Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

18 results about "Nitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, a nitride is a compound of nitrogen where nitrogen has a formal oxidation state of −3. Nitrides are a large class of compounds with a wide range of properties and applications. The nitride ion, N³⁻, is never encountered in protic solution because it is so basic that it would be protonated immediately. Its ionic radius is estimated to be 140 pm.

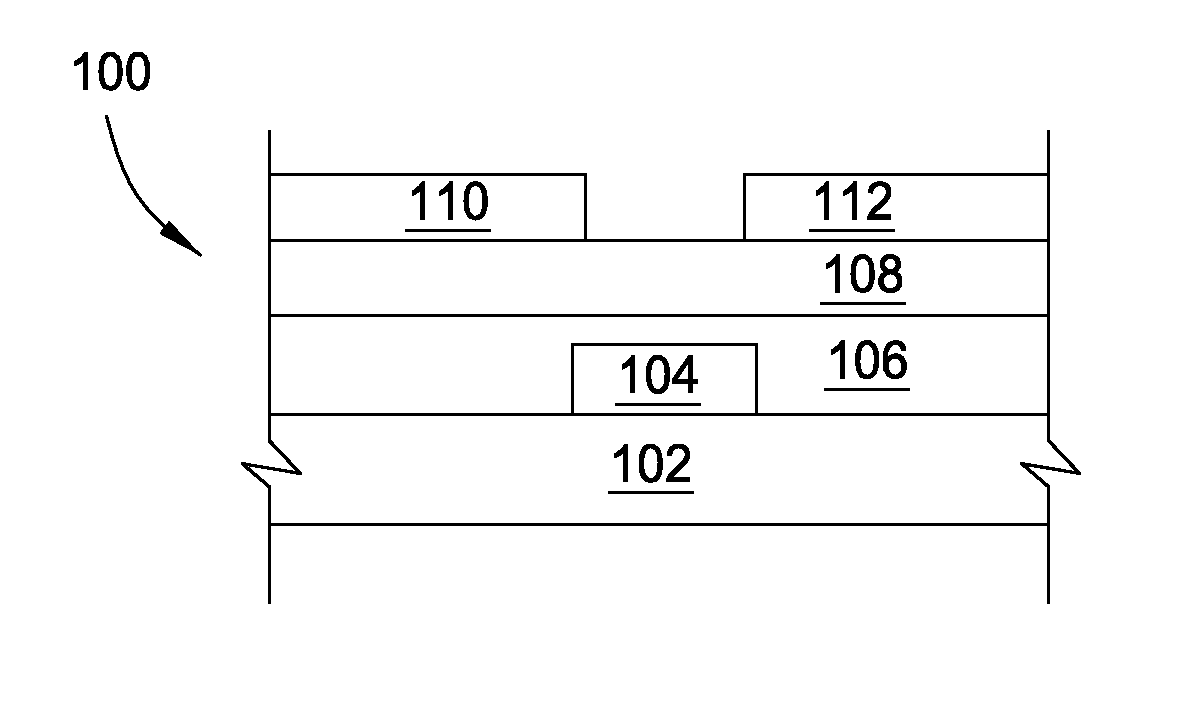

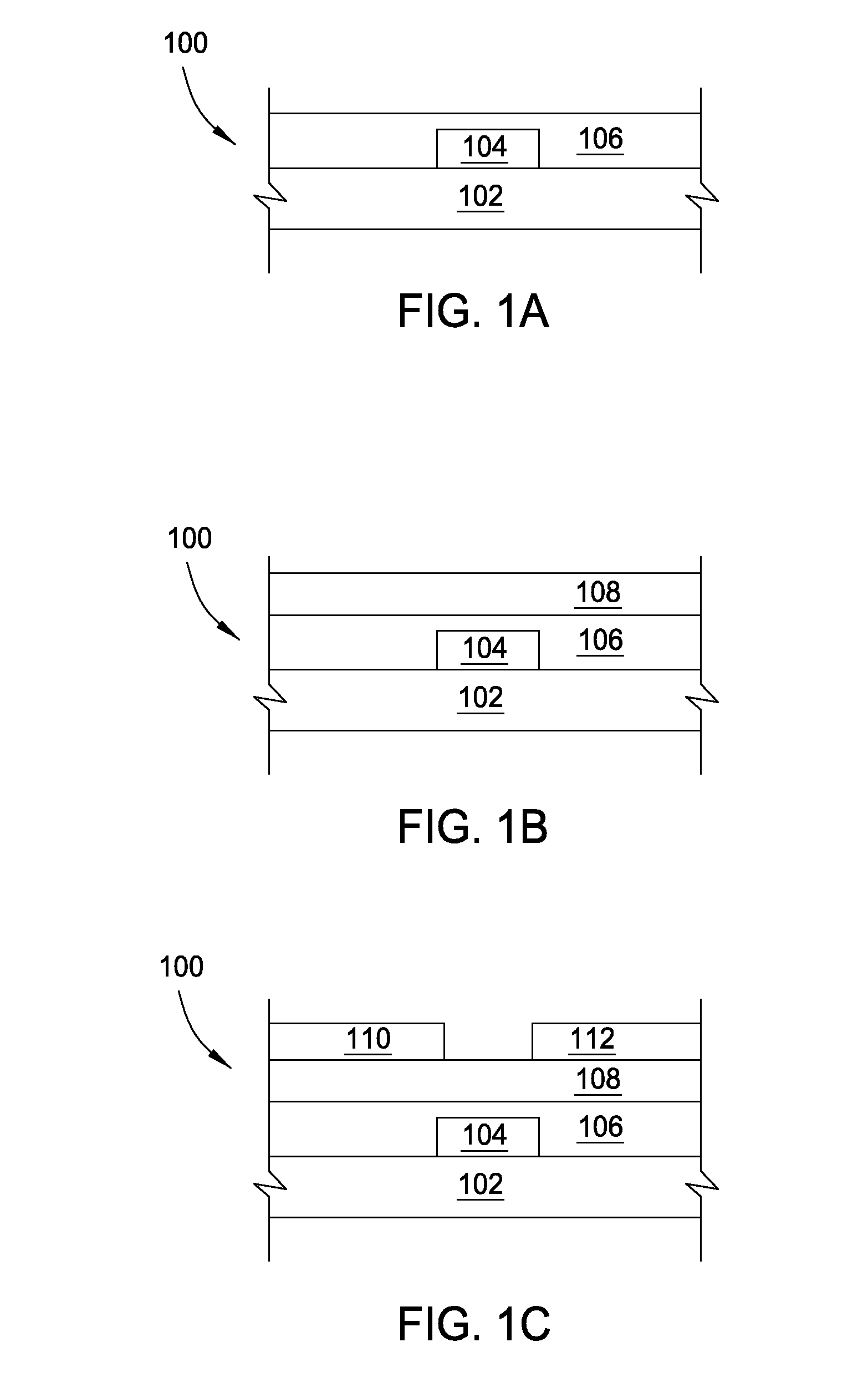

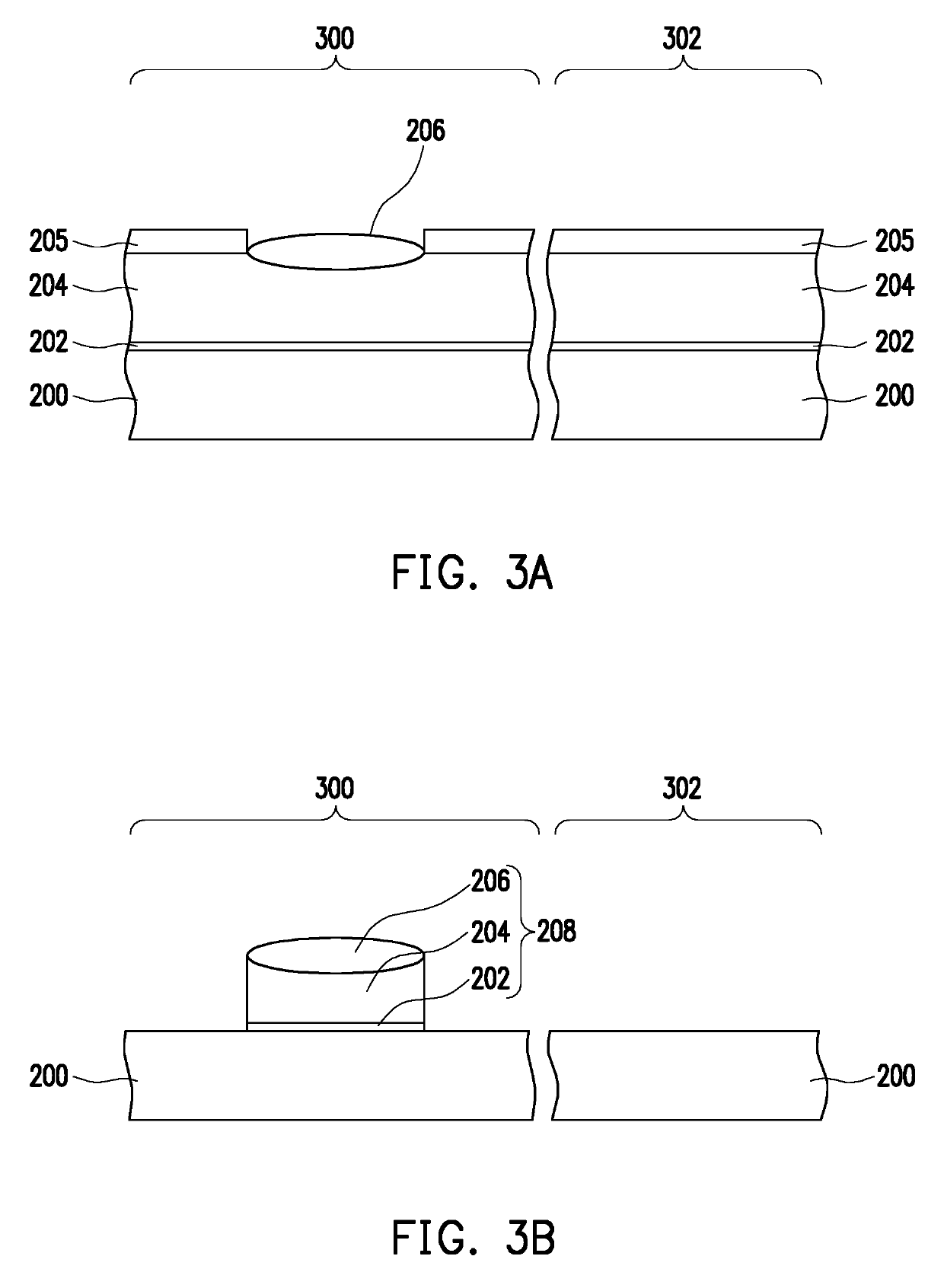

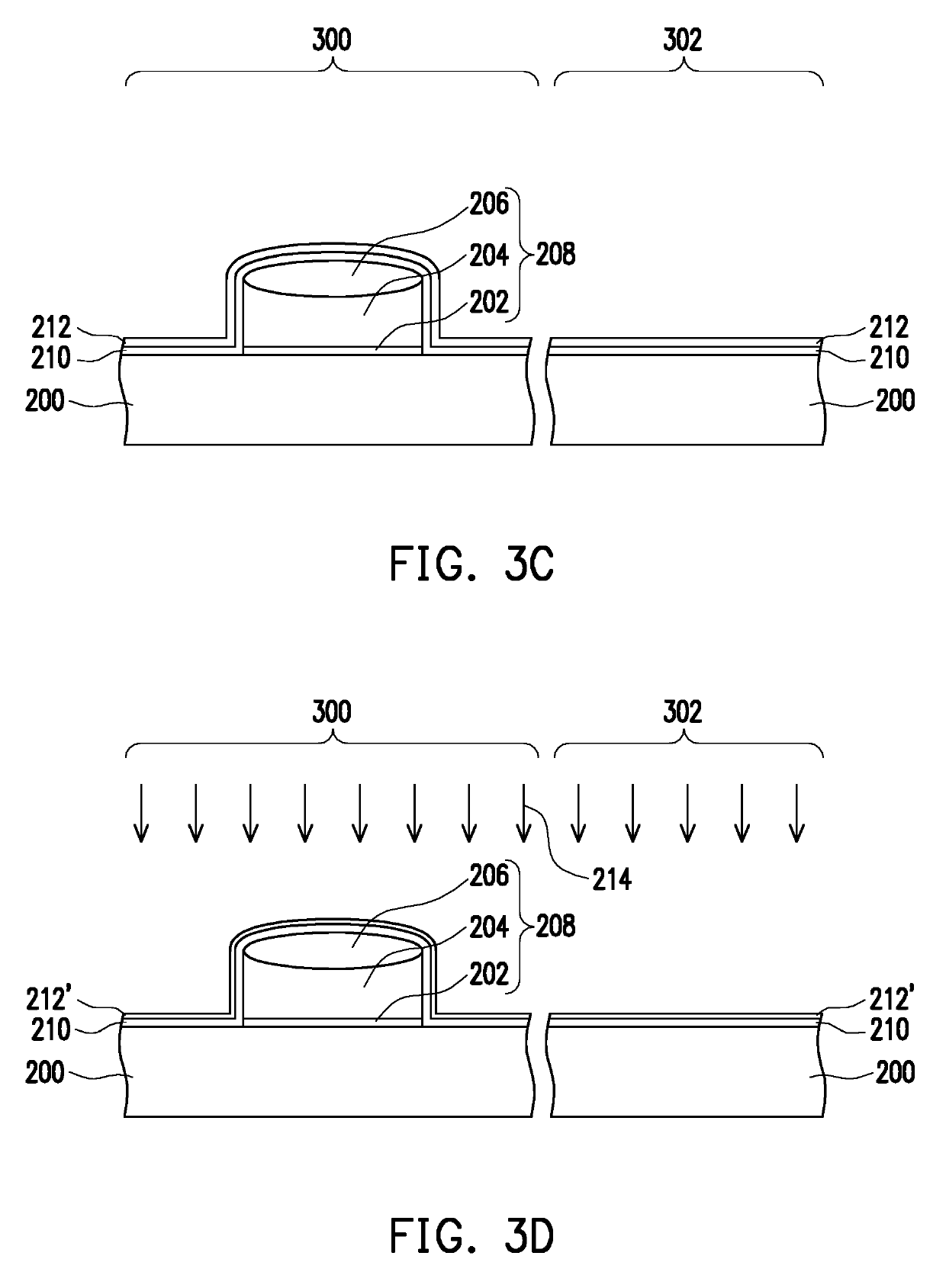

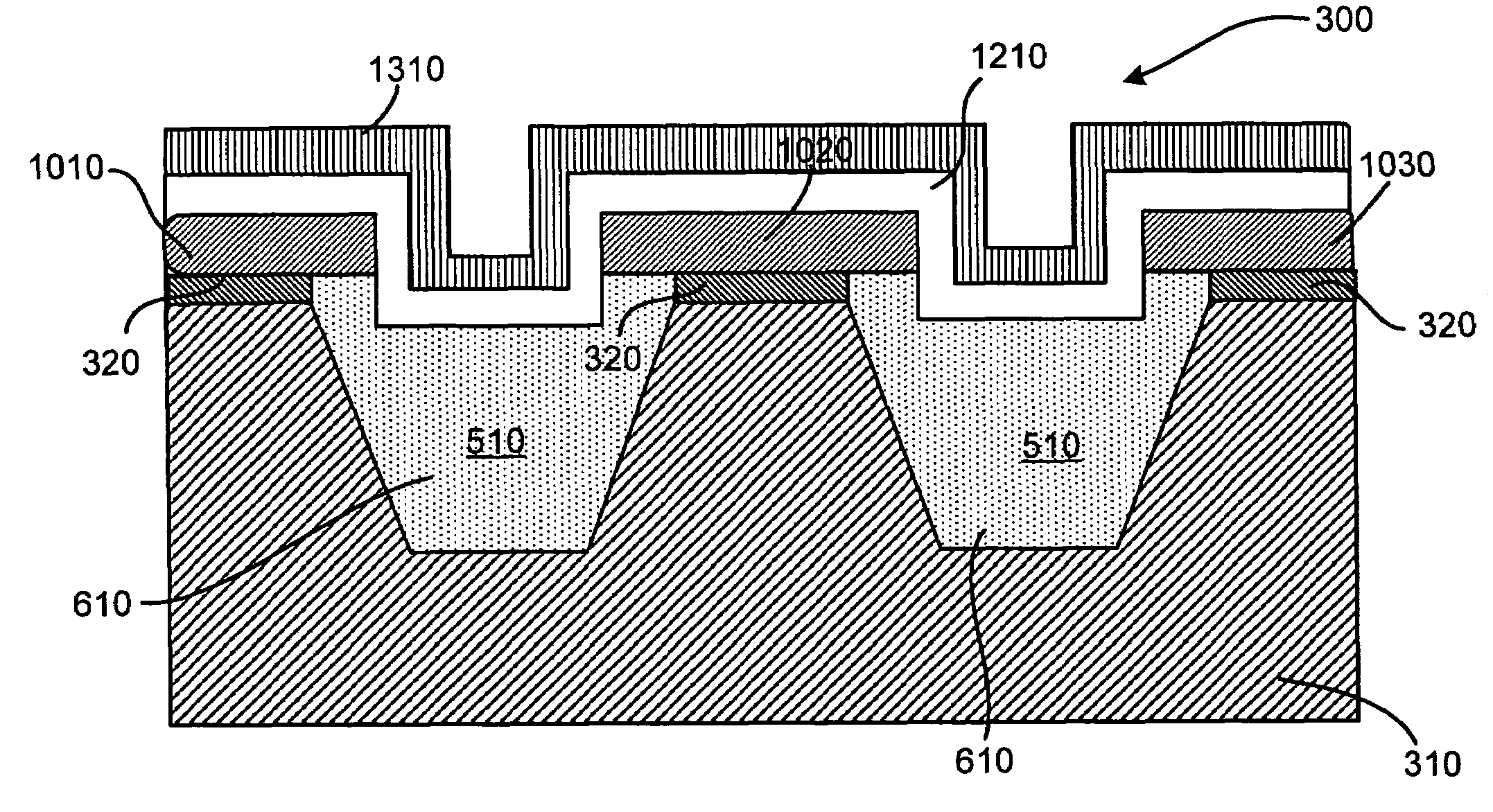

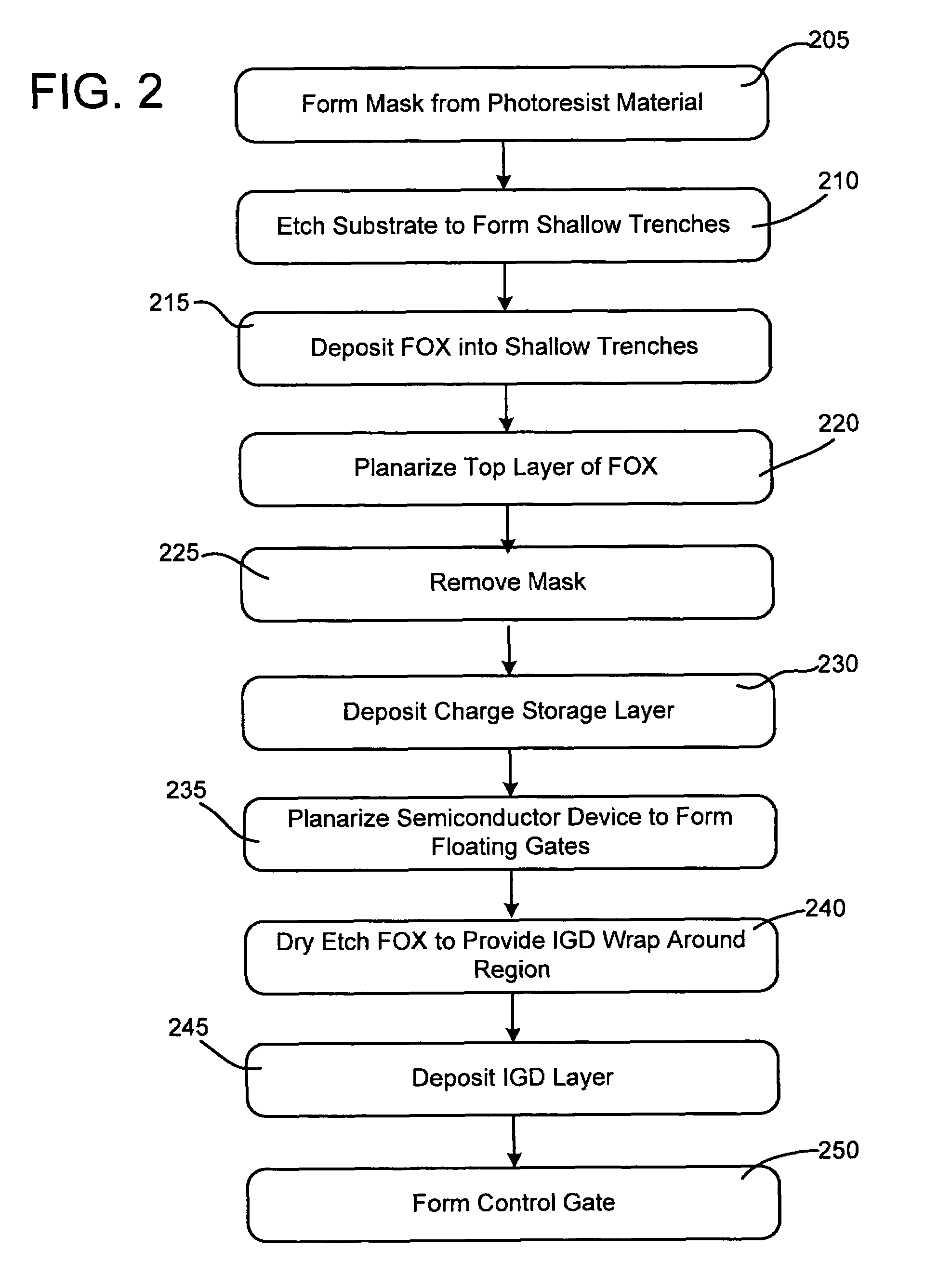

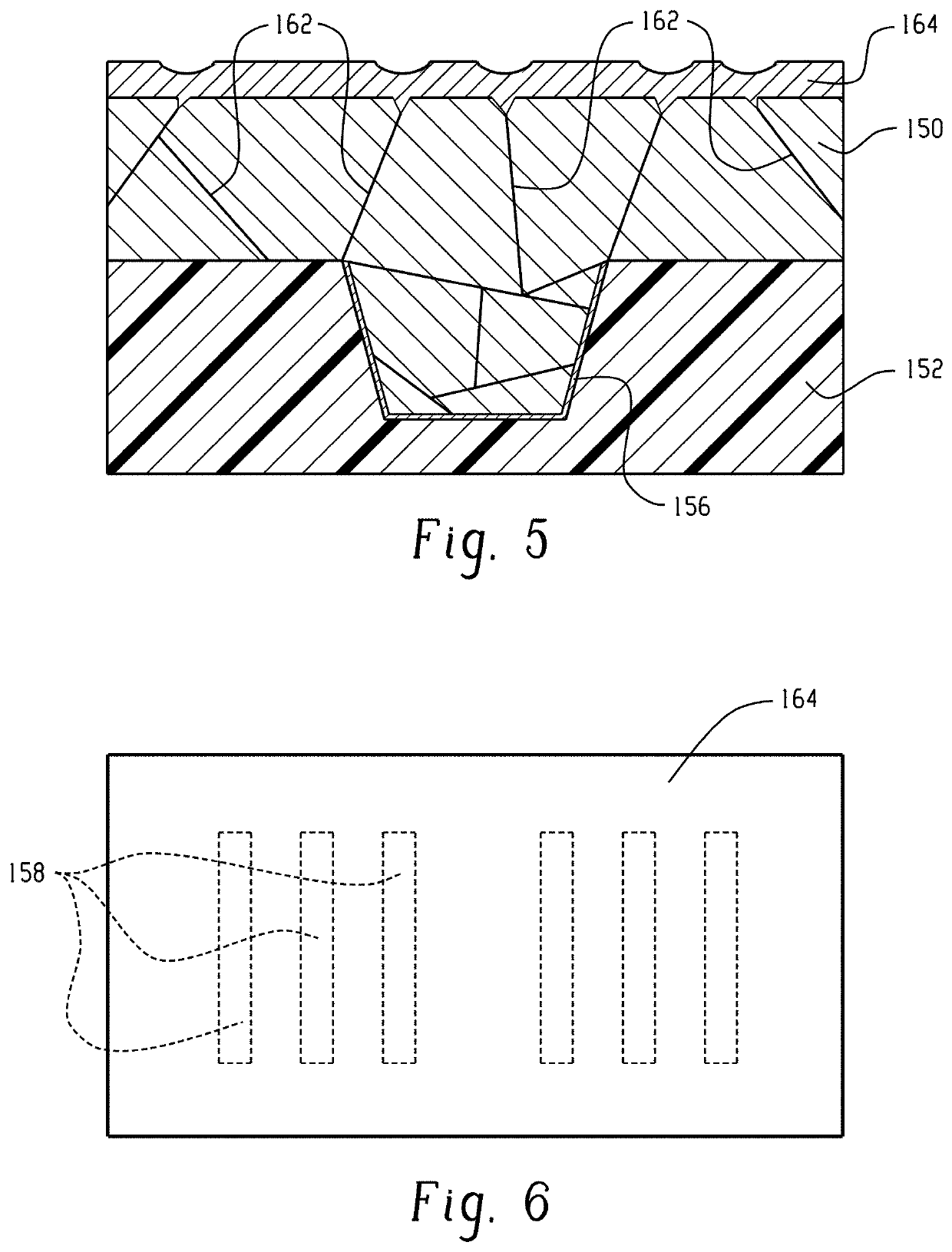

Technique for perfecting the active regions of wide bandgap semiconductor nitride devices

InactiveUS20050164475A1Lower average currentHigh densityPolycrystalline material growthFrom solid stateEngineeringNitride

This invention pertains to e lectronic / optoelectronic devices with reduced extended defects and to a method for making it. The method includes the steps of depositing a dielectric thin film mask material on a semiconductor substrate surface; patterning the mask material to form openings therein extending to the substrate surface; growing active material in the openings; removing the mask material to form the device with reduced extended defect density; and depositing electrical contacts on the device.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

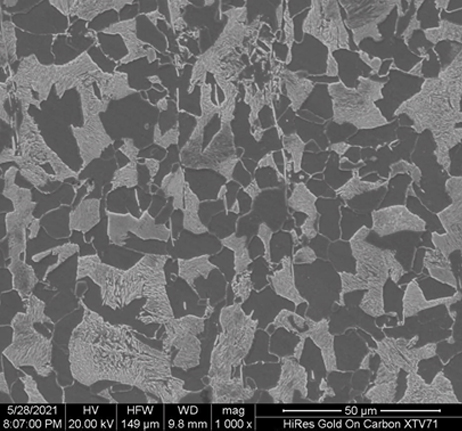

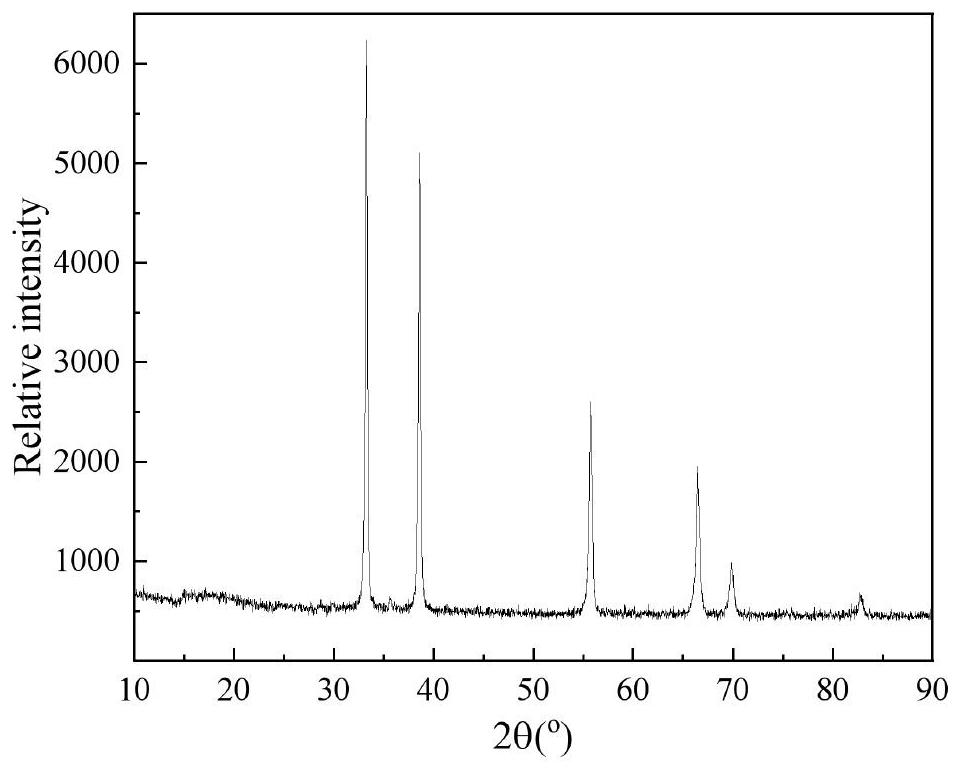

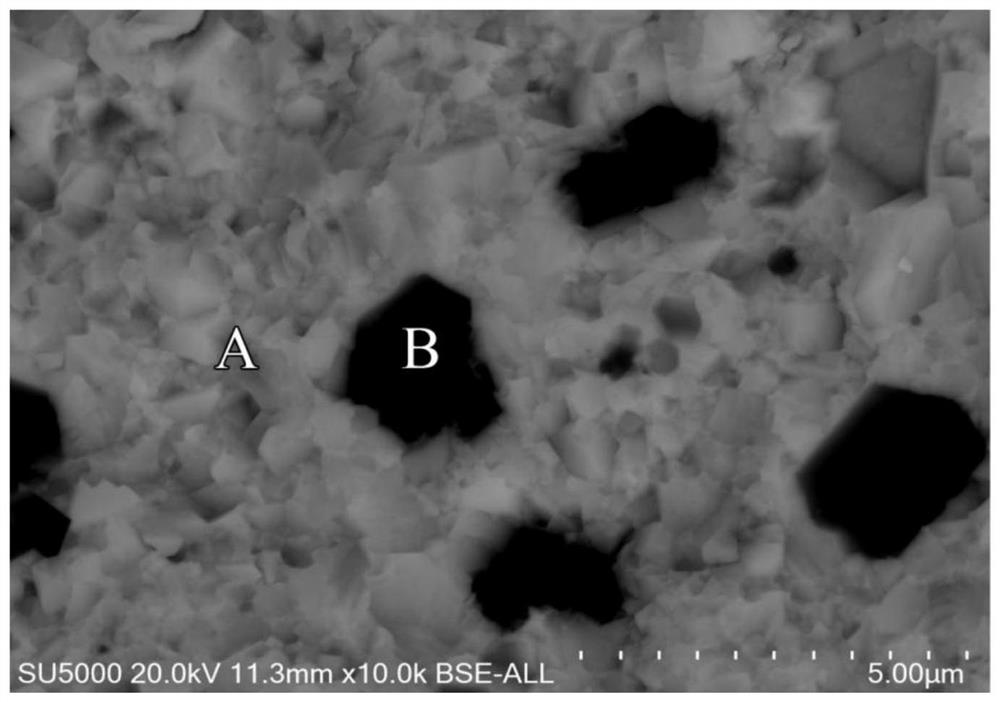

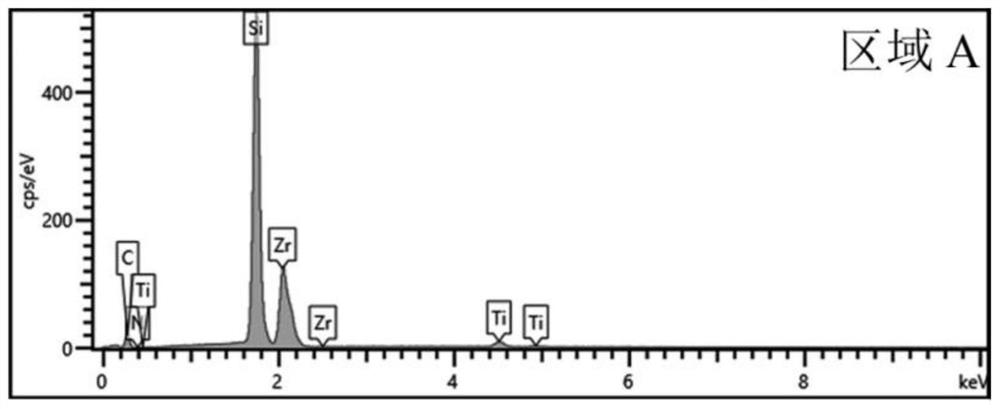

High-hardness and high-elasticity-modulus multi-component nitride coating and preparation method thereof

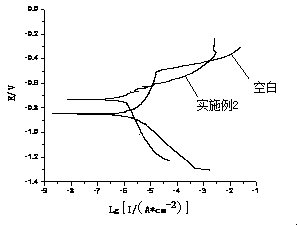

InactiveCN106835037AIngredient ControlHigh hardnessVacuum evaporation coatingSputtering coatingSputteringAlcohol

The present invention is a multi-component nitride coating with high hardness and high elastic modulus. Its chemical formula is AlCrTiZrNbN, and the atomic ratios of Al, Cr, Ti, Zr, Nb and N are respectively 8-12%: 8-12 %: 8~12%: 8~12%: 8~12%: 48~52%, the thickness of the coating is 2~5μm. The present invention also provides a method for preparing the above-mentioned nitride coating. Firstly, the surface of the substrate is subjected to mirror polishing, then ultrasonically cleaned with acetone and alcohol, and after vacuum ion cleaning, the AlCrTiZrNbN layer is deposited by radio frequency reactive sputtering, wherein AlCrTiZrNbN is mostly The component nitride coating is composed of AlCrTiZrNb alloy target with equiatomic molar ratio in (Ar+N 2 ) atmosphere prepared. The coating of the invention has high hardness and high modulus of elasticity, and can be used as a novel protective coating for various service occasions such as cutting tools and molds.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

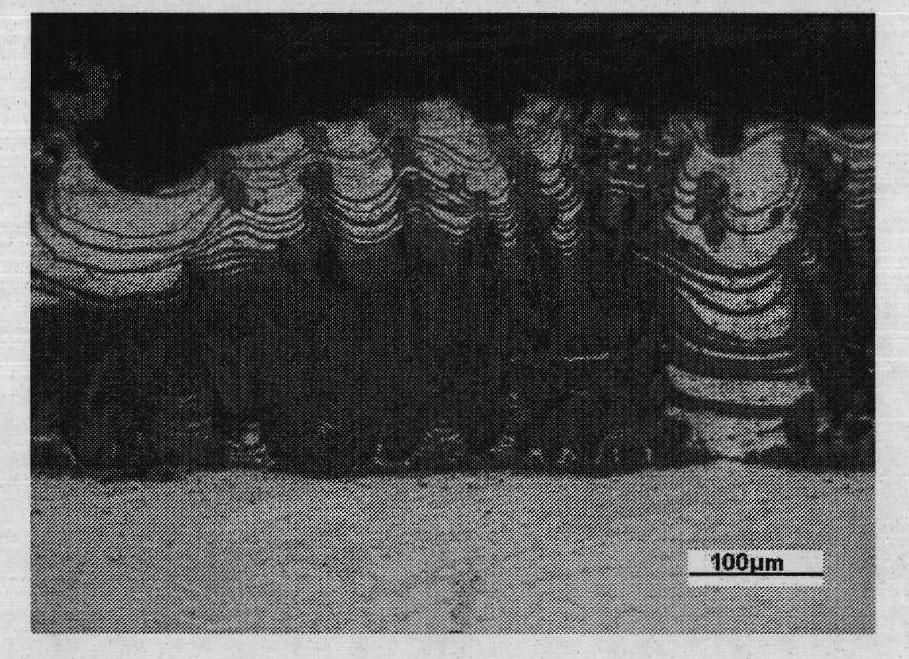

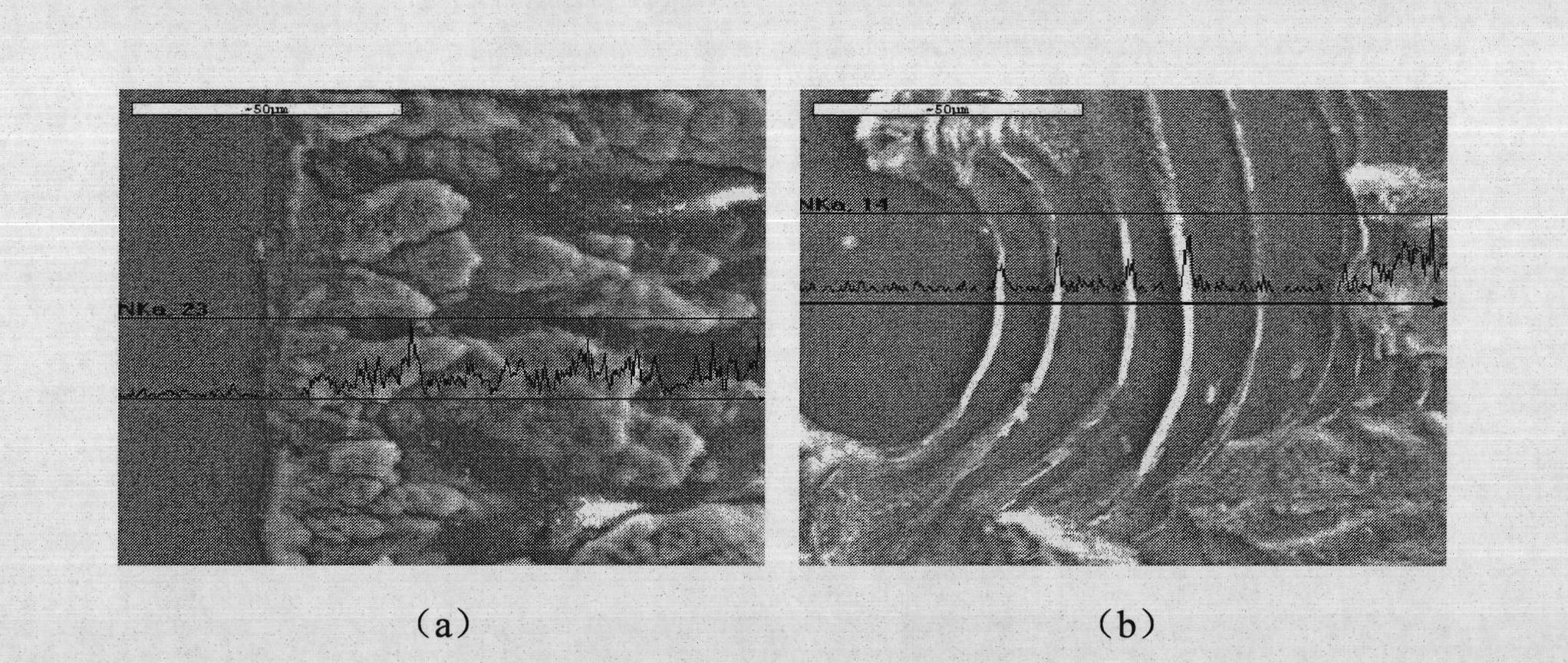

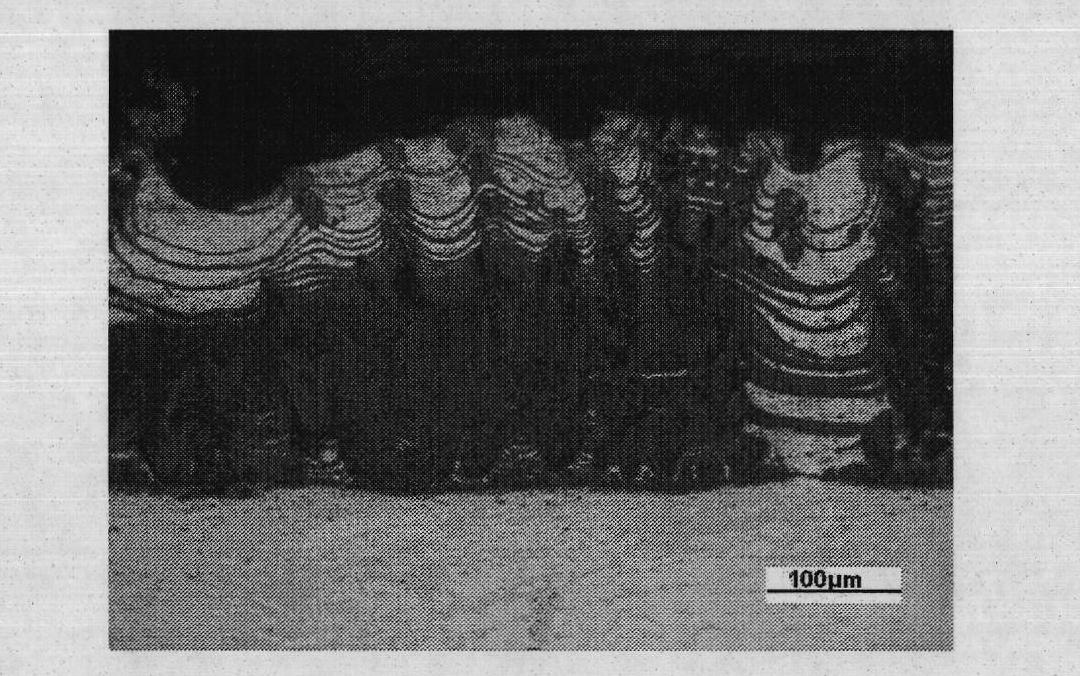

Aluminum and aluminum alloy matrix aluminum nitride reinforced gradient composite surface layer

InactiveCN101880854AImprove wear resistanceSolid state diffusion coatingSurface gradientSurface layer

Owner:JILIN UNIV

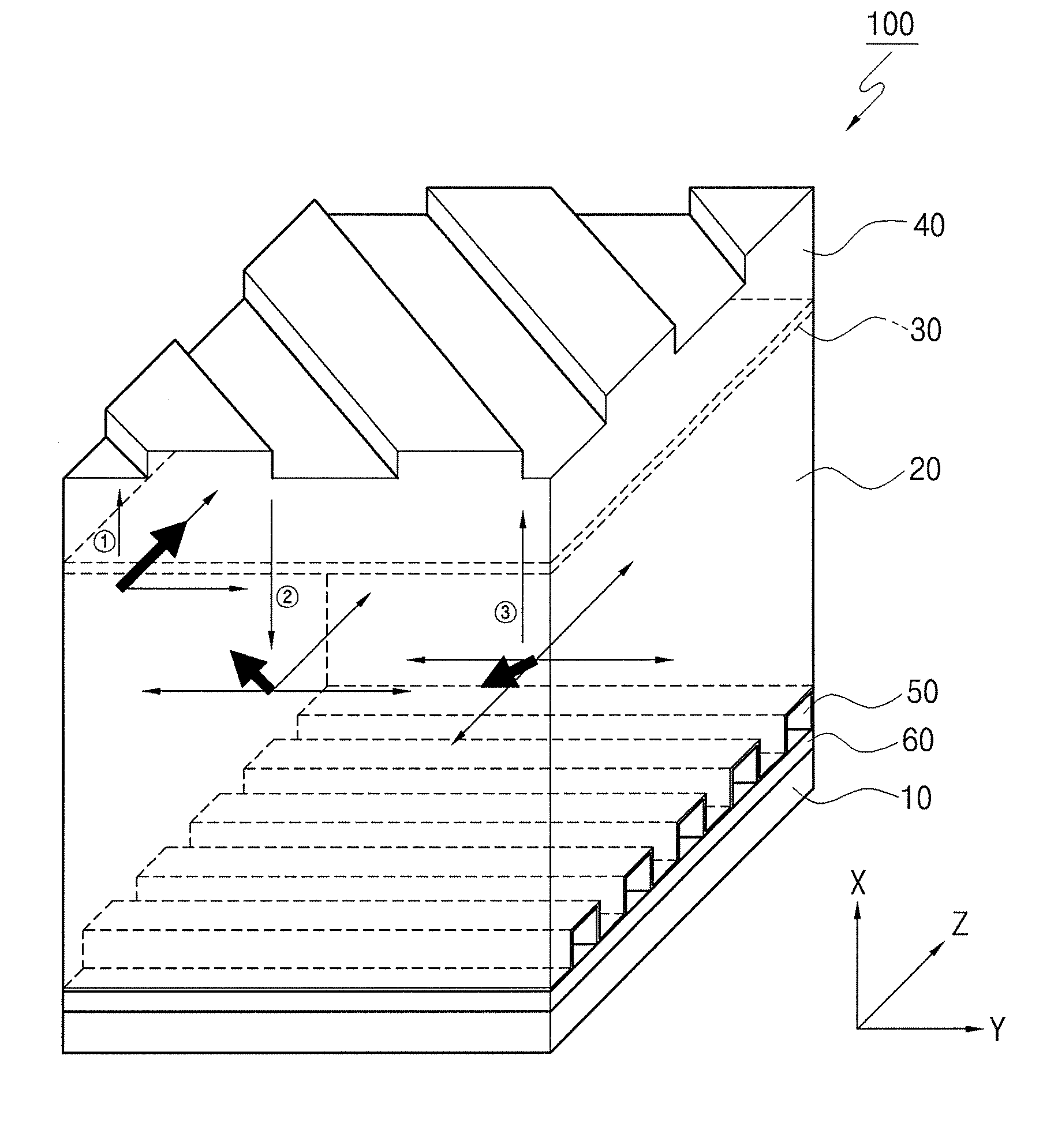

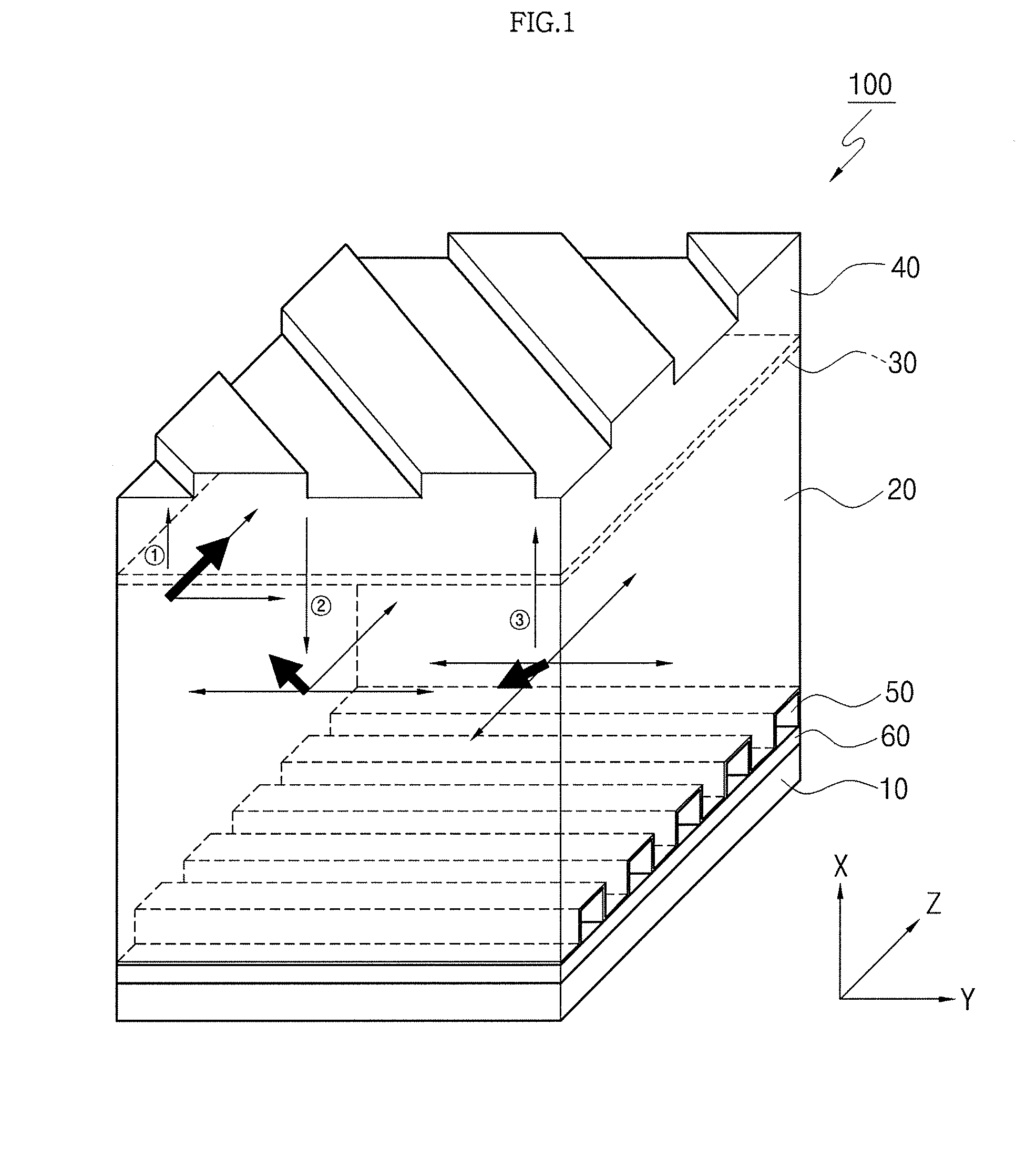

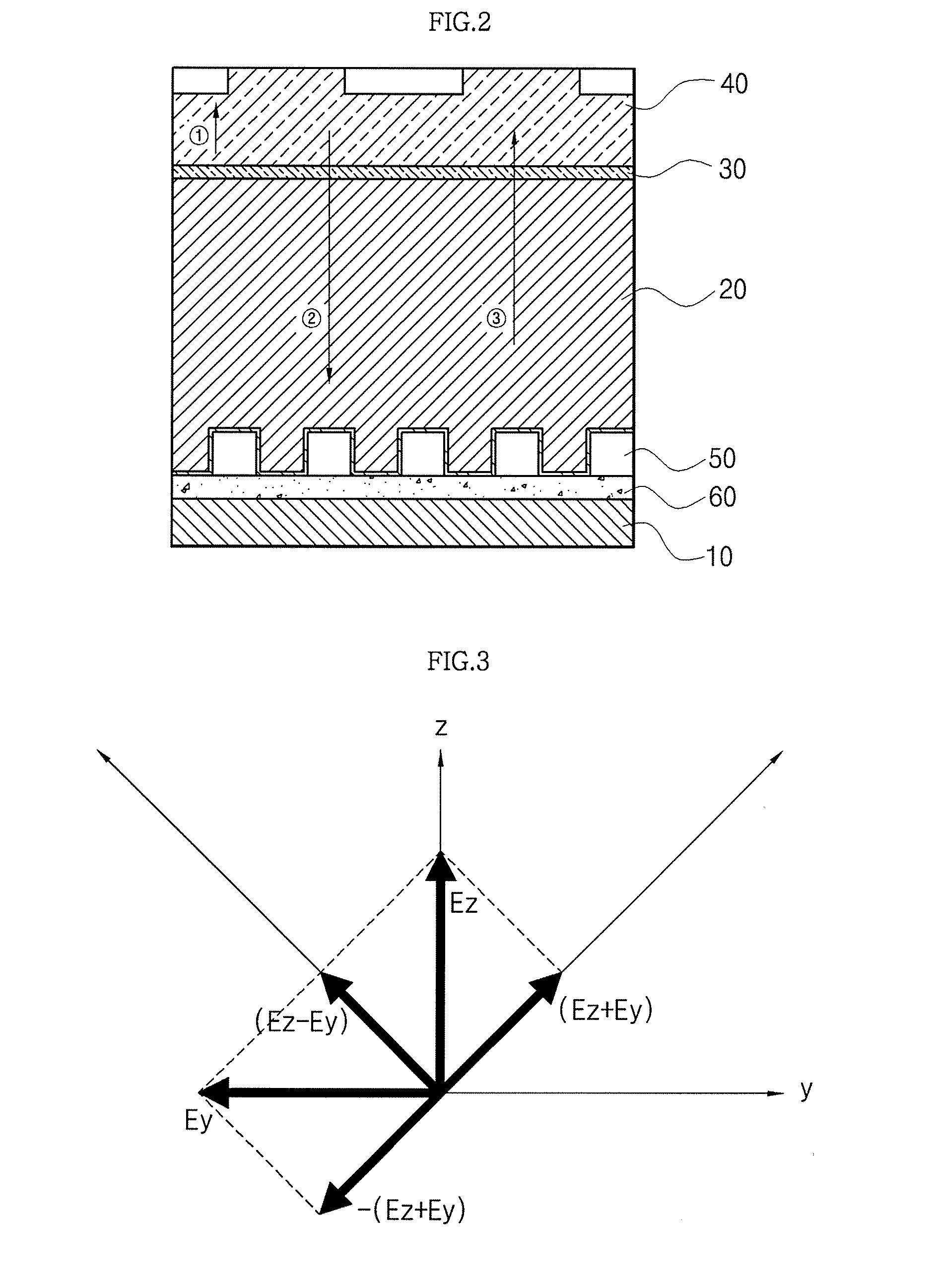

Polarized light emitting diode

ActiveUS20080290336A1Reduce in quantityReduce manufacturing costOptical resonator shape and constructionSemiconductor/solid-state device manufacturingGratingQuantum well

Owner:KOREA UNIV IND & ACADEMIC CALLABORATION FOUND

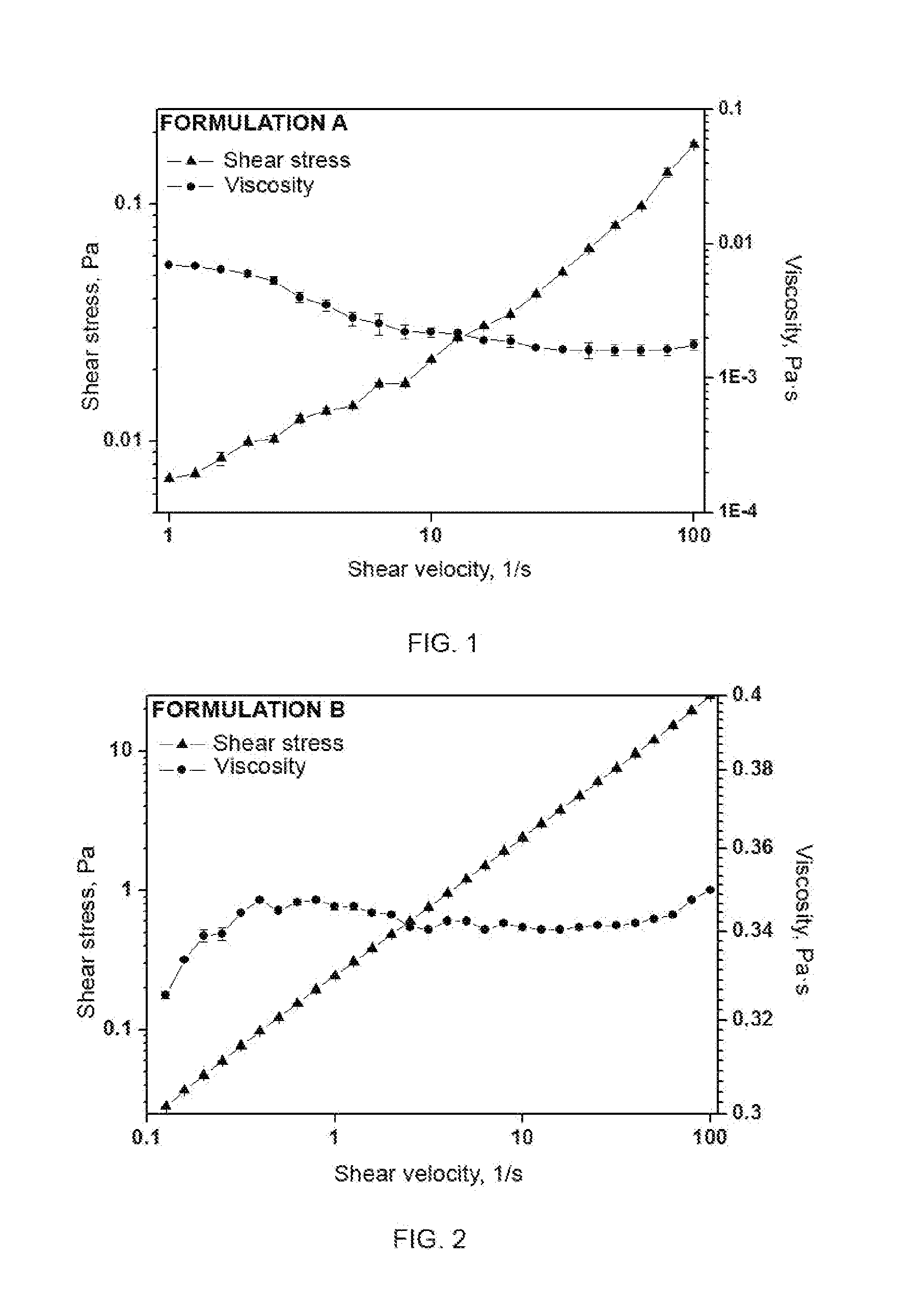

Formulation of inks containing ceramic nanoparticles

InactiveUS20150152239A1Facilitate redispersionImprove wettabilityMaterial nanotechnologyNanostructure manufactureNanoparticleSolvent

Owner:ABENGOA SOLAR NEW TECH SA

Aluminum alloy surface titanium dioxide conversion coating solution and using method thereof

InactiveCN103924229AUniform colorImprove corrosion resistanceMetallic material coating processesTitanium oxideConversion coating

Owner:无锡铱美特科技有限公司 +1

Thin film semiconductors made through low temperature process

ActiveUS20140363934A1Semiconductor/solid-state device manufacturingSemiconductor devicesZinc nitrideDeposition temperature

Owner:APPLIED MATERIALS INC

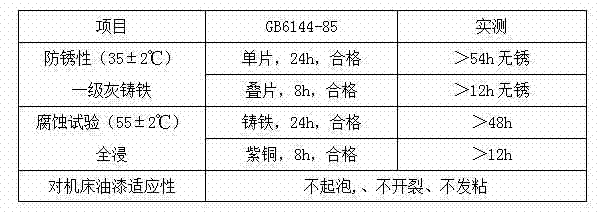

Abrasive-containing emulsifying compound metal cutting solution and preparation method thereof

ActiveCN104120020AExcellent lubricating and anti-wear propertiesImprove the lubrication effectLubricant compositionWater basedSodium metasilicate

Owner:山东斯瑞药业有限公司

High heat input welding resistant building steel and production method thereof

ActiveCN114150228AImprove welding effectGood anti-fatigueHeat treatment process controlProcess efficiency improvementNiobiumHeat cycling

Owner:NORTHEASTERN UNIV

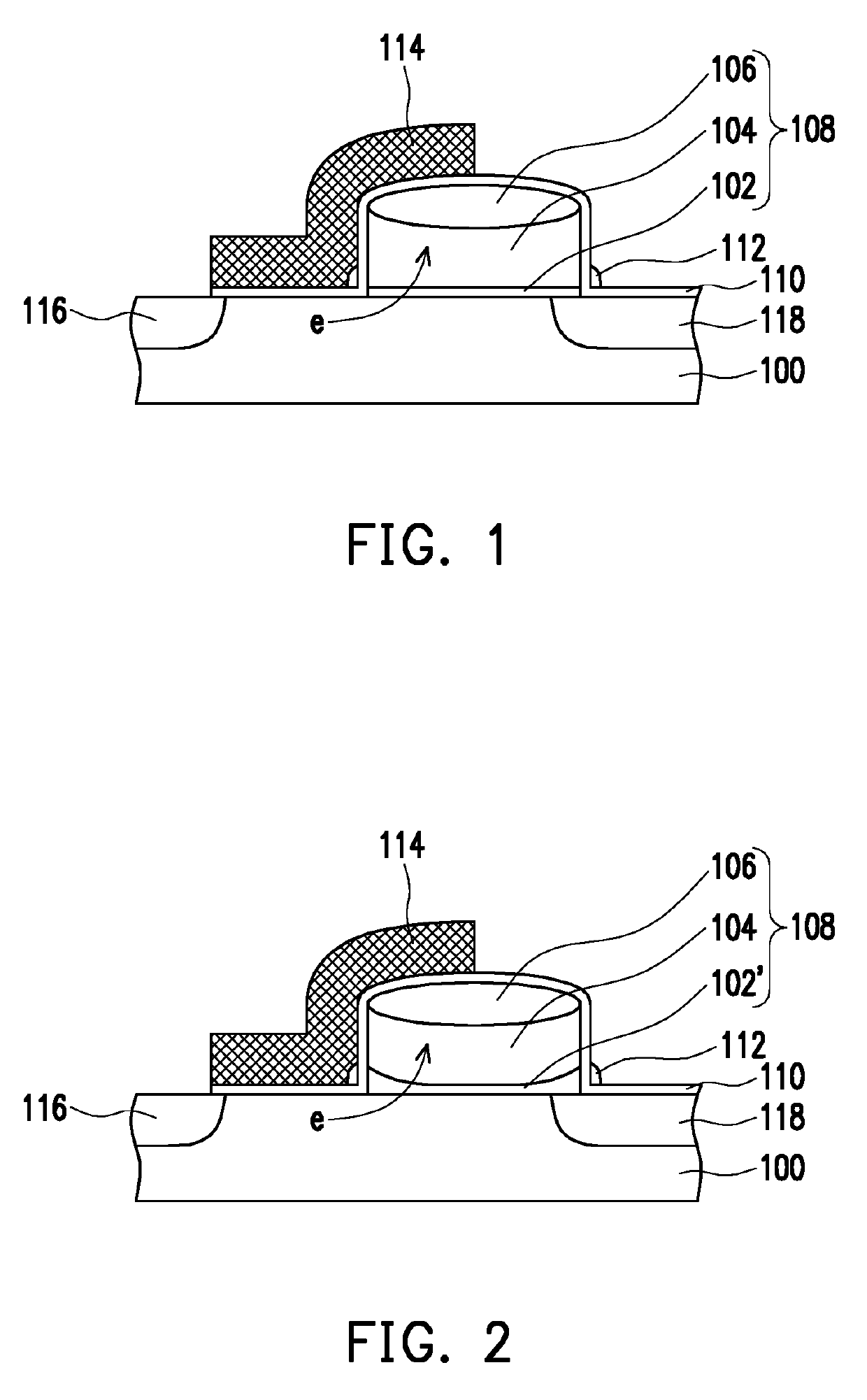

Method for fabricating semiconductor device

Owner:UNITED MICROELECTRONICS CORP

System and method for improving oxide-nitride-oxide (ONO) coupling in a semiconductor device

Owner:GLOBALFOUNDRIES US INC +1

Oxide layer and method for manufacturing grid electrode of flash memory containing same

InactiveCN101996873AImprove flatnessUniform thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesManufacturing gridNitride

The invention provides a method for manufacturing an oxide layer, which comprises the following steps of: providing a nitride layer; performing plasma surface treatment on the nitride layer; and forming the oxide layer by utilizing a process of high aspect ratio. The invention also provides a method for manufacturing a grid electrode of a flash memory. A manufacturing method of a second oxide layer in the flash memory is the same as that of the oxide layer. Oxides manufactured by the method have high flatness and uniform thickness.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Microwave reactor vessel

ActiveUS10245574B1Chemical/physical/physico-chemical stationary reactorsCarbideNitride

A microwave reactor constructed to produce a homogeneous heat distribution across the body of the microwave reactor subsequent exposure to microwave irradiation. The microwave reactor includes a body having an exterior wall transparent to microwave irradiation. A microwave sensitized element layer is adjacent the exterior wall and is comprised of a carbide mixture wherein the carbide mixture includes a carbide mixed with either a metal oxide, a ferrite or a nitride. The carbide mixture is in granular form wherein the carbide has a larger particle size than the other component. The microwave sensitized element layer further includes a metal layer that extends the length thereof. The metal layer is positioned in various arrangements within or adjacent to the carbide mixture. The body further includes an inner layer adjacent to the microwave sensitized layer opposite the exterior wall. The inner layer is transparent to microwave irradiation.

Owner:SHORE GJERGJI JOSIF

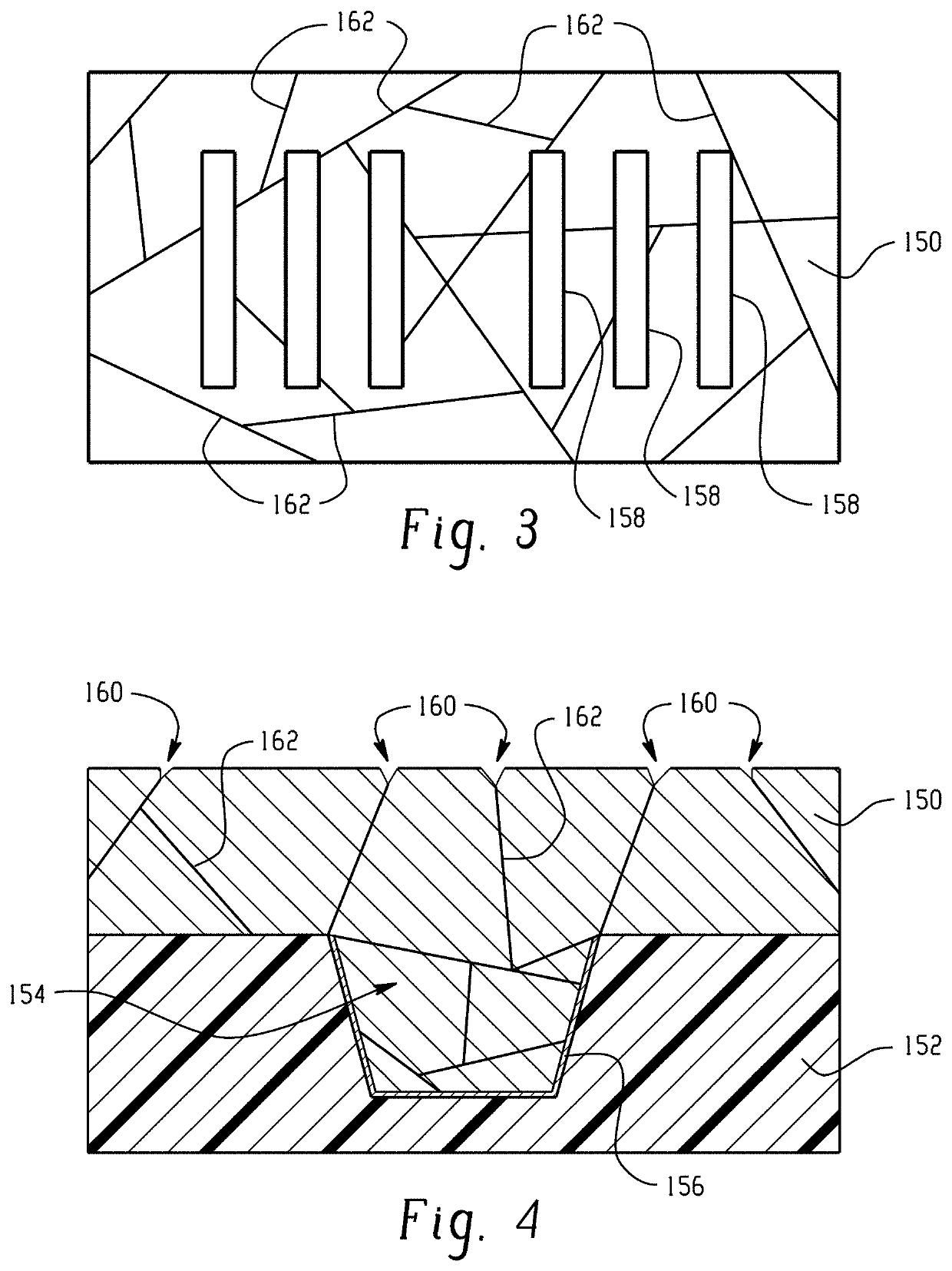

Metal surface preparation for increased alignment contrast

ActiveUS20210210434A1Improving alignment contrastIncrease alignment contrastSemiconductor/solid-state device detailsSolid-state devicesNitrideCondensed matter physics

Owner:IBM CORP

Semiconductor device and method of manufacturing the same

ActiveUS20060214245A1Maintain relatively stableInhibited DiffusionSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialNitrogen

The semiconductor device includes a semiconductor substrate, a gate insulating film formed in contact with an upper side of the semiconductor substrate, and a gate electrode formed on the upper side of the gate insulating film and made of metal nitride or metal nitride silicide. A buffer layer for preventing diffusion of nitrogen and silicon is interposed between the gate insulating film and the gate electrode. Preferably, the buffer layer has a thickness of 5 nm or less. In the case where gate electrode contains Ti elements, and the gate insulating film contains Hf elements, the buffer layer preferably contains a titanium film.

Owner:RENESAS ELECTRONICS CORP

Method for preparing carbonitride-silicide solid solution composite ceramic at low temperature by reaction hot pressing sintering technology

PendingCN113999013AFacilitated DiffusionPromote interactionComposite ceramicCarbide

Owner:HARBIN UNIV OF SCI & TECH

Stainless steel separation piece and preparation method thereof

ActiveCN109355637AExtended service lifeQuality improvementChemical vapor deposition coatingChromium carbideCarbon nitride

Owner:GUANGDONG SHUANGHONG NEW MATERIAL TECH CO LTD +1

Endless metal ring and method of producing the same

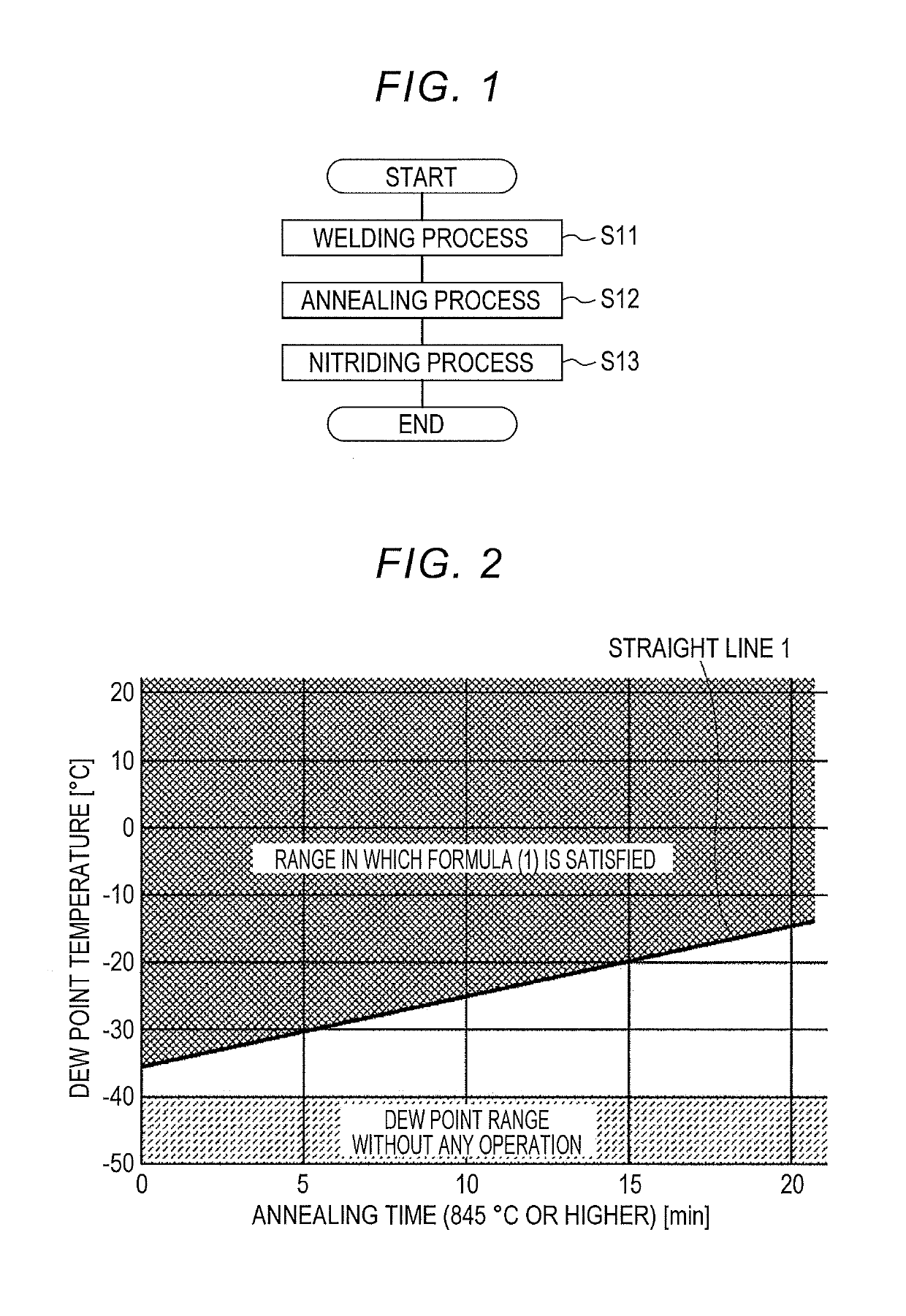

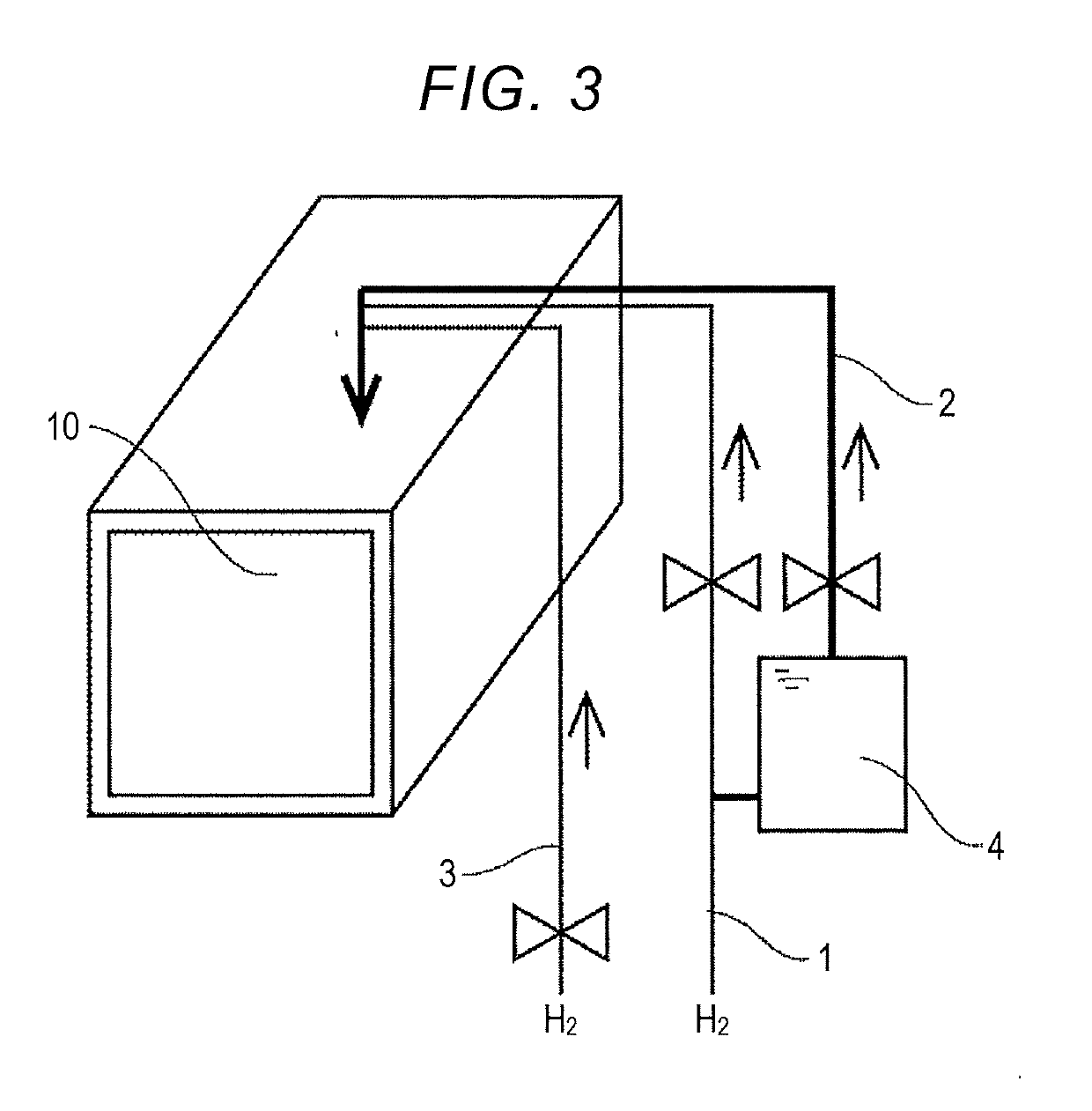

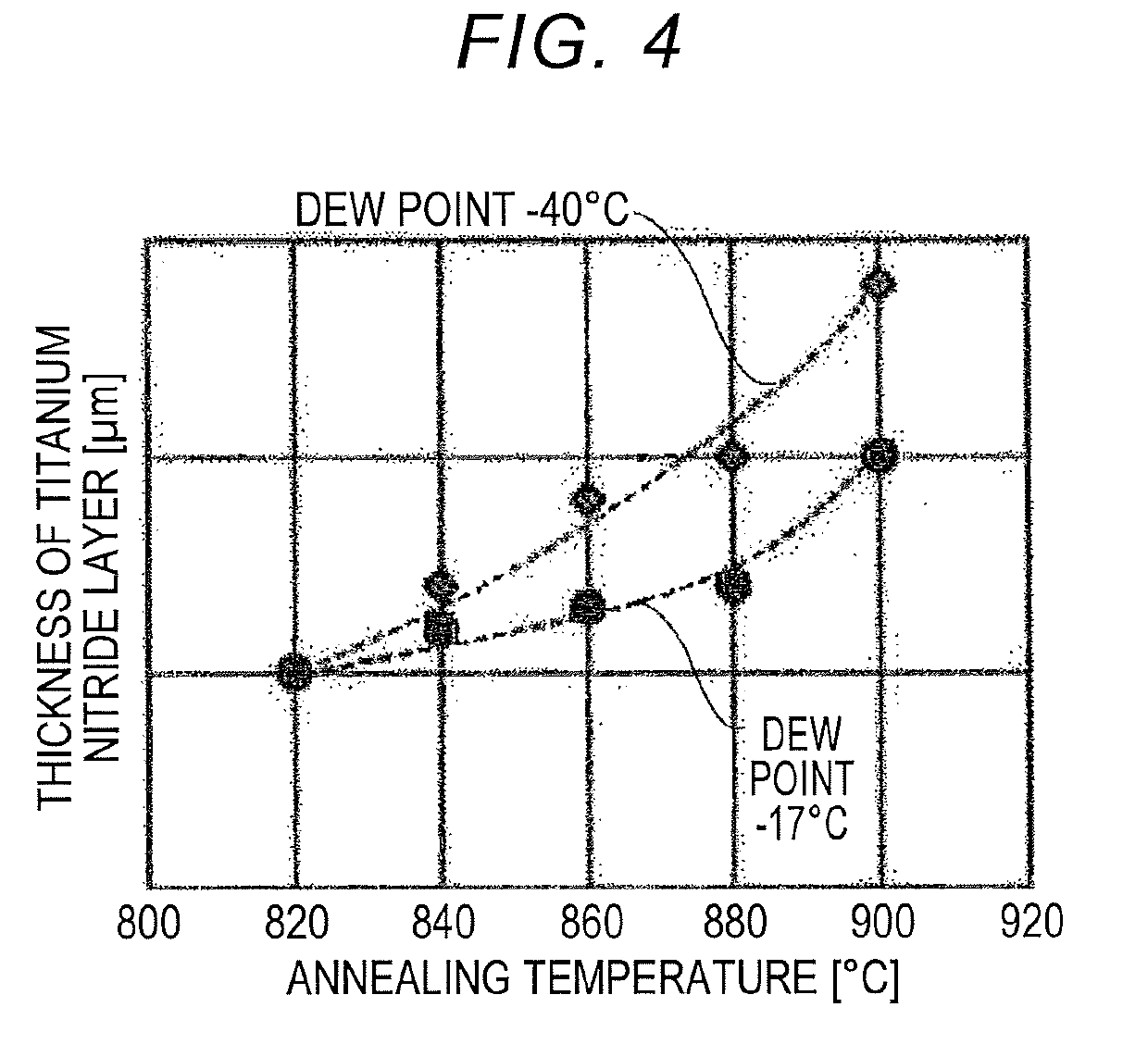

InactiveUS20190331197A1Reduce Shrinkage ProblemsImprove fatigue strengthV-beltsMetal-working apparatusSheet steelMartensite

Owner:TOYOTA JIDOSHA KK

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap