Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Nitriding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nitriding is a heat treating process that diffuses nitrogen into the surface of a metal to create a case-hardened surface. These processes are most commonly used on low-carbon, low-alloy steels. They are also used on medium and high-carbon steels, titanium, aluminium and molybdenum. In 2015, nitriding was used to generate unique duplex microstructure (Martensite-Austenite, Austenite-ferrite), known to be associated with strongly enhanced mechanical properties...

Ionic nitriding heat treatment technique of 35CrMoV toothed sleeve or toothed ring for centrifugal compressor

ActiveCN106893822AHigh strengthHigh hardnessFurnace typesSolid state diffusion coatingHardnessUltimate tensile strength

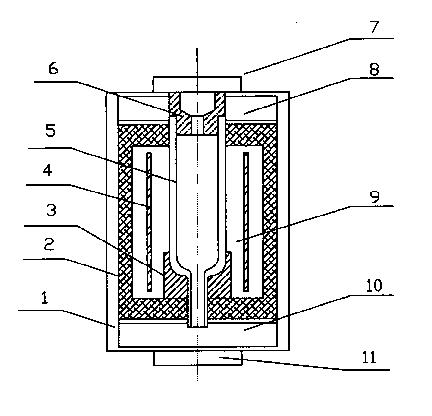

The invention discloses an ionic nitriding heat treatment technique of a 35CrMoV toothed sleeve or toothed ring for a centrifugal compressor and belongs to the technical field of heat treatment techniques. The ionic nitriding heat treatment technique comprises the following steps that (1) normalizing treatment is conducted, specifically, the normalizing temperature is 900 DEG C, the heat preservation time is (effective thickness / 40mm) hours, and then air cooling is conducted; (2) quenching treatment is conducted, specifically, the quenching temperature is 900 DEG C, the heat preservation time is (effective thickness / 40mm) hours, and then oil cooling is conducted; (3) tempering treatment is conducted, specifically, the tempering temperature is 600 DEG C, the heat preservation time with the unit being hour is 1.5 times the quenching heat preservation time, and then air cooling is conducted; and (4) ionic nitriding treatment is conducted, specifically, ionic nitriding is conducted at the temperature of 520 DEG C for 18.0-25.0 h, furnace cooling is conducted till the temperature is lowered to be 200 DEG C, and then a product is moved out of a furnace and subjected to air cooling. The contact-fatigue strength of a workpiece treated through ionic nitriding heat treatment can be greatly improved owing to the fact that the core strength and hardness are improved.

Owner:SHENYANG TURBO MASCH CORP

System for recycling silicon powder in polycrystalline silicon reduction tail gas and method thereof

InactiveCN111661827AHigh activityReduced activityNitrogen compoundsHalogenated silanesSlagSolid content

The invention discloses a system for recycling silicon powder in polycrystalline silicon reduction tail gas and a method thereof, the recycling system comprises a main filter and a residual liquid filter which are connected in sequence, a silicon powder outlet of the residual liquid filter is connected with a nitriding furnace, and an outlet of the nitriding furnace is connected with a grinder. Through cooperative filtering of the main filter and the residual liquid filter, the solid content of drying liquid in the residual liquid filter is increased, drying energy consumption can be reduced,and the drying effect can be enhanced. Compared with an existing silicon slag recovery method, the method has the advantages that the separated silicon powder basically has no silane residue on the surface, is high in activity, can be directly fed into a nitriding furnace to be used for manufacturing silicon nitride powder, and is high in recycling value. The method is low in energy consumption and good in drying effect, the silicon powder discharged out of the filter is high in activity and can be directly recycled, meanwhile, the silicon powder with low value is changed into a silicon nitride product with higher additional value, and the economic value of polycrystalline silicon reduction reaction byproducts is increased.

Owner:SICHUAN YONGXIANG POLY SILICON

Method for preparing feeding nozzle for continuous high-purity alumina melting furnace and continuous melting furnace

Owner:SHANDONG UNIV OF TECH

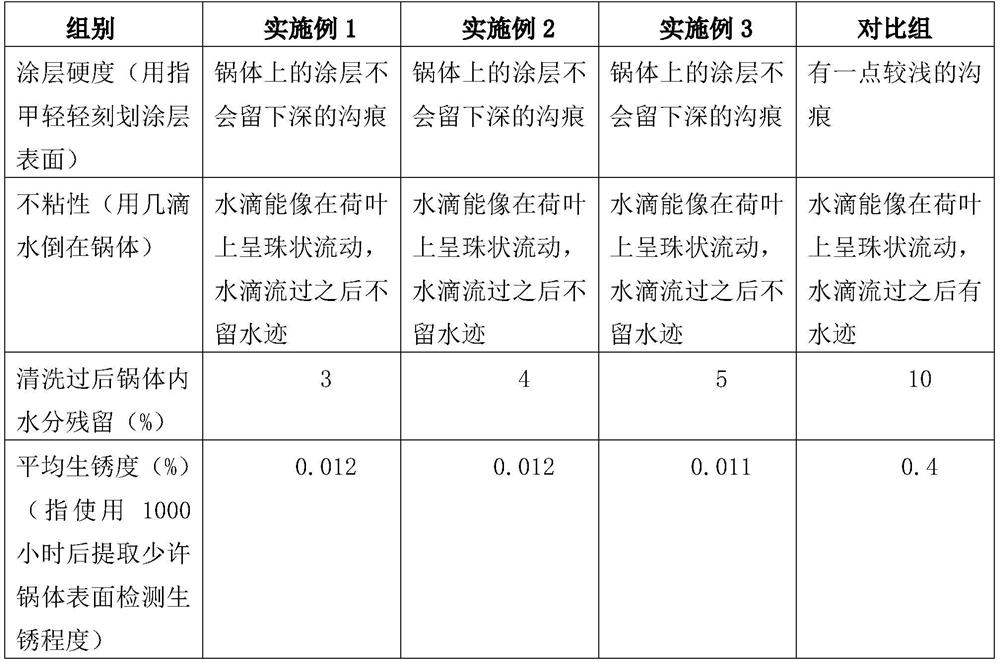

Manufacturing process suitable for pure iron or composite iron non-stick pan

ActiveCN111633381AGood non-stickExtended service lifeCooking-vessel materialsPolishing machinesPunchingManufacturing technology

Owner:ZHEJIANG FOSCOM KITCHENWARE CO LTD

Preparation method of nano TiN coating film of root canal file

PendingCN114214620AImprove stabilityChange brittlenessSolid state diffusion coatingNitrogen gasTitanium alloy

Owner:沈阳博尔雅生物科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap