Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

121results about "Dispersed particle filtration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

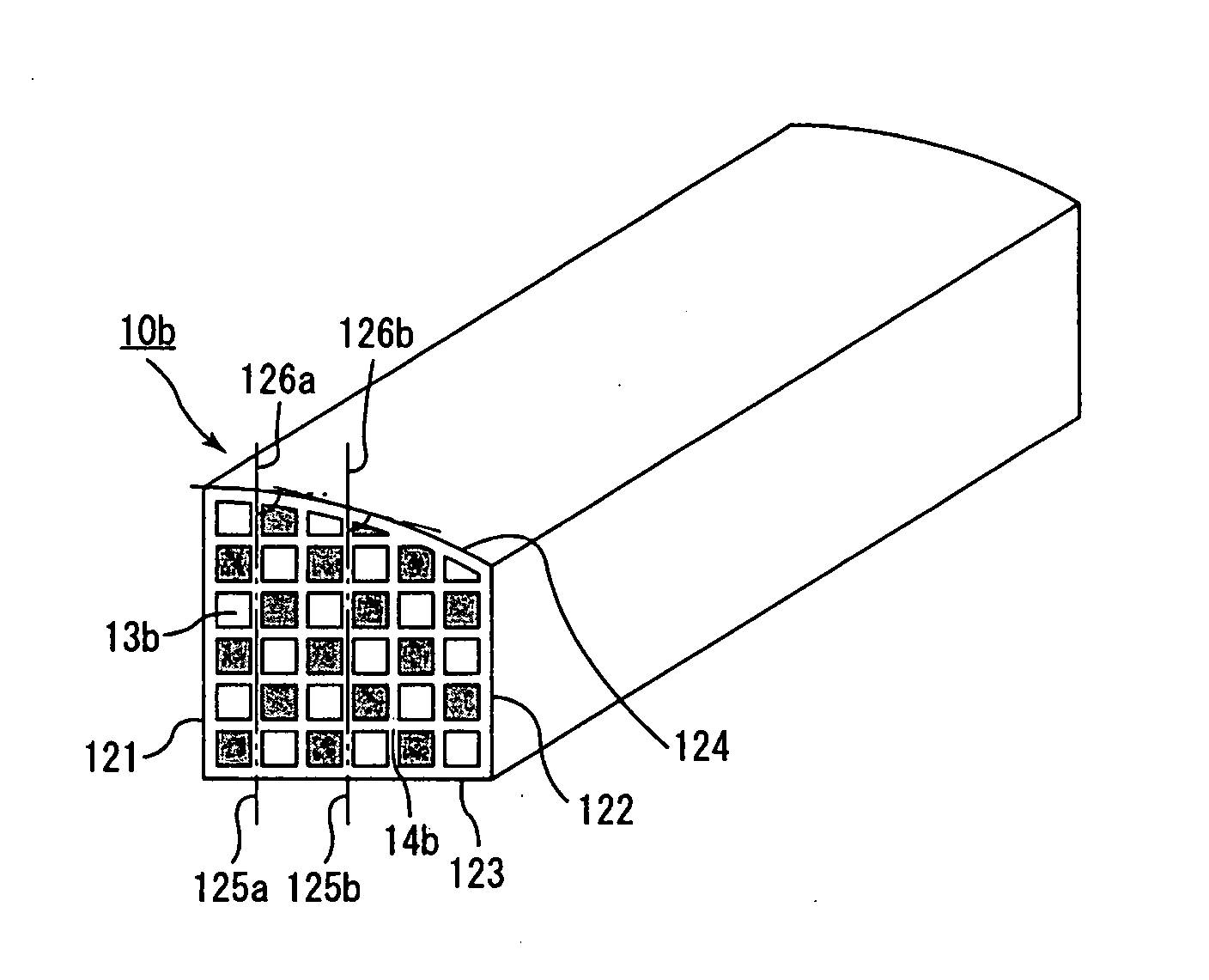

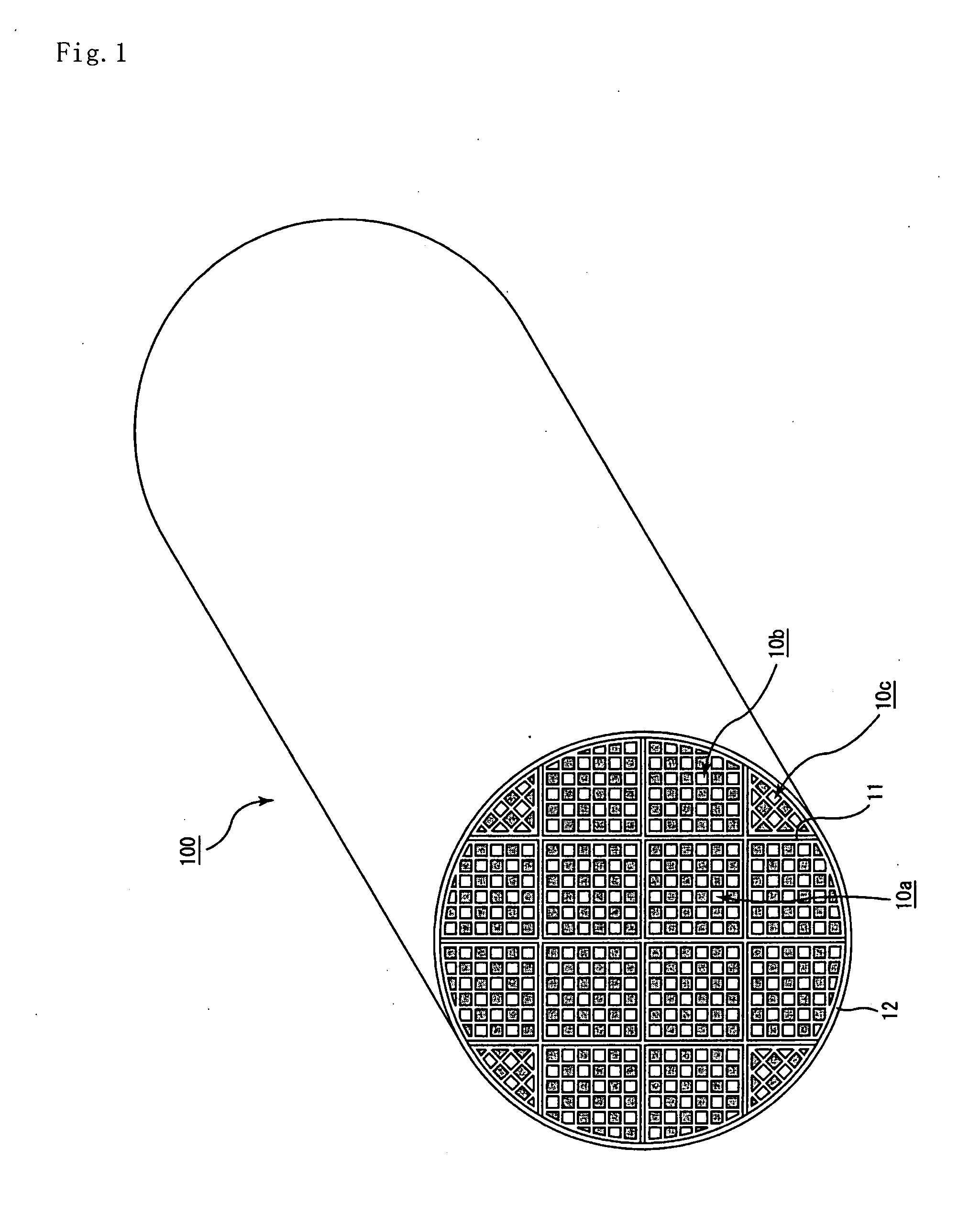

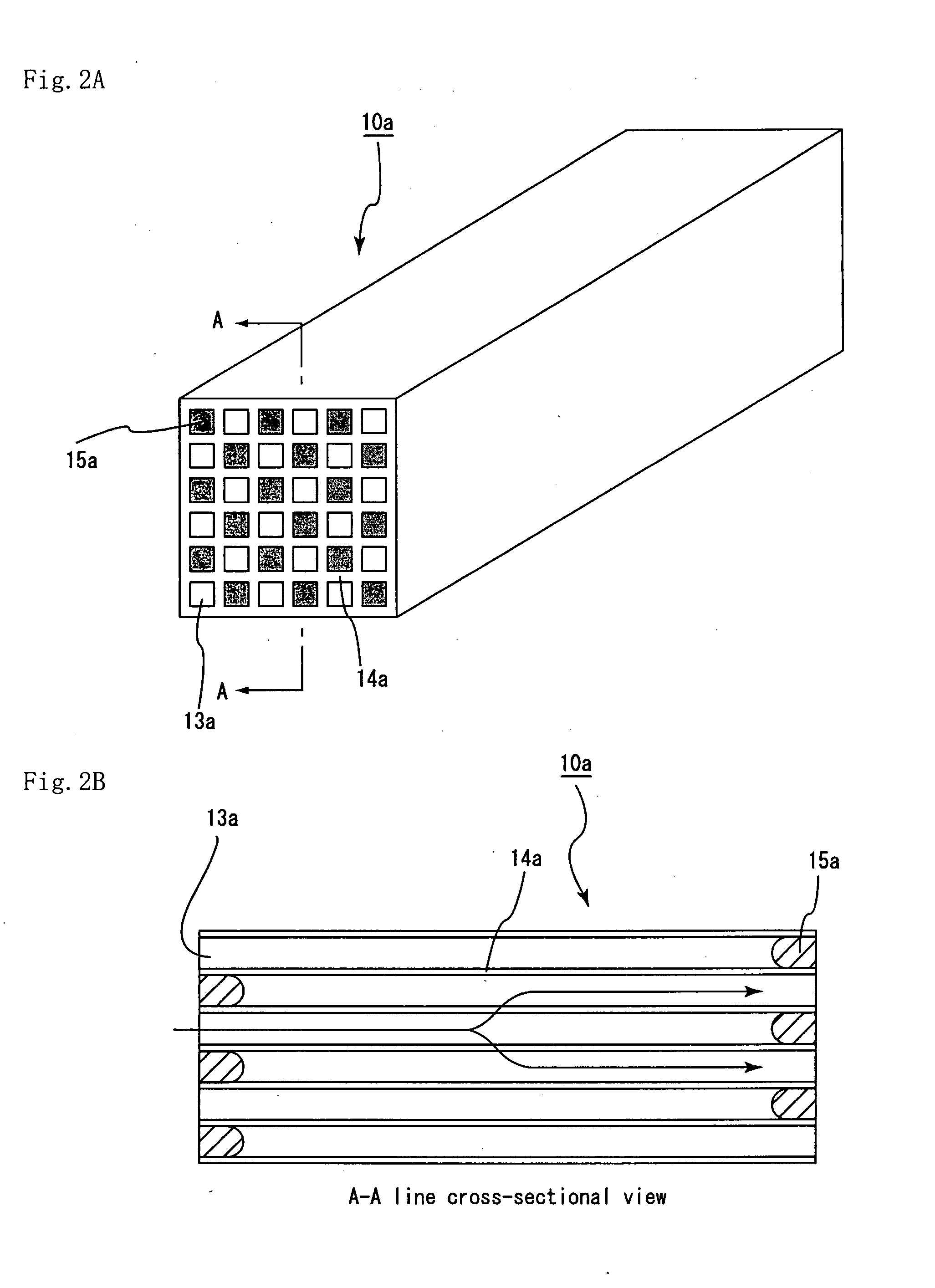

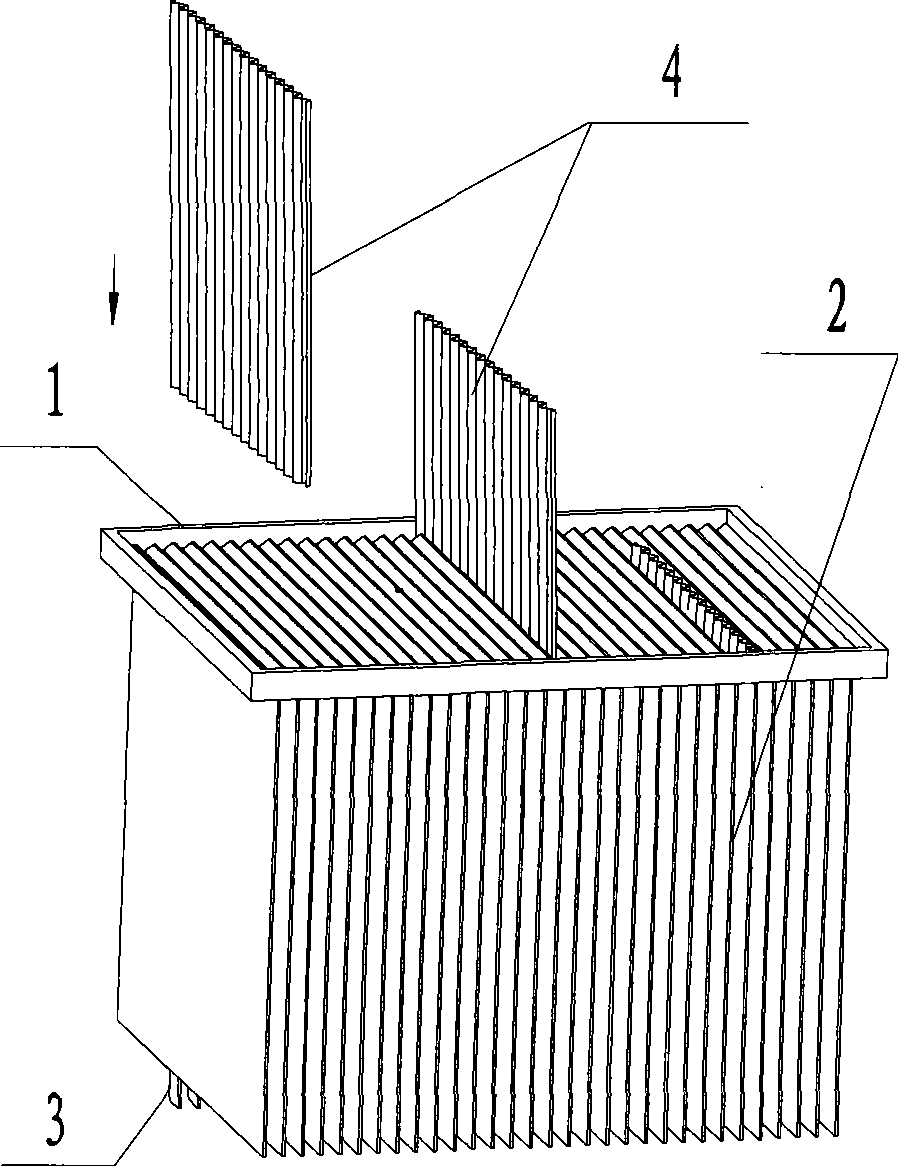

Honeycomb structured body

InactiveUS20070212517A1Dispersed particle filtrationLayered productsHoneycomb structureHoneycomb like

Owner:IBIDEN CO LTD

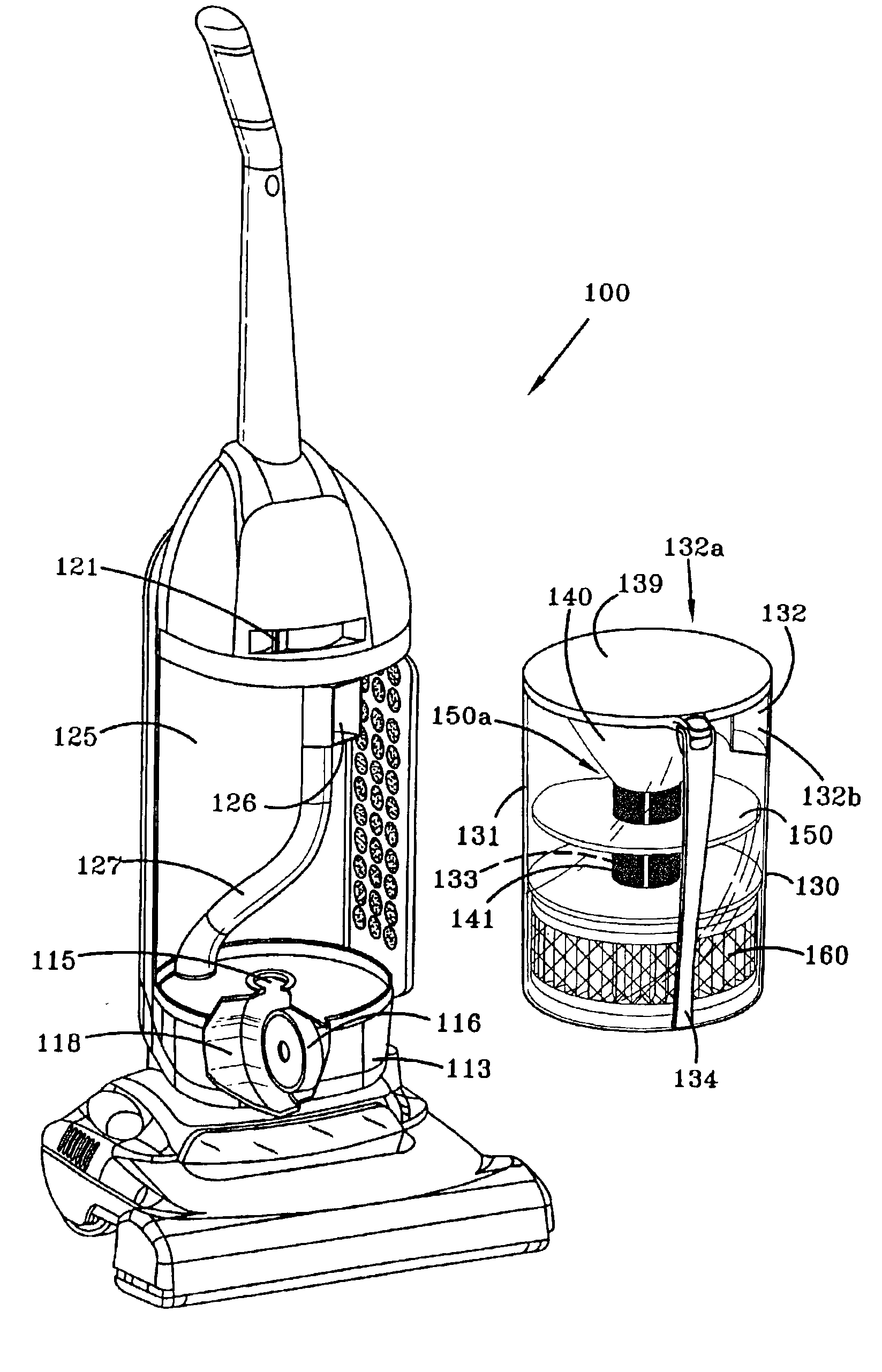

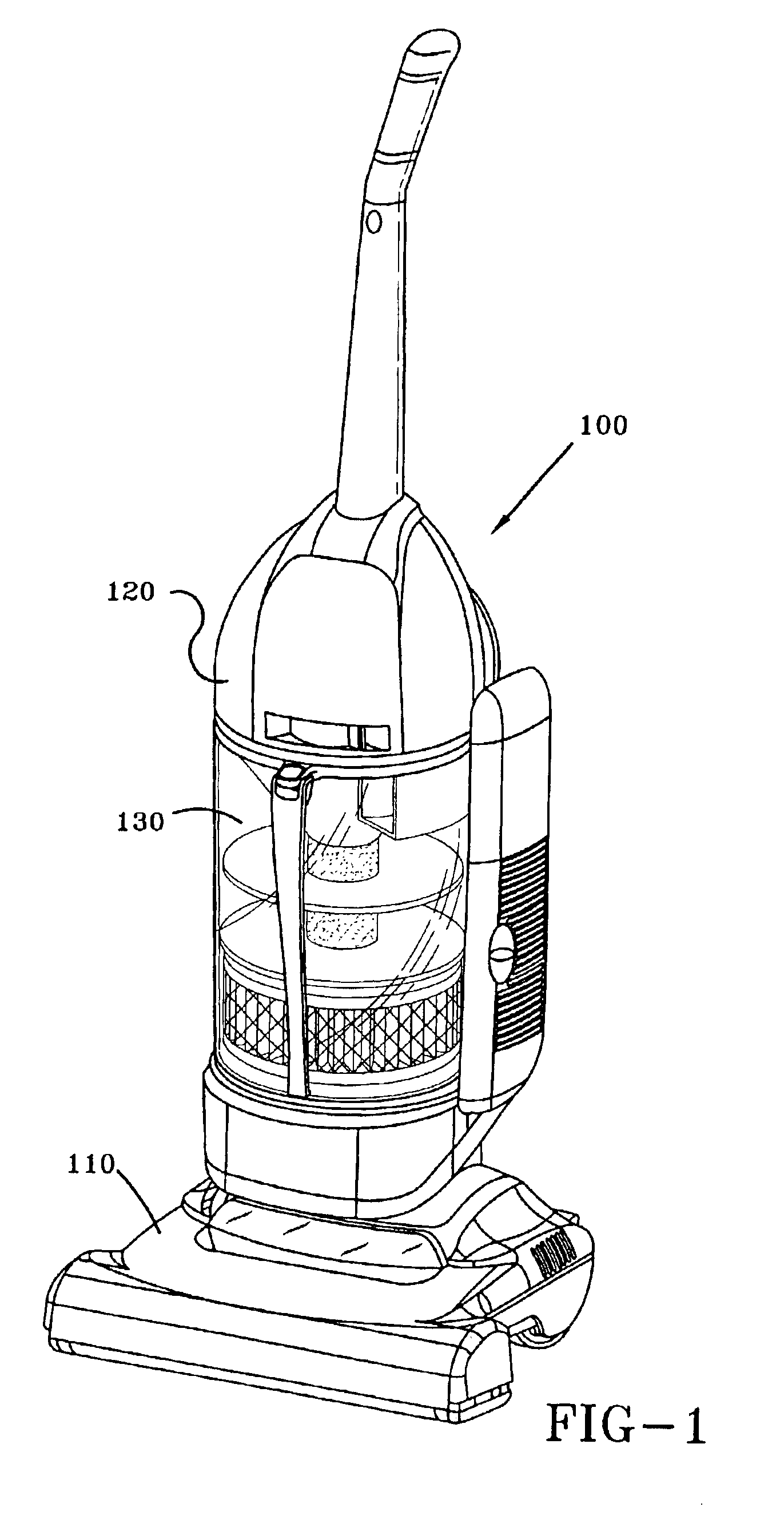

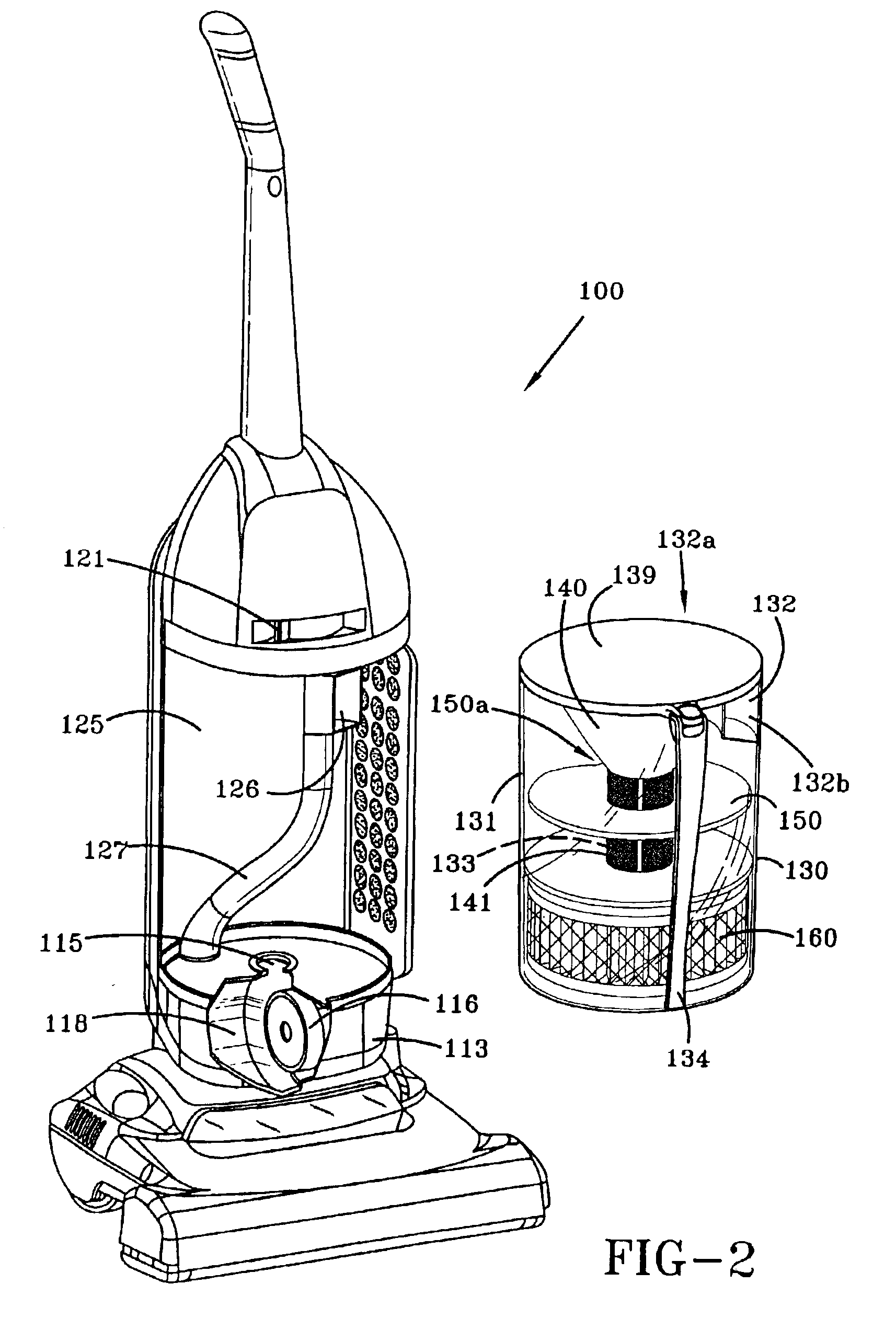

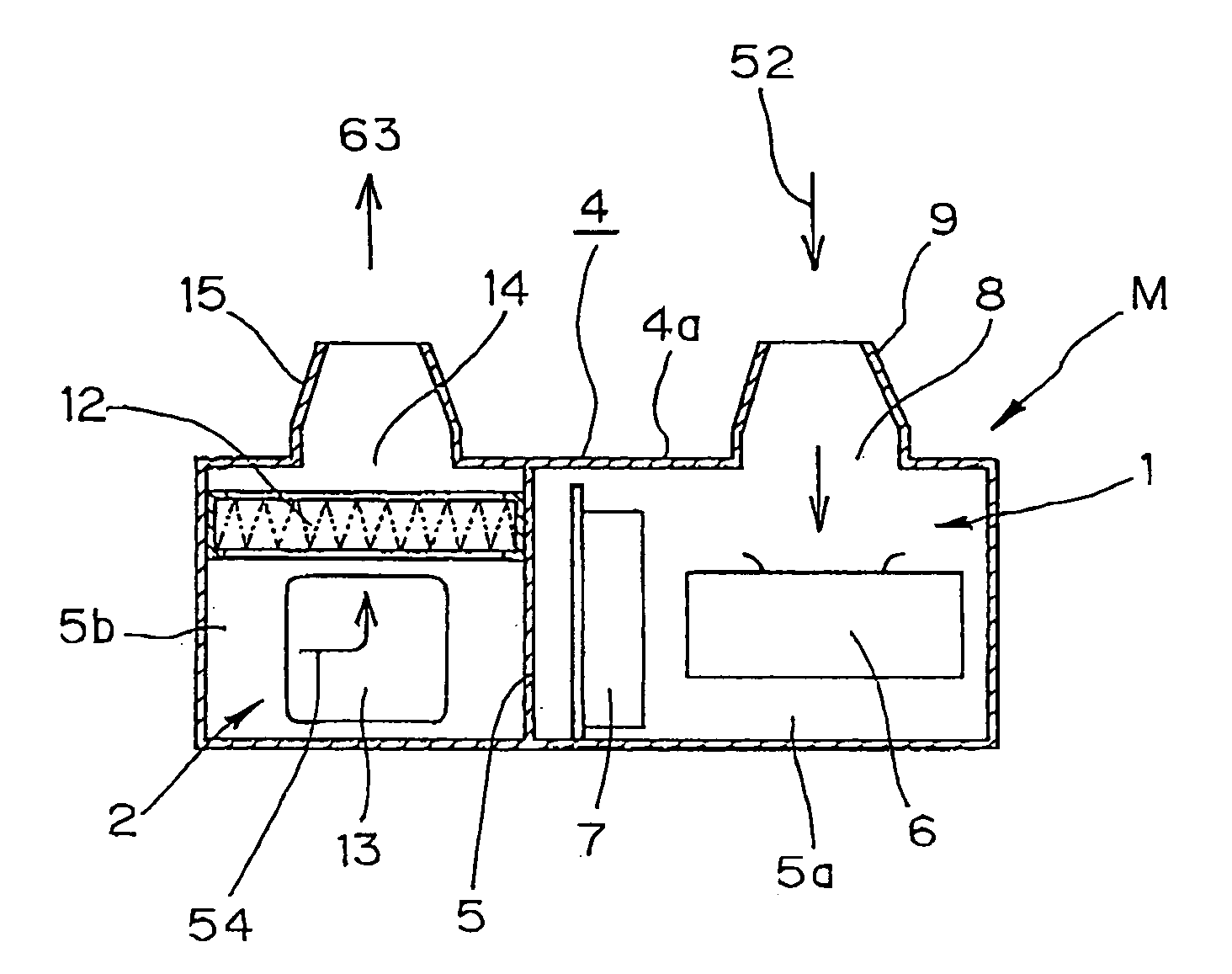

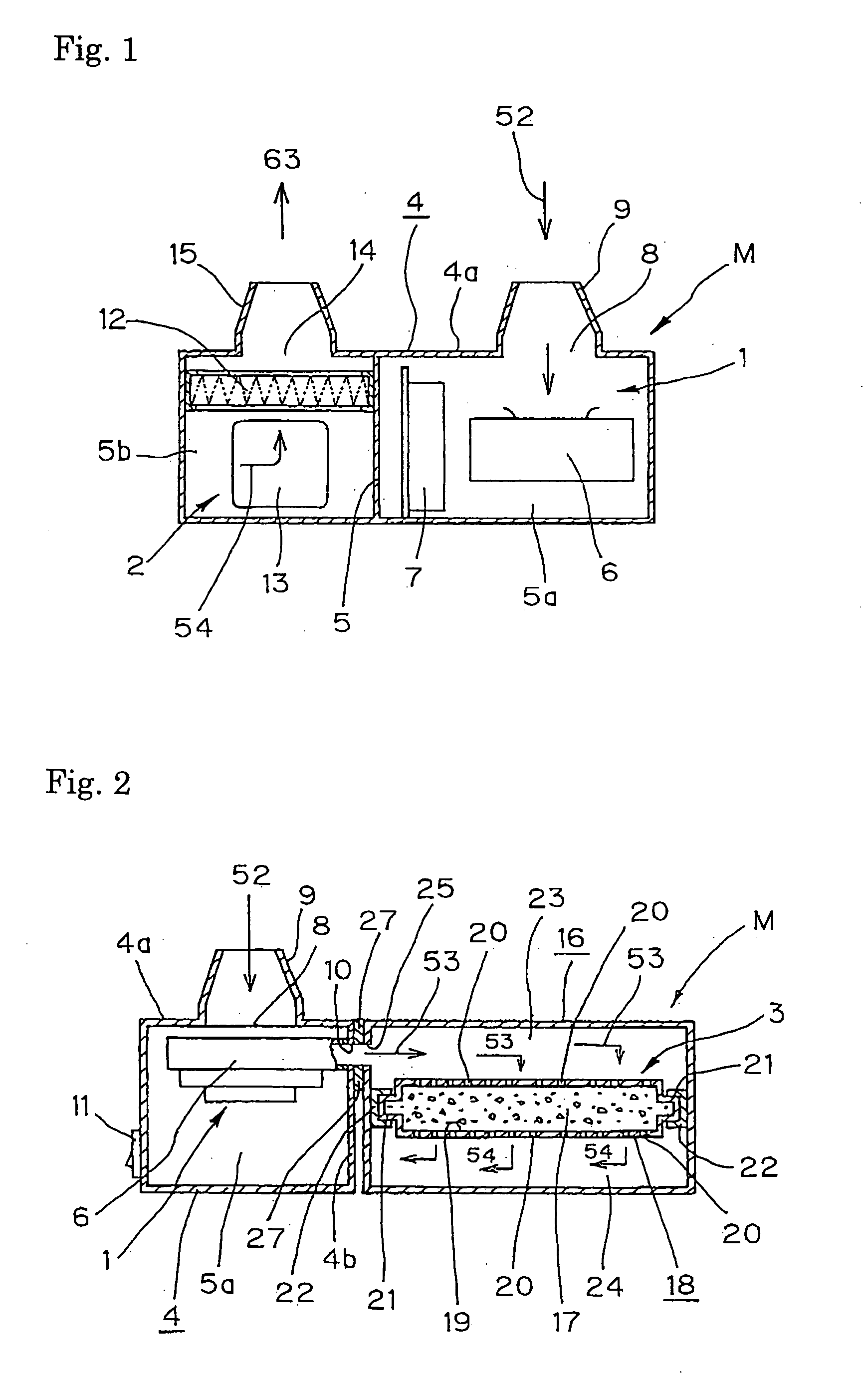

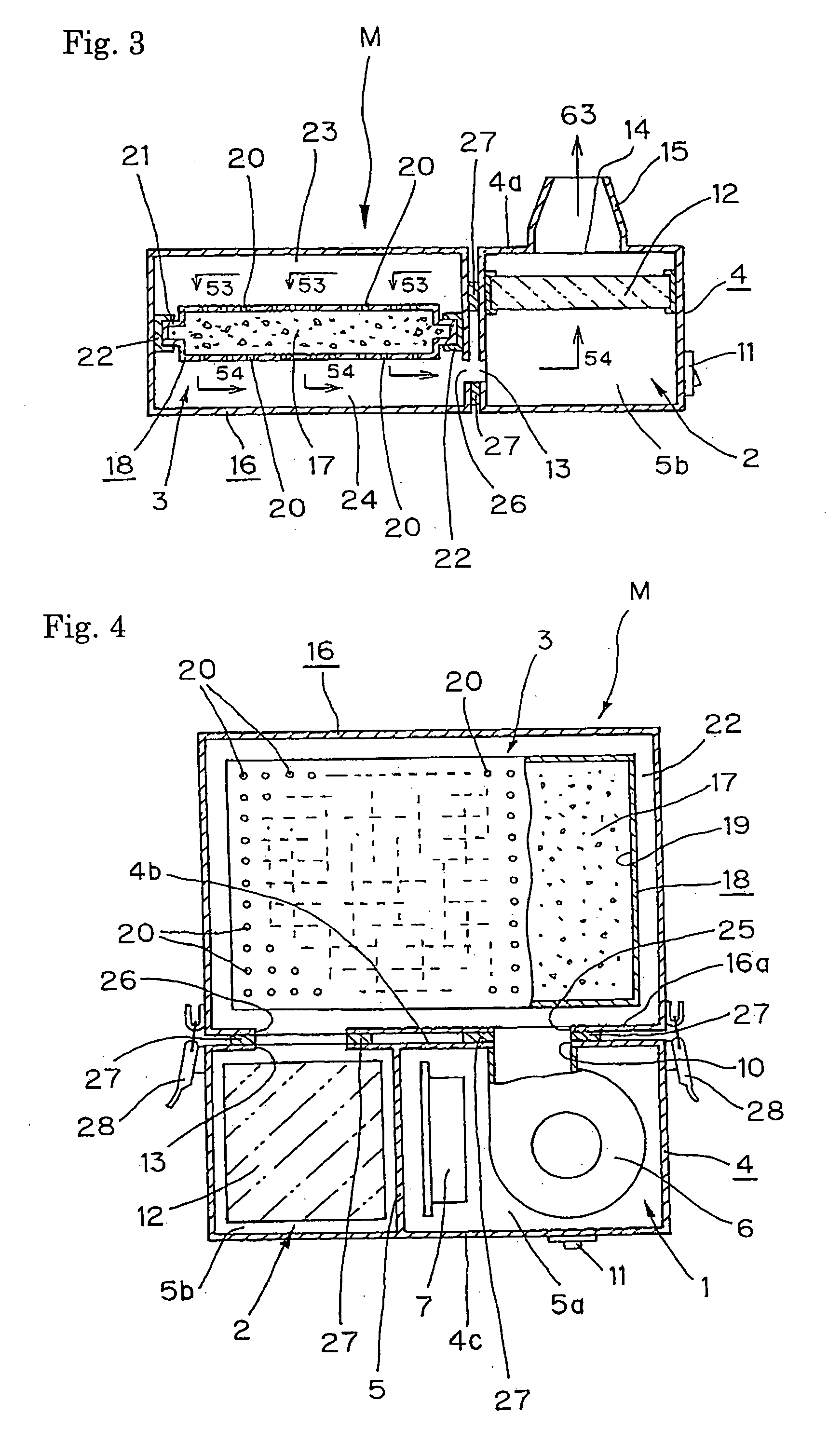

Dirt collecting system for a floor care appliance

InactiveUS6896719B2Improve filtering effectEasy to emptyCleaning filter meansCombination devicesEngineeringGuide tube

Owner:HEALTHY GAIN INVESTMENTS

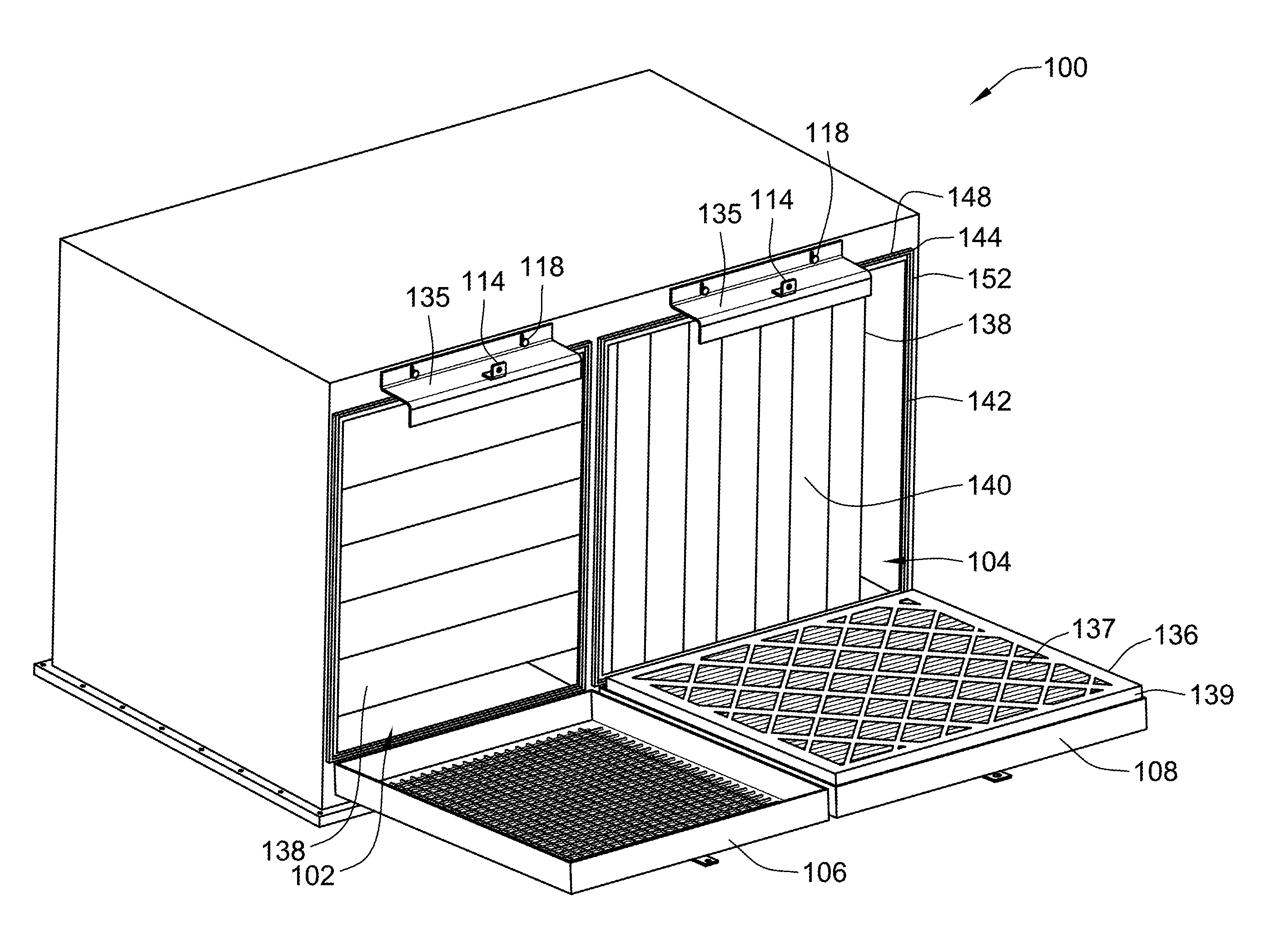

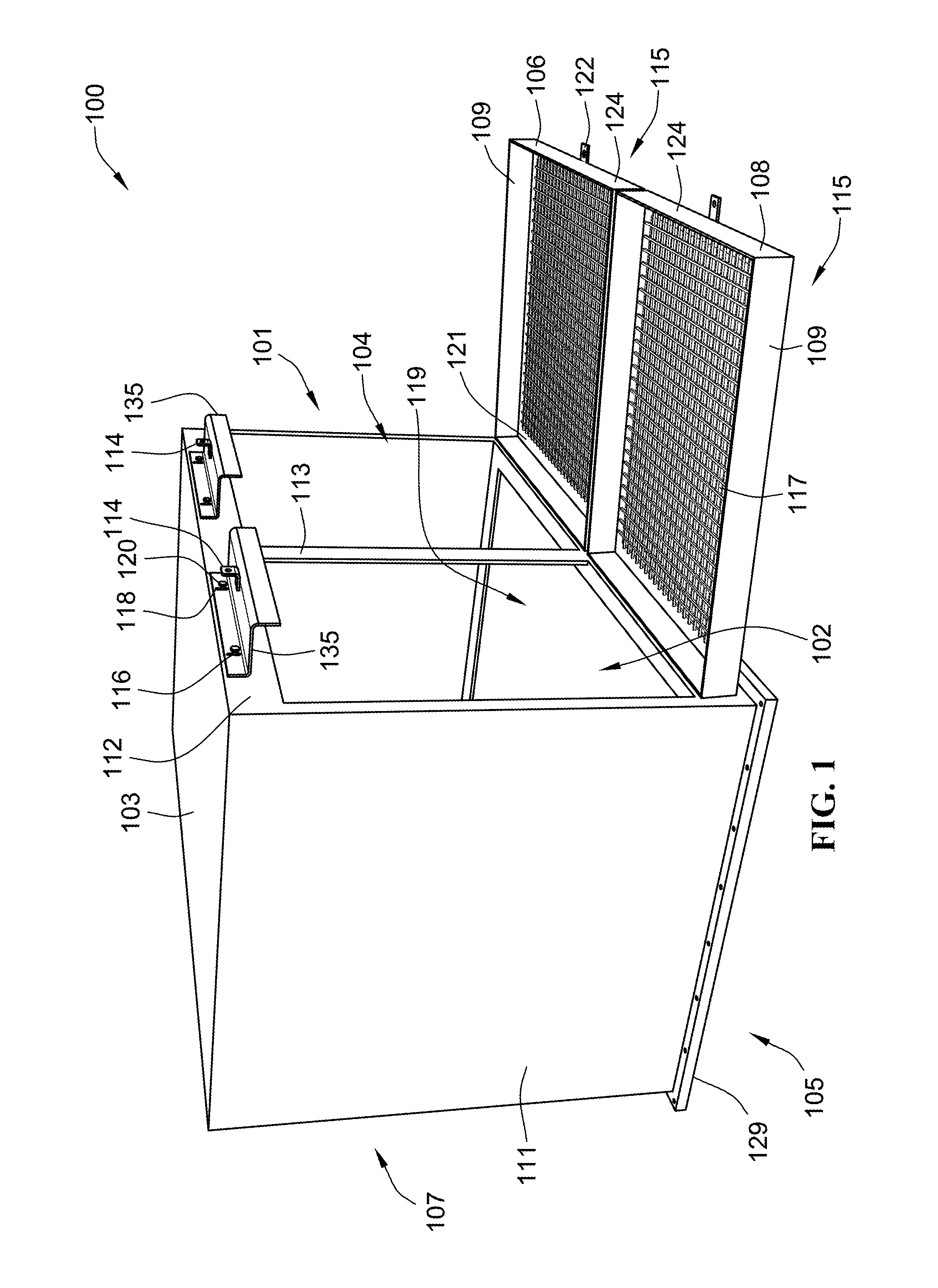

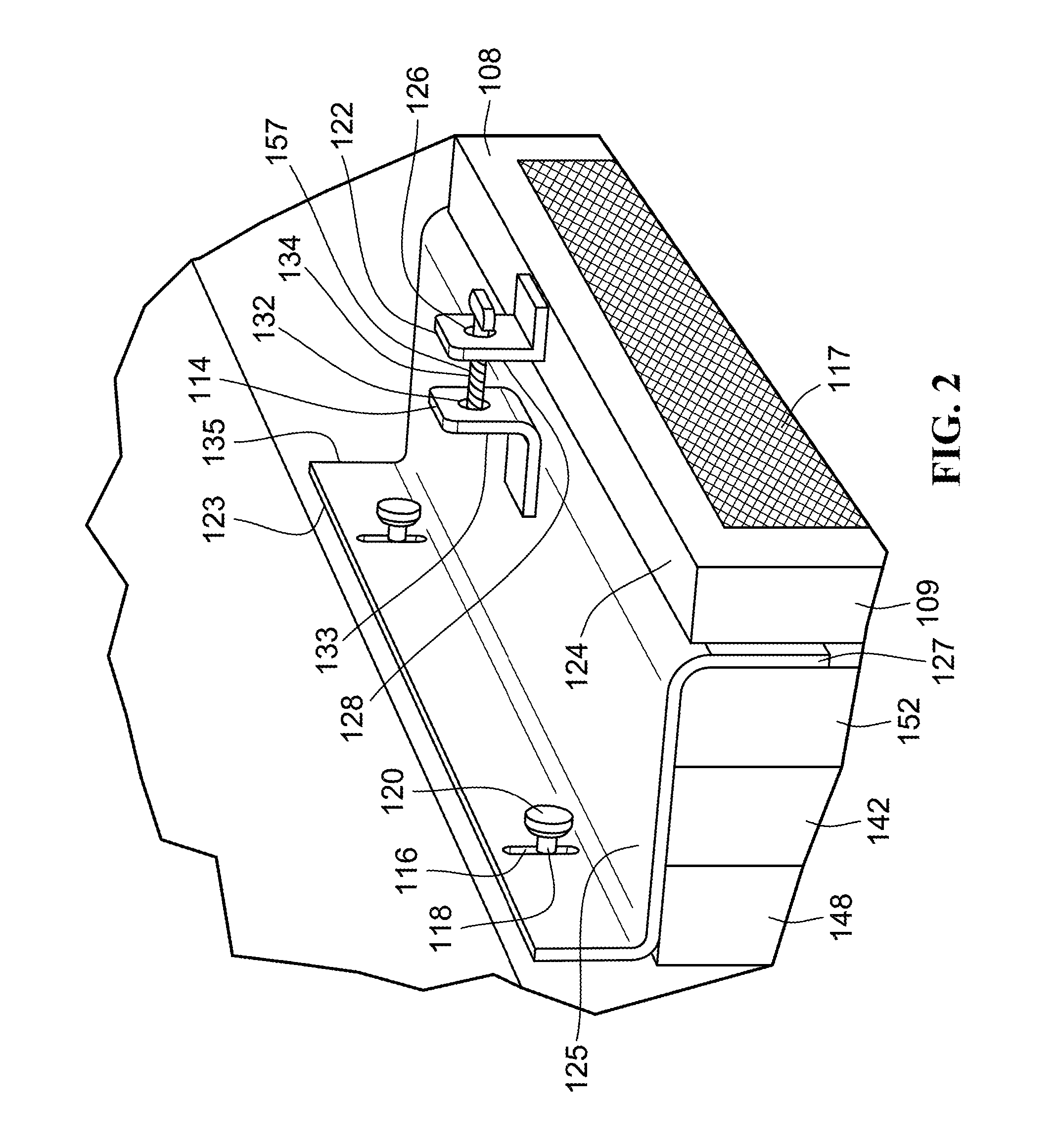

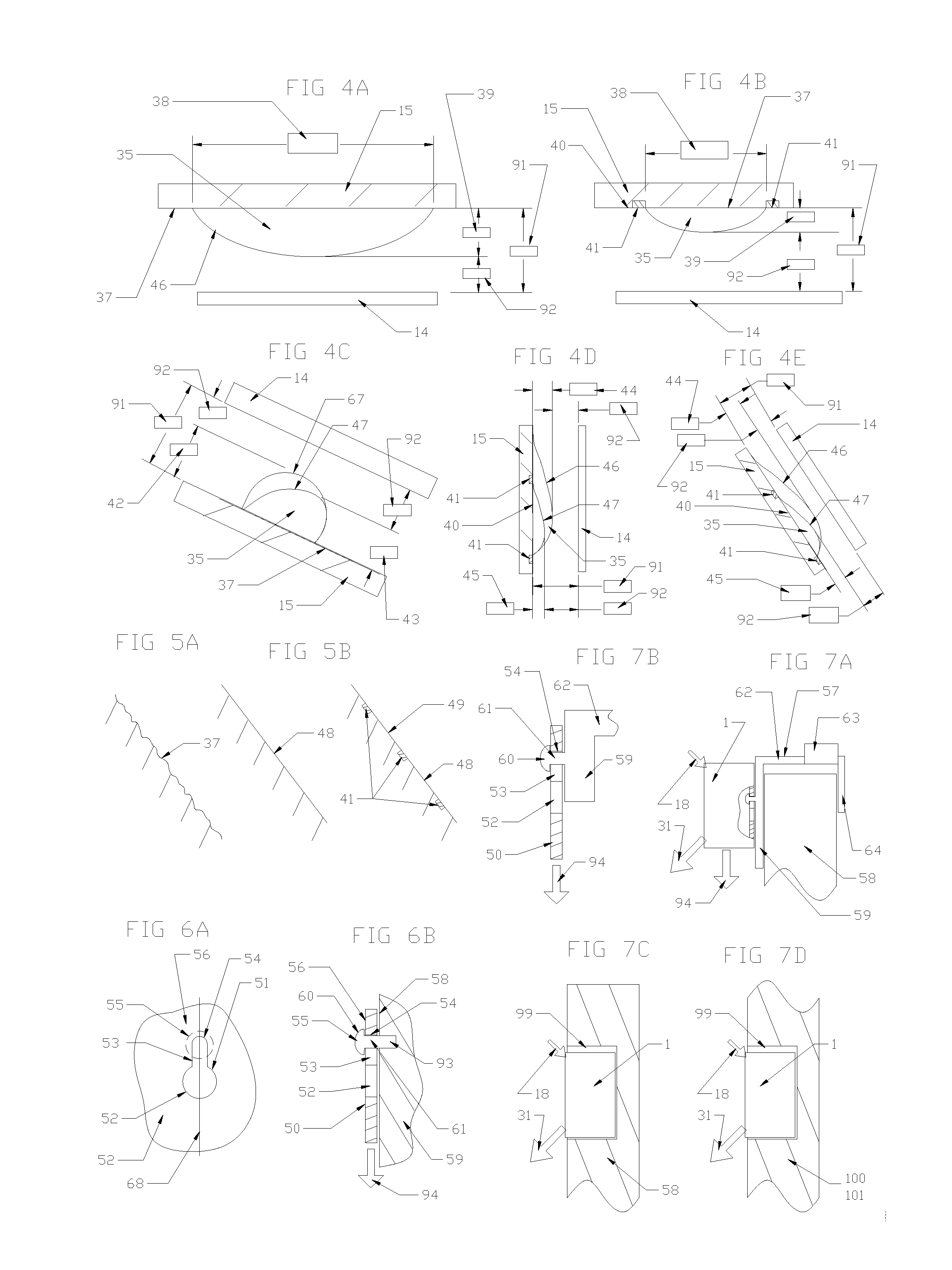

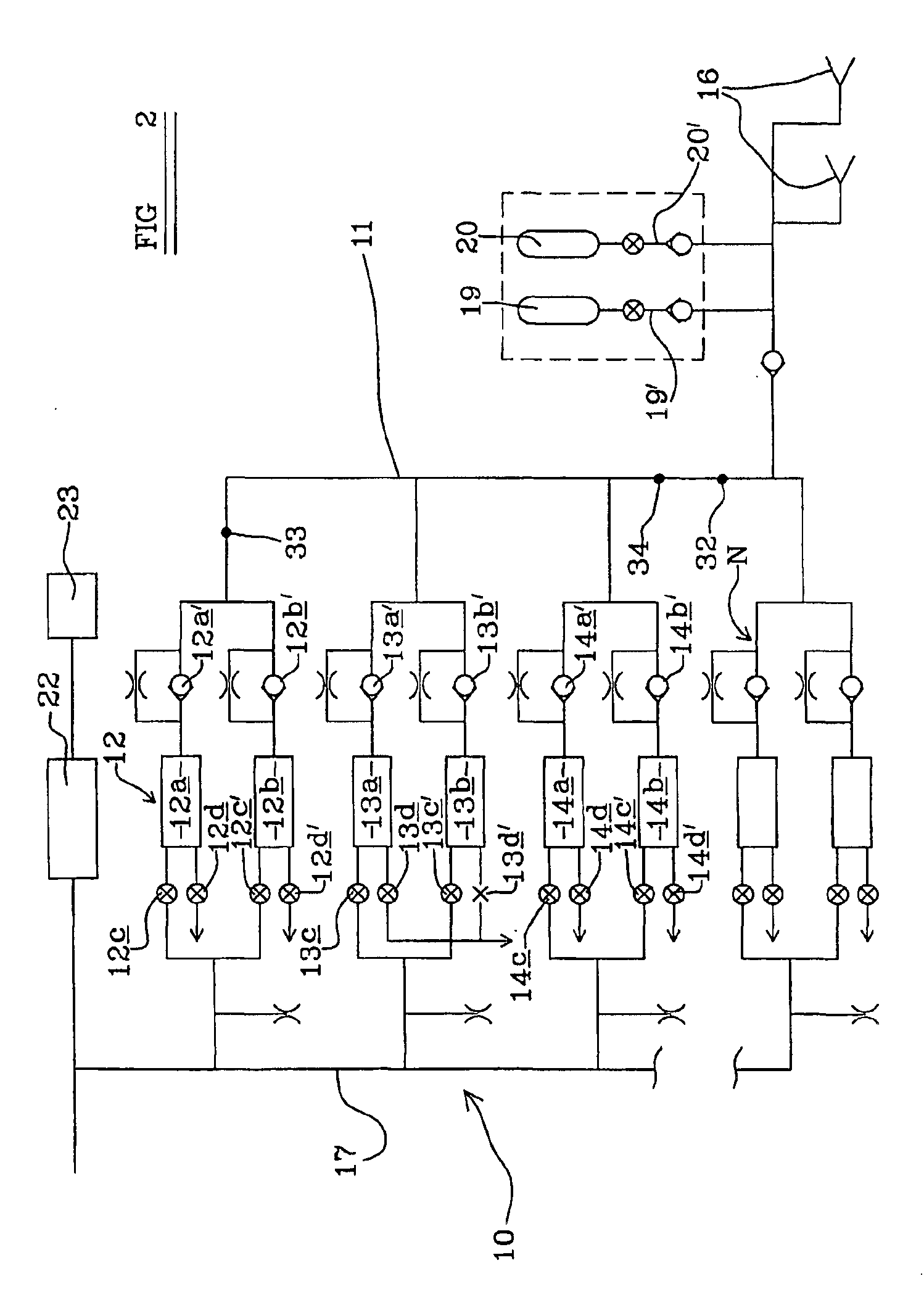

V-Bank Air Filtration System Such as for Animal Confinement

ActiveUS20110308210A1Easy to compressCombination devicesDispersed particle filtrationPre filteringHinge angle

Owner:PARKER HANNIFIN CORP

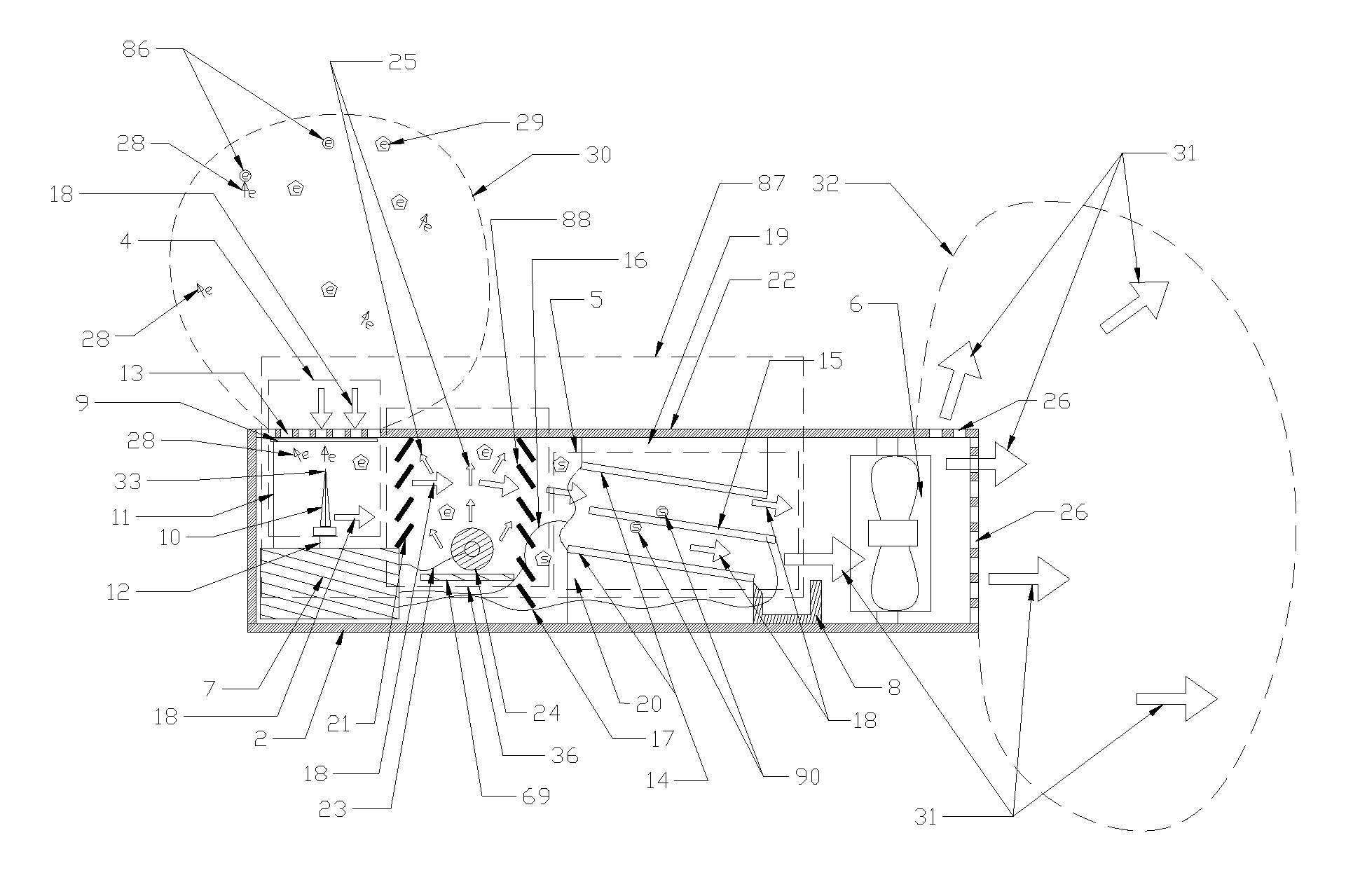

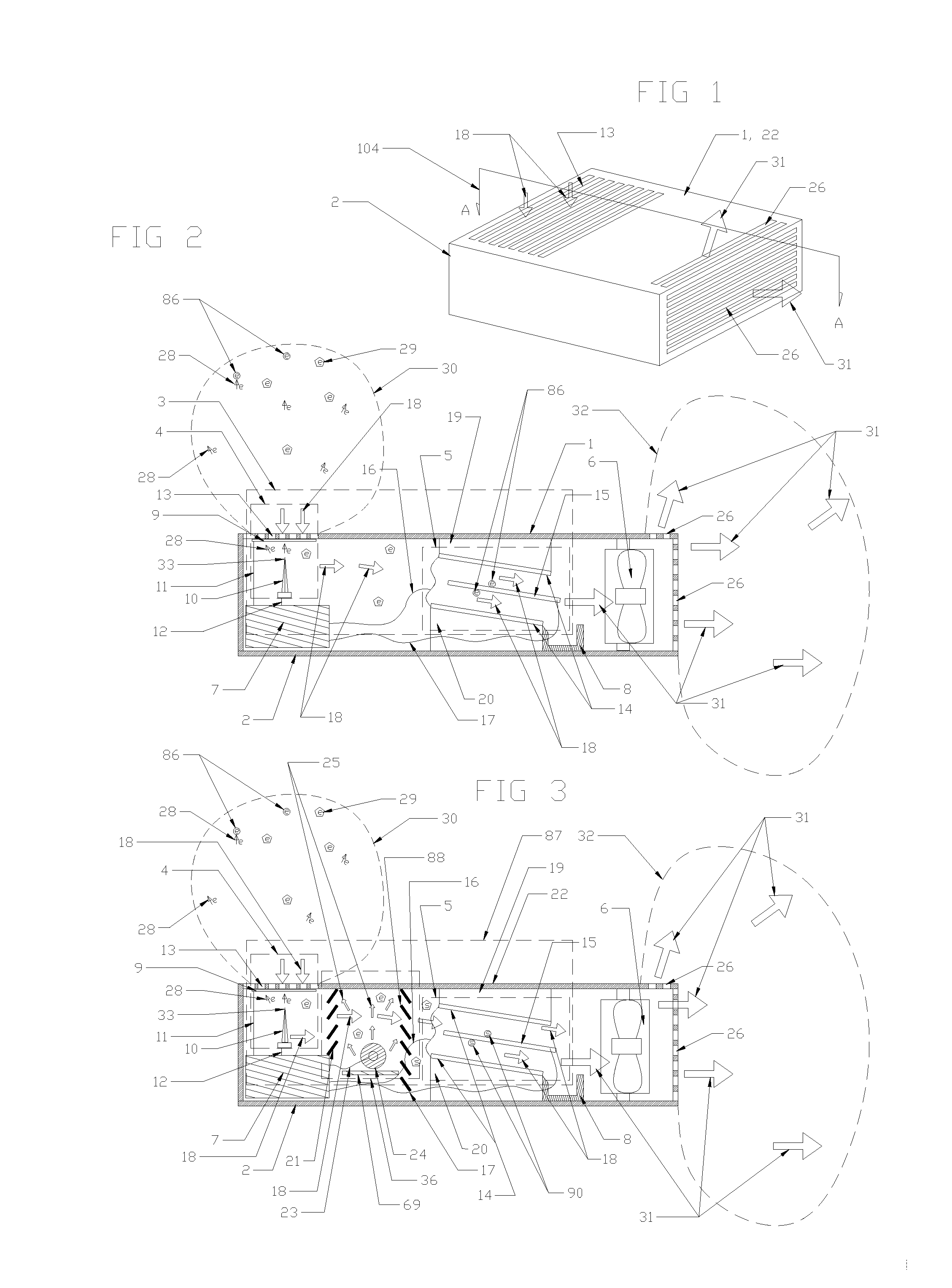

Dust Prevention And Removal Device

ActiveUS20100064895A1Reduce the amount requiredLess dustCombination devicesAuxillary pretreatmentInterior spaceParticulates

A device is provided that is capable of circulating air throughout a personal space as well as collecting and preventing the build up of dust and other particulate matter by drawing in air from the surrounding environment and removing some dust, allergens and other such particulate matter therefrom. The filtered air is then expelled out of the device and back into the surrounding environment. The device includes a housing defining an interior space having a motor and fan assembly disposed therein. The housing includes an inlet with a filter provided therein such that air drawn in through the inlet is filtered. The air is then expelled through a circumferentially disposed outlet. The filter element preferably includes a lock and key system configured to prevent operation of the device in the absence of a properly keyed filter.

Owner:SC JOHNSON & SON INC

Supercharged electrostatic air filtration device

InactiveUS20100307332A1Small physical bodyImprove efficiencyBreathing filtersDispersed particle filtrationAir cleaningIonization

Owner:YUEN PETER SILTEX

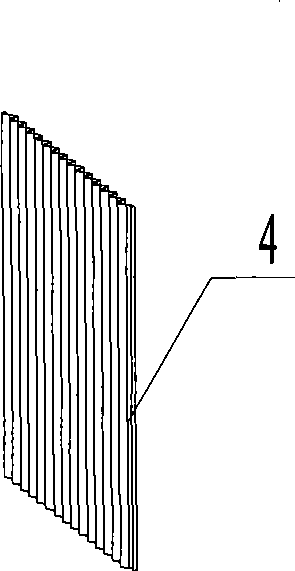

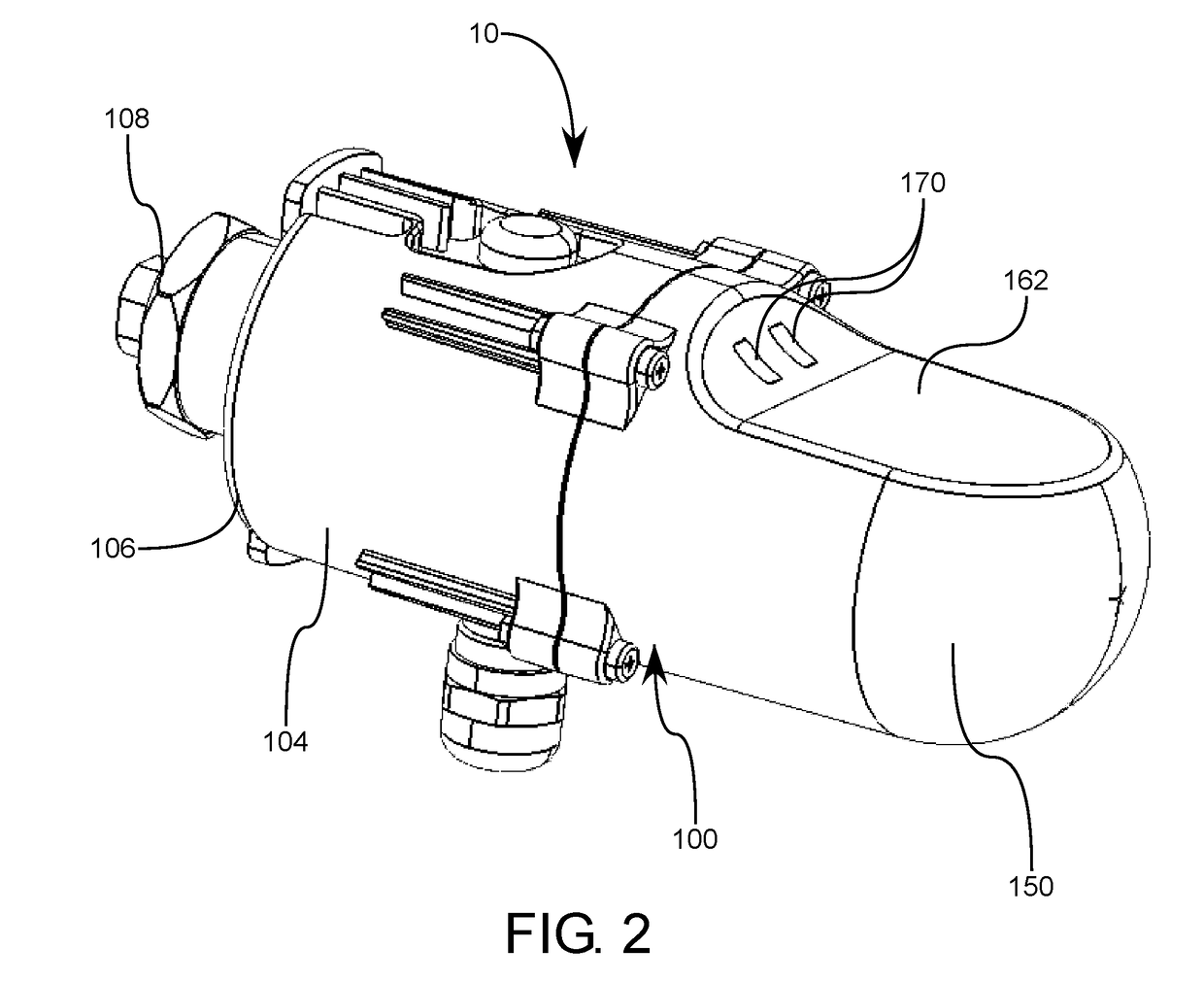

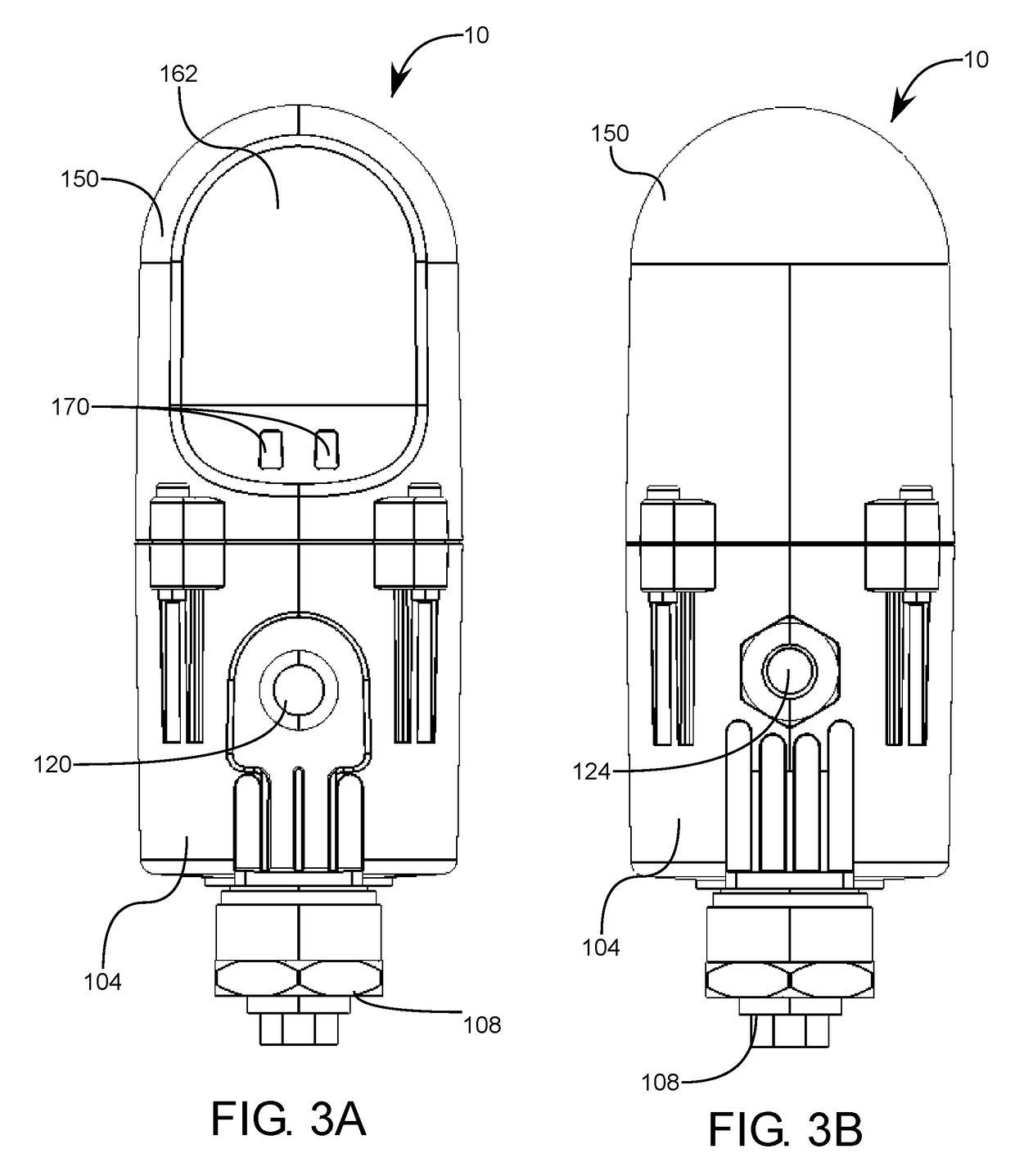

Hydrogen on demand electrolysis fuel cell system

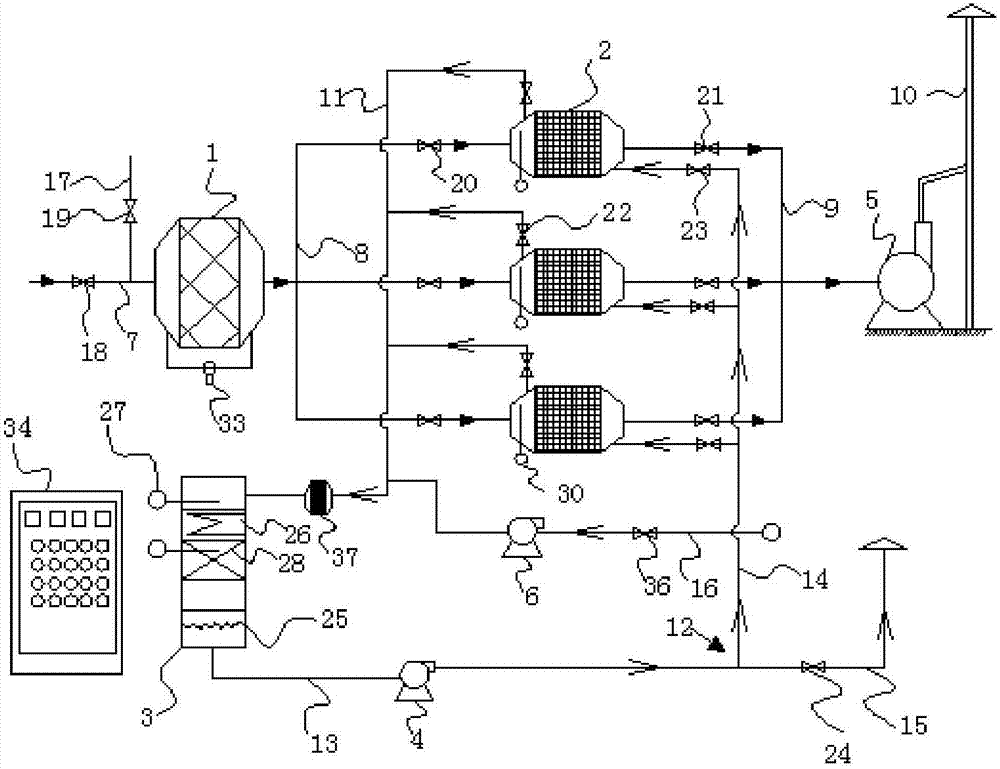

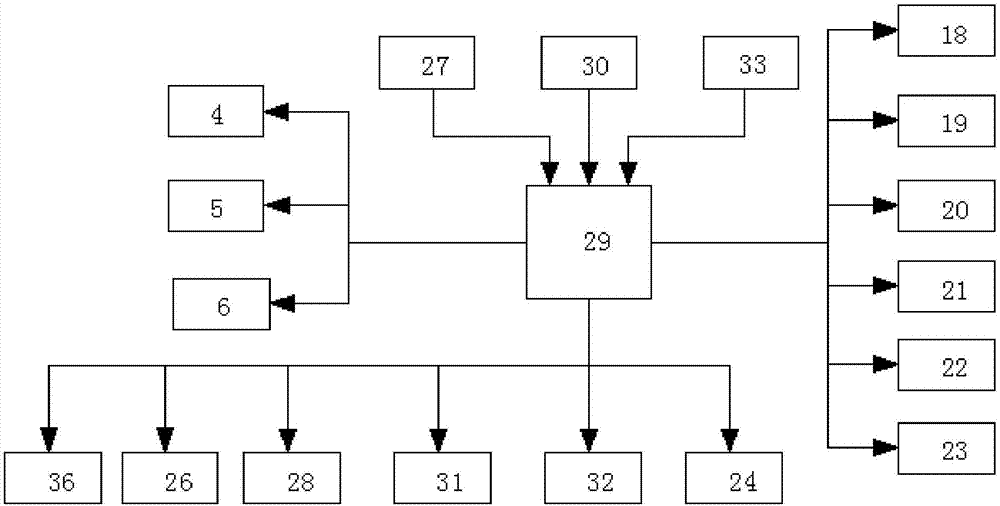

InactiveUS20140262819A1Improve fuel economyEmission reductionCellsPhotography auxillary processesElectrolysisHydrogen

A hydrogen and oxygen (HHO) gas on-demand electrolysis fuel cell system for use with internal combustion engines is disclosed. This hydrogen on-demand (HOD) system integrates with the engine control module (ECM) or other control system that regulates the operation of an internal combustion engine in order to supply HHO to the engine and improve the engine's overall fuel efficiency. This system includes an electrolyte fluid reservoir outfitted with level, pressure and temperature sensors; a pump and heat exchanger; a uniquely-configured electrolyzer; and a filter. The combined engine and HOD system is controlled and regulated by an electronic control system (ECS) and a combustion control module (CCM). The CCM is installed on the engine such that it actively intercepts the electronic signals from the engine manufacturer's ECM to continuously coordinate the functions and operations of the HOD system and the engine.

Owner:NRG LOGISTICS

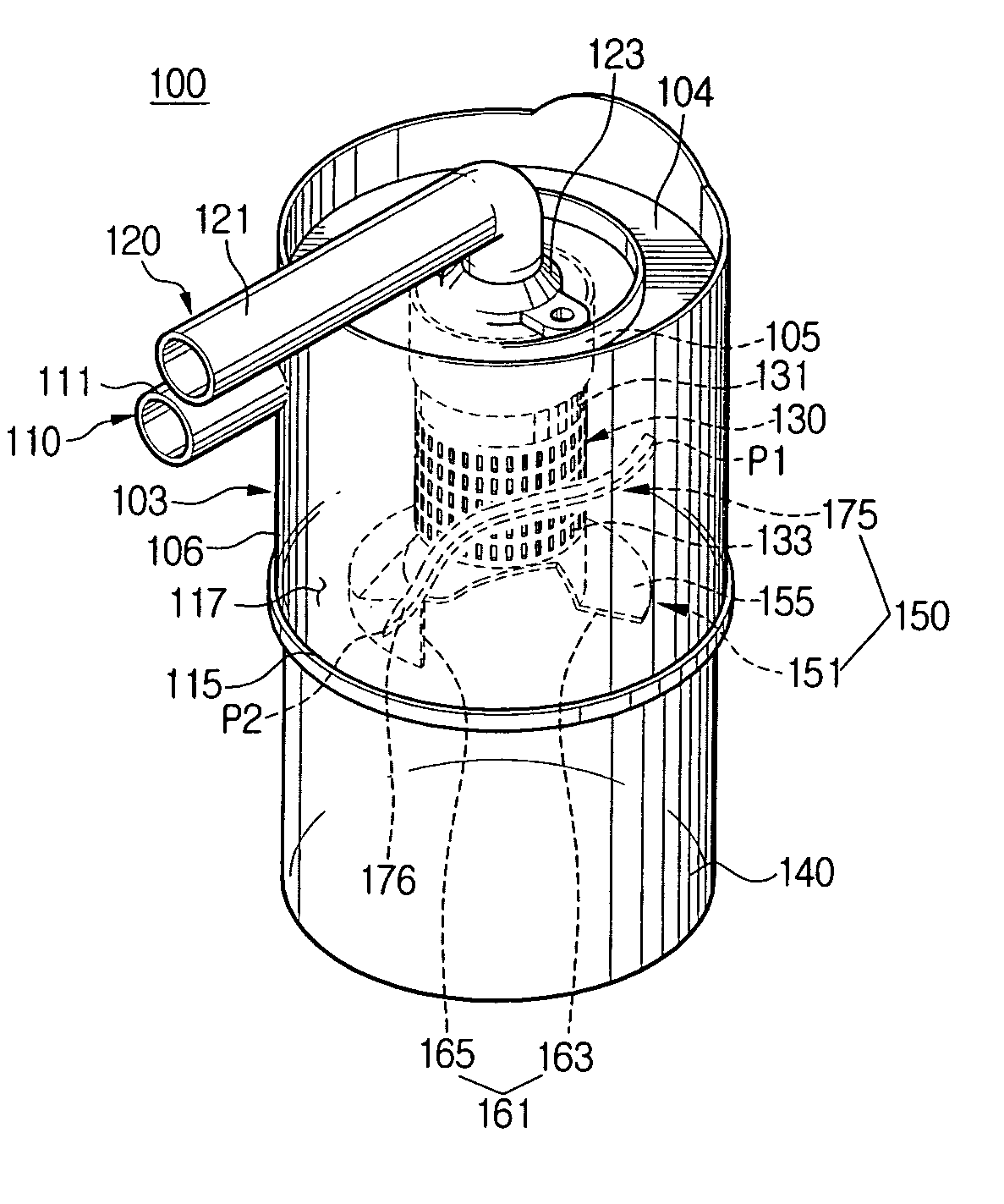

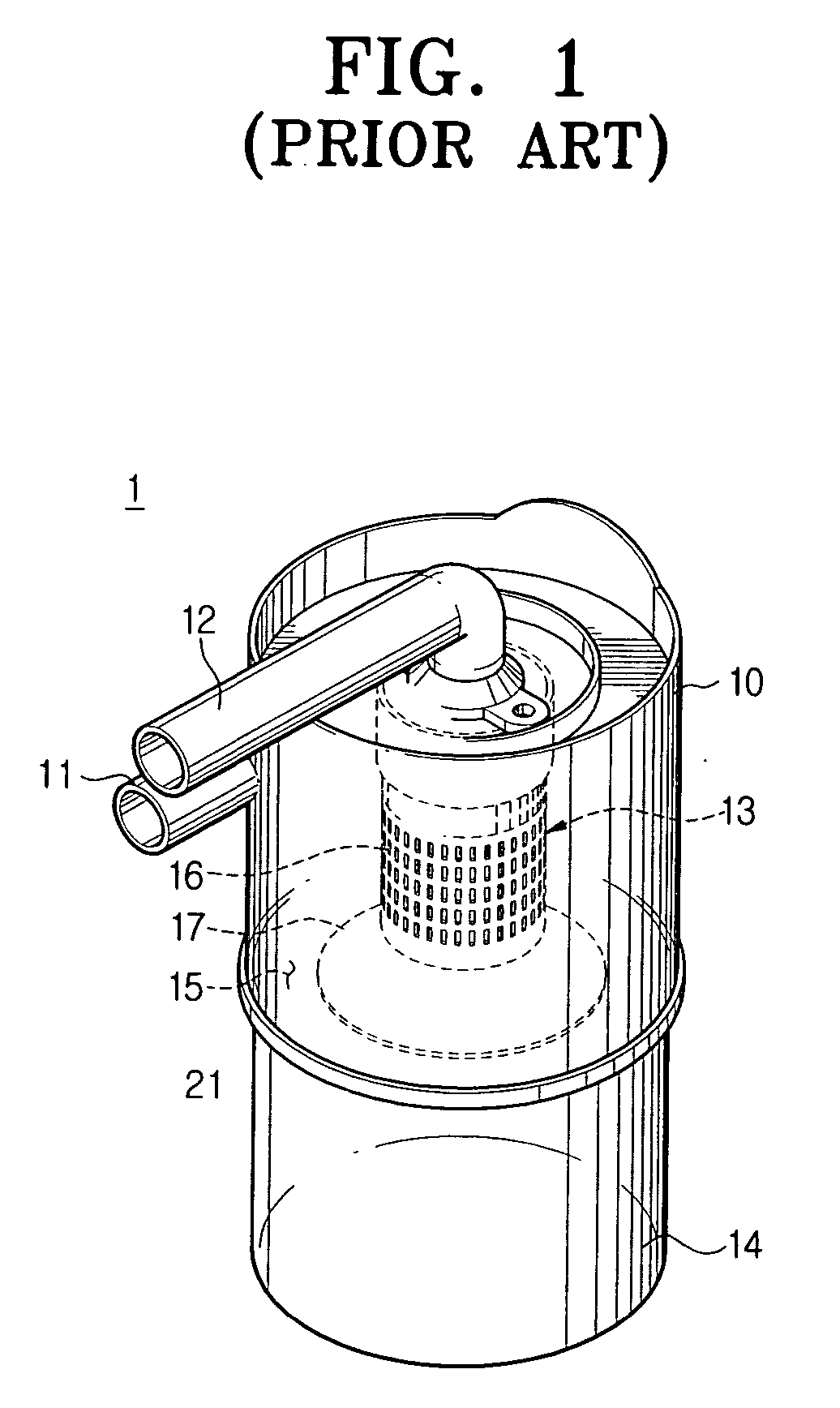

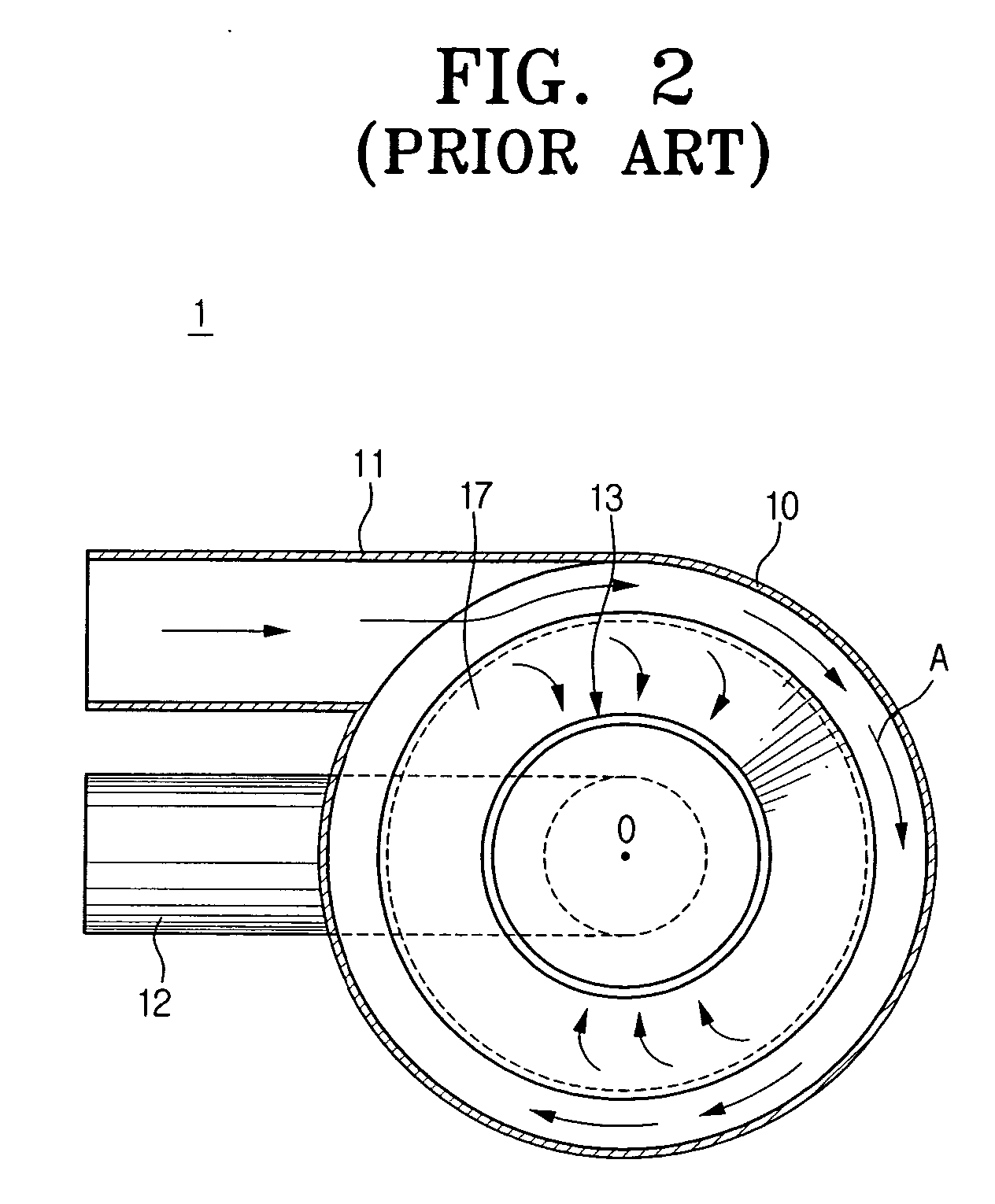

Grille for a cyclone vacuum

InactiveUS20060130441A1Simple structureAvoid problemsCleaning filter meansCombination devicesEngineeringVacuum cleaner

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Air cleaning system

InactiveUS20050284114A1Avoid performanceCombination devicesDucting arrangementsAir cleaningEngineering

The present invention provides a structure of an air cleaning system that prevents a suction performance from being decreased, the air cleaning system including a cabinet provided to a ceiling or a wall, discharging purified air to a room, and having a first inlet formed on a side thereof for drawing room air, a fan is provided to a cabinet and drawing air into the cabinet, a filter for purifying the room air flowed into the cabinet via the fan, and at least one panel for selectively opening / closing the first inlet of the cabinet.

Owner:LG ELECTRONICS INC

Filter

InactiveCN101462019ASmall apertureHigh densityDispersed particle filtrationBiochemical engineeringFiltration

Owner:薛文伟

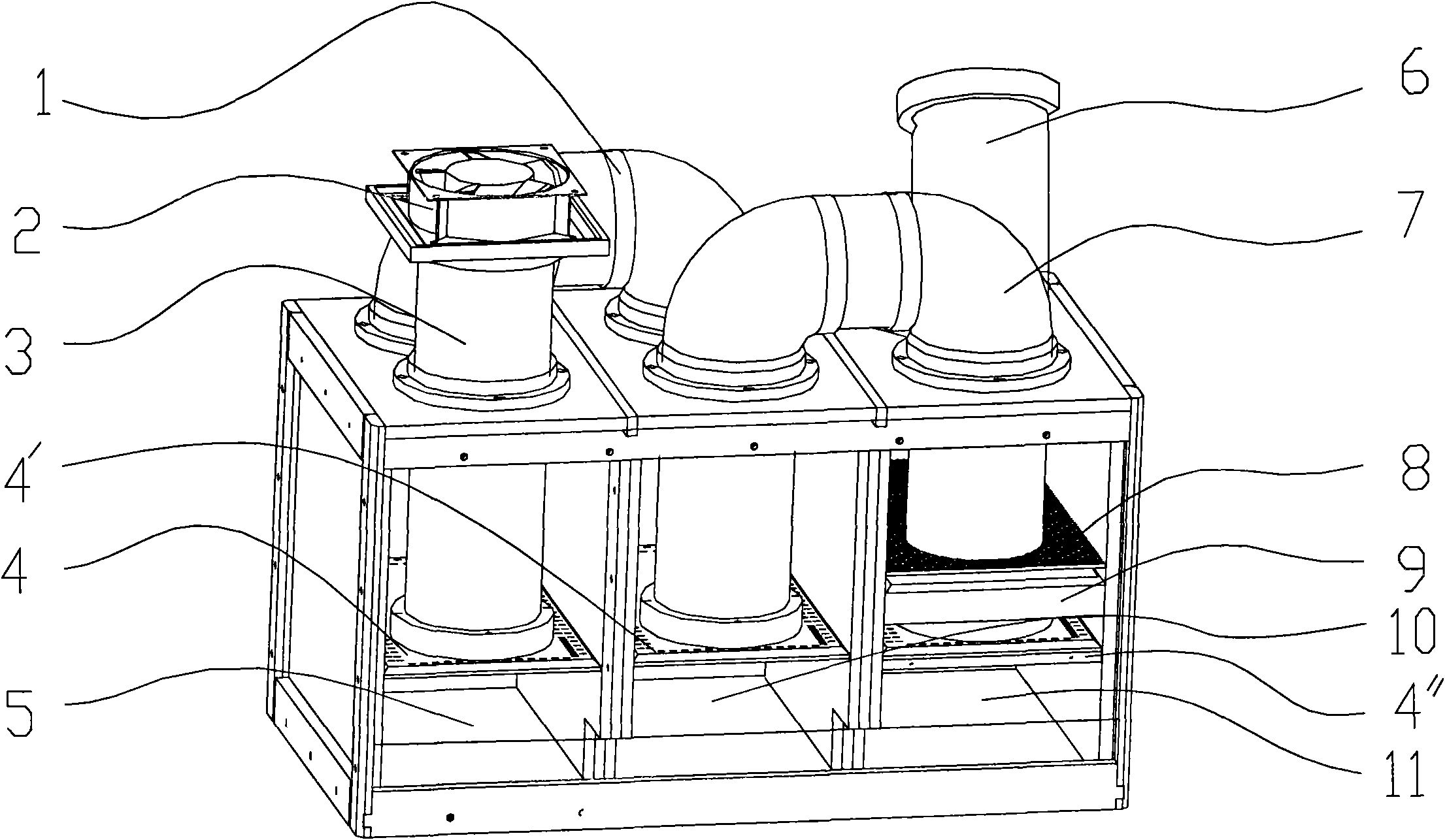

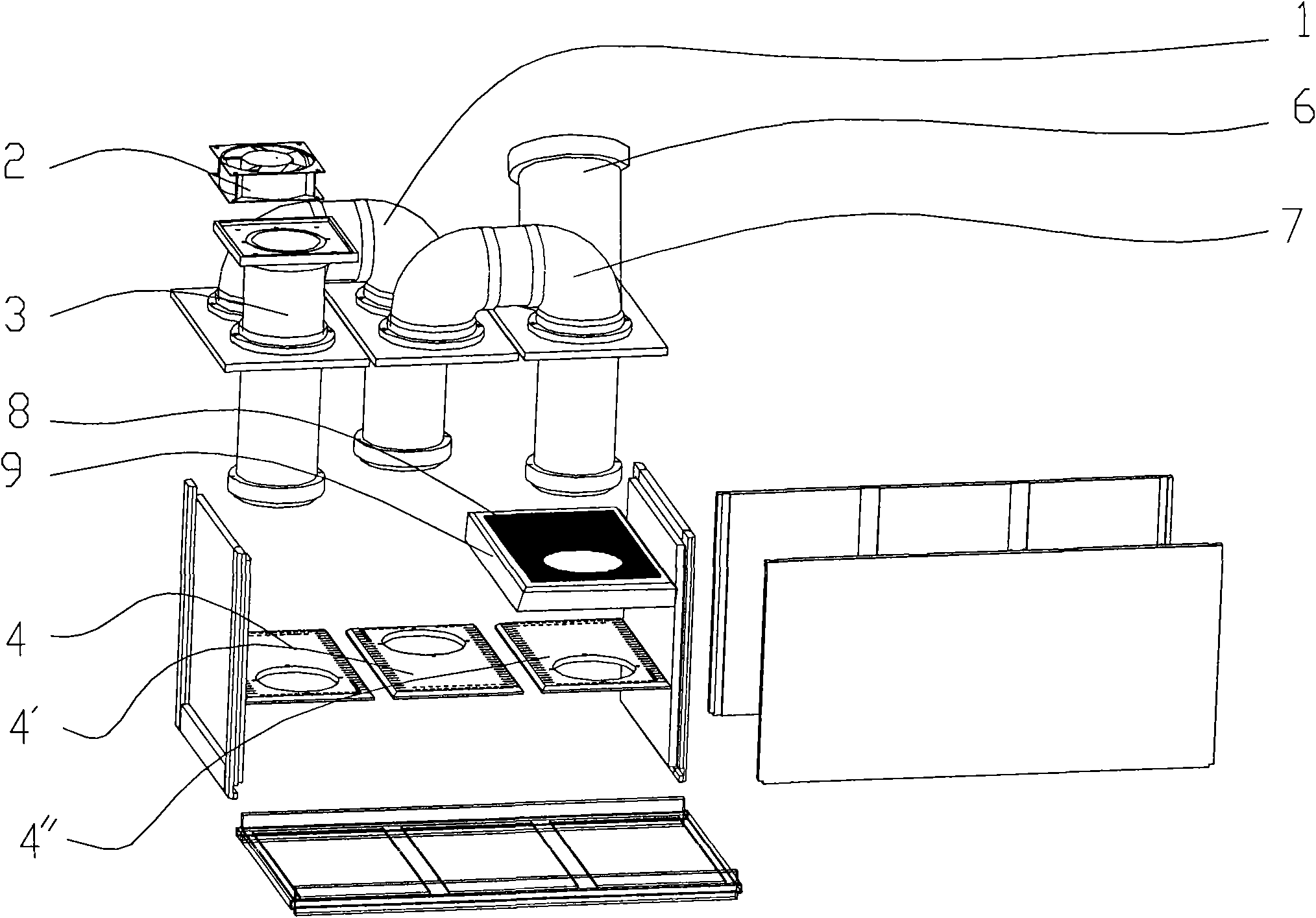

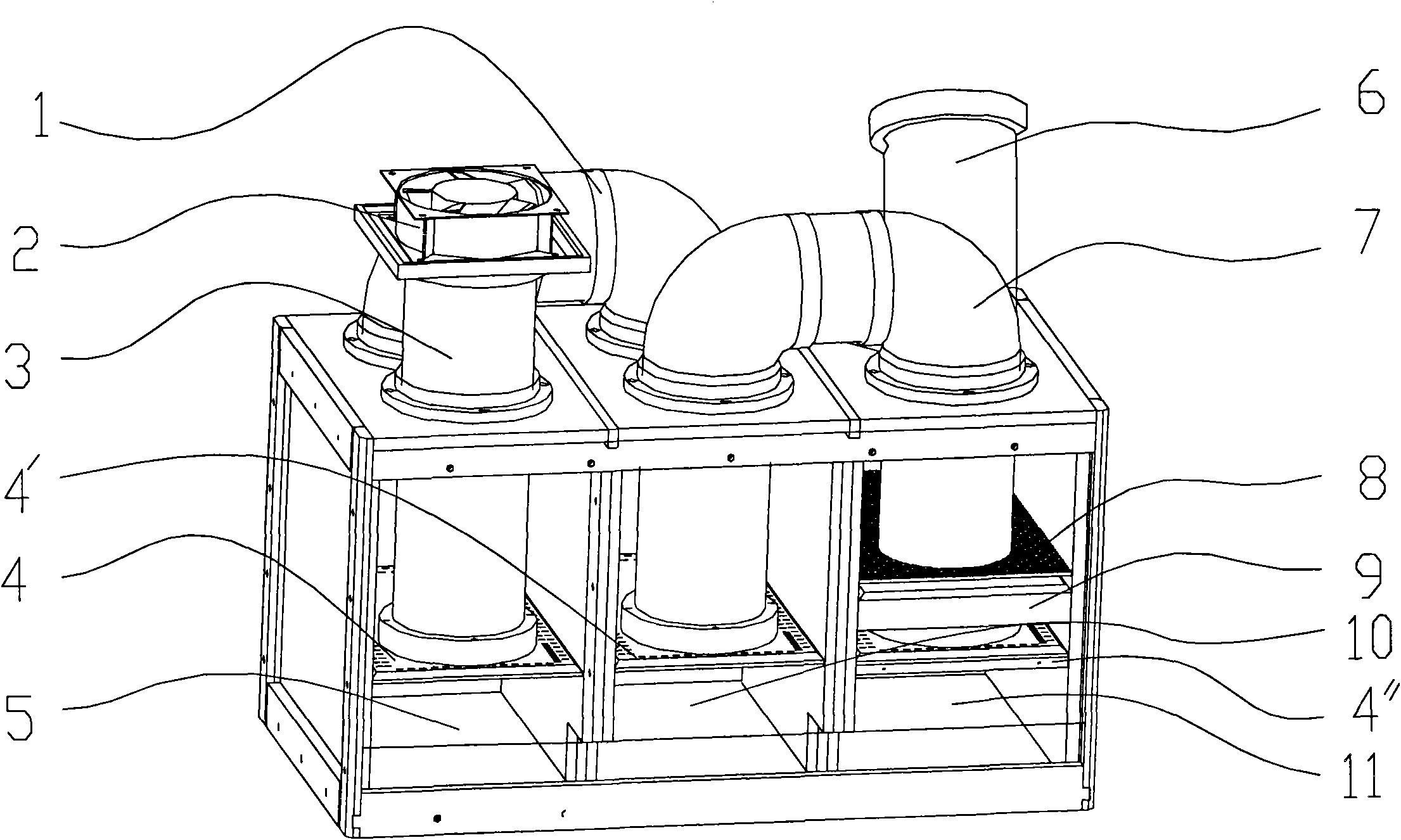

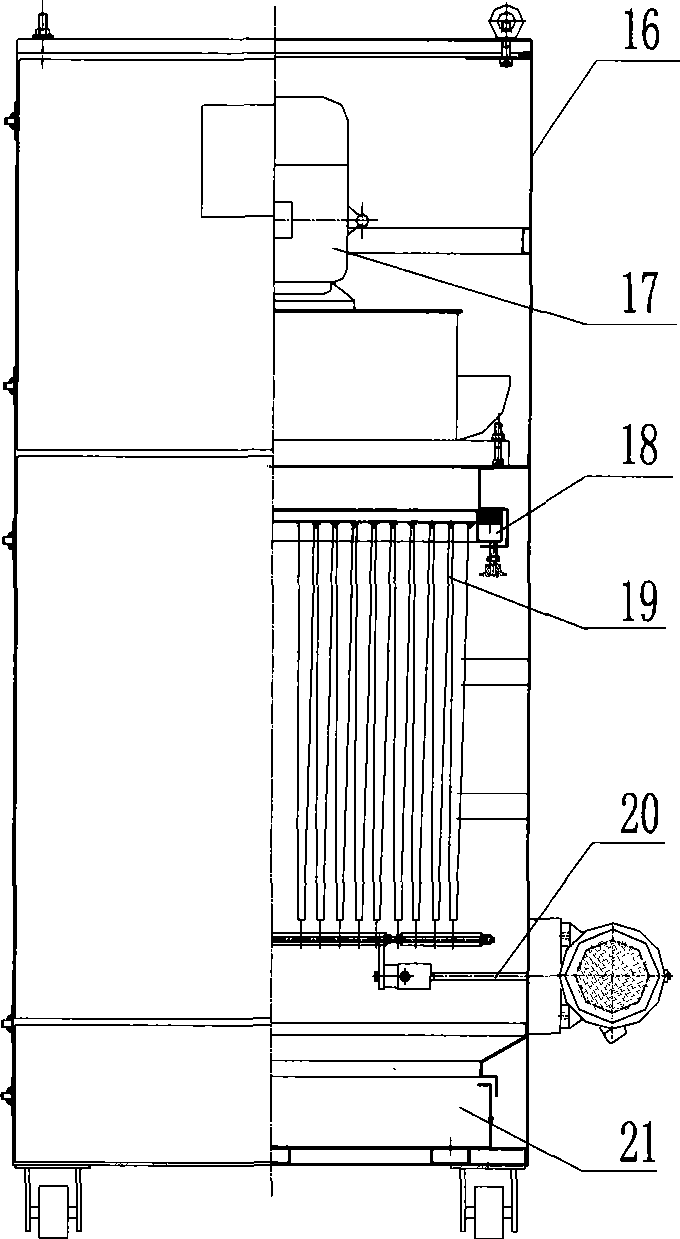

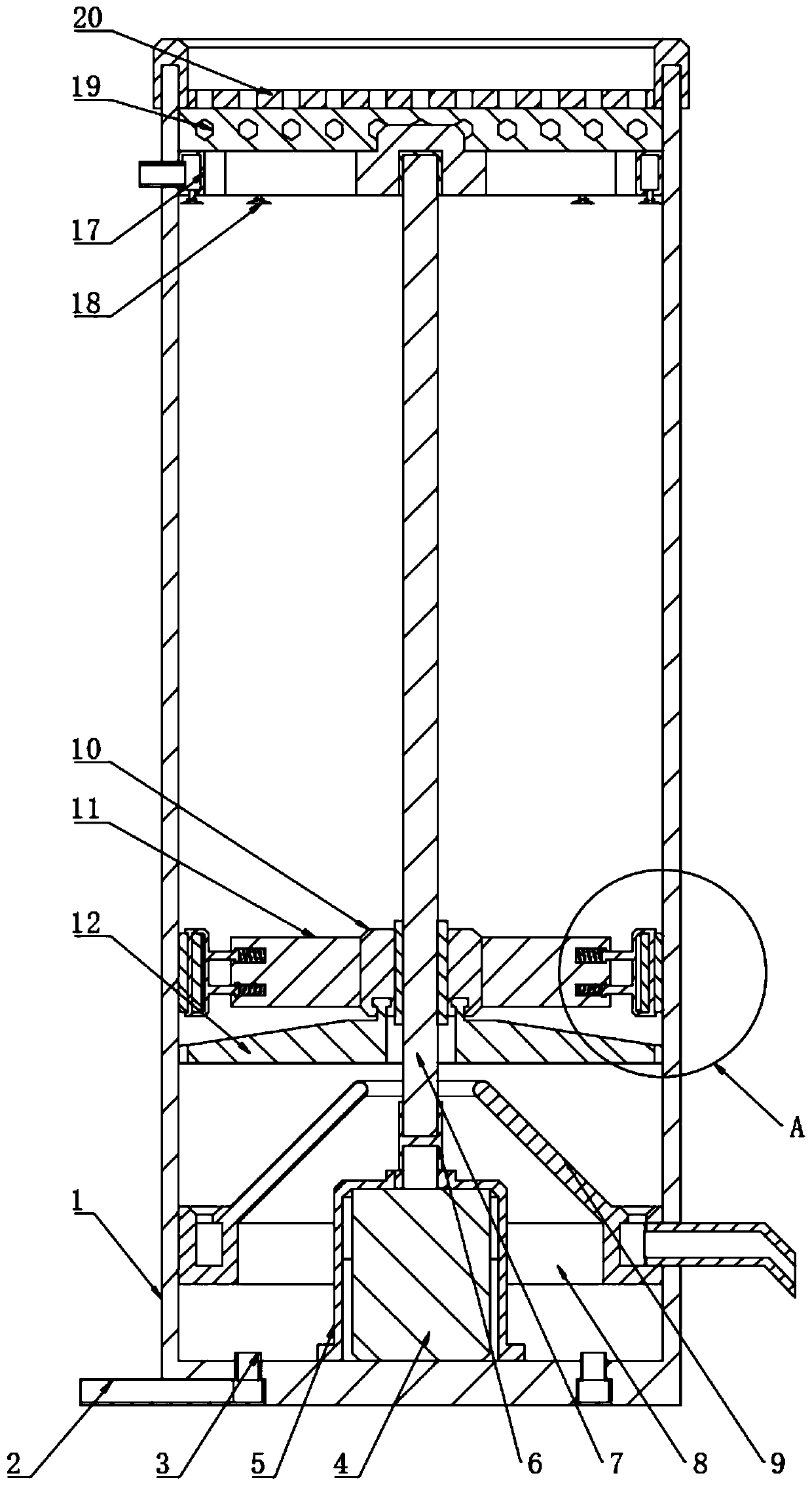

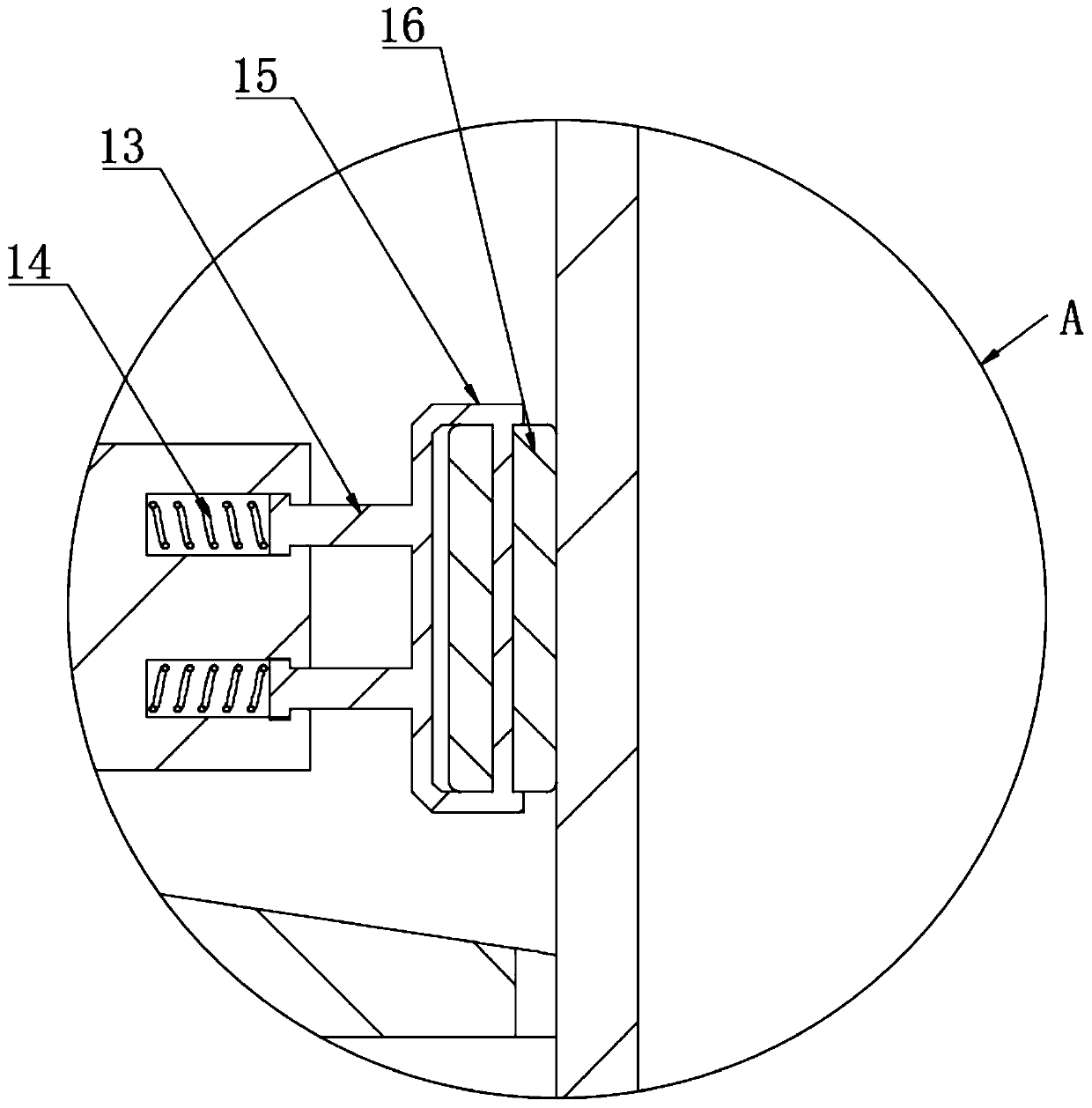

Efficient filter-bag dust separation device

InactiveCN101385928AExtended service lifeGood vibration effectDispersed particle filtrationConvex structureEngineering

Owner:NANFANG ENVIRONMENT PURIFYING EQUIP HANGZHOU

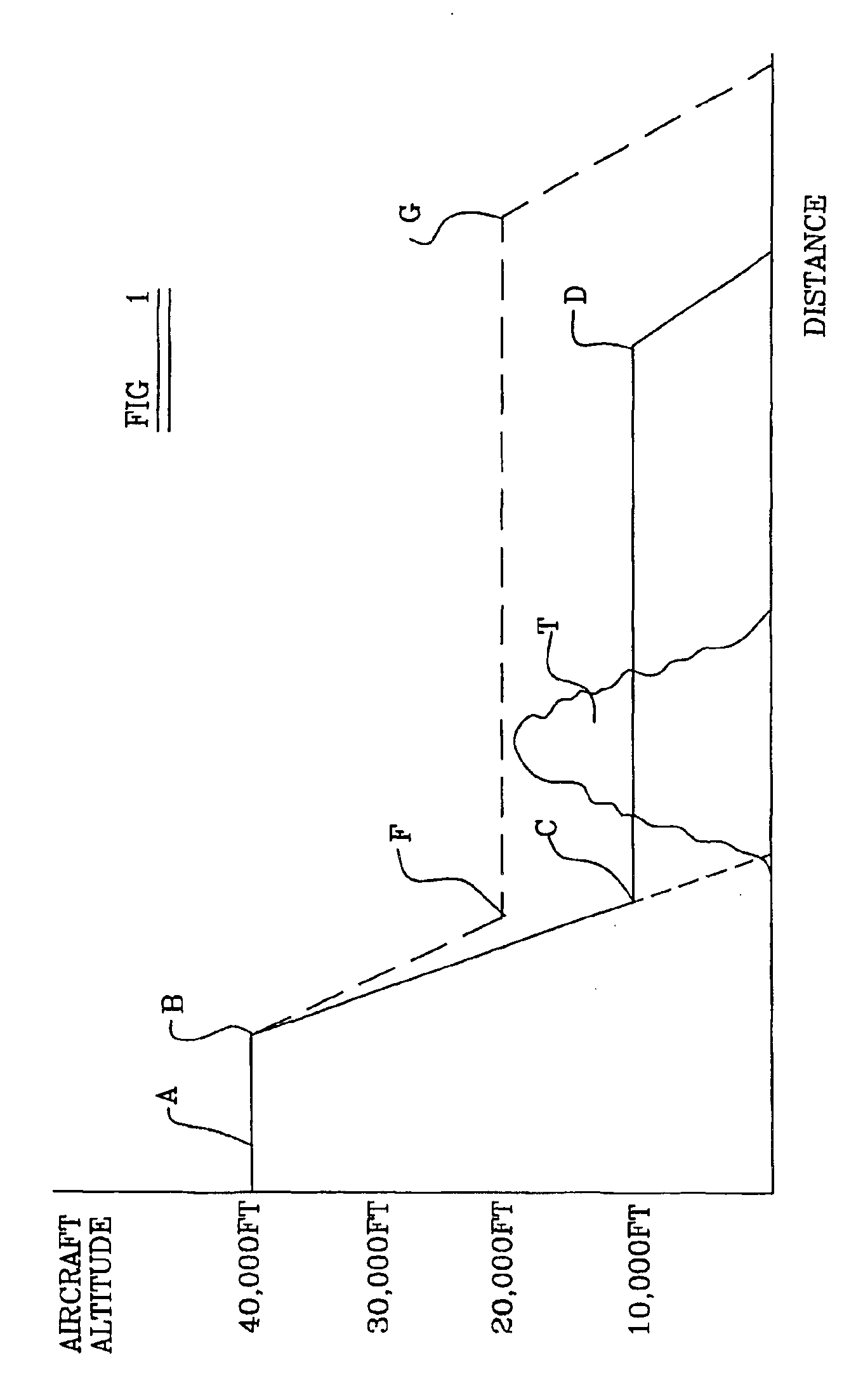

Life support system

InactiveUS6846347B2Reduce weightImprove securityDispersed particle filtrationAir-treatment apparatus arrangementsBreathing gasProduct gas

Owner:HONEYWELL NORMALAIR GARRETT HLDG

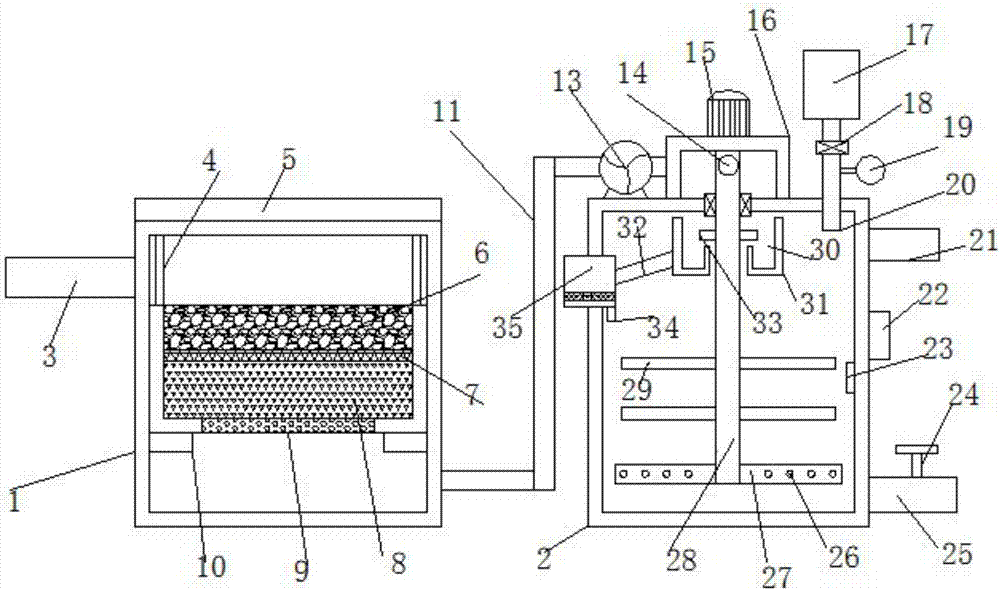

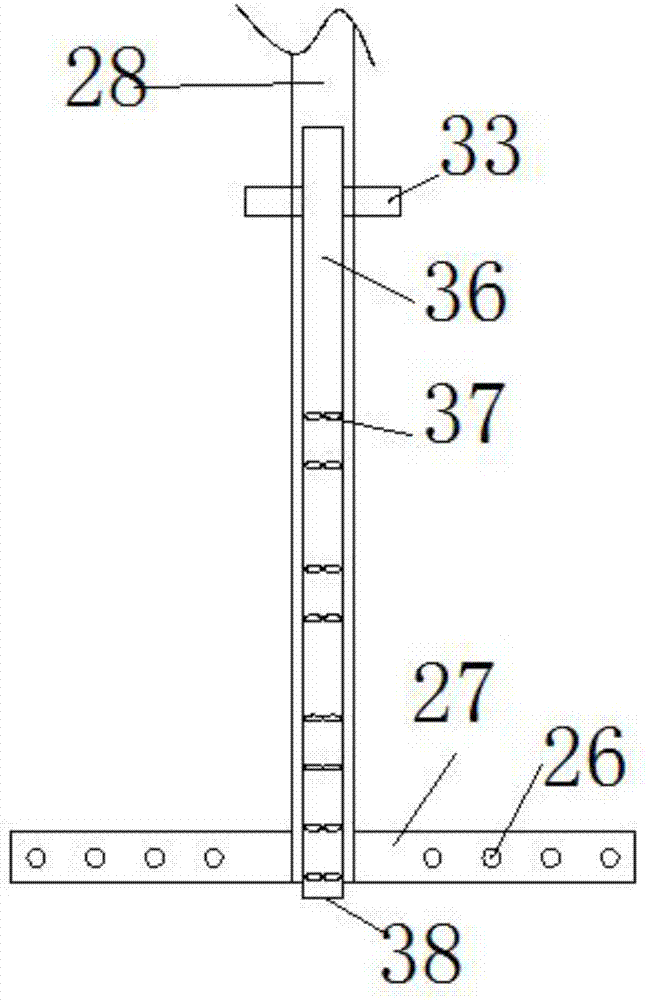

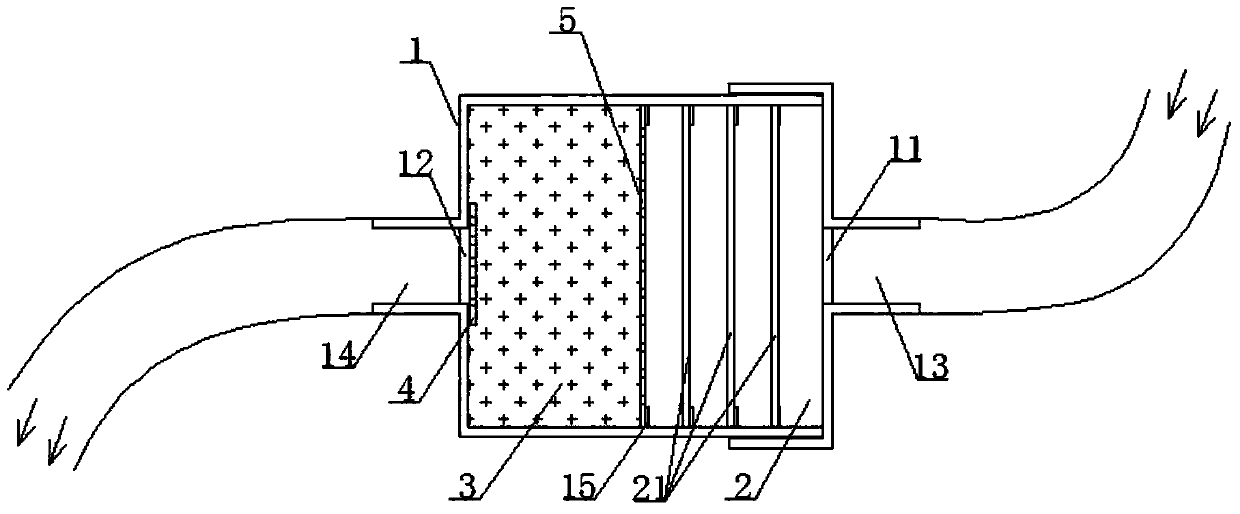

Test room for volatile organic matters of complete automobile

ActiveCN102012417AExtended service lifeAvoid damageDispersed particle filtrationMaterial analysisAir filtrationAir filter

The invention discloses a test room for volatile organic matters of a complete automobile. The test room comprises a test box, a circulating air channel, an evaporator and a heater, a circulating fan and an air filter combination device, wherein, the circulating air channel is arranged in the test box; the evaporator and the heater are arranged in the circulating air channel; the air filter combination device is longitudinally arranged in the test box; the air filter combination device separates the test space of the test box from the circulating air channel in the lower space of the test box so that the air in the test space is filtered through the air filter combination device and then enters the circulating air channel; the air filter combination device is longitudinally arranged on the rear end of the test box and is parallel to the rear wall of the test box; and the air filter combination device can be also longitudinally arranged at the inner side of the side wall of the test box and is parallel to the side wall of the test box. The test room has the advantages that the air filter combination device is effectively prevented from being damaged by the automobile during the test process, the service life of the test room is prolonged, the cost is lowered and maintenance or replacement is facilitated.

Owner:DONGGUAN CITY SIMPLEWELL TECH

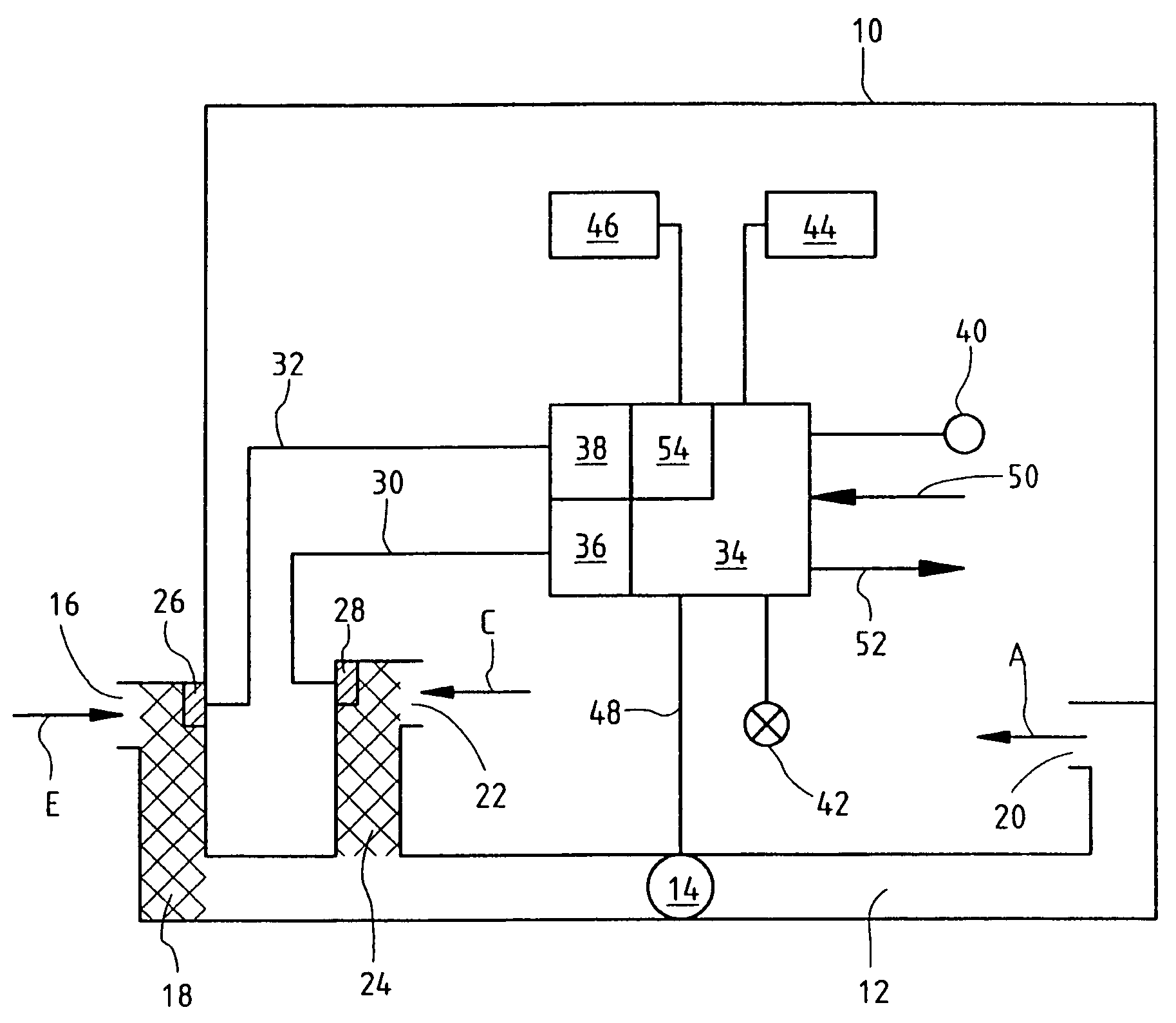

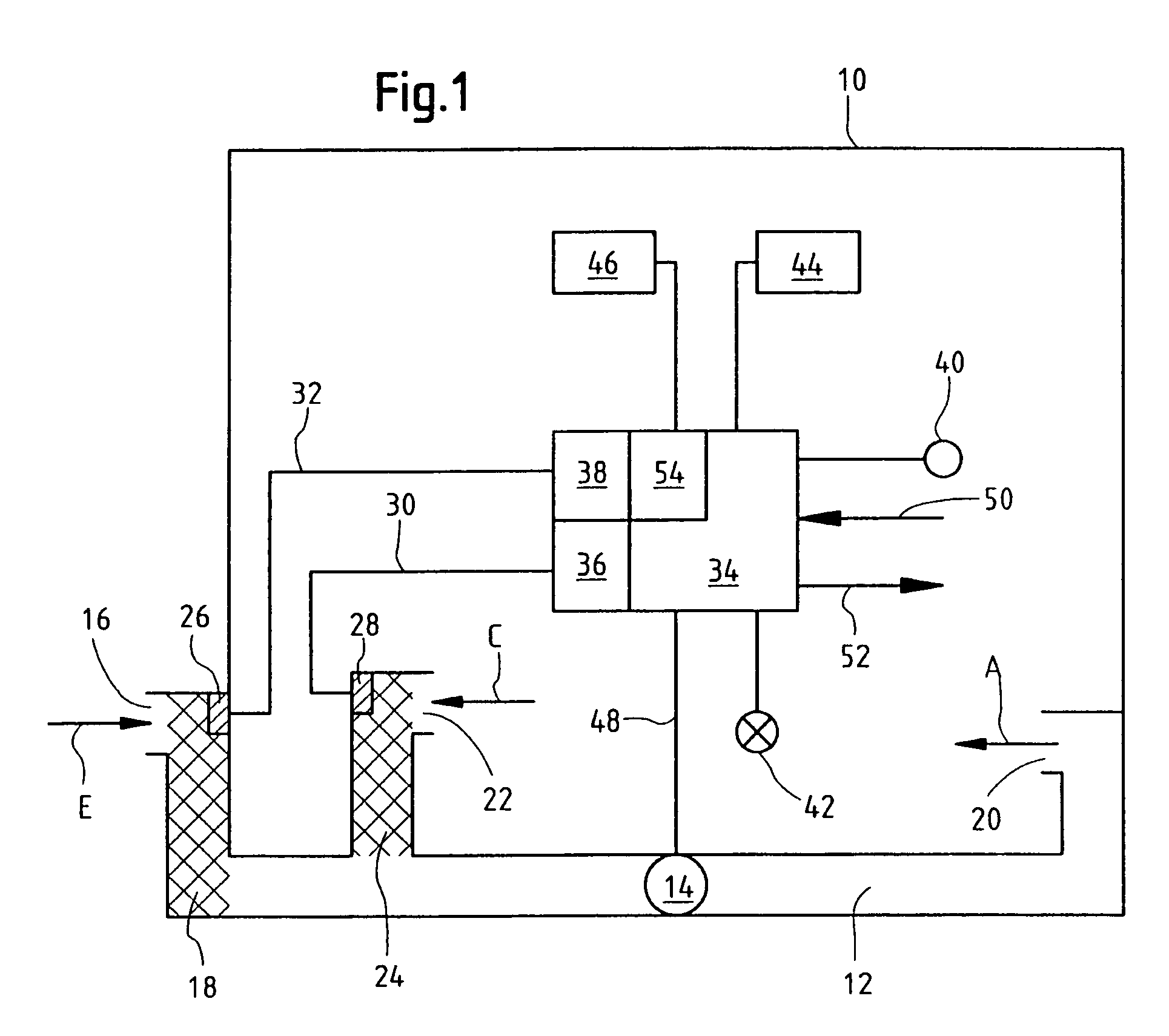

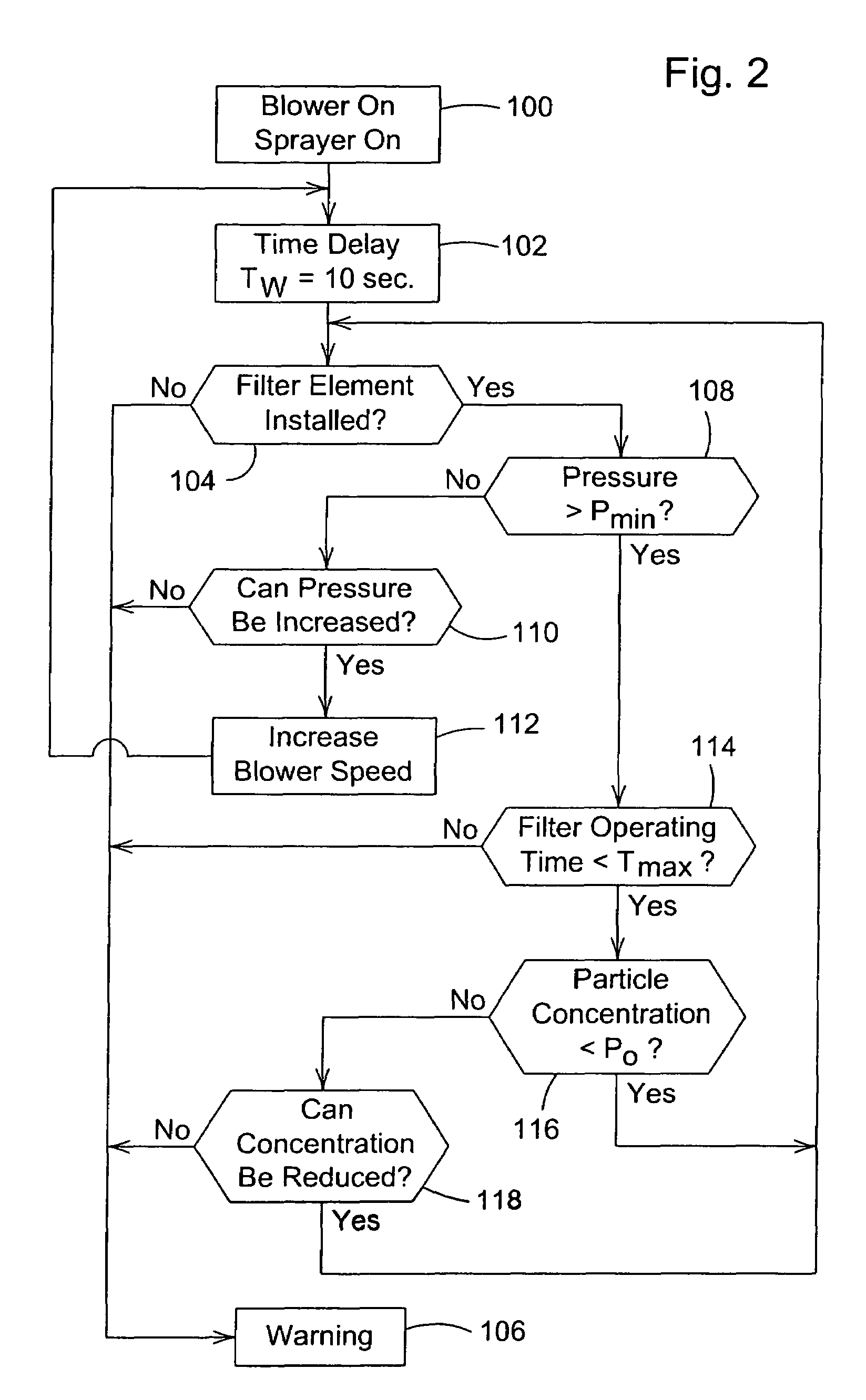

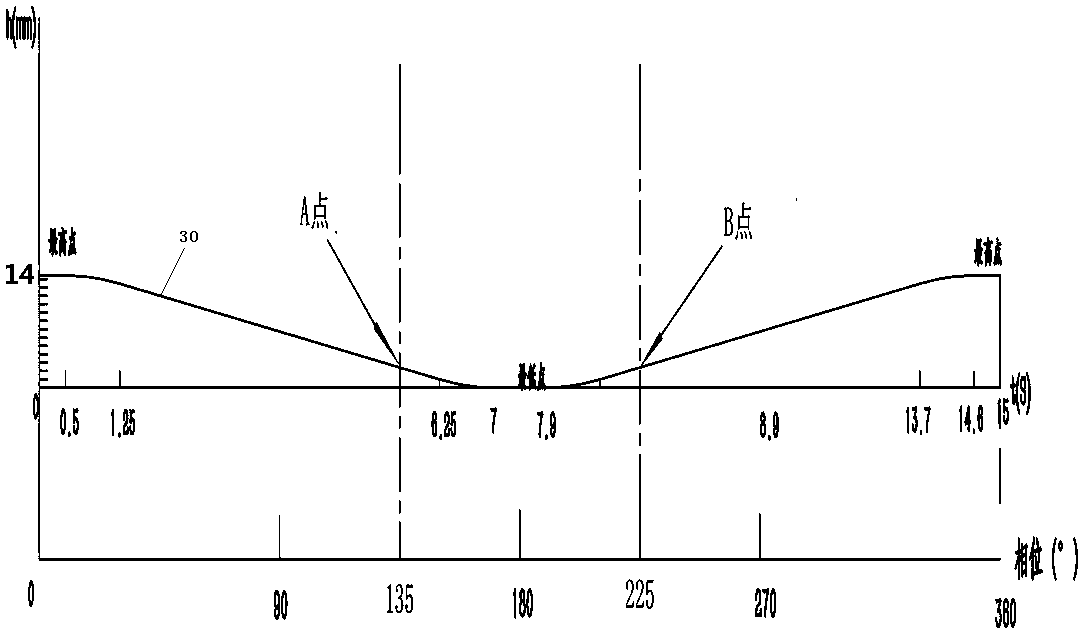

Monitoring arrangement for compartment air contamination

Owner:DEERE & CO

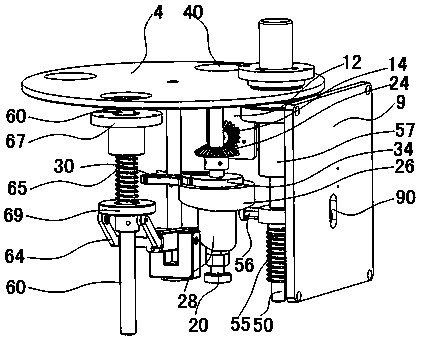

Automatic filter membrane replacement device

Owner:青岛绿蓝环保技术有限公司

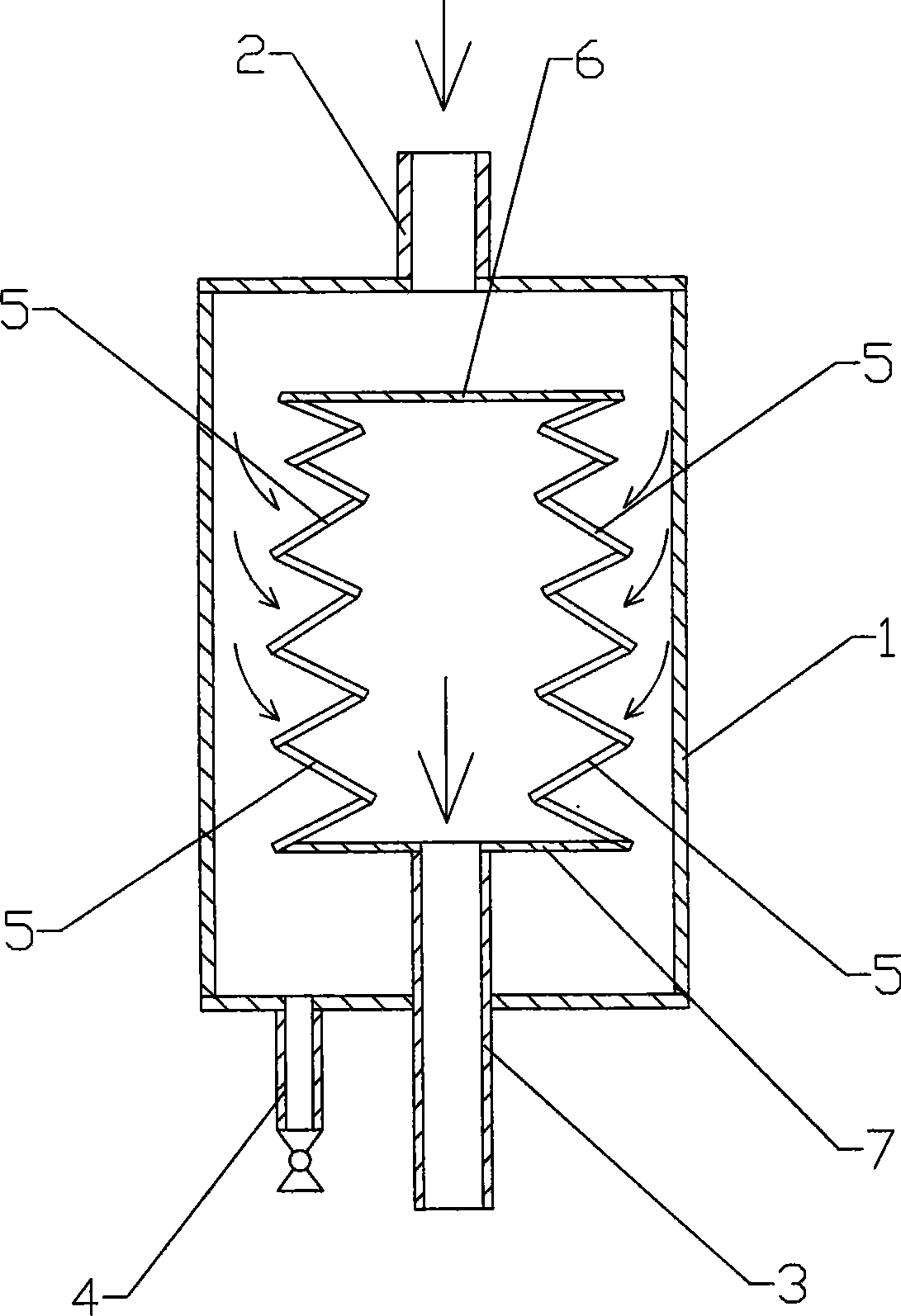

Compound filter element capable of being repeatedly used under microwave conditions and preparing method and activating method of compound filter element

ActiveCN110203993ADispersed particle filtrationSpecific water treatment objectivesActivated carbonMicrowave

The invention discloses a compound filter element capable of being repeatedly used under microwave conditions and a preparing method and activating method of the compound filter element. The compoundfilter element comprises an element body shell, an element body inner wall, activated carbon filler and element body partition plates. The element body partition plates are arranged at the two ends ofeach section of activated carbon filler respectively. The element body shell and the element body inner wall are each of a micro-pore structure. The element body partition plates are each of a porousstructure. The material of the element body shell has the ceramic-level strength and sealing performance and has the characteristics of high temperature resistance and corrosion resistance; meanwhile, microwaves can penetrate through the element body shell and can act on the element body inner wall and the element body partition plates; the element body inner wall can reach the process temperature required for microwave-activation of the filter element; the material of the element body partition plates is rapidly heated under the microwave conditions and has the advantages of being resistantto high temperature, thermal shock and corrosion and having the micro-pore structure; the compound filter element has the advantages of being repeatedly used, high in element body strength, high in thermal shock resistance, resistant to acid and alkali corrosion and resistant to high temperature.

Owner:WUHU YIYI PRECISION MASCH CO LTD

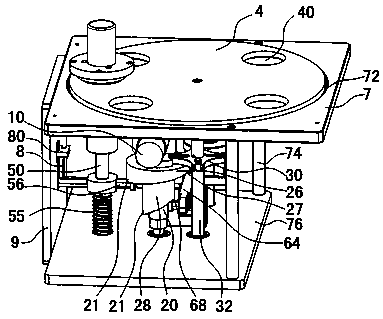

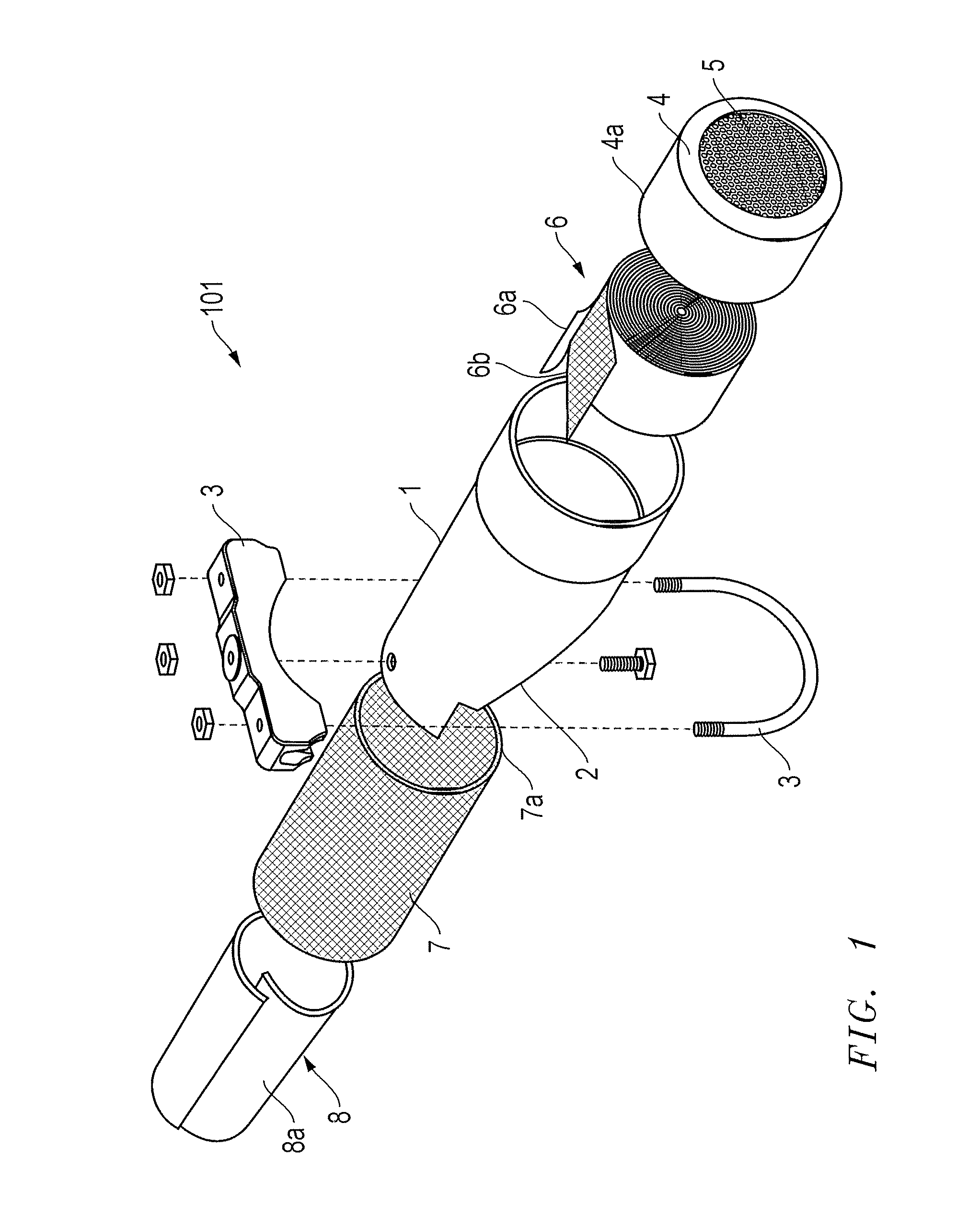

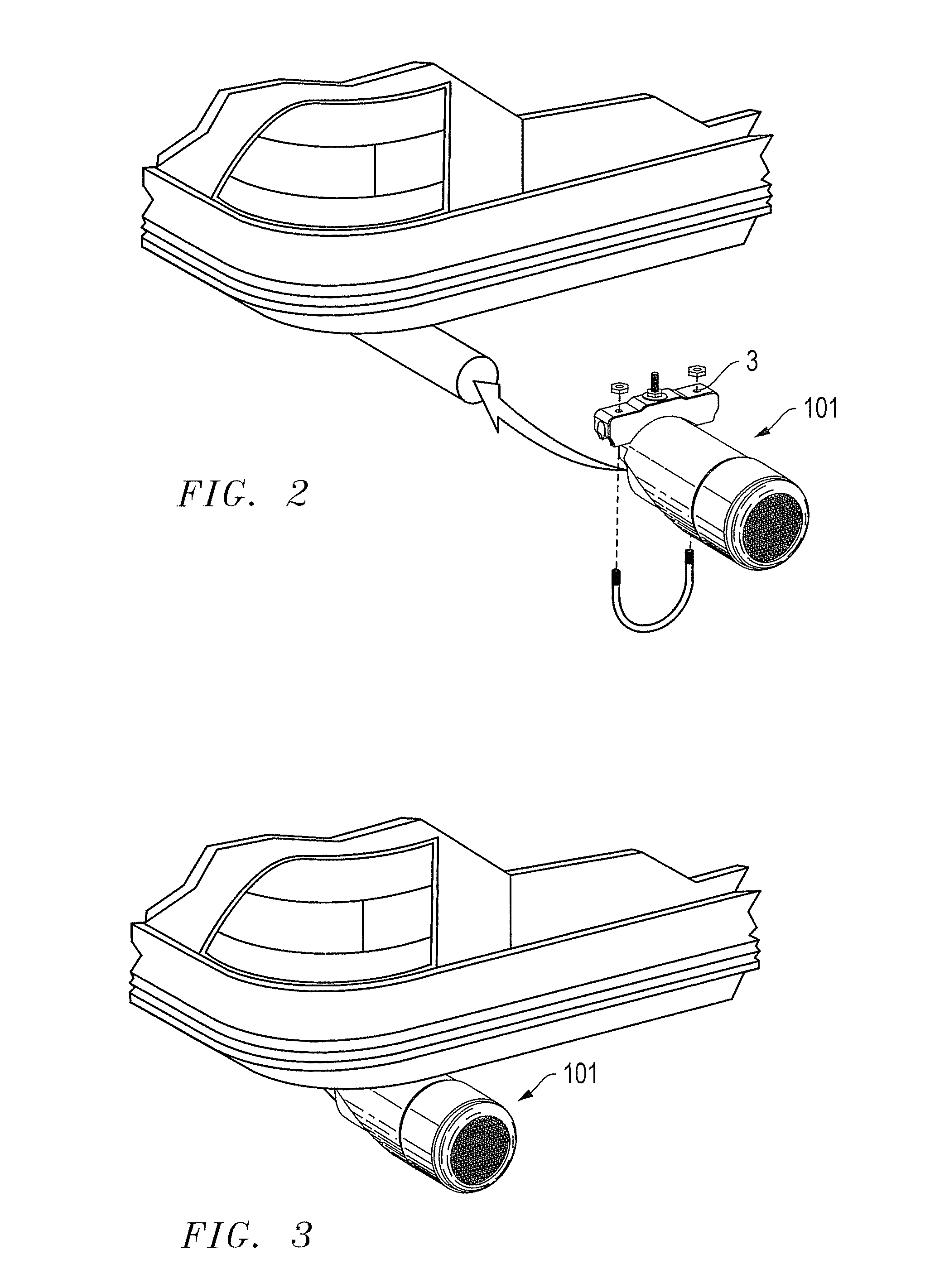

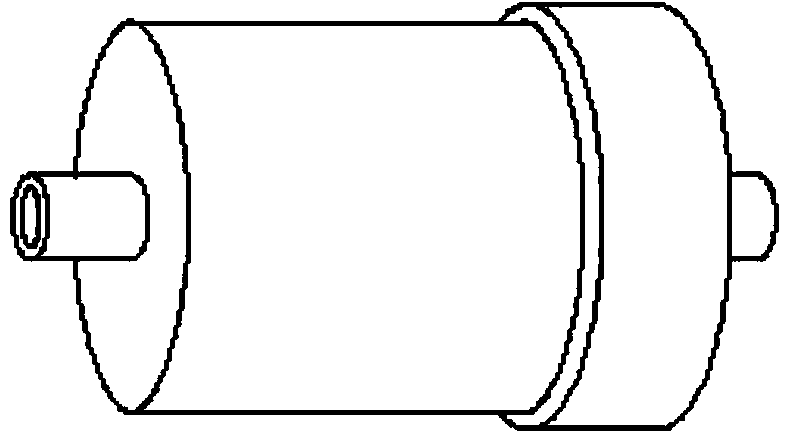

Device & Method for the Reduction of Emissions

InactiveUS20080053068A1Reduce environmental pollutionCurbing alarming effectInternal combustion piston enginesDispersed particle filtrationFiberBobbin

Owner:SABERTEC LLC

Ship waste gas desulfuration device and method

ActiveCN107998761AImprove the mixing effectFully purifiedGas treatmentDispersed particle filtrationActivated carbonMixing effect

Owner:唐山伟德船用设备有限公司

Solar photovoltaic panel dust removal device for sand and dust land

InactiveCN112620205AAvoid damageReduce scratchesDispersed particle filtrationPhotovoltaicsDust controlEngineering

The invention discloses a solar photovoltaic panel dust removal device for sand and dust land, and relates to the technical field of power generation facilities. The solar photovoltaic panel dust removal device for the sand and dust land comprises a photovoltaic panel and a sand and dust removal device, wherein sliding frames are arranged at the front end and the rear end of the upper surface of the photovoltaic panel; sliding ways are formed in the front faces of the sliding frames; and the upper surface of the photovoltaic panel is in lap joint with the bottom of the sand and dust removal device. According to the solar photovoltaic panel dust removal device for the sand and dust land, a cleaning device is arranged on the sand and dust removal device, an air blower conveys strong wind power to the cavity of a rotary drum, the wind power is focused and blown into a dust removal box through air gathering holes, sand on the upper surface of the corresponding photovoltaic panel in the dust removal box can be blown up under the action of the strong wind power, the rotary drum is driven to rotate anticlockwise under the action of a motor, and sand and dust in the dust removal box are blown into a sand storage bag along with the wind direction, so that the sand and dust on the photovoltaic panel are cleaned and collected without coming into contact with the photovoltaic panel, and damage to the photovoltaic panel is avoided.

Owner:SUZHOU BOLI NEW ENERGY TECH CO LTD

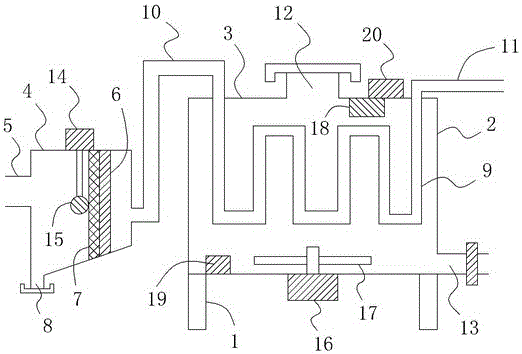

Spray booth organic waste gas treatment system

Owner:JIANGSU YONGYI ENVIRONMENTAL PROTECTION TECH CO LTD

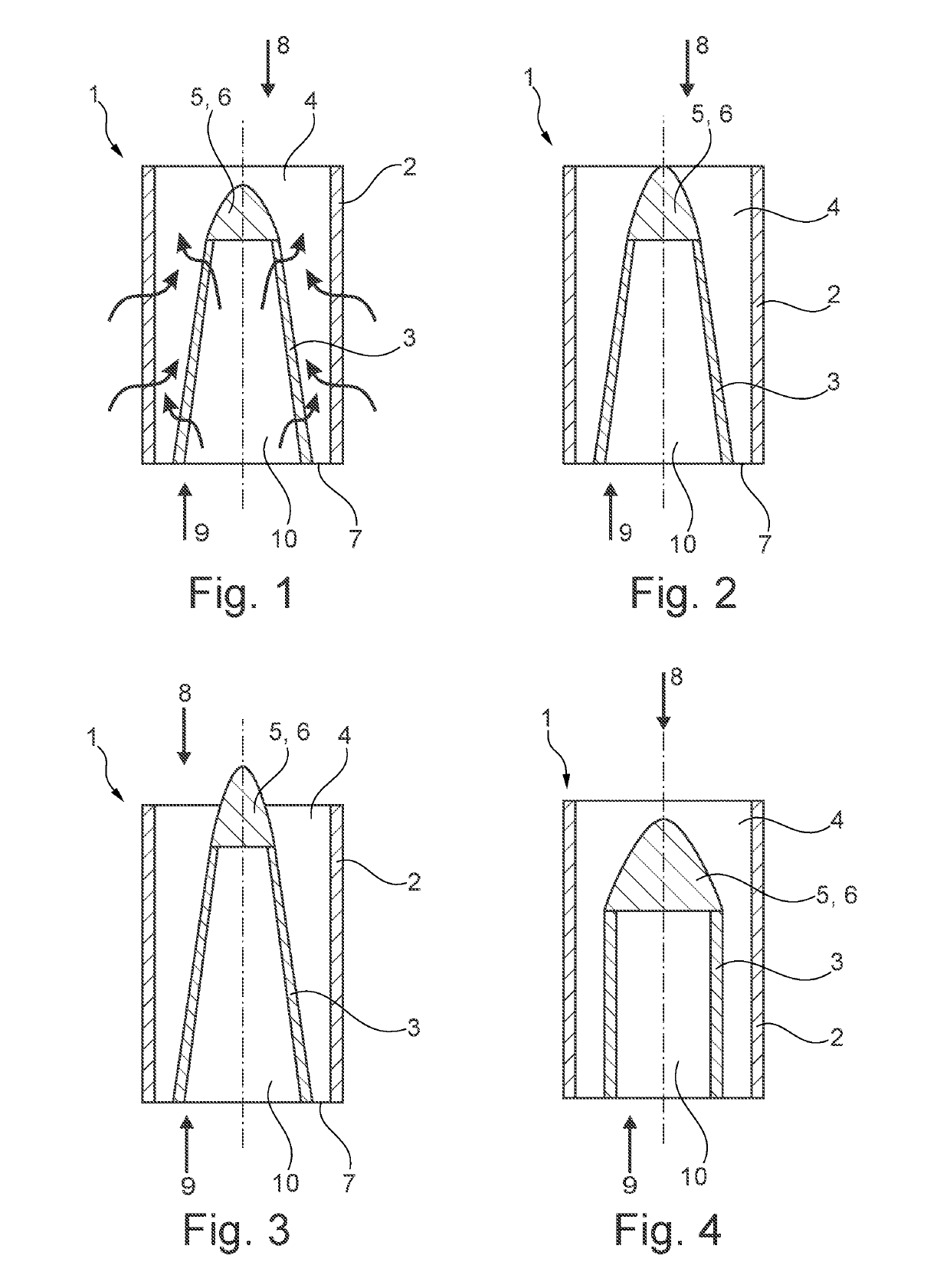

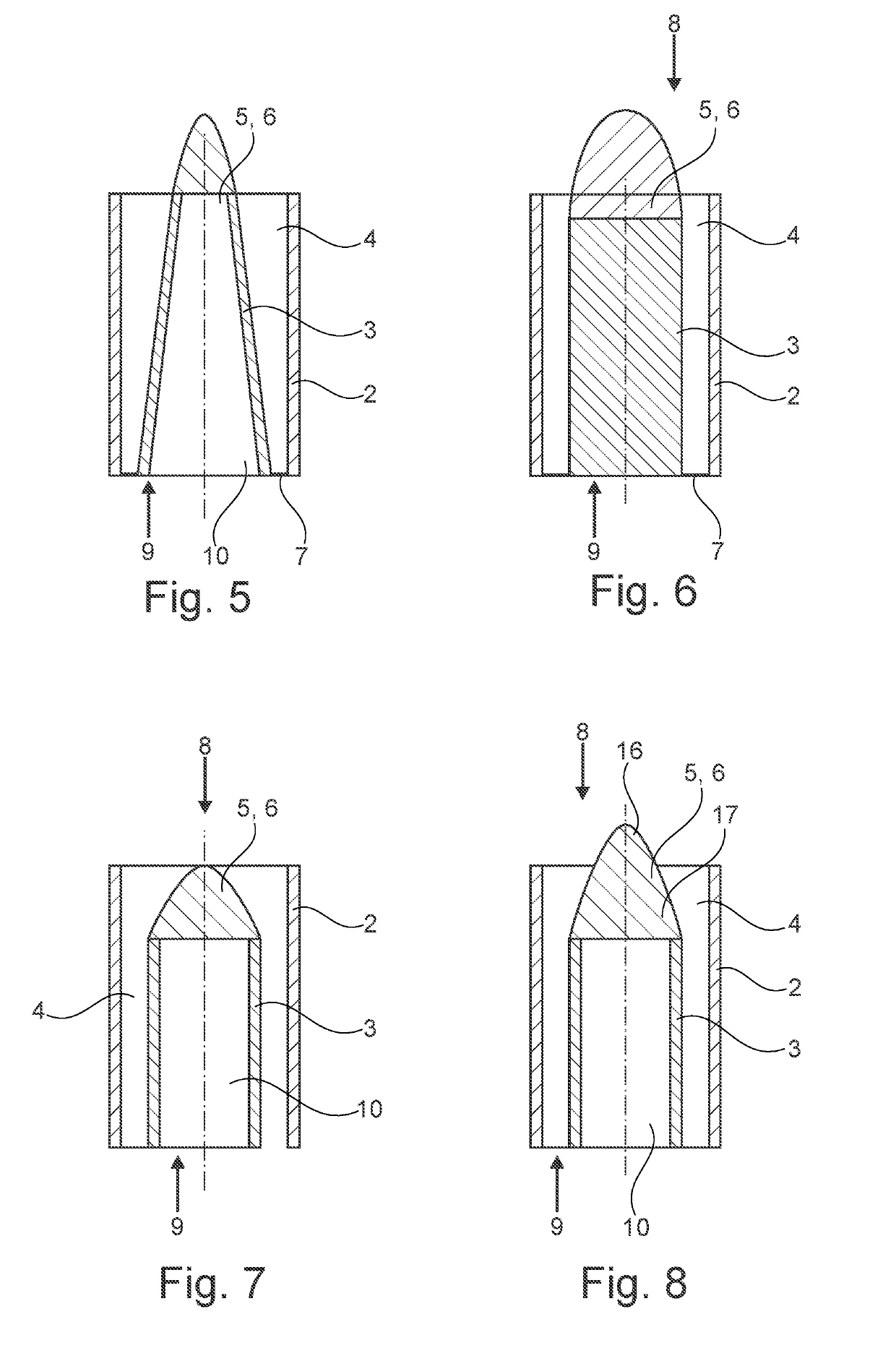

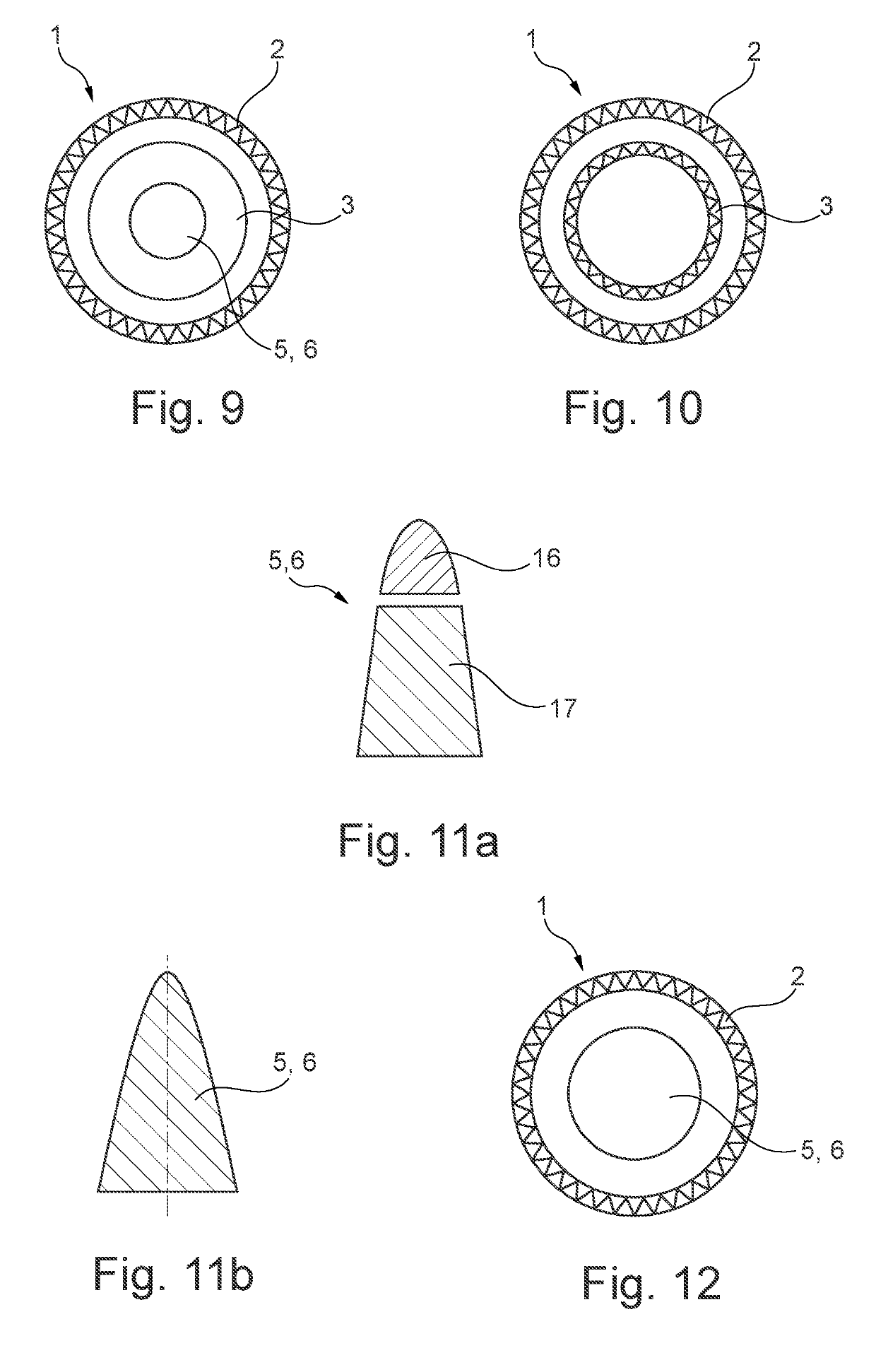

Divided flow guiding device, kit comprising base body and end piece of a flow guiding device, filter unit and method for cleaning

ActiveUS20190247778A1Easy to cleanAxial length is largeDispersed particle filtrationTransportation and packagingCleaning methodsFilter material

Owner:CAMFIL APC GMBH

Air-purifying device for a front-opening unified pod

InactiveUS20050268580A1Maintain purityCombination devicesAuxillary pretreatmentCompound (substance)Engineering

Owner:CAMBRIDGE FILTER JAPAN +2

Surgical smoke filter

InactiveCN104188724ACompact structureEasy to useDispersed particle filtrationDiagnosticsCo2 absorptionEngineering

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

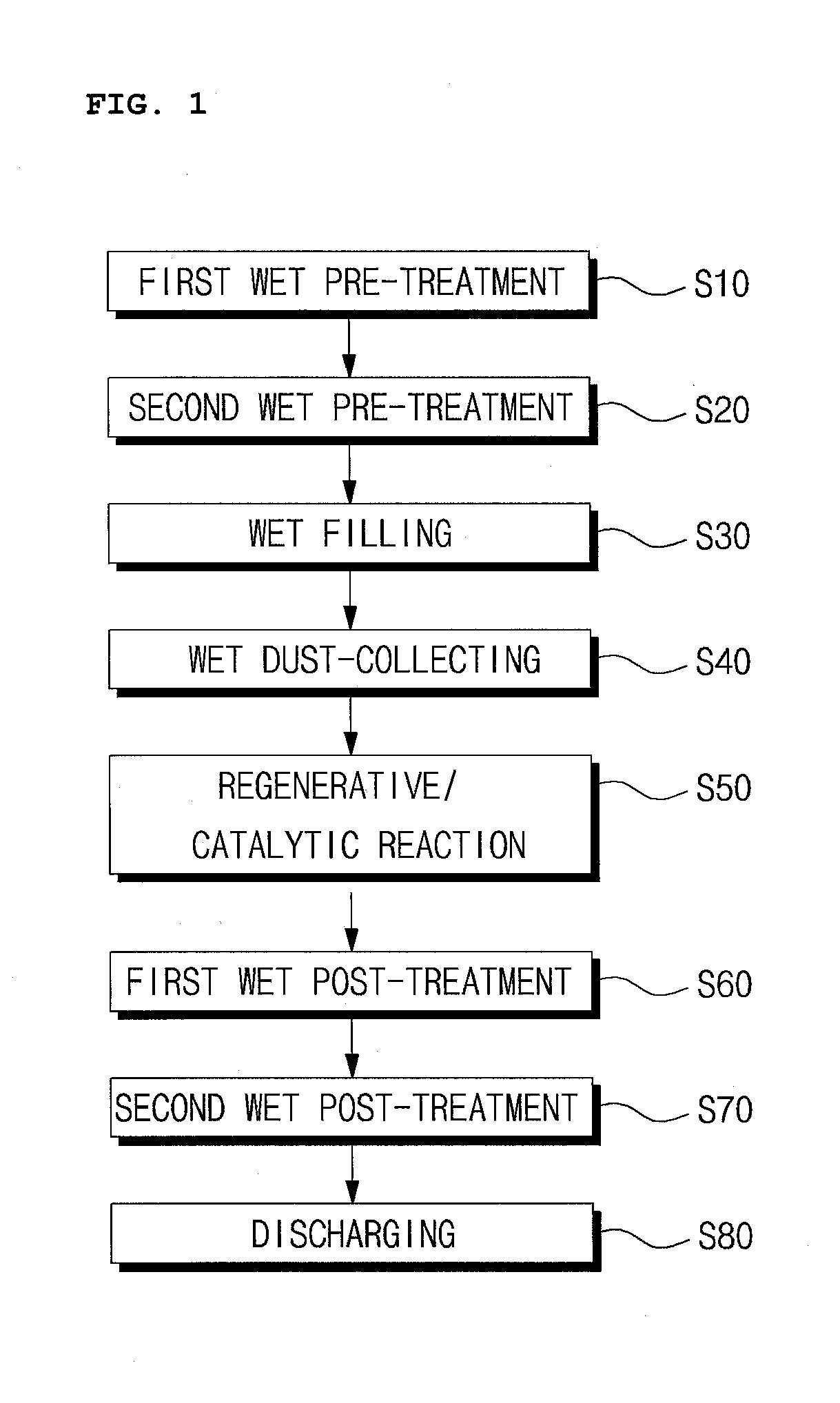

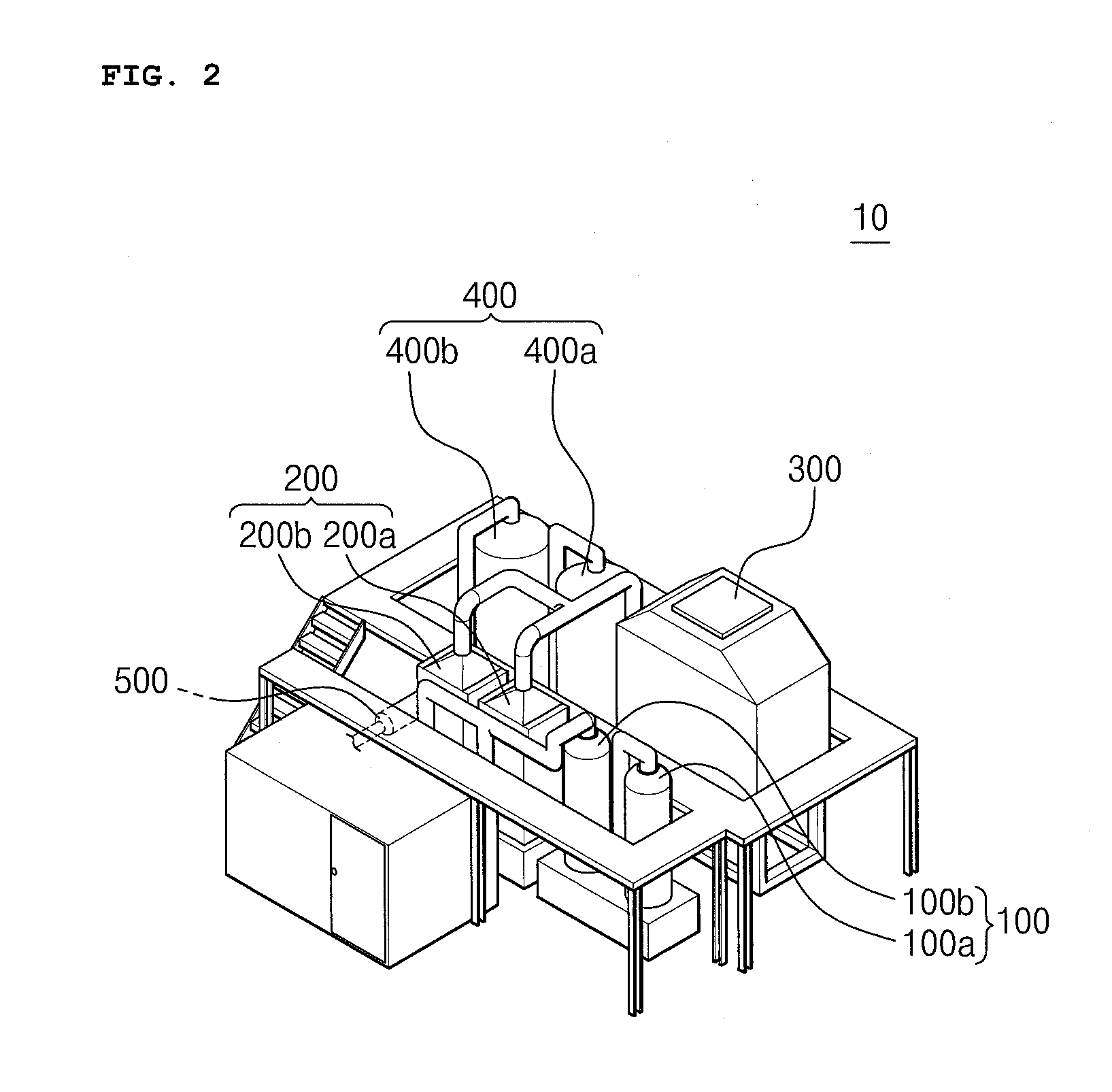

Apparatus and method for treating perfluoro-compound

Owner:GLOBAL STANDARD TECH

Novel heat energy recovery device

Owner:CHENGDU XUNDE SCI & TECH

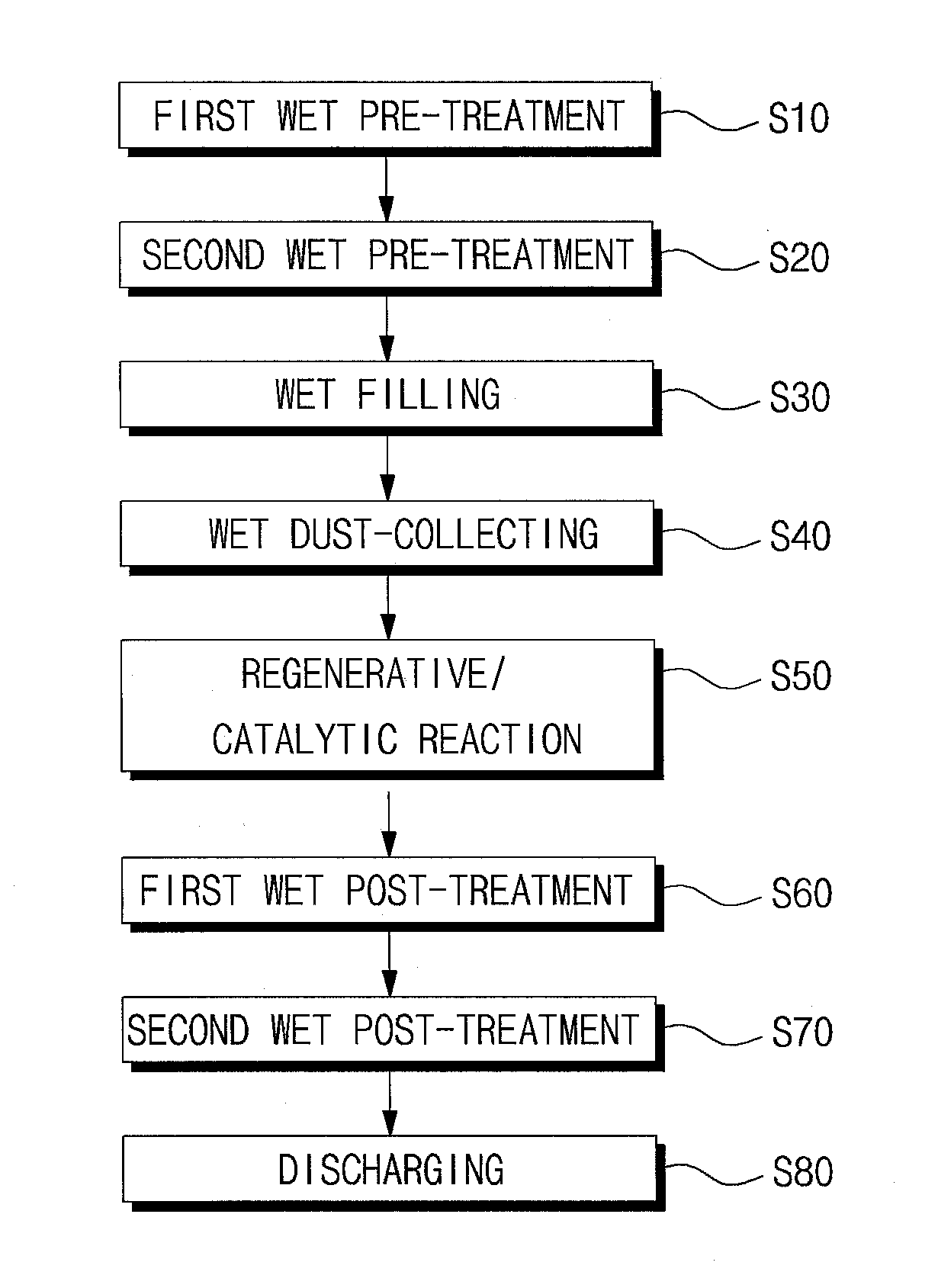

Flue gas desulfurization and denitration system and method

The invention discloses a flue gas desulfurization and denitration system and method, and belongs to the technical field of flue gas processing. The system comprises a pre-deduster, a rotating spray desulfurization and denitration system, an induced draft fan and a chimney, a circulating fluidized bed desulfurization system is arranged between the rotating spray desulfurization and denitration system and the induced draft fan, and a flue gas mixing axial adjustment damper is arranged between the rotating spray desulfurization and denitration system and the circulating fluidized bed desulfurization system; the system further comprises a booster conveying fan, a material conveying pump I and a material conveying pump II. Accordingly, the rotating spray desulfurization and denitration systemand the circulating fluidized bed desulfurization system are combined, step-by-step desulfurization and denitration on flue gas are achieved, and the desulfurization and denitration efficiency is high; due to step-by-step desulfurization and denitration, the system and method can be applied to desulfurization and denitration processing of the flue gas high in sulfur content and nitrate content, and the application range is high.

Owner:NANJING SHIBO ENVIRONMENTAL PROTECTION TECH CO LTD

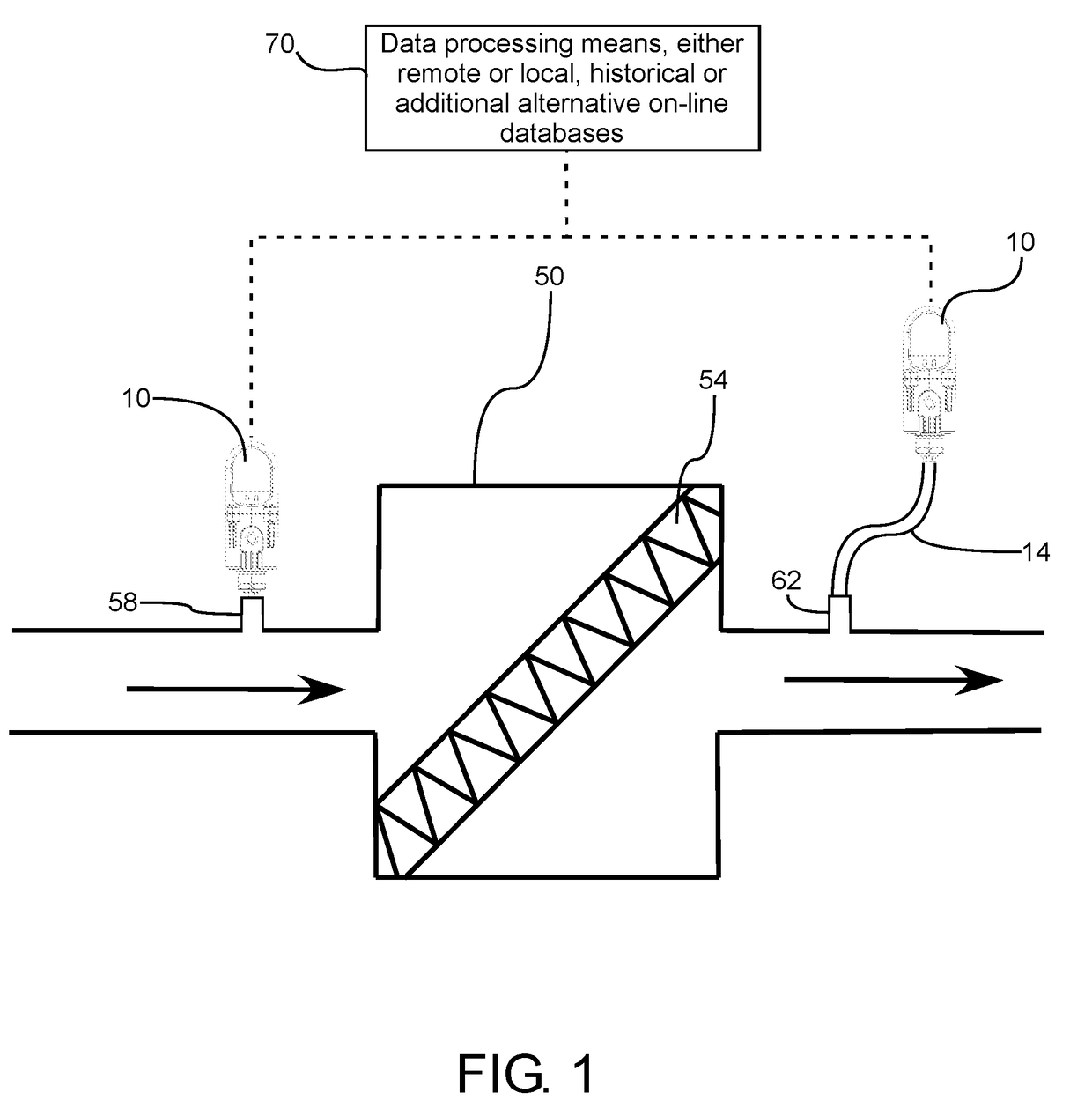

Filter element sensor module having processing and wireless communication capablilities

ActiveUS20190090036A1Sub-station arrangementsDispersed particle filtrationComputer moduleEngineering

Owner:MANN HUMMEL GMBH

Flue gas white smoke removal equipment for intelligent production factory of rubber plant

Owner:山东保蓝环保有限公司

Suspension type bridge for building decoration

PendingCN114530804AAvoid accumulationEasy maintenanceElectrical apparatusDispersed particle filtrationStructural engineeringBuilding renovation

Owner:HUZHOU SOMAOTE TECH CO LTD

High-efficiency filter sheets for air microfiltration membrane filters

InactiveCN108031209AHigh mechanical strengthIncreased mechanical toughnessDispersed particle filtrationFiltration separationPolyvinyl chlorideFilter effect

The present invention relates to a high-efficiency filter sheet for air microfiltration membrane filters. The high-efficiency filter sheet comprises a polyvinyl chloride fiber layer and a polytetrafluoroethylene fiber layer, wherein fiber filaments in the polyvinyl chloride fiber layer and the polytetrafluoroethylene fiber layer are respectively in a unidirectional arrangement, and an included angle between the fiber filaments in the polyvinyl chloride fiber layer and the fiber filaments in the polytetrafluoroethylene fiber layer is 60-65 DEG. According to the high-efficiency filter sheet, a double layer combination of the polyvinyl chloride fiber layer and the polytetrafluoroethylene fiber layer is used, and a specific angle between the fiber filaments is set, so that windage resistance and filtering effect of the filter sheet are improved; the introduced polytetrafluoroethylene fiber layer has superhigh mechanical strength and structural toughness, so that vibration caused by strongwind can be effectively suppressed, and airflow in a dust collection chamber of a vacuum cleaner is stabilized; and a filling layer is additively arranged, so that the filtering effect of the filter sheet is further improved.

Owner:SUZHOU QINGRUI AIR SYST

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap