Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66 results about "Cellulose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

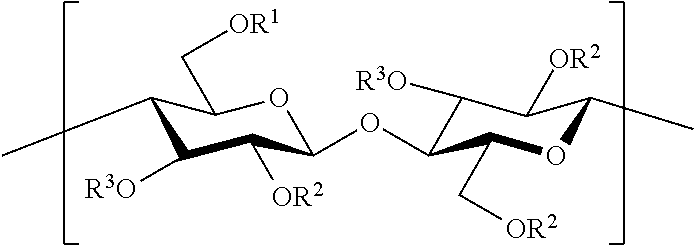

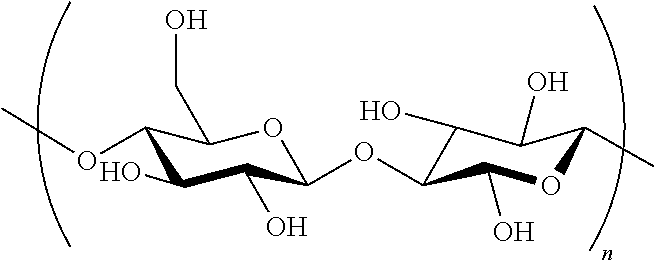

Cellulose is an organic compound with the formula (C₆H₁₀O₅)ₙ, a polysaccharide consisting of a linear chain of several hundred to many thousands of β(1→4) linked D-glucose units. Cellulose is an important structural component of the primary cell wall of green plants, many forms of algae and the oomycetes. Some species of bacteria secrete it to form biofilms. Cellulose is the most abundant organic polymer on Earth. The cellulose content of cotton fiber is 90%, that of wood is 40–50%, and that of dried hemp is approximately 57%.

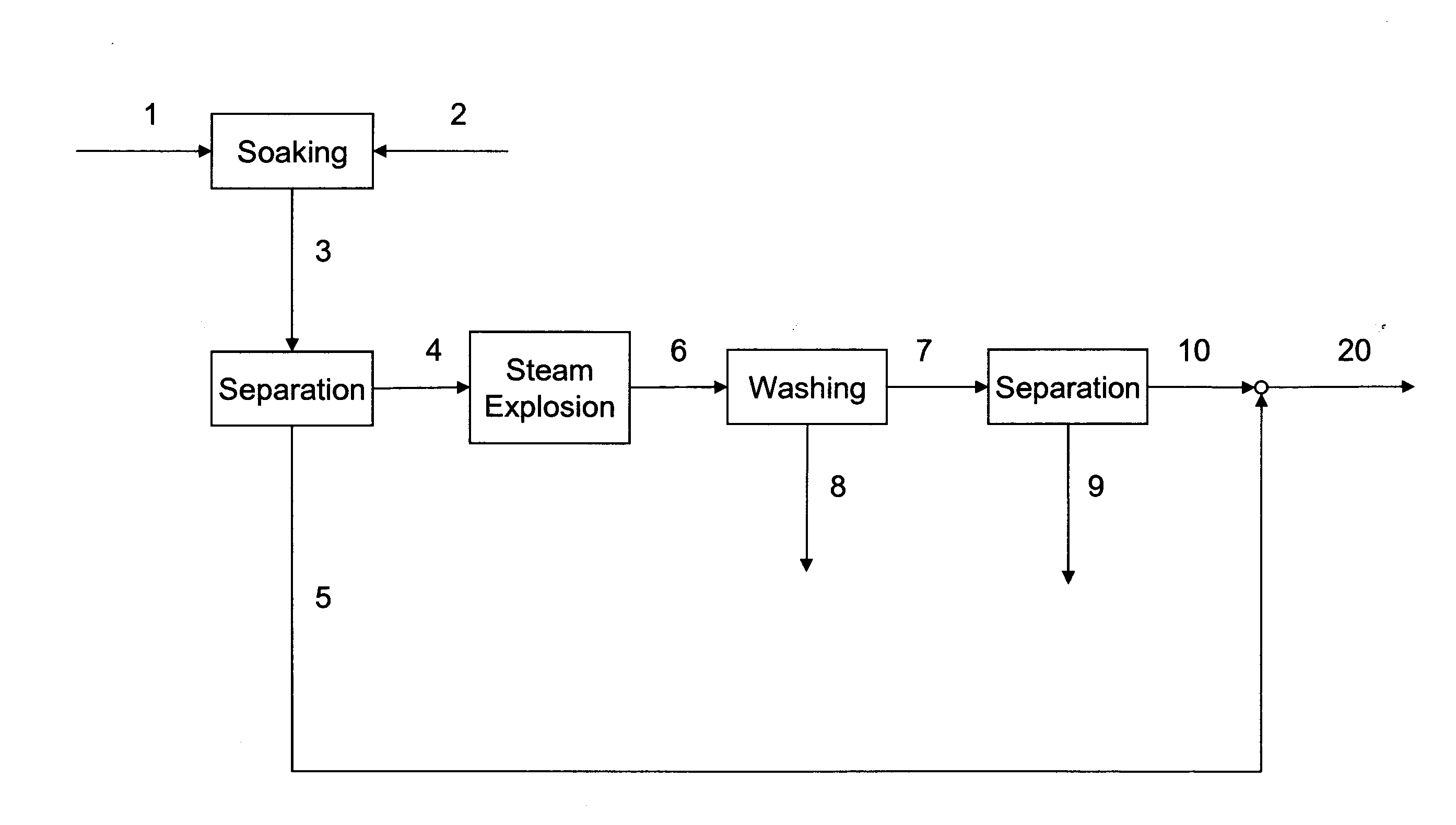

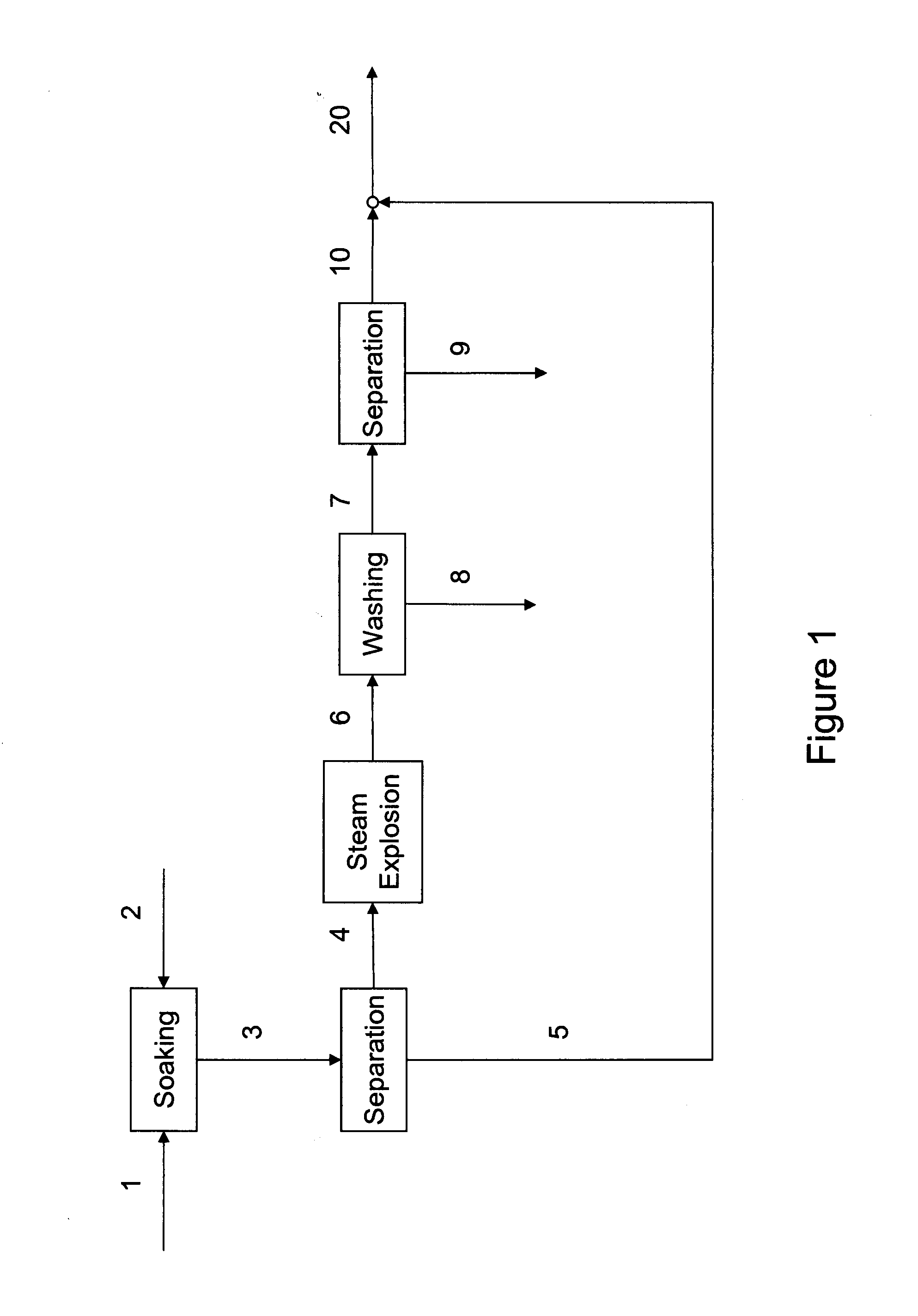

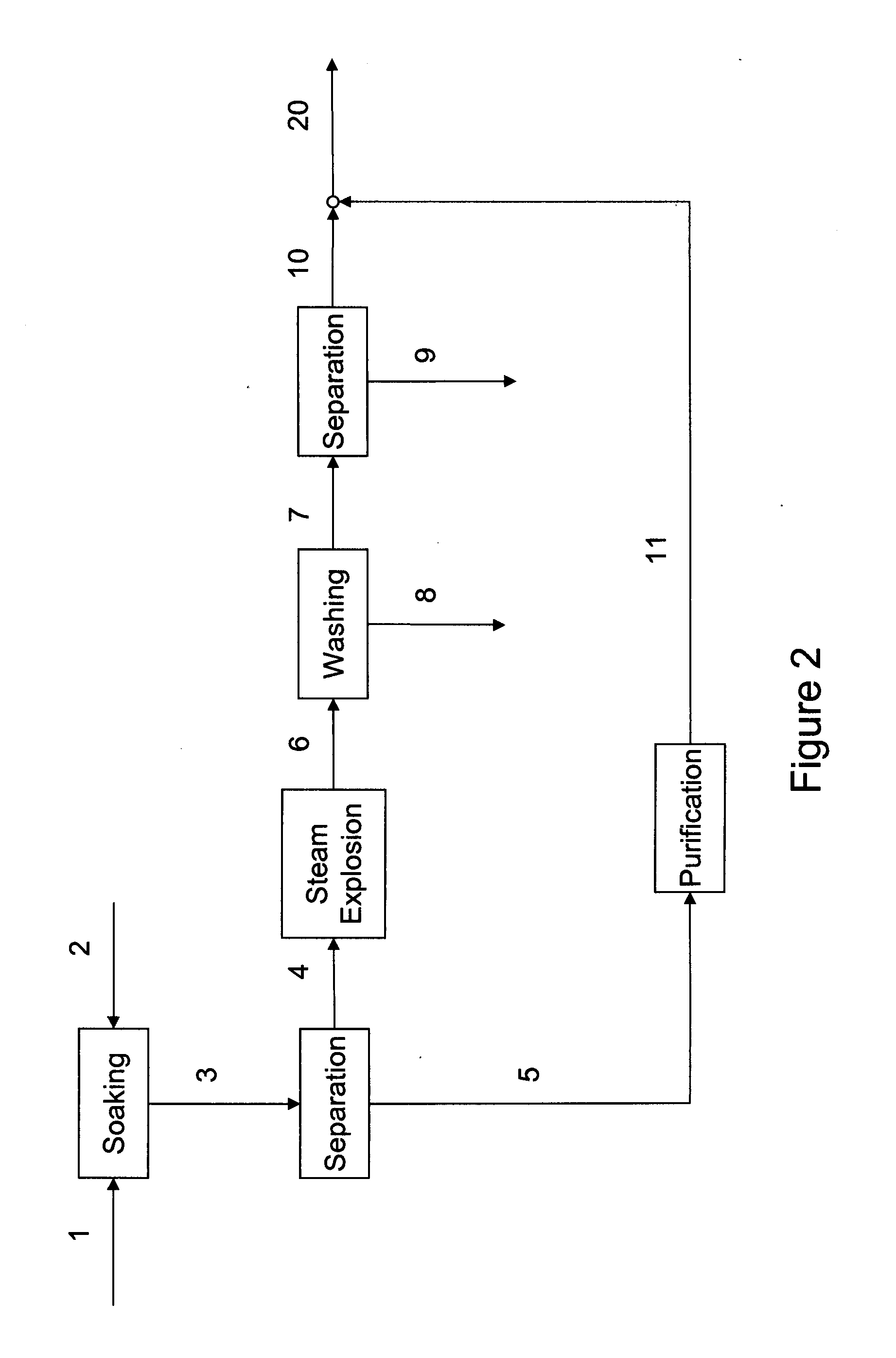

Biomass pretreatment process

Owner:CHEMTEX ITAL +1

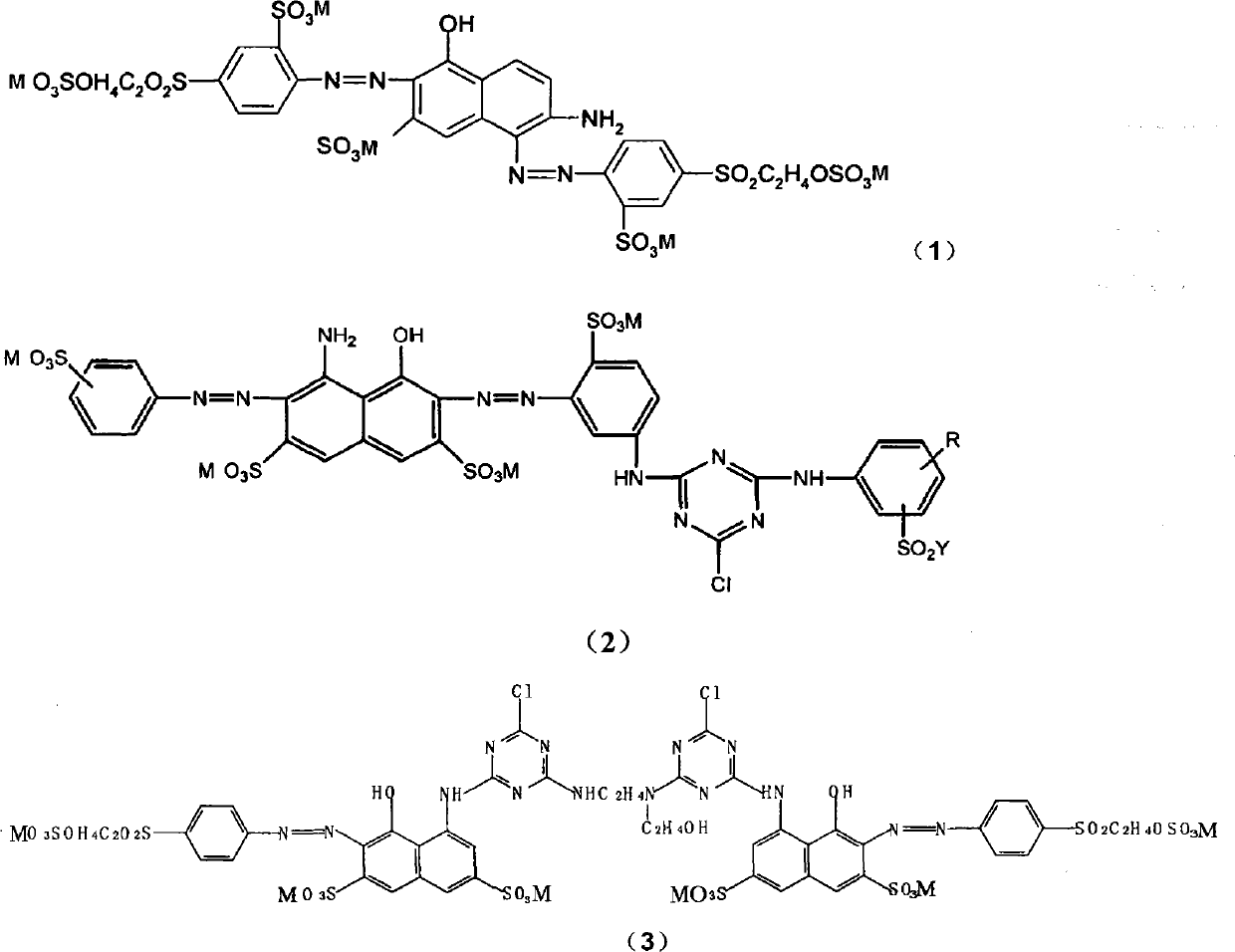

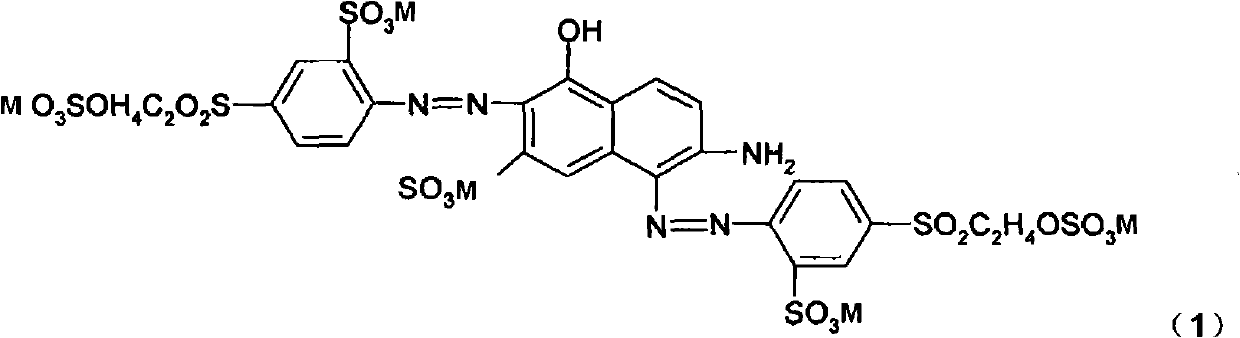

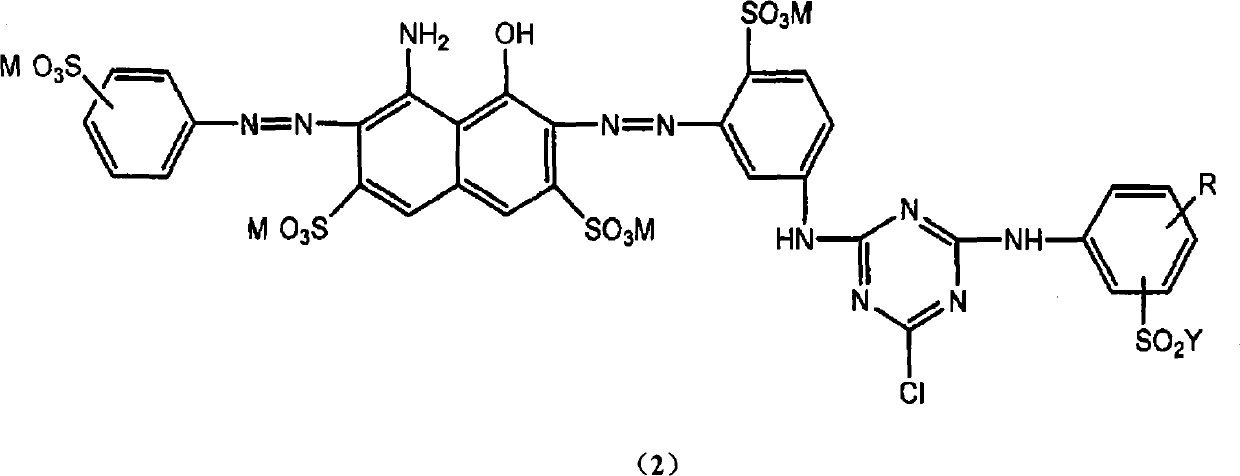

Composite active black dye

Owner:WUJIANG YISHENG TEXTILE

Coating having heat-insulation and reflection functions, and preparation method thereof

InactiveCN107267011AWith heat insulation reflective functionImprove economyReflecting/signal paintsCelluloseMicrosphere

Owner:HEFEI ZEJUN ELECTRICAL EQUIP CO LTD

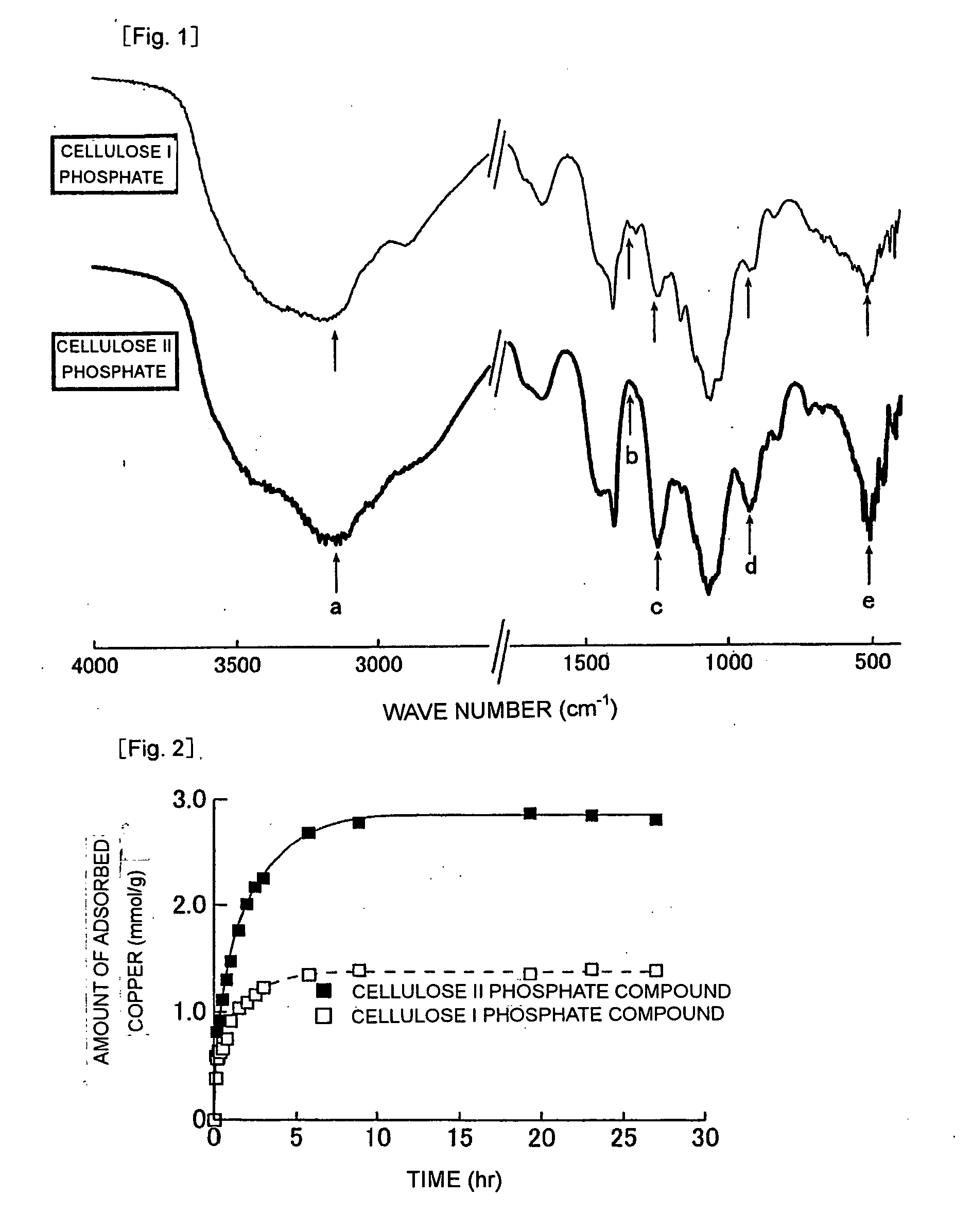

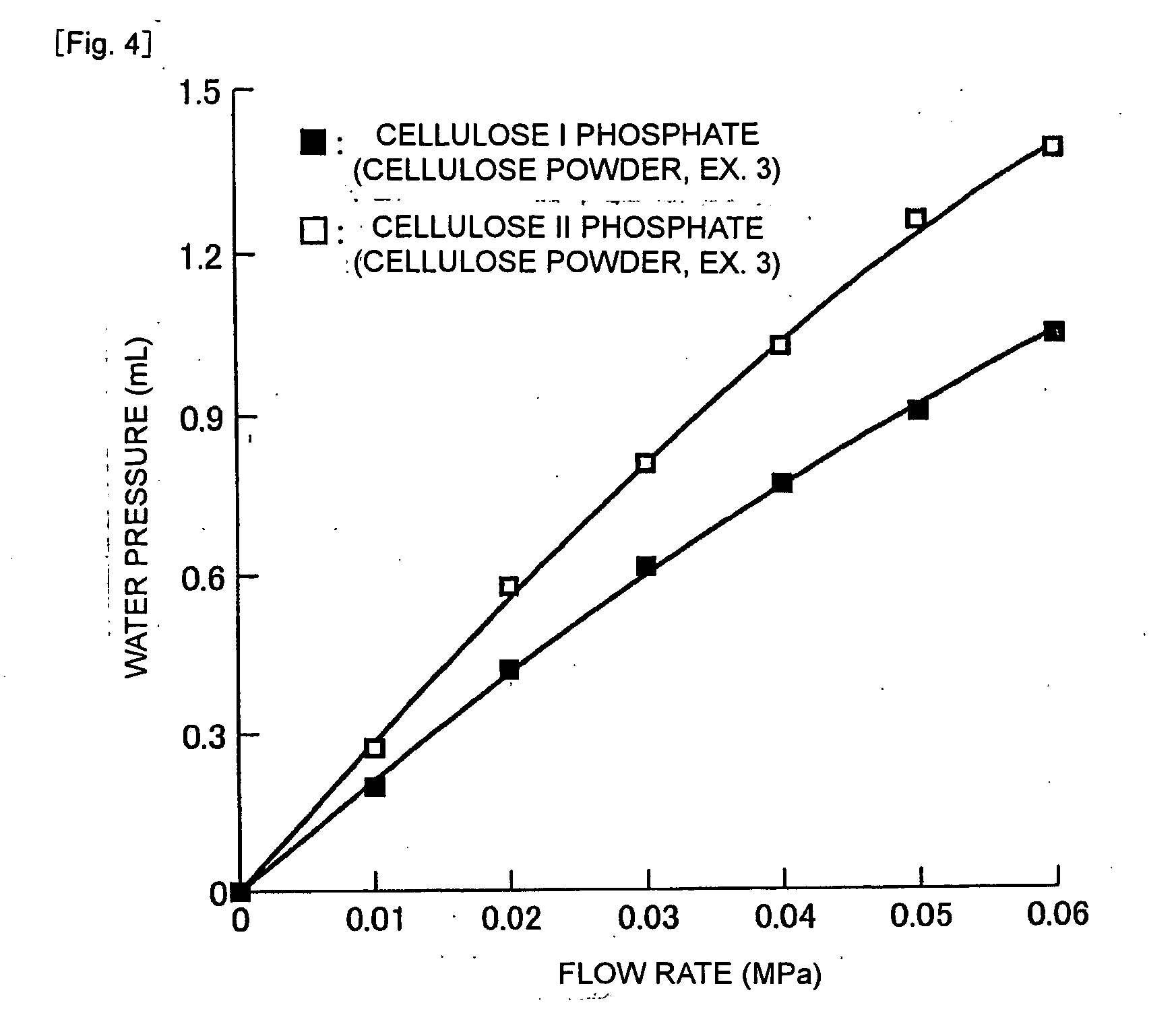

Cellulose II phosphate ester and metal-adsorbing material using the same

InactiveUS20070093654A1Large capacityGood water permeabilitySugar derivativesOther chemical processesIonCellulose

Owner:KOWA CO LTD

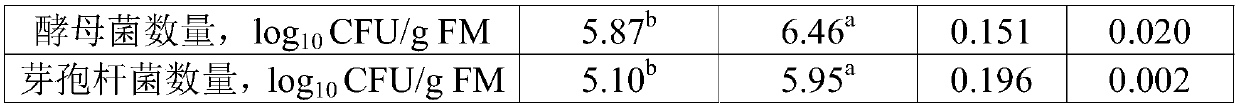

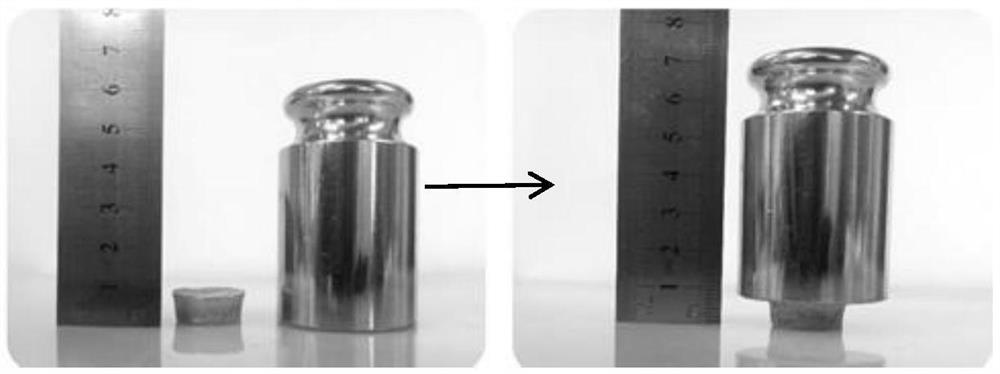

Metal aerogel with high specific surface area and preparation method thereof

InactiveCN105970193ALow densityHas metallic propertiesLiquid/solution decomposition chemical coatingAerogel preparationCelluloseChemical plating

The invention discloses metal aerogel with a high specific surface area and a preparation method thereof. The method comprises the steps that (1) cellulose aerogel is placed in a sensitizing solution to be soaked and then is washed with water; (2) the treated cellulose aerogel is soaked in a metal chemical plating solution for chemical plating, and metal / cellulose composite aerogel is obtained; (3) the metal / cellulose composite aerogel is placed in a LiOH / urea solution, the process of removing a cellulose aerogel template is conducted at a low temperature, and a nanometer porous metal solution is obtained; and (4) the prepared nanometer porous metal solution is washed with water, then is subjected to solvent exchange with acetone and is dried, and the metal aerogel with the high specific surface area is obtained. The method adopting the cellulose aerogel as the template for preparing the metal aerogel with the high specific surface area is provided for the first time. The cellulose aerogel has a high specific surface area and is of a pore structure suitable for chemical plating. Meanwhile, the template is easy to remove after the chemical plating, and reference is provided for preparation of metal aerogel with other templates.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Preparation method of lignocellulose/montmorillonite rubber reinforcing agent and rubber reinforcing method

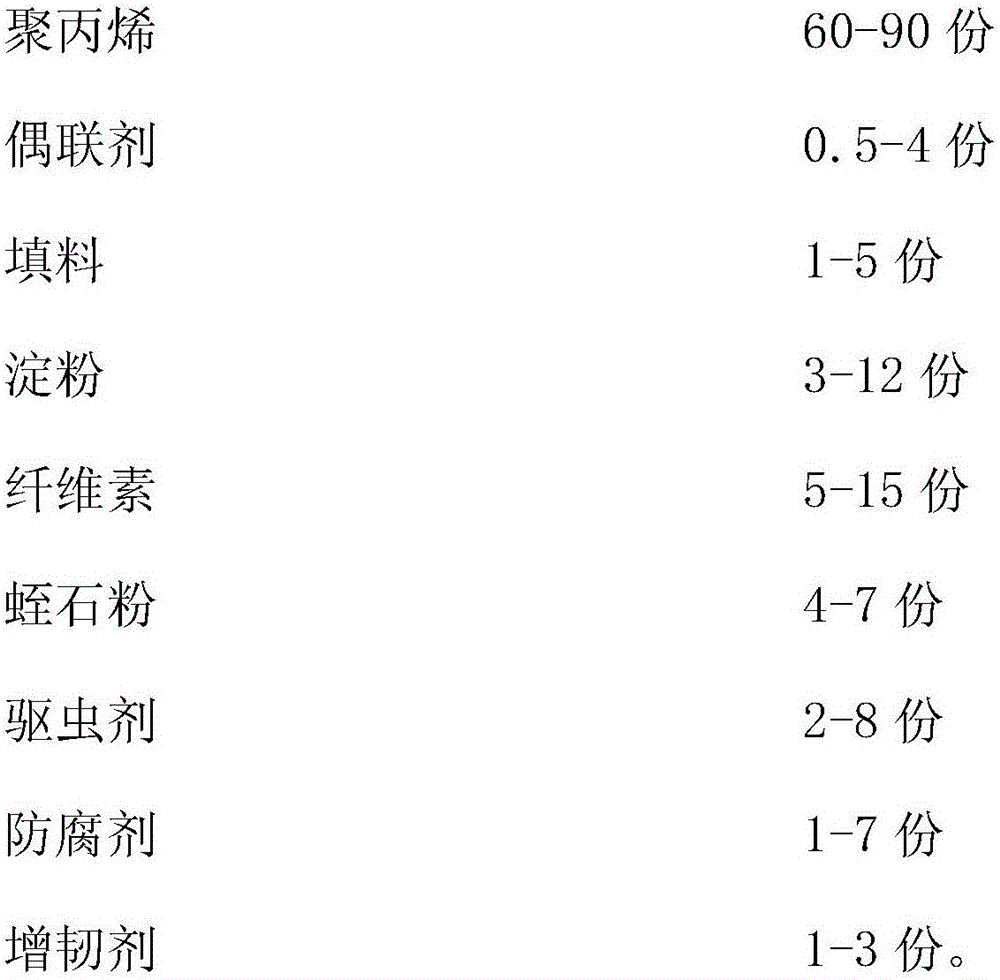

The invention discloses a preparation method of a lignocellulose / montmorillonite rubber reinforcing agent and a rubber reinforcing method. The preparation method of the lignocellulose / montmorillonite rubber reinforcing agent comprises the following steps of dispersing a silane coupling agent into anhydrous ethanol, diluting the mixture by adding deionized water, and adding lignocellulose to be uniformly stirred to obtain lignocellulose suspension liquid; and adding montmorillonite into the lignocellulose suspension liquid to be reacted for 4-8 hours in a stirring manner at the temperature of 80 DEG C, washing the reaction product to be neutral after the reaction is ended, and drying and ball-milling the reaction product to obtain the lignocellulose / montmorillonite rubber reinforcing agent. The rubber reinforcing agent prepared from the lignocellulose and the montmorillonite is rich in raw materials, simple in preparation process and capable of substituting partial carbon black, a reinforcing effect similar to the carbon black can be obtained and the consumption of petrochemical resources is reduced; the lignocellulose / montmorillonite rubber reinforcing agent is an environment-friendly material.

Owner:ANHUI UNIV OF SCI & TECH

Flash rust-proof acrylic roof waterproof coating and preparation method thereof

InactiveCN109796825AAnti-rust and waterproof effect lasts for a long timeImprove UV protection effectAnti-corrosive paintsCelluloseUltraviolet

The invention relates to the field of water proofing of metal roofs and particularly discloses a flash rust-proof acrylic roof waterproof coating which is prepared from, by weight, the following raw materials: 30-50 parts of an acrylic emulsion, 25-60 parts of antirust slurry, 1-5 parts of a plasticizer, 0.3-5 parts of a dispersing agent, 0.1-1 part of a defoaming agent, 0.1-1 part of a base material wetting agent, 0.1-2 parts of an anti-flash rust additive, 1-4 parts of a film forming assistant, 3-10 parts of water, 0.01-0.5 part of cellulose ether, 0.1-0.5 part of a bactericide, 0.01-0.5 part of a coupling agent and 0.01-0.5 part of a pH adjusting agent. The flash rust-proof waterproof effect of the roof waterproof coating with a flash rust-proof function is longer lasting than that of acommon metal roof waterproof coating, the anti-ultraviolet effect is good, and the service life of a base material is prolonged. The waterproof coating has high elongation rate, good elasticity, strong base layer deformation resistance, the capability of shielding cracks, water proofing and breathability.

Owner:KESHUN WATERPROOF TECH CO LTD

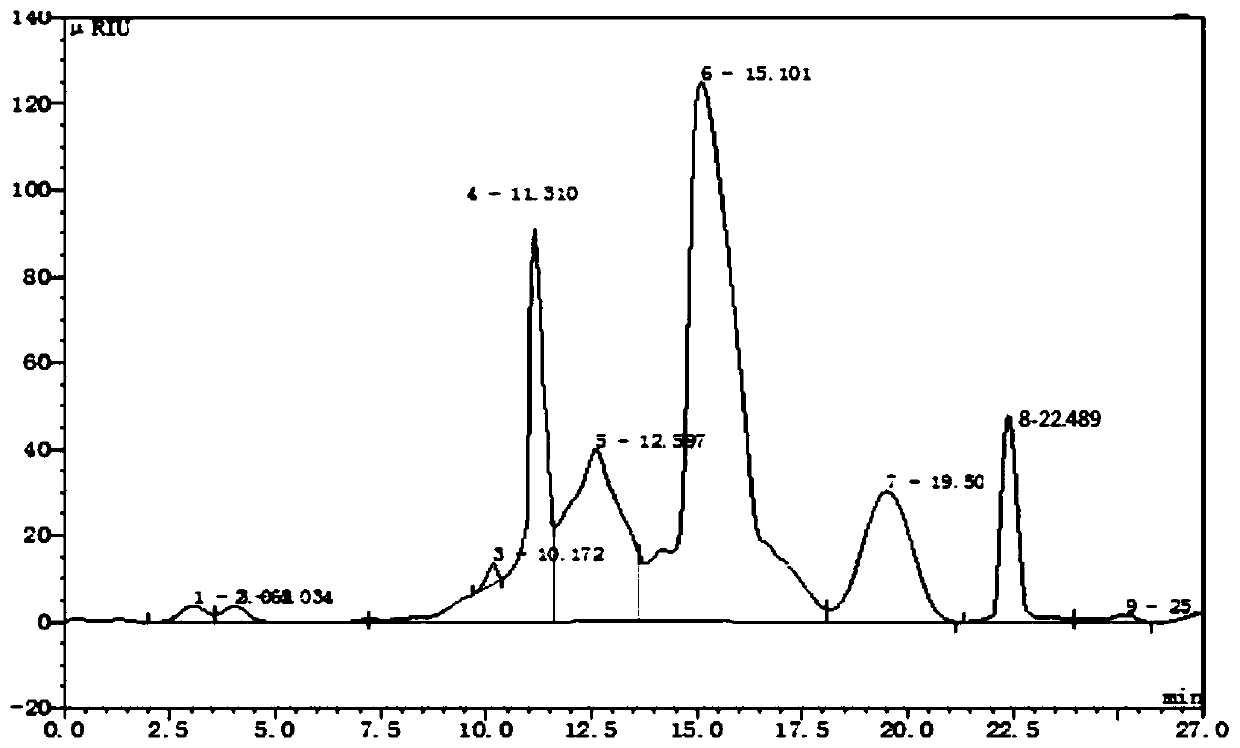

Pitaya peel-based edible packaging film and preparation method thereof

ActiveCN105419370AFull edible medicinal valueAvoid pollutionWrappersFlexible coversCellulosePolymer science

The invention provides a preparation method for a pitaya peel-based edible packaging film. The preparation method is characterized by comprising the following steps: (1) washing and stripping and slicing pitaya peels; (2) performing blanching treatment; (3) adding water and pulping to obtain pitaya peel pulp, wherein the mass ratio of matter obtained in the step (2) to the water is (15 to 45):100; (4) adding a thickening agent and a plasticizer into the pitaya peel pulp, wherein the mass ratio of the thickening agent to the pitaya peel pulp is (0 to 0.4):100, and the mass ratio of the plasticizer to the pitaya peel pulp is (0 to 0.3):100; the thickening agent is sodium alginate or sodium carboxymethylcellulose, and the plasticizer is glycerinum or sorbitol; (5) performing homogenization treatment at a treatment rate of 15000 to 20000 r / min for 5 to 8min; then, performing degassing treatment and standing to obtain shaped pulp; (6) casting and drying, and then performing film uncovering to obtain the pitaya peel-based edible packaging film. The invention also provides the packaging film prepared by the preparation method.

Owner:SICHUAN AGRI UNIV

Cellulose nanosheet material and preparation method thereof

The invention discloses a cellulose nanosheet material. The thickness and the transverse size of the cellulose nanosheet material can be both adjusted and controlled, the thickness is 1-100 nm, the transverse size is 0.1-30 [mu] m, more than 80% of the cellulose nanosheet material is a single layer, the thickness of the single layer is 4 nm+ / -1 nm, in addition, the cellulose nanosheet material is smooth in surface, and the AFM (Atomic Force Microscope) measurement shows that the fluctuation of the surface is within 0.1 nm. The invention further discloses a preparation method of the cellulose nanosheet material. The preparation method comprises the following steps: firstly, performing mixed grinding on a cellulosic material and a lyophobic material so as to gradually separate cellulose into flakes, and further performing ultrasonic dispersion and separation to remove the lyophobic material, thereby obtaining the cellulose nanosheet material. The cellulose nanosheet material disclosed by the invention is of a layered, orientated and crystal structure, and is high in polydispersity in transverse size and morphology.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

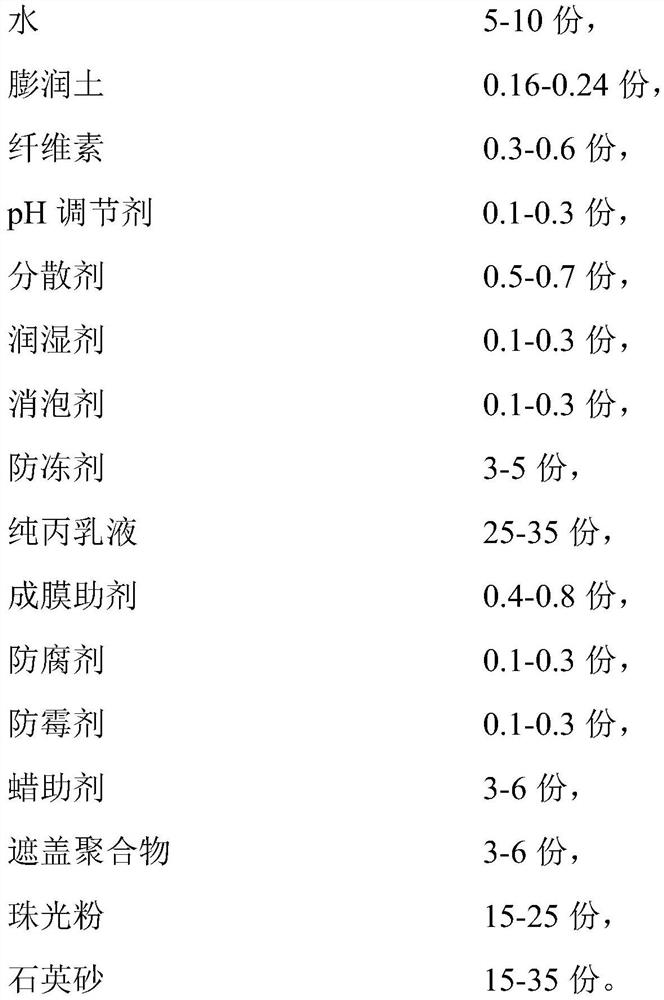

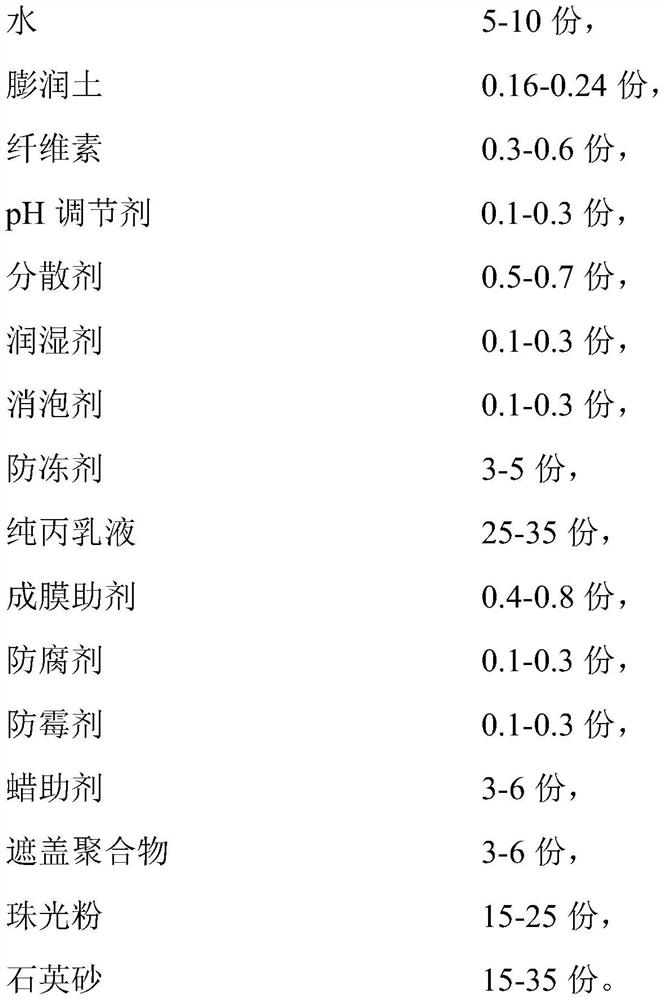

Artistic coating and preparation method thereof

Owner:珠海展辰新材料股份有限公司

Preparation for water-soluble high-substitution cellulose sodium sulfate

Owner:ZHEJIANG UNIV

Method for enhancing anti-freeze and tensile properties of cellulose ion hydrogel, anti-freeze stretchable cellulose ion hydrogel and application

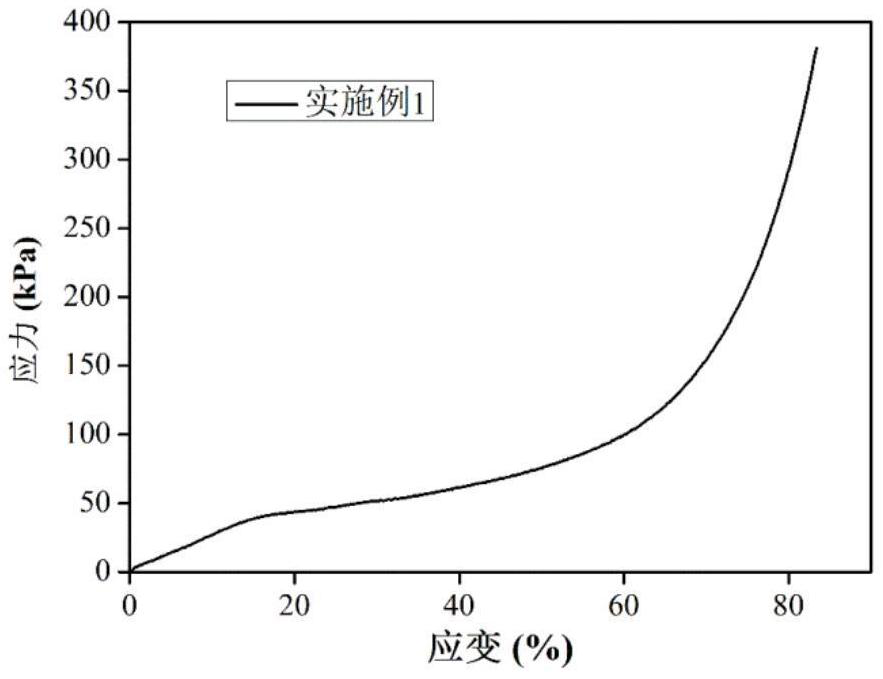

The invention provides a method for enhancing the anti-freeze and tensile properties of cellulose ion hydrogel, anti-freeze stretchable cellulose ion hydrogel and application, relating to the technical field of ion hydrogel. The method for enhancing the anti-freeze and tensile properties of the cellulose ion hydrogel comprises steps as follows: enabling the cellulose ion hydrogel to be immersed into a chlorinated metal salt solution, and dipping for 10-40min to obtain the anti-freeze stretchable cellulose ion hydrogel. Current cellulose ion hydrogel has the technical problems that the tensileproperty is poor and tensile and wire properties can lose at low temperature as well. According to the method, by enabling the cellulose ion hydrogel to be immersed in the chlorinated metal salt solution, metal ions and chloride ions in chlorinated metal salt enter the cellulose ion hydrogel, so that the anti-freeze property of the cellulose ion hydrogel is effectively improved, and the prepared anti-freeze stretchable cellulose ion hydrogel still has good mechanical property and chemical property at the low temperature.

Owner:SOUTH CHINA UNIV OF TECH

Process for dispersing cellulose esters into elastomeric compositions

Owner:EASTMAN CHEM CO

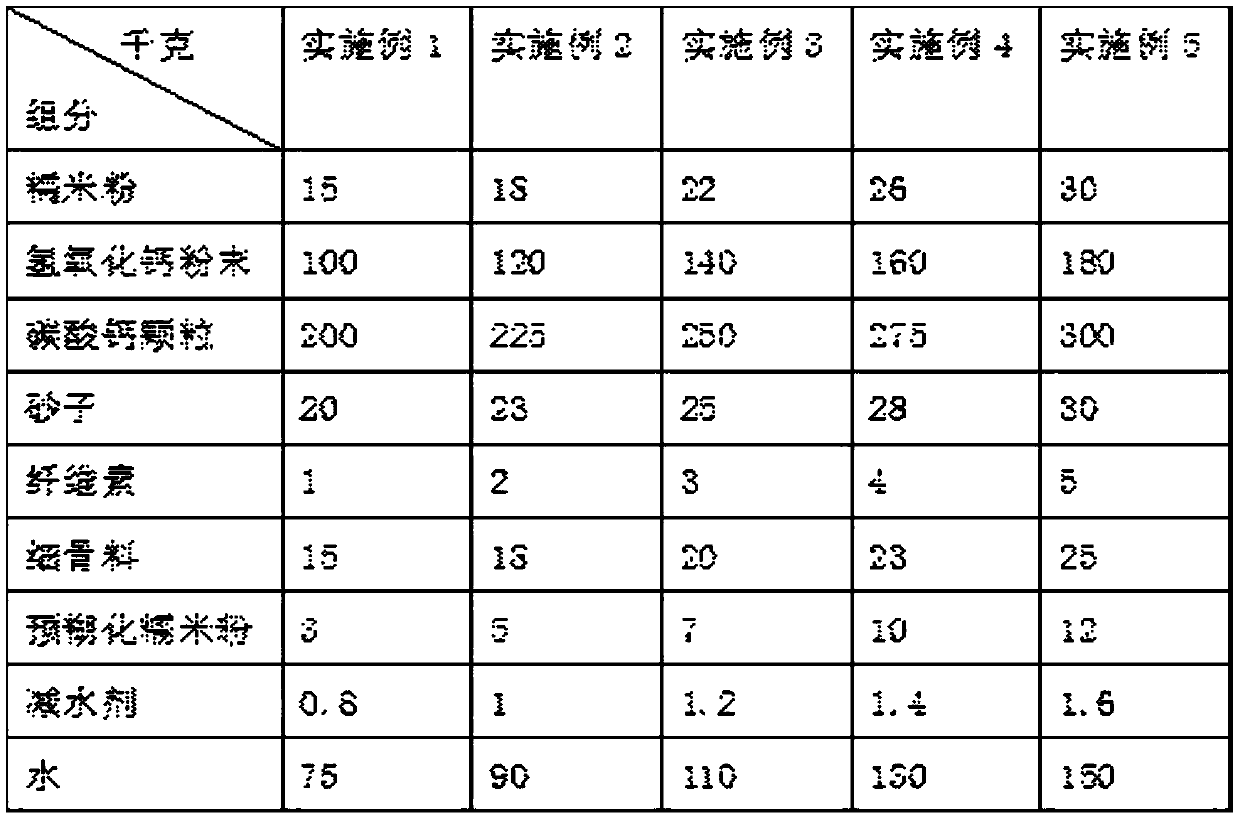

Sticky-rice mortar and preparation method thereof

Owner:中兴文建工程集团有限公司

Aqueous porcelain imitating coating material

Owner:NANTONG XINGYU PAINT

Method for preparing biological-based plastics by using wood fibers as raw material

The invention discloses a method for preparing biological-based plastics by using wood fibers as a raw material. The method comprises the steps: crushing wood fiber biomasses, then carrying out ball milling to obtain a powder material; dissolving a modifying reagent by using a solvent, adding the powder material for performing a modification reaction; and after the modification reaction is ended, washing and drying the product to obtain the biological-based plastics. The method has the main advantages that 1, the raw material is wide in source and low in cost; 2, cellulose, hemicellulose and lignin in the wood fiber biomasses are compressively utilized, and a conventional single modification mode in which the cellulose is modified and utilized by separation, extraction and modification is changed; 3, a conventional pretreatment mode adopting a chemical method is changed through ball milling and pretreatment, and a large quantity of highly-corrosive reagents and solvents are prevented from being used; 4, the modification process is simple and easy to operate, a normal-temperature or low-temperature reaction is achieved, the reaction time is short, the industrial application prospect is wide; 5, the prepared product can be prepared into a plastics product through forming processes of extrusion molding, extruding and the like, and the plastic product is good in mechanical property.

Owner:NANJING FORESTRY UNIV

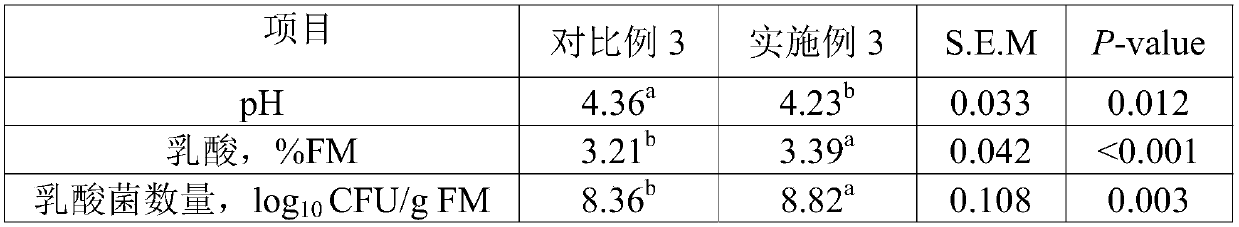

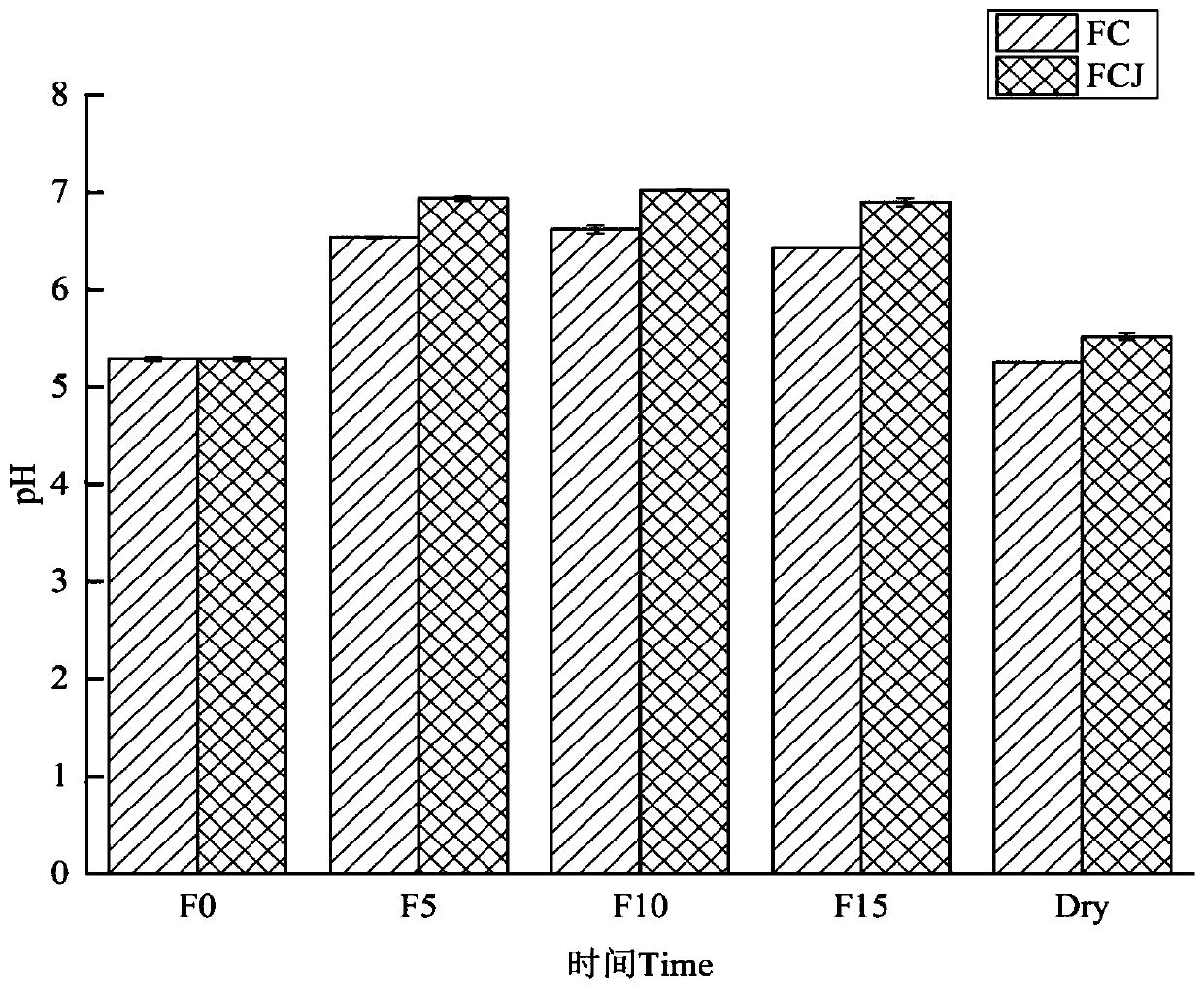

Production method of fiber-containing rumination fermented feed

InactiveCN111345395AImprove digestibilityHelps destroy the crystal structureFood processingAnimal feeding stuffCelluloseFiber

Owner:COFCO NUTRITION & HEALTH RES INST +1

Compound selected from sulfated cellulose and salts thereof and dermatitis therapeutic agent

InactiveUS20060199784A1Improve hydrolysis resistanceQuality improvementCosmetic preparationsOrganic active ingredientsCutaneous symptomCellulose

Owner:JNC PETROCHEM +1

Method for preparing biomass fuel by catalyzing rice straw

InactiveCN108913176ASmall particle sizeIncreases chances of effective chemical reaction collisionsPhysical/chemical process catalystsBiofuelsCelluloseChemical reaction

The invention discloses a method for preparing biomass fuel by catalyzing rice straw. The method comprises the following steps that the rice straw serves as a main raw material, primary pretreatment is carried out on the rice straw so as to obtain straw powder, then secondary pretreatment is carried out on the straw powder so as to obtain a straw suspension II. According to the method, the structure of cellulose is changed through the pre-treatment process, the size of particles of the cellulose is decreased, the probability of effective chemical reaction collision between cellulose moleculesand a solvent is improved, and the yield of a final target product is increased; and a catalyst carrier is used for adsorbing a catalyst, then the carrier is taken as a unit, a target substrate is catalyzed, and therefore a good effect is achieved.

Owner:ANHUI SHENGBAO NEW ENERGY TECH CO LTD

Preparation method of cellulose composite aerogel

InactiveCN111849019AImprove structural stabilityWith impact resistanceMethylene bisacrylamideCellulose

The invention discloses a preparation method of cellulose composite aerogel. The preparation method comprises the following steps: (1) preparing a cellulose solution, (2) sequentially adding N, N-methylene bisacrylamide and dopamine hydrochloride into the cellulose solution, and putting the mixture into an oven for reaction to prepare cellulose composite hydrogel, and (3) carrying out primary freeze drying, solvent replacement and secondary freeze drying on the cellulose composite hydrogel to obtain the cellulose composite aerogel. The cellulose composite aerogel prepared by the preparation method is good in structural stability, has impact resistance, and is simple and controllable in preparation method, low in pollution and low in cost.

Owner:HOHAI UNIV

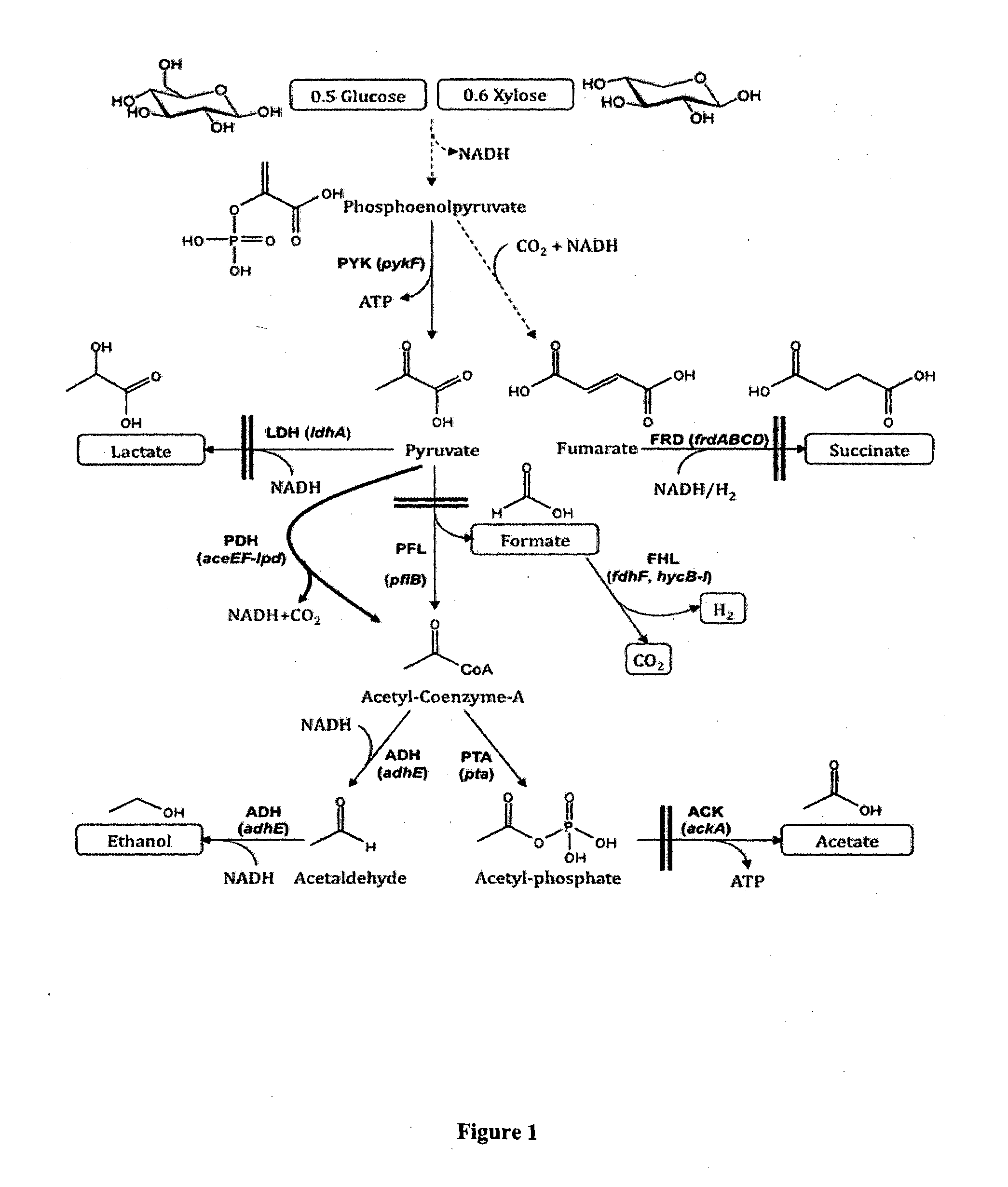

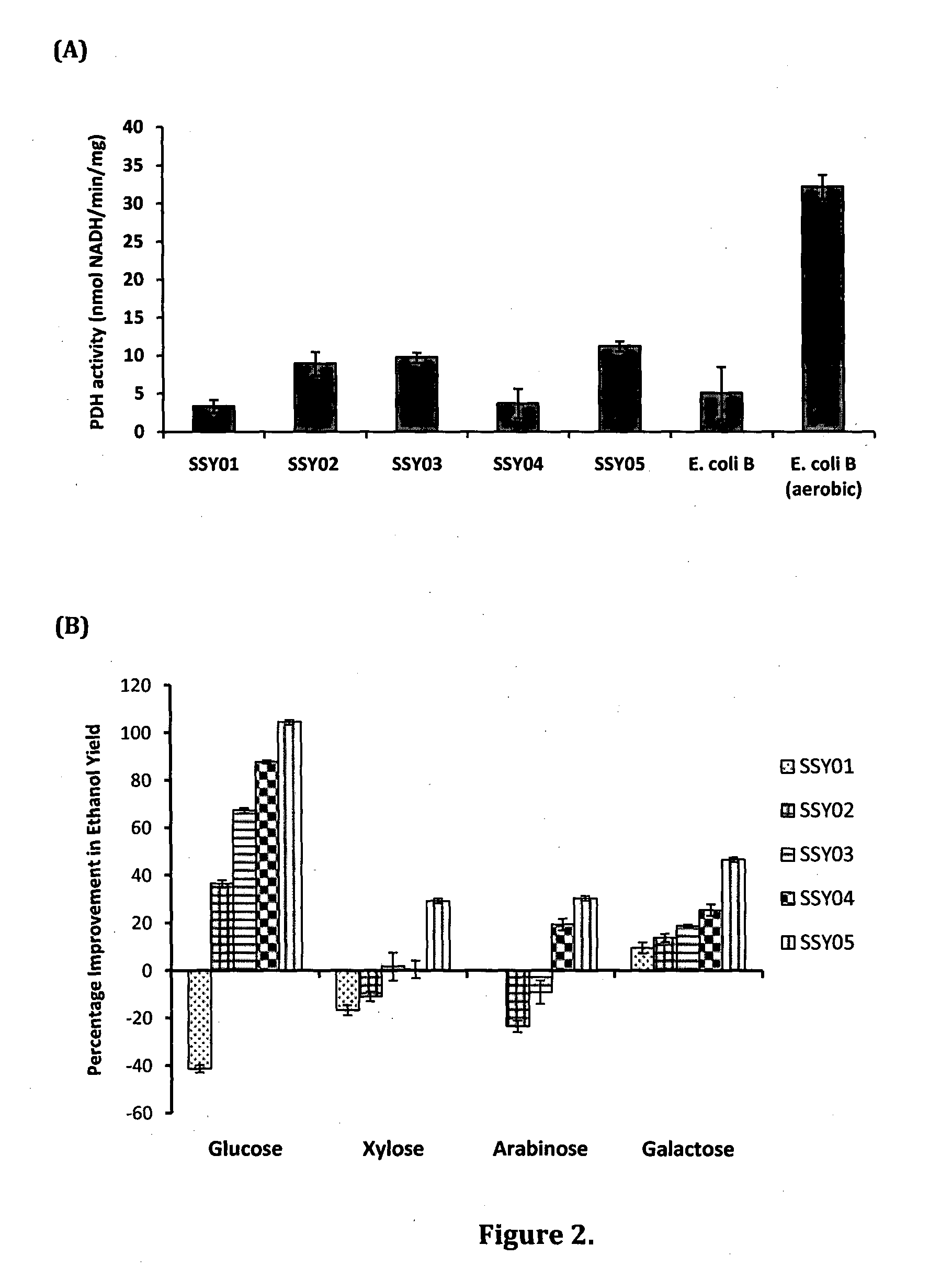

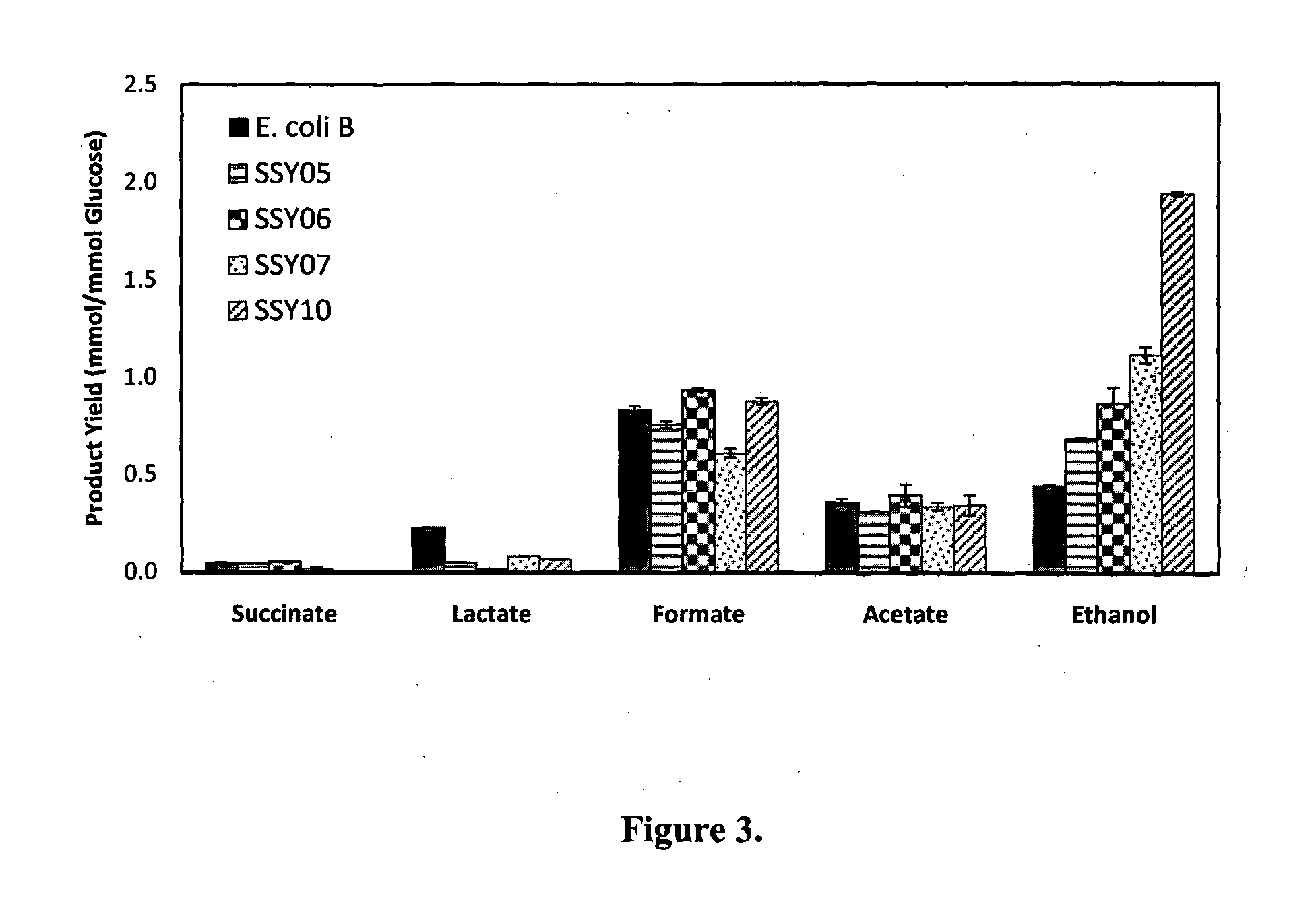

Modified bacteria for the production of bioalcohol

Owner:DEPT OF BIOTECHNOLOGY MINIST OF SCI & TECH GOVERNMENT OF INDIA +1

Flame-retardant yarn/fabric/clothing

Owner:SINOPPE BEIJING CO LTD

Food packaging bag and preparation method thereof

Owner:安徽明诚塑业有限公司

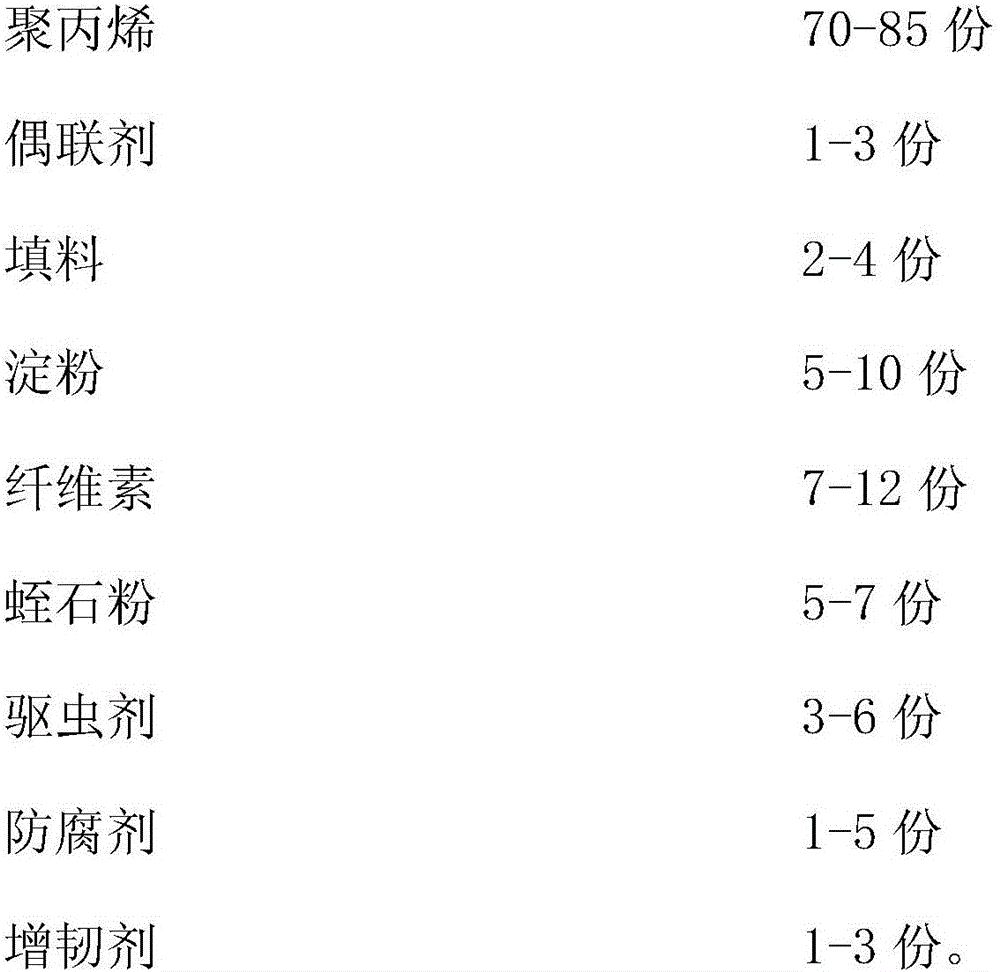

Degradable capacitor plastic shell and preparation method thereof

Owner:TONGLING XINTAI ELECTRIC APP & CAPACITOR

Extraction method and application of phellinus igniarius polysaccharide

Owner:宁波御菌生物技术有限公司

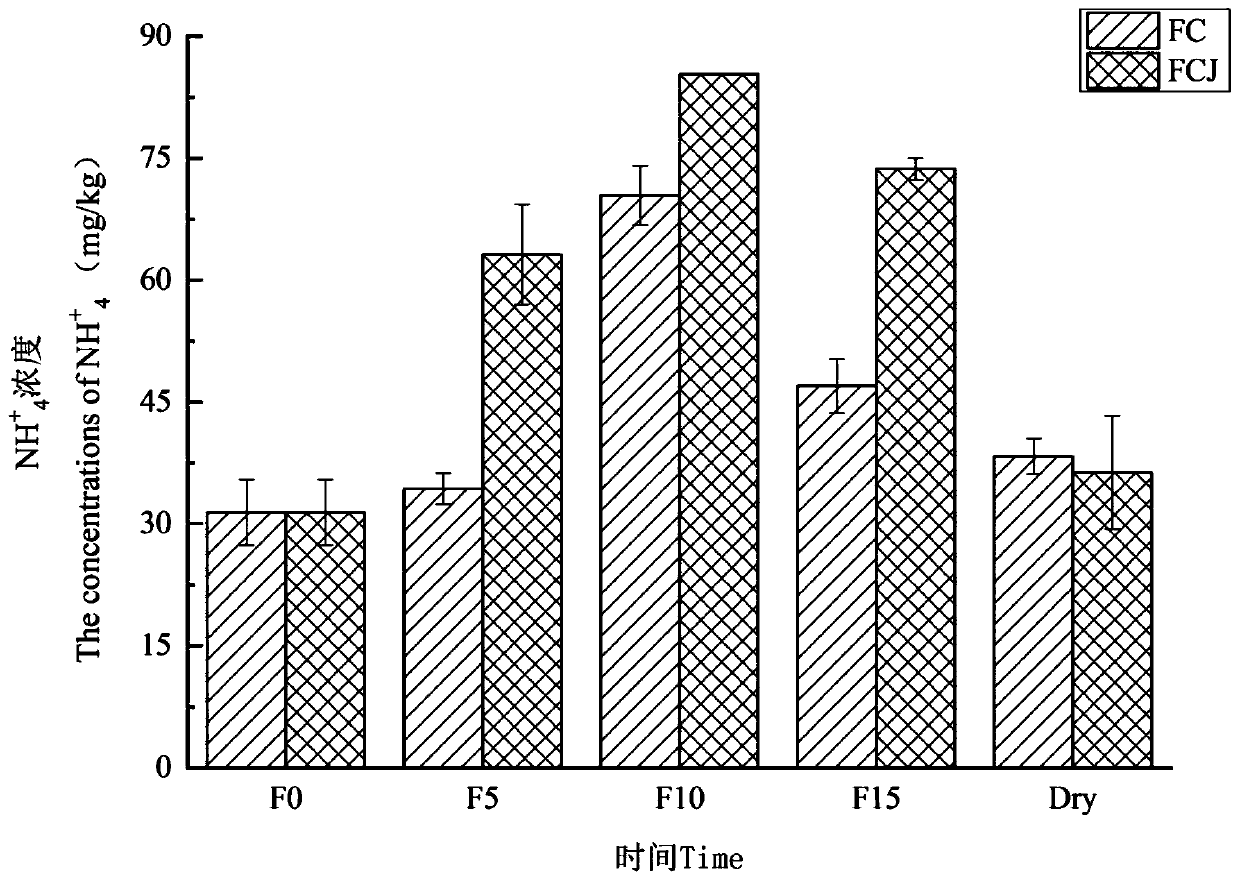

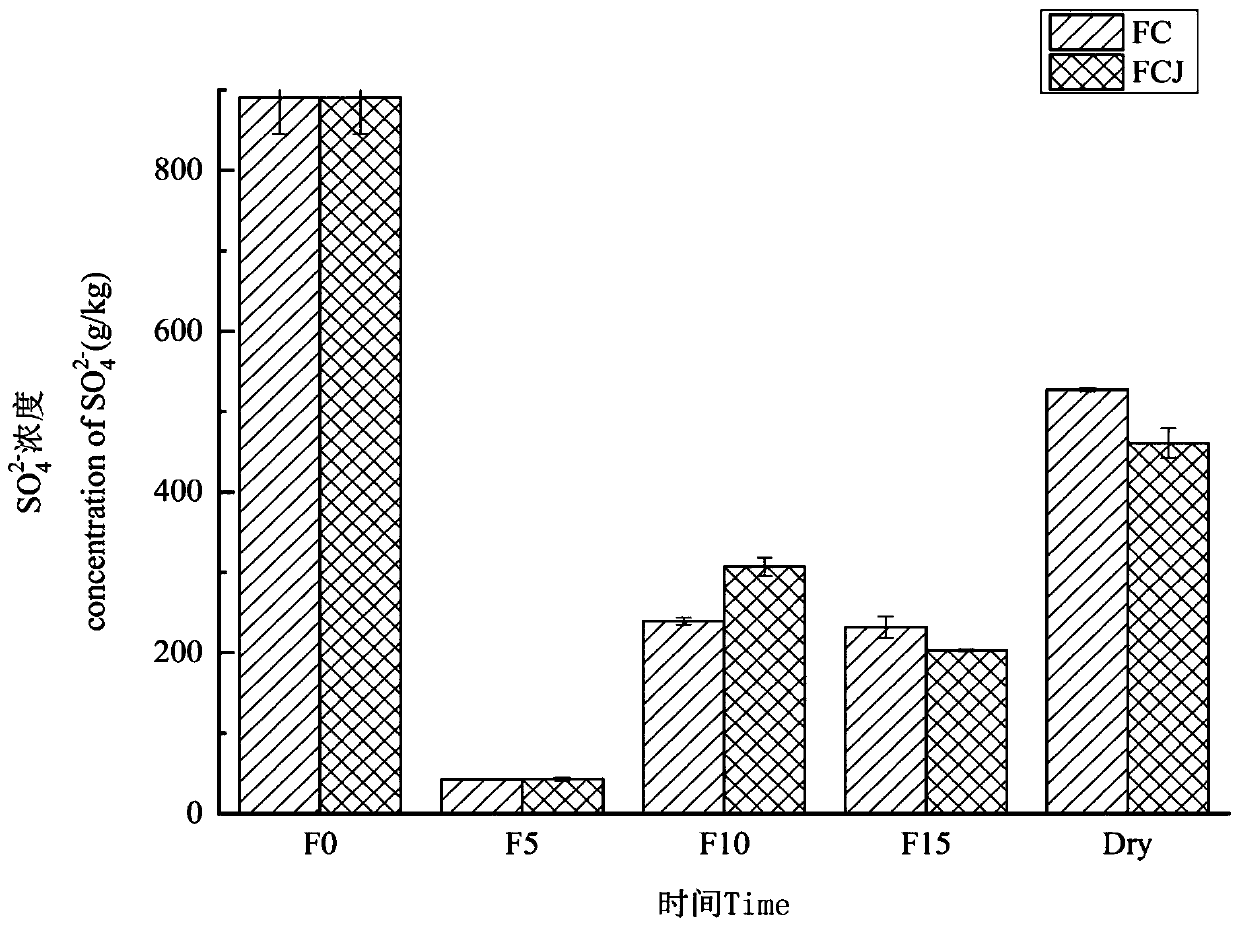

Composition for reductive soil sterilization and application of composition

InactiveCN110178854APromote decompositionIncrease concentrationBiocideAgriculture tools and machinesCelluloseMicrobial agent

Owner:SHENYANG AGRI UNIV

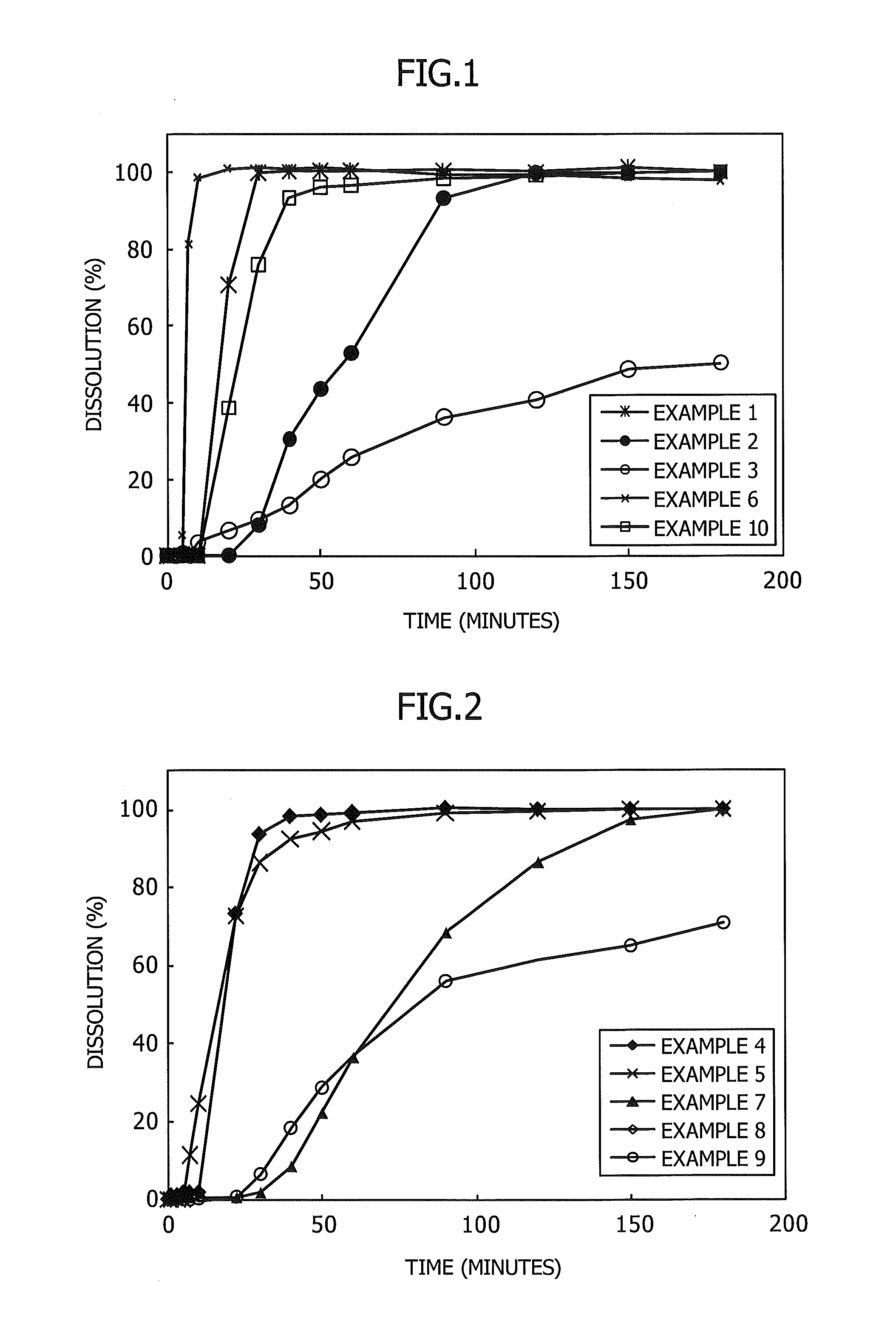

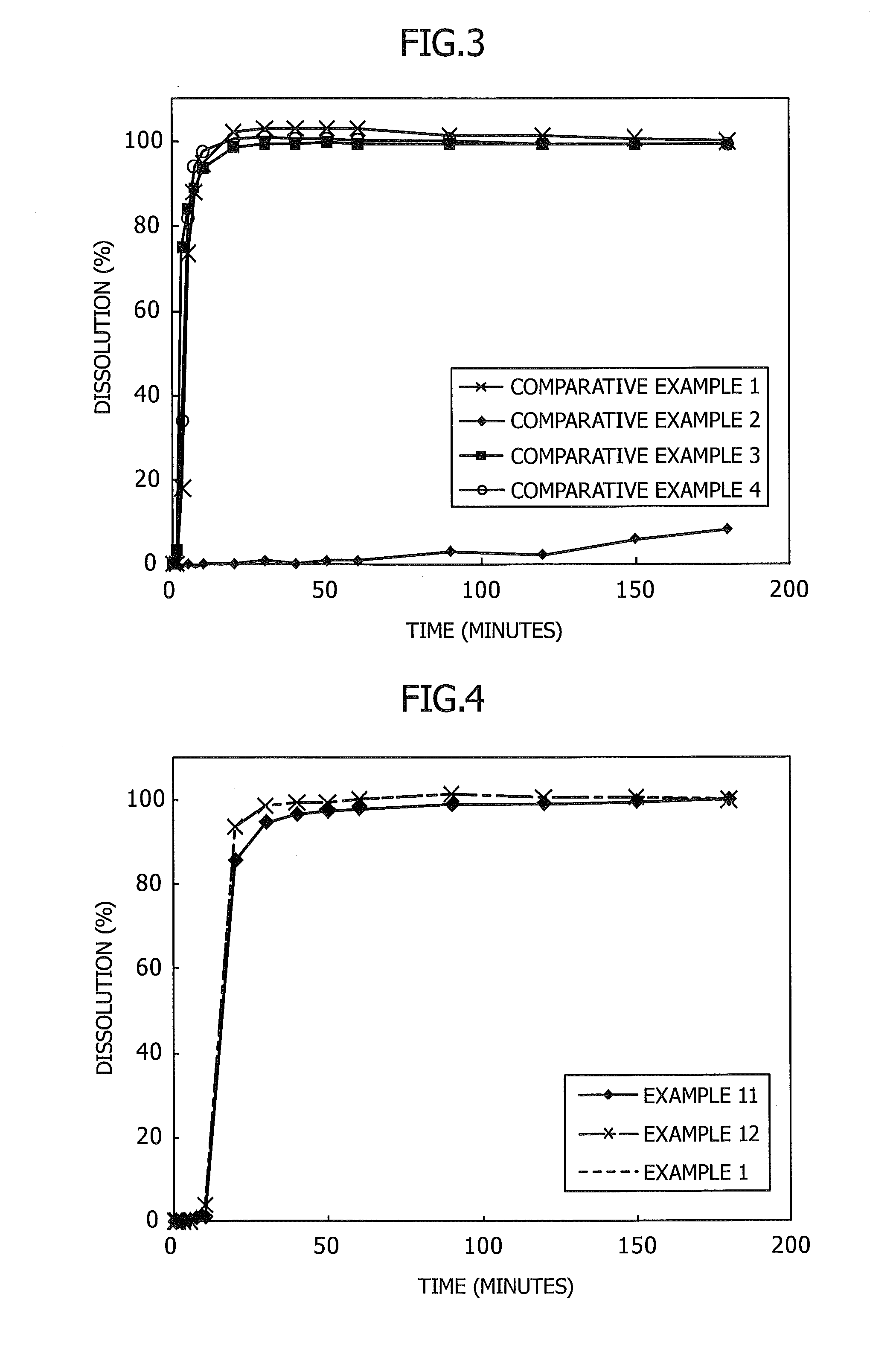

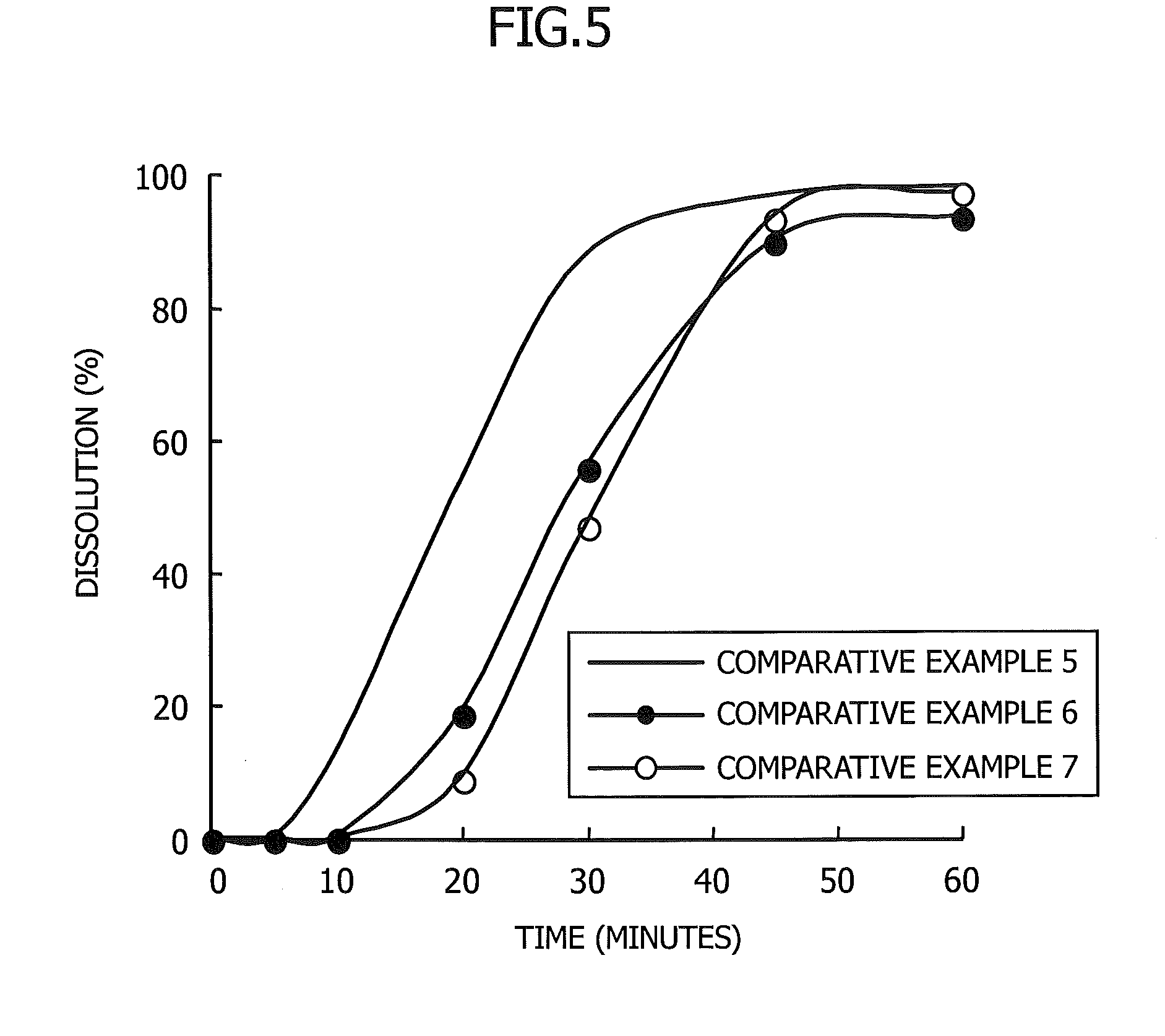

Coating Composition, Solid Preparation Coated Therewith, and Method for Preparing Solid Preparation

Owner:SHIN ETSU CHEM IND CO LTD

Shield grouting material and preparation method thereof

Owner:北京华阳众信建材有限公司

Medical hydrocolloid dressing and preparation method thereof

InactiveCN110101899APromote orderly growthPromote wound healingMicrocapsulesBandagesBurn woundBiomedical engineering

The invention provides a medical hydrocolloid dressing and a preparation method thereof. The medical hydrocolloid dressing is prepared from, by total mass percentage, 30-60% of an adhesive, 20%-50% ofsodium carboxymethyl cellulose, 0.5%-20% of bioactive glass, 0.5%-10% of beeswax, 0.5-30% of olive oil, and 0.5-40% of microcapsule wall materials. The hydrocolloid dressing can be widely used, is suitable for protecting and treating various surface wounds including ulcers, diabetic feet, lower extremity venous / arterial ulcers, pressure sores, post-operative incisions, skin donor site wounds, burn wounds and the like, and has the effects of alleviating wound bleeding, relieving inflammation and pain, effectively absorbing exudates, maintaining a moist environment, promoting rapid wound regeneration and healing, and preventing and reducing scars.

Owner:湖北中部医疗科技有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap