Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

111 results about "Cathode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cathode is the electrode from which a conventional current leaves a polarized electrical device. This definition can be recalled by using the mnemonic CCD for Cathode Current Departs. A conventional current describes the direction in which positive charges move. Electrons have a negative electrical charge, so the movement of electrons is opposite to that of the conventional current flow. Consequently, the mnemonic cathode current departs also means that electrons flow into the device's cathode from the external circuit.

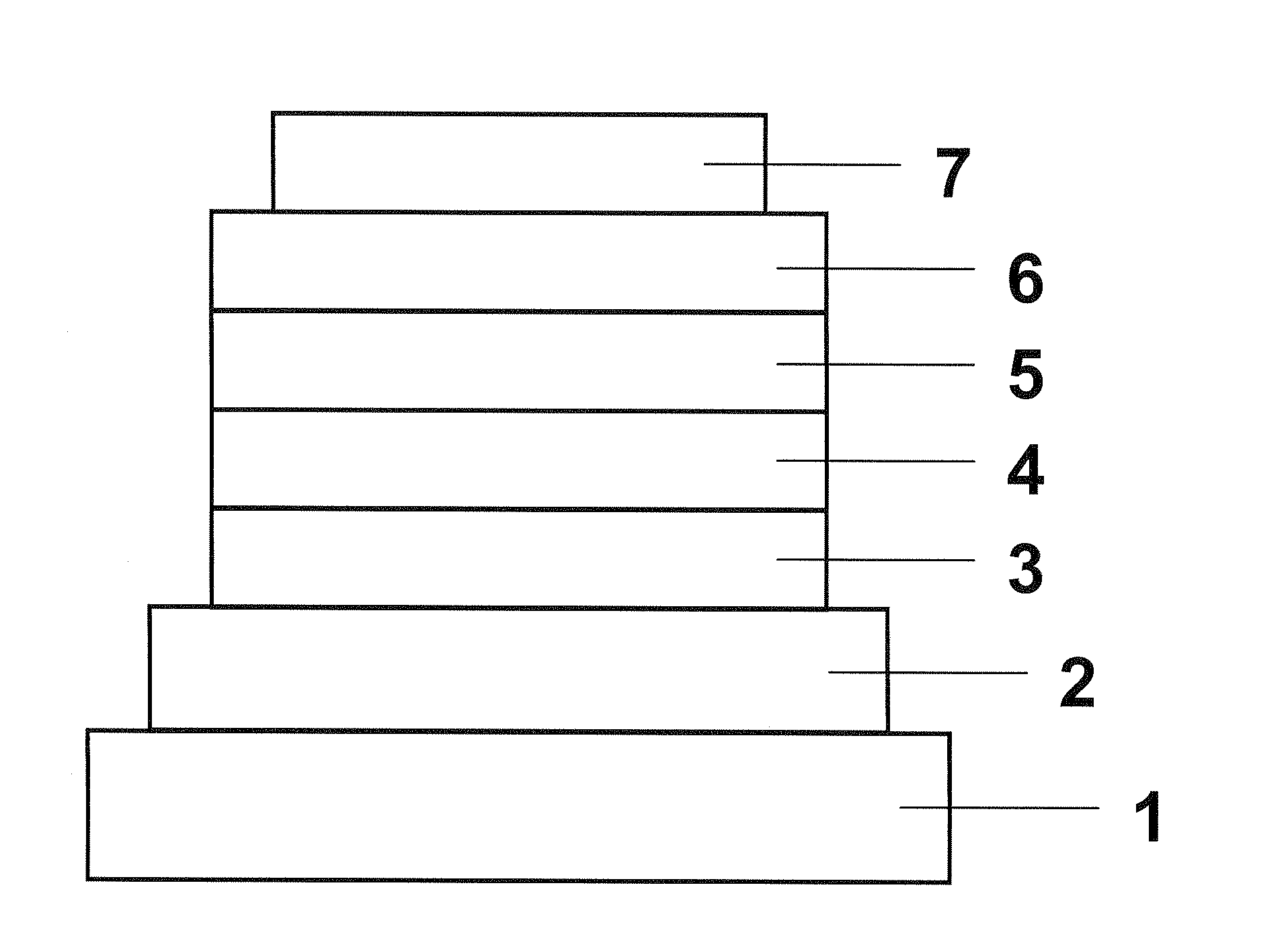

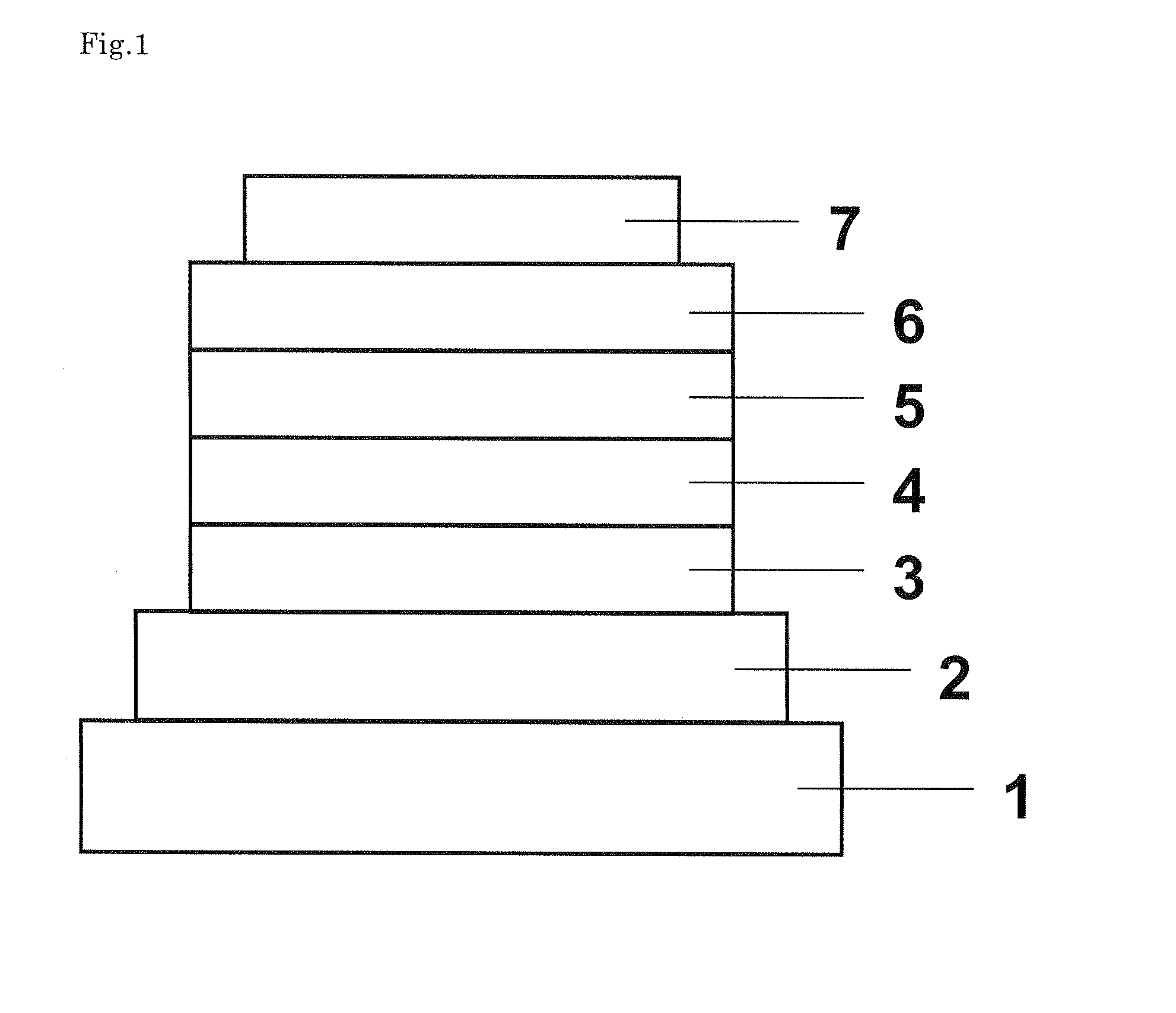

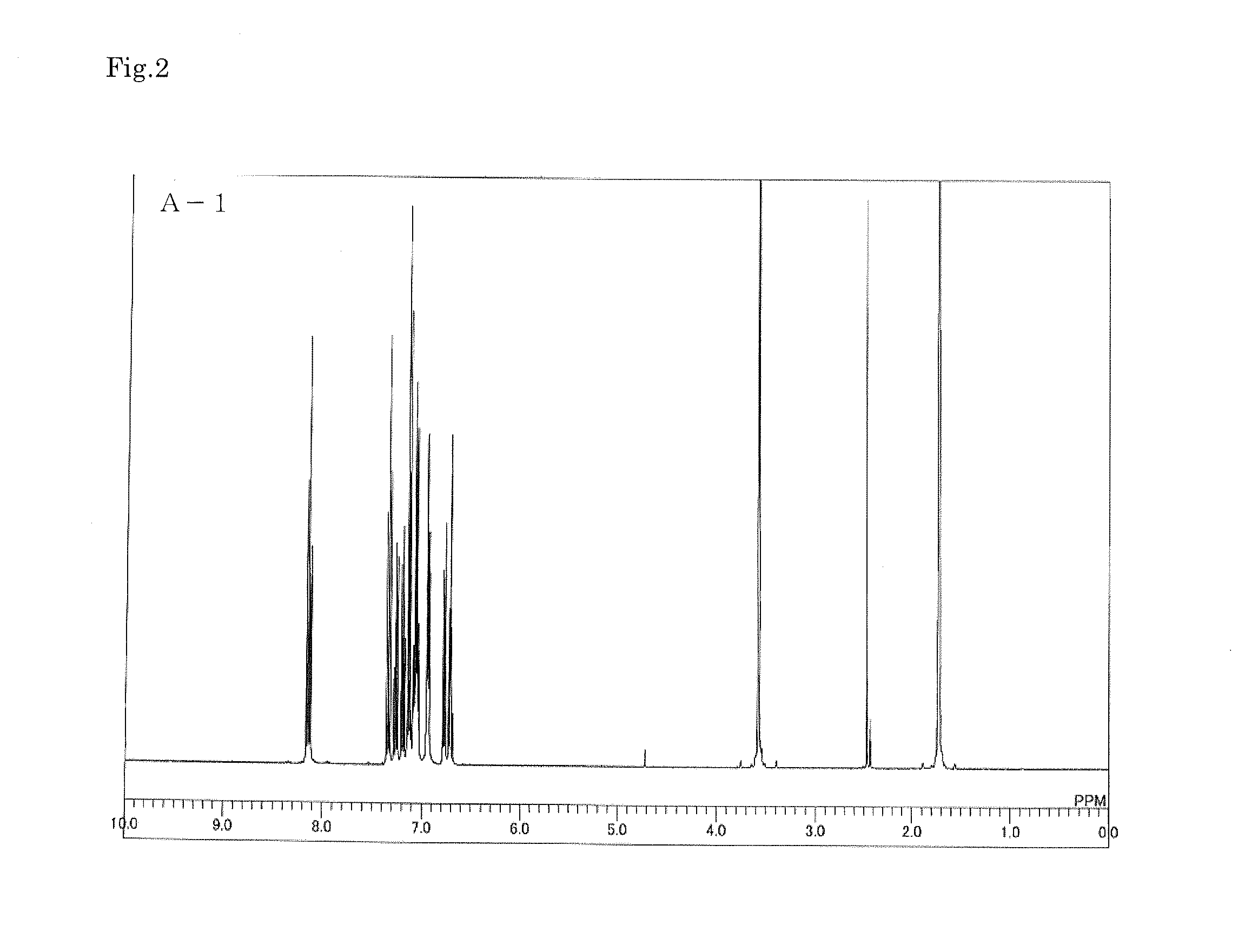

Organic electroluminescent device

ActiveUS20120319095A1Improve stabilityImprove featuresOrganic chemistrySolid-state devicesArylDopant

Owner:NIPPON STEEL CHEMICAL CO LTD

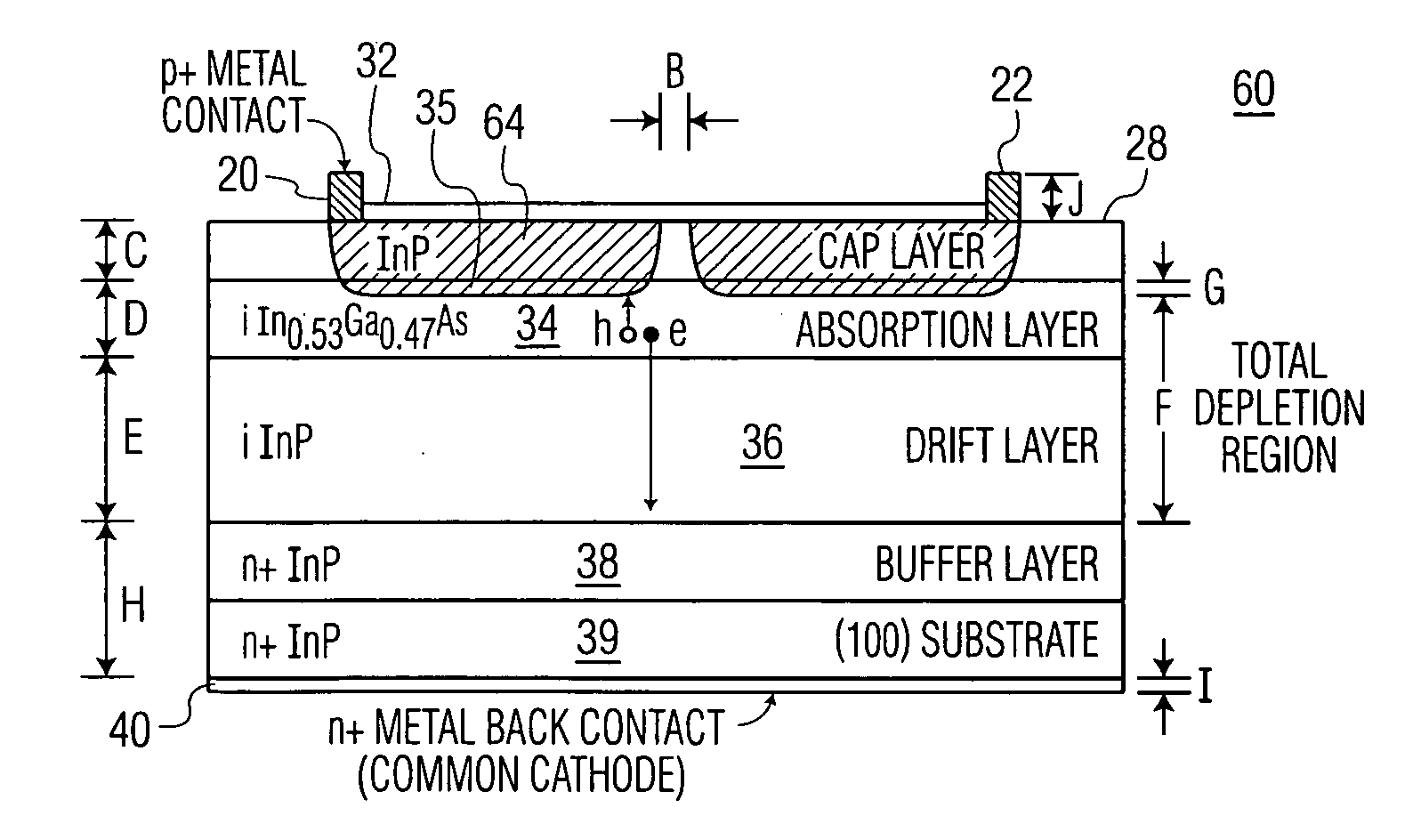

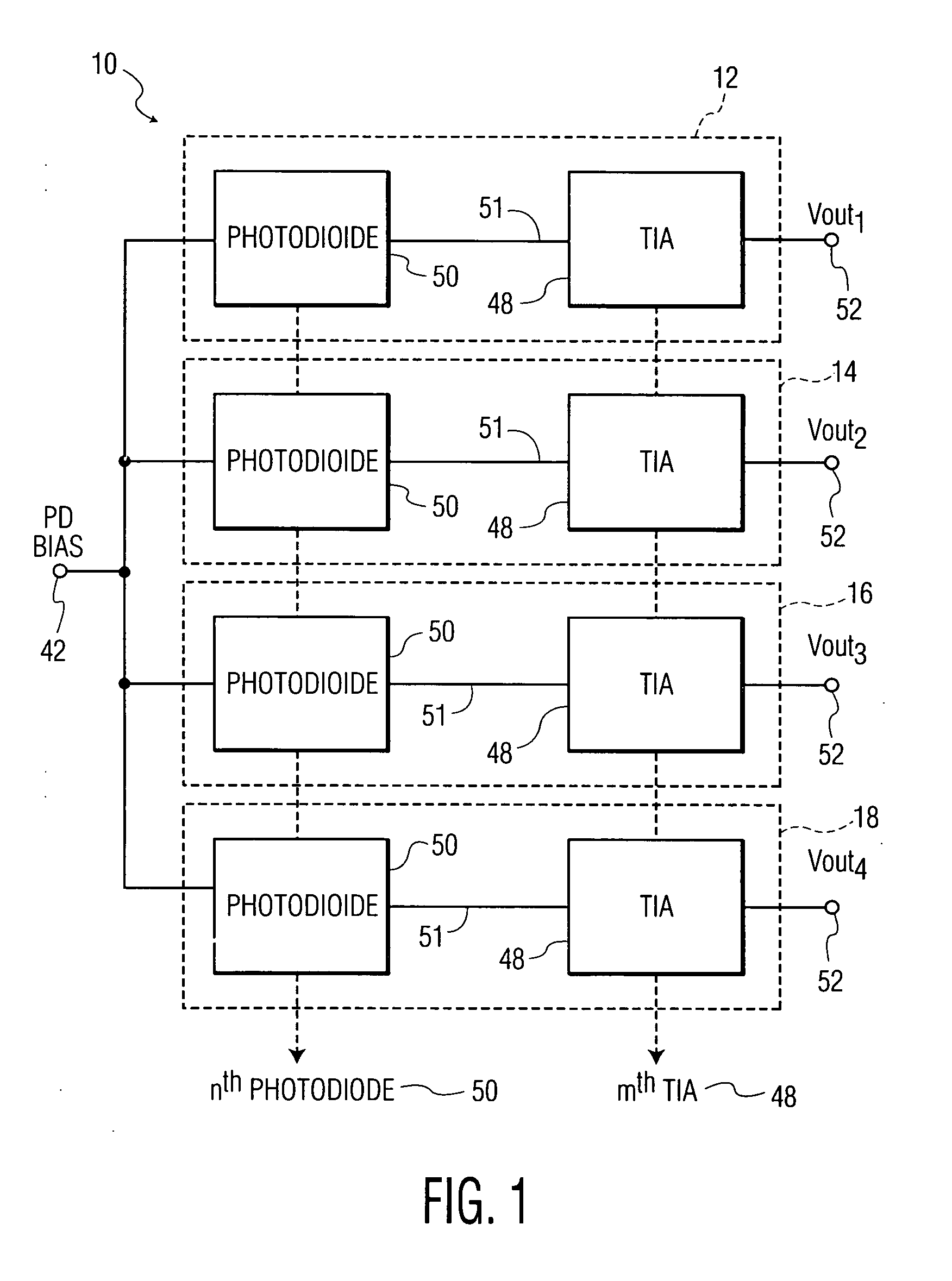

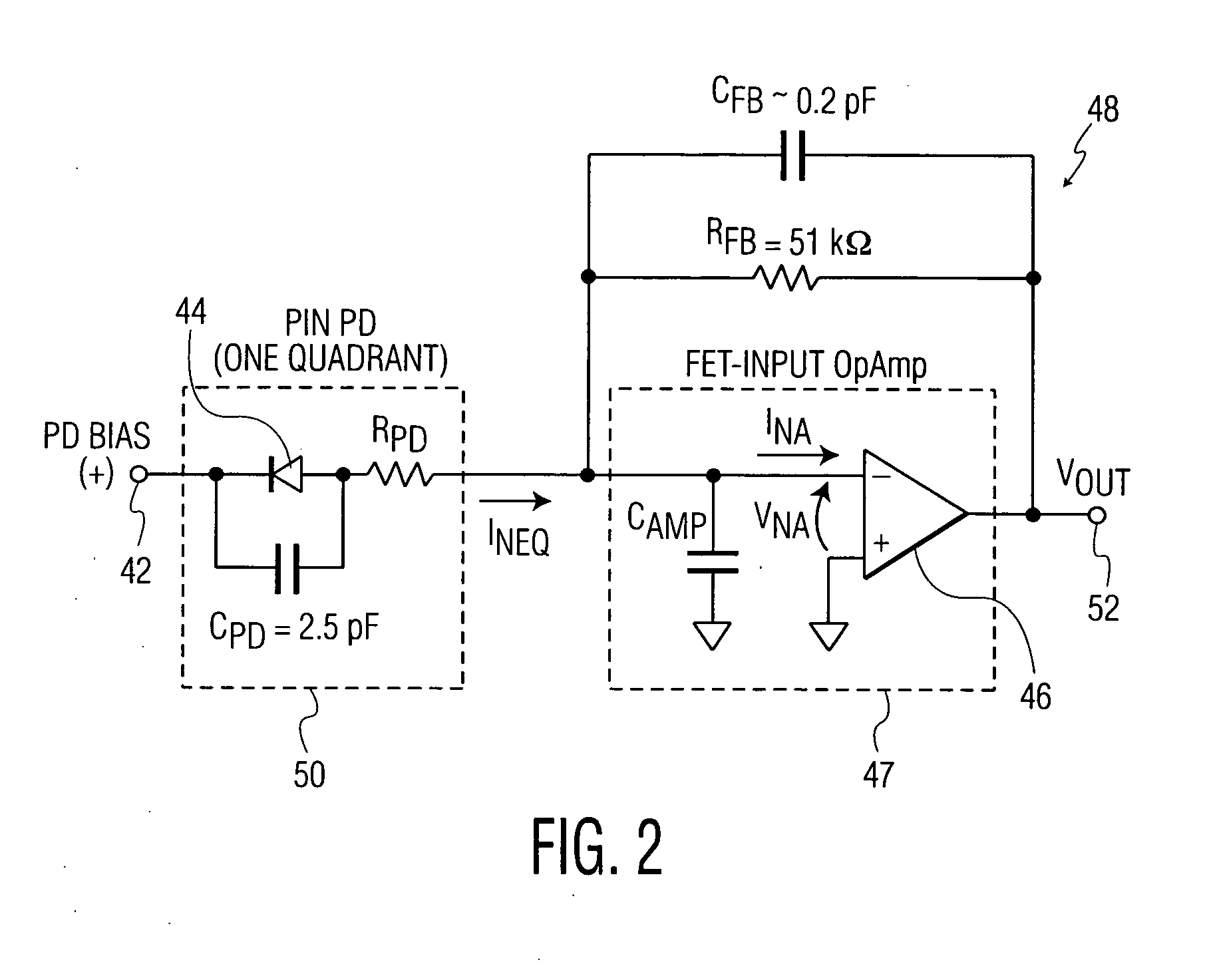

Low-noise large-area photoreceivers with low capacitance photodiodes

Owner:DISCOVERY SEMICON

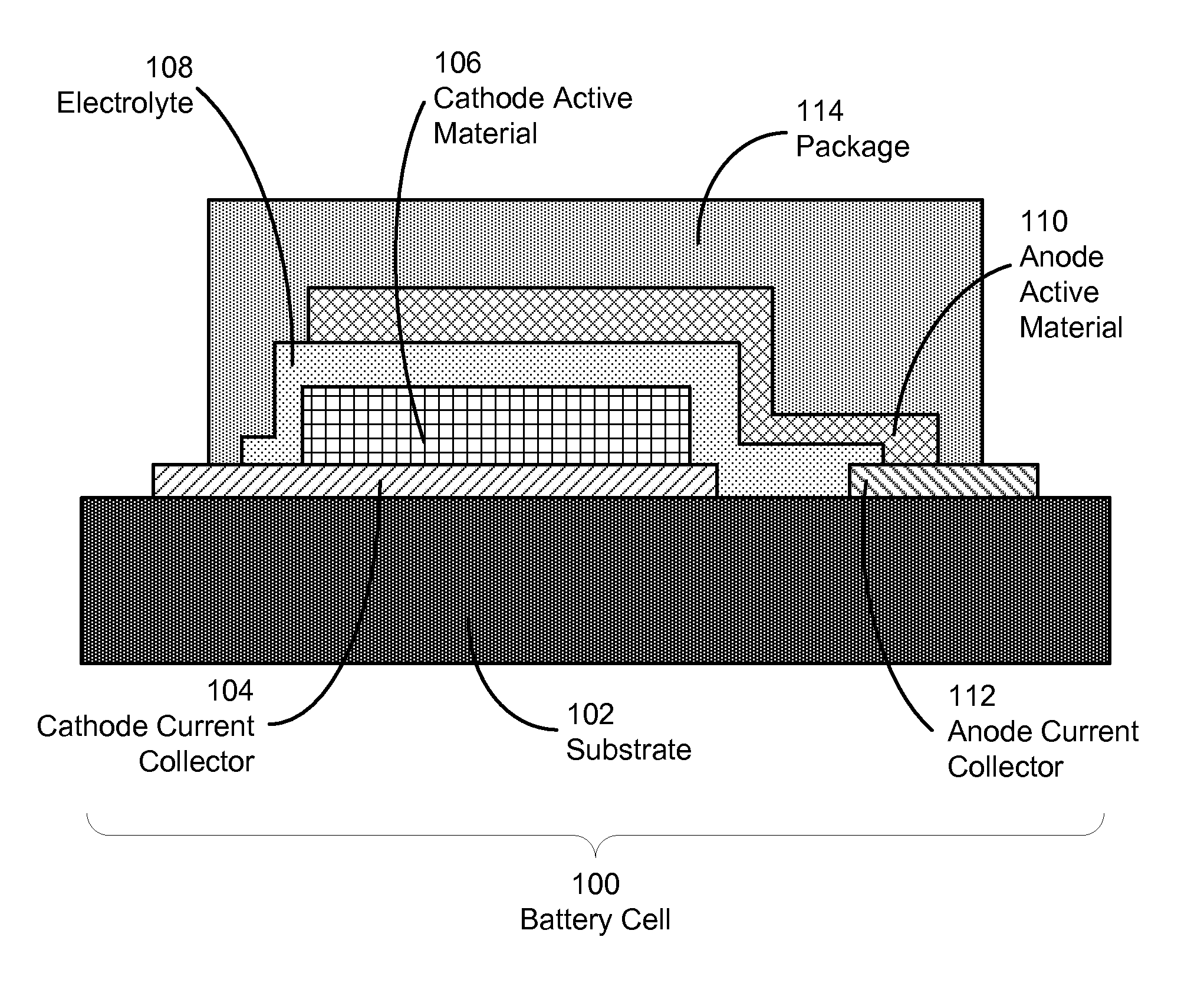

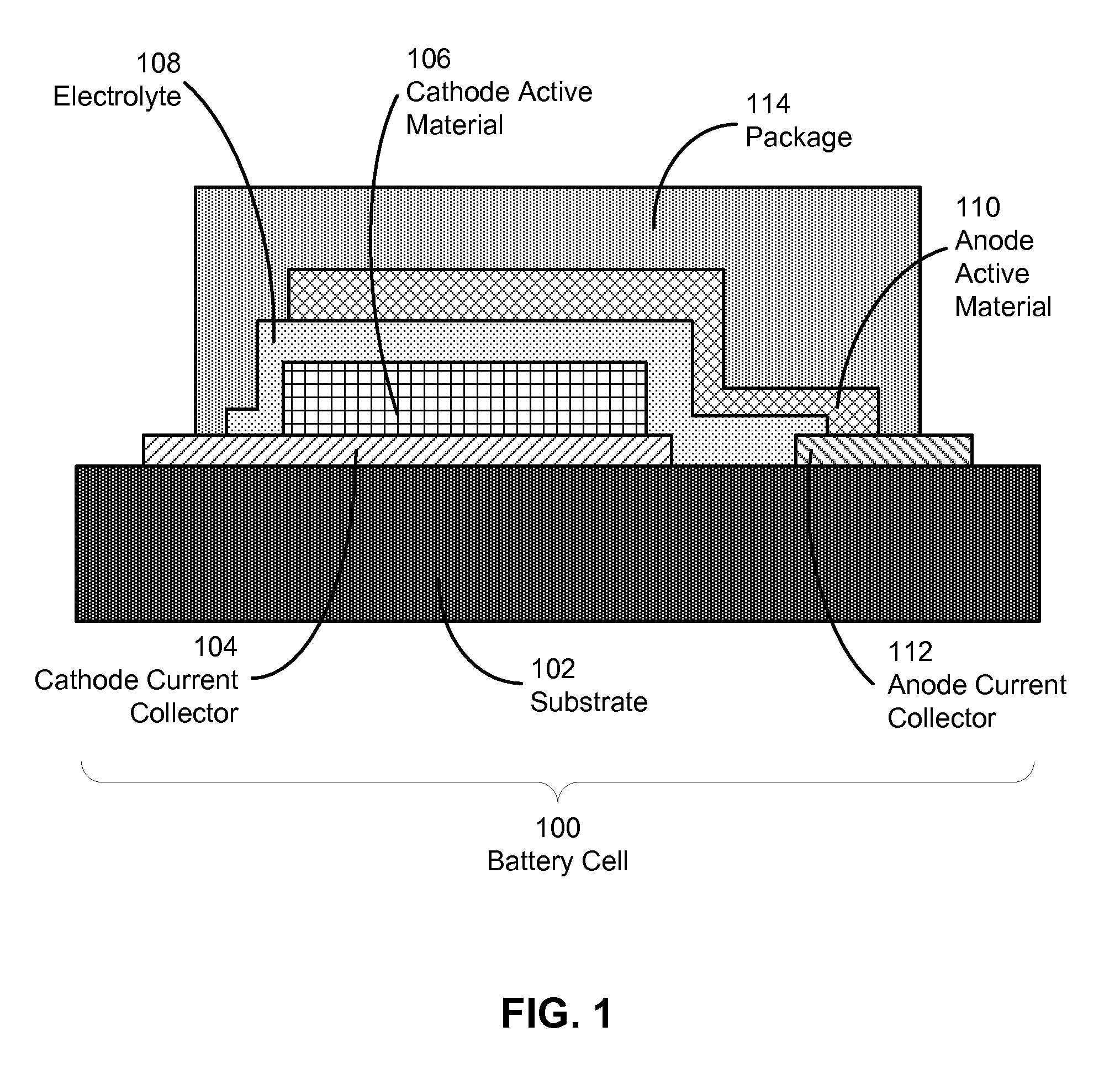

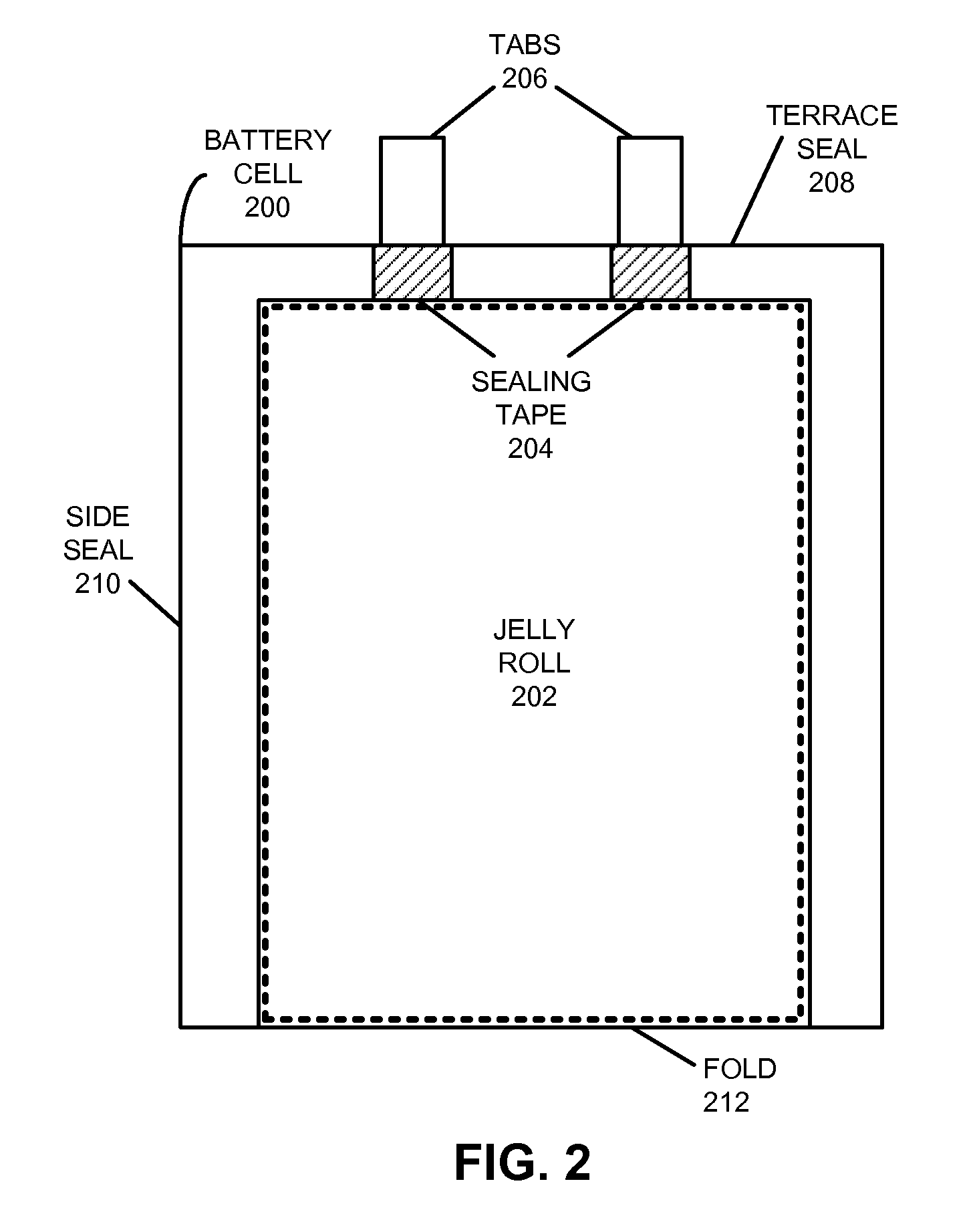

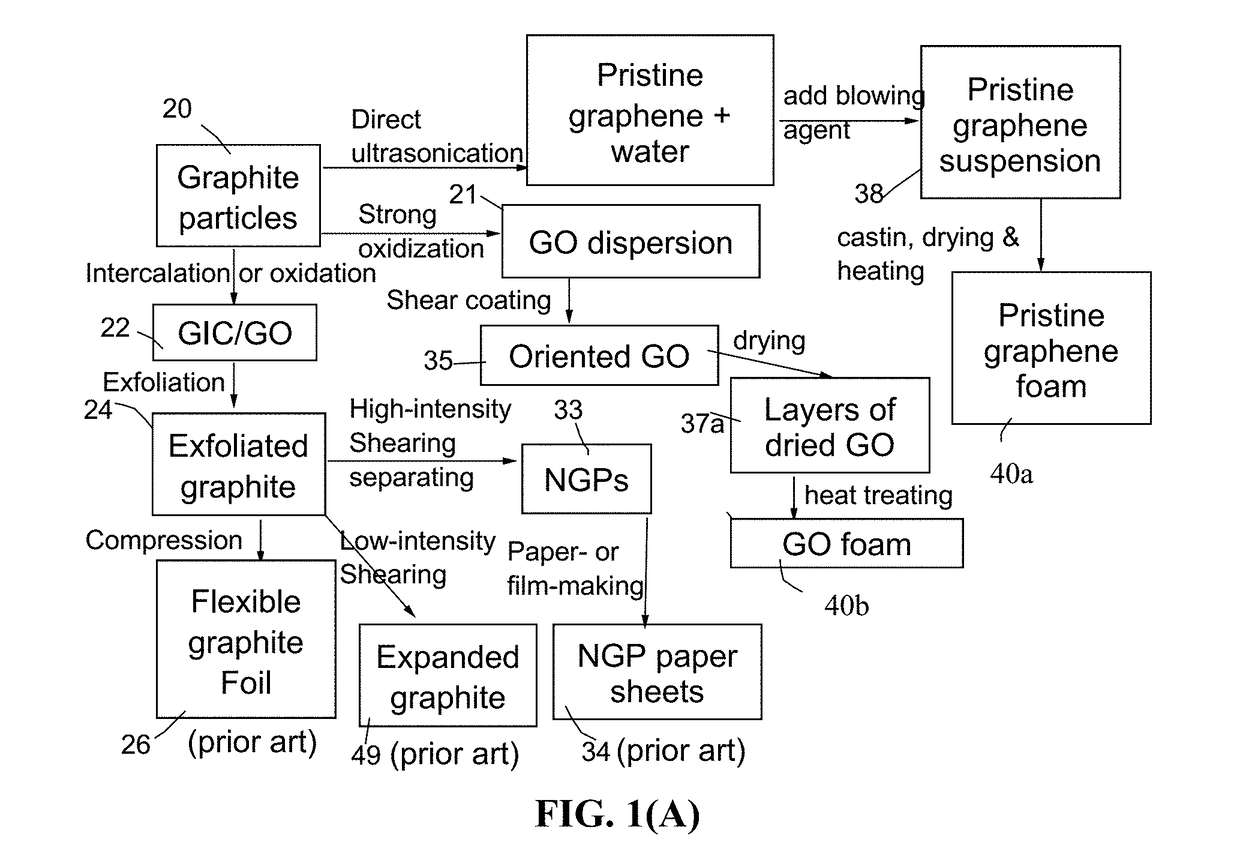

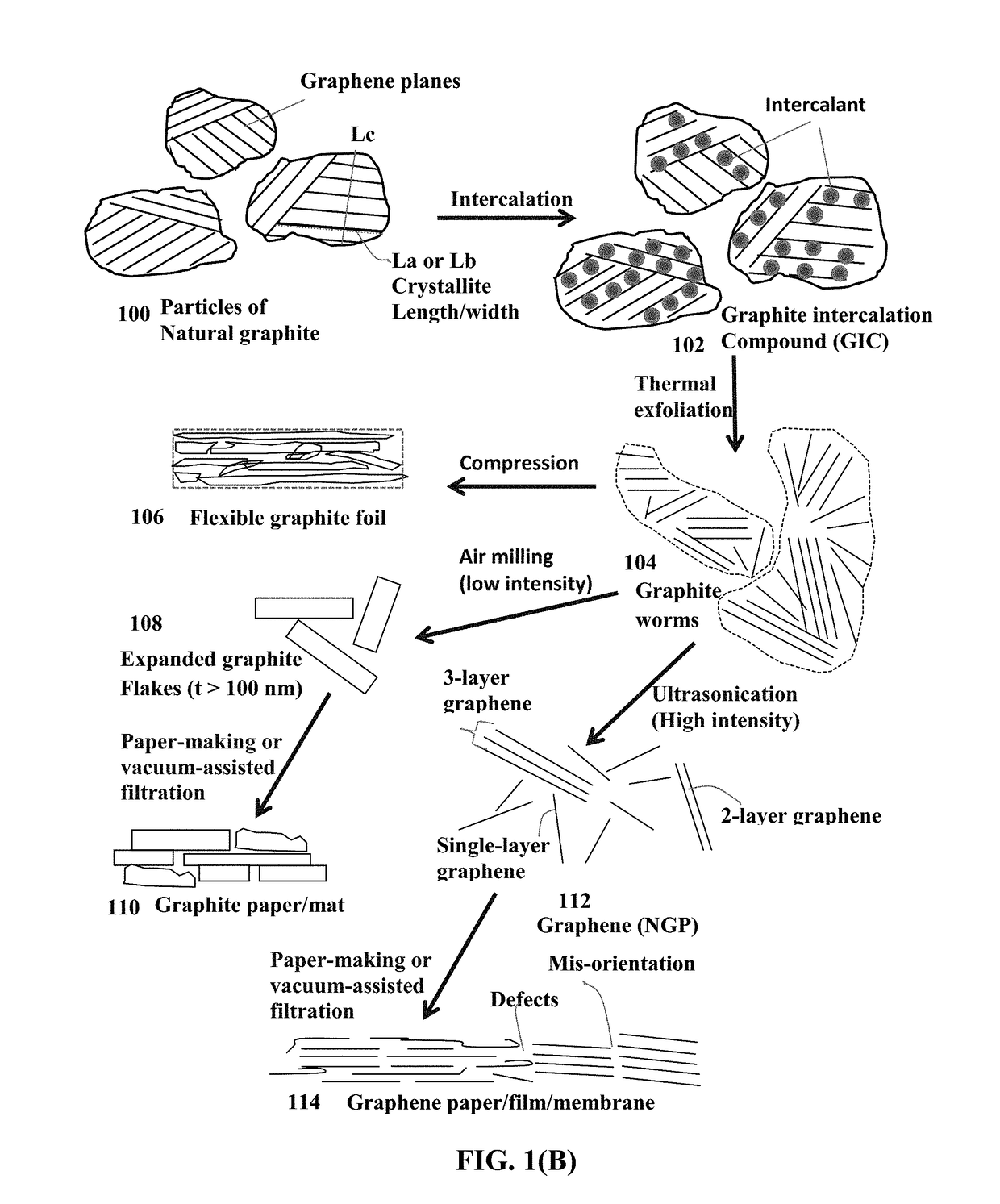

Graphene current collectors in batteries for portable electronic devices

InactiveUS20130095389A1Reduce manufacturing costIncrease energy densityElectrode carriers/collectorsSolid electrolyte cellsManufacturing cost reductionEngineering

Owner:APPLE INC

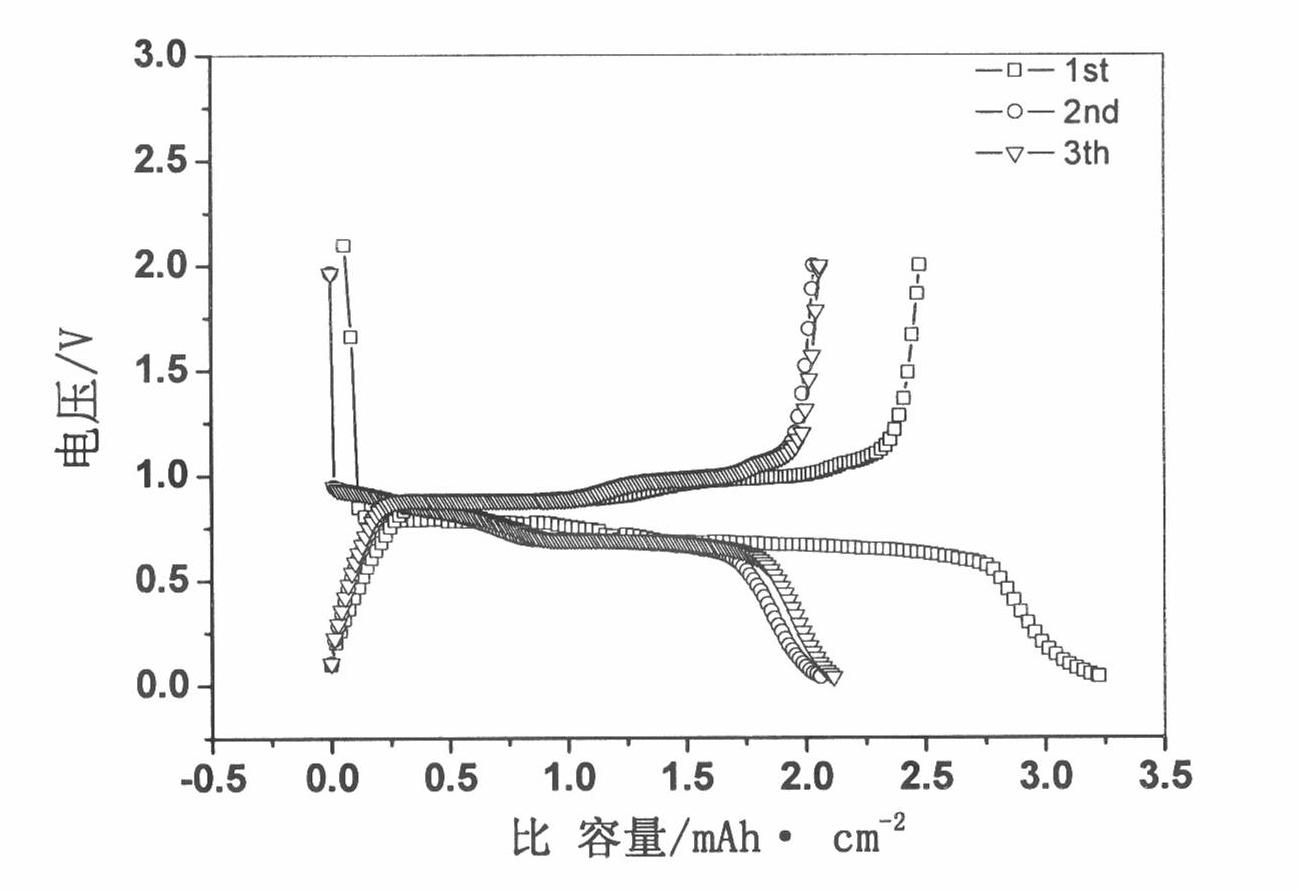

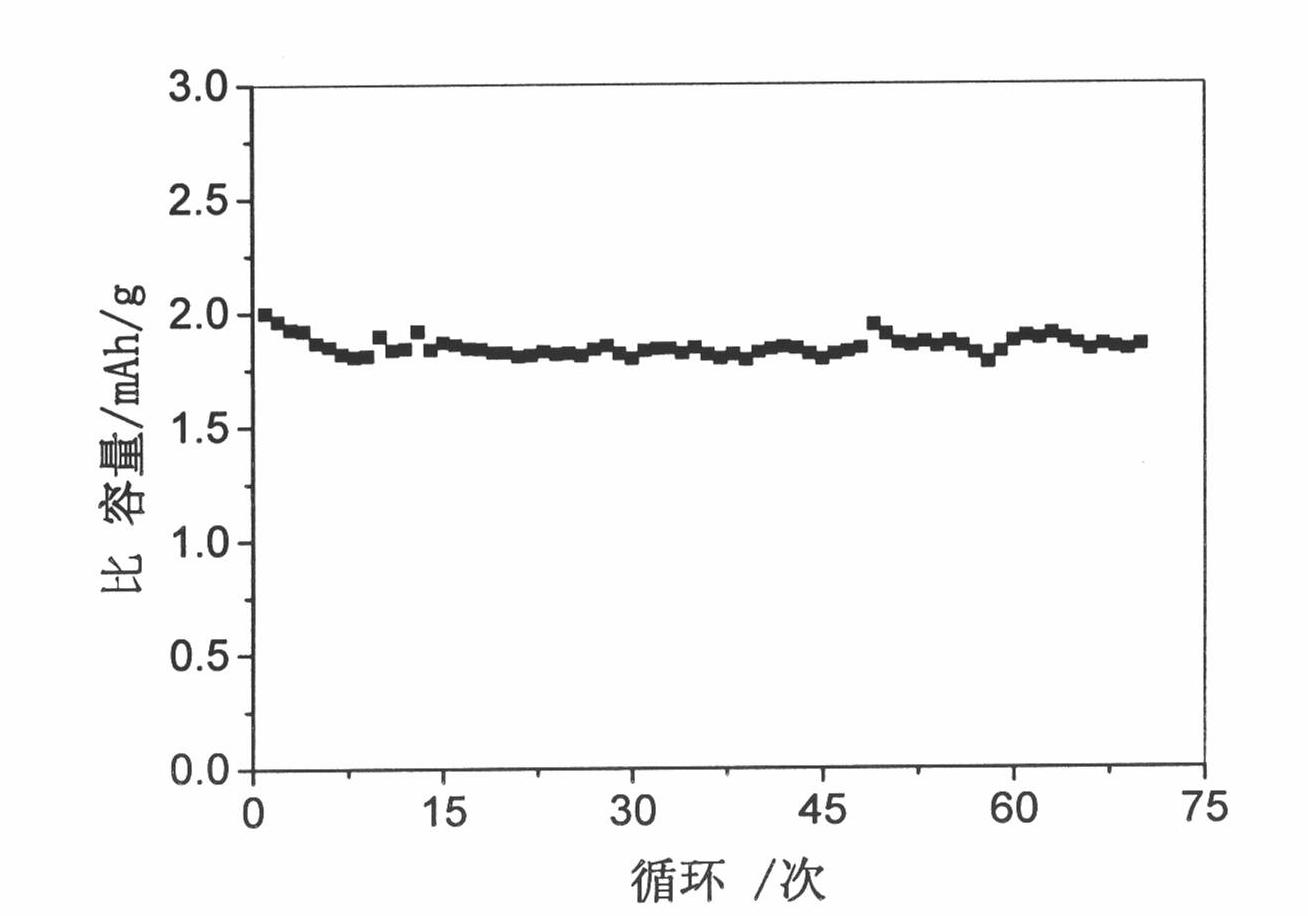

Non-aqueous solution aluminum ion secondary battery and preparation method thereof

InactiveCN104993130AGood chemical stabilityImprove thermal stabilityCell electrodesFinal product manufactureAluminum IonElectrical battery

Belonging to the technical field of batteries, the invention relates to a non-aqueous solution aluminum ion secondary battery and a preparation method thereof. The secondary battery can be widely applied in electronics, communication, electric vehicle and other fields. The aluminum ion battery provided by the invention contains a battery anode, a battery cathode, a diaphragm and an aluminum-containing non-aqueous solution electrolyte. Specifically, the cathode active material can be carbon, graphite, carbon nanotube, graphene, super carbon, WS2 and MoS2, V2O5, TiO2 and other materials having nano-layered, tubular, linear and other structures, and the anode is aluminum-containing metal or alloy. The non-aqueous solution aluminum ion secondary battery provided by the invention has the characteristics of high specific capacity, high coulomb efficiency, long service life and environmental protection, safety and reliability, stable cycle performance, and quick charging, etc.

Owner:BEIJING ALUMINUM ENERGY S&T

Light-emitting element using spirofluorene derivative and electronic appliance

ActiveUS20080206598A1Improve hole transport abilityReduce power consumptionOrganic chemistryDischarge tube luminescnet screensLight emitting deviceElectron

Owner:SEMICON ENERGY LAB CO LTD

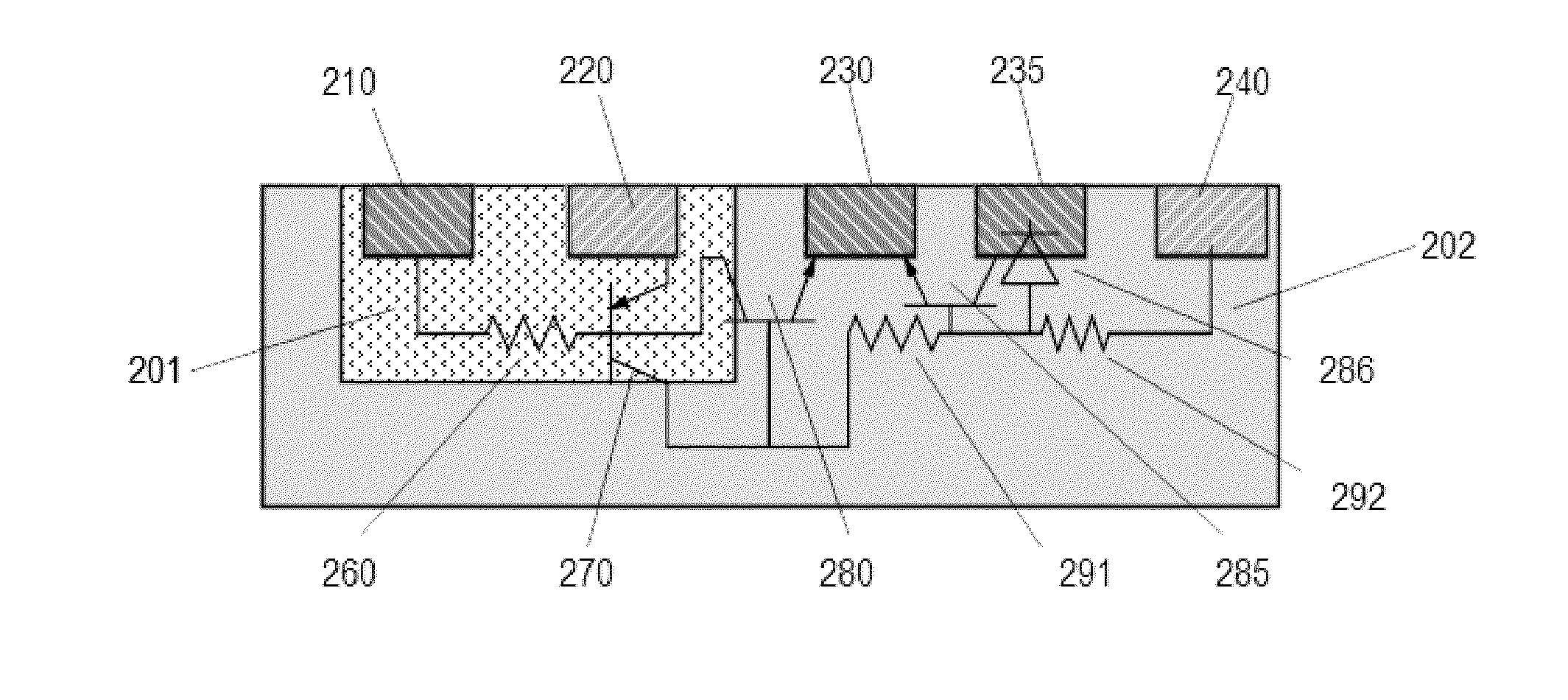

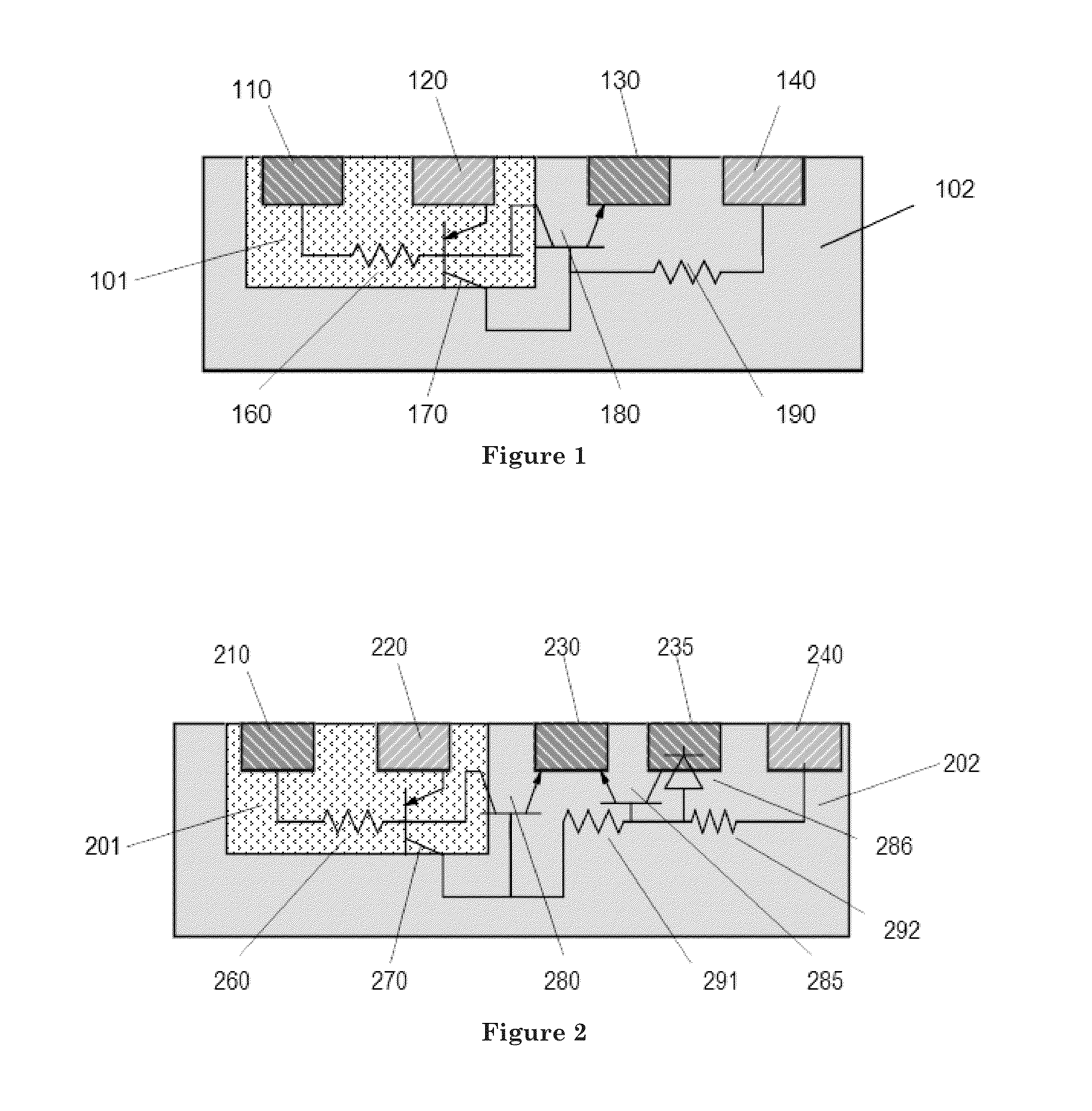

Printed active device

ActiveUS20150270089A1Reduce manufacturing costLow costAdditive manufacturing apparatusControl electrodesElement spaceElectrical connection

Owner:BRITISH TELECOMM PLC

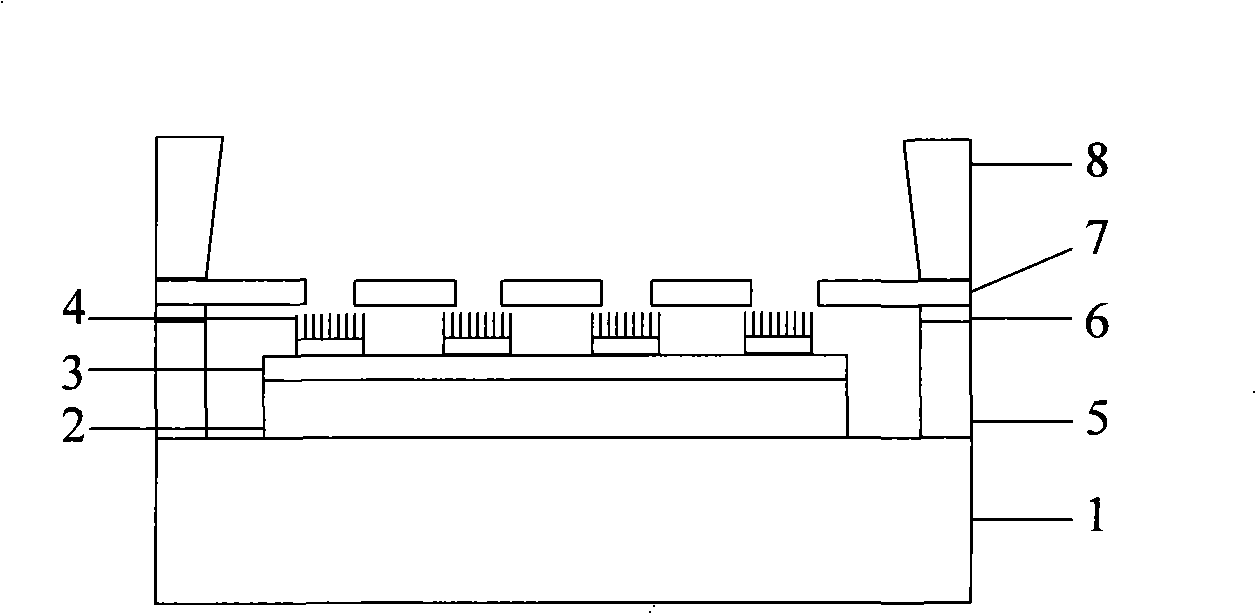

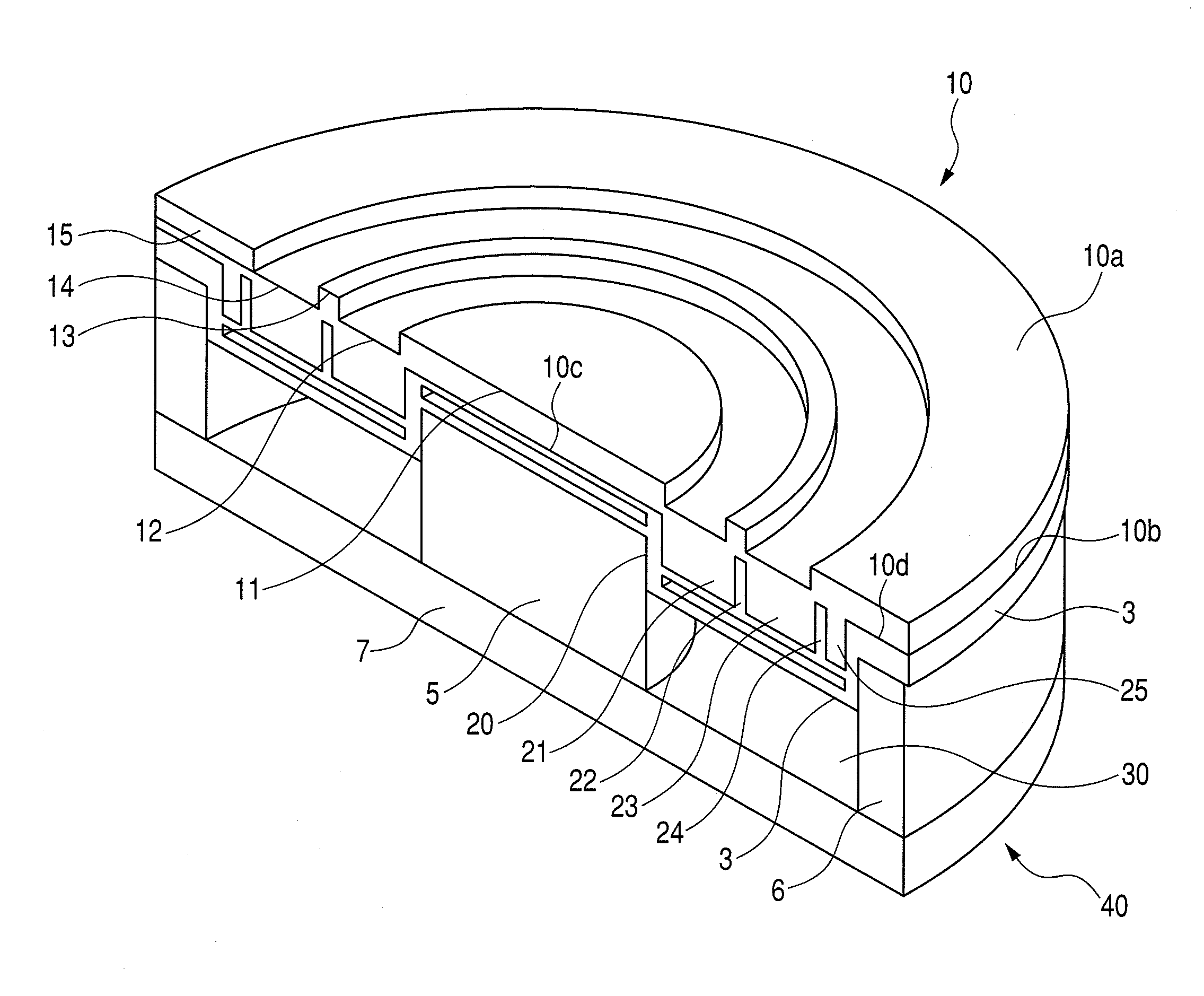

Solid-oxide-fuel-cell cathode gas flow field plate and preparation method thereof

ActiveCN104253280AEfficient use ofFully contactedFinal product manufactureCollectors/separatorsIsosceles trapezoidFuel cells

The invention discloses a solid-oxide-fuel-cell cathode gas flow field plate which is used to uniformly distribute an oxidation gas and collect cathode current. The cathode gas flow field plate is formed by multiple tooth-shaped ripple blocks which are in parallel connection and have same dimension, each tooth-shaped ripple block is formed by two tooth-shaped ripple strips (3 and 4) which are in parallel arrayed connection after being staggered at a distance (7), each tooth-shaped ripple strip (3 and 4) is formed by multiple flat-top bosses (2) and flat plates (1) which are in alternate connection, each flat-top boss (2) has a tooth-shaped contour, the flat plates (1) are connected with the root parts of the flat-top bosses (2) to form tooth-shaped ripples, and the cross section of each flat-top boss (2) has a shape same to the shape of an isosceles trapezoid without a bottom edge. The cathode gas flow field plate of a fuel cell is capable of overcoming the problems that a conventional flow field is large in gas pressure reduction and low in fuel utilization rate. By employing a roll forming technology for preparing the flow field plate, the flow field plate is simple in technology, can be precisely formed and high in product qualified rate.

Owner:HUAZHONG UNIV OF SCI & TECH

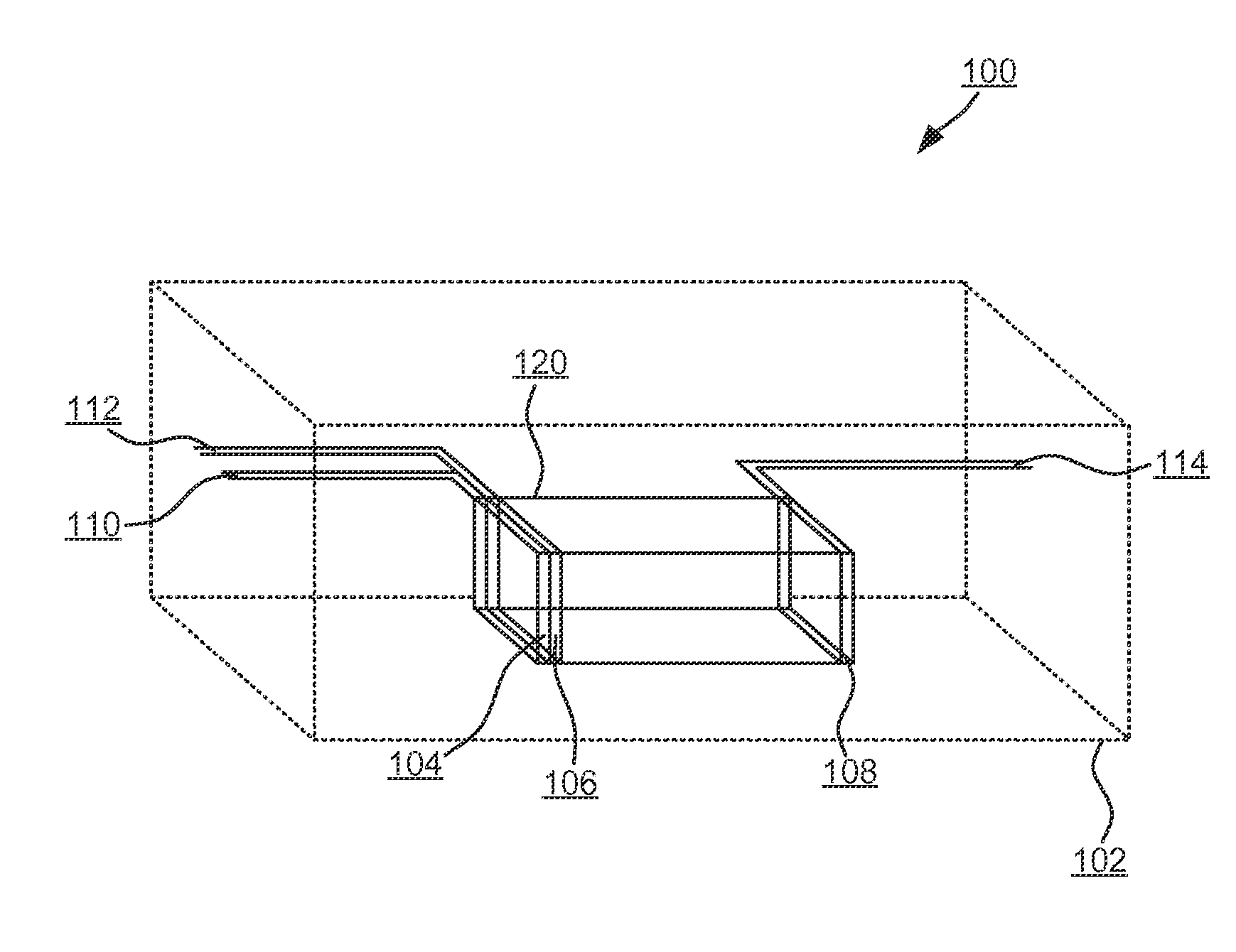

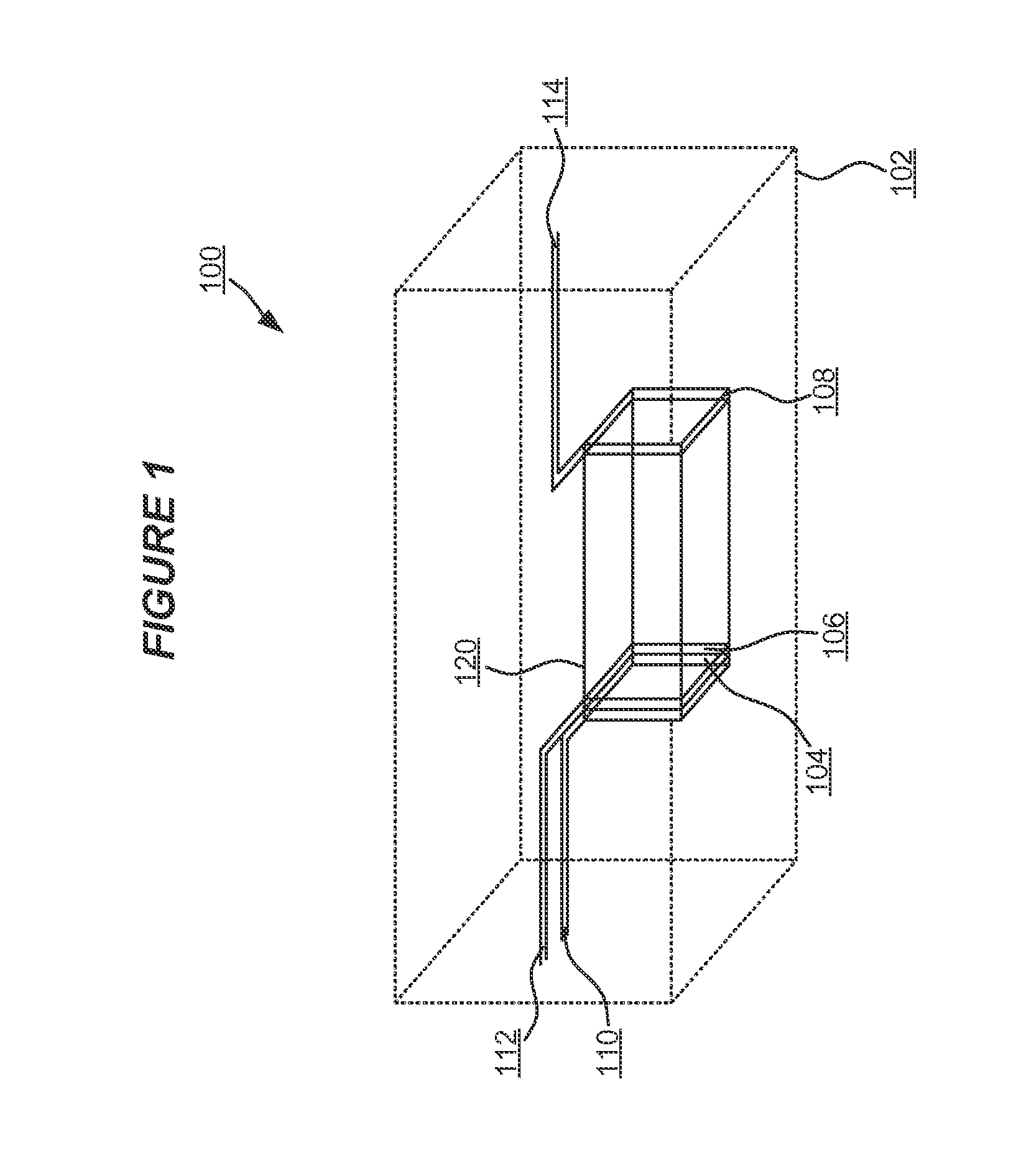

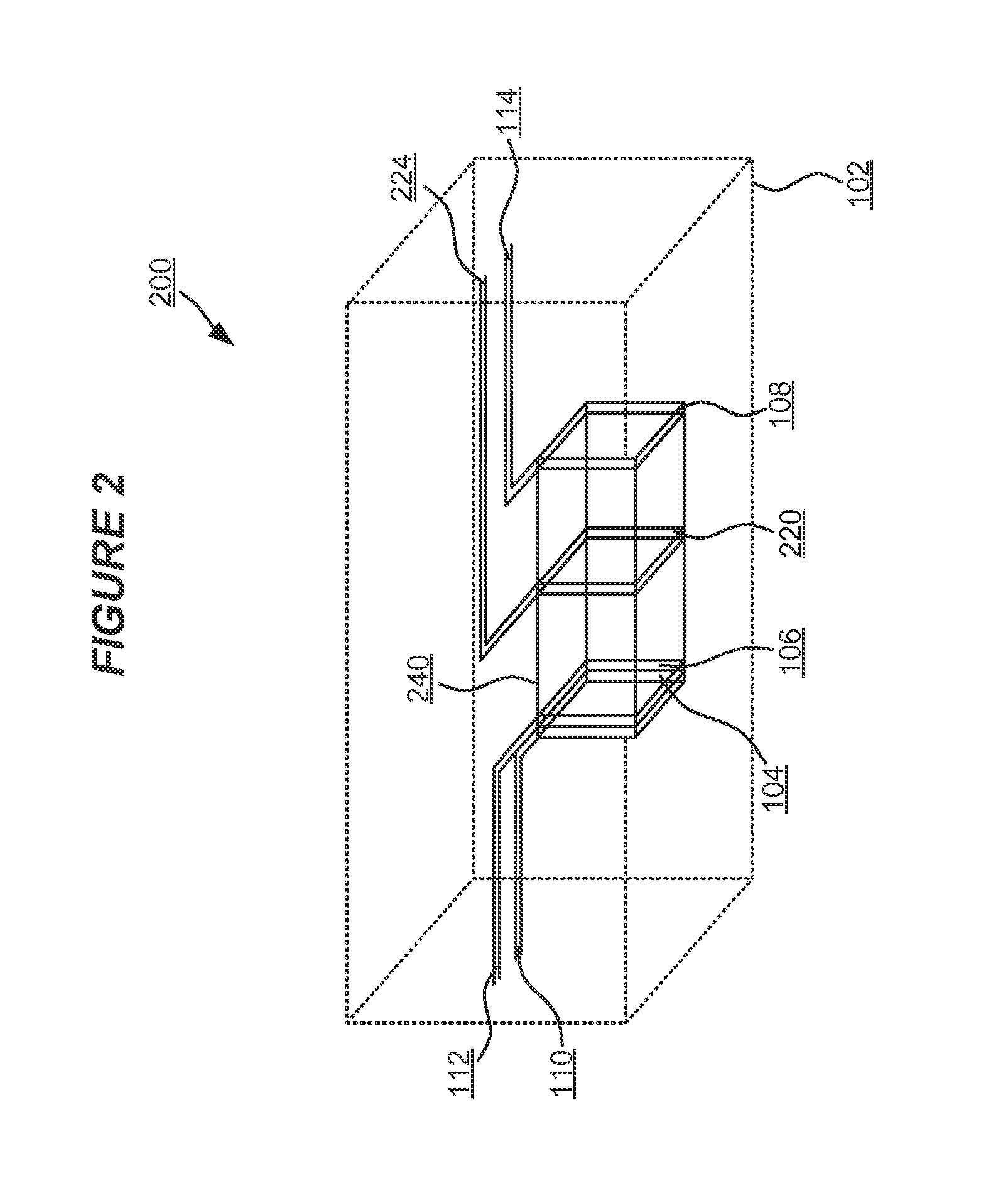

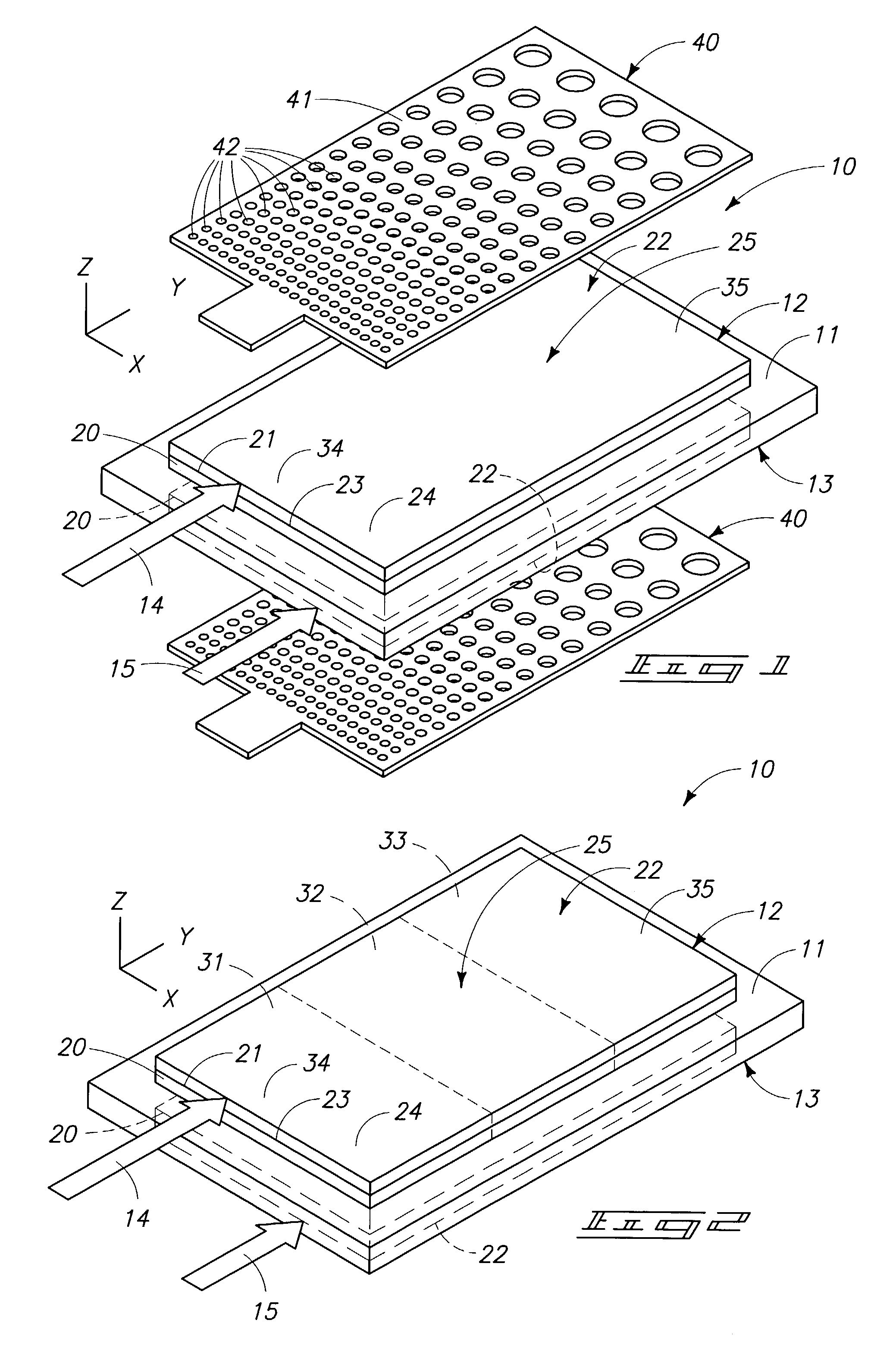

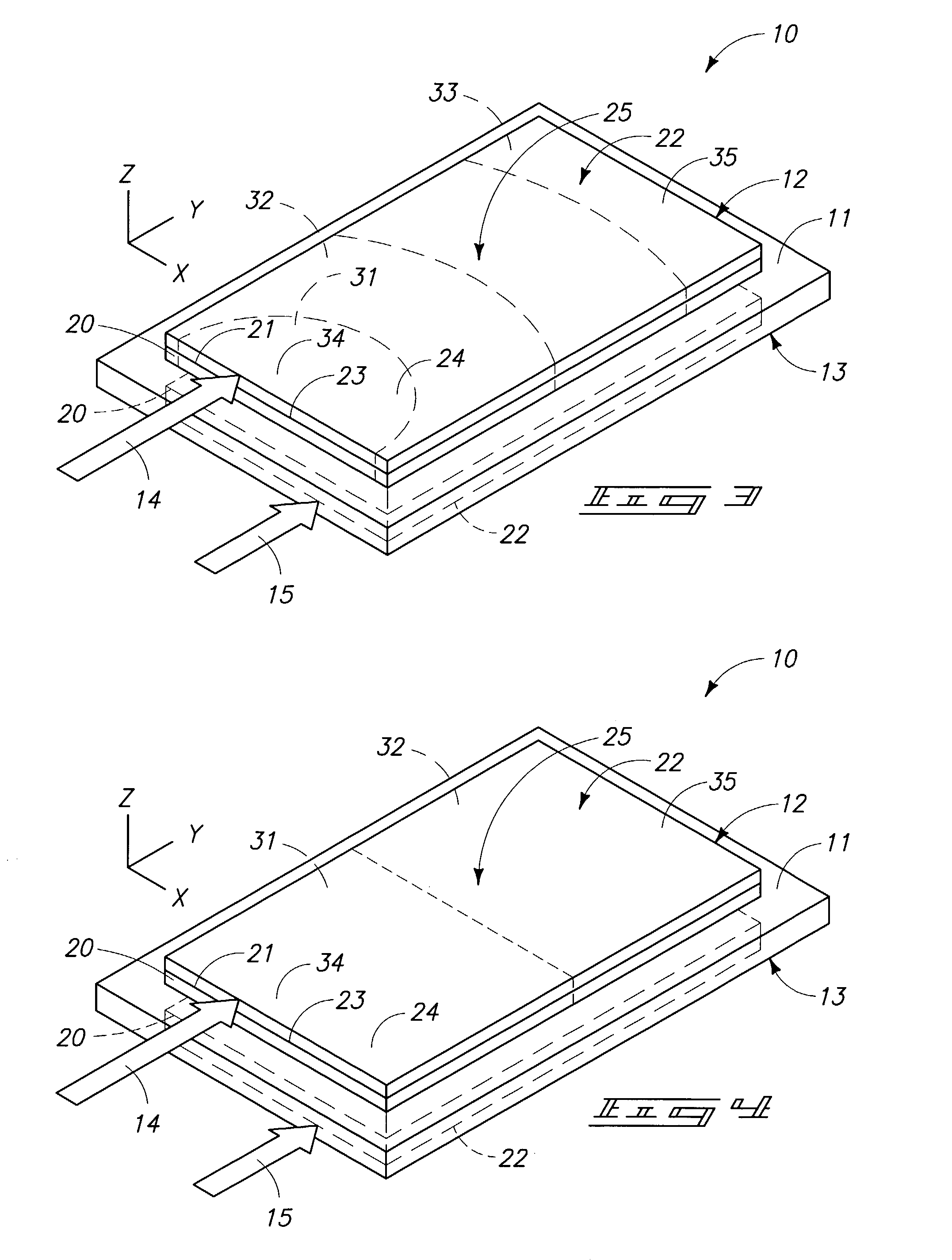

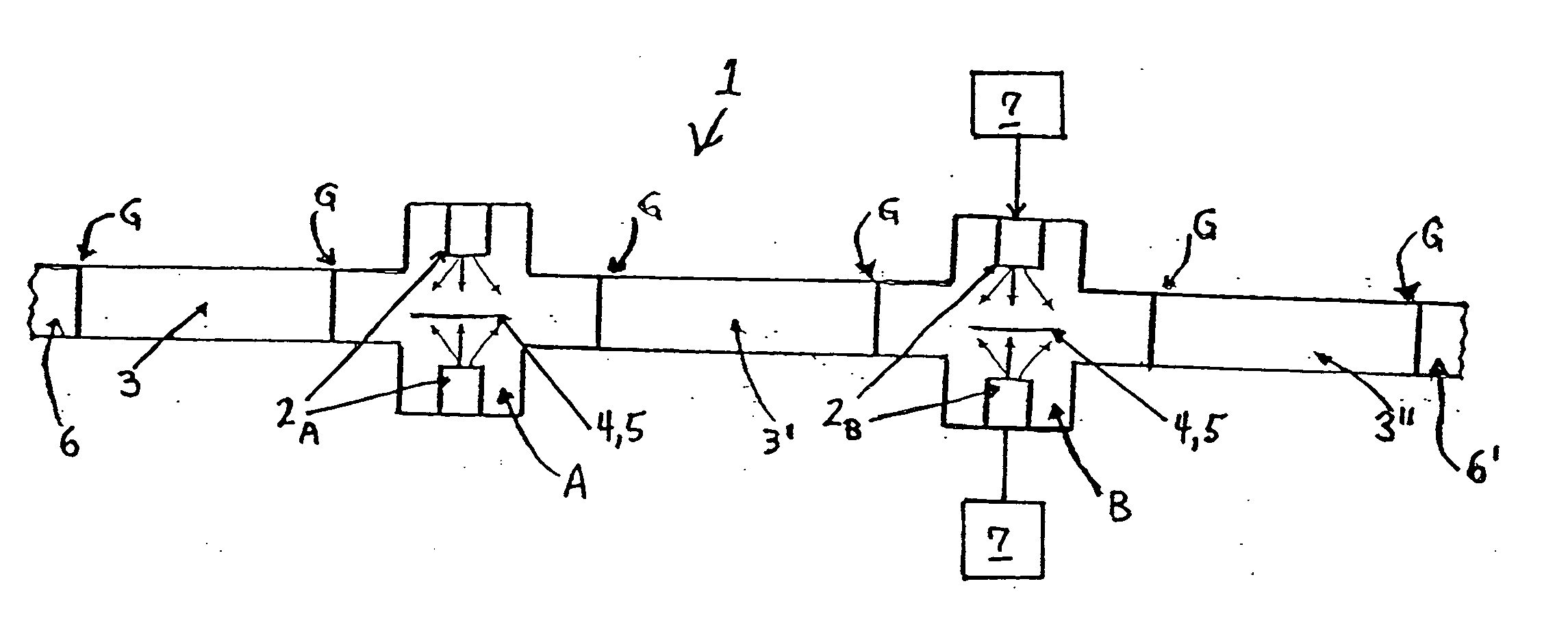

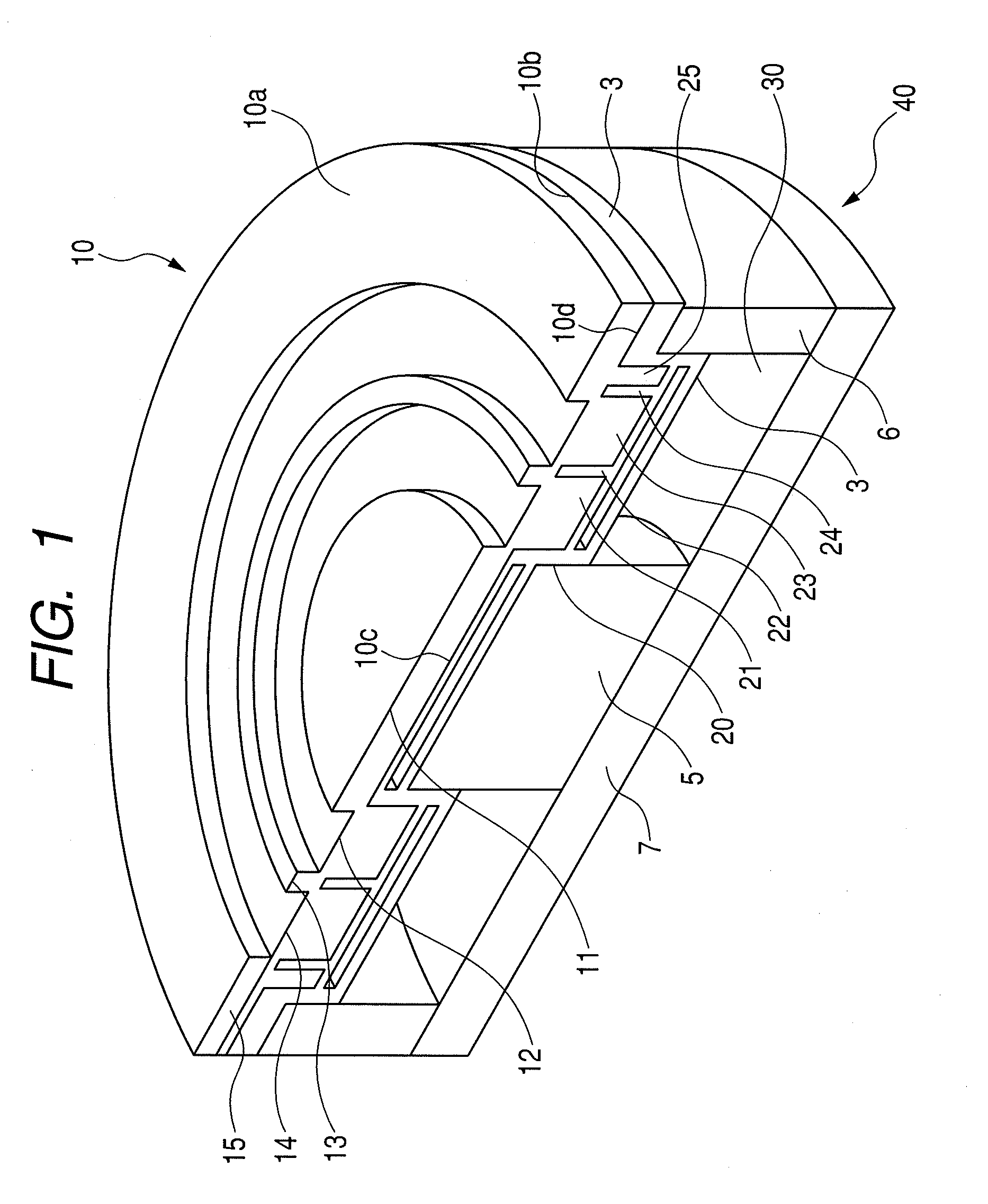

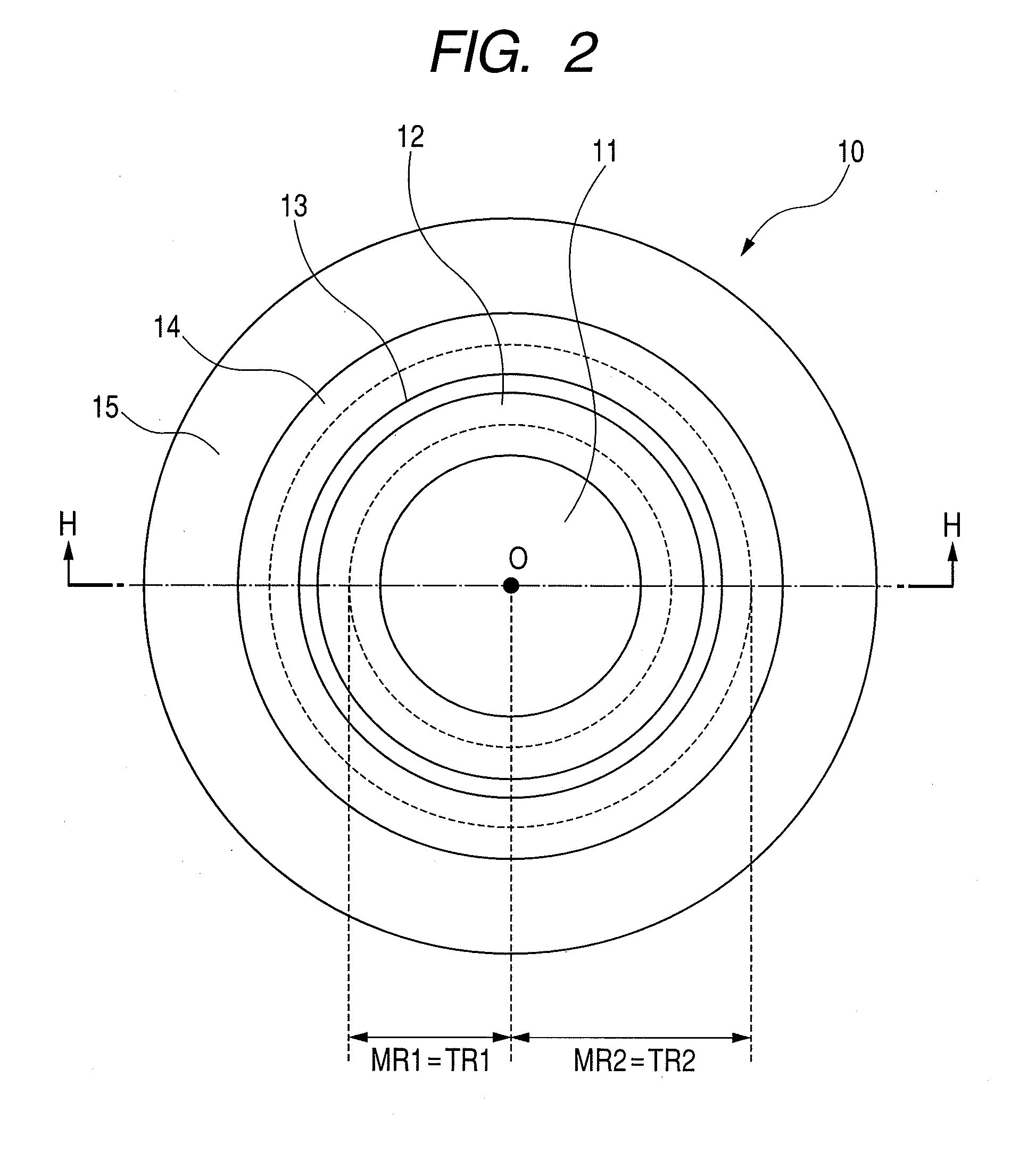

Current collector for use in a fuel cell

ActiveUS7056608B2Improve cooling effectHeat energyElectrode carriers/collectorsFuel cell auxillariesFuel cellsIon-exchange membranes

Owner:EMERGENT POWER

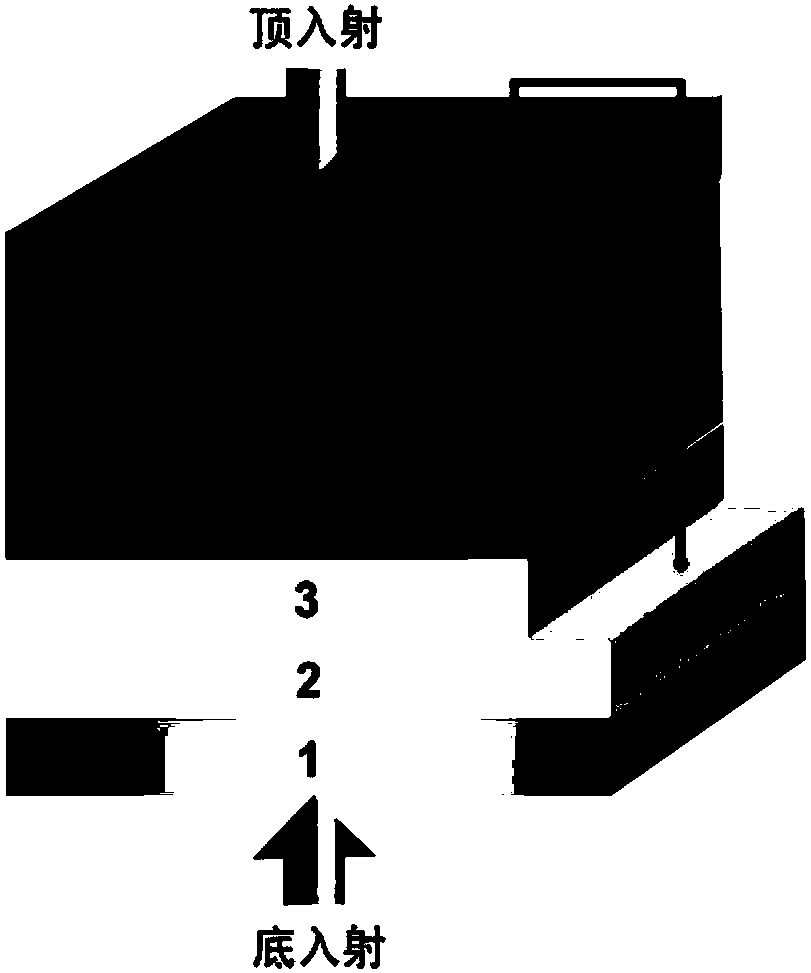

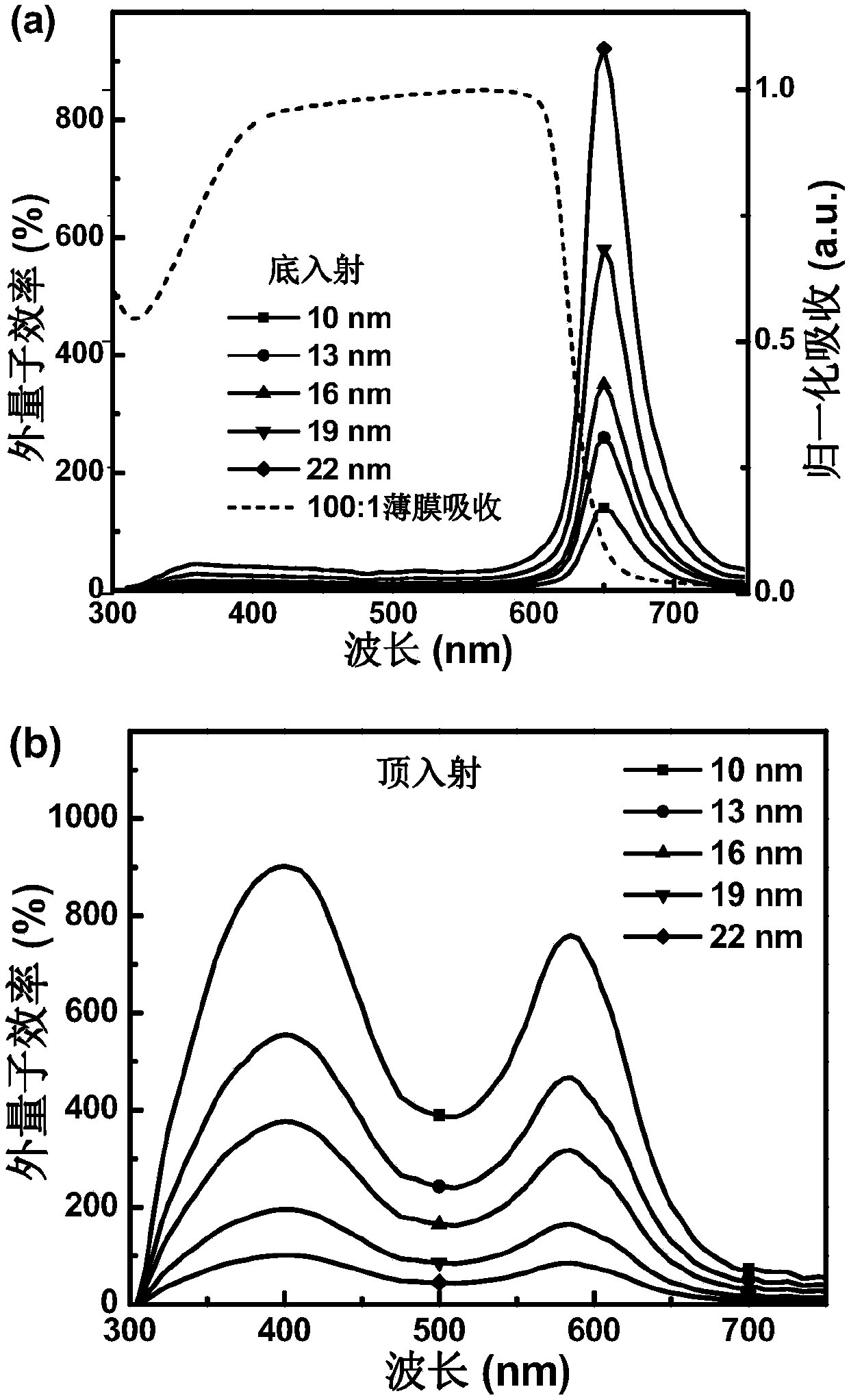

Multiplication type organic photoelectric detector with narrowband and broadband optical detection capabilities

InactiveCN107591484ASolid-state devicesSemiconductor/solid-state device manufacturingPhotovoltaic detectorsBroadband

Owner:BEIJING JIAOTONG UNIV

Double turntable light-sensitive cell liquid membrane reactor photocatalysis organic wastewater processing method

ActiveCN101353186AAchieving Bipolar OxidationReduce light lossWater/sewage treatment by irradiationWater/sewage treatment by oxidationEngineeringOxygen

Owner:SHANGHAI JIAO TONG UNIV

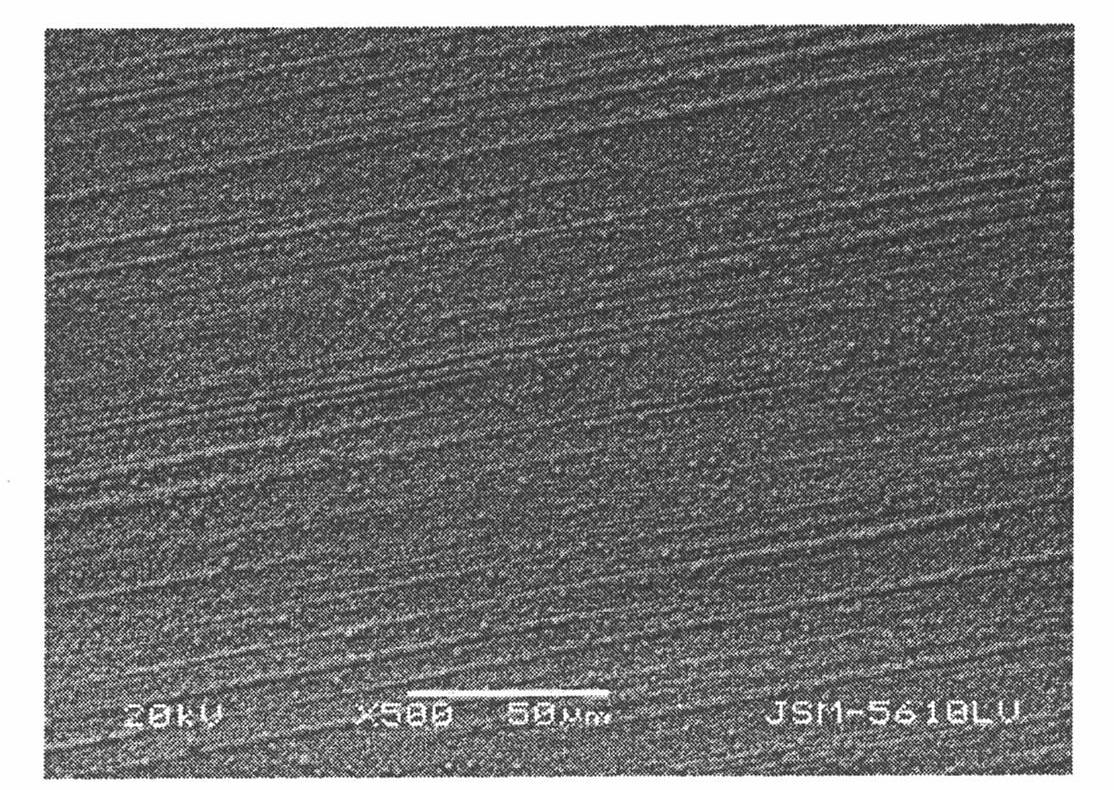

Method for preparing diamond-like composite coating on surface of piston ring

InactiveCN101665940AImprove wear resistanceImprove the lubrication effectVacuum evaporation coatingSputtering coatingLow temperature plasmaMagnetic filtration

The invention relates to a method for preparing a diamond-like composite coating with high hardness and good abrasion proof and self lubricating properties on the surface of a piston ring. In the method, a nitriding layer with high bonding strength, high hardness and good abrasion resistance is formed on the surface of the piston ring by the low-temperature plasma nitriding treatment, a non-hydrogen diamond-like surface layer with solid lubricating property is deposited by the combination of magnetic filtration cathode arc and magnetic control sputtering, and finally the nitriding / diamond-likecomposite coating, which is dense and smooth and possesses excellent abrasion proof and self-lubricating properties, is obtained on the surface of the piston ring. Compared with the durionising piston ring or CrN plating piston ring, the coating of the piston ring of the invention has higher comprehensive performance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Rapid molding method based on electrorheological fluid, and apparatus thereof

A rapid molding method based on an electrorheological fluid, and an apparatus thereof are provided. The electrorheological fluid is jetted to a deposition base station with electric field, the electrorheological fluid is rapidly cured through utilizing an electrorheological effect, and the electrorheological fluid deposits on the deposition base station layer by layer to construct a three dimensional entity; a liquid storage container, a driving pump and a nozzle are sequentially communicated through a pipeline to form an electrorheological fluid conveying path; two control lines are set by a computer, a first control line controls the flow of the driving pump, and a second control line controls the three dimension movement of the nozzle through a servo mechanism; and electrodes which comprise an anode and a cathode closely adhere to two sides of a model to be deposited on the deposition base station to provide the electric field required by the curing of the electrorheological fluid. The apparatus which utilizes the electrorheological effect of the electrorheological fluid and utilizes the electric field to replace a temperature control module and a constant temperature environment in traditional fusion jet rapid molding has the advantages of simple structure, substantial reduction of the cost and energy, and realization of micromation; and the method and the apparatus can be applied to fields of prosthesis models, industrial design, mechanical manufacturing, three dimensional scene display, entertainment and art, and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

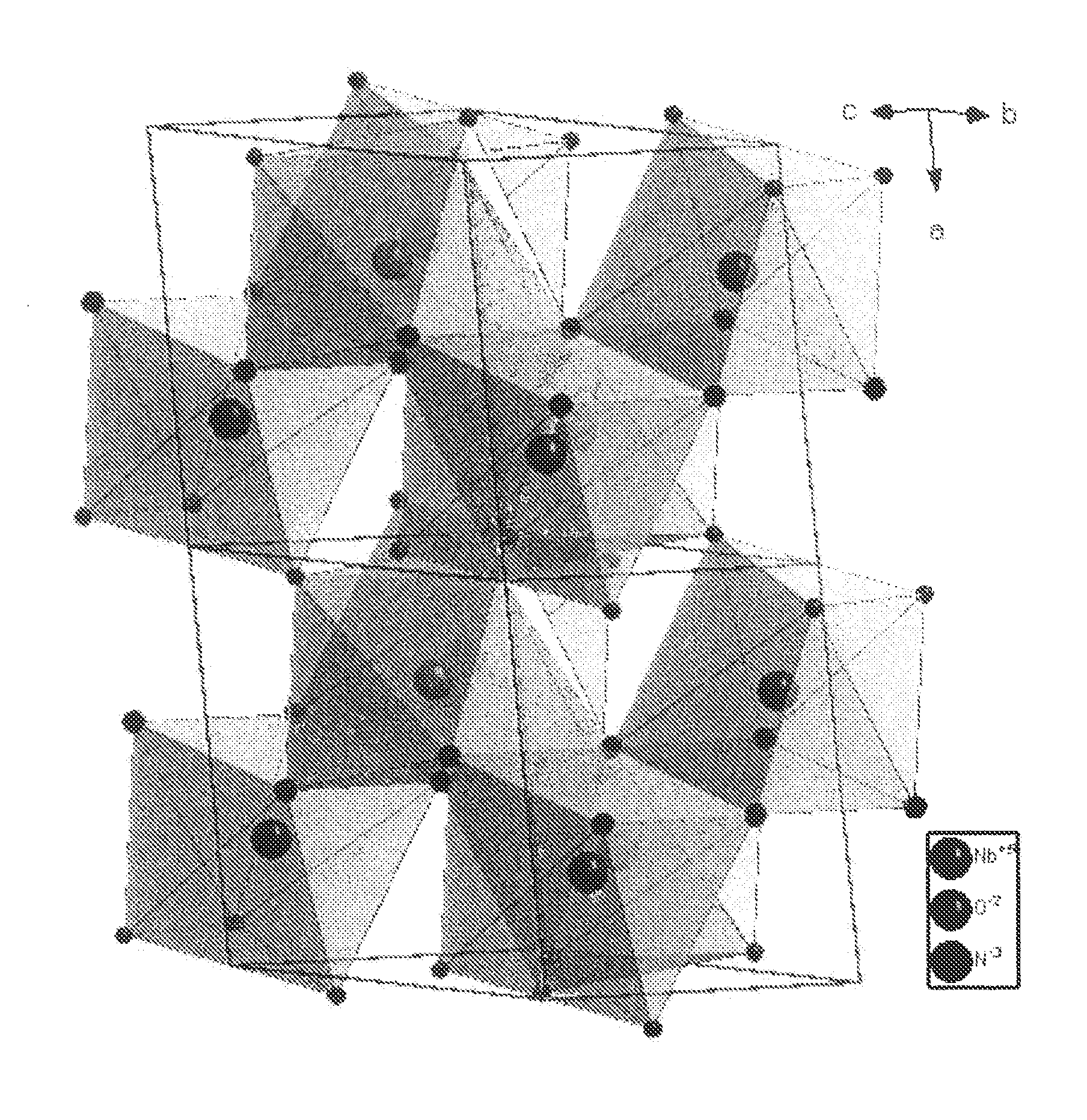

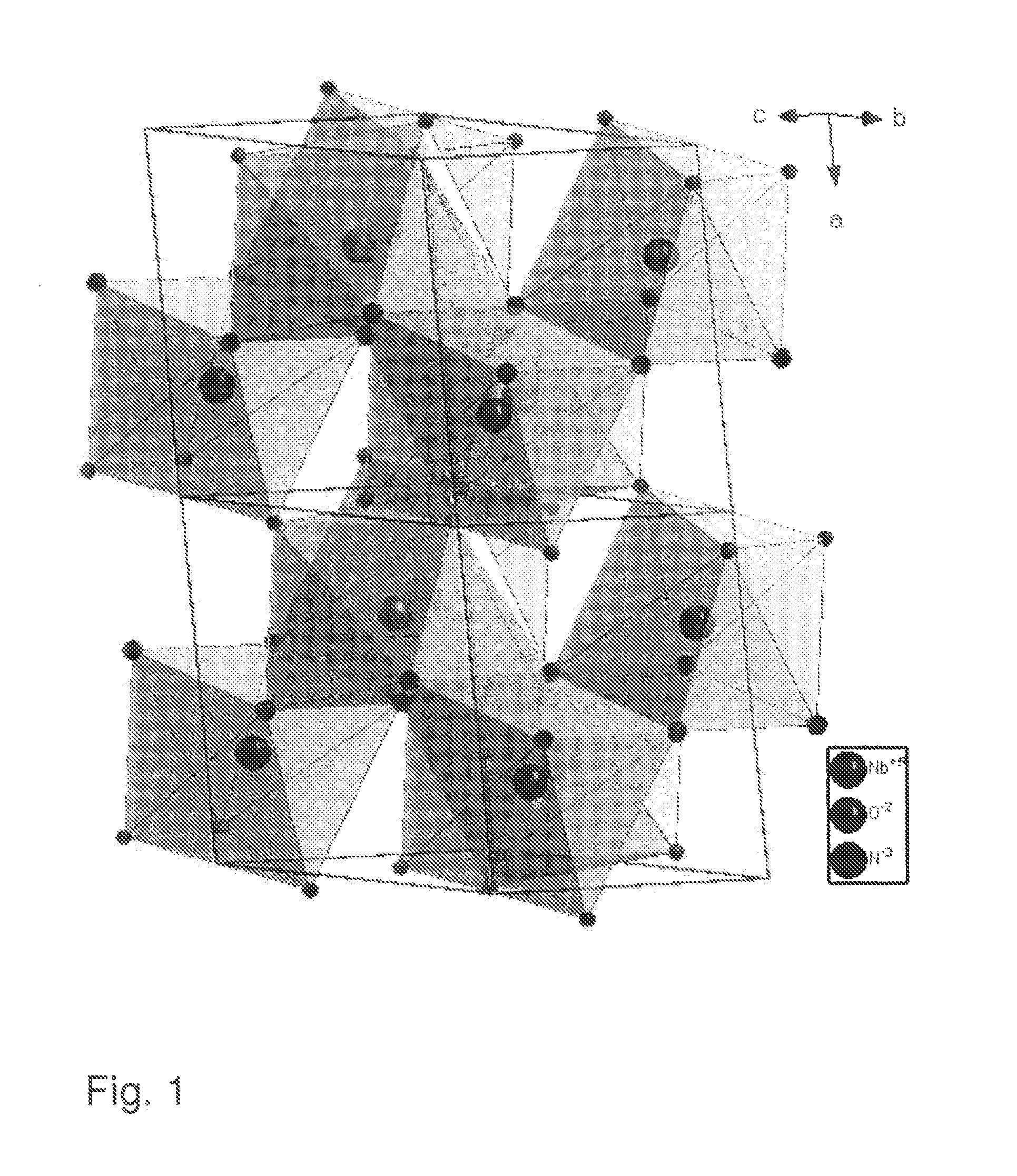

Transition metal oxidenitrides

ActiveUS20110305949A1Weight increaseImprove electrical performanceMaterial nanotechnologyNitrogen compoundsElectrical conductorNanoparticle

Owner:BELENOS CLEAN POWER HLDG

Metal and carbon nanotube or carbon fiber film emission array cathode as well as preparation method thereof

InactiveCN101355001AEasy to implementSimple processCathode ray tubes/electron beam tubesDischarge tube/lamp detailsFiberCarbon fibers

Owner:SHANGHAI JIAO TONG UNIV

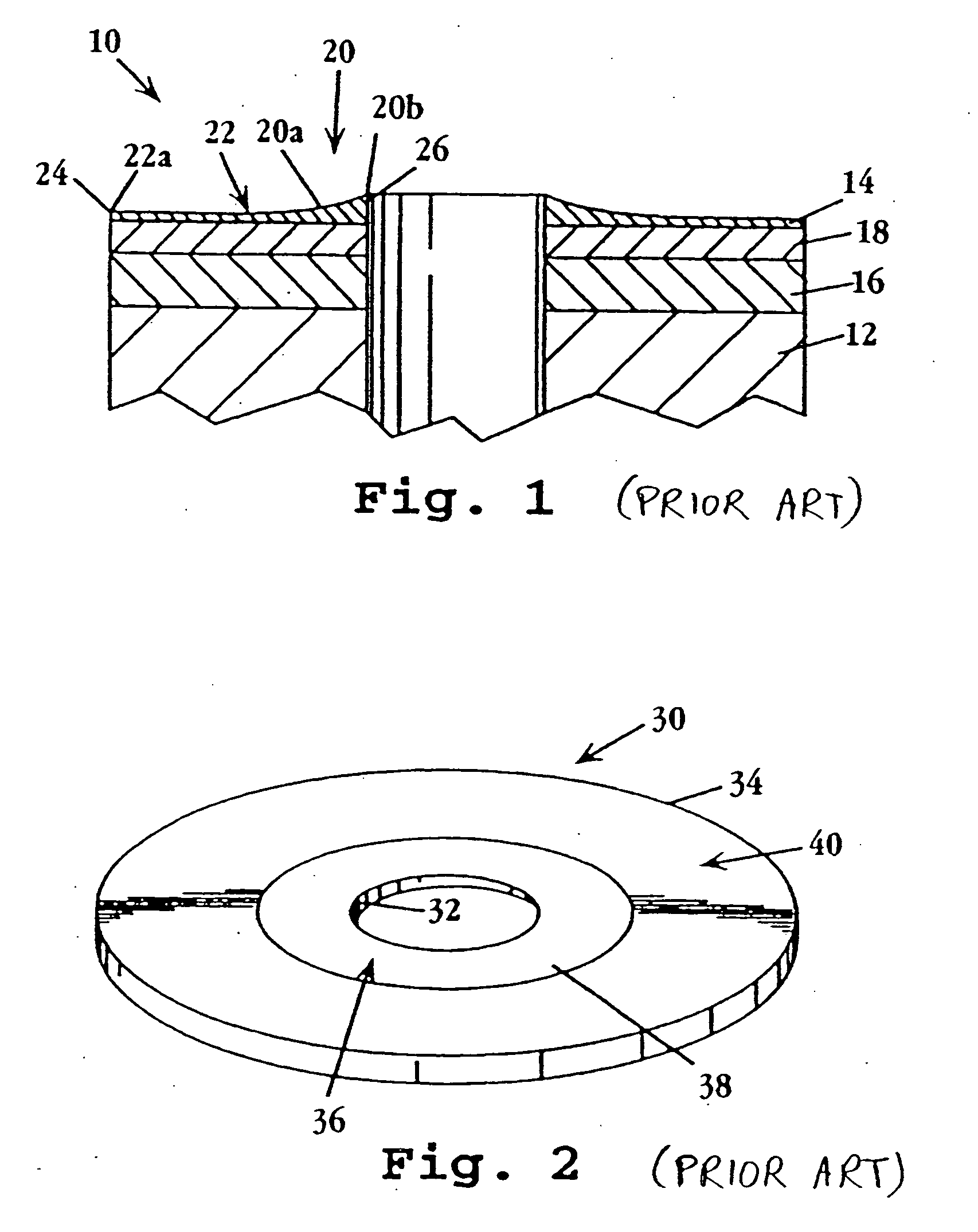

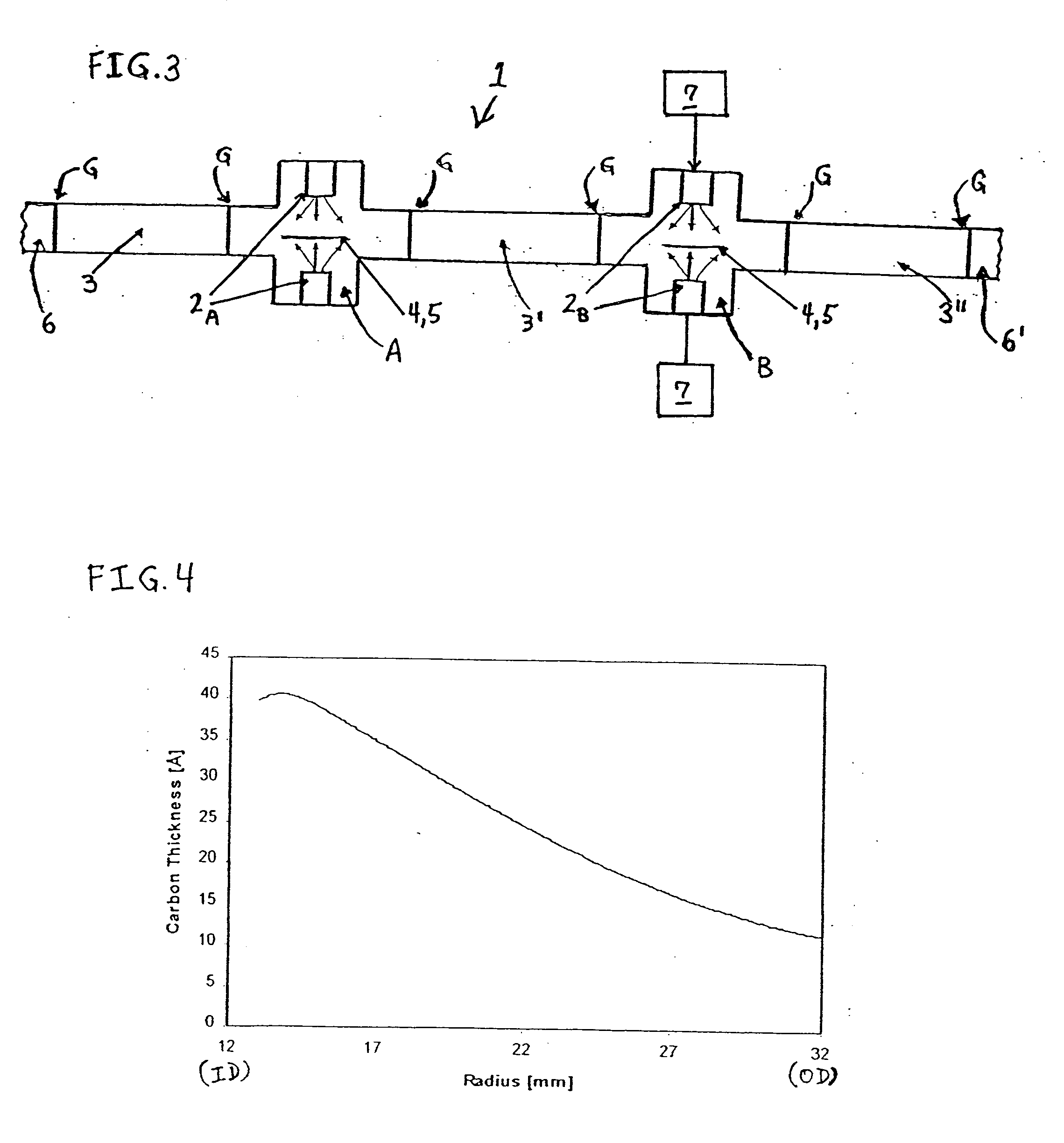

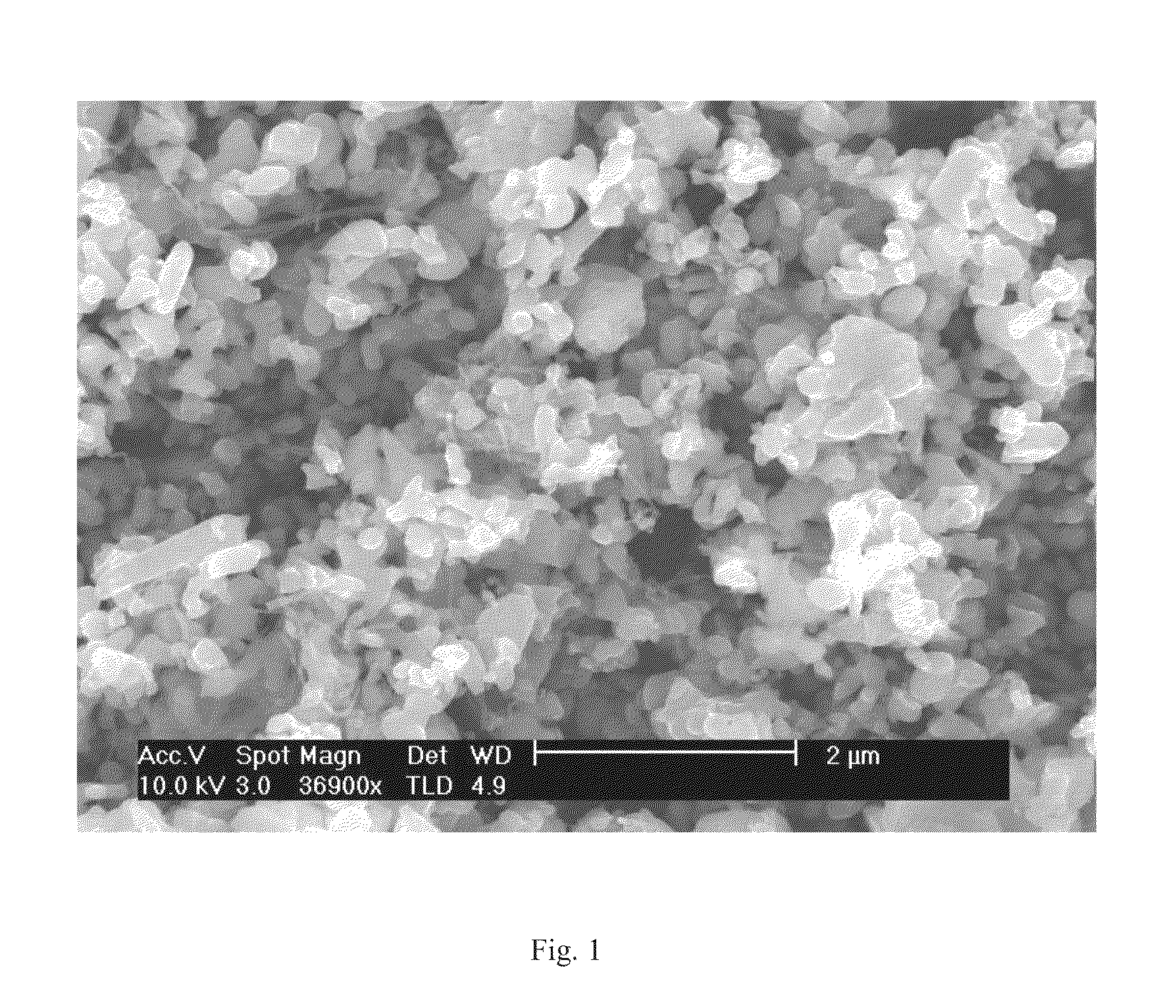

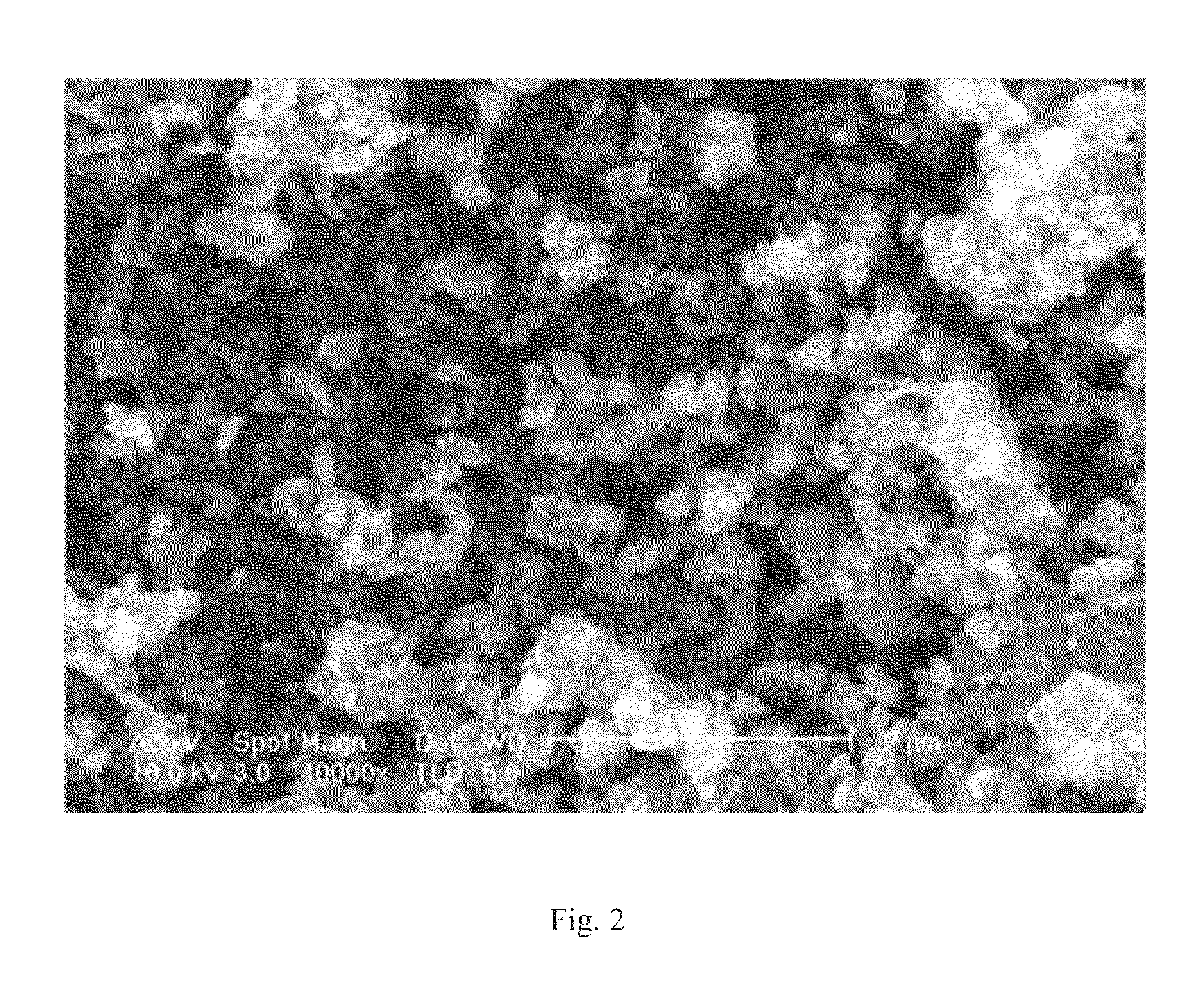

Thickness gradient protective overcoat layers by filtered cathodic arc deposition

InactiveUS20050249983A1Simple methodApparatus is enlargedCellsProtective coatings for layersCathodic arc depositionMaterials science

Owner:SEAGATE TECH LLC

Auto-thermal evaporative liquid-phase synthesis method for cathode material for battery

InactiveUS20140239235A1Simple processReduce energy consumptionNon-metal conductorsPhosphatesInternal resistanceSynthesis methods

Owner:SHENZHEN DYNANONIC

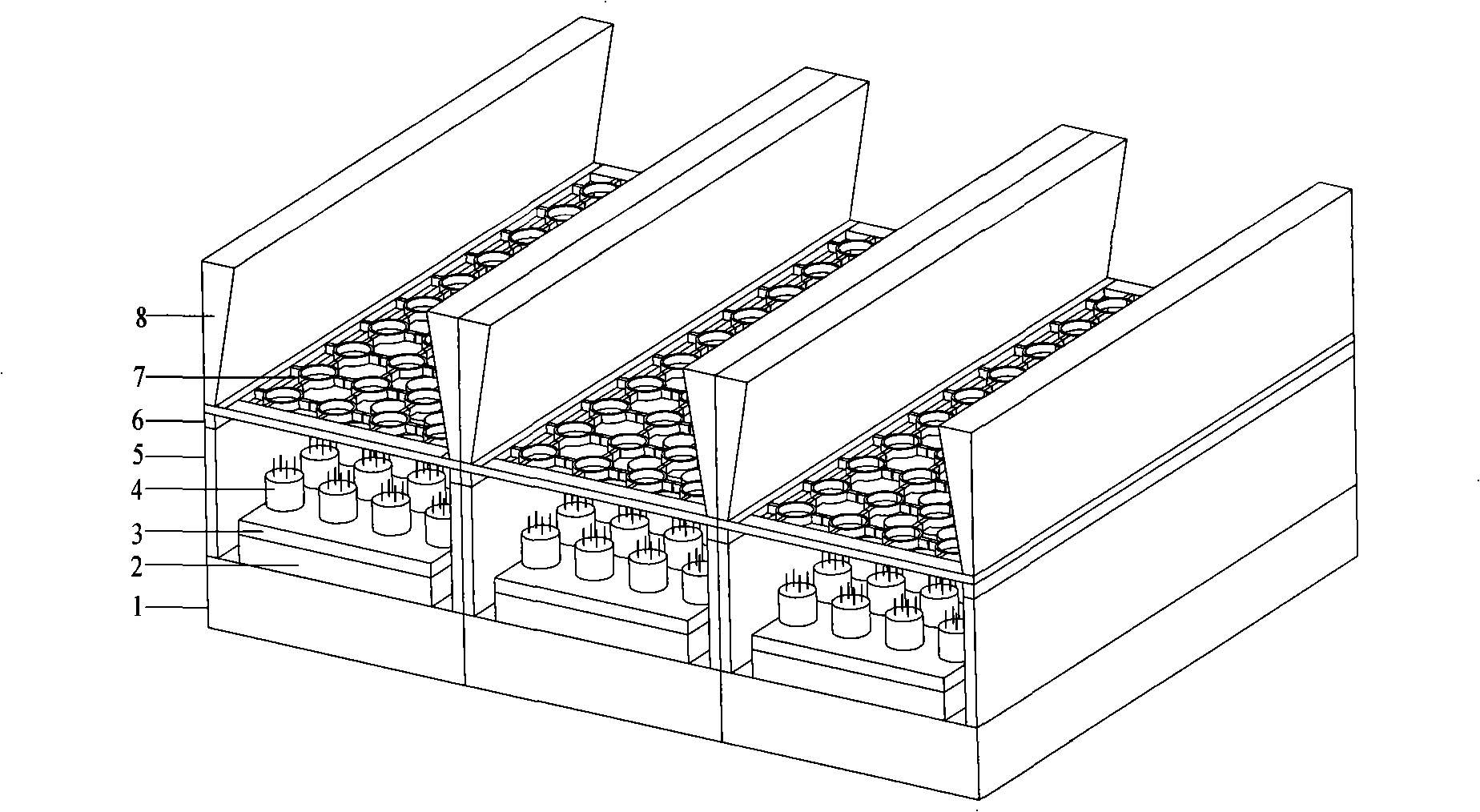

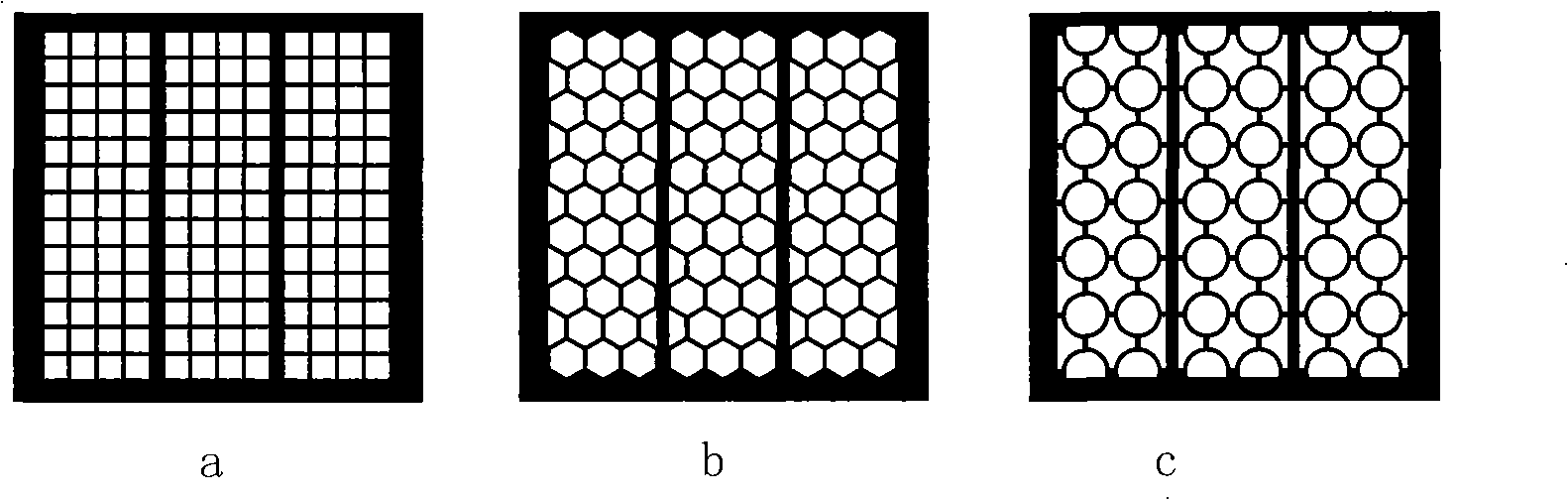

Method and device for electrolytic machining of massive array tiny pits through wedge-shaped runner

ActiveCN103600144APrevent inflowConsistent strengthMachining electrodesElectrical-based machining electrodesElectrolysisEngineering

The invention discloses a method and a device for electrolytic machining of massive array tiny pits through a wedge-shaped runner, and belongs to the technical field of electrolytic machining. The method includes processing the surface of a mask plate to enable the surface to fit with the surface of a workpiece anode; fixing a wedge-shaped tool cathode above the mask plate to enable the wedge-shaped runner to be formed between the wedge-shaped tool cathode and the mask plate; connecting the workpiece anode and the wedge-shaped tool cathode with an anode and a cathode of a power source respectively; feeding an electrolyte into the wedge-shaped runner, wherein the electrolyte reaches the surface of the workpiece anode through penetrating group holes in the mask plate; switching on the power source for electrolytic machining. The runner is arranged to be wedge-shaped, so that electric field intensity and electrolyte flowing speed are enabled to be progressively increased along the direction of the runner, both corrosion strength and speed of a workpiece are enabled to tend to be uniform, and uniformity and machining accuracy of electrolytic machining are improved. A PDMS (polydimethylsiloxane) template is taken as the mask plate, bonding strength of the mask plate and the workpiece anode can be guaranteed, stray corrosion, of the electrolyte, to places around a machining area can be effectively reduced, and locality and uniformity of electrolytic machining can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

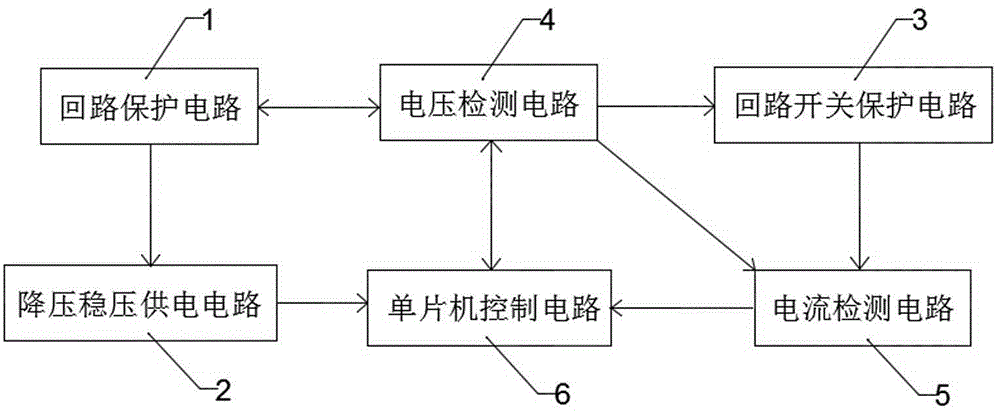

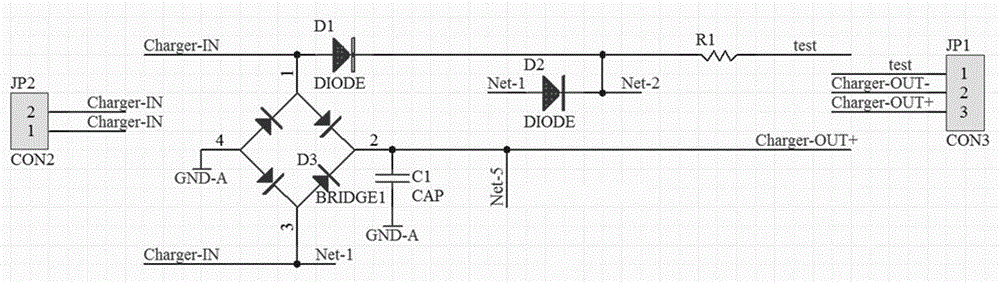

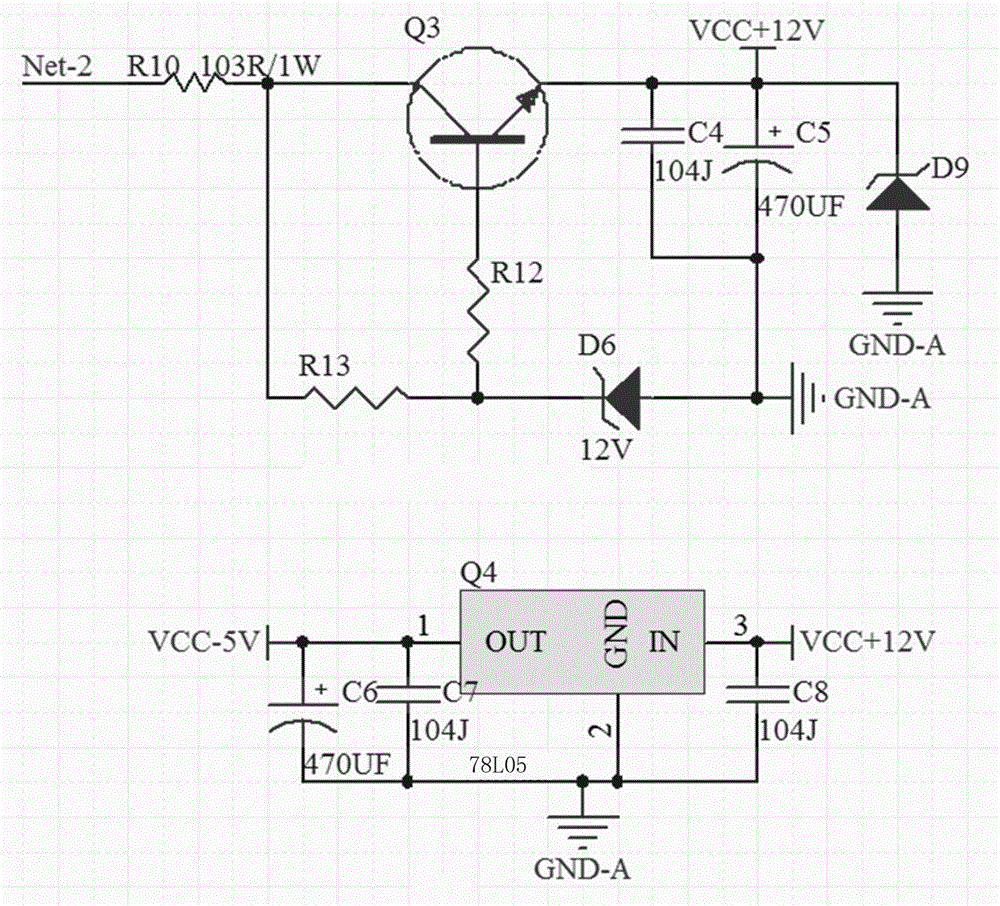

Safe power supply circuit

InactiveCN104979881AServe as a safety protection functionPlay a protective functionBatteries circuit arrangementsCurrent/voltage measurementOvervoltageElectric cars

Owner:ANHUI ZHENGMIN VEHICLE IND

Magnetron sputtering cathode, magnetron sputtering apparatus, and method of manufacturing magnetic device

Owner:CANON ANELVA CORP

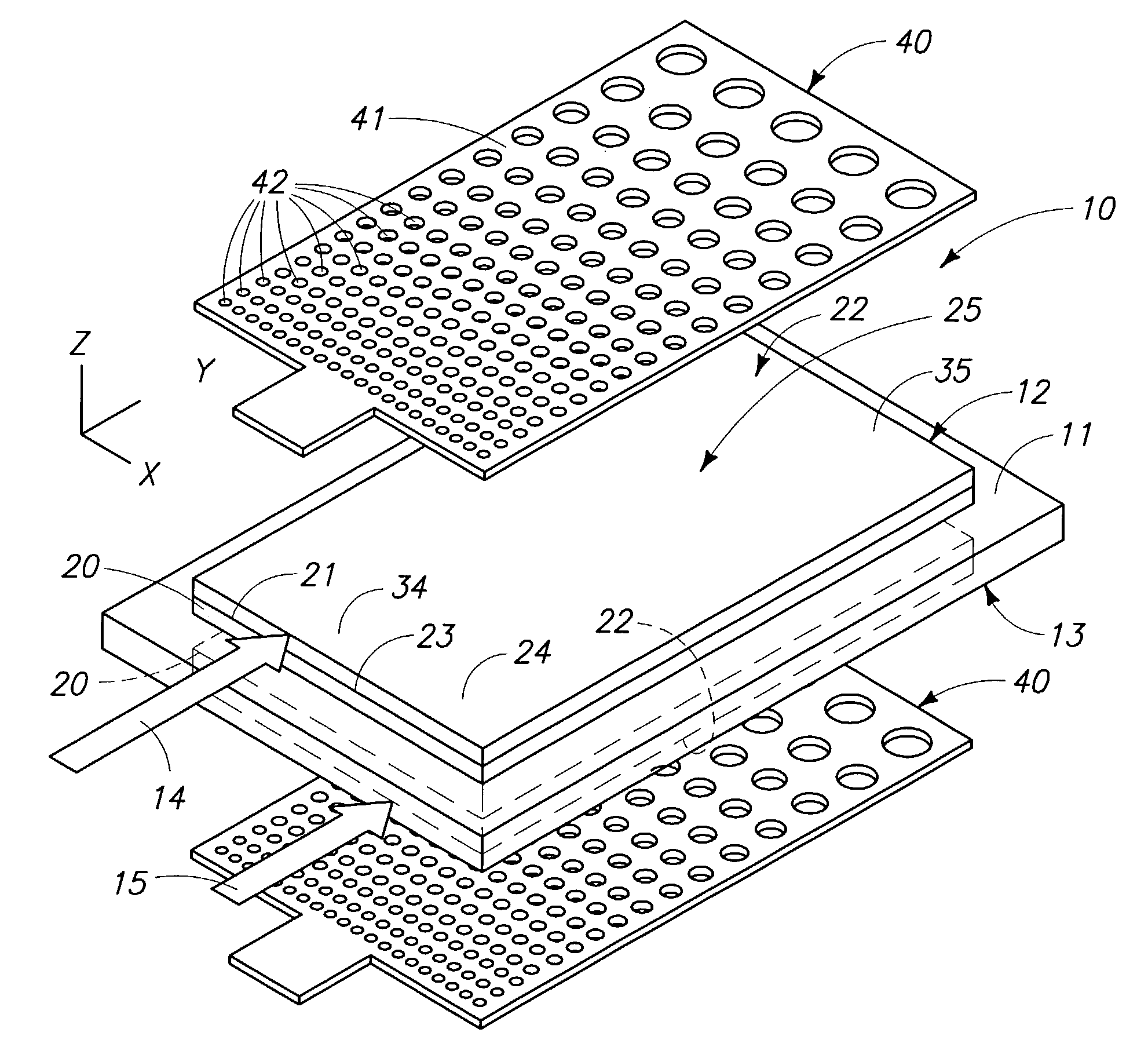

Direct oxidation fuel cells with improved cathode gas diffusion media for low air stoichiometry operation

InactiveUS20080176112A1Promote oxidationSimple methodNanotechFuel cell auxillariesFuel cellsEngineering

A cathode for use in a direct oxidation fuel cell (DOFC) comprises a gas diffusion medium (GDM) including a backing layer and a microporous layer comprising a fluoropolymer and an electrically conductive material, wherein loading of the fluoropolymer in the microporous layer is in the range from about 10 to about 60 wt. %. In use, a concentrated solution of a liquid fuel is supplied to an anode and an oxidant to the cathode of the fuel cell, and the fuel cell may be operated at a low oxidant stoichiometry ξc not greater than about 2.5.

Owner:PANASONIC CORP +1

Preparation method of paper-graphite-CoPd thin film electrode

InactiveCN103904337AImprove electroreduction performanceSolve the problem of poor cathode activityCell electrodesElectricityThin film electrode

Owner:HARBIN ENG UNIV

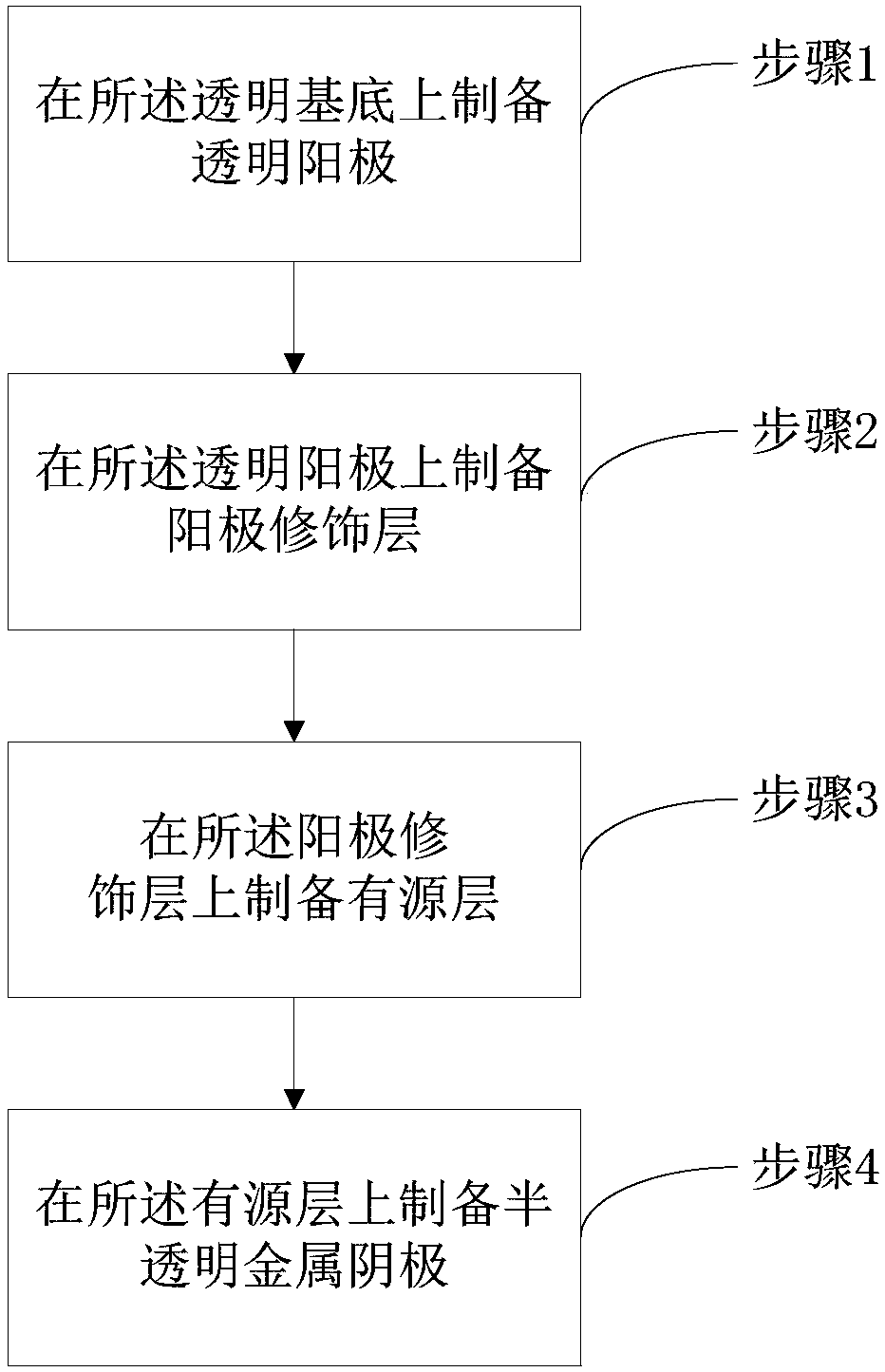

Naphthalimide-selenophene-based organic n-type semiconductor polymer material, preparation method and application thereof

ActiveCN108864415AImprove mobilityImprove thermal stabilitySolid-state devicesSemiconductor/solid-state device manufacturingElectronChemistry

The invention discloses a naphthalimide-selenophene-based organic n-type semiconductor polymer material, a preparation method and application thereof, in particular to an n-type organic conjugated polymer semiconductor material based on long-chain naphthalimide as an electron pulling unit and selenophene and biselenophene and terselenophene as derivatives as an electron feeding unit and a preparation method thereof, and application of the polymer as a cathode interface modification layer material in a perovskite solar cell. The naphthalimide and selenophene derivative based n-type conjugated polymer semiconductor disclosed by the invention has the advantages of solution processing, high electron mobility, excellent thermal stability, appropriate energy level and the like, and is an ideal perovskite solar cell cathode interface modification material.

Owner:NANJING UNIV OF POSTS & TELECOMM

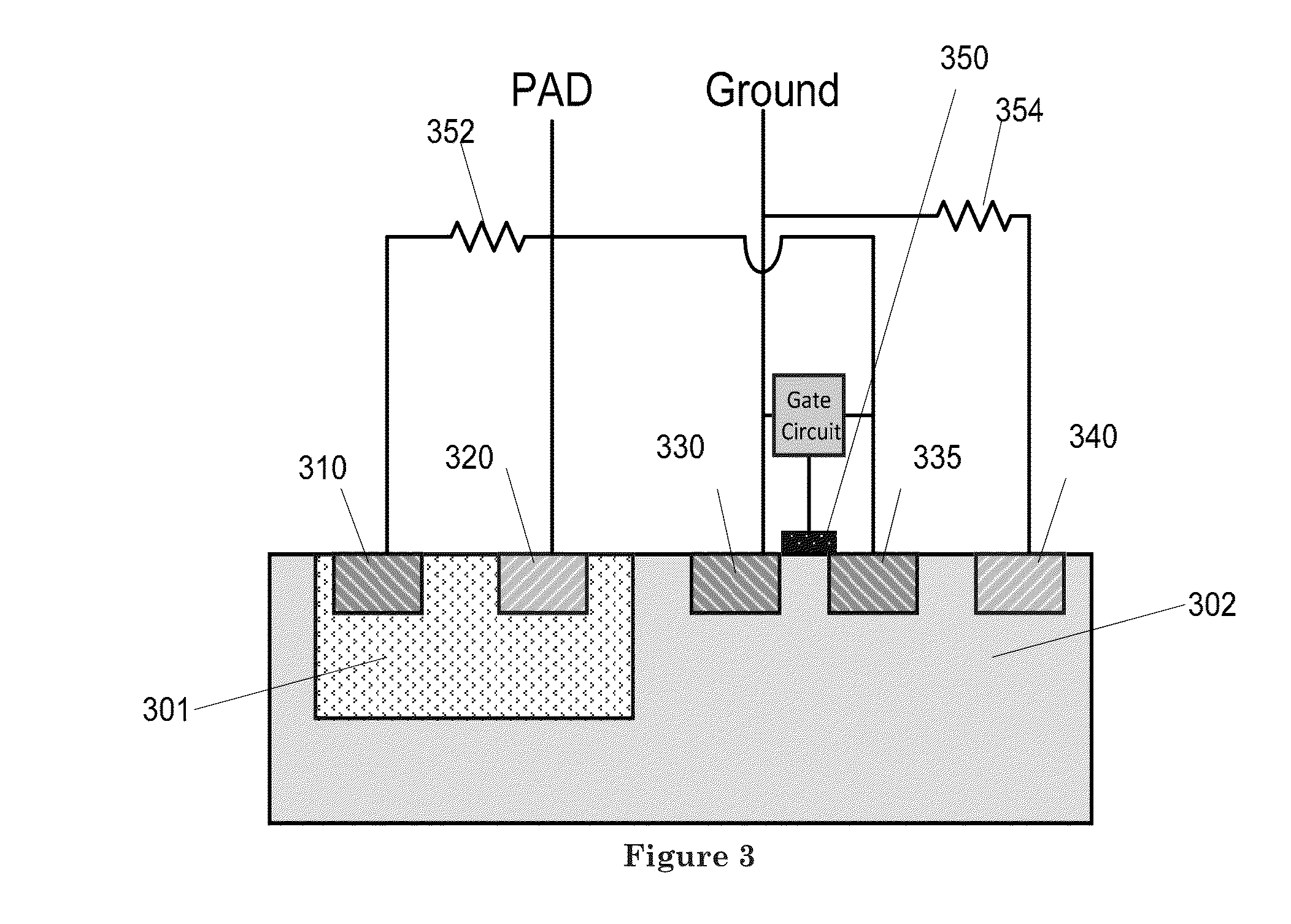

Semiconductor device for electrostatic discharge protection

ActiveUS20150091056A1Speed up triggeringSpeedTransistorSolid-state devicesPower semiconductor deviceDevice material

Owner:SOFICS BVBA

Method of producing corundum layer on metal parts

InactiveUS20060207884A1Shorten molding timeImprove the immunityAnodisationSurface layerGradual increase

Owner:SHPAKOVSKY VOLODYMYR +2

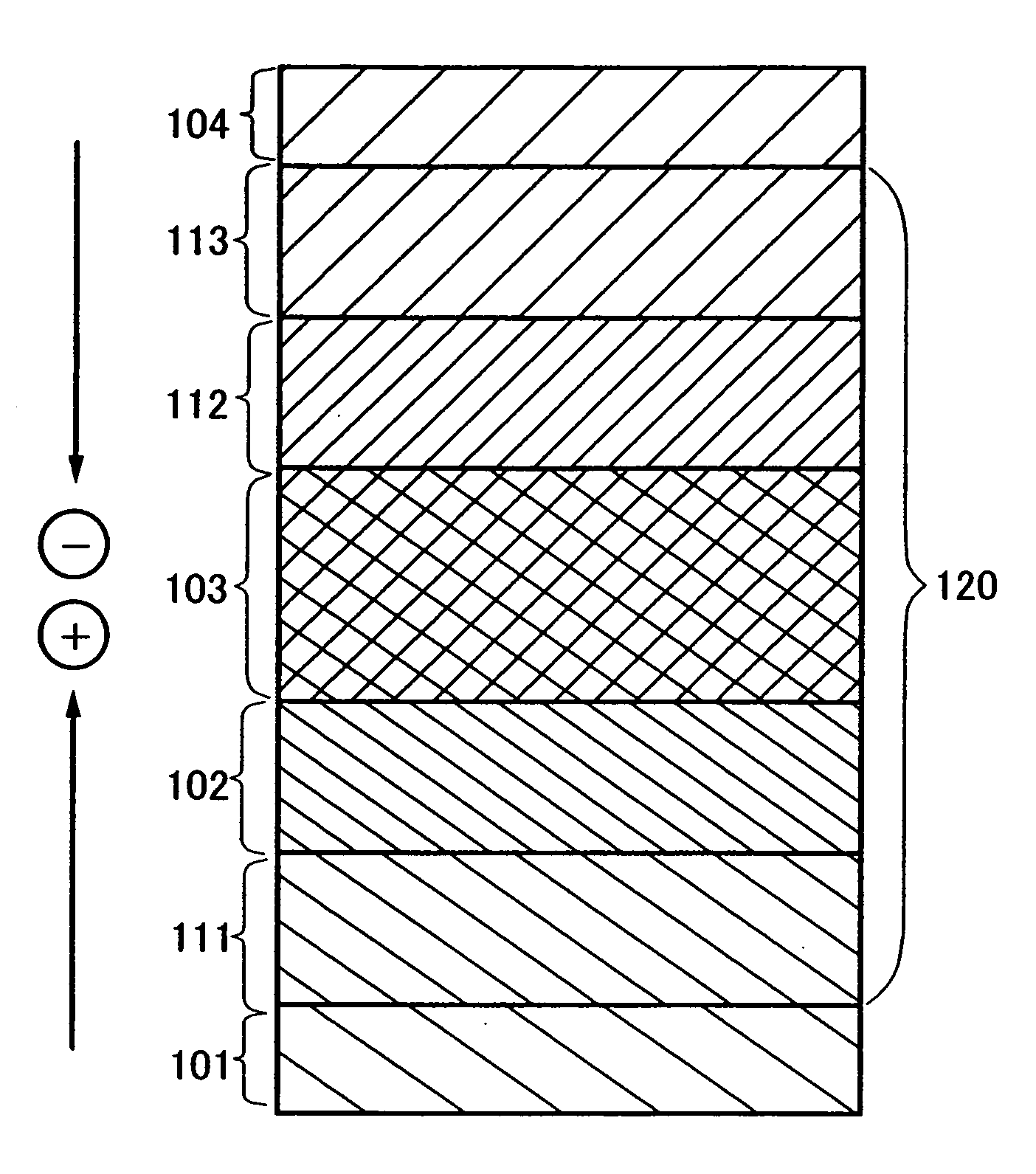

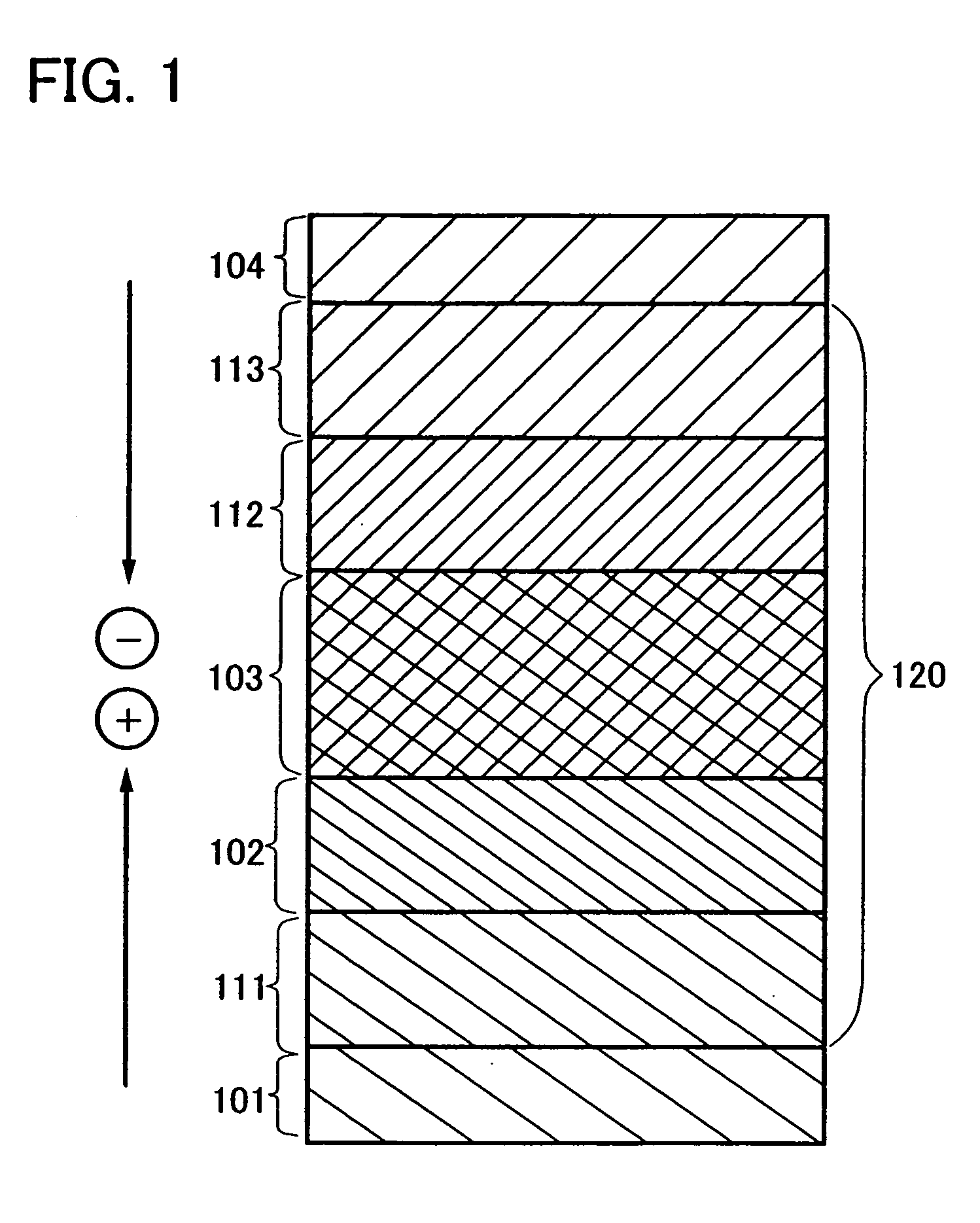

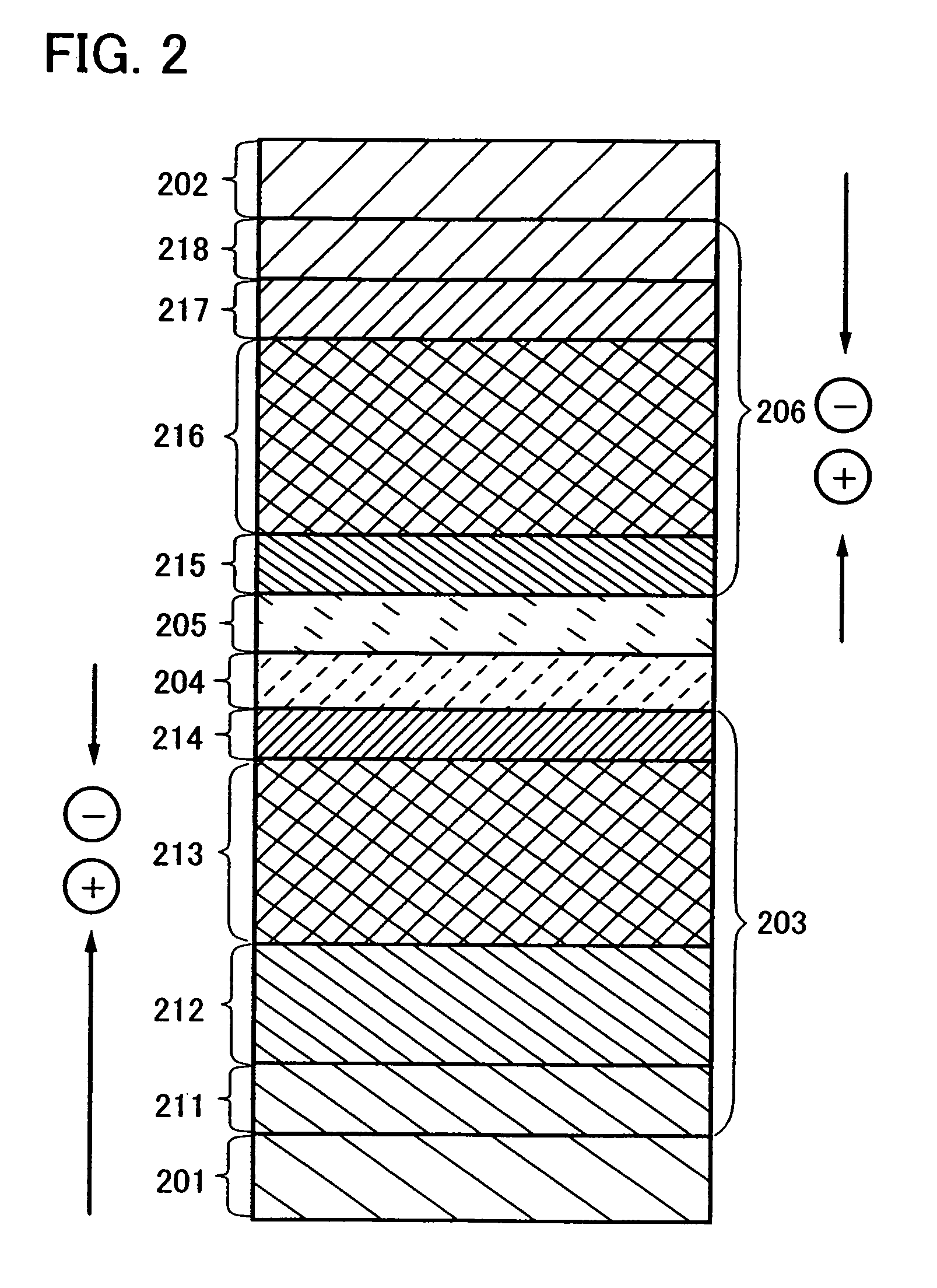

Production method of lithium-ion power battery improving battery consistency

InactiveCN102280665AImprove consistencyTotal weight controlCell electrodesFinal product manufacturePower batteryEngineering

The invention discloses a production method of a lithium ion power battery with consistency improved. According to the invention, anode sheets and cathode sheets are obtained through coating and cutting technologies, and are graded according to the weight of each sheet; a total weight of anode sheets in a single battery is controlled through steps that: a group of anode sheets with a total anode sheet number required by the single battery is weighed, wherein the anode sheets can be selected from a middle weight grade, or can be randomly selected from at least two weight grades; according to ameasured weight, anode sheets in the grade of a larger weight are replaced by anode sheets in the grade of a smaller weight, or anode sheets in the grade of a smaller weight are replaced by anode sheets in the grade of a larger weight; finally, the total weight of the anode sheets is controlled within a required total weight range. With the production technology modification provided by the invention, consistency of the lithium ion power battery is greatly improved, service life of the lithium ion power battery is prolonged, and application safety of the lithium ion power battery is ensured.

Owner:SHANDONG SHANGCUN ENERGY

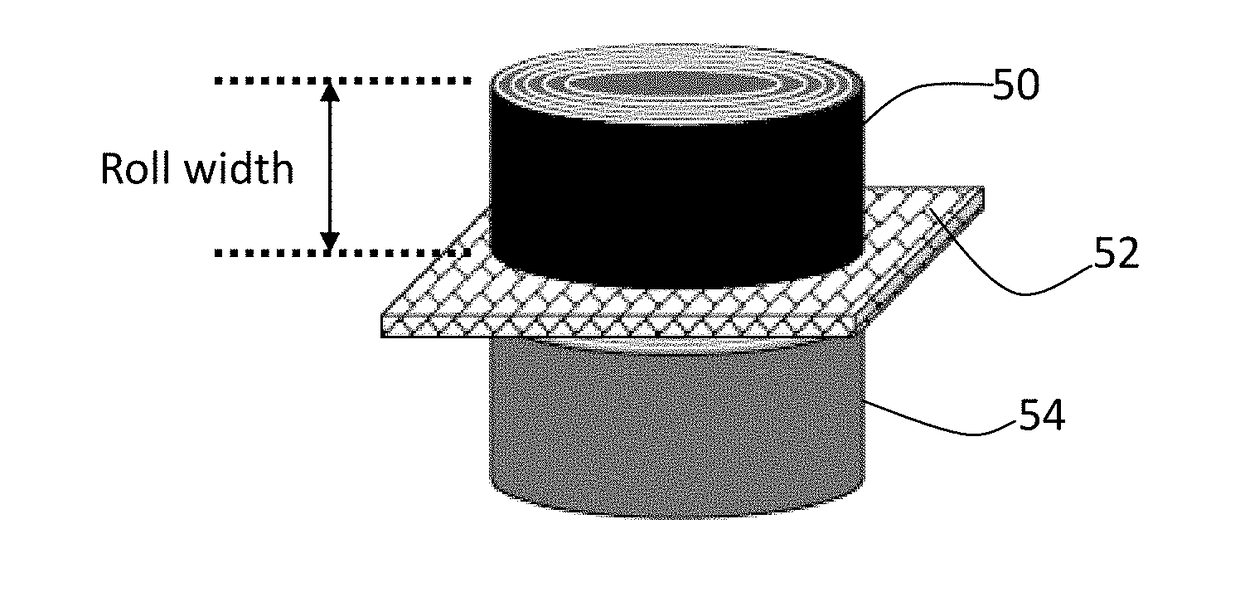

Rolled Supercapacitor and Production Process

ActiveUS20180330893A1Reduce electrolyte layer thicknessImprove directionHybrid capacitor separatorsHybrid capacitor electrodesSupercapacitorOptoelectronics

Owner:NANOTEK INSTR GRP LLC

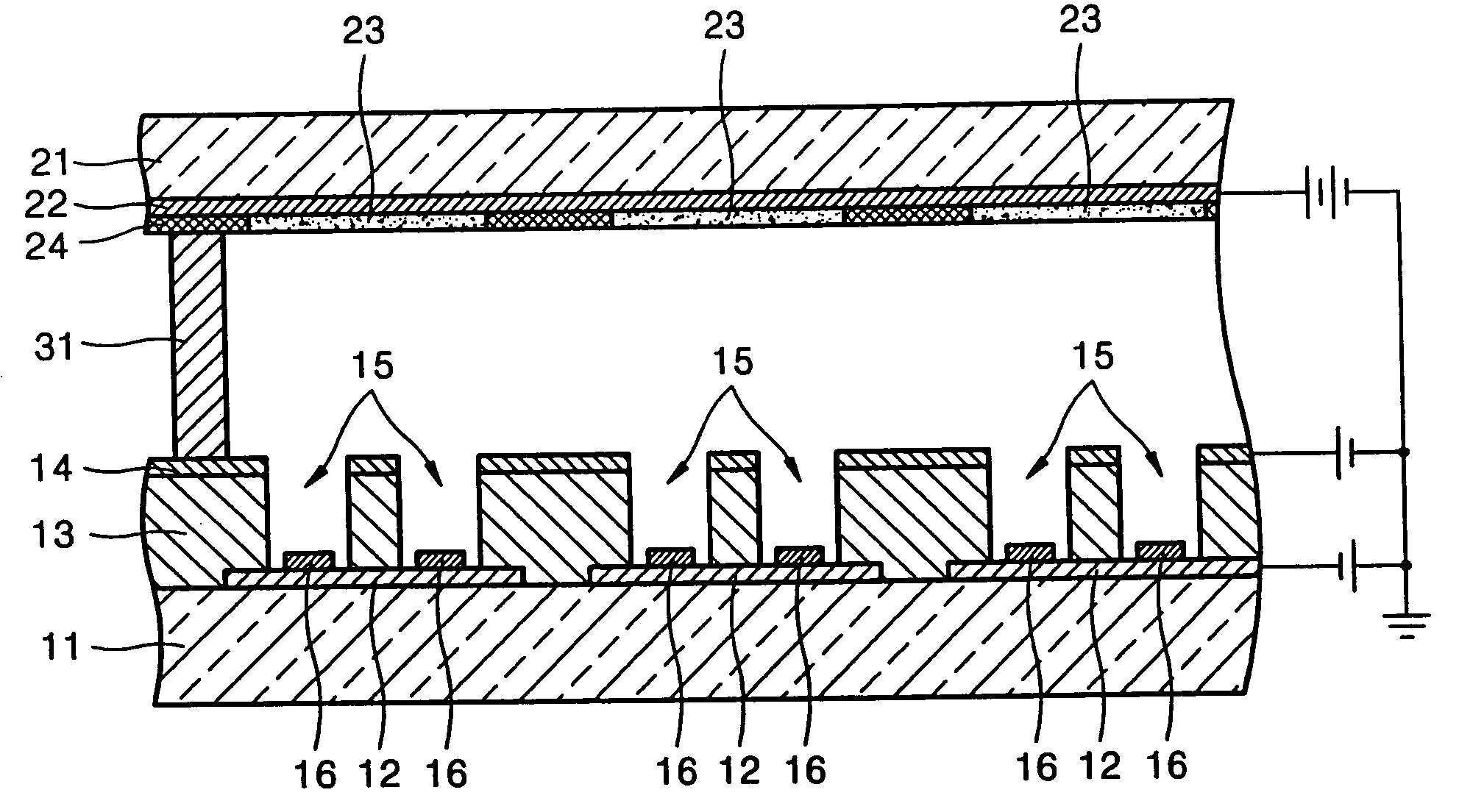

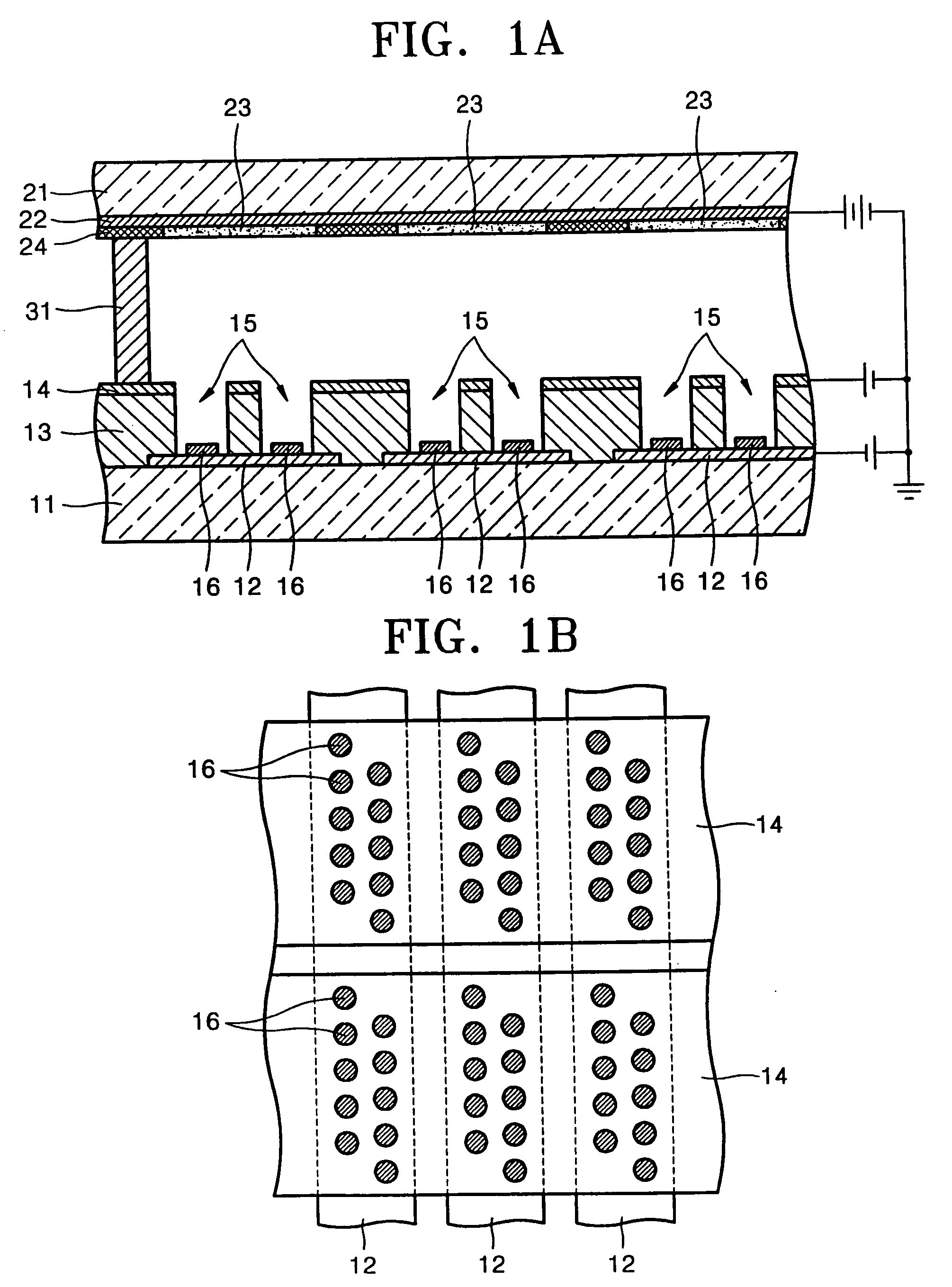

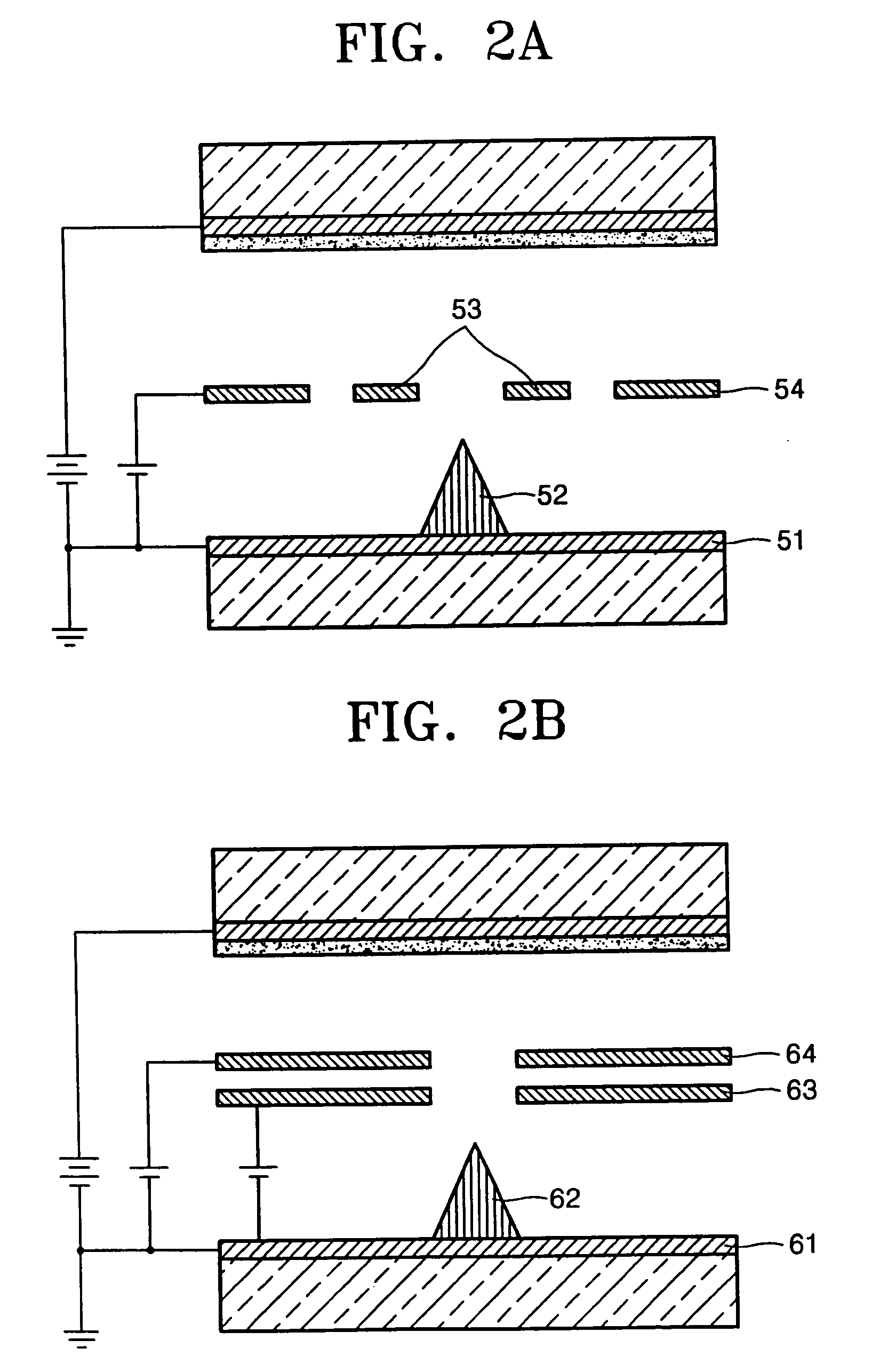

Field emission display (FED) and method of manufacture thereof

InactiveUS20050258738A1Improves electron beam focusingTotal current dropControl electrodesDischarge tube luminescnet screensOptoelectronicsCathode

Owner:SAMSUNG SDI CO LTD

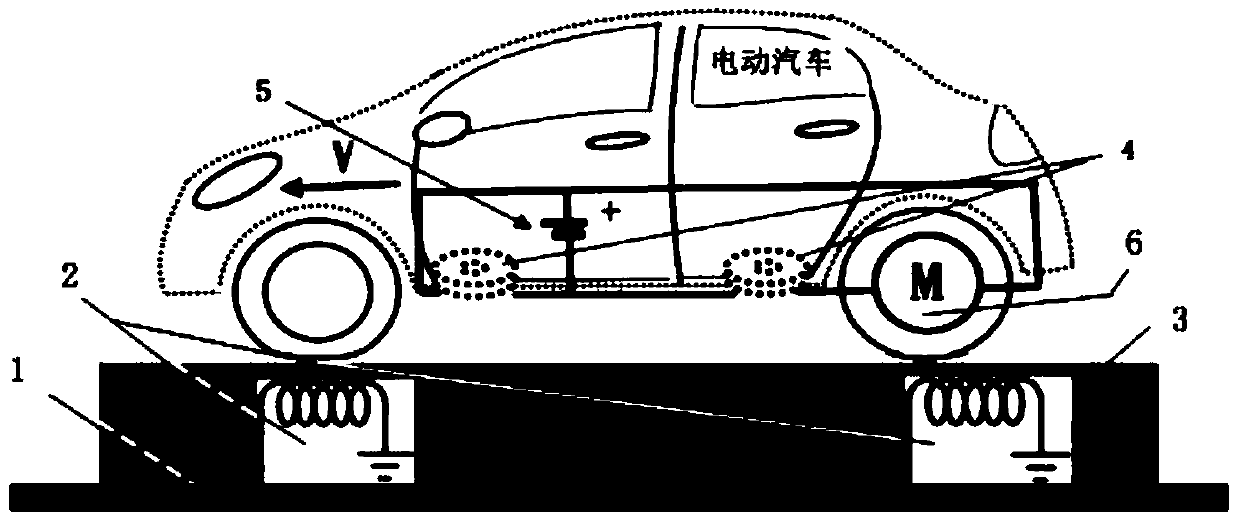

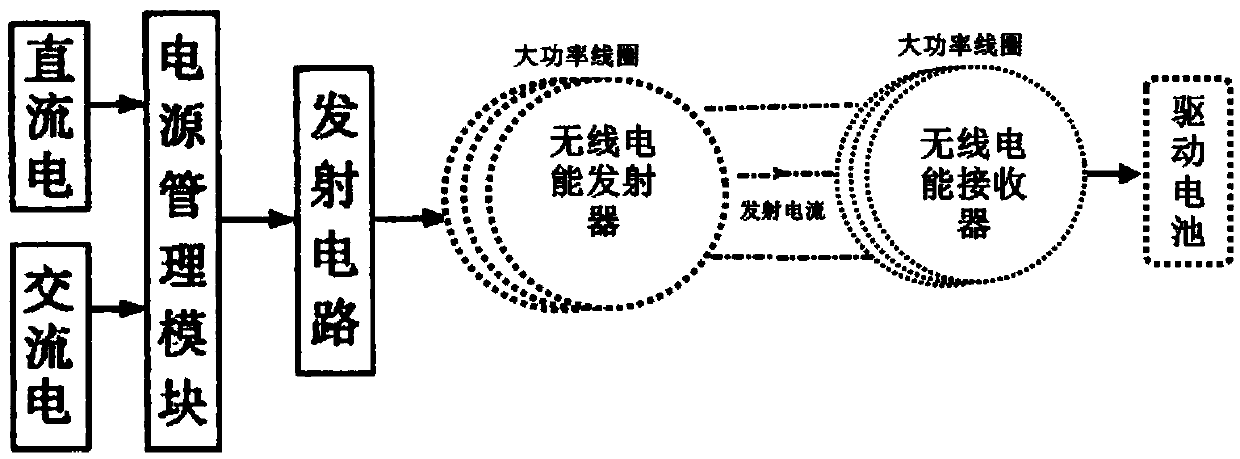

City lane realizing charging during driving of electric automobile

InactiveCN103997078AAlleviate the defects of insufficient power battery and short driving distanceElectromagnetic wave systemBatteries circuit arrangementsDrive wheelElectrical battery

Owner:HENAN SUDA ELECTRIC AUTOMOBILE TECH

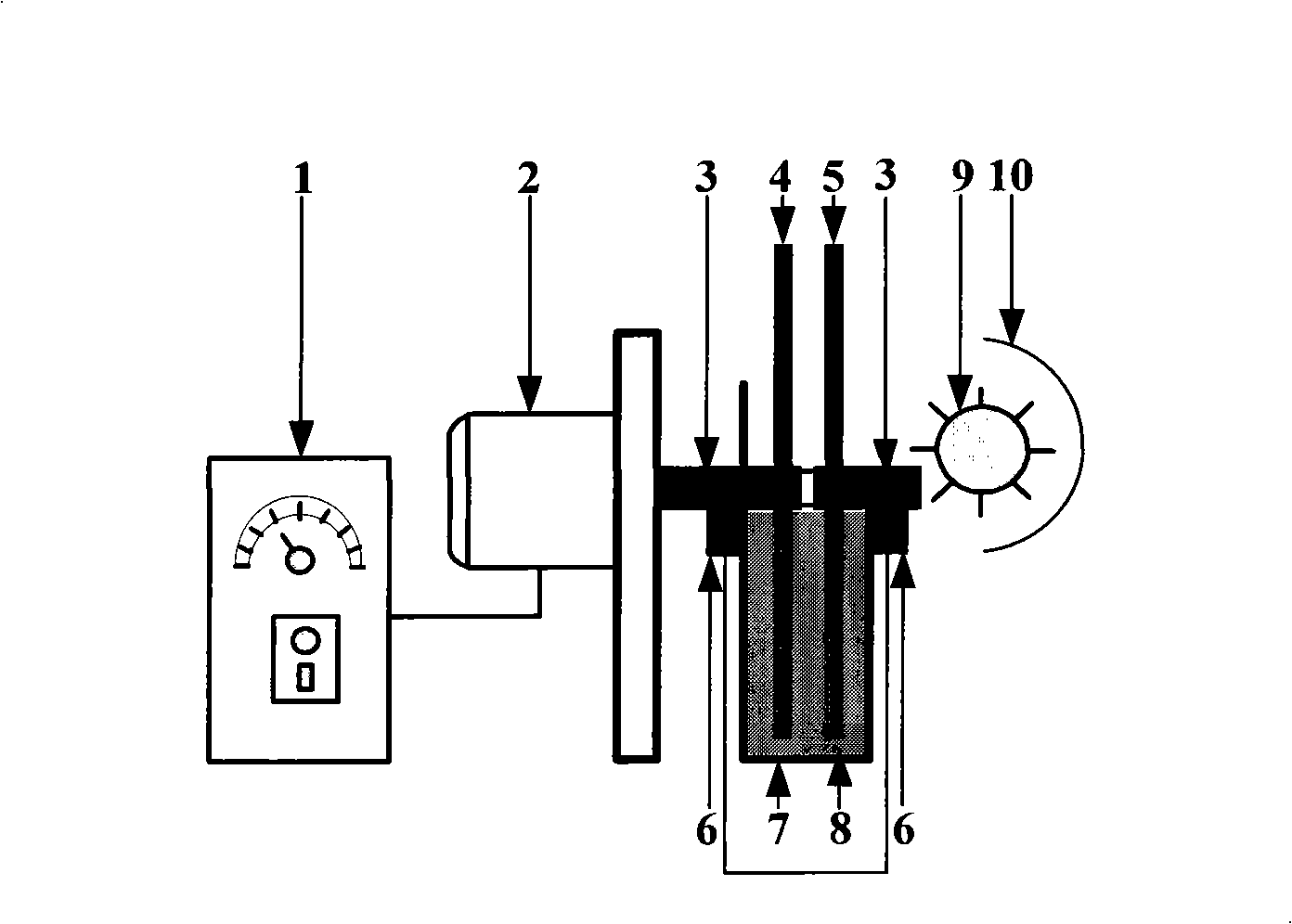

Preparation method of TiC ceramic coating

InactiveCN1807700AImprove bindingGuaranteed bondingElectrolytic inorganic material coatingElectrochemical responseCeramic coating

The invention discloses a TiC ceramic coating preparing method, which comprises the following steps: 1) placing block metal Ti electrode(1) and working electrode(4) in coal oil(2); 2) connecting anode of impulsing power source(3) to block metal Ti electrode(1); linking up with cathode of impulsing power source(3) and work electrode(4); 3) making connection with impulsing power source(3); carrying on electrochemical reaction with Ti metallic ion released form metal and C ion ionized from coal oil(2); compounding ceramic coating(5) of ceramic film TiC and depositing on the surface of work electrode. The invention improves the stability of craft and cementing property of basilemma.

Owner:GUANGDONG UNIV OF TECH

Lithium ion battery cathode and its preparation method and battery

InactiveCN102487136AOmit mixingOmit coatingElectrode carriers/collectorsSecondary cellsElectrical batteryAlloy

Owner:BYD CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap