Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

152results about "Gas treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stink and odor removal liquid with sterilizing plants, and preparation method and application thereof

Owner:深圳市寰保化工科技有限公司

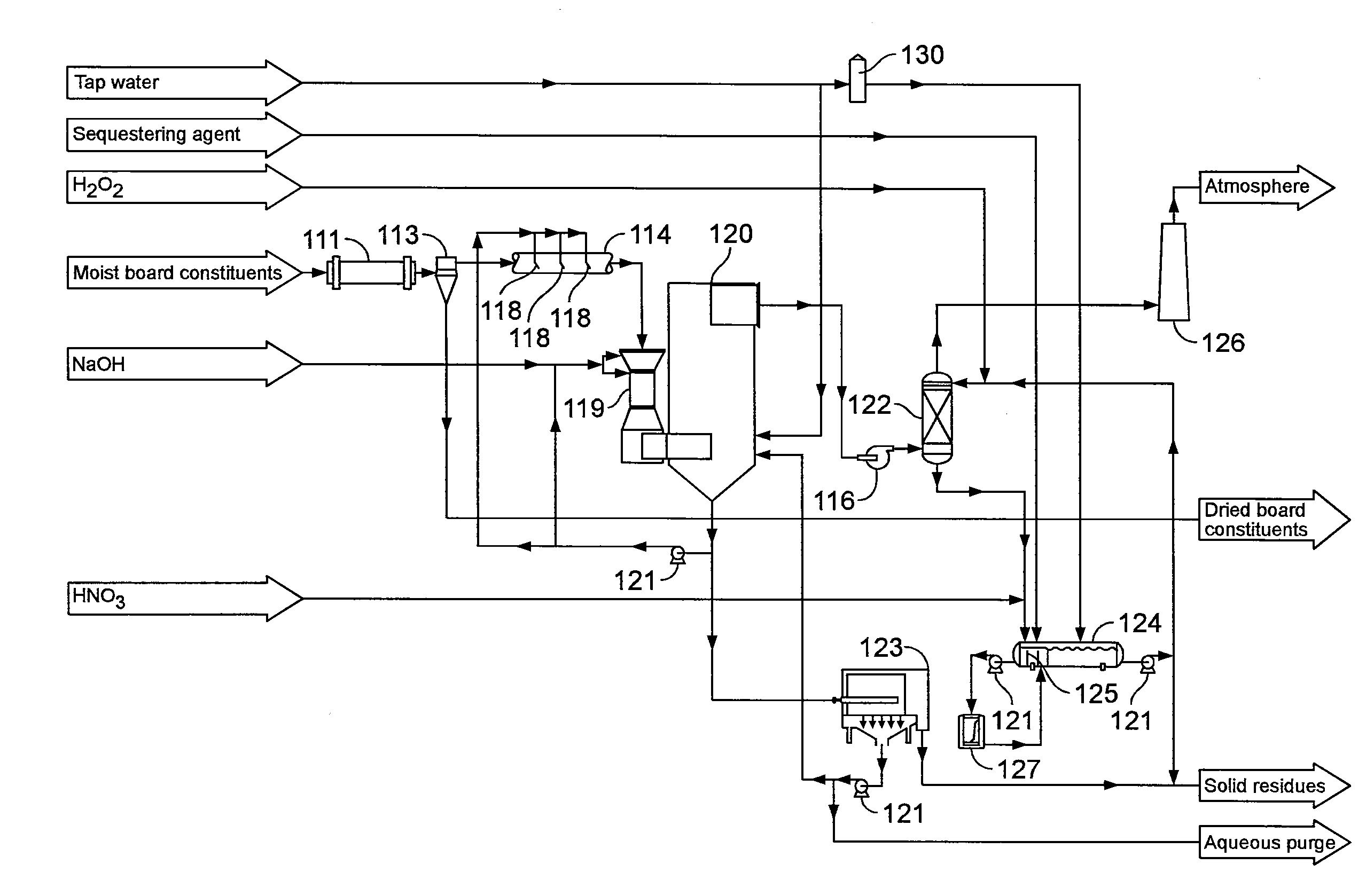

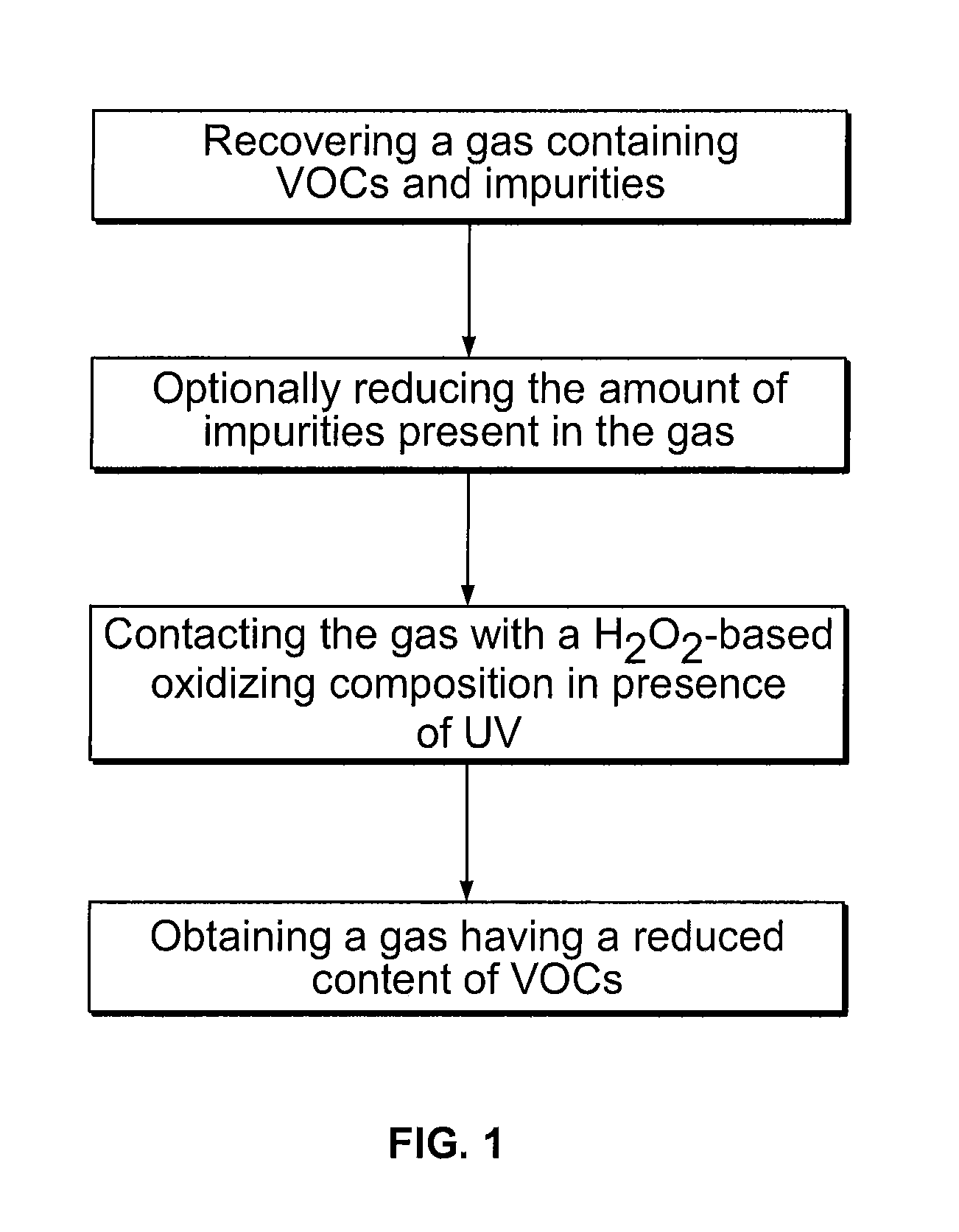

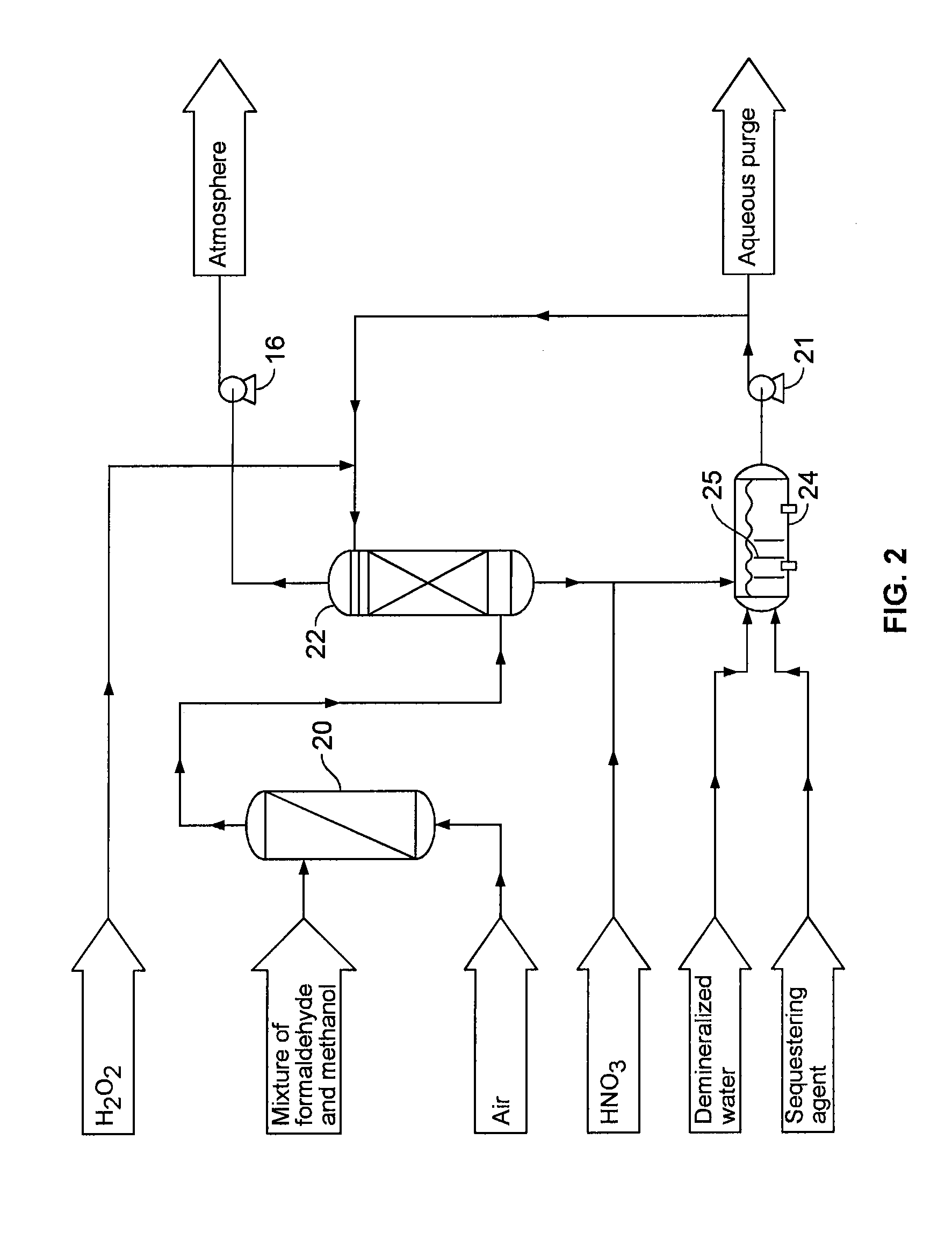

Process for reducing the content of water soluble volatile organic compounds in a gas

ActiveUS20100258428A1Reduce contentGas treatmentOrganic chemistryVolatile organic compoundEnvironmental chemistry

Owner:UNIBOARD CANADA +1

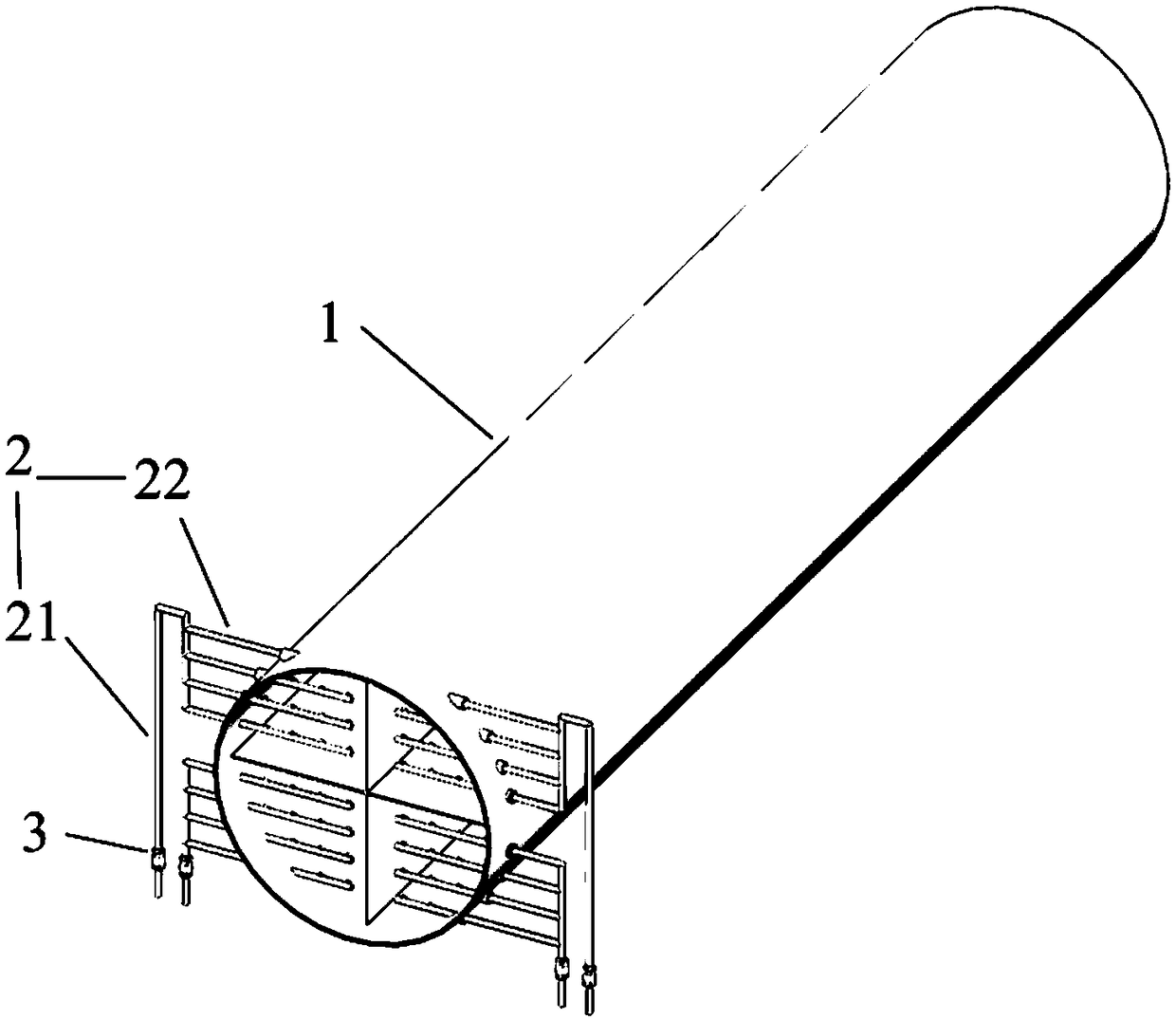

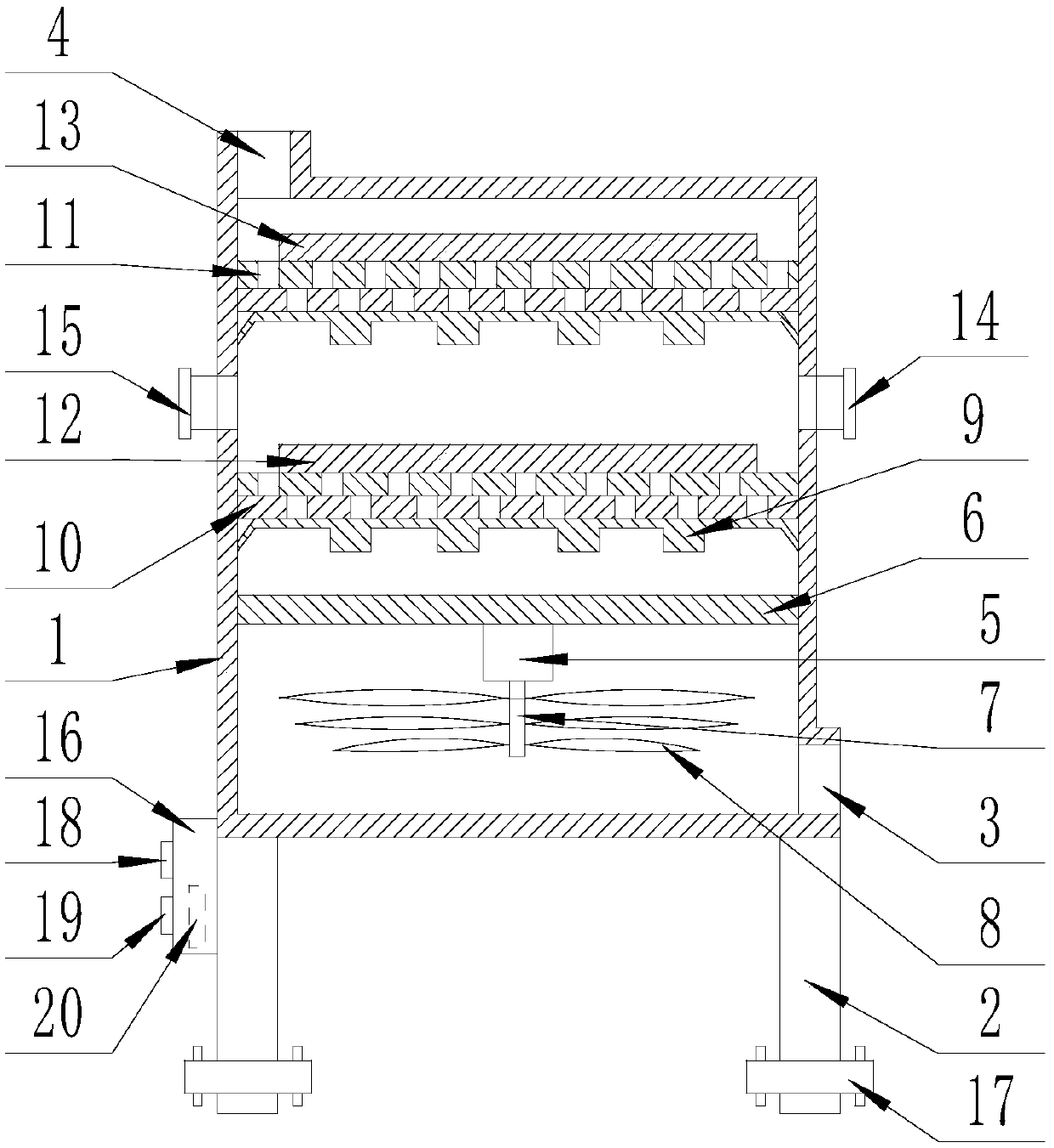

Zoning oxidation ozone distributor, and arrangement mode and applications thereof

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

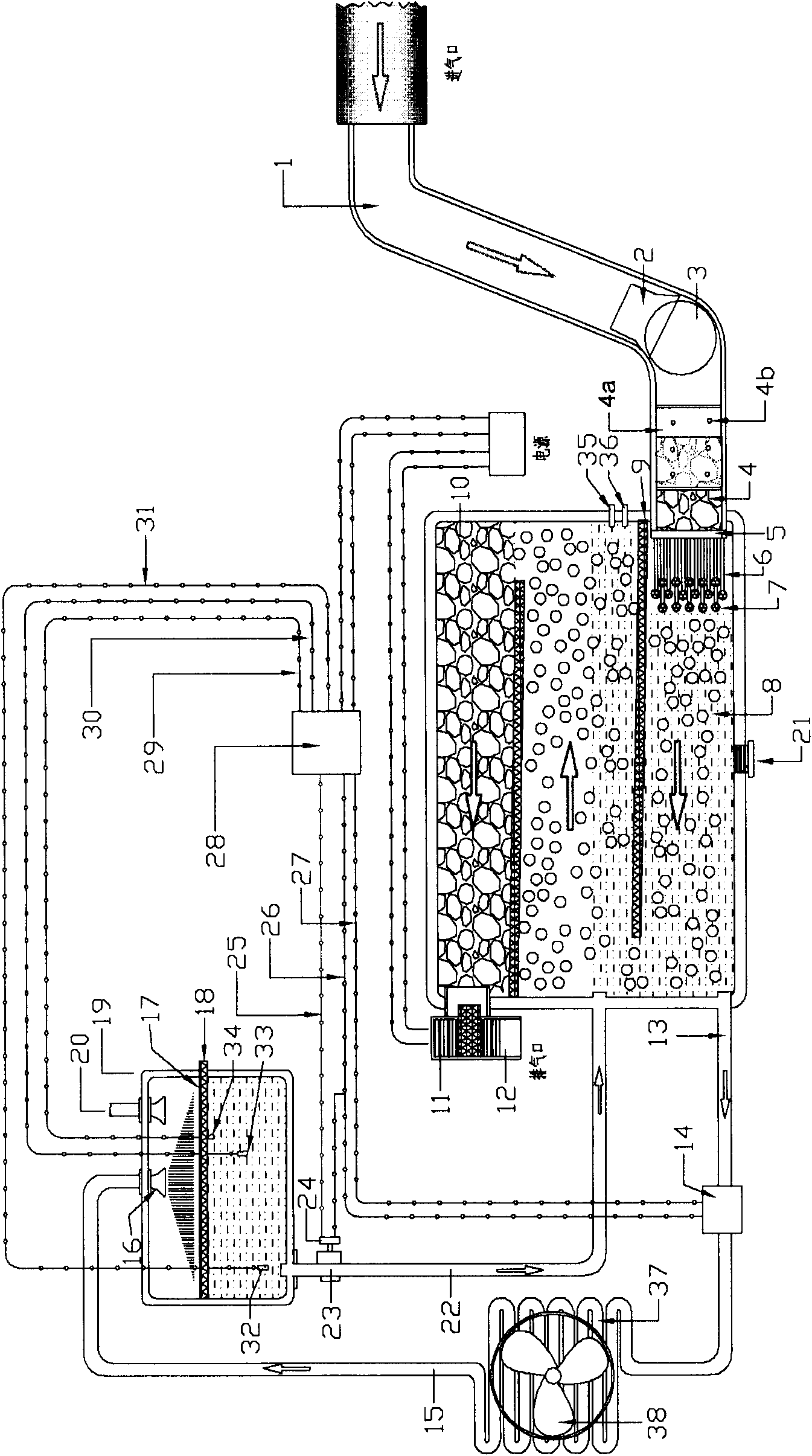

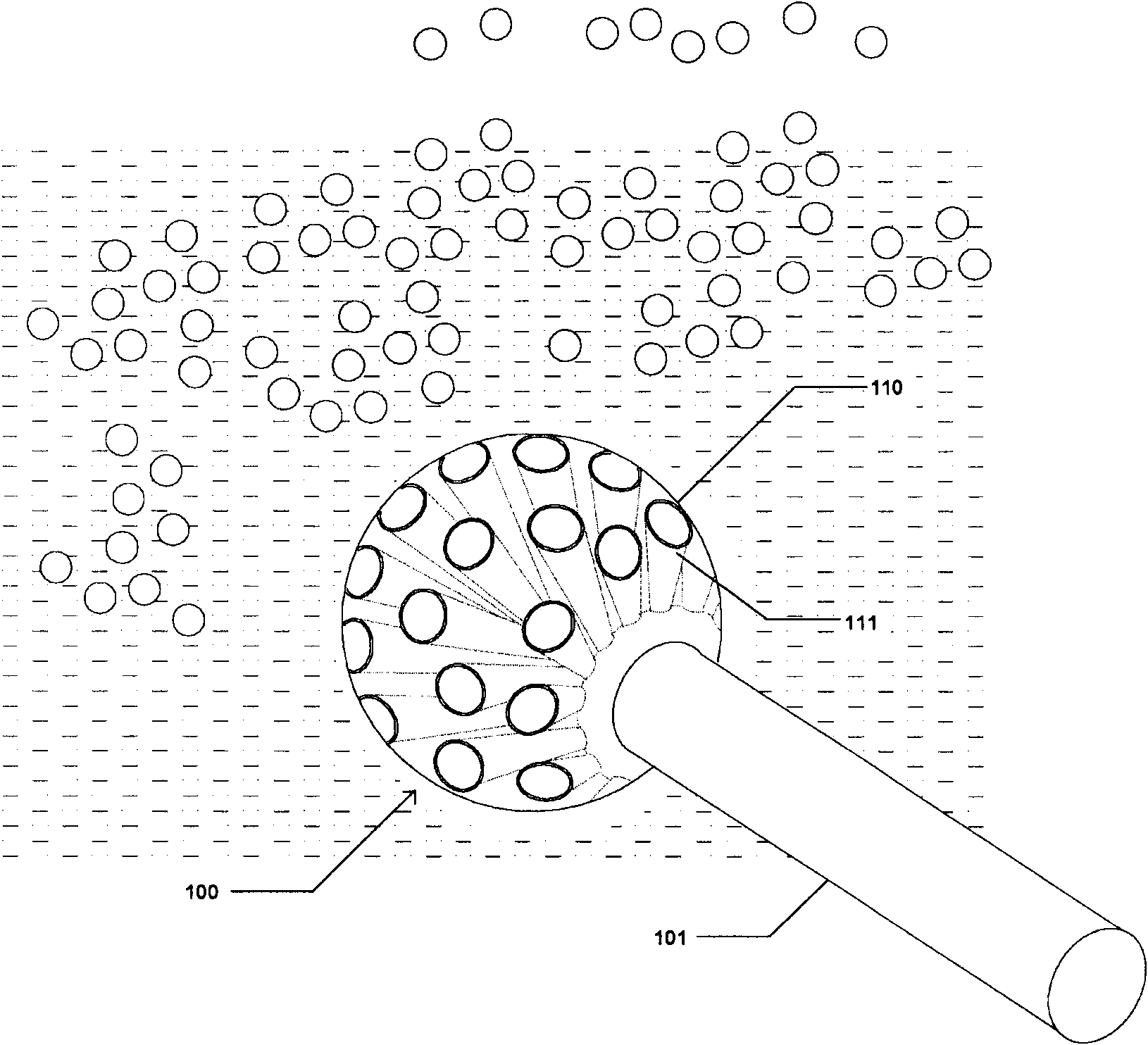

Automobile exhaust gas purifier and method for purifying automobile exhaust gas

InactiveCN102373990AGas treatmentInternal combustion piston enginesAutomotive engineeringSuspended particles

Owner:林鹰良

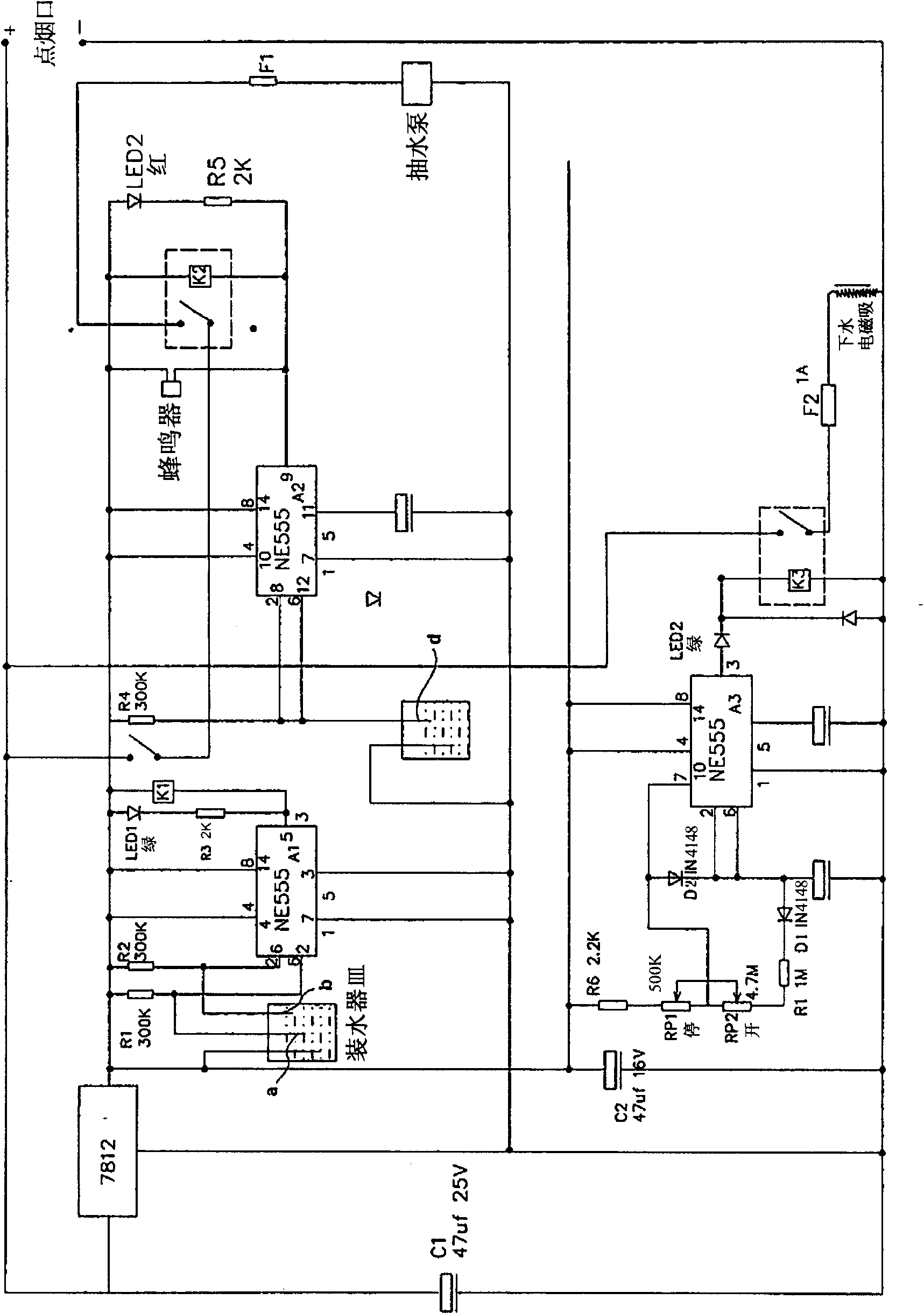

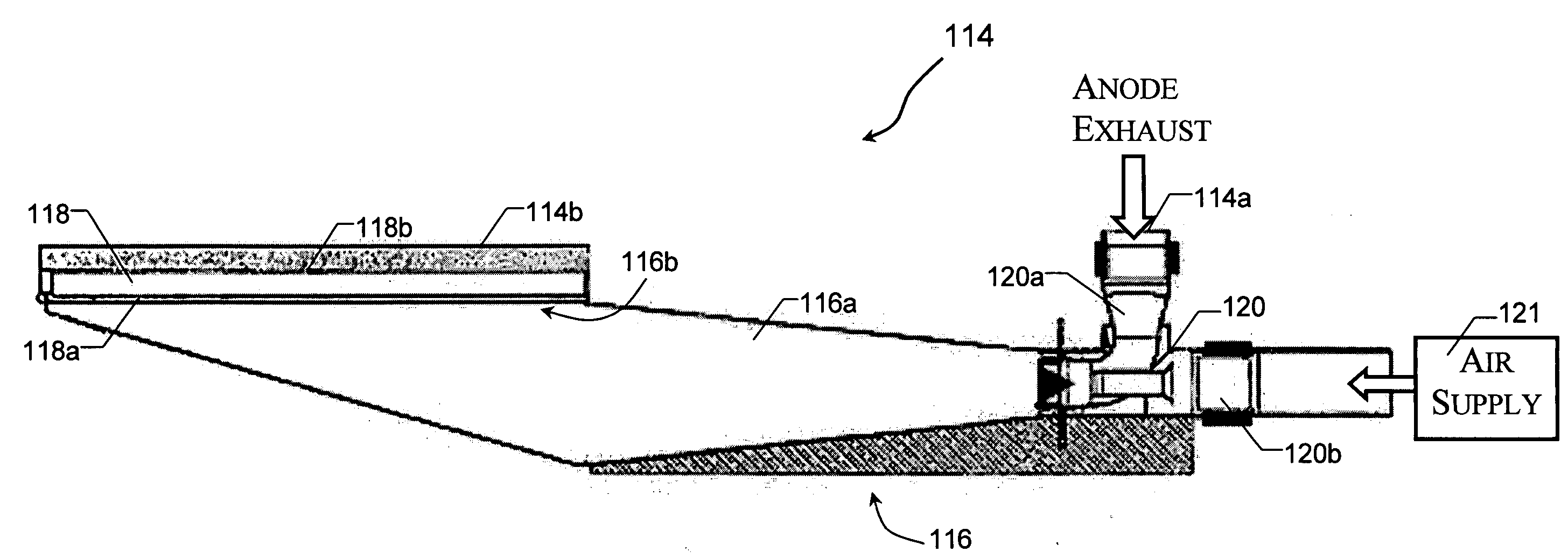

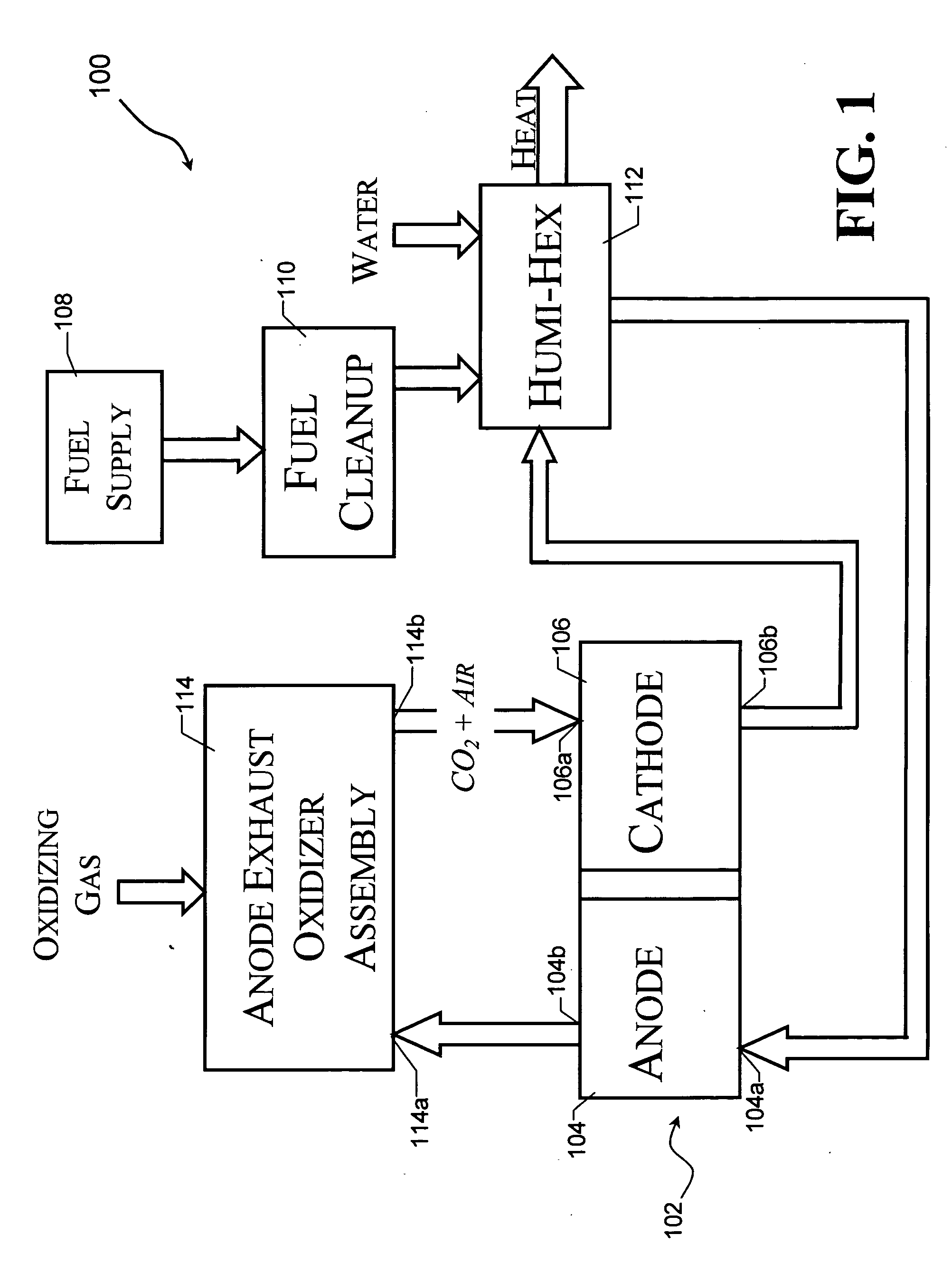

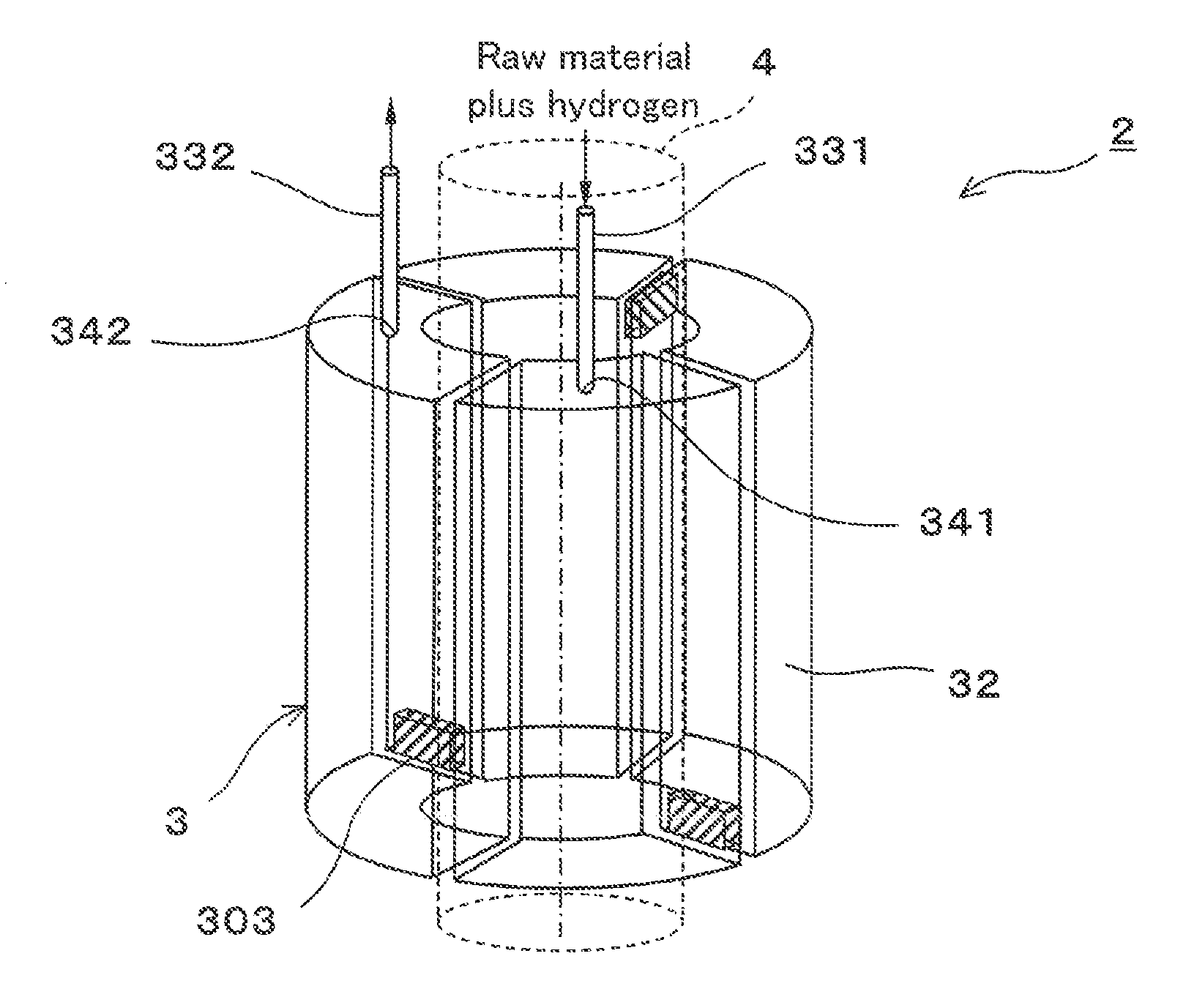

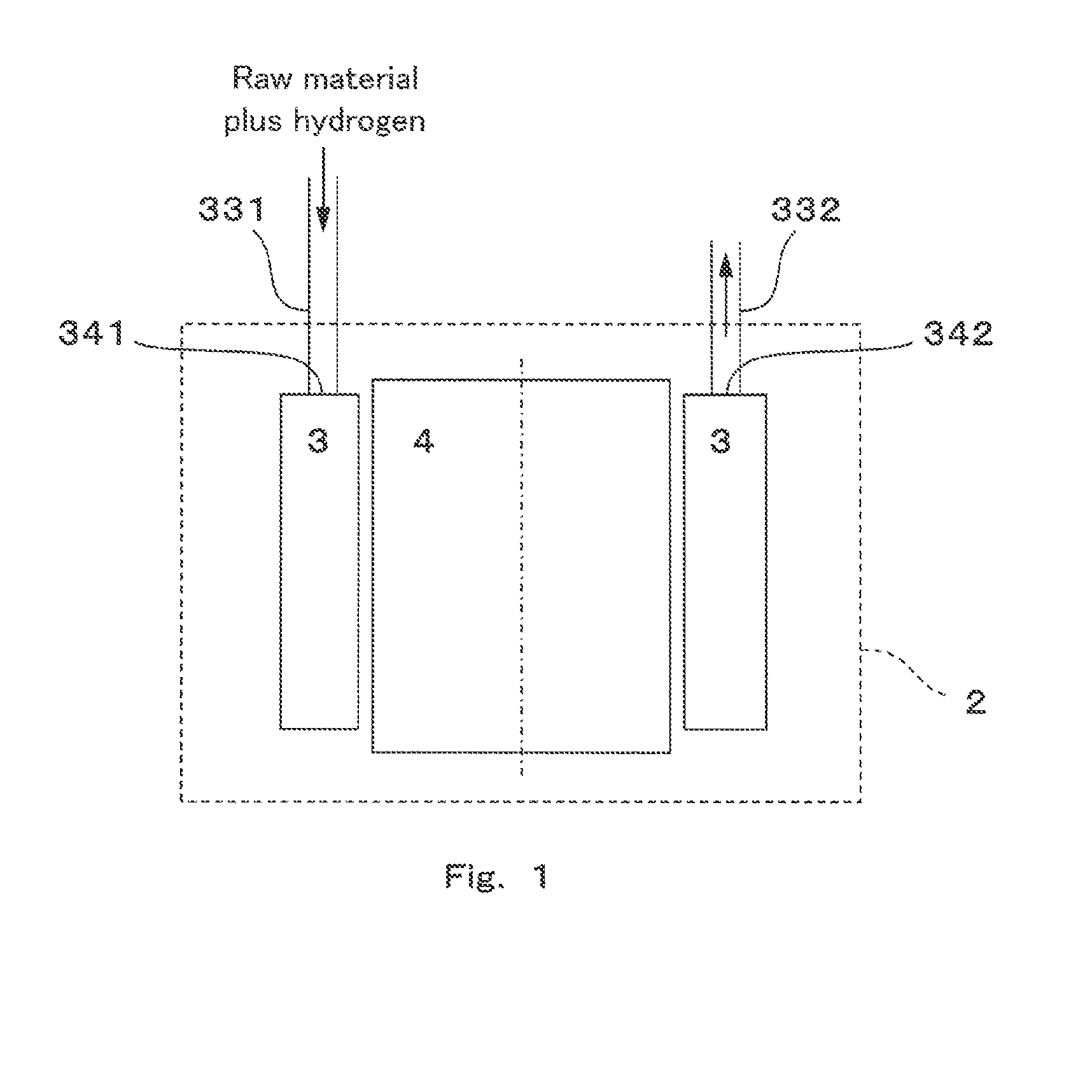

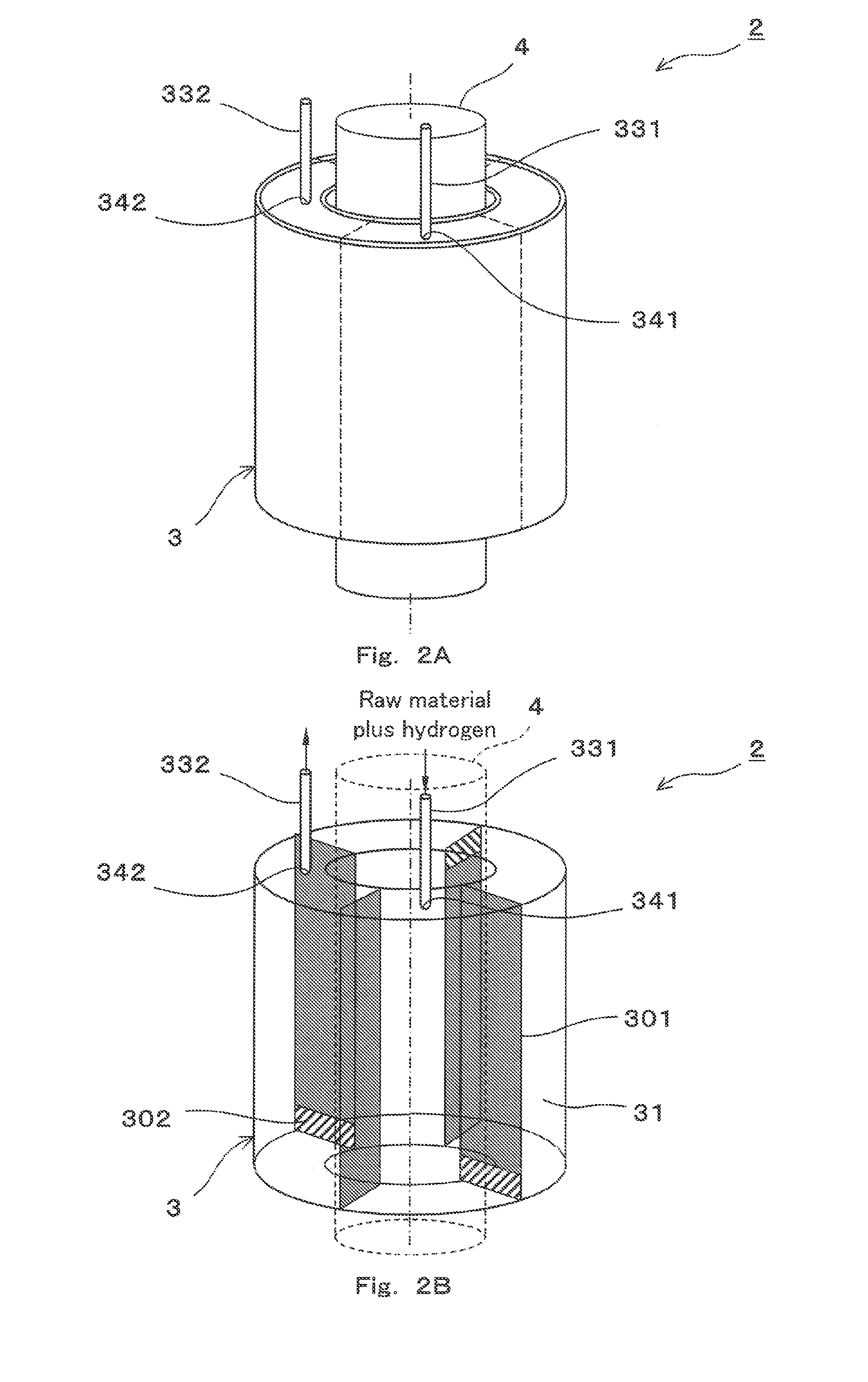

Hydrogen on demand electrolysis fuel cell system

InactiveUS20140262819A1Improve fuel economyEmission reductionCellsPhotography auxillary processesElectrolysisHydrogen

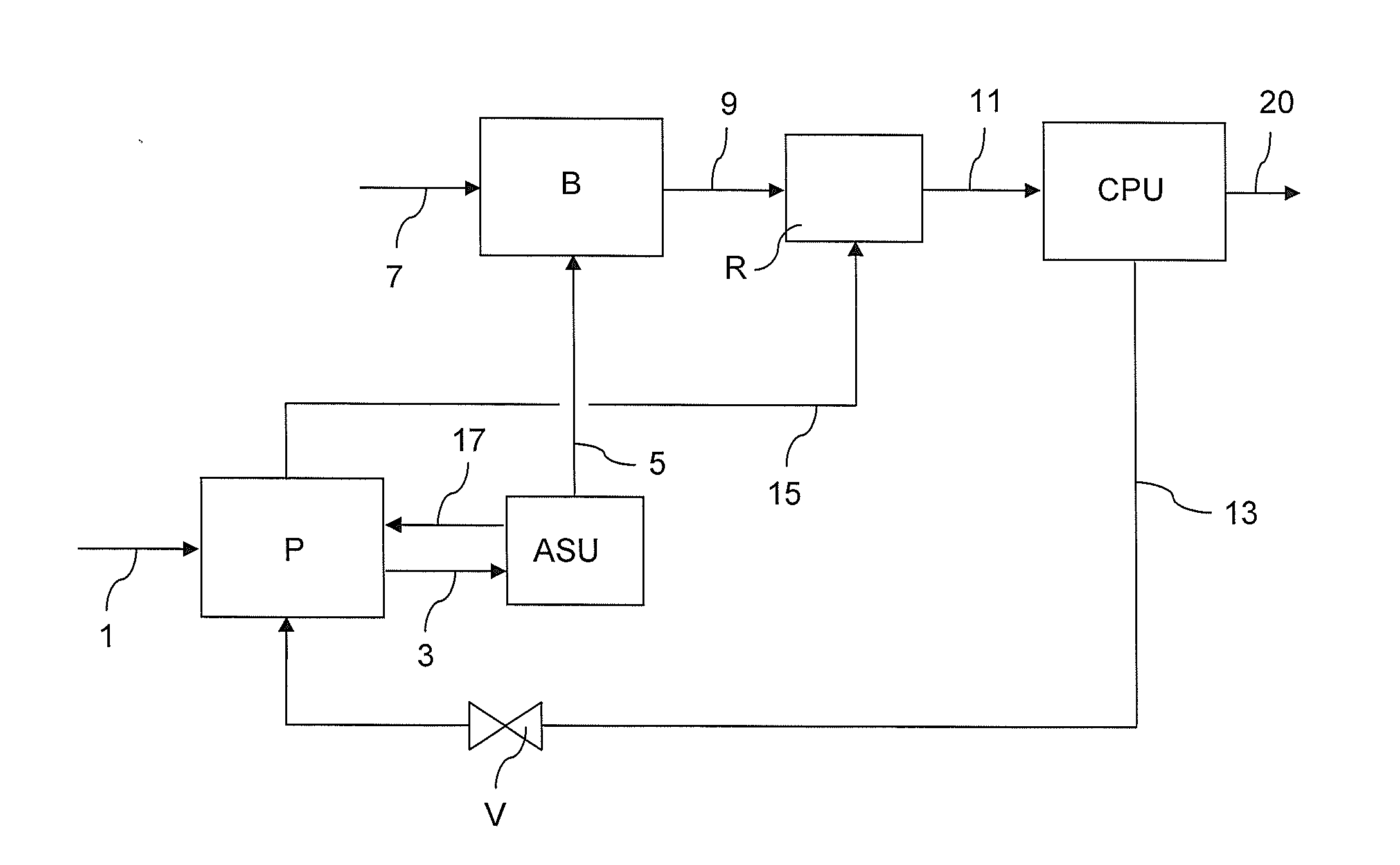

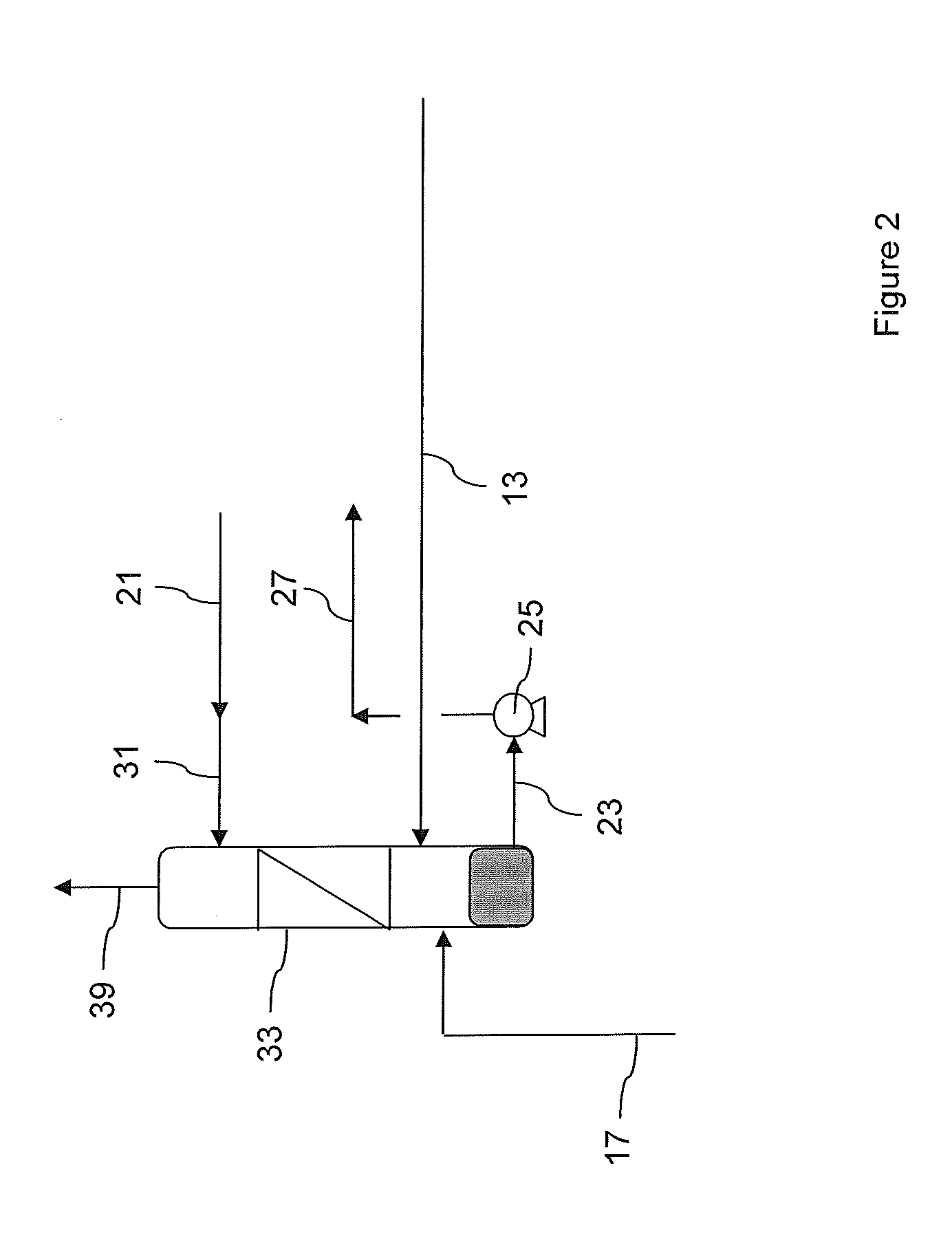

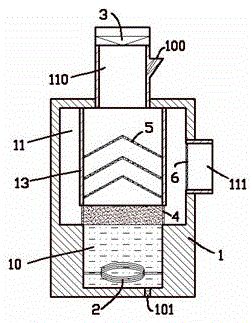

A hydrogen and oxygen (HHO) gas on-demand electrolysis fuel cell system for use with internal combustion engines is disclosed. This hydrogen on-demand (HOD) system integrates with the engine control module (ECM) or other control system that regulates the operation of an internal combustion engine in order to supply HHO to the engine and improve the engine's overall fuel efficiency. This system includes an electrolyte fluid reservoir outfitted with level, pressure and temperature sensors; a pump and heat exchanger; a uniquely-configured electrolyzer; and a filter. The combined engine and HOD system is controlled and regulated by an electronic control system (ECS) and a combustion control module (CCM). The CCM is installed on the engine such that it actively intercepts the electronic signals from the engine manufacturer's ECM to continuously coordinate the functions and operations of the HOD system and the engine.

Owner:NRG LOGISTICS

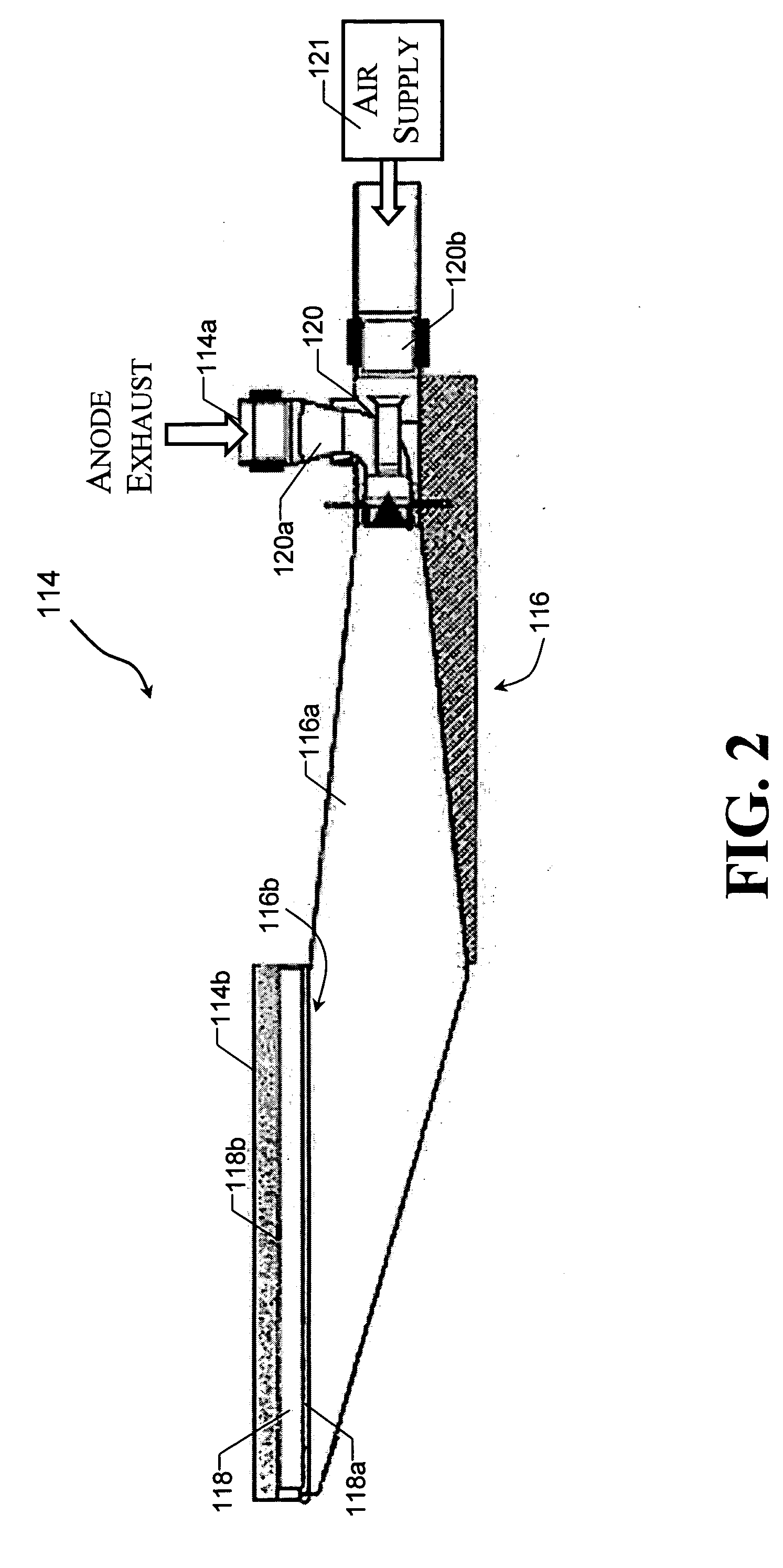

In-situ removal of electrolyte from gas oxidizer

Owner:FUELCELL ENERGY INC

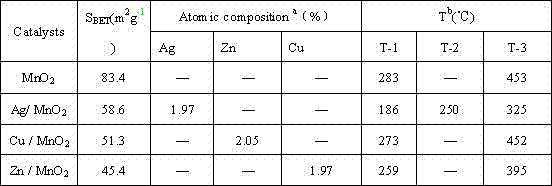

Novel method for removing indoor formaldehyde by nano manganese dioxide

Owner:TIANJIN CITY CENTSTAGE TECH INCUBATOR COMPANY

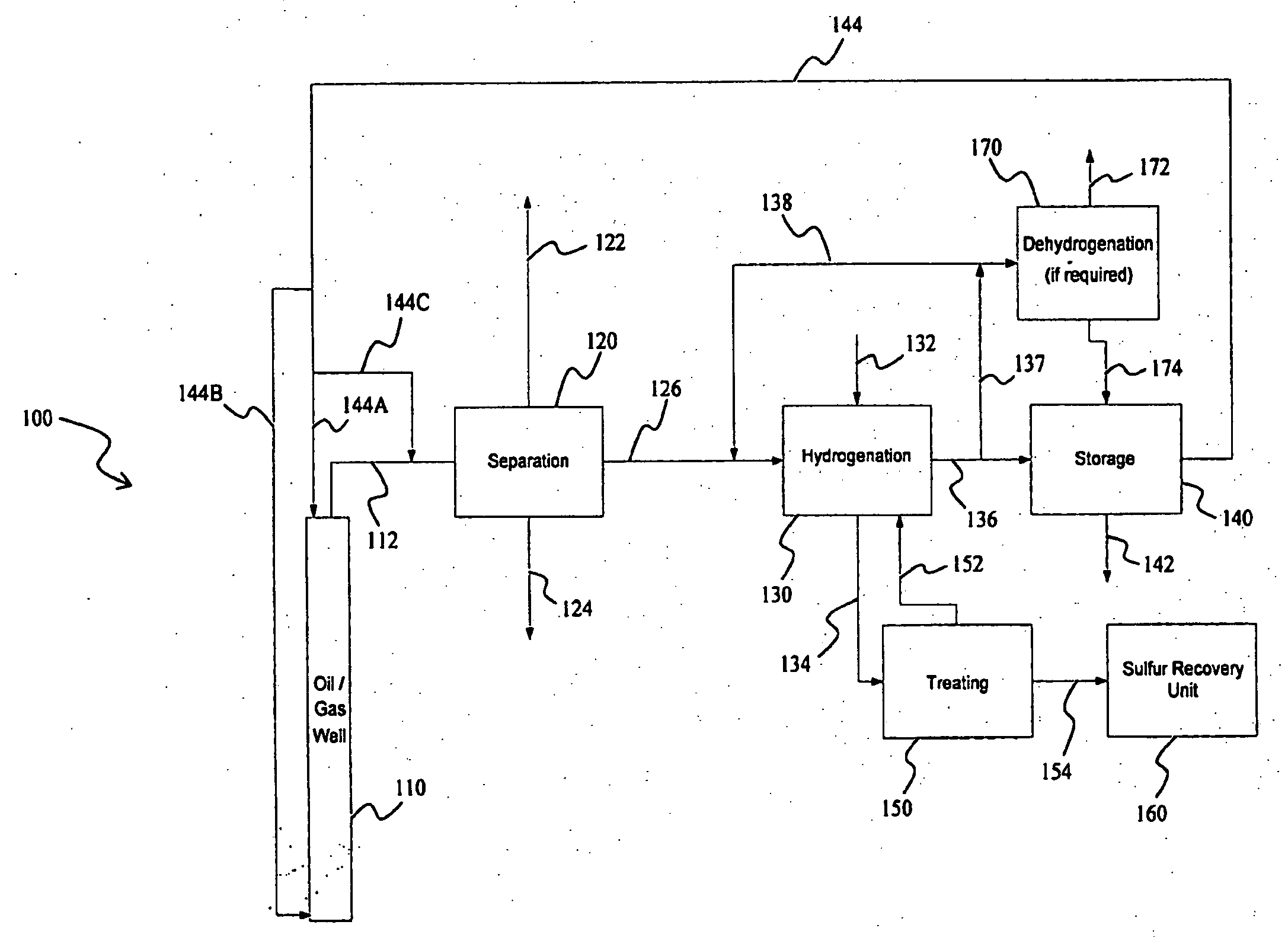

Hydrocarbon Based Sulfur Solvent Systems and Methods

Owner:FLUOR TECH CORP

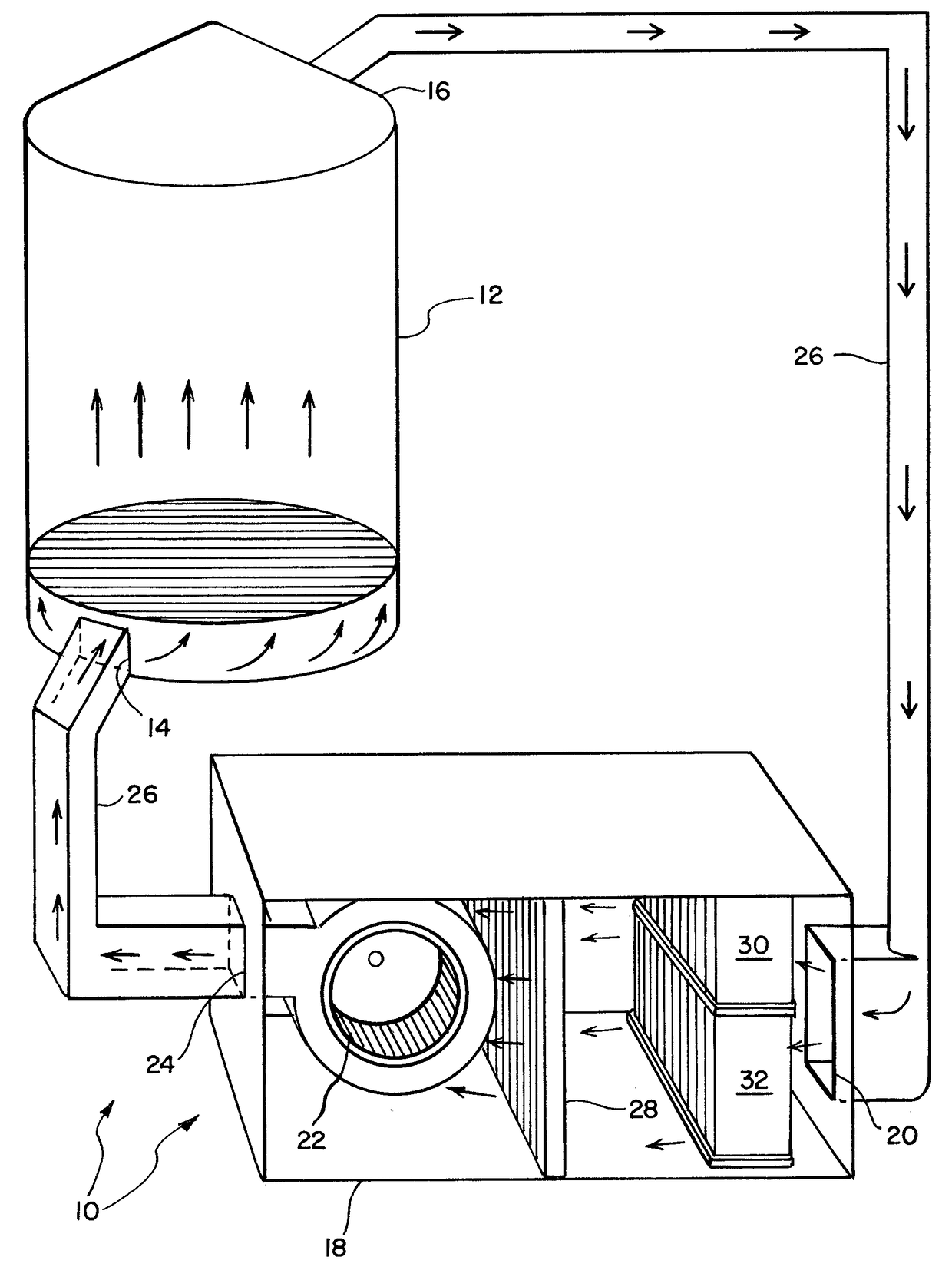

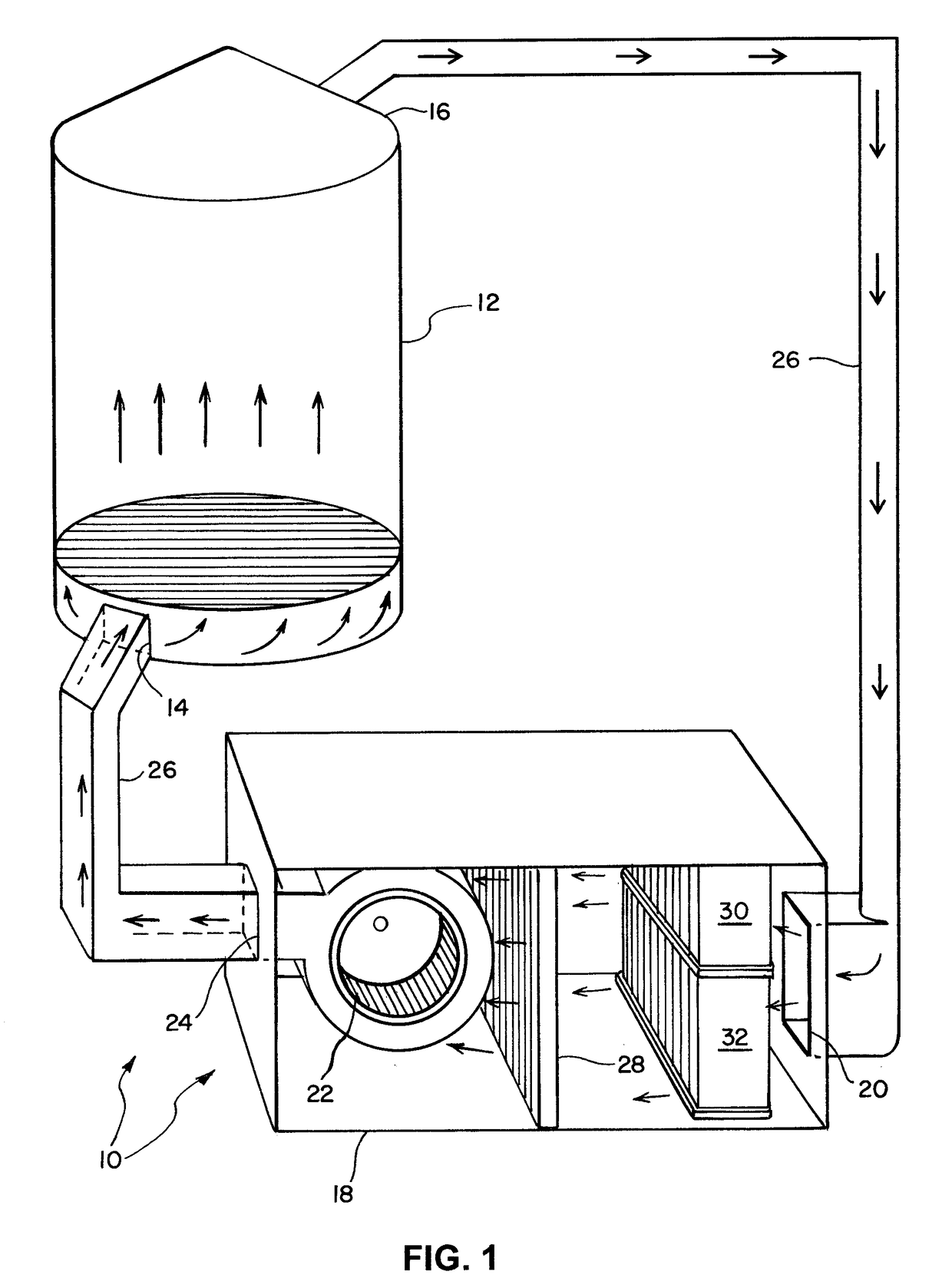

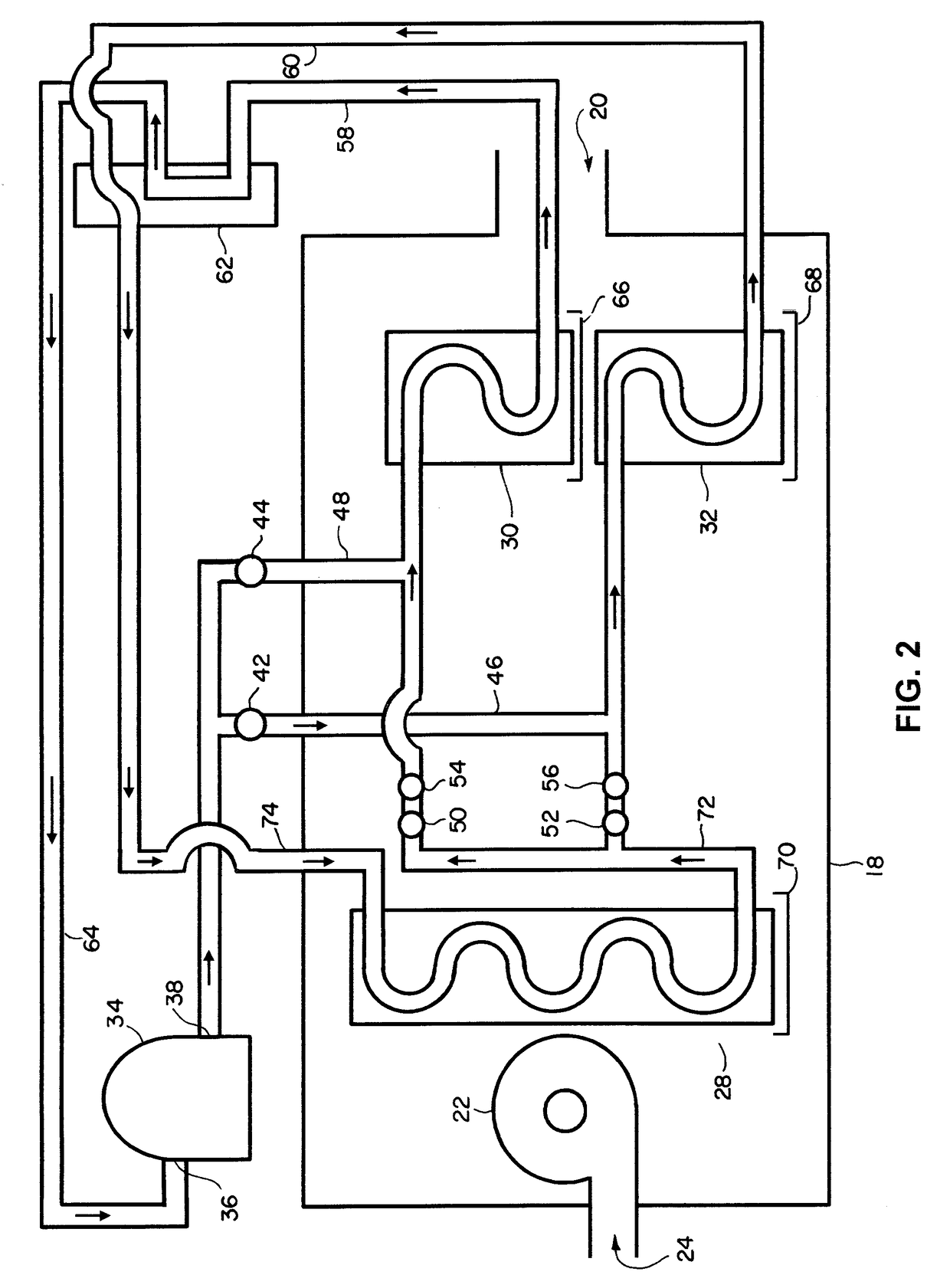

Crop drying system

ActiveUS20170115061A1Increase the ambient temperatureQuantity minimizationFruit and vegetables preservationGas treatmentClosed loopMoisture

Owner:LOEBACH DAVID R

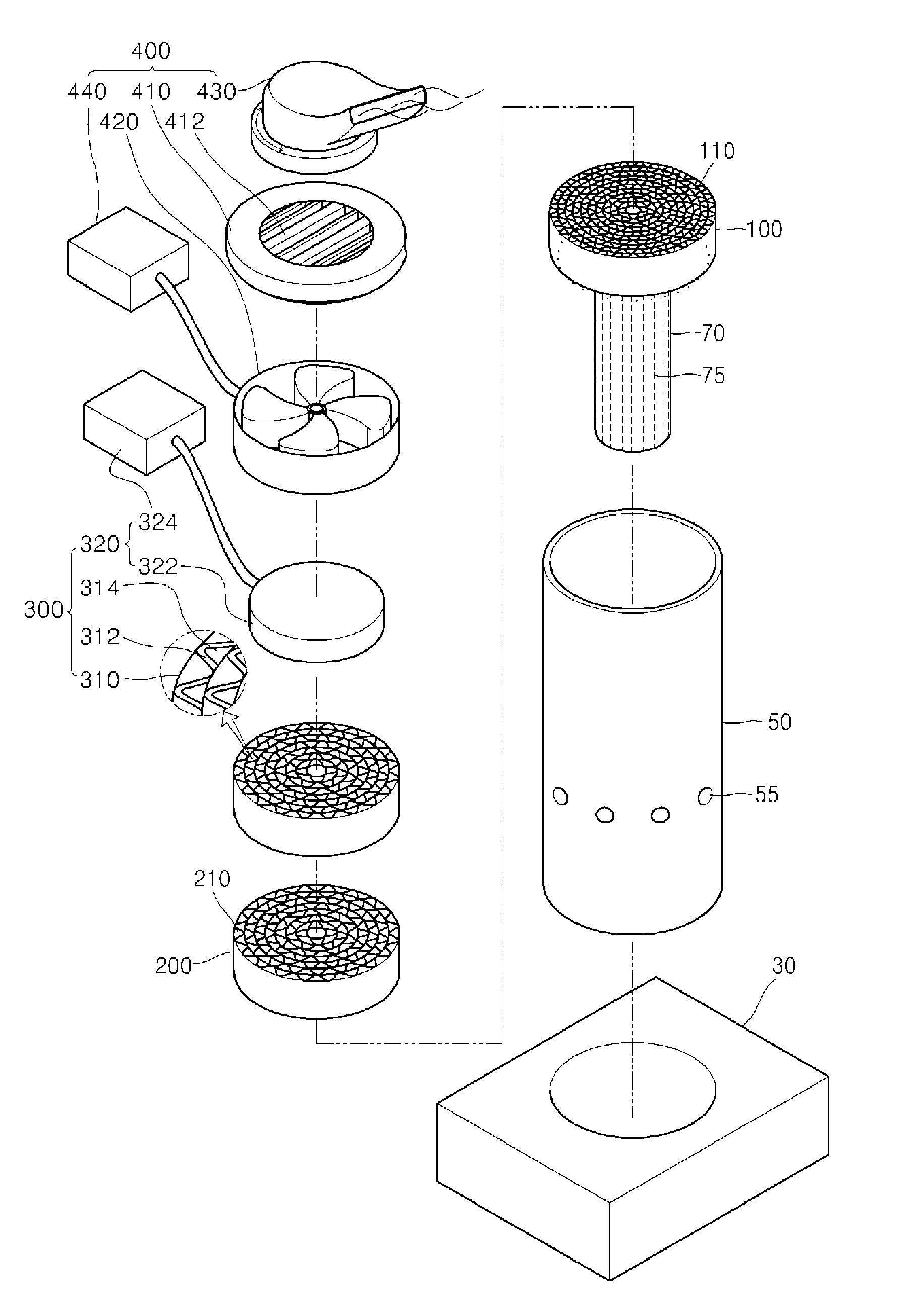

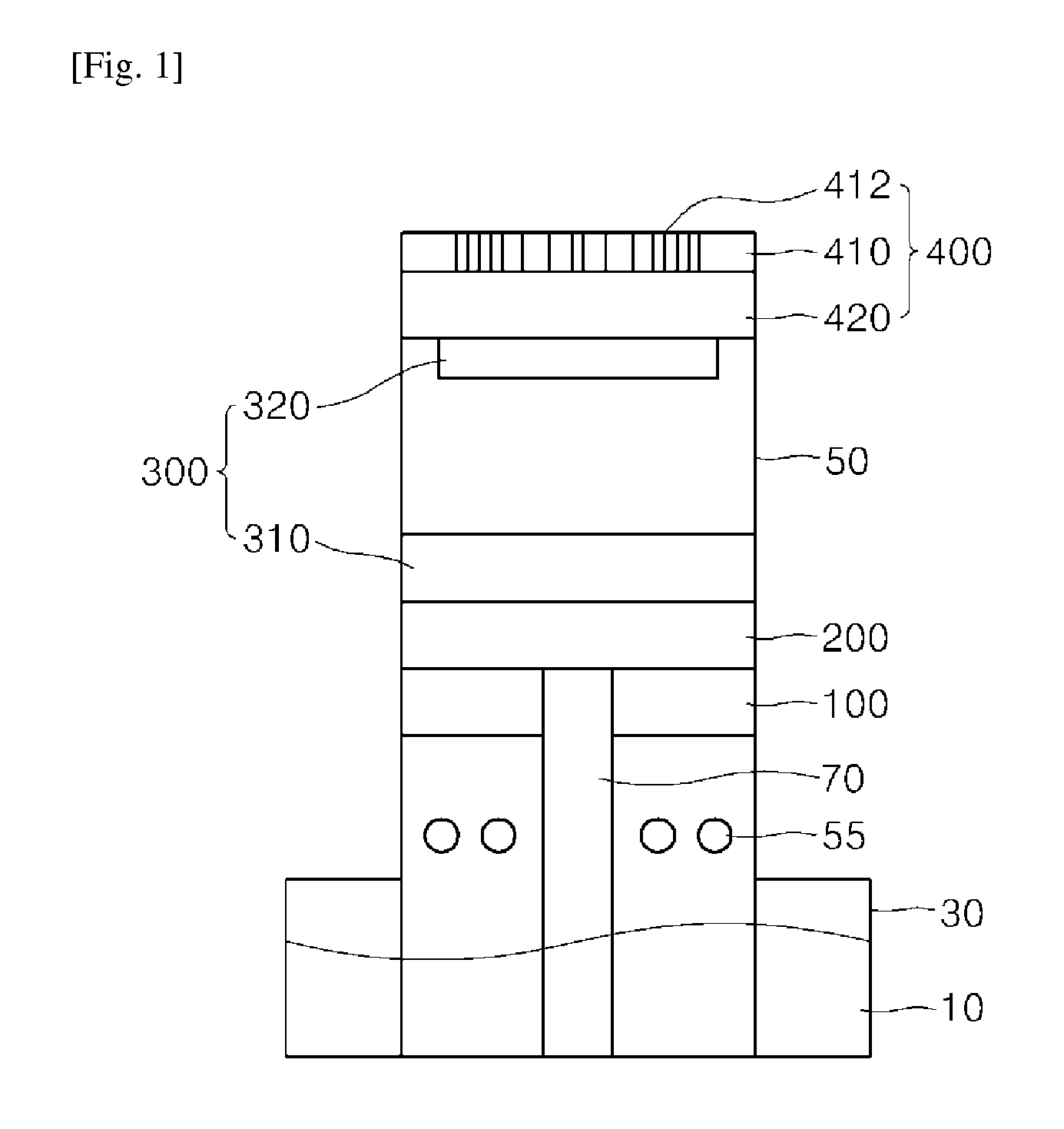

Humidifier apparatus using a photocatalyst having an air-cleaning function

ActiveUS20130330238A1Improve energy efficiencyReduce operating costsGas treatmentMechanical apparatusAir cleaningEngineering

Owner:LG HAUSYS LTD

Apparatus and Integrated Process for Separating a Mixture of Carbon Dioxide and at Least One Other Gas and for Separating Air by Cryogenic Distillation

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

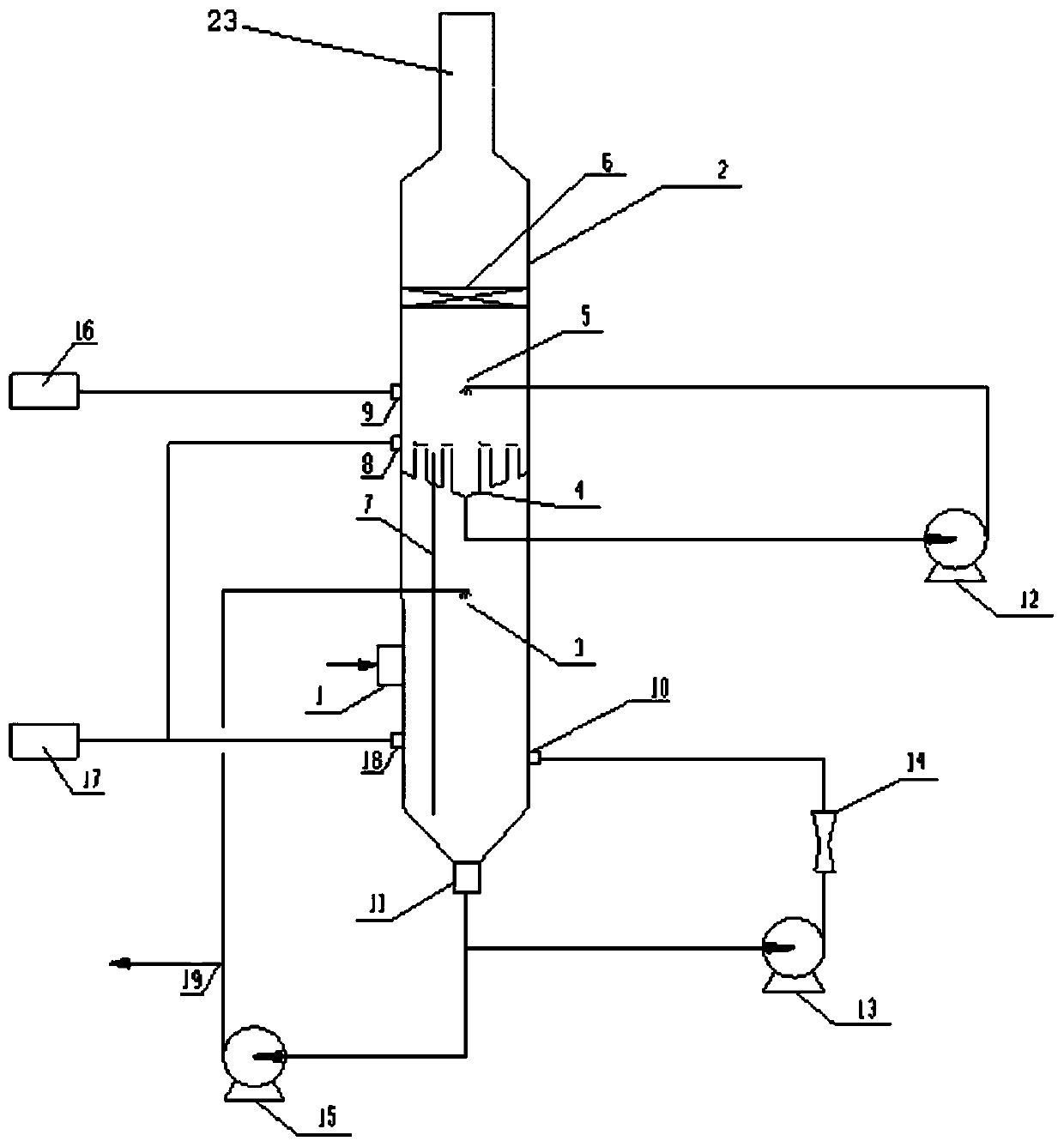

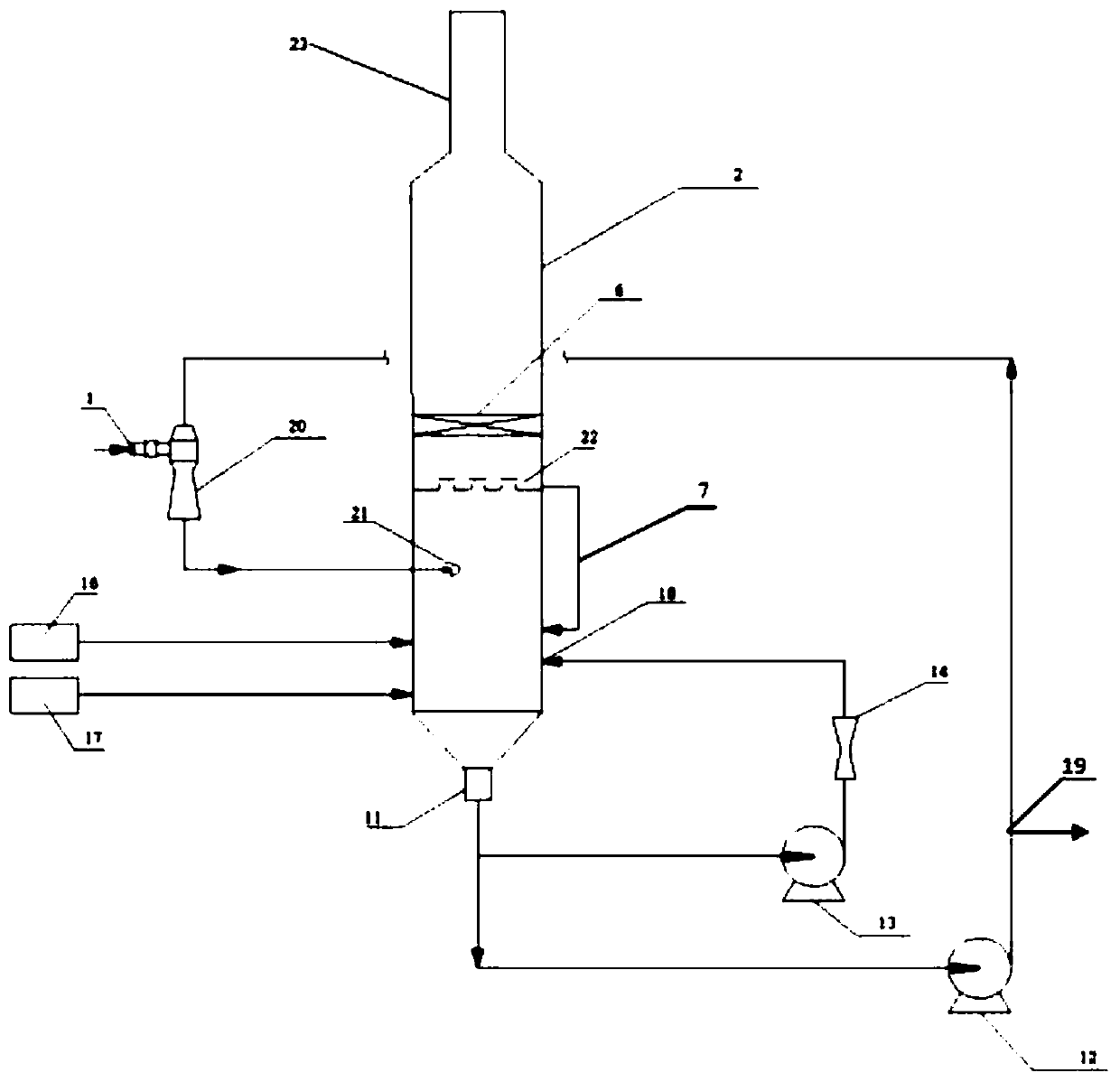

Ship waste gas desulfuration device and method

ActiveCN107998761AImprove the mixing effectFully purifiedGas treatmentDispersed particle filtrationActivated carbonMixing effect

Owner:唐山伟德船用设备有限公司

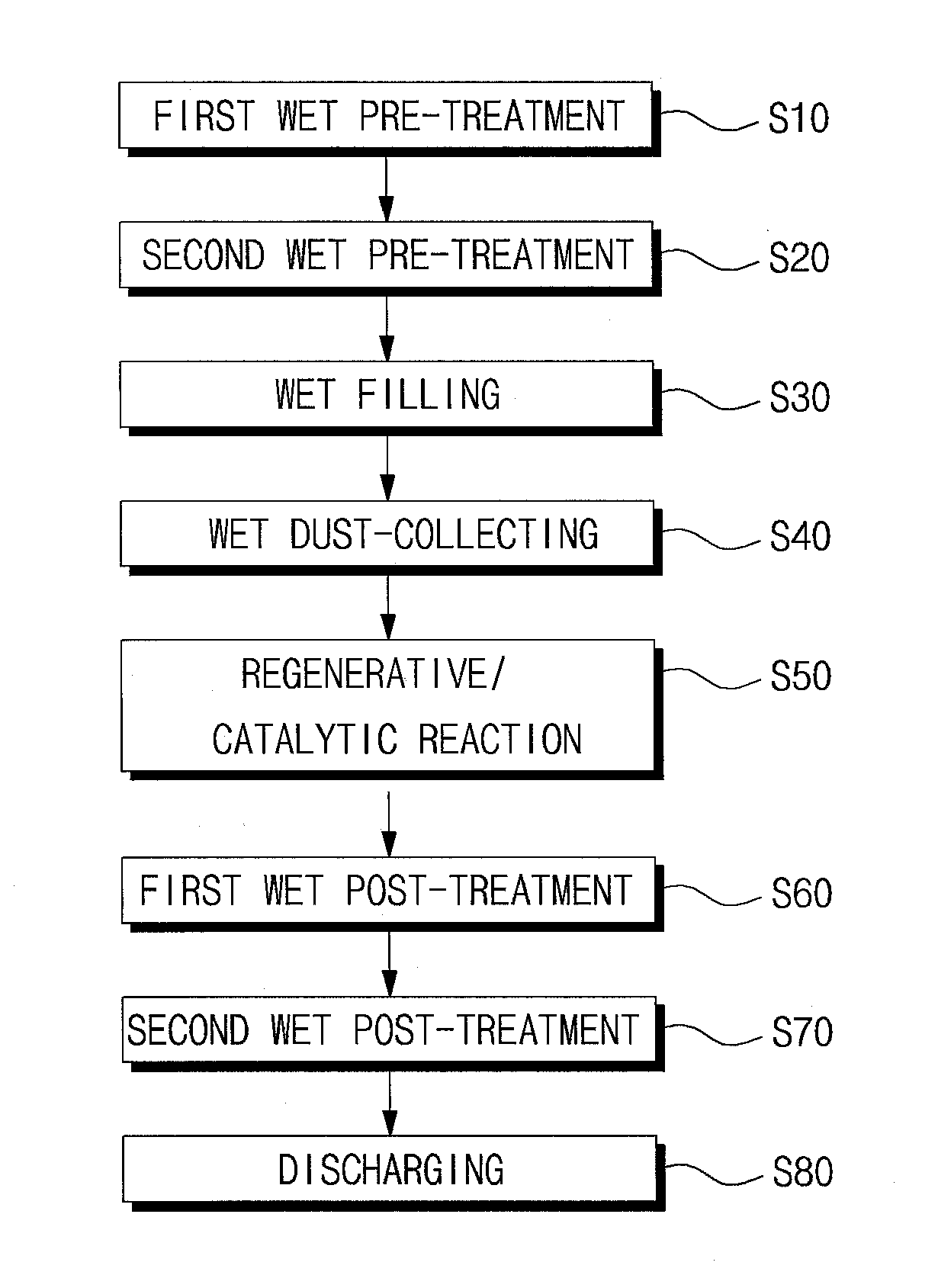

Method for increasing concentration of carbon dioxide in tail gas of lime rotary kiln

InactiveCN110683544AIncrease concentrationHigh purityCalcium/strontium/barium carbonatesMaterial nanotechnologyCo2 absorptionDust control

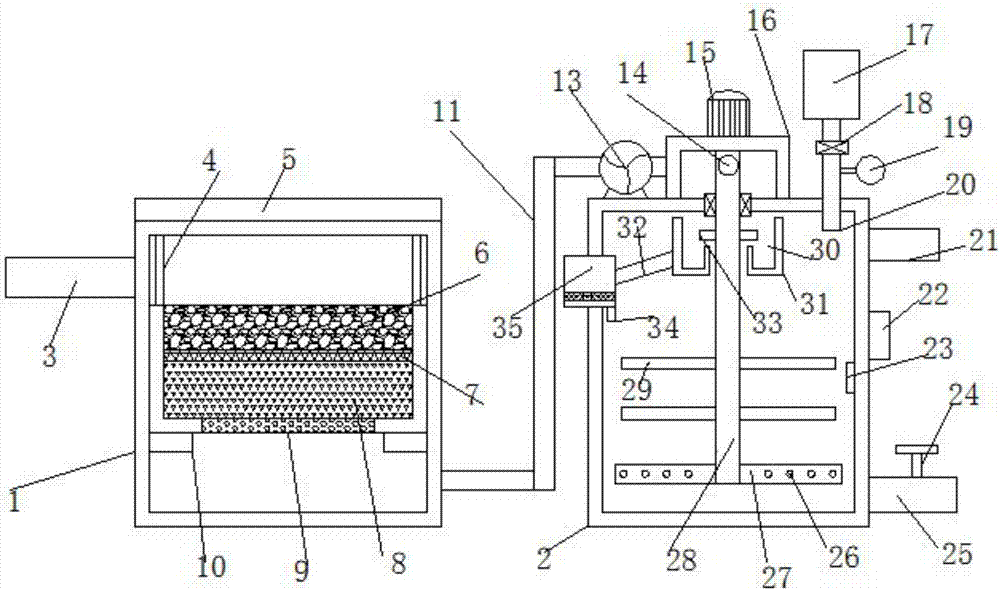

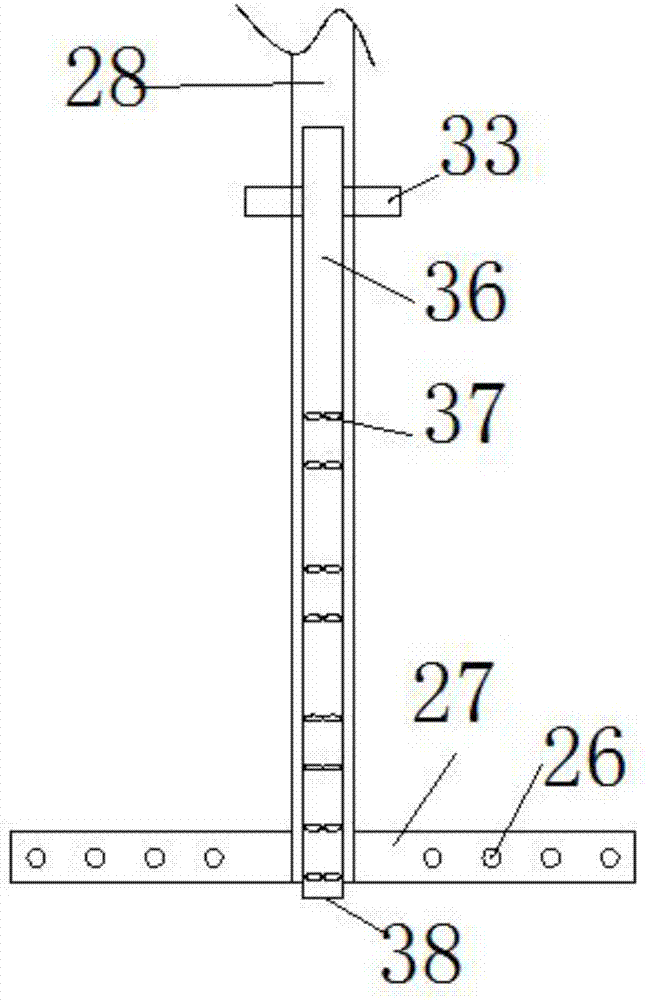

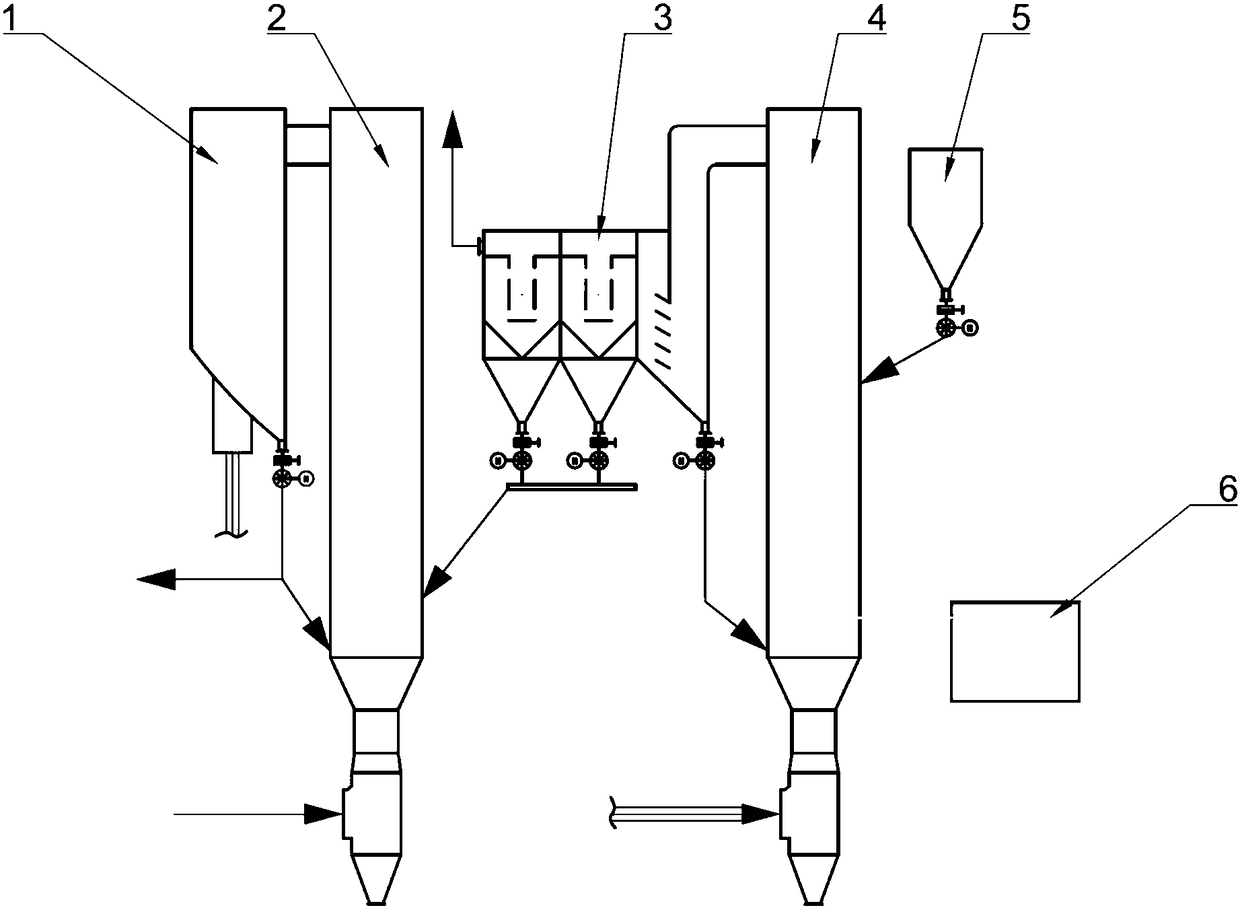

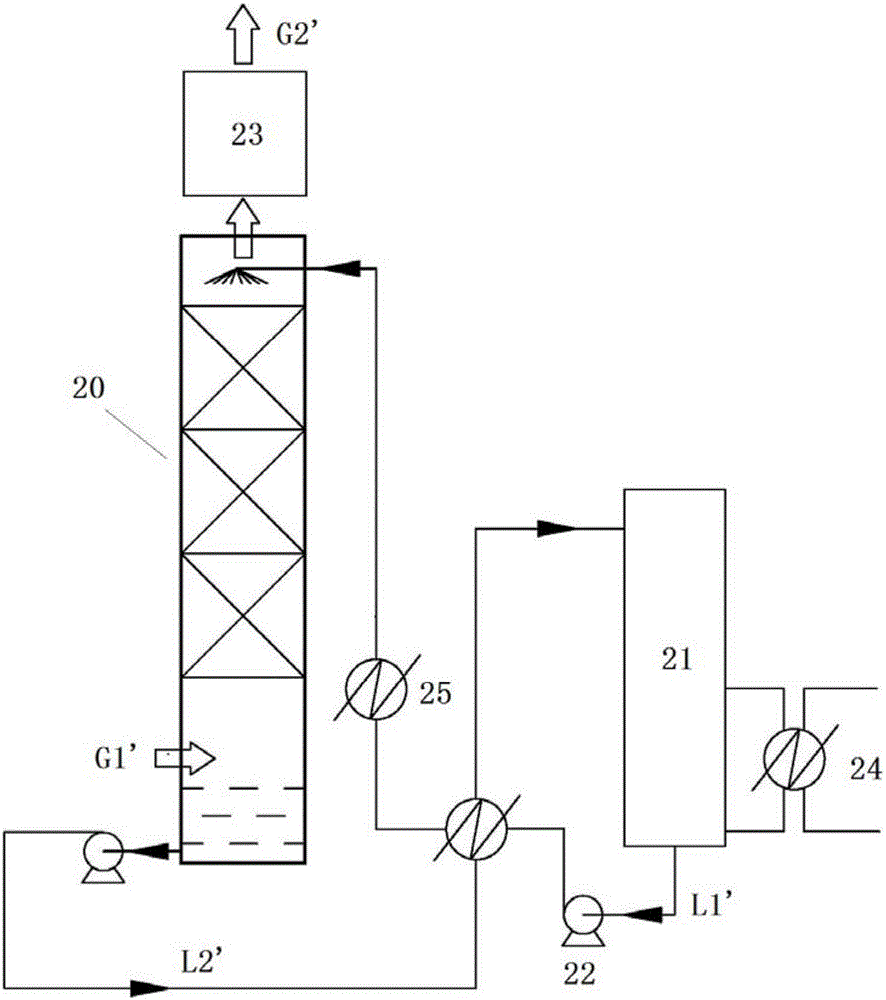

The invention discloses a method for increasing the concentration of carbon dioxide in tail gas of a lime rotary kiln. The method is characterized by comprising the following steps: (1) the tail gas of the lime kiln passes through dedusting equipment to remove dust particles; (2) the dedusted tail gas is sprayed through a washing tower, the sprayed tail gas is desulfurized through a desulfurizingtower; (3) the desulfurized tail gas passes through a booster fan to enter a surge flask and then is conveyed into a carbon dioxide absorption tower, alkanolamine in the absorption tower absorbs the carbon dioxide, and the tail gas is metered and then emptied; (4) a carbon-dioxide-absorbed alkanolamine solution is pressurized through a rich solution pump to enter a regeneration tower; (5) the carbon-dioxide-absorbed alkanolamine solution is heated in the regeneration tower to desorb the carbon dioxide, the desorbed carbon dioxide is cooled, dried, analyzed and stored; and (6) a regenerated barren solution is cooled by a barren solution cooler and then pressurized through a barren solution pump to enter an absorption tower, and the carbon dioxide is absorbed again. An enrichment technologyfor the carbon dioxide in the tail gas of the lime rotary kiln brings certain economic benefits for enterprises while according with national industrial structure adjustment and environmental protection.

Owner:HUBEI UNIV

Device and technology for flue gas desulfurization through soda ash method

PendingCN110433637ANo noiseAchieve securityCombination devicesGas treatmentSulfite saltSodium sulfite

Owner:大连汉诺工程技术有限公司

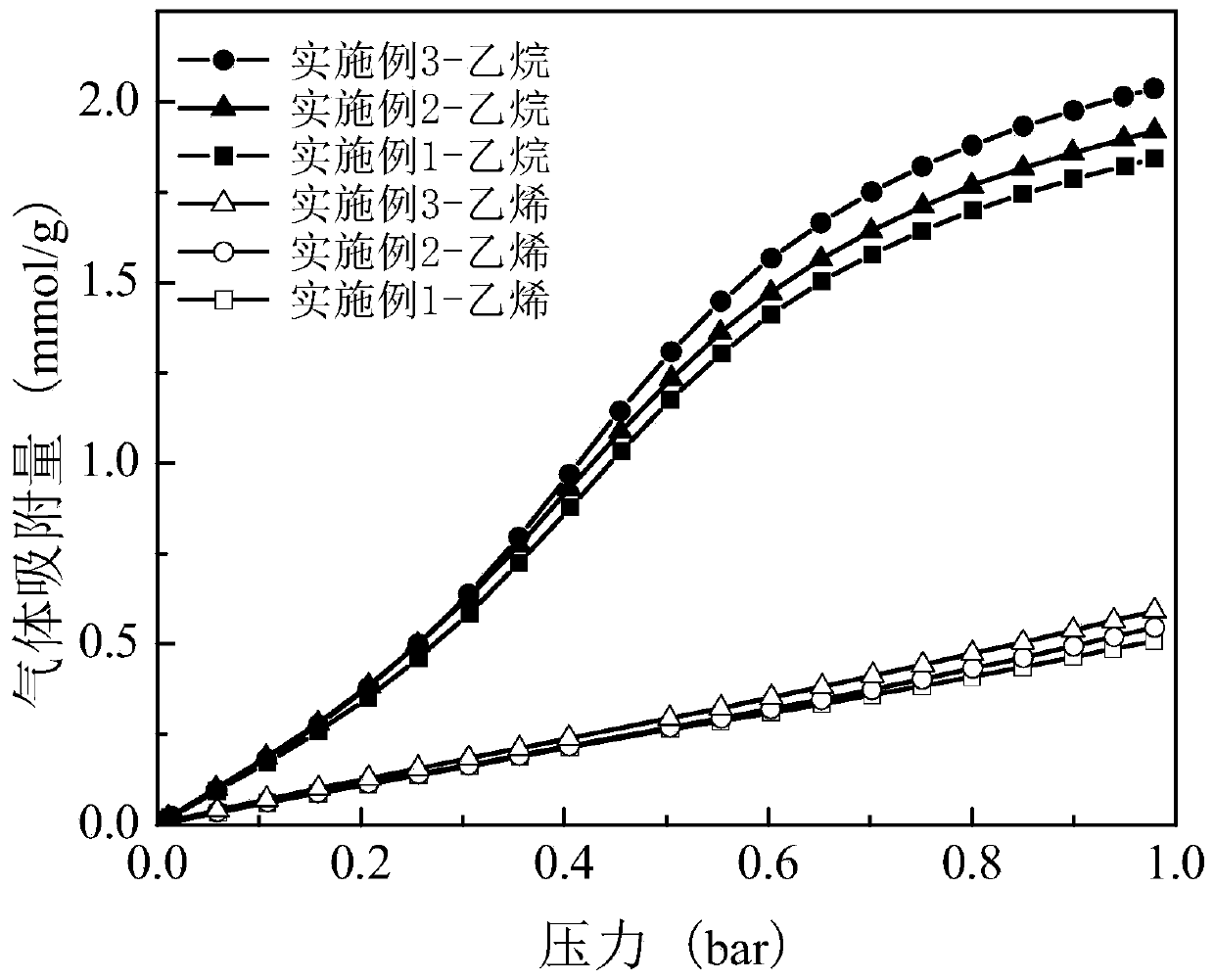

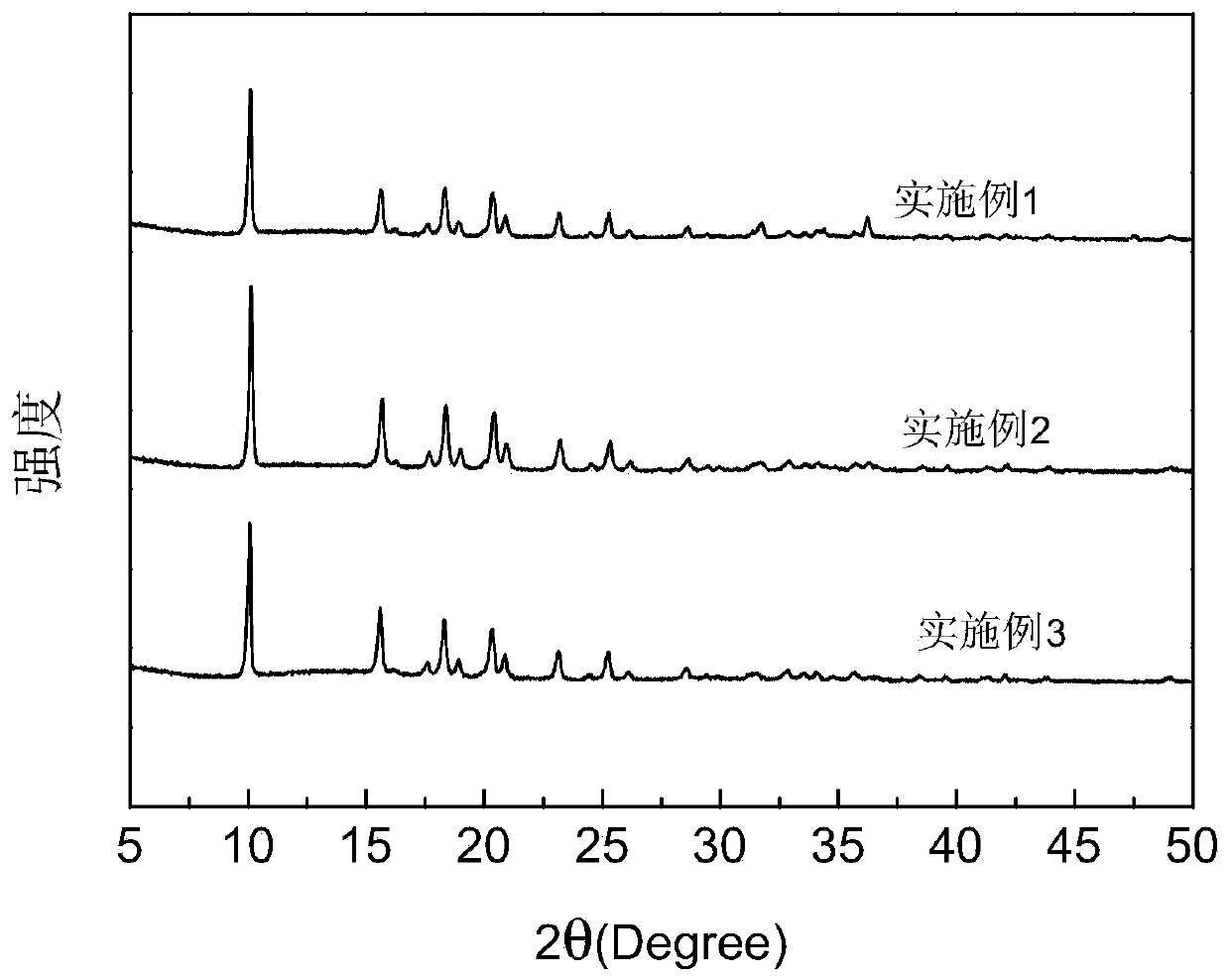

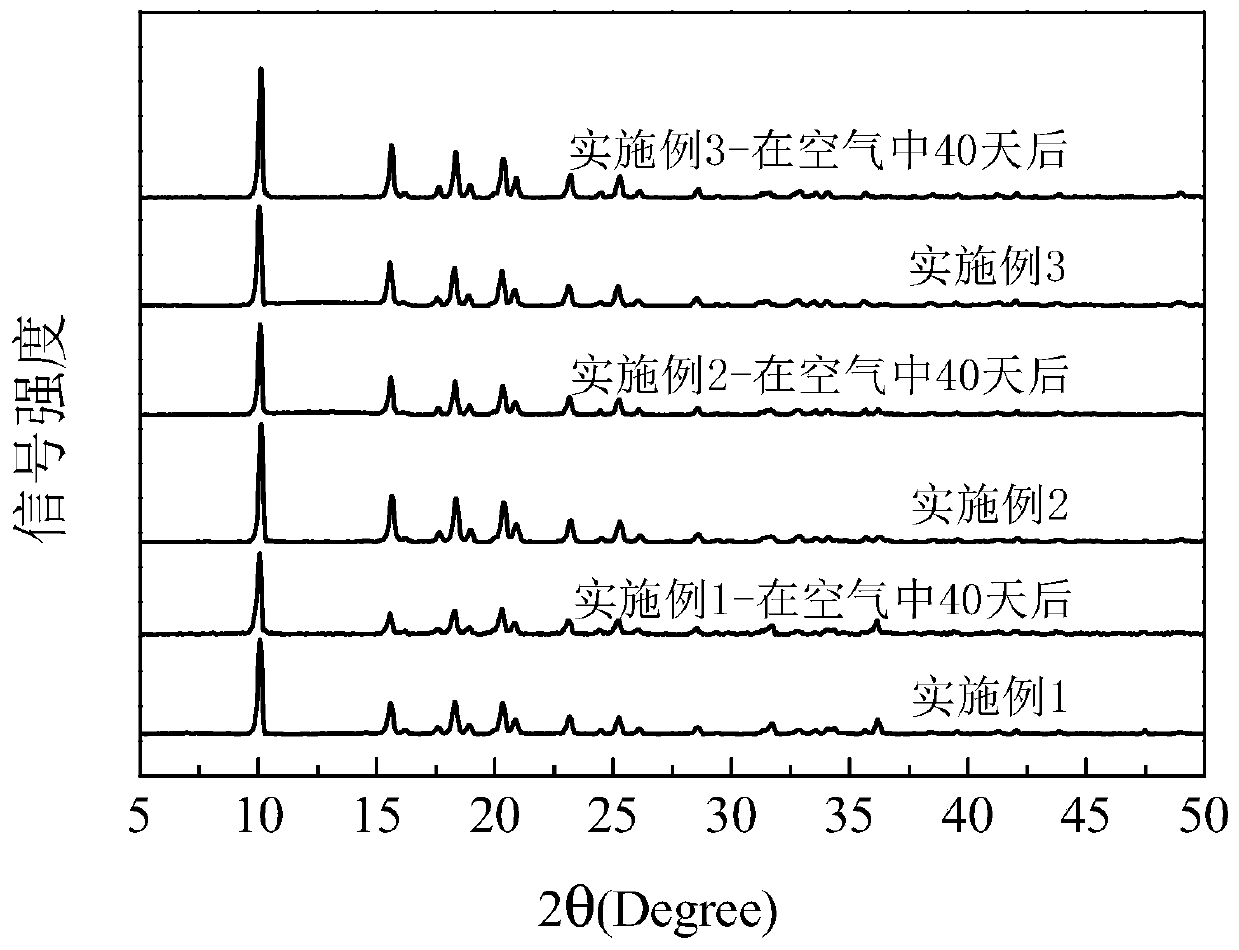

Room-temperature preparation method of metal-organic framework material preferentially adsorbing ethane

PendingCN110075805AGood alkane selectivityGood adsorption and separation performanceGas treatmentOther chemical processesAlkaneN dimethylformamide

Owner:SOUTH CHINA UNIV OF TECH

Spray booth organic waste gas treatment system

Owner:JIANGSU YONGYI ENVIRONMENTAL PROTECTION TECH CO LTD

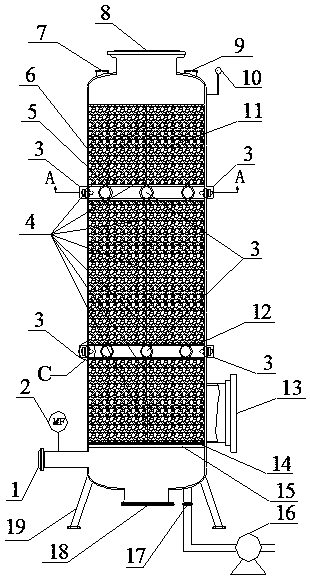

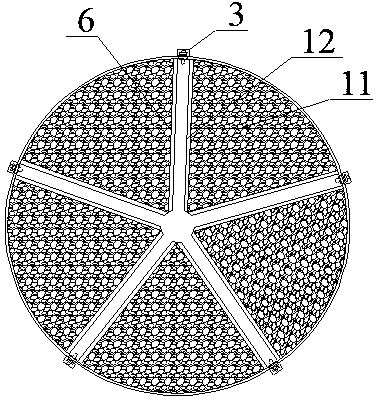

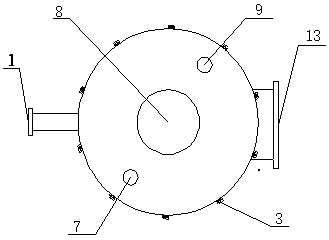

Adsorption device

InactiveCN105498441AReduce gas distribution spaceIncrease profitGas treatmentDispersed particle separationEngineeringAirflow

Owner:王晓晓

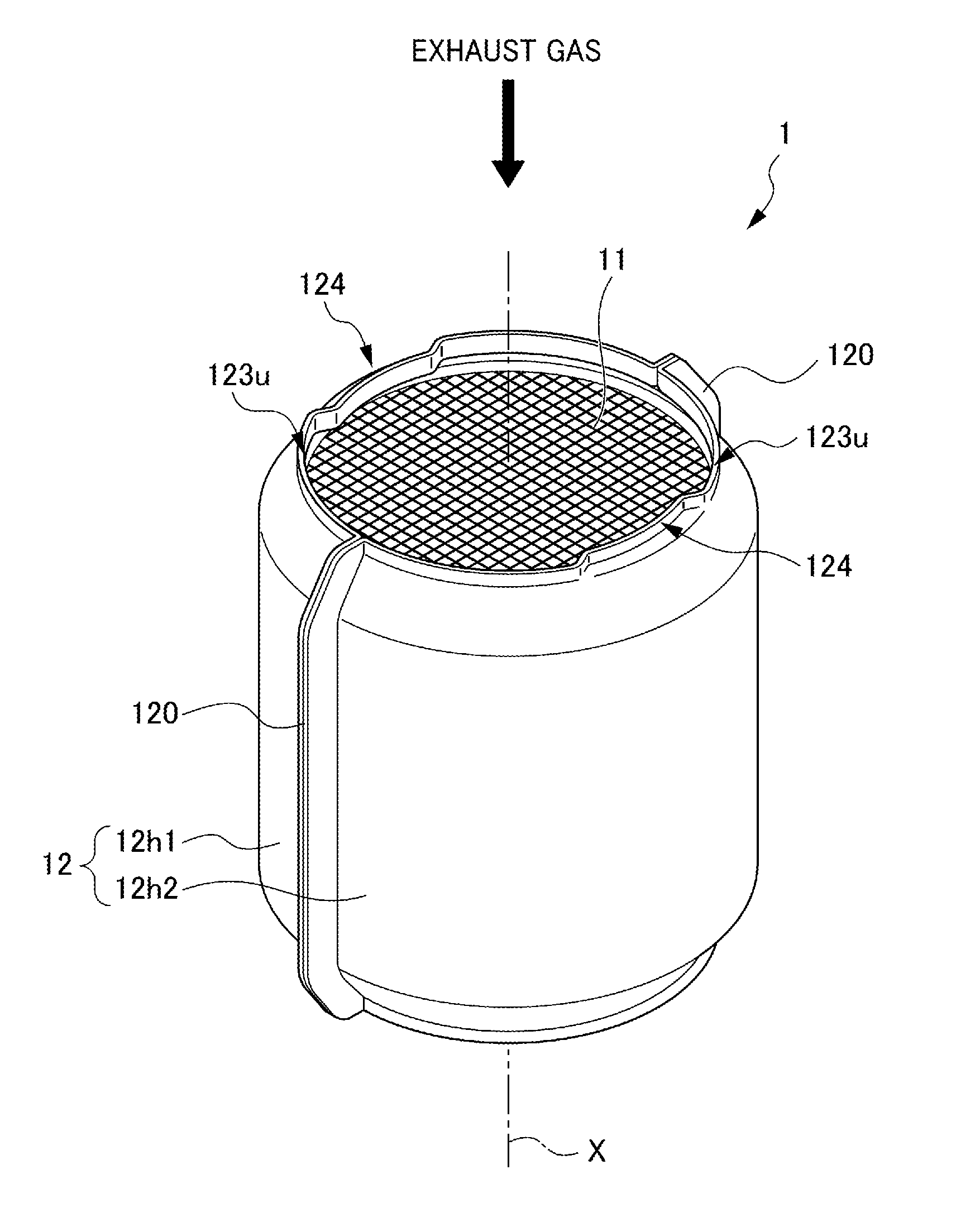

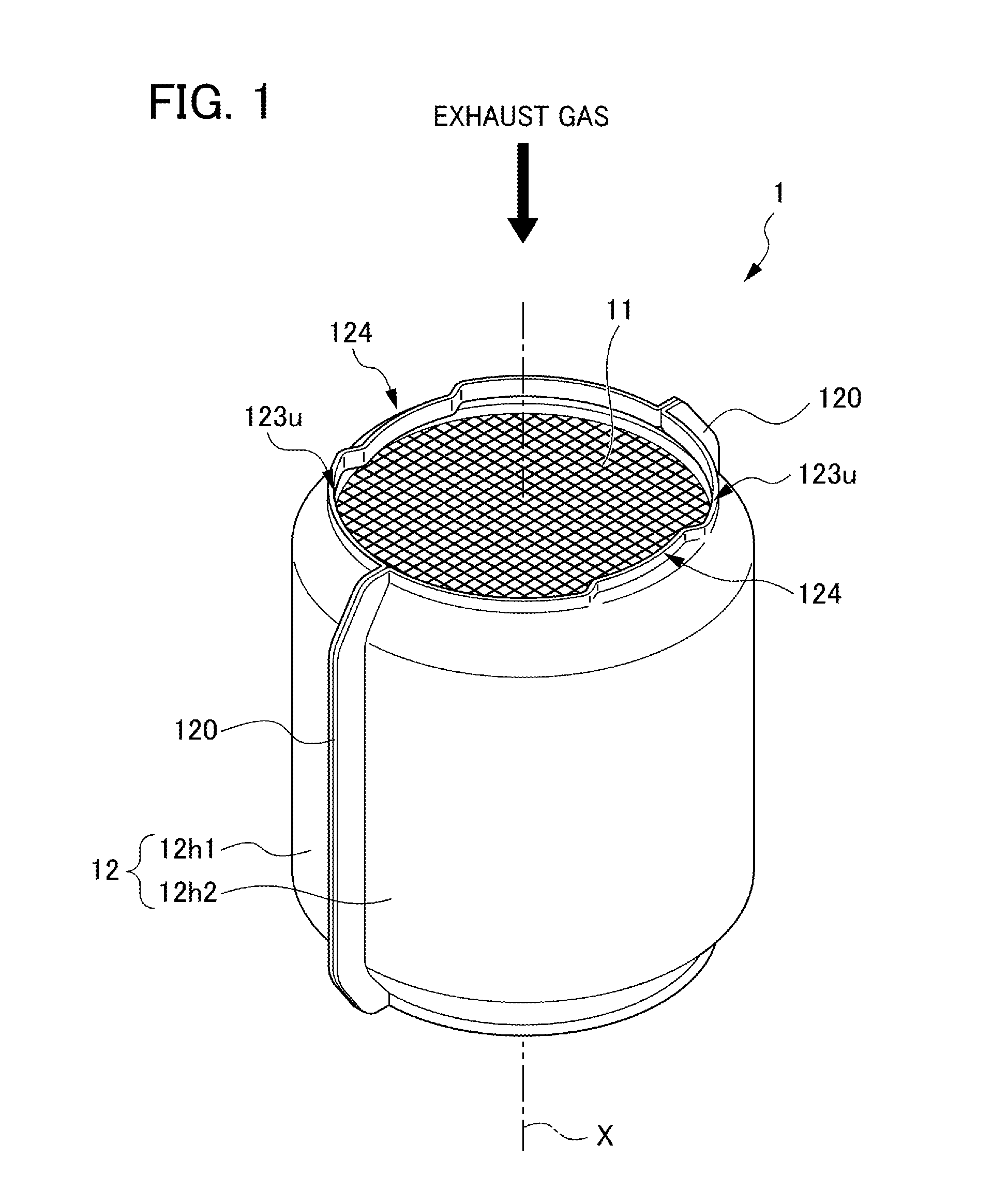

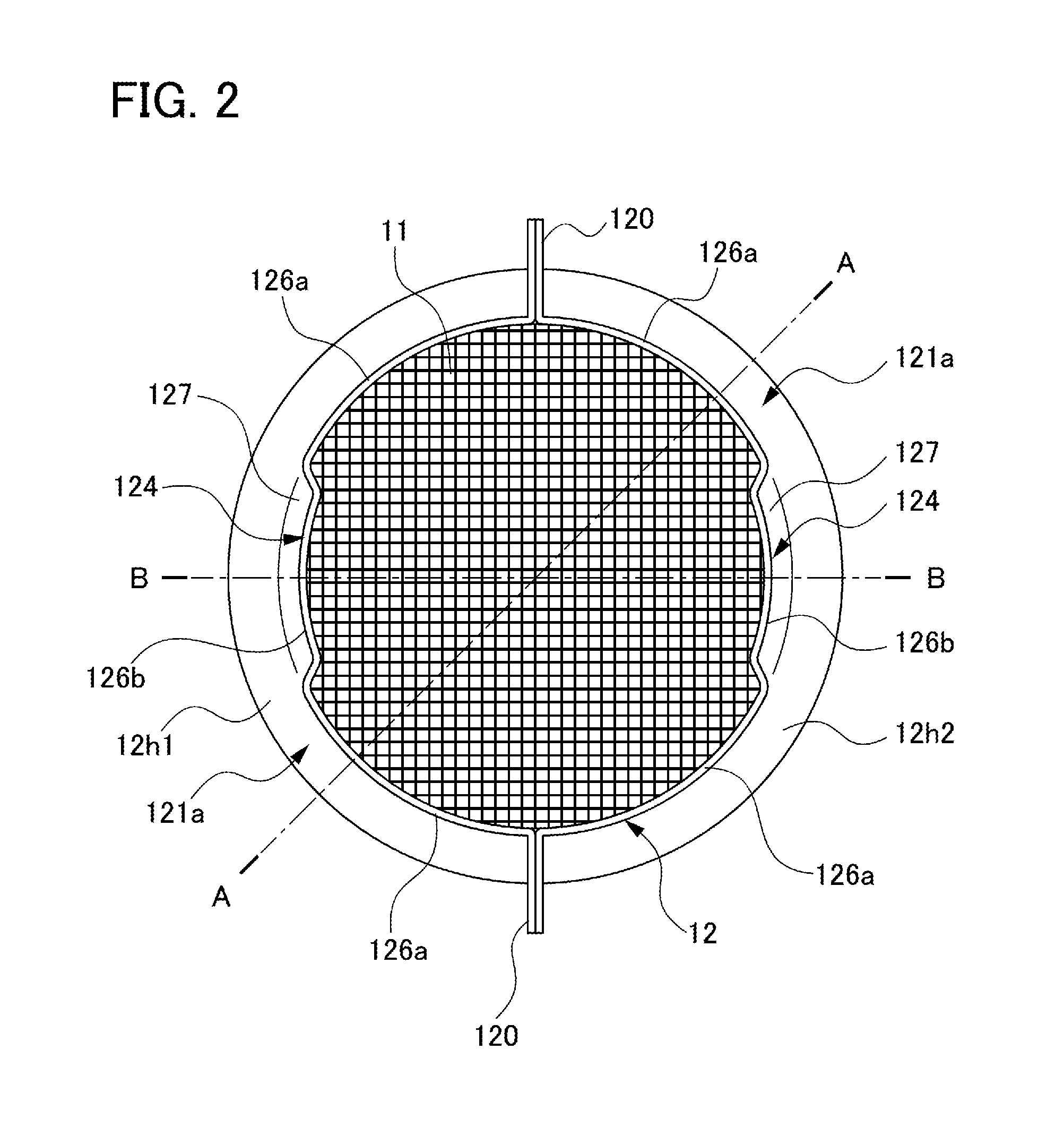

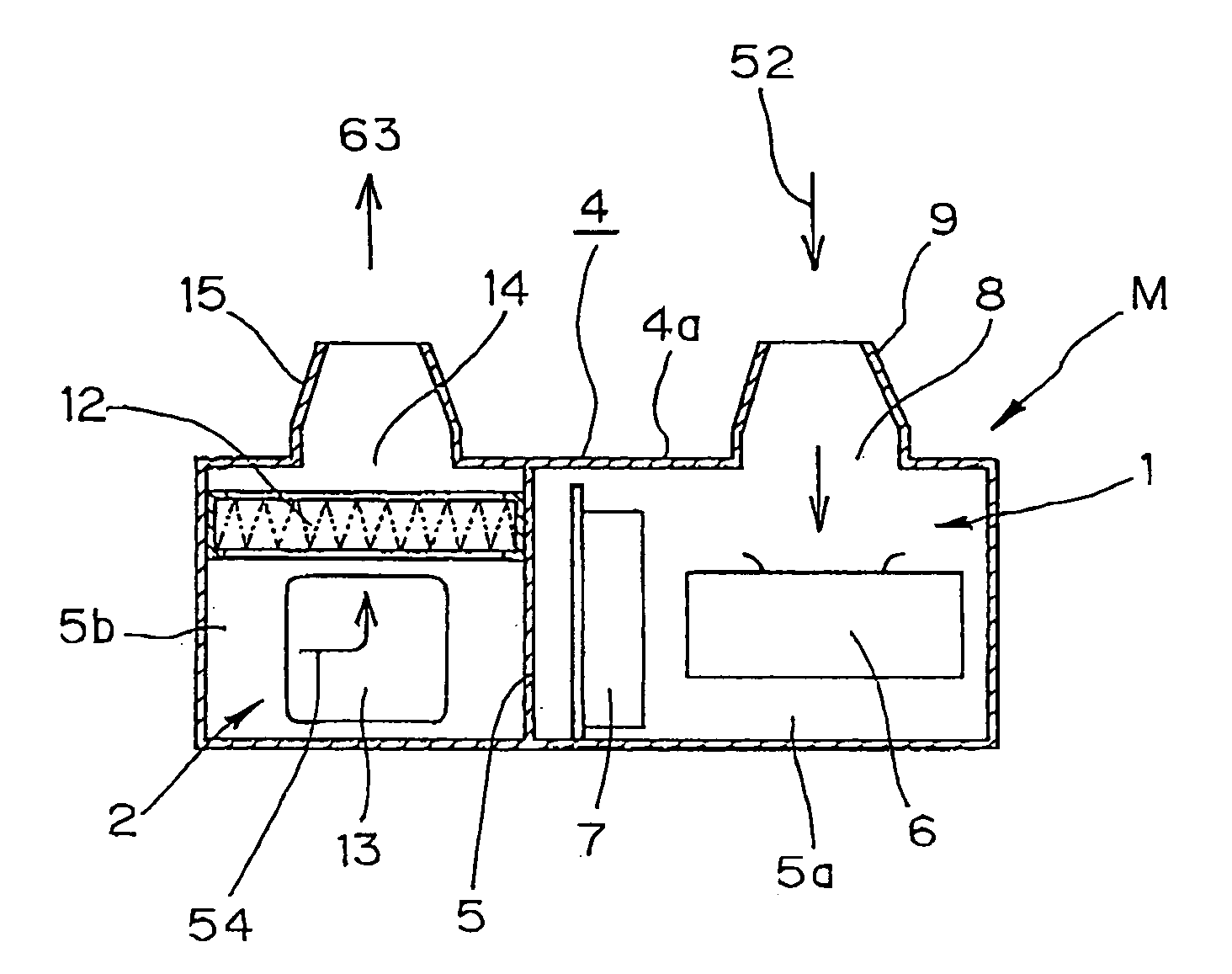

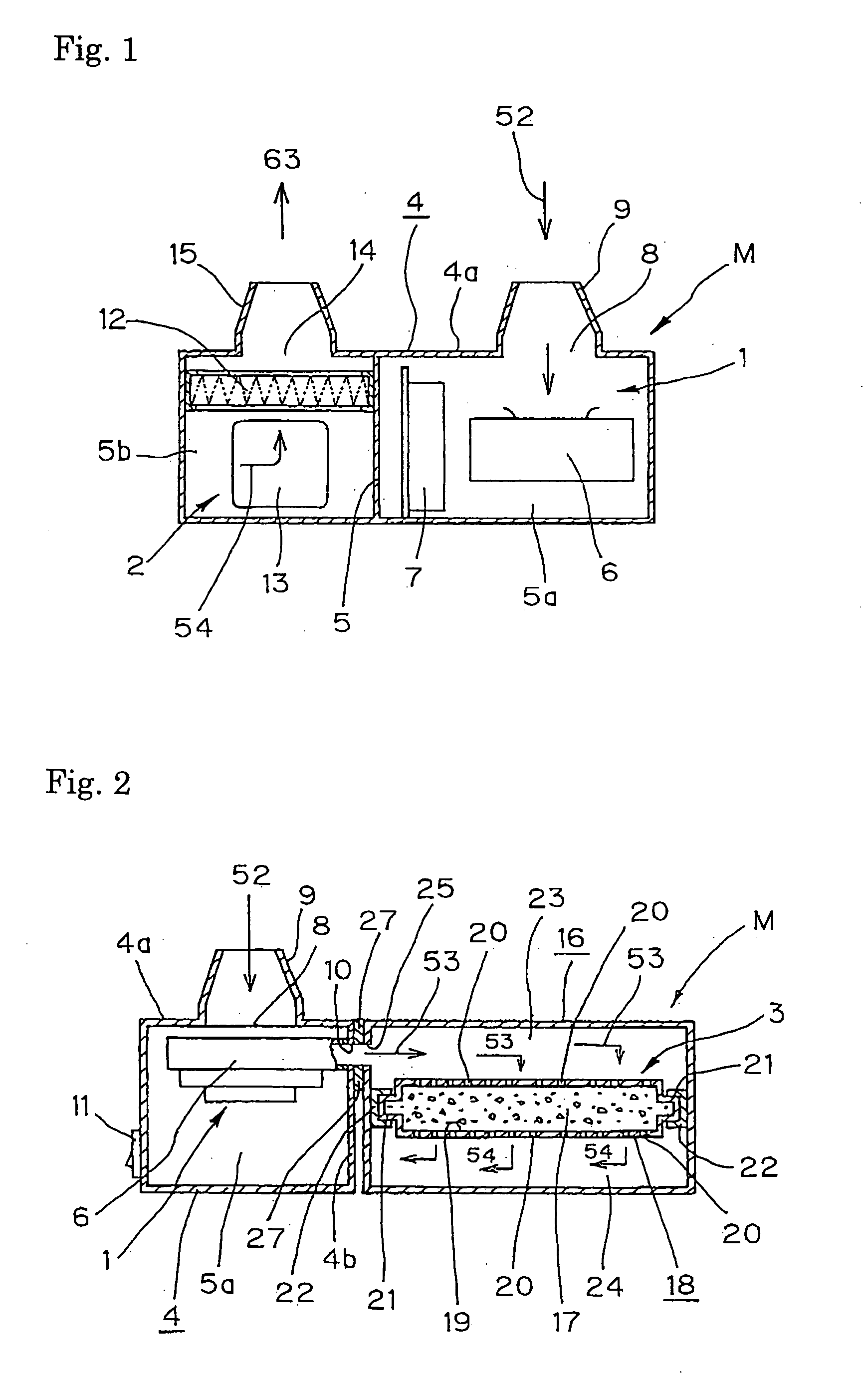

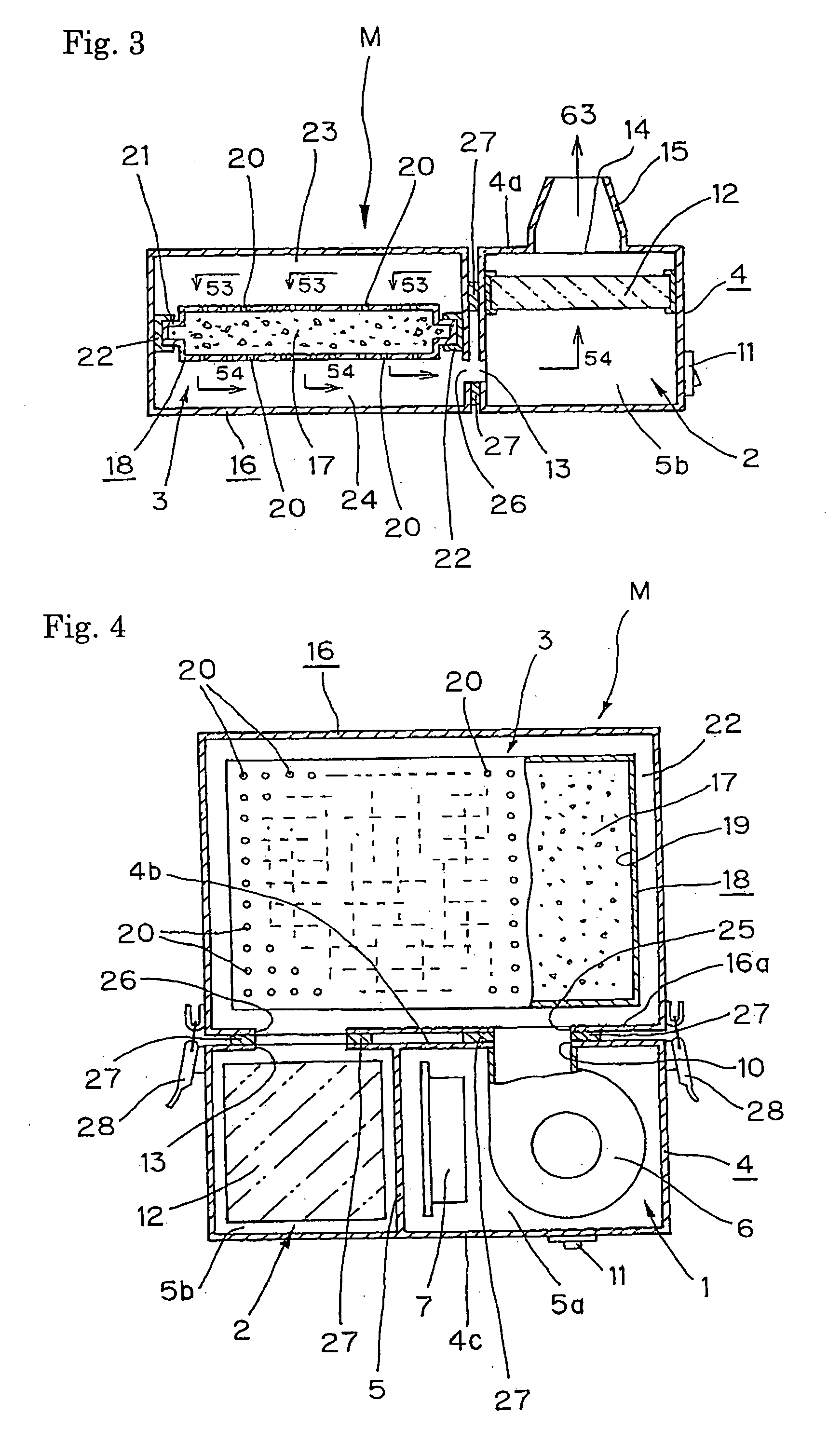

Exhaust gas purifying device for internal combustion engine

ActiveUS20160348552A1Loss of effective volumeReliable retentionGas treatmentInternal combustion piston enginesExhaust gasExhaust fumes

Owner:HONDA MOTOR CO LTD

Air-purifying device for a front-opening unified pod

InactiveUS20050268580A1Maintain purityCombination devicesAuxillary pretreatmentCompound (substance)Engineering

Owner:CAMBRIDGE FILTER JAPAN +2

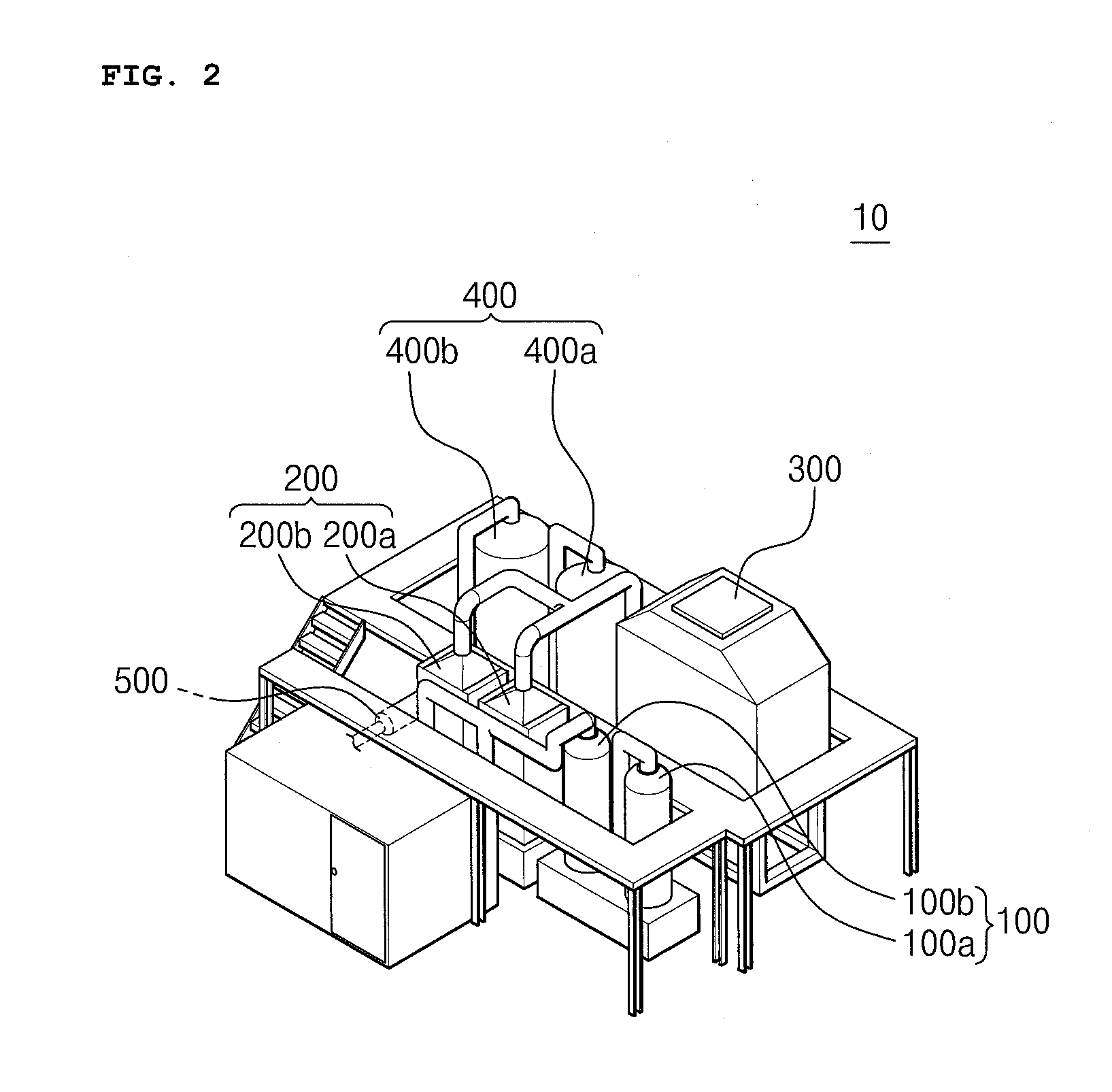

Apparatus and method for treating perfluoro-compound

Owner:GLOBAL STANDARD TECH

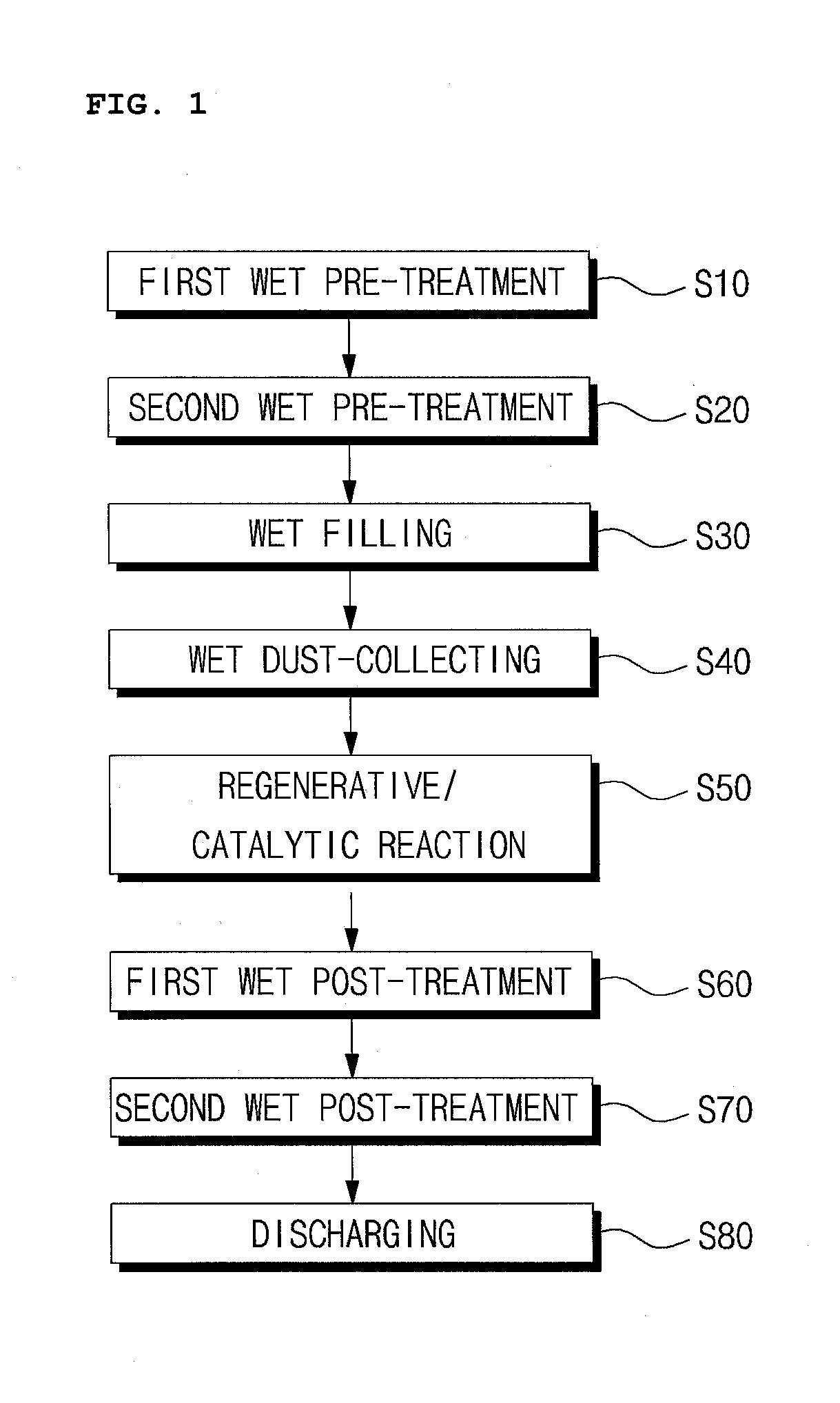

Flue gas desulfurization and denitration system and method

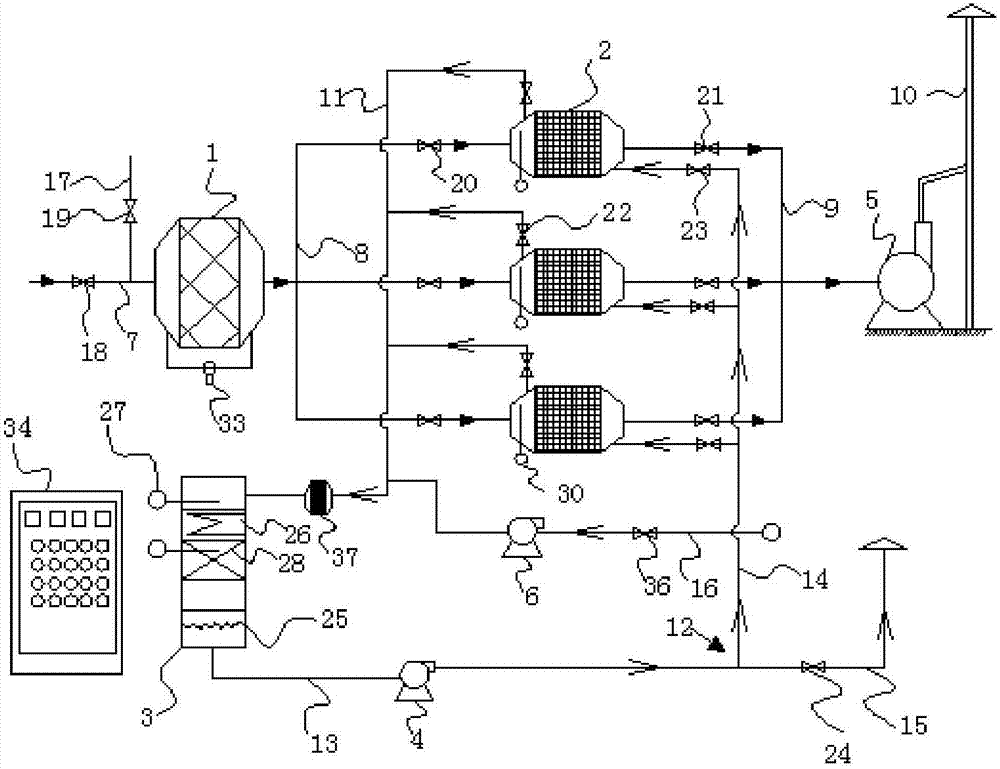

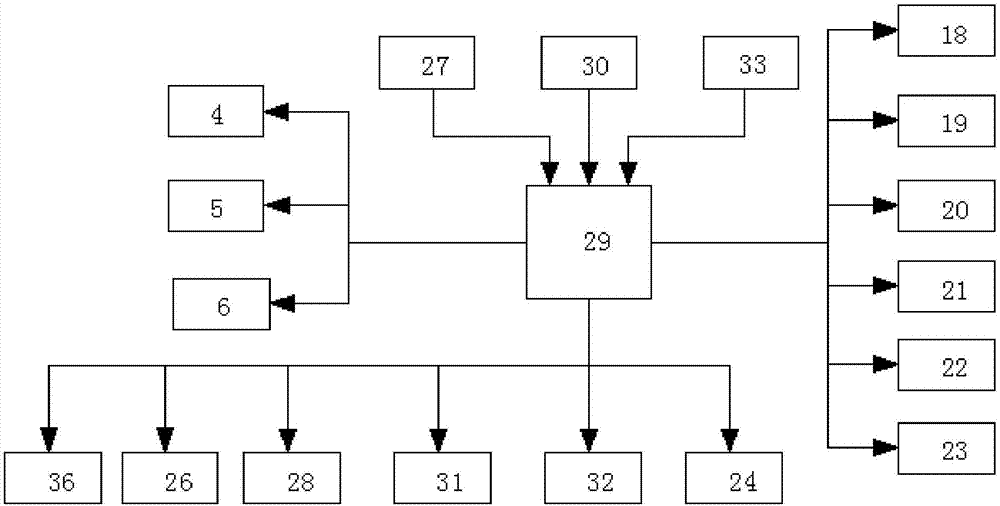

The invention discloses a flue gas desulfurization and denitration system and method, and belongs to the technical field of flue gas processing. The system comprises a pre-deduster, a rotating spray desulfurization and denitration system, an induced draft fan and a chimney, a circulating fluidized bed desulfurization system is arranged between the rotating spray desulfurization and denitration system and the induced draft fan, and a flue gas mixing axial adjustment damper is arranged between the rotating spray desulfurization and denitration system and the circulating fluidized bed desulfurization system; the system further comprises a booster conveying fan, a material conveying pump I and a material conveying pump II. Accordingly, the rotating spray desulfurization and denitration systemand the circulating fluidized bed desulfurization system are combined, step-by-step desulfurization and denitration on flue gas are achieved, and the desulfurization and denitration efficiency is high; due to step-by-step desulfurization and denitration, the system and method can be applied to desulfurization and denitration processing of the flue gas high in sulfur content and nitrate content, and the application range is high.

Owner:NANJING SHIBO ENVIRONMENTAL PROTECTION TECH CO LTD

Powdery active coke combined desulfurization and denitration system and method

PendingCN108144443AImprove effective utilizationImprove desulfurization and denitrification efficiencyGas treatmentDispersed particle separationGas solidBaghouse

Owner:SHANDONG UNIV

Simulated ecological air purifier

Owner:SHENZHEN MEIZHAO ENERGY & ENVIRONMENT TECH

Embedded microwave cyclic adsorption-desorption column and operation method thereof

InactiveCN110090527AAchieve recyclingEvenly heatedGas treatmentOther chemical processesMicrowaveEngineering

Owner:CHANGZHOU UNIV

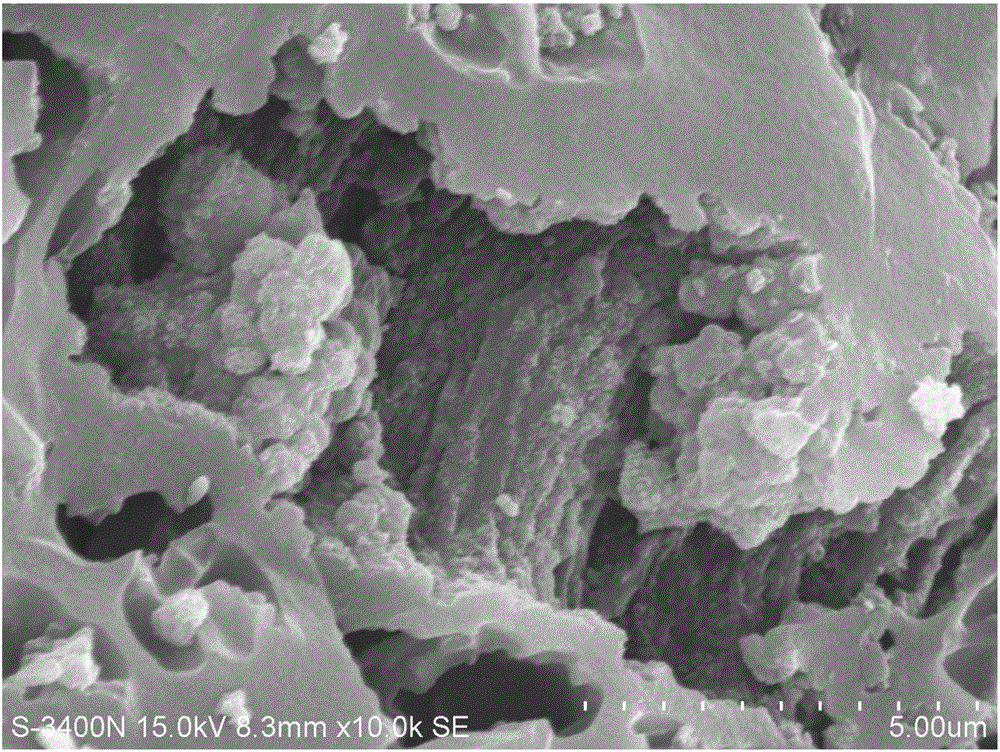

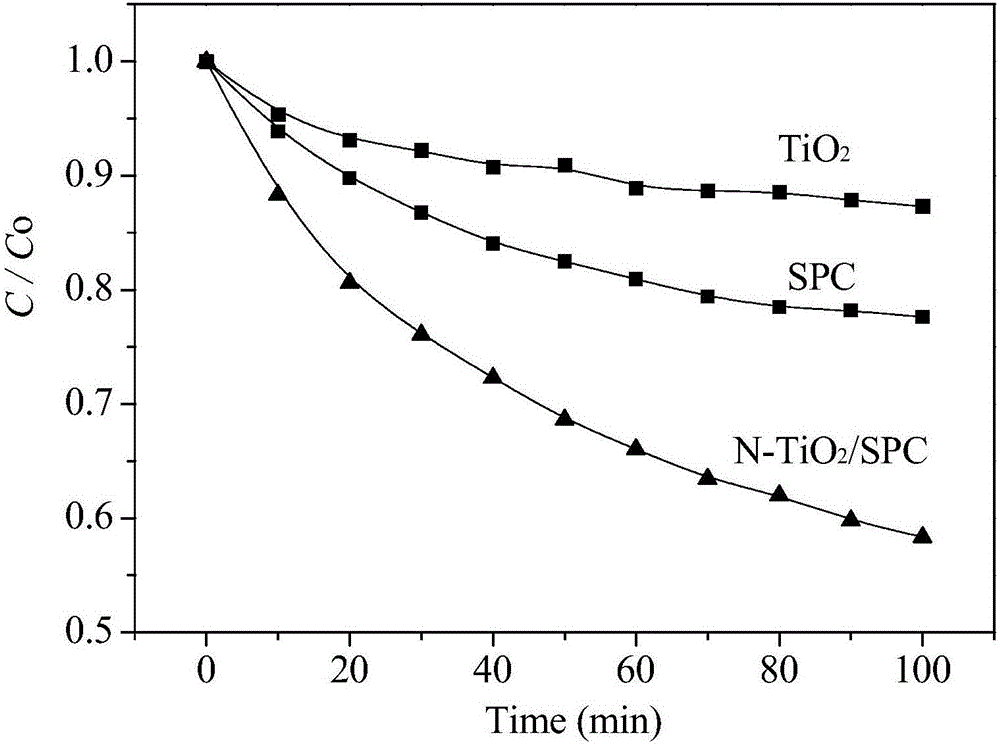

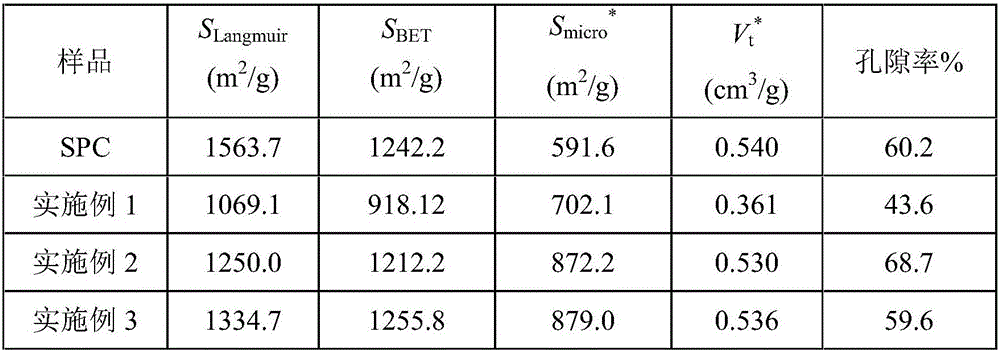

Bifunctional adsorbent of N-TiO2 silkworm-excrement porous carbon and preparation method of bifunctional adsorbent

InactiveCN106268641AGood dispersionHigh reactivityGas treatmentPhysical/chemical process catalystsPorous carbonShielding gas

Owner:GUANGXI UNIV

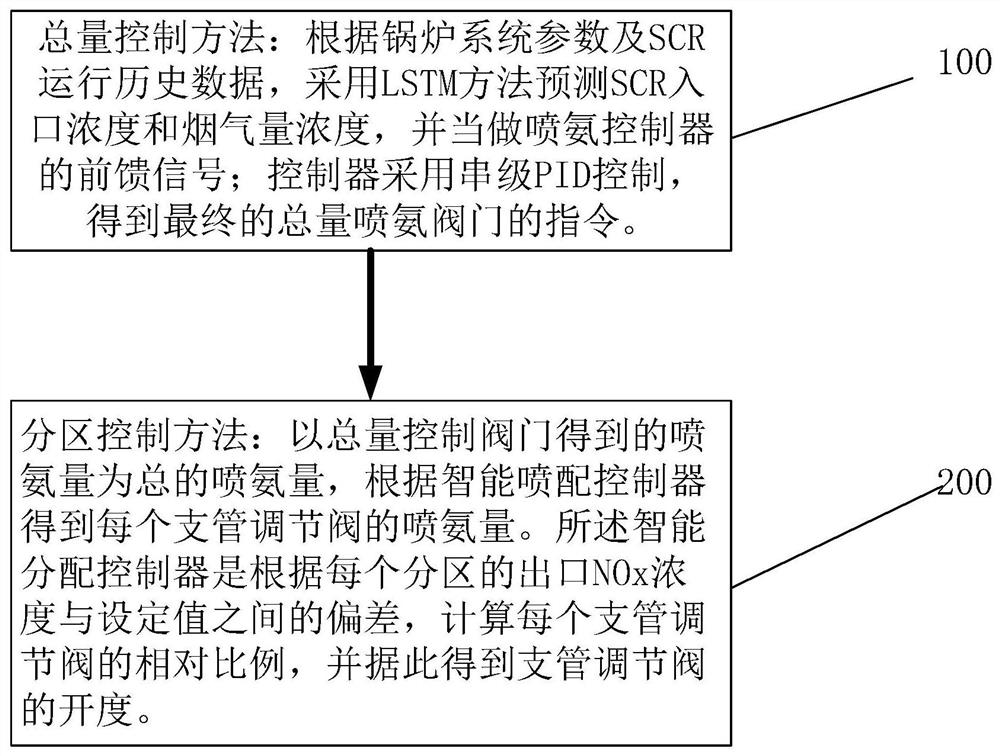

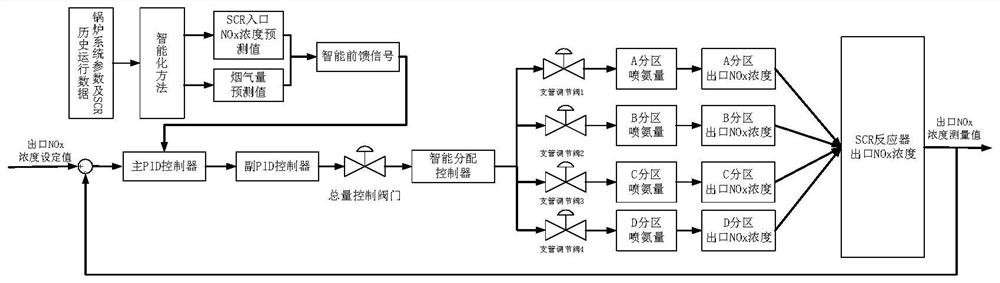

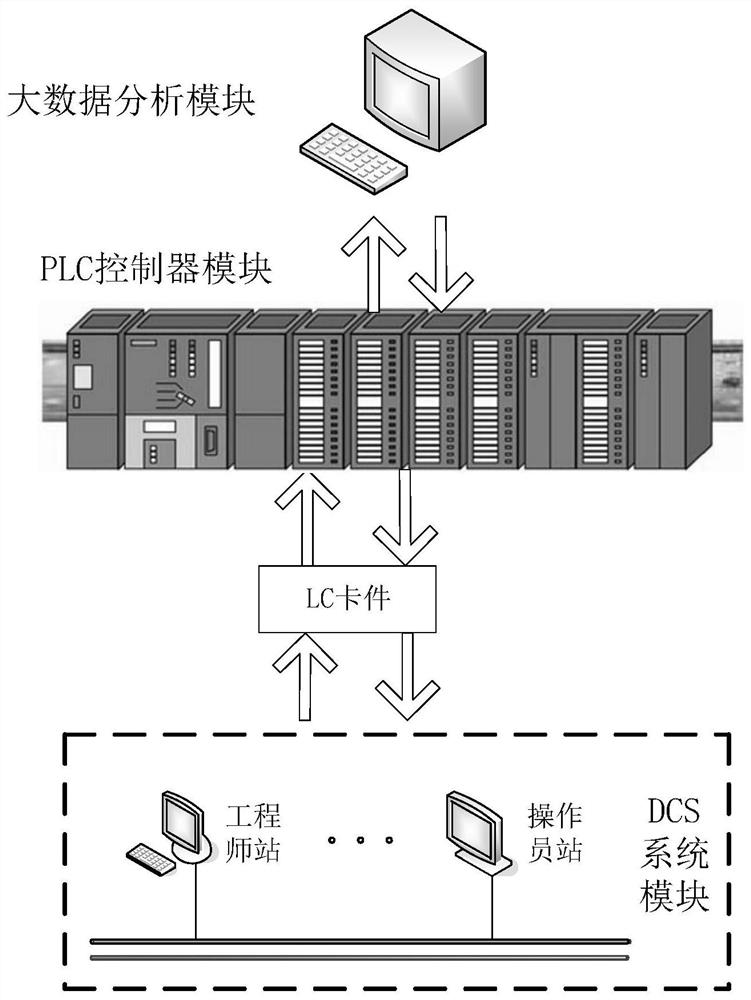

Intelligent dynamic partition ammonia spraying control method and system

InactiveCN111880504AGas treatmentDispersed particle separationProcess engineeringSystems engineering

Owner:DATANG ENVIRONMENT IND GRP

Desulfurization wastewater zero discharging system and method based on waste heat reuse under low-load working condition

PendingCN107973475AIncrease temperatureSolve the problem of incomplete evaporationGas treatmentLighting and heating apparatusFlue gasEvaporation

Owner:DATANG ENVIRONMENT IND GRP

Hydrodesulfurization device, hydrogen generator and fuel cell system

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Preparation method of porous rod-shaped spinel structured catalyst

InactiveCN105854892AHigh catalytic activitySynthesis temperature is lowGas treatmentDispersed particle separationAnhydrous ethanolPtru catalyst

The invention relates to a preparation method of a catalyst, and concretely relates to a preparation method of a porous rod-shaped spinel structured catalyst. The preparation method comprises the following steps: respectively preparing an A type metal salt solution and a B type metal salt solution by using deionized water; measuring the above two solutions, and uniformly mixing the two solutions under magnetic stirring to obtain a clarified dark blue solution; gradually adding an NH4(OH) solution to the above obtained mixed solution, and adding cetyltrimethylammonium chloride to water to form gel; preparing an aqueous solution of hydrazine hydrate, continuously heating the above stirred mixed solution, and cooling the heated mixed solution to room temperature in order to obtain a green fluffy solid product; washing the solid product with deionized water and anhydrous ethanol multiple times, and drying the washed solid product to obtain solid powder; and transferring the solid powder to a quartz reactor, and heating and calcining the solid powder to obtain fluffy powder. The catalyst solves the technical problem of unsatisfactory purification of PM in diesel car tail gas.

Owner:SHENYANG UNIV

Ionic liquid dehumidifying method and system for regulating gas humidity

InactiveCN106076078AEfficient removalQuick removalGas treatmentDispersed particle separationHigh humidityIonic liquid

Owner:SUZHOU MOEWE ENVIRONMENTAL ENG CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap