Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67 results about "Polyethylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyethylene or polythene (abbreviated PE; IUPAC name polyethene or poly(methylene)) is the most common plastic. As of 2017, over 100 million tonnes of polyethylene resins are produced annually, accounting for 34% of the total plastics market. Its primary use is in packaging (plastic bags, plastic films, geomembranes, containers including bottles, etc.). Many kinds of polyethylene are known, with most having the chemical formula (C₂H₄)ₙ. PE is usually a mixture of similar polymers of ethylene with various values of n. Polyethylene is a thermoplastic; however, it can become a thermoset plastic when modified (such as cross-linked polyethylene).

Solid-type filter stick formed by granular assembling and preparation method thereof

Owner:SHANGHAI HUABAO BIOLOGICAL TECH

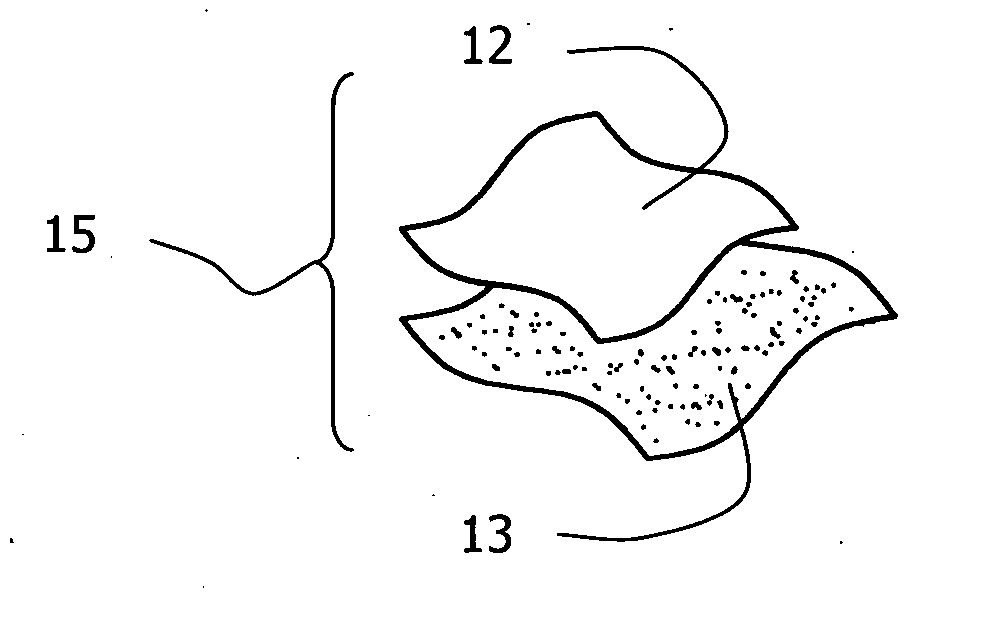

Fibers capable of heat storage and temperature adjustment

InactiveCN101845683AReduce leakageImprove thermal stabilityFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterCore component

Owner:YINGBAO FIBER TECH RENHUA

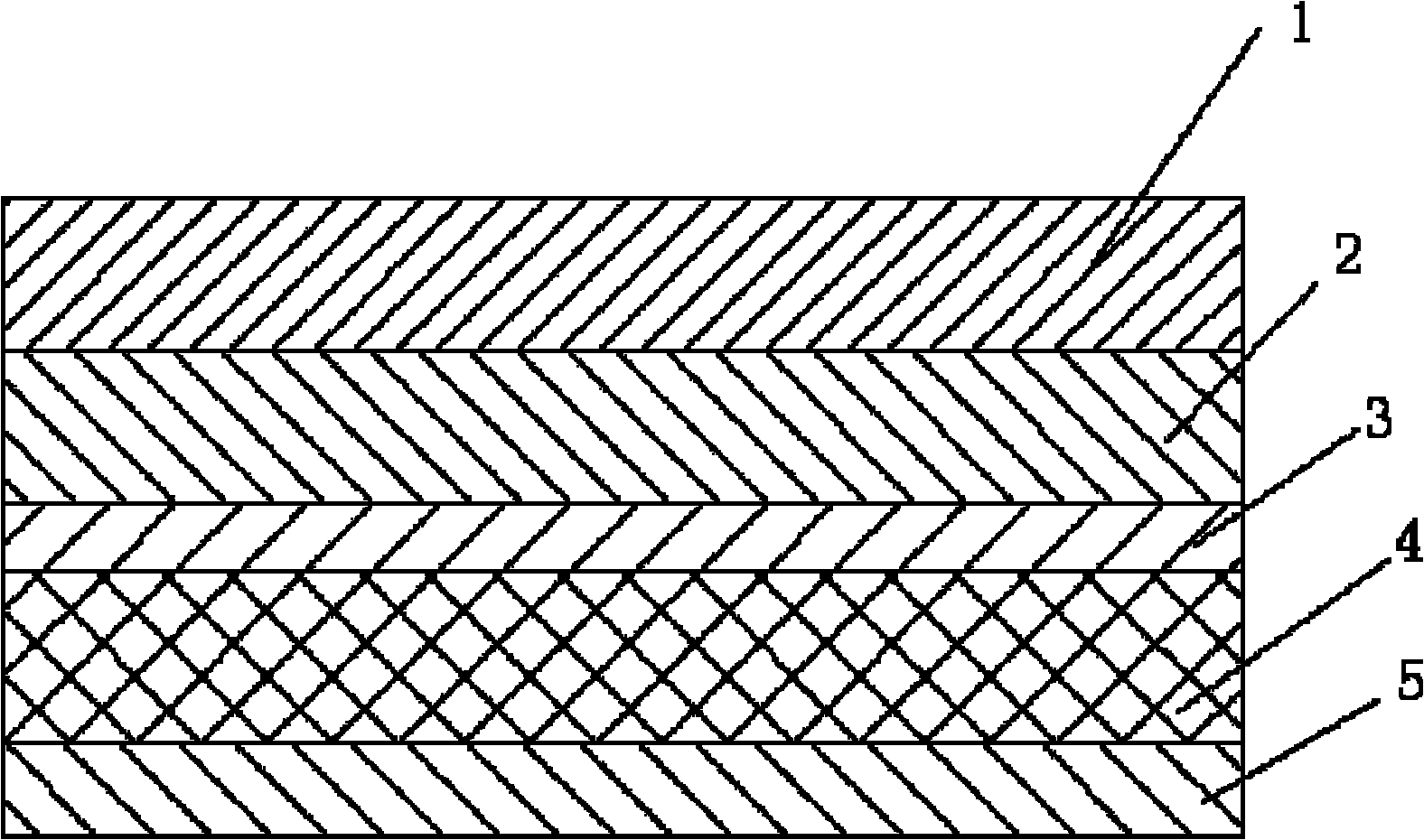

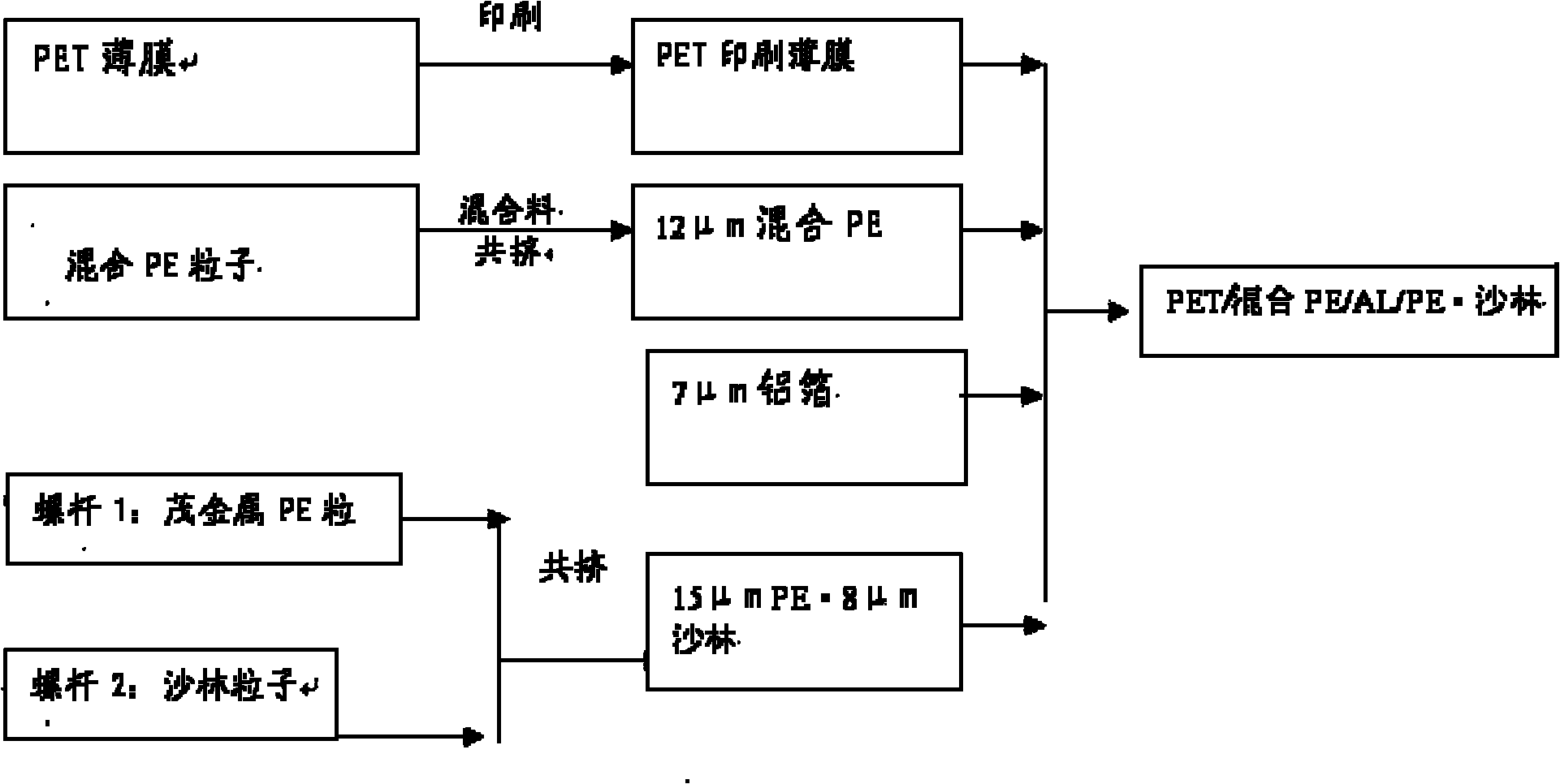

Lithium battery flexible packaging film and its manufacturing method

Owner:上海紫江彩印包装有限公司

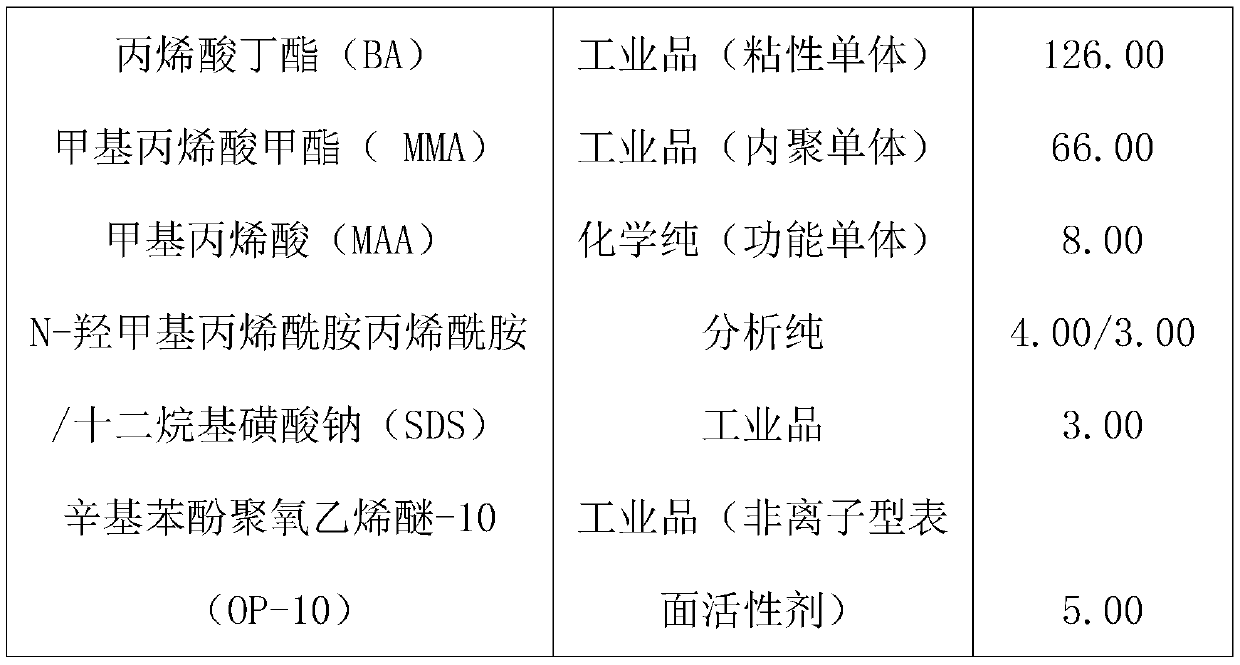

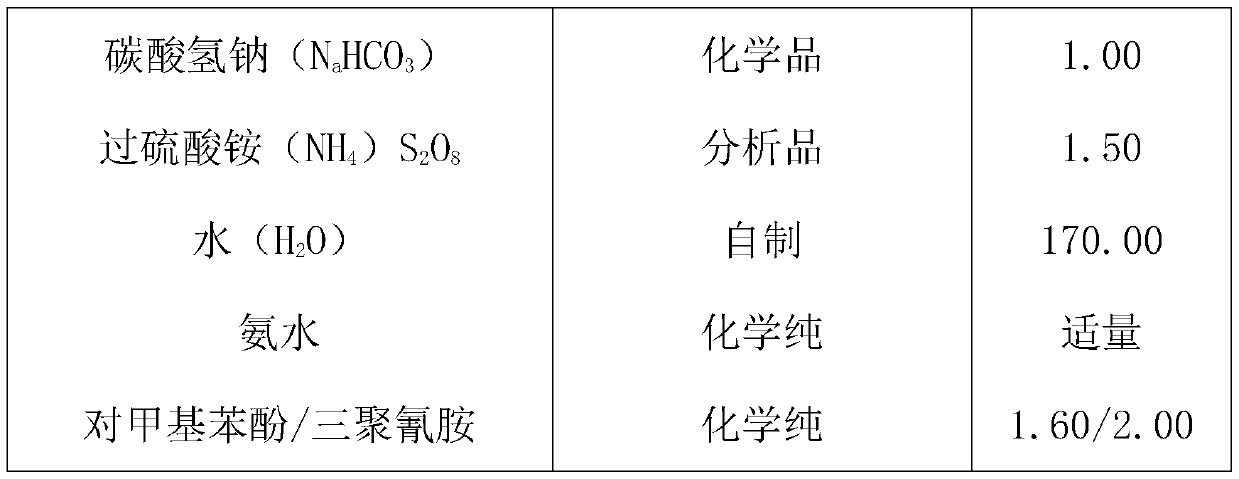

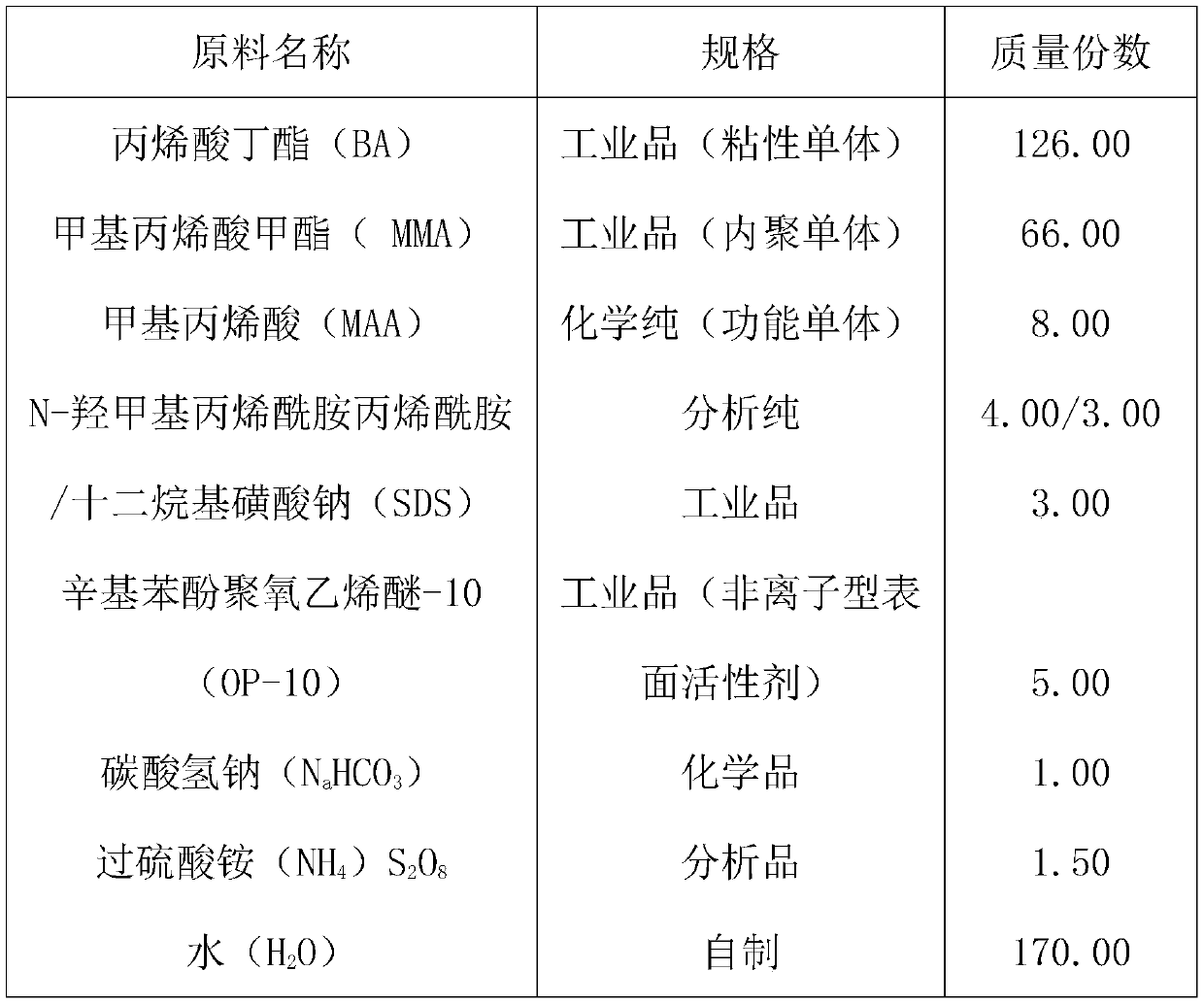

Vinyl acetate-ethylene copolymer emulsion as electrostatic spinning adhesive and synthesis method thereof

ActiveCN102030857AGood adhesionImprove water resistanceMonocarboxylic acid ester polymer adhesivesLiquid surface applicatorsCross-linkPolymer science

The invention relates to a vinyl acetate-ethylene copolymer emulsion as an electrostatic spinning adhesive and a synthesis method thereof. Organic peroxides and zinc formaldehyde sulfate are taken as an initiator; vinyl acetate, ethylene, acrylic ester monomers and cross-linking monomer N-hydroxymethyl acrylamide are taken as comonomers; a nonionic emulsifier, and the synthetic emulsion and the protective colloid of an amphoteric emulsifier are matched to be taken as an emulsification system; and the copolymer emulsion is prepared through emulsion polymerization. Compared with the VAE (vinyl acetate-ethylene) emulsion prepared by the conventional preparation method, the product in the invention has the advantages of good water resistance, strong adhesion on low-surface-energy materials (polyethylene, polypropylene and the like), fine grain and the like. The vinyl acetate-ethylene copolymer emulsion is suitable for being as the adhesive to be applied to the field of the electrostatic spinning in textile industry and the fields of waterproofing and packaging.

Owner:CHINA PETROCHEMICAL CORP +1

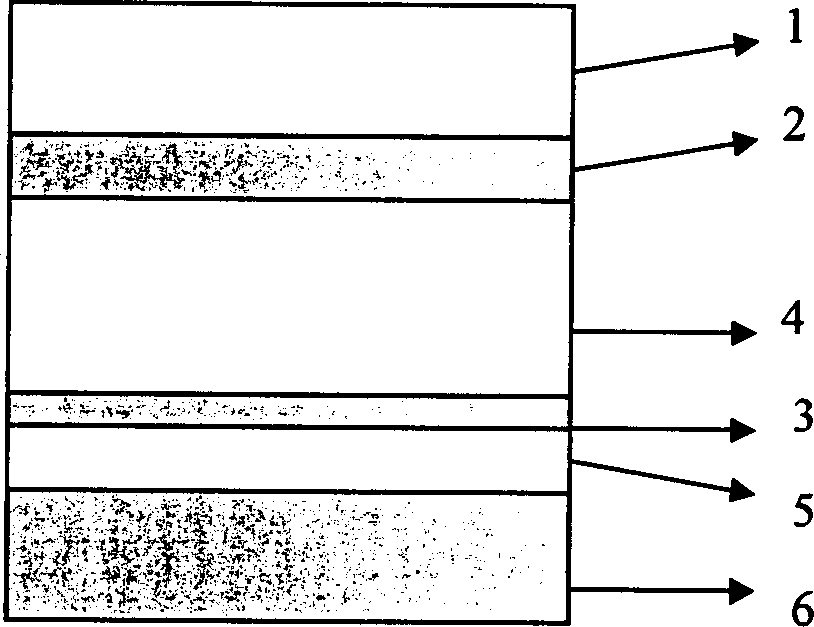

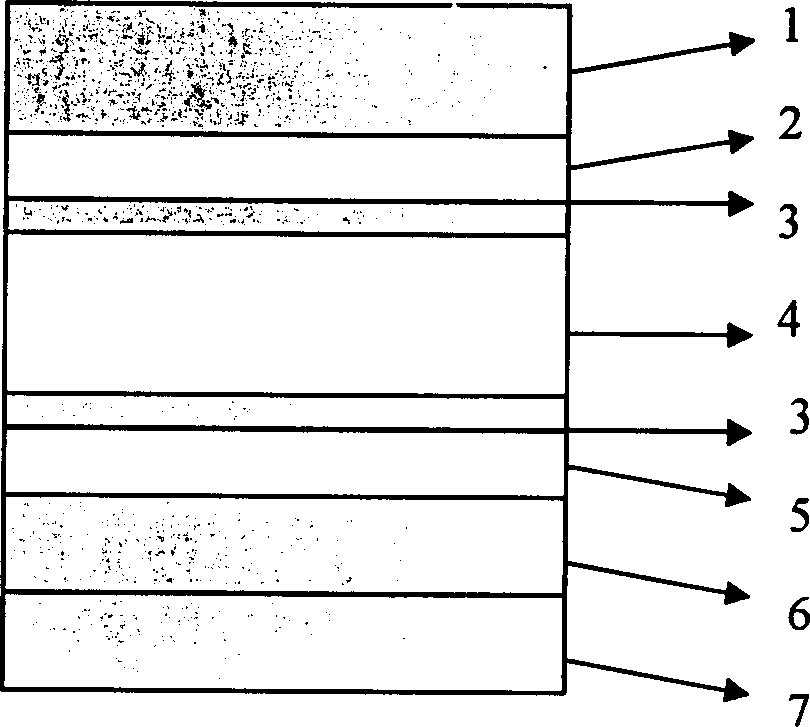

Method for preparing high-temperature resistant microporous membrane

ActiveCN103811704AClearly definedEasy to understandCell component detailsPolymer sciencePolypropylene

Owner:SUZHOU GREEN POWER NEW ENERGY MATERIALS CO LTD

SPA cover with metalized moisture barrier and method of manufacture

Owner:PENG XUE WEN +2

Ink resin composite used for plastic gravure printing and preparation method thereof

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

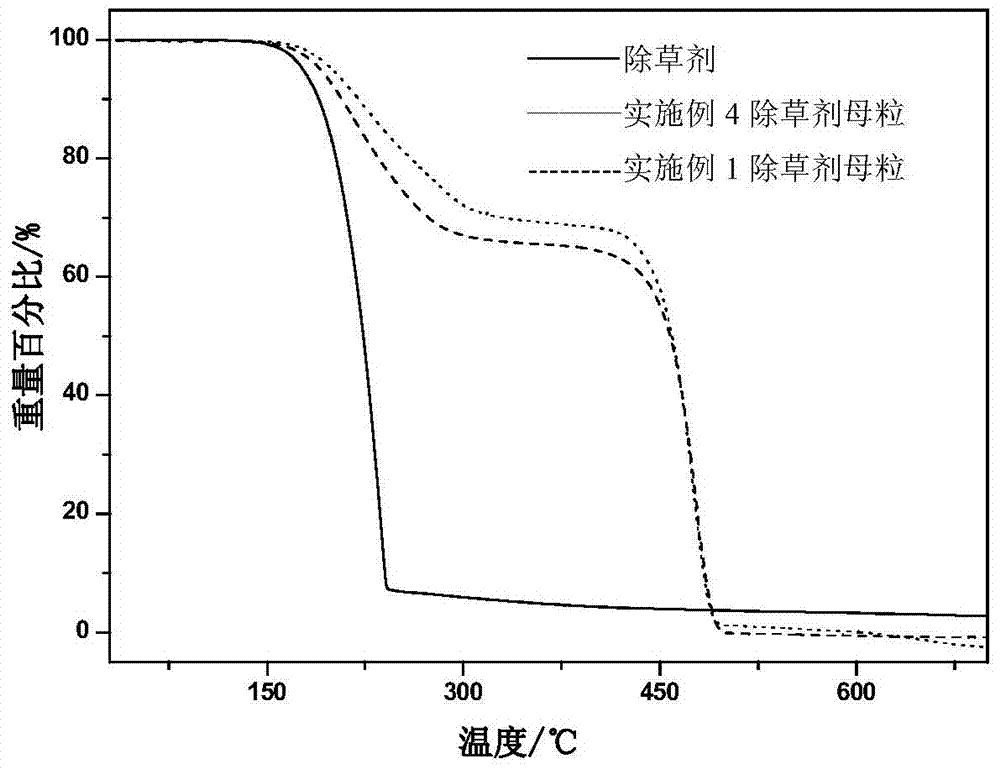

Weeding mulching film and preparation method and application thereof

Owner:GUANGDONG PROVINCIAL BIOENGINEERING INST (GUANGZHOU SUGARCANE IND RES INST)

Method of Treating Paper Forming Wire Surface

ActiveUS20120043040A1Non-fibrous pulp additionFats/resins/pitch/waxes removal in pulpPolymer sciencePolyethylene glycol

A method for inhibiting resinous and sticky substances from filling or forming deposits on or within papermaking forming wire, by applying to said wire an effective inhibiting amount of a composition comprising at least one cationic agent selected from the group consisting of (a) cationic polyureas, (b) hydrophobically modified cationic polymers, (c) alkylammonium or / and alkylimidazolium salts, and optionally at least one nonionic amphiphilic copolymer selected from (i) hydrophobically modified polyethylene glycols], (ii) hydrophobically modified cellulose ethers, (iii) copolymers of vinyl alcohol and vinyl alkonate, (iv) polyoxyalkylene block copolymers, and (v) hydrophilically modified polydimethylsiloxanes.

Owner:SOLENIS TECH CAYMAN

Super large caliber and non-excavation-use PE pollution discharge tubular product and manufacturing method thereof

The invention relates to a super large caliber and non-excavation-use PE pollution discharge tubular product and a manufacturing method thereof, wherein, the tubular product are manufactured by the following materials which are arranged according to the following mass percentage after the steps of pelleting and extrusion molding: 60-85% of PE100 pipeline special material; 5-15% of calcium carbonate superfine powder; 7-22% of unit triplet blending modified resin; 1-3% of high molecular weight polyethylene; and 0.2-2% of fluoropolymer. The method comprises the following steps: mixing PE100 pipeline special material accounting for 20-30% of total volume of addition evenly with other components according to proportion and obtaining master batch by extrusion and pelleting; mixing the excess PE100 pipeline special material evenly with the master batch and colorant and drying the mixture for 2-4 hours at the temperature of 0-80 DEG C; and then obtaining fixed-length tubular products after the steps of extrusion, vacuum sizing, cooling and cutting. The tubular products has the characteristic of integration; hot welding is carried out on the pipelines; the pipelines have fine flexibility and scratching-and-cracking-resisting capcacity; in addition, the pipelines has more unique technological and economic advantages when applied to drag construction of non-excavation works.

Owner:ANHUI YOUYI PIPES

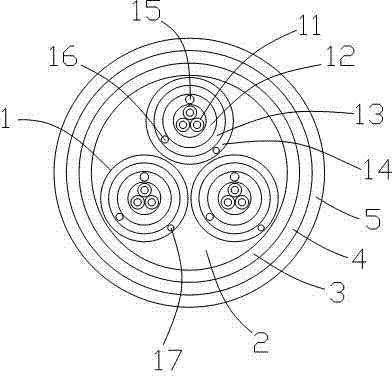

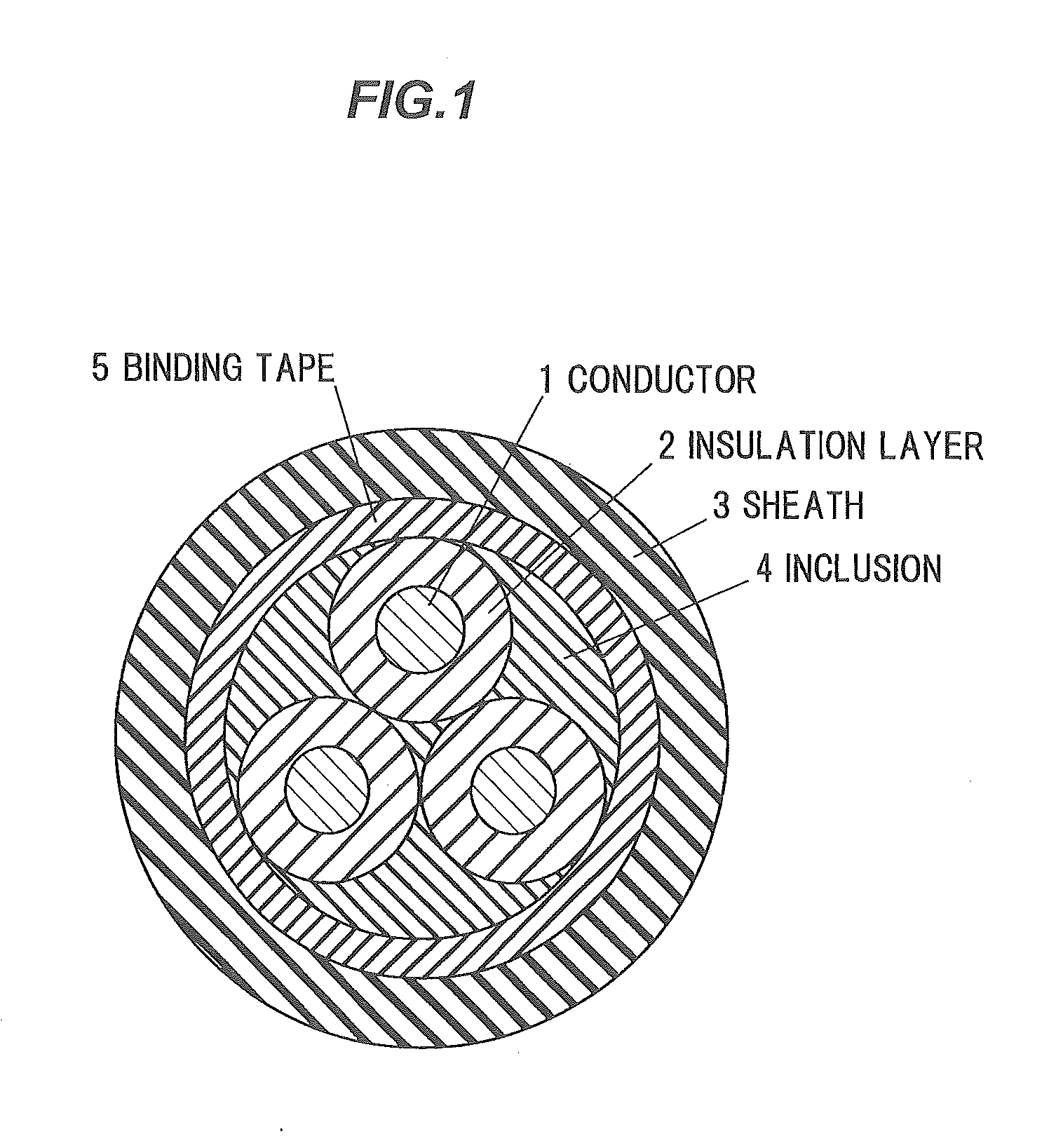

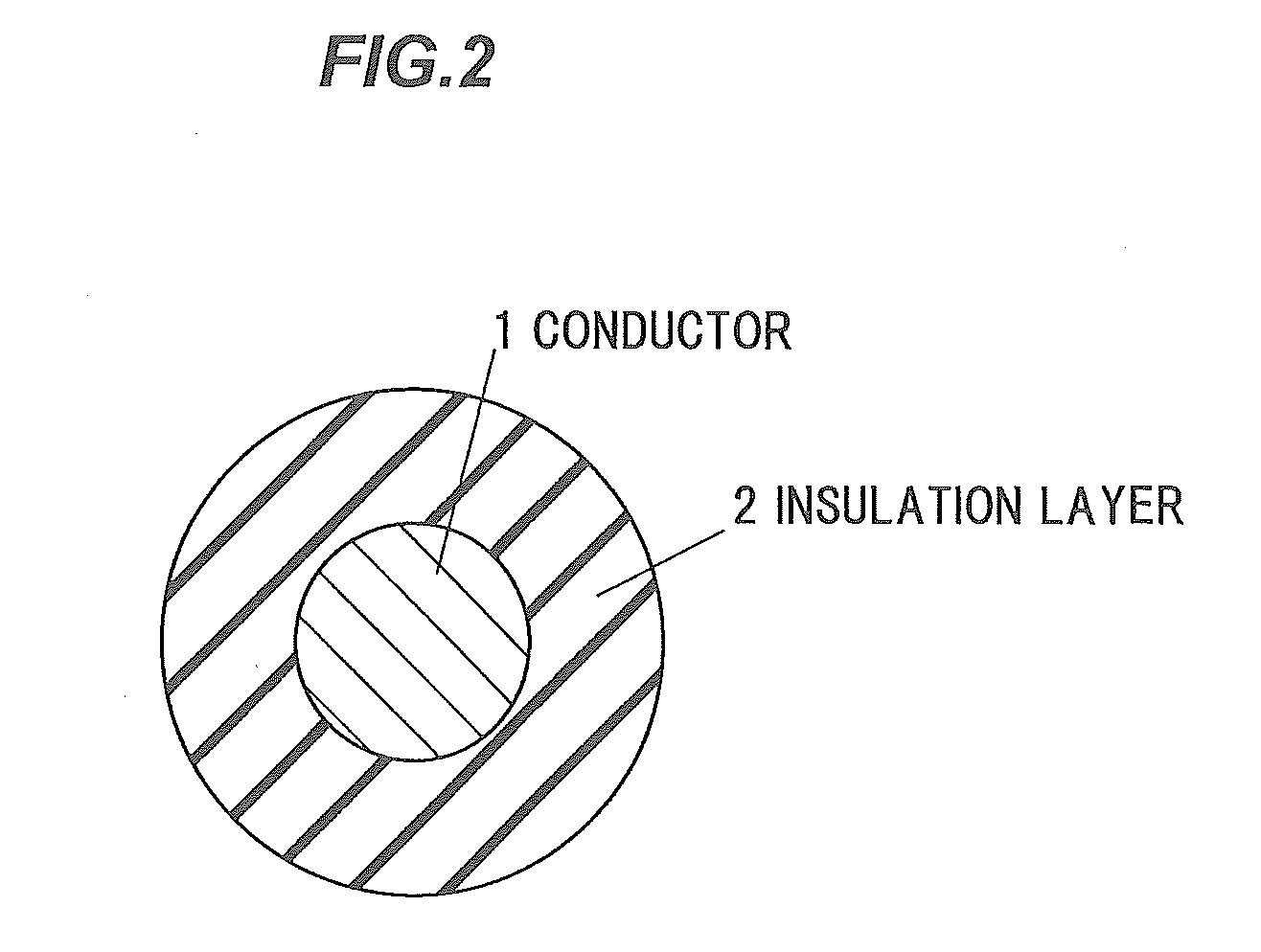

Lightning protected cable for communication base station

ActiveCN103325489ALower the resistance valueSmall short-term calorific valueCommunication cablesInsulated cablesAluminium hydroxideEngineering

The invention belongs to the technical field of cables and relates to a lightning protected cable for a communication base station. The lightning protected cable for the communication base station comprises a cable core, an inner protecting sleeve, an armor layer, an outer protecting sleeve and a ground layer. The lightning protected cable for the communication base station is characterized in that a first protecting layer is arranged outside the cable core, the inner protecting sleeve is arranged outside the first protecting layer, a second protecting layer is arranged outside the inner protecting sleeve, the ground layer is arranged outside the second protecting layer, the armor layer is arranged outside the ground layer, and the armor layer is coated with the outer protecting sleeve; the armor layer is a single-face film covering steel belt and the face, in contact with the ground layer, of the armor layer is a non-film-covering face; the first protecting layer and the second protecting layer are both mica tapes; the outer protecting sleeve comprises, by weight, the following raw materials of 71 parts of polyethylene, one part of anti-oxygen 1010, 12 parts of aluminum hydroxides, 0.5 part of HK-type antistatic agent, 3 parts of ethyl acetate, 1 part of carbon black, 10 parts of zirconium oxide and 1.5 parts of polyethylene wax. The lightning protected cable for the communication base station has the advantages of being simple in manufacturing, high in production speed, capable of enabling the electrical resisting rate of the ground layer to be low, low in maintaining cost, small in dust adsorption, pressure resistant, and good in flame resistance.

Owner:JIANGSU ZHONGLI GRP CO LTD

Aluminum conductor cable core drainage cable

InactiveCN103928093AAnti-agingCold-resistantInsulated cablesInsulated conductorsElectrical conductorEngineering

Owner:ANHUI GAOGOU CABLE

Injection moulding process of polyethylene (PE) material pieces for infusion apparatus

Owner:江西科伦医疗器械制造有限公司

Insulating pipeline spray coating opening mending method

A spray method for reparing the isulating layer at the connection position bewteen two insulating pipes includes such steps as blasting sand, treatnig the surface, brushing the priming paint, spraying polyurethane foam, and spraying polyurea paint.

Owner:大庆油田建设集团

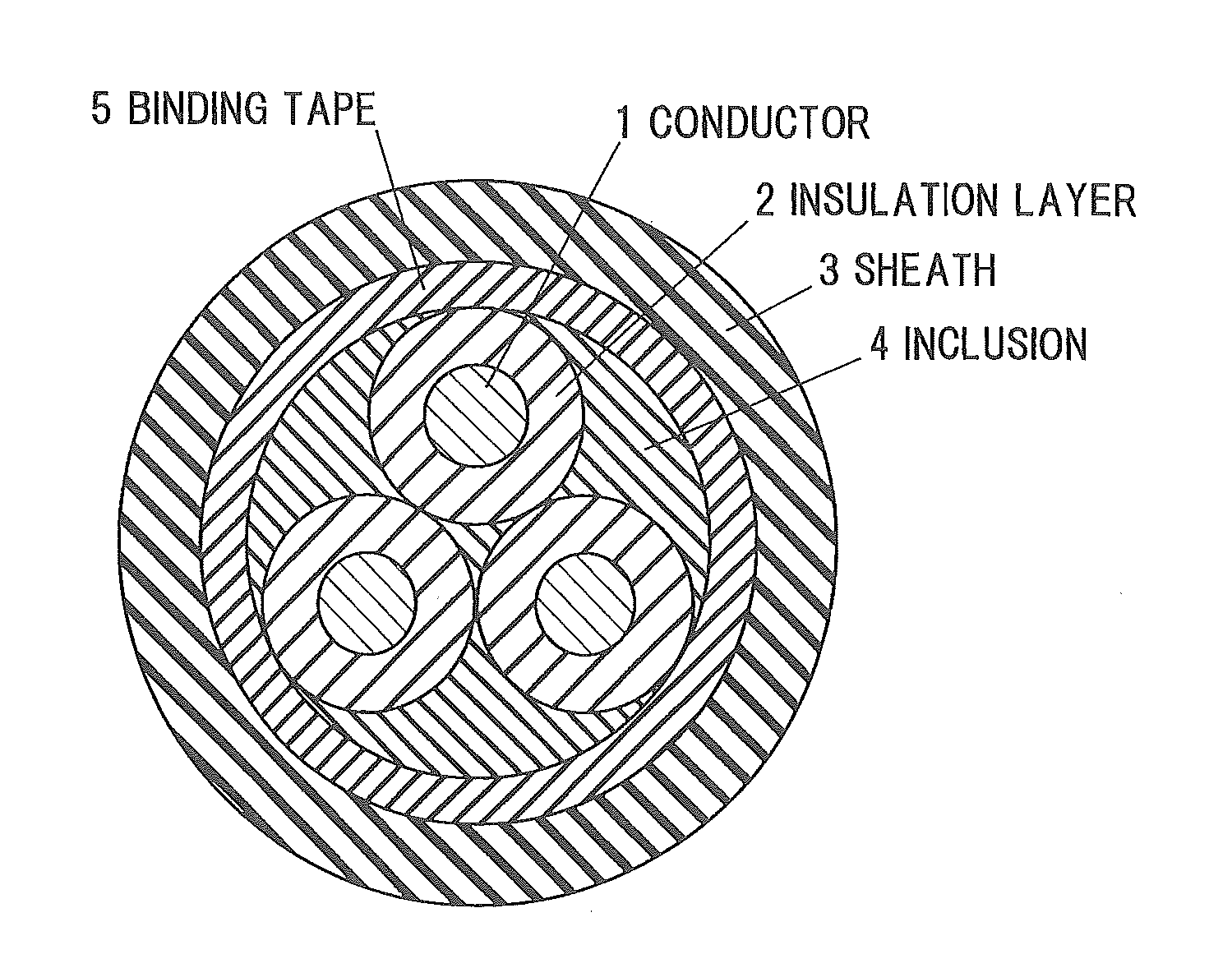

Fluorine-including elastomer composition, and insulated wire and insulated cable using the same

InactiveUS20140377557A1Good toughnessGood appearanceRubber insulatorsPlastic/resin/waxes insulatorsTetrafluoroethylenePolyethylene

A fluorine-including elastomer composition includes a fluororesin component including a first fluorine-including copolymer including a tetrafluoroethylene and an α-olefin having a carbon number of 2 to 4 and a second fluorine-including copolymer including an ethylene-tetrafluoroethylene copolymer, a polyethylene resin mixed in an amount of 10 to 50 parts by mass per 100 parts by mass of the fluororesin component, and a crosslinking aid. A mass ratio of the first fluorine-including copolymer to the second fluorine-including copolymer is 90:10 to 10:90.

Owner:HITACHI METALS LTD

Decomposable environmentally-friendly heat-insulation packaging bag

Owner:桐城市人和包装有限公司

Coating material for sealing coal wall of gob-side coal roadway

Owner:SHANDONG UNIV OF SCI & TECH

Oxidation-resistant polymer film with memory function

InactiveCN105670128ASimple componentsLow costFixed capacitor dielectricBulk chemical productionPolymer scienceOxidation resistant

Owner:汤卓群

Mixing technology for lead, boron and polyethylene

A process for mixing lead-boron polyethylene related to the material mixing process of radioactive masking material comprising the steps of, mixing lead and boron evenly, high speed mixing and plasticizing of polyethylene in heated mixer, and mixing the lead-boron mixture with polyethylene in heated mixer evenly. The process according to the invention realizes simple operation process, less pollution, even product mixing, thus can be widely applied into the mixing process for lead-containing material.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

High-strength composite fiber non-woven cloth and preparation method thereof

ActiveCN106427147AFirmly connectedClosely connectedProtective equipmentSynthetic resin layered productsEpoxyAlcohol

The invention discloses high-strength composite fiber non-woven cloth and a preparation method thereof. Ultrahigh-strength high-modulus polyethylene fibers are used as base materials, the polyethylene fiber obtained after fiber placement is subjected to a series of homogenization, parallelization and straight and upright arrangement and placed in a modified epoxy resin solution for sizing treatment in an environment of 60-80 DEG C, then the formed polyethylene fiber layers are subjected to composite lamination, and the non-woven cloth is prepared, wherein the modified epoxy resin solution is prepared by adding and mixing an adhesion agent, a filling agent, an insulating filler, fire retardant, white carbon black and ethyl alcohol, the mass of hydroxyl chemigum accounts for 8-12% of the mass of the modified epoxy resin solution, and the content of vinyl cyanide accounts for 18-30% of the content of hydroxyl chemigum. The non-woven clothes with different thicknesses are prepared by lamination of the polyethylene fiber layers, an antiknock device can be made from different types of non-woven cloths according to explosion sites and use environment, and the non-woven cloths with different thicknesses are different in anti-explosion range so as to sufficiently withstand the impact of a bullet.

Owner:JIANGSU LINRY NEW MSTAR TECH

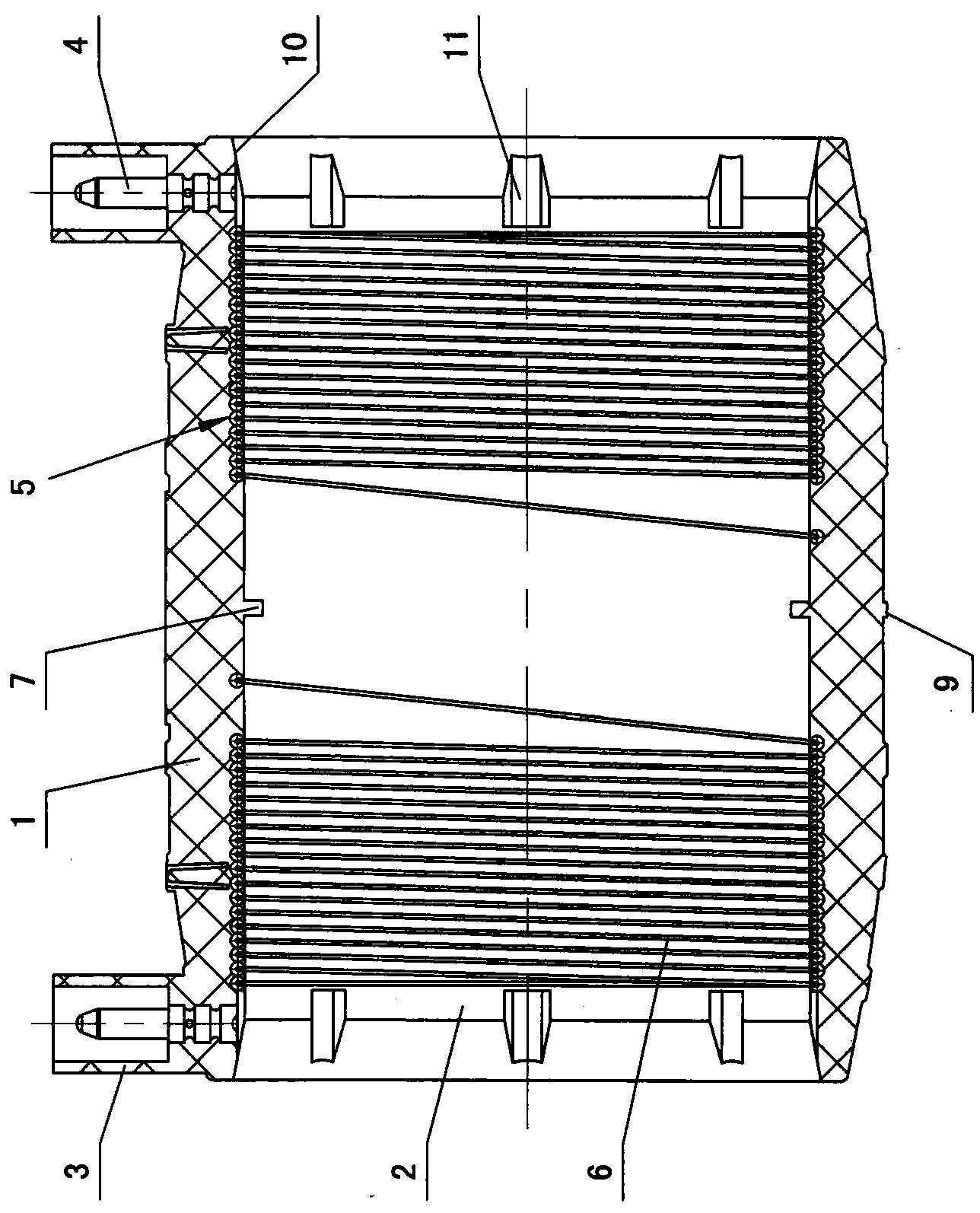

Steel strip reinforced polyethylene helically corrugated tube and production method thereof

InactiveCN103697250AIncrease contact surfaceHigh bonding strengthRigid pipesBack stressCompression molding

The invention relates to a steel strip reinforced polyethylene helically corrugated tube and a production method thereof. A steel screen is welded at the feet of a V-shaped steel strip, a polyethylene layer is wound and coated with the bent steel strip, and the outer part of the steel strip is coated with the polyethylene layer. The production method comprises the steps of (1) molding of an inner layer, (2) compression molding of the steel strip, (3) welding of the steel screen through the steel strip, (4) bending and winding of the steel strip with a steel wire screen, and (5) molding of an outer layer. The steel strip reinforced polyethylene helically corrugated tube has the beneficial effects that the steel strip has certain spring-back stress in the compression process, so that after the steel screen is welded to the steel strip, the contact area of the steel strip and the outer side of a polyethylene tube is increased, the adhesion strength is improved, the product yield is improved, the shape and quality of a product are stabilized, and the safety of the product is ensured.

Owner:TIANJIN SHENGXIANG PLASTIC PIPE IND

Method for preparing wear-resistant plastic particles by using waste polystyrene

InactiveCN110760138AImprove wear resistanceSolve the defect of poor wear resistanceCyclohexanoneSilicic acid

The invention discloses a method for preparing wear-resistant plastic particles by using waste polystyrene. The method specifically includes the following steps that (1) the waste polystyrene and liquid paraffin are put into a reactor for heat treatment under the nitrogen environment, then cobalt powder is added for natural cooling, and pretreated polystyrene is obtained; (2) tetraethyl orthosilicate is added into a chitosan solution, hydrochloric acid is added and then placed in a water bath, glutaraldehyde is added, and chitosan / silica particles are obtained by reaction; (3) the pretreated polystyrene is added into cyclohexanone after being cut into granules and dried, and polyvinyl pyrrolidone is added, stirred and dissolved, and then dried particles are added to obtain a coating solution; and (4) after the coating solution is treated, a film is scraped on a substrate, removed after phase transfer, and melted and extruded with a plasticizer and a lubricant through a twin-screw extruder. According to the method, by increasing the bond strength between the polystyrene and silicon dioxide, significant improvement of the wear resistance of the polystyrene is realized, and the methodis suitable for large-scale and industrial production.

Owner:ANHUI GUANHONG PLASTIC IND

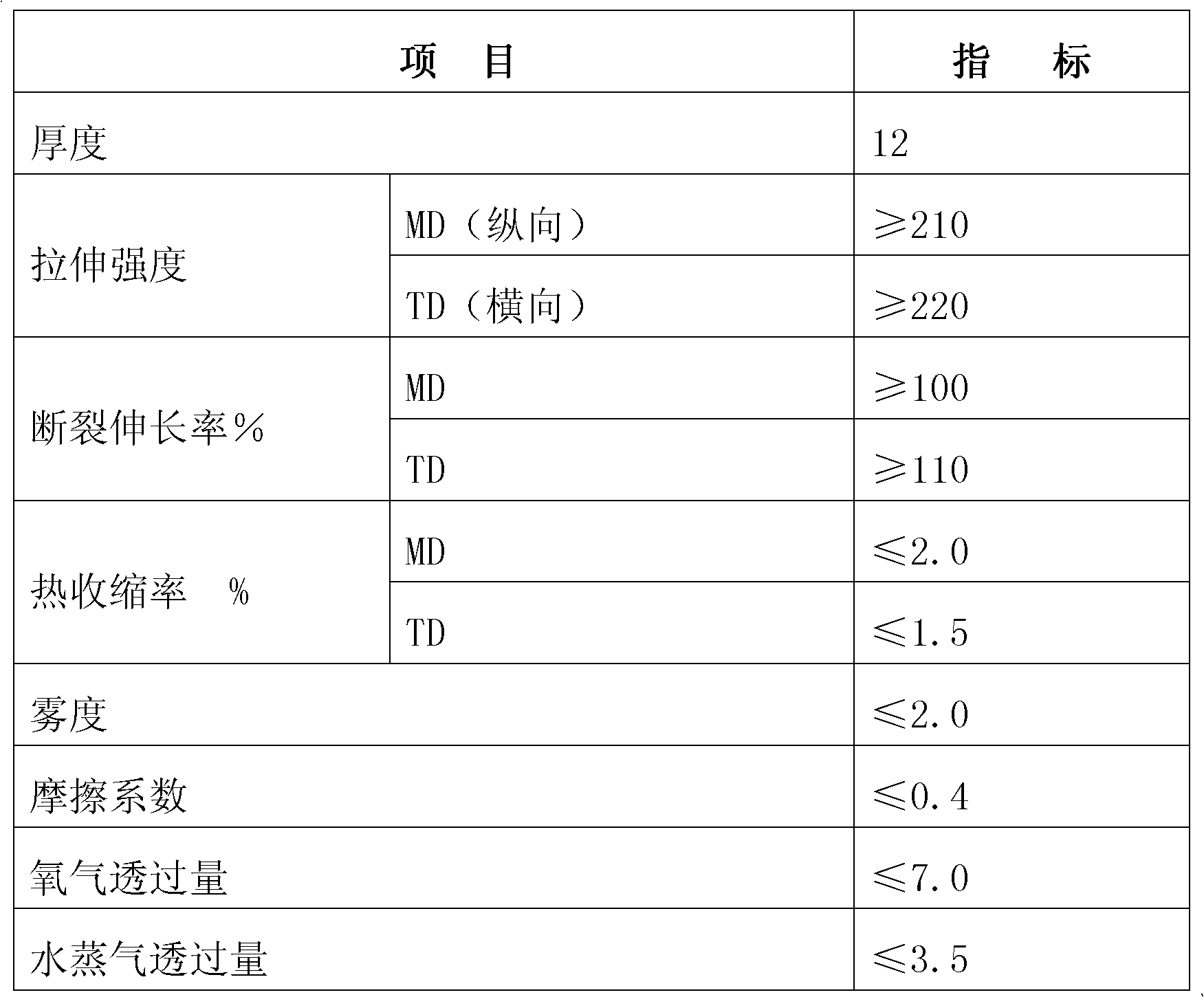

Medical packaging film

ActiveCN102152542AHigh barrierPrevent brittle and fragile problemsWrappersFlexible coversAdhesiveCost Controls

Owner:HUANGSHAN NOVEL

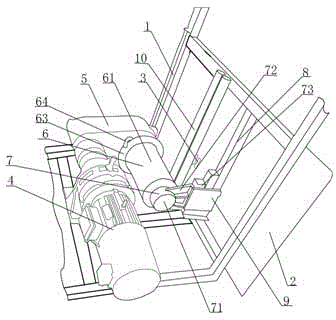

Wasted plastic steel wound polyethylene drainage pipe recovering device and technology

Owner:开源塑业科技(南通)有限公司

Fireproof material for strongbox

Owner:QINGDAO DAFANG WISDOM NETWORK TECH CO LTD

Degradable capacitor plastic shell and preparation method thereof

Owner:TONGLING XINTAI ELECTRIC APP & CAPACITOR

Method for determining carbon black content of PE reclaimed material by using combustion method

InactiveCN108445144AReduce the chance of being oxidized by airReduce the chance of oxidationWeighing by removing componentChemical analysis using combustionCombustionNitrogen atmosphere

The invention relates to the testing technical field of black polyethylene plastics for wires and cables, and discloses a method for determining carbon black content of a PE reclaimed material by using a combustion method, the method includes initial weighing of a PE sample, pyrolysis, weighing after the pyrolysis, combustion, weighing after the combustion, and other steps. In the process ofweighing after the pyrolysis, after cooling in a nitrogen atmosphere to 400 DEG C-450DEG C, the opening of a combustion tube is opened, a combustion boat is dragged to the opening for cooling for 5 min, andthe combustion boat is taken out of the combustion tube. The accuracy of detection of the carbon black content in the PE reclaimed material can be improved by changing of temperature of oxygen introduction in the combustion method or heat insulating time of nitrogen gas introduction at 600DEG C or changing of the temperature of oxygen introduction in the combustion method from 600 DEG C to 850 DEG C, so that the result of the method is substantially consistent with the result of a thermogravimetric analysis method.

Owner:JIANGYIN ECOSENBOTTOM POLYMER CO LTD

High-heat-resisting self-lubricating PVC/NBR composite foam board and preparation method thereof

InactiveCN106221064AGood compatibilityImprove heat resistanceEnvironmental resistancePolymer science

Owner:CHUZHOU HONGYUAN SPRAYING

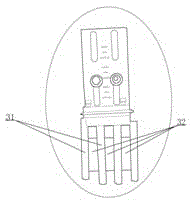

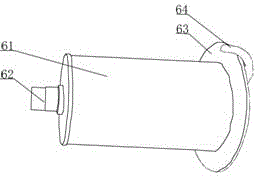

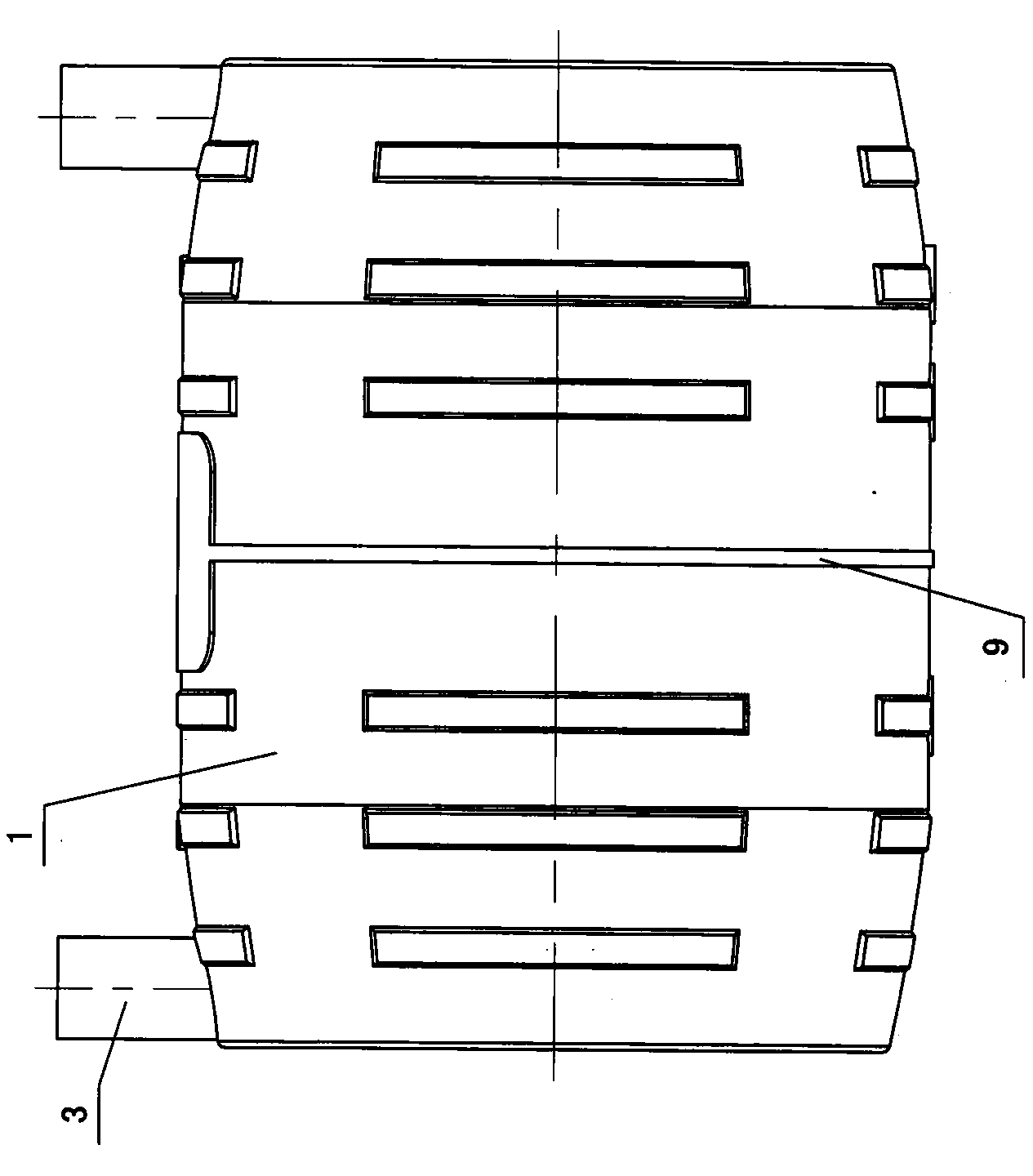

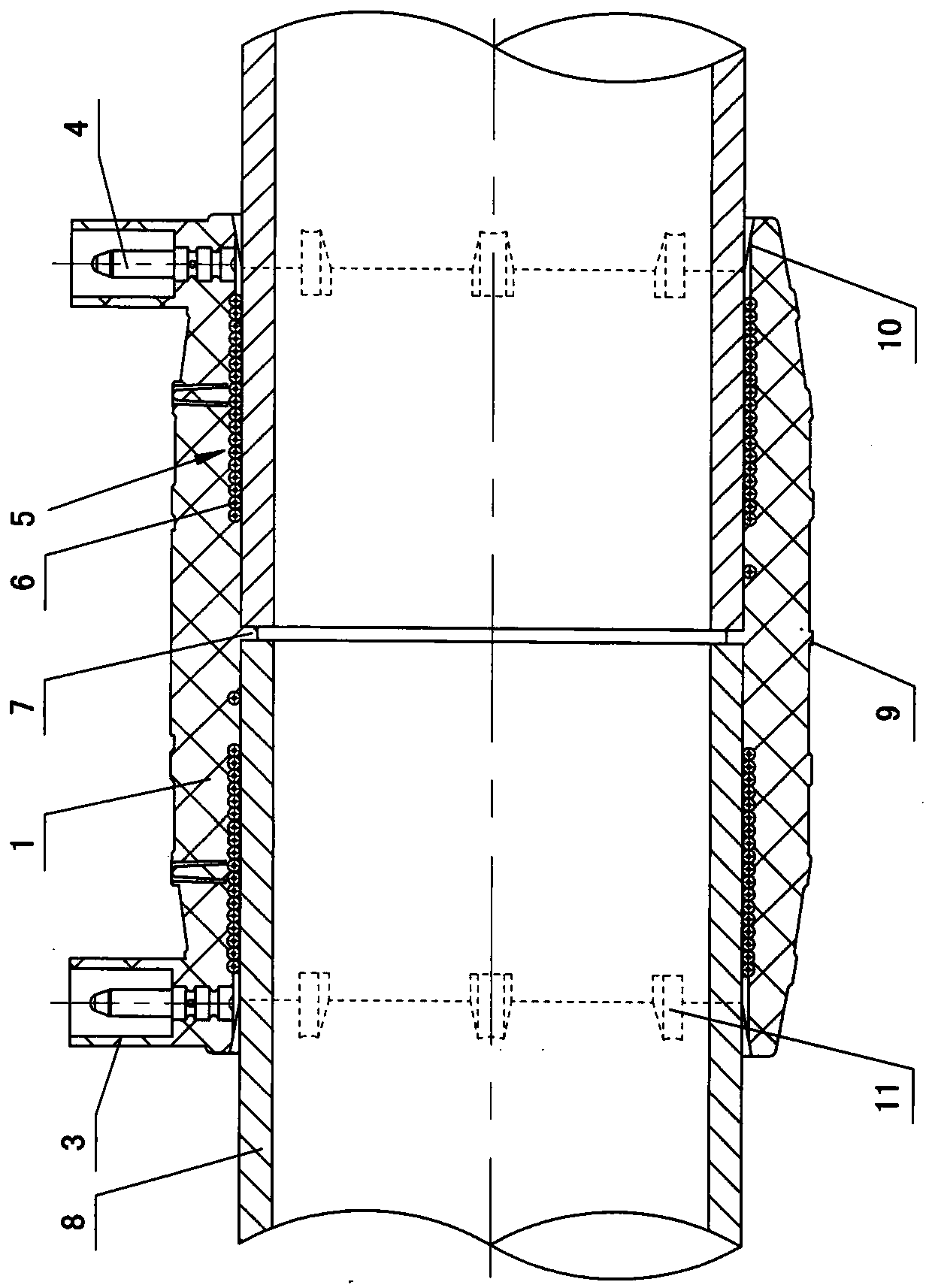

External display mark of polyethylene electro-fusion socket pipe fitting and limiting device for resistance wires

ActiveCN103968177AGuarantee welding qualityEasy to assemblePipe connection arrangementsPipe fittingArchitectural engineering

Owner:YONGGAO CO LTD

Sealing adhesive used for automobile part changing

Owner:绩溪县徽洋车桥有限责任公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap