Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7 results about "Wafer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In electronics, a wafer (also called a slice or substrate) is a thin slice of semiconductor, such as a crystalline silicon (c-Si), used for the fabrication of integrated circuits and, in photovoltaics, to manufacture solar cells. The wafer serves as the substrate for microelectronic devices built in and upon the wafer. It undergoes many microfabrication processes, such as doping, ion implantation, etching, thin-film deposition of various materials, and photolithographic patterning. Finally, the individual microcircuits are separated by wafer dicing and packaged as an integrated circuit.

Semiconductor processing equipment and process control method thereof

ActiveCN111489949AImprove yieldImprove accuracyElectric discharge tubesFinal product manufactureWaferProcess engineering

The embodiment of the invention provides semiconductor processing equipment and a process control method thereof. The semiconductor processing equipment comprises a cavity, a lifting assembly, a baseand a temperature measuring assembly, wherein the base and the temperature measuring assembly are arranged in the cavity; the lifting assembly is used for bearing and driving wafers to be selectivelylocated at multiple stations above the base, the multiple stations correspond to the multiple target temperature values in a one-to-one mode, and the distance between each station and an upper surfaceof the base is inversely proportional to the corresponding target temperature value; and the temperature measuring assembly is arranged at positions where the lifting assembly is in contact with thewafers and is used for acquiring actual measurement temperature values of the wafers in real time. According to the embodiment of the invention, the purpose of adjusting the target temperature value according to different types of wafers and different processes is achieved, and the requirement for temperature change in the process can be met such that the yield of the wafers is effectively improved, and the process efficiency is greatly improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

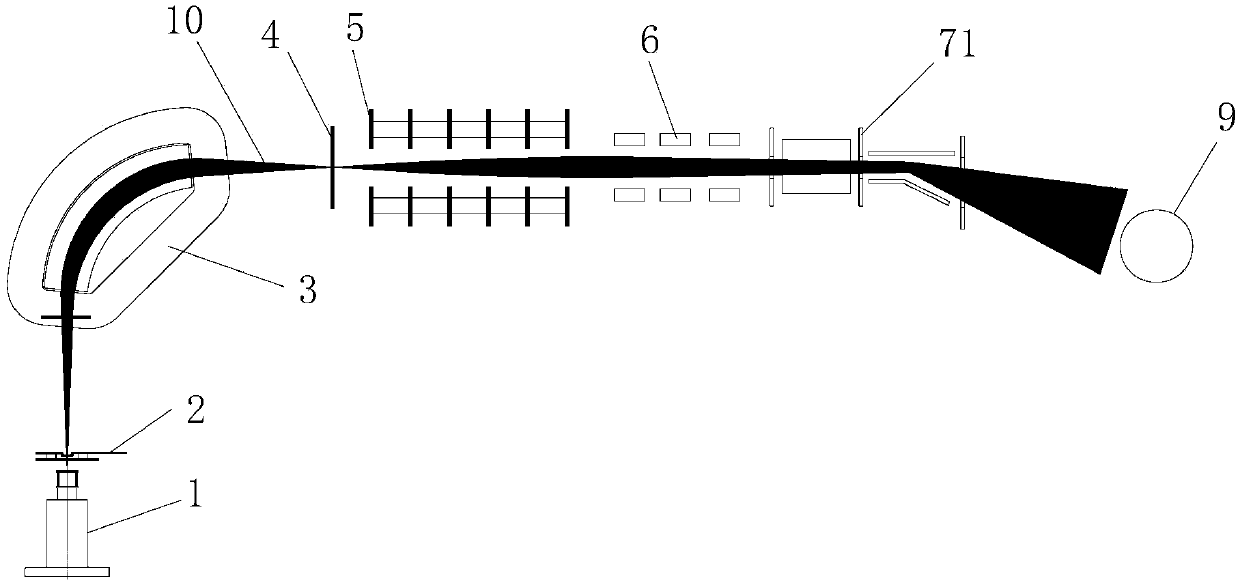

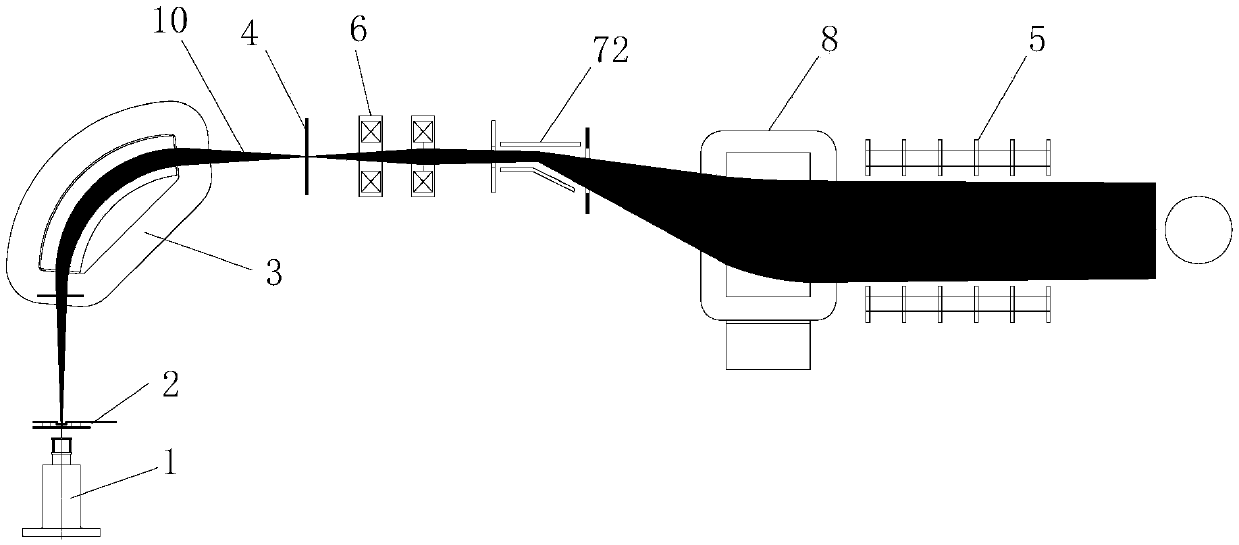

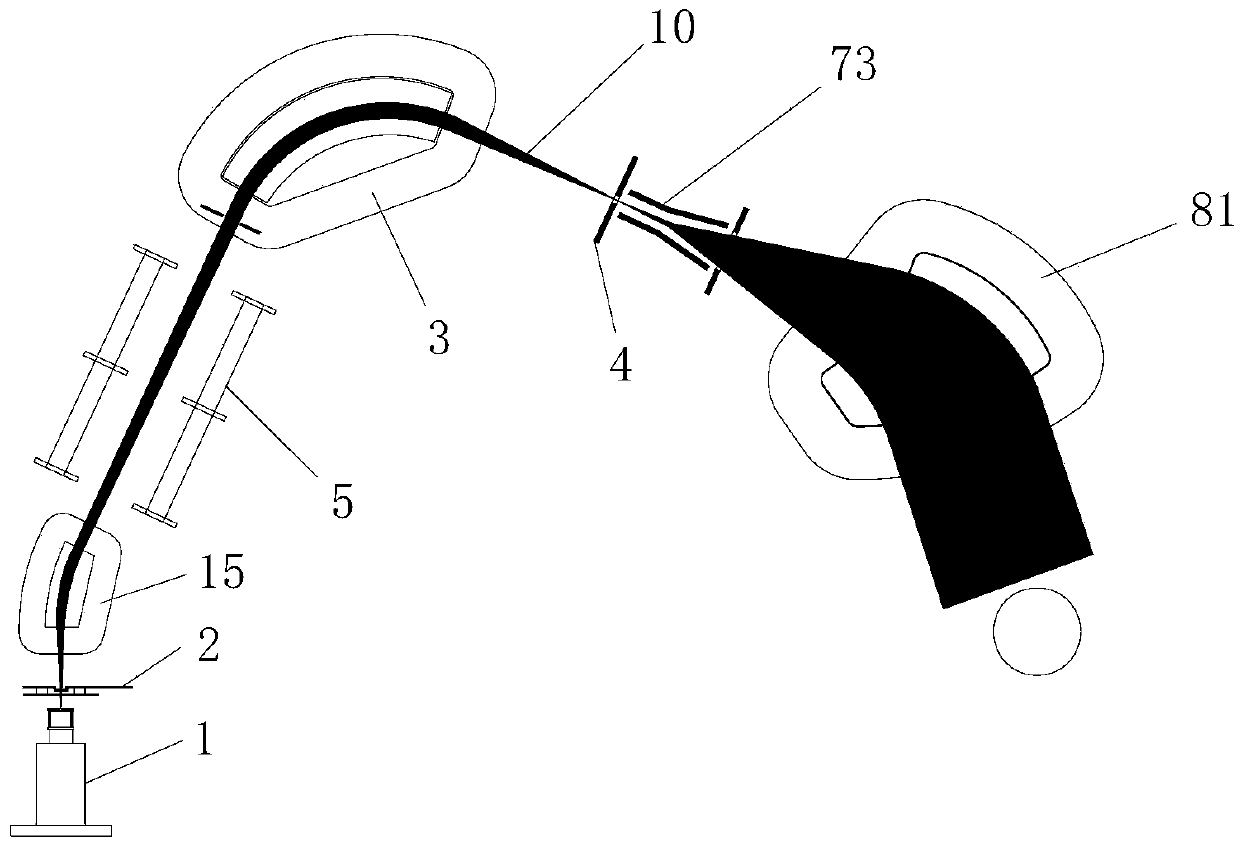

Ion implantation device

ActiveCN111063599AFacilitate multi-level accelerationImprove resolutionElectric discharge tubesSemiconductor/solid-state device manufacturingMedicineWafer

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

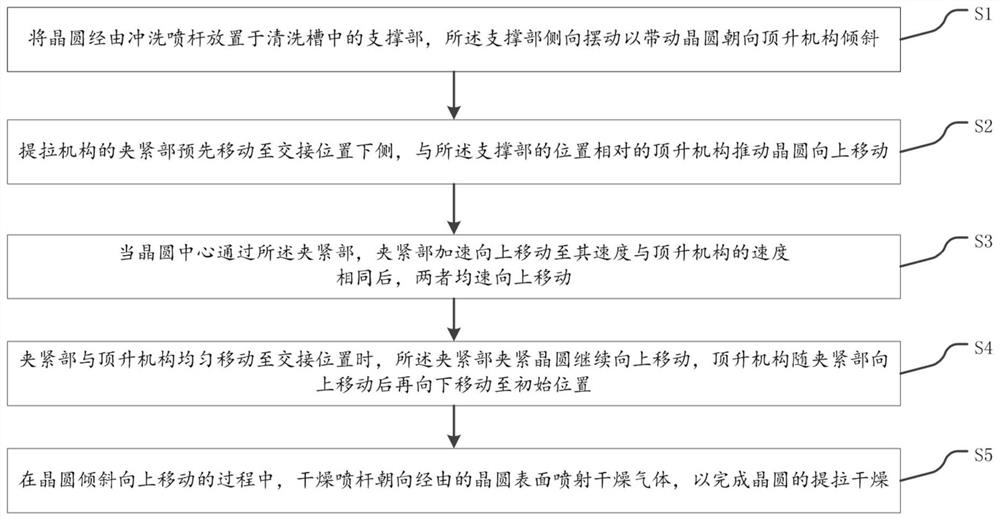

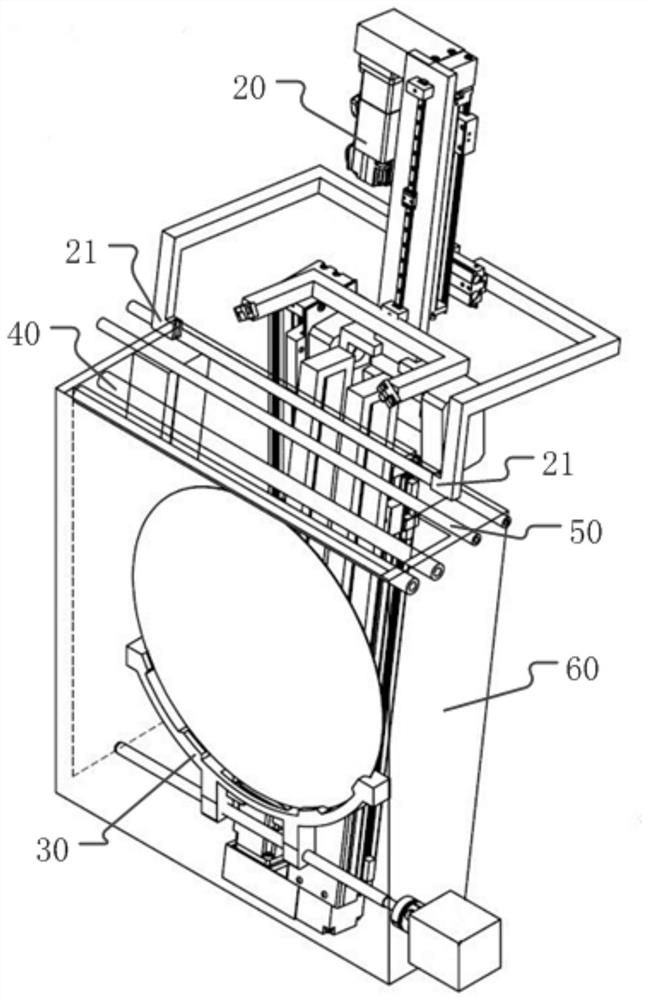

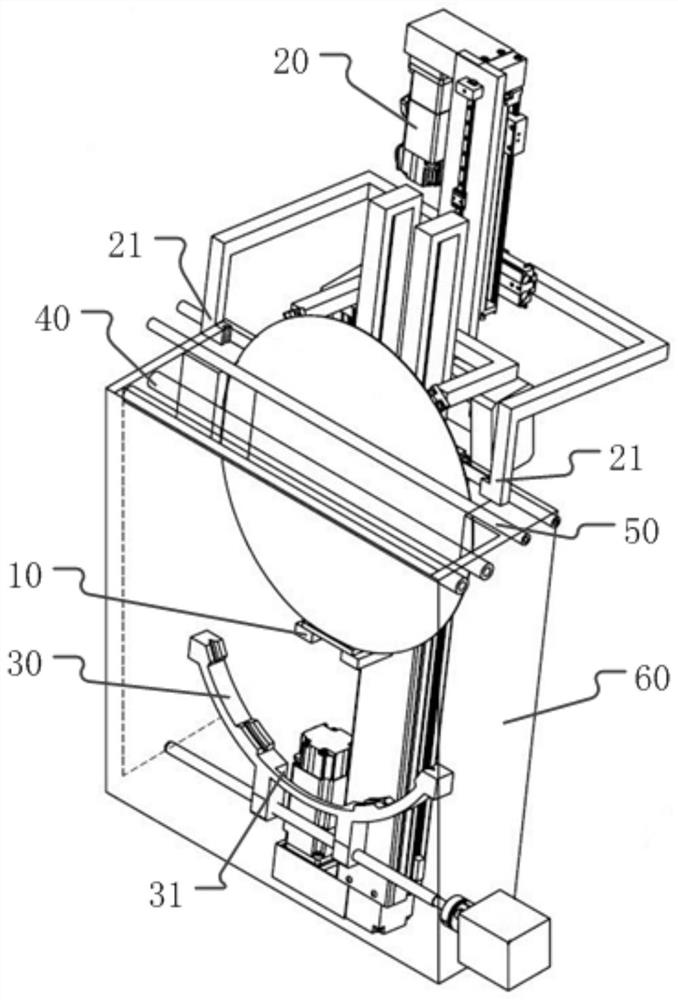

Wafer lifting and drying method and wafer drying device

ActiveCN114001526ASmooth handoverAccurate handoverDrying solid materials without heatDrying gas arrangementsWaferStructural engineering

Owner:HWATSING TECH

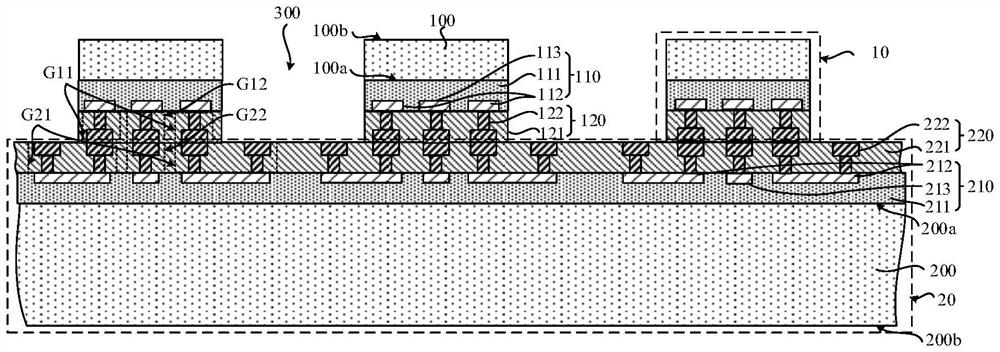

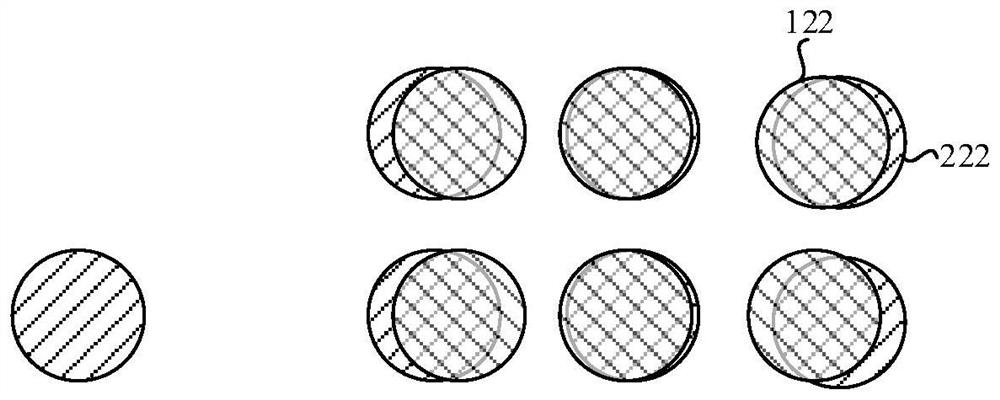

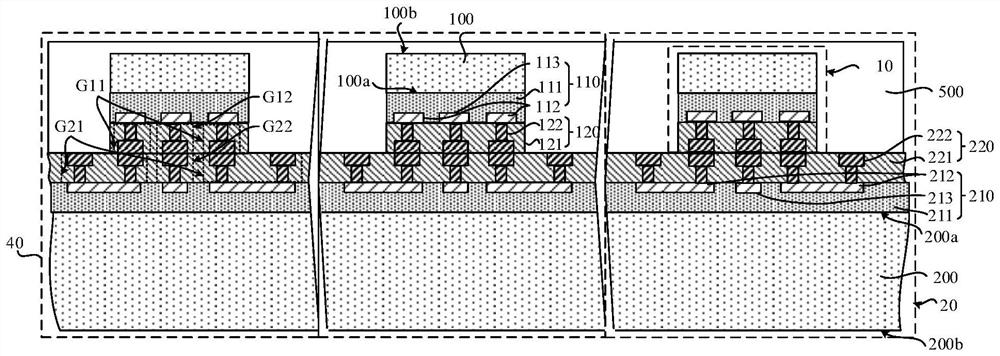

Semiconductor structure and semiconductor device

PendingCN114171483AAffect the subsequent processAffect the test effectSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureDevice material

Owner:WUHAN XINXIN SEMICON MFG CO LTD

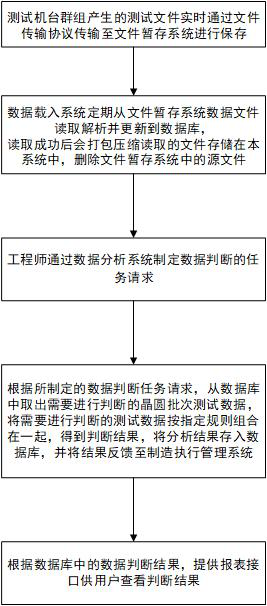

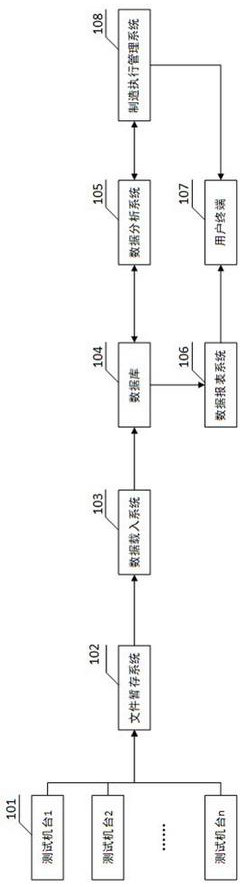

Test method and system based on acceptability of semiconductor wafer

PendingCN114090353AImprove developmentEasy maintenanceSemiconductor/solid-state device testing/measurementFaulty hardware testing methodsData setWafer

Owner:中电九天智能科技有限公司

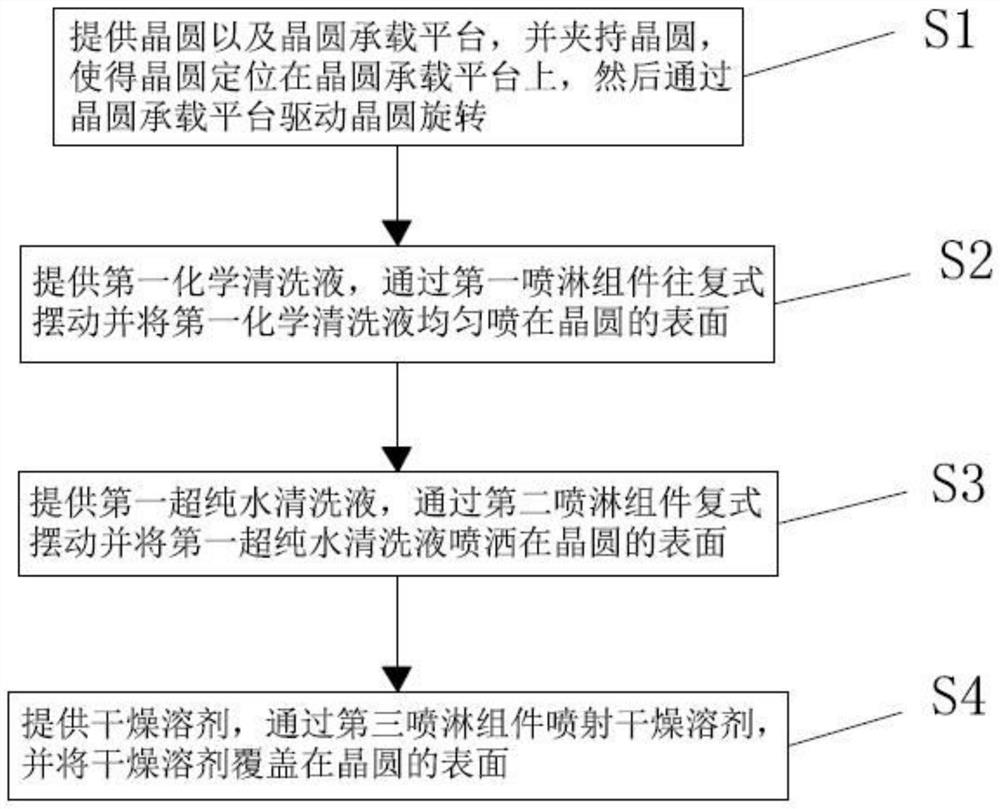

Control method for effectively achieving rotation and spraying in single wafer cleaning process

ActiveCN114405909AImprove adhesionThorough responseFinal product manufactureSemiconductor/solid-state device manufacturingSurface reactionMetallurgy

Owner:ULTRON SEMICON (SHANGHAI) CO LTD

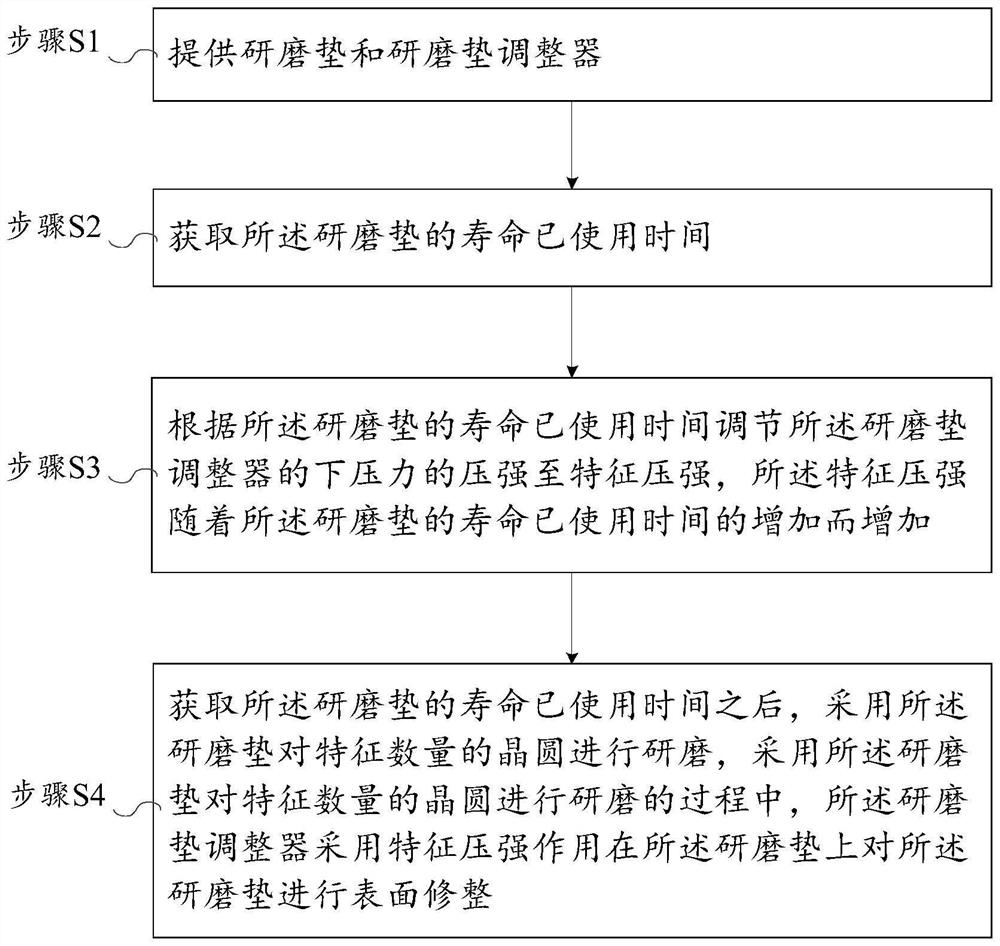

Wafer grinding method

Owner:北京晶亦精微科技股份有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap