Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72 results about "Surface layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The surface layer is the layer of a turbulent fluid most affected by interaction with a solid surface or the surface separating a gas and a liquid where the characteristics of the turbulence depend on distance from the interface. Surface layers are characterized by large normal gradients of tangential velocity and large concentration gradients of any substances (temperature, moisture, sediments et cetera) transported to or from the interface.

Cleaning member, image forming apparatus provided with a cleaning blade member, and process cartridge detachably attachable on the image forming apparatus

A cartridge detachably attachable on an image forming apparatus a photosensitive member as an image bearing member and a cleaning blade member polycarbonate resin having a viscosity average molecular weight of 1.5x104 or less is blended with the surface layer of the image bearing member, and the peak value of tan delta of the dynamic viscoelastic characteristic of the cleaning blade member appears at 12 DEG C. or less.

Owner:CANON KK

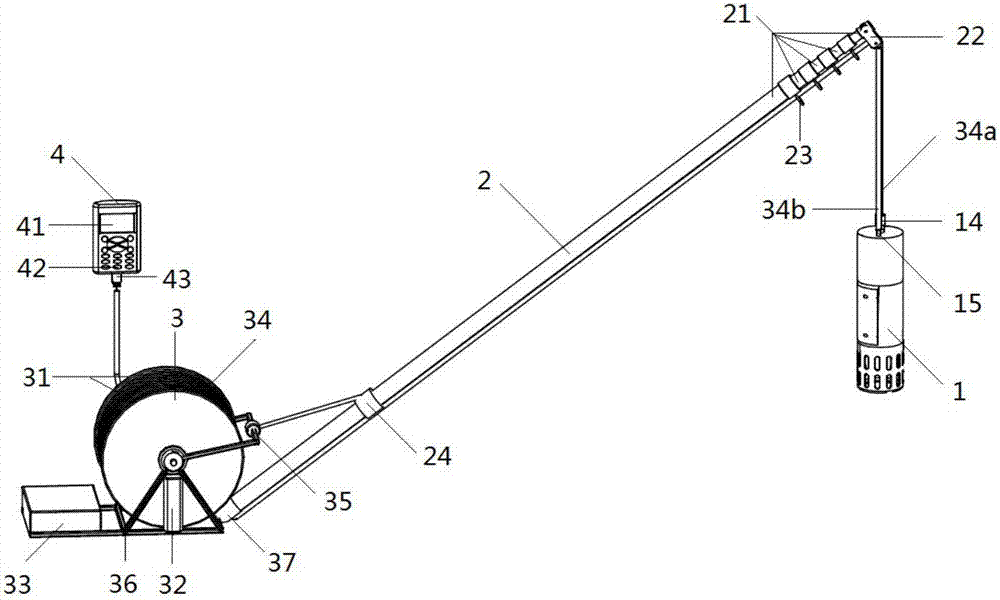

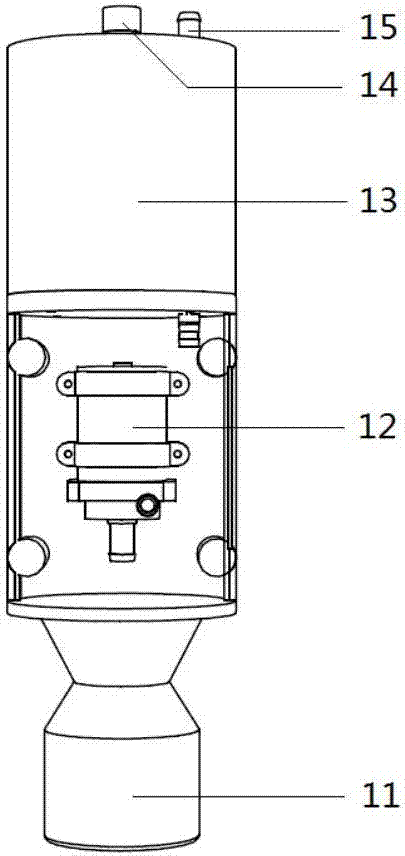

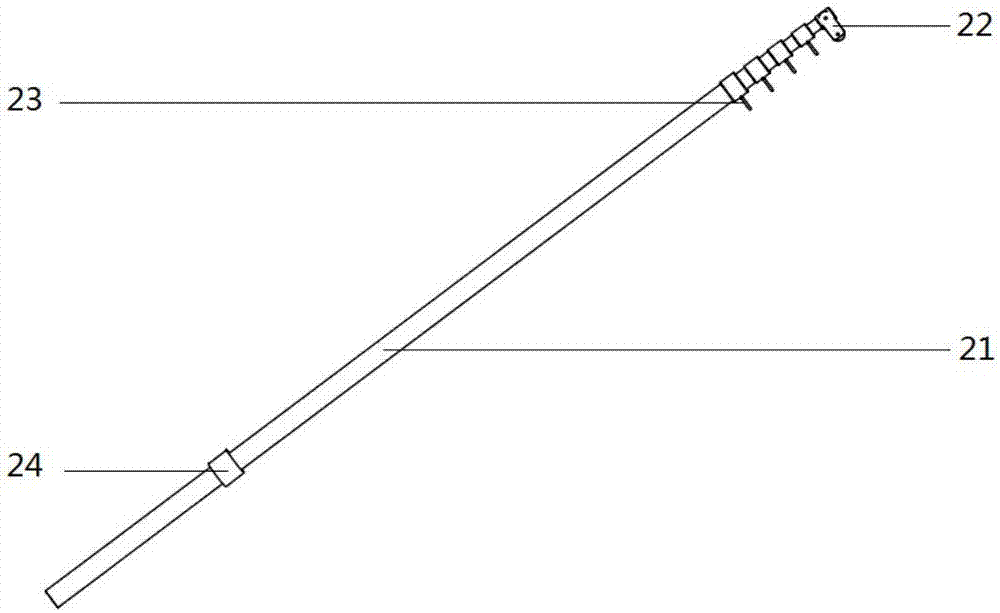

Portable water quality sampler

Owner:INST OF REMOTE SENSING & DIGITAL EARTH CHINESE ACADEMY OF SCI +1

Asphalt modified thermoplastic polyolefin water-proof coiled material and preparation method thereof

InactiveCN101550729AImproves UV resistanceExcellent ozone resistanceRoof covering using flexible materialsBuilding insulationsPolymer sciencePolyolefin

Owner:胜利油田大明新型建筑防水材料有限责任公司

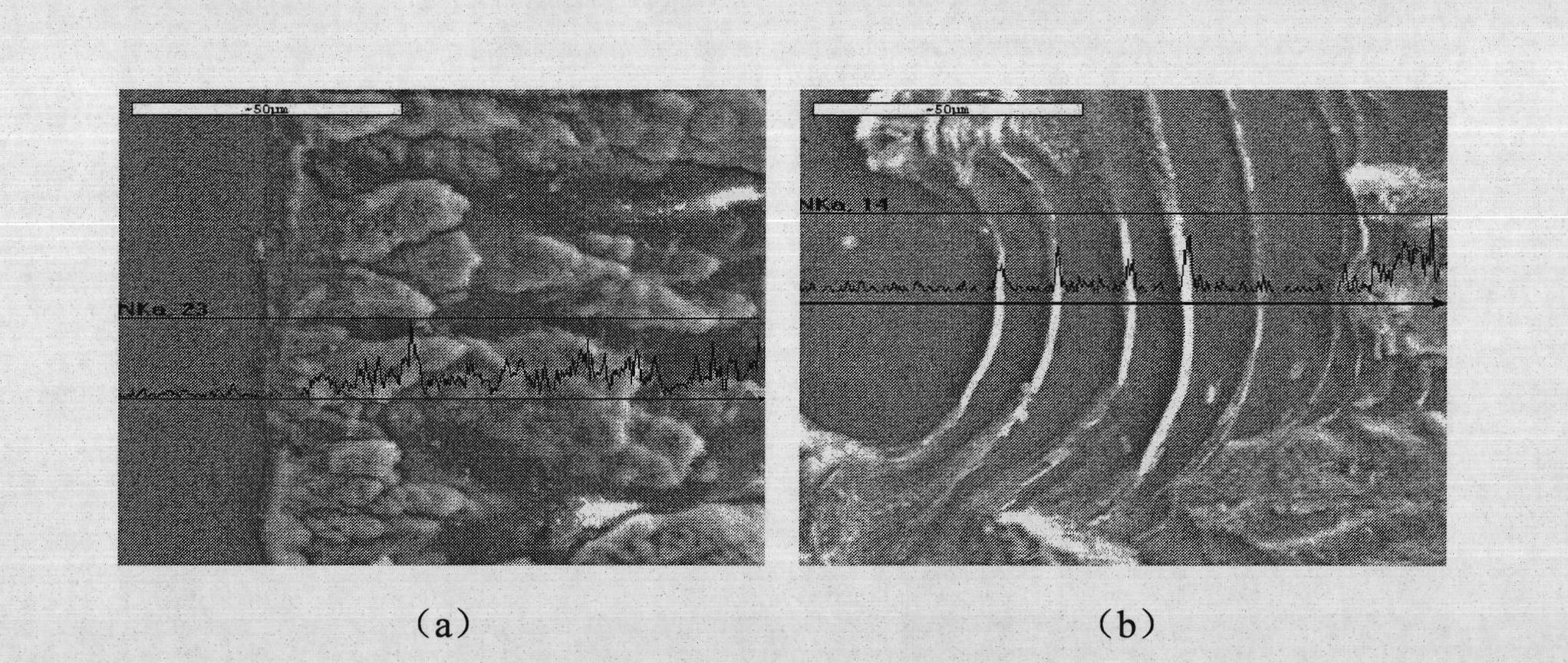

Method for preparing diamond-like composite coating on surface of piston ring

InactiveCN101665940AImprove wear resistanceImprove the lubrication effectVacuum evaporation coatingSputtering coatingLow temperature plasmaMagnetic filtration

The invention relates to a method for preparing a diamond-like composite coating with high hardness and good abrasion proof and self lubricating properties on the surface of a piston ring. In the method, a nitriding layer with high bonding strength, high hardness and good abrasion resistance is formed on the surface of the piston ring by the low-temperature plasma nitriding treatment, a non-hydrogen diamond-like surface layer with solid lubricating property is deposited by the combination of magnetic filtration cathode arc and magnetic control sputtering, and finally the nitriding / diamond-likecomposite coating, which is dense and smooth and possesses excellent abrasion proof and self-lubricating properties, is obtained on the surface of the piston ring. Compared with the durionising piston ring or CrN plating piston ring, the coating of the piston ring of the invention has higher comprehensive performance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

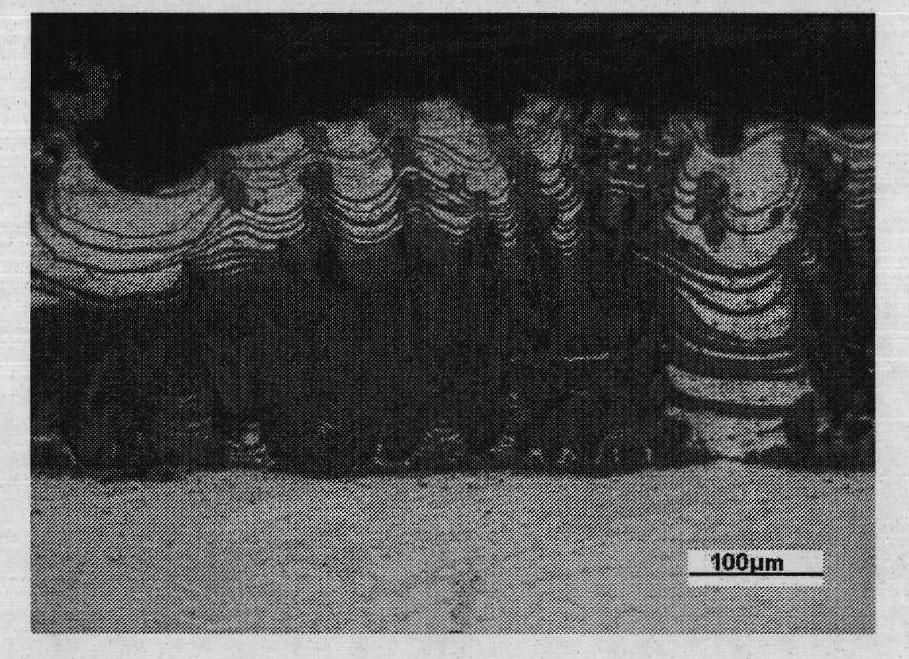

Aluminum and aluminum alloy matrix aluminum nitride reinforced gradient composite surface layer

InactiveCN101880854AImprove wear resistanceSolid state diffusion coatingSurface gradientSurface layer

Owner:JILIN UNIV

High-strength corrosion-resistant micro-alloying copper pipe and manufacturing method thereof

The invention discloses a high-strength corrosion-resistant micro-alloying copper pipe material which consists of the following components in percentage by weight: 0.005-0.04% of phosphorus, 0.2-1.0% of tin, 0-0.04% of lanthanum, 0-0.04% of cerium, 0-0.1% of nickel, 0-0.1% of zinc, 0-0.05% of cobalt, 0-0.1% of manganese, 0-0.05% of zirconium and the balance of copper. By combining phosphorus with rare earth lanthanum and / or cerium to obtain a deoxidizer of molten copper, the content of oxygen in melt is further reduced, the grain structure is refined, the recrystallization temperature is increased to prevent abnormal growth of the weld structure grain, and the ductility and thermal conductivity of copper are further improved. Through solid solution strengthening of tin and improvement of an oxide film on a surface layer, the strength and corrosion resistance of a matrix are improved. By adding trace amount of zinc, nickel and manganese subjected to solid solution into the copper matrix, the strength of the copper matrix is improved; by adding cobalt or zirconium and dispersing into the copper matrix, the strength and heat resistance of the copper matrix are improved; the combination effect is better than the performance and using effect of the existing oxygen-free copper pipe or single phosphorus deoxidization copper pipe.

Owner:NINGBO JINTIAN COPPER TUBE +1

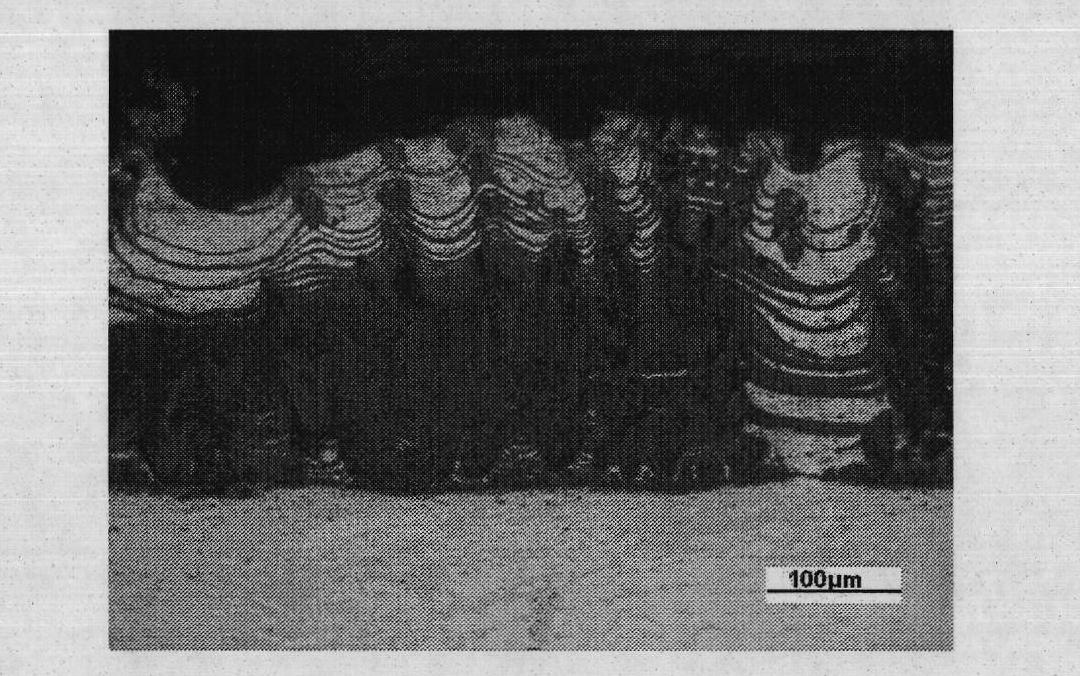

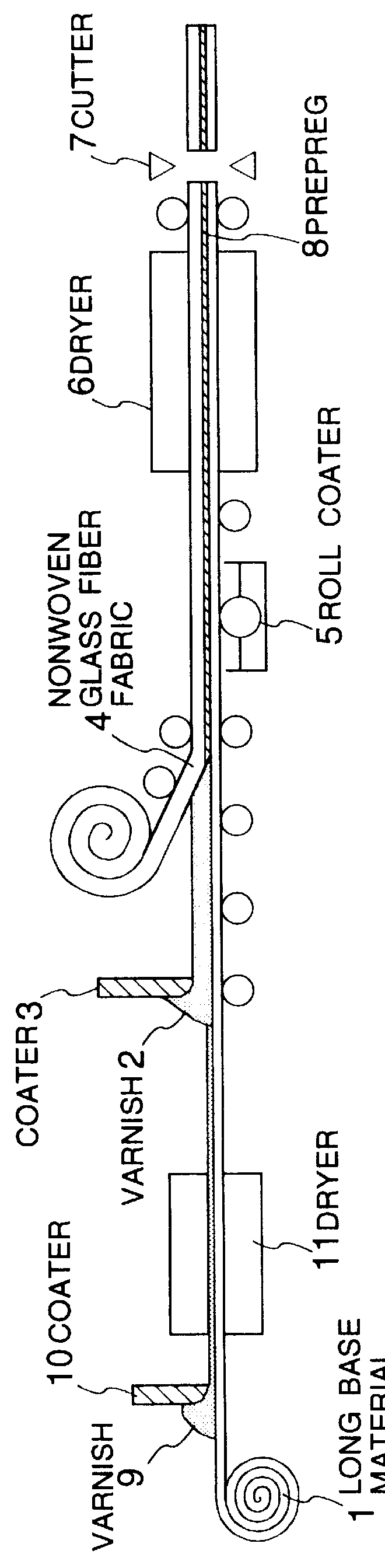

Laminated board and process for production thereof

InactiveUS6124220AGood molding effectLow costAnimal housingGlass/slag layered productsCentral layerSurface layer

Owner:SUMITOMO BAKELITE CO LTD

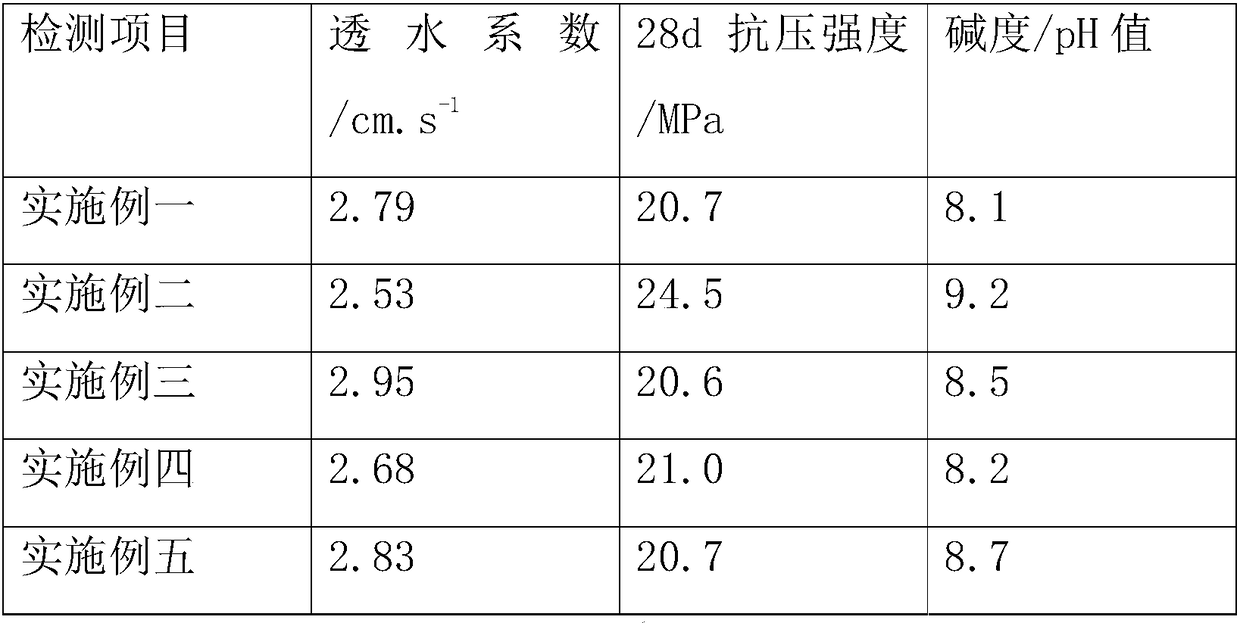

Plant growth type porous concrete suitable for plant growth

ActiveCN108101452AHigh compressive strengthHigh strengthExcrement fertilisersBioloigcal waste fertilisersFiberCompost

Owner:CHONGQING JIAOTONG UNIVERSITY

Asphalt pavement structure suitable for Tibet plateau area and construction method thereof

InactiveCN106868972AImprove road performanceImprove bending deformationIn situ pavingsSurface layerRoad surface

The invention relates to an asphalt pavement structure suitable for the Tibet plateau area and a construction method thereof. The asphalt pavement structure suitable for the Tibet plateau area sequentially comprises a cushion layer, a semi-rigid base layer, a penetrable layer, an SBR emulsified asphalt lower sealing layer, a lower surface layer, a bonding layer and an upper surface layer from bottom to top. The construction method of the asphalt pavement structure suitable for the Tibet plateau area comprises the following steps of (1) tamping and leveling a roadbed, (2) laying the cushion layer on the roadbed, (3) laying a cement stabilized sand gravel layer on the cushion layer, (4) flatly laying a low-shrinkage super-early-strength cement stabilized macadam layer, (5) laying the penetrable layer, (6) laying the SBR emulsified asphalt lower sealing layer, (7) laying the lower surface layer, (8) laying the bonding layer, and (9) laying the upper surface layer.

Owner:QINGHAI ACAD OF TRANSPORTATION SCI +1

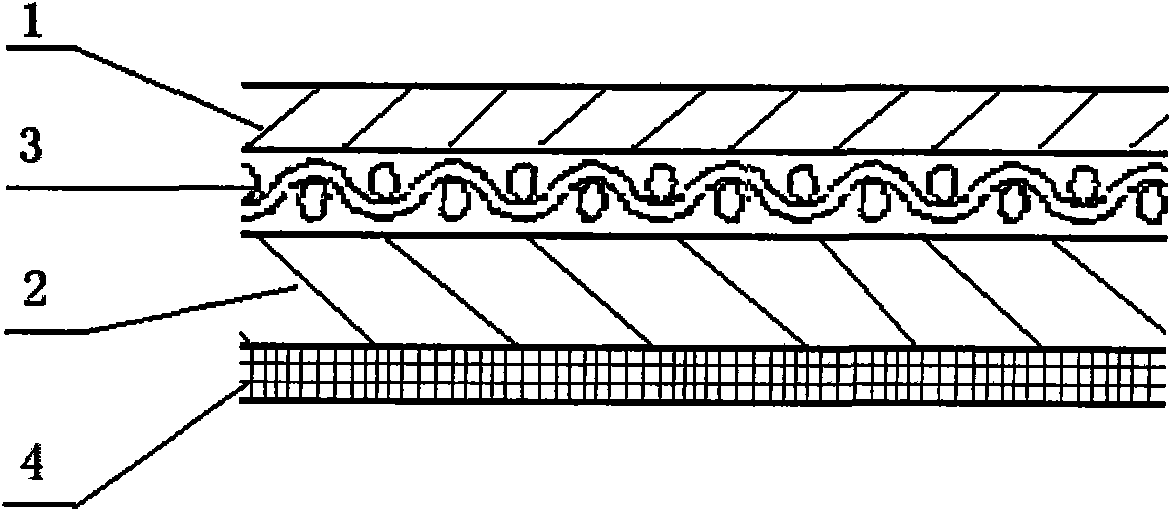

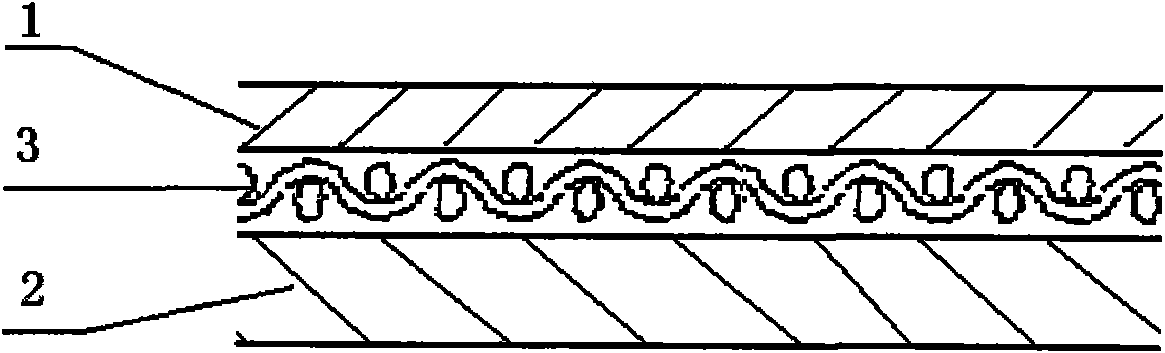

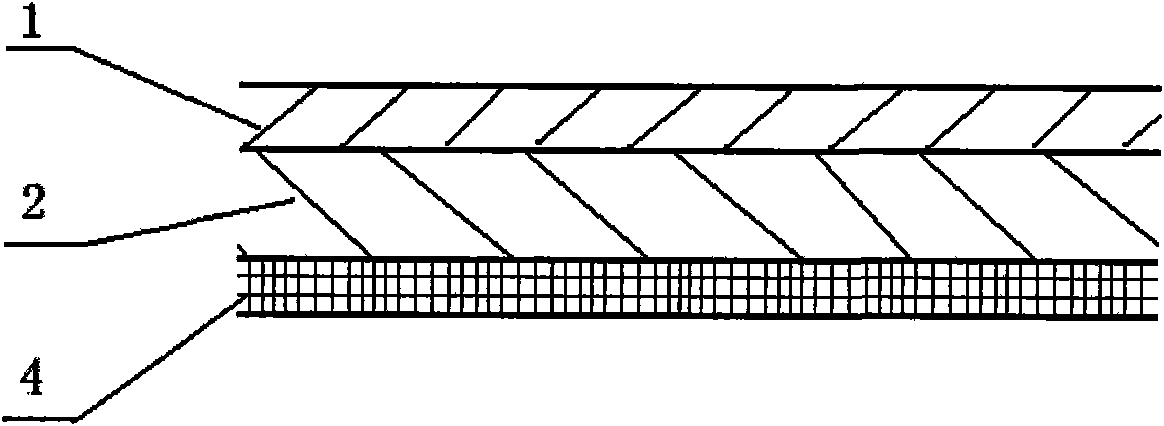

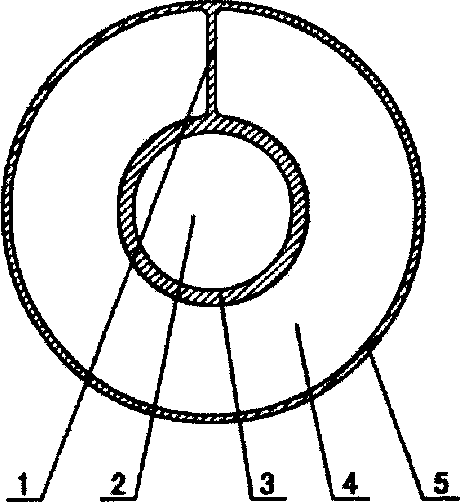

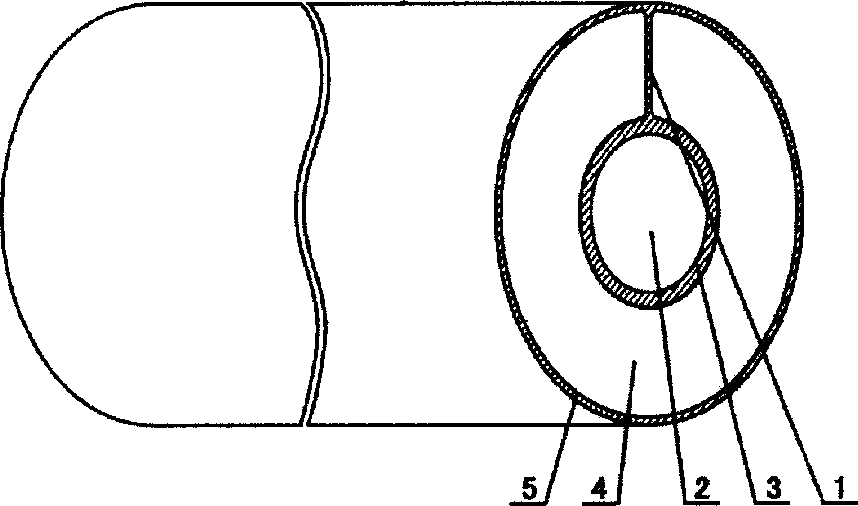

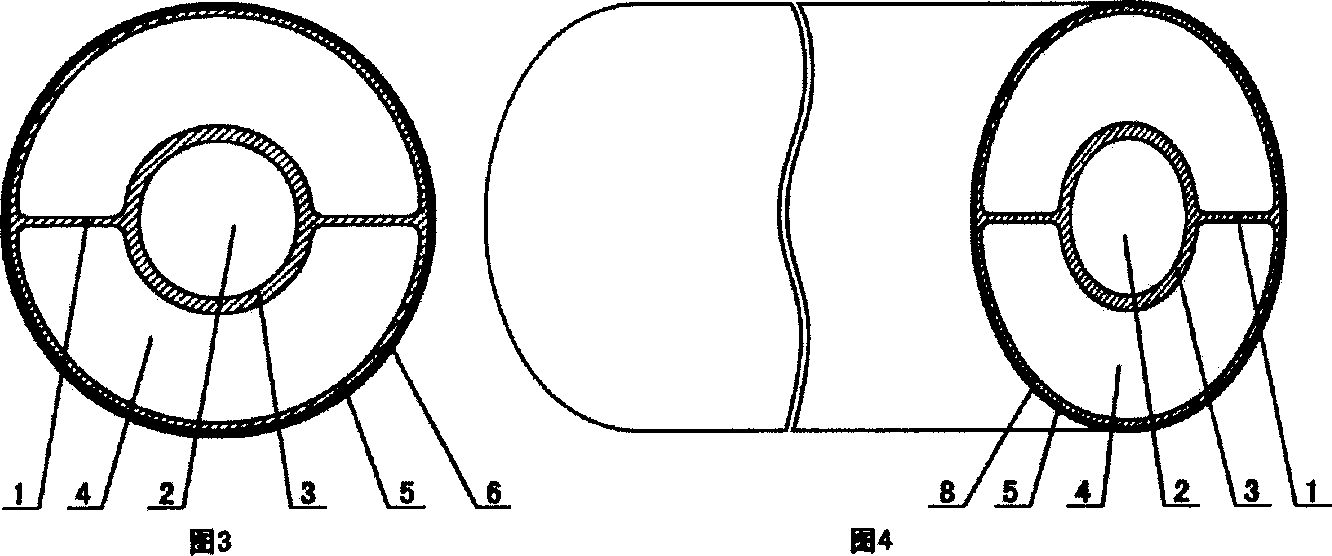

Laminated heat-preserving plastic composite pipe

InactiveCN1837667AFlexibleSimple structureThermal insulationPipe protection by thermal insulationSurface layerPliability

Owner:徐宝安

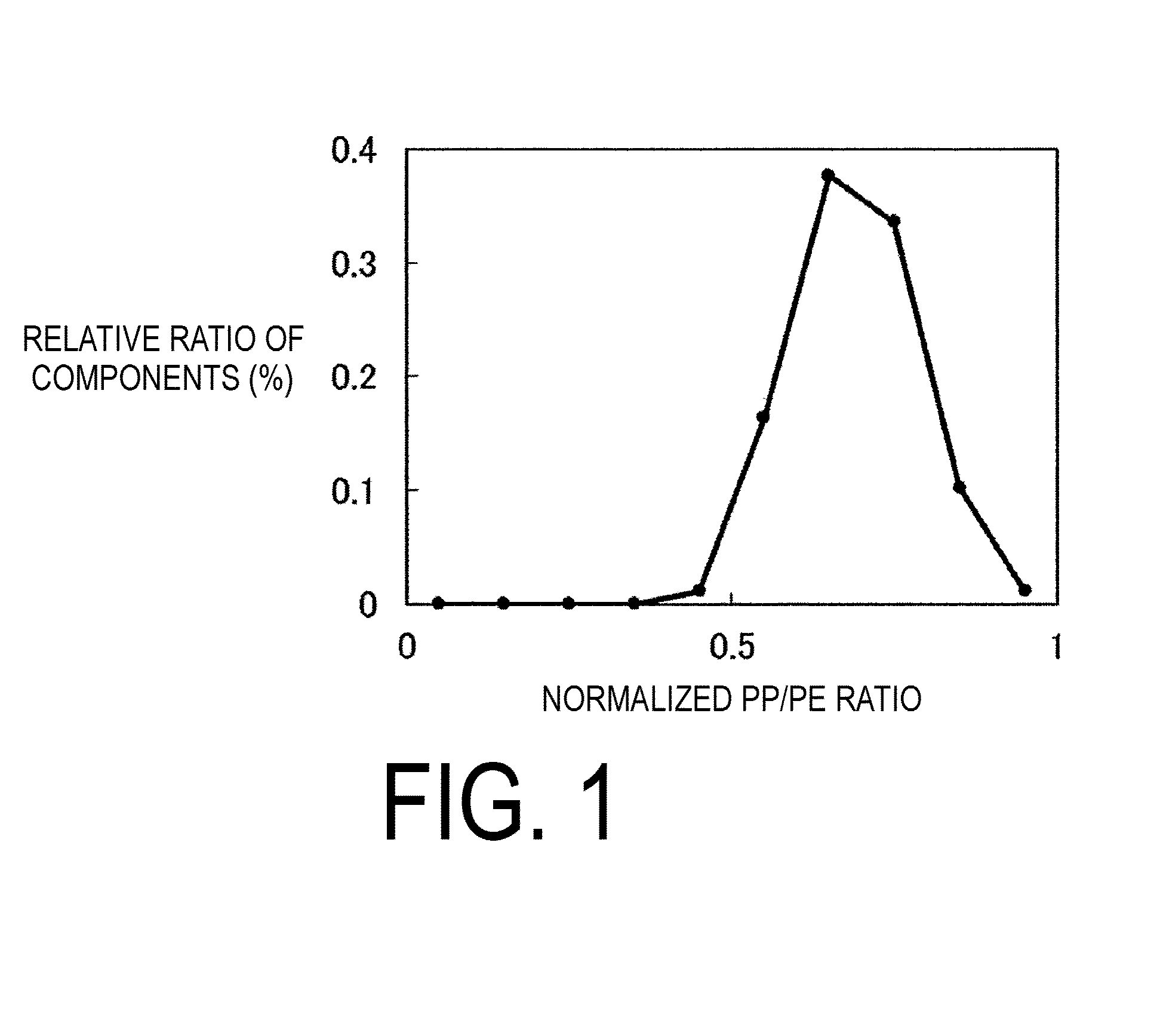

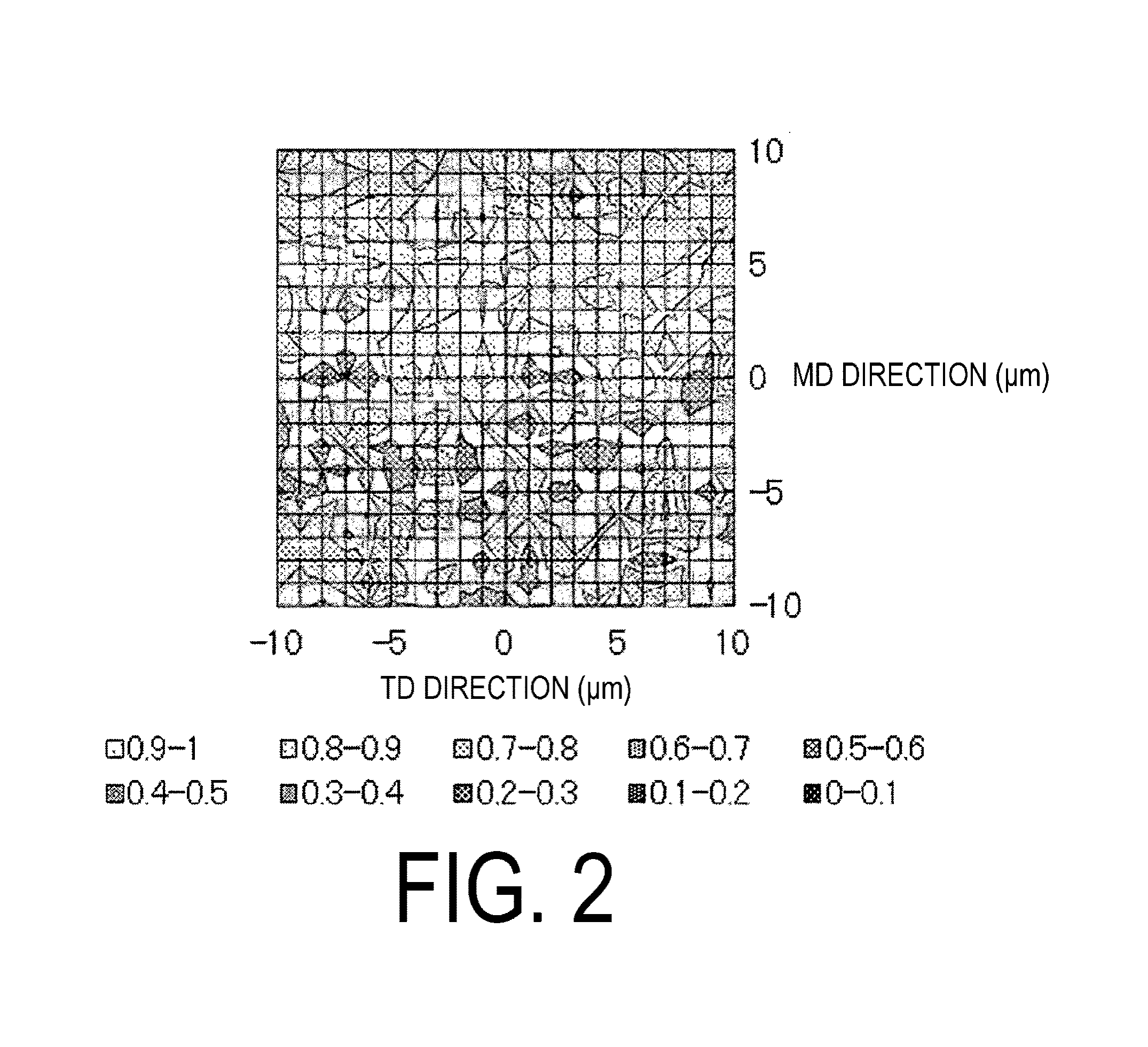

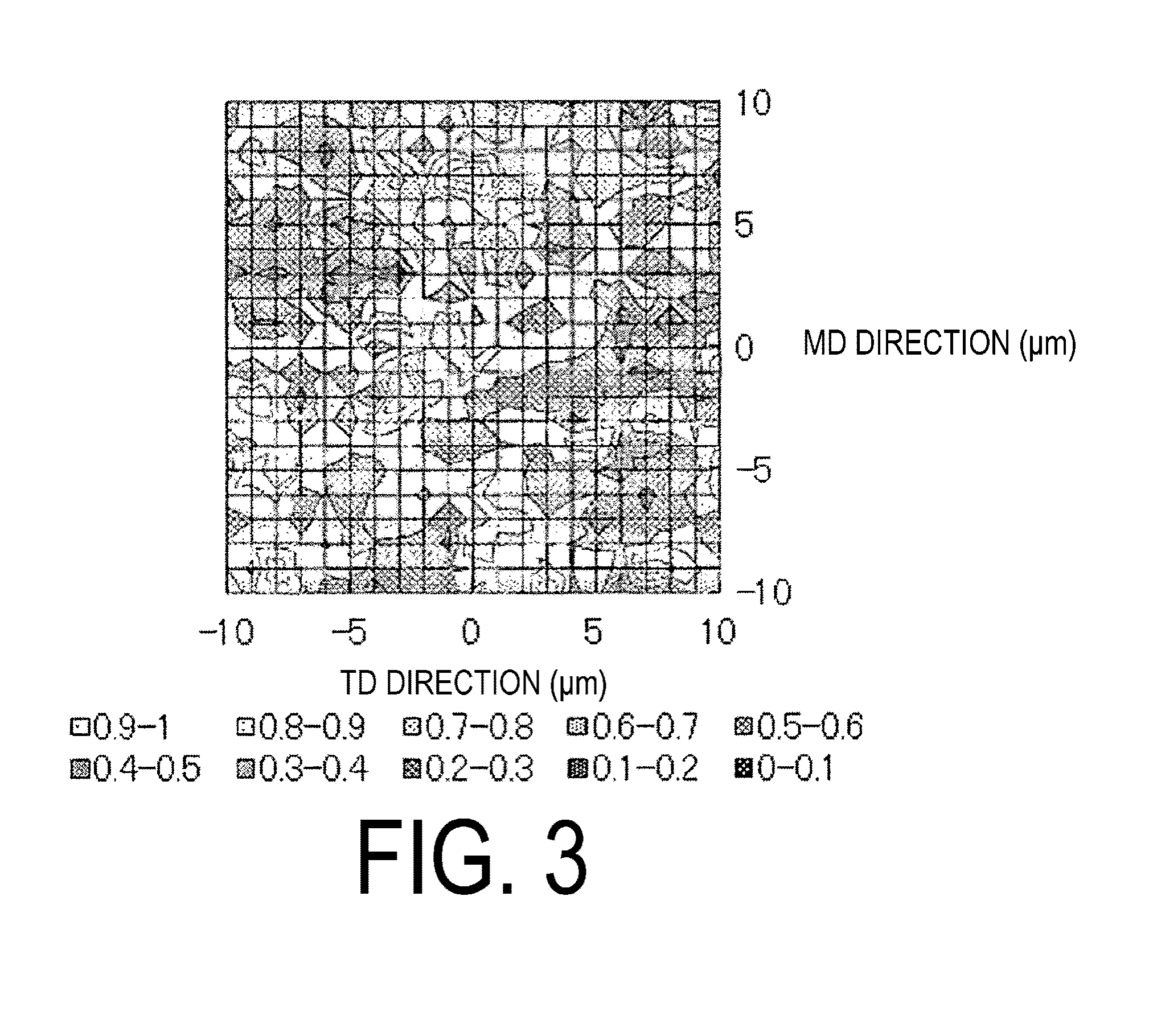

Multilayer, microporous polyolefin membrane, and production method thereof

ActiveUS20160118639A1Improve permeabilityHigh strengthSemi-permeable membranesMembranesIn planePolymer science

Owner:TORAY IND INC

Ceramic floor tile with diatom mud and method for manufacturing ceramic floor tile

InactiveCN105298081AReduce processing difficultyNice appearanceCeramic shaping apparatusFlooringSurface layerEthylic acid

Owner:佛山市高明区生产力促进中心

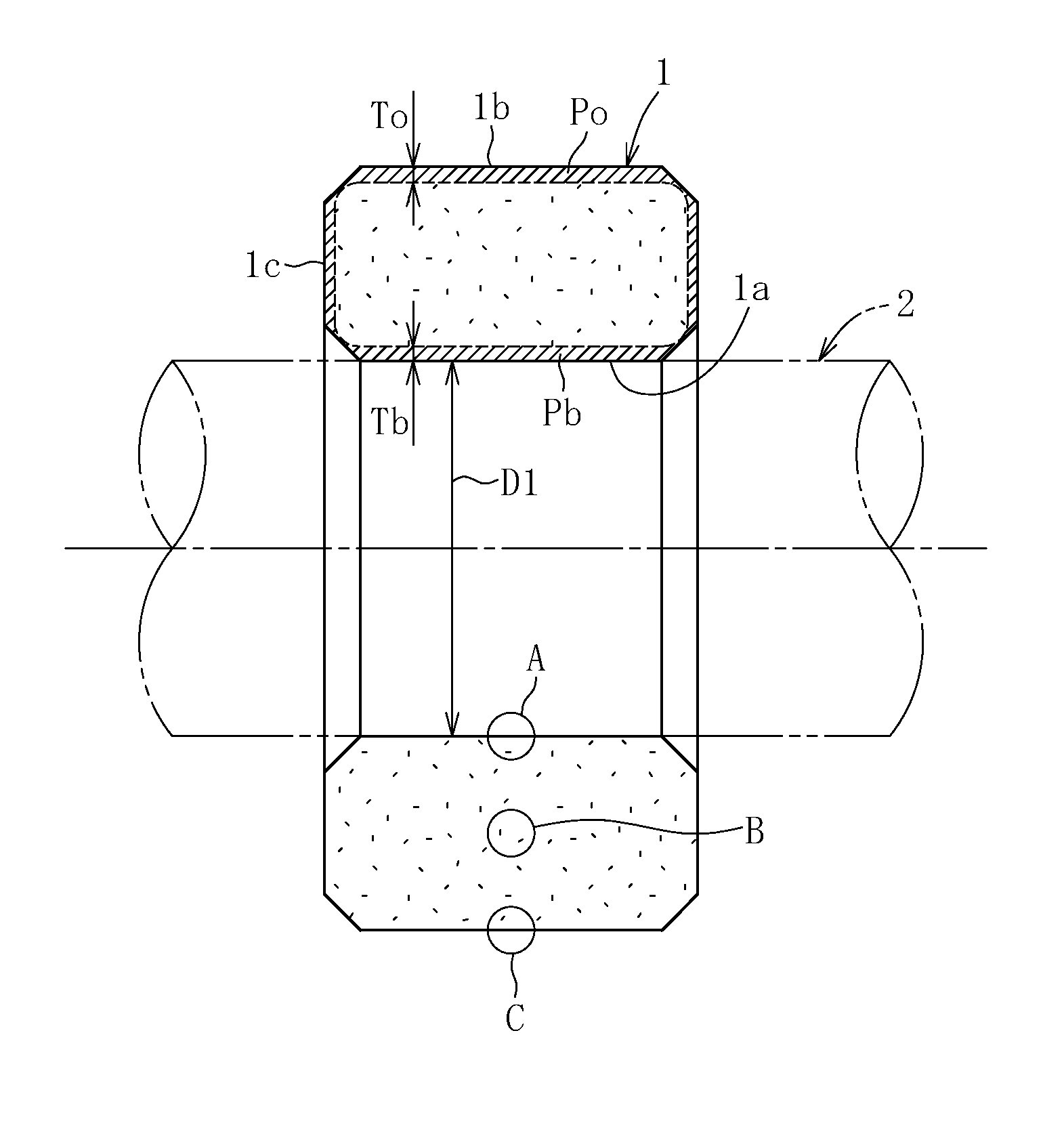

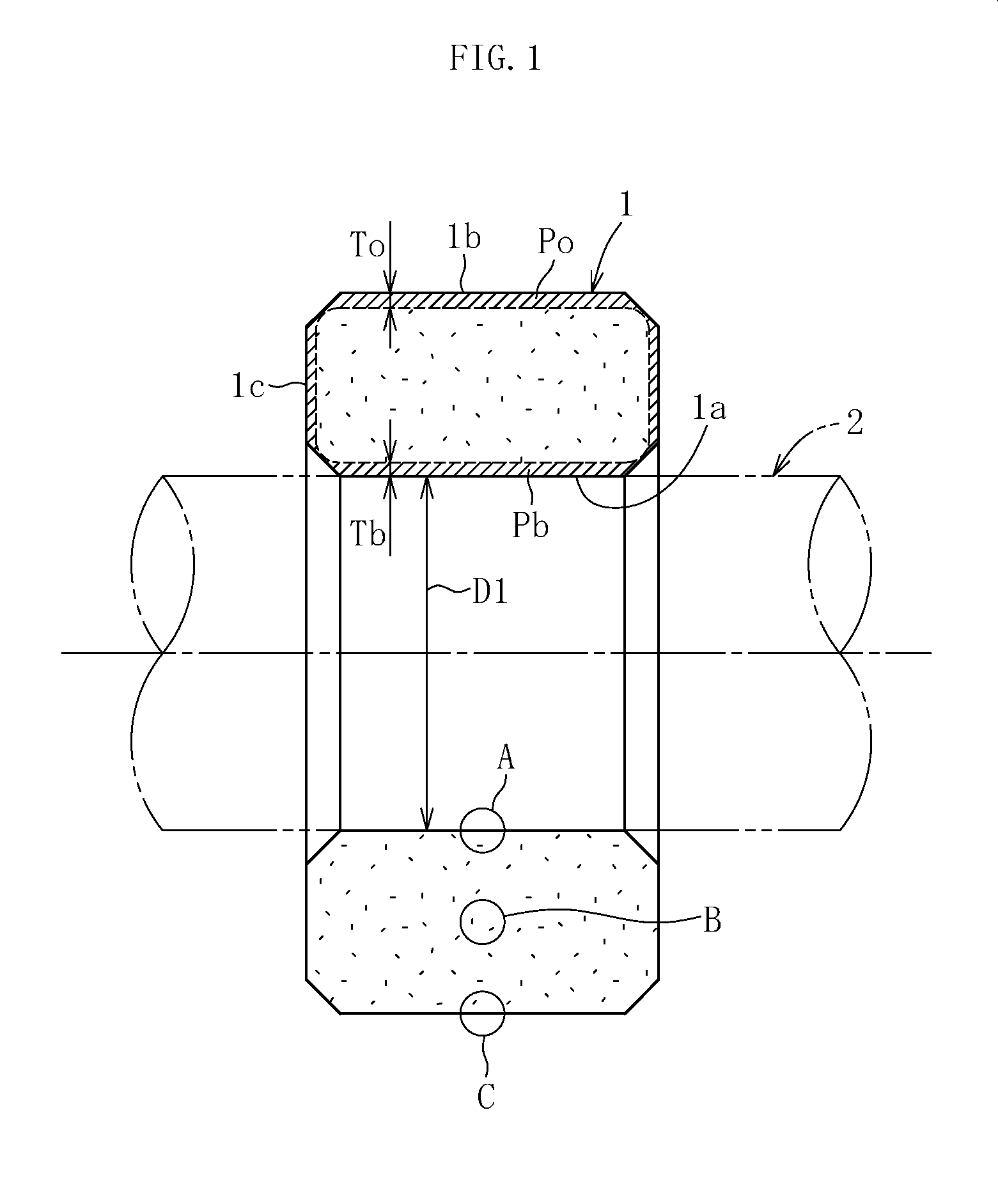

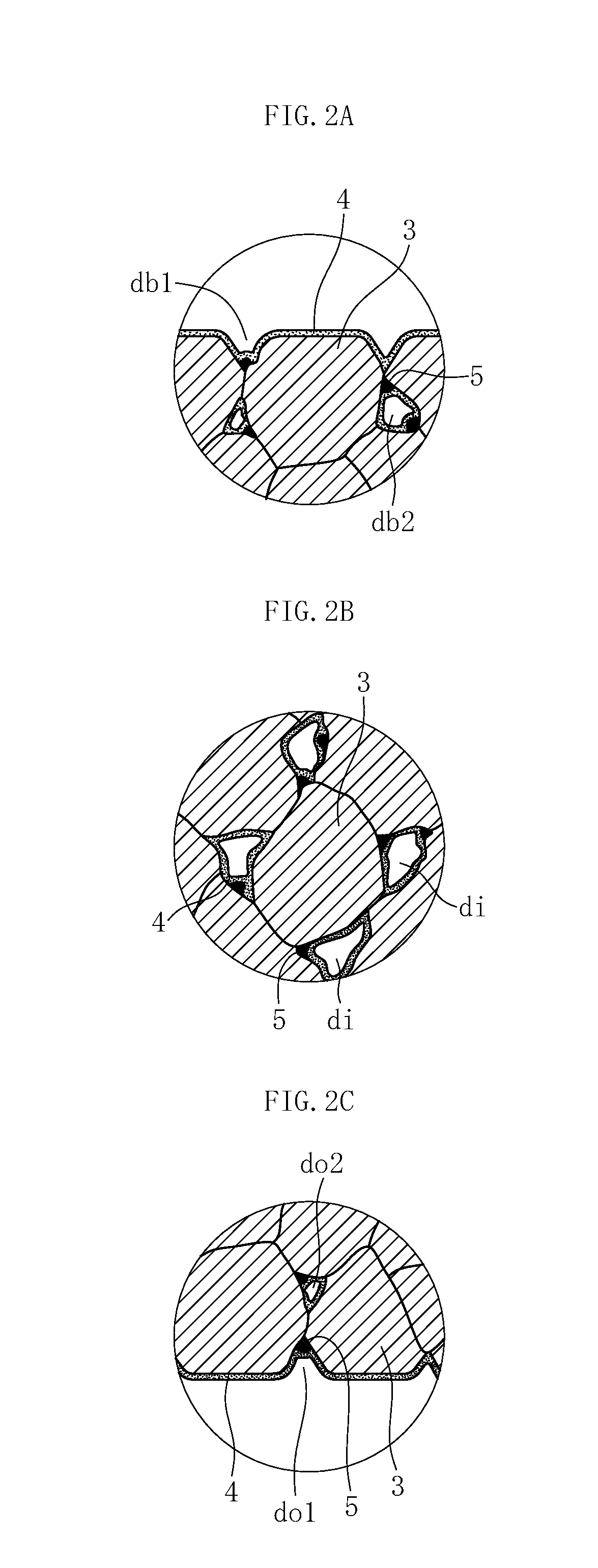

Sintered bearing and manufacturing method for same

InactiveUS20150064045A1Increase production capacityLow costTransportation and packagingShaftsAluminiumSurface layer

Owner:NTN CORP

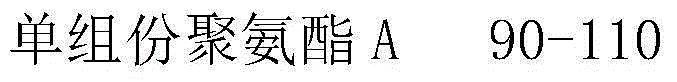

Infrared stealth textile coating fabric

ActiveCN105034523ALow infrared reflectanceImprove stealth performanceSynthetic resin layered productsCross-linkPolymer science

Owner:CTA HI TECH TEXTILES

Method of producing corundum layer on metal parts

InactiveUS20060207884A1Shorten molding timeImprove the immunityAnodisationSurface layerGradual increase

Owner:SHPAKOVSKY VOLODYMYR +2

Medical sterilization packaging bag

ActiveCN103072739AImprove packaging antibacterial rateGuarantee the safety of useBagsSacksSurface layerNonwoven fabric

Owner:SHANGHAI JIANZHONG MEDICAL PACKAGING

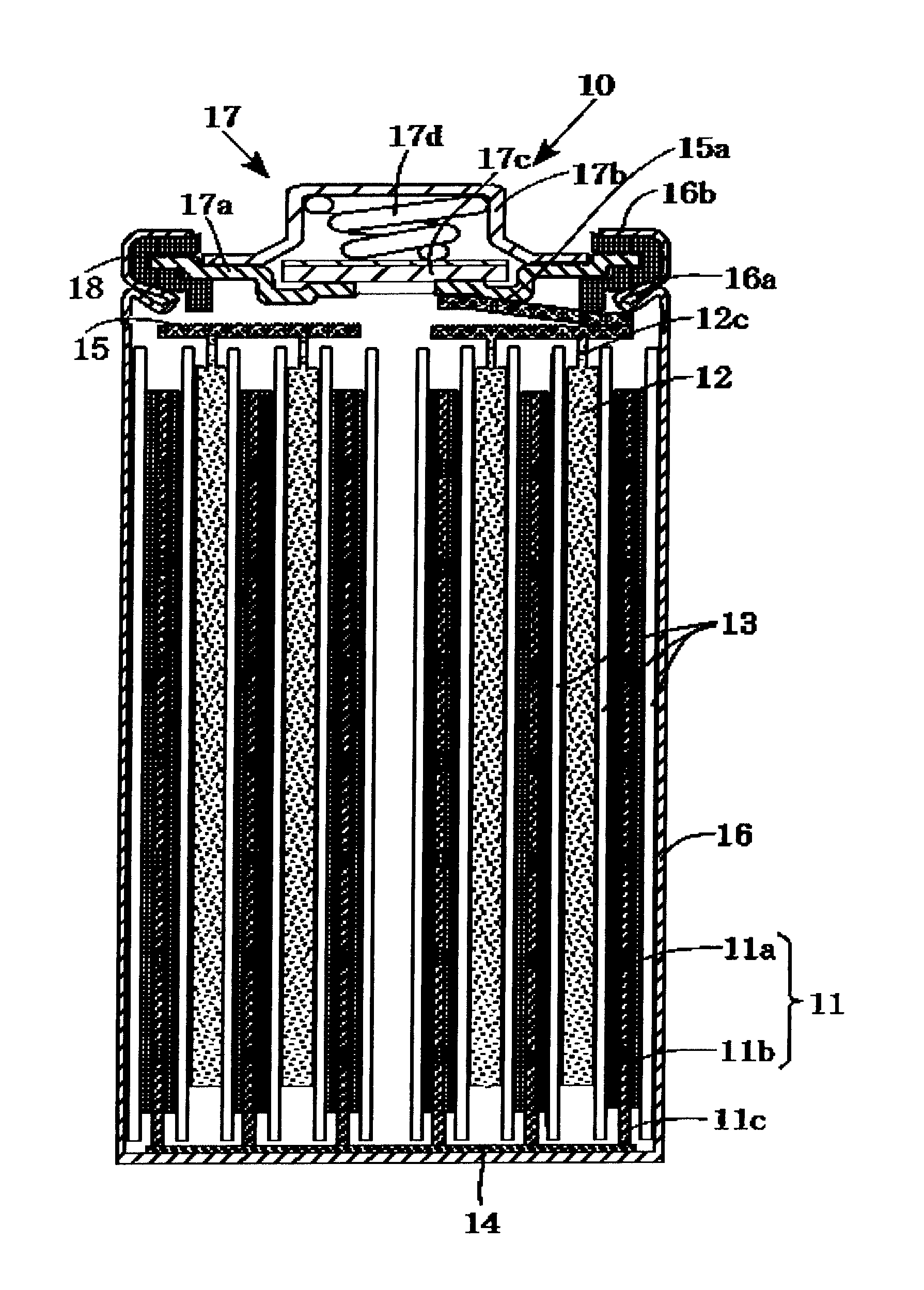

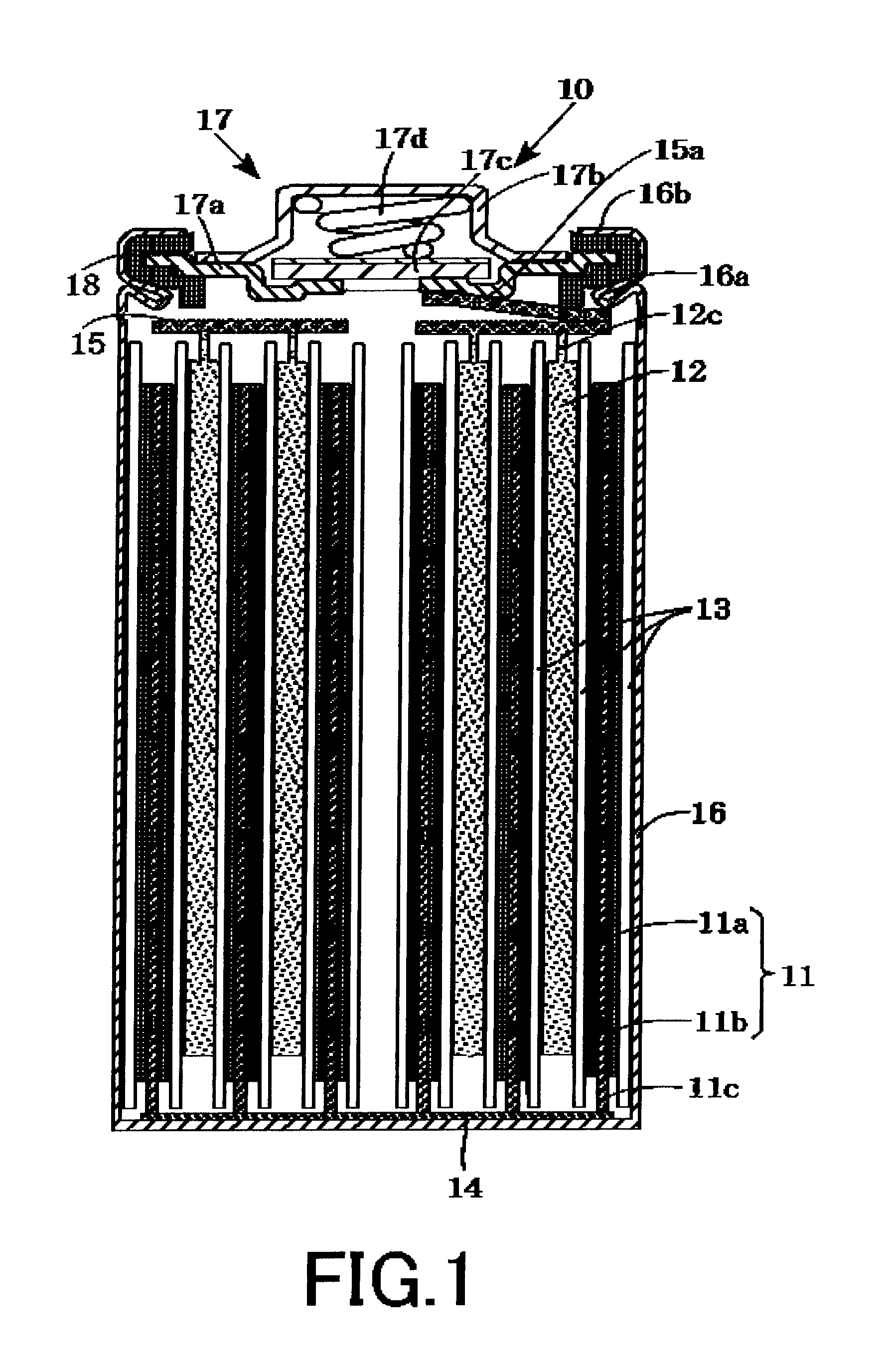

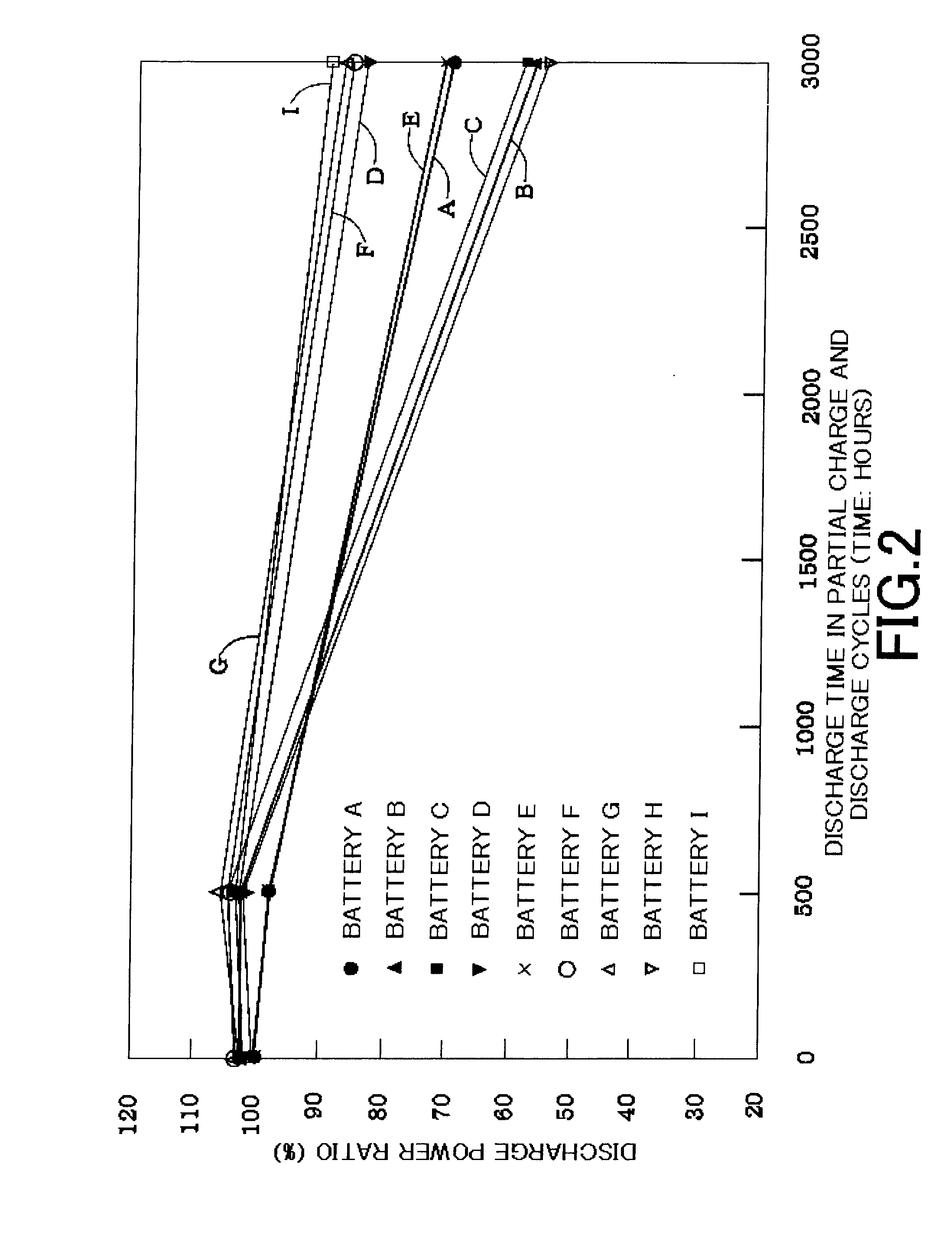

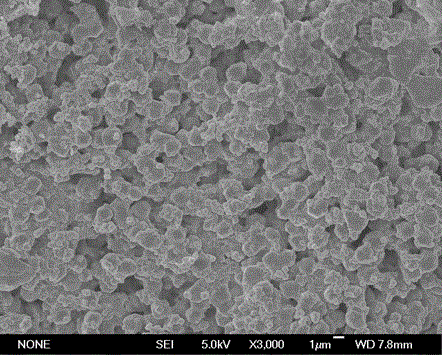

Hydrogen storage alloy for alkaline storage battery, and alkaline storage battery and alkaline storage battery system each including negative electrode having the alloy

ActiveUS20110229755A1Increase output powerIncrease discharge powerHydrogenMultiple metal hydridesRare-earth elementSurface layer

Owner:SANYO ELECTRIC CO LTD

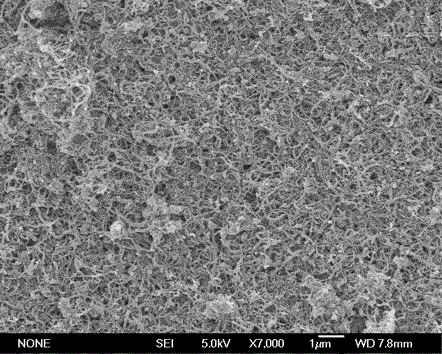

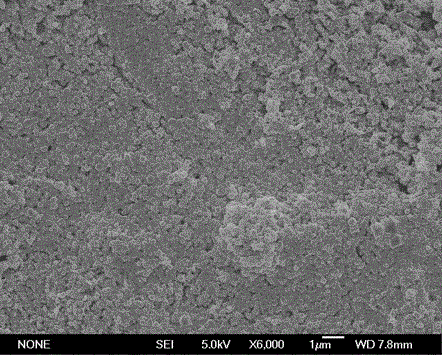

Novel metal-organic framework material separation membrane based on carbon nanotube substrate and preparation method thereof

InactiveCN105771685AHigh selectivityImprove permeabilitySemi-permeable membranesSurface layerFiltration

Owner:BEIJING FORESTRY UNIVERSITY

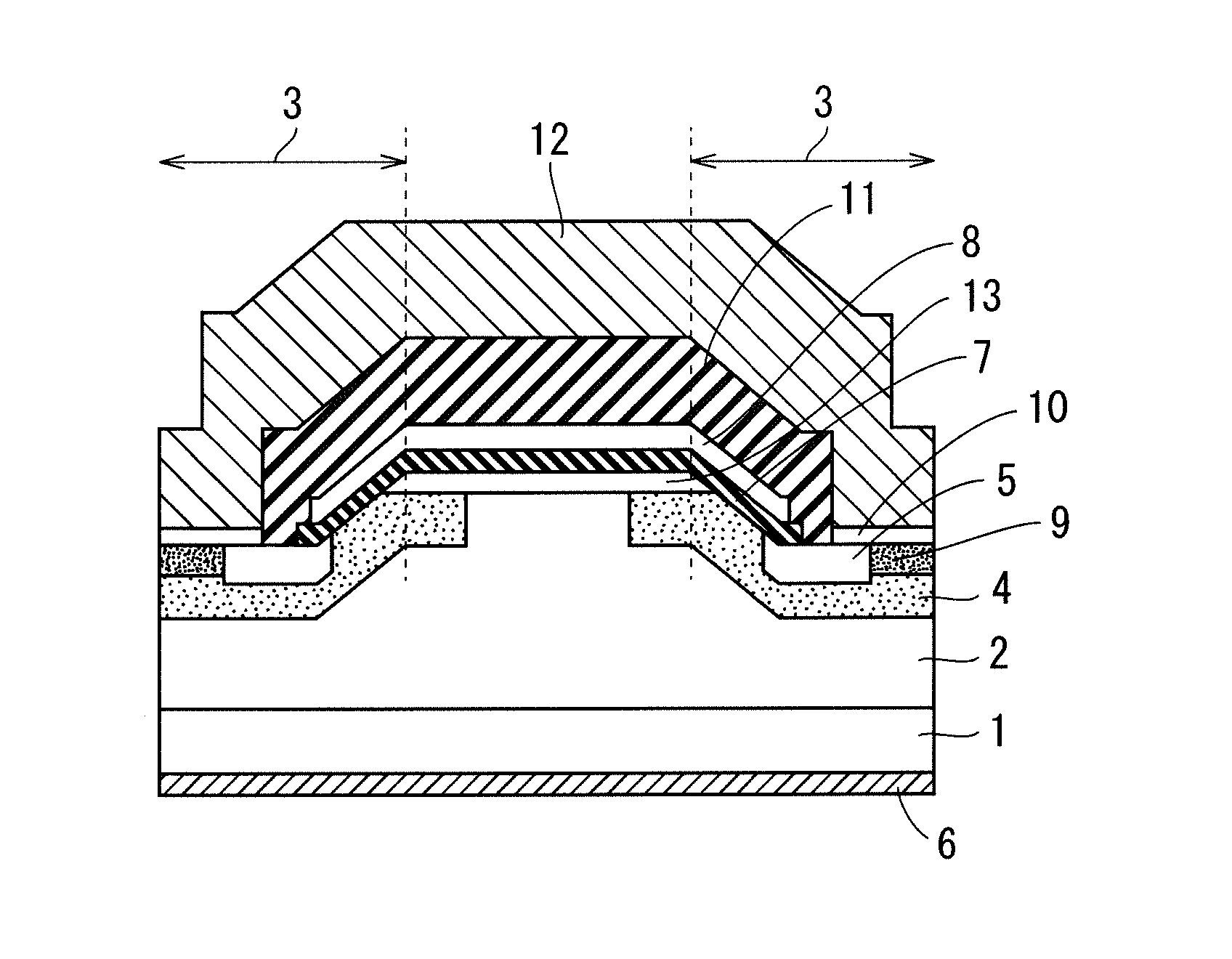

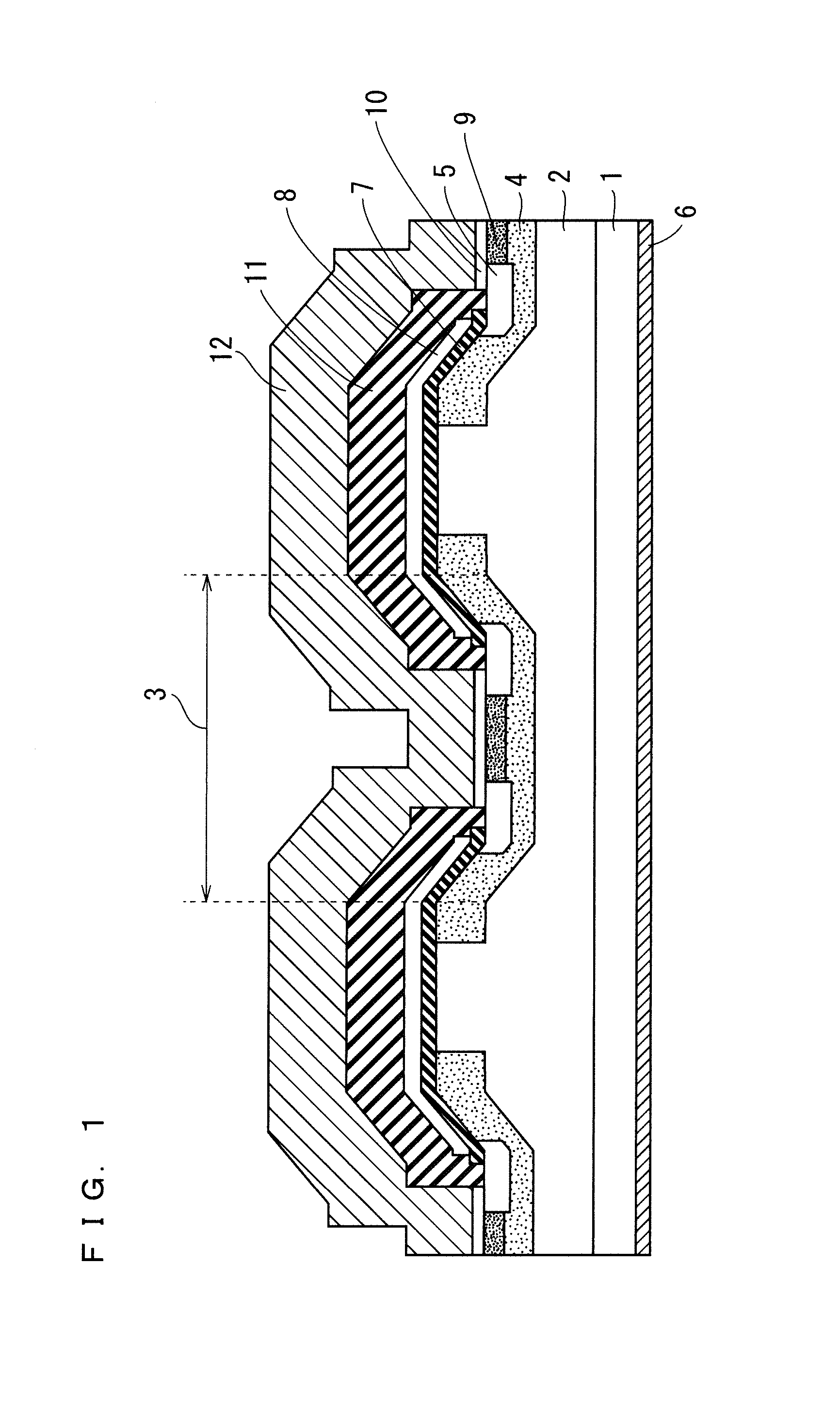

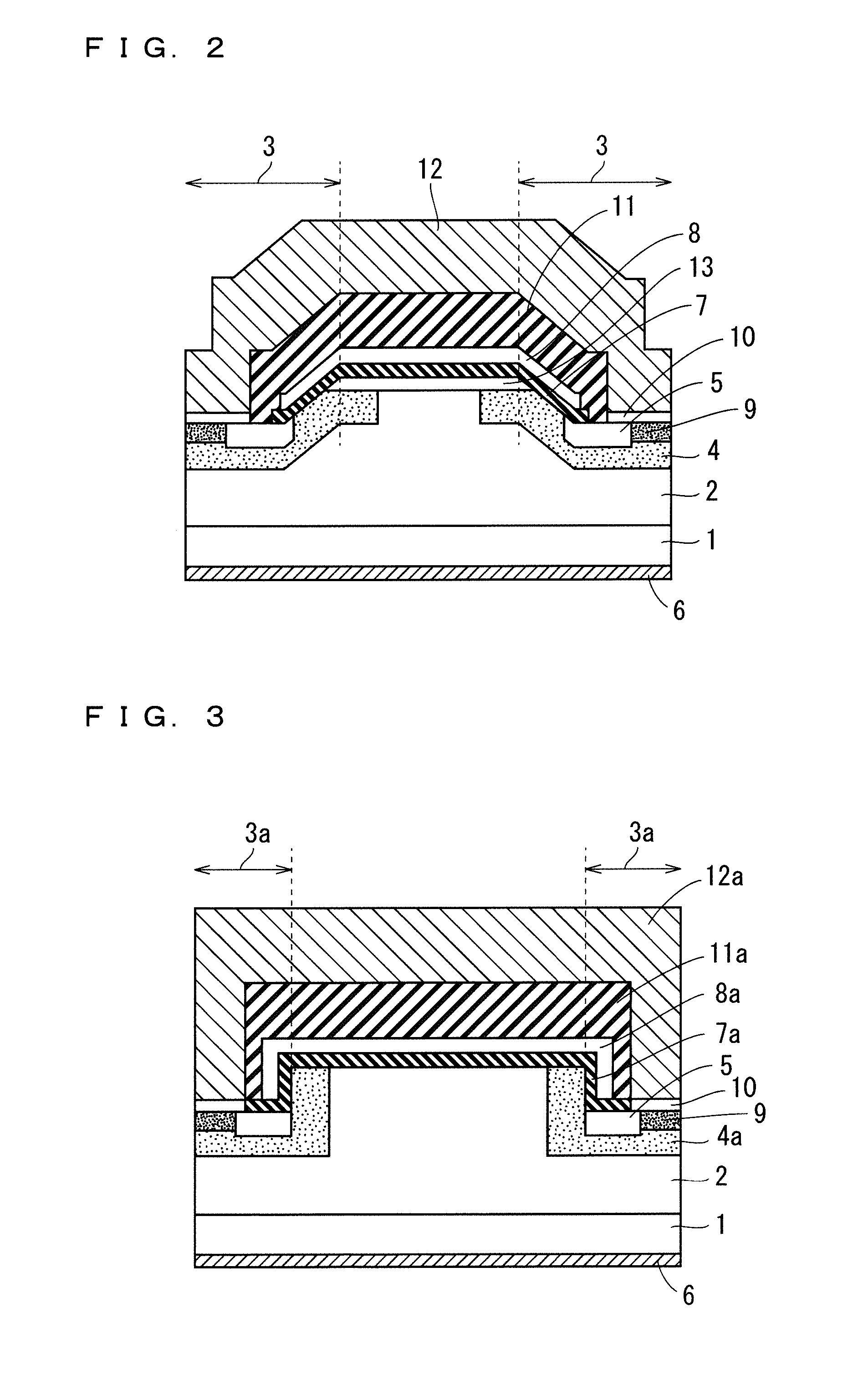

Silicon carbide semiconductor device

ActiveUS20160225905A1Reduce channel resistanceImprove reliabilityTransistorSemiconductor/solid-state device manufacturingPhysicsSurface layer

Owner:MITSUBISHI ELECTRIC CORP

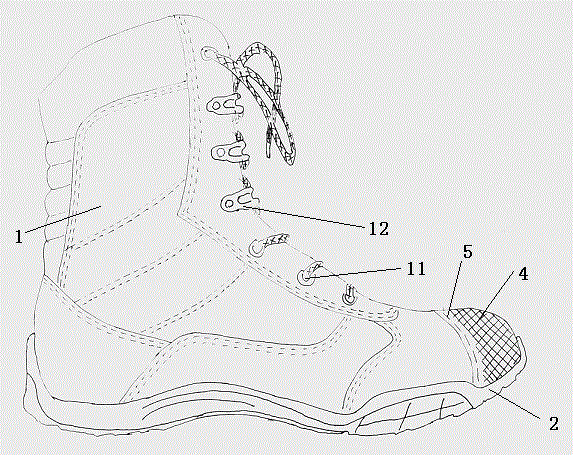

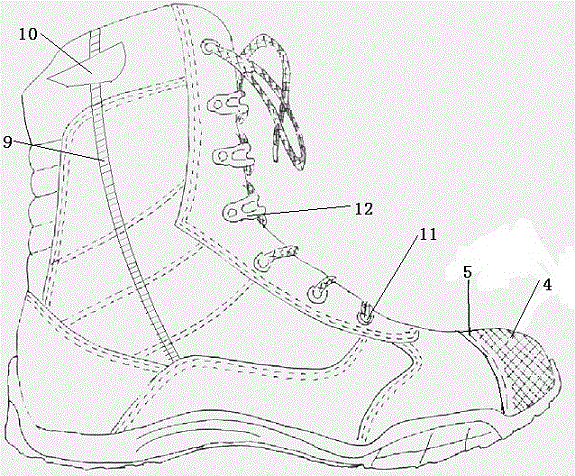

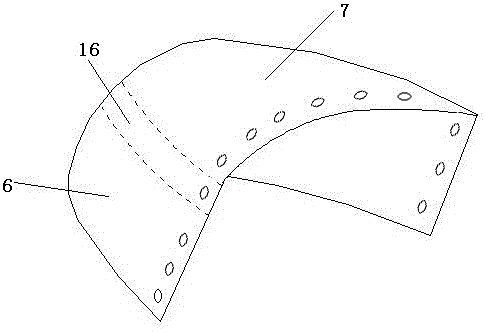

Safety shoe with external steel toe and production process of safety shoe

The invention discloses a safety shoe with an external steel toe and a production process of the safety shoe, and belongs to the technical field of labor protection appliances. The safety shoe comprises an upper, shoe sole, a tongue and the steel toe. The steel toe is arranged at the head portion of the upper. The safety shoe is characterized in that the steel toe is arranged on the outer layer of the surface skin of the upper, the inner side of the steel toe and the surface layer of the surface skin of the upper are connected in a glued mode, the bottom end of the steel toe is attached to the corresponding position of the edge of the bottom of the upper and fixedly connected with the shoe sole, the edges of the top face and the side face of the steel toe are evenly provided with a plurality of fixing holes, the positions, corresponding to the fixing holes, of the surface skin of the upper are provided with connecting holes, and mark threads penetrate through the fixing holes and the connecting holes so that the upper and the steel toe can be fixedly connected. The safety shoe is simple in structure and easy to produce and manufacture; the external steel toe is novel, fashionable and attractive, the comfort and safety are improved, and the safety shoe is durable in use and has wide market space.

Owner:江苏凯高鞋业有限公司

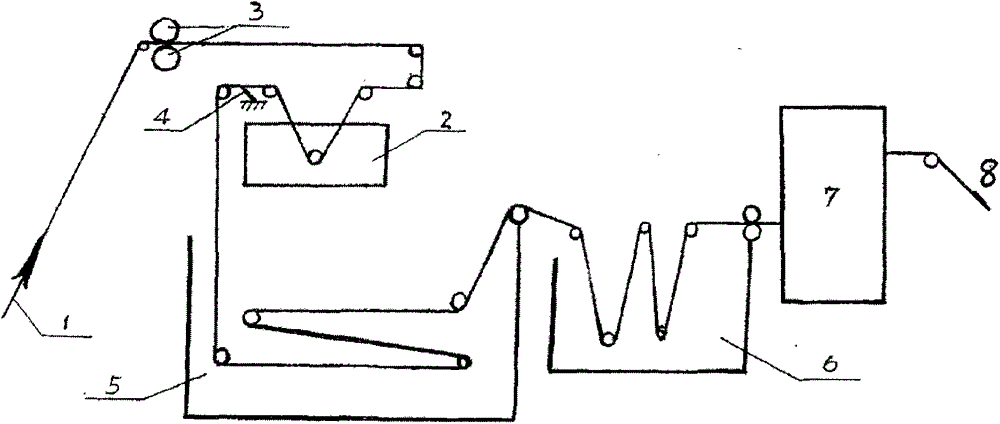

Method for making coated filter cloth through wet process

InactiveCN103952914AHigh porosityHigh Solids RetentionFibre treatmentFiltration separationPorosityYarn

Owner:刘冠利

Automobile trim material combined with non-woven fabric and woven fabric

InactiveCN105034535ASignificant advantage effectLow priceSynthetic resin layered productsLaminationSodium bicarbonateWarm water

Owner:湖北南泽汽车复合材料有限公司

Surface layer abrasion-proof paper

ActiveCN101148849AHighly transparentExtended service lifeSpecial paperPaper/cardboardSurface layerWear resistant

The surface wear resistant paper for making decorating thermosetting laminated sheet contains stuffing and assistant. It has high transparency, high wear resistance, long service life, environment friendship and other advantages. It is applied widely for the surface of furniture, vehicle, ship, airplane, floor, instrument, etc.

Owner:SHANDONG QIFENG SPECIAL PAPER

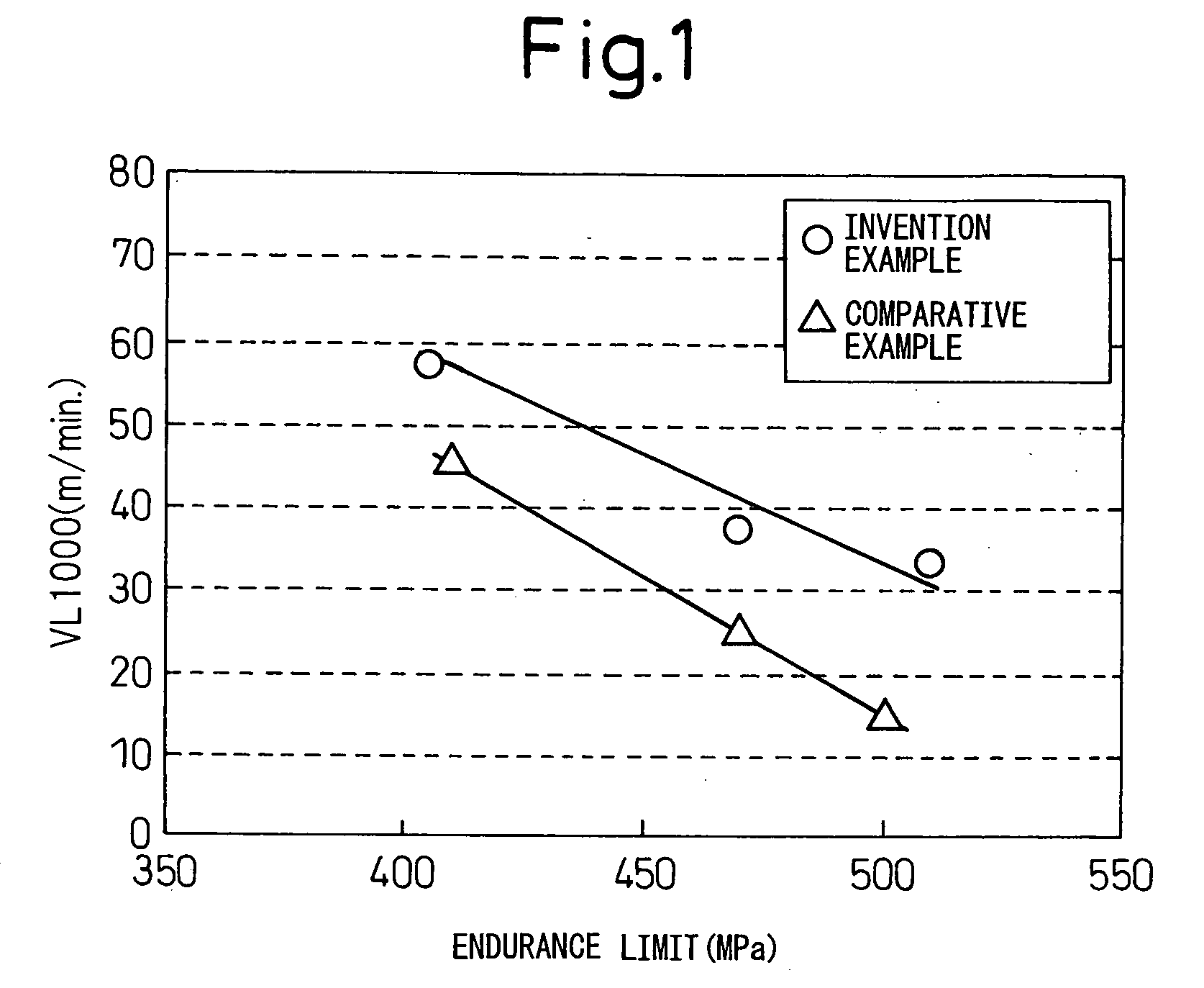

Fine grain surface layer steel part and method of production of same

InactiveUS20090095383A1Strength differenceMetal-working apparatusSurface layerUltimate tensile strength

Owner:NIPPON STEEL CORP

Quartz rod cutting process

ActiveCN109795041ANo vibrationThere will be no cutting deformationPolyureas/polyurethane adhesivesWax adhesivesWaxHydrofluoric acid

Owner:扬州美和光电科技有限公司

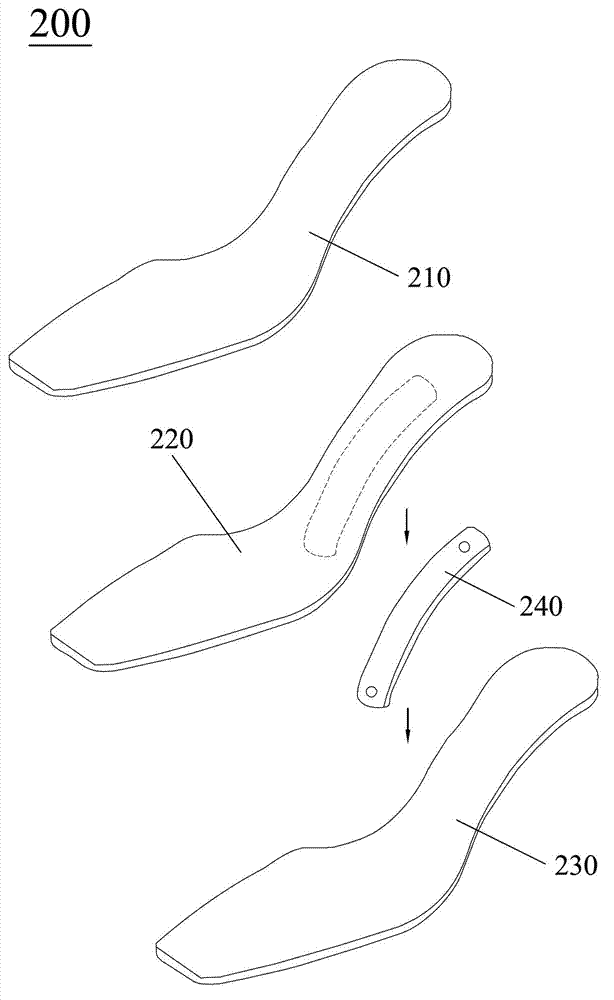

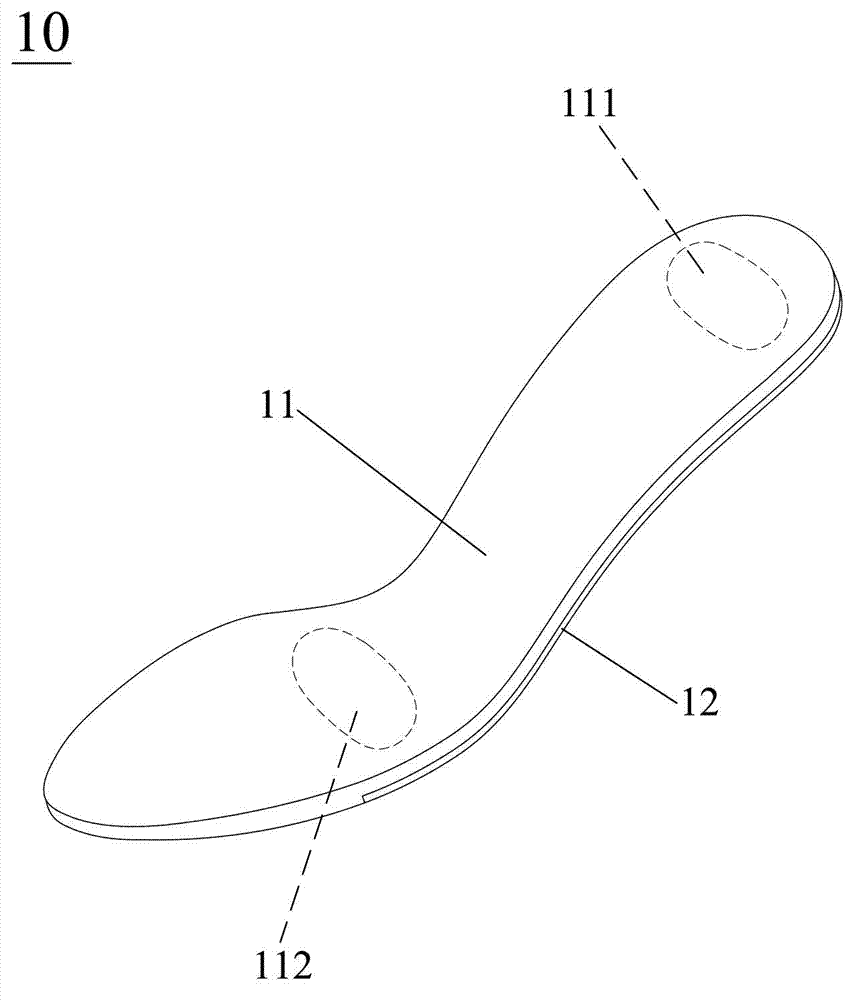

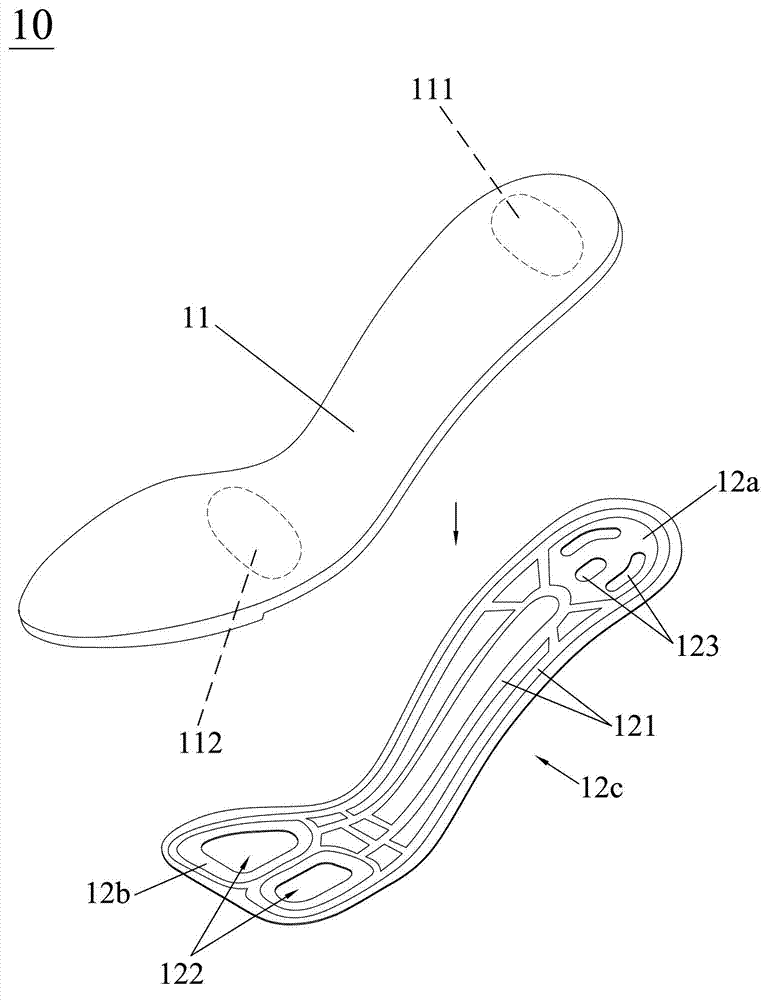

Increasing insole with massage convex points

Owner:ALAYA FOOTWEAR

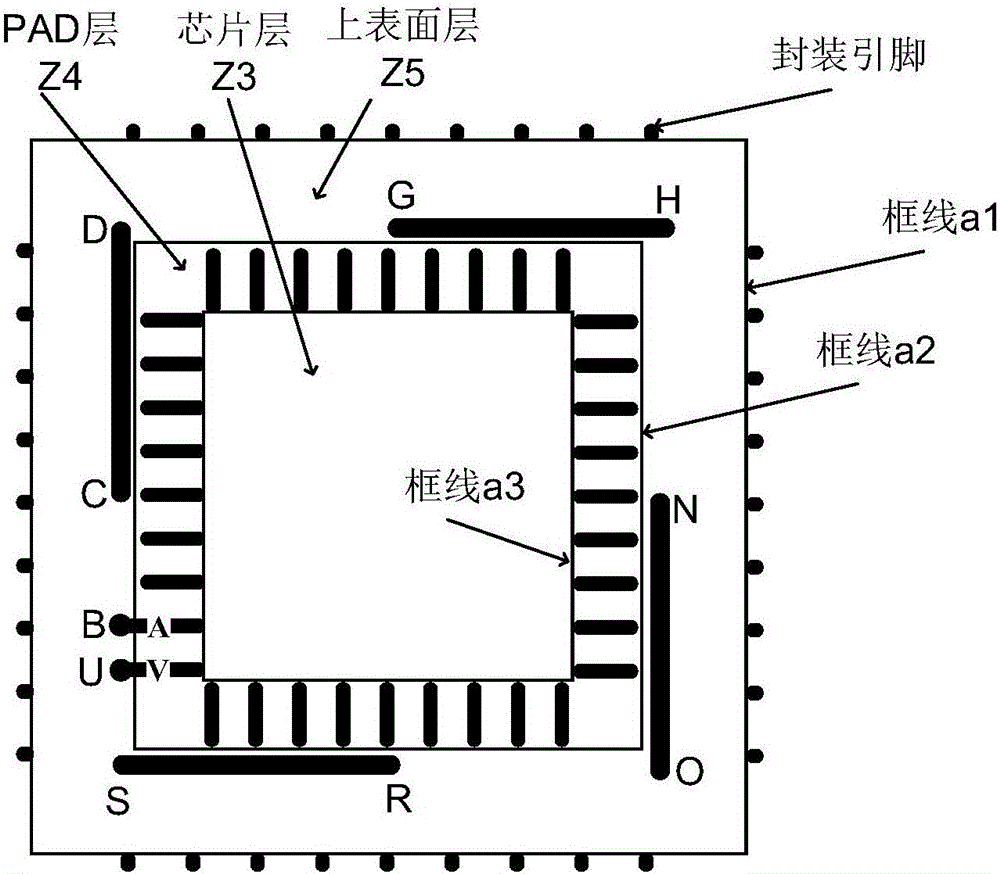

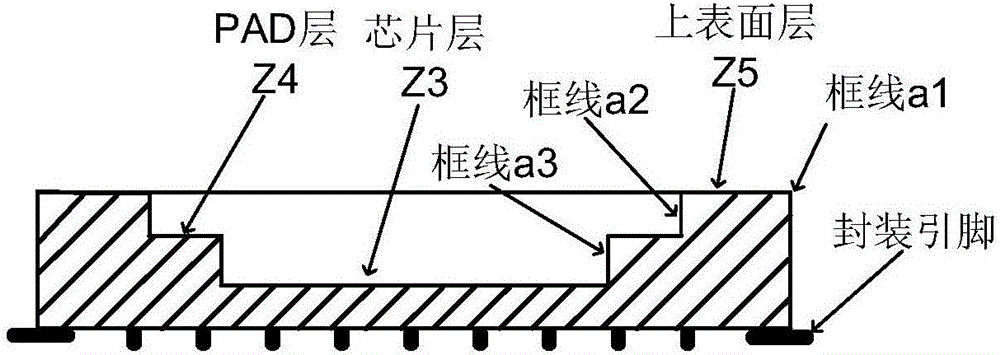

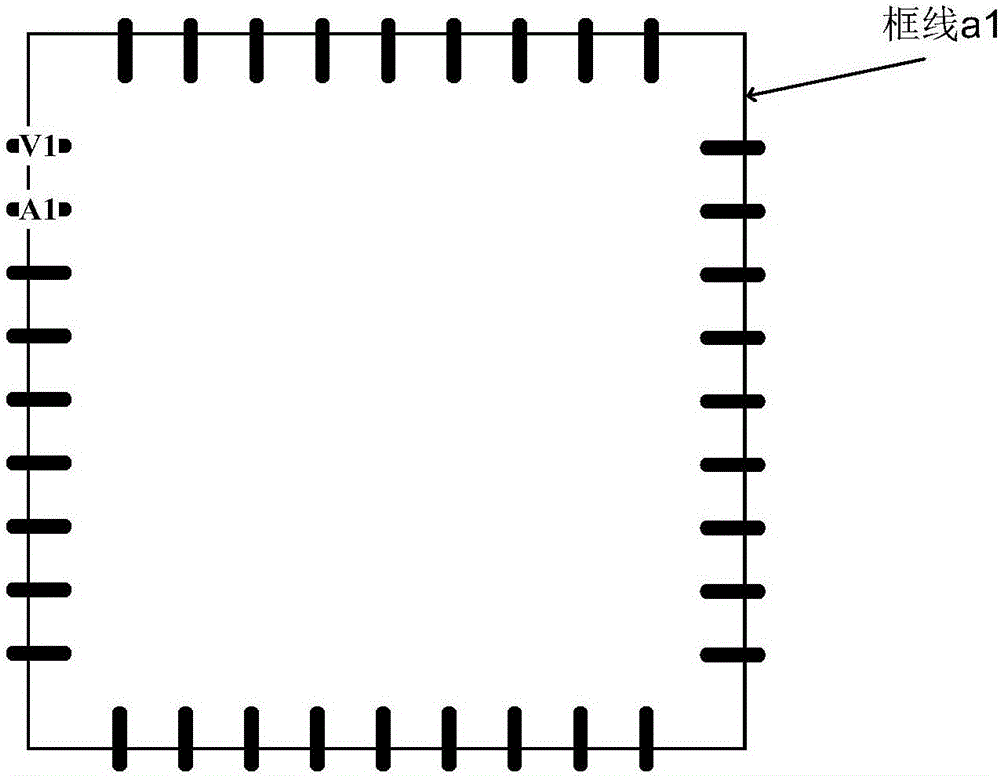

Safe packaging structure used for anti-attack chip, and packaging integrity detection method

ActiveCN106548986AEnsure safetyEffective detectionSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsSurface layerCo-fired ceramic

Owner:TIANJIN UNIV

Preparation method of pearlescent anti-crease waterproof moisture-permeable polyurethane synthetic leather

InactiveCN105568701AImprove wear resistanceImprove wrinkle resistanceTextiles and paperWater basedFiber

Owner:HANGZHOU FUYANG WEIWEN ENVIRONMENTAL PROTECTION TECH CO LTD

Fabric and usage thereof

The invention aims at providing fabric. The fabric comprises a surface layer which is formed by mutual interweaving of warp yarn and weft yarn, an inner layer and a plurality of filling cavities for be filled with down feathers, the filling cavities are arranged between the surface layer and the inner layer at intervals, at least one of the warp yarn and the weft yarn comprises special-shaped fiber yarn which is made of a plurality of special-shaped filaments, and the weight of the special-shaped fiber yarn in the fabric accounts for a preset proportion. After the special-shaped fiber yarn and non-special-shaped fiber yarn are mutually interwoven and the fabric is formed, and covering coefficients of the surface layer and the inner layer of the fabric are both greater than 1600. Compared with the prior art, in the same warp and weft yarn density, pores are smaller, the number of the pores is larger, the pores are smaller than the diameter of the down feathers, and therefore the down feathers can be prevented from getting out of the fabric, and through the usage of the number of the pores, the fabric permeability is improved and the fabric comfort is ensured.

Owner:ZHEJIANG YISHA TEXTILE TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap