Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59 results about "Ceramic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A ceramic (Ancient Greek: κεραμικός — keramikós, "potter's", from κέραμος — kéramos, "potter's clay") is a solid material comprising an inorganic compound of metal, non-metal or metalloid atoms primarily held in ionic and covalent bonds. Common examples are earthenware, porcelain, and brick.

Method for Producing Ceramic Layers

InactiveUS20090202732A1Efficient methodReduce internal stressPretreated surfacesPressure inorganic powder coatingHeat sensitiveProduct gas

Owner:SIEMENS AG

Method for preparing silicon carbide ceramic material with low residual silicon by adopting multi-step reaction sintering method

ActiveCN106478105ASolve the mechanical propertiesSolving Elasticity ProblemsHeat conductingYoung's modulus

Owner:咸阳瞪羚谷新材料科技有限公司

Method for metallizing ceramic surface and method for connecting ceramic with aluminum

ActiveUS20120121896A1Hot-dipping/immersion processesSoldering apparatusMicrometerAlloy thin film

A process for metalizing a ceramic surface or attaching a ceramic to a metal is provided. The process may comprise: immersing the ceramic into an aluminum or aluminum alloy melt, making the ceramic move or stay still relative to the melt to adhere the melt to the ceramic; and then removing the ceramic from the melt to unaffectedly cool the film adhered thereto. The process can attach an aluminum or aluminum alloy thin film having a thickness of several to tens of micrometers on a ceramic surface. The thin film is formed by solidification, and does not have microscopic faults such as oxide film inclusions or pores, therefore having proper physical of mechanical properties of aluminum. Ceramics or a ceramic and a metal can be brazed via the surface metalizing film, the bonding strength of their interface can over the strength of aluminum itself.This invention discloses a process for metalizing the surface of a ceramic and a process for attaching a ceramic to a metal. A process for attaching an aluminum or aluminum alloy thin film to a ceramic surface comprises the steps of: immersing a ceramic surface to be metalized into a aluminum or aluminum alloy melt, and making the ceramic move or stay still relative to the melt to adhere the melt of the aluminum or aluminum alloy to the metalizing surface of the ceramic; and then removing the metalizing surface of the ceramic from the melt to unaffectedly cool the aluminum or aluminum alloy liquid film adhered thereto to obtain a ceramic having the aluminum or aluminum alloy thin film attached to the surface. The process to attaching aluminum or aluminum alloy thin film on the surface of a ceramic of the present invention can attach an aluminum or aluminum alloy thin film having a thickness of several micrometers to tens of micrometers on the surface of a ceramic. The thin film is formed by the solidification of the aluminum of aluminum alloy liquid film attached on the surface of a ceramic, and it does not have the microscopic faults such as oxide film inclusions or pores, therefore having the proper physical of mechanical properties of aluminum. Ceramics or a ceramic and a metal can be brazed via the surface metalizing film, the bonding strength of their interface can over the strength of aluminum itself.

Owner:TSINGHUA UNIV

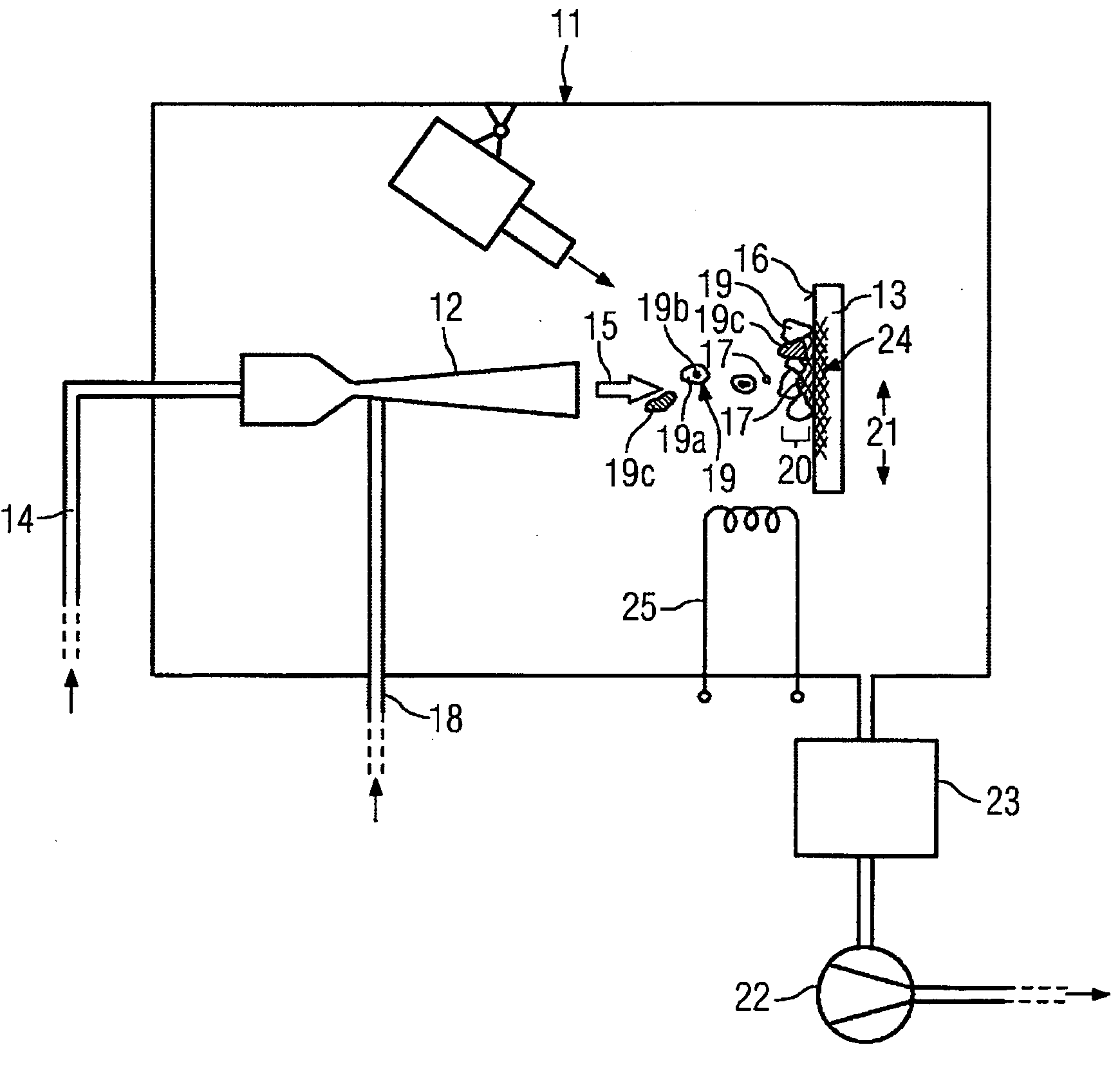

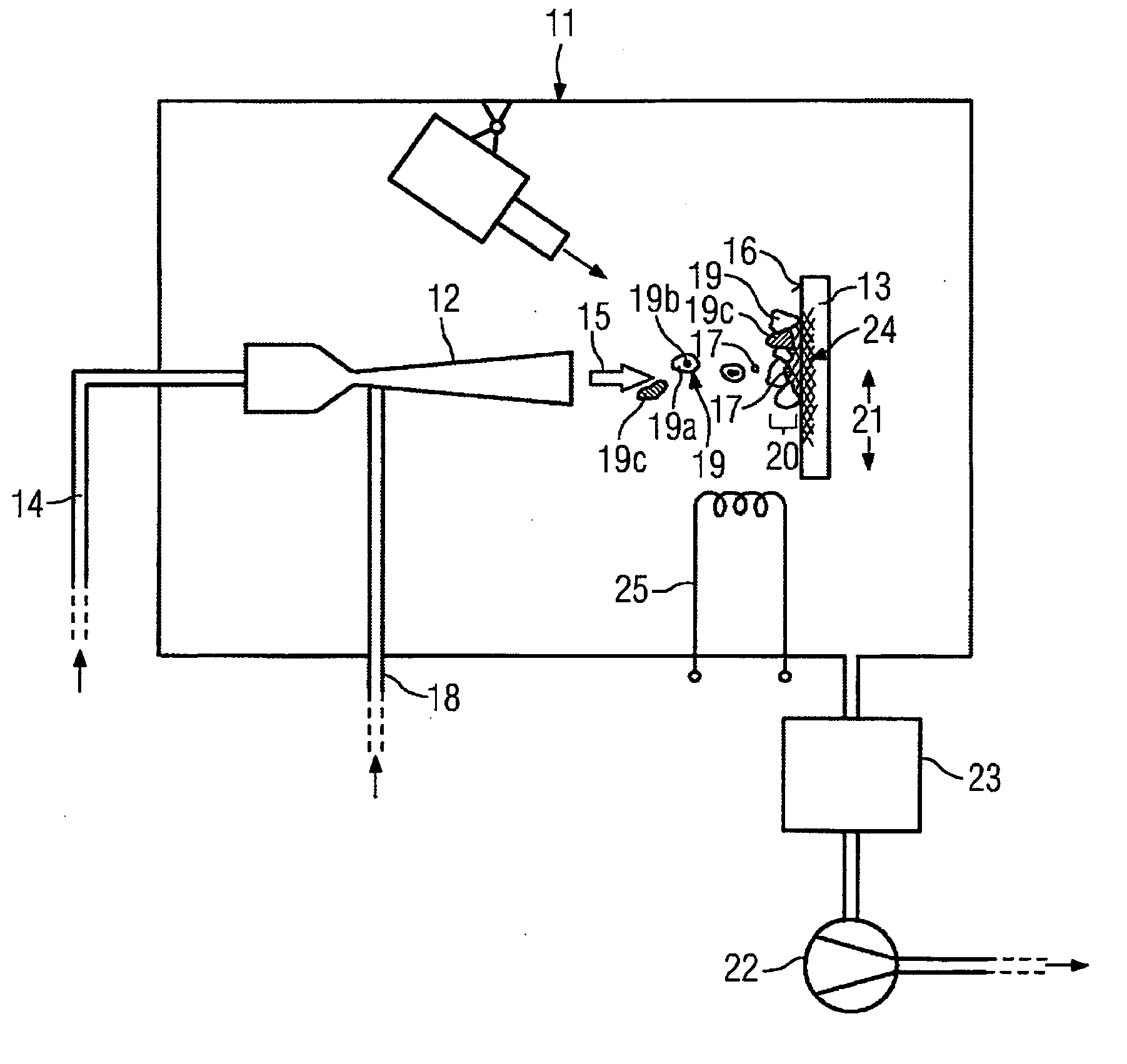

Method of Fabricating Thin Film by Microplasma Processing and Apparatus for Same

InactiveUS20120021132A1Reduce necessityLiquid surface applicatorsMolten spray coatingIonRaw material

Provided is a method of fabricating, with satisfactory adhesion, a thin film of a metal or a metallic-compound, such as a metal oxide or nitride, on a substrate made of a high-melting-point material such as silicon or ceramics by using a metal or metallic-compound target as the primary raw material so as to eliminate the necessity of using harmful gases such as organometallic gas, and by using an atmospheric-pressure plasma generated under atmospheric pressure as a reaction field and also as a heat source. Additionally provided is an apparatus for fabricating the thin film. The thin-film fabrication method by microplasma processing includes the steps of disposing a raw material for thin-film fabrication in one or more tubes (A) having a uniform inner diameter throughout, introducing an inert gas and applying a high-frequency voltage to the narrow tubes (A) to generate high-frequency plasma in the narrow tubes (A), heating / evaporating the raw material while maintaining the flow rate of the plasma gas in the narrow tubes (A) and maintaining the plasma gas temperature high, ejecting the evaporated material from the narrow tubes (A) to spray it onto the substrate, heating the substrate with the plasma, and depositing the sprayed material on the substrate under atmospheric pressure.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Fiber reinforced ceramic-based composite material antenna cover for wave band W and preparation method thereof

ActiveCN109400194AReduce penetration rateReduce penetrationRadiating element housingsElectricitySilicon dioxide

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

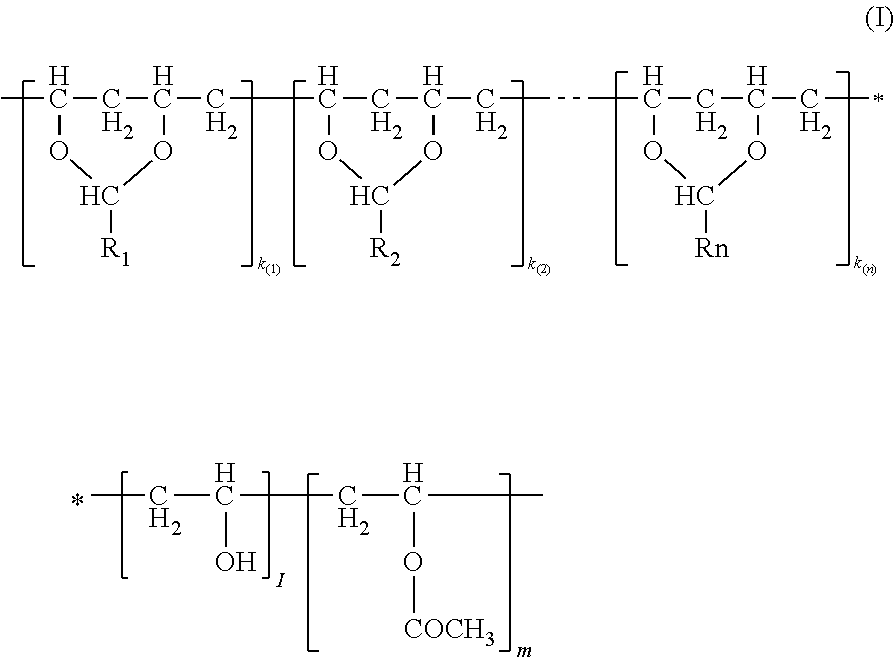

Thermoplastic polymer composition and molded article

InactiveUS20130122289A1Excellent in flexibility propertyImprove mechanical propertiesNon-fibrous pulp additionNon-macromolecular adhesive additivesPolyvinyl alcoholGlass transition

Owner:KURARAY CO LTD

Ceramic glaze drying device

ActiveCN110044137APromote shakingFull heating effectDrying solid materials with heatDrying gas arrangementsWater vaporDrive shaft

Owner:GUANGDONG VOCATIONAL & TECHNICAL COLLEGE

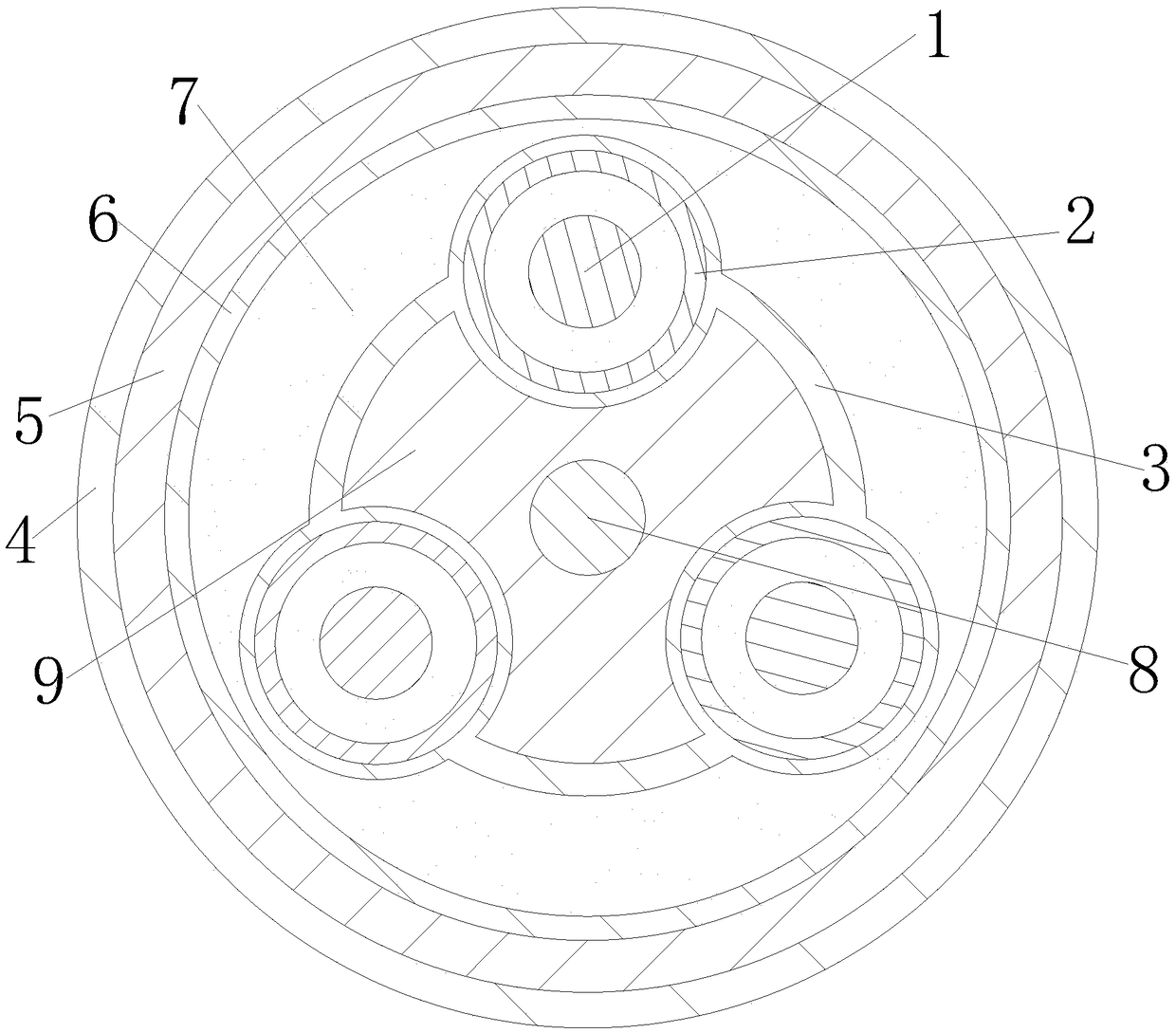

Microbe filter made from micropore ceramics

InactiveCN1727032AIncrease killEnhanced inhibitory effectSemi-permeable membranesFiltration separationCalcium biphosphateAntibiotic Agents

Owner:TSINGHUA UNIV

Unleaded piezoelectric ceramic consisting of B-site composite Bi-based compound and preparation method thereof

Owner:GUILIN UNIV OF ELECTRONIC TECH

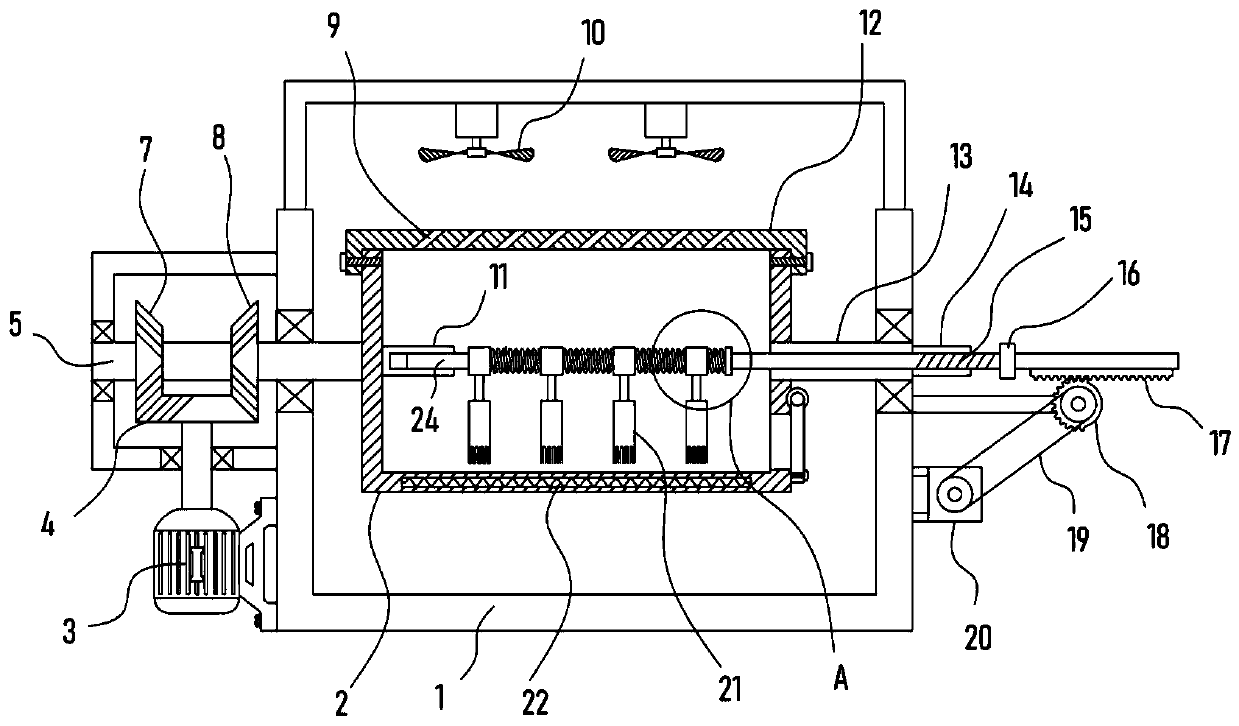

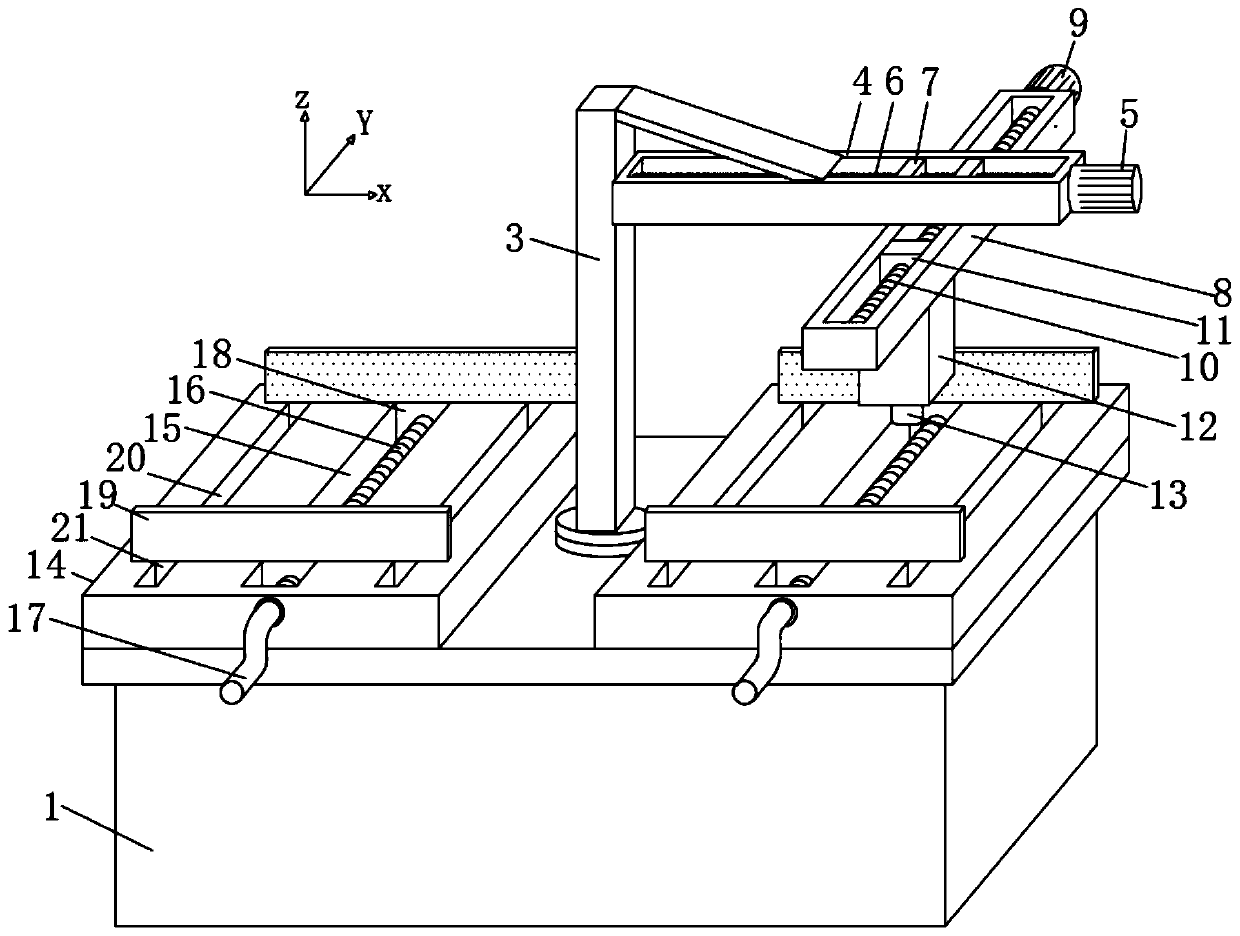

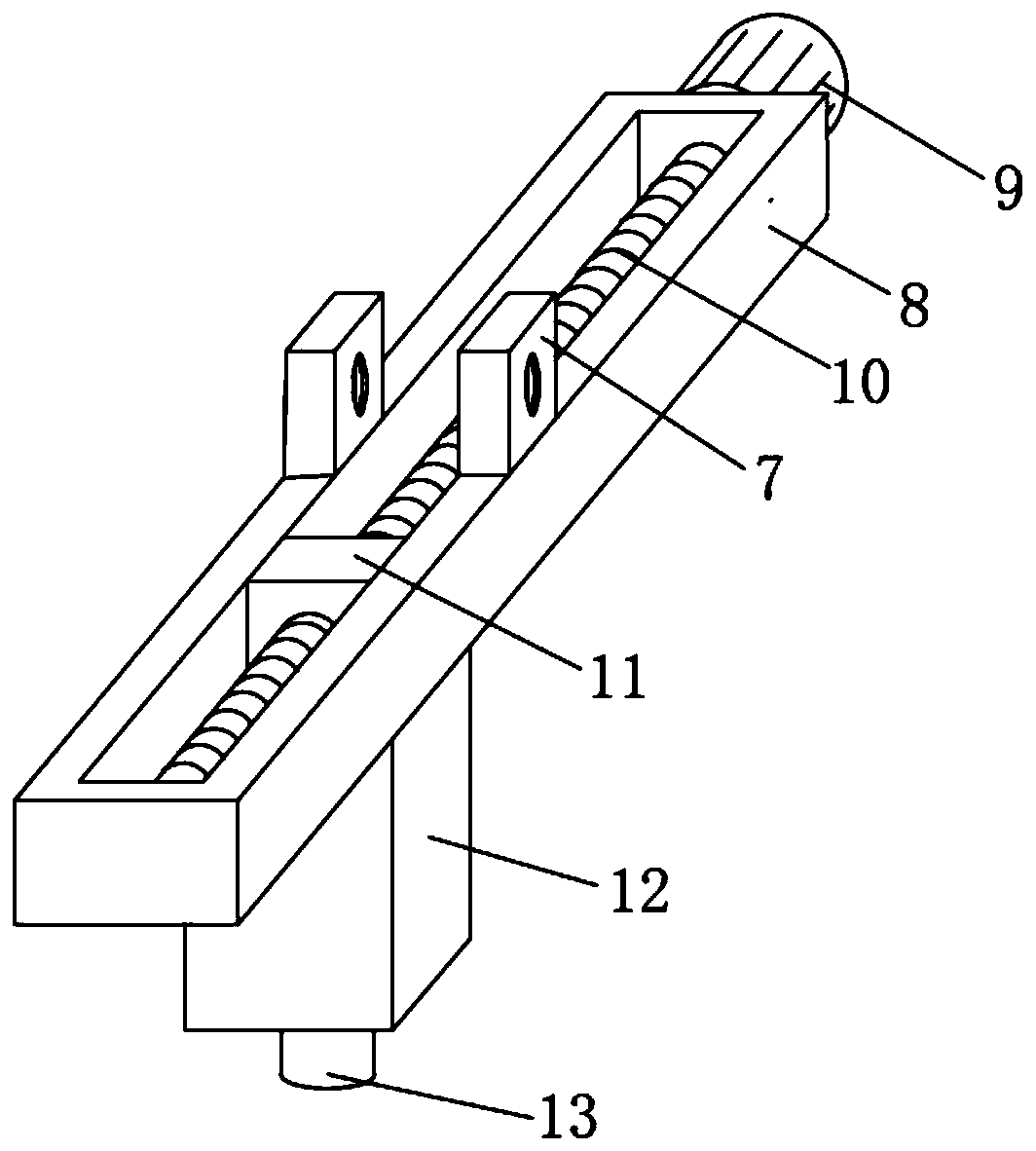

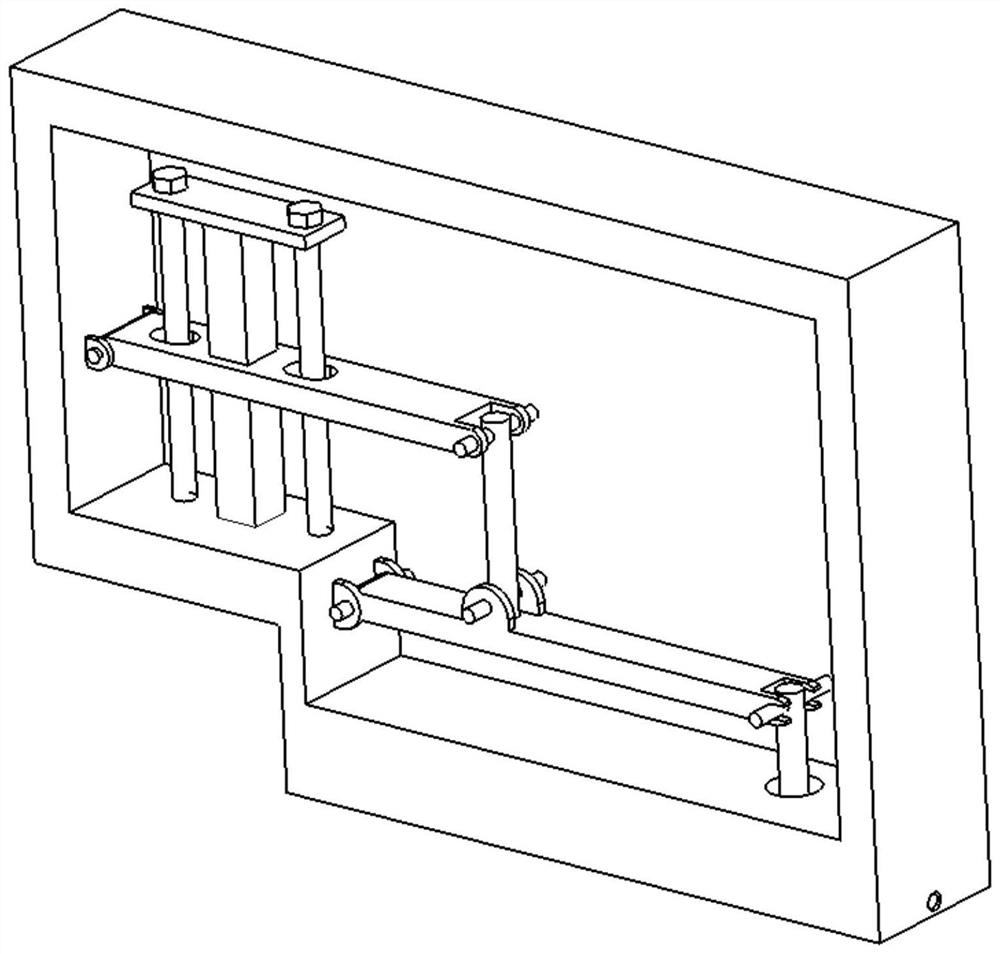

Full-automatic material distribution device and production process used for producing micro powder polished tiles

The invention discloses a full-automatic material distribution device and production process used for producing micro powder polished tiles. The full-automatic material distribution device comprises a main conveying belt for conveying micro powder, a line micro powder distribution mechanism, a material distribution mechanism, a material supplement mechanism, a grid feeding mechanism and an extrusion machine are sequentially arranged above the main conveying belt in the conveying direction, the line micro powder distribution mechanism, the material distribution mechanism and the material supplement mechanism sequentially distribute different types of powdery materials on the main conveying belt and then overlap the powdery materials step by step, and the grid feeding mechanism cuts the mixed powdery materials on the main conveying belt according to the specification of polished tiles and then feeds the materials into the extrusion machine for extrusion formation. The full-automatic material distribution device is ingenious and practical in structure. Ceramic micro power polished tiles produced through the full-automatic material distribution device are fine in texture, natural and vivid, the patterns of finished tiles are natural in transition, novel and irregular, and the decoration effect of ceramic micro powder polished tiles is greatly improved.

Owner:GUANGDONG HUIYA CERAMICS CO LTD

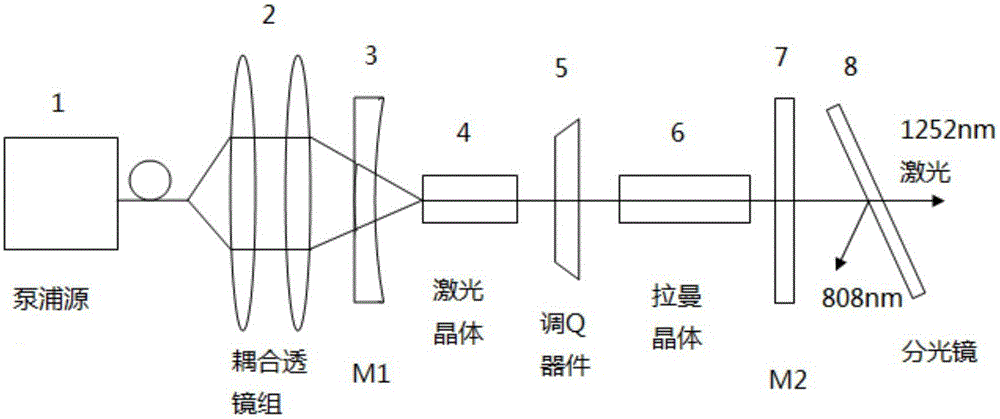

1.2 micron wavelength all-solid-state raman laser

InactiveCN105140775ACompact structureEasy to useLaser using scattering effectsActive medium materialDielectricRaman amplifiers

Owner:SHANDONG UNIV

Window pane with sintered conductive ceramic.

ActiveUS20110039113A1Improve conductivityGood lookingNon-conductive material with dispersed conductive materialGlass/slag layered productsElectrical conductorGlass sheet

The present invention provides a window glass with conductive ceramic fired body which is capable of not only ensuring a good conductivity of the fired body but also exhibiting an improved appearance on both an interior side and an exterior side of a vehicle when the window glass is used for vehicles. The window glass with conductive ceramic fired body according to the present invention includes at least one glass plate having main surfaces, and the conductive ceramic fired body including a feeding point and a linear portion which is disposed on either one of the main surfaces of the glass plate, at least a part of the linear portion being placed in a visible region of the window glass and formed by successively laminating a first colored layer, a conductor layer and a second colored layer on the main surface, wherein the first colored layer and the second colored layer each include a pigment and a glass component, and the conductor layer includes silver and the glass component.

Owner:NIPPON SHEET GLASS CO LTD

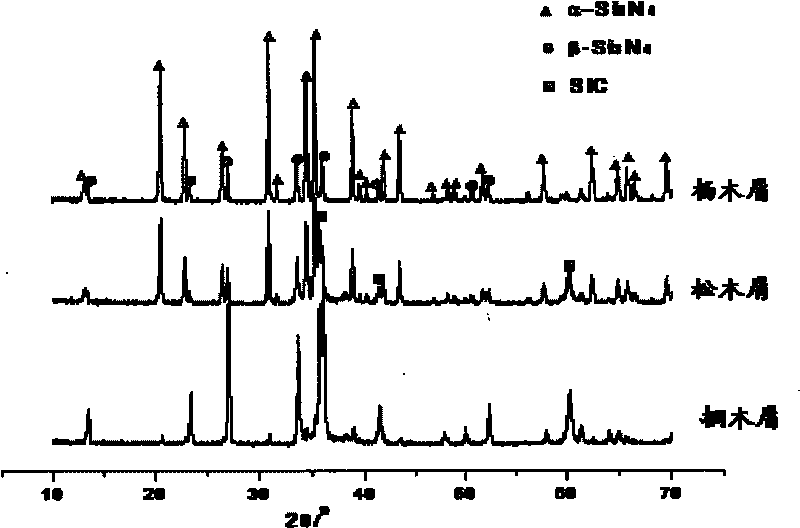

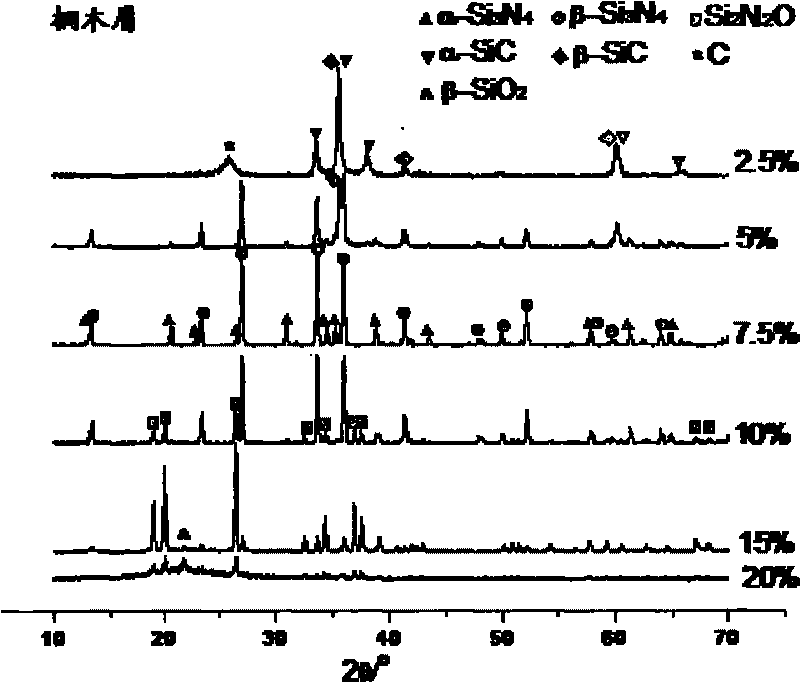

Method for preparing silicon nitride powder with saw dust

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High grade quartz ceramic and preparation method thereof

Owner:苏州创新陶瓷有限公司

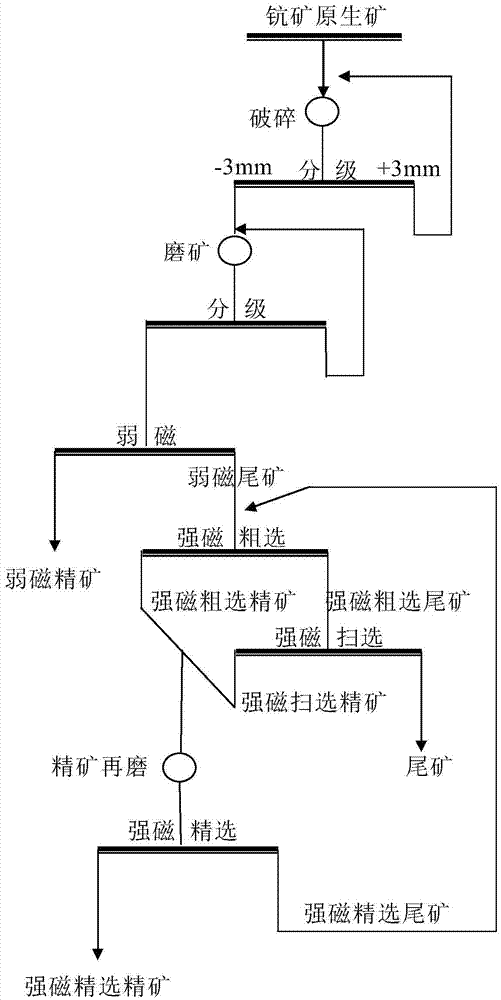

Mineral separation and enrichment method for primary scandium ore

ActiveCN105435958ASimple processEconomically reasonableMagnetic separationWet separationChemical industryEnrichment methods

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

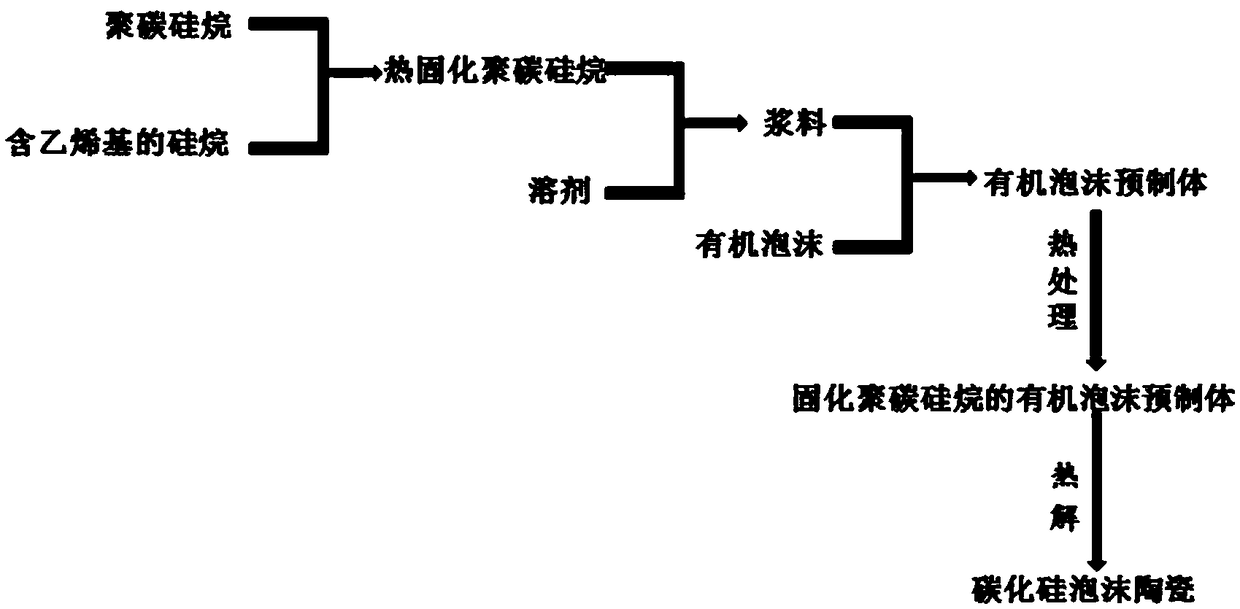

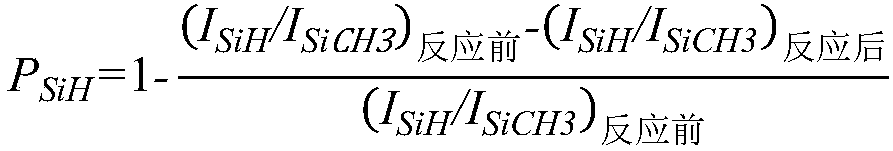

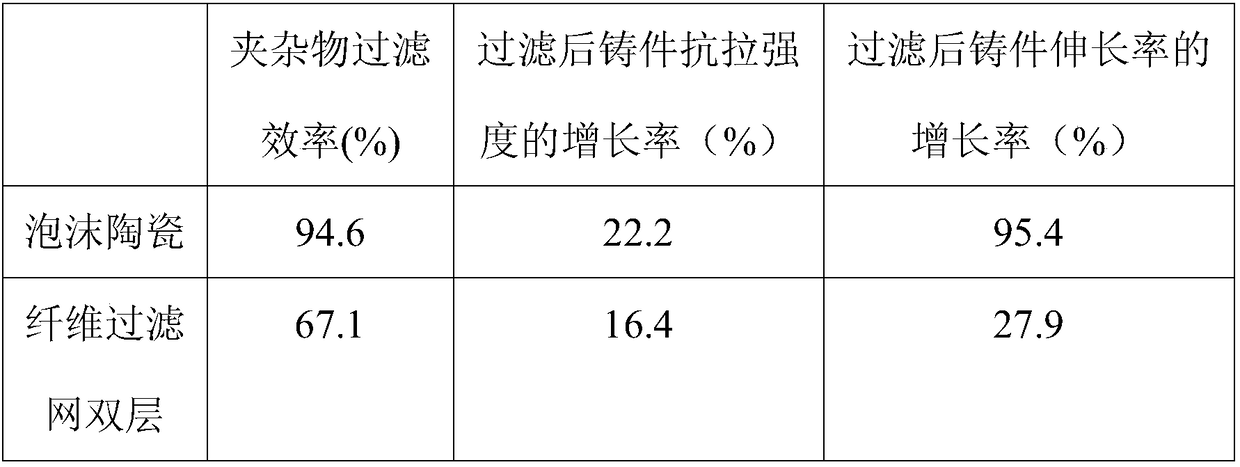

Silicon carbide foamed ceramic, and liquid metal filter produced therefrom

InactiveCN108558409ANo foamingControl pore structureCeramicwareStationary filtering element filtersFiltrationHydrosilylation

Owner:俞雪利

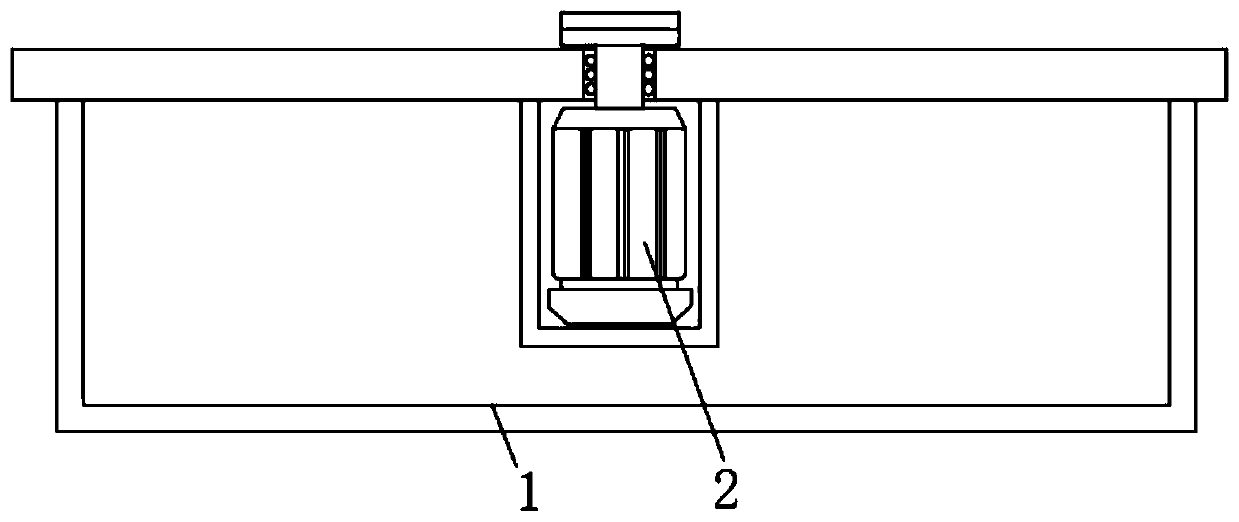

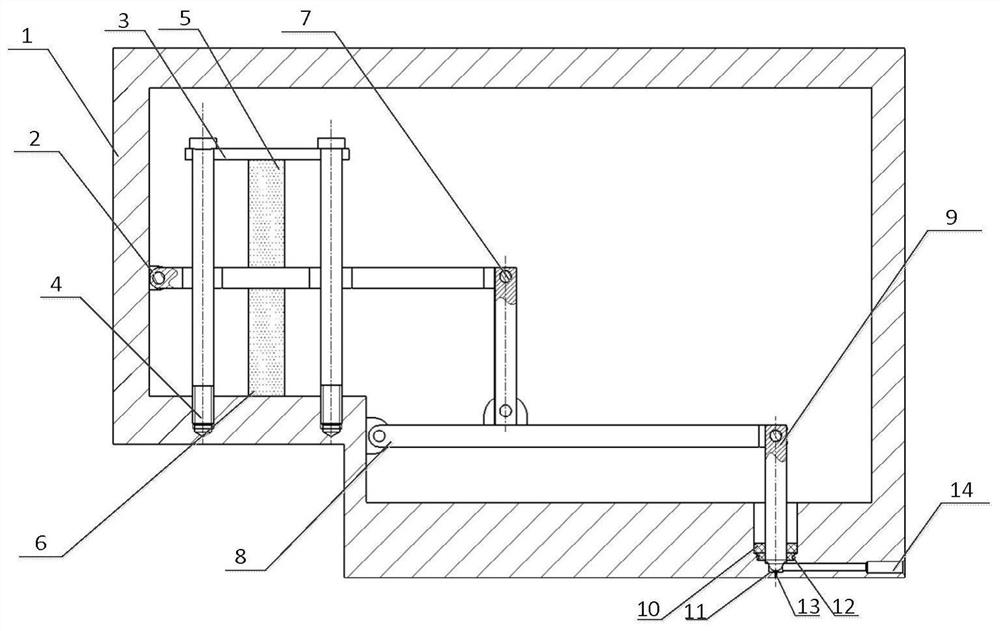

Laser cutting machine for precision ceramic

InactiveCN110125537AAvoid driftingImprove work efficiencyLaser beam welding apparatusMotor driveLaser cutting

Owner:SUZHOU GENFU MACHINERY SCI & TECH

Novel acrylic pressure-sensitive adhesive

ActiveCN108192019AWide range of bondingGood adhesionNon-macromolecular adhesive additivesAmide/imide polymer adhesivesFiberPolyester

Owner:SHANGHAI BAOLIJIA NEW MATERIAL CO LTD

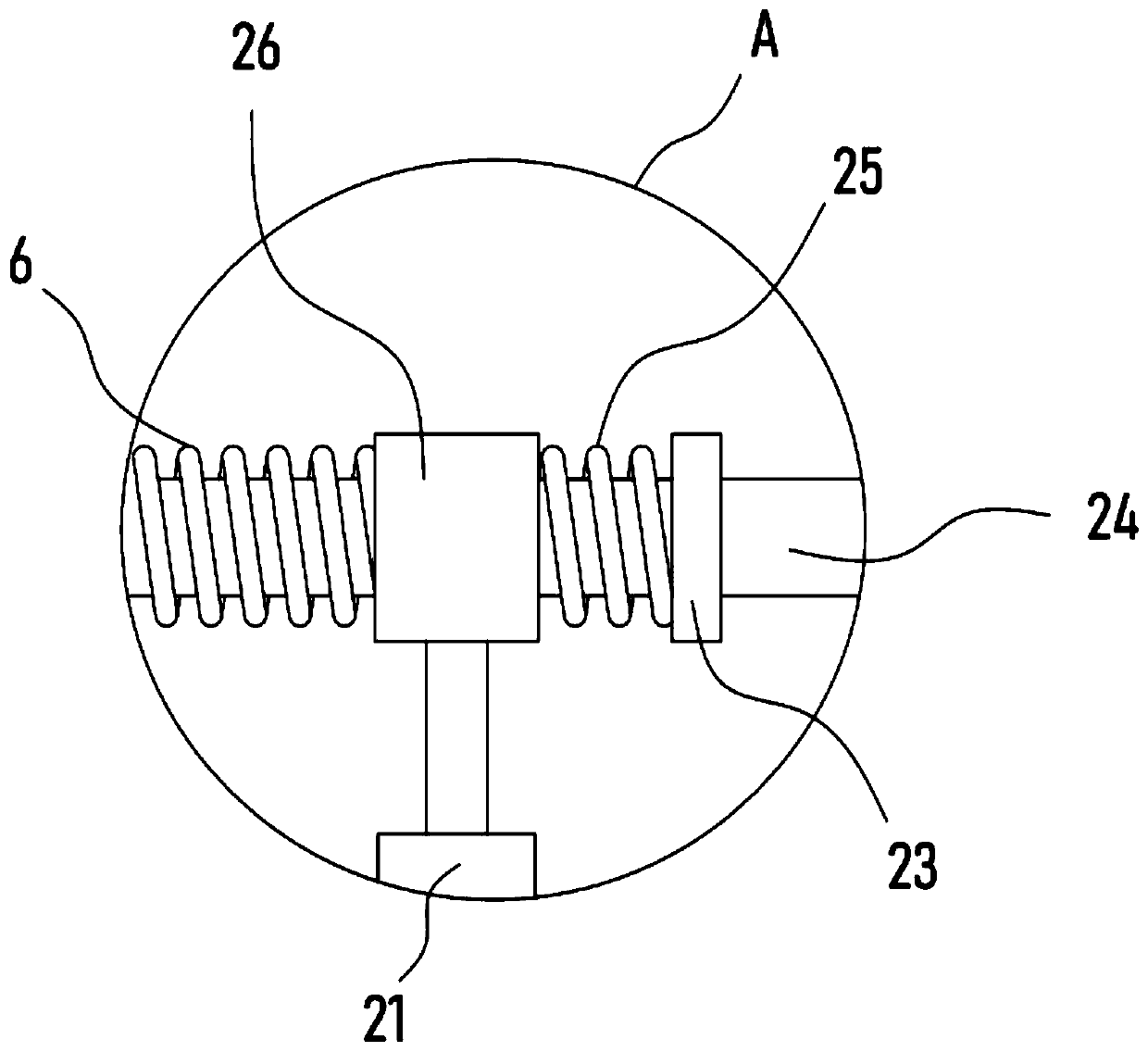

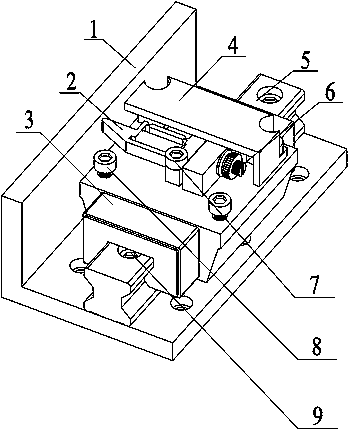

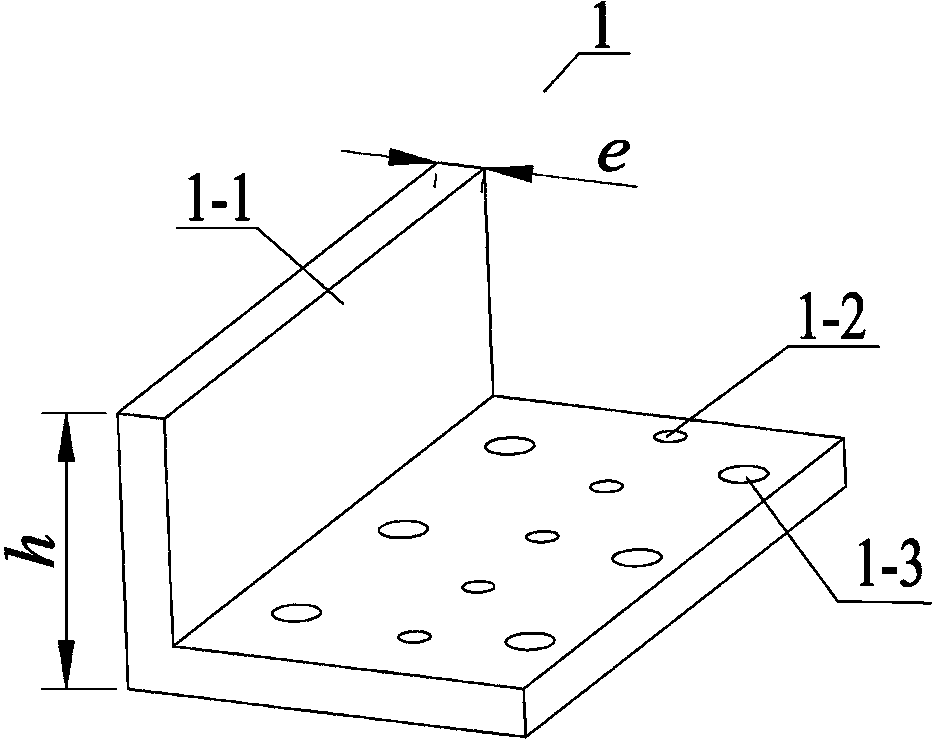

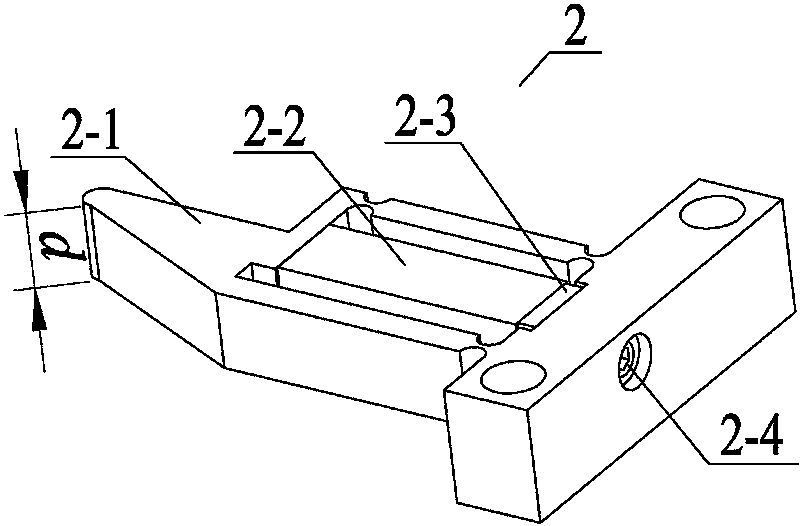

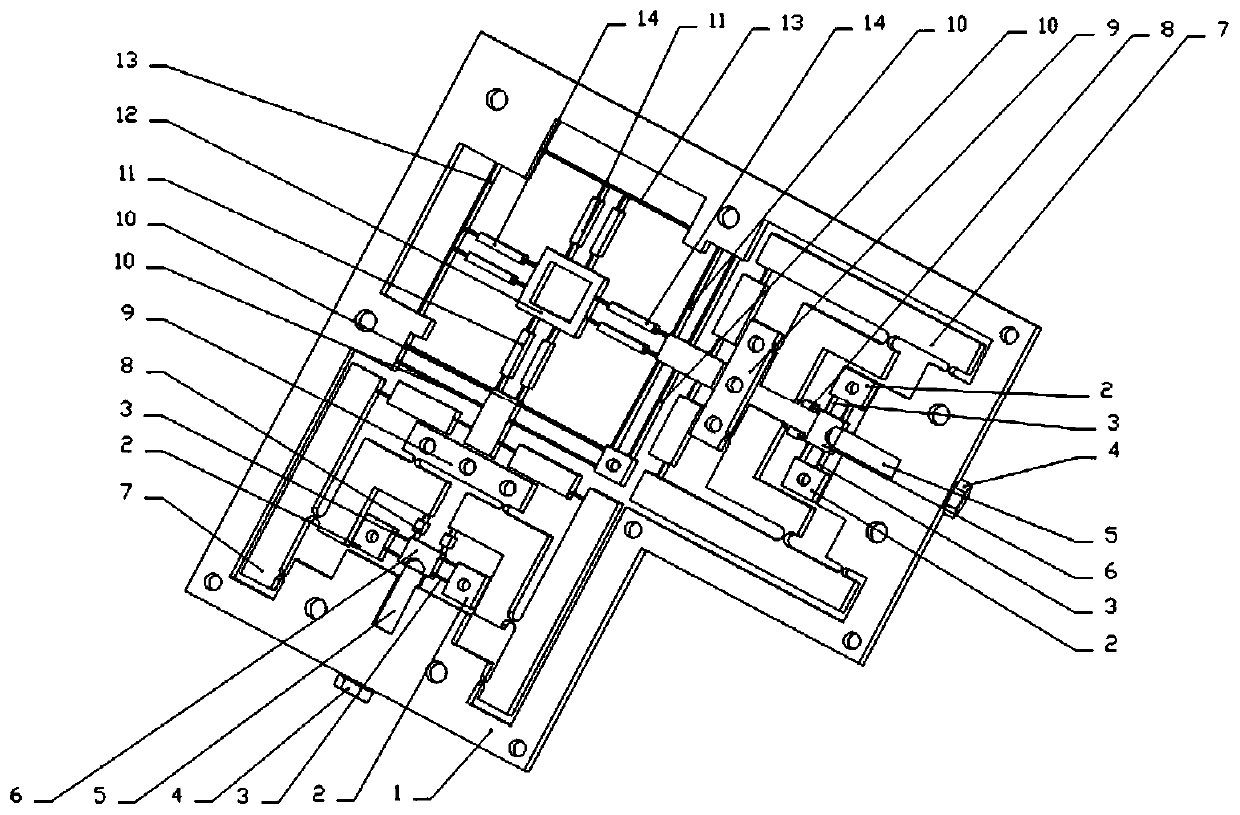

Long-stroke high-precision piezoelectric displacement platform and driving method thereof

ActiveCN108062968AImprove mechanical output characteristicsIncrease the bearing areaInstrument housingMicro nanoEngineering

Owner:CHANGCHUN UNIV OF TECH

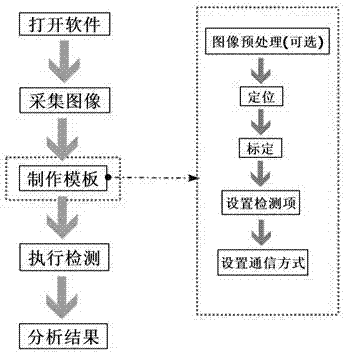

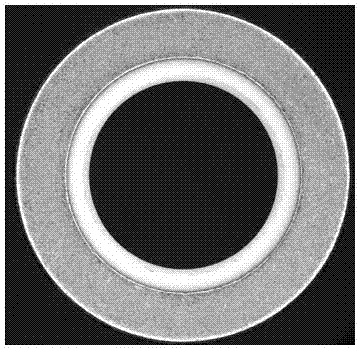

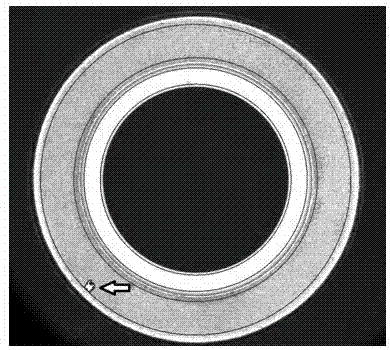

Ceramic defect visual inspection method

InactiveCN107421955AImprove detection rateImprove detection accuracyOptically investigating flaws/contaminationVisual inspectionWork flow

Owner:XIJING UNIV

Domestic ceramic with high toughness, and production method thereof

Owner:福建省德化县嘉威陶瓷有限公司

Method for producing silicon carbide (SiC) ceramics by polysilicon wire-electrode cutting scraps

The invention discloses a method for producing silicon carbide (SiC) ceramics by polysilicon wire-electrode cutting scraps and belongs to the field of production of functional materials, aiming to solve the problem that scraps are always discarded directly at present. The method includes adding SiC powder to a raw material, namely the polysilicon wire-electrode cutting scraps, and then sintering the mixture to obtain the SiC ceramics. As the polysilicon wire-electrode cutting scraps are taken as the raw material for producing the SiC ceramics, production process is simplified and production cost is lowered.

Owner:SHAANXI JUJIEHAN CHEM CO LTD

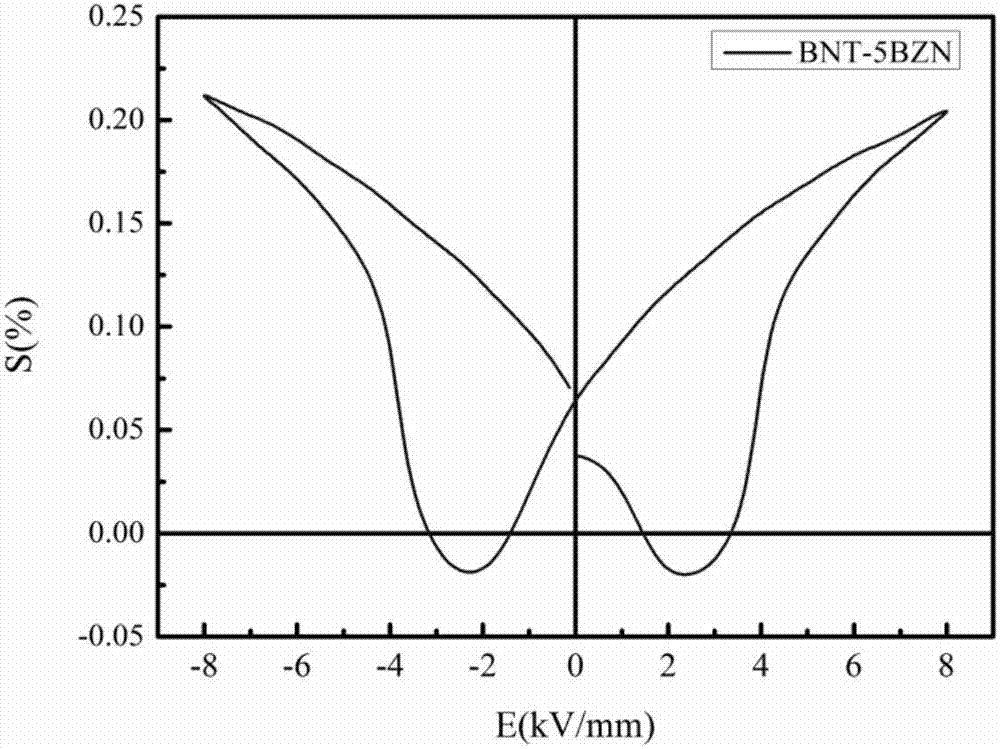

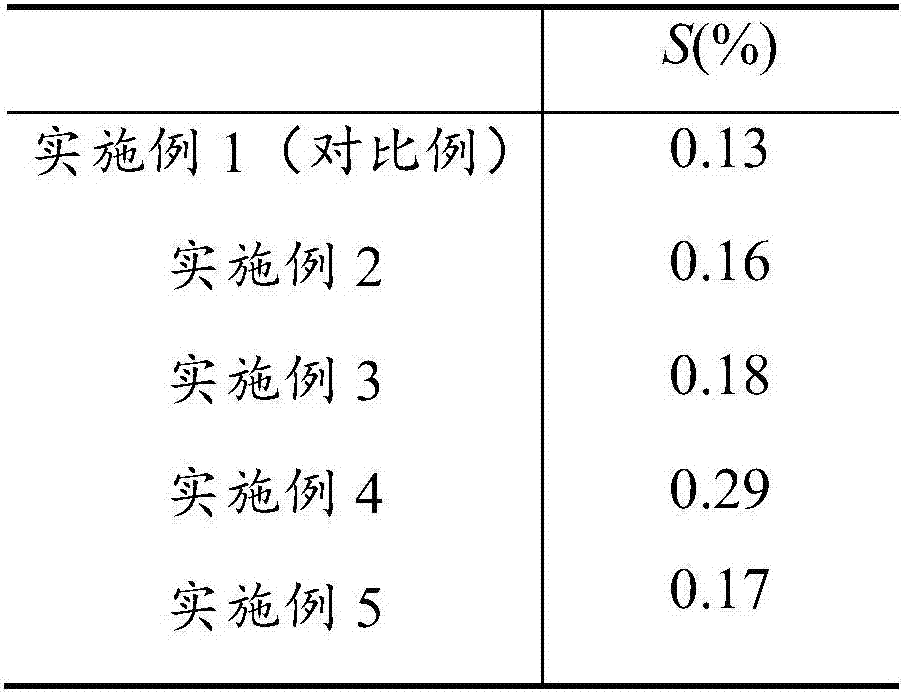

BNT-BZN binary lead-free electrostrictive strain ceramic and preparation

ActiveCN106966720ATwo stepMaterial requirements

Owner:BEIJING UNIV OF TECH

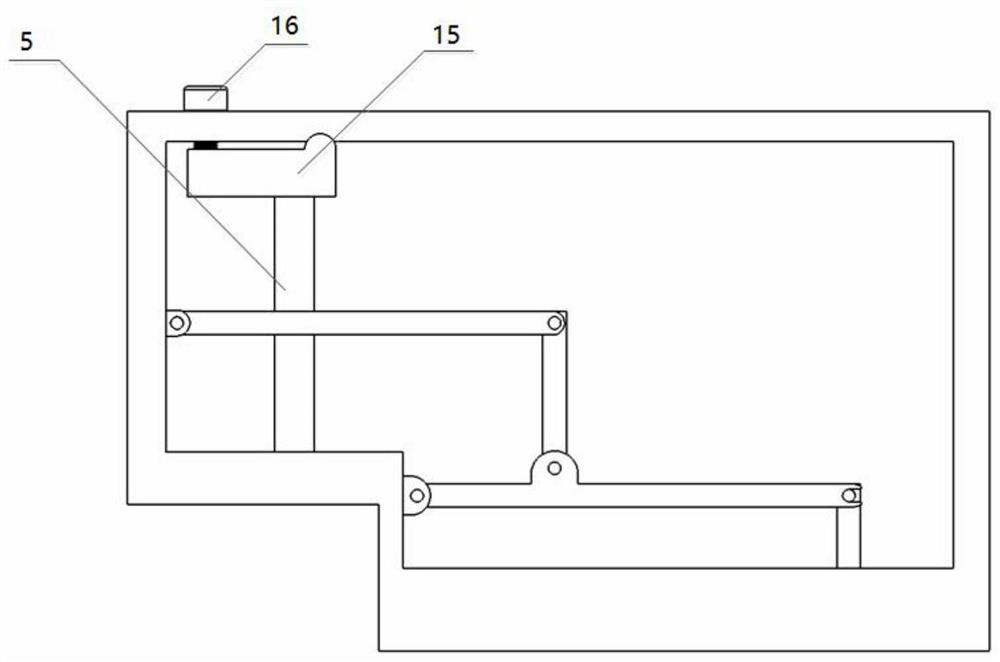

Three-stage displacement amplification flexible precision locating platform with two degrees of freedom

InactiveCN110310696AIncrease translational output rangeIncrease stiffnessInstrumental componentsMicro nanoThree stage

Owner:TIANJIN UNIV

Method for preparing green glaze ceramic cup artwork

Owner:ANHUI HONGFU CRAFTS

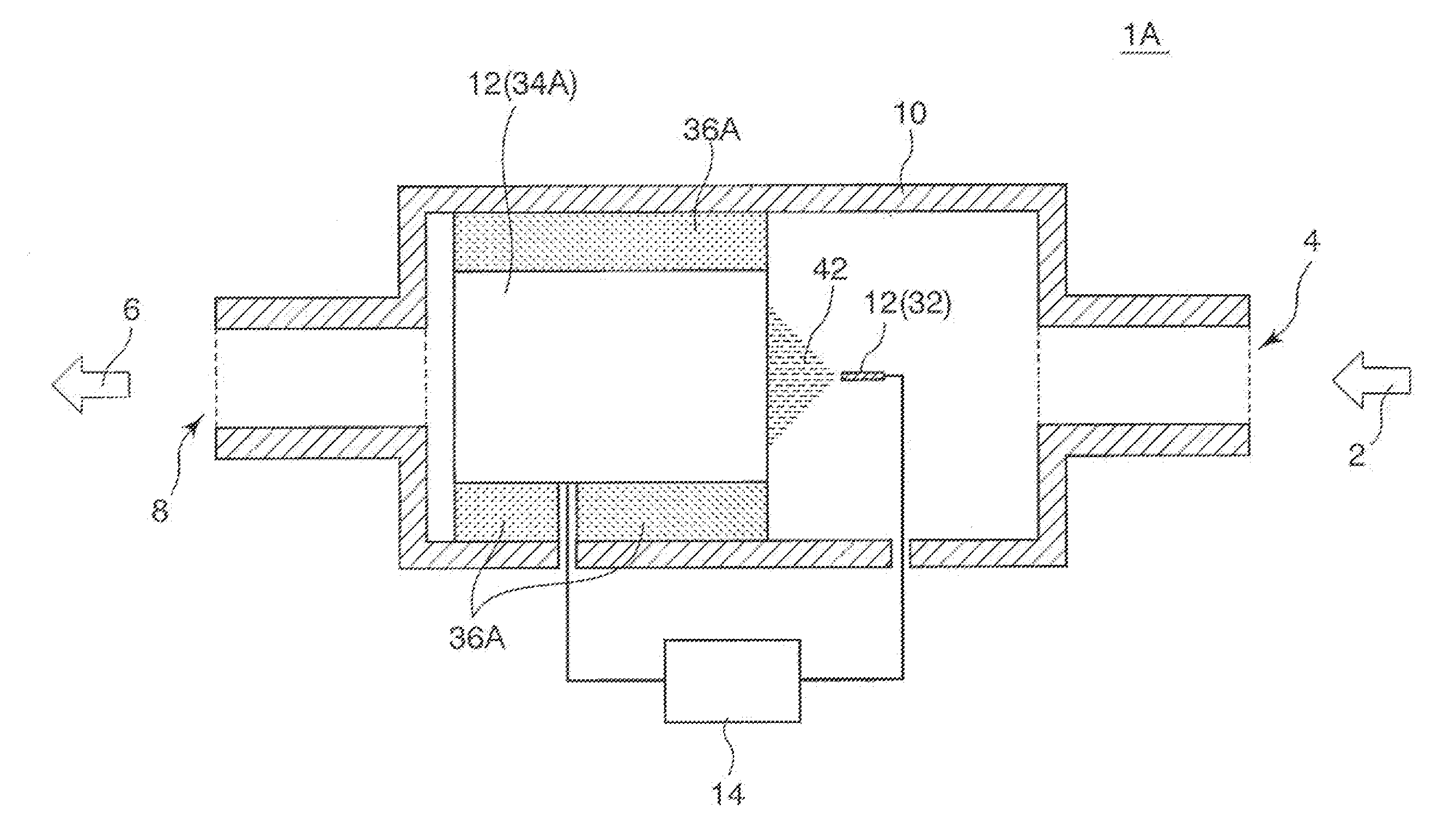

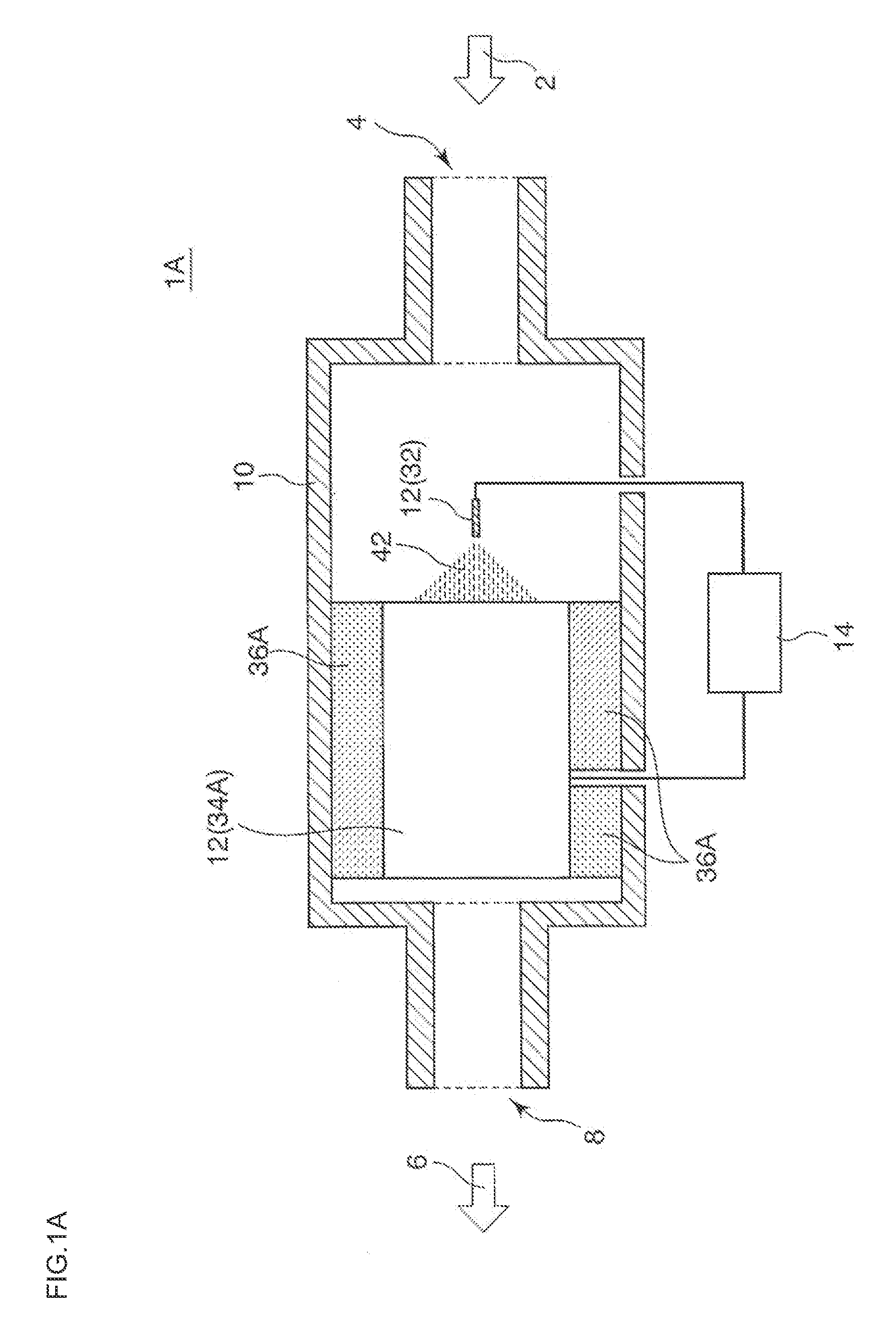

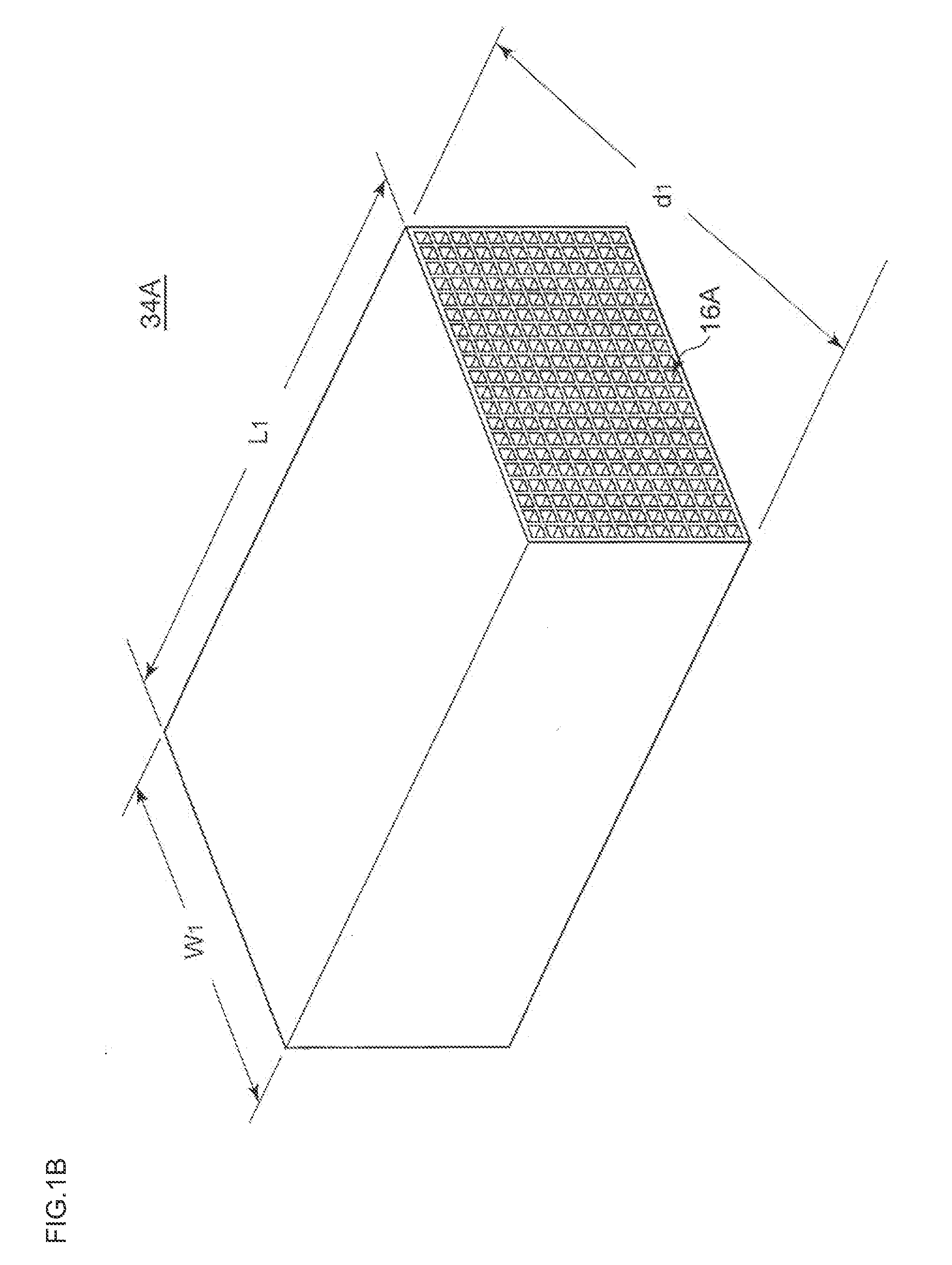

Reactor

InactiveUS20100247402A1Improve reaction efficiencyReduce power consumptionHydrogenHydrogen/synthetic gas productionInterior spaceHoneycomb

Owner:NGK INSULATORS LTD

Anti-corrosion acrylic acid epoxy resin powder paint for ceramic

ActiveCN104312235AWidely producedAnti-corrosive paintsPowdery paintsGlycidyl methacrylateDi-tert-butyl peroxide

Owner:SWANCOR JIANGSU NEW MATERIALS CO LTD

Ultrahigh-frequency surface-mounted ceramic vertical interconnection structure and packaging structure

InactiveCN112614813ASimple designSimple and fast operationSemiconductor/solid-state device detailsSolid-state devicesRadio frequency signalBroadband

The invention provides an ultrahigh-frequency surface-mounted ceramic vertical interconnection structure and a packaging structure, belonging to the technical field of chip packaging microwave signal interconnection. The ultrahigh-frequency surface-mounted ceramic vertical interconnection structure comprises a ceramic medium, a front pin bonding pad, a back pin bonding pad and a similar coaxial structure, wherein the front pin bonding pad is arranged on the front surface of the ceramic medium, and a GND region is arranged around the front pin bonding pad; the back pin bonding pad is arranged on the back surface of the ceramic medium, and another GND region is arranged around the back pin bonding pad; the similar coaxial structure comprises a radio frequency signal vertical transition hole and a grounding vertical transition hole which are arranged in parallel; and the radio frequency signal vertical transition hole is arranged to be perpendicular to the ceramic front pin bonding pad. The packaging structure comprises the ultrahigh-frequency surface-mounted ceramic vertical interconnection structure. The ultrahigh-frequency surface-mounted ceramic vertical interconnection structure of the invention has the advantages that the vertical transmission performance of radio frequency can be improved, and the transmission of DC-40GHz broadband high-frequency signals can be realized between ceramics; and the structure is a vertical interconnection structure, good vertical transmission of radio frequency signals can be realized within 40 GHz, and return loss S11 and S22 are superior to -10 dB.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

High temperature resistant cable

Owner:ANHUI HAINA CABLE GRP

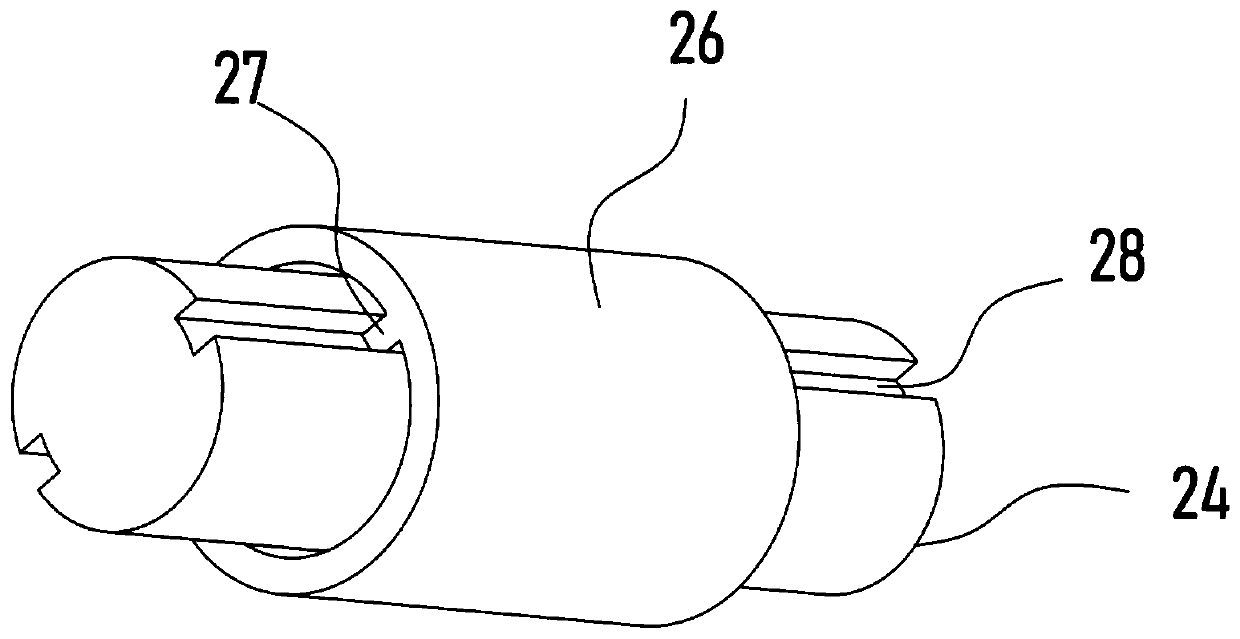

Bilateral actuating jet dispensing valve with two-stage amplifying mechanism and glue spraying method of bilateral actuating jet dispensing valve

ActiveCN113856997AHigh force transmission efficiencyFixed distanceLiquid surface applicatorsCoatingsReciprocating motionEngineering

Owner:上海盛普流体设备股份有限公司 +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap