Flexible lithium-ion battery capable of working around clock and preparation method thereof

A lithium-ion battery, all-weather technology, used in the manufacture of electrolyte batteries, secondary batteries, battery electrodes, etc., can solve the problems of low sample conductivity, low service life, difficult mass production, etc., to improve electrochemical performance, The effect of shortening movement distance and improving orderliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

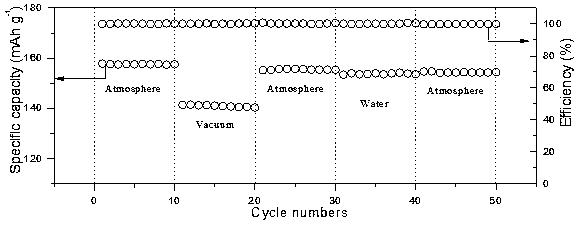

Image

Examples

Embodiment 1

[0014] The pre-stretching treatment of the carbon nanotube macroscopic tube continuum, and the preparation method of the carbon nanotube macroscopic tube continuum refer to the patent ZL201310013214.8. The above-mentioned carbon nanotube macroscopic tube continuum is pulled out of the reaction chamber through a mechanical rod. The mechanical rod is made of high temperature resistant steel or hard alloy. The movement of the mechanical rod is driven by a motor at a constant speed. Its speed outside the reaction chamber is 0.5 m / min, the speed in the reaction chamber is 0.01 m / min, the tensile stress applied to the continuum by the control mechanical rod is 120 MPa, and the continuum is stressed for 3 seconds.

[0015] In the preparation of the flexible carbon nanotube macroscopic film, the stressed carbon nanotube macroscopic tube continuum is adhered to a roller covered with a flexible substrate, the flexible substrate is paper, and the diameter of the roller is 50 cm. Keep th

Embodiment 2

[0020]The pre-stretching treatment of the carbon nanotube macroscopic tube continuum, and the preparation method of the carbon nanotube macroscopic tube continuum refer to the patent ZL201310013214.8. The above-mentioned carbon nanotube macroscopic tube continuum is pulled out of the reaction chamber through a mechanical rod. The mechanical rod is made of high-temperature-resistant hard alloy. The movement of the mechanical rod is driven by a motor at a constant speed, and its speed outside the reaction chamber is 10. m / min, the speed in the reaction chamber is 0.1 m / min, the tensile stress applied to the continuum by the control mechanical rod is 100MPa, and the continuum is stressed for 10 seconds.

[0021] In the preparation of the flexible carbon nanotube macroscopic film, the stressed carbon nanotube macroscopic tube continuum is adhered to a roller covered with a flexible substrate, the flexible substrate is aluminum foil, and the diameter of the roller is 40 cm. Keep t

Embodiment 3

[0026] The pre-stretching treatment of the carbon nanotube macroscopic tube continuum, and the preparation method of the carbon nanotube macroscopic tube continuum refer to the patent ZL201310013214.8. The above-mentioned carbon nanotube macroscopic tube continuum is pulled out from the reaction chamber through a mechanical rod. The mechanical rod is made of high-temperature-resistant steel. The movement of the mechanical rod is driven by a motor at a constant speed, and its speed outside the reaction chamber is 9 m / Minutes, the speed in the reaction chamber is 0.5 m / min, the tensile stress on the continuum is 120MPa by the control mechanical rod, and the continuum is stressed for 5 seconds.

[0027] In the preparation of the flexible carbon nanotube macroscopic film, the stressed carbon nanotube macroscopic tube continuum is adhered to a roller covered with a flexible substrate, the flexible substrate is copper foil, and the diameter of the roller is 20 cm. Keep the contin

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap