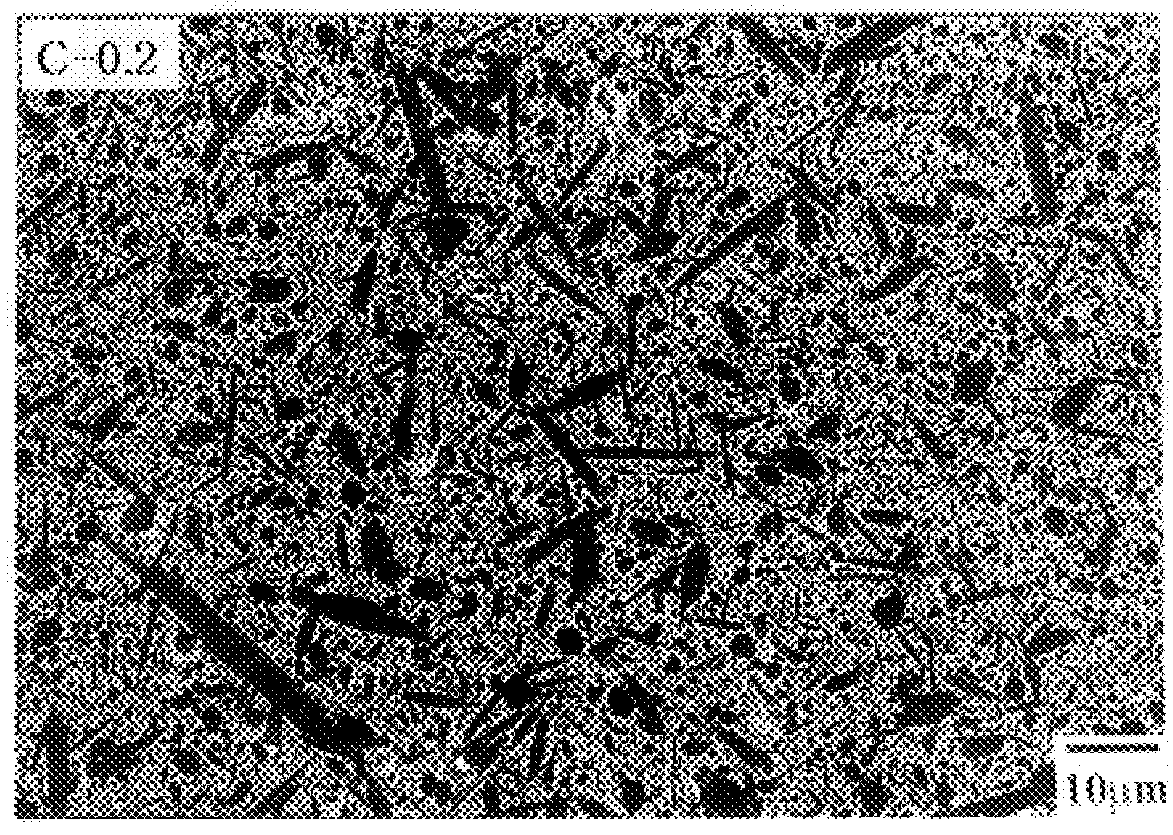

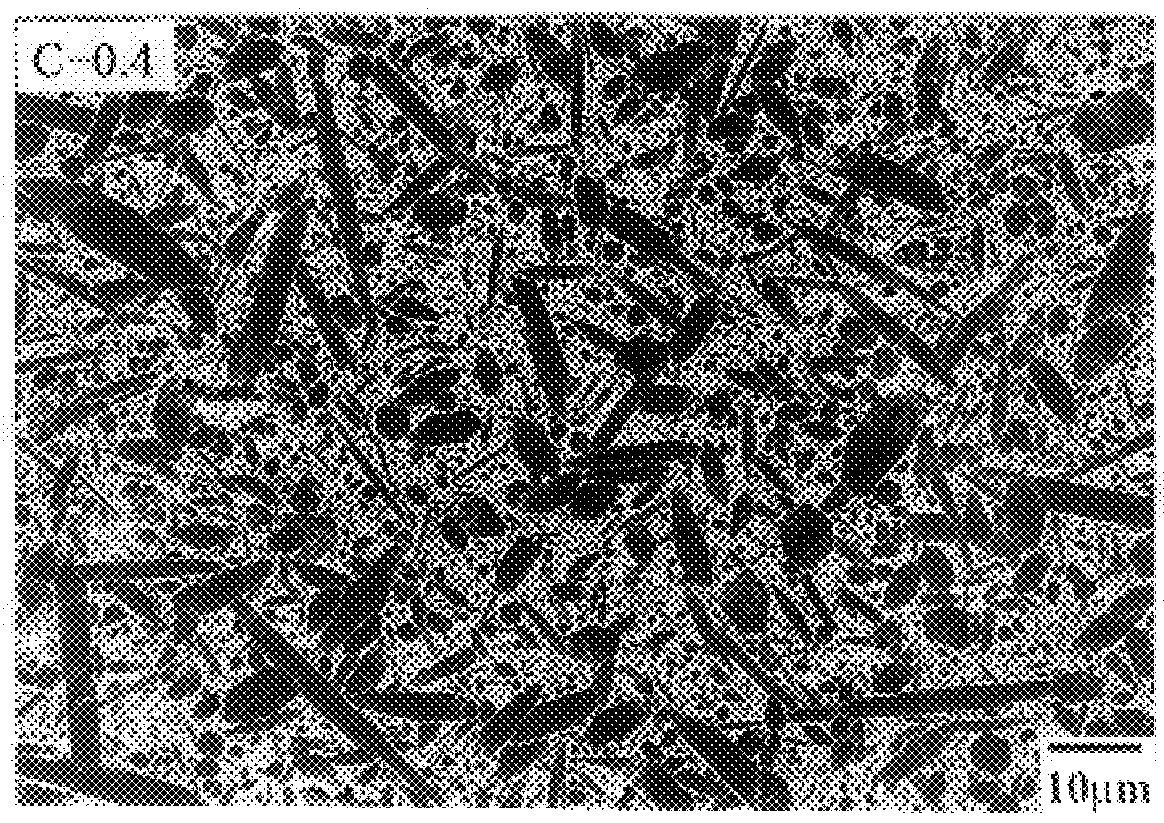

Method for preparing silicon nitride ceramic with high strength and toughness

InactiveUS6232252B1High strengthImprove toughnessCeramic shaping apparatusClaywaresHigh intensityReduction treatment

Provided with a method for preparing a silicon nitride ceramic with high strength and toughness including: mixing 0.2-0.9 wt % of carbon (C) powder with silicon nitride powder containing 5.0-6.0 wt % of yttria (Y2O3) and 1.0-2.0 wt % of alumina (Al2O3) added thereto as a sintering agent, and preparing a molding; subjecting the molding to a carbothermal reduction treatment at 1400-1500° C.; and gas pressure sintering the molding at a temperature above 1850° C. after the carbothermal reduction treatment.

Owner:KOREA INST OF MASCH & MATERIALS

Preparation method of far infrared antibacterial ceramic

InactiveCN106866115AReduce manufacturing costTake advantage ofCeramic materials productionClaywaresSpray GranulationEmissivity

Owner:SICHUAN UNIV

Preparation method of residual-sludge-based particle electrode carrier

InactiveCN105218073AImprove processing efficiencyReduce processing energy consumptionWater/sewage treatmentCeramic materials productionSludgeDyeing wastewater

Owner:HARBIN UNIV OF SCI & TECH

Domestic ceramic with high toughness, and production method thereof

Owner:福建省德化县嘉威陶瓷有限公司

Environment-friendly antique imitation porcelain with firewood-calcined porcelain imitation texture and production method thereof

Owner:FUJIAN QUANZHOU LONGPENG GROUP

Surface concave-convex pattern sculpturing molding method for Jianshui purple pottery white mud device

InactiveCN110078474AStrong three-dimensional senseStrong light and shadow effectDecorative surface effectsClaywaresSurface patternKiln

Owner:方志坚

Preparation method of pyrite tailing ceramsite proppant

ActiveCN105801162AHigh strengthLight weightCeramic materials productionCeramicwareHigh pressureLow density

Owner:GONGYI CITY GUANGMING CHEM

Blue-in-green rice-pattern glaze and application method thereof

ActiveCN107473589ABreak through the decorative effectNo side effectsClaywaresSilicon dioxideNatural mineral

The invention discloses a blue-in-green rice-pattern glaze and an application method thereof. The blue-in-green rice-pattern glaze is prepared from the following natural mineral raw materials and industrial chemical engineering raw materials in percentage by mass: 72.25 to 72.39% of SiO2 (silicon dioxide), 15.13 to 15.50% of Al2O3 (aluminum oxide), 0.71 to 0.73% of Fe2O3 (ferric oxide), 2.61 to 2.93% of K2O (potassium oxide), 1.23 to 2.22% of Na2O (sodium oxide), 6.64 to 6.93% of CaO (calcium oxide), and 0.28 to 0.45% of MgO (magnesium oxide) through proportioning, ball milling and screening. The blue-in-green rice-pattern glaze has the advantages that the blue-in-green decoration effect is realized without adding of oxide coloring agent, the decoration effect of the traditional rice-pattern porcelain in Jingdezhen is broken, most of raw materials are natural mineral raw materials, the sources are rich, the cost is low, any side effect to a human body is avoided, and the market space is broad.

Owner:JINGDEZHEN CERAMIC UNIV

Active carbon antibacterial health ceramic and preparation method thereof

InactiveCN104193297AGood health effectImprove antibacterial propertiesClaywaresActivated carbonGlaze

Owner:DOSHAN NEW STRATEGY INTPROP CULTURECO

Fibers and Nonwovens Made from uncross-linked alkyd oligomers

Owner:THE PROCTER & GAMBLE COMPANY

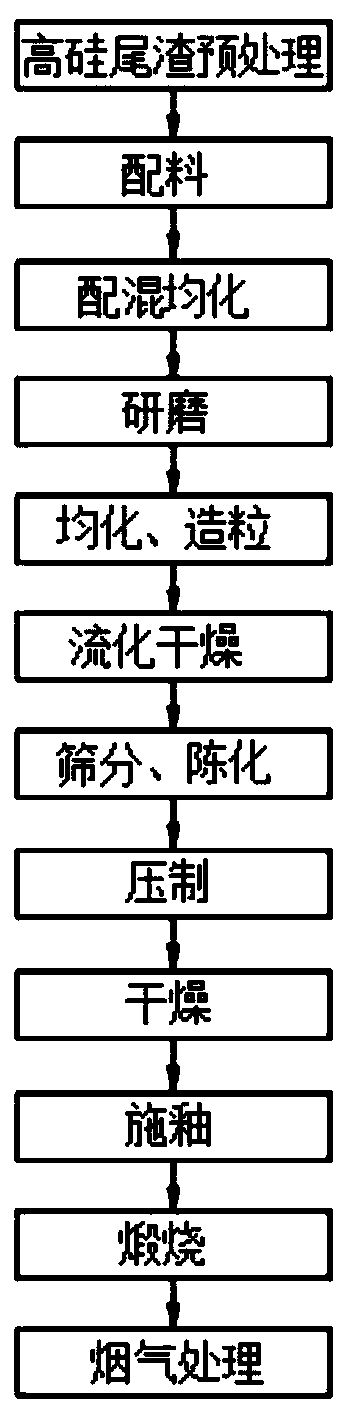

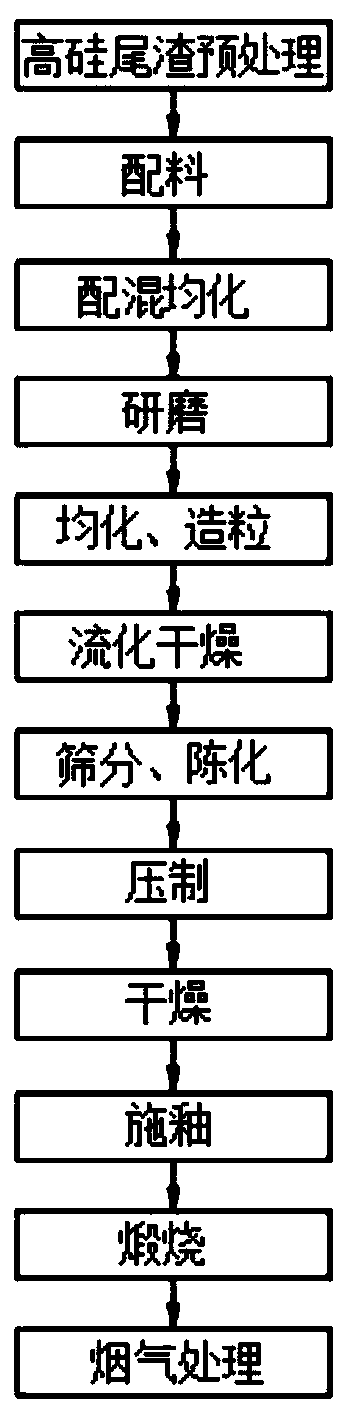

Method for preparing European type interlocked tiles by using high-silicon tailings

InactiveCN110041050APromote sustainable developmentReduce sulfur contentCeramic materials productionClaywaresAluminiumFlue gas

The invention discloses a method for preparing European type interlocked tiles by using high-silicon tailings and relates to the technical field of resource utilization of dressing and smelting wasteresidues. The method comprises the following steps: step 1) pretreating the high-silicon tailings; step 2) preparing materials; step 3) mixing and homogenizing; step 4) grinding; step 5) homogenizingand granulating; step 6) fluidizing and drying; step 7) sieving and ageing; step 8) compressing; step 9) drying; step 10) glazing; step 11) calcining, and step 12) treating flue gas. The method disclosed by the invention has the advantages of novel design and simple technology; the high-silicon tailings are utilized as a main raw material, harmless and resourceful utilization of the high-silicon tailings is achieved, and sustainable development of the whole golden industrial chain is improved; bauxite, Laiyang clay and quartz are utilized as auxiliary materials, so that the whole performance of a product is better; by means of high-temperature calcining, FeS2 in the high-silicon tailing can be slowly decomposed; thus, the sulfur content in the European type interlocked tiles is reduced, and the product is ensured to achieve environmental friendliness and reach the standard.

Owner:ZHAOYUAN ZHAOJIN JINHE TECH +1

Ceramic tile green body produced by ceramic waste and preparation method thereof

InactiveCN107857567ALow costProtect environmentCeramic materials productionClaywaresScrapSodium silicate

The invention discloses a ceramic tile green body produced by ceramic waste. The ceramic tile green body is characterized by being prepared from the following raw materials in percentage by weight: 15-35% of clay, 40-60% of polishing waste, 10-30% of waste green body powder, 0-10% of sand, 0.5-3% of talcum, 0.5-1% of sodium silicate, 0.2-0.5% of a water reducing agent and the balance of water. Theceramic tile green body is produced by the processed waste green body and the waste powder in the process of producing semi-finished products of ceramic factories; the waste raw materials are fully utilized; the cost is reduced; meanwhile, the water reducing agent is added into the ceramic material, so that the ceramic products can be degraded into powder under the natural condition; the environment is protected.

Owner:恩平市新锦成陶瓷有限公司

Evaluation method of solid waste for preparing lightweight aggregate

InactiveCN112573850ASolve the evaluation problem of whether it is suitable for lightweight aggregateIn line with the direction of sustainable developmentCeramic materials productionCeramicwareProcess engineeringEnvironmental engineering

The invention discloses an evaluation method of solid waste for preparing lightweight aggregate. The method comprises the following steps: 1, carrying out basic performance detection on the solid waste; 2, according to a basic performance detection result of the solid waste, selecting the solid waste to prepare lightweight aggregate, and carrying out proportioning design; 3, proportioning according to a proportioning design result, and preparing solid waste lightweight aggregate raw material balls; 4, roasting the solid waste lightweight aggregate raw material balls to obtain a solid waste lightweight aggregate sample; 5, performing performance detection on the solid waste lightweight aggregate sample; and 6, evaluating the solid waste for preparing the lightweight aggregate according to aperformance detection result. Starting from the basic performance of the fixed waste, the solid waste lightweight aggregate sample is prepared through proportion design and performance detection in sequence, the feasibility of preparing the lightweight aggregate from the solid waste is comprehensively evaluated, the method has the advantages of being accurate, efficient, quick and objective, andan effective means is provided for comprehensive utilization of various solid wastes.

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

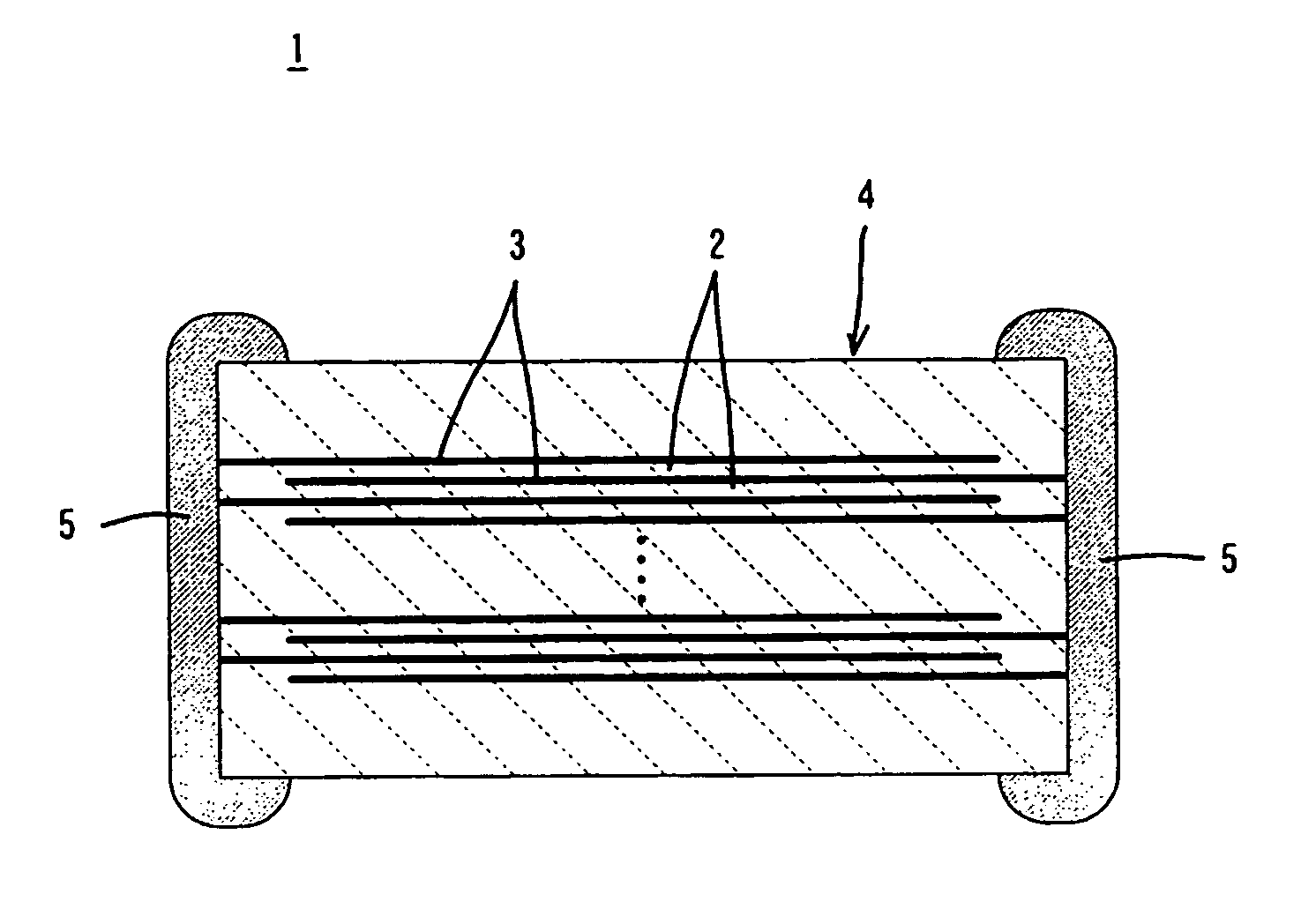

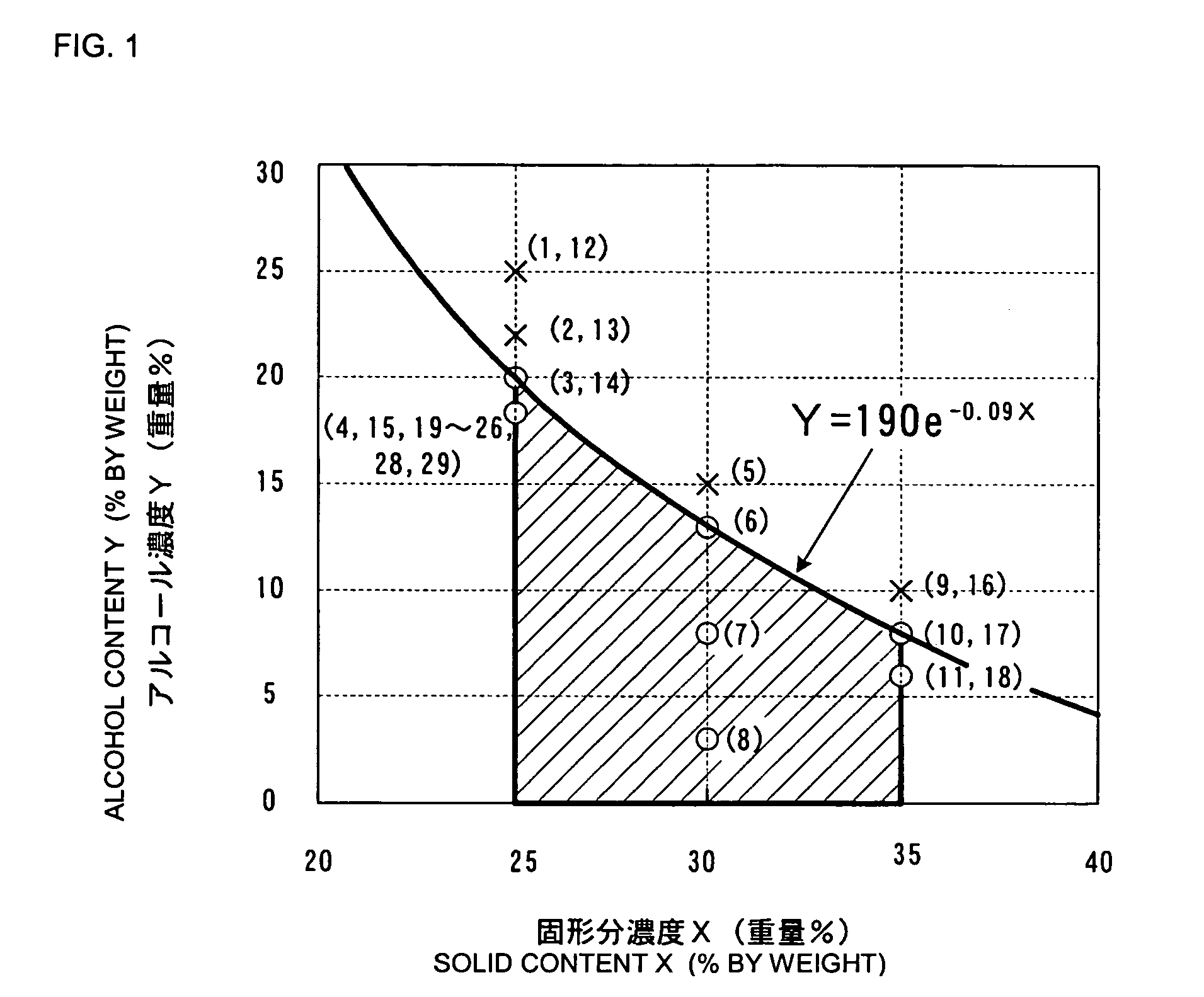

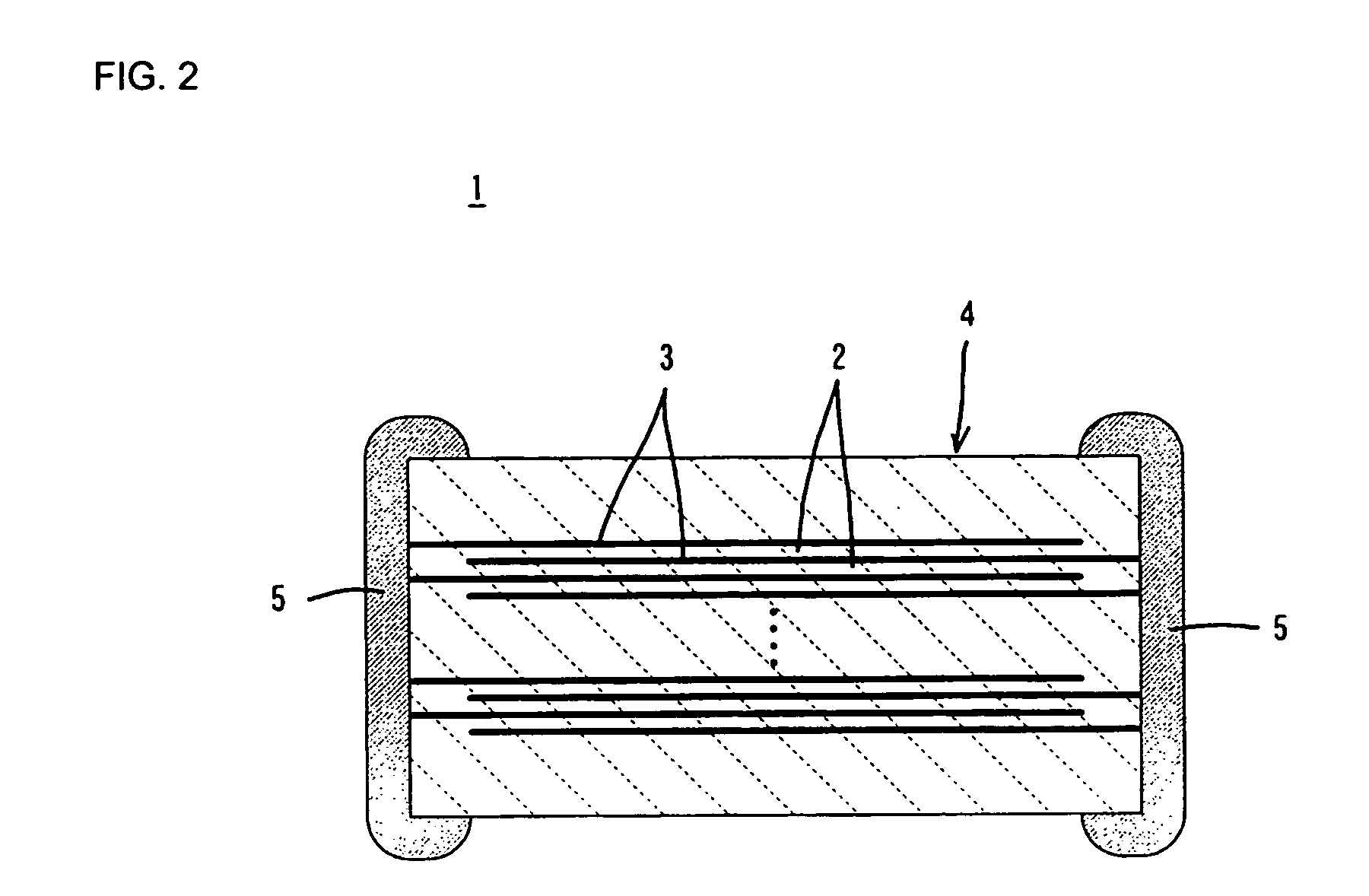

Water-soluble acrylic binder, method for producing the same, ceramic slurry composition, method for producing the same, monolithic ceramic electronic part and method for manufacturing the same

InactiveUS20050206049A1Good molding effectReduce slurry viscosityLamination ancillary operationsLayered product treatmentAlcohol contentSlurry

Owner:MURATA MFG CO LTD

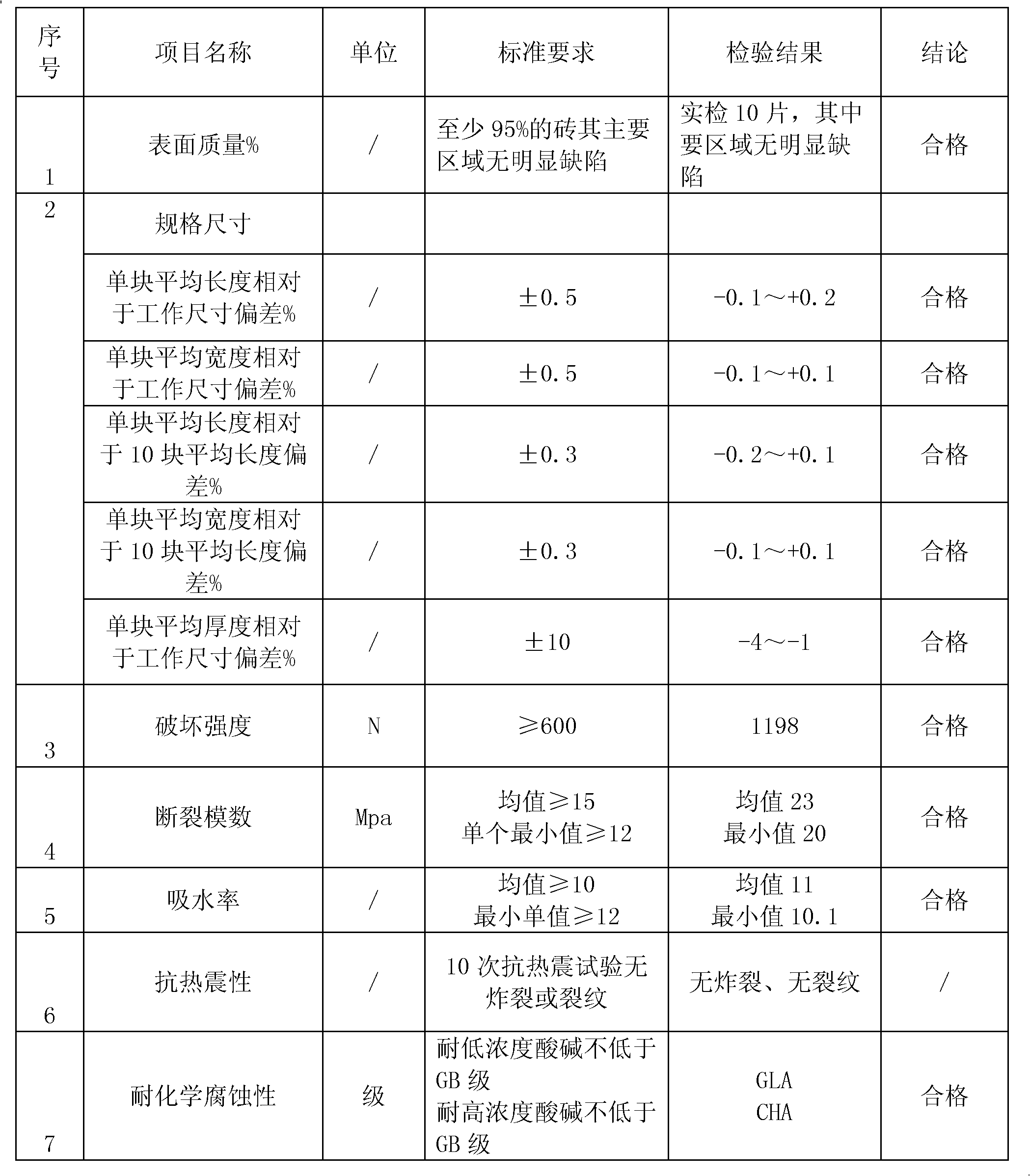

Refractory ceramic tile and preparation method thereof

Owner:HEFEI MINGYOU HIGH TEMPERATURE TECH CO LTD

Mineral ceramic and preparation method thereof

InactiveCN110218074AImprove physiological functionGood health effectWater/sewage treatment by neutralisationClaywaresSodium BentonitePotassium feldspar

Owner:郑晓亮

Celadon blank making technology through overweight pressure one-time moulding

InactiveCN106187077AHigh refractorinessWith natural lusterCeramic shaping apparatusClaywaresPotassiumHigh intensity

The invention provides a celadon blank making technology through overweight pressure one-time moulding. The celadon blank making technology comprises the following steps of (1) preparing raw material powder; (2) performing compression moulding; (3) performing sintering on compressed blanks, wherein the sintering temperature is controlled to 1190-1300 DEG C; and (4) trimming the blanks so as to obtain the celadon blank. Raw materials for preparing the raw material powder comprise 35-45% of Longyan kaolin, 15-20% of celadon blank clay powder, 8-20% of potassium feldspar, 7-12% of quartz, 3-8% of hematite, 5-10% of Zijin clay, 6-10% of bone ash, 9-15% of nanometer alpha-Al2O3 powder, and 5-10% of filler. According to the celadon blank making technology disclosed by the invention, the refractoriness of blanks is greatly improved, besides, the made blank has the advantages of being high in strength, natural in glossiness, and fine in texture, and the celadon blank can be produced in batches, and the production cost is reduced.

Owner:LONGQUAN HONGXIN PORCELAIN CO LTD

Ceramic steel material

Owner:HUZHOU ZHIWEI TECHNICAL SERVICE CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap