Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

185 results about "Impurity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Impurities are chemical substances inside a confined amount of liquid, gas, or solid, which differ from the chemical composition of the material or compound. Impurities are either naturally occurring or added during synthesis of a chemical or commercial product. During production, impurities may be purposely, accidentally, inevitably, or incidentally added into the substance.

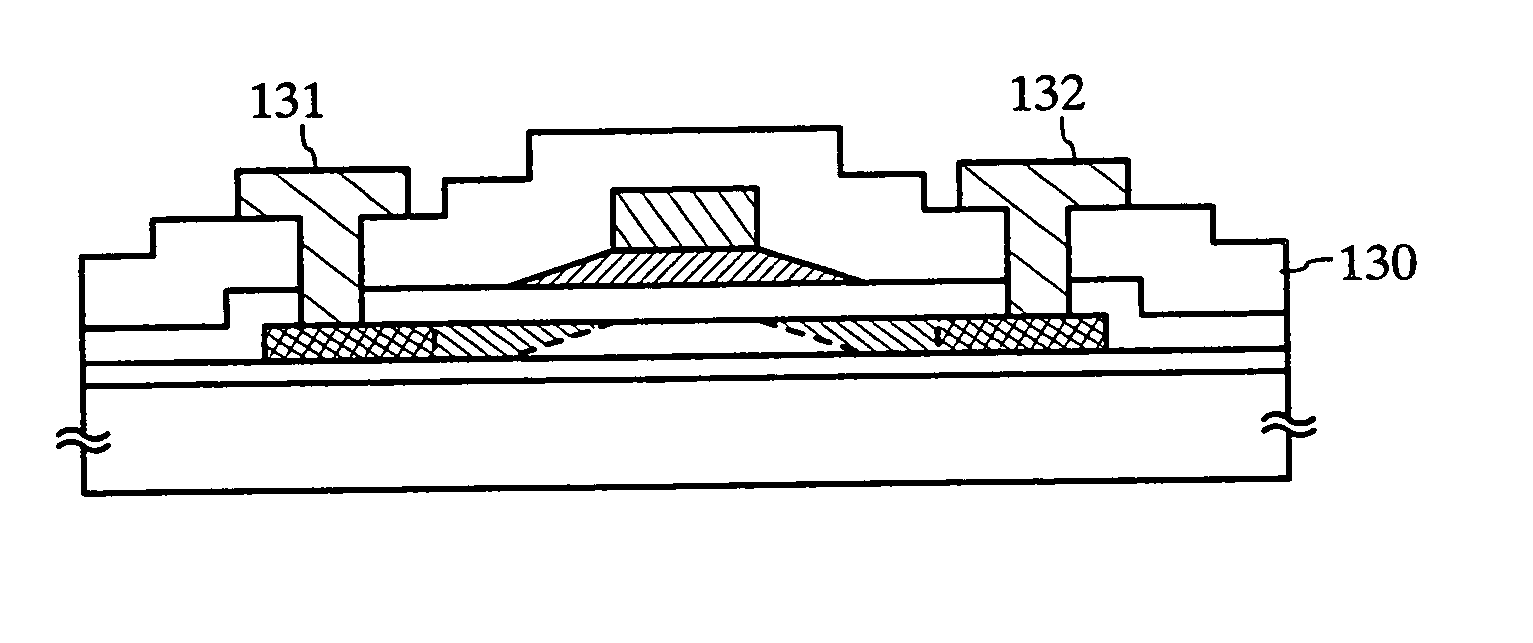

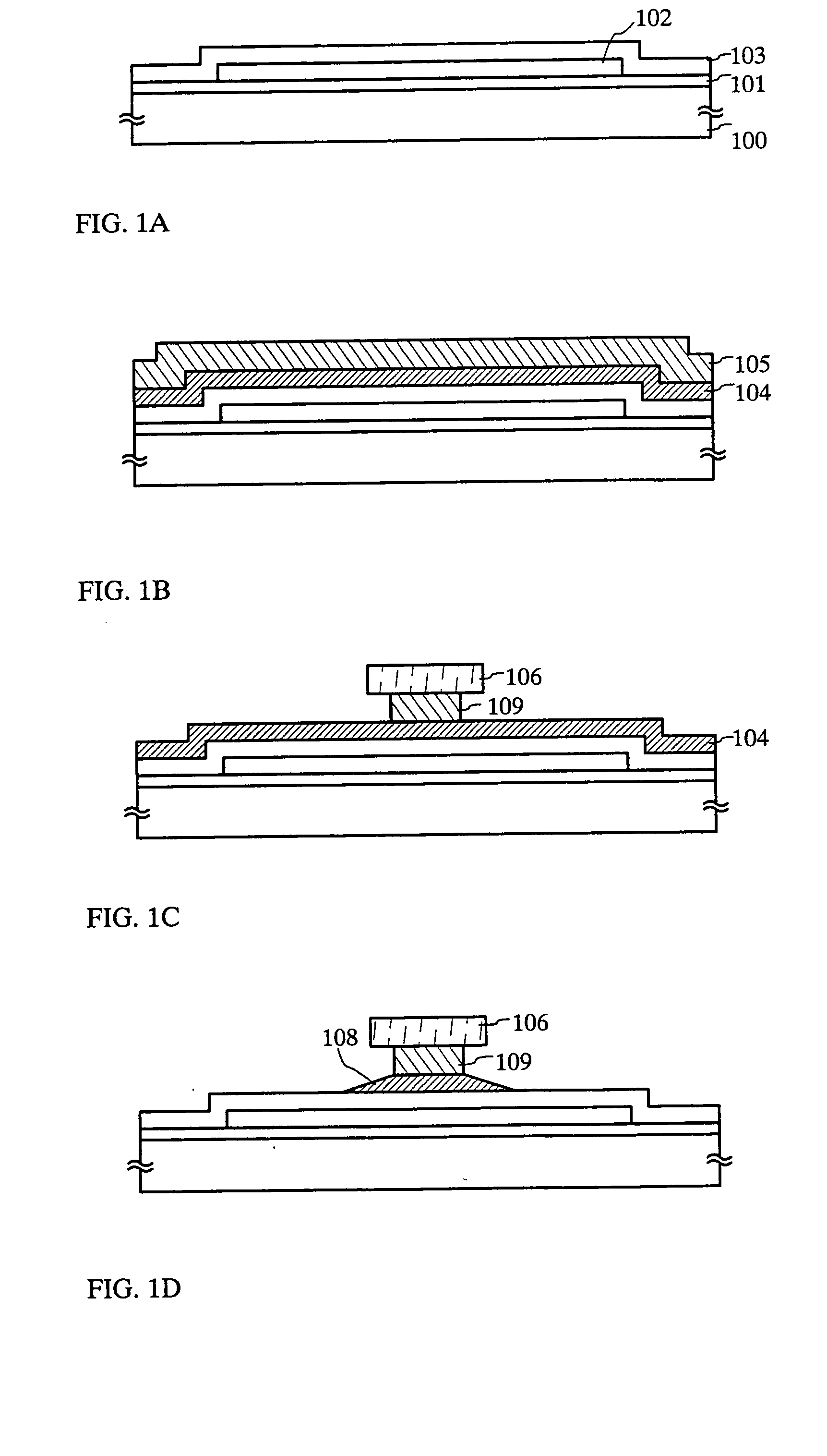

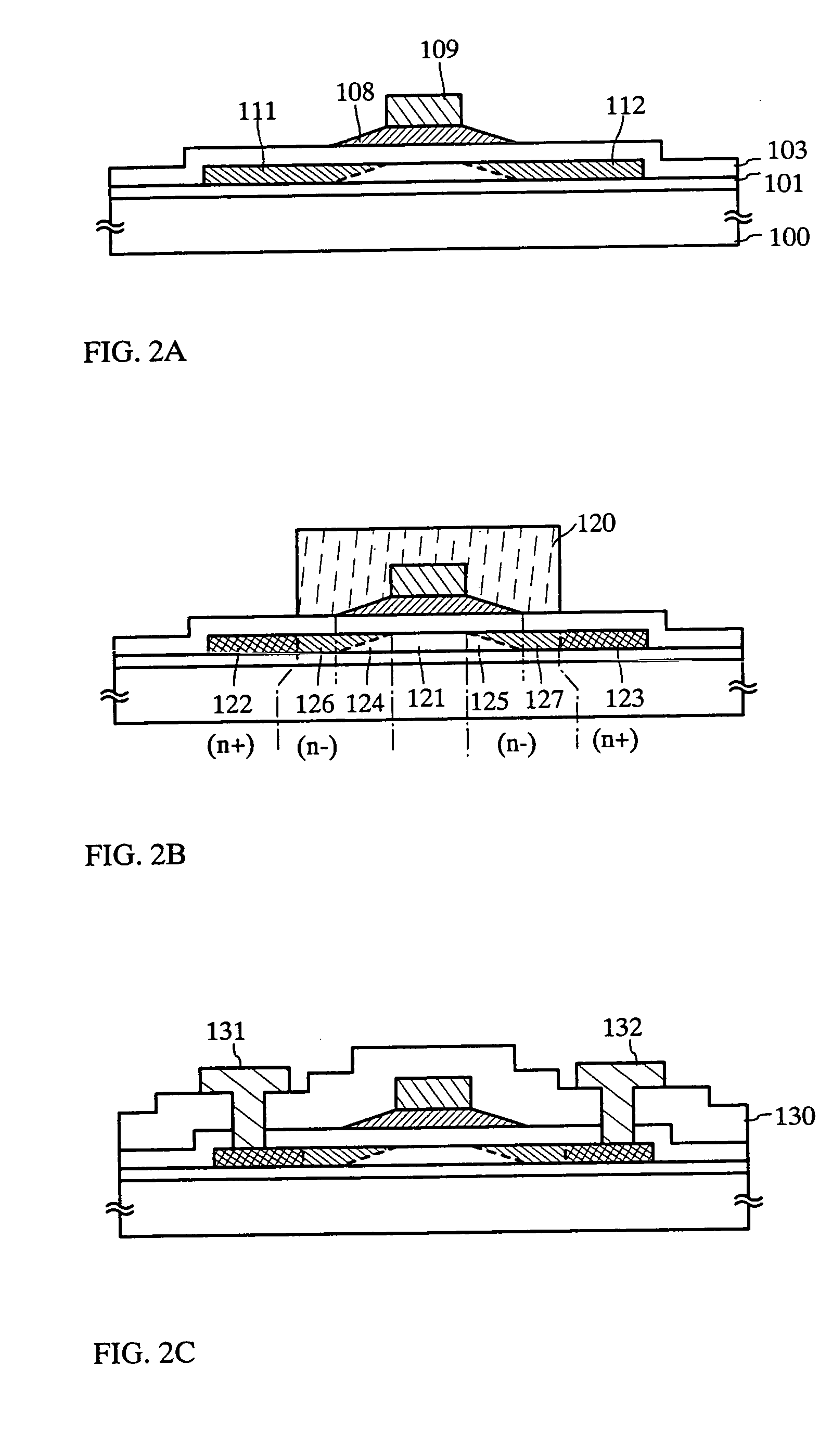

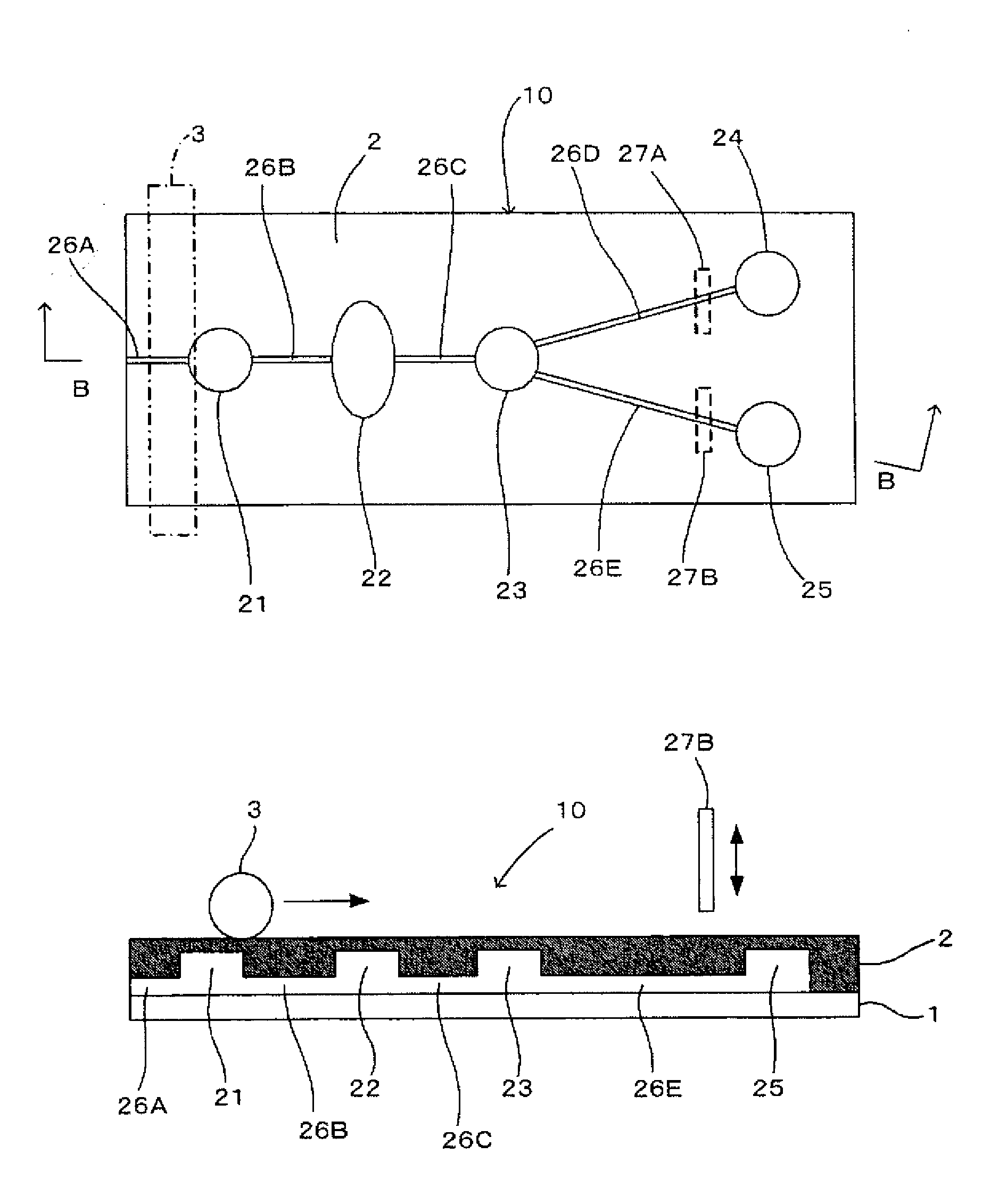

Method of fabricating a semiconductor device

Owner:SEMICON ENERGY LAB CO LTD

3D printer

InactiveUS20170050389A1Improve liquidityImprove printing qualityManufacturing enclosuresManufacturing recyclingEngineering3d printer

Disclosed is a 3D printer including a resin container which is filled with a photocurable liquid resin; a circulating pipe which forms a circulating channel through which the liquid resin is drained out of the resin container and then returned to the resin container; a circulating pump which circulates the liquid resin in the circulating channel; a heating unit which heats the liquid resin; and a filter which filters out impurities from the liquid resin in the circulating channel. According to the present invention, there is provided a 3D printer, in which cured floaters are easily removed by increasing fluidity of a liquid resin, a printed object is improved in quality, and the liquid resin is automatically replenished.

Owner:LEE BYUNG KEUK

Steel for enamel and production method thereof

The invention discloses a steel for enamel, and is characterized by comprising the following chemical elements by mass: not more than 0.020% of C, not more than 0.05% of Si, 0.10-0.50% of Mn, not more than 0.03% of P, 0.003-0.050% of S, 0.001-0.03% of Al, 0.001-0.015% of N, 0.005-0.050% of O, not more than 0.005% of Ca, not more than 0.005% of Mg, not more than 0.10% of Cu, not more than 0.10% of Cr, not more than 0.10% of Ni, not more than 0.10% of Mo, at least one of 0.0005-0.003% of B, not more than 0.01% of Nb, not more than 0.02% of V, and 0.001-0.05% of Ti, and the balance of Fe and other inevitable impurities, wherein N(%)*Ti(%) is not more than 3*10<-4>. Correspondingly, the invention further discloses a production method of the steel for enamel. The steel for enamel has excellent comprehensive performance.

Owner:BAOSHAN IRON & STEEL CO LTD

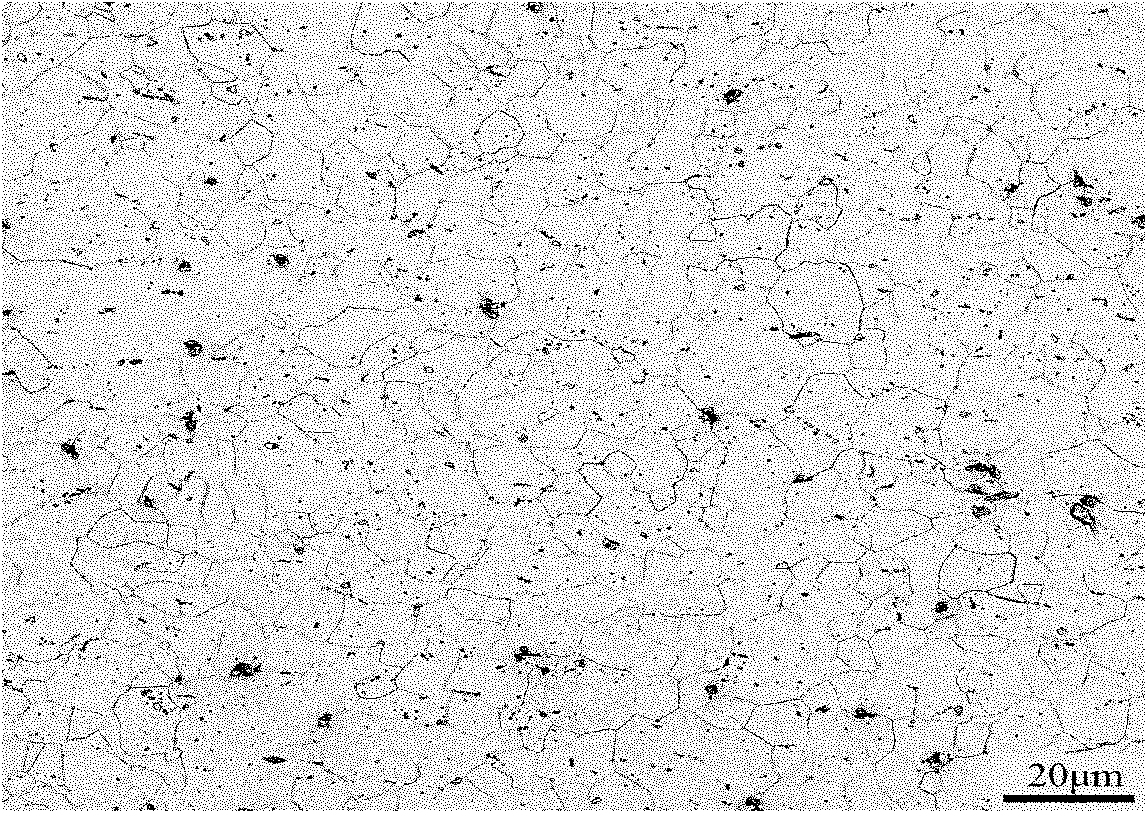

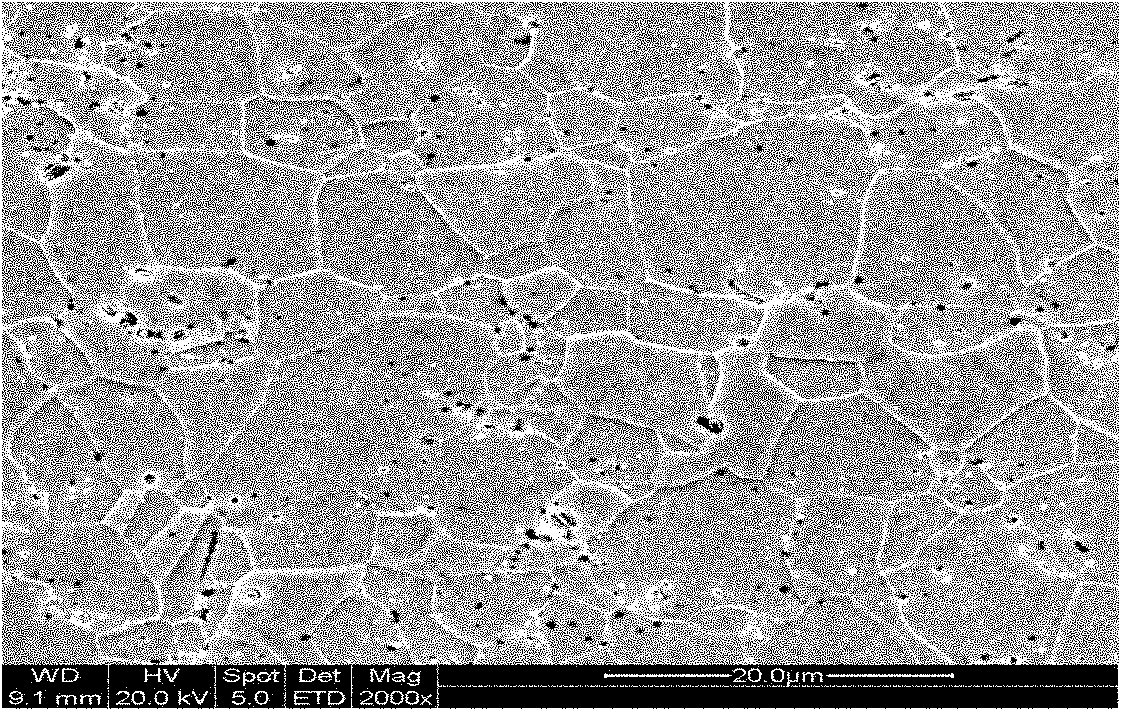

Deformed Al-Mn series alloy and preparing process thereof

Owner:ZHENGZHOU UNIV

Valine purification method

ActiveCN101798273AEasy to operateGood choiceIon-exchange process apparatusIon-exchanger regenerationPurification methodsFiltration

The invention relates to a valine purification method, which comprises the following steps: A. adding flocculating agents into valine fermentation liquid for fast precipitating solid impurities, and obtaining primary filter liquid through filtering supernatant; B. adding activated carbon into the primary filter liquid obtained in the step A, wherein the added activated carbon accounts for 1+ / -0.5weight percent of the filter liquid, carrying out stirring and decoloration at 60 + / - 5 DEG C, and then, obtaining secondary filter liquid through filtration; C. using an industrial chromatographic column for separating inorganic salt and heteroacid, and then, using a sodium filter membrane for removing pigment and small molecular impurities to obtain a clear and colorless valine solution; D. concentrating the filter liquid for crystallization to obtain crude valine products; and E. shaking a transmission belt and raising the temperature to 220 + / - 10 DEG C, and carrying out sublimation to remove alanine and isoleucine to obtain pharmaceutical grade competitive valine products. The method has the characteristics of simple operation, good selectivity, cleanness and environment protection, so the yield and the quality of the valine are obviously improved.

Owner:ZHAODONG XINGHU BIOTECHNOLOGY CO LTD

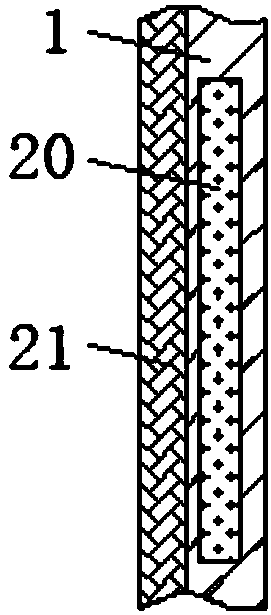

Chemical treatment cartridge and method of using same

InactiveUS20080035576A1Easy extractionEnsure safetyIon-exchange process apparatusAnalysis using chemical indicatorsChemical treatmentDistillation

Owner:YOKOGAWA ELECTRIC CORP

Preparation process for extracting crude sodium heparin from pig lungs

The invention relates to a preparation process for extracting crude sodium heparin from pig lungs, which comprises the following steps: mincing fresh pig lungs into slurry, carrying out heat insulation and enzymolysis to obtain an enzymolysis liquid, filtering the enzymolysis liquid to collect filtrate, carrying out ion exchange adsorption treatment on the filtrate, washing and eluting resin, precipitating sodium heparin, and drying to obtain crude sodium heparin. The enzymolysis method employed by the invention can thoroughly dissolve pig lung slurry and effectively improve and stabilize the quality of the product and the yield of sodium heparin; and simultaneously, the obtained crude sodium heparin has low impurity content and high titer.

Owner:TIANJIN BAODI AGRI & TECH CO LTD

A vine tea mask capsule and a method of preparing the same

InactiveCN102552092ABacteriostaticWith whiteningCosmetic preparationsToilet preparationsIrritationToxin

Owner:FUJIAN AGRI & FORESTRY UNIV

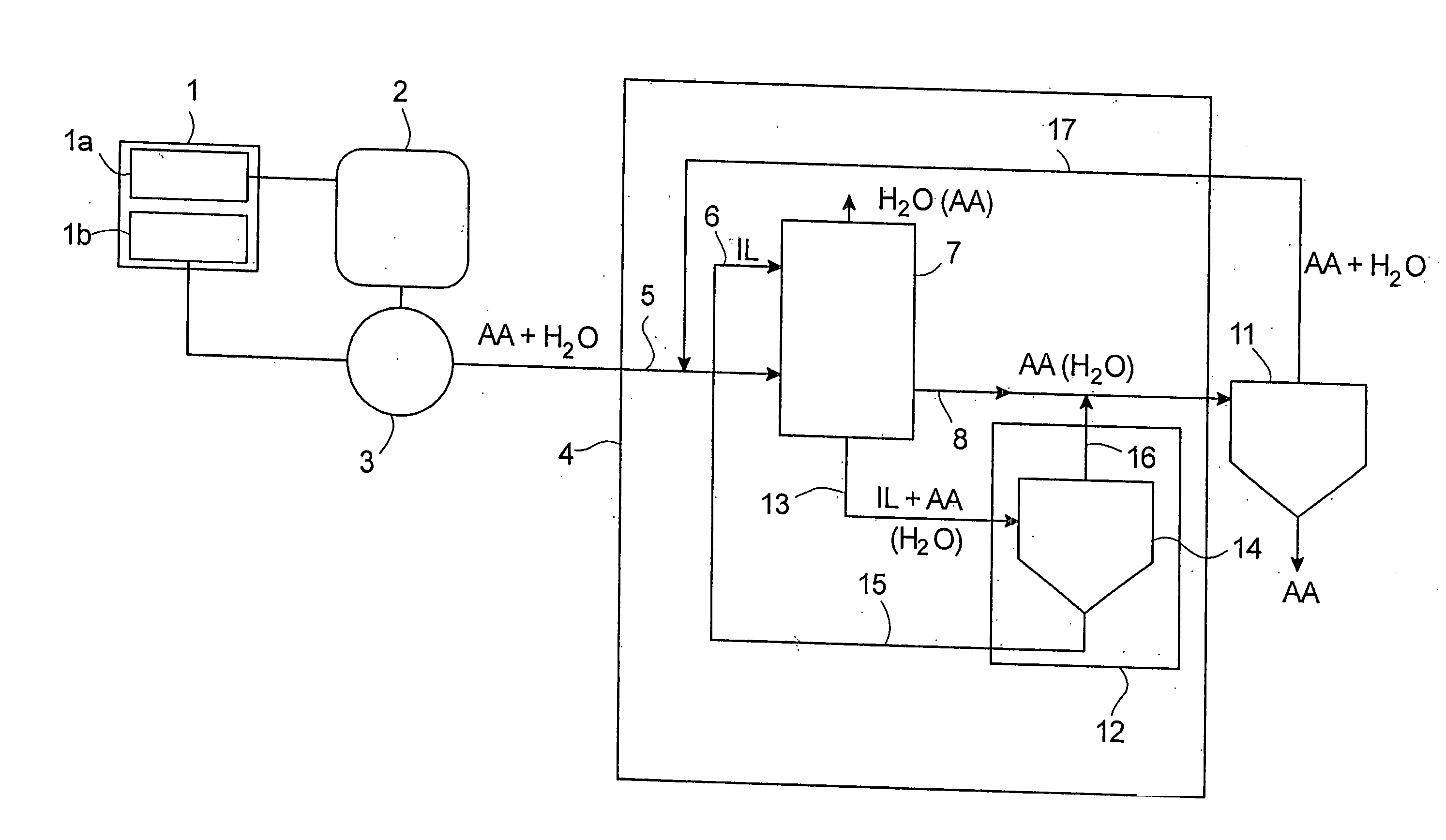

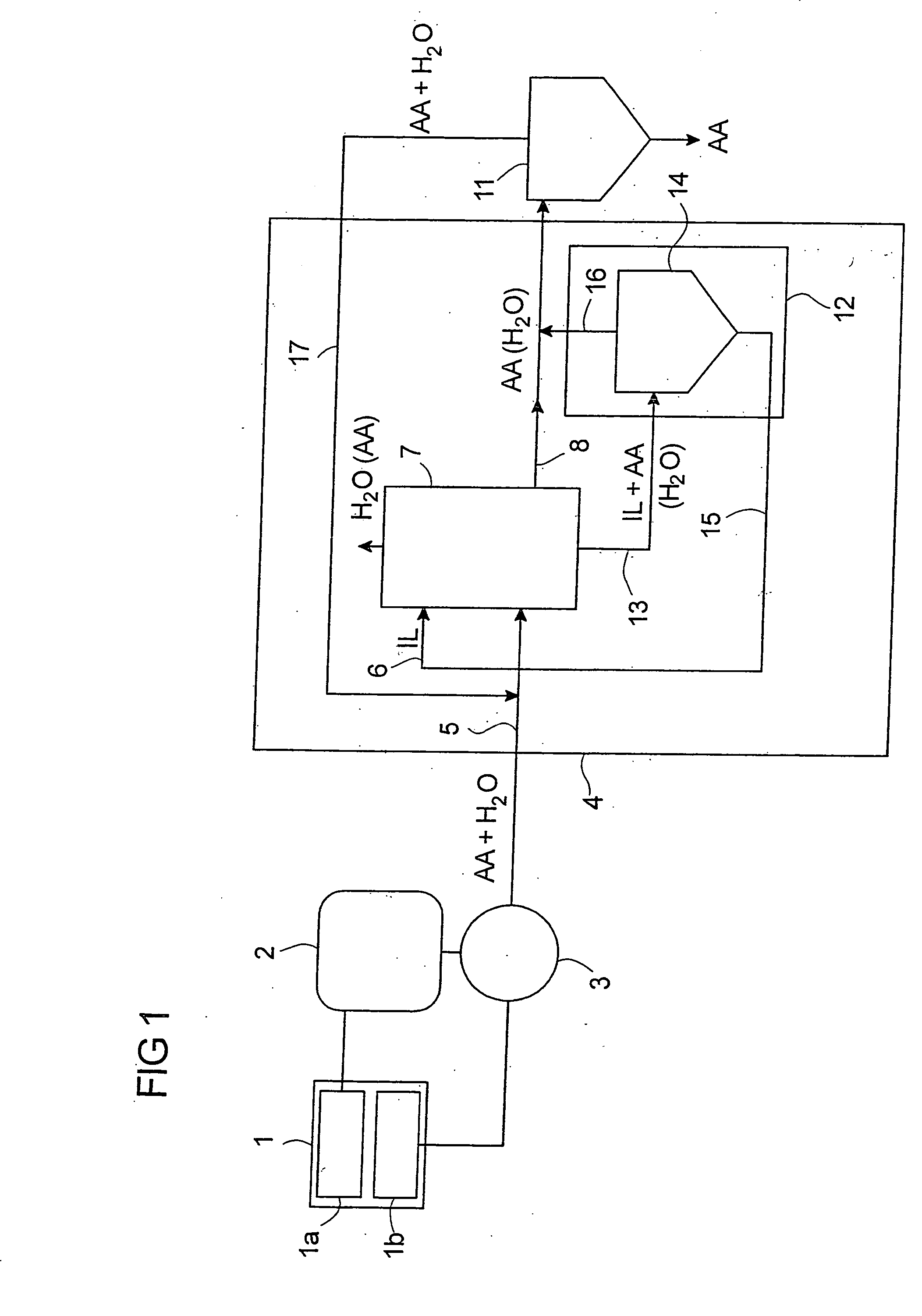

Method for the separation of monomers from a composition containing a monomer

InactiveUS20070004903A1High purityIncrease moistureCarboxylic compound separation/purificationMeth-Double bond

Owner:STOCKHAUSEN GMBH & CO KG

Method for purifying citrulline from watermelon

InactiveCN101880245AReduce loadExtend your lifeUrea derivatives preparationOrganic compound preparationAcid waterCitrulline

Owner:NANJING ZELANG AGRI DEV

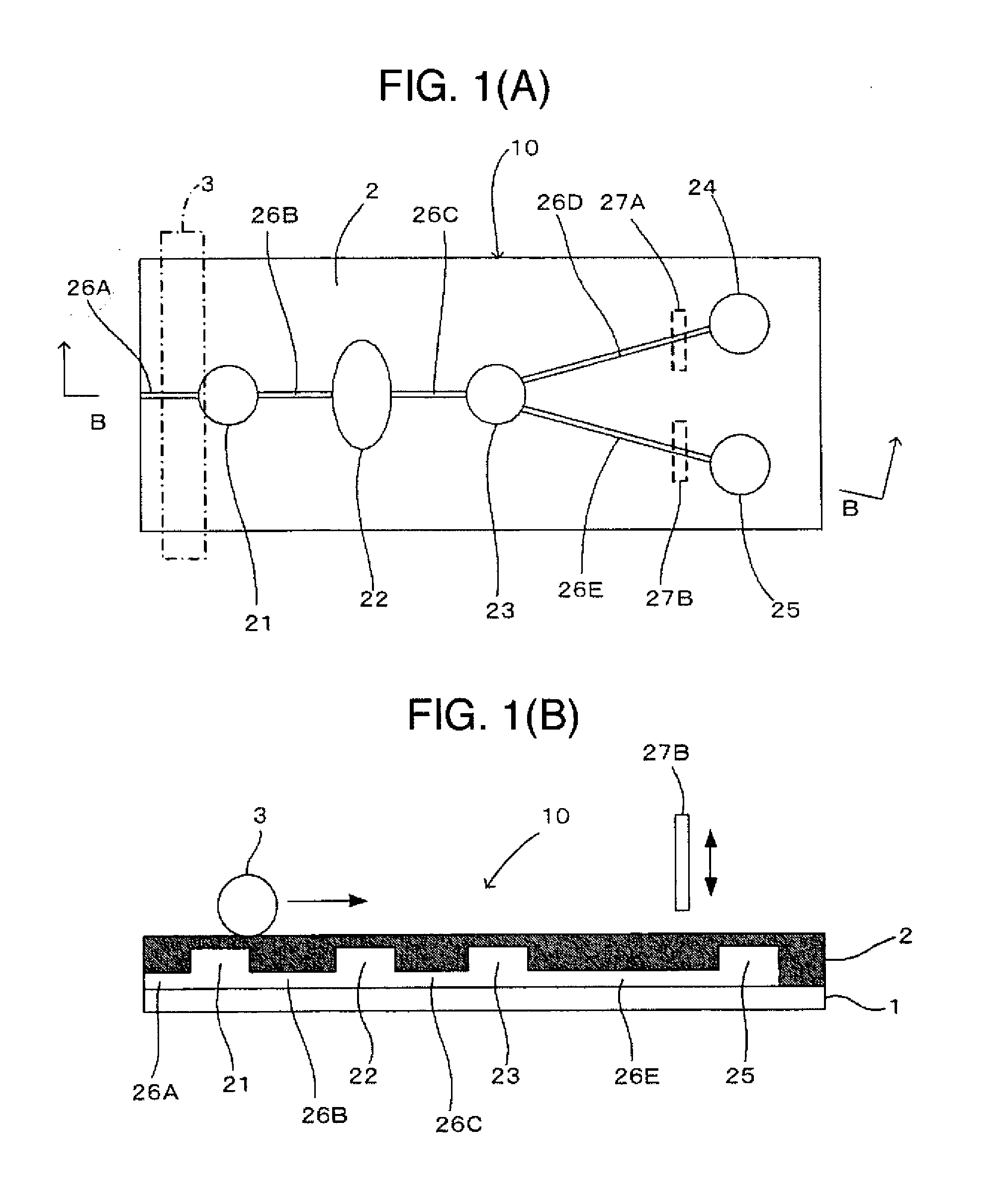

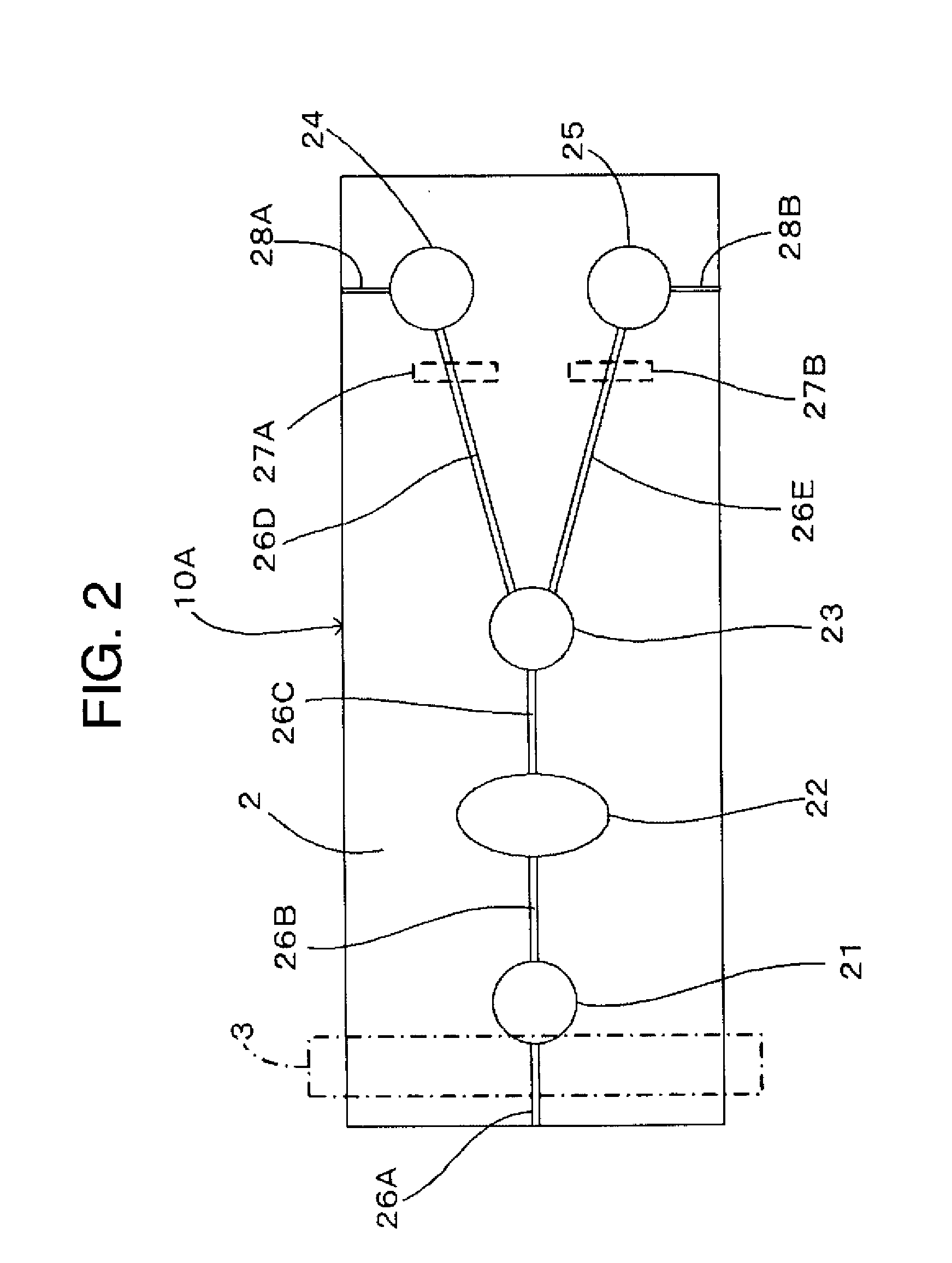

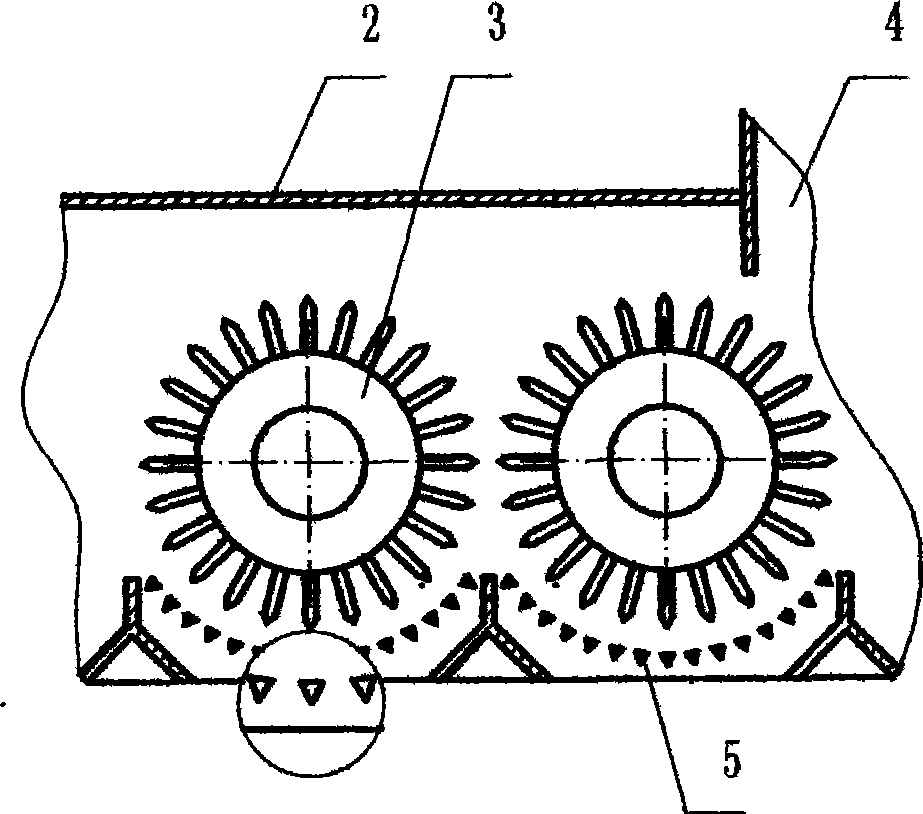

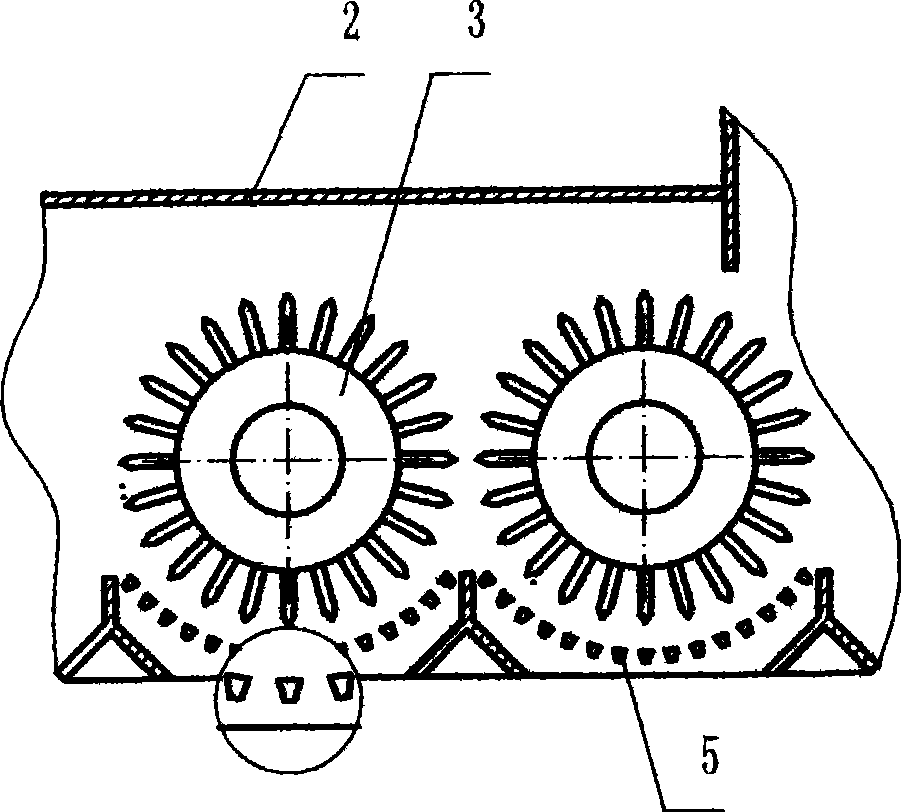

Cotton cleaning mechanism and constituted cotton-picker

InactiveCN101451280AReduce complexityReduce damageFibre cleaning/openingPicking devicesCotton fibreEngineering

Owner:黄军干

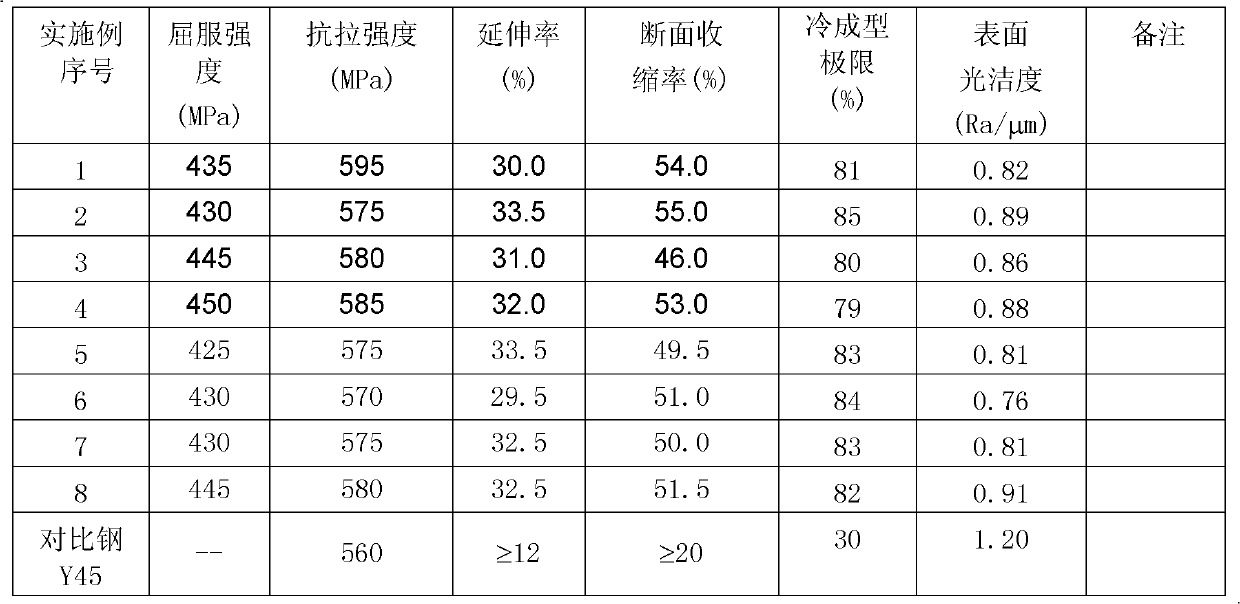

Environment-friendly high-performance graphitized free cutting steel

Owner:WUHAN IRON & STEEL (GROUP) CORP

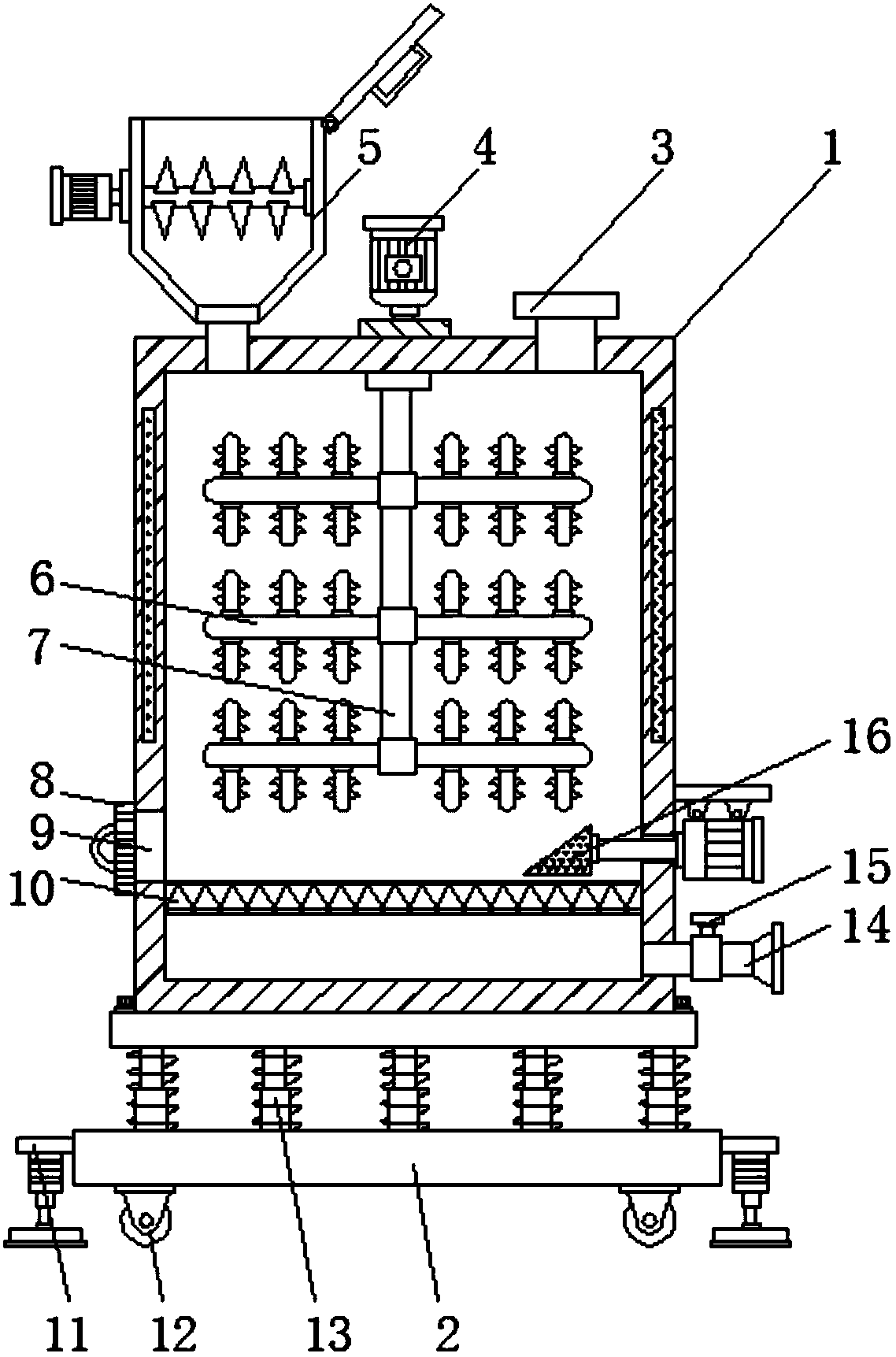

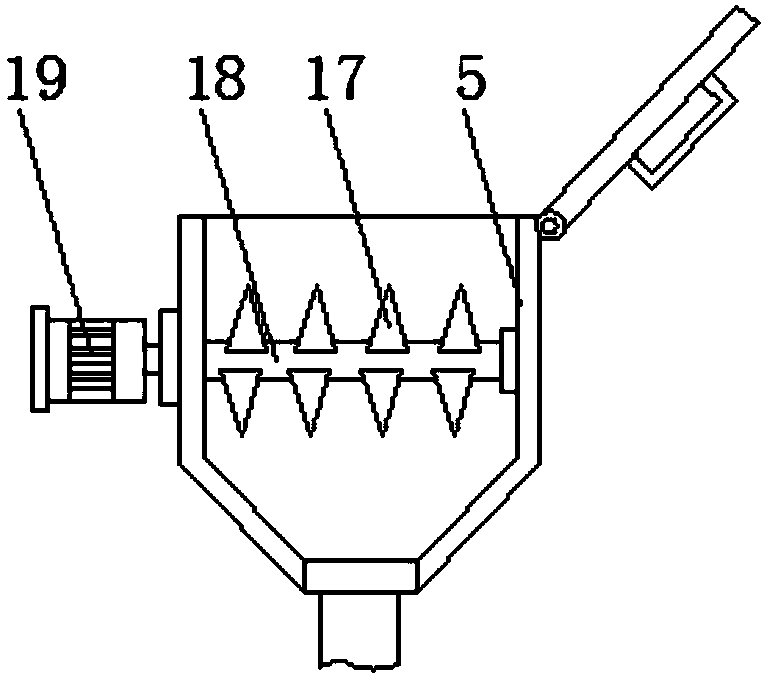

Slurry stirring device for coated fabric production

PendingCN108607463AStir wellEffective crushing and refiningRotary stirring mixersTransportation and packagingPulp and paper industryReducer

Owner:浙江唐艺织物整理有限公司

Sulfur erosion resisting steel and smelting method thereof

Owner:攀钢集团成都钢铁有限责任公司

Ultra-pure gadolinium oxide and electrochemical reduction fully-closed type extracting production process thereof

ActiveCN101824537AEfficient removalLarge amount of processingRare earth metal compoundsProcess efficiency improvementRare-earth elementPhase ratio

Owner:QIANDONG RARE EARTH GRP

Purifier

InactiveCN101284691AExtend your lifeSimple structureWater/sewage treatment bu osmosis/dialysisFiltrationImpurity

The invention relates to the field of water treatment, particularly to the deep filtration and purification of drinking water, and comprises a filter element, an inlet and an outlet pipeline interfaces, and a water path switcher connected between the inlet and the outlet pipeline interfaces and the filter element, wherein the water path switcher comprises two switching disks with 2 to 16 switching positions and a plurality of switching water gaps that are arranged in the switching positions on the contact surface between the two switching disks and respectively communicate with the water paths. The water path switcher further comprises a pressing component and a closed switching interface formed at the periphery of the switching water gaps by the contact surface of the two switching disks with overlapping axis of rotation; the two switching disks contact each other and can rotationally change the relative switching positions. The invention has the advantages of simple and practical structure, low cost, good repercussion effect, improved purifying effect and prolonged service life of the filter element. Through the switching of the water path switcher, multiple layers of the filter element or multi-stage filter element can be thoroughly washed layer by layer or stage by stage, and the impurities can be discharged layer by layer or stage by stage.

Owner:杜也兵

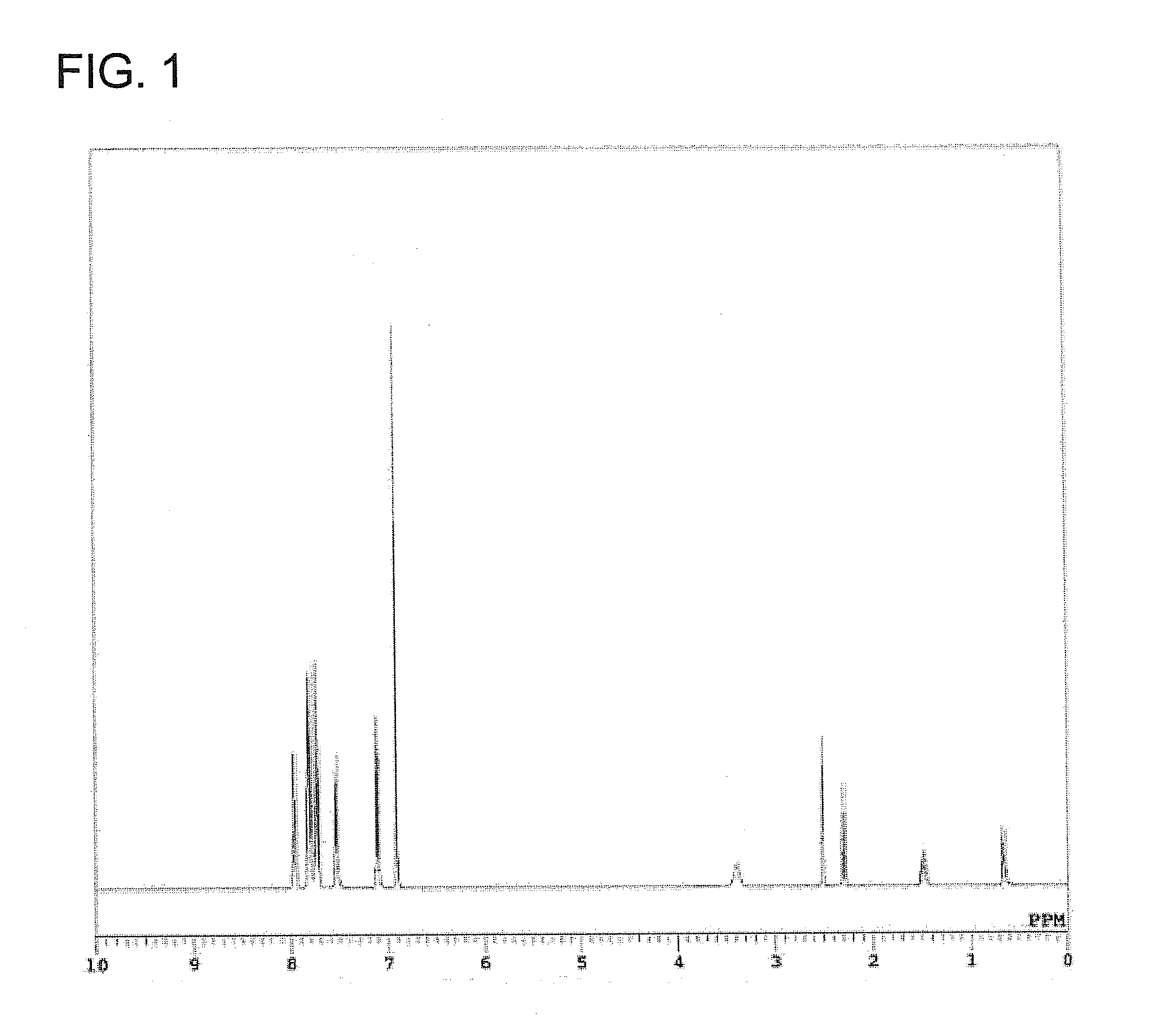

Method for preparing LCZ696

ActiveCN105330609AReduce generationPrecipitation state is goodOrganic compound preparationOrganic chemistry methodsSodium acetateReaction temperature

The invention discloses a method for preparing LCZ696. Please see the synthesis route in the specification. When sodium acetate is used as alkali in the compound III preparation process, the conversion rate is high, hydrolysis impurities are few, system stability is good, and the reaction time is greatly shortened; in the compound I preparation process, acetone and normal heptanes with the mass ratio between 5 to 1and 10 to 1 serve as cocrystallization solvent, the reaction temperature of 35-45 DEG C is adopted, a sodium hydroxide solution is dropwise added into a reaction system at a certain speed at the temperature of 35-45 DEG C, generation of hydrolysis products can be greatly reduced, the solid precipitation state is good, purity is high, aminolysis impurities and hydrolysis impurities can be effectively controlled, and the LCZ696 can directly serve as crude drug to be used for preparations.

Owner:NANJING CHIA TAI TIANQING PHARMA +1

Mushroom powder rich in vitamin D2, and preparation method and application thereof

InactiveCN109527530AMeet the process requirementsAvoid over dryingOrganic active ingredientsFruits/vegetable preservation by irradiation/electric treatmentUltraviolet lightsNitrogen gas

The invention relates to the field of domestic fungus processing, and discloses a mushroom powder rich in vitamin D2, and a preparation method and an application thereof. The preparation method comprises the following steps: slicing a mushroom raw material, and performing ultraviolet irradiation treatment in an environment having a temperature of 20-55 DEG C and a relative humidity of 50-85%, wherein the ultraviolet light irradiation is a combination of 280-315 nm UVB irradiation and 200-280 nm UVC irradiation, and the water content of the mushroom raw material is not less than 20%; drying theultraviolet-irradiated mushroom raw material under a nitrogen-filling condition; and crushing the dried mushroom raw material. The conversion rate of ergosterol into the vitamin D2 is improved by controlling the wavelength, temperature and humidity conditions during ultraviolet irradiation treatment, and a nitrogen-protected drying process is adopted to avoid the vitamin D2 from forming isomer impurities or from being degraded and lost in order to improve the quality of the mushroom powder product.

Owner:瞿瀚鹏

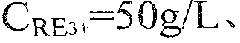

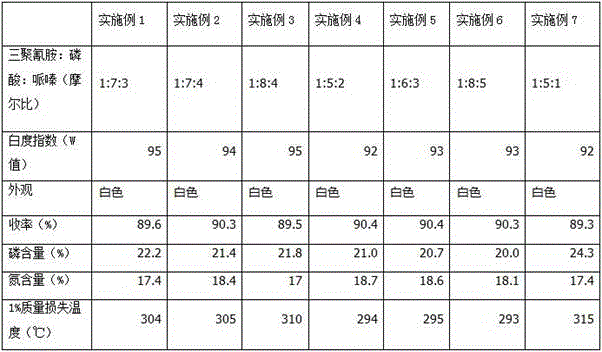

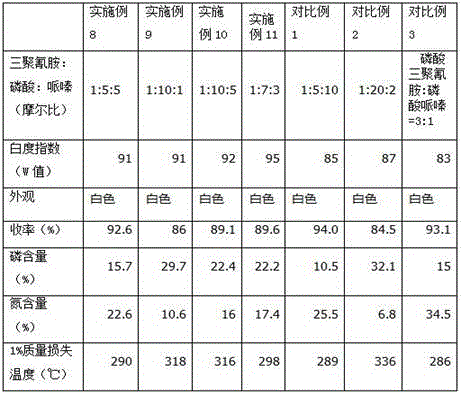

Halogen-free flame retardant and preparation method thereof and flame-retardant polyolefin composition composed of same

ActiveCN105837855AImprove thermal stabilityThe content of functional components is flexible and adjustableOrganic chemistryPolymer sciencePolyolefin

Owner:KINGFA SCI & TECH CO LTD

Process for producing latent catalyst and epoxy resin composition

InactiveUS20090234080A1High yieldGood fluidityOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyPhosphonium

Owner:SUMITOMO BAKELITE CO LTD

Flux for removing iron from Mg alloy and its preparing process

Owner:SHANGHAI JIAO TONG UNIV

Ultra-low carbon martensitic stainless steel seamless tube and manufacturing method thereof

InactiveCN108277438AHigh tensile strengthHigh yield strengthFurnace typesHeat treatment furnacesMartensitic stainless steelHigh pressure

The invention discloses an ultra-low carbon martensitic stainless steel seamless tube. The ultra-low carbon martensitic stainless steel seamless tube is prepared from ultra-low carbon martensitic stainless steel. The ultra-low carbon martensitic stainless steel is prepared from the following components in percentage by mass: less than or equal to 0.03% of C, 0.1-0.5% of Si, 0.2-0.5% of Mn, less than or equal to 0.015% of P, less than or equal to 0.002% of S, 12.2-13.2% of Cr, 5.2-5.7% of Ni, 1.9-2.1% of Mo, 0.1-1.6% of Cu and the balance of Fe and other impurities. The seamless tube can be suitable for oil and gas fields. The invention also provides a manufacturing method of the seamless tube. The manufacturing method comprises the following steps: smelting; tube blank thermal processing;steel tube thermal processing; and thermal treatment, wherein the heating temperature of tube blank thermal processing is 1200-1280 DEG C, the heating temperature of tube manufacturing by means of anextruding method is 1150-1250 DEG C, the heating temperature of tube manufacturing by means of a perforating cold rolling method is 1200-1280 DEG C, and the temperatures for thermal treatment are as follows: quenching at 900-1050 DEG C and tempering at 550-680 DEG C. The seamless tube provided by the invention has excellent strength and corrosion resistance in a CO2 and Cl<-> coexisting corrosionenvironment and in high-temperature and high pressure conditions.

Owner:TAIYUAN IRON & STEEL (GRP) CO LTD

Hot-rolled steel strip for high strength electric resistance welding pipe and manufacturing method thereof

InactiveUS7501030B2Low costIncreasing costFurnace typesWelding/cutting media/materialsElectrical resistance and conductanceSolderability

A hot-rolled steel strip having superior low temperature toughness and weldability, which is suitably used as a starting material for high strength electric resistance welding pipe, is provided at a low cost without constructing new production facilities and increasing cost. The hot-rolled steel strip is low carbon steel containing at least one of about 0.5.% or less of Cu, about 0.5% or less of Ni, and about 0.5% or less of Mo, wherein Pcm represented by the following equation (1) is 0.17 or less:Pcm=(% C)+(% Si) / 30+((% Mn)+(% Cu)) / 20+(% Ni) / 60+(% Mo) / 7+(% V) / 10 Equation (1),(where (% M) indicates the content of element M on a mass percent basis), and the balance includes Fe and incidental impurities. In addition, in the entire microstructure, the ratio of bainitic ferrite, which is a primary phase, is controlled to be about 95 percent by volume or more.

Owner:JFE STEEL CORP

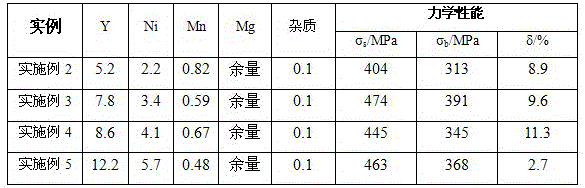

High-strength Mg-Y-Ni-Mn alloy and manufacturing method thereof

ActiveCN105543605ASignificant diffusion strengthening effectImprove acceleration performanceIngot castingRoom temperature

Owner:CHONGQING UNIV

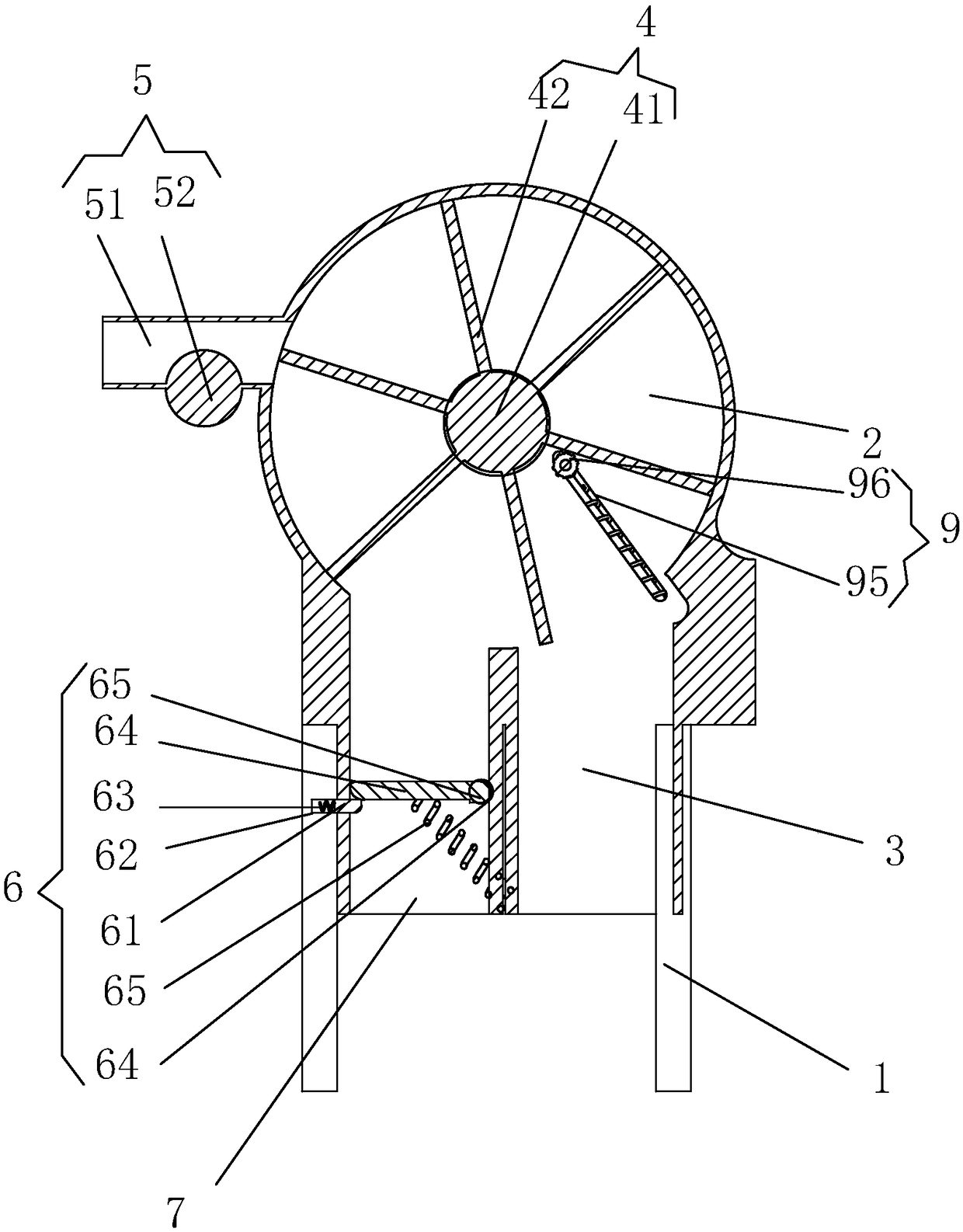

Sewage impurity filtering device

ActiveCN108096912AImprove filtration efficiencyAutomatic separationSpecific water treatment objectivesTreatment involving filtrationEngineeringSewage

Owner:CHINA RESOURCE REUSE XUZHOU RESOURCE REUSE DEV CO LTD

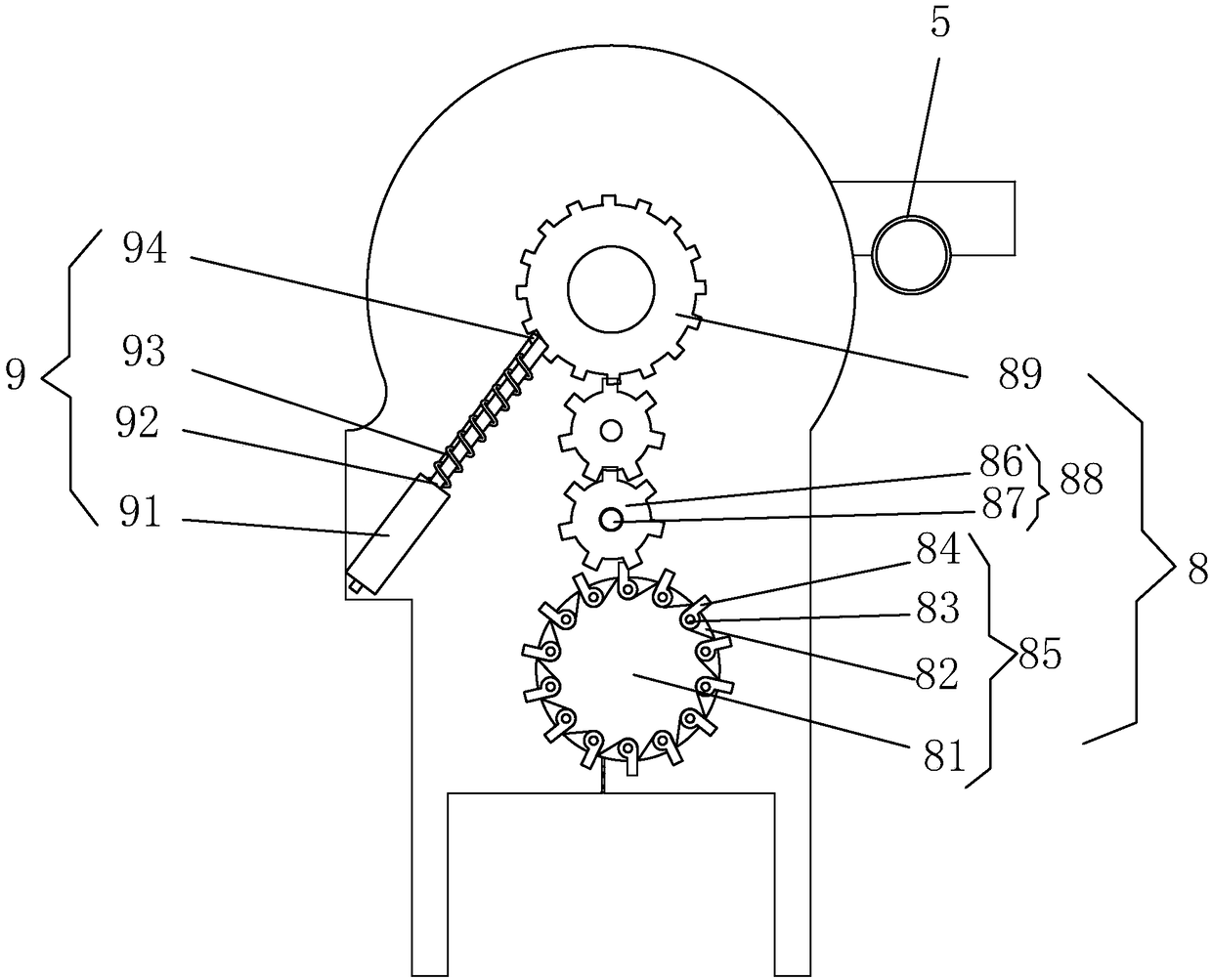

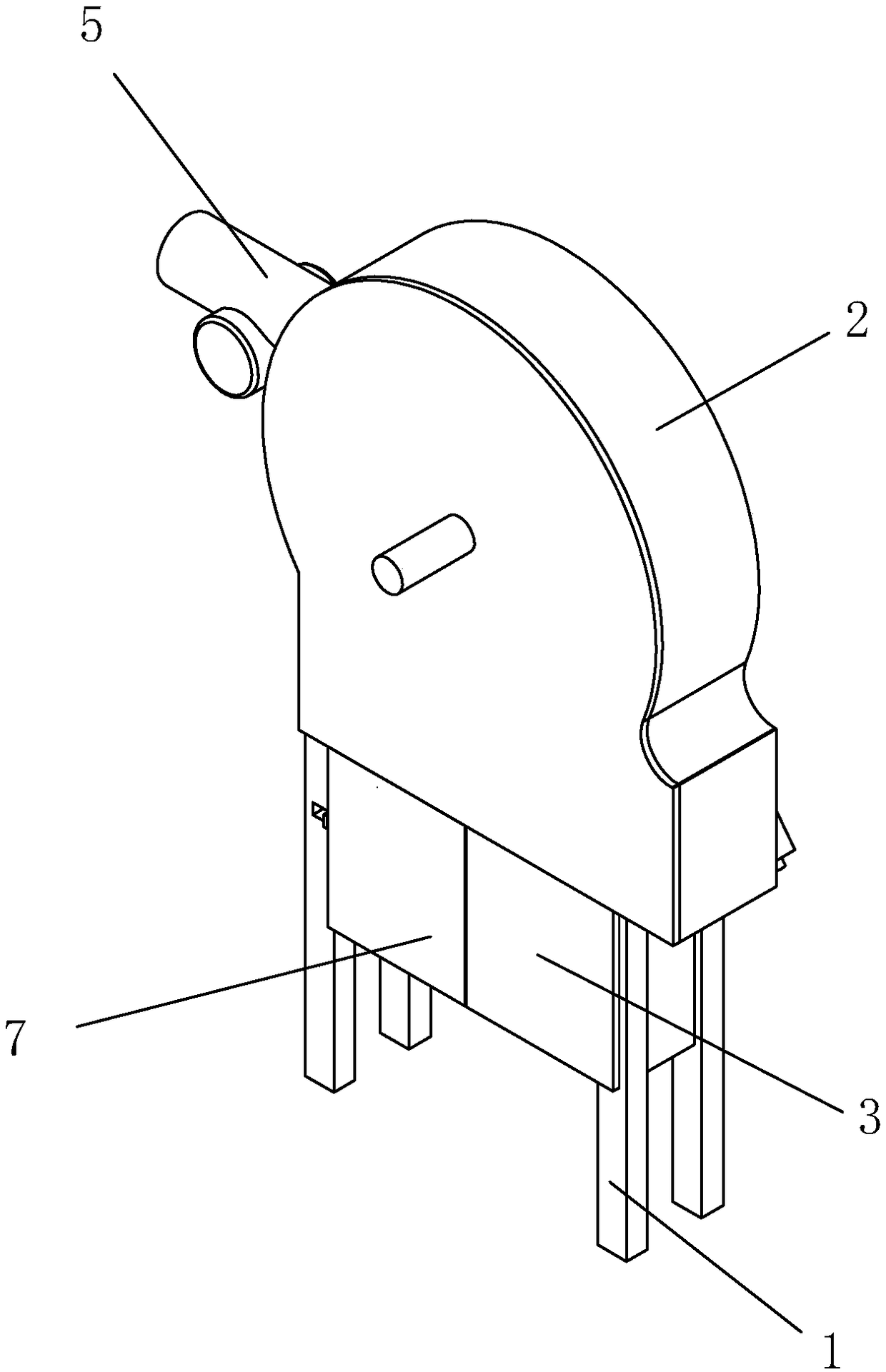

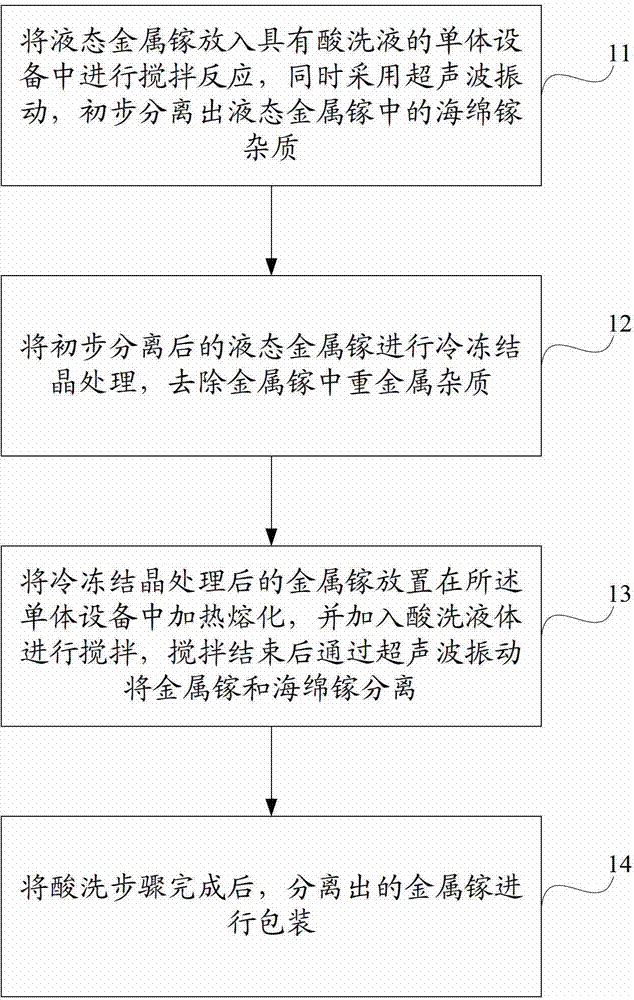

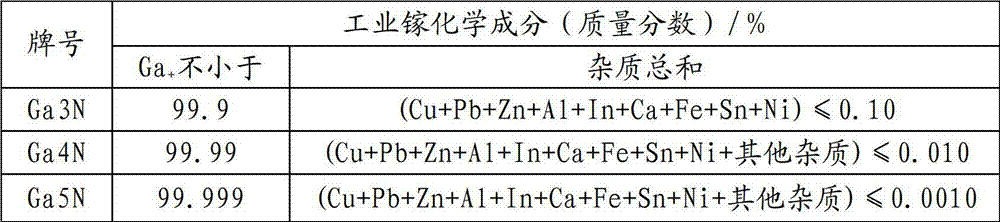

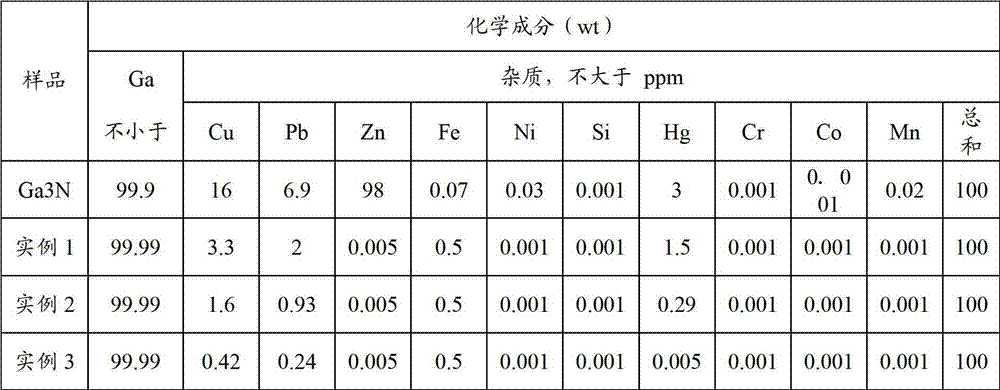

Purification method for gallium

ActiveCN103031450AQuality assuranceTo achieve the purpose of purificationProcess efficiency improvementAutomatic controlPurification methods

Owner:BEIJING JIYA SEMICON MATERIAL

Preparation method of power diode

ActiveCN104576361AReduce reverse leakage currentLower forward voltage dropSemiconductor/solid-state device manufacturingSemiconductor devicesPhotoresistImpurity

The invention provides a preparation method of a power diode. The preparation method comprises the following steps: providing a substrate and growing an N type layer; forming a terminal protection ring; forming an oxide layer, and performing knot guiding on the terminal protection ring; forming a gate oxide layer, and depositing a polycrystalline silicon layer on the gate oxide layer; forming an N type heavily doped region; forming a P+ region; performing ion bombardment on a wafer, etching photoresist, and enlarging the photo-etched window; forming a P type body region; performing thermal annealing to activate the injected impurities; performing front metallization and back metallization. According to the preparation method of the power diode, the photo-etched window is enlarged by the ion bombardment to the photoresist which is used as a masking layer when being injected to form the P type body region; the ion bombardment time can be adjusted to control the feature size of the polycrystalline silicon photoresist, so as to adjust the length of the P type body region, namely the length of an MOS channel, and optimize the relation between the reverse leakage current and the forward voltage drop of the device.

Owner:CSMC TECH FAB2 CO LTD

Method for preparing chitosan with ultrahigh deacetylation degree from euphausia superba as raw material

Owner:SHENZHEN INST OF ADVANCED TECH

Production method of low-molecular weight tremella polysaccharide

The invention provides a production method of low-molecular weight tremella polysaccharide. The production method comprises the following steps of using alcohol to settle tremella polysaccharide fermenting liquid produced by a fermenting method, acidifying, discoloring, removing protein, refining, drying, and the like, so as to obtain a low-molecular weight tremella polysaccharide product. The low-molecular weight tremella polysaccharide has the advantages that the wall breaking and the hydrolysis are combined by acidifying, so that the operation is simplified, and the yield rate can reach 26g / L; the relative molecular weight of the prepared tremella polysaccharide is lower than 100kDa, the content is greater than 80%, the content of protein is smaller than 0.5%, the yield rate is high, the content is high, the impurity is less, and the low-molecular weight tremella polysaccharide can be widely applied to the fields of medicines and daily chemicals.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD +1

Resin adsorption treatment process of high-salt wastewater containing amine system

PendingCN109912098AEfficient removalBiotoxicMultistage water/sewage treatmentWater/sewage treatment by sorptionAdditive ingredientDesorption

The invention discloses a resin adsorption treatment process of a high-salt wastewater containing an amine system. The resin adsorption treatment process mainly comprises the following specific steps:adjusting the pH value of raw water, feeding the adjusted raw mater into a raw water pool, pumping the raw water into a precise filter and filtering out mechanical impurities; enabling outlet water to enter a resin adsorption tower; enabling outlet water after resin adsorption to enter a resin outlet water tank, performing triple effect evaporation for evaporative crystallization and enabling mother liquid to return to a raw water buffer tank; performing desorption after adsorption, washing with water and enabling washing water to enter the raw water pool; performing desorption with methanol,evaporating desorption liquid and enabling evaporated methanol to enter a rectifying tower for refining; washing with water, feeding washing water into the rectifying tower for refining, recycling methanol at the top of the tower and feeding kettle residues into a dehydrogenation tower; enabling an ingredient at the top of the dehydrogenation tower to return to the rectifying tower and feeding kettle residues into the raw water pool. Compared with the prior art, the resin adsorption treatment process has the advantages of being low in operating cost, low in investment cost of equipment and high in removal rate, causing no secondary pollution, being cleaner, being high in selectivity and good in regeneration of the equipment and having reusability.

Owner:NANJING JIANDI ENVIRONMENTAL ENG CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap