Conductive slurry organic carrier and preparation and application thereof

An organic carrier and conductive paste technology, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc. It can improve the rheological properties and printing properties, the raw materials are cheap, and the vapor pressure can be changed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

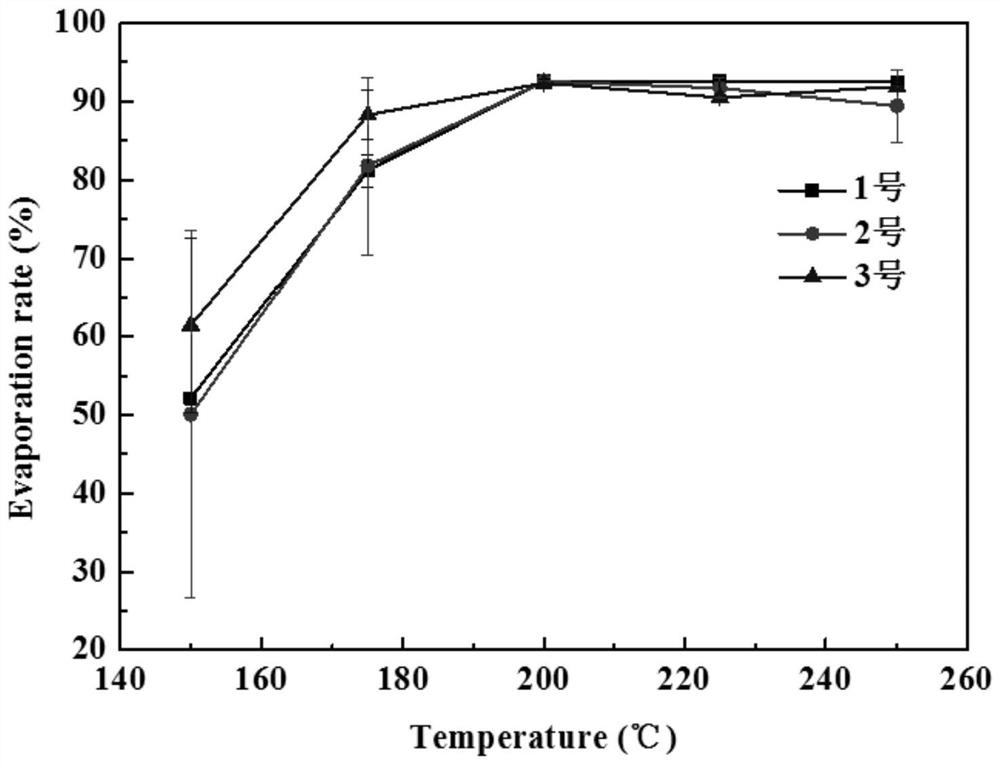

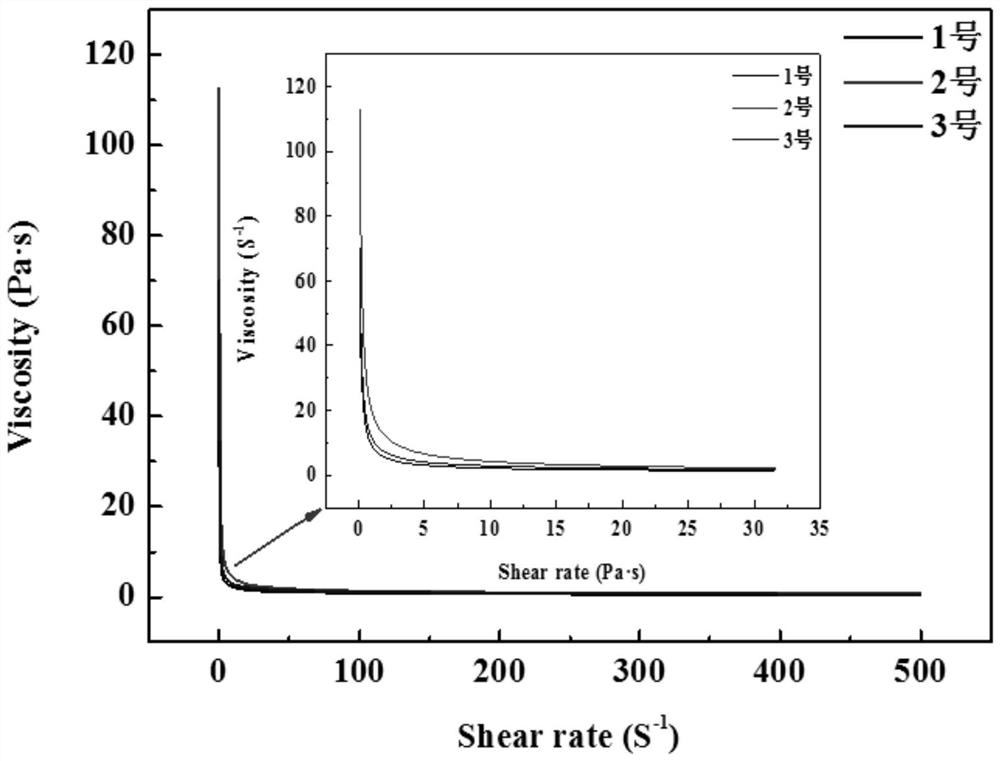

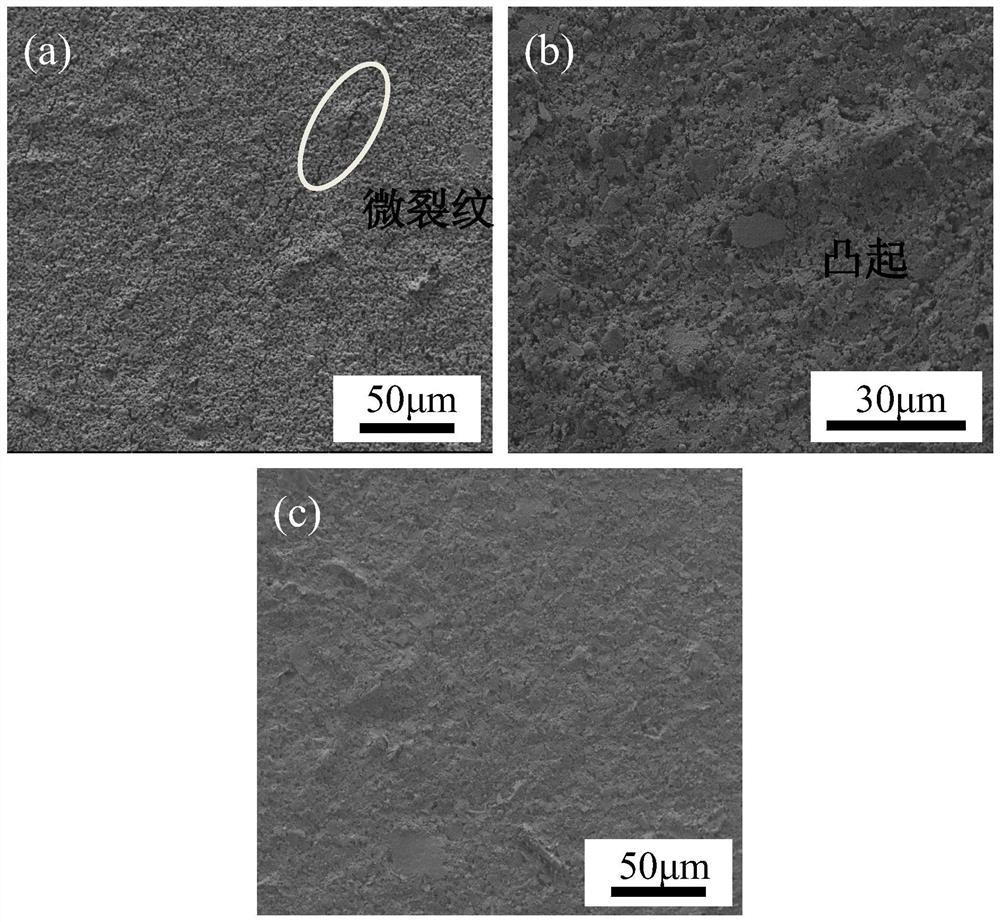

[0038] The organic vehicle for the conductive paste of the present embodiment and its preparation and application are carried out as follows:

[0039] (1) Weigh 16g each of n-hexanol, diethylene glycol butyl ether acetate, and terpineol according to the mass ratio of 1:1:1, put them in a beaker and stir on a magnetic stirrer to make a uniform solvent.

[0040] (2) Weigh 3 g of polyvinylpyrrolidone (molecular weight: 1,300,000) and add it to the prepared solvent, place it on a magnetic stirrer and stir for 10 h until the PVP is completely dissolved in the solvent to obtain a viscous transparent liquid.

[0041] (3) Weigh 1g of castor oil and add it to the viscous liquid, place it on a magnetic stirrer until it is evenly stirred to obtain the required conductive paste organic vehicle.

[0042](4) Mix the prepared organic carrier and silver powder according to the mass ratio of 1:2 (the silver powder includes spherical silver powder with an average grain size of 1 μm and flake silve

Embodiment 2

[0045] The preparation method of the novel intermetallic compound based on high-entropy alloy diffusion welding in this embodiment is carried out in the following steps:

[0046] (1) Weigh 24g of n-hexanol and diethylene glycol butyl ether acetate according to the mass ratio of 1:1, put them in a beaker and stir on a magnetic stirrer to make a uniform solvent.

[0047] (2) Weigh 3 g of polyvinylpyrrolidone (molecular weight: 1,300,000) and add it to the prepared solvent, place it on a magnetic stirrer and stir for 10 h until the PVP is completely dissolved in the solvent to obtain a viscous transparent liquid.

[0048] (3) Weigh 1g of castor oil and add it to the viscous liquid, place it on a magnetic stirrer until it is evenly stirred to obtain the required conductive paste organic vehicle.

[0049] (4) Mix the prepared organic carrier and silver powder according to the mass ratio of 1:2 (the silver powder includes spherical silver powder with an average grain size of 1 μm and f

Embodiment 3

[0052] The preparation method of the novel intermetallic compound based on high-entropy alloy diffusion welding in this embodiment is carried out in the following steps:

[0053] (1) Weigh 48g of n-hexanol, place it in a beaker and stir on a magnetic stirrer to make a uniform solvent.

[0054] (2) Weigh 3 g of polyvinylpyrrolidone (molecular weight: 1,300,000) and add it to the prepared solvent, place it on a magnetic stirrer and stir for 10 h until the PVP is completely dissolved in the solvent to obtain a viscous transparent liquid.

[0055] (3) Weigh 1g of castor oil and add it to the viscous liquid, place it on a magnetic stirrer until it is evenly stirred to obtain the required conductive paste organic vehicle.

[0056] (4) Mix the prepared organic carrier and silver powder according to the mass ratio of 1:2. The silver powder includes spherical silver powder with an average grain size of 1 μm and flake silver powder with a size of 1-5 μm and a thickness of 500 nm, and its m

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap