Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Labor saving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

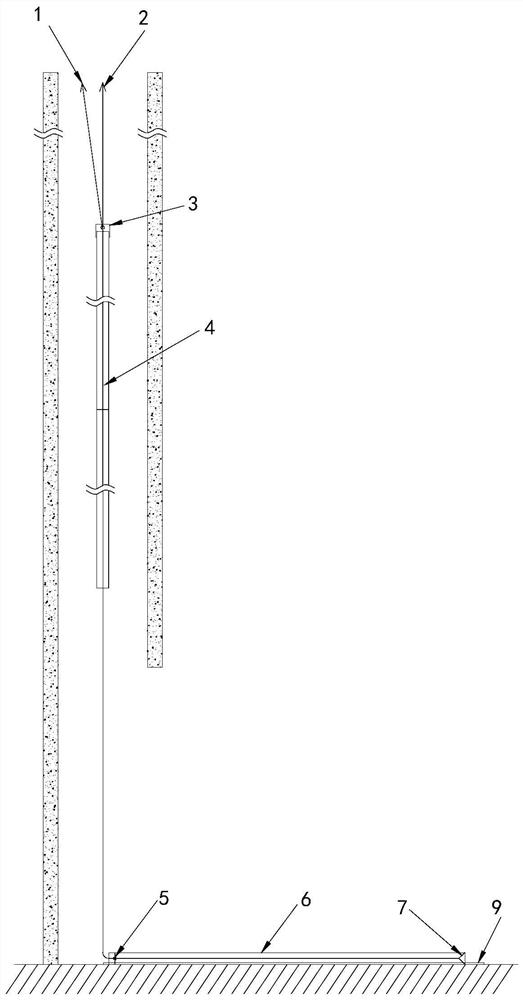

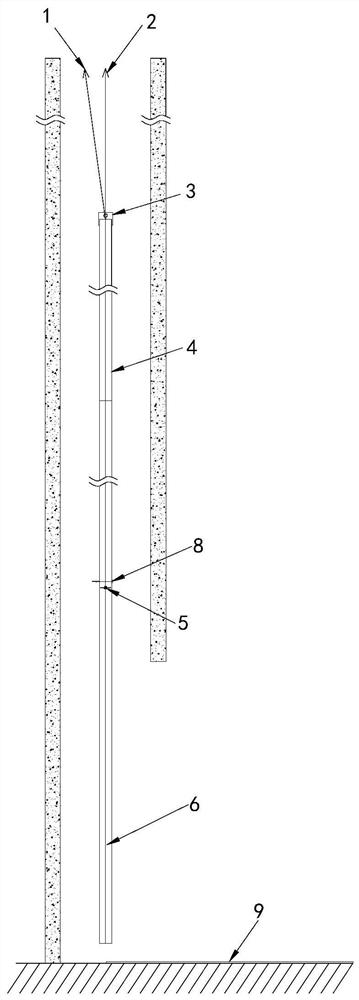

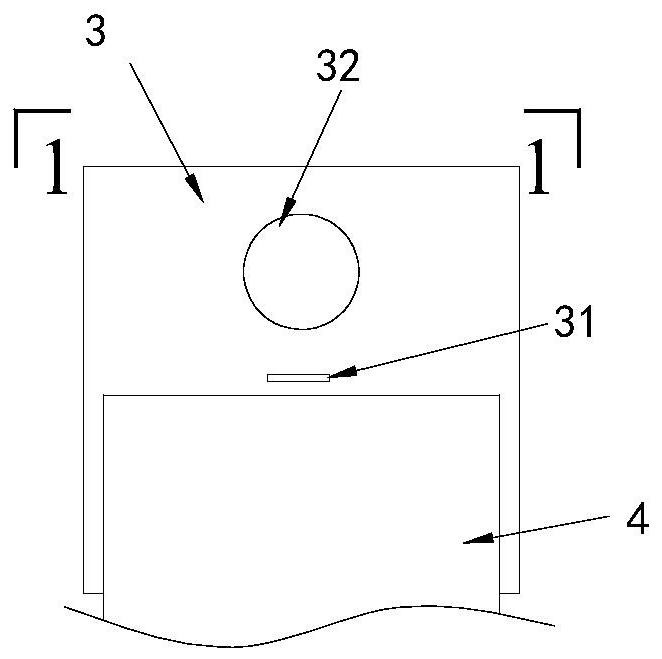

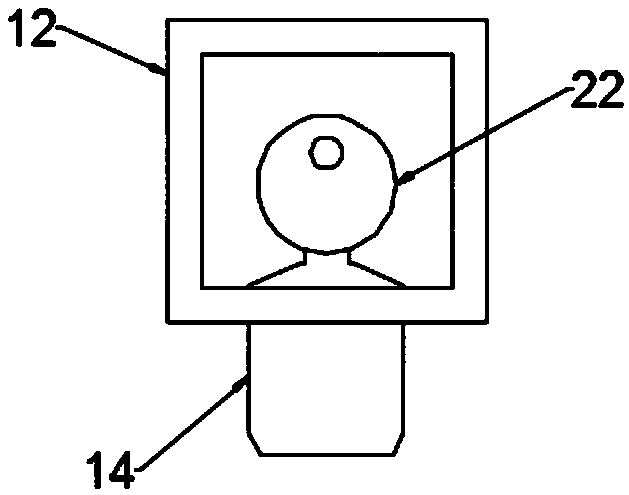

Automatic centering reverse installation method for vertical shaft pipelines

ActiveCN111962821ALabor savingReduce labor intensityBuilding material handlingVertical ductsBuilding constructionIndustrial engineering

Owner:GUANGDONG IND EQUIP INSTALLATION

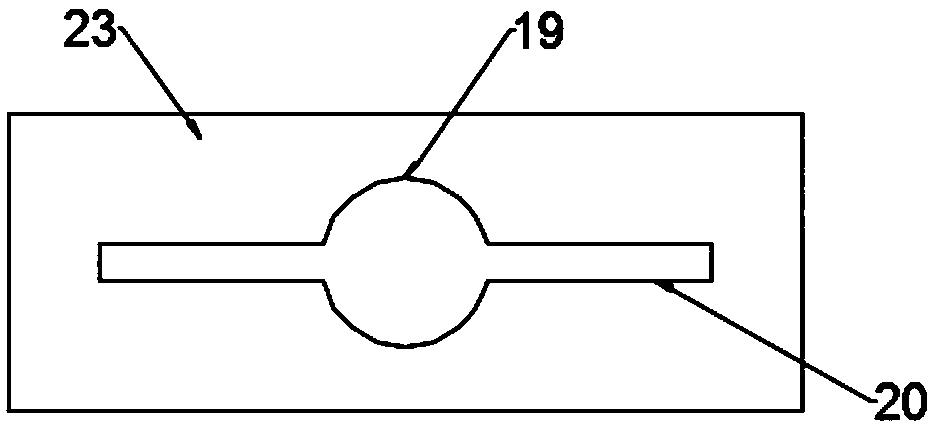

Fabric rolling drum with improved structure

Owner:SHAANXI DUKEPU GARMENT

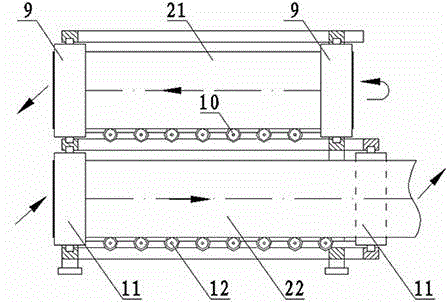

Ultrasonic continuous sterilization device and method thereof

The invention provides an ultrasonic continuous sterilization device, comprising a raw material tank, a heating device, a heat exchanging device, an ultrasonic processing device, a liquid storage device and a controller. The heating device is connected with the heat exchanging device. The raw material tank, the heat exchanging device, the ultrasonic processing device and the liquid storage device are sequentially connected through pipelines. The controller is respectively connected with the heating device, the heat exchanging device, the ultrasonic processing device and control valves on the pipelines. The ultrasonic processing device comprises an ultrasonic barrel, a plurality of ultrasonic probes, ultrasonic transducers and ultrasonic generators, wherein the ultrasonic transducers and the ultrasonic generators are arranged corresponding to the ultrasonic probes, the ultrasonic generators adopt different frequencies and are all arranged in the controller, and the ultrasonic probes are correspondingly distributed on the periphery of the ultrasonic barrel in a stagered junction mode. The invention also provides a method realized by the devices, i.e. feed liquid is firstly heated by the heat exchanging device, and then dynamic and continuous ultrasonic sterilization processing is carried out by the ultrasonic processing device. The invention adopts the technology combining low-temperature heating and ultrasonic processing, and has the advantages of good sterilization effect, high efficiency and the like.

Owner:SOUTH CHINA UNIV OF TECH

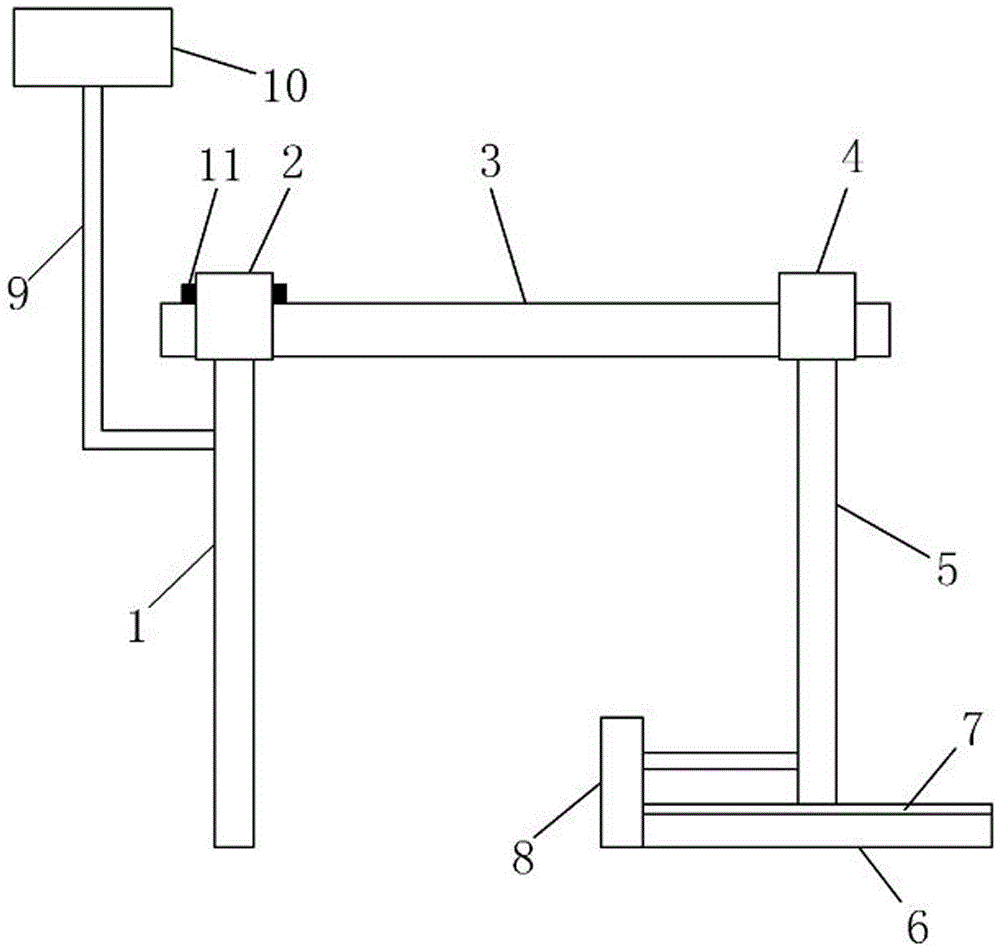

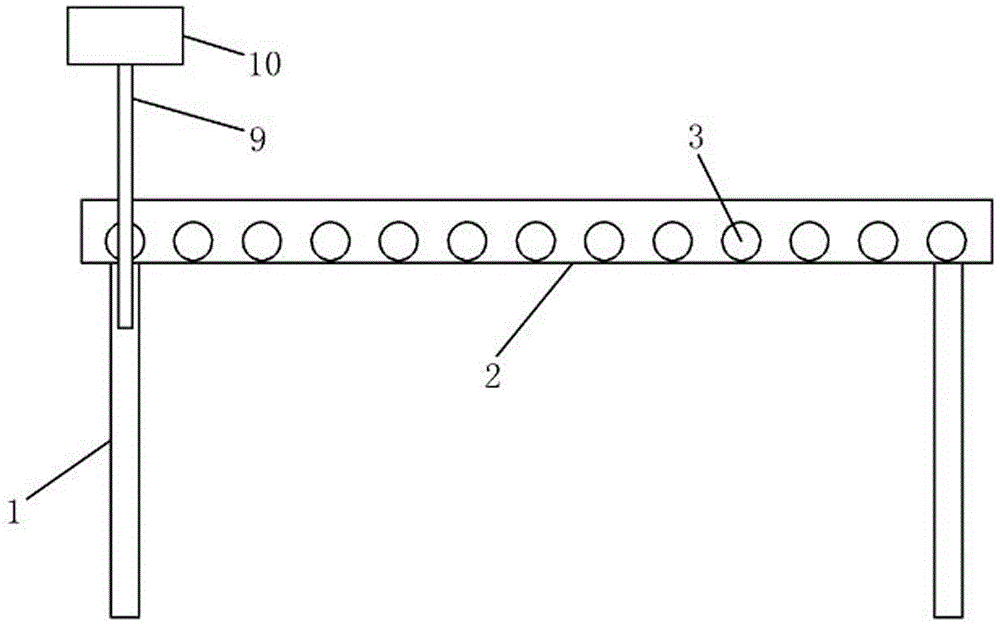

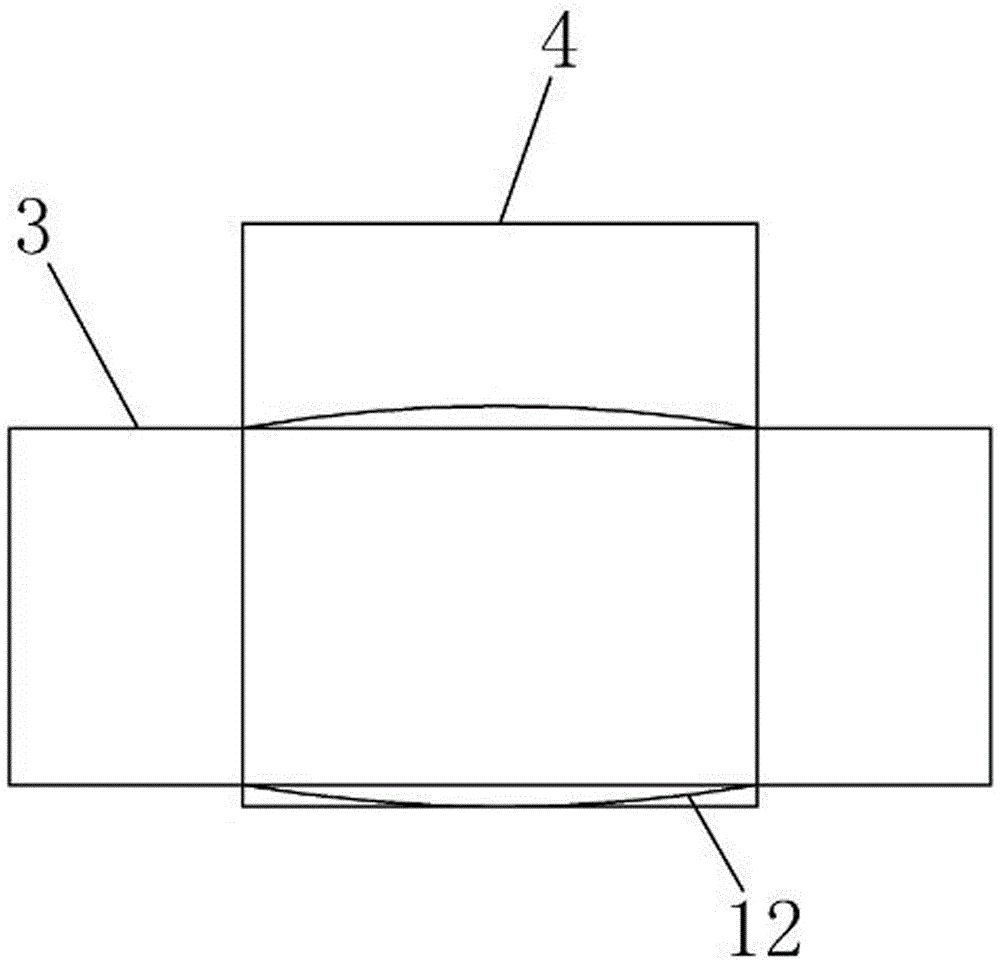

Vacuum panel sucking and hoisting crane

ActiveCN104016216AEnsure damage-free handlingReduce heavy laborTravelling cranesLoad-engaging elementsGear wheelEngineering

The invention relates to a vacuum panel sucking and hoisting crane. The vacuum panel sucking and hoisting crane comprises a rack, a walking mechanism, a hoisting mechanism and a vacuum chuck group, wherein the walking mechanism comprises a linear guide rail and a movable machine head, the linear guide rail is horizontally arranged on the rack, the movable machine head is capable of linearly reciprocating on the linear guide rail through a gear and a rack, the hoisting mechanism is arranged in the movable machine head and is capable of moving up and down relative to the movable machine head, a cross beam is arranged at the lower part of the hoisting mechanism, a panel detection sensing probe is connected to the cross beam through a detection rod, and a plurality of vacuum chucks are arranged on the cross beam. The vacuum panel sucking and hoisting crane provided by the invention is especially suitable for sucking and hoisting of stainless steel, and can be applied to feeding of a veneer reeling machine, thereby reducing heavy labor of manual carrying, and ensuring undamaged carrying of panels; meanwhile, through transmission of signals between upstream equipment and downstream equipment, unattended operation can be realized, and the labor is maximally saved; the vacuum sucking and hoisting crane has the characteristics of high efficiency, safety, rapidness, and labor saving.

Owner:JIANGSU CHANGCHENG ARCHIVES EQUIP

Automatic lifting type algae turf system and artificial algae field establishing method thereof

InactiveCN104429911AProtection securityReduce harmClimate change adaptationCultivating equipmentsAlgaeSeedling

Provided are an automatic lifting type algae turf system and an artificial algae field establishing method thereof. A plurality of square algae turf frames provided with mesh structures are included, and algae seedlings are arranged at each mesh. Four floaters are connected to the top ends of four right-angle bending heads of each square algae turf frame, and the bottom ends are connected with rope cables and settlers. Each square algae turf frame is fixed between two mooring ropes. The artificial algae field establishing method comprises the steps that before casting, the algae seedlings are clamped in the middle of the four sides of each mesh through algae clamps; and two anchors are cast in an incident-flow direction, after tensioning, a first square algae turf frame is cast in a downstream direction, and repeated operation is carried out in sequence. Large-area artificial algae field establishing can be achieved easily, automatic sinking can be achieved under the sea state of heavy storm wave, the safety of an algae turf and algae is protected, the structure is simple, assembling is easy, operation is convenient, cost is low, the method is suitable for large floating type algae field establishing in most sea areas in China, the application range is wide, and large market potential is achieved.

Owner:OCEAN UNIV OF CHINA

Automatic workpiece conveying device

ActiveCN104261148AImprove production efficiencyLabor savingLoading/unloadingControl systemEngineering

Owner:宁波长华布施螺子有限公司

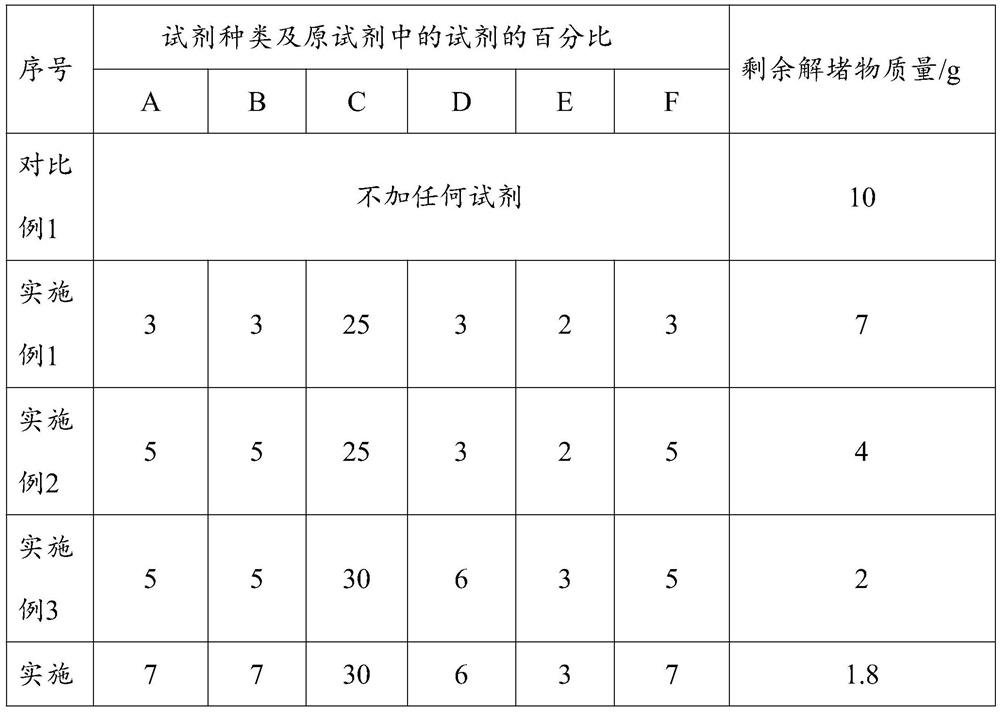

Novel gas well blockage-removing agent

Owner:成都欣明化工有限公司

Automatic tray filler suitable for tray filling of small-capacity bottles

Owner:连云港千樱医疗设备有限公司

Stone plastic composite floor automatic registration printing system

Owner:江阴市福诺新型装饰材料有限公司

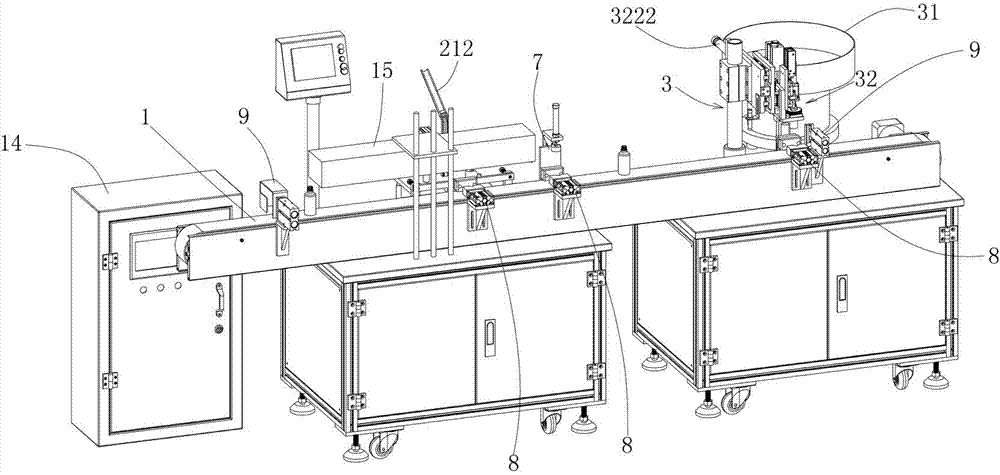

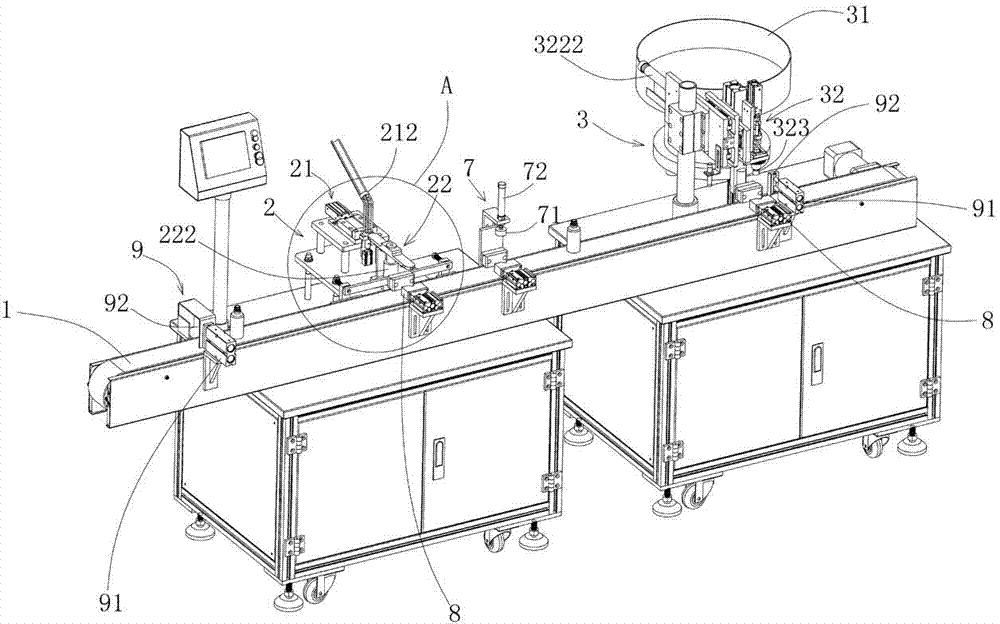

Sealing and cap screwing production line for glass bottles with metal caps

InactiveCN103895912ALabor savingIncrease productivityThreaded caps applicationWrapper twisting/gatheringElectromagnetic inductionAluminium

Owner:宁波爱用机械科技有限公司

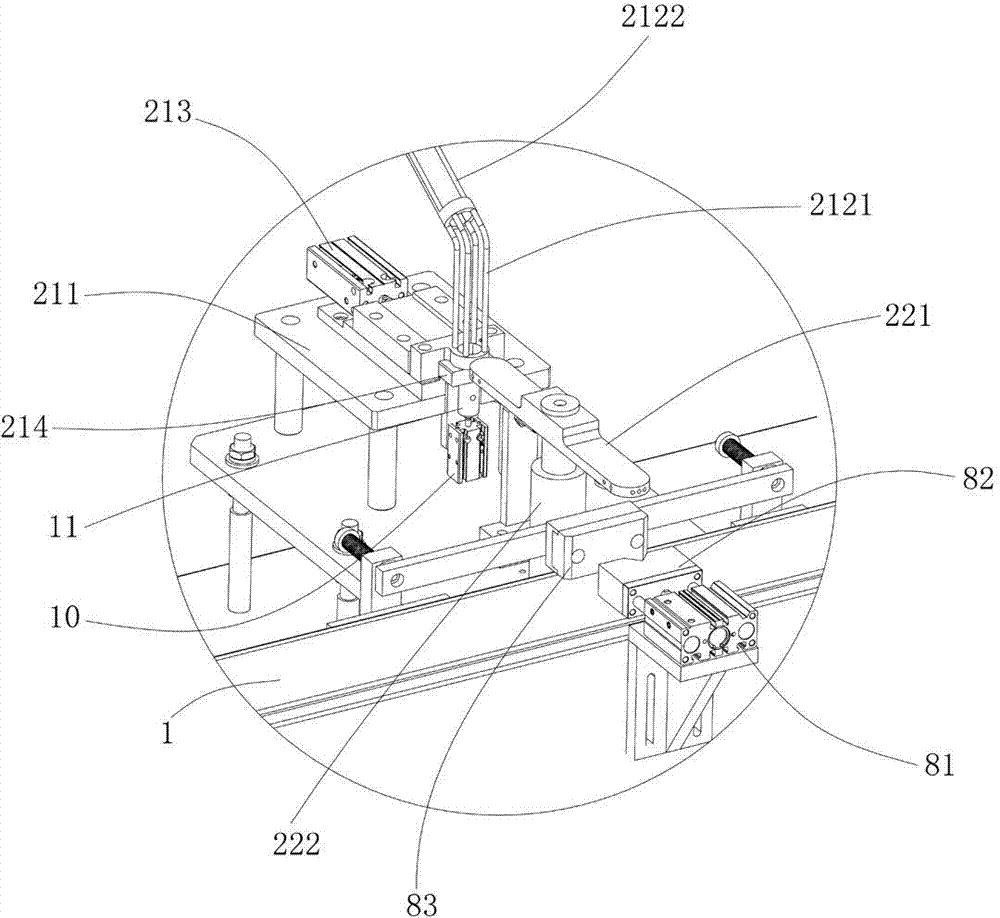

Feeding device of limiting switch assembling machine

InactiveCN105798575ALabor savingReduce manufacturing costMetal working apparatusChange positionsCoupling

Owner:SUZHOU ISHIMARU ERI PML PRECISION MECHANISM CO LTD

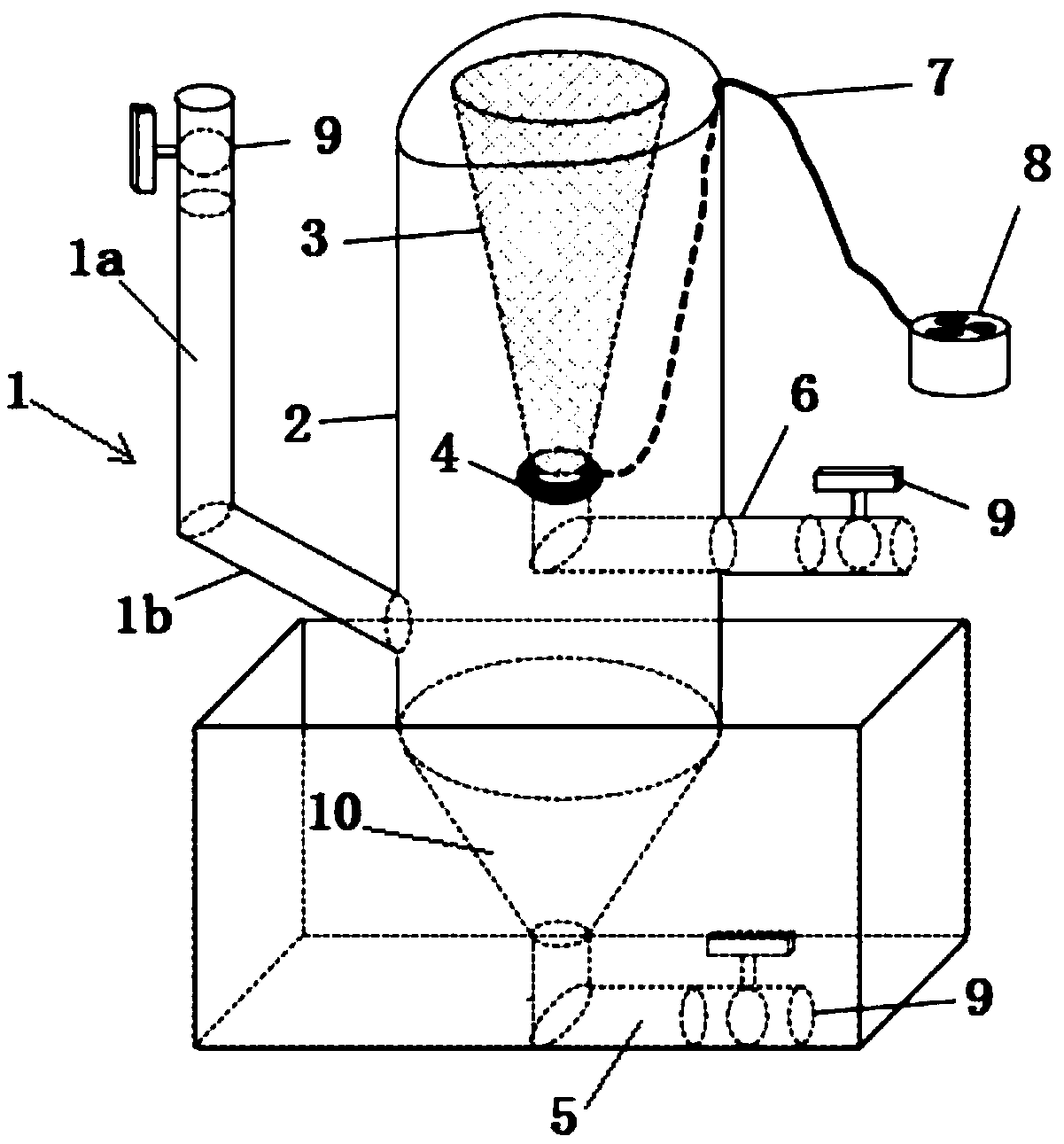

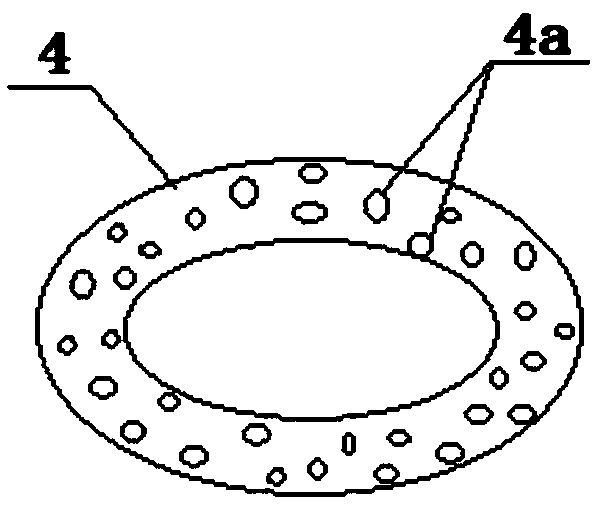

Filter device coupled with air float function

ActiveCN108715487AEasy to controlLabor savingMultistage water/sewage treatmentTreatment involving filtrationAir pumpAquaculture

Owner:SHANGHAI OCEAN UNIV

Automatic cloth unbundling and unfolding device

PendingCN112678292AIncrease productivityLabor savingArticle unpackingWebs handlingCotton materialIndustrial engineering

Owner:刘长庆

Method for preventing and controlling weeds of container nursery

Owner:JIANGSU ACAD OF FORESTRY

Interactive automatic welding system based on three-dimensional vision

InactiveCN112958974ALower programming skill requirementsHigh degree of automationProgramme-controlled manipulatorWelding/cutting auxillary devicesRemote controlSoftware engineering

The invention discloses an interactive automatic welding method based on three-dimensional vision. The interactive automatic welding method comprises the following steps that an interactive automatic welding system based on the three-dimensional vision is built; a three-dimensional model of a to-be-welded workpiece is obtained; a workpiece coordinate system and a robot coordinate system are aligned by using three-dimensional vision; to-be-welded features are selected in an interactive interface, and a welding track is generated; and welding is performed using a robot. According to the interactive automatic welding method, three-dimensional vision is combined with an interaction system, and the online programming or on-site teaching process is changed into an automatic welding system based on image interaction. Compared with traditional online programming and field teaching schemes, the automation degree is higher, labor is saved, and efficiency is improved; meanwhile, the programming skill requirement on front-line operators is also effectively reduced; and in addition, remote control can be achieved through the method, or one worker can control multiple devices, and unmanned flexible welding can be achieved.

Owner:XIAN CHISHINE OPTOELECTRONICS TECH CO LTD

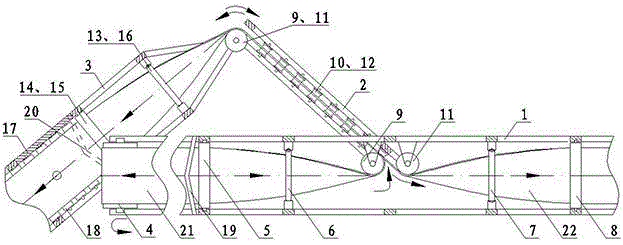

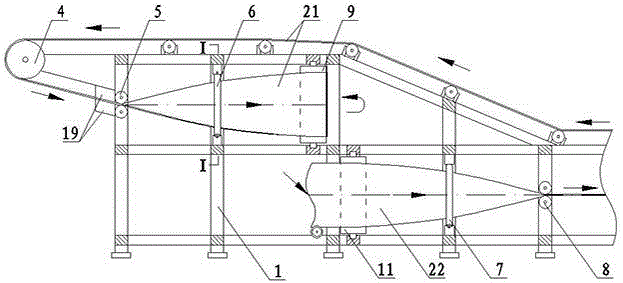

Turning method of belt conveyor and matched device

InactiveCN105317457AConducive to safety managementLabor savingEarth drilling and miningUnderground transportBelt conveyorBogie

Owner:LYUSHUIDONG COAL MINE OF SICHUAN HUAYINGSHAN COALIND

Double-material oiling machine

Owner:宁国市柯美自动化设备制造有限公司

Automatic production line for plates

InactiveCN105947532AImprove work efficiencyLabor savingRoller-waysElectrical connectionIndustrial engineering

Owner:桂林健威科技发展有限公司

Jack cover plate feeding device for socket assembling machine

InactiveCN105773118AIncrease productivityLabor savingMetal working apparatusAgricultural engineeringManipulator

Owner:SUZHOU HONGPU PRECISION MOLD

Conversion method for five blanking stock bins of lifter

Owner:HUNAN DONGTINGCHUN RICE IND

Doubling machine for metallic threads

The present invention discloses a tinsel yarn assembler. It contains payoff frame, annealing furnace and yarn-rewinding mechanism. The top portion and bottom portion of said payoff frame are respectively equipped with disk shaft and ceramic ring. The described yarn-rewinding mechanism contains supporting frame, the upper portion and lower portion of each of two sides of said supporting frame are respectively equipped with yarn-guiding wheel and yarn-rewinding disk, and the upper portion and lower portion of said annealing furnace are respectively with yarn tension controller and spindle. Said invention also provides the working principle of said tinsel yarn assembler and its operation method.

Owner:陈惠良

Automatic iron core column pie winding and binding machine

ActiveCN104733174AEasy to placeReduce laborTransformers/inductances detailsInductances/transformers/magnets manufactureElectrical connectionConductor Coil

The invention discloses an automatic iron core column pie winding and binding machine. The automatic iron core column pie winding and binding machine comprises a support, and a workbench is arranged on the support; the automatic iron core column pie winding and binding machine further comprises a chassis fixing device, an automatic rotating device and an adhesive tape part; the chassis fixing device comprises a base, a chassis is placed on the base, and the chassis is manufactured to a mould according to the level of a iron core column pie; the automatic rotating device comprises a distribution box and a motor which are in electrical connection, an output shaft of the motor penetrates through the base to be in transmission connection with the bottom of the chassis; the adhesive tape part comprises an adhesive tape which is wound on an adhesive tape reel, and the end of the outer side of the adhesive tape is detachably connected with a silicon steel sheet on the chassis; the adhesive tape reel is arranged on a support column in a sleeving mode, and the bottom of the support column is fixed on the workbench, and the adhesive tape reel rotate around the support column to release the adhesive tape. According to the automatic iron core column pie winding and binding machine, after the silicon steel sheet is installed on the moulded chassis, the end, exposed outside, of the adhesive tape is fixed on the silicon steel sheet, the chassis is driven to rotate after the motor is started to enable the adhesive tape to be wound on the silicon steel sheet, the motor is controlled to automatically rotate by the distribution box, therefore, automatic winding and binding of the adhesive tape are achieved, and labor is saved.

Owner:WEIFANG WUZHOU HAOTE ELECTRICAL CO LTD

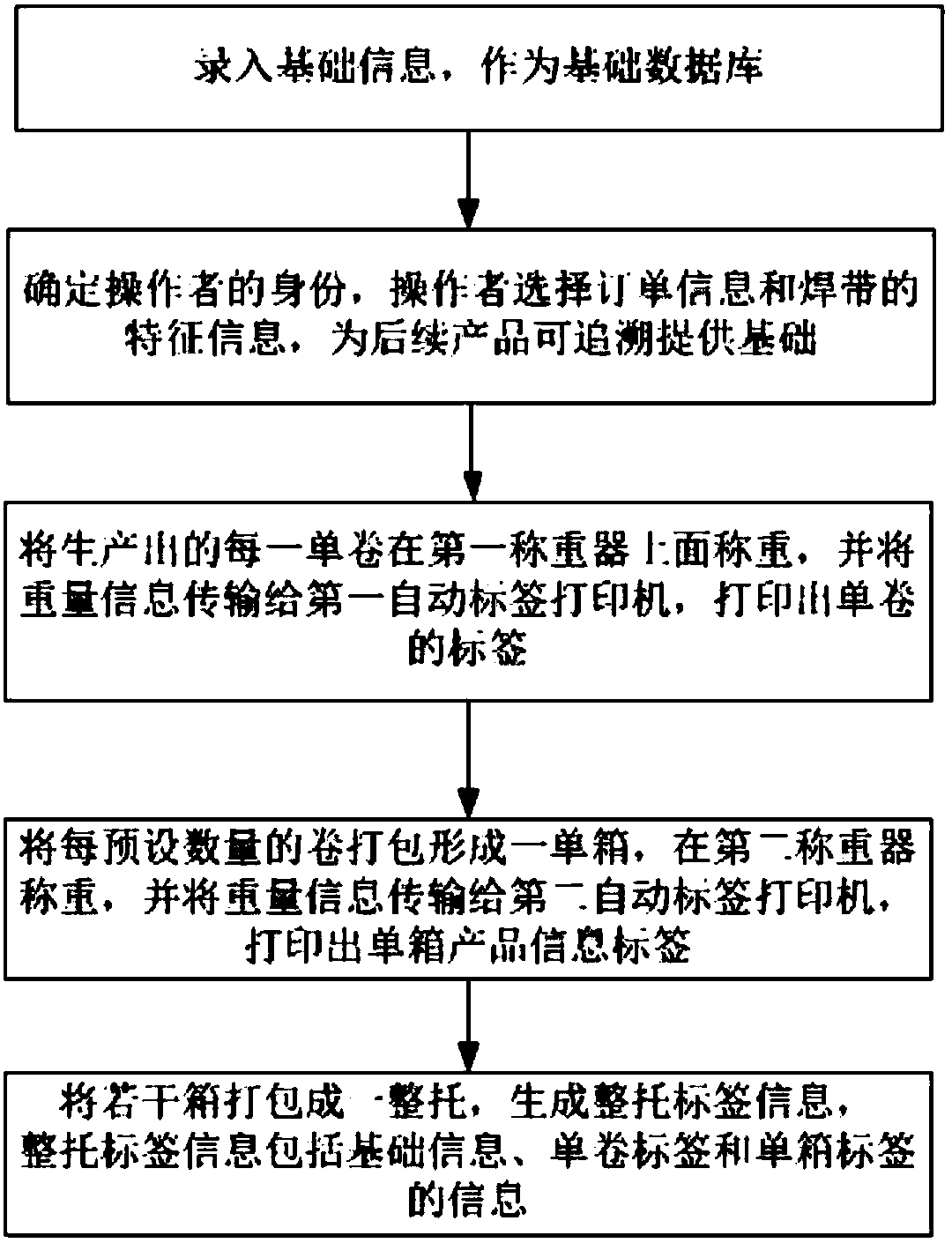

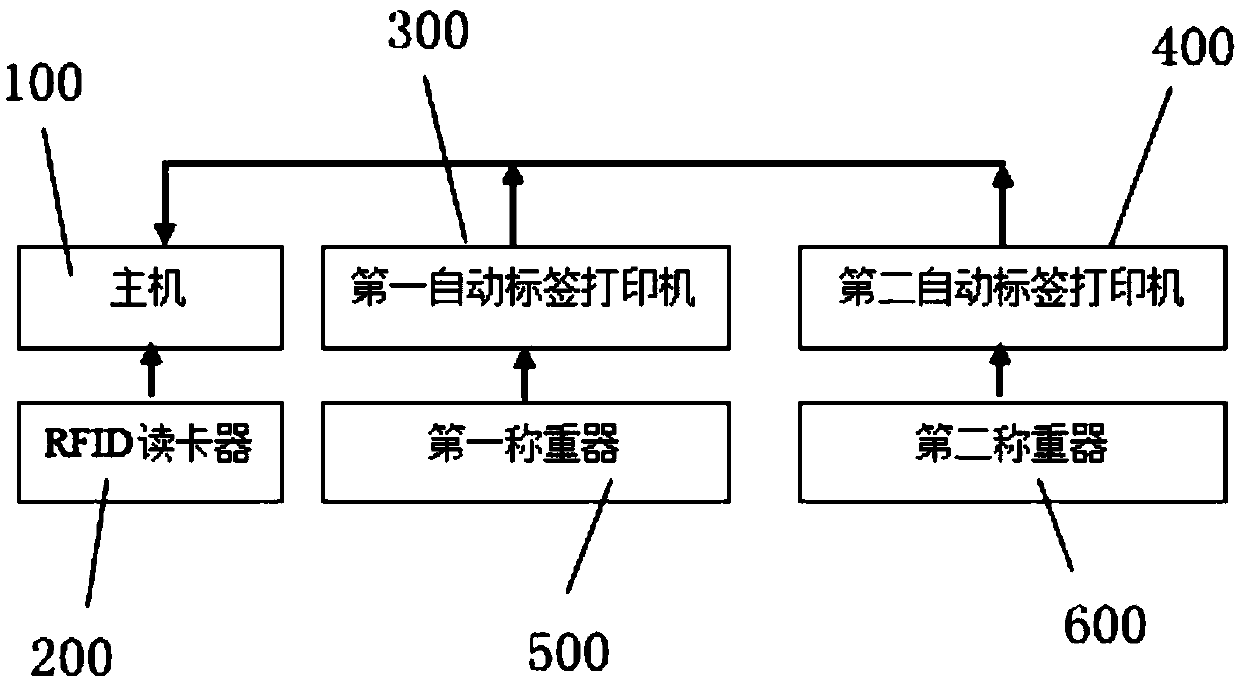

Automatic packing and weighing method and system for welding strips

InactiveCN107814011AImprove accuracy and traceabilityLabor savingCo-operative working arrangementsLabelling machinesSoftware engineeringTraceability

Owner:苏州为能新型材料有限公司

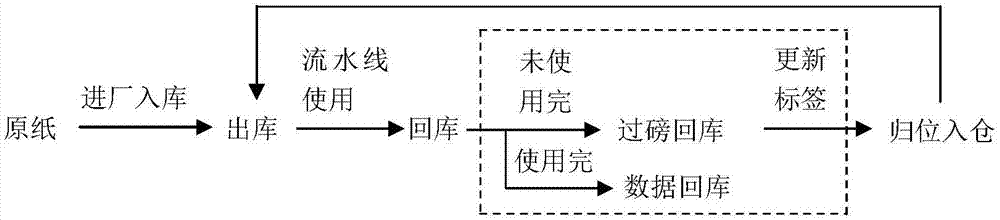

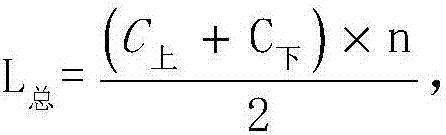

Intelligent metering method for remnant base paper rolls of corrugated paper board assembly line

ActiveCN107478652AReduce operating costsIncrease profitMaterial analysis by optical meansPaper sheetOperational costs

The invention relates to the technical field of packaging, in particular to an intelligent metering method for remnant base paper rolls of a corrugated paper board assembly line. The intelligent metering method for the remnant base paper rolls of the corrugated paper board assembly line comprises steps as follows: a plurality of base paper feeding positions are arranged in the conveying direction of the assembly line at intervals, a base paper feeding frame is arranged in each base paper feeding position, and two base paper feeding rolls located on two sides of each base paper feeding frame are arranged on the base paper feeding frame; each base paper feeding roll is provided with lap recording sensors and incremental encoders, the lap recording sensors are used for monitoring the number of paper feeding laps of base paper clamped on the corresponding base paper feeding roll, the incremental encoders are used for monitoring the length of each lap after the base paper on the base paper feeding roll passes by one lap, and the lap recording sensors and the incremental encoders are connected with a controller. Intelligent metering can be realized, the operation cost of an enterprise is reduced, labor is saved, and the utilization rate of enterprise resources is increased.

Owner:DACHENG PACKAGING PROD SUZHOU

Rubber hose vulcanization vehicle

The invention provides a rubber hose vulcanization vehicle and belongs to the technical field of special-shaped hose vulcanization. The rubber hose vulcanization vehicle comprises a frame. An angle-adjustable movable angle frame is arranged on the frame. Fixed bases are distributed on the movable angle frame. A positioning hole is formed in each fixed base. A mold pipe core is fixed to each pipe core base. A positioning rod is arranged on each pipe core base. The positioning rods extend into the corresponding positioning holes in the fixed bases and are locked and fixed through locking bolts.The rubber hose vulcanization vehicle solves the problems that the existing special-shaped pipe vulcanization operation is not convenient, the production efficiency is low, the labor cost is high, andmolds are likely to be collided.

Owner:GUIZHOU JINGZHONG RUBBER & PLASTIC IND CO LTD

Intermittent feeding type sand sieving device for building

ActiveCN108906576AImprove screening efficiencyAvoid affecting the screening effectSievingScreeningCircular cavitySieve

The invention discloses an intermittent feeding type sand sieving device for building. The intermittent feeding type sand sieving device comprises a storage cavity and a sieving cavity and is characterized in that the storage cavity is arranged at the upper end of the left side of the sieving cavity and communicated with the sieving cavity through a discharge outlet, a transverse plate is fixedlymounted in the sieving cavity, the inner side of the transverse plate is provided with a circular cavity, a first eccentric wheel is arranged on the inner side of the circular cavity, push rods are symmetrically arranged at the left end and the right end of the first eccentric wheel, fixing parts are mounted at the lower ends of the push rods, the lower ends of the fixing parts are hinged to one ends of the connecting rods, and the other ends of the connecting rods are hinged to the upper end of a sieve plate. The intermittent feeding type sand sieving device has the advantages that the deviceis novel in design, a second eccentric wheel rotates to drive a retaining plate to move vertically in a reciprocating manner to intermittently open the discharge outlet so as to achieve intermittentfeeding, and accordingly the sieving effect can be effectively prevented from being affected by the fact that excessive sand enters the sieving cavity at the same time; the push rods move leftwards and rightwards to drive the sieve plate to swing in a reciprocating manner through the connecting rods, and accordingly the sieving efficiency of the sieve plate is increased, and high practicality is achieved.

Owner:安徽谦源项目管理有限公司

Anti-pollution device for hard-chromium plating processing during micro-arc oxidation treatment

The invention discloses an anti-pollution device for hard-chromium plating processing during micro-arc oxidation treatment, and relates to the technical field of micro-arc oxidation treatment. The anti-pollution device for hard-chromium plating processing during micro-arc oxidation treatment comprises a liquid-plating tank, wherein a heat preservation layer is arranged fixedly to the outer wall of the liquid-plating tank in a sleeving manner; a cleaning tank is fixedly mounted to the outer wall of the other side of the heat preservation layer; support plates are fixedly connected to the outer surfaces of the tops of the cleaning tank and the liquid-plating tank; a back plate is fixedly connected to the adjacent side walls of the two groups of support plates; and a conveying mechanism is arranged on the back plate. According to the anti-pollution device for hard-chromium plating processing during micro-arc oxidation treatment disclosed by the invention, through cooperative application of a long threaded rod sliding plate, a sliding rod sleeve, a sliding rod, a servo motor, a short rotary rod, a rotary disc, a connecting rod, a first bevel gear, a second bevel gear, a long rotary rod, a first belt pulley, a second belt pulley and a first belt, workpieces can be quickly cleaned, and the cleaned workpieces can be quickly soaked into hard-chromium plating solutions.

Owner:CHENGDU ERKUI NEW MATERIAL TECH CO LTD

Reinforced concrete intelligent stirring device

InactiveCN111300641AQuality improvementAvoid pollutionMixing operation control apparatusIngredients proportioning apparatusReinforced concreteElectric machine

The invention provides a reinforced concrete intelligent stirring device. The reinforced concrete intelligent stirring device comprises a stirring device, a stirring motor mounted on one side of the stirring device, a first hopper, a second hopper, two discharging barrels, weighing assemblies, a cement feeding assembly, a sand feeding assembly, a cement stock bin and a sand stock bin, wherein thefirst hopper and the second hopper are located above the stirring device; the two discharge barrels are installed on the bottom side of the first hopper and the bottom side of the second hopper respectively, the weighing assemblies are installed at the bottom sides of the discharge barrels; the cement feeding assembly is connected with the top side of the first hopper, and the sand feeding assembly is connected with the top side of the second hopper; and the cement stock bin is connected with the cement feeding assembly, and the sand stock bin is connected with the sand feeding assembly. The reinforced concrete intelligent stirring device has the advantages of being high in intelligence degree and high in precision.

Owner:CHANGDE XIAOPING BUILDING MATERIALS CO LTD

Full-automatic assembling machine for small American hose clamp

PendingCN109664097AHigh degree of automationImprove securityAssembly machinesMetal working apparatusEngineeringEnergy conservation

The invention discloses a full-automatic assembling machine for a small American hose clamp. The full-automatic assembling machine for the small American hose clamp comprises a lower machine frame, arotating platform, a plurality of assembling stations, a steel ring feeding plate, a base feeding plate, an adjusting screw feeding plate, three feeding mechanisms, a discharging mechanism, a base riveting mechanism and a control mechanism. The rotating platform is rotationally installed at the center of the upper surface of a lower machine frame. A drive mechanism driving the rotating platform torotate is arranged below the rotating platform. A plurality of assembly stations are fixedly connected along the edge of the rotating platform. The angles formed by every two adjacent assembly stations and the center of the rotating platform are identical. The three feeding mechanism correspond to the base feeding plate, the adjusting screw feeding plate and the steel ring feeding plate correspondingly and are installed on the lower machine frame around the rotating platform. By the adoption of the technical scheme, the full-automatic assembling machine for the small American hose clamp effectively improves the automation degree of production of the small American hose clamp, reduces labor needed during production and greatly improves the yield. In addition, an air source is used as a power source, better energy conservation and environment protection are achieved during equipment operation, and the safety is higher.

Owner:CIXI ZHIJIU AUTOMATION EQUIP CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap