Polarized light emitting diode

a light-emitting diode and polarized technology, applied in the direction of lasers, optical resonator shape and construction, semiconductor lasers, etc., can solve the problems that the technology described above has not been presented, and achieve the effect of reducing the total number of parts and reducing the manufacturing cost of lcds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]Hereinafter, a preferred embodiment of the present invention will be explained in detail with reference to the accompanying drawings.

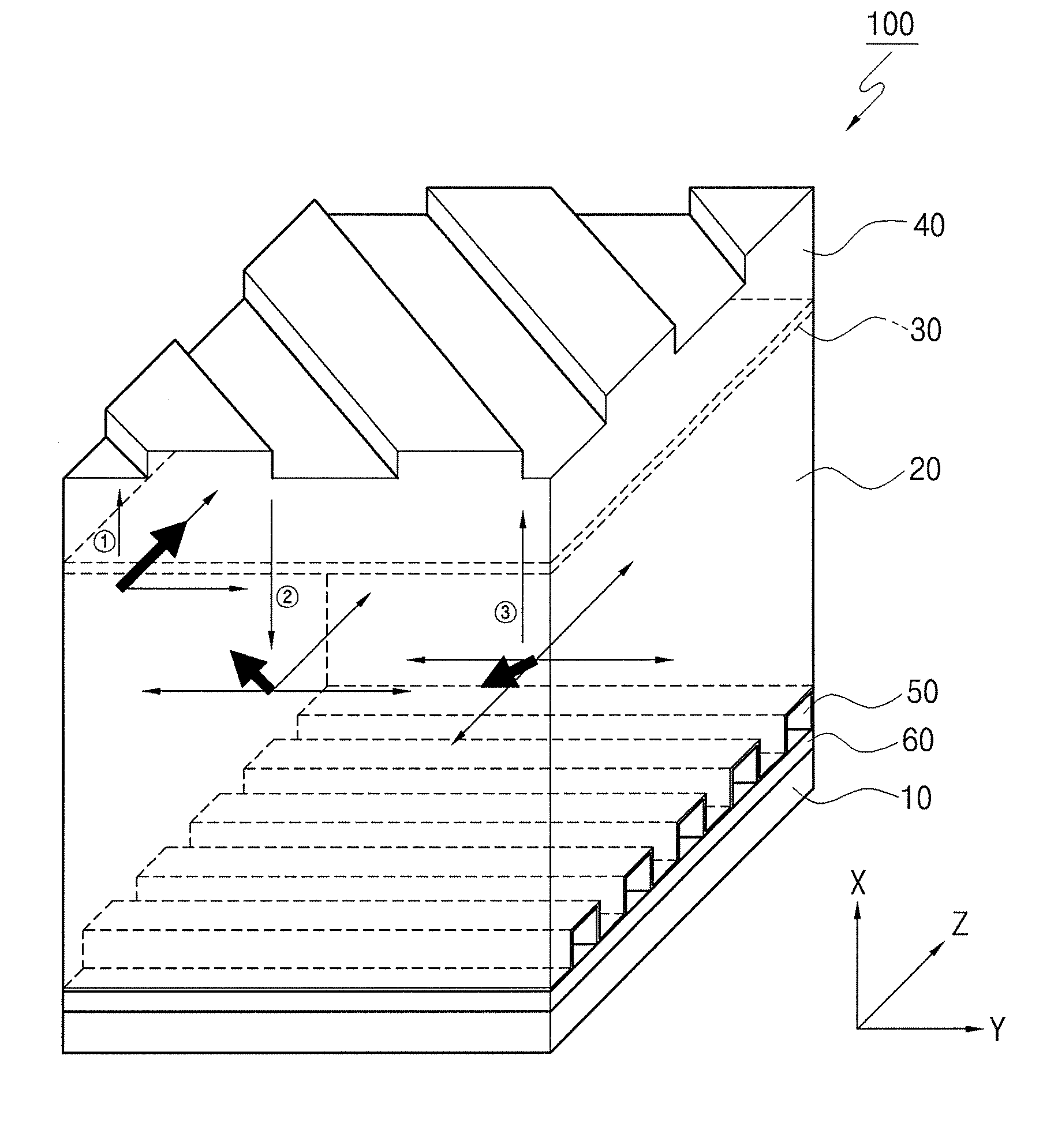

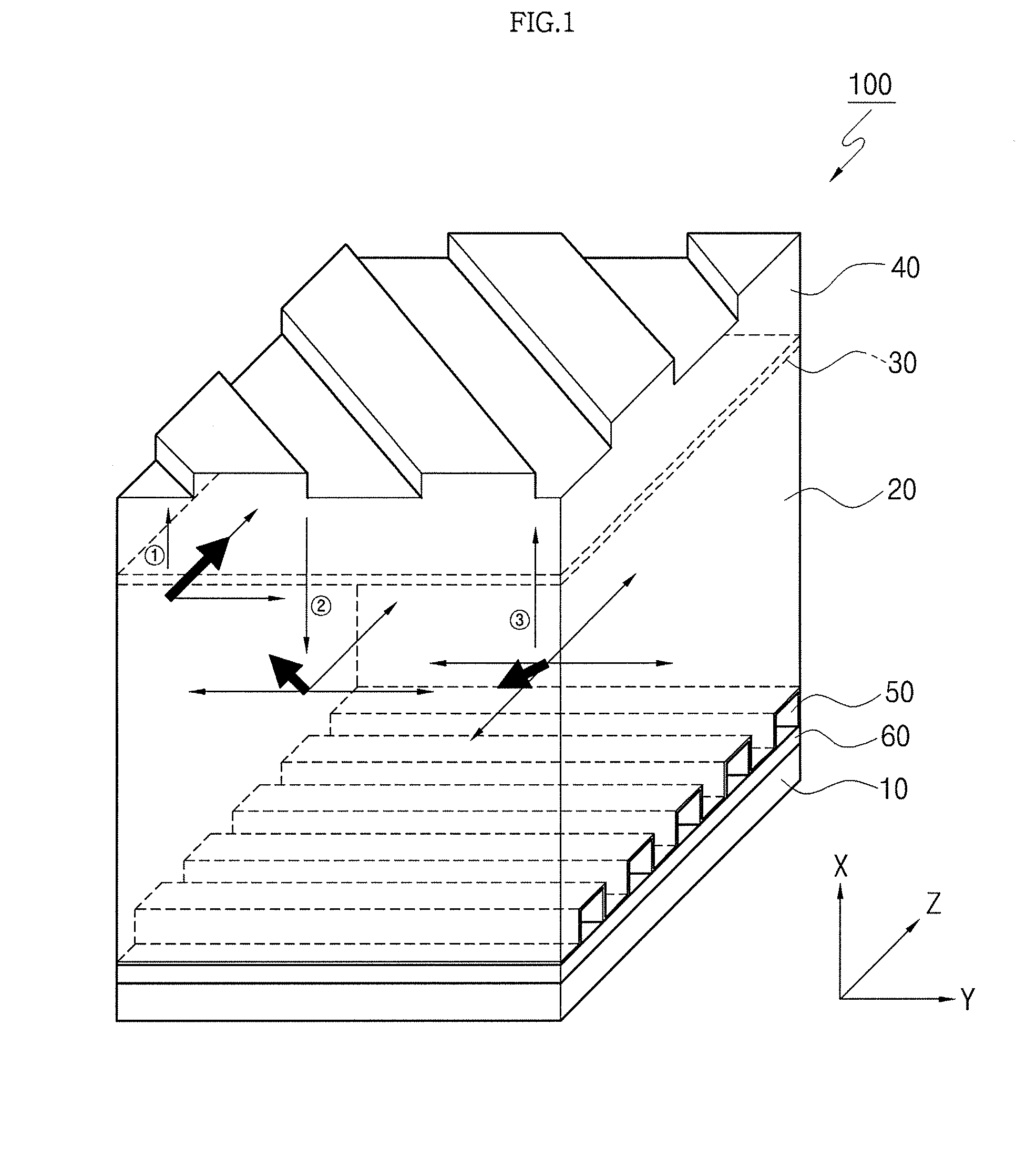

[0023]FIG. 1 is a perspective view of a polarized LED according to the present invention and FIG. 2 is a sectional view of the polarized LED according to the present invention.

[0024]As shown in FIGS. 1 and 2, the polarized LED 100 according to the present invention comprises a nitride thin film 20 formed on a substrate 10, and a quantum well layer 30 formed on the nitride thin film 20. Preferably, the nitride thin film 20 includes at least one of GaN, InN and AlN and the substrate 10 includes a sapphire substrate.

[0025]According to the present invention, the structure of the LED 100 comprising the elements as described above is modified and improved. In detail the LED 100 has a structure for emitting most light, which is generated from the quantum well layer 30, in the front direction thereof.

[0026]As described above, in order to emit most of the li

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap