Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

451results about How to "Increase productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel mold for prefabricated concrete lintel of distribution box, and assembly structure and construction method of steel mold

ActiveCN114012874AGuarantee the construction qualityIncrease productivityMould fastening meansMould palletsArchitectural engineeringAssembly structure

Owner:CHINA MCC17 GRP

Manufacturing process of high-carbon tool steel SK85 cold-rolled wide steel strip

The invention discloses a manufacturing process of a high-carbon tool steel SK85 cold-rolled wide steel strip. The process is characterized in that steel is subjected to converter smelting, LF furnacerefining and slab continuous casting to obtain continuous casting slabs with the thickness ranging from 210 mm to 230 mm, the continuous casting slabs are heated and subjected to hot continuous rolling and laminar cooling to reach the coiling temperature, a hot-rolled wide steel strip with the thickness ranging from 2.5 mm to 6.0 mm is obtained, the coiled hot-rolled wide steel strip is put in storage and slowly cooled to the room temperature, and the obtained metallographic structure is thin-sheet-shaped pearlite; the total reduction of first cold rolling is controlled to be 20%-50% after acid pickling of the hot-rolled wide steel strip, then spheroidizing annealing is conducted, the Vickers hardness HV5 is 180 or below, and the spheroidizing rate is 92% or above; after the steel strip is subjected to primary spheroidizing annealing, secondary cold rolling is conducted, the total reduction of cold rolling is controlled to be 30%-85%, and a cold-rolled wide steel strip with the finished product specification being 0.70-3.00 mm thick is obtained; the steel strip subjected to secondary cold rolling is further spheroidized and annealed, the Vickers hardness HV5 is 175 or below, and the spheroidizing rate is 94% or above; and then third cold rolling is conducted, the total reduction of cold rolling is controlled to be 50%-85%, and the cold-rolled wide steel strip with the finishedproduct specification being 0.10-0.70 mm thick is obtained.

Owner:新余钢铁股份有限公司

Fruit surface defect detection method based on image marking

InactiveCN105424709AAccurate Defect DetectionStatistically accurateOptically investigating flaws/contaminationImage conversionVisual perception

A fruit surface defect detection method based on image marking includes the following steps that firstly, a surface picture of a to-be-detected fruit is taken and saved, and an original image is obtained; secondly; the original picture is uploaded to a server to be analyzed and processed; processing of the server includes the steps that a, the obtained original image is converted into a space where the visual system of human beings is applied, and an H component and an I component are extracted; b, dynamic threshold segmentation is performed on the H component; c, gray histogram statistics is performed on the I component, segmentation is performed through a fixed threshold method, and a threshold is selected between two wave peaks; d, the H value segmentation result and the I value segmentation result are operated, and a binary image with defect areas is obtained; denoising is performed on the obtained binary image; f, the binary image is enhanced, hole noise may exist in the defect areas, and filling is performed on the noise; g, the obtained binary image is marked, and the number and the area of defects are calculated; a detection result is output; labor intensity of workers is reduced, and production efficiency is improved.

Owner:SHAANXI UNIV OF SCI & TECH

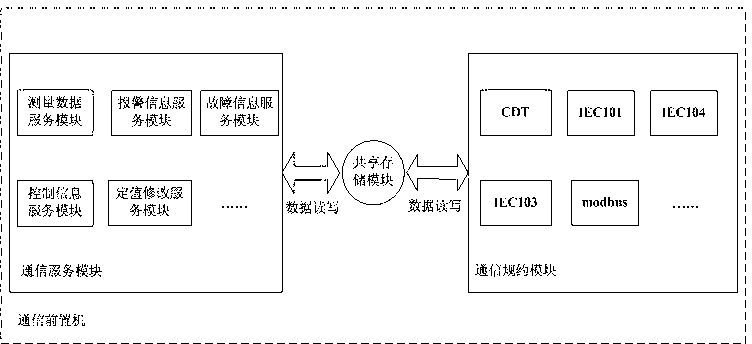

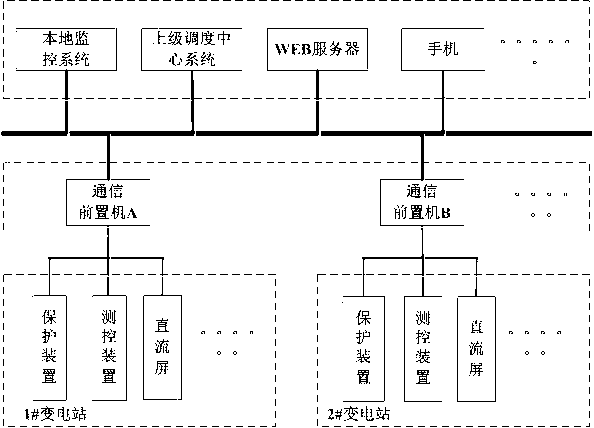

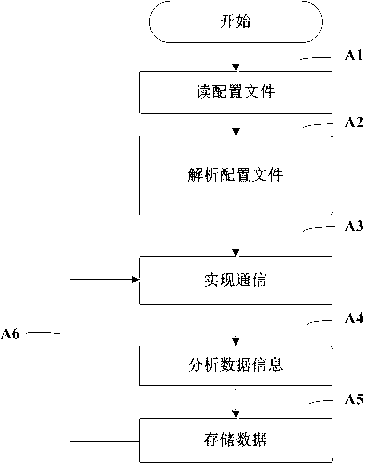

WCF realization-based communication front-end processor system and communicating method

InactiveCN103347037AIncrease productivityGood interactivityTransmissionInteroperability ProblemReal-time computing

The invention discloses a windows communication foundation (WCF) realization-based communication front-end processor system comprising a communication protocol module, a communication service module and a sharing storage module. Specifically, the communication protocol module is responsible for analyzing a communication protocol to realize communication with an automation device; and the communication service module is used for forwarding data received by the communication protocol module to a client by a service way. In addition, the invention also discloses a communication front-end processor-based communicating method. The communication protocol module configures a file by analyzing to realize communication with an automation device; data of the automation device are stored in the sharing storage module in real time; the client accesses the communication service module; and the communication service module reads the data directly from the sharing storage module. According to the invention, interoperability between systems is ensured; out-of-process, cross-device and cross-platform communication is realized; and operation in different operating systems is realized; and characteristics of security and trustworthiness are realized.

Owner:成都瑞科电气有限公司

Mold/non-mode combined pulling process and device

InactiveCN102133582AImproving the process conditions of drawing formingReduce consumptionDrawing profiling toolsEngineeringMechanical engineering

The invention belongs to the technical field of metal plastic processing, and particularly provides a mold / non-mold combined pulling process and a device. The device is characterized in that a pulling mold is directly installed between a heater and a cooling machine of a non-mold pulling device, the waste heat of non-mold pulling is utilized fully, so that the mold puling and sizing with temperature can be completed before the non-mold pulling is molded, and the surface quality is improved. In the invention, the pulling force is reduced greatly, the intermediate heat treatment or heating process of the traditional process is saved, the mold consumption is reduced, the energy resource is saved, the production cost is lowered, a high-quality metal product can be pulled and molded in short flow range, and the advantages that the deformation amount of the non-mold pulling is large, the precise of the mold pulling size is high and the like can be realized.

Owner:UNIV OF SCI & TECH BEIJING

Work cutting apparatus and method for cutting work

InactiveUS6889586B2Improve accuracyIncrease productivityGuide fencesShearing machinesRotational axisSurface mounting

A work cutting apparatus comprises a bed. The bed has an upper surface provided with a column including a rail slidably mounted with a slider. The slider has a front surface mounted with a supporting portion supporting two end portions of a rotating shaft. The rotating shaft is mounted with a plurality of cutting blade blocks. Each of the cutting blade blocks includes a plurality of cutting blades and a thicker cutting blade at each end of the cutting blade block. A table provided with a recess having a V-shaped section is disposed on the bed right beneath the cutting blade blocks. A plurality of works are disposed in the recess, each fixed by a fixing member. The cutting blades lowered while rotating, thereby cutting the works. During this operation, coolant is discharged from a plurality of supplying ports of a coolant supplying portion as well as from a supplying port of a coolant supplying path.

Owner:PROTERIAL LTD

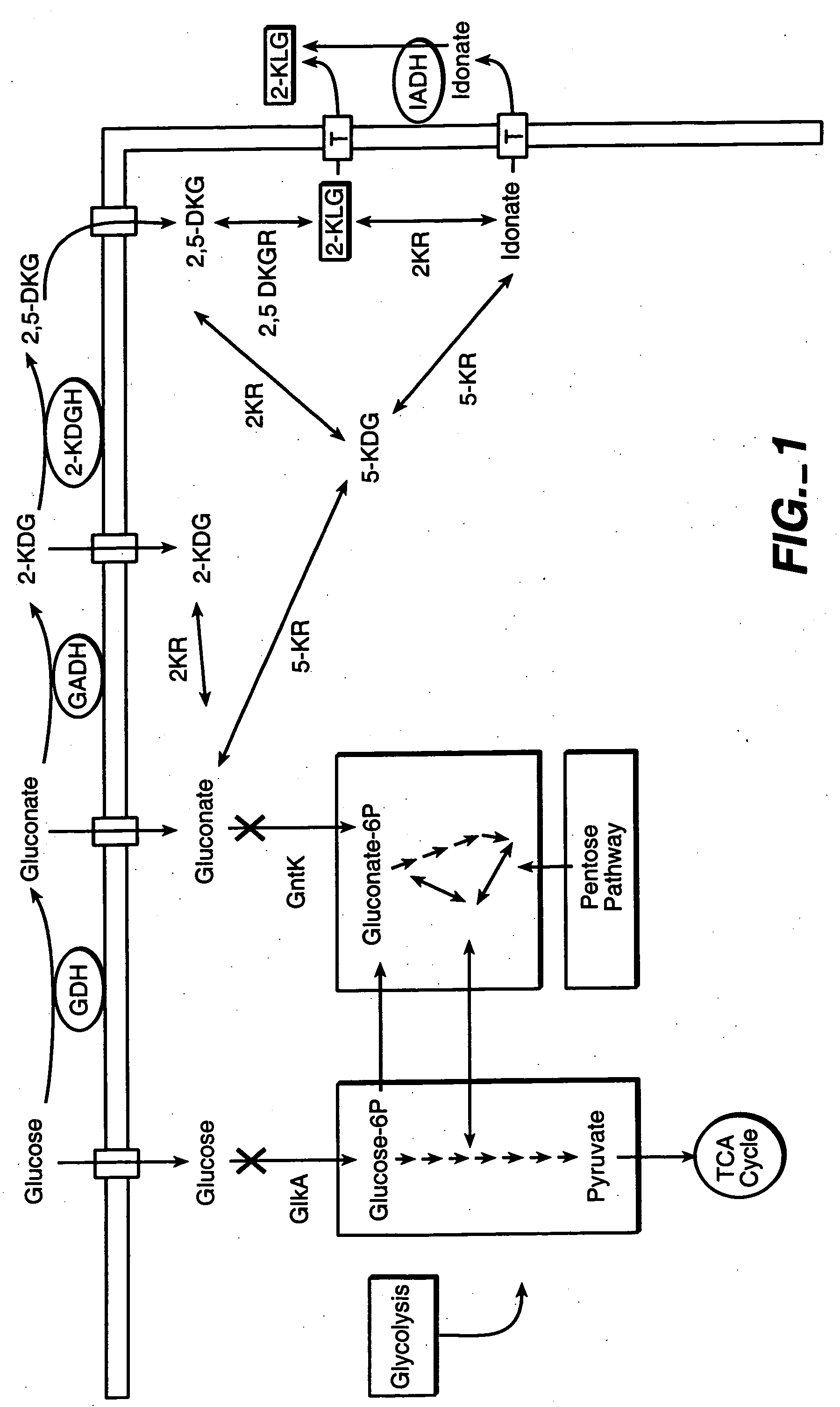

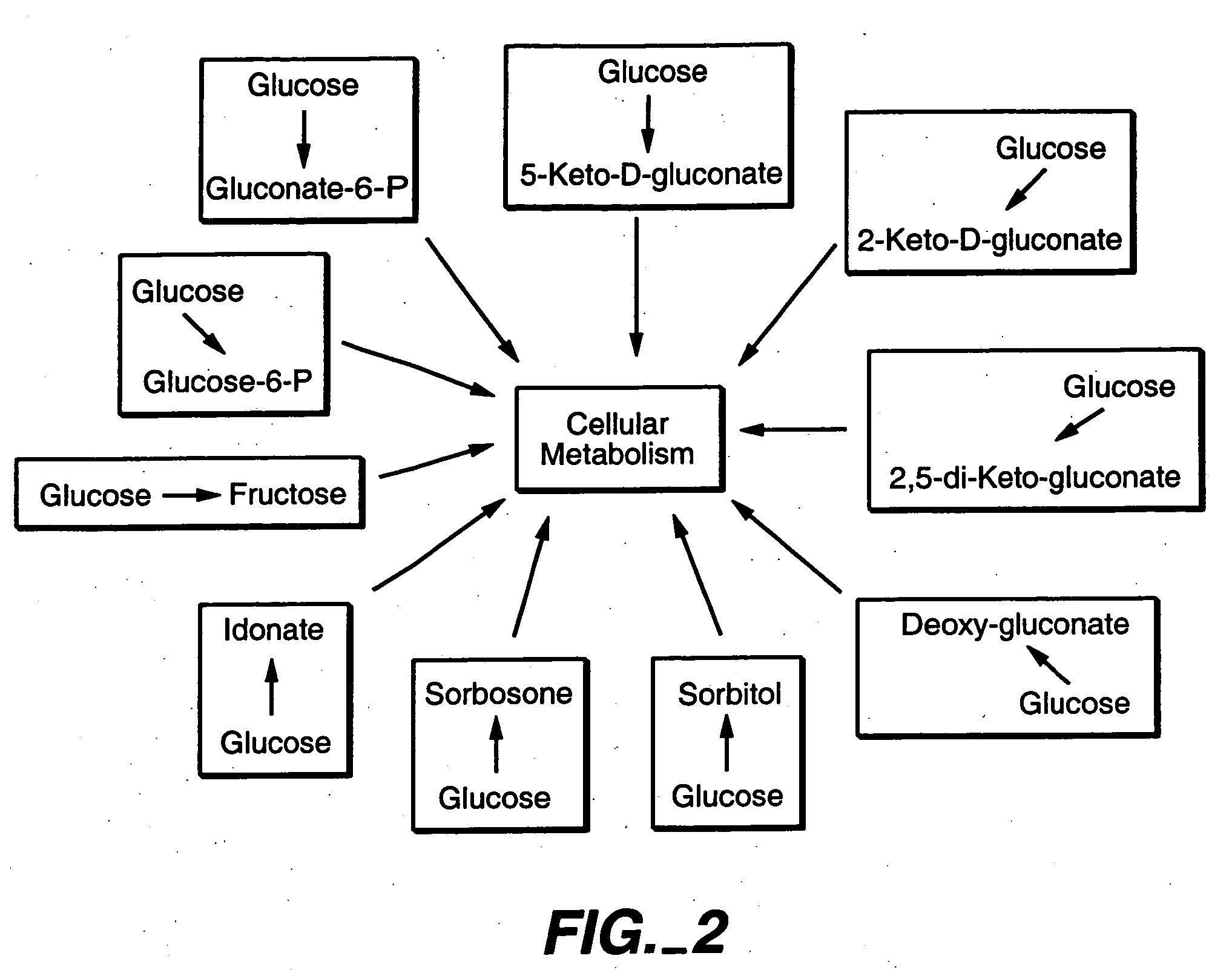

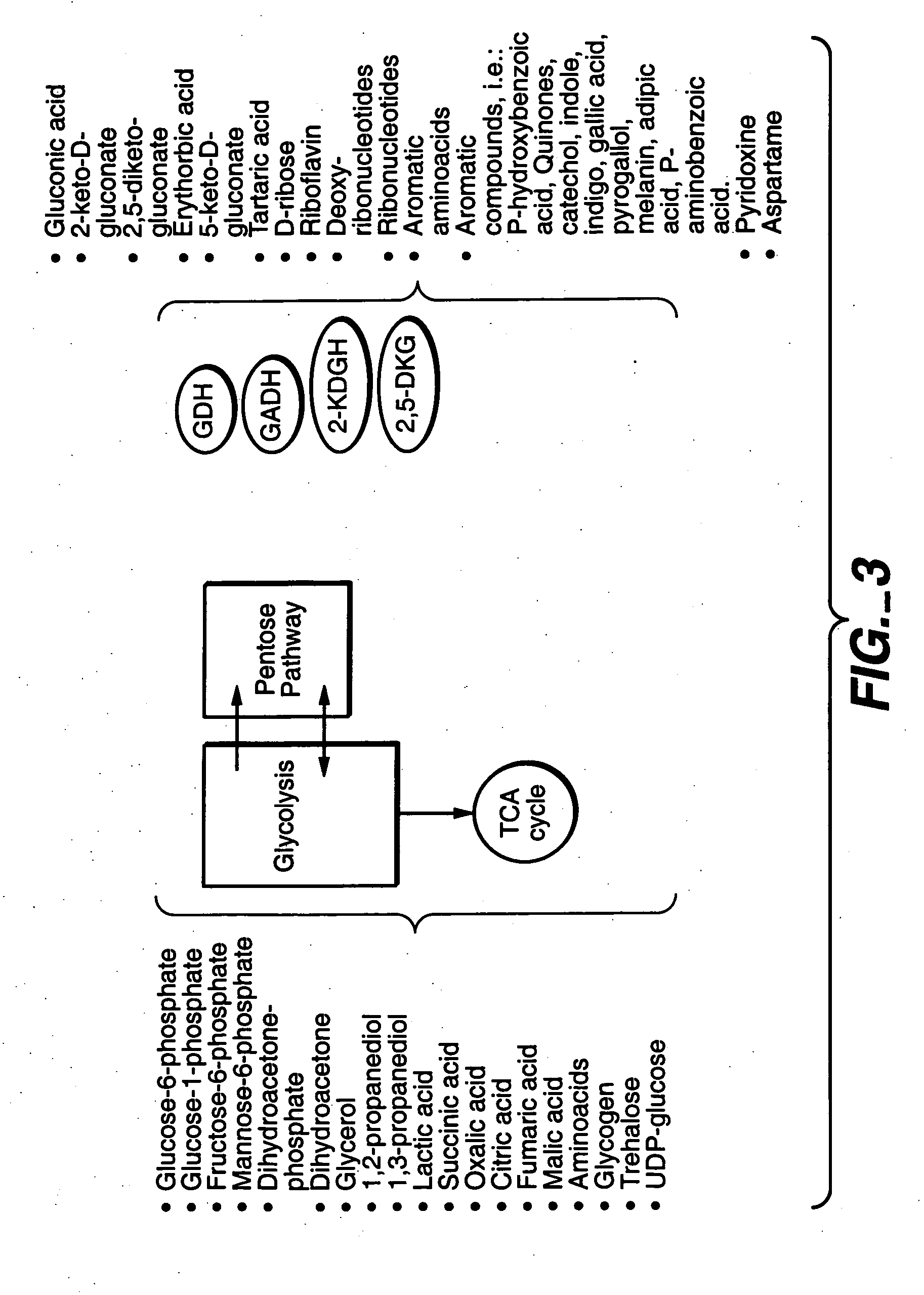

Methods for the production of products in host cells

InactiveUS20060068477A1Increase productivityDNA/RNA fragmentationFermentationAcid amino sequencesAmino acid

Owner:DODGE TIMOTHY +1

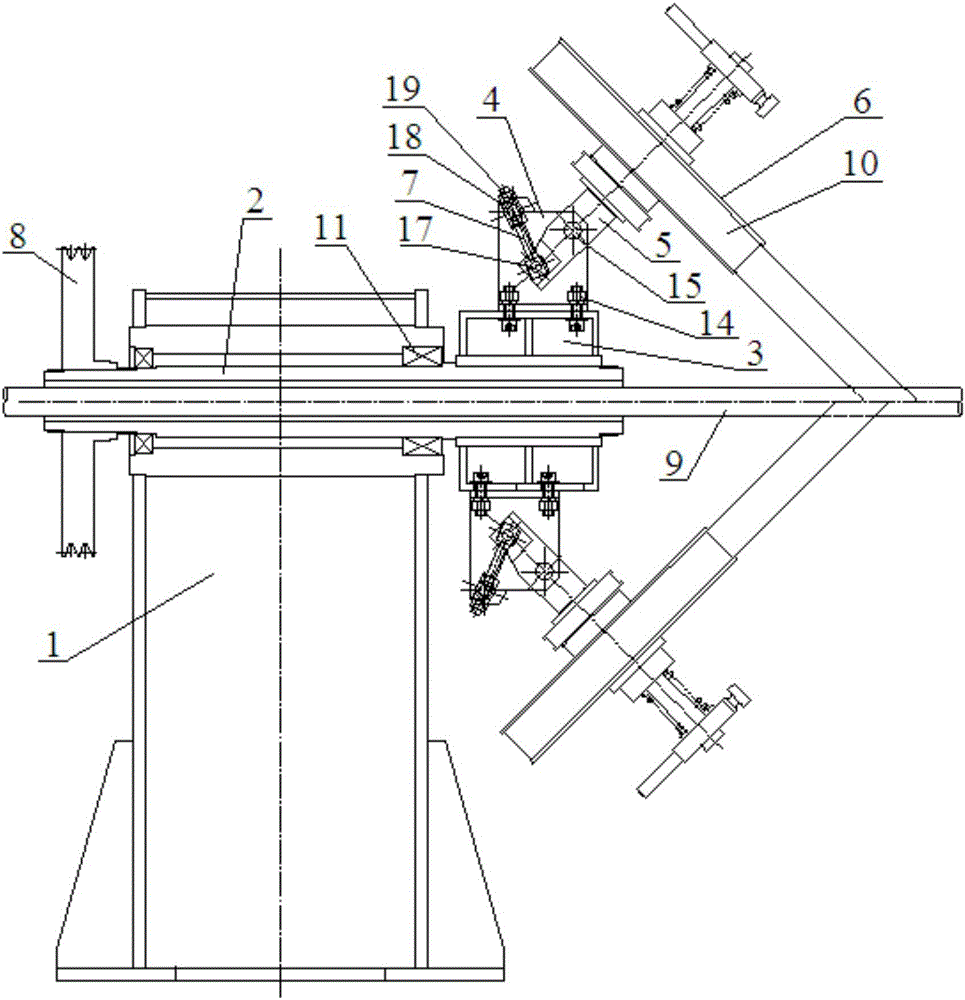

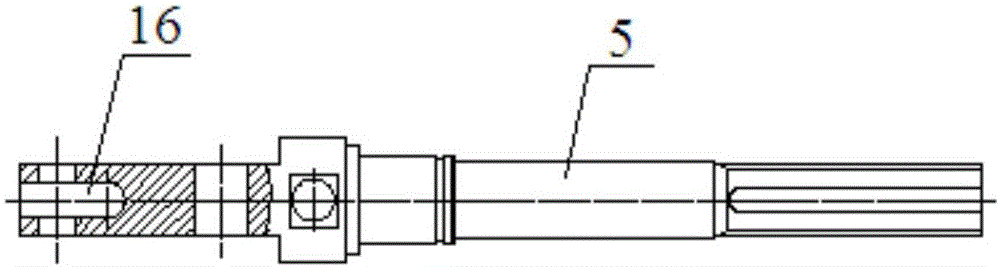

Cylinder liner combined machining machine tool

ActiveCN104801977AMeet the needs of basic functionsSimple structureTailstocks/centresOther manufacturing equipments/toolsHigh volume manufacturingEngineering

The invention relates to a cylinder liner combined machining machine tool. The machine tool comprises a machine tool body, wherein a motor device, an apron driving device, a tailstock driving device and three sets of guide rails are installed on the machine tool body, an upper apron is installed on the upper set of guide rails, an external turning tool is installed on the upper apron, a down-cutting device is installed on the lower set of guide rails, a facing tool set is installed on the down-cutting device, a headstock and a double-station complex programming tailstock are installed on the main guide rails in the middle, a headstock spindle is driven by the motor device to rotate, a boring tool and an expansion combination device are installed at the front end of the headstock spindle, a material pushing device is installed on the top of the headstock, and the double-station complex programming tailstock is a tailstock device which is provided with a telescopic hydraulic chuck mechanism and a hydraulic center mechanism at the same time. According to the cylinder liner combined machining machine tool, the machining efficiency and the accuracy of cylinder liners can be greatly improved; a production unit can formed when an automatic feeding and discharging device is further arranged so that automatic production can be achieved, the production cost can be greatly reduced, the productivity of enterprises can be improved, and the cylinder liner combined machining machine tool is particularly applicable to mass production of cylinder liners.

Owner:NING XIA XIN RUI CHANG CHENG JI CHUANG YOU XIAN GONG SI

Propping agent for resin coating film and preparation method thereof

InactiveCN102899019AImprove water resistanceImproves breakage resistanceFluid removalBreakage rateResin coating

The invention discloses a propping agent for a resin coating film and a preparation method thereof. The propping agent comprises an aggregate, a resin, a curing agent and a dispersing agent, wherein the dosage of the resin is 1%-10% of the weight of the aggregate; the dosage of the curing agent is 0.5%-5% of the weight of the aggregate; and the dosage of the dispersing agent is 0.2%-2% of the weight of the aggregate. The propping agent for the resin coating film provided by the invention has the functions of allowing oil gas to smoothly penetrate and preventing water from penetrating through the propping agent, so that the separating effect of oil gas and water is enhanced by the functions and the oil extraction cost is lowered; due to the excellent hydrophobic property of the resin film, the propping agent has excellent water resistance, the anti-breaking capability of the propping agent is increased and the long-term flow-guiding effect is good; a triple film coating technology is adopted by the invention and the calcium stearate is taken as a dispersing agent, so that the quality is greatly increased, the yield is increased to above 80%, the cost is greatly lowered and the production efficiency is increased; and the preparation method provided by the invention is simple, the product yield is high and the breakage rate of the product is obviously reduced.

Owner:YIXING TENGFEI OIL FRACTARING PROPPANT

High-speed wrapping machine

InactiveCN106024211AImprove rigidityNot easy to looseInsulating conductors/cablesEngineeringSupport plane

The invention discloses a high-speed wrapping machine. The high-speed wrapping machine comprises a wrapping support and a hollow main shaft, the right end of the hollow main shaft is provided with a rotation support, multiple installation planes are respectively arranged around the rotation support, and multiple support frames are respectively installed on the installation planes; and the high-speed wrapping machine comprises multiple aslant arranged reel shafts, the central portions of the multiple reel shafts are each provided with a reel, the rear portions of the multiple rear shafts are respectively correspondingly rotationally installed on the multiple support frames, the multiple support frames are each provided with an adjustment screw rod, and the rear ends of the adjustment screw rods are respectively in rotational connection with the rear ends of the reel shafts rotationally installed on the support frames. The application performance is good, the adjustment is simple, the locking is reliable, the safety is high, the rigidity of the rotation support is high, during high-speed rotation, loosening is not easily generated, the problem of adjustment of the angle of a wrapping band in a wire and cable production process and the pitch problem of coverage of multiple wrapping bands are solved, the production efficiency is improved, and the high-speed wrapping machine is suitable for a wrapping machine rotating at a high speed.

Owner:WUHU ELECTROTECHN MACHINERY

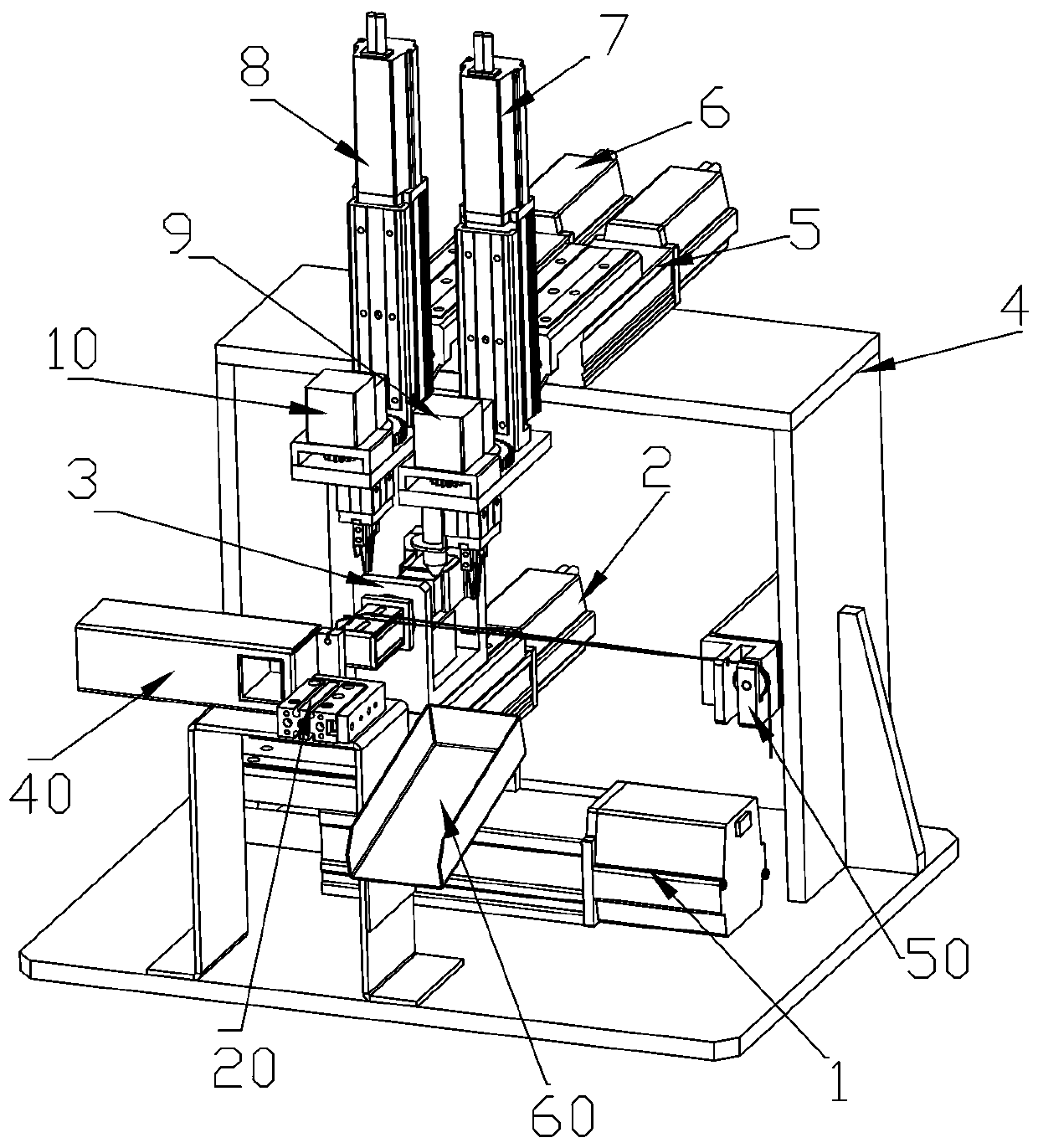

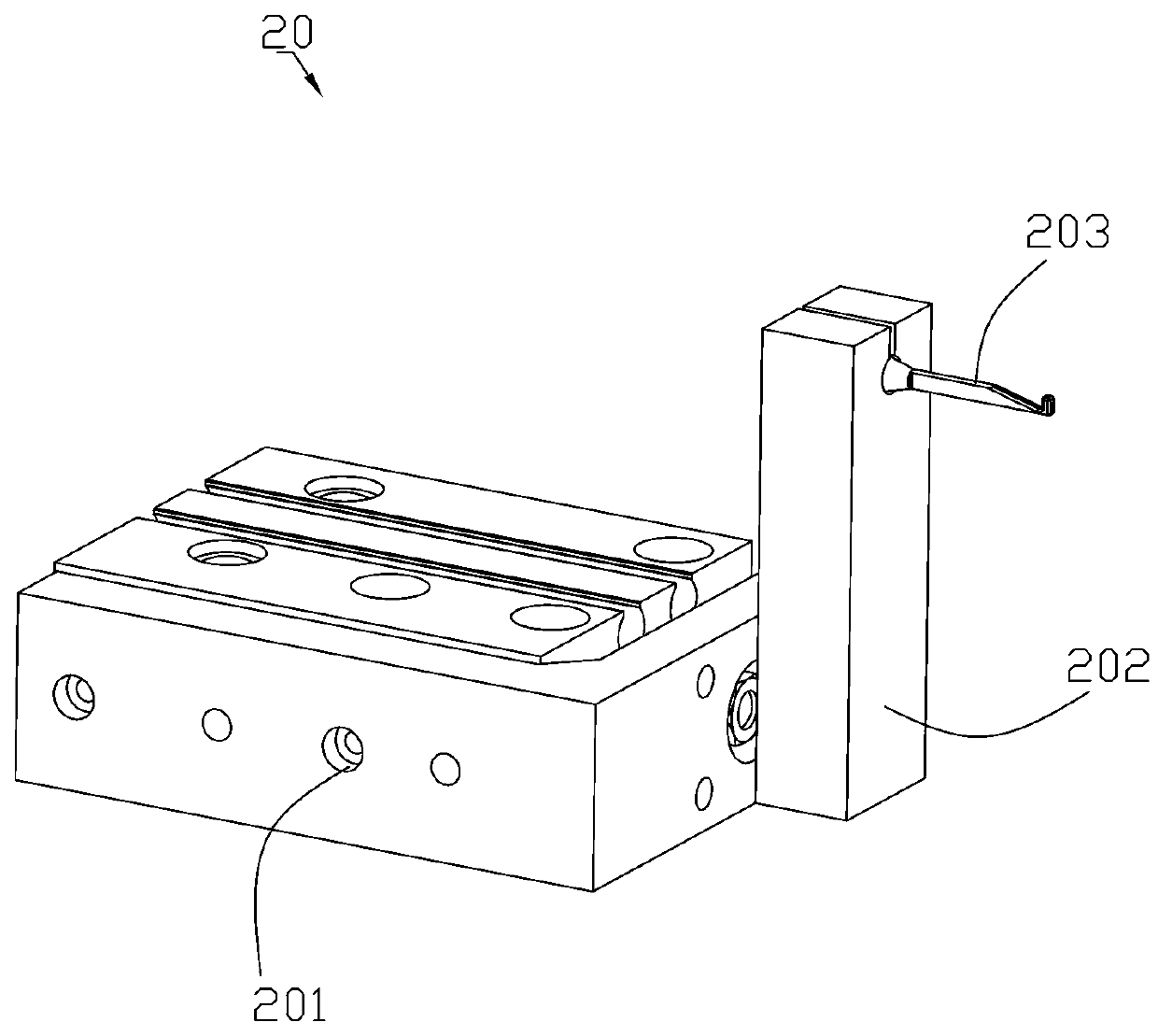

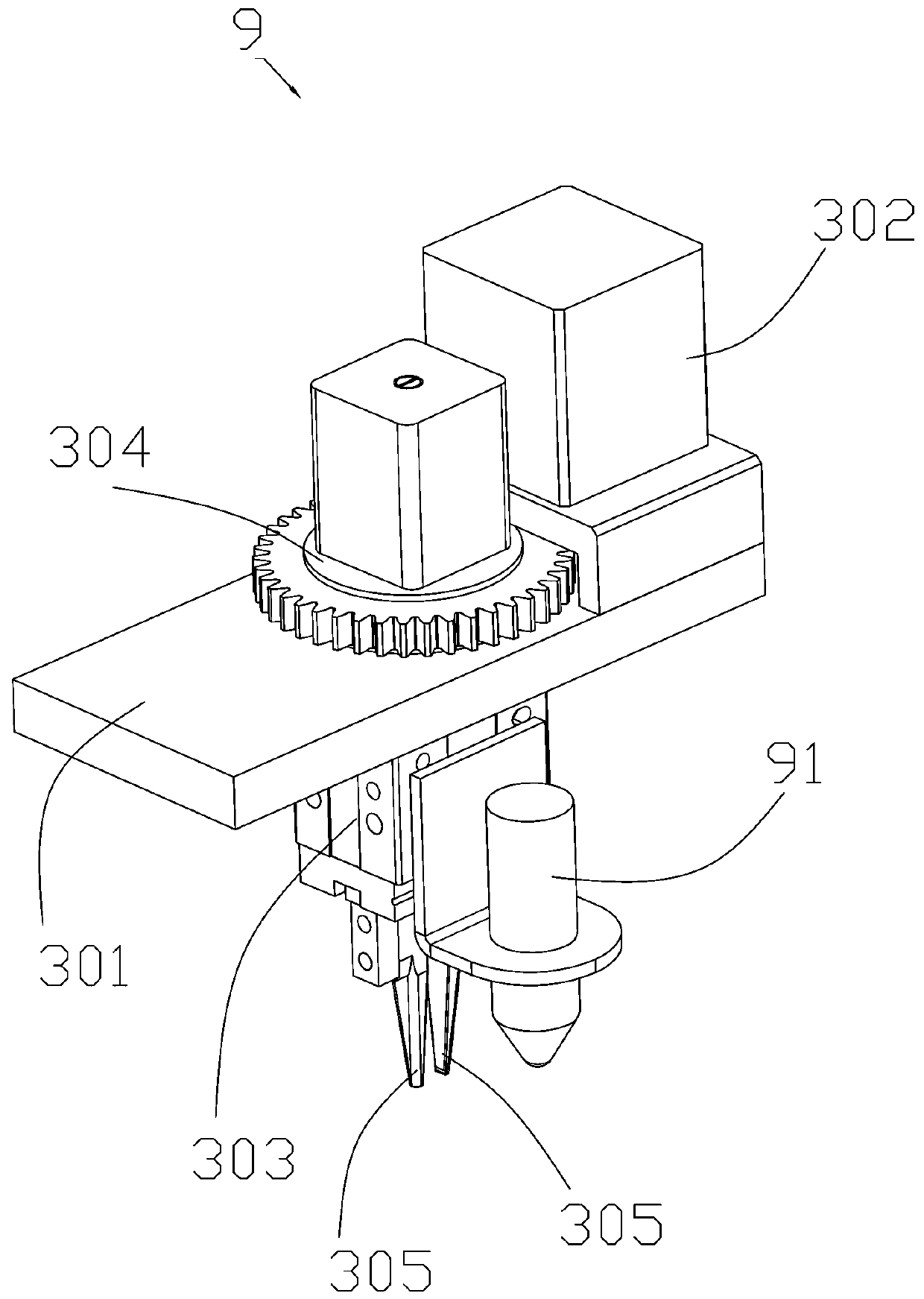

Integrated intelligent primary and secondary pole coil winding robot

Owner:WUHAN CHENYANG ELECTRONICS TECH

Automatic labeling system and method for hard disk

InactiveCN1838304AReduce labor intensityIncrease productivityStampsRecord information storageBarcodeEngineering

This invention relates to an automatic labeling system and method for hard disk, which comprises: a convey mechanism to convey the tray carried HD, a scanner to the HD identification bar code, a printer for label, a label operating mechanism to receive the output label and stick on HD, and a host connected all former mechanisms to control the printer to print HD information on label for output. This invention reduces labor and cost to improve efficiency.

Owner:YITUO SCI & TECH CO LTD SHENZHEN

Lithium ion battery diaphragm cutting and positioning device

ActiveCN112510321AImprove pass rate and efficiencyIncrease productivityCell component detailsElectrolyte accumulators manufactureBattery cellElectrical and Electronics engineering

Owner:江西量子新能源科技有限公司

Electric Sovent pipe fitting cutter

ActiveCN102806576AEasy disassemblyIncrease productivityMetal working apparatusIndustrial engineeringPipe fitting

Owner:GUANGDONG LIANSU TECH INDAL

Preparation method of quaternary ammonium cationic monomer aqueous solution

InactiveCN104744275AImprove utilization efficiencyIncrease productivityAmino-hyroxy compound preparationOrganic compound preparationAcrylic acidAmmonium

Owner:浙江友联化学工业有限公司

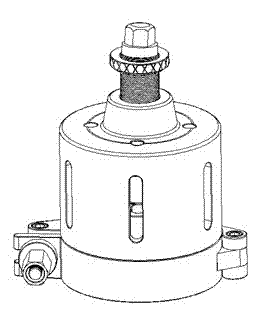

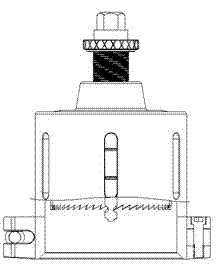

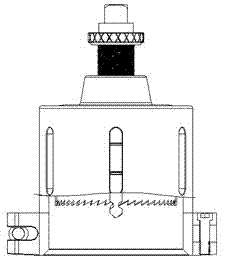

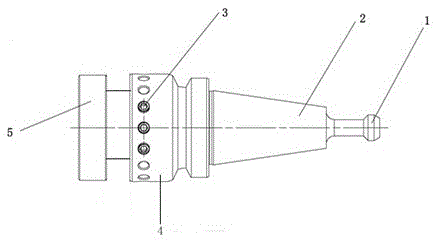

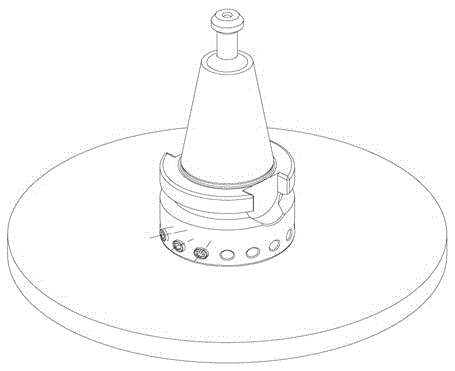

High-speed high-precision integral tool handle structure for grinding, milling and wiredrawing

InactiveCN105666215AReduce manufacturing difficultyIncrease productivityPositioning apparatusMetal-working holdersEngineeringMachine tool

Owner:段家乡

Preparation method of battery pole piece

PendingCN112670435AIncrease productivityLow costElectrode manufacturing processesCurrent collectorDie cutting

Owner:HIGHPOWER TECH HUIZHOU

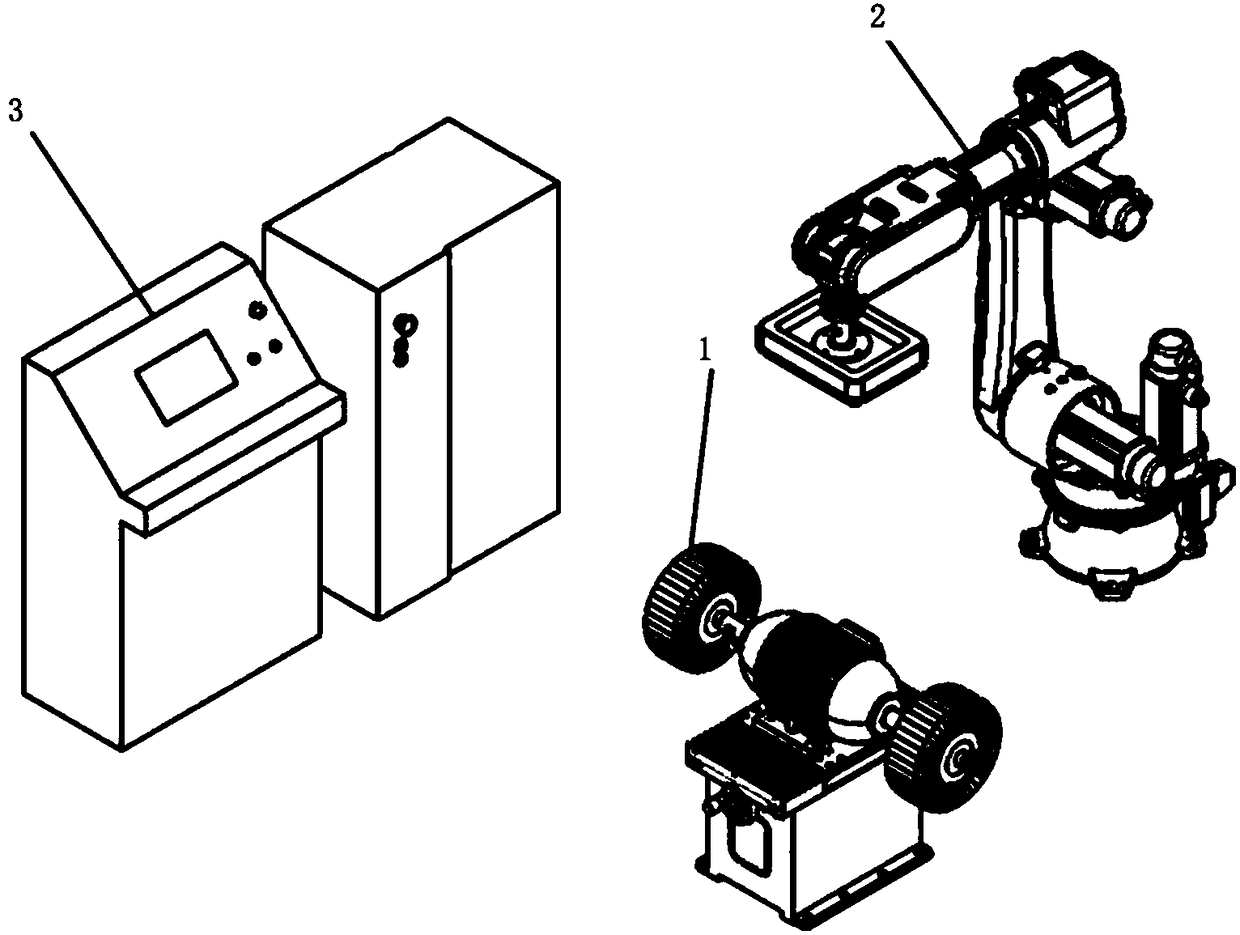

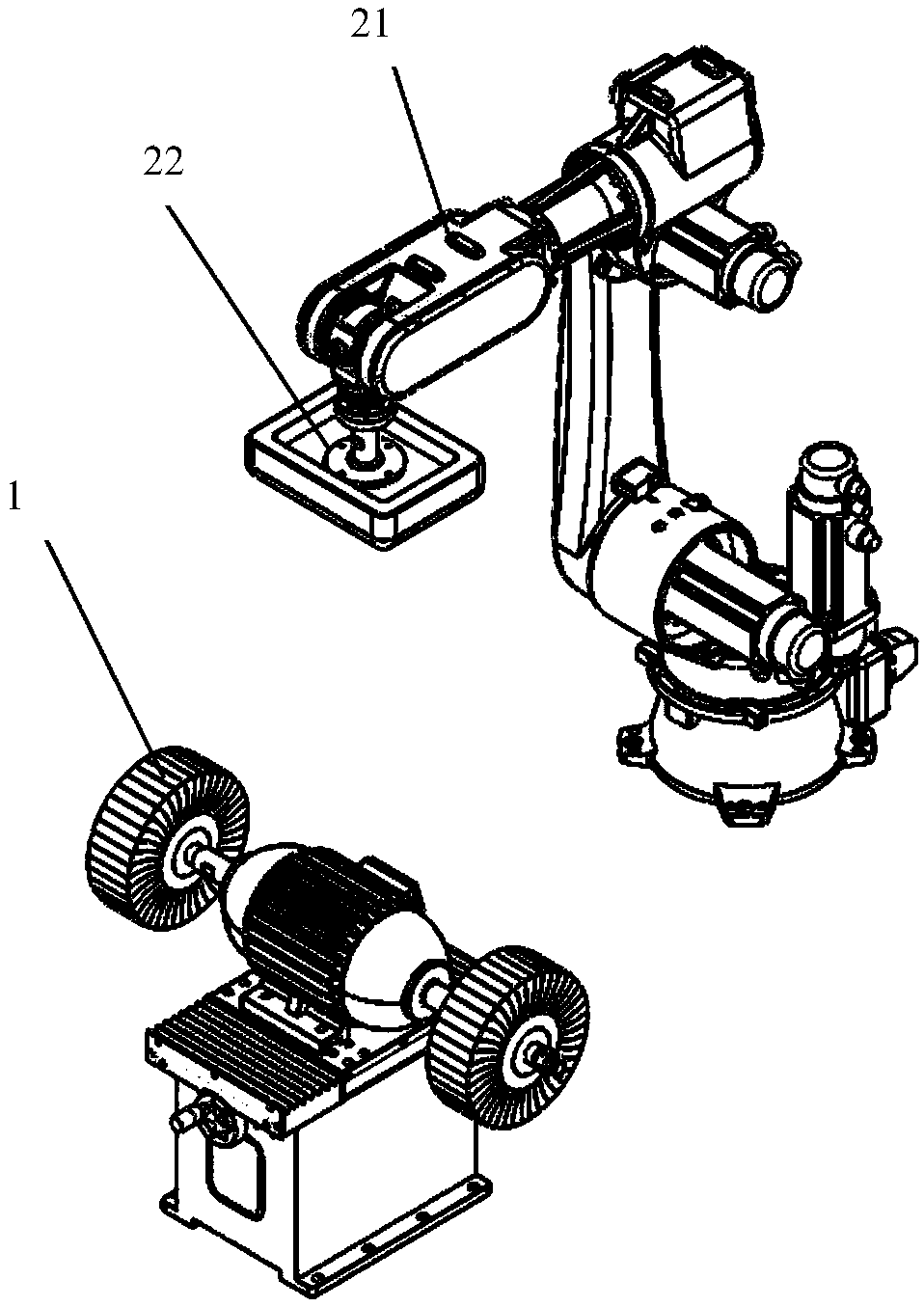

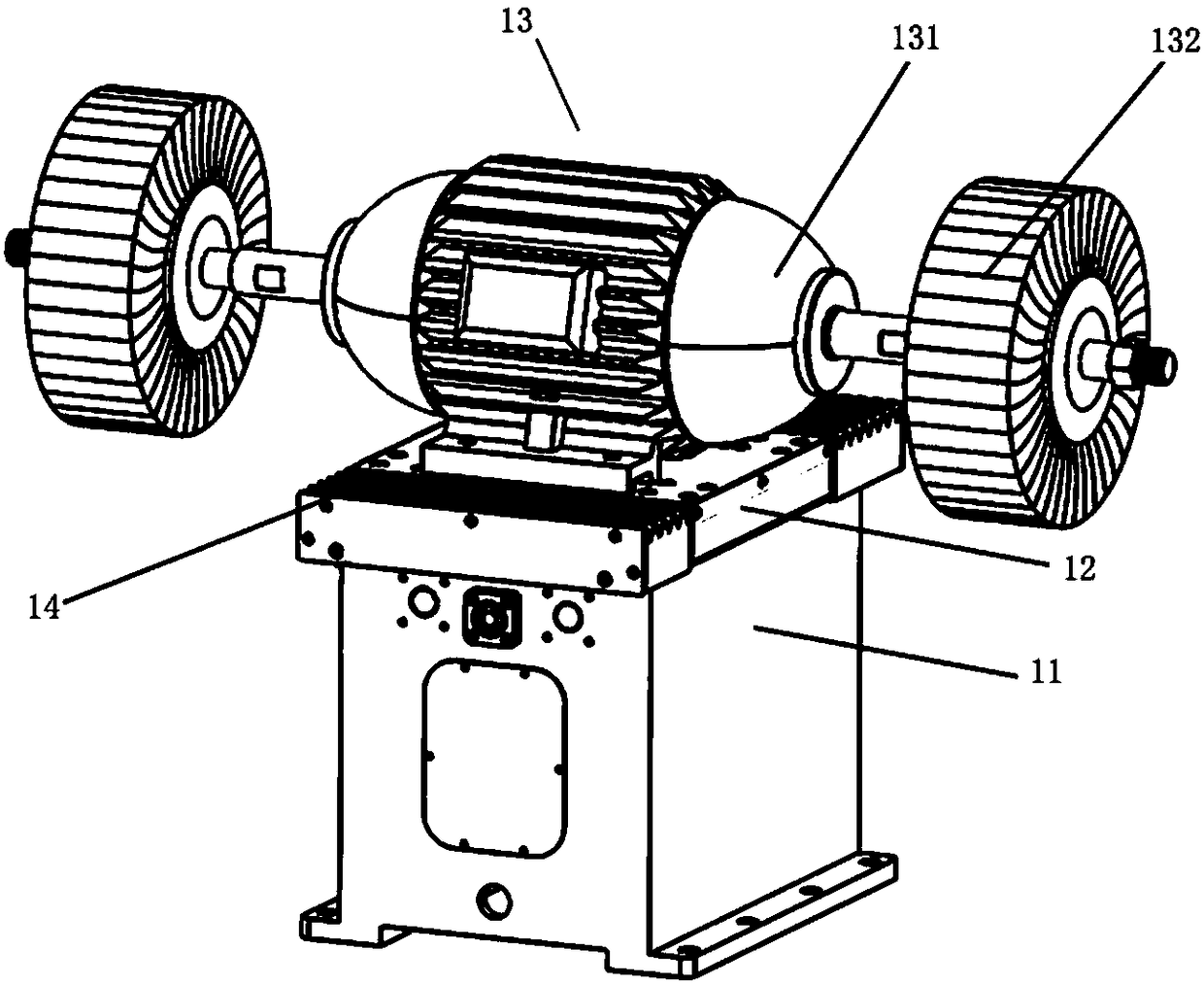

Pressure-controllable industrial robot grinding and polishing system and grinding and polishing method

PendingCN108296962AImprove grinding and polishing effectImprove production efficiency and product qualityPolishing machinesGrinding drivesPulp and paper industryIndustrial robot

The invention provides a pressure-controllable industrial robot grinding and polishing system. The pressure-controllable industrial robot grinding and polishing system is characterized by comprising apolishing device, a feeding device and a controller, and the polishing device comprises a fixed base, a mounting seat, a polishing mechanism, first slide rails, a position adjusting mechanism and a cylinder. The cylinder is connected with the mounting seat, and the mounting seat is slidably connected with the first slide rails to realize that the cylinder pushes the mounting seat to move in the length direction of the first slide rails to drive the polishing mechanism to move. The cylinder is connected with the controller to enable the controller to control the cylinder to control grinding pressure between the polishing mechanism and a workpiece. The cylinder is disposed on the fixed base through the position adjusting mechanism. The pressure-controllable industrial robot grinding and polishing system can improve grinding and polishing effects and improve production efficiency and product quality. The invention further provides an industrial robot grinding and polishing method which is capable of realizing constant grinding pressure between the polishing mechanism and the workpiece, effectively improving the grinding and polishing effects and improving the production efficiency and the product quality.

Owner:FOSHAN INST OF INTELLIGENT EQUIP TECH +1

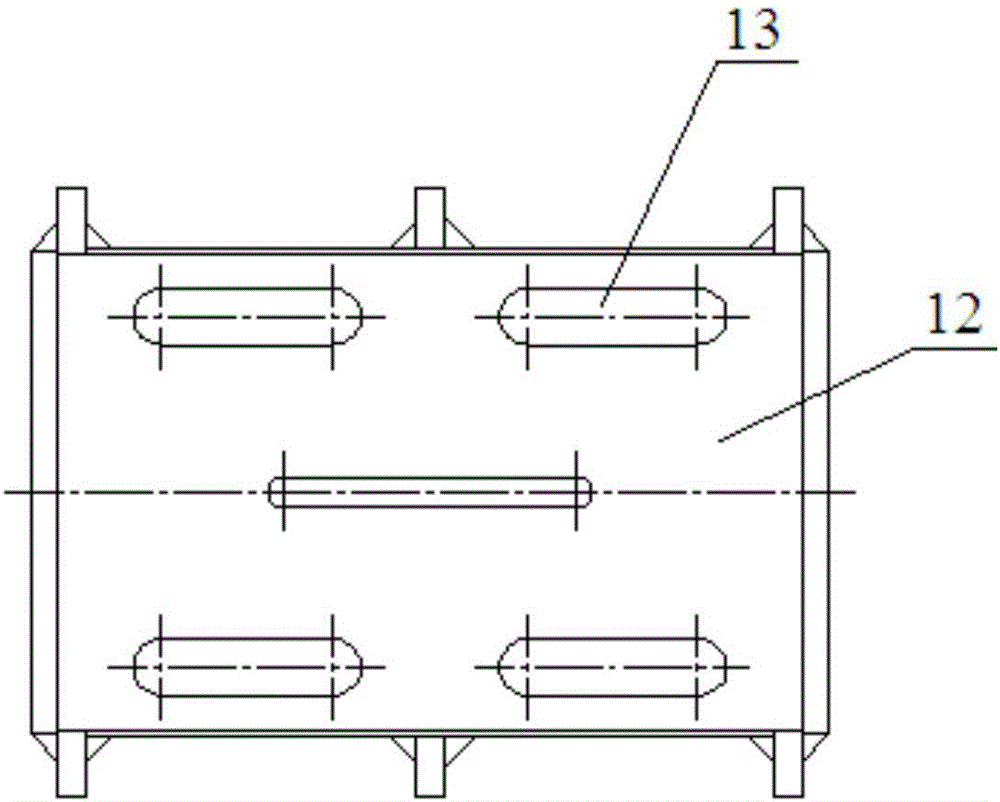

Ultrasonic continuous sterilization device and method thereof

The invention provides an ultrasonic continuous sterilization device, comprising a raw material tank, a heating device, a heat exchanging device, an ultrasonic processing device, a liquid storage device and a controller. The heating device is connected with the heat exchanging device. The raw material tank, the heat exchanging device, the ultrasonic processing device and the liquid storage device are sequentially connected through pipelines. The controller is respectively connected with the heating device, the heat exchanging device, the ultrasonic processing device and control valves on the pipelines. The ultrasonic processing device comprises an ultrasonic barrel, a plurality of ultrasonic probes, ultrasonic transducers and ultrasonic generators, wherein the ultrasonic transducers and the ultrasonic generators are arranged corresponding to the ultrasonic probes, the ultrasonic generators adopt different frequencies and are all arranged in the controller, and the ultrasonic probes are correspondingly distributed on the periphery of the ultrasonic barrel in a stagered junction mode. The invention also provides a method realized by the devices, i.e. feed liquid is firstly heated by the heat exchanging device, and then dynamic and continuous ultrasonic sterilization processing is carried out by the ultrasonic processing device. The invention adopts the technology combining low-temperature heating and ultrasonic processing, and has the advantages of good sterilization effect, high efficiency and the like.

Owner:SOUTH CHINA UNIV OF TECH

General assembly line for motor assembly

ActiveCN102820741AImprove assembly qualityImprove skill levelManufacturing dynamo-electric machinesGeneral assemblyEngineering

The invention provides a general assembly line for motor assembly. The general assembly line comprises a track, wherein a carrying flat wagon is arranged on the track; a plurality of stator outlet box mounting tables, at least one collector ring hot jacket table, at least one rotor air duct assembly table, a plurality of assembling and calibration small shaft tables, a plurality of cooler assembly tables and a plurality of motor warehousing tables are arranged on the two sides of the track in the track direction in sequence; a pneumatic suspension crane is arranged above the stator outlet box assembly tables; a rotor assembly machine is arranged beside the stator outlet box mounting tables; a collector ring heating roaster and a pneumatic suspension crane are arranged beside the collector ring hot sleeve table; and a track gantry tower crane is arranged above the cooler mounting tables. According to the general assembly line, a motor is carried through the carrying flat wagon and a turnover flat wagon, so that the potential knocking hazard is reduced, the time of waiting the crane during motor assembly is shortened, a production mode that fixed persons are allocated on fixed duties is conveniently adopted, the motor assembly quality is reliable, and the production efficiency is greatly increased.

Owner:XIANGTAN ELECTRIC MFG CORP LTD

Resin sand casting equipment and casting process

InactiveCN111673070AIncrease productivityReduce equipment downtimeMould handling equipmentsHydraulic cylinderIndustrial engineering

Owner:ANHUI HAILI PRECISION CASTING CO LTD

Multi-head drill rotary disc clamp

ActiveCN106736680AEasy to operateIncrease productivityBoring/drilling machinesMetal-working holdersDrillEngineering

Owner:ANHUI HAOFANG ELECTROMECHANICS

Wind turbine blades with reinforcing, supporting and stabilizing components and enlarged swept area

ActiveUS8629570B1Low costEasy constructionWind motor controlWind energy with garvitational potential energyTurbine bladeHorizontal axis

A rotor assembly for a horizontal-axis wind turbine with blades support attachments. Each end of the supporting elements is fixedly or rotatably attached to one blade. In a new and improved embodiment, the blades start from the support element, skipping the swept area inside these elements but at the same time increasing many times the total swept area with substantially reduced cost. The support elements might be additionally attached to already existing wind turbine rotors. The reinforcing elements support and protect the blades from bending, breaking or falling apart in strong and gusty winds. The rotor of a wind turbine occasionally will rotate with speeds higher then normal and if the blades are not reinforced and properly balanced the whole assembly may start wobbling and then break apart from the tower or the blades may be damaged or may bend or break.

Owner:KAMENOV KAMEN GEORGE

Surface drilling device for flocked cloth

InactiveCN107097292AHigh degree of automation integrationIncrease productivityLiquid surface applicatorsCoatingsDrill bitPetroleum engineering

The invention discloses a surface drilling device for flocked cloth. The surface drilling device comprises a base and a movable drilling assembly arranged at the upper end of the base, wherein a fixture is inserted into a fixture fixed groove; the flocked cloth needing to drill is clamped on a sliding panel; the sliding panel is controlled by a servo motor to move leftwards and rightwards; successively, the movable drilling assembly moves by a control shaft fixed base of the servo motor; a drilling head is controlled by a lifting air cylinder to move downwards; and the drilling head is controlled by the motor to rotate to carry out drilling. The surface drilling device for the flocked cloth is high in automatic integration degree, is beneficial for improving production efficiency, and greatly reduces defective rate; meanwhile, by adopting a multi-shaft drilling way, the surface drilling device for the flocked cloth greatly improves the adjustability of the device, and is beneficial for improving the drilling efficiency.

Owner:JIASHAN SHENGLAISI CASHMERE

Rotor shaft pressing machine for manufacturing micro motor

InactiveCN104158354AEasy to installIncrease productivityManufacturing dynamo-electric machinesMicro motor

Owner:SHANDONG JINGLU IND CONTROL SYETEM

Preparation method of graphene complex film with high thermal conductivity

ActiveCN108503383AGood thermal conductivityIncrease productivitySemiconductor devicesSemiconductor/solid-state device detailsAblationCarbonization

Owner:厦门呈昱实业有限公司

Winding and strapping machine for medical infusion tube

InactiveCN104085554AHigh degree of automationRealize automatic strappingBinding material applicationBundling machine detailsEngineeringMedical equipment

The invention provides a winding and strapping machine for a medical infusion tube, and belongs to the technical field of processing equipment of medical equipment. The winding and strapping machine solves the problems that an existing infusion tube is low in winding and strapping quality and efficiency. The winding and strapping machine for the medical infusion tube comprises a rack. The rack is connected with two conveying belts in a rotating mode, each conveying belt is fixedly connected with multiple material supporting rods, the rack is fixedly connected with a working table, the working table is connected with a main shaft in a sliding mode in the vertical direction and provided with a first driving mechanism and a second driving mechanism, the main shaft is fixedly connected with a main plate which is connected with two winding rods, a clamping mechanism is arranged on the material supporting rods, the main plate is connected with a strapping body, and the strapping body is provided with a strapping device. The winding and strapping machine for the medical infusion tube can wind the infusion tube automatically and strap the infusion tube automatically after the infusion tube is wound, is high in automation degree and improves production efficiency.

Owner:郭嘉川

Short-flow preparation method of rare earth doped modified ammonium paratungstate powder

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

High-speed pipe cutting equipment with automatic feeding function

ActiveCN111360422AGuarantee personal safetyIncrease productivityConveyor partsLaser beam welding apparatusAutonomationIndustrial engineering

Owner:DONGGUAN GLORYSTAR LASER TECH

Fuse shaping and cutting structure

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap