Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

491results about How to "Reduce manufacturing cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drinking dispenser for bedridden patients

InactiveUS7207968B1Good control feelingEasy constructionDispensing apparatusOral administration deviceSolenoid valveLow voltage

A gravity-fed drinking dispenser for unassisted self-administration of liquids by a bedridden user includes a non-pressurized liquid container adapted to be positioned above the user's head, a flexible tubing assembly connected therewith with a mouthpiece at its free end, and a normally closed solenoid valve between the container and the mouthpiece which, when opened, allows liquid to flow by gravity to the mouthpiece. A low-voltage D.C. electrical source connected with the solenoid valve supplies direct current thereto. Operation of the solenoid valve is controlled by an ergonomic pressure-sensitive microswitch connected between the power source and the solenoid valve, which has a generally oval-shaped housing with a bulbous upper portion shaped to receive the palm of the user and allow the user to put their fingers around it and actuate the microswitch by applying light pressure thereto for unassisted self-administration of liquids.

Owner:HARCINSKE JOHN C

Light guide module having embedded LED

InactiveUS20050100288A1Improve light guide efficiencyExtended service lifeInput/output for user-computer interactionCoupling light guidesLight guideOptoelectronics

A light guide module of optical mouse is disclosed. The light guide module comprises a LED die within a light guide input of light guide means. The light guide input comprises an internal paraboloid. Light emitted by the LED die and parallel reflected from the paraboloid is impinged on a light guide output.

Owner:SUNPLUS TECH CO LTD

Compliant Electrical Contact and Assembly

ActiveUS20090111289A1Sufficient complianceReduce manufacturing costElectrically conductive connectionsCoupling device detailsShunt DeviceSkew angle

A compliant electrical contact and an assembly employing a plurality of the contacts that provides an interface between two electrical devices. The contact has a convoluted spring with convolutions and a contact point at each end. In one contact embodiment, the convolutions have appendages which electrically short adjacent convolutions throughout a significant portion of the compression range of the contact. An appendage may be a single finger that extends from one convolution toward the adjacent convolution, a pair of opposed fingers that extend toward each other from adjacent convolutions, or machined edges on adjacent convolutions. In some configurations, the fingers or a surface on the appendage or fingers are at a skew angle to the direction of compression. In another contact embodiment, a shunt attached at one contact point and parallel to the spring spans most or all of the convolutions longitudinally. The shunt electrically shorts adjacent convolutions by wiping on the abutting surface of the shunt or by a wiper extending from the convolution to the shunt. Alternatively, the shunt electrically shorts the two contact points, bypassing the convolutions. The contact is placed within a through aperture in a dielectric panel that has openings at each end through which the contact points protrude.

Owner:ARDENT CONCEPTS INC

Method for preparing biodiesel by lowering value of high acid palm oil

InactiveCN101230309ALow acid valueHigh catalytic activityFatty acid esterificationBiofuelsAlcoholBiodiesel

The invention provides a method which uses palm oil to prepare biologic diesel oil and can lower the high acid value. The method uses solid super acids of SO>4<2- > / ZrO2, SO4< 2- > / TiO2, and SO4< 2- > / xZrO<2- yTiO2 as catalyst, and uses low-carbon alcohol as esterifying agent to pre-treat the high acid value palm oil, can effectively lower the acid value of the oil, and can ensure the acid vale of the obtained biologic diesel oil to easily meet the standard (less than 0.8mgKOH / g, ASTM). The catalyst used by the invention has high catalytic activity, and is reusable. The process flow is simple, the production cost is decreased, and the environmental pollution is reduced greatly.

Owner:SICHUAN UNIV

Non-aqueous solution aluminum ion secondary battery and preparation method thereof

InactiveCN104993130AGood chemical stabilityImprove thermal stabilityCell electrodesFinal product manufactureAluminum IonElectrical battery

Belonging to the technical field of batteries, the invention relates to a non-aqueous solution aluminum ion secondary battery and a preparation method thereof. The secondary battery can be widely applied in electronics, communication, electric vehicle and other fields. The aluminum ion battery provided by the invention contains a battery anode, a battery cathode, a diaphragm and an aluminum-containing non-aqueous solution electrolyte. Specifically, the cathode active material can be carbon, graphite, carbon nanotube, graphene, super carbon, WS2 and MoS2, V2O5, TiO2 and other materials having nano-layered, tubular, linear and other structures, and the anode is aluminum-containing metal or alloy. The non-aqueous solution aluminum ion secondary battery provided by the invention has the characteristics of high specific capacity, high coulomb efficiency, long service life and environmental protection, safety and reliability, stable cycle performance, and quick charging, etc.

Owner:BEIJING ALUMINUM ENERGY S&T

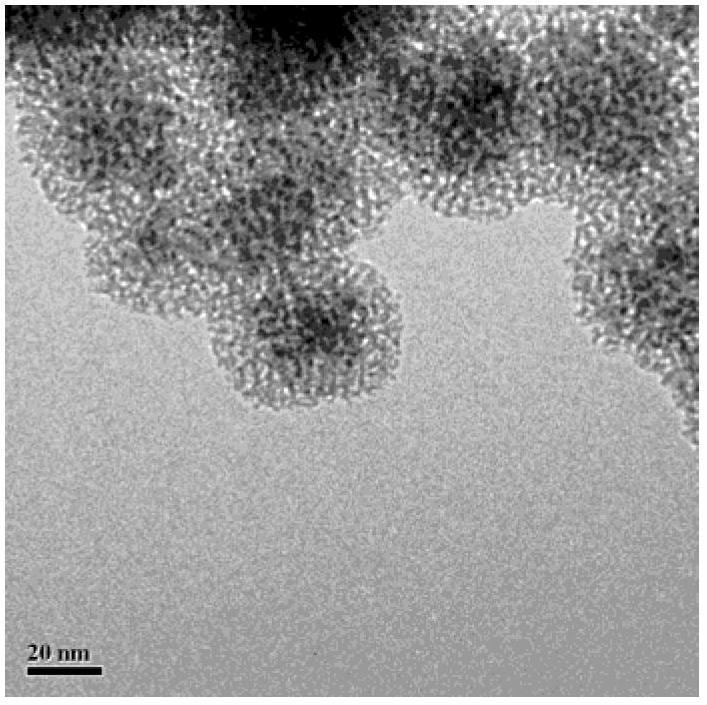

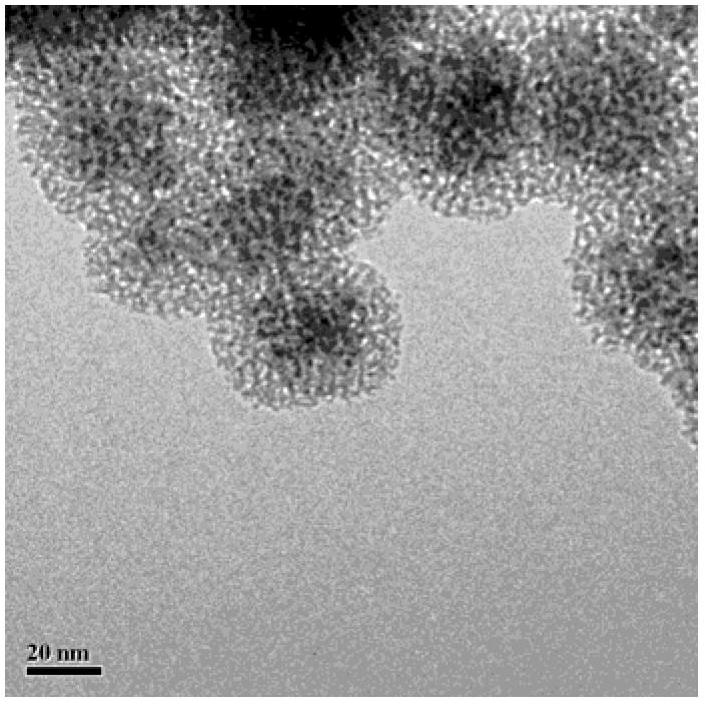

Fe3O4/CuO/pSiO2 catalyst and preparation method thereof

InactiveCN102688760AEfficient separation and recoveryReduce churnOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsChemistryActive agent

The invention relates to a Fe3O4 / CuO / pSiO2 (porous silica) catalyst, a preparation method thereof and application thereof in olefin epoxidation reaction. The preparation method comprises the following processes of: obtaining Fe3O4 microspheres serving as magnetic cores by adopting a co-precipitation method, and modifying the surfaces of the Fe3O4 microspheres by using polyvinyl pyrrolidone (PVP) in order to improve the adsorption effect of the surfaces of the Fe3O4 microspheres on metal cations; coating a CuO nano shell layer on the surfaces of the Fe3O4 microspheres by using copper acetate as a copper source through hydrothermal synthesis; and finally, coating the porous silicon dioxide shell layer by using cetyl trimethyl ammonium bromide (CTAB) as a surfactant and using ethyl orthosilicate as a silicon source, and thus obtaining a composite catalytic material with a magnetic Fe3O4 / CuO / pSiO2 core-shell structure. The catalytic performance of the composite material is researched by respectively using epoxidation reaction of styrene and cyclooctene as probe reaction, and the results prove that the catalytic material has high reaction activity and selectivity, and the catalytic material is easy to separate and recover by introducing the magnetic ores; and the catalytic material has a good circulating effect, still can keep excellent catalytic performance by dozens of times of circulation, and has a great application prospect.

Owner:UNIV OF SCI & TECH BEIJING

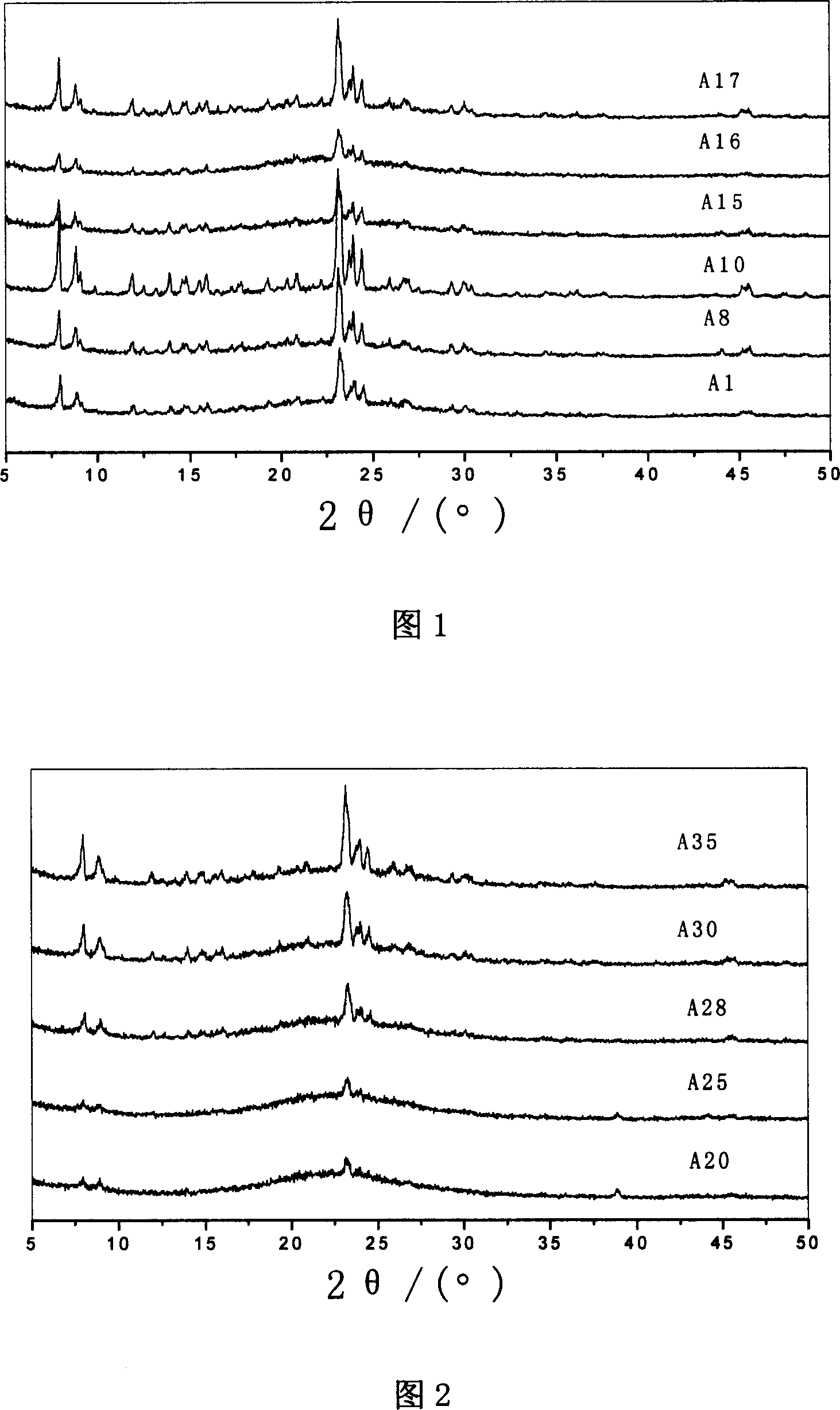

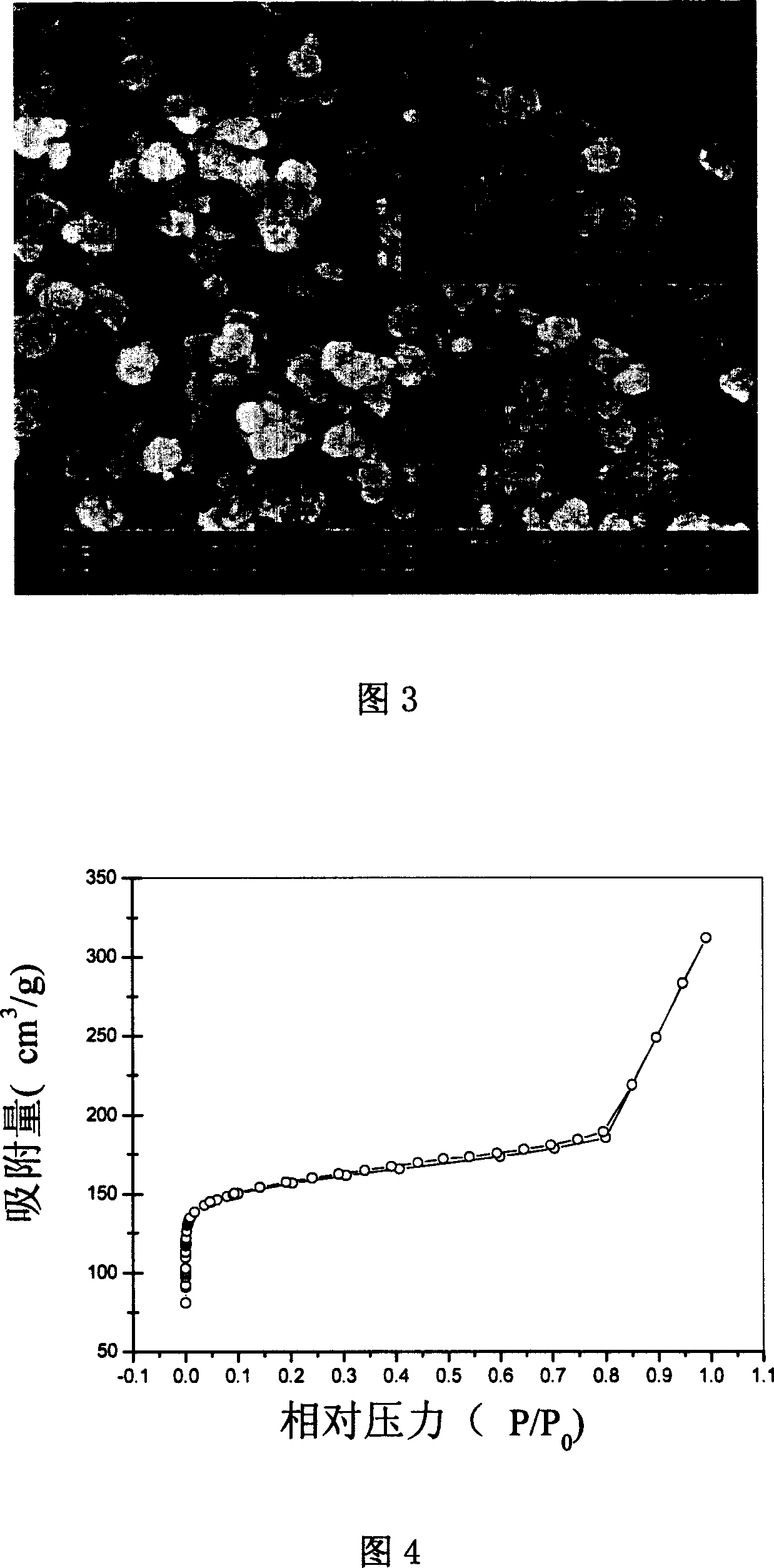

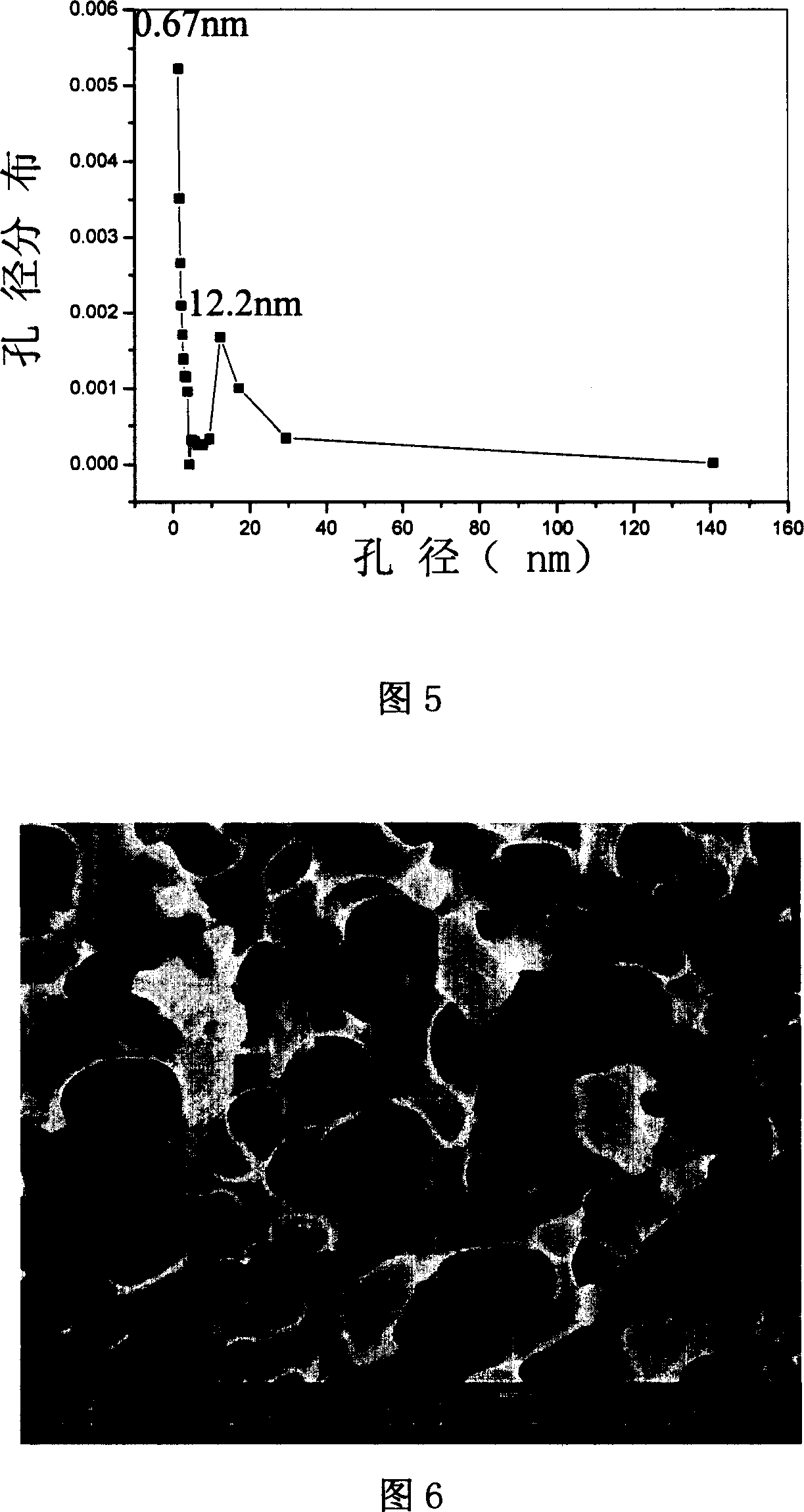

Method for synthesizing ZSM-5 zeolite with multilevel pore canals

ActiveCN101003380AThe operation process is simpleReduce manufacturing costMolecular sieve catalystsPentasil aluminosilicate zeoliteSucrose solutionCompound s

This invention discloses a method for synthesizing multi-level porous ZSM-5 zeolite. The method comprises: soaking monolithic silica gel column in sucrose solution, drying, polymerizing, carbonizing to obtain C-Si composite, wetting the C-Si composite with a mixed solution of Al source, inorganic alkali, organic amine and water, crystallizing, and recovering the product. The obtained ZSM-5 zeolite has multi-level pores, including micrometer-scale macropores, mesopores and micropores. The macropores can shorten the diffusion distances of reactive molecules, reduce the pressure decrease of the equipment, raise the unit processing capacity of the equipment, and make the adjustment and control of the product selectivity easier. The mesopores can provide large inner specific surface area, which is meaningful to the catalytic reaction of macromolecules.

Owner:CHINA PETROLEUM & CHEM CORP +2

Method for casting rotary axis casts of aerogenerators

ActiveCN101618425AImprove yieldReduce manufacturing costFoundry mouldsFoundry coresMetallurgyBlock effect

The invention discloses a method for casting rotary axis casts of aerogenerators, which comprises the steps of mould manufacture, the manufacture of sand moulds and moulding by casting. In the step b of the manufacture of sand moulds, a top sprue (1) is used as an inlet of iron liquor, and is alternately communicated with runners; a bottom runner is communicated with an ingate communicated with a cast mould cavity; the runners are designed into a first runner (3), a second runner (4) and a circular runner (5); the ingate is designed into a plurality of radial runners (6) for communicating the circular runner (5) and the cast mould cavity; filtering apparatuses are arranged on the first runner (3) and the second runner (4), and are also arranged between each radial runner (6) and the circular runner (5); and in the step c of moulding by casting, the casting temperature is controlled from 1310 DEG C to 1350DEG C; and finally, a cast (2) is obtained. The method for casting rotary axis cast of aerogenerator has the advantages of good residue blocking effect and low production cost.

Owner:RIYUE HEAVY IND

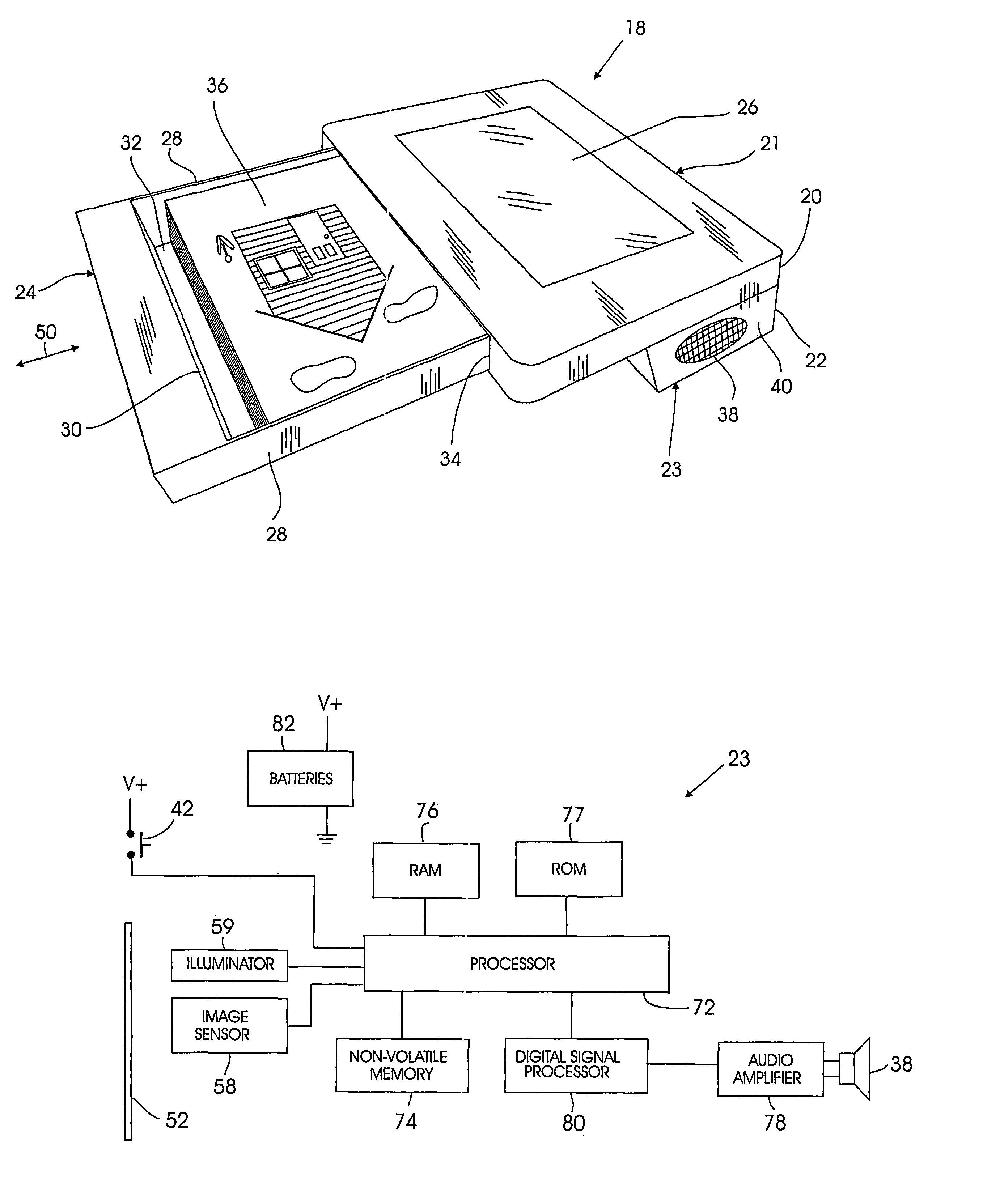

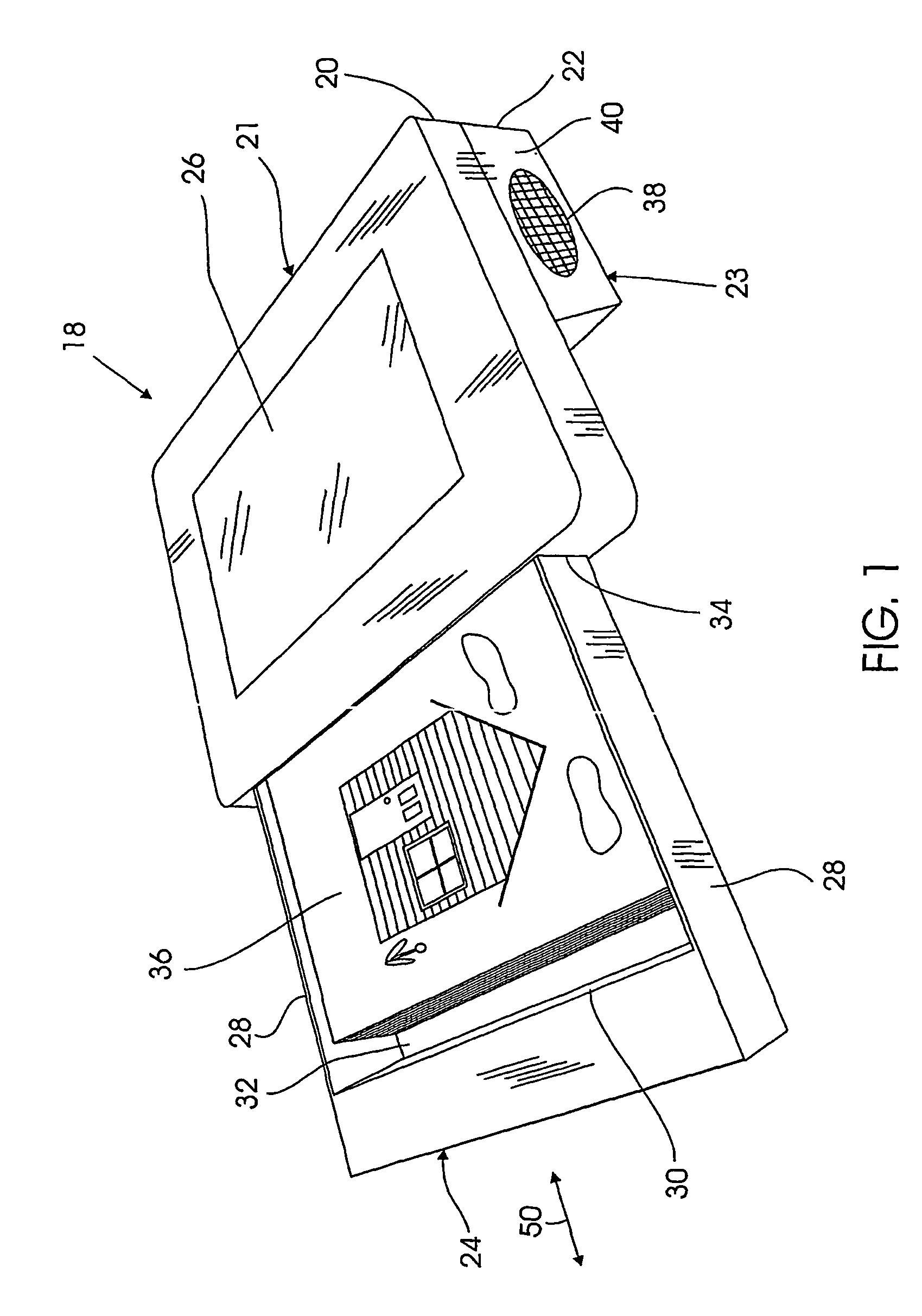

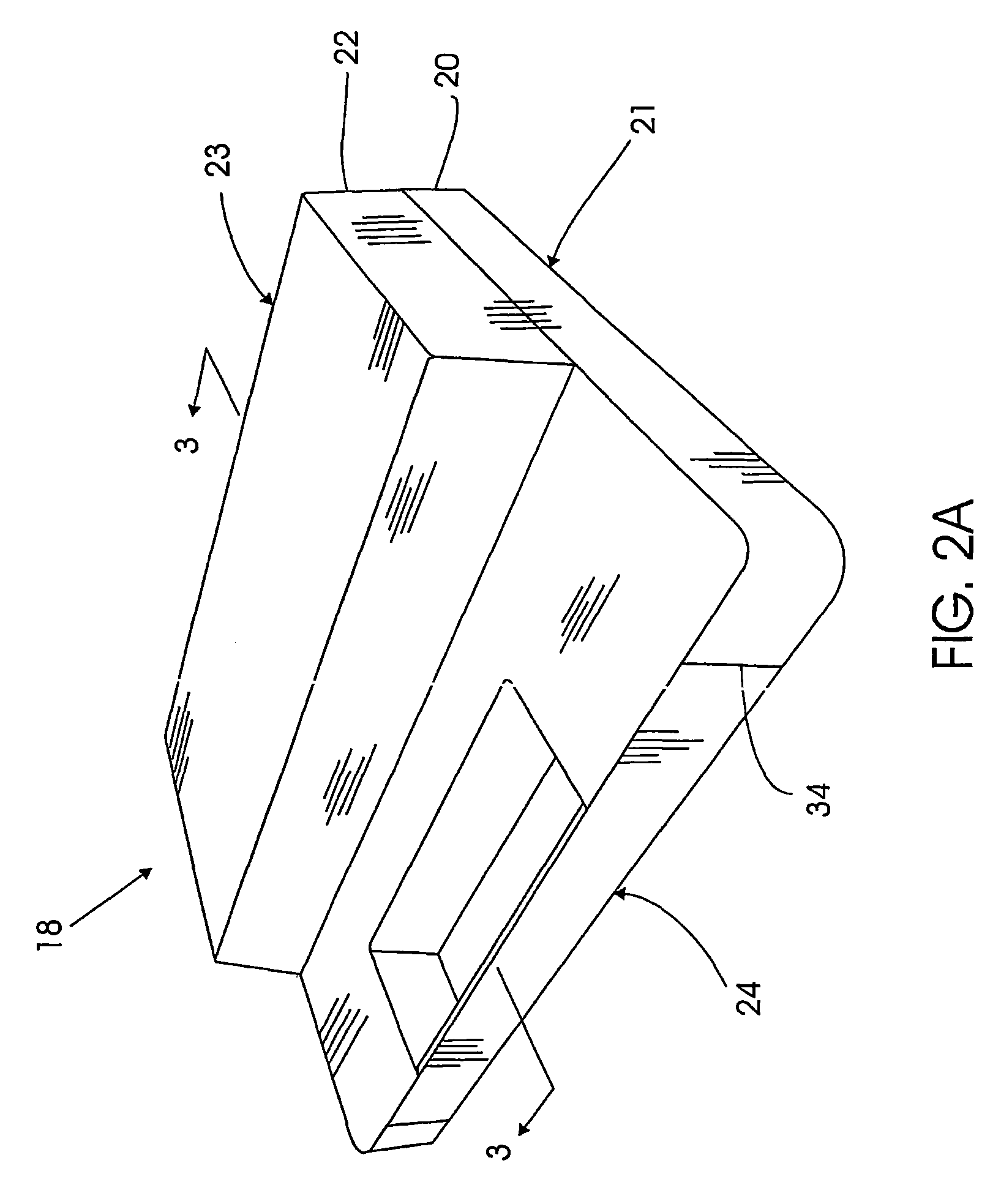

Picture changer with recording and playback capability

InactiveUS6990293B2Reduce manufacturing costLow priceProjectorsAdvertisingImage converterAudio frequency

Owner:HU RON

Blade driving mechanism for a table saw

InactiveUS20060191393A1Simple structureEasy to adjustMetal sawing devicesShearing machinesTransverse axisGear wheel

The present invention provides a blade driving mechanism for a table saw, wherein the table saw comprises a main frame and a saw blade mounted to and driven by the blade driving mechanism, and the blade driving mechanism comprises an electrical motor mounted to the main frame, with the motor being capable of sliding with respect to the main frame; a belt driving system for transferring the rotation of an output shaft of the motor to the saw blade; a center-distance setting means connected between the motor and the saw blade, for adjustably setting the center-to-center distance between the motor and the saw blade; and a saw-blade height adjusting device being operable to adjust the height of the of the saw blade. saw-blade height adjusting device comprises a transverse shaft being capable of rotating about a horizontal axis; a handwheel fixed to the outer end of the transverse shaft for driving the transverse shaft to rotate; a vertical screw shaft coupled with the transverse shaft by a set of bevel gears and is driven by the transverse shaft to rotate about a vertical axis; a nut mounted on and engaged with the screw shaft and being capable of moving along the screw shaft by the rotation of the screw shaft; and a guide connected to the nut and supporting the saw blade.

Owner:QINGDAO D& D ELECTRO MECHANICAL TECH

Method for producing ethanol from crop straw

ActiveCN101186943AEasy to separateTake advantage ofBiofuelsMicroorganism based processesSolid componentFiltration

The invention provides a process for producing ethanol with raw materials of straws. The process comprises preliminary treatment to crops straws, solid-liquid separation, hydrolyzed solid components and fermentation with yeasts after hyperfiltration and filtration enrichment by RO combination. The invention can simultaneously conduct evaporating concentration to liquid components, and produce corresponding by-product of lignosulfonate by adding sulfonating agent. The ethanol producing process of the invention greatly decreases the cost of industrial production which ferments straws to produce ethanol, and efficiently utilizes all the ingredients of crops straws.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

Boron-containing semi-high speed steel cold roller and manufacturing method thereof

InactiveCN101407891AReduce manufacturing costReduce the amount addedProcess efficiency improvementElectric furnaceIngotMolten steel

The invention relates to a boron-containing semi high-speed steel cold roller and a manufacturing method thereof and belongs to the field of steel rolling technology. The existing cold rollers have the problems of poor wear-resistance, high production cost and the like. The invention obtains the boron-containing semi high-speed steel cold roller by pouring the molten steel with the compositions of the following weight percentages of 0.30 to 0.45 of C, 3.8 to 4.2 of Cr, 0.2 to 0.6 of Si, 0.2 to 0.6 of Mn, 0.5 to 0.8 of Mo, 0.2 to 0.4 of Ni, 0.3 to 0.6 of Cu, 0.6 to 1.0 of B, 0.3 to 0.7 of V, 0.6 to 0.8 of Ti, 0.1 to 0.3 of Nb, 0.03 to 0.10 of N, 0.25 to 0.45 of Al, less than 0.03 of S, less than 0.04 of P and the residual quantity of Fe into an outer layer of the cold roller and adopting ductile cast iron as a core part or directly pouring the molten steel into ingots. The roller has the advantages of high hardness and intensity, good toughness and wear-resistance, simple production process, low cost, etc.

Owner:BEIJING UNIV OF TECH

Method for synthesizing citric acid ester type compound

InactiveCN101830803AHigh catalytic activityRich sourcesOrganic compound preparationCarboxylic acid esters preparationChemical synthesisBenzene

The invention discloses a method for synthesizing a citric acid ester type compound, which belongs to the technical field of chemical synthesis. The method comprises the following steps of: using citric acid and fatty alcohol as main raw materials, and using benzene sulfonic acid or amino benzene sulfonic acid as a catalyst; and performing esterification and the purification processes of acetylation, neutralization, washing, drying, distillation and the like. The catalyst has rich sources, a low cost and high activity, can be separated from an esterification liquid easily after the neutralization, is coke-free during the distillation, has less corrosion to equipment, and is safe and environment-friendly; the water generated by the esterification is separated out by adopting a binary heterogeneous separation technique, and no water separating agent is additionally added; and acetyl citric acid ester is produced by adopting an esterification-acetylation continuous synthesis method, the flow is greatly simplified, and a synthesis process is shortened. The citric acid ester prepared by the method has the advantages of high quality, high purity, low degree of color and wide applicationrange.

Owner:NORTHWEST NORMAL UNIVERSITY

Alcohol crossed circle manufacturing technique with potatoes as the main materials

The invention relates to an alcohol dual manufacturing technique with tuber as the main material in the alcohol fermentation industry technique, which comprises the following steps: mixing starch and the last anaerobic fermentation digestive liquid; heating, liquefying and reducing the temperature by adding maxilase and mixing homogeneously; adding the last distillery slop; saccharifying by adding glucoamylase; reducing the temperature; inoculating the extended culture distillery yeast; culturing in the constant temperature; acquiring the product alcohol by distilling; using distillery slop as the water for the next saccharifying and adjusting acid; cooling the rest slop and inoculating the last activated sludge in order to produce methane with anaerobic fermentation; recovering the activated sludge and digestive liquid by separating anaerobic fermentation liquid; making the digestive liquid back to the proportioning procedure as the technology water; circulating sequentially. The invention only needs a step anaerobic fermentation of distillery slop, which reduces investment of accommodation area and capital assets, can circulate anaerobic fermentation digestive liquid, achieves zero discharge of the wastewater from fermentation, achieves the circulation of the water resource and reduces the cost of alcohol.

Owner:JIANGNAN UNIV

Valine purification method

ActiveCN101798273AEasy to operateGood choiceIon-exchange process apparatusIon-exchanger regenerationPurification methodsFiltration

The invention relates to a valine purification method, which comprises the following steps: A. adding flocculating agents into valine fermentation liquid for fast precipitating solid impurities, and obtaining primary filter liquid through filtering supernatant; B. adding activated carbon into the primary filter liquid obtained in the step A, wherein the added activated carbon accounts for 1+ / -0.5weight percent of the filter liquid, carrying out stirring and decoloration at 60 + / - 5 DEG C, and then, obtaining secondary filter liquid through filtration; C. using an industrial chromatographic column for separating inorganic salt and heteroacid, and then, using a sodium filter membrane for removing pigment and small molecular impurities to obtain a clear and colorless valine solution; D. concentrating the filter liquid for crystallization to obtain crude valine products; and E. shaking a transmission belt and raising the temperature to 220 + / - 10 DEG C, and carrying out sublimation to remove alanine and isoleucine to obtain pharmaceutical grade competitive valine products. The method has the characteristics of simple operation, good selectivity, cleanness and environment protection, so the yield and the quality of the valine are obviously improved.

Owner:ZHAODONG XINGHU BIOTECHNOLOGY CO LTD

Picking claw

The invention provides a picking claw used for automatically picking fruits and belongs to the technical field of agricultural intelligent equipment. The picking claw comprises a fruit adsorber used for adsorbing target fruits, a fruit clamping device which is connected with the fruit adsorber in a matched mode and used for clamping the target fruits, and a fruit twisting device which is connected with the fruit clamping device, matched with the fruit adsorber and the fruit clamming device and used for twisting the target fruits, so that the target fruits are separated from plants. By means of a twisting fruit separating method of the picking claw, the problems that the postures of the fruit stems of fasciation short fruit stem type fruits which are represented by tomatoes are diverse and the fruits can not be accurately positioned or be accurately cut and separated are solved. Meanwhile, the picking claw is simple in structure, low in manufacturing cost and easy to control.

Owner:INTELLIGENT EQUIP TECH RES CENT OF BEIJING ACAD OF AGRI & FORESTRY

Antigen-specific T lymphocyte freezing medium and preparation method and application thereof

ActiveCN107148967AReduce operating proceduresLow pollution rateDead animal preservationSodium Chloride InjectionT lymphocyte

The invention provides an antigen-specific T lymphocyte freezing medium, comprising freezing medium A and freezing medium B; the freezing medium A includes, by volume, 30-40% of plasmalyte electrolyte injection, 30-40% of glucose and sodium chloride injection, 5-15% of dextran glucose injection and 15-25% of human albumin solution; the freezing medium B includes, by volume, 20-30% of plasmalyte electrolyte injection, 20-30% of glucose and sodium chloride injection, 5-15% of dextran glucose injection, 15-25% of human albumin solution and 10-20% of dimethyl sulfoxide; the freezing medium A and the freezing medium B are stored separately; in use, the freezing medium A and the freezing medium B are mixed in a ratio of 1:(0.5-2), forming the antigen-specific T lymphocyte freezing medium. The antigen-specific T lymphocyte freezing medium is capable of enabling less crystal to form in cells, increasing cell survival rate and maintaining tumor-killing ability of cells. The invention also provides a preparation method and application of the antigen-specific T lymphocyte freezing medium and antigen-specific T lymphocyte injection.

Owner:CHENZHOU BINZE MEDICAL LAB CO LTD

Material and method used for TA2/0Cr18Ni9Ti welded by high-entropy effect

InactiveCN102676904AImprove performanceSimple preparation stepsWelding/cutting media/materialsSoldering mediaElectrical resistance and conductanceAlloy

The invention discloses a high-entropy interlayer alloy, which comprises the following components in atomic percentage: 5-10% of Ti, 5-10% of Fe, 25-30% of Al, 15-20% of Ni, 30-35% of Cu and 5-10% of Cr. The invention also discloses a method for welding TA2 / 0Cr18Ni9Ti by the high-entropy effect, which comprises the following steps that: high-entropy interlayer alloy is placed between the two plates to be welded, the high-entropy interlayer alloy is in a foil folding structure, and the high-entropy interlayer alloy and local parent metal are subjected to heat fusing by an interface resistor ina resistance spot welding mode, so that the high performance welding of TA2 / 0Cr18Ni9Ti can be realized. According to the method and the high-entropy interlayer alloy of the method, which are disclosed by the invention, the high-entropy interlayer alloy has the advantages of favorable strength, toughness and corrosion resistance, is easy to process and form and is convenient to weld and assembly. The preparation method has the advantages of simple step and low manufacture cost and is convenient to popularize.

Owner:XIAN UNIV OF TECH

Mold/non-mode combined pulling process and device

InactiveCN102133582AImproving the process conditions of drawing formingReduce consumptionDrawing profiling toolsEngineeringMechanical engineering

The invention belongs to the technical field of metal plastic processing, and particularly provides a mold / non-mold combined pulling process and a device. The device is characterized in that a pulling mold is directly installed between a heater and a cooling machine of a non-mold pulling device, the waste heat of non-mold pulling is utilized fully, so that the mold puling and sizing with temperature can be completed before the non-mold pulling is molded, and the surface quality is improved. In the invention, the pulling force is reduced greatly, the intermediate heat treatment or heating process of the traditional process is saved, the mold consumption is reduced, the energy resource is saved, the production cost is lowered, a high-quality metal product can be pulled and molded in short flow range, and the advantages that the deformation amount of the non-mold pulling is large, the precise of the mold pulling size is high and the like can be realized.

Owner:UNIV OF SCI & TECH BEIJING

Transparent anti-static polyvinylidene fluoride piezoelectric material and preparation method thereof

InactiveCN103102623AImprove antistatic performanceExcellent piezoelectric propertiesCarbon nanotubePolyvinylidene difluoride

The invention relates to a transparent anti-static polyvinylidene fluoride piezoelectric material and a preparation method thereof. The filler is very difficult to uniformly disperse by adding carbon nano-tubes, graphene or zinc oxide to PVDF (Polyvinylidene Fluoride) material in the prior art; and the material is directly transmitted to be conductive from insulating, and is not attractive. The polyvinylidene fluoride piezoelectric material is a mixture of polyvinylidene fluoride and ionic liquid. The preparation method of the transparent anti-static polyvinylidene fluoride piezoelectric material comprises the following steps of: drying the polyvinylidene fluoride and the ionic liquid for 24 hours to 48 hours at 80 DEG C to 110 DEG C in a vacuum environment; adding the dried polyvinylidene fluoride and ionic liquid in a mass ratio of 100:(0.5-40) to a fusion smelting device for melting-blending at 180 DEG C to 200 DEG C to obtain a mixture; and discharging the mixture from the melting-blending device, cooling the mixture to normal temperature and crystallizing the cooled mixture to obtain the polyvinylidene fluoride piezoelectric material. The polyvinylidene fluoride piezoelectric material disclosed by the invention has good antistatic property, good piezoelectricity and excellent transparency. According to the preparation method of the polyvinylidene fluoride piezoelectric material disclosed by the invention, the normal melting-blending device is only needed to be used, and the industrial preparation is simple.

Owner:HANGZHOU NORMAL UNIVERSITY

Catalyst for preparing aldehyde by two-phase catalytic hydrogen formylation reaction and application thereof

ActiveCN101722048ASolve inseparableReduce churnOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionSolventSurface-active agents

The invention relates to a catalyst which uses alcohol and water as a solvent and contains water soluble phosphine ligands and rhodium compounds and a method for preparing high-carbon aldehyde by a two-phase catalytic hydrogen formylation reaction by using alpha-olefin above C5 as a raw material. The invention overcomes the defects that the reaction rate of a hydrogen formylation reaction of high-carbon alpha-olefin above C5 is low, and the addition of a surface active agent for improving the reaction rate can generate two-phase emulsification and dissolution and cause phase separation difficulty and the increase of rhodium catalyst loss in a traditional two-phase water soluble rhodium-phosphine catalytic process. The invention can improve the reaction rate or avoid the emulsification, thereby reducing the rhodium catalyst loss. The innocuous and environment-friendly mixed solvent of the alcohol and the water is adopted and can be recycled, and the production cost is greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Overwater emergency rescue device of unmanned aerial vehicle

InactiveCN108248865AGuaranteed timelinessHigh delivery accuracyAircraft lightsLaunching weaponsRemote controlEmergency rescue

The invention provides an overwater emergency rescue device of an unmanned aerial vehicle. The device includes a putting control mechanism, a putting bracket, dehooking devices, life buoys, ropes andan LED searchlight; the putting control mechanism comprises a remote control receiver, a steering engine, a camera and a wireless image sending system; the remote control receiver and the camera are arranged on the putting bracket, the camera is linked with the wireless image sending system, and the remote control receiver is linked with the input end of the steering engine and controls the dehooking devices to be opened through the steering engine to put down the life buoys; the putting bracket is installed on the bottom of the unmanned aerial vehicle and consists of a bracket cross girder and a bracket vertical girder, the dehooking devices are arranged on the bracket cross girder and connected with the life buoys through the ropes, and the life buoys sleeve the bracket vertical girder.By loading the device on the unmanned aerial vehicle, fast arrival to a rescue scene can be achieved, rescue workers can accurately put down the life buoys according to images photographed by the camera, the accuracy of putting the life buoys is high, and timely rescue is achieved.

Owner:CHENGDU CAIZHI SHENGYOU TECH LLC

Ultrathin hermetic anti-theft fast food box

ActiveCN106608422AImprove securityIncrease pleasant dining moodRemovable lids/coversLidsEngineeringThin sheet

The invention belongs to the technical field of fast food boxes and relates to an ultrathin hermetic anti-theft fast food box. The ultrathin hermetic anti-theft fast food box comprises a box body and a box cover. A first buckling portion is annularly arranged at the lower edge of the box cover; a second buckling portion is annularly arranged at the upper edge of the box body, the first buckling portion and the second buckling portion can be hermetically buckled; at least one part of the second buckling portion of the box body is an easily broken part which is structured such that fragments of the buckling portion are integrally formed at the notch of the box body on the outer wall through easily broken thin sheets which are arranged in a spaced manner to form the easily broken part, and more than one strip-like hole is formed between the box body and the easily broken part of the box body through the thin sheets. The fast food box has the advantages that the fast food box is simple in structure; whether the box is opened or not can be judged by judging whether the easily broken part is matched or not to remind the diner to judge whether foods in the fast food box are short or are polluted or not; as the strip-holes and openings are formed, the anti-theft function is increased on the premise of not increasing the production cost, or even reducing the production cost, the product grade is high, and the fast food box is suitable for being popularized and applied in fast food industry.

Owner:朱金玲

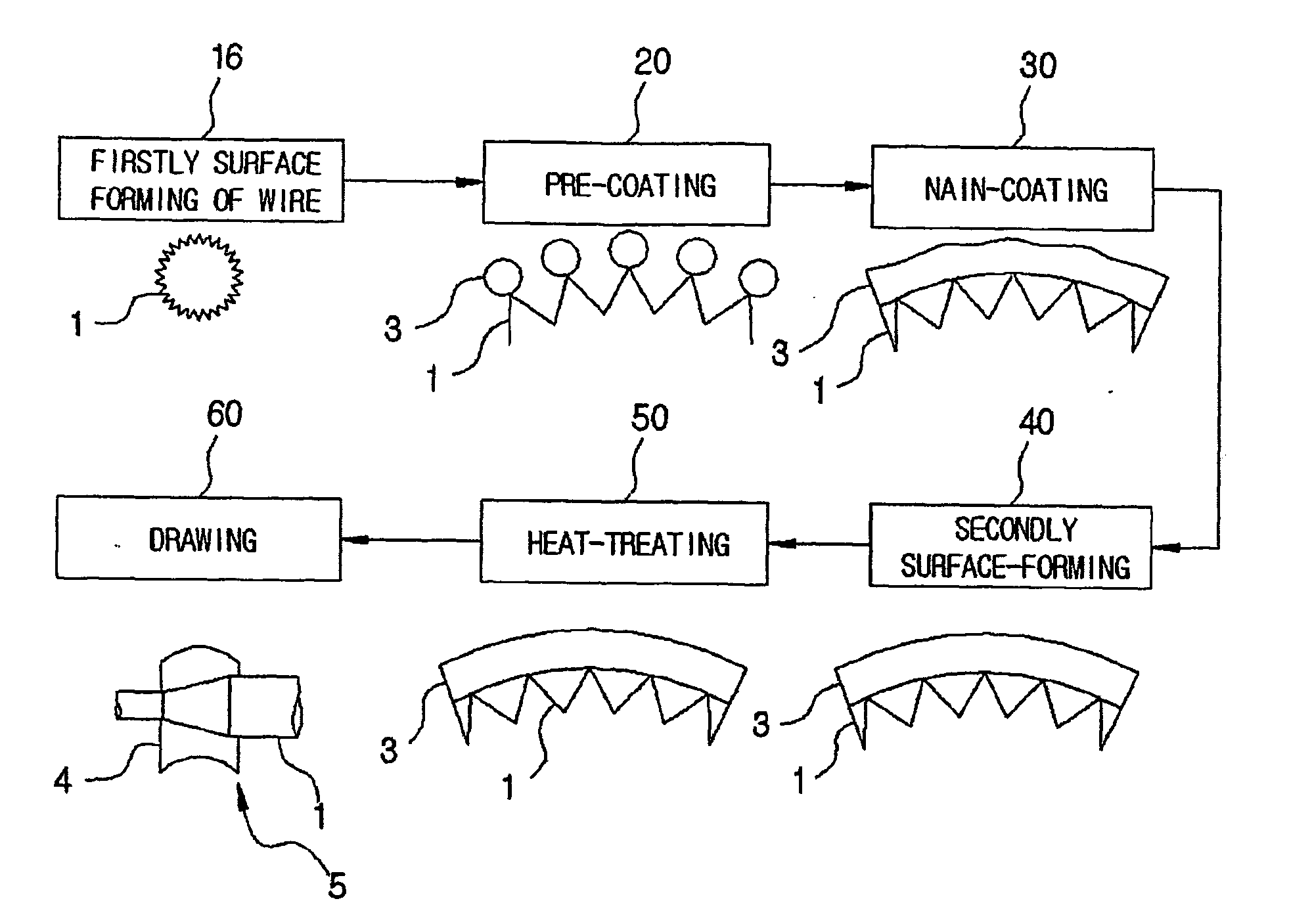

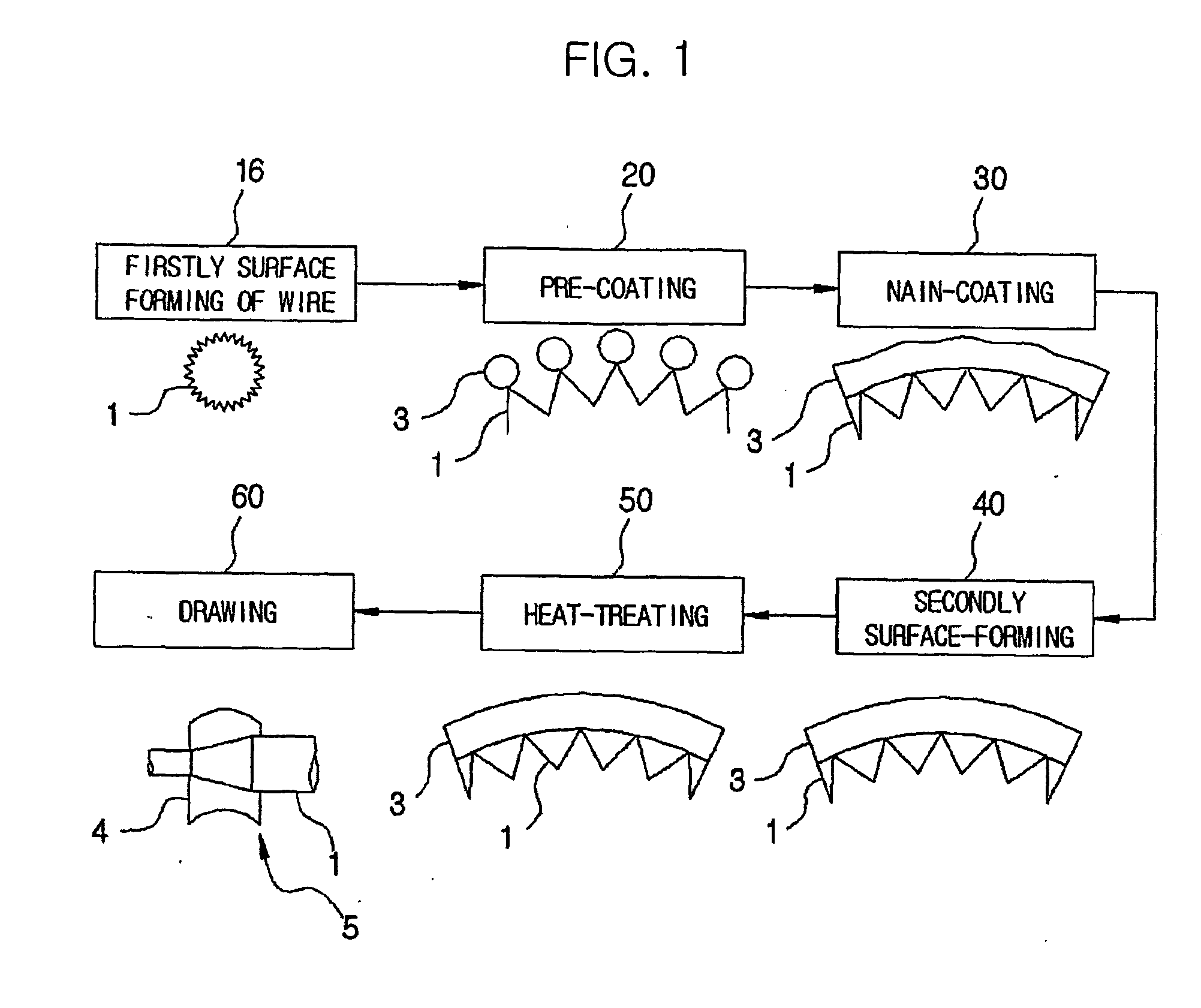

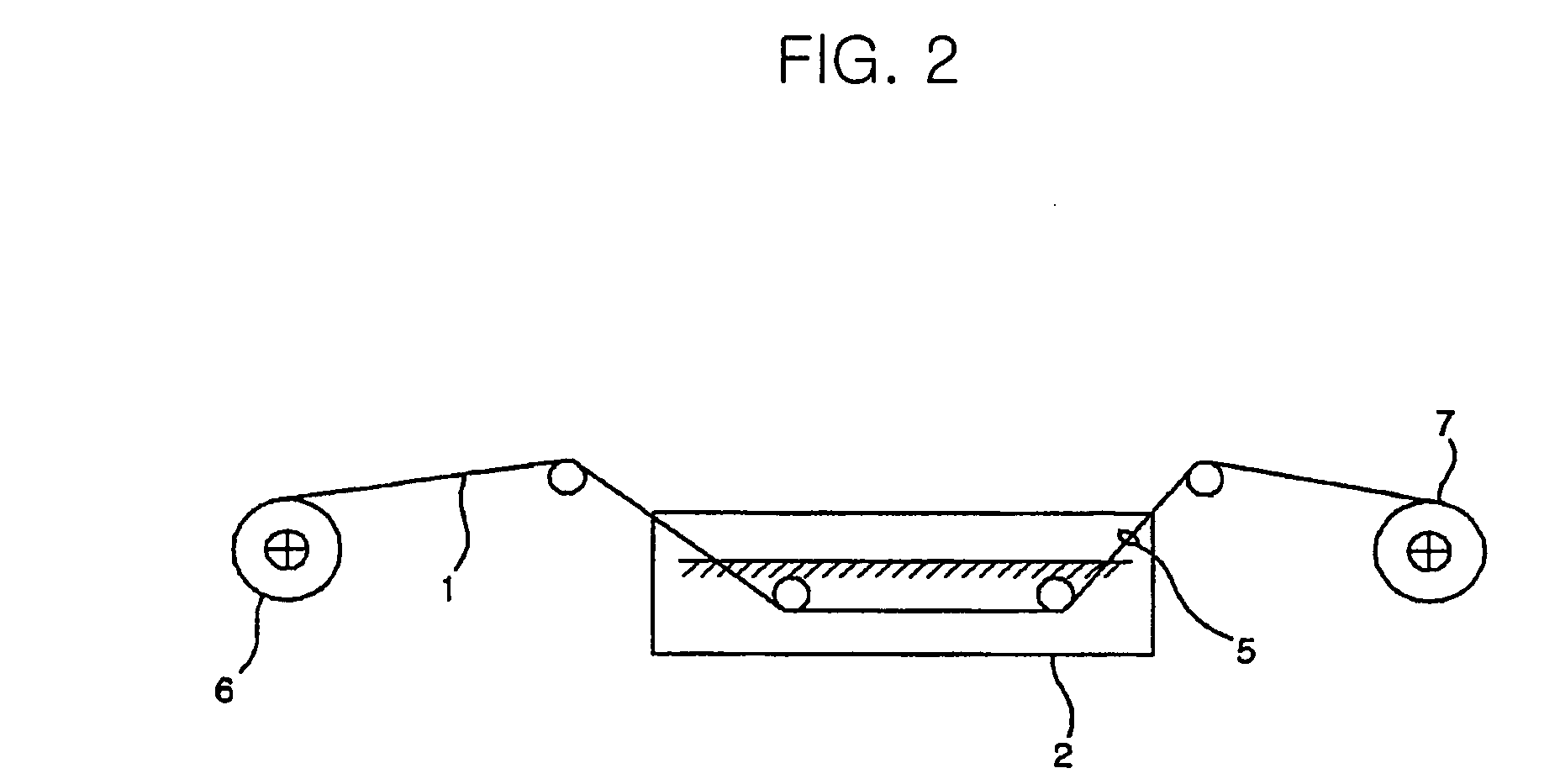

Method of manufacturing zinc-coated electrode wire for electric discharge processors using hot dip galvanizing process

InactiveUS20060138091A1Reduce manufacturing costReduce waste generationHot-dipping/immersion processesElectrical-based machining electrodesHot-dip galvanizationSizing

Owner:PUNG KUK

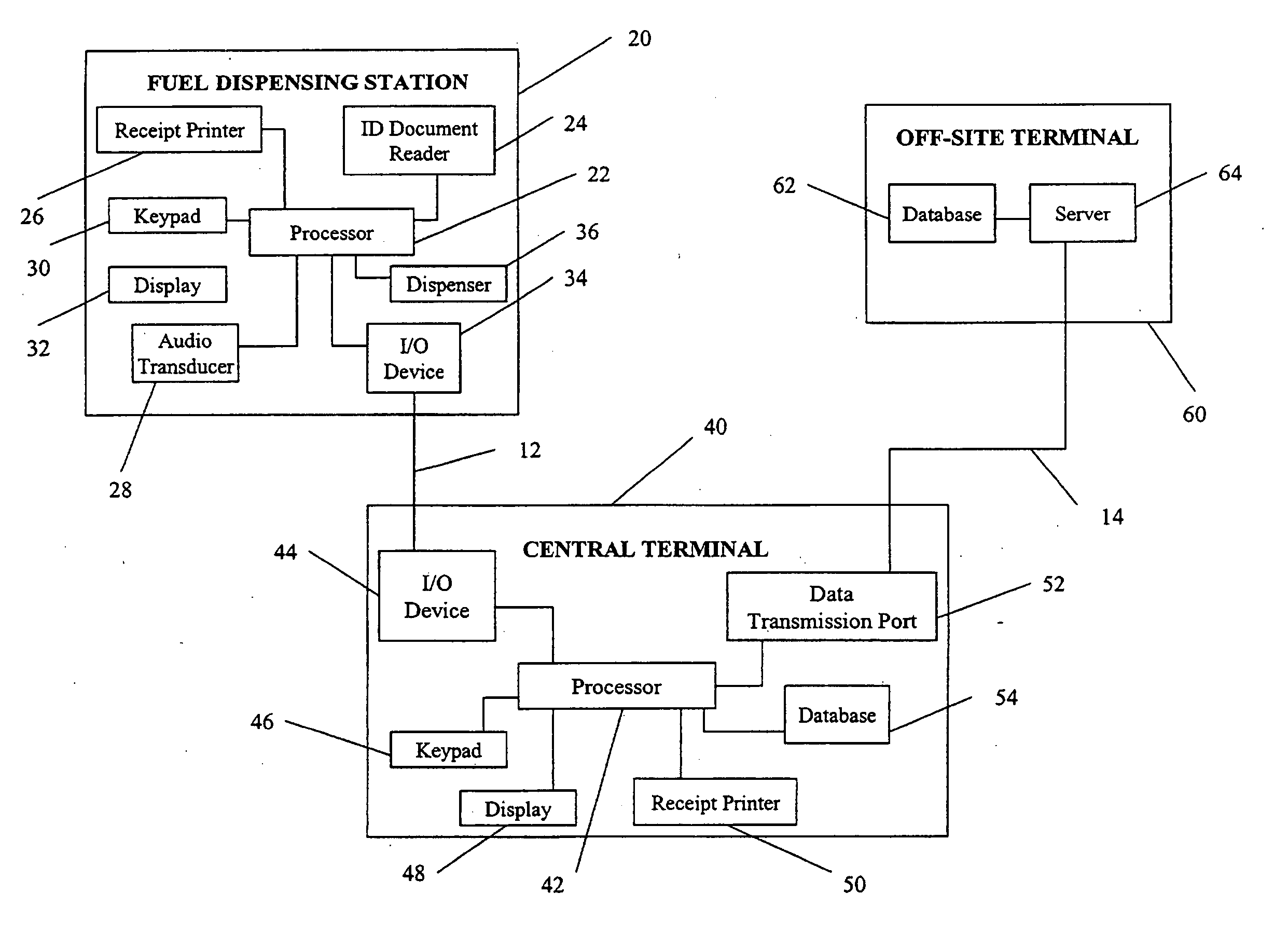

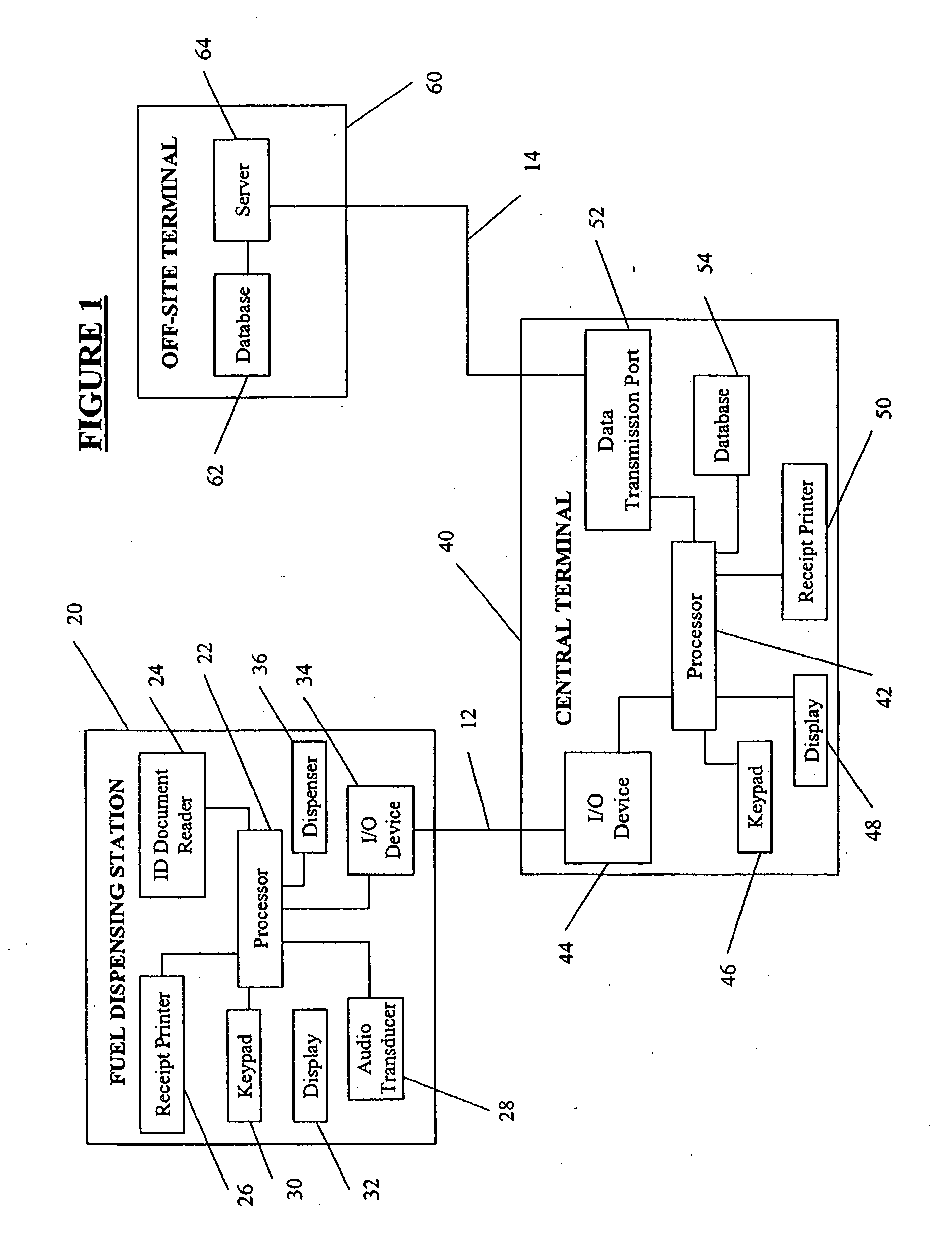

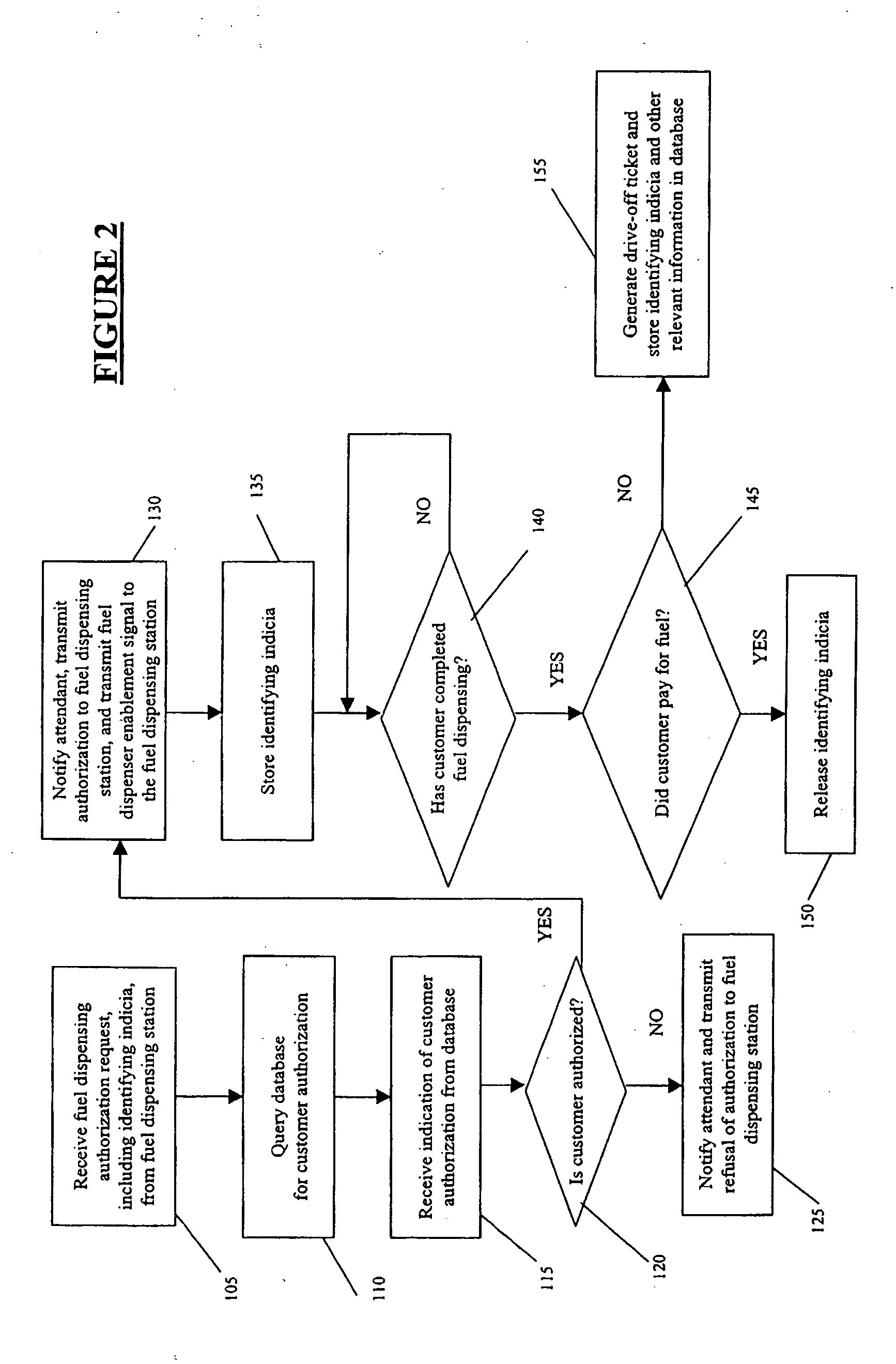

Methods and systems for customer validation using an indentification document and/or one or more pins

InactiveUS20060108413A1Reduce manufacturing costComplete banking machinesTicket-issuing apparatusPaper documentDocument preparation

Owner:PUMP ON

Cylinder liner combined machining machine tool

ActiveCN104801977AMeet the needs of basic functionsSimple structureTailstocks/centresOther manufacturing equipments/toolsHigh volume manufacturingEngineering

The invention relates to a cylinder liner combined machining machine tool. The machine tool comprises a machine tool body, wherein a motor device, an apron driving device, a tailstock driving device and three sets of guide rails are installed on the machine tool body, an upper apron is installed on the upper set of guide rails, an external turning tool is installed on the upper apron, a down-cutting device is installed on the lower set of guide rails, a facing tool set is installed on the down-cutting device, a headstock and a double-station complex programming tailstock are installed on the main guide rails in the middle, a headstock spindle is driven by the motor device to rotate, a boring tool and an expansion combination device are installed at the front end of the headstock spindle, a material pushing device is installed on the top of the headstock, and the double-station complex programming tailstock is a tailstock device which is provided with a telescopic hydraulic chuck mechanism and a hydraulic center mechanism at the same time. According to the cylinder liner combined machining machine tool, the machining efficiency and the accuracy of cylinder liners can be greatly improved; a production unit can formed when an automatic feeding and discharging device is further arranged so that automatic production can be achieved, the production cost can be greatly reduced, the productivity of enterprises can be improved, and the cylinder liner combined machining machine tool is particularly applicable to mass production of cylinder liners.

Owner:NING XIA XIN RUI CHANG CHENG JI CHUANG YOU XIAN GONG SI

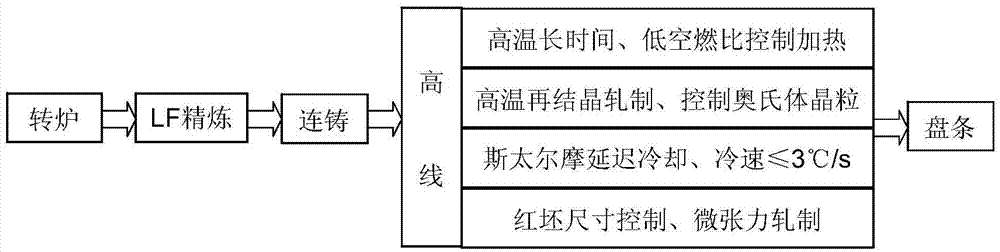

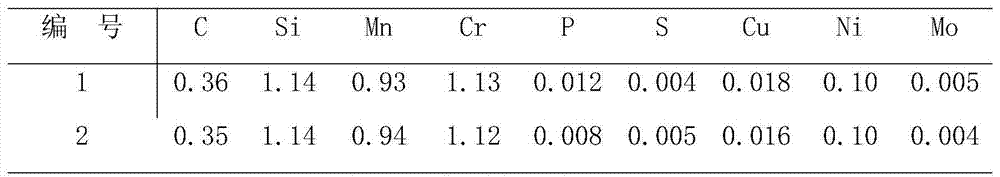

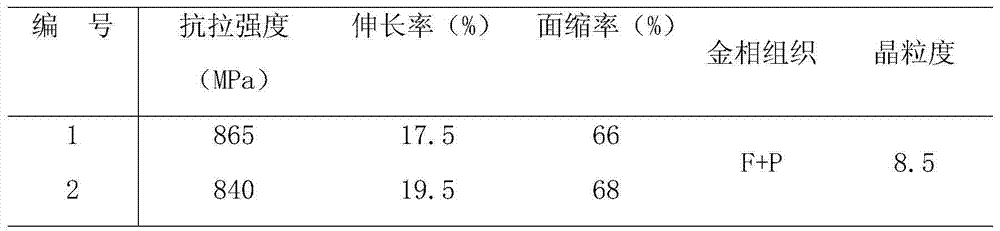

Production technology of wire rod for solid surfacing welding wires

ActiveCN103667925AReduce manufacturing costImprove deposition efficiencyWelding/cutting media/materialsSoldering mediaPearliteEconomic benefits

The invention discloses a production technology of a wire rod for solid surfacing welding wires. The wire rod comprises the components in percentage by weight as follows: 0.32-0.39% of C, 1.10-1.40% of Si, 0.80-1.10% of Mn, 1.10-1.40% of Cr, smaller than or equal to 0.025% of S, smaller than or equal to 0.025% of P, smaller than or equal to 0.30% of Ni, smaller than or equal to 0.25% of Cu, smaller than or equal to 0.10% of Mo and the balance of Fe and inevitable impurities. A process route comprises blowing by a converter, refining by an LF (ladle furnace), continuous casting and high-speed wire rolling. The solid surfacing welding wires produced through the technology have the advantages of low production cost, high deposition and welding efficiency, convenience in automatic operation and the like; according to the production technology of the wire rod for the solid surfacing welding wires, the component design of medium carbon and high silicon and chrome is adopted in chemical component, and the cost increase caused by addition of a large number of Ni, Mo, V, Ti alloys and the like in the past is avoided, so that the production technology has obvious economic benefits; the produced wire rod is stable in mechanical property, the tensile strength is 840-890 MPa, the elongation is 17%-20%, the area reduction is 60%-70%, the metallographic structure is F (ferrite) +P (pearlite), the grain size is grade 8.0-9.0, and the size deviation is + / -0.15 mm.

Owner:TIANJIN IRON & STEEL GRP

Heptatridecafluorooctylpropyl polyhedral oligomeric silsesquioxane and functionalized derivates thereof

The invention provides a preparation method for heptatridecafluorooctylpropyl polyhedral oligomeric silsesquioxane and functionalized derivates thereof. The preparation method comprises the steps as follows: adding tridecafluorooctylpropyl trimethoxy silane into an organic solvent, adding de-ionized water and NaOH, heating, stirring, reacting under reflux condition, washing by a washing solvent, and drying to obtain trisilanol sodium salt of heptatridecafluorooctylpropyl polyhedral oligomeric silsesquioxane; and adding trisilanol sodium salt into an organic reagent, dropwise adding hydrochloric acid, triethylamine and a silane coupling agent, stirring a mixture at normal temperature for reaction, removing generated deposit, carrying out rotary evaporation, removing the solvent, obtaining white crystals, dissolving the crystals in methanol, filtering for collecting insoluble parts, and carrying out vacuum drying to obtain a T8-type monofunctional tridecafluorooctylpropyl POSS (polyhedral oligomeric silsesquioxane) monomer. The preparation method can obtain long branch chain type active fluorine-containing POSS, is simple and easy in process, low in cost, high in yield and higher in product purity, and is suitable for large-scale industrial production.

Owner:HOHAI UNIV

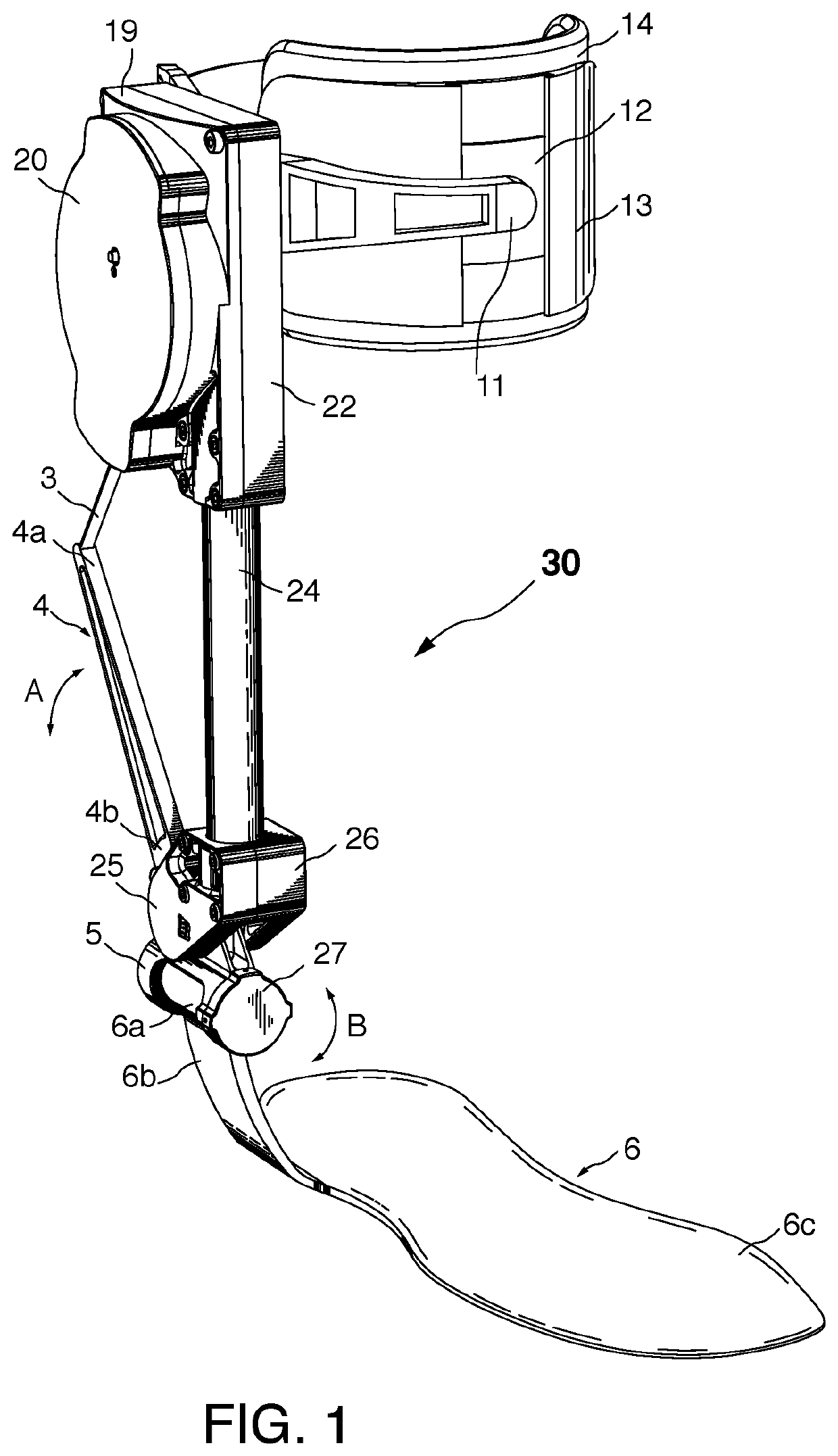

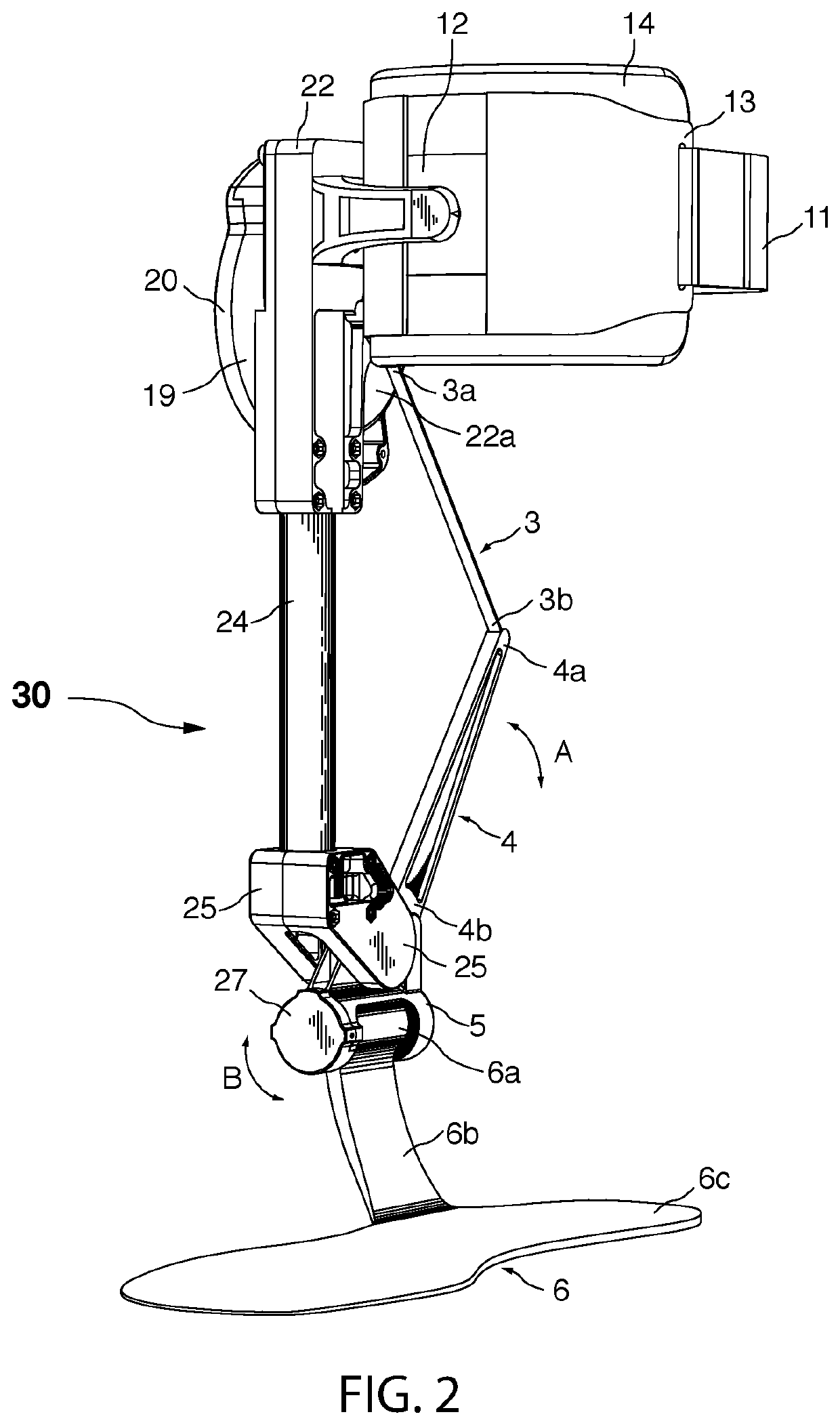

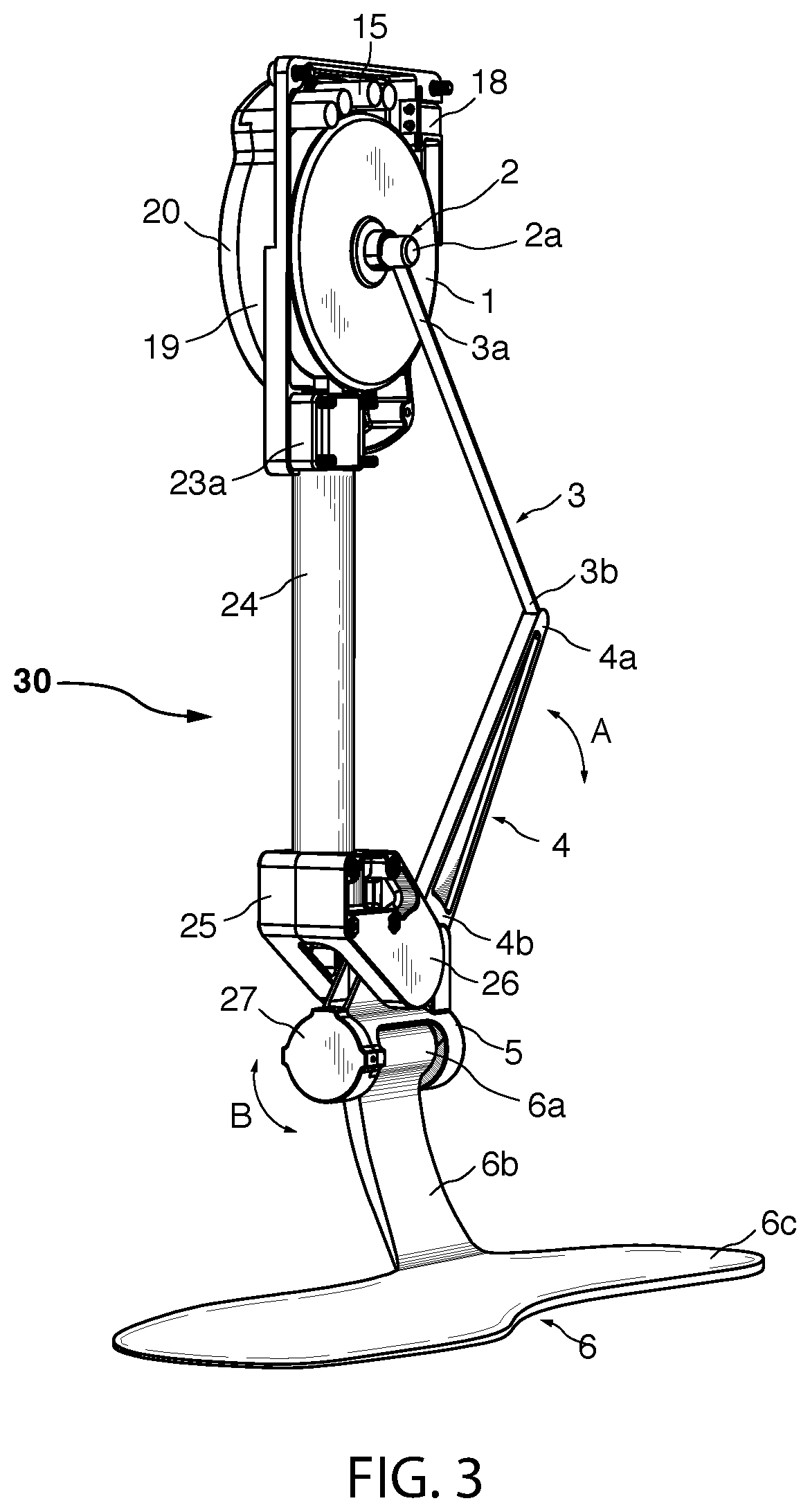

Wearable joint augmentation system

ActiveUS20200016020A1Smooth connectionReduce manufacturing costProgramme-controlled manipulatorChiropractic devicesPhysical therapyControl system

Owner:DEPHY INC

Method for producing coating ultra-sense paper

InactiveCN101250835AProcessing into excellent performanceEasy to processSpecial visual effect coatingsCoatings with pigmentsFiberBenzene

The invention relates to a method for preparing a coating hypersensitive paper, which comprises the following steps: firstly, adopting fiber 100% as raw material, beating, dispensing, drawing the vibrator for fixation, modeling, drying, gluing and drying to produce the hypersensitive base stock which is provided with natural and native texture. The hypersensitive base stock is coated and manufactured through a 1760mm coater which velocity is 150 / min and the coating quantity area is 15g / m2. The coating paint comprises dye and latex adhesive, wherein the dye is selected from specially processed titanium oxide and kaolin, the particle size of titanium oxide and kaolin is less than 2 mum. The latex adhesive adopts benzene latex and starch to blend together. The hypersensitive base stock surface of the invention forms a natural and native texture dull base stock on the net without pressing, polishing and dressing. The prepared coating hypersensitive paper has the advantages of reducing manufacturing procedure, increasing natural and native texture of the paper and stereo aesthetics, reducing reflection light, which is non-excited in eyes, soft and comfortable in scene, easy in preparation and low in preparation cost.

Owner:SHANDONG KAILI SPECIAL PAPER

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap