Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about "Electrolyte accumulators manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

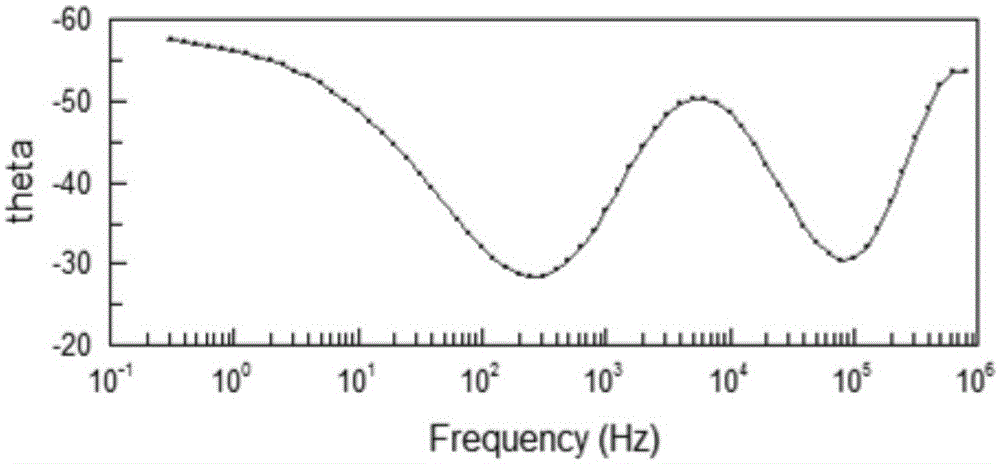

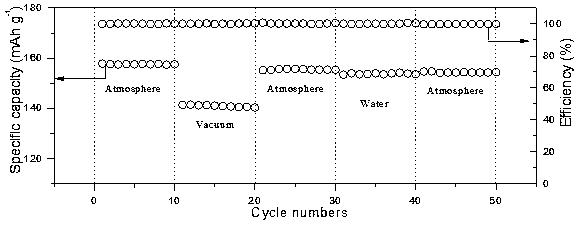

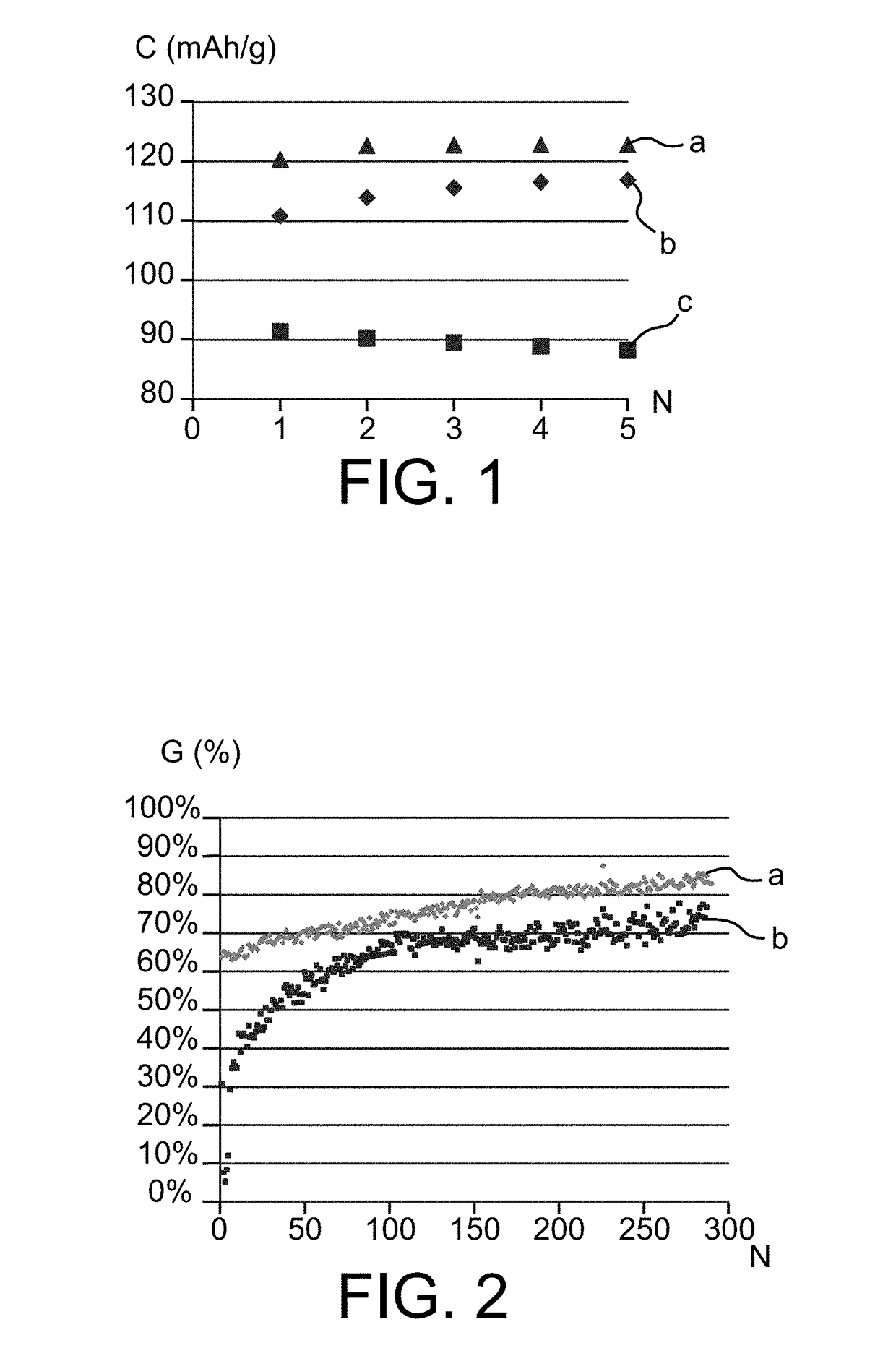

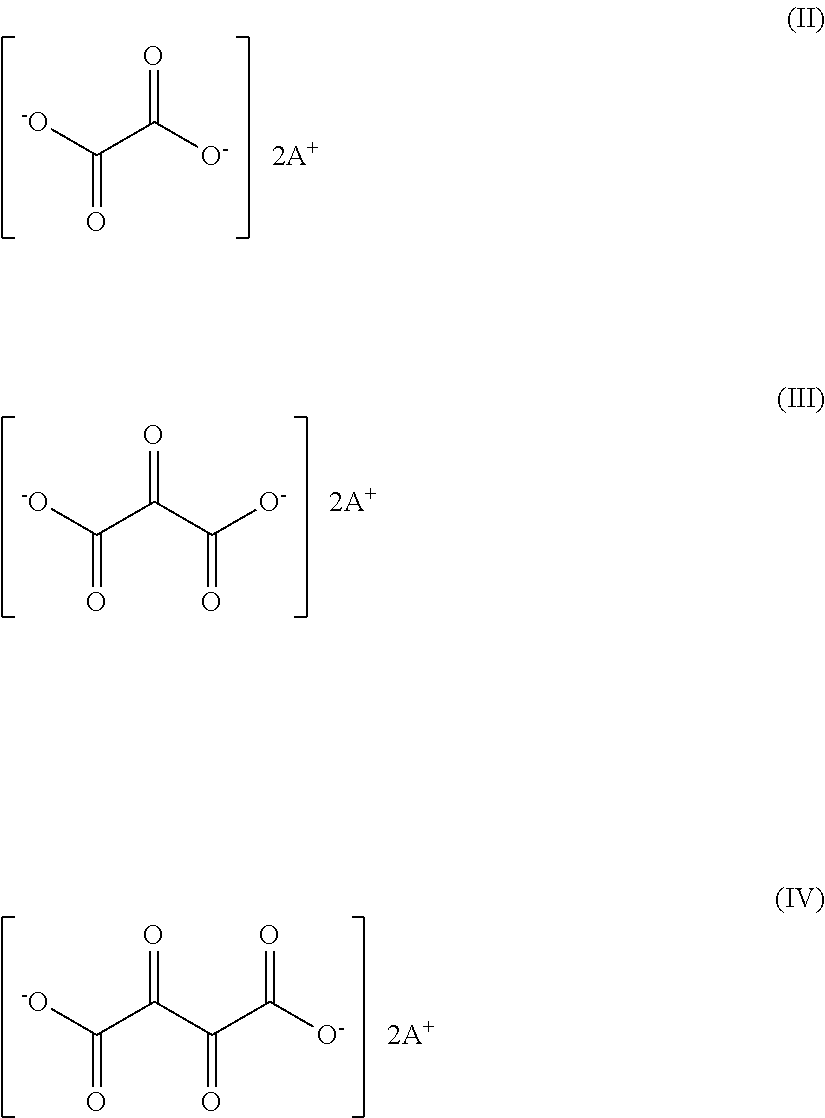

Non-aqueous solution aluminum ion secondary battery and preparation method thereof

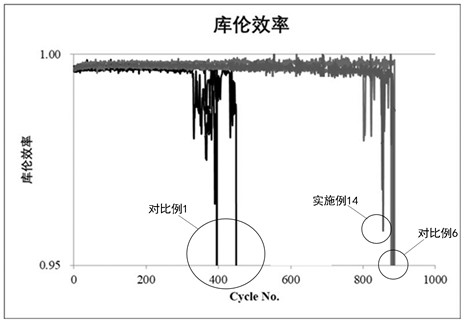

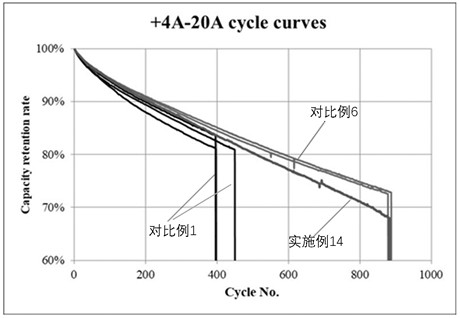

InactiveCN104993130AGood chemical stabilityImprove thermal stabilityCell electrodesFinal product manufactureAluminum IonElectrical battery

Belonging to the technical field of batteries, the invention relates to a non-aqueous solution aluminum ion secondary battery and a preparation method thereof. The secondary battery can be widely applied in electronics, communication, electric vehicle and other fields. The aluminum ion battery provided by the invention contains a battery anode, a battery cathode, a diaphragm and an aluminum-containing non-aqueous solution electrolyte. Specifically, the cathode active material can be carbon, graphite, carbon nanotube, graphene, super carbon, WS2 and MoS2, V2O5, TiO2 and other materials having nano-layered, tubular, linear and other structures, and the anode is aluminum-containing metal or alloy. The non-aqueous solution aluminum ion secondary battery provided by the invention has the characteristics of high specific capacity, high coulomb efficiency, long service life and environmental protection, safety and reliability, stable cycle performance, and quick charging, etc.

Owner:BEIJING ALUMINUM ENERGY S&T

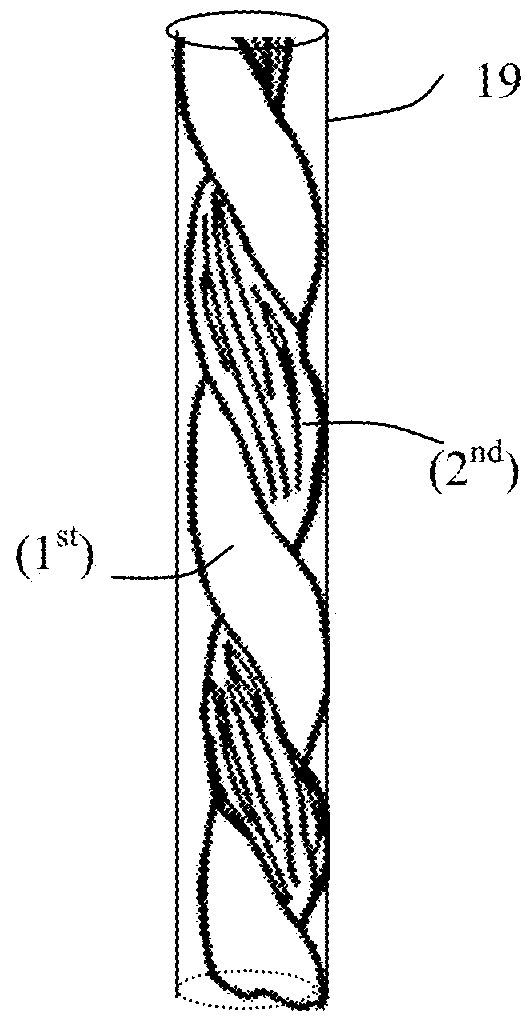

Process for producing flexible and shape-conformal rope-shape alkali metal batteries

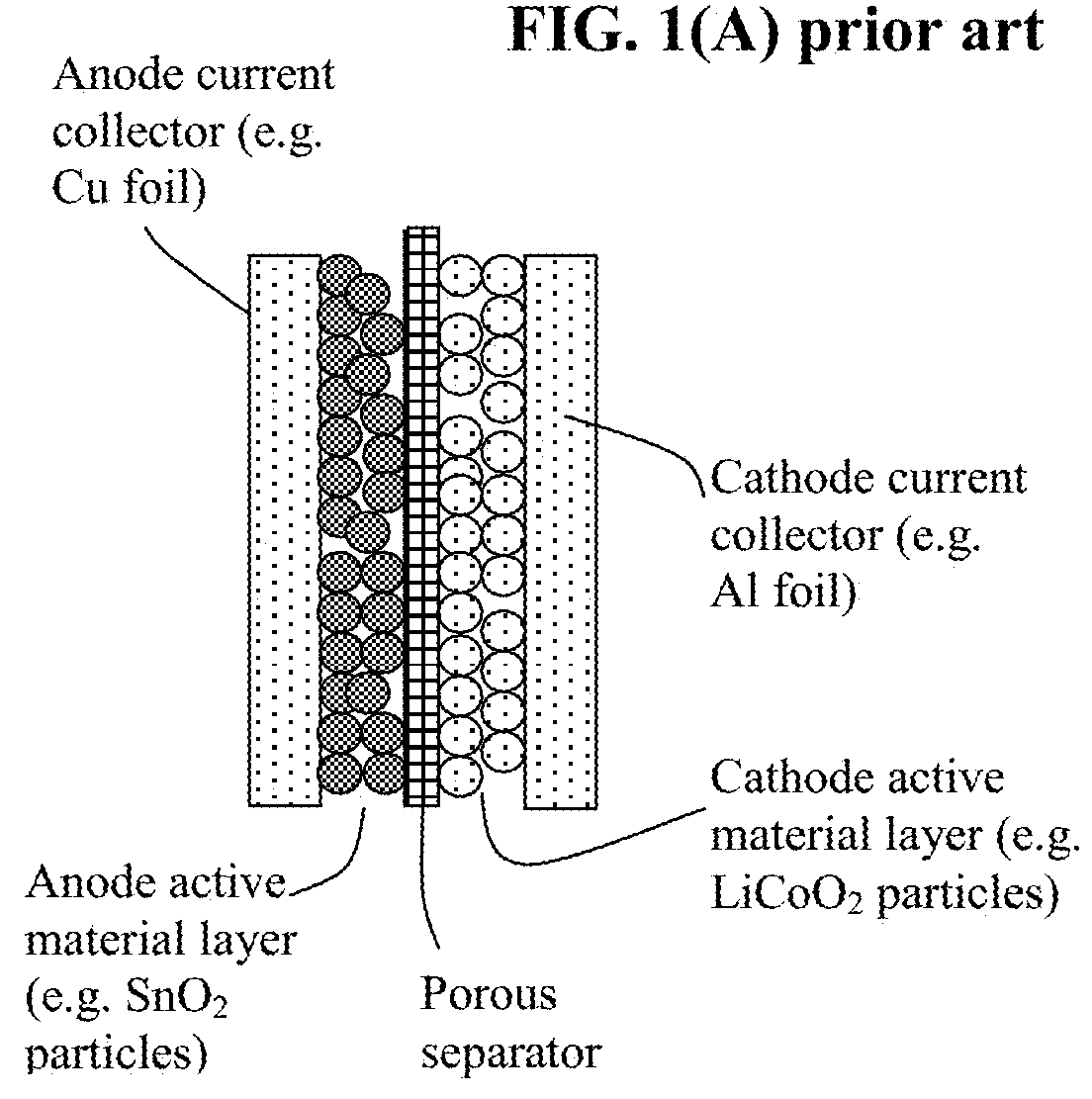

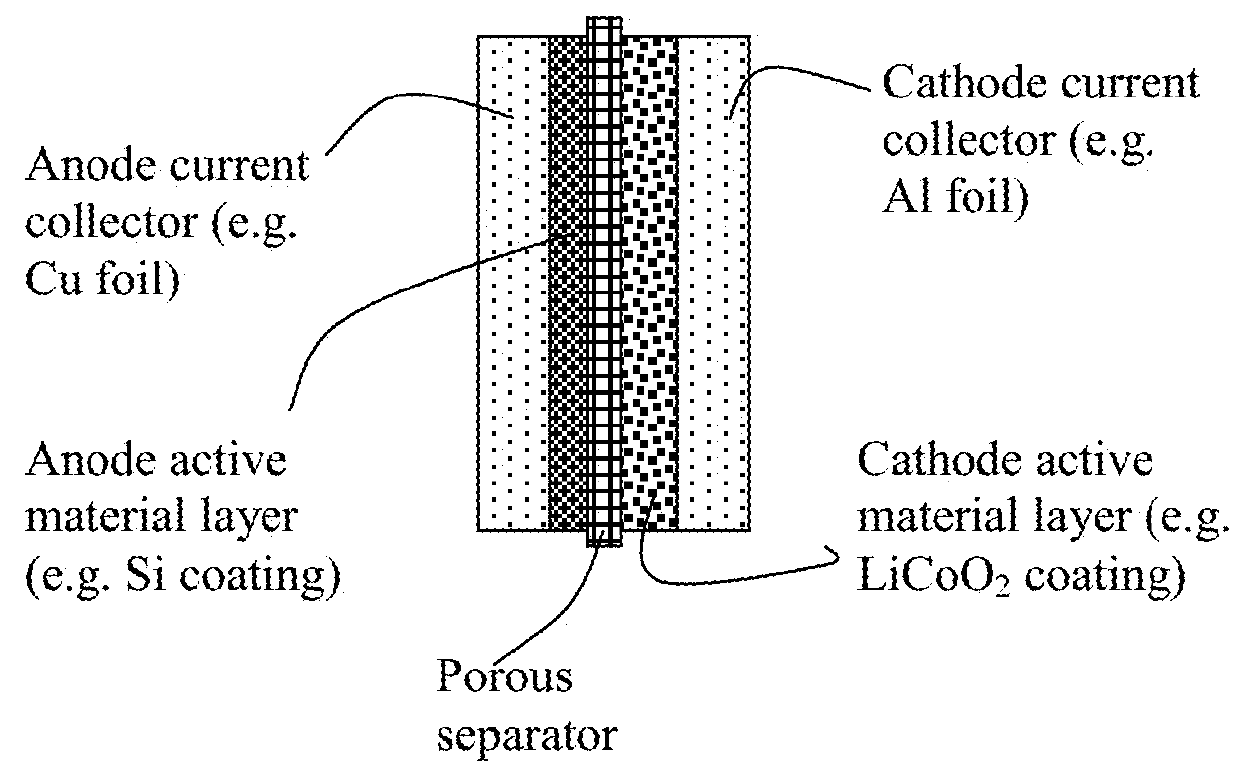

ActiveUS10008747B1Maximize contact areaMaximize interfacial areaFinal product manufactureElectrode carriers/collectorsYarnMaterials science

Owner:GLOBAL GRAPHENE GRP INC

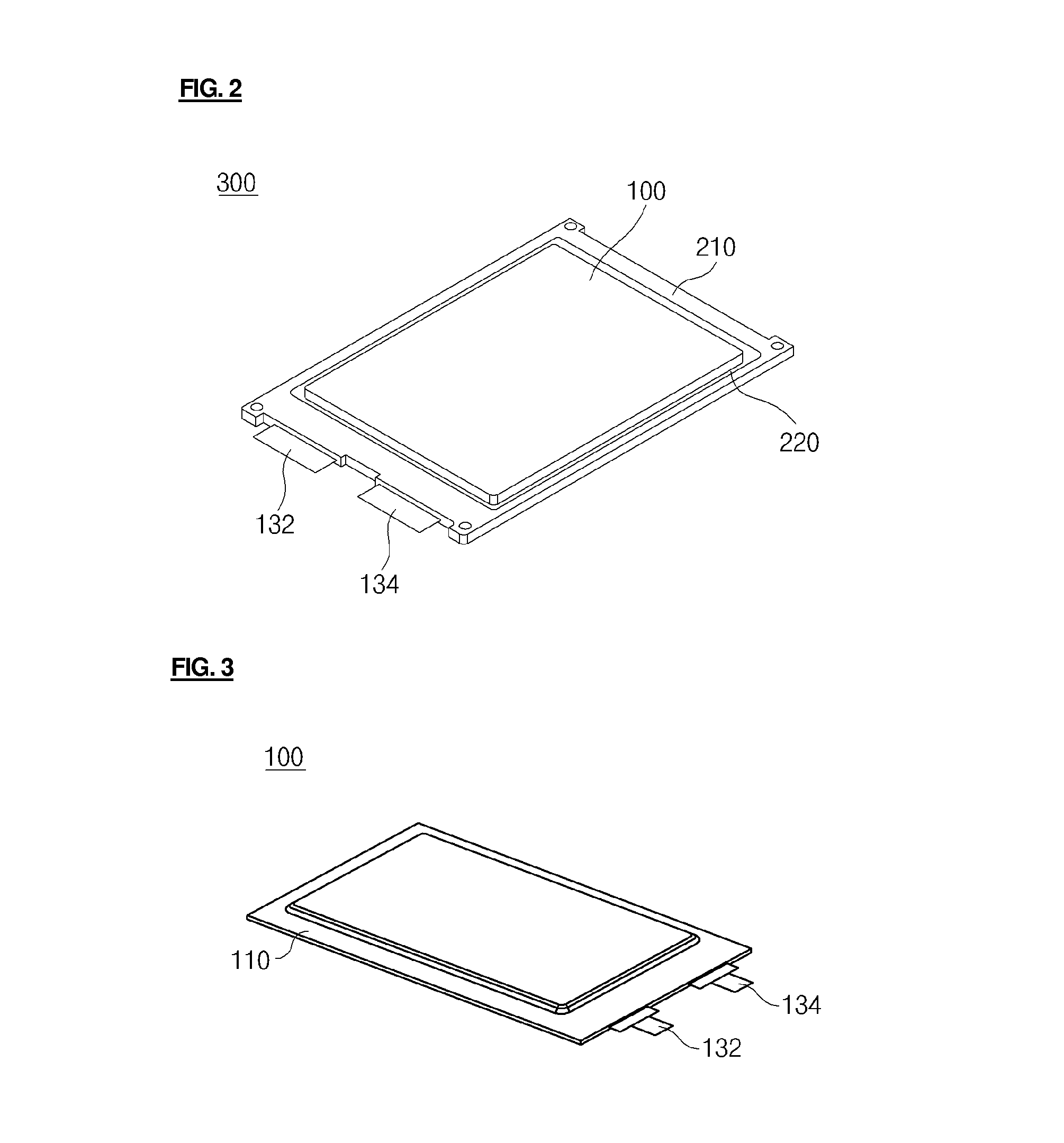

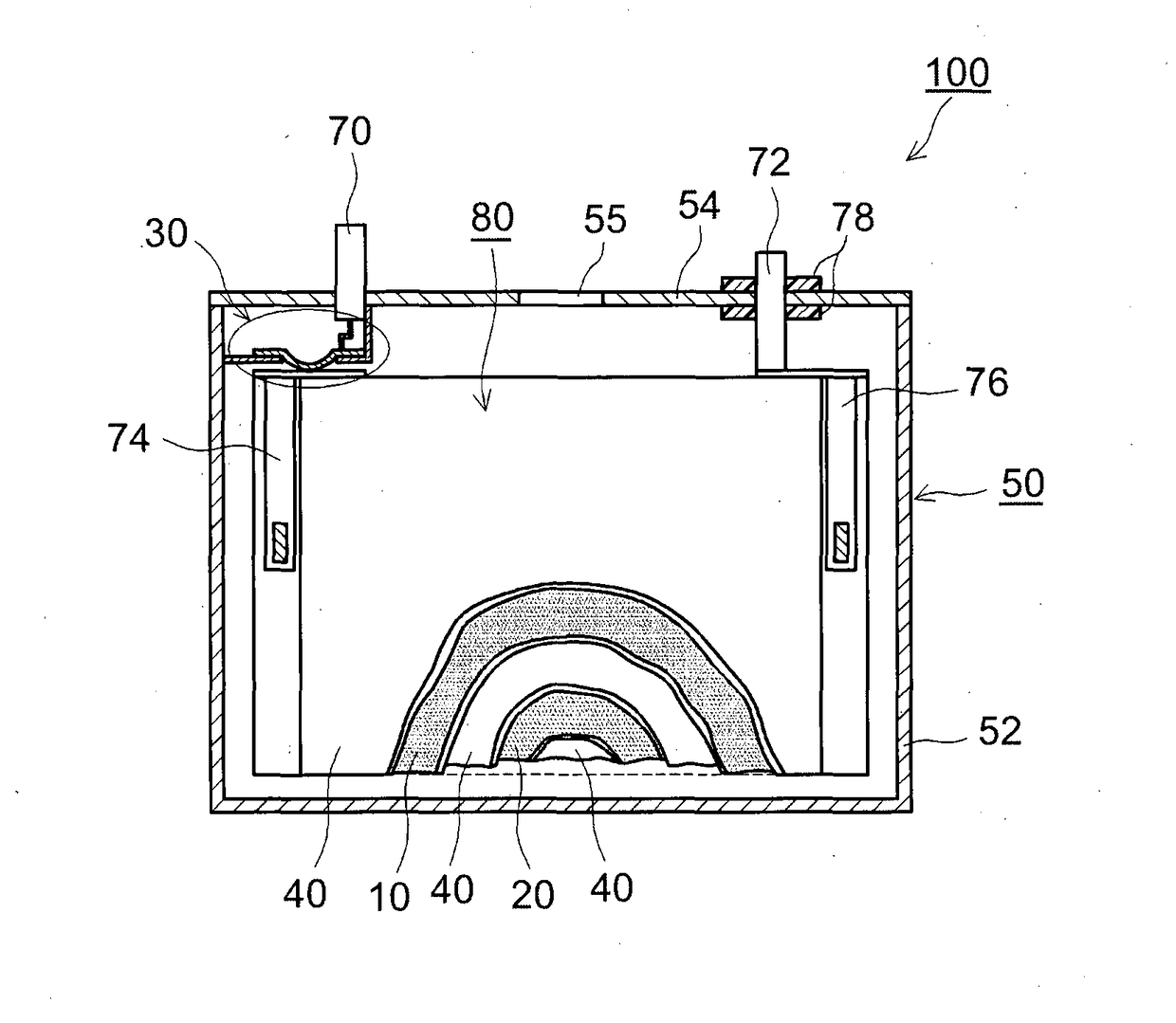

Battery module

ActiveUS20160197387A1Easy dischargeIncrease temperatureSmall-sized cells cases/jacketsFinal product manufactureDischarge efficiencyEngineering

Owner:LG ENERGY SOLUTION LTD

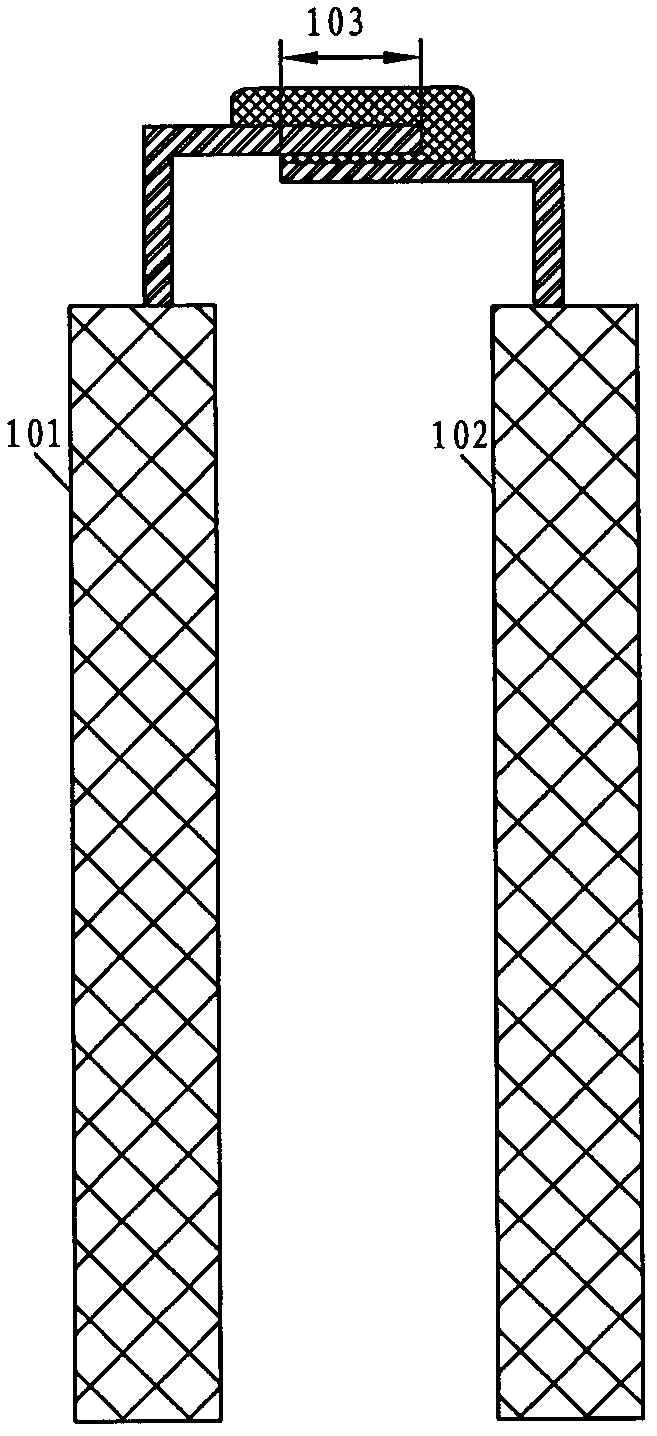

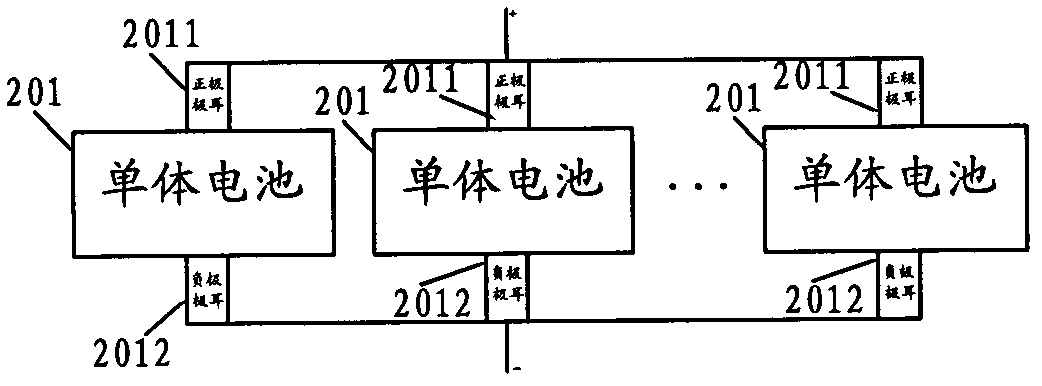

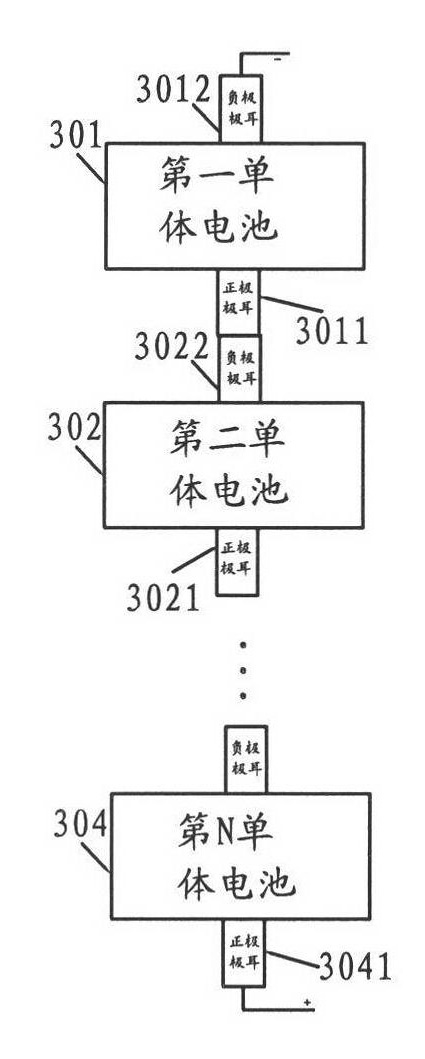

Lithium ion battery pack and soldering method for single batteries therein

ActiveCN102332611AAvoid bloatingFinal product manufactureCell component detailsBattery cellMaterials science

Owner:SHENZHEN GREPOW BATTERY CO LTD

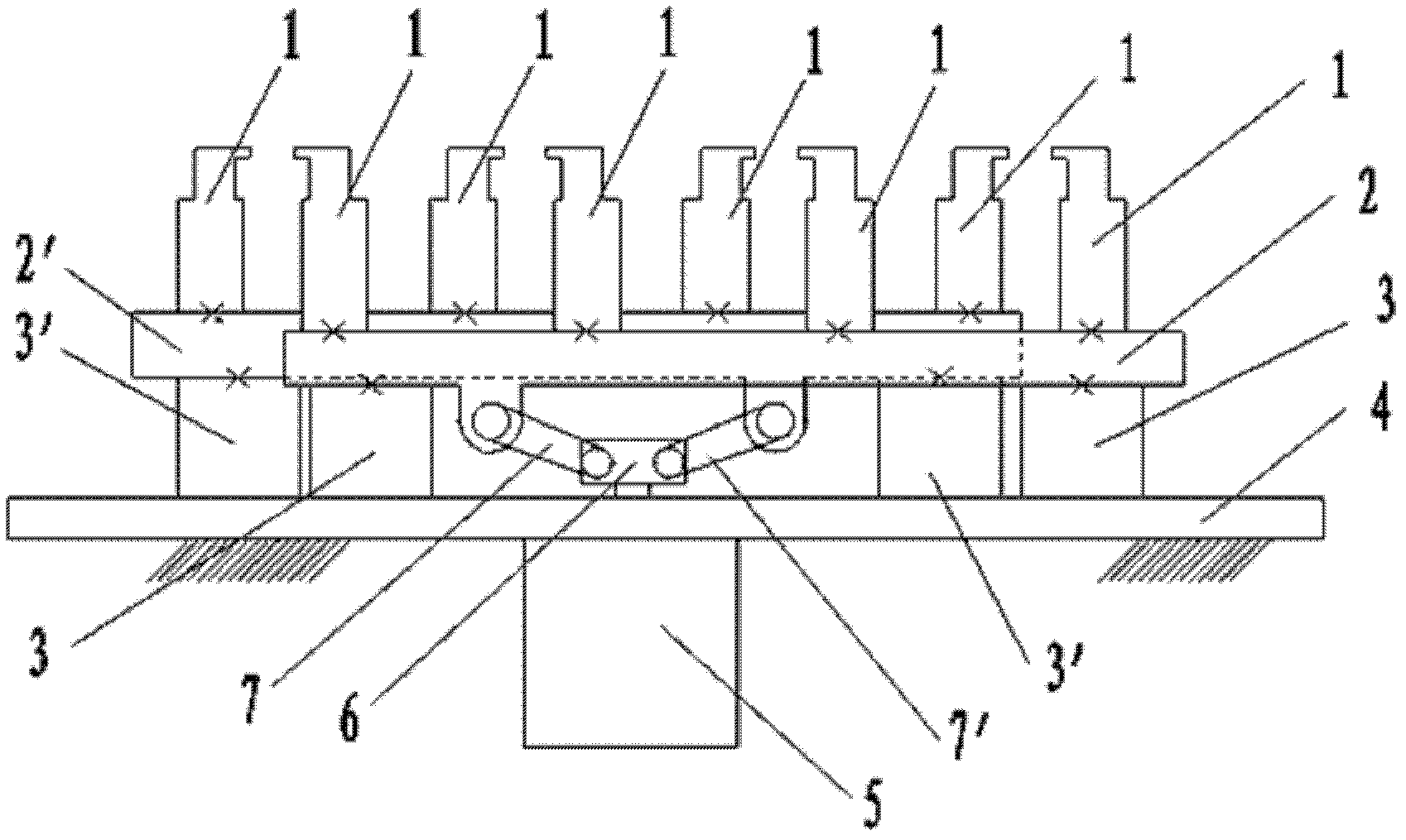

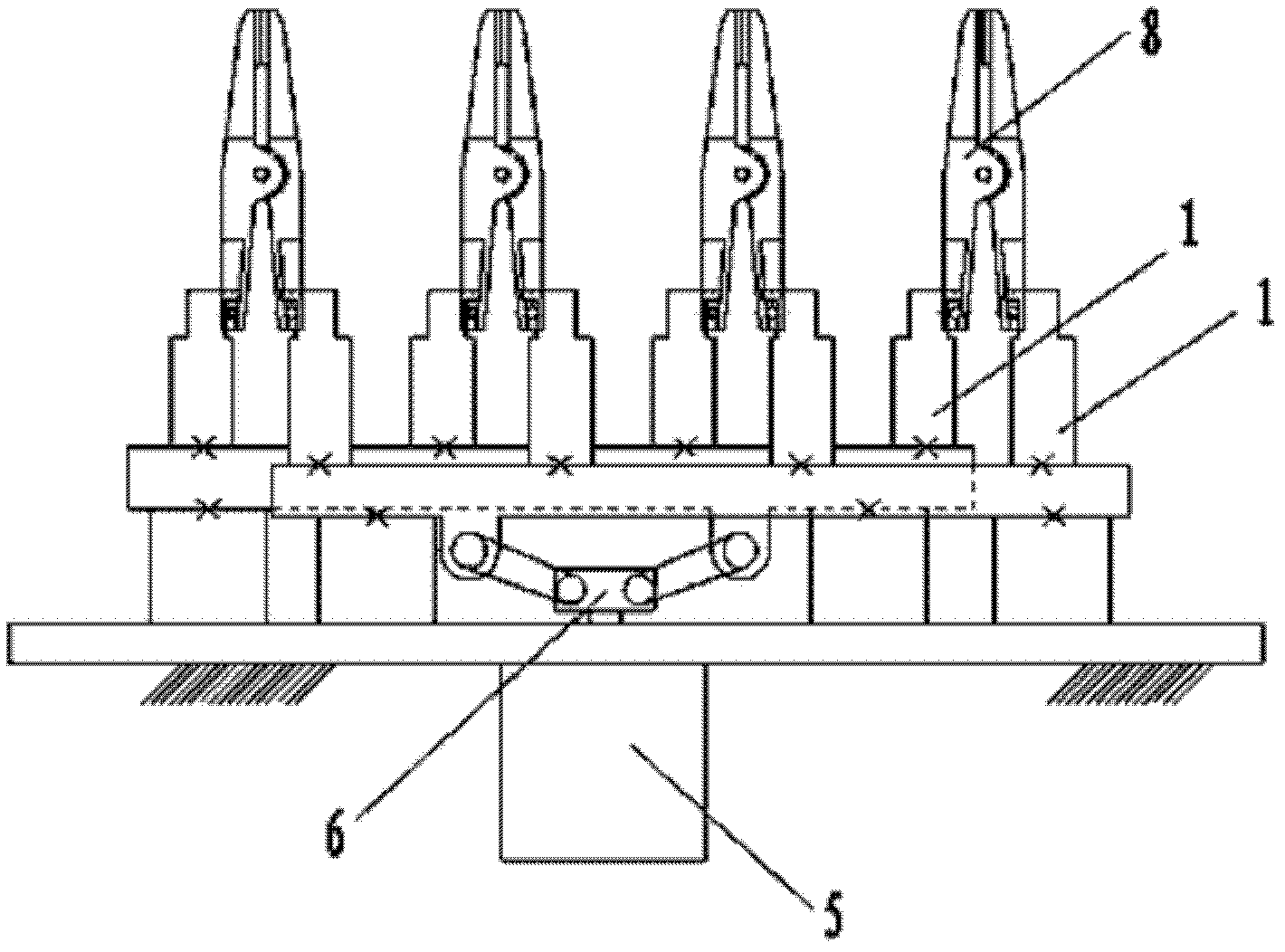

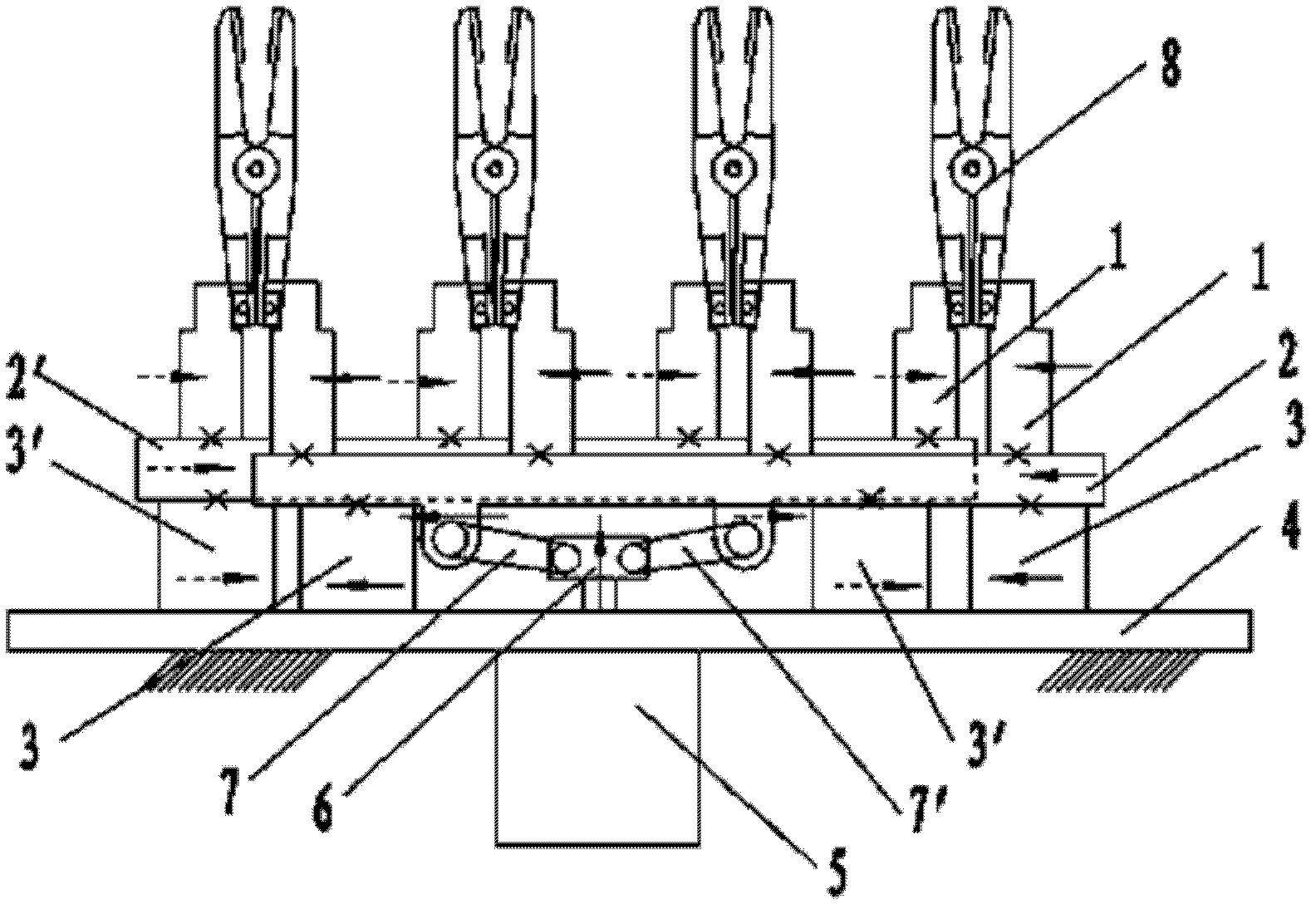

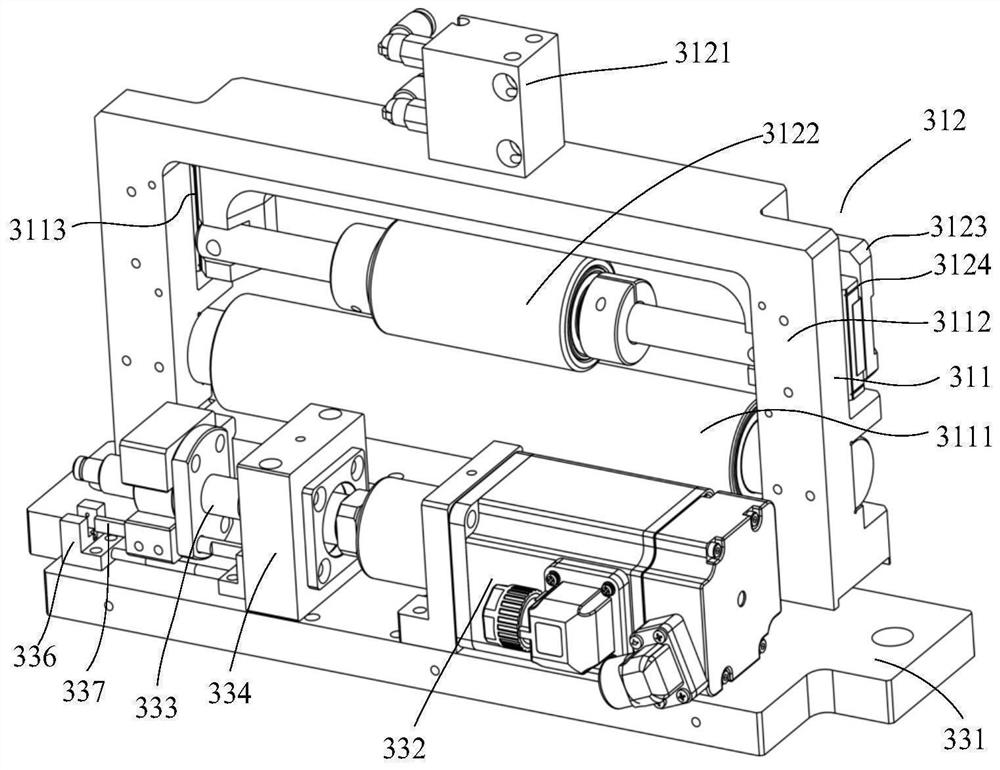

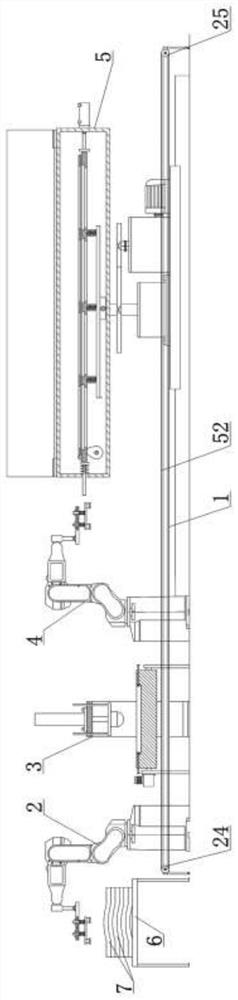

Automatic electrode clamp opening and closing device for formation of lithium battery

InactiveCN102509811ARealize automatic opening and closingTroubleshoot automated operationsFinal product manufactureElectrolyte accumulators manufactureEngineeringSlide plate

The invention relates to an automatic electrode clamp opening and closing device for the formation of a lithium battery. The device comprises a cylinder, first sliding blocks, second sliding blocks, a first sliding plate and a second sliding plate. The cylinder is fixed on a support plate. A connecting block is arranged on the head part of a piston rod of the cylinder. The first sliding plate is arranged on the first sliding blocks, and the second sliding plate is arranged on the second sliding blocks. The connecting block is connected with the first sliding plate through a first motion mechanism, and is connected with the second sliding plate through a second motion mechanism. When the cylinder does piston motion, the first and second sliding blocks are driven by the first and second sliding plates to do linear motion along the support plate, and only motion towards or away from each other in motion. At least one stirring fork for stirring an electrode clamp is arranged on the first sliding plate. Stirring forks of which the number is the same as that of the stirring forks on the first sliding plate are arranged on the second sliding plate. The stirring forks on the first and second sliding plates are arranged in pairs. By the device, the electrode clamps can be automatically opened and closed.

Owner:DONGHUA UNIV

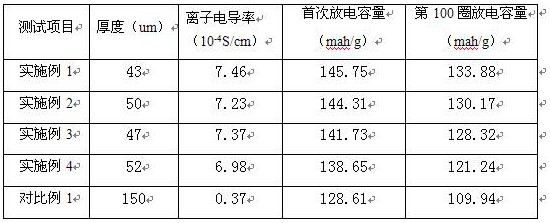

Solid-state electrolyte, lithium battery cell and lithium battery

InactiveCN109935896AImprove interfacial adhesionImprove wettabilityMaterial nanotechnologyFinal product manufactureSolid state electrolyteShear modulus

The invention relates to the field of lithium batteries, in particular to a solid-state electrolyte, a lithium battery cell and a lithium battery. The solid-state electrolyte is an anti-perovskite solid-state electrolyte, and includes one or more super base clusters selected from Li3Se+, Li3S+ and Li3O+ and one or more super halogen clusters selected from BH4-, AlH4-, BF4-, FeH4-, CoH4- and NiH4-.The solid-state electrolyte exhibits a nanowire morphology. Therefore, the solid-state electrolyte has an electrochemical window above 5V and excellent interfacial adhesion, wettability and lithium ion conductivity, and the molecular skeleton of the solid-state electrolyte has good tolerance. Based on the structural characteristics of the solid-state electrolyte, the solid-state electrolyte has the advantages of high shear modulus, high Young's modulus and capability of inhibiting the growth of lithium dendrites.

Owner:CHENGDU DACHAO TECH CO LTD

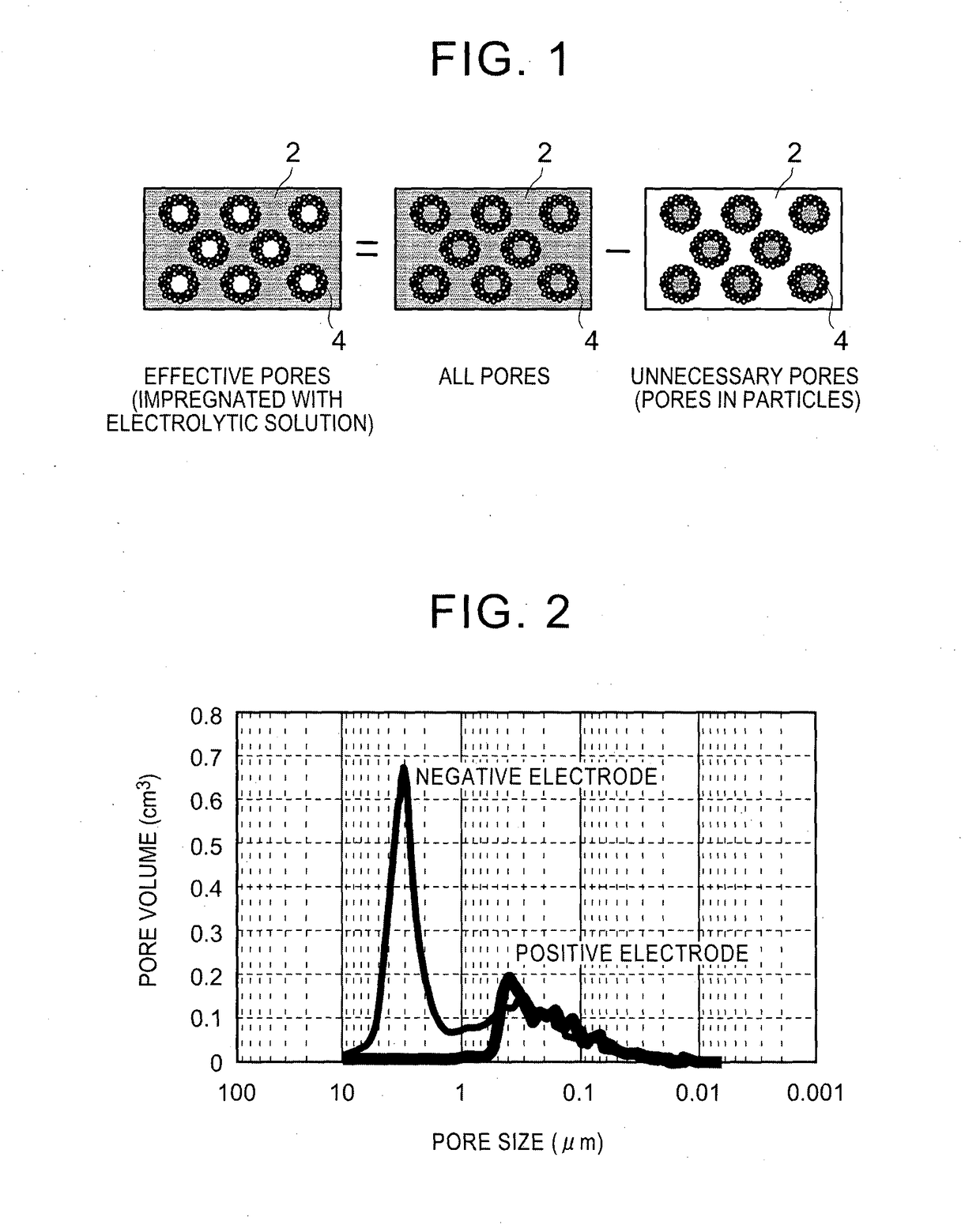

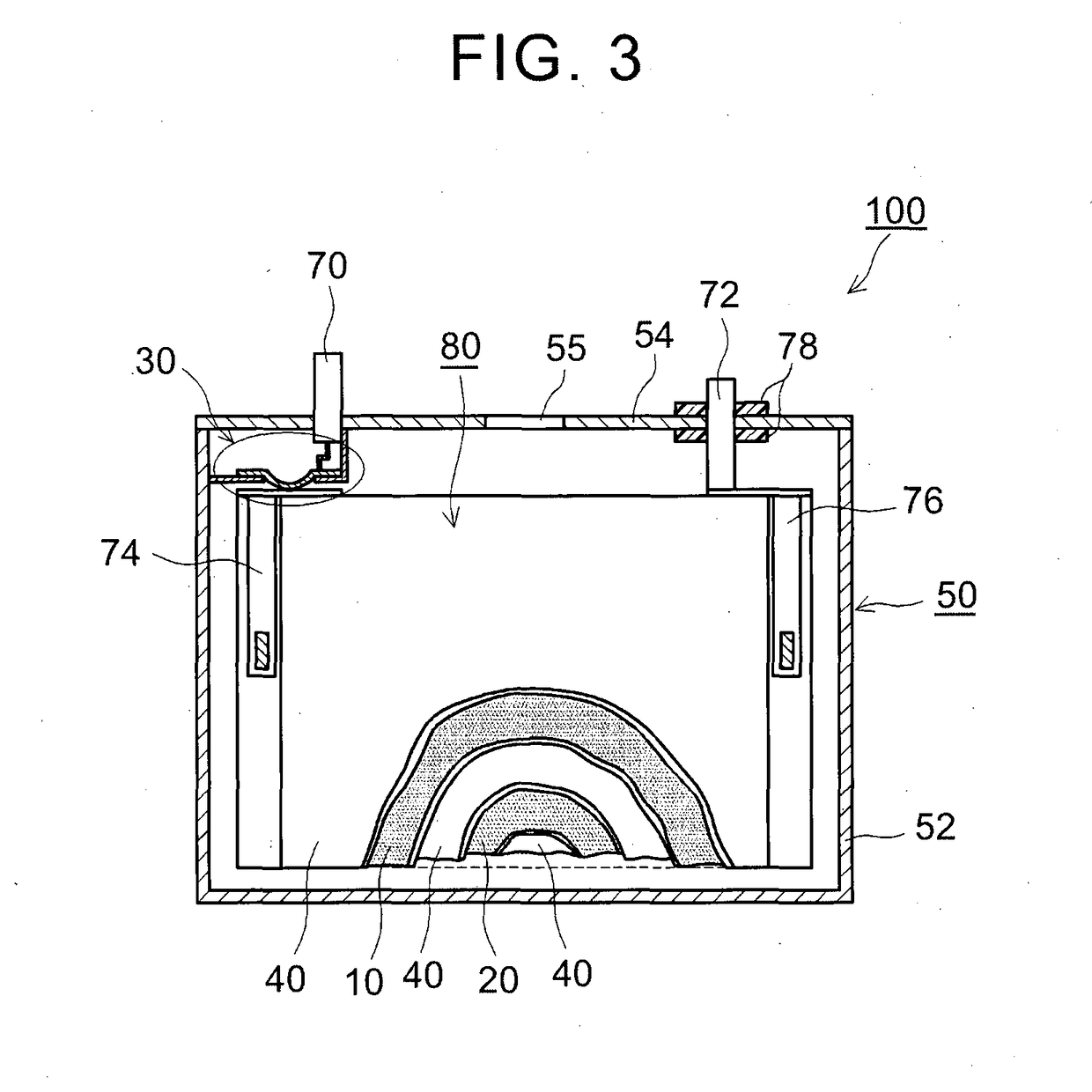

Nonaqueous secondary battery

ActiveUS20170077486A1Accurate operationStable controlFinal product manufactureNegative electrodesEngineeringElectrode

Owner:TOYOTA JIDOSHA KK

Production method of lithium-ion power battery improving battery consistency

InactiveCN102280665AImprove consistencyTotal weight controlCell electrodesFinal product manufacturePower batteryEngineering

The invention discloses a production method of a lithium ion power battery with consistency improved. According to the invention, anode sheets and cathode sheets are obtained through coating and cutting technologies, and are graded according to the weight of each sheet; a total weight of anode sheets in a single battery is controlled through steps that: a group of anode sheets with a total anode sheet number required by the single battery is weighed, wherein the anode sheets can be selected from a middle weight grade, or can be randomly selected from at least two weight grades; according to ameasured weight, anode sheets in the grade of a larger weight are replaced by anode sheets in the grade of a smaller weight, or anode sheets in the grade of a smaller weight are replaced by anode sheets in the grade of a larger weight; finally, the total weight of the anode sheets is controlled within a required total weight range. With the production technology modification provided by the invention, consistency of the lithium ion power battery is greatly improved, service life of the lithium ion power battery is prolonged, and application safety of the lithium ion power battery is ensured.

Owner:SHANDONG SHANGCUN ENERGY

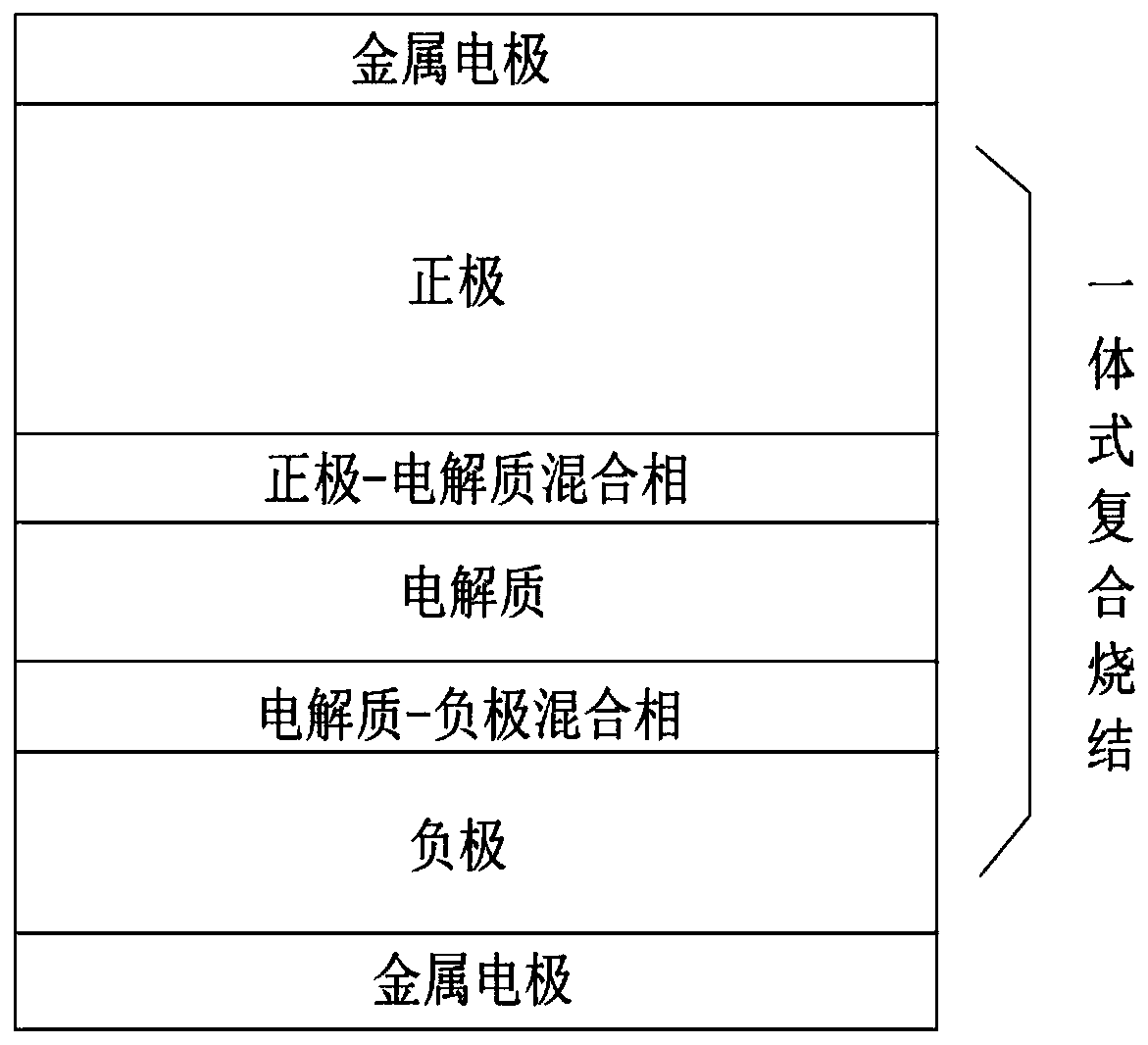

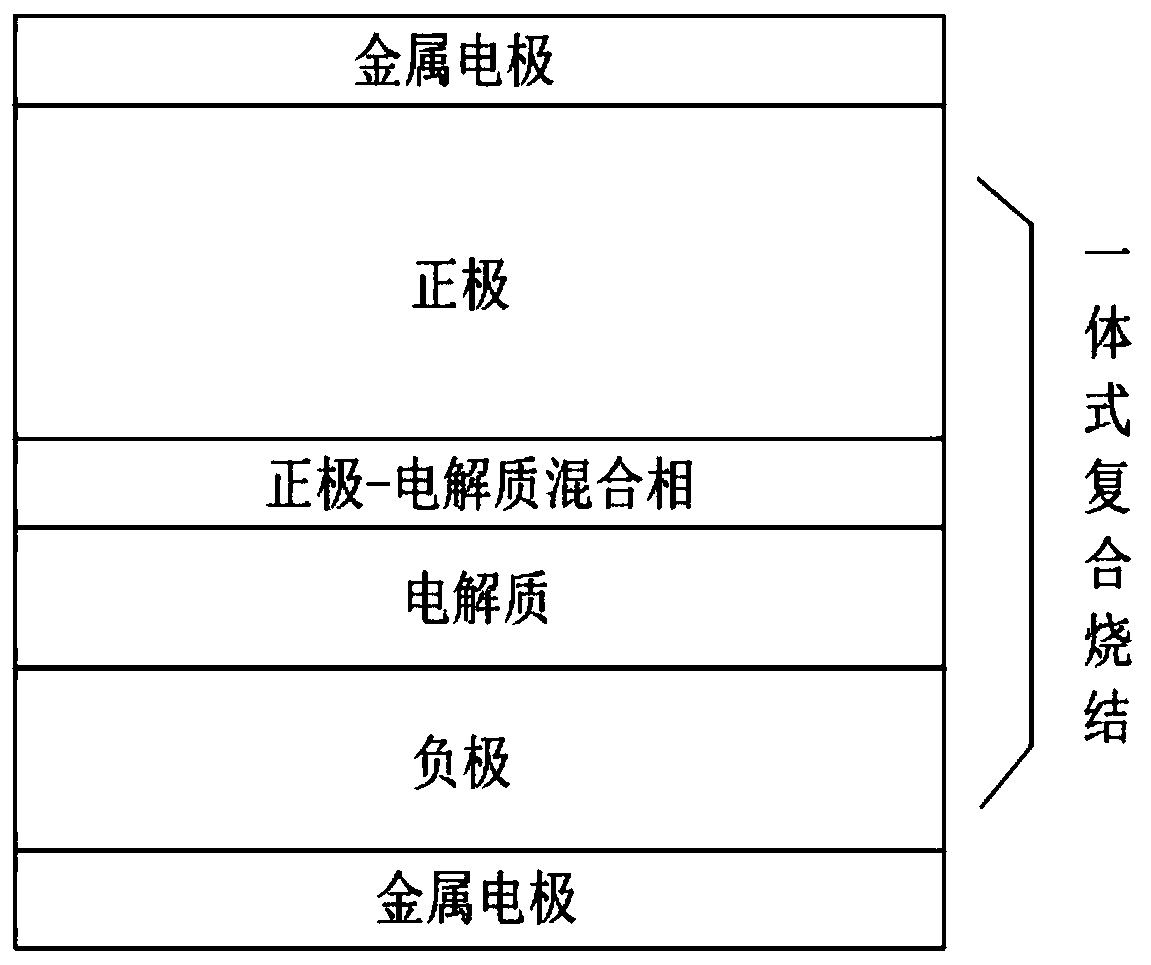

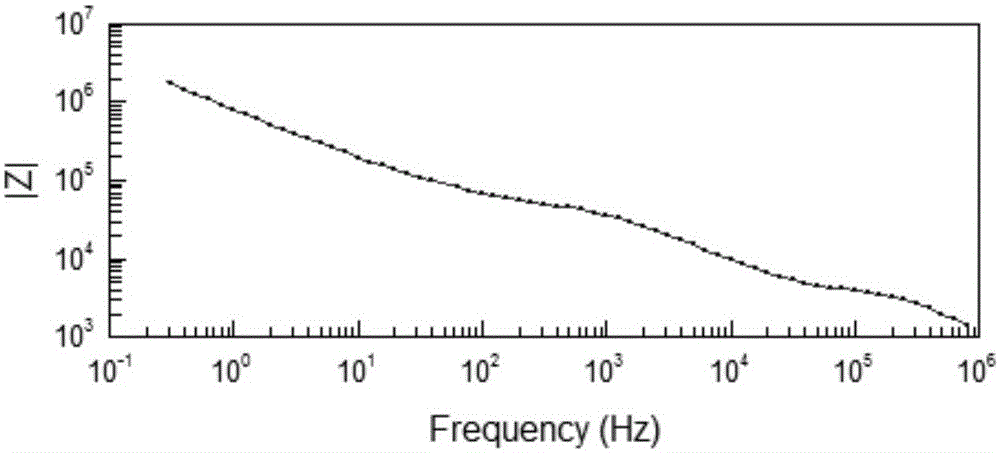

All-solid-state lithium ion battery and integrated composite sintering preparation process thereof

InactiveCN110165286AImprove Interface StabilityEnhanced interfacial transport propertiesFinal product manufactureSecondary cells manufactureLithium oxideSolid state electrolyte

Owner:浙江国能锂业有限责任公司

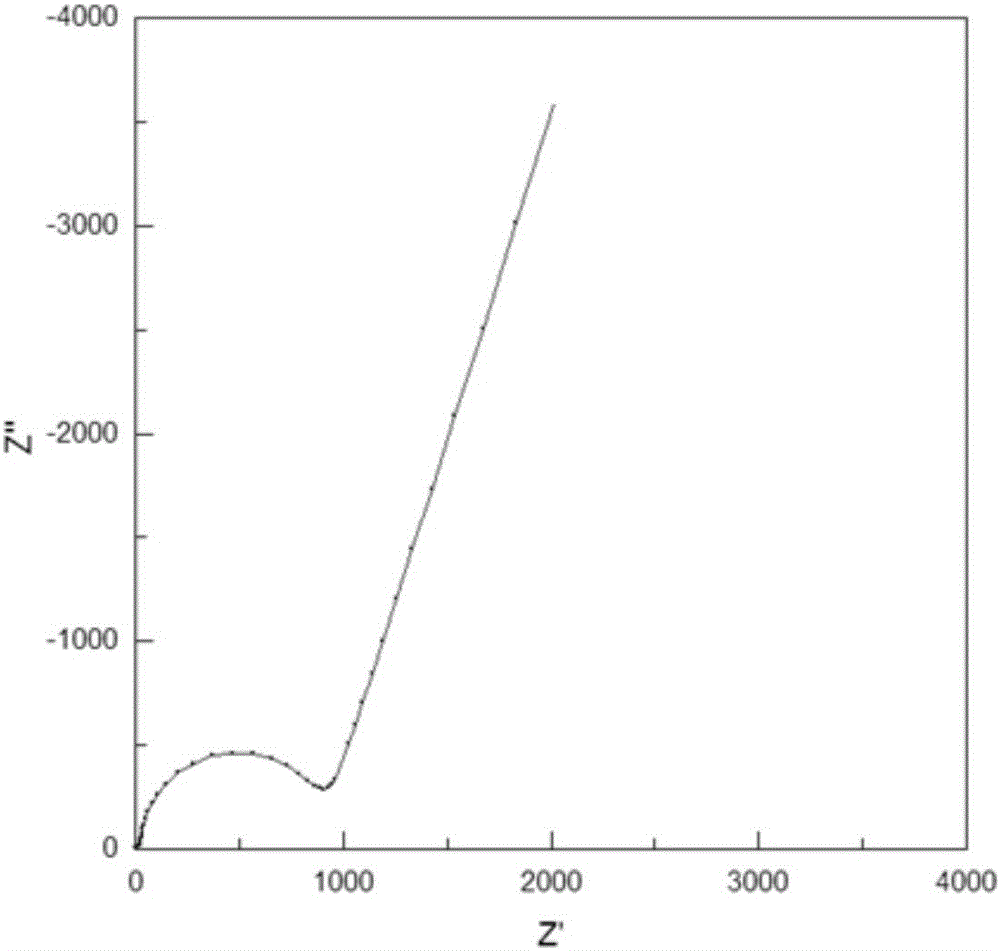

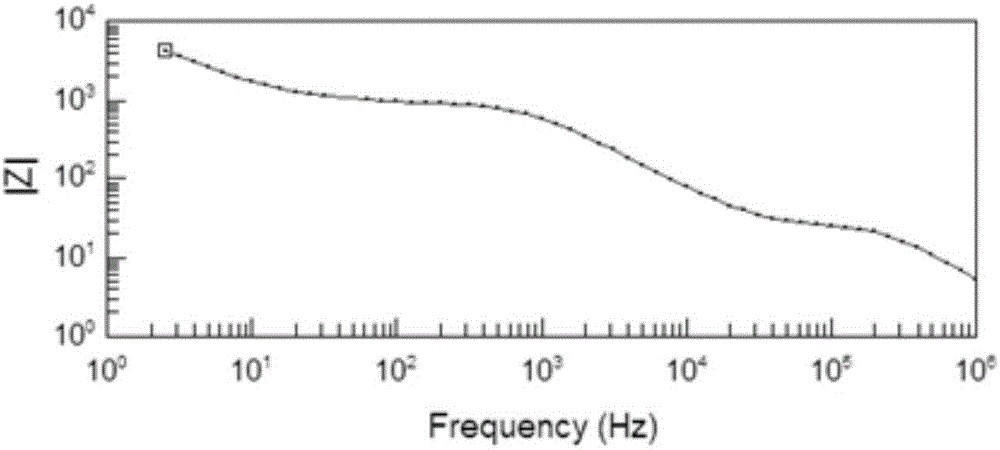

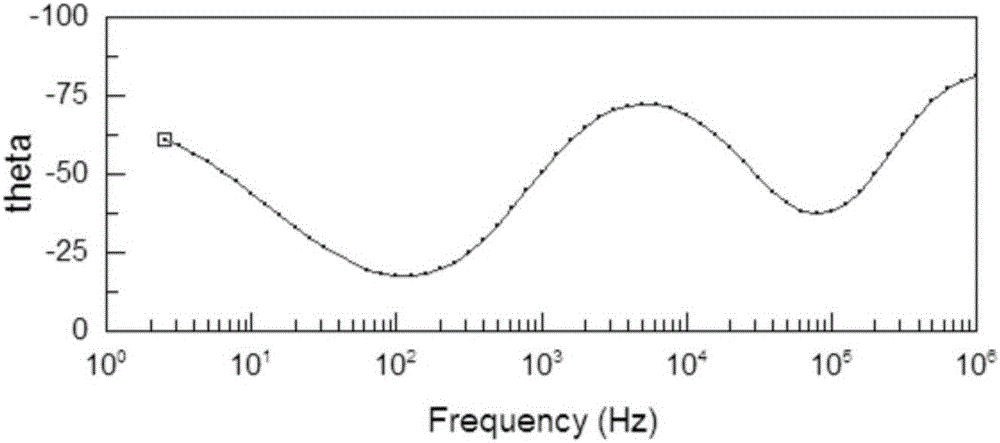

Na<+> superionic conductor (NASICON) type lithium-ion solid electrolyte collaboratively doping with F<->, B<3+> and Y<3+> ions and preparation method thereof

InactiveCN105140559ASmall hindranceReduce transmission bottleneckFinal product manufactureElectrolyte accumulators manufactureLithiumPhysical chemistry

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Flexible lithium-ion battery capable of working around clock and preparation method thereof

ActiveCN108649230AHigh degree of orderImprove electrochemical performanceFinal product manufactureElectrode carriers/collectorsCarbon nanotubeEngineering

Owner:JIANGXI UNIV OF SCI & TECH

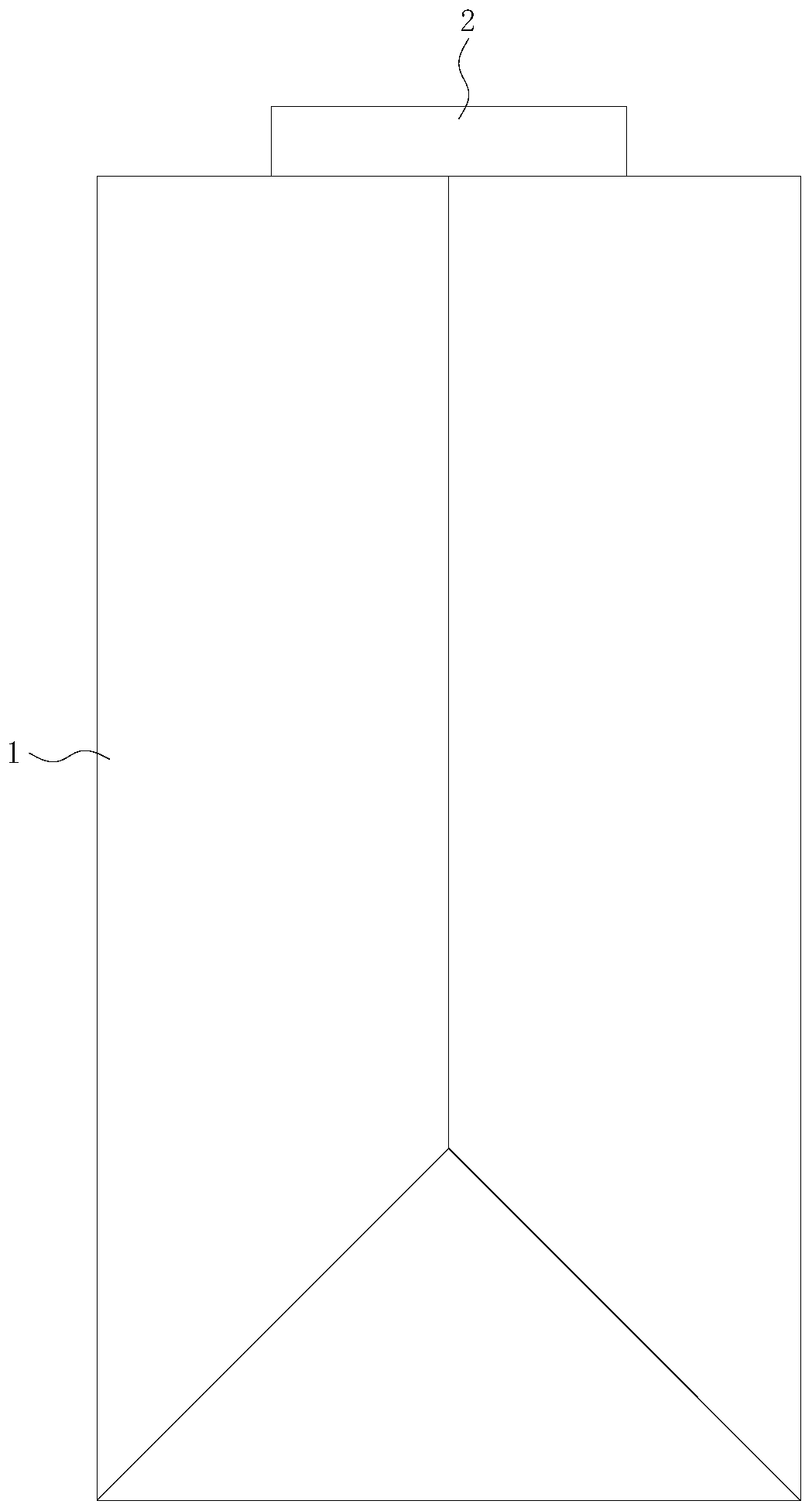

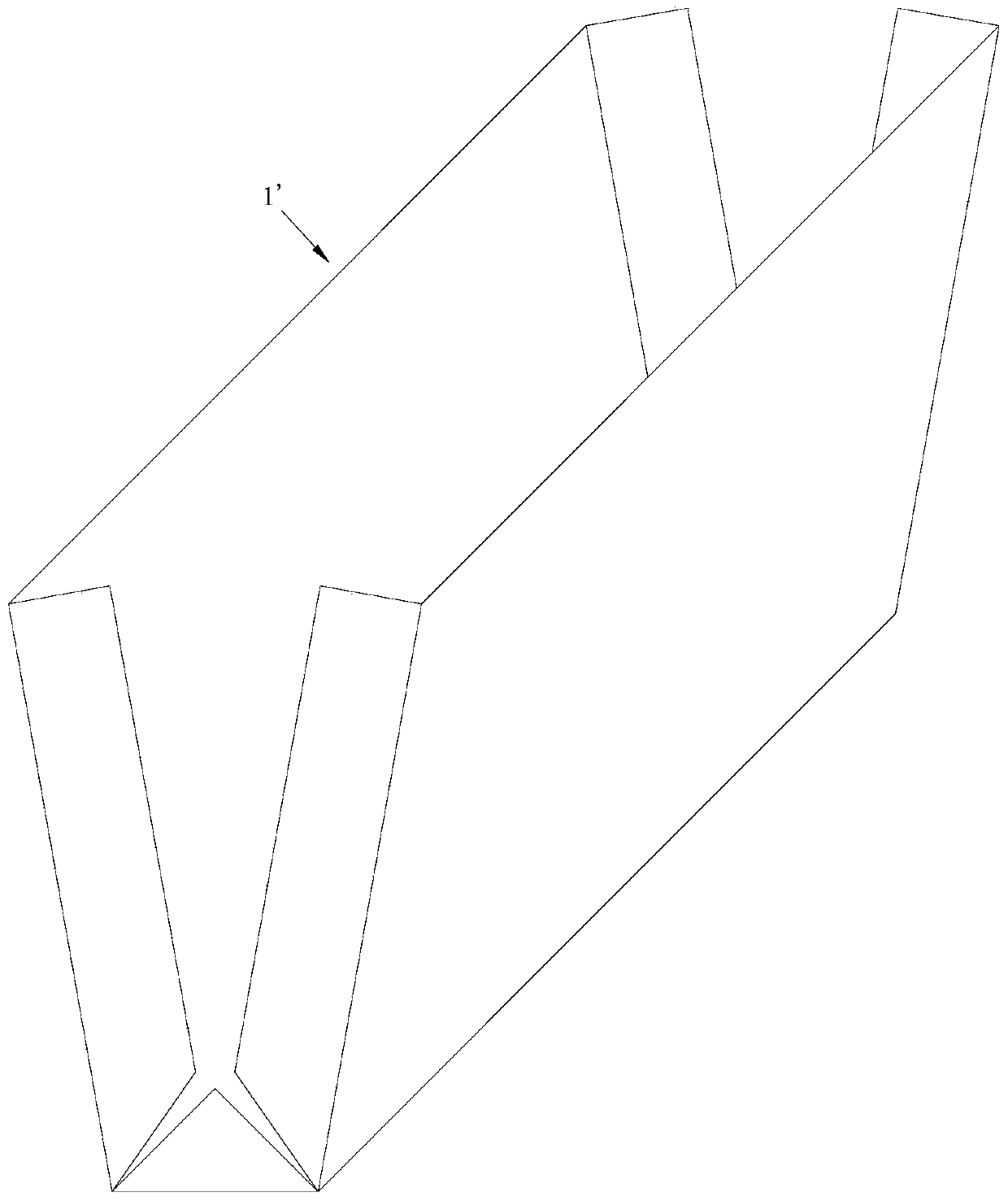

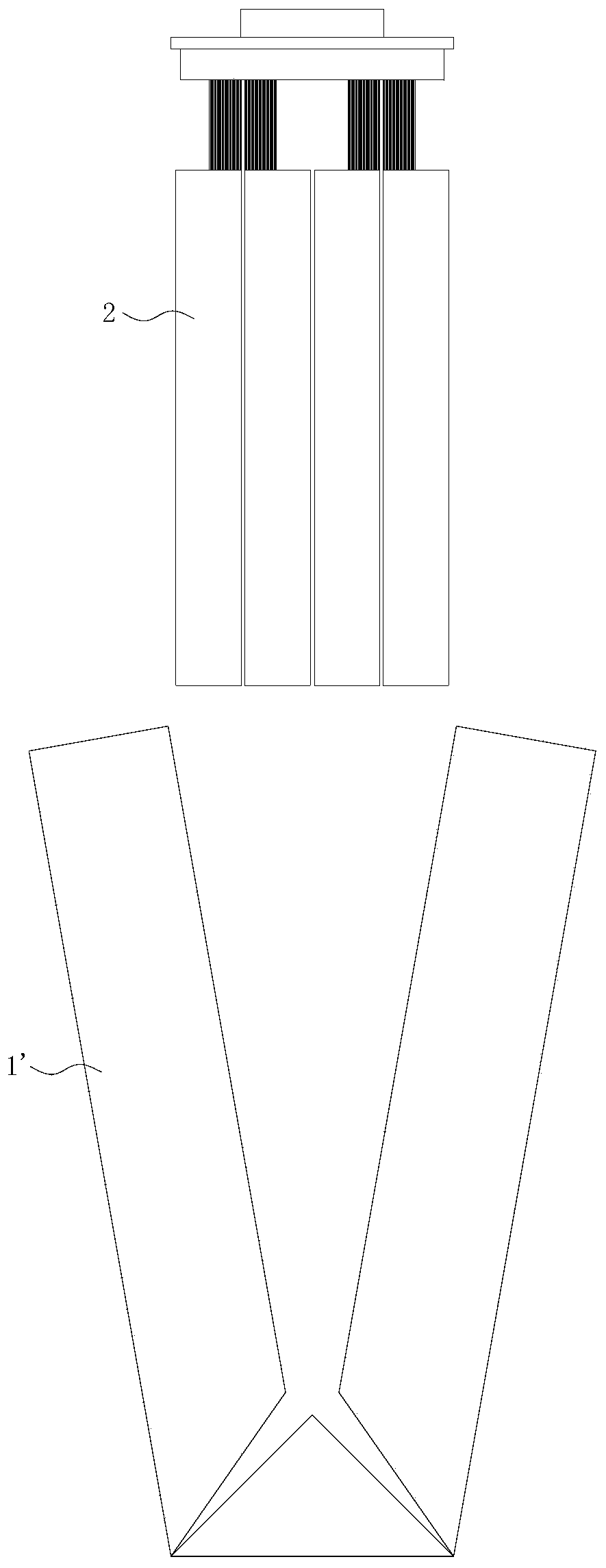

Electrode assembly, manufacture method thereof and lithium secondary battery

InactiveCN103887472AEasy to processExtend your lifeFinal product manufactureLi-accumulatorsLithiumEngineering

The invention discloses an electrode assembly which comprises a first polar plate, and two second polar plates, wherein active material layers are coated on two surfaces of the first polar plate, the first polar plate is continuously bent into a Z shape of a vertical cross-section along the length direction of the first polar plate, an active material layer is coated on one surface of the second polar plate, each second polar plate is continuously bent into a Z shape of a vertical cross-section along the length direction of the second polar plate, two surfaces of the first polar plate, coated with the active material layers, are respectively opposite to surfaces of the two second polar plates, coated with the active material layers, an isolating layer is arranged between the surfaces of the first polar plate, which are opposite to the second polar plates, and the first polar plate and the second polar plates are respectively provided with a contact region with connected leads. The electrode assembly is low in requirement of production equipment, is easy to process and manufacture, and is relatively prolonged in service life. The material utilization rate of the electrode assembly can be increased, the cost is lowered, and the energy density of a battery is improved, so that the volume of the electrode assembly is relatively reduced under the same capacity.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI +1

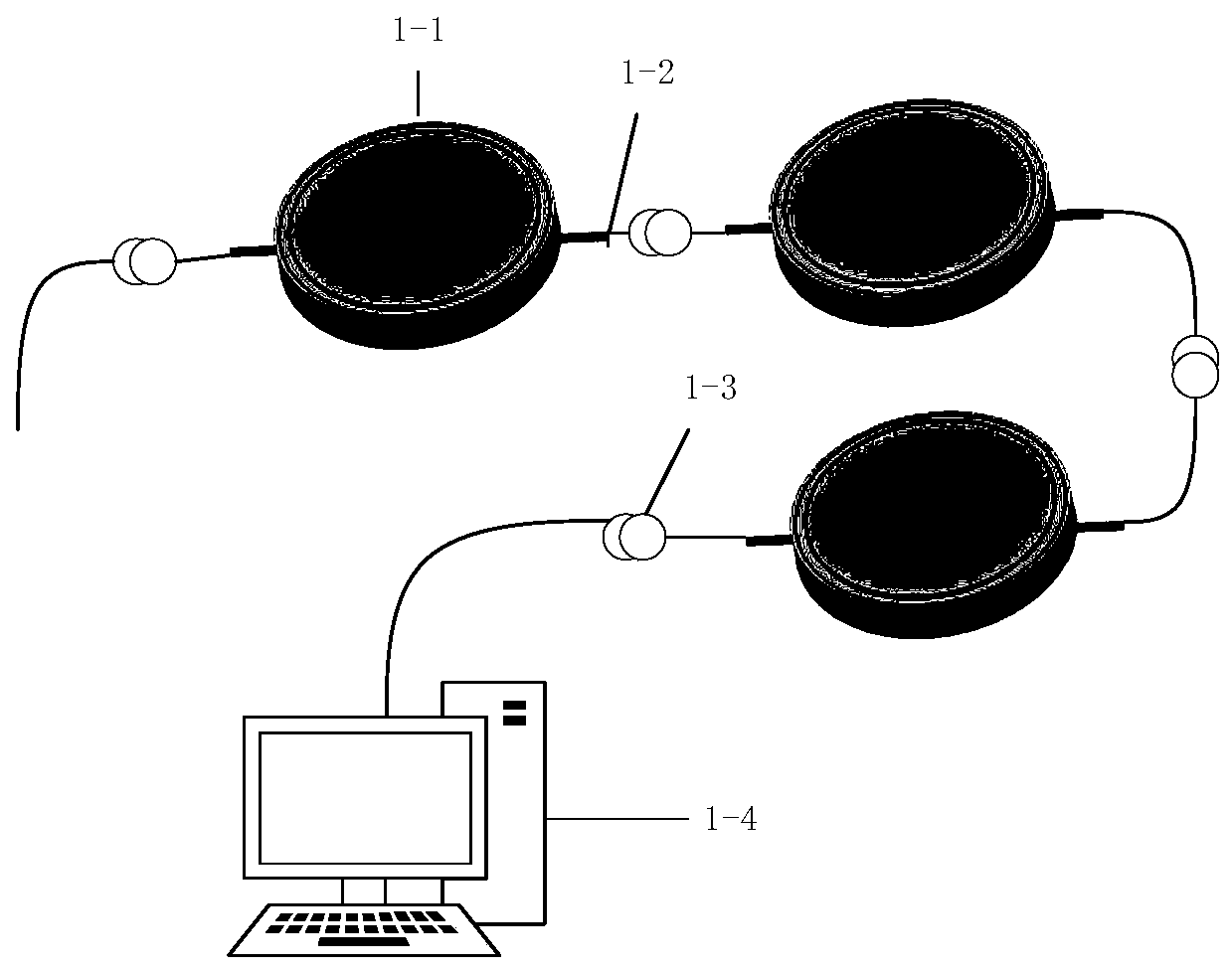

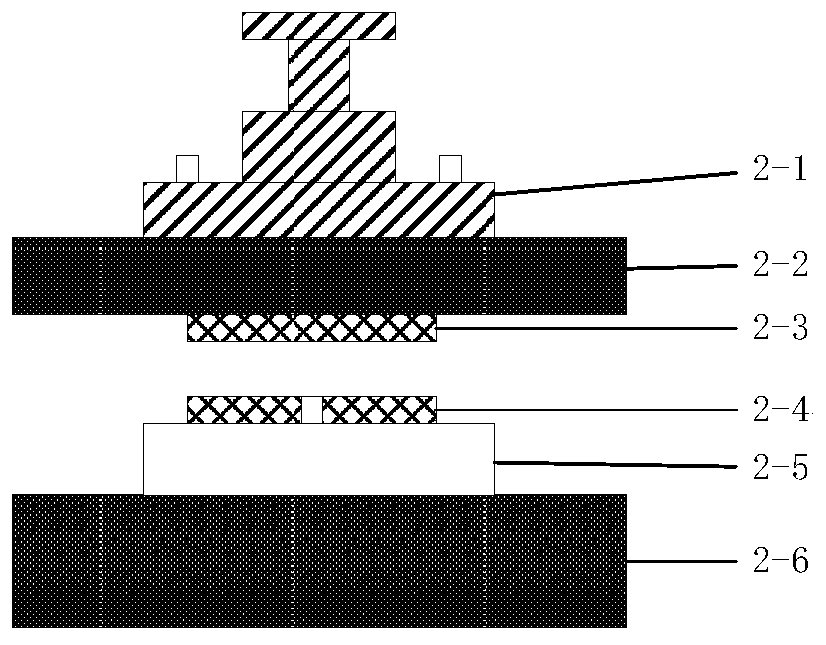

Embedding method of lithium battery sensing optical fiber

InactiveCN110690505AAffect physical sizeAffect temperature measurement performanceFinal product manufactureThermometers using physical/chemical changesPhysical chemistryEngineering

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI +1

Method for producing a sodium-ion battery

InactiveUS20180316044A1Loss in capacity of battery is lessFinal product manufactureElectrode collector coatingElectrolysisDecomposition

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

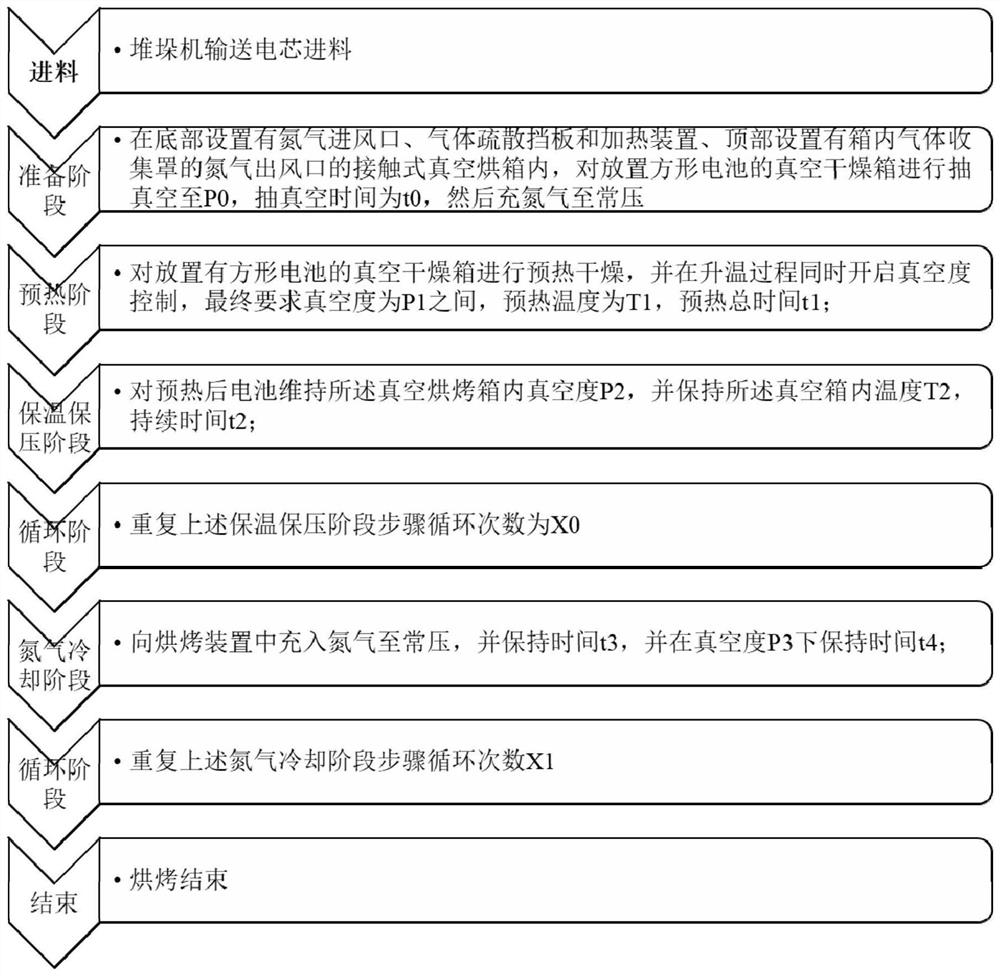

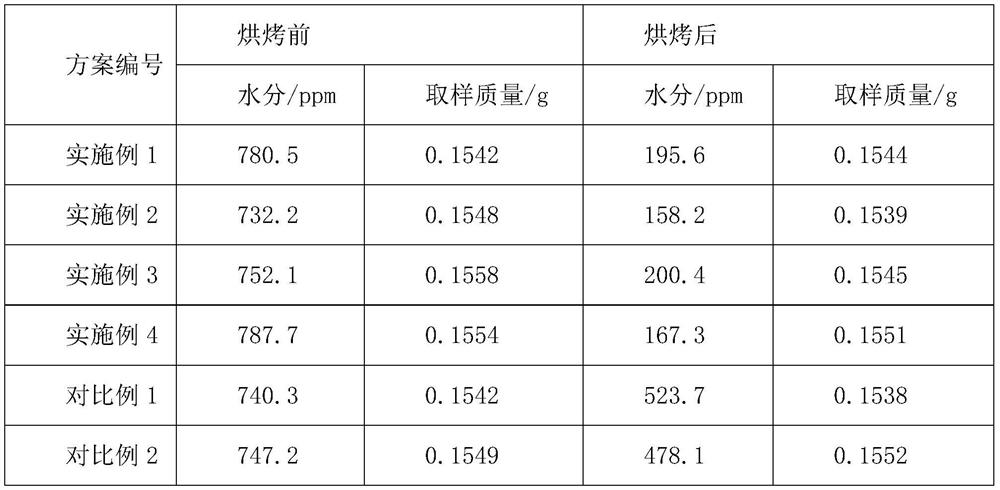

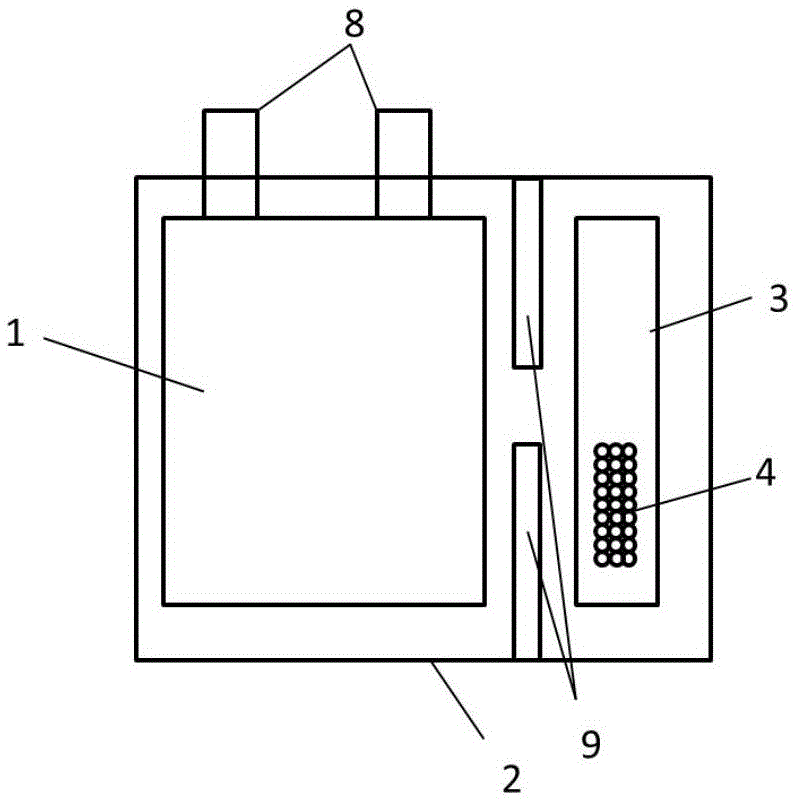

Rapid baking method for square lithium ion battery

ActiveCN112864463AReduce moistureImprove playbackFinal product manufactureDrying machines with local agitationEngineeringNitrogen gas

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

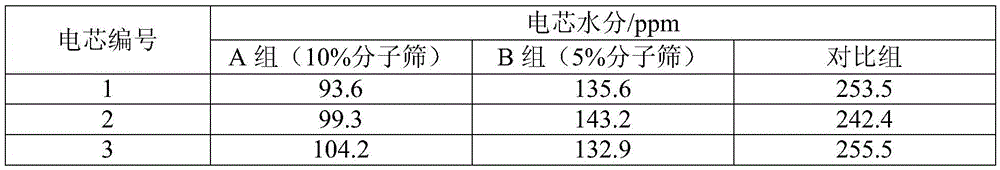

Method for lowering water content in flexibly packaged lithium ion battery in pre-charging formation process

InactiveCN106785051AGood effectReduce the impactFinal product manufactureSecondary cells charging/dischargingMolecular sievePressure system

Owner:RISESUN MENGGULI NEW ENERGY SCIENCE & TECHNOLOGY CO LTD

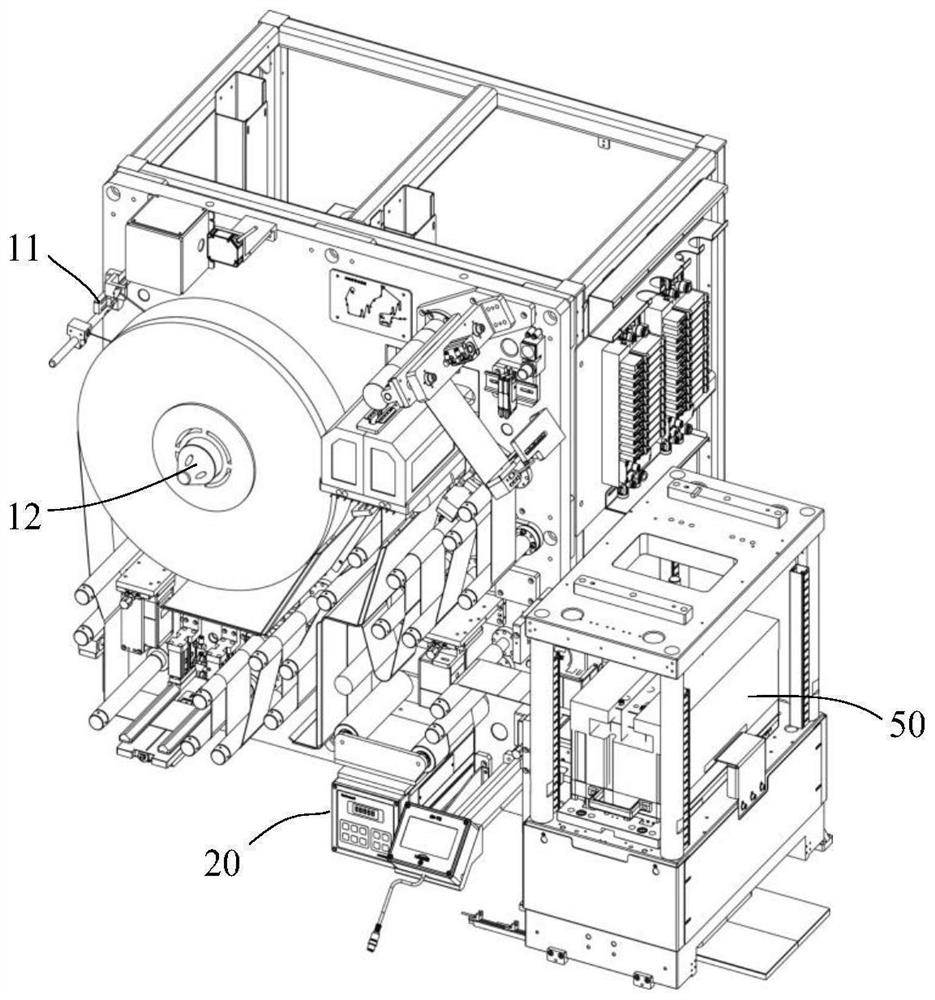

Deviation rectifying system and method for cutting and stacking all-in-one machine

ActiveCN112875379AHigh accuracy of deviation correctionReduce offsetAssembling battery machinesFinal product manufactureStructural engineeringMachine

Owner:中山科瑞自动化技术有限公司

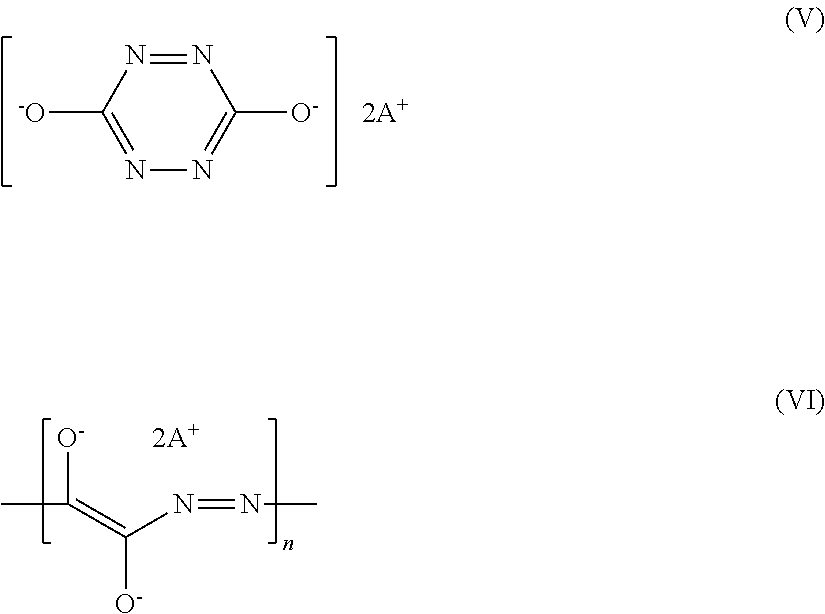

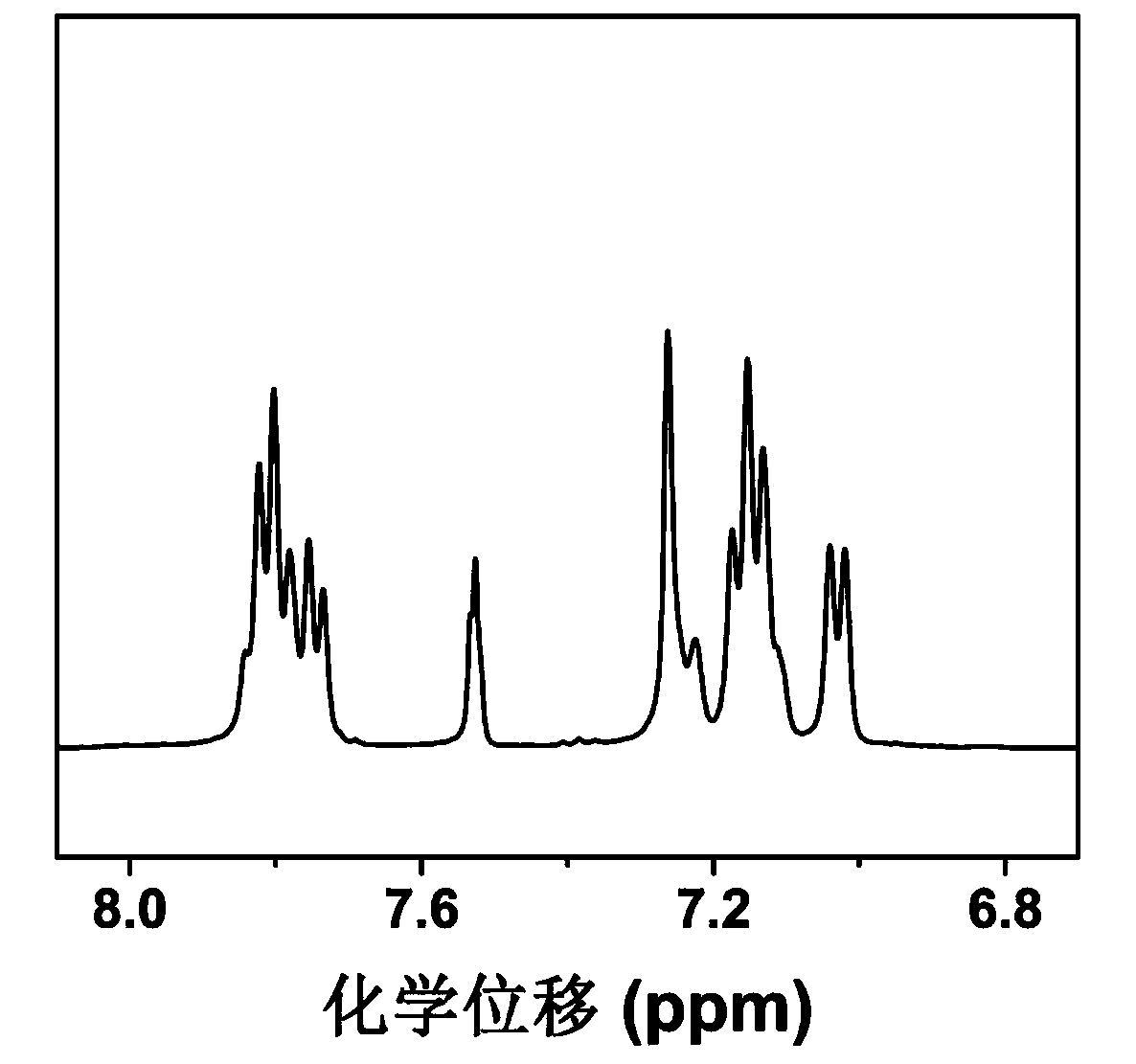

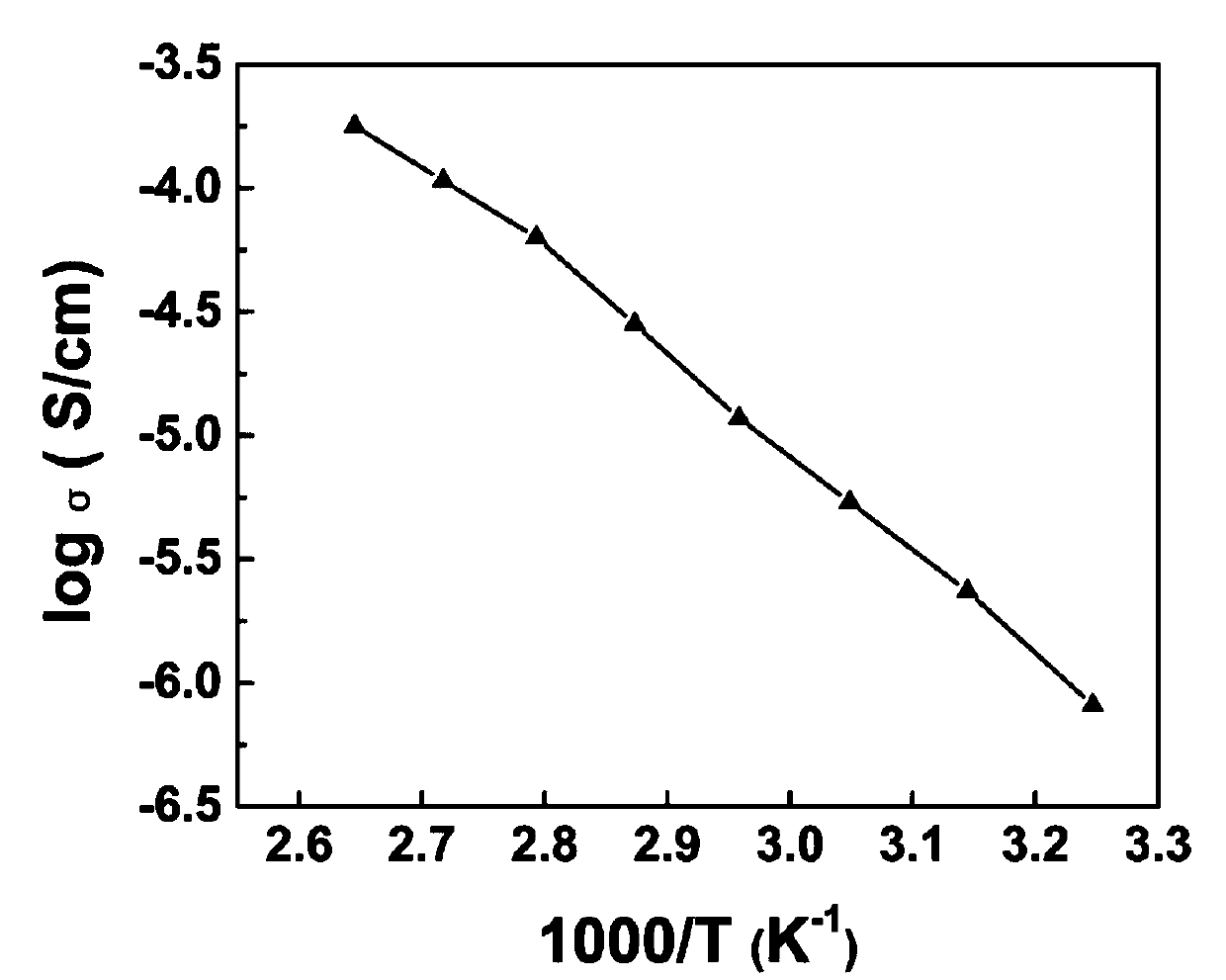

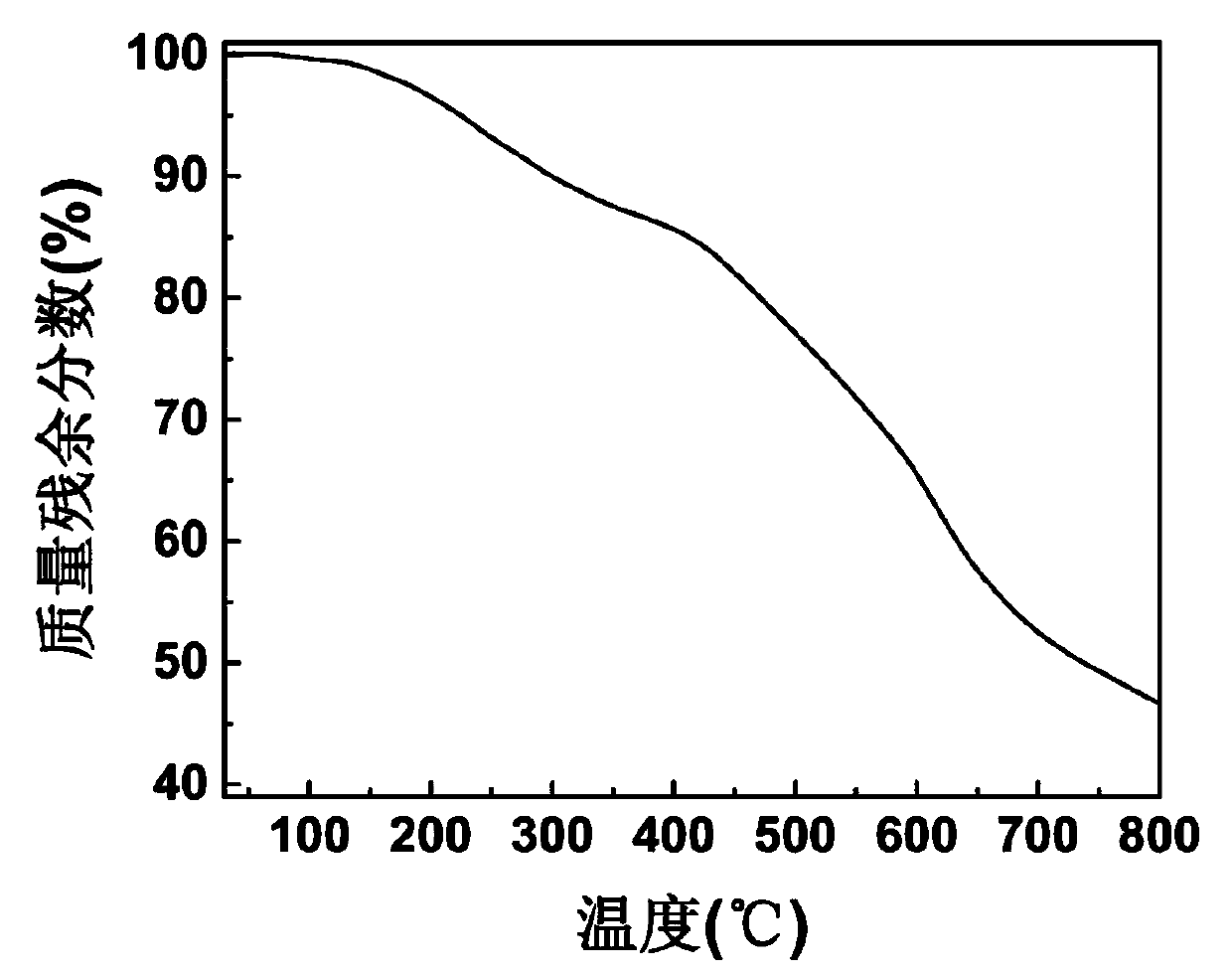

Comb polymer electrolyte and preparation and application thereof

ActiveCN107658501AImprove mechanical propertiesHigh thermodynamic stabilityFinal product manufactureElectrolyte accumulators manufactureLithiumPolymer electrolytes

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of pole group of high-capacity lithium-ion power battery

InactiveCN104638304AFinal product manufactureElectrolyte accumulators manufactureElectrical batteryPower battery

Owner:TIANJIN LISHEN BATTERY

Preparation method of thick-film lithium battery and thick-film lithium battery

InactiveCN113013374AHigh degree of bindingReduce the ratioElectrode rolling/calenderingFinal product manufactureInternal resistanceHigh energy

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a preparation method of a thick-film lithium battery and the prepared lithium ion battery. The preparation process of the lithium ion battery comprises the following steps: covering a current collector with positive and negative electrode materials in a coating manner, then carrying out rolling treatment, combining a diaphragm with the positive and negative electrodes into a complete battery cell in a winding or lamination manner, and packaging the battery cell to obtain the thick-film lithium battery. The positive and negative current collectors adopt a latticed structure, so that the electron transmission rate in the electrode is improved, the internal resistance of the battery is greatly reduced, and meanwhile, the overall cost of the battery is further reduced and the energy density is improved by adopting the high-coating-amount electrode. The preparation process is simple, the repeatability is good, and large-scale production can be realized.

Owner:ZHEJIANG GODSEND POWER TECH

NASICON lithium-ion solid electrolyte synergistically doped with F<-> and Y<3+> ions and preparation method thereof

InactiveCN105070944AFinal product manufactureElectrolyte accumulators manufactureElectrolyteElectrical resistivity and conductivity

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

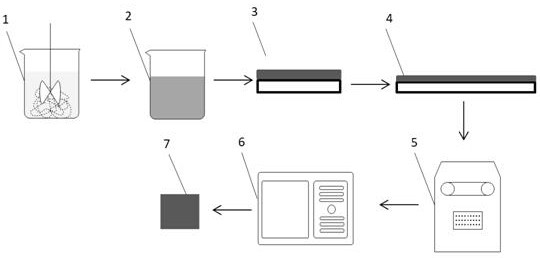

Continuous preparation method of an ultrathin ceramic chip solid composite electrolyte of lithium battery

InactiveCN112582684AGood effectThe preparation process is continuousFinal product manufactureElectrolyte accumulators manufactureGreen tapeComposite electrolyte

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Manufacturing method of battery and battery

PendingCN111029660AAvoid the risk of short circuitsIncrease capacityAssembling battery machinesFinal product manufactureMechanical engineeringBattery capacity

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

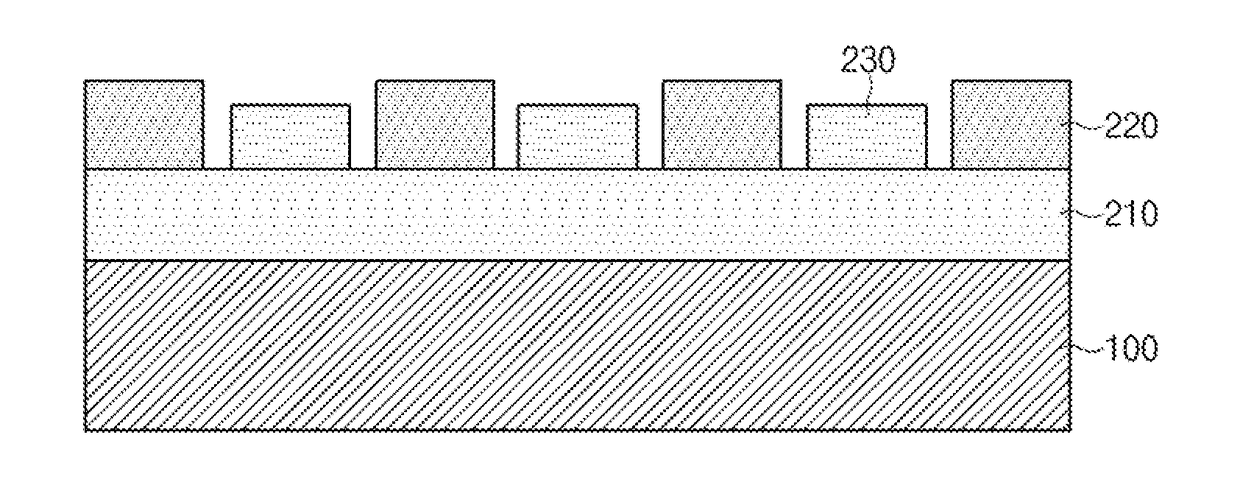

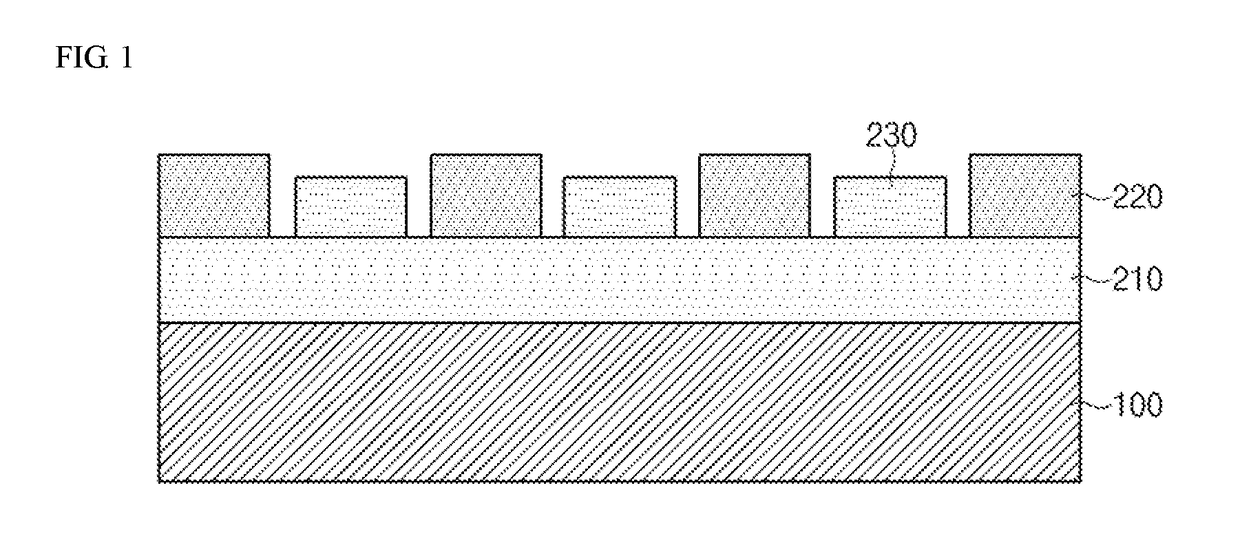

Thin film all-solid-state battery

PendingCN114530628AHigh strengthIncrease the interface contact areaCell electrodesFinal product manufactureSolid state electrolyteElectrical battery

The invention belongs to the technical field of electrochemistry, and particularly relates to an all-solid-state thin film battery. The all-solid-state thin film battery comprises a positive electrode layer, a negative electrode layer, an all-solid-state diaphragm layer and a flexible battery polar plate, wherein the positive electrode layer and the negative electrode layer are positioned in the same plane; a gap is formed between the positive electrode layer and the negative electrode layer; the positive electrode layer is formed by mixing a positive electrode active material, a solid electrolyte, a conductive additive and a binder according to a certain process; the negative electrode layer is formed by compounding graphite and a solid electrolyte, or consists of lithium metal and Li-Al, Li-In and Li-Sn alloy; the all-solid-state diaphragm layer is composed of a solid electrolyte with ultrahigh ionic conductivity; the flexible battery pole plates are respectively composed of ultrathin aluminum foils and copper foils; and the contact sides of the solid electrolyte layer and the positive electrode and the negative electrode adopt latticed extension structures. According to the invention, the risk of contact short circuit caused by the stacking structure of the positive electrode layer and the negative electrode layer is fundamentally avoided, and the ionic conductivity is greatly improved.

Owner:FUDAN UNIV

Lithium ion battery and preparation method thereof

ActiveCN114824281ANegative electrodesElectrolyte accumulators manufactureLithium electrodeEngineering

Owner:天鹏锂能技术(淮安)有限公司

Pressurizing shaping and high-temperature aging integrated device for battery production and use method thereof

ActiveCN113471545AShorten positioning timeAchieve positioningAssembling battery machinesFinal product manufactureEngineeringBattery cell

Owner:广东立一科技有限公司

Negative electrode and secondary battery including the same

ActiveUS20180309162A1Capacity of electrodeFaster rateFinal product manufactureElectrode carriers/collectorsEngineeringVolume expansion

Owner:LG ENERGY SOLUTION LTD

Flexible battery and preparation method thereof

InactiveCN110556587AMeeting the demand for bendable batteriesFinal product manufactureNon-aqueous electrolyte accumulator electrodesState of artElectrical connection

Owner:北京旭江科技有限公司 +1

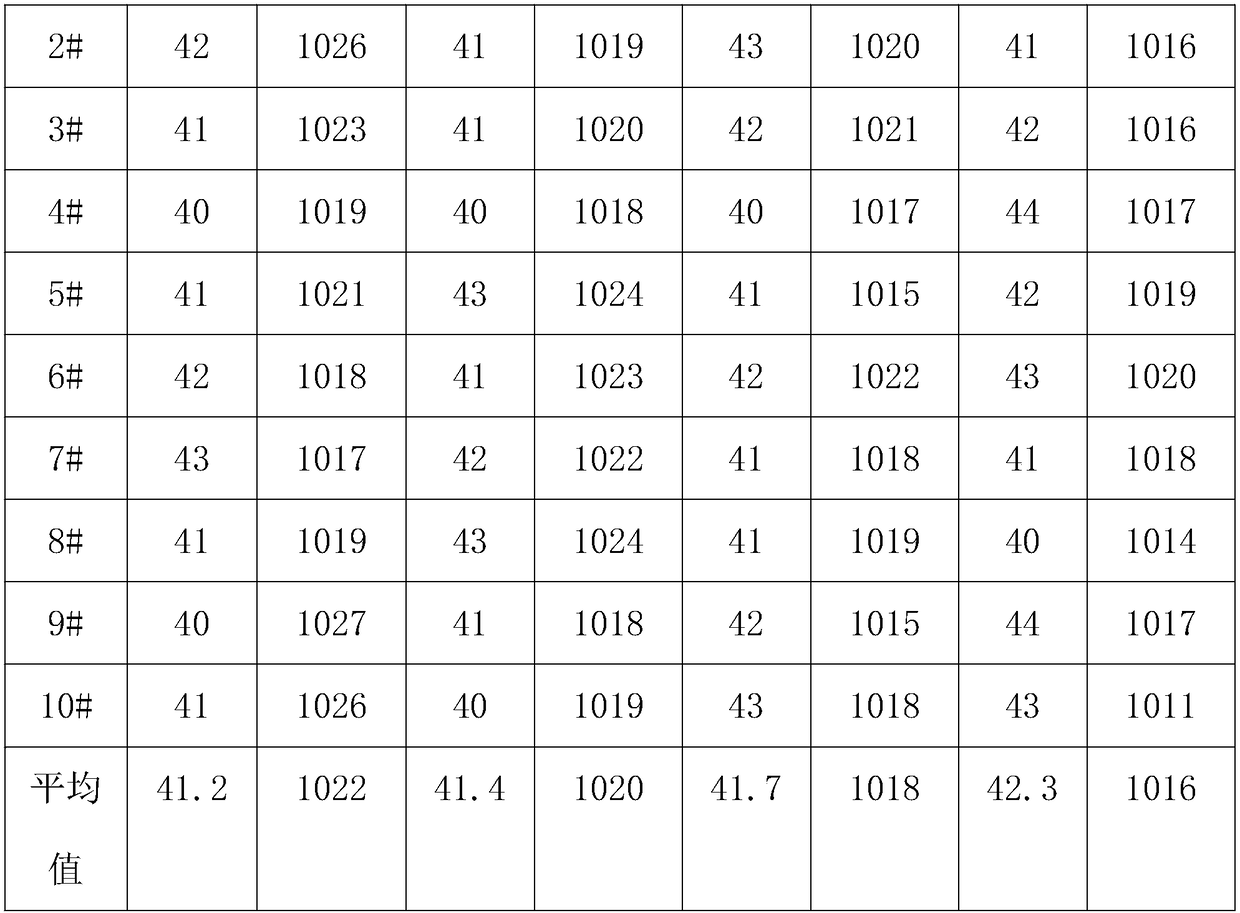

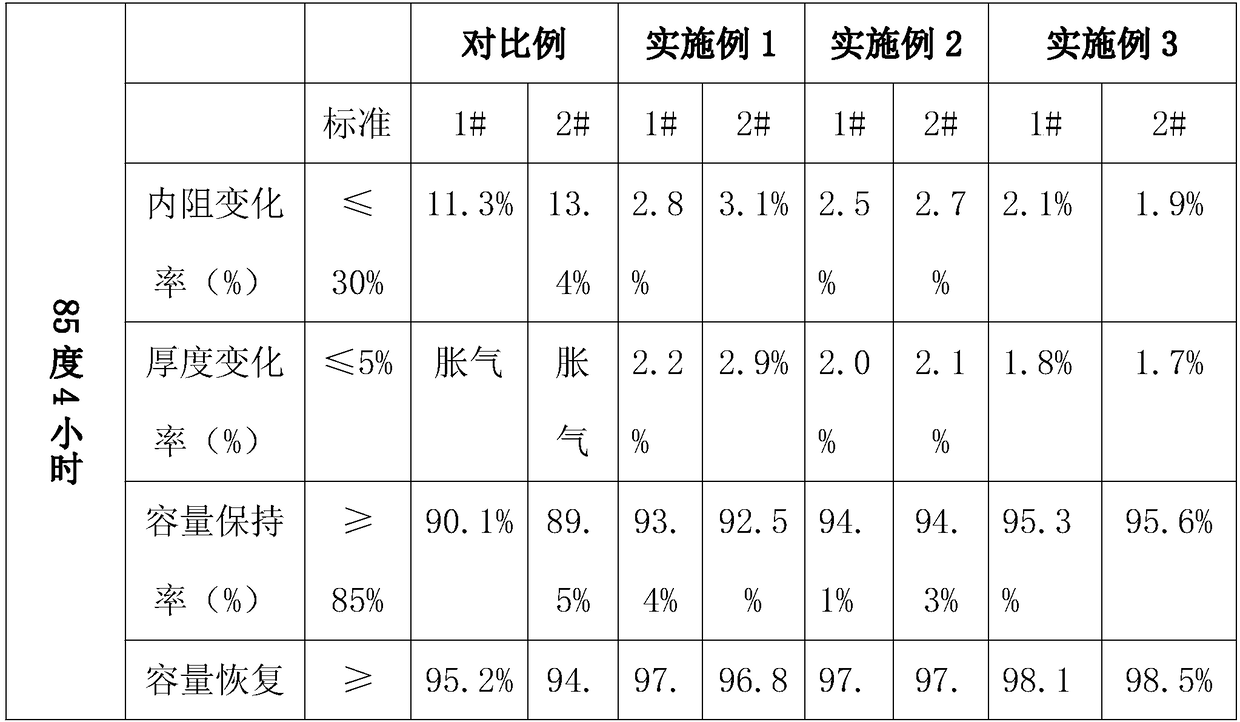

Manufacturing method of high-temperature resistant ternary lithium ion battery

InactiveCN108400389AImprove pass rateImprove high temperature resistanceFinal product manufactureElectrolyte accumulators manufactureManufacturing technologyMetal foil

Owner:MEIZHOU LIANGNENG NEW ENERGY SCI & TECHCO

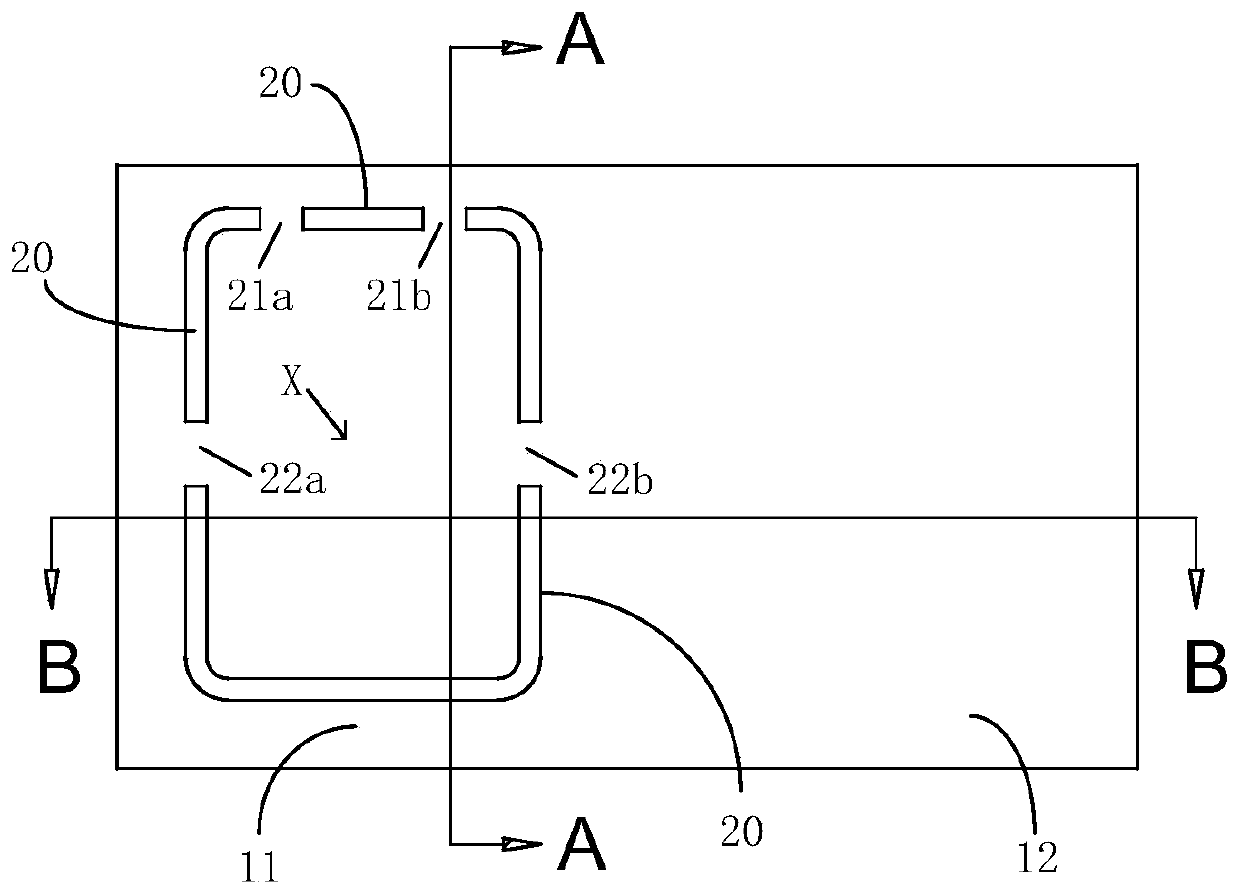

Adhesive bonding mechanism and device

PendingCN111710916ASimple structureReduced debugging effortFinal product manufactureElectrolyte accumulators manufactureAdhesive beltStructural engineering

The invention discloses an adhesive bonding mechanism. The adhesive bonding mechanism comprises a fixing assembly and an adhesive bonding assembly; the adhesive bonding assembly is arranged on the fixing assembly; the fixing assembly is used for installing the adhesive bonding assembly; the adhesive bonding assembly can relatively move along the fixing assembly. The invention further provides an adhesive bonding device. The adhesive bonding device is simple in structure; the structure of an existing adhesive bonding mechanism is changed, so that an integrated structure is divided into the fixing assembly and the adhesive bonding assembly; the fixing assembly is used for debugging, and the adhesive bonding assembly is used for replacing and maintaining adhesive paper; since the functions are split, when the adhesive bonding mechanism is abnormal in adhesive bonding, the adhesive bonding assembly is directly pulled out, so that parts can be replaced, the whole adhesive bonding mechanismdoes not need to be detached, and therefore, time is saved, and debugging work after adhesive tapes are replaced is reduced; and in addition, the distance between the adjacent adhesive bonding mechanisms is adjusted through an adjusting mechanism, so that adhesive bonding at different intervals is achieved.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap