Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

123 results about "Temperature control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Temperature control is a process in which change of temperature of a space (and objects collectively there within), or of a substance, is measured or otherwise detected, and the passage of heat energy into or out of the space or substance is adjusted to achieve a desired temperature.

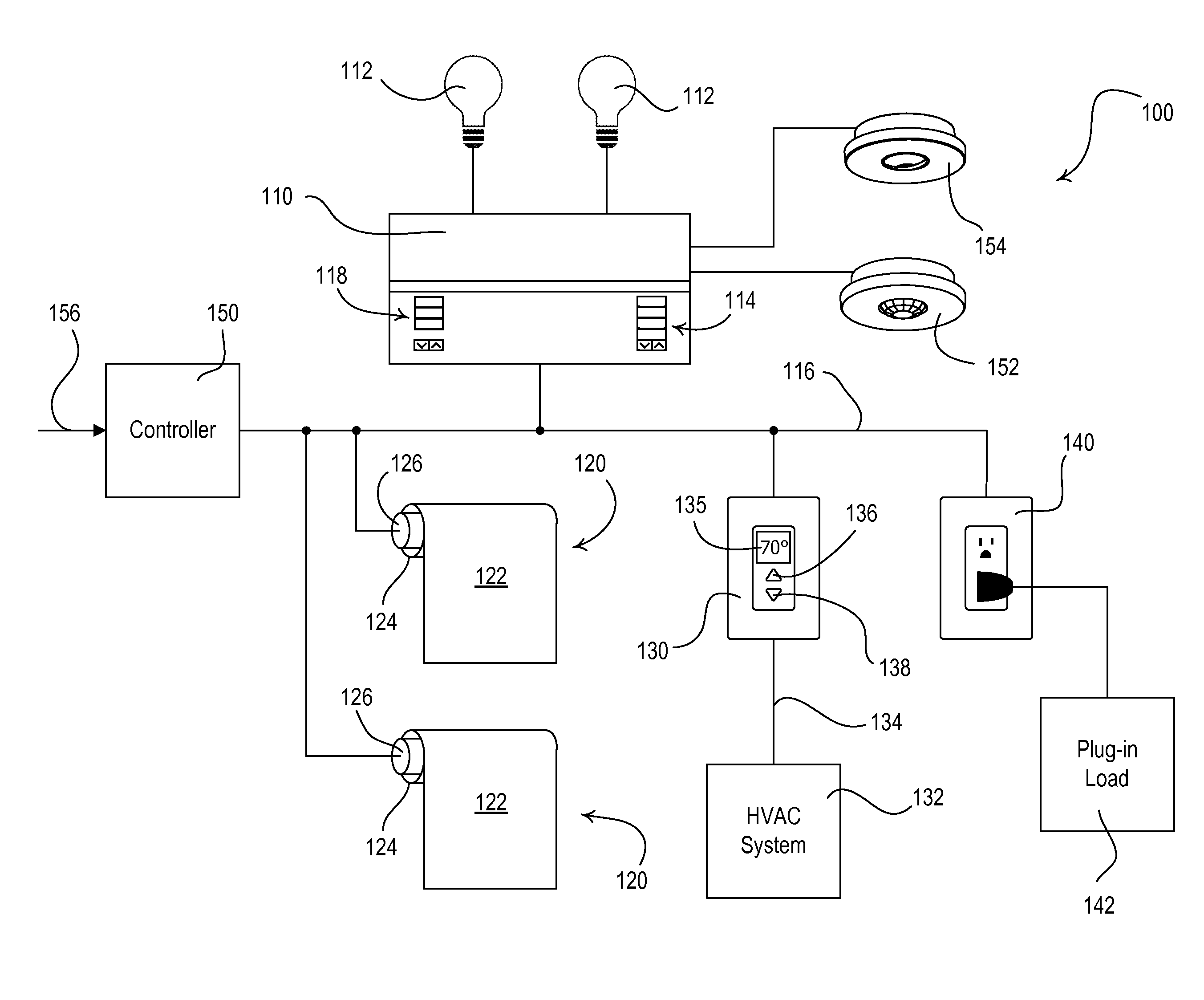

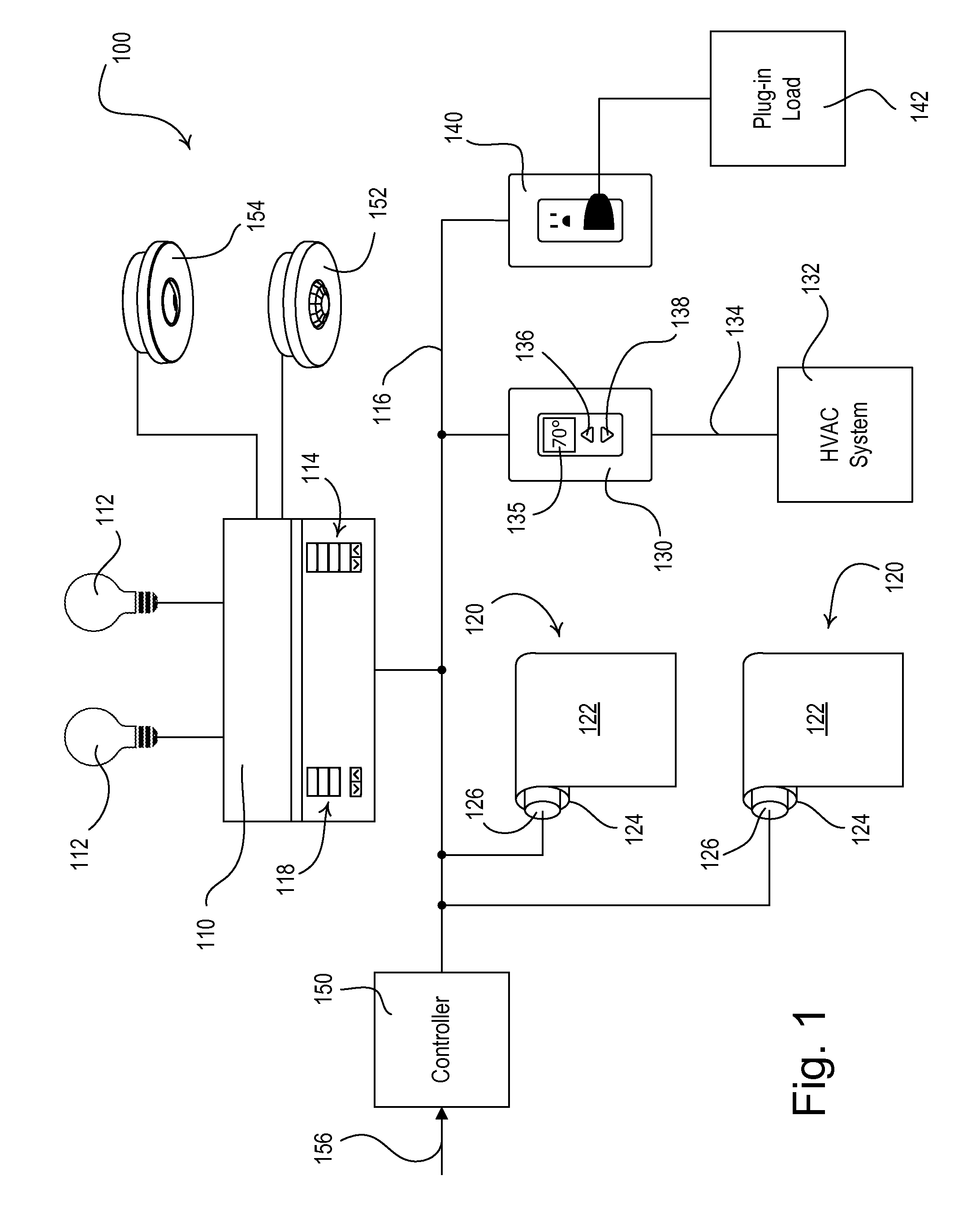

Load Control System Having An Energy Savings Mode

ActiveUS20110031806A1Reduce the amount of powerReduce power consumptionDc network circuit arrangementsMetering/charging/biilling arrangementsTemperature controlControl system

Owner:LUTRON TECH CO LLC

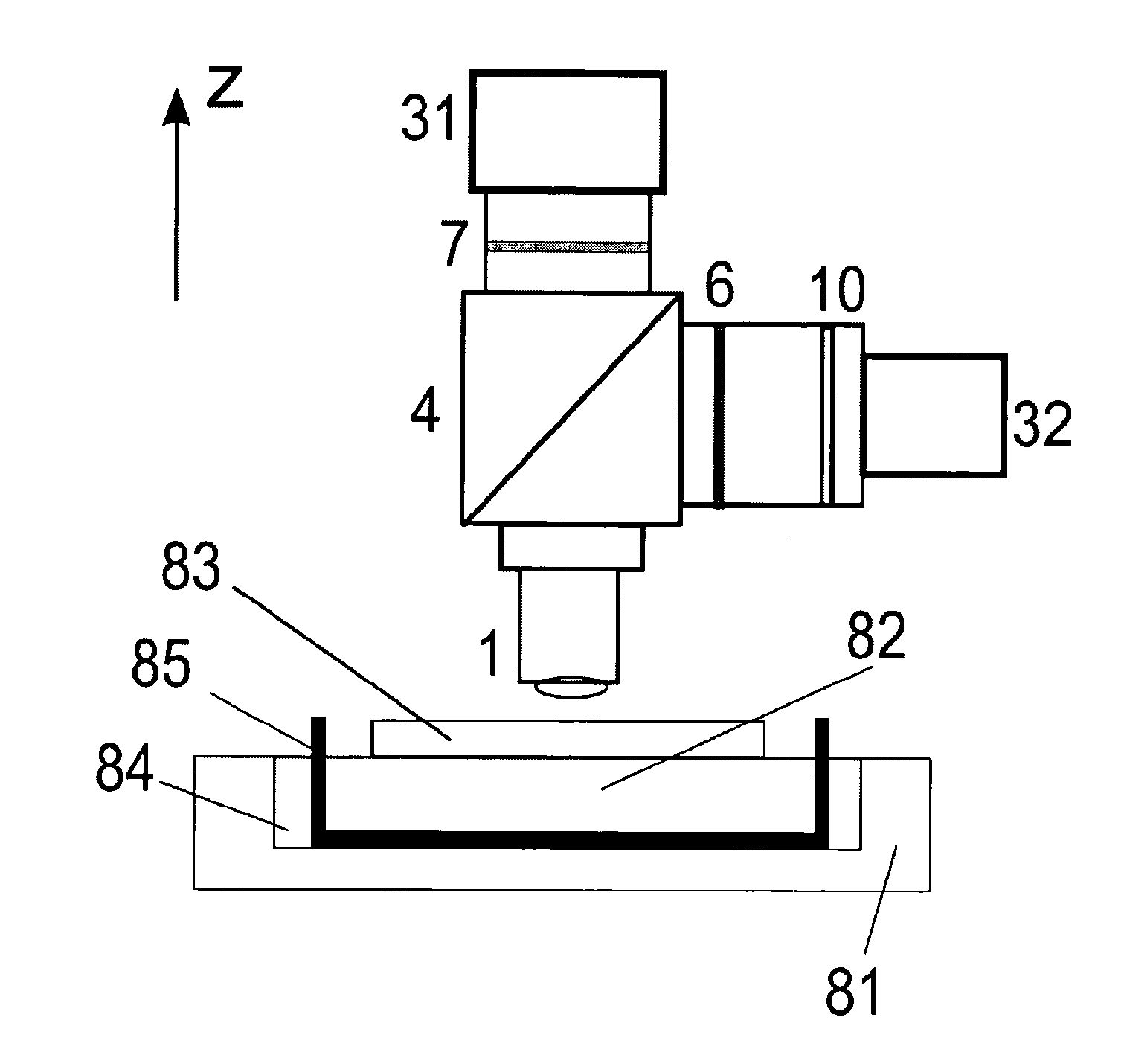

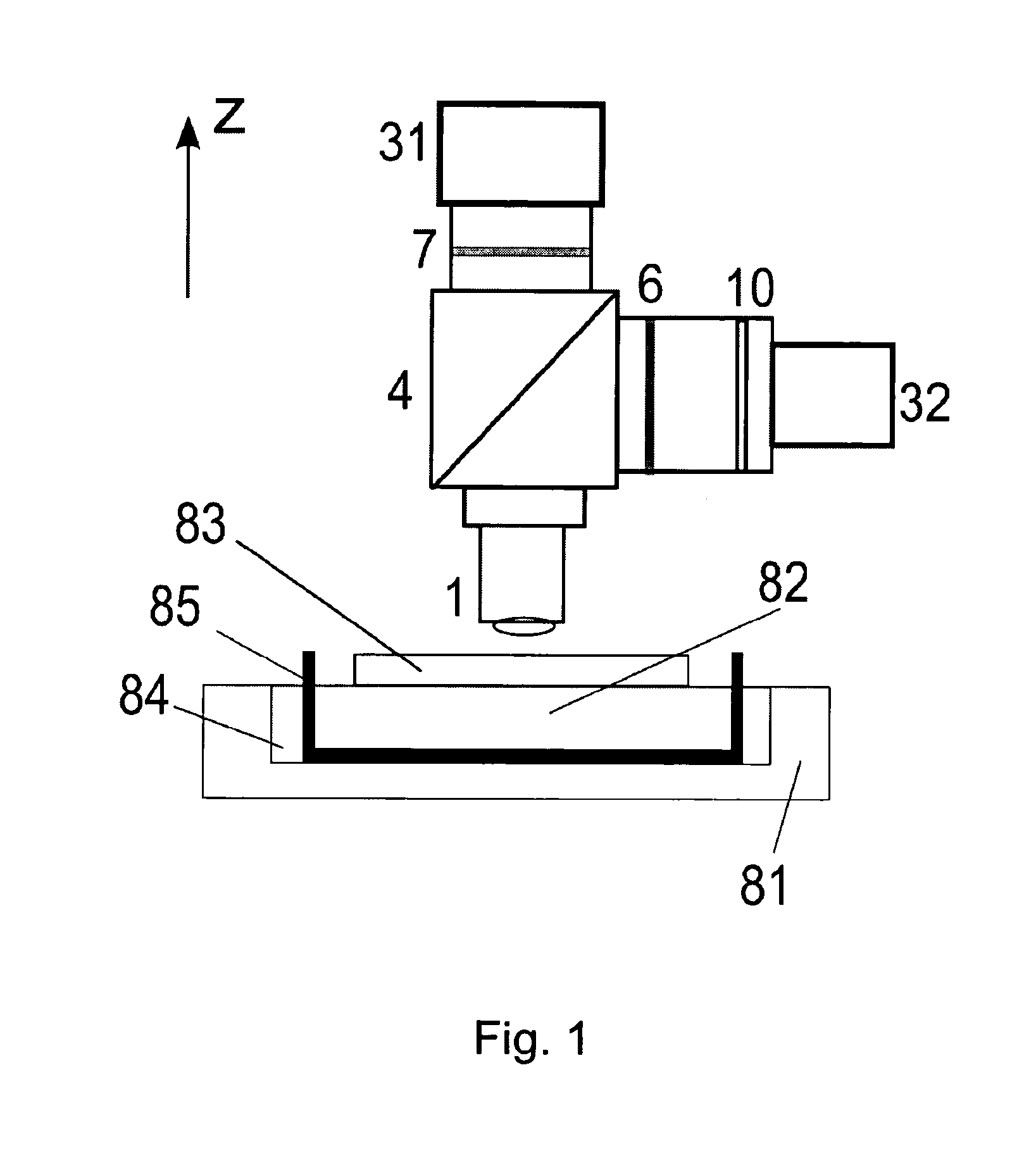

Method and device for particle analysis using thermophoresis

ActiveUS20110084218A1High initial setup costsNanoparticle analysisPhotometryTemperature controlElectricity

Owner:NANOTEMPER TECH GMBH

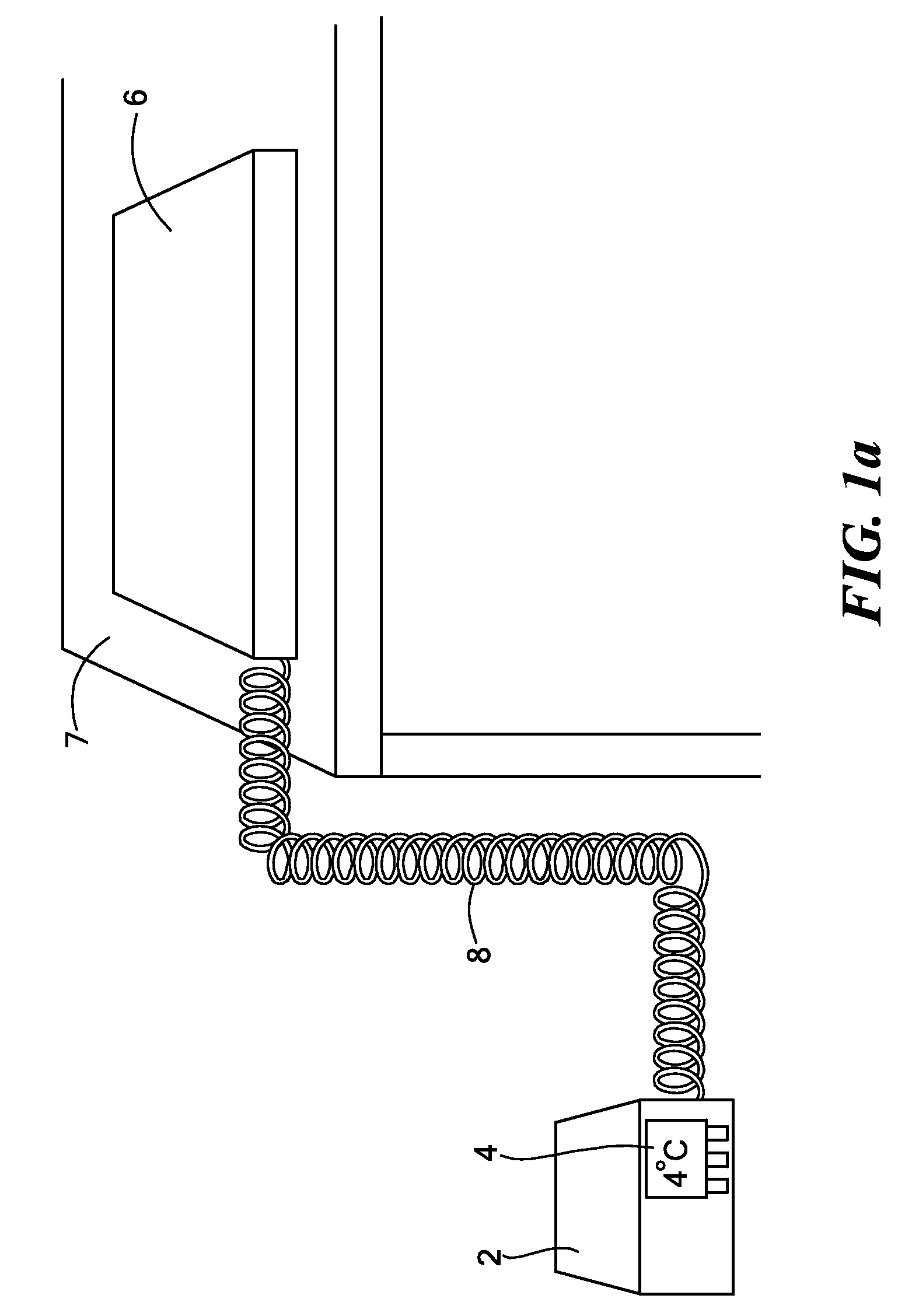

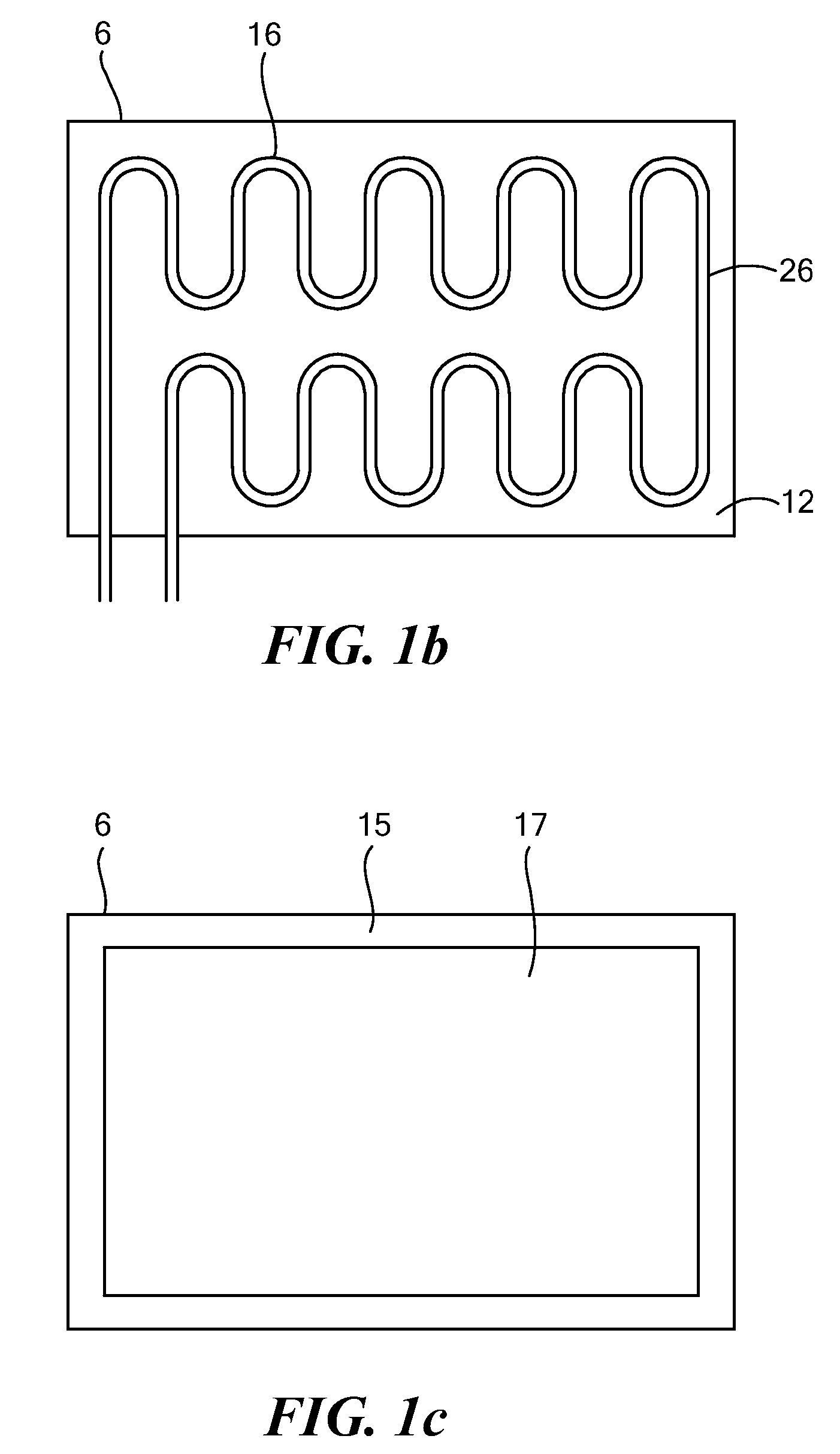

Laboratory Temperature Control With Ultra-Smooth Heat Transfer Surfaces

InactiveUS20080029248A1Decreased emissivitySludge treatmentHeating or cooling apparatusTemperature controlElectrical resistance and conductance

Owner:SAGE SCI

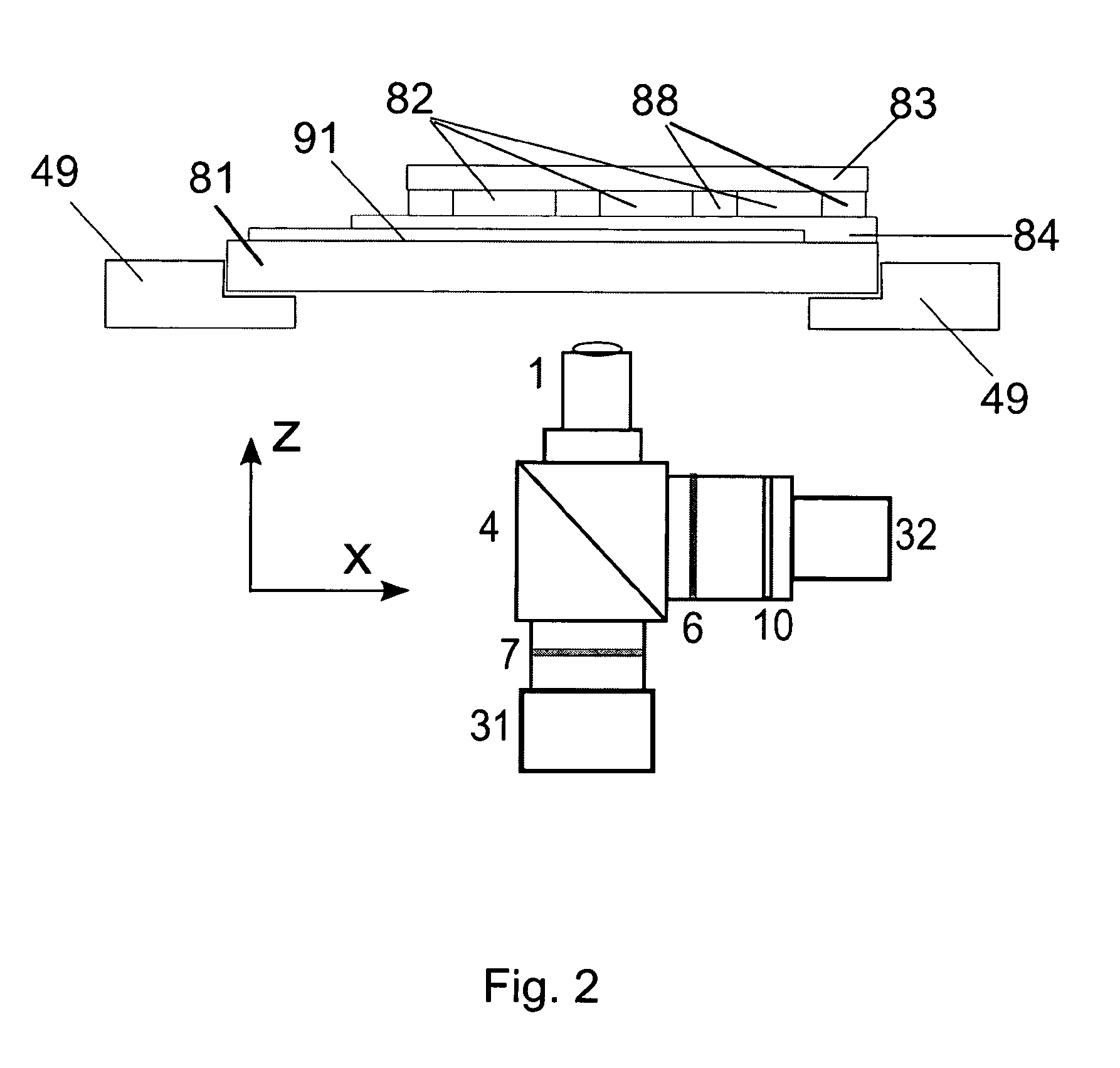

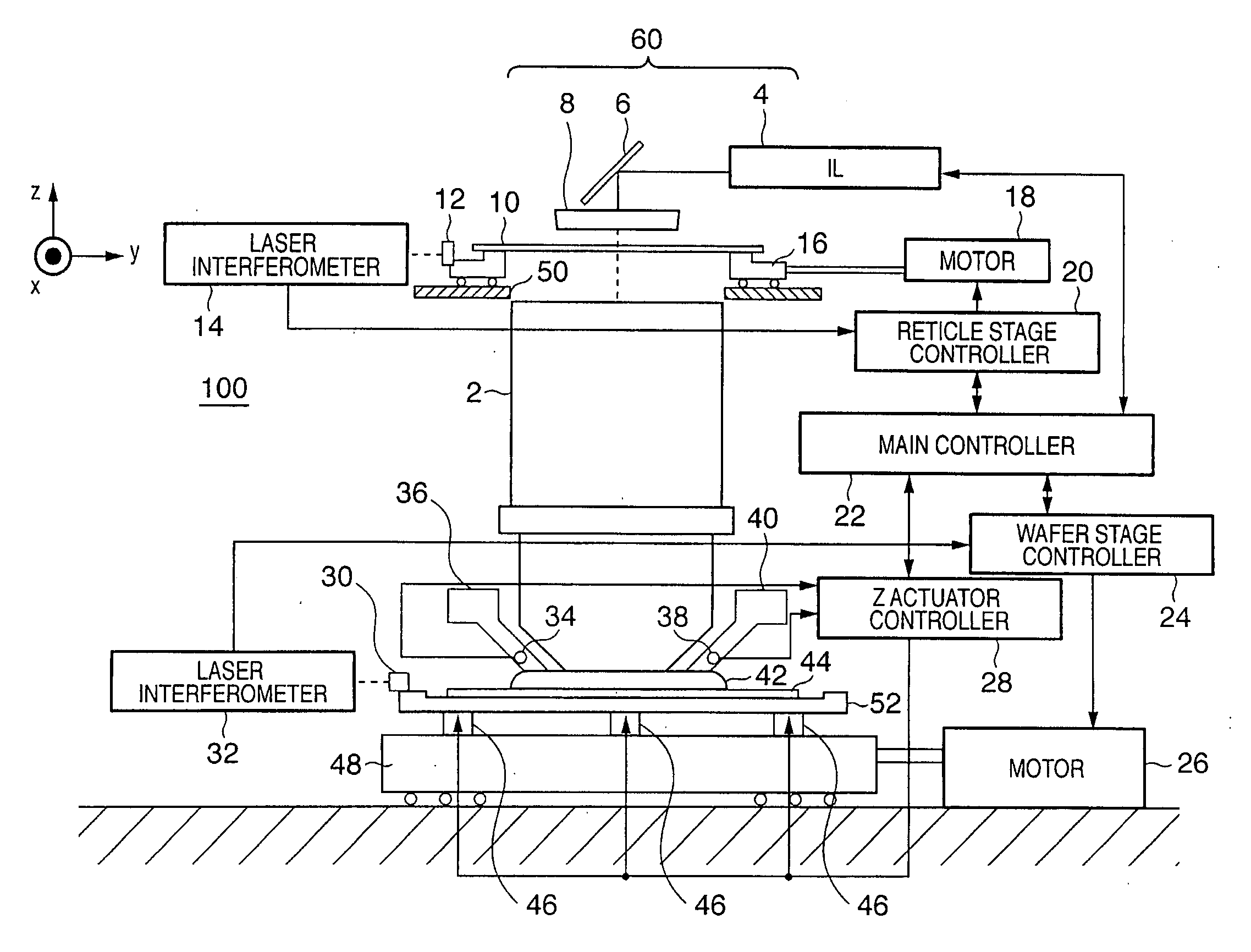

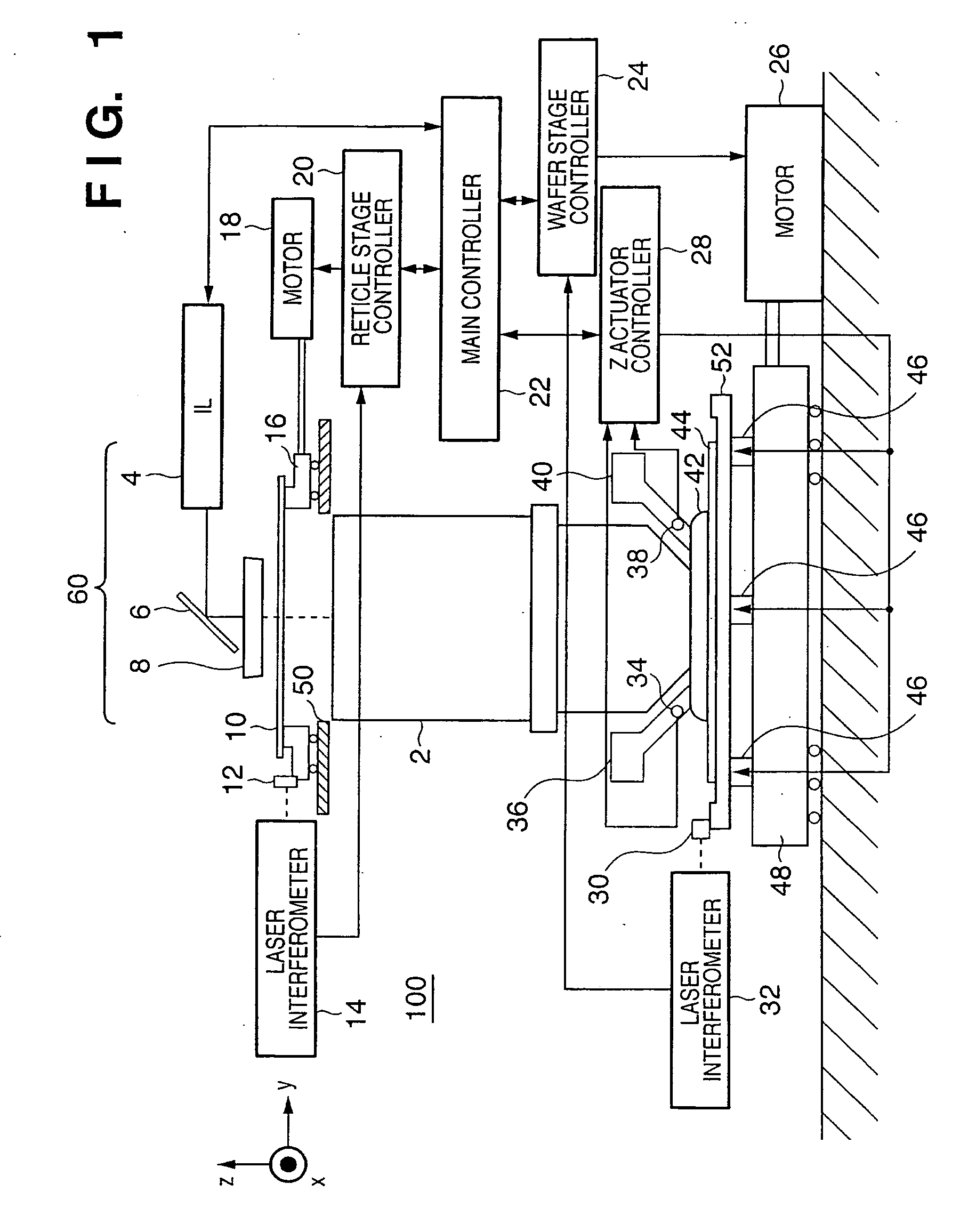

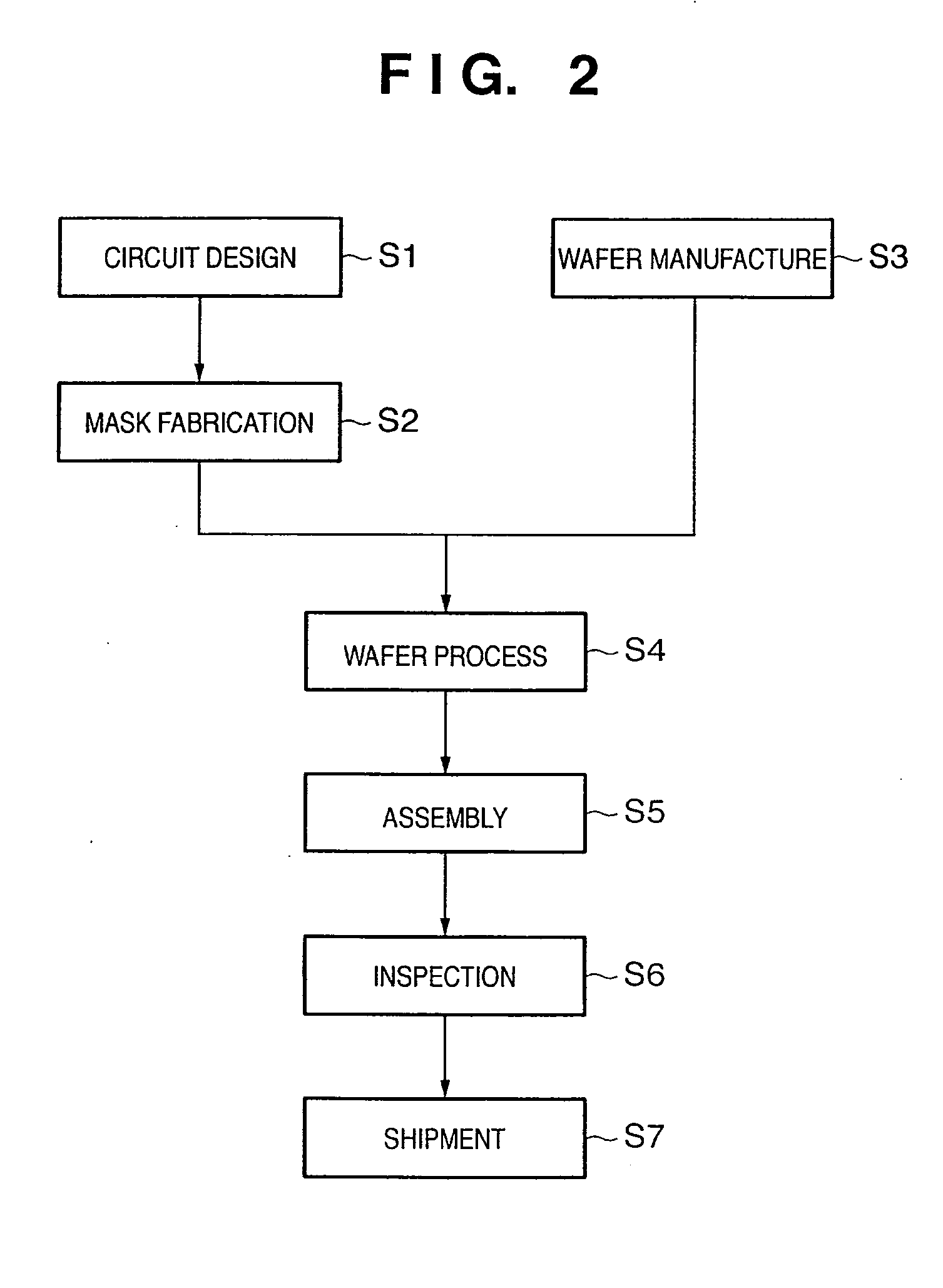

Immersion exposure apparatus, immersion exposure method, and device manufacturing method

InactiveUS20060209280A1Suppress degradation in imaging performanceImprove accuracyCannulasPhotomechanical apparatusTemperature controlBiomedical engineering

Owner:CANON KK

Non-road diesel engine combustor DPF regeneration temperature control method

InactiveCN107100703AReliable regeneration temperature managementClosed-loop control stabilityInternal combustion piston enginesExhaust apparatusTemperature controlCombustor

Owner:KAILONG HIGH TECH

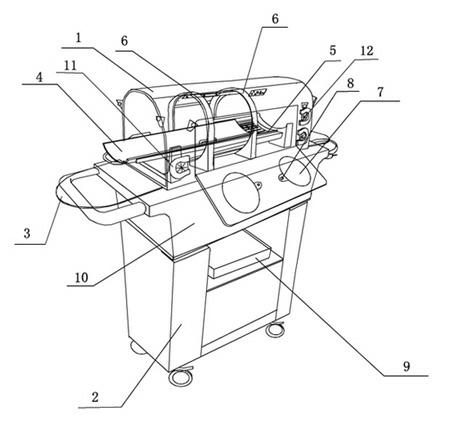

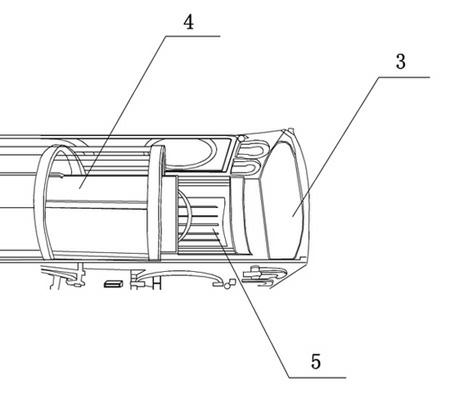

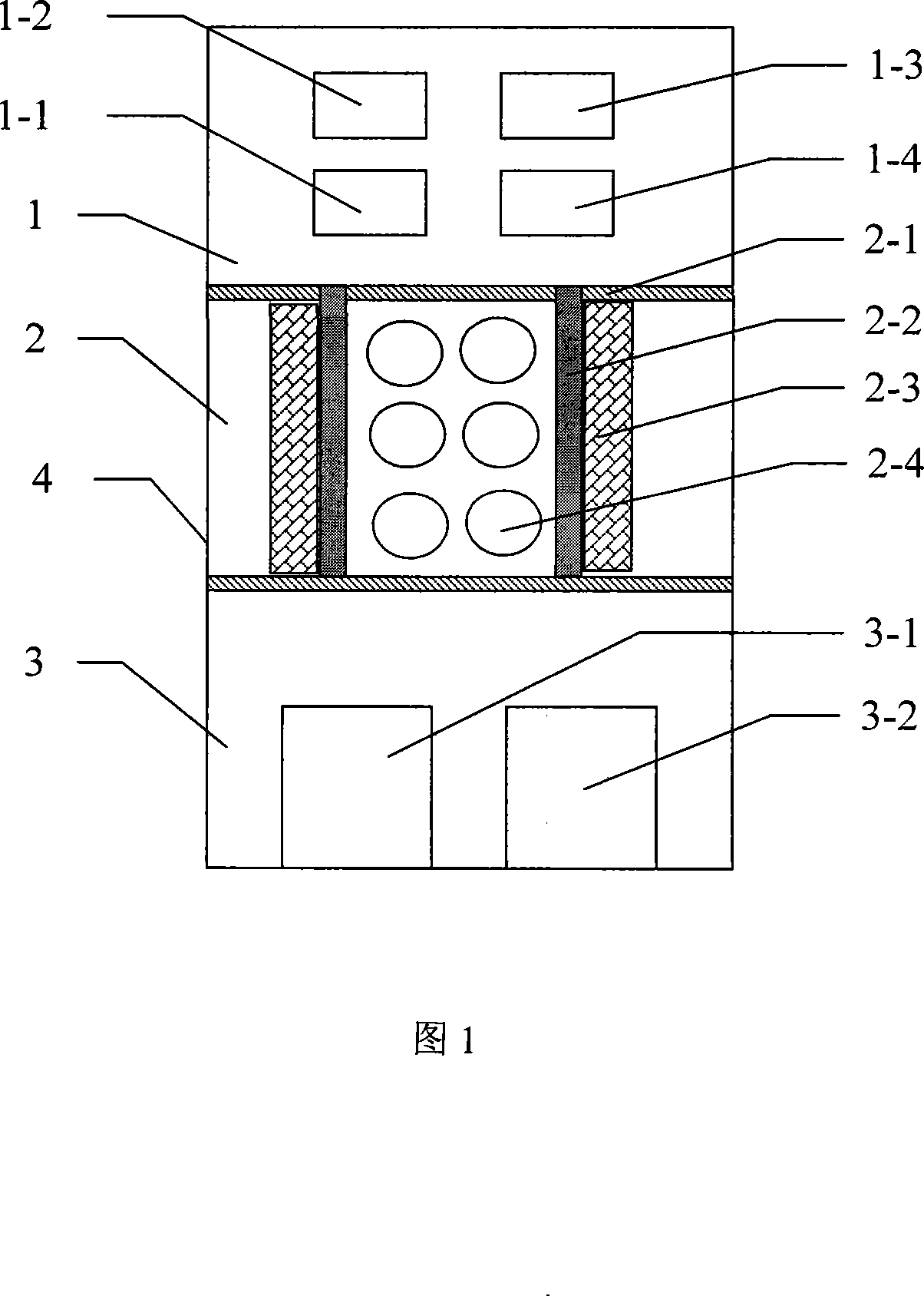

Infant incubator compatible with magnetic resonance

ActiveCN102551978AQuality improvementGuarantee the safety of lifeBaby-incubatorsSensorsTemperature controlWireless transmission

Owner:美时医疗技术(上海)有限公司

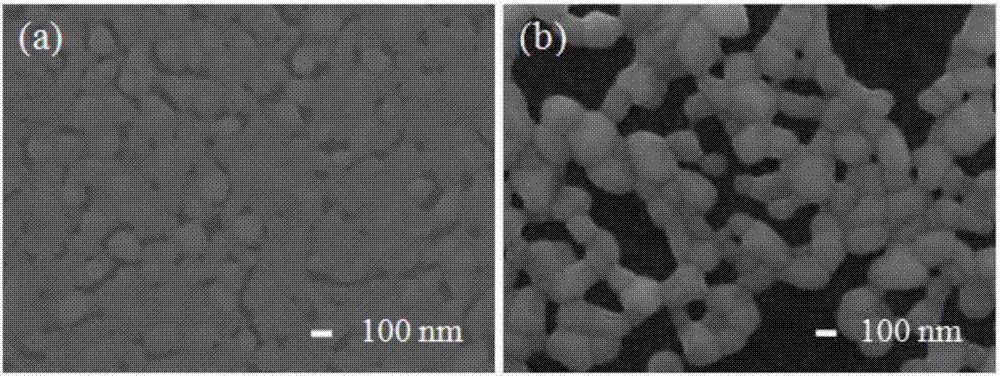

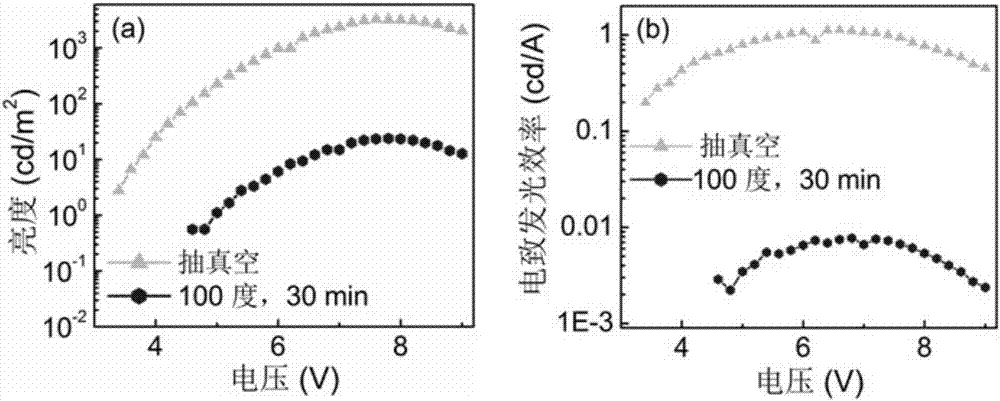

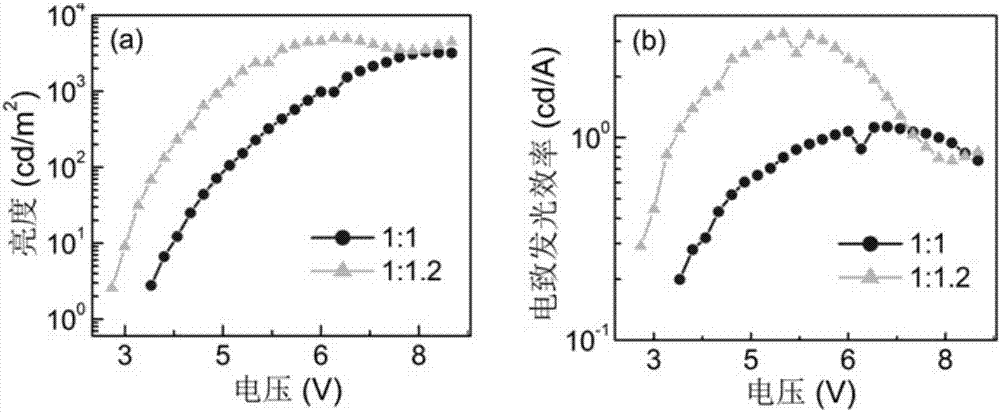

Method for preparing all-Inorganic perovskite film

InactiveCN107221612AEasy to prepareEasy to operateSolid-state devicesSemiconductor/solid-state device manufacturingTemperature controlOrganic solvent

Owner:SOUTHWEST UNIVERSITY

Rapid molding method based on electrorheological fluid, and apparatus thereof

A rapid molding method based on an electrorheological fluid, and an apparatus thereof are provided. The electrorheological fluid is jetted to a deposition base station with electric field, the electrorheological fluid is rapidly cured through utilizing an electrorheological effect, and the electrorheological fluid deposits on the deposition base station layer by layer to construct a three dimensional entity; a liquid storage container, a driving pump and a nozzle are sequentially communicated through a pipeline to form an electrorheological fluid conveying path; two control lines are set by a computer, a first control line controls the flow of the driving pump, and a second control line controls the three dimension movement of the nozzle through a servo mechanism; and electrodes which comprise an anode and a cathode closely adhere to two sides of a model to be deposited on the deposition base station to provide the electric field required by the curing of the electrorheological fluid. The apparatus which utilizes the electrorheological effect of the electrorheological fluid and utilizes the electric field to replace a temperature control module and a constant temperature environment in traditional fusion jet rapid molding has the advantages of simple structure, substantial reduction of the cost and energy, and realization of micromation; and the method and the apparatus can be applied to fields of prosthesis models, industrial design, mechanical manufacturing, three dimensional scene display, entertainment and art, and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

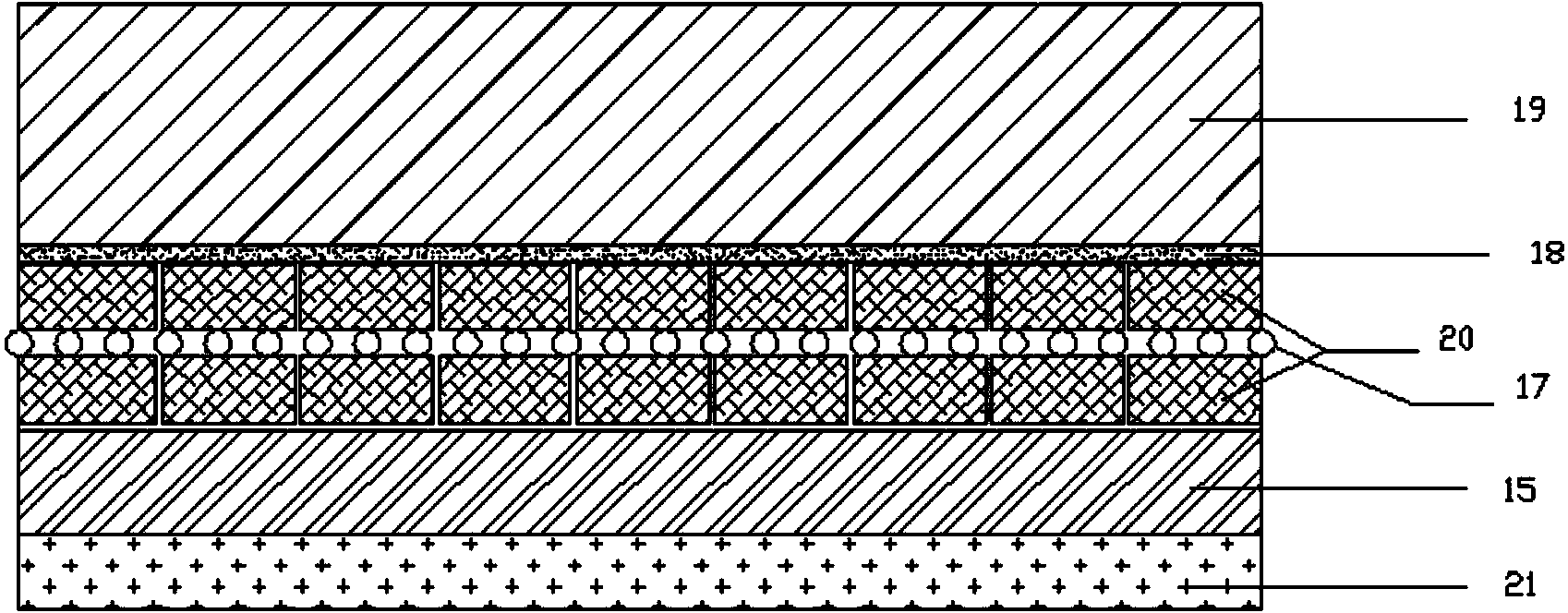

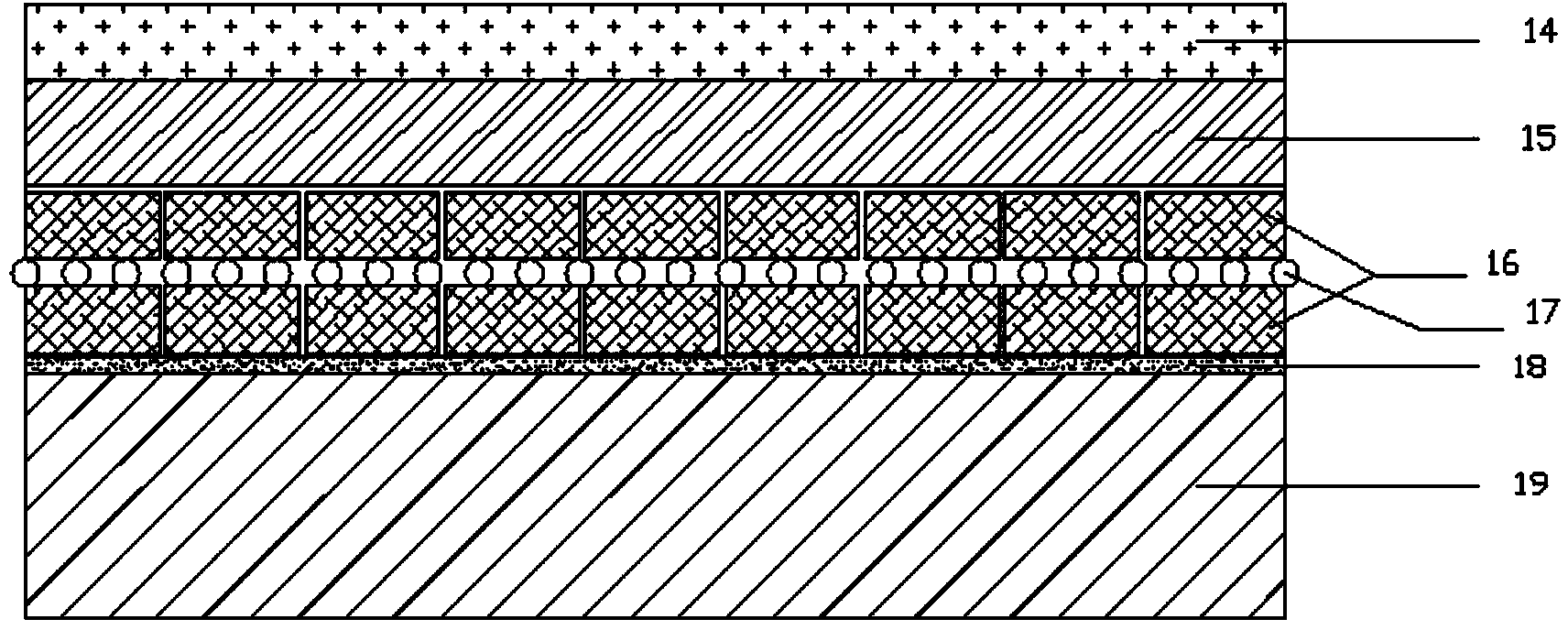

Phase-change energy storage type radiant heating and cooling tail end device and control method

InactiveCN104048379ARealize indoor temperature regulationReduce the temperatureCeilingsLighting and heating apparatusCapillary networkEngineering

Owner:SOUTHEAST UNIV

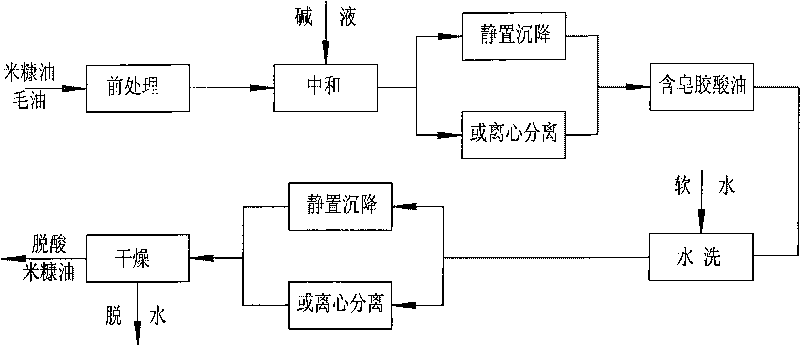

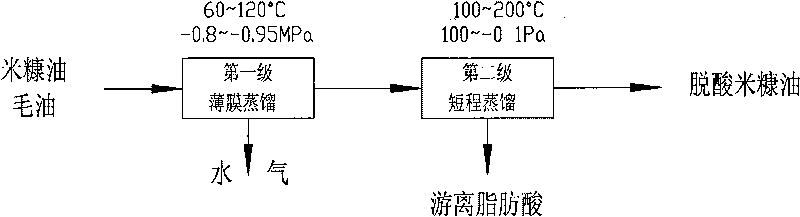

Method for refining rice bran oil by using short distance distillation

InactiveCN101705148ANo effectNo pollution in the processFatty-oils/fats refiningDistillationOleic Acid Triglyceride

Owner:SOUTH CHINA UNIV OF TECH

Smart chair for students

InactiveCN106263597AEasy to monitor in real timeEnsure good postureStoolsSchool benchesTemperature controlWireless transceiver

The present invention relates to the field of smart chairs, and in particular to a smart chair for students. The smart chair comprises a seat, a seat back, handrails, a head support device, a toolbox unit, and a smart camera. A central processor, a wireless transceiver, a temperature controller and a voice announcer are integrated in the seat back, thermal resistance wires are evenly distributed in the seat, the temperature controller is electrically connected with the thermal resistance wires, the head support device has a pressure sensor inside, the central processor is electrically connected with the smart camera, the wireless transceiver device, the temperature controller, the voice announcer and the pressure sensor. The central processor communicates with the mobile monitoring terminal through the wireless transceiver device. The invention has the advantages of strong function and can cool the seat in the cold days. The chair can ensure that the user's sitting position is correct and the user's eyesight and the health of the bones can be protected. The setting of the toolbox does not cause the desk to be disheveled by the tool; the smart camera captures the image video signal to facilitate the guardian or teacher to monitor the learning of the student in real time.

Owner:张佳琪

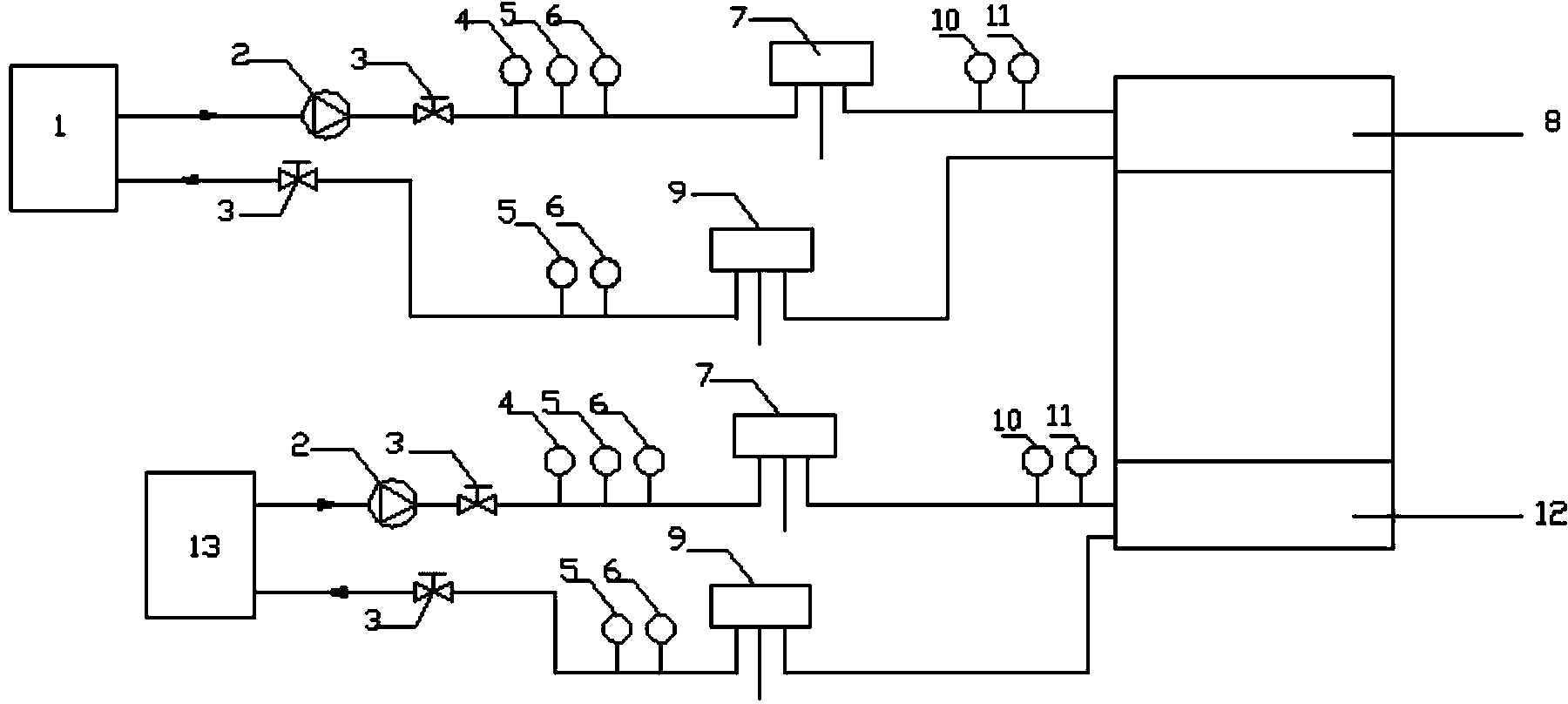

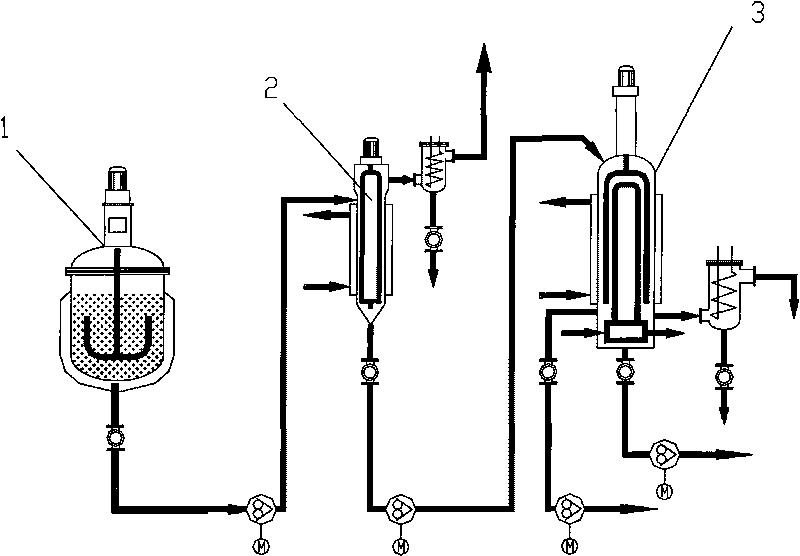

Method for controlling temperature of crude oil for emulsion of rolling mill and control device

InactiveCN101575044AUniform temperatureImprove the heating effectTank wagonsTemperature controlEmulsion

The invention relates to a method for controlling temperature of crude oil for emulsion of a rolling mill and a control device. The method comprises the steps of: arranging a heating device on the outer part of a crude oil tank; adopting a circulation heating pump arranged at the tail of the crude oil tank to transfer crude oil to a heat exchanger for heat exchange; simultaneously adopting a temperature controller on the crude oil tank to control the on and off of the heating device; and transferring crude oil to the top of the crude oil tank for outer circulation heating so as to keep the temperature of crude oil inside the crude oil tank at a preset value. A control device comprises the heating device consisting of the circulation heating pump and the heat exchanger, the temperature controller, a steam control valve, a steam trap and pipelines connecting the components, wherein the circulation heating pump is arranged at the tail of the crude oil tank, the heat exchanger is arranged on the side of the crude oil tank and the temperature controller is arranged on the crude oil tank. The invention has the advantages of good heating effect, equal crude oil temperature, high temperature-control property and precision, simple and convenient operation process, non-steam entering the crude oil and non-impact on crude oil quality.

Owner:BAOSTEEL ENG & TECH GRP

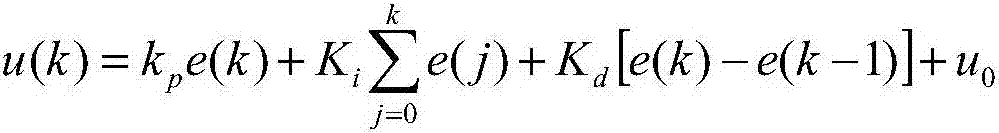

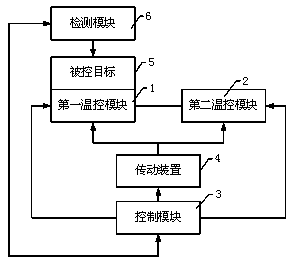

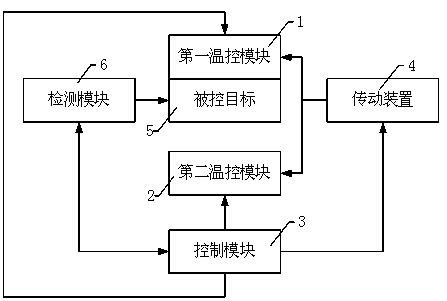

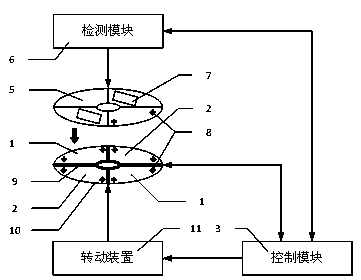

Device and method applied in gradient temperature control

ActiveCN103777662ABioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlControl algorithm

Owner:ZHEJIANG UNIV

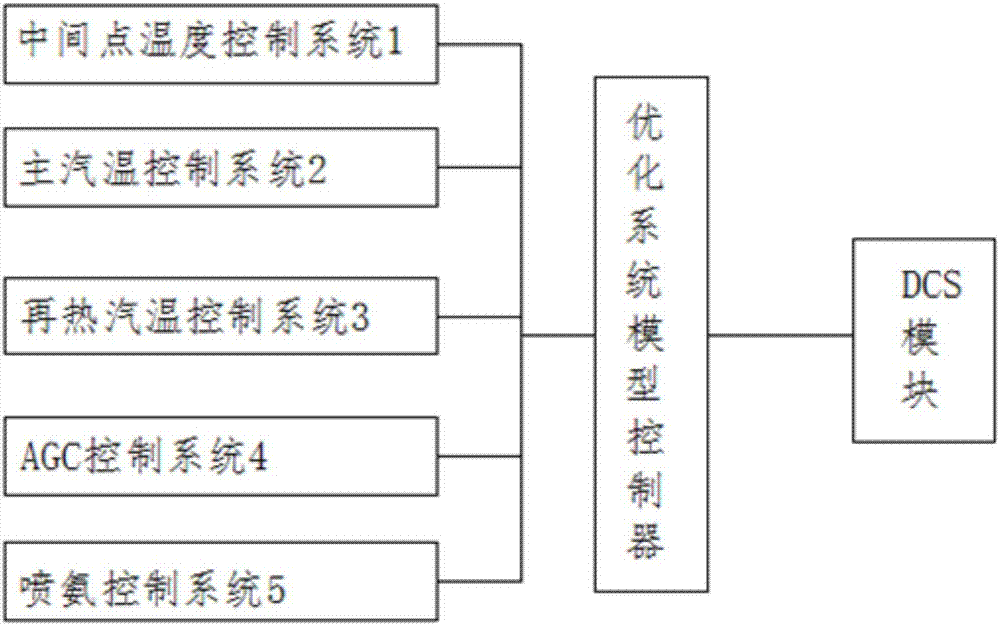

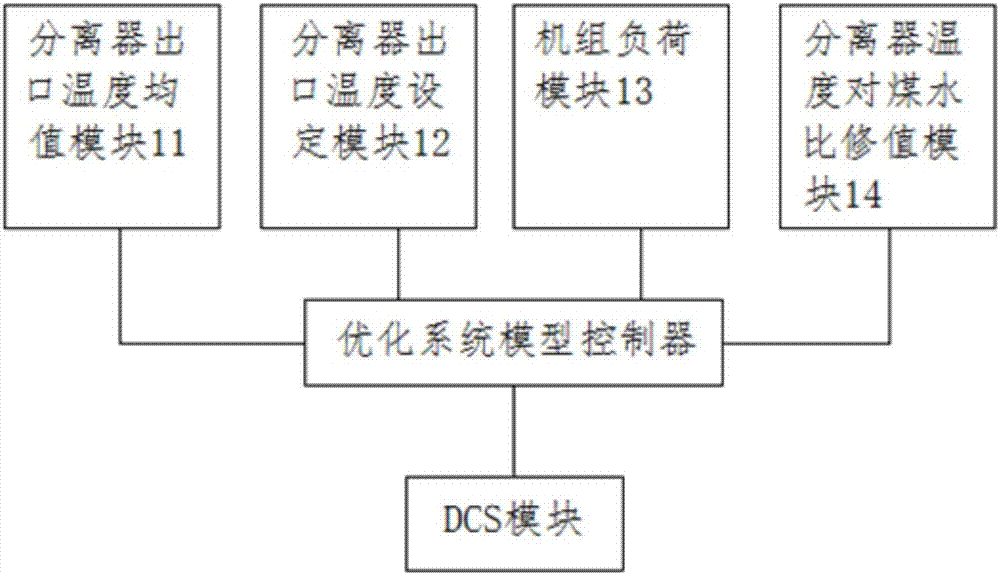

Ultra-supercritical thermal generator set coordinated control system

Owner:JIANGSU DATANG INT LUSIGANG POWER GENERATION

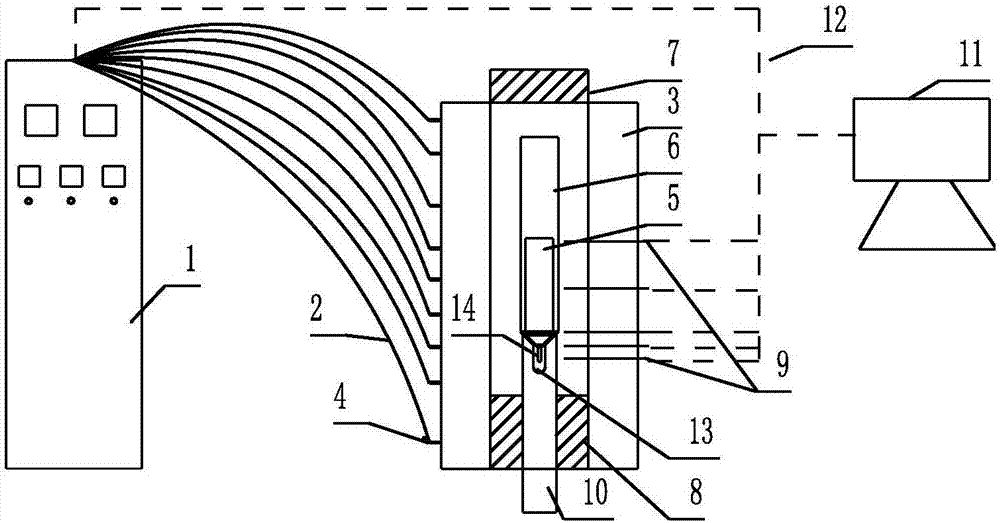

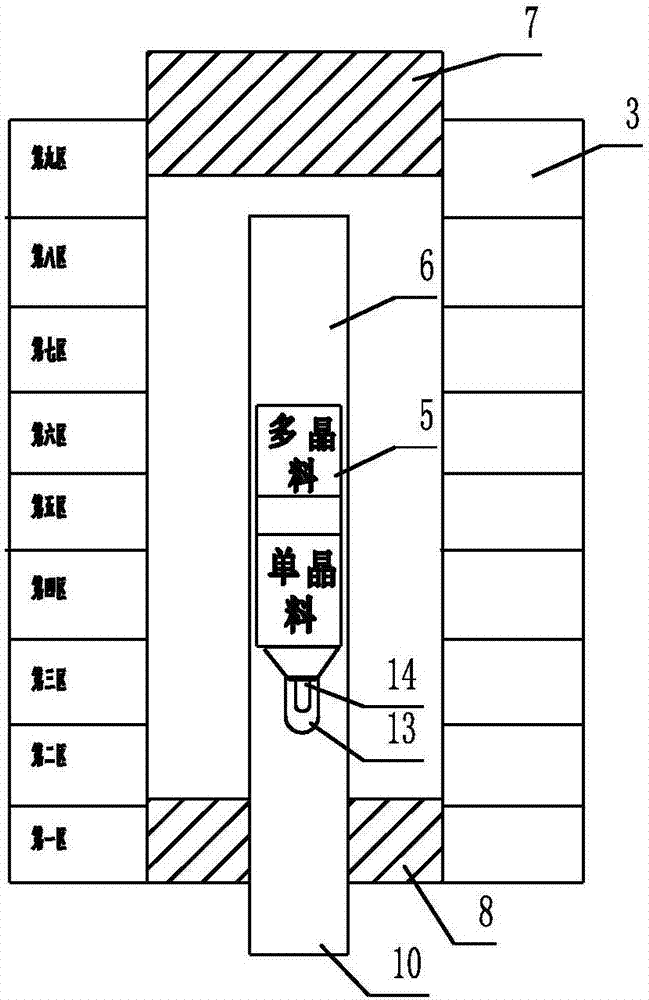

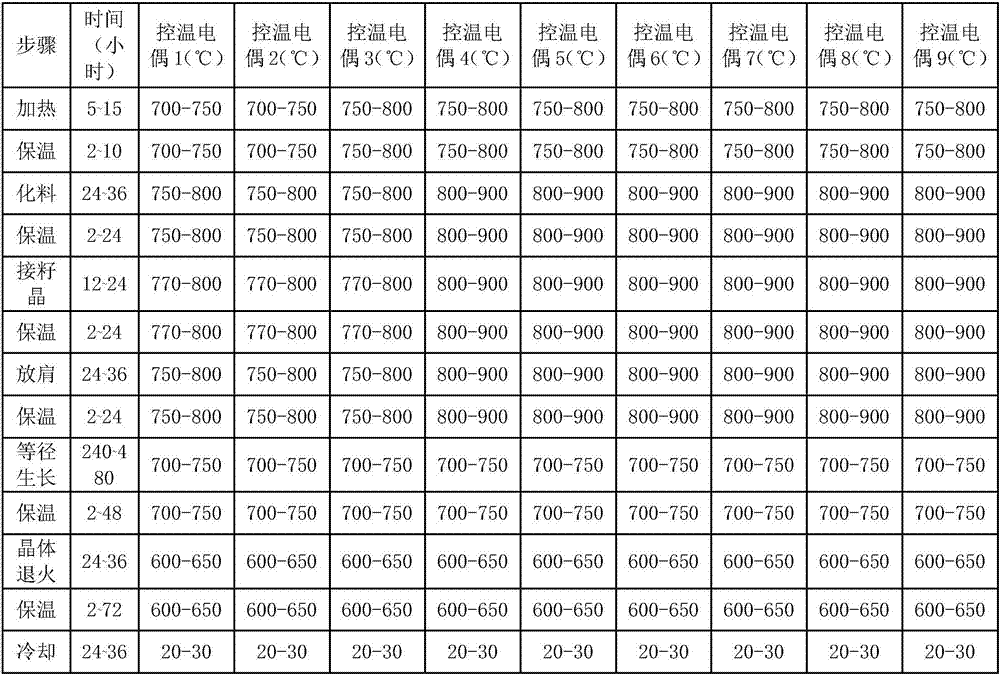

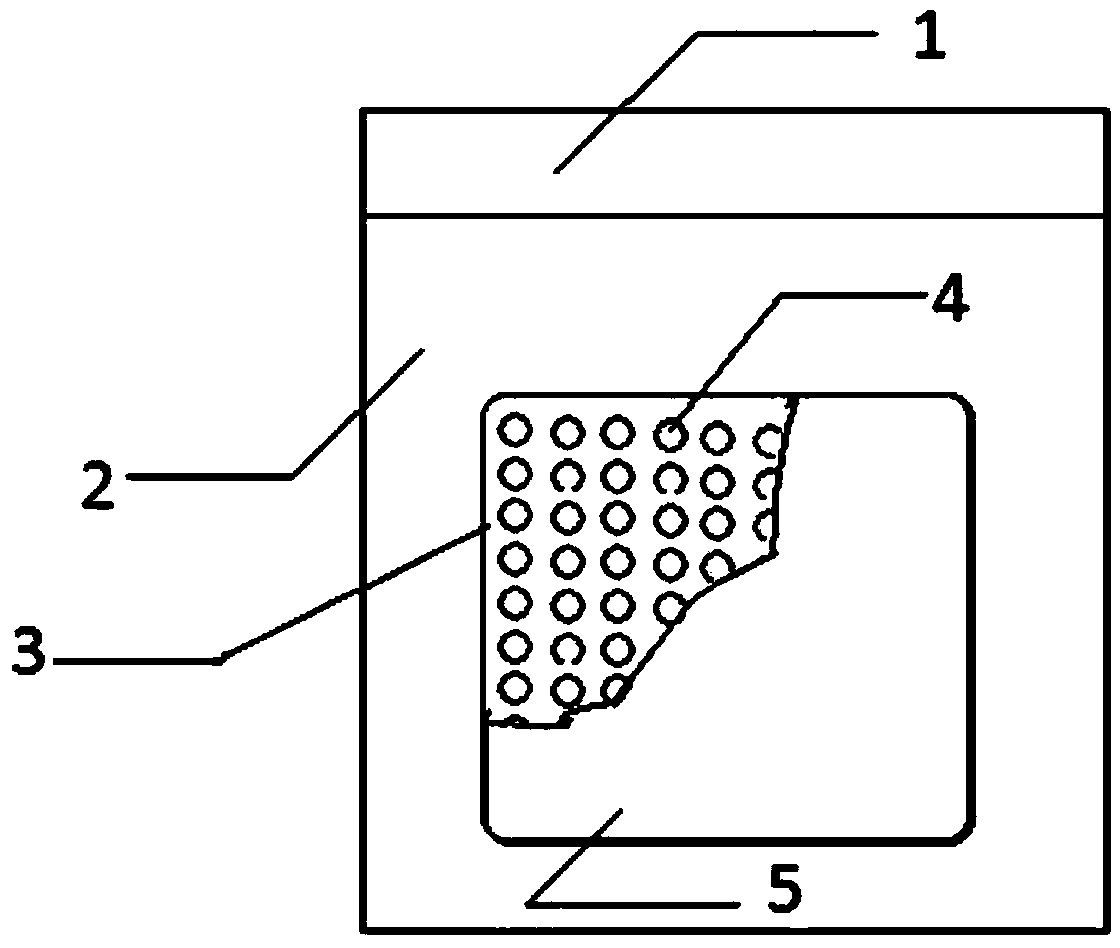

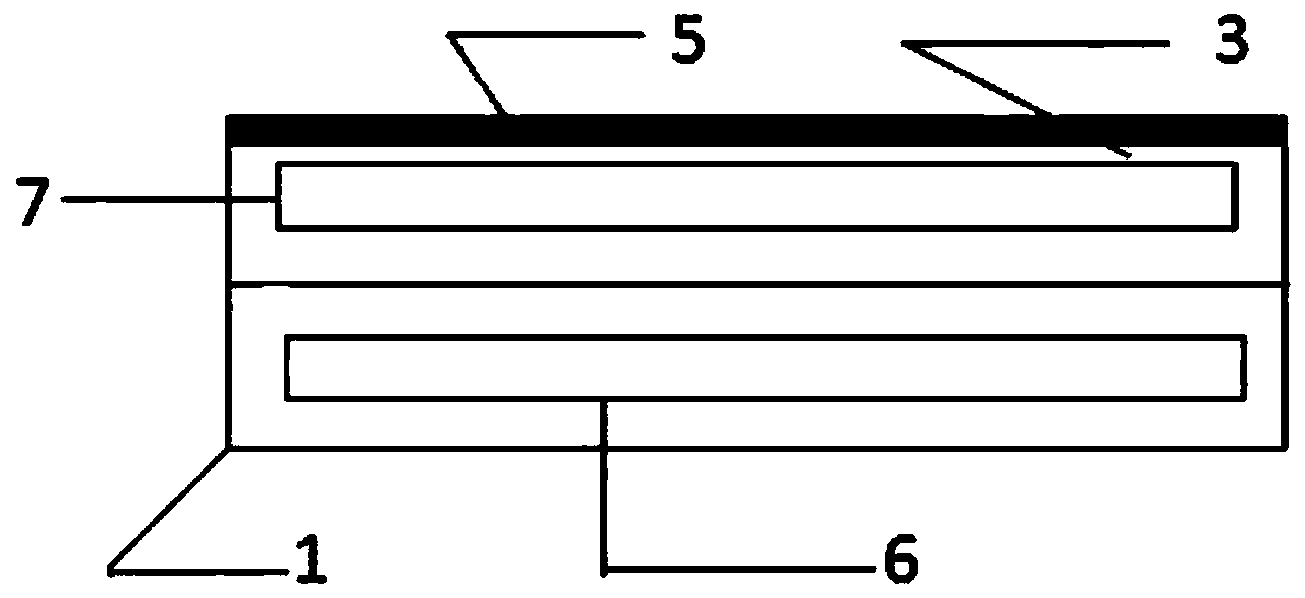

Novel single-crystal furnace for zinc cadmium telluride single crystal and growth process

PendingCN107059132AAchieve growthImprove the growing environmentPolycrystalline material growthFrom frozen solutionsTemperature controlCrucible

Owner:磐石创新(江苏)电子装备有限公司

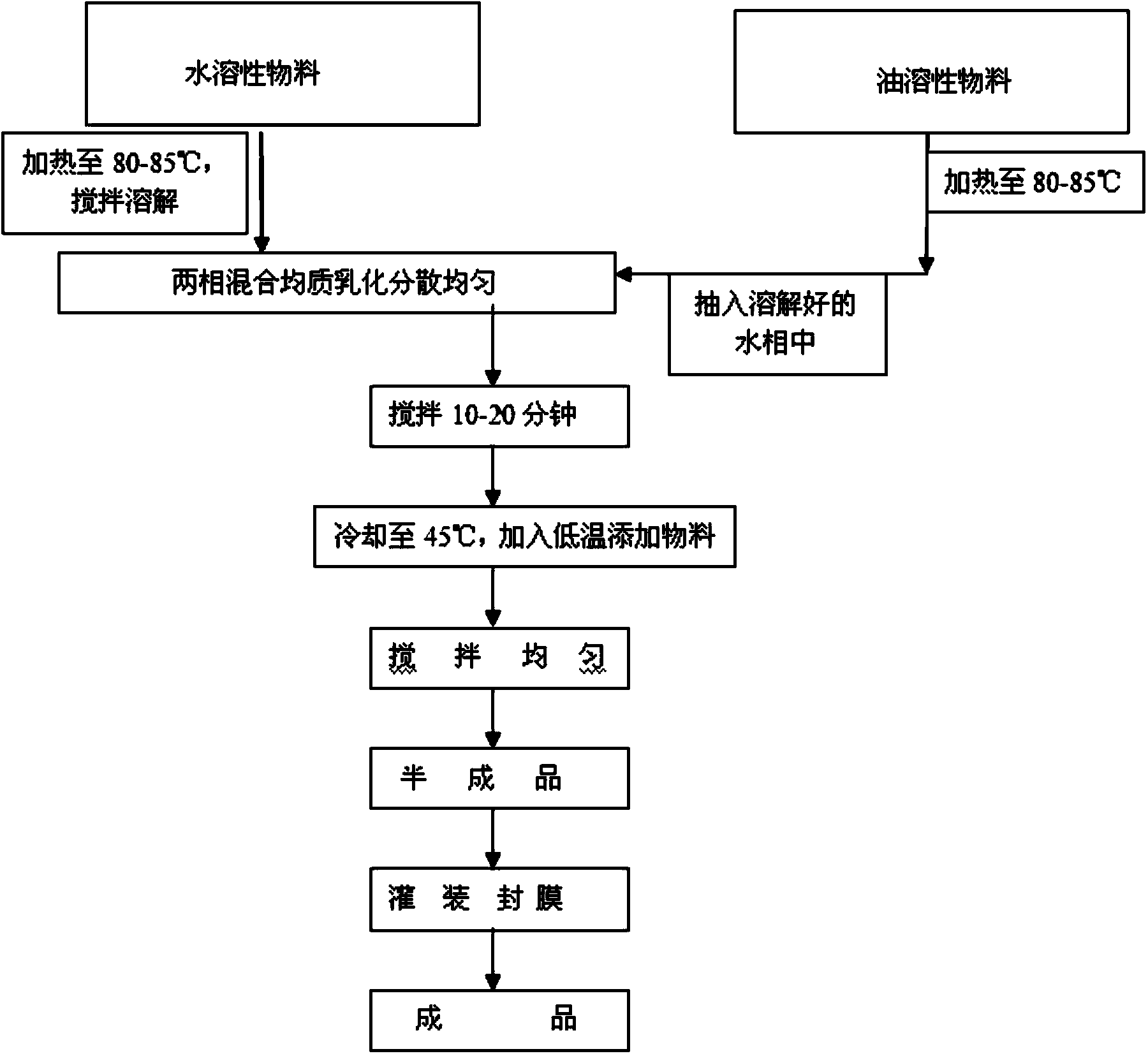

Facial mask and preparation method thereof

ActiveCN103908415AReduce water lossEasy to keepCosmetic preparationsToilet preparationsTemperature controlIrritation

Owner:康博士日化集团有限公司

Intelligent mattress system

InactiveCN105146963ASleep Quality MonitoringSleep quality reportStuffed mattressesSpring mattressesTemperature controlSystems design

The invention discloses an intelligent mattress system. The intelligent mattress system comprises a main body mattress laid on a bed of a user, a temperature control unit used for controlling the surface temperature of the main body mattress to be within a preset range, a sleep recording unit used for recording sleep information of the user, an analysis unit used for analyzing the sleep information of the user to obtain a sleep quality report and a display unit used for displaying the sleep quality report. The intelligent mattress system realizes reasonable design, can favorably and efficiently monitor the sleep quality of the user and analyze to generate the report to be checked by the user, and therefore, has the technical effect of guaranteeing the sleep quality of the user.

Owner:CHENGDU WANZHE WORLD NETWORK TECH CO LTD

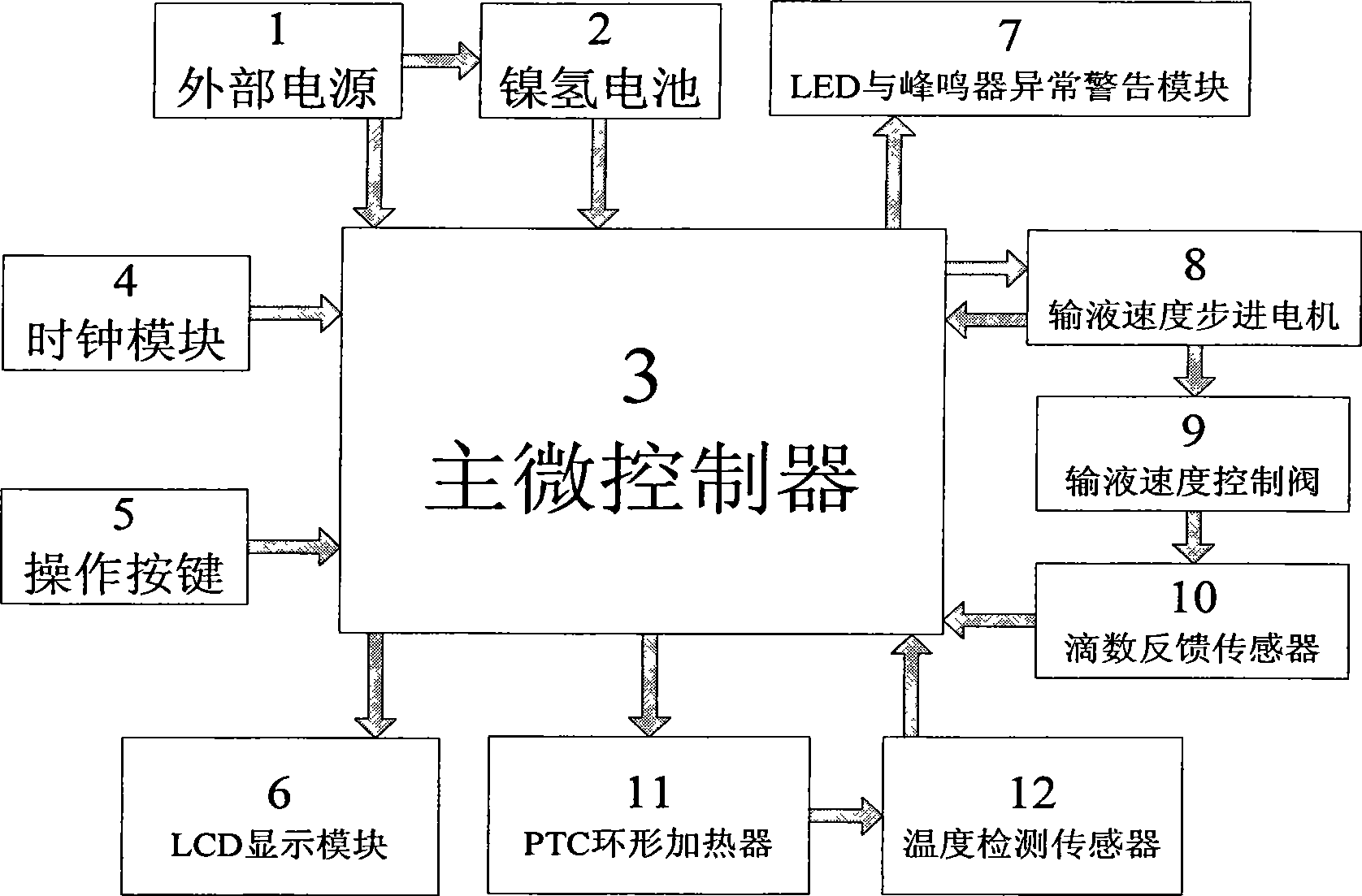

Infusion speed and temperature controller

Owner:GUANGZHOU UPREAL MEDICAL SCI TECH

Method for adjusting resistance value of NTC thermistor chip

InactiveCN102136328AHigh precisionRealize precise resistance adjustment processNegative temperature coefficient thermistorsTemperature controlElectrical resistance and conductance

Owner:ZHAOQING EXSENSE ELECTRONICS TECH

Device for testing contamination characteristic of segmental temperature control coal burning boiler

InactiveCN102879415AImprove stabilityIncrease flexibilityMaterial thermal analysisTemperature controlCombustor

Owner:中国东方电气集团有限公司

Wine aging method and device by physical field

ActiveCN101168714AFlexible handlingImprove wine qualityAlcoholic beverage preparationTemperature controlVoltage generator

Owner:SOUTH CHINA UNIV OF TECH

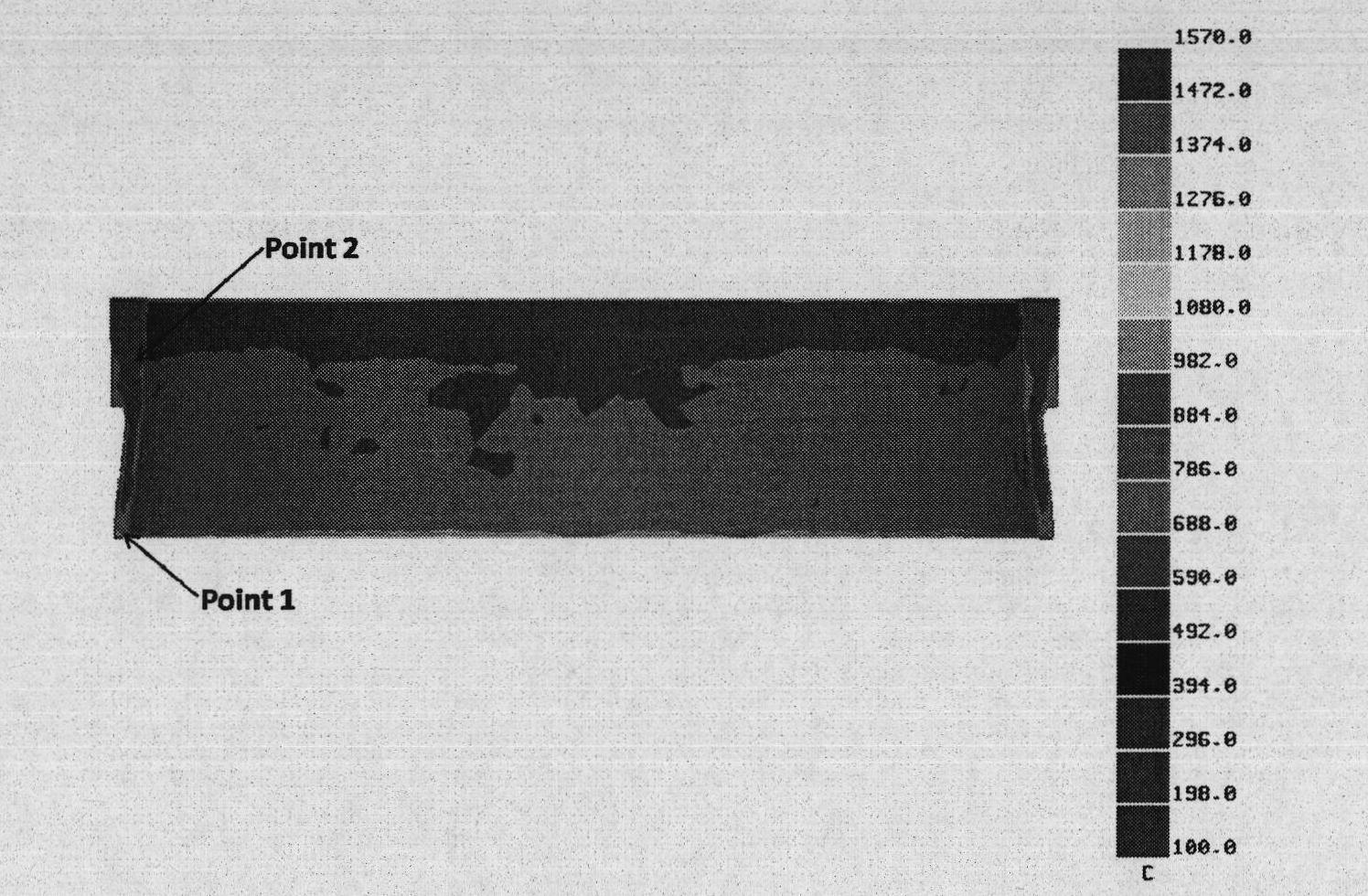

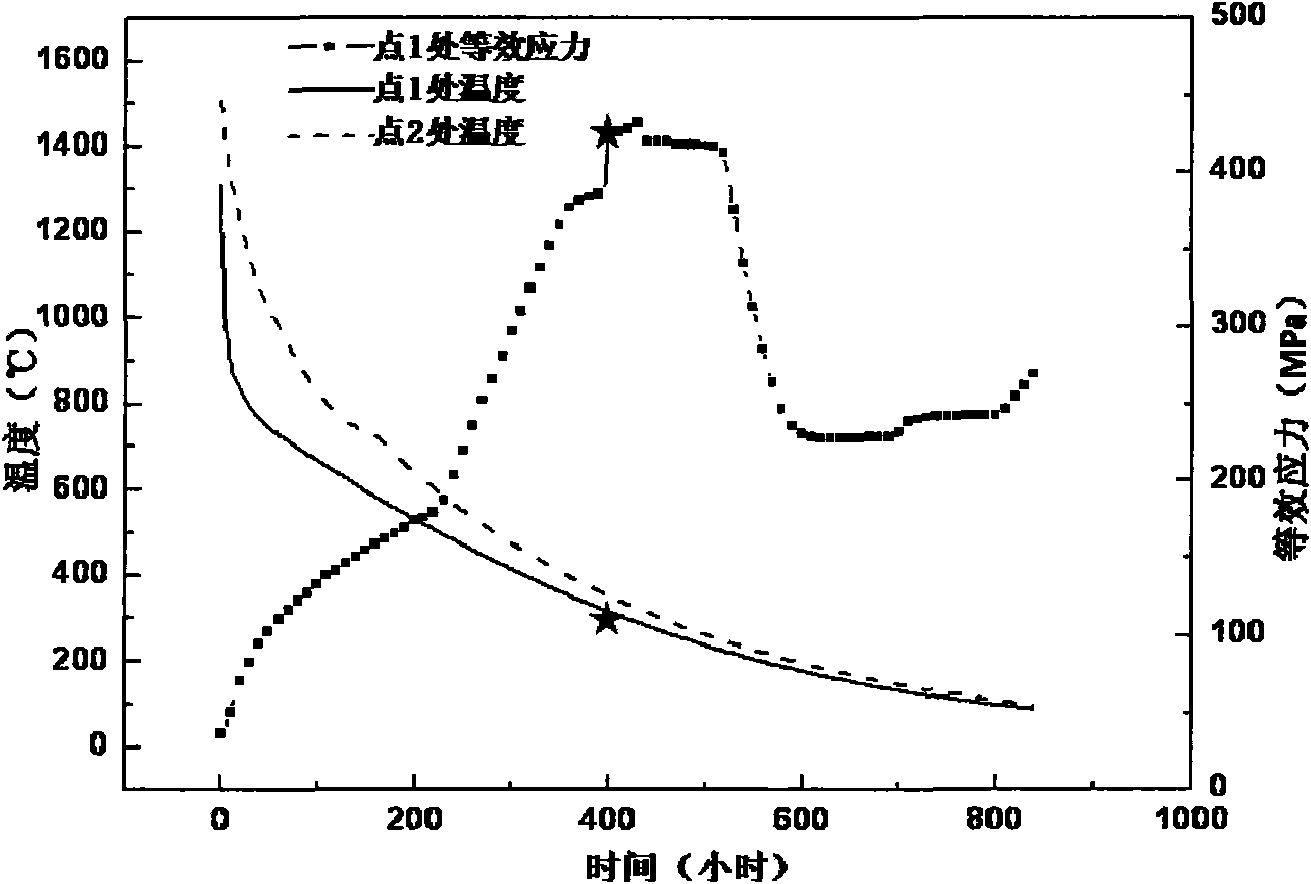

High-temperature shakeout process applied to large-size martensitic stainless steel cast

ActiveCN102211179AReduce the use of sand boxesShorten the timeTemperature controlMartensitic stainless steel

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

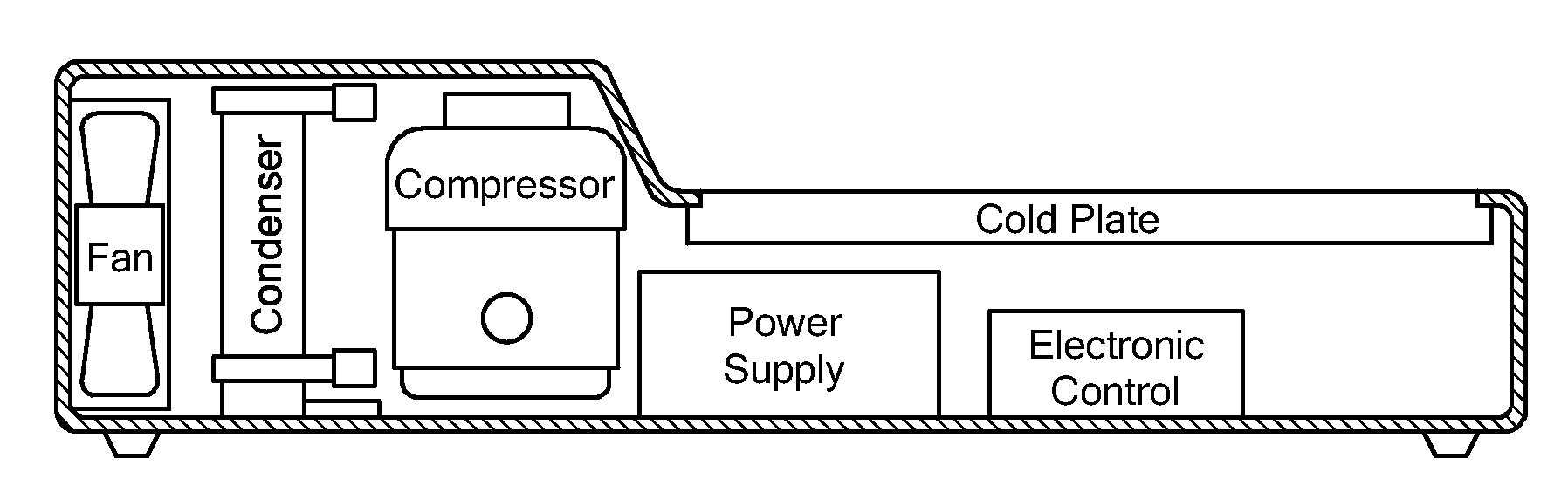

Method and device for quickly decreasing temperature

InactiveCN106325063ARealize automatic controlFast cooling rateCompression machinesThermometer testing/calibrationAutomatic controlEngineering

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

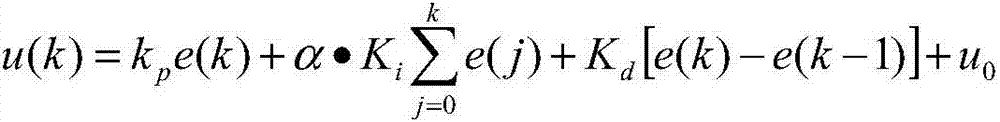

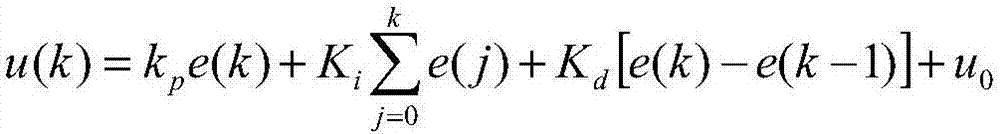

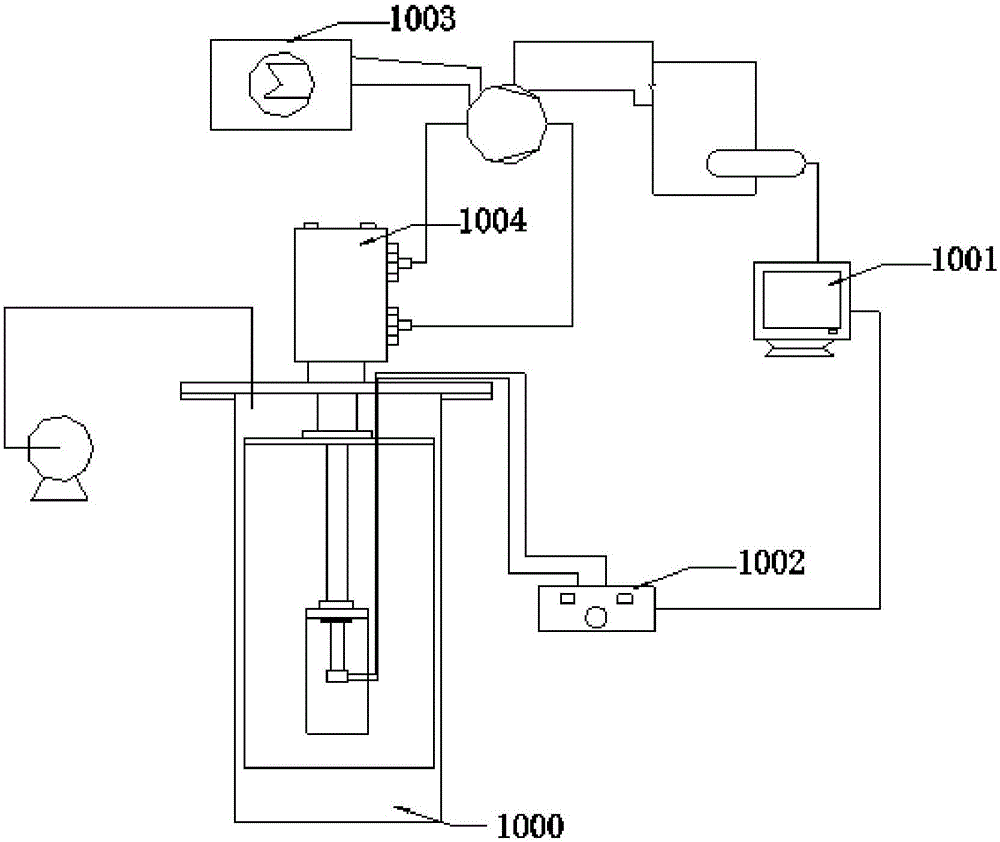

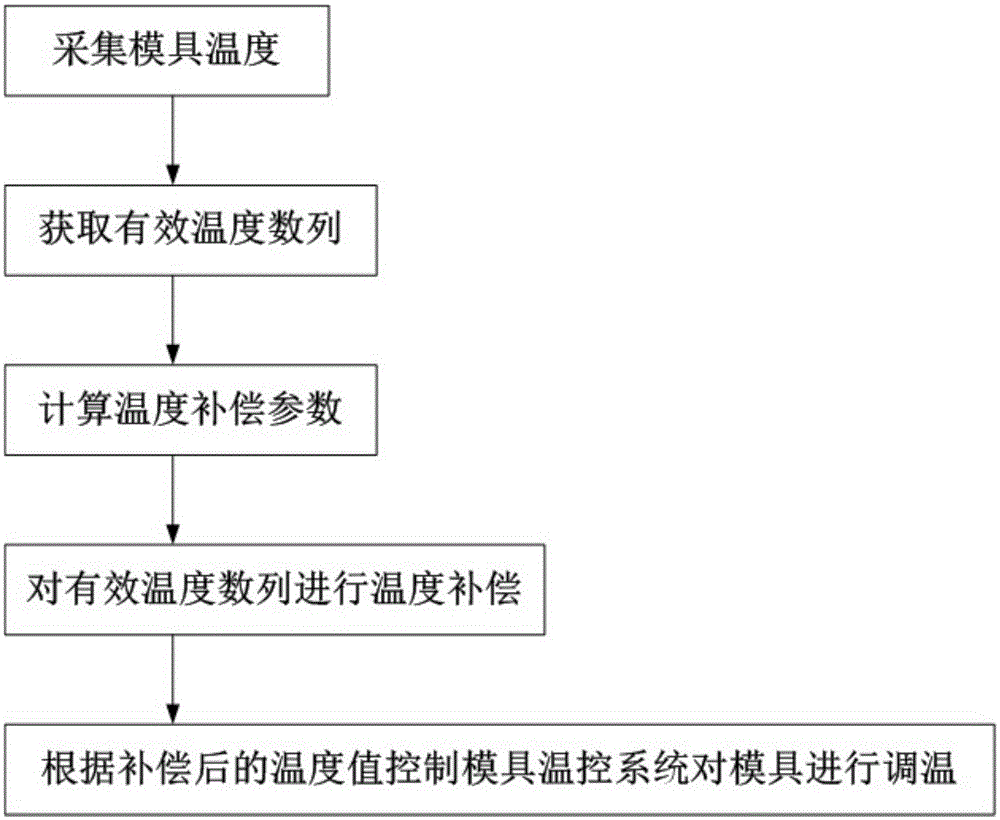

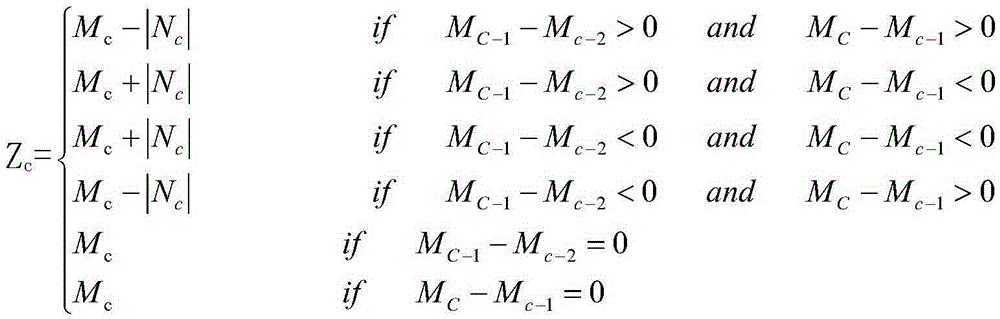

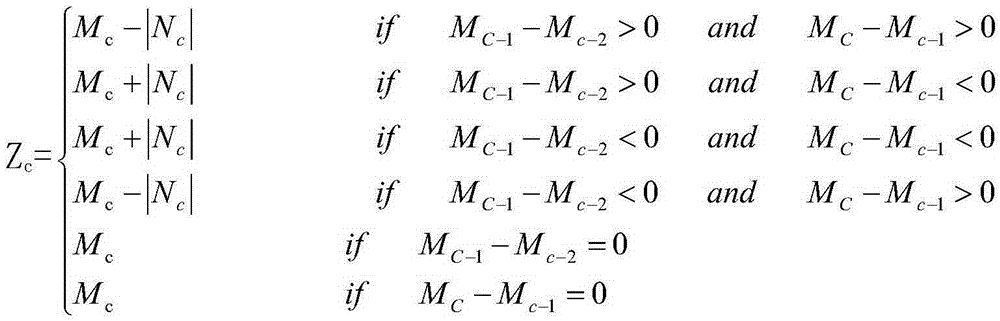

Adaptive control method of die temperature

InactiveCN105242709AQuality assuranceGuaranteed adaptabilityTemperatue controlTemperature controlAutomatic control

Owner:CHONGQING TECH & BUSINESS INST

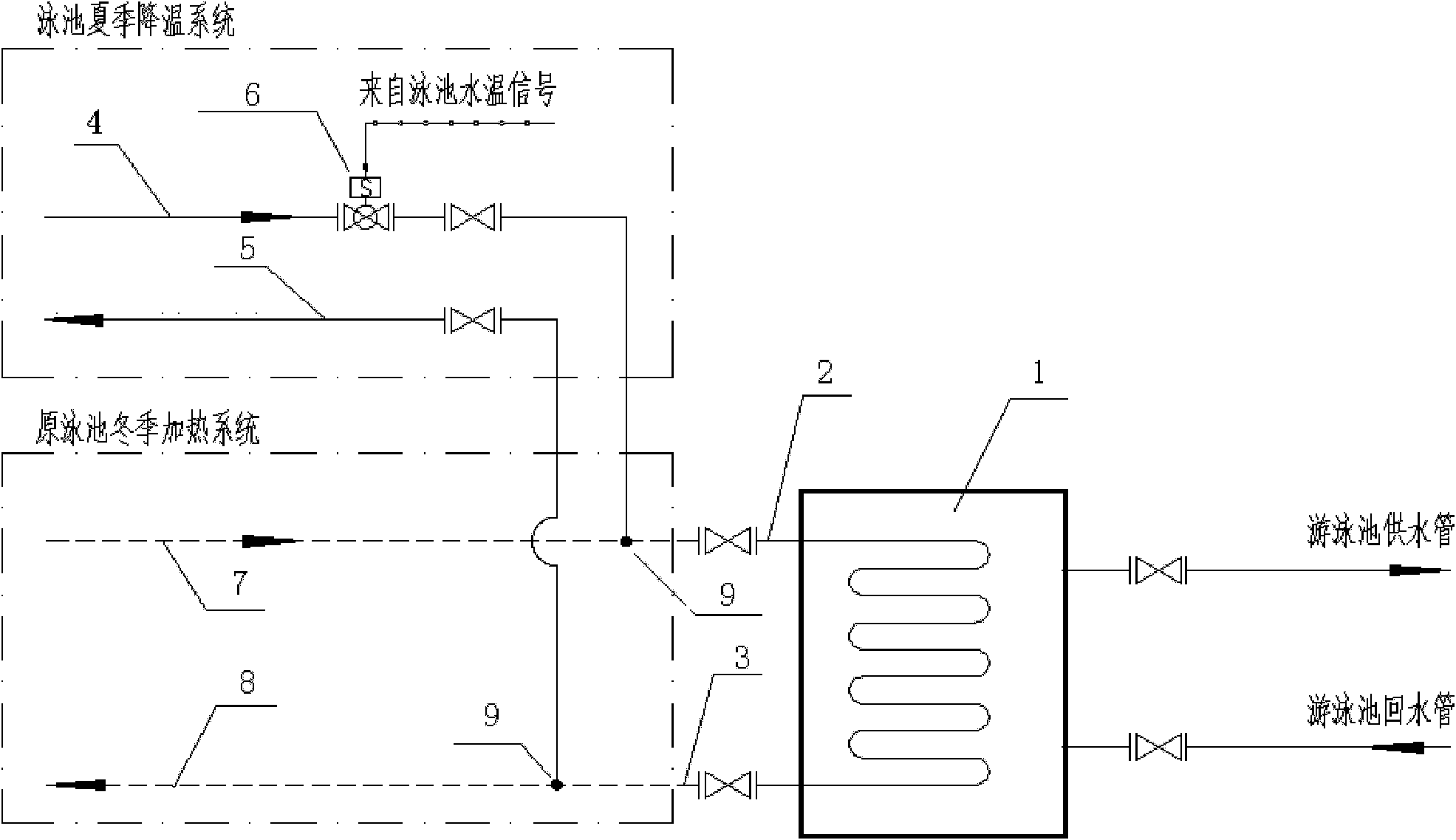

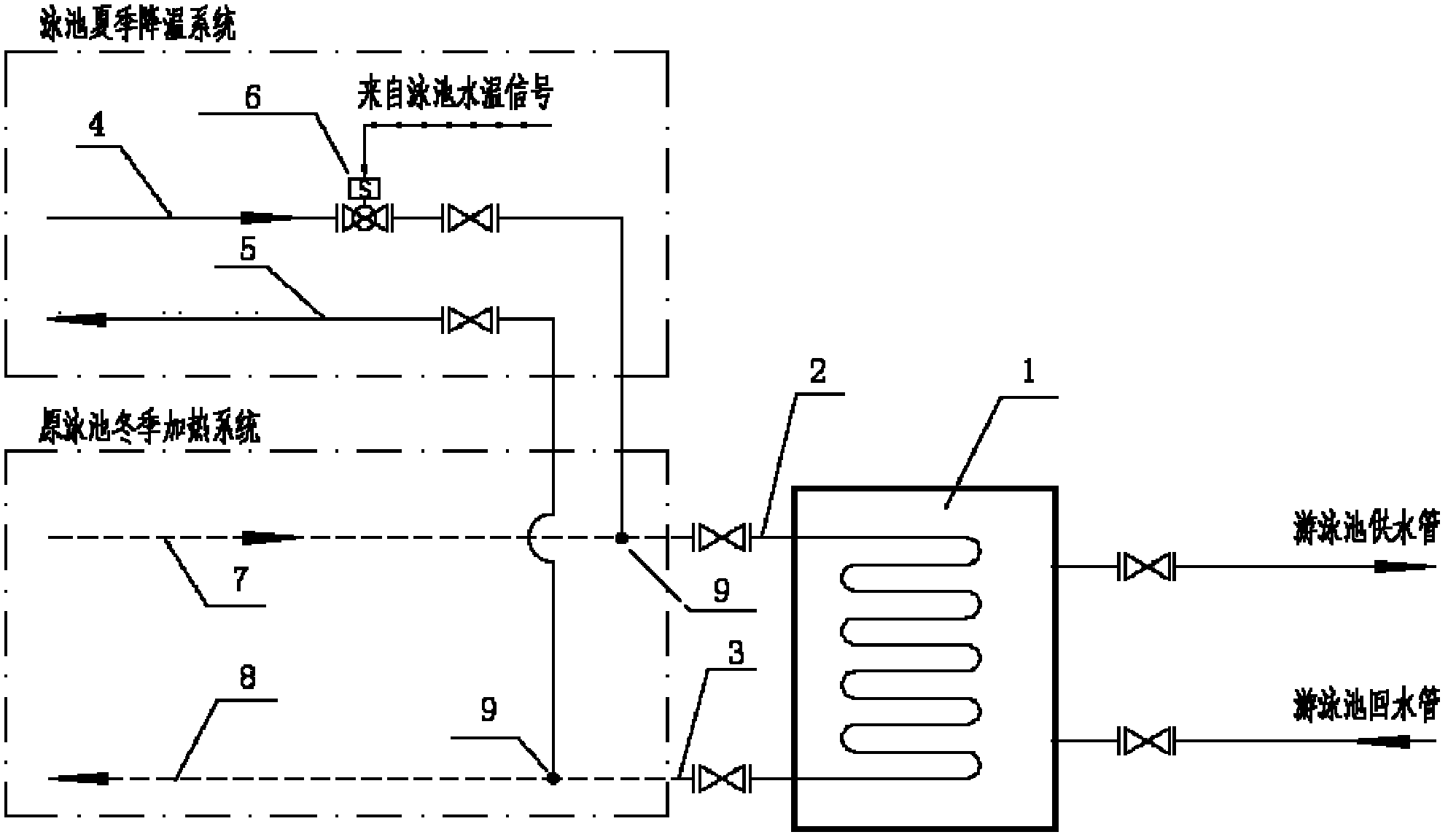

Water temperature adjustment device and water temperature control method for swimming pool

InactiveCN102493683ALow costNo human controlGymnasiumSwimming poolsTemperature controlControl signal

Owner:上海现代建筑设计(集团)有限公司

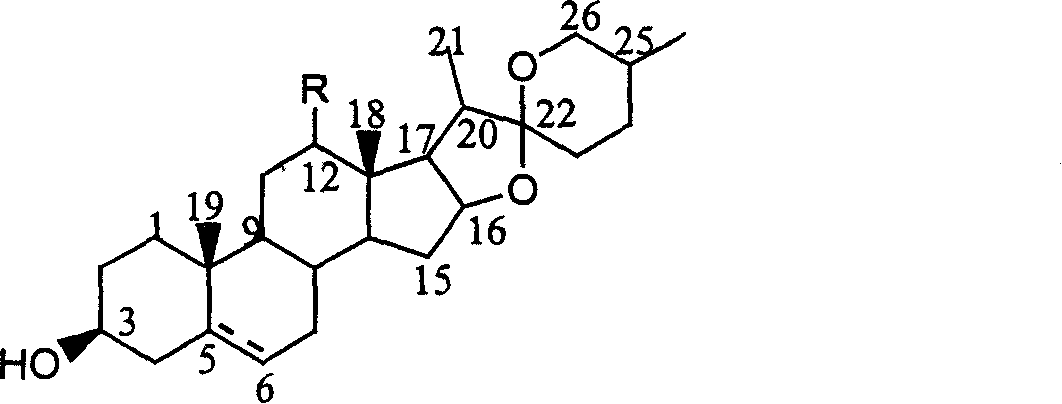

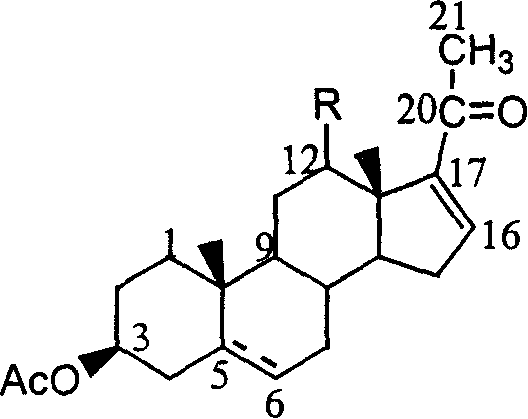

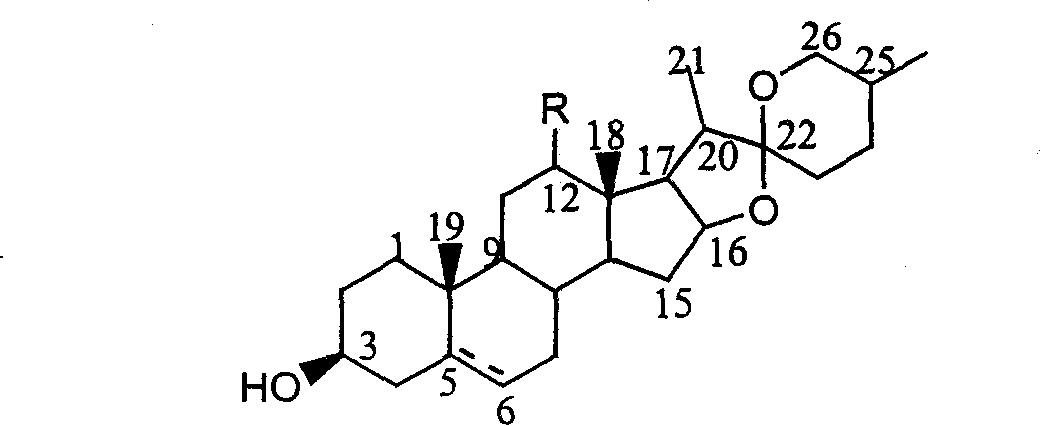

Method for synthesizing 16-dehydropregndiketonic alcohol acetic ester and its analogs

InactiveCN1884297AImprove utilizationEliminate pollutionSteroidsChemical synthesisTemperature control

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

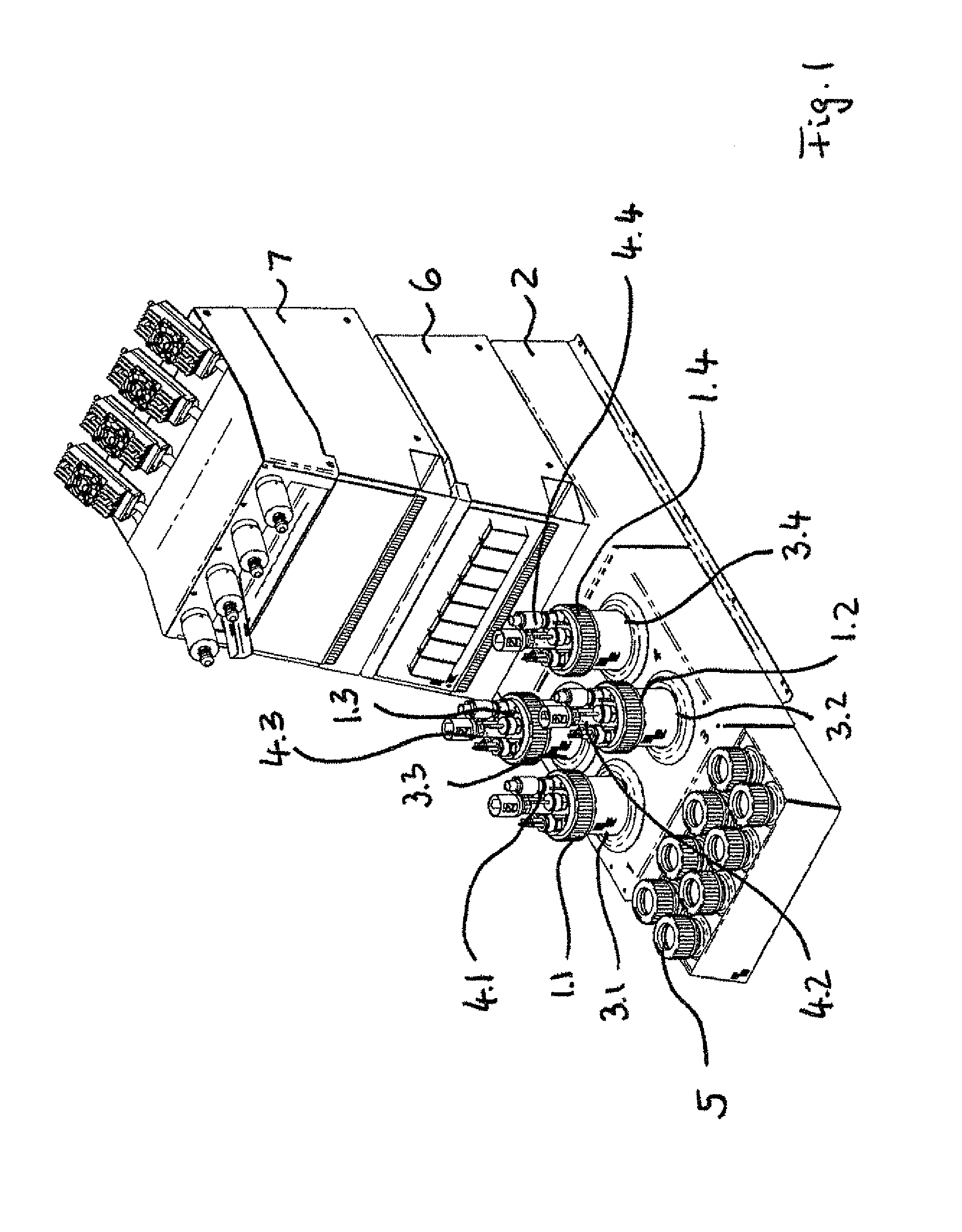

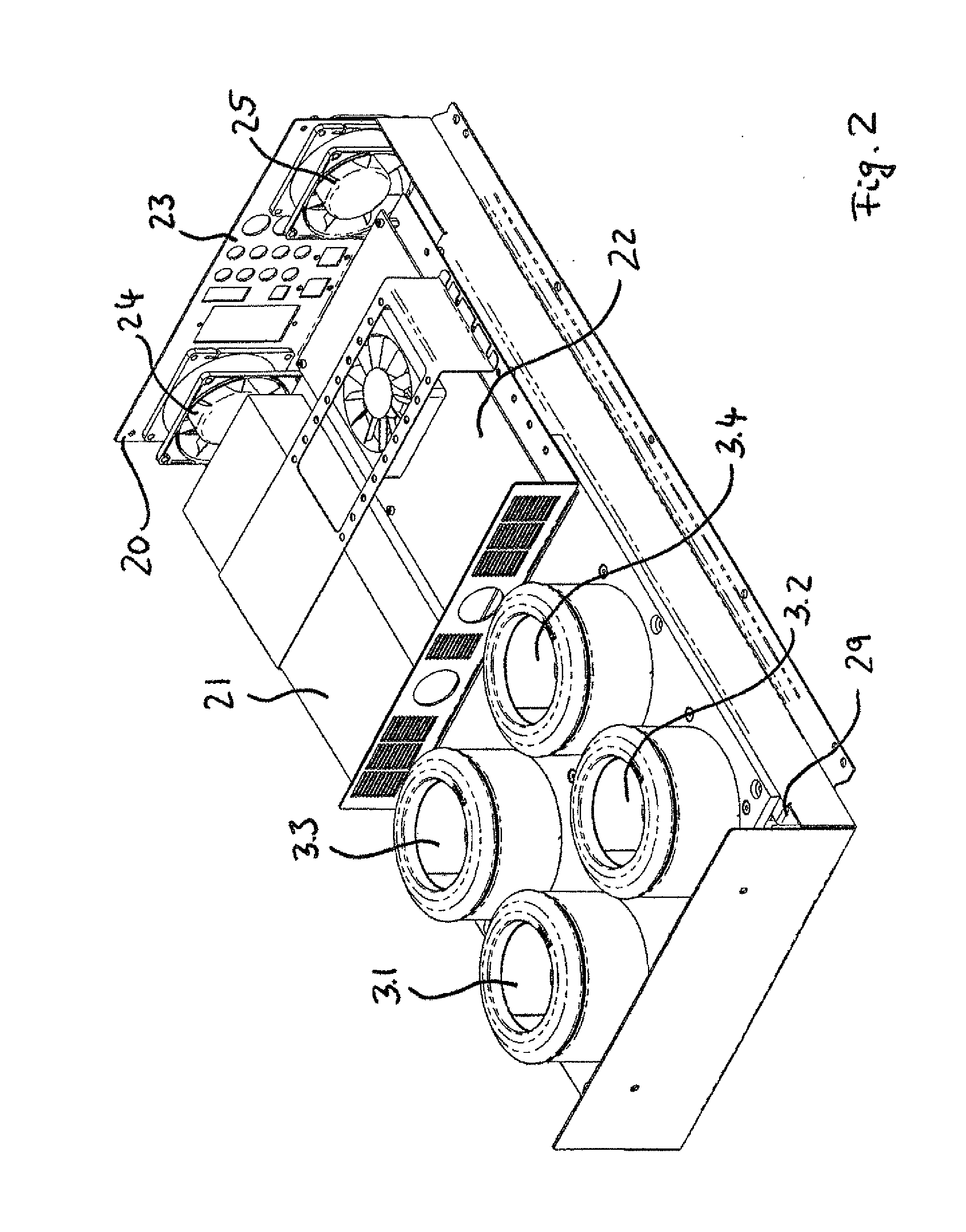

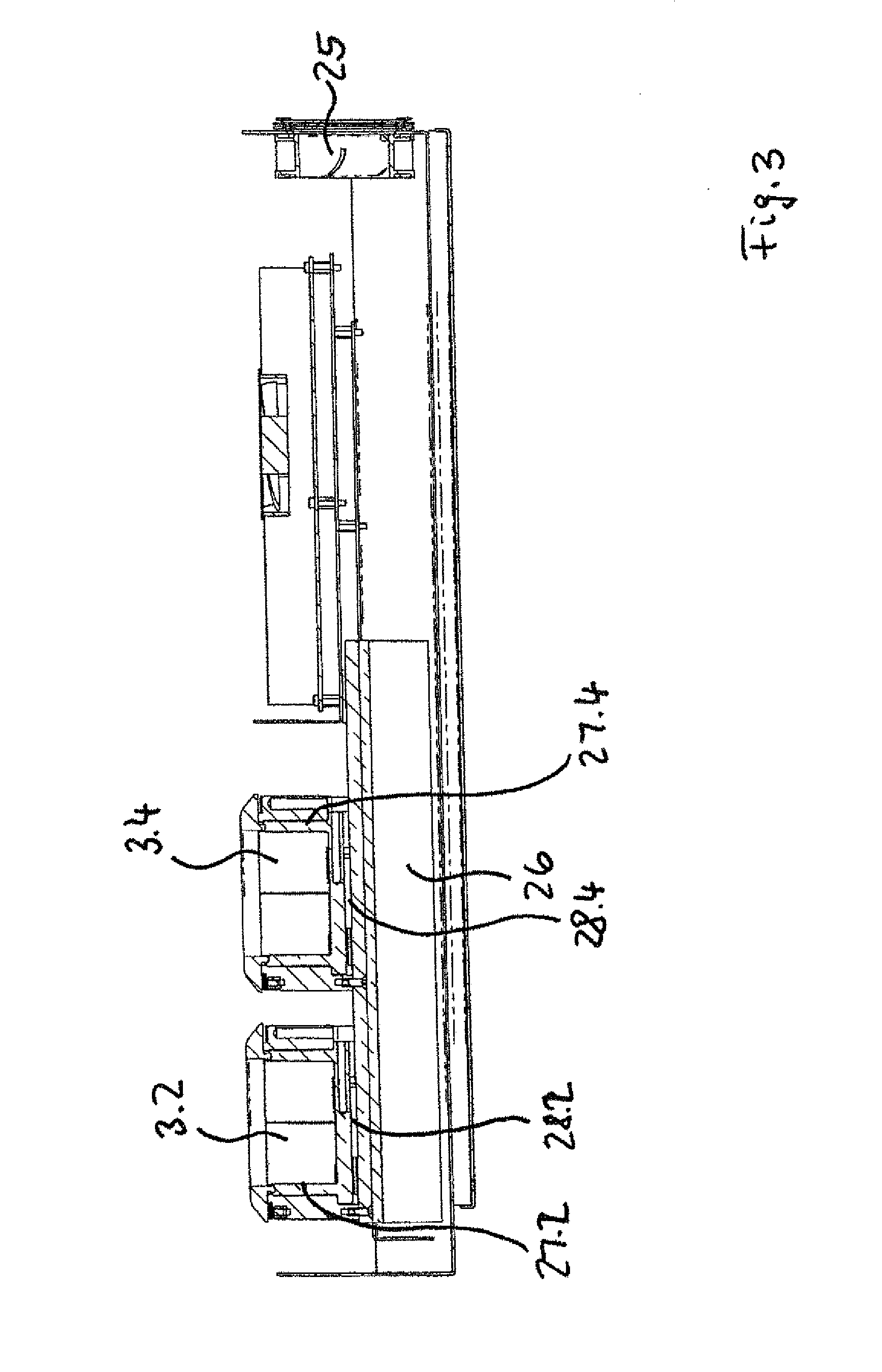

Method for controlled operation of a biotechnological apparatus and bioreactor system

ActiveUS20140255910A1Easy to operateDc network circuit arrangementsBioreactor/fermenter combinationsTemperature controlBioreactor

Owner:DASGIP INFORMATION & PROCESS TECH

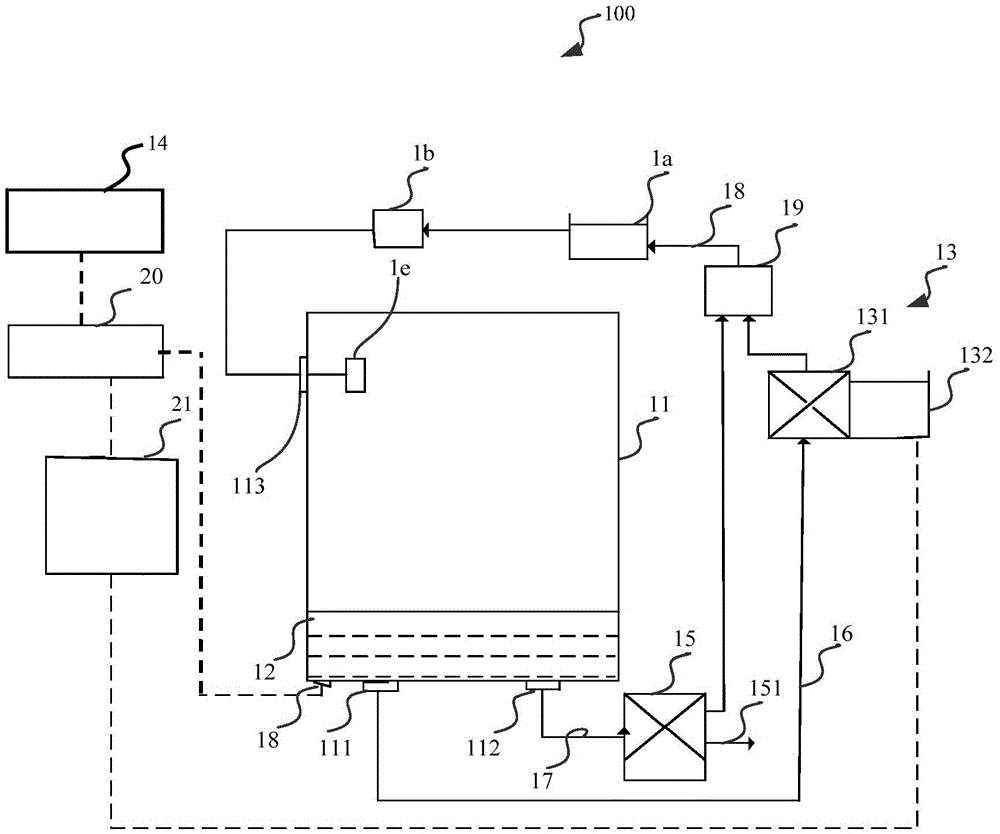

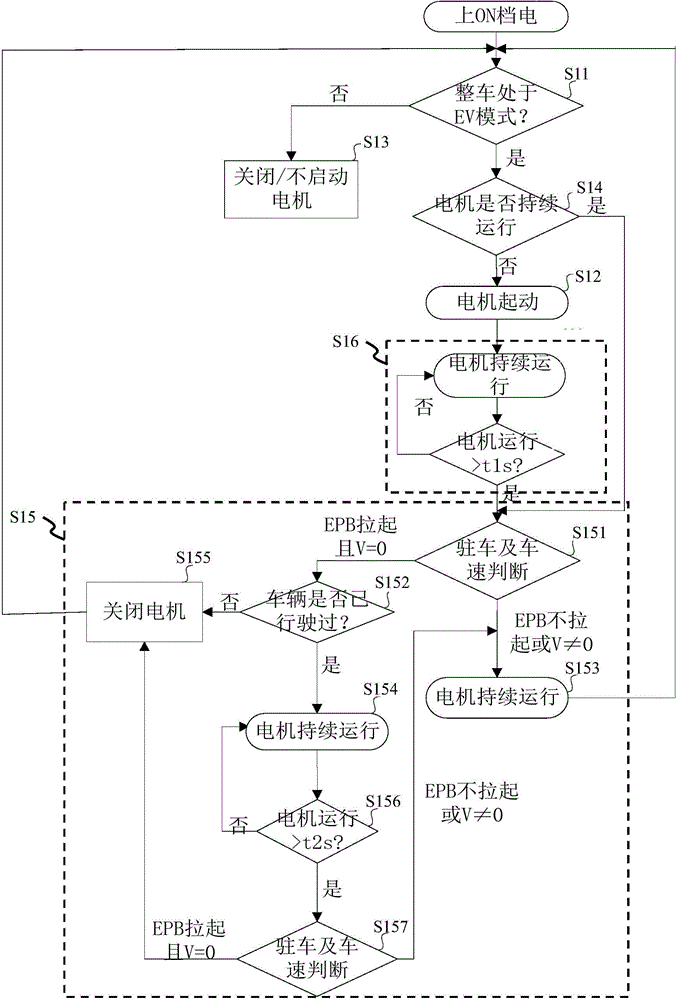

Speed changing box lubricating method and system suitable for hybrid electric vehicle

Owner:BYD CO LTD

Thermochromic material and thermochromic clothes

InactiveCN103045229AKnow your body temperatureTenebresent compositionsProtective garmentTemperature controlSolvent

Owner:周明彦

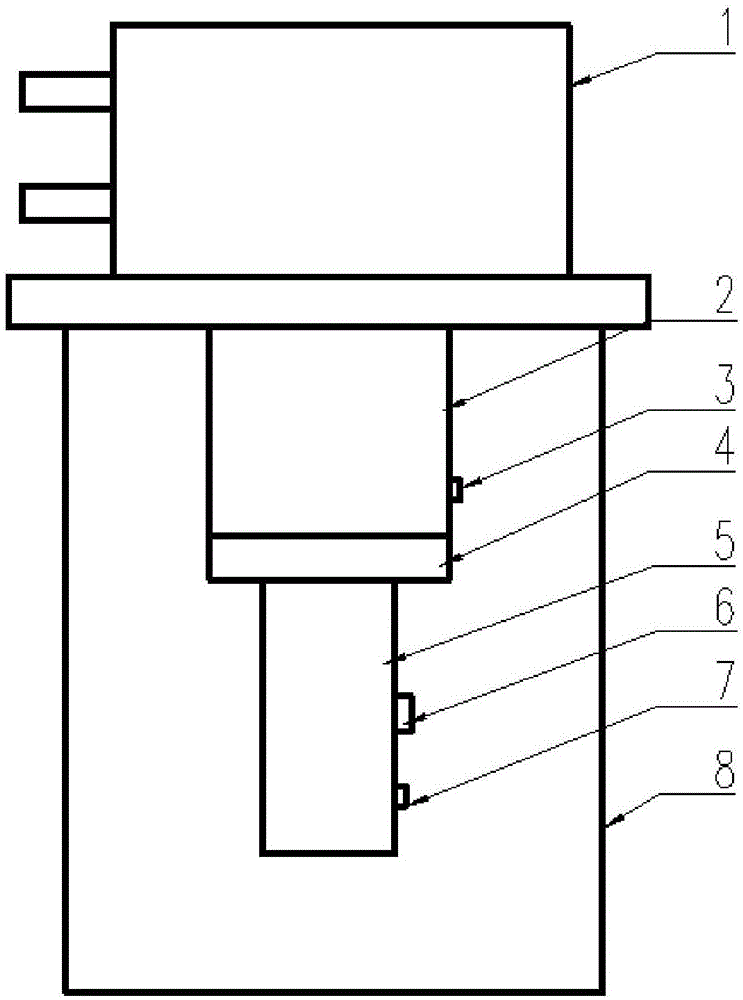

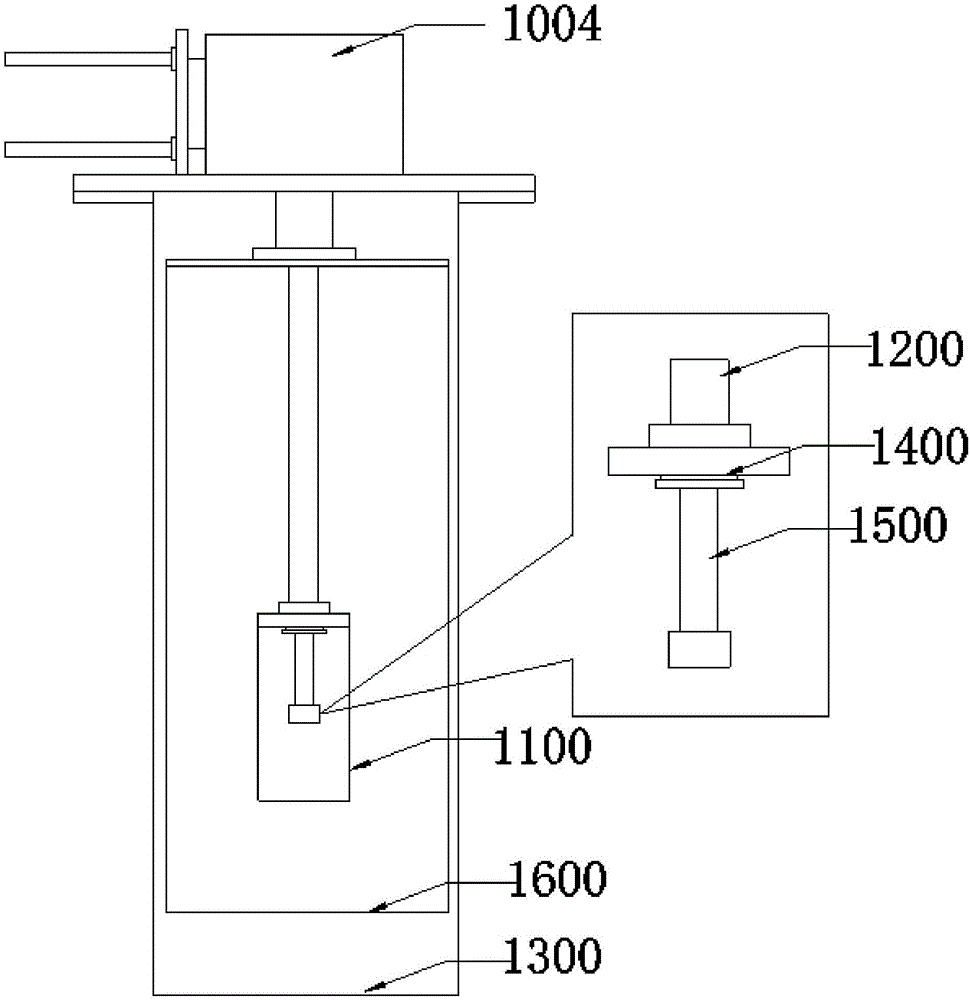

Temperature-controllable electric field induction platform

ActiveCN106816226ARealize the processing effectRealization of process conditionsCable/conductor manufactureSilicon-controlled rectifierEngineering

The invention provides a temperature-controllable electric field induction platform. The temperature-controllable electric field induction platform comprises a clamping portion, a temperature keeping portion and an electric field generation portion, wherein the clamping portion is arranged on a work platform (16) in the temperature keeping portion, temperature of a temperature control box of the temperature keeping portion is controlled through a temperature control heating system composed of a PID silicon controlled rectifier temperature control component (21), thermocouples (19) and (20) and ten sets of resistor heating components (18), and the electric field generation portion can generate a 50kV-voltage power frequency AC electric field and a DC electric field. The platform mainly satisfies requirements of a complete sulfuration process of preformed liquid state silicone rubber while being applied to electric field induction processing manufacturing, ordered arrangement is realized under the orientation induction action of the electric field, conductive particles of the conductive rubber are made to form a more effective flow path, the heating portion can provide a heat source for rubber sulfuration, and the platform can provide an external high-field-intensity field for the conductive rubber when influence of the external electric field on conductive performance of materials is tested.

Owner:BEIJING UNIV OF TECH +4

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap