Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

21 results about "Tailings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tailings are the materials left over after the process of separating the valuable fraction from the uneconomic fraction (gangue) of an ore. Tailings are distinct from overburden, which is the waste rock or other material that overlies an ore or mineral body and is displaced during mining without being processed.

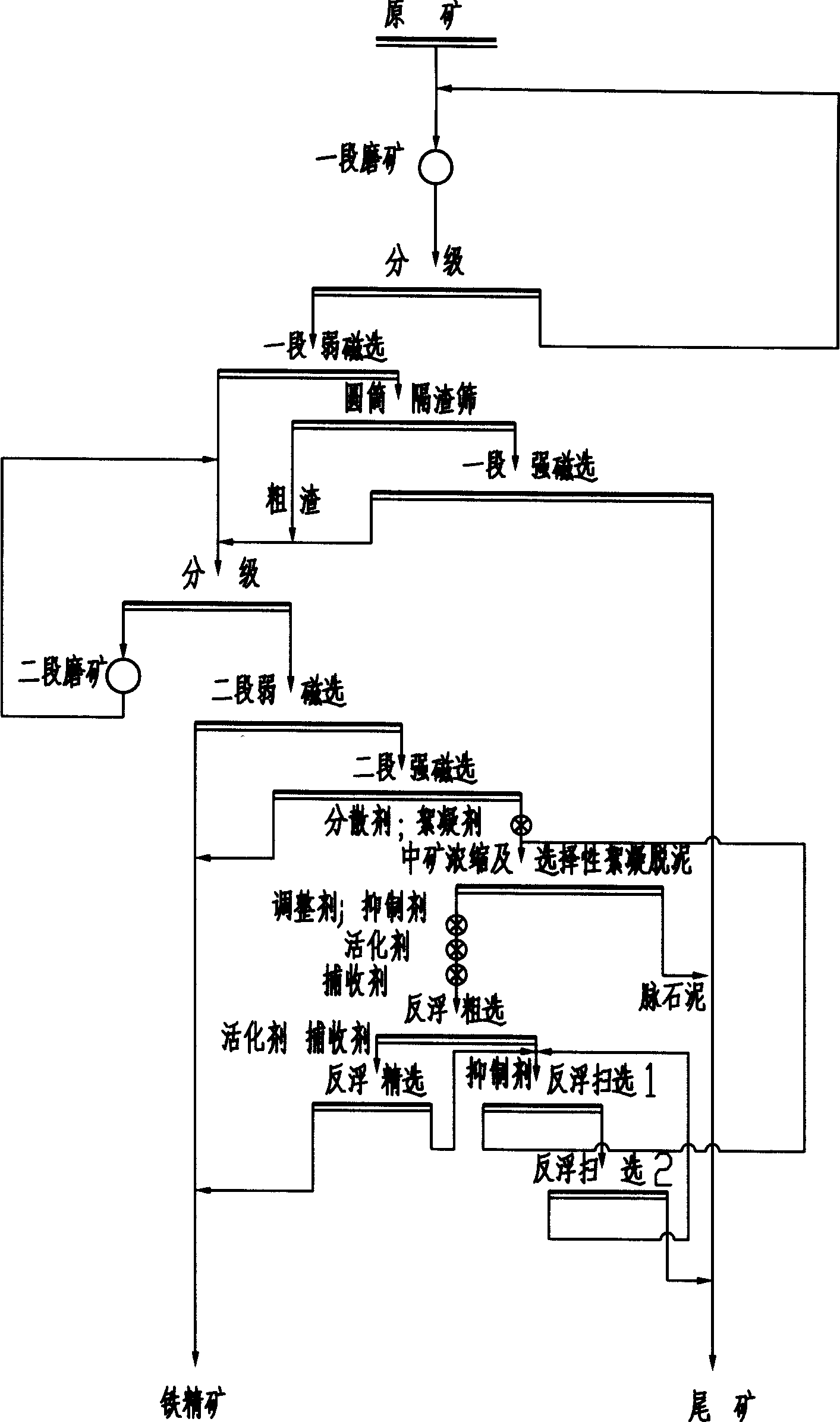

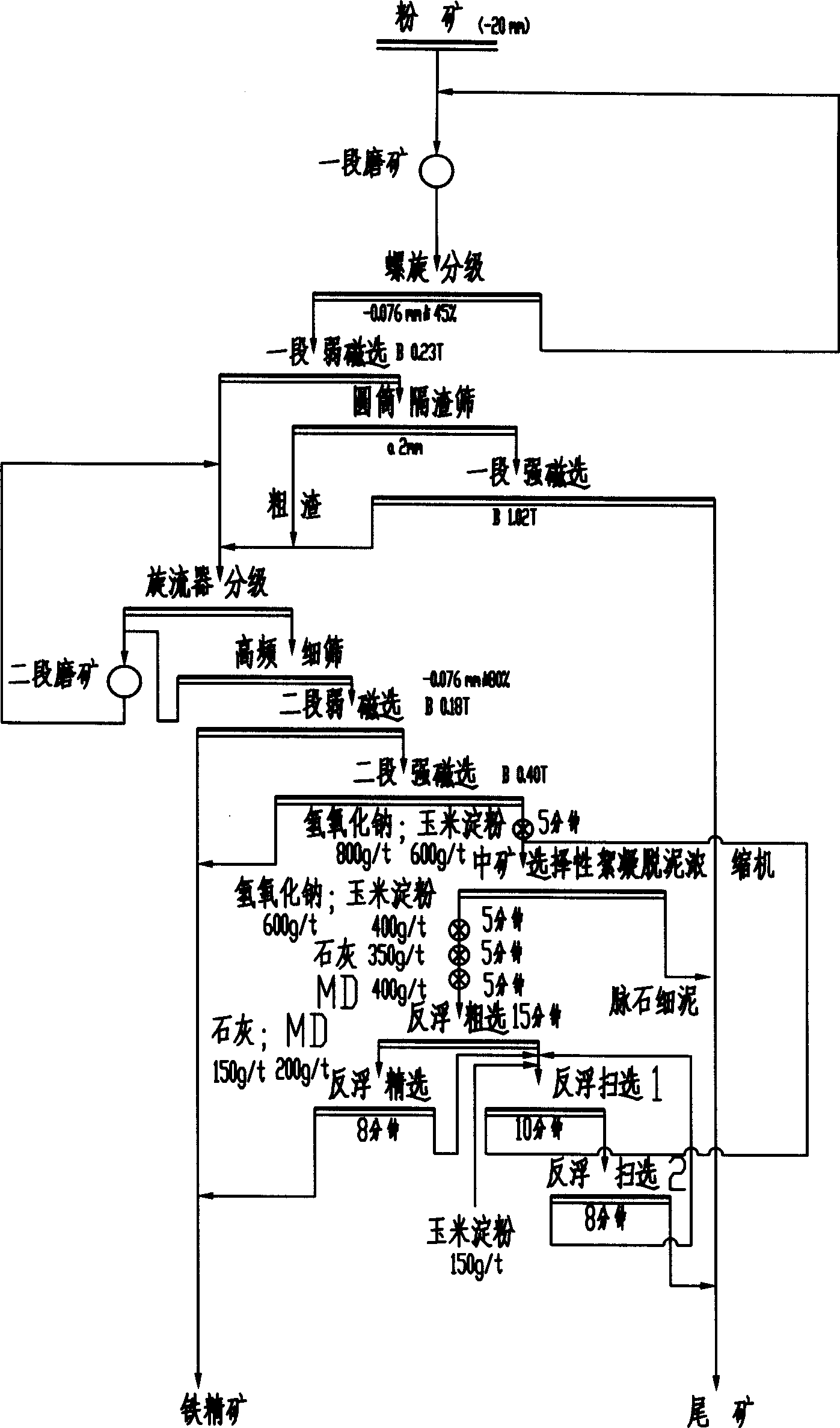

Beneficiation method for recycling specularite

InactiveCN101428248AReduce consumptionReduce the number of equipmentDifferential sedimentationFlotationIronstoneSlag

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

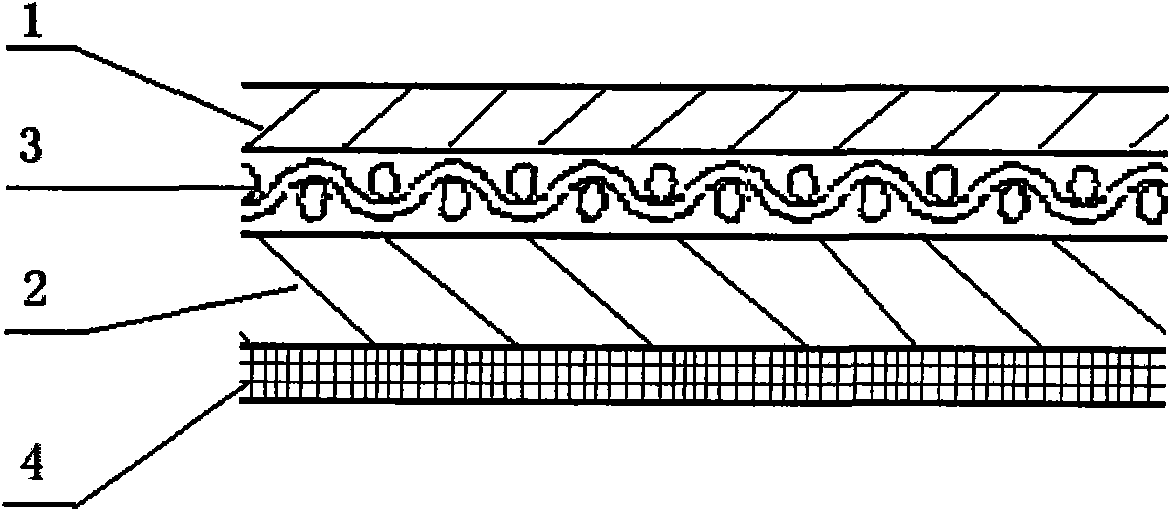

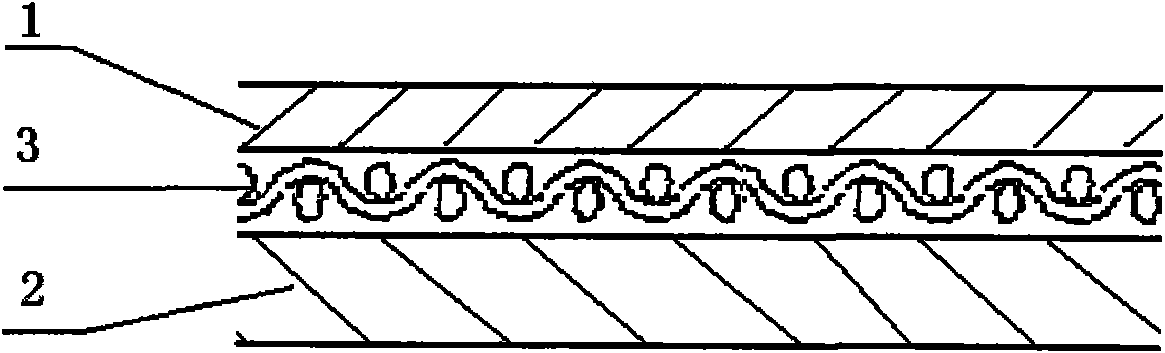

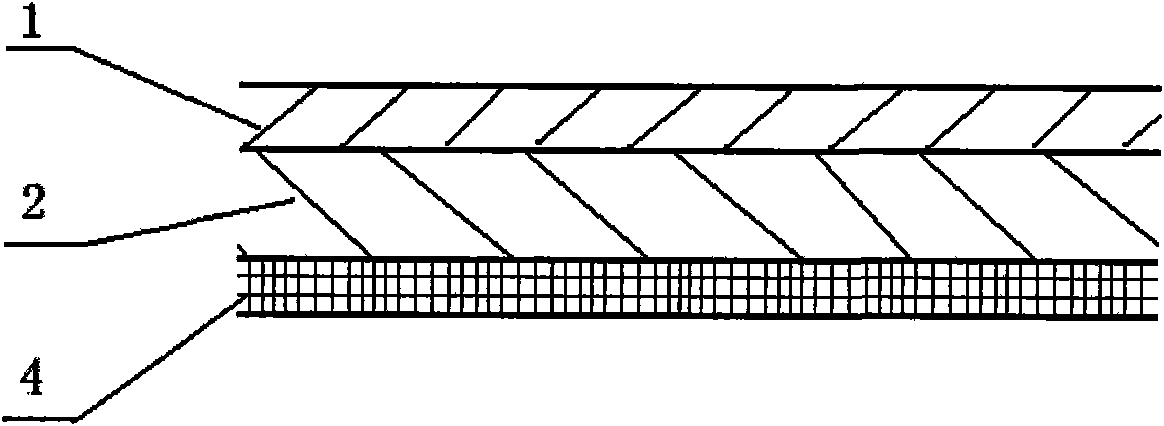

Asphalt modified thermoplastic polyolefin water-proof coiled material and preparation method thereof

InactiveCN101550729AImproves UV resistanceExcellent ozone resistanceRoof covering using flexible materialsBuilding insulationsPolymer sciencePolyolefin

Owner:胜利油田大明新型建筑防水材料有限责任公司

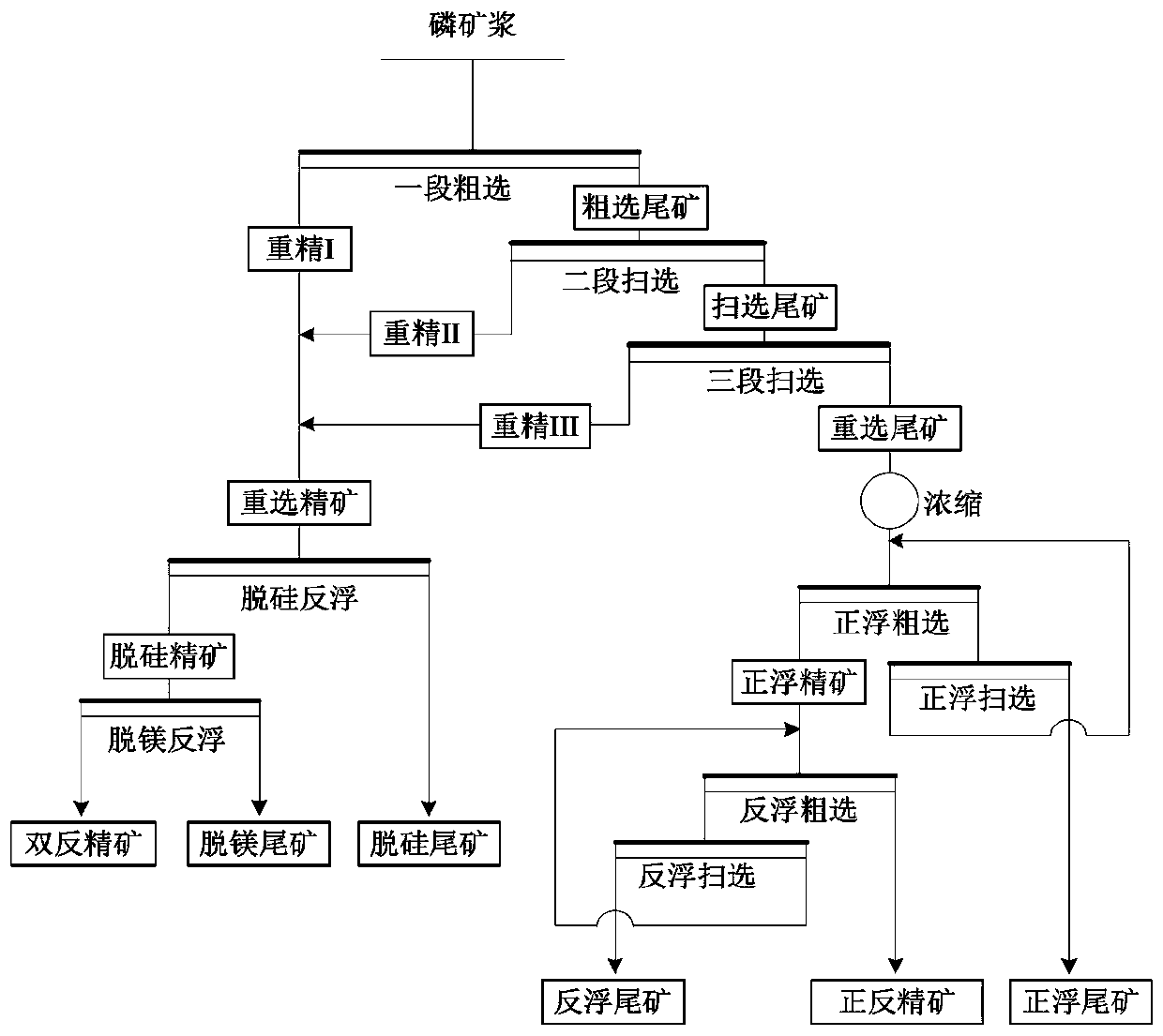

Mineral separation method for recycling iron, rare earth, fluorite and niobium from iron tailings of associated multi-metal minerals

The invention relates to a mineral separation method for recycling iron, rare earth, fluorite and niobium from iron tailings of associated multi-metal minerals, and belongs to the fields of mineral process engineering and comprehensive recycling of resources. The mineral separation method for recycling iron, rare earth, fluorite and niobium from iron tailings of associated multi-metal minerals comprises the following steps: carrying out low intensity magnetic separation and high intensity magnetic separation pre-concentration by taking bayan obo tailings as raw materials, then carrying out fluid bed roasting on obtained pre-concentrated concentrates, and carrying out low intensity magnetic separation operation on roasted minerals obtained by roasting so as to obtain weak-magnetism concentrates and rare-earth-containing weak-magnetism tailings; and carrying out rare earth flotation operation on the weak-magnetism tailings to obtain rare earth flotation concentrates and rare earth flotation tailings finally, then carrying out acid leaching process on the rare earth flotation tailings to obtain niobium-enriched slag and acid pickling tailings, and meanwhile, carrying out fluorite flotation operation on pre-concentrated strong-magnetism tailings to obtain fluorite flotation concentrates and fluorite flotation tailings. By the method, fluorite concentrates, iron core concentrates, rare earth concentrates and the niobium-enriched slag are obtained finally, and thus, the bayan obo tailings are utilized comprehensively.

Owner:NORTHEASTERN UNIV LIAONING

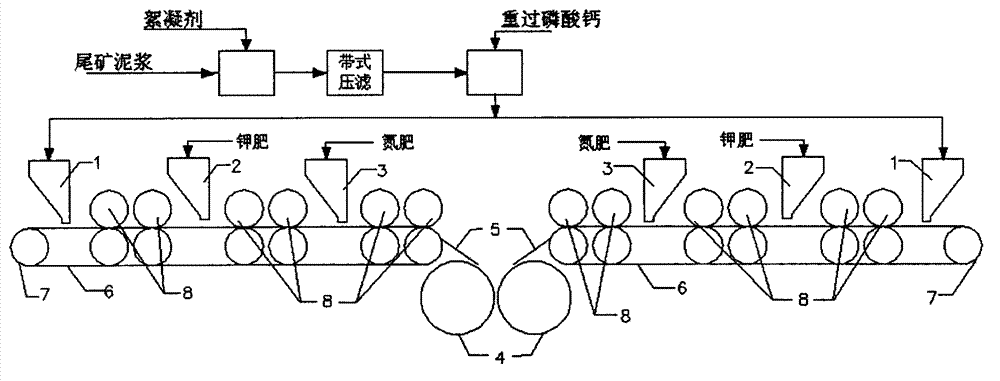

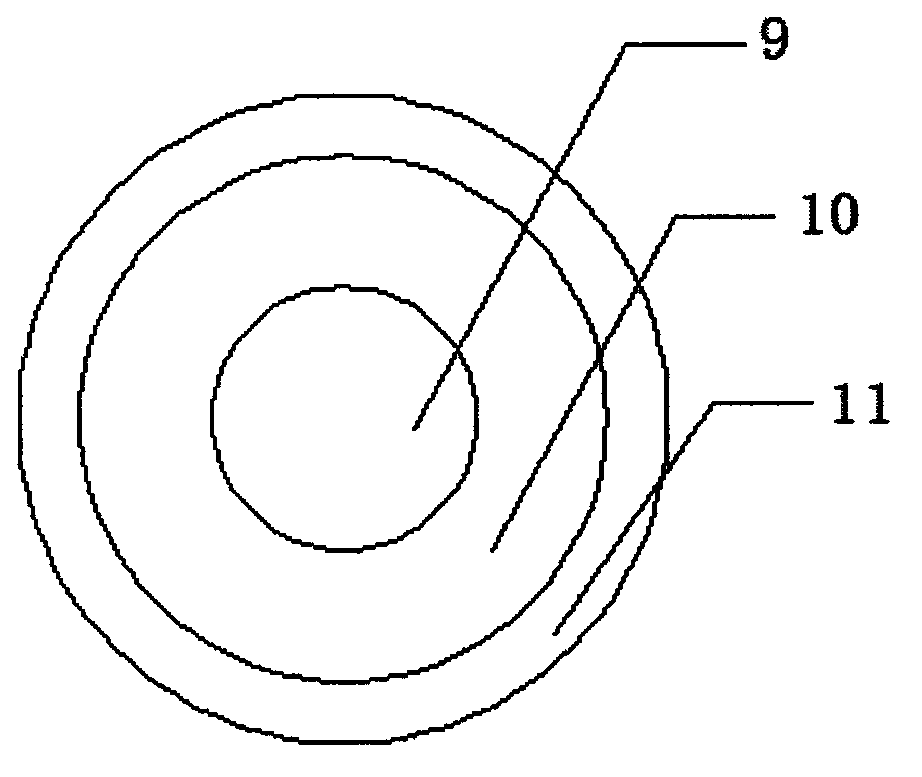

Method and equipment for producing slow-release compound fertilizer from manganese ore tailings

InactiveCN103204743AReduce processing costsSolving Stacking Handling IssuesFertiliser formsFertilizer mixturesElectrolysisManganese

Owner:赵阳臣

Glass ceramics prepared from tailings obtained by nickel-molybdenum ore dressing and smelting and preparation method thereof

The invention provides glass ceramics prepared from tailings obtained by nickel-molybdenum ore dressing and smelting and a preparation method thereof. The glass ceramics use the tailings obtained by nickel-molybdenum ore dressing and smelting as main raw materials and silica or quartz sand (SiO2), limestone or calcite (CaCO3), sodium carbonate (Na2CO3), alumina (Al2O3), potassium carbonate (K2CO3), magnesium oxide (MgO) and calcium fluoride (CaF2) as auxiliary raw materials. The preparation method comprises the steps of grinding the tailings obtained by nickel-molybdenum ore dressing and smelting and the auxiliary raw materials, sieving the powder with a 20-mesh sieve, and mixing the powder uniformly in a mixer to obtain a base batch; melting the base batch at the temperature of 1450-1550 DEG C, homogenizing and clarifying the melt to obtain qualified molten glass, and then forming a base glass plate or granules through moulding by casting or water quenching of the molten glass; finally filling the base glass plate or the granules into a mould, and then carrying out crystallization thermal treatment, thus obtaining the glass ceramics prepared from the tailings obtained by nickel-molybdenum ore dressing and smelting. The preparation process is simple in operation course and has the effects of not only expanding the way of resource comprehensive utilization of the tailings obtained by nickel-molybdenum ore dressing and smelting but also reducing the environmental pollution of the tailings.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Glass ceramics made from high silicon iron tailings and manufacturing method thereof

The invention relates to the technical field of solid waste resource utilization, in particular to glass ceramics made from high silicon iron tailings, which is characterized by comprising the raw materials in parts by weight: 30-70 parts of the iron tailings, 15-40 parts of quartz, 5-20 parts of calcium carbonate, 3.5-6.5 parts of aluminum oxide, 8.5-9.5 parts of sodium carbonate, 4-5 parts of zinc oxide, 3-6 parts of barium carbonate and 1-3 parts of borax. The manufacturing method of the glass ceramics comprises the following steps: putting the glass ceramics blended materials in a kiln for melting into molten glass; allowing the molten glass to directly flow into water for water quenching to form glass particles; and paving the glass particles in a refractory die, crystallizing the paved particles in a tunnel kiln, a shuttle kiln or a chamber electric furnace, and grinding and cutting the crystallized glass ceramics to finally obtain the finished product of the glass ceramics. The invention can reduce stockpile of the tailings, alleviate environmental pollution, realize comprehensive resource utilization, improve product performances and lower production cost, thus having good social benefit and good economic benefit.

Owner:ANSTEEL GRP MINING CO LTD

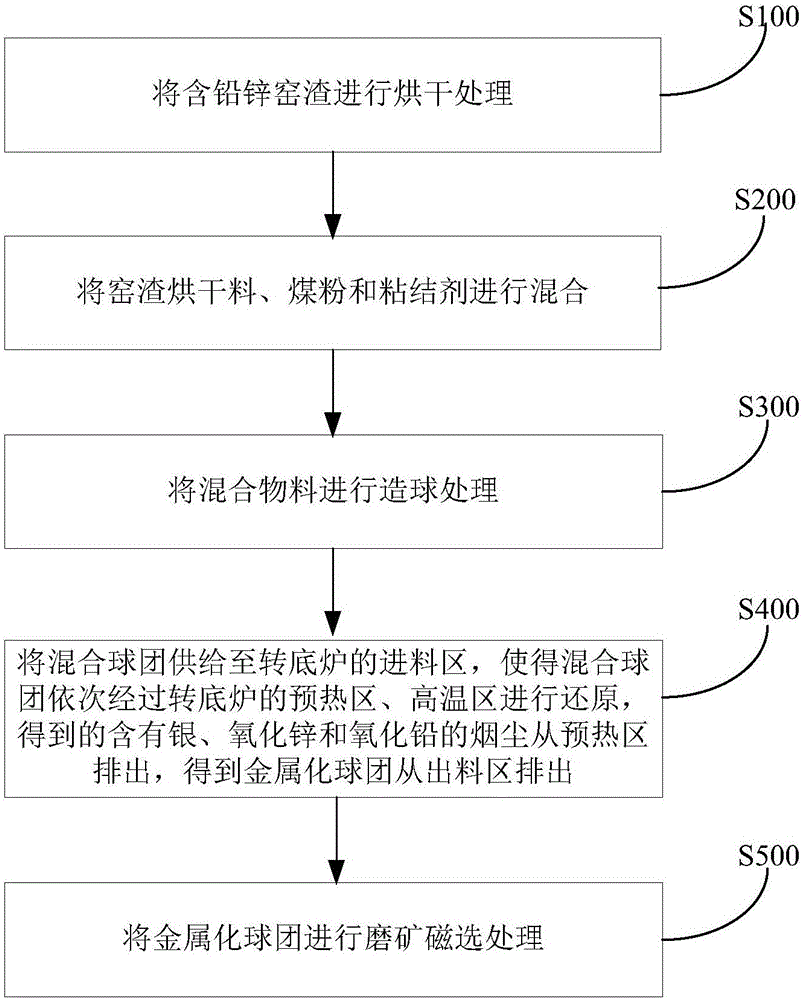

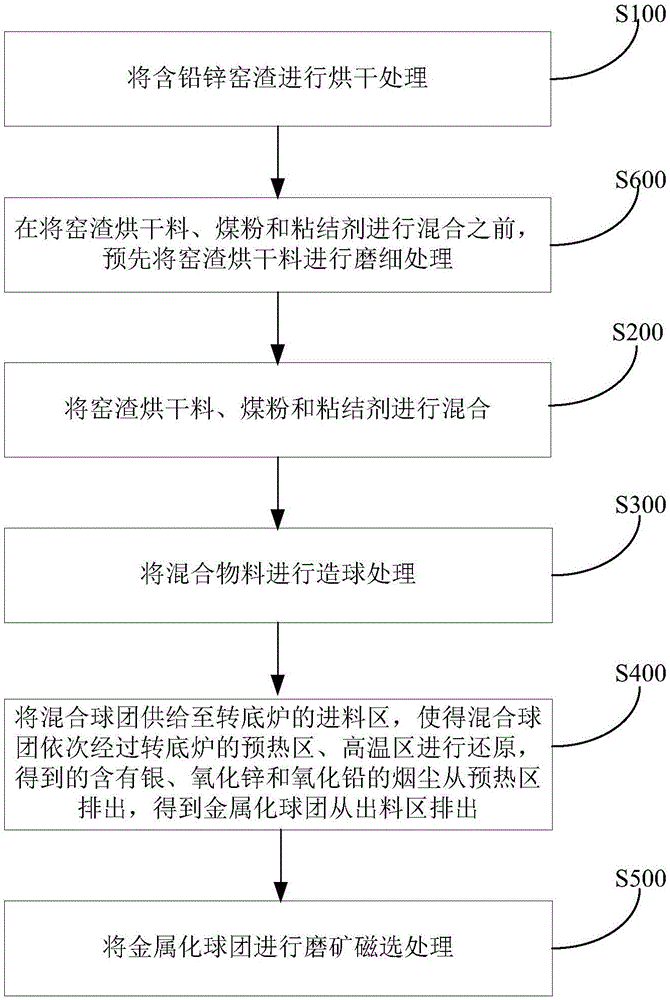

Method and system for treatment of kiln slag including lead and zinc

InactiveCN106148715AAchieve recyclingRealize resource utilizationProcess efficiency improvementIron powderSlag

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

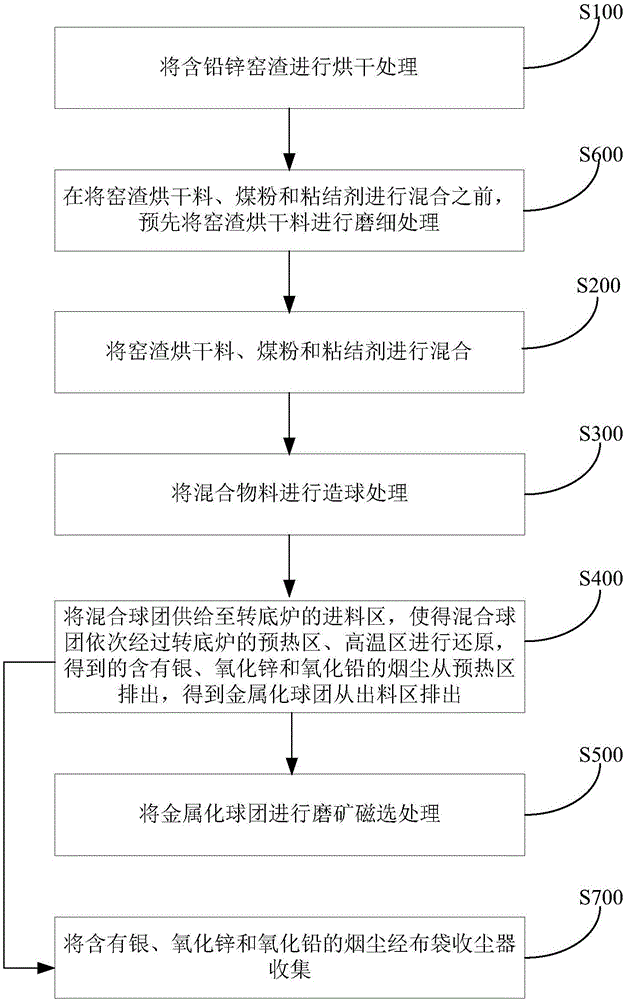

Mineral separation and enrichment method for primary scandium ore

ActiveCN105435958ASimple processEconomically reasonableMagnetic separationWet separationChemical industryEnrichment methods

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

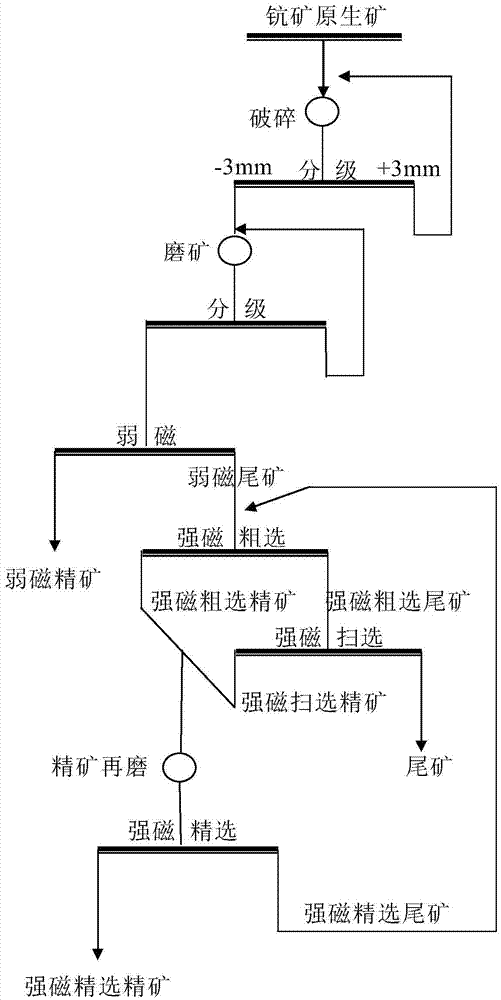

Gravity separation-flotation combined beneficiation process for phosphate ores

PendingCN110369120AReduce grinding costsReduce adverse effectsFlotationWet separationPhosphoriteReverse flotation

Owner:HUBEI XINGFA CHEM GRP CO LTD

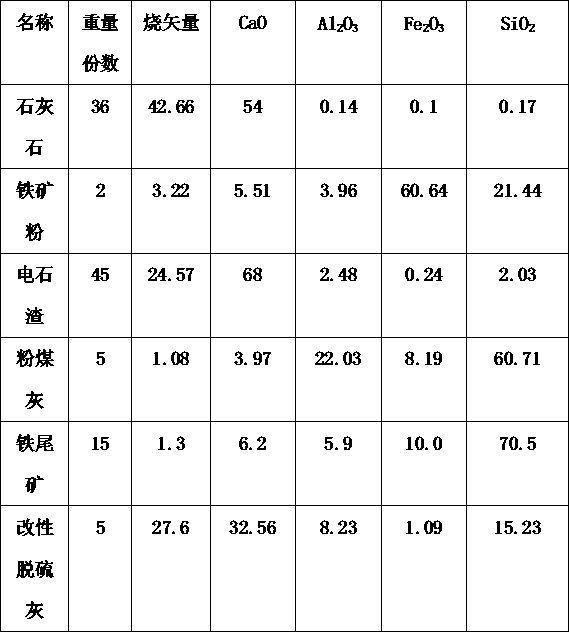

High-volume industrial solid waste composite Portland cement and preparation method thereof

Owner:张延年

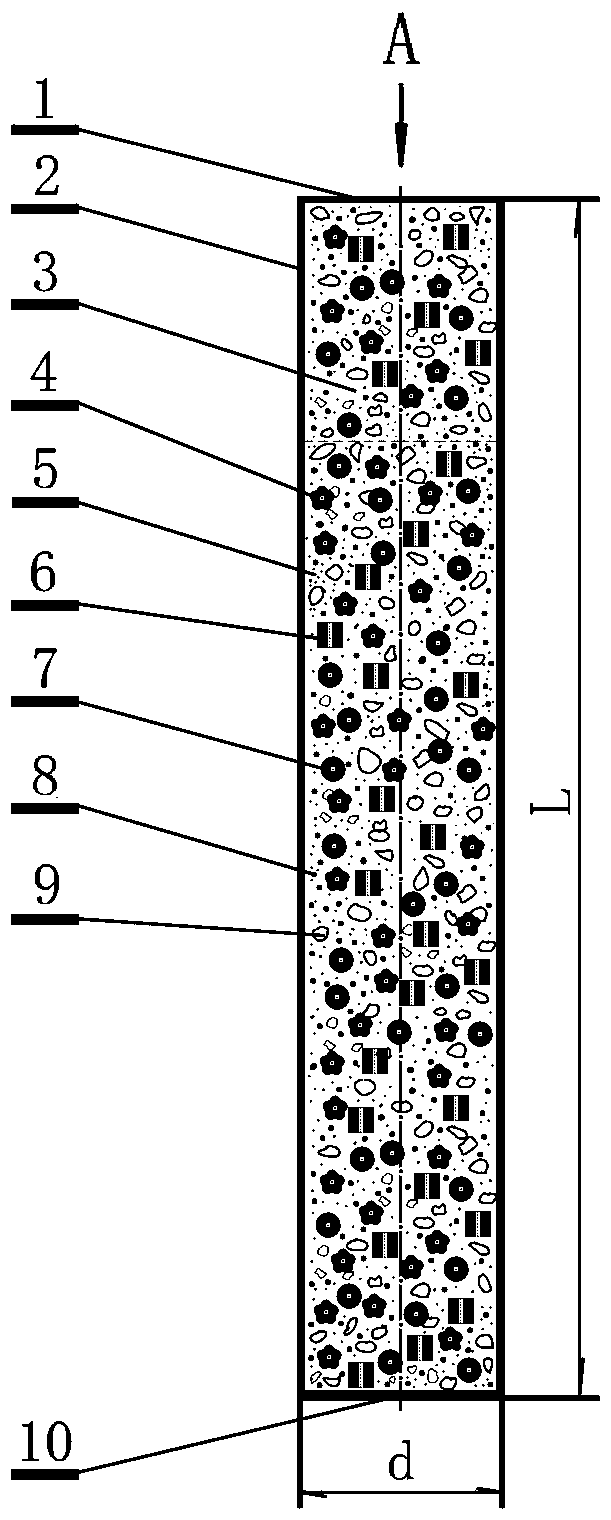

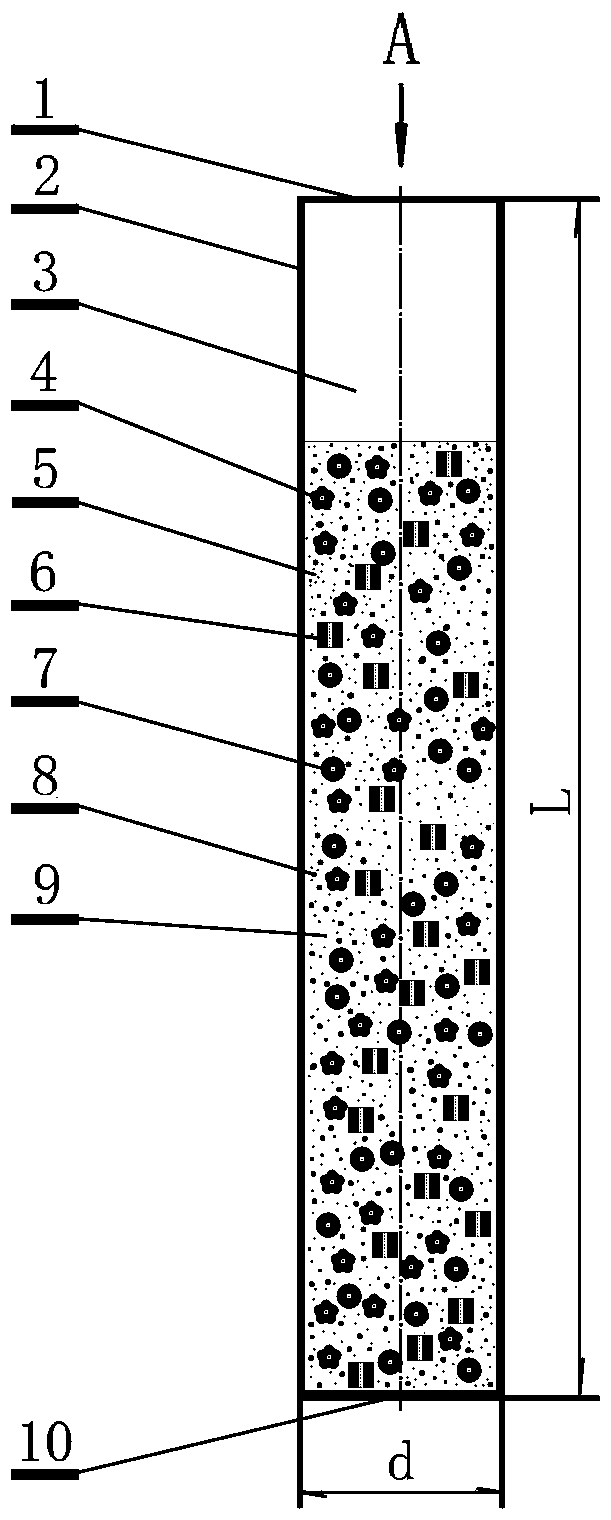

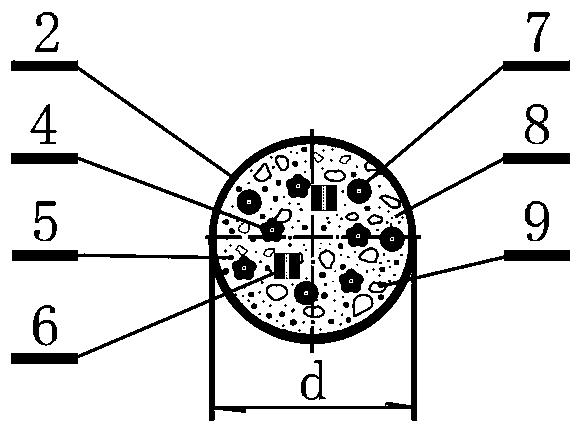

Preparation method of pyrite tailing ceramsite proppant

ActiveCN105801162AHigh strengthLight weightCeramic materials productionCeramicwareHigh pressureLow density

Owner:GONGYI CITY GUANGMING CHEM

Oxidative degradation method for cyanide in cyaniding tailings

InactiveCN107890622AReduce consumptionPromote decomposition and releaseChemical protectionVacuum extractionHigh pressure

Owner:FUJIAN SHUANGQISHAN MINING +1

Method for preparing composite type fracturing propping agent by utilizing gold ore tailings and zirconium oxide

InactiveCN102718493AImprove microstructureOvercoming brittlenessSolid waste disposalFluid removalZirconium hydrideExpanded clay aggregate

The invention discloses a method for preparing a composite type fracturing propping agent by utilizing gold ore tailings and zirconium oxide. The method comprises the steps of mixing the gold ore tailings, alumina powders and high-temperature zirconium oxide chopped fibers, then adding gum water solution, mixing uniformly, conducting wet grinding and then pelleting; putting particles into alumina crucible and arranging into a silicon carbide rod resistor furnace, heating to 1230 DEG C from the room temperature at the heating speed being 5 DEG C / min-10 DEG C / min, keeping the temperature for 0.5h-1h, heating to 1350 DEG C-1400 DEG C at the heating speed being 5 DEG C / min-7 DEG C / min, keeping the temperature for 2h-3h; and cooling the particles in the furnace and then taking out the particles, and screening the particles by a 20-40 meshes sieve so as to obtain the composite type fracturing propping agent. According to the method, fibers (crystal whiskers) necessary for enhancing the strength and toughness is provided by integrating the concept of composite materials integrated with a non-compact ceramic propping agent and adopting the high-temperature reaction self generation mode, and the composite type fracturing propping agent with high strength, high toughness, low density and low damage rate is prepared by two measures, namely fiber reinforcement and particle reinforcement.

Owner:SHAANXI UNIV OF SCI & TECH

Method for extracting Fe from ion ore tailings

InactiveCN1765520ARaise the gradeAlleviate the lack ofMagnetic separationOrganic acidEconomic benefits

Owner:毕舒

Method for concentrating platinum and palladium from platinum-palladium flotation concentrates

InactiveCN108722675AHigh precious metal contentHigh enrichment ratioFlotationMass ratioPt element

Owner:GUANGDONG INST OF RARE METALS

Preparation method of multi-function zeolite-tailing water absorbing and storing nutrient bag for desert

InactiveCN108812203ARich in nutrientsImprove fertilizer efficiencySuperphosphatesRoot feedersEcological environmentNormal growth

Owner:蒋文兰

Application of cold clay and method using cold clay to manufacture artistic furniture and craft tools

InactiveCN105564118AImprove performance qualityReduce consumptionOrnamental structuresCeramic shaping apparatusEnergy consumptionTailings

Owner:古早木语(天津)艺术创作有限公司

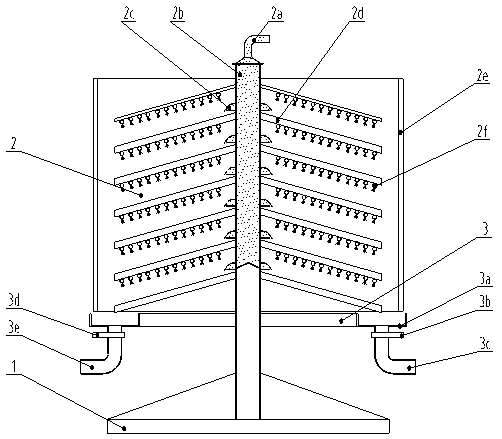

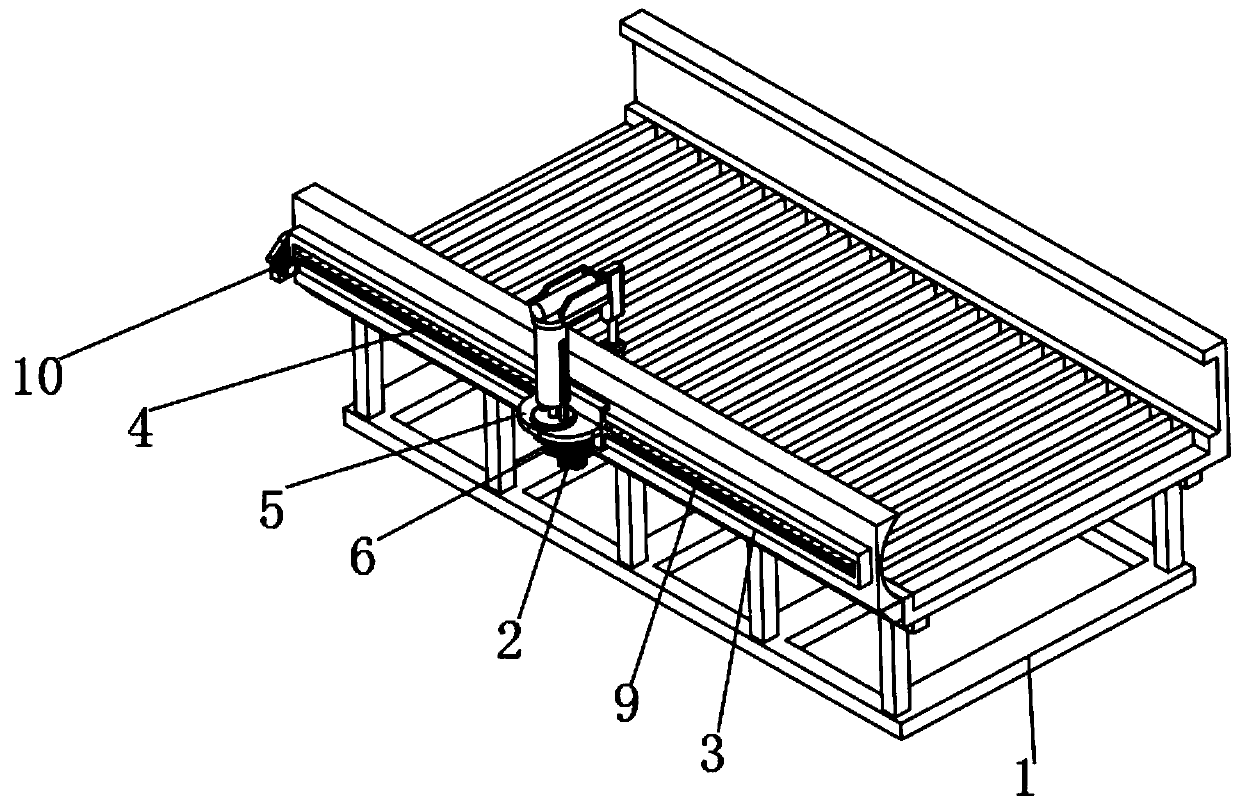

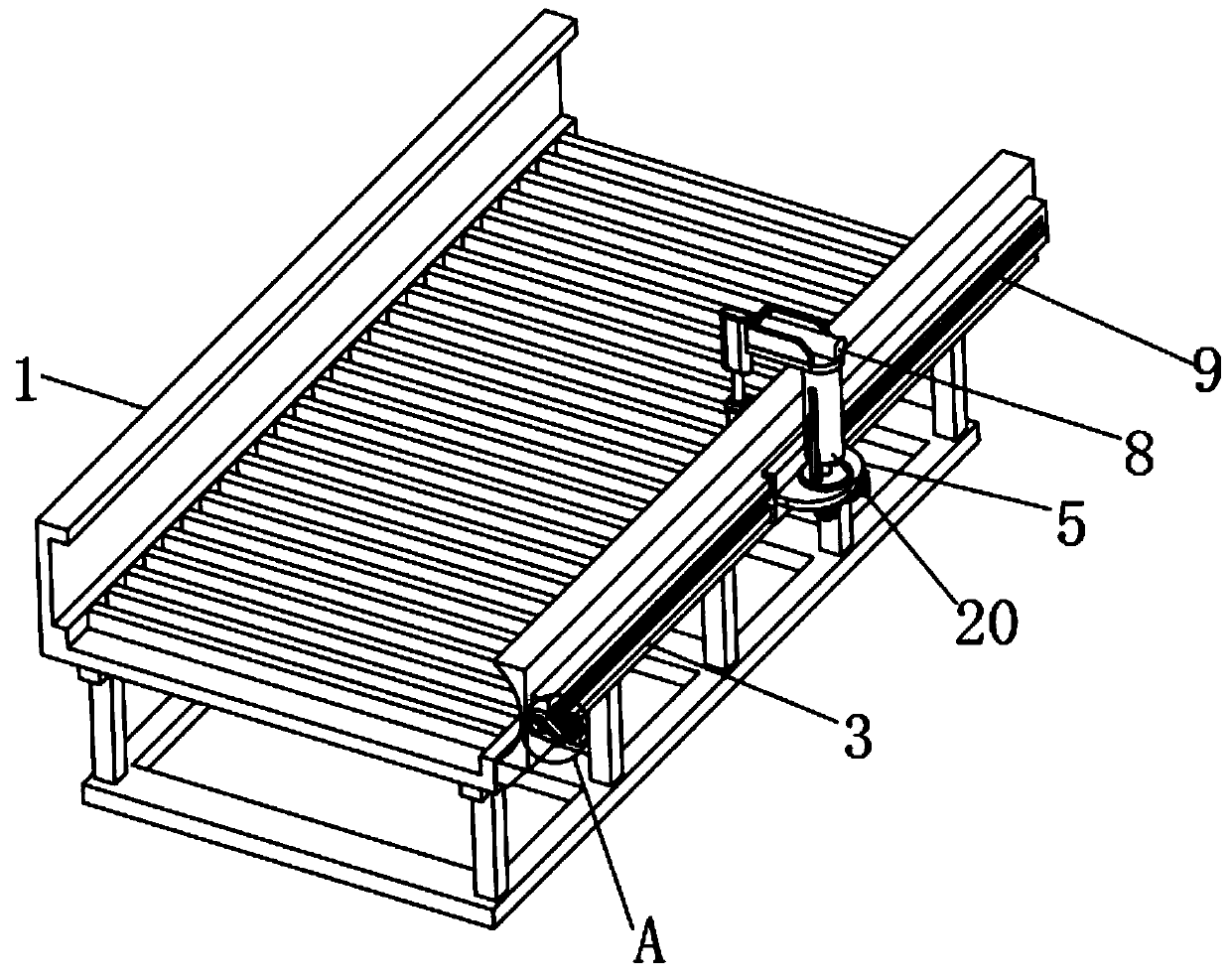

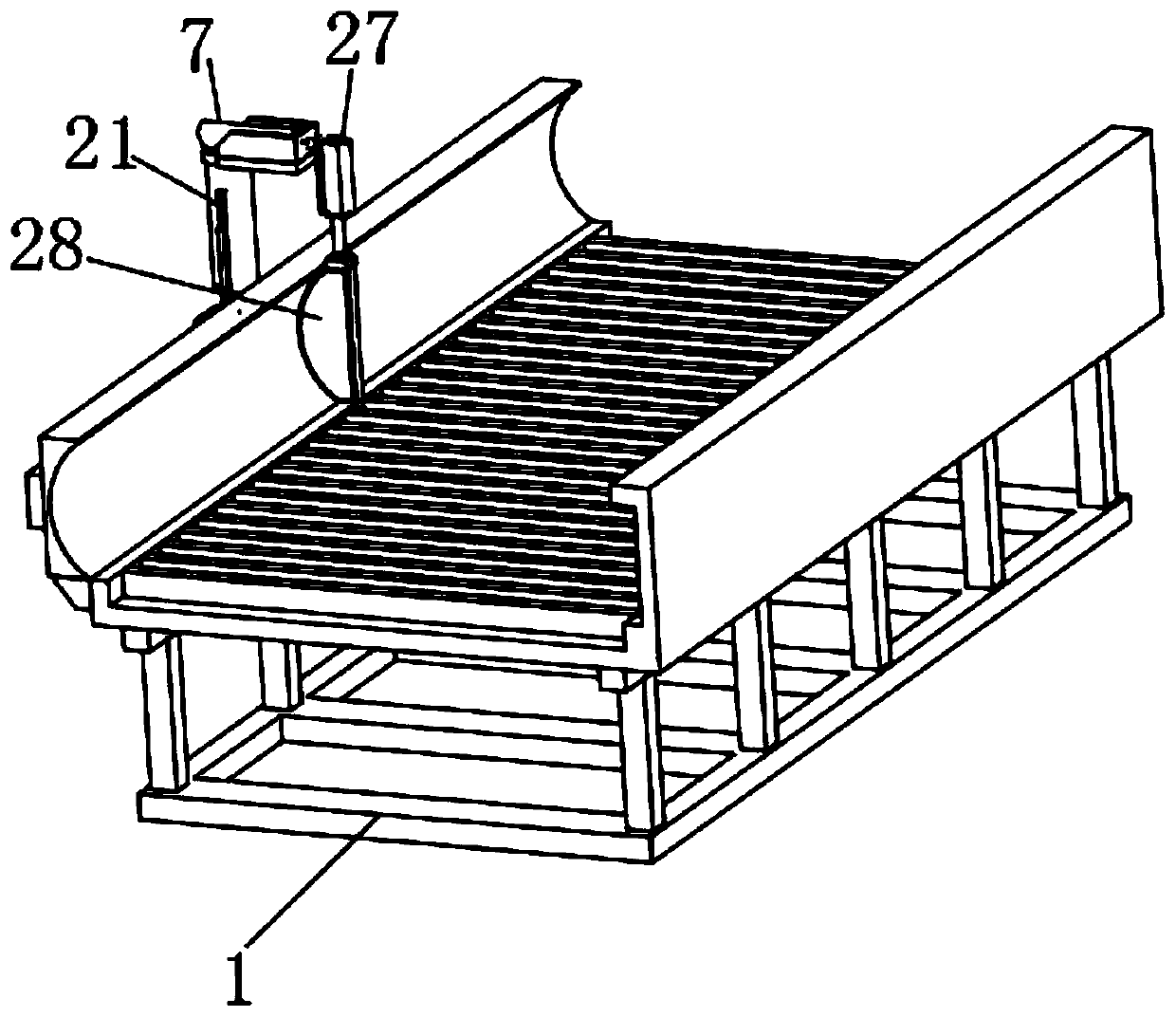

Efficient tailing sorting machine

PendingCN108283986ARealize recyclingReduce stacking landWet separationEconomic benefitsSmall footprint

Owner:云南天顶科技有限公司

Acidic lithium slag-Portland cement-silica fume composite cementing material and preparation method thereof

ActiveCN110877970AImprove flexural performanceAccurate control of densityCeramicwareFoaming agentSludge

The invention discloses an acidic lithium slag-Portland cement-silica fume composite cementing material. The composite cementing material comprises Portland cement, acidic lithium slag, silica fume, agraphene material, iron tailings and a light filler. The invention further discloses a preparation method of the composite cementing material. The preparation method comprises the following steps: taking and uniformly mixing fly ash, 15-25 parts by weight of sludge, oyster shell powder, clay, water and fusible foaming particles, granulating the obtained mixture, and firing the granulated mixtureto obtain the light filler; mixing the Portland cement with silica fume, and grinding the obtained mixture to obtain a first ground product; respectively grinding the acidic lithium slag, the graphenematerial and the iron tailings; mixing the first ground product, the acidic lithium slag powder, the graphene powder and the iron tailing powder to obtain a second ground product; and uniformly mixing the second ground product with the light filler to obtain the finished cementing material product. A foaming agent is not used, the density of the material is controlled by utilizing the light filler, and the material density can be accurately controlled, so that the quality of the finished product is improved.

Owner:HUNAN LVSHENG TECH DEV CO LTD

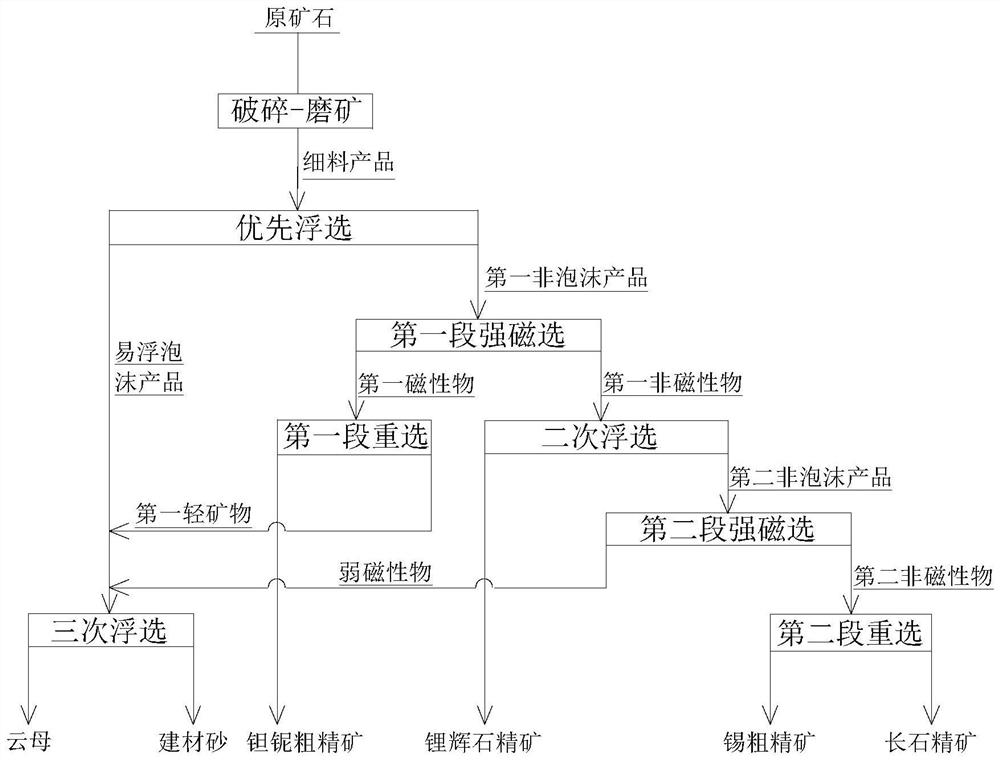

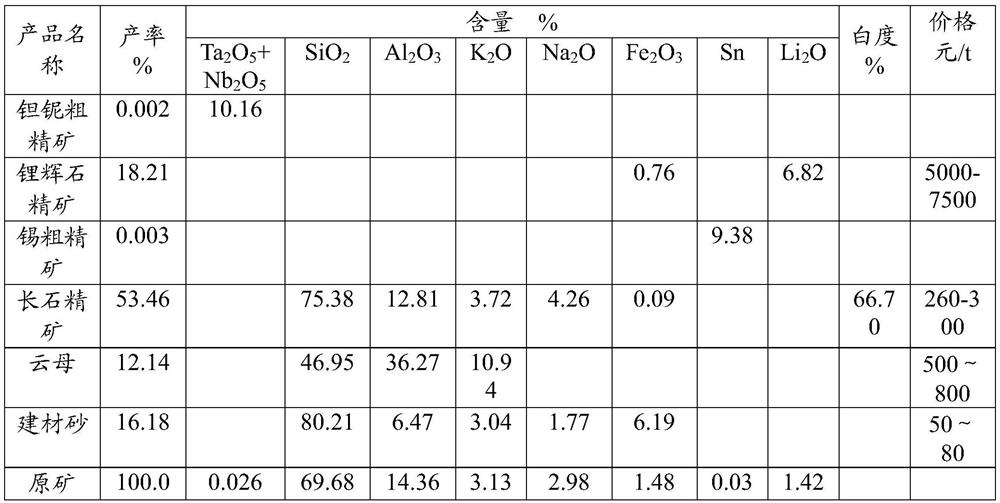

Comprehensive utilization method of pegmatite containing tantalum niobium, cassiterite, feldspar and spodumene

PendingCN114588998AImprove recycling ratesTake advantage ofHigh gradient magnetic separationFlotationNiobiumMagnetic separation

Owner:SHANDONG HUATE MAGNET TECH

Matte glaze prepared from gold ore tailing powder and processing equipment of matte glaze

ActiveCN111362576ARealize the role of sortingImprove production efficiencyWet separationClaywaresGold panningSlurry

Owner:丽水古唐瓷业有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap