Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

258results about "Final product manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

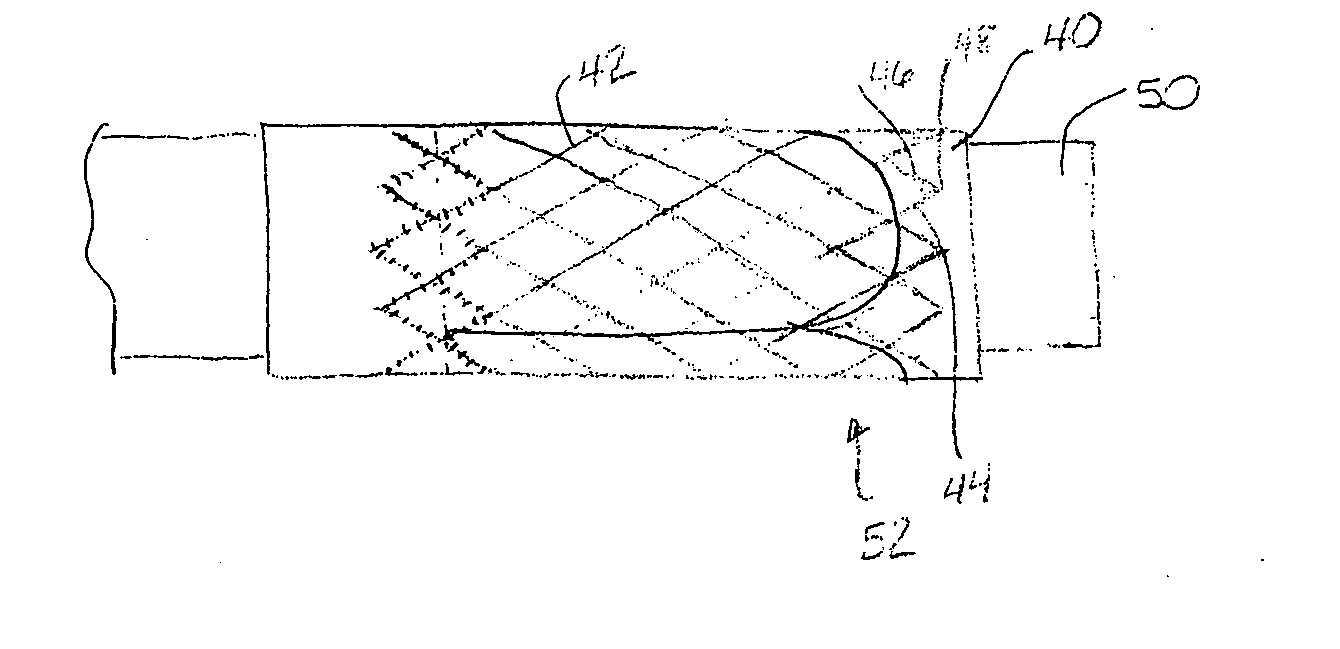

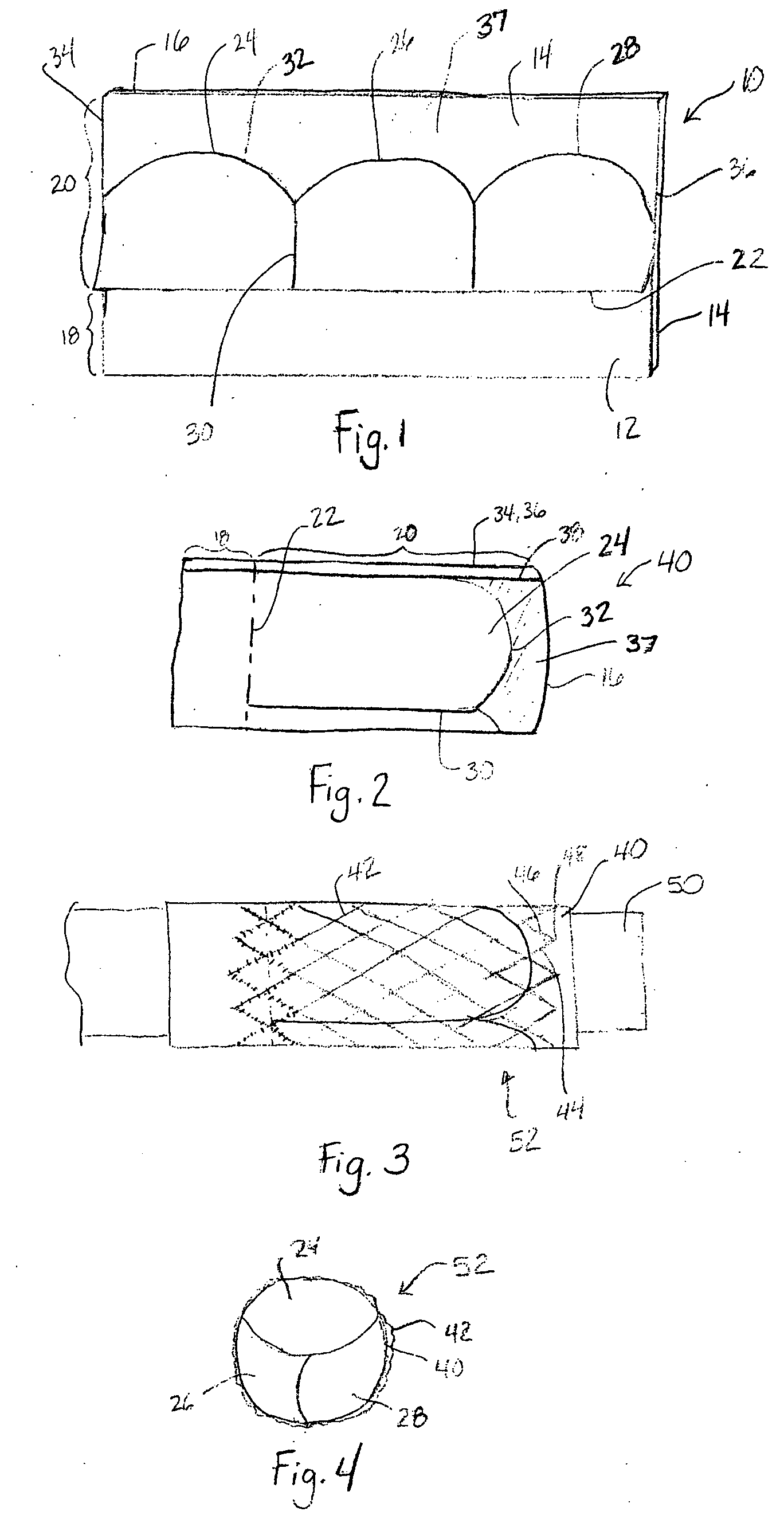

Prosthetic cardiac valve formed from pericardium material and methods of making same

ActiveUS20070233228A1Barrier to undesired abrasionPrevent and minimize valve leakageCell electrodesHeart valvesProsthetic valveProsthesis

Owner:MEDTRONIC INC

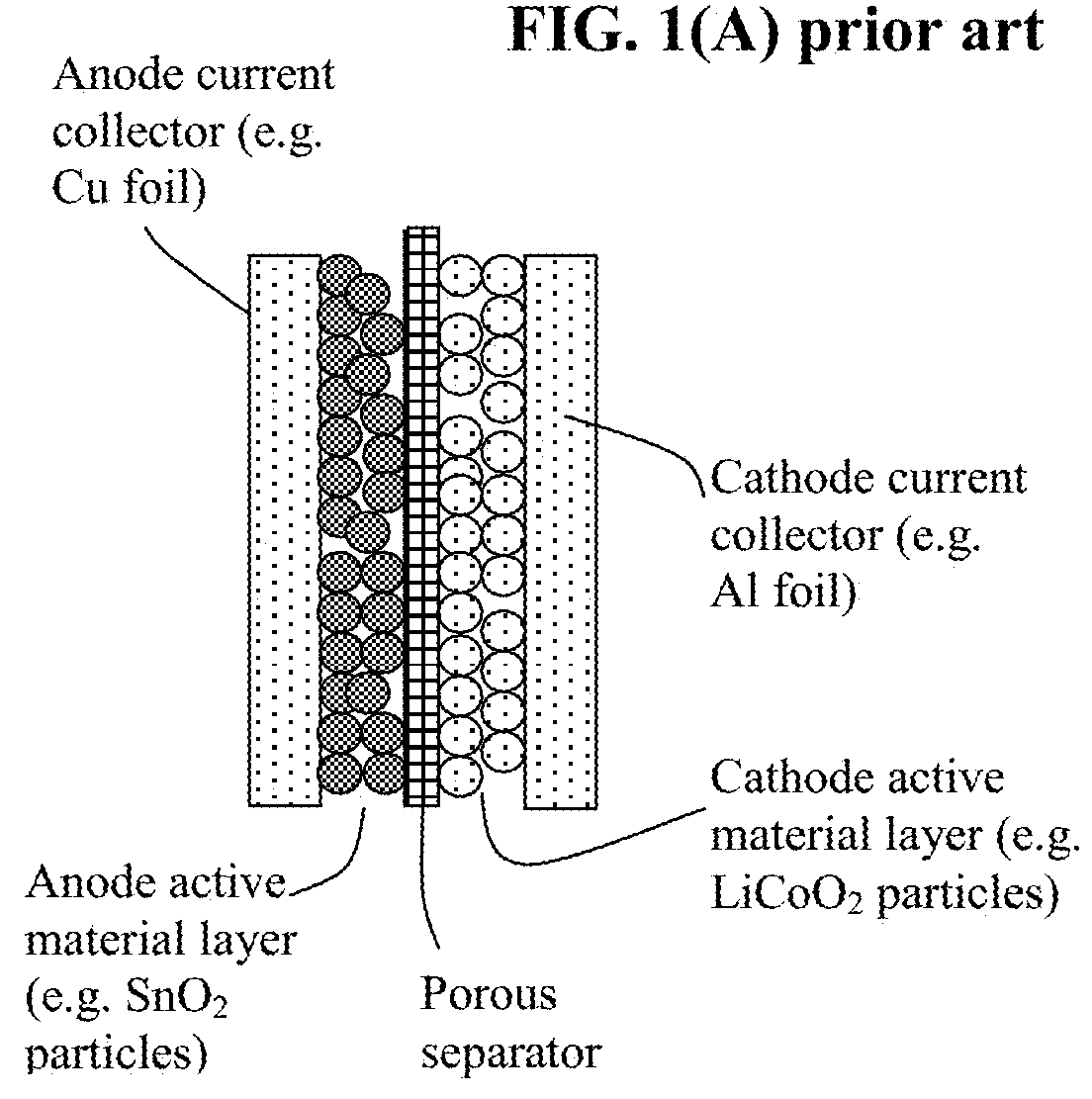

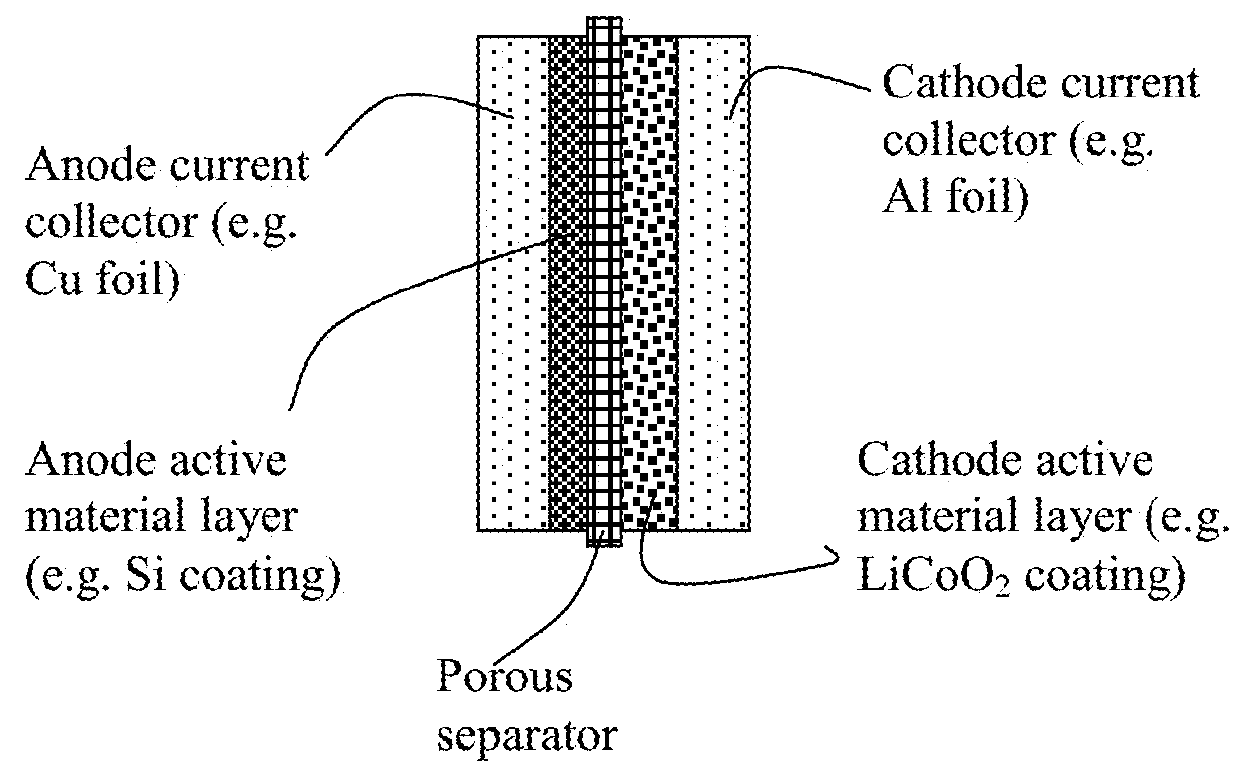

Nonaqueous electrochemical cell with improved energy density

InactiveUS6849360B2Electrode manufacturing processesFinal product manufactureHigh rateCurrent collector

Owner:ENERGIZER BRANDS

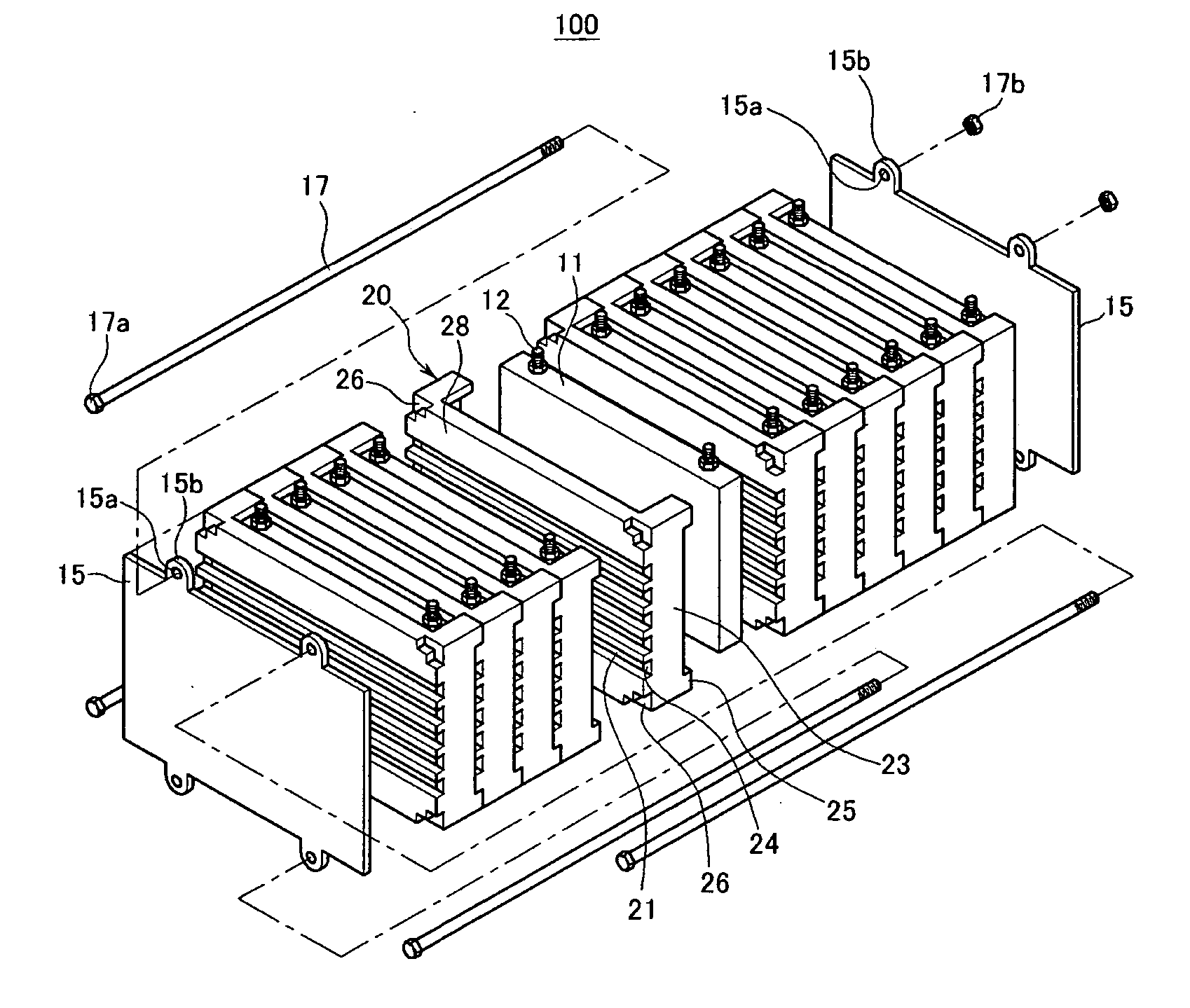

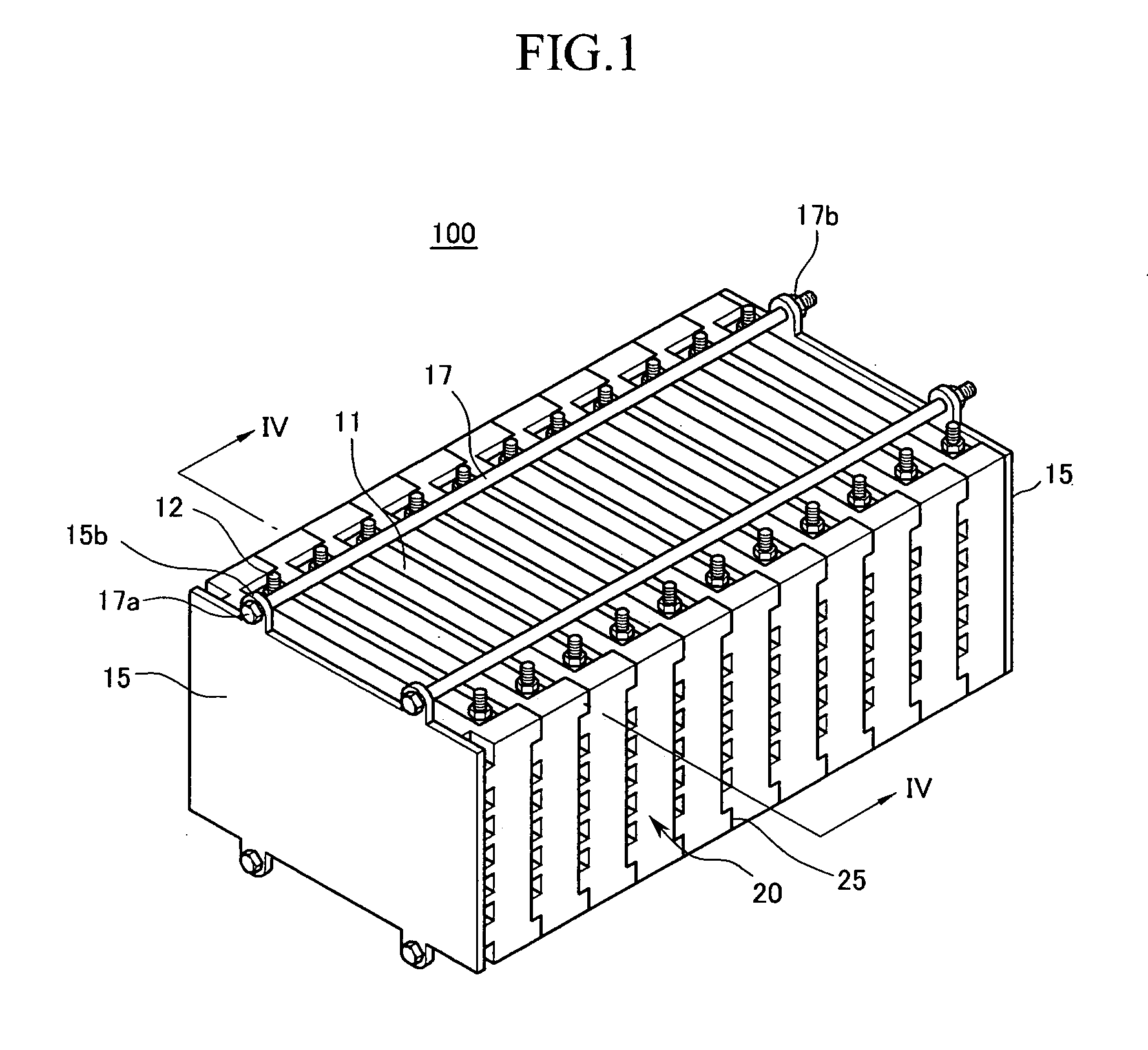

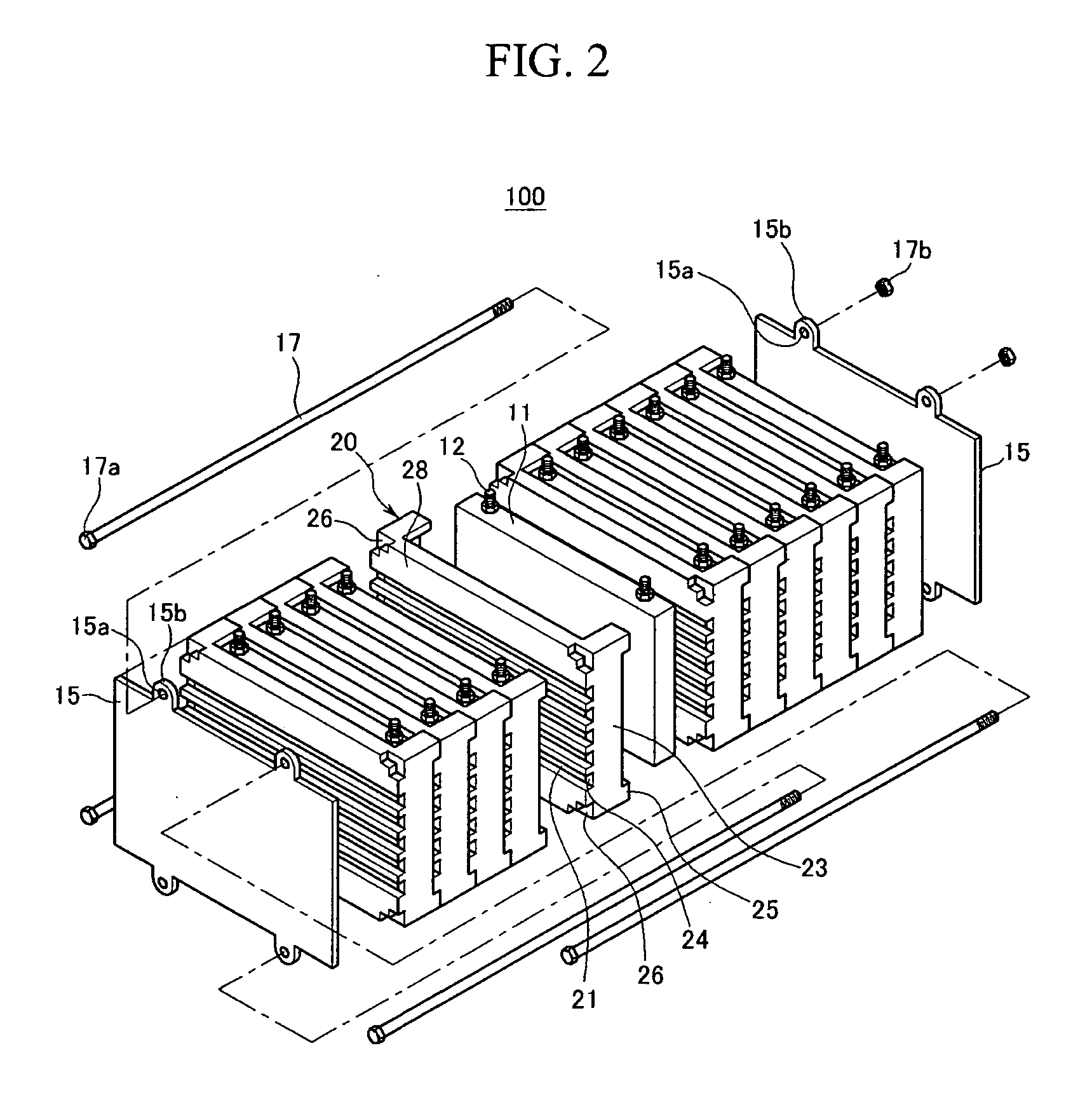

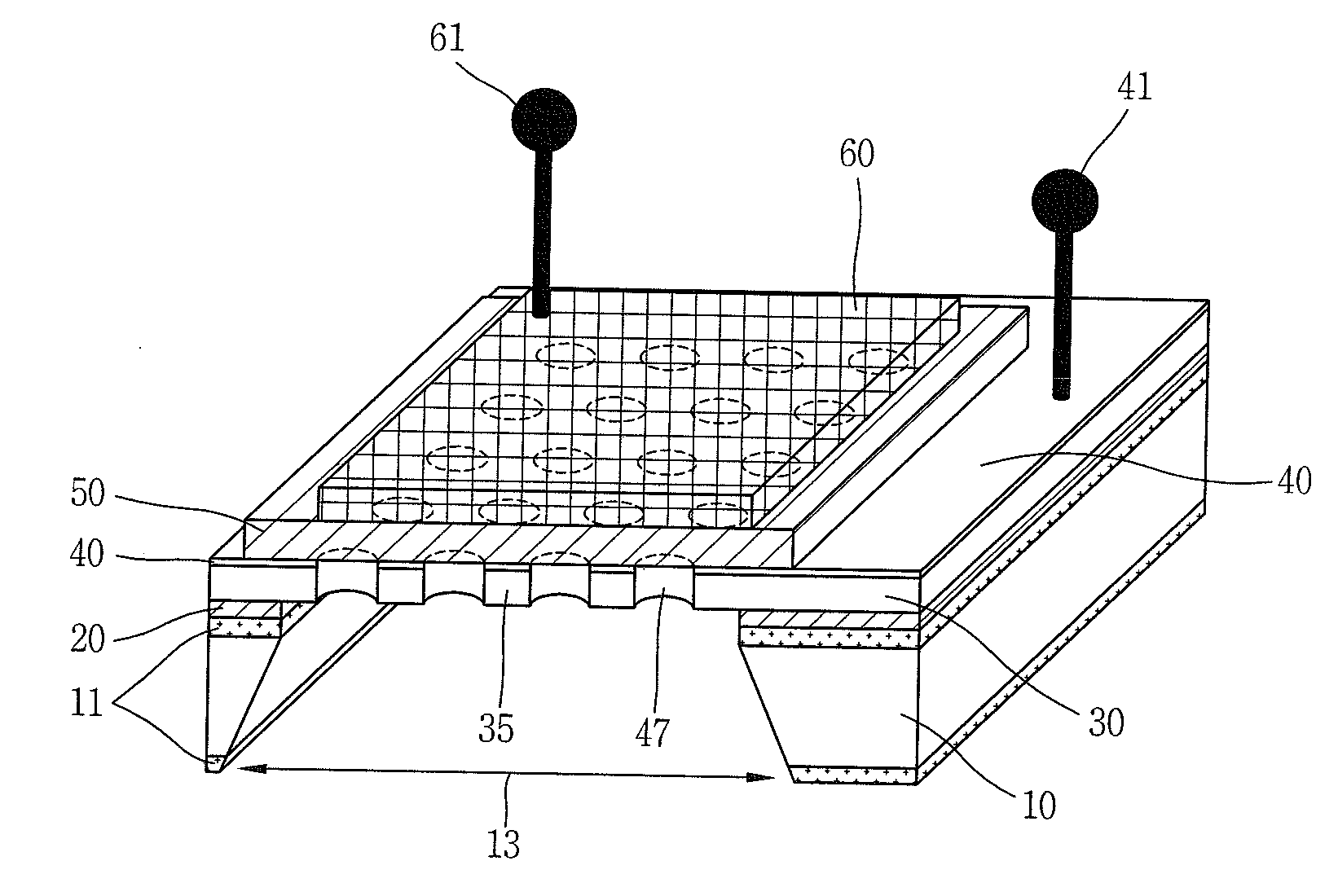

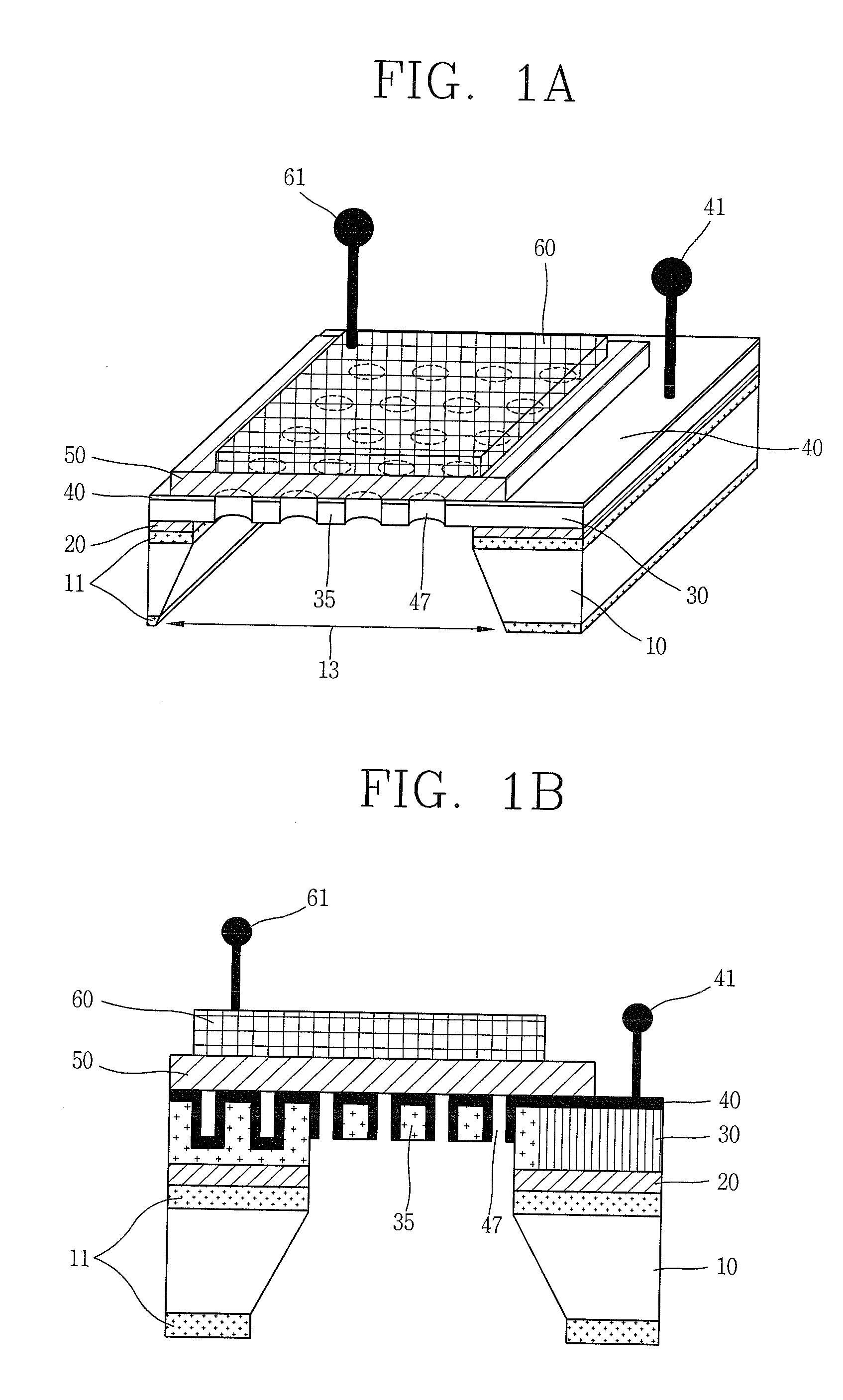

Battery module with improved cell barrier between unit cells

ActiveUS20070037051A1Improved unit cell cooling performanceEasy to makePrimary cell to battery groupingFinal product manufactureBiomedical engineering

Owner:SAMSUNG SDI CO LTD

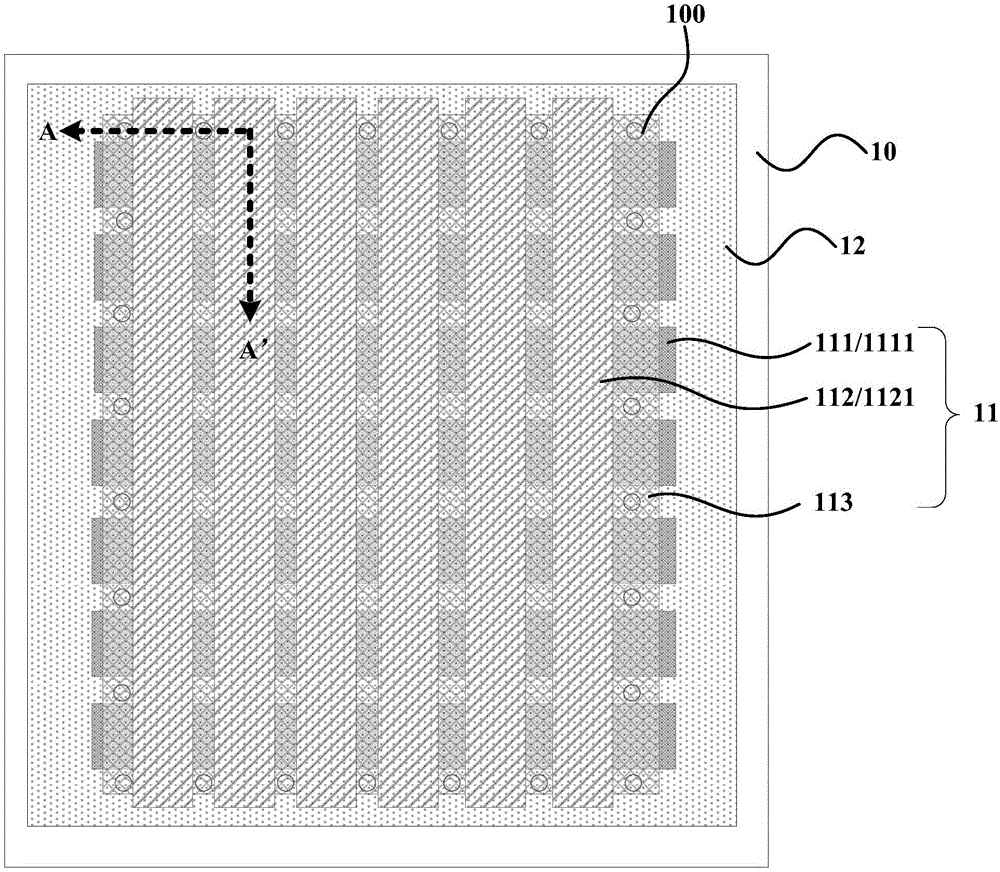

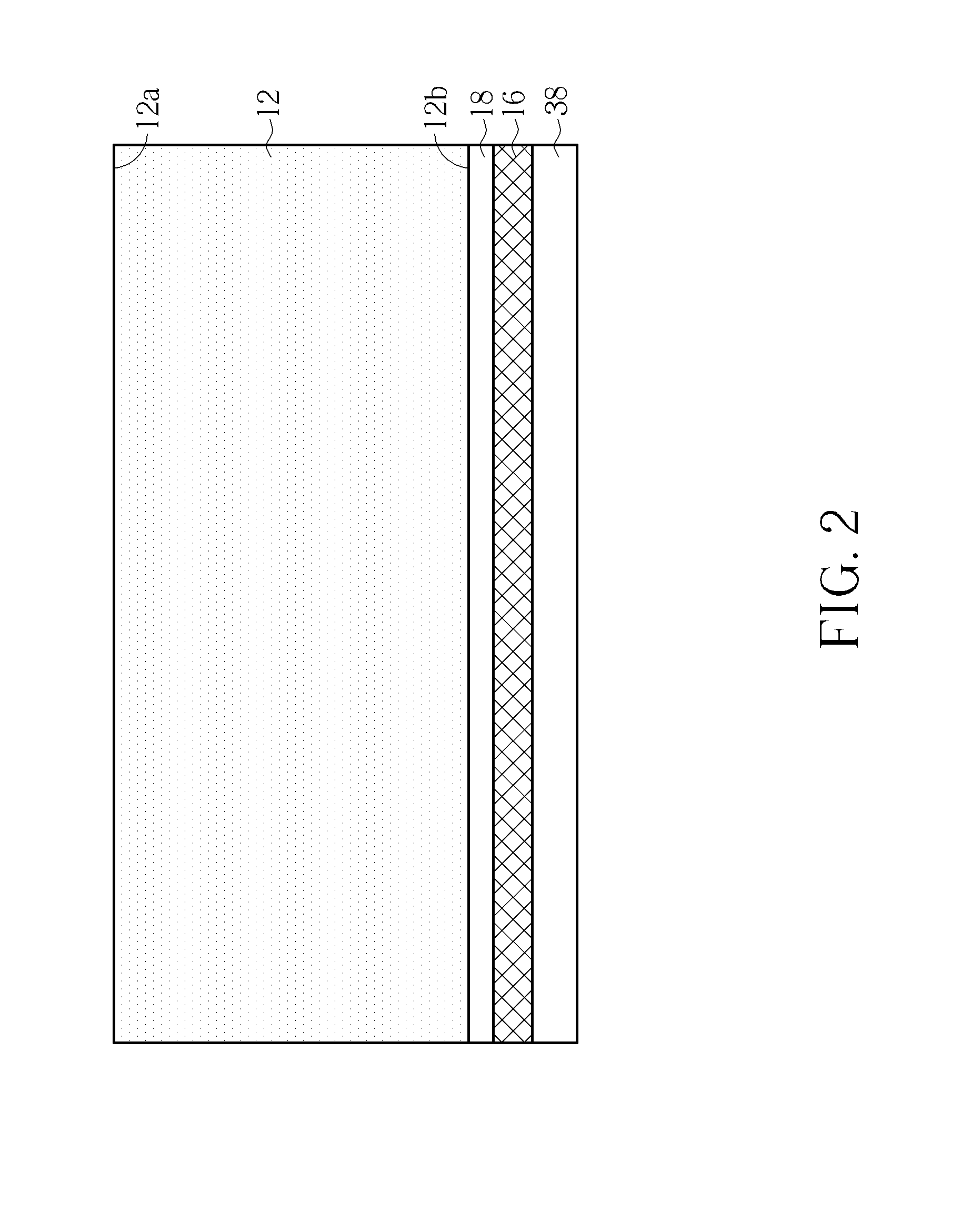

Organic light emitting display panel and manufacturing method

ActiveCN106449702APrevent peelingImprove adhesionFinal product manufactureSolid-state devicesOptoelectronicsSurface plate

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

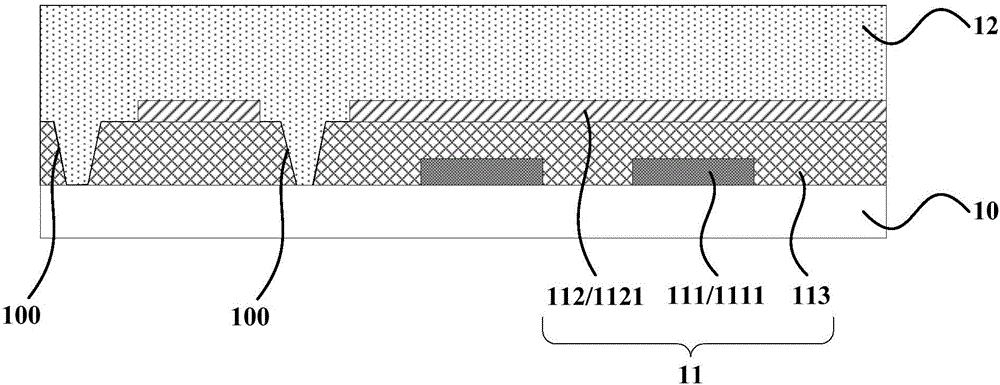

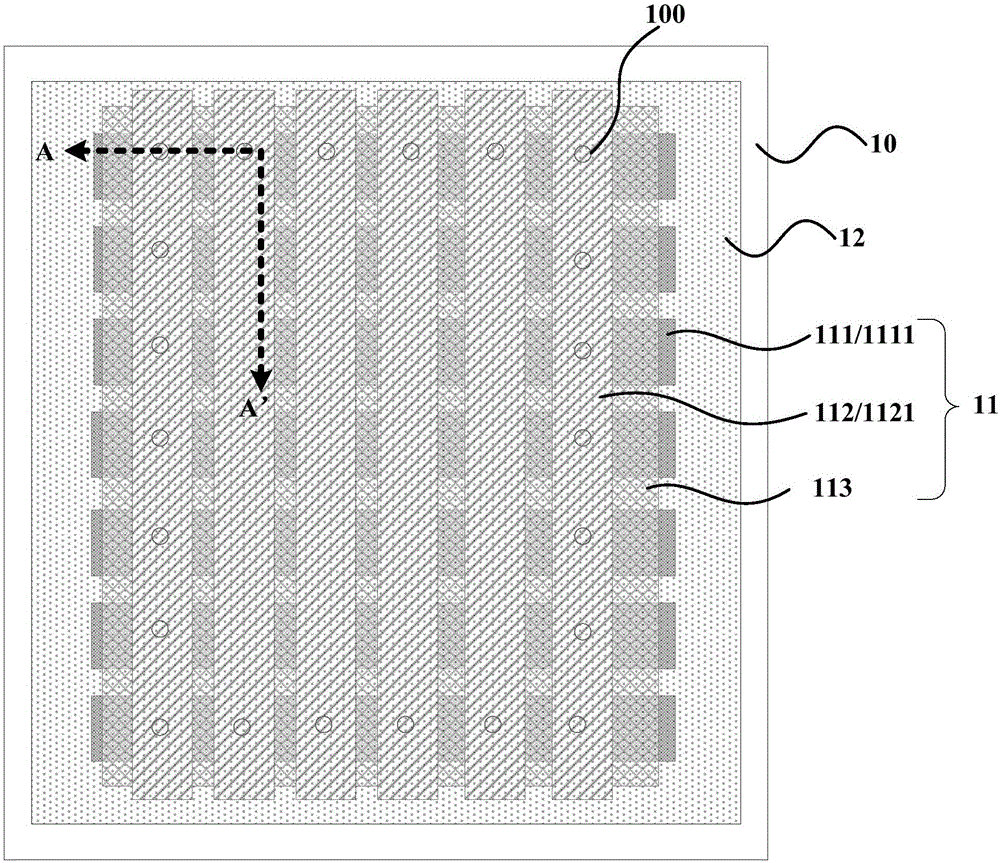

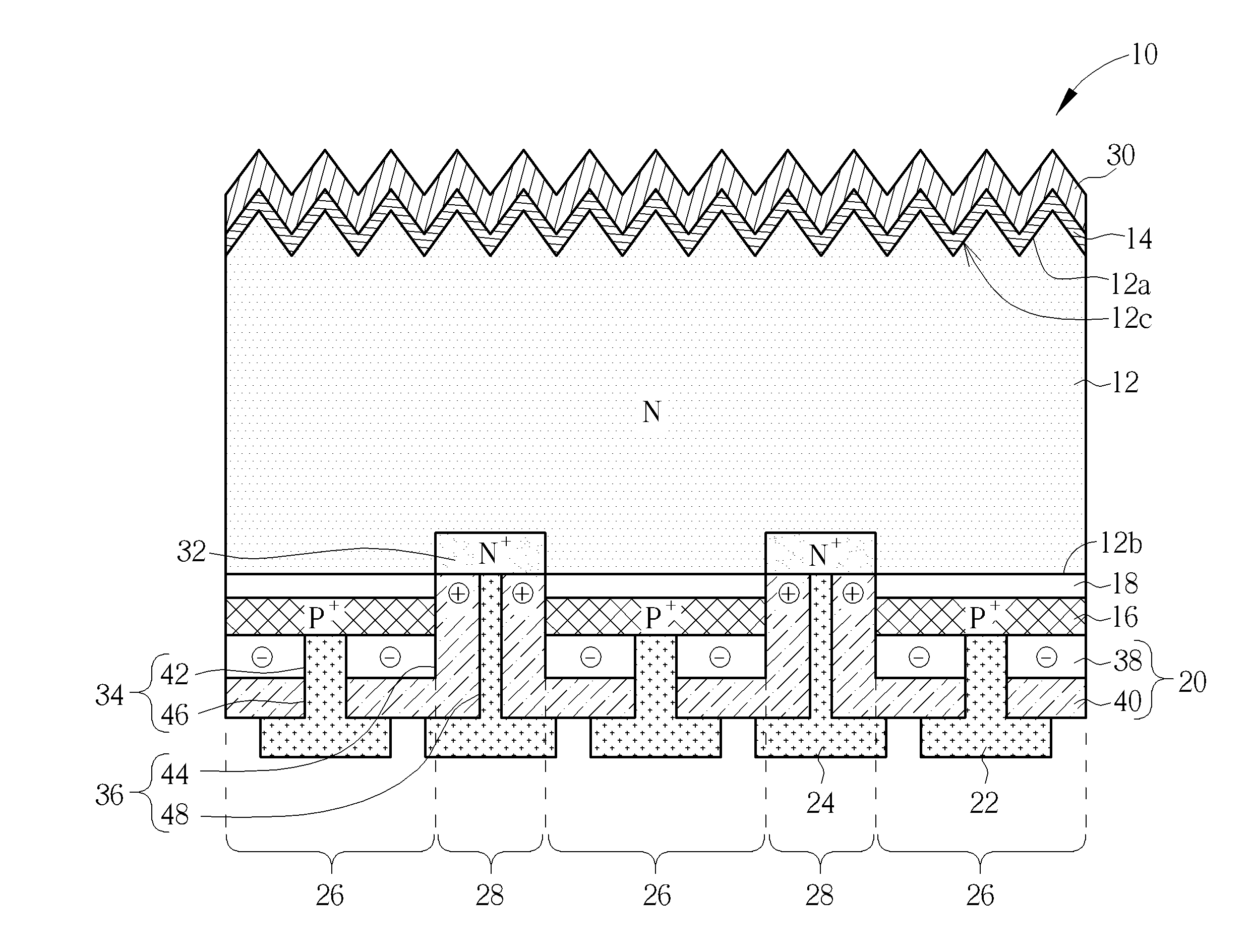

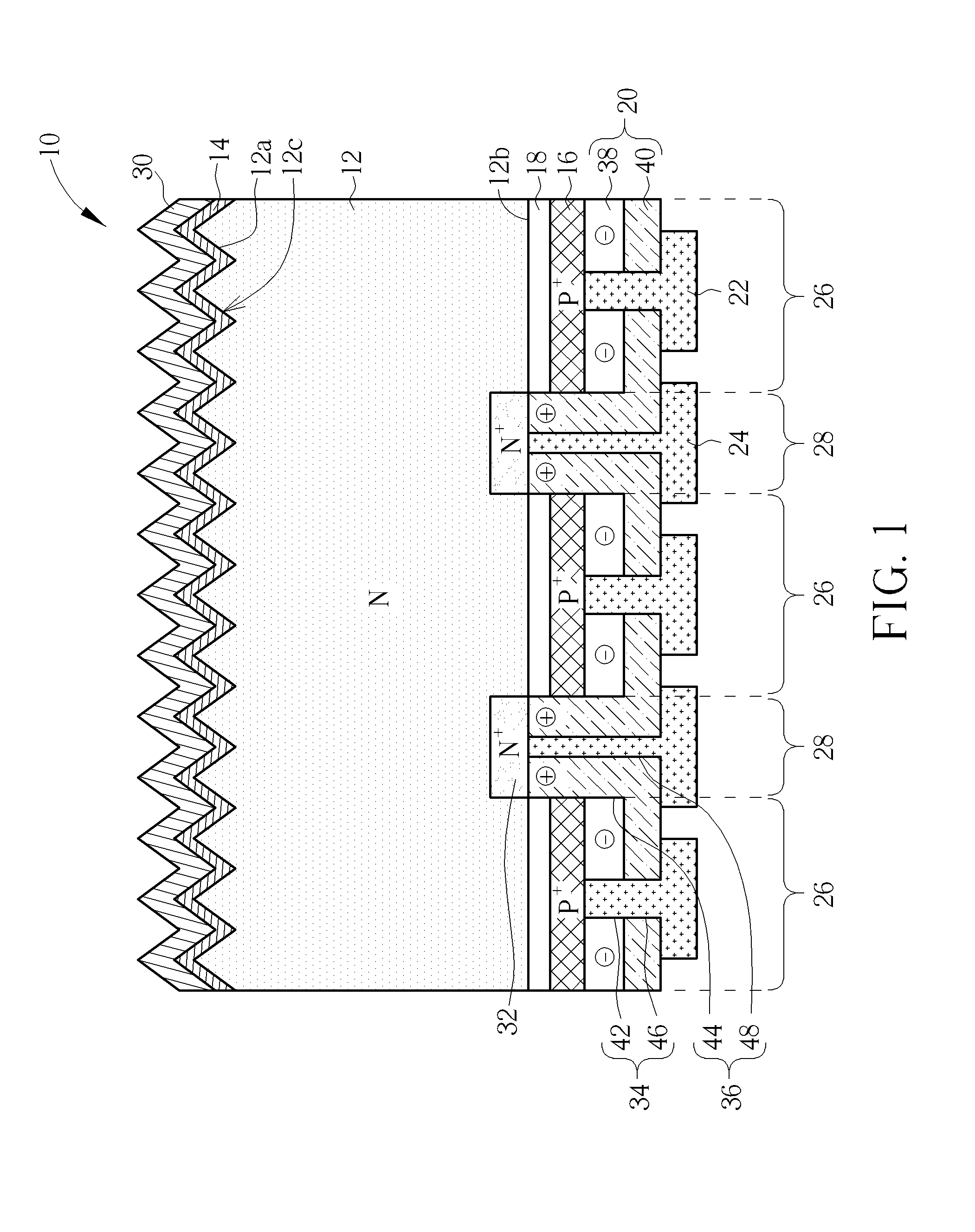

Solar cell and method for making thereof

ActiveUS20140096821A1Reduce generationImprove photoelectric conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingSolar cellSemiconductor

Owner:AU OPTRONICS CORP

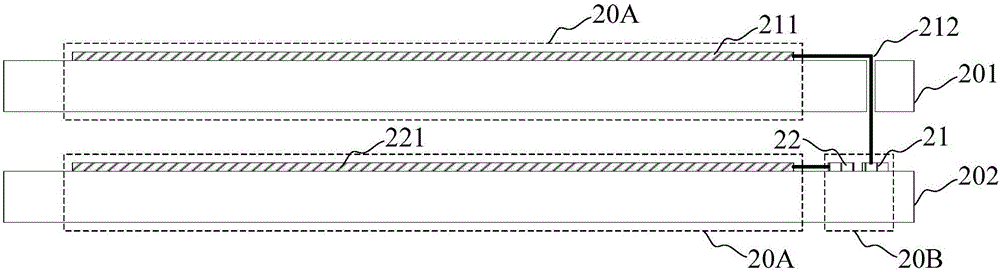

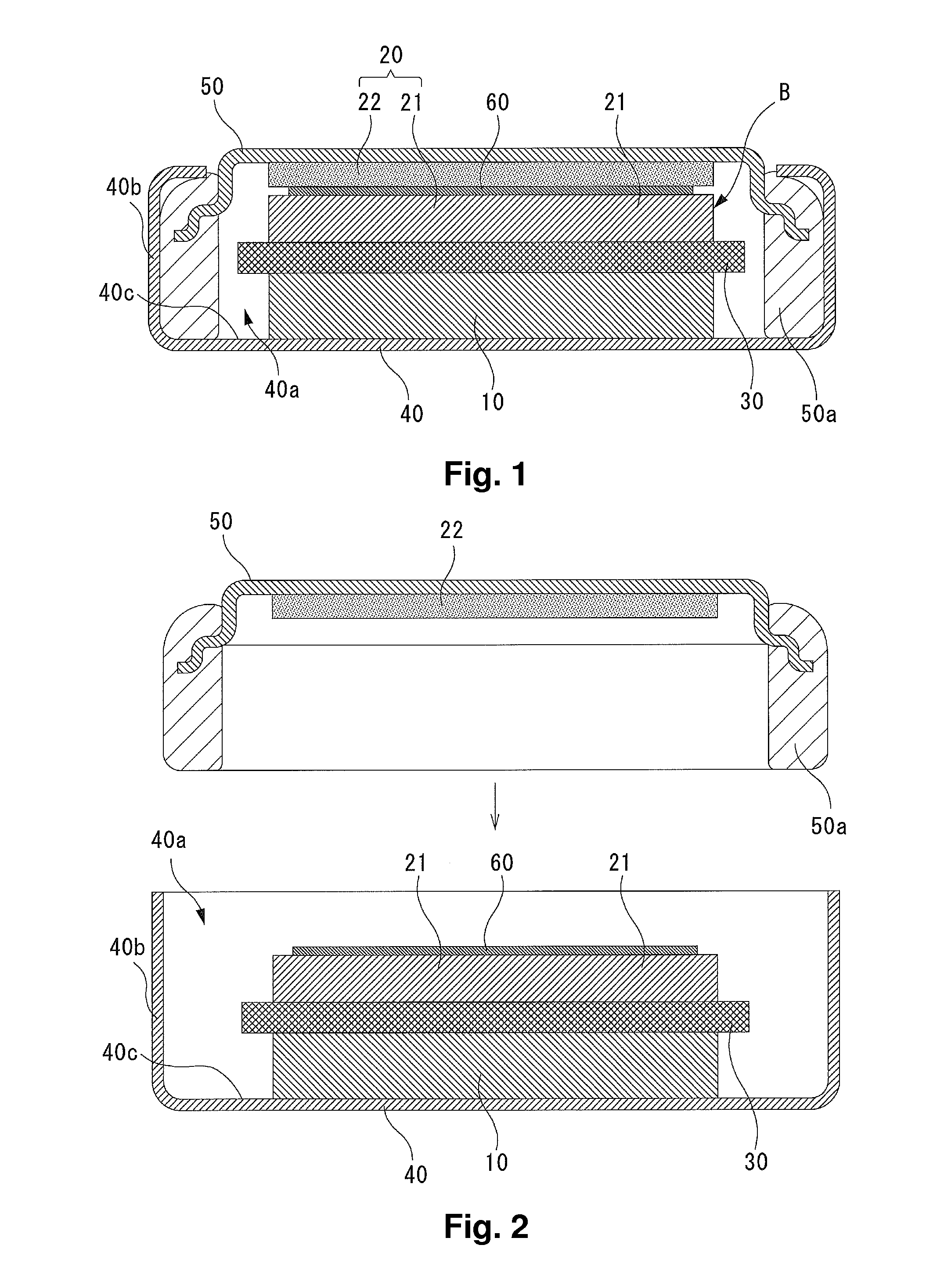

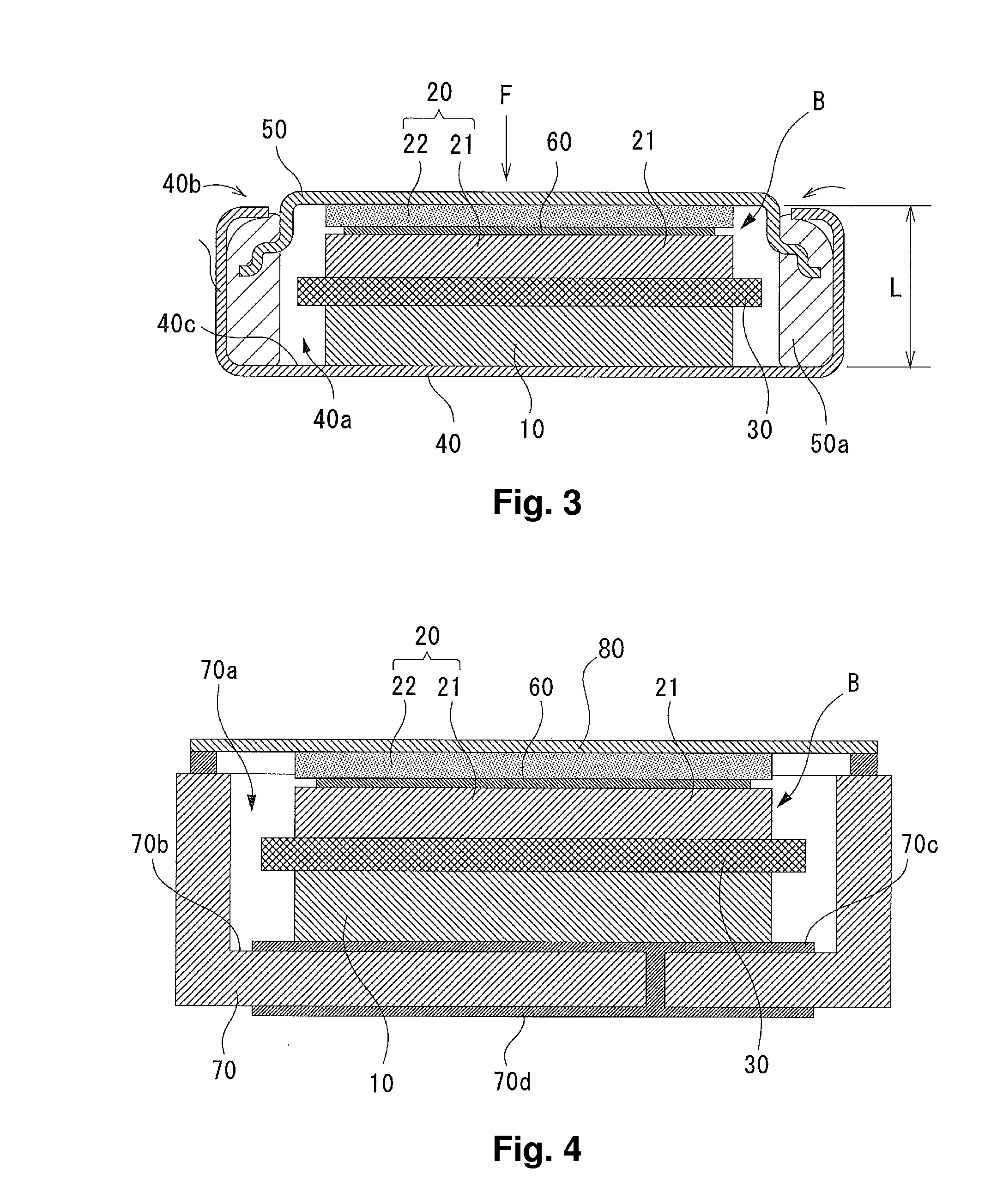

Non-aqueous electrolyte battery and method for producing the same

InactiveUS20060216609A1Process safetyAvoid it happening againMaterial thermal conductivityFinal product manufactureEngineeringNon aqueous electrolytes

Owner:HITACHI MAXELL ENERGY LTD

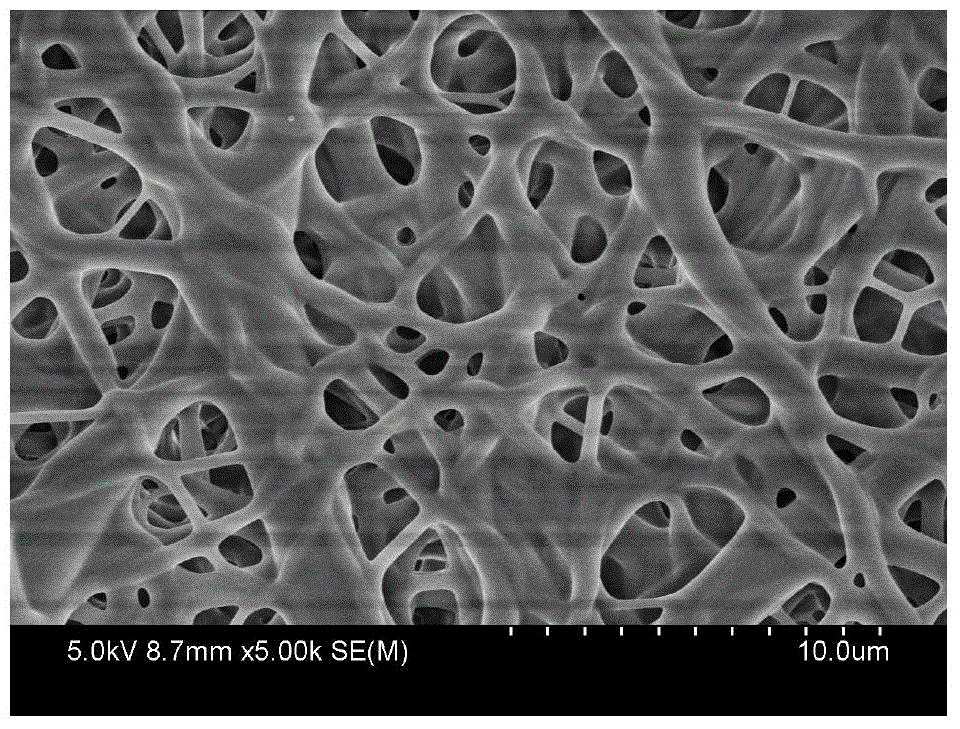

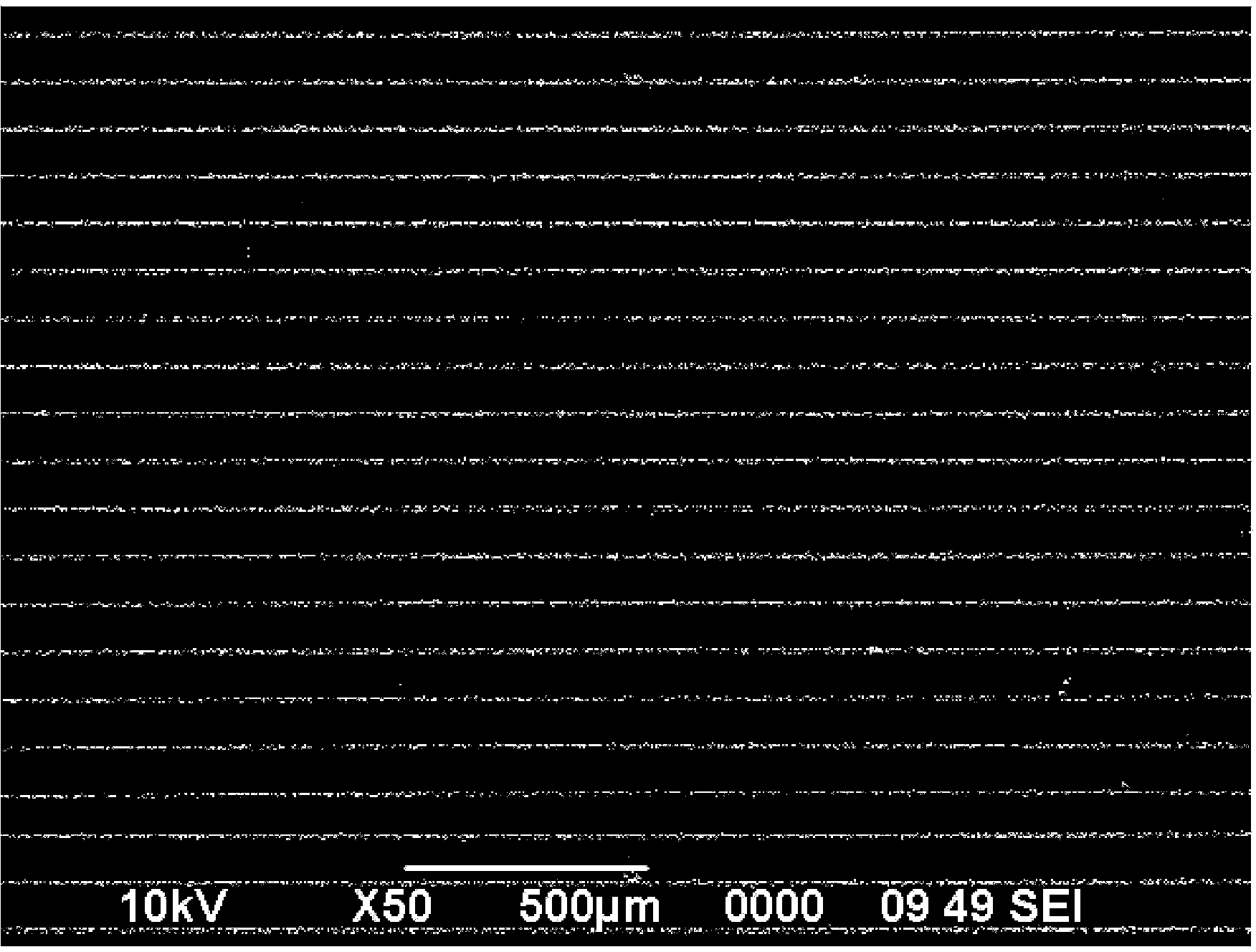

Non-aqueous solution aluminum ion secondary battery and preparation method thereof

InactiveCN104993130AGood chemical stabilityImprove thermal stabilityCell electrodesFinal product manufactureAluminum IonElectrical battery

Belonging to the technical field of batteries, the invention relates to a non-aqueous solution aluminum ion secondary battery and a preparation method thereof. The secondary battery can be widely applied in electronics, communication, electric vehicle and other fields. The aluminum ion battery provided by the invention contains a battery anode, a battery cathode, a diaphragm and an aluminum-containing non-aqueous solution electrolyte. Specifically, the cathode active material can be carbon, graphite, carbon nanotube, graphene, super carbon, WS2 and MoS2, V2O5, TiO2 and other materials having nano-layered, tubular, linear and other structures, and the anode is aluminum-containing metal or alloy. The non-aqueous solution aluminum ion secondary battery provided by the invention has the characteristics of high specific capacity, high coulomb efficiency, long service life and environmental protection, safety and reliability, stable cycle performance, and quick charging, etc.

Owner:BEIJING ALUMINUM ENERGY S&T

Solar cell and method of manufacture thereof, and solar cell module

ActiveUS20130312827A1Lower resistanceImprove efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingPhotoelectric conversionSolar cell

Disclosed is a solar cell having a collecting electrode on one main surface of a photoelectric conversion section. The collecting electrode includes a first electroconductive layer and a second electroconductive layer in this order from the photoelectric conversion section side, and further includes an insulating layer between the first electroconductive layer and the second electroconductive layer. The first electroconductive layer includes a low-melting-point material, and a part of the second electroconductive layer is conductively connected with the first electroconductive layer through, for example, an opening in the insulating layer. The second electrode layer is preferably formed by a plating method. In addition, it is preferable that before forming the second electroconductive layer, annealing by heating is carried out to generate the opening section in the insulating layer.

Owner:KANEKA CORP

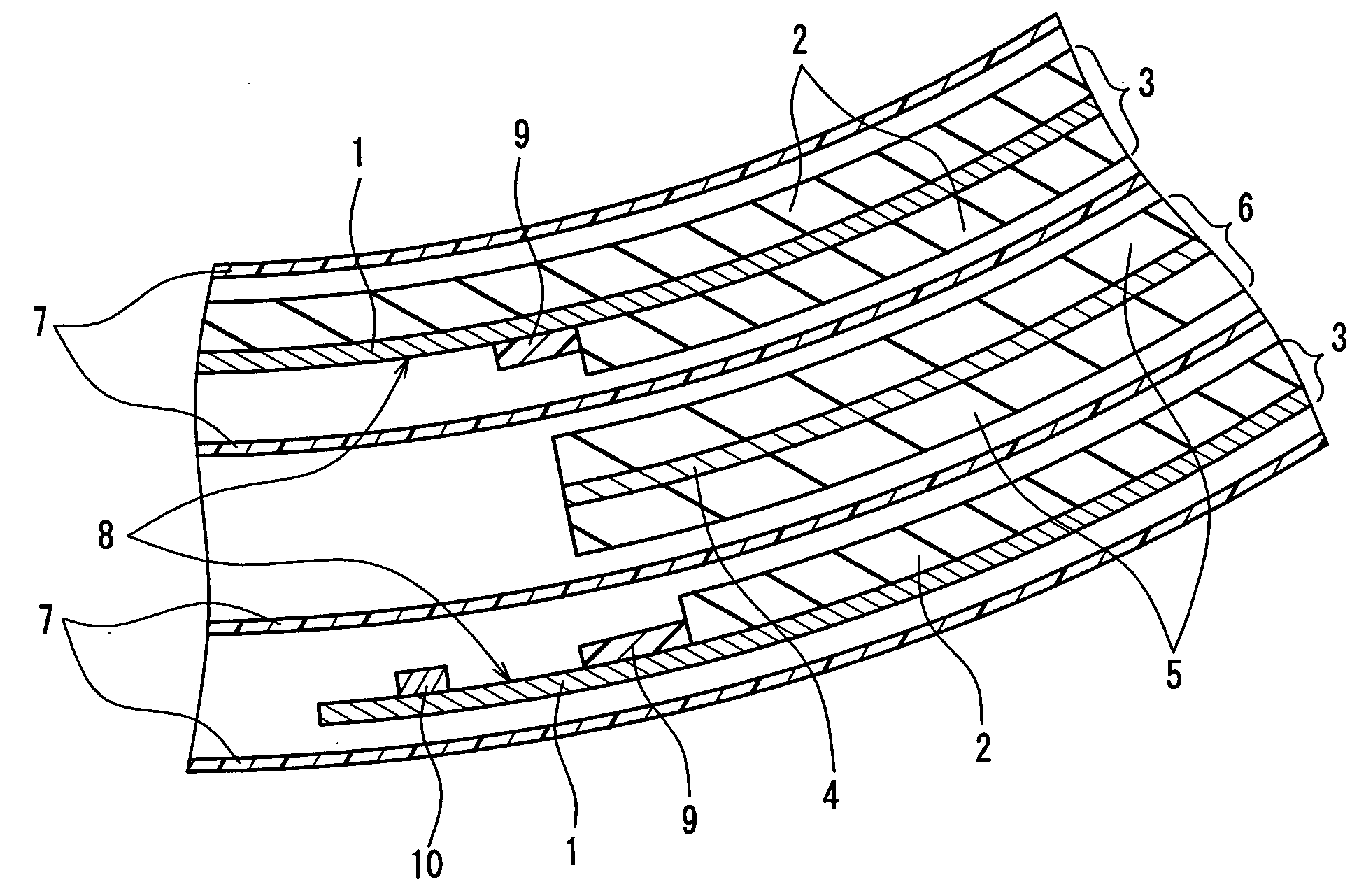

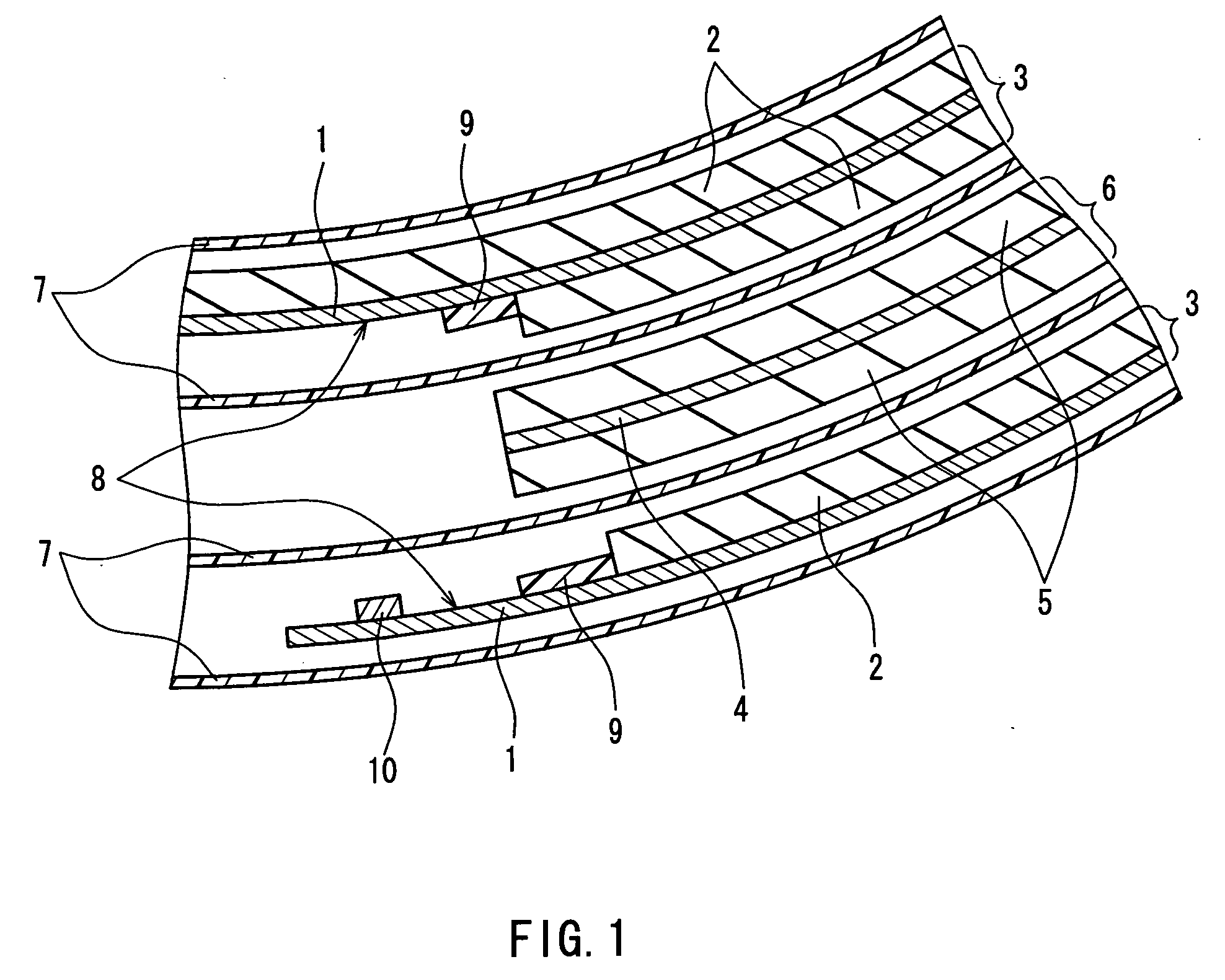

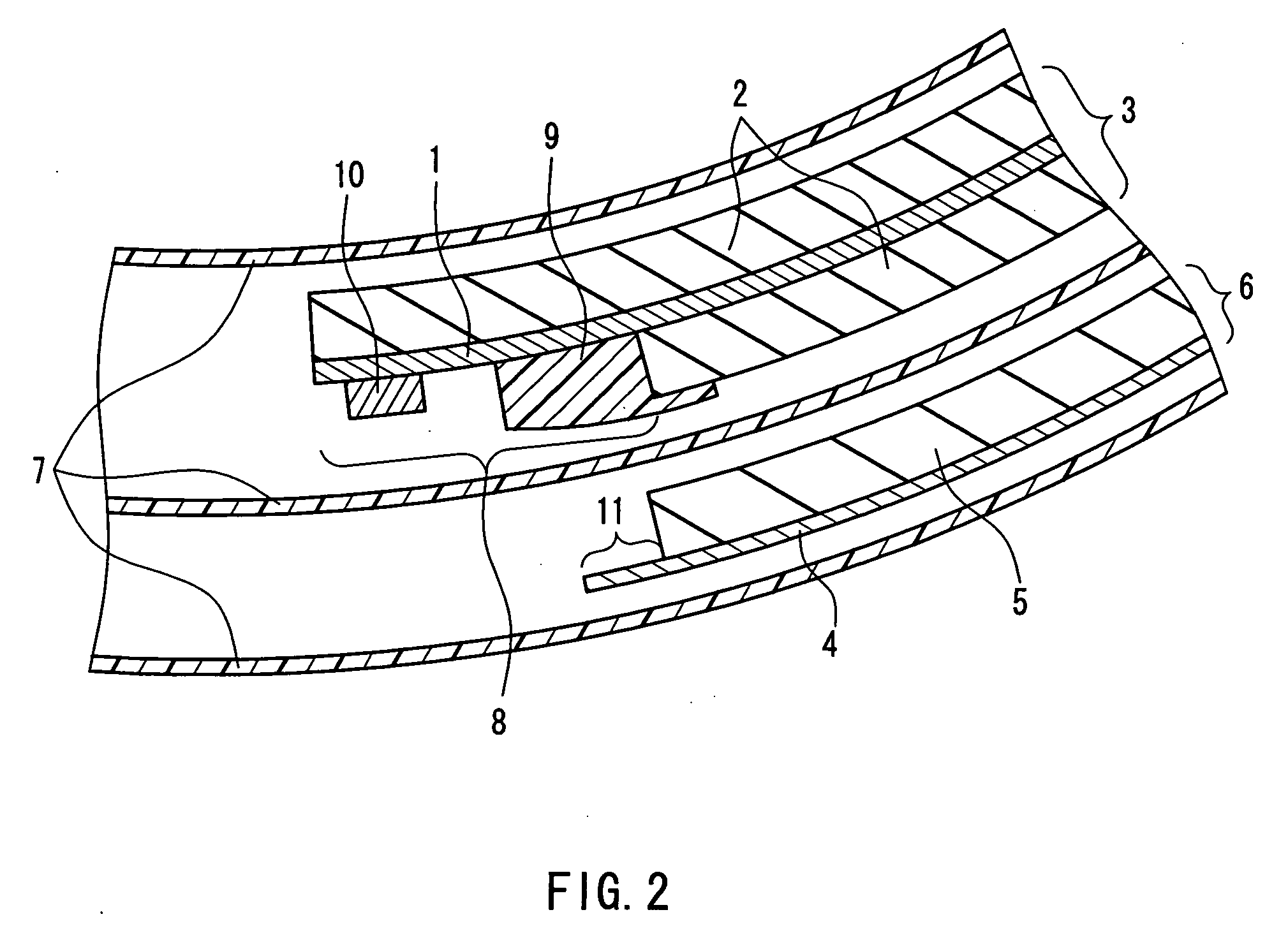

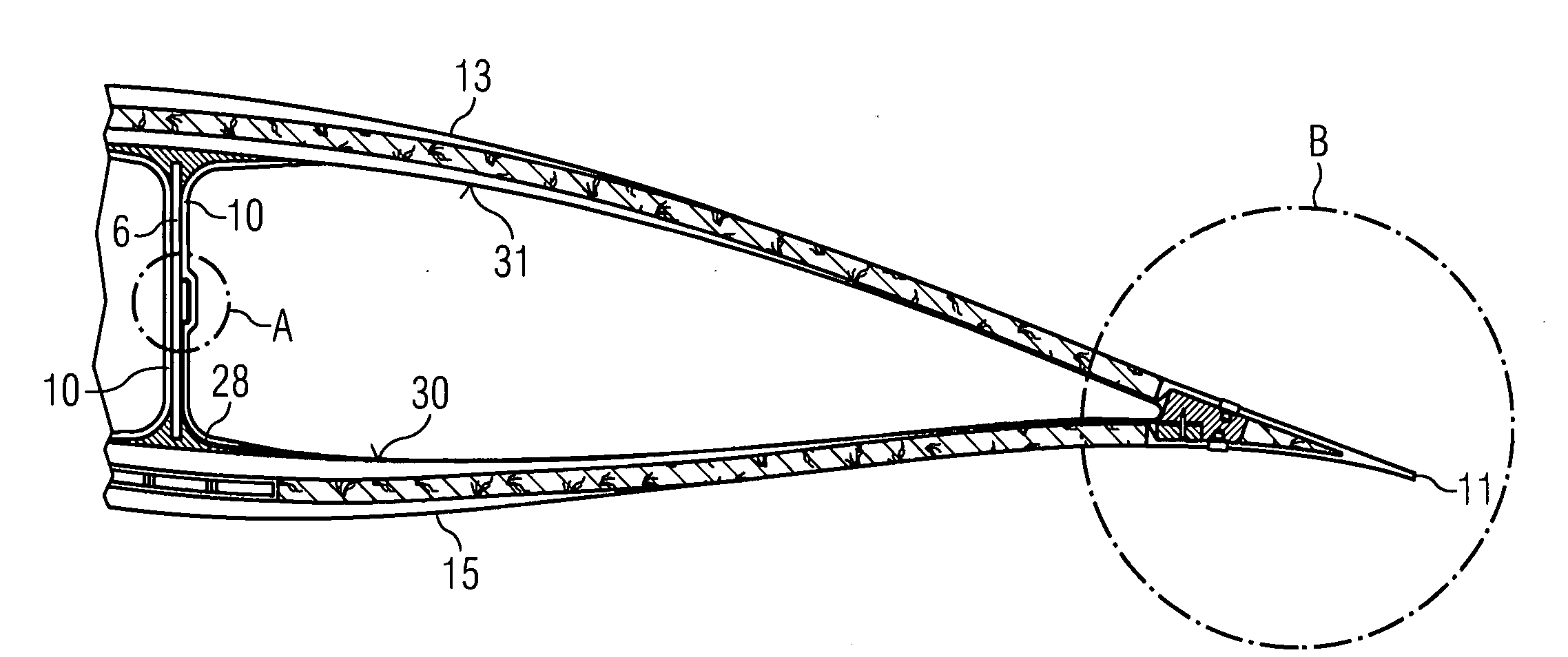

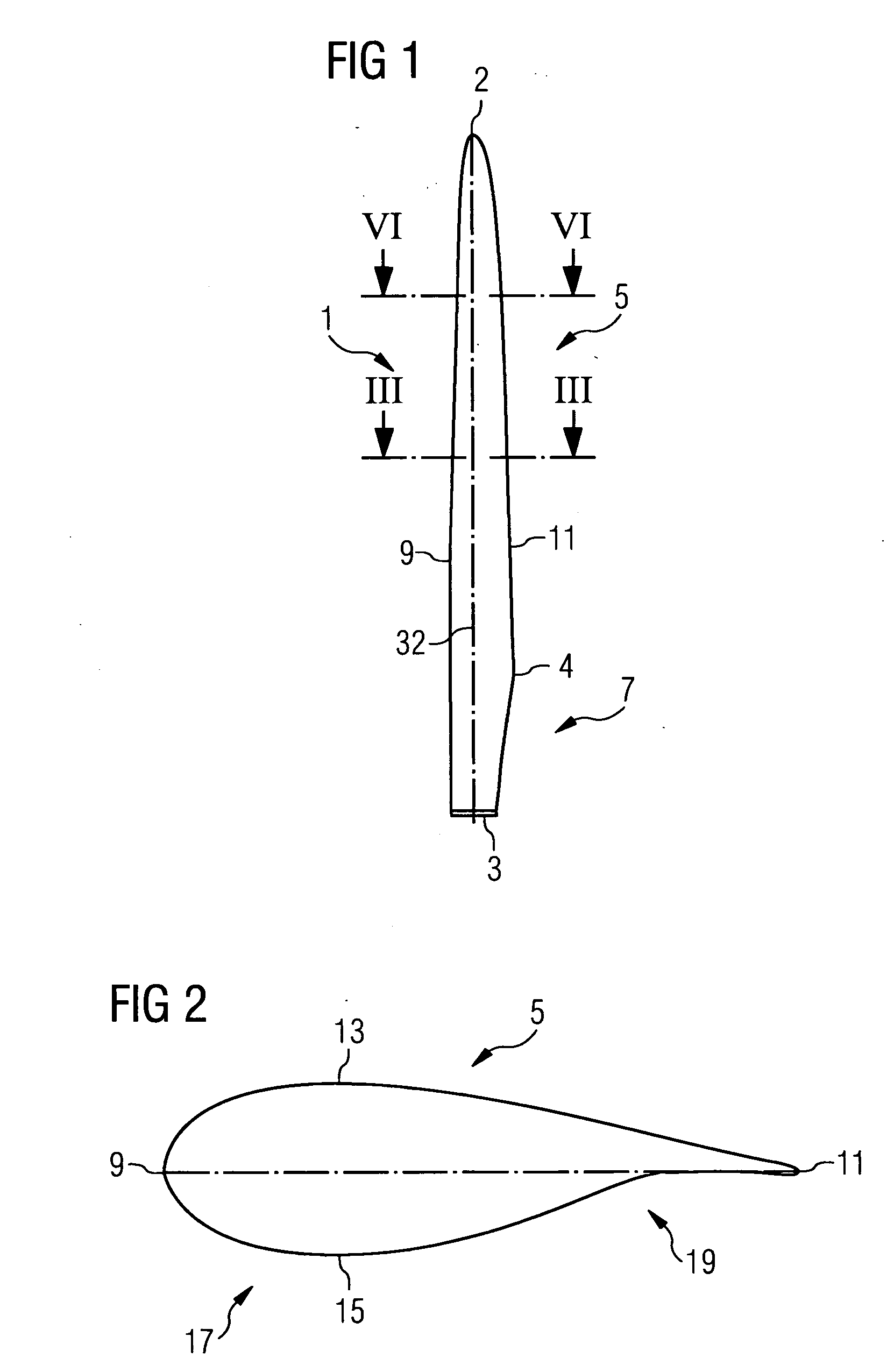

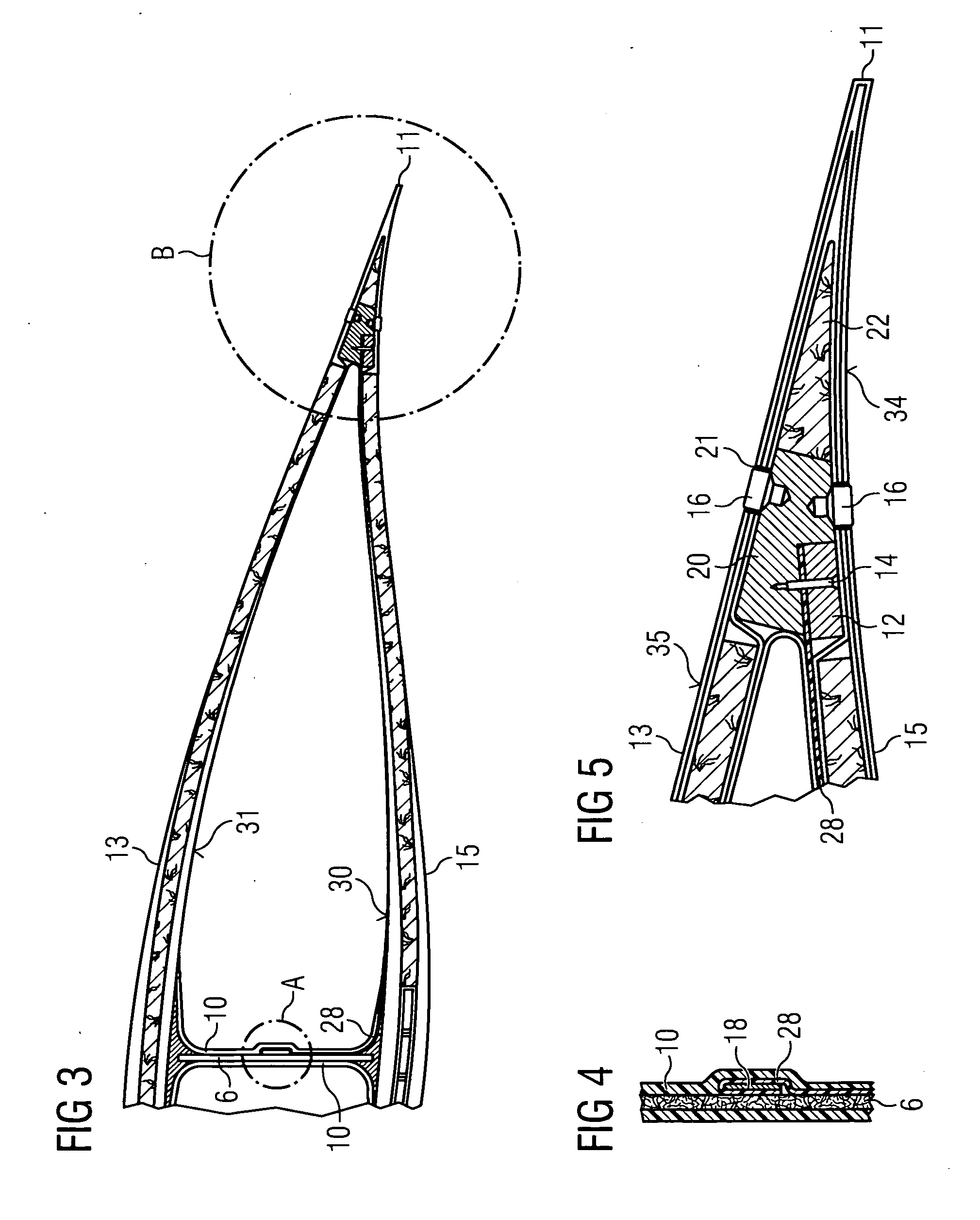

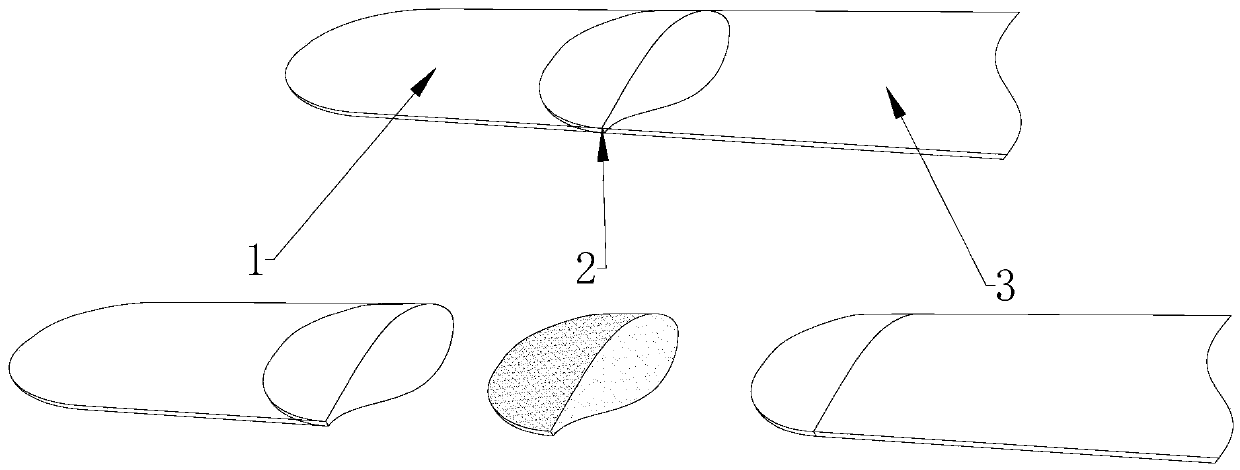

Wind Turbine Blade with an Integrated Lightning Conductor and Method for Manufacturing the Same

ActiveUS20090257881A1Reduce mechanical stressEasy to mergeFinal product manufactureLaminationElectrical conductorTurbine blade

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

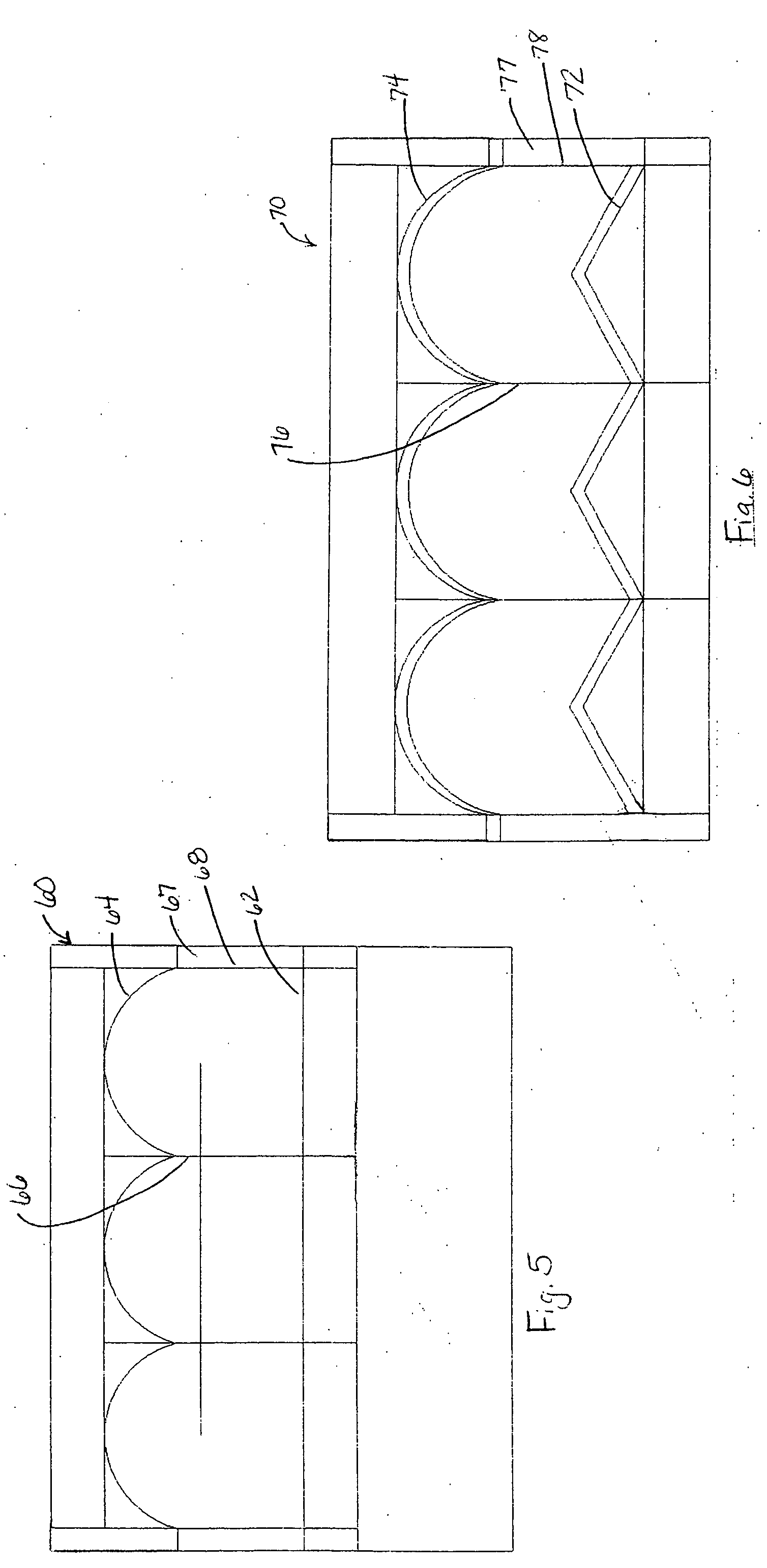

Solid-oxide-fuel-cell cathode gas flow field plate and preparation method thereof

ActiveCN104253280AEfficient use ofFully contactedFinal product manufactureCollectors/separatorsIsosceles trapezoidFuel cells

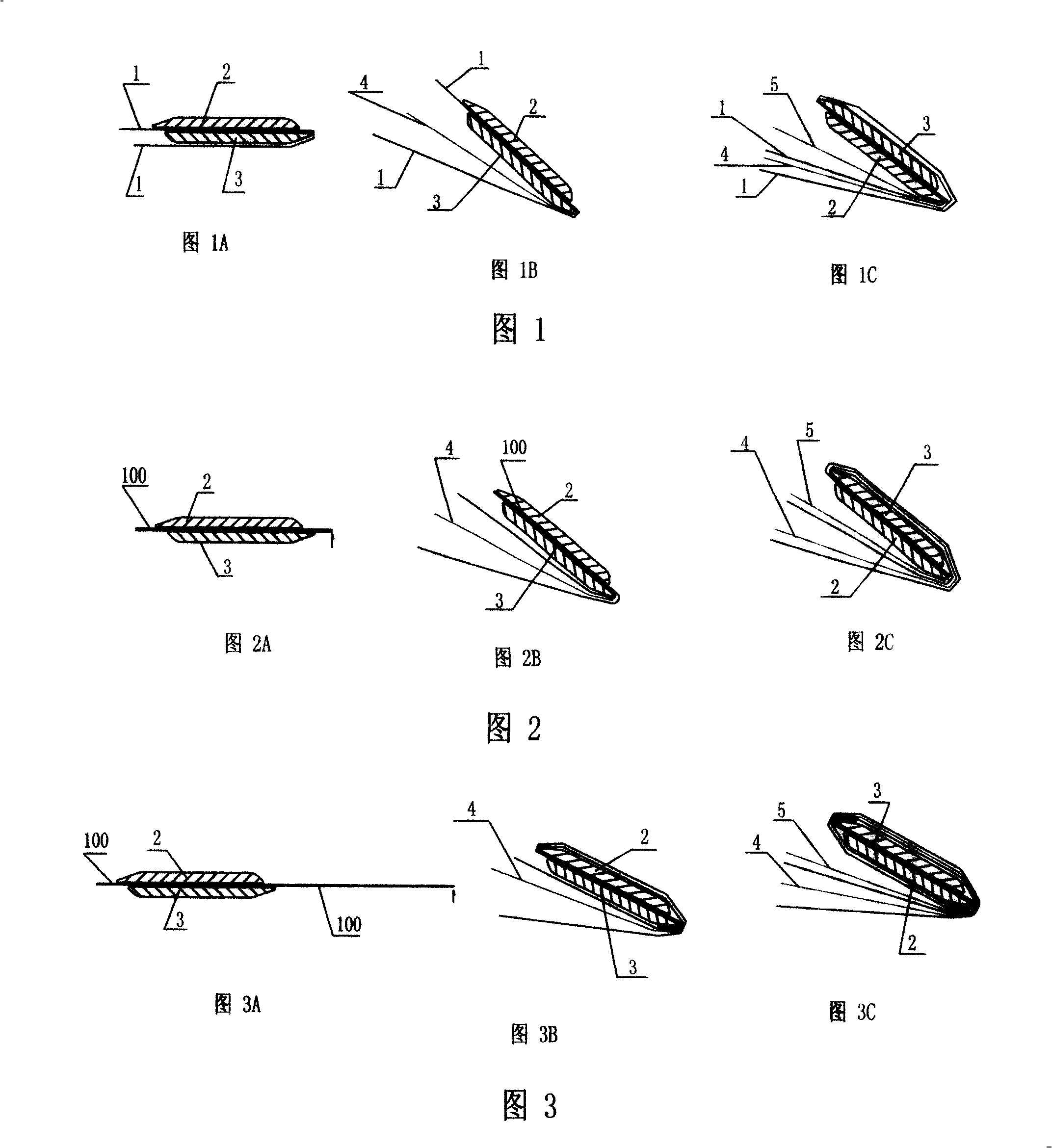

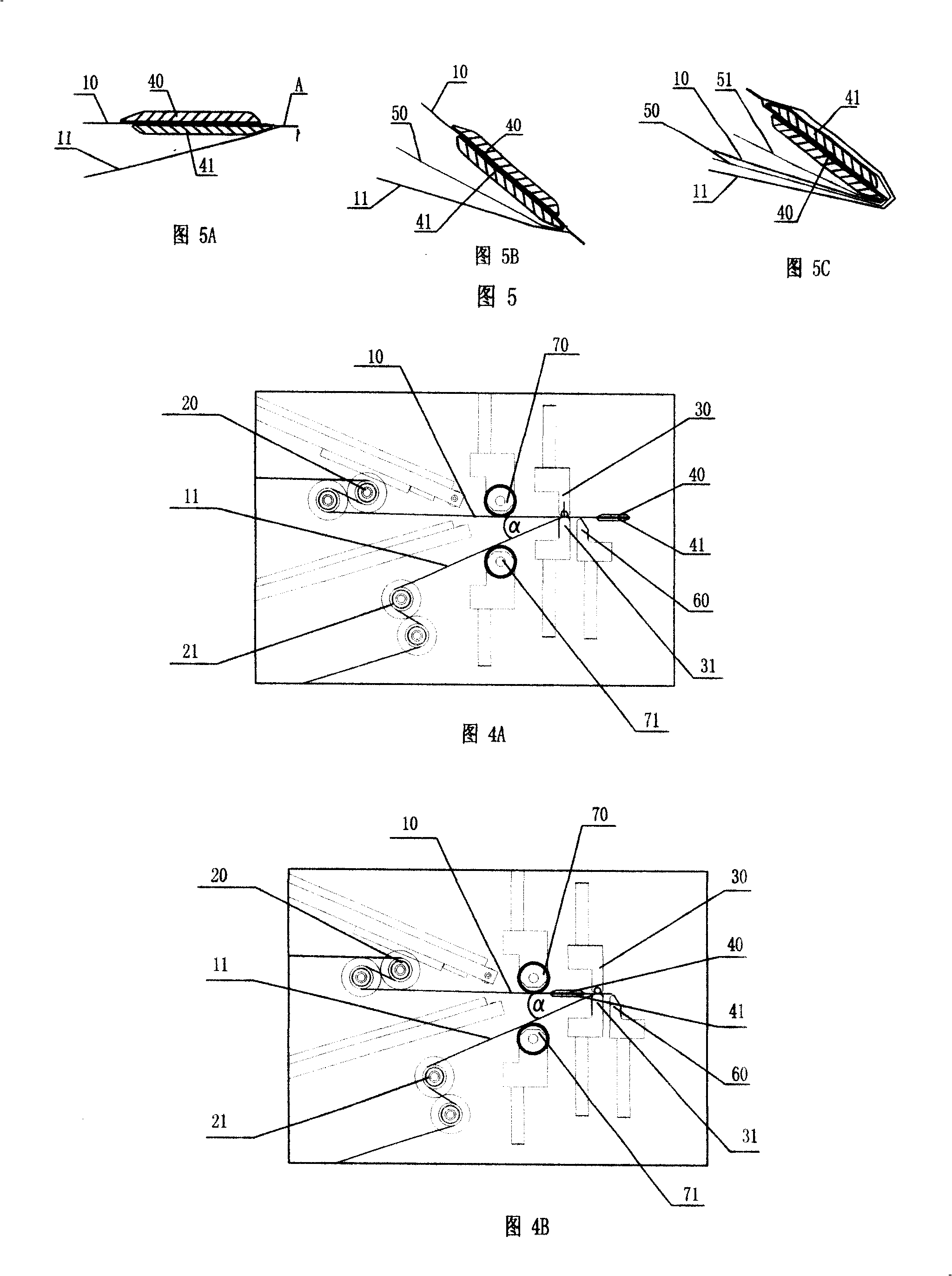

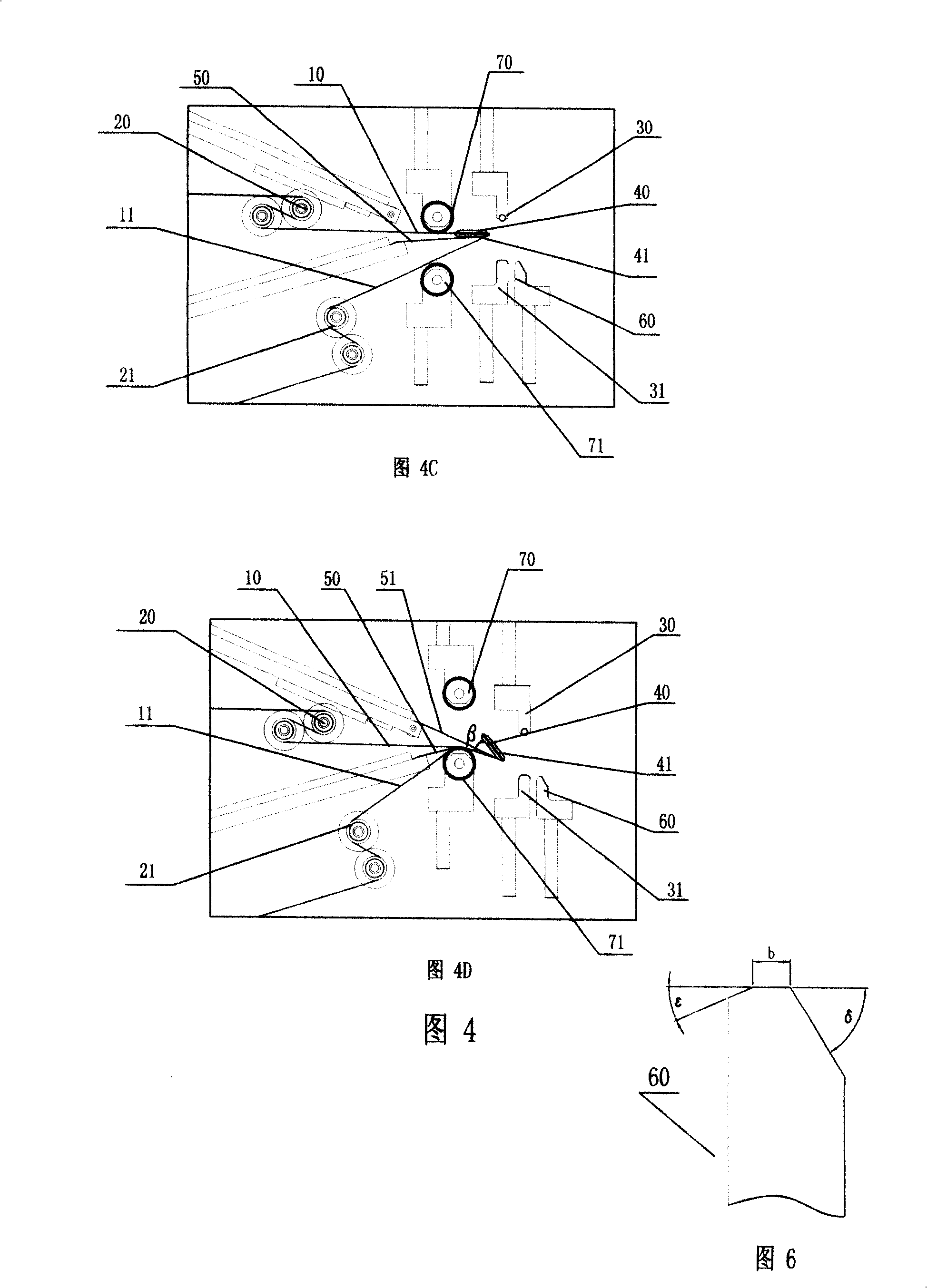

The invention discloses a solid-oxide-fuel-cell cathode gas flow field plate which is used to uniformly distribute an oxidation gas and collect cathode current. The cathode gas flow field plate is formed by multiple tooth-shaped ripple blocks which are in parallel connection and have same dimension, each tooth-shaped ripple block is formed by two tooth-shaped ripple strips (3 and 4) which are in parallel arrayed connection after being staggered at a distance (7), each tooth-shaped ripple strip (3 and 4) is formed by multiple flat-top bosses (2) and flat plates (1) which are in alternate connection, each flat-top boss (2) has a tooth-shaped contour, the flat plates (1) are connected with the root parts of the flat-top bosses (2) to form tooth-shaped ripples, and the cross section of each flat-top boss (2) has a shape same to the shape of an isosceles trapezoid without a bottom edge. The cathode gas flow field plate of a fuel cell is capable of overcoming the problems that a conventional flow field is large in gas pressure reduction and low in fuel utilization rate. By employing a roll forming technology for preparing the flow field plate, the flow field plate is simple in technology, can be precisely formed and high in product qualified rate.

Owner:HUAZHONG UNIV OF SCI & TECH

Composite electrolyte membrane based on functional polymer and preparation method thereof, and lithium-sulfur secondary cell

Owner:NAT UNIV OF DEFENSE TECH

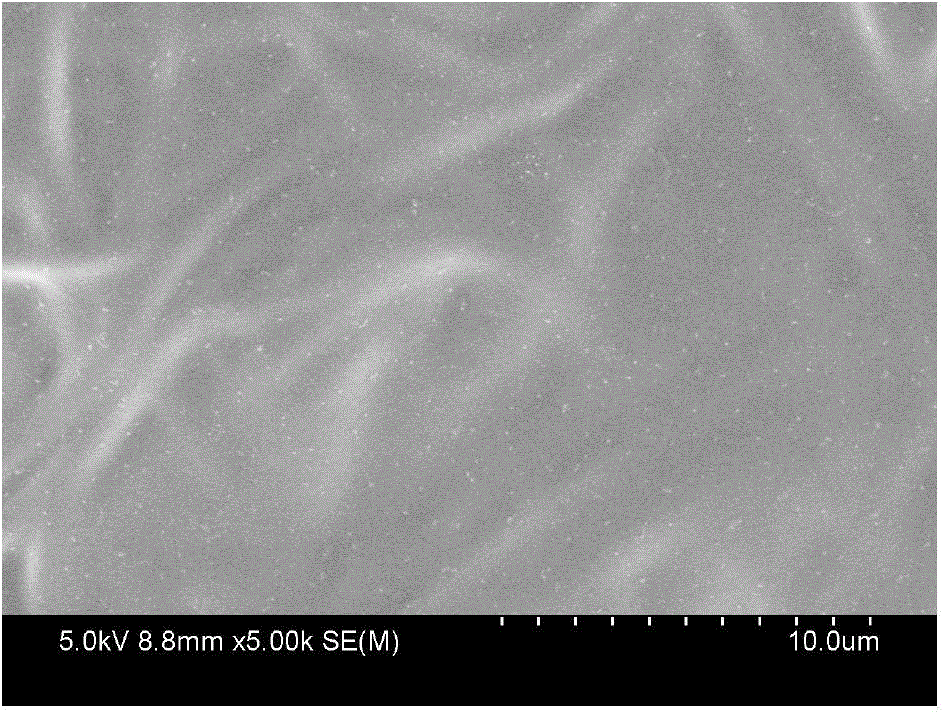

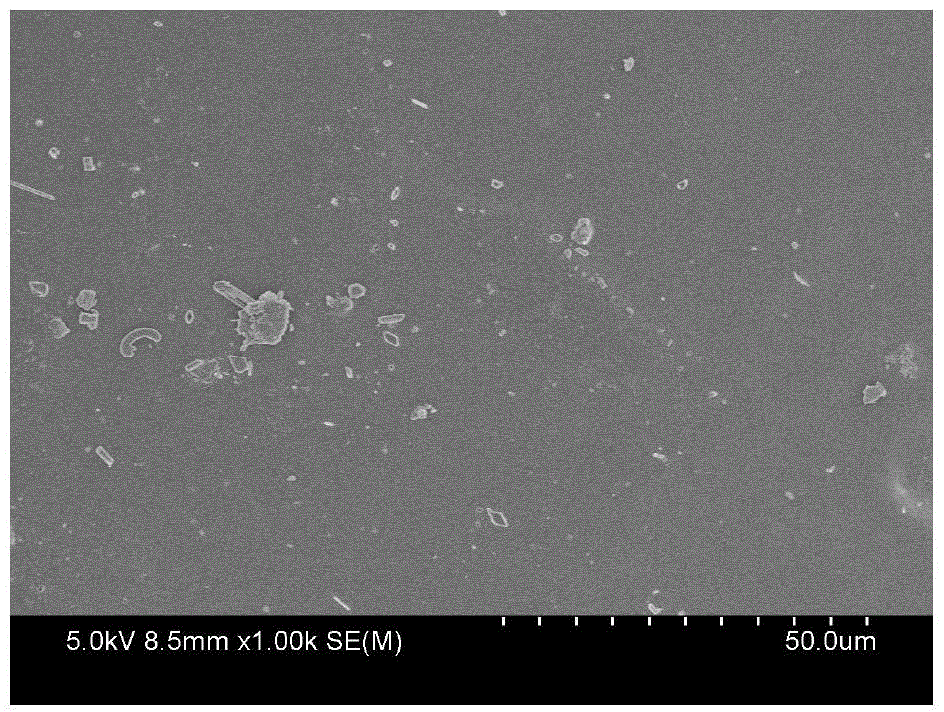

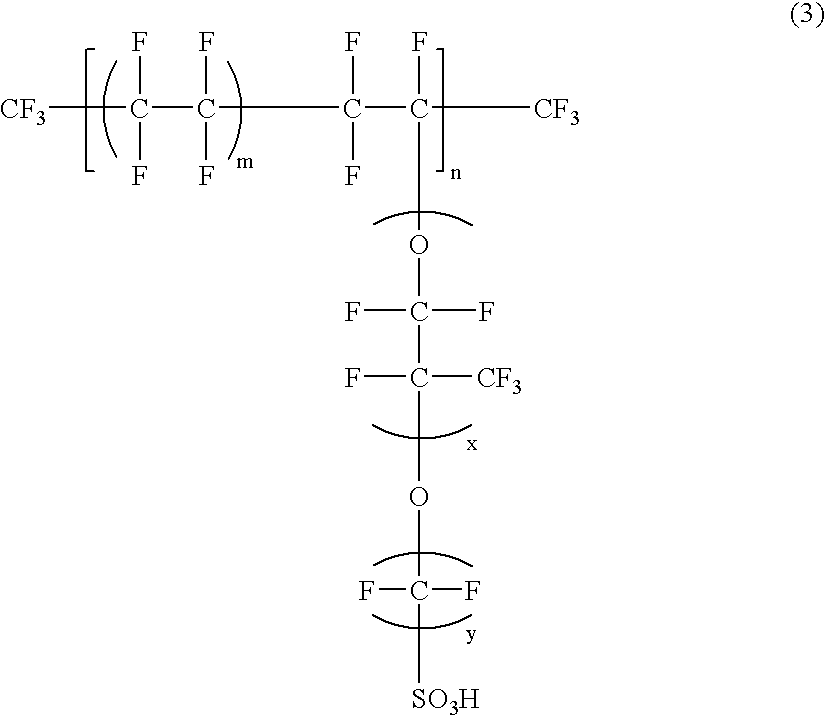

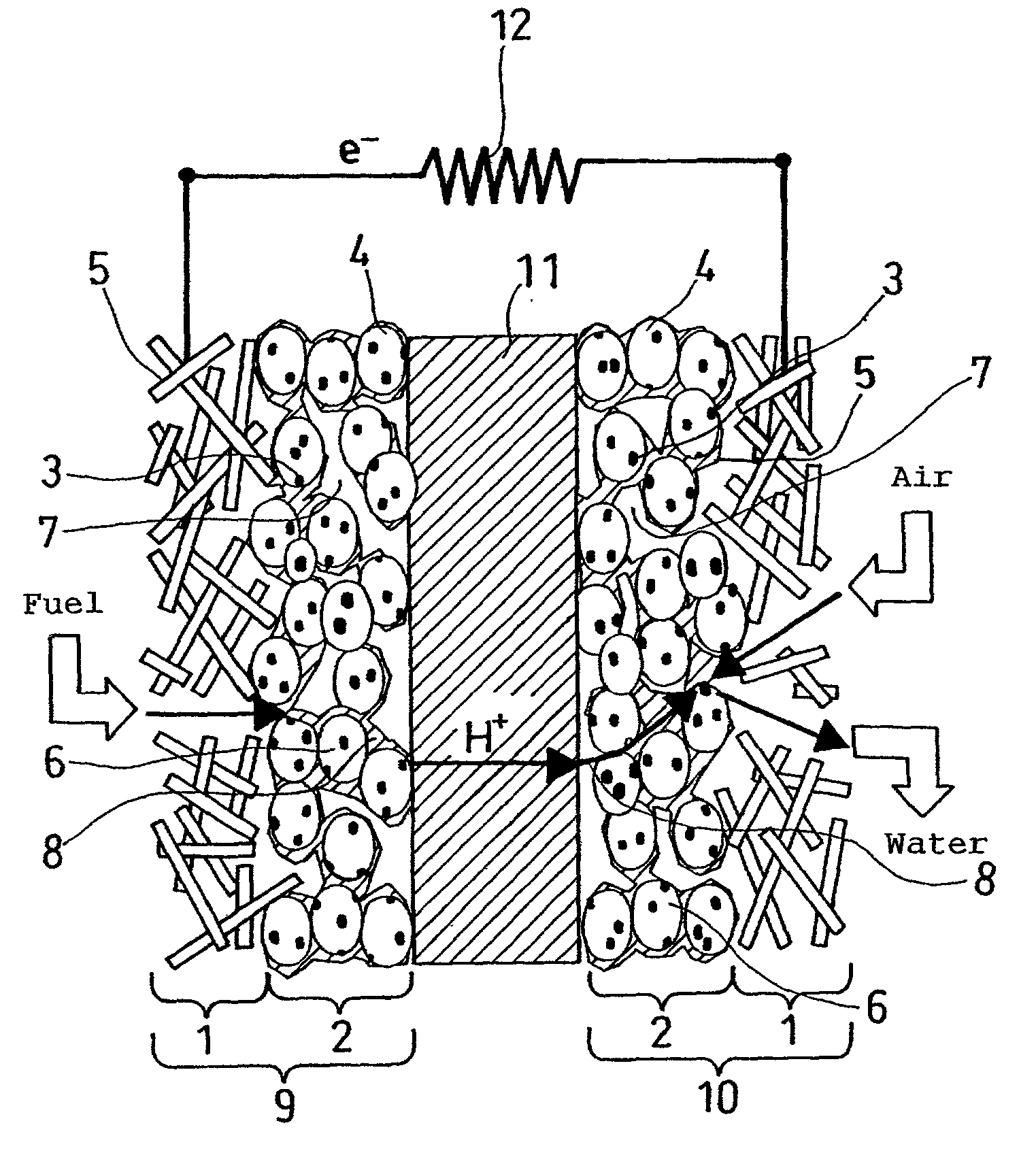

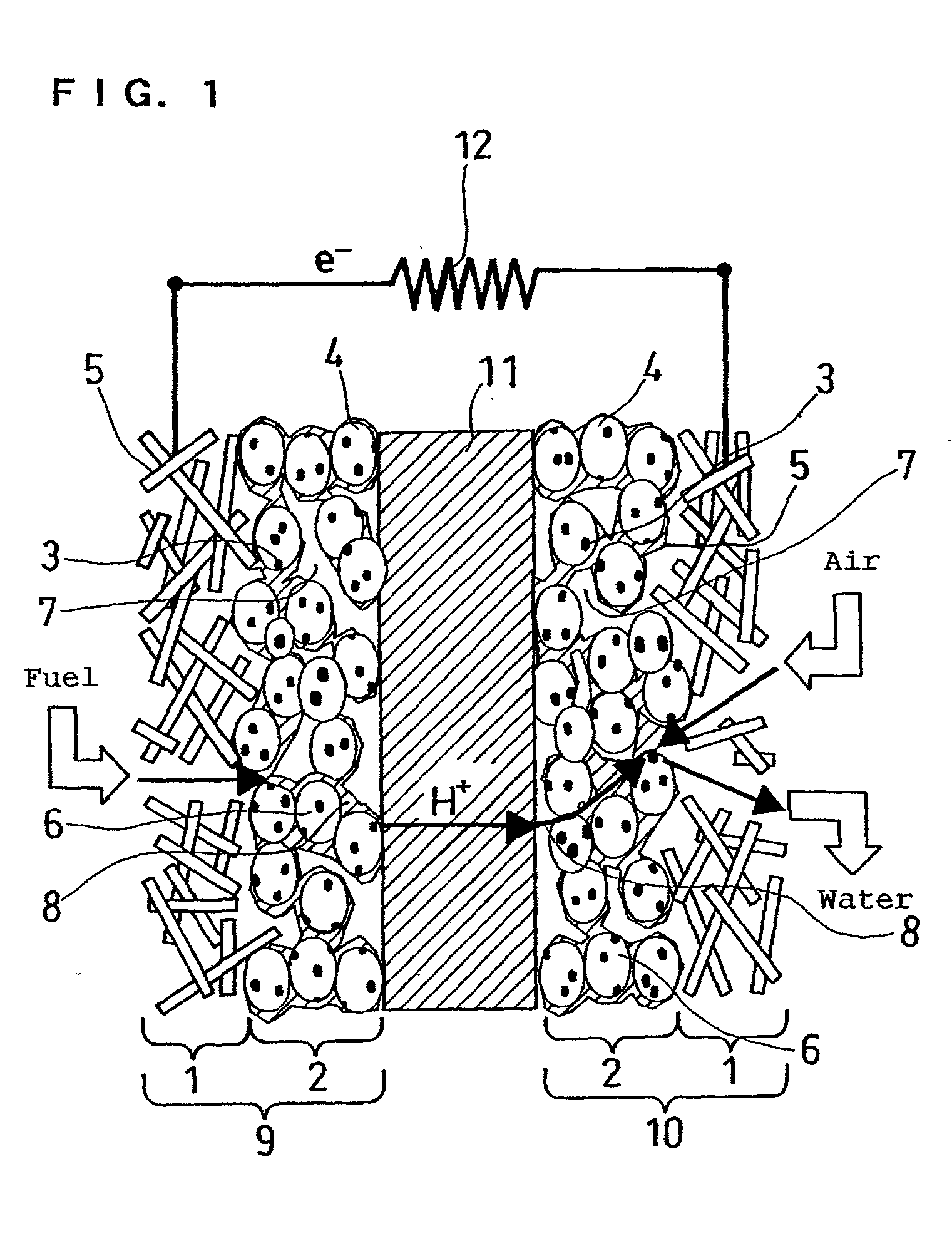

Polyelectrolyte fuel cell and production method therefor

InactiveUS20020182478A1Final product manufactureActive material electrodesPolyelectrolyteCarbon particle

Owner:PANASONIC CORP

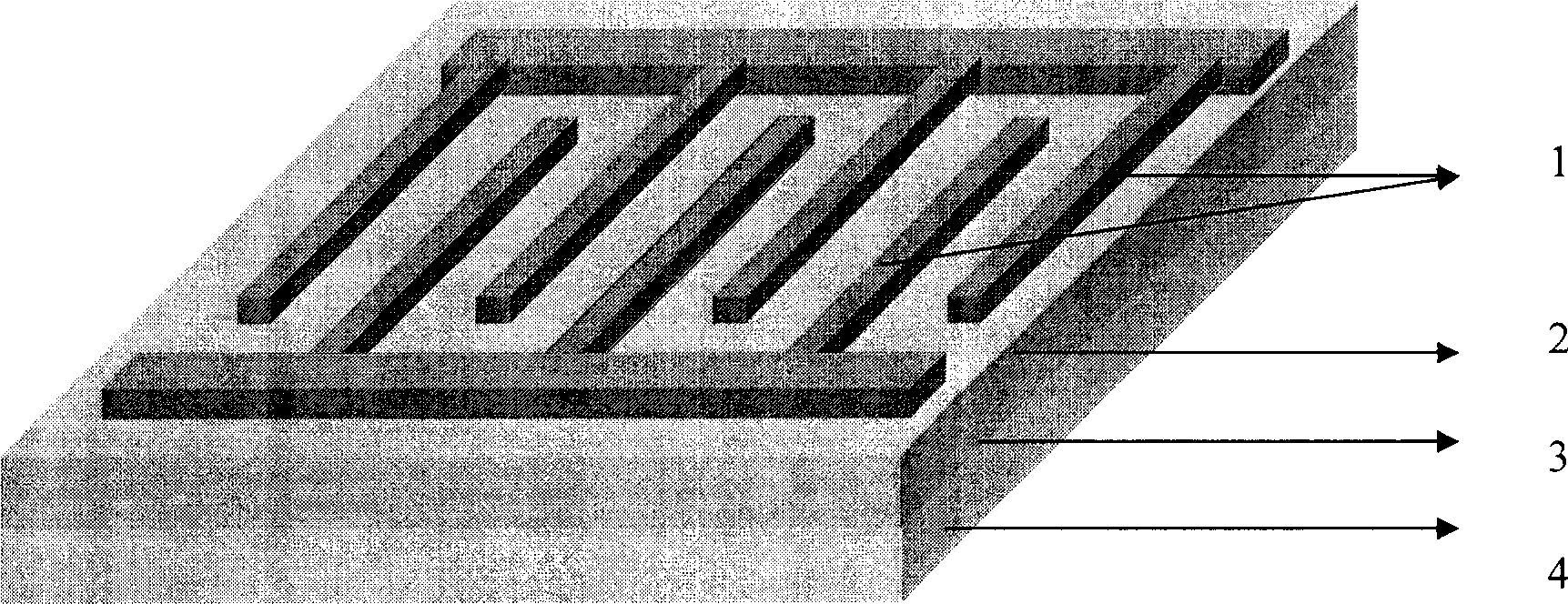

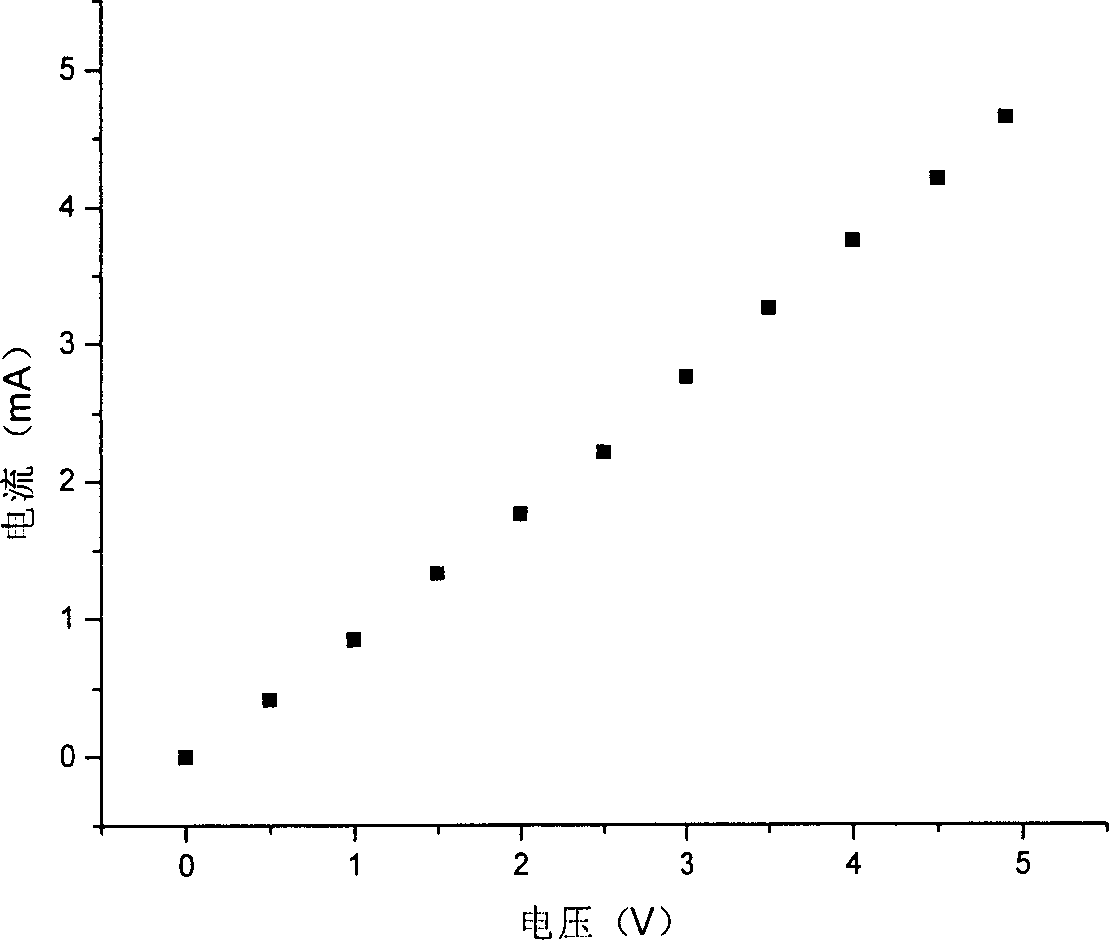

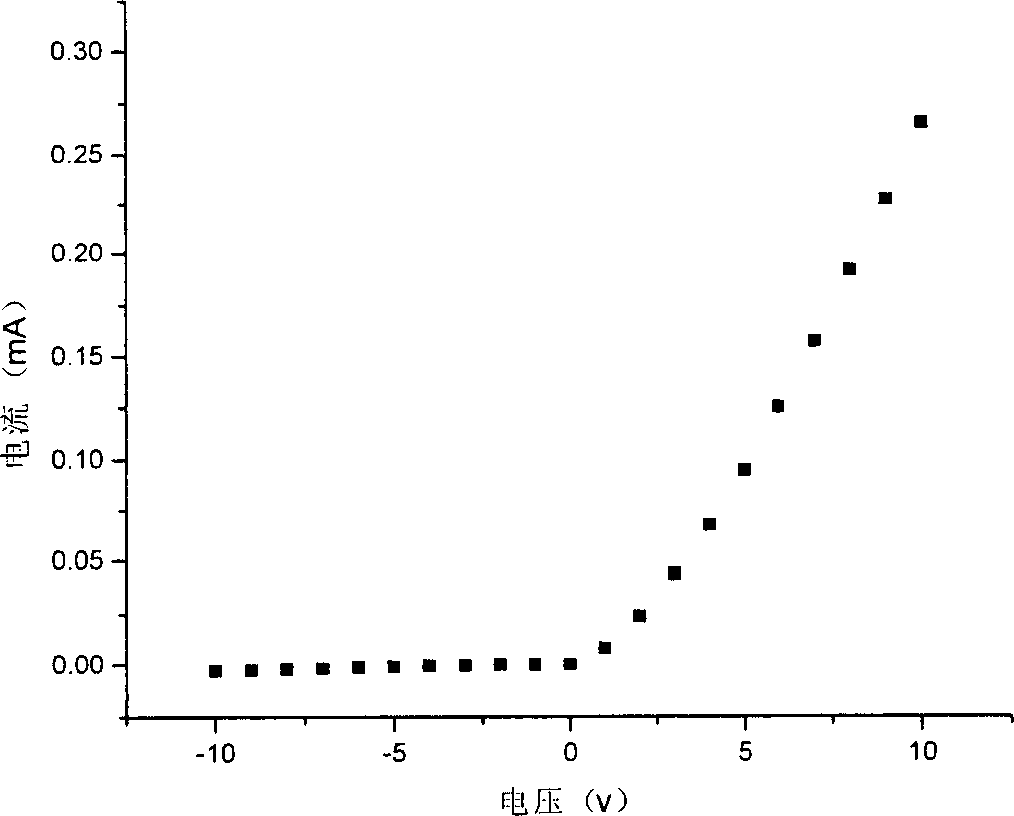

Metal/semiconductor/metallic structure TiO2 ultraviolet photodetector and preparation

Owner:JILIN UNIV

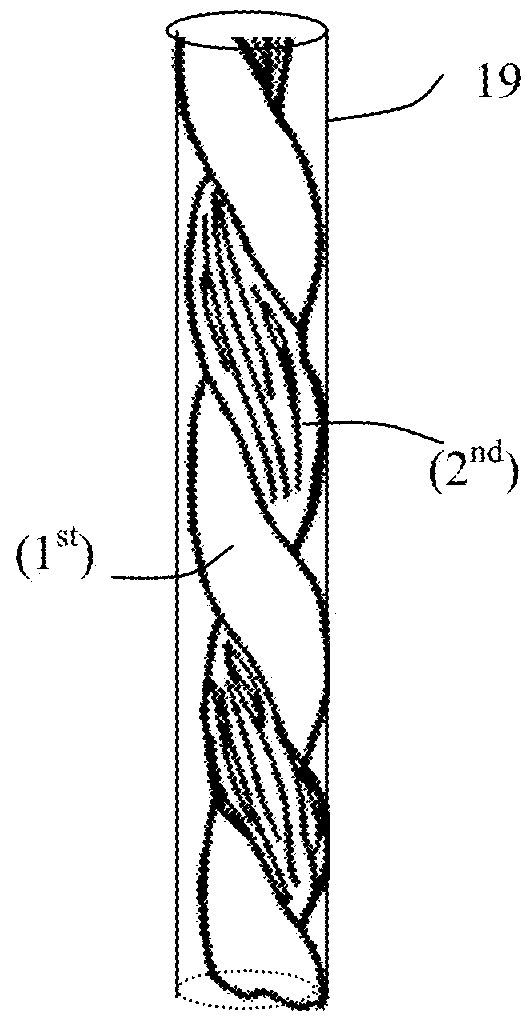

Winding method of lithium ion battery coiled core

ActiveCN101246970AConsistent tensionGuaranteed reliabilityFinal product manufactureSecondary cellsSemi automaticEngineering

Owner:GEESUN AUTOMATION TECH

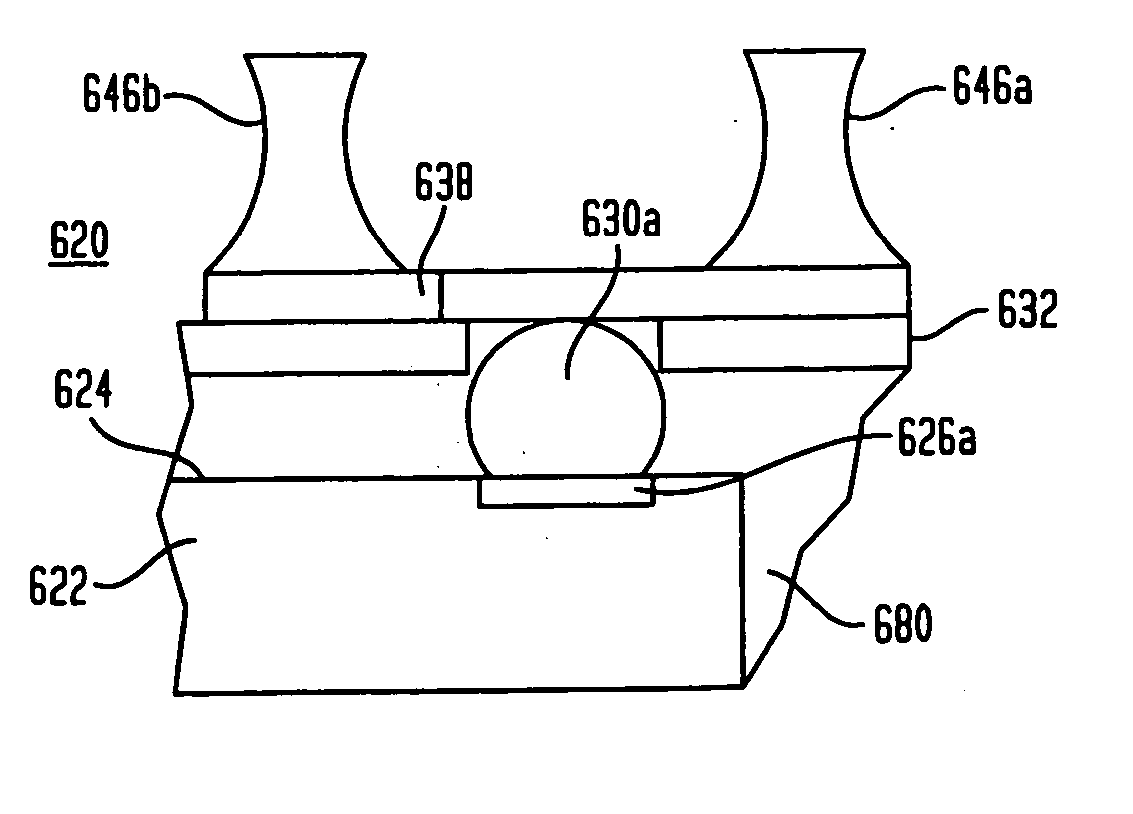

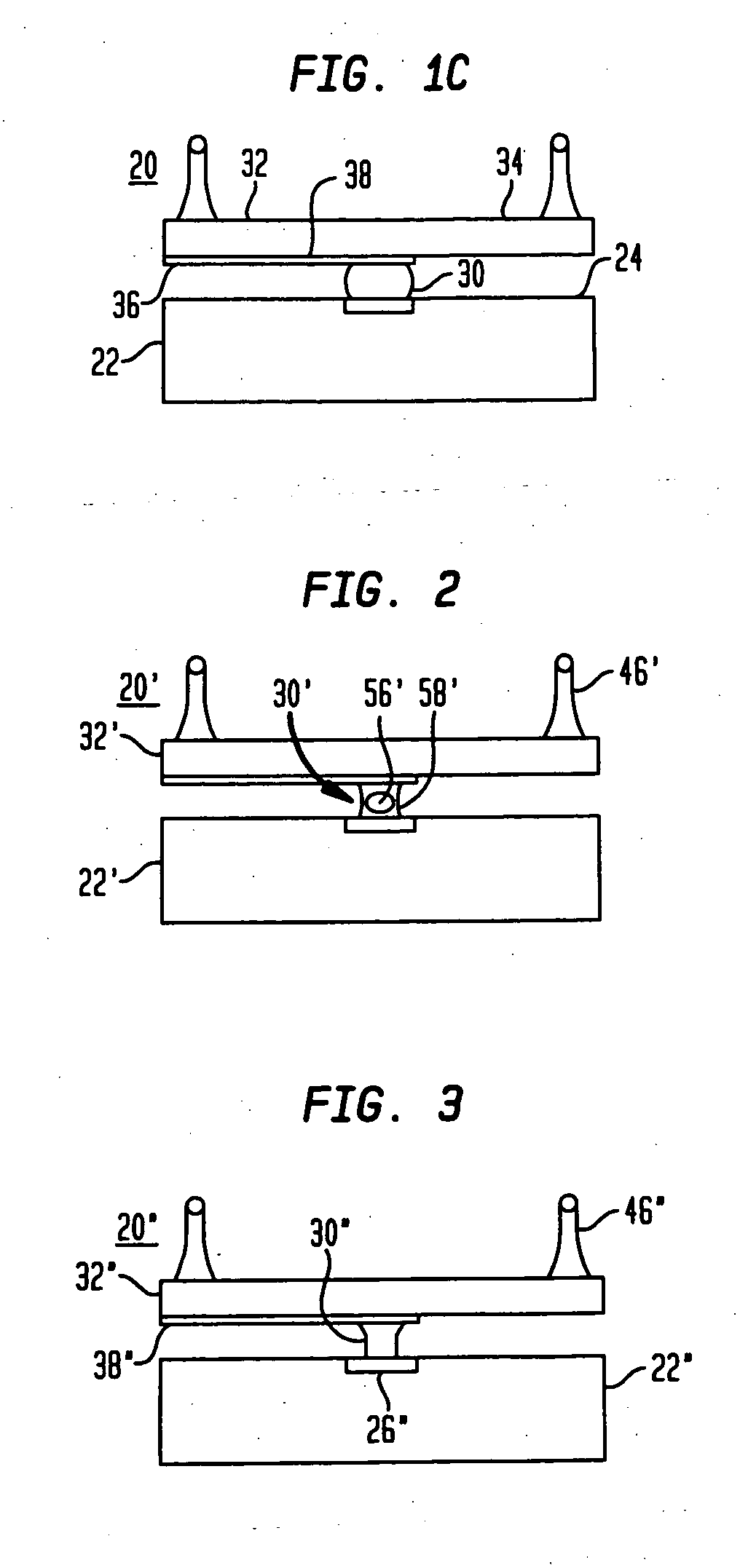

Microelectronic packages and methods therefor

InactiveUS20060249857A1Easy to testAvoid the needElectrical measurement instrument detailsSemiconductor/solid-state device detailsElectronic componentElectronic packaging

Owner:TESSERA INC

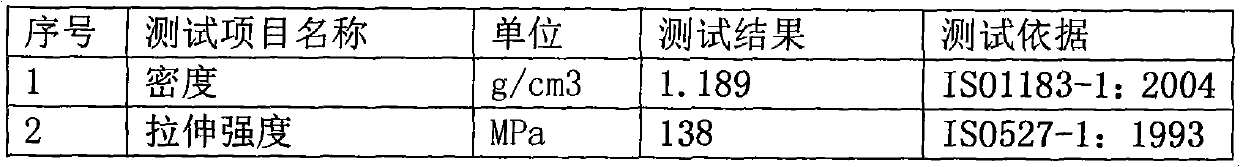

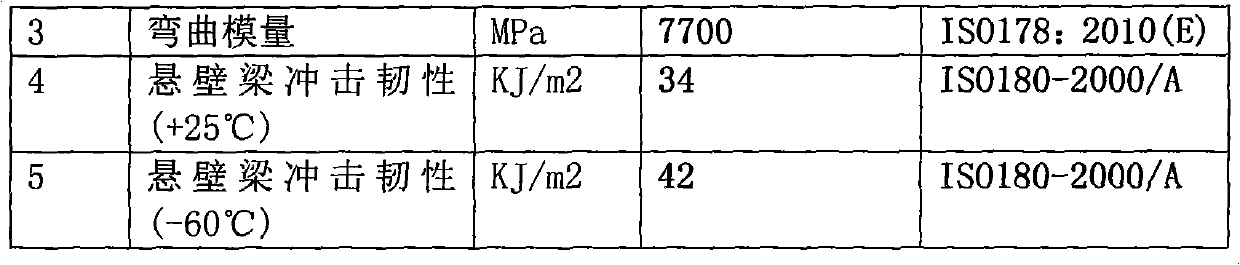

Long-fiber enhanced thermoplastic composite material vane used for wind energy generator

InactiveCN102675740ALow shrinkageLow temperature impact resistanceFinal product manufactureMachines/enginesGlass fiberPhoto aging

Owner:BEIJING NASHENGTONG ADVANCED MATERIAL & TECH CO LTD

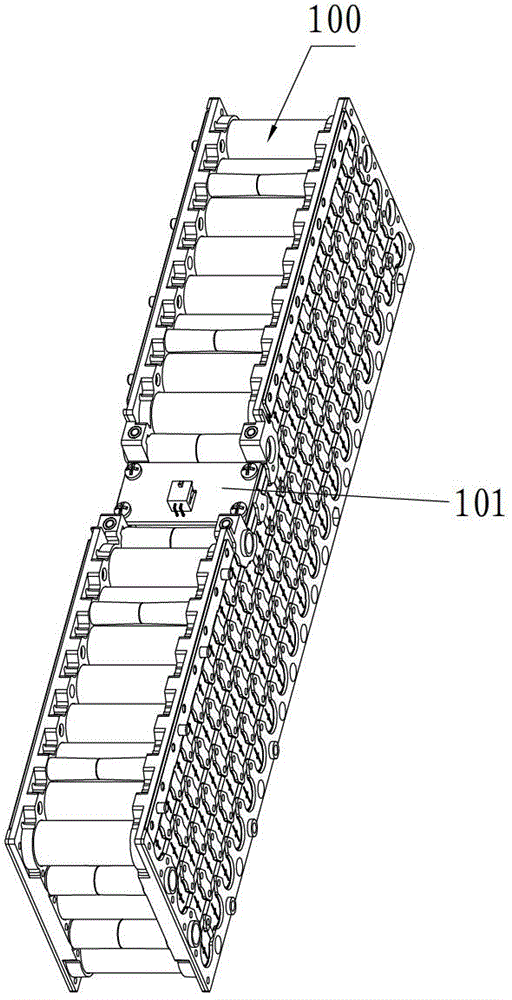

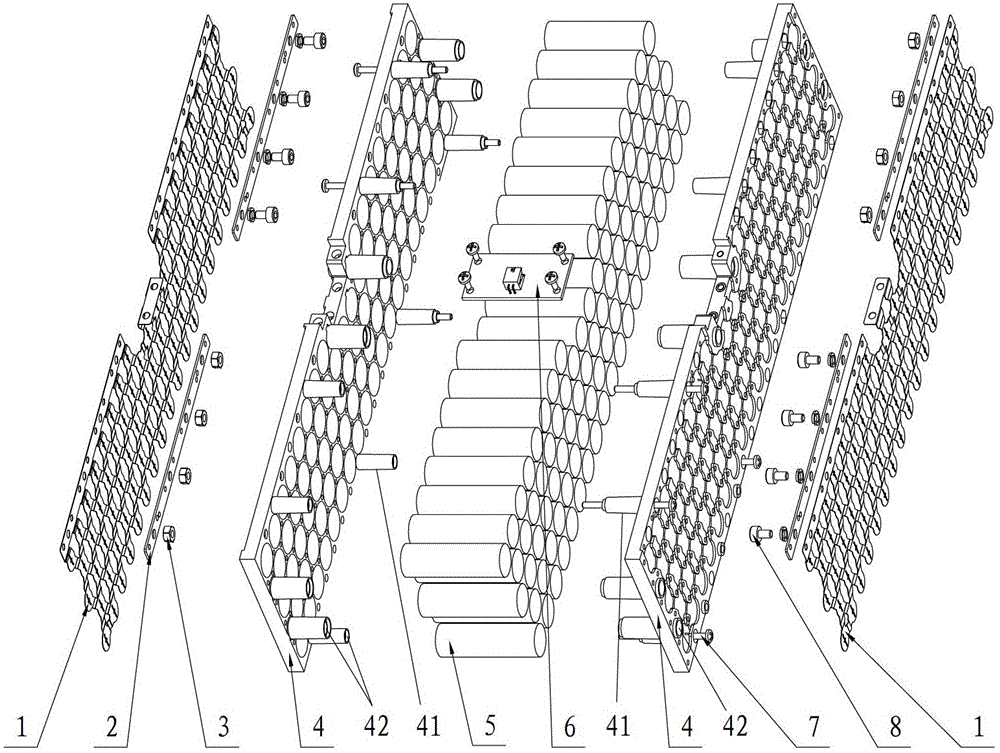

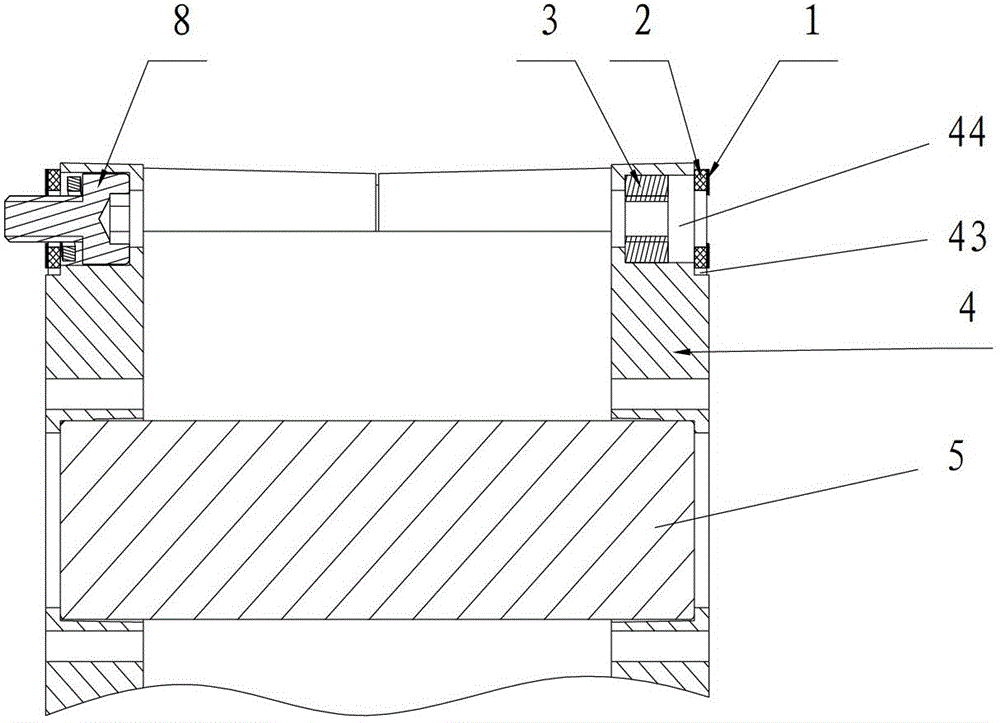

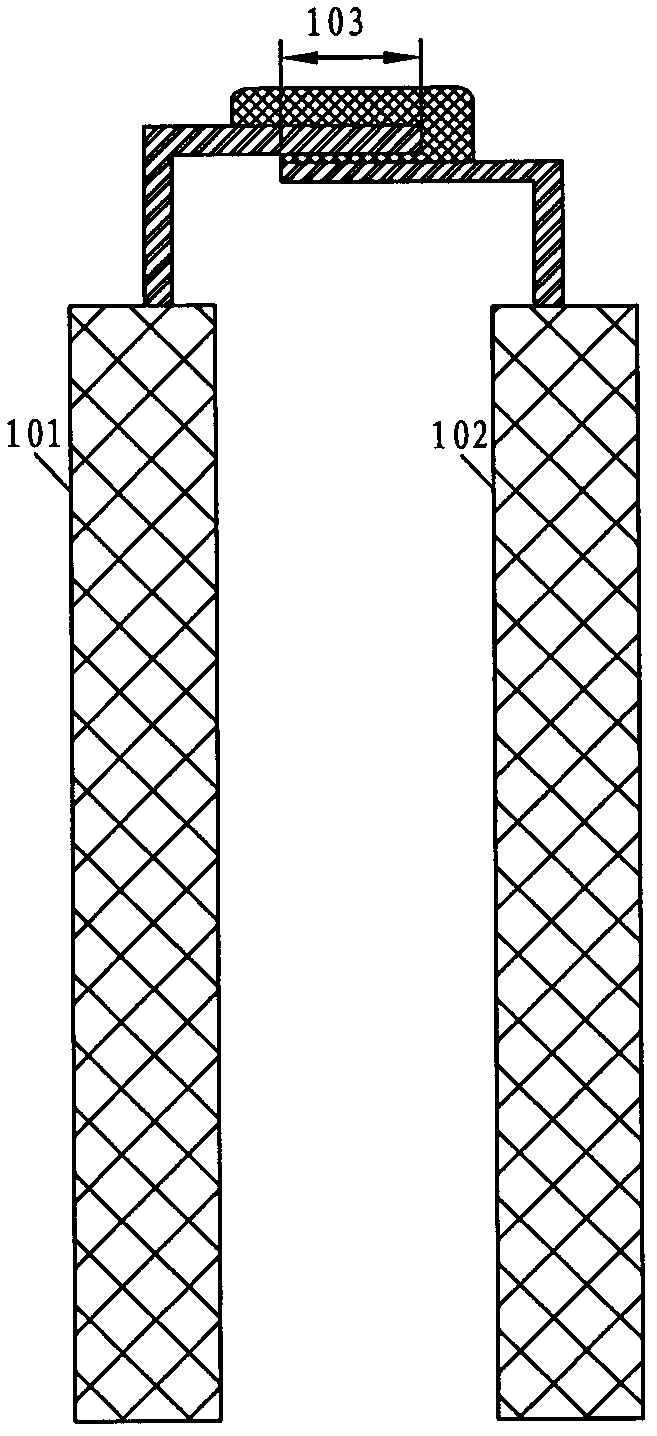

Cylindrical power battery module structure

Owner:欣旺达惠州新能源有限公司

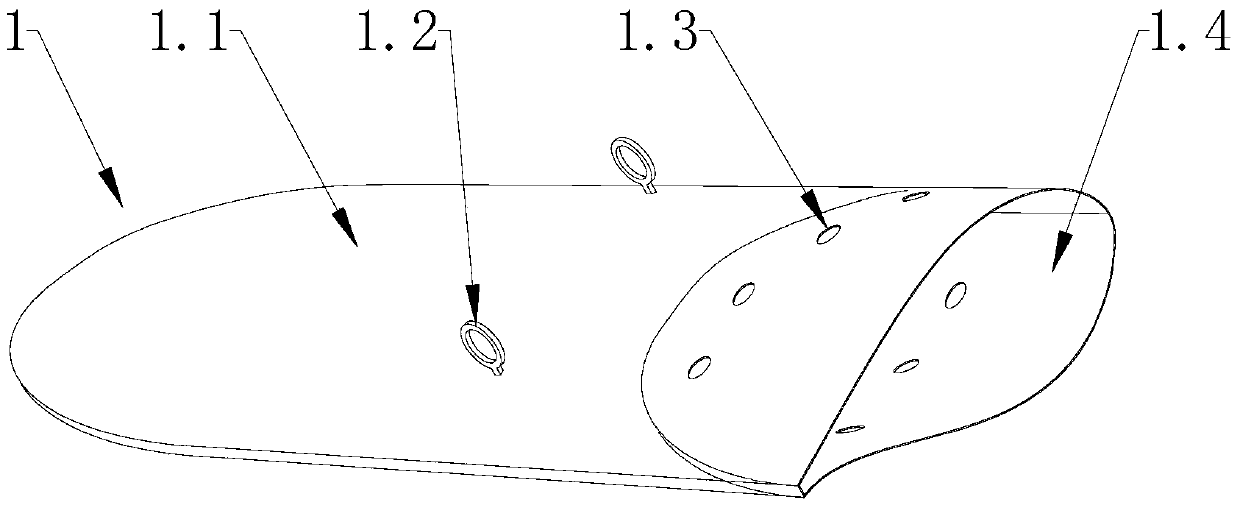

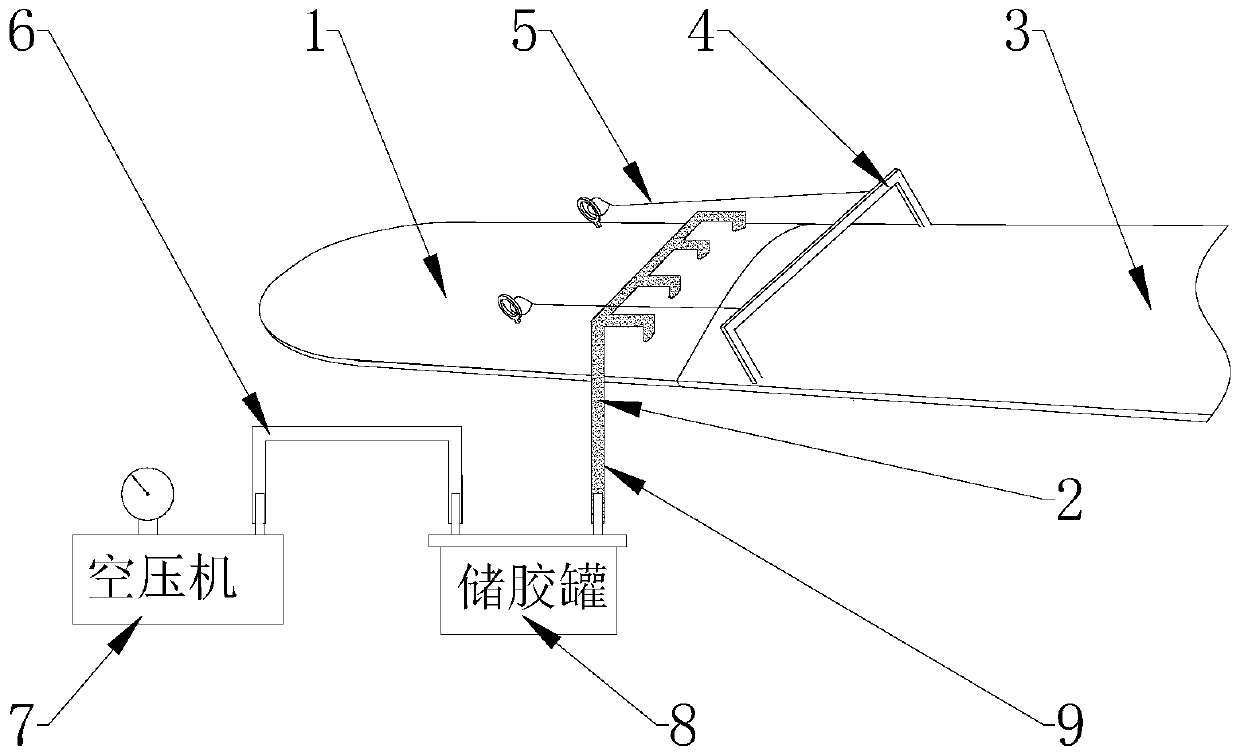

Wind power blade tip lengthening method

InactiveCN105500696AIncrease the lengthHigh bonding strengthEngine manufactureFinal product manufactureElectricityAdhesive

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

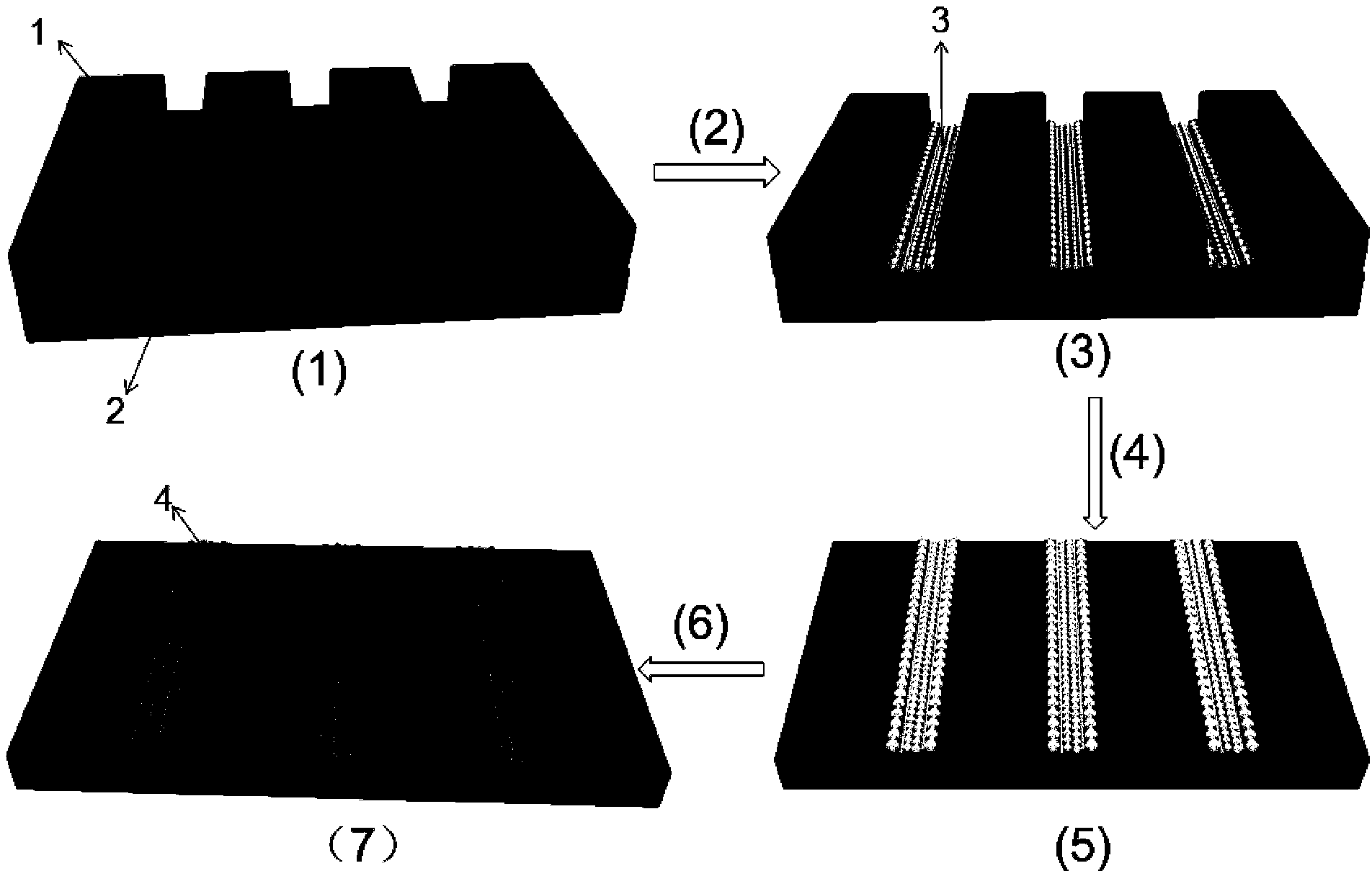

Method for preparing solar cell silver wire grid electrode based on photolithographic mask method and liquid phase method

ActiveCN103367541AFinal product manufacturePhotomechanical exposure apparatusSolar cell efficiencyElectrochemical response

Owner:SOUTH CHINA NORMAL UNIVERSITY

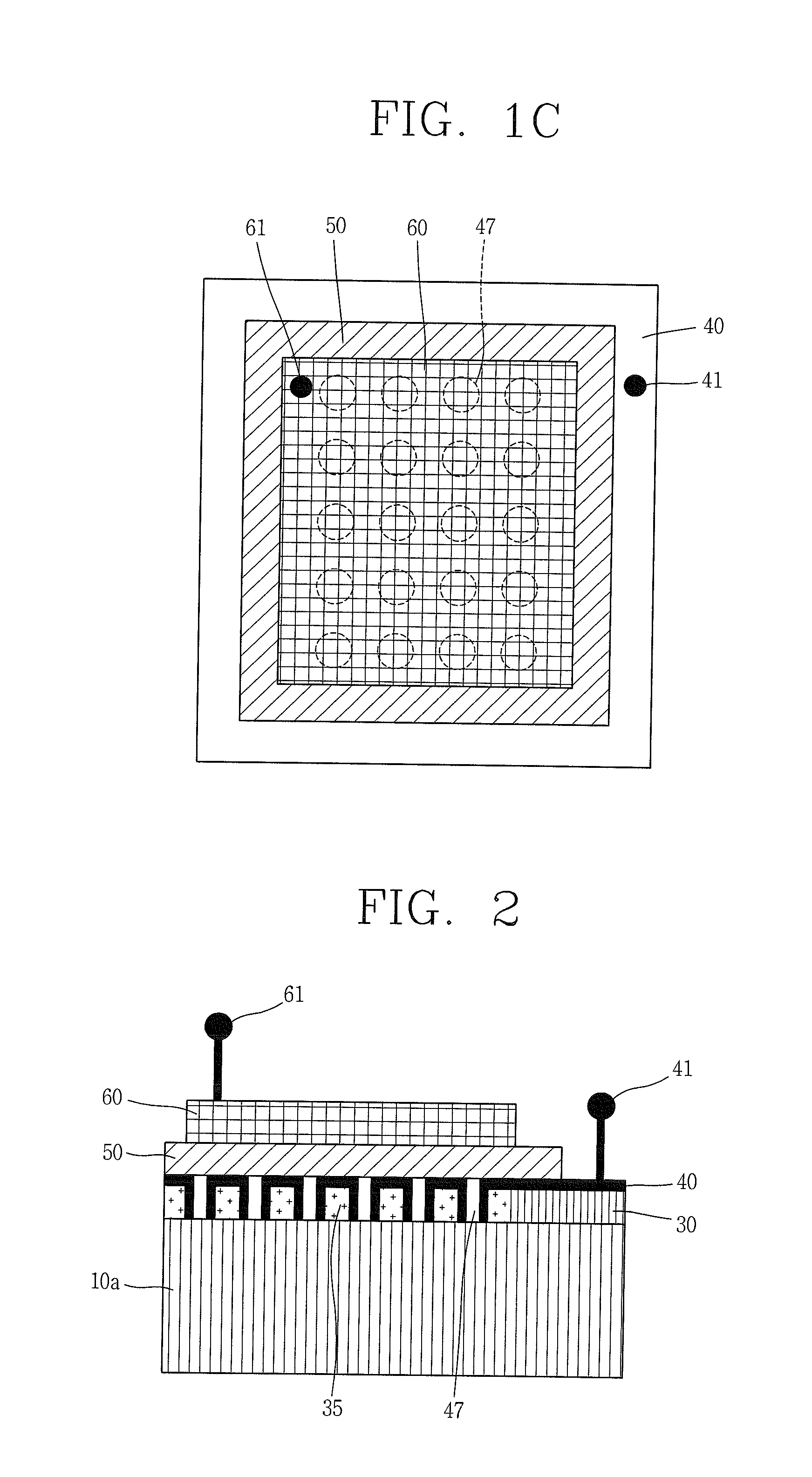

Micro fuel cell, fabrication method thereof, and micro fuel cell stack using the same

InactiveUS20090181278A1Keep the structure stablePrevent coagulationAnodisationMaterial nanotechnologyAnodizingMicro cell

Owner:KOREA INST OF SCI & TECH

Process for producing flexible and shape-conformal rope-shape alkali metal batteries

ActiveUS10008747B1Maximize contact areaMaximize interfacial areaFinal product manufactureElectrode carriers/collectorsYarnMaterials science

Owner:GLOBAL GRAPHENE GRP INC

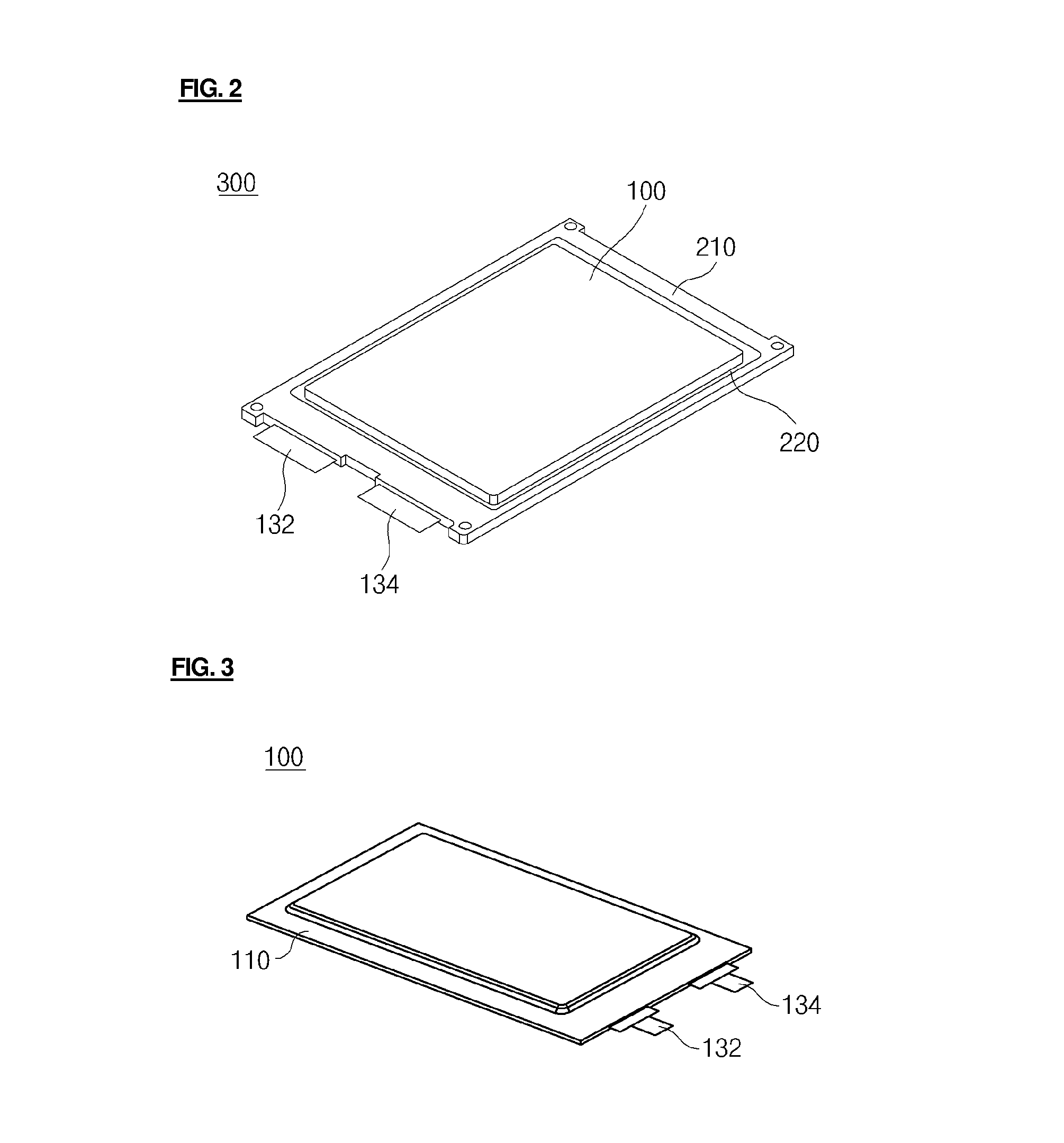

Battery module

ActiveUS20160197387A1Easy dischargeIncrease temperatureSmall-sized cells cases/jacketsFinal product manufactureDischarge efficiencyEngineering

Owner:LG ENERGY SOLUTION LTD

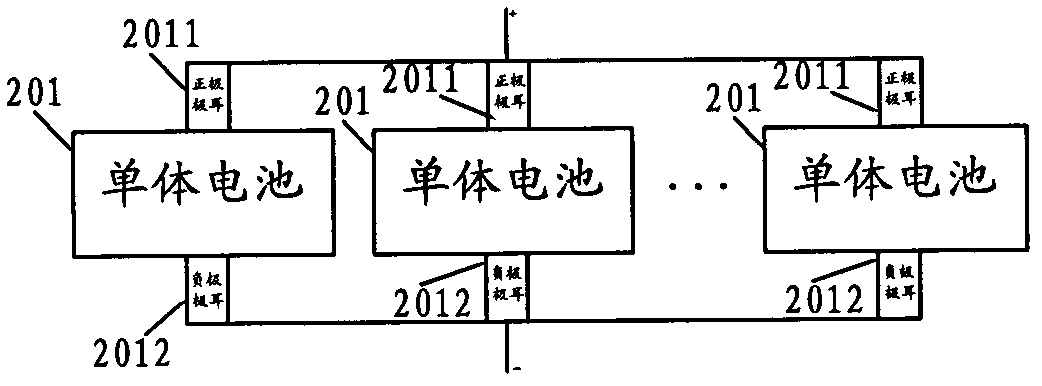

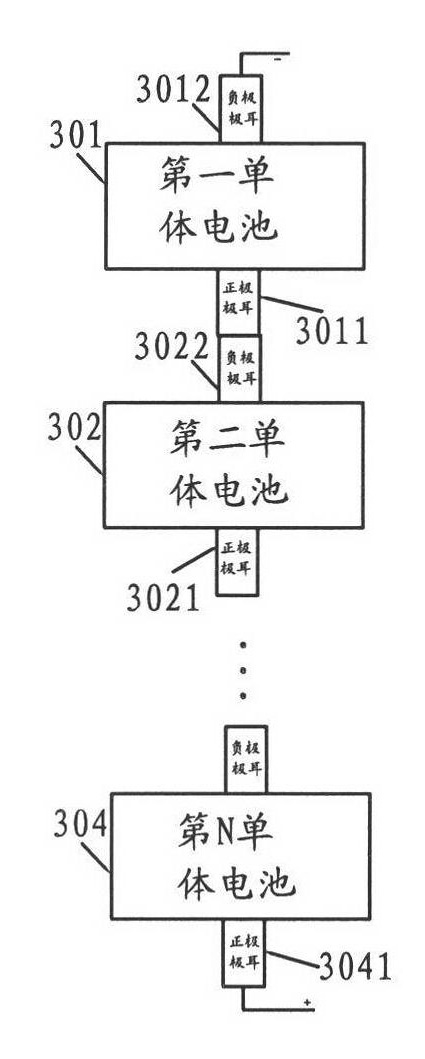

Lithium ion battery pack and soldering method for single batteries therein

ActiveCN102332611AAvoid bloatingFinal product manufactureCell component detailsBattery cellMaterials science

Owner:SHENZHEN GREPOW BATTERY CO LTD

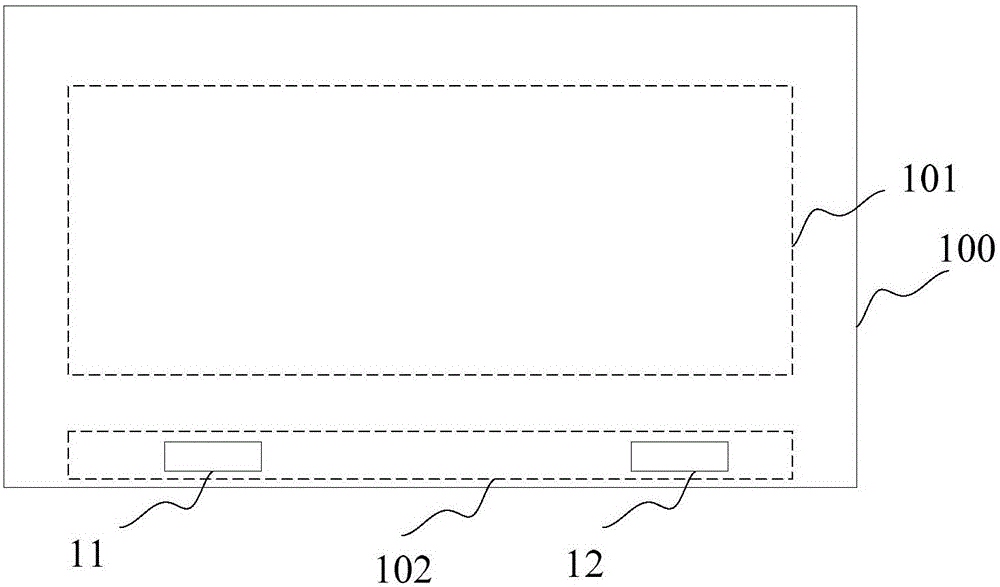

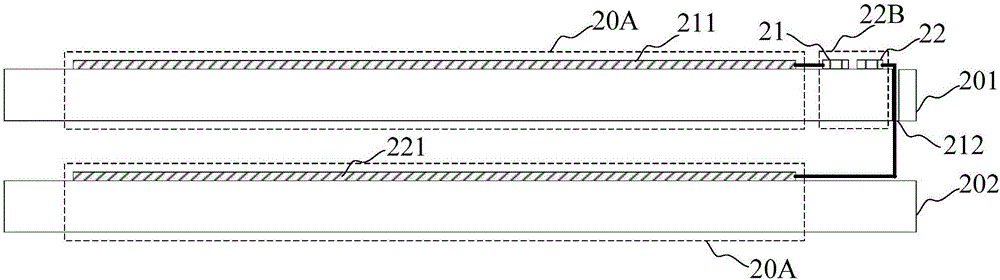

Display substrate, display panel, display device and binding method

InactiveCN106847827AReduce bonding timesSolve the low yield rate of mass productionDigital data processing detailsFinal product manufactureBinding numberPrinted circuit board

The invention discloses a display substrate, a display panel, a display device and a binding method, and belongs to the field of display devices. The display substrate includes a transparent substrate body which includes a display region and a binding region located on the periphery of the display region; the binding region is provided with a first binding terminal connected with a touch control electrode, and a second binding terminal connected with a display electrode; one of the touch control electrode and the display electrode is located in the display region, the other of the touch control electrode and the display electrode is located on another transparent substrate body, and the another transparent substrate body is opposite to the transparent substrate body. The first binding terminal and the second binding terminal are both located on the transparent substrate body of the display substrate and therefore can be bound to a flexible printed circuit board at the same time, no secondary binding is needed, the binding number is reduced, time is saved, labor is saved, and the low production yield problem is solved at the same time.

Owner:BOE TECH GRP CO LTD +1

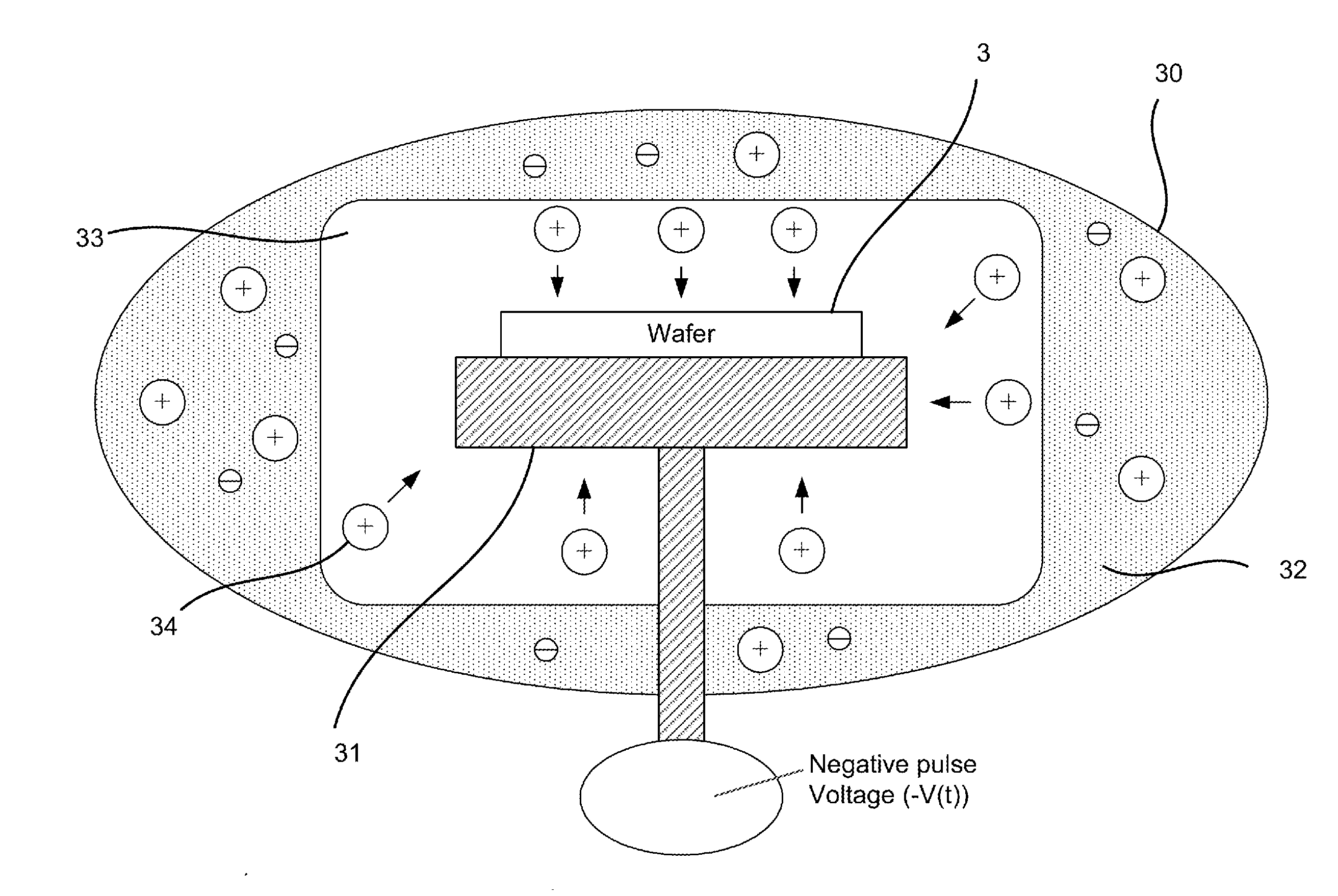

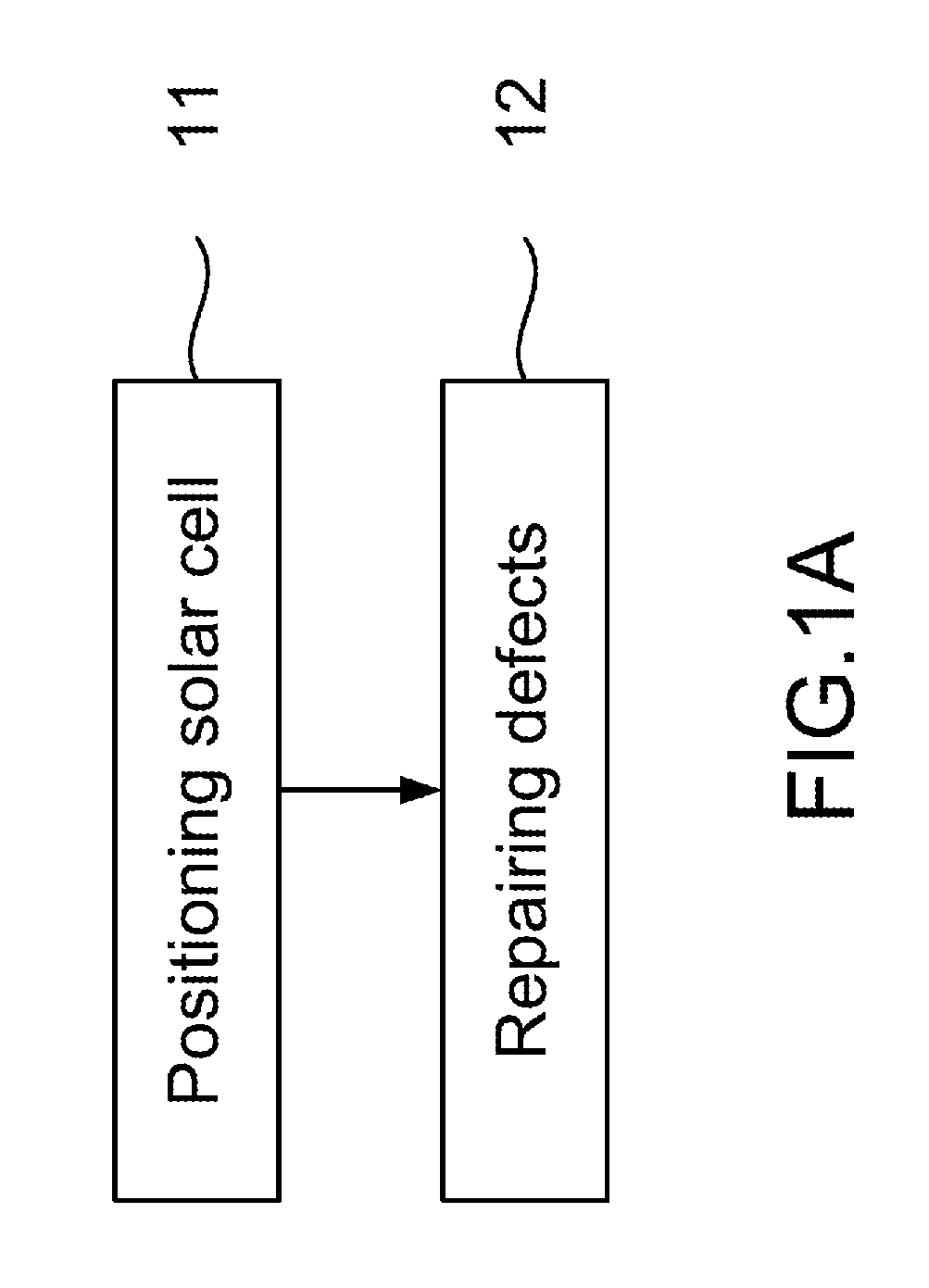

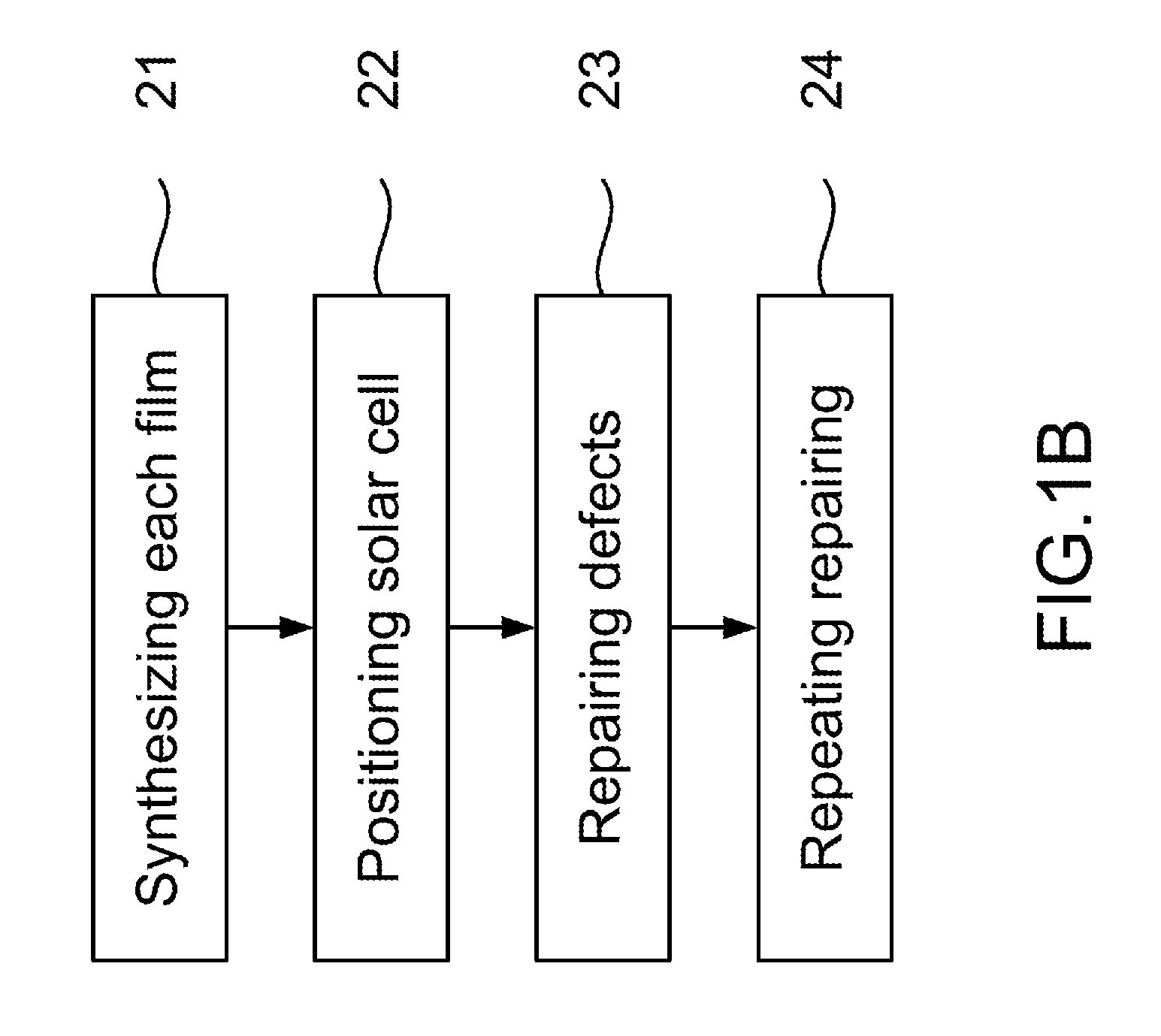

Solar Cell Defect Passivation Method

ActiveUS20110053351A1Improve photovoltaic conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingPlasma-immersion ion implantationPhotovoltaic conversion efficiency

Owner:INST NUCLEAR ENERGY RES ROCAEC

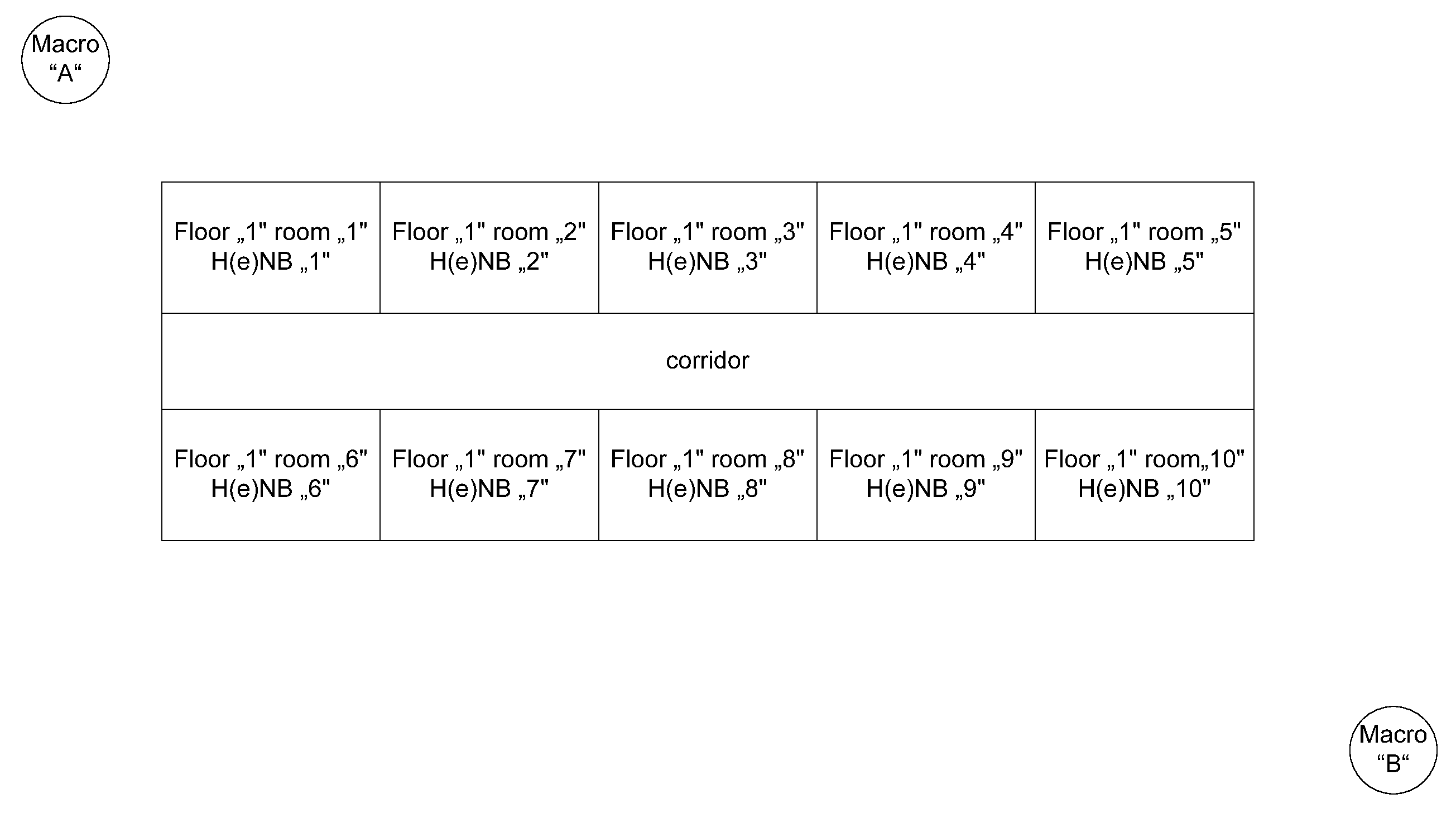

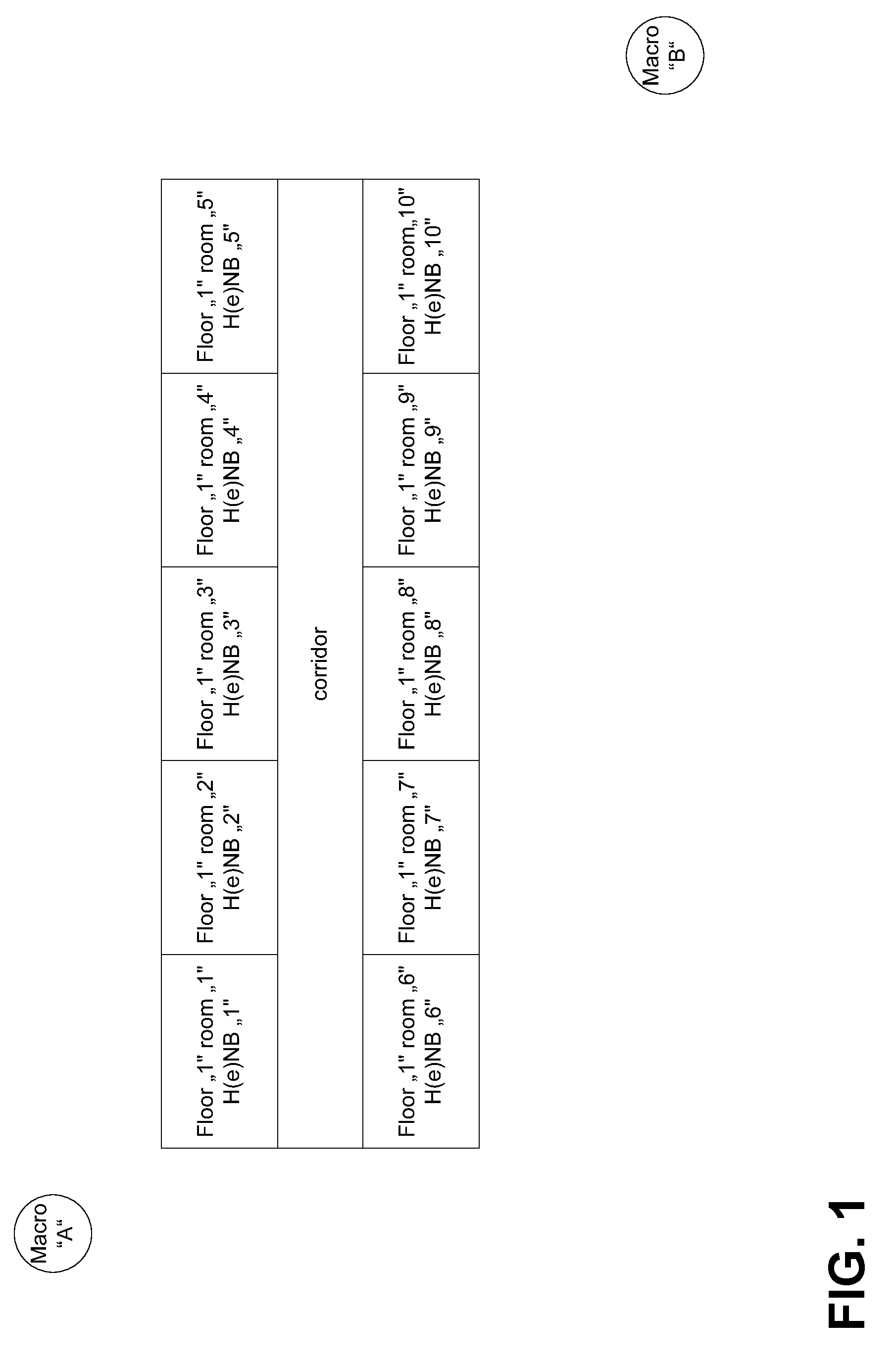

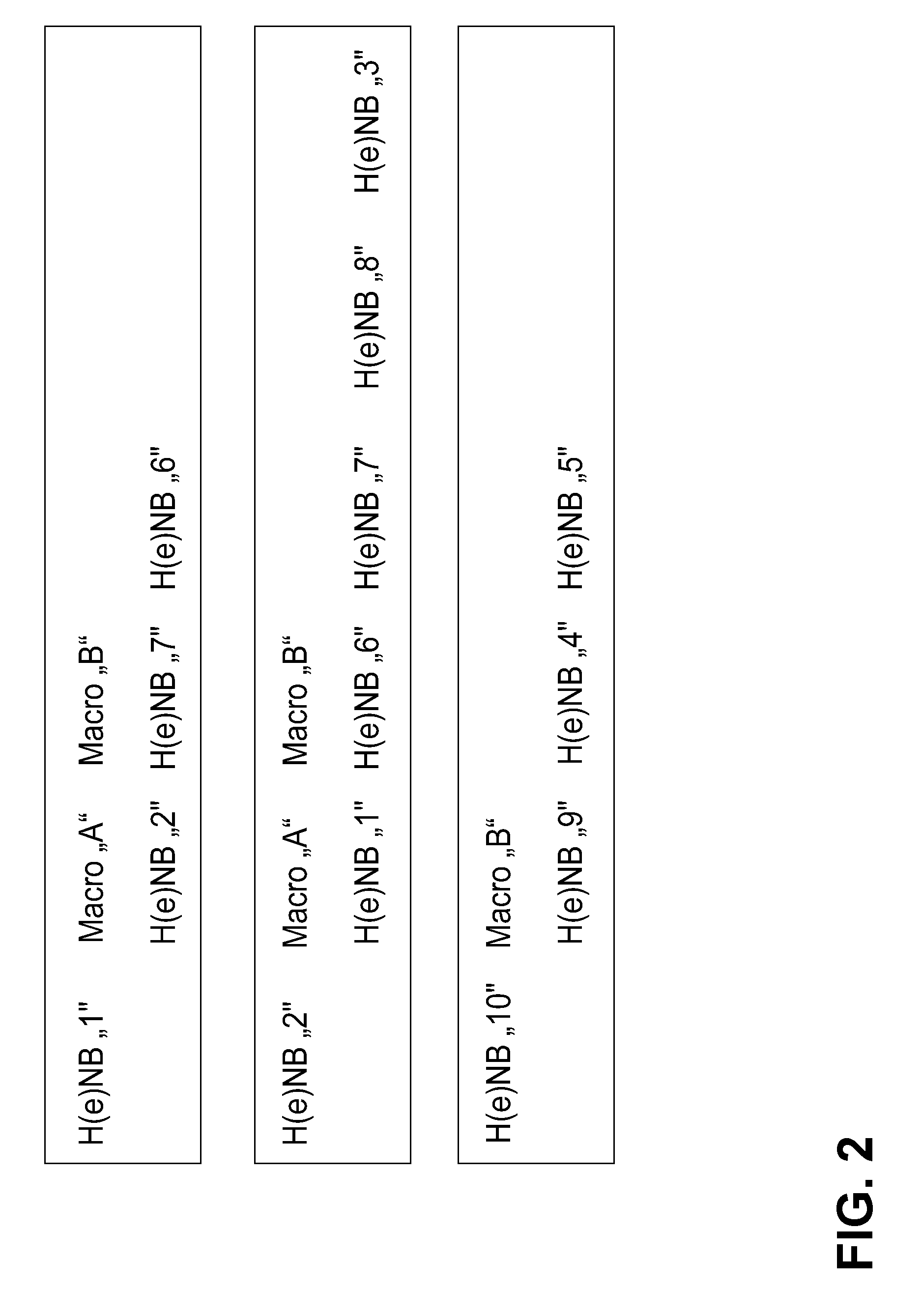

Establishing and Maintenance of a Neighbour Relationship Between Access Nodes in a Wireless Communications Network

InactiveUS20130237221A1Easy maintenanceKept up-to-dateFinal product manufactureNetwork topologiesComputer networkInformation storage

Owner:NOKIA SOLUTIONS & NETWORKS OY

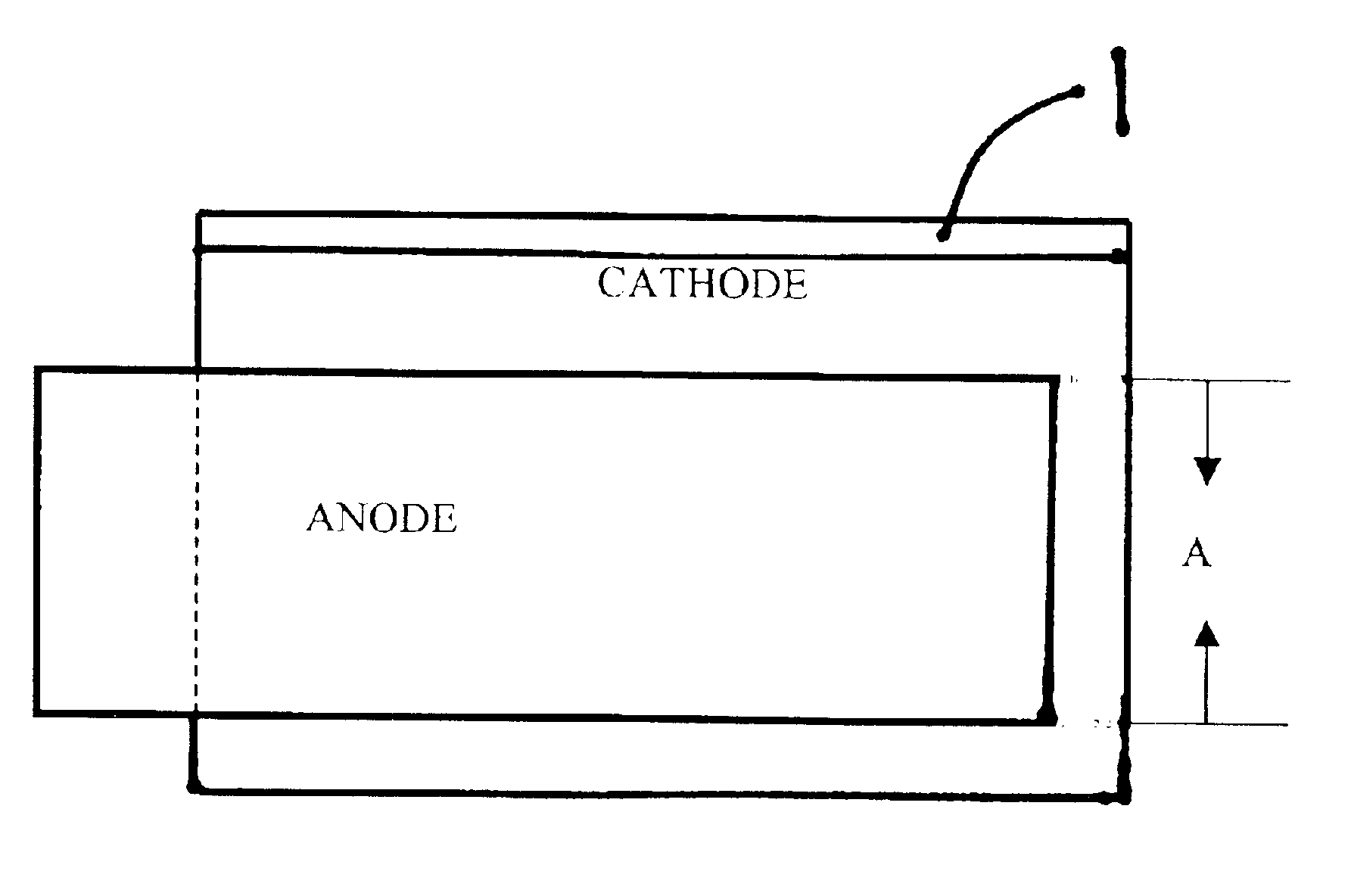

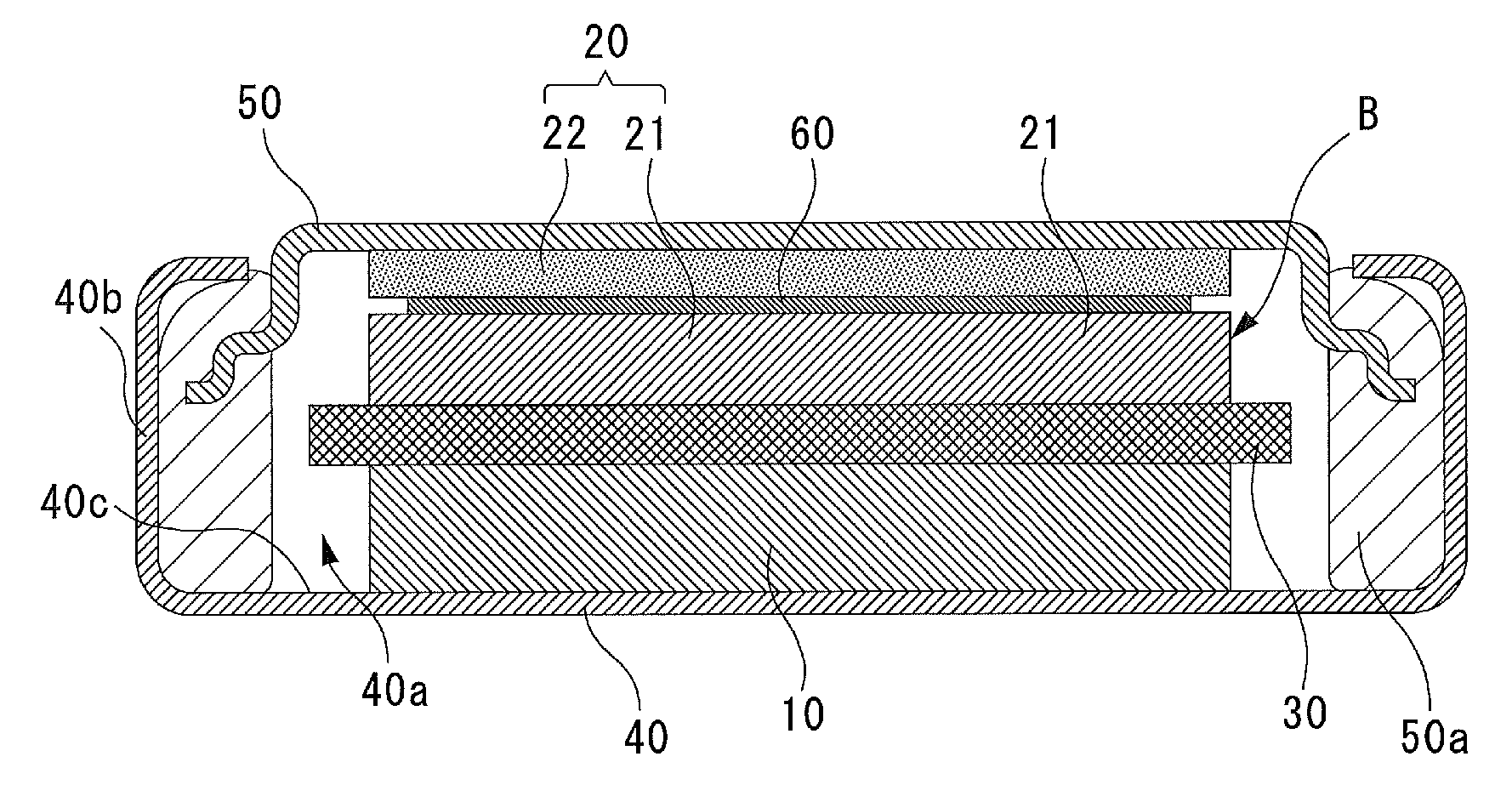

Electrochemical device

InactiveUS20120134075A1Increase productivityExcellent cycle characteristicsCell electrodesHybrid capacitor electrodesLithium metalEngineering

Owner:TAIYO YUDEN KK

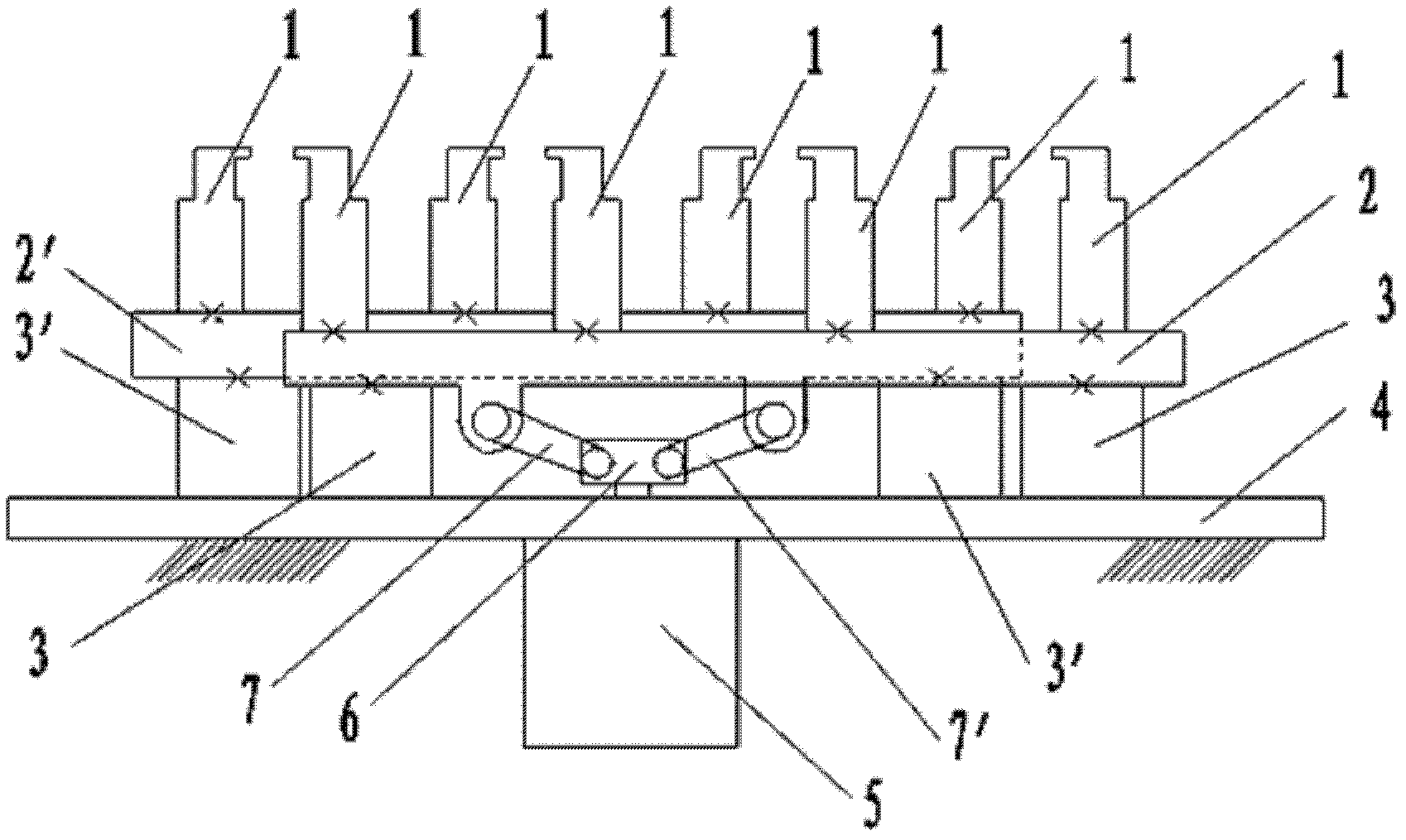

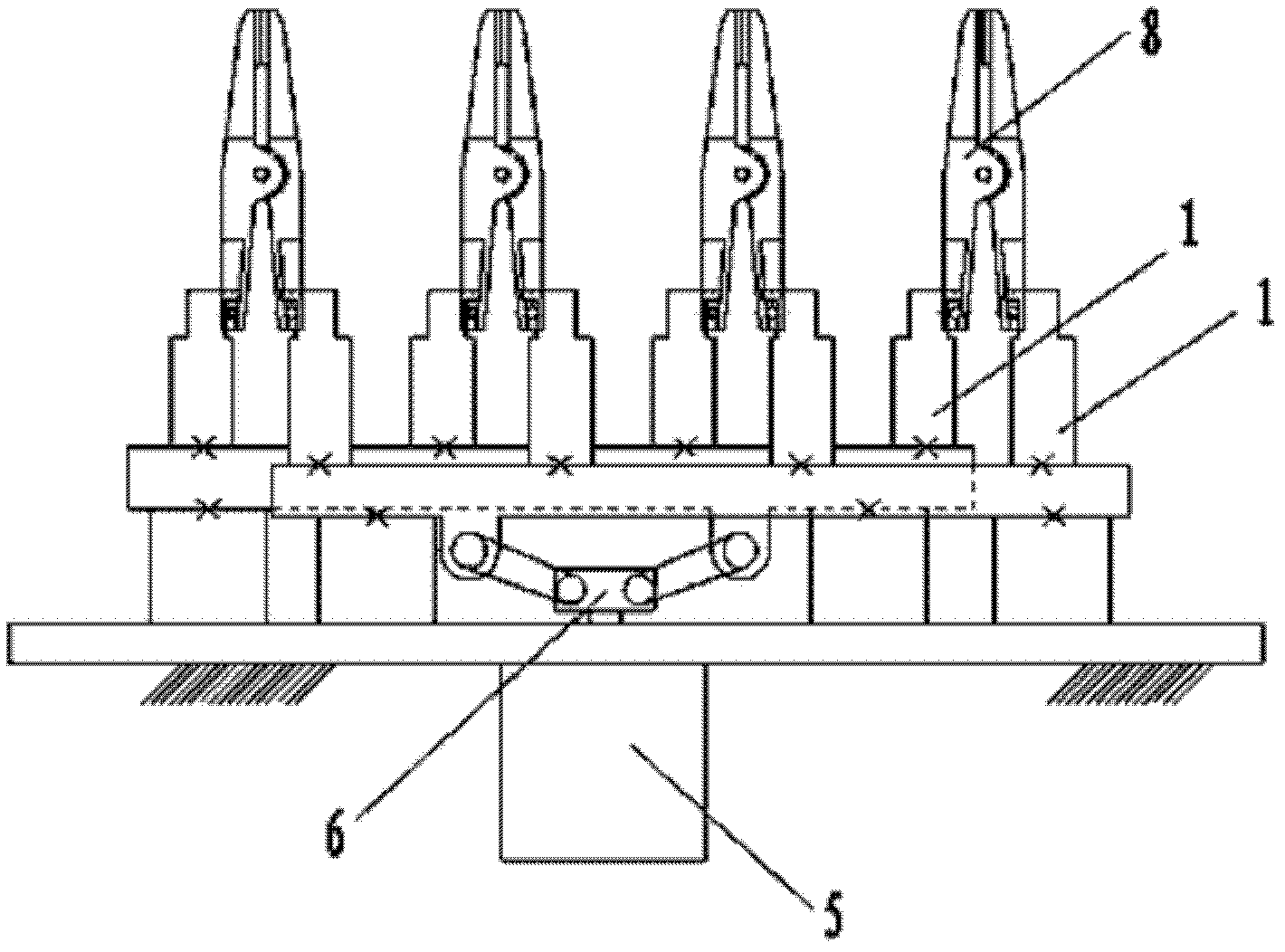

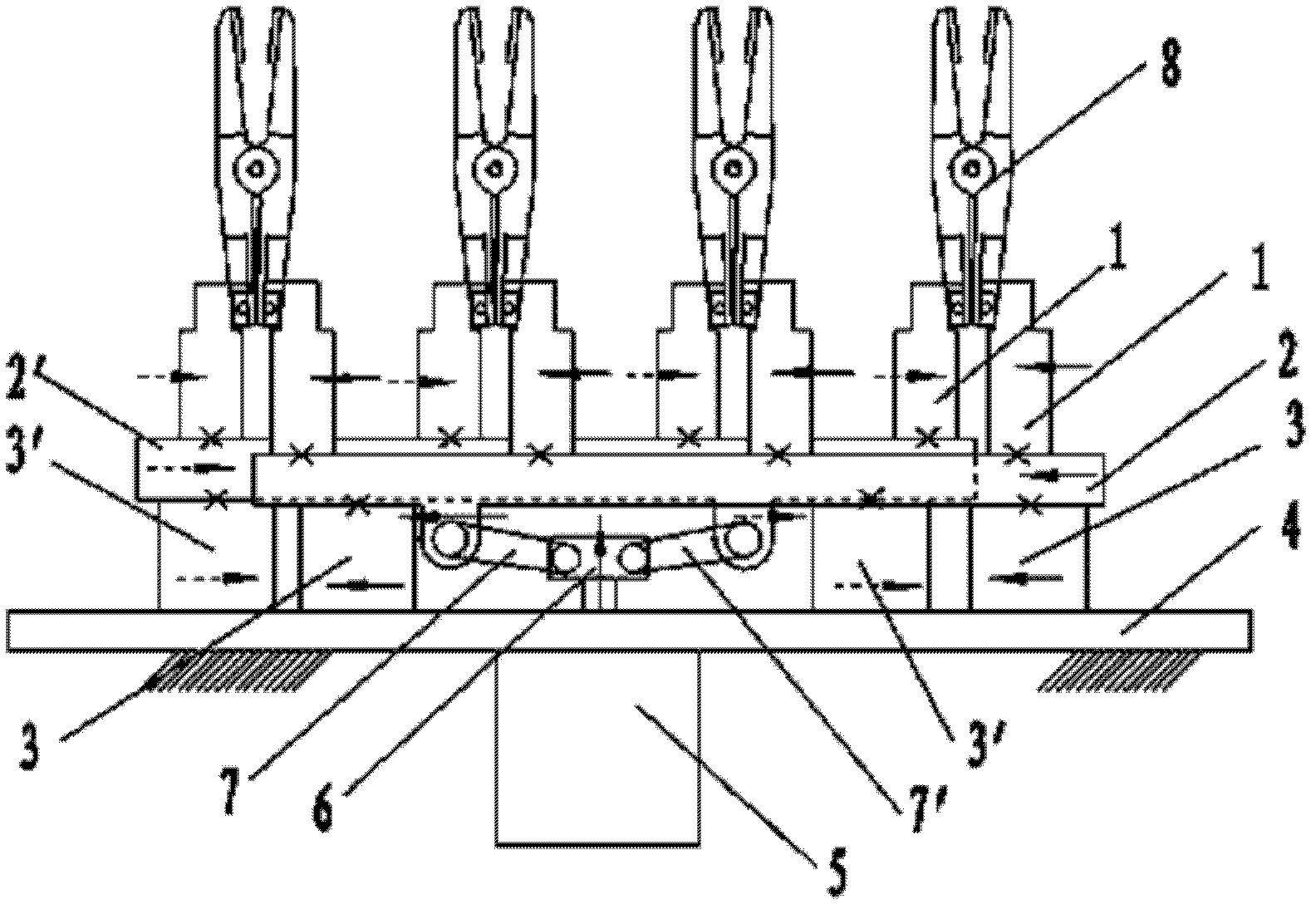

Automatic electrode clamp opening and closing device for formation of lithium battery

InactiveCN102509811ARealize automatic opening and closingTroubleshoot automated operationsFinal product manufactureElectrolyte accumulators manufactureEngineeringSlide plate

The invention relates to an automatic electrode clamp opening and closing device for the formation of a lithium battery. The device comprises a cylinder, first sliding blocks, second sliding blocks, a first sliding plate and a second sliding plate. The cylinder is fixed on a support plate. A connecting block is arranged on the head part of a piston rod of the cylinder. The first sliding plate is arranged on the first sliding blocks, and the second sliding plate is arranged on the second sliding blocks. The connecting block is connected with the first sliding plate through a first motion mechanism, and is connected with the second sliding plate through a second motion mechanism. When the cylinder does piston motion, the first and second sliding blocks are driven by the first and second sliding plates to do linear motion along the support plate, and only motion towards or away from each other in motion. At least one stirring fork for stirring an electrode clamp is arranged on the first sliding plate. Stirring forks of which the number is the same as that of the stirring forks on the first sliding plate are arranged on the second sliding plate. The stirring forks on the first and second sliding plates are arranged in pairs. By the device, the electrode clamps can be automatically opened and closed.

Owner:DONGHUA UNIV

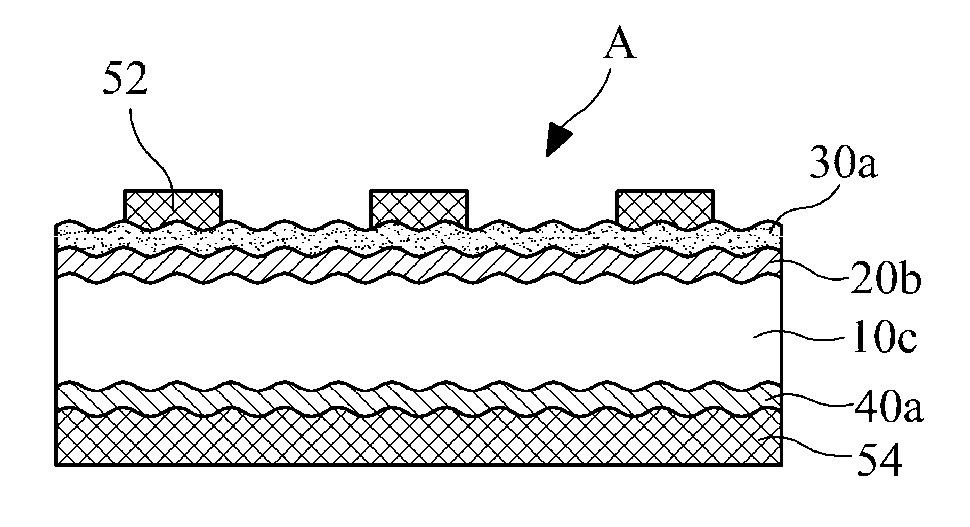

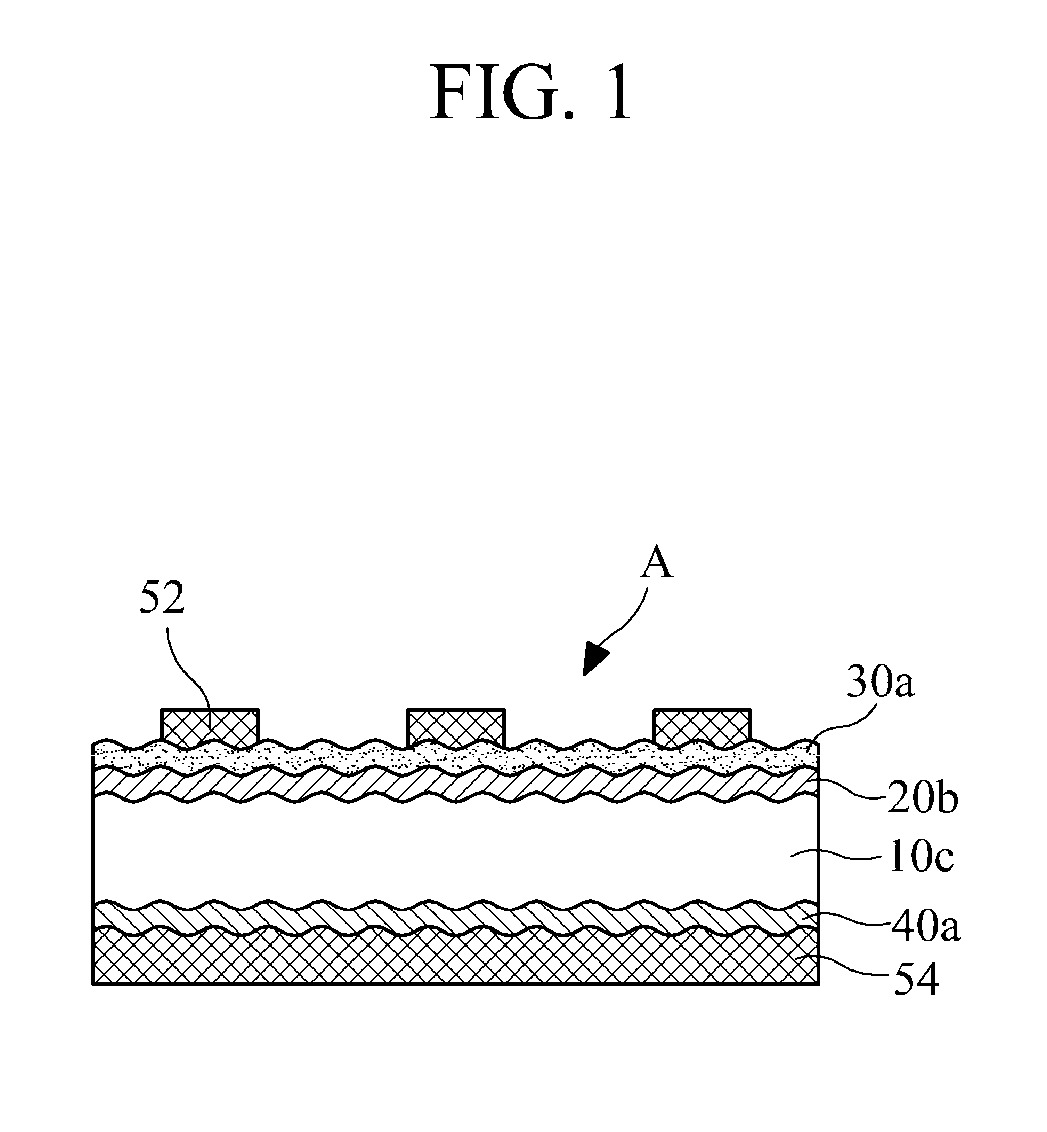

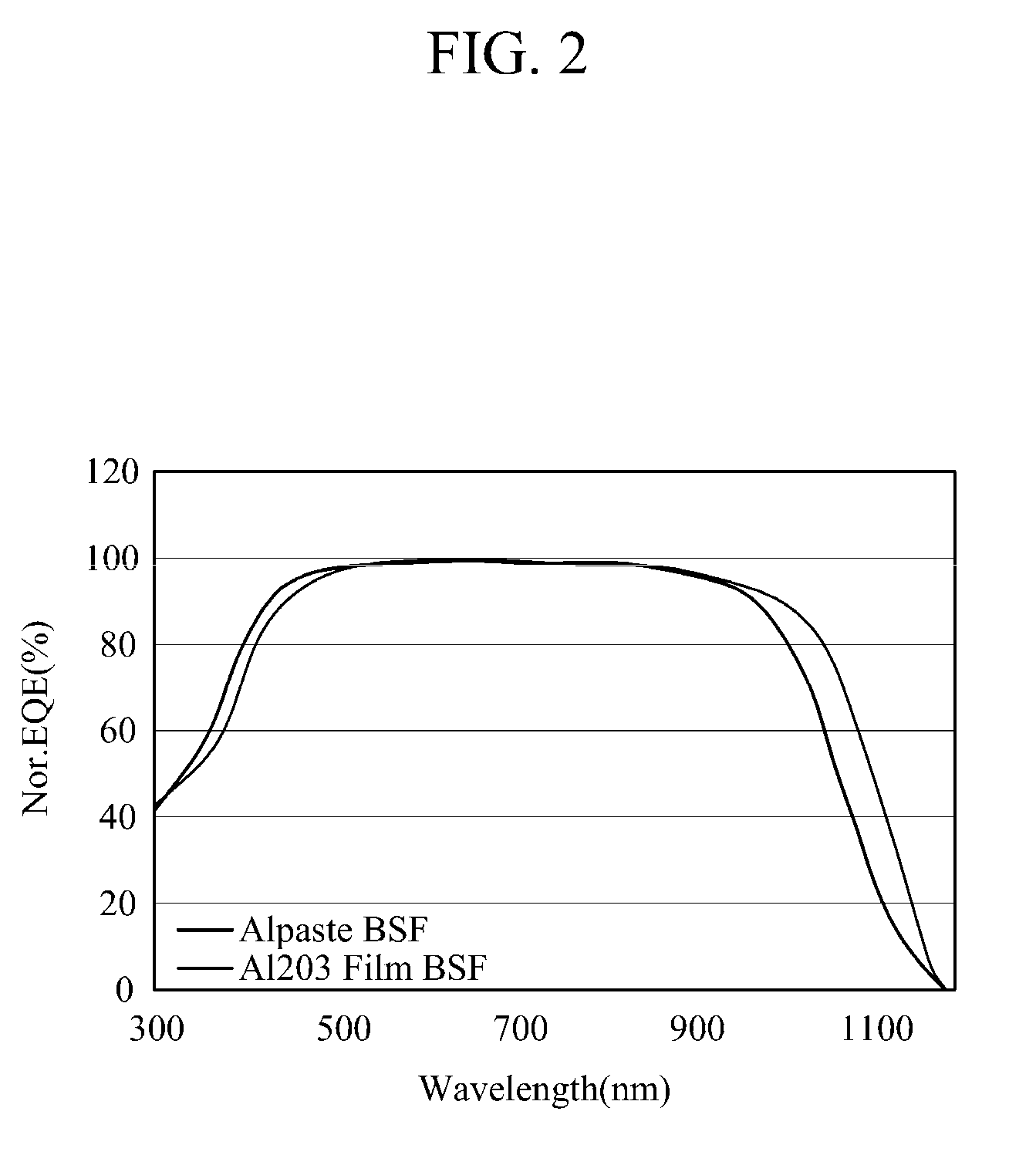

Solar cell and method of fabricating the same

InactiveUS20110083735A1High opto-electric conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingBack surface fieldEngineering

Owner:WONIK IPS CO LTD

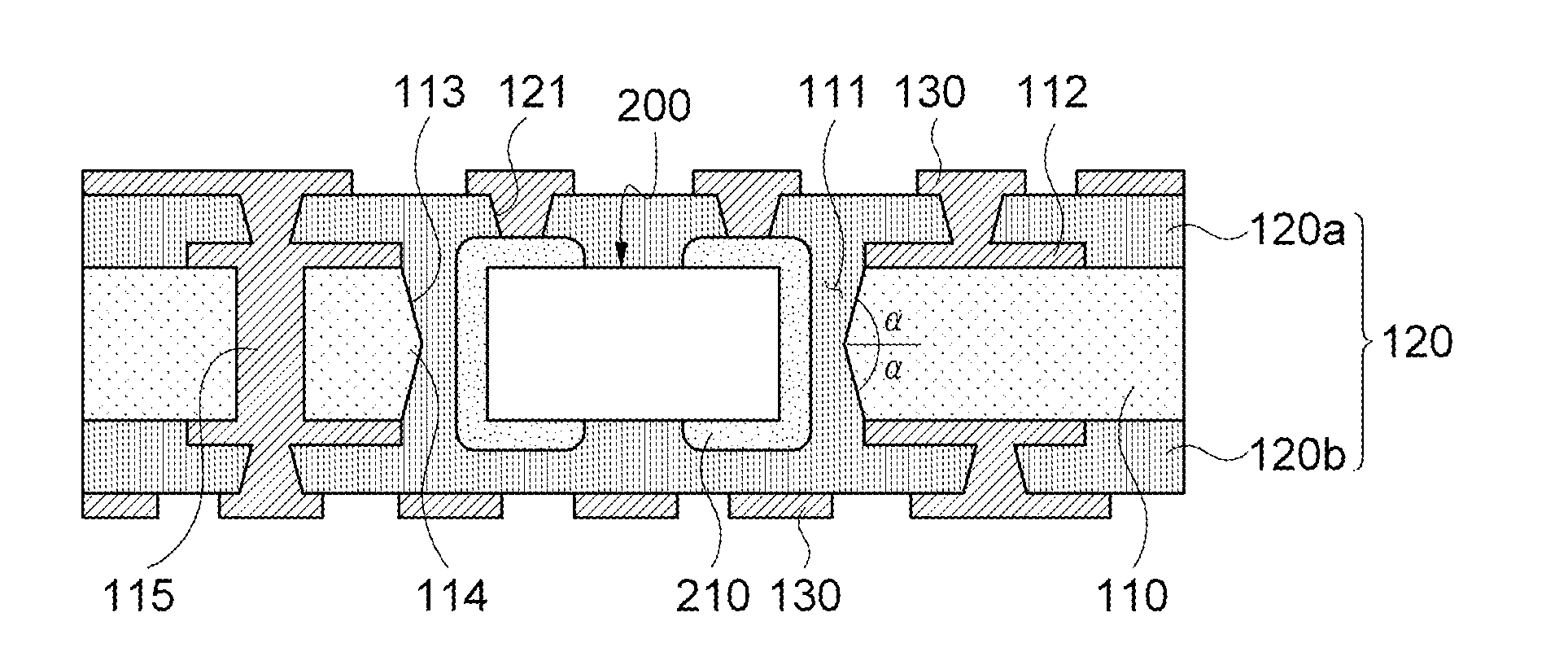

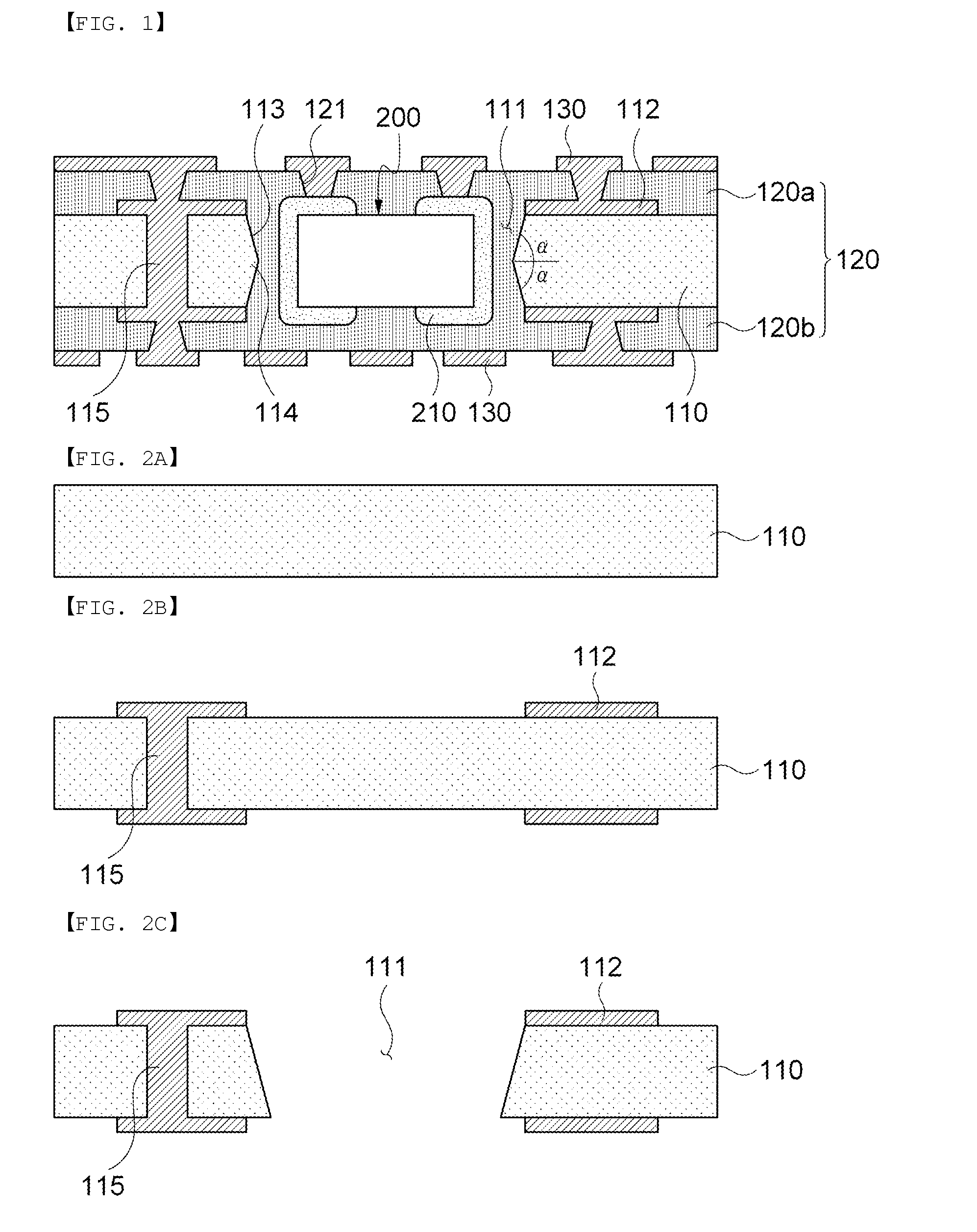

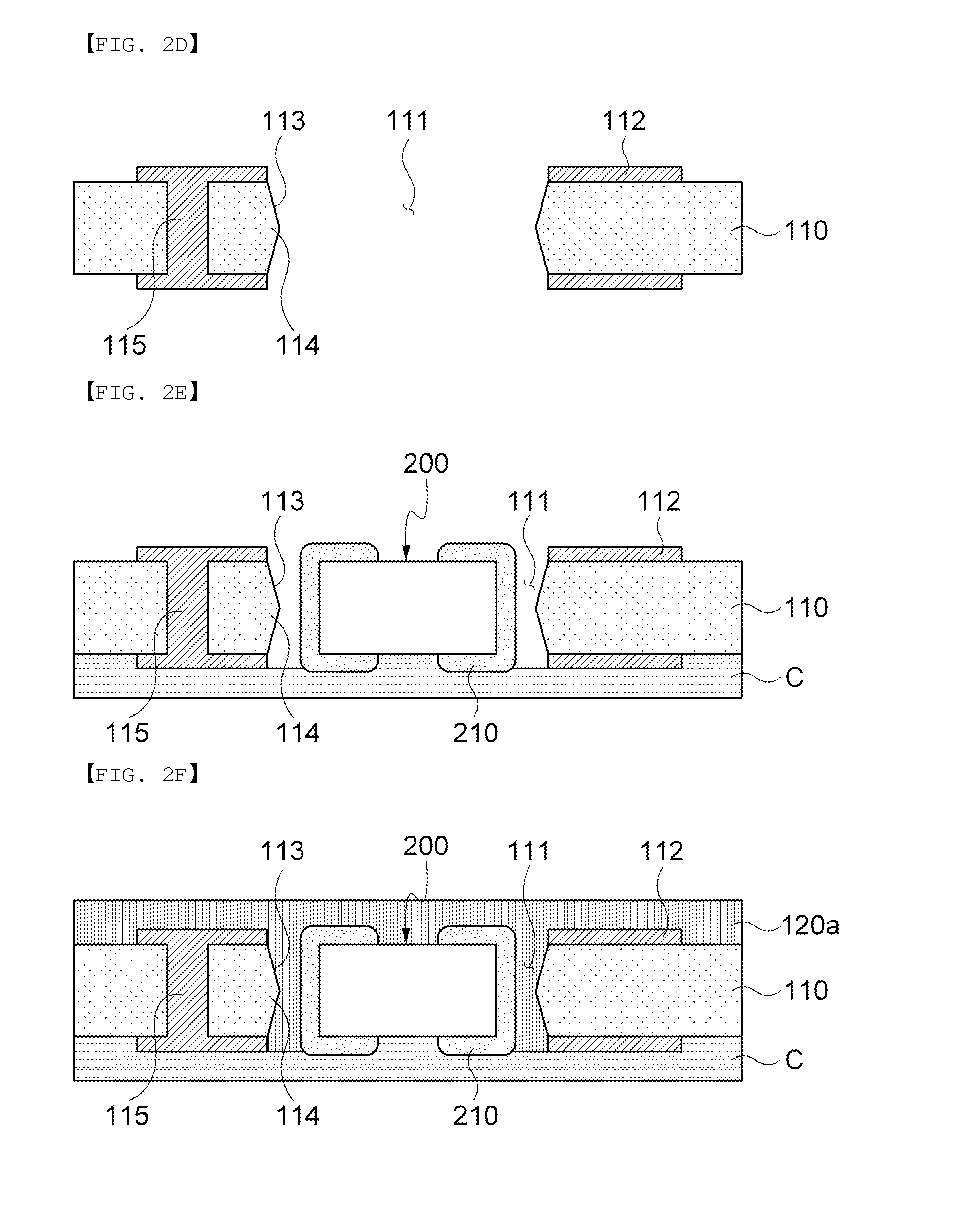

Printed circuit board including electronic component embedded therein and method for manufacturing the same

ActiveUS20140321084A1Improve reliabilityHigh yieldPrinted circuit assemblingPrinted electric component incorporationEngineeringElectronic component

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap