Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76 results about "Lubricant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A lubricant is a substance, usually organic, introduced to reduce friction between surfaces in mutual contact, which ultimately reduces the heat generated when the surfaces move. It may also have the function of transmitting forces, transporting foreign particles, or heating or cooling the surfaces. The property of reducing friction is known as lubricity.

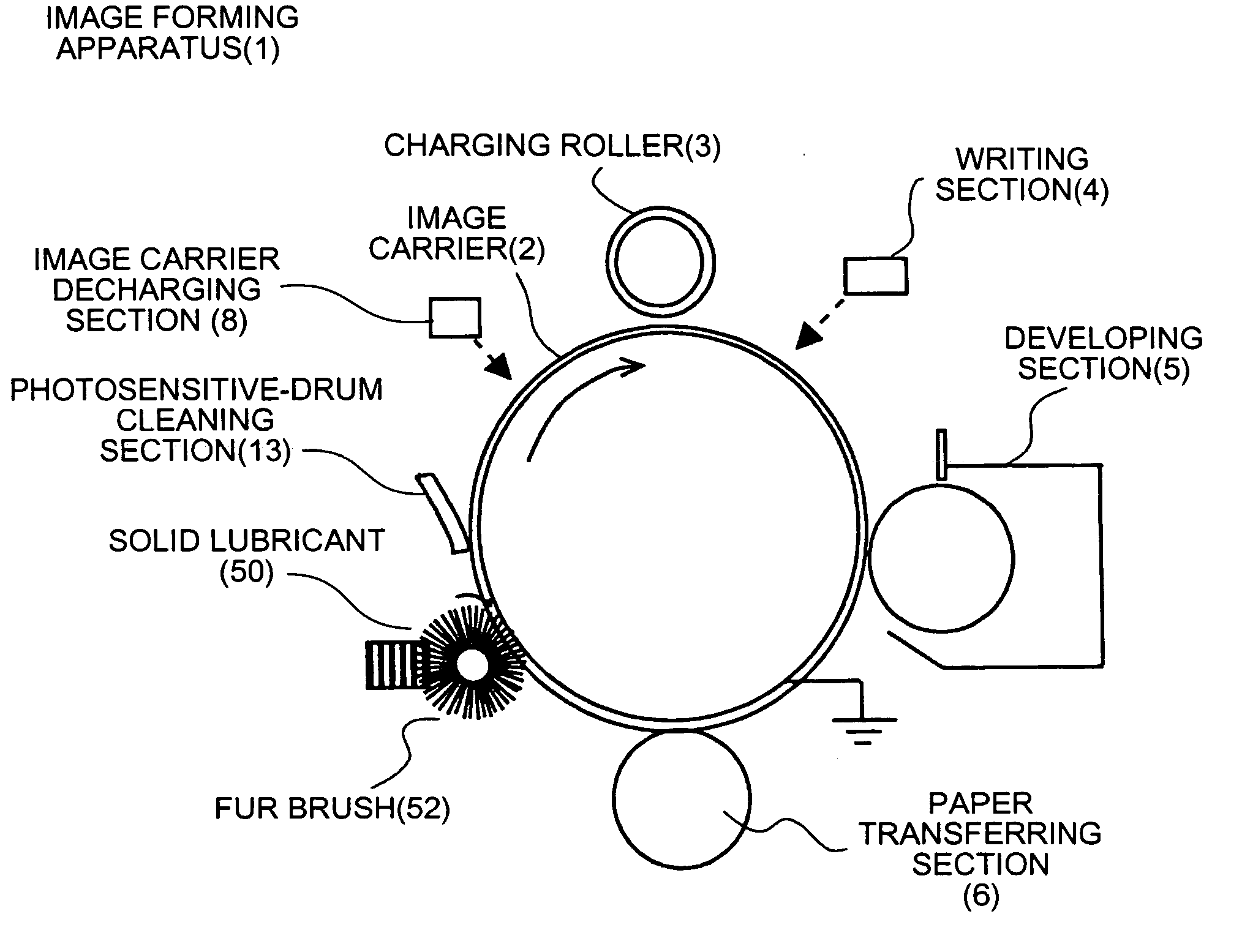

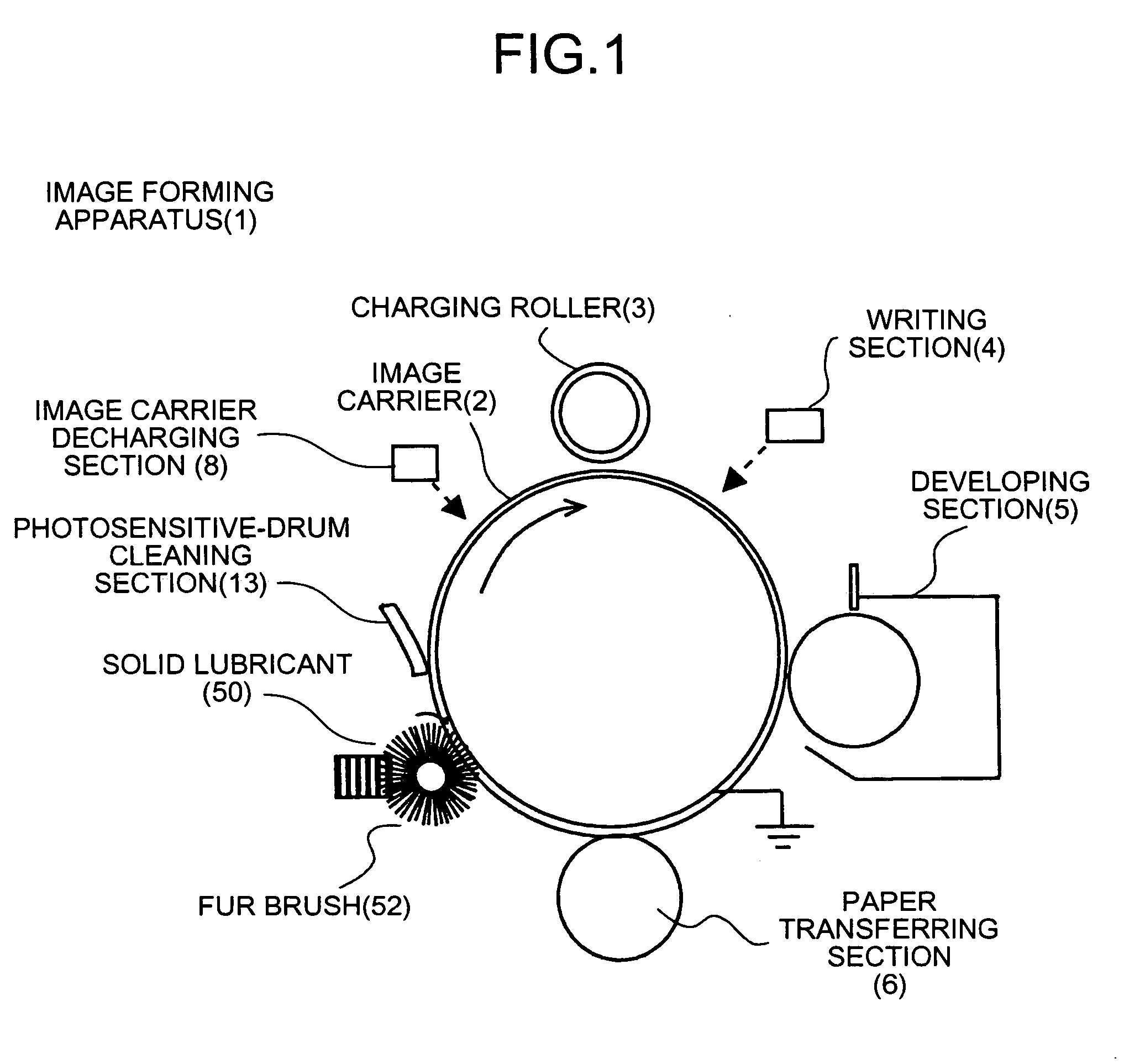

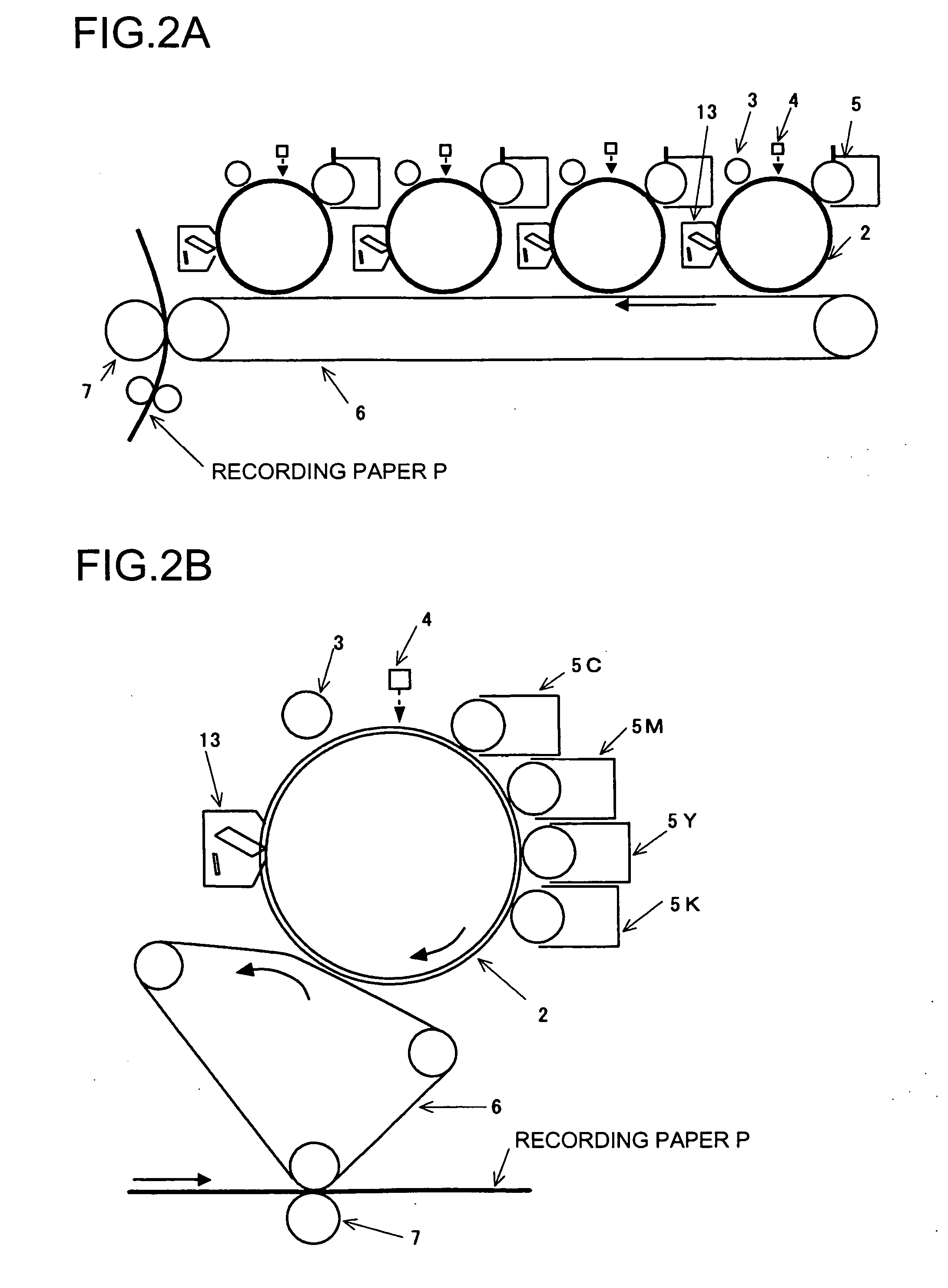

Lubricant applying unit, process cartridge, image forming apparatus, and image forming method

Owner:RICOH KK

Preparation method of thermoplastic polyurethane elastomer

InactiveCN103059554AImprove mechanical propertiesImprove heat resistancePolyethylene glycolHydrolysis

Owner:DONGGUAN JIXIN POLYMER SCI & TECH

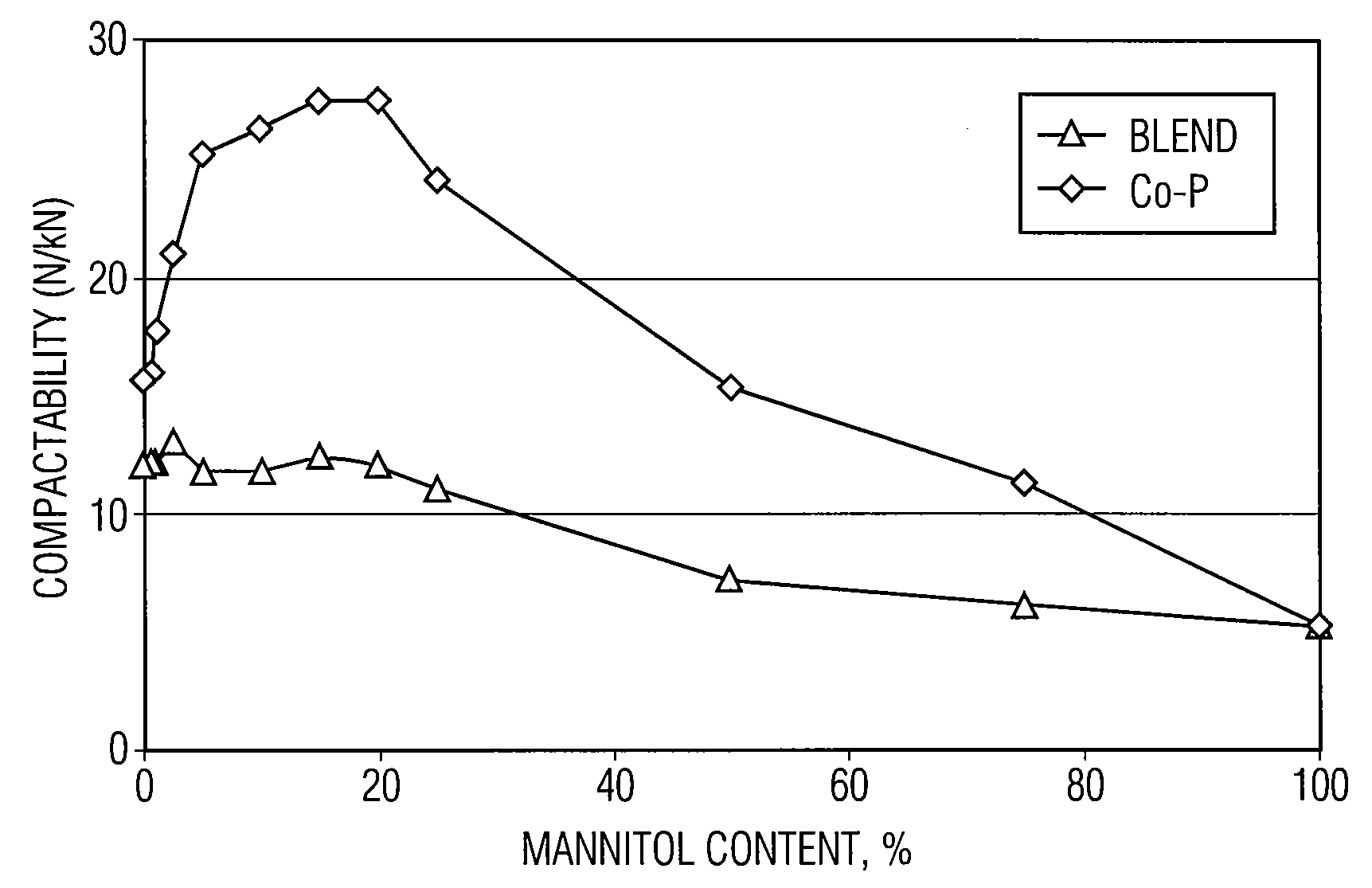

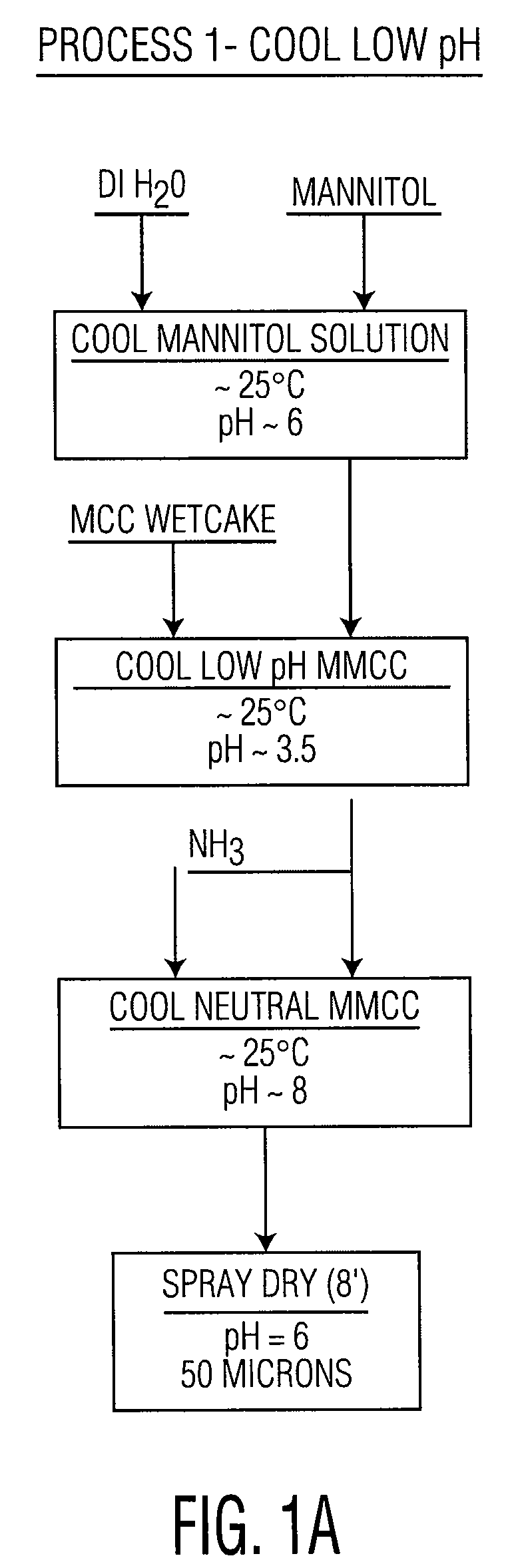

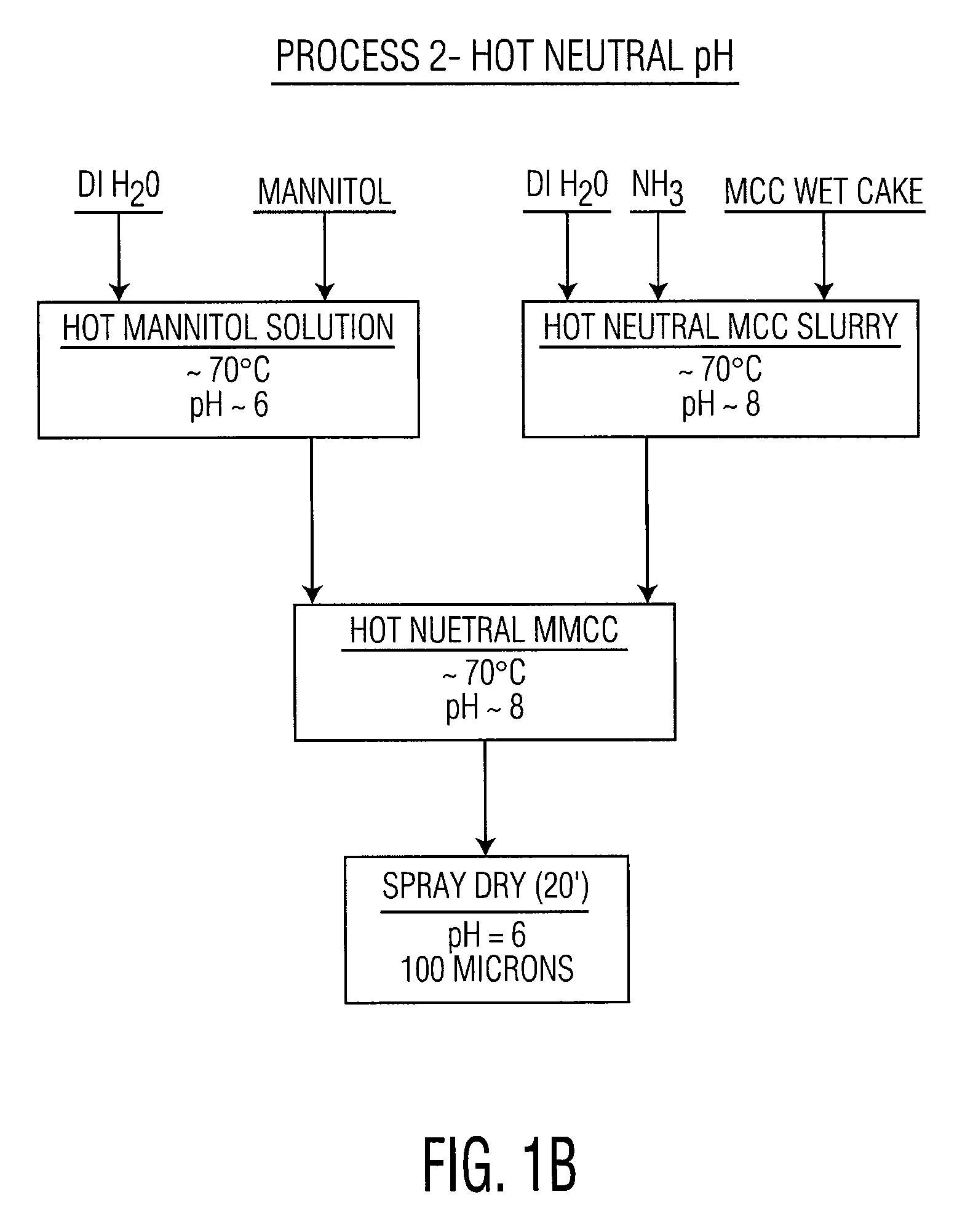

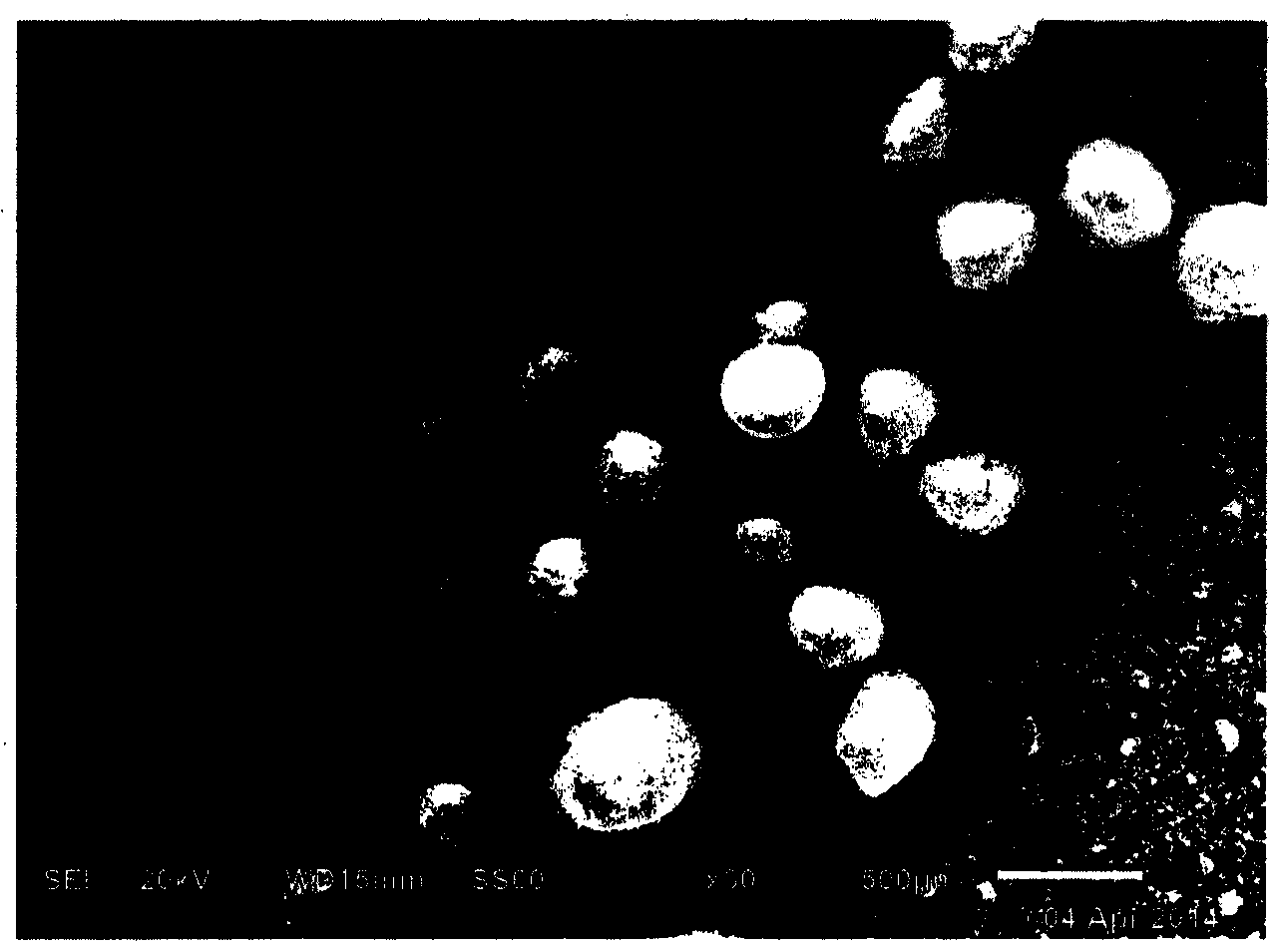

Co-processed microcrystalline cellulose and sugar alcohol as an excipient for tablet formulations

ActiveUS20080131505A1Improve the compaction effectWood working apparatusPill deliveryParticulatesMANNITOL/SORBITOL

Owner:DUPONT NUTRITION USA INC

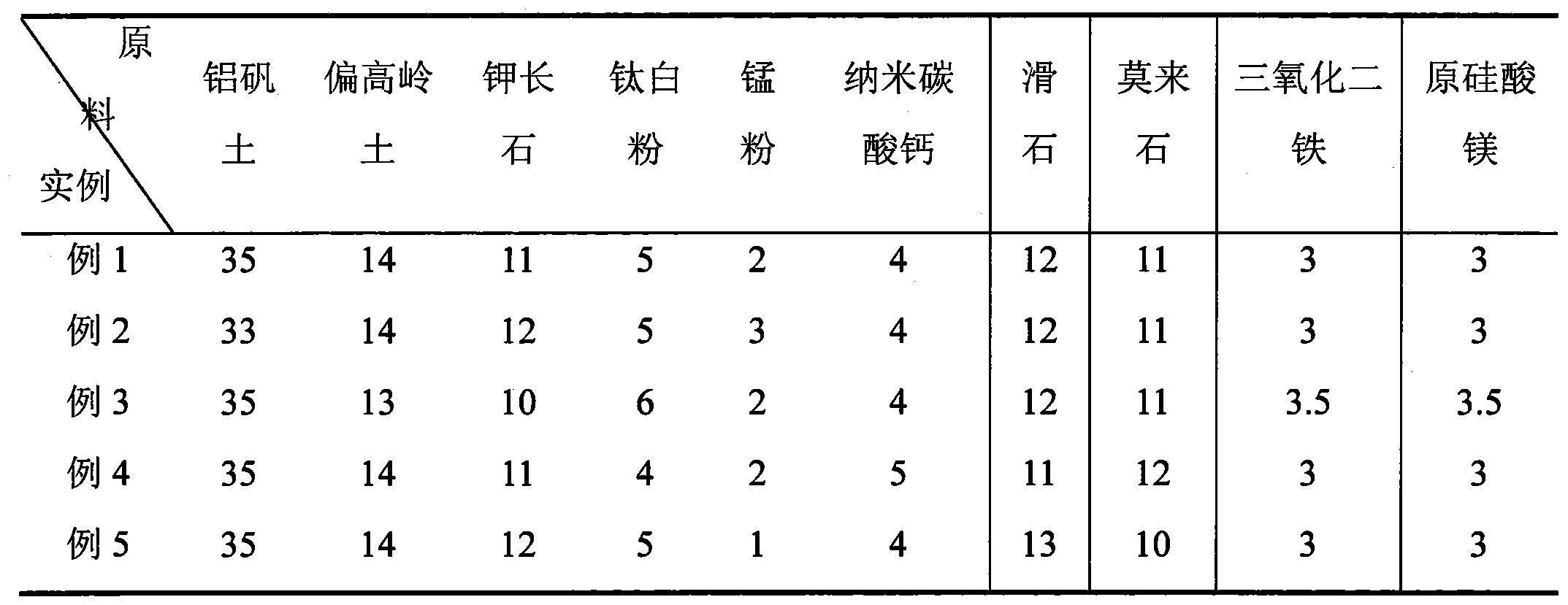

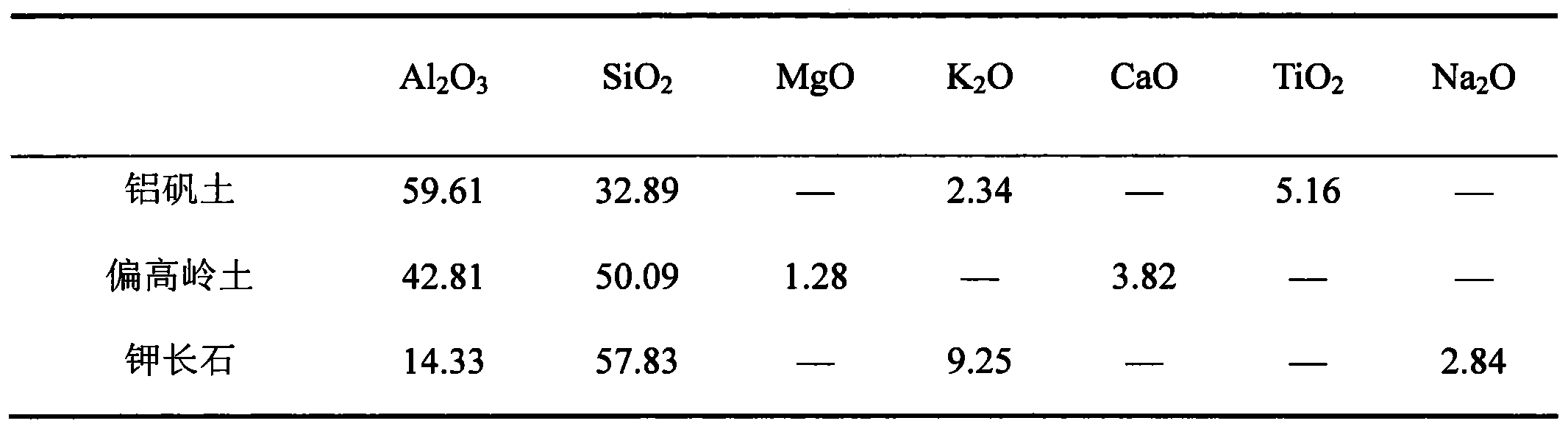

New low-density high-intensity ceramsite fracturing propping agent and preparation method thereof

ActiveCN104099082AAppropriate dispersionEnhancement effect is goodFluid removalDrilling compositionMagnesium orthosilicateExpanded clay aggregate

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

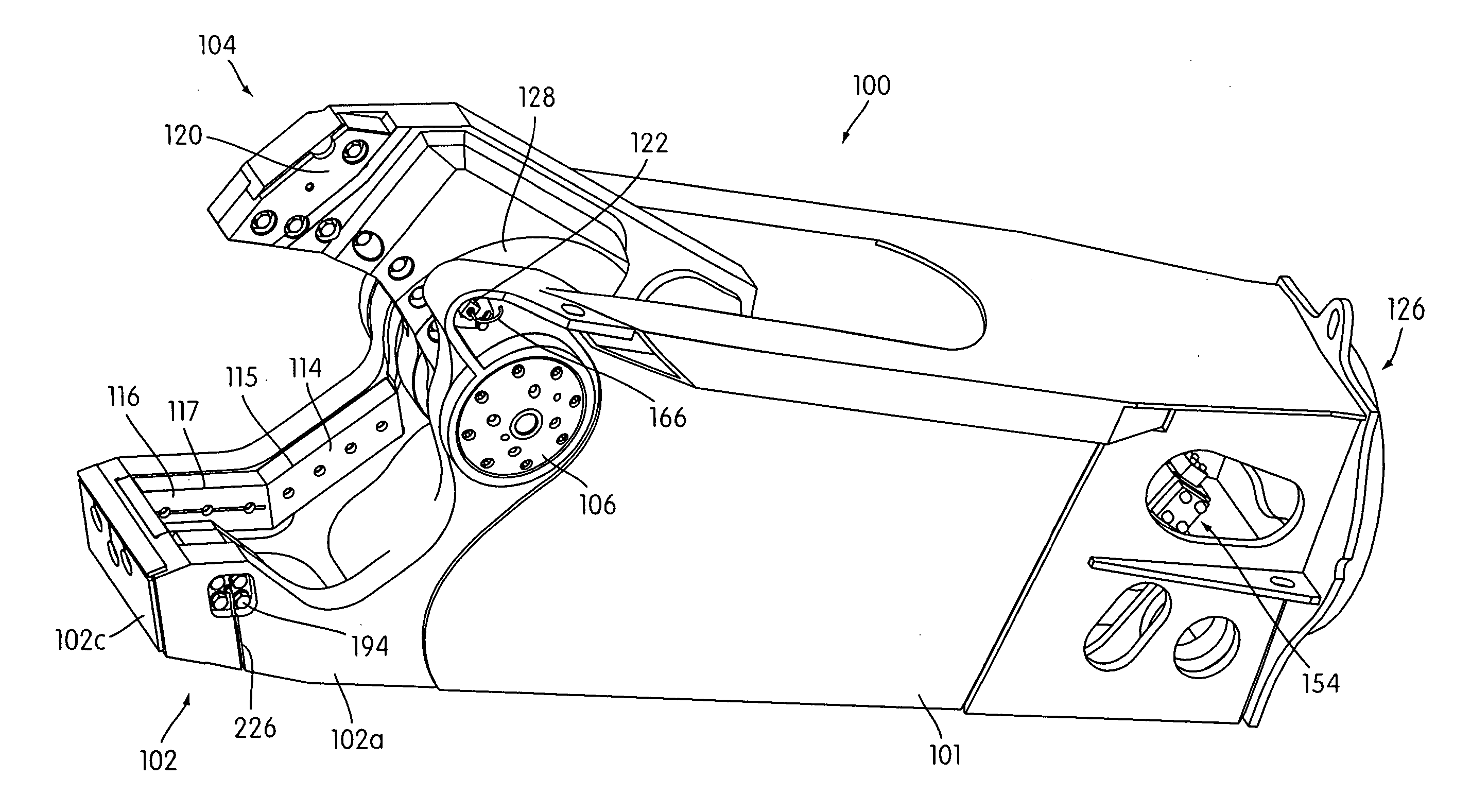

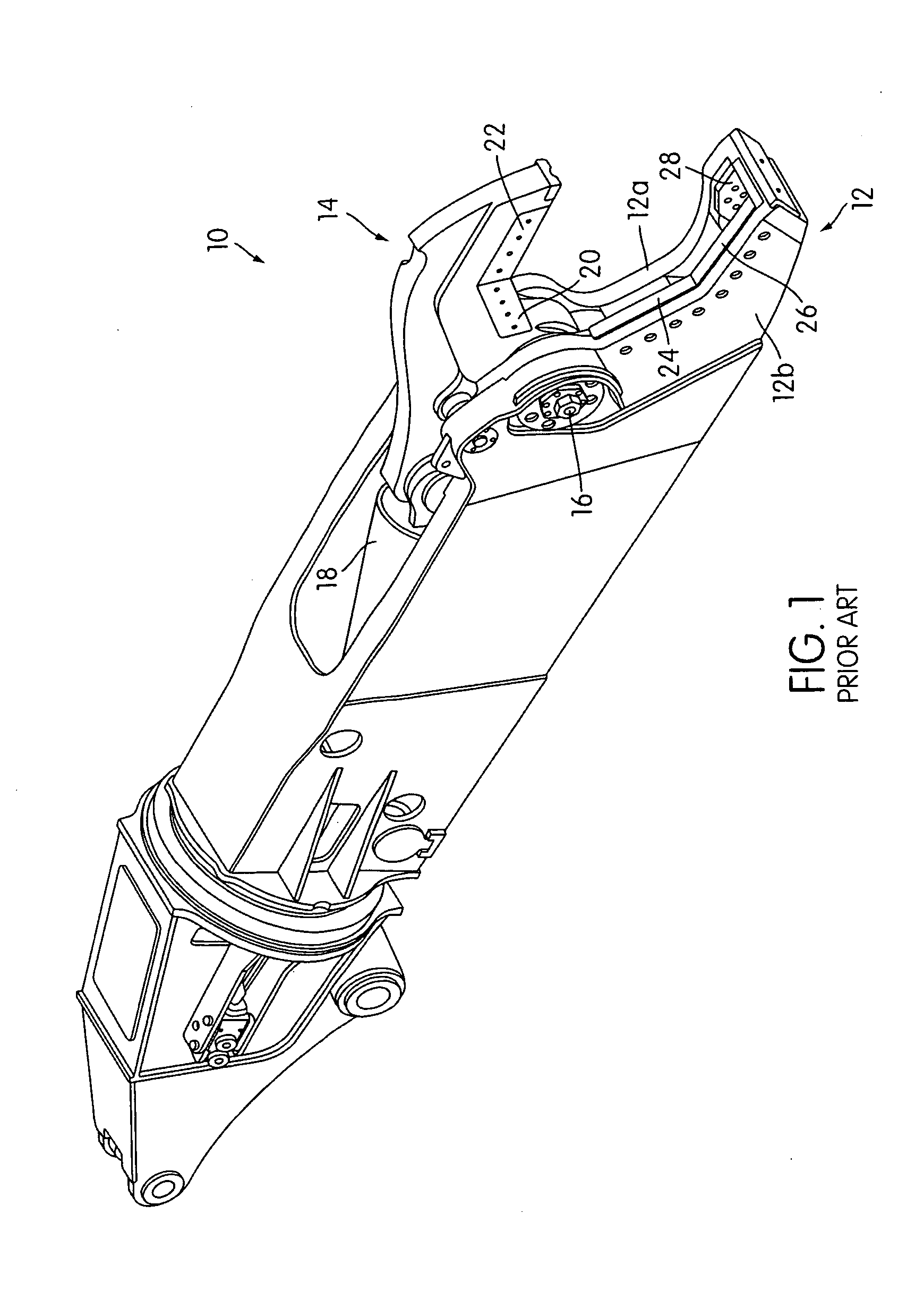

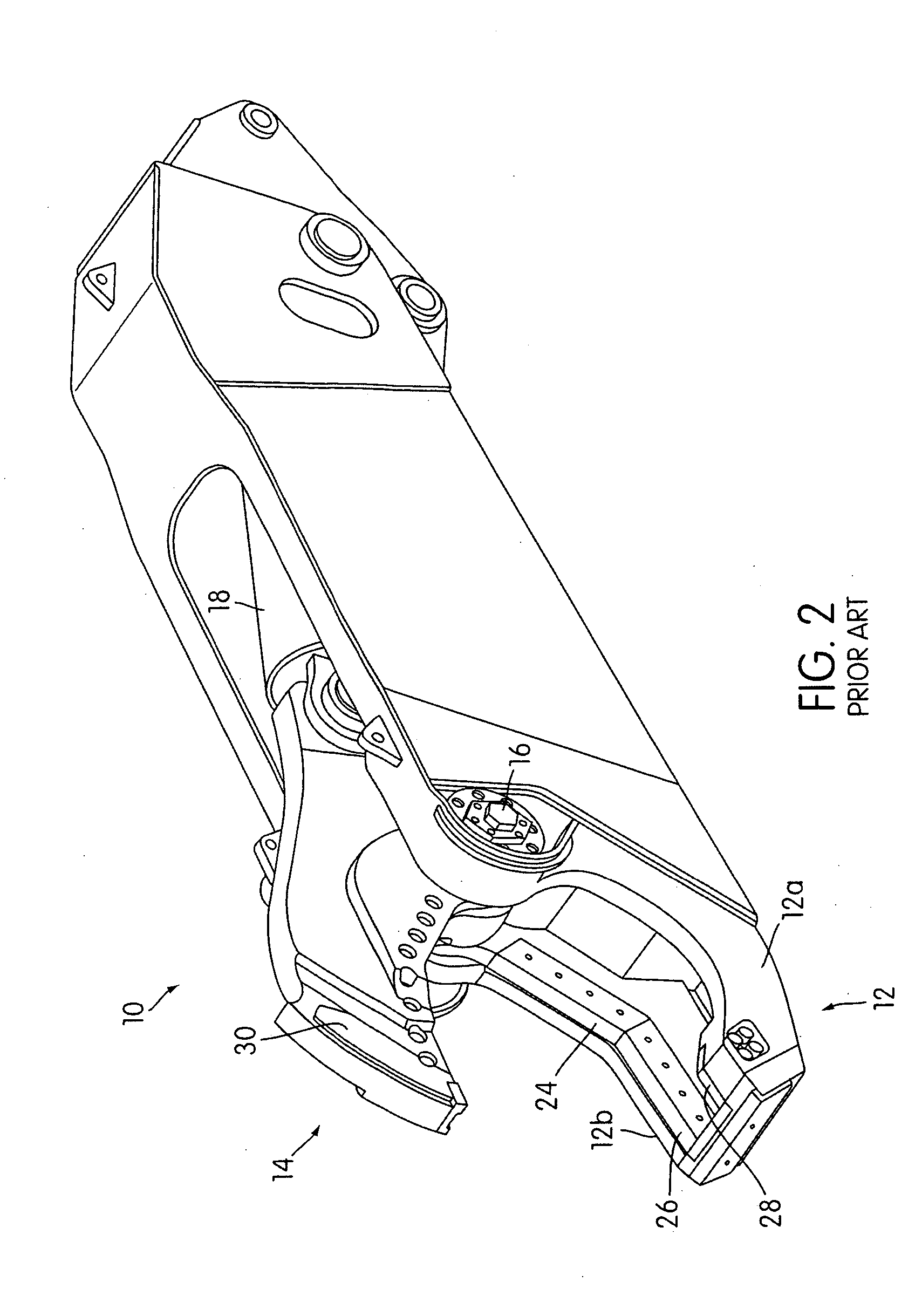

Lubricating system for material-processing shears

Owner:STANLEY WORKS THE

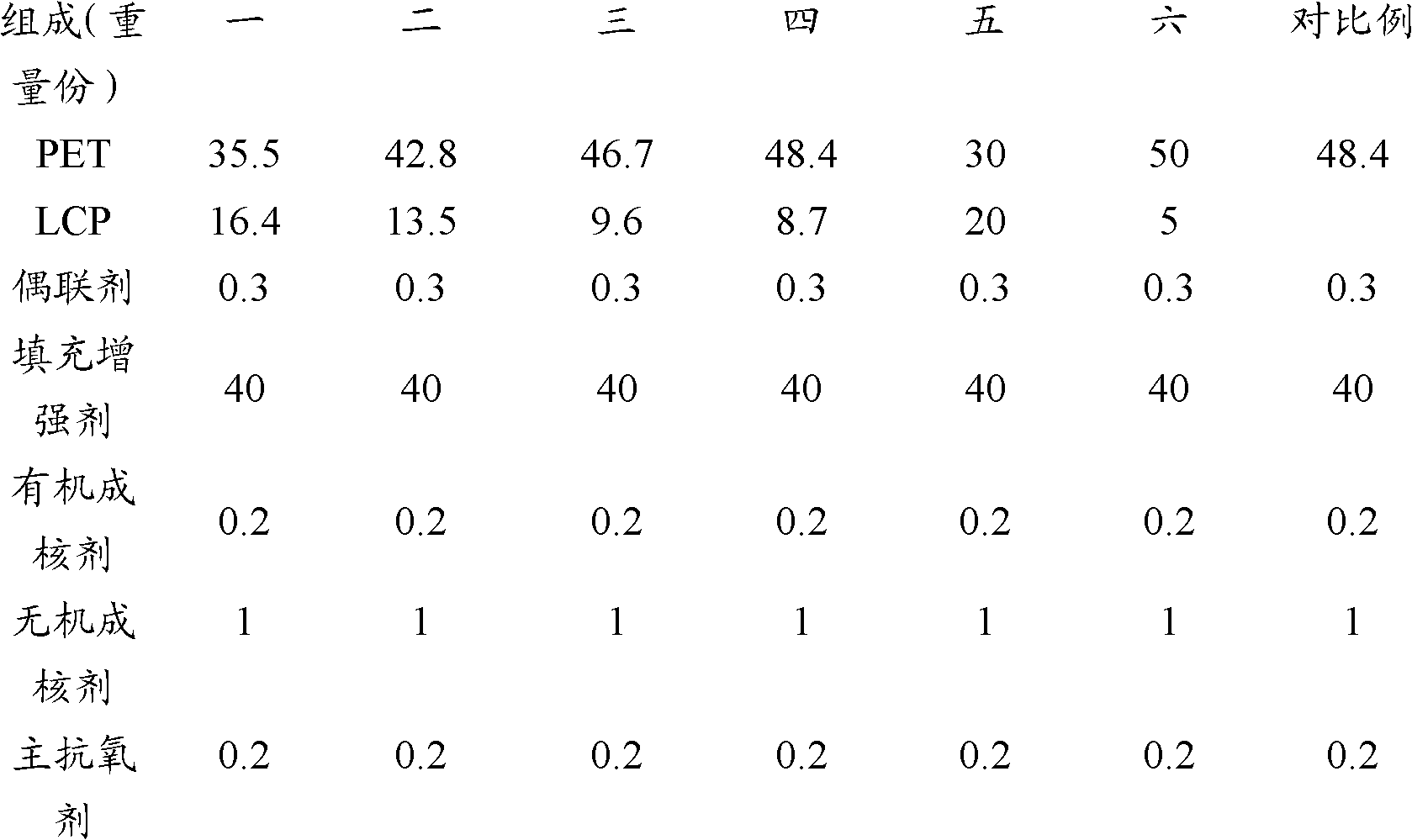

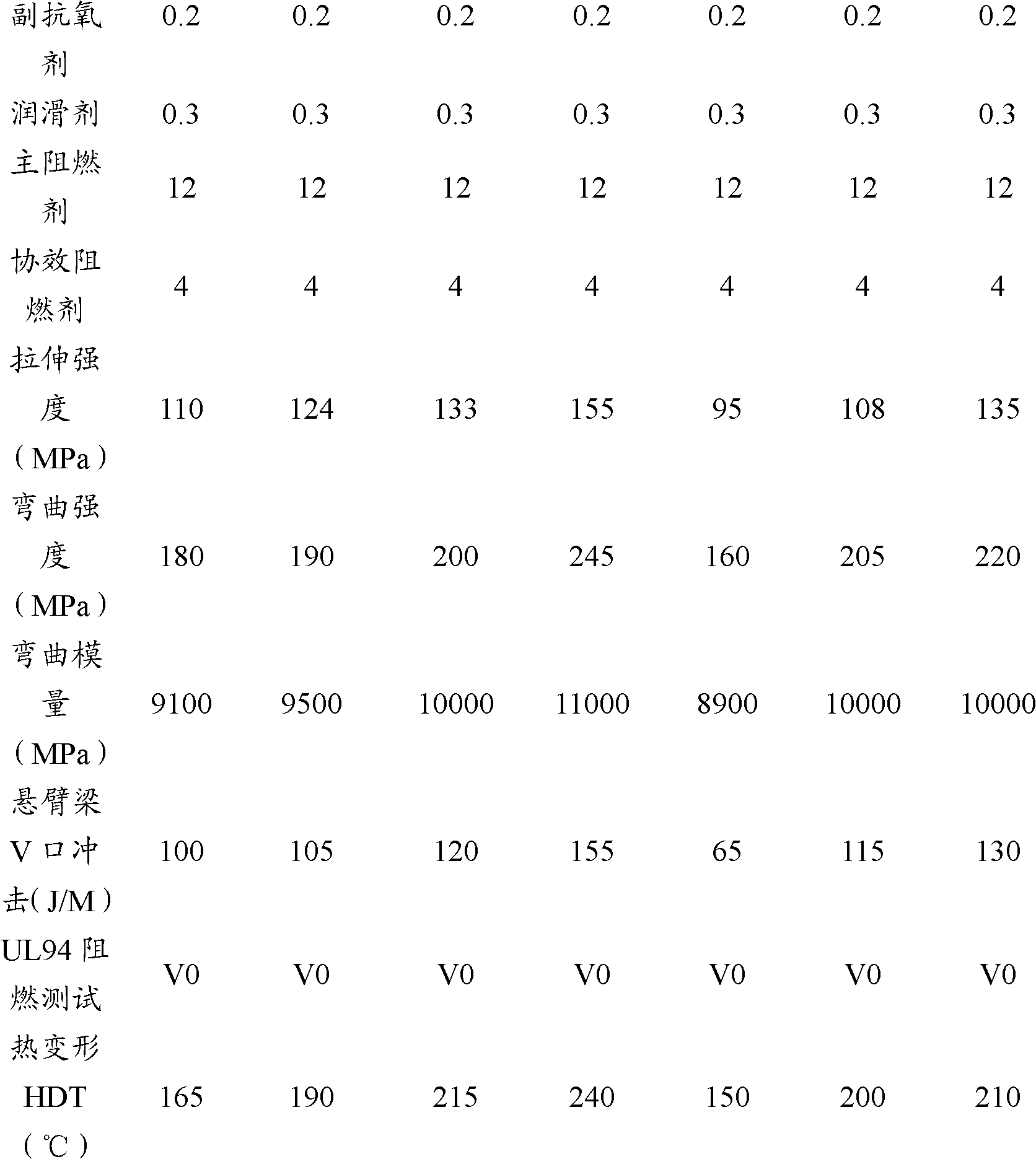

Polyethylene terephthalate (PET)/liquid crystal polymer (LCP) engineering plastics as well as preparation method and application thereof

InactiveCN102040812AImprove performanceHigh crystallinityPolyethylene terephthalate glycolAntioxidant

Owner:SHENZHEN KEJU NEW MATERIAL

Production process of polyester water-resistant emery cloth with high adhesive power

InactiveCN107139087AImprove waterproof performanceLower surface energyNon-macromolecular adhesive additivesLiquid surface applicatorsEpoxyRubber material

The invention discloses a production process of high-adhesion polyester water-resistant abrasive cloth, which adopts water-resistant sandpaper as a cloth base for production; after scraping the sand-planted surface of the cloth base, corona treatment is performed on the sand-planted surface of the cloth base; Squeegee coating material, base rubber material and re-adhesive compound are all added with heat-dissipating materials and heat-conducting materials; the abrasive used for sand planting is diamond abrasive grain; the diamond abrasive grain layer (3) is coated with a re-adhesive layer (4) , the substrate (1) is a non-woven material; by mass percentage, the components of the primer layer (2) and the contents of each component are: 50% to 75% of epoxy modified phenolic resin, 15% to 15% of softening agent 35%, thickening lubricant 2%~5%, tackifier 8%~15%, the sum of the mass percentages of the above-mentioned components is 100%; by mass percentage, the components and The content of each component is: 60%-75% of water-based epoxy resin, 2%-10% of internal mixed antistatic agent, 15%-35% of auxiliary materials, and the sum of the mass percentages of the above-mentioned components is 100%.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

Antimicrobial lubricant for wood fiber-plastic composites

ActiveUS20050256231A1Prevent rotCoatings with pigmentsNon-macromolecular organic additionSulfateWood fibre

The invention relates to a polymer-cellulosic fiber composition comprising a polymer, a cellulosic fiber, and a quaternary ammonium alkyl salt wherein the latter imparts antimicrobial properties to the composition and functions as a lubricant during the formation of the composition. The quaternary ammonium alkyl salts may be alkyl carboxylate, alkyl sulfate, alkyl sulphonate, alkyl phosphate, or alkyl phosphite. Certain of the salts are new compositions of matter. The method of extruding and the extrudate are also claimed.

Owner:ARXADA LLC

Polylactic acid/polyester alloy and preparation method thereof

The invention relates to a polylactic acid / polyester alloy and a preparation method thereof. The polylactic acid / polyester alloy comprises the following components in percentage by weight: polylactic acid, polyester, a compatilizer, a flexibilizer, an antioxidant and a lubricant. The preparation method comprises the following steps: firstly, proportioning the raw materials and mixing at a room temperature; and respectively carrying out melting extrusion, carrying out ultrasonic treatment at the first late stage, extruding at the second stage and pelletizing, so as to obtain degradable, high-impact-resistant and high-heat-resistant polylactic acid / polyester alloy. Compared with an existing method, the controllable ultrasonic treatment is utilized; and a similar polylactic acid-g-polyester structure is formed by in-situ reaction, so that the heat resistance of the polyester and the biodegradability of the polylactic acid are reserved; and meanwhile, a toughening system with a core-shell structure is formed in an alloy system through interface interaction of a special toughening compatilizer, so that the alloy product with high impact resistance, high heat resistance and high biodegradability can be obtained.

Owner:FINE BLEND POLYMER SHANGHAI CO LTD

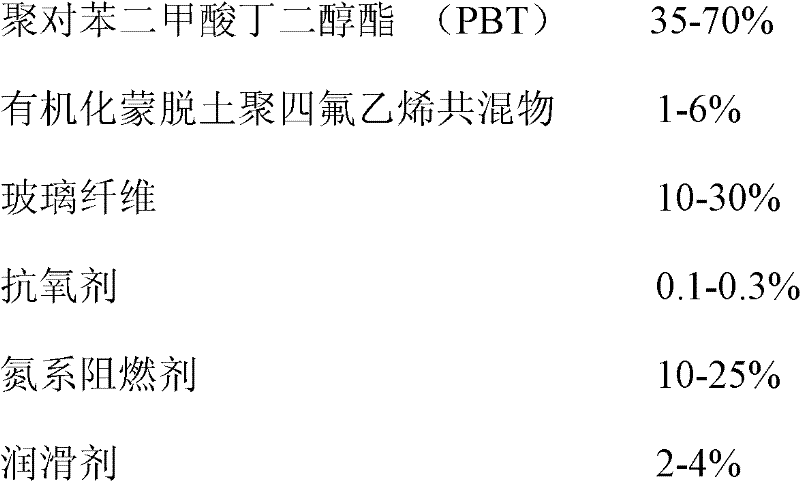

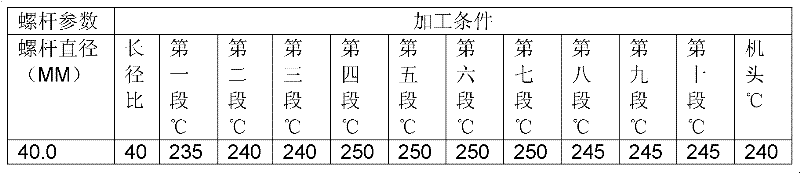

Halogen-free flame-retardant polybutylene terephthalate PBT (polybutylece terephthalate) composite material and preparation method thereof

ActiveCN102391624APhenomenon that limits floating fibersExcellent surface finishPolytetramethylene terephthalateAlkali free

Owner:LONGJAR SHANGHAI IND

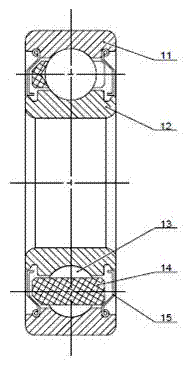

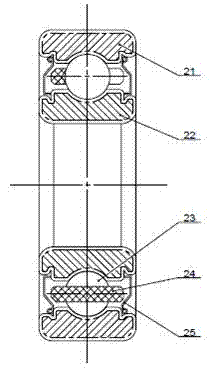

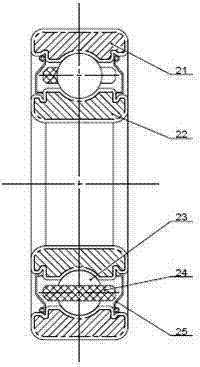

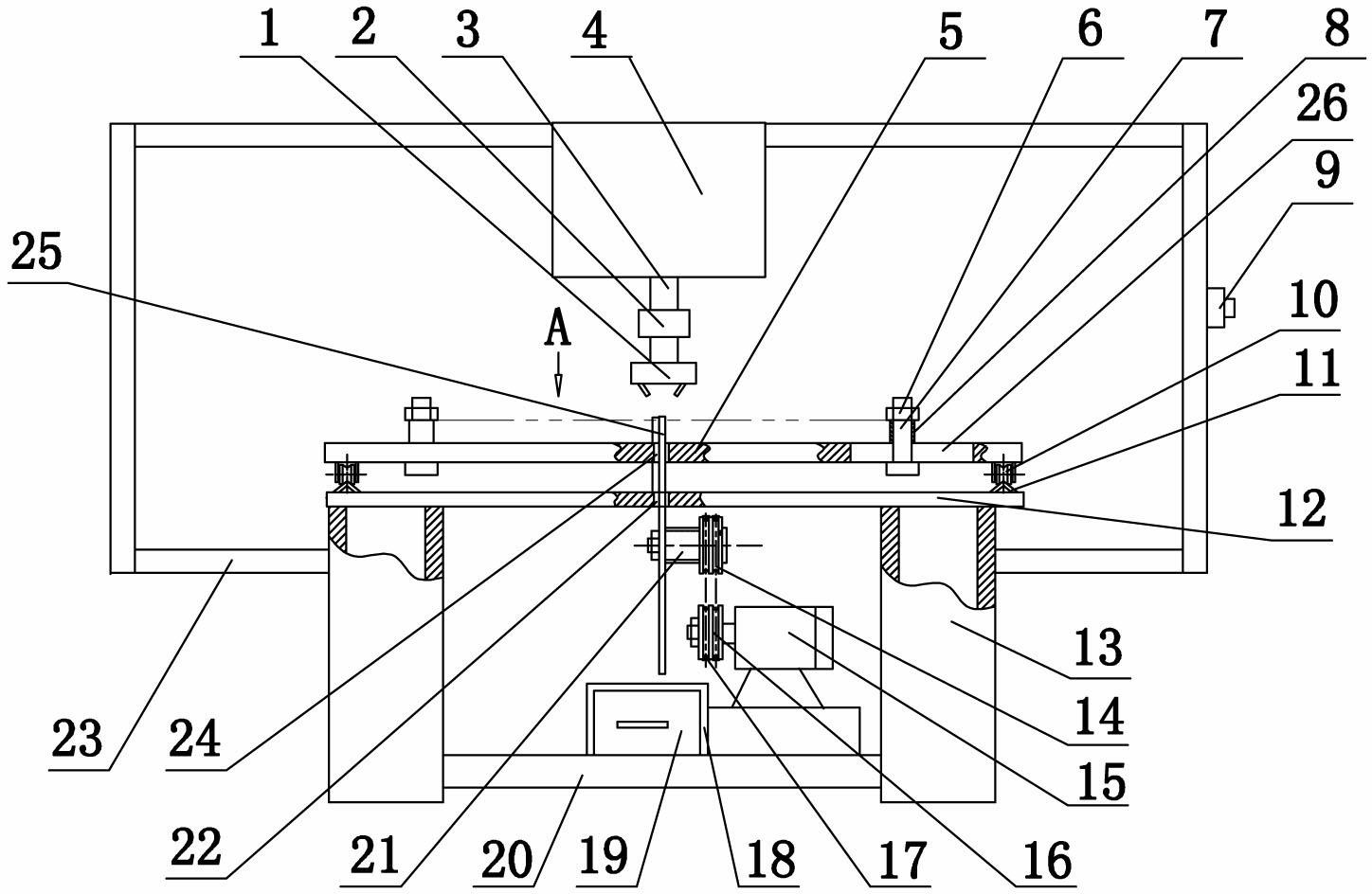

Carbon-graphite keeper rolling bearing used for performing protection and antifriction treatment and manufacturing method of carbon-graphite keeper rolling bearing

InactiveCN102562813ANo corrosionImprove operational reliabilityBearing componentsRolling-element bearingCarbon graphite

Owner:SHANGHAI F&S BEARING TECH

Antibacterial and hydrolysis-resistant thermoplastic polyurethane elastomer

Owner:中天科盛(上海)企业发展股份有限公司

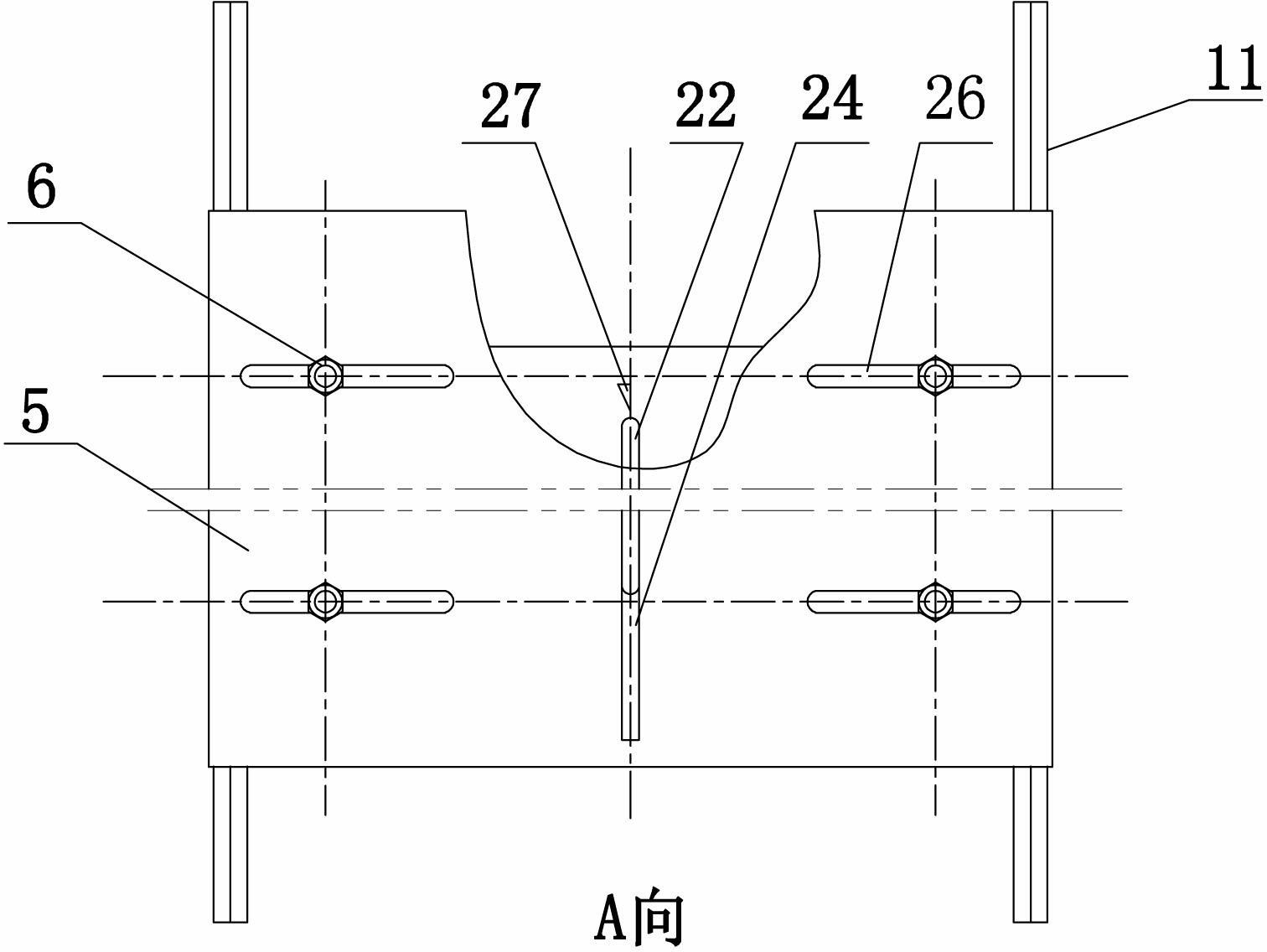

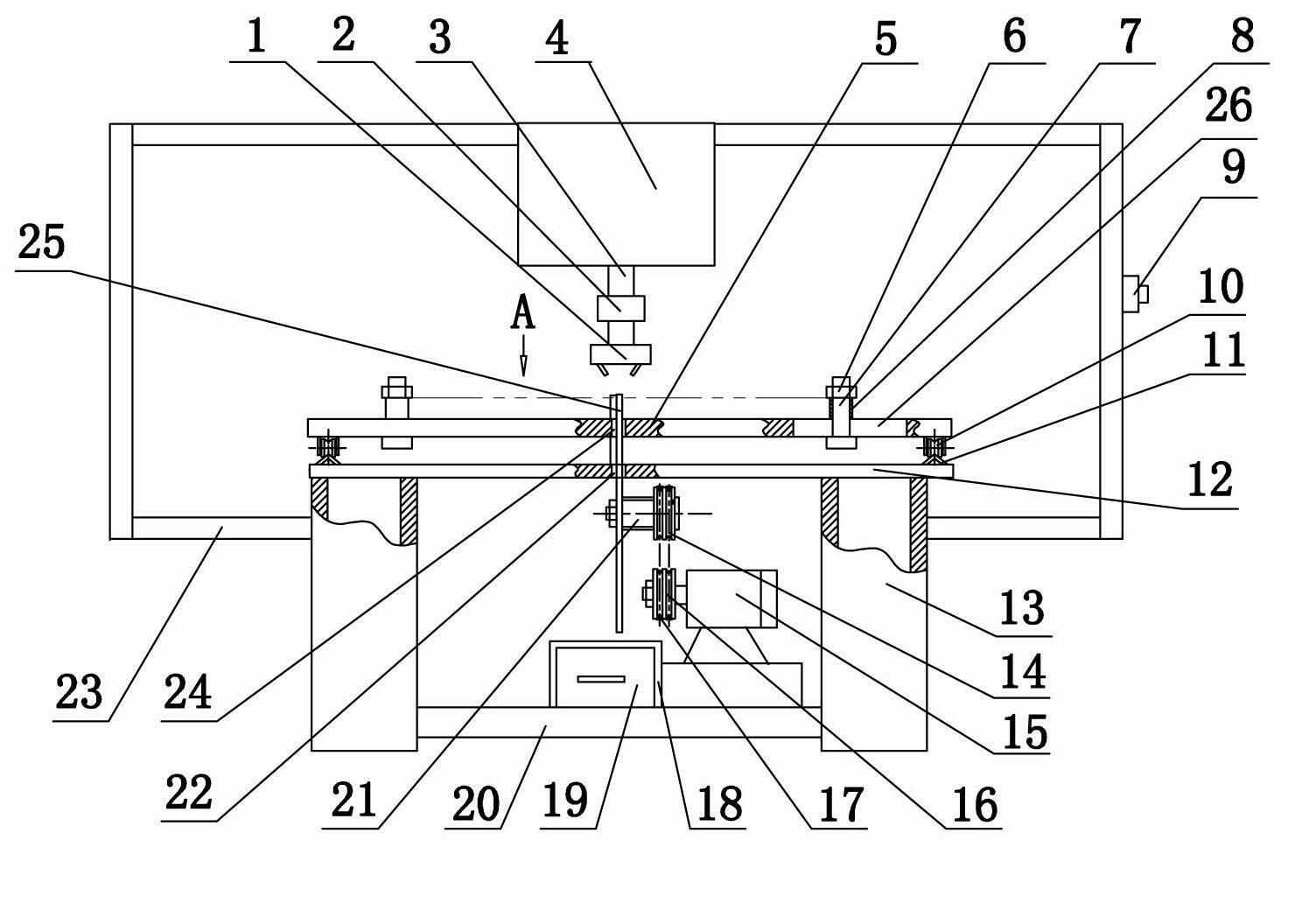

Adhesive tape cutting machine

Owner:ANSTEEL GRP MINING CO LTD

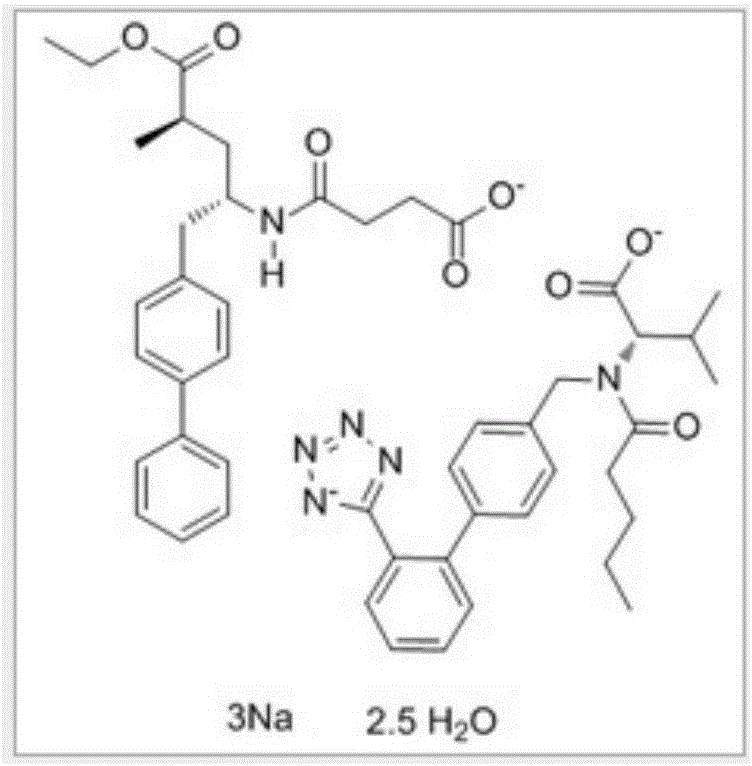

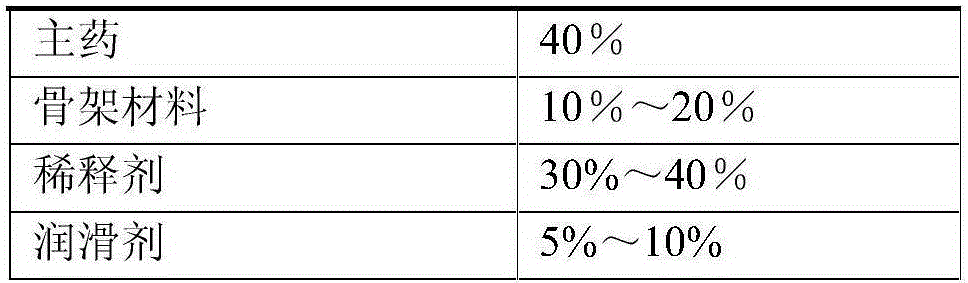

Preparation method of LCZ696 sustained release matrix tablet for treatment of heart failure

ActiveCN105748420AReduce releaseStable blood concentrationPill deliveryPharmaceutical non-active ingredientsSustained Release TabletSide effect

Owner:SHANDONG ACADEMY OF PHARMACEUTICAL SCIENCES

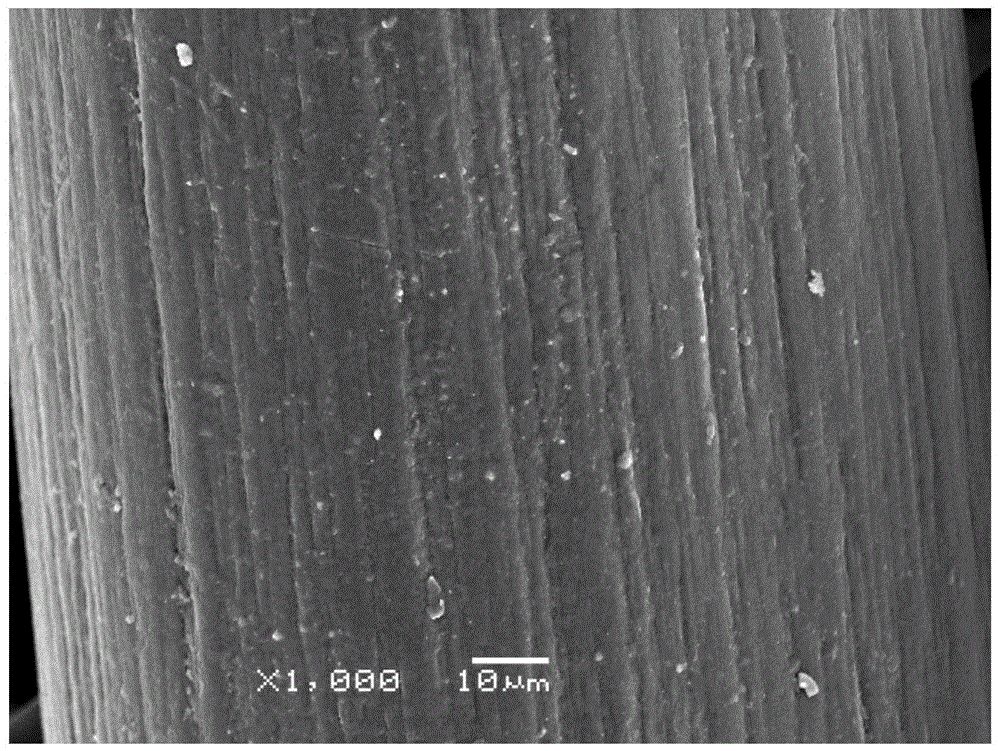

Superconducting niobium pipe and preparation method thereof

ActiveCN103219459ALow residual resistivity dropSuperconductor device manufacture/treatmentHydrogenIngot

The invention relates to the technical field of metal materials and provides a superconducting niobium pipe and a preparation method thereof. The preparation method comprises the specific steps of: forging superconducting niobium ingots, wherein the temperature during a forging process is lower than or equal to 60 DEG C; carrying out first thermal treatment on the forged superconducting niobium ingots; coating a lubricating agent on the surfaces of the superconducting niobium ingots after the first thermal treatment, and carrying out reverse extrusion; and carrying out secondary thermal treatment on the superconducting niobium ingots after the reverse extrusion, so as to obtain the superconducting niobium pipe. According to the superconducting niobium pipe and the preparation method thereof, the forging temperature is controlled in a forging process, and the lubricating agent is coated on the surfaces of the niobium ingots in an extrusion process, so that the carbon absorption, the hydrogen absorption and the oxygen absorption of the niobium ingots in a machining process are effectively avoided, and the decreasing amplitude of the residual resistivity of the prepared superconducting niobium pipe is relatively small.

Owner:NINGXIA ORIENT TANTALUM IND

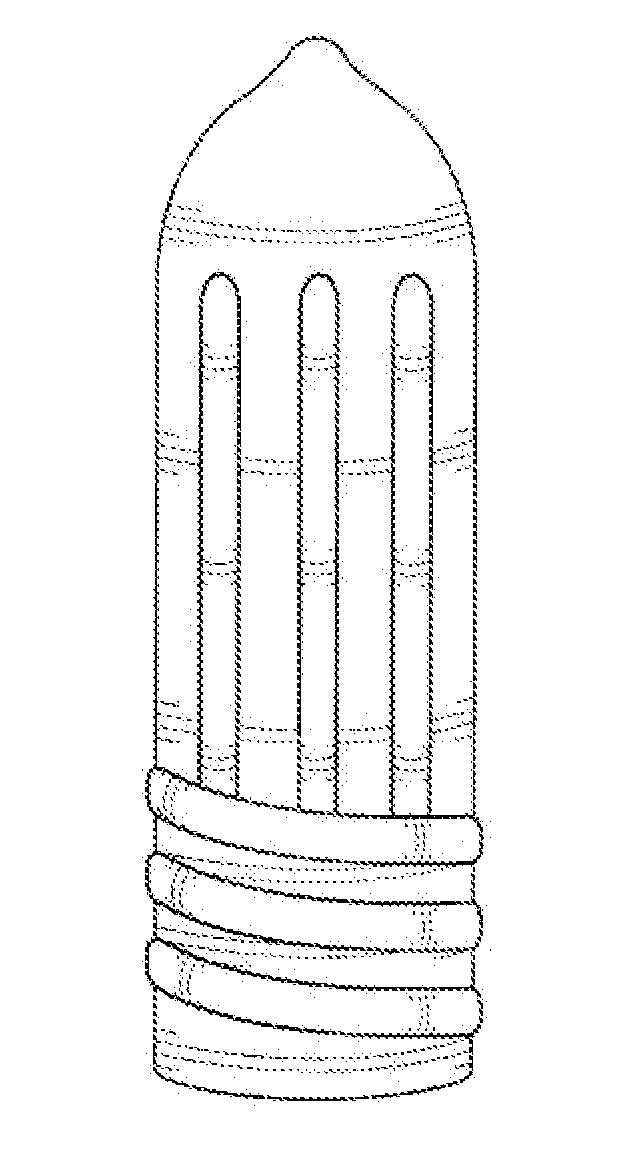

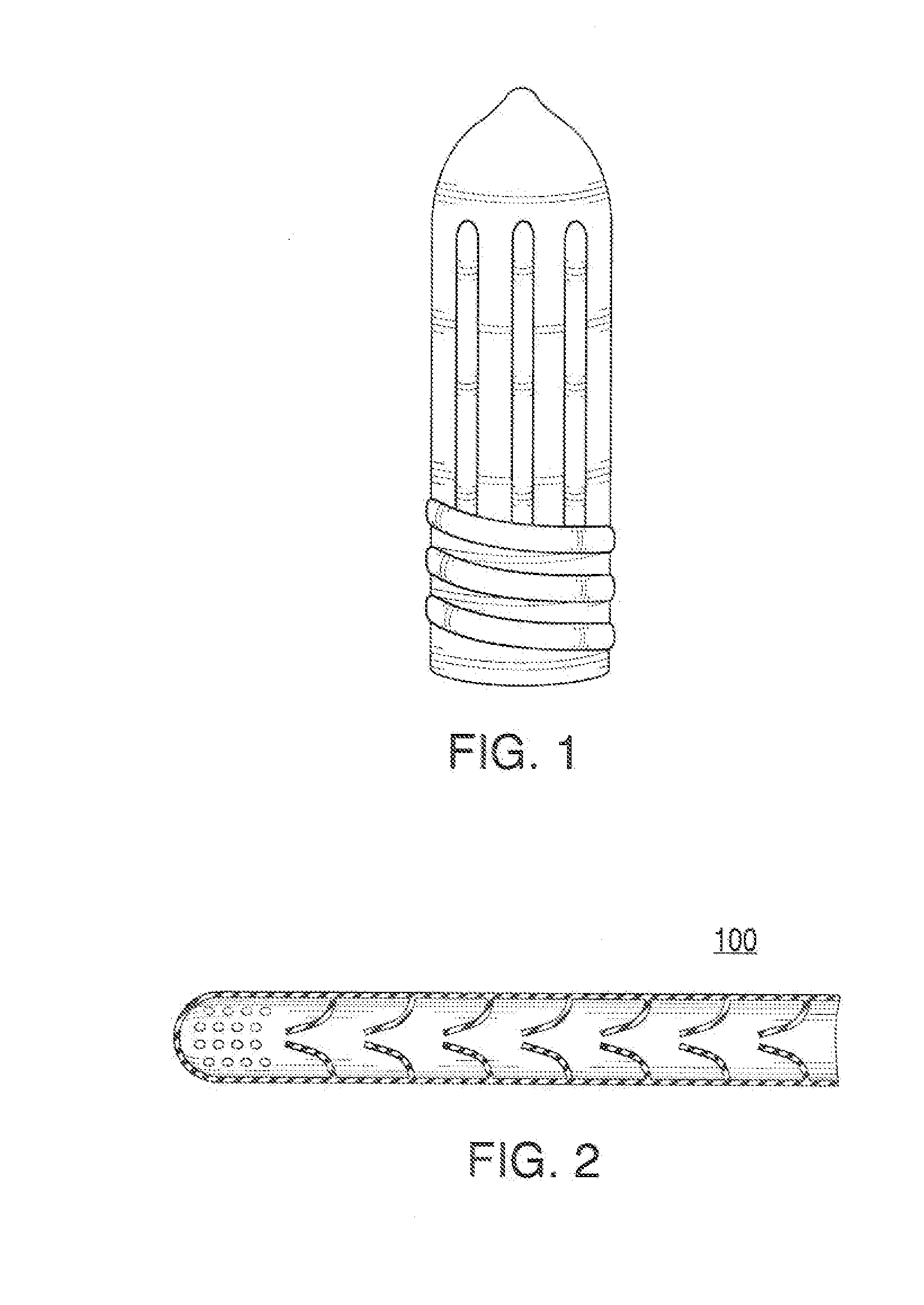

Lubricated Condom

Owner:HUI LAP SHUN

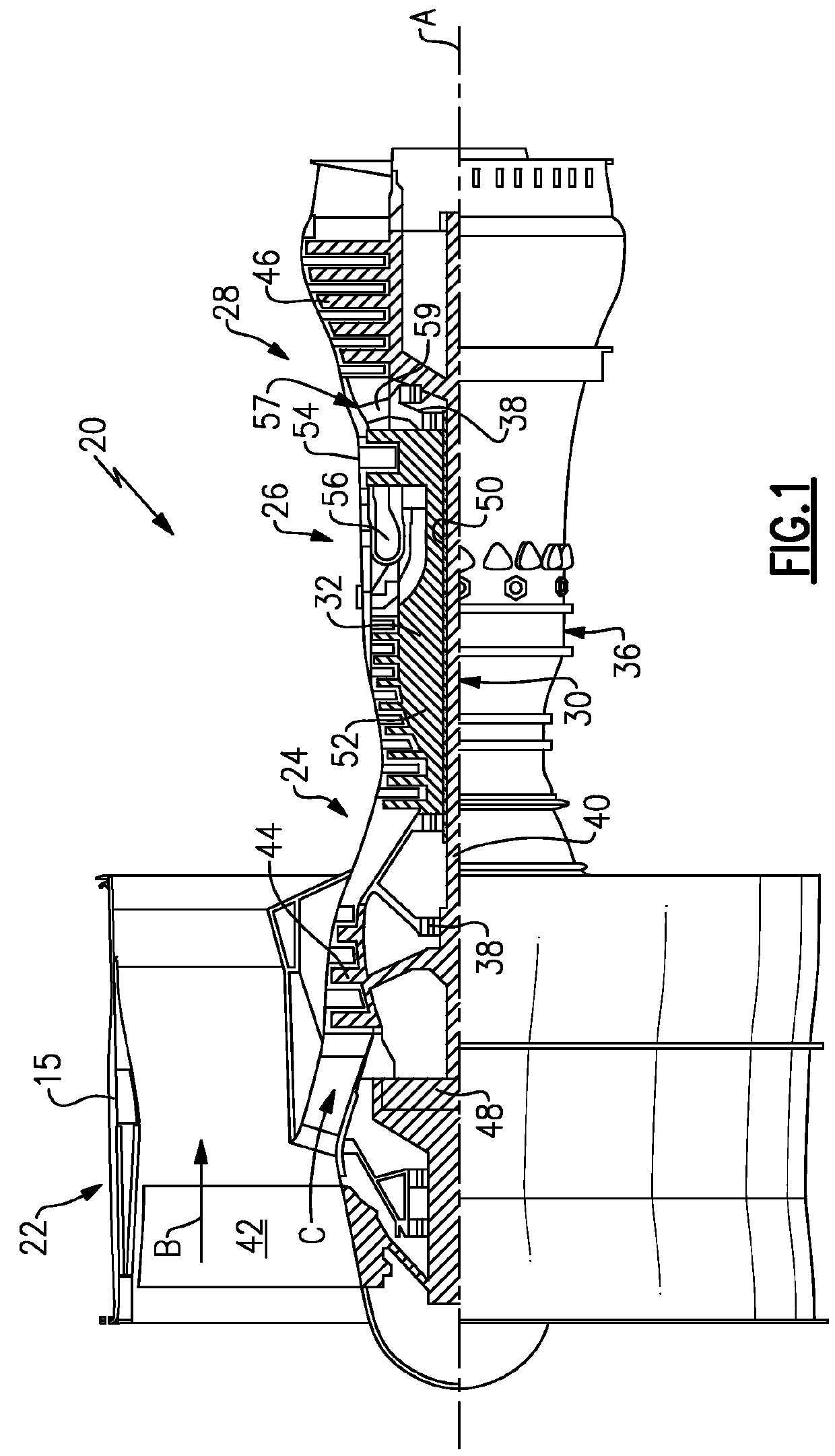

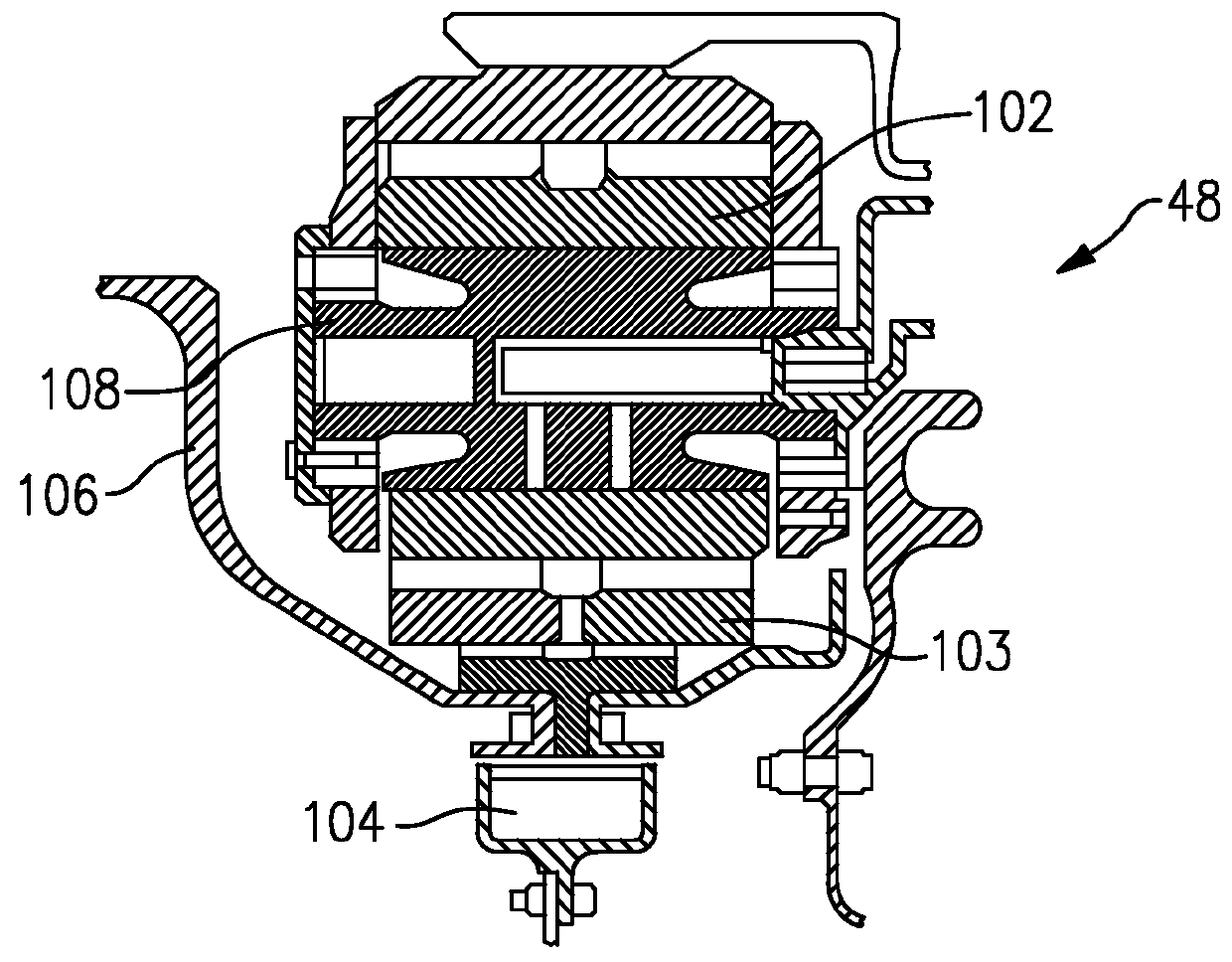

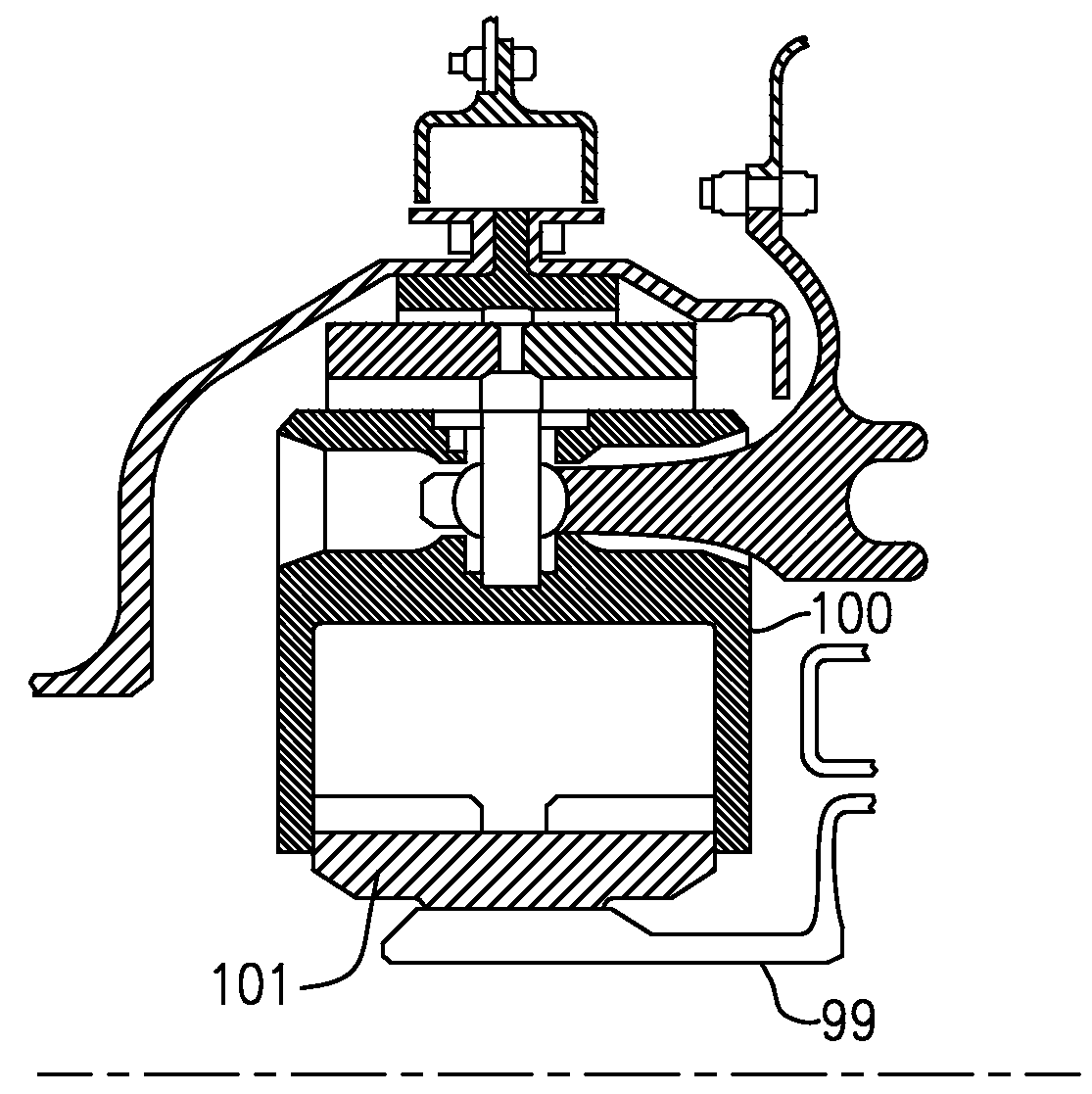

Geared gas turbine engine with oil deaerator and air removal

Owner:RAYTHEON TECH CORP

Lubricants for power transmission

InactiveUS20070037716A1Improvement factorPoint becomes highOrganic chemistryAdditivesAlcoholPhotochemistry

There is provided lubricants for power transmission which exhibit not only a high coefficient of traction but also a high flash point. The lubricants for power transmission according to the present invention contains an alicyclic alcohol carboxylic diester compound represented by the general formula (1): R1—CO—O—(X1)m-Z-(X2)n—O—CO—R2 (1) wherein Z is a cycloalkylene group having 3 to 12 carbon atoms; R1 and R2 are each independently a chain hydrocarbon group having 3 to 20 carbon atoms; X1 and X2 are each independently a linear or branched alkylene group having 1 to 5 carbon atoms; and m and n are respectively an integer of 0 or 1.

Owner:IDEMITSU KOSAN CO LTD

Production method for preparing polyvinyl chloride fibers for hair by melting method

ActiveCN104611781ALow shrinkageSmall shrinkageWigsMonocomponent halogenated hydrocarbon artificial filamentPlasticizerBoiling point

Owner:邵阳美丽来发制品有限公司

High-impact flame-retardant reinforced PC/ABS alloy material and preparation method thereof

Owner:四川鑫达企业集团有限公司

Preparation method and preparation device for PET multi-layer composite sheet

The invention discloses a preparation method of a PET multi-layer composite sheet. The preparation method comprises the following steps: (1) treating a PET raw material and a PETG raw material respectively; (2) mixing the treated PET raw material and PETG raw material by a metering pump; (3) carrying out upper-layer and lower-layer distribution for the two types of raw materials through a material distributor; (4) obtaining a sheet from the raw materials treated by upper and lower layering through a molding die head; (5) cooling and sizing the obtained sheet by water of 30 degrees; (6) coating the sheet with a lubricating agent and an antistatic agent after intermediate sizing by a push coating device; (7) drying the sheet after being coated with the lubricating agent and the antistatic agent; (8) cutting boundary materials of the obtained sheet according to required specifications; and (9) drawing out the sheet with the boundary materials being cut, and then rolling to obtain a finished product. According to the preparation method disclosed by the invention, the PET multi-layer composite sheet can be produced by the device, and the device can be used for changing physical properties of the PET multi-layer composite sheet.

Owner:SHANGHAI KUNYUAN NEW MATERIALS CO LTD

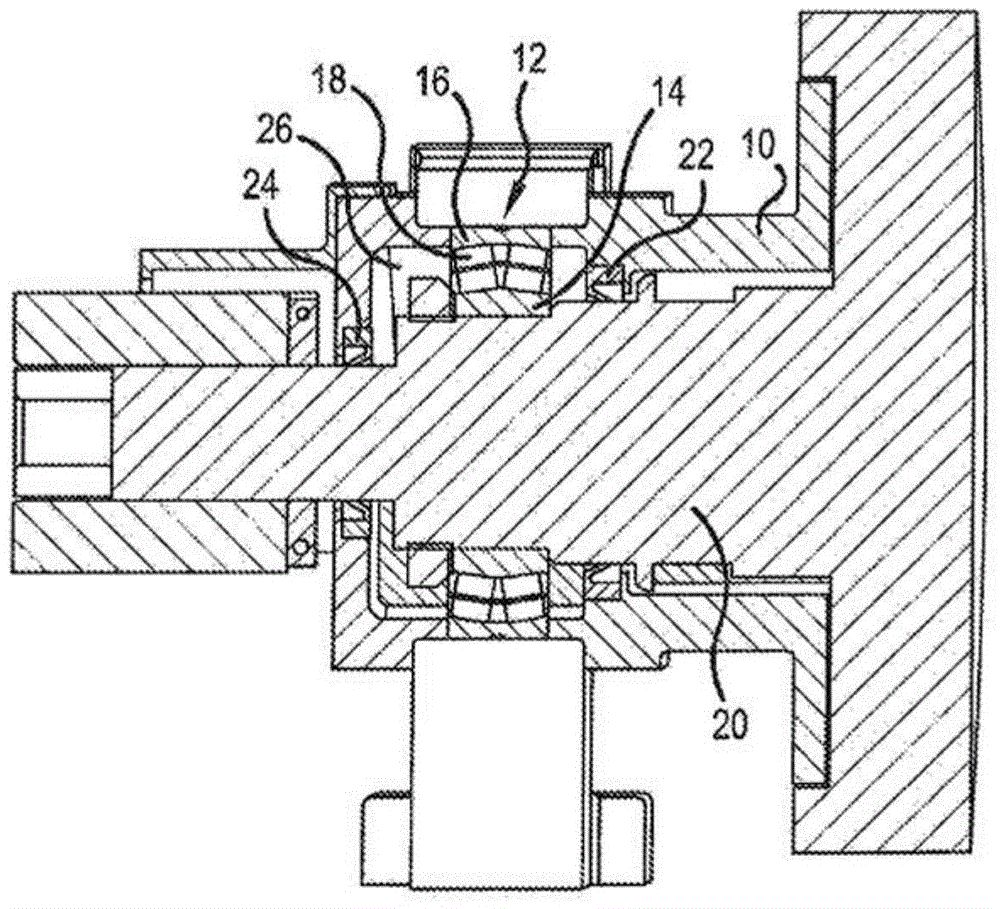

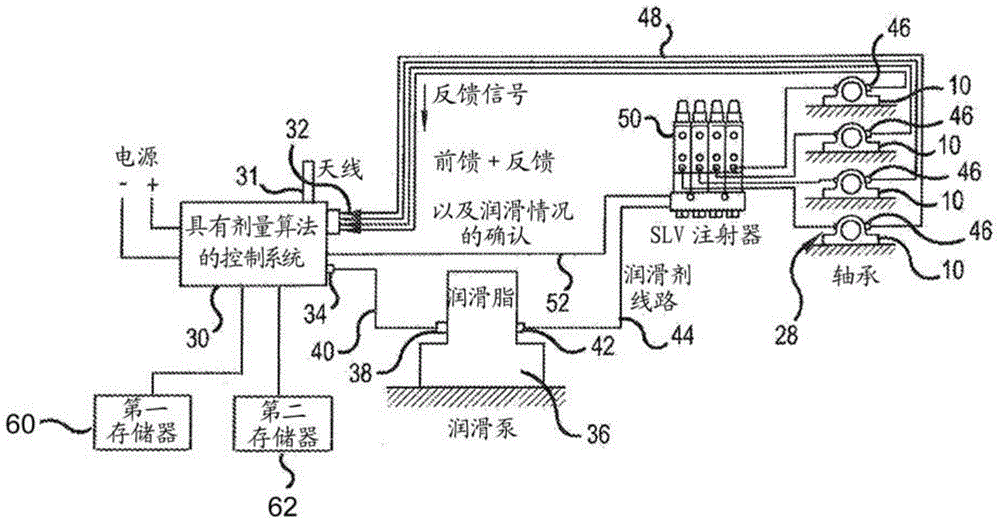

Bearing system with lubricated exclusion seal

Owner:LINCOLN INDUSTRIES CORP +1

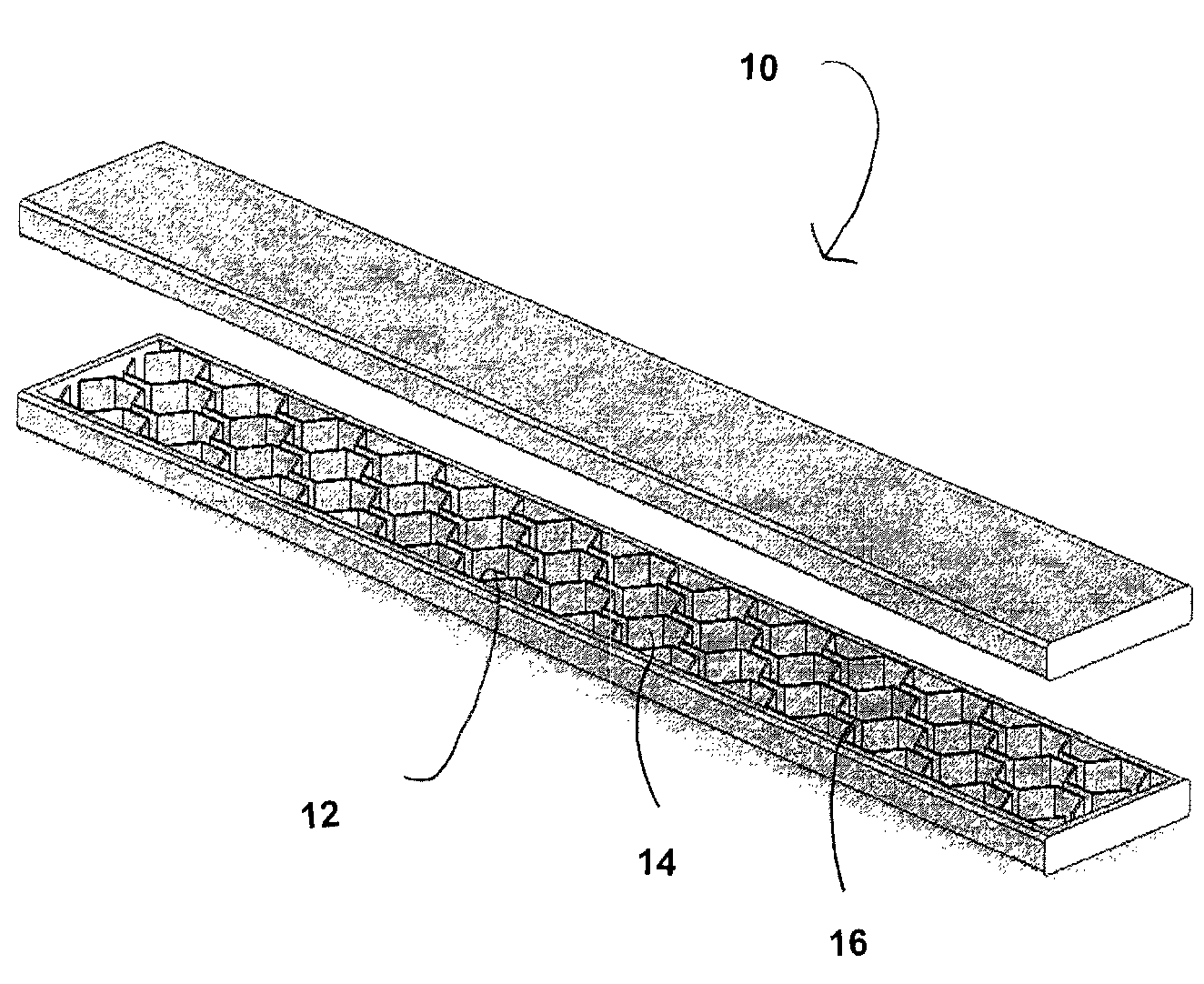

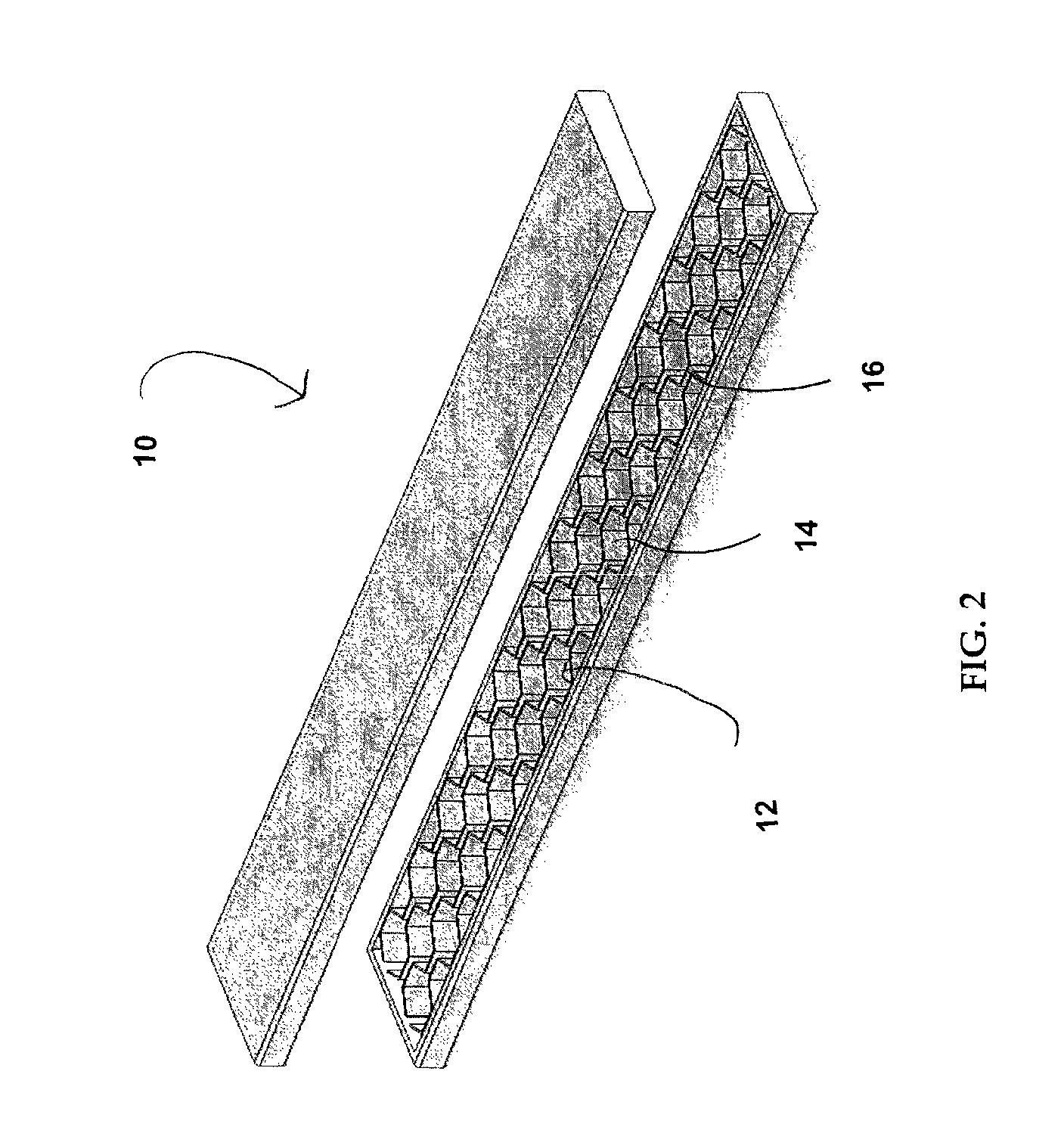

Rigid structure lubricant

InactiveUS7449433B1Increase and decrease rigidityIncrease and decrease and wear rateBearing componentsRail lubricationFiberPlastic materials

Owner:ENVIRONMENTAL LUBRICANTS MFG

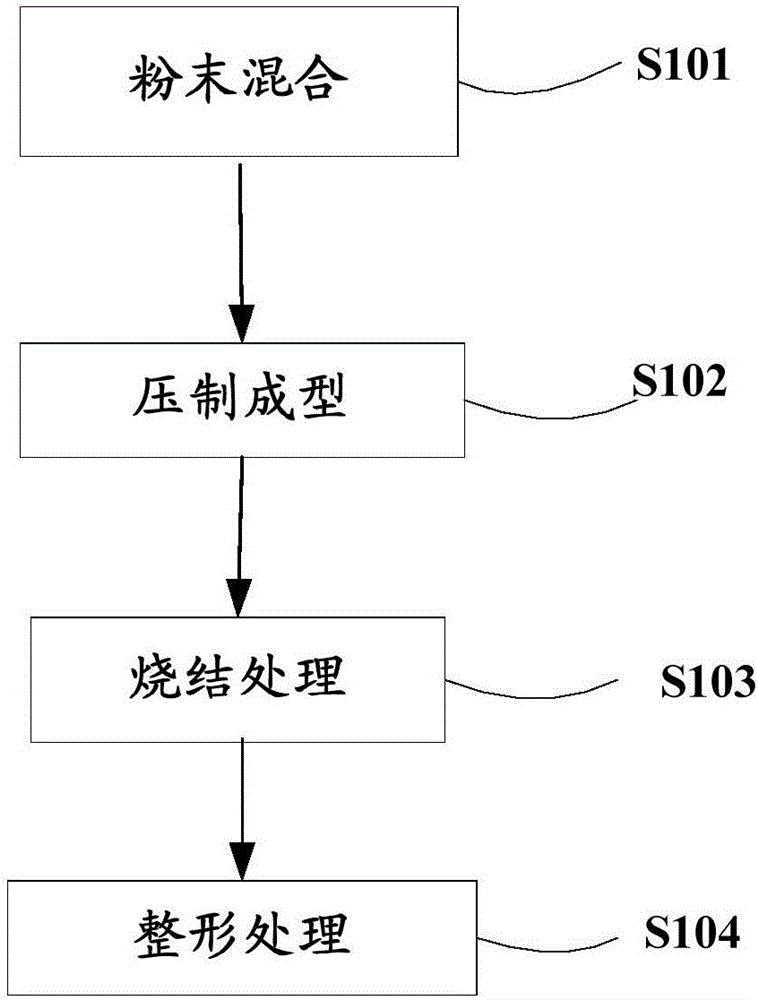

Novel powder metallurgical gear

InactiveCN106041095AUniform densityLarge elongationTransportation and packagingMetal-working apparatusCarbon fibersALUMINUM STEARATES

Owner:黄宇

Methanol gasoline

InactiveCN106957697ALow costImprove performanceLiquid carbonaceous fuelsFuel additivesGasoline fuelAntioxidant

Owner:泸州清大能源股份有限公司

Viscosity Modifiers Comprising Blends of Ethylene-Based Copolymers

The present invention is directed to polymer blend compositions for use as viscosity modifiers comprising at least two ethylene-based copolymer components. The viscosity modifiers described herein comprise a first ethylene-based copolymer having an ethylene content of from about 44 to about 52 wt % and / or a heat of fusion of from about 0 to about 15 J / g and a second ethylene-based copolymer having an ethylene content of from about 68 to about 75 wt % and / or a heat of fusion of from about 40 to about 65 J / g. The invention is also directed to lubricant compositions comprising a lubricating basestock and a polymer blend of the invention.

Owner:EXXONMOBIL CHEM PAT INC

Aging-resistant polyvinyl chloride plastic

Owner:湖南凯誉电气科技有限公司

Nickel alloy automobile starting motor planetary gear and manufacturing method thereof

InactiveCN106270527AHigh precisionAvoid defects such as high noise and wear resistanceMetal-working apparatusPortable liftingHigh energyGear wheel

Owner:HAIAN YINGQIU POWDER METALLURGY CO LTD

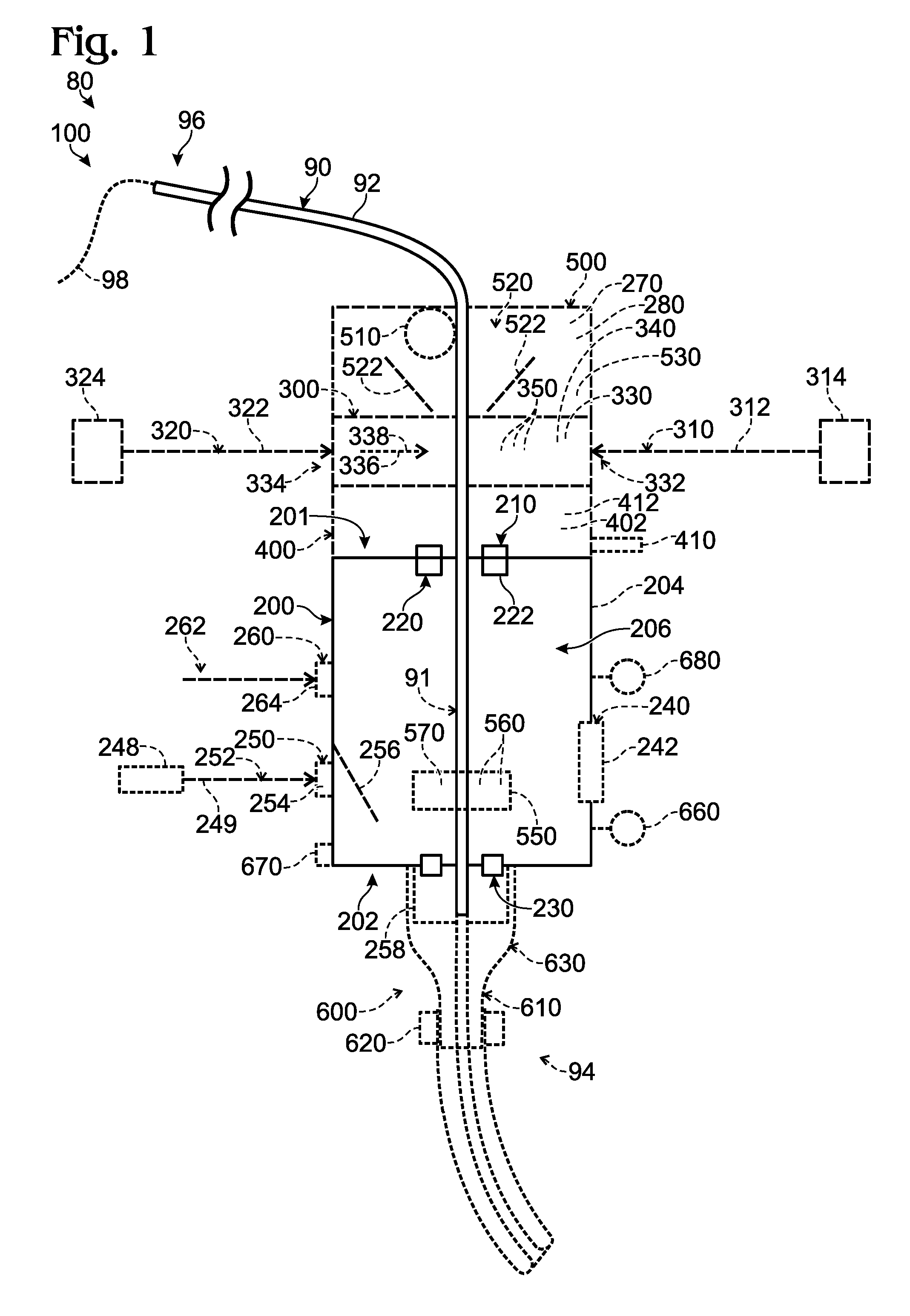

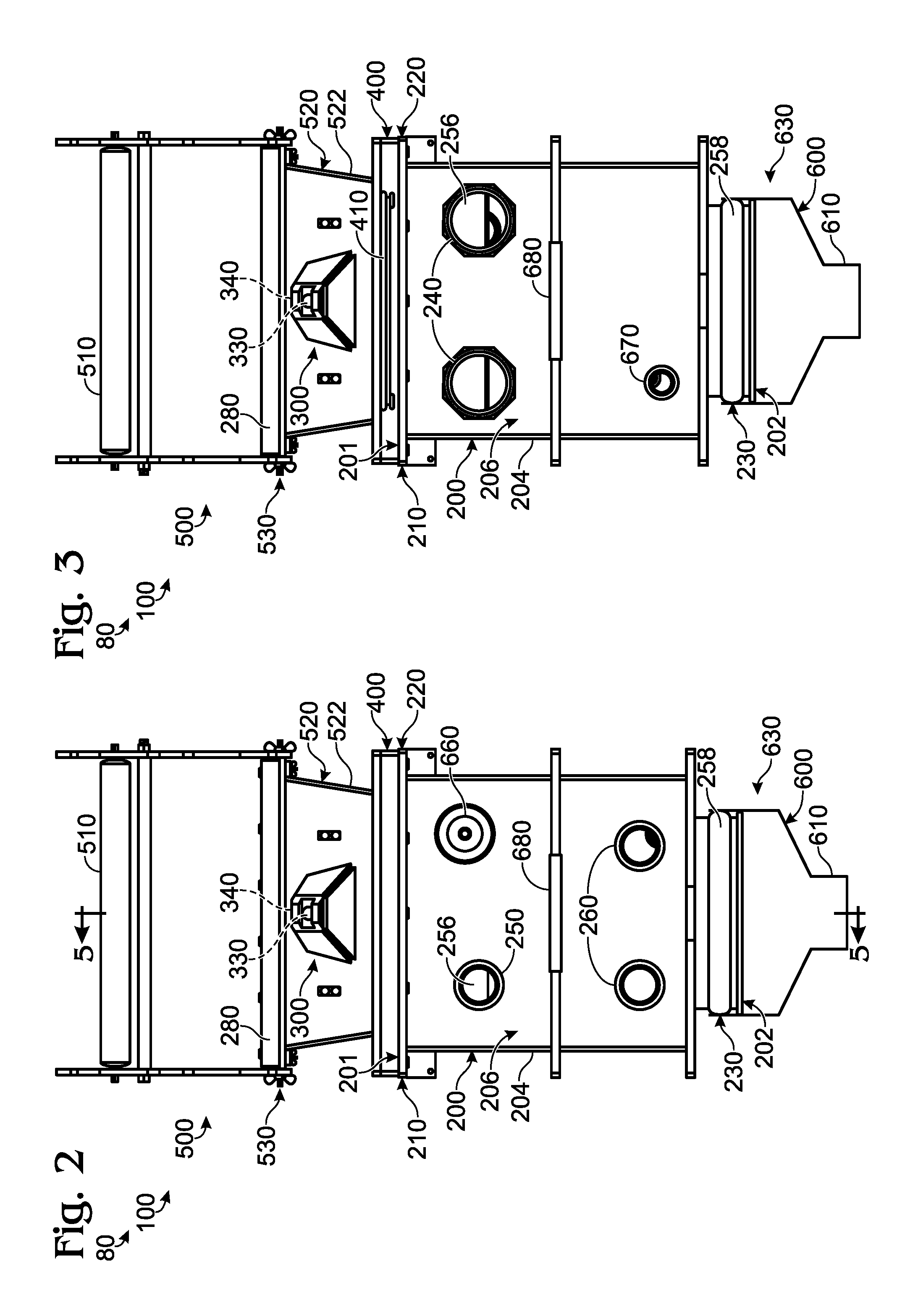

Tubing everting apparatus, assemblies, and methods

Owner:EMAGINEERED SOLUTIONS INC

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap