Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

105 results about "Alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An alloy is a combination of metals or a combination of one or more metals with non-metallic elements. For example, combining the metallic elements gold and copper produces red gold, gold and silver becomes white gold, and silver combined with copper produces sterling silver. Elemental iron, combined with non-metallic carbon or silicon, produces alloys called steel or silicon steel. The resulting mixture forms a substance with properties that often differ from those of the pure metals, such as increased strength or hardness. Unlike other substances that may contain metallic bases but do not behave as metals, such as aluminium oxide (sapphire), beryllium aluminium silicate (emerald) or sodium chloride (salt), an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductility, opaqueness, and luster. Alloys are used in a wide variety of applications, from the steel alloys, used in everything from buildings to automobiles to surgical tools, to exotic titanium-alloys used in the aerospace industry, to beryllium-copper alloys for non-sparking tools. In some cases, a combination of metals may reduce the overall cost of the material while preserving important properties. In other cases, the combination of metals imparts synergistic properties to the constituent metal elements such as corrosion resistance or mechanical strength. Examples of alloys are steel, solder, brass, pewter, duralumin, bronze and amalgams.

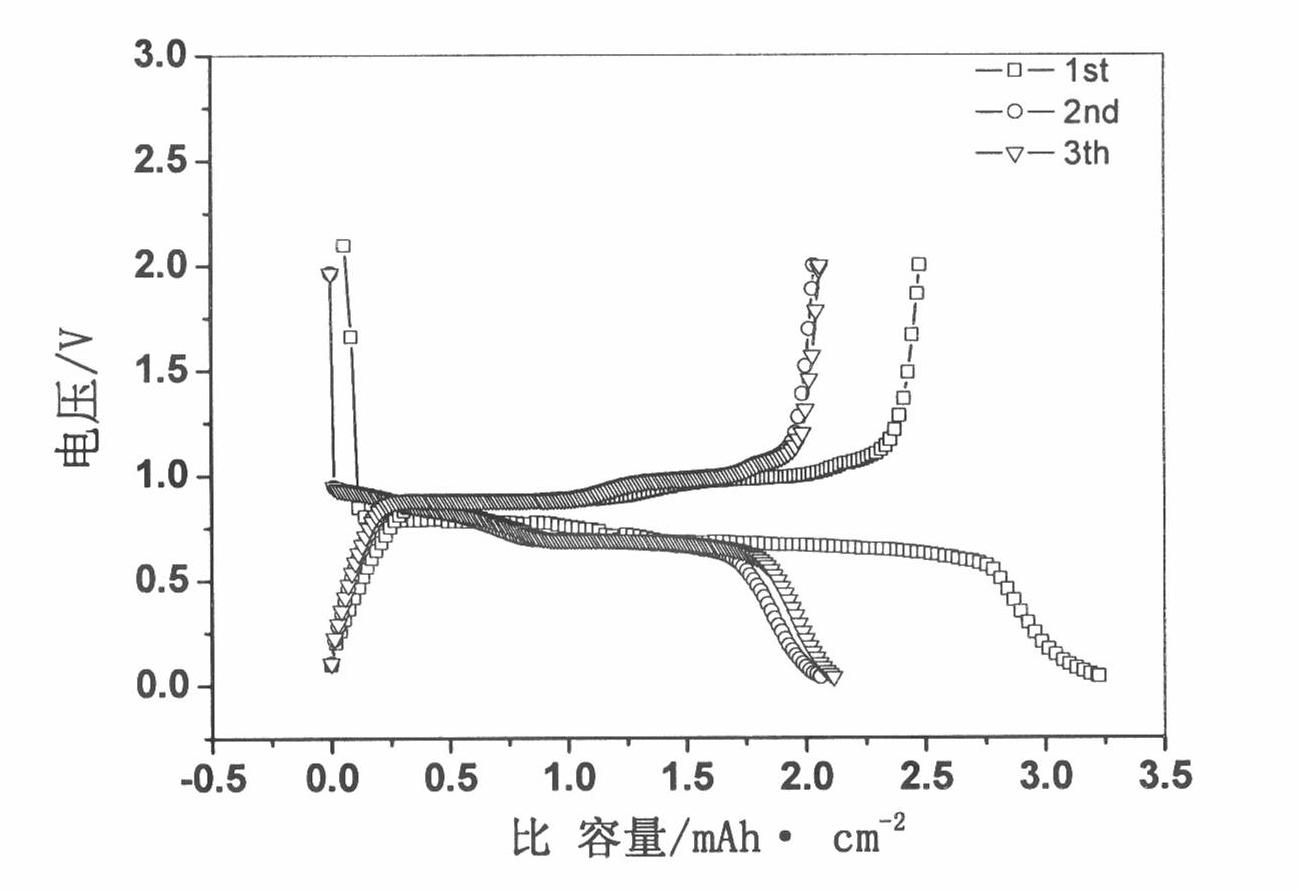

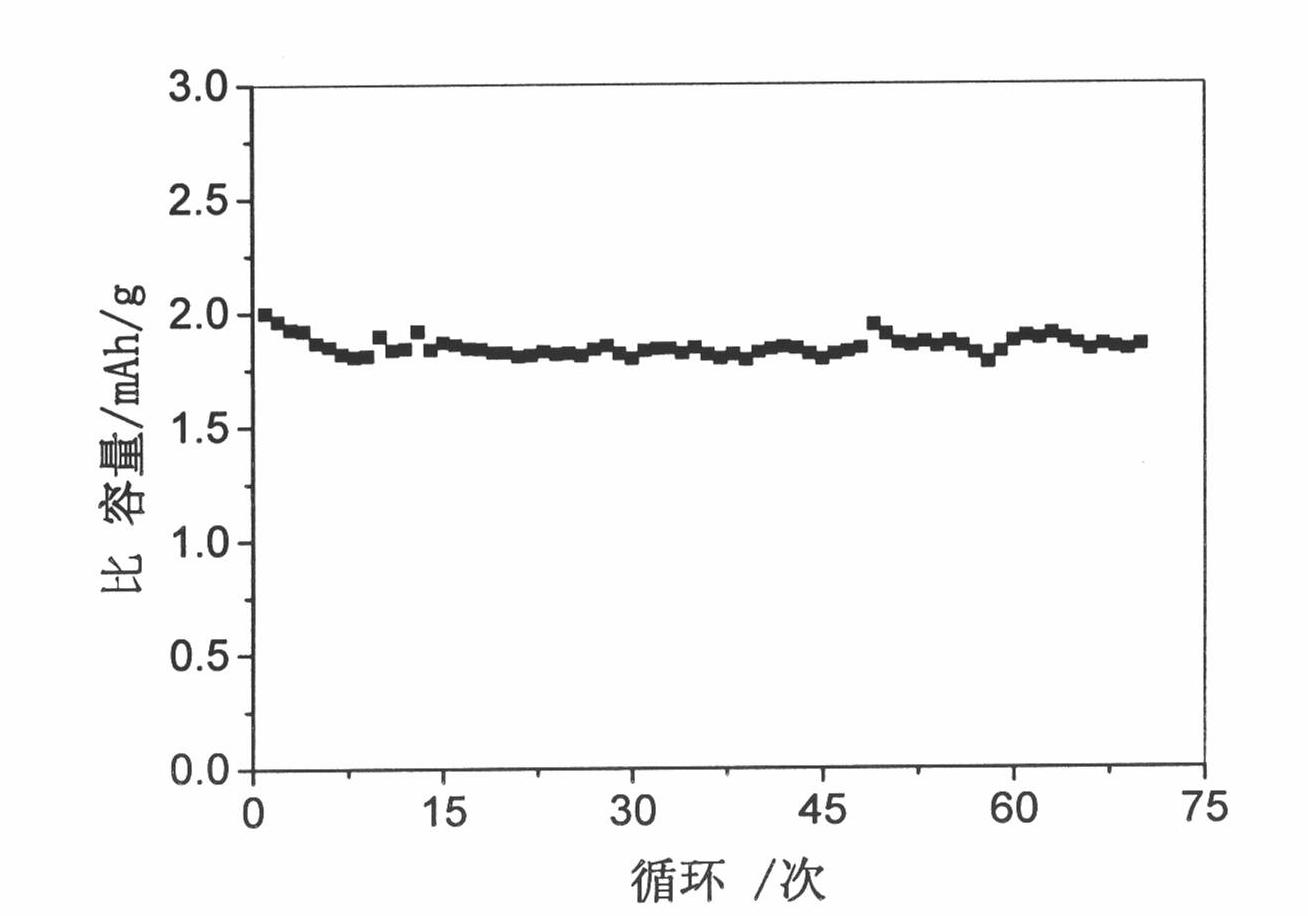

Non-aqueous solution aluminum ion secondary battery and preparation method thereof

InactiveCN104993130AGood chemical stabilityImprove thermal stabilityCell electrodesFinal product manufactureAluminum IonElectrical battery

Belonging to the technical field of batteries, the invention relates to a non-aqueous solution aluminum ion secondary battery and a preparation method thereof. The secondary battery can be widely applied in electronics, communication, electric vehicle and other fields. The aluminum ion battery provided by the invention contains a battery anode, a battery cathode, a diaphragm and an aluminum-containing non-aqueous solution electrolyte. Specifically, the cathode active material can be carbon, graphite, carbon nanotube, graphene, super carbon, WS2 and MoS2, V2O5, TiO2 and other materials having nano-layered, tubular, linear and other structures, and the anode is aluminum-containing metal or alloy. The non-aqueous solution aluminum ion secondary battery provided by the invention has the characteristics of high specific capacity, high coulomb efficiency, long service life and environmental protection, safety and reliability, stable cycle performance, and quick charging, etc.

Owner:BEIJING ALUMINUM ENERGY S&T

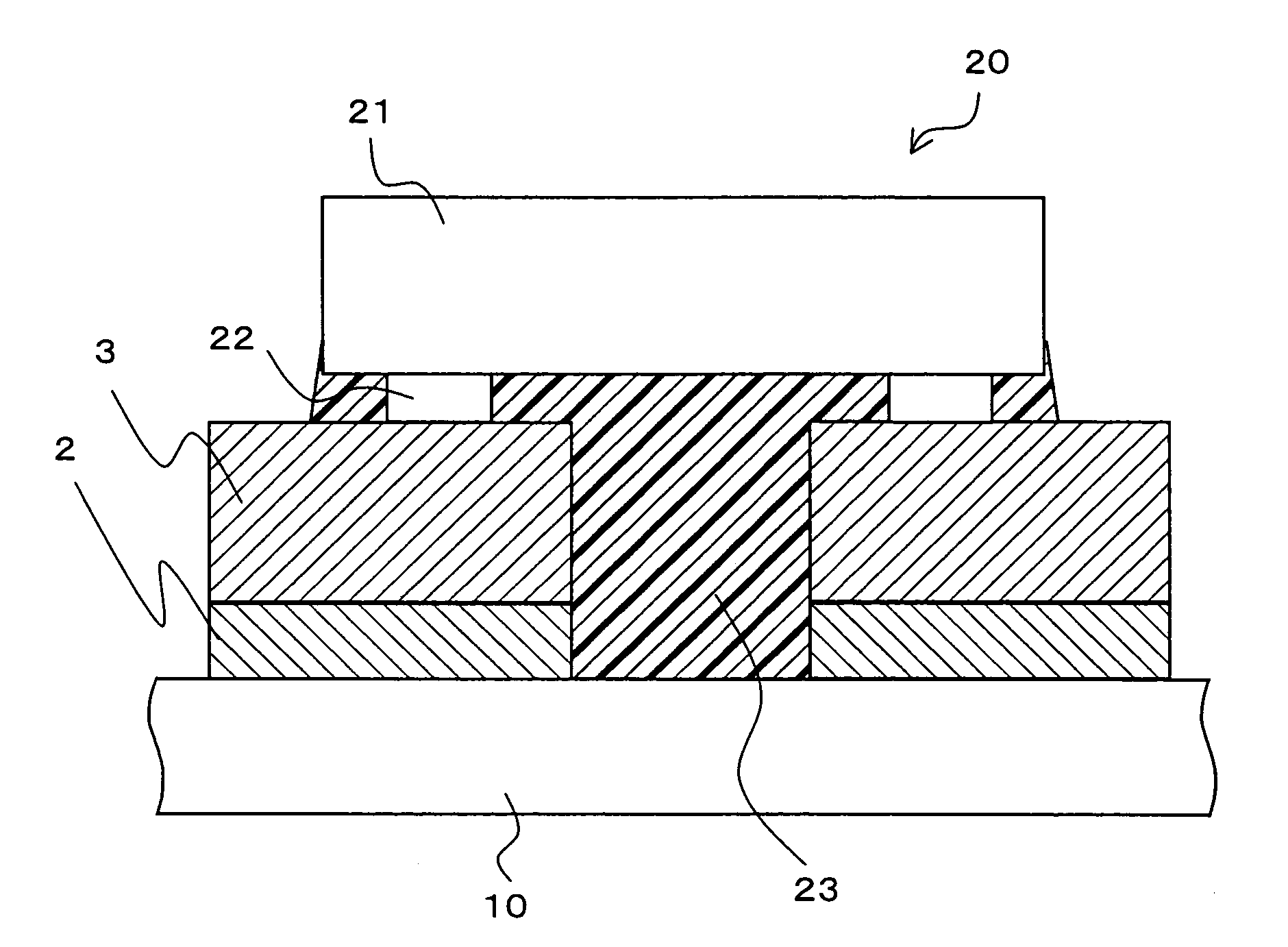

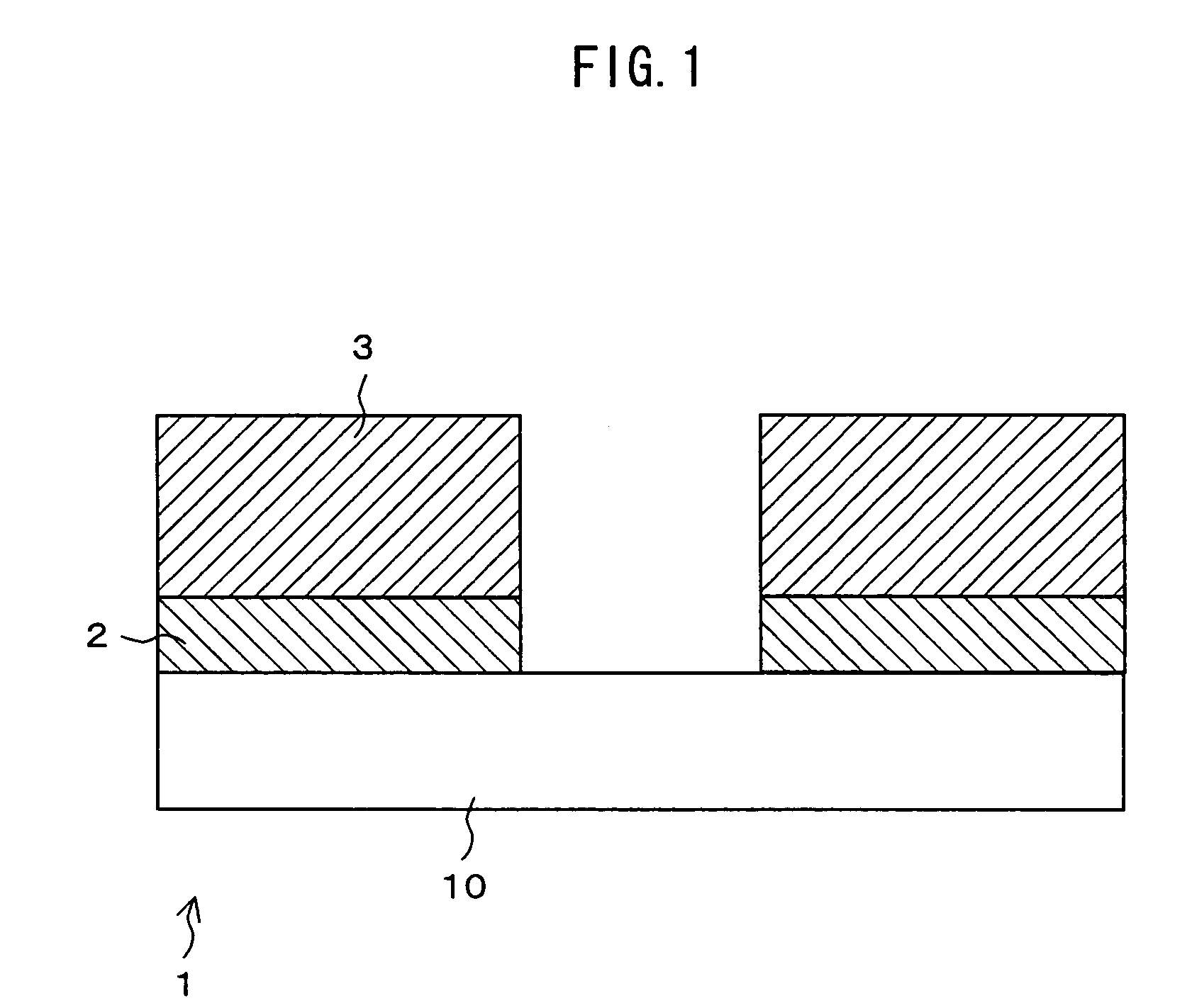

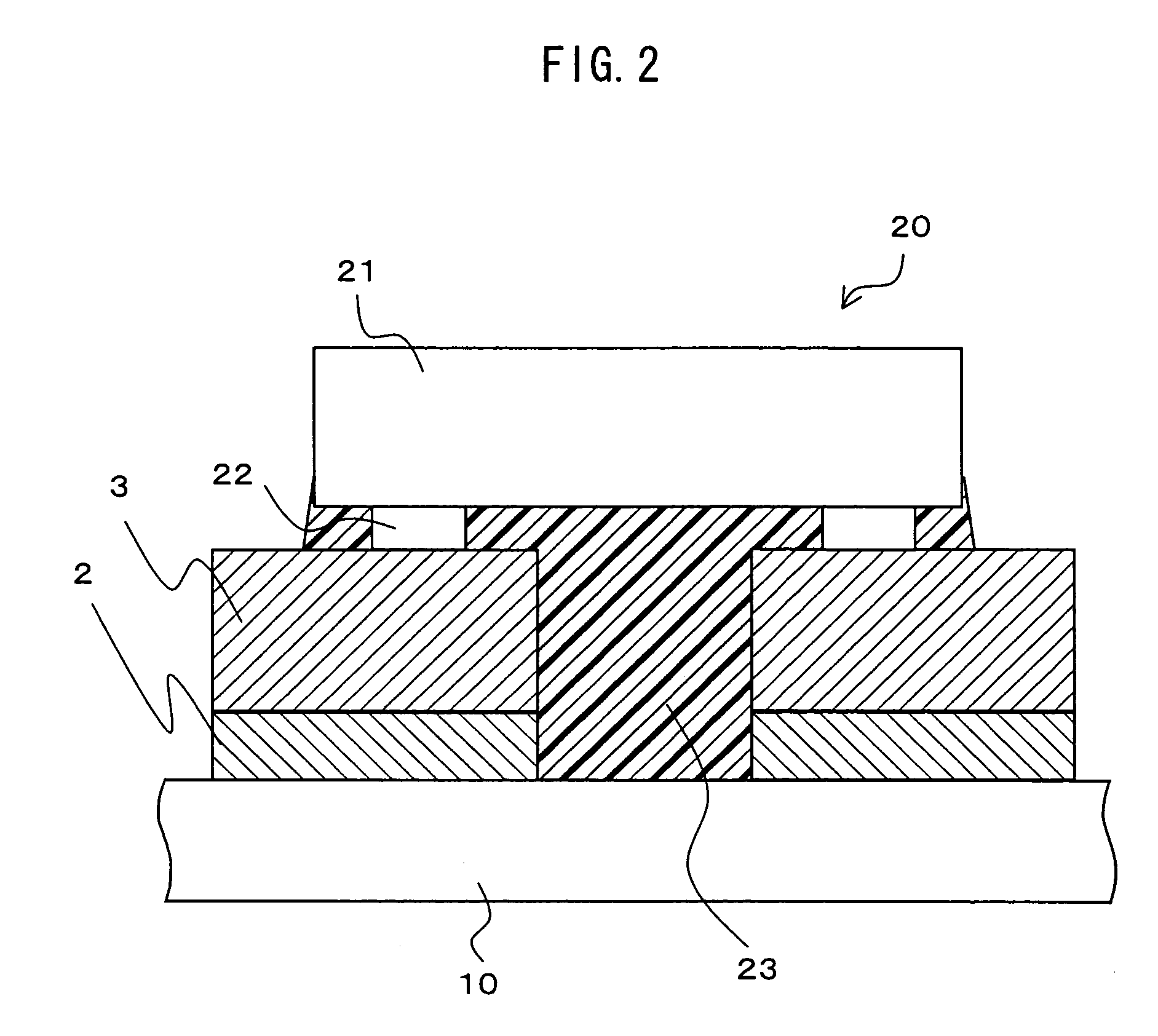

Semiconductor carrier film, and semiconductor device and liquid crystal module using the same

ActiveUS7164205B2Increase productionFine pitchSemiconductor/solid-state device detailsSolid-state devicesAlloyConductive materials

Owner:SHARP KK +1

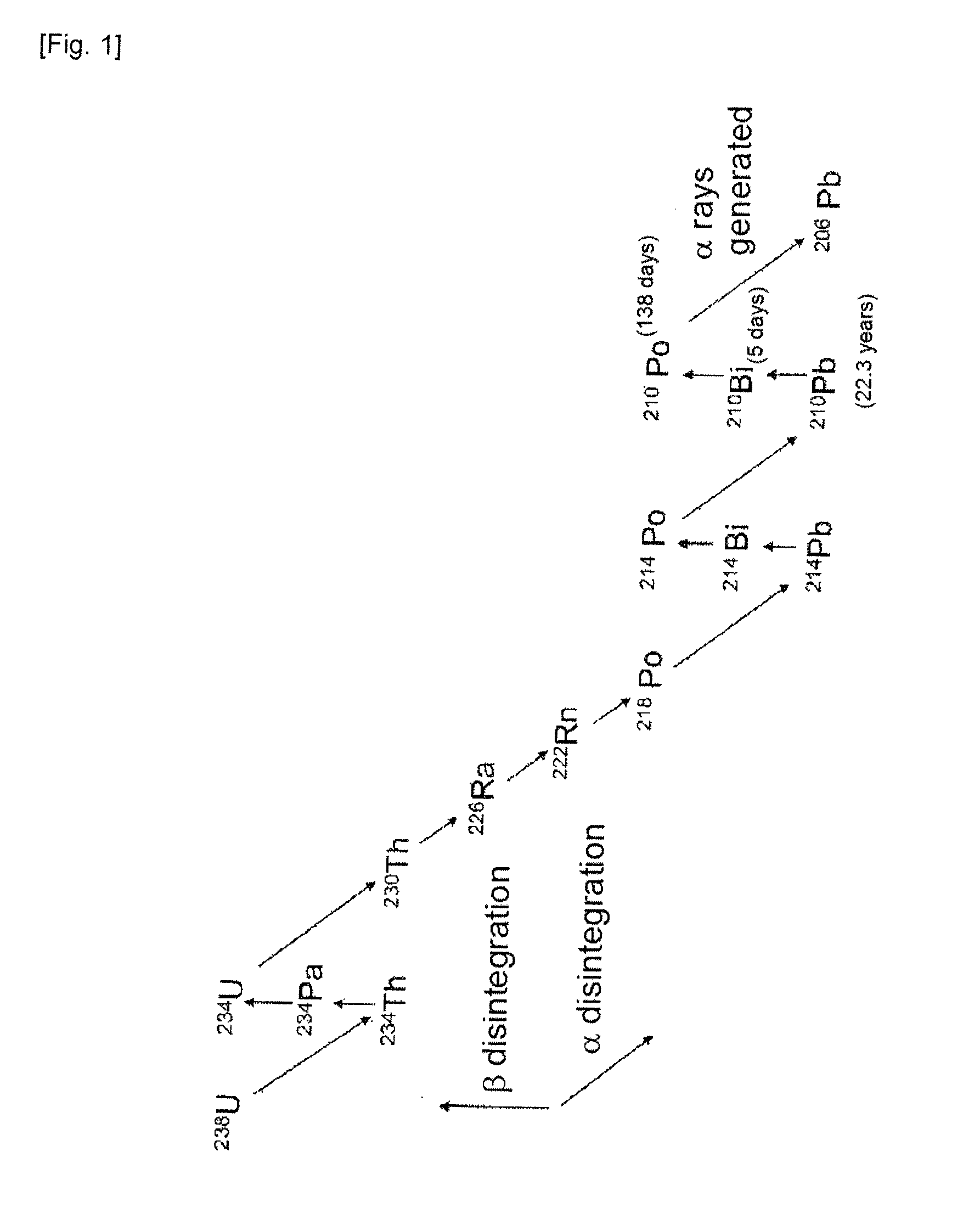

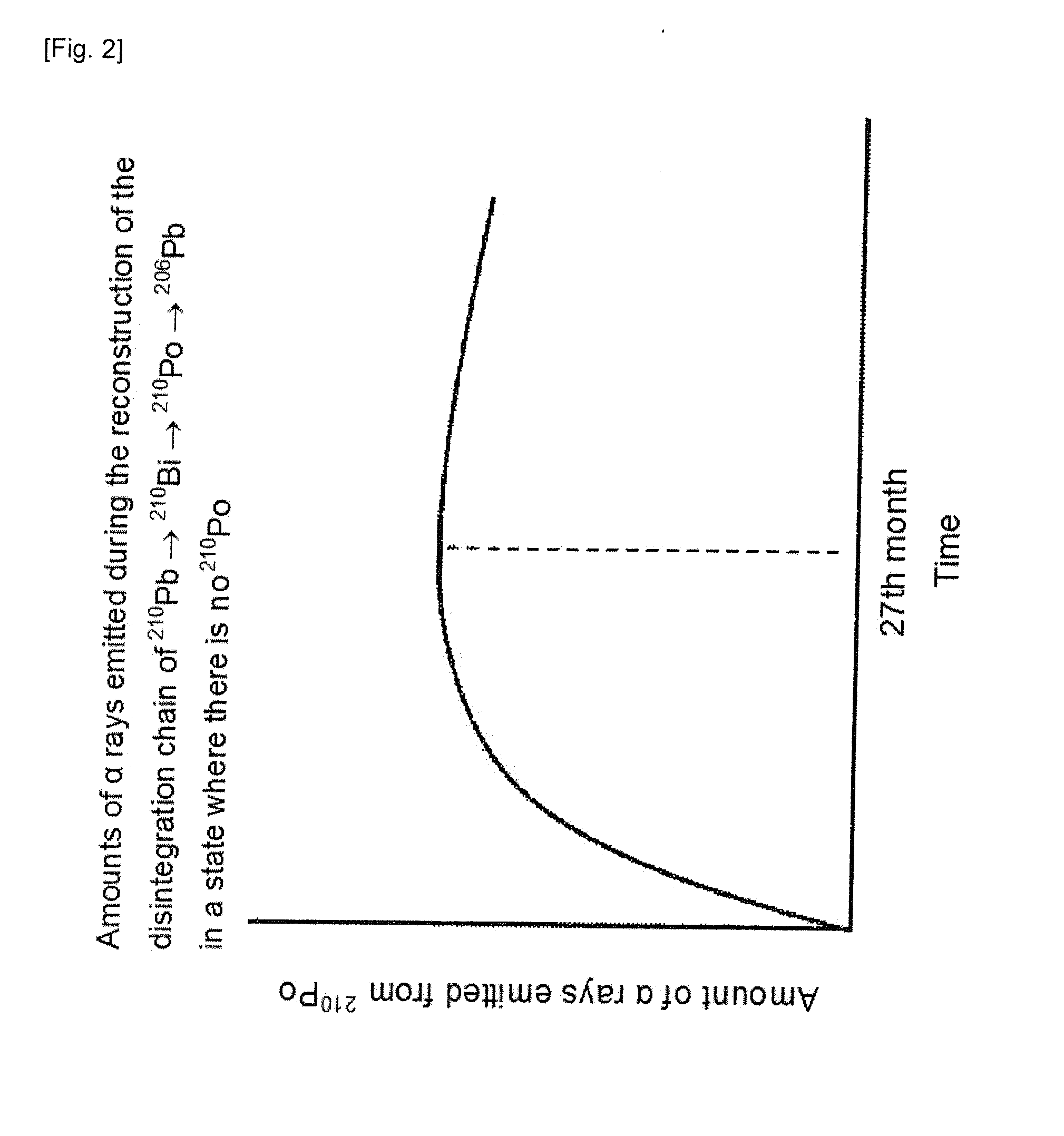

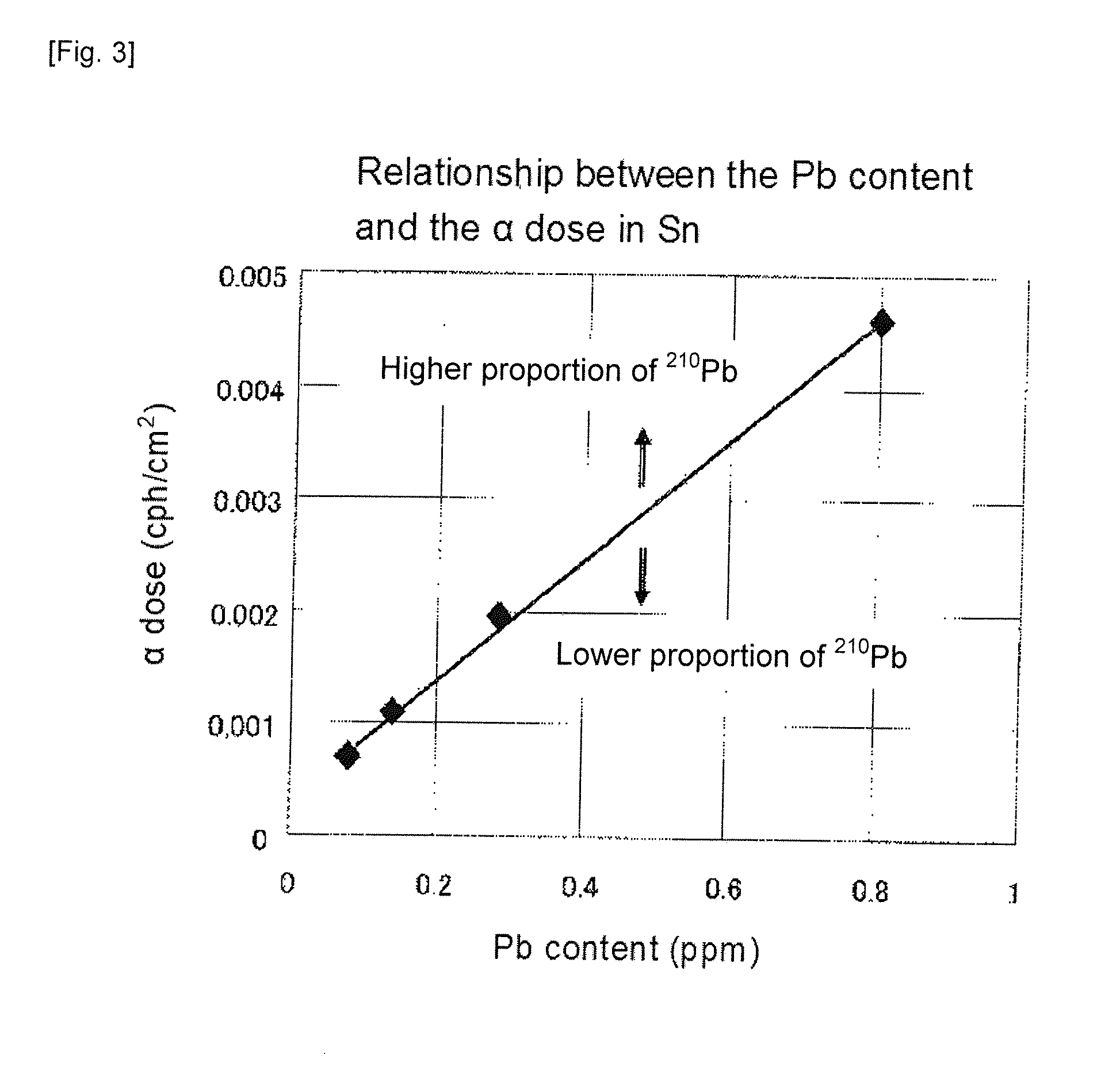

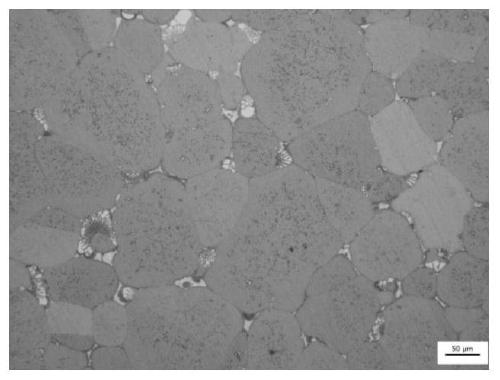

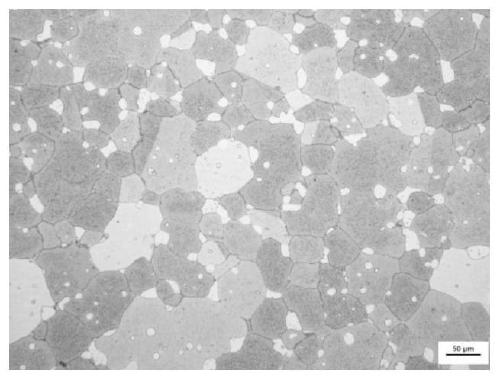

Low alpha-Dose Tin or Tin Alloy, and Method for Producing Same

ActiveUS20130028786A1Improve compactnessLow cell capacityPhotography auxillary processesWelding/cutting media/materialsSemiconductor chipAlloy

Owner:JX NIPPON MINING& METALS CORP

Nickel base powder high temperature alloy and preparation method and application thereof

Owner:BEIJING CISRI GAONA TECH +1

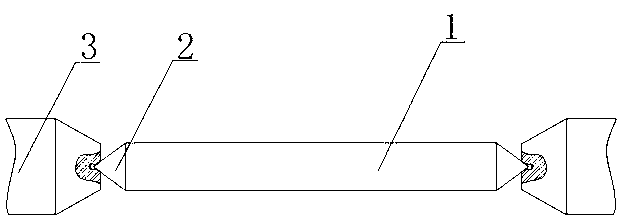

Material and method used for TA2/0Cr18Ni9Ti welded by high-entropy effect

InactiveCN102676904AImprove performanceSimple preparation stepsWelding/cutting media/materialsSoldering mediaElectrical resistance and conductanceAlloy

The invention discloses a high-entropy interlayer alloy, which comprises the following components in atomic percentage: 5-10% of Ti, 5-10% of Fe, 25-30% of Al, 15-20% of Ni, 30-35% of Cu and 5-10% of Cr. The invention also discloses a method for welding TA2 / 0Cr18Ni9Ti by the high-entropy effect, which comprises the following steps that: high-entropy interlayer alloy is placed between the two plates to be welded, the high-entropy interlayer alloy is in a foil folding structure, and the high-entropy interlayer alloy and local parent metal are subjected to heat fusing by an interface resistor ina resistance spot welding mode, so that the high performance welding of TA2 / 0Cr18Ni9Ti can be realized. According to the method and the high-entropy interlayer alloy of the method, which are disclosed by the invention, the high-entropy interlayer alloy has the advantages of favorable strength, toughness and corrosion resistance, is easy to process and form and is convenient to weld and assembly. The preparation method has the advantages of simple step and low manufacture cost and is convenient to popularize.

Owner:XIAN UNIV OF TECH

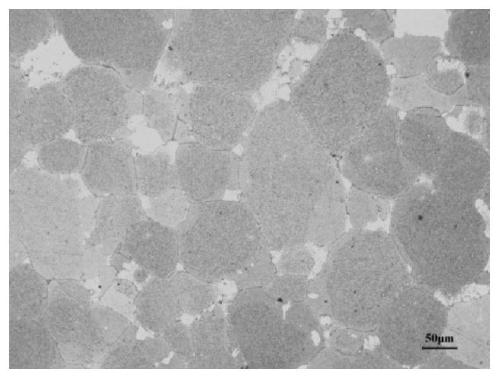

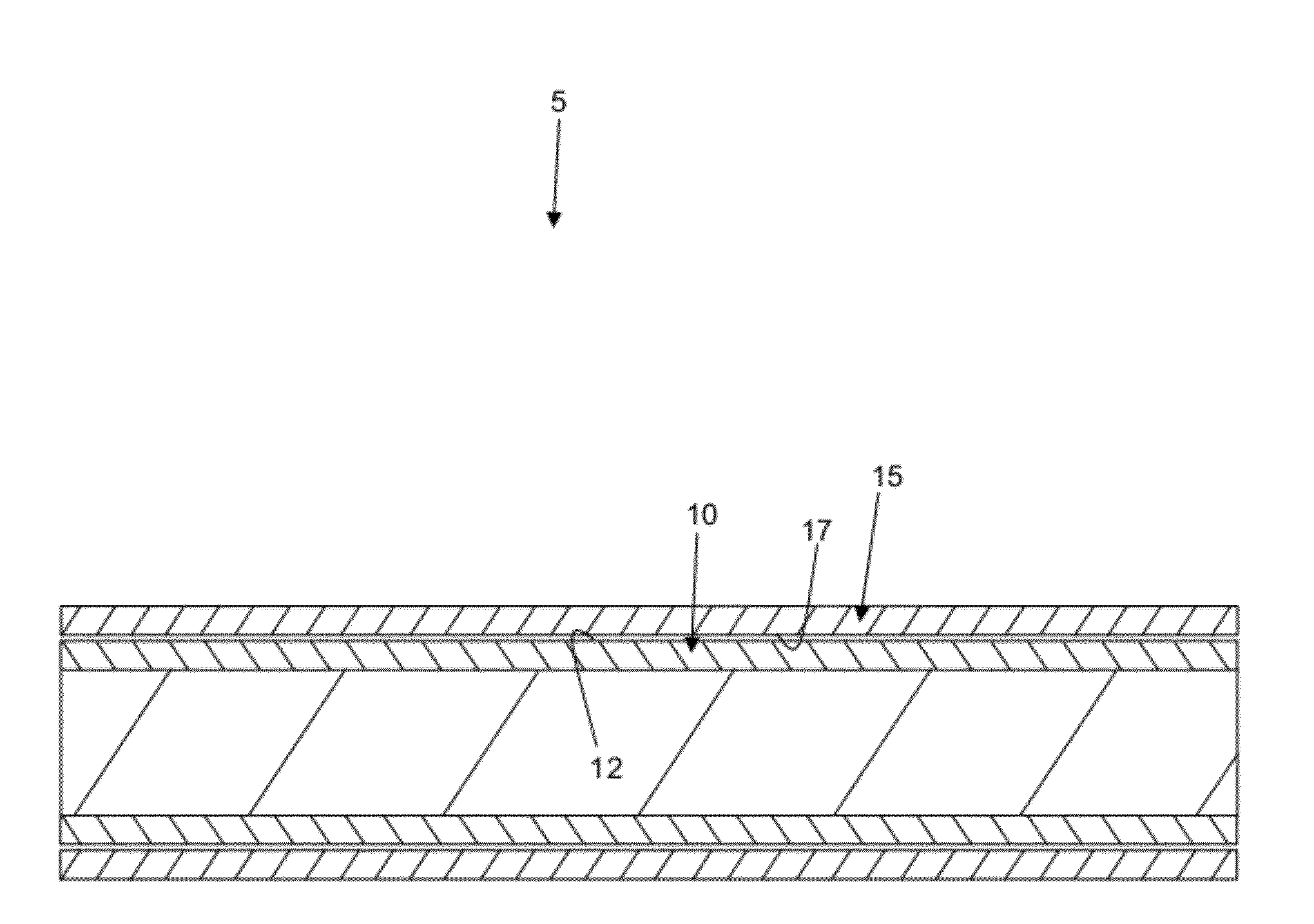

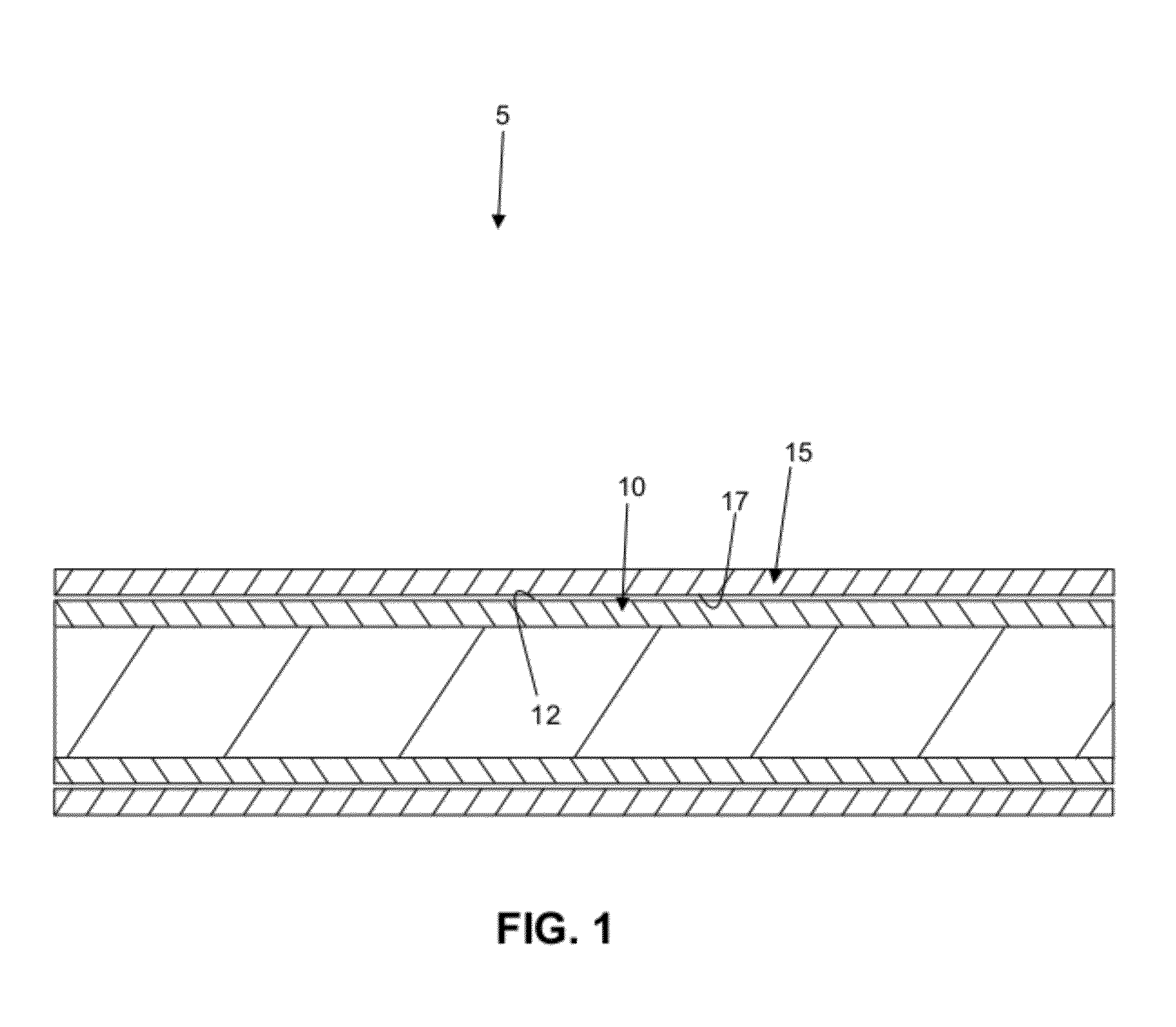

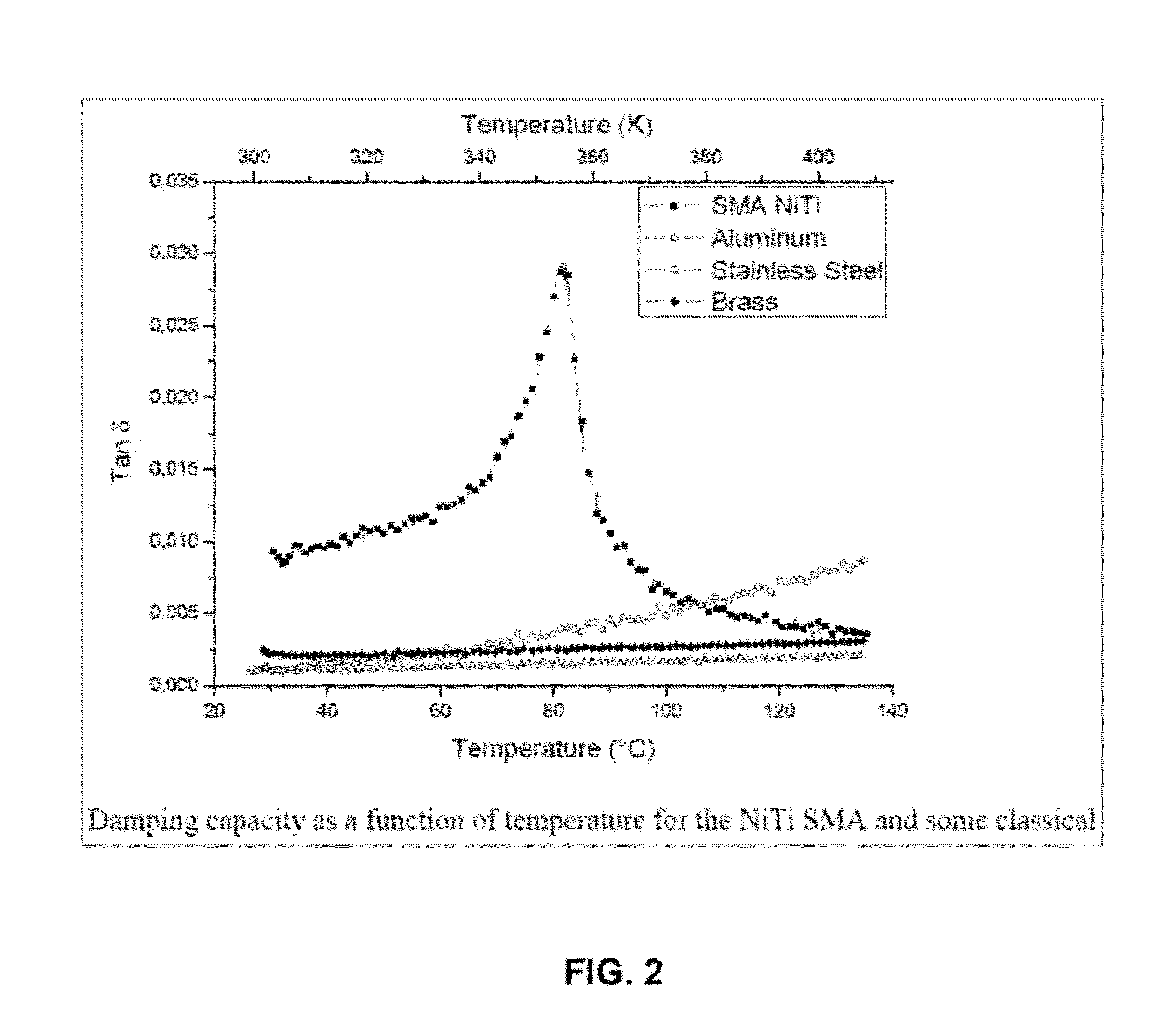

Composite gun barrel with outer sleeve made from shape memory alloy to dampen firing vibrations

ActiveUS20120227302A1Improve accuracyAdding to weightMuzzle attachmentBarrelsShape-memory alloyAlloy

Owner:ATI FLOWFORM PROD

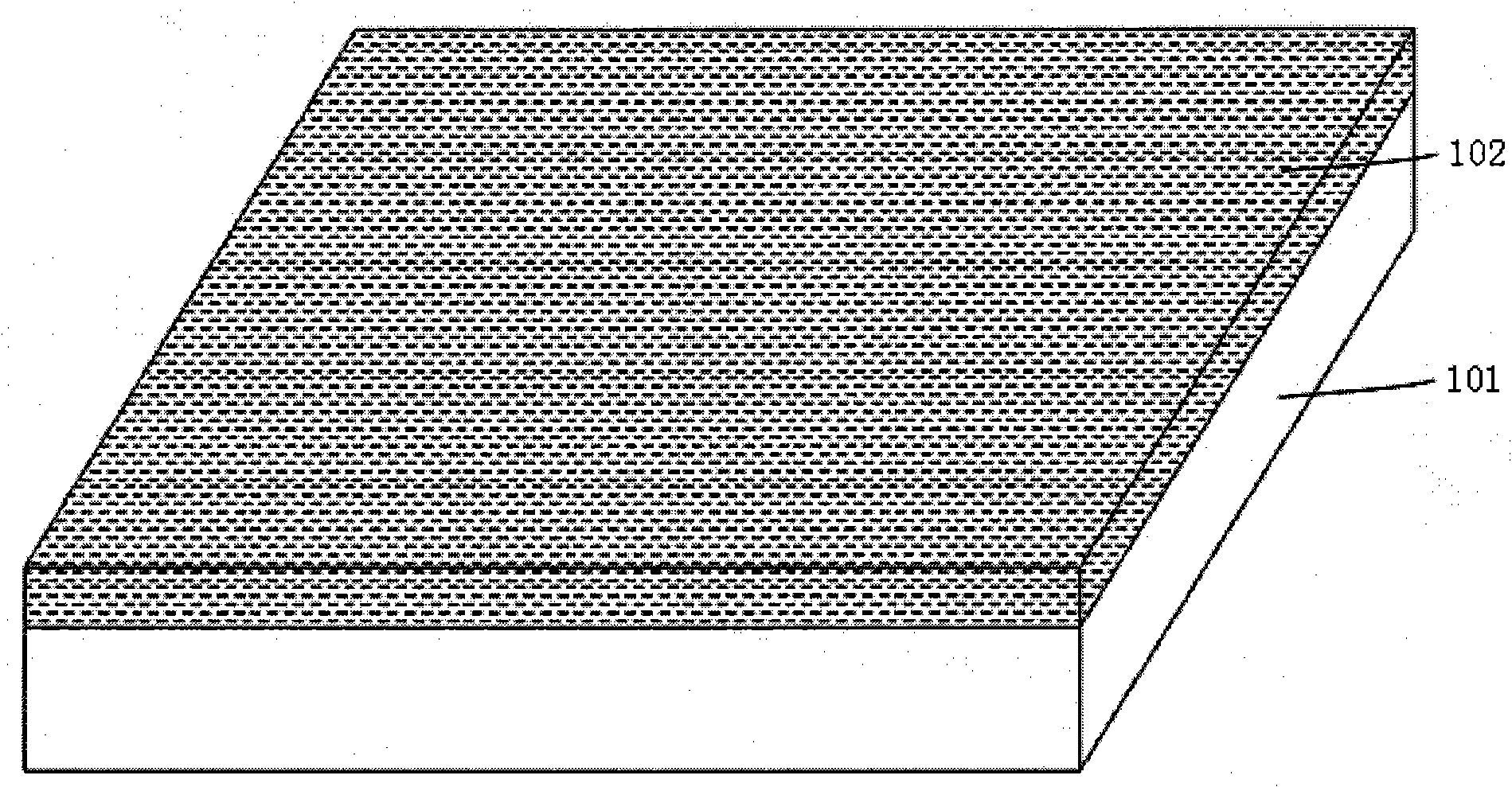

Target material and thin membrane manufactured with the target material

InactiveCN101245443AReduce manufacturing costReduce complexityVacuum evaporation coatingSputtering coatingElemental compositionPowder mixture

The invention mainly provides a target, the elemental composition of which is IBx-IIIAy-VIAz, wherein, IB is selected from at least one of the group as follows: Cu and Ag; IIIA is selected form at least one of the group as follows: In and Ga; VIA is selected from as least one of the group as follows: S, Se and Te; x, y and z are respectively atomic percents of contents of IB, IIIA and VIA while the x is more than or equal to 0 and less than 1, so is the y, the z is more than 0 and less than 1 and the sum of the x, the y and the z is equal to 1; the production method of the target comprises: pre-alloy is formed: the pre-alloy is synthesized by one element of the target and more than one other element in the elemental composition of the target; powder production: the pre-alloy is produced to be powder; powder mix: the powder is directly mixed or mixed with powder of other elements or pre-alloy powder; sintering: the powder mixture forms the target after sintering. The invention also provides a thin-film used in solar battery, which is made by sputtering the target.

Owner:SOLAR APPLIED MATERIALS TECHNOLOGY CORPORATION

Working roll for rolling medium-thickness plate with high grade and high strength and manufacture method thereof

ActiveCN101954378AImprove wear resistanceImproved roll shape retentionRollsMetal rolling arrangementsChemical compositionWork roll

The invention discloses a working roll for rolling a medium-thickness plate with high grade and high strength and a manufacture method thereof. The working roll is applied to a medium-thickness plate rolling mill of a rolling steel industry. A working layer comprises the following alloy components in percentage by weight: 3.00-3.50 percent of C, 0.40-1.20 percent of Si, 0.50-1.20 percent of Mn, not more than 0.10 percent of P, not more than 0.05 percent of S, 1.30-2.50 percent of Cr, 3.20-4.50 percent of Ni, 0.20-1.00 percent of Mo, 0.20-2.00 percent of W and 1.00-1.50 percent of V. A roll core comprises the following chemical components in percentage by weight: 2.80-3.50 percent of C, 2.00-2.50 percent of Si, 0.50-1.00 percent of Mn, not more than 0.10 percent of P, not more than 0.05 percent of S, 0.20-0.50 percent of Cr, 0.20-0.60 percent of Ni, not more than 0.20 percent of Mo and not more than 0.30 percent of Re. The working roll manufactured by adopting a centrifugal composite casting process and two-section tempering production at 400-550 DEG C for 25-30 hours is the working roll for rolling the medium-thickness plate with high grade and high strength, which has the advantages of high abrasion resistance and less hardness reduction.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

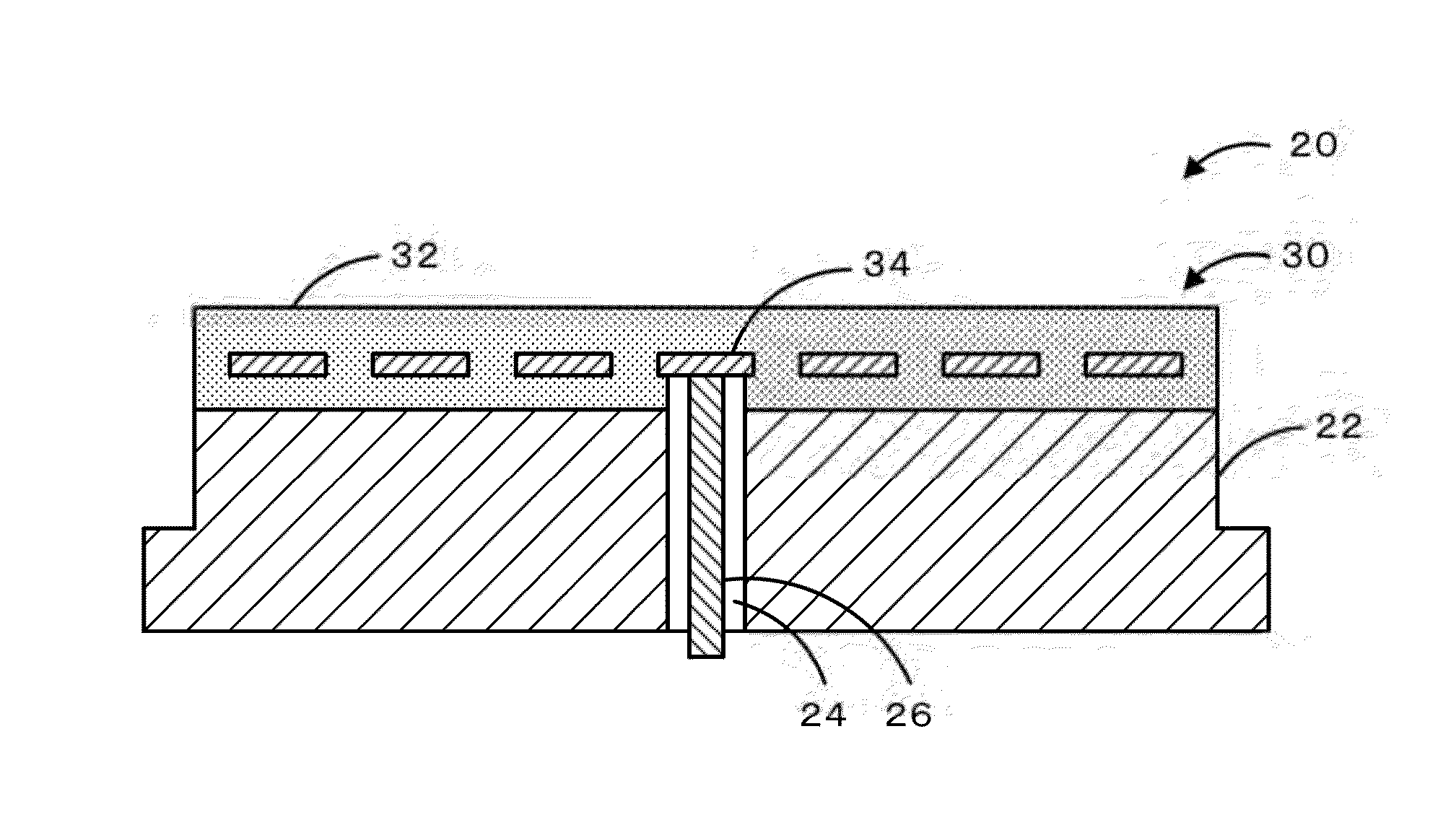

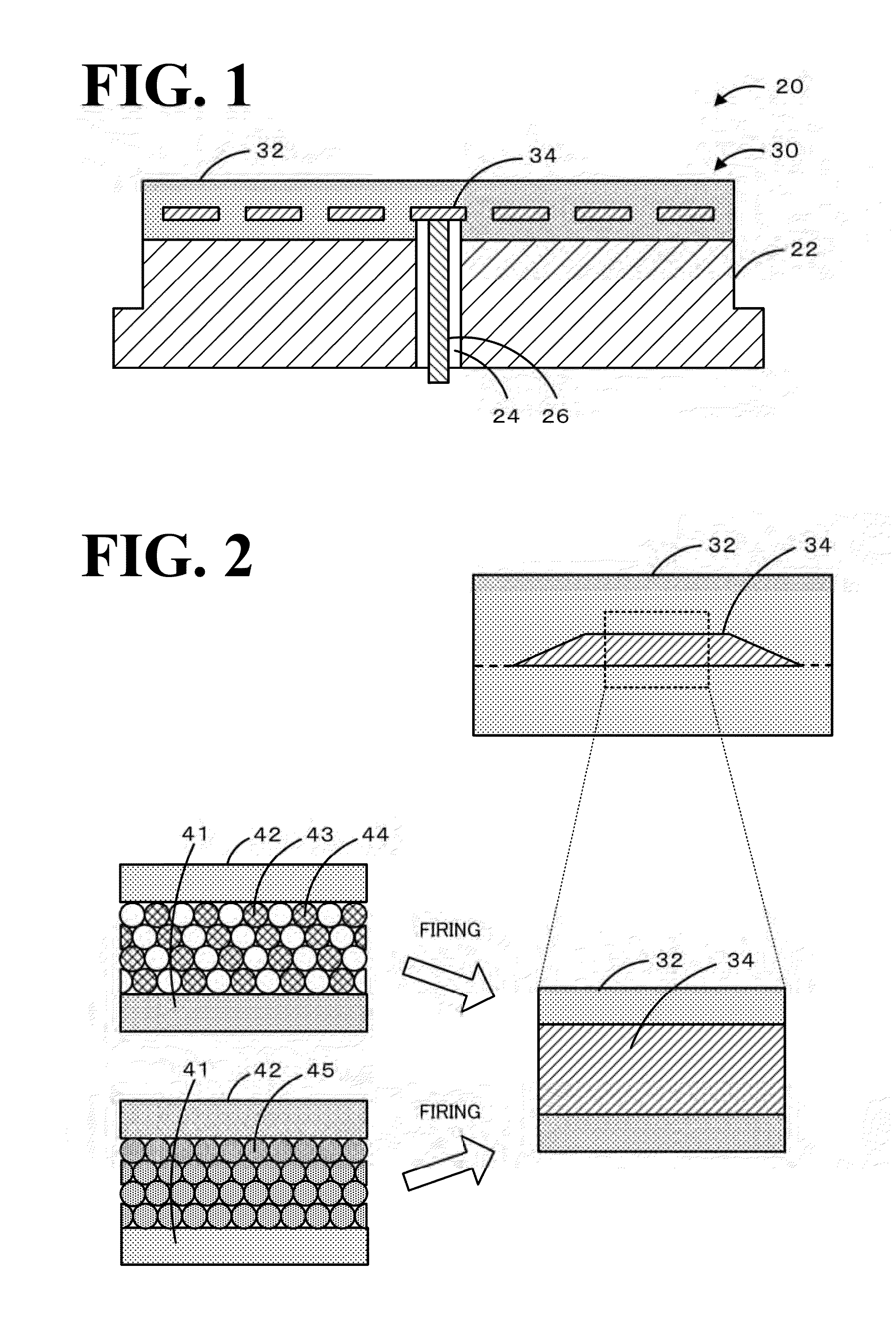

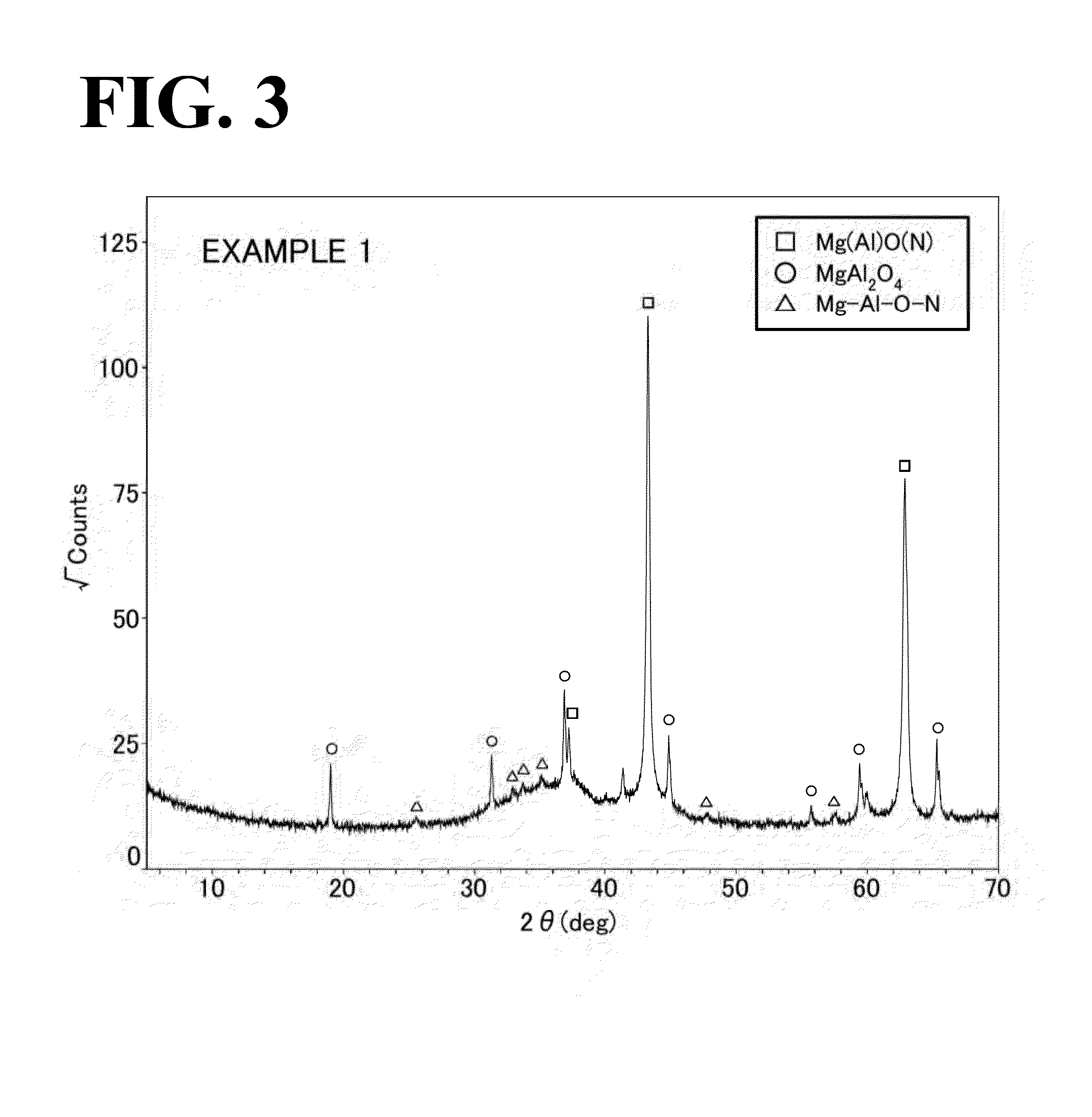

Ceramic member and member for semiconductor manufacturing equipment

ActiveUS20140285943A1Avoid crackingLow resistivitySemiconductor/solid-state device manufacturingPositioning apparatusRutheniumAlloy

Owner:NGK INSULATORS LTD

Method for grinding excircles of axial hard alloy

InactiveCN102699775ALow costReduce manufacturing costRevolution surface grinding machinesAlloyMachining

Owner:CHENGDU HANGWEI PRECISION CUTTING

Preparation process of vanadium-nitrogen alloy

The invention discloses a preparation process of a vanadium-nitrogen alloy. The preparation process comprises the steps that a vanadium-containing compound is subjected to mechanical activation treatment at first, a reaction promoter, graphene and a binder are added to obtain qualified mixed materials, the mixed materials are subjected to aging treatment and fed into a calcining kiln to be calcined, a drying stage, a carbonization stage, a nitridation stage and a cooling stage are sequentially carried out, a product is discharged from the kiln, and the vanadium-nitrogen alloy finished productwith the vanadium content larger than or equal to 77.0% is obtained. According to the preparation process, quality is good, product quality is stable, the production process is stable, and the production cost is low.

Owner:涂绪洋

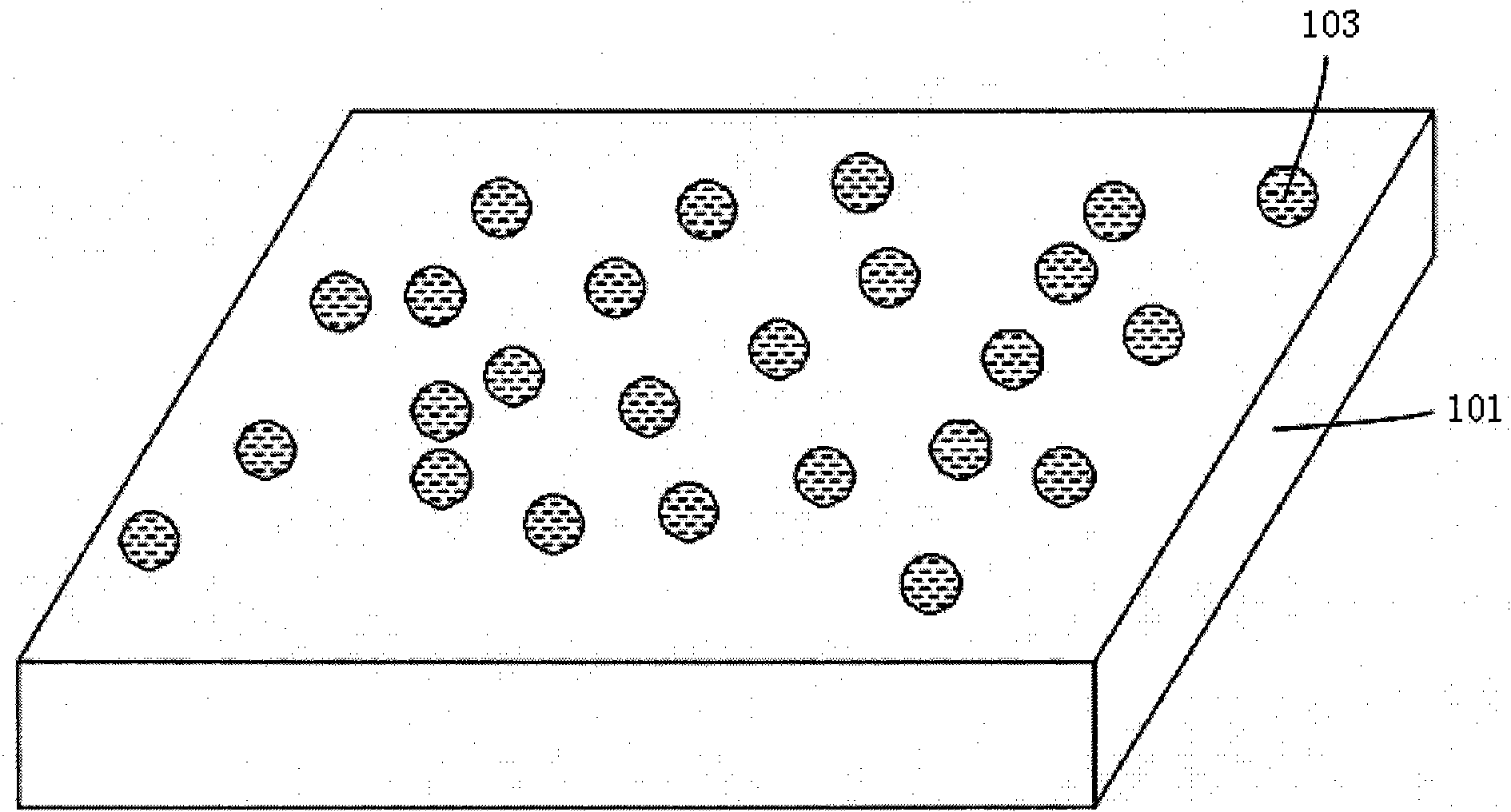

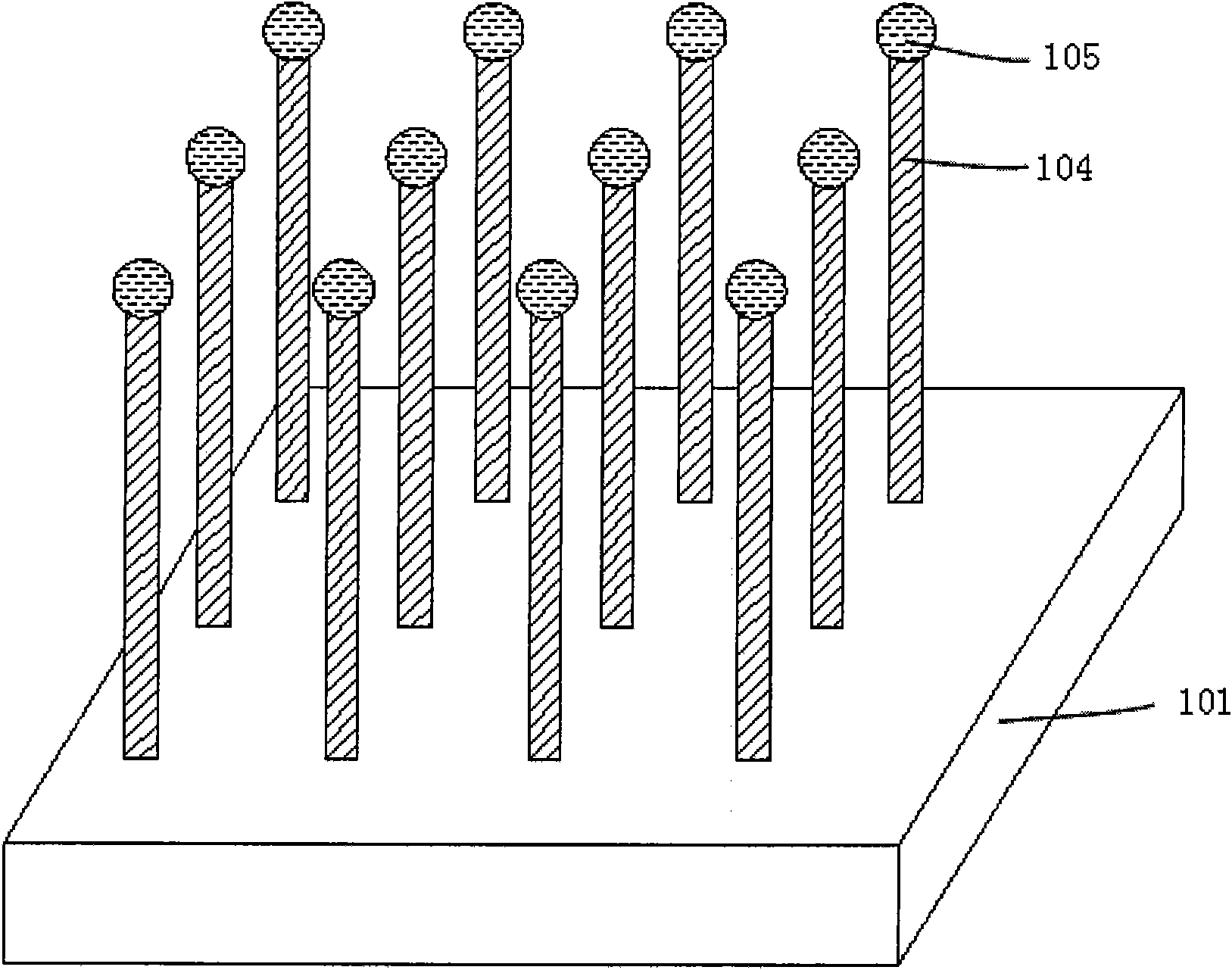

Nanowire MOS transistor based on III-V element and preparation method thereof

InactiveCN101783367ASimple structureEasy to manufactureSemiconductor/solid-state device manufacturingSemiconductor devicesNanowireSource material

Owner:FUDAN UNIV

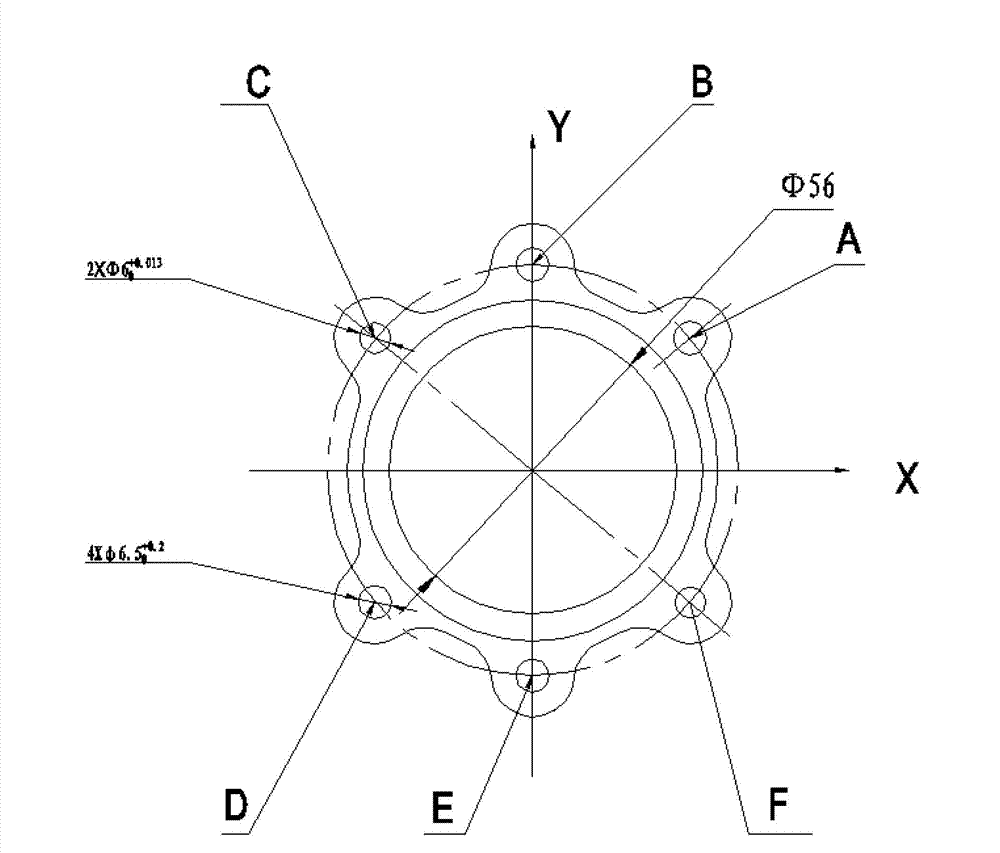

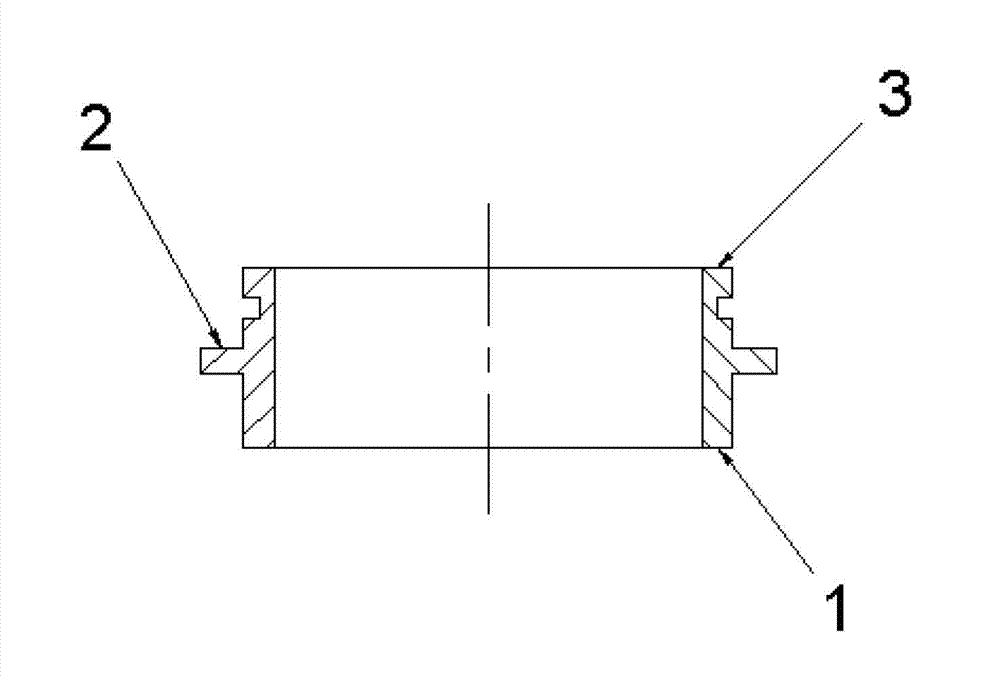

Method for processing pin hole of intermediate case lining

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Polylactic acid/polyester alloy and preparation method thereof

The invention relates to a polylactic acid / polyester alloy and a preparation method thereof. The polylactic acid / polyester alloy comprises the following components in percentage by weight: polylactic acid, polyester, a compatilizer, a flexibilizer, an antioxidant and a lubricant. The preparation method comprises the following steps: firstly, proportioning the raw materials and mixing at a room temperature; and respectively carrying out melting extrusion, carrying out ultrasonic treatment at the first late stage, extruding at the second stage and pelletizing, so as to obtain degradable, high-impact-resistant and high-heat-resistant polylactic acid / polyester alloy. Compared with an existing method, the controllable ultrasonic treatment is utilized; and a similar polylactic acid-g-polyester structure is formed by in-situ reaction, so that the heat resistance of the polyester and the biodegradability of the polylactic acid are reserved; and meanwhile, a toughening system with a core-shell structure is formed in an alloy system through interface interaction of a special toughening compatilizer, so that the alloy product with high impact resistance, high heat resistance and high biodegradability can be obtained.

Owner:FINE BLEND POLYMER SHANGHAI CO LTD

Method of preparing carbon-coated metal nanowire conductive thin film

InactiveCN106971771ALow costEasy to manufactureNon-conductive material with dispersed conductive materialSemiconductor devicesAlloySolar cell

The invention discloses a method of preparing a carbon-coated metal nanowire conductive thin film. A certain amount of metal nanowires is dispersed in a glucose solution, and a hydro-thermal reaction is carried out in a condition of 160 to 200 DEG C for 1 to 5 hours. The metal nanowire is a gold, silver, copper and the like metal nanowire or an alloy and a mixture. The metal nanowire transparent conductive thin film can be prepared through spraying or a thin film transfer method. The method is simple and easy to operate, and the metal nanowire conductive thin film stability can be improved obviously, and the method can promote application of the metal nanowire transparent conductive thin film in the field of an optoelectronic device such as a solar cell.

Owner:JIANGHAN UNIVERSITY

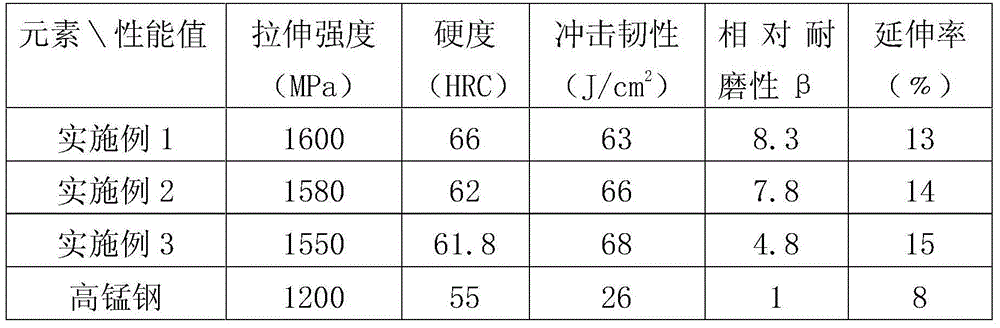

Boron-bearing chromium molybdenum nickel wear-resistant alloy and preparation method thereof

Owner:GUANGXI UNIV

Silicon-calcium-barium-magnesium desoxidant for steelmaking and/or electroslag

The invention relates to a silicon-calcium-barium-magnesium desoxidant for steelmaking and / or electroslag. The desoxidant is composed of the following chemical components in mass percent: 20-50% of Si, 10-40% of Ca, 5-20% of Ba, 2-10% of Mg, 0-10% of RE, not larger than 0.030% of P, not larger than 0.040% of S, 0-2% of C and the balance of Fe. The preparation method comprises the following steps: firstly smelting iron and silicon in a melting furnace to an intermediate alloy, adding barium, calcium, magnesium and / or rare earth, melting and casting to an alloy block, and controlling the specific gravity of the silicon-calcium-barium-magnesium desoxidant to 3-5 g / cm<3>. When in use, the silicon-calcium-barium-magnesium desoxidant is directly thrown into a steel furnace and / or an electroslag remelting crystallizer slag bath, the specific gravity of the desoxidant is increased, the vapor pressure is reduced, the desoxidant is deposited at a slag-steel interface to generate a CaO-BaO-SiO2 type impurity, and the CaO-BaO-SiO2 type impurity is larger in granule, lower in melting point, easy to be captured by the slag and easy to float to be removed, so that the cleanness of molten steel is improved.

Owner:ZHONGYUAN SPECIAL STEEL

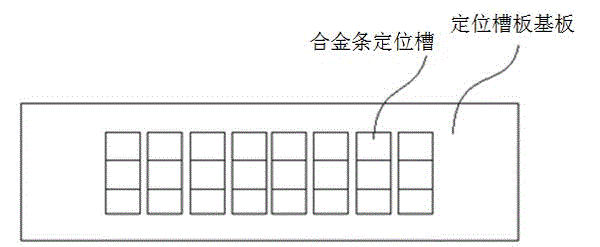

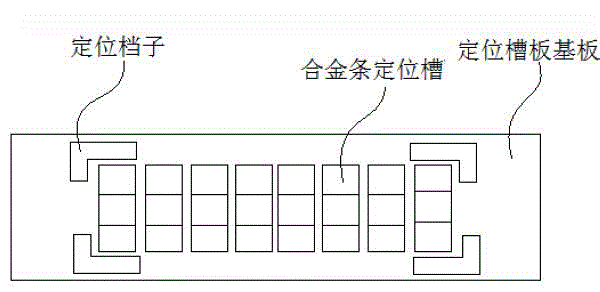

Double-sided bonding method applicable to hard alloy bars in hard alloy hard-surface machining process and application thereof

ActiveCN104976200APrecise processing sizeHigh speedMaterial gluingWelding apparatusMachined surfaceAlloy

Owner:株洲金韦硬质合金有限公司

Chromium-containing alloy bar material and preparation method thereof

ActiveCN109112398AImproved particle sizeAchieve fine grain strengthening effectChemical compositionEconomic benefits

The invention relates to a chromium-containing alloy bar material and a preparation method thereof. Al and N are added in a process of smelting steel with the trade mark of 40Cr to obtain the chromium-containing alloy bar material containing 0.020 to 0.030 weight percent of the Al and 0.007 to 0.010 weight percent of the N. Under the condition that existing equipment and technology are not changed, the problem that the grain size of the alloy bar material is large in a 40Cr steel low-rolling-ratio processing process is solved through adjusting chemical components; the grain size of a steel product is obviously changed under the matching effect of the Al and the N and a fine crystal reinforcing effect is realized. Under the same rolling condition, the grain size can be improved by 1.5 to 2.0 grades when being compared with that of existing 40Cr steel, and the problem that the capability of existing equipment is not enough so that the grain size is relatively high solved; the equipment investment is reduced and the chromium-containing alloy bar material has good economic benefits and application prospect.

Owner:CHENGDE JIANLONG SPECIAL STEEL

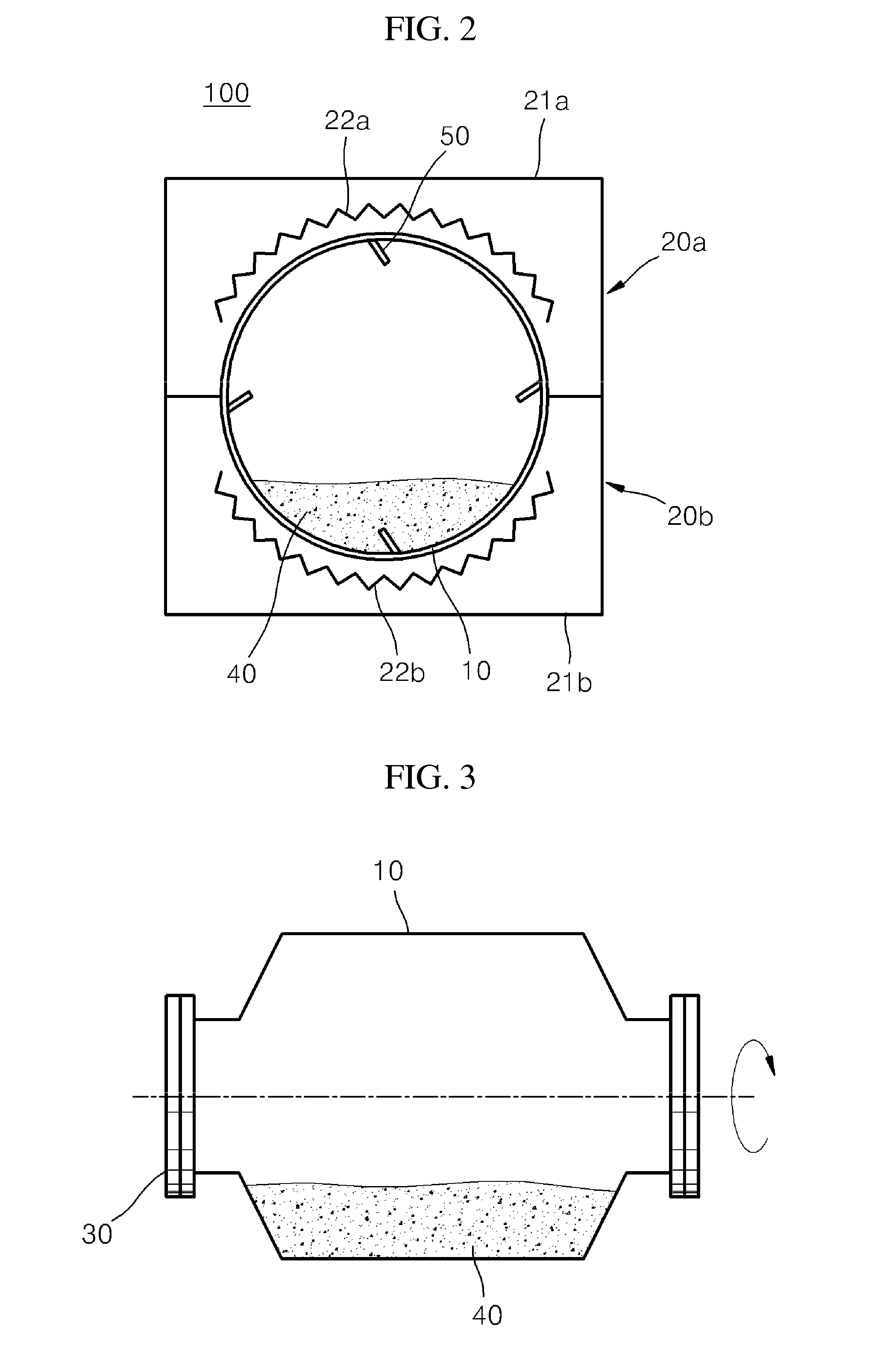

Apparatus for manufacturing compound powder, method of manufacturing iron-boron compound powder by using the apparatus, boron alloy powder mixture, method of manufacturing the boron alloy powder mixture, combined powder structure, method of manufacturing the combined powder structure, steel pipe, and method of manufacturing the steel pipe

ActiveUS20140096858A1High hardnessLow melting pointHeat treatmentsLiquid surface applicatorsPowder mixtureAlloy

Owner:KMT CO LTD

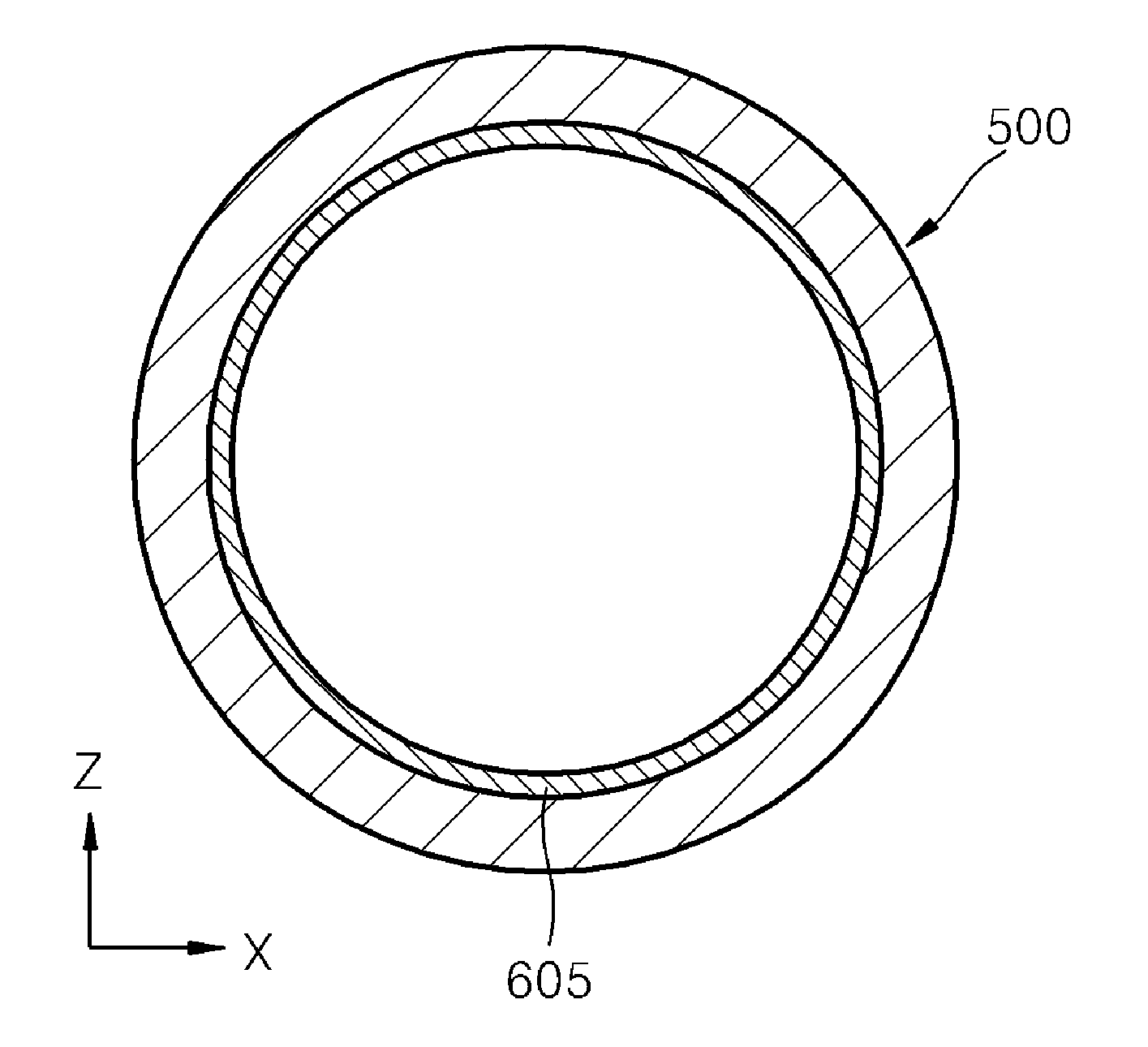

Aluminum base alloy containing boron and manufacturing method thereof

InactiveUS7125515B2Evenly distributedNuclear energy generationCasting safety devicesBoron containingAlloy

Owner:KOBE STEEL LTD

Alloy material with high temperature coefficient of resistance and preparation method thereof

The invention provides an alloy material with high temperature coefficient of resistance. The alloy material is prepared by adding six metal components as the additives to nickel-ferrum alloy, and smelting same to obtain the product, wherein the six metal components are respectively germanium, zirconium, cerium, titanium, aluminum and ferrum; and the alloy material comprises the following components in percentage by weight: 50-65% of component Ni, 14-21% of component Cr, 0.1-0.9% of component Ge, 0.15-0.5% of component Ce, 0.2-1% of component Zr, 1.1-3.5% of component Ti, 0.5-2% of component Al, and the balance of component Fe. The invention also provides a preparation method of the alloy material. The alloy material prepared by the preparation method provided by the invention is of 8.2g / cm<3> based on the density, and has the resistivity of 1.53 (microhm.megabyte.20 DEG C); and the alloy material has temperature coefficient of resistance of 240aR / *10<-6>DEG / C under 100-800 DEG C; and the temperature is in good linear relation to the resistivity.

Owner:WUHAN XINYUAN TUOER TECH CO LTD

Reduced height combination ramp and load leveler

A reduced height combination ramp and load leveler includes at least two lengthwise support members, a plurality of cross members and plurality of cross treads. A retention tube is secured to each end of the at least two lengthwise support members. The at least two lengthwise support members and the plurality of cross members are preferably fabricated from an aluminum alloy having a tensile strength of at least 50,000 to reduce a height of the combination ramp and load leveler. Two stake receivers allow a single ramp to be used as a load leveler. Each stake receiver is sized to removably receive an adjustable stake. A ramp stand includes a support base and an adjustable tube receiver that is vertically positionable relative to the support base. The adjustable tube receiver retains the retention tubes.

Owner:MOTIS LLC

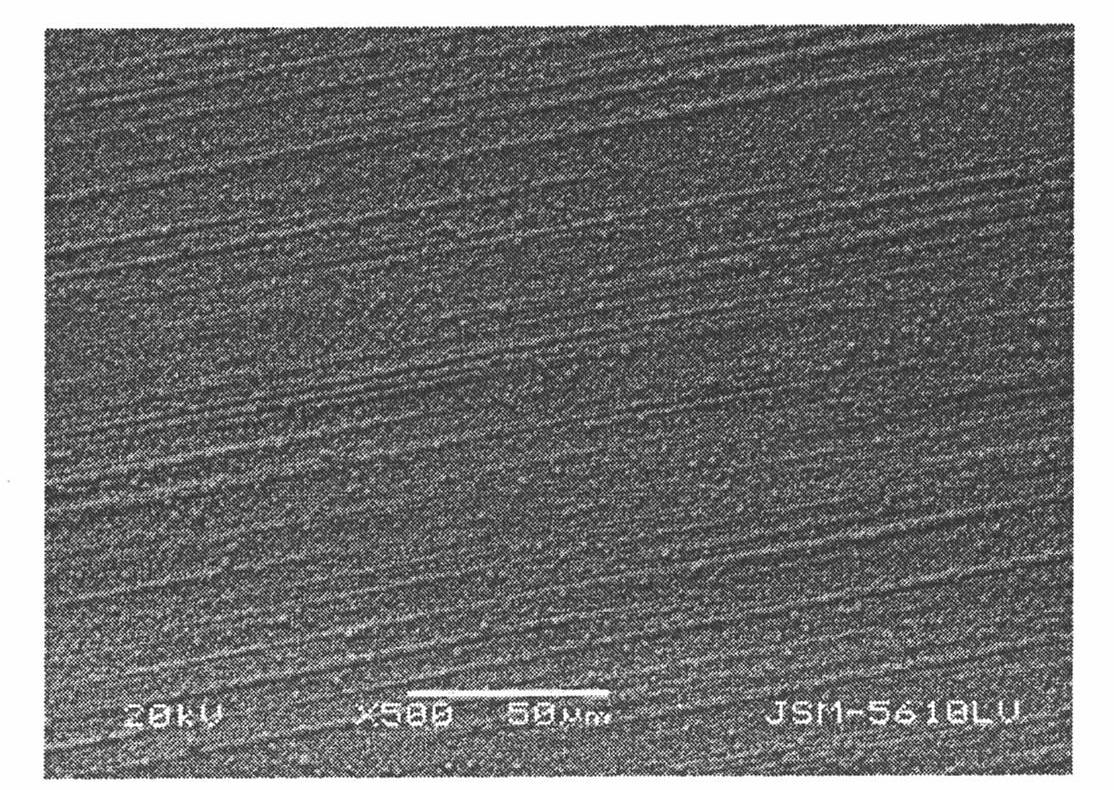

Lithium ion battery cathode and its preparation method and battery

InactiveCN102487136AOmit mixingOmit coatingElectrode carriers/collectorsSecondary cellsElectrical batteryAlloy

Owner:BYD CO LTD

Boron-phosphorus alloy cast iron used in air compressor cylinder block and its manufacturing process

InactiveCN102268587AImprove wear resistanceImprove tensile propertiesProcess efficiency improvementElectric furnaceAlloyCylinder block

Owner:ZHUJI HUAJIA AIR COMPRESSOR

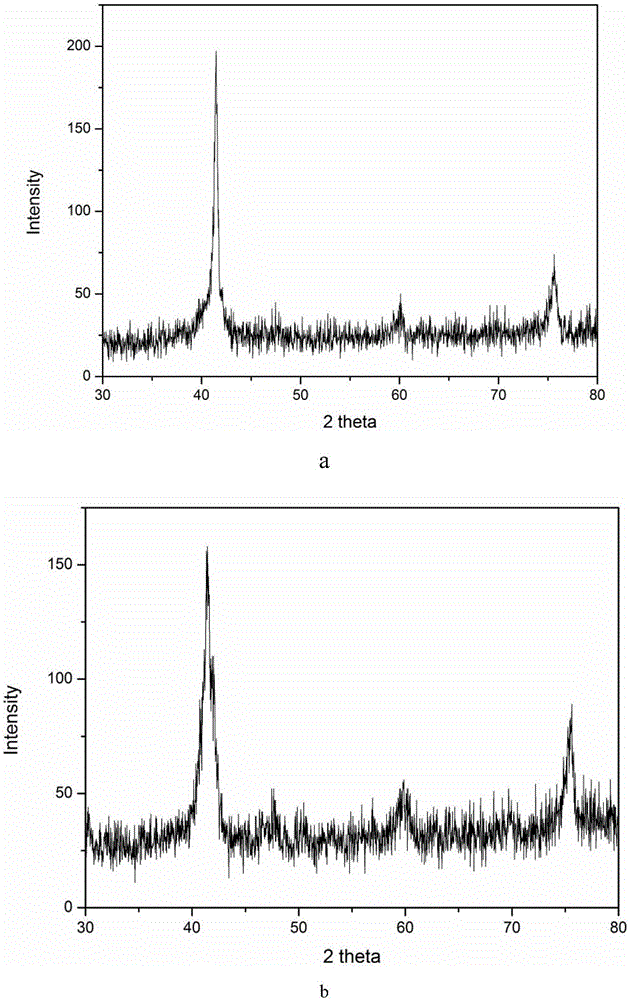

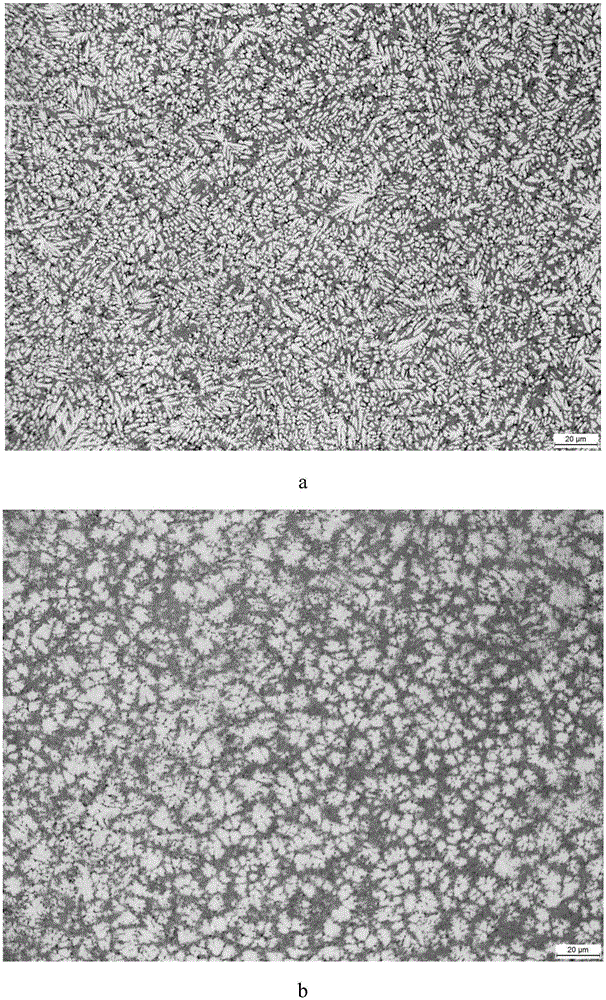

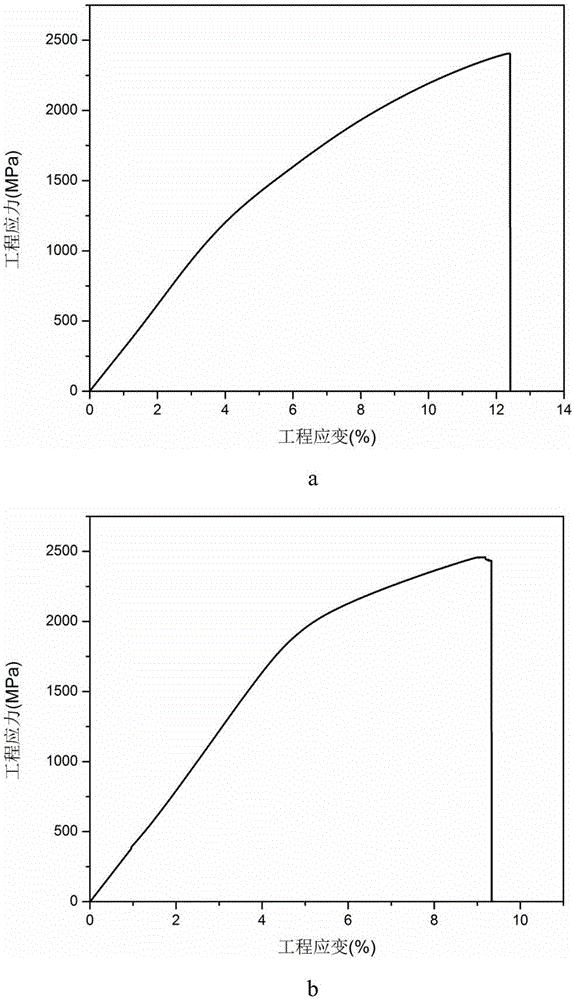

(Ti-Cu-Ni-Zr)-Sn amorphous composite and preparation method thereof

The invention relates to a (Ti-Cu-Ni-Zr)-Sn amorphous composite and a preparation method of the (Ti-Cu-Ni-Zr)-Sn amorphous composite. The (Ti-Cu-Ni-Zr)-Sn amorphous composite comprises Ti, Cu, Ni, Zr and Sn, and an atomic percent of the composite is as follows: (Ti[45]Cu[39-42.5]Ni[7.5-11]Zr[5])[98]Sn[2]. The Ti-based amorphous composite with high rupture strength and certain plasticity is obtained by selecting an alloy system free from a toxic element Be, reasonably adjusting an element proportion and adding a little element Sn. The prepared alloy comprises an amorphous phase and a beta-Ti dendritic crystal reinforcing phase, so that the alloy shows superhigh mechanical property matching, the yield strength sigma[y] is greater than or equal to 1310MPa, the compressive strength sigma[bc] is greater than or equal to 2460MPa, and the plastic strain epsilon[p] before rupture is greater than or equal to 9.3%.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

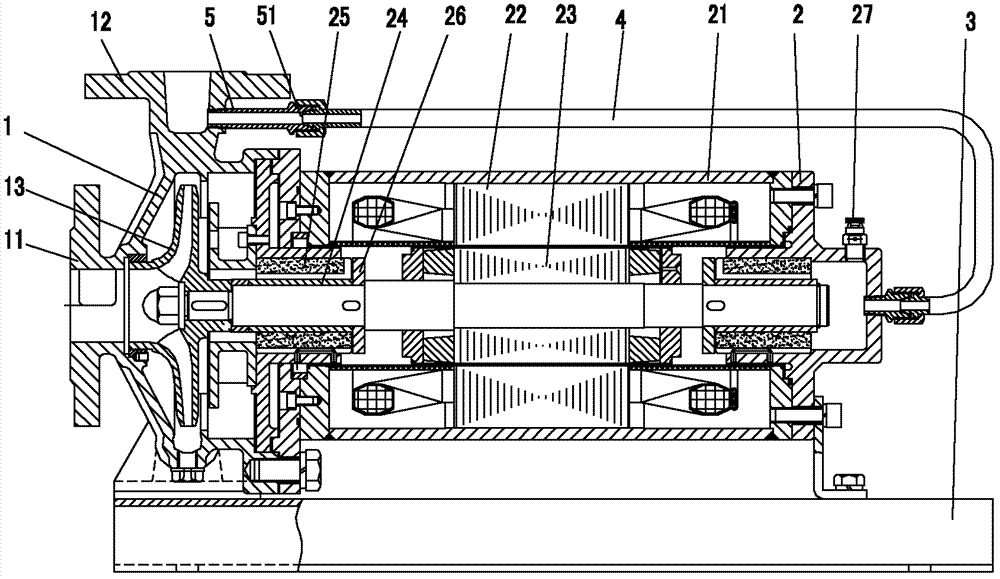

Low-noise horizontal chemical shielding pump

Owner:上海佰诺泵阀有限公司

Heat treatment method for recovering performance of K465 alloy turbine blade

ActiveCN103643188ARecovery performance (creep) effect is obviousSquare shapeFurnace typesHeat treatment furnacesTurbine bladeAlloy

The invention discloses a heat treatment method for recovering the performance of a K465 alloy turbine blade and belongs to the technical field of metallurgy. The heat treatment method comprises the following steps of 1, blade feeding, 2, furnace heating and then heat preservation: in vacuum or inert gas protective atmosphere, carrying out heat preservation at a temperature of 950-960 DEG C for 40-45min, carrying out heat preservation at a temperature of 1190-1200 DEG C for 2-2.5h and carrying out heat preservation at a temperature of 1230 DEG C for 4-4.5h, and 3, furnace cooling: (1), carrying out cooling from a temperature of 1230 DEG C to a temperature of 1000 DEG C at a cooling rate of 40+ / -25 DEG C / min by inert gas-based differential pressure cooling, and (2), feeding inert gas at a temperature of 1000 DEG C, carrying out cooling to a temperature of 300 DEG C, and opening a furnace door at a temperature below 300 DEG C and carrying out cooling. The heat treatment method can obviously recover the performance (such as creep deformation) of the K465 alloy turbine blade after a service cycle. Through the heat treatment method, transgranular gamma' polygonal or flower basket-shaped morphology is transformed into the cubical morphology so that morphology squaring is promoted.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

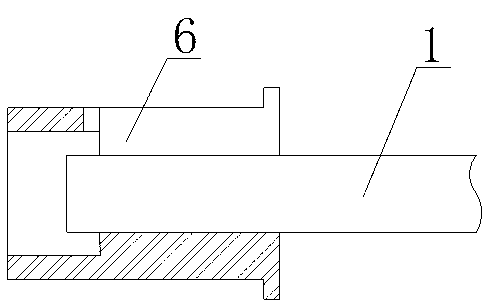

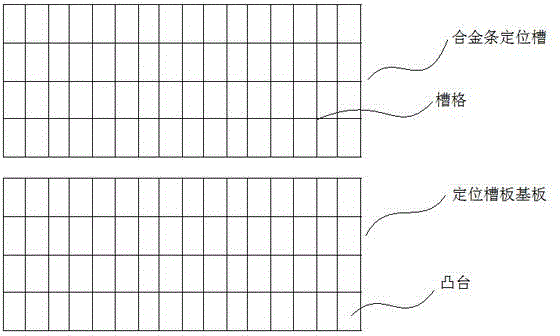

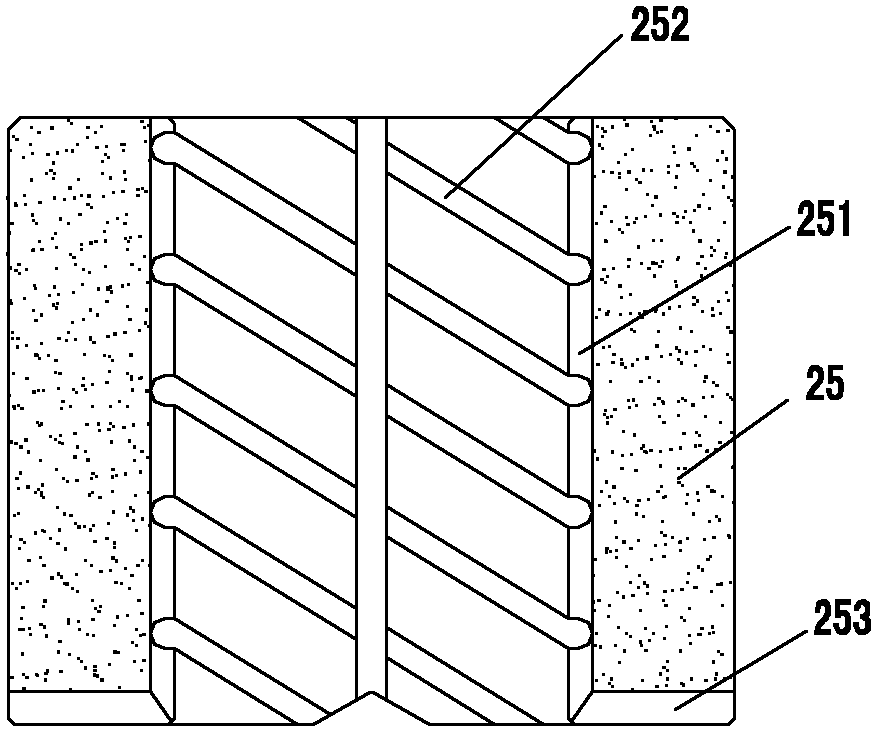

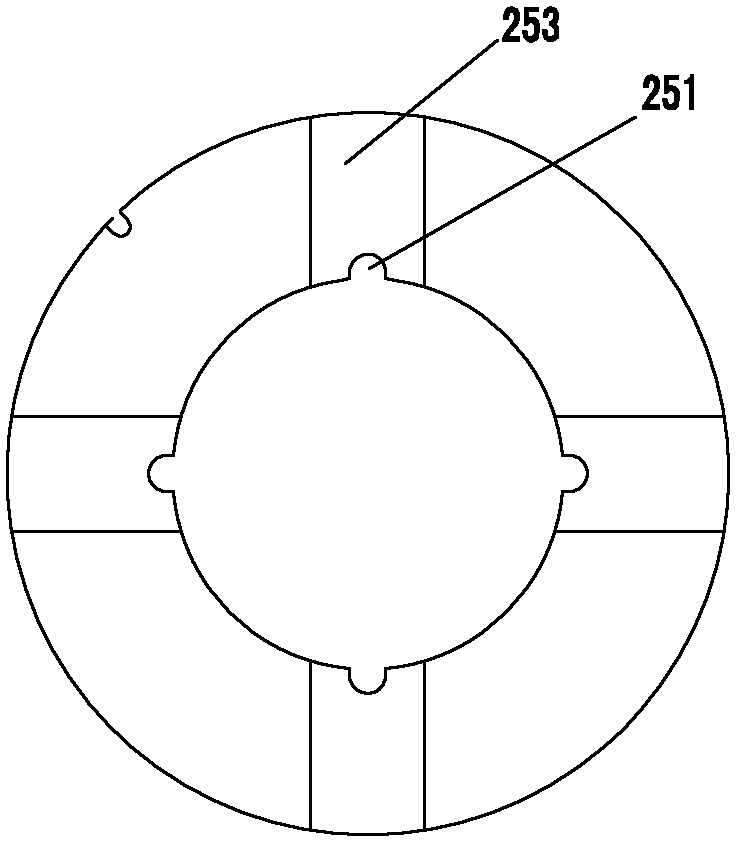

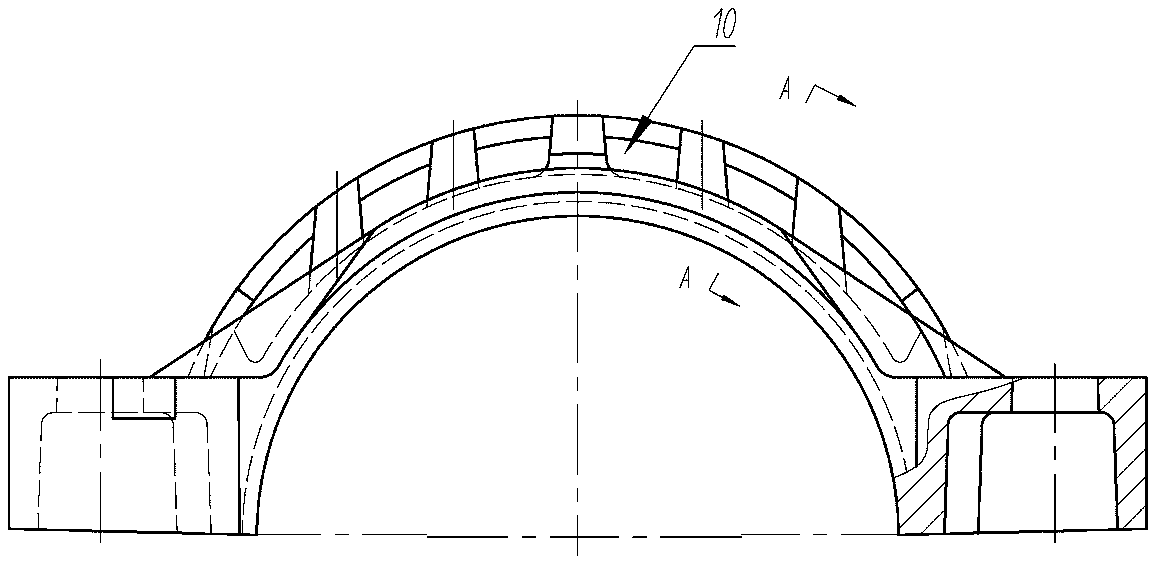

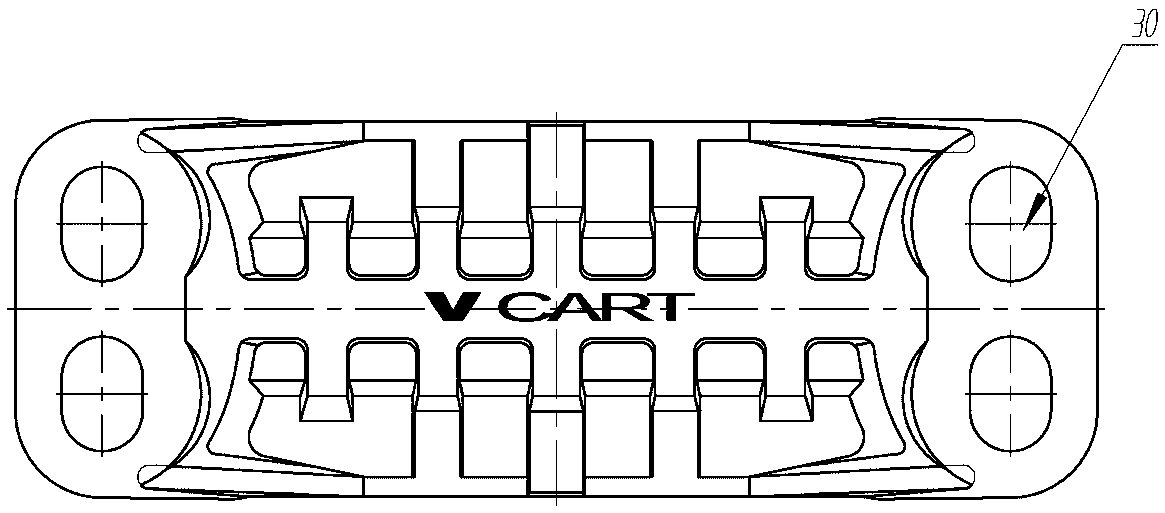

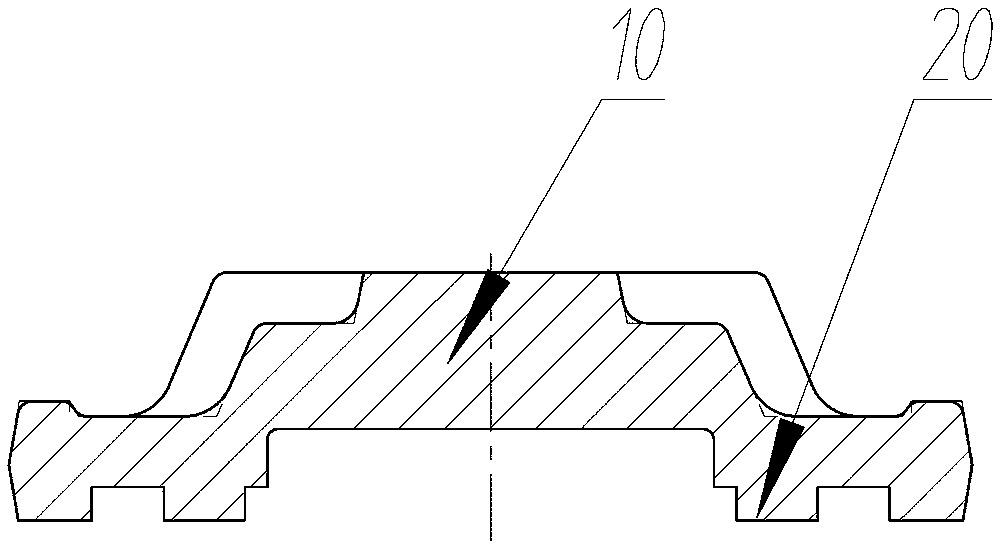

Shape memory alloy pipe connection device

InactiveCN105526440AFast connectivityQuick disassemblySleeve/socket jointsMemory effectShape-memory alloy

Owner:黄竹磬 +1

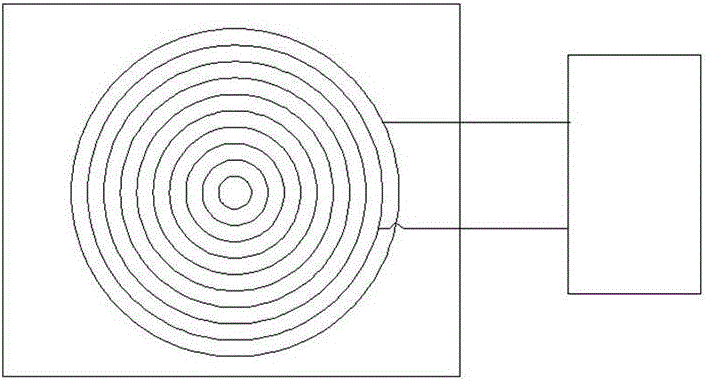

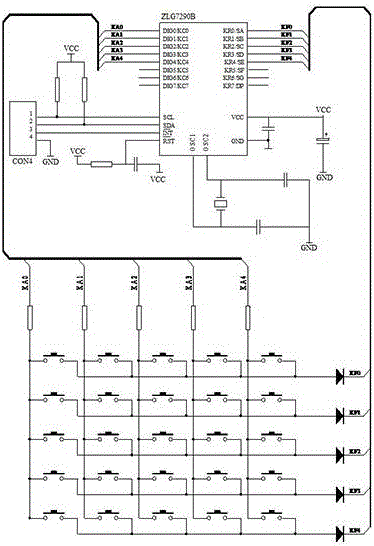

Flat open aluminum alloy window automation control device and automatic control system thereof

InactiveCN105867207AChange structureAvoid driftingProgramme controlComputer controlAutomatic controlAlloy

Owner:青岛工学院

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap