Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

127 results about "Room temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Colloquially, room temperature is the range of air temperatures that most people prefer for indoor settings, which feel comfortable when wearing typical indoor clothing. Human comfort can extend beyond this range depending on humidity, air circulation and other factors. In certain fields, like science and engineering, and within a particular context, room temperature can mean different agreed-on ranges. In contrast, ambient temperature is the actual temperature of the air (or other medium and surroundings) in any particular place, as measured by a thermometer. It may be very different from usual room temperature, for example an unheated room in winter.

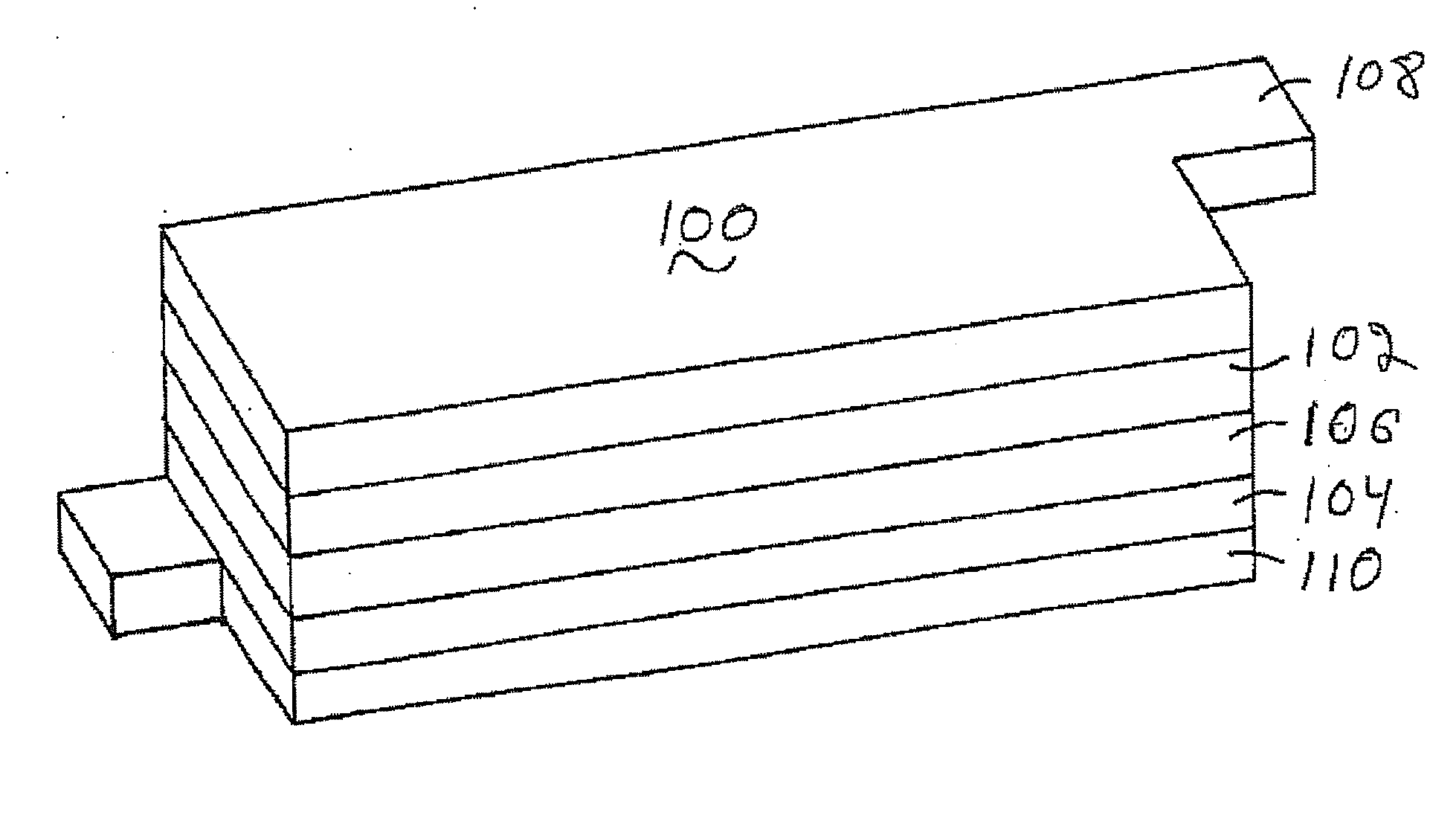

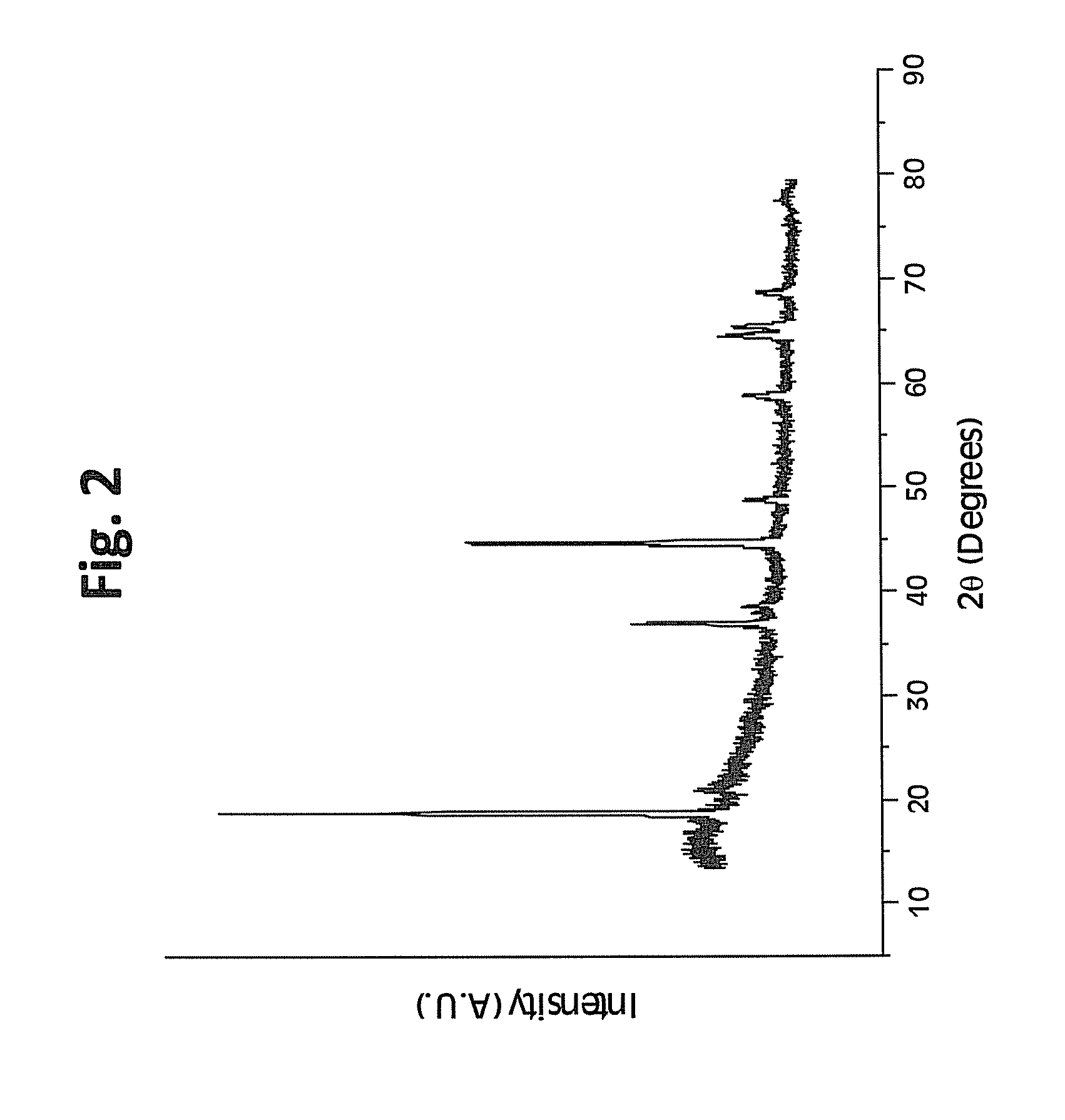

Positive electrode materials for lithium ion batteries having a high specific discharge capacity and processes for the synthesis of these materials

ActiveUS20100086853A1Electrode manufacturing processesAlkali metal oxidesDischarge rateLithium-ion battery

Owner:IONBLOX INC

Variable air volume system including BTU control function

InactiveUS6879881B1Improving environmental comfortIncrease volumeMechanical apparatusLighting and heating apparatusVariable air volumeAir volume

A method, as well as a controller, for controlling room temperature with a variable air volume system having a plurality of zones wherein the thermal transfer rate with respect to each of such zones is maintained at a substantially constant value notwithstanding changes in the temperature of the supply air thereby providing improved efficiency and environmental comfort.

Owner:SIEMENS IND INC

Water-based airplane surface cleaning agent and preparation method thereof

ActiveCN101955854AThe formula is scientific and reasonableSimple production processInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsWater basedSurface cleaning

The invention relates to a water-based airplane surface cleaning agent, which is prepared by uniformly mixing the following components in percentage by weight: 21 to 30 percent of degradable surfactant, 5 to 7 percent of metal corrosion inhibitor, 0.3 to 2 percent of pH regulating agent, 1.7 to 5 percent of stabilizer, and the balance of deionized water. A preparation method comprises the following steps: (1) weighing the pH regulating agent, the degradable surfactant, the metal corrosion inhibitor, the stabilizer and the deionized water according to the ratio of weight percent; (2) adding the pH regulating agent, the metal corrosion inhibitor, the degradable surfactant and the stabilizer into the deionized water at the room temperature of between 23 and 25 DEG C; and (3) stirring the liquid at constant speed of 60 to 80r / min for 20 to 40 minutes to ensure that no bubble is generated in the liquid to prepare the cleaning agent after uniform mixing. The invention has scientific and reasonable formula and simple process without special equipment, and the cleaning agent has the advantages of strong cleaning capability, short cleaning time, low cost, high efficiency and is safe and reliable for use.

Owner:BEIJING KAILAN AVIATION TECH CO LTD

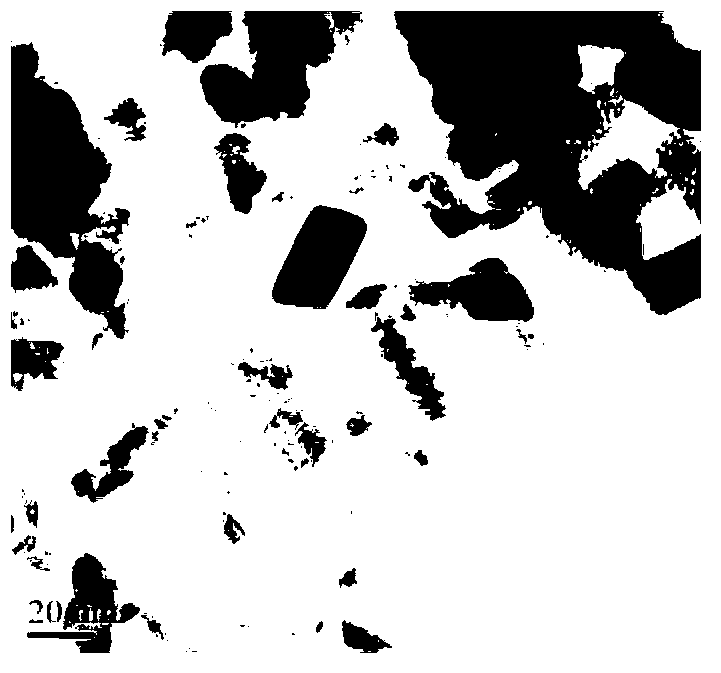

Preparation method of submicron CuS (copper sulphide) classification ball

The invention discloses a preparation method of submicron CuS (copper sulphide) classification balls. The method comprises the following steps: adding polymer into a good solvent to dissolve and remove big gel particles; adding copper source solution to the good solvent and stirring; adding sulfur source solution and then stirring; reacting the reaction liquid under 100-1,000 KPa at 100-200 DEG C; naturally cooling to the room temperature to obtain black precipitate; and washing and drying the precipitate to obtain the classification balls. The classification balls has the advantages of cheap and readily available templates, environmental friendliness, safety without toxicity, renewability and high water solubility, the contents of raw materials are abundant in nature and the operation of the reaction system is simple; the size and structure of the prepared classification ball are adjustable: the diameter can be controlled by adjusting the molar weight of the added precursor, the template concentration, the reaction temperature and time and the like; the operation is simple; and the prepared classification balls have wide application value in the fields of catalyst, catalyst carrier, optical equipment, sensor, lithium-ion rechargeable battery cathode material, superconductor and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +1

Method for preparing ZnWO4 nanorod photocatalysis material

InactiveCN102935360APhotocatalyticWith photocatalytic effectMetal/metal-oxides/metal-hydroxide catalystsTungsten compoundsHeat treatedNanorod

Owner:SHAANXI UNIV OF SCI & TECH

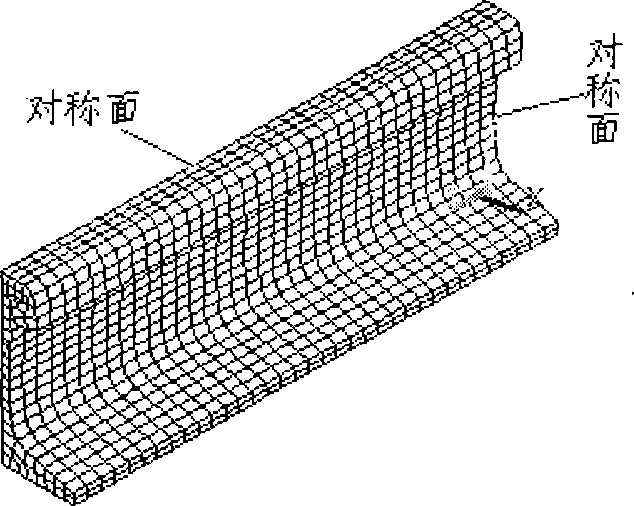

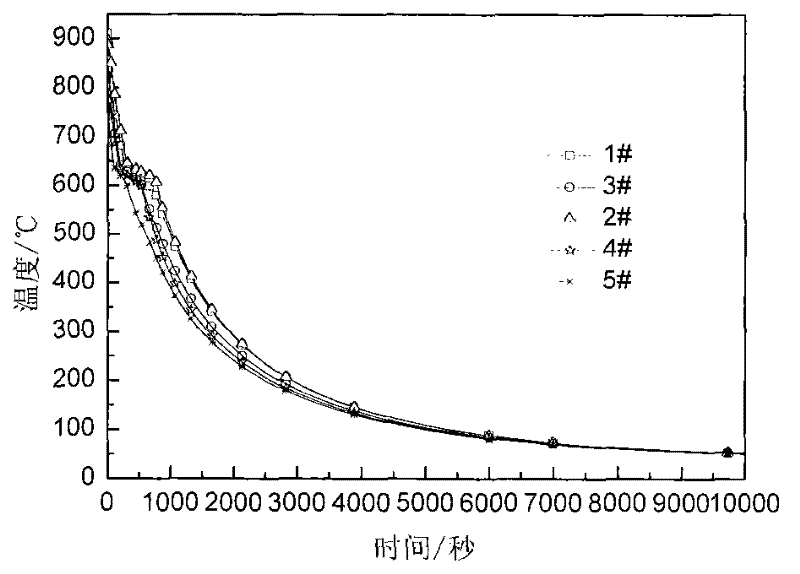

Method for Residual Stress Control of 100-meter Heavy Rail

InactiveCN102284503AControl flatnessImprove straightnessRoll mill control devicesMetal rolling arrangementsRoom temperatureDeformation control

Owner:INNER MONGOLIA UNIV OF SCI & TECH

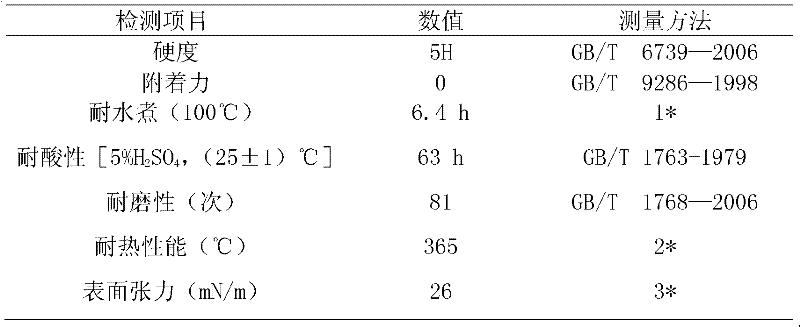

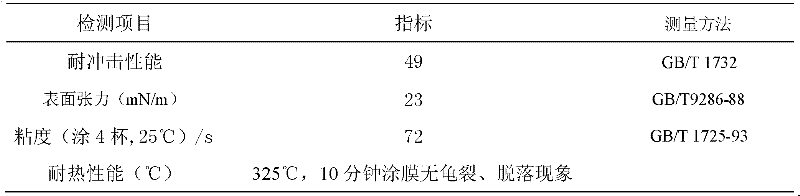

Preparation method of hyperbranched polyester modified organic silicon resin and coating comprising resin

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

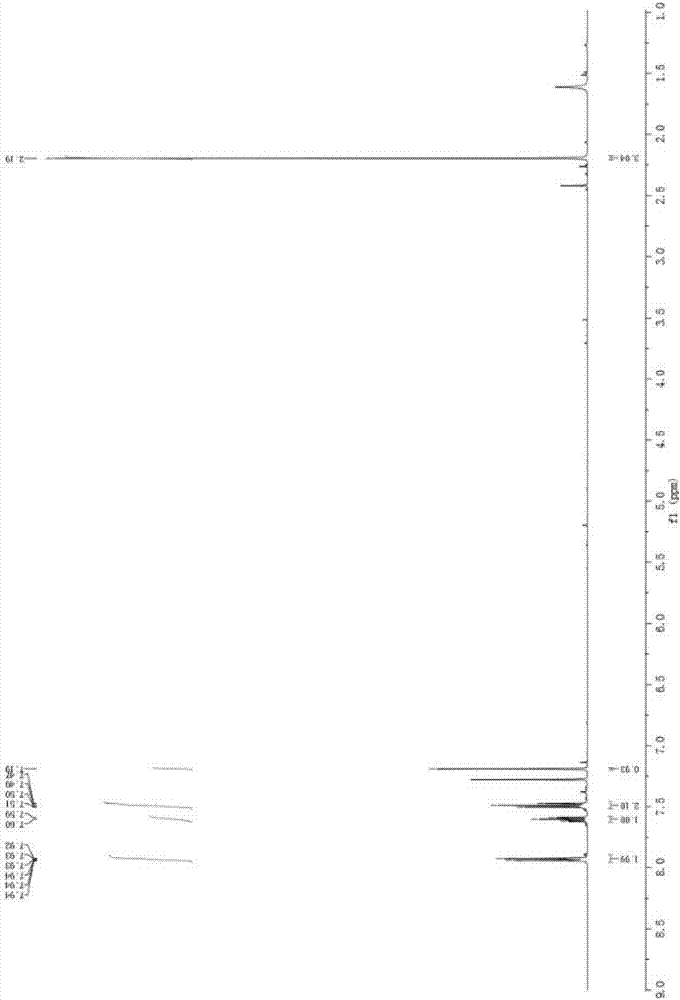

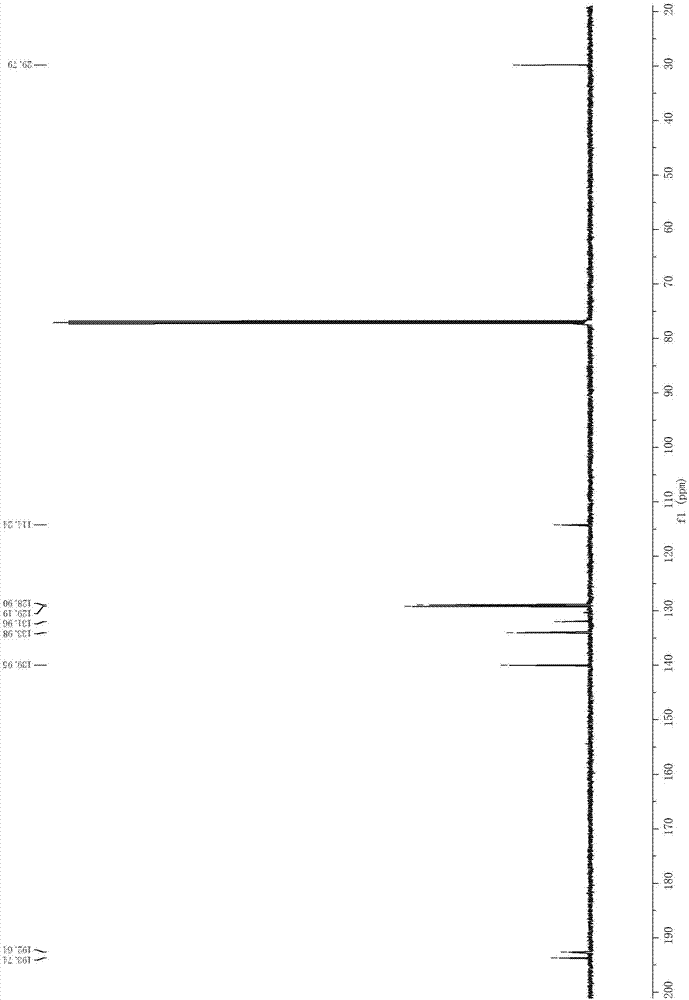

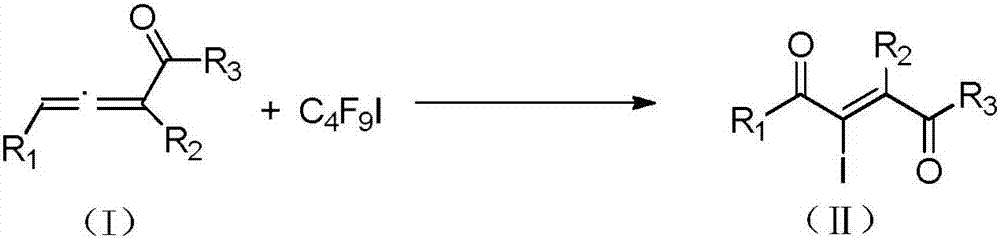

Method for preparing 2-iodine amyl -2-ene-1,4-diketone derivative by adopting visible light catalysis

ActiveCN107011145AMild reaction conditionsEasy to operateOrganic compound preparationCarboxylic acid esters preparationIodidePollution

Owner:ZHEJIANG UNIV OF TECH

Visible-light-driven photocatalyst for degrading dye in wastewater, and preparation and application thereof

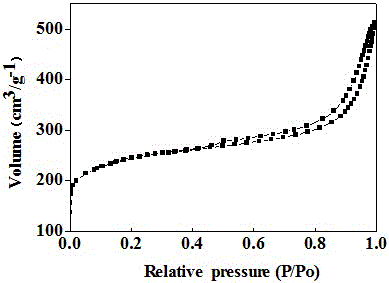

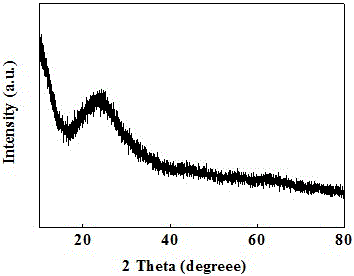

ActiveCN106732741AHigh activityGood dispersionWater/sewage treatment by irradiationMolecular sieve catalystsMesoporous silicaLight driven

Owner:BINZHOU UNIV

1,4-di(2,4-diamino phenoxy) benzenoid form high-temperature epoxy adhesive and preparation method thereof

InactiveCN103122231AGood adhesionGood viscosity controllabilityEpoxynovolac adhesivesBenzeneOrganic solvent

Owner:DONGHUA UNIV +1

Method for preparing liquid fluorescent brightener composition of diphenylvinyl triazine compounds

ActiveCN102477227AImprove performanceWith strong fluorescenceStyryl dyesLuminescent/fluorescent substance additionRoom temperatureAniline

The present invention relates to a production process of a chemical additive special for papermaking, in particular to a method for preparing a liquid fluorescent brightener composition of diphenylvinyl triazine compounds. The invention mainly solves the problems of low fluorescence intensity and low brightness of a single-component liquid fluorescent brightener. The method adopts cyanuric chloride, 4,4'-diamino-2,2'-stilbenedisulfonic acid (DSD acid), aniline, monoethanolamine and 1-R1-2-R2-acrylamide as raw material, and employs four-step reaction. The inventive liquid fluorescent brightener composition has convenient usage, good acid resistance, and good storage stability at a room temperature, and is suitable for continuous adding and metering during automatic production.

Owner:JIANGSU JINGUANG CHEM TECH CO LTD

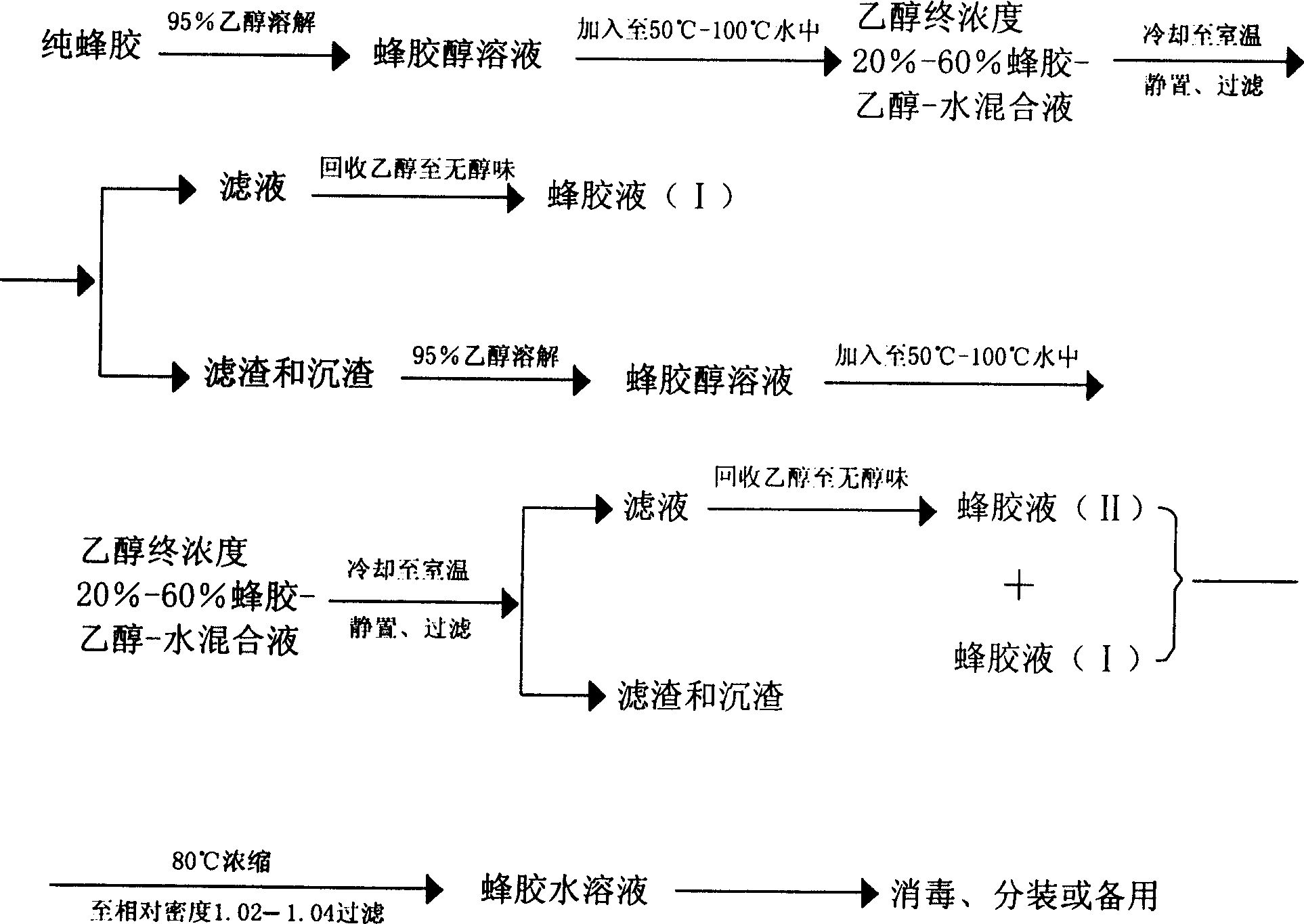

Process for preparing bee glue water solution and use

InactiveCN1682770ASimple processHigh in flavonoidsAnthropod material medical ingredientsMetabolism disorderAlcohol contentPropolis

Owner:ZHEJIANG ACAD OF TRADITIONAL CHINESE MEDICINE

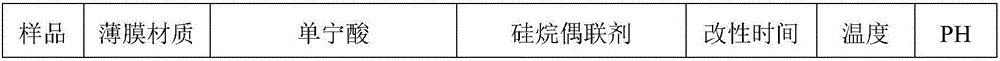

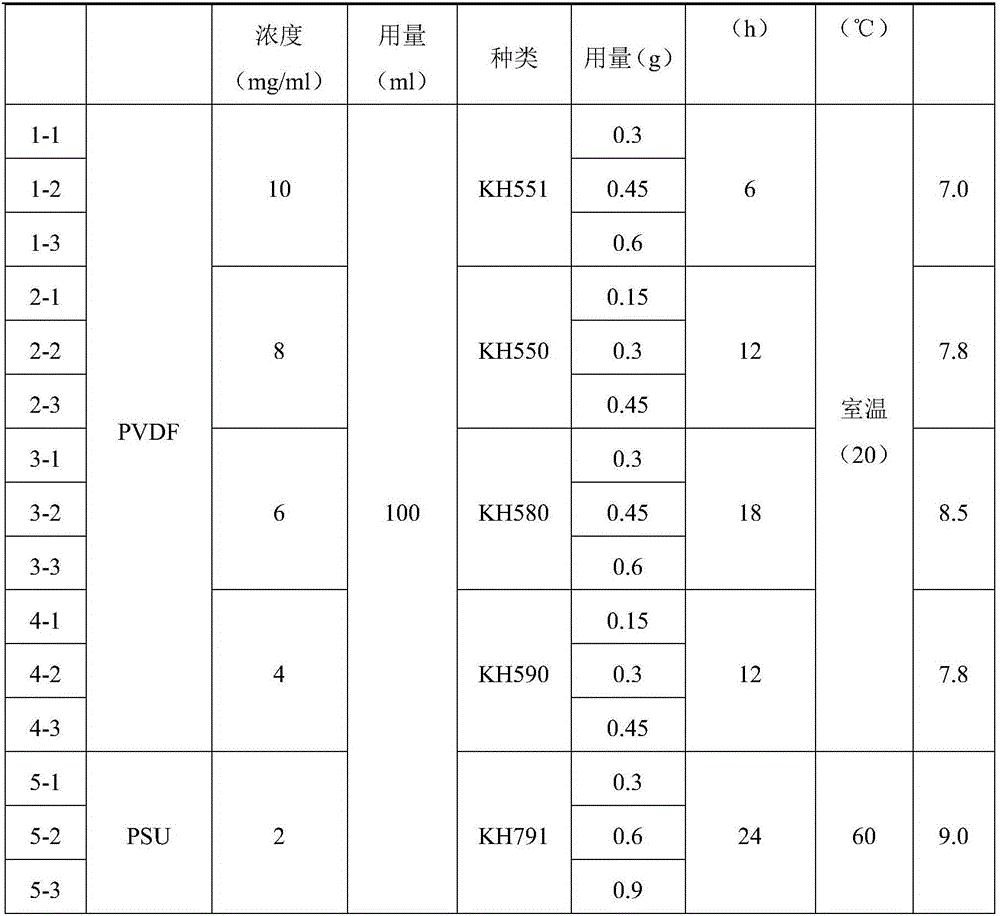

Hydrophobic polymer film composite coating hydrophiling modification method

ActiveCN106310958AImprove hydrophilicityImprove stabilityMembranesSemi-permeable membranesPolymer scienceHydrophobic polymer

Owner:WUHAN UNIV OF TECH

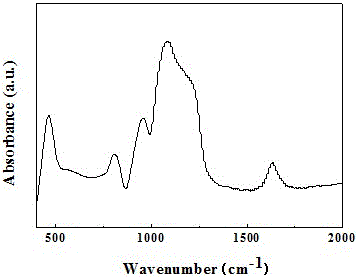

Preparation method of silicon dioxide used for tooth paste

The invention discloses a preparation method of silicon dioxide used for tooth paste. According to the invention, a two-stage alkali-adding method is adopted, and the method comprises the steps that: a certain amount of sodium silicate water solution and a certain amount of sulfuric acid water solution are prepared firstly; the sulfuric acid water solution is added into a reaction kettle at ordinary temperature, wherein the adding amount is 50% of needed sulfuric acid; the sodium silicate water solution is added until the pH reaches 7-8; the temperature is increased to 70-80 DEG C; mixing is performed for 1-2 h; the rest sodium silicate solution is added into the reaction slurry; the temperature is increased to 70-80 DEG C; the sulfuric acid water solution is added until the pH reaches 4-5; the heat temperature is preserved for 20-30 min; water washing, drying and smashing are conducted to obtain tooth-paste-used silicon dioxide. The silicon dioxide has proper abrasion amount and good thickening property.

Owner:FUJIAN SANMING TONGSHENG CHEM

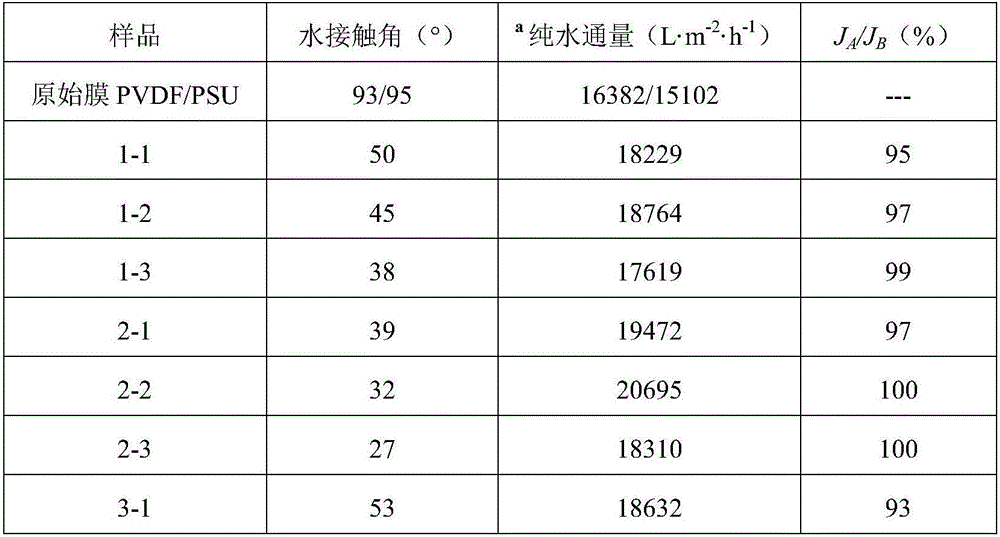

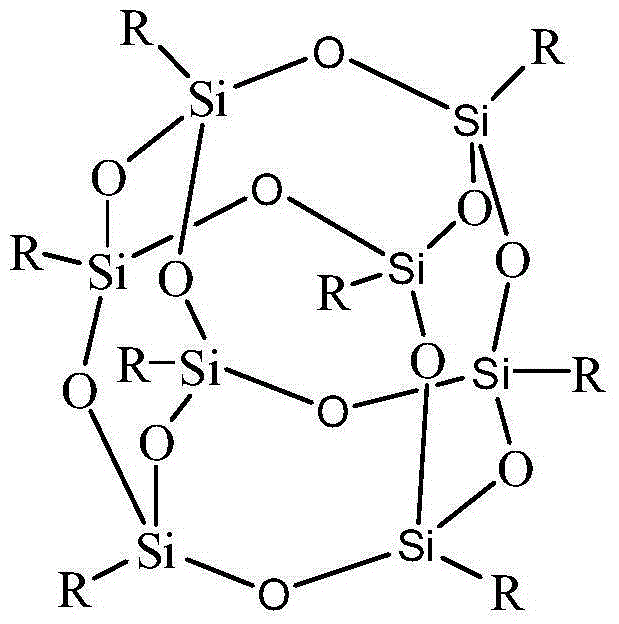

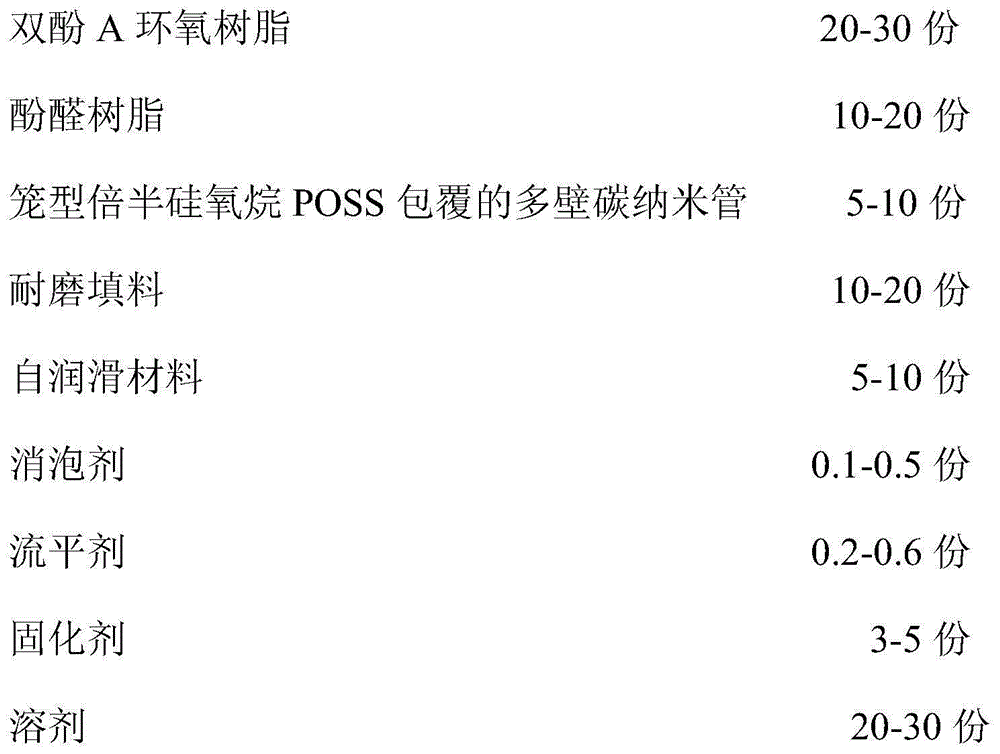

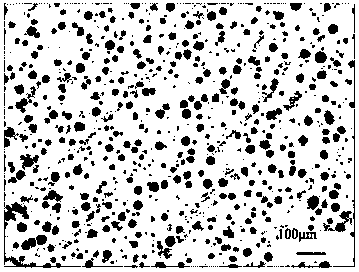

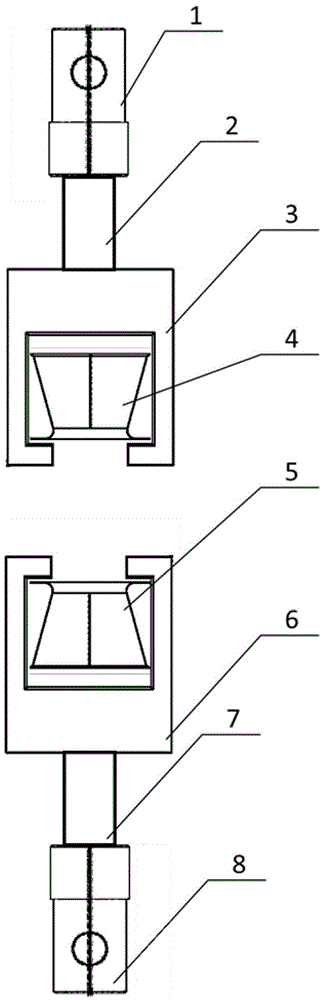

Anti-corrosion and wear-resisting coating for throwing disc of pneumatic type feeder and preparation method of coating

InactiveCN105062300AImprove corrosion resistanceImprove high temperature resistanceAnti-corrosive paintsEpoxy resin coatingsMultiwalled carbonRoom temperature

Owner:JINHU JIEDA MACHINERY MFR

SPS connection method for tungsten and molybdenum dissimilar refractory metals

ActiveCN108262483AEfficient connectionFacilitated DiffusionRoom temperatureUltimate tensile strength

Owner:HEFEI UNIV OF TECH

Antirust oil and preparation method thereof

InactiveCN107653045AWork fasterImprove rust resistanceLubricant compositionAntioxidantRoom temperature

The invention relates to antirust oil and a preparation method thereof. The antirust oil is prepared from the following components by weight percent: 20 to 35 percent of film forming agent, 5 to 15 percent of antirust agent, 0.1 to 5 percent of co-solvent, 0.1 to 2 percent of antioxidant and 40 to 75 percent of basic oil. The preparation method comprises the following steps: preparing all raw materials according to the components and the weight ratio, adding the basic oil into a reactor, heating and stirring, when the temperature is increased to 90 to 120 DEG C, adding the antirust agent, theco-solvent and the antioxidant, sufficiently stirring, completely dissolving, lowering the temperature in the reactor to 50 to 80 DEG C, then slowly adding the film forming agent and the residual basic oil, sufficiently stirring, completely dissolving, cooling to the room temperature, detecting, discharging the material, thus obtaining the antirust oil. The antirust oil of the invention is high inactually completely drying speed and has good antirust effects for the long-term storage and transportation of various metals such as iron, copper, aluminum, magnesium alloy and the like.

Owner:SHANGHAI YOUDAO NEW ENERGY TECH CO LTD +1

High-strength nodular cast iron for automobile flywheels and high-density cast molding method thereof

ActiveCN104404363AIncrease the cross-sectional areaImprove high temperature strengthFoundry mouldsFoundry coresHigh densityDynamic balance

Owner:湖北丹江口志成铸造股份有限公司

Brittle material tensile test fixture

InactiveCN105651597AFast loadingMeet the requirements of mandatory Annex 37Strength propertiesUniversal jointRoom temperature

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

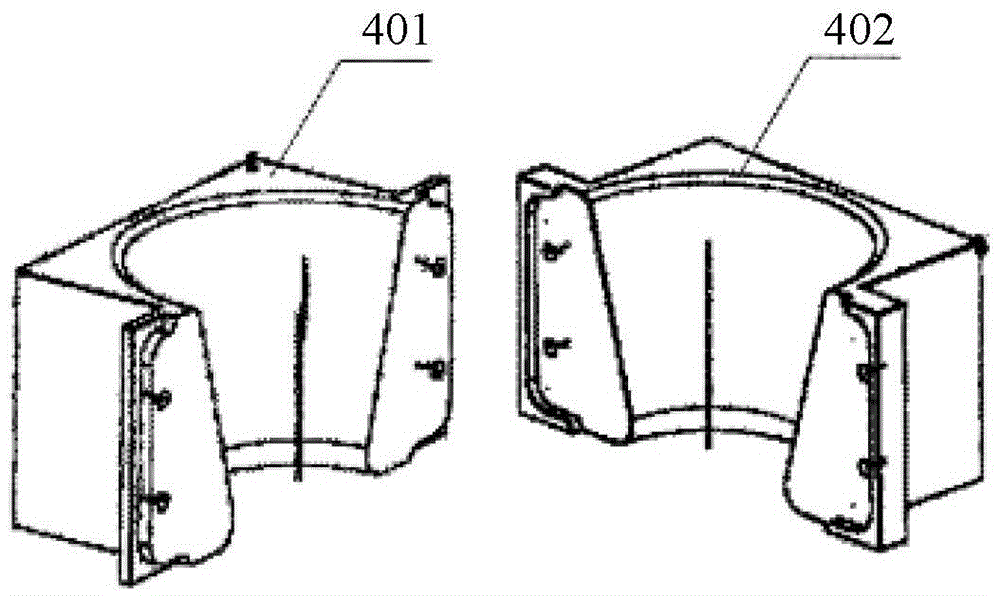

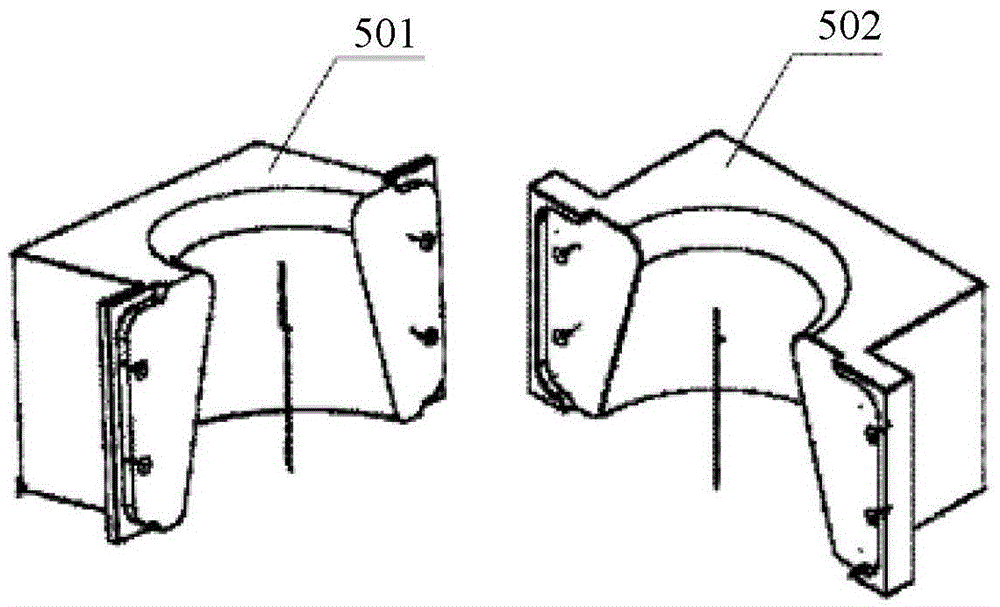

High-strength Mg-Y-Ni-Mn alloy and manufacturing method thereof

ActiveCN105543605ASignificant diffusion strengthening effectImprove acceleration performanceIngot castingRoom temperature

Owner:CHONGQING UNIV

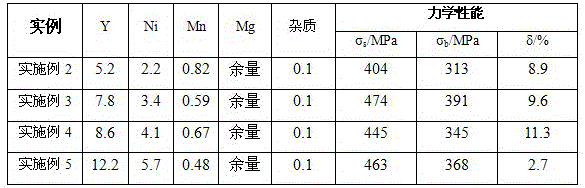

Method for the Generation of Nuclear Hyper-Antipolarization in Solids Without the Use of High Magnetic Fields or Magnetic Resonant Excitation

InactiveUS20120087867A1Density of defect is largeEasy to implementNMR/MRI constrast preparationsSensorsElectronNuclear Overhauser effect

Owner:UCL BUSINESS PLC +2

Method for extracting humus from pig manure maize straw compost

InactiveCN104672470AImprove extraction efficiencyLittle changeOrganic chemistryFertilizer mixturesRoom temperatureCompost

The invention relates to a method for extracting humus from the pig manure maize straw compost. The method comprises the following steps: (1) adding the pig manure maize straw compost into an extracting solution, performing vibrating extraction for 2-4 hours at room temperature, centrifuging and removing the filter residue to obtain a supernate for later use, wherein the extracting solution is obtained by mixing 0.1M of NaOH and 0.1 M of Na4P2O7 according to a volume ratio of 1:1; and (2) adjusting the pH value of the supernate to 1, fully stirring, standing overnight at room temperature, centrifuging, collecting the supernate and the precipitate to respectively obtain the fulvic acid FA and the humic acid HA. The method for extracting the humus from the pig manure maize straw compost provided by the invention is high in efficiency and extraction ratio and is an effective extracting method with strong pertinency.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI +1

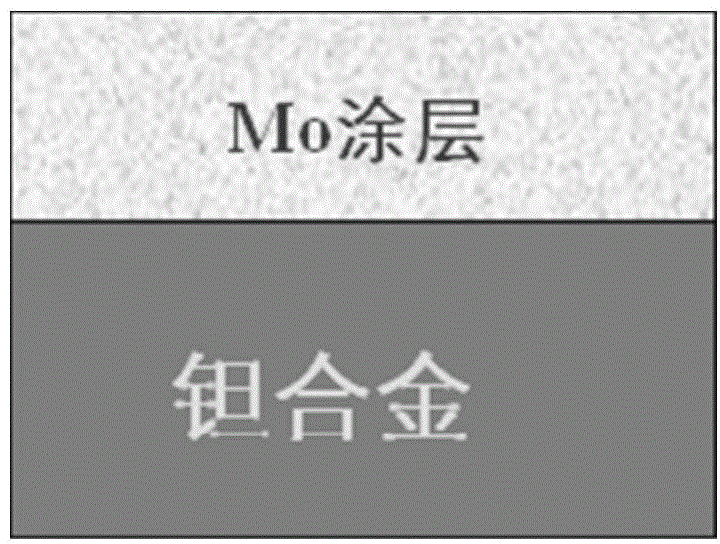

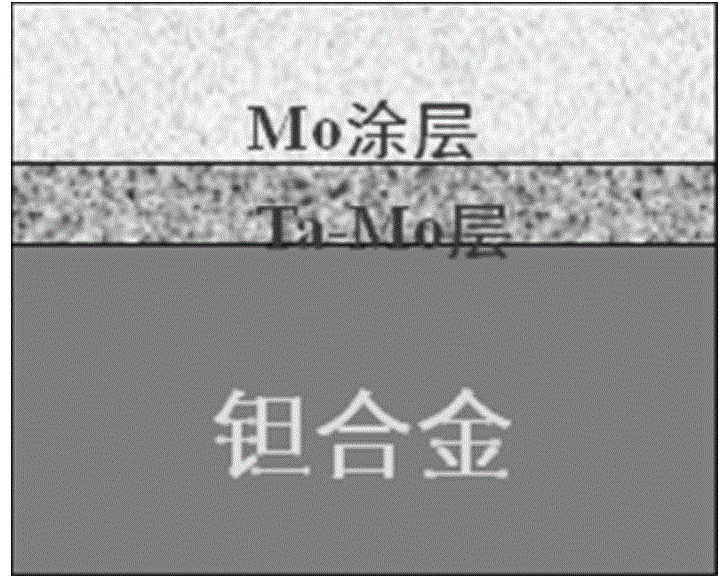

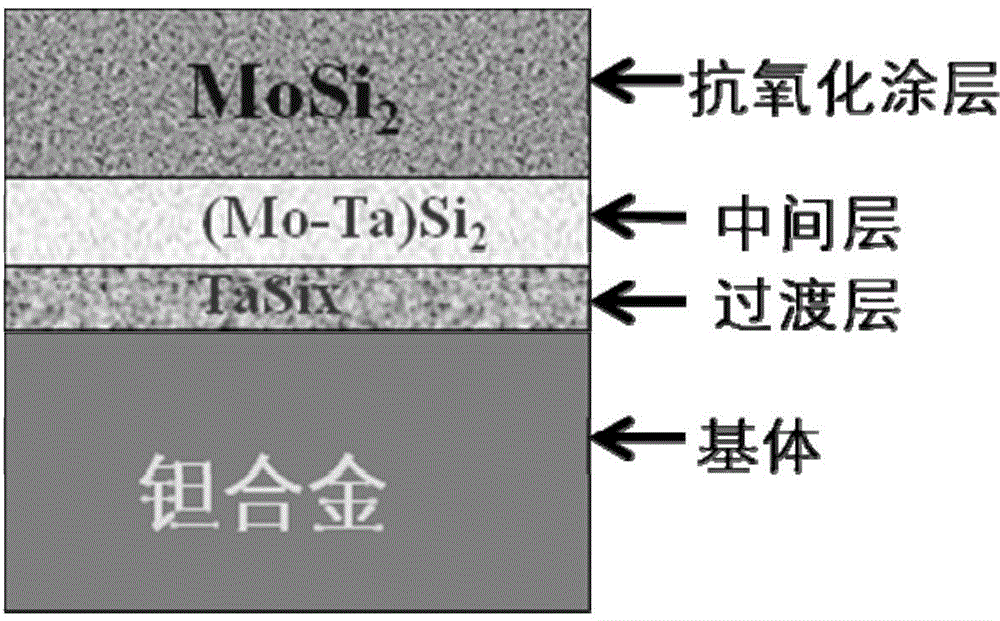

Method for preparing anti-oxidation coating on surface of tantalum alloy material

ActiveCN104630722AImprove bindingVacuum evaporation coatingSputtering coatingOxidation resistantRoom temperature

The invention relates to a method for preparing an anti-oxidation coating on the surface of a tantalum alloy material, belonging to the technical field of high-temperature coatings. According to the method provided by the invention, the preparation of a molybdenum coating is realized by a vacuum arc deposition method, diffusion between the molybdenum coating and a tantalum alloy matrix is realized by a vacuum heat treatment technology, and the binding force between the coating and the matrix is improved; the preparation of a molybdenum silicide gradient coating is realized by a vacuum activation pack cementation technology; meanwhile, in a silicatization process, a molybdenum silicide composite coating is formed through a silicon diffusion reaction to obtain an anti-oxidation layer, and the middle layer is a middle transition layer of tantalum silicide; and the anti-oxidation life of the coating is 50 hours at 1,800 DEG C, and the thermal shock life at 1,800 DEG C to room temperature reaches 1,300 times. Through the examination of a high-speed high-temperature airflow washout test, when the airflow speed is 1.2km / s, the anti-washout life is 7 hours at 1,600 DEG C, and the anti-washout life is 4 hours at 1,700 DEG C.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Polylactic acid/polyester alloy and preparation method thereof

The invention relates to a polylactic acid / polyester alloy and a preparation method thereof. The polylactic acid / polyester alloy comprises the following components in percentage by weight: polylactic acid, polyester, a compatilizer, a flexibilizer, an antioxidant and a lubricant. The preparation method comprises the following steps: firstly, proportioning the raw materials and mixing at a room temperature; and respectively carrying out melting extrusion, carrying out ultrasonic treatment at the first late stage, extruding at the second stage and pelletizing, so as to obtain degradable, high-impact-resistant and high-heat-resistant polylactic acid / polyester alloy. Compared with an existing method, the controllable ultrasonic treatment is utilized; and a similar polylactic acid-g-polyester structure is formed by in-situ reaction, so that the heat resistance of the polyester and the biodegradability of the polylactic acid are reserved; and meanwhile, a toughening system with a core-shell structure is formed in an alloy system through interface interaction of a special toughening compatilizer, so that the alloy product with high impact resistance, high heat resistance and high biodegradability can be obtained.

Owner:FINE BLEND POLYMER SHANGHAI CO LTD

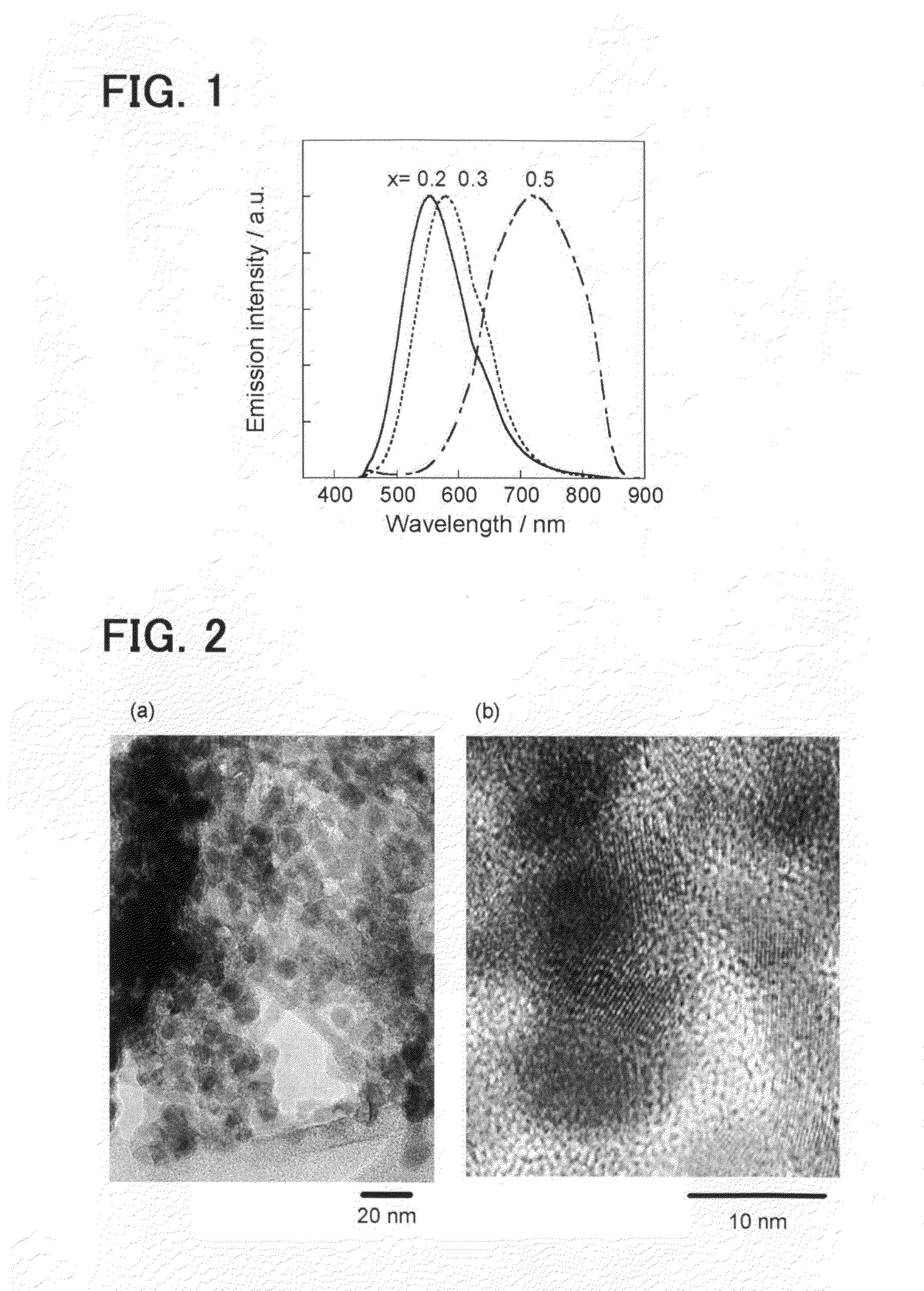

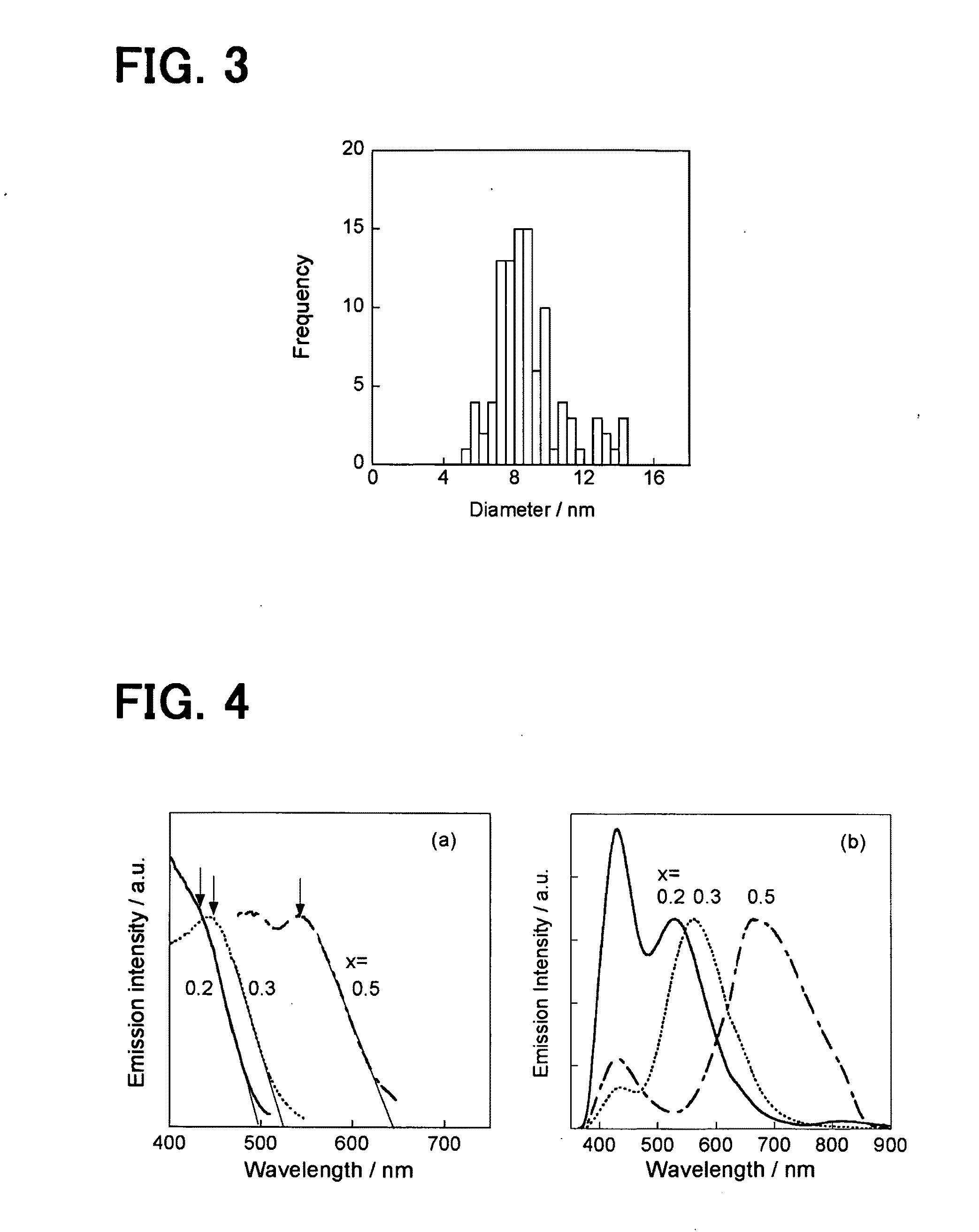

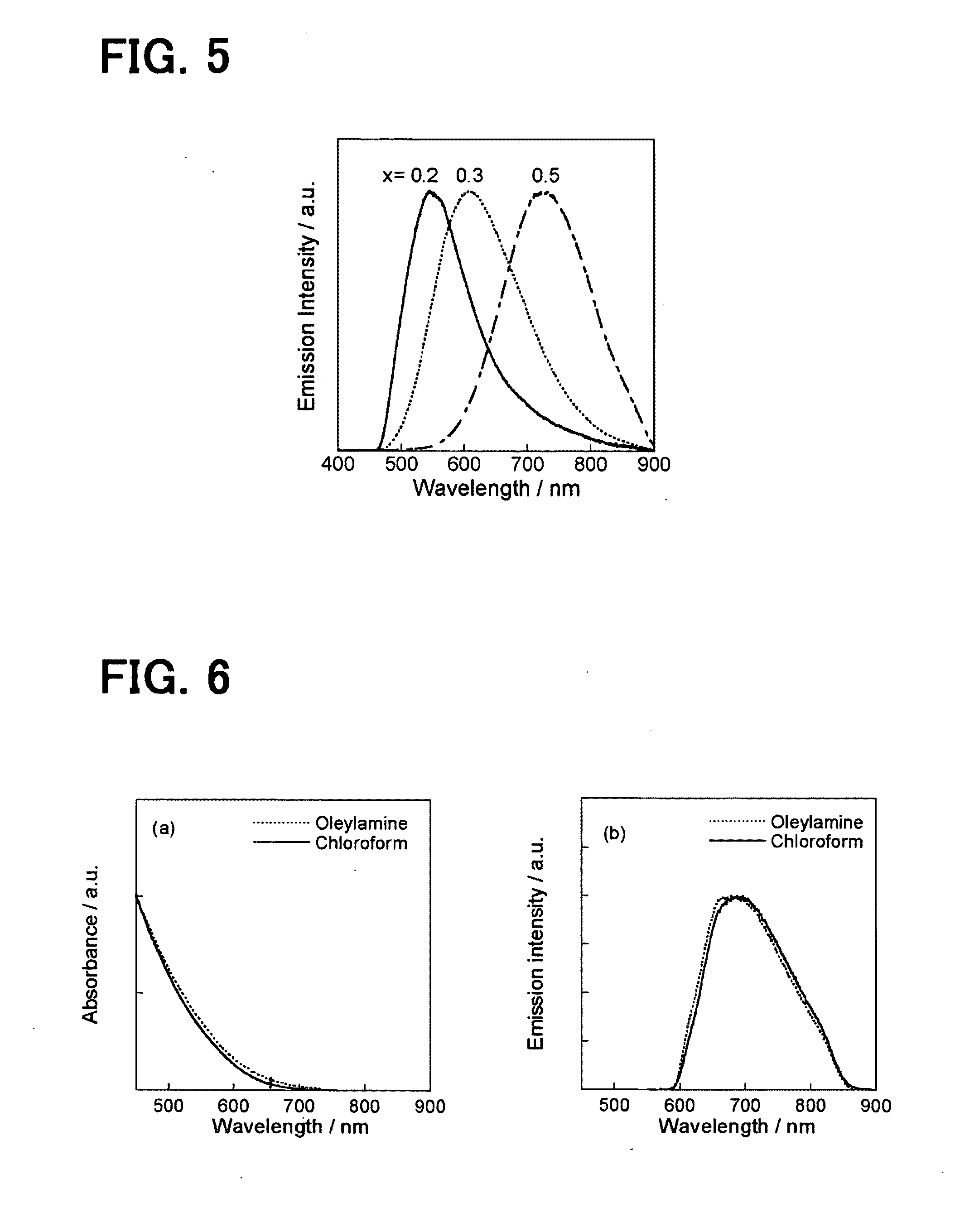

Semiconductor nanoparticle and method of producing the same

Owner:NAGOYA UNIVERSITY +3

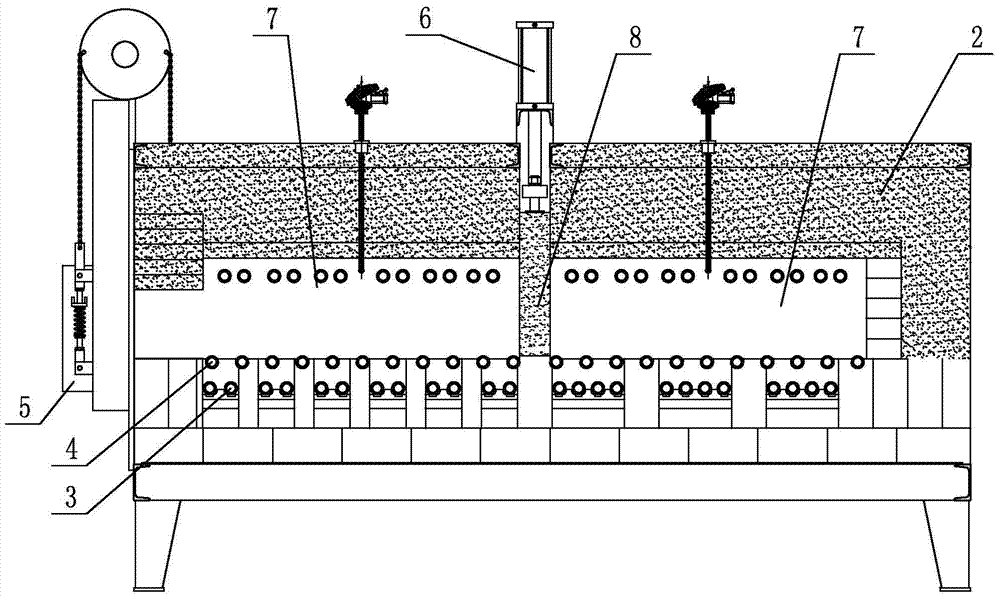

Mobile roller-type van-type heating furnace and hot-forming subsection strengthening technique

ActiveCN104729278AReduce volumeLess investmentFurnace typesHeat treatment furnacesPunchingRoom temperature

Owner:YANCHENG KEAO MECHAICAL

Peroxide Gel Compositions

InactiveUS20070183987A1Easy to optimizeHigh peroxide concentrationCosmetic preparationsHair cosmeticsDecompositionNuclear chemistry

Owner:JENSEN STEVEN D

Method for preparing platinum-carbon catalyst

InactiveCN104801298AImprove stabilityGood repeatabilityMetal/metal-oxides/metal-hydroxide catalystsFiltrationSolvent

The invention belongs to the technical field of catalysis and relates to a method for preparing a platinum-carbon catalyst which is high in activity and stability. The method comprises the following steps: 1, preparing a chloroplatinic acid alcohol solution : diluting the chloroplatinic acid with an alcohol solvent I so as to obtain the chloroplatinic acid alcohol solution; 2, preparing a sodium hydroxide solution : dissolving sodium hydroxide into an alcohol solvent II so as to obtain the sodium hydroxide solution; 3, preparing an activated-carbon-loaded platinum-carbon catalyst: adding the chloroplatinic acid alcohol solution prepared in advance in an activated carbon carrier, then adding the sodium hydroxide solution and carrying out microwave reduction; 4, cooling and drying, after completion of microwave reduction in the step 3, cooling the mixture to room temperature, adding deionized water, the volume of which is the same as that of the mixture, carrying out extraction filtration and washing, and carrying out vacuum drying on the catalyst. According to the invention, the operation is quick and simple, process stability and repeatability are good, active component particles are distributed uniformly, the particle size range is narrow and the fact that the particle size is controllable is realized according to the quantity of sodium hydroxide and the solvents; the catalyst prepared through the preparation method is high in activity and good in stability.

Owner:QINGDAO UNIV OF SCI & TECH

Novel high-chromium ferritic heat resistant steel and thermo-mechanical treatment process

InactiveCN102994888AImprove high temperature performanceIncrease service temperatureRoom temperatureThermal stability

Owner:TIANJIN UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap