Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46 results about "Continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous production is a flow production method used to manufacture, produce, or process materials without interruption. Continuous production is called a continuous process or a continuous flow process because the materials, either dry bulk or fluids that are being processed are continuously in motion, undergoing chemical reactions or subject to mechanical or heat treatment. Continuous processing is contrasted with batch production.

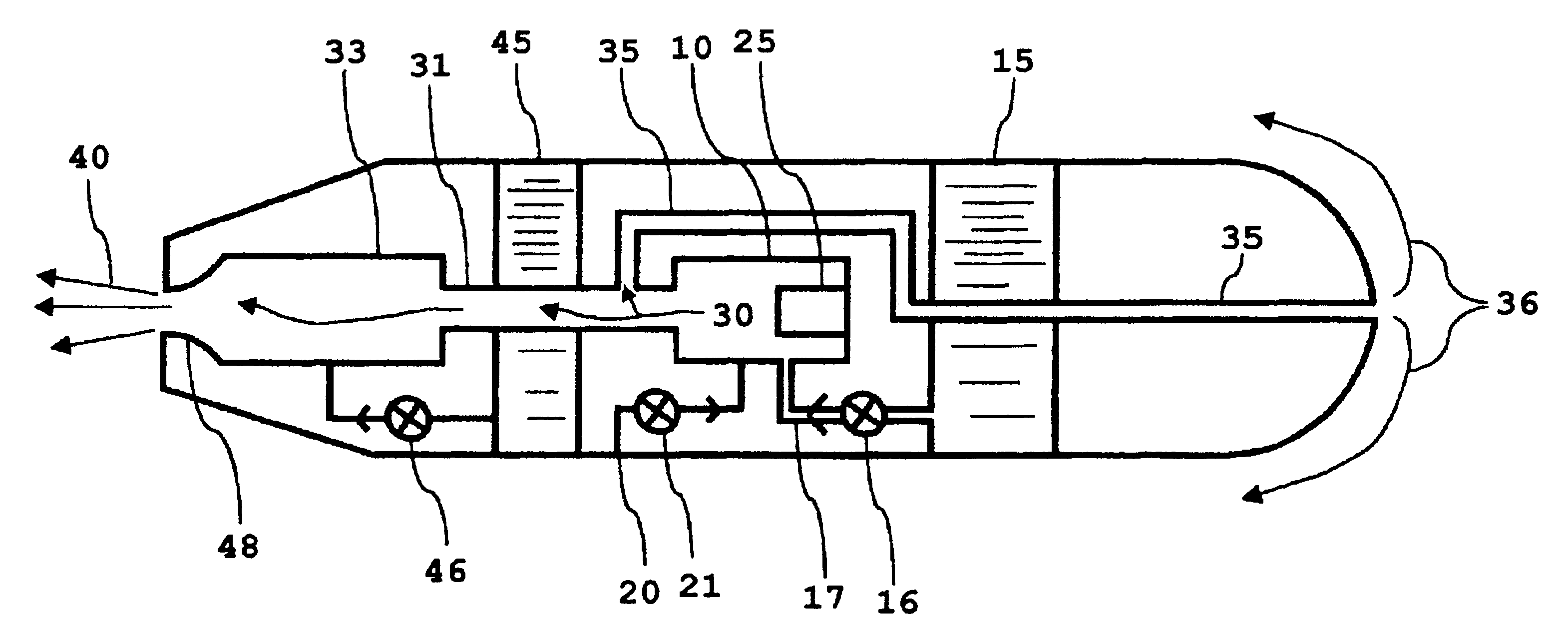

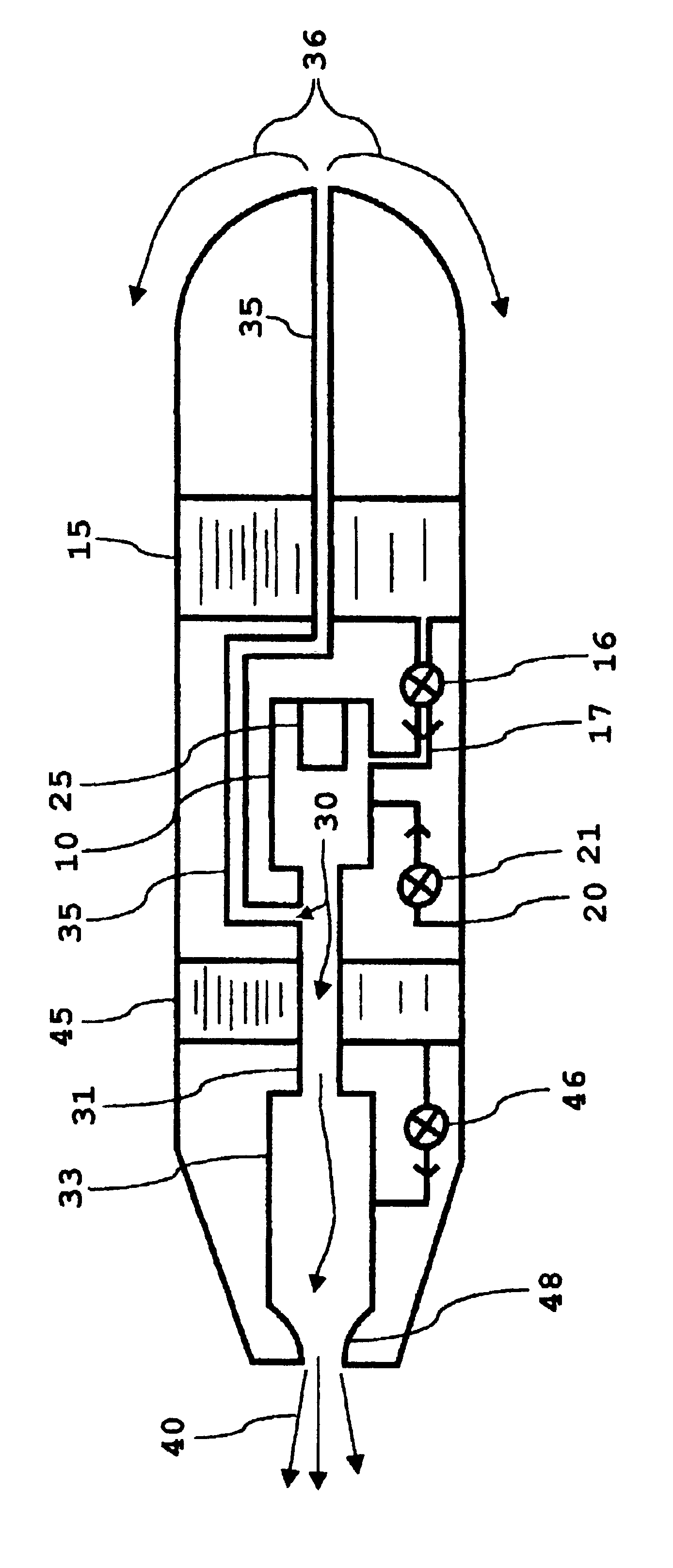

Gas generating process for propulsion and hydrogen production

InactiveUS6849247B1Reduce the temperatureProducing energyLoomsHydrogen productionMetallic materialsSlurry

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

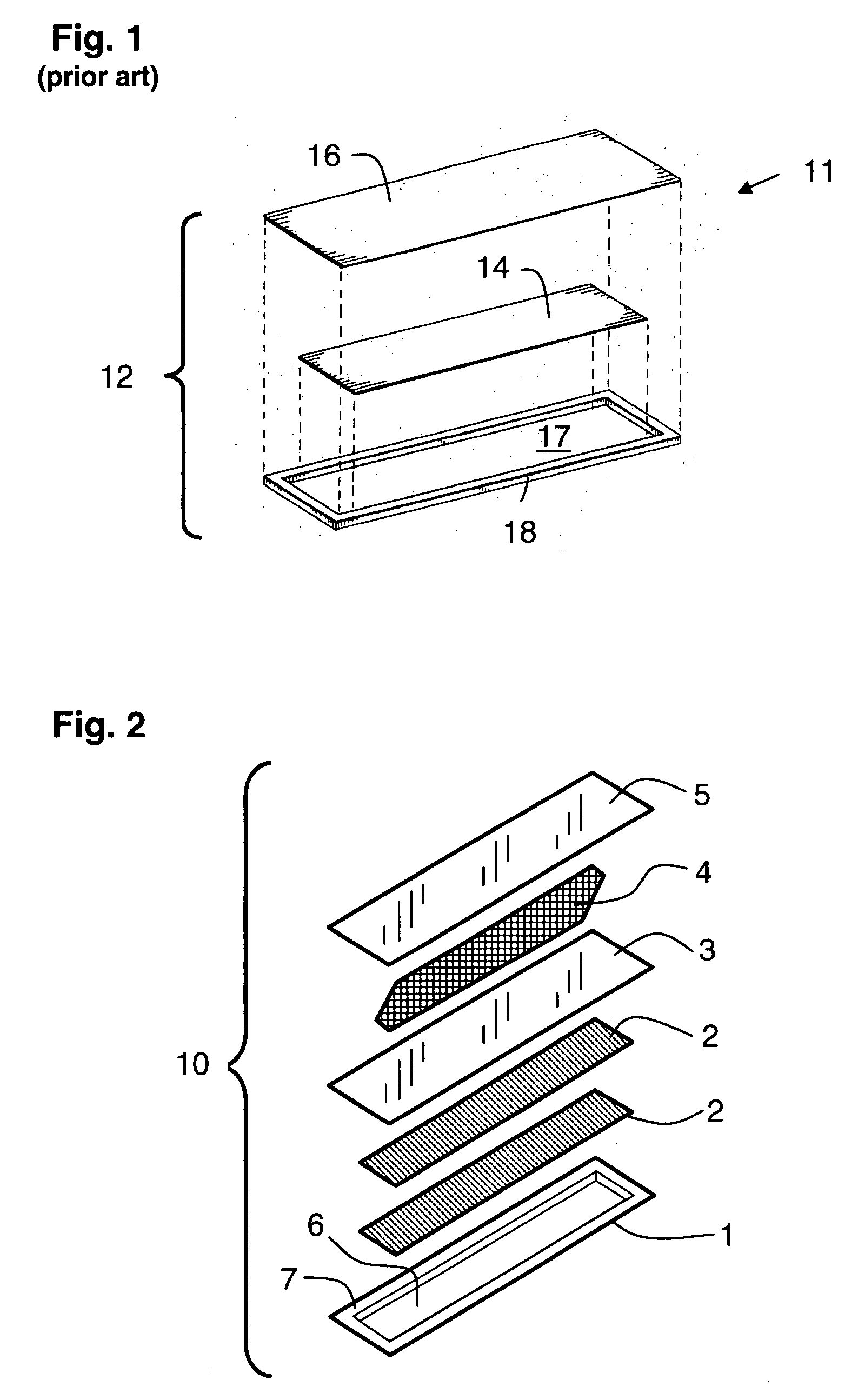

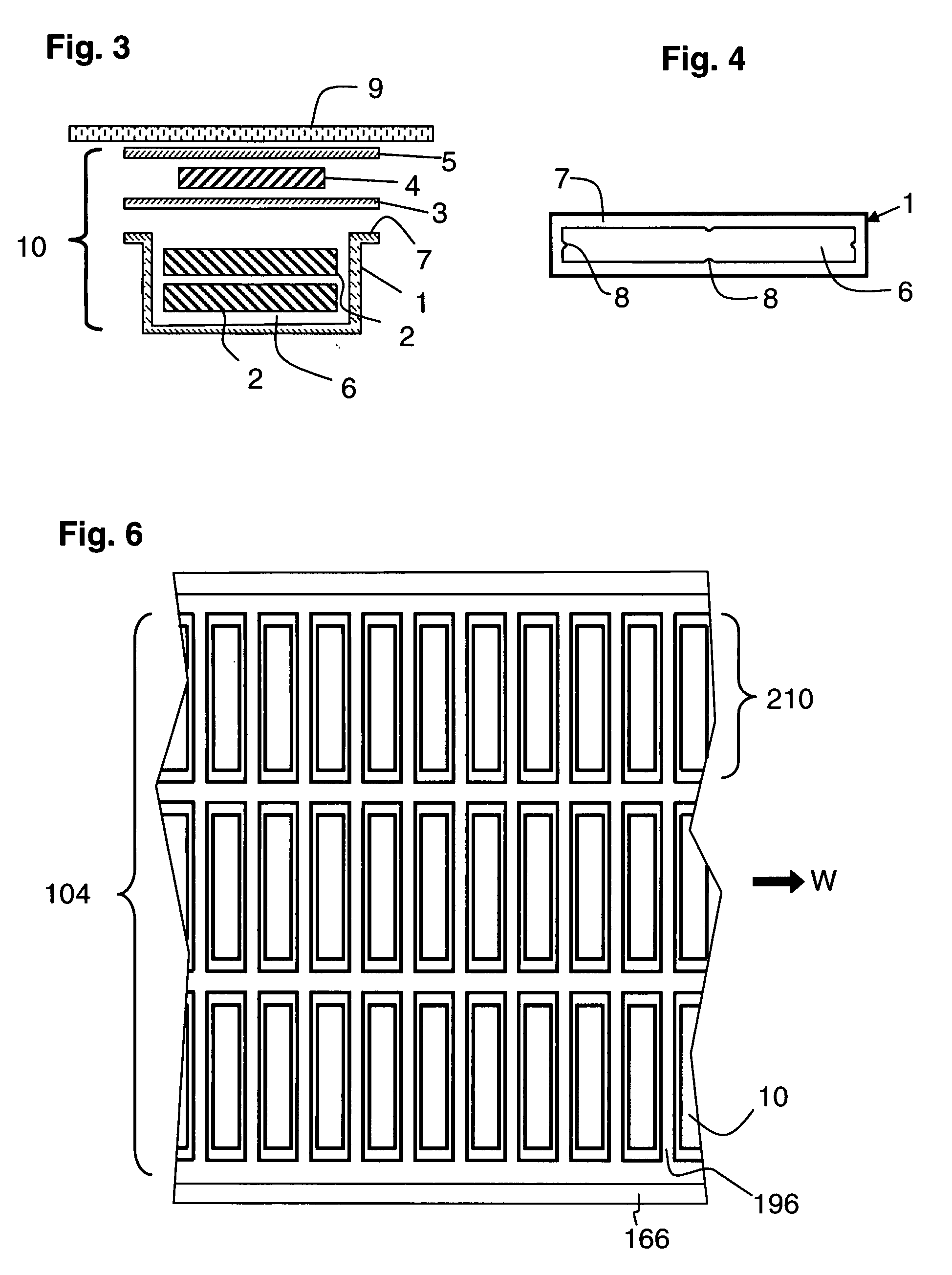

Electronic article surveillance marker

InactiveUS20070194927A1Improve production yieldImprove reliabilityElectronic circuit testingBurglar alarm by hand-portable articles removalMagnetic tension forceMonitoring system

Owner:PHENIX LABEL

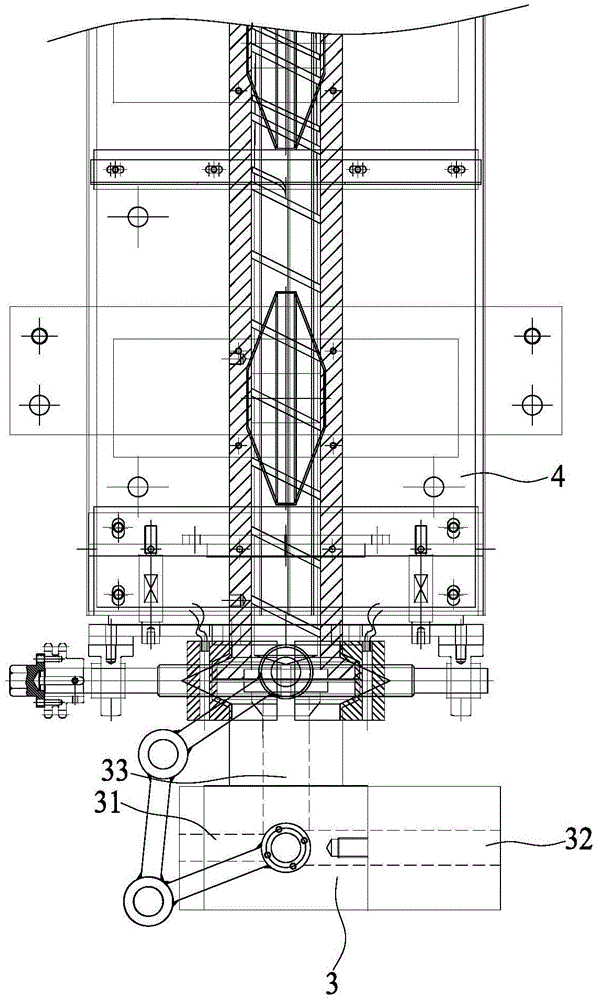

Automatic profiling device with movement automatically controlled

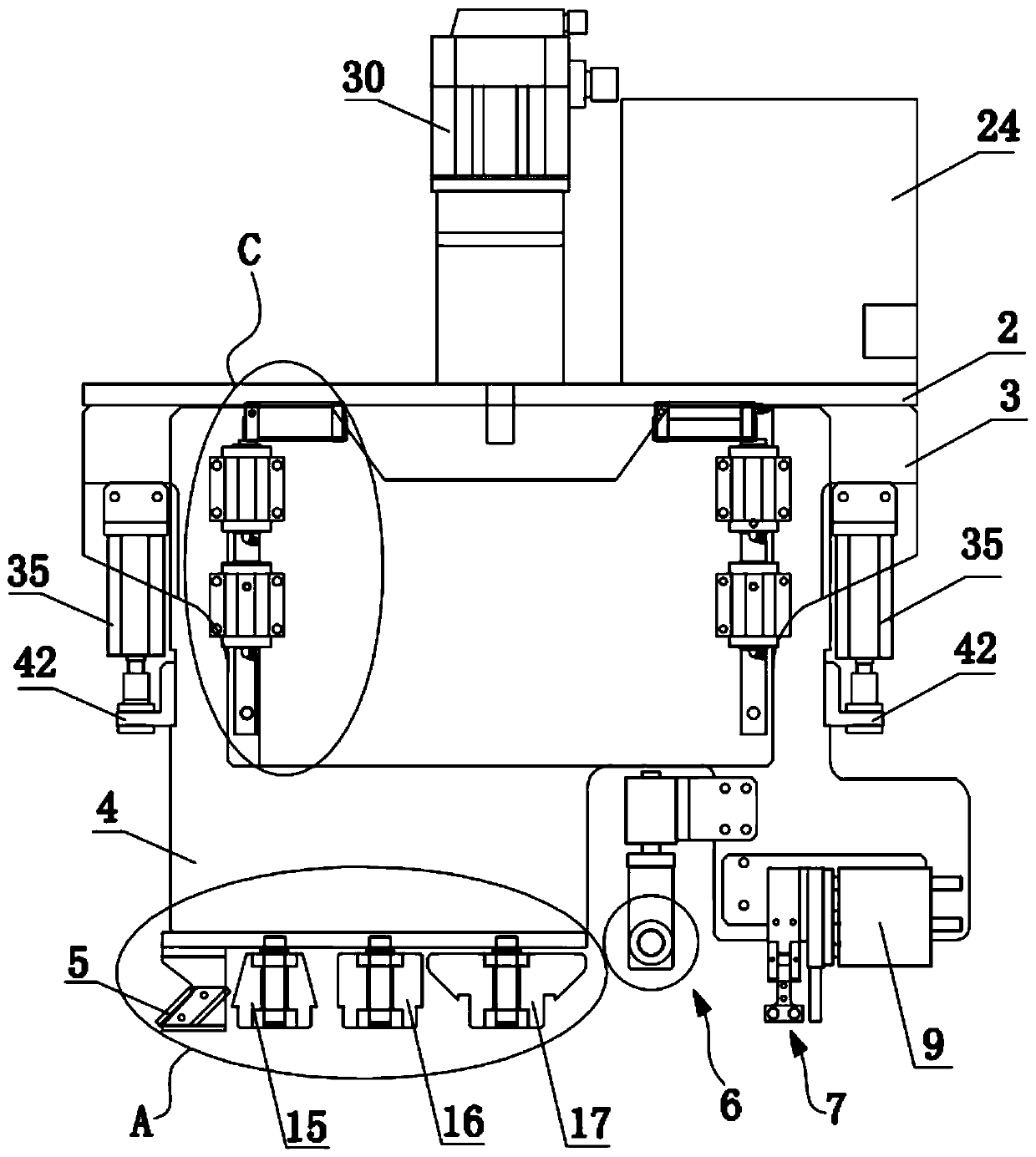

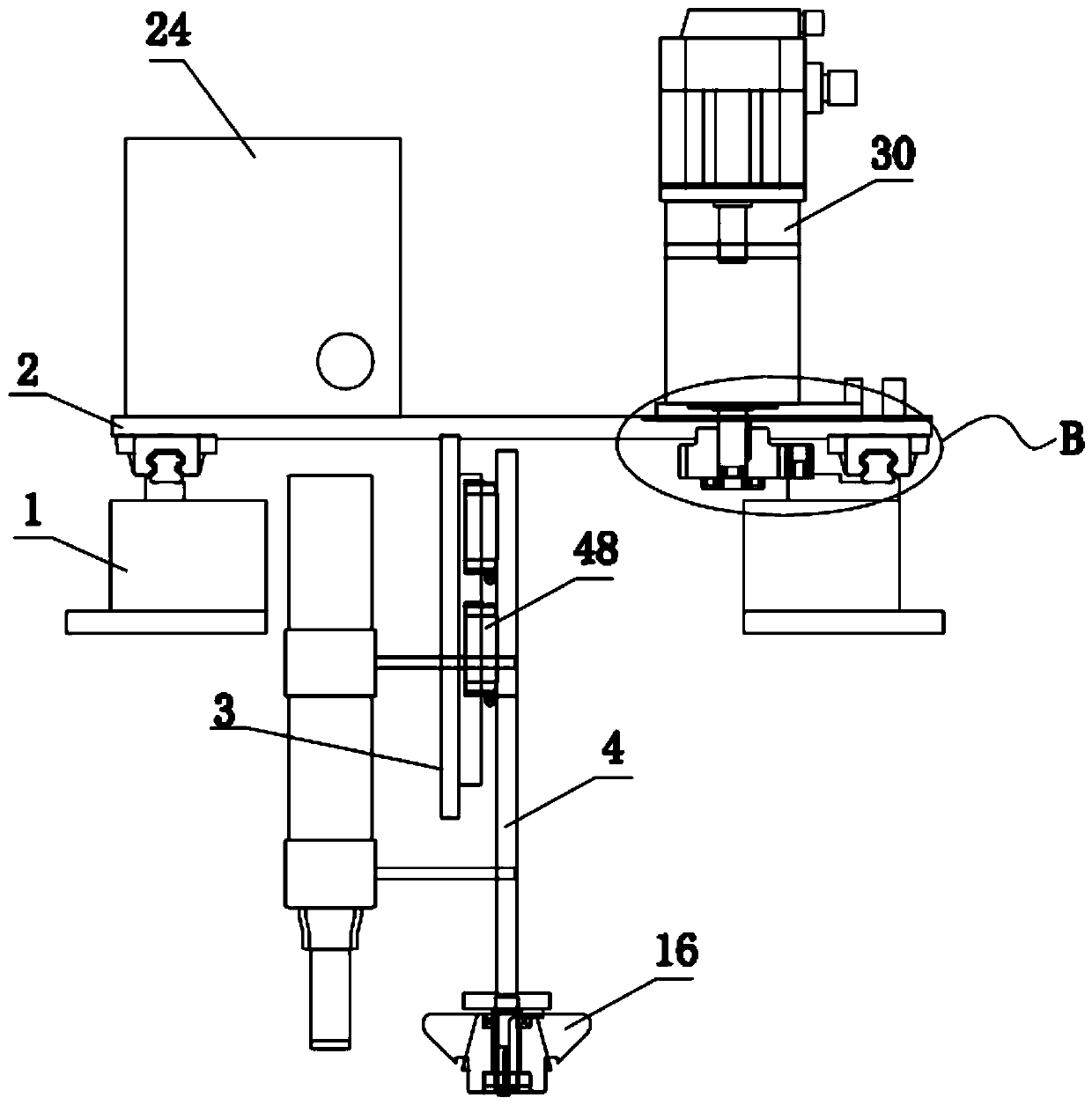

The invention discloses an automatic profiling device with the movement automatically controlled. The automatic profiling device comprises a base table, an upper die, a lower die, a cam and a driving mechanism; the base table is horizontally arranged and is provided with a guide hole penetrating through the upper end face and the lower end face of the base table, a first guide column, a second guide column, a first ejection rod and a second ejection rod, wherein the first guide column, the second guide column, the first ejection rod and the second ejection rod are vertically arranged on the periphery of the guide hole; a die cavity is formed in the upper end face of the lower die, a first ejection hole and a second ejection hole are formed in the bottom of the die cavity, the lower die is provided with a first guide hole and a second guide hole, and a guide column is arranged on the lower end face of the lower die; the lower die is located on the base table, the first guide column penetrates through the first guide hole, the second guide column penetrates through the second guide hole, the first ejection rod penetrates through the first ejection hole, the second ejection rod penetrates through the second ejection hole, and the guide column penetrates through the guide hole and extends to the part below the base table; the upper die is located above the lower die and is fixed; the cam is located below the base table and abuts against the lower end of the guide column; the driving mechanism is used for driving the cam to rotate. According to the automatic profiling device, continuous production of work-piece profiling is realized.

Owner:WUHU TONGCHUANG MOULD MASCH CO LTD

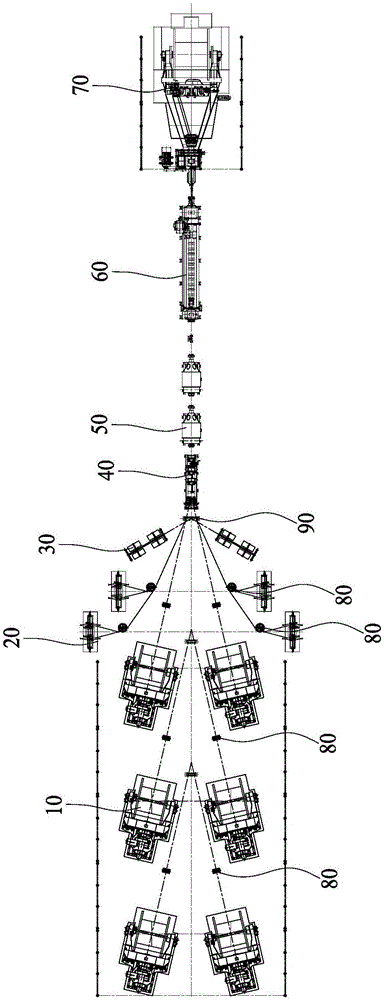

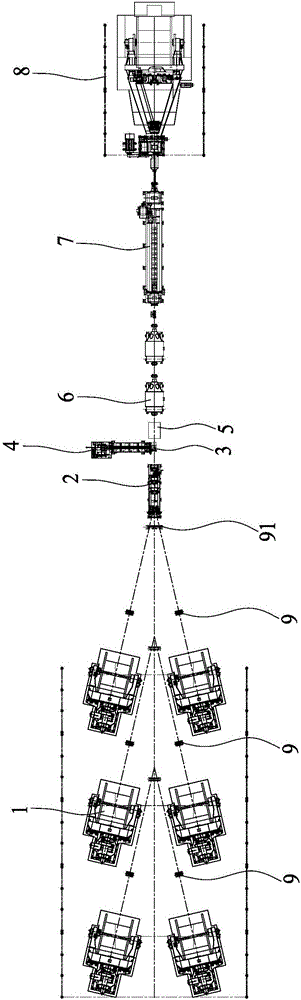

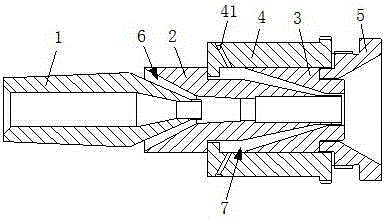

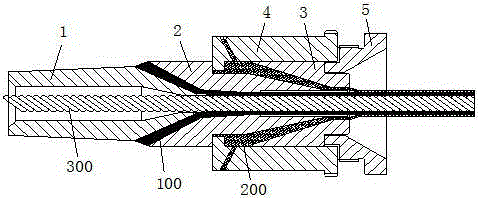

Pressure filling type cable former and cable forming process

ActiveCN106448940AFilled tightlyStable structureCable/conductor manufactureEngineeringMechanical engineering

Owner:FUJIAN NANPING SUN CABLE +1

Process and corresponding apparatus for continuously producing gaseous hydrogen to be supplied to micro fuel cells and integrated system for producing electric energy

A process for the production of hydrogen for micro fuel cells, comprises the successive steps of: continuously supplying a catalytic bed with an aqueous solution of sodium borohydride, the catalytic bed being made of at least one metal chosen among cobalt, nickel, platinum, ruthenium with obtainment of hydrogen and of a by-product comprising sodium metaborate, continuously recovering the hydrogen thus obtained and supplying, with said hydrogen as it is as obtained, a micro fuel cell which transforms hydrogen into electric energy. An apparatus provides continuous supply of hydrogen to a micro fuel cell. An integrated system structured for continuously producing and supplying hydrogen to a micro fuel cell and for converting the continuously supplied hydrogen into electric energy.

Owner:STMICROELECTRONICS SRL

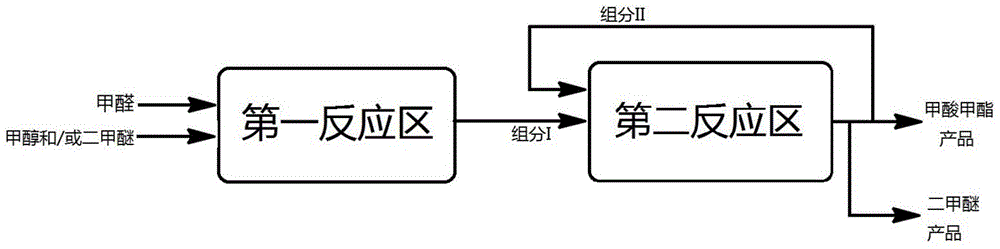

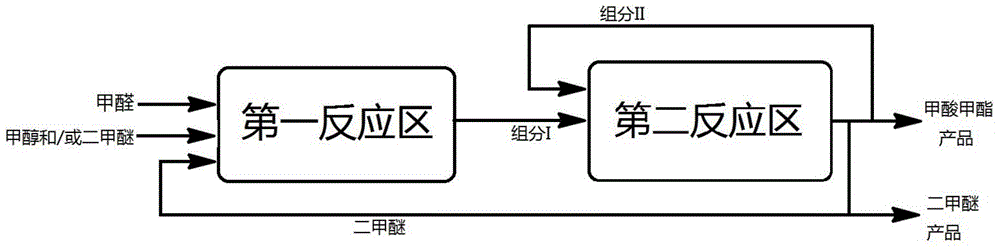

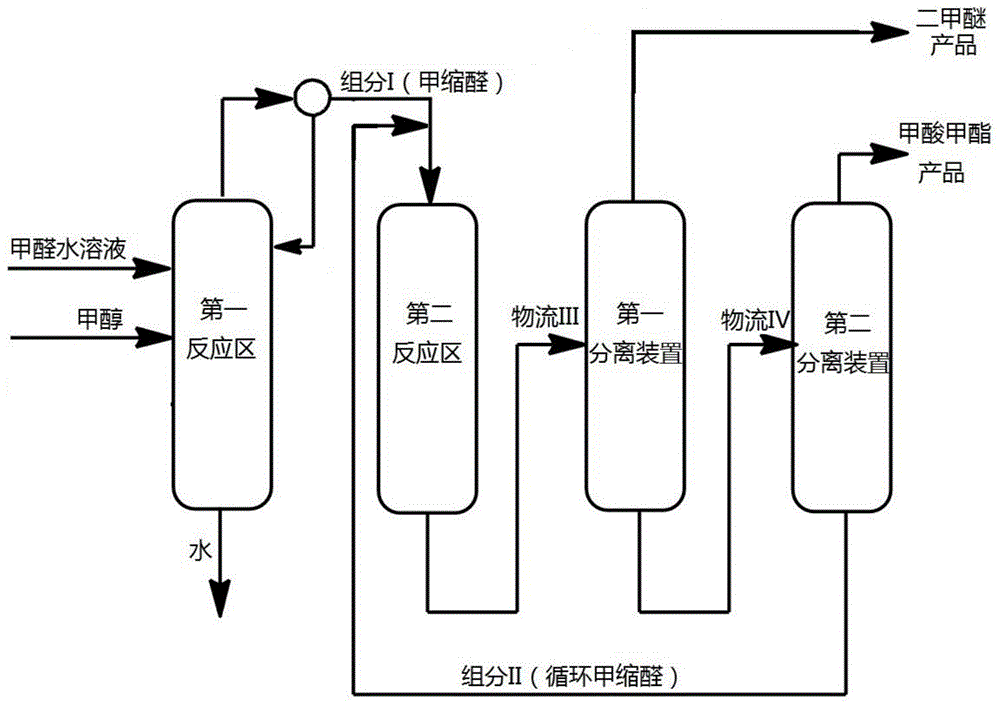

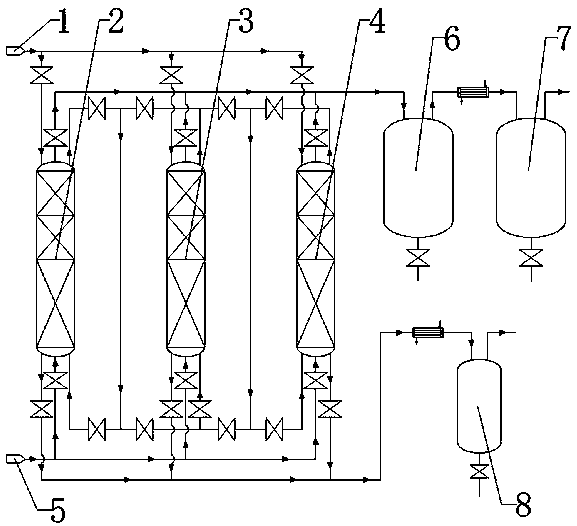

Method for preparing methyl formate and coproducing dimethyl ether

ActiveCN105669452AEasy to separateReduce energy consumptionOrganic compound preparationCarboxylic acid esters preparationGas phaseReaction zone

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Electron-grade hydrochloric acid production method

PendingCN109761196ASimple processEasy to operateChlorine/hydrogen-chloride purificationParticulatesAbsorption of water

Owner:江苏梅兰化工有限公司

Methylal purifying method

InactiveCN104961631AWide range of usesLower quality requirementsOrganic chemistryOrganic compound preparationHazardous substanceDesiccant

Owner:HAIMEN MINGYANG IND

High-quality ceramic stone machining system

InactiveCN107913778AAvoid unmanageable problemsImprove product qualityMagnetic separationGrain treatmentsIron removalStone particle

The invention discloses a high-quality ceramic stone machining system. The high-quality ceramic stone machining system comprises a slurry inlet pipe, a grinding mechanism for grinding slurry, a filtering mechanism for filtering the slurry, a drying mechanism for drying ceramic stone particles, and an iron removal mechanism for removing iron in the ceramic stone particles. The high-quality ceramicstone machining system has the beneficial effects that the slurry can be subjected to adsorbing impurity removal after being dried and formed, iron scraps in the slurry are reduced, and the problem that due to the fact that impurity removal is carried out before an overall process, the iron scraps mixed in the work process cannot be treated is avoided; the product quality is improved, a continuousproduction mode of grinding, filtering and screening, drying and iron removing can be formed, and machining efficiency is greatly improved; and the overall structure is simple, and very good market generalization performance is achieved.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

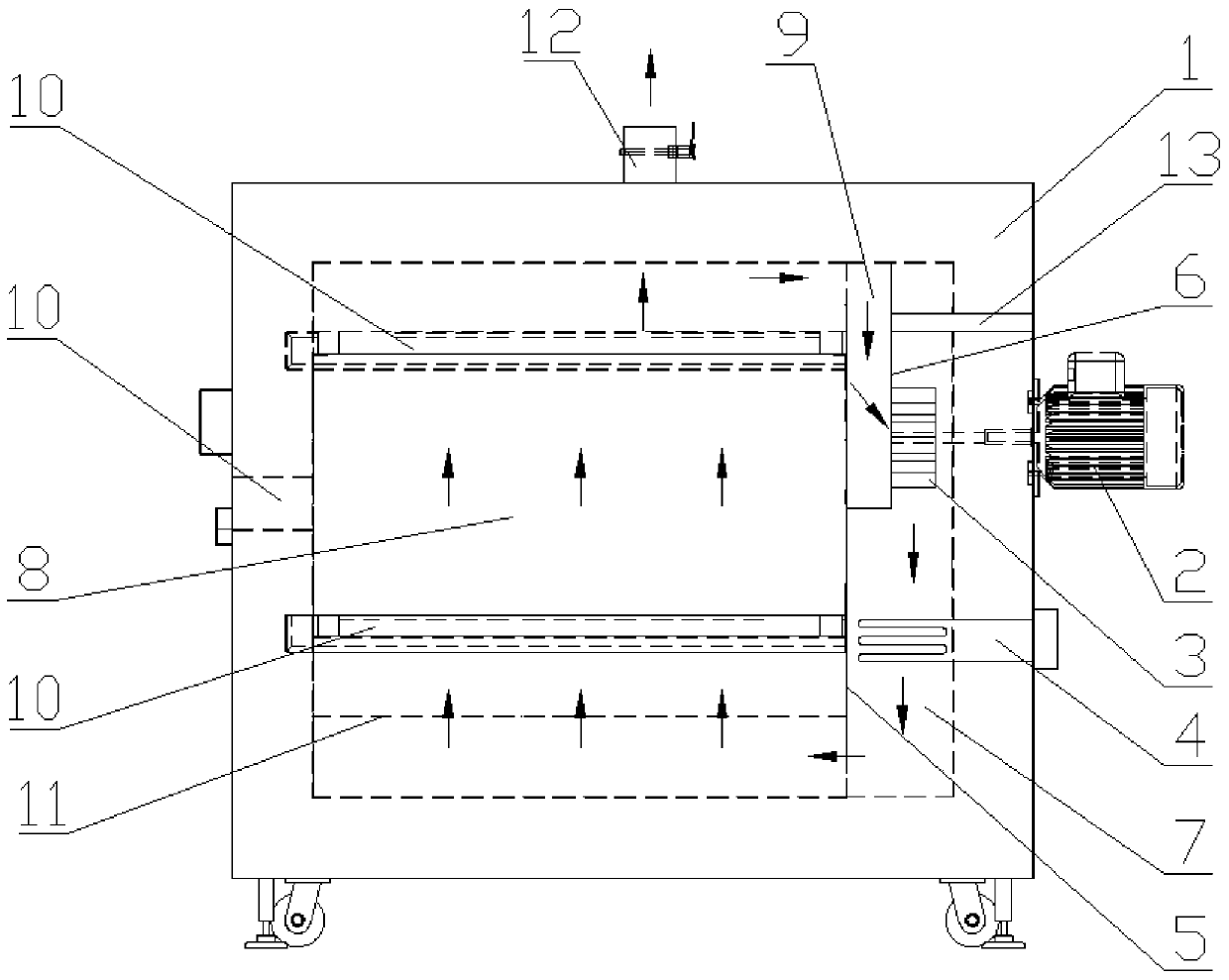

Pre-oxidation equipment of PAN (polyacrylonitrile)precursor end and end connection method

Owner:ATA CARBON FIBER TECH GUANGZHOU

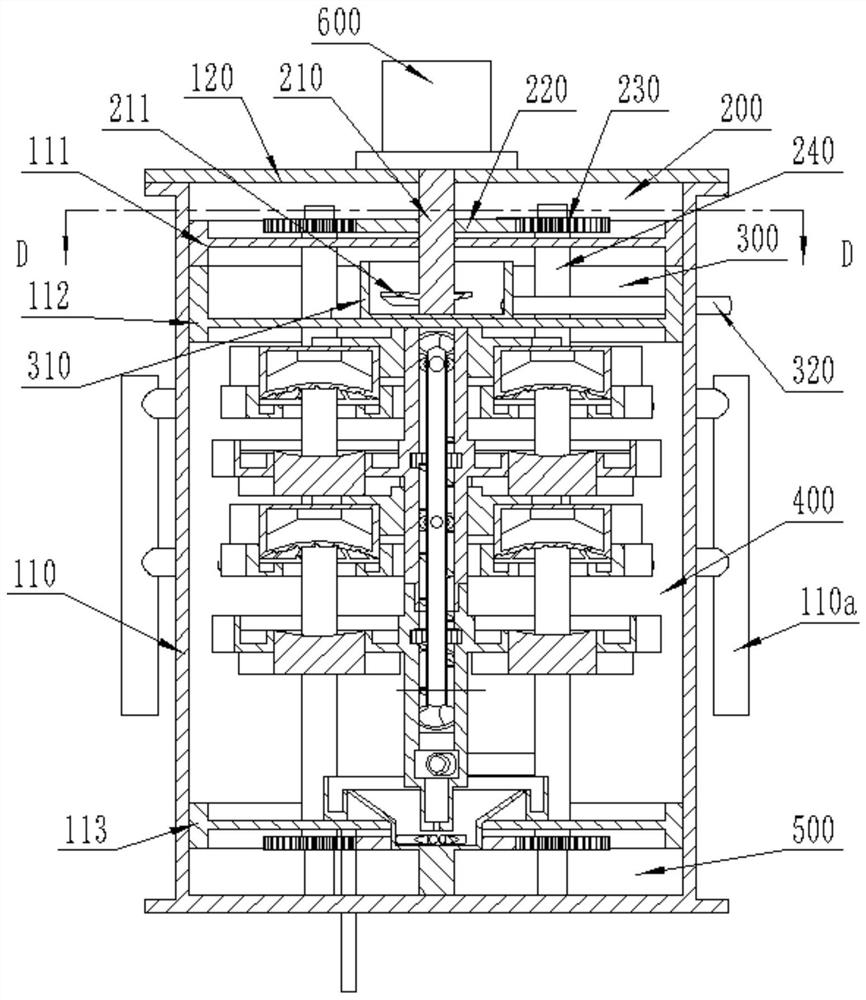

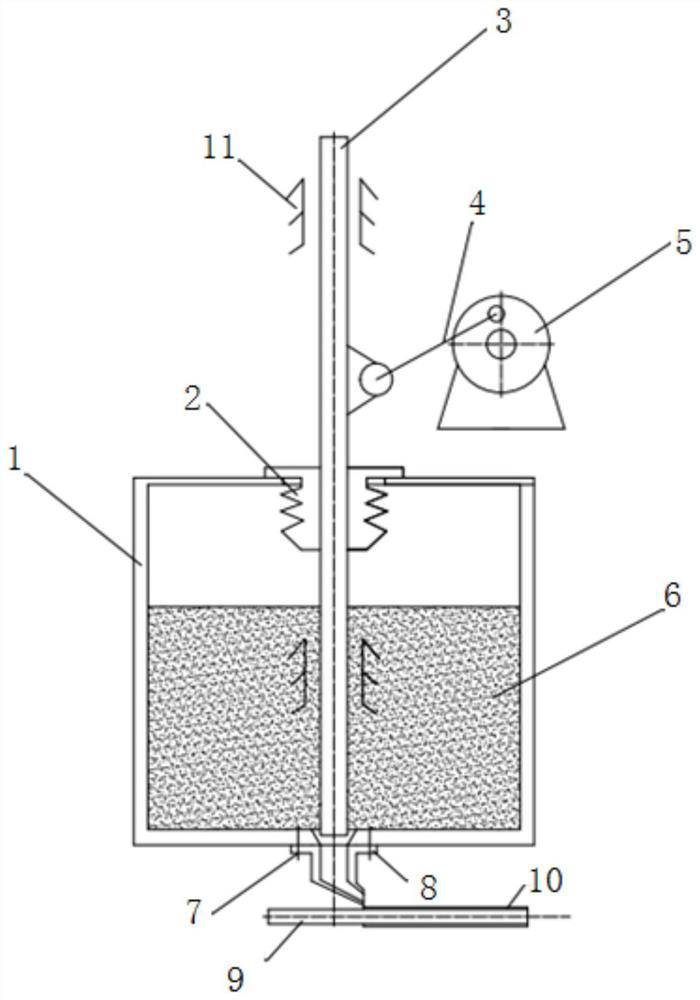

Continuous production equipment and process for hexafluoropropylene oxide oligomer

PendingCN111530383AContinuous operationReduce consumptionChemical recyclingCarboxylic acid halides preparationOligomerPtru catalyst

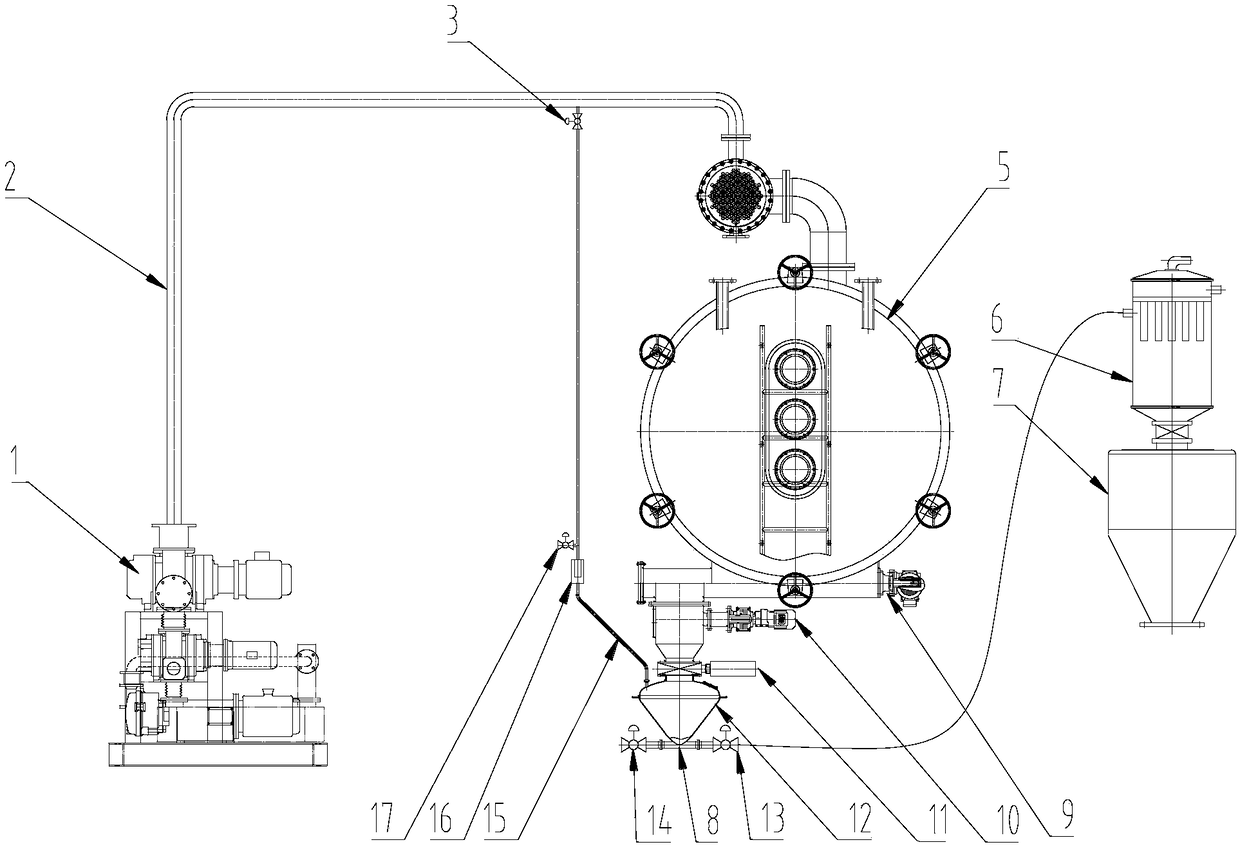

The invention provides continuous production equipment and a continuous production process for a hexafluoropropylene oxide oligomer. The continuous production equipment comprises a stirring kettle anda liquid phase separation kettle, wherein a stirrer is arranged in the stirring kettle; a discharge pipe is arranged at the bottom of the stirring kettle; a discharge pipe is arranged at the bottom of the liquid phase separation kettle; the discharging pipe is communicated with the discharge pipe through a feeding pipe; the feeding pipe is provided with a conveying pump; the top of the stirring kettle is communicated with the top of the liquid-phase separation kettle through a liquid-phase circulating pipe and a gas-phase circulating pipe respectively; the liquid-phase circulating pipe is provided with a circulating pump; the gas-phase circulating pipe is provided with a condenser; one end of the liquid-phase circulating pipe, which is positioned at the liquid-phase separation kettle, extends into the lower part of the liquid-phase separation kettle; and one end of the liquid-phase circulating pipe, which is positioned at the stirring kettle, is connected with a nozzle. The equipmentand the process have the advantages of continuous production, simplicity in operation, high production efficiency, stable product quality and the like, meanwhile, the catalyst, the solvent and byproducts can be recycled, and the process is low in cost and environmentally friendly.

Owner:JIUDING FLUORIN CHEM CO LTDZHANGPING FUJIAN

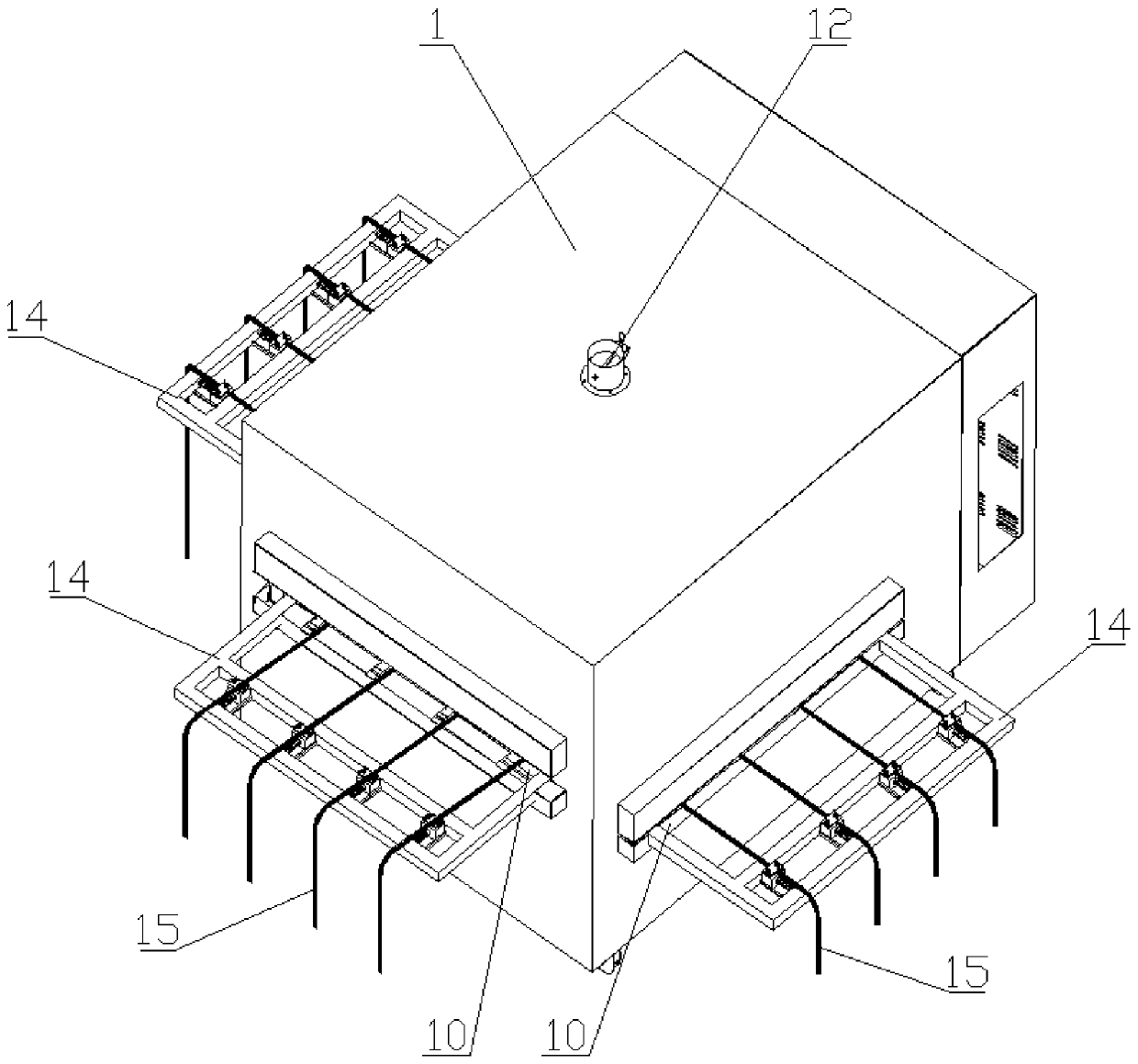

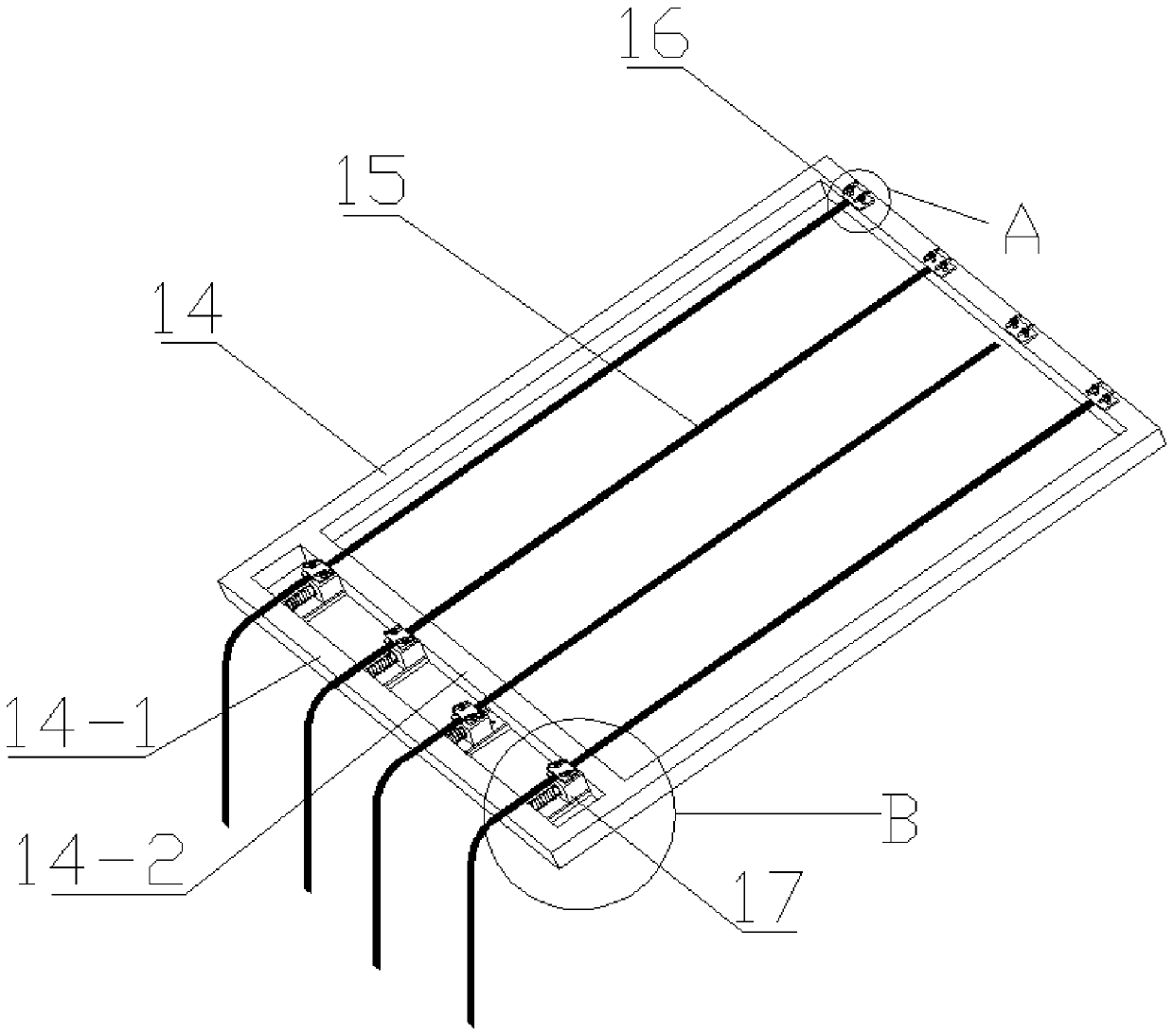

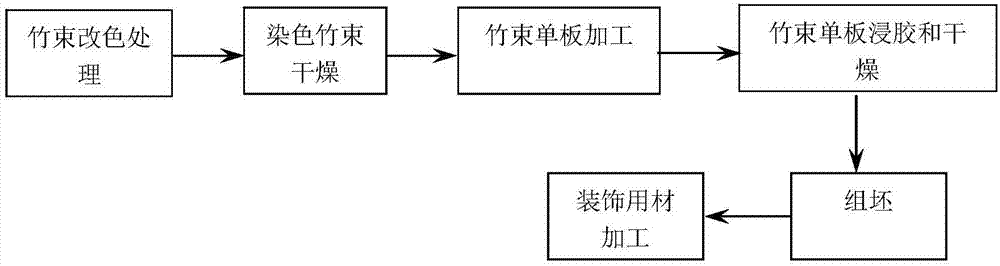

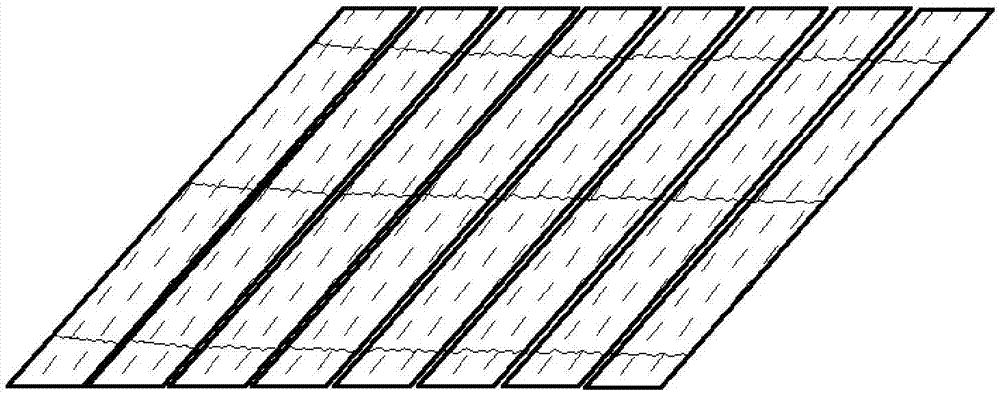

Manufacturing method of bamboo-based heterochromous laminated decorative plate

ActiveCN106926330AVariety of colorsFacilitate continuous productionOther plywood/veneer working apparatusWood treatment detailsChange colorSingle plate

Owner:国家林业局竹子研究开发中心

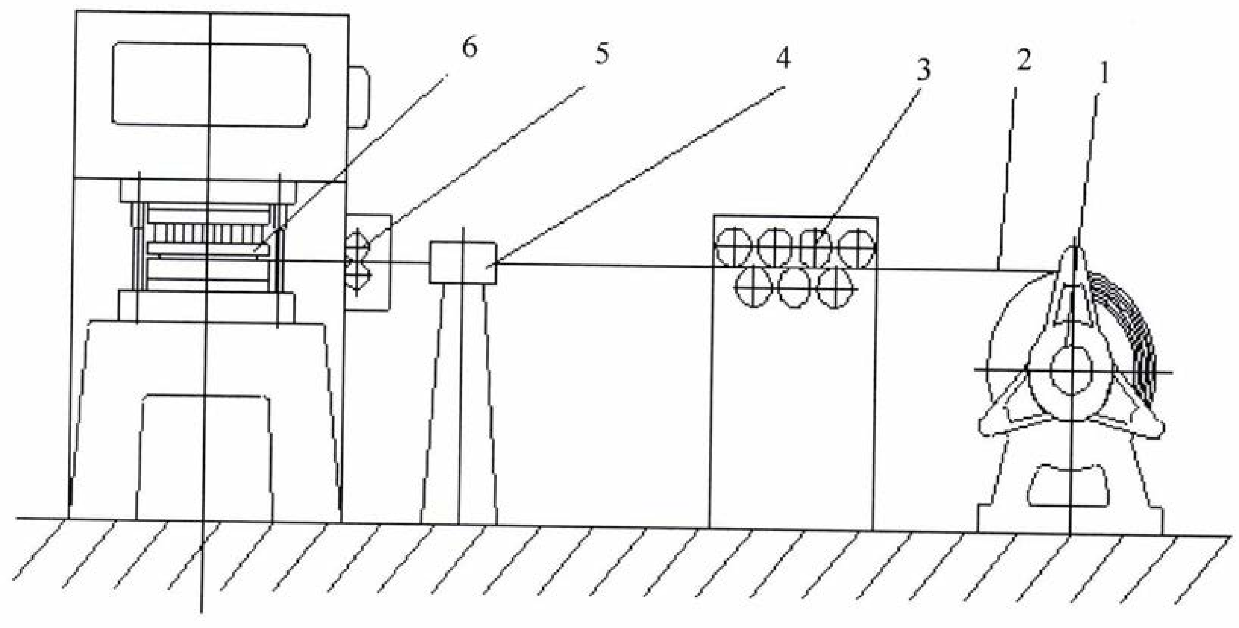

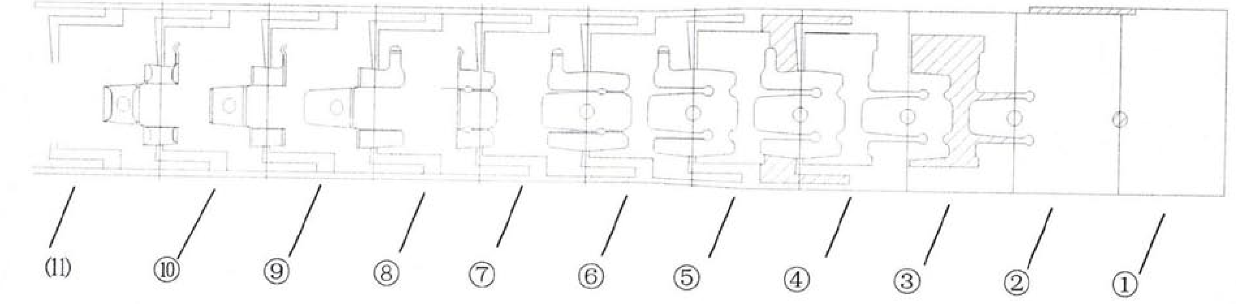

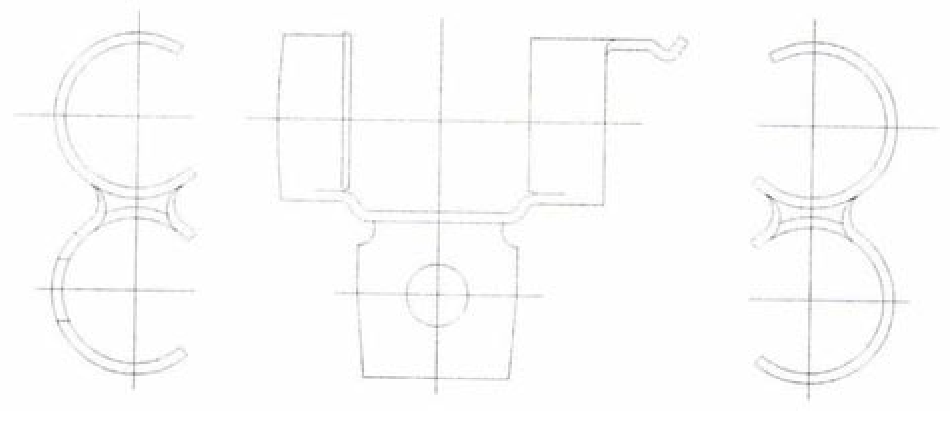

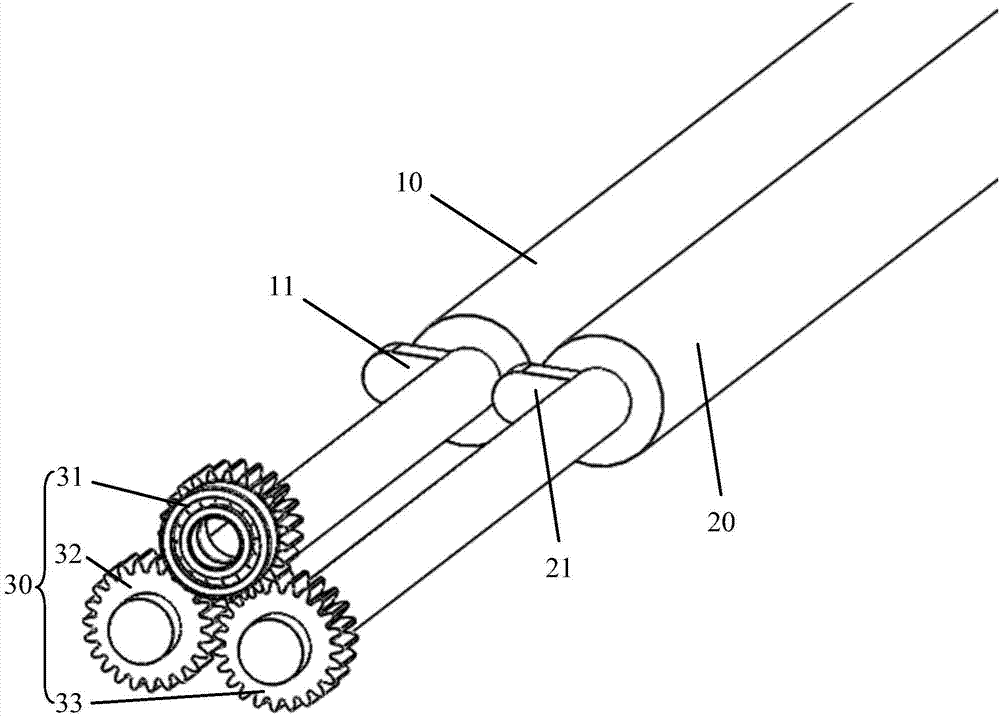

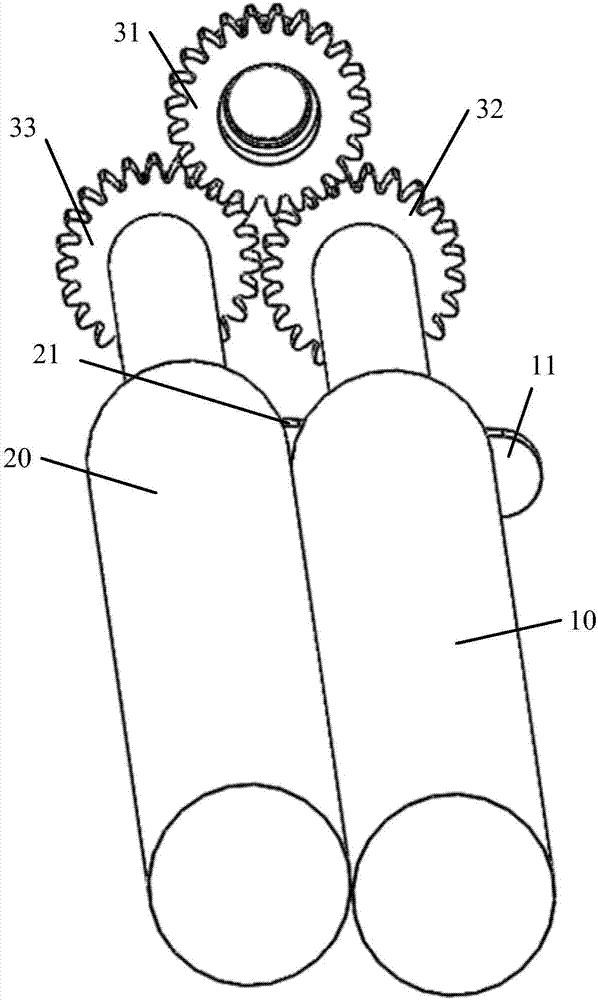

A kind of automatic production method of elastic chain

ActiveCN106507885BReduce consumptionEven and reasonable feedingAmmunition loadingPunchingManufacturing technology

Owner:HEILONGJIANG NORTH TOOLS CO LTD

Method for crimping high-pressure cross-linking three-layer co-extrusion continuous produced disc-exchanging conductor

InactiveCN102945710ANo drop in tensile strengthLow technical requirementsConnections effected by permanent deformationCable/conductor manufactureCross-linkElectrical resistance and conductance

Owner:HENGYANG HENGFEI CABLE CO LTD

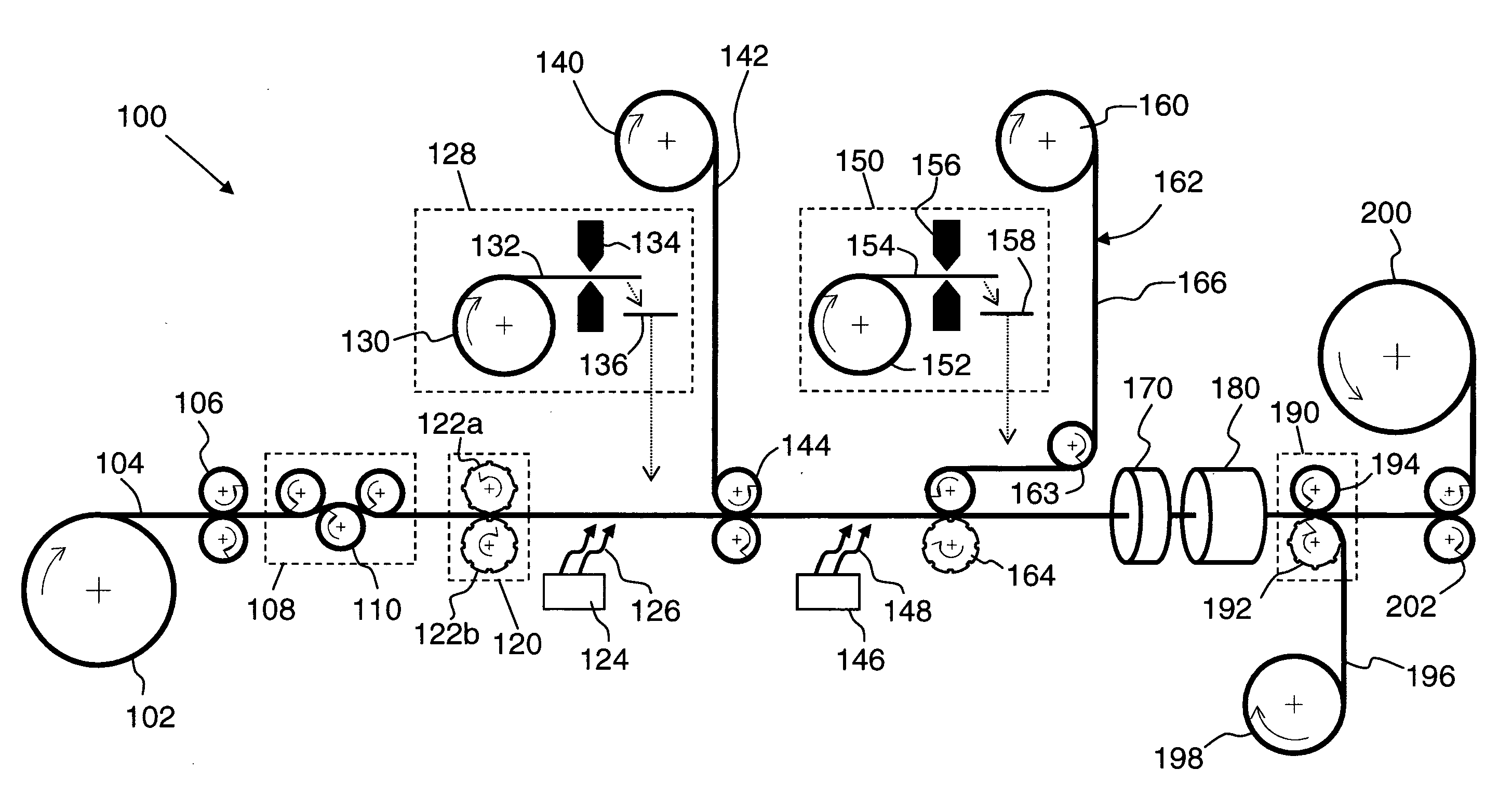

Ribbon cutter apparatus and method for making sandwich baked goods

A method for the continuous production of sandwich baked goods having a high volume of filler includes conveying a bottom base cake, detecting the position of the base cake, and extruding a filler through a die aperture to form a ribbon in response to the detection of the position of the bottom base cake. In response to detection of the base cake, a signal or timing mechanism may activate a guillotine knife or blade to open the die aperture to allow filler to be deposited on the bottom base cake and to close the die aperture to sever or cut the ribbon to a predetermined dimension. The severing prevents further flow of the filler through the die aperture until the next bottom base cake is detected and the die aperture is again opened to allow filler to be deposited on the next bottom base cake.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

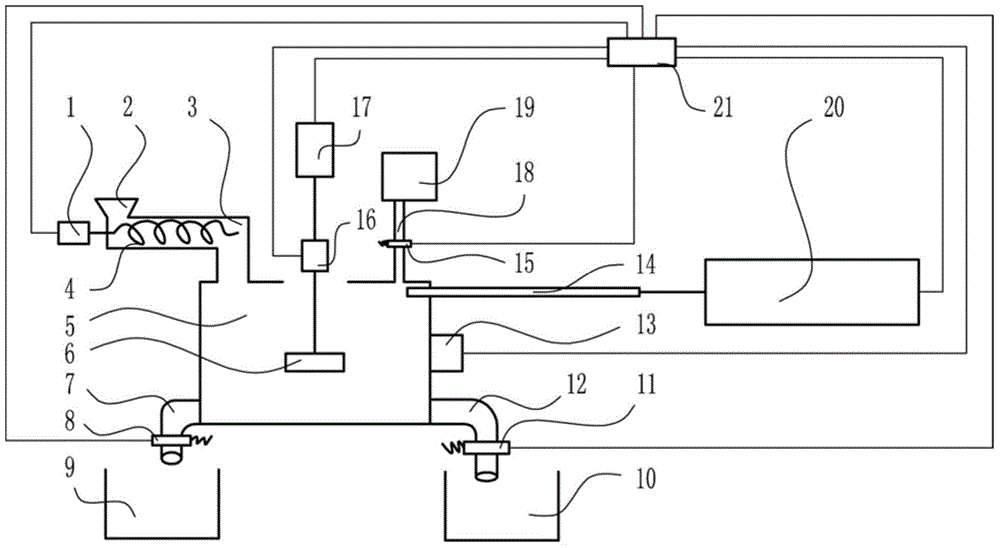

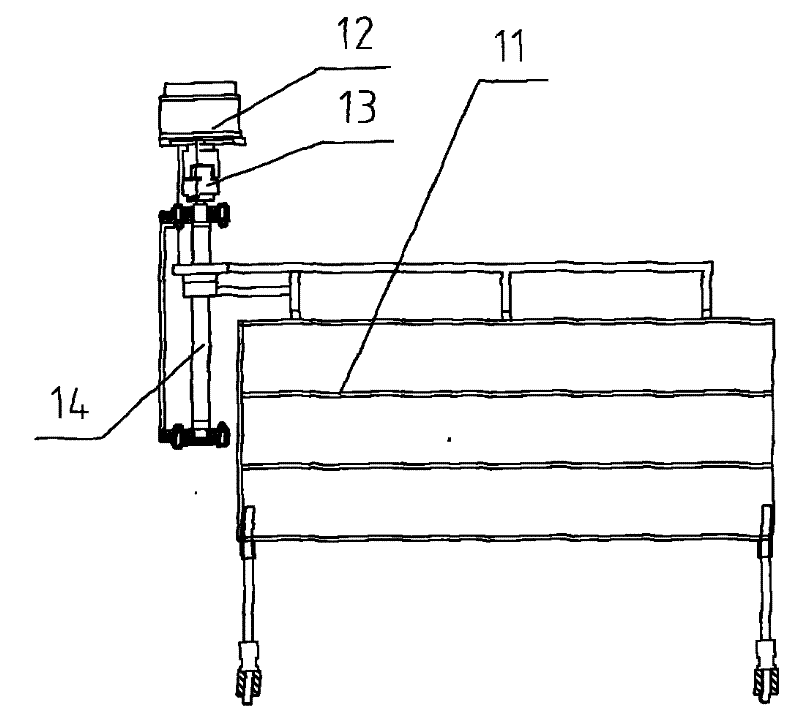

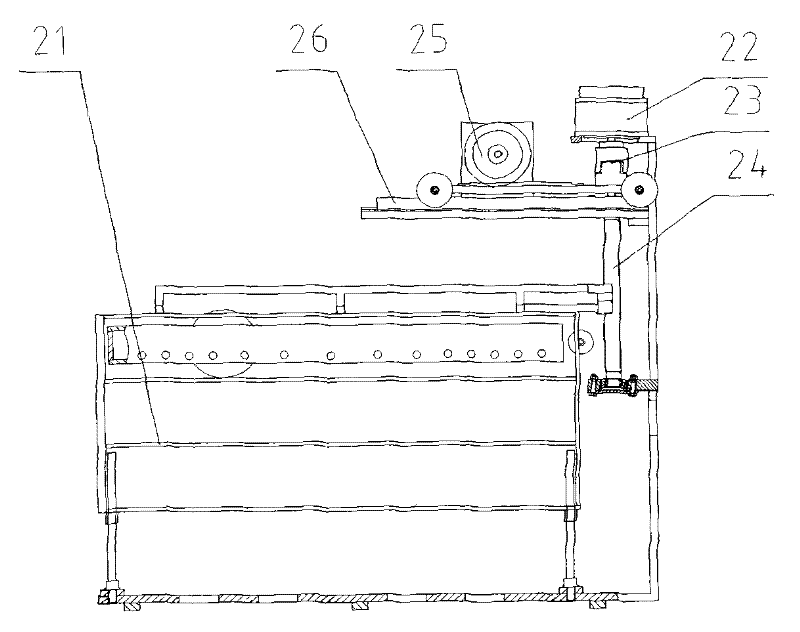

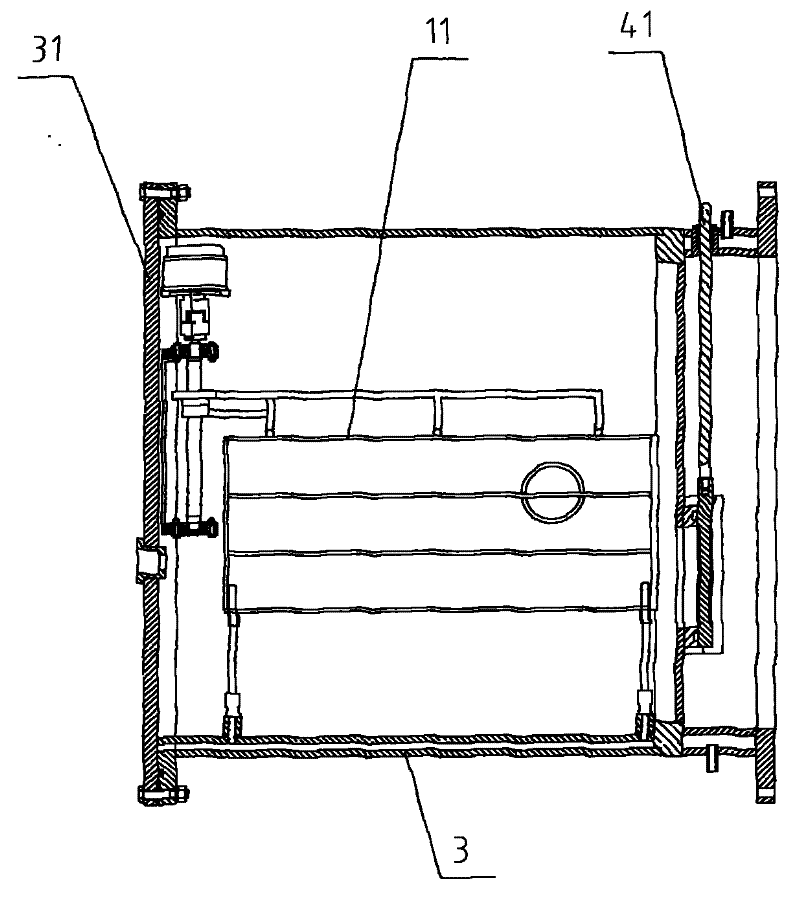

Full-automatic tarpaulin production line

PendingCN111058681ARealize automatic continuous productionIncrease productivityTents/canopiesSevering textilesHot pressContinuous production

The invention relates to the technical field of tarpaulin production, in particular to a full-automatic tarpaulin production line. The production line comprises a punching device and a machining device, wherein the machining device comprises a rack, an operating platform arranged under the rack, a machining forming mechanism arranged on the rack, a supporting base used for connecting the machiningforming mechanism with the rack in a sliding mode, and a power transmission mechanism driving the supporting base, the machining forming mechanism comprises a fixed plate and a sliding plate, a cutter is arranged under the sliding plate, the machining forming mechanism further comprises a rope arranging device, a flanging device, a heat sealing device, a hot pressing device, a clamping device, amoving device and a cutting device, the sliding plate slides on the fixed plate through a driving device, and the machining forming mechanism further comprises a length control device, a controller and a detecting element. The production line is high in automatic integration degree, the quality of finished products is guaranteed, automatic continuous production can be effectively achieved, manpower is saved, the occupied space is small, and the production line can adapt to dotting of tarpaulins of different sizes, and meet different production requirements.

Owner:青岛铭宇智能设备有限公司

Vacuum belt type dryer material dust continuous discharge system

PendingCN108946175AGuaranteed filter effectImprove drying recoveryDrying solid materials without heatDrying machines with progressive movementsBuffer tankInlet valve

Owner:常州朗脉洁净技术有限公司

Continuous decontamination process for organic chlorination reaction byproduct hydrochloric acid

Owner:河南昊海实业有限公司

Traditional Chinese medicine microwave extraction device

ActiveCN104784965AAutomate operationRealize continuous productionEnergy based chemical/physical/physico-chemical processesSolid solvent extractionMicrowaveHelical blade

Owner:江苏传承中药有限公司

Batch feeding and discharging system and method for continuous production type vacuum atmosphere furnace

Owner:QINGDAO UNIV OF SCI & TECH +1

Polyimide microdenier fiber and preparation method thereof

ActiveCN107151833AImprove performanceThe spinning process is simple and fastArtificial filament washing/dryingFilament/thread formingYarnFiber

The invention discloses a polyimide microdenier fiber and a preparation method of the polyimide microdenier fiber, and belongs to the field of fiber preparation. The polyimide microdenier fiber and the preparation method solve the problems of high end breakage rate, high yarn unevenness rate and low production efficiency of the conventional preparation method of the polyimide microdenier fiber. The preparation method of the polyimide microdenier fiber comprises the following steps: dissolving soluble components in a polyamide acid bicomponent nascent fiber by solvents, and then performing washing, drying, thermal imidization and drafting treatment. The filament number of the polyimide microdenier fiber is 0.5-1.1dtex; the tensile strength of the polyimide microdenier fiber is equal to or greater than 4.0cN / dtex. The preparation method is simple, convenient and quick in spinning technology, low in production cost, stable and safe in spinning process, energy-saving and environmentally friendly; industrial and continuous production is easy to realize; the organic solvents used in the spinning process are easy to recycle; a spinning end breakage rate is reduced; a yarn unevenness rate is increased; the production efficiency is further improved. The polyimide microdenier fiber obtained by the preparation method is excellent in comprehensive performance.

Owner:CHANGCHUN HIPOLYKING

Sponge abrasive material and preparation method thereof

InactiveCN108000377AAvoid indistinguishableRealization of long-term continuous productionAbrasion apparatusFire retardantUltimate tensile strength

The invention discloses a sponge abrasive material and a preparation method thereof, and relates to the field of abrasive materials. The sponge abrasive material comprises the following components of,by weight, 0.999-1 part of a polyurethane elastic material, 0.001-0.01 part of color paste, 1-20 parts of hard abrasive materials and 0.02-0.08 part of a flame retardant, the hard abrasive materialsare evenly distributed between foam formed by the polyurethane elastic material and the flame retardant, the color paste has different colors, and the hard abrasive materials are one or several of steel sand, brown corundum, garnet and the like. The sponge abrasive material and the preparation method thereof have the beneficial effects that the problem that the type of the hard abrasive materialsis difficult to distinguish after the hard abrasive materials are wrapped with polyurethane sponge is avoided, according to the preparation method of the sponge abrasive material, the wrapping strength of the sponge abrasive material is improved, the service life is prolonged, meanwhile, the problem of continuous production of the sponge abrasive material is solved, the efficiency is improved, theyield is increased,, and consumption is reduced.

Owner:SHANDONG TAA CLOUD IND ENG TECH CO LTD

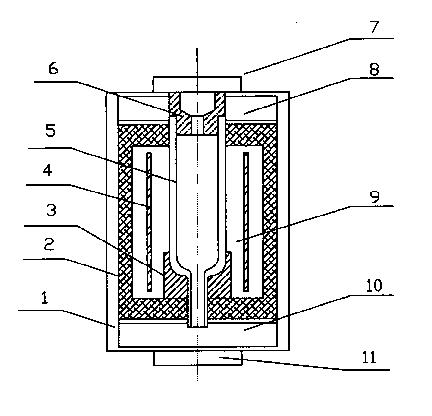

Method for preparing feeding nozzle for continuous high-purity alumina melting furnace and continuous melting furnace

Owner:SHANDONG UNIV OF TECH

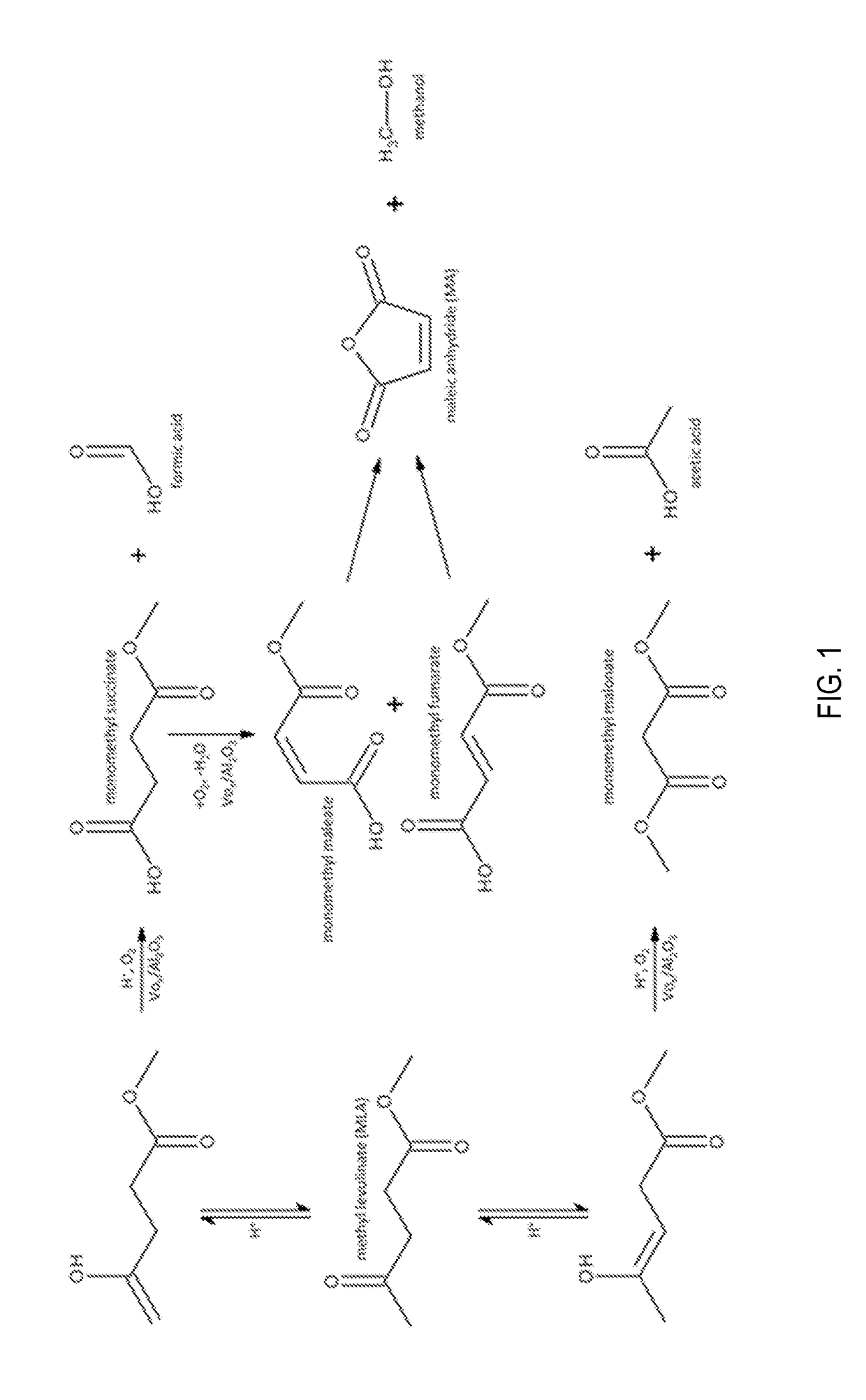

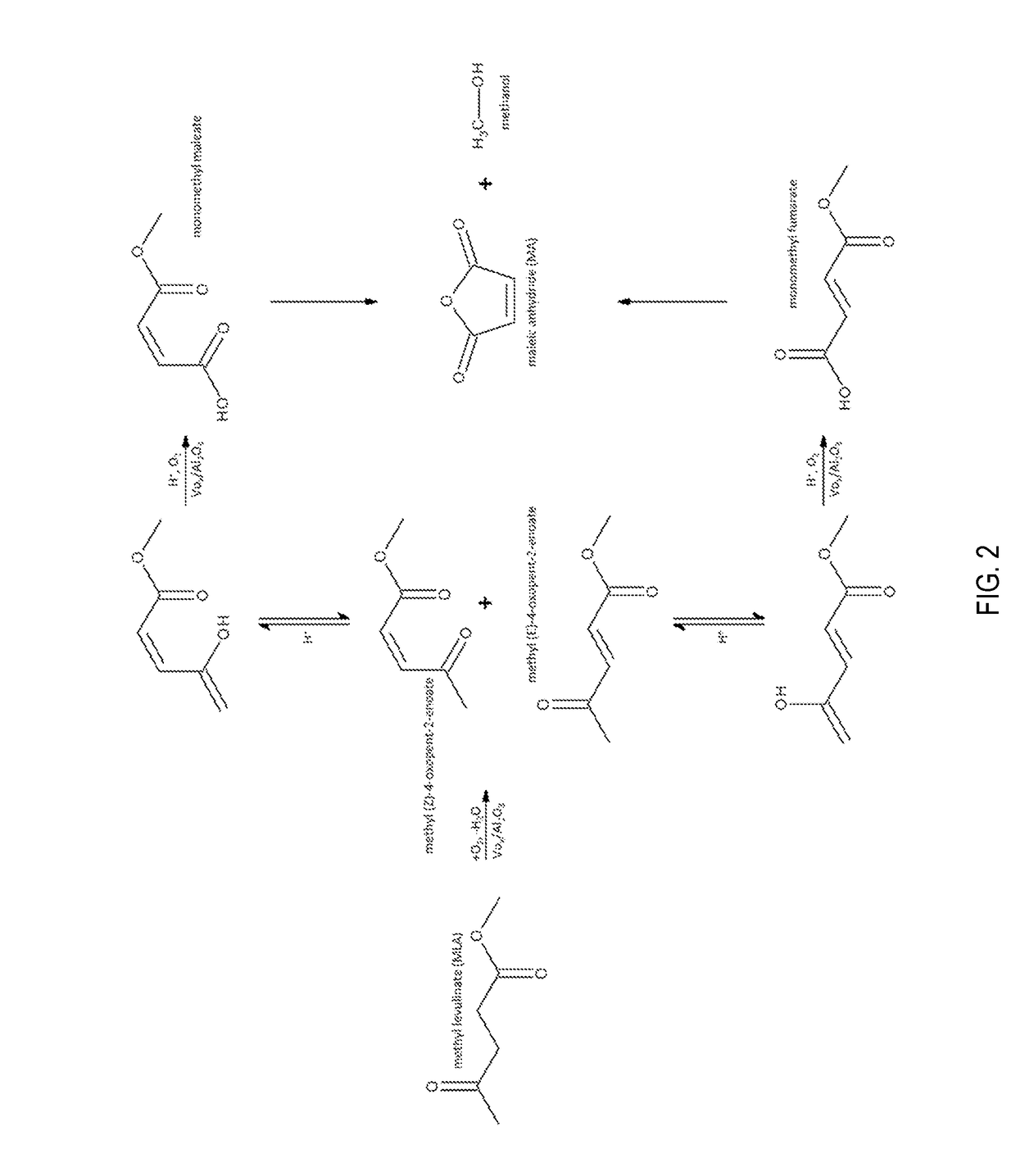

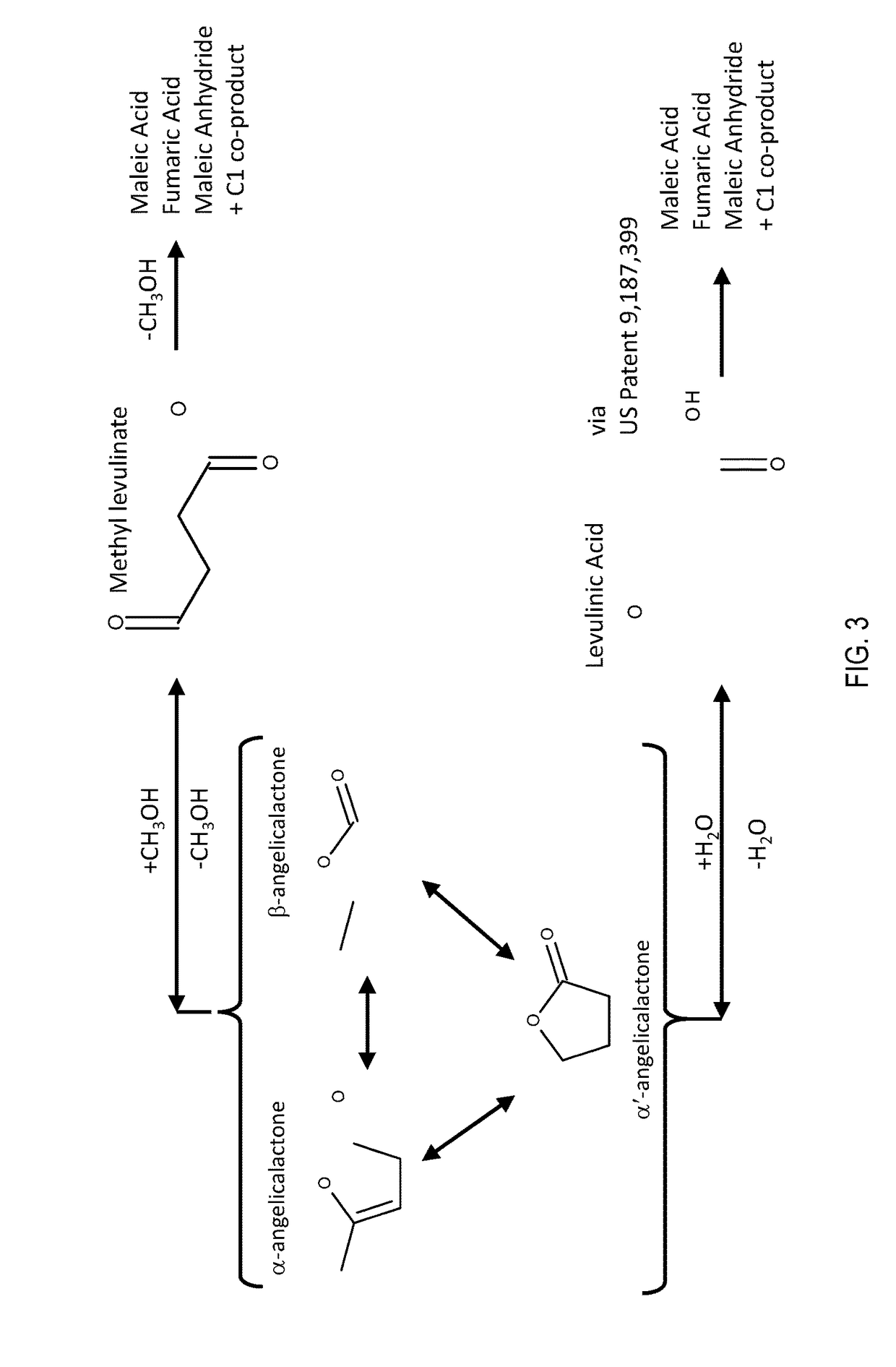

Production of maleic acid, fumaric acid, or maleic anhydride from levulinic acid analogs

ActiveUS20180354883A1Promote formationLow melting pointOrganic compound preparationCatalyst activation/preparationLevulinic acidPropanoic acid

Owner:SYRACUSE UNIVERSITY

Core pulling die with automatic cleaning function

Owner:四川美霖科技有限责任公司

Redundancy control method for flame cutting system of continuous casting machine

PendingCN114625055AGuaranteed stabilityImplement redundant configurationProgramme controlComputer controlProcess engineeringContinuous production

The invention belongs to the technical field of continuous casting of steel and iron, and relates to a redundancy control method for a flame cutting system of a continuous casting machine, which is characterized in that a time control program is added in an optimized logic control program by taking a flame cutting machine clamping signal as a reference, and cutting end electrical limit is replaced by taking the flame cutting machine clamping signal as the reference and matching with delay time. A holding clamp loosening signal of the flame cutting machine is used as a reference to be matched with different delay times to replace cutting machine swing gun initial electrical limiting and cutting machine original electrical limiting. Whether each simulation electrical limit is put into use or not can be put into or removed from an HMI picture, and the delay time can be adjusted on the HMI picture in real time according to different production working conditions. After any electrical limit of the flame cutting machine breaks down, the limit can be quickly simulated for use, the on-line first-aid repair operation time can be shortened by 30 minutes per time, the potential safety hazard of high-temperature on-line first-aid repair is thoroughly solved, and the stability of continuous production of a casting machine is effectively guaranteed.

Owner:SHANDONG LAIGANG YONGFENG STEEL & IRON

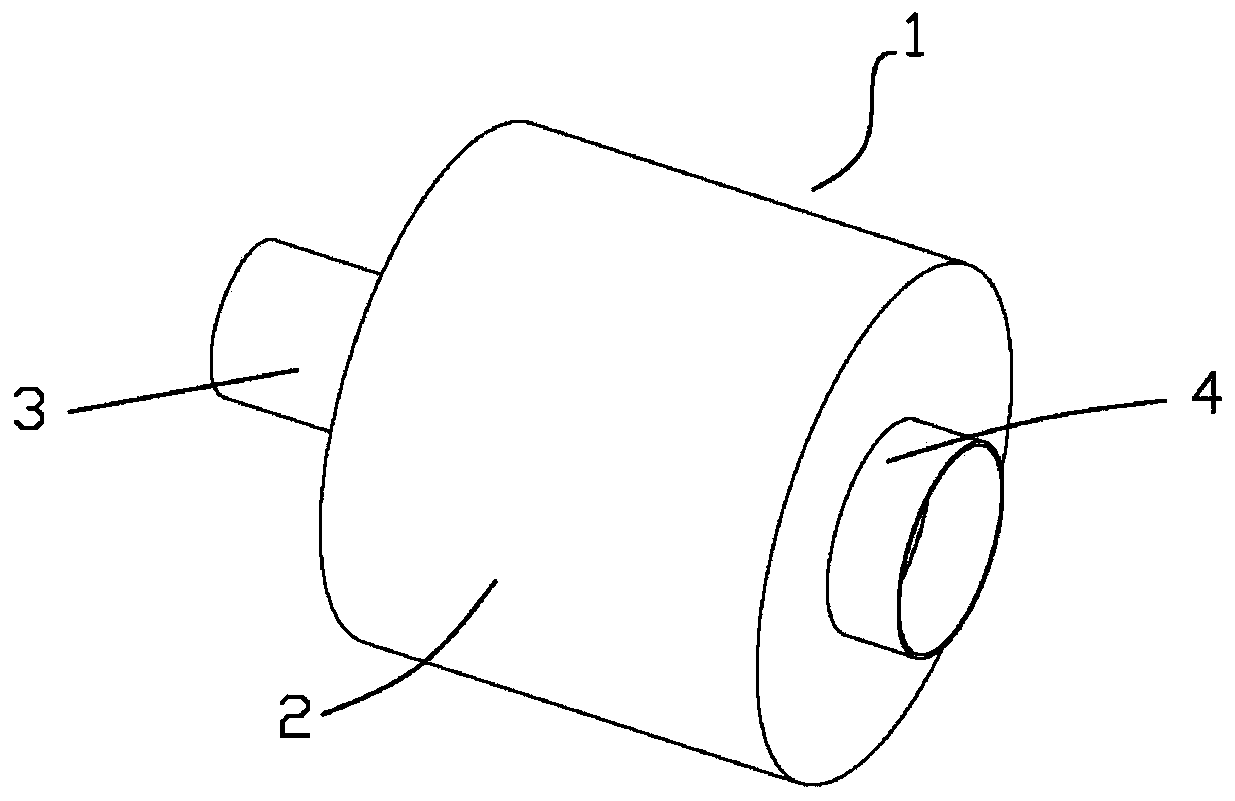

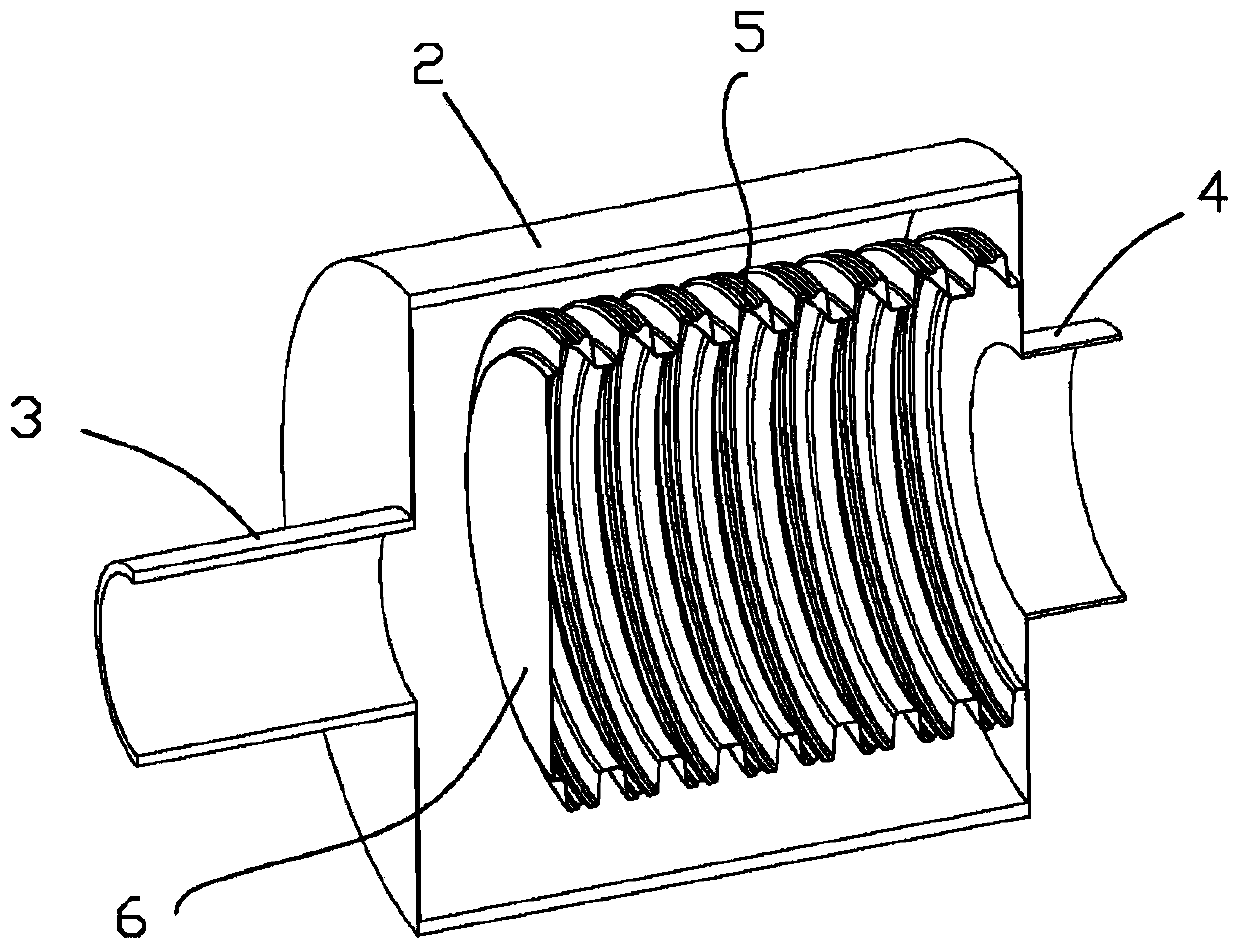

Automatic corrugated pipe sensor of instrument

InactiveCN110095221AWith spacer chemical propertiesStrong stretching force and low tensionFluid pressure measurement using elastically-deformable gaugesAlloyHigh pressure

Owner:唐根林

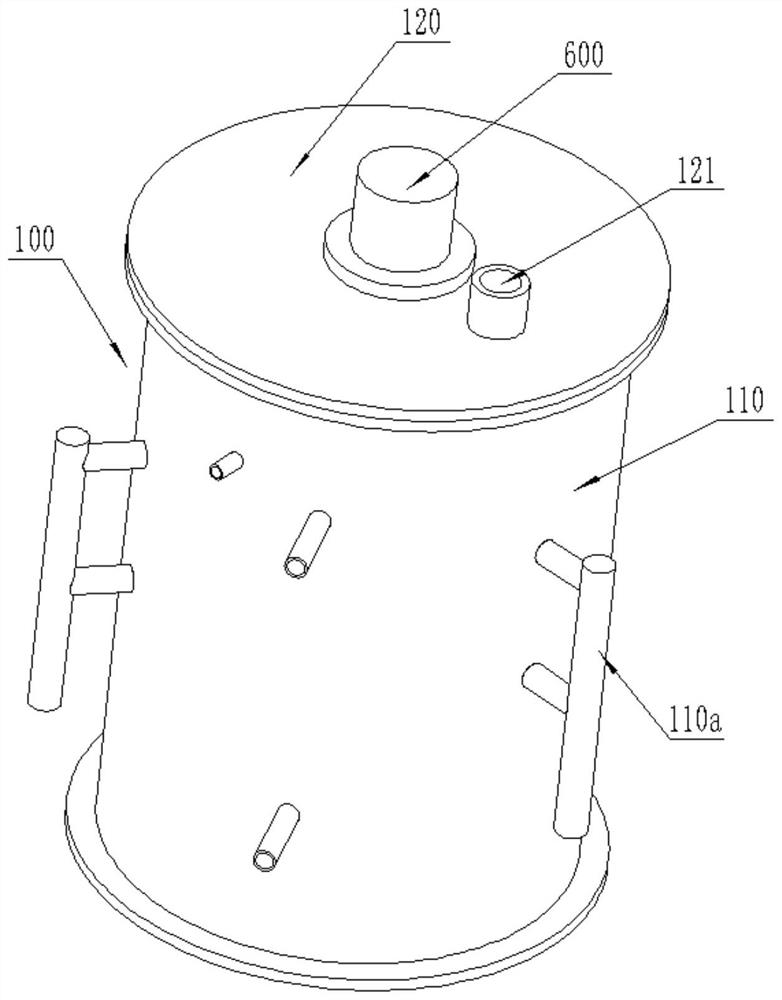

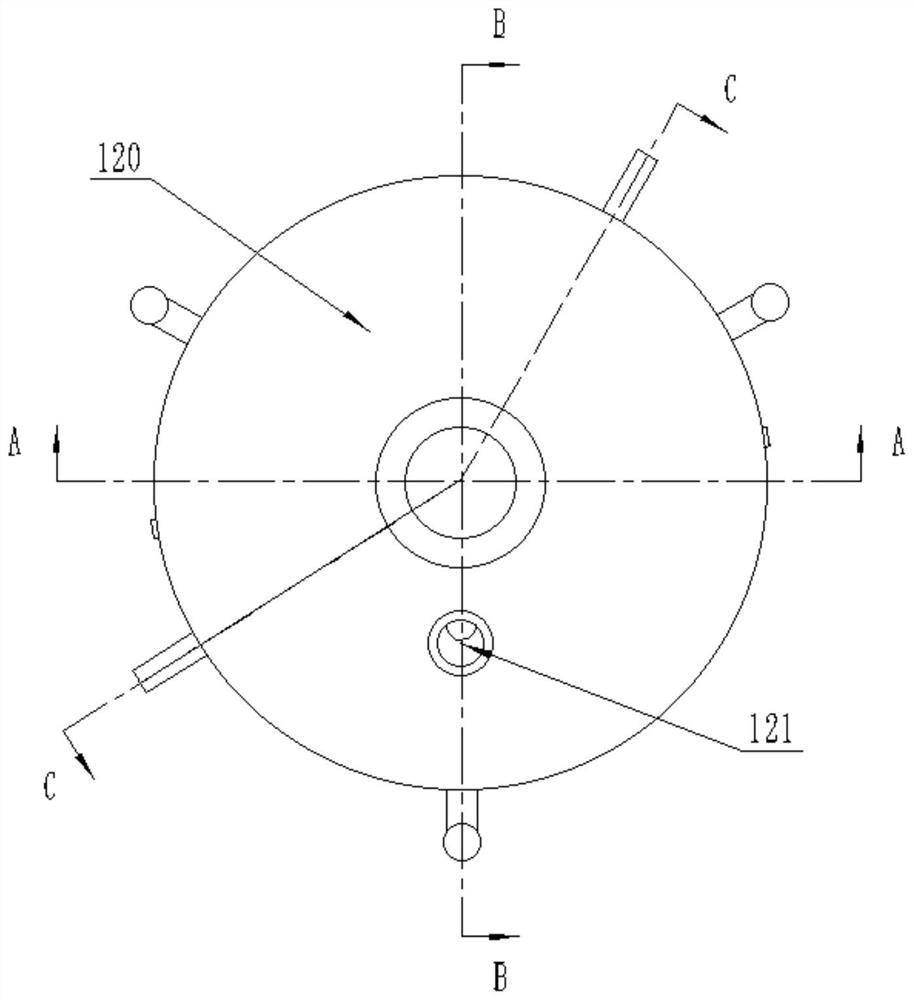

Surrounding centrifugal sucrose-6-ester continuous production equipment and production method

ActiveCN112933635AIncrease productivityShorten transition timeEsterified saccharide compoundsSugar derivativesSucroseElectric machinery

Owner:安徽金禾化学材料研究所有限公司

Device and method capable of accurately controlling molten copper to clad copper-clad steel

PendingCN114220608AOutflow controlSolve the problem that accumulation is easy to occur and the production cannot be carried out normallyMetal/alloy conductorsCable/conductor manufactureElectric machineGraphite

Owner:韦玛实业集团有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap