Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

22 results about "Sputtering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In physics, sputtering is a phenomenon in which microscopic particles of a solid material are ejected from its surface, after the material is itself bombarded by energetic particles of a plasma or gas. It occurs naturally in outer space, and can be an unwelcome source of wear in precision components. However, the fact that it can be made to act on extremely fine layers of material is exploited in science and industry—there, it is used to perform precise etching, carry out analytical techniques, and deposit thin film layers in the manufacture of optical coatings, semiconductor devices and nanotechnology products.

Copper or copper alloy target/copper alloy backing plate assembly

Owner:JX NIPPON MINING& METALS CORP

Method for preparing diamond-like composite coating on surface of piston ring

InactiveCN101665940AImprove wear resistanceImprove the lubrication effectVacuum evaporation coatingSputtering coatingLow temperature plasmaMagnetic filtration

The invention relates to a method for preparing a diamond-like composite coating with high hardness and good abrasion proof and self lubricating properties on the surface of a piston ring. In the method, a nitriding layer with high bonding strength, high hardness and good abrasion resistance is formed on the surface of the piston ring by the low-temperature plasma nitriding treatment, a non-hydrogen diamond-like surface layer with solid lubricating property is deposited by the combination of magnetic filtration cathode arc and magnetic control sputtering, and finally the nitriding / diamond-likecomposite coating, which is dense and smooth and possesses excellent abrasion proof and self-lubricating properties, is obtained on the surface of the piston ring. Compared with the durionising piston ring or CrN plating piston ring, the coating of the piston ring of the invention has higher comprehensive performance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High-hardness and high-elasticity-modulus multi-component nitride coating and preparation method thereof

InactiveCN106835037AIngredient ControlHigh hardnessVacuum evaporation coatingSputtering coatingSputteringAlcohol

The present invention is a multi-component nitride coating with high hardness and high elastic modulus. Its chemical formula is AlCrTiZrNbN, and the atomic ratios of Al, Cr, Ti, Zr, Nb and N are respectively 8-12%: 8-12 %: 8~12%: 8~12%: 8~12%: 48~52%, the thickness of the coating is 2~5μm. The present invention also provides a method for preparing the above-mentioned nitride coating. Firstly, the surface of the substrate is subjected to mirror polishing, then ultrasonically cleaned with acetone and alcohol, and after vacuum ion cleaning, the AlCrTiZrNbN layer is deposited by radio frequency reactive sputtering, wherein AlCrTiZrNbN is mostly The component nitride coating is composed of AlCrTiZrNb alloy target with equiatomic molar ratio in (Ar+N 2 ) atmosphere prepared. The coating of the invention has high hardness and high modulus of elasticity, and can be used as a novel protective coating for various service occasions such as cutting tools and molds.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

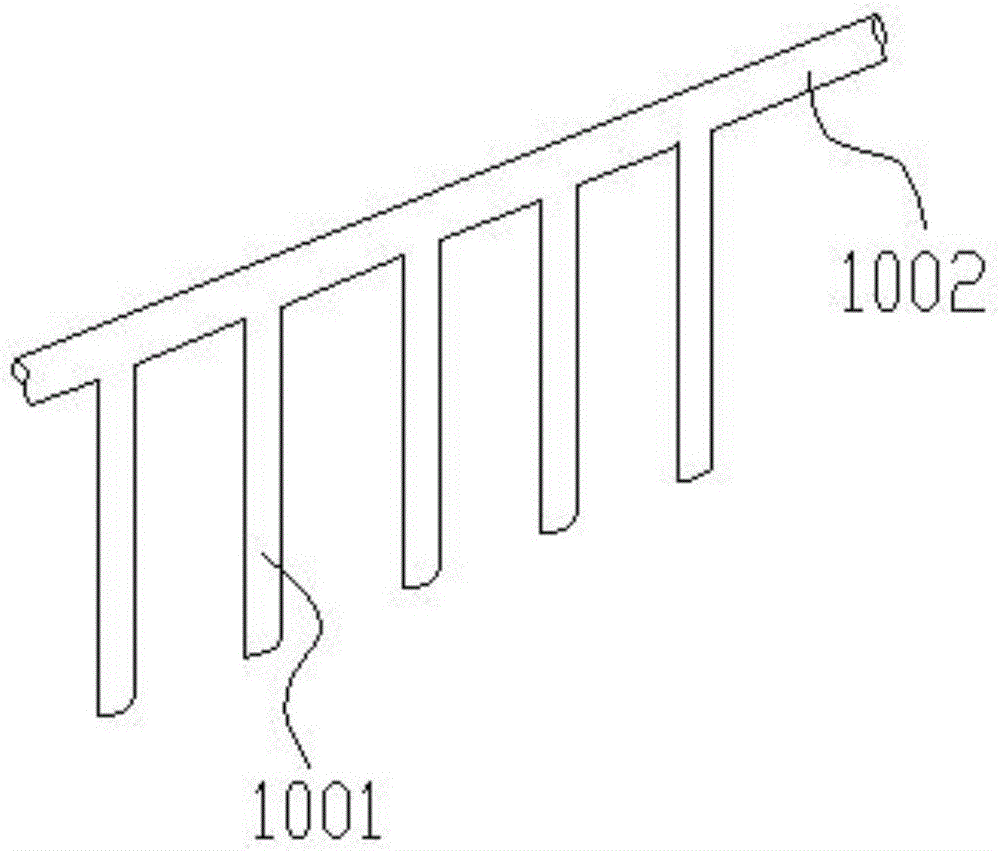

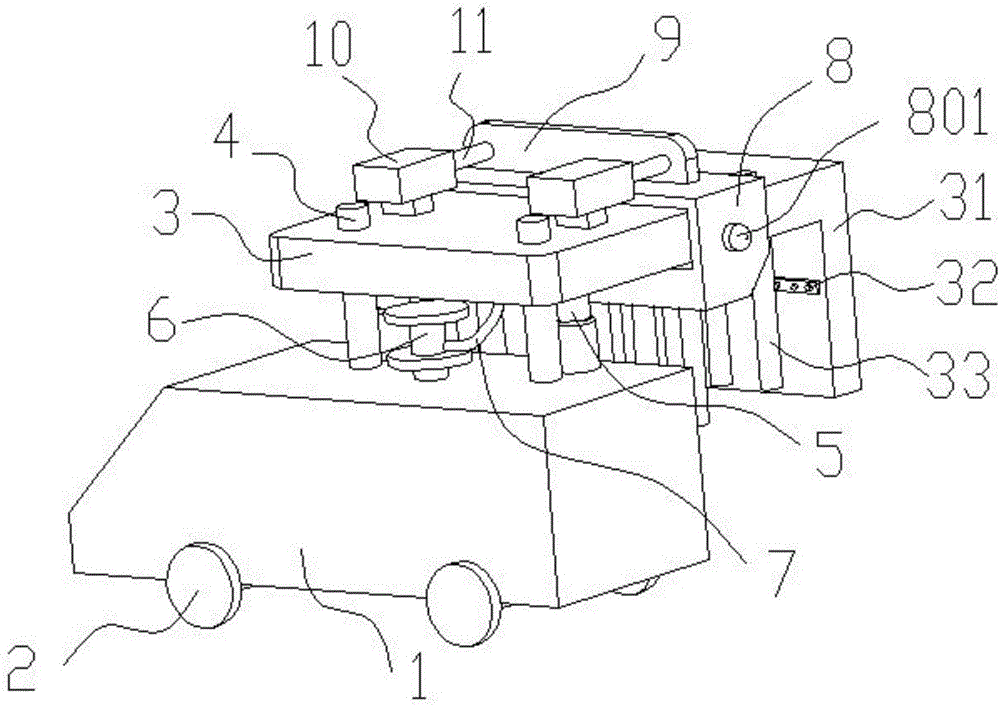

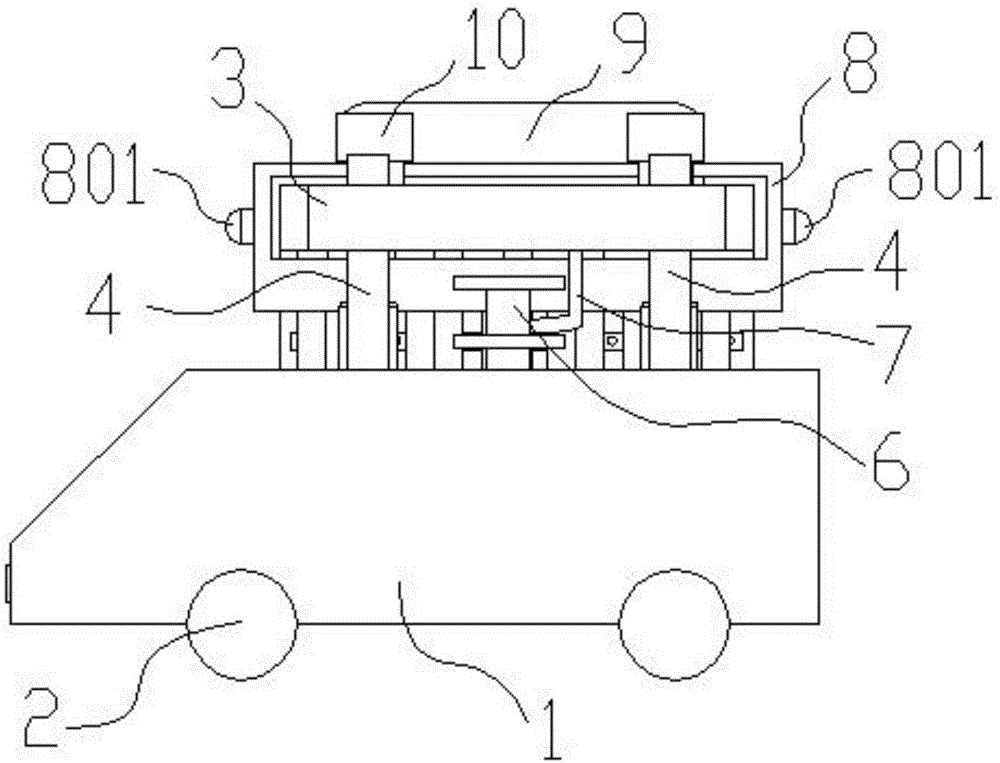

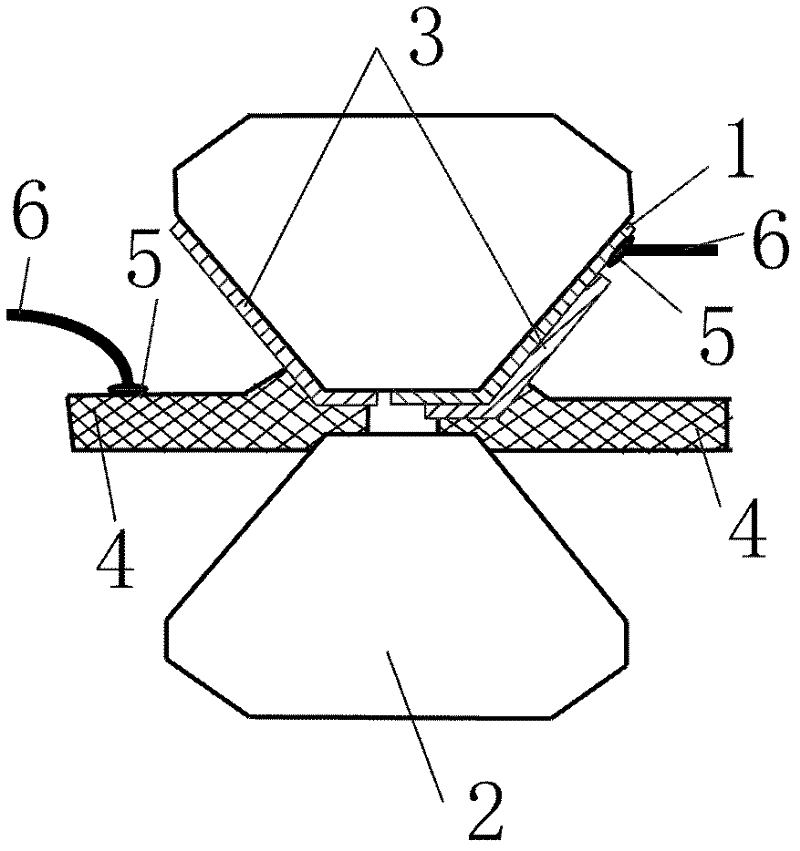

Road guardrail automatic cleaning car

Owner:山东瑞源康生物医药有限公司

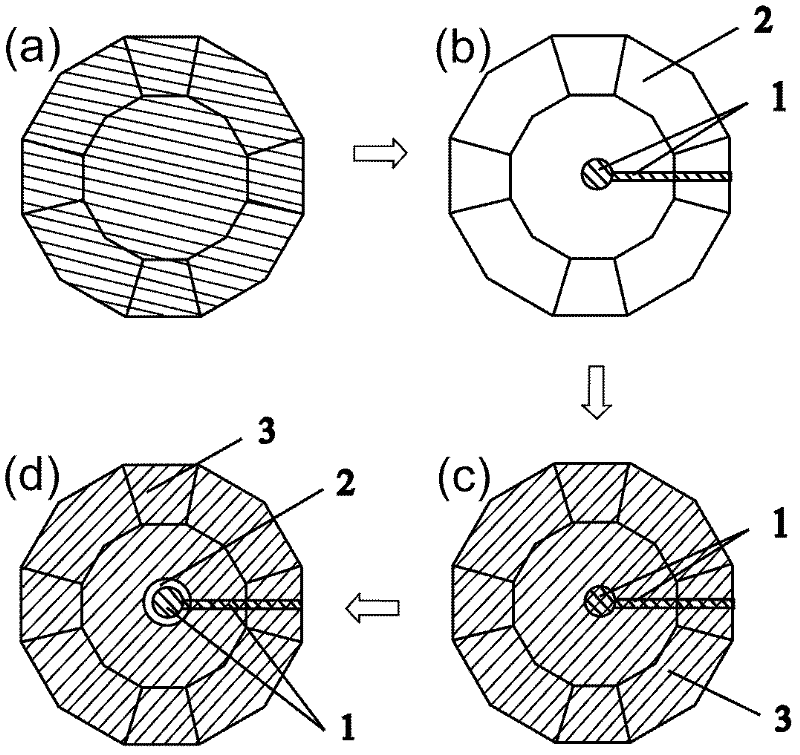

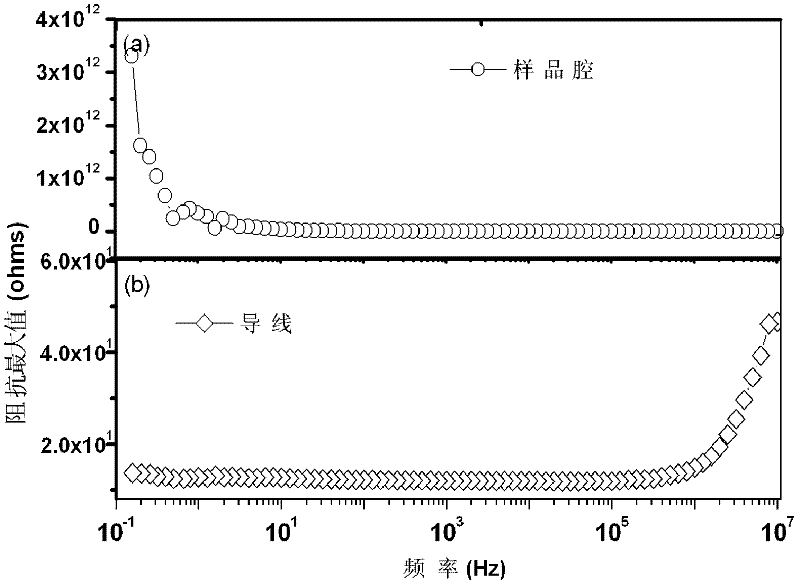

Electrode for high-voltage in-situ impedance spectroscopy measurement and its preparation method and application

InactiveCN102288824AFix fixitySolve insulation problemsResistance/reactance/impedenceEtchingInsulation Problem

Owner:JILIN UNIV

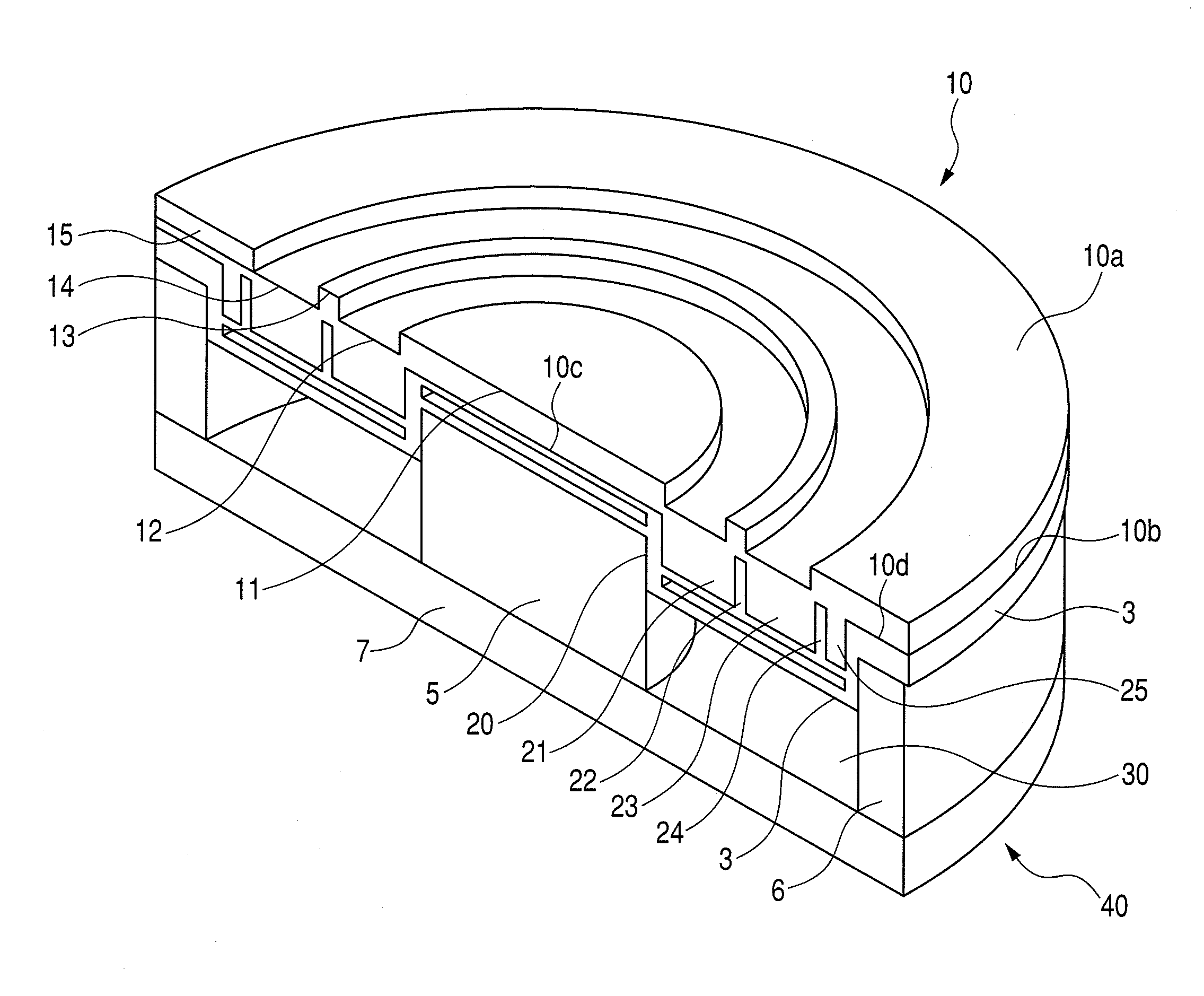

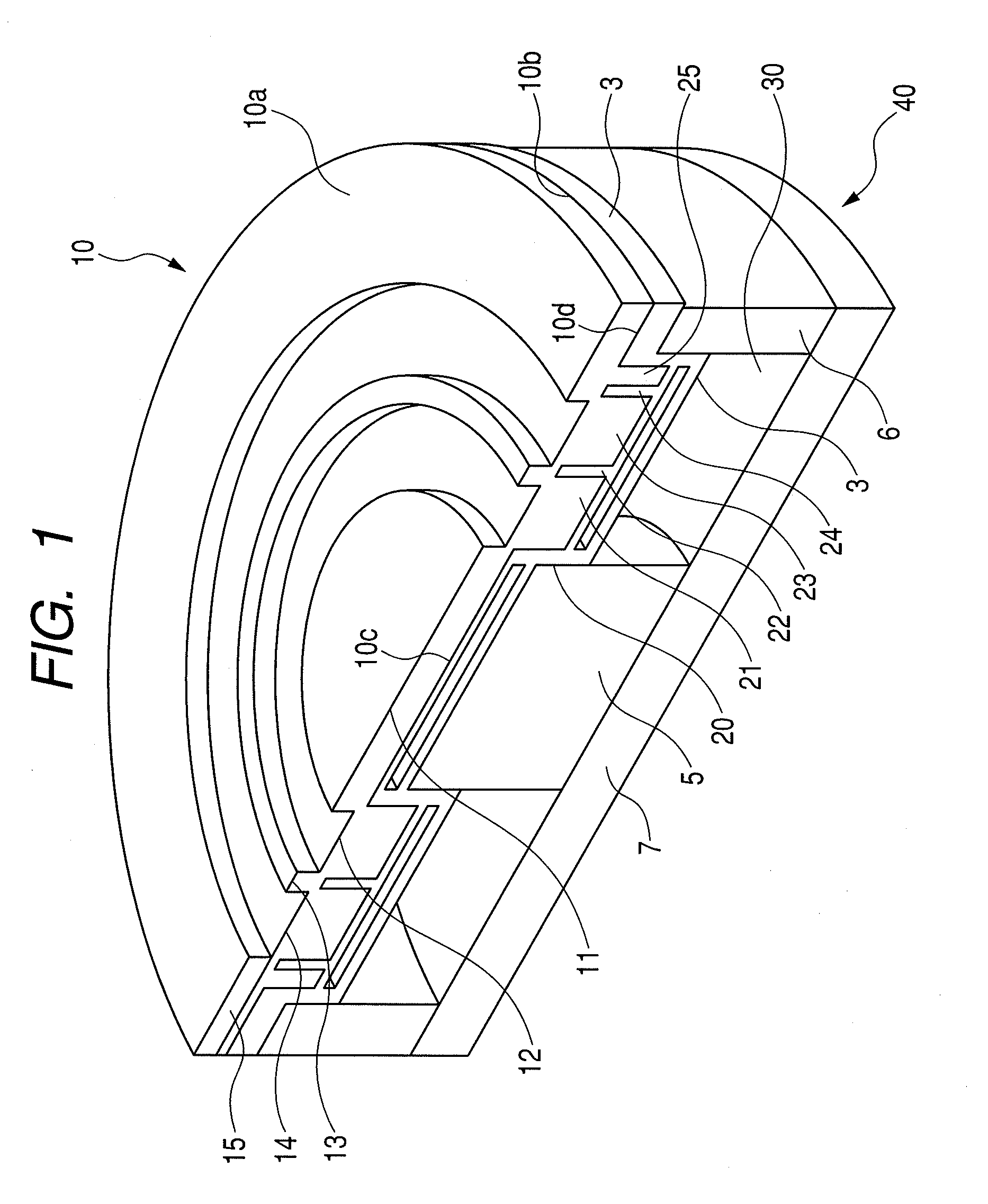

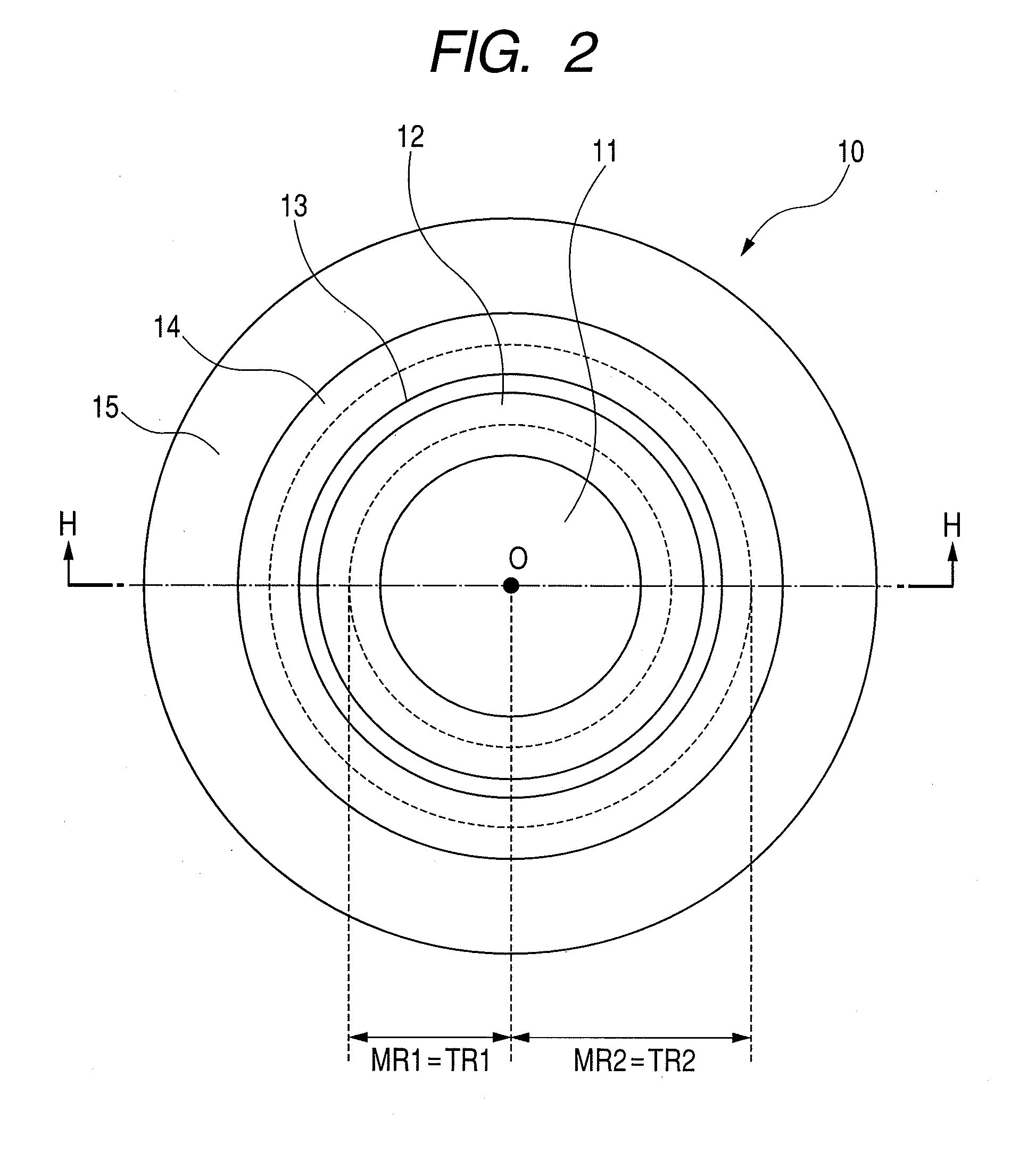

Magnetron sputtering cathode, magnetron sputtering apparatus, and method of manufacturing magnetic device

Owner:CANON ANELVA CORP

Manufacturing method of surface mounted device resistor

ActiveCN102082017ALow costReduce dosageResistors adapted for applying terminalsSilver pasteSputtering

Owner:UNIROYAL ELECTRONICS IND

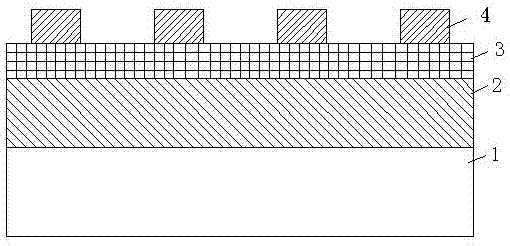

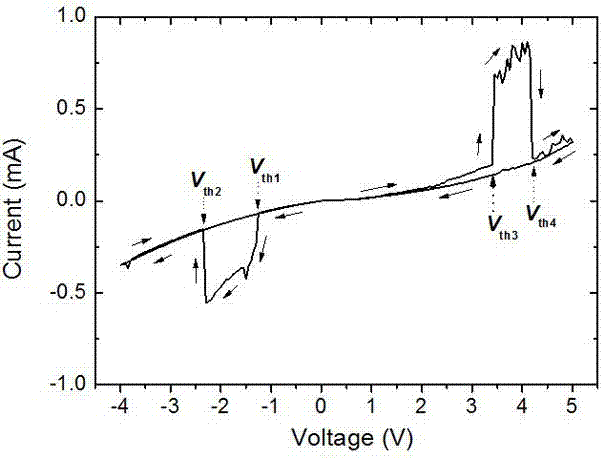

Complementary type resistive random access memory and preparation method thereof

InactiveCN107240642AAvoid crosstalkSimple chemical structureElectrical apparatusSputteringMedia layer

Owner:HENAN INST OF ENG

Nano multi-layer composite solid lubricating film layer with long service life under space irradiation and preparation thereof

ActiveCN112760607AAchieve self-lubricationReduce coefficient of frictionVacuum evaporation coatingSputtering coatingSputteringAlloy substrate

The invention discloses a nano multi-layer composite solid lubricating film layer with a long service life under space irradiation and preparation thereof. The nano multi-layer composite solid lubricating film layer composed of a Ti binding layer, a TiN bearing layer and an AgTiNi / MoS2Ti nano multi-layer lubricating functional layer is deposited on a titanium alloy substrate, an aluminum alloy substrate, a stainless steel substrate, a bearing steel substrate and the like by adopting a closed magnetic field unbalanced magnetron sputtering technology. The nano multi-layer composite film layer can reliably serve for a long time in strong space irradiation environments such as low-orbit high atomic oxygen density, medium-high-orbit high electron proton density and high ultraviolet irradiation dose, and is high in bearing capacity and low in friction coefficient, thus, the service life of a moving part of a spacecraft exposed in the space irradiation environments can be greatly prolonged, and the reliability of the moving part is improved. In addition, the preparation method has the characteristics that the process is environment-friendly and flexible, the film thickness is uniform, the compactness is good, the preparation process of the film layer is controlled in a programmed manner, the modulation period of the film layer is easy to regulate and control, and batch treatment can be realized, industrial production is easy to realize, and the good application prospect is achieved.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Manufacturing method for attenuation sheet

Owner:NO 43 INST OF CHINA ELECTRONICS TECH GRP CETC

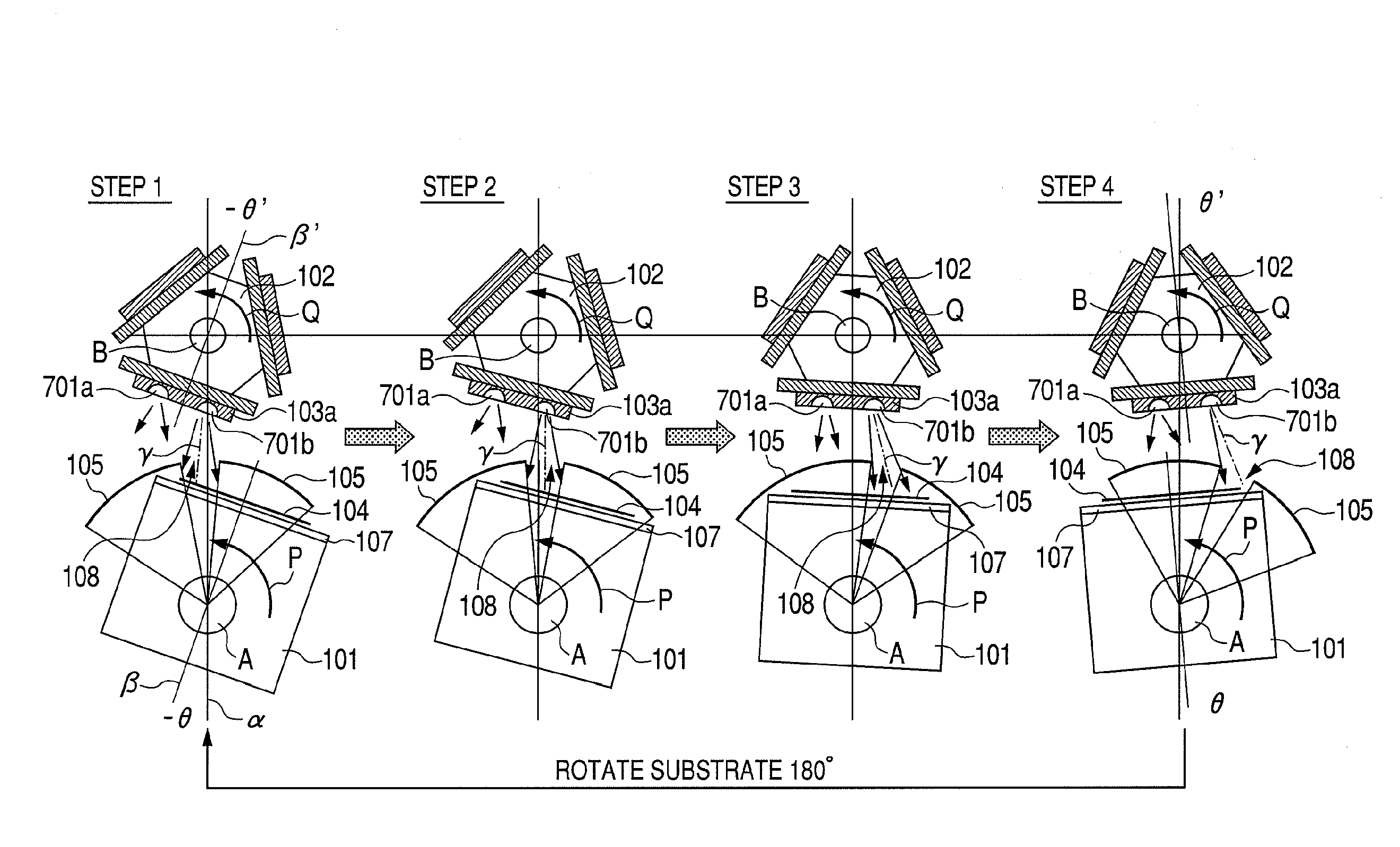

Sputtering apparatus and film forming method

InactiveUS20100155227A1Reduce columnar growthImprove film qualityCellsElectric discharge tubesSputteringEngineering

Owner:CANON ANELVA CORP

Cu-Mn alloy film, Cu-Mn alloy sputtering target material and Cu-Mn alloy film manufacturing method

ActiveCN104212997AImprove display qualityVacuum evaporation coatingSputtering coatingSputteringLight reflectance

The invention provides a Cu-Mn alloy film, Cu-Mn alloy sputtering target material and Cu-Mn alloy film manufacturing method meeting new requirements for low reflection required by electrode films or wiring films to improve display quality of plane display elements with high definition. The Cu-Mn alloy film is formed by in a way that when metal component is viewed as 100atom%, the metal component comprises 32 to45atom% Mn, Cu and unavoidable impurities; visible light reflectance of the Cu-Mn alloy film is 30% below; and the reflectance is suitable for the electrode films or the wiring films for the plane display element.

Owner:PROTERIAL LTD

Baking-free long water gap for large-plate-blank continuous casing low-carbon and low-silicon steel and preparation process of baking-free long water gap

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

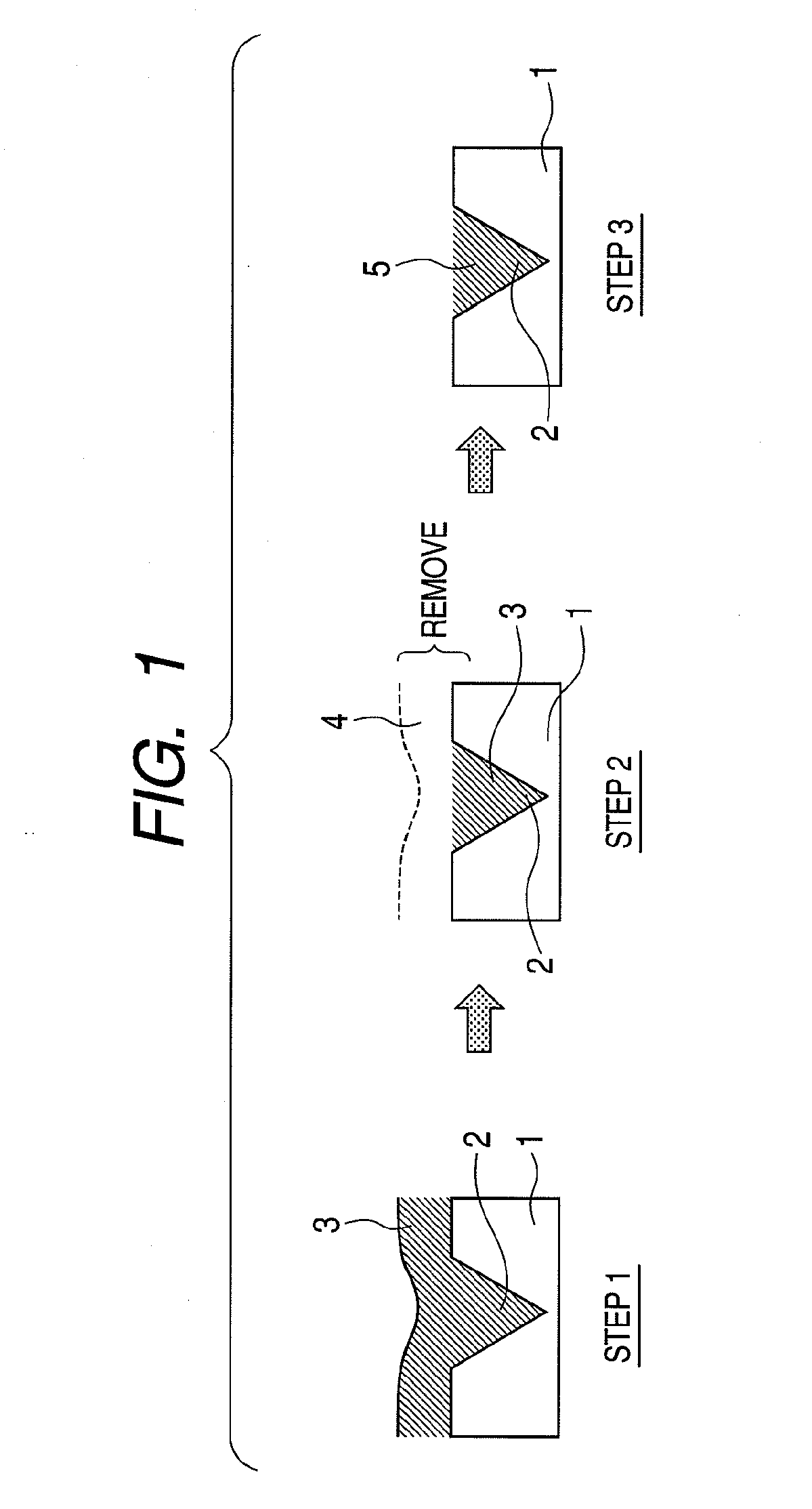

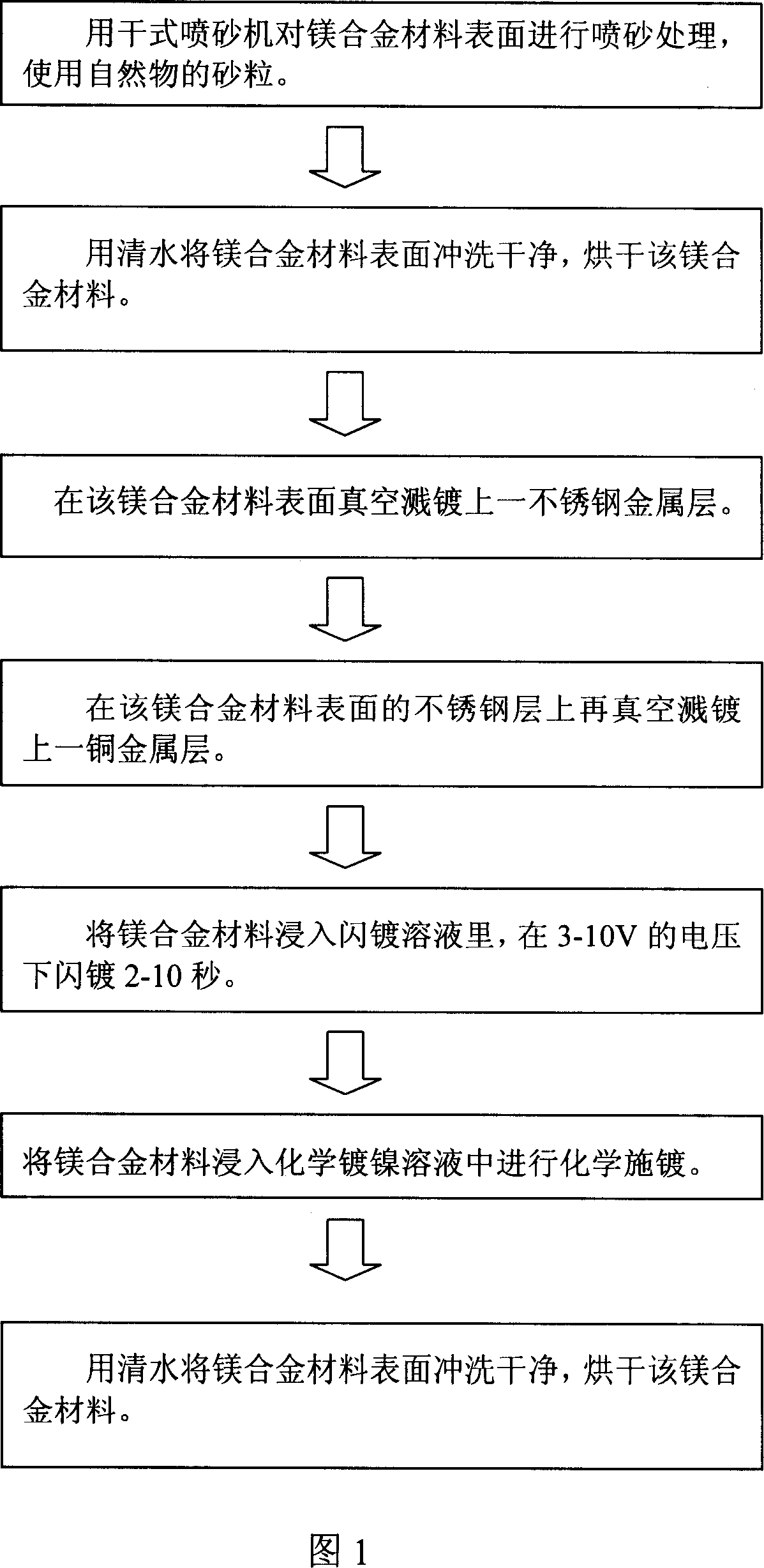

Magnesium-alloy surface treatment

InactiveCN1940136AImprove corrosion resistanceImprove wear resistanceSuperimposed coating processElectroless nickelSputtering

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

High-resistivity high-entropy alloy film and preparation method thereof

ActiveCN110129732AIncrease temperatureHigh hardnessVacuum evaporation coatingSputtering coatingSputteringHigh entropy alloys

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Cleaning method for improving uniformity of Schottky barrier layer

InactiveCN106935486AImprove uniformityEfficient removalSemiconductor/solid-state device manufacturingSputteringSchottky barrier

Owner:TIANJIN ZHONGHUAN SEMICON CO LTD

Preparation method of silicon tube sputtering target material

ActiveCN112410737ASelf-strength is goodHigh hardnessSiliconVacuum evaporation coatingSputteringUltrasound device

Owner:光洋新材料科技(昆山)有限公司

Ion transport layer for inorganic electrochromism and preparation method of assembly composite membrane system

PendingCN114326241AImprove discoloration efficiencyLoose structureNon-linear opticsSolid state electrolyteElectrochromism

The invention relates to an inorganic electrochromism ion transport layer and assembly composite film system preparation method, which is characterized in that a WO3-based film, an AlPO4-based film, a NiO-based film and a TCO layer are sequentially prepared on a glass substrate / TCO layer through a chemical liquid phase method or a magnetron sputtering method, the WO3-based film, the NiO-based film and the TCO layer are prepared through the magnetron sputtering method, and the WO3-based film, the AlPO4-based film, the NiO-based film and the TCO layer are arranged on the glass substrate / TCO layer. The ion transmission layer AlPO4-based thin film is prepared by adopting a magnetron sputtering method or a chemical liquid phase deposition method. The invention has the advantages that: a novel solid electrolyte material, namely an AlPO4-based material, is adopted as the ion transmission layer; and the AlPO4-based ion transport layer can be prepared by adopting a chemical liquid phase deposition method. Compared with a radio frequency mode needed by magnetron sputtering, the liquid phase method is lower in cost and higher in efficiency. Meanwhile, the AlPO4-based ion transport layer prepared by the liquid phase method enables the film structure to be loose and the ion mobility to be higher due to the characteristics of the preparation method, and the finally prepared assembly has higher color changing efficiency.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

Low-temperature sputtering graphene transparent electrode thin-film solar cell

PendingCN114497249A'Chemical composition optimizationOptimize chemical compositionVacuum evaporation coatingSputtering coatingSolar cellMaterials science

The invention provides a low-temperature sputtering graphene transparent electrode thin-film solar cell, which is applied to the technical field of solar cells, and is characterized in that a molybdenum thin film with the thickness of about 0.35-1.0 micron is plated on a soda-lime glass substrate or a flexible substrate with sodium, and a photovoltaic'copper-zinc-tin-selenium 'thin film layer with the thickness of about 0.7-1.5 microns or the standard thickness of 1.0 micron is plated on the molybdenum thin film; plating a p-n junction film on the upper surface of the copper-zinc-tin-selenium film layer; cadmium sulfide or zinc sulfide with the thickness of 0.05 micron is plated on the copper-zinc-tin-selenium thin film and the crystal; plating an insulating layer zinc oxide with the thickness of about 0.1 micron on the cadmium sulfide or the zinc sulfide; plating a graphene transparent conductive film with the thickness of about 0.35-1.9 microns on the zinc oxide as a front electrode, plating nickel with the thickness of about 0.05 microns on the front electrode, and plating an aluminum film with the thickness of about 3.0 microns on the nickel; plating a layer of protective nickel with the thickness of about 0.05 micron on the aluminum film; a soda-lime cover glass or other flexible cover layer having a thickness of about 1.0 to 4.0 mm is placed on the protective nickel.

Owner:项芳利

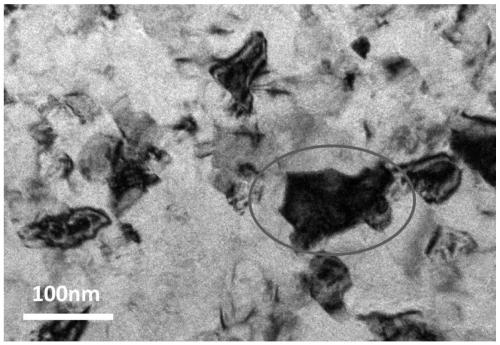

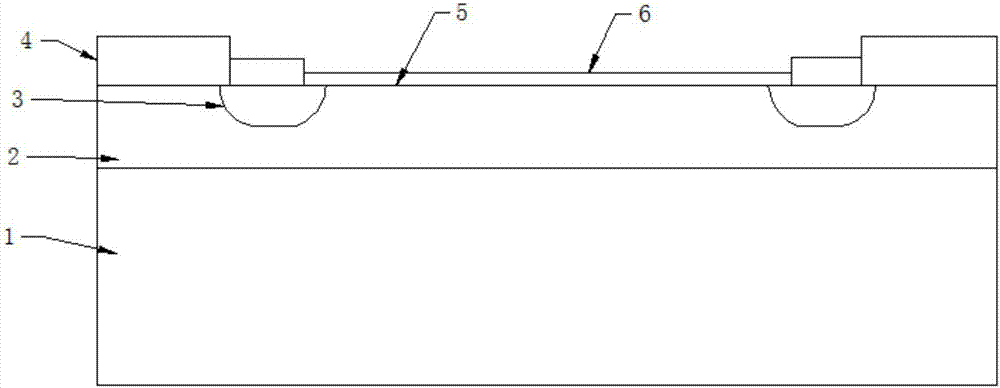

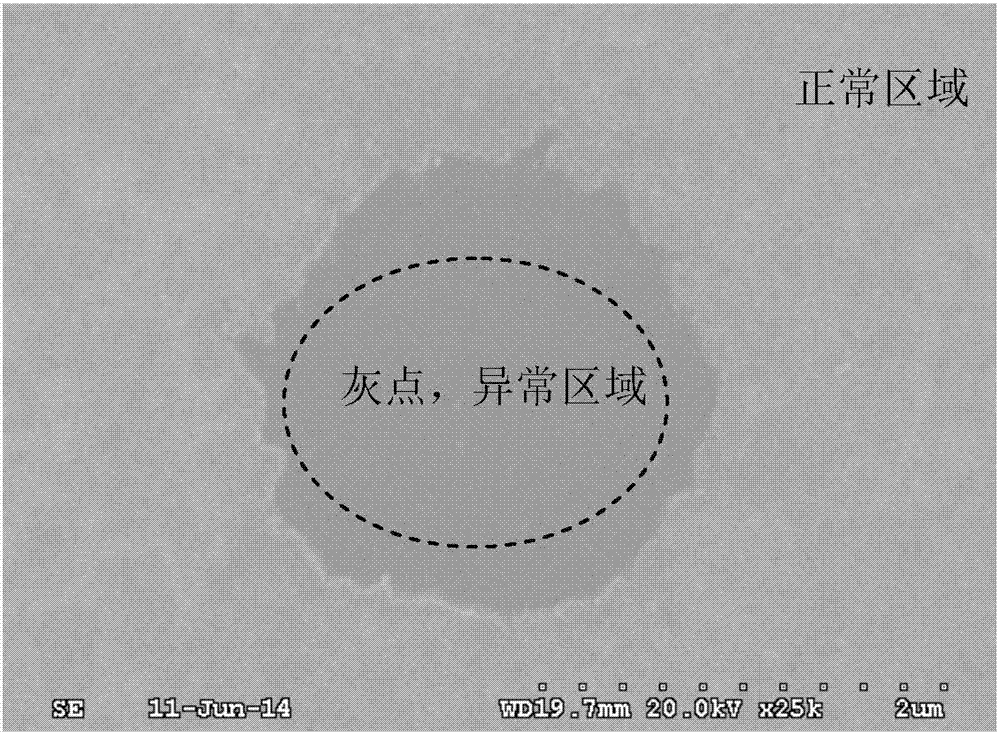

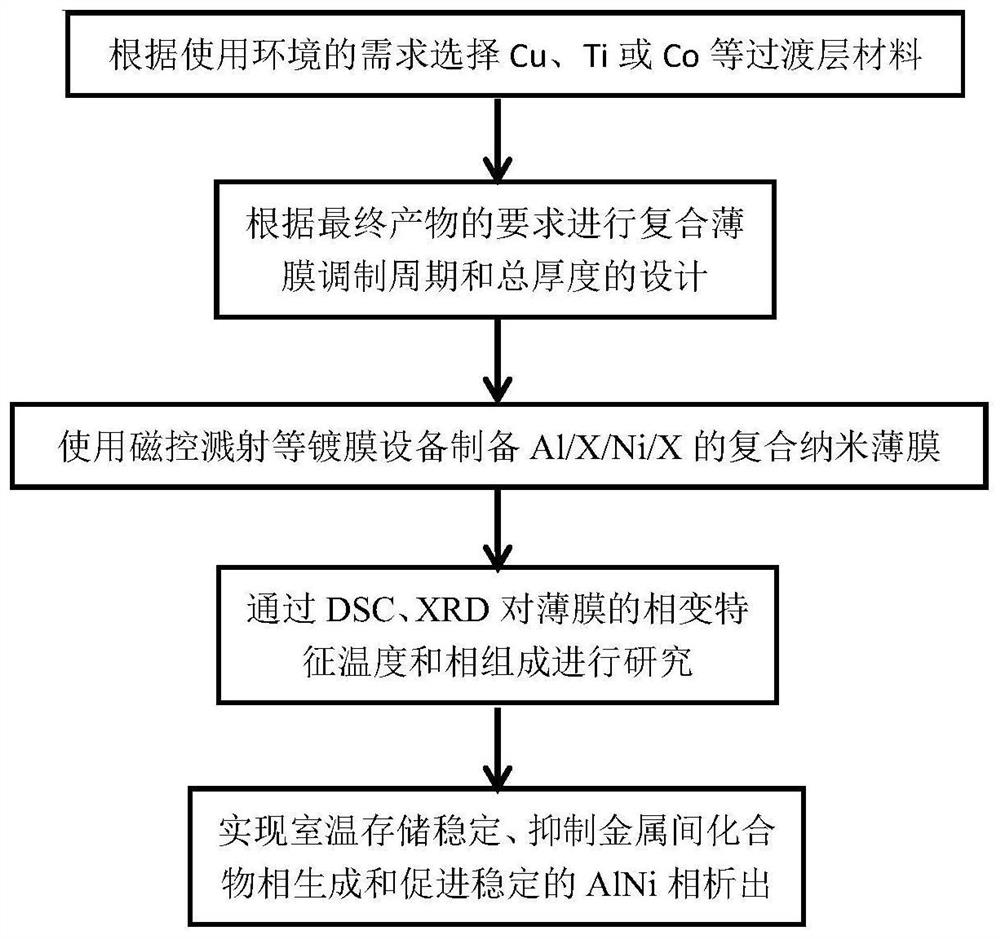

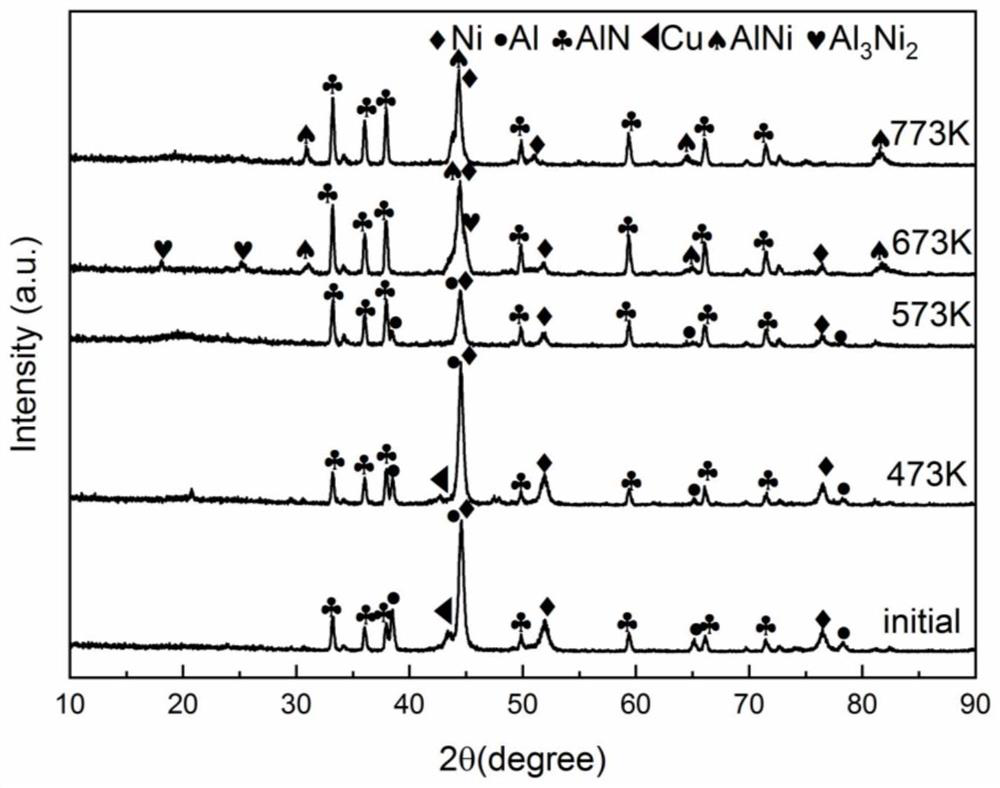

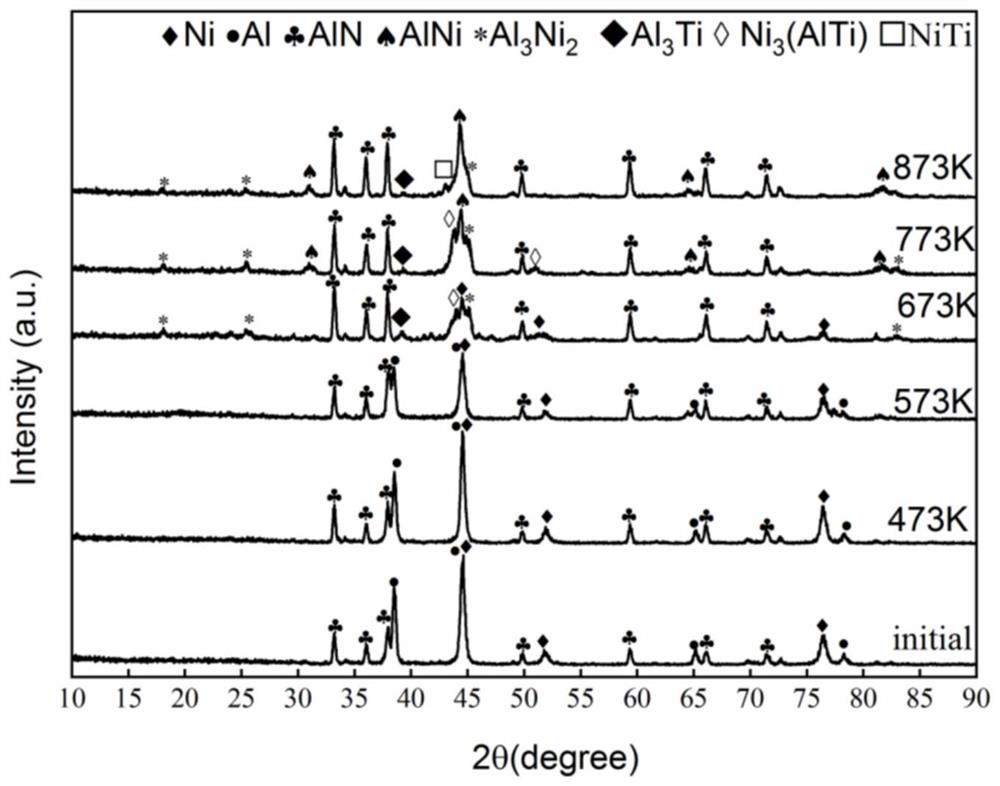

Method for inhibiting generation of ordered intermetallic compound in phase change process of Al-Ni nano multilayer film

ActiveCN113481467AInhibition of interdiffusion behaviorGuaranteed storage stabilityVacuum evaporation coatingSputtering coatingSputteringComposite film

Owner:UNIV OF SCI & TECH BEIJING

High-entropy alloy film on surface of bore of barrel and preparation method of high-entropy alloy film

ActiveCN114657514AHigh melting pointHigh hardnessVacuum evaporation coatingSputtering coatingSputteringHigh entropy alloys

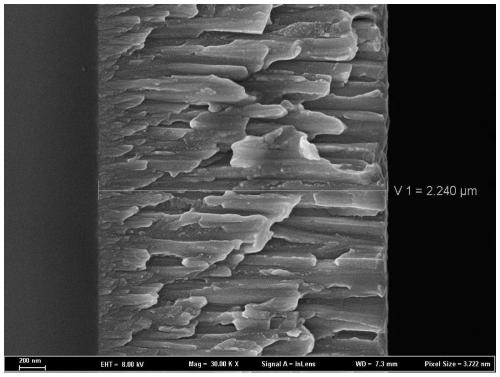

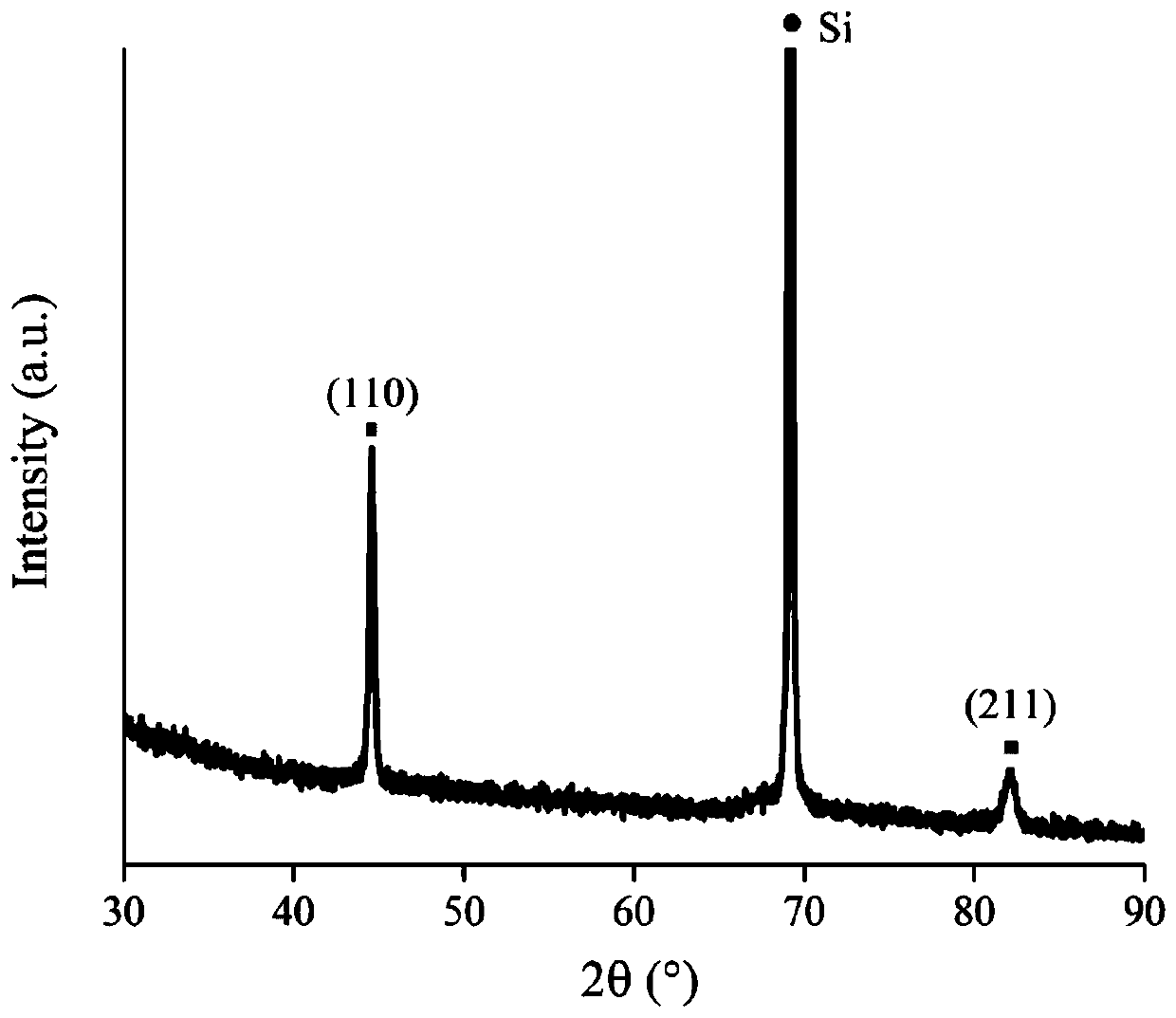

The invention discloses a high-entropy alloy film on the surface of a barrel inner bore and a preparation method of the high-entropy alloy film. A barrel inner bore base body is sequentially subjected to ultrasonic cleaning and plasma cleaning; a plasma sputtering method is adopted, and a WMoTaNb layer is deposited on the surface of the body tube inner bore base body subjected to plasma cleaning based on a WMoTaNb target; a plasma sputtering method is adopted, and a WMoTaNbSi gradient transition layer is deposited on the WMoTaNb layer on the basis of the WMoTaNb target and the Si target; a plasma sputtering method is adopted, a WMoTaNbSi layer is deposited on the WMoTaNbSi gradient transition layer on the basis of a WMoTaNb target and a Si target, and a high-entropy alloy film is obtained; the high-entropy alloy film is prepared on the surface of the inner bore to replace an original Cr coating, the high-entropy alloy film has the advantages of being high in melting point, low in heat conductivity, high in hardness, resistant to abrasion, good in high-temperature stability and the like, the problems that a traditional electroplating Cr coating is prone to generating thermal stress cracks and the like can be solved, and then the service life of the barrel is prolonged.

Owner:XIAN TECH UNIV

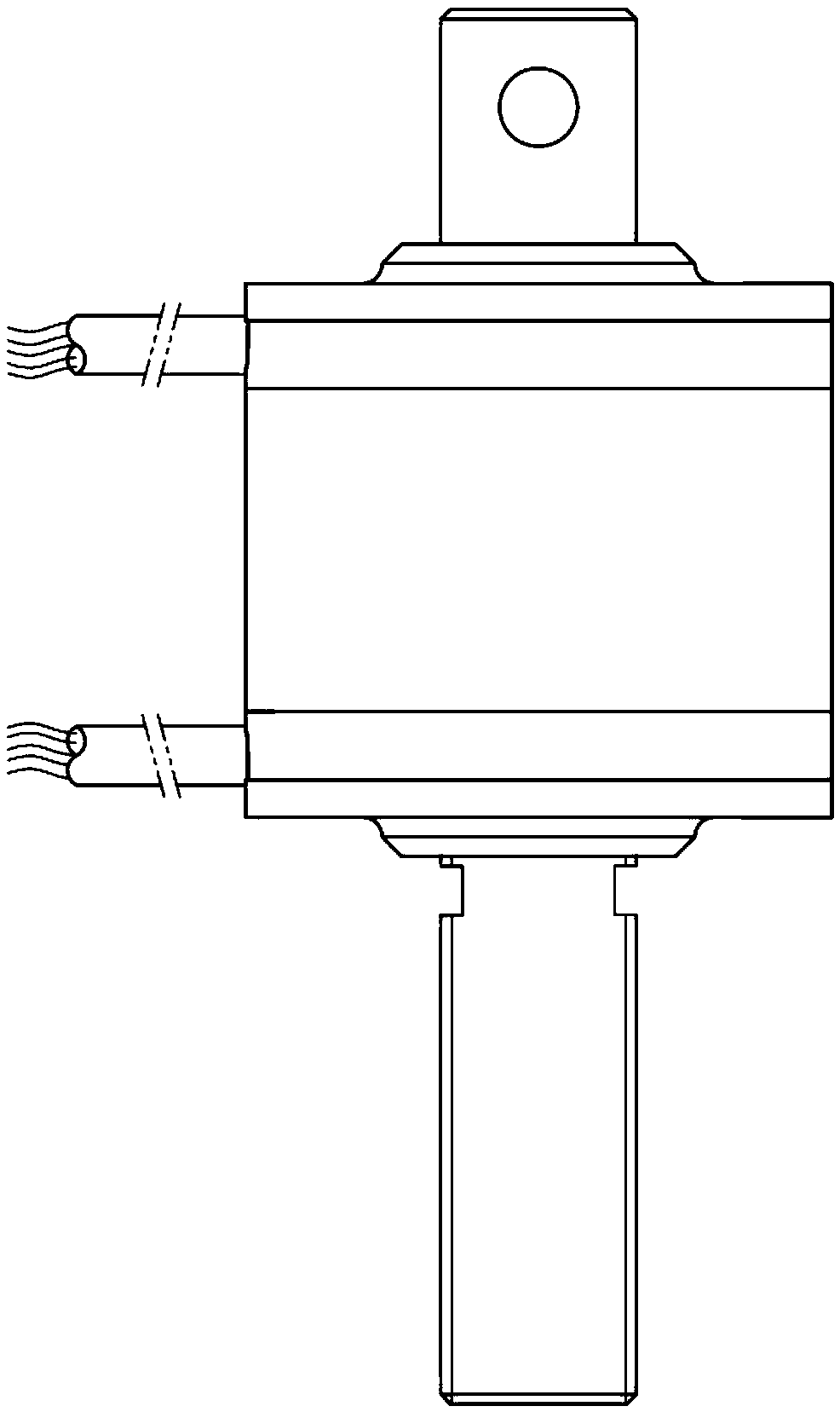

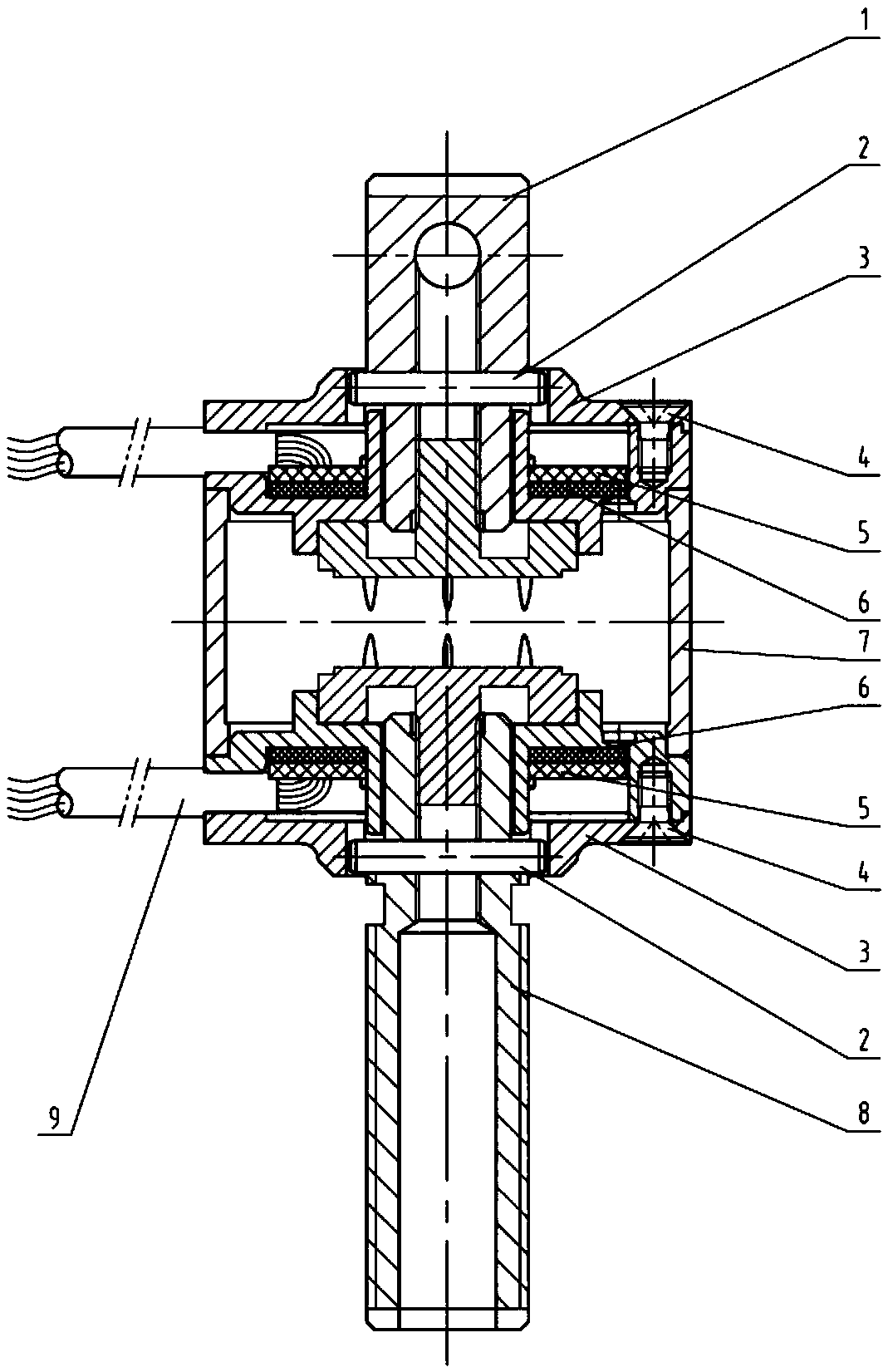

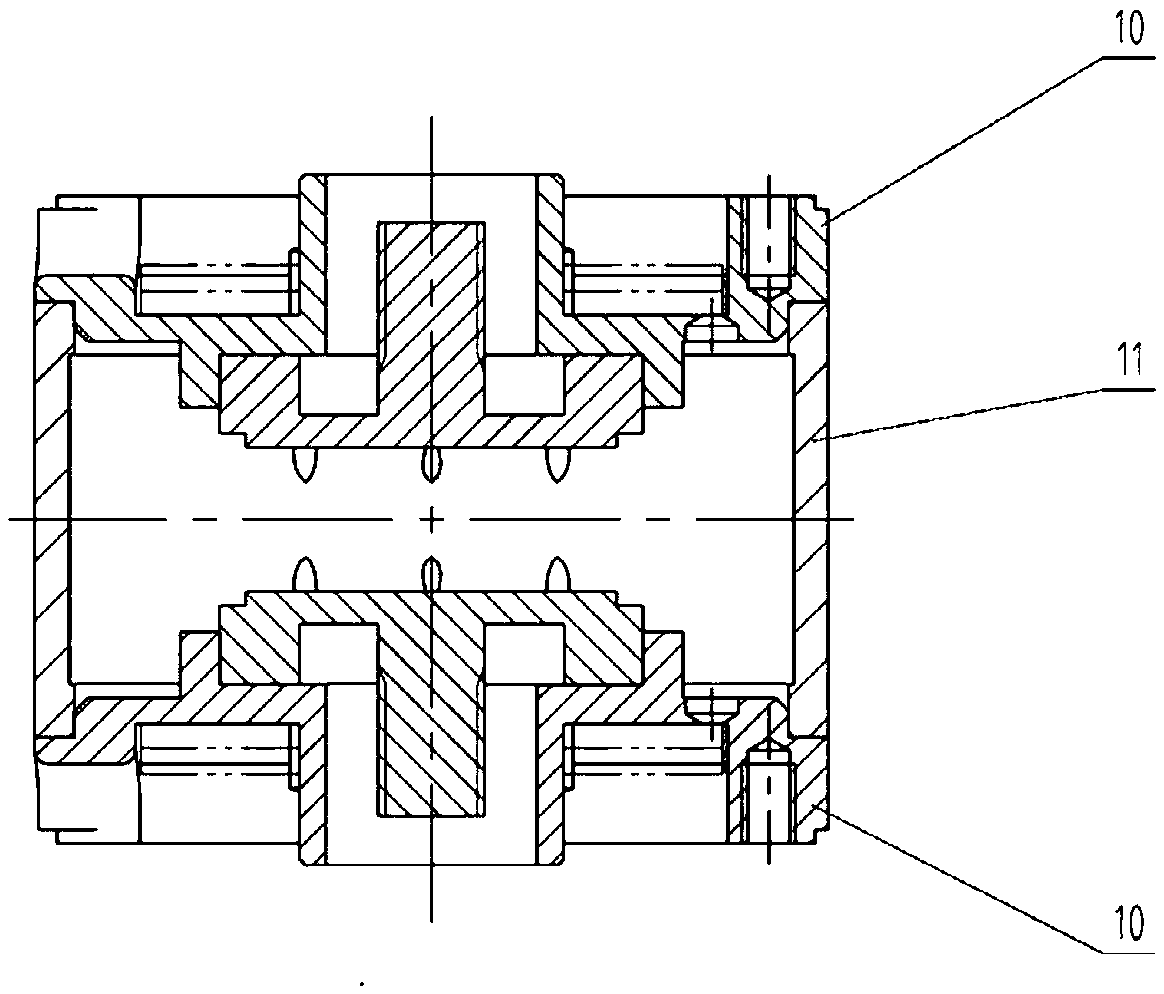

Thin-film sputtering force transducer adapting to lunar environment

ActiveCN105509936ANot easy to interfereImprove stabilityForce measurementElectrical resistance and conductanceSputtering

Owner:BEIJING SATELLITE MFG FACTORY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap