Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

207 results about "Corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corrosion is a natural process that converts a refined metal into a more chemically-stable form such as oxide, hydroxide, or sulfide. It is the gradual destruction of materials (usually metals) by chemical and/or electrochemical reaction with their environment. Corrosion engineering is the field dedicated to controlling and stopping corrosion.

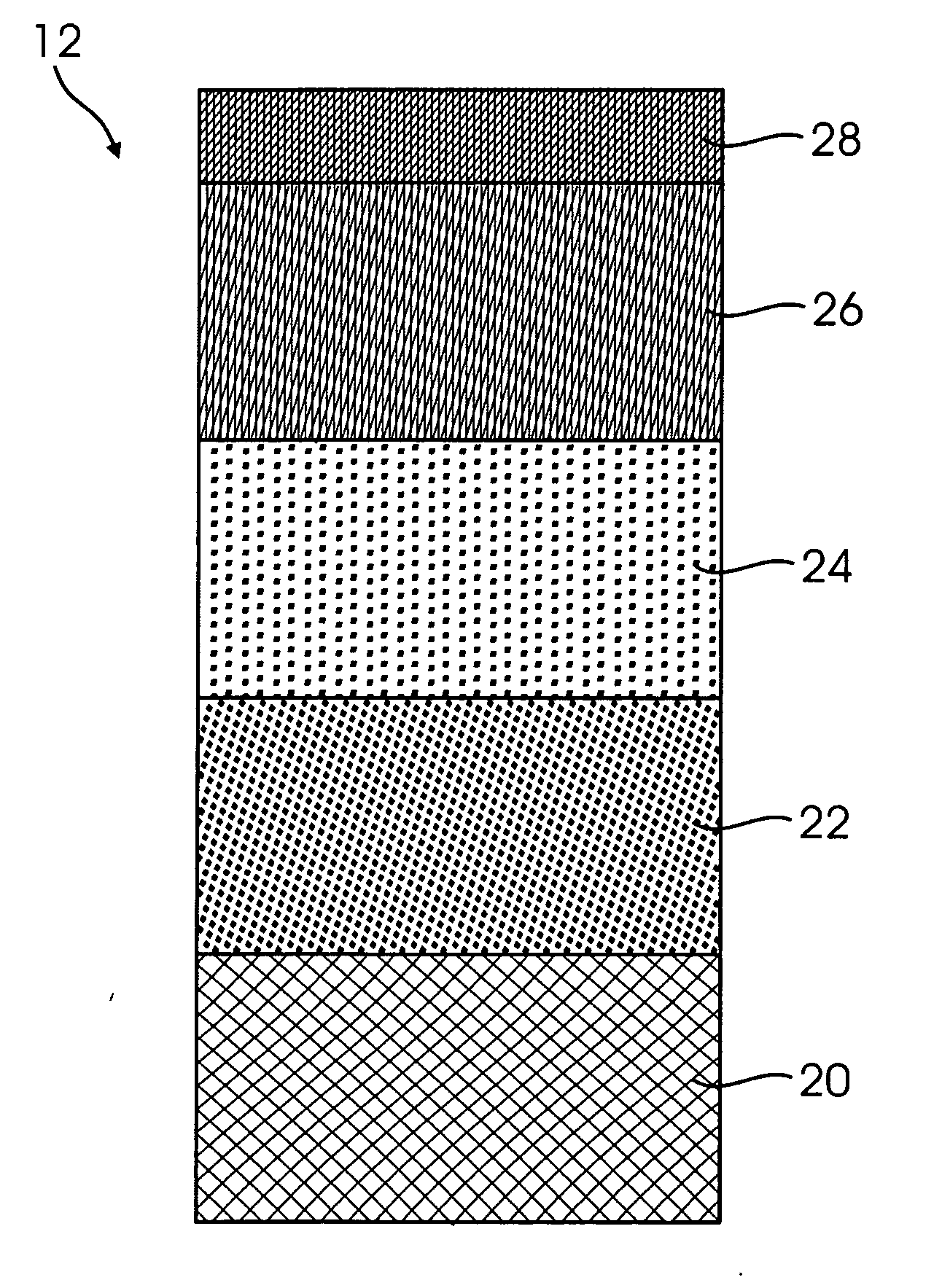

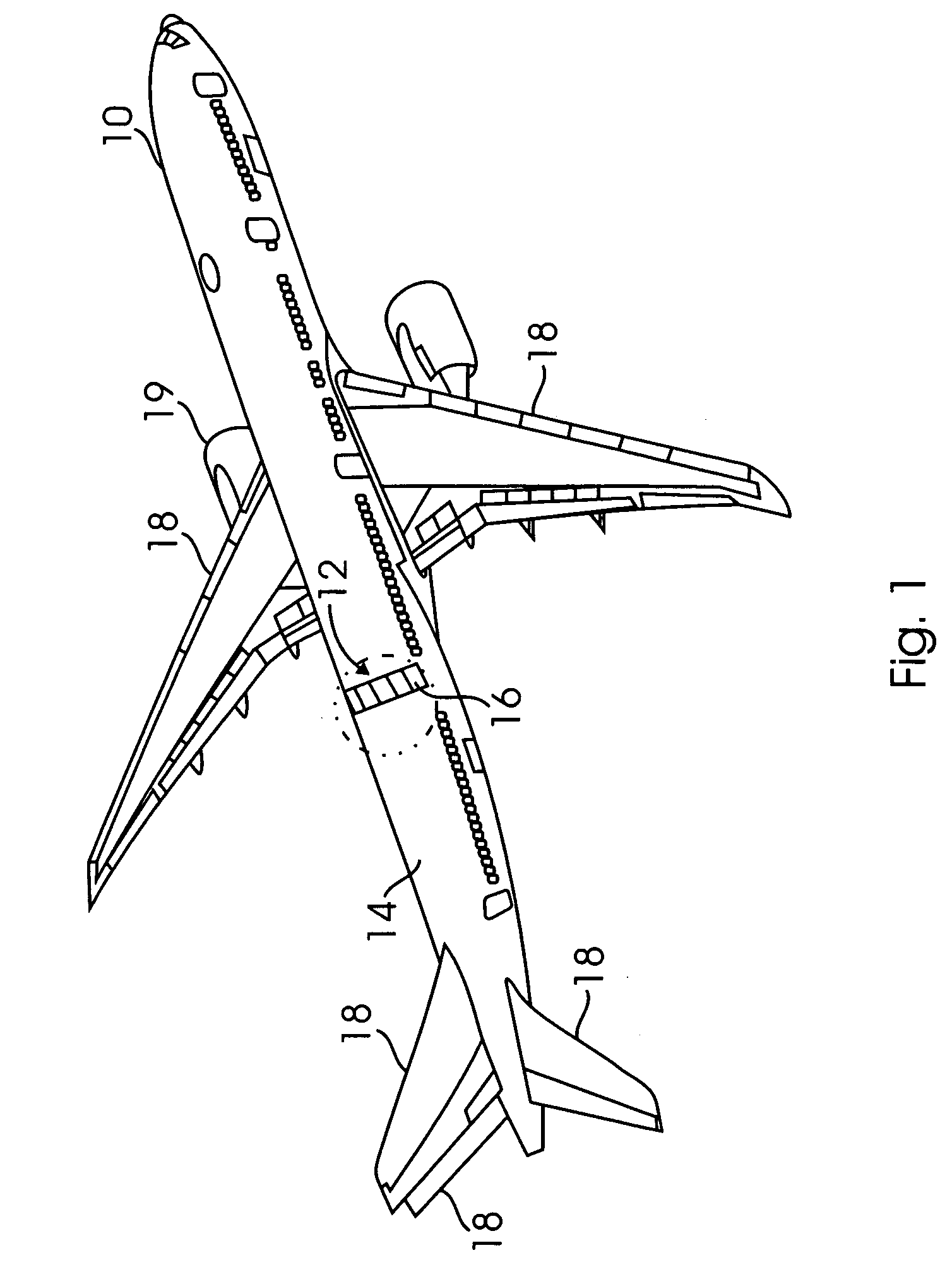

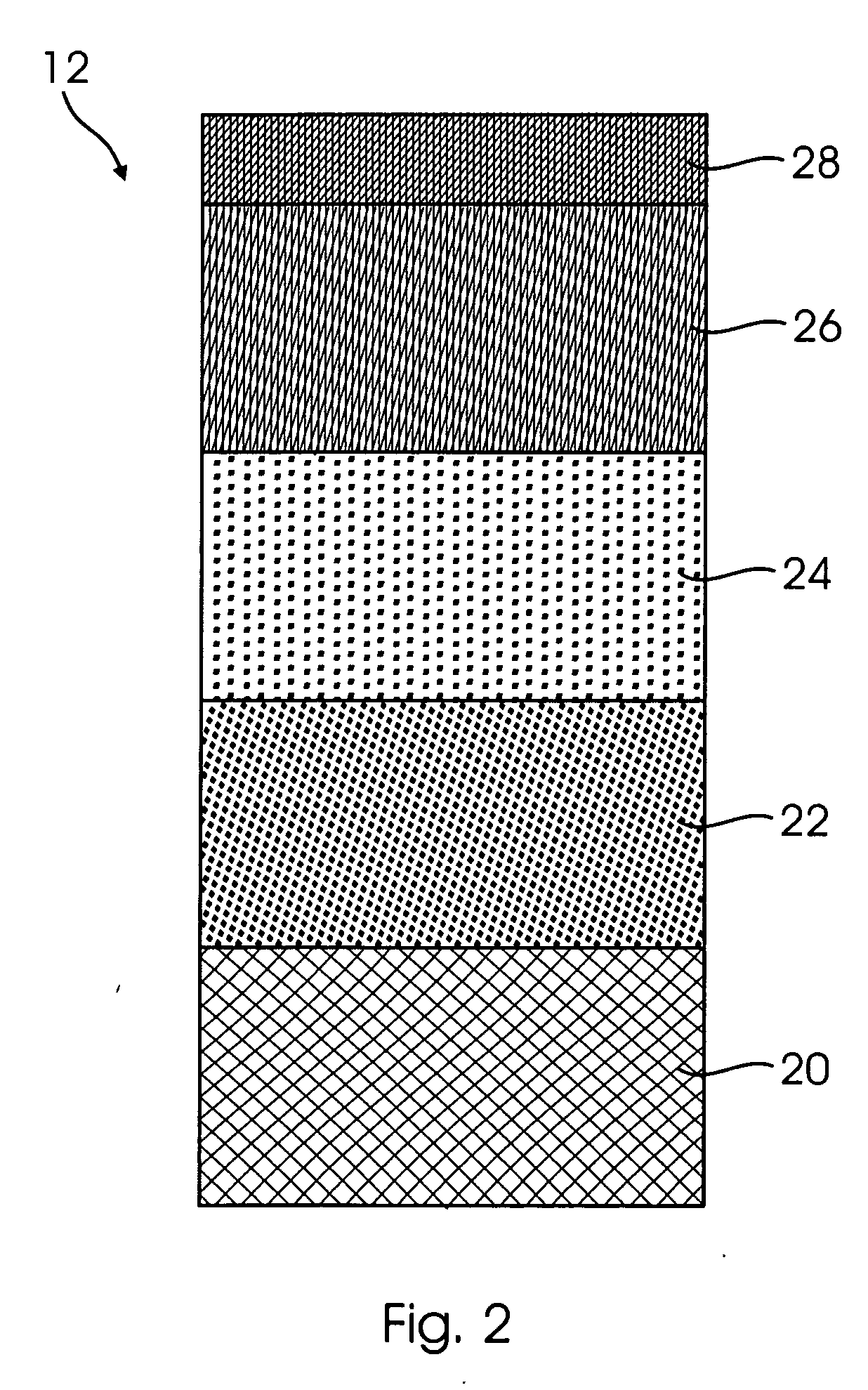

Method and system for exterior protection of an aircraft

InactiveUS20070141927A1Improve structural durabilityReduce weightAircraft lighting protectorsSynthetic resin layered productsEngineeringMetal

Owner:THE BOEING CO

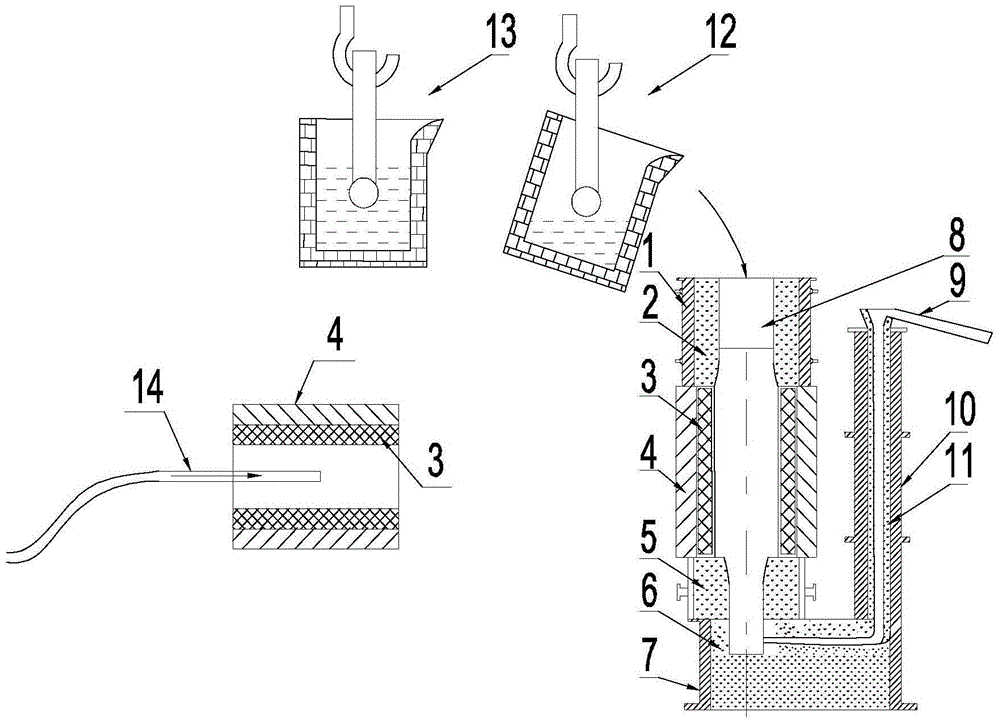

Method for enhancing surface of magnesium aluminium alloy by laser remelting

InactiveCN101532134AHigh strengthImprove corrosion resistanceMolten spray coatingSuperimposed coating processOxygenLaser beams

The invention relates to a method for enhancing the surface of magnesium aluminium alloy by laser remelting, aiming at enhancement processing of the surfaces of magnesium aluminium alloy plates and magnesium aluminium alloy rods by the methods of flame spraying of alloyed powder and laser remelting. The method is characterized by cleansing the surface of the magnesium aluminium alloy, carrying out oxy-acetylene flame spraying on the alloyed powder, namely aluminium nickel alloy powder, nickel-chromium-boron-silicon-iron master alloy powder and neodymium powder, carrying out remelting and curing on the surface of the magnesium aluminium alloy on a laser processor, carrying out omnibearing radiation by laser beams according to trace curves set by computer programs so that a nickel base alloy layer is melted and cured on the surface of the magnesium aluminium alloy to form the alloy layer, therefore, the hardness of the surface of magnesium aluminium alloy is greatly improved by 8-10 times as high as that before processing, the wearing resistance and corrosion resistance of the surface of magnesium aluminium alloy are greatly improved respectively by 56% and 56.4%. The method has short process flow, easy realization, safety, stability and reliability and firm solid melting layer, is not easy to fall off and can enhance the surfaces of the magnesium aluminium alloys with various profiles.

Owner:TAIYUAN UNIV OF TECH

Preoxidized-composite electrolyzing method for removing arsenic in groundwater

InactiveCN101139150ALow toxicityImprove adsorption capacityMultistage water/sewage treatmentWater/sewage treatment by oxidationElectrolysisFenton reagent

A method to remove arsenic in underwater by preoxidation-combined electrolyzing relates to a method to remove arsenic from underwater, belonging to the technical field of water treatment. The present invention has solved the defect that more expensive pure nulvalent iron and slower corrosion speed of the pure nulvalent iron have limited the absorption of arsenic on the nulvalent iron. The present invention includes the following steps: the underwater containing arsenic is pre-oxidized by ozone, potassium ferrate, potassium permanganate, H2O2, photocatalysis oxidation reagent or Fenton reagent, thereby transferring As(III) to As(V). The water pre-oxidized passes through a filtering bed containing cast-iron scrap and carbon granules. The oxidizer left in the preoxidation section promotes the reaction of the step.

Owner:HARBIN INST OF TECH

Method for synthesizing sec-butyl alcohol

InactiveCN102731250AIncrease reaction rateImprove conversion ratePreparation by ester-hydroxy reactionPreparation by alcoholysisButeneMethyl acetate

Owner:FUZHOU UNIV

Method for preparing silicon carbide ceramic material with low residual silicon by adopting multi-step reaction sintering method

ActiveCN106478105ASolve the mechanical propertiesSolving Elasticity ProblemsHeat conductingYoung's modulus

Owner:咸阳瞪羚谷新材料科技有限公司

Method of risisting high-temp. oxidation and heat corrosion for high-temp. alloy

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

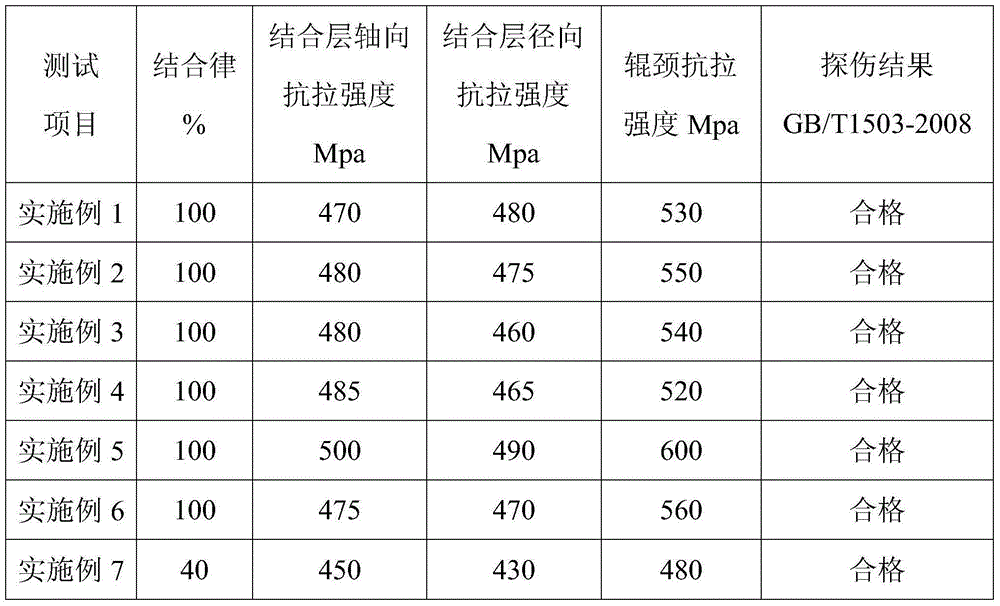

Manufacturing method for high-vanadium high-speed steel composite roll

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

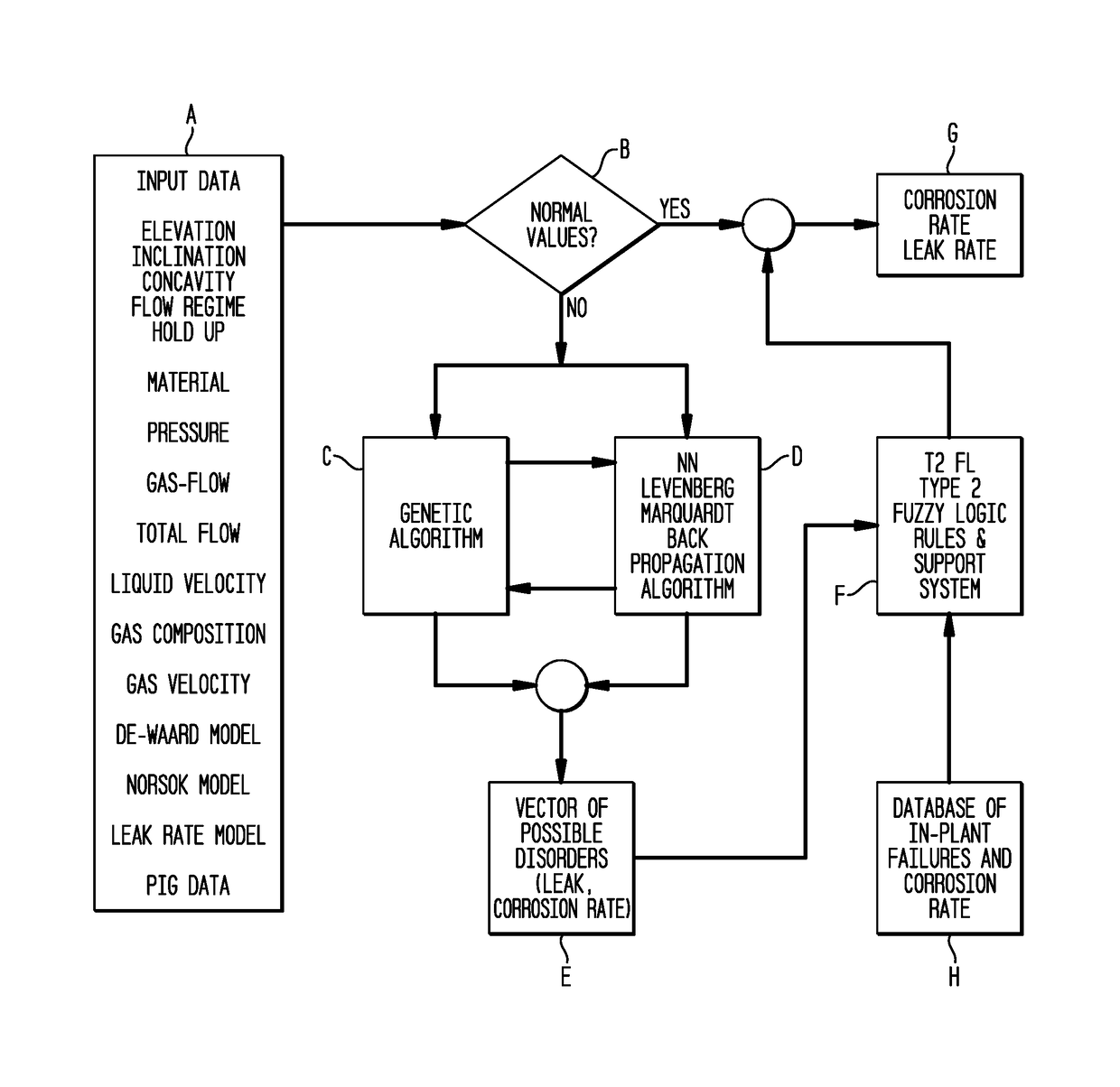

Artificial intelligence based algorithm for predicting pipeline leak and corrosion detection

InactiveUS20180365555A1Improve reliabilityReduce operating costsPipeline systemsNeural architecturesArtificial Intelligence SystemCorrosion

Owner:LINDE AG

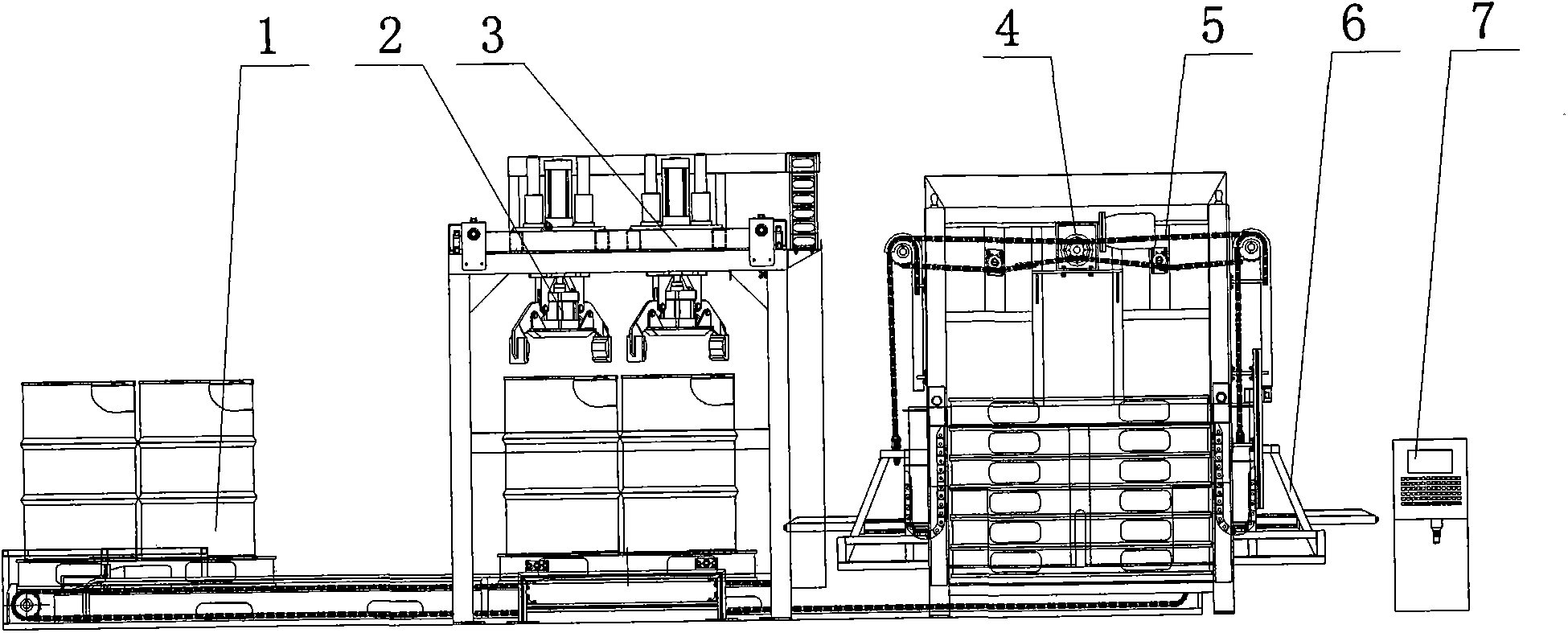

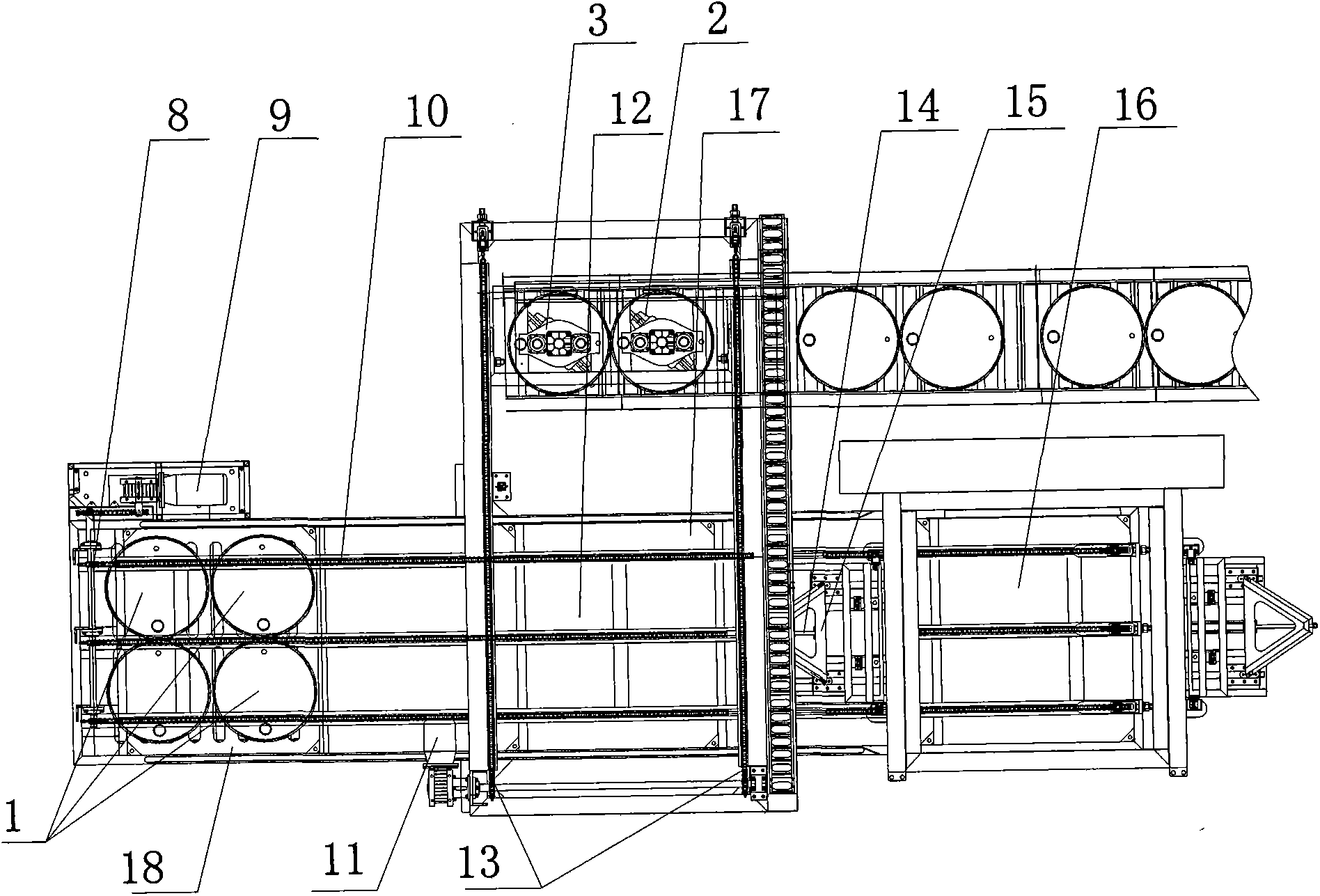

Full-automatic 200L steel drum transfer type stacking system and transfer stacking method thereof

Owner:CHANGCHUN BEIFANG INSTR EQUIP

Material and method used for TA2/0Cr18Ni9Ti welded by high-entropy effect

InactiveCN102676904AImprove performanceSimple preparation stepsWelding/cutting media/materialsSoldering mediaElectrical resistance and conductanceAlloy

The invention discloses a high-entropy interlayer alloy, which comprises the following components in atomic percentage: 5-10% of Ti, 5-10% of Fe, 25-30% of Al, 15-20% of Ni, 30-35% of Cu and 5-10% of Cr. The invention also discloses a method for welding TA2 / 0Cr18Ni9Ti by the high-entropy effect, which comprises the following steps that: high-entropy interlayer alloy is placed between the two plates to be welded, the high-entropy interlayer alloy is in a foil folding structure, and the high-entropy interlayer alloy and local parent metal are subjected to heat fusing by an interface resistor ina resistance spot welding mode, so that the high performance welding of TA2 / 0Cr18Ni9Ti can be realized. According to the method and the high-entropy interlayer alloy of the method, which are disclosed by the invention, the high-entropy interlayer alloy has the advantages of favorable strength, toughness and corrosion resistance, is easy to process and form and is convenient to weld and assembly. The preparation method has the advantages of simple step and low manufacture cost and is convenient to popularize.

Owner:XIAN UNIV OF TECH

Welded aluminum sheets and process therefore

Owner:NOVELIS INC

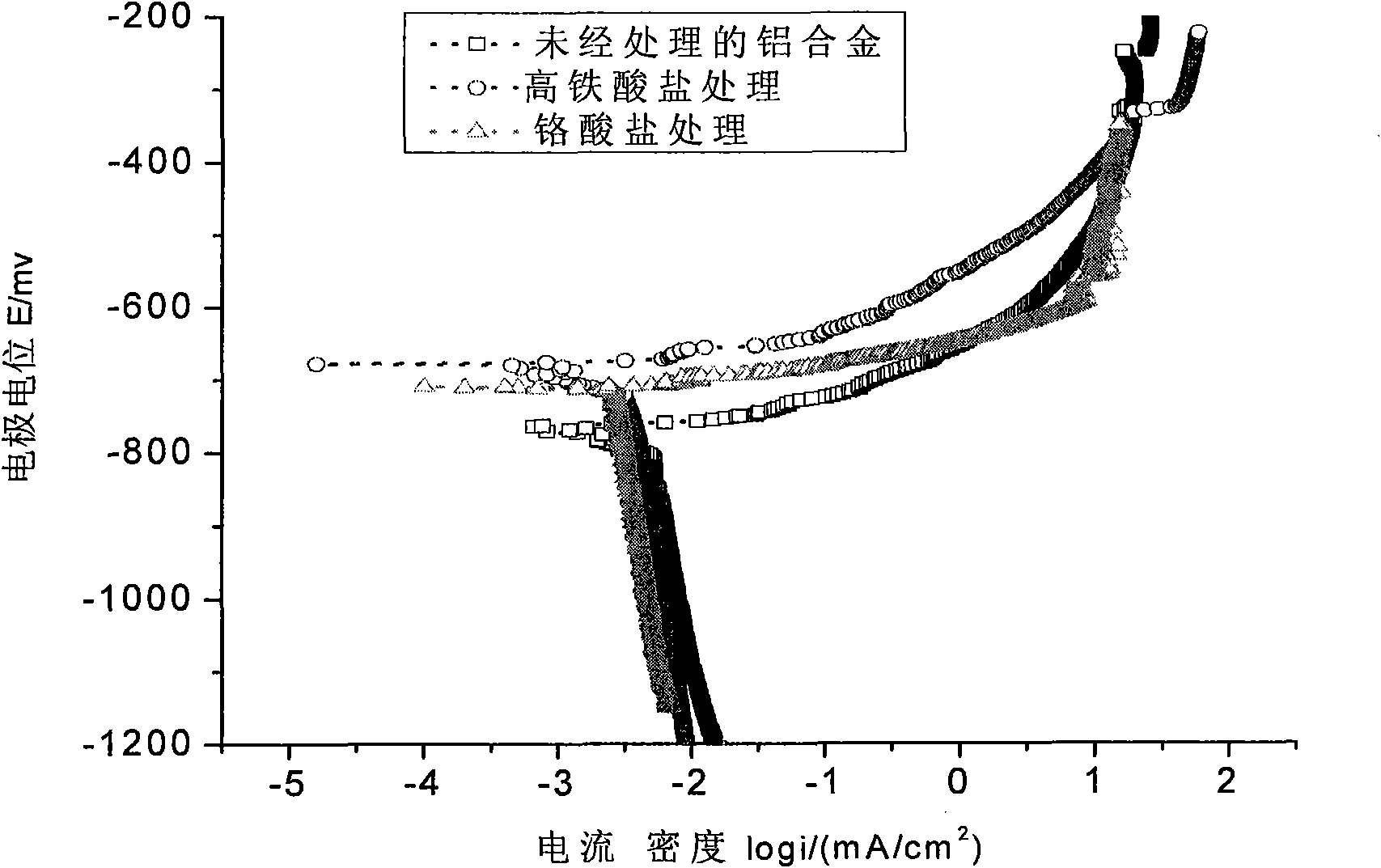

Organic and inorganic composite aluminium alloy non-chromium passivation treatment fluid

InactiveCN101565826AWith "self-healing" functionImprove corrosion resistanceMetallic material coating processesAcrylic resinPhosphoric acid

Owner:UNIV OF SCI & TECH BEIJING

Lubricating oil special for motorcycle engine and preparing method thereof

ActiveCN104031729AExtended service lifeThe steps are simple and environmentally friendlyLubricant compositionAntioxidantViscosity index

The invention discloses a lubricating oil special for a motorcycle engine, and belongs to the technical field of lubricating oil. The lubricating oil is obtained through a reaction carried out on 80 parts to 90 parts of base oil, 2 parts to 5 parts of abrasion resistance agents, 5 parts to 10 parts of corrosion resistance agents, 2 parts to 5 parts of cleaning factors, 5 parts to 15 parts of antioxidant, 1 part to 3 parts of metal deactivator and 8 parts to 12 parts of viscosity modifier. The base oil is composed of 30 parts to 40 parts of PAO and 40 parts to 50 parts of naphthenic base oil. The cleaning factors are any one of metal-based sodium or metal-based calcium or metal-based magnesium. The invention further discloses a preparing method of the lubricating oil. According to the lubricating oil special for the motorcycle engine, the cost of the base oil is controlled, and the better viscosity index and the high abrasion resistance performance can be ensured at the same time; viscous black carbon mud particles wrapped on engine parts can be effectively removed through matched addition of auxiliaries, the service life of the engine is prolonged, the equipment maintenance cost is reduced, and the clean abrasion protection mode is provided for the motorcycle engine. The preparing method of the lubricating oil is simple in steps, environmentally friendly, and easy to implement.

Owner:BAOJIE LUBRICATING OIL ZHENJIANG CO LTD

Ceramics particle strengthened composite material lining metal tube and manufacturing method thereof

InactiveCN101900227AExtended service lifeImprove wear resistanceCorrosion preventionPipe protection against corrosion/incrustationPolyesterManufacturing technology

The invention discloses a ceramics particle strengthened composite material lining metal tube and a manufacturing method thereof, belonging to the field of composite wear-resistant tubes. 4,4-Diphenylmethane diisocyanate (MDI), polyester glycol, 1,4-butanediol (BD), ceramics particles and the like serve as raw materials to prepare composite material liquid castables, and a centrifugal casting technology is adopted to cast polyurethane base ceramics particle strengthened composite material lining layers on the inner wall of an outer thimble. The invention has the beneficial effect that the prepared ceramics particle strengthened composite material lining metal tube has excellent abrasive resistance and corrosion-resistance and greatly improves service life. The raw materials of the invention are easy to be obtained, manufacturing technology is simple, cost is low and economic benefit is obvious and practical application and mass production are beneficial for factories.

Owner:XUZHOU SHENGHAI MACHINERY MFG TECH

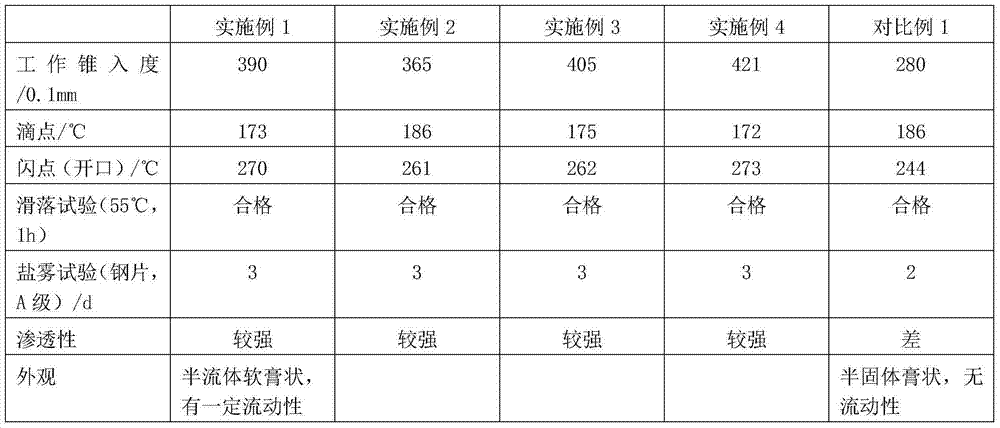

Lubricating grease composition for elevator wire ropes and preparation method thereof

ActiveCN103484218AImprove adhesionImprove permeabilityLubricant compositionMicrocrystalline waxOleic Acid Triglyceride

Owner:WUJIANG JUNDA ELEVATOR PARTS

Method for effectively restraining generation of sulfur trioxide and waste acid in smelting smoke

InactiveCN107144144AInhibitionReduce corrosionIncreasing energy efficiencyWaste heat treatmentSulfateSmelting process

Owner:CENT SOUTH UNIV

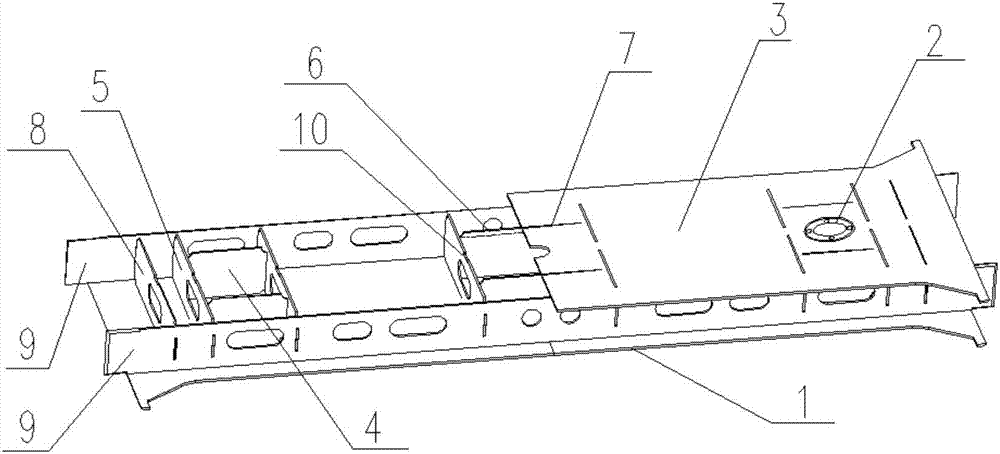

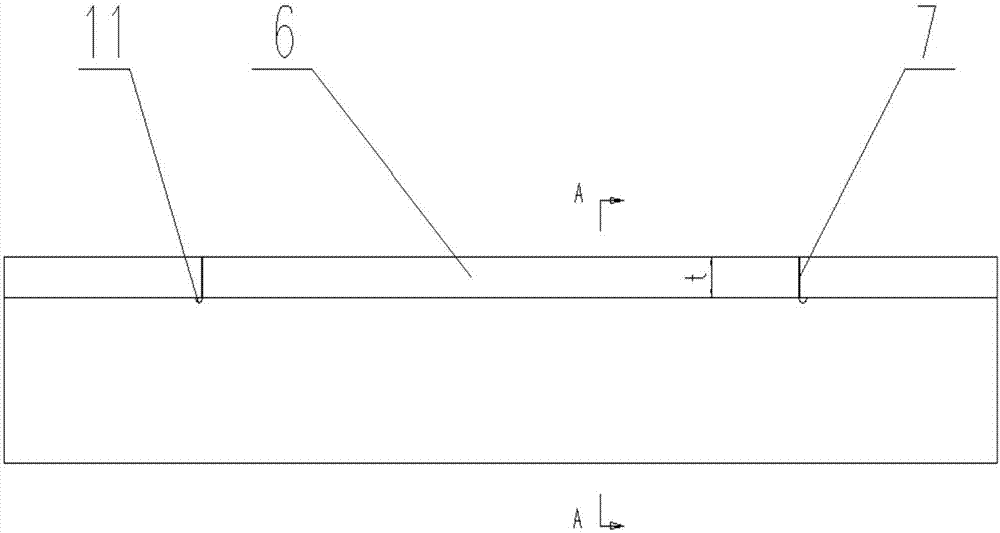

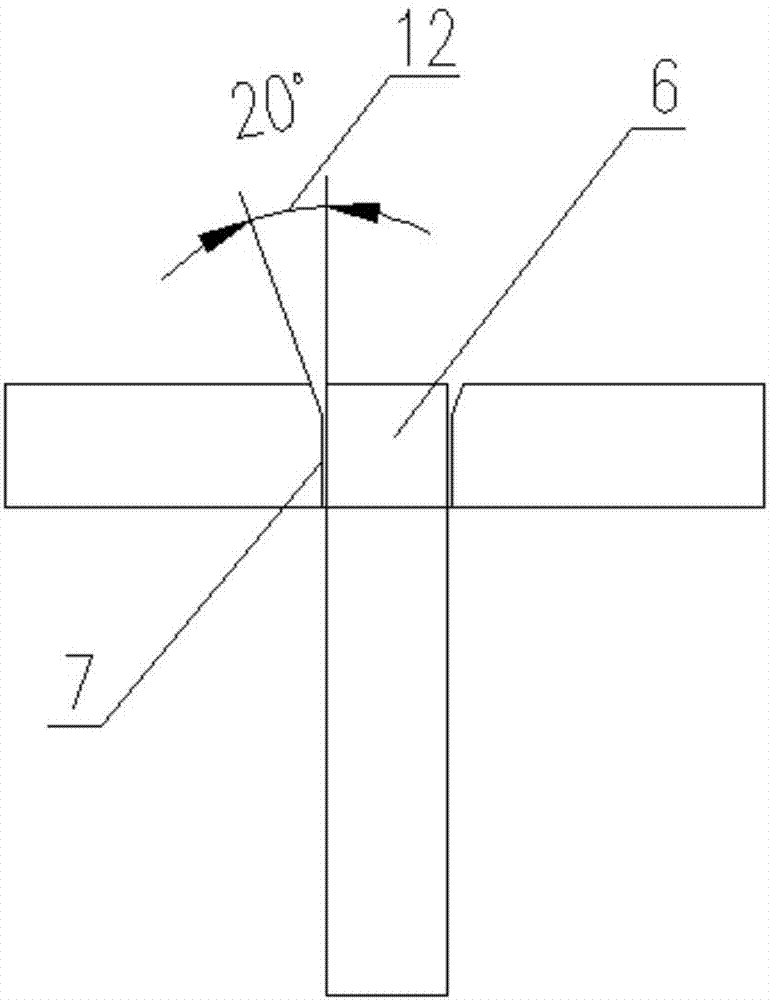

Composite welding method of pillow beam, pillow beam and rail vehicle with pillow beam

InactiveCN106964902AAchieve lightweightImprove corrosion resistanceUnderframesWorkpiece edge portionsManufacturing technologyEngineering

Owner:CRRC QINGDAO SIFANG CO LTD

Method and device for electrolytic machining of massive array tiny pits through wedge-shaped runner

ActiveCN103600144APrevent inflowConsistent strengthMachining electrodesElectrical-based machining electrodesElectrolysisEngineering

The invention discloses a method and a device for electrolytic machining of massive array tiny pits through a wedge-shaped runner, and belongs to the technical field of electrolytic machining. The method includes processing the surface of a mask plate to enable the surface to fit with the surface of a workpiece anode; fixing a wedge-shaped tool cathode above the mask plate to enable the wedge-shaped runner to be formed between the wedge-shaped tool cathode and the mask plate; connecting the workpiece anode and the wedge-shaped tool cathode with an anode and a cathode of a power source respectively; feeding an electrolyte into the wedge-shaped runner, wherein the electrolyte reaches the surface of the workpiece anode through penetrating group holes in the mask plate; switching on the power source for electrolytic machining. The runner is arranged to be wedge-shaped, so that electric field intensity and electrolyte flowing speed are enabled to be progressively increased along the direction of the runner, both corrosion strength and speed of a workpiece are enabled to tend to be uniform, and uniformity and machining accuracy of electrolytic machining are improved. A PDMS (polydimethylsiloxane) template is taken as the mask plate, bonding strength of the mask plate and the workpiece anode can be guaranteed, stray corrosion, of the electrolyte, to places around a machining area can be effectively reduced, and locality and uniformity of electrolytic machining can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Epoxy resin-enhanced laminated insulating profile and preparation method thereof

The invention discloses an epoxy resin-enhanced laminated insulating profile. The epoxy resin-enhanced laminated insulating profile comprises modification polymers and a reinforcing material, wherein the modification polymers include epoxy resin, a curing agent, a promoting agent, a flame retardant, a wetting dispersant and a solvent; the reinforcing material is a fiber material; the components of the modification polymers are mixed to form a modification polymer solution, the reinforcing material is soaked into the modification polymer solution and is finally subjected to hot press molding to form the epoxy resin-enhanced laminated insulating profile. The epoxy resin-enhanced laminated insulating profile is integrated with lightness, flame retardance, corrosion resistance and insulativity, has extremely high mechanical property, excellent electrical insulation property and halogen-free flame retardance, is environmentally friendly, is high in use safety and can be applied to industries and fields including State Grid Corporation of China, new energy resources, energy conservation, consumption reduction and track traffic which have high requirements to material performance and special working conditions and environments.

Owner:SICHUAN D&F ELECTRICAL TECH

Cleaning fluid used for automatic biochemical analyzer

ActiveCN101470123AEasy to cleanLow costNon-ionic surface-active compoundsDetergent mixture composition preparationCITRATE ESTERSurface-active agents

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

Solar photoelectric photo-thermal integrated assembly and solar combined heat and power generation system thereof

InactiveCN103594538AEliminates the effects of thermal contact resistanceEliminate the effects ofPV power plantsEnergy industryCells panelMetal sheet

The invention relates to a solar photoelectric photo-thermal integrated assembly and a solar combined heat and power generation system of the solar photoelectric photo-thermal integrated assembly. The solar photoelectric photo-thermal integrated assembly is characterized by comprising a photovoltaic cell panel provided with a metal outer frame, a metal sheet type heat exchanger and a heat-preservation material layer, wherein the metal sheet type heat exchanger and the heat-preservation material layer are sequentially arranged on the back surface of the photovoltaic cell panel in parallel and in an overlapped mode, and are rapidly fixed in the metal outer frame of the photovoltaic cell panel through a metal fixing clamp, and the standard photovoltaic cell panel can be rapidly modified into the photoelectric photo-thermal integrated assembly. The photoelectric photo-thermal integrated assembly has the advantages of being compact in structure, high in efficiency, small in pressure loss, light in weight, flexible to install, high in pressure bearing performance, resistant to corrosion, low in cost and the like, further reduces the initial investment and installation space of a medium and low temperature solar thermoelectric system, lowers the operation expenses of the system, and is suitable for civil and industrial occasions requiring for both heat and power.

Owner:SHANGHAI LVJIAN ENERGY TECH

Good-weather and water resistance water-based alkyd resin

Owner:深圳海德新材料科技有限公司

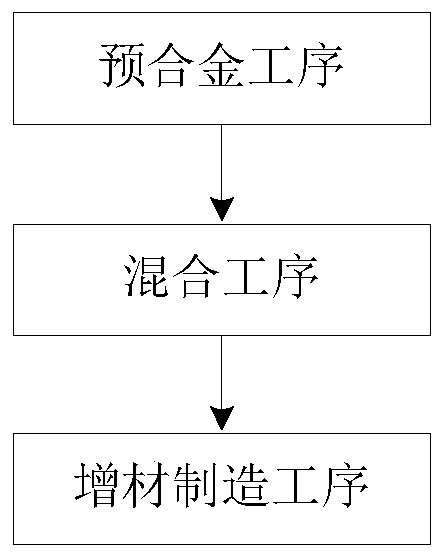

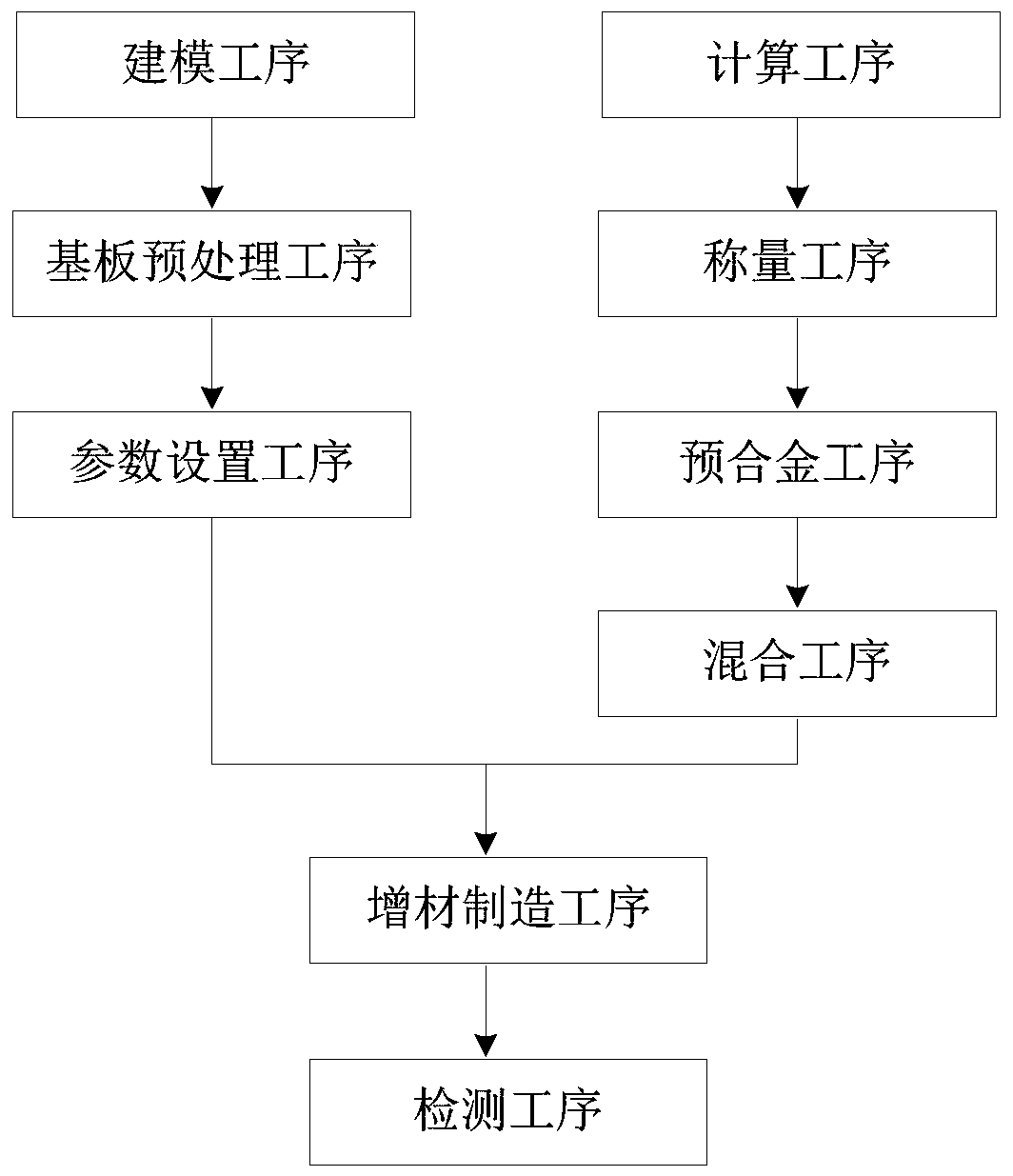

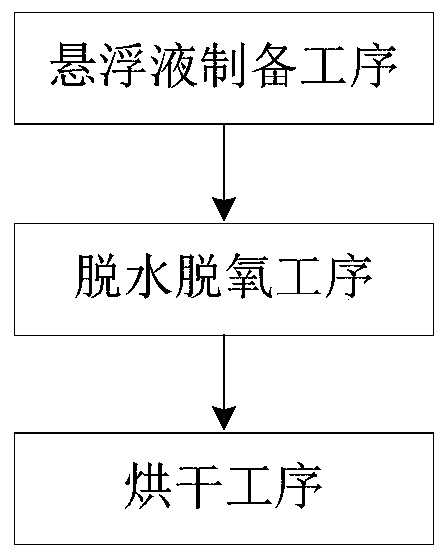

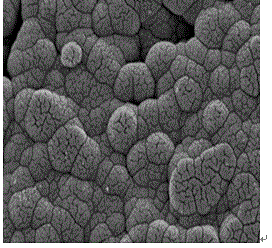

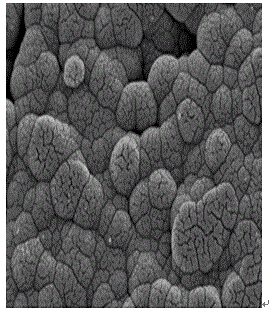

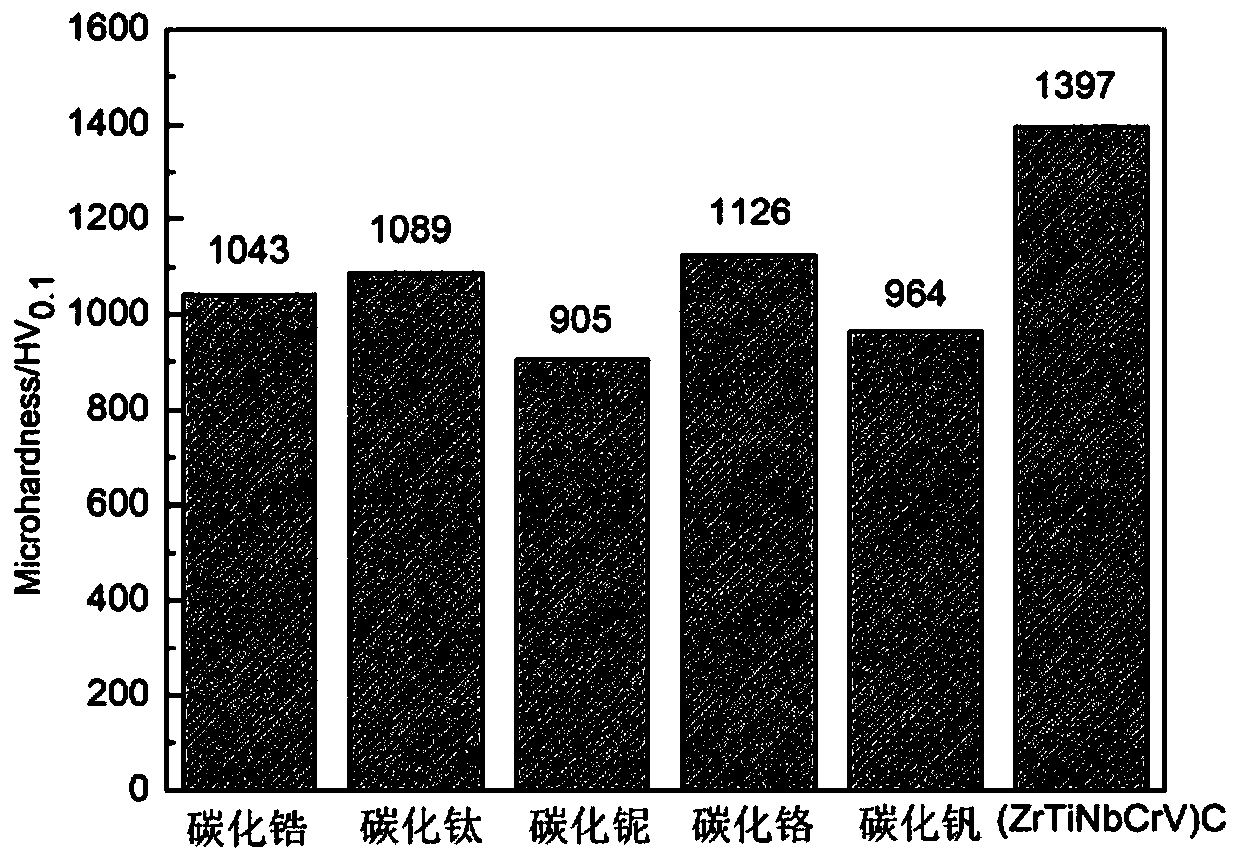

Alloying component and preparation method thereof

ActiveCN110592411AImprove distributionFull play formAdditive manufacturing apparatusIncreasing energy efficiencyHigh entropy alloysCarbon nanotube

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

Process for the preparation of thermoplastic polyamide and polyester compositions exhibiting increased melt flow and articles formed therefrom

Owner:EI DU PONT DE NEMOURS & CO

Method for preparing sodium antimonate from antimony oxide ore via alkaline approach

ActiveCN103866121AHigh recovery rateImprove qualityProcess efficiency improvementWastewaterPre treatment

The invention discloses a method for preparing sodium antimonate from an antimony oxide ore via an alkaline approach. The method comprises the following steps: (1) leaching the antimony oxide ore, (2) purifying filtrate, and (3) oxidizing the purified filtrate. The method is high in recovery rate, the leaching rate of antimony is 95-99%, the direct recovery rate of sodium antimonate is 90-95%, the whole process is performed under an alkaline environment, the requirement on corrosion resistance of equipment is not high, no complicated pretreatment is required in the process, the needed raw materials are nontoxic and harmless, the alkaline liquid is recyclable, neither waste water nor waste gas is generated in the process, and waste residues are nontoxic and harmless.

Owner:XIKUANG SHANXING ANTIMONY CO LTD

Method for producing high-count yarns from vinylon and polyester fibers, and cotton by blending

Owner:JIHUA 3509 TEXTILE

Acidic electroplating zinc-nickel alloy electrolyte, preparation method and electroplating method

Owner:南通创源电化学科技有限公司

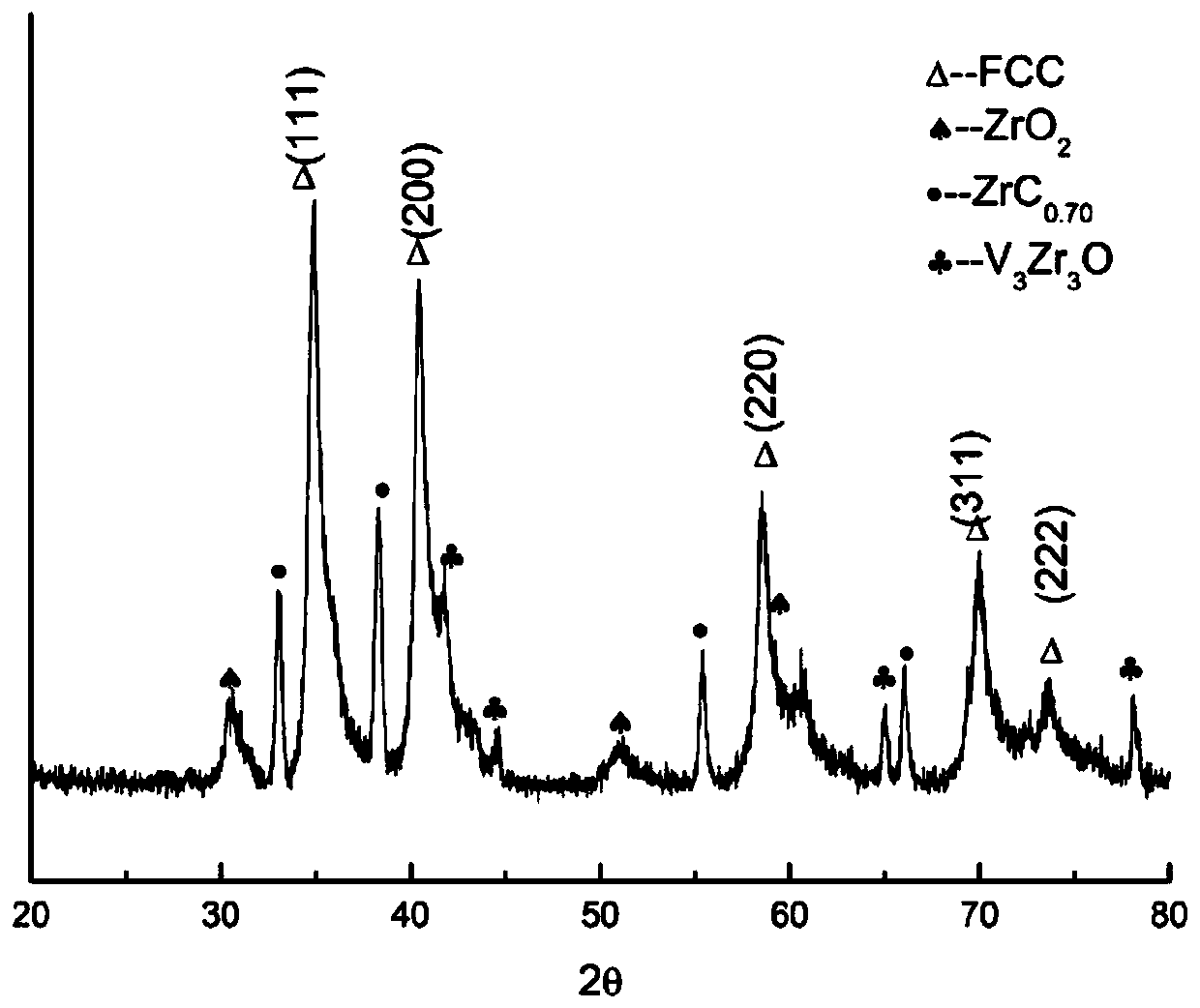

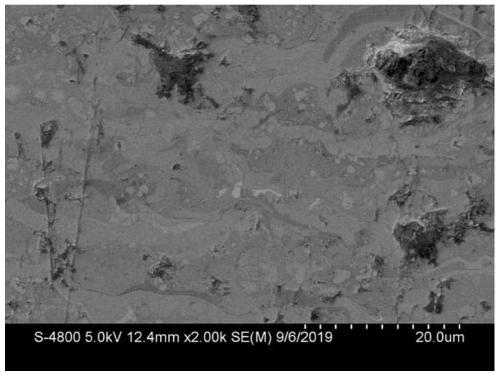

Preparation method of high-entropy ceramic coating

Owner:HEBEI UNIV OF TECH

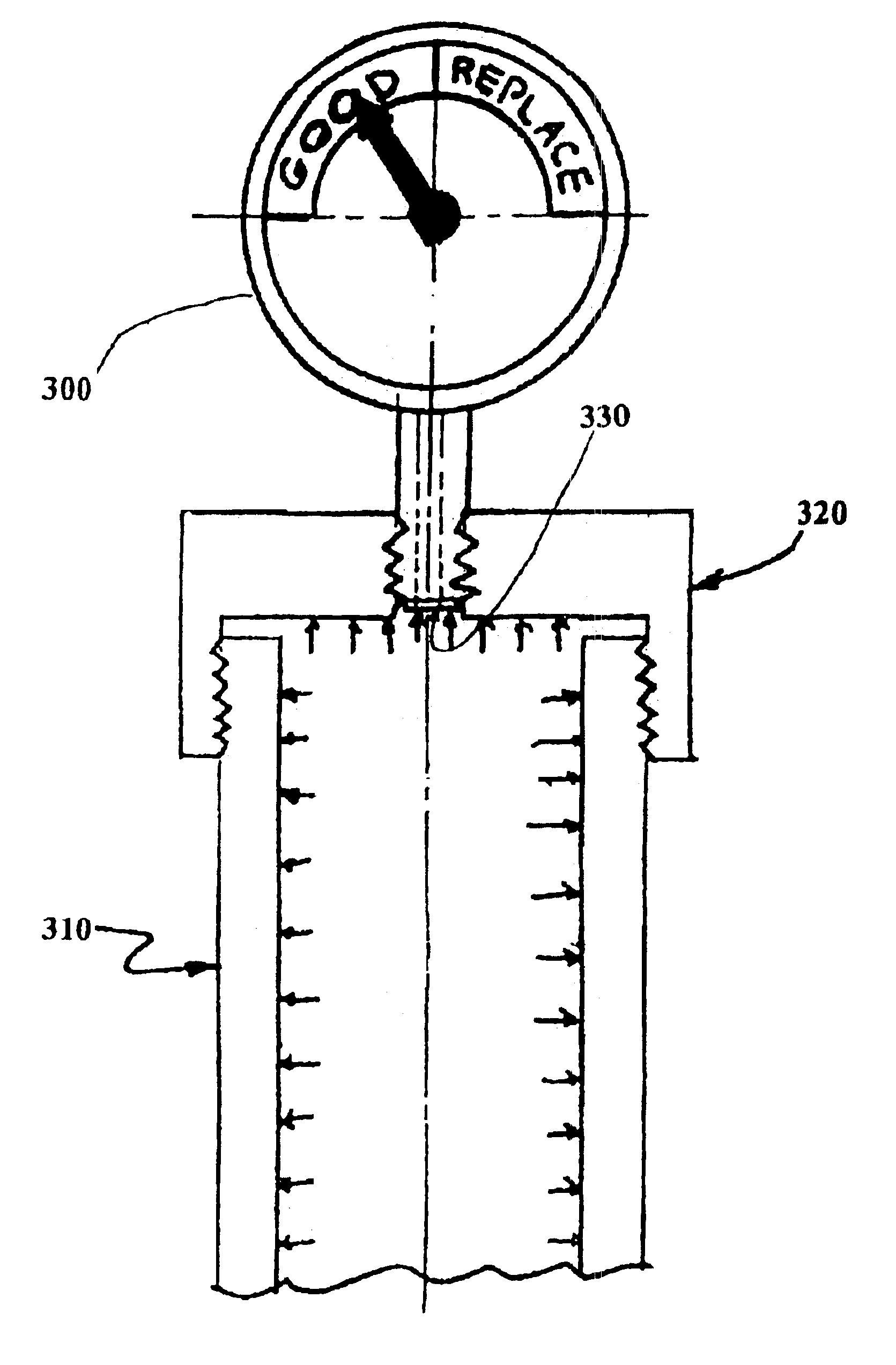

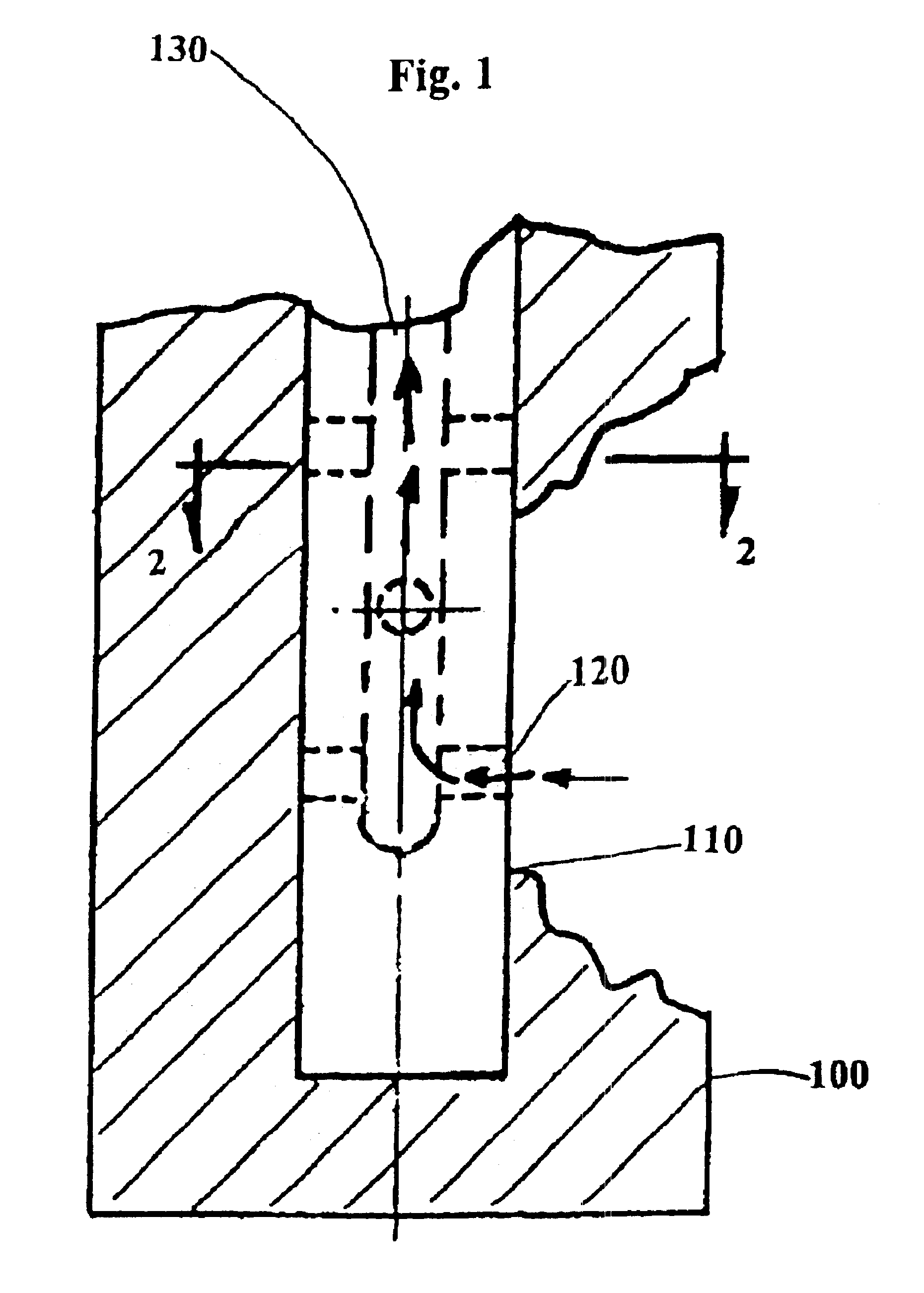

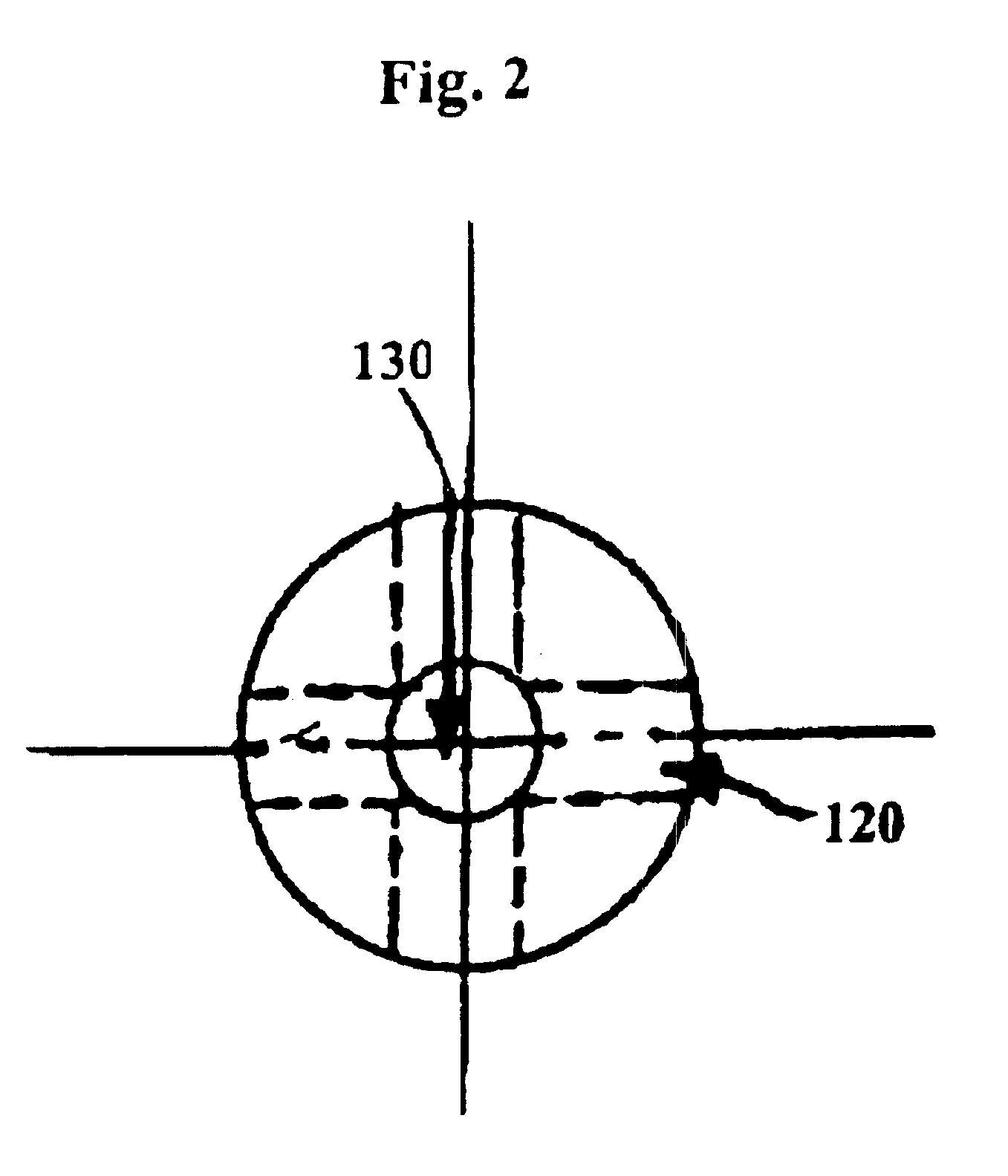

Anode rod depletion indicator

InactiveUS6903540B2Weather/light/corrosion resistanceResistance/reactance/impedenceEngineeringFuel supply

Owner:KEAN JAMES G

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap