Divided flow guiding device, kit comprising base body and end piece of a flow guiding device, filter unit and method for cleaning

a flow guiding device and flow guiding technology, which is applied in the field of filter cartridges, can solve the problems of incomplete flow guiding device portion of filter cartridges, and achieve the effects of reducing the distance between the nozzle and the filter cartridge, improving the cleaning result, and optimizing the cleaning resul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

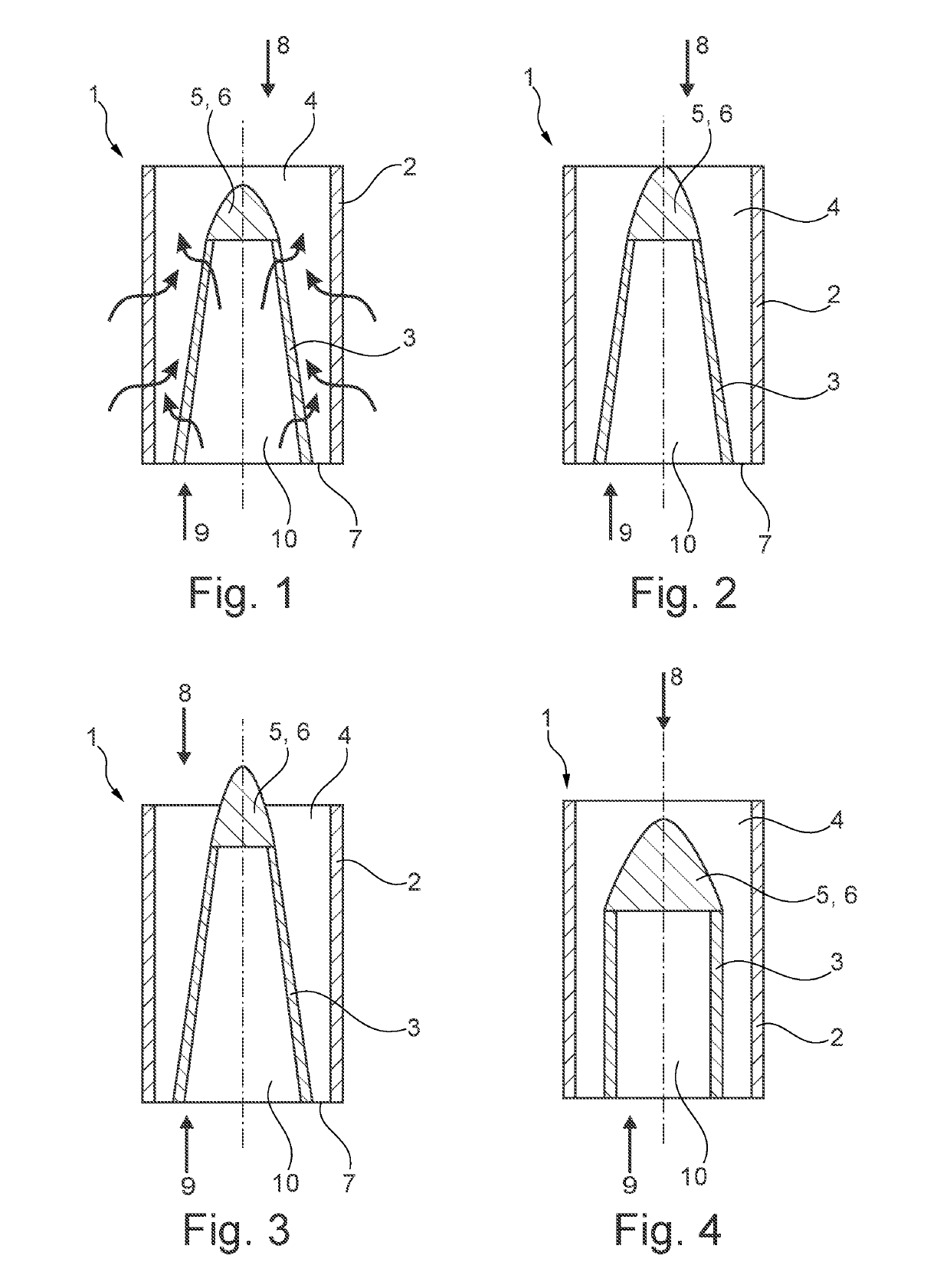

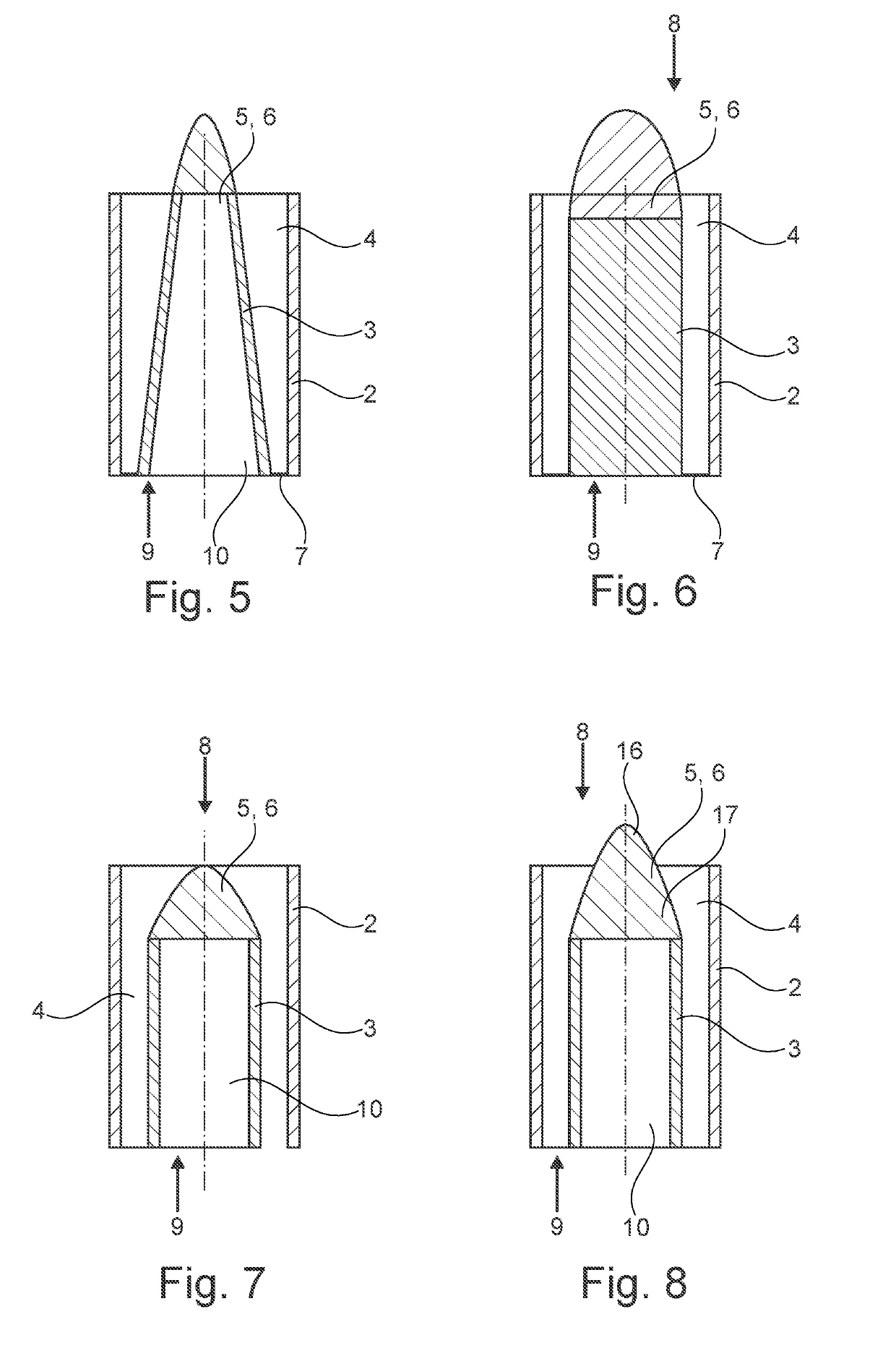

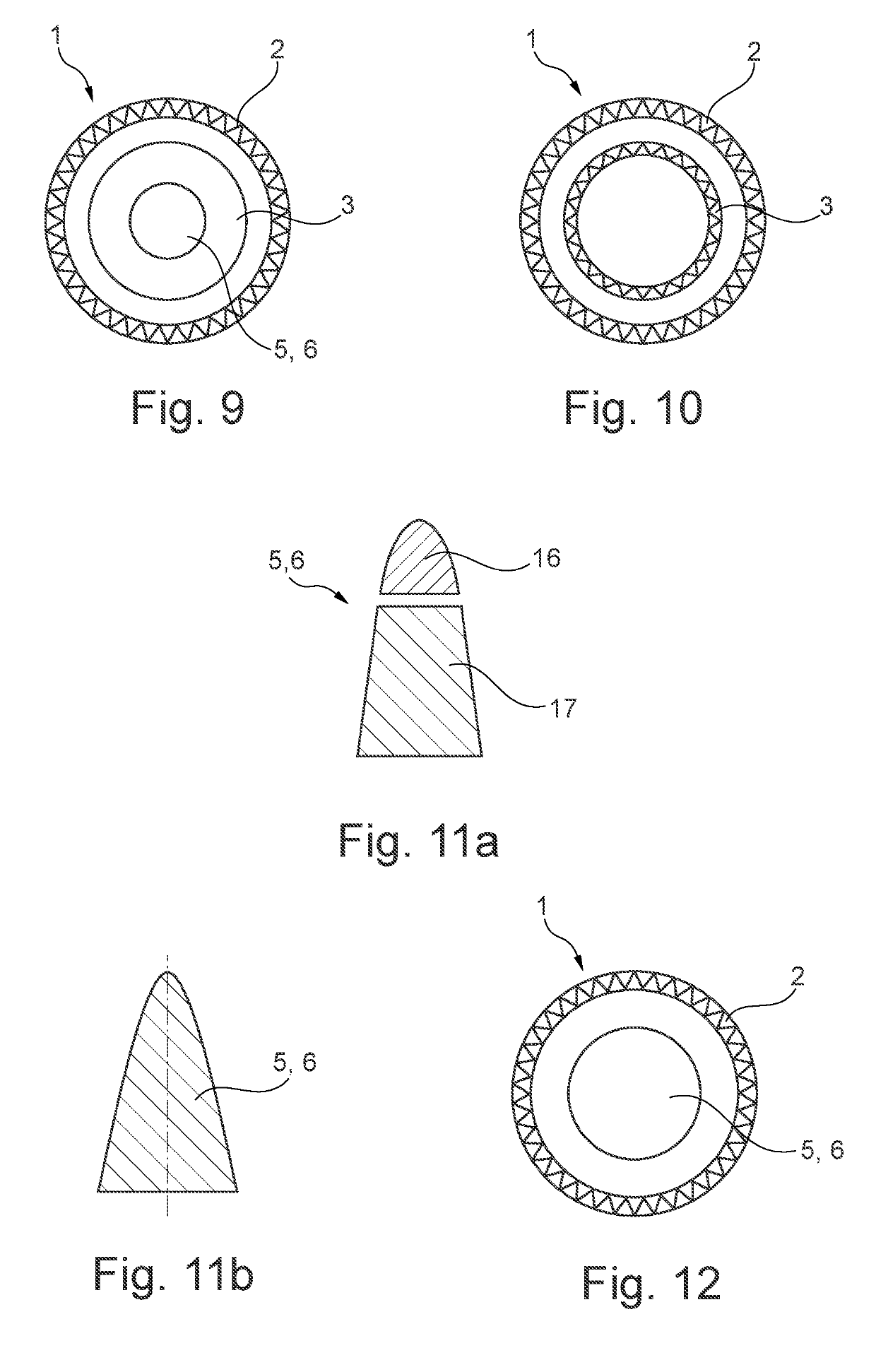

[0105]FIG. 1 illustrates a filter cartridge 1 for removing impurities from a dirty gas flow to be filtered. The filter cartridge 1 includes a cylindrical filter element 2, also referred to as an outer pack, with the filter element 2 being made from filter material. In the cylindrical filter element 2 a filter insert 3 is inserted. The filter insert 3 is also referred to as an inner pack. The filter insert 3 is made from filter material. The filter element 2 and the filter insert 3 are arranged coaxially to each other. Within the filter cartridge 1 thus an inner space 4 is formed which is ring-shaped in the area between the filter element 2 and the filter insert 3. The filter material of the filter element 2 and of the filter insert 3 is designed so that it is cleaned when compressed air flow which flows against a flow direction of the dirty gas flow is applied. The filter cartridge 1 includes a cap 6 in the form of a flow guiding device 5 which is disposed and designed with respect to

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap