Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50 results about "Oxidizing agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, an oxidizing agent (oxidant, oxidizer) is a substance that has the ability to oxidize other substances — in other words to accept their electrons. Common oxidizing agents are oxygen, hydrogen peroxide and the halogens.

Electrically controlled solid propellant

Owner:DIGITAL SOLID STATE PROPULSION

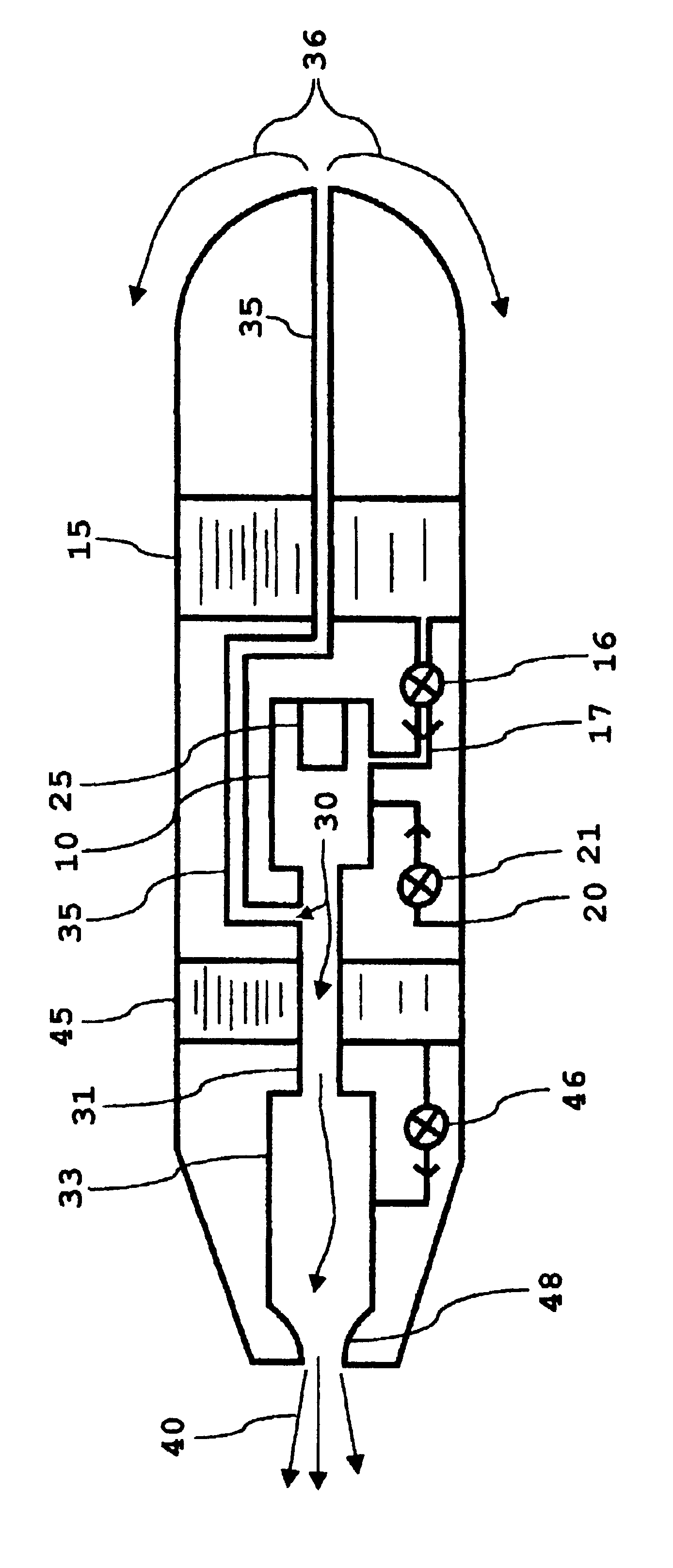

Gas generating process for propulsion and hydrogen production

InactiveUS6849247B1Reduce the temperatureProducing energyLoomsHydrogen productionMetallic materialsSlurry

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

Chemical Mechanical Polishing Slurry Composition for Polishing Phase-Change Memory Device and Method for Polishing Phase-Change Memory Device Using the Same

InactiveUS20090001339A1Increase chanceMinimize occurrenceOther chemical processesSolid-state devicesHigh ratePhase-change memory

Owner:CHEIL IND INC

Preoxidized-composite electrolyzing method for removing arsenic in groundwater

InactiveCN101139150ALow toxicityImprove adsorption capacityMultistage water/sewage treatmentWater/sewage treatment by oxidationElectrolysisFenton reagent

A method to remove arsenic in underwater by preoxidation-combined electrolyzing relates to a method to remove arsenic from underwater, belonging to the technical field of water treatment. The present invention has solved the defect that more expensive pure nulvalent iron and slower corrosion speed of the pure nulvalent iron have limited the absorption of arsenic on the nulvalent iron. The present invention includes the following steps: the underwater containing arsenic is pre-oxidized by ozone, potassium ferrate, potassium permanganate, H2O2, photocatalysis oxidation reagent or Fenton reagent, thereby transferring As(III) to As(V). The water pre-oxidized passes through a filtering bed containing cast-iron scrap and carbon granules. The oxidizer left in the preoxidation section promotes the reaction of the step.

Owner:HARBIN INST OF TECH

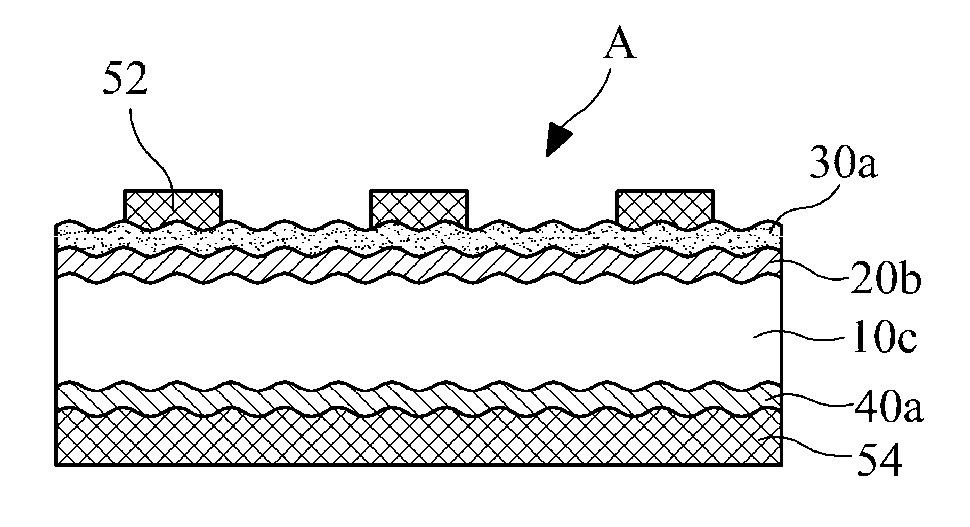

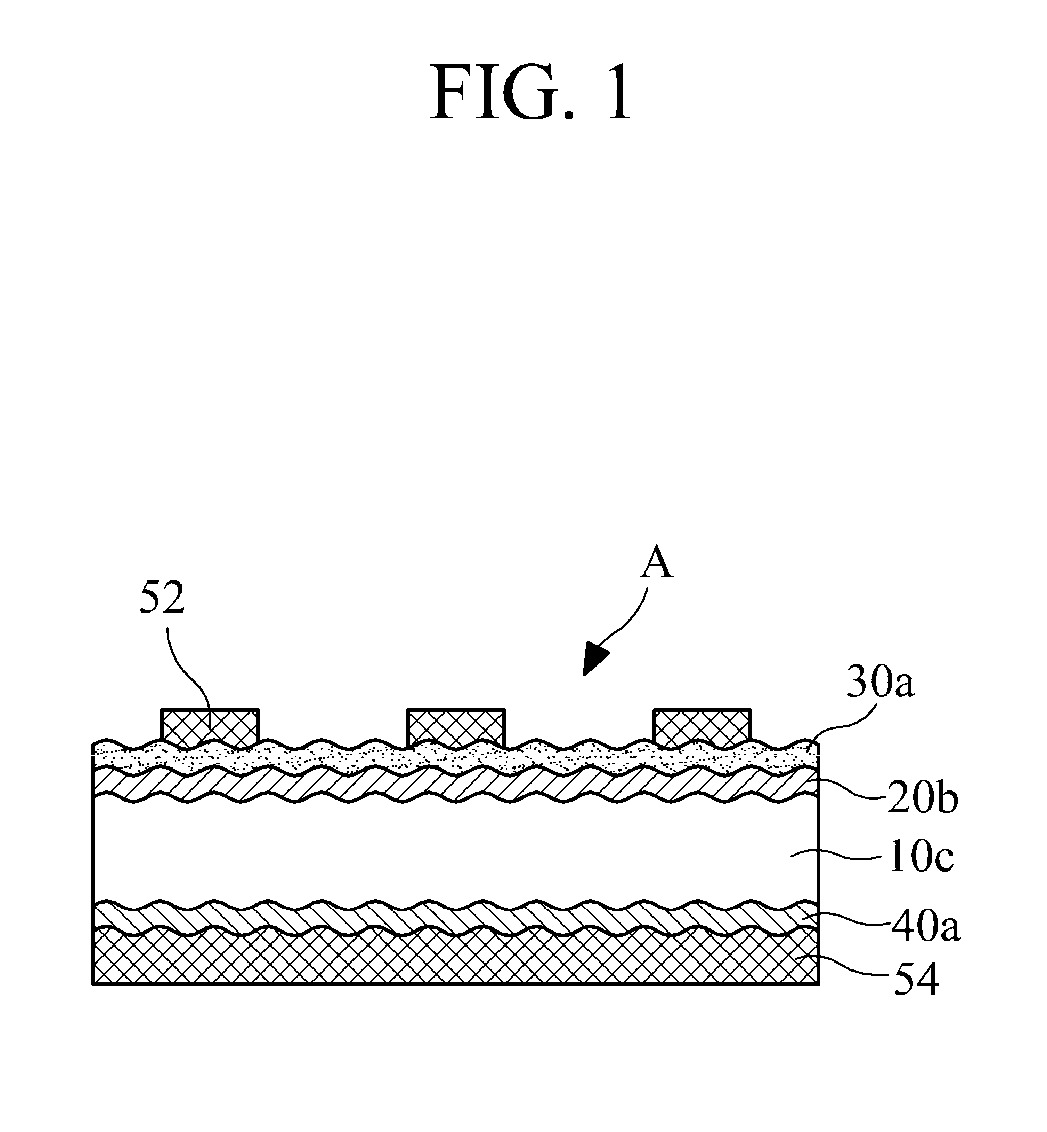

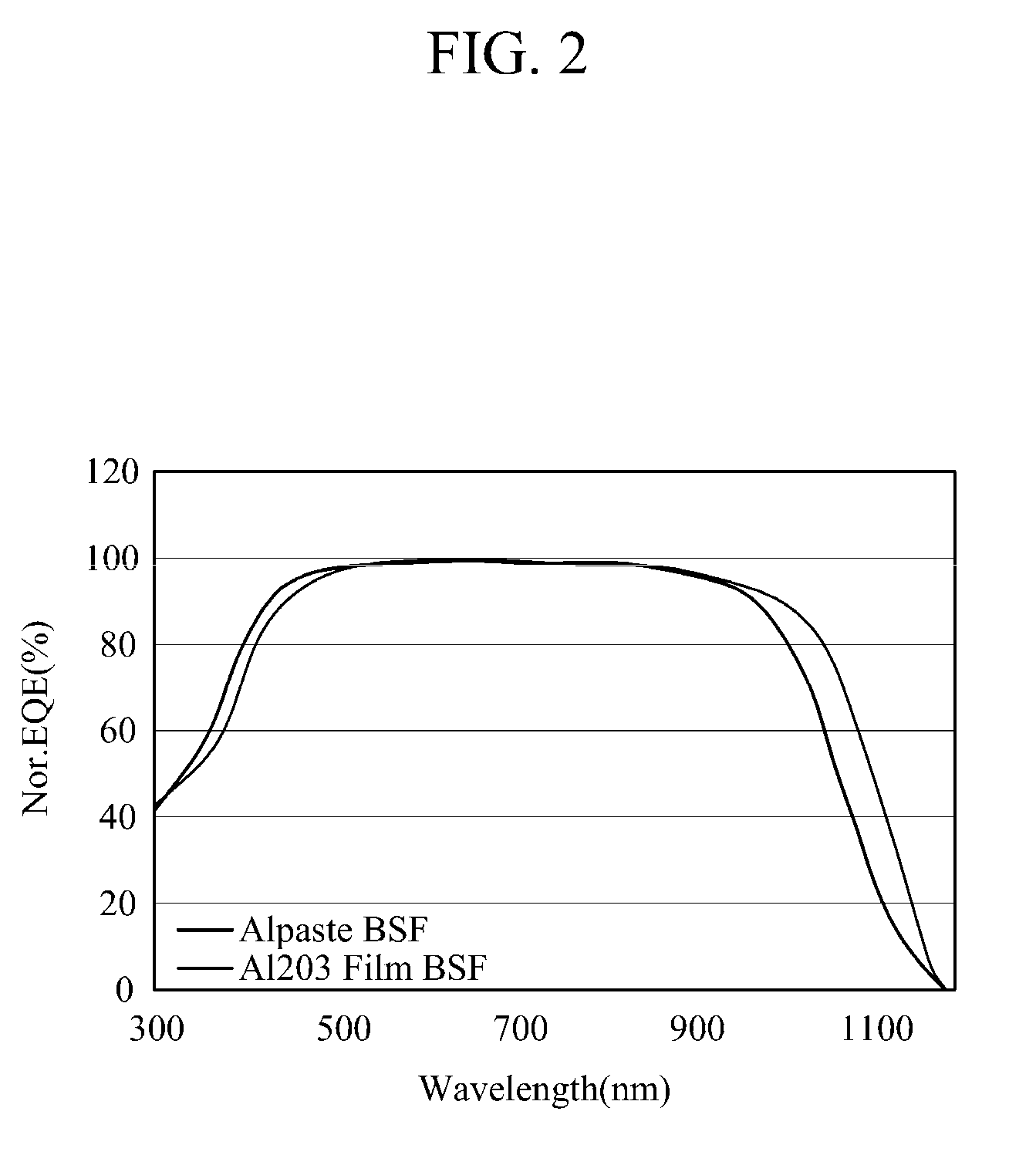

Solar cell and method of fabricating the same

InactiveUS20110083735A1High opto-electric conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingBack surface fieldEngineering

Owner:WONIK IPS CO LTD

Preparation and application of chemical oxidation repair additive for organic matter-contaminated soil

InactiveCN106433682AImprove the coordination effectPromote dissolutionContaminated soil reclamationOrganic fertilisersPotassium persulfatePersulfate

The invention discloses a preparation method and application of a chemical oxidation repair additive for organic matter-contaminated soil. The chemical oxidation repair additive for the organic matter-contaminated soil is prepared by adopting persulfate to oxidize a bisphenol compound and alpha-amino acid in an alkaline aqueous solution. The chemical oxidation repair additive is directly added into the organic matter-contaminated soil, and organic pollutants in the soil are subjected to oxidative degradation by taking a potassium persulfate solution and a hydrogen peroxide solution as oxidizing agents, and using ferric oxide, which is inherent in the soil, as a catalyst. The preparation method is simple in technology, mild in conditions, low in cost and environmentally-friendly, and can realize large-scale production; when the chemical oxidation repair additive is used for repairing the organic matter-contaminated soil, the organic pollutants are efficiently and rapidly degraded, and secondary pollution is not produced; therefore, the chemical oxidation repair additive for the organic matter-contaminated soil has wide application prospect.

Owner:UNIV OF JINAN

Direct oxidation fuel cells with improved cathode gas diffusion media for low air stoichiometry operation

InactiveUS20080176112A1Promote oxidationSimple methodNanotechFuel cell auxillariesFuel cellsEngineering

A cathode for use in a direct oxidation fuel cell (DOFC) comprises a gas diffusion medium (GDM) including a backing layer and a microporous layer comprising a fluoropolymer and an electrically conductive material, wherein loading of the fluoropolymer in the microporous layer is in the range from about 10 to about 60 wt. %. In use, a concentrated solution of a liquid fuel is supplied to an anode and an oxidant to the cathode of the fuel cell, and the fuel cell may be operated at a low oxidant stoichiometry ξc not greater than about 2.5.

Owner:PANASONIC CORP +1

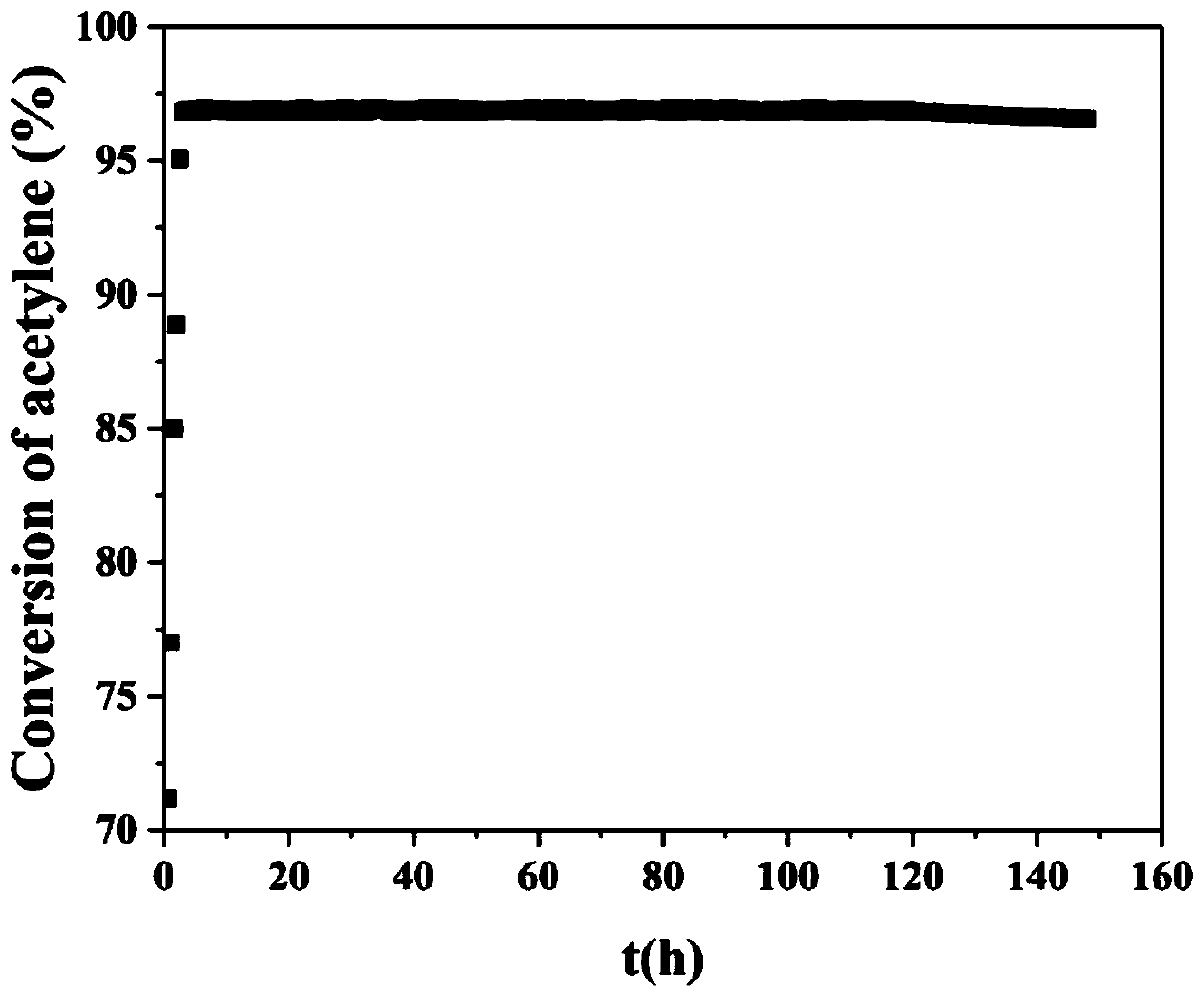

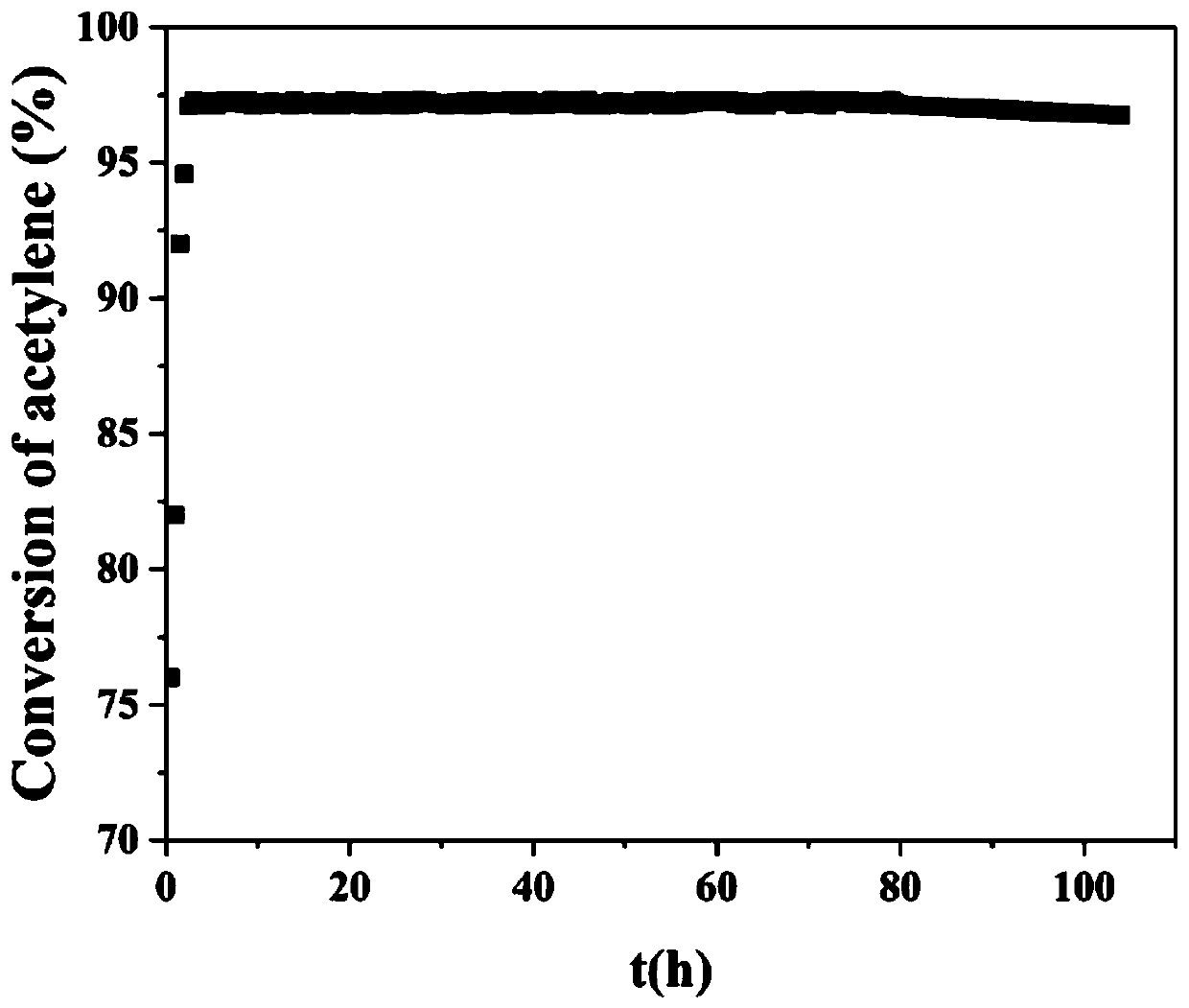

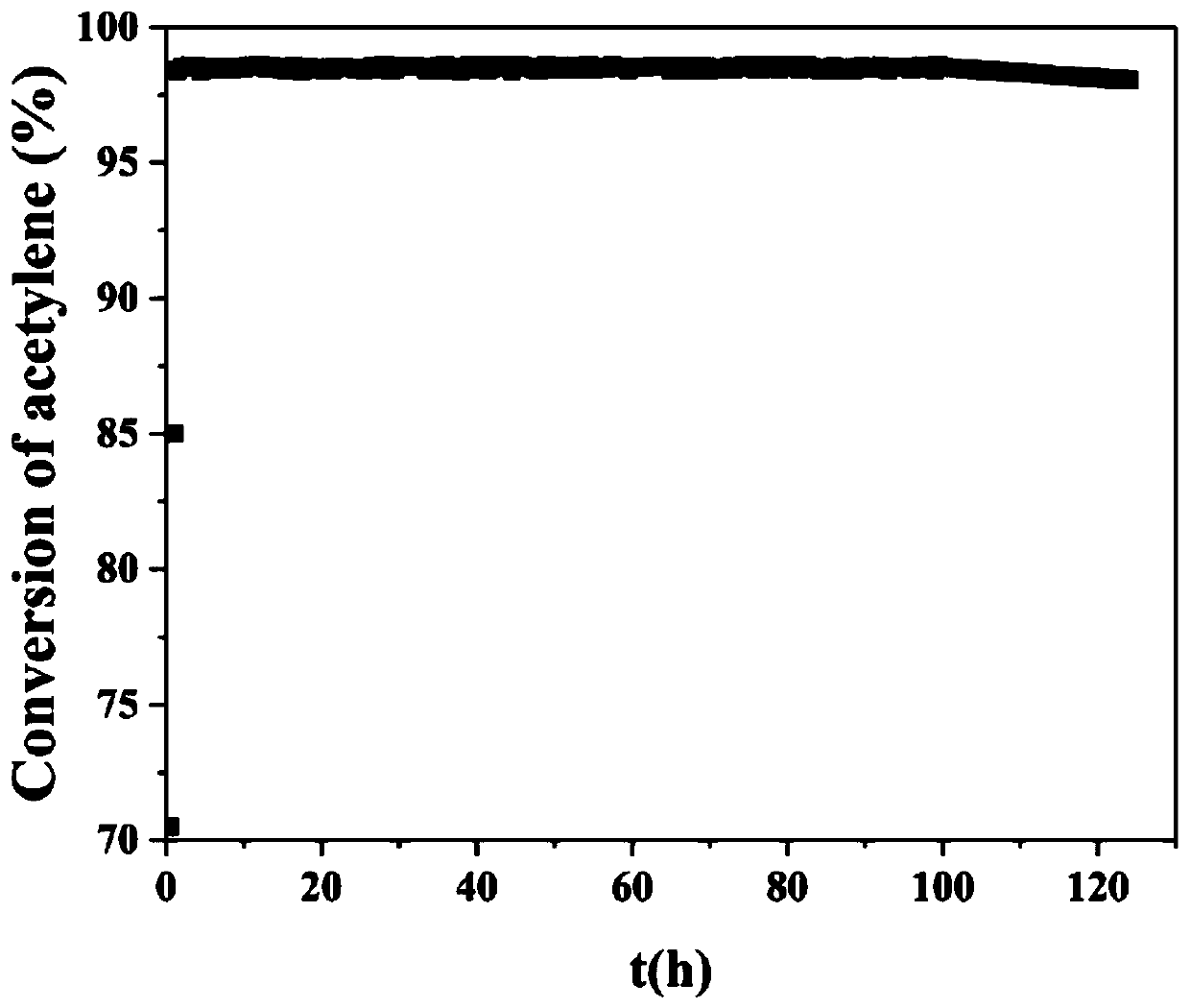

Trivalent copper catalyst and preparation method thereof and application to hydrochlorination of acetylene

ActiveCN110743621AStable structureImprove stabilityPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystNitrogenous heterocyclic compound

Owner:ZHEJIANG UNIV OF TECH

Basic metal nitrate, process for producing the same and gas generating agent composition

InactiveUS20070119530A1Enhanced interactionDecrease in decomposition temperatureNitrogen-metal/silicon/boron binary compoundsExplosivesGuanidine derivativesSlag

Owner:ZHOU XINGXI +5

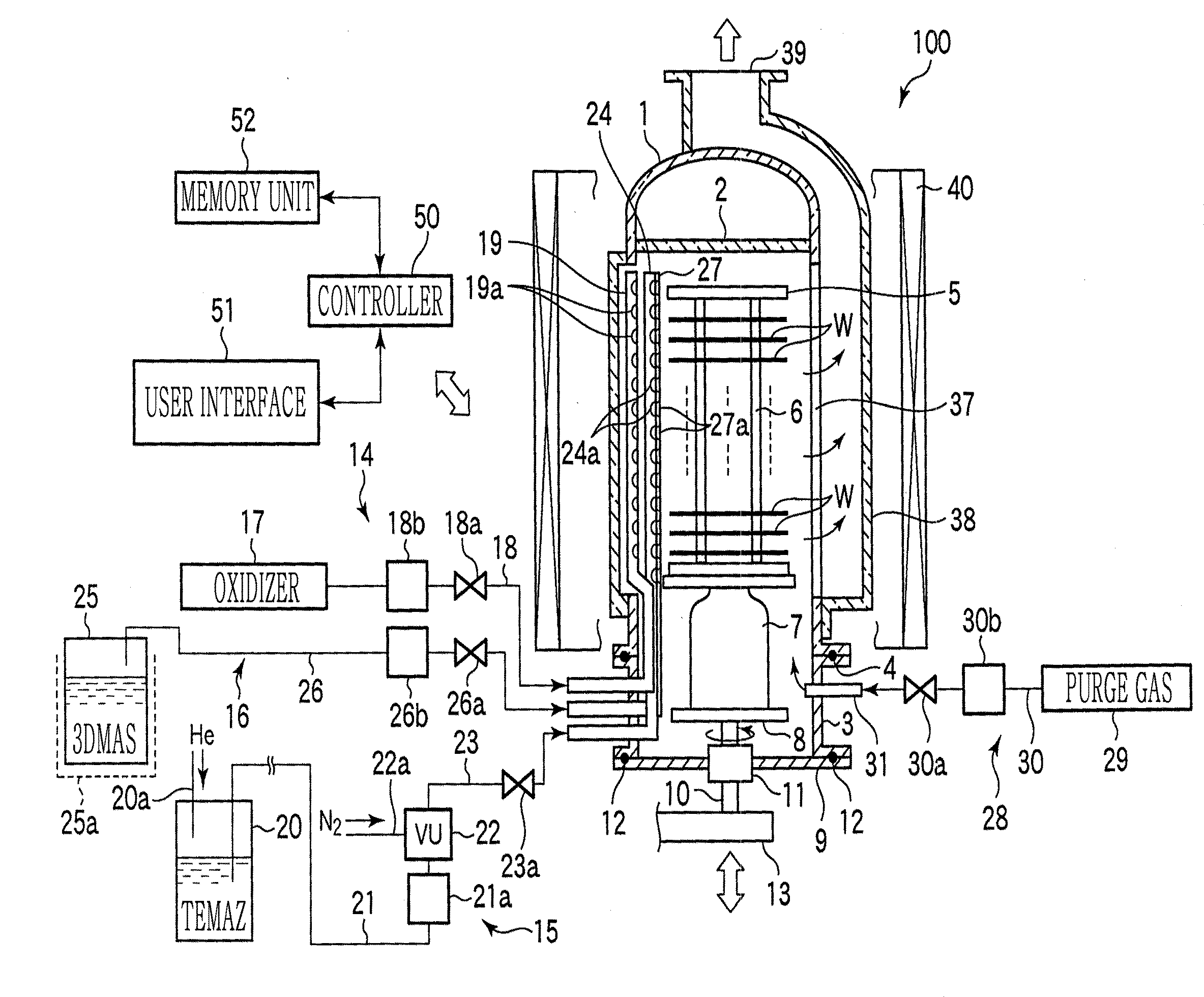

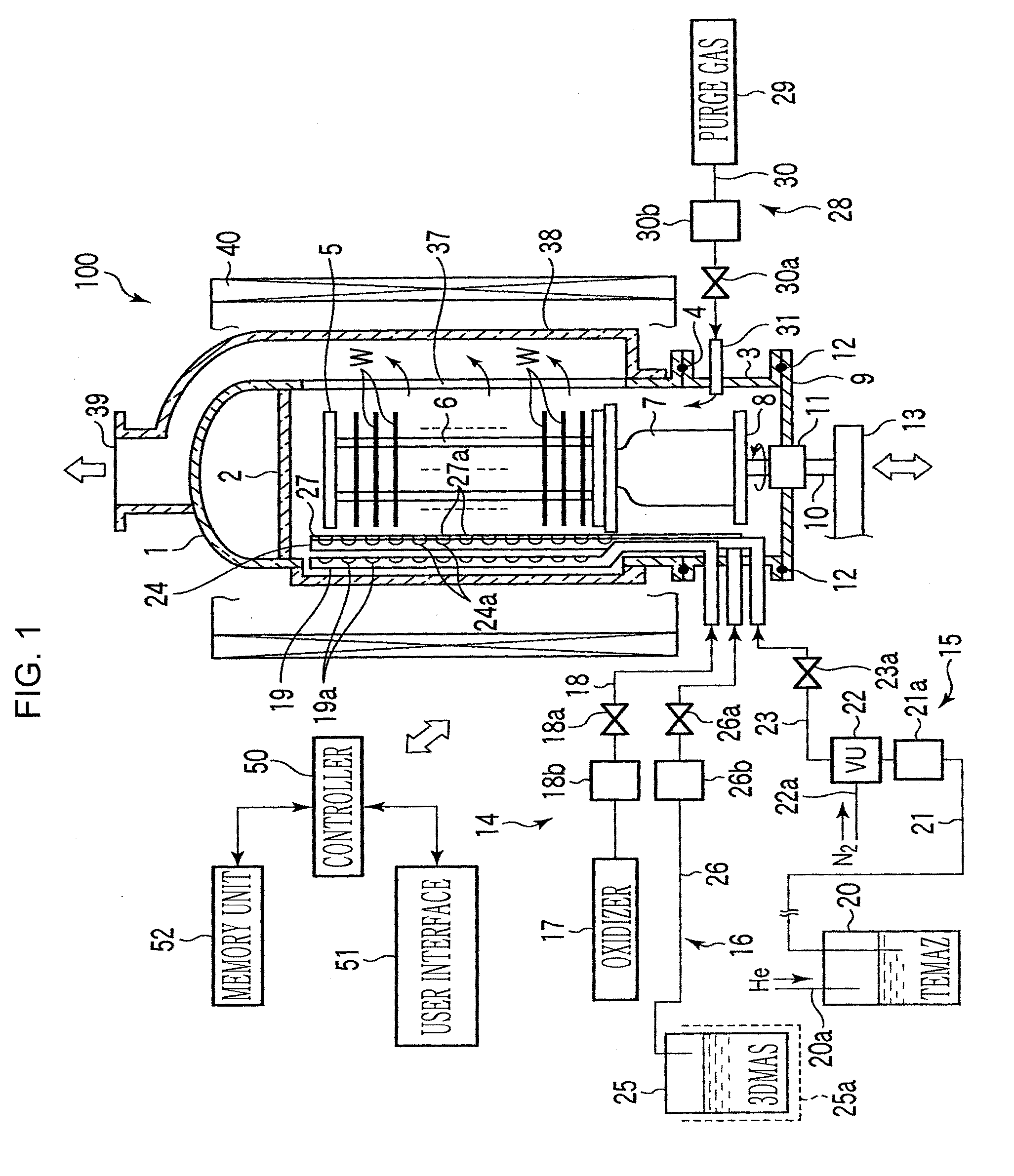

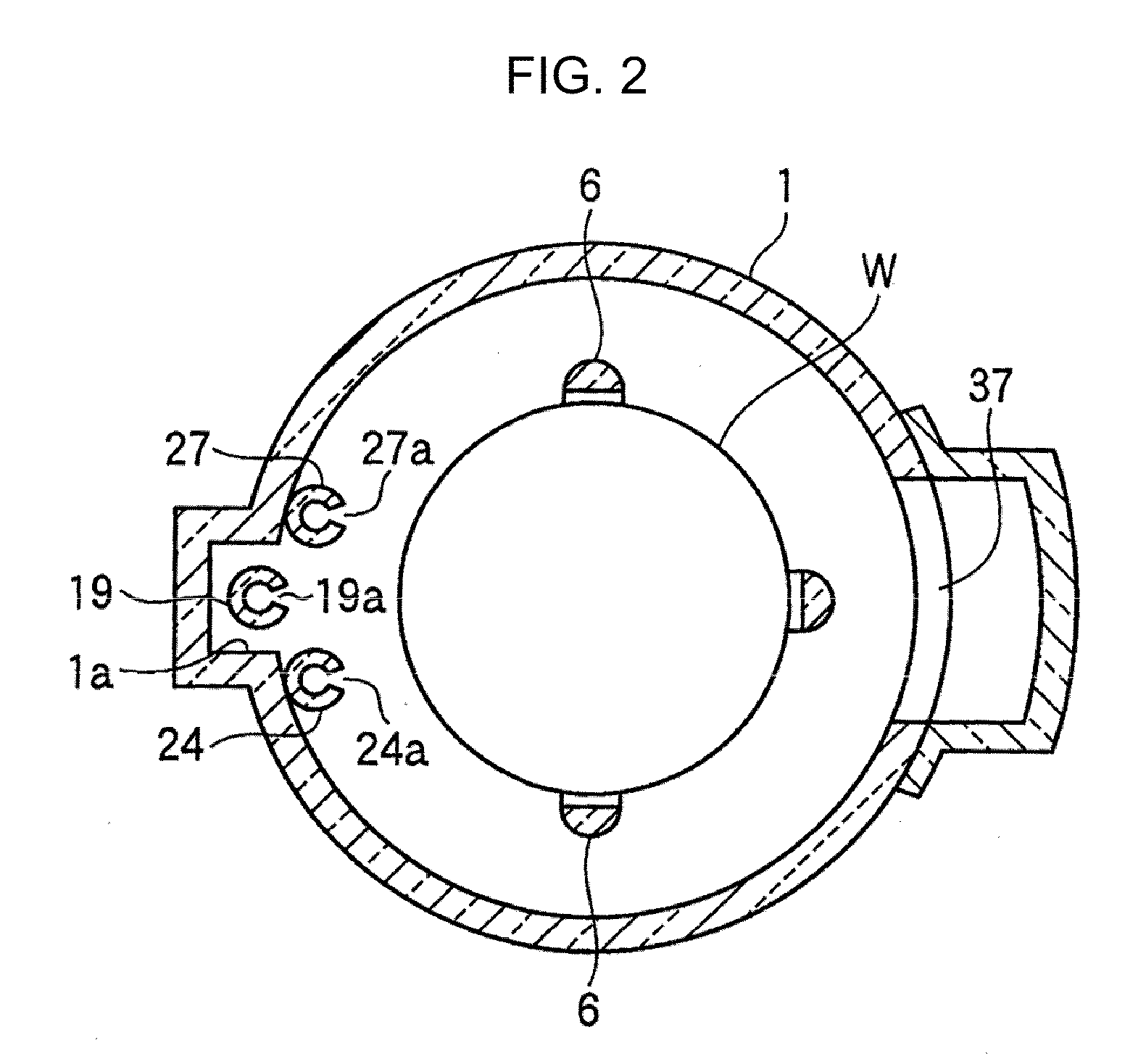

Film forming method and film forming apparatus

ActiveUS20100035439A1Solve the large leakage currentLiquid surface applicatorsSemiconductor/solid-state device manufacturingEngineeringOxidizing agent

Owner:TOKYO ELECTRON LTD

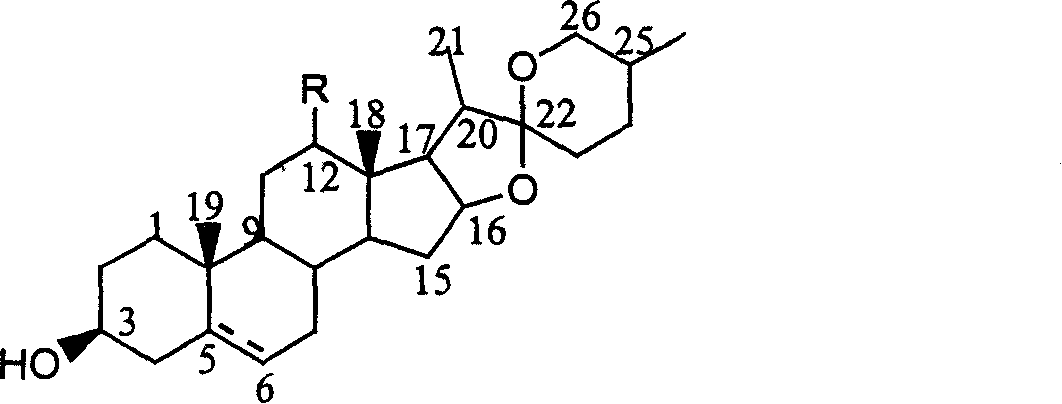

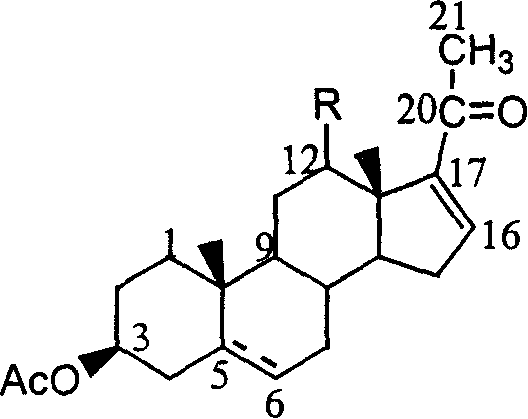

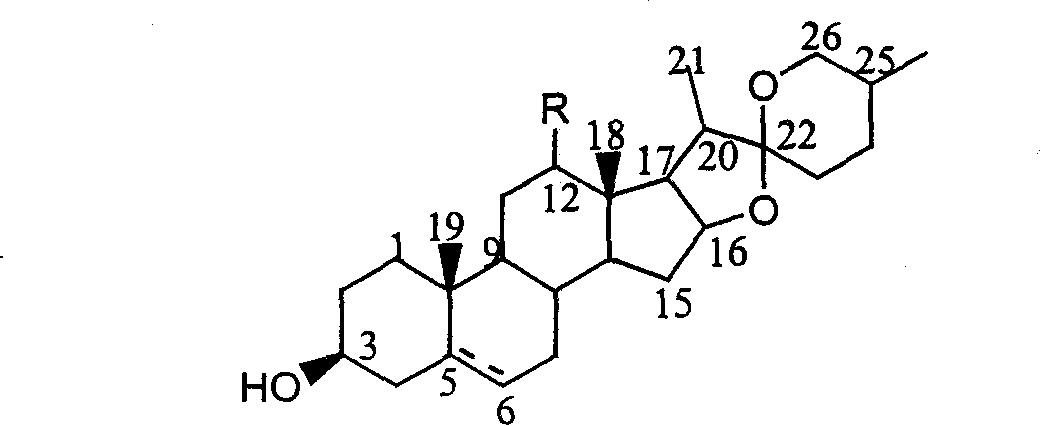

Method for synthesizing 16-dehydropregndiketonic alcohol acetic ester and its analogs

InactiveCN1884297AImprove utilizationEliminate pollutionSteroidsChemical synthesisTemperature control

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

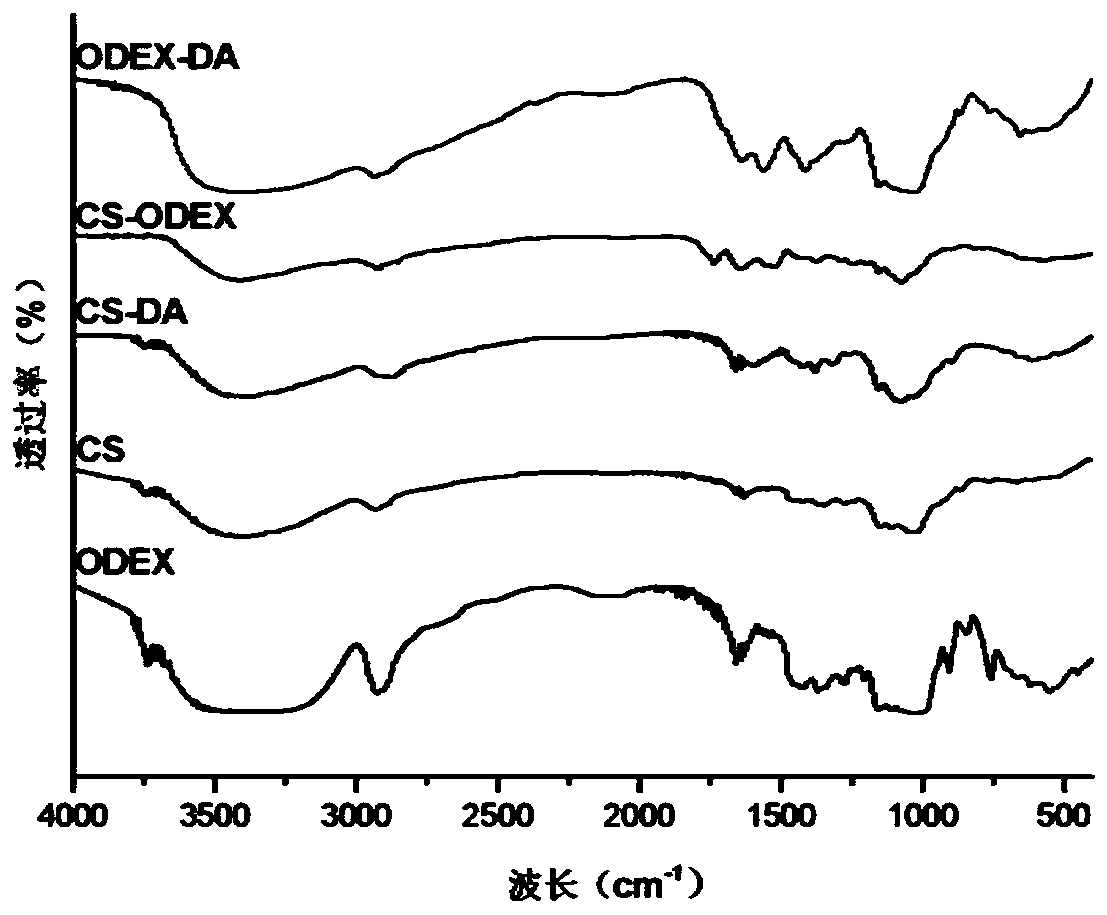

Mussel-imitated underwater high-viscosity hydrogel preparation method

Owner:SOUTHEAST UNIV

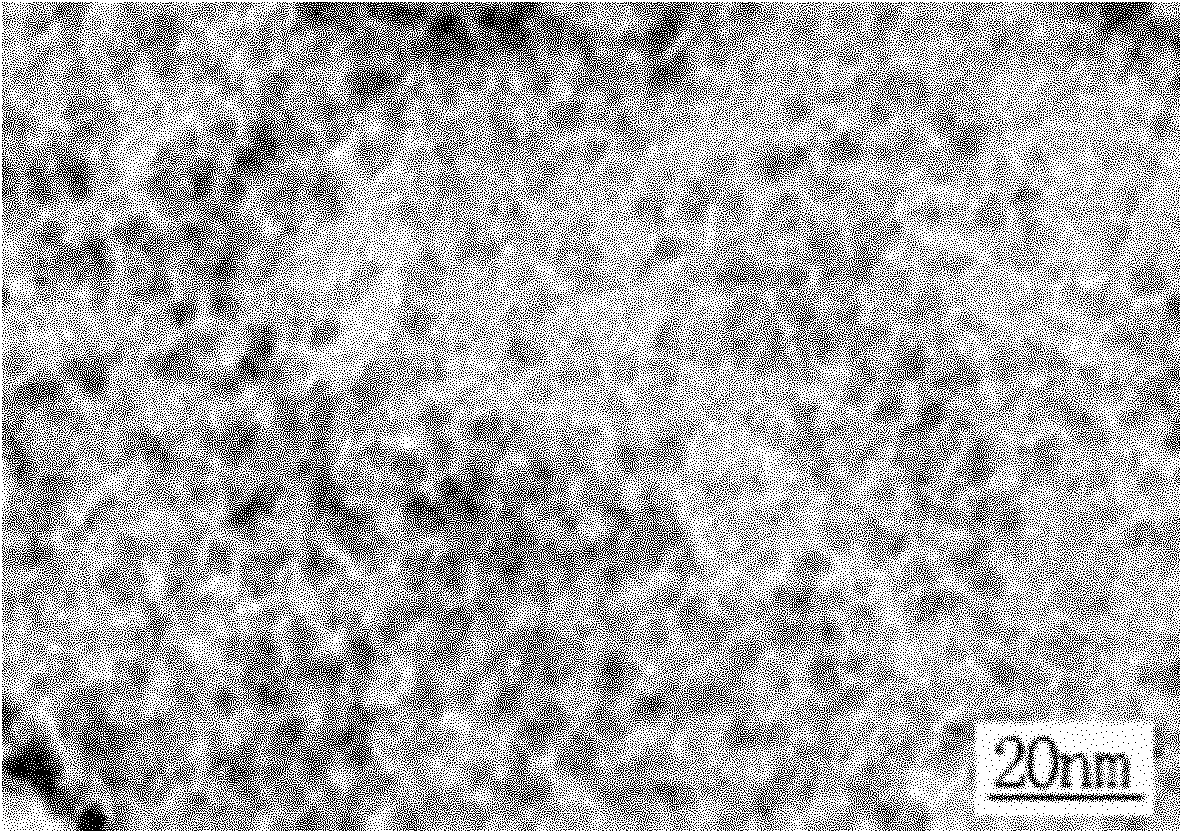

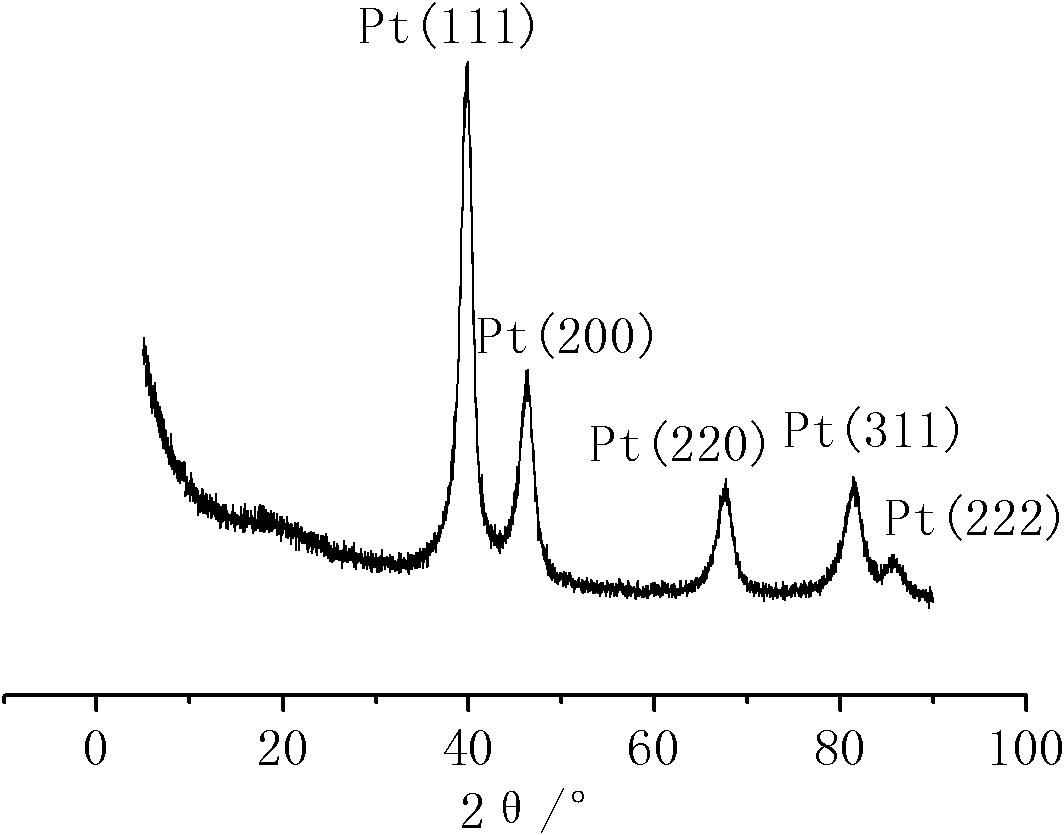

Polypyrrole/nanometer platinum composite conductive fiber and preparation method thereof

InactiveCN102011313AImprove conductivityMeet different conductivity requirementsSynthetic fibresNatural fibresFiberPolypyrrole

Owner:泉州红瑞兴纺织有限公司

Polymeric viscosity modifiers

Owner:THE PROCTER & GAMBLE COMPANY

Fluorine-carbon surfactant and method of producing the same

InactiveCN101279217AReduce surface tensionReduce manufacturing costTransportation and packagingMixingAdditive ingredientHigh surface

Owner:上海亚孚化工科技有限公司

Hair color cartridge and compositions for use in the hair color cartridge

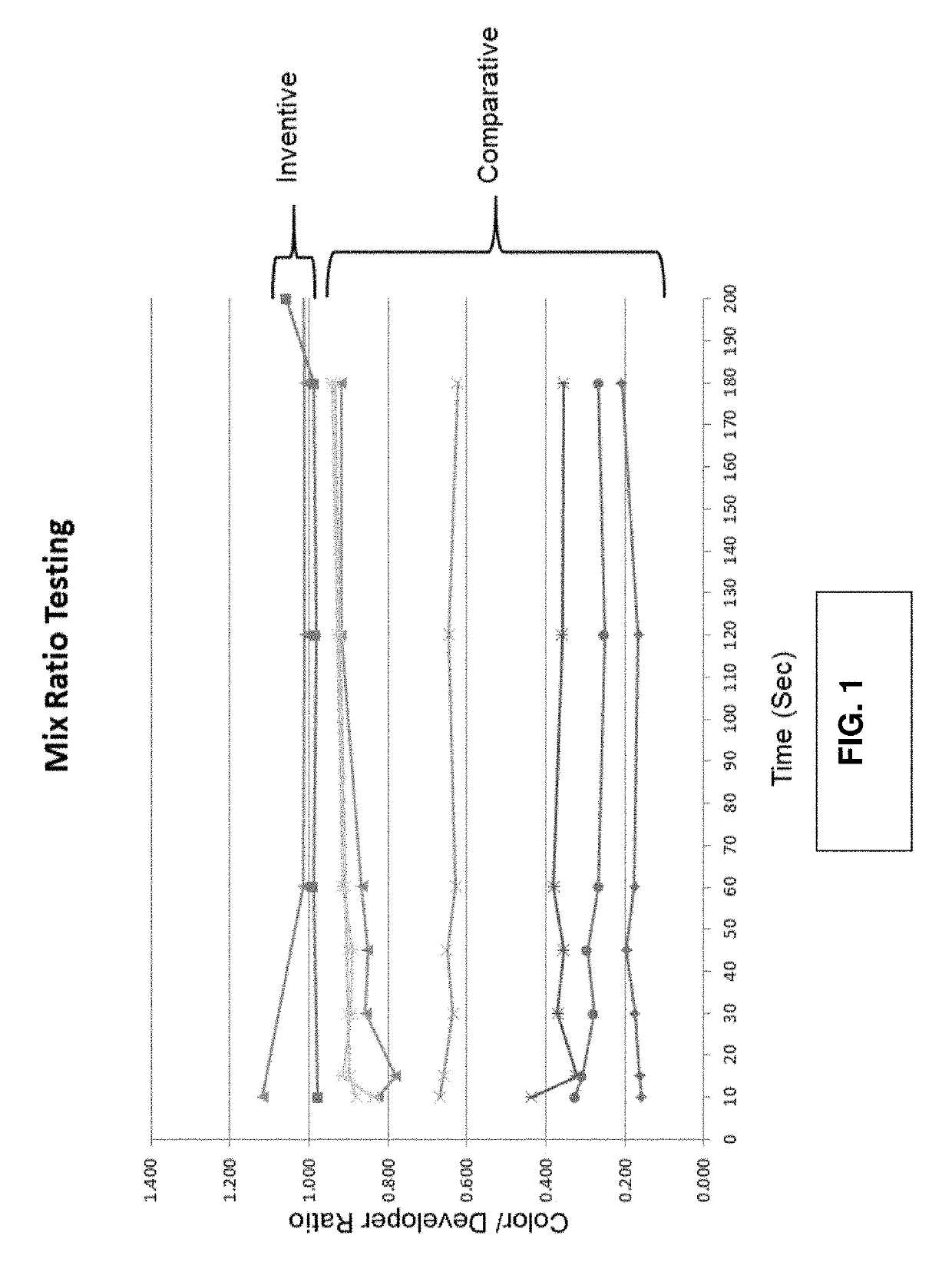

ActiveUS20190191844A1Combine accuratelyImprove consistencyCosmetic preparationsHair cosmeticsHair streamsWater soluble

Owner:LOREAL SA

Synthesis method of 2-(2-chloroethoxy) acetic acid

InactiveCN101844978AZero costSimple and fast operationOrganic compound preparationCarboxylic compound preparationAcetic acidOrganic solvent

The invention relates to a synthesis method of 2-(2-chloroethoxy) acetic acid, which belongs to the technical field of the preparation and the application of fine chemical engineering products. The invention particularly belongs to the synthesis method of 2-(2-chloroethoxy) acetic acid. The invention uses 2-chloroethoxy ethanol as starting materials, uses water as solvents, and uses nitric acid for direct oxidization to obtain products. The reaction process is shown as the accompanying drawing. The invention adopts water as the solvents, and uses the nitric acid as oxidizing agents for efficiently oxidizing the 2-chloroethoxy ethanol into corresponding acids. The method has the advantages of simple operation, low price of raw materials, easy acquisition of raw materials, simple requirement on equipment, simple after treatment and the like. In addition, the use of the organic solvent has nearly zero cost, and the invention conforms to the environmental protection industrial production requirements, so the invention has wide application prospects.

Owner:NANKAI UNIV

Method for depositing a dielectric material

InactiveUS20090311878A1Many timesReduce processing timeSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringOxidizing agent

A depositing method for a dielectric material is provided, where the dielectric material has the first and the second primary elements, and a single precursor includes the first and the second primary elements. The depositing method includes pulsing the single precursor, purging a redundant part of the single precursor, pulsing an oxidant for oxidizing the single precursor, and purging a redundant part of the oxidant.

Owner:NAN YA TECH

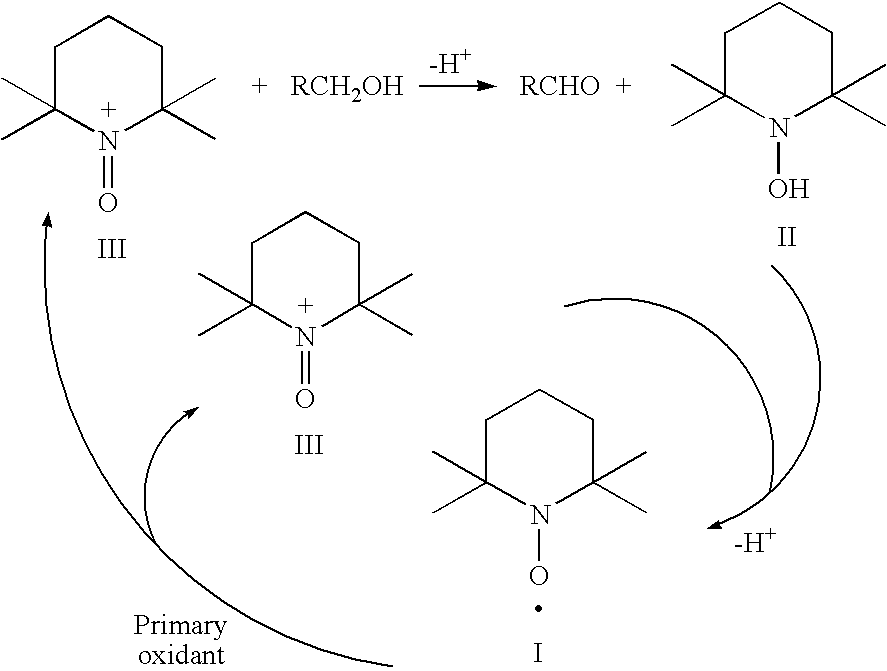

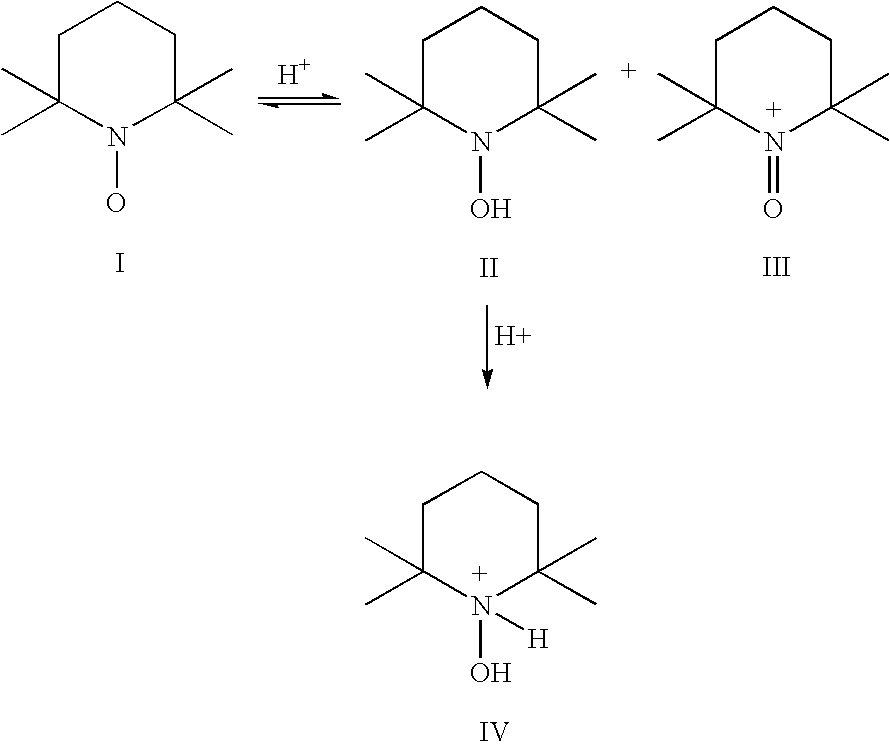

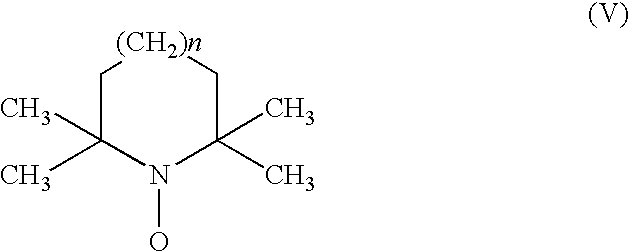

Process for the separation of organic hydroxylamine and nitrosonium compounds and its use in the oxidation of hydroxy compounds

InactiveUS20050154233A1Easy to recycleOrganic compounds purification/separation/stabilisationCarbonyl group formation/introductionProtonationHydroxylamine compound

Owner:SCA HYGIENE PROD AB

Copper-containing laminated etching solution, etching method and application thereof

ActiveCN112342548ALow costReduce processing costsSolid-state devicesSemiconductor/solid-state device manufacturingChemical treatmentOrganic base

The invention relates to the field of metal surface chemical treatment, in particular to a copper-containing laminated etching solution, an etching method and application thereof. The etching solutioncomprises a main agent, and by weight, the main agent comprises, 1-20 parts of an oxidizing agent, 0.01-1 part of a fluorine ion source, 0.01-5 parts of inorganic acid, 1-15 parts of organic acid, 1-15 parts of organic alkali, 0.01-5 parts of a hydrogen peroxide stabilizer, 0.01-1 part of a metal corrosion inhibitor and the balance solvent, wherein the total weight parts are 100. The etching solution is low in cost, free of phosphorus, environmentally friendly and low in waste liquid treatment cost; cracks at different metal interfaces can be effectively inhibited; the copper-containing laminated etching solution has high copper ion loading capacity, and has excellent etching characteristics, wherein the unilateral CD-Loss is smaller than 0.9 micrometer, and the taper is 35-45 degrees; and the chamfering problem can be solved, bubbles of an insulating layer are effectively avoided, and meanwhile the step of copper pre-dissolving can be omitted.

Owner:JIANGSU HEDA ELECTRONIC TECH CO LTD +1

Method for preparing electrolytic manganese by using pyrolusite

PendingCN110331284AAchieve regenerationAchieve recyclingPhotography auxillary processesProcess efficiency improvementElectrolysisPyrolusite

The invention discloses a method for preparing electrolytic manganese by using pyrolusite, and the method comprises the following steps of leaching manganese ore: crushing pyrolusite, mixing a mixed solution containing ammonium sulfate, manganese sulfate and ferrous sulfate with pyrolusite particles to obtain slurry, and leaching; neutralizing and precipitating iron: adding calcium-based neutralizer into the slurry, adjusting pH value, adding oxidant to enable Fe<2+> concentration in the solution to be lower than 1 mg / L, and filtering to obtain manganese sulfate solution and iron hydroxide filter residue; carrying out heavy metal removal: adding a vulcanizing agent into the manganese sulfate solution to enable the concentration of heavy metal ions in the solution to be lower than 1 mg / L, and then filtering to obtain vulcanized slag and electrolyte; and carrying out electrolytic recovery of manganese metal: electrolyzing the obtained electrolyte to prepare electrolytic manganese and electrolytic manganese anolyte containing sulfuric acid. The method can effectively solve the problem that dithionate is generated in the pyrolusite sulfur dioxide leaching method, thereby causing the problems of high electrolysis energy consumption, high sulfur content of electrolytic manganese and large amount of iron-containing waste residue generated in the pyrolusite ferrous sulfate leaching method.

Owner:GUIZHOU UNION MAGANESE CORP CO LTD

Additive-free odorless super-stain-resistant acrylate emulsion and preparation method thereof

InactiveCN111205387AEasy to wrapIntertwined closelyAntifouling/underwater paintsPaints with biocidesPolymer scienceFunctional monomer

Owner:广东巴德富新材料有限公司

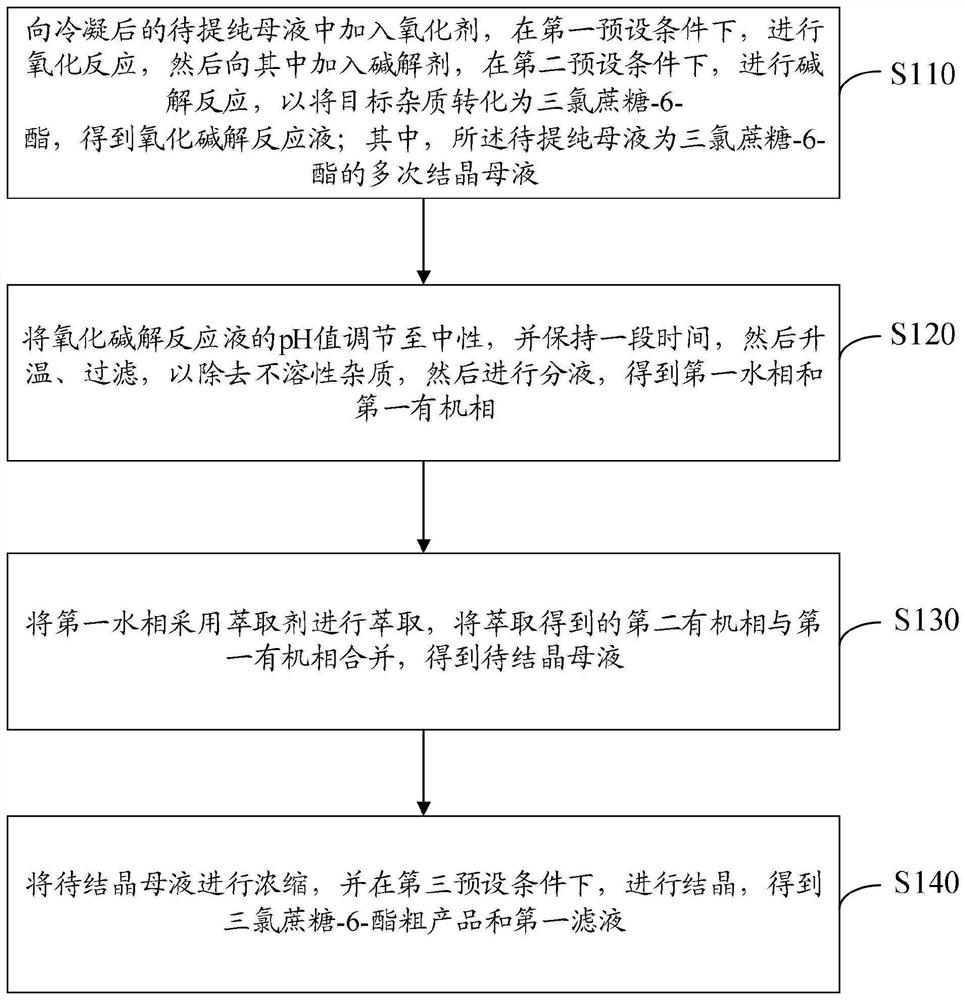

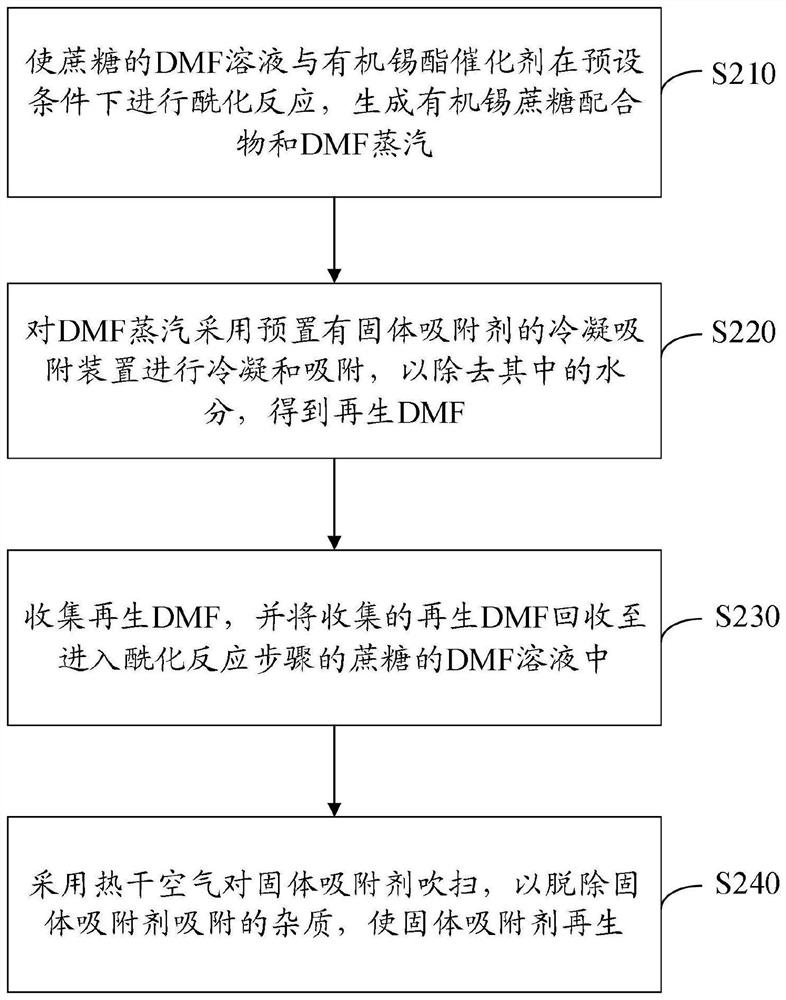

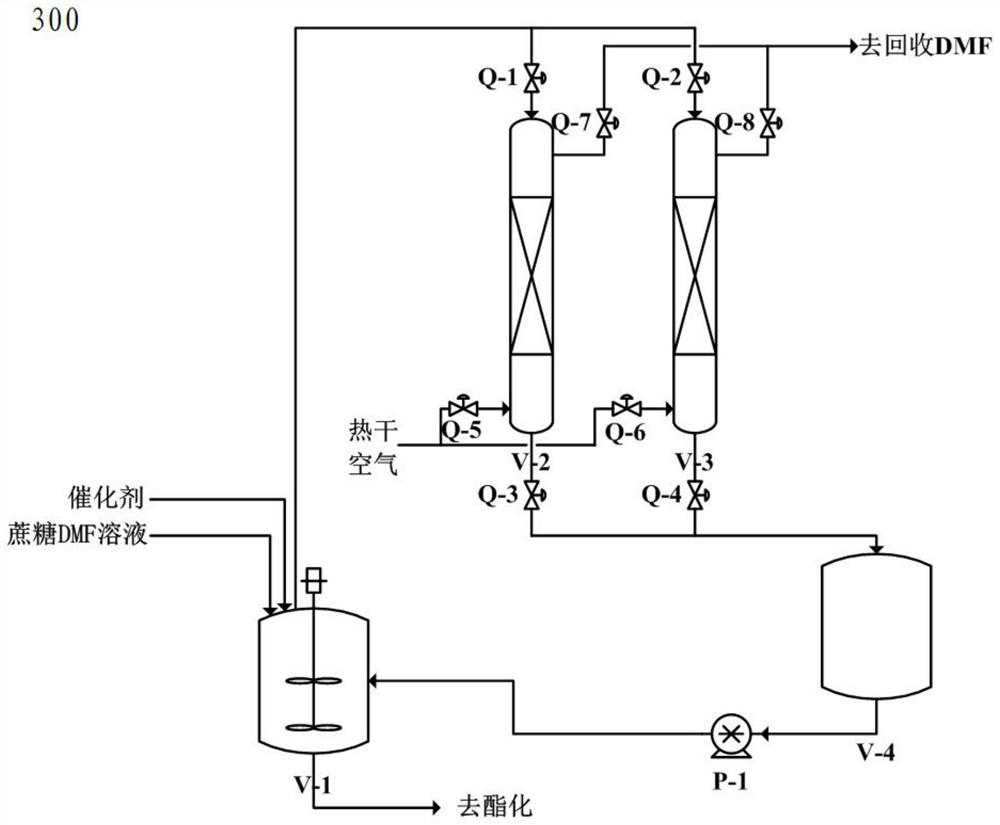

Sucralose-6-ester purification method

ActiveCN113939524AHigh purityHigh yieldEsterified saccharide compoundsSugar derivativesSucrosePhysical chemistry

Owner:ANHUI JINGHE IND

Dental Polymerizable Core Build-Up Material of Separately Packed Type

ActiveUS20070249752A1Easy to operateImprove mechanical propertiesImpression capsTeeth fillingMethacrylateMeth-

Owner:KURARAY NORITAKE DENTAL

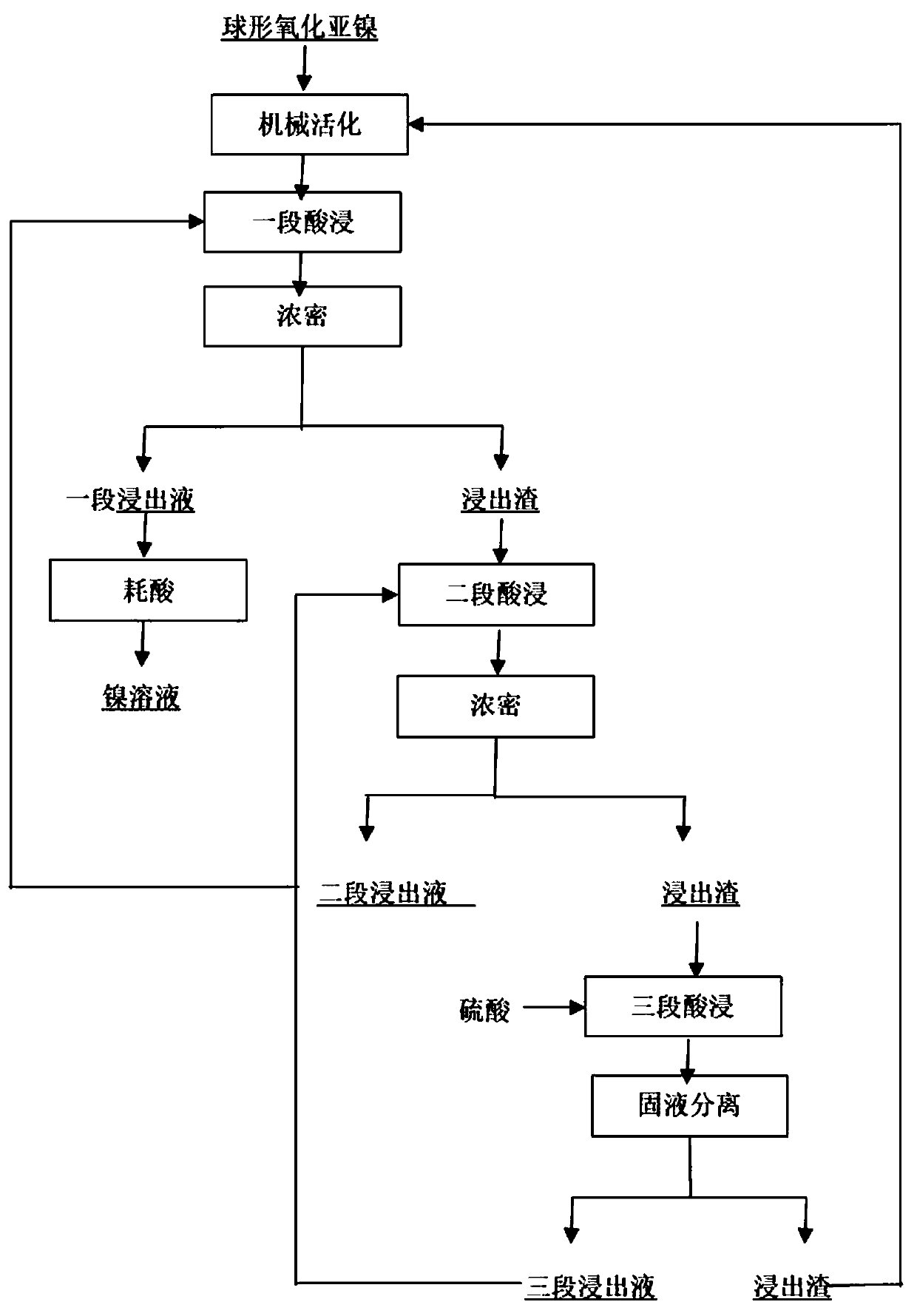

Method for recycling spherical nickel oxide after mechanical activation using three-section countercurrent acid leaching

InactiveCN110468289AGuaranteed leaching rateReduce solubilityNickel halidesNickel sulfatesSpherical shapedBiological activation

Owner:JINCHUAN GROUP LIMITED +1

Method for rapidly activating proton exchange membrane fuel cell

InactiveCN111600048ALower the potential on the cathode sideIncrease optionalityFuel cellsEngineeringProton exchange membrane fuel cell

The invention relates to a method for rapidly activating a proton exchange membrane fuel cell. The method comprises the following steps: 1, enabling a proton exchange membrane fuel cell stack to be inan on-load state with rated power of 5%-30%, and then opening an inlet and outlet valve of fuel; 2, waiting for 3-10 s, introducing an oxidizing agent, and operating for 3-60 s; 3, gradually loadingto 5%-90% of the rated power according to the step length of 5%-30% of the rated power, wherein the interval between every two step lengths is 3-60 s; 4, reducing the electric potential of the singlecathode side of the fuel cell stack to be below 0.1 V by adopting a mode, and maintaining the potential for 0.05-60 s; and 5, recovering the power of the fuel cell stack to 95-120% of the rated working point power, and operating for 5-60 s. According to the invention, a universal fundamental activation and recovery method is provided for the nature of performance degradation of the proton exchangemembrane fuel cell, that is, the electric potential of the cathode side of the fuel cell is reduced, so that the cathode electric potential of the fuel cell can be reduced in many ways, and the selectivity, the operability and the convenience are greatly improved.

Owner:BEIJING CHINA HYDROGEN GREEN ENERGY TECH CO LTD +1

Oil washing agent for carbon dioxide displacement as well as preparation method and application thereof

Owner:SHANDONG DESHI CHEM IND CO LTD +2

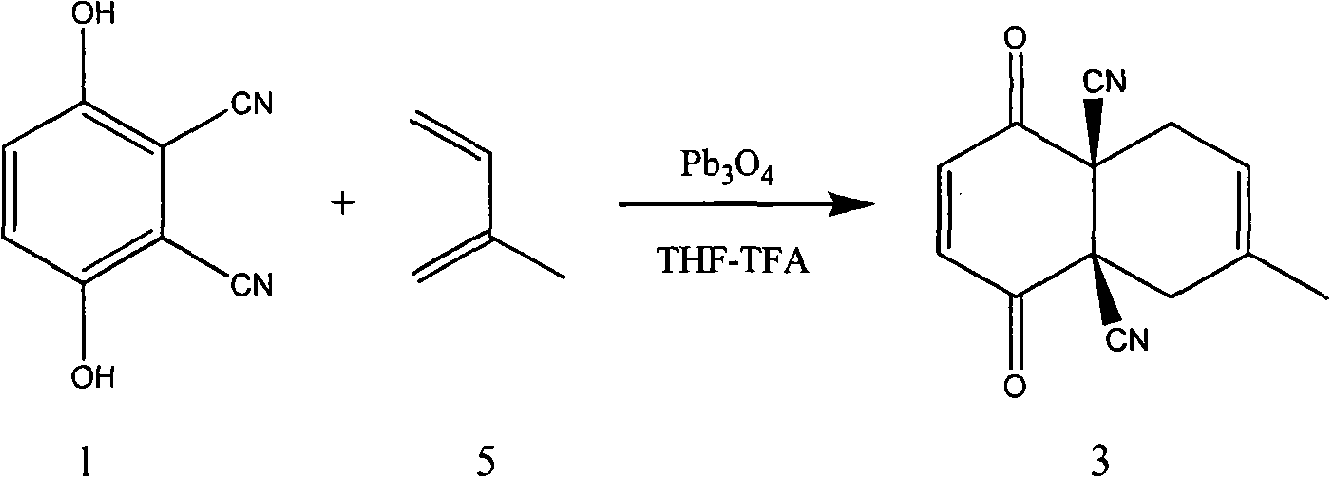

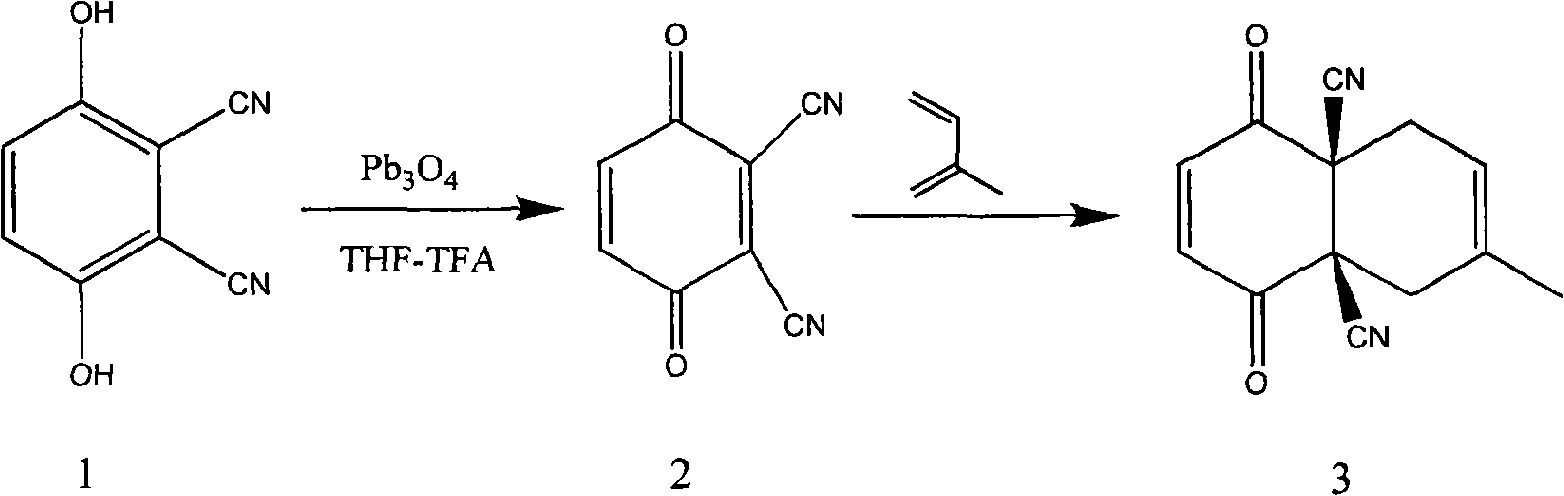

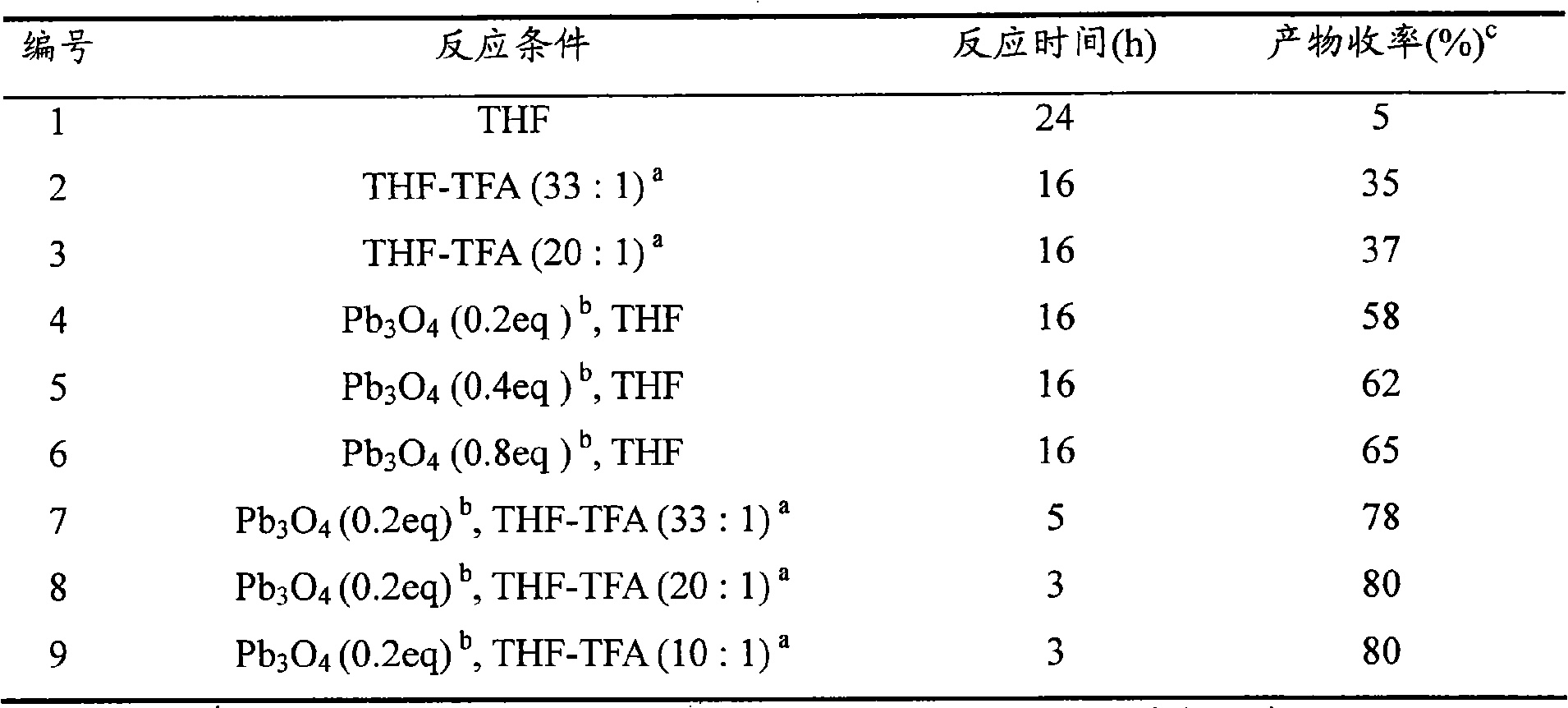

Synthetic method of carbocyclic compound

InactiveCN101570460AEasy to purifyHigh yieldCarboxylic acid nitrile preparationOrganic compound preparationOrganic solventLead(II,IV) oxide

Owner:SOUTHWEST UNIVERSITY

Method for lightening keratinic fibers with an emulsion containing an alcalin agent and an oxidising composition

The invention provides a method for lightening keratinic fibers with an emulsion containing an alcolin agent and an oxidizing composition. The present disclosure therefore relates to a method for lightening keratin materials, in which the following are used: (a) a direct emulsion (A) comprising at least one fatty substance in an amount greater than 25% by weight, such as greater than 50%, at least one surfactant; at least one alkaline agent and an amount of water greater than 5% by weight, of the total weight of the emulsion, (b) a composition (B) comprising at least one oxidizing agent. It also relates to a multi-compartment device comprising, in one compartment, an emulsion (A), in another compartment a composition (B) comprising at least one oxidizing agent.

Owner:LOREAL SA

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap