Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49 results about "Grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool.

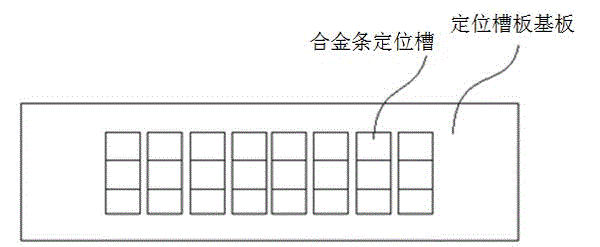

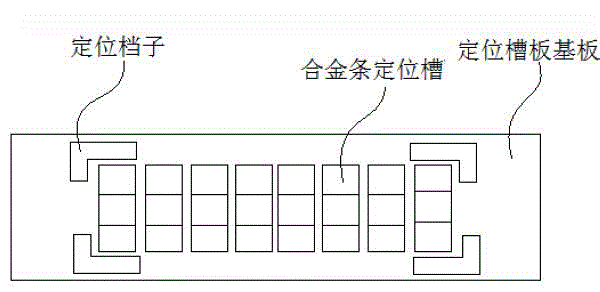

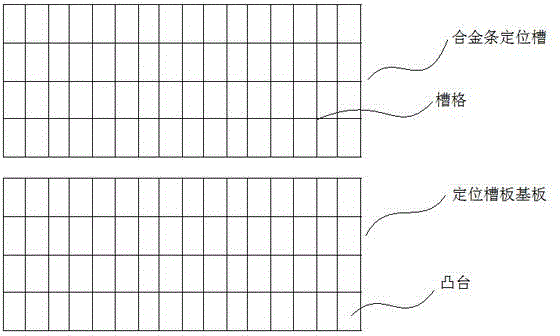

Double-sided bonding method applicable to hard alloy bars in hard alloy hard-surface machining process and application thereof

ActiveCN104976200APrecise processing sizeHigh speedMaterial gluingWelding apparatusMachined surfaceAlloy

Owner:株洲金韦硬质合金有限公司

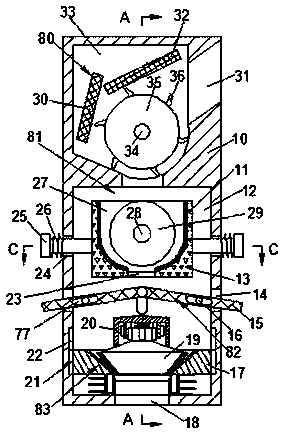

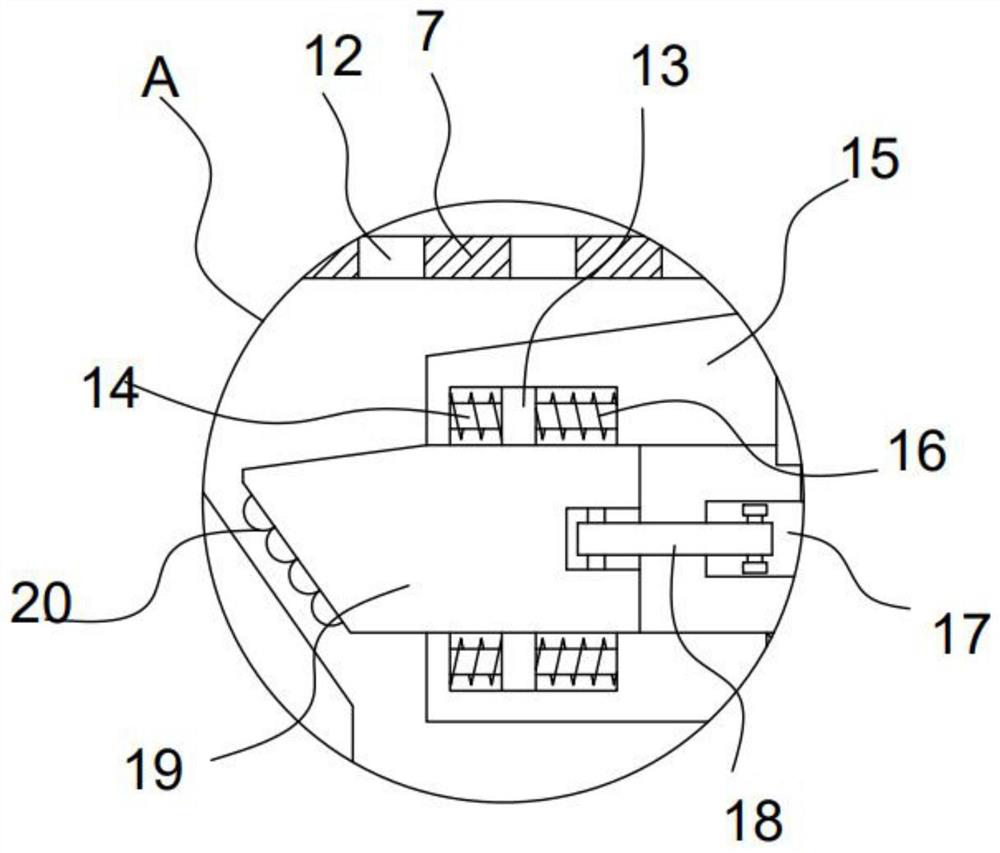

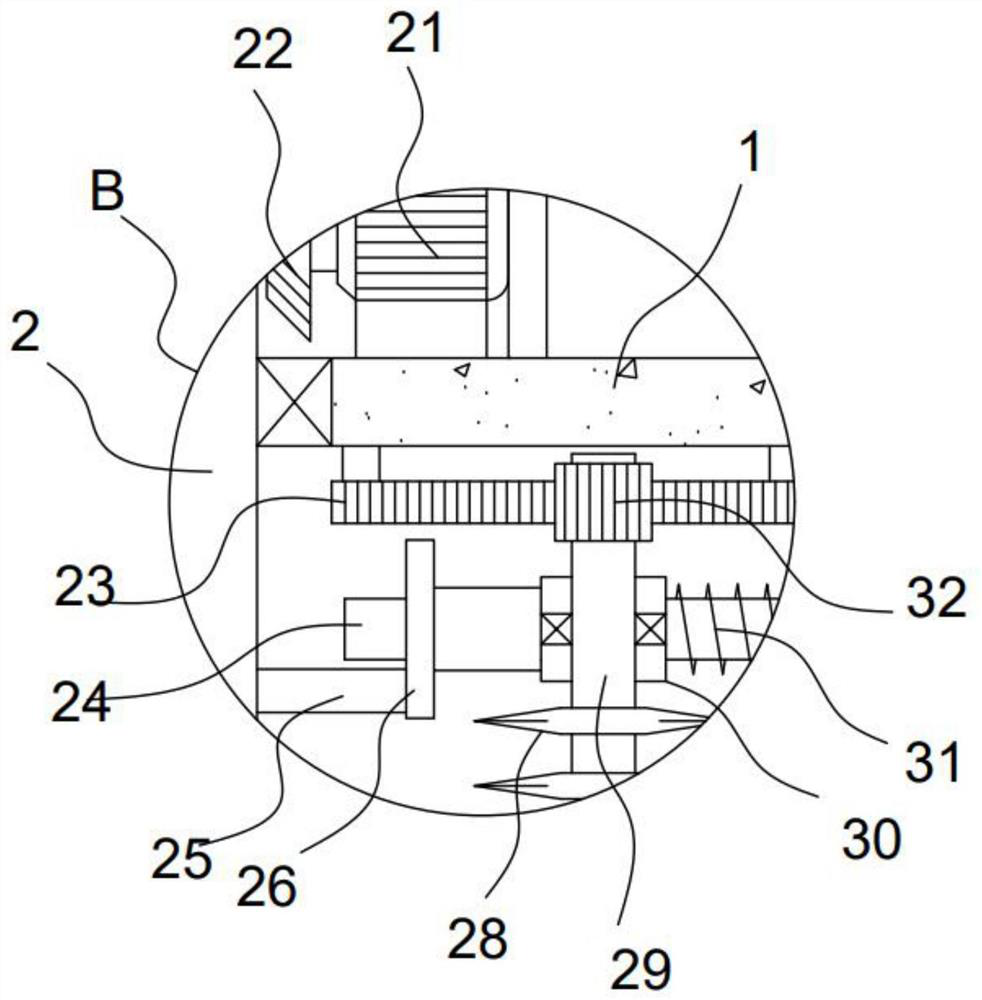

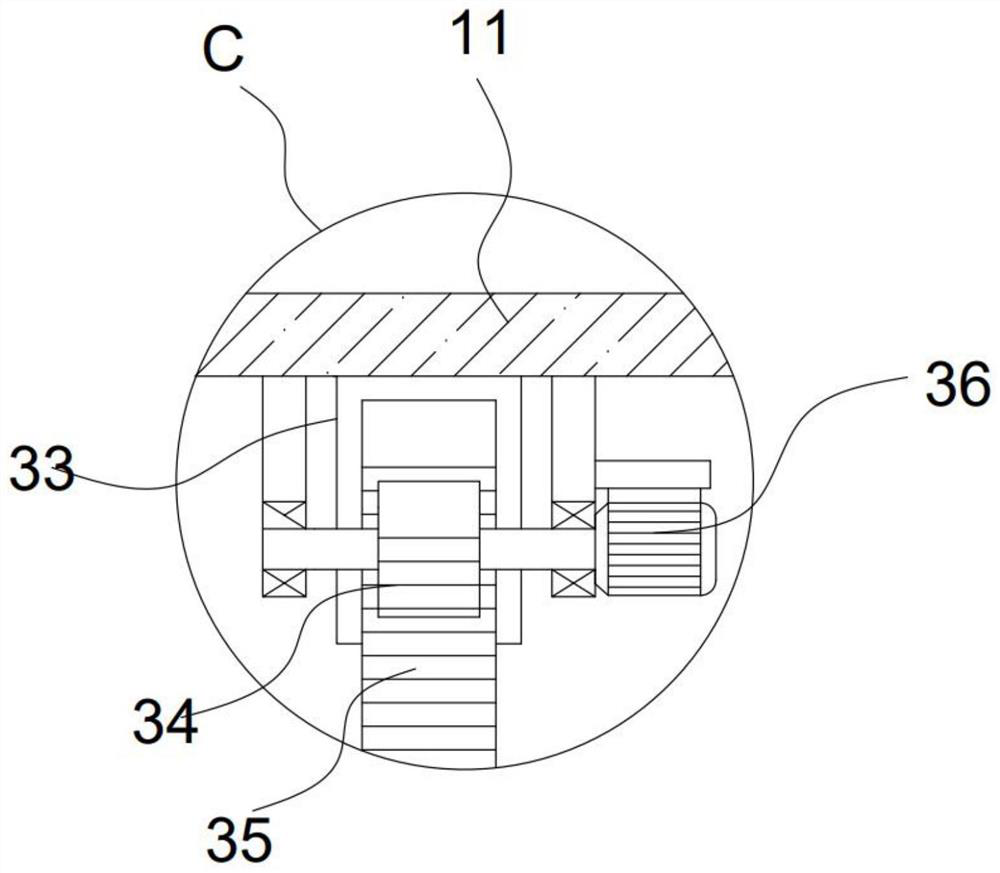

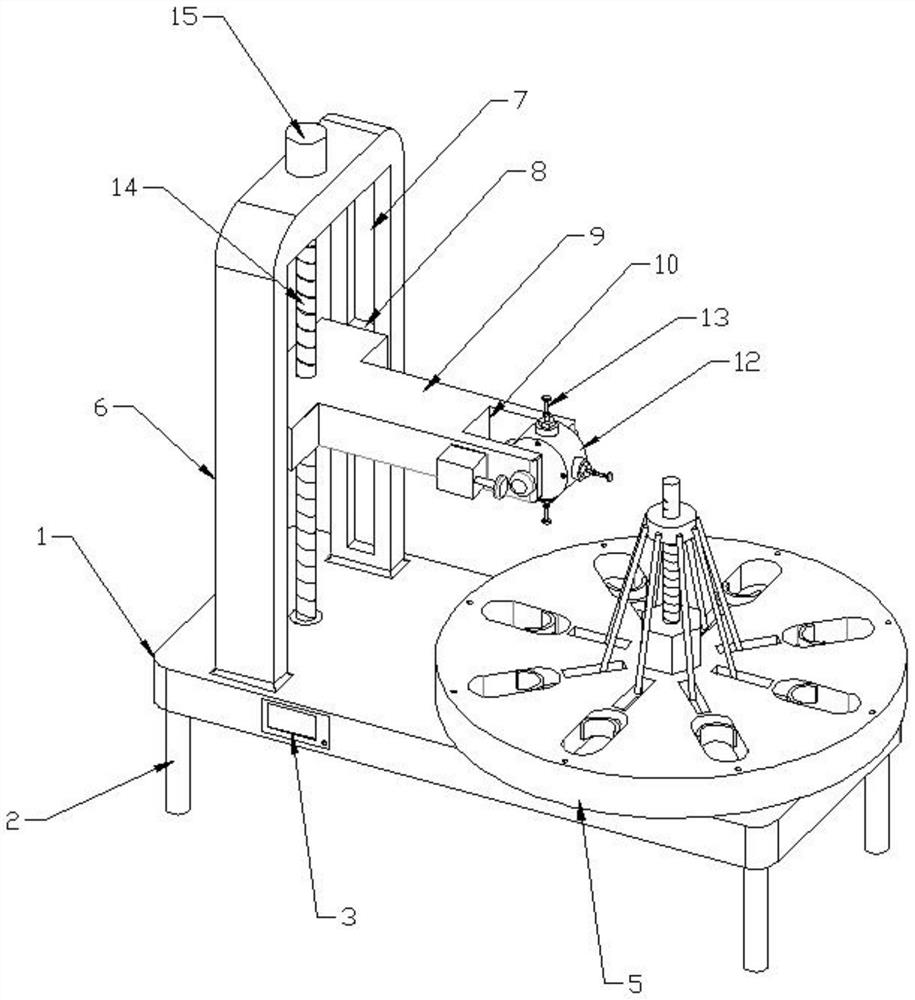

Automatic cutting, grinding and polishing machine for PCB

InactiveCN107378707AAccurate cutting positionImprove processing efficiencyGrinding feed controlGrinding machinesVertical planeWorkspace

The invention provides an automatic cutting, grinding and polishing machine for a PCB. The automatic cutting, grinding and polishing machine comprises a machine body, a working region, a clamping jaw, an action executing unit and a control panel, wherein the machine body is provided with a horizontal plane and a vertical plane which is perpendicular to the horizontal plane and is positioned at one side of the horizontal plane; the working region is arranged on the horizontal plane, and comprises a polishing disc, a grinding disc, a cutting disc and a laser aligning device; the action executing unit is arranged on the vertical plane, and the clamping jaw is connected with the action executing unit and is driven by the action executing unit to move in the vertical plane; and the control panel is arranged on the machine body and is positioned at one side of the working region. The automatic cutting, grinding and polishing machine for the PCB provided by the invention can realize advanced determining as well as automatic continuous cutting, grinding and polishing treatment of the PCB, is accurate in cutting position, is high in processing efficiency, is good in continuity, and sufficiently meets the needs, on product structure checking, of a laboratory of the PCB.

Owner:KUNSHAN HUANSHENG ELECTRONICS CO LTD

Natural stone crushing and grinding equipment

InactiveCN111389567ASimple and fast operationReduce manufacturing costSievingScreeningCrushed stoneStructural engineering

Owner:杭州瑞芳容科技有限公司

Grinding device for electrical carbon product

Owner:徐州全兴电碳制品有限公司

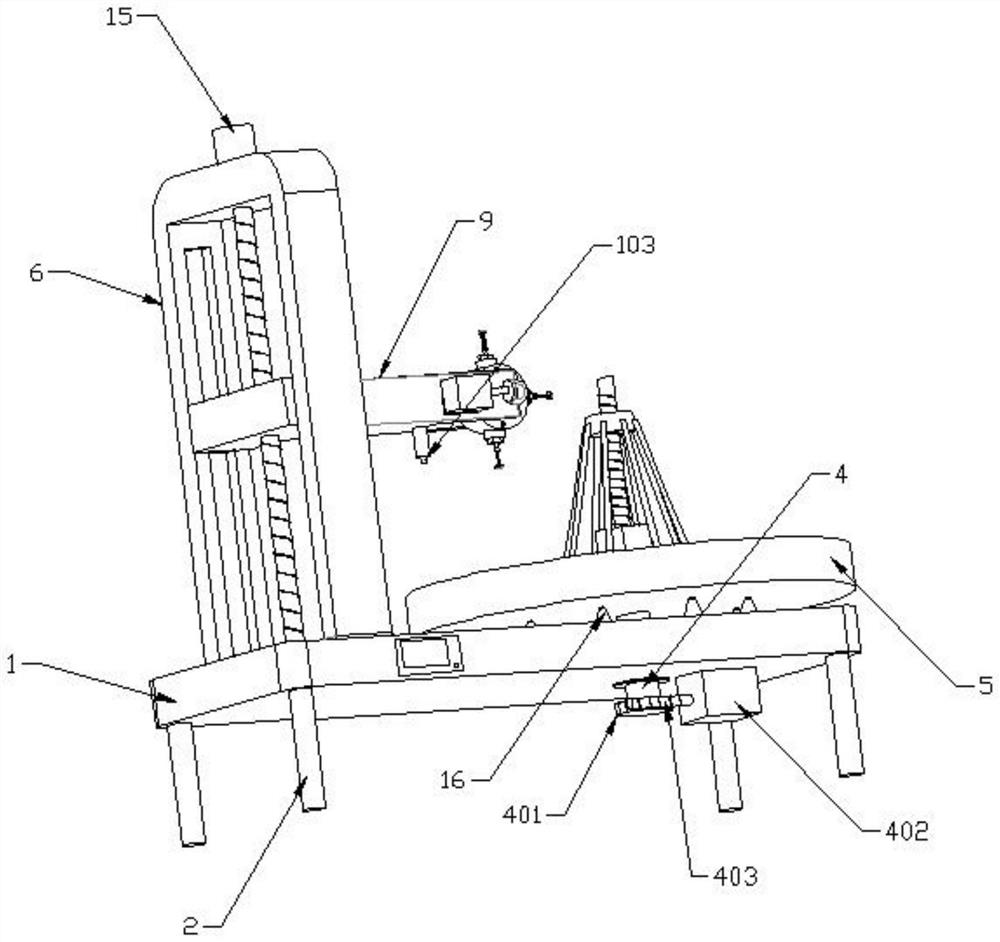

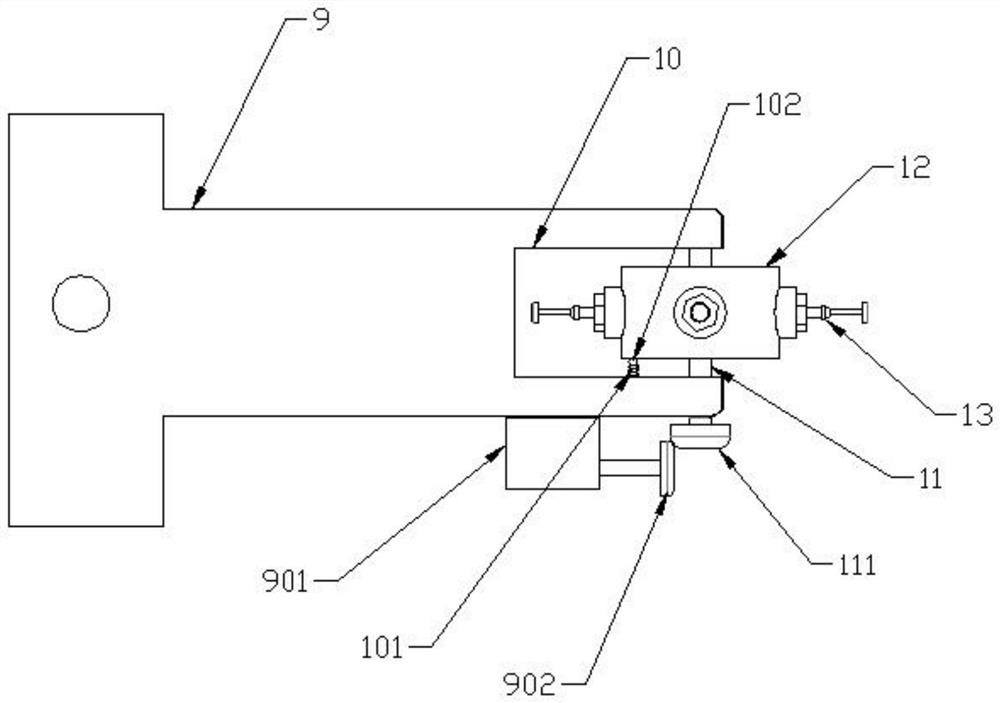

Cutting machine for production and processing of fitness equipment

Owner:南通力人健身器材有限公司

Lens thickness processing system and processing technology thereof

ActiveCN111515850AAchieve grinding workEasy to grindLapping machinesGrinding/polishing apparatusEngineeringWorkbench

Owner:深圳市晶龙达光学实业有限公司

Accurate grinding device for producing waterproof agent

Owner:上海桑格化工科技有限公司

Grinding device for producing nanometer material

Owner:LINYI UNIVERSITY

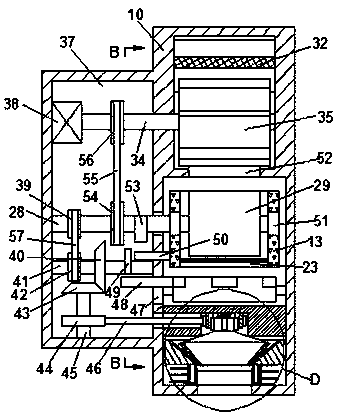

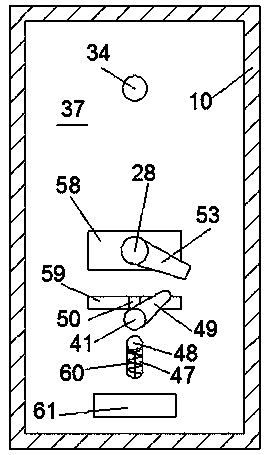

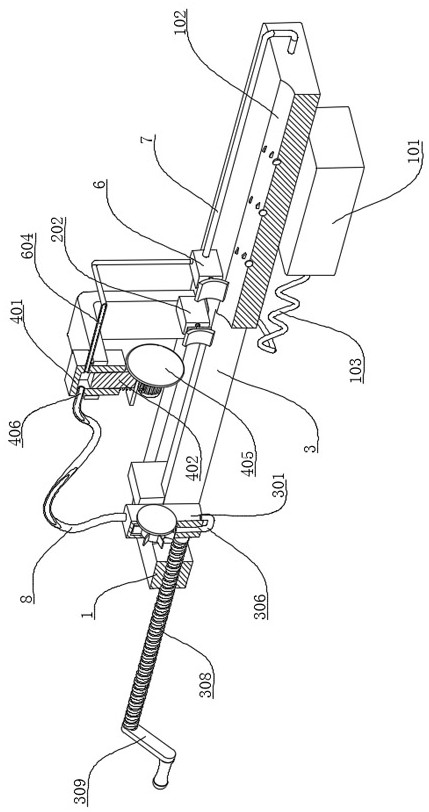

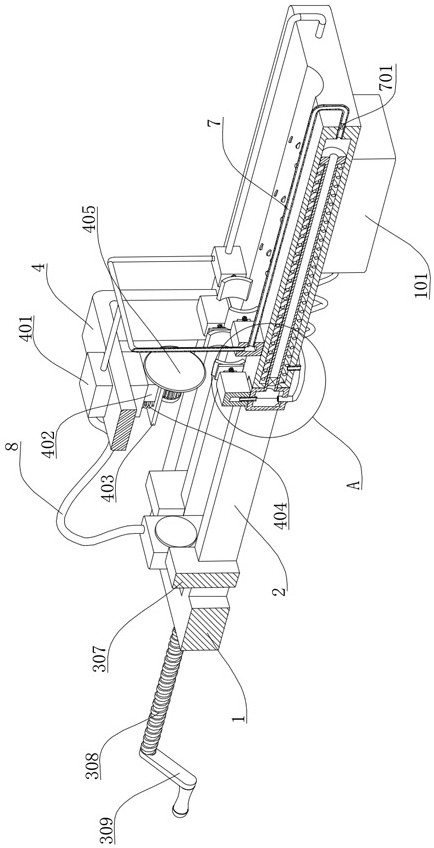

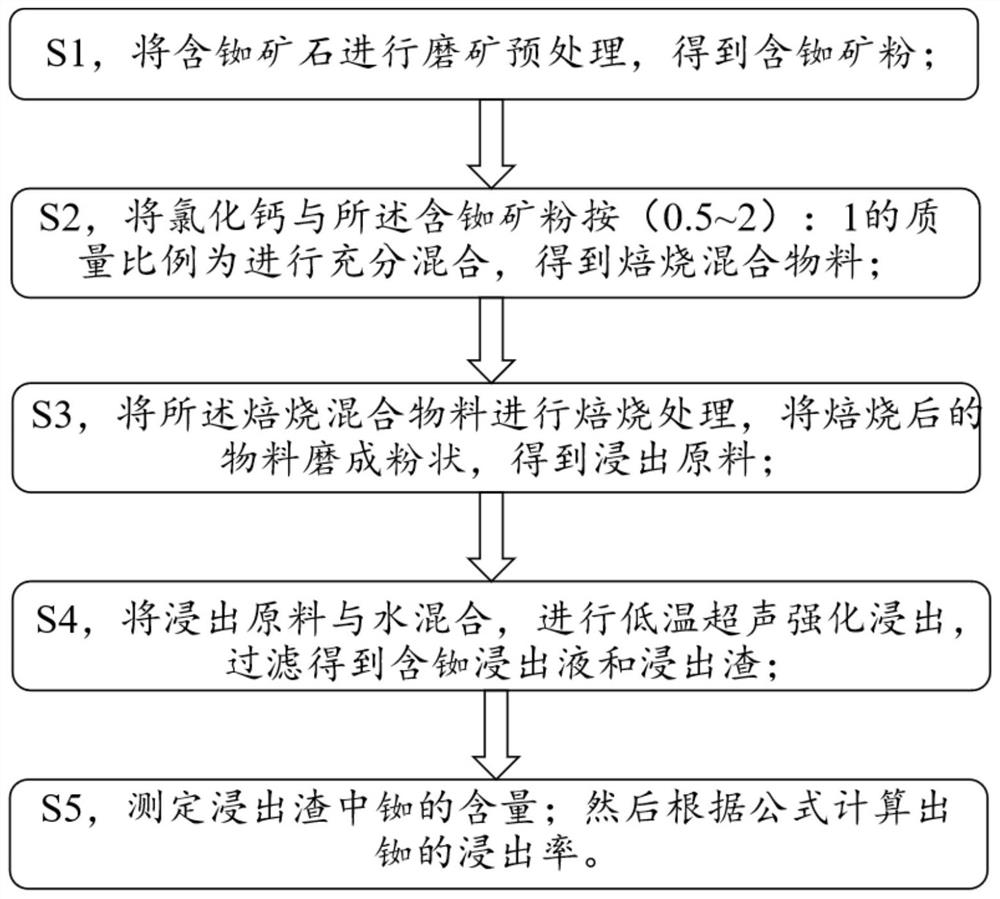

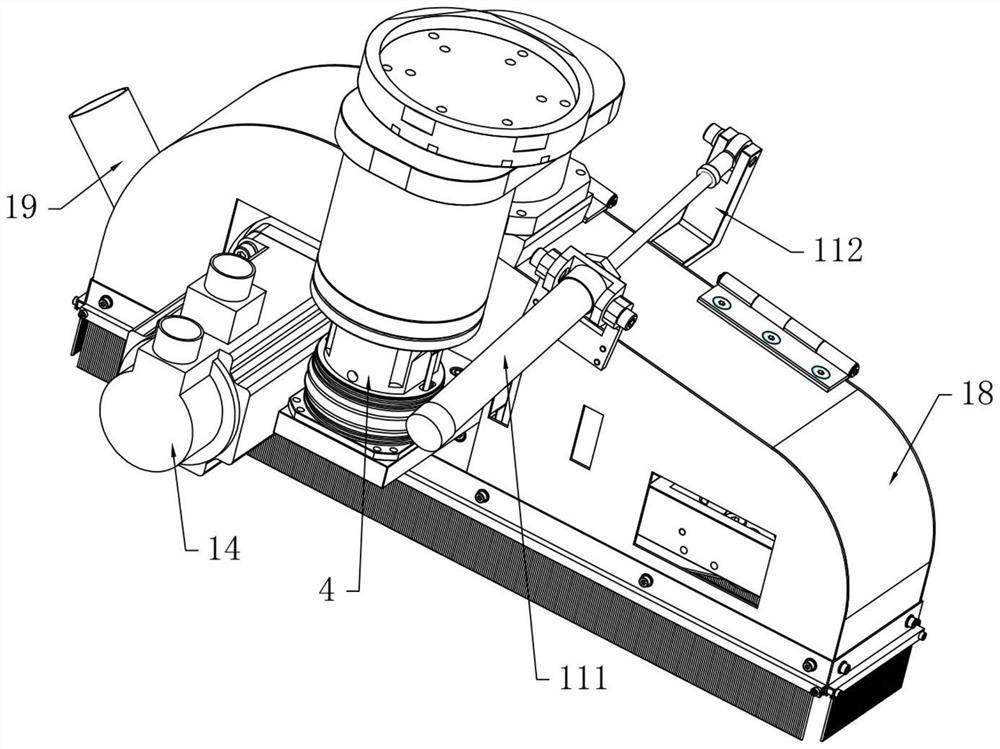

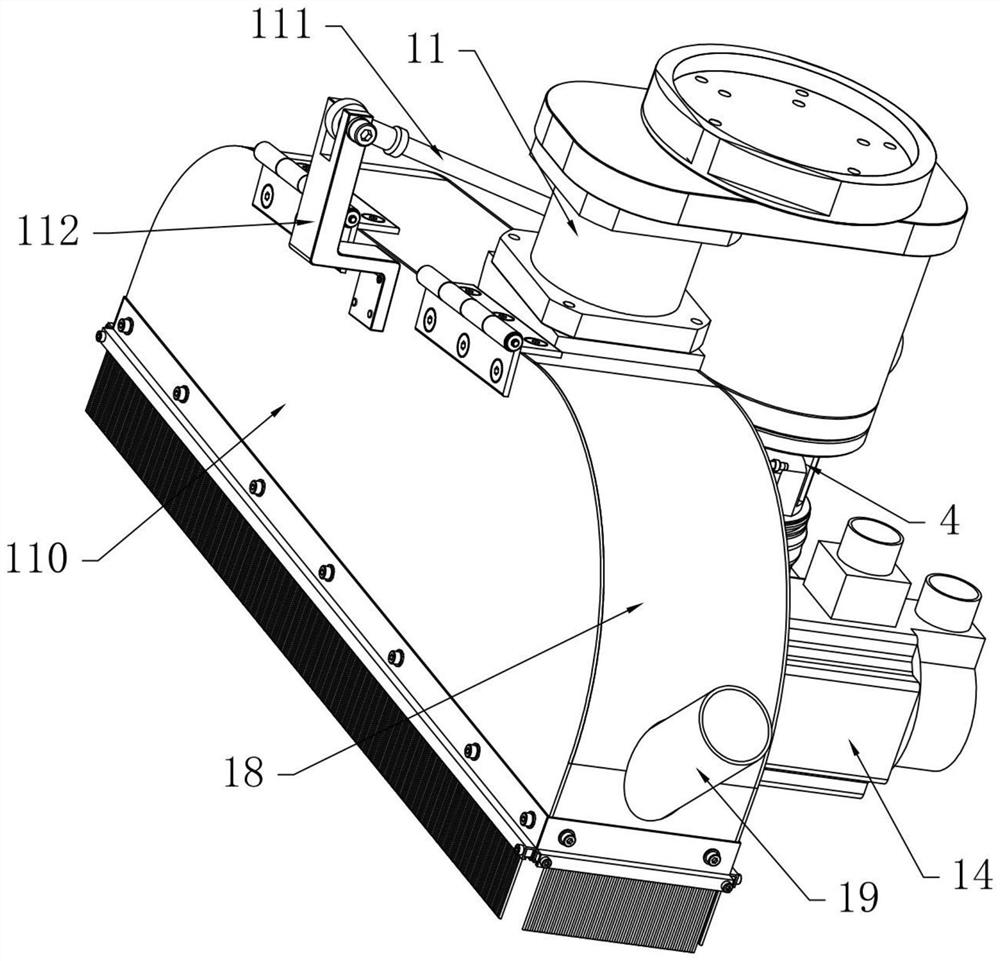

Multi-function grinding filing machine head and grinding filing machine

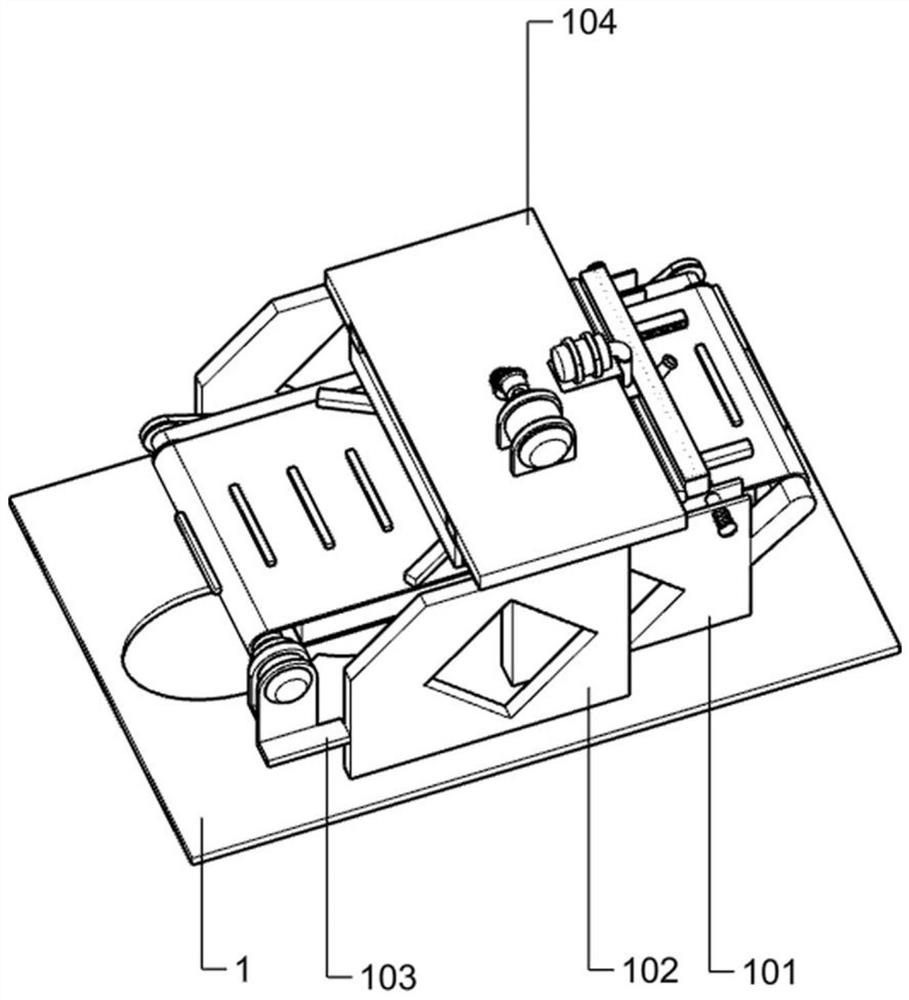

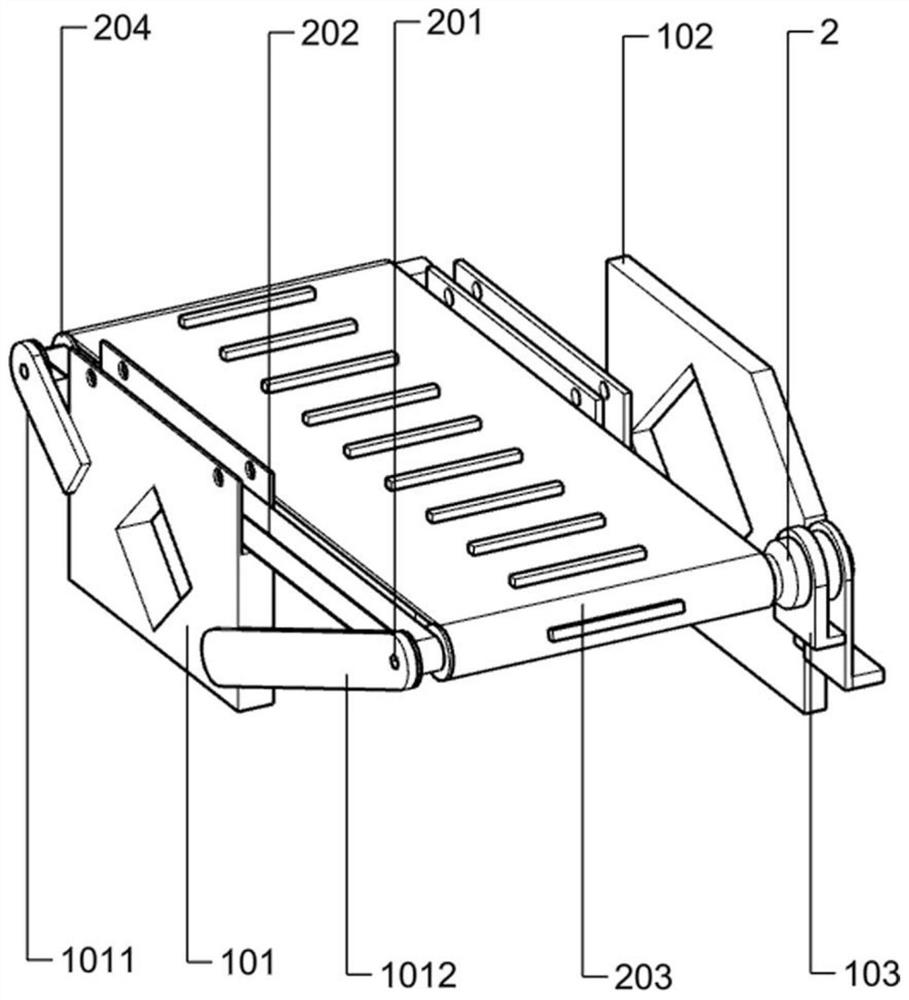

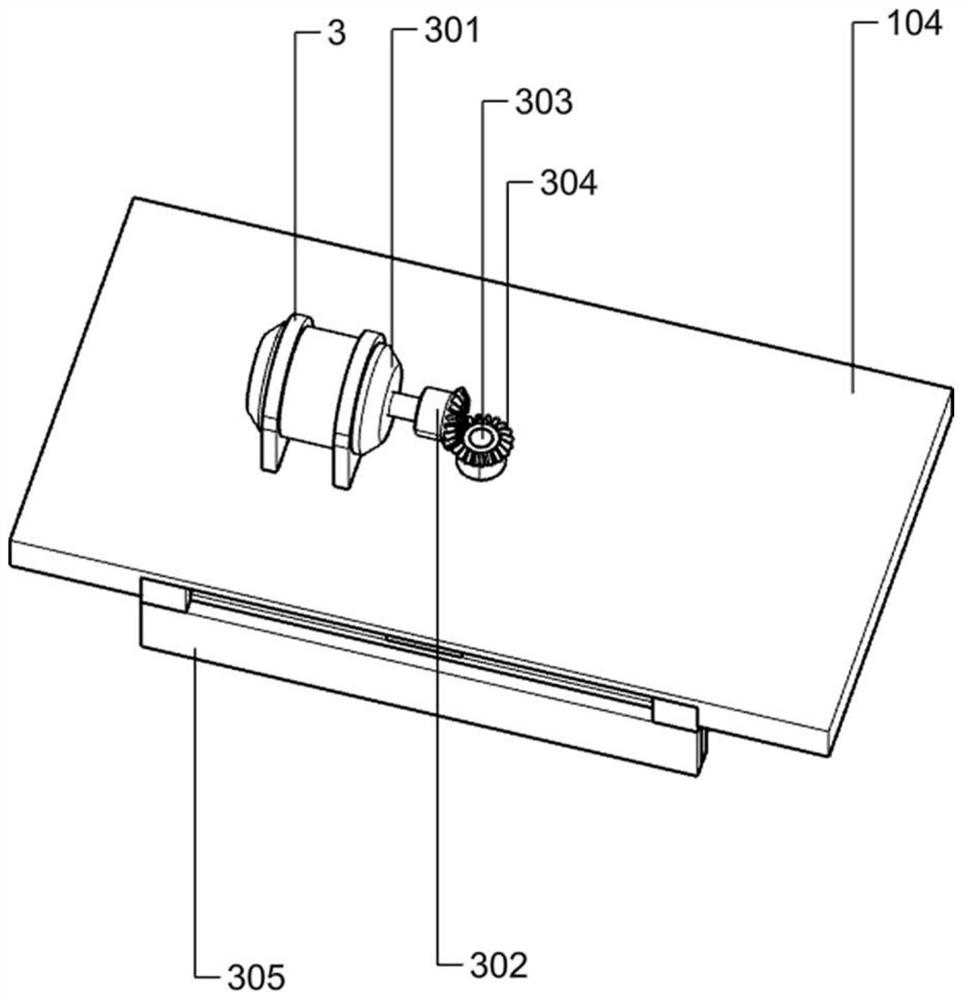

PendingCN109834542ABest orientation adjustmentAdapted to grinding tasksEdge grinding machinesGrinding drivesEngineeringMachine

The invention provides a multi-function grinding filing machine head and a grinding filing machine, and relates to the field of grinding equipment. The grinding problems that the grinding angle adjustment effect of an existing rotary support is not ideal and the existing rotary support is not suitable for longitudinal line welding inside and outside the cylinder are solved, the multi-function grinding filing machine head includes a machine seat, a power assembly, and a rotary support; the power assembly is provided with a grinding spindle for mounting and driving grinding tools, and the powerassembly is mounted on the machine seat; the machine seat is mounted on an inner ring of the rotary support, and the machine seat and the power assembly can rotate with rotation of the inner ring of the rotary support; and an axis of the grinding spindle is parallel to the rotary surface of the rotary support, and the grinding task of circumferential and longitudinal weld bead welding inside and outside a cylinder vessel can be adapted; and the multi-function grinding filing machine head of the grinding filing machine can adapt to the grinding task of circumferential and longitudinal weld beadwelding inside and outside of the cylinder vessel.

Owner:张敏

Edging device for high-density fiber cement fireproof board

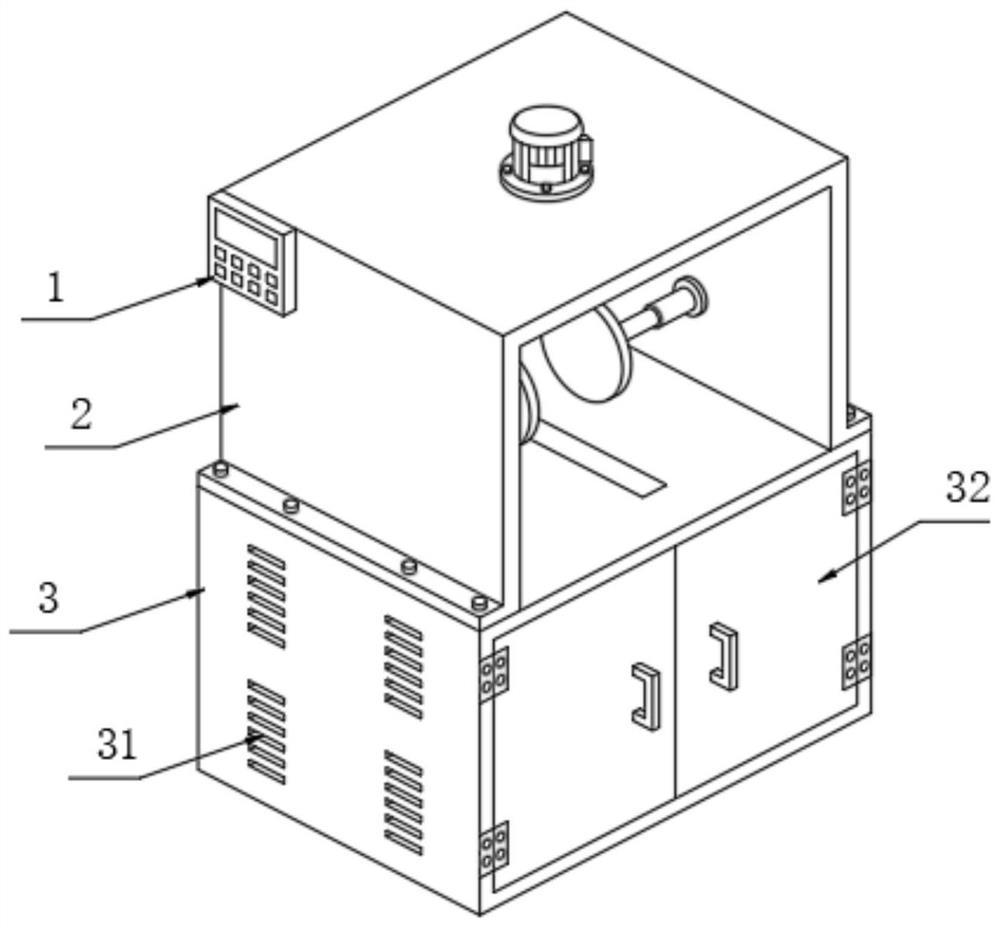

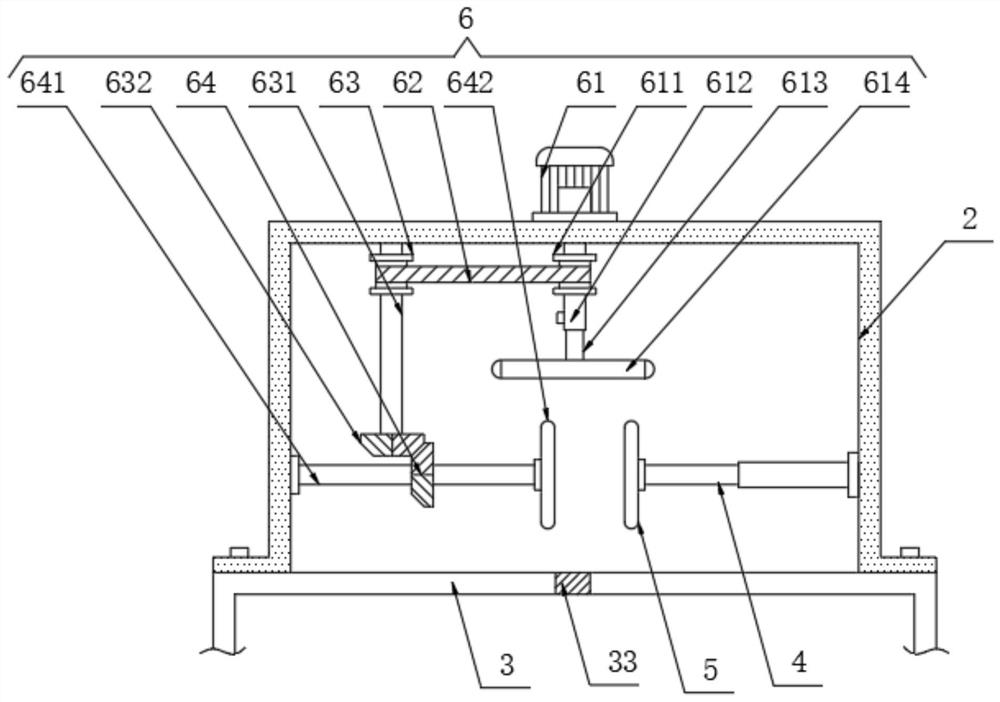

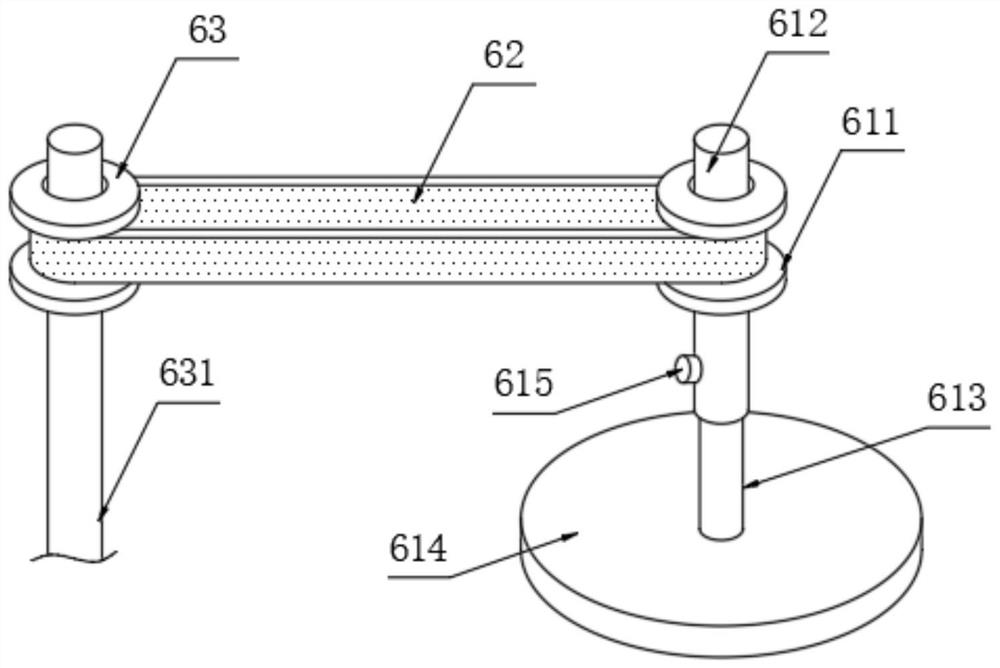

InactiveCN111660162AStable positionAvoid affecting the working environmentEdge grinding machinesGrinding drivesFiberThermodynamics

The invention belongs to the field of cement fireproof board processing equipment, and in particular is an edging device for a high-density fiber cement fireproof board. Aiming at the problem that manual handheld grinders are required for existing grinding operations, which is time-consuming and laborious, has low grinding efficiency, and is easy to produce large amounts of dust during the grinding to cause pollution of the surrounding environment, the following solution is proposed that the edging device comprises an operating table, wherein the top of the operating table is fixedly installedwith a raised platform, the top of the raised platform is fixedly installed with a placement board, the top of the placement board is placed with a fireproof board, two grooves are formed on the topof the placement board, clamping plates are slidably installed in both grooves, and the sides of the two clamping plates close to each other are in contact with two sides of the clamping plate respectively. The edging device has a reasonable structure and convenient operation. During the edging operation, the grinding head can be controlled automatically for grinding to save time and labor and have high grinding efficiency, and the dust generated can be processed while grinding without polluting the surrounding environment.

Owner:要虎岭

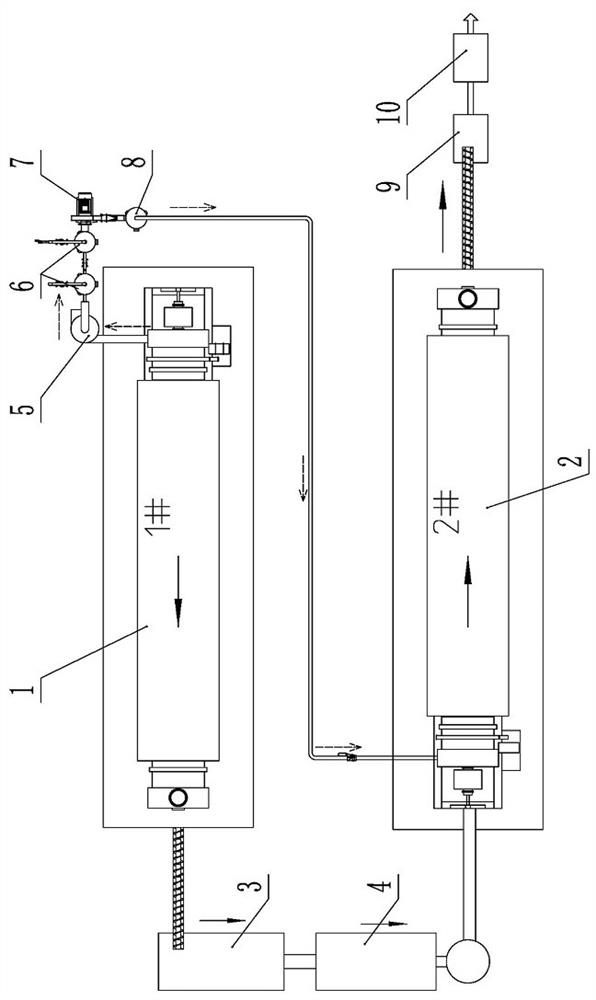

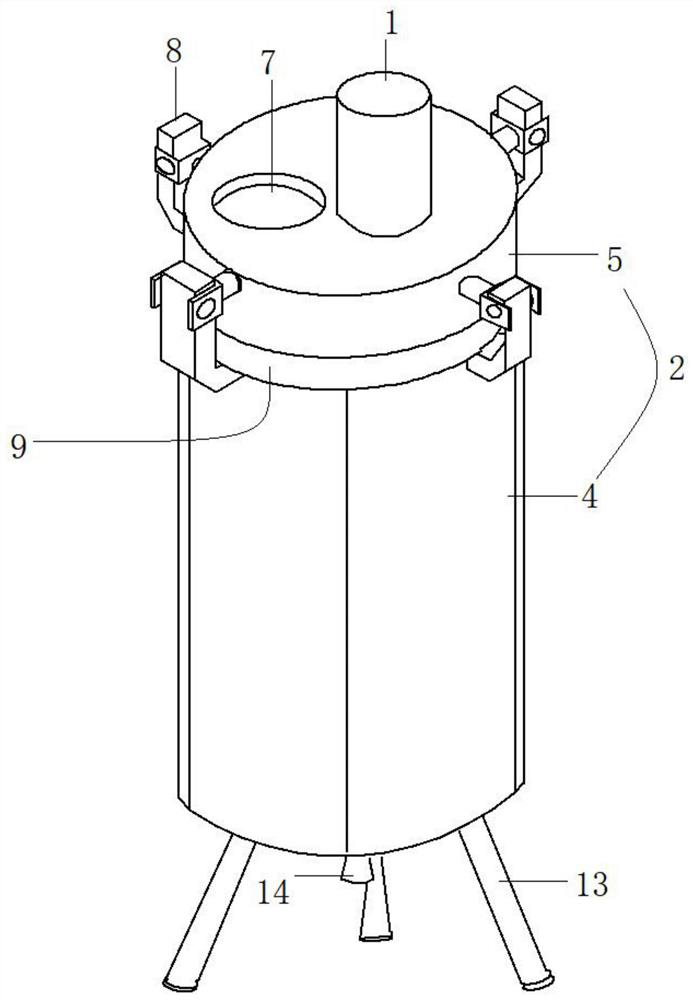

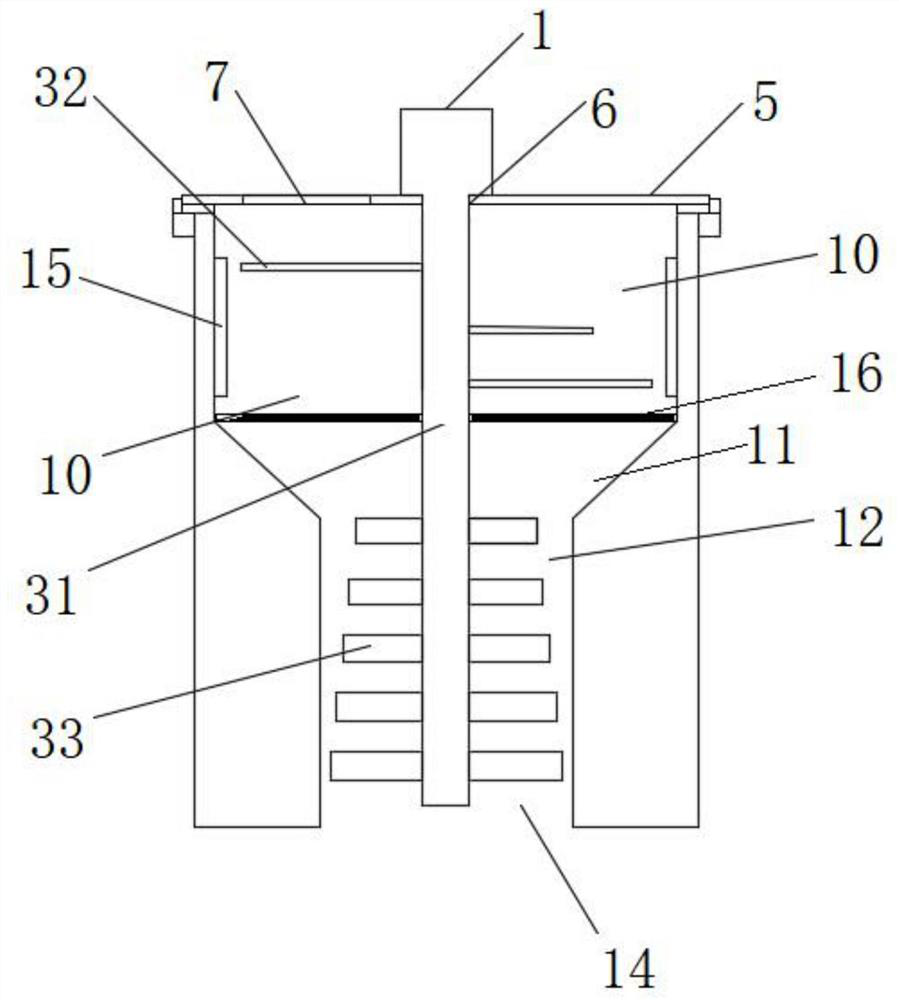

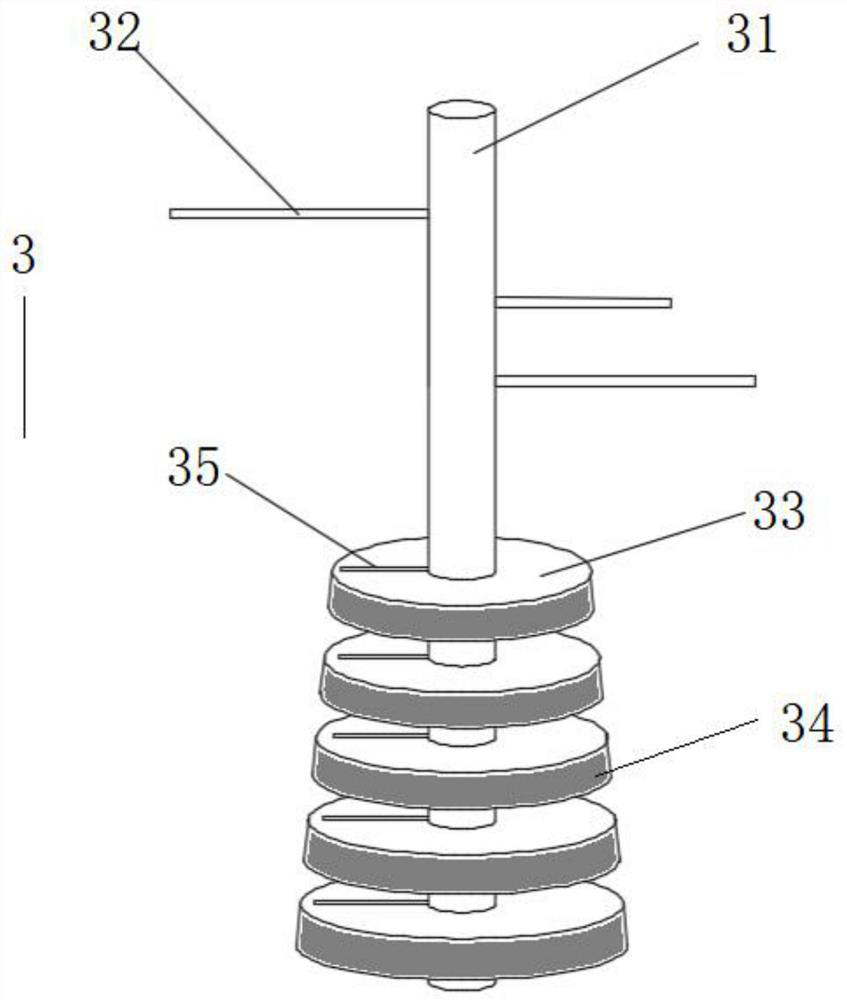

Raw material pretreatment device for hydrogen purification

InactiveCN113210089ARealize the rotary shredding effectImprove chopping effectGrain treatmentsReciprocating motionStructural engineering

Owner:WUHU MEDIUM HYDROGEN NEW ENERGY TECH CO LTD

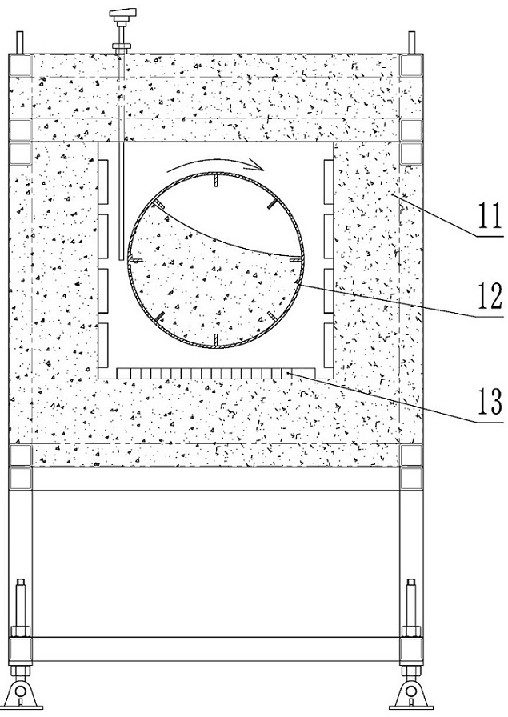

Preparation process and system for producing high-grade titanium-rich material by utilizing ilmenite

ActiveCN111733336AThere is no limit to the choice of materialsLow failure rateRotary drum furnacesMagnetic separationDust controlIlmenite

Owner:湖南碳谷装备制造有限公司

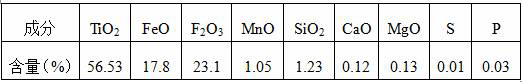

Method for extracting rubidium from rubidium-containing ore through ultrasonic strengthening

Owner:WUHAN UNIV OF SCI & TECH

Manufacturing process for glasses frame

Owner:重庆亚美欧眼镜有限公司

Belt sander

PendingCN112123118AQuick changeEasy to change clothesBelt grinding machinesSanderStructural engineering

Owner:SUNRISE INSTR CO LTD

Metal automatic grinding seal device

Owner:CHENGDU NINGJIA HONGFU TECH CO LTD

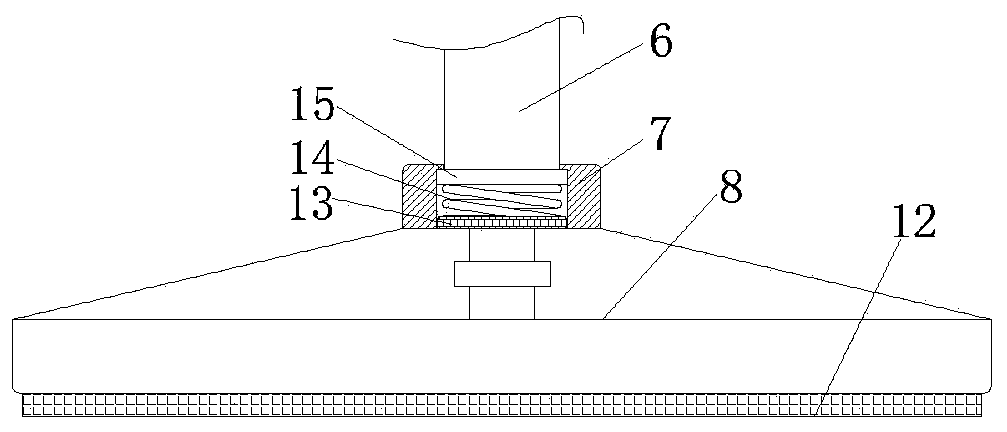

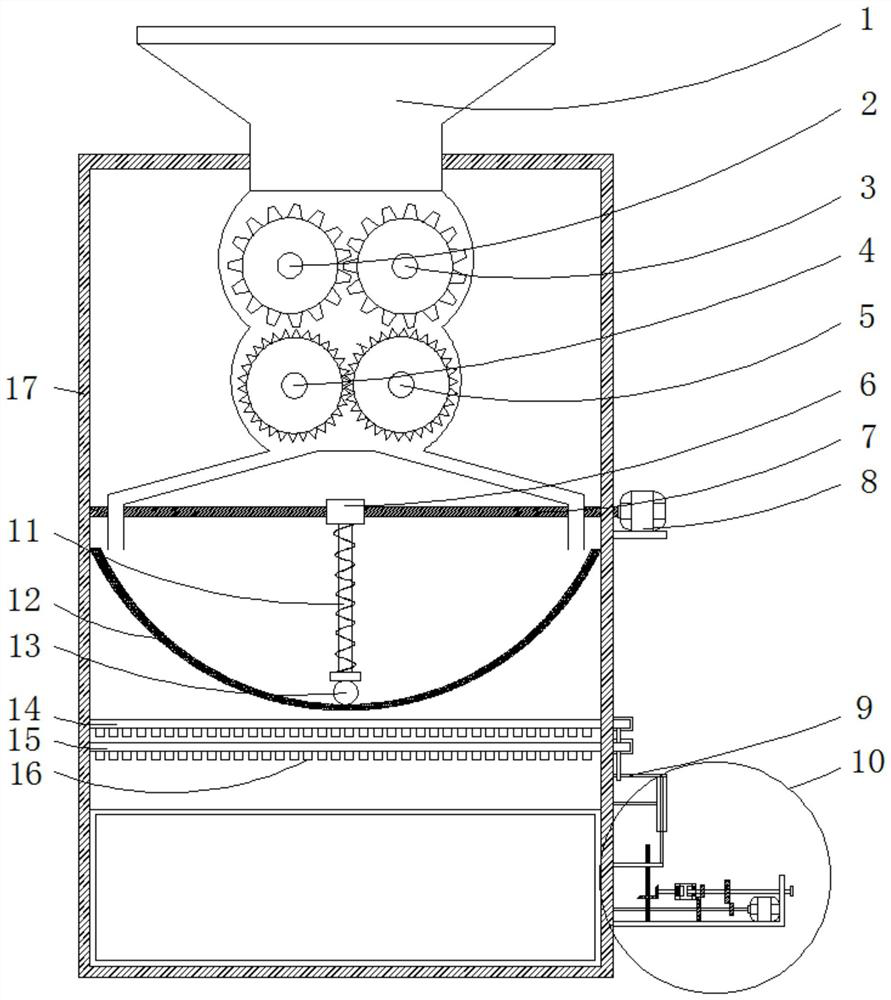

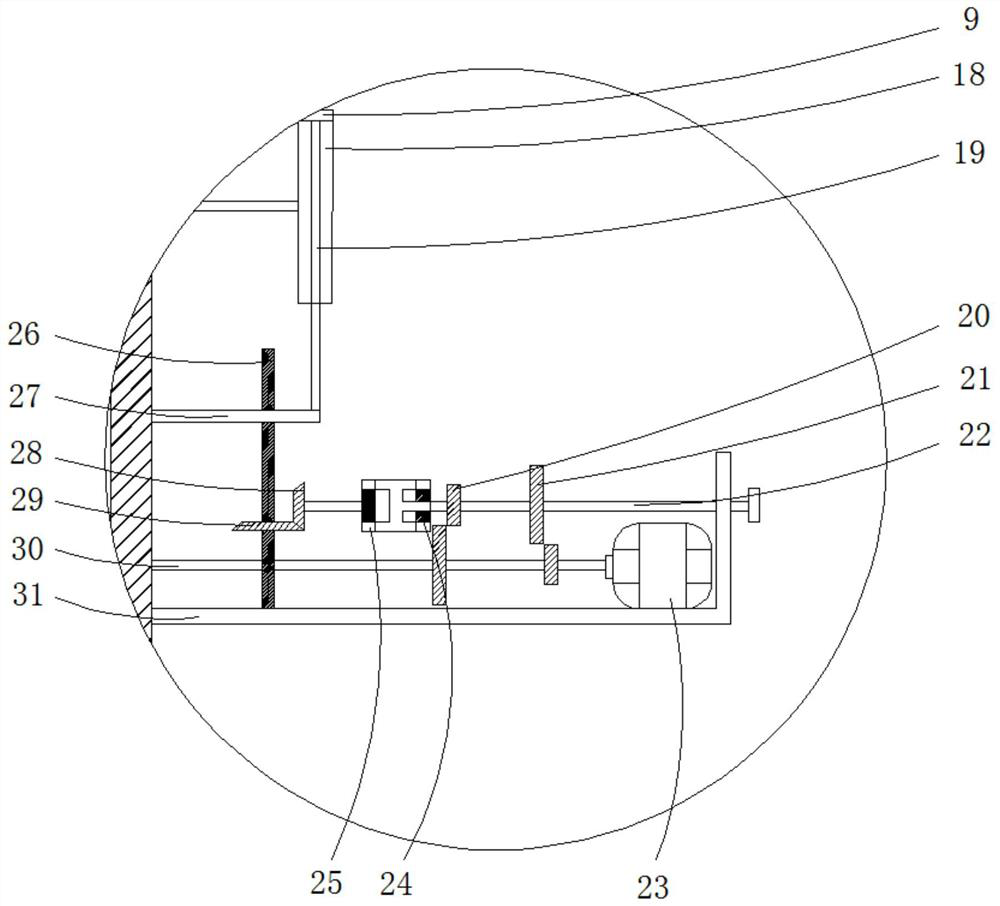

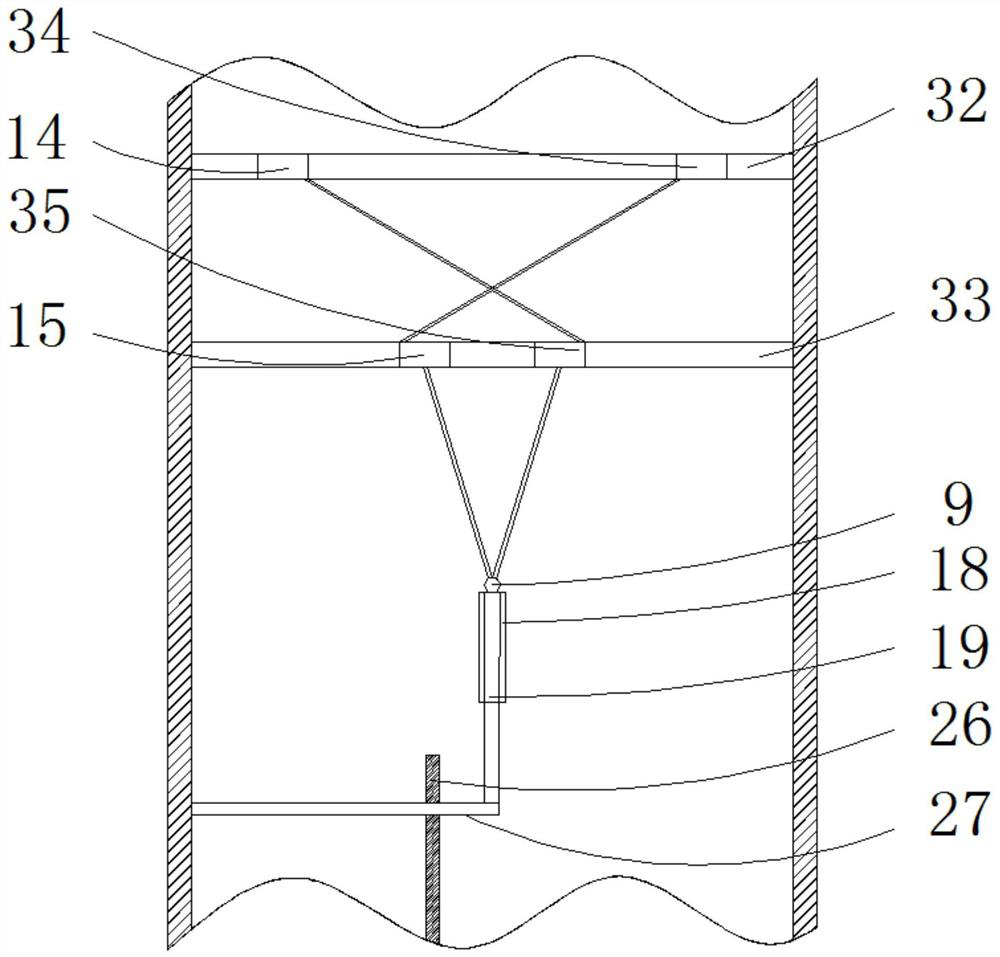

Multifunctional livestock raising smashing equipment capable of preventing fodder from caking

InactiveCN111545279AIncrease speedQuick grindingFeeding-stuffGrain treatmentsAgricultural scienceCrop livestock

Owner:TARIM UNIV

Spiral bevel gear rough milling cutter of novel structure

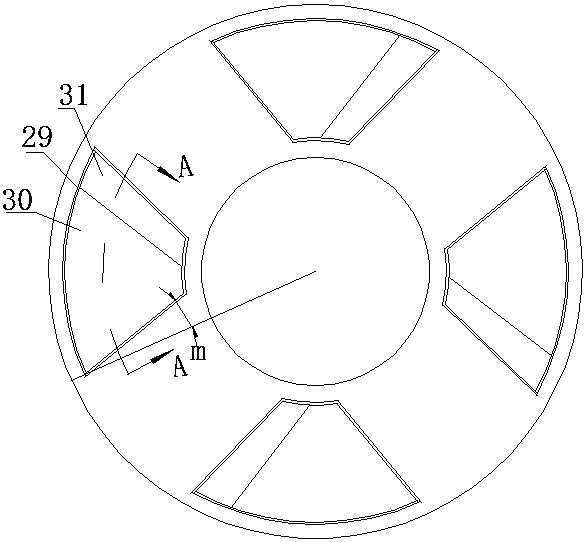

InactiveCN112404608AWarranty requirementsGear teeth manufacturing toolsGear teethTool bitMilling cutter

The invention discloses a spiral bevel gear rough milling cutter product. The spiral bevel gear rough milling cutter product comprises cutter heads, an angular positioning pin, two compression screws,a cutter disc, a gasket and a blind rivet, and is characterized in that the cutter heads are clamped on the cutter disc, the angular direction is determined through the angular positioning pin, clamping is conducted in the radial direction through the two compression screws, the two compression screws are placed on the rear end face of a hole of the cutter disc, and the blind rivet penetrates through the gasket and is screwed into threaded holes in the rear ends of the cutter heads. The cutter heads are clamped on the cutter disc and are uniformly distributed at 24 positions in the circumferential direction to form cutter teeth of the product, the assembled product is ensured to meet the requirements that the axial run-out requirement is 0.04 and the radial run-out is 0.02, and the clamped cutter disc is clamped on a special cutter shaft. The spiral bevel gear rough milling cutter product mainly aims to change the structural shapes of the cutter disc and the cutter teeth and reduce the machining difficulty of the cutter teeth. Therefore, a universal high-precision grinding machine can be used for machining products.

Owner:HARBIN DONGAN LIFENG CUTTER

Chinese medicinal material grinding device

Owner:YUEYANG INTEGRATED TRADITIONAL CHINESE & WESTERN MEDICINE HOSPITAL SHANGHAI UNIV OF CHINESE TRADITIONAL MEDICINE

Insulation rubber surface processing device

InactiveCN111015395AGood surface treatmentExtended service lifeLiquid surface applicatorsGrinding drivesEngineeringMaterials science

The invention discloses an insulation rubber surface processing device. The insulation rubber surface processing device comprises a shell, and is characterized in that a feeding cavity is formed in the shell, a transmission cavity is arranged behind the feeding cavity, a grinding box is arranged in the feeding cavity and internally provided with a grinding cavity, a grinding mechanism for grindingthe insulation rubber surface is arranged in the grinding cavity, and the grinding mechanism comprises a first shaft rotationally connected to the rear side wall of the grinding cavity and extendingforwards and backwards. By means of the insulation rubber surface processing device, the insulation rubber surface can be conveniently processed; by arranging a brightener smearing mechanism, the insulation rubber surface can be smeared with a brightener, the insulation rubber surface is more durable in use, and the service life of the insulation rubber surface is prolonged; and by arranging a collecting mechanism, insulation rubber can be directly packaged, and labor is saved.

Owner:DONGYANG ZONGTIAN ELECTRONICS TECH CO LTD

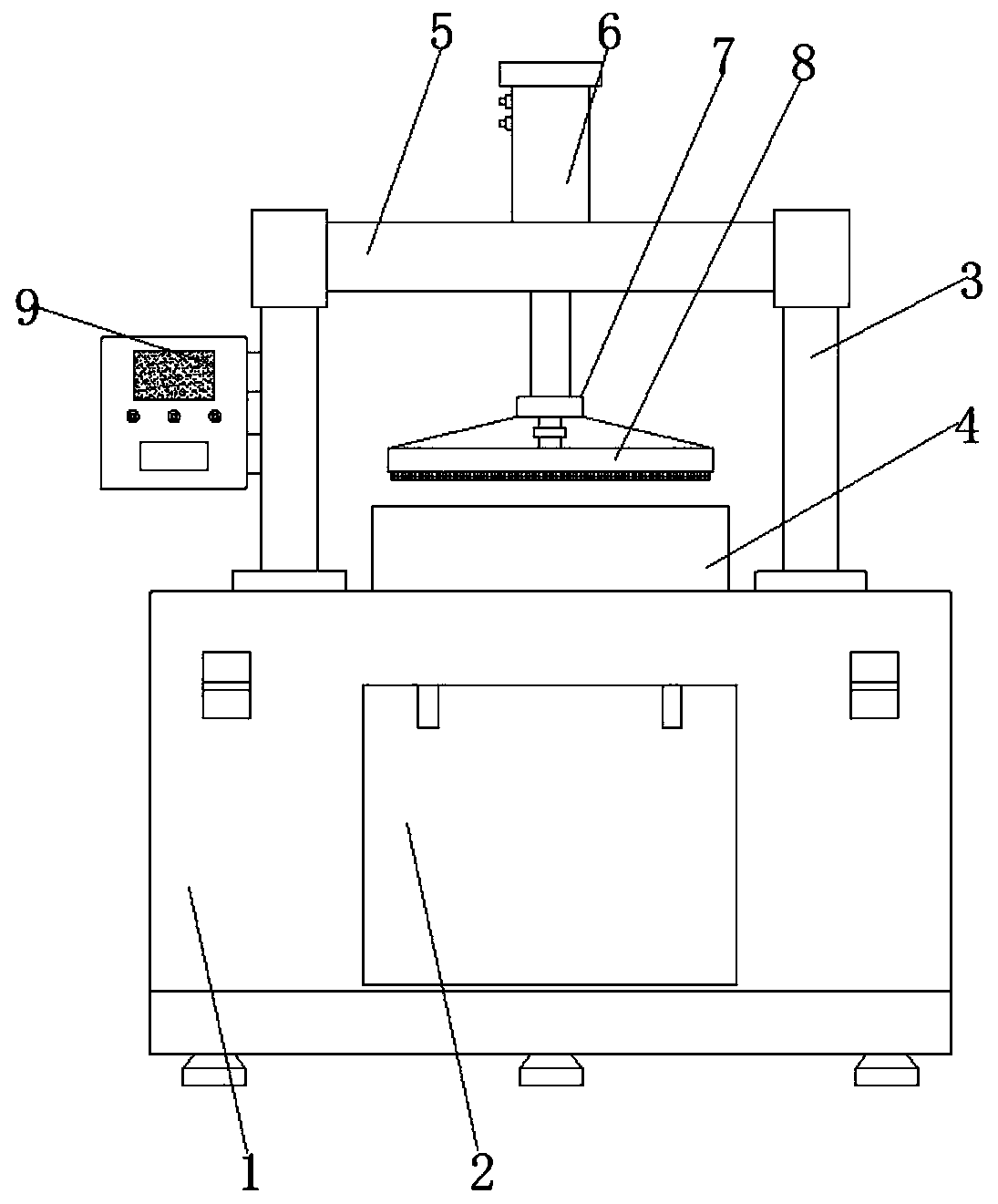

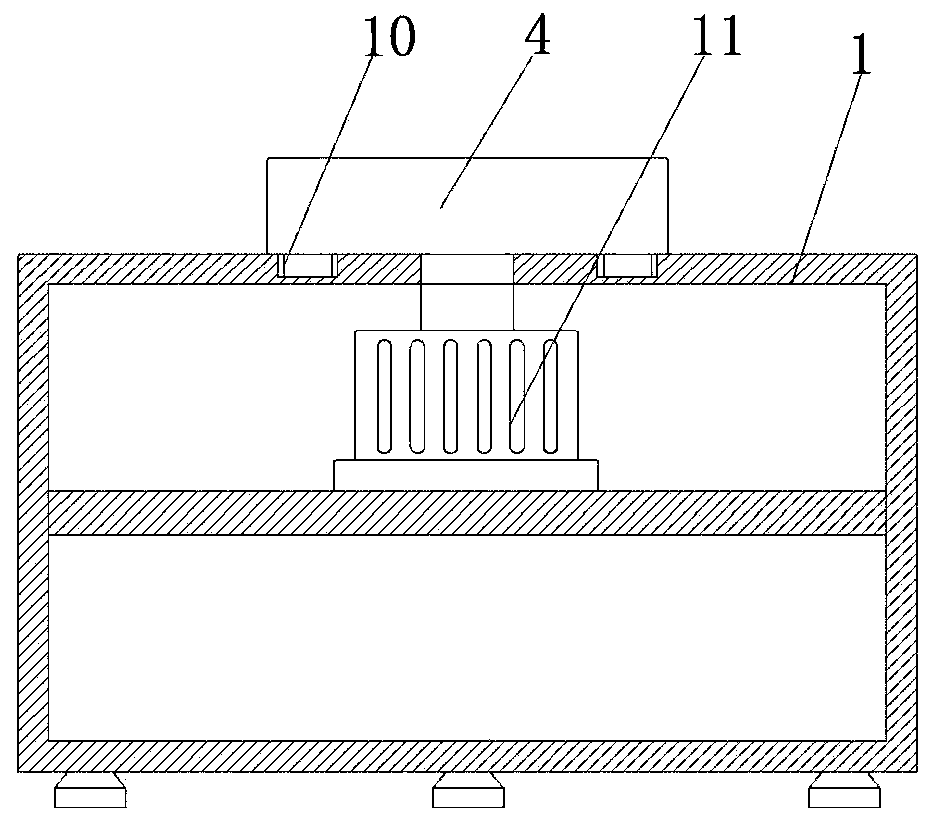

Grinding and polishing device and process

InactiveCN112621558AReduce processImprove processing efficiencyLapping machinesLapping toolsLiquid storage tankProcess engineering

The invention discloses a grinding and polishing device and process, and relates to the technical field of grinding and polishing. The grinding and polishing device comprises a U-shaped frame and a bottom plate, a transverse rod is fixedly connected to one side of the middle of the U-shaped frame, a top plate is slidably connected to the top of the transverse rod, a collecting pool is fixedly connected to the middle of the top of the bottom plate through a supporting column, and the bottom of the collecting pool is fixedly connected with a collecting pipe. By arranging the top plate, raw materials do not need to be moved when the raw materials are processed, a grinding head and a liquid outlet pipe can be used for processing the raw materials at different working procedure time by moving the top plate, and therefore the purposes of saving the working procedures and improving the processing efficiency are achieved; and by arranging the collecting pipe, when polishing is carried out, polishing liquid in the collecting pool can be discharged, the polishing liquid enters a liquid storage tank again to be recycled, then the polishing liquid is pumped out again through a submersible pump, and therefore the purpose of reutilization is achieved.

Owner:寻瀚之

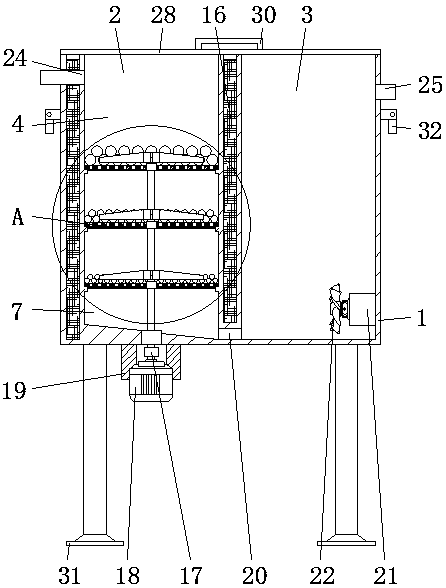

Roller supporting device of stepping type multi-station centerless roller cylindrical grinding machine

ActiveCN114147598APrevent jumpingImprove coaxialityRevolution surface grinding machinesGrinding drivesEngineeringMachine

The invention belongs to the technical field of roller grinding, and particularly discloses a stepping type multi-station centerless roller cylindrical grinding machine roller supporting device which comprises a roller supporting device body, a roller servo jacking device and a roller air cylinder jacking device, the roller supporting device body comprises a supporting plate, a roller jacking plate and a driving mechanism, and a roller can be placed on the top of the supporting plate; roller jacking plates parallel to the supporting plate are arranged on the front portion and the rear portion of the upper portion of the supporting plate correspondingly, the roller jacking plates are movably connected with the supporting plate, and under the action of a driving mechanism, the roller jacking plates can vertically move upwards relative to the supporting plate to jack rollers or vertically move downwards to be away from the rollers. The ejection head and the air cylinder extension rod ejection head can horizontally move left and right to approach and eject the roller or be far away from the roller, so that the roller is prevented from jumping during machining, the coaxiality of the roller after arc opening and fine grinding is improved, the quality of finished products is improved, and the machining precision is improved.

Owner:QINGYAN PRECISION BEARING RES INST (LUOYANG) CO LTD +1

Preparation method of single-sided high-glossiness 6061-H22 state aluminum alloy mirror plate

Owner:河南明晟新材料科技有限公司

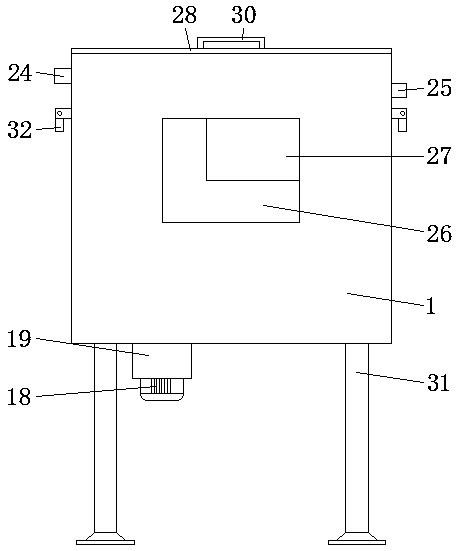

Microwave ceramic production equipment

PendingCN113695003AQuality improvementGrind fullyRotary stirring mixersGrain treatmentsProcess engineeringMaterials science

The invention discloses microwave ceramic production equipment, and relates to the technical field of microwave ceramic production. Aiming at the problem that traditional microwave ceramic production equipment can only perform single grinding or stirring and the like, the following scheme is provided. The microwave ceramic production equipment comprises a first box body, and two grinding rollers are rotationally connected to the inner walls of the front surface and the back surface of the first box body. According to the microwave ceramic production equipment, raw materials can be ground more sufficiently, the quality of microwave ceramic is improved, the evenly-mixed microwave ceramic raw materials can be conveniently transported, workers can conveniently conduct next-step operation, the ground microwave ceramic raw materials can be screened, the situation that the quality of microwave ceramic finished products is affected due to the fact that the raw materials which are not ground sufficiently enter the next procedure is avoided, the ground raw materials can be mixed uniformly, the defective product production rate is reduced, the whole device is driven by one motor to move, the use cost is saved, grinding, mixing and transportation are integrated, the production time of the microwave ceramics is greatly saved, the operation is simple, and the use is convenient.

Owner:聂政

Grinding and polishing device and method based on glass machining

ActiveCN113696004AChange heightReduce the difficulty of manual cleaningGrinding carriagesRevolution surface grinding machinesPolishingEngineering

Owner:湖北浠玻实业有限公司

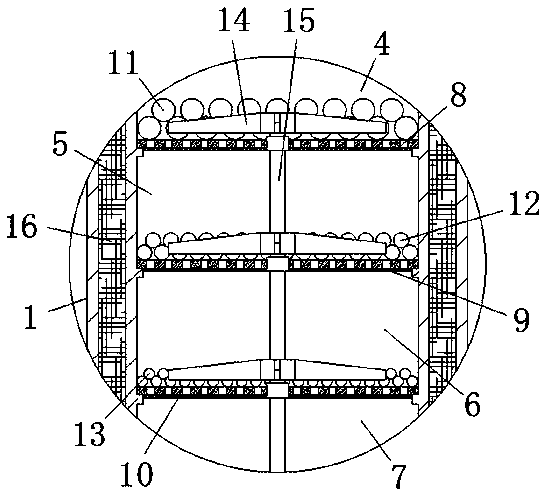

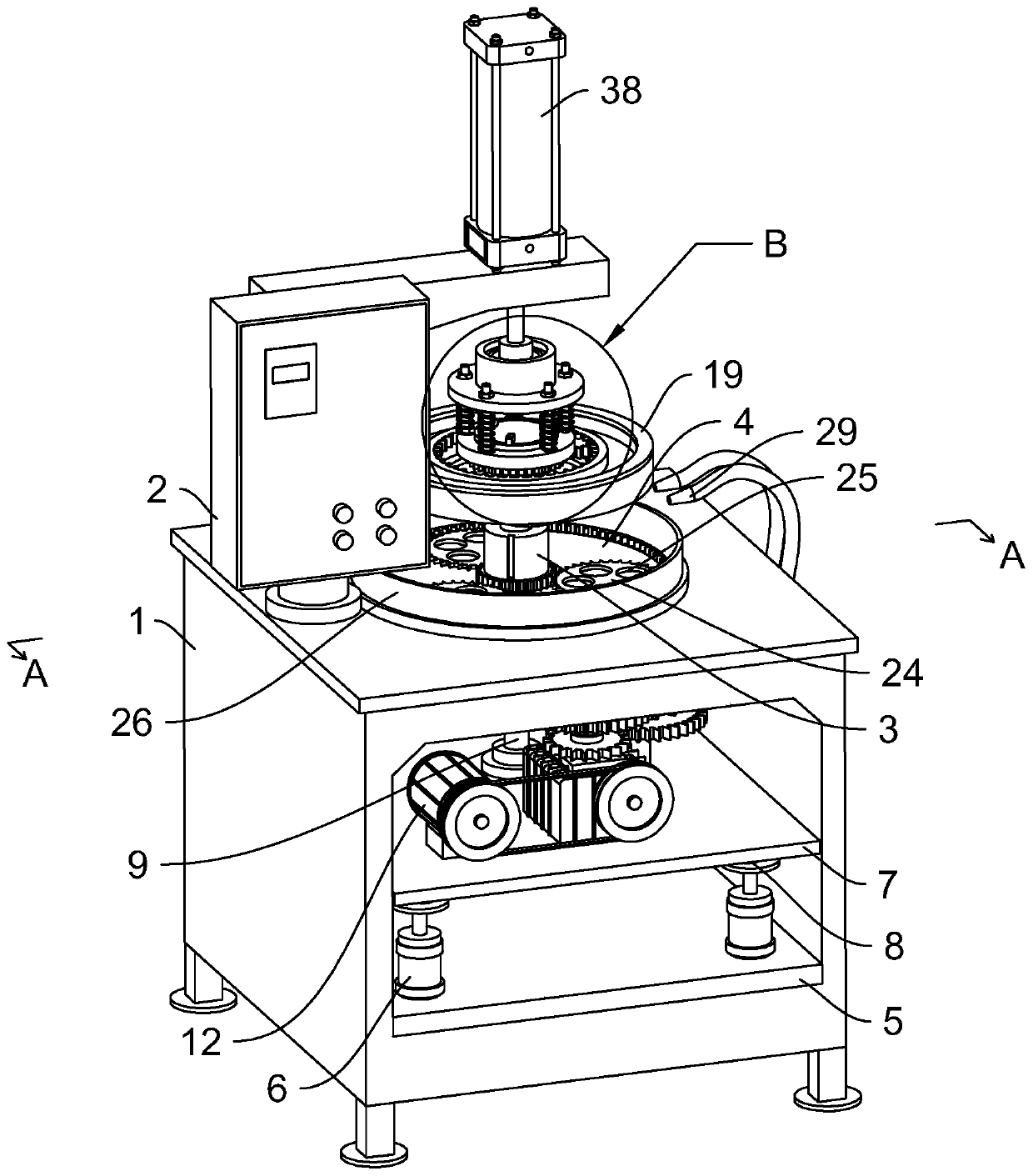

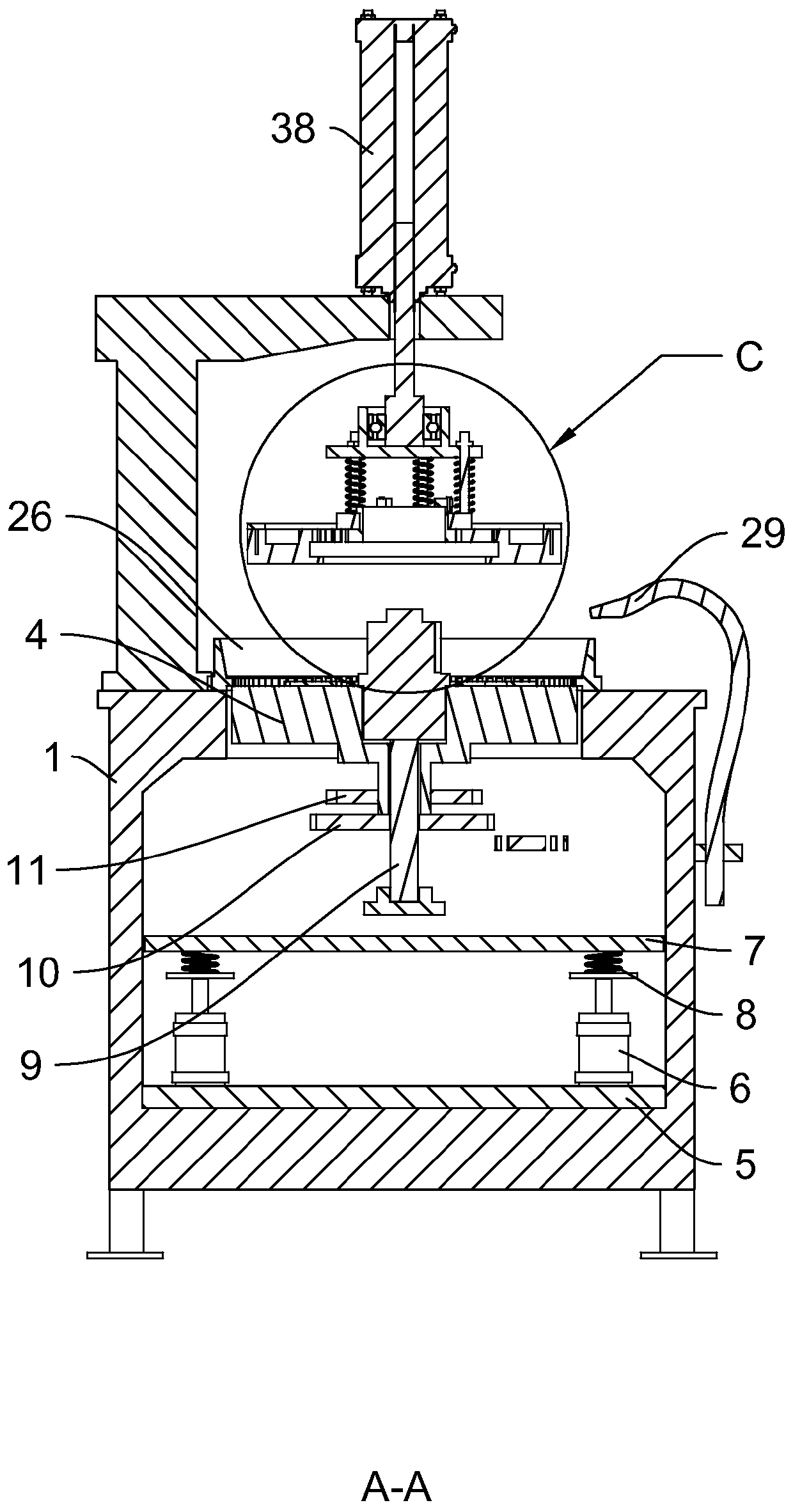

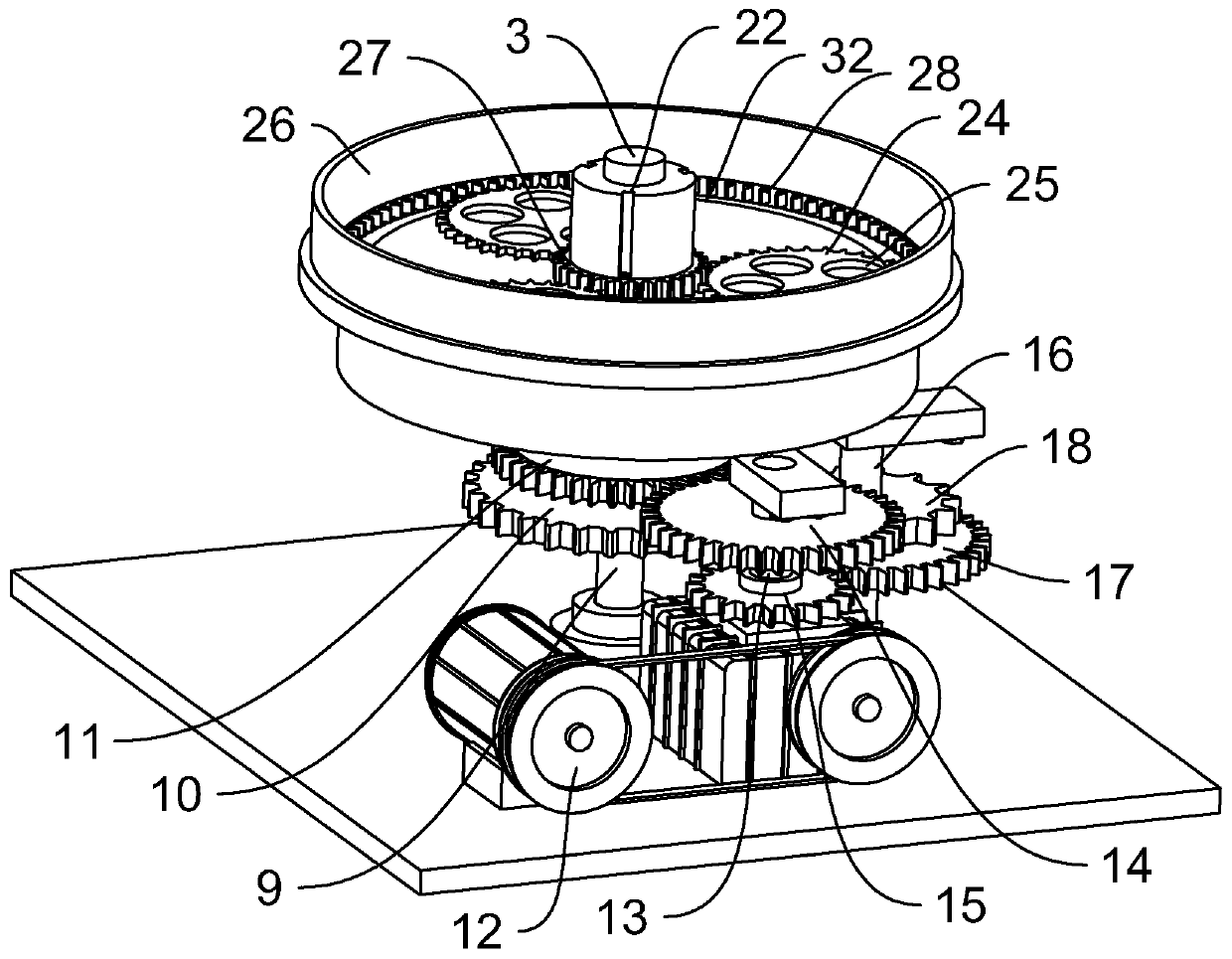

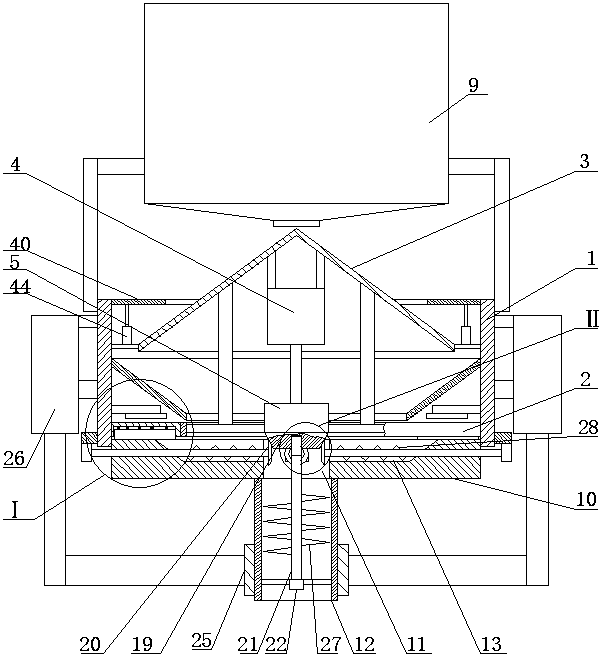

Bearing ring channel ultra-fine grinding device

ActiveCN111761503APrecise processingImprove processing qualityGrinding machine componentsSuperfinishing machinesClassical mechanicsControl theory

The invention relates to a bearing ring channel ultra-fine grinding device, and relates to the technical field of bearing machining. The device comprises a base and a driving mechanism disposed on thebase, and the base is provided with a spindle box, a workpiece compaction device, a channel position adjustment sliding table and a pendulum shaft device. The driving mechanism is connected to and provides a power source for the spindle box and the pendulum shaft device, the spindle box is disposed opposite to the workpiece compaction device, and a to-be-machined bearing ring is disposed betweenthe spindle box and the workpiece compaction device. The pendulum shaft device is arranged on and fixedly connected with the upper surface of the channel position adjustment sliding table. One end ofthe pendulum shaft device is provided with an ultra-fine head provided with oilstone. The pendulum shaft device controls the ultra-fine head to swing. The ultra-fine head is located above the bearingring between the main shaft box and the workpiece compaction device and is used for machining the bearing ring. The channel position adjustment sliding table adjusts the relative position of the pendulum shaft device and the to-be-machined bearing ring. Machining of a bearing ring channel is more accurate through the ultra-fine head, and the machining quality of the bearing ring channel is improved.

Owner:NINGBO ANJIESEN PRECISION MACHINE MFG

Building decoration layer stripping device and stripping method thereof

InactiveCN111576905AAvoid Manual EradicationEfficient eradication constructionUsing liquid separation agentBuilding repairsStructural engineeringWater curtain

The invention provides a building decoration layer stripping device and a building decoration layer stripping method thereof. The device comprises two guide rods arranged in the same direction, a supporting cross rod and a water jetting device, wherein the two guide rods are arranged in the same direction; first traveling mechanisms traveling in the axial direction of the guide rods are arranged on the two guide rods correspondingly; the two ends of the supporting cross rod are connected to the first traveling mechanisms of the two guide rods correspondingly; a second traveling mechanism traveling in the axial direction of the supporting cross rod is mounted on the supporting cross rod; the water jetting device is mounted on the second traveling mechanism; a water jet hole and a circle ofwater curtain holes arranged in the circumferential direction of the water jet hole are formed in the water jetting device; and the water get hole and the water curtain holes are each provided with awater inlet end and a water outlet end; and the distance from the water curtain holes to the water jet hole gradually increases from the water inlet ends of the water curtain holes to the water outletends of the water curtain holes. Through the building decoration layer stripping device, the problems that labor force is wasted and great dust pollution can be generated during the engineering construction process of removing building decoration layers through a traditional method of removing the decoration layers of walls through manual grinding are solved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

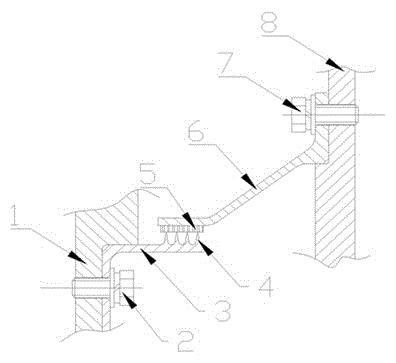

Self-rotating paraffin scraping, centralizing and sucking assisting device

PendingCN111980629AReduce coefficient of frictionReduce frictionDrilling rodsCleaning apparatusCouplingEngineering

The invention relates to the field of oil exploitation machinery, and discloses a self-rotating paraffin scraping, centralizing and sucking assisting device. The device comprises a rod body, a coupling, a rotation guiding sliding sleeve, a centralizing sleeve, a pressing cap and balls. A longitudinal zigzag turn-back type closed track is engraved in the middle part of the rod body around the outersurface, the cross section of the zigzag turn-back type closed track is in a concave semicircular arc shape and is matched with the shape of the balls, and the upper vertex and the lower vertex of the zigzag turn-back type closed track are located on the same circumferential line of the rod body correspondingly; and a radial annular protrusion is arranged at the bottom end of the rotation guidingsliding sleeve, spiral flow passing channels are evenly formed in the outer face of the centralizing sleeve, and radial annular circular beads are arranged on the inner wall of the centralizing sleeve. According to the a self-rotating paraffin scraping, centralizing and sucking assisting device, self-rotating uniform grinding, centralizing, sucking assisting and paraffin scraping are organicallycombined, so that multiple functions are realized through one device; the service life is obviously prolonged, the uniform grinding, centralizing and sucking assisting effects are remarkable; and forced and thorough paraffin scraping is carried out on the inner wall of a pipe column, so that the repair-free period of an oil well is comprehensively prolonged.

Owner:DONGYING CHANGXIANG PETROLEUM EQUIP CO LTD

Inner wall polishing device for deep-hole precision part

InactiveCN114800091AEasy to grindReasonable structural designRevolution surface grinding machinesGrinding drivesDrive shaftPolishing

Owner:南通凯石机电科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap