Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

24 results about "Chemical formula" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A chemical formula is a way of presenting information about the chemical proportions of atoms that constitute a particular chemical compound or molecule, using chemical element symbols, numbers, and sometimes also other symbols, such as parentheses, dashes, brackets, commas and plus (+) and minus (−) signs. These are limited to a single typographic line of symbols, which may include subscripts and superscripts. A chemical formula is not a chemical name, and it contains no words. Although a chemical formula may imply certain simple chemical structures, it is not the same as a full chemical structural formula. Chemical formulas can fully specify the structure of only the simplest of molecules and chemical substances, and are generally more limited in power than are chemical names and structural formulas.

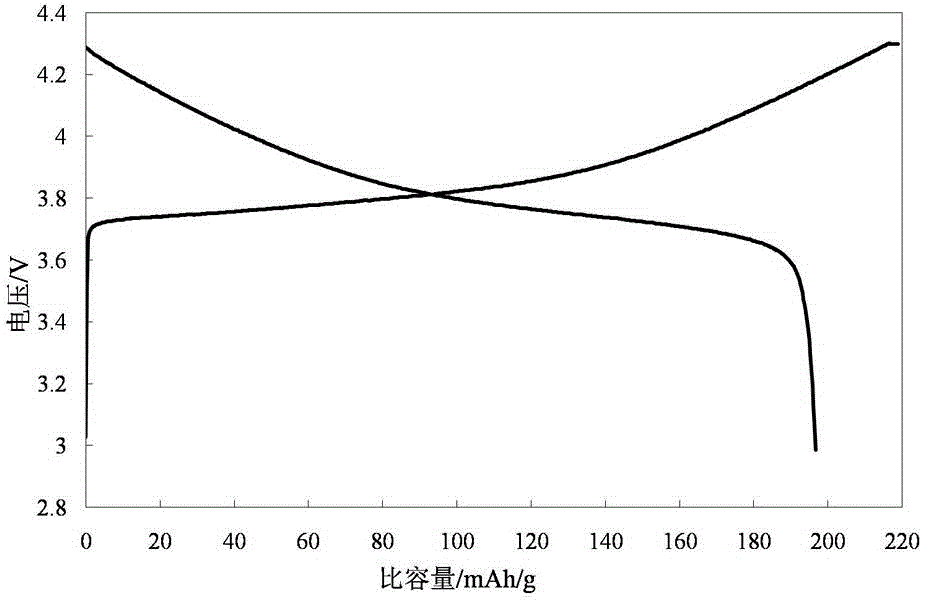

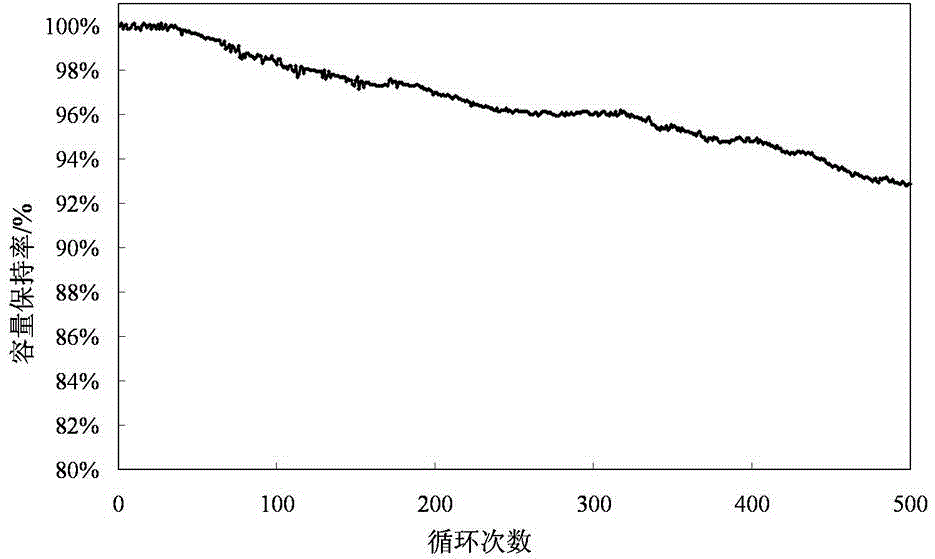

Surface coating modified lithium ion battery cathode material and preparation method thereof

InactiveCN104577093AImprove securityNo significant reduction in specific capacityCell electrodesLithium iron phosphatePhysical chemistry

Owner:ZHEJIANG MEIDARUI NEW MATERIAL TECH CO LTD

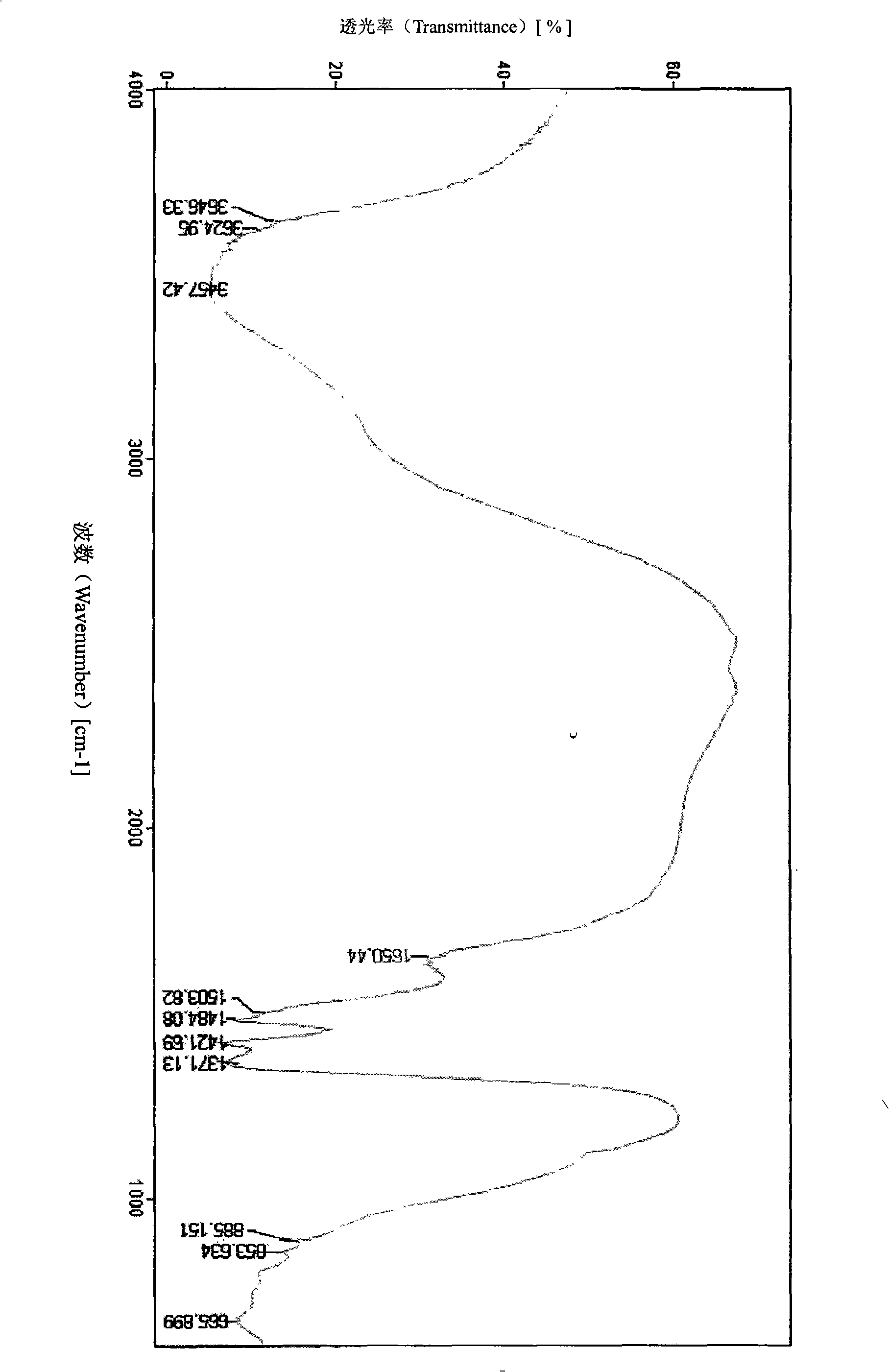

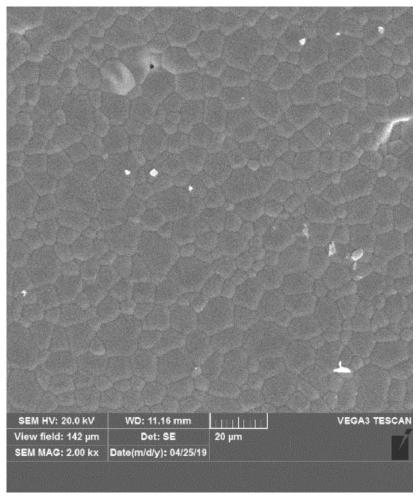

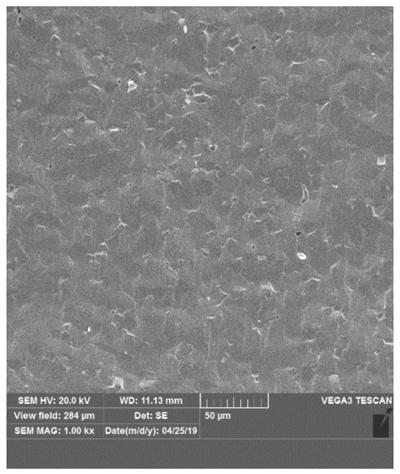

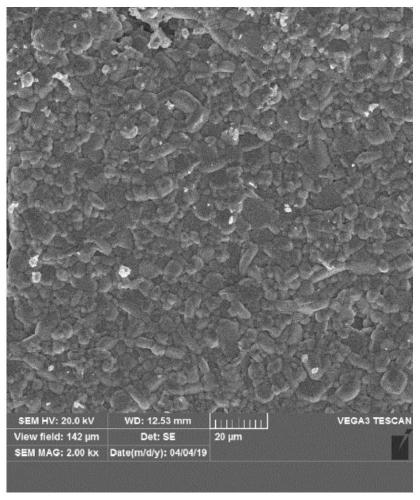

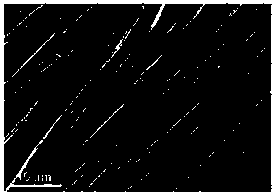

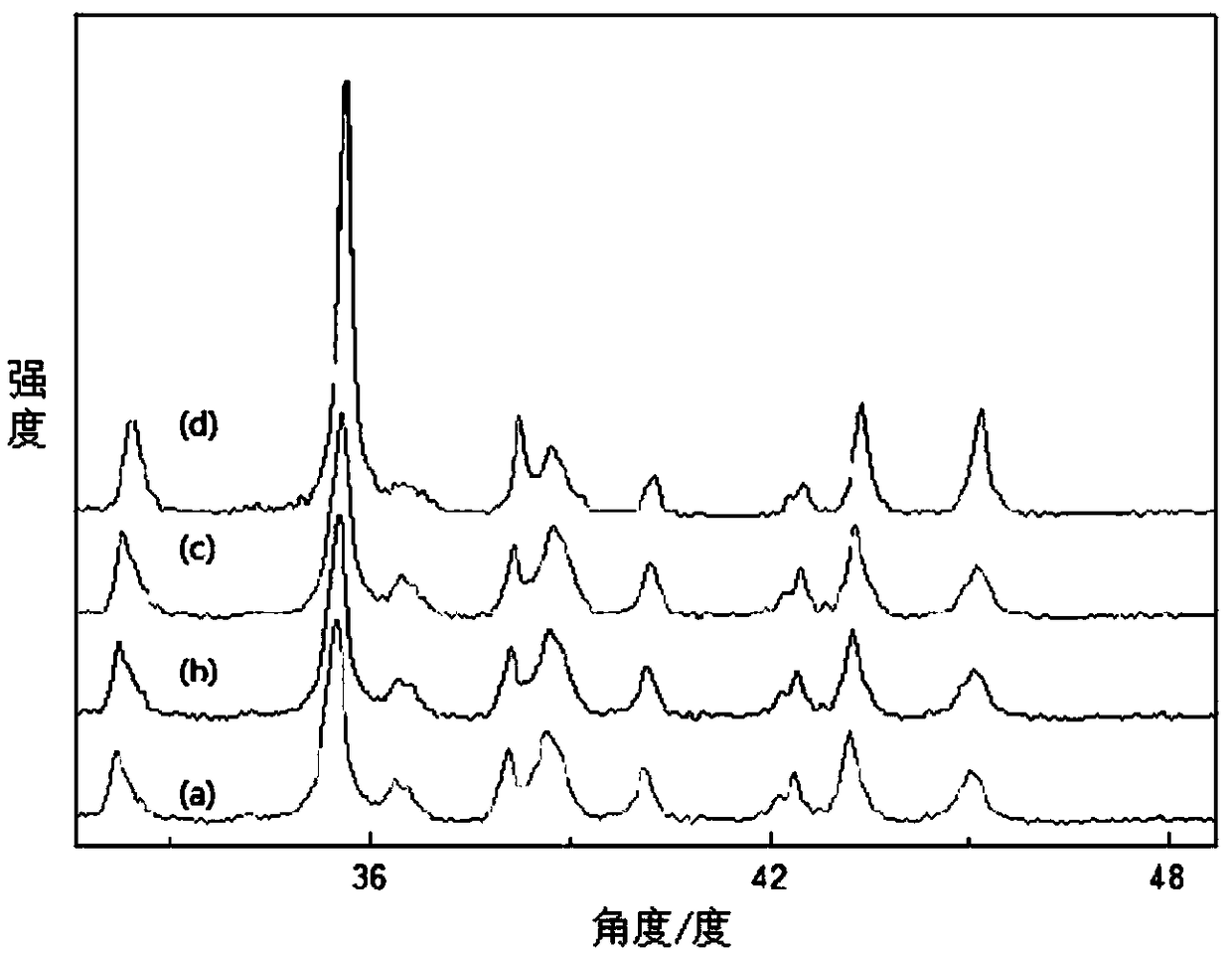

High-hardness and high-elasticity-modulus multi-component nitride coating and preparation method thereof

InactiveCN106835037AIngredient ControlHigh hardnessVacuum evaporation coatingSputtering coatingSputteringAlcohol

The present invention is a multi-component nitride coating with high hardness and high elastic modulus. Its chemical formula is AlCrTiZrNbN, and the atomic ratios of Al, Cr, Ti, Zr, Nb and N are respectively 8-12%: 8-12 %: 8~12%: 8~12%: 8~12%: 48~52%, the thickness of the coating is 2~5μm. The present invention also provides a method for preparing the above-mentioned nitride coating. Firstly, the surface of the substrate is subjected to mirror polishing, then ultrasonically cleaned with acetone and alcohol, and after vacuum ion cleaning, the AlCrTiZrNbN layer is deposited by radio frequency reactive sputtering, wherein AlCrTiZrNbN is mostly The component nitride coating is composed of AlCrTiZrNb alloy target with equiatomic molar ratio in (Ar+N 2 ) atmosphere prepared. The coating of the invention has high hardness and high modulus of elasticity, and can be used as a novel protective coating for various service occasions such as cutting tools and molds.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

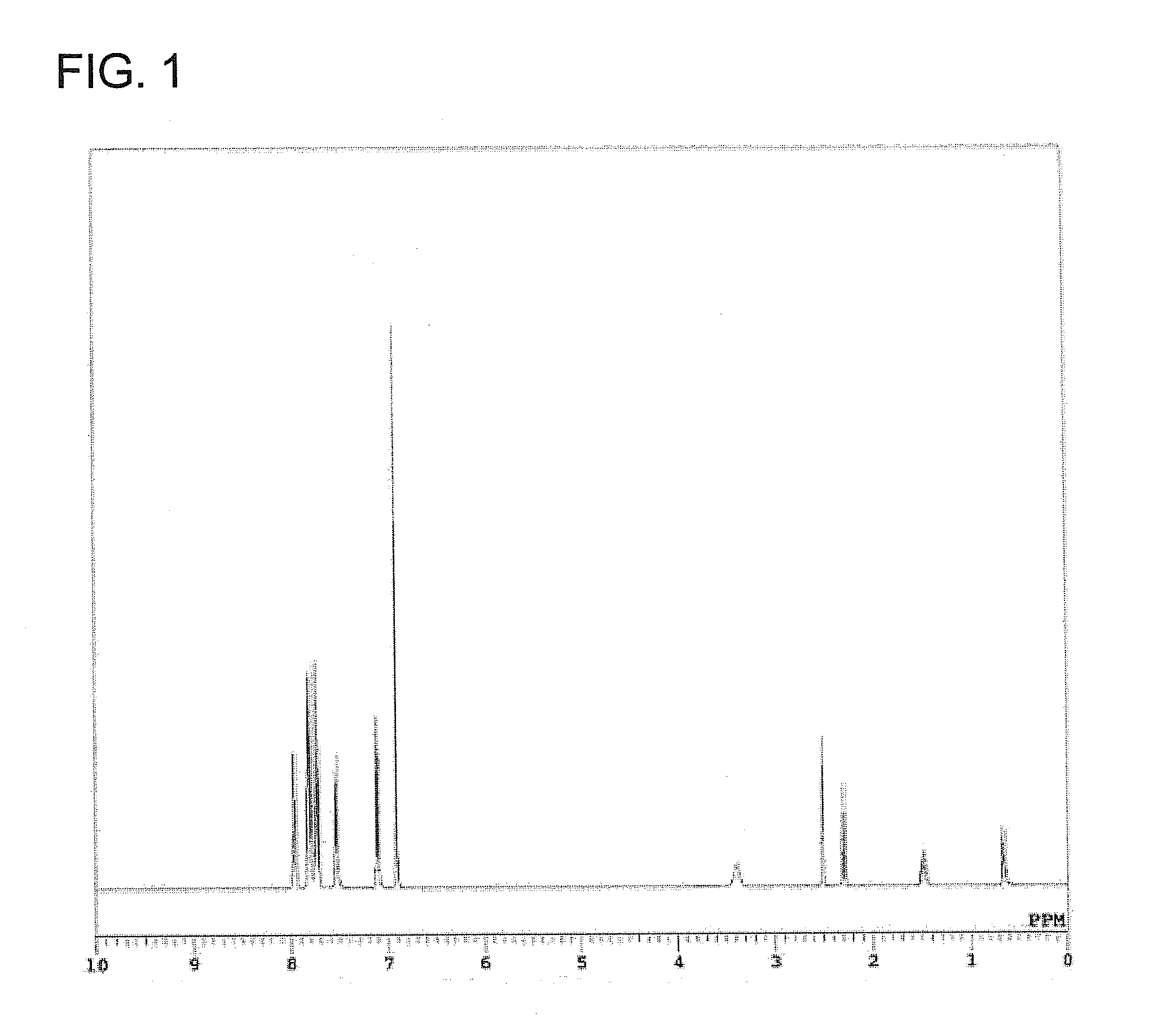

Process for producing latent catalyst and epoxy resin composition

InactiveUS20090234080A1High yieldGood fluidityOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyPhosphonium

Owner:SUMITOMO BAKELITE CO LTD

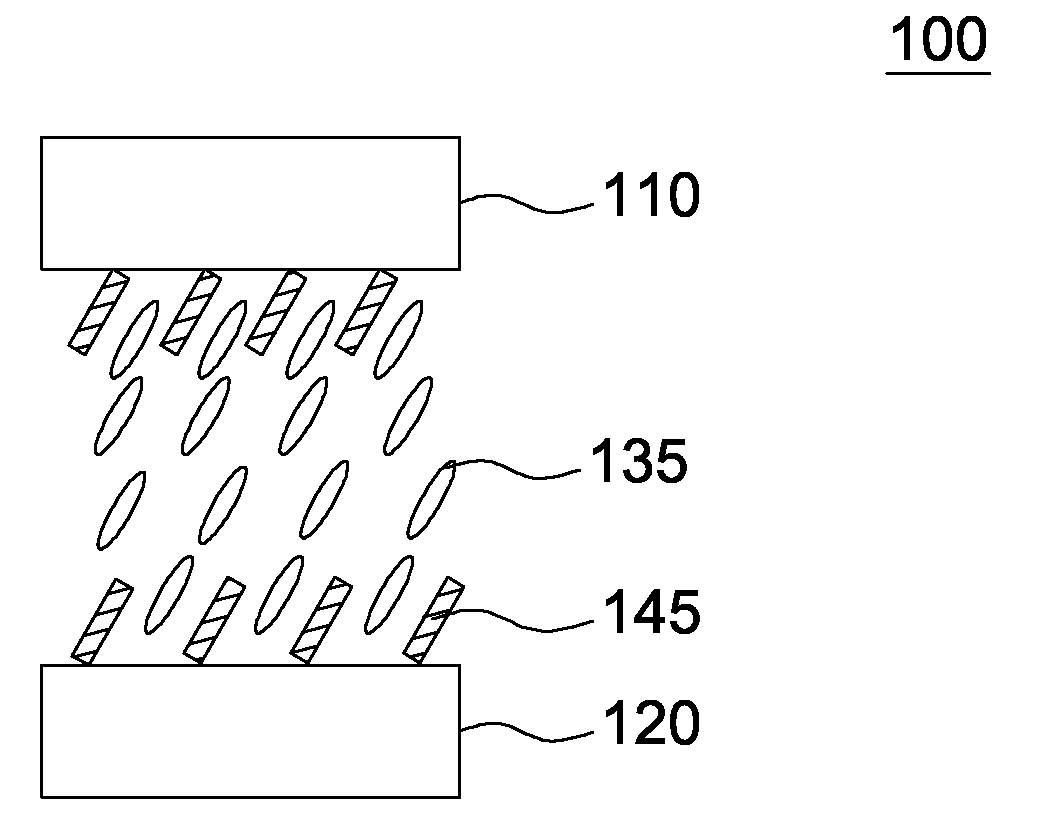

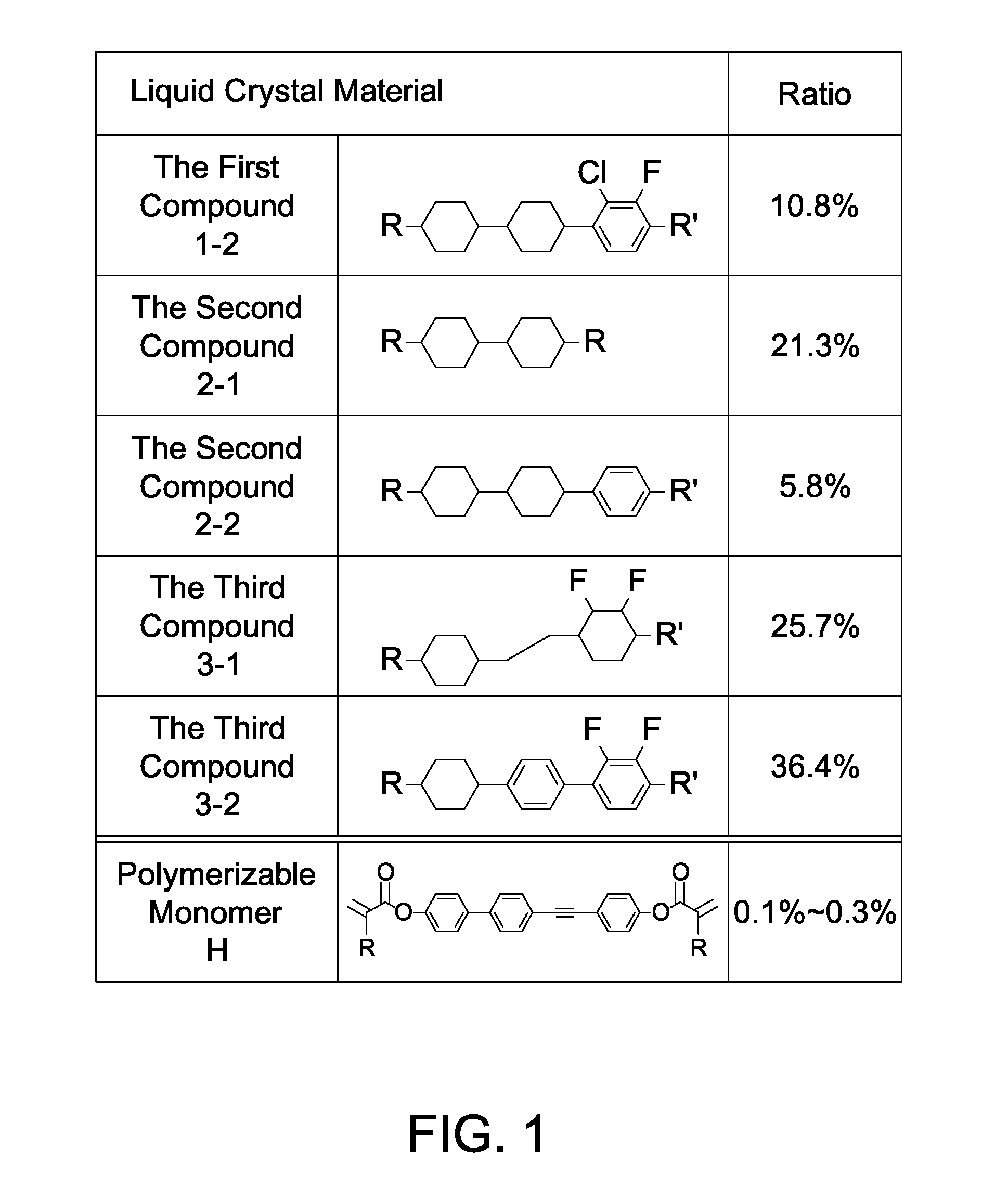

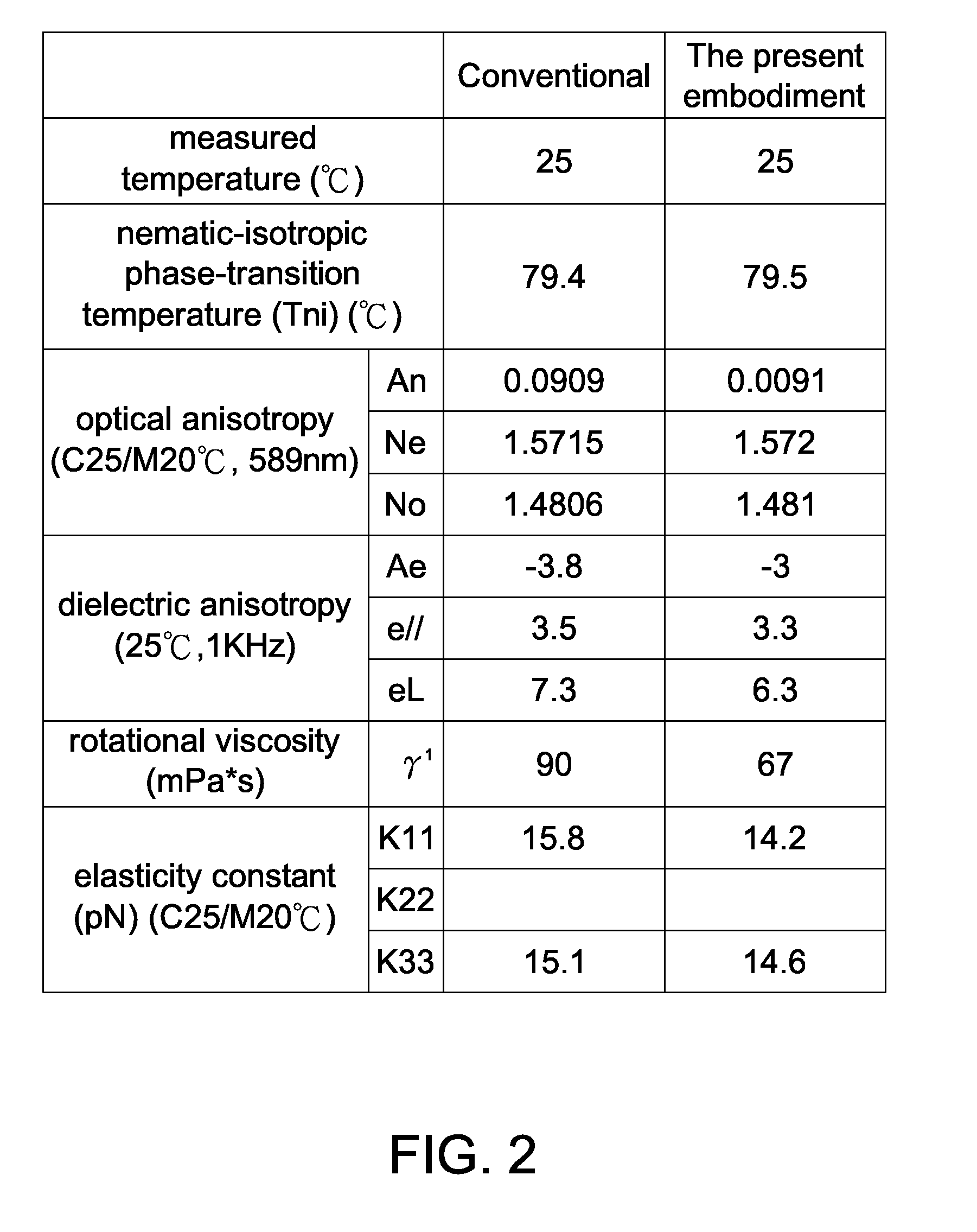

Polymerizable monomer and liquid crystal material applied to display panel

ActiveUS20110080551A1Convenient ArrangementShorten production timeLiquid crystal compositionsHalogenated hydrocarbon preparationCrystallographyThio-

Owner:AU OPTRONICS CORP

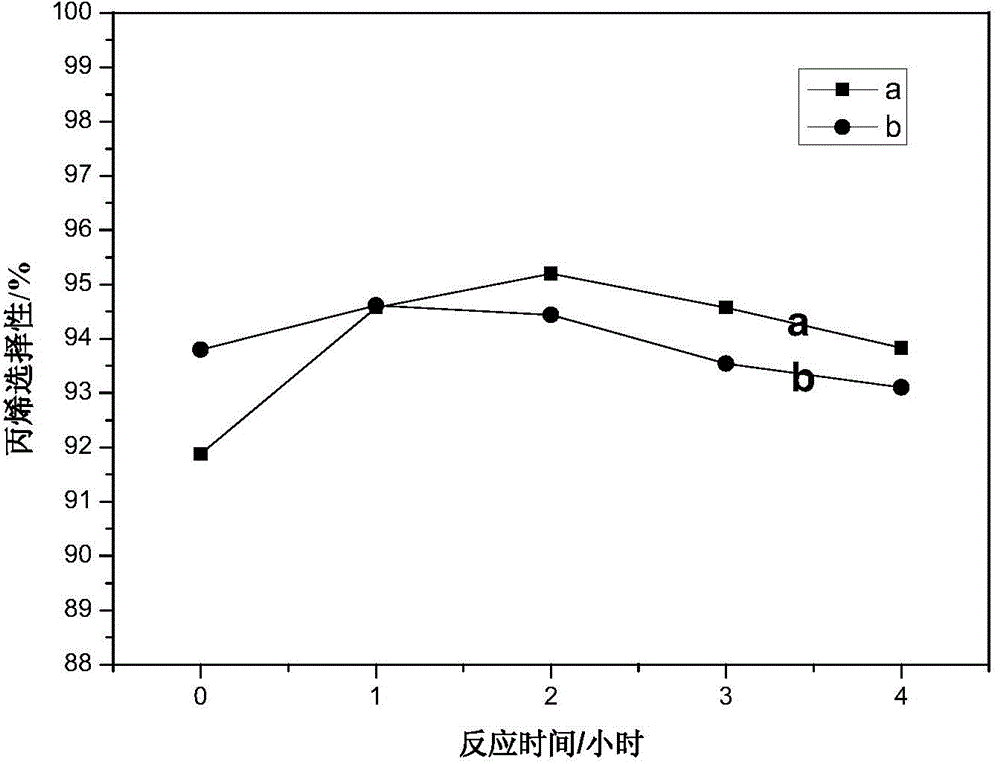

Catalyst for production of propylene through catalytic dehydrogenation of propane, and preparation method thereof

InactiveCN104941640AHigh selectivitySimple processHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsActive componentDehydrogenation

Owner:NANKAI UNIV

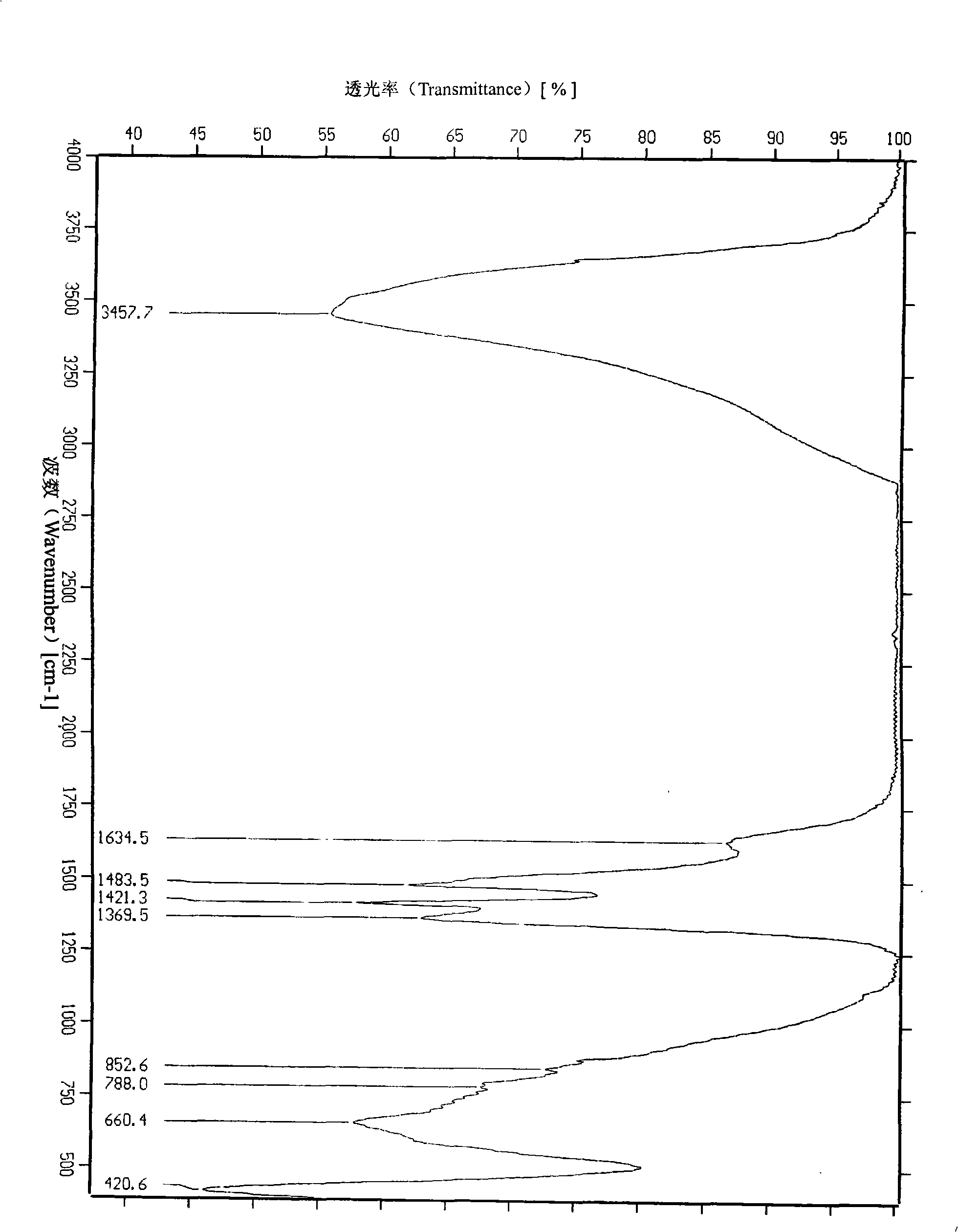

Iodine reducing laminar material and method for processing iodine-enrichment water

InactiveCN1768960AIodine reduction effect is goodInorganic anion exchangersWater/sewage treatment by ion-exchangeMaterials scienceSodium hydroxide

Owner:BEIJING UNIV OF CHEM TECH

Method of preparing aluminum magnesium carbonate

InactiveCN101343078AHigh purityHigh yieldAluminium compoundsMagnesium carbonatesMedicinal chemistryCarbonate

Owner:IL YANG PHARMA CO LTD

Microwave ferrite material, preparation method thereof and microwave communication device

Owner:SHENZHEN SUNLORD ELECTRONICS

LC-Q-TOF/MS detection technique for 544 pesticide residues in citrus fruits

InactiveCN105784898AImprove throughputChange qualitative modeComponent separationMass numberRetention time

The invention provides an LC-Q-TOF / MS detection technique for 544 pesticide residues in citrus fruits. In a TOF / MS mode, LC-Q-TOF / MS measures the retention time of each pesticide standard substance under specified chromatographic and mass spectrometric conditions, an ionization form and a chemical formula of each compound under an ESI source are determined, the exact mass number for parent ions of each compound is obtained, and a TOF / MS database is formed. In a Q-TOF / MS mode, fragment ion mass spectra of each pesticide standard substance in 3-5 different collision energies are collected respectively, the collected information is introduced into PCDL software, and a Q-TOF / MS database is formed. Through comparison of the retention time and first-level mass spectrometry and second-level mass spectrometry information of citrus fruit samples, whether the samples contain the pesticide residues is determined, compounds having higher first-level score are subjected to second-level confirmation, and if the second-level score is higher, related pesticide residues are confirmed to be detected out. The method has the advantages of high speed, high throughput, high precision, high reliability and the like, and can accurately screen the pesticides in the citrus fruits.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

Preparation method of anode material LiMxNiyMn2-x-yO4

InactiveCN102810666AUniform particle size distributionImprove consistencyCell electrodesFree coolingRoom temperature

Owner:SICHUAN UNIV

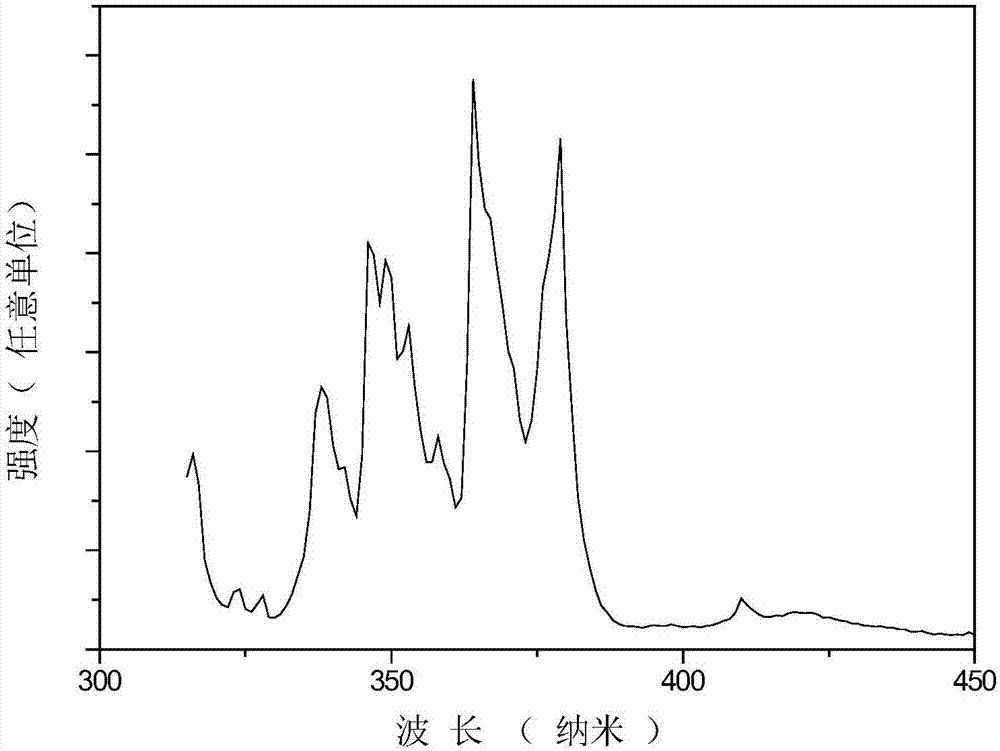

Composite material for enhancing photoluminescence of rare earth Er ions and preparation method thereof

Owner:NANJING UNIV

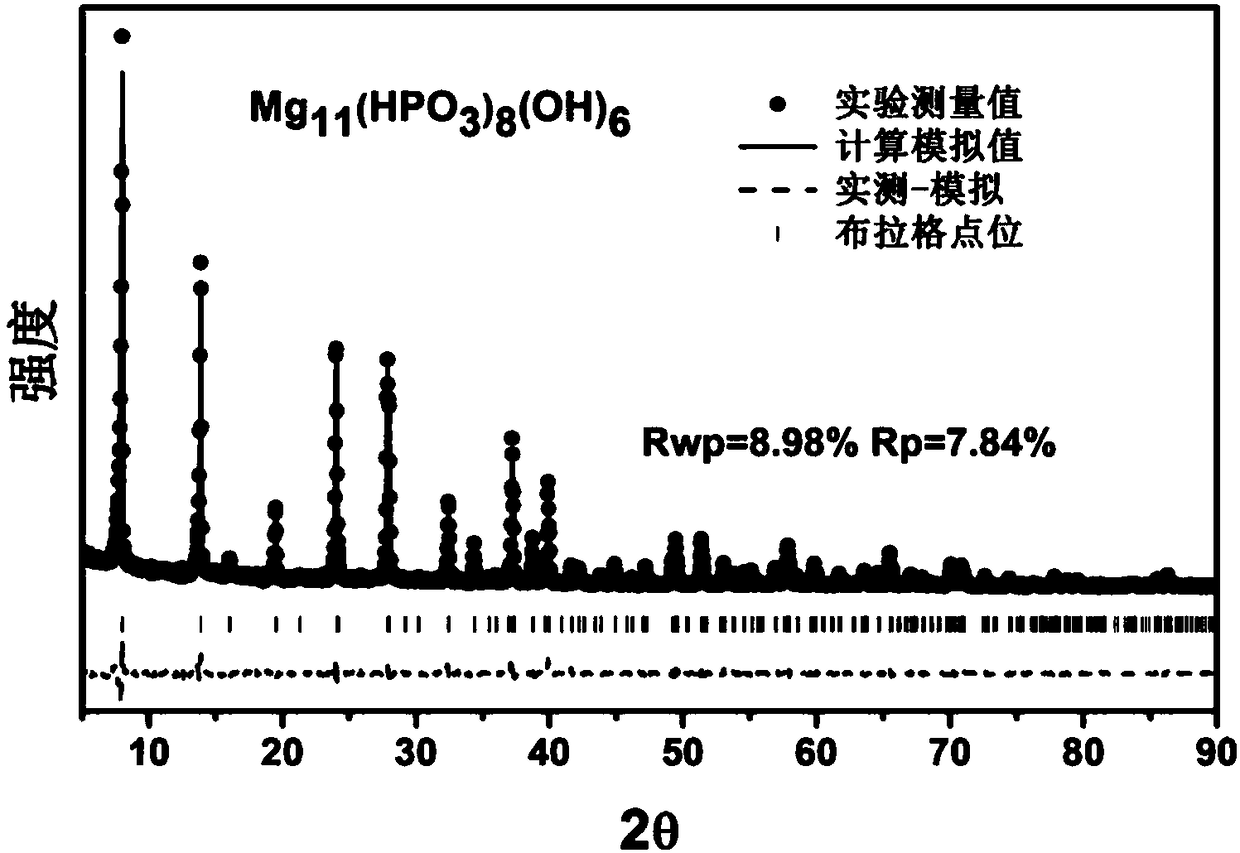

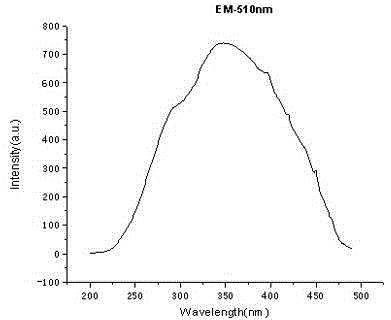

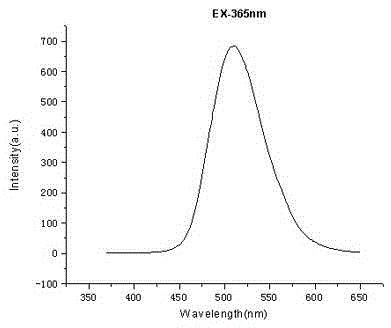

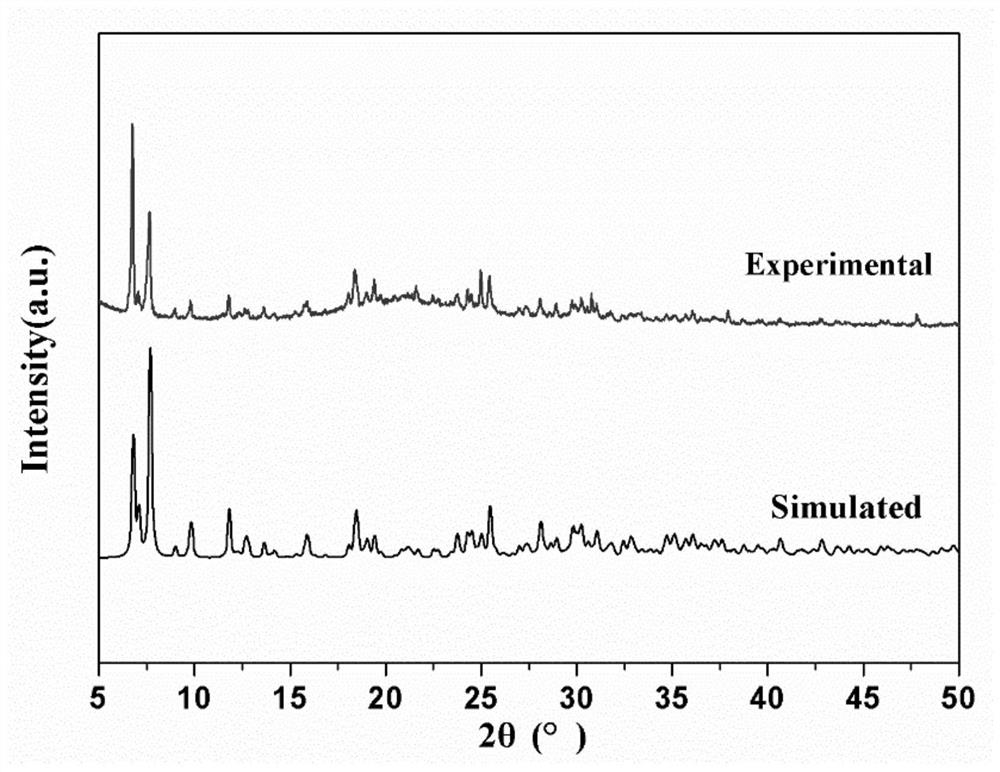

Crystal material, and preparation method and application thereof

ActiveCN108193268AHigh UV-Vis-NIR high reflectivityImprove performancePolycrystalline material growthFrom normal temperature solutionsPhosphorous acidMagnesium Acetate Tetrahydrate

Owner:SOUTH CHINA UNIV OF TECH

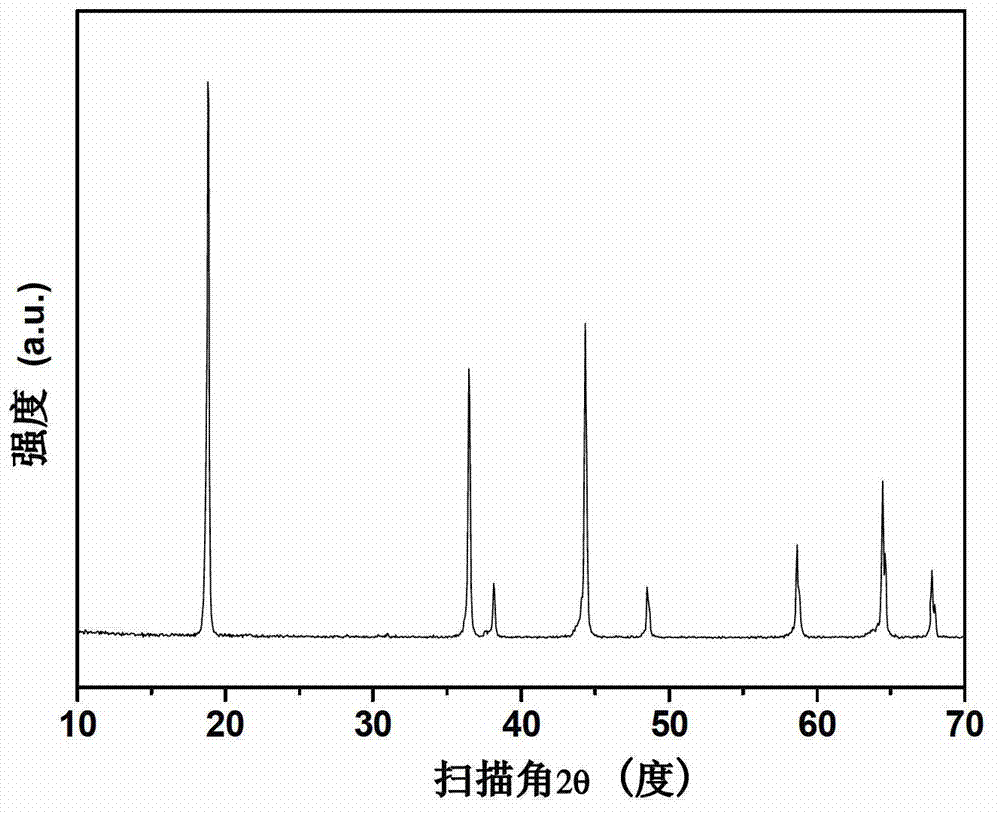

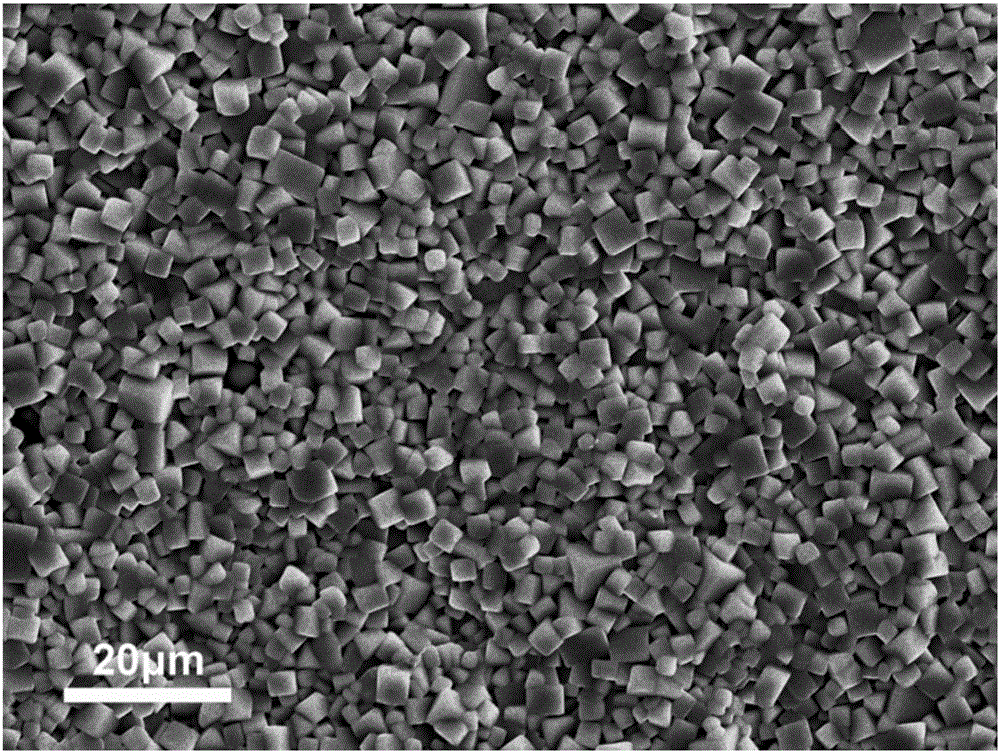

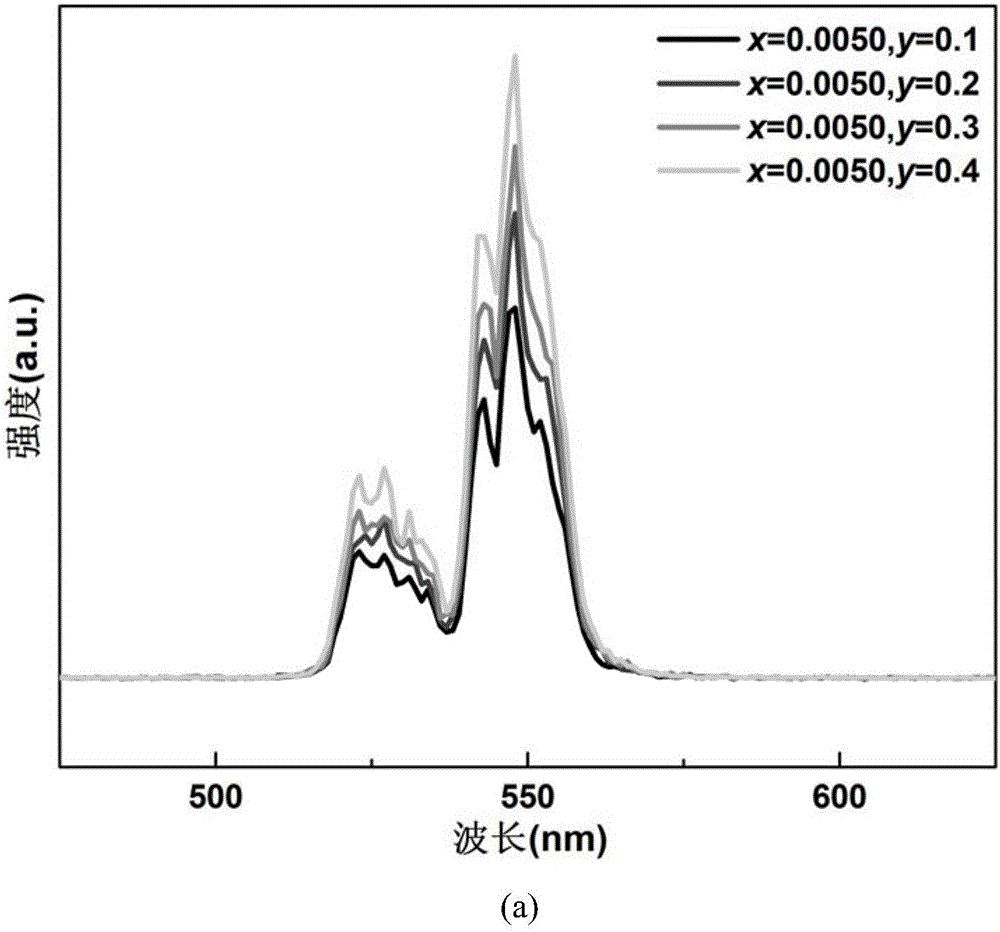

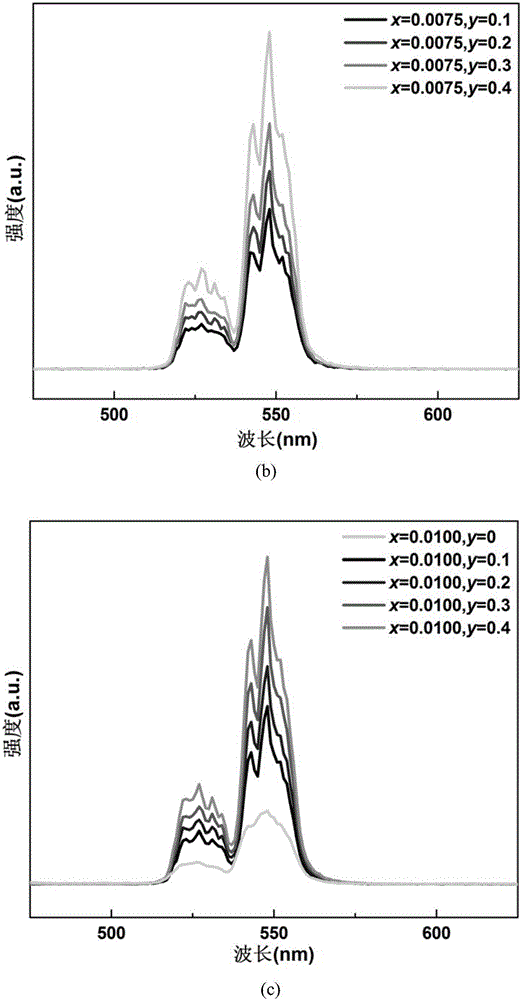

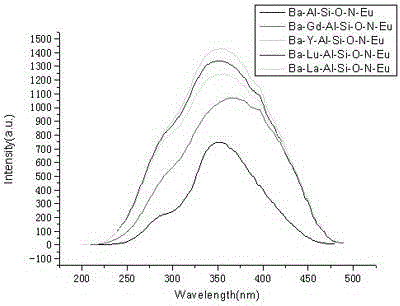

Rare-earth-doped nitrogen oxide green fluorescent powder and preparation method thereof

InactiveCN104610967AImprove luminosityWide effective excitation rangeLuminescent compositionsNitrogen oxidesRare earth ions

Owner:JIANGXI UNIV OF SCI & TECH

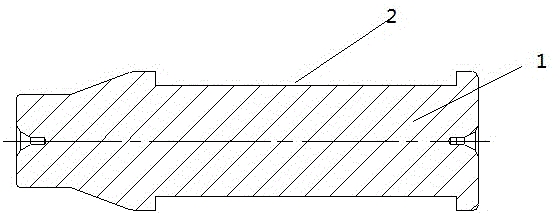

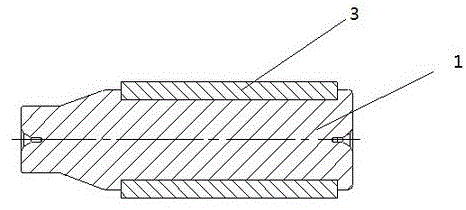

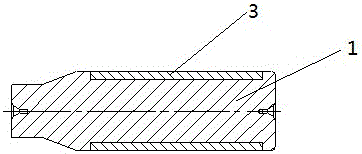

Manufacturing process for improving abrasion resistance of outer circle surface of plunger

InactiveCN106011724ATechnical requirements are metImprove wear resistanceMolten spray coatingThermal sprayingChemical composition

Owner:中石化四机石油机械有限公司 +1

Comb polymer electrolyte and preparation and application thereof

ActiveCN107658501AImprove mechanical propertiesHigh thermodynamic stabilityFinal product manufactureElectrolyte accumulators manufactureLithiumPolymer electrolytes

Owner:HUAZHONG UNIV OF SCI & TECH

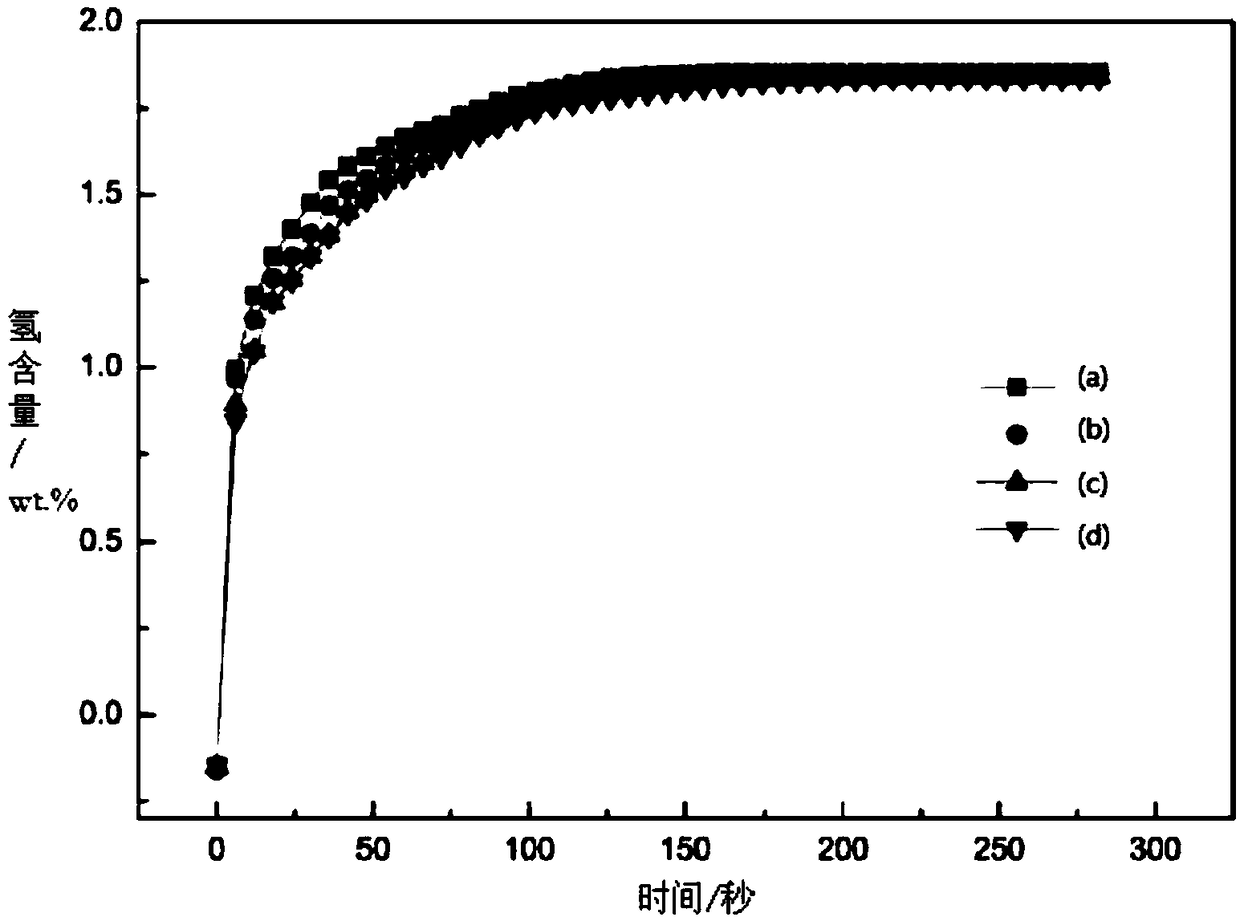

Zr-Fe alloy for tritium storage and preparation method thereof

InactiveCN108149070ALow costFast rate of hydrogen absorption and desorption (tritium)Electric arc furnaceDesorption

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Pyrrolo[3,2-D]Pyrimidin-4-One Derivative as Myeloperoxidase Inhibitor

InactiveUS20090124640A1Treat multipleDelay progressOrganic active ingredientsBiocideKetonePharmaceutical formulation

The present invention relates to a new compound A: [Chemical formula should be inserted here. Please see paper copy] a process for its preparation, pharmaceutical formulations containing said therapeutically active compound and to the use of said active compound in therapy. The compound is an inhibitor of the enzyme MPO and is thereby particularly useful in the treatment or prophylaxis of neuroinflammatory disorders, cardiovascular disorders and respiratory disorders.

Owner:ASTRAZENECA AB

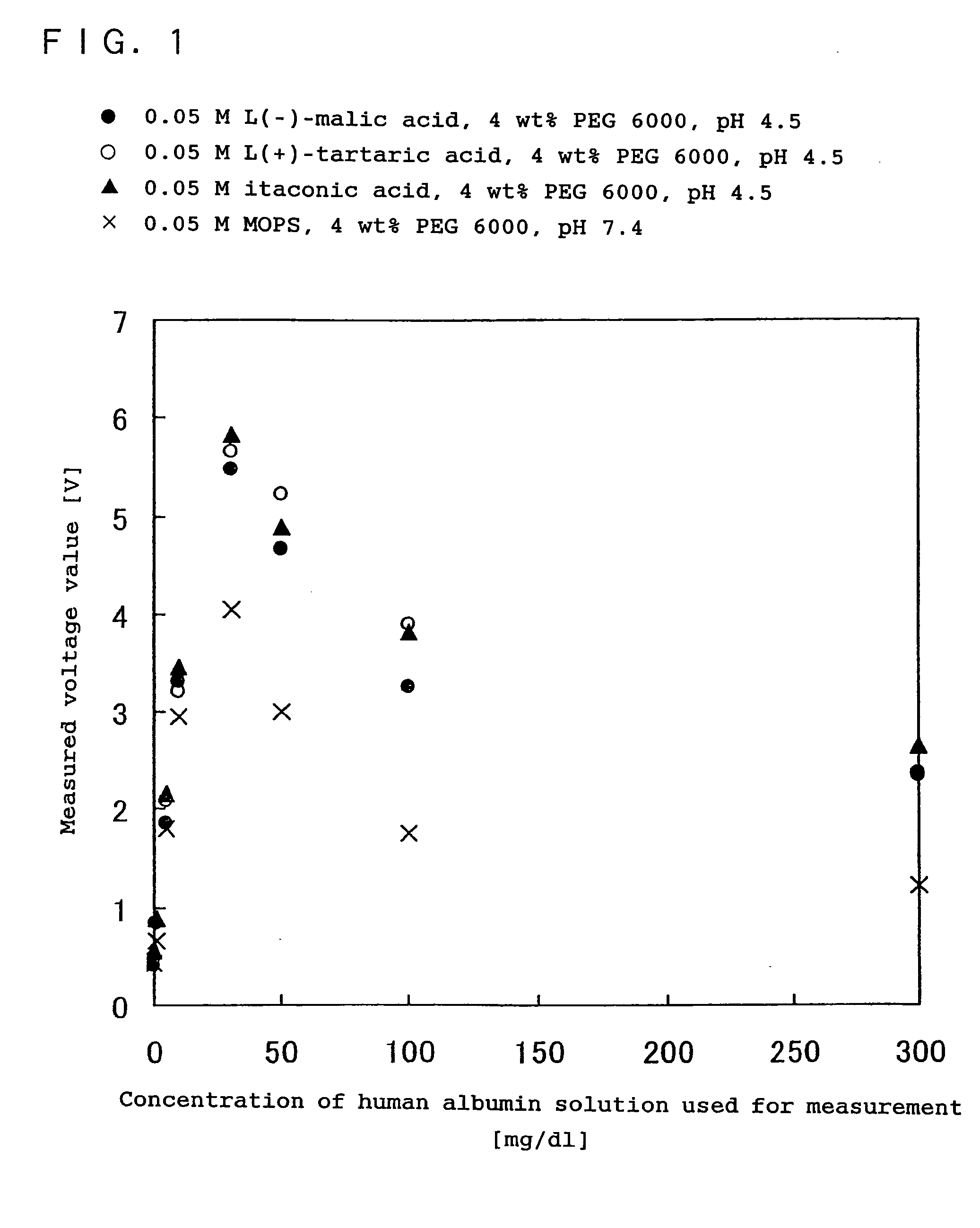

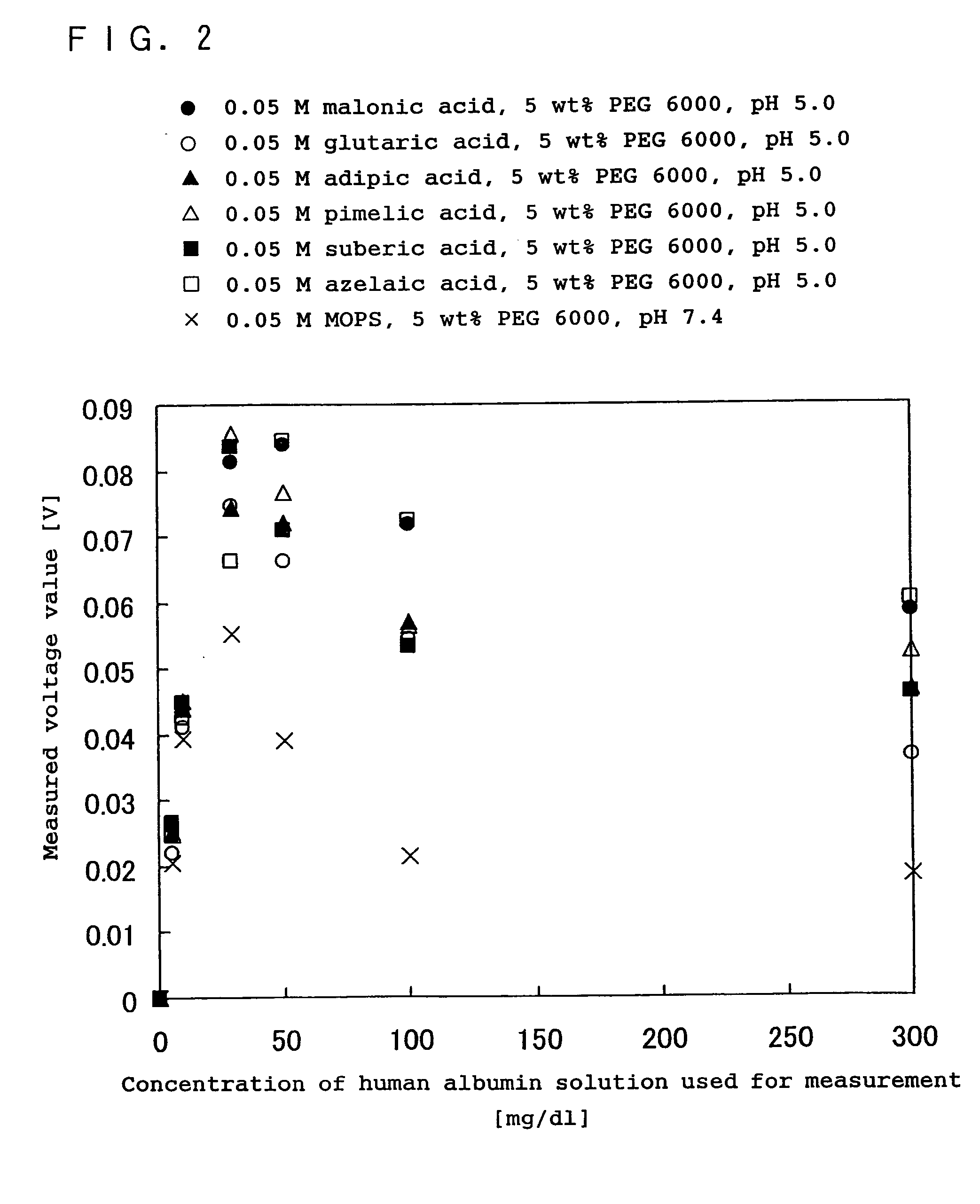

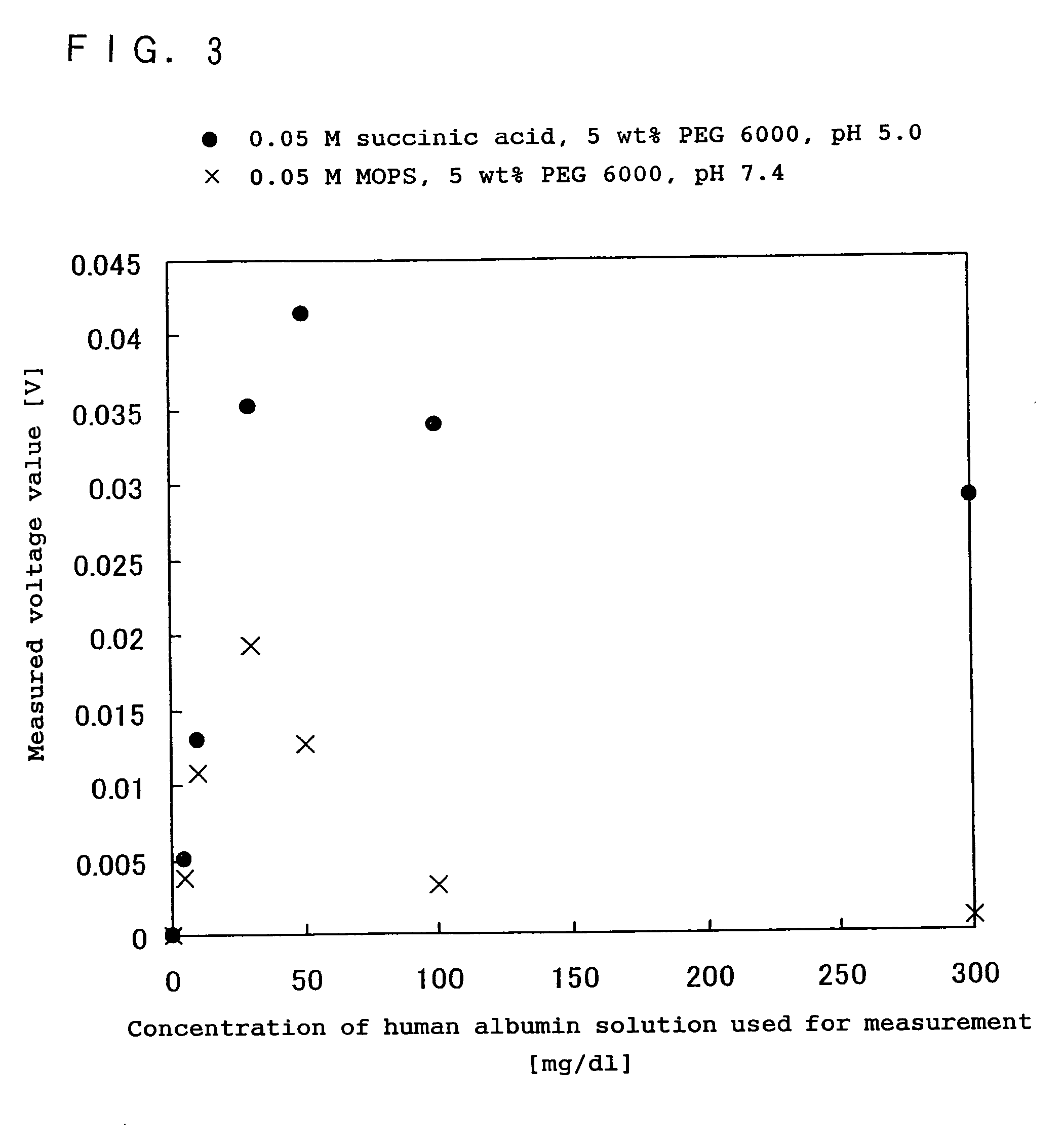

Immunoreaction measurement method

Owner:PHC HLDG CORP

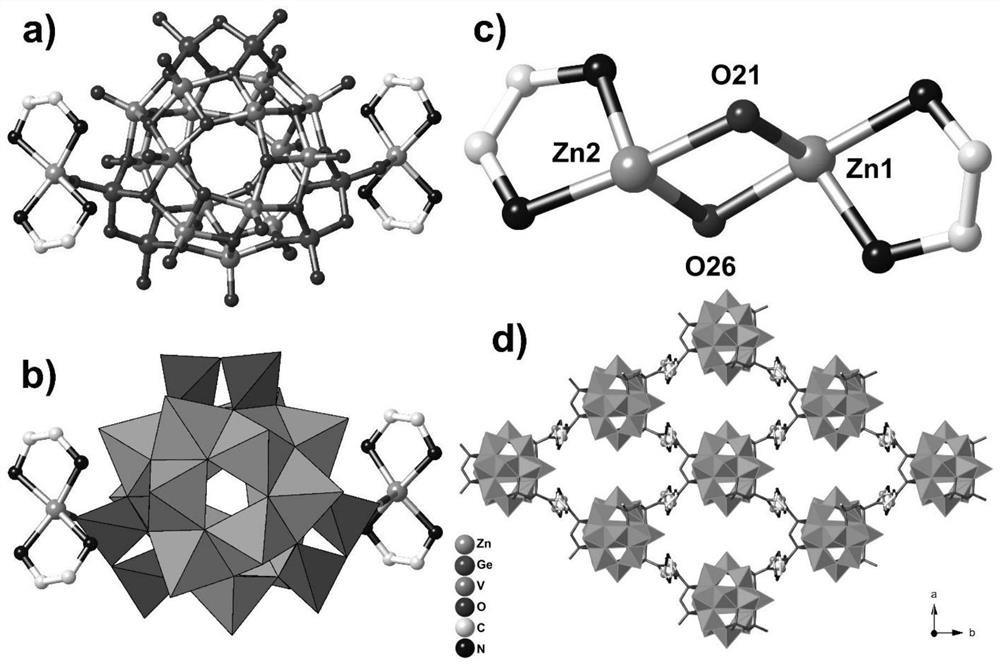

Two-dimensional layered germanium-vanadium-oxygen cluster compound as well as synthesis method and application thereof

ActiveCN113402567AHas magnetic application valueImprove bindingOrganic chemistry methodsGroup 5/15 organic compounds without C-metal linkagesEthylenediaminesTerephthalic acid

Owner:NINGDE NORMAL UNIV

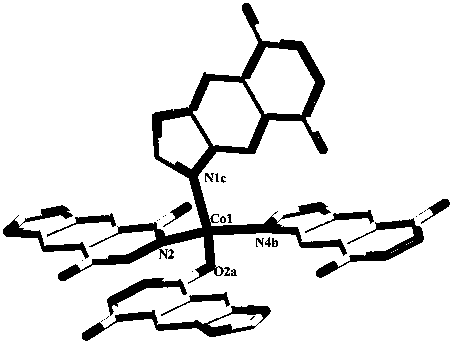

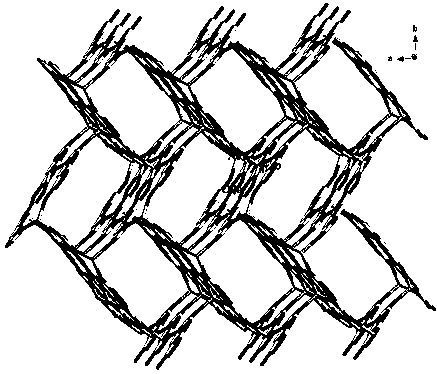

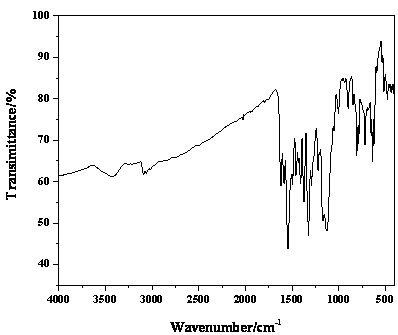

Coordination-polymer magnetic material based on in-situ ligand reaction and preparation method thereof

ActiveCN108948371AImprove stabilityImprove water stabilityOrganic/organic-metallic materials magnetismProtonationNetwork structure

Owner:NINGXIA UNIVERSITY

Green zincate fluorescent powder and preparation method thereof

ActiveCN106893583AWide excitation bandwidthMild preparation conditionsLuminescent compositionsRare-earth elementZincate

Owner:CHINA JILIANG UNIV

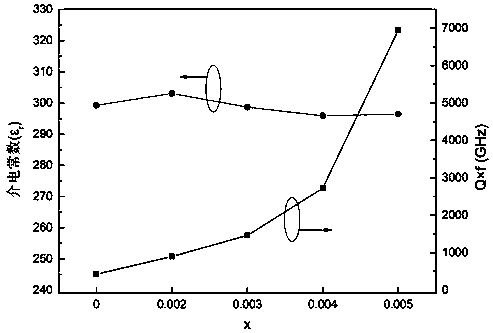

Strontium titanate ceramic with high dielectric constant and low dielectric loss

InactiveCN108129146AExcellent dielectric propertiesHigh utility valueStrontium titanium oxideDielectric loss

Owner:EAST CHINA UNIV OF SCI & TECH

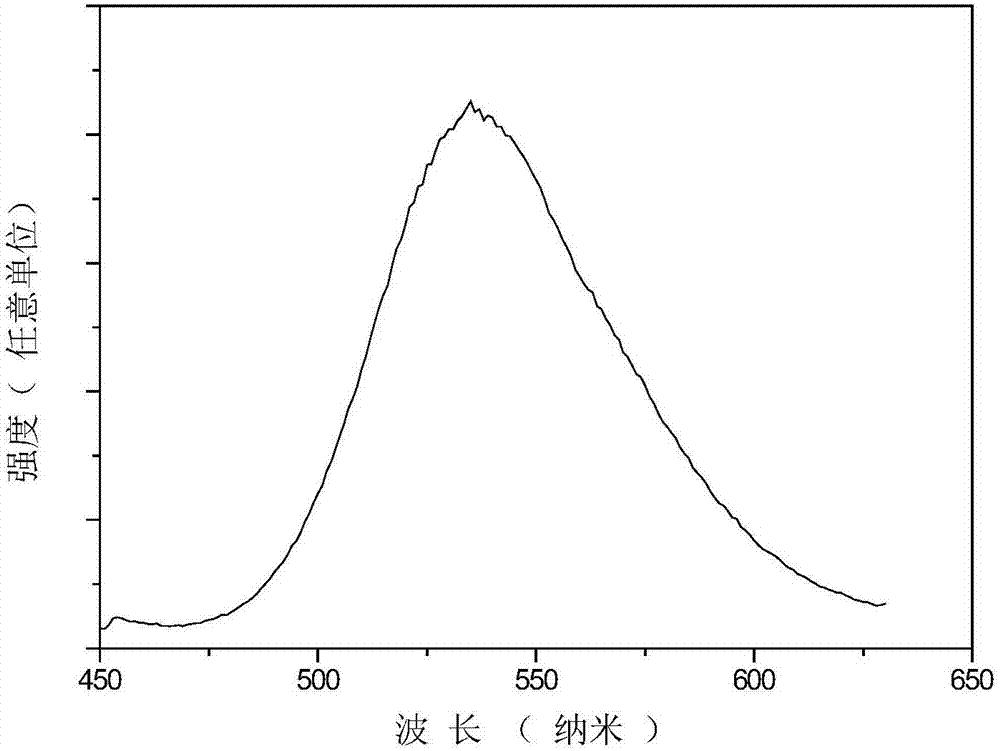

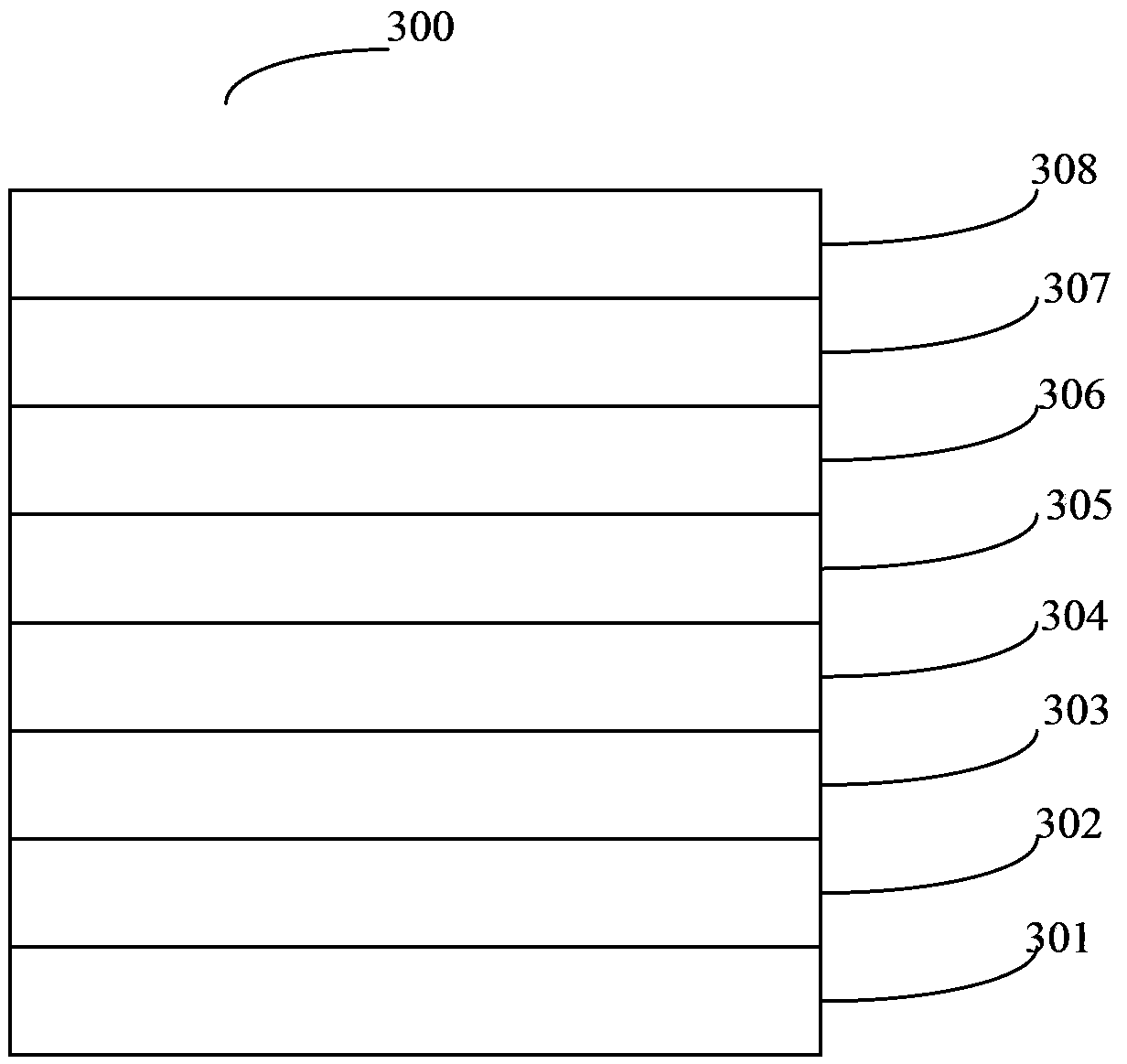

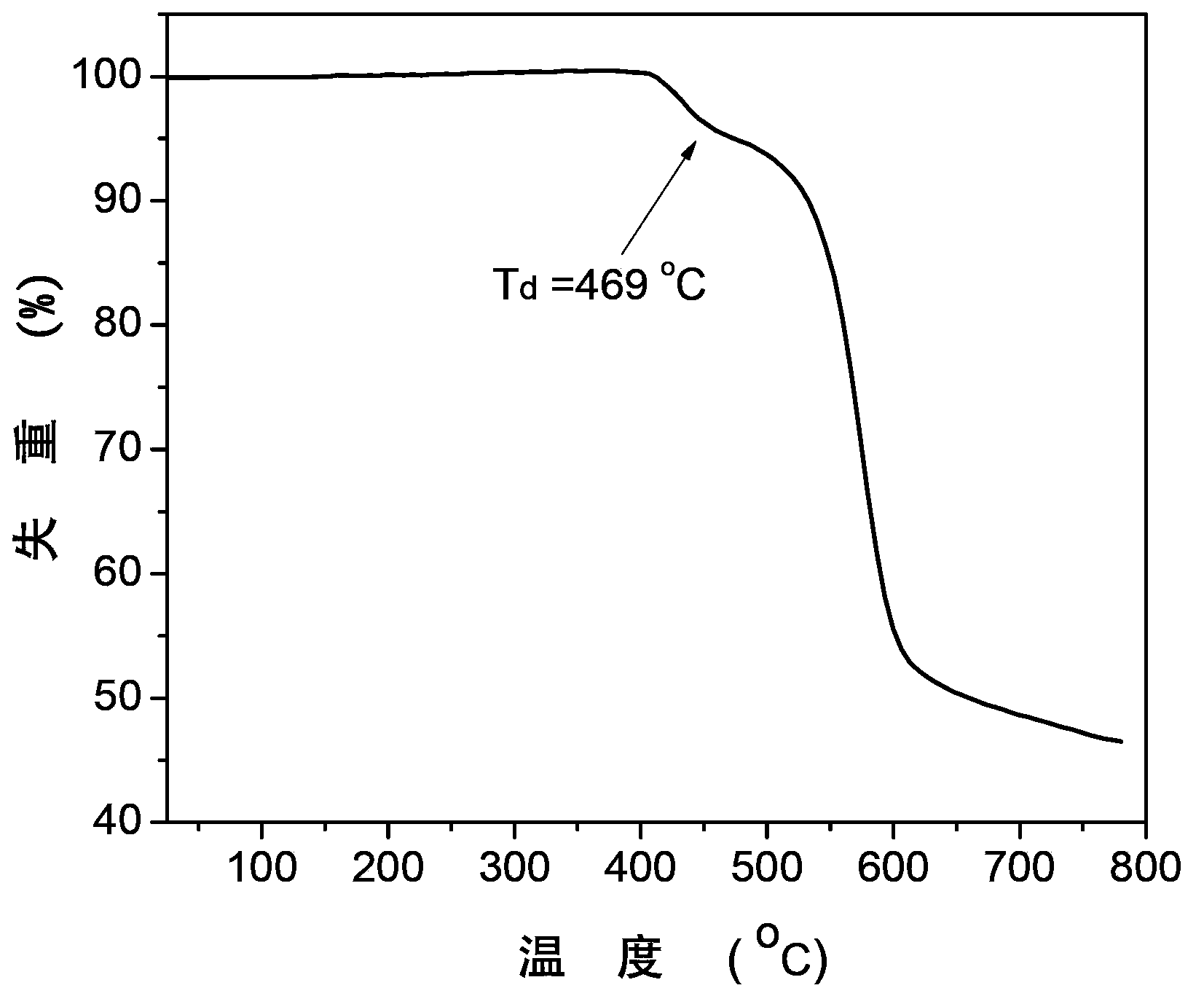

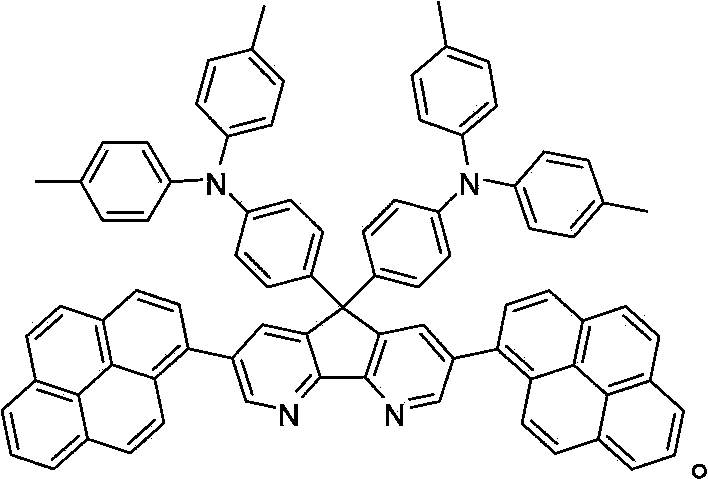

Organic semiconductor material, preparation method and electroluminescent device

InactiveCN103450191APossesses hole transport propertiesHave electron transport propertiesOrganic chemistrySolid-state devicesQuantum yieldElectricity

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

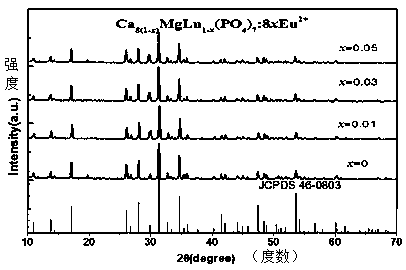

Single matrix white LED (light emitting diode) white fluorescent powder

InactiveCN109679653ACrystal field fitLaunch implementationEnergy efficient lightingLuminescent compositionsThermal stabilityUltimate tensile strength

Owner:HUIZHOU UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap