Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Improve production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Characteristic building elevation surveying and mapping method based on images

InactiveCN103322911AImprove production efficiencyEnrich the feature elements of detailed componentsUsing optical meansCritical dimensionSurveyor

The invention provides a characteristic building elevation surveying and mapping method based on images. Firstly, a typical component CAD graph representing the style of a characteristic building is obtained in a method based on the images, a characteristic component database is built, then a wall face critical dimension is obtained as a constraints by means of photogrammetry, the typical component CAD graph on the building is deformed to generate a characteristic component consistent with the size of the building to be measured, and a surveying and mapping CAD graph of the characteristic building is generated. By means of texture synthesis and texture clipping, corresponding areas having large-area repetition structure characteristics on the wall face are quickly filled. Only one structure unit is measured for the repetition structure characteristics, and other repeated units are quickly generated by means of copying. The method can precisely measure the size of an elevation of the building, can accurately describe partial detail characteristics of a characteristic component, has the advantages of being low in cost, convenient, flexible and efficient, and can be widely used in elevation surveying and mapping of characteristic buildings of various types.

Owner:GUILIN DARONG CULTURE TECH CO LTD

Press

InactiveUS20130276505A1Improve production efficiencyShorten the timePressesMechanical engineeringVertical axis

A press including a number of pairs of dies each clamped by a driving source to press set work pieces in a vertical direction, and a revolver holding the pairs of dies and rotatable around a vertical axis, wherein the revolver by rotating moves any pair of dies to a pressing position where pressing process is performed.

Owner:KOJIMA PRESS IND CO LTD

Video watching point generation method and device, computer equipment and storage medium

ActiveCN109842805AImprove accuracyImprove production efficiencySelective content distributionComputer engineeringComputer equipment

Owner:PING AN TECH (SHENZHEN) CO LTD

Automatic workpiece conveying device

ActiveCN104261148AImprove production efficiencyLabor savingLoading/unloadingControl systemEngineering

Owner:宁波长华布施螺子有限公司

Riveting device for guide needle and aluminum foil of aluminum electrolytic capacitor

InactiveCN106363091AImprove production efficiencySimple structureMetal-working feeding devicesCapacitor terminalsDrive motorAluminum electrolytic capacitor

Owner:TONGLING YUANFENG ELECTRONICS

Variable optical power wavelength division multiplexer and preparation method thereof

ActiveCN109613656AAvoid waiting timeImprove production efficiencyOptical light guidesWavelength-division multiplex systemsArrayed waveguide gratingControl circuit

Owner:BROADEX TECH

One-step form grinding method for double races

InactiveCN102463515AImprove production efficiencyAbrasive surface conditioning devicesGrinding machinesEngineeringGrinding wheel

The invention discloses a one-step form grinding method for double races, which includes the following steps: step 1: an emery wheel is mounted on a bracket, the emery wheel and the bracket are formed into a grinding wheel dresser, the bracket is fixed on a machine tool platform, and the central line of the emery wheel needs to be in parallel with the central line of the spindle of a grinding wheel; step 2: the emery wheel is rotated at high speed to dress the grinding wheel, so that the grinding wheel is formed into a shape required by grinding; and step 3: the dressed grinding wheel is used for grinding the inner and the outer races of a wind power bearing until the shapes of the inner and the outer races fully accord with the shape of the emery wheel and the requirement of a drawing. The one-step form grinding method for the double races increases the race-making precision.

Owner:SHANGHAI OUJIKETE SLEWING BEARING CO LTD

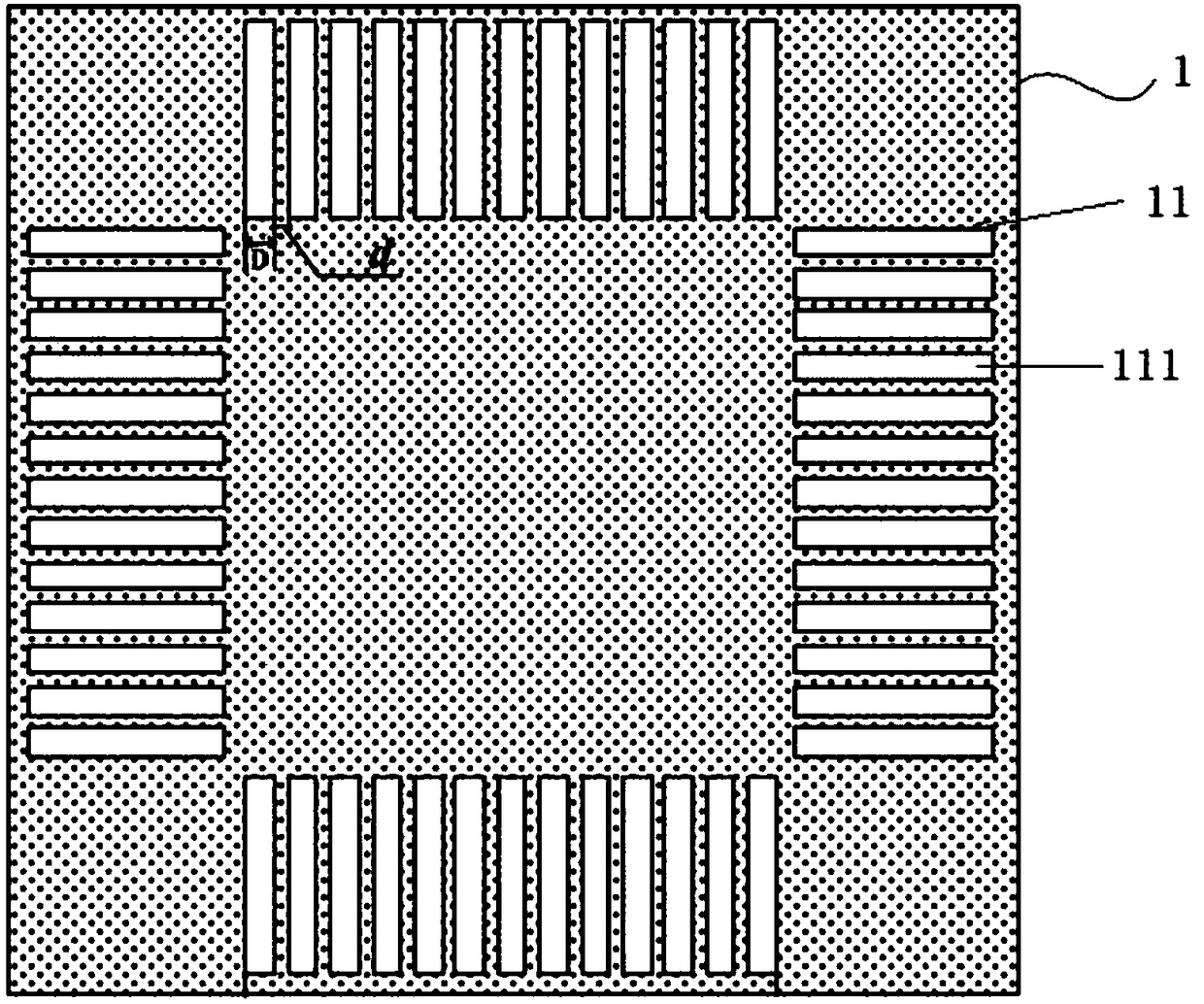

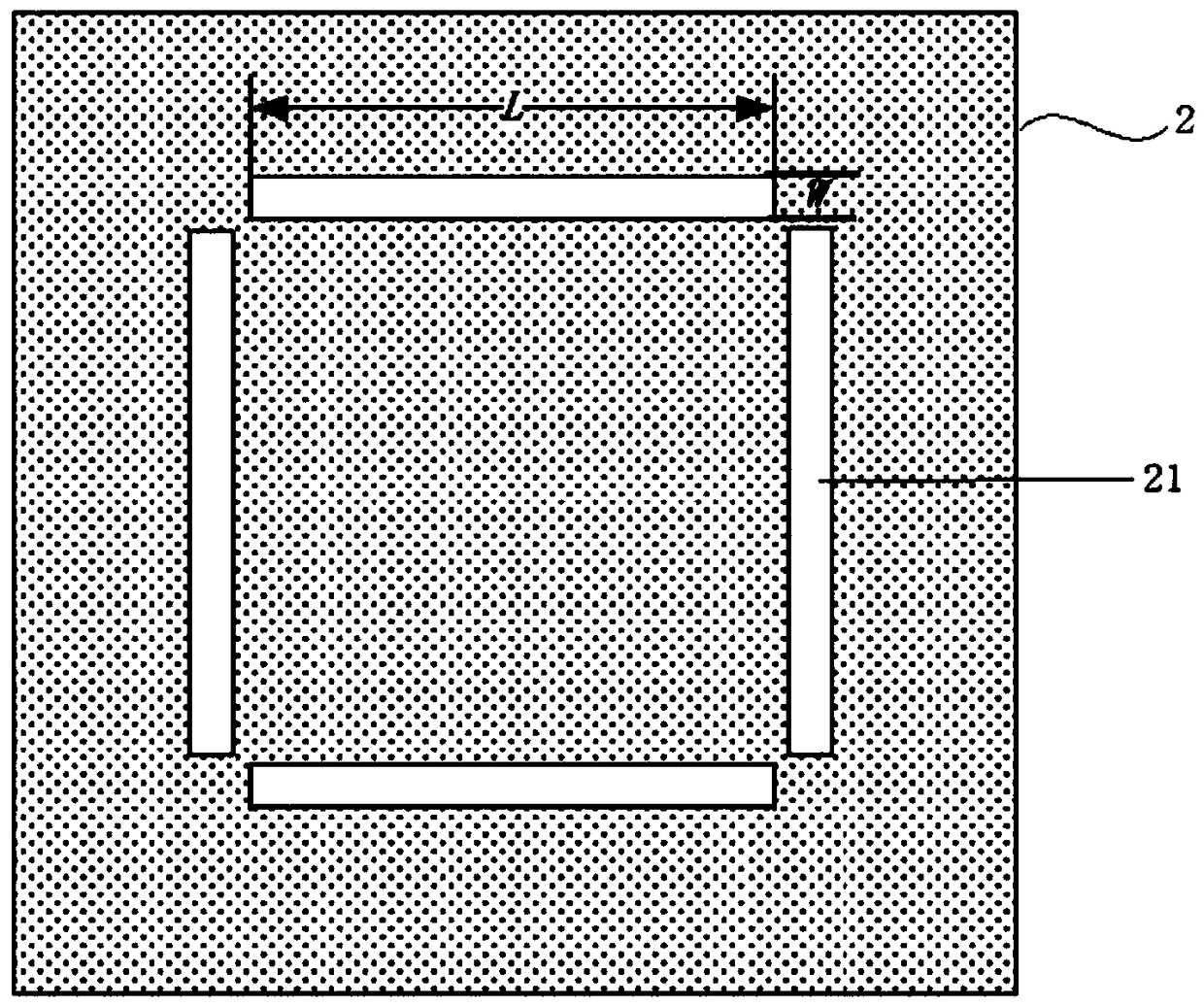

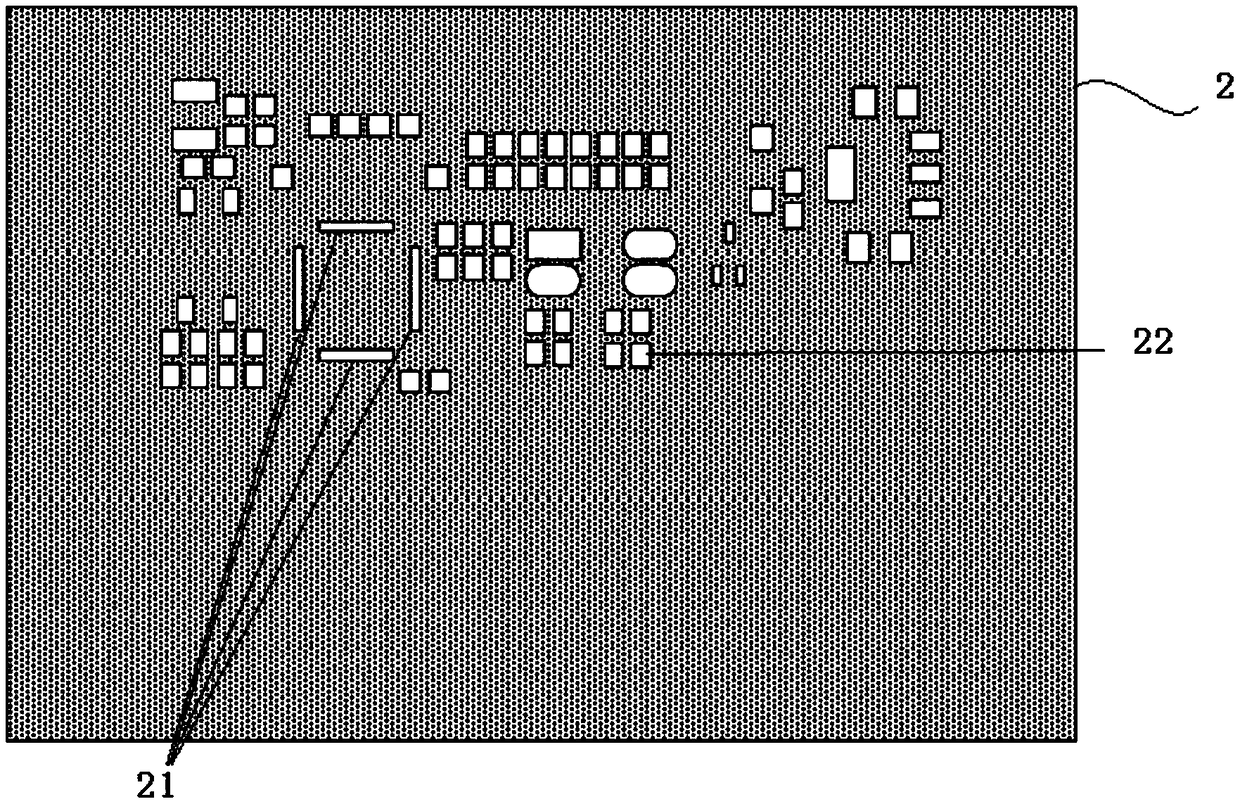

Multi-group symmetrical array high-power optical fiber coupling semiconductor laser packaging structure and method

InactiveCN112886390AQuality improvementAvoid mutual interferenceSemiconductor laser arrangementsLaser arrangementsErbium lasersOptical fiber coupler

The invention relates to a multi-group symmetrical array high-power optical fiber coupling semiconductor laser packaging structure and method, and belongs to the technical field of semiconductor laser packaging. The structure comprises a shell, an R-type single-group laser, an L-type single-group laser, a polarization beam combiner and an optical fiber coupler, the shell is a cuboid, one side of the cuboid is provided with a groove, a step is arranged on one side of the lower surface of the groove, the R-type single-group laser and the L-type single-group laser are arranged at the two ends of the upper surface of the step respectively, the polarization beam combiner is arranged on the lower surface of the groove in front of the step, and the optical fiber coupler is arranged on the shell on the other side of the lower surface of the groove. According to the invention, a problem of mutual interference possibly occurring in space beam combination of the high-power single-group laser is avoided, the light source quality is obviously improved, and meanwhile, the problem of non-uniform heat dissipation of the high-power single-group laser is avoided.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

Apodizing device and method for realizing single exposure

InactiveCN102221727AEasy to implementImprove production efficiencyElectromagnetic transmissionOptical light guidesDirect currentFiber

Owner:WUHAN UNIV OF TECH

Image display device, correction data generation method, and image correction device and method, as well as image correction system

InactiveUS20160163252A1Decrease in amountImprove production efficiencyCathode-ray tube indicatorsBrightness perceptionCalculator

Owner:MEGACHIPS

Self-adaptive irrigation system pipeline water hammer impact reducing device

ActiveCN110220043AImprove production efficiencyImprove reliabilityValve members for absorbing fluid energyPipe elementsWater dischargeDistribution system

The invention discloses a self-adaptive irrigation system pipeline water hammer impact reducing device. The self-adaptive irrigation system pipeline water hammer impact reducing device comprises a valve inlet pipeline, a reducer and a water hammer response channel; the reducer and the outer wall of the valve inlet pipeline form a closed annular cavity; the edge of an isolating reinforcement plateis connected with the inner wall of the reducer and the outer wall of the valve inlet pipeline separately; a pressure relief action block is fit with the inner wall of the reducer and the outer wall of the pipeline; the isolating reinforcement plate and the first end face of the pressure relief action block form a pressure relief cavity; a water discharging port is formed in the pressure relief cavity; the isolating reinforcement plate and the second end face of the pressure relief action block form an action cavity; the water hammer response channel communicates with the action cavity and aninner cavity of the valve inlet pipeline; a pressure relief hole and a pipeline hole are completely staggered under the normal water conveying state, and the pressure relief hole communicates with thepipeline hole under the pressure relief state; and the self-adaptive irrigation system pipeline water hammer impact reducing device can actively respond the water hammer impact of the valve in an irrigation distribution network, effectively reduce the water hammer impact, guarantee the safety of a key part of an irrigation water distribution network and improve the stability of an irrigation water distribution system, and is suitable for the multi-user random irrigation water distribution network working condition.

Owner:XI AN JIAOTONG UNIV

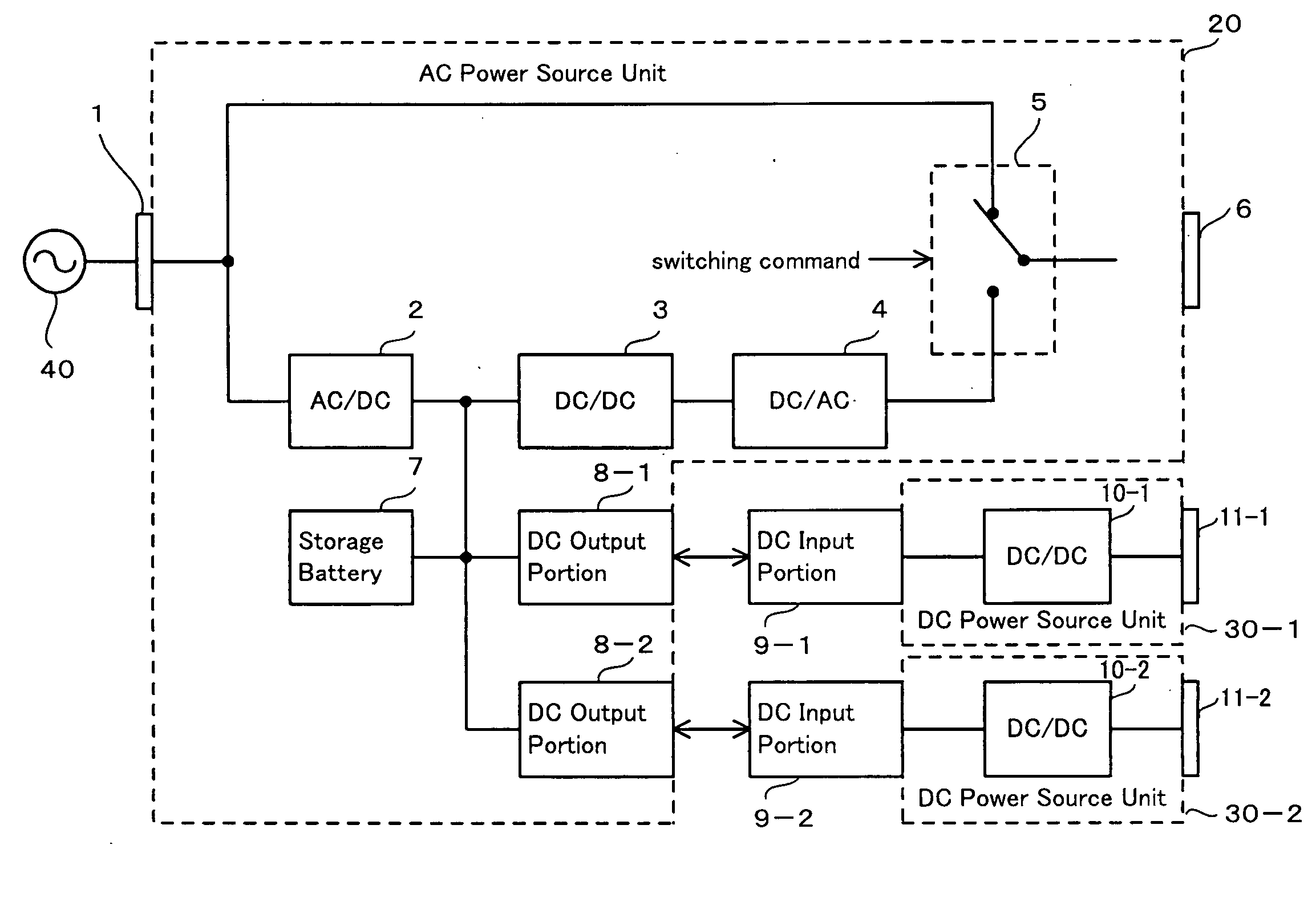

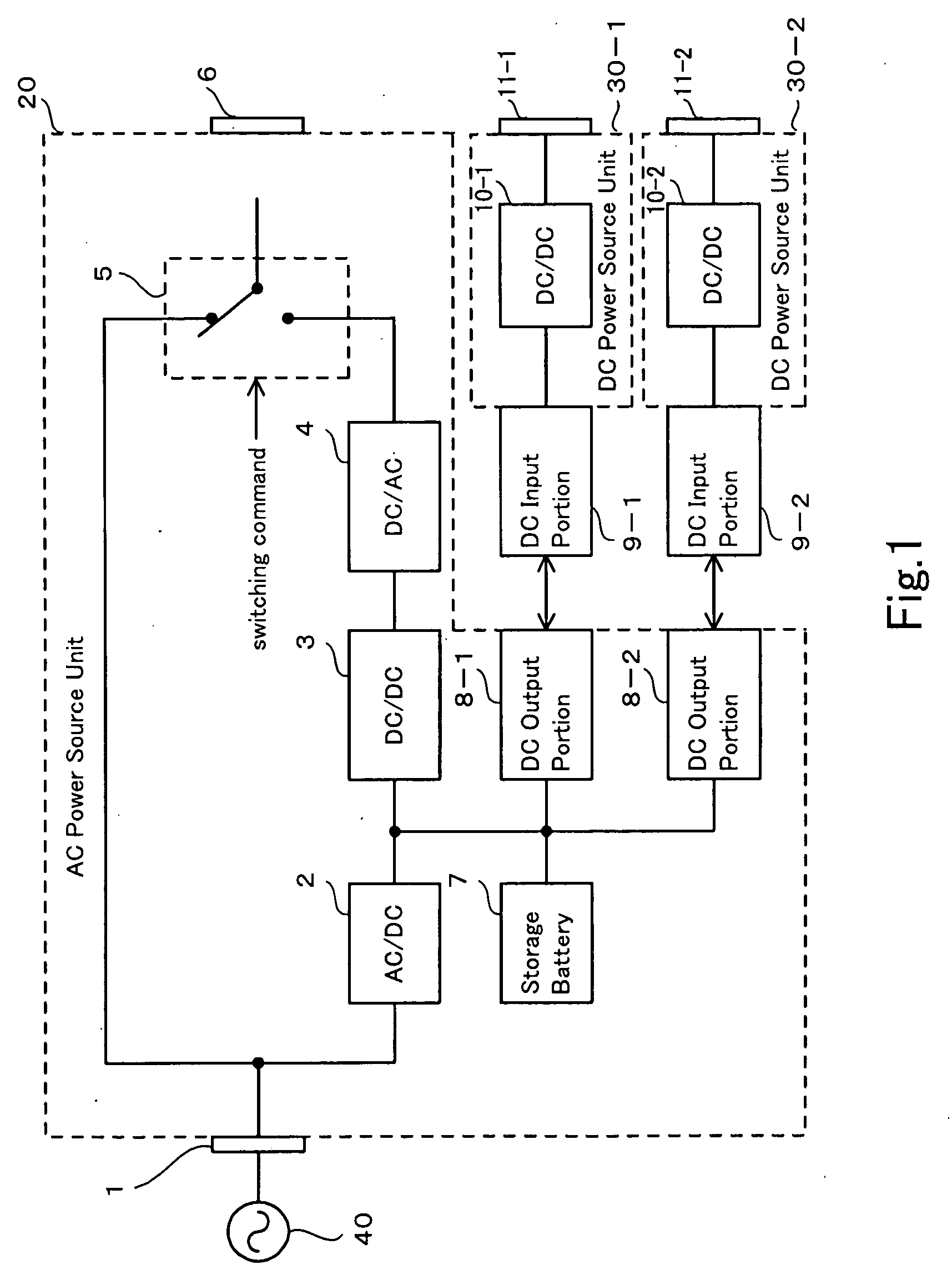

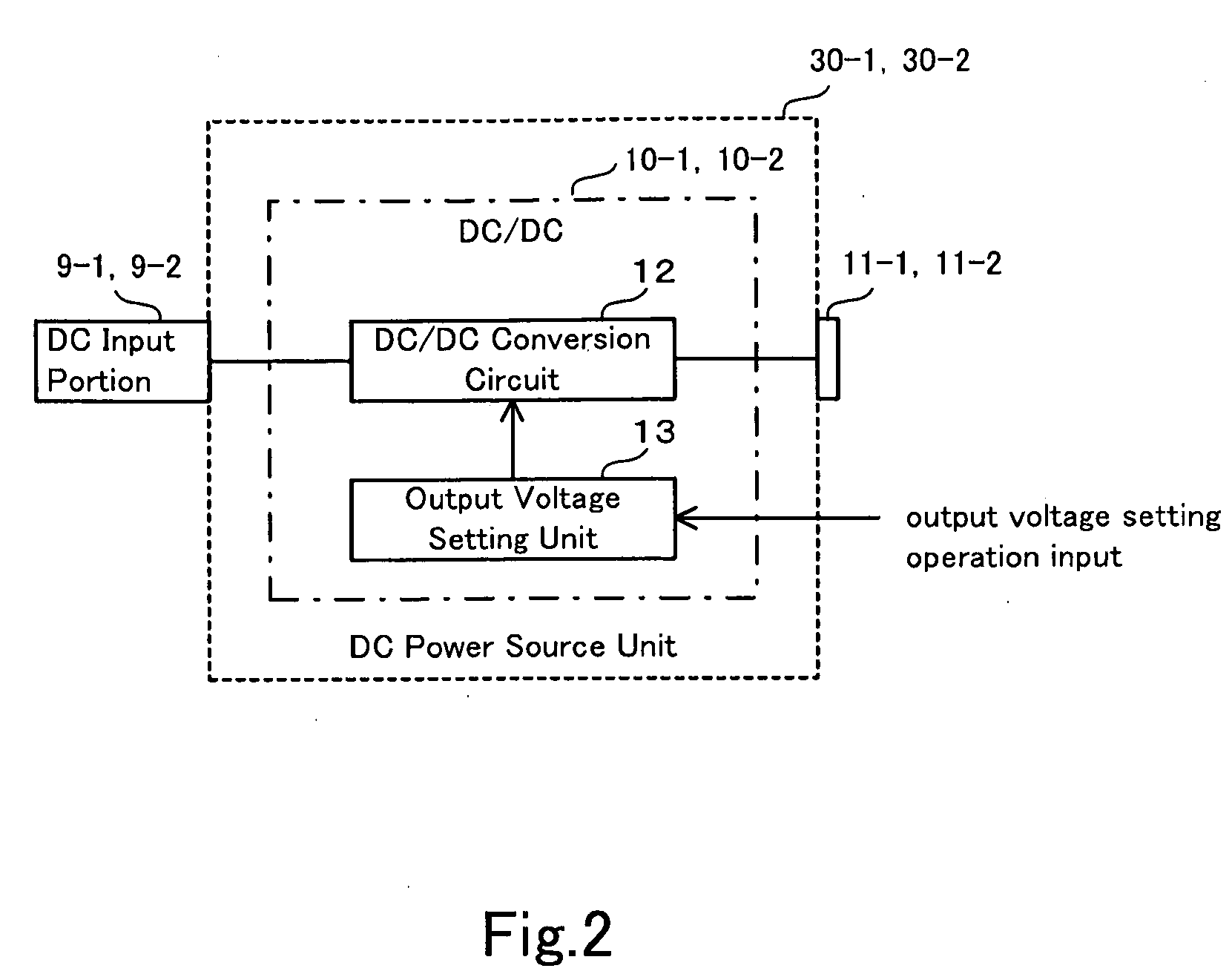

Uninterruptible Power Supply

InactiveUS20090091189A1Improve production efficiencyEnhances efficiency inventory managementDc network circuit arrangementsBatteries circuit arrangementsAC powerUninterruptible power supply

Owner:FUJI ELECTRIC CO LTD

Non-stick coating layer and coating process thereof

InactiveCN111171682ASmall coefficient of static frictionLower coefficient of dynamic frictionPretreated surfacesSpecial surfacesPolymer sciencePapermaking

The invention discloses a non-stick coating layer, which is prepared from the following raw materials in parts by weight: 40 to 50 parts of epoxy acrylate, 25 to 32 parts of polyacrylic acid fluorine-containing ester, 25 to 32 parts of poly (vinylidene fluoride-trifluoroethylene), 10 to 15 parts of polytetrafluoroethylene powder, 2.5 to 4 parts of a suspension dispersing agent, 1 to 1.4 parts of aleveling agent and 1.5 to 2 parts of a curing agent. The non-stick coating layer has excellent lubricating performance and excellent non-stick performance, can completely meet the use requirements ofvarious processing molds (such as various plastic demolding, baking molds and papermaking and textile industries), contains no demolding agent (the production efficiency can be improved), and has excellent durability; in addition, no silicone oil is contained, and the product is prevented from being polluted; the adhesive force with a base material is large, the loading capacity is large, the impact resistance is good, the flexibility is good, the comprehensive performance is good, and the service life is long.

Owner:CHENGRUN (JIAXING) NEW MATERIAL TECH CO LTD

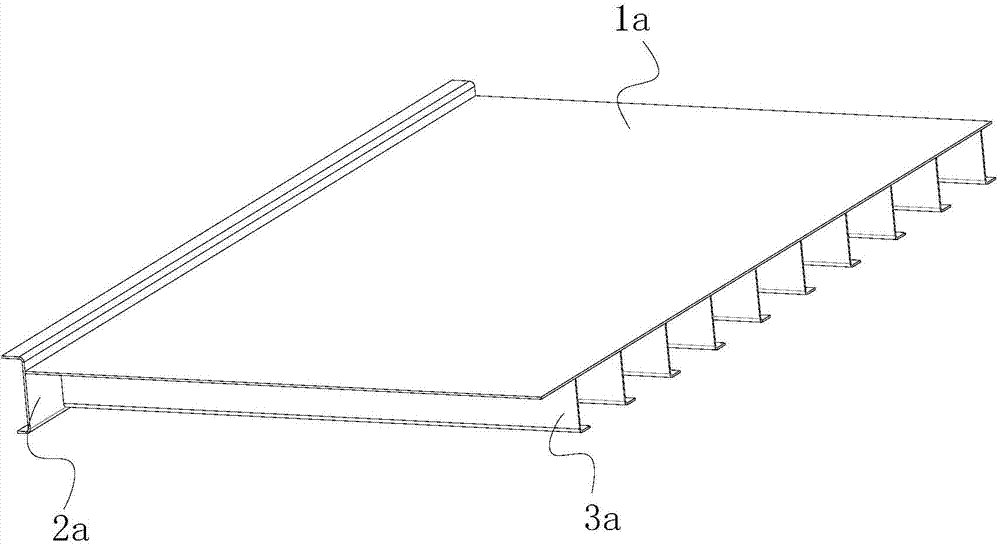

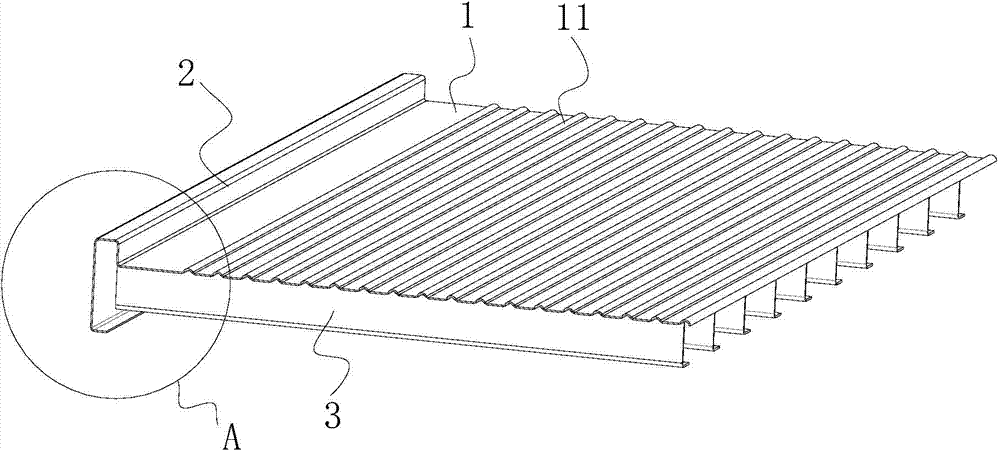

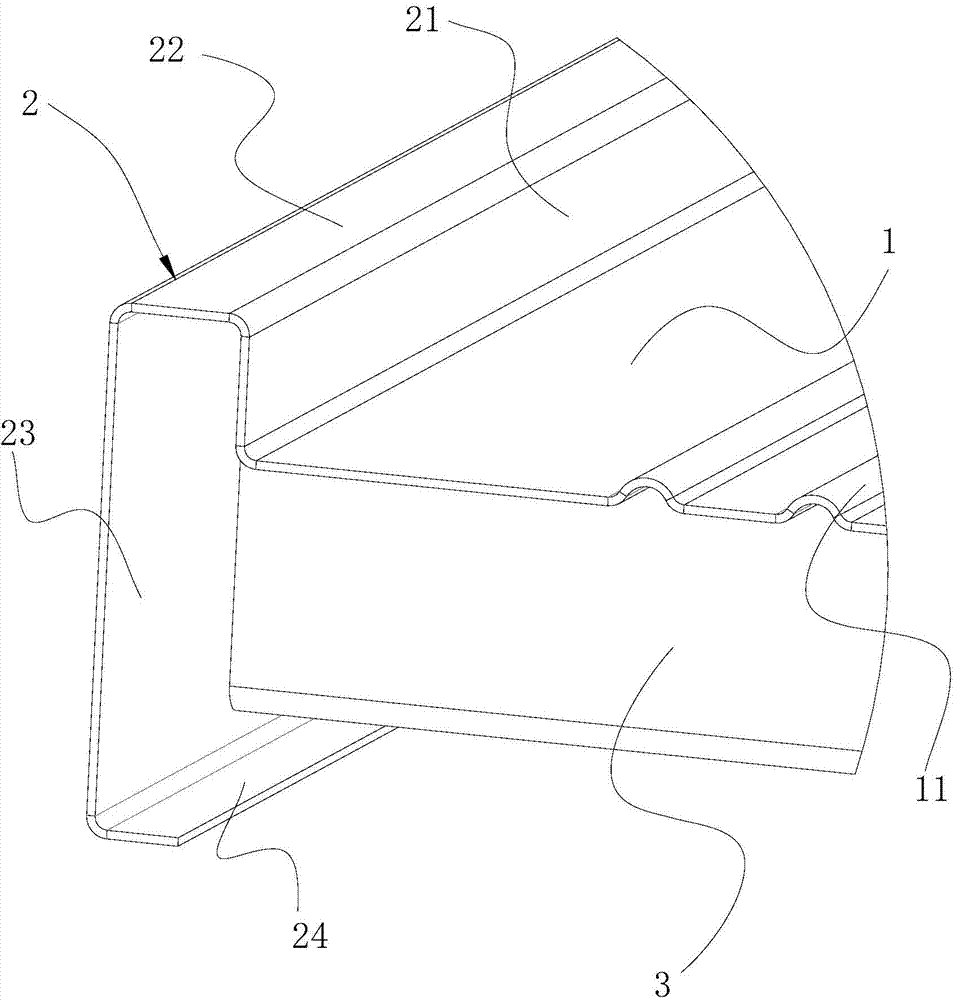

Container and steel floor chassis thereof

ActiveCN104743287AImprove manufacturing efficiencyReduce labor costsLarge containersManufacturing efficiencyUltimate tensile strength

The invention discloses a container and a steel floor chassis thereof. The steel floor chassis comprises a steel floor, bottom side beams positioned at transverse two sides of the steel floor, and multiple bottom cross beams longitudinally arranged below the steel floor and fixedly connected with the steel floor, wherein the two ends of the bottom cross beams are fixedly connected with the two bottom side beams; and the bottom side beams are bent from the side edges of the steel floor, and are integrally molded with the steel floor. The steel floor chassis improves the manufacturing efficiency, reduces the cost, and improves the whole strength.

Owner:GUANGDONG XINHUI CIMC SPECIAL TRANSPORT EQUIPS +2

Financial IC card fabrication data generation method

InactiveCN105205423ASolve the disadvantages of the generation processSimple configurationDigitally marking record carriersState of artMaintainability

The invention discloses a financial IC card fabrication data generation method which includes a Velocity template engine basic data preparation step; a Velocity template engine original fabrication data preparation step; a fabrication task execution step, and the like. The method overcomes the defects caused during the fabrication data generation of a financial IC card data preparation system, realizes quick generation of fabrication data through the method of simple configuration of the Velocity template and a user-defined engine, can be used for efficiently and flexibly generating fabrication data of different algorithms, improves the generation efficiency of fabrication data of the financial IC card data preparation system, and improves the system operability and maintainability; the Velocity has a perfect log record method, and can be combined with the user-define engine to shield difference of different algorithms and different data types and simplify configuration of the financial IC card data preparation system, thereby improving the running efficiency and reducing the maintenance cost.

Owner:CETC CYBERSPACE SECURITY TECH CO LTD

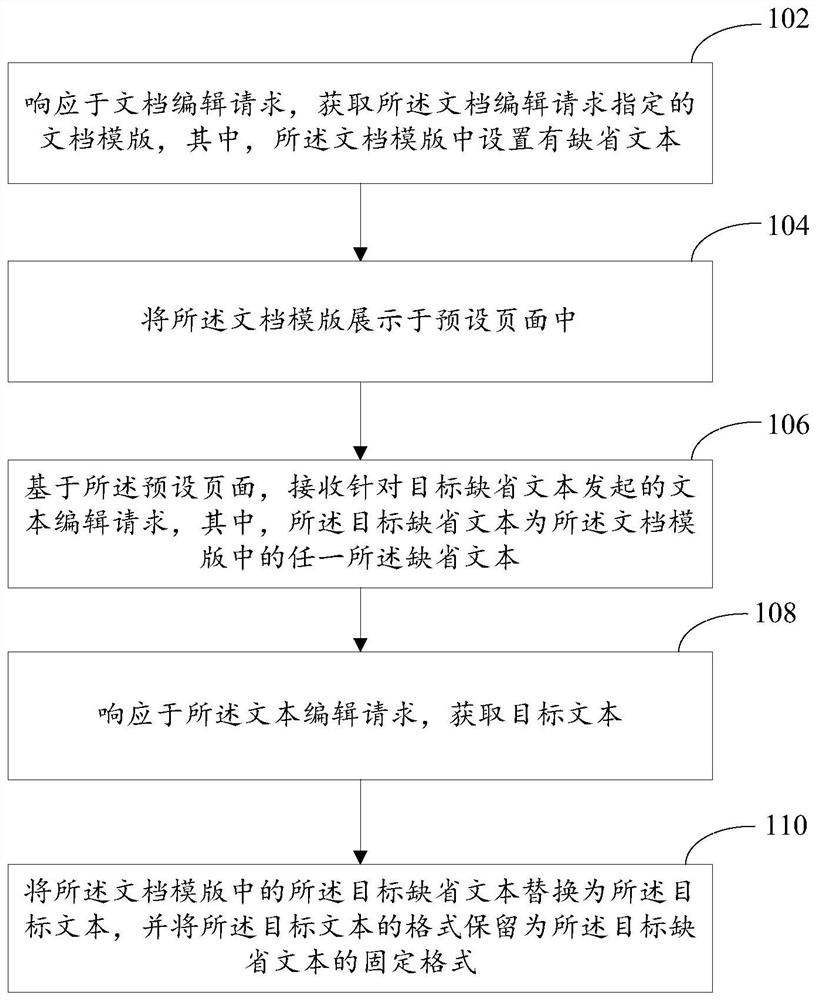

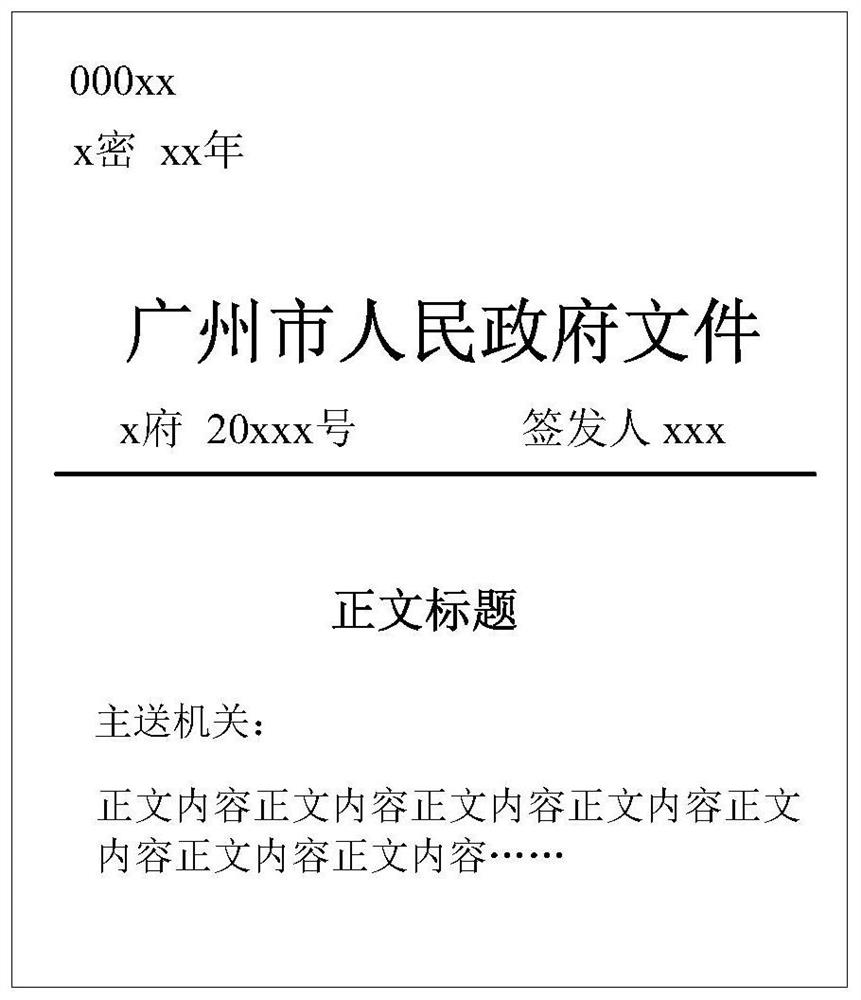

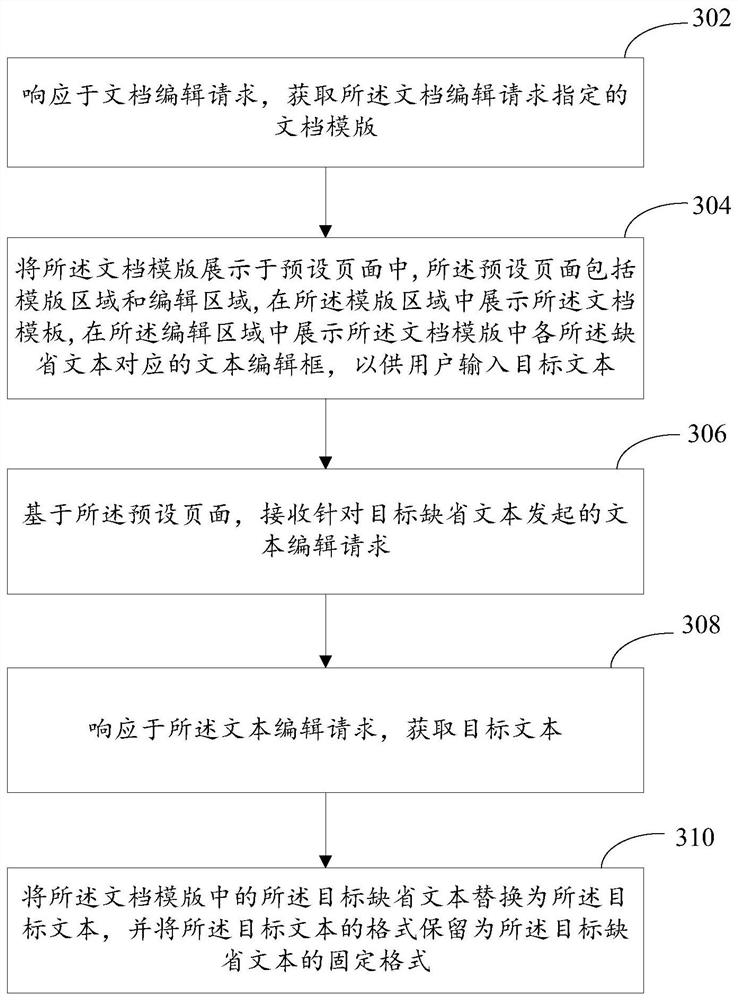

Template-based document editing method and device

PendingCN113642304AImprove production efficiencyImprove convenienceNatural language data processingInformation retrievalText editing

The invention provides a template-based document editing method and device. The template-based document editing method comprises the following steps: in response to a document editing request, obtaining a document template specified by the document editing request, wherein default texts are set in the document template; displaying the document template in a preset page; receiving a text editing request initiated for a target default text based on the preset page, wherein the target default text is any default text in the document template; in response to the text editing request, obtaining a target text; and replacing the target default text in the document template with the target text, and reserving the format of the target text as a fixed format of the target default text. By adopting the method, the document can be quickly generated based on the document template, and the format in the document editing process can be ensured to be unchanged.

Owner:ZHUHAI KINGSOFT OFFICE SOFTWARE +2

Machining method for steel members

ActiveCN106695253AImprove production efficiencyReduce processing stepsStrutsPillarsEconomic benefitsMachining

The invention belongs to the technical field of building materials and provides a machining method for steel members. According to the method, firstly, the number of target steel members needing to be machined and required parameters are determined; then, the shapes and sizes of combined steel members are determined, and corresponding bed-jigs are prepared; main part assembling of the combined steel members and part assembling and welding are completed on the bed-jigs; and finally, according to the number of the target steel members and the required parameters, the combined steel members are cut, and then a preset number of target steel members with preset length are obtained. According to the machining method for the steel members, after a steel raw material is assembled and welded into one combined steel member, cutting is carried out, and at least two steel members with the same cross section form and the same length or different lengths are obtained. Compared with an existing machining method for independent one-by-one assembling and welding of the single steel raw material, the machining method has the beneficial effects that the machining procedures are reduced, the manufacturing efficiency of the steel members is greatly improved, the cost is reduced easily, and the considerable economic benefits are created.

Owner:CHINA CONSTR STEEL STRUCTURE GUANGDONG CO LTD +1

Carton manufacturing equipment

InactiveCN109968734AImprove production efficiencyImprove stabilityPaper-makingBox making operationsCartonEnergy consumption

The invention discloses carton manufacturing equipment. The equipment comprises a packaging carton edge sealing machine body, wherein a conveying cavity is formed in the machine body in a left and right penetrating mode, a conveying belt groove with an upward opening is formed in the lower side of the conveying cavity in a communicating mode, conveying rotating shafts are arranged in the conveyingbelt groove in a left-right symmetric mode, the front ends and the rear ends of the conveying rotating shafts are rotationally connected with the front end wall and the rear end wall of the conveyingbelt groove respectively, conveying wheels are fixedly arranged on the conveying rotating shafts, and the conveying wheels are in power connection through a conveying belt. The equipment is simple instructure and convenient to operate, the edge sealing device is used for binding to-be-sealed edges of a packaging carton, in the binding process, a reversing device controls rotation direction of the conveying belt, so that the packaging carton is moved to the right side of the edge sealing device, after the edge sealing device descends to a lifting cavity, the carton retracts to the edge sealing device to be bound, the equipment is used in the later package forming process, and full-automatic packaging and forming of the equipment are achieved. Compared with traditional manual edge sealing,the equipment has the advantages that the time is saved, the carton manufacturing efficiency is high, the edge sealing integrity is good, and the energy consumption is low.

Owner:HANGZHOU ZHIAI PACKAGING PROD CO LTD

An electronic code management system and platform of an electronic coupon

The invention discloses a management system for an electronic code of an electronic coupon, including an electronic code generation module, an electronic code storage module an an electronic code issuing module, wherein an electronic code generated by the electronic code generation module comprises a main code; an auxiliary code and a check code, the uniqueness of the electronic code is ensured bythe random code; Generation efficiency is improved, the electronic code storage module respectively obtains a ciphertext full text and a ciphertext index through two encryption algorithms; the security of the electronic code is ensured; and finally, the electronic code issuing module adopts a serial issuing mode for the electronic codes of the same inventory unit, so that repeated issuing is avoided, the issuing efficiency is improved, and therefore, the system realizes the closed loop of the electronic code service, guarantees the safety and high efficiency of the electronic codes to a certain extent, and is more suitable for actual application requirements. In addition, the invention further provides an electronic code management platform of the electronic coupon, and the function of the electronic code management platform corresponds to the function of the system.

Owner:GUANGZHOU PINWEI SOFTWARE

Structure improved glass mould

The invention relates to a structure improved glass mould. The glass mould includes a pair of bottle half-dies, each bottle half-die has a bottle half-die cavity and a bottle bottom die cooperating cavity under the bottle half-die cavity, first axial exhaust holes are arranged in the semi-arc direction of the bottle half-die, and extend downward from the top of the bottle half-die to an air outletring groove, which is arranged on the outer wall of the bottle half-die, second axial exhaust holes are arranged in the semi-arc direction of the bottle half-die and on the inner sides of the first axial exhaust holes, the second axial exhaust holes correspond to the neck and shoulder area of the bottle half-die, and the bottle half-die cavity and the second axial exhaust holes are communicated by radial exhaust holes. The glass mould is characterized in that: an edge accelerated cooling mechanism is formed around the semi-arc direction of the bottle half-die corresponding to a position abovethe air outlet ring groove on the outer wall of the bottle half-die, switches off the lower ends of the first axial exhaust holes, and enables communication of the lower ends of the first axial exhaust holes with itself. The structure improved glass mould can improve the manufacturing efficiency of glass containers with rectangular cross-sections and guarantee the quality of glass containers.

Owner:CHANGSHU JIANHUA MOLD TECH

Desulfurization synergist for calcium-based wet desulfurization, preparation and application method thereof

InactiveCN108176217AImprove the safety of useAvoid direct dischargeGas treatmentDispersed particle separationCarboxyl radicalPhysical chemistry

Relating to the technical field of desulfurization synergists, the invention discloses a desulfurization synergist for calcium-based wet desulfurization, and a preparation and application method thereof. The desulfurization synergist comprises 50-70% of an acrylic copolymer and 30-50% of a polysaccharide compound by mass percentage. The acrylic copolymer is prepared by copolymerization reaction ofa carboxyl-containing monomer and an inert monomer in a mass ratio of 1:2-5. The desulfurization synergist provided by the invention has simple composition, can effectively improve the desulfurization efficiency, reduce the calcium-sulfur ratio of calcium-based wet desulfurization, lower the operation energy consumption of the desulfurization system, and ensure the system stability and the purityof the gypsum by-product, and effectively avoids some small molecule substances in the composition from entering the atmosphere along with flue gas.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

Hydration, film and deep cooling separation combined process for separating ethene cracking gas

InactiveCN100404482CImprove production efficiencyReduce overhead cooling loadHydrocarbon by hydrocarbon crackingHydrocarbon purification/separationChemistryEthylene

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

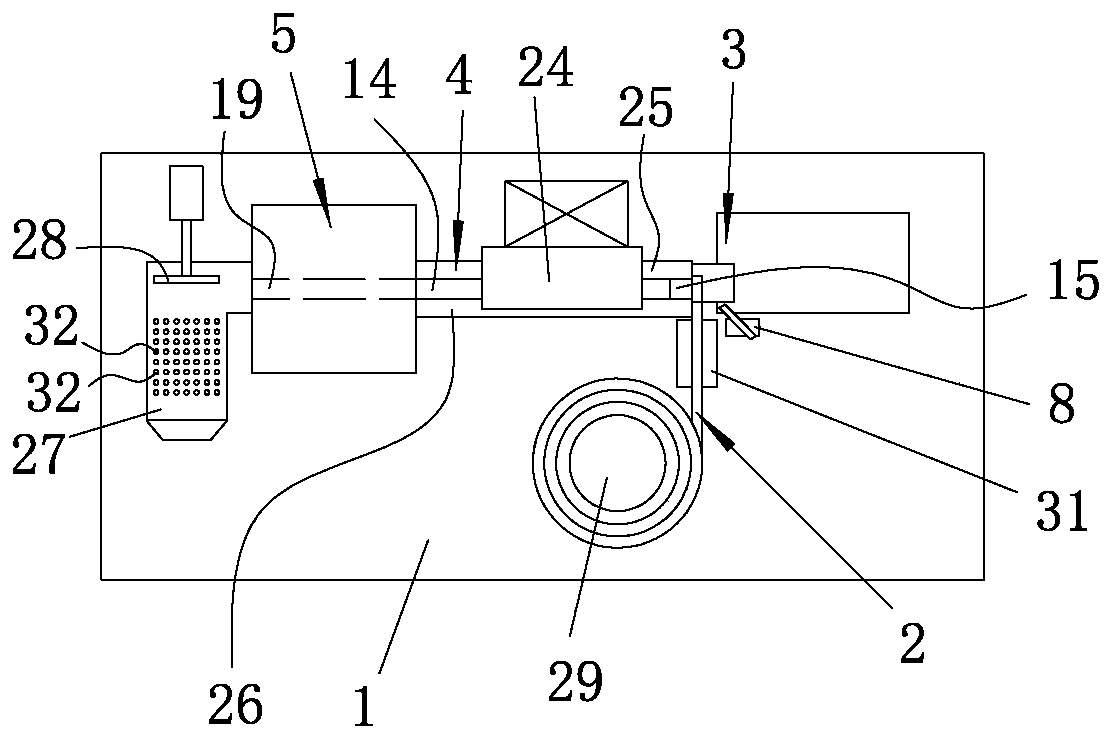

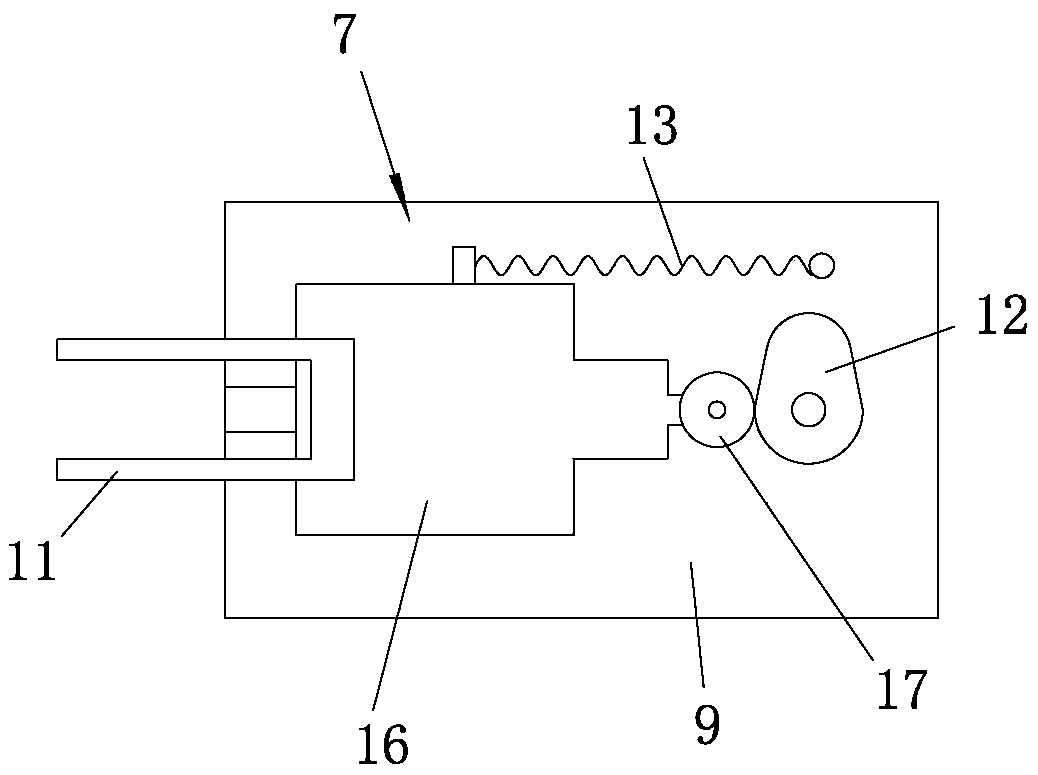

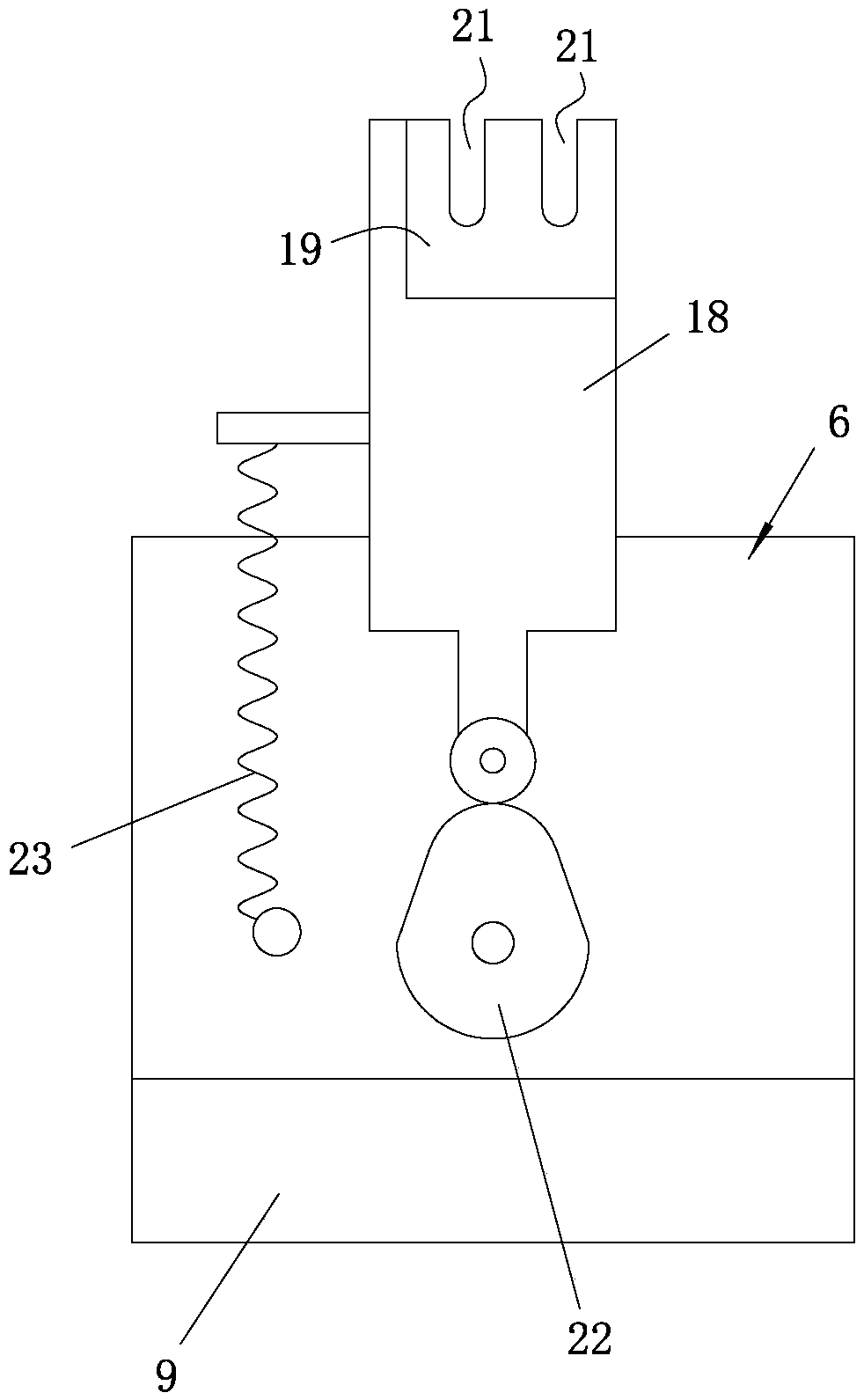

Automatic magnet magnetizer

PendingCN111383817AAutomatic provisioningImprove magnetization efficiencyMagnetic bodiesPhysicsTransfer mechanism

The invention relates to the technical field of magnetizer magnetizing, in particular to an automatic magnet magnetizer. The magnet magnetizer comprises a machine table, a feeding mechanism, a transferring mechanism, a guiding mechanism and a magnetizing mechanism; the feeding mechanism, the transferring mechanism, the guiding mechanism and the magnetizing mechanism are arranged on the machine table, a jacking assembly lifts magnetizers supplied by the feeding mechanism to be flush with the guiding mechanism, a pushing assembly pushes the magnetizers jacked by the jacking assembly into the guiding mechanism, and an electronic counter calculates the number of the magnetizers entering the guiding mechanism; the pushing assembly comprises a first bracket, a thimble arranged in a sliding manner, a first cam arranged in a rotating manner, a first driving part for driving the first cam, and a first elastic part for driving the thimble to prop against the first cam; the other end of the thimble props against the magnetizer lifted by the jacking assembly to enter the guide mechanism; the jacking assembly and the pushing assembly are matched to achieve automatic one-by-one feeding of the magnetizers, so the magnetizing mechanism can magnetize the magnetizers arranged in a stacked mode at a time, the magnetizing efficiency of the magnetizers is improved, and then the manufacturing efficiency of the magnets is improved.

Owner:DONGGUAN JINCONN NEW MATERIAL CO LTD

Method for manufacturing wall with insulation board by adopting energy-saving bolts

InactiveCN112609982AAvoid situations where the quantity does not meet the requirementsImprove securityWallsHeat proofingAnchor boltBlind hole

The invention discloses a method for manufacturing a wall with an insulation board by adopting energy-saving bolts. The method comprises the following steps of: fixedly connecting the insulation board to the inner surface of an outer template by using blind hole energy-saving bolts, wherein the insulation board is provided with anchor bolts protruding out of the inner surface of the insulation board; fixedly connecting an inner template with the outer template through a central split screw; forming a cavity for pouring a concrete wall between the inner side of the insulation board and the inner template; pouring concrete into the cavity by adopting through hole energy-saving bolts at the position where the central split screw passes through the outer template; and after the concrete reaches a solidification standard, detaching the central split screw, detaching the inner template and the outer template from the wall, and fixedly connecting the insulation board to the wall under the action of the anchor bolts. By the method, the installation firmness and the fitting degree between the insulation board and the wall are effectively ensured, and the construction period of a building can be effectively shortened.

Owner:黄江敏

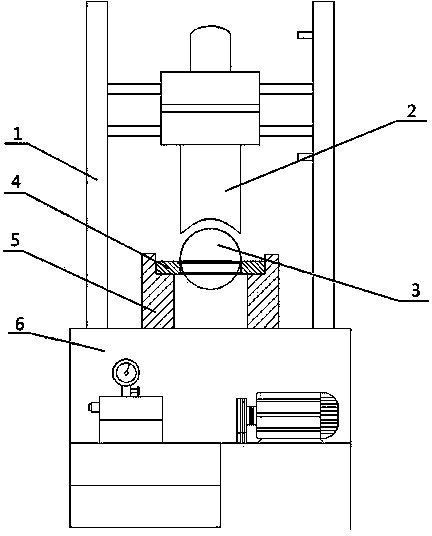

Hydraulic machine provided with device for inner hole finish machining through steel ball

Owner:TAIZHOU HONGXIANG POWER MACHINERY

Method and device for generating interface document

PendingCN113900706AAutomatically generate uniformImprove production efficiencyProgram documentationVersion controlAnnotationComputer engineering

Owner:BANK OF CHINA

Preparation method of novel nano composite antibacterial material

PendingCN114342940AImprove broad-spectrum and bactericidal effectImprove production efficiencyAnimal repellantsBiocideAqueous solutionBactericidal effect

Owner:JIANGSU INST OF ECONOMIC & TRADE TECH

Steel mesh and manual reflow soldering method by using the same

PendingCN109310012AImprove production efficiencyImprove the efficiency of manual reflow solderingElectrical componentsPrinted circuit assemblingAdhesiveEngineering

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD

Diiocyanate-scavenging packaging laminates

InactiveUS20190085159A1Undesirable effectLower Level RequirementsWrappersFlexible coversPolyolMedical product

The present invention is directed to packaging laminates for containing a food or pharmaceutical / medical product which includes an exterior film, a multilayer interior film comprising a diisocyanate-scavenging layer and an adhesive-contact layer, and a polyurethane adhesive layer bonding the exterior film to the multilayer interior film. The present invention reduces the amount of any unreacted diisocyanate precursor and primary amines which can migrate to a product in packaging assemblies formed with a polyurethane adhesive. This is achieved when an interior film (commonly known as a sealant film) includes a layer comprising a non-polymeric polyol which is not in direct contact with the polyurethane adhesive. With this approach, the nonpolymeric polyol reacts with any residual diisocyanate and / or primary amines which migrates from the polyurethane adhesive through the laminated assembly and thus, neutralizes any potential undesirable effects of these compounds.

Owner:BEMIS COMPANY INC

Cutter loading system for numerical control cutter grinding machine

InactiveCN104772663AImprove production efficiencyRealize CNC automatic productionGrinding feedersOther manufacturing equipments/toolsMechanical engineeringNumerical control

Owner:DJTOL GRINDING MACHINE GRP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap