Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

550 results about "Manufacturing engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing Engineering is a branch of professional engineering that shares many common concepts and ideas with other fields of engineering such as mechanical,chemical, electrical and industrial engineering. Manufacturing engineering requires the ability to plan the practices of manufacturing; to research and to develop tools, processes, machines and equipment; and to integrate the facilities and systems for producing quality products with the optimum expenditure of capital.

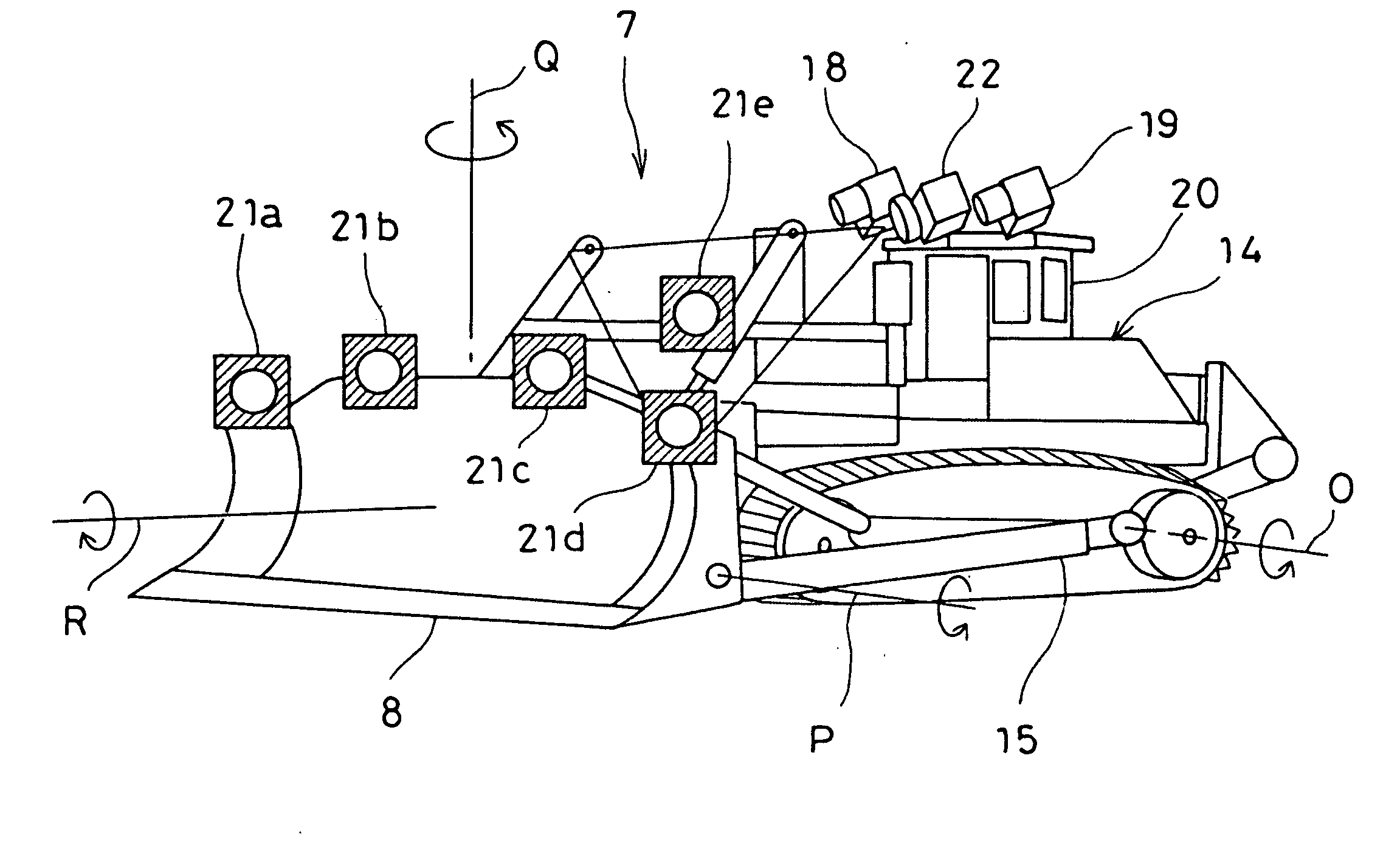

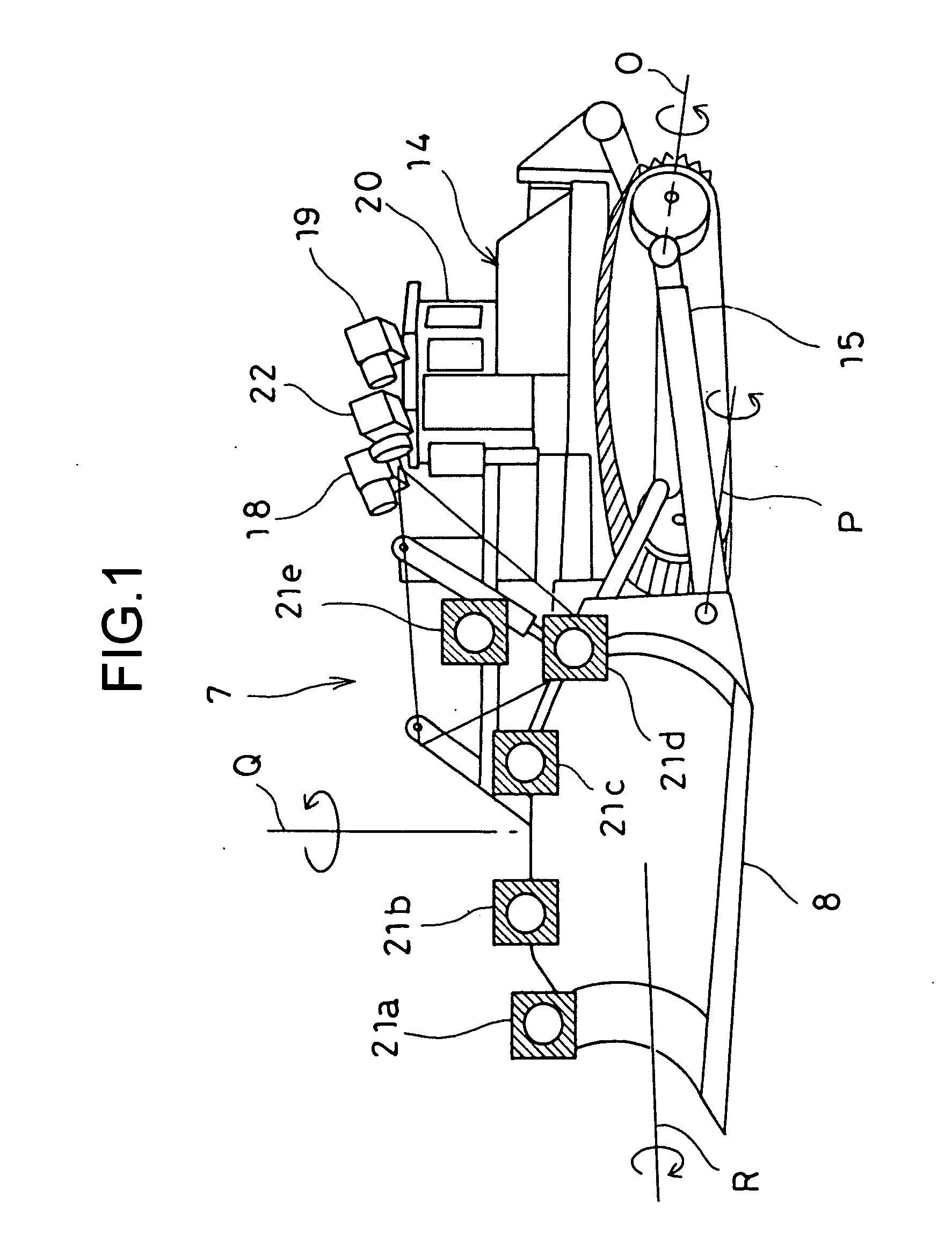

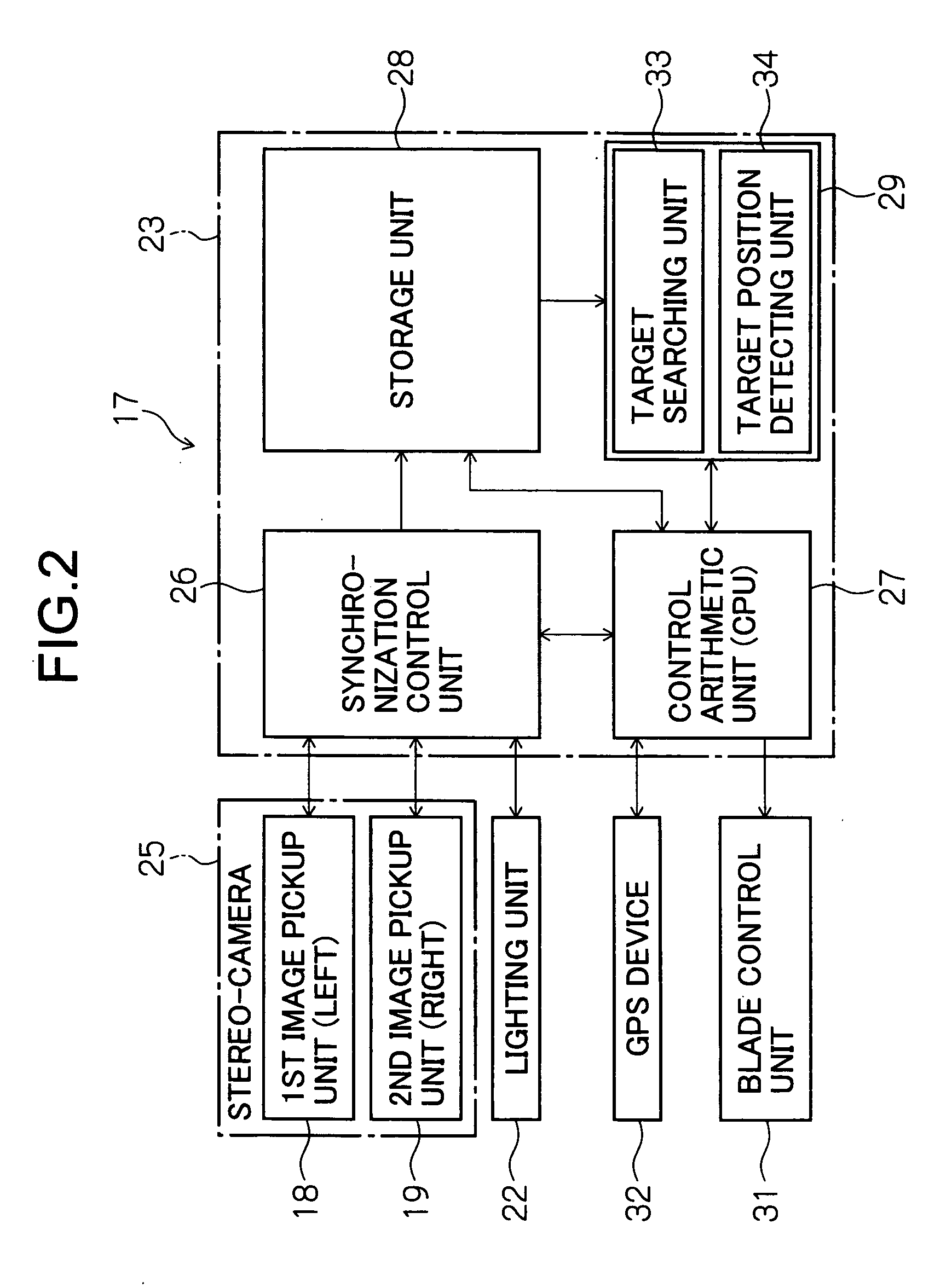

Industrial machine

ActiveUS20100121540A1Easy extractionAccurate detectionAnalogue computers for trafficPosition fixationVisual field lossIndustrial machine

Owner:KK TOPCON

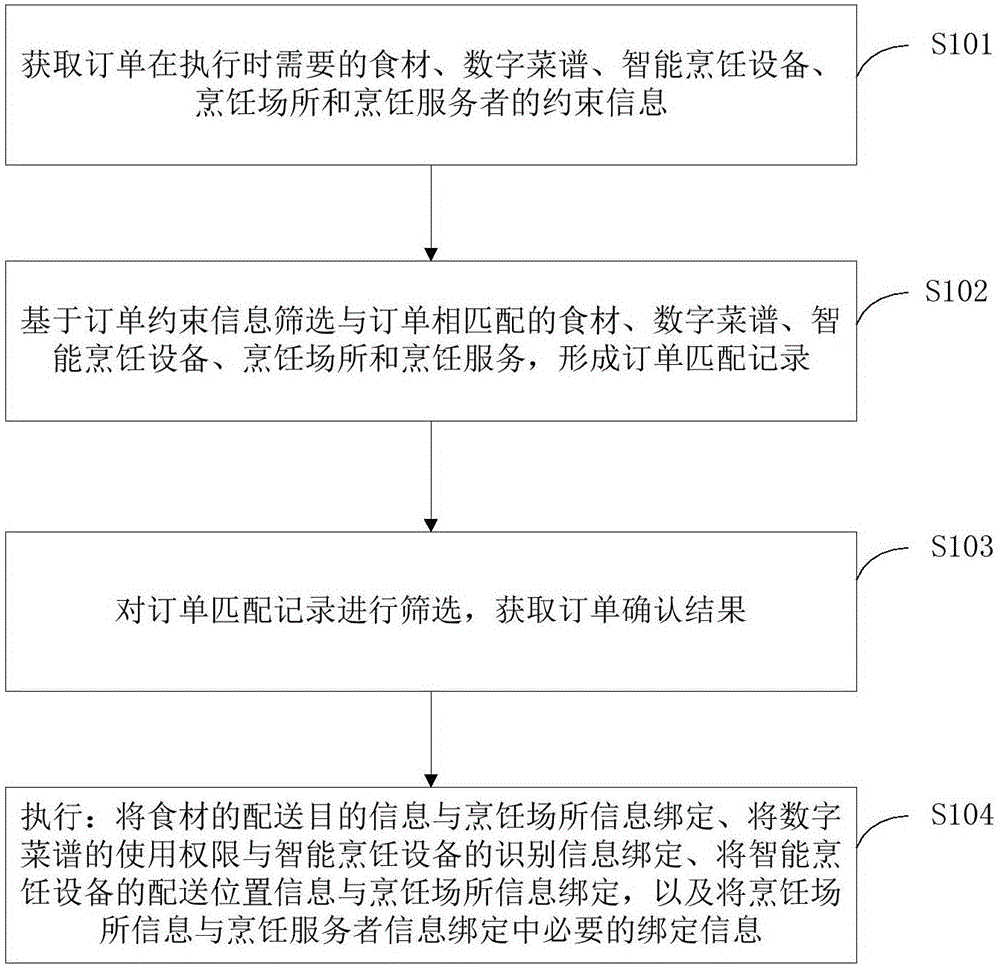

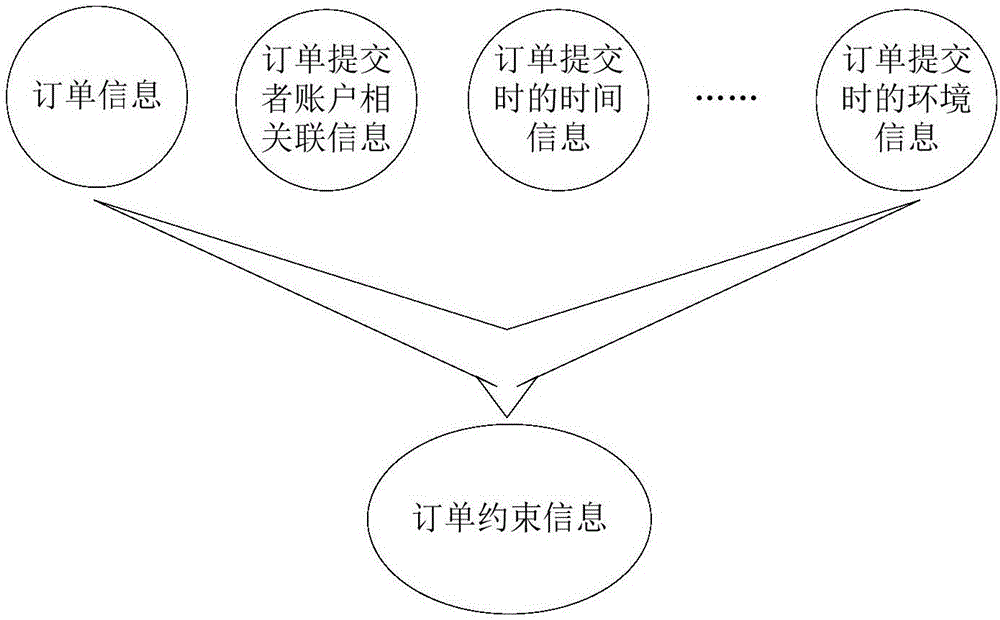

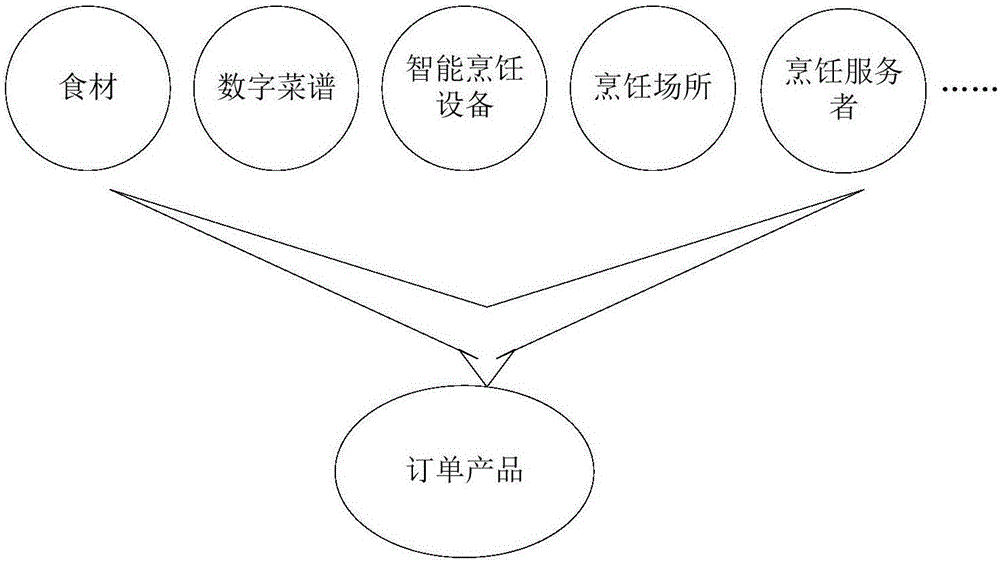

Catering order processing method

InactiveCN106557968AImprove simplicityMeet individual needsBuying/selling/leasing transactionsFood materialOrder processing

Owner:珠海优特智厨科技有限公司

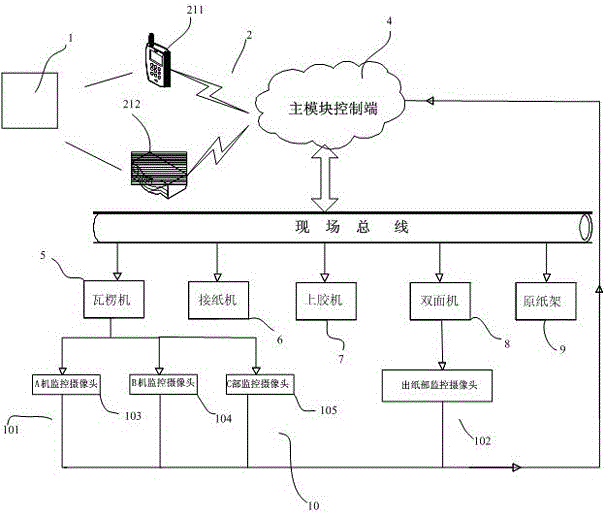

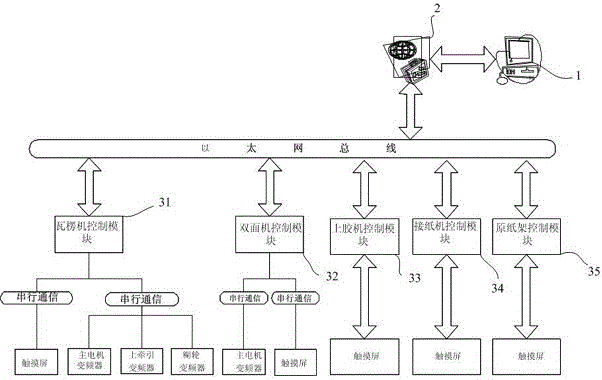

Informationized full-intelligent carton production linkage management method

ActiveCN108177946AReduce on-site manpowerReduce lossControl devices for conveyorsStacking articlesPaperboardEnterprise resource planning

The invention belongs to the technical field of intelligent logistics management, and concretely relates to an informationized full-intelligent carton production linkage management method, which comprises the following steps of according to customer orders, forming work order information through decomposing order information, and carrying out carton board purchase operation through an ERP (Enterprise Resource Planning) system according to the work order information; warehousing; feeding a carton board of each tray to an automatic logistics paper feeding area; stacking trays, separating, and feeding the carton boards separated from the trays to corresponding storage belts of a storage area; controlling a feeding shuttle bus for directly taking the carton boards at the storage belt parts onwhich the carton boards are required for the corresponding orders are located, and after taking the carton boards, directly feeding to an inlet of a carton board feeding machine; and passing the carton boards through the carton board feeding machine, a printer, a carton board receiving machine, a carton board transferring machine, a laminating machine, a stacking machine and a labelling machine, and finally packaging. The informationized full-intelligent carton production linkage management method provided by the invention has the advantages of high production continuity degree, high working reliability, compact flow and high automation degree, so that the actual working efficiency of a whole production flow can be effectively improved.

Owner:LONG LI DE LD INTELLIGENT TECH CORP LTD +1

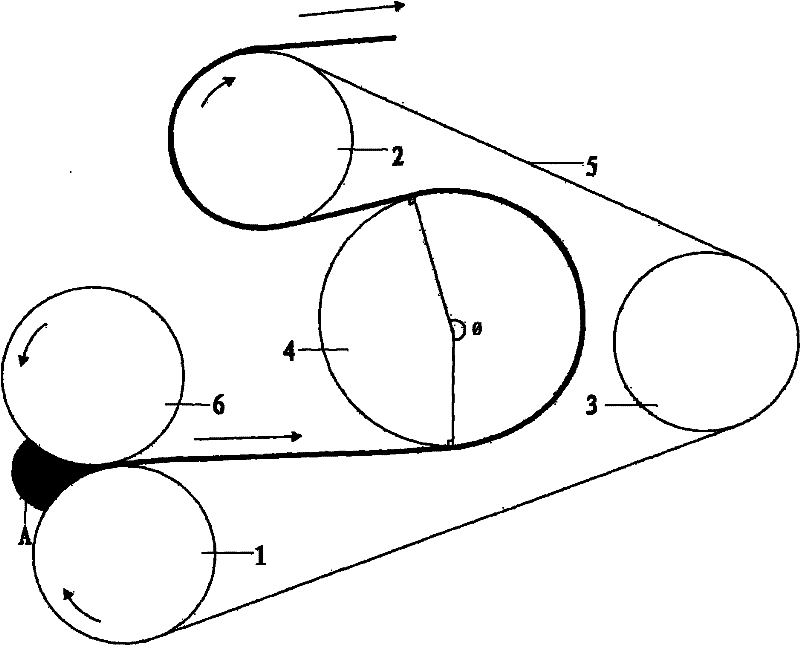

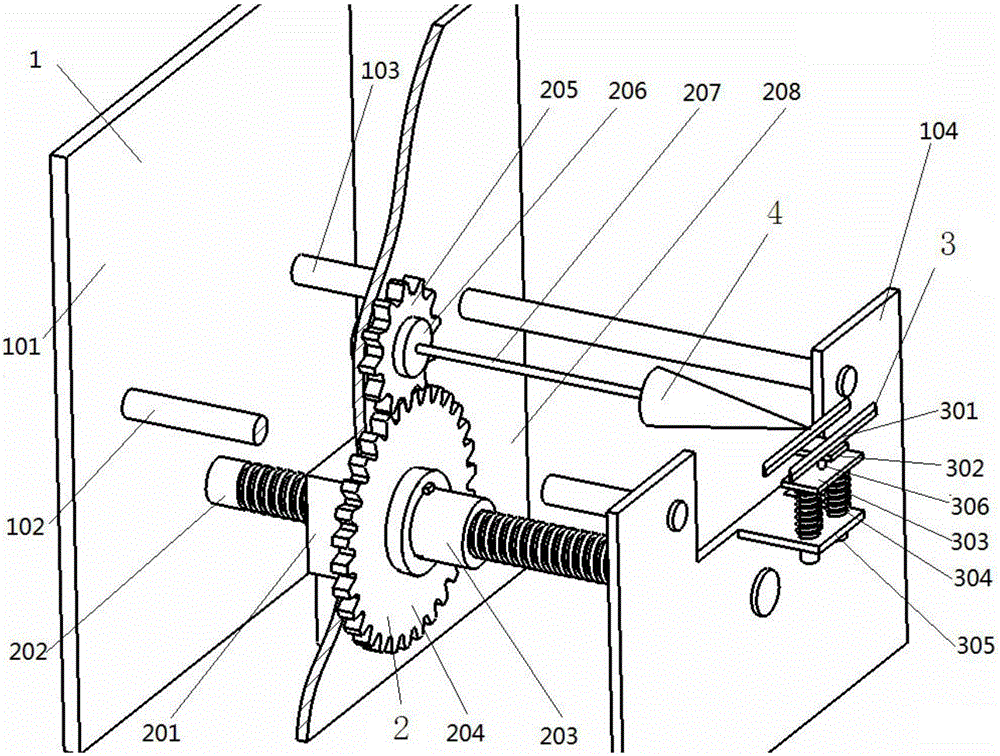

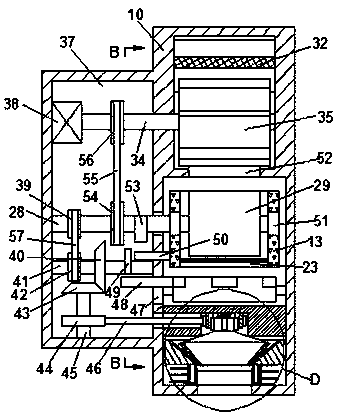

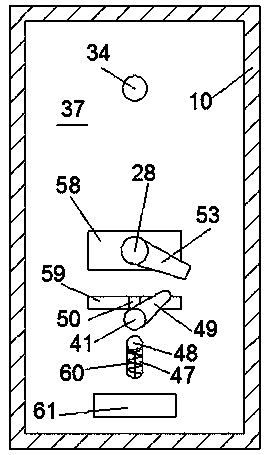

Punching and grooving device for manufacturing small wood vehicle wheels

InactiveCN111070340AImprove work efficiencyStationary drilling machinesMulti-purpose machinesMachineAutomotive engineering

The invention relates to a punching and grooving device, in particular to a punching and grooving device for manufacturing small wood vehicle wheels. The technical objective is to design and provide the punching and grooving device for manufacturing the small wood vehicle wheels which is capable of simultaneously punching and grooving the wood vehicle wheels, convenient to operate and high in working efficiency, and is capable of collecting the punched and grooved wood vehicle wheels. The punching and grooving device for manufacturing the small wood vehicle wheels comprises a base, a rotatingshaft, a circular frame and the like, wherein the rotating shaft is rotationally connected to the middle of the top of the base, the rotating shaft is connected with the base through a bearing seat, and the circular frame capable of placing the wood vehicle wheels is fixedly connected to the top end of the rotating shaft. According to the punching and grooving device for manufacturing the small wood vehicle wheels, the proper number of wood vehicle wheels are put into the circular frame to be fixed by a clamping mechanism, a punching machine is started, a pushing plate is pushed to move downwards, the punching machine can punch the wood vehicle wheels, a grooving ring grooves the wood vehicle wheels, and the situation that a punching tool does not need to be taken by a human hand to punchthe wood vehicle wheels, and then a grooving tool is replaced for grooving is avoided, so that the working efficiency is high.

Owner:龙立明

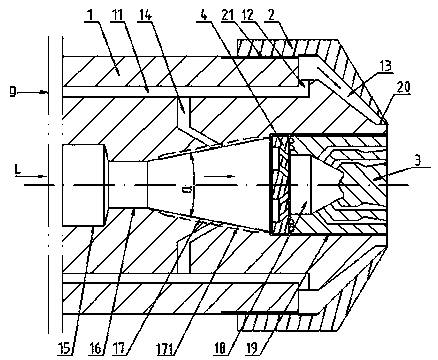

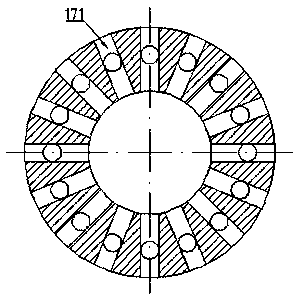

Method for continuously cooking grass raw materials and equipment used in same

ActiveCN101906729ASmooth dischargeFinely-divided material pretreatmentBlack liquorPulp and paper industry

The invention provides a method for continuously cooking grass raw materials, comprising the following steps: (1) preparing the grass raw materials before dipping to obtain the prepared grass raw materials before dipping; (2) transferring the prepared fibrous raw materials into an impregnator through a screw feeder, adding impregnation liquid for dipping treatment, putting the prepared grass raw materials in a digester and adding impregnation liquid to the digester at the same time, and then adding hot black liquor for primary cooking to obtain the primarily cooked grass raw materials; and (3) adding cooking liquor to the primarily cooked grass raw materials for secondary cooking to obtain pulp of the grass raw materials. The method of the invention achieves the purpose of continuously cooking the grass raw materials with large liquor ratio, shortens cooking time, reduces energy consumption and improves uniformity of the pulp. The invention further provides cooking equipment used in the method.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

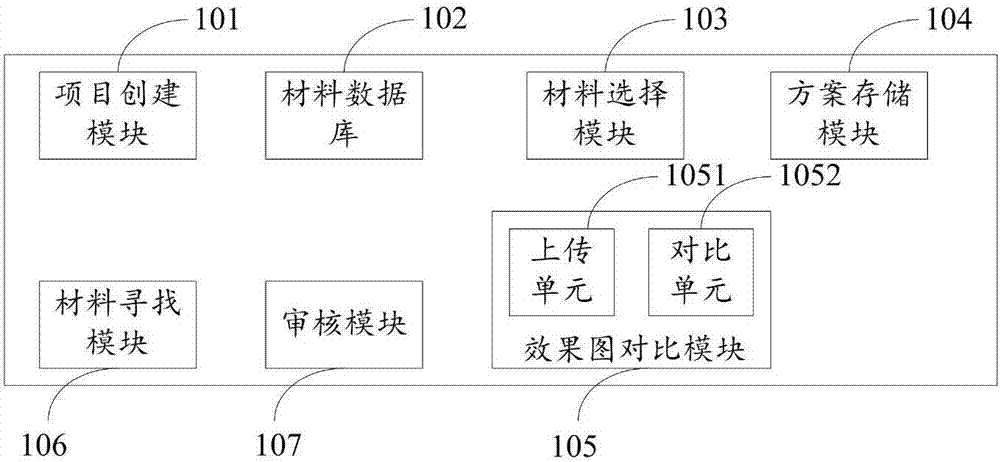

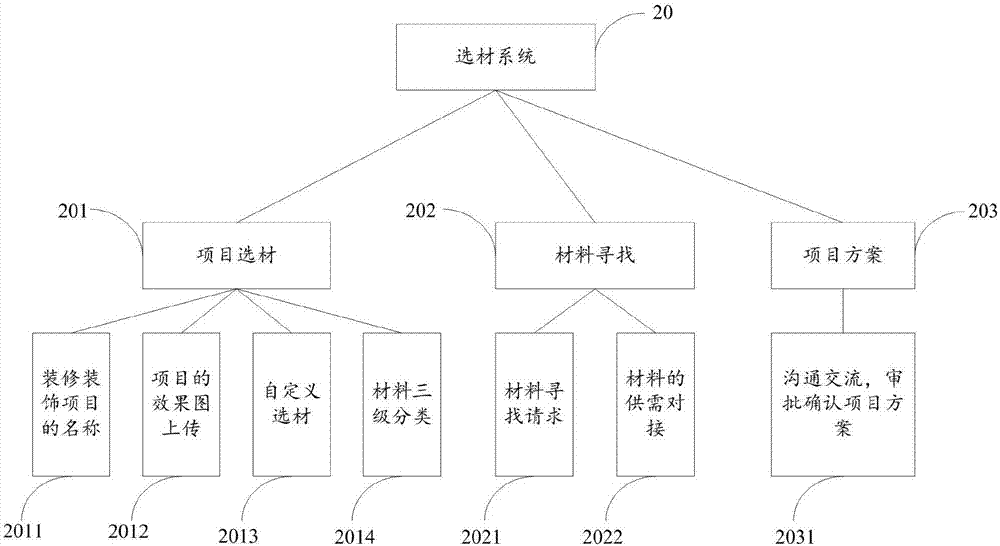

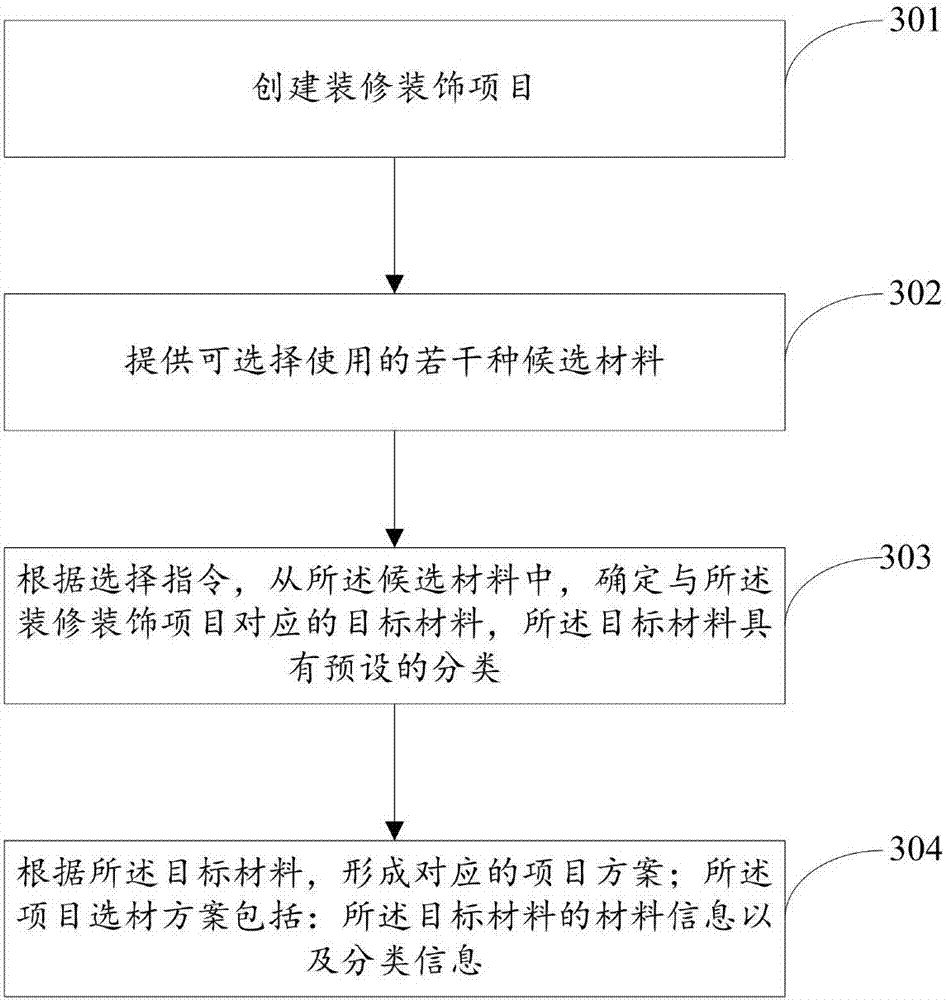

Material selection system for decoration materials and material selection method thereof

InactiveCN107180147AImplement previewAvoid duplicationSpecial data processing applicationsComputer moduleSoftware design

Owner:QIAODUOTIANGONG SHENZHEN TECH CO LTD

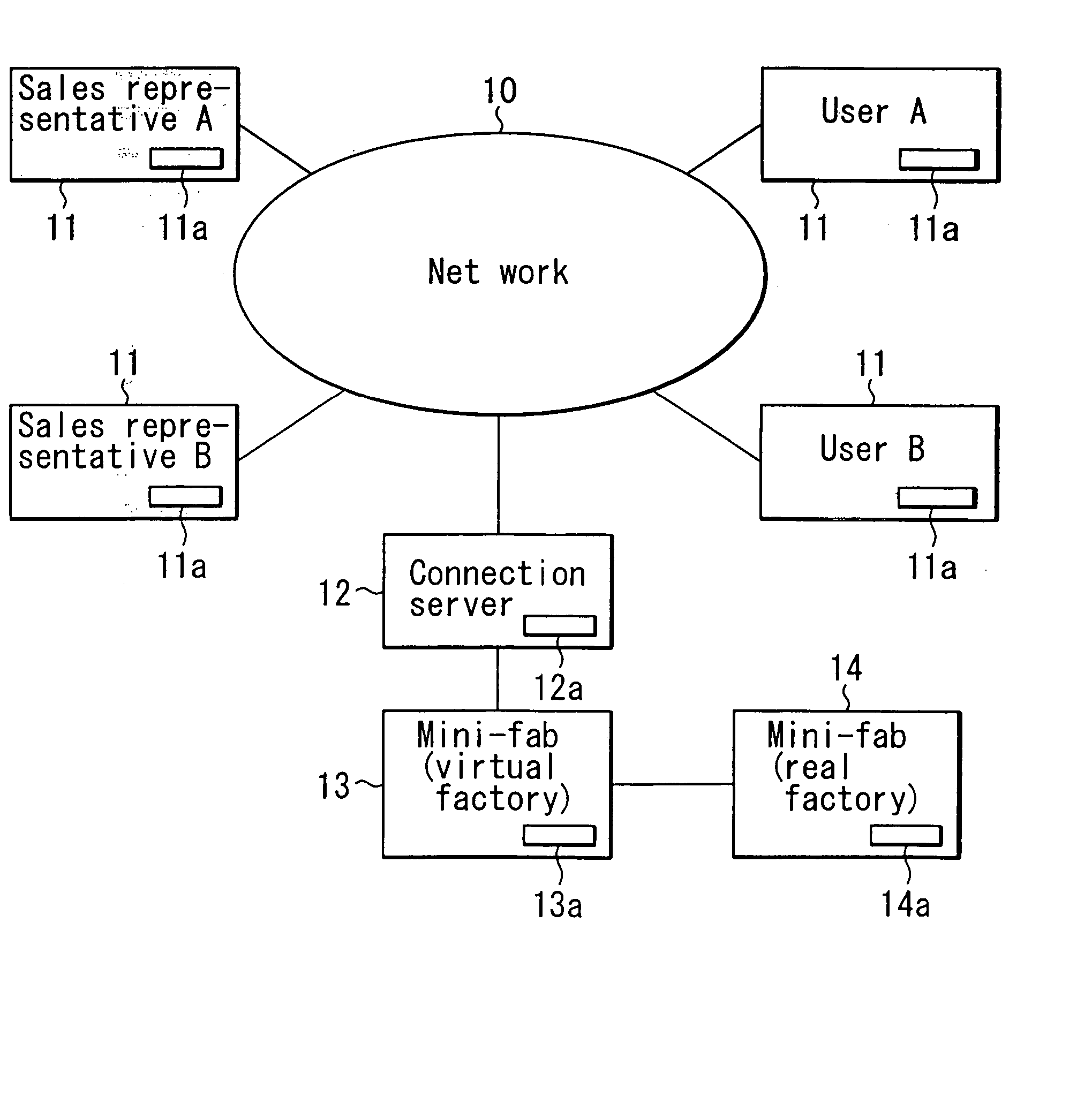

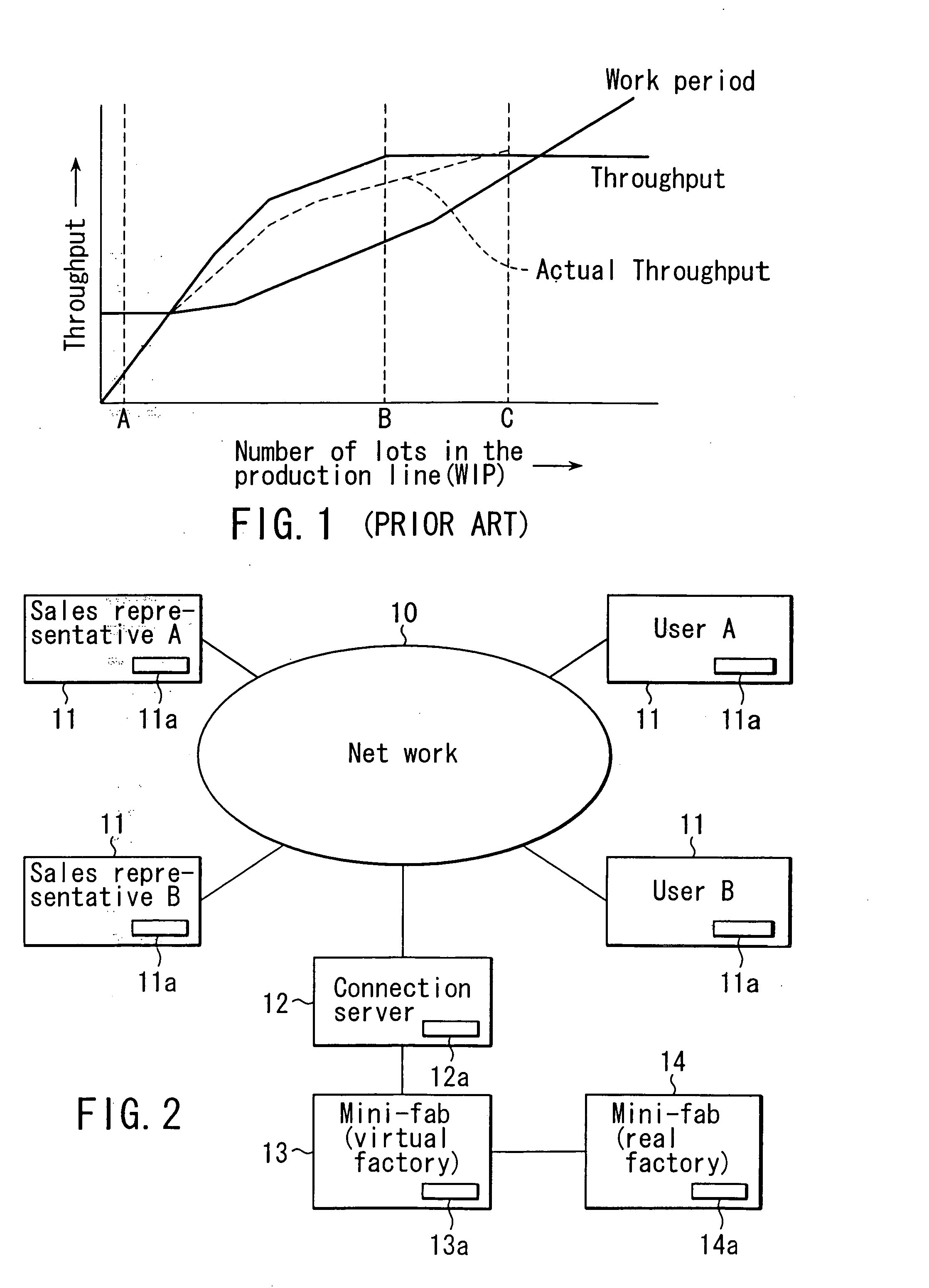

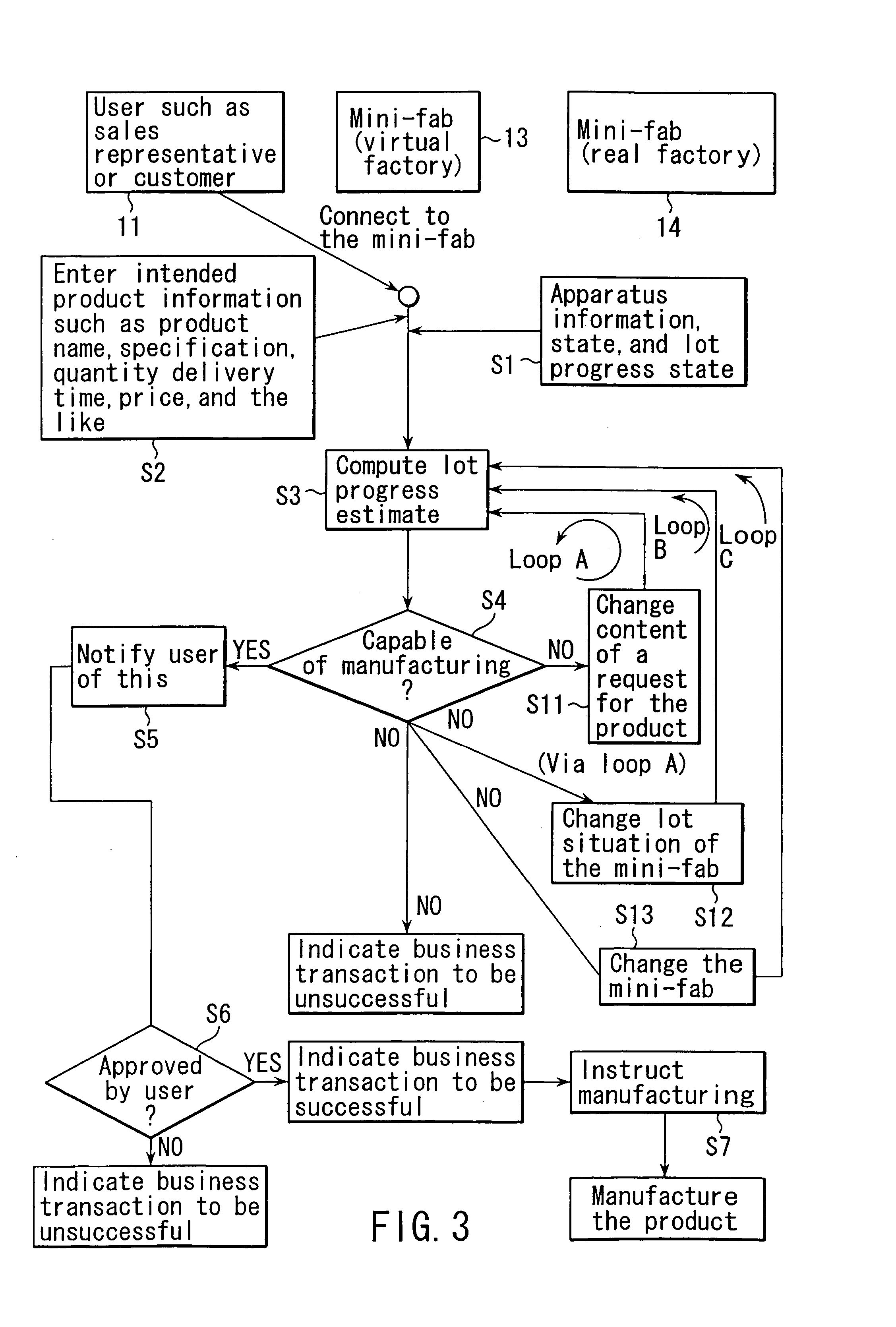

Electronic commerce method for semiconductor products, electronic commerce thereof, production system, production method, production equipment design system, production equipment design method, and production equipment manufacturing method

InactiveUS20050010492A1Increase business opportunitiesBuying/selling/leasing transactionsResourcesProduction lineE-commerce

Owner:MITSUTAKE KUNIHIRO +1

Paper making method with pulp and product of high-surface-intensity offset printing paper

ActiveCN103526630AImprove retentionHigh strengthWater-repelling agents additionInorganic compound additionCalcium silicateFiber

The invention discloses a paper making method with pulp and a product of high-surface-intensity offset printing paper. The paper making method with the pulp comprises the steps that (1) multi-hole calcium silicate and mixed wood pulp fibers are subjected to mixing pulping, mixed pulp is obtained; (2) retention and drainage agents A, sizing agents and retention and drainage agents B are added into the mixed pulp in sequence, even stirring is carried out, papermaking pulp is obtained; (3) the papermaking pulp is subjected to papermaking, squeezing and drying, body paper is obtained; (4) surface sizing agents are used for carrying out surface sizing on the body paper, and the offset printing paper is obtained. The multi-hole calcium silicate is used as the papermaking padding, during a papermaking process, paper pulp / padding medium-high-concentration mixing pulping, CS / CPAM double-element retention and surface sizing agent formula improving and other measures are used, the padding retention rate is improved, paper intensity is effectively improved, and the waterproof performance, the oil resistance, the paper surface intensity, the tensile strength and other performance indexes of paper are obviously improved.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

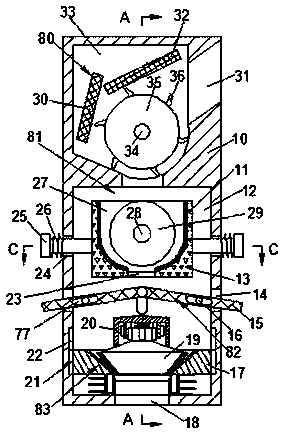

Coin processing apparatus and method

InactiveUS20030220064A1Easy to follow upImprove accuracyWrapping material feeding apparatusCoin countersCoinIndustrial engineering

A coin processing apparatus has an opening for receiving a plurality of coins of different types, a coin sensor adapted to determine a respective type of individual coins among the plurality of coins, a controller operatively coupled to the coin sensor, a coin separator operatively coupled to the controller and capable of separating the individual coins from the plurality of coins under control of the controller. Moreover, the apparatus has a coin packaging device comprising a coin inlet, a supply of packaging material and a packaging mechanism capable of producing a plurality of coin bags from the supply, so that at least two different coin types are packaged in the coin bags in a continuous operation.

Owner:SCAN COIN IND AB

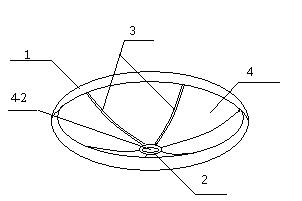

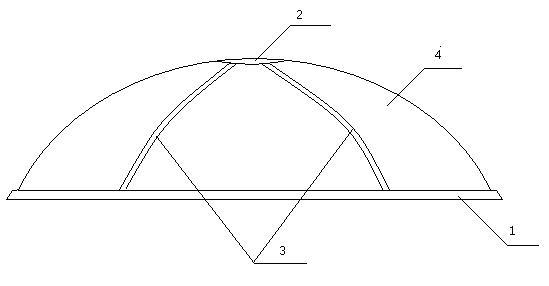

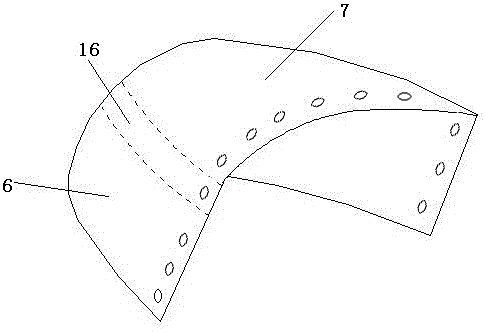

Reflecting surface of deployable antenna based on shape memory polymer and manufacturing method of skeleton structure thereof

ActiveCN101847786AAntenna adaptation in movable bodiesManufacturing engineeringMechanical engineering

Owner:HARBIN INST OF TECH

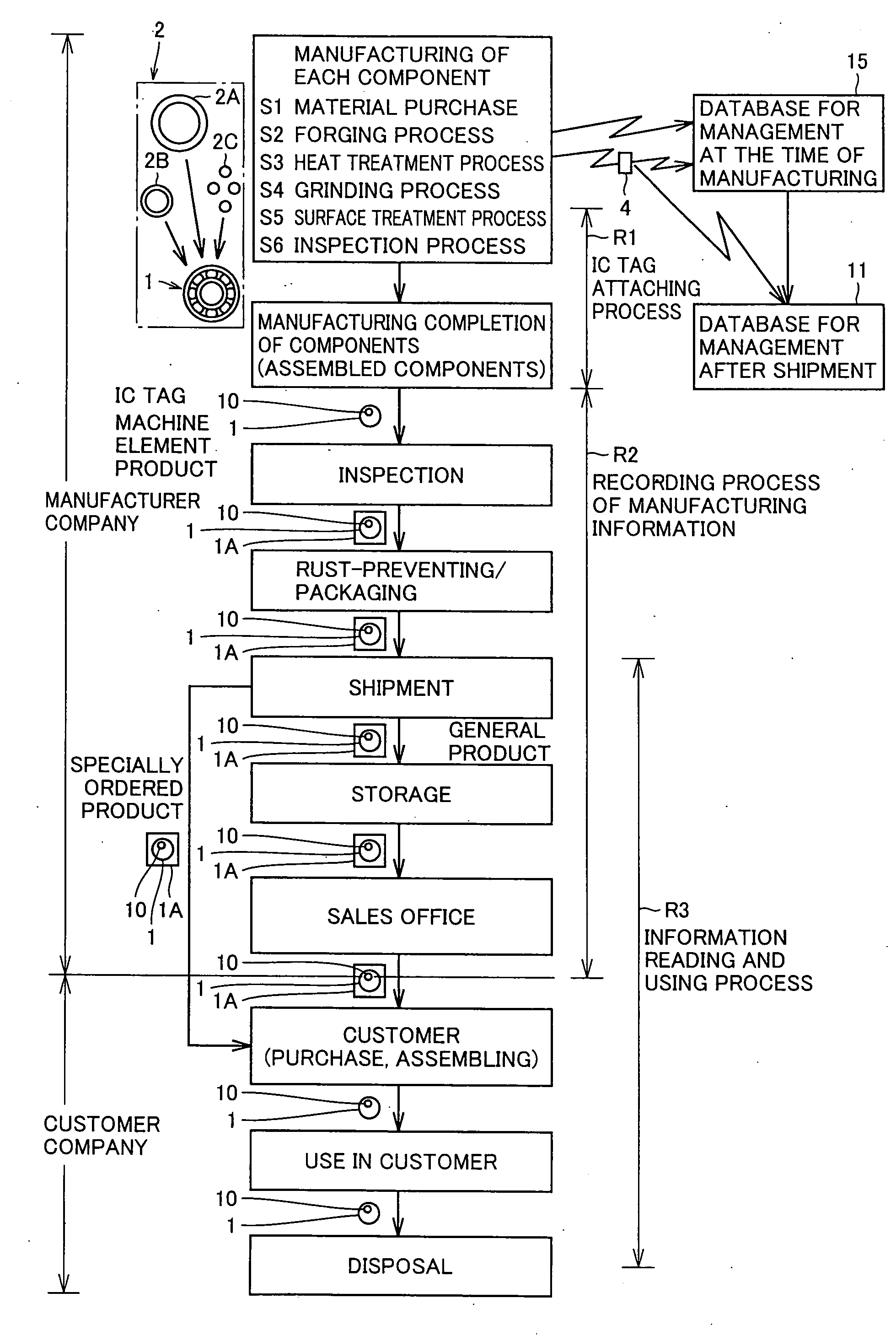

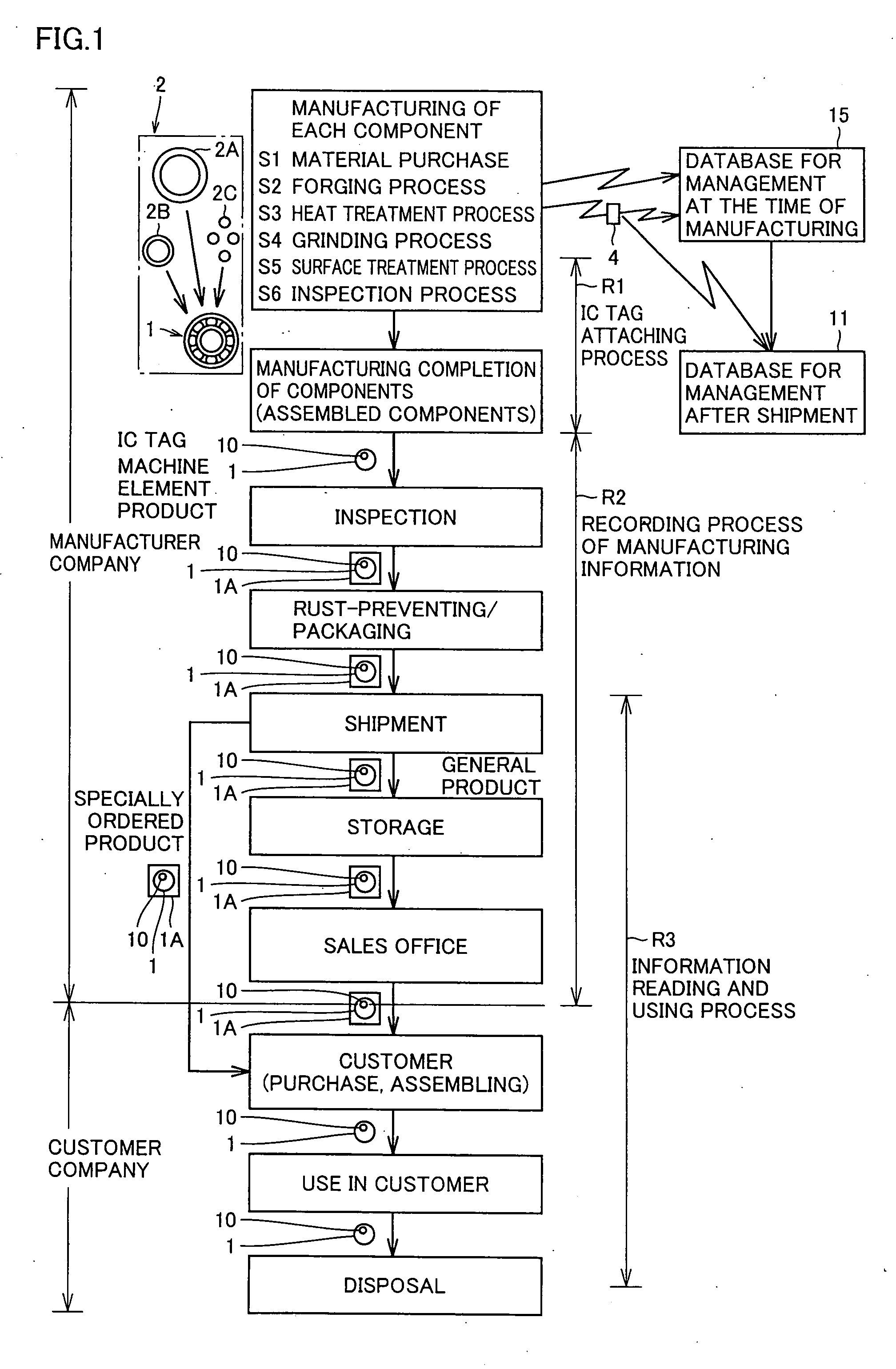

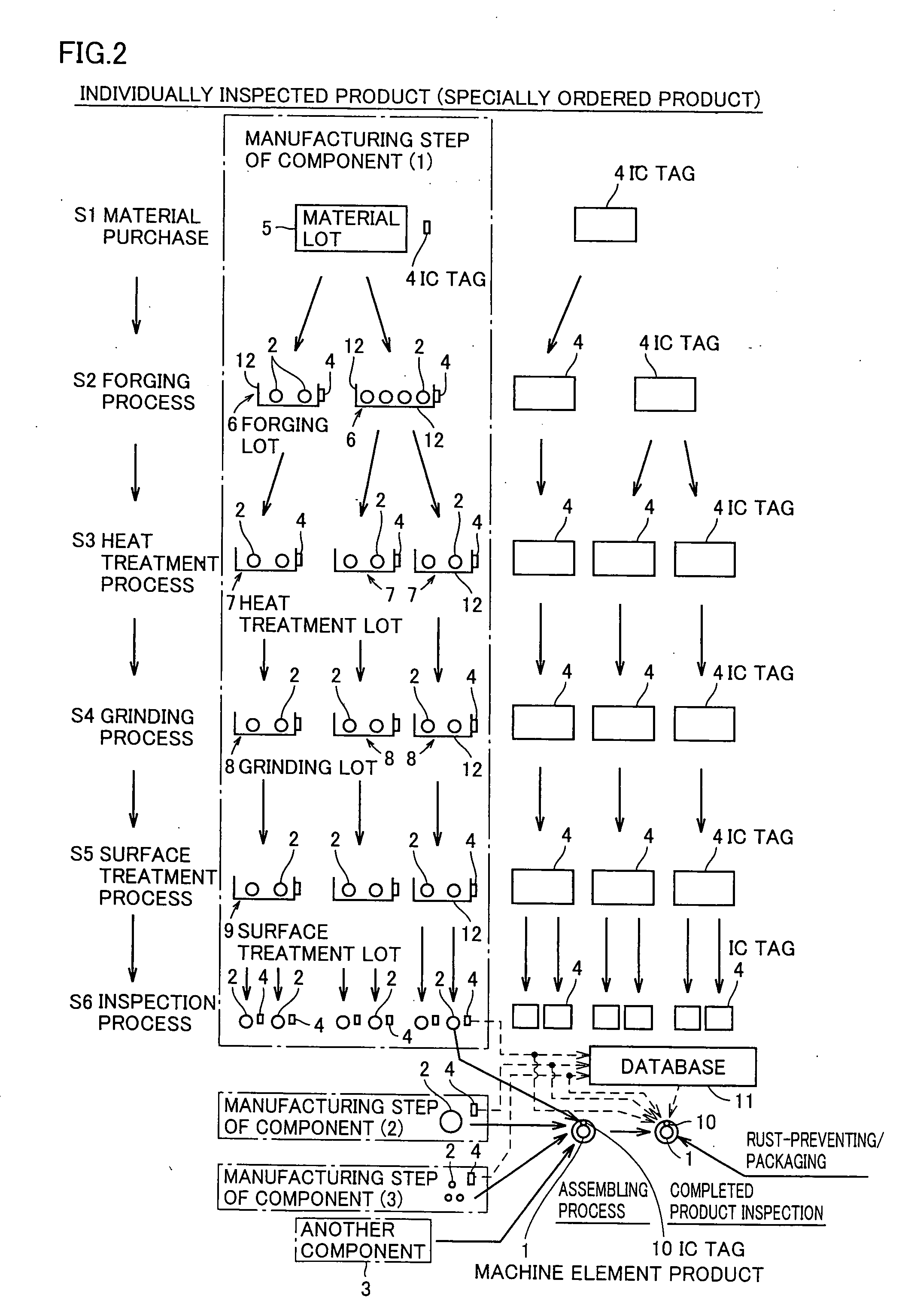

Quality Management Method For Aerospace Machine Element Product and Aerospace Bearing

InactiveUS20080191004A1Easy to manageRolling contact bearingsBearing assemblyAviationQuality management

Owner:NTN CORP

Semiconductor processing equipment and process control method thereof

ActiveCN111489949AImprove yieldImprove accuracyElectric discharge tubesFinal product manufactureWaferProcess engineering

The embodiment of the invention provides semiconductor processing equipment and a process control method thereof. The semiconductor processing equipment comprises a cavity, a lifting assembly, a baseand a temperature measuring assembly, wherein the base and the temperature measuring assembly are arranged in the cavity; the lifting assembly is used for bearing and driving wafers to be selectivelylocated at multiple stations above the base, the multiple stations correspond to the multiple target temperature values in a one-to-one mode, and the distance between each station and an upper surfaceof the base is inversely proportional to the corresponding target temperature value; and the temperature measuring assembly is arranged at positions where the lifting assembly is in contact with thewafers and is used for acquiring actual measurement temperature values of the wafers in real time. According to the embodiment of the invention, the purpose of adjusting the target temperature value according to different types of wafers and different processes is achieved, and the requirement for temperature change in the process can be met such that the yield of the wafers is effectively improved, and the process efficiency is greatly improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Manufacturing process of rubber product production equipment

Owner:上海创奇特种橡胶制品有限公司

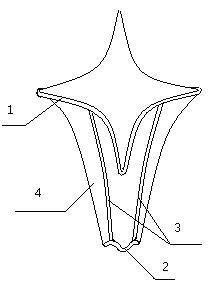

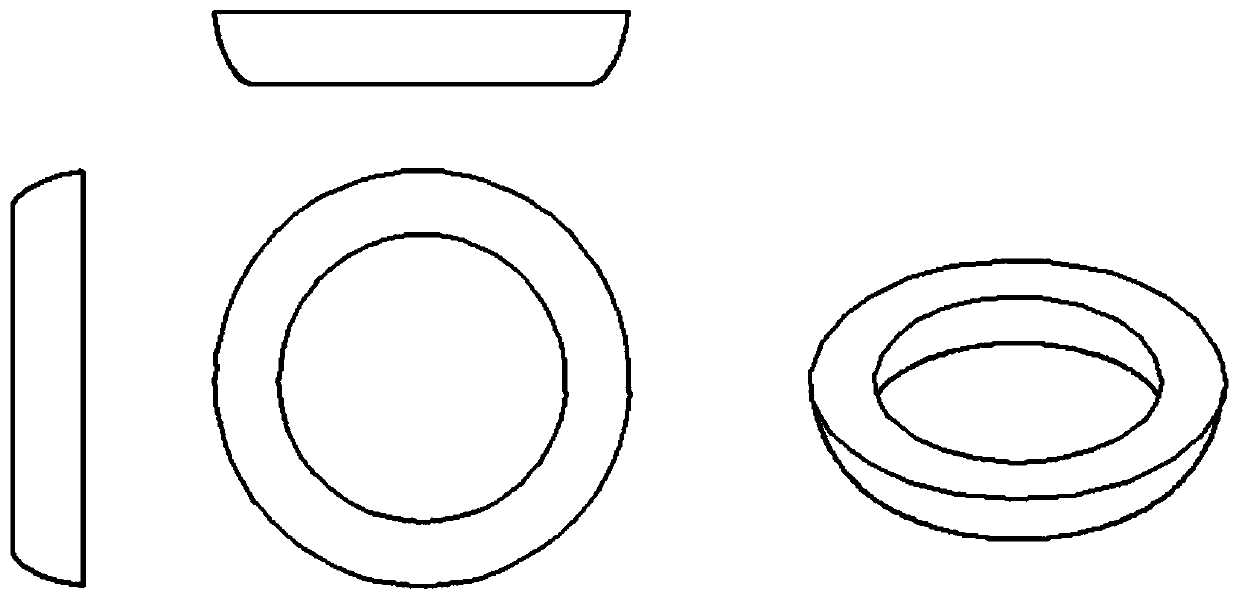

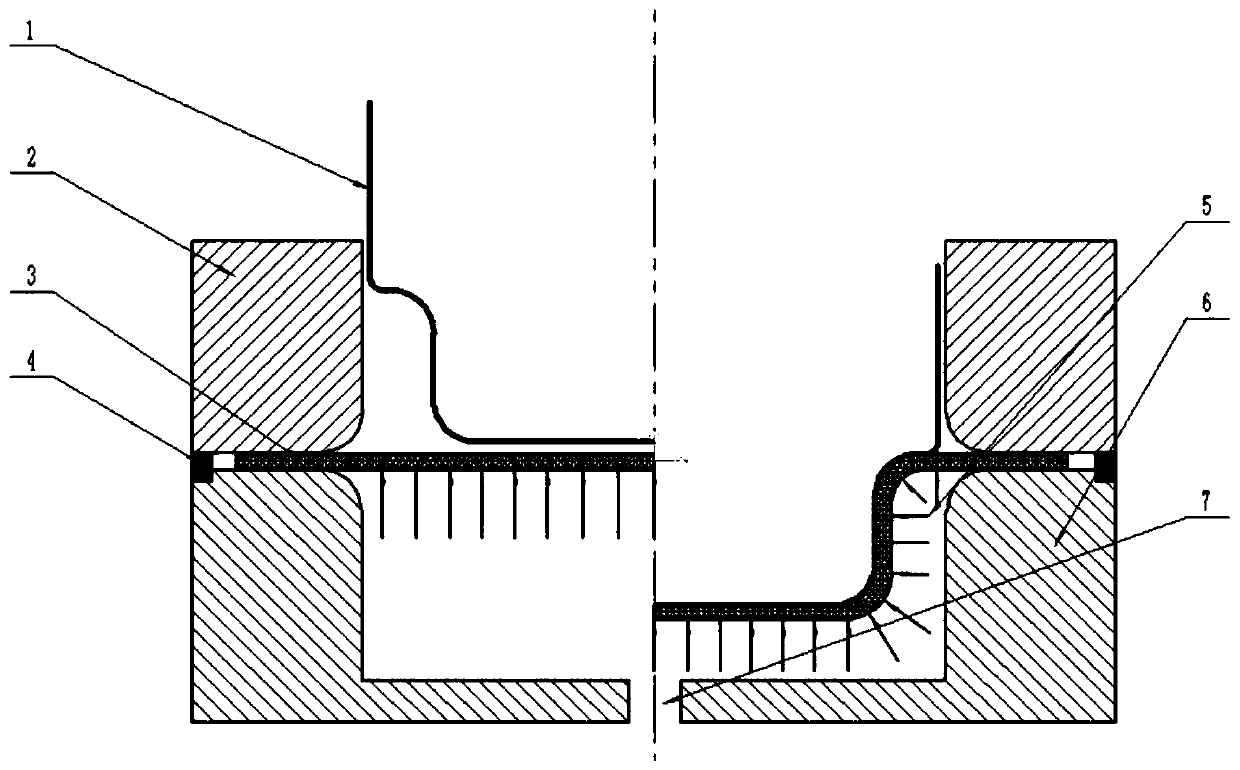

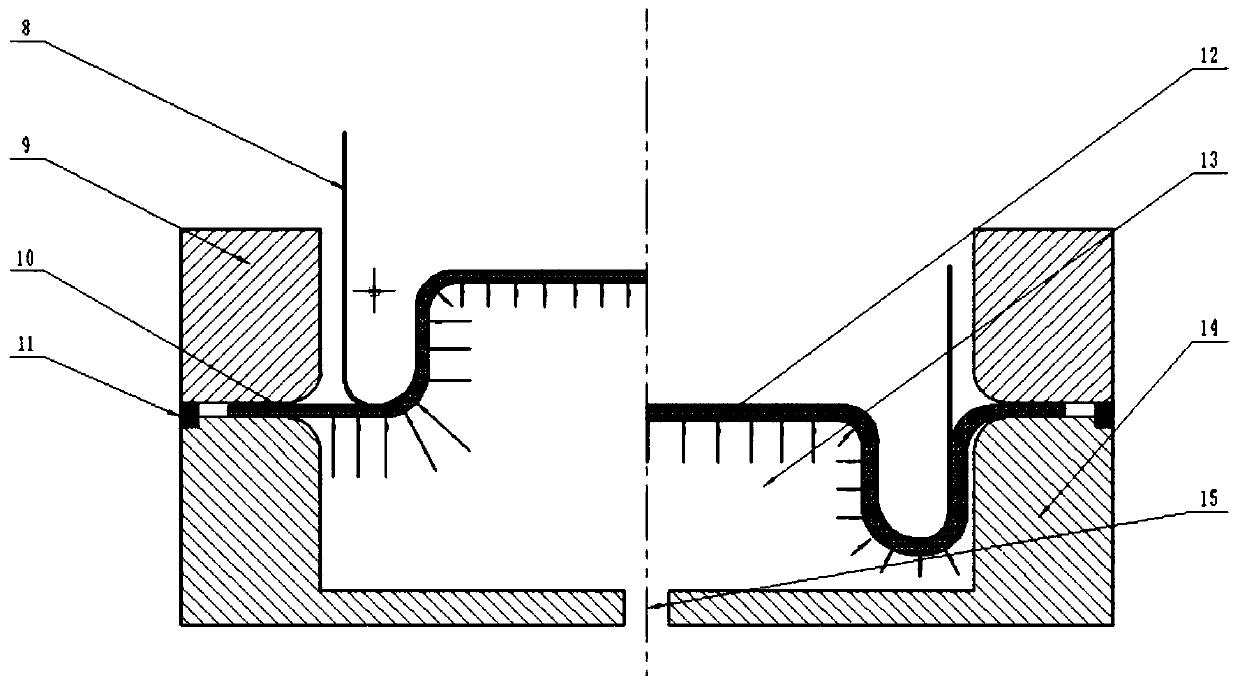

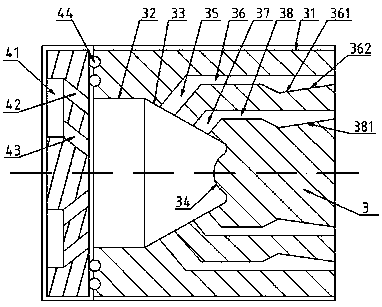

Integral liquid-filling forming method for large annular lip part

The invention provides an integral liquid-filling forming method for a large annular lip part, belongs to the technical field of aviation aerospace sheet metal forming, and can solve the problem thatlarge annular lip parts are difficult to integrally form. The method comprises the steps of design and manufacturing of a transition forming die and a final forming die, selection and debugging of technological parameters, post-processing and the like. According to the method, a novel technology of multi-step liquid-filling forming is carried out on the basis of guaranteeing integral forming of the lip parts; and the integral forming of the lip parts is realized through a two-sequence liquid filling forming process and a one-sequence shaping process. The method has the advantages of being highin forming limit, high in size precision, good in surface quality, low in cost and the like, and can effectively reduce the problems of uneven deformation, thinning or serious wrinkling in local areas, difficult elimination of resilience and the like in a traditional stamping mode, so that the local defects of the lip are reduced and the advantages are remarkable. Meanwhile, the technology can bepopularized to other parts with similar characteristics, and has good development potential.

Owner:BEIHANG UNIV

Corrugated board production line intelligent control system

InactiveCN105759751AQuality improvementReduce defective rateTotal factory controlProgramme total factory controlControl signalRemote control

Owner:QINGDAO MEIDA INTELLIGENT TECH CO LTD

Tool changing trolley and PCB drilling and milling machine

PendingCN111586974AEasy to recycleRealize unmannedInsulating layers/substrates workingRobot handMachine

The invention belongs to the technical field of PCB processing, and discloses a tool changing trolley which comprises a trolley body, at least two layers of supporting plates arranged in the trolley body in a sliding manner, a tool box placing plate mounted on the supporting plate and sliding along with the supporting plate, a tool box fixed on the toolbox placing plate and used for placing a tool, and a manipulator arranged on the trolley body and used for taking and placing the toolbox. According to the tool changing trolley, at least two layers of supporting plates are arranged, so that atleast two layers of tool boxes can be placed, multi-layer placement of tools is achieved, the tool placing number is increased, and the working efficiency of the tool changing trolley is improved. Theinvention further provides a PCB drilling and milling machine with the tool changing trolley, unmanned, intelligent and flexible tool changing procedures can be achieved, a movable tool holder is matched with the tool changing trolley, tools can be changed while machining is conducted, the equipment utilization rate is increased, and recovery and grinding management of the tools are facilitated.

Owner:SUZHOU VEGA TECH CO LTD

Technology for making double-layer knitted inner container thermal shirt

ActiveCN103960787AEnsure production efficiencyQuality assuranceWarp knittingNon-woven fabricsMechanical engineeringIndustrial engineering

Owner:苏州新超针纺织有限公司

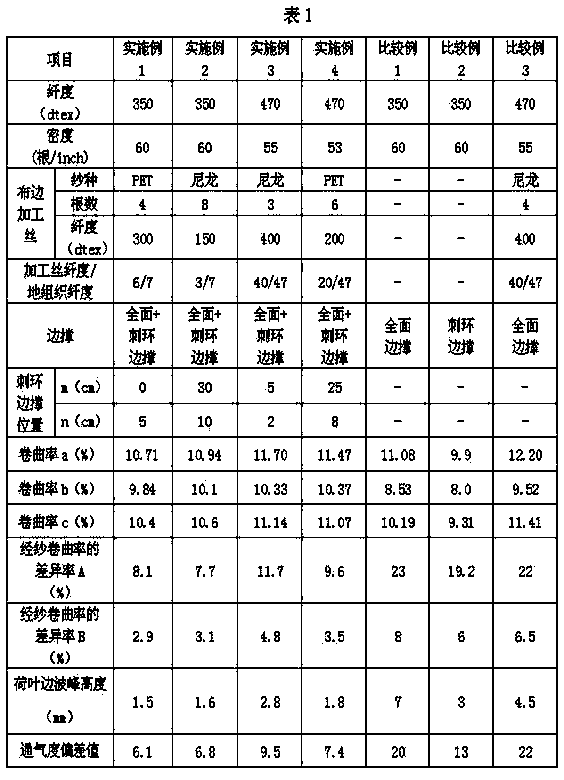

Fabric for safety air bag and production method of fabric

ActiveCN104278392ALow utilization efficiencyGood fixation effectPedestrian/occupant safety arrangementSelvedgesAirbag deploymentMechanical engineering

Owner:TORAY IND INC

Pretreatment process of linen fabric

InactiveCN104611936APhysical treatmentBiochemical fibre treatmentEnvironmental geologyManufacturing engineering

Owner:SUZHOU CHENHENG WEAVING

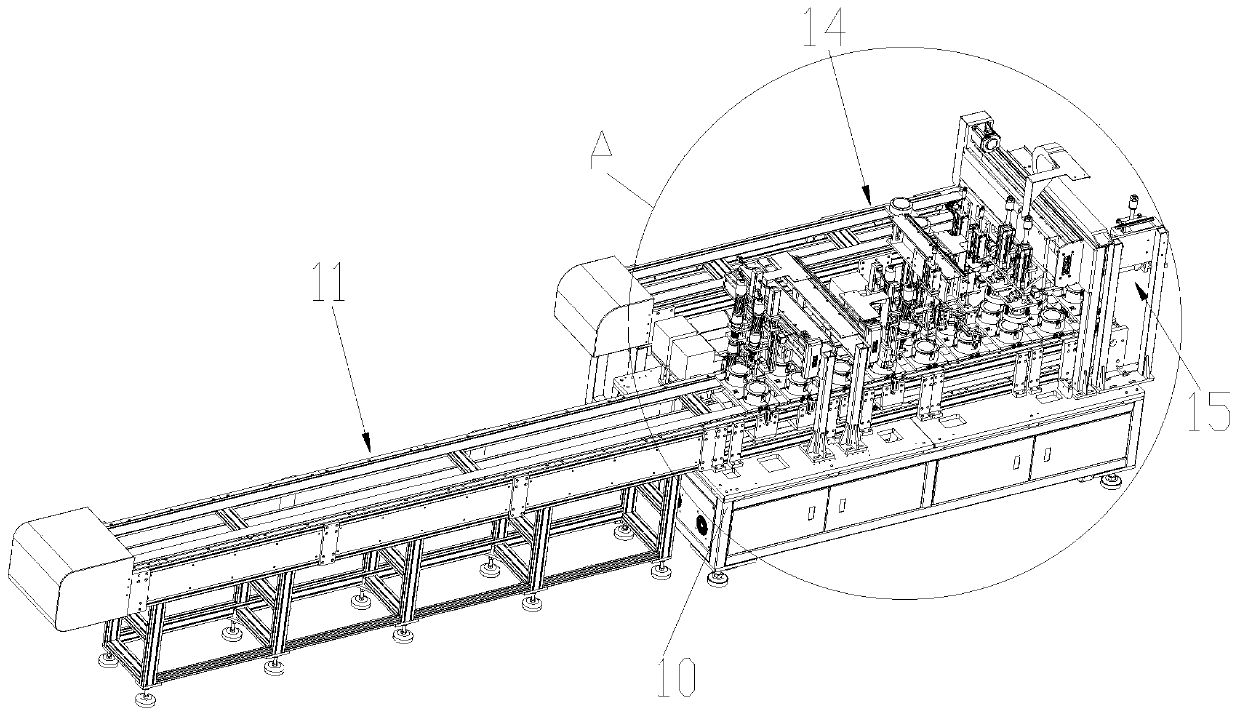

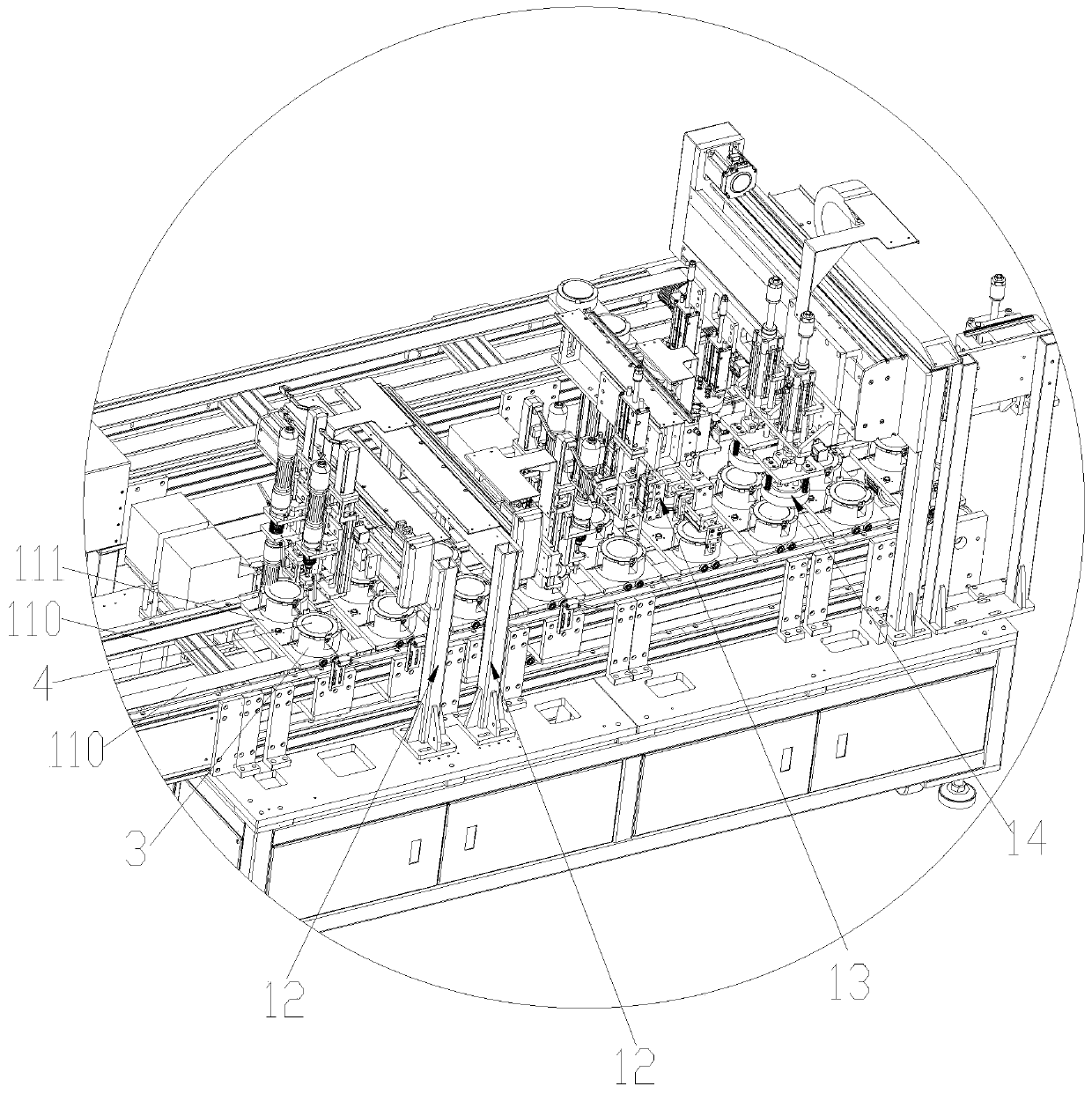

Automatic sorting and processing assembly line of logistics warehouse

ActiveCN111545477AImprove work efficiencyIncrease sliding forceStacking articlesSortingLogistics managementProcess engineering

The invention relates to an automatic sorting and processing assembly line of a logistics warehouse. The automatic sorting and processing assembly line of the logistics warehouse comprises a sorting device and conveying and stacking devices, wherein the conveying and stacking devices are symmetrically arranged front and back on the left side of the sorting device, and the lower ends of the sortingdevice and the conveying and stacking devices are arranged on the existing working ground. According to the design concept of the sorting-stacking integrated structure, automatic sorting of goods inthe logistics warehouse is carried out, the adopted sorting device can be used for screening different specification types of packages in a uniform shape integrally, the screened goods can be rapidlytransported and stacked by the aid of the arranged conveying and stacking devices, and compared with a traditional manual sorting and arranging mode, the automatic cooperation operation mode between the sorting device and the conveying and stacking devices greatly improves working efficiency.

Owner:ZHEJIANG YIXINGDA WISDOM TECH CO LTD

Automatic cutting, grinding and polishing machine for PCB

InactiveCN107378707AAccurate cutting positionImprove processing efficiencyGrinding feed controlGrinding machinesVertical planeWorkspace

The invention provides an automatic cutting, grinding and polishing machine for a PCB. The automatic cutting, grinding and polishing machine comprises a machine body, a working region, a clamping jaw, an action executing unit and a control panel, wherein the machine body is provided with a horizontal plane and a vertical plane which is perpendicular to the horizontal plane and is positioned at one side of the horizontal plane; the working region is arranged on the horizontal plane, and comprises a polishing disc, a grinding disc, a cutting disc and a laser aligning device; the action executing unit is arranged on the vertical plane, and the clamping jaw is connected with the action executing unit and is driven by the action executing unit to move in the vertical plane; and the control panel is arranged on the machine body and is positioned at one side of the working region. The automatic cutting, grinding and polishing machine for the PCB provided by the invention can realize advanced determining as well as automatic continuous cutting, grinding and polishing treatment of the PCB, is accurate in cutting position, is high in processing efficiency, is good in continuity, and sufficiently meets the needs, on product structure checking, of a laboratory of the PCB.

Owner:KUNSHAN HUANSHENG ELECTRONICS CO LTD

Shell stripping device and method for crushing shells of bamboo shoots

PendingCN105852162ACompact structureReduce volumeVegetable peelingReciprocating motionStructural engineering

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

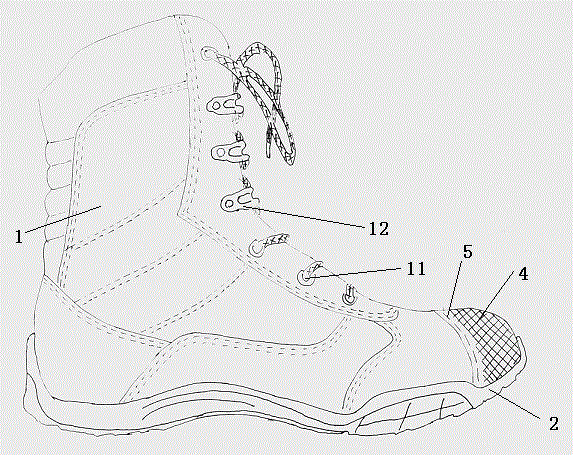

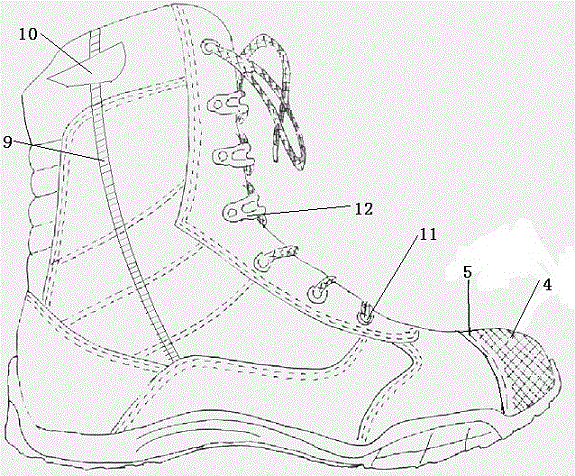

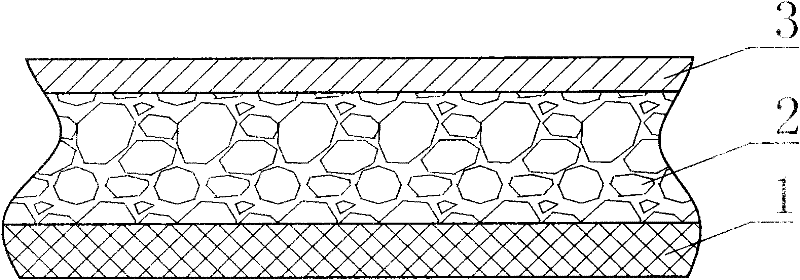

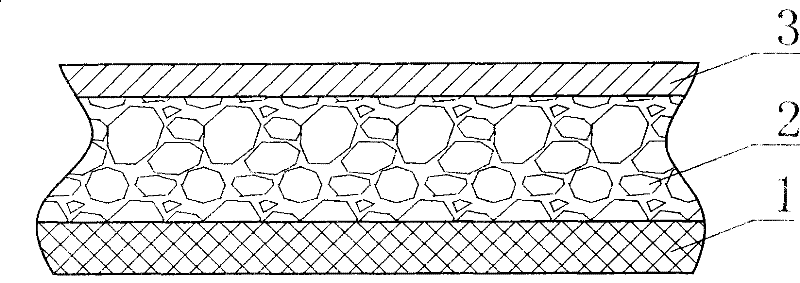

Safety shoe with external steel toe and production process of safety shoe

The invention discloses a safety shoe with an external steel toe and a production process of the safety shoe, and belongs to the technical field of labor protection appliances. The safety shoe comprises an upper, shoe sole, a tongue and the steel toe. The steel toe is arranged at the head portion of the upper. The safety shoe is characterized in that the steel toe is arranged on the outer layer of the surface skin of the upper, the inner side of the steel toe and the surface layer of the surface skin of the upper are connected in a glued mode, the bottom end of the steel toe is attached to the corresponding position of the edge of the bottom of the upper and fixedly connected with the shoe sole, the edges of the top face and the side face of the steel toe are evenly provided with a plurality of fixing holes, the positions, corresponding to the fixing holes, of the surface skin of the upper are provided with connecting holes, and mark threads penetrate through the fixing holes and the connecting holes so that the upper and the steel toe can be fixedly connected. The safety shoe is simple in structure and easy to produce and manufacture; the external steel toe is novel, fashionable and attractive, the comfort and safety are improved, and the safety shoe is durable in use and has wide market space.

Owner:江苏凯高鞋业有限公司

Straw carbonization and separation technique and separating device used thereby

InactiveCN101735836AAchieve refinementBiofuelsDispersed particle separationCombustible gasCarbonization

The invention discloses a straw carbonization and separation technique and a separating device used thereby to realize the carbonization of the straw and extract various useful substances, such as wood tar oil, wood vinegar, mixed combustible gas and the like in a carbonization process. The technique comprises the following steps of: processing the straw into segmented straw, sending the segmented straw into a furnace kiln and igniting to heat the segmented straw at a high temperature to produce smoke gas and placing the treated straw into a sharp quenching multi-pipe separating device to extract wood tar oil; extracting mixture of wood tar oil and wood vinegar liquid in a multi-layer staggered separating device; extracting wood vinegar liquid in an internal rotation centrifugal separating device; and sending remaining gas into a purification tower to purify and controlling the temperature to be between 60 and 80 DEG C. The invention has the advantages that: a new straw carbonization and separation technique is developed and the extraction of various useful substances, such as wood tar oil, wood vinegar and mixed combustible gas, is realized when bio-carbon is produced.

Owner:崔宝玲

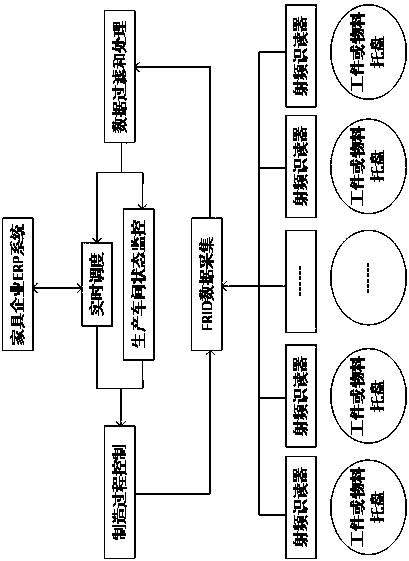

Internet of things perception method for furniture flexible production

Owner:黑龙江省科学院智能制造研究所

Automatic down lamp assembling equipment

PendingCN111002030AGripping headsAssembly machinesManufacturing engineeringElectrical and Electronics engineering

Owner:江苏阳铭互联智能系统有限公司

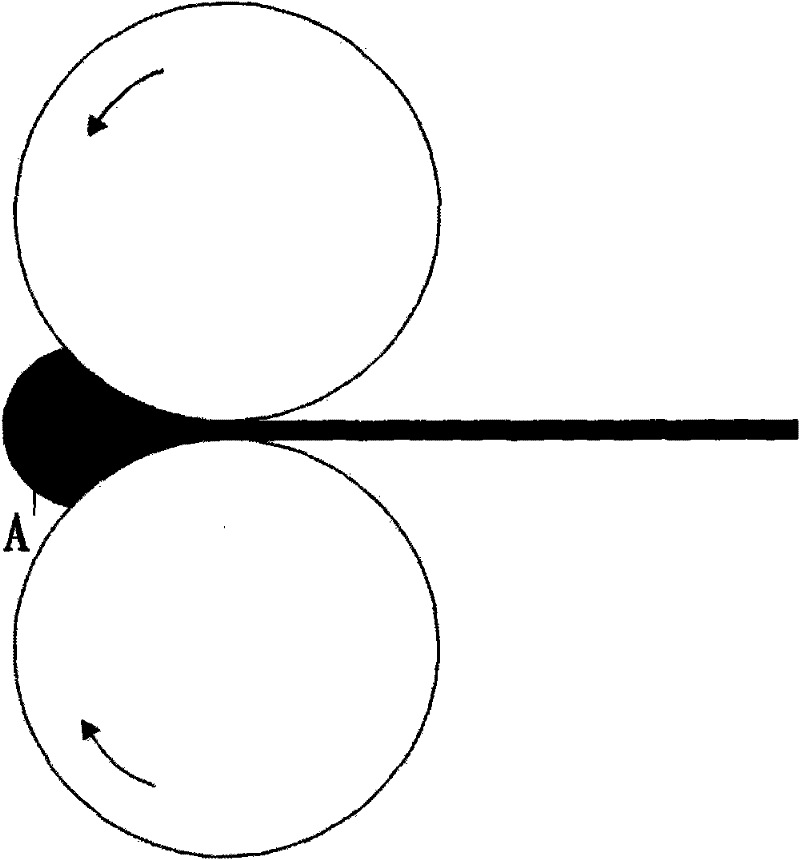

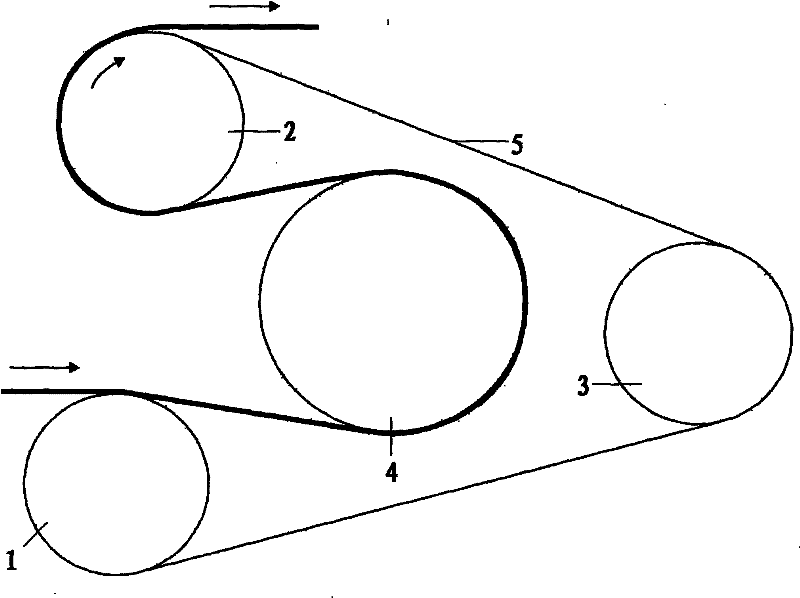

Steel bending equipment for steel machining

InactiveCN112139303AAvoid scratchesAvoid damageShaping toolsMetal-working feeding devicesStructural engineeringContact position

The invention discloses steel bending equipment for steel machining, and belongs to the technical field of steel machining. The steel bending equipment comprises a machine body, lubricating oil tanks,a base, roll shafts, an oil storage box, a positioning mechanism and a mounting seat, wherein the machine body is fixedly installed on the base through a side connecting plate, hydraulic machines arefixedly installed at the top of the machine body, and one ends of hydraulic rods installed at the output ends of the hydraulic machines penetrate through and extend to the outer side of the machine body to be fixedly provided with a bending plate. According to the steel bending equipment, the roller shafts are installed on the equipment, when steel is bent and pressure is applied to the bent position of the steel, the roll shafts replace a bent face to make contact with the steel, and when pressure is applied for bending, the steel can be bent along the smooth surfaces of the roll shafts, compared with traditional bending treatment, the situation that the surface of the steel is scratched and damaged is avoided, and meanwhile, the lubricating oil tanks are installed on the outer side of the equipment in a matched mode, the contact positions between the roll shafts and the steel can be effectively lubricated, and the bending smoothness is further improved.

Owner:赵桂荣

Natural stone crushing and grinding equipment

InactiveCN111389567ASimple and fast operationReduce manufacturing costSievingScreeningCrushed stoneStructural engineering

Owner:杭州瑞芳容科技有限公司

Muddy substrate simulation wall painting and manufacturing process thereof

InactiveCN102673284AMeet printable requirementsImprove manufacturing speedDecorative surface effectsSpecial artistic techniquesHigh volume manufacturingBuilding construction

Owner:王强

Pigment spraying device for ceramic product production process

Owner:景德镇一牧堂陶瓷科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap