Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78results about "Polycrystalline material growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

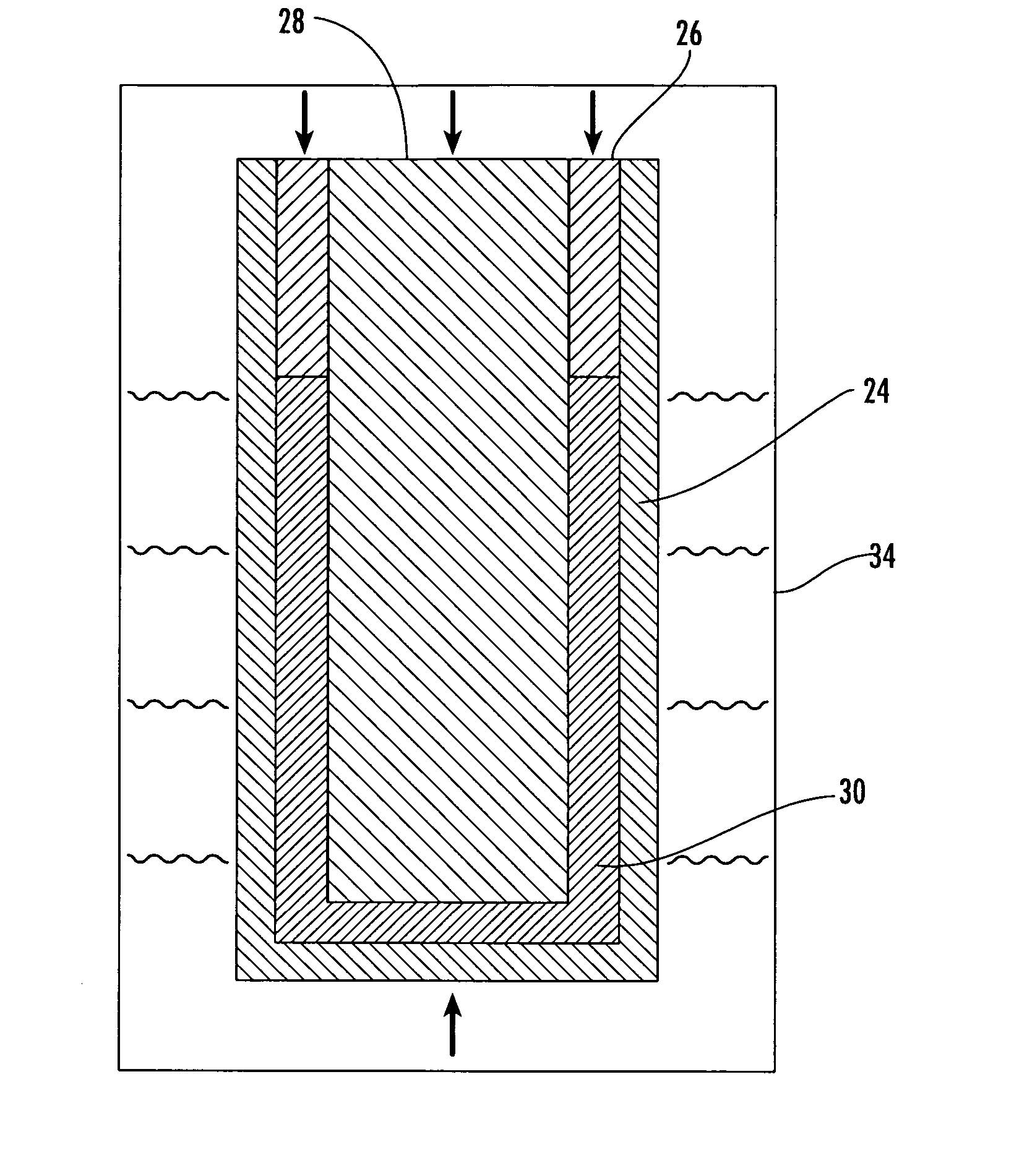

Technique for perfecting the active regions of wide bandgap semiconductor nitride devices

InactiveUS20050164475A1Lower average currentHigh densityPolycrystalline material growthFrom solid stateEngineeringNitride

This invention pertains to e lectronic / optoelectronic devices with reduced extended defects and to a method for making it. The method includes the steps of depositing a dielectric thin film mask material on a semiconductor substrate surface; patterning the mask material to form openings therein extending to the substrate surface; growing active material in the openings; removing the mask material to form the device with reduced extended defect density; and depositing electrical contacts on the device.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Process for manufacturing a gallium rich gallium nitride film

Owner:GALLIUM ENTERPRISES

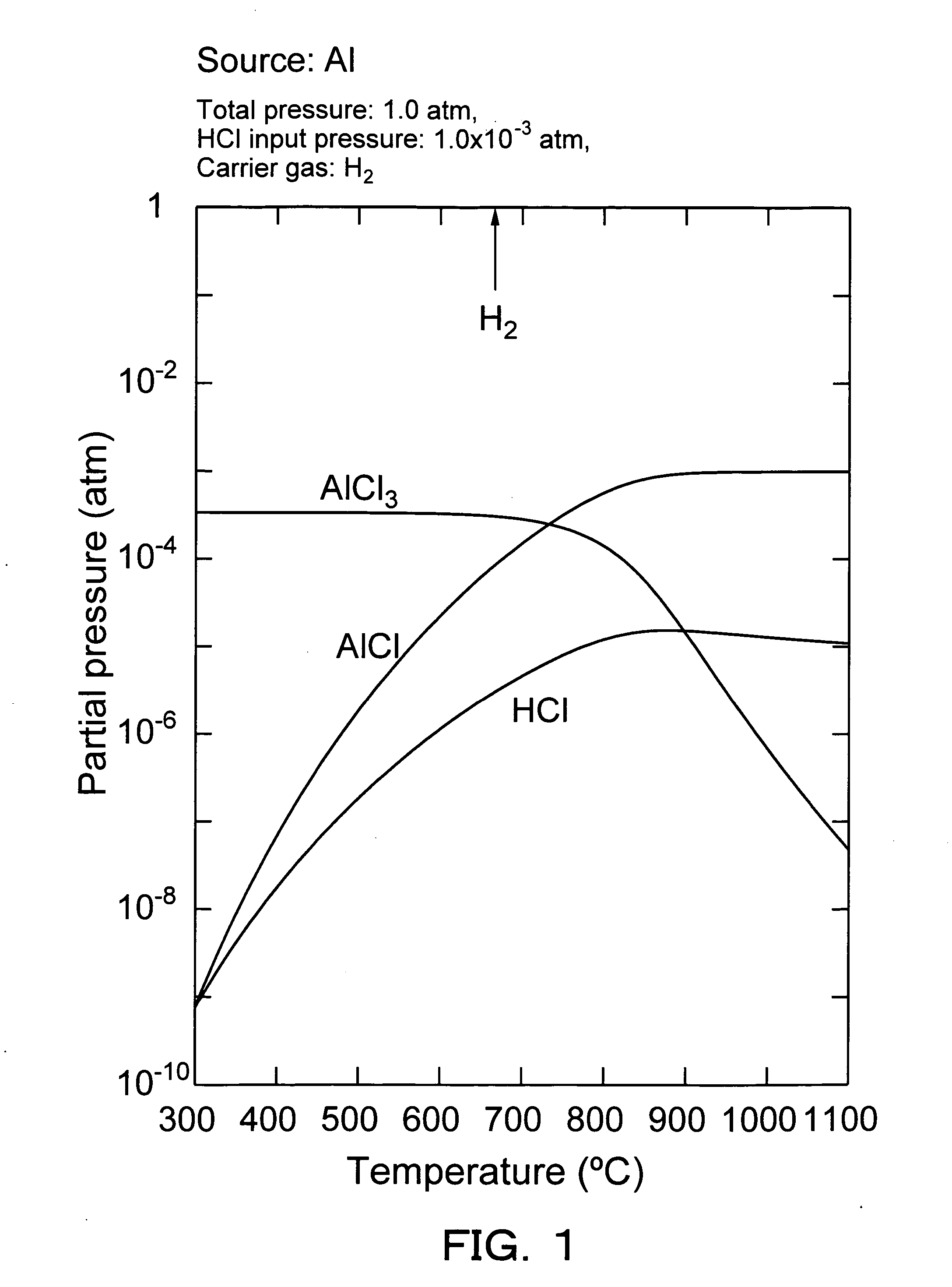

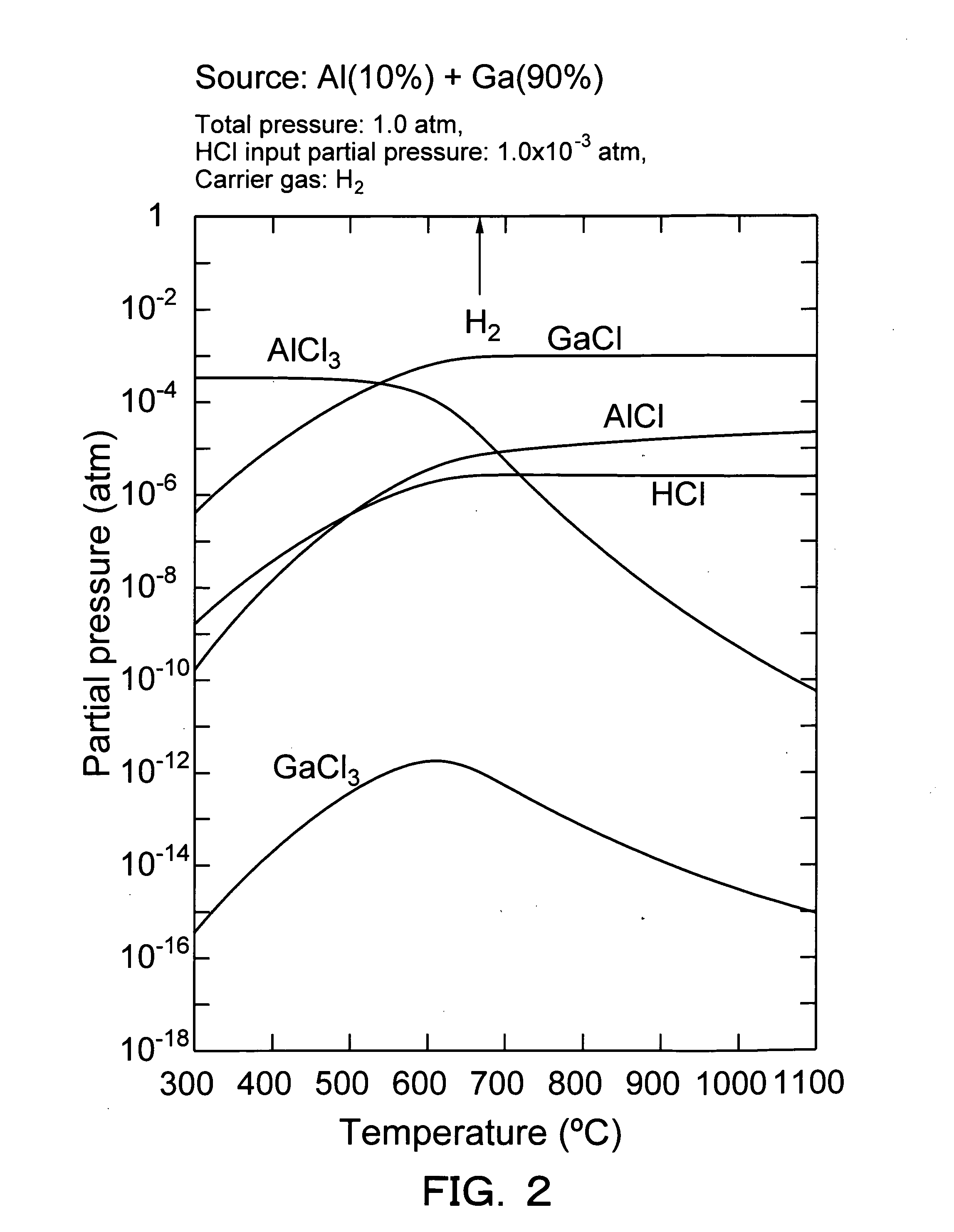

Vapor phase growth method for al-containing III-V group compound semiconductor, and method and device for producing al-containing IIl-V group compound semiconductor

InactiveUS20050166835A1Inhibits the formation of cracksAfter-treatment apparatusPolycrystalline material growthHydrogen halideGas phase

Owner:NOKODAI TLO KK

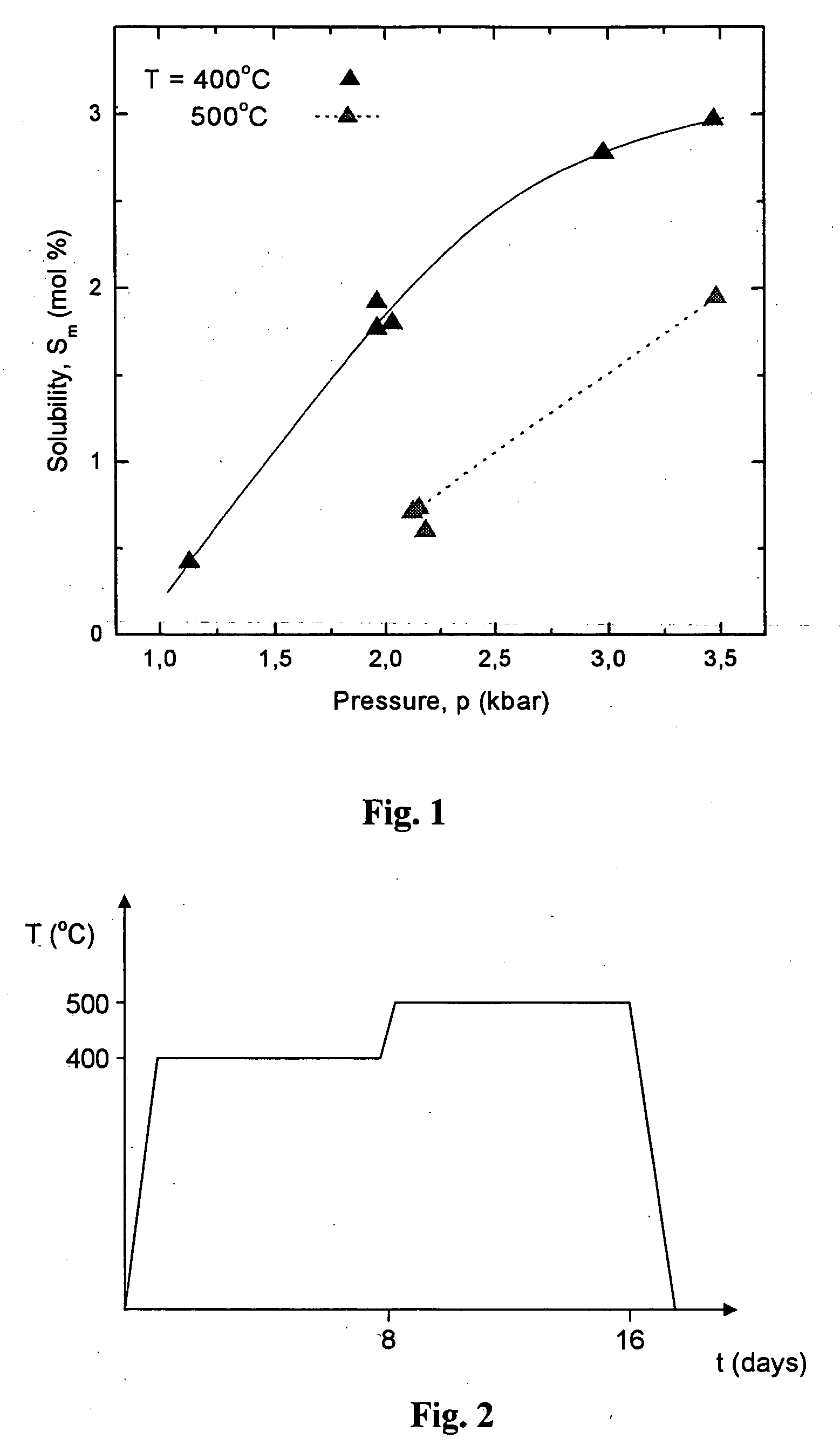

Method of manufacturing bulk single crystal of gallium nitride

Owner:AMMONO SP Z O O (PL) +1

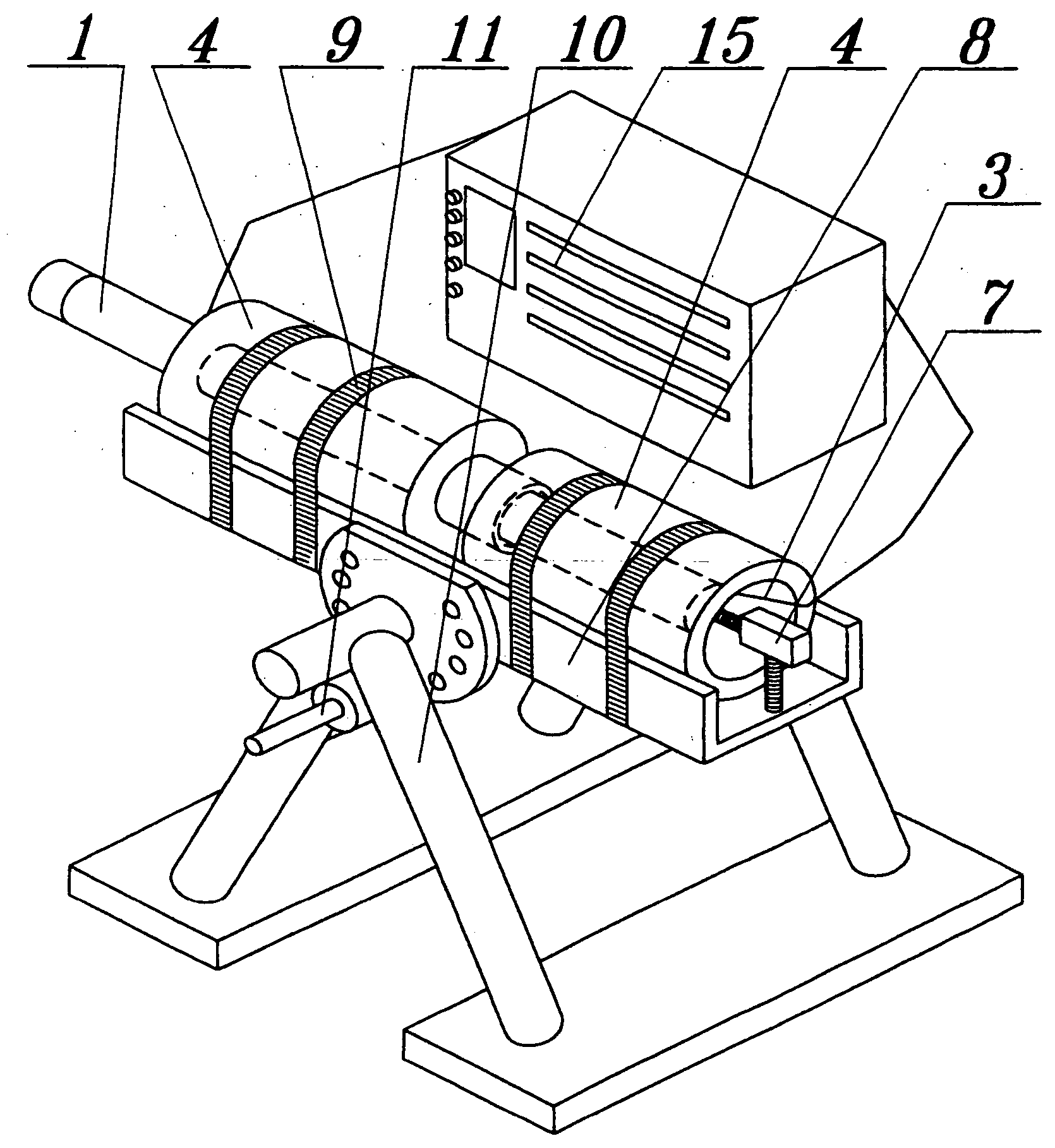

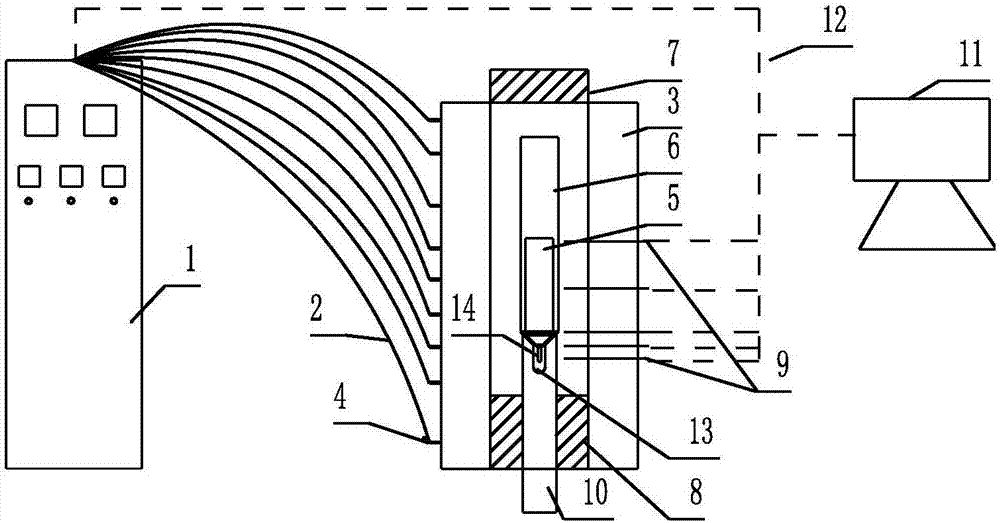

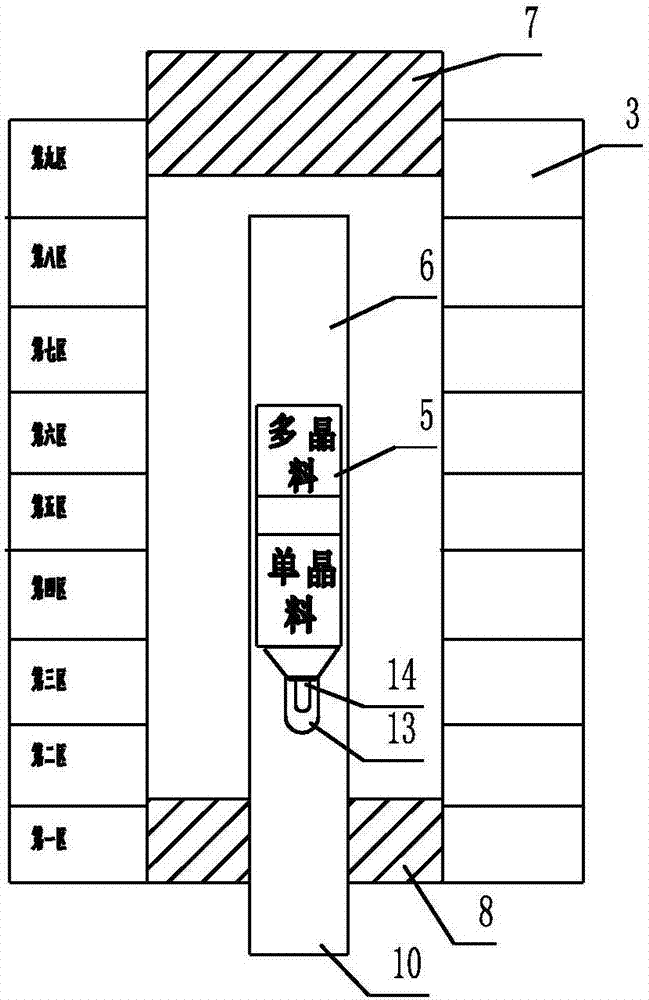

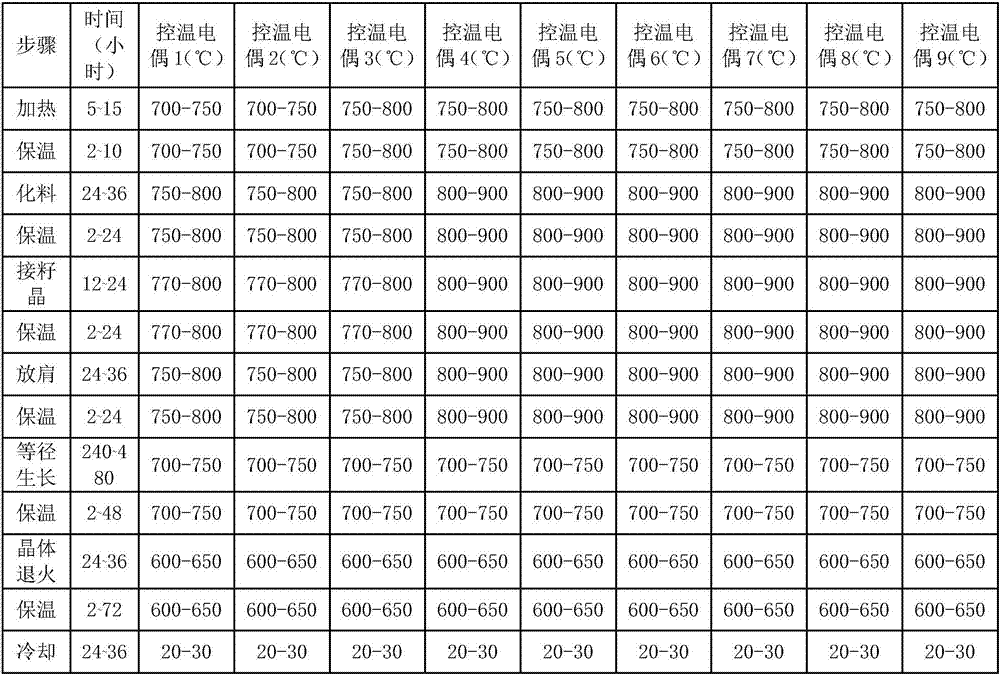

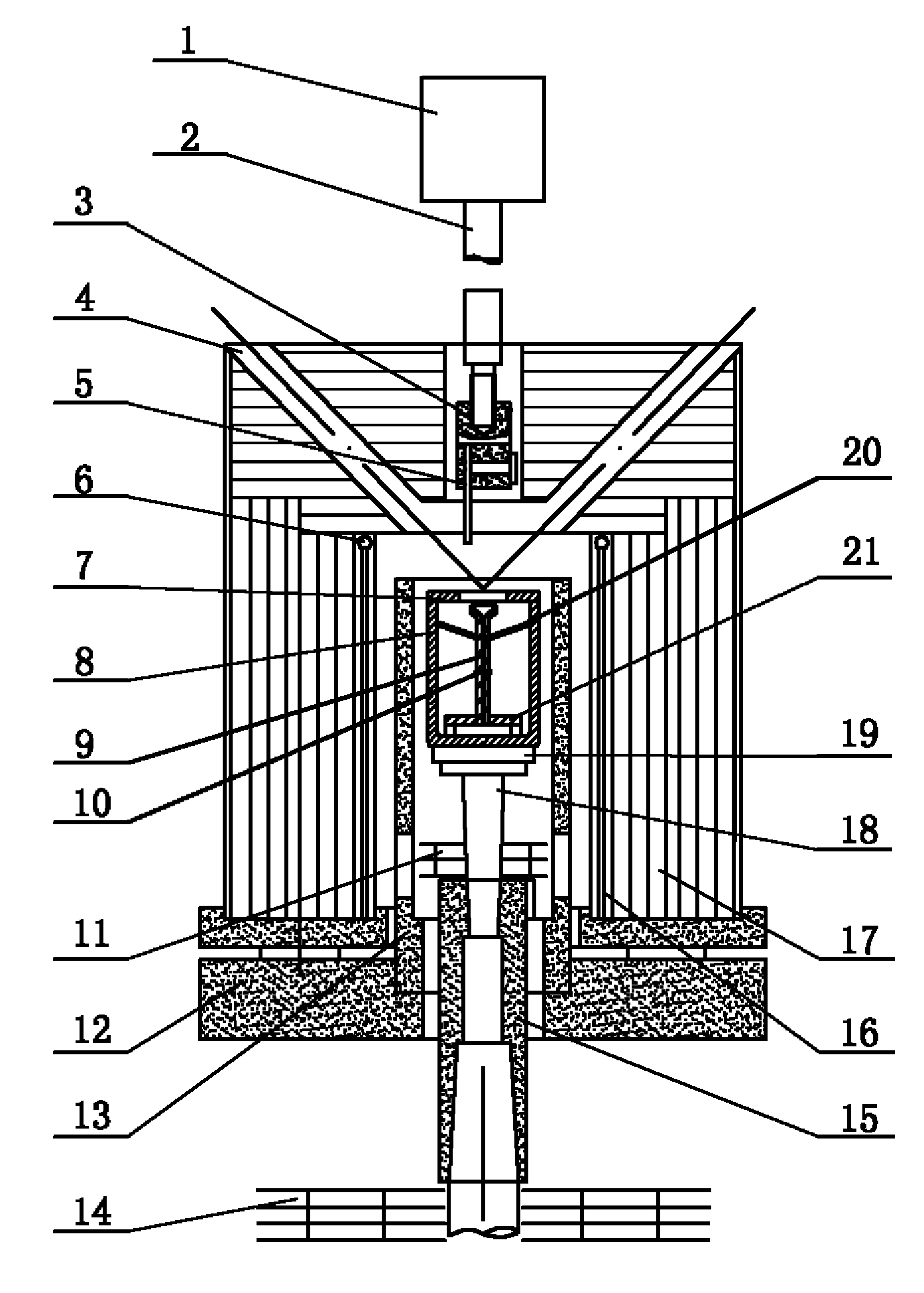

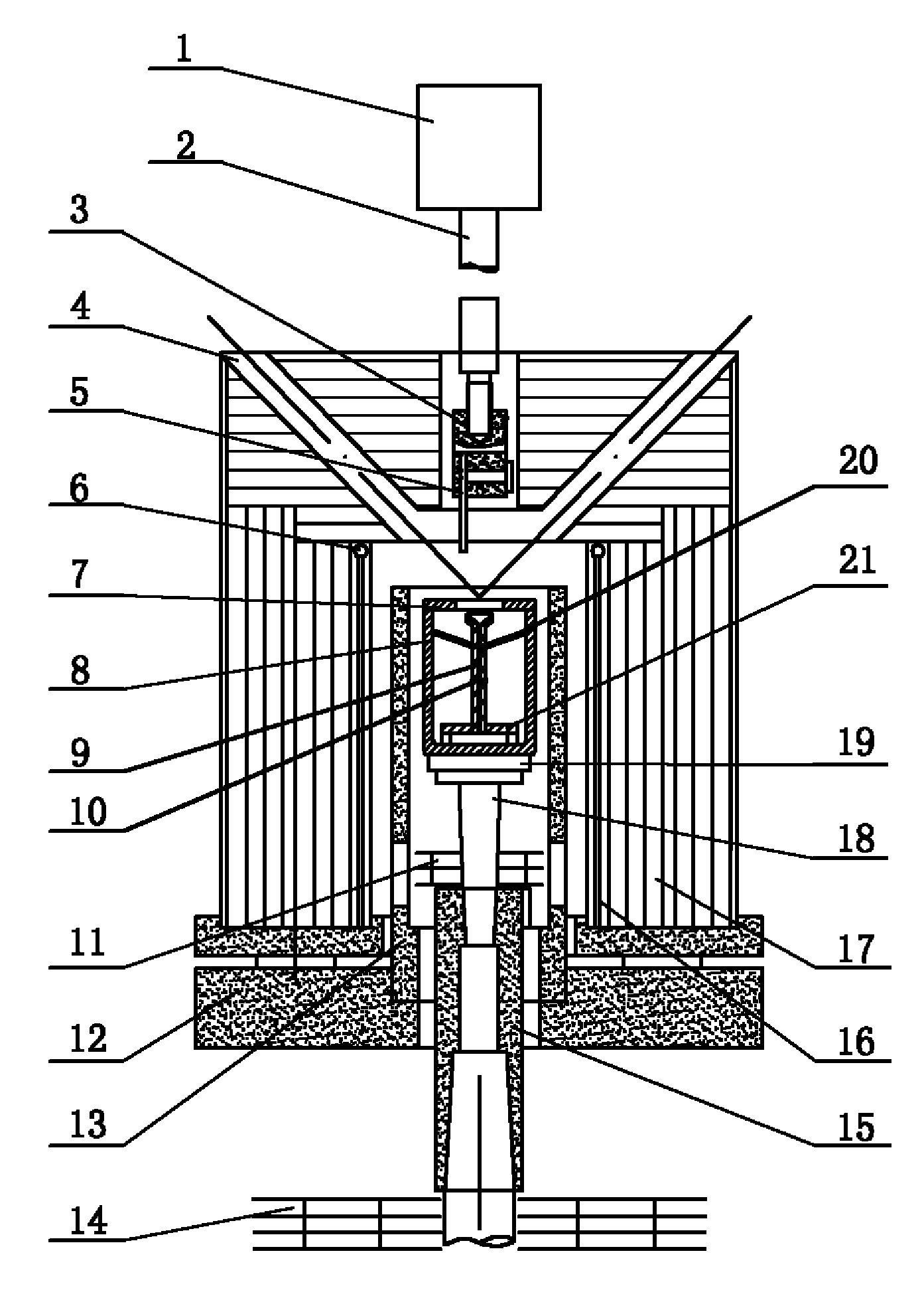

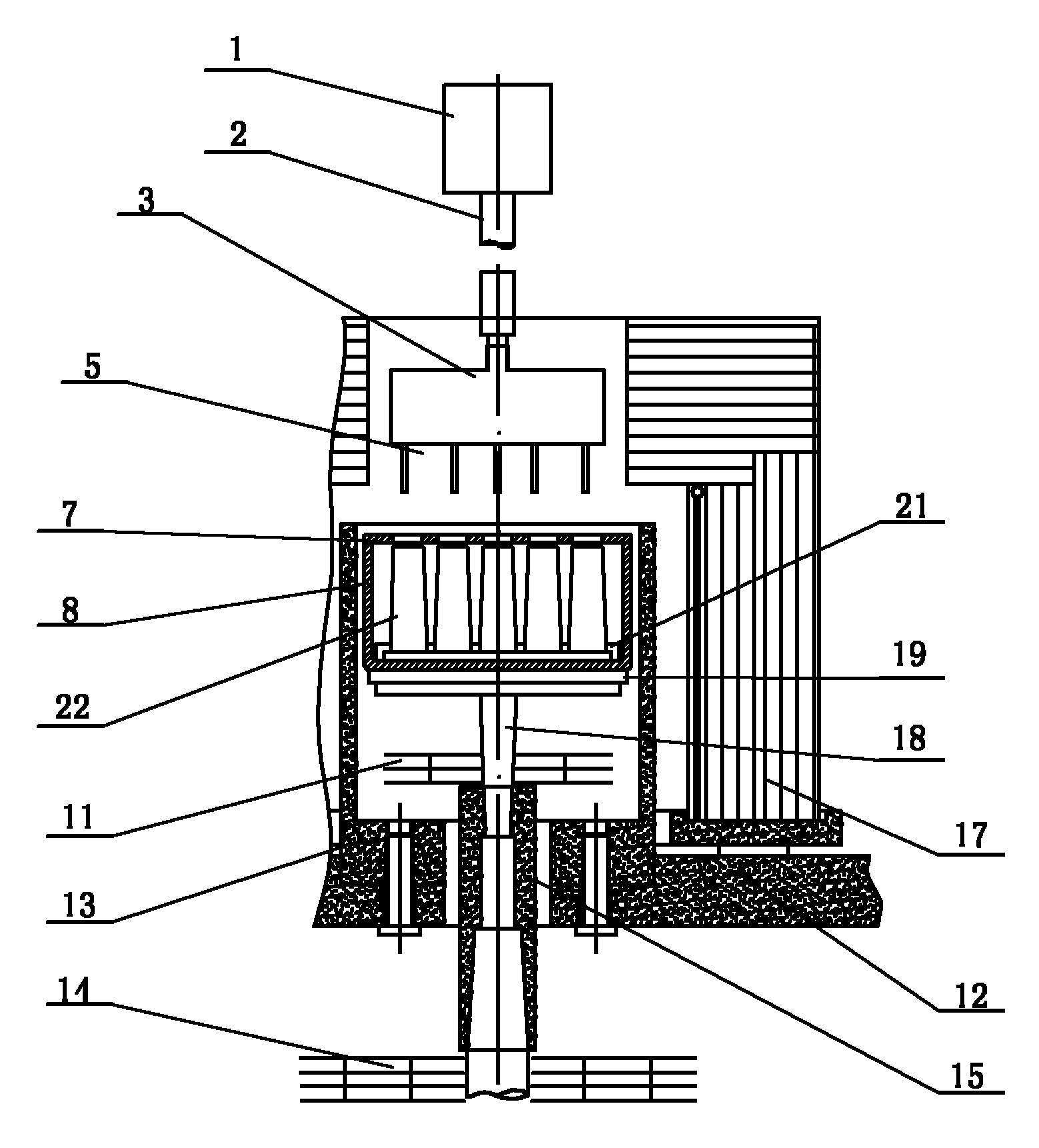

Method and apparatus for preparing major diameter single crystal

InactiveCN1847468AMake up for heat lossHigh Inductive Heat InputPolycrystalline material growthBy zone-melting liquidsSingle crystalEngineering

Owner:SCHOTT AG

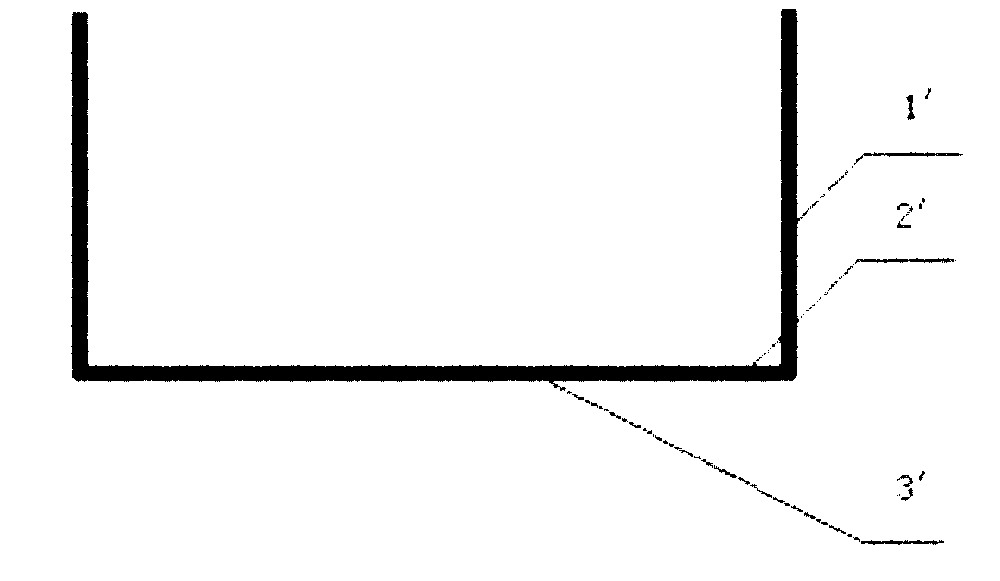

Crucible and substrate slice for growing and casting monocrystalline silicon

ActiveCN101935869AReduce dosageReduce manufacturing costPolycrystalline material growthFrom frozen solutionsCrucibleSeed crystal

Owner:ZHEJIANG UNIV

Dense, shaped articles constructed of a refractory material and methods of preparing such articles

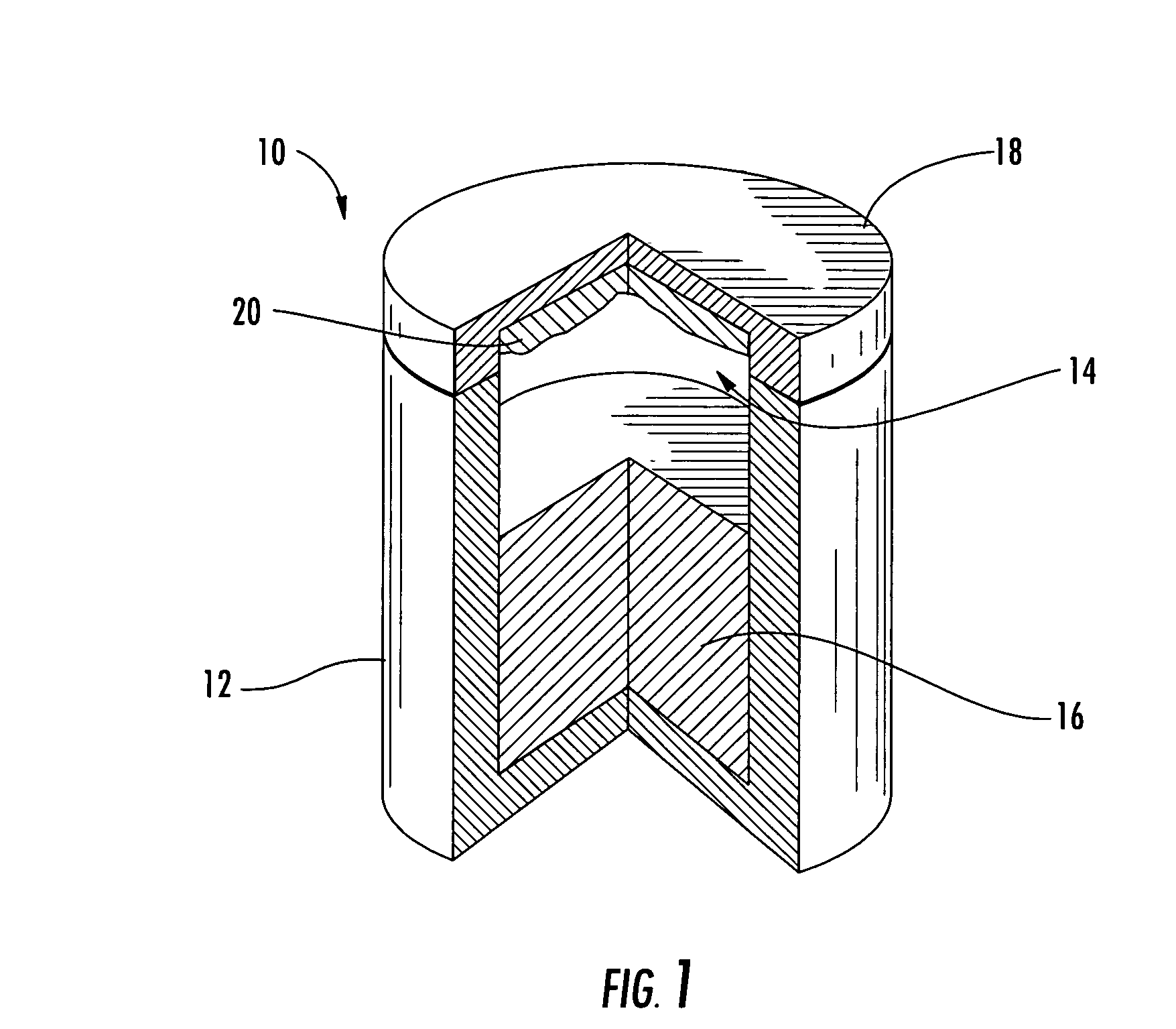

ActiveUS20060280640A1High utilization yieldUniform material propertiesPolycrystalline material growthCeramic shaping apparatusPorosityCrucible

Owner:NORTH CAROLINA STATE UNIV +6

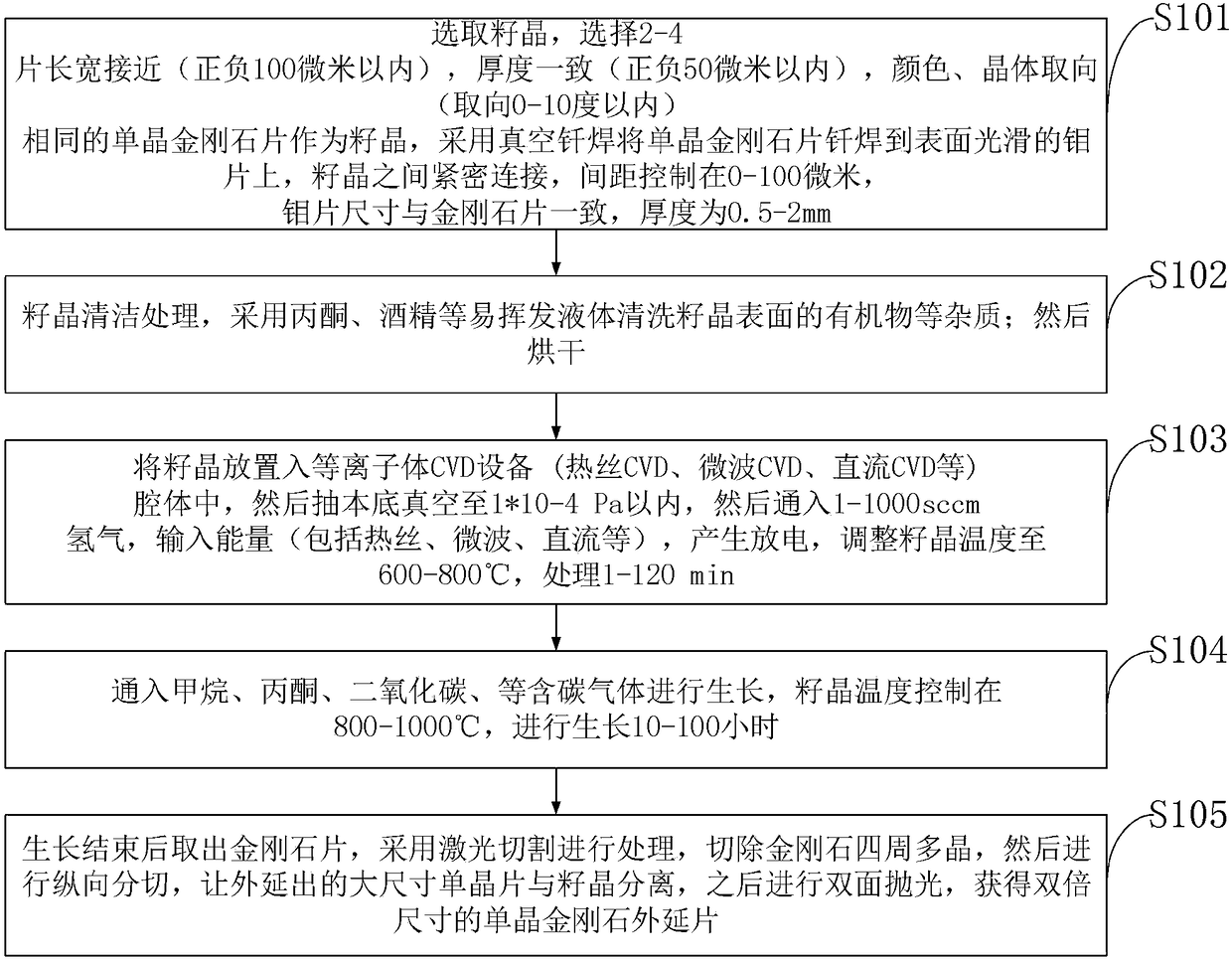

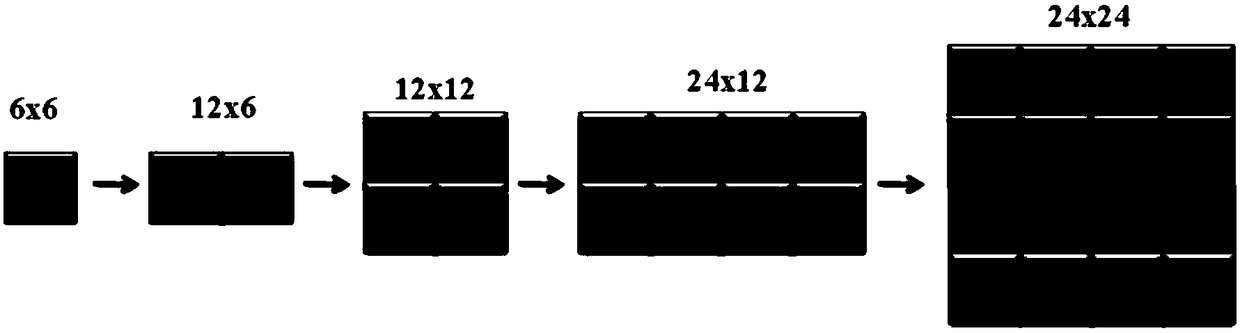

Method and system for splicing and growing single-crystal diamond

InactiveCN108103570APolycrystalline material growthFrom chemically reactive gasesBottle neckChemistry

Owner:湖北碳六科技有限公司

Novel single-crystal furnace for zinc cadmium telluride single crystal and growth process

PendingCN107059132AAchieve growthImprove the growing environmentPolycrystalline material growthFrom frozen solutionsTemperature controlCrucible

Owner:磐石创新(江苏)电子装备有限公司

Oxygen atmosphere control preparation method for alpha-axis oriented Yt-Ba-Cu-O superconductive thick film

InactiveCN1970849APolycrystalline material growthSuperconductors/hyperconductorsSingle crystalCopper

Owner:SHANGHAI JIAO TONG UNIV

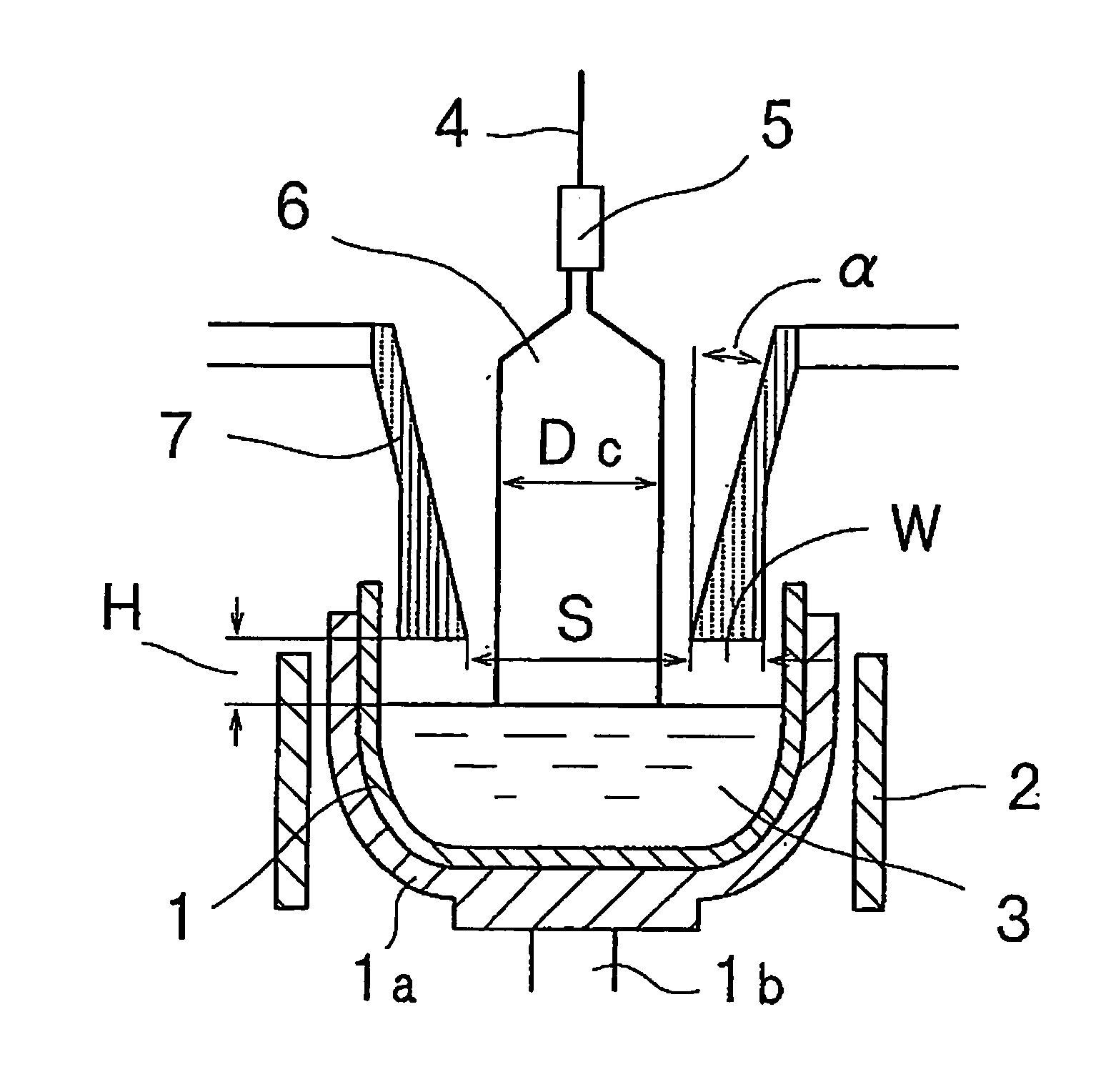

Method for growing silicon single crystal, and silicon wafer

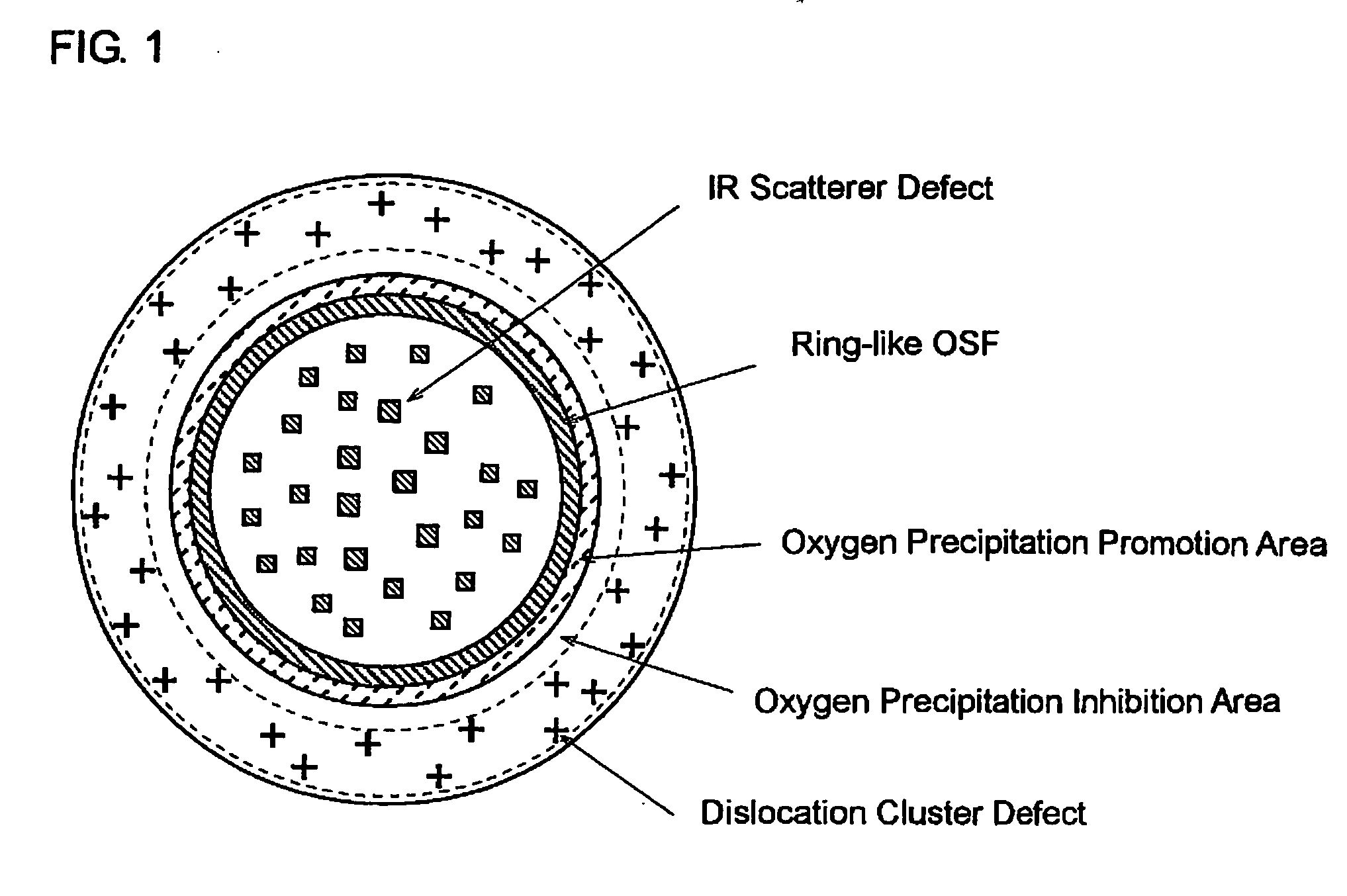

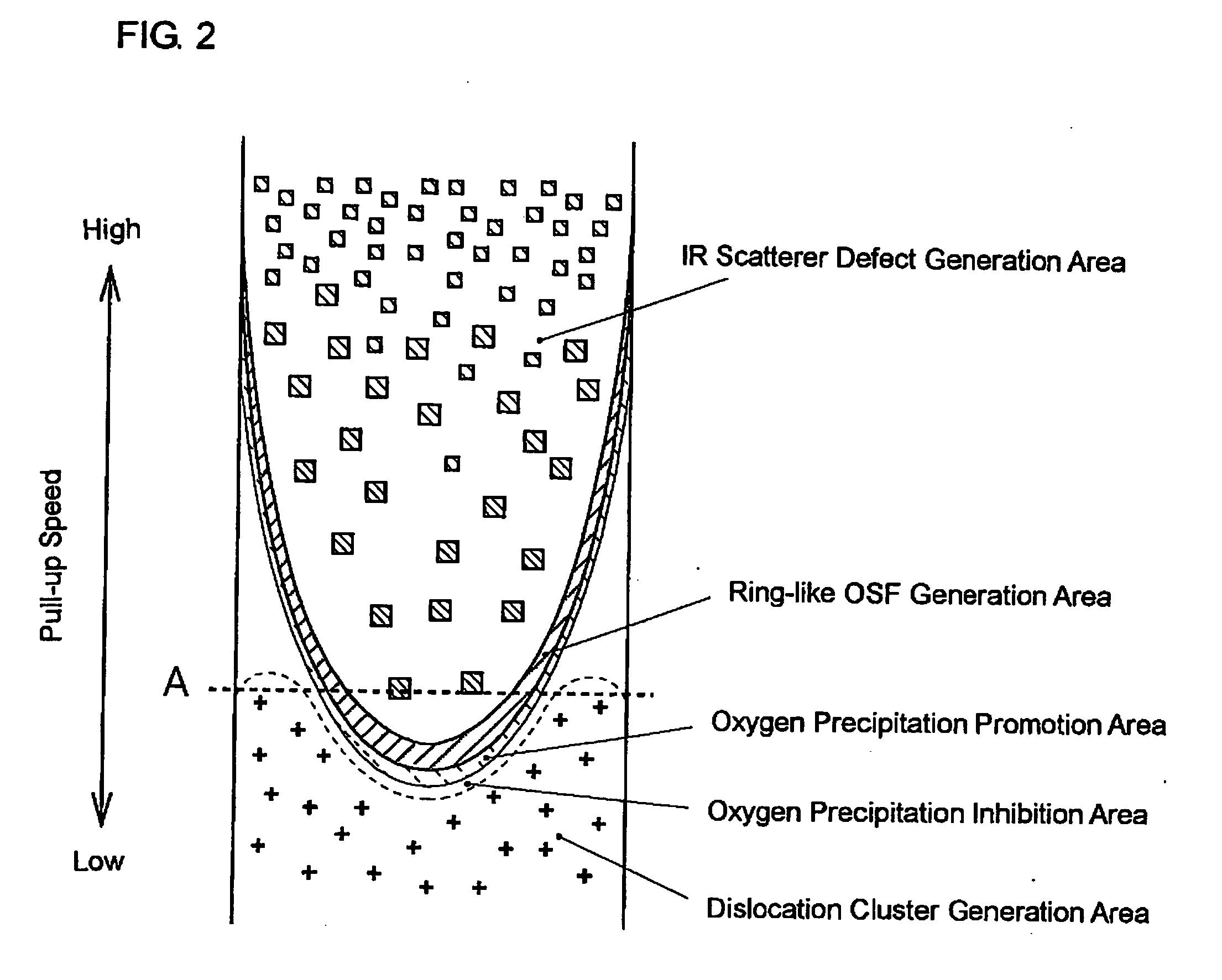

InactiveUS20060225639A1Stable productionEasy to adaptPolycrystalline material growthBy pulling from meltHigh densityMiniaturization

Owner:SUMCO CORP

Seeding mold for growing silicon crystals by using orientated solidification method and crystal growing method

InactiveCN102146580AFix placement issuesEliminate dislocationsPolycrystalline material growthFrom frozen solutionsSpontaneous nucleationDislocation

Owner:GREENERGY CRYSTAL TECH

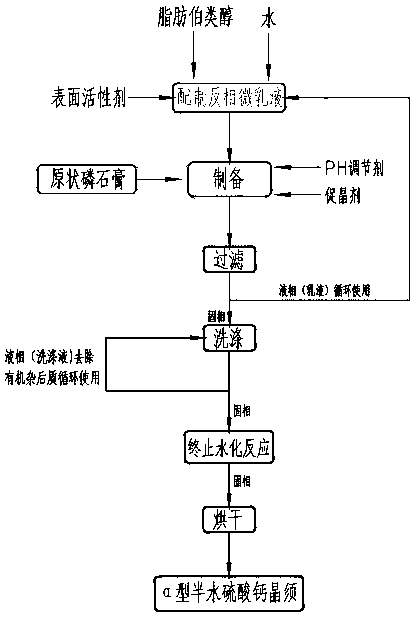

Method for preparing nano-scale alpha-type calcium sulfate hemihydrate whiskers from phosphogypsum in reverse microemulsion system

ActiveCN110835780APolycrystalline material growthFrom normal temperature solutionsActive agentCalcium Sulfate Hemihydrate

Owner:KUNMING UNIV OF SCI & TECH

Synthesis method of platy-ZnSe fluorescent nano monocrystal

InactiveCN101787564APolycrystalline material growthFrom normal temperature solutionsSolventQuantum yield

Owner:YUNNAN UNIV

Electronic device grade single crystal diamonds and method of producing the same

ActiveUS20160201221A1Reduce crystal defect densityPolycrystalline material growthUltra-high pressure processesMicrowaveSingle crystal

Owner:IIA TECH

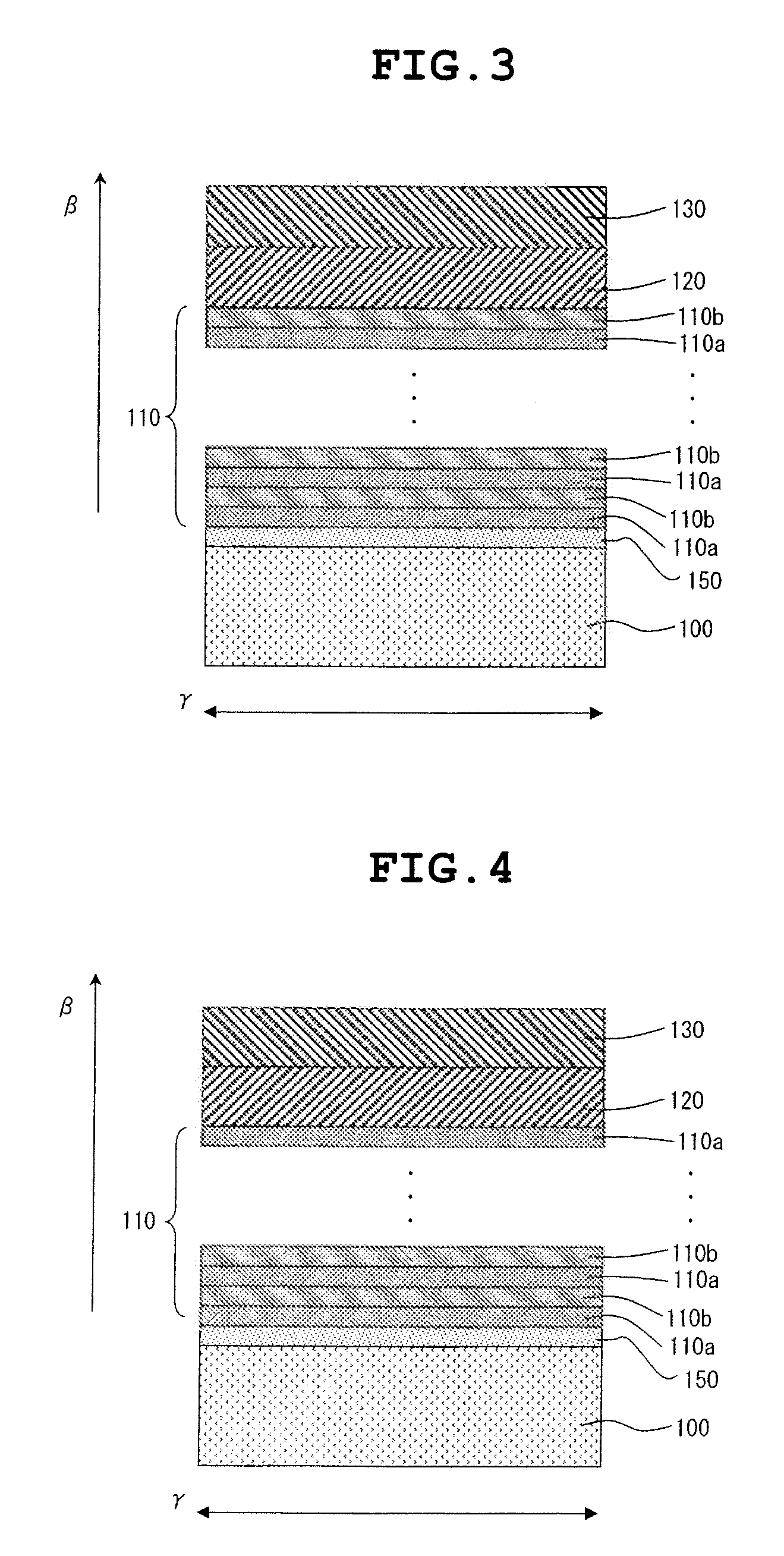

Nanostructuring process for ingot surface, wafer manufacturing method, and wafer using the same

InactiveUS20120193764A1Improve surface strengthReduce generationMaterial nanotechnologyPolycrystalline material growthWaferingMetallurgy

The instant disclosure relates to a nanostructuring process for an ingot surface prior to the slicing operation. A surface treatment step is performed for at least one surface of the ingot in forming a nanostructure layer thereon. The nanostructure layer is capable of enhancing the mechanical strength of the ingot surface to reduce the chipping ratio of the wafer during slicing.

Owner:SINO AMERICAN SILICON PROD

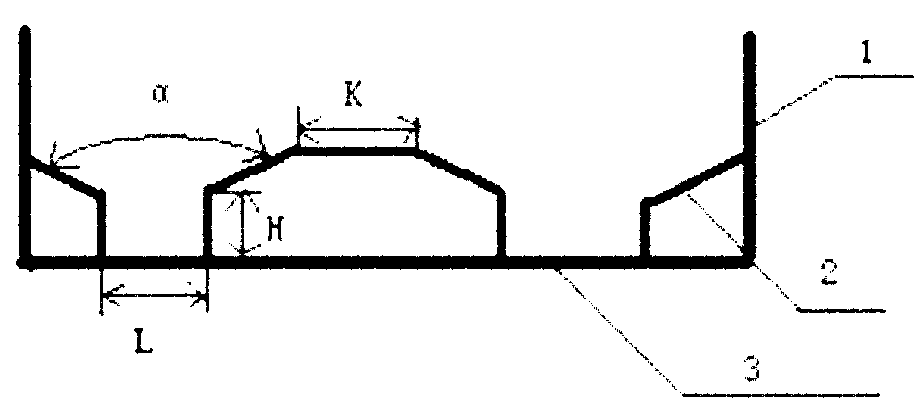

Guide die structure for growing extra-thick monocrystal alumina wafer

InactiveCN101899705APolycrystalline material growthBy pulling from meltThermal insulationSeed crystal

Owner:无锡金岩光电晶体科技有限公司

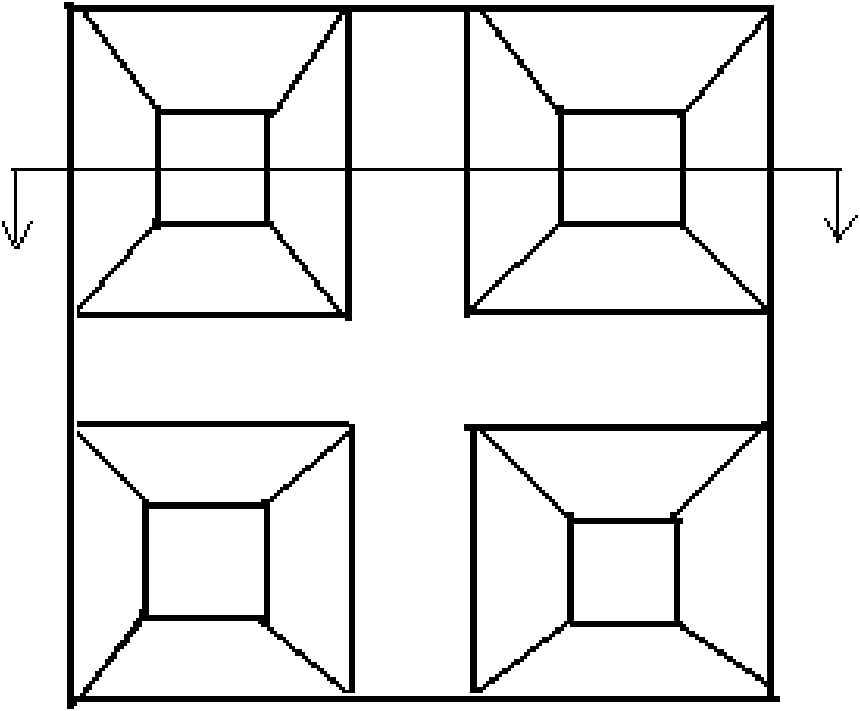

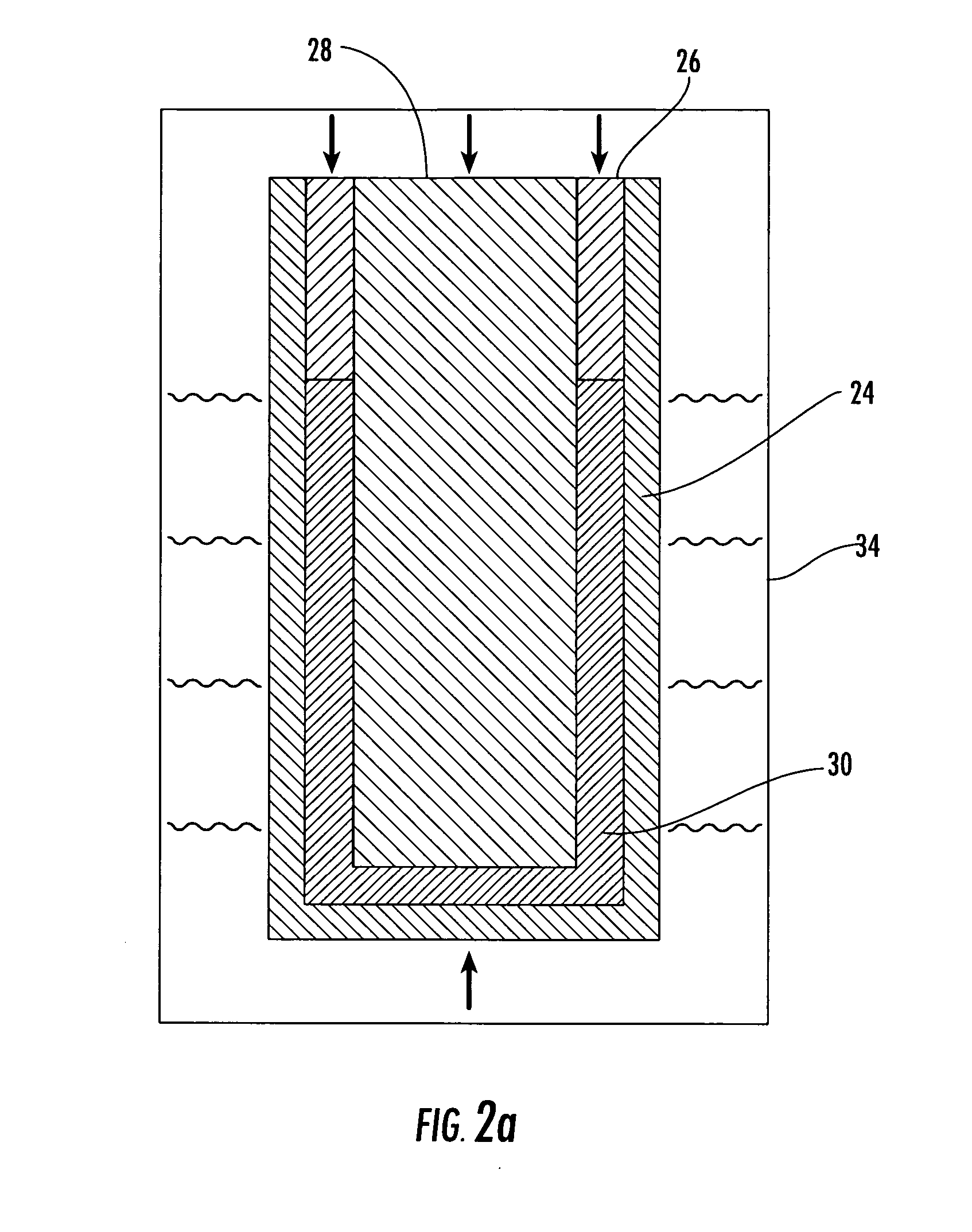

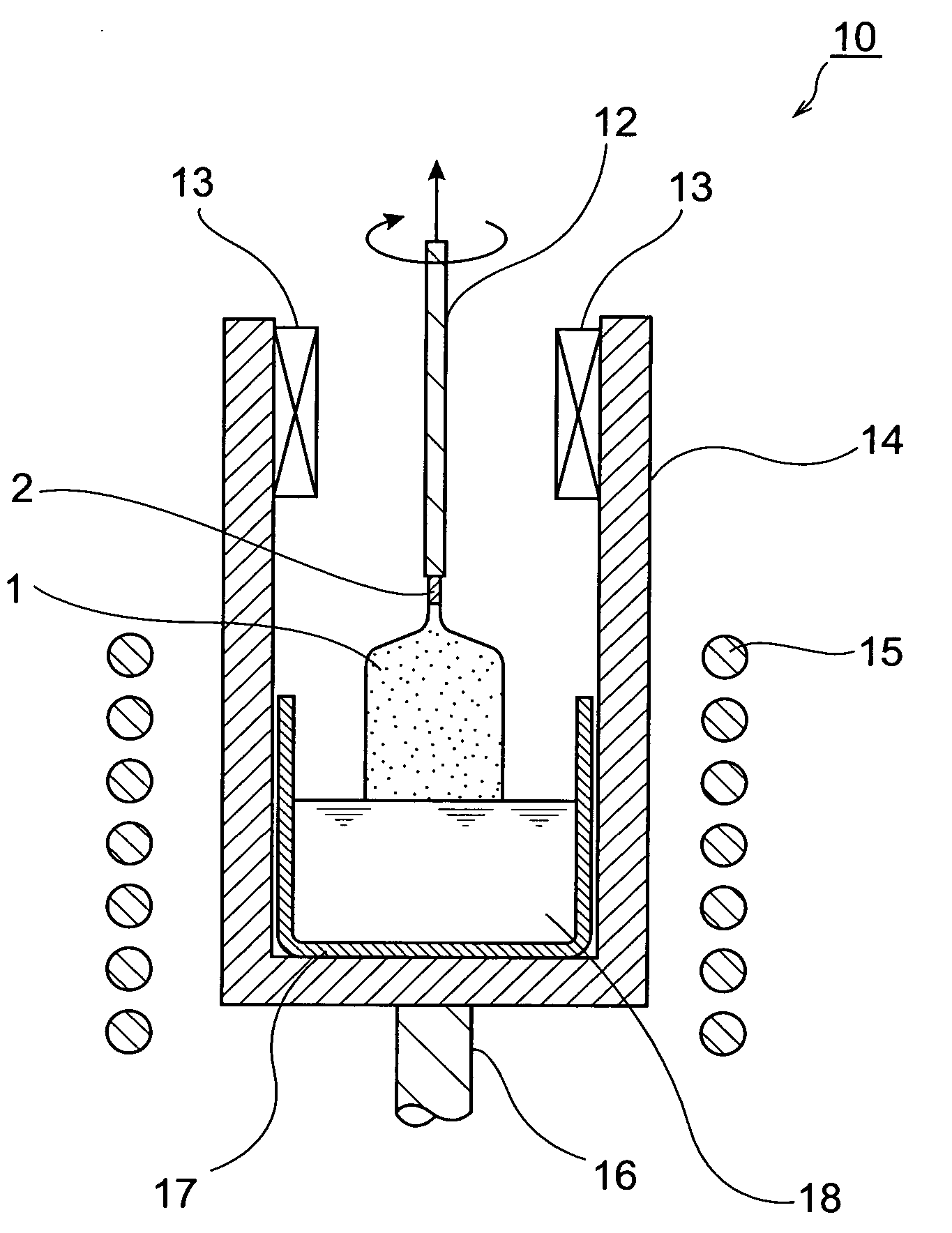

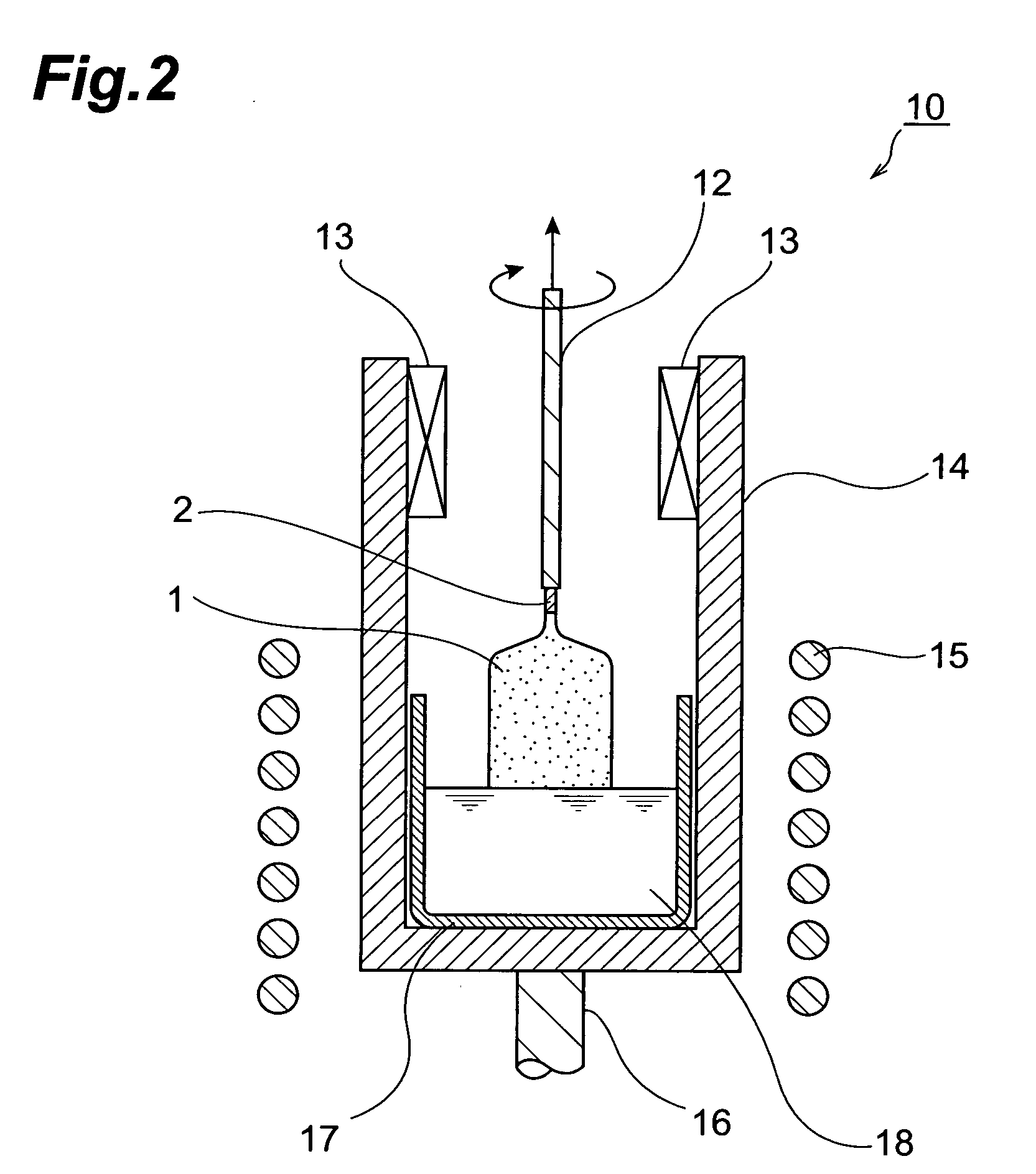

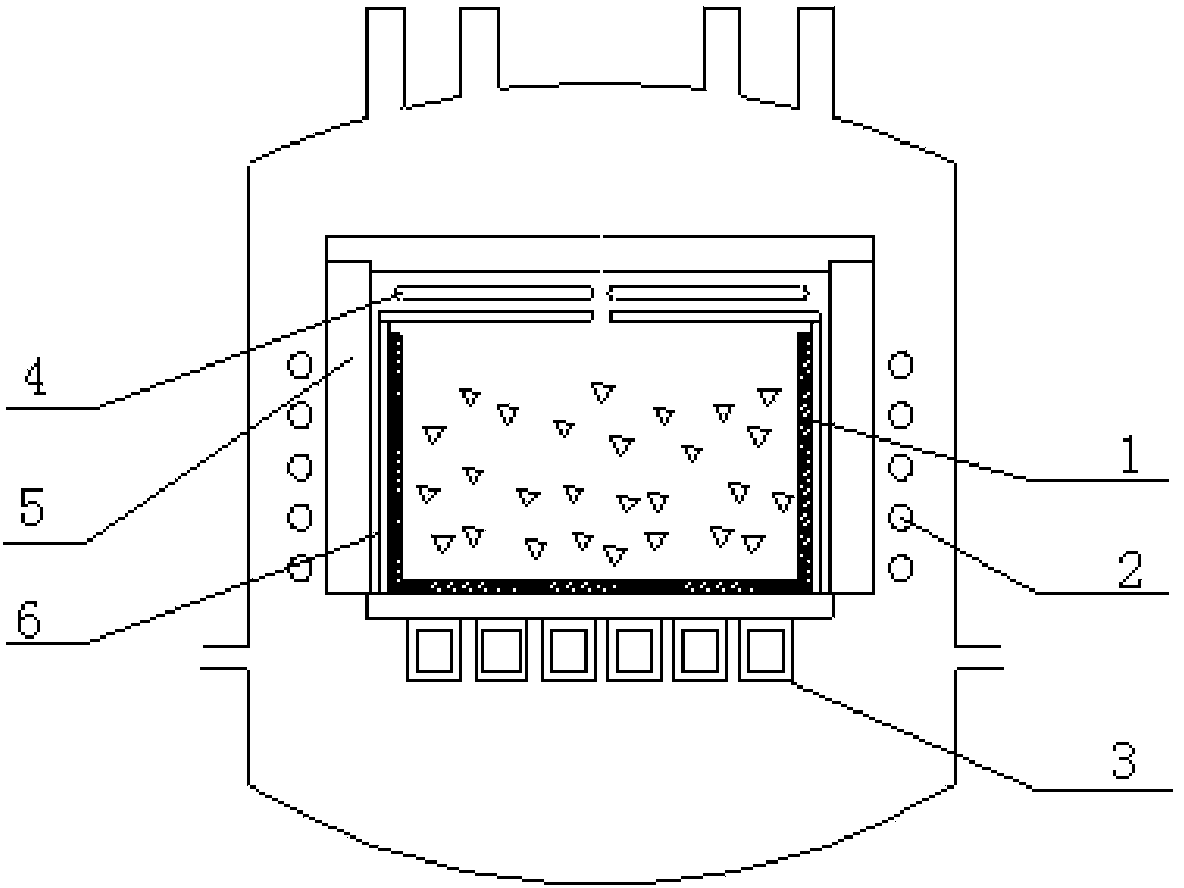

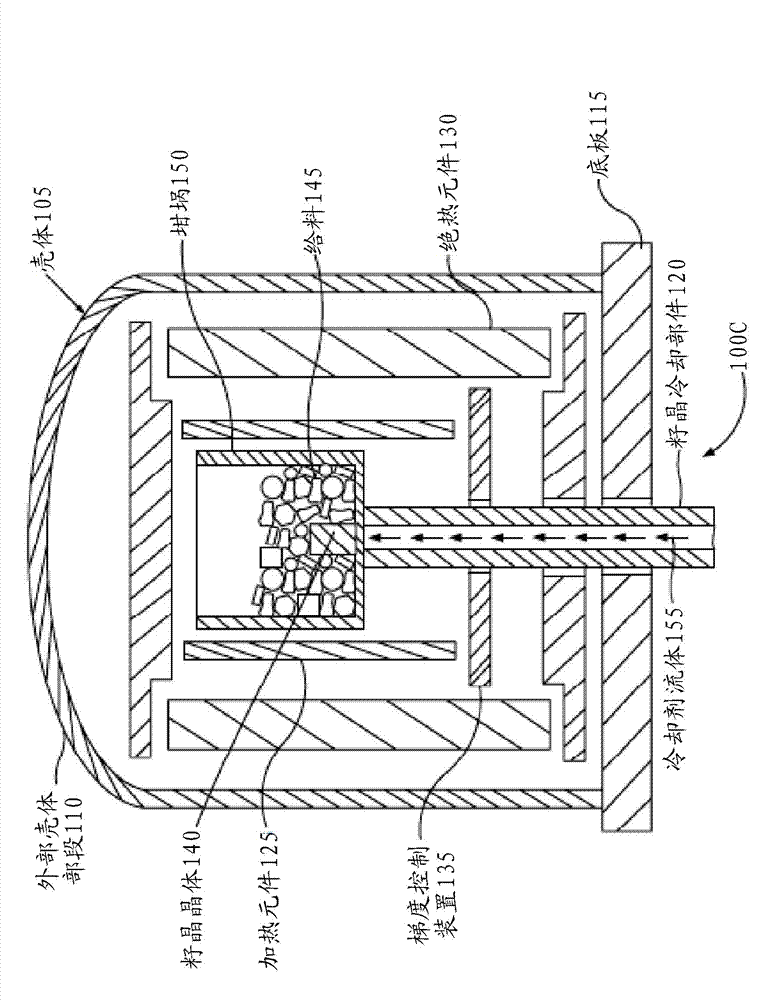

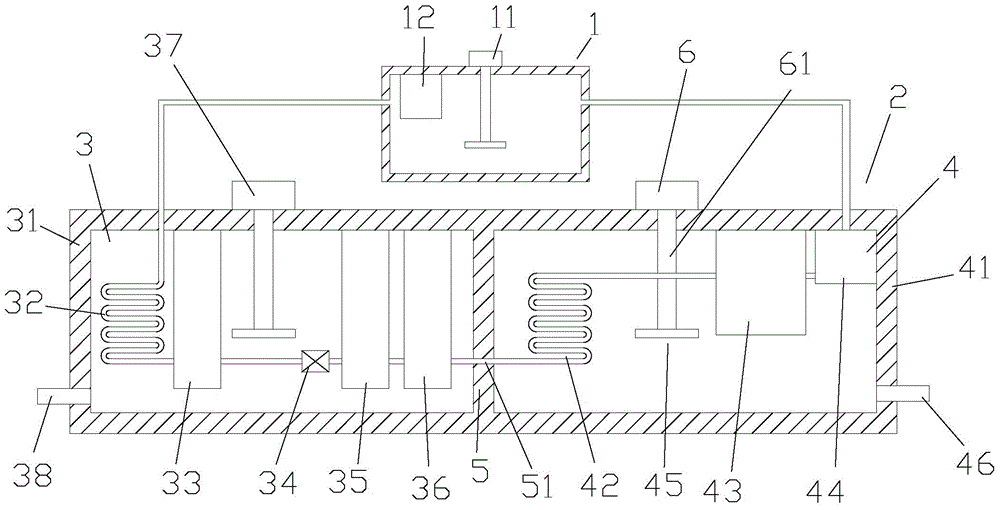

Ingotting furnace for polycrystalline silicon and quasi single crystal silicon and application method for ingotting furnace

ActiveCN103966657AReduce heat lossImprove securityPolycrystalline material growthFrom frozen solutionsDirectional solidificationPolycrystalline silicon

The invention discloses an ingotting furnace for polycrystalline silicon and quasi single crystal silicon and an application method for the ingotting furnace. The ingotting furnace comprises a quartz crucible, wherein first induction heating devices are arranged on the outer side of the quartz crucible, second induction heating devices are arranged at the bottom of the quartz crucible, third induction heating devices are arranged at the top of the quartz crucible, a graphite crucible is arranged outside the quartz crucible, a thermal insulating layer is arranged between the quartz crucible and the graphite crucible, and the first induction heating devices are arranged on the outer side of the graphite crucible in a surrounding manner. According to the ingotting furnace for the polycrystalline silicon and the quasi single crystal silicon and the application method for the ingotting furnace, provided by the invention, through the adoption of the double-layered crucible, a plurality of induction heating devices are arranged at different positions, so that the vortex current can be generated in polycrystalline silicon raw materials and solution by adopting the alternating magnetic field generated by spiral coils; because the induction coils are positioned out of the high-temperature thermal regions, the hot loss is less when heating is conducted; through the optimal design of the coil distribution of the induction heating devices, the accurate directional temperature gradient in the furnace can be realized, the direction of the crystal growth can be controlled better, and the directional solidification can be conducted quickly.

Owner:江苏盎华光伏工程技术研究中心有限公司

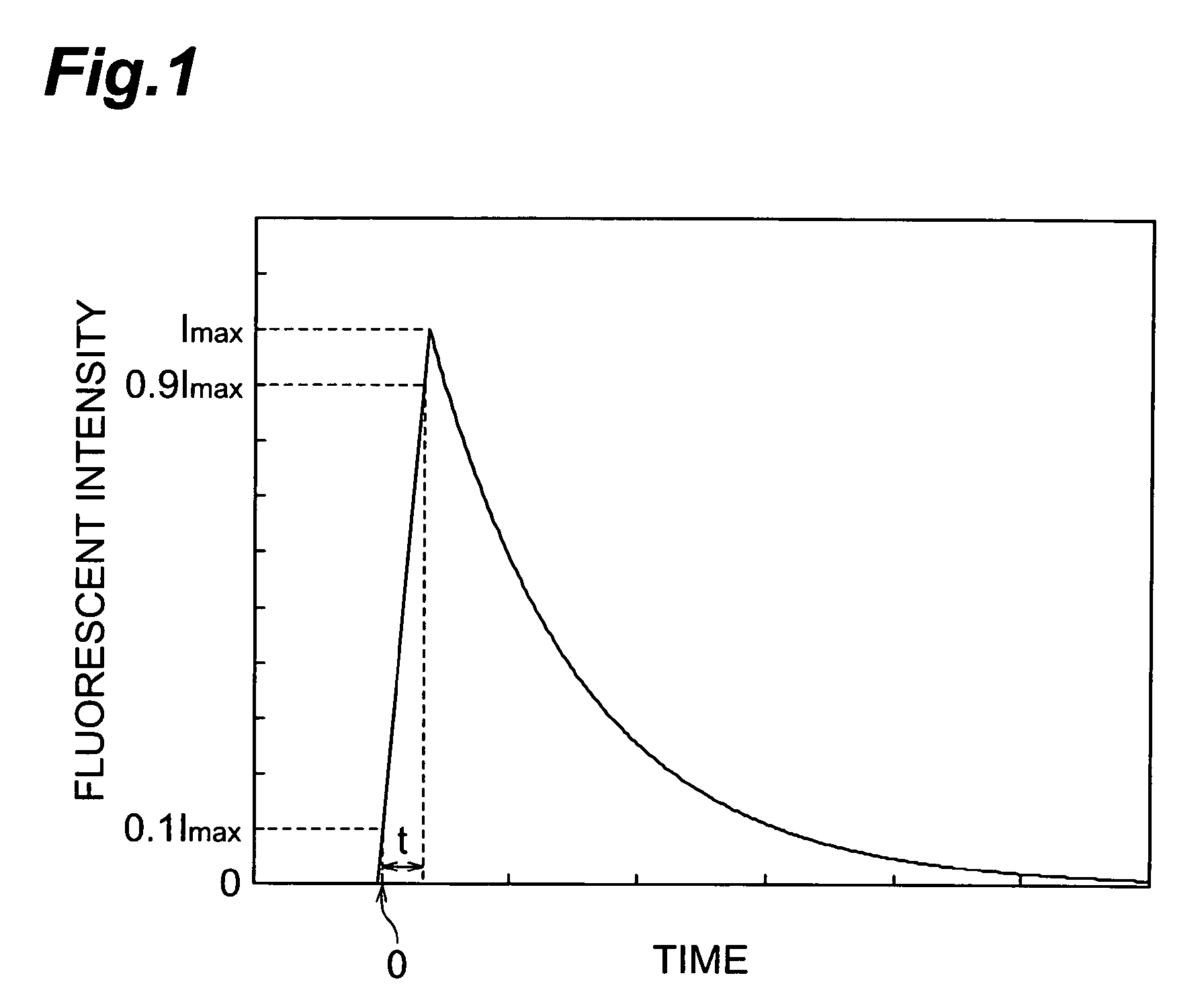

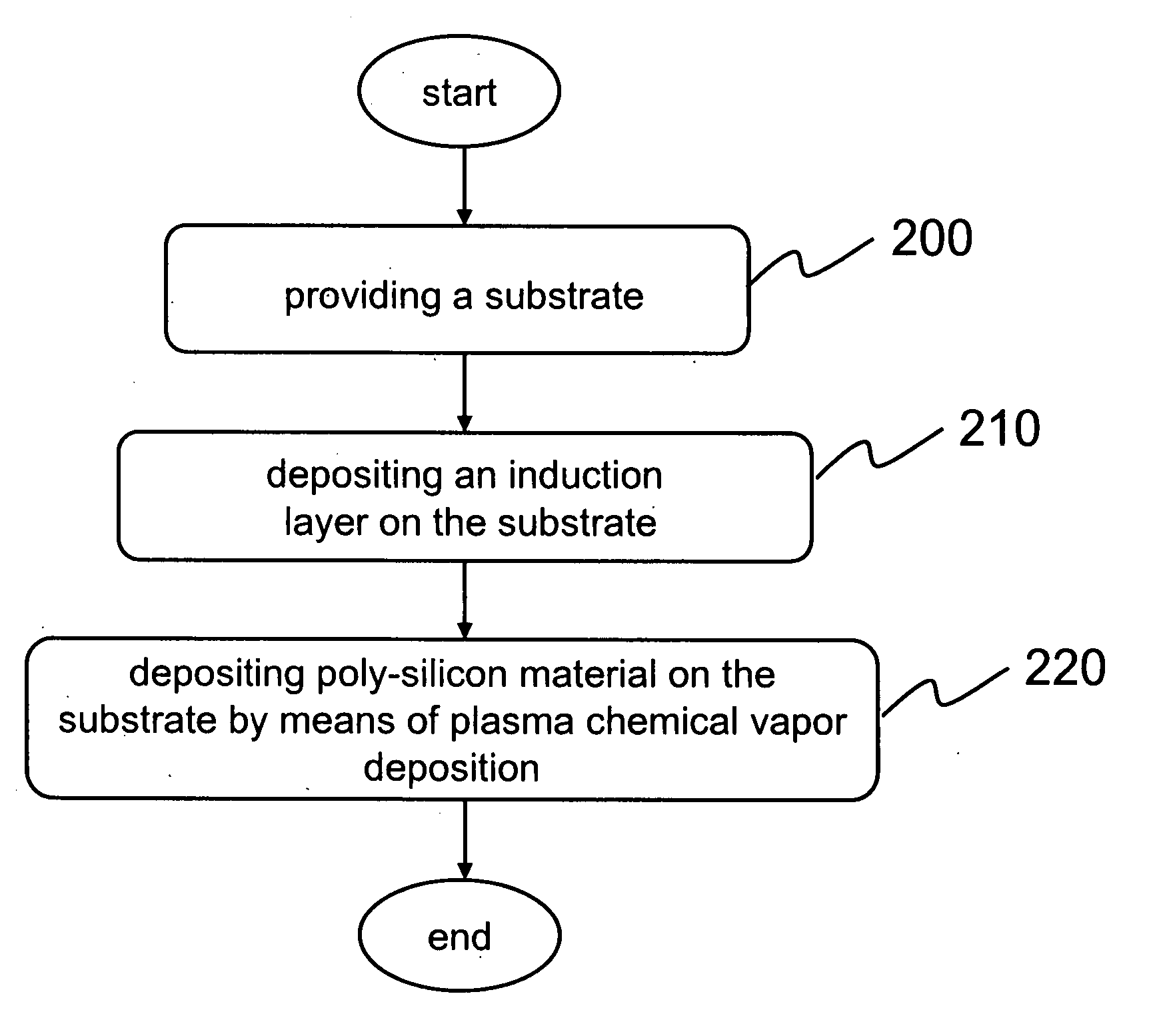

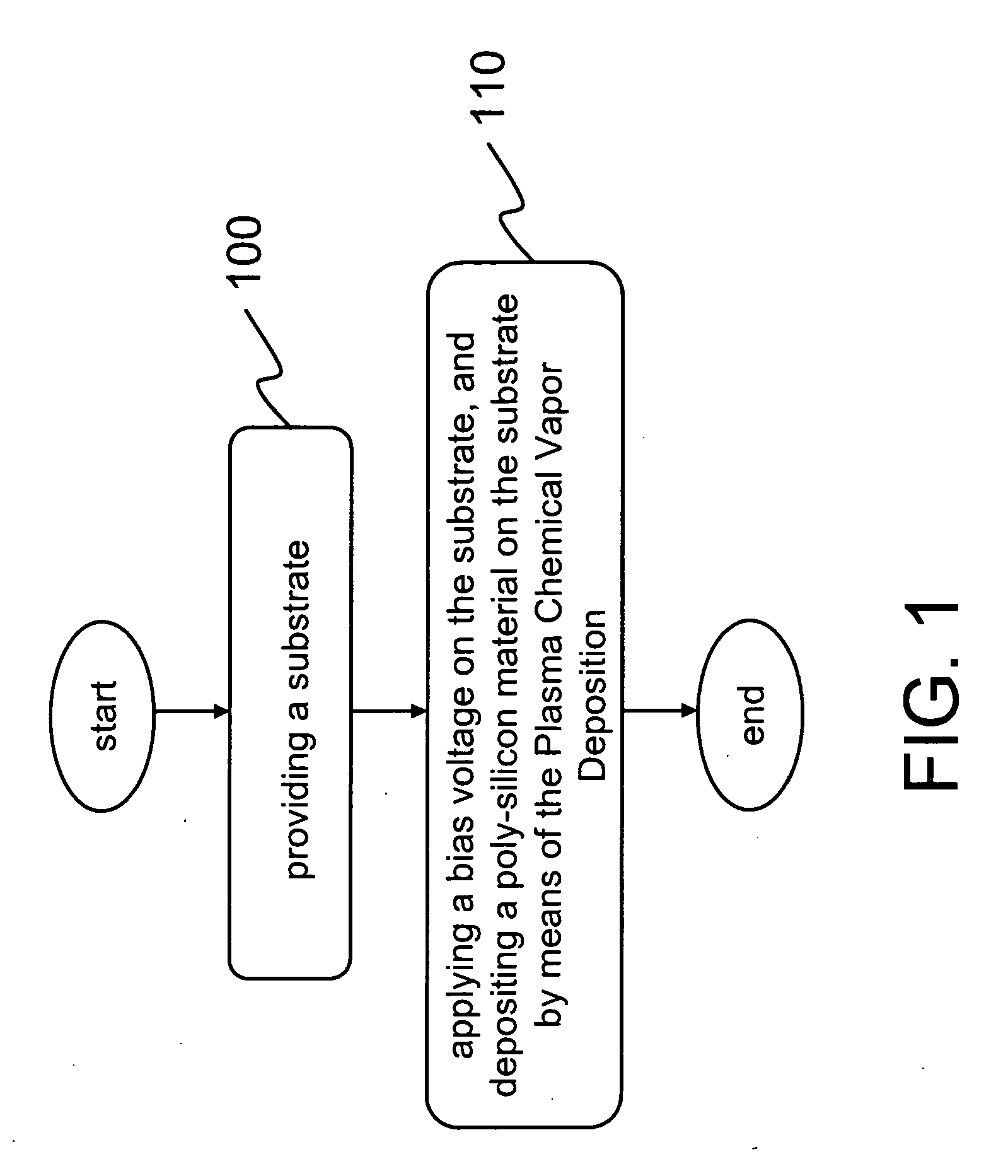

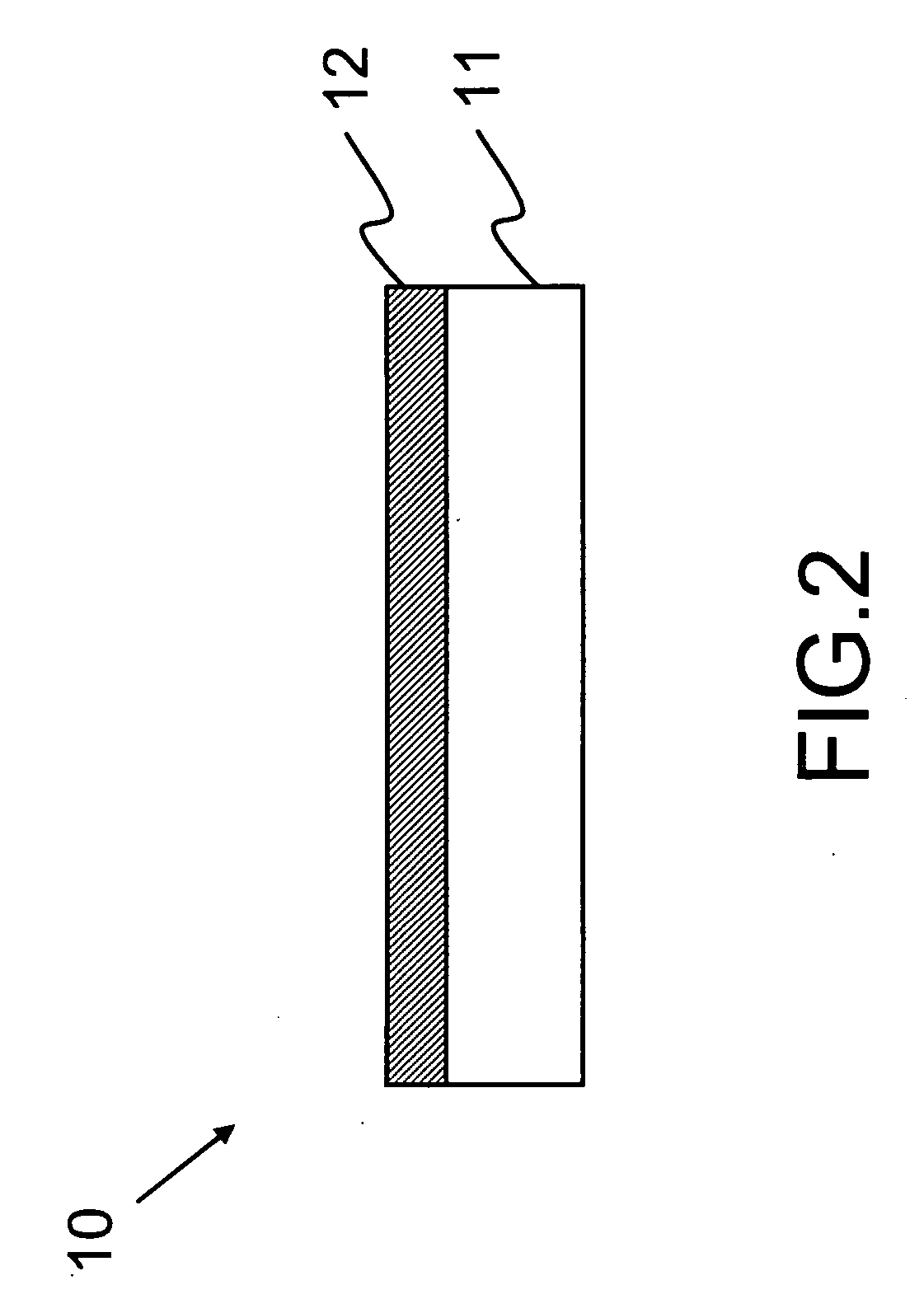

Element of low temperature poly-silicon thin film and method of making poly-silicon thin film by direct deposition at low temperature and inductively-coupled plasma chemical vapor deposition equipment therefor

InactiveUS20070077735A1Quality improvementReduce thicknessPolycrystalline material growthSolid-state devicesInductively coupled plasmaSilicon thin film

Owner:IND TECH RES INST

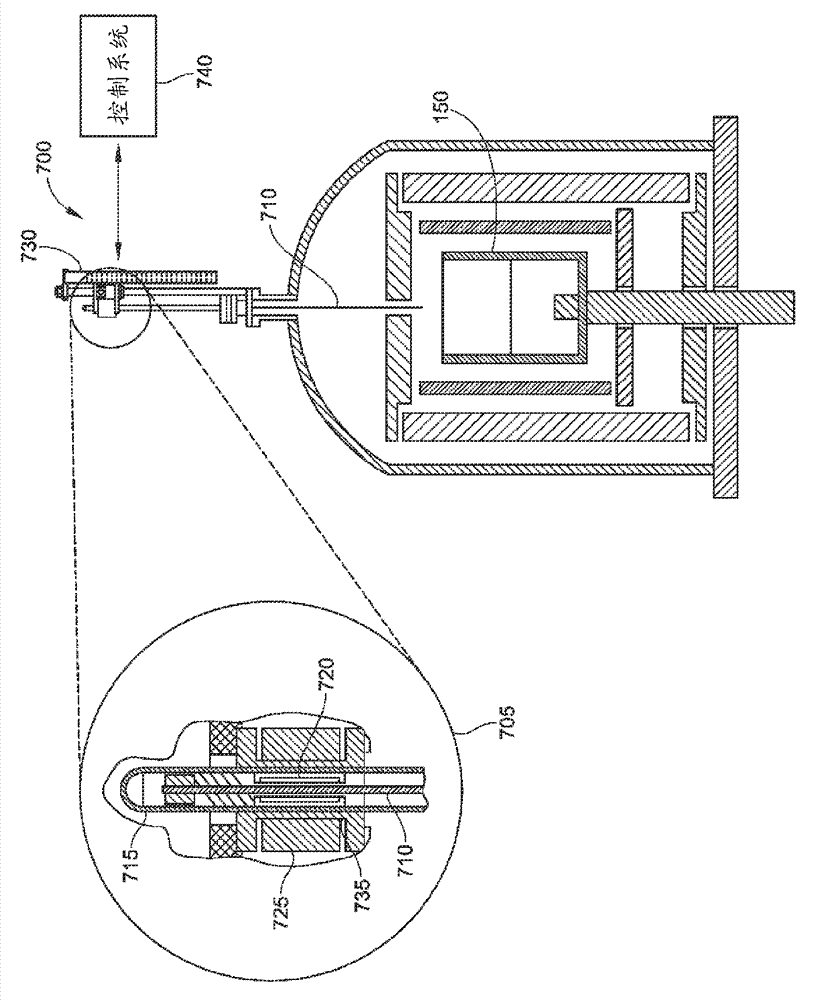

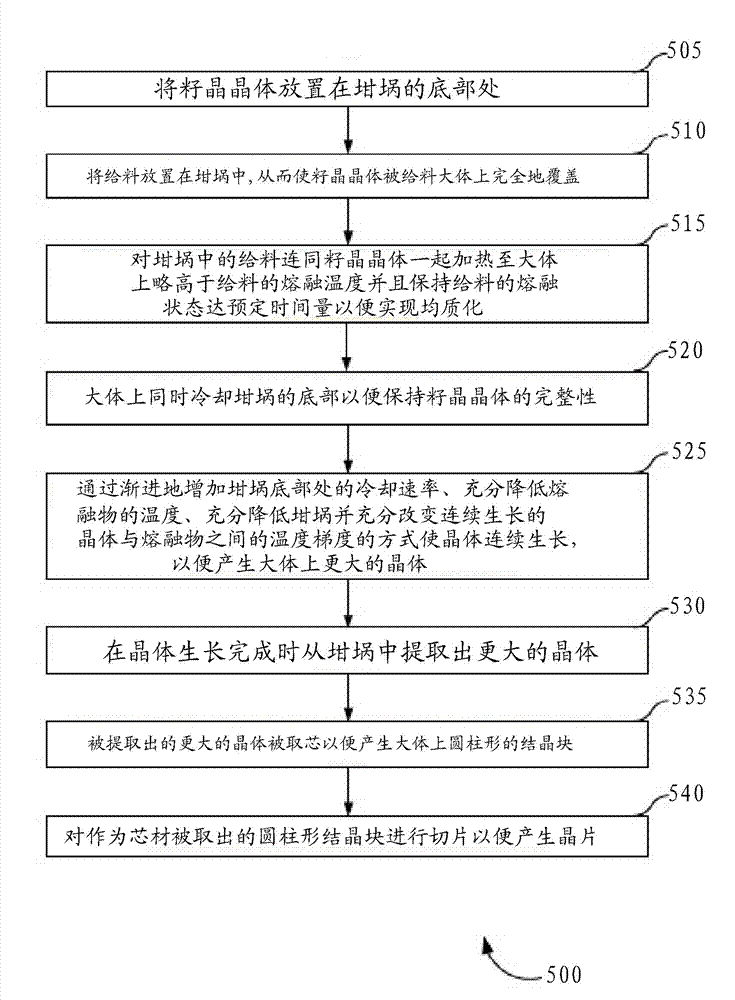

Crystal growth methods and systems

Owner:ADVANCED RENEWABLEENERGY COMPANY

Manufacture method for ZnO based compound semiconductor crystal and ZnO based compound semiconductor substrate

InactiveUS20070152233A1Polycrystalline material growthVacuum evaporation coatingChemistryCompound semiconductor

Owner:STANLEY ELECTRIC CO LTD +1

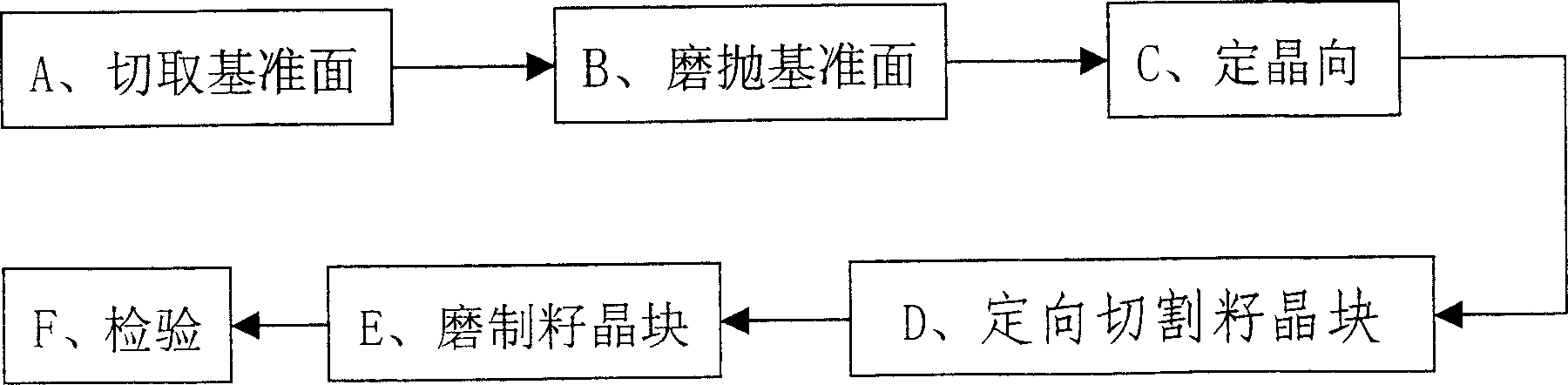

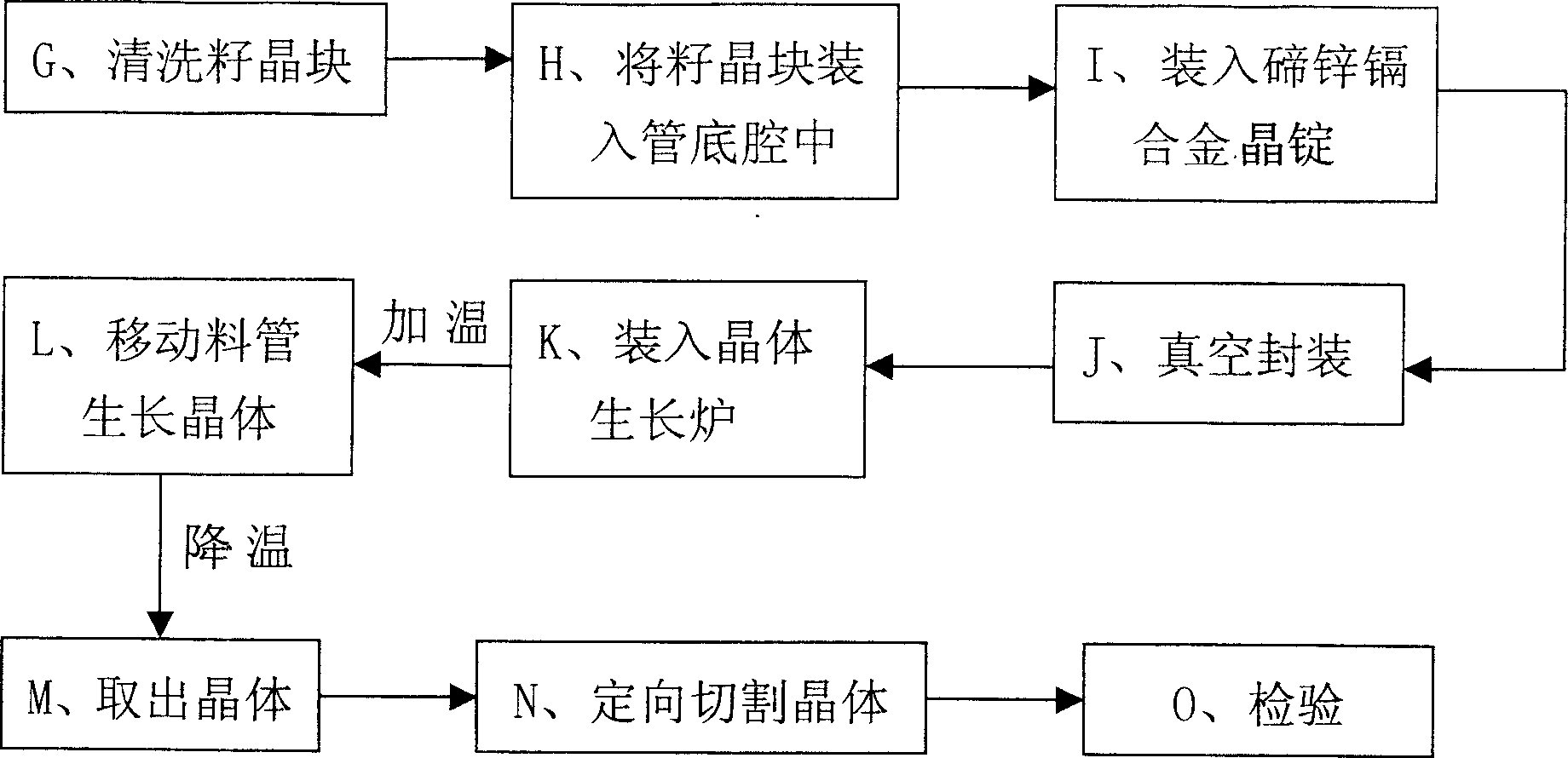

Technique for growing Cd-Zn-Te crystal

Owner:KUNMING INST OF PHYSICS

Method for preparing polysilicon

InactiveCN1727525AReduce the temperatureLower threshold voltagePolycrystalline material growthSemiconductor/solid-state device manufacturingFine lineSemiconductor materials

A process for preparing polycrystal silicon includes preparing non-crystal silicon film on glass substrate, preparing a thin Ni layer, photoetching the Ni layer to become fine lines, laser annealing, removing excessive Ni, and laser annealing again for crystallizing the silicon film. Its advantages are short time and low substrate temp.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Manufacturing method of semiconductor device

InactiveCN102468153AEfficient reorganizationIncrease etch ratePolycrystalline material growthAfter-treatment detailsPulsed laser beamCrystalline silicon

In a manufacturing method of a semiconductor device, a substrate including single crystalline silicon is prepared, a reformed layer that continuously extends is formed in the substrate, and the reformed layer is removed by etching. The forming the reformed layer includes polycrystallizing a portion of the single crystalline silicon by irradiating the substrate with a pulsed laser beam while moving a focal point of the laser beam in the substrate.

Owner:DENSO CORP

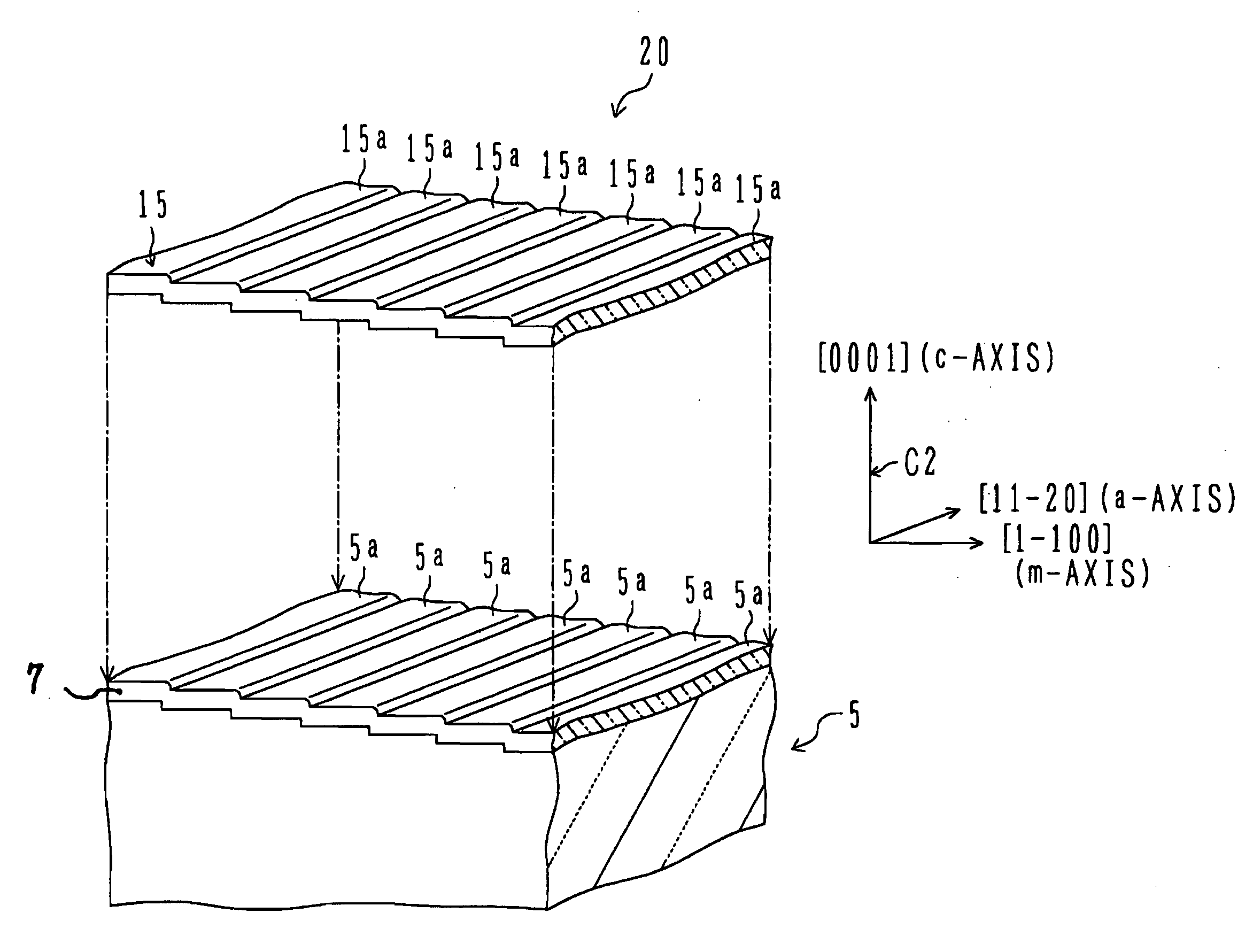

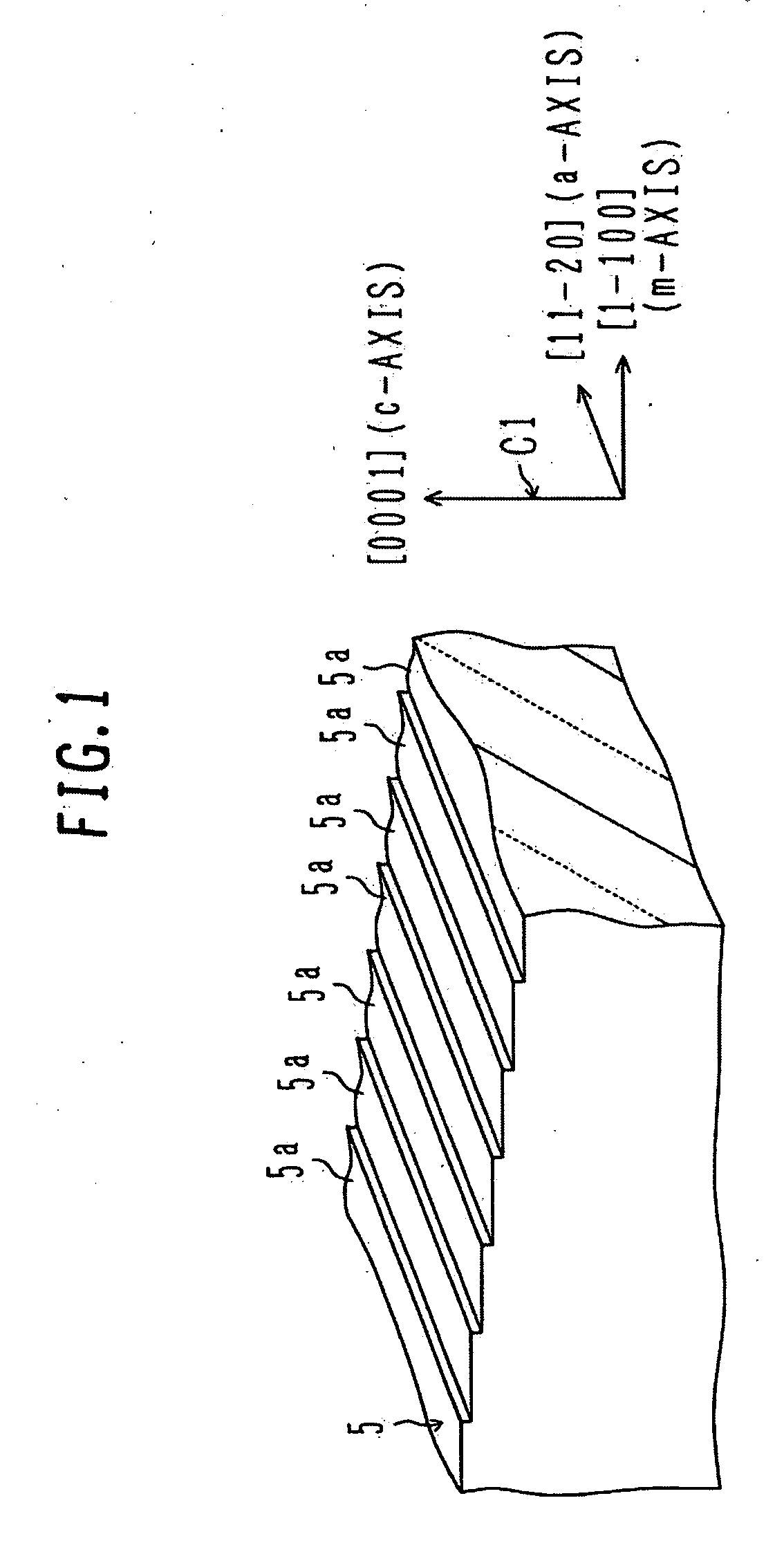

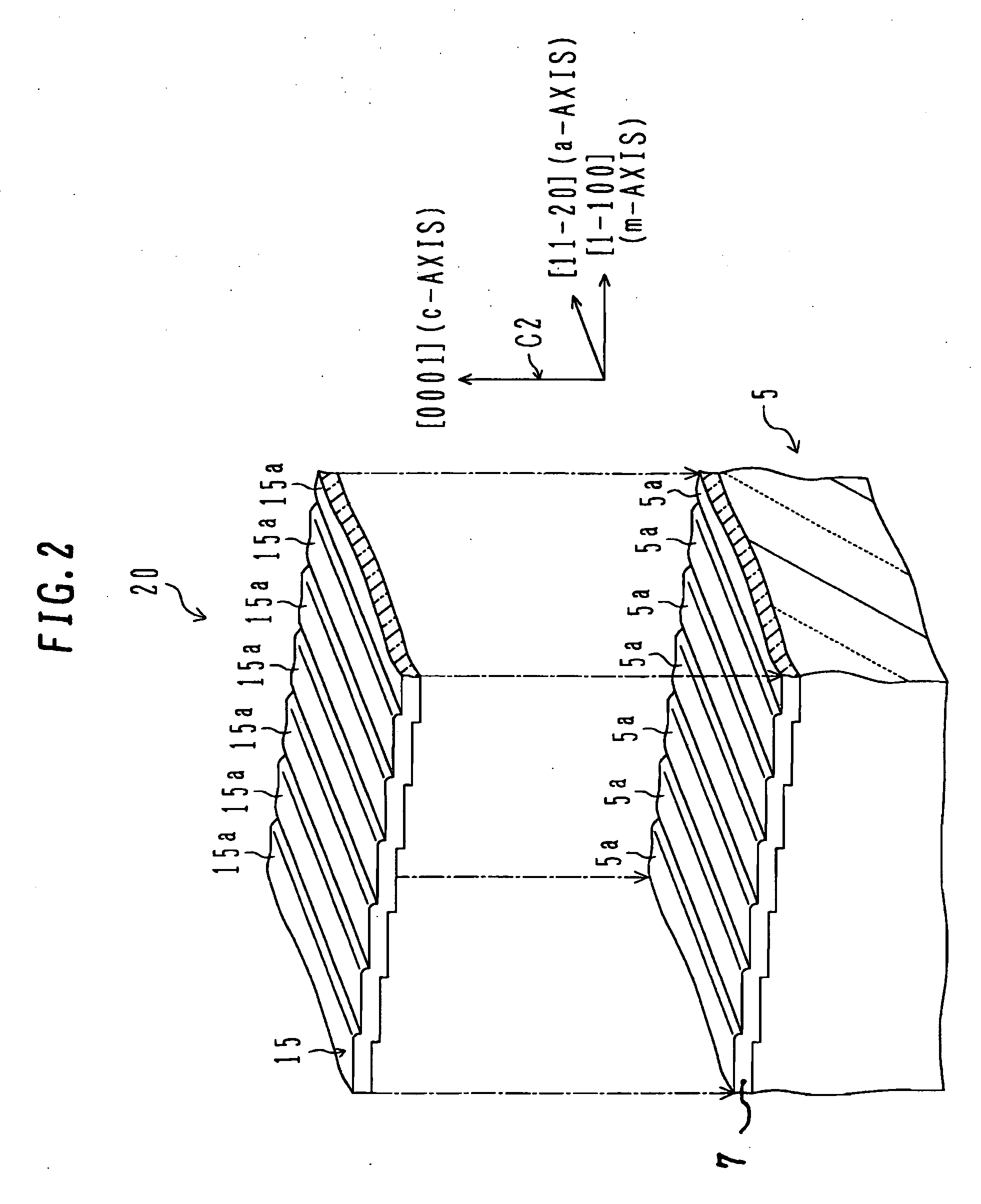

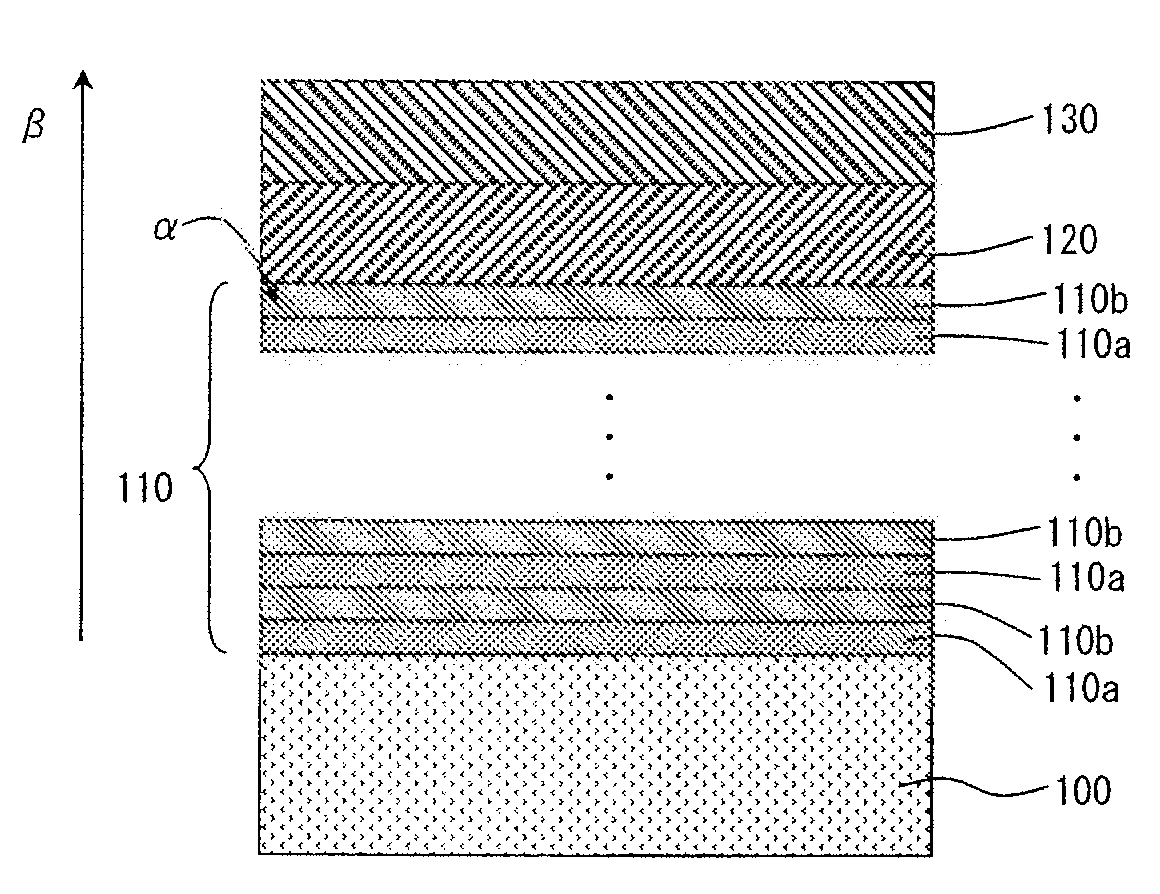

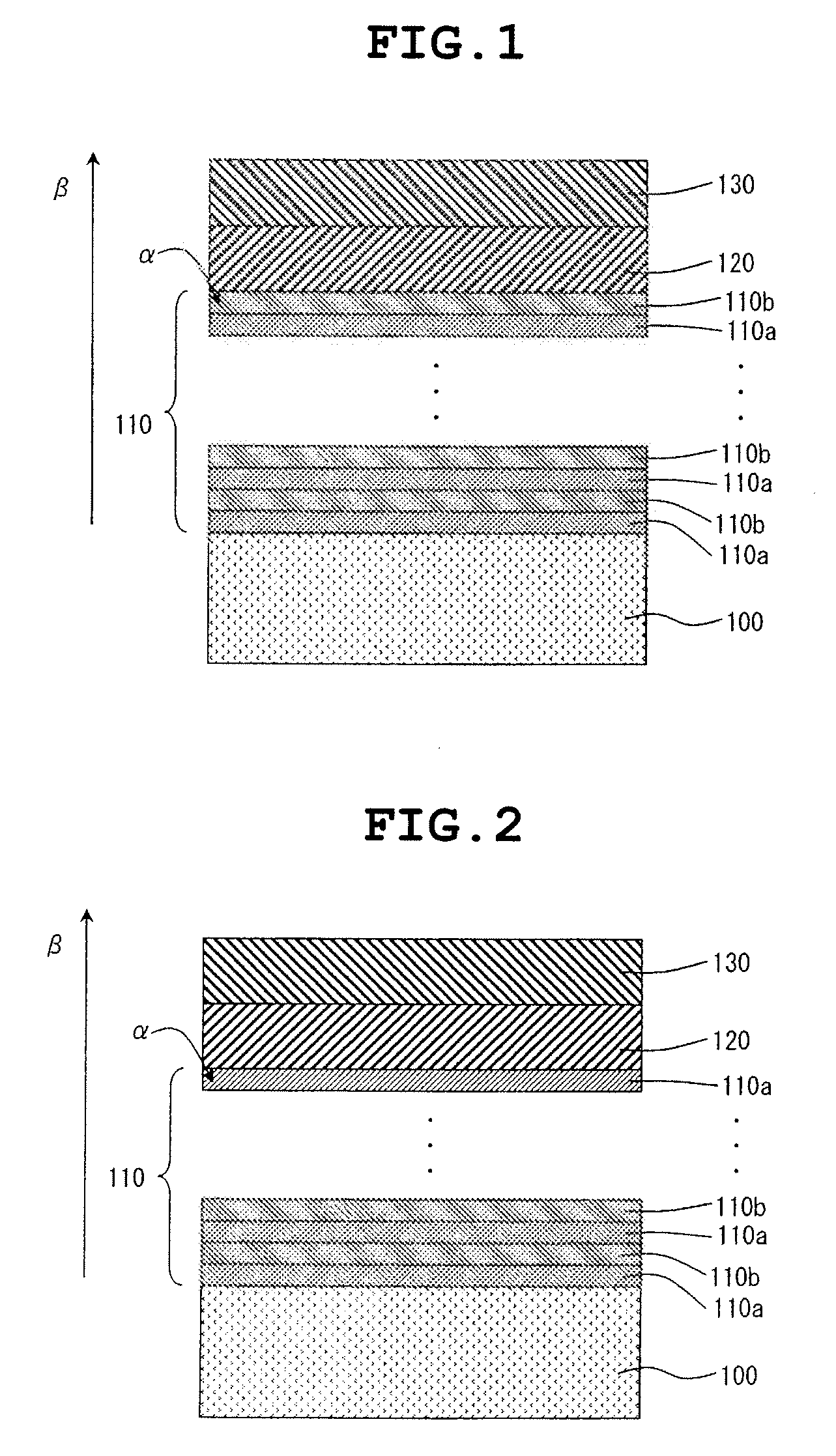

Compound semiconductor substrate

InactiveUS20090065812A1Polycrystalline material growthSemiconductor/solid-state device manufacturingCrystal planeCrystallographic defect

Owner:COVALENT MATERIALS CORP

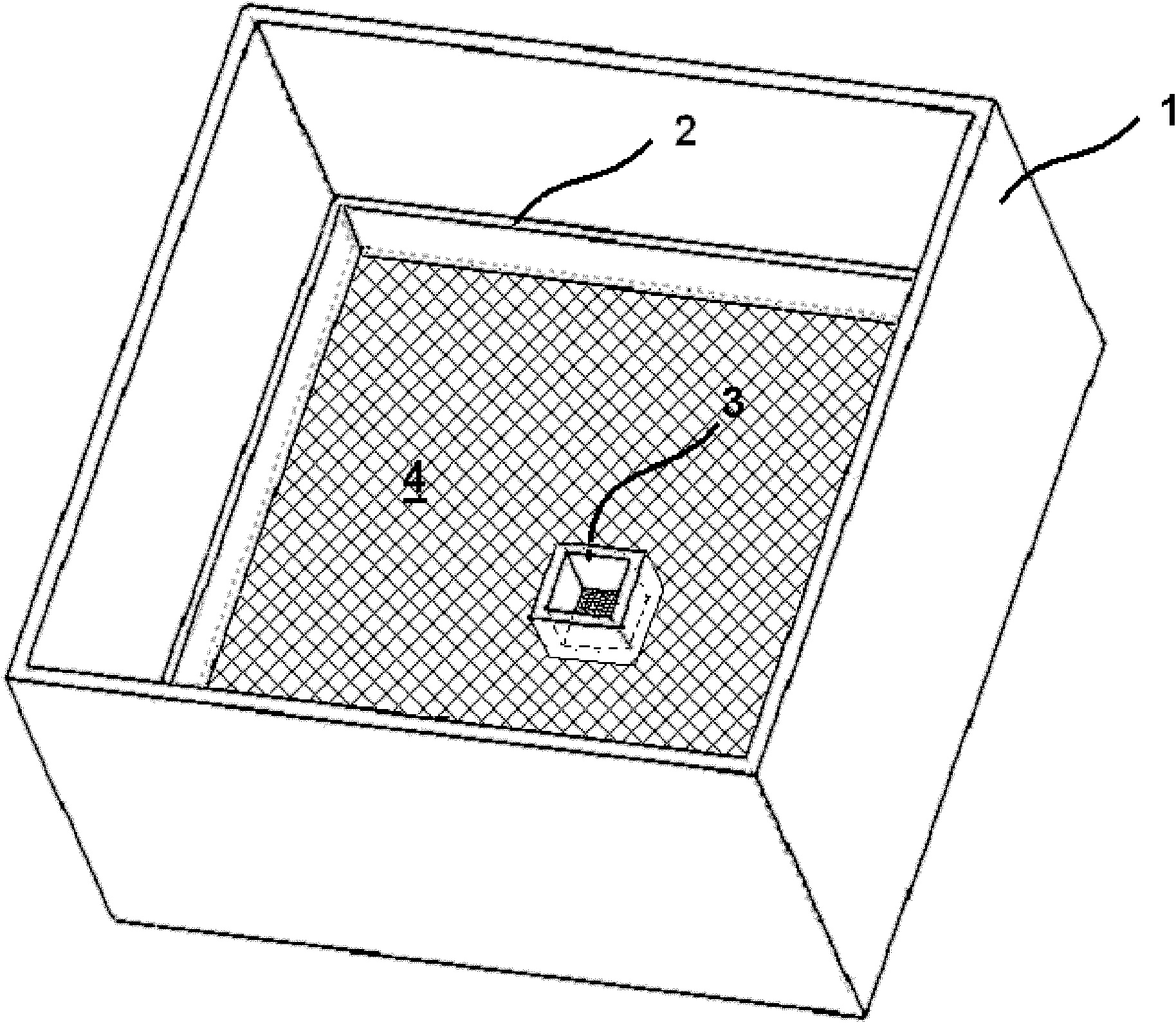

Circulating mass crystal continuous culture apparatus

InactiveCN104562175APolycrystalline material growthFrom normal temperature solutionsWater tanksCatheter

Owner:JIANGNAN UNIV

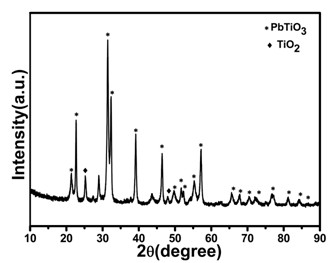

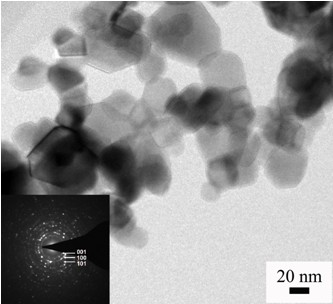

Preparation method of perovskite structure lead titanate single crystal nanoparticles

ActiveCN102677145AAchieve synthesisEasy to separatePolycrystalline material growthFrom normal temperature solutionsDispersityNanoparticle

Owner:ZHEJIANG UNIV

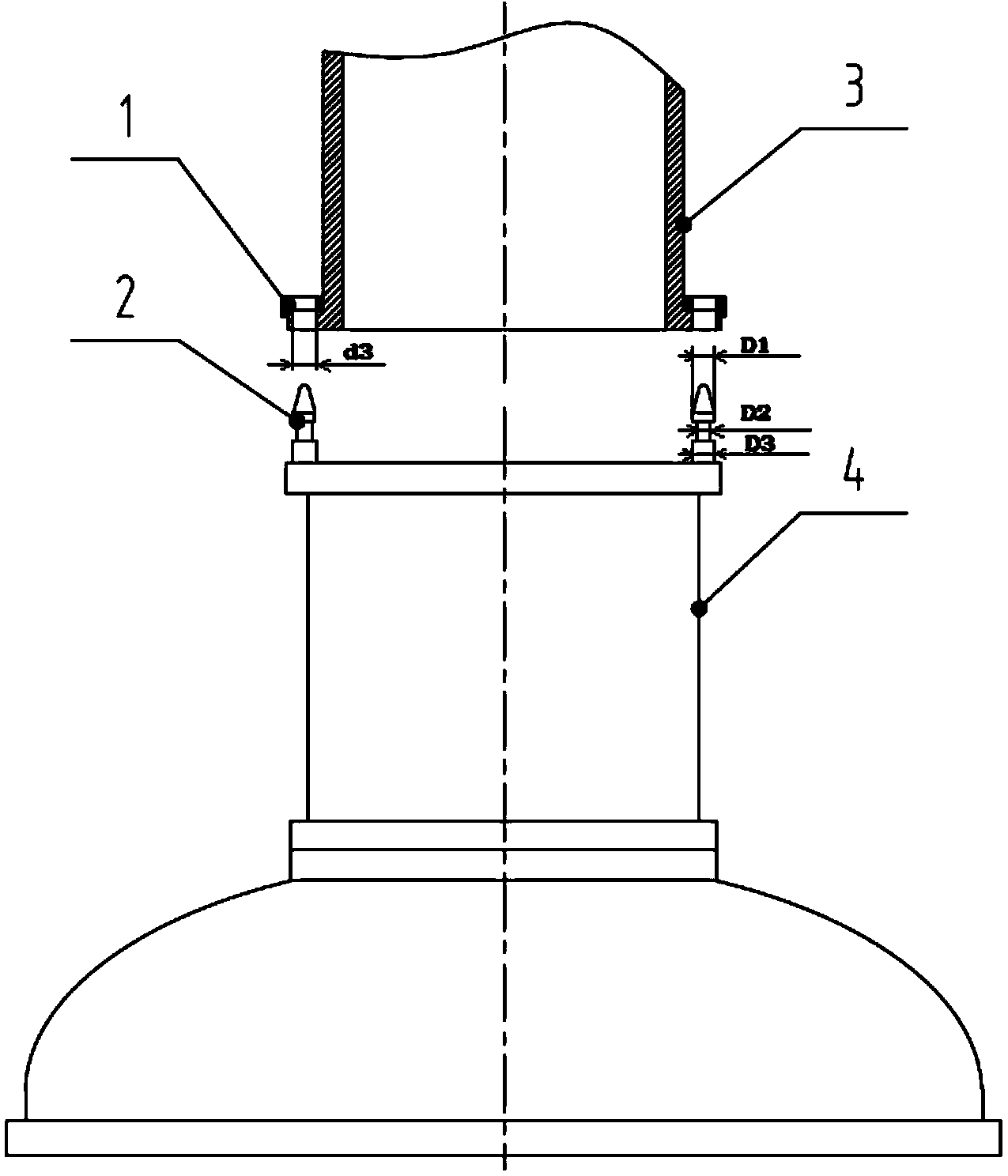

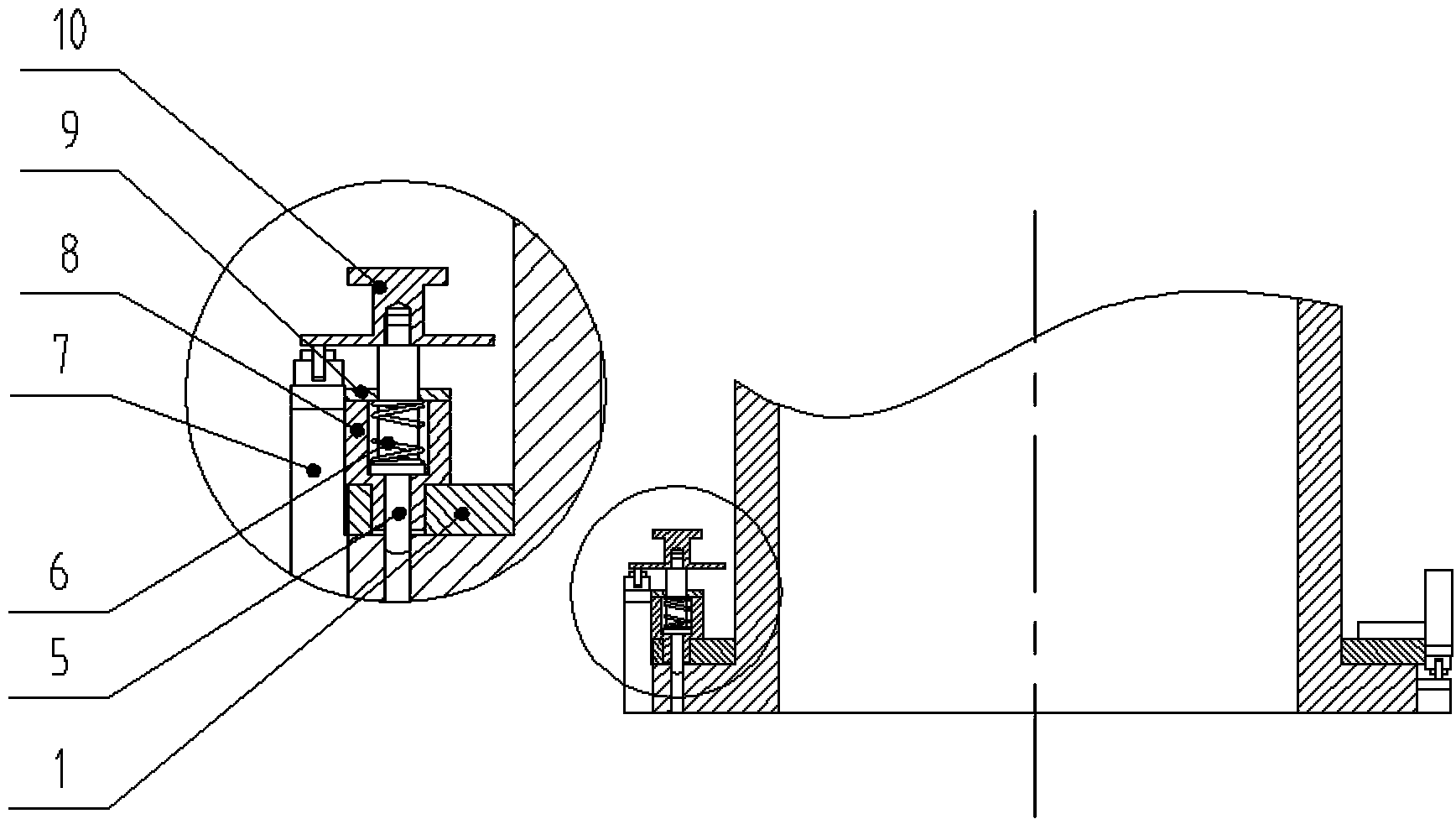

Mounting plate assembly for monocrystalline silicon growth furnace

ActiveCN104213190AConvenient and safe crystal extractionShorten the timePolycrystalline material growthBy pulling from meltEngineeringCooling time

Owner:ZHEJIANG JINGSHENG MECHANICAL & ELECTRICAL

Method for growing optical crystal

InactiveCN103938264APolycrystalline material growthFrom normal temperature solutionsEngineeringHigh pressure

Owner:SANMING GANGLE CRYSTAL ELECTRONICS

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap