Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about "Non-conductive material with dispersed conductive material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

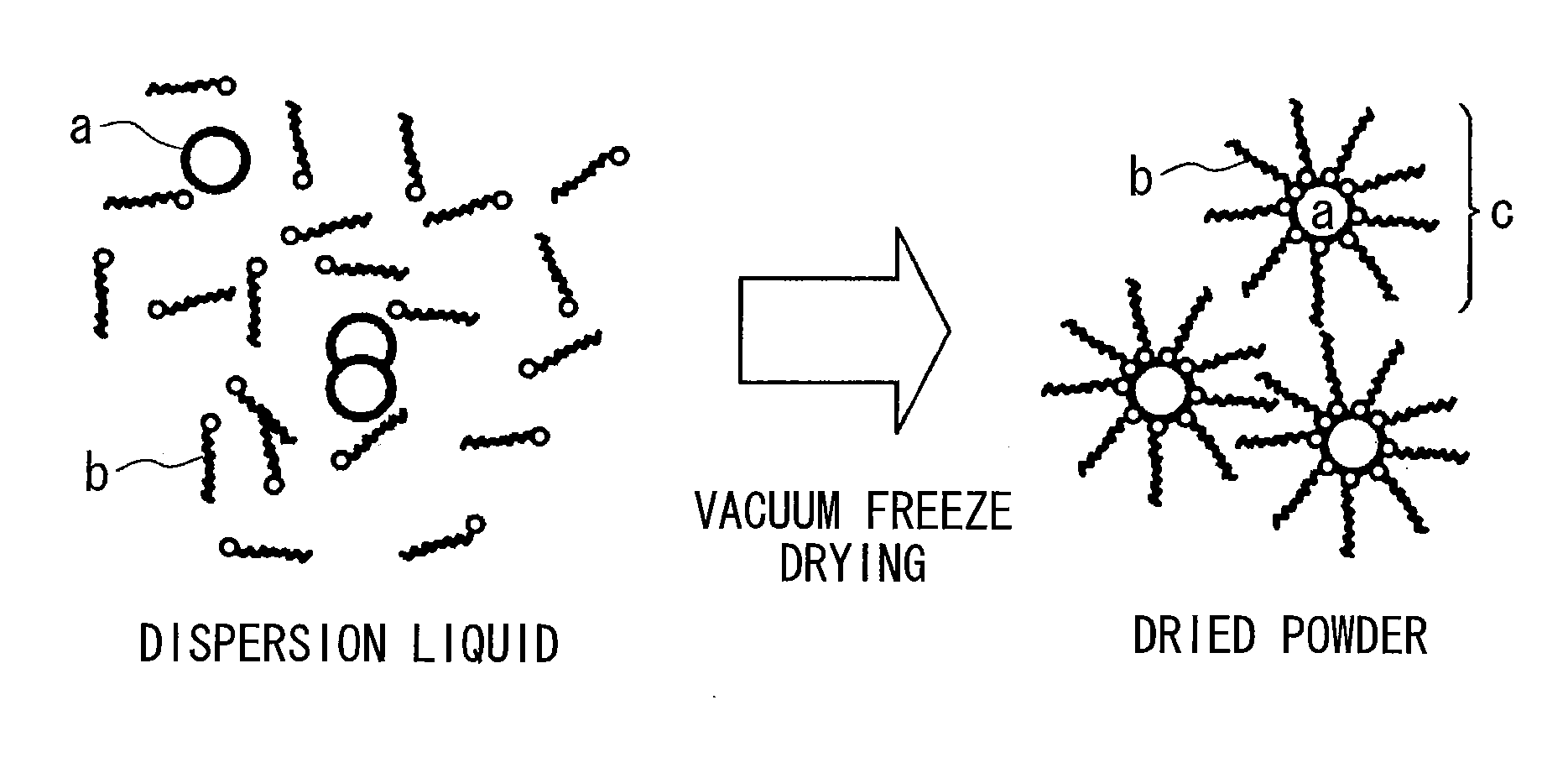

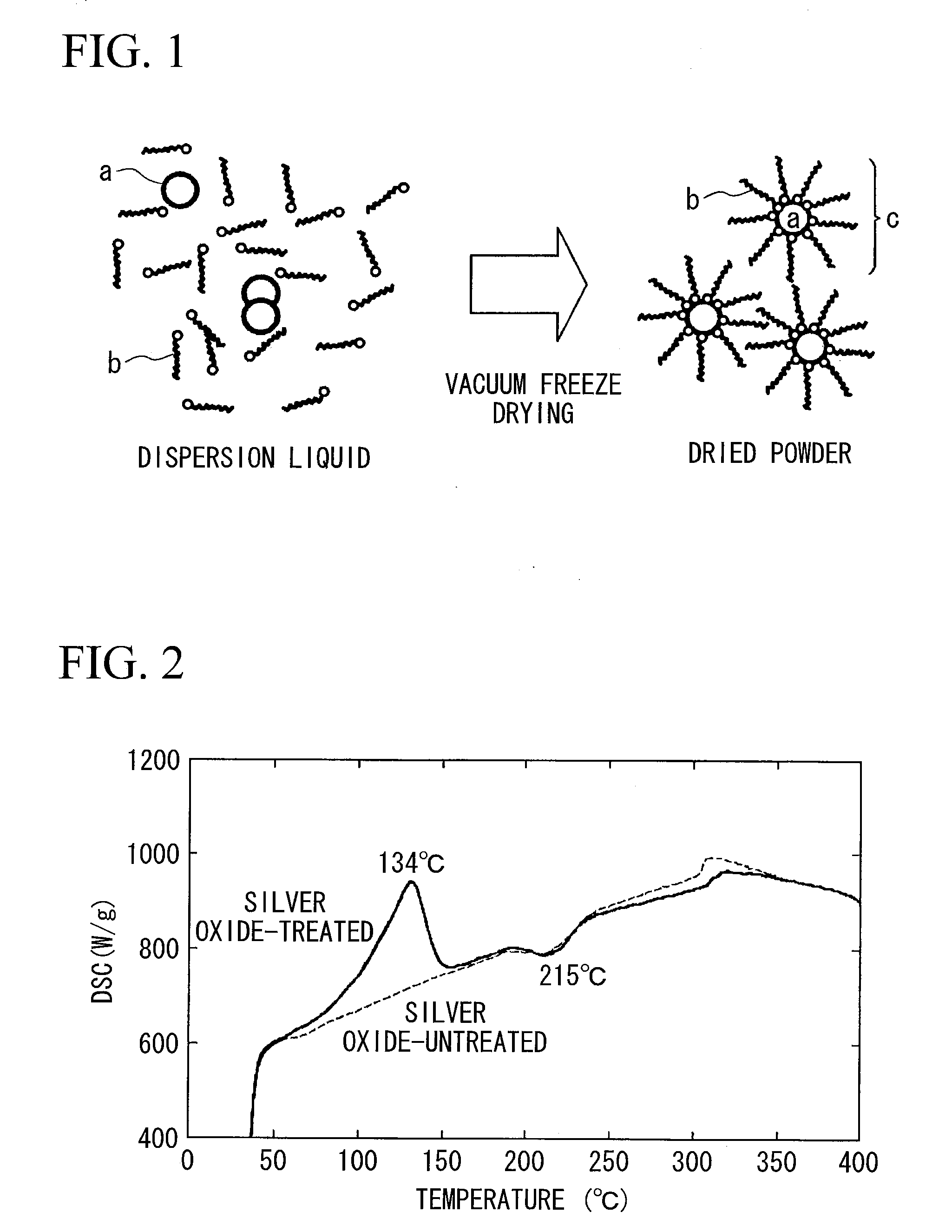

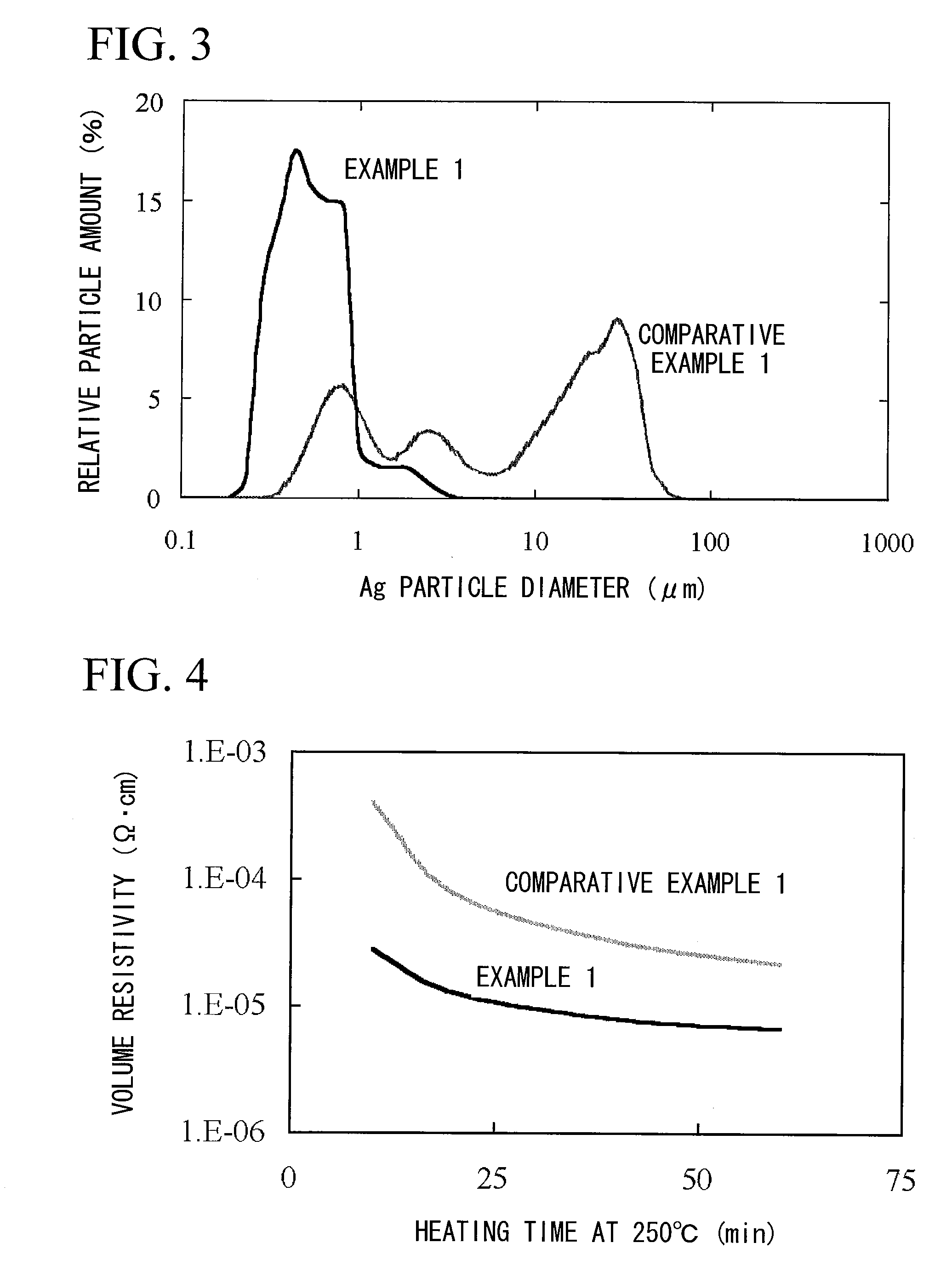

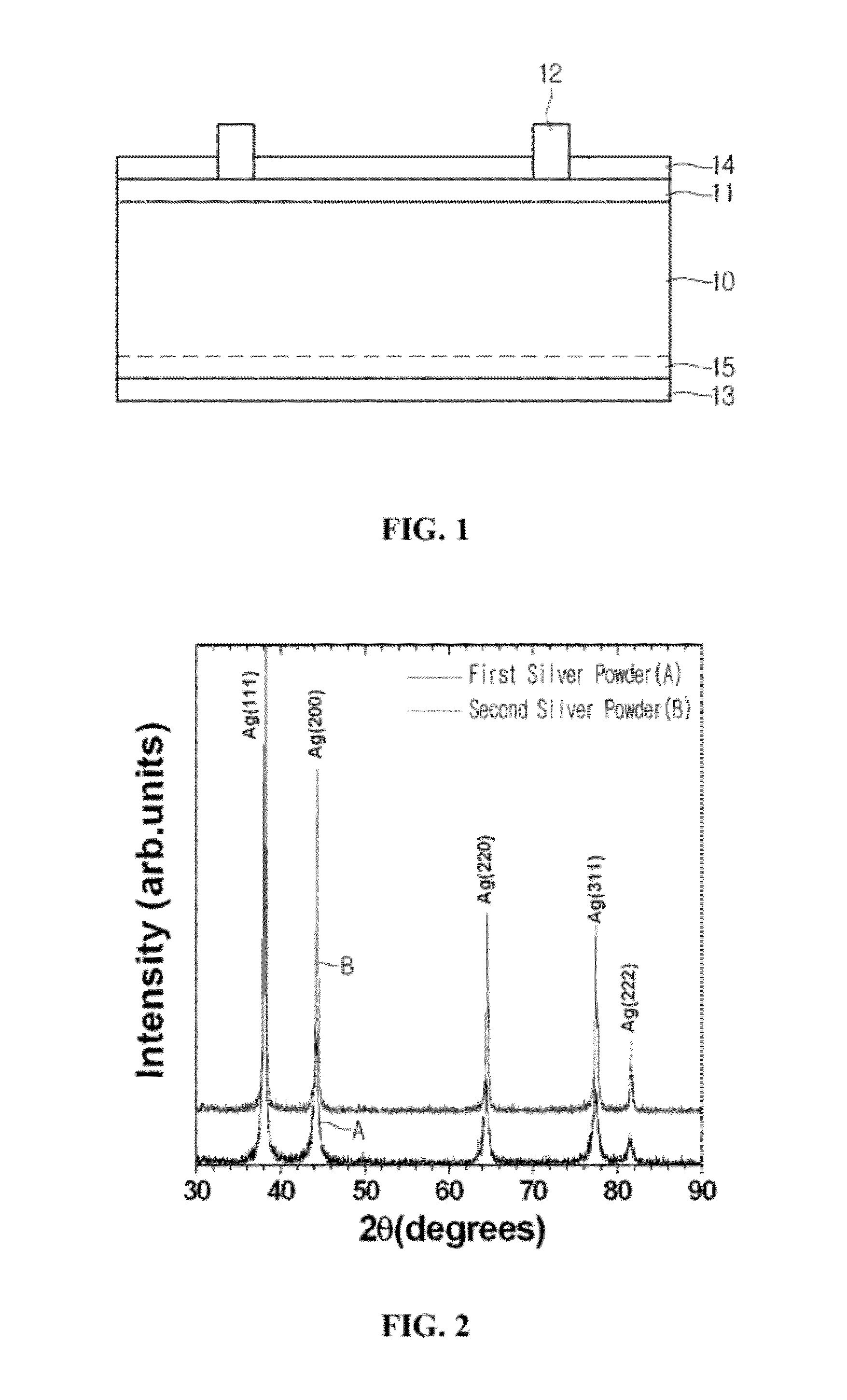

Method for producing surface-treated silver-containing powder and silver paste using surface-treated silver-containing powder

InactiveUS20090146117A1Easy to produceConvenient and stableMetal-working apparatusConductive materialSilver pastePhosphate

Owner:DAINIPPON INK & CHEM INC

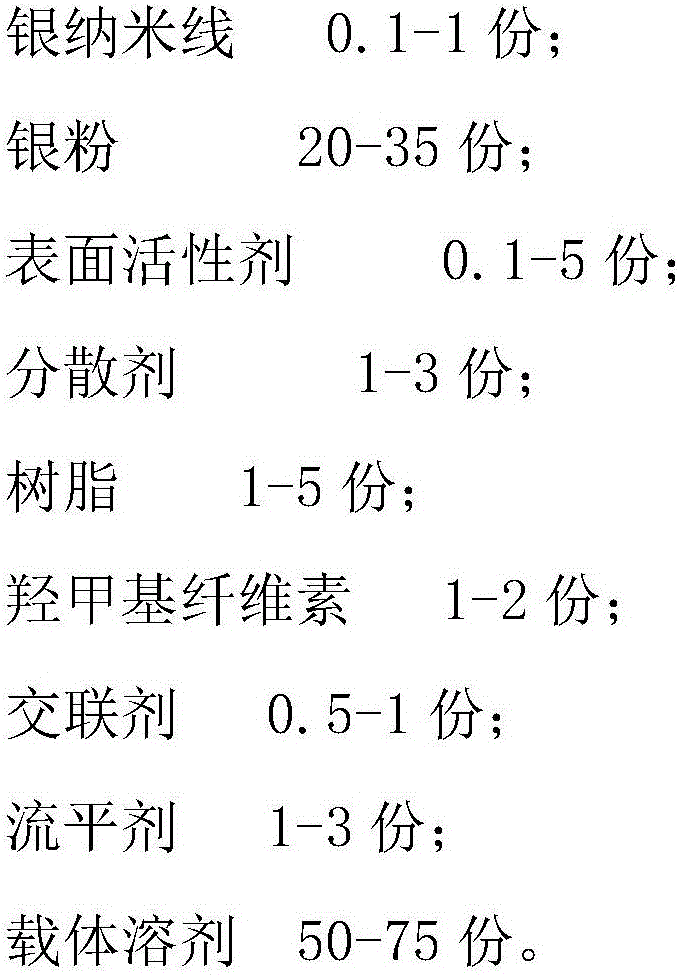

Low-temperature conductive silver paste and preparation method and application thereof

InactiveCN106024100ATo conductionImprove folding resistanceNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteElectromagnetic shielding

Owner:浙江星隆新材料科技有限公司

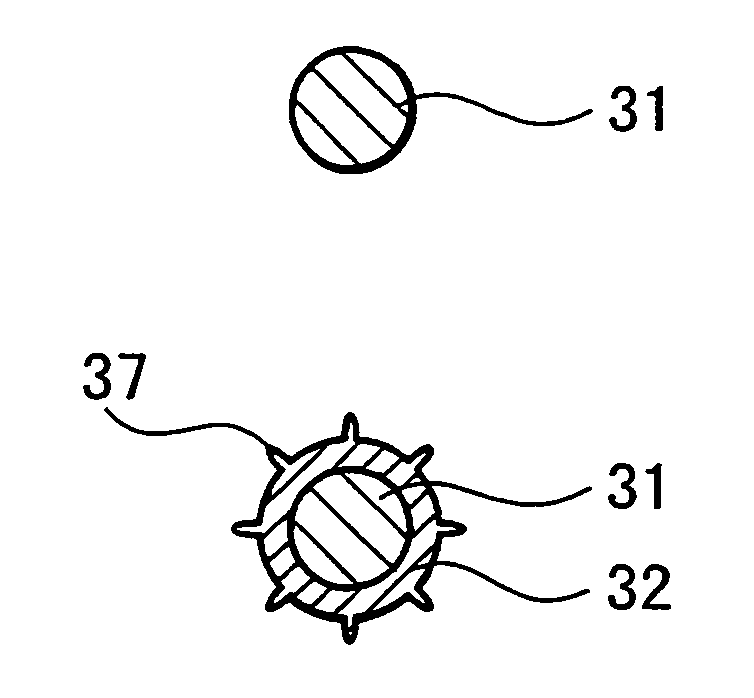

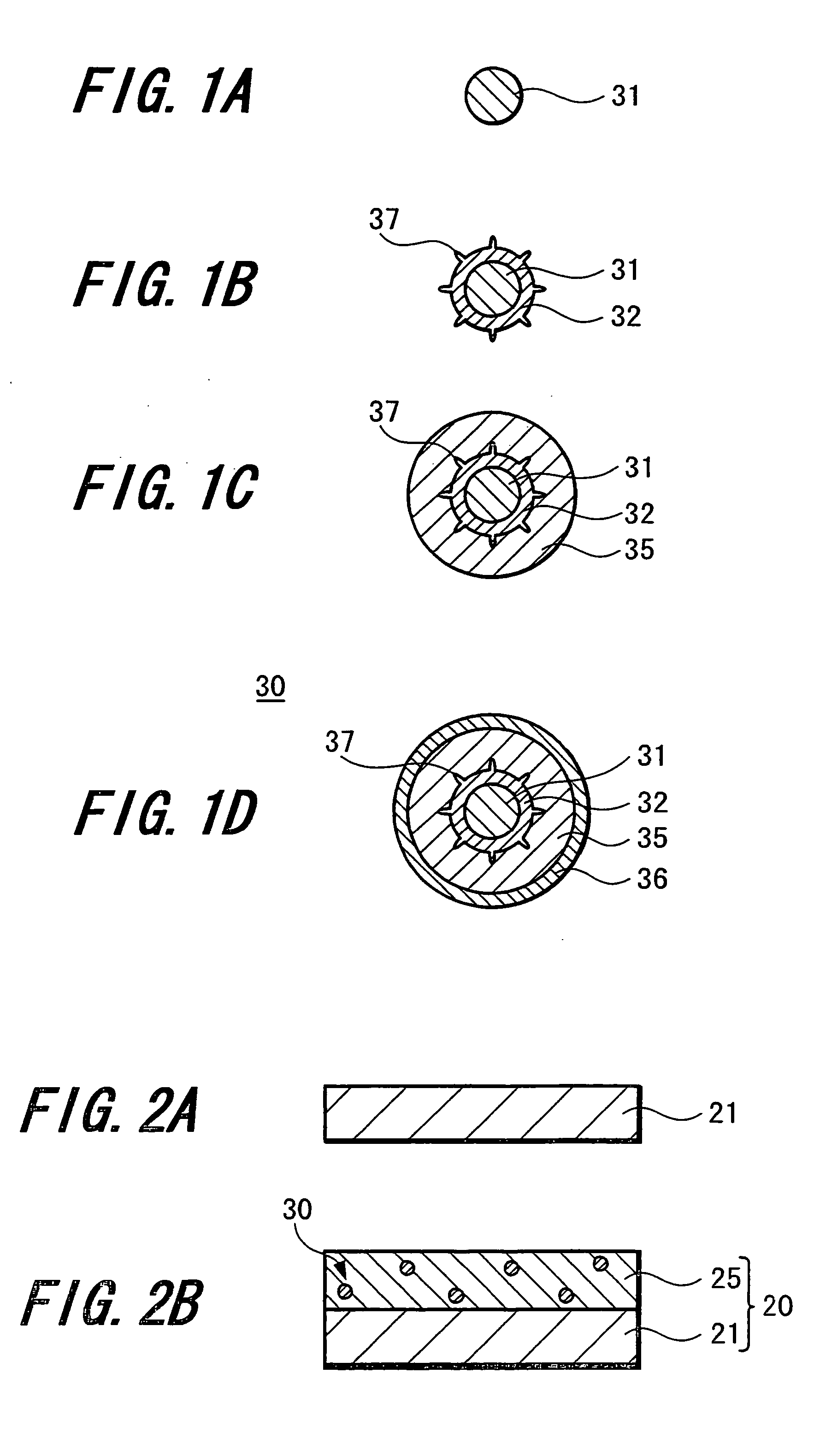

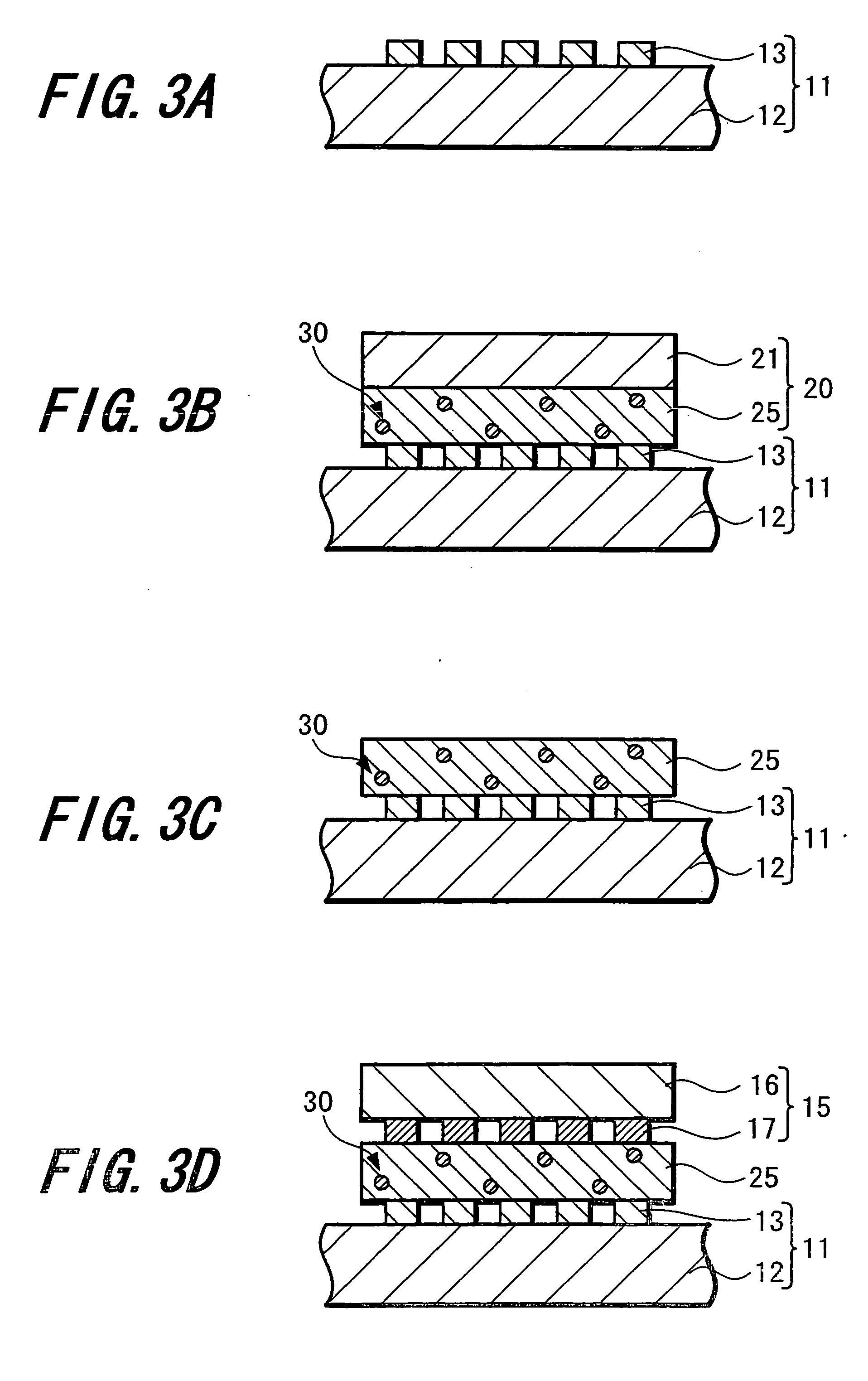

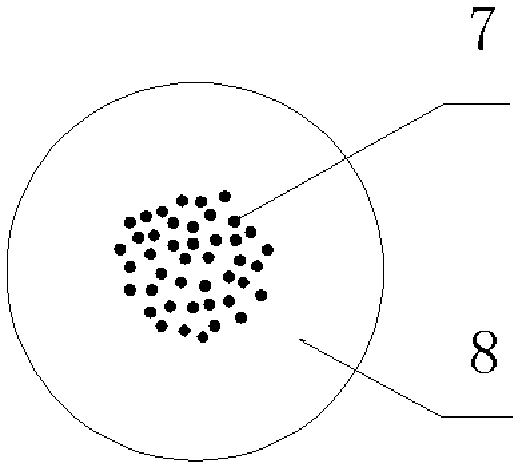

Conductive particle and adhesive agent

ActiveUS20060054867A1Avoid deformationReliable electrical connectionNon-insulated conductorsSolid-state devicesResin coatingMaterials science

Owner:SONY CORP +1

Aqueous Primer Composition

Owner:KANSAI PAINT CO LTD

Modified Conjugated Diene Polymer, Polymerization Intitiator, Method of Producing the Same, and Rubber Composition

InactiveUS20080033110A1Improving low heat buildupEnhanced interactionNon-metal conductorsSilicon organic compoundsAlkaline earth metalEthylene Homopolymers

Owner:BRIDGESTONE CORP

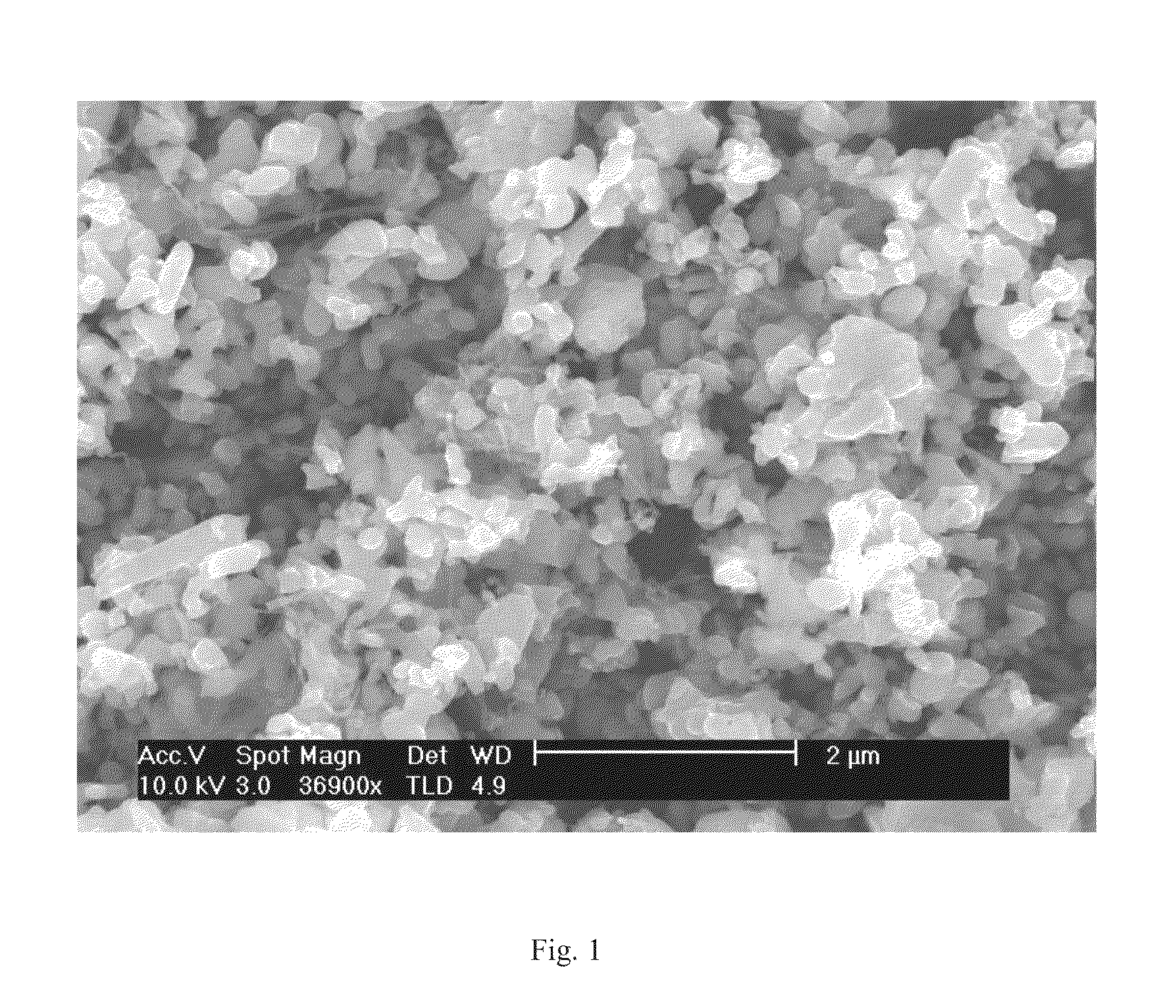

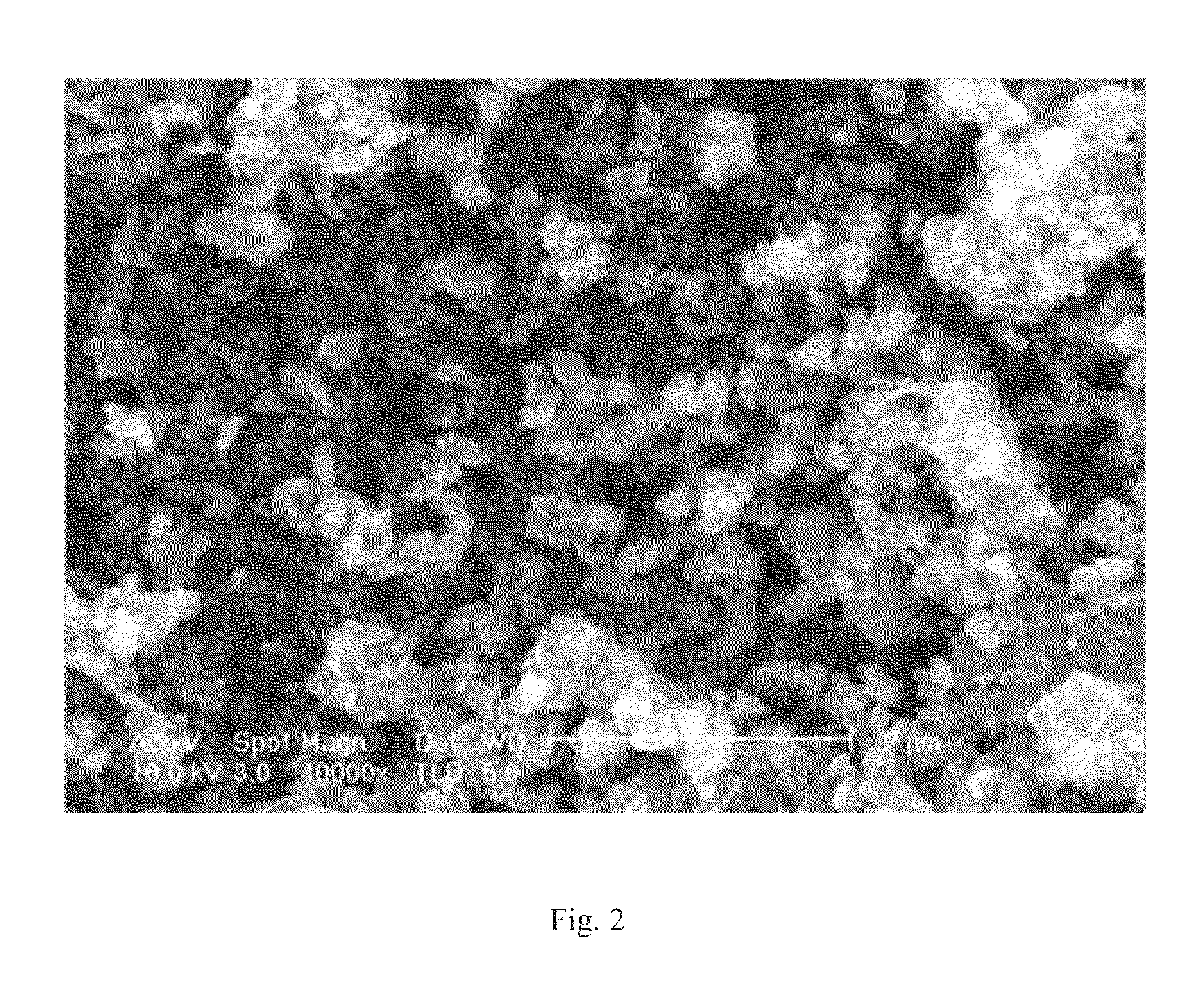

Auto-thermal evaporative liquid-phase synthesis method for cathode material for battery

InactiveUS20140239235A1Simple processReduce energy consumptionNon-metal conductorsPhosphatesInternal resistanceSynthesis methods

Owner:SHENZHEN DYNANONIC

Article and associated device

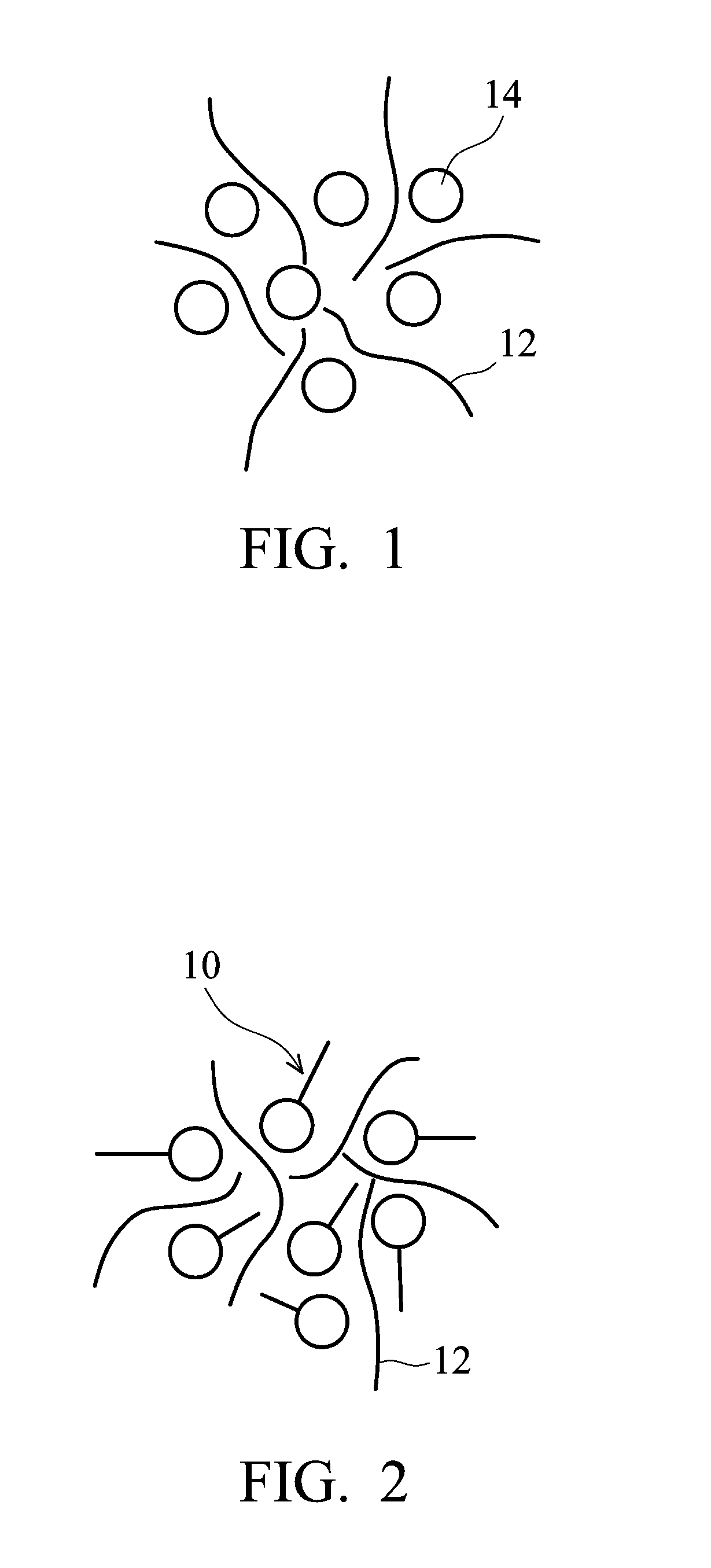

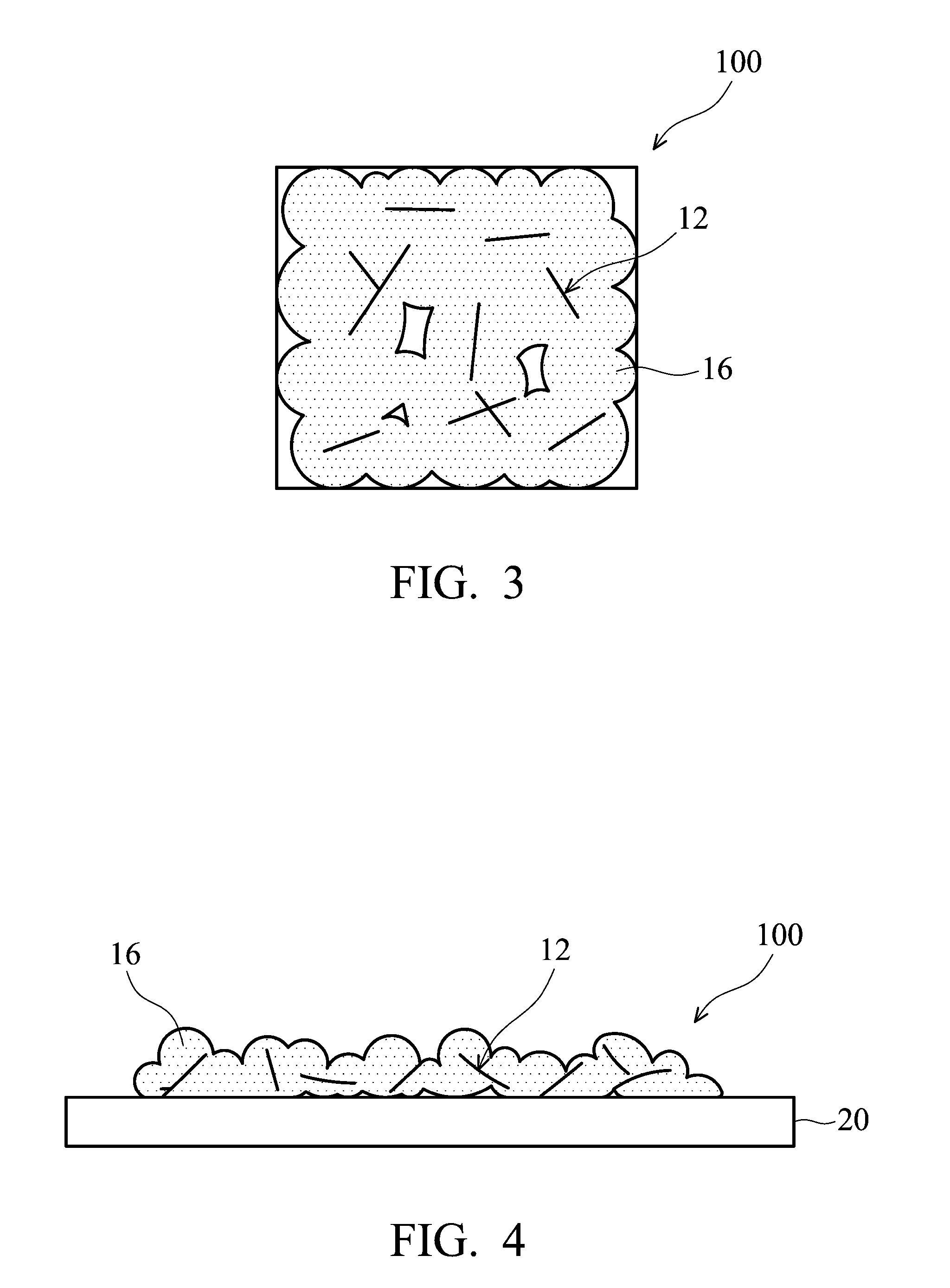

An article includes a composition including a filler dispersed in a polymeric matrix. The filler is electrically conducting in a temperature range and the filler has a Curie temperature. The composition has a trip temperature at which electrical resistance of the composition increases with increase in temperature, and the trip temperature of the composition is determined by the Curie temperature of the filler. The filler is present in the polymeric matrix in an amount determined by a property of one or both of the polymeric matrix or the filler. An associated device is provided.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Low-silver-content composite conductive silver paste and preparation method thereof

InactiveCN104282356AImprove conductivityReduce silver contentNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteScreen printing

The invention relates to a low-silver-content composite conductive silver paste and a preparation method thereof, and belongs to the technical field of electroconductive slurry. The low-silver-content composite conductive silver paste can be used for screen printing. At present, the conductive silver paste preparation technology in China is high in production cost, complex in preparation technology and the like. According to the low-silver-content composite conductive silver paste, silver-plated copper powder and silver-plated glass powder are adopted to replace pure silver powder, so that the production cost of the silver paste is effectively reduced; the mode that spherical particles and platy particles are combined is selected, so that the conductivity of the silver paste is improved; the silver-plated glass powder with the low specific density is adopted, so that the stability of the conductive silver paste is improved, and the storage life of the silver paste is prolonged. The problems existing in silver paste production at present in China are well solved, the sliver paste preparation technology is simple, the silver paste is good in conductivity and impressionability (including automatic and semi-automatic screen printing and the like), and high in adhesion capacity with various substrates such as a PET film, and has significant application value.

Owner:肖淑勇

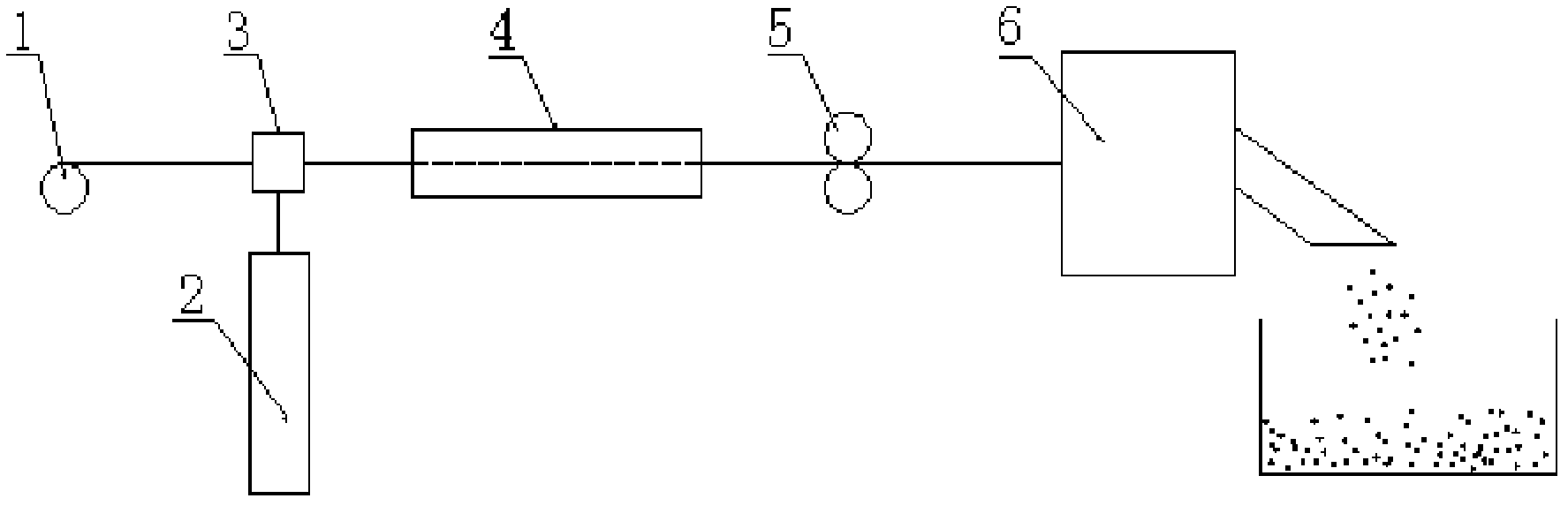

Method of preparing carbon-coated metal nanowire conductive thin film

InactiveCN106971771ALow costEasy to manufactureNon-conductive material with dispersed conductive materialSemiconductor devicesAlloySolar cell

The invention discloses a method of preparing a carbon-coated metal nanowire conductive thin film. A certain amount of metal nanowires is dispersed in a glucose solution, and a hydro-thermal reaction is carried out in a condition of 160 to 200 DEG C for 1 to 5 hours. The metal nanowire is a gold, silver, copper and the like metal nanowire or an alloy and a mixture. The metal nanowire transparent conductive thin film can be prepared through spraying or a thin film transfer method. The method is simple and easy to operate, and the metal nanowire conductive thin film stability can be improved obviously, and the method can promote application of the metal nanowire transparent conductive thin film in the field of an optoelectronic device such as a solar cell.

Owner:JIANGHAN UNIVERSITY

Method for preparing stainless steel fiber resin matrix composite conductive plastics

ActiveCN102617986AImprove mechanical propertiesImprove conductivityNon-conductive material with dispersed conductive materialMethod testEpoxy

Owner:SHENZHEN FRD SCI & TECH

Electrically conductive composition and fabrication method thereof

ActiveUS20110101283A1Electric discharge heatingRadiation applicationsConductive polymerConductive materials

Owner:IND TECH RES INST

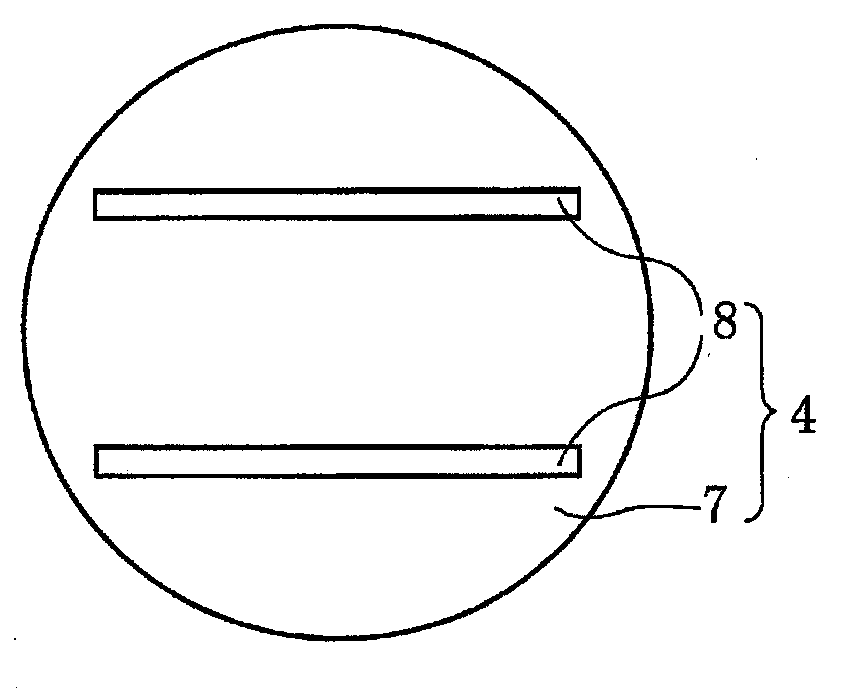

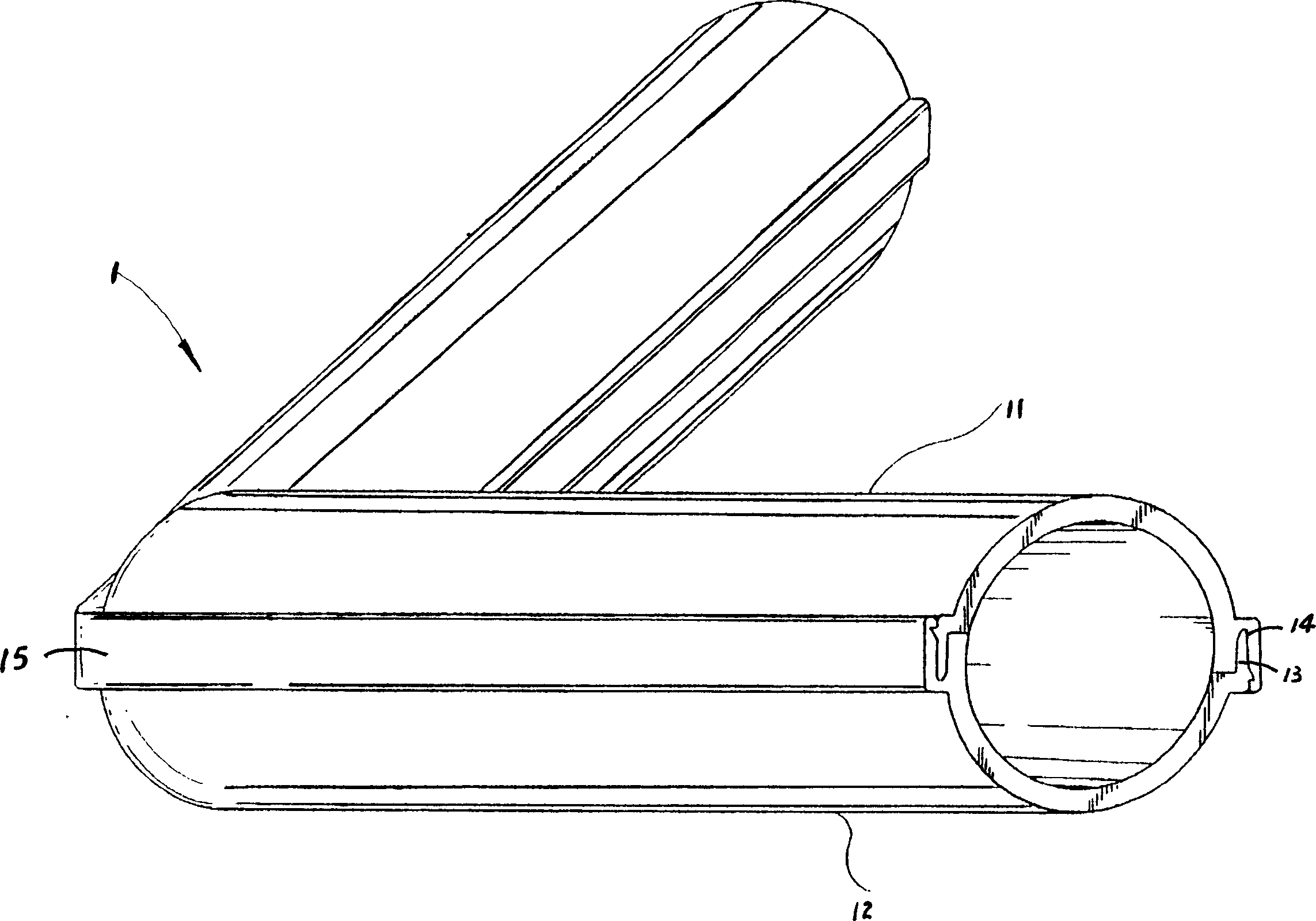

Window pane with sintered conductive ceramic.

ActiveUS20110039113A1Improve conductivityGood lookingNon-conductive material with dispersed conductive materialGlass/slag layered productsElectrical conductorGlass sheet

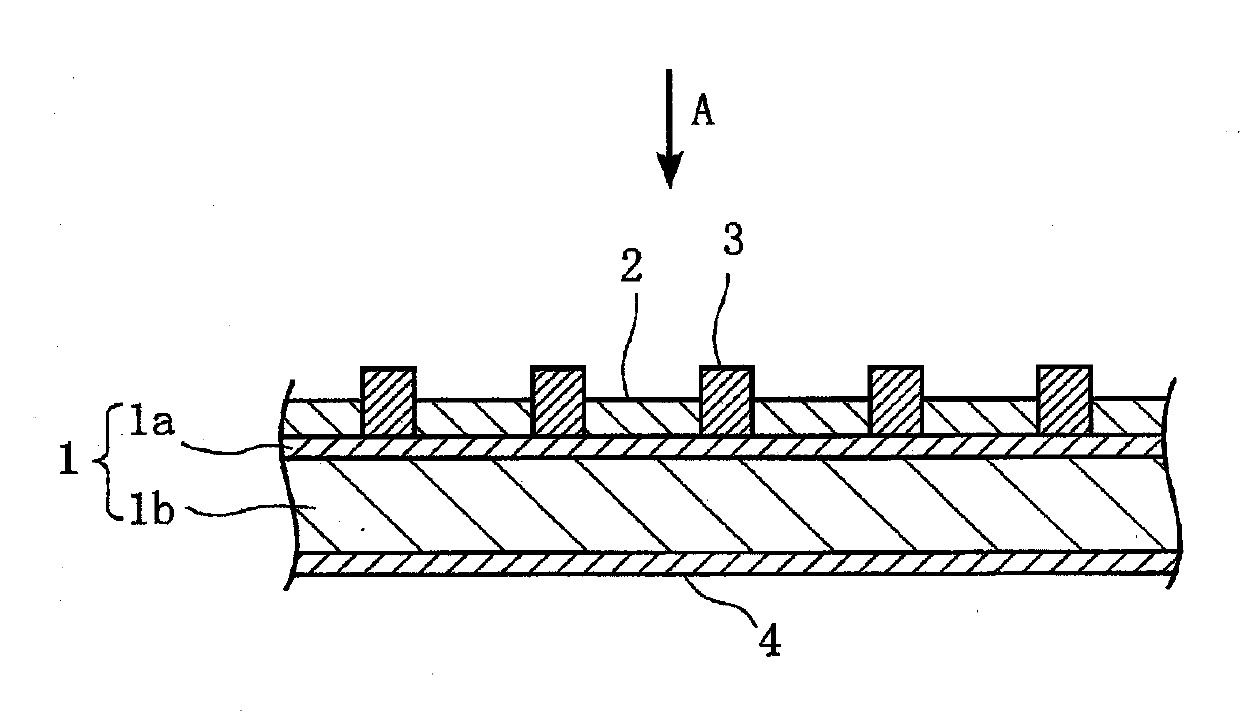

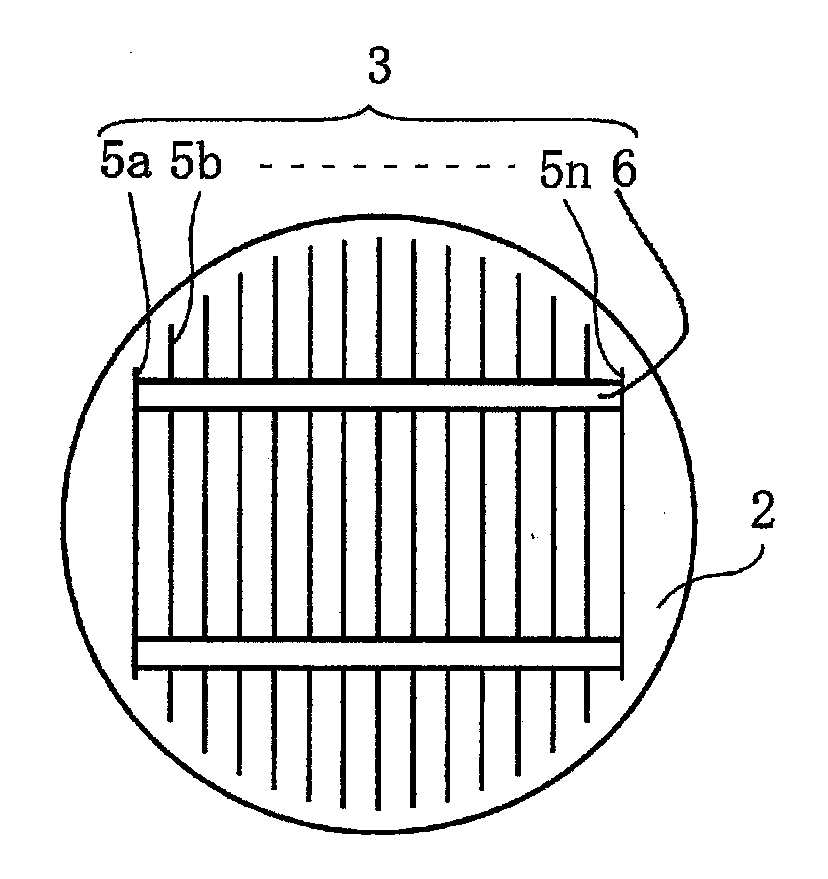

The present invention provides a window glass with conductive ceramic fired body which is capable of not only ensuring a good conductivity of the fired body but also exhibiting an improved appearance on both an interior side and an exterior side of a vehicle when the window glass is used for vehicles. The window glass with conductive ceramic fired body according to the present invention includes at least one glass plate having main surfaces, and the conductive ceramic fired body including a feeding point and a linear portion which is disposed on either one of the main surfaces of the glass plate, at least a part of the linear portion being placed in a visible region of the window glass and formed by successively laminating a first colored layer, a conductor layer and a second colored layer on the main surface, wherein the first colored layer and the second colored layer each include a pigment and a glass component, and the conductor layer includes silver and the glass component.

Owner:NIPPON SHEET GLASS CO LTD

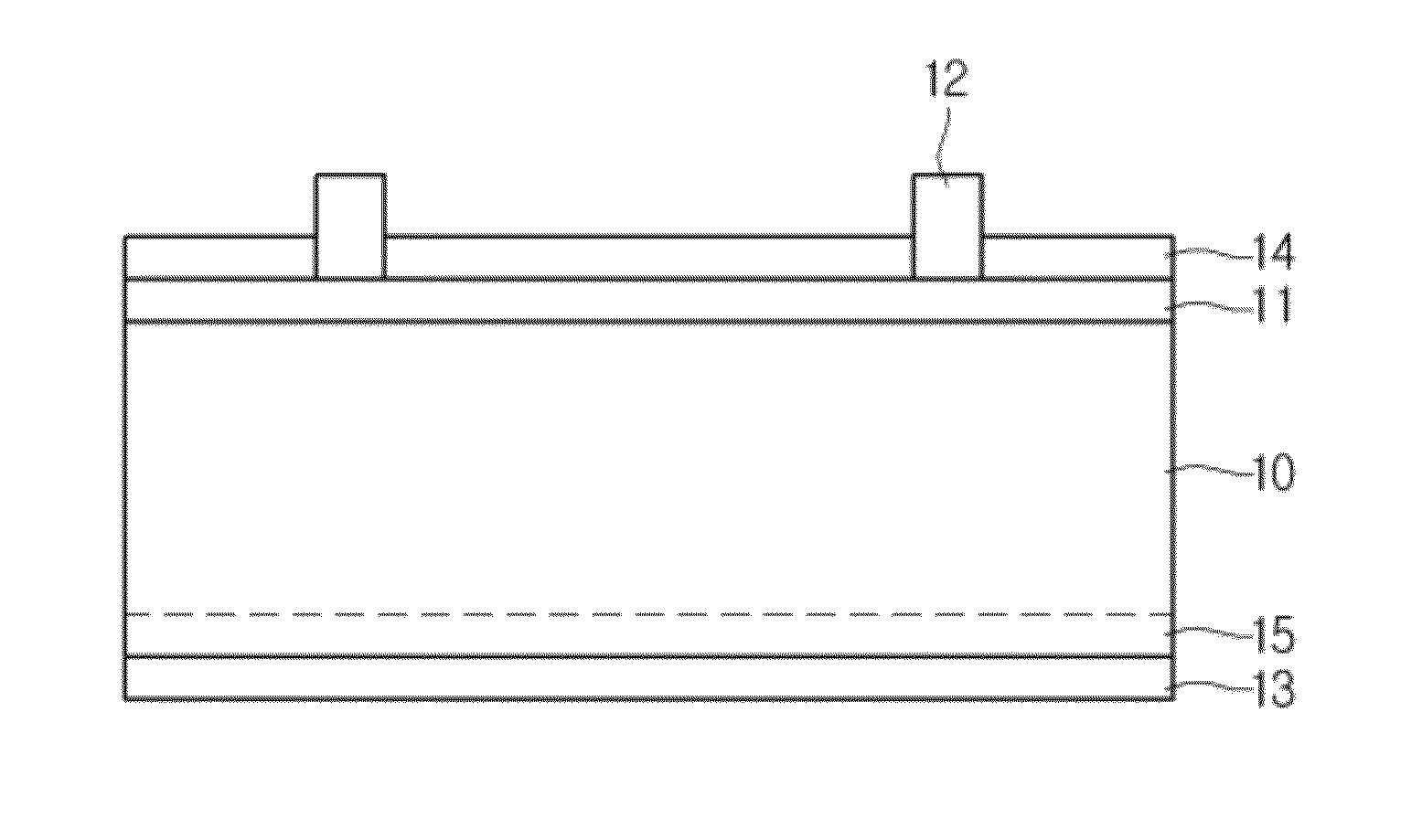

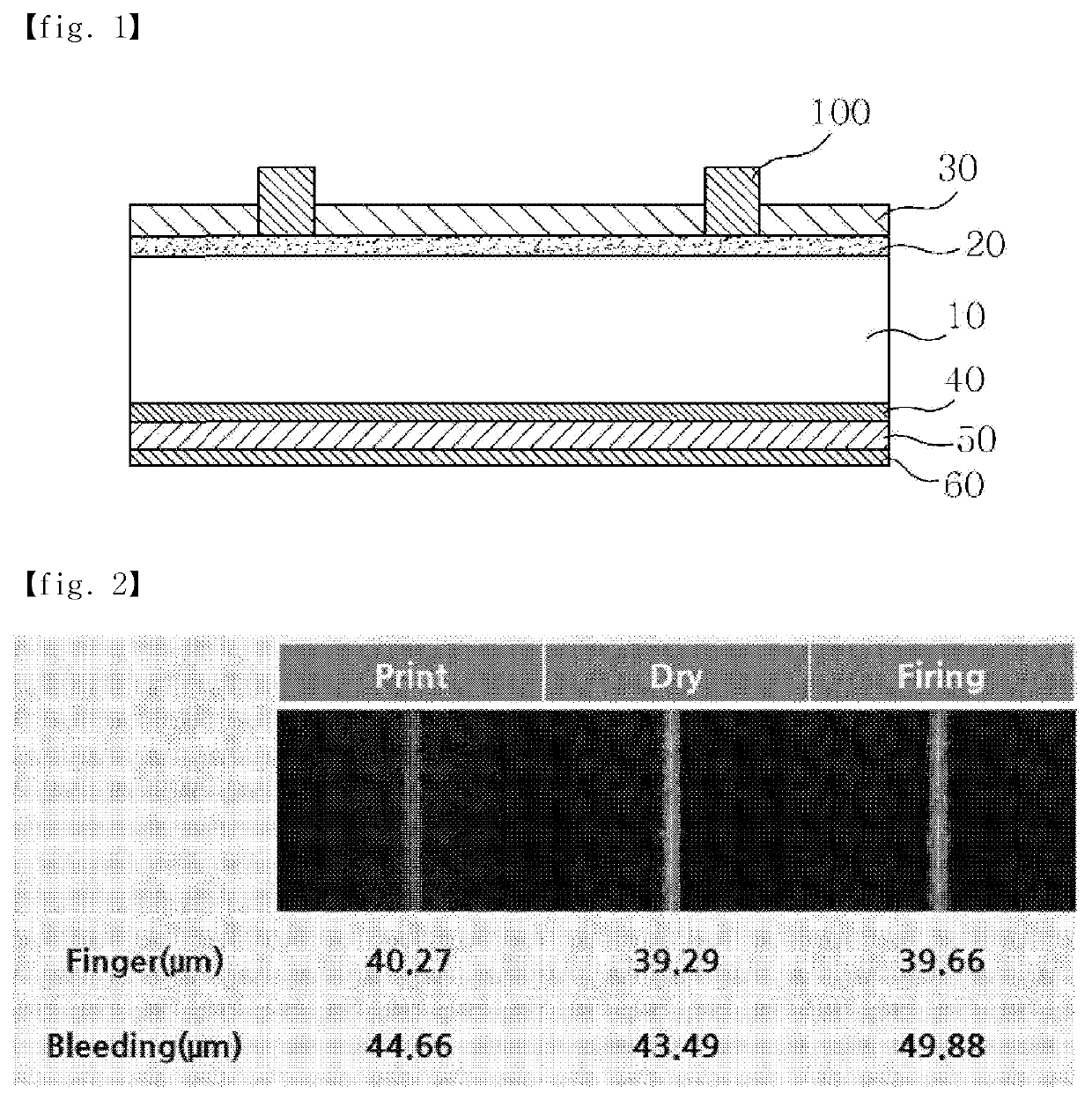

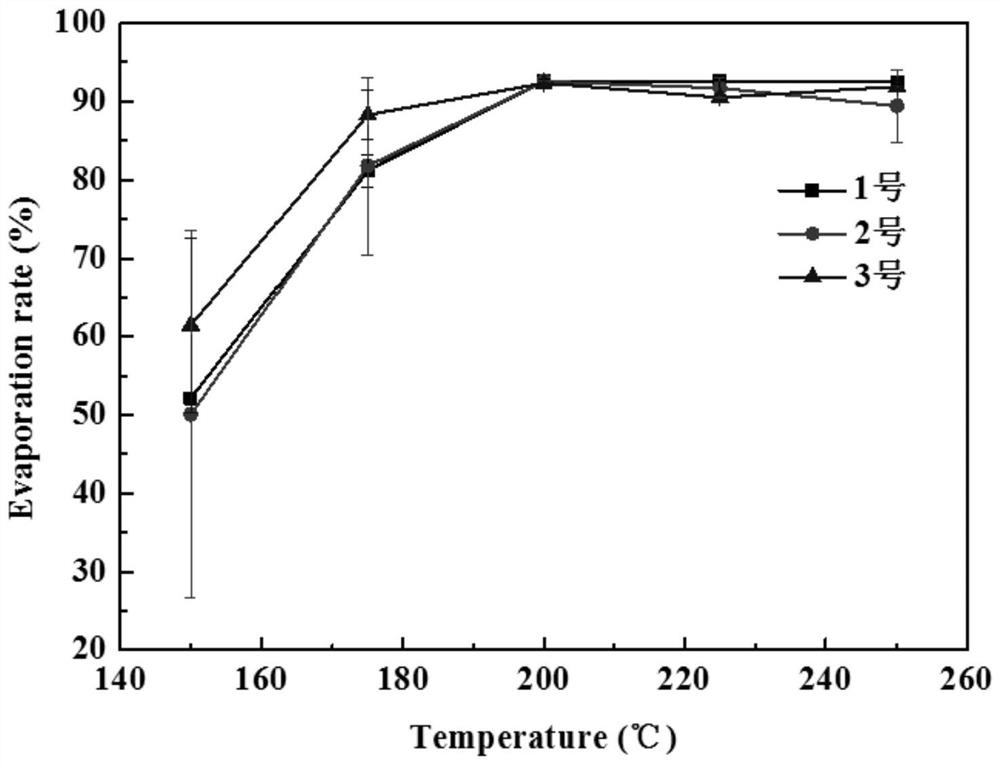

Conductive paste and solar cell

ActiveCN104813414APrevent sinteringPromote sinteringNon-conductive material with dispersed conductive materialPhotovoltaic energy generationLine resistanceConductive paste

Owner:HERAEUS PRECIOUS METALS NORTH AMERICA CONSHOHOCKEN

Solar energy electrical conduction slurry and preparation method thereof

InactiveCN102938260ANon-conductive material with dispersed conductive materialCable/conductor manufactureWeather resistanceSilane coupling

Owner:DONGFANG ELECTRIC YIXING MAGI SOLAR POWER TECH

Photo-curing conductive adhesive for touch panel

InactiveUS20140284527A1Avoid wasting electricityLow curing temperatureConductive materialEster polymer adhesivesAdhesiveMetal particle

A photo-curing conductive adhesive for a touch panel includes an adhesive in an amount within the range of 20 to 30 wt % and the metal particle composition in an amount within the range of 70 to 80 wt %.

Owner:ETURBOTOUCH TECH

Method for preparing conductive filler of antistatic materials

InactiveCN106189378AGood antistatic effectImprove antistatic performanceOther chemical processesNon-conductive material with dispersed conductive materialDispersityElectricity

Owner:NINGBO JIANGDONG SUOLEISI ELECTRONICS TECH

Shield haf type wire and cable protective sleeve

InactiveCN1858948AEasy to replaceEasy maintenanceCable installations in underground tubesNon-conductive material with dispersed conductive materialPolyolefinMetal powder

Owner:周宝茂 +2

Conductive paste composite

InactiveUS20120103410A1Simple processLarge aspect ratioMaterial nanotechnologyConductive materialConductive pasteOptoelectronics

Owner:LG INNOTEK CO LTD

Low-temperature curing touch screen conductive silver paste suitable for laser etching processing

InactiveCN106898411AApparatus for manufacturing conducting/semi-conducting layersNon-conductive material with dispersed conductive materialSolventWeather resistance

Owner:北京市合众创能光电技术有限公司

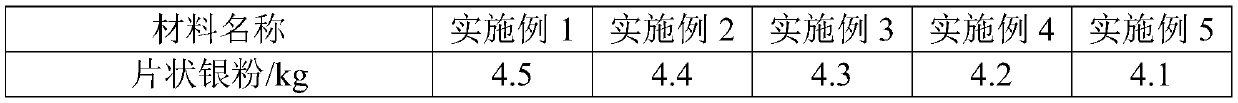

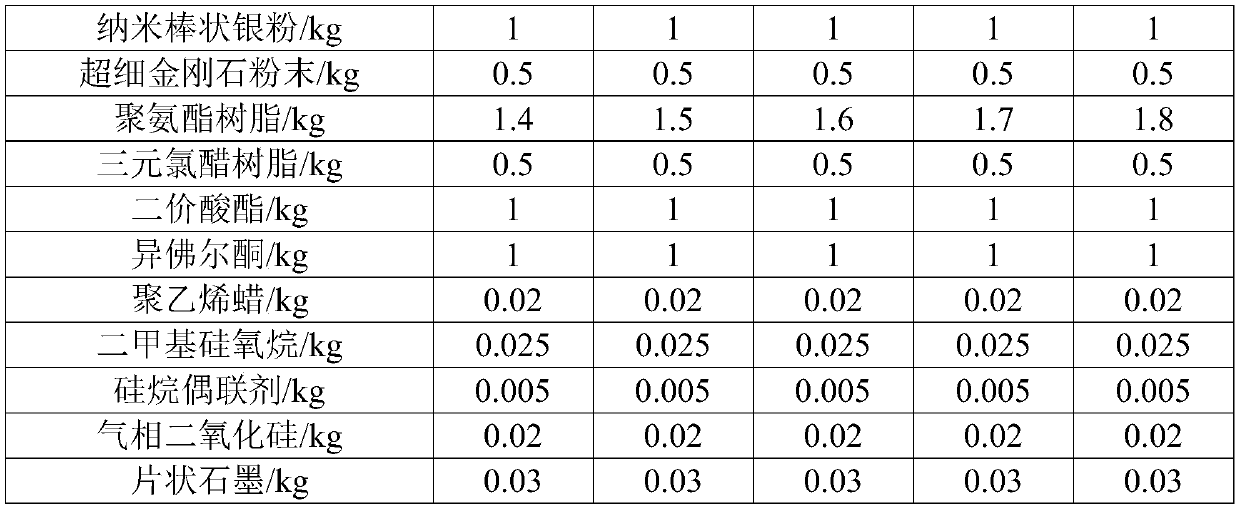

Low-temperature conductive silver paste for automobile safety belt alarming and preparation method thereof

InactiveCN111489847AEffective defoamingEffective simulation of printing effectsNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteAutomobile safety

Owner:SHANGHAI BAOYIN ELECTRONICS MATERIALS CO LTD

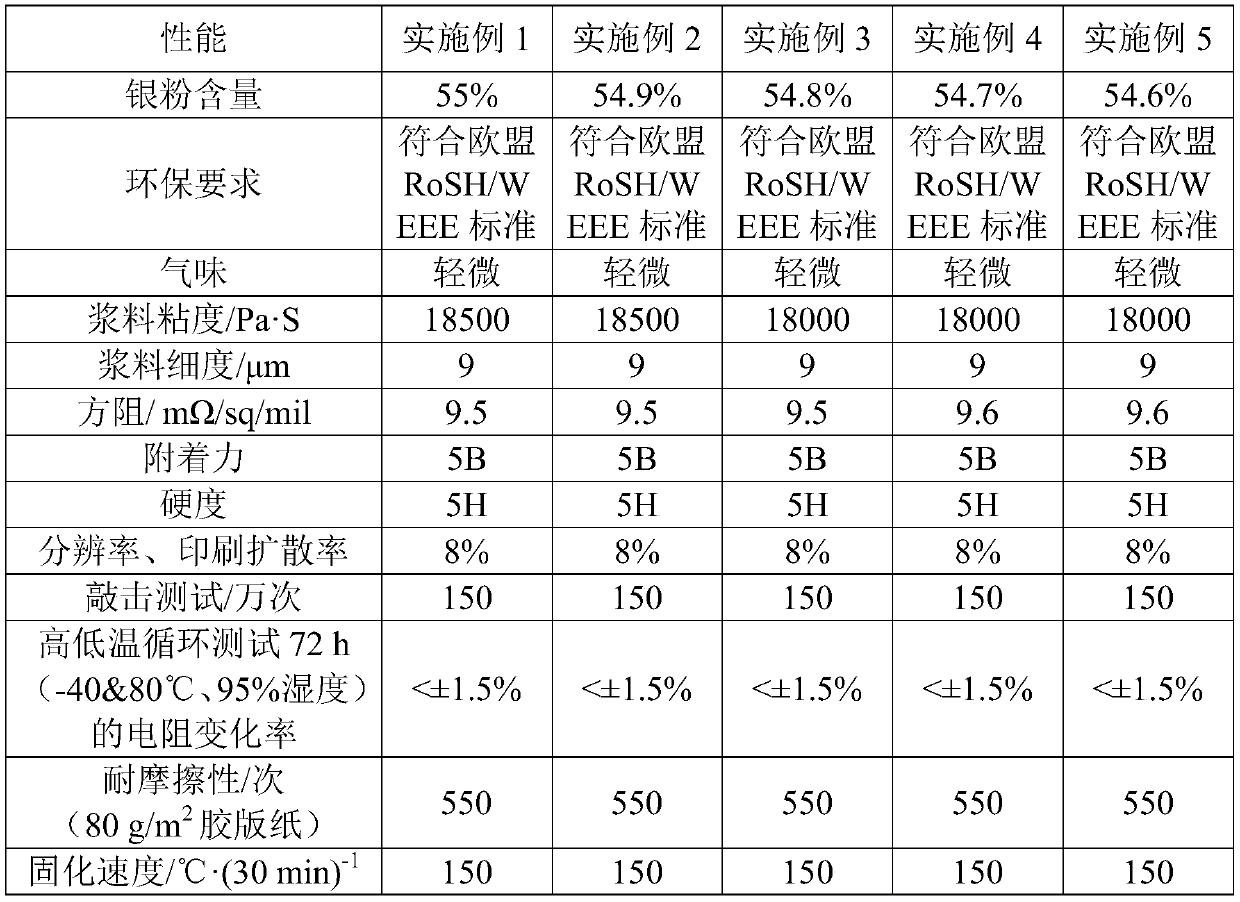

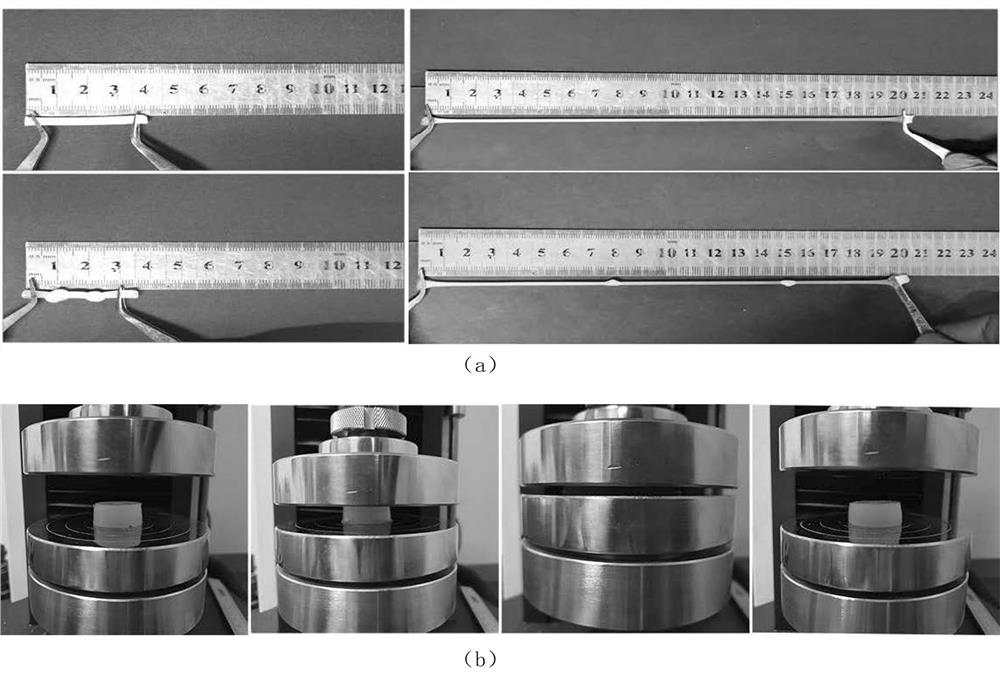

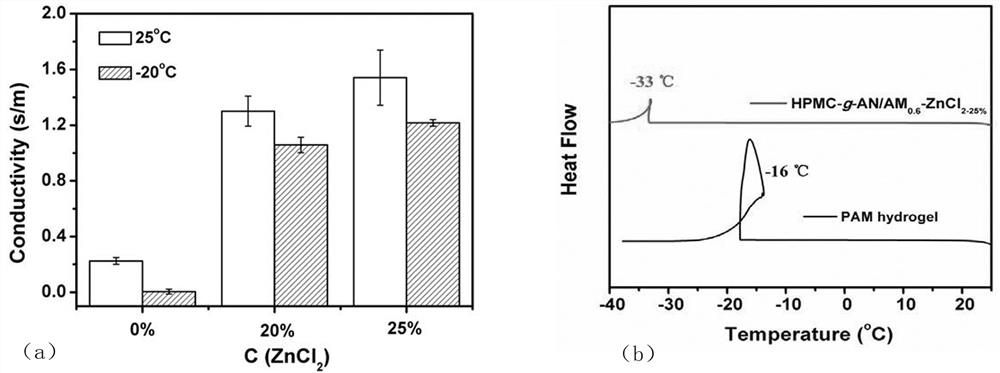

Preparation method of cellulose-based conductive hydrogel

ActiveCN112142918AImprove tensile propertiesImprove stress resistanceNon-conductive material with dispersed conductive materialCellulosePolymer science

Owner:NORTHWEST UNIV

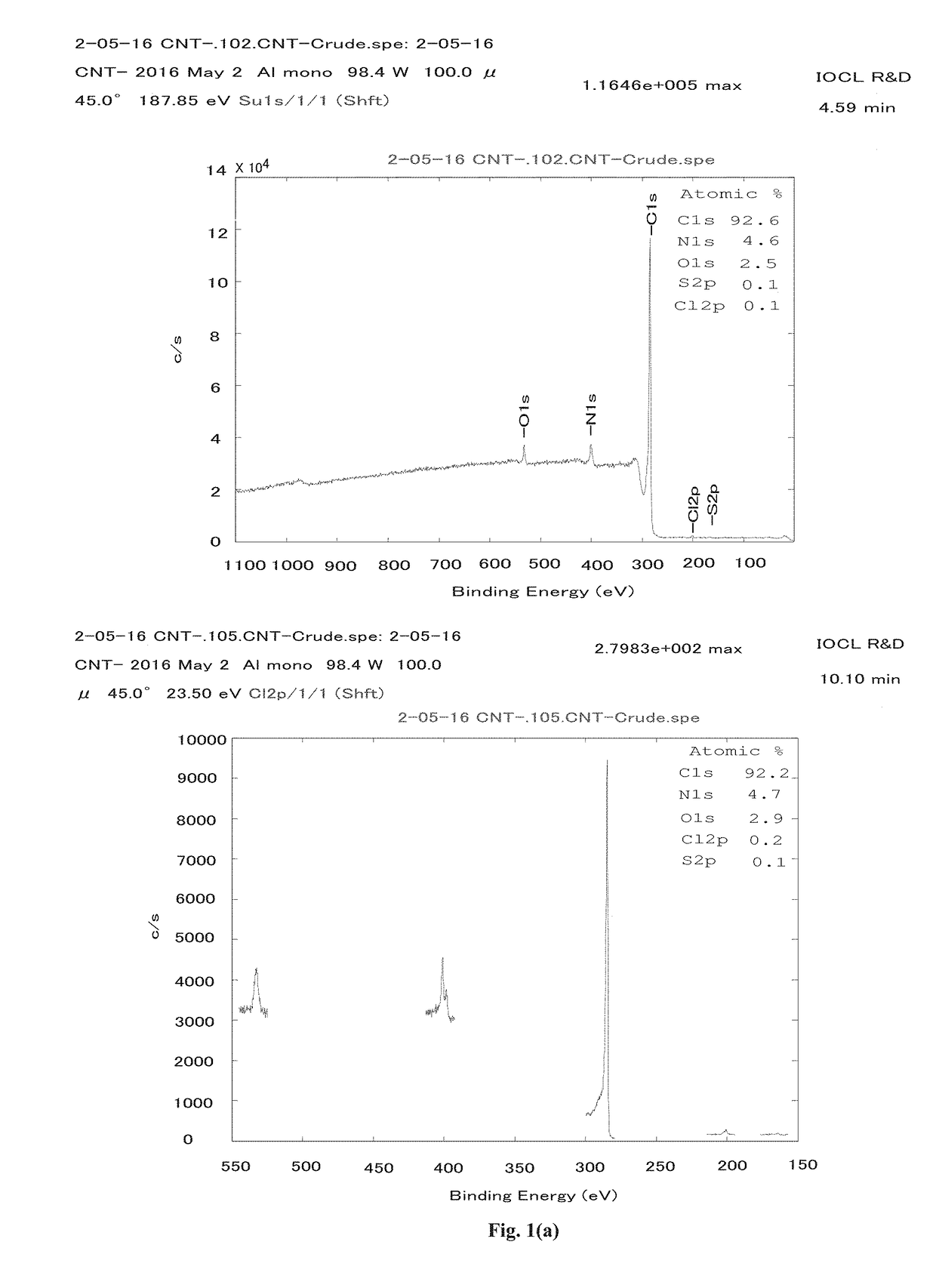

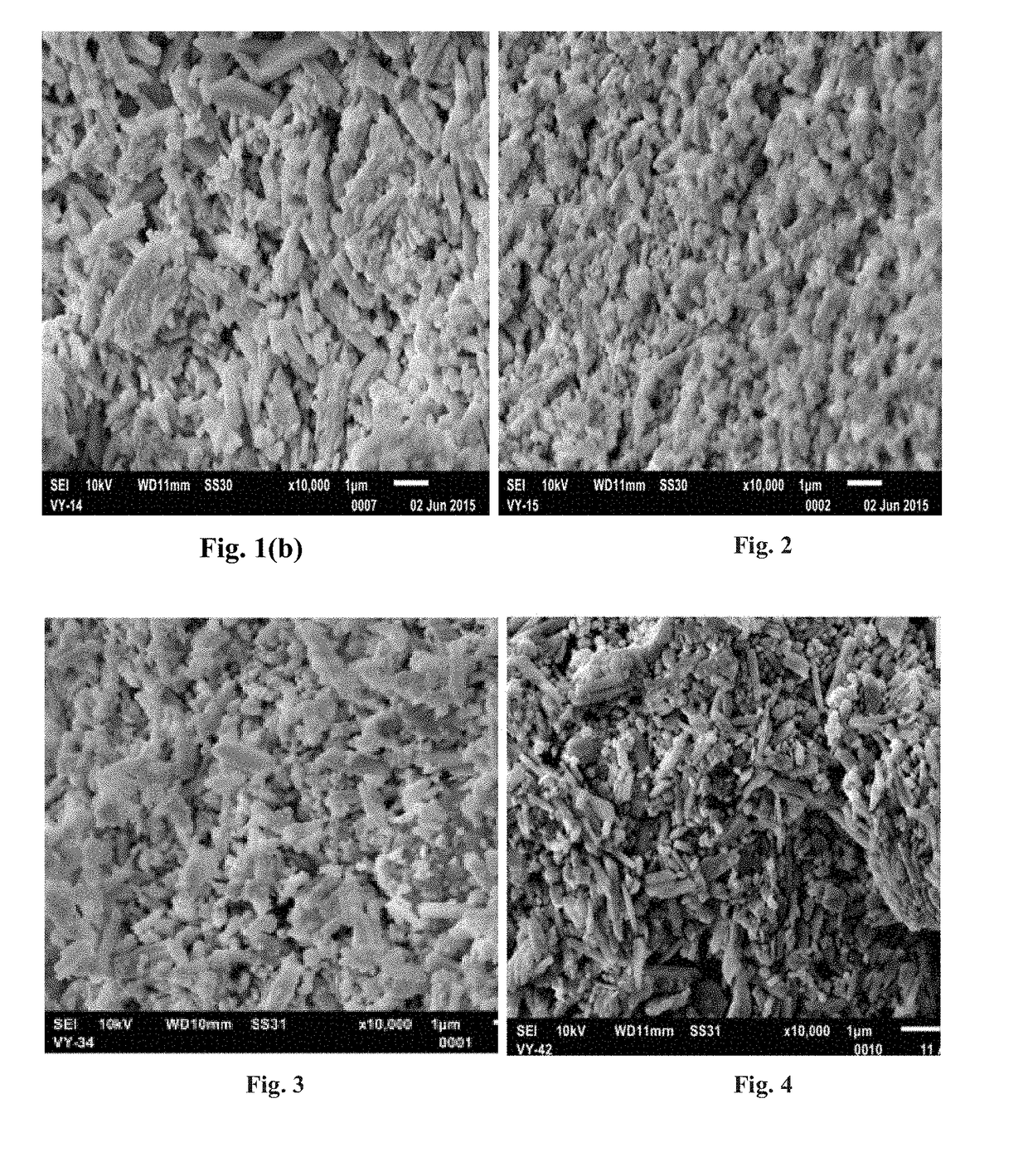

Compositions for preparing expander free electrodes for lead acid battery and performance thereof

ActiveUS20180337397A1Increase battery capacityImprove efficiencyMaterial nanotechnologyLead-acid accumulatorsSulfurHeteroatom

Owner:INDIAN OIL CORPORATION

Preparation method for solar cell conductive mixed paste containing polyethylene vinyl acetate

ActiveCN103117130AImprove photoelectric conversion efficiencyImprove conductivityNon-conductive material with dispersed conductive materialCable/conductor manufacturePolyethylene vinyl acetateEpoxy

Owner:重庆新锐科技服务有限公司

High efficiency local back electrode aluminum paste for crystalline silicon solar cells and its application in perc cells

ActiveUS20190006539A1Reduce leakage currentImprove efficiencyNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilicon solar cellCrystalline silicon

Owner:NANTONG T SUN NEW ENERGY CO LTD

Automatic production process of graphene electrocondution slurry

ActiveCN112885500AExtended service lifeImprove conductivityNon-conductive material with dispersed conductive materialCable/conductor manufactureEpoxyMetallurgy

Owner:WUXI DONGHENGNEWENERGYTECHNOLOGYCO LTD

Conductive paste for solar cell electrode and solar cell manufactured using same

InactiveUS20200024180A1Improve shrinkageImprove power generation efficiencyNon-conductive material with dispersed conductive materialPhotovoltaic energy generationConductive pasteEngineering

Owner:LS MNM INC

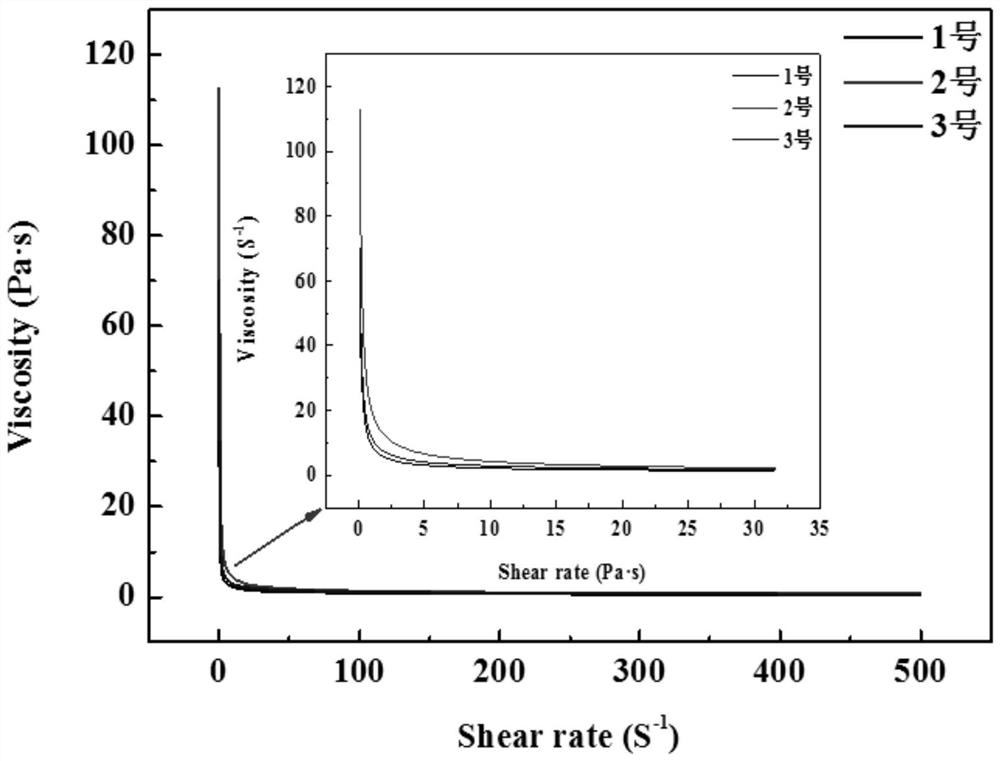

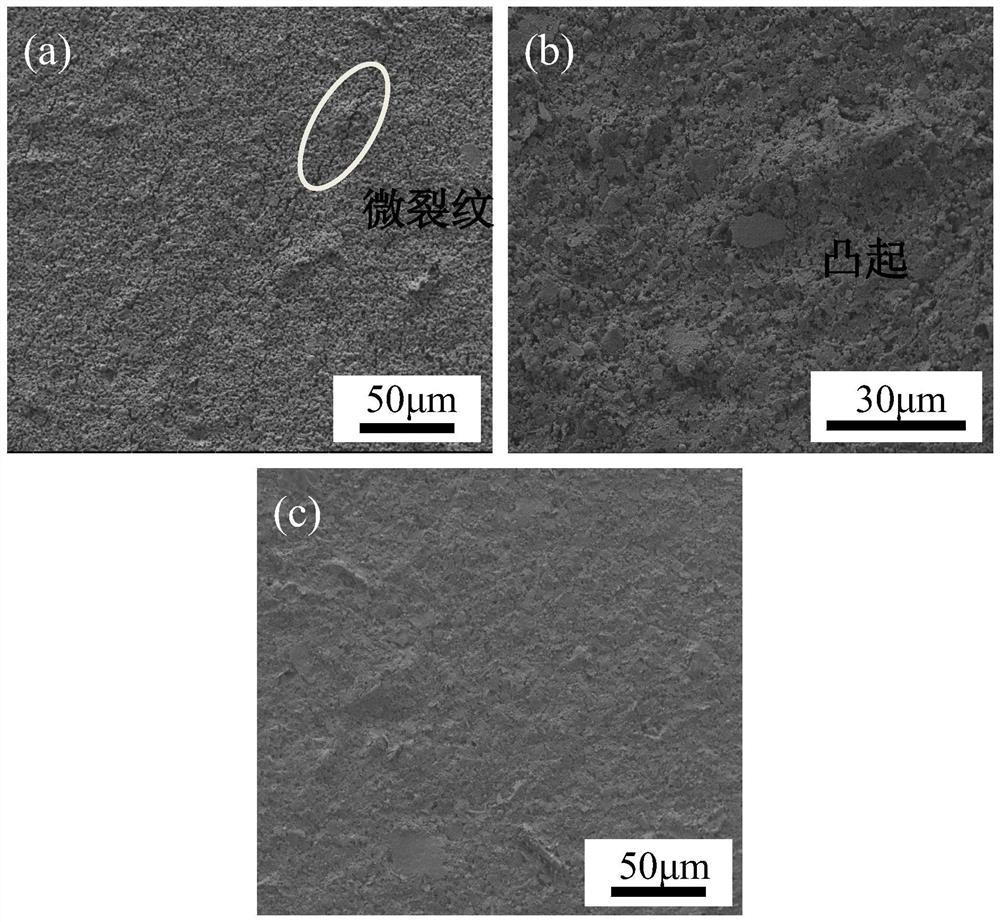

Conductive slurry organic carrier and preparation and application thereof

ActiveCN114049985ANon-conductive material with dispersed conductive materialCable/conductor manufactureDiethylene glycol monobutyl ether acetateSilver paste

Owner:CENT SOUTH UNIV

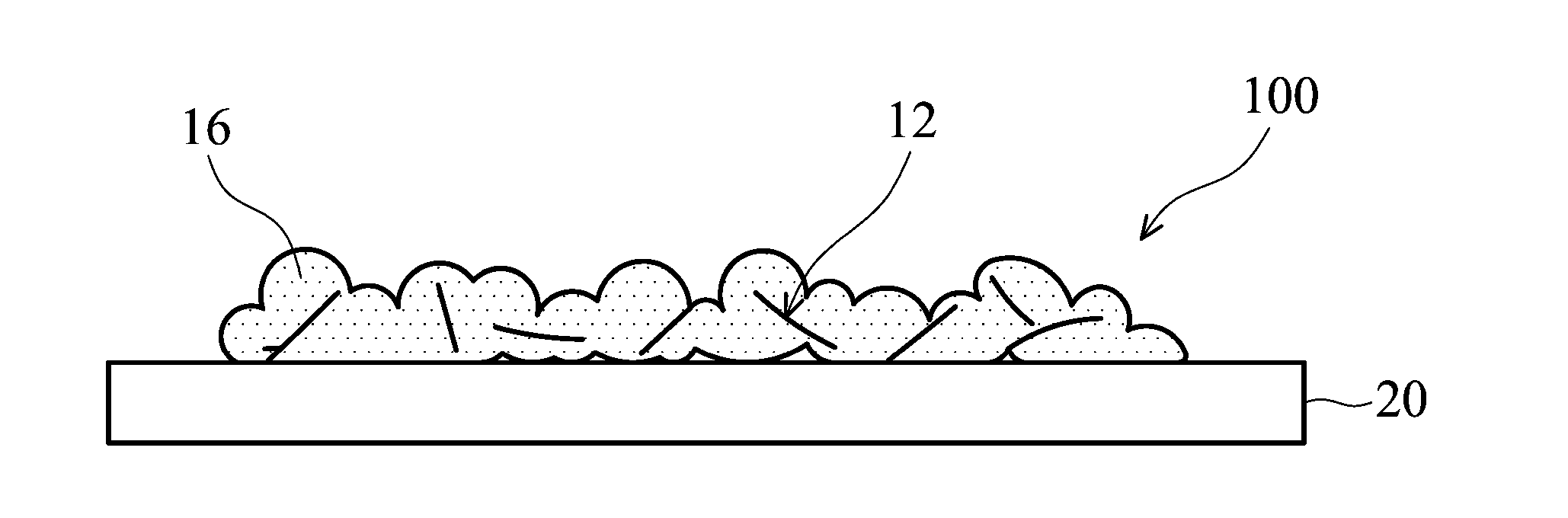

Method of manufacturing flexible conductive wire, flexible conductive wire, and display device

InactiveUS20210358661A1Material nanotechnologyConductive layers on insulating-supportsPolystyreneDisplay device

A method of manufacturing a flexible conductive wire, a flexible conductive wire, and a display device are provided. The method manufacturing the flexible conductive wire includes: forming a zinc oxide nano-monomer into a patterned substrate, coating a carboxylated silver / 3,4-ethylenedioxythiophene: polystyrenesulfonic acid solution on the patterned substrate, and curing the patterned substrate and the carboxylated silver / 3,4-ethylenedioxythiophene: polystyrenesulfonic acid solution to form a flexible conductive wire. Display performance of a display panel can be improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Solar cell conductive paste containing phthalic acid ester

ActiveCN103117104AImprove photoelectric conversion efficiencyImprove conductivityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteConductive paste

Owner:铜陵汇恒电子科技有限公司

Main gate electrode for double-sided battery imbricate assembly

PendingCN113744915ALow costReduce Fragmentation RateNon-conductive material with dispersed conductive materialCable/conductor manufactureAcrylic resinPhysical chemistry

The invention discloses a main gate electrode for a double-sided battery imbricate assembly, and relates to the field of electrodes. The main gate electrode comprises the following components in percentage by weight: 20-30% of flake powder, 60-72% of ball powder, 2-6% of thermosetting acrylic resin and 0-2% of hydrogenated bisphenol F resin, the curing agent comprises 0.5 to 1 percent of silicone oil, 0.2 to 0.6 percent of dispersing agent and 0.1 to 0.7 percent of thixotropic agent; and 2-4% of an active solvent. According to the main gate electrode for the double-sided battery imbricate assembly, the cost of the assembly battery can be reduced, the fragmentation rate of the imbricate assembly is reduced. Meanwhile, minority carrier recombination does not exist in the main gate area of the battery, and the conversion efficiency of the battery is improved.

Owner:JIANGSU ZHENGNENG ELECTRONICS TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap