Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3 results about "Oxidative degradation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation and application of chemical oxidation repair additive for organic matter-contaminated soil

InactiveCN106433682AImprove the coordination effectPromote dissolutionContaminated soil reclamationOrganic fertilisersPotassium persulfatePersulfate

The invention discloses a preparation method and application of a chemical oxidation repair additive for organic matter-contaminated soil. The chemical oxidation repair additive for the organic matter-contaminated soil is prepared by adopting persulfate to oxidize a bisphenol compound and alpha-amino acid in an alkaline aqueous solution. The chemical oxidation repair additive is directly added into the organic matter-contaminated soil, and organic pollutants in the soil are subjected to oxidative degradation by taking a potassium persulfate solution and a hydrogen peroxide solution as oxidizing agents, and using ferric oxide, which is inherent in the soil, as a catalyst. The preparation method is simple in technology, mild in conditions, low in cost and environmentally-friendly, and can realize large-scale production; when the chemical oxidation repair additive is used for repairing the organic matter-contaminated soil, the organic pollutants are efficiently and rapidly degraded, and secondary pollution is not produced; therefore, the chemical oxidation repair additive for the organic matter-contaminated soil has wide application prospect.

Owner:UNIV OF JINAN

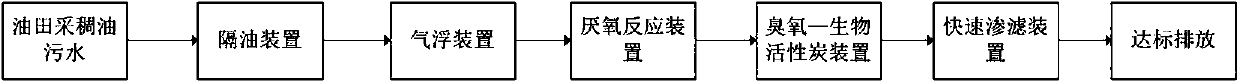

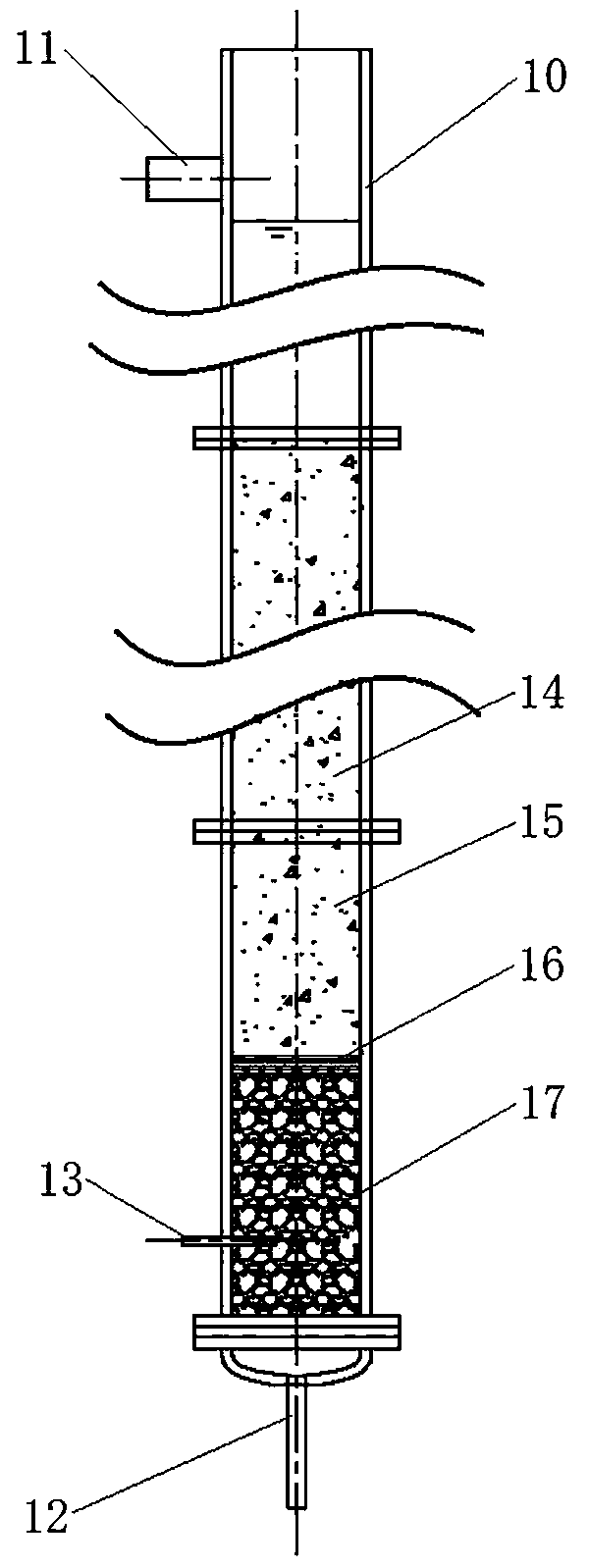

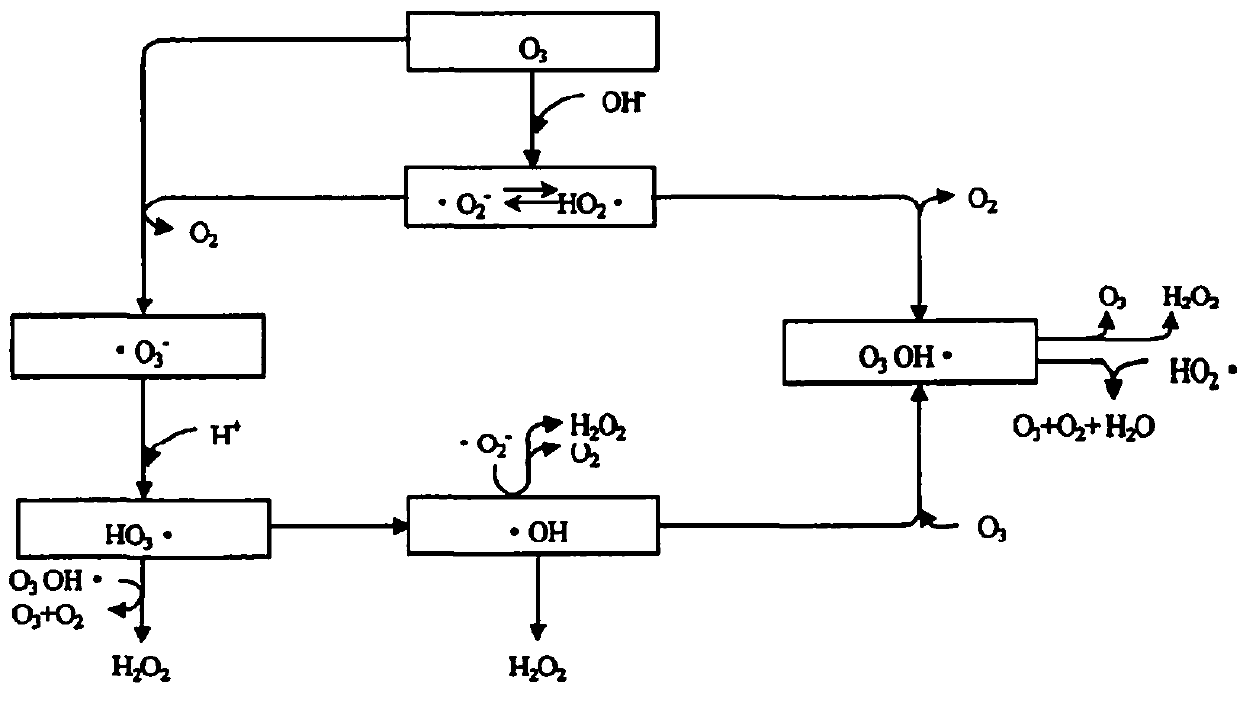

Waste water deep treatment method for thickened oil extracted in oil field

InactiveCN107601787AWaste water treatment from quariesMultistage water/sewage treatmentAnaerobic decompositionOxidative degradation

Owner:德兰梅勒(北京)分离技术股份有限公司

Oxidative degradation method for cyanide in cyaniding tailings

InactiveCN107890622AReduce consumptionPromote decomposition and releaseChemical protectionVacuum extractionHigh pressure

Owner:FUJIAN SHUANGQISHAN MINING +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap