Wasted plastic steel wound polyethylene drainage pipe recovering device and technology

A waste polyethylene, recycling device technology, applied in the direction of pipeline laying and maintenance, pipe/pipe joints/pipe fittings, machinery and equipment, etc., can solve the problems of high cost, labor, low efficiency, etc., to reduce recycling costs, device design Simple, speed-up results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further illustrate and introduce the present invention, introduce below in conjunction with accompanying drawing of description:

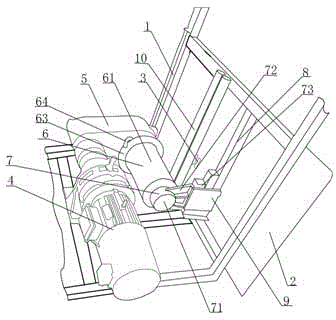

[0021] Refer to attached figure 1 , waste polyethylene plastic steel winding drainage pipe recovery device, it includes a frame 1, a feed partition 2, a feed port 3, a drive motor 4, a speed change gear box 5, a drum 6, and the frame 1 is a square Bracket, the upper end inside the bracket is equipped with a control box, the lower end inside the bracket is equipped with a drive motor 4, one end of the drive motor 4 is connected with a speed change gear box 5, and the speed change gear box 5 is installed on one side of the lower end of the inside of the bracket, and the other end of the speed change gear box 5 One end is connected with a drum 6, and one end of the drum 6 is fixedly connected to the gear box, and the other end of the drum 6 is supported by the support arm 7, and the feed separator 2 is installed between the brackets on

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap