Nonaqueous electrochemical cell with improved energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

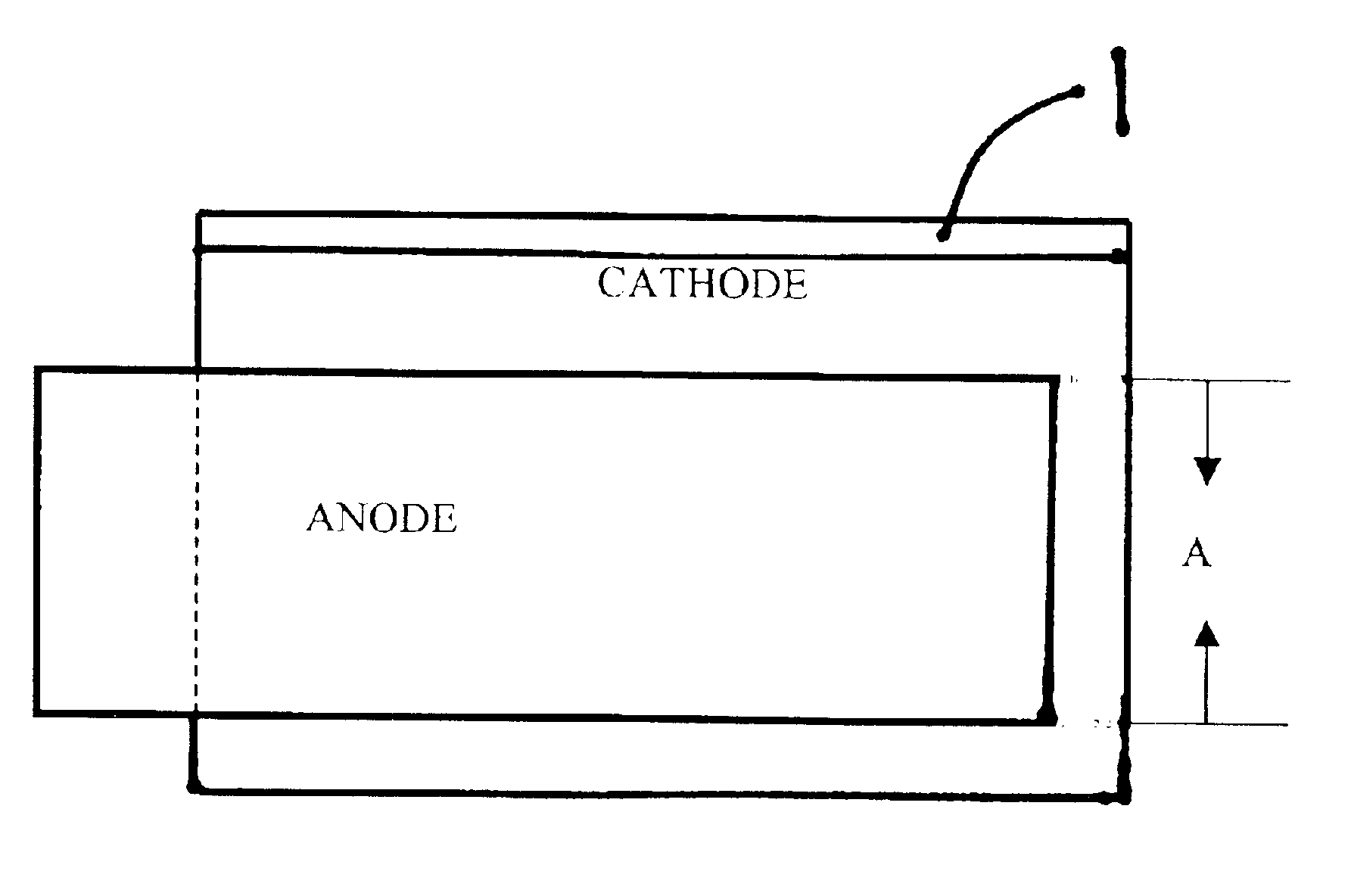

Image

Examples

example

An electrochemical cell comprising lithium as the active anode material and pyrite as the active cathode material is constructed as follows. A continuous strip of lithium metal foil 0.006 inches thick by 1.535 inches wide and alloyed at 0.5 weight percent with aluminum is provided. An aluminum cathode current collector continuous strip 0.001 inches thick by 1.72 inches wide is provided. The aluminum cathode collector strip is full hard standard alloy 1145-H19 aluminum and both surfaces are flame cleansed to remove oils and improve adhesion of the coating to the substrate surface.

A cathode coating slurry is prepared using the following solids:

WeightMaterialpercent (dry)cm3 / 100 gmsFeS292.019.087Acetylene black1.40.733Highly crystalline synthetic graphite4.01.777Fumed silica0.30.136Micronized PTFE0.30.136Kraton2.02.19824.067 cm3 / 100 gms4.155 gm / cm3

Battery grade iron pyrite with a purity level of 95 percent by weight available from Chemetall is sieved through a 230 mesh screen to rem

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap