Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97 results about "Environmentally friendly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environmentally friendly or environment-friendly, (also referred to as eco-friendly, nature-friendly, and green) are sustainability and marketing terms referring to goods and services, laws, guidelines and policies that claim reduced, minimal, or no harm upon ecosystems or the environment. Companies use these ambiguous terms to promote goods and services, sometimes with additional, more specific certifications, such as ecolabels. Their overuse can be referred to as greenwashing.

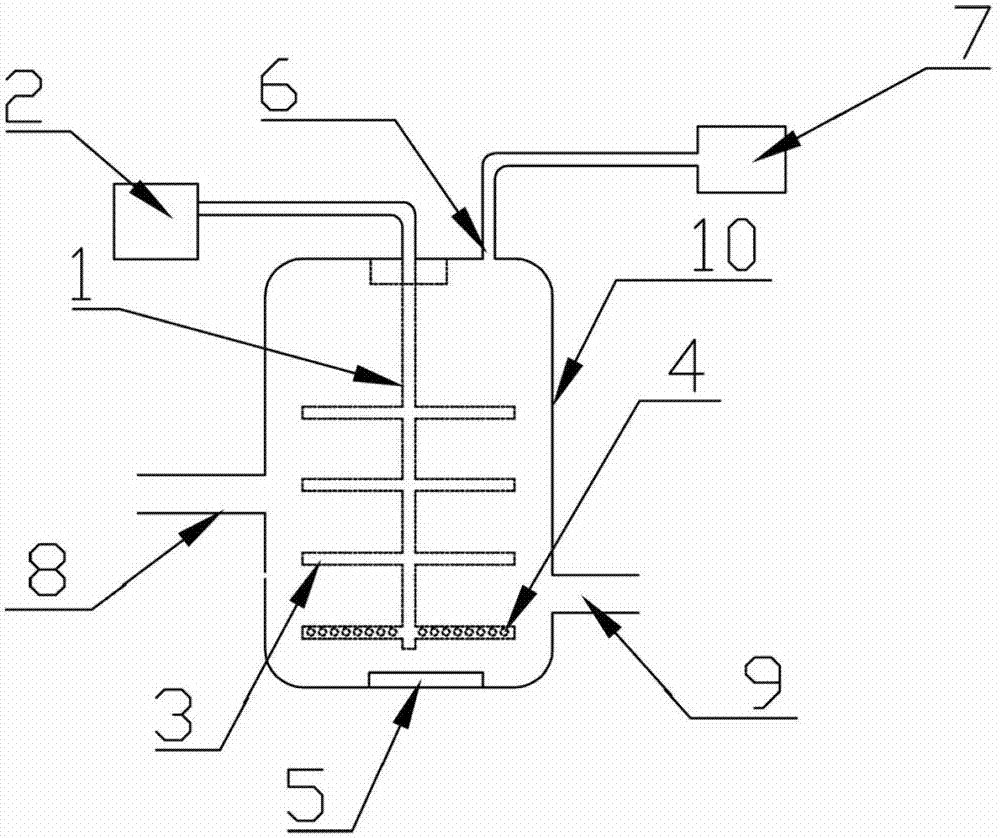

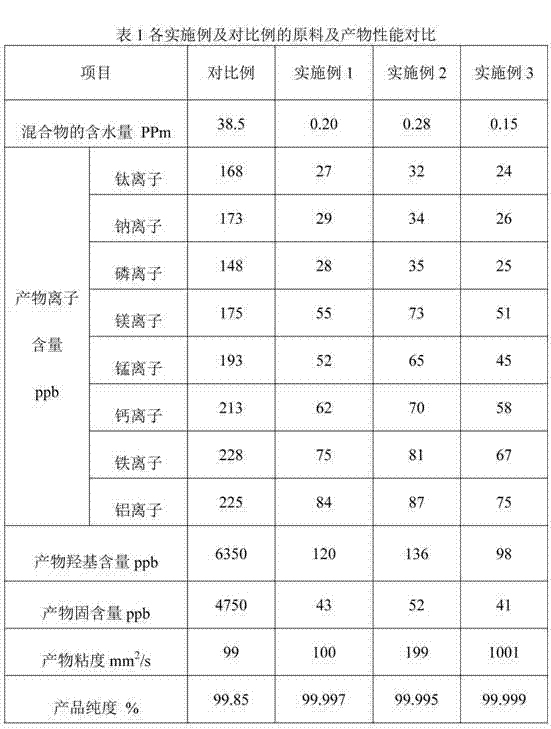

Continuous preparation technology of high-purity low-viscosity dimethicone

ActiveCN103073722AHigh purityMaintain catalytic activityChemical recyclingPtru catalystSilicone fluid

Owner:YICHANG COLLIN SILICON MATERIAL CO LTD

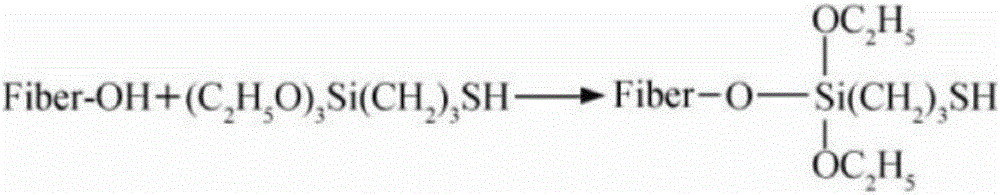

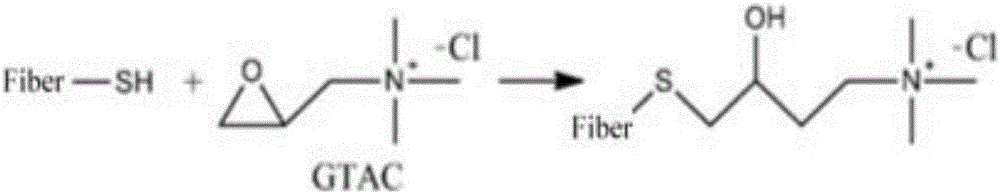

Durable cotton fabric antifungal finishing method based on click chemistry

InactiveCN105821654AImprove hydrophilic dyeabilityHas antibacterial functionBiochemical fibre treatmentVegetal fibresAntifungalSilanes

Owner:DONGHUA UNIV +1

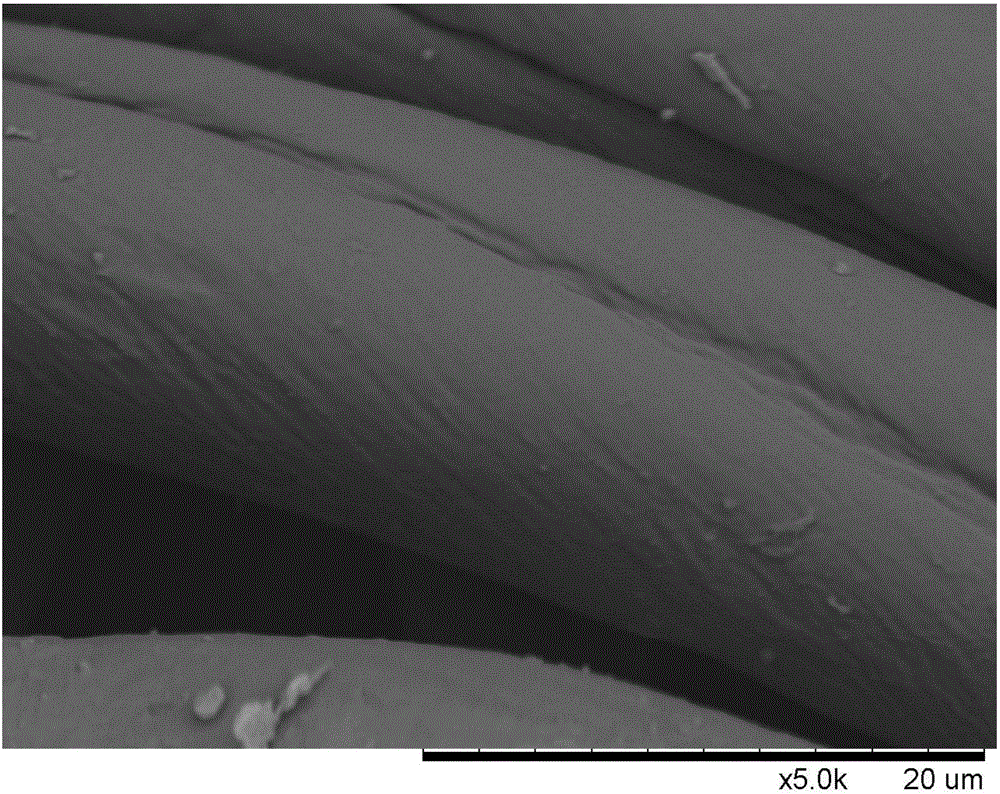

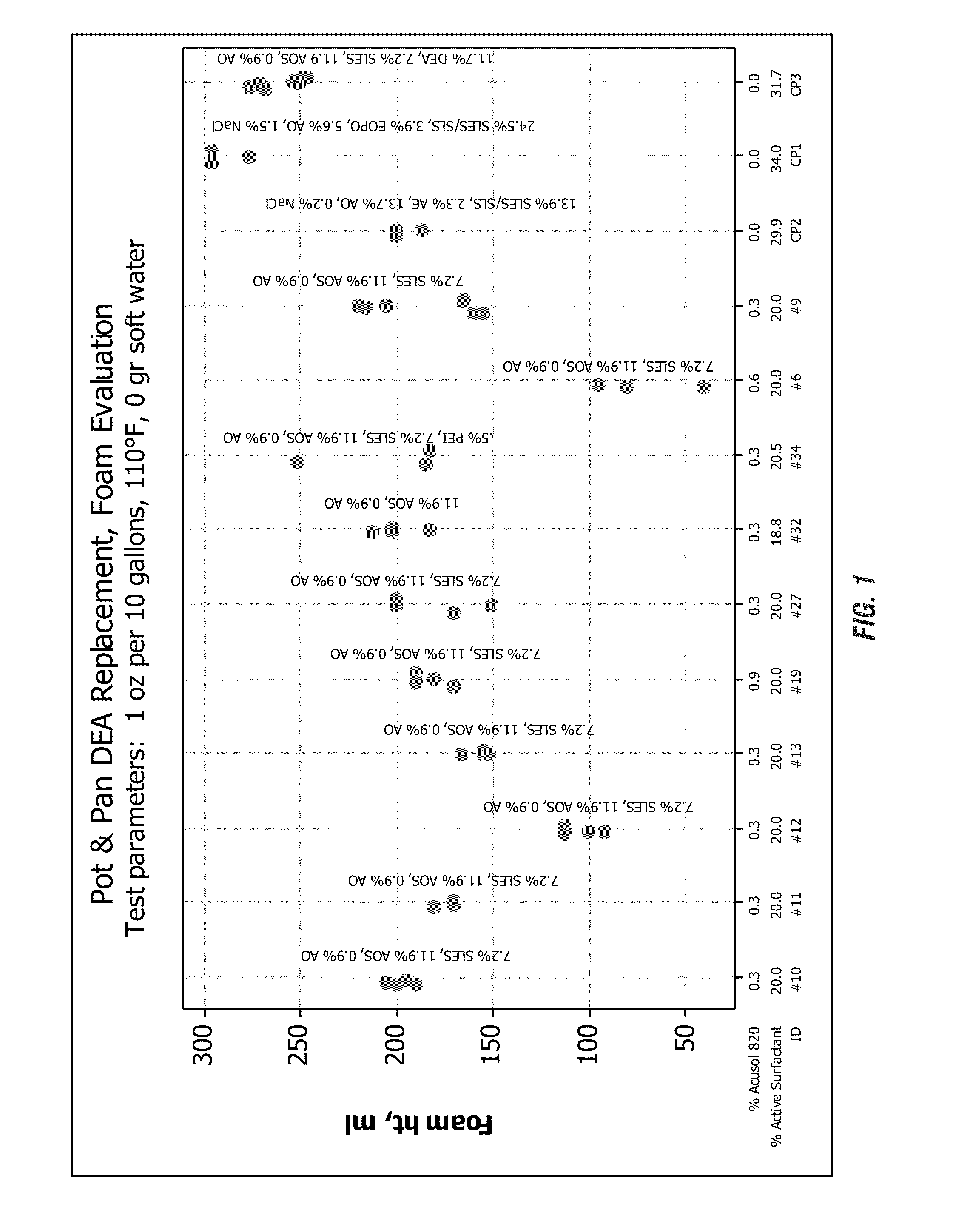

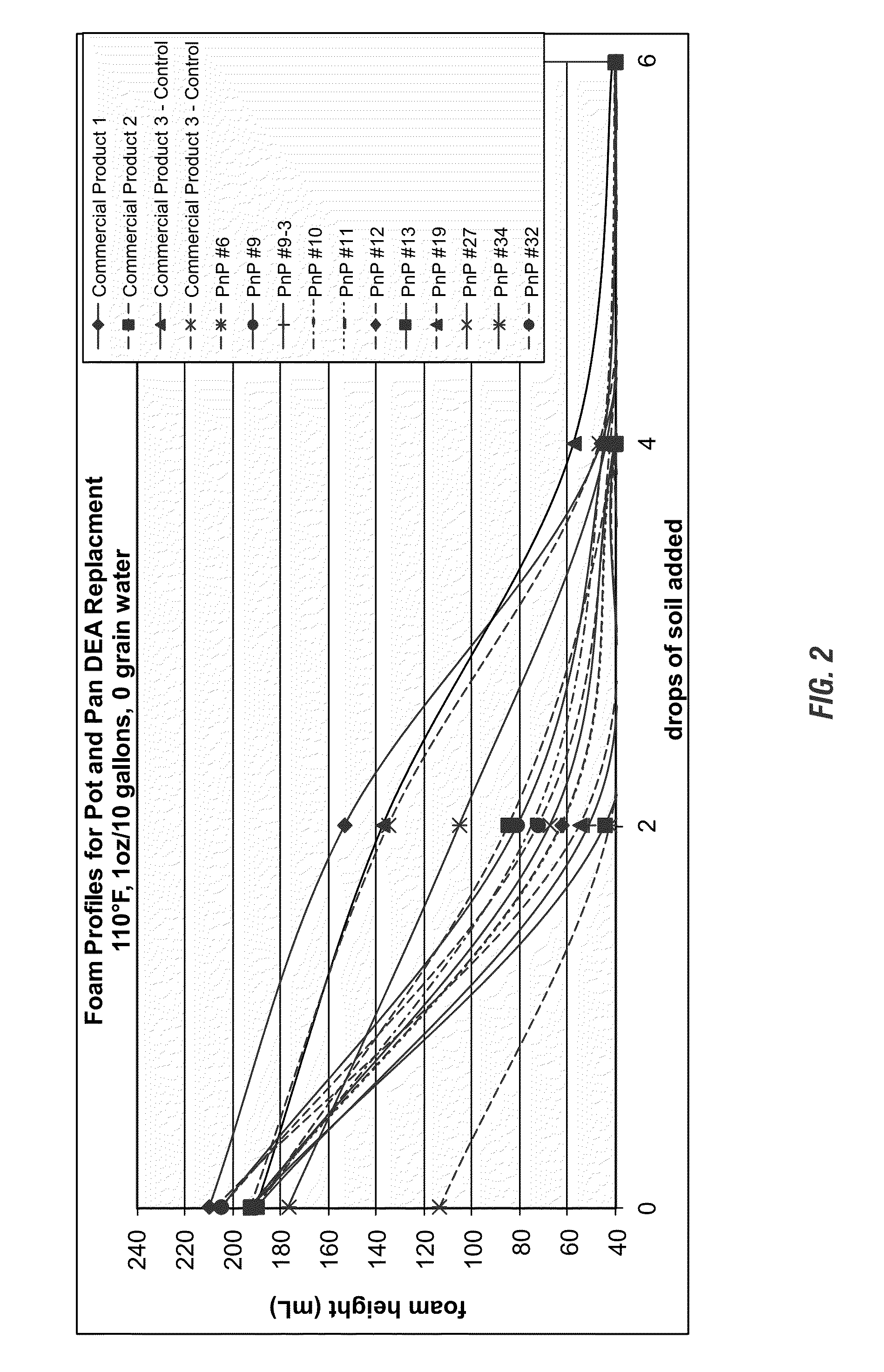

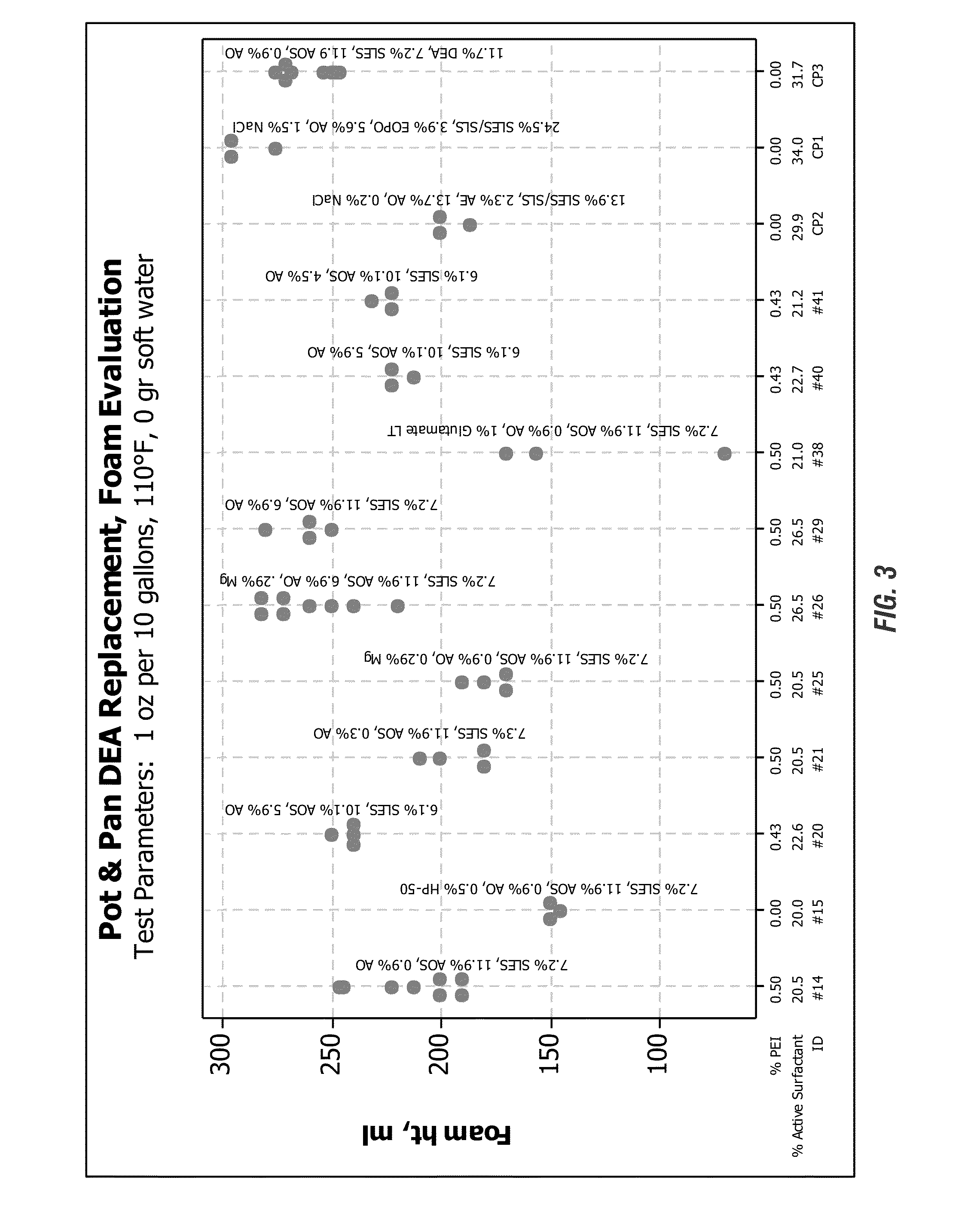

Foam stabilization with polyethyleneimine ethoxylates

ActiveUS20140148374A1Provide stabilityCosmetic preparationsOrganic detergent compounding agentsElectrostatic interactionCocamide DEA

Owner:ECOLAB USA INC

Epoxy resin-enhanced laminated insulating profile and preparation method thereof

The invention discloses an epoxy resin-enhanced laminated insulating profile. The epoxy resin-enhanced laminated insulating profile comprises modification polymers and a reinforcing material, wherein the modification polymers include epoxy resin, a curing agent, a promoting agent, a flame retardant, a wetting dispersant and a solvent; the reinforcing material is a fiber material; the components of the modification polymers are mixed to form a modification polymer solution, the reinforcing material is soaked into the modification polymer solution and is finally subjected to hot press molding to form the epoxy resin-enhanced laminated insulating profile. The epoxy resin-enhanced laminated insulating profile is integrated with lightness, flame retardance, corrosion resistance and insulativity, has extremely high mechanical property, excellent electrical insulation property and halogen-free flame retardance, is environmentally friendly, is high in use safety and can be applied to industries and fields including State Grid Corporation of China, new energy resources, energy conservation, consumption reduction and track traffic which have high requirements to material performance and special working conditions and environments.

Owner:SICHUAN D&F ELECTRICAL TECH

Textile with flame retardancy and water repellency, and production method thereof

The invention discloses a textile with flame retardancy and water repellency, and a production method thereof. The textile with flame retardancy and water repellency contains flame-retardant polyester fibers. Bromine element content of the textile with flame retardancy and water repellency is less than or equal to 5 micrograms per gram. Fluorine element content of the textile with flame retardancy and water repellency is less than or equal to 5 micrograms per gram. One or more non-halogen flame-retardant treating agents and one or more non-fluorine water-repellent treating agents are prepared into the textile with flame retardancy and water repellency through functional finishing. The textile with flame retardancy and water repellency is safe and environmentally friendly. After the textile with flame retardancy and water repellency is washed 5 times, the necessary frequency of exposure under flame for burning is great than or equal to 3 and the water repellency reaches or exceeds a second level. The textile with flame retardancy and water repellency can be utilized for preparation of shower curtains, tents, window curtains, outdoor gym suits and the like.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Preparation and application of chemical oxidation repair additive for organic matter-contaminated soil

InactiveCN106433682AImprove the coordination effectPromote dissolutionContaminated soil reclamationOrganic fertilisersPotassium persulfatePersulfate

The invention discloses a preparation method and application of a chemical oxidation repair additive for organic matter-contaminated soil. The chemical oxidation repair additive for the organic matter-contaminated soil is prepared by adopting persulfate to oxidize a bisphenol compound and alpha-amino acid in an alkaline aqueous solution. The chemical oxidation repair additive is directly added into the organic matter-contaminated soil, and organic pollutants in the soil are subjected to oxidative degradation by taking a potassium persulfate solution and a hydrogen peroxide solution as oxidizing agents, and using ferric oxide, which is inherent in the soil, as a catalyst. The preparation method is simple in technology, mild in conditions, low in cost and environmentally-friendly, and can realize large-scale production; when the chemical oxidation repair additive is used for repairing the organic matter-contaminated soil, the organic pollutants are efficiently and rapidly degraded, and secondary pollution is not produced; therefore, the chemical oxidation repair additive for the organic matter-contaminated soil has wide application prospect.

Owner:UNIV OF JINAN

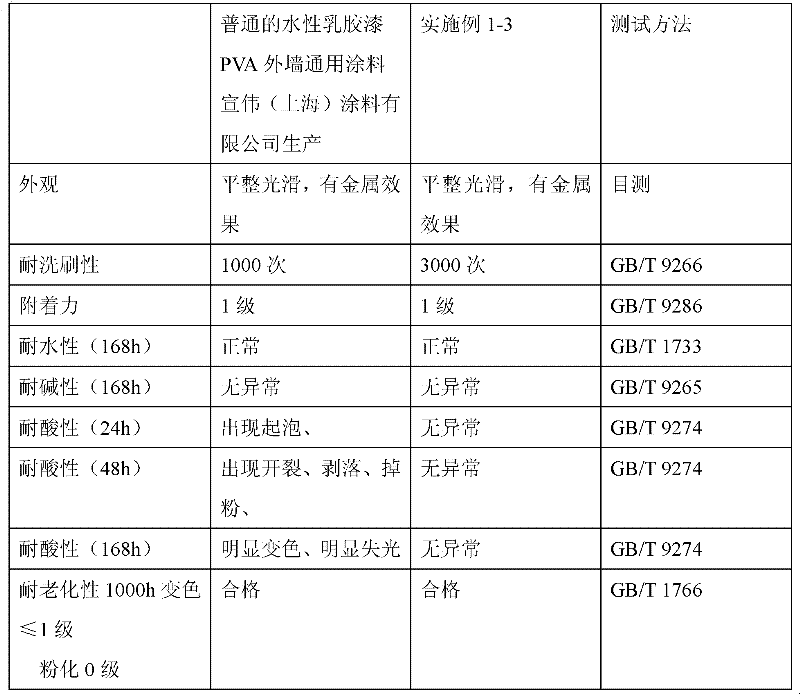

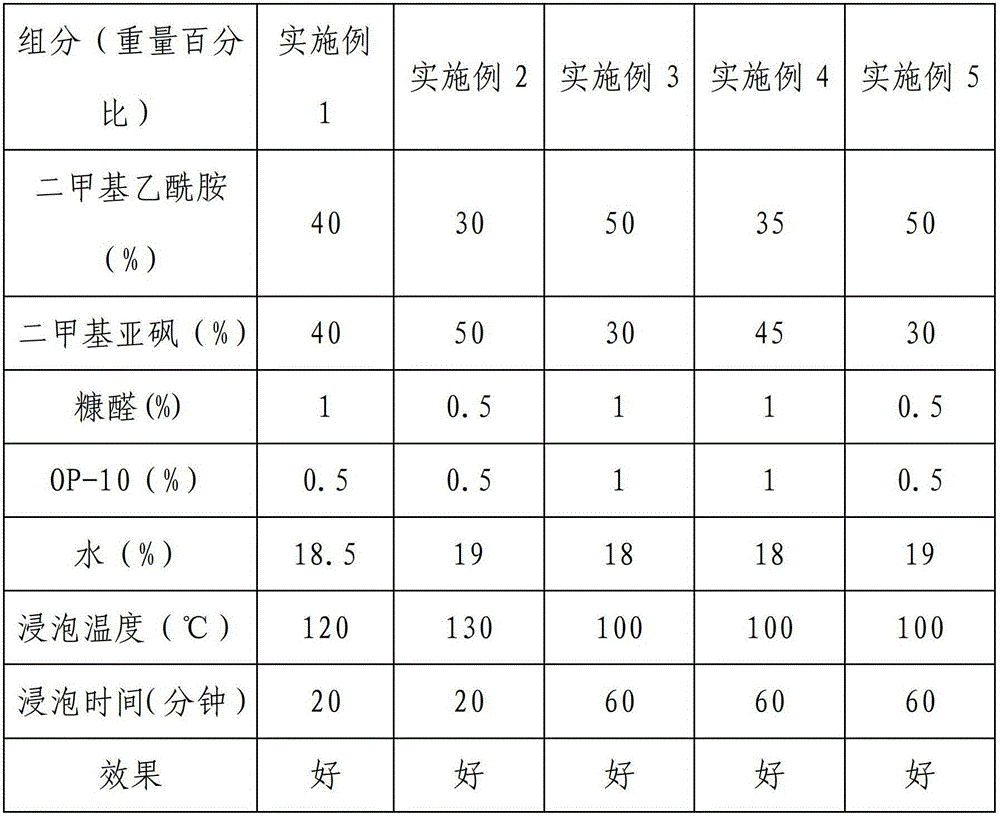

Environment-friendly water-based imitation stone coating and its raw materials, preparation method and application

Owner:上海三银制漆有限公司

Environment protection type weakly acidic deburring softening solution and preparation method and use method thereof

Owner:JIANGSU AISEN SEMICON MATERIAL CO LTD

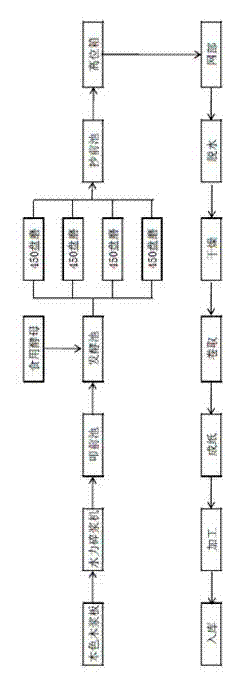

Production technology of all-wood-pulp unbleached ecological environmentally-friendly toilet paper

InactiveCN102733225ASimple processEasy to operatePulp beating methodsRaw material divisionNatural fiberEnvironmentally friendly

The invention relates to the technical field of papermaking technologies, and concretely relates to a production technology of all-wood-pulp unbleached ecological environmentally-friendly toilet paper. The technology concretely comprises the following steps: 1, defibering 100% by mass of unbleached wood pulp plates with a waterpower pulper, adding edible yeasts having a weight being 0.1% of the weight of the resulting unbleached wood pulp, and fermenting at 28-30DEG C for 4-6h; 2, beating the fermented pulp with a millstone mill, wherein beating parameters comprise that the beating concentration is 3.8-4.0%, the beating degree is 42-45DEG SR, and the wet weight is 4-5g; and 3, sequentially carrying out operations of wet end shaping, squeezing dehydration, drying, reeling, rewinding and slitting on the beaten pulp to obtain the toilet paper. The technology of the invention has the advantages of simplicity, convenient operation, and no bleaching in the product production process, no addition of any chemical additives; and the toilet paper of the invention has the characteristics of softness, fineness, durability, and radiation of a natural fiber fragrance, and can reach requirements of food level paper for daily life.

Owner:卜祥生

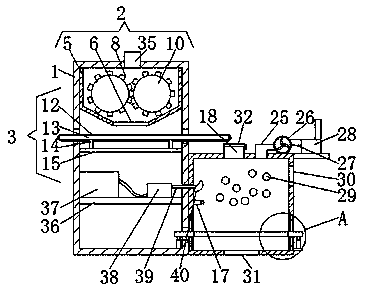

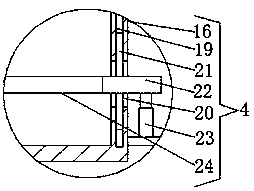

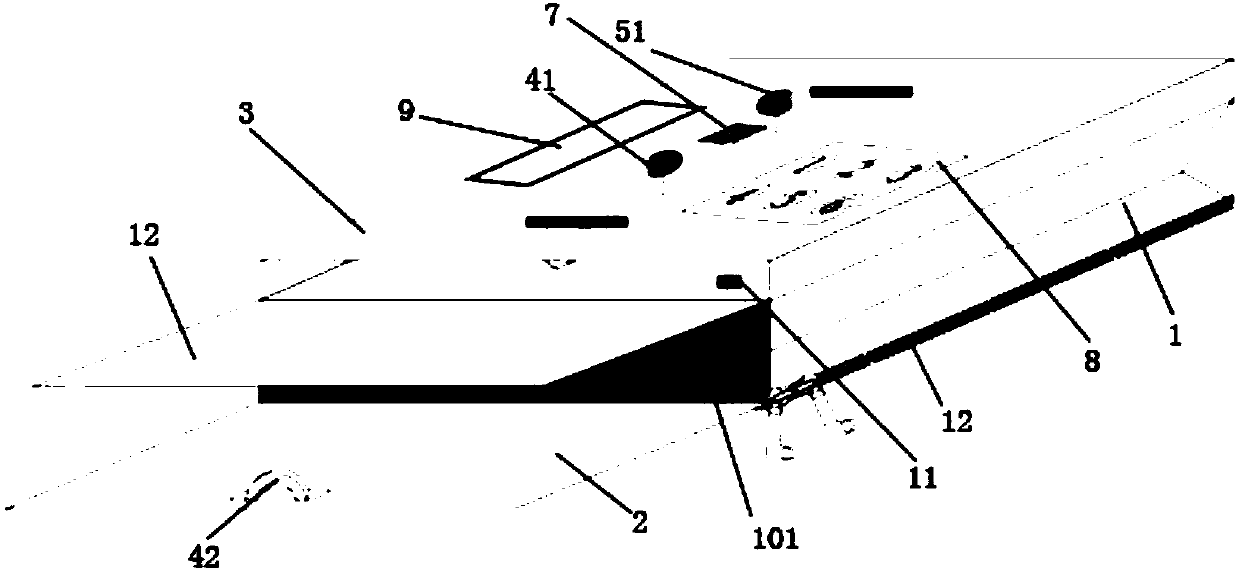

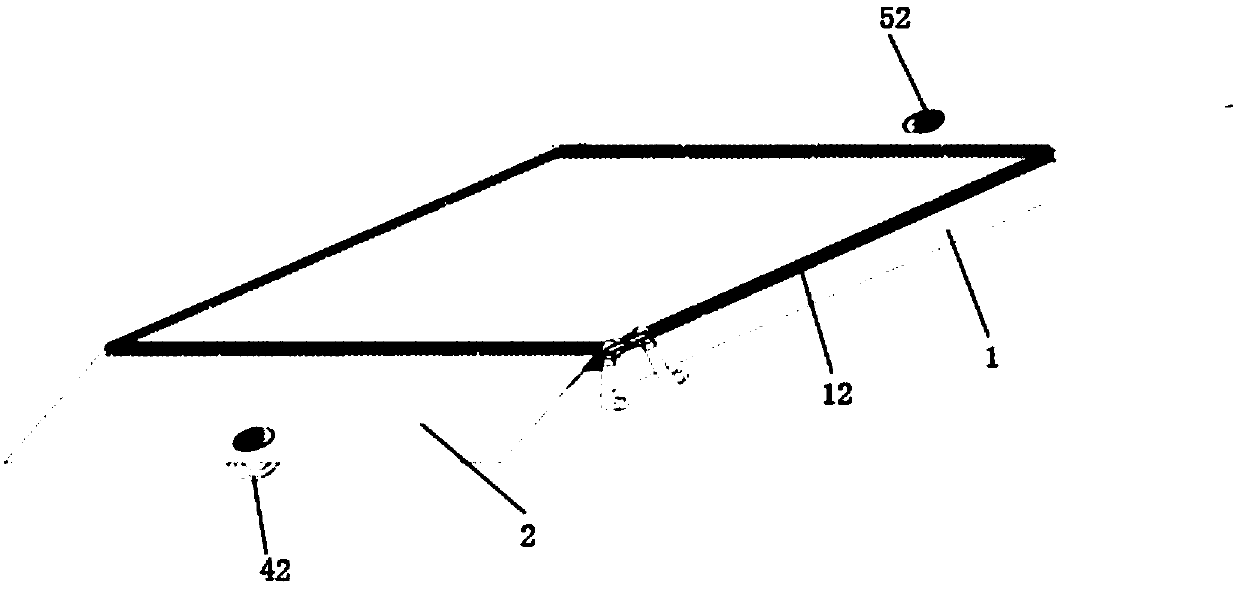

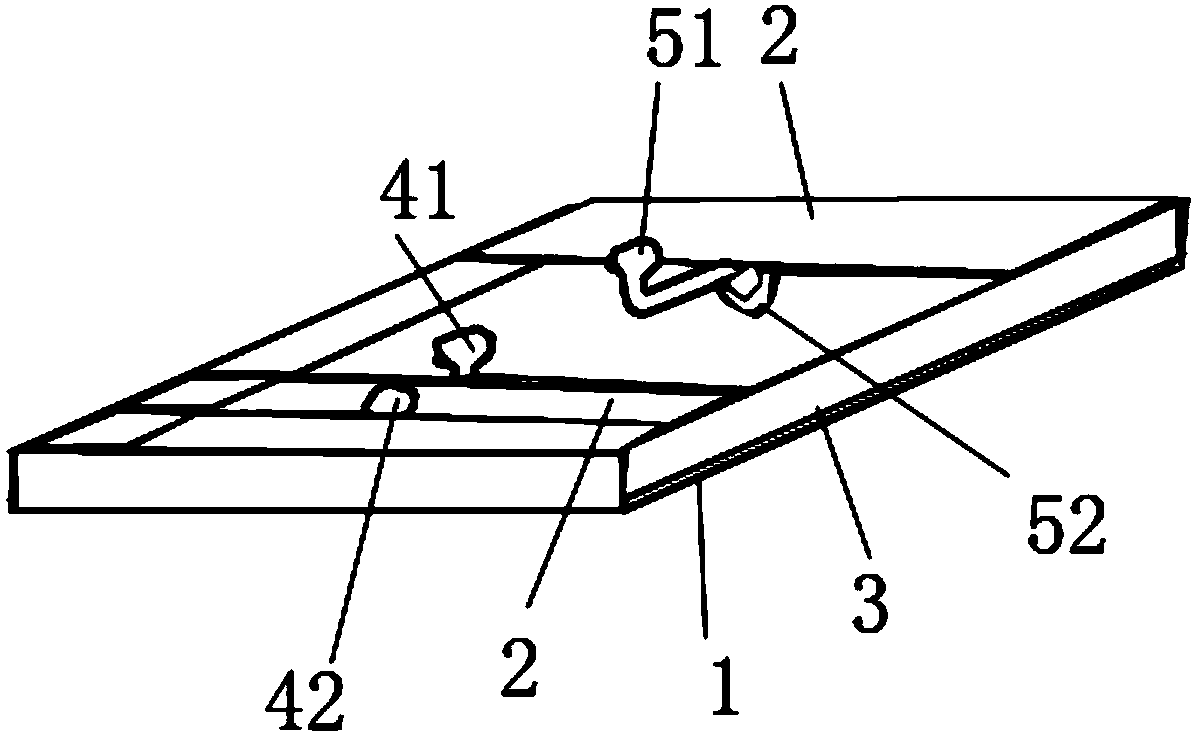

Environment-friendly garbage incineration device

InactiveCN109595560AIncinerator apparatusChamber safety arrangementEnvironmentally friendlyEngineering

Owner:单卫光

Environment-friendly concentrated liquid detergent for clothing materials

InactiveCN106047529AEasy to rinseConserve waterInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsAlkaneSodium bicarbonate

The invention provides an environment-friendly concentrated liquid detergent for clothing materials. The liquid detergent is environmentally friendly and easily degradable, does not stimulate the human body and has multiple functions of purifying, softening, fragrance depositing and the like. The environment-friendly concentrated liquid detergent comprises the following components in percentage by weight: 10%-15% of fatty alcohol-polyoxyethylene ether, 15%-20% of alkyl glycoside, 10%-12% of dodecyl dimethyl betaine, 6%-8% of seconary alkane sulphonate sodium, 3%-6% of fatty acid alkanol amide, 0-2% of citric acid, 0-2% of sodium carbonate, 0-2% of sodium bicarbonate, 0-1% of a flavoring agent and the balance of softened water.

Owner:ANHUI TAILONG CHENGYA GRP CO LTD

Environmentally-friendly starch adhesive

Owner:IND TECH RES INST

Efficient environmentally friendly ecological insecticide for garden and preparation method thereof

InactiveCN107136126AReach driveDigestive system malfunctionBiocideDead animal preservationSpodoptera lituraArge pagana

Owner:HEFEI SHENWO HORTICULTURE CO LTD

Decomposable environmentally-friendly heat-insulation packaging bag

Owner:桐城市人和包装有限公司

Shared express bag

Owner:上海钊易数码科技有限公司

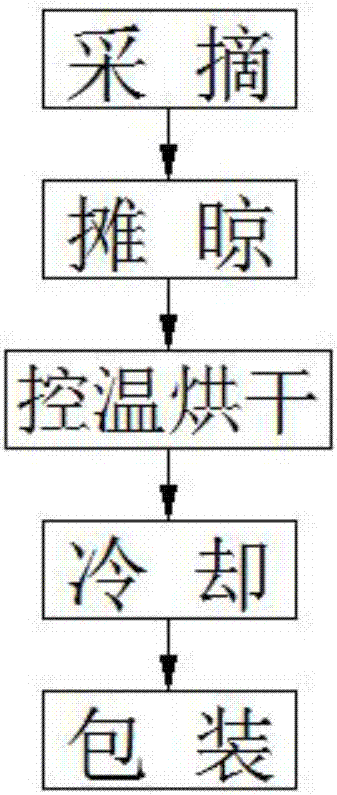

Processing method of novel environmentally-friendly persimmon cakes

The invention discloses a processing method of novel environmentally-friendly persimmon cakes. The processing method comprises the following steps of selecting persimmons; peeling the selected persimmons; performing baking for three times, wherein the baking temperature and the baking time are strictly controlled; performing kneading twice to obtain persimmon cakes; and finally, performing vacuum packing. According to the method disclosed by the invention, advanced equipment is adopted for processing, the preparation and processing cycle is short, the production efficiency is high, and the method is not restricted by weather. The yield of the persimmon cakes is stable, the persimmon cakes are red bright in color, high in sugariness, good in hygienic indexes, and long in quality guarantee period, and the processing method builds a solid foundation for the condition that the persimmon cakes enter supermarkets or are subjected to export sales.

Owner:KEXI AGRI PROD BREEDING & MARKETING PROFESSIONAL COOP IN PINGLE COUNTY

Engine leakage detection technology

InactiveCN101995318AJudging the situation of oil spillNo damageDetection of fluid at leakage pointEnvironmentally friendlyAutomotive engineering

Owner:JIANGLING MOTORS

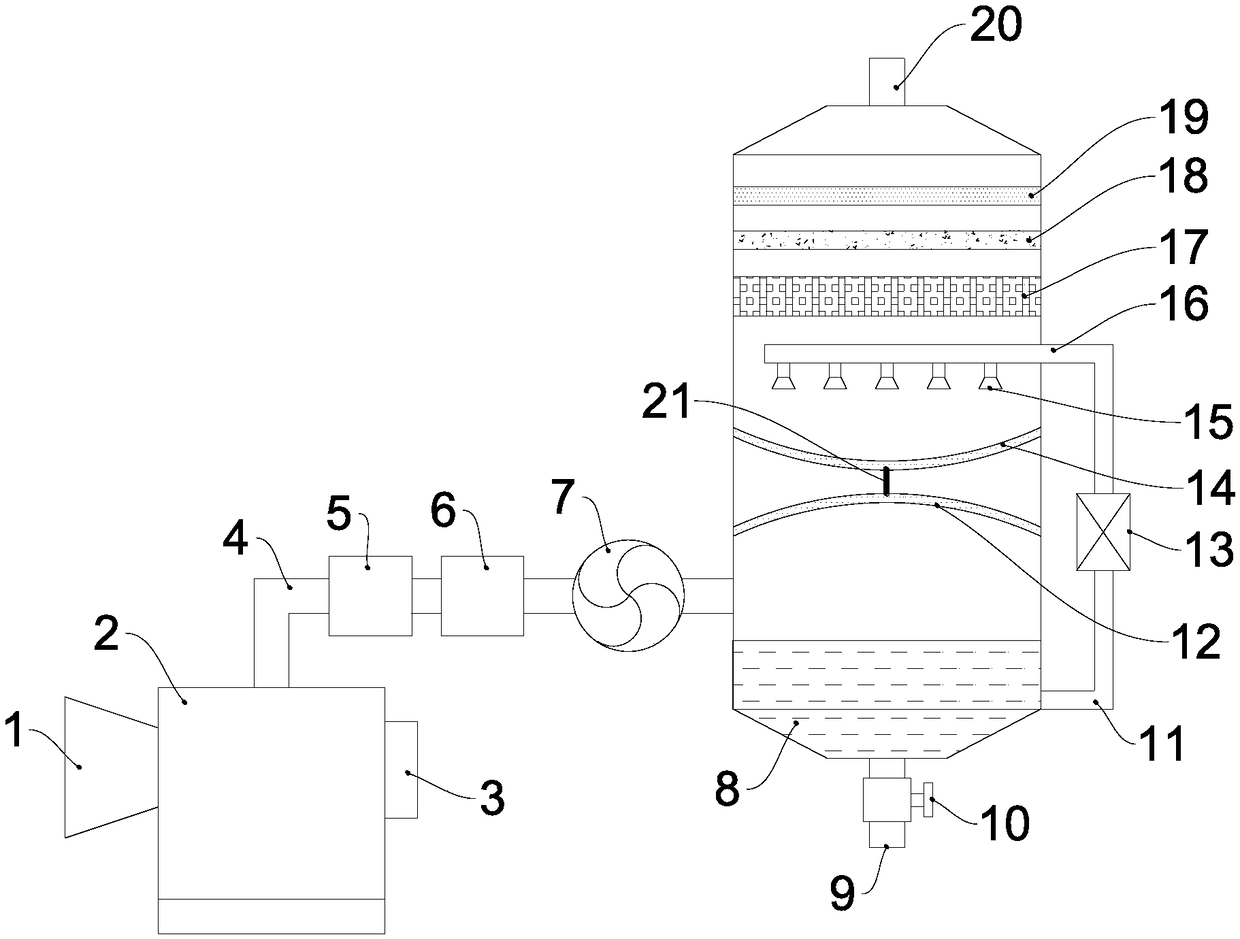

Environmentally friendly efficient disposable continuous waste gas treatment device

InactiveCN108114594AEasy to control and useImprove purification efficiencyCombination devicesIncinerator apparatusThermal energyEnvironmental engineering

Owner:苏州艾捷尔斯生物科技有限公司

Anticoagulation method for surface of medical polymer material or product

Owner:天津协和生物科技发展有限公司

Preparation method of golden chrysanthemum

Owner:东至县文元瓷砖加工厂

Fertilizer application method special for top Chinese prickly ash green food

InactiveCN108848841AEffective absorptionImprove utilization efficiencyFertilising methodsAgricultural sciencePhosphate fertilizer

Owner:GUIZHOU NORMAL UNIVERSITY

Washing agent

ActiveCN104946417ANo harmOrganic detergent compounding agentsSurface-active detergent compositionsEngineeringStain

The invention discloses a washing agent. The washing agent comprises, by mass, 10% to 50% of emulsified detergents, 10% to 30% of penetrants and 20% to 40% of wetting agents. Compared with the prior art, the washing agent has the advantages of being environmentally friendly, efficient and capable of being used for soaking ultrasonic wave oil removing washing of various materials, having remarkable effects on various stubborn oil stains and being capable of being completely degraded and free of injuries in the human body and damage to the environment.

Owner:SHENZHEN HENGWEIXIANG SCI & TECH CO LTD

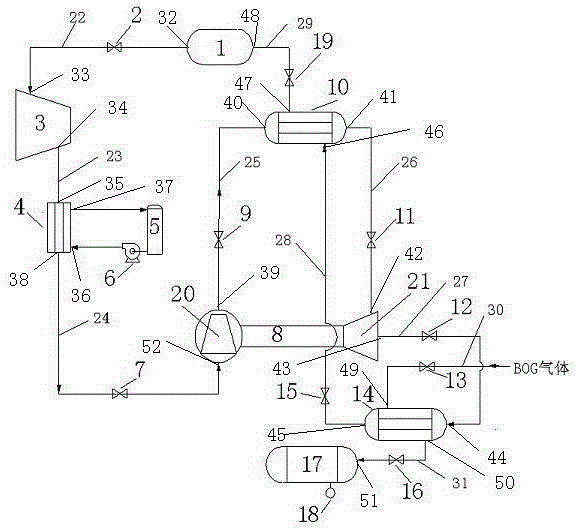

Efficient and energy-saving BOG (boil-off gas) recycling device

Owner:JIANGSU AEROSPACE HEWLETT ENVIRONMENTAL PROTECTION TECH

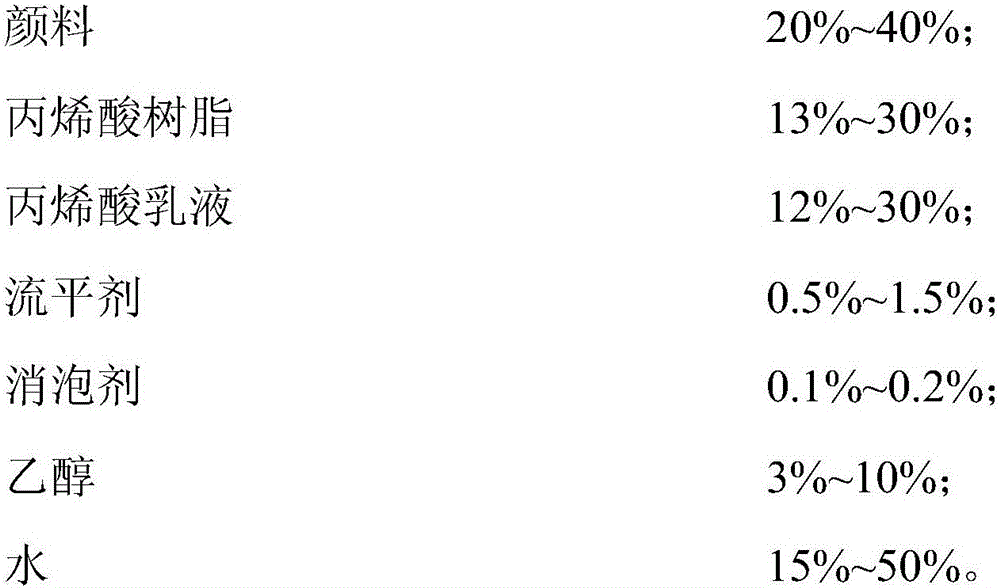

Waterborne printing ink for food package printing and preparation method of printing ink

Owner:JINAN UNIVERSITY

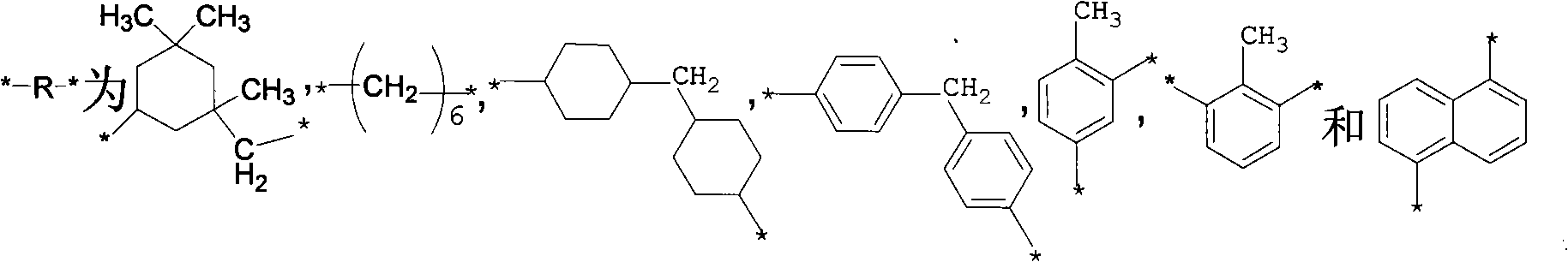

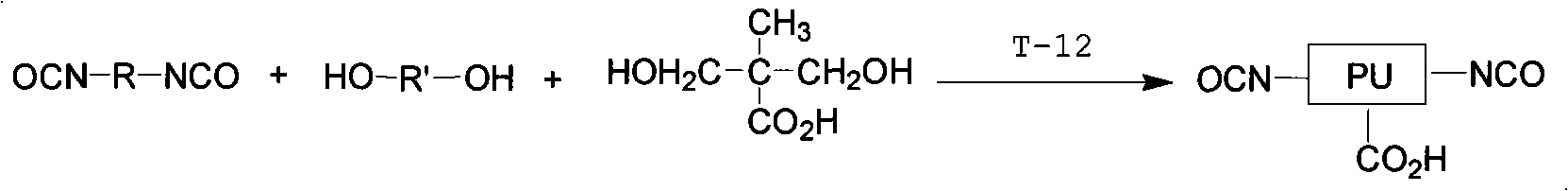

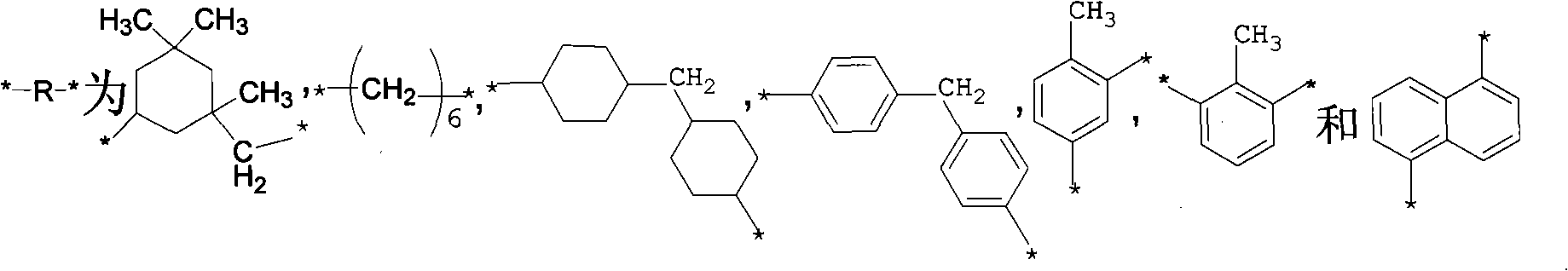

Room-temperature self-crosslinking fluorine-containing water-based PU dispersion, preparation method and application thereof

Owner:江苏裕廊石油化工有限公司

Under-forest ecological plantation method for dendrobium officinale

Owner:GUANGXI FORESTRY RES INST

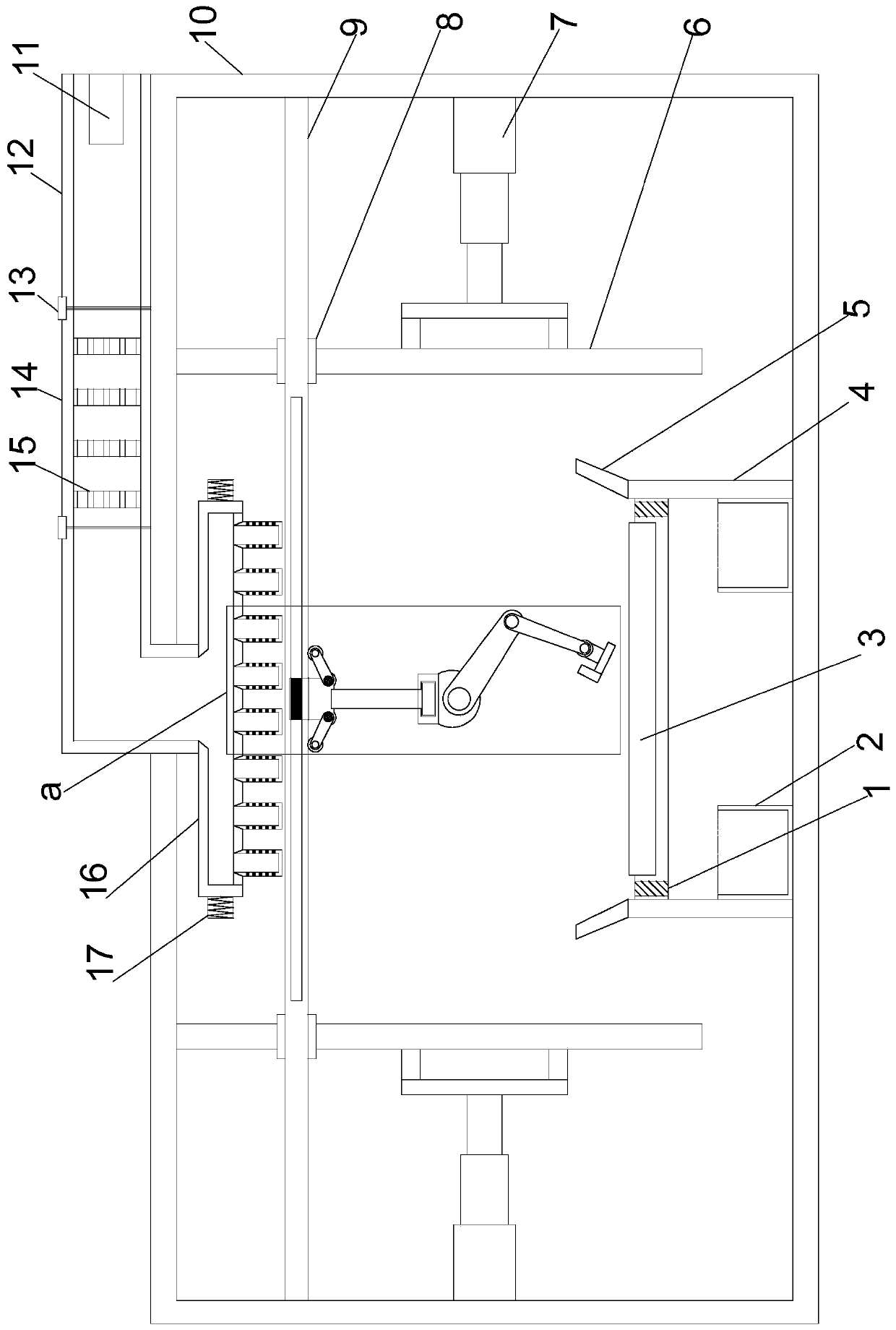

Numerical control machine tool equipment capable of improving equipment reliability by improving environmental friendliness

ActiveCN111546122ADispersed particle filtrationMaintainance and safety accessoriesProcessing accuracyEnvironmentally friendly

Owner:JILIN UNIV

Preparation method of ultrahigh molecular weight polyethylene monofilament

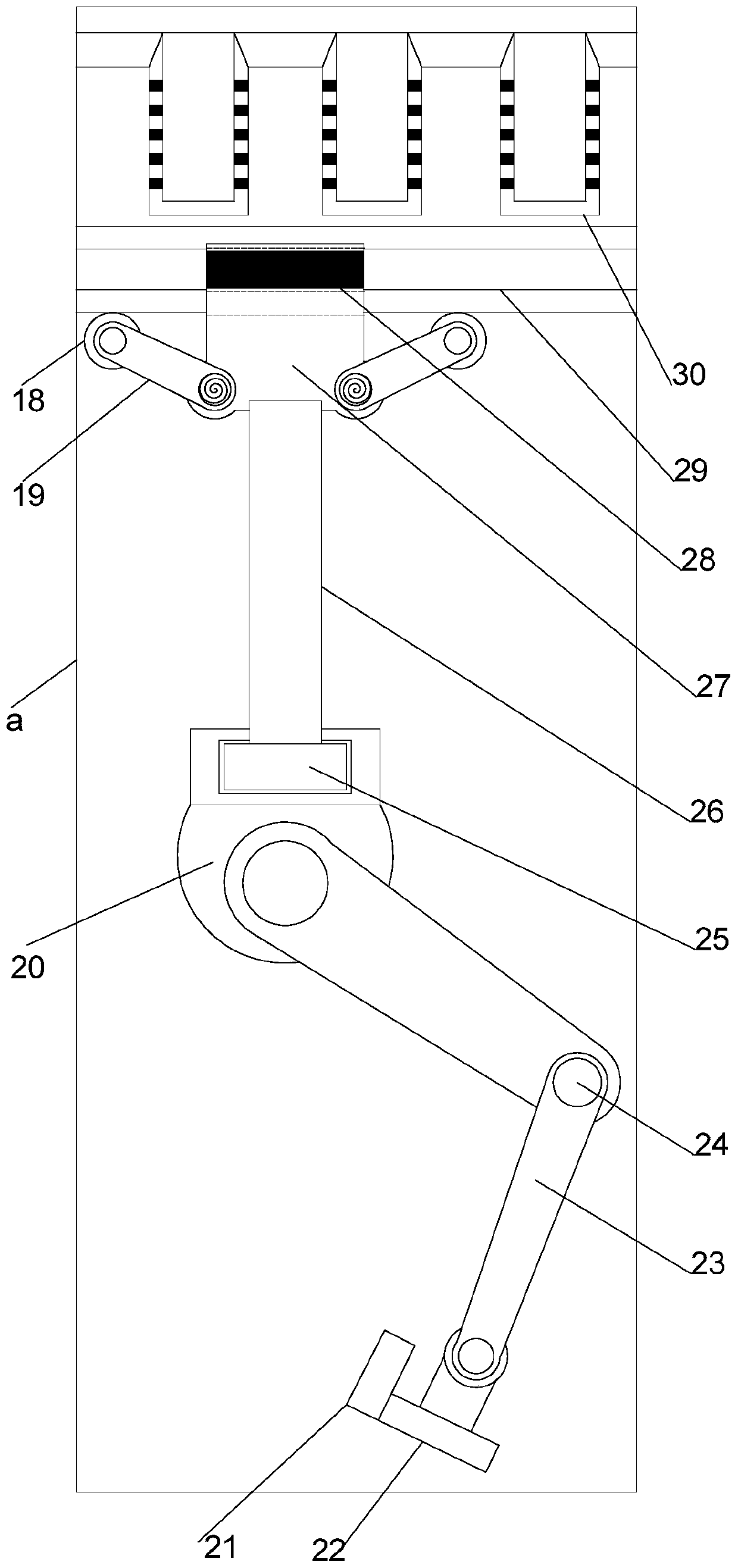

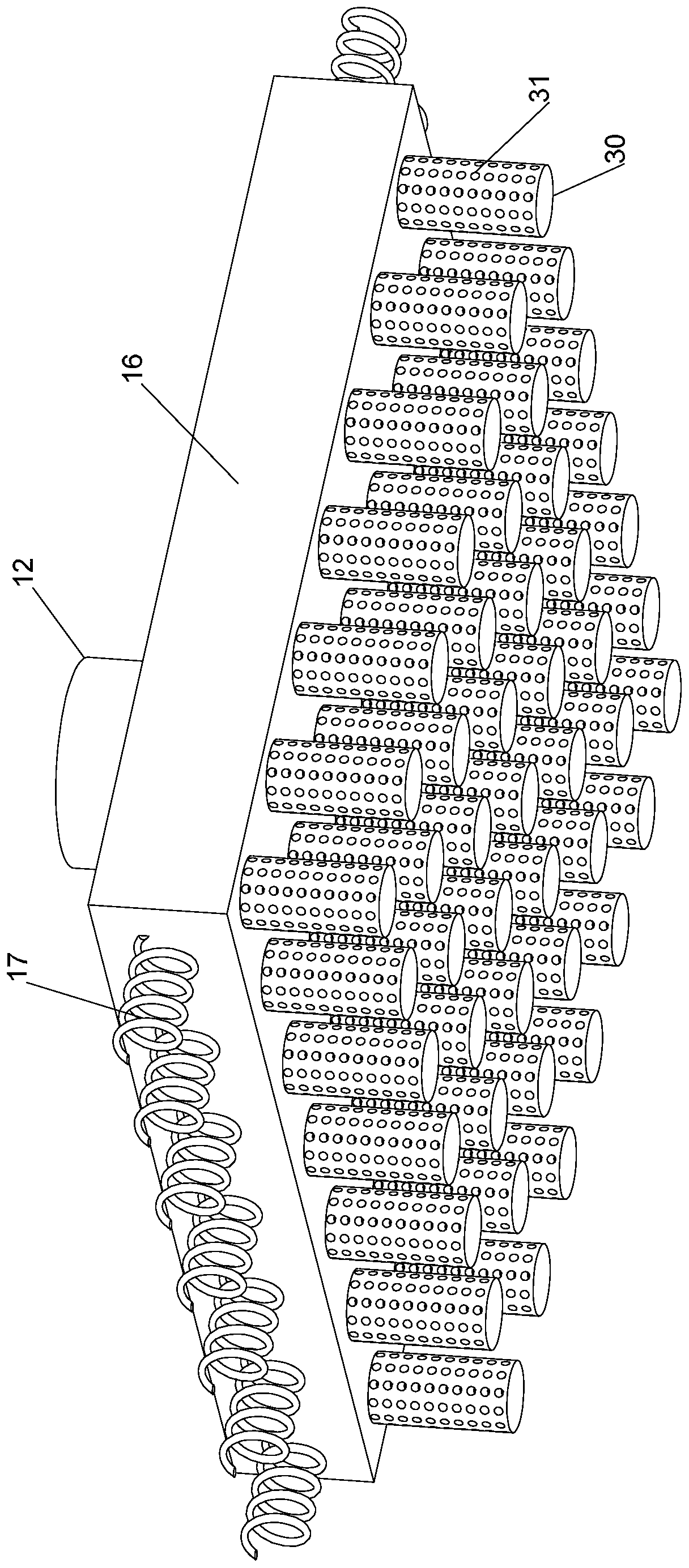

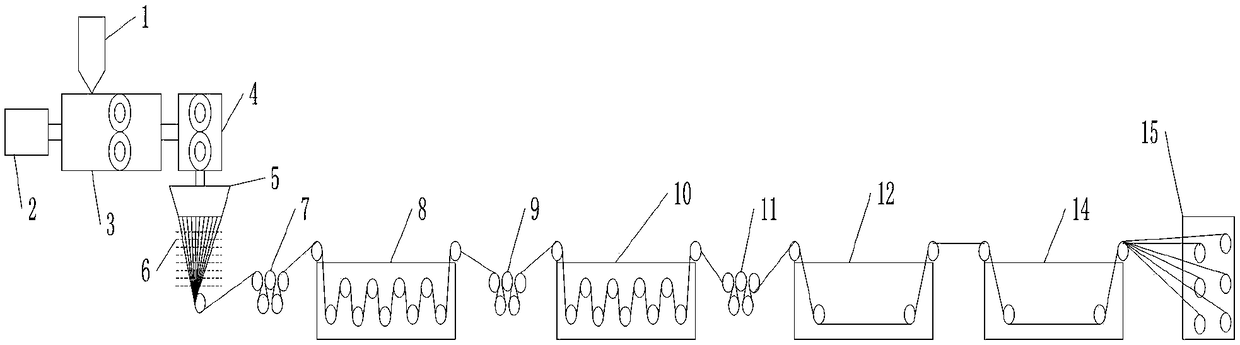

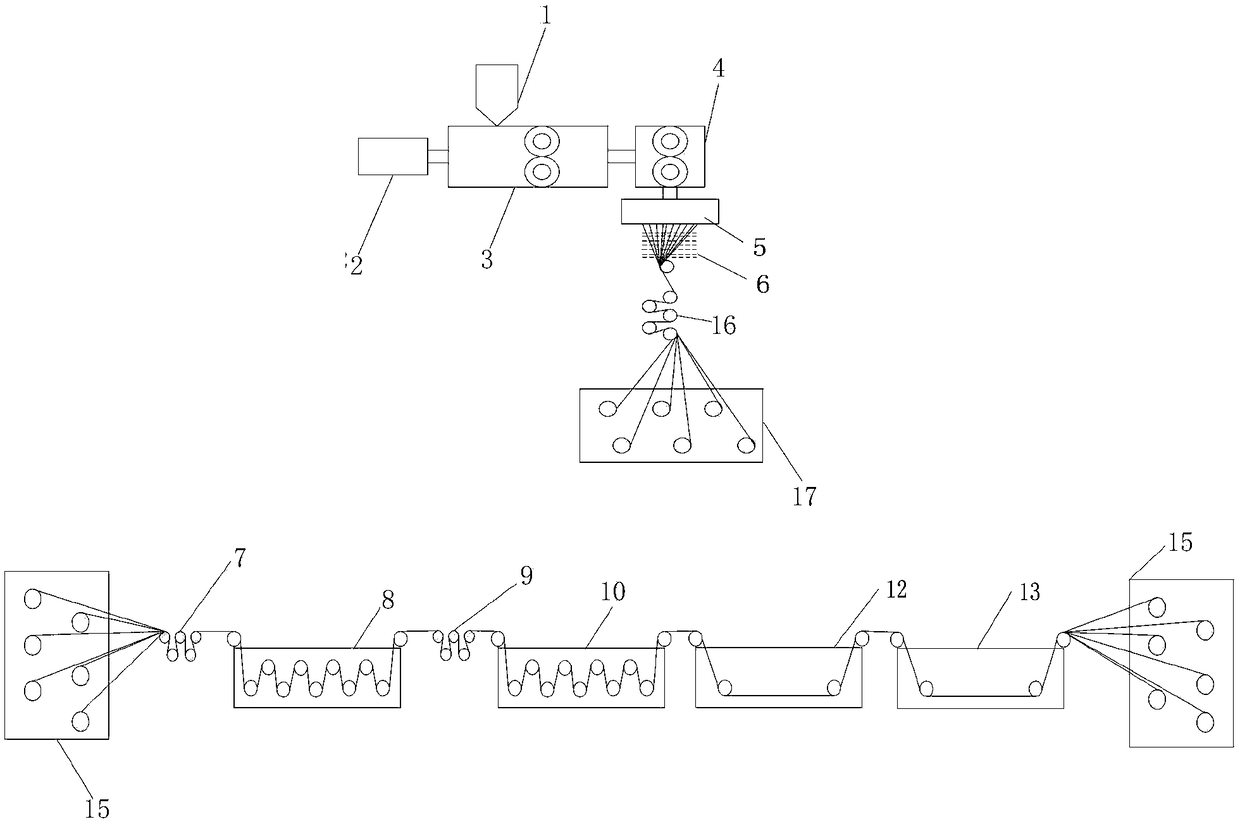

InactiveCN109487349AHigh strengthImprove uniformityFilament forming substance formingSpinning head liquid feederEnvironmentally friendlyThermal treatment

The invention discloses a preparation method of an ultrahigh molecular weight polyethylene monofilament. The preparation method comprises the following steps that an ultrahigh molecular weight polyethylene composite agent obtained through melting and kneading treatment is adopted, a special screw extruding device is adopted for performing sufficient melting and mixing on the composite agent, and extrusion and conveying are performed; furthermore, a booster pump is adopted for improving pressure of a fusion system, meanwhile, a melt is quantitively pressed into a spinning die head or a spinningbox to perform extrusion spinneret, after water bath or oil bath or air bath cooling is performed, primary monofilaments are obtained, the obtained primary monofilaments are subjected to doffing, after multi-heating stretching is performed, the primary monofilaments can be directly and continuously subjected to water bath drafting, multi-stage heat roller drafting and hot air stretching and thensubjected to thermal treatment, and oiling is performed to obtain the high-strength high-modulus polyethylene monofilaments. The problems that molecules are nested and arranged difficultly, and macromolecule winding is series, so that melt flowability and uniformity are poor are well solved, and the monofilaments are high in strength, good in uniformity, simple in production technology, high in efficiency and environmentally friendly.

Owner:郭海洋

Fireproof door core and preparing method thereof

InactiveCN107082617AImprove fire resistanceGood heat insulationFireproof doorsCeramicwareFiberZinc borate

Owner:合肥市旺友门窗有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap