High-strength Mg-Y-Ni-Mn alloy and manufacturing method thereof

A mg-y-ni-mn, high-strength technology, applied in the field of wrought magnesium alloys and its manufacturing, can solve the problems of only 1.1% elongation, increase the difficulty of alloy preparation, and low alloy elongation, so as to improve the strength at room temperature Toughness, easy operation, and simple alloying element formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

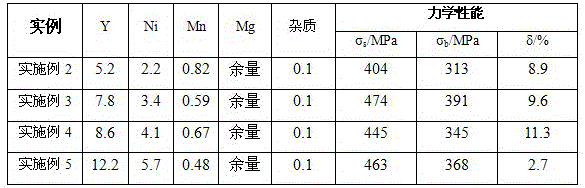

Examples

Embodiment 1

[0025] Example 1: A high-strength Mg-Y-Ni-Mn alloy, alloy composition (weight percent): Y-10.2%, Ni-4.4%, Mn-0.45% impurity elements less than 0.1%, and the rest is Mg.

[0026] The manufacture method of this high-strength Mg-Y-Ni-Mn alloy is carried out as follows:

[0027] Step 1: In a vacuum melting furnace, the ingot is melted, and argon is introduced for protection, and alloying elements are added according to weight percentage Y=10.2%, Ni=4.4%, Mn-0.45%. Among them, Y and Ni are added in the form of 30Y-70Ni master alloy, and Mn is added in the form of Mg-3Mn master alloy.

[0028] Insulate at 850°C and stir with electromagnetic induction to fully melt the raw materials. After the alloy is completely melted, continue to stand at 850°C for 10 minutes, and then cast.

[0029] Step 2: Homogenize the smelted magnesium alloy ingot. The process parameters are: put the ingot into the furnace and raise the temperature to 540°C, then stop the furnace and cool down to 450°C after th

Embodiment 2

[0034] Example 2: A high-strength Mg-Y-Ni-Mn alloy, alloy composition (weight percent): Y-5.2%, Ni-2.2%, Mn-0.82%, less than 0.1% of impurity elements, and the rest is magnesium.

[0035] The manufacture method of this high strength Mg-Ni-Y alloy is the same as embodiment 1.

Embodiment 3

[0036] Example 3: A high-strength Mg-Y-Ni-Mn alloy, alloy composition (weight percent): Y-7.8%, Ni-3.4%, Mn-0.59%, less than 0.1% of impurity elements, and the rest is magnesium.

[0037] The manufacture method of this high strength Mg-Ni-Y alloy is the same as embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap