Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47 results about "Carbon fibers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon fibers or carbon fibres (alternatively CF, graphite fiber or graphite fibre) are fibers about 5–10 micrometres in diameter and composed mostly of carbon atoms. Carbon fibers have several advantages including high stiffness, high tensile strength, low weight, high chemical resistance, high temperature tolerance and low thermal expansion. These properties have made carbon fiber very popular in aerospace, civil engineering, military, and motorsports, along with other competition sports. However, they are relatively expensive when compared with similar fibers, such as glass fibers or plastic fibers.

Process for preparing precursor fiber of cellulose base carbon fiber

InactiveCN1587457AImprove thermal stabilityImprove carbonization yieldMonocomponent cellulose artificial filamentFiberCarbon fibers

The present invention relates to preparation process of precursor fiber of cellulose base carbon fiber in chemical fiber production. The preparation process includes mixing concentrated NMMO aqua and carbon black for carbon black water in the weight ratio of 20-10000, decomprssion distillation to obtain NMMO / carbon black solution with water content 24-28 wt%, adding the mixtue of sliced cellulose pulp and NMMO / carbon black solution in the weight ratio of 5-15 to 100 into dissolving reactor, swelling and stirring at 70-90 deg.c, raising the temperature to 90-120 deg.c, stirring and decomprssion distillation to eliminate water and form cellulose / NMMO / carbon black spinning liquid with water content of 12-14 wt%, and dry-wet spinning to obtain the precursor fiber. The present invention has high carbonizing yield, high mechanical performance of the carbon fiber, raised spinnability of the spinning liquid, non-toxic solvent, high solvent recovering rate and environment friendship.

Owner:DONGHUA UNIV

Preparation method and application of water-soluble carbon fiber sizing agent

InactiveCN104975508AImprove protectionImprove smoothnessFibre treatmentFibre chemical featuresFiberCarbon fibers

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

Long-fiber enhanced thermoplastic composite material vane used for wind energy generator

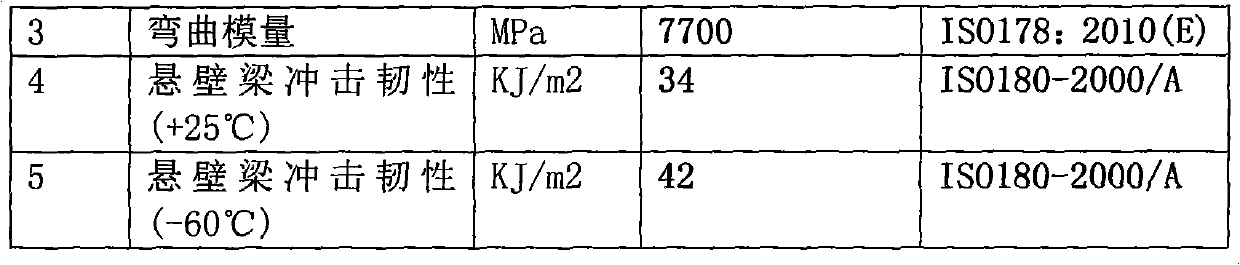

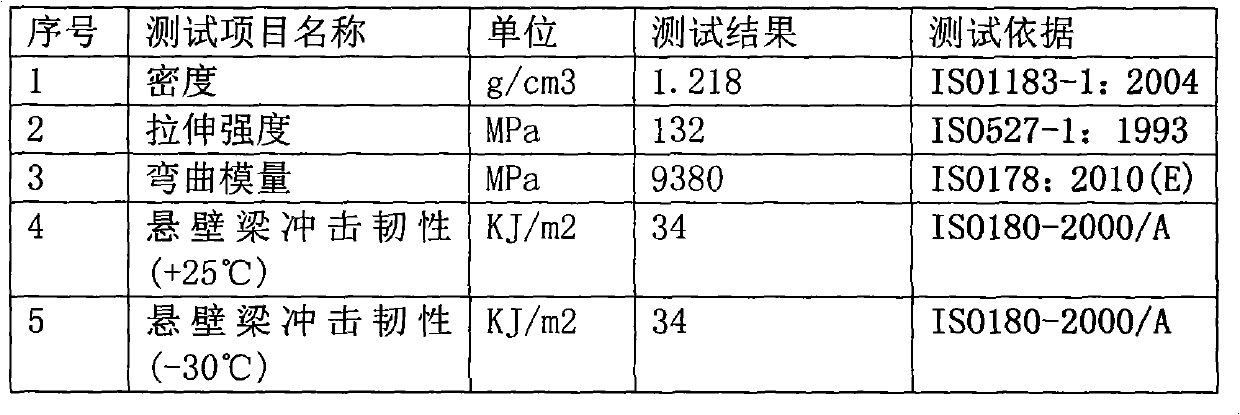

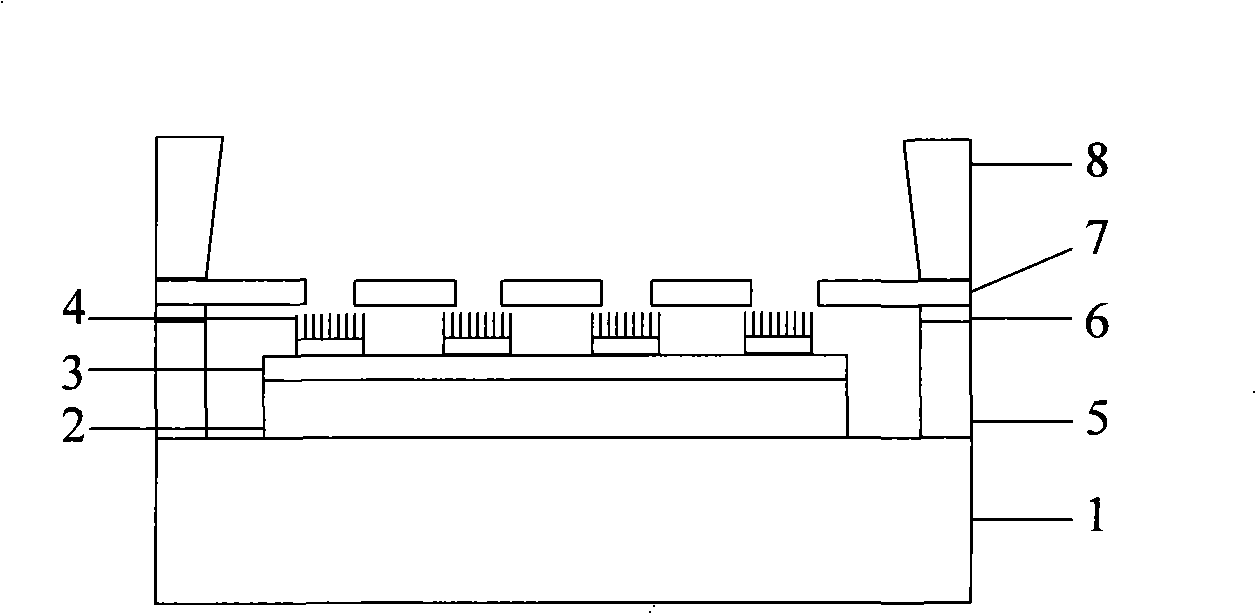

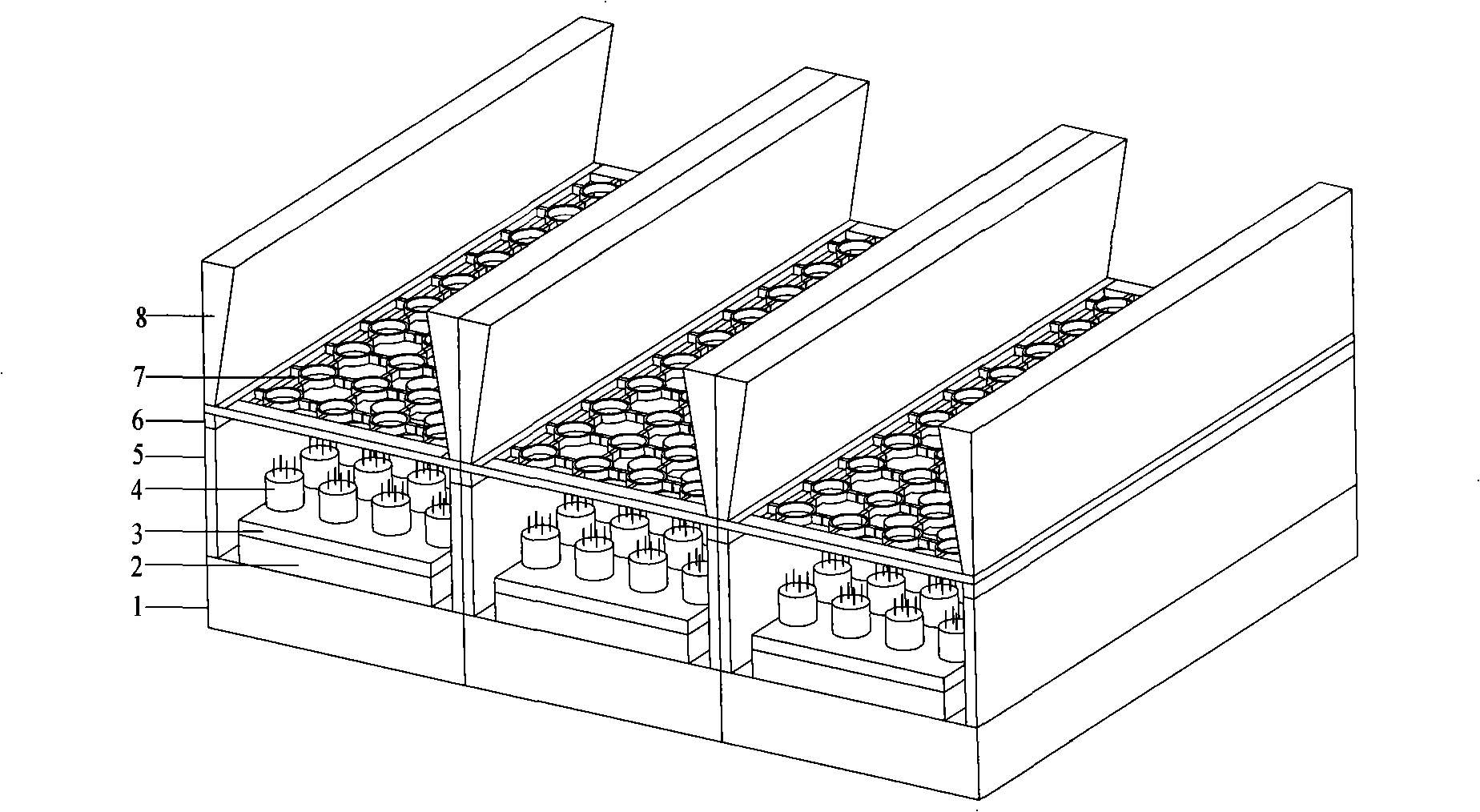

InactiveCN102675740ALow shrinkageLow temperature impact resistanceFinal product manufactureMachines/enginesGlass fiberPhoto aging

Owner:BEIJING NASHENGTONG ADVANCED MATERIAL & TECH CO LTD

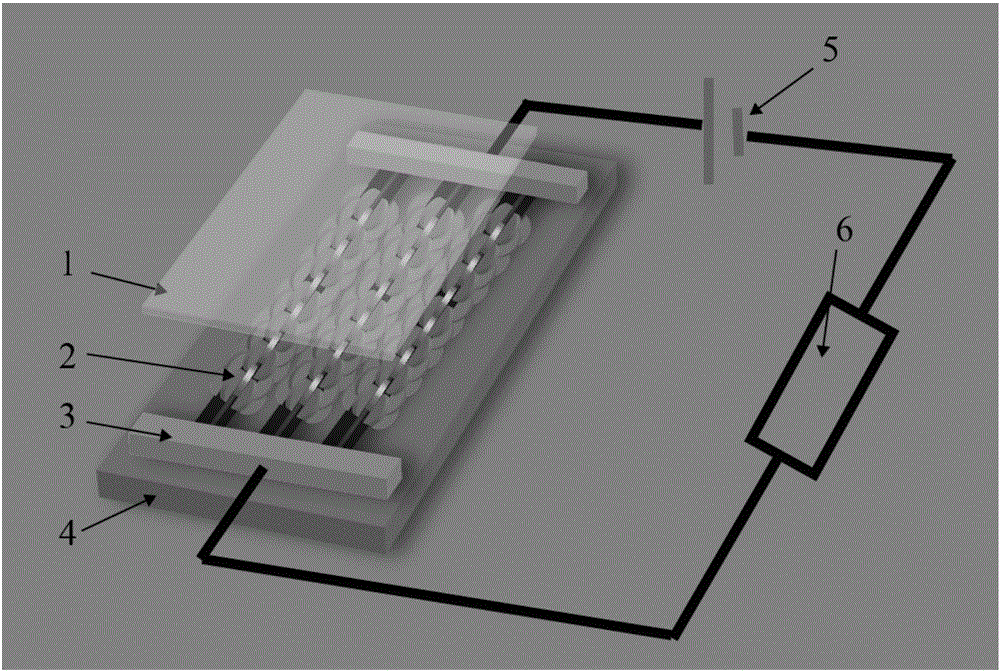

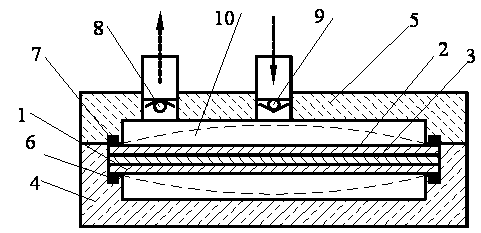

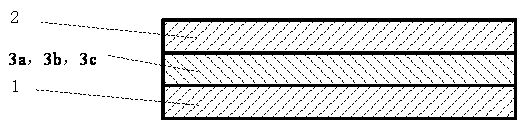

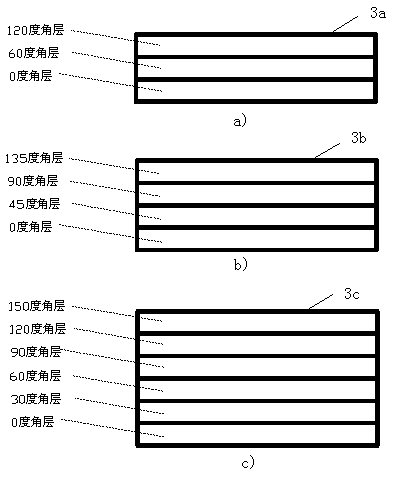

Metal and carbon nanotube or carbon fiber film emission array cathode as well as preparation method thereof

InactiveCN101355001AEasy to implementSimple processCathode ray tubes/electron beam tubesDischarge tube/lamp detailsFiberCarbon fibers

Owner:SHANGHAI JIAO TONG UNIV

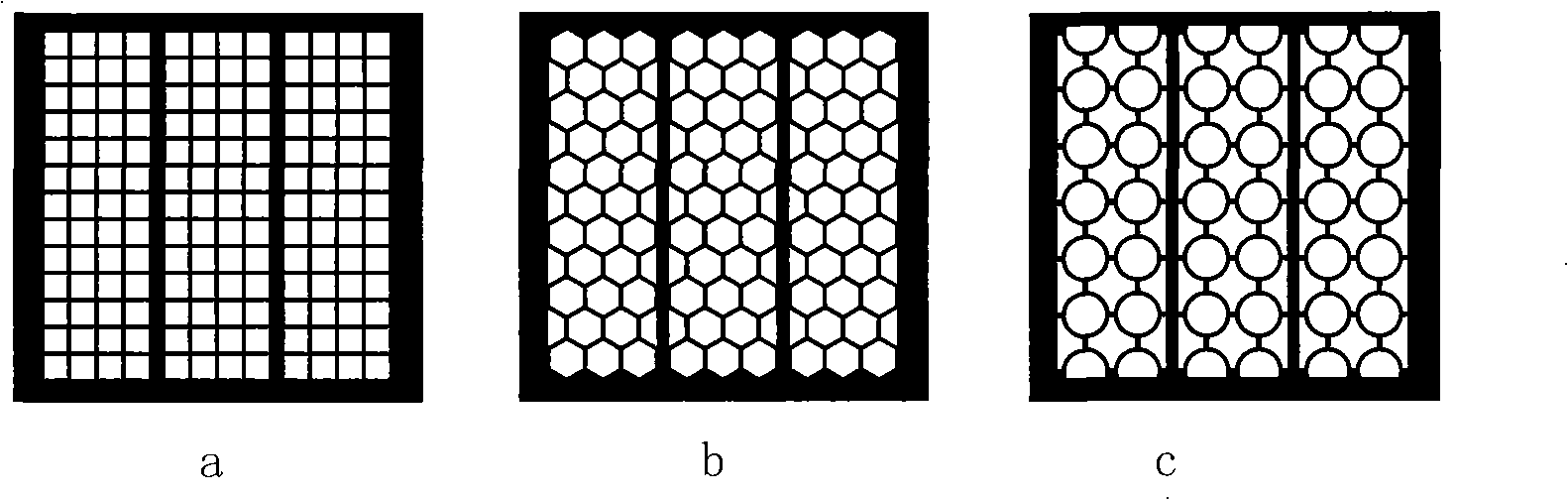

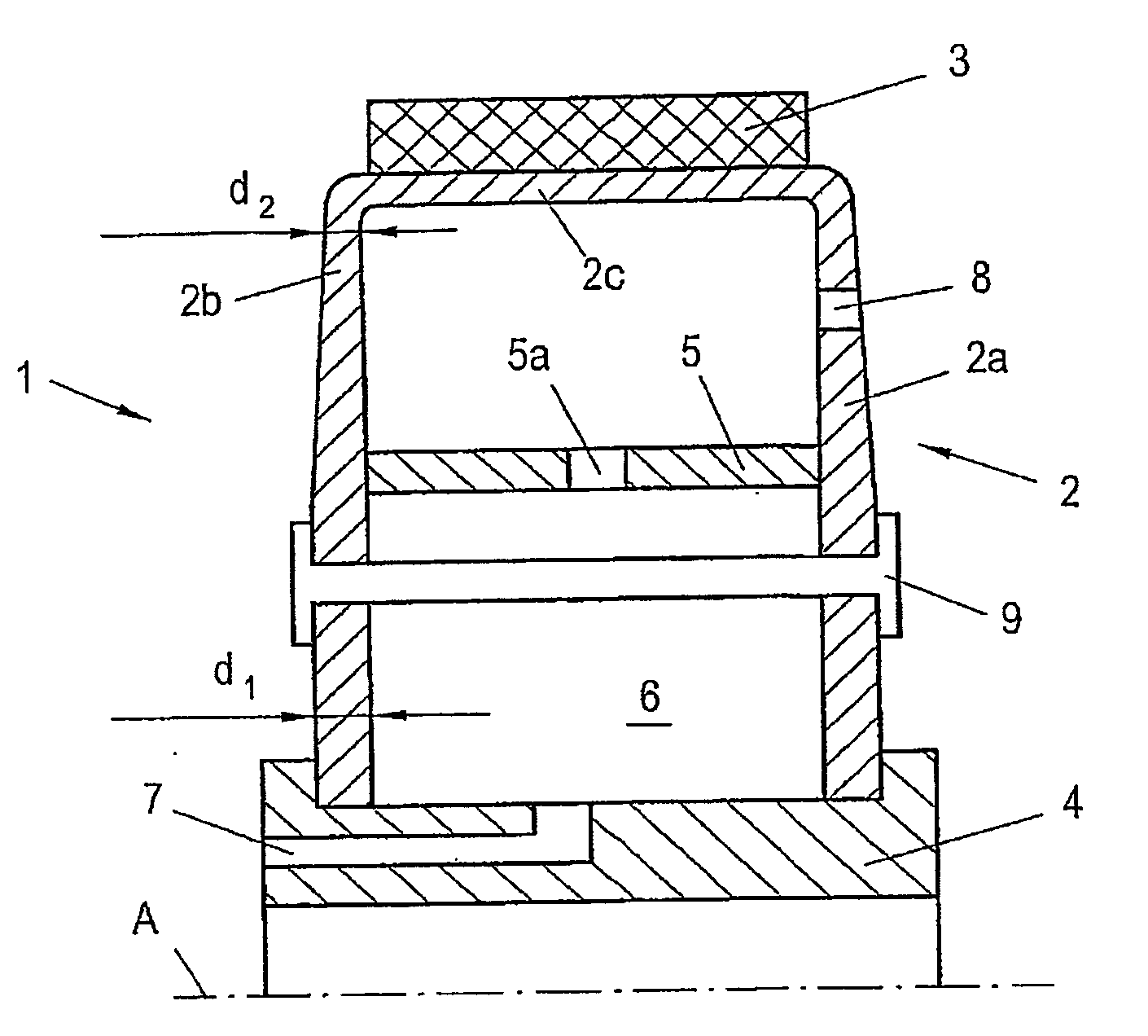

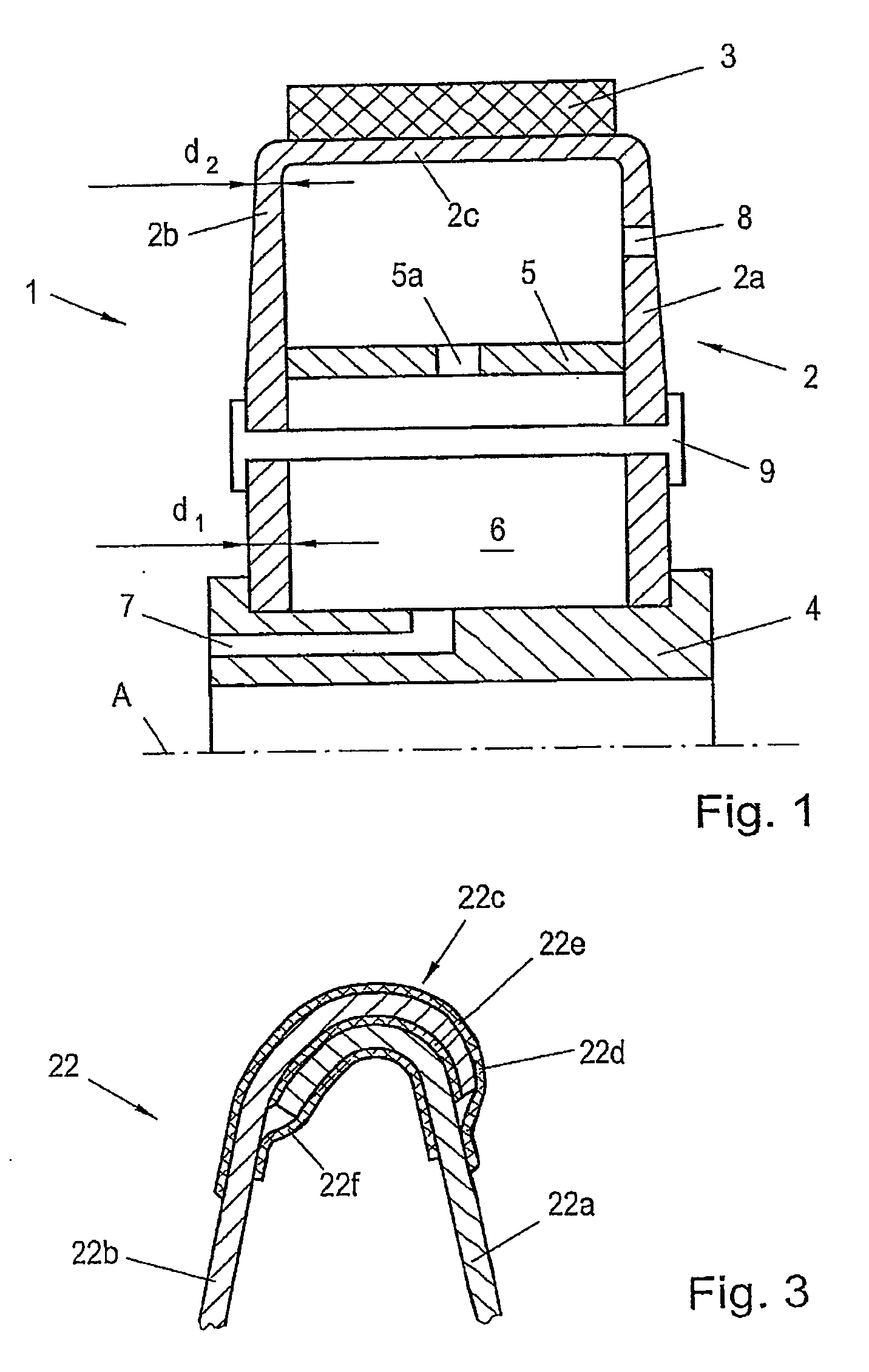

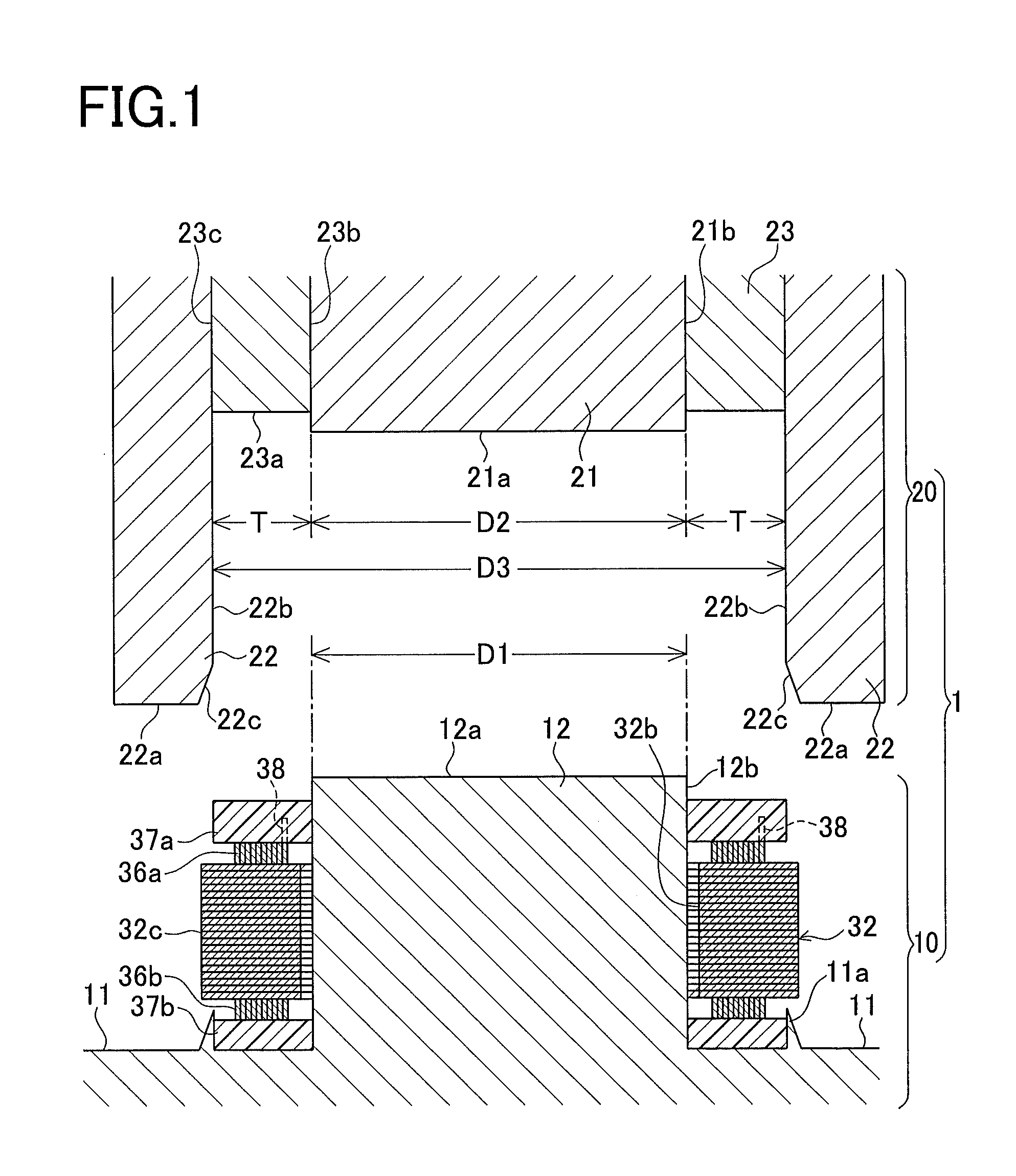

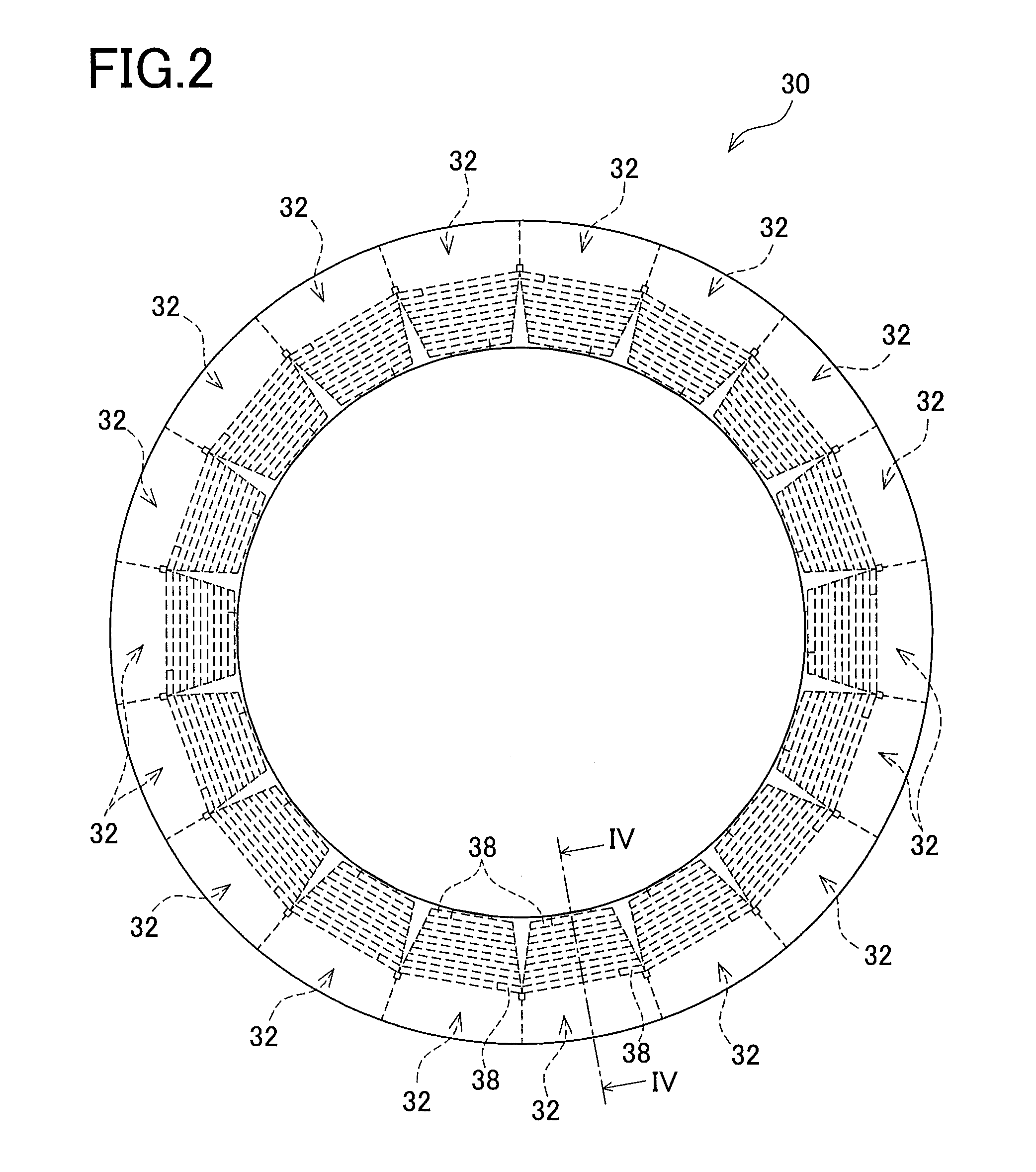

Base for a Rotating Grinding or Cutting Tool, and Grinding or Cutting Tool Produced Therefrom

ActiveUS20100022169A1Revolution surface grinding machinesOther chemical processesGlass fiberCarbon fibers

Owner:ASEN NORBERT

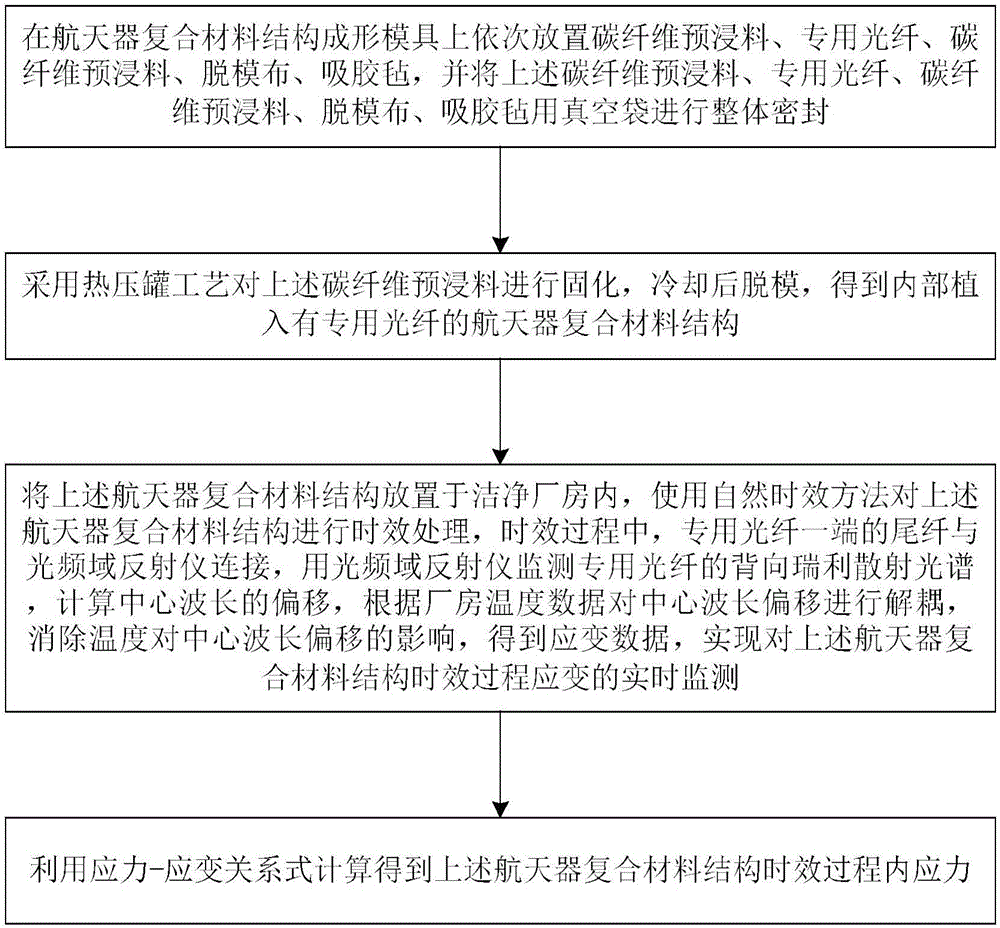

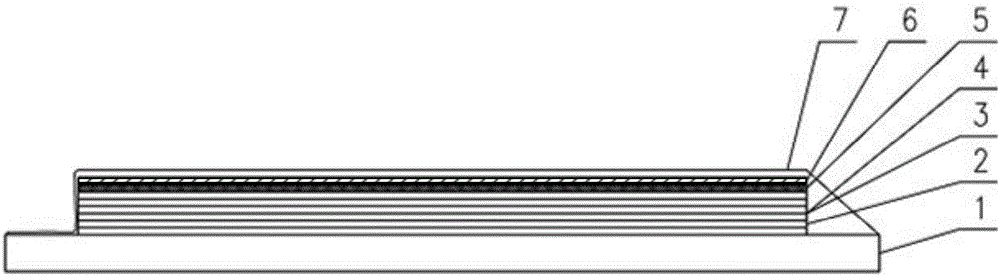

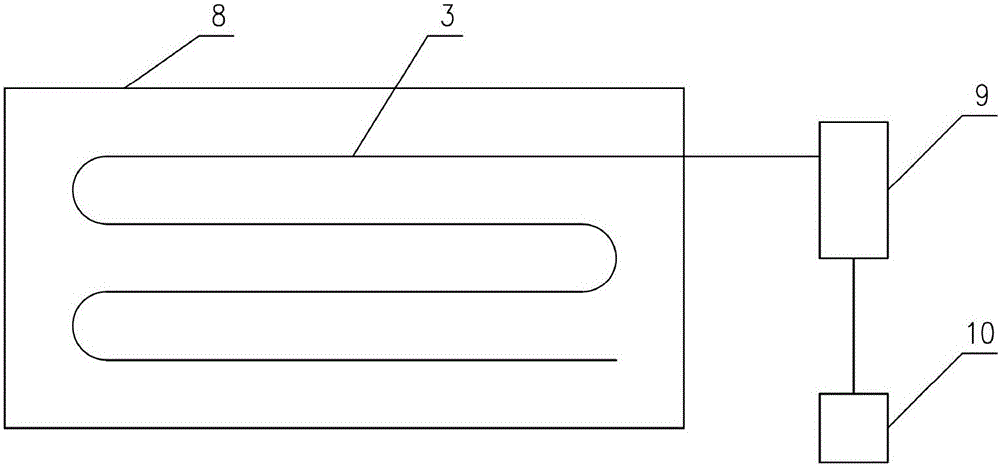

Monitoring method of internal stress of spacecraft composite material structure in aging process

InactiveCN106595919AHigh spatial resolutionHigh measurement accuracyForce measurement by measuring optical property variationRayleigh scatteringFiber

Owner:SHANGHAI INST OF SATELLITE EQUIP

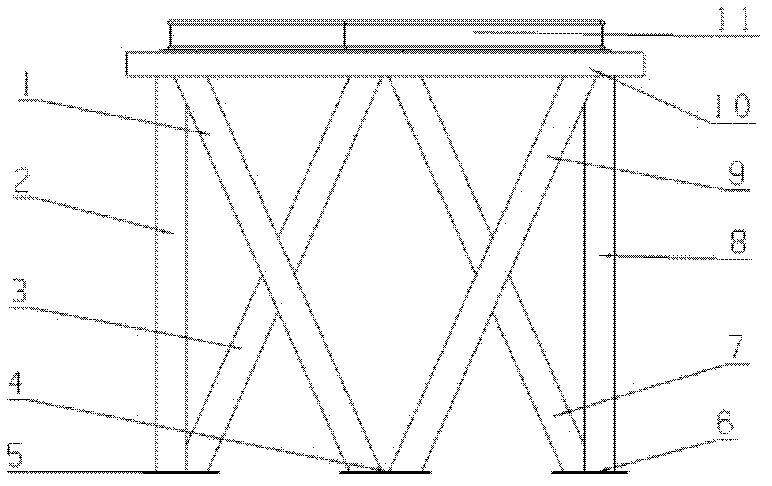

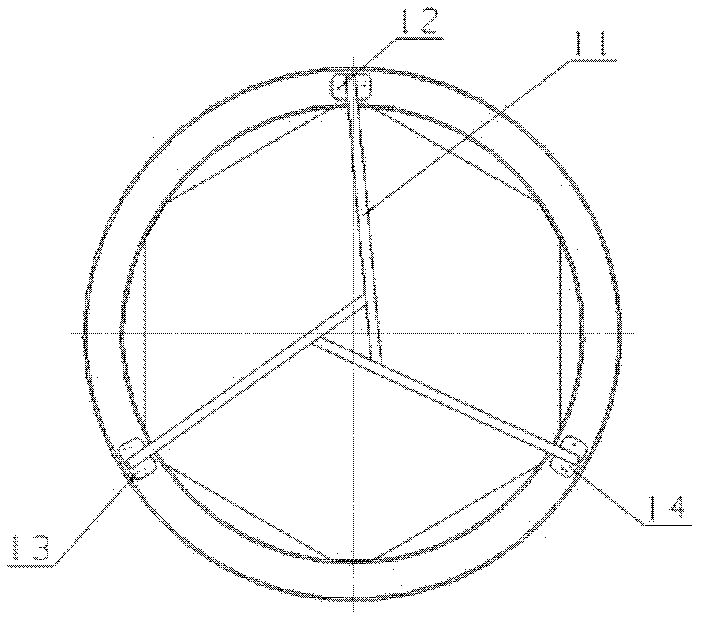

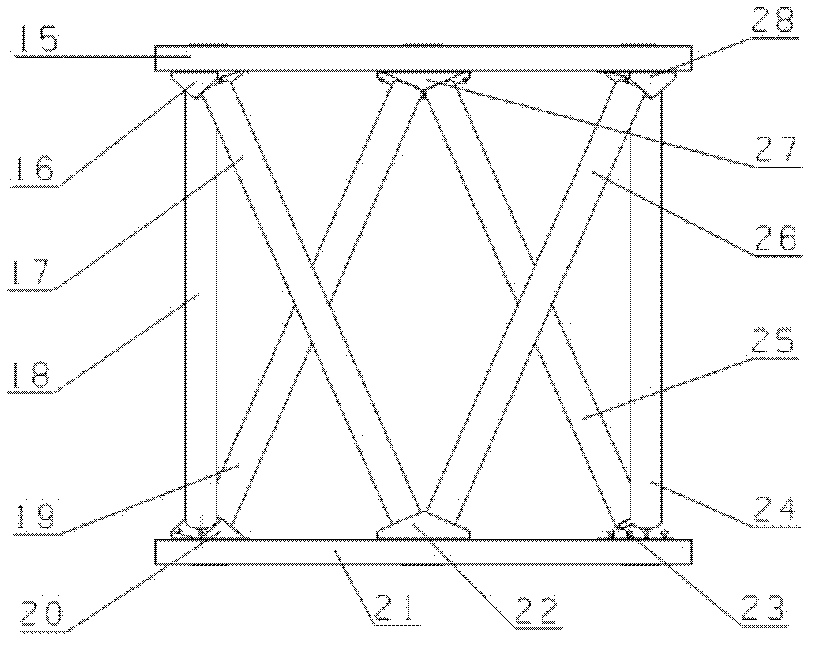

Ring-shaped carbon fiber truss support structure of coaxial three-reflector spatial optical system

Owner:CHANGGUANG SATELLITE TECH CO LTD

Wind resistant concrete roof component and system and method for forming same

A roof system includes a roof panel formed of concrete and an architectural surface such as a corrugated surface. A first layer of reinforcing material is disposed along and spaced inwardly from a first surface of the roof panel, and an optional second layer of reinforcing material is disposed along and spaced inwardly from a second surface of the roof panel. The first layer of reinforcing material is spaced from the second layer of reinforcing material. The reinforcing material may be formed of fiber-reinforced polymer mesh, made with carbon fibers or glass fibers. FRP rebar may be used in conjunction with FRP mesh to provide added structural strength. The roof panel may include one or more elongated ribs having a thickness greater than adjacent portions of the roof panel. In other aspects, concrete structures with reinforcing material may be used for either roof panels or wall applications.

Owner:FLORIDA INTERNATIONAL UNIVERSITY

Preparation method of polyacrylonitrile-based hollow carbon fibers

InactiveCN109576824AMake up for the vacancyEfficient use ofWet spinning methodsConjugated synthetic polymer artificial filamentsCarbon fibersCarbonization

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

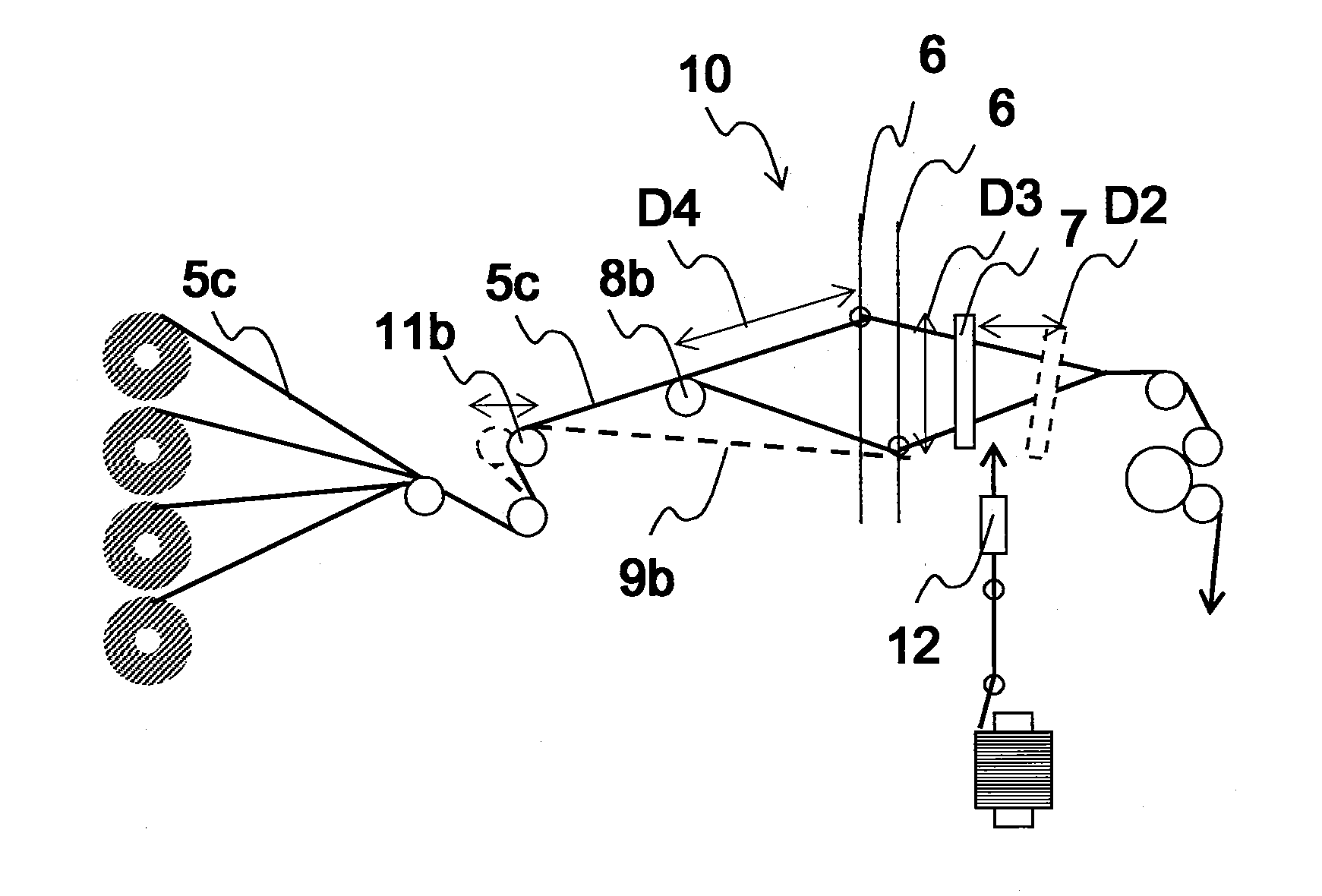

Method for producing carbon fiber woven fabric

ActiveUS20100032049A1Quality improvementImprove productivityLoomsWoven fabricsProduction rateCarbon fibers

Owner:TORAY IND INC

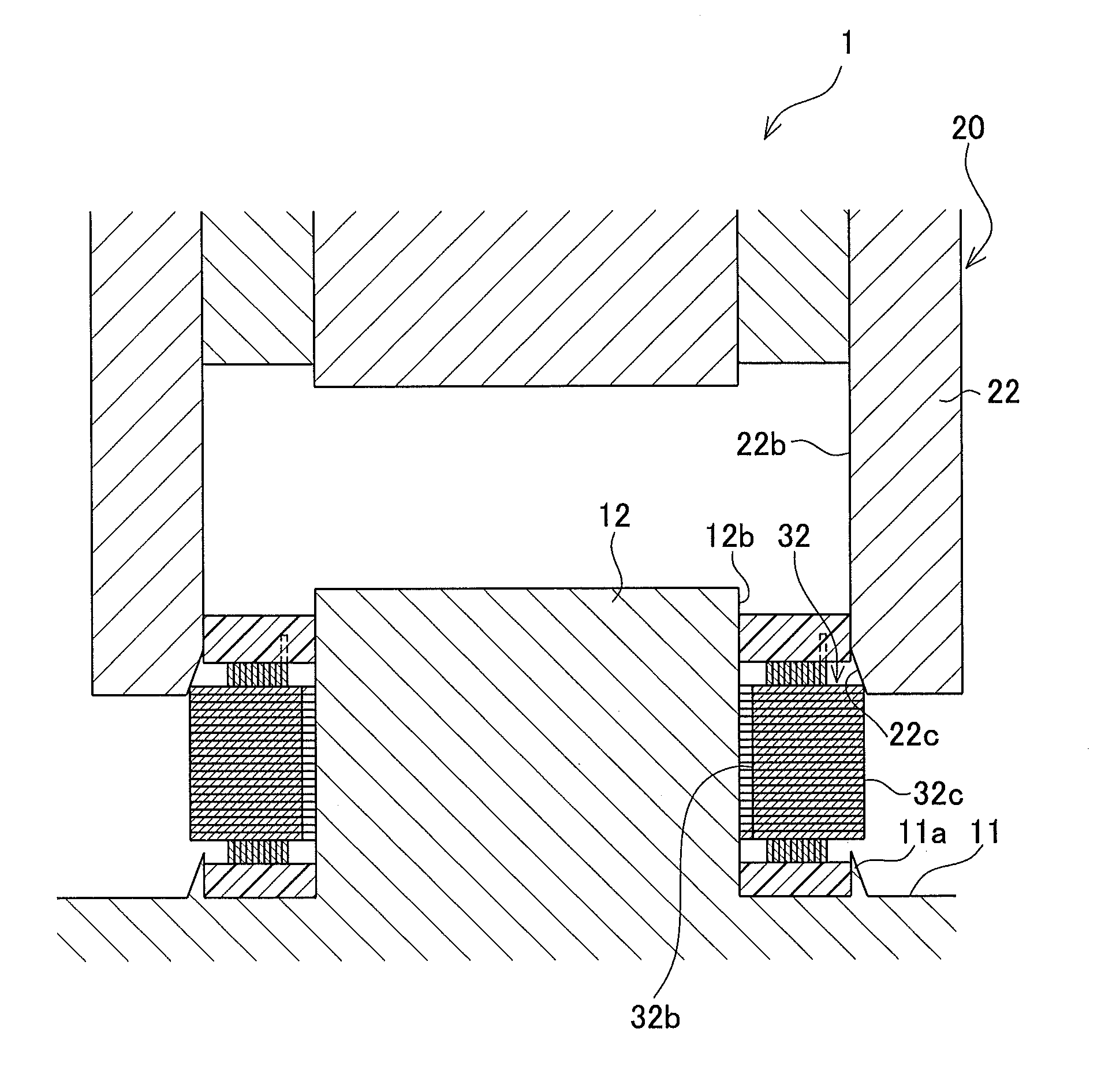

Stator manufacturing method and stator

Owner:TOYOTA JIDOSHA KK

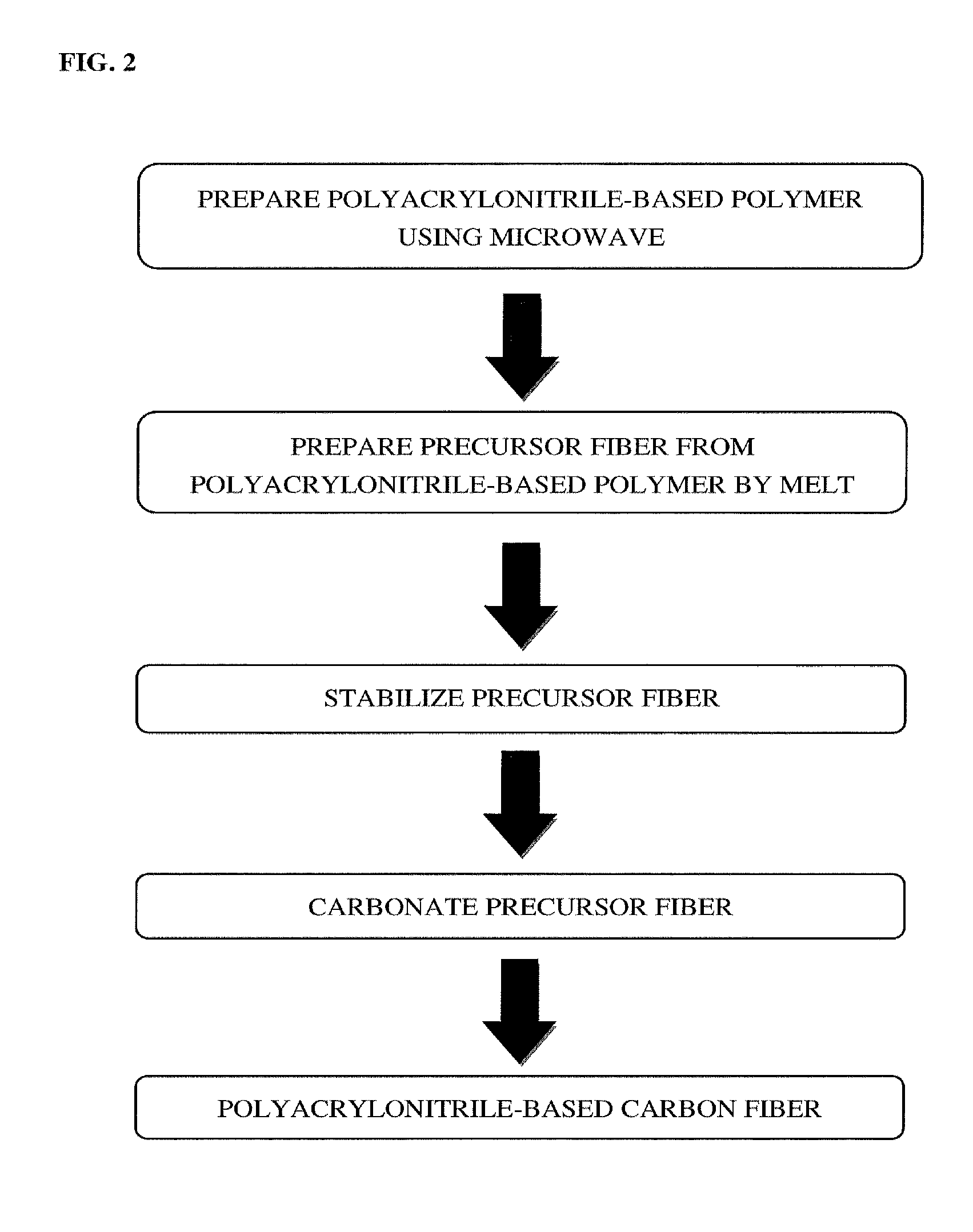

Method for preparing polyacrylonitrile-based polymer for preparation of carbon fiber using microwave and method for preparing carbon fiber using the same

ActiveUS20120288434A1Short polymerization timeLot of preparationFibre chemical featuresEnergy based chemical/physical/physico-chemical processesPolymer scienceCarbon fibers

Owner:TFJ GLOBAL INC

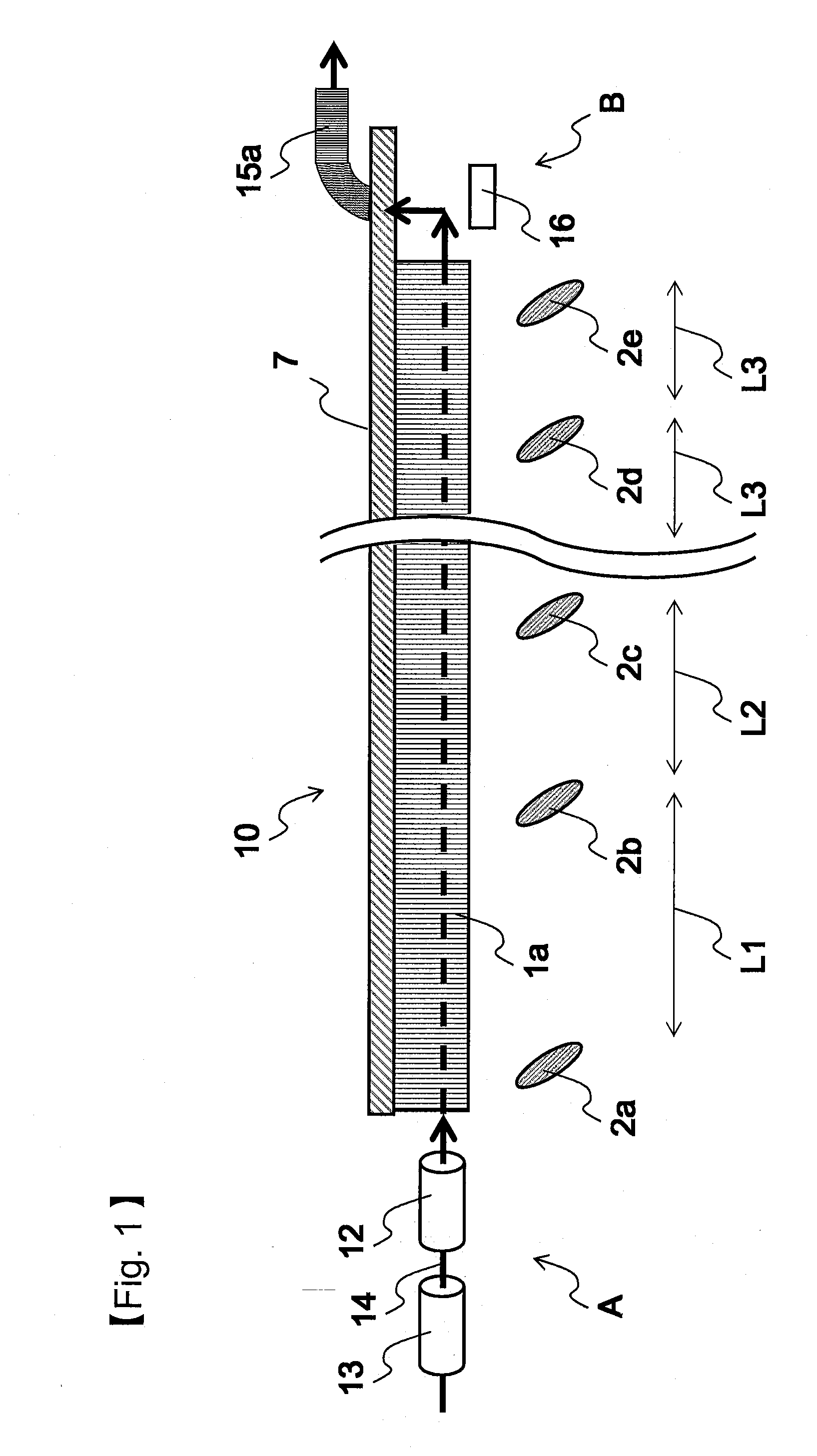

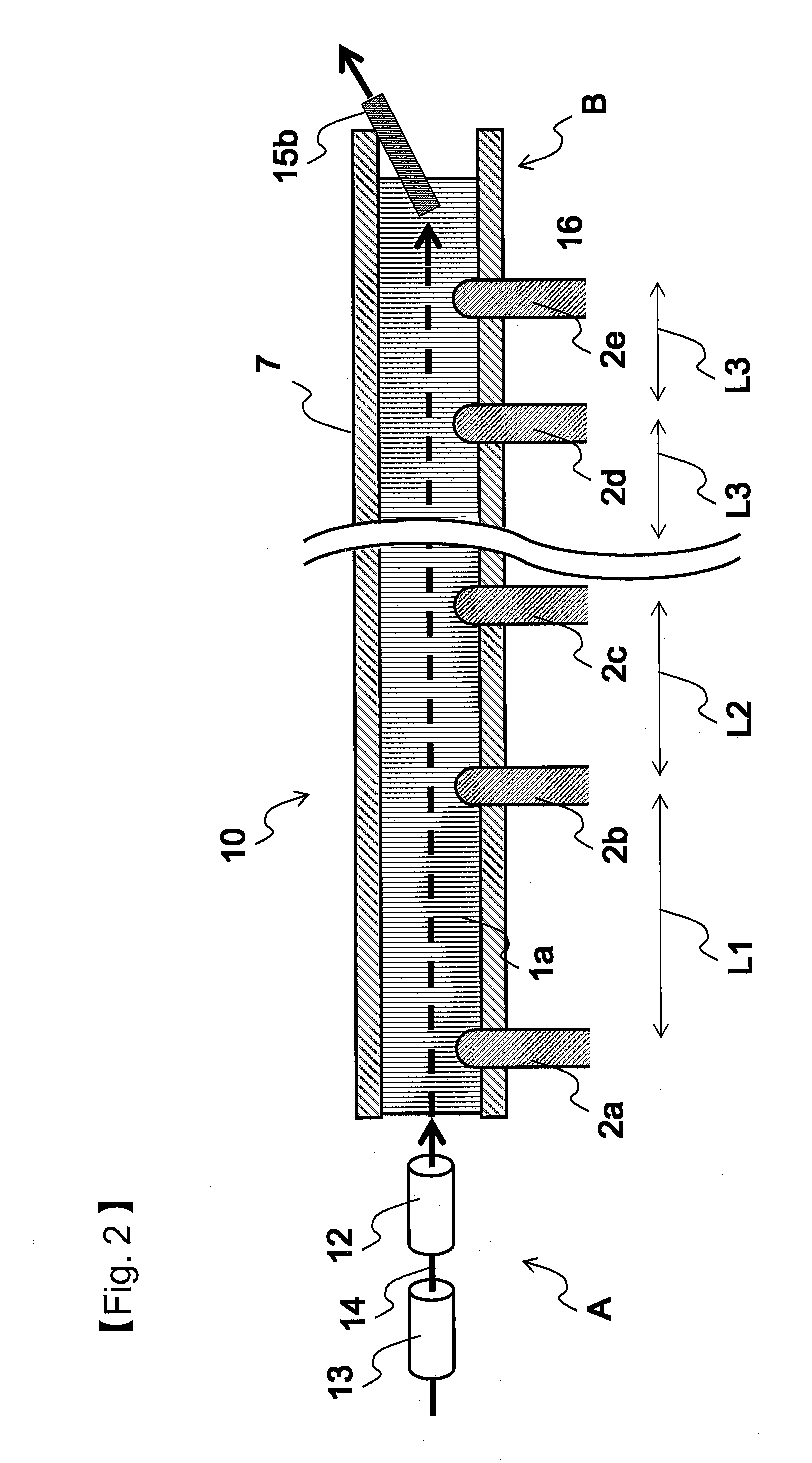

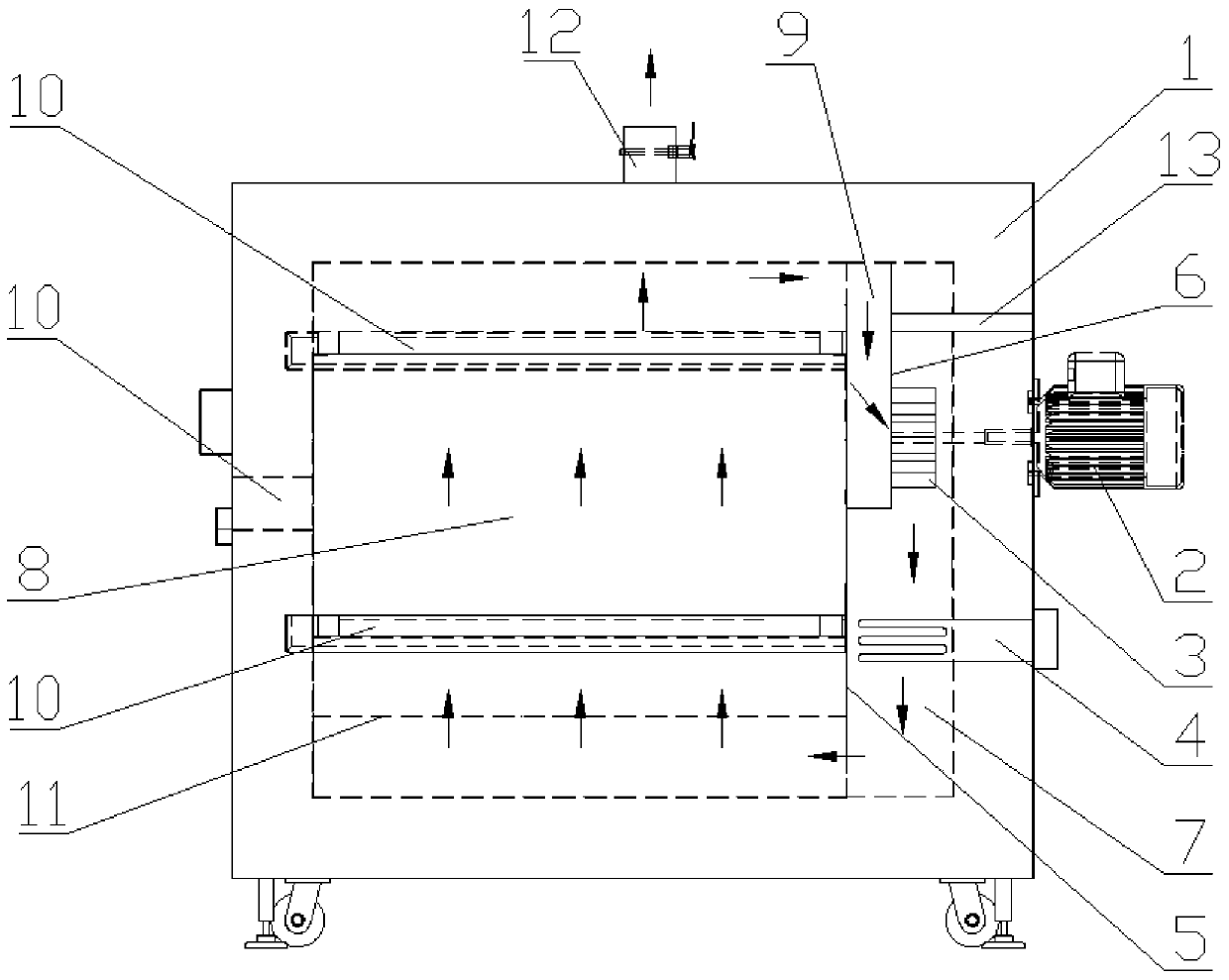

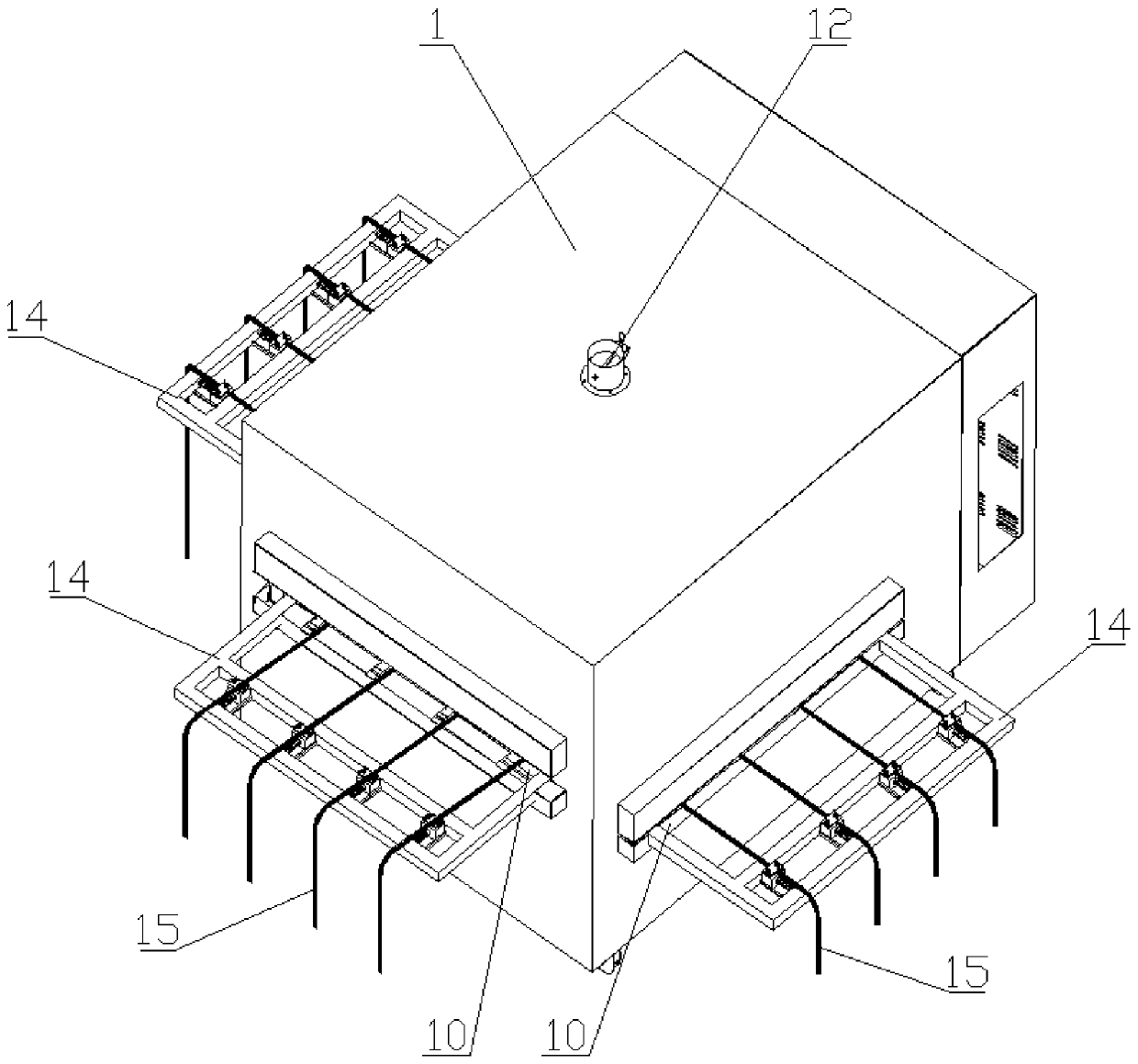

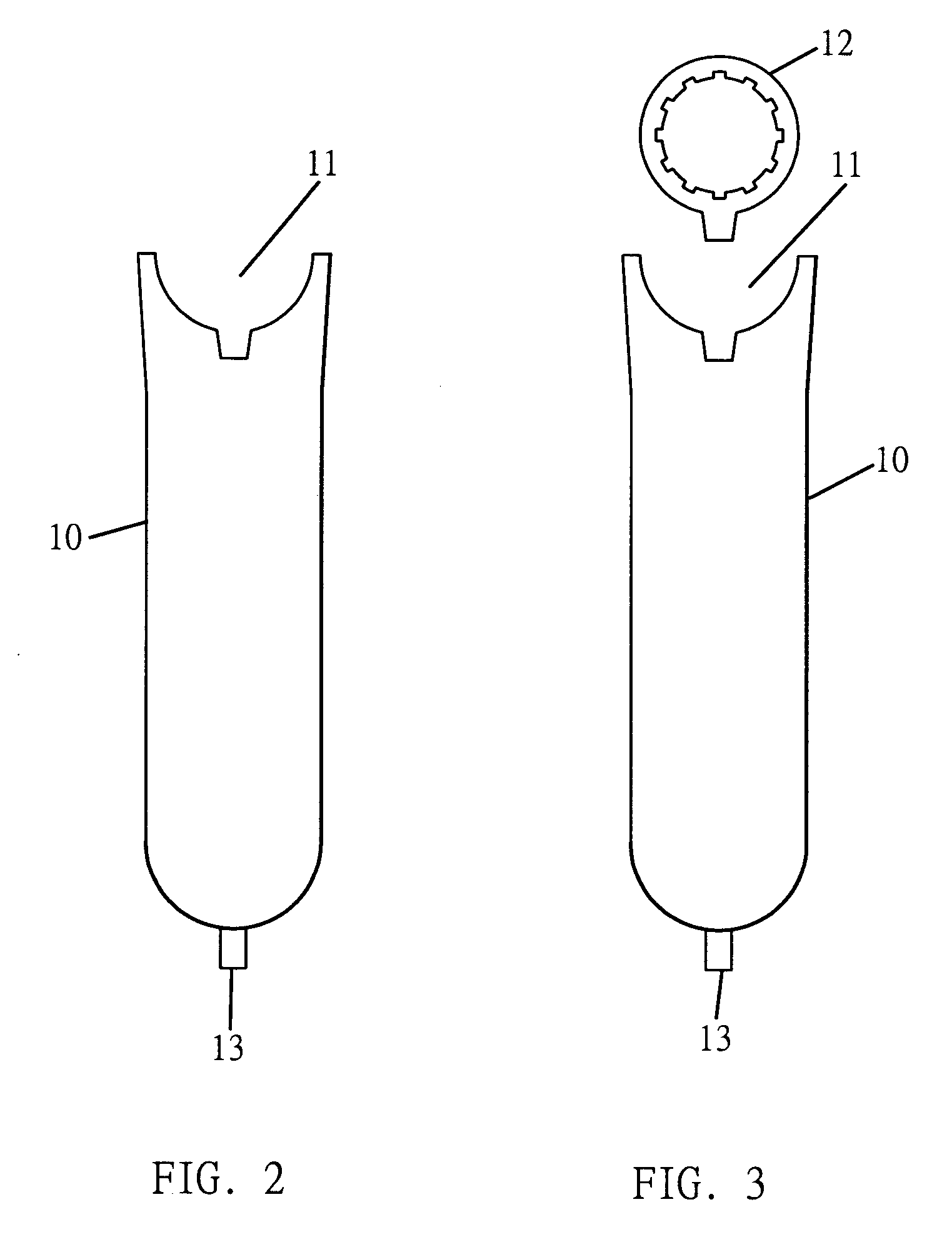

Pre-oxidation equipment of PAN (polyacrylonitrile)precursor end and end connection method

Owner:ATA CARBON FIBER TECH GUANGZHOU

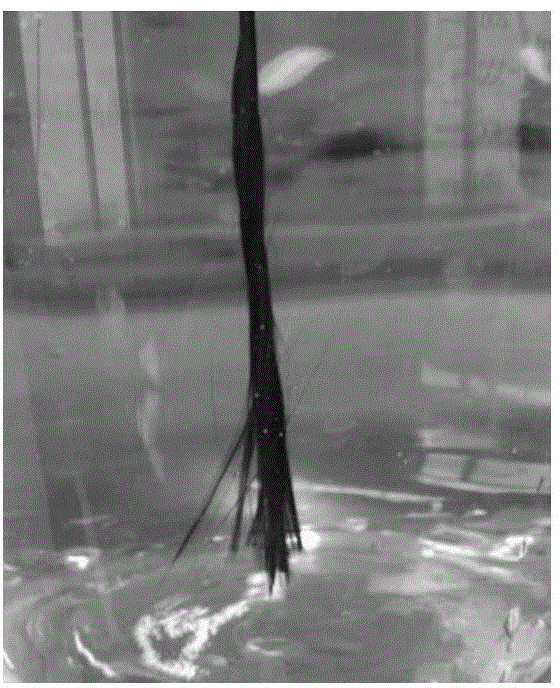

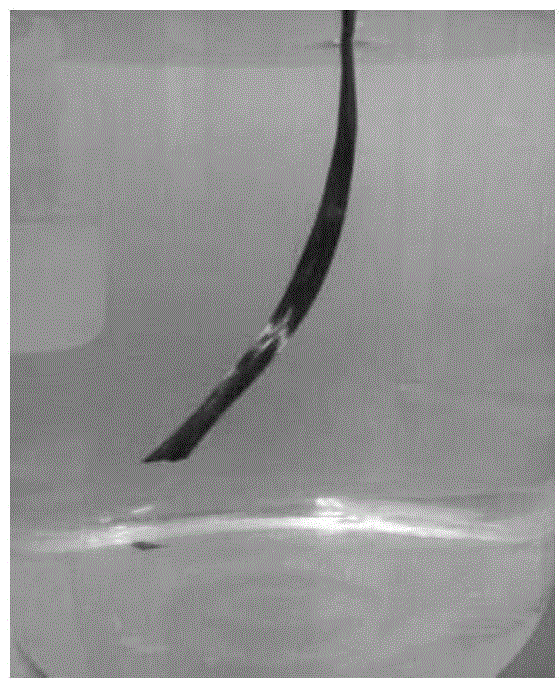

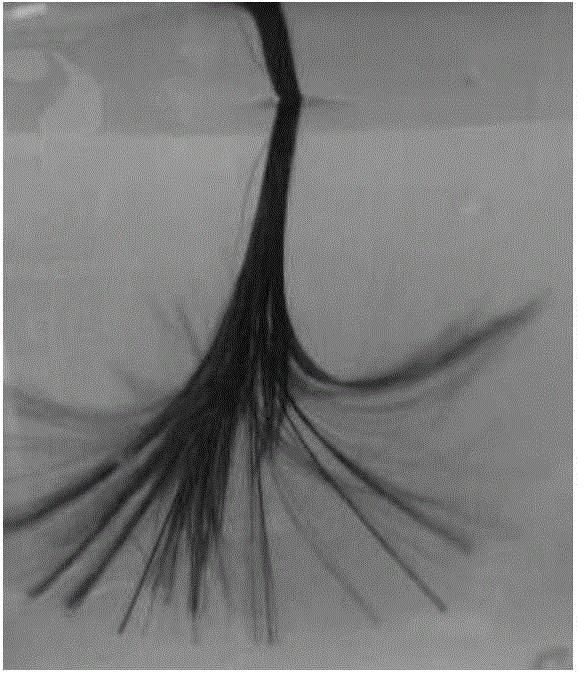

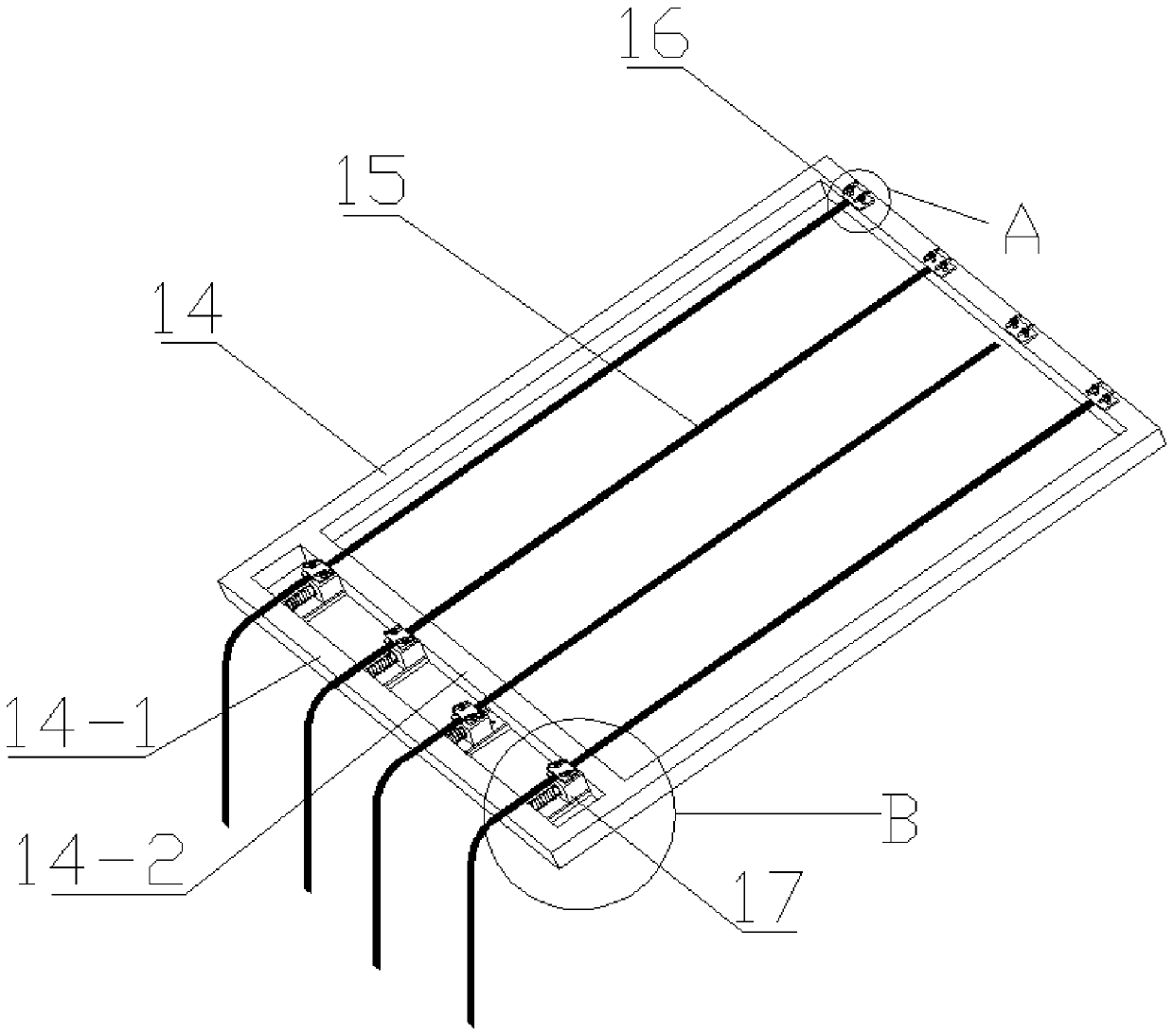

Connection method for carbon fiber yarns and metal sheet for heating

The invention relates to a connection method for carbon fiber yarns and a metal sheet for heating, which is characterized in that the method comprises the following steps of: 1) stranding: stranding 3-10 beams of adjacent carbon fiber yarns at the end of carbon fiber cloth into one strand; 2) coating adhesive: evenly coating conductive adhesive doped with curing agent at a position at which the stranded carbon fiber yarns are in contact with the metal sheet; 3) wrapping felts: wrapping 1-2 layers of thin carbon fiber felts on the surface of the carbon fiber yarns coated with the conductive adhesive to enable the conductive adhesive to infiltrate the thin carbon fiber felts; 4) sheathing: sheathing a metal sheet clamp on the carbon fiber yarns into which the conductive adhesive infiltrates, clockwise turning a clamping knob to tightly clamp the carbon fiber yarns until the conductive adhesive flows out of the two ends of the clamp; and 5) curing: fixing the clamp, placing at room temperature and controlling curing time to be 24-72h. Compared with the prior art, the connection method has the advantages of simplicity, effectiveness, economy, durability, even and firm connection position, stable and reliable performance and the like.

Owner:JIANGSU YUEKE NEW MATERIAL

Environment-friendly ceramic coating material for water faucet

InactiveCN106189561ACorrosion resistantWear-resistantAnti-corrosive paintsCarbon fibersPolybutylene terephthalate

Owner:朱燕华

Novel powder metallurgical gear

InactiveCN106041095AUniform densityLarge elongationTransportation and packagingMetal-working apparatusCarbon fibersALUMINUM STEARATES

Owner:黄宇

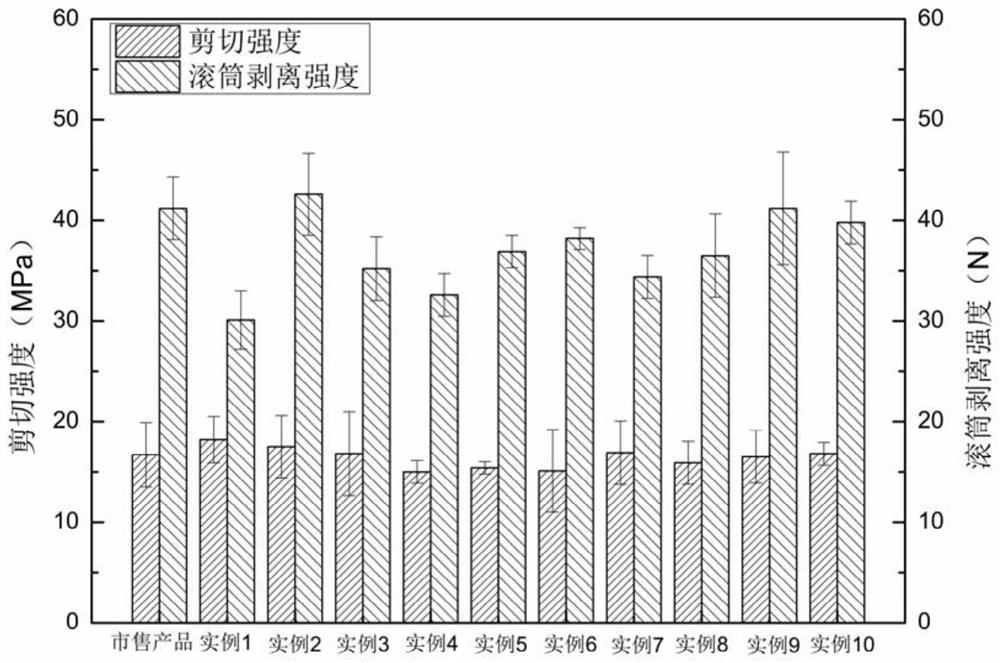

Ultralight bulletproof cloth and manufacture method thereof

Owner:广东军铠防护科技有限公司

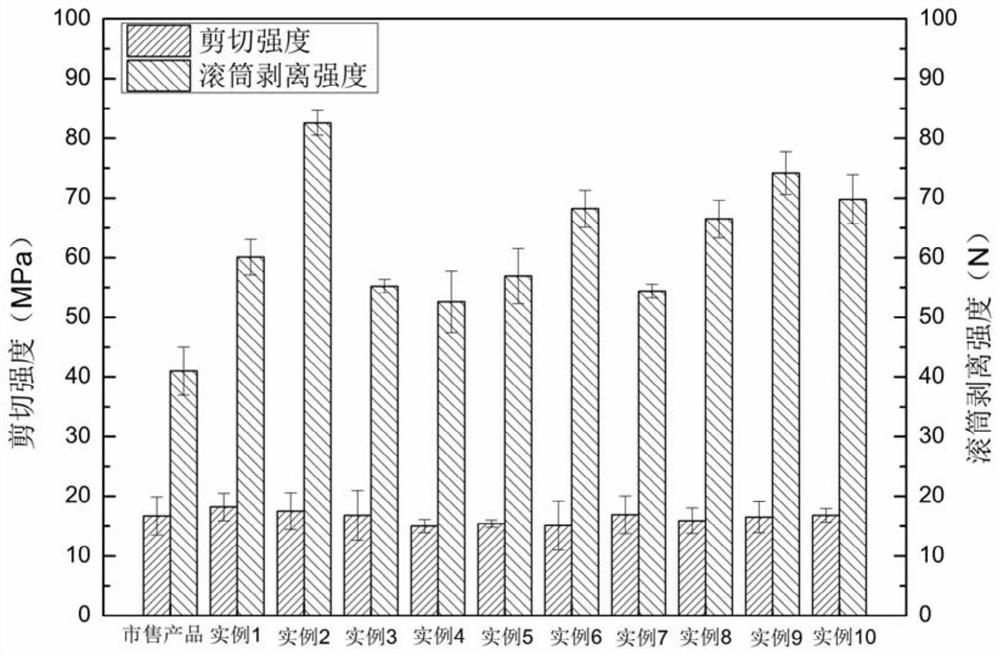

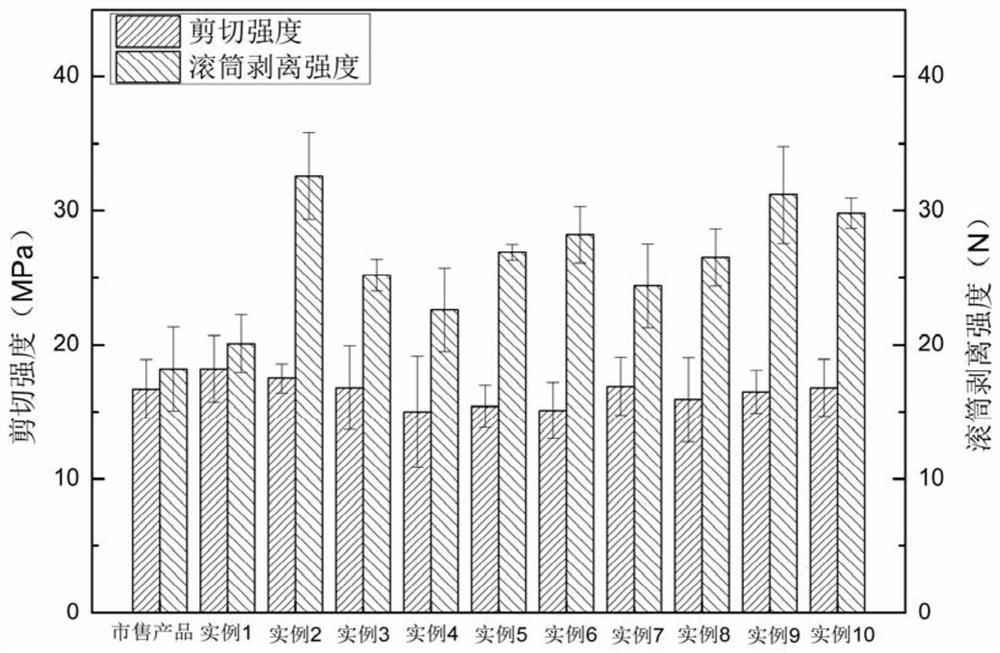

Lightweight high-toughness military shelter structural adhesive and preparation method thereof

InactiveCN111876118AHigh tensile strengthHigh impact strengthMacromolecular adhesive additivesEpoxy resin adhesivesFiberCarbon fibers

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

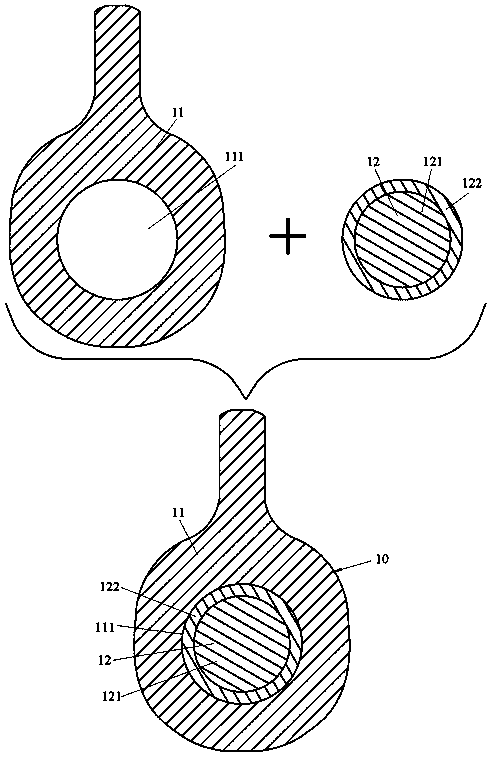

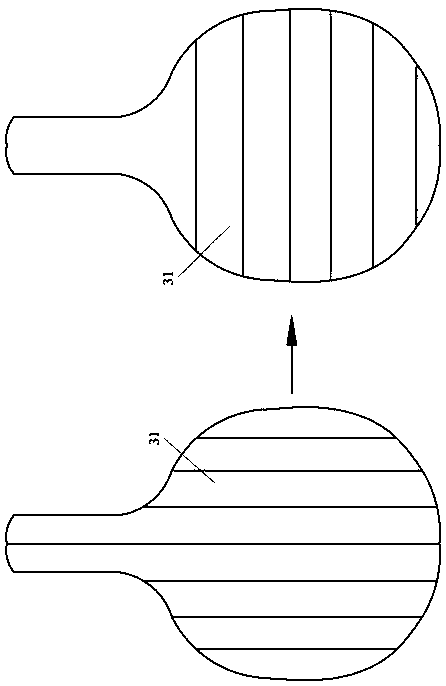

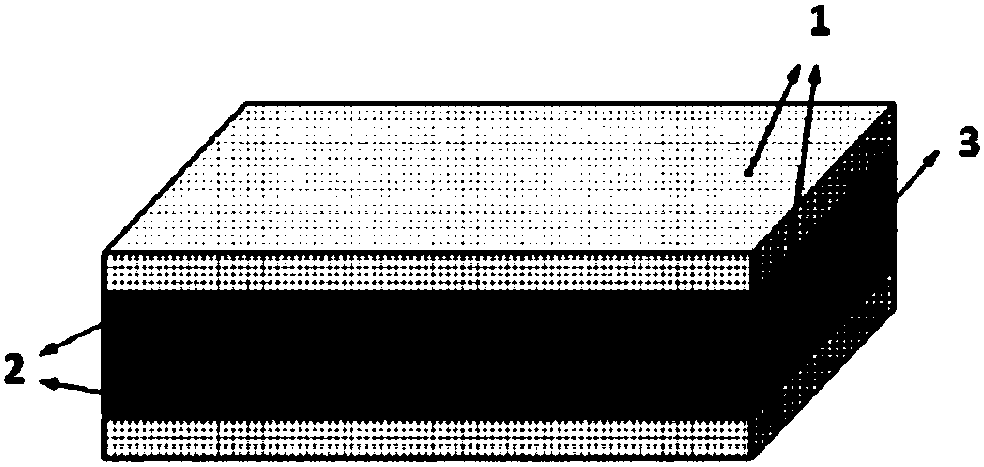

Ultra-light amorphous reinforced carbon fiber table tennis bat and preparation method thereof

ActiveCN111420375ASolve poor ball control performanceSolve the weakness of poor hand feelingSynthetic resin layered productsLaminationFiberCarbon fibers

Owner:广东嘉明体育用品有限公司

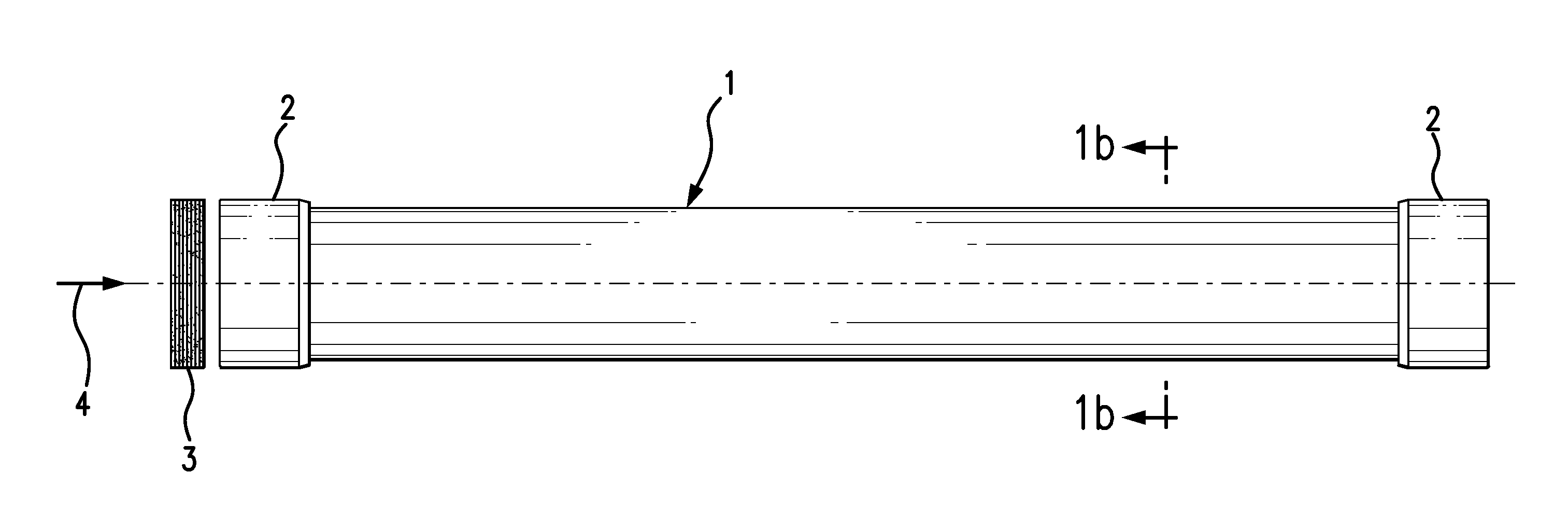

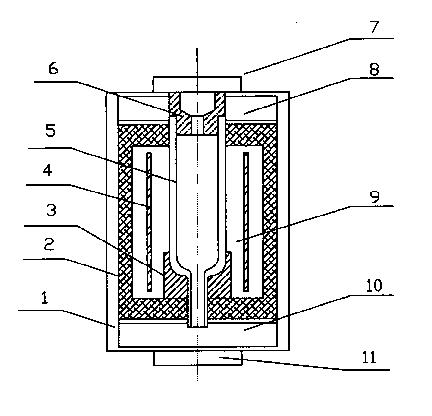

Optical fiber composite low-voltage power cable

PendingCN106876030AAvoid damageGuaranteed reliabilityInsulated cablesPower cables including optical transmission elementsCarbon fibersPower cable

The invention is applicable to the technical field of a cable, and discloses an optical fiber composite low-voltage power cable. The optical fiber composite low-voltage power cable comprises an outer insulating composite sleeve, conductors and an optical unit, wherein the outer insulating composite sleeve comprises an outer sheath insulating layer, a metal armor layer, an inner lining insulating layer and a warping tape layer; each conductor comprises a metal core wire and a core wire insulating sleeve; the optical unit comprises a composite protection sleeve and optical fibers positioned in the composite protection sleeve; the optical fibers comprise 12 fiber cores; a cladding layer is arranged on the exterior of each fiber core; a polyacrylonitrile carbon fiber bundle is also arranged in the protection sleeve; the polyacrylonitrile carbon fiber bundle is sleeved with a shaping sleeve; the composite protection sleeve comprises a silica gel pipe and a coating layer on the inner side of the silica gel pipe; the thickness of the silica gel pipe is greater than or equal to 25% of the diameter of each conductor; and the interior of the warping tape layer is filled with a non-hygroscopic filler. The optical fiber composite low-voltage power cable provided by the invention can prevent the optical unit from being damaged caused by pulling and bending, so as to ensure communication reliability and continuity, so that the product has excellent reliability.

Owner:SHENZHEN BENDAKANG CABLE

Flame retardation material based on fireproof coating and preparing method for the same

InactiveCN108515746AReduce weight lossImprove heat resistanceLamination ancillary operationsLaminationFiberGlass fiber

Owner:HARBIN ENG UNIV

Degradable capacitor plastic shell and preparation method thereof

Owner:TONGLING XINTAI ELECTRIC APP & CAPACITOR

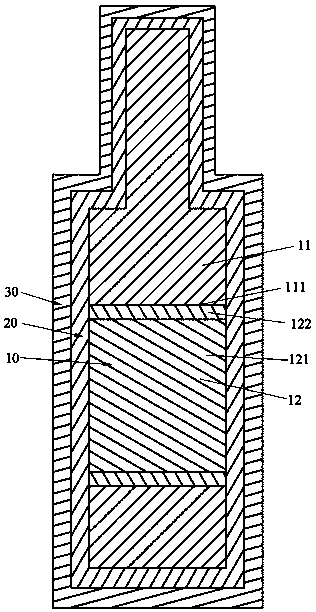

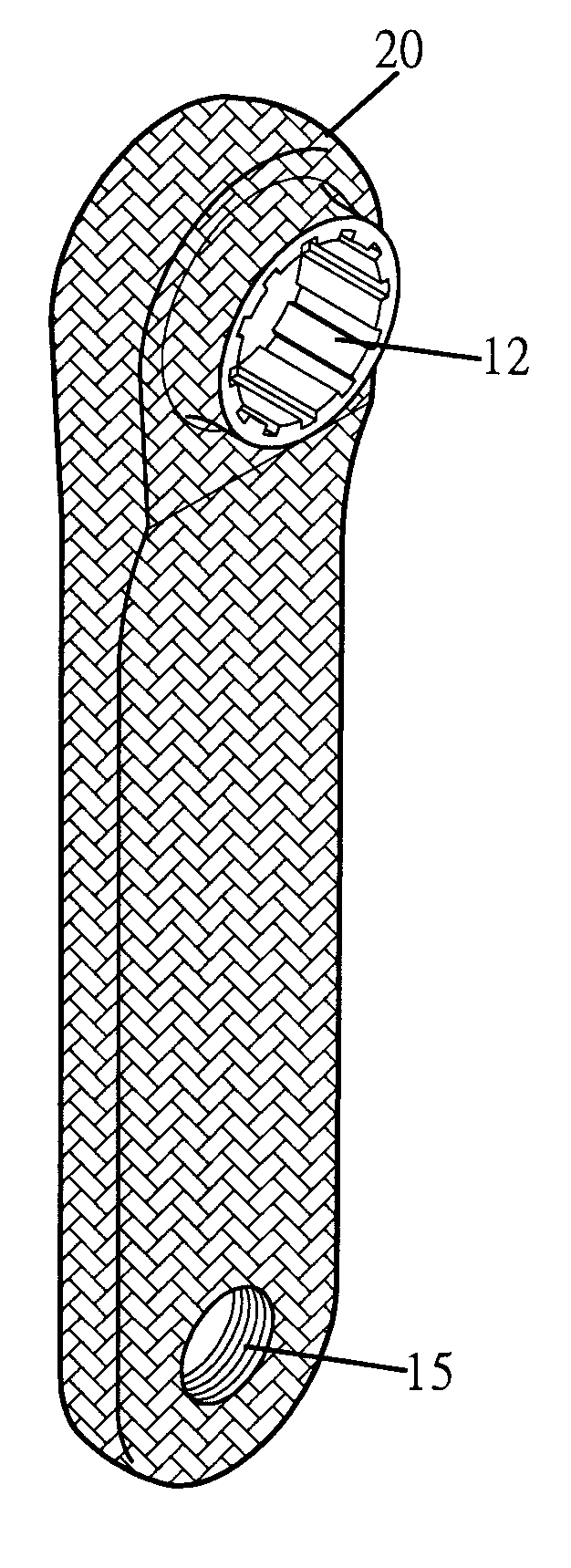

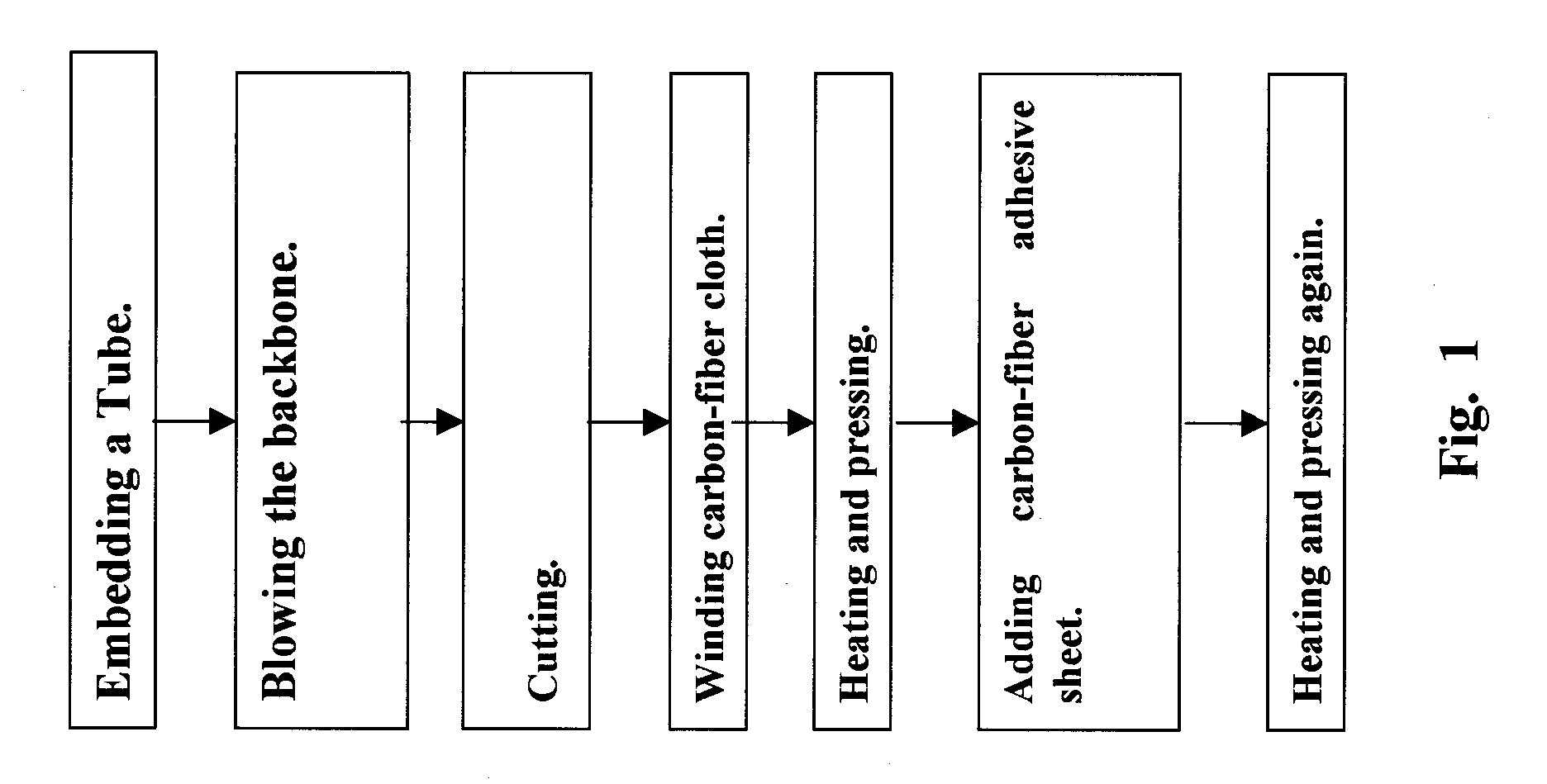

Method For Manufacturing Bicycle Crank

InactiveUS20080307652A1Preferred strengthLow costVehicle cranksMetal-working apparatusFiberCarbon fibers

Owner:TIEN HSIN INDS

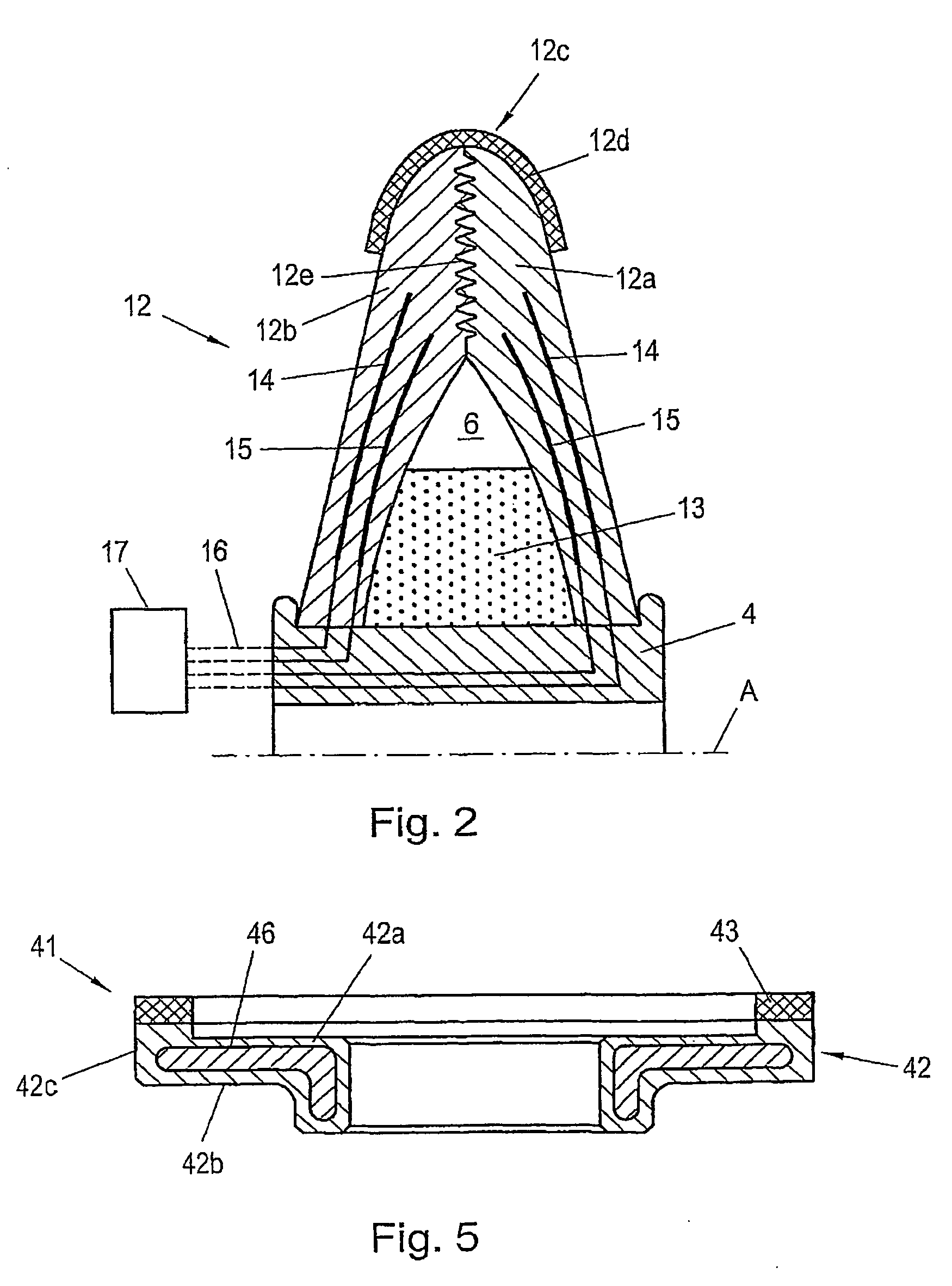

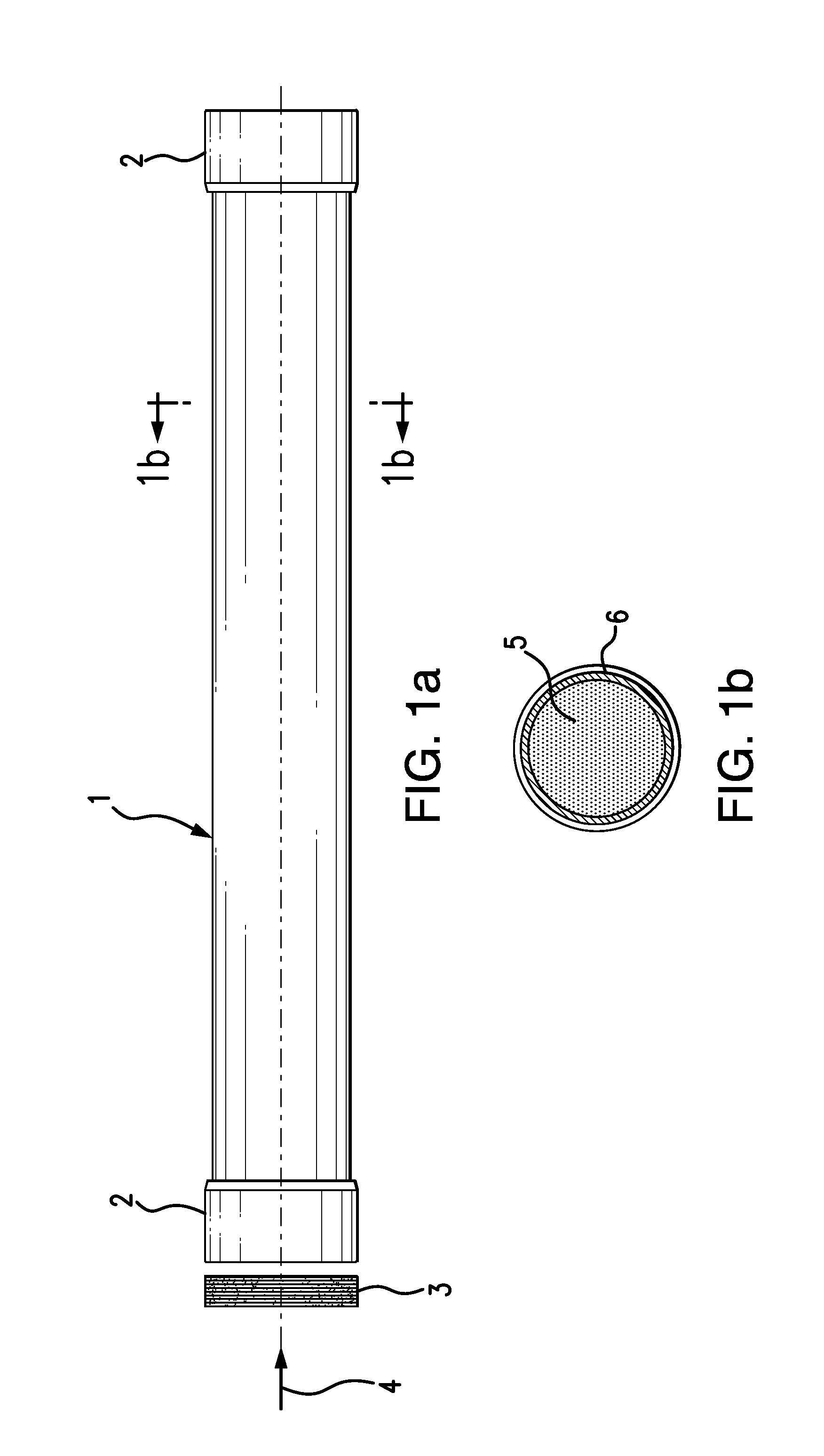

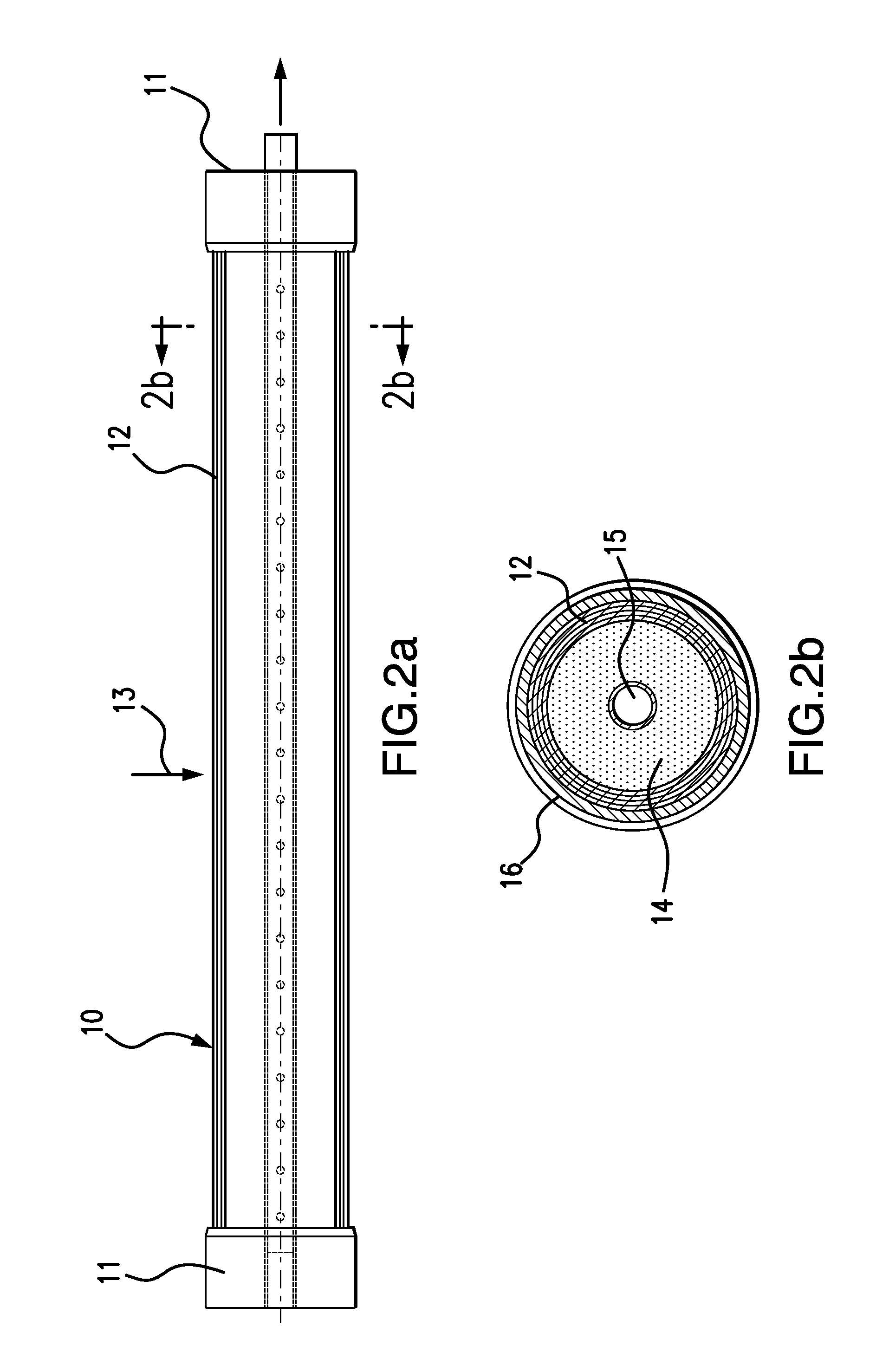

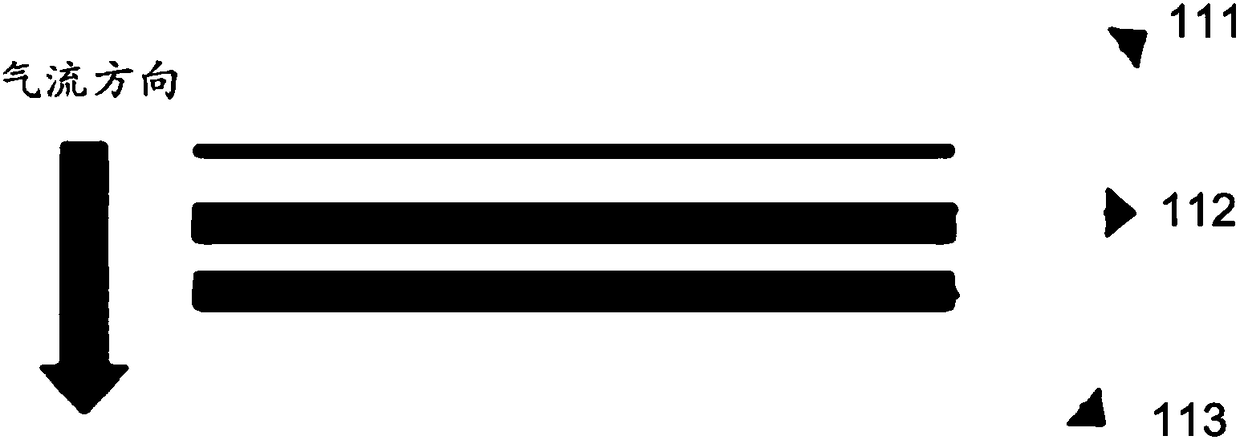

Gas separation membrane module with integrated filter

InactiveUS20160303507A1Reduced space requirementsEliminate needSemi-permeable membranesMembranesActivated carbonFiber

Owner:GENERON IGS

Efficient photoelectric converter based on carbon fiber@ tungsten disulfide nanosheet core-shell composite structure and preparation method of efficient photoelectric converter

InactiveCN106229359ASimple structureSimple preparation equipmentFinal product manufacturePhotovoltaic energy generationEnvironmental resistanceFiber

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Piezoelectric pump vibrator with multiaxial fiber-reinforced resin gasket

InactiveCN103321881ALong repeated fatigue lifeHigh strengthFlexible member pumpsPositive-displacement liquid enginesGlass fiberCarbon fibers

Owner:CHONGQING ZHONGLEI SCI & TECH

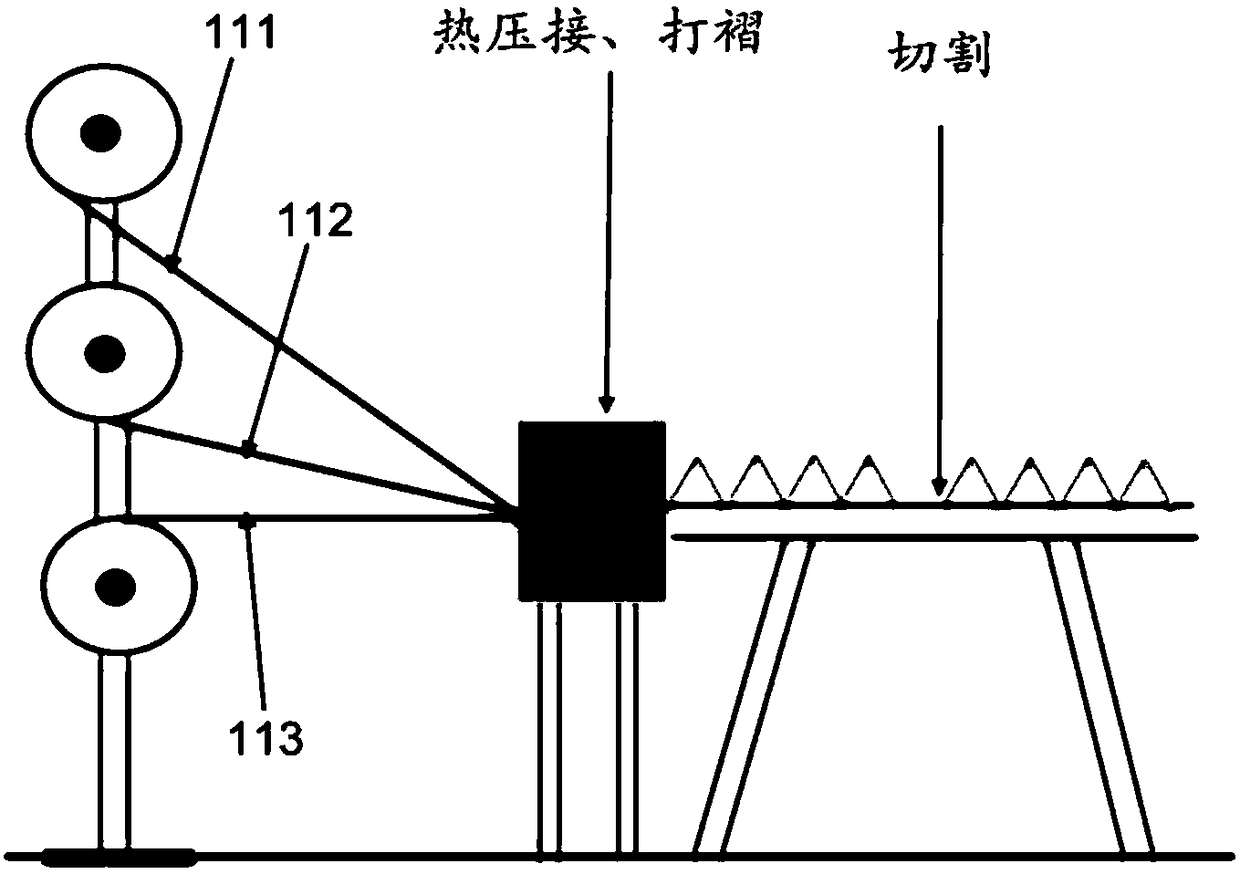

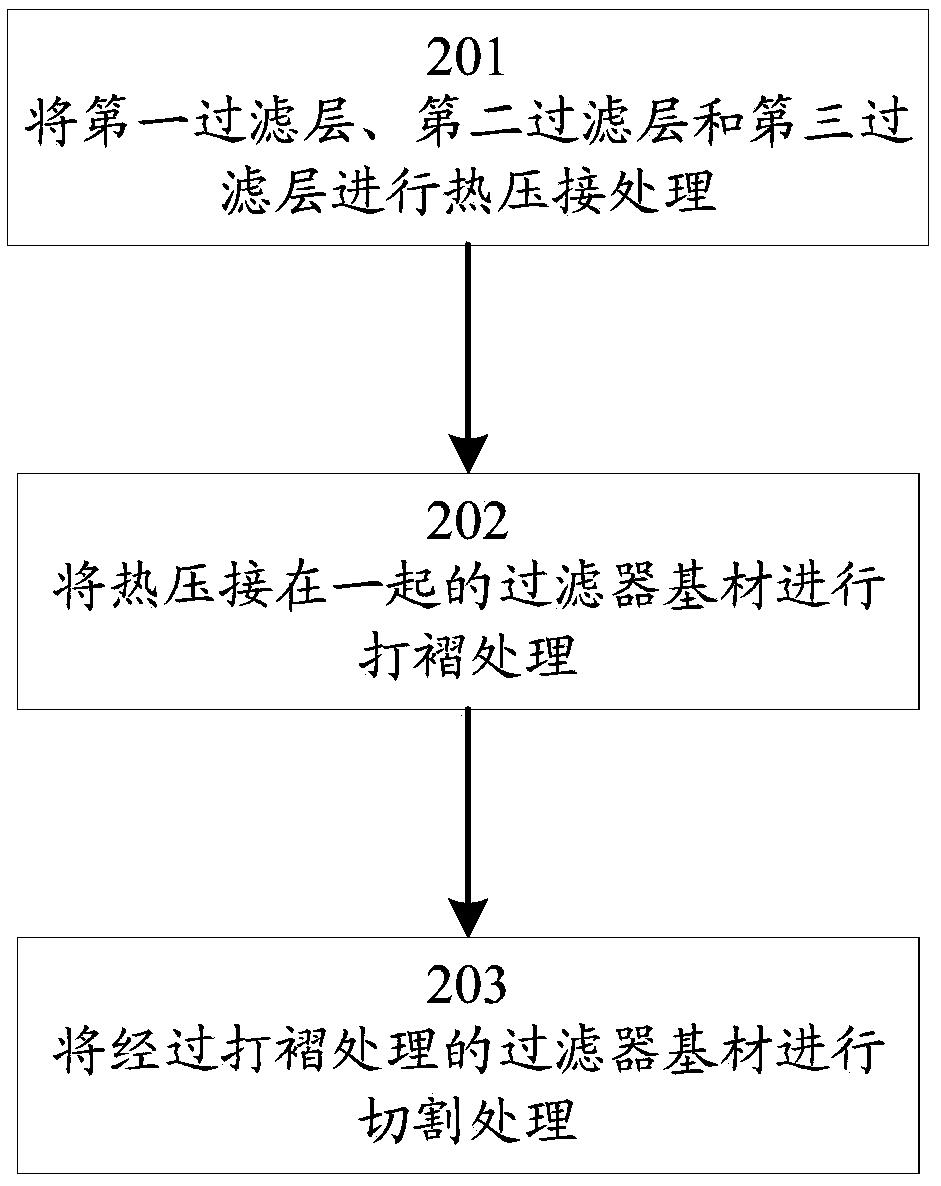

Automobile air conditioner filter

InactiveCN108211554AWide range of specific surface areaSmall filter resistanceGas treatmentDispersed particle filtrationFiberCarbon fibers

Owner:VALEO AUTOMOTIVE AIR CONDITIONING HUBEI CO LTD

Method for preparing feeding nozzle for continuous high-purity alumina melting furnace and continuous melting furnace

Owner:SHANDONG UNIV OF TECH

Explosion-proof glass

Owner:湖南创安防爆电器有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap