Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Guarantee product quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

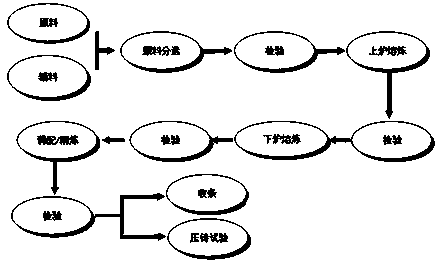

Manufacturing process of high-carbon tool steel SK85 cold-rolled wide steel strip

The invention discloses a manufacturing process of a high-carbon tool steel SK85 cold-rolled wide steel strip. The process is characterized in that steel is subjected to converter smelting, LF furnacerefining and slab continuous casting to obtain continuous casting slabs with the thickness ranging from 210 mm to 230 mm, the continuous casting slabs are heated and subjected to hot continuous rolling and laminar cooling to reach the coiling temperature, a hot-rolled wide steel strip with the thickness ranging from 2.5 mm to 6.0 mm is obtained, the coiled hot-rolled wide steel strip is put in storage and slowly cooled to the room temperature, and the obtained metallographic structure is thin-sheet-shaped pearlite; the total reduction of first cold rolling is controlled to be 20%-50% after acid pickling of the hot-rolled wide steel strip, then spheroidizing annealing is conducted, the Vickers hardness HV5 is 180 or below, and the spheroidizing rate is 92% or above; after the steel strip is subjected to primary spheroidizing annealing, secondary cold rolling is conducted, the total reduction of cold rolling is controlled to be 30%-85%, and a cold-rolled wide steel strip with the finished product specification being 0.70-3.00 mm thick is obtained; the steel strip subjected to secondary cold rolling is further spheroidized and annealed, the Vickers hardness HV5 is 175 or below, and the spheroidizing rate is 94% or above; and then third cold rolling is conducted, the total reduction of cold rolling is controlled to be 50%-85%, and the cold-rolled wide steel strip with the finishedproduct specification being 0.10-0.70 mm thick is obtained.

Owner:新余钢铁股份有限公司

Cefmetazole sodium proliposome preparation

ActiveCN101623264AThe encapsulation efficiency has not decreasedImprove stabilityOrganic active ingredientsAntibacterial agentsCholesterolPhospholipid

The invention provides a cefmetazole sodium proliposome preparation which comprises the following components by weight part: 1 part of cefmetazole sodium, 3-15 parts of liposome carrier and 2-10 parts of proppant, wherein the liposome carrier comprises polyene phosphatidyl choline, cholesterol and oleinic acid according to a weight ratio of (4-20):(1-5):1. The cefmetazole sodium proliposome preparation has good preparation stability and cannot crack because of dewatering, fusion, ice crystal generation, and the like in a freeze-drying process; and after hydrated re-dissolution, the cefmetazole sodium proliposome preparation still can maintain good entrapment rate.

Owner:HAINAN LINGKANG PHARMA CO LTD

Separating and recycling equipment and method for magnetic mud in cutting waste liquid

InactiveCN103785536AGuarantee product qualityIncrease productivityMagnetic separationAbrasiveLiquid waste

Owner:盛秋生 +1

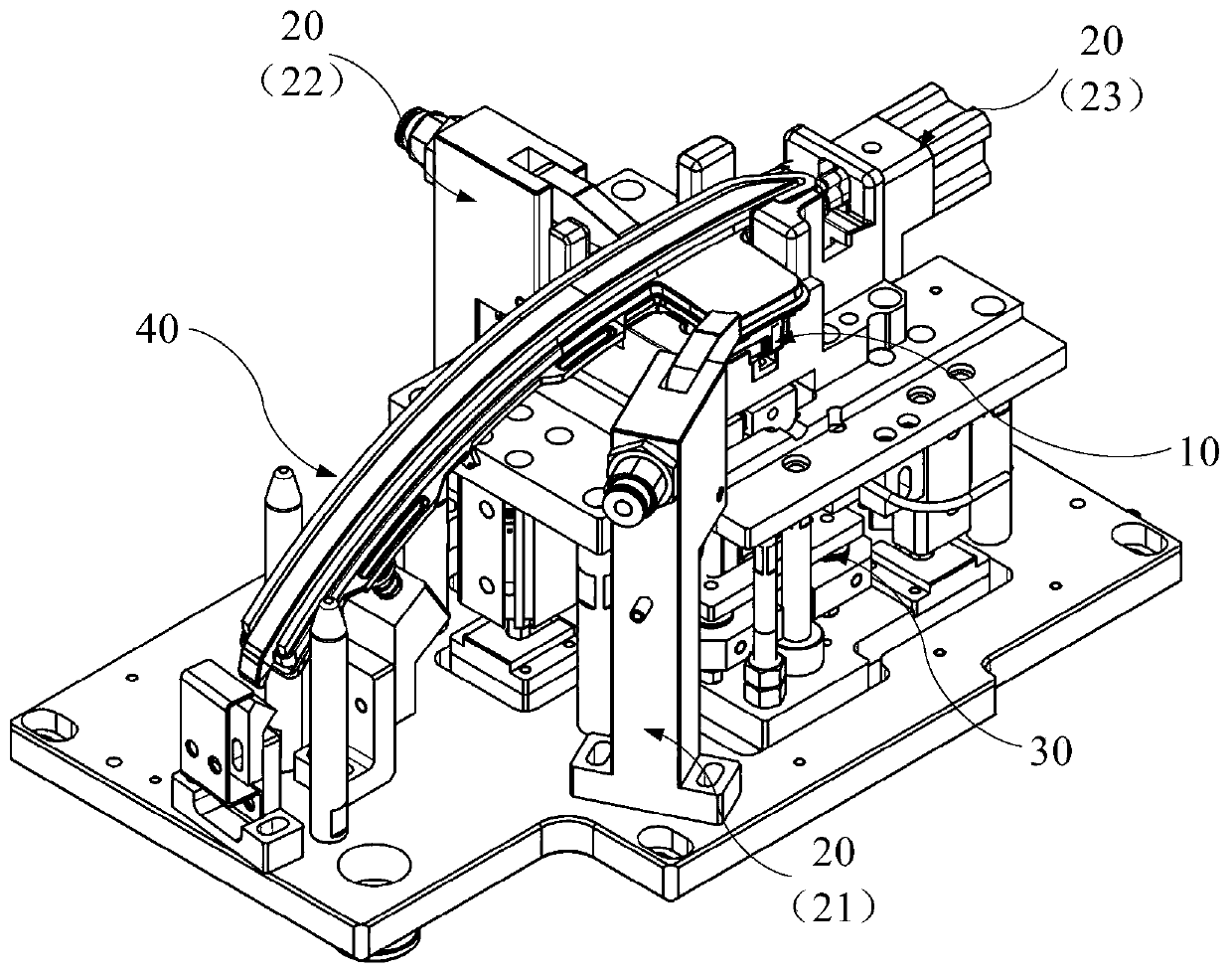

Metal cable connector welding machine

InactiveCN104779508AMeet welding requirementsReasonable designLine/current collector detailsCable/conductor manufactureCopper conductorEngineering

A metal cable connector welding machine comprises a fixed copper conductor (1), a sliding copper conductor (2), bolts (3), push rods (4), slide rods (5), a cable slot I (6), a handle (7), a connecting rod (8), a power regulator (9) and a work bench (10), and is characterized in that the other ends of the slide rods (5) are connected with the handle (7) through the connecting rod (8); ends of two metal cables requiring welding are placed in the cable slot I (6) and a cable slot II (11) respectively and tightened by bolts (3), the handle (7) pushes the slide rods (5) on the push rods (4) through the connecting rod (8), two ends of each cable are contacted and powered on, the cables are molten, and welding is completed. The metal cable connector welding machine is reasonable in design, simple in structure, reliable in action and convenient to operate and can feasibly meet the cable welding requirement, and the product quality is ensured.

Owner:JIANGSU GANGHONG WIRE & CABLE CO LTD

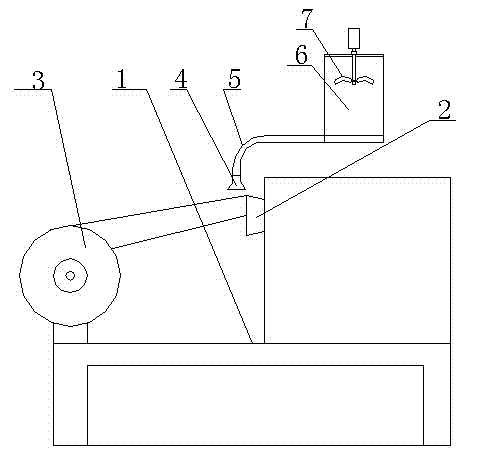

Plastic wire former

InactiveCN104514039AReduce bondingGuarantee product qualityFilament manufactureEngineeringWater tanks

Owner:HENAN SHENGSHI PLASTICS IND

Automatic batten foot pier production equipment

ActiveCN106272733AGuarantee product qualityIncrease productivityProfiling/shaping machinesBattenEngineering

Owner:徐冬波

Artificial intelligence sheet metal part producing system

ActiveCN105642781AAvoid DimensionsGuarantee product qualityMaterial gluingMetal working apparatusDigital controlElectric control

Owner:XUZHOU DKEC ELECTRICAL TECH

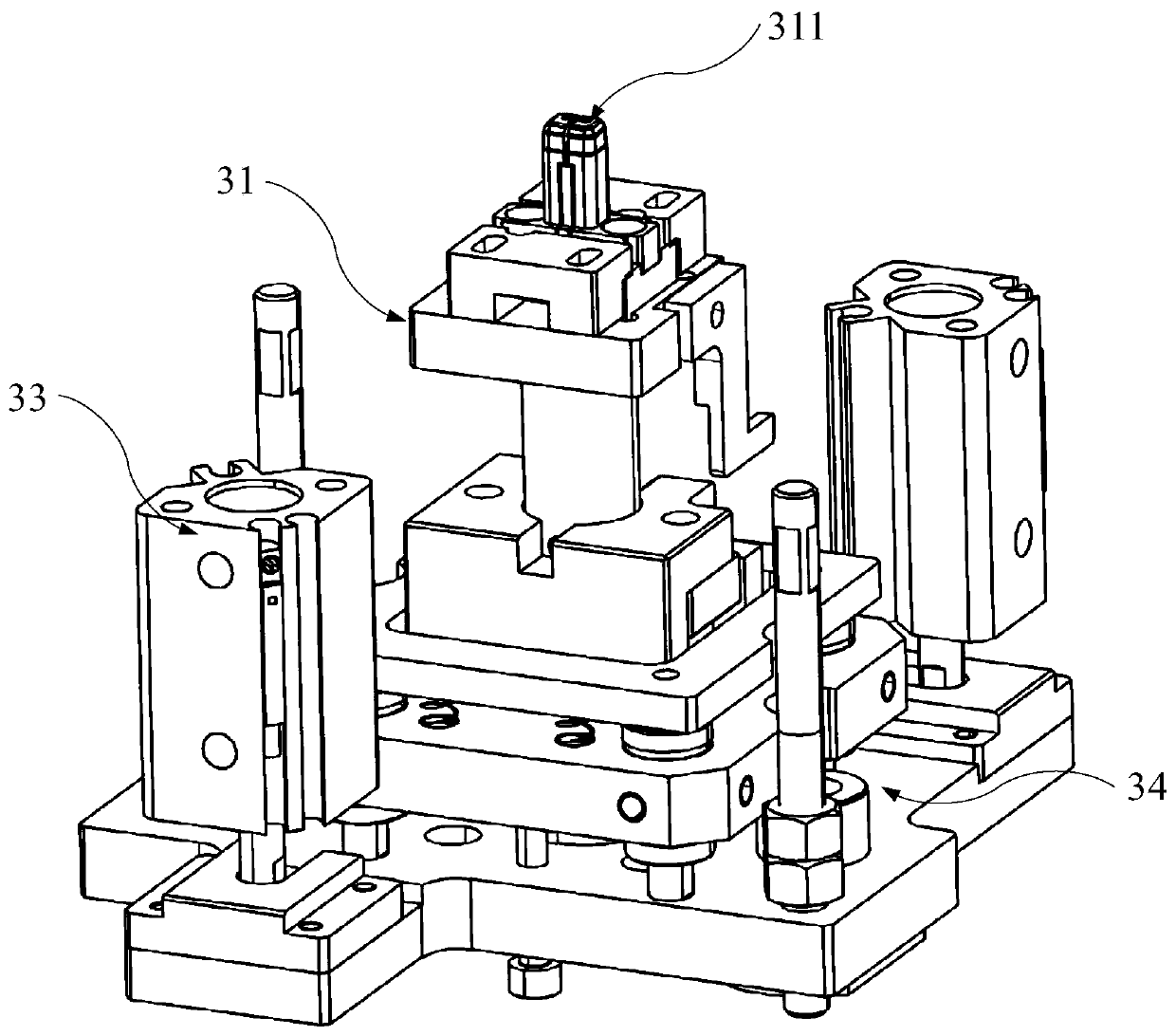

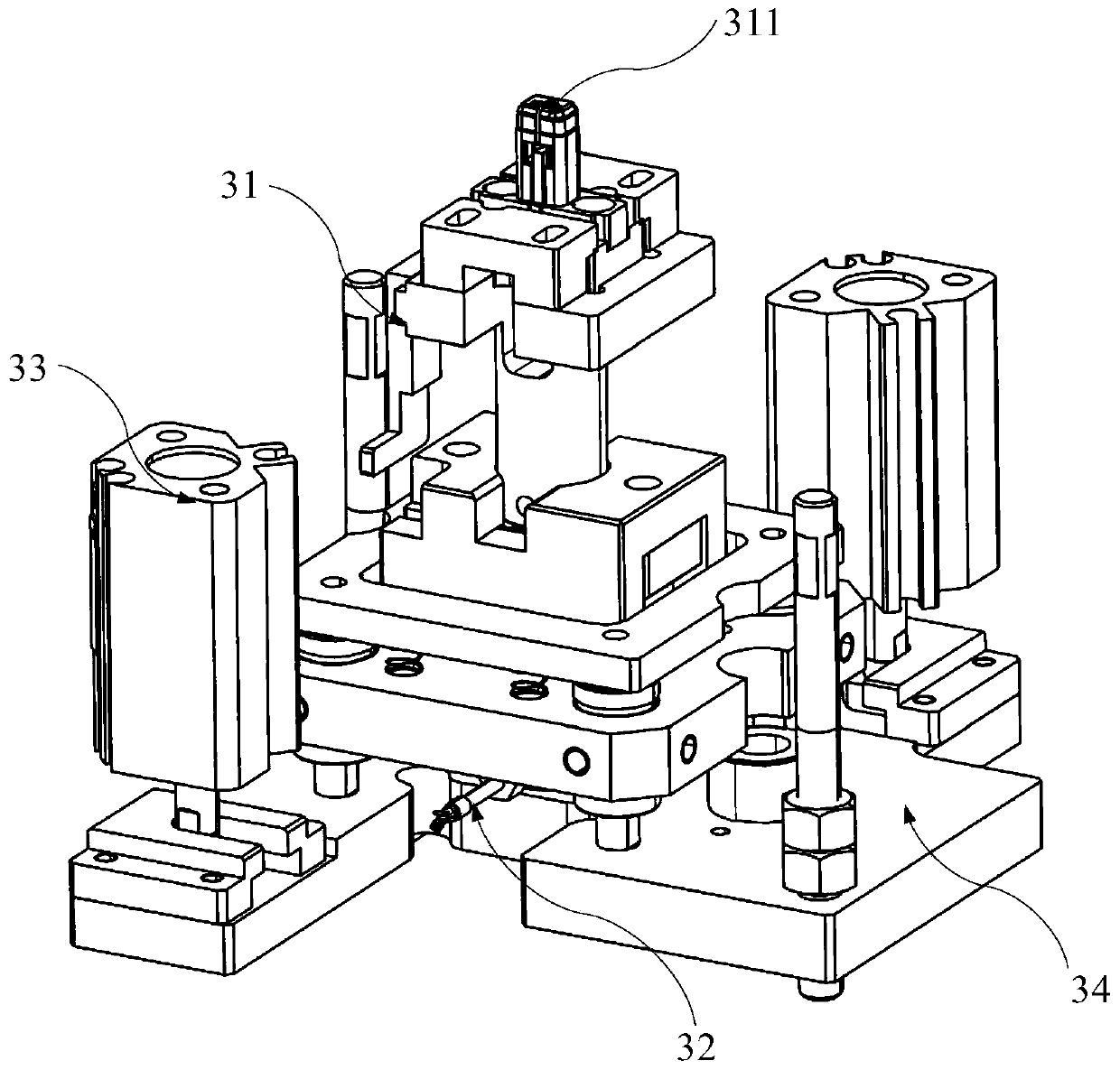

Sheet breaking device

ActiveCN109755177AGuarantee product qualityImprove efficiencySemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD +1

Rock wool belt heat preservation fireproof composite board cutting device

InactiveCN109047925AEasy to operateGuarantee product qualityLarge fixed membersMetal working apparatusAutomationEngineering

Owner:合肥神舟建筑集团有限公司

High-strength aluminum alloy and production process thereof

Owner:烟台三和新能源科技股份有限公司

Buckle suitable for swimming goggles

Owner:YOUNG SPORTING GOODS SHZHOU

Wind turbine generator tower base control cabinet detection and test device

PendingCN107357285AGuarantee product qualityImprove error rateElectric testing/monitoringDisconnectorElectric control

Owner:XIANGTAN ELECTRIC MFG CORP LTD

Pressing and flattening device for bag making machine

ActiveCN105109103AMeet production needsCompact structureContainer making machineryEngineeringMachine

The invention relates to a pressing and flattening device for a bag making machine. The pressing and flattening device for the bag making machine is characterized in that the pressing and flattening device comprises two single-edge shaping mechanisms which are mounted on a support. The two single-edge shaping mechanisms are of the same structure and are oppositely and symmetrically arranged. Each single-edge shaping mechanism comprises a sliding block, a connecting rod, a spring, a shaft, a bearing and a flattening wheel, wherein the sliding block is mounted in a long groove in the support and can move leftwards and rightwards, and the upper end of the connecting rod is connected with the sliding block; the rear end of the shaft is mounted at the lower end of the connecting rod through a hinge shaft, the shaft can rotate around the hinge shaft, and the flattening wheel is mounted on the shaft through a bearing support; the upper end of the spring is connected to the connecting rod, and the lower end of the spring is tightly pressed on the shaft. The pressing and flattening device for the bag making machine is compact in structure, convenient to operate, highly adjustable and capable of meeting the requirements for producing packaging bags of dimensions, improving working efficiency, relieving labor intensity and guaranteeing product quality.

Owner:WUXI KING MO MACHINERY

Terminal detection device and detection method

InactiveCN111174686AAvoid poor detection accuracyGuarantee product qualityElectrical/magnetic solid deformation measurementComputer scienceControl engineering

Owner:GUANGZHOU WEISI VEHICLE PART CO LTD

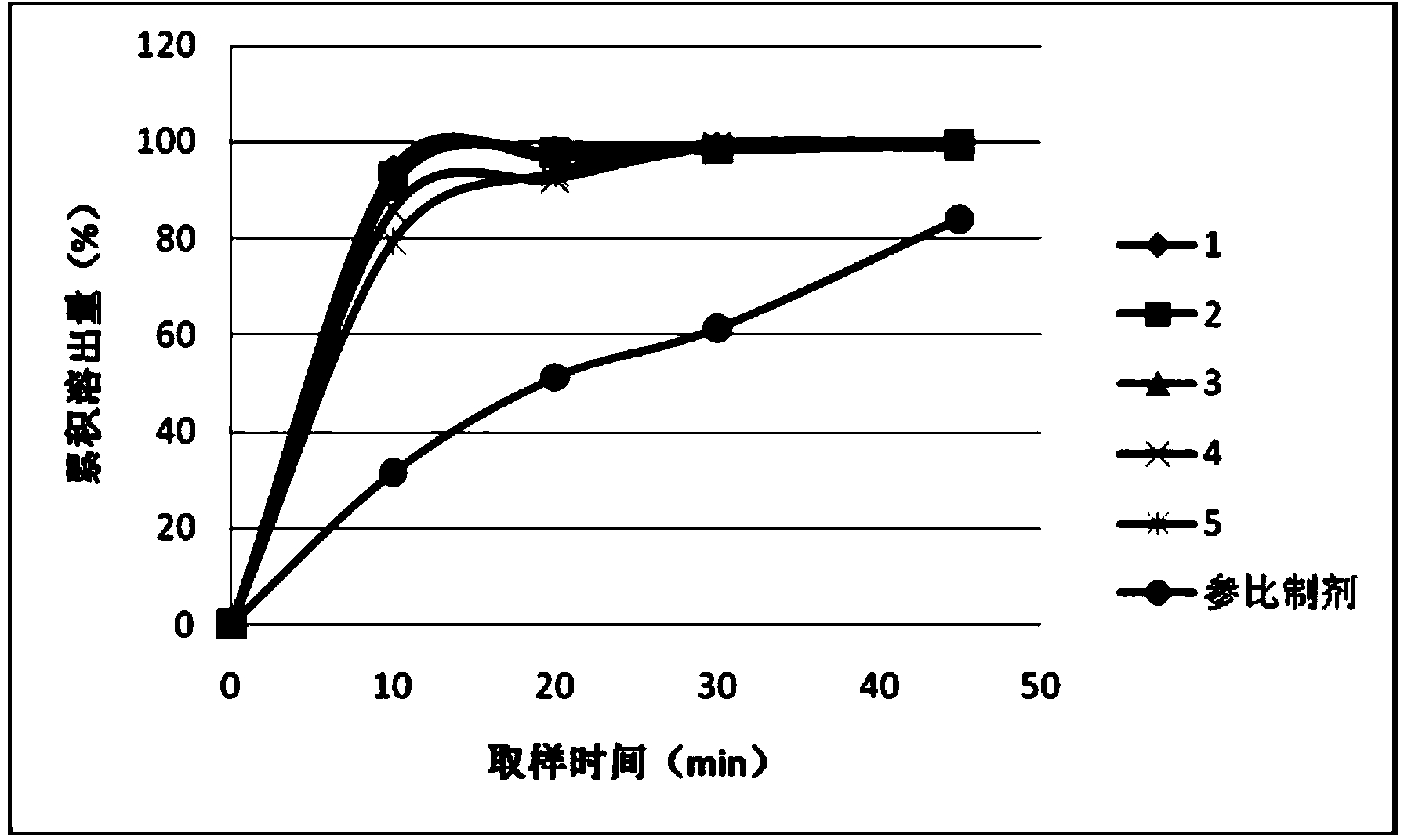

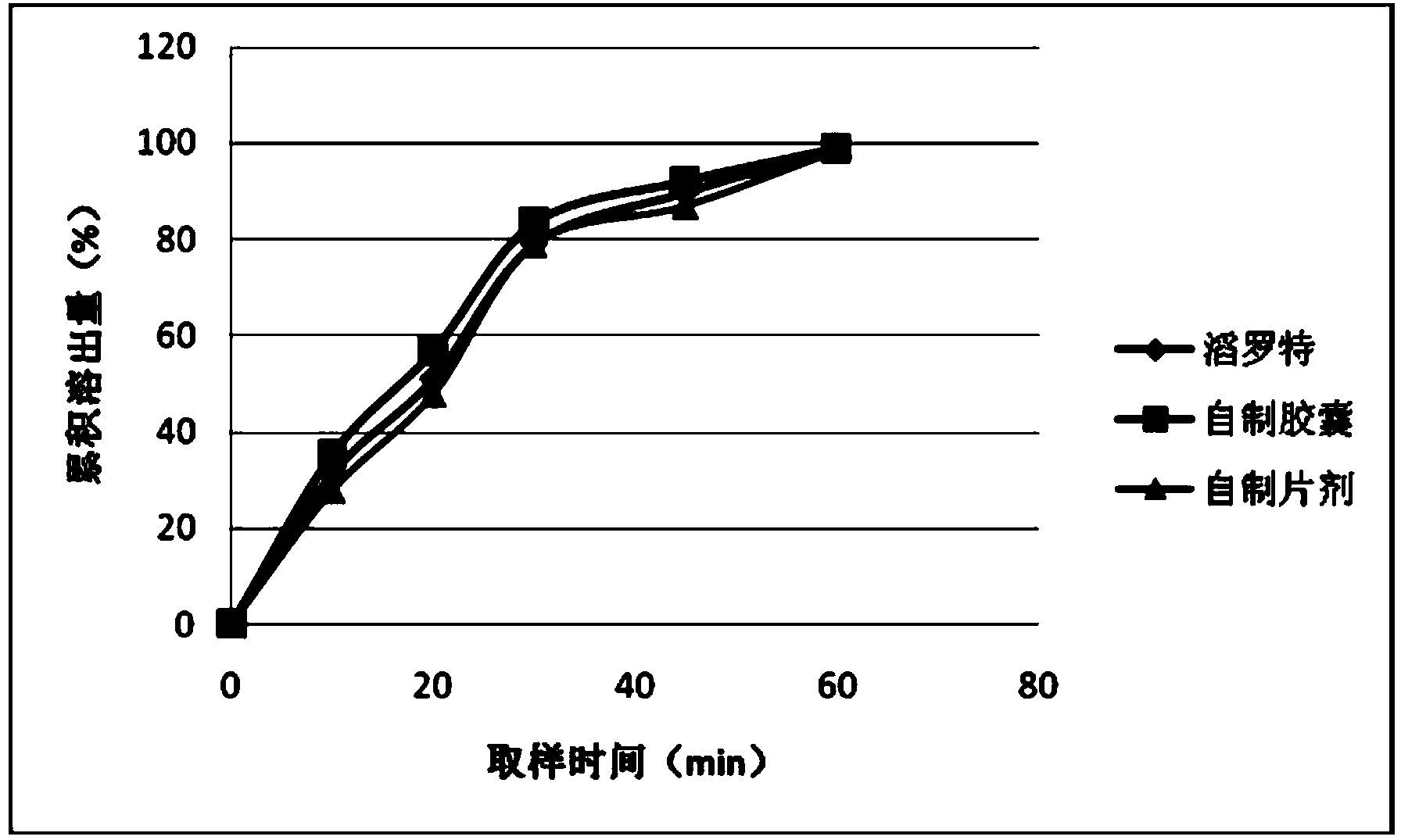

Preparation method of bezoar ursodesoxycholic acid preparation

ActiveCN104367561AGuarantee product qualityImprove liquidityOrganic active ingredientsNervous disorderInitial burstParticle-size distribution

The invention discloses a preparation method of bezoar ursodesoxycholic acid preparation. The preparation method of the bezoar ursodesoxycholic acid preparation comprises the following steps: sieving a bezoar ursodesoxycholic acid raw material and an auxiliary material for later use, wherein particle size distribution D90 of the raw material is required to be less than 150 microns, and the particle size distribution D90 of the auxiliary material is required to be less than 120 microns; mixing bezoar ursodesoxycholic acid, a diluent and a disintegrating agent, collecting a material accounting for about 10-15% of production lot size to be taken as (a) for later use; adding a lubricating agent accounting for 85-90% of the production lot size, mixing, and collecting material taken as (b) for later use; carrying out dry granulation on the material (b); straightening the material obtained in the step 3, sieving, mixing the sieved material with the material (a), carrying out dry granulation on the mixed material, and then straightening and sieving; adding the material obtained in the step 4 into the rest lubricating agent, mixing, and collecting a material; and preparing the preparation by adopting the material obtained in the step 5. The preparation method of the bezoar ursodesoxycholic acid preparation has the advantages that the problem of material fluidity can be solved and the phenomenon that no initial burst release of the bezoar ursodesoxycholic acid preparation is caused under the specified dissolution condition can be avoided.

Owner:广州远跖恒创医药科技有限公司

Combined electrode for spot welding of rear baffle plate and connecting plate of automobile

InactiveCN102744511AEasy to manufactureGuarantee product qualityElectrode featuresBiochemical engineeringElectrode

Owner:JIANGSU FUTAO VEHICLE PARTS

Equalizing charge management system of lithium ion power battery pack

InactiveCN101938015AGuarantee product qualityGuaranteed production efficiencyBatteries circuit arrangementsElectric powerAlternating currentCentral processing unit

Owner:广东卡达克汽车科技有限公司

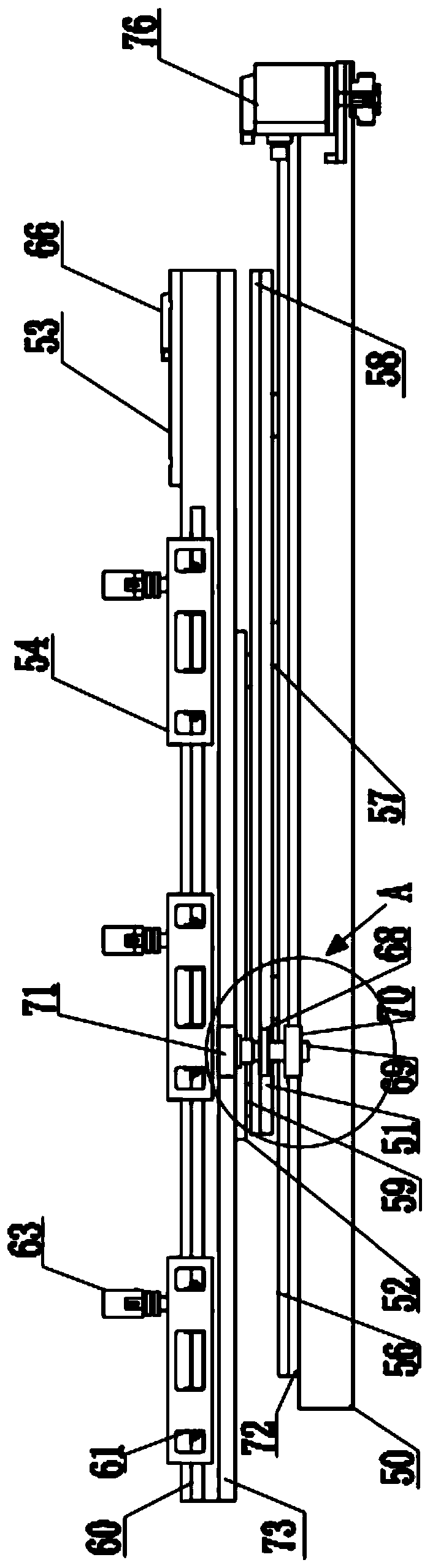

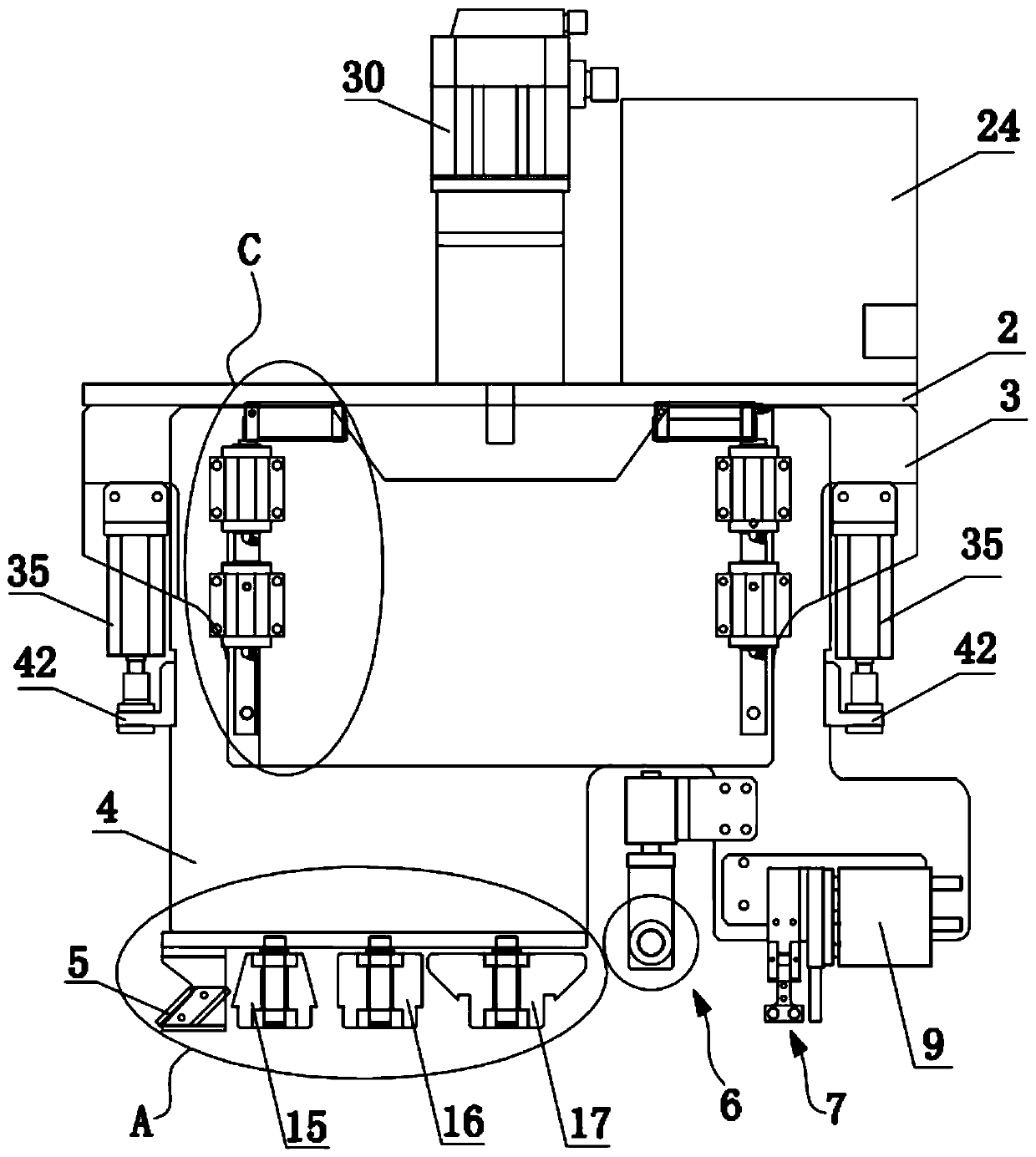

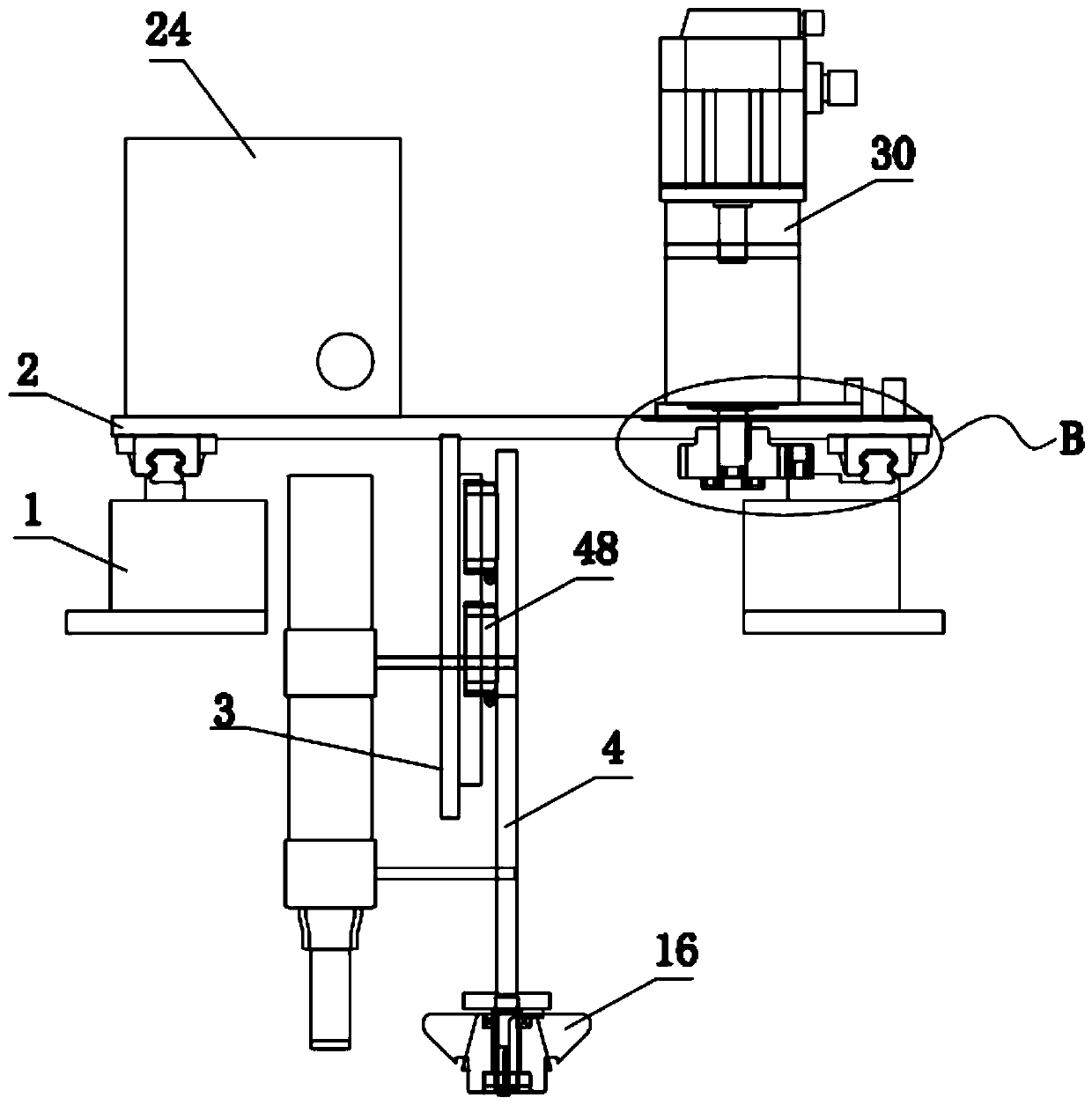

Full-automatic tarpaulin production line

PendingCN111058681ARealize automatic continuous productionIncrease productivityTents/canopiesSevering textilesHot pressContinuous production

The invention relates to the technical field of tarpaulin production, in particular to a full-automatic tarpaulin production line. The production line comprises a punching device and a machining device, wherein the machining device comprises a rack, an operating platform arranged under the rack, a machining forming mechanism arranged on the rack, a supporting base used for connecting the machiningforming mechanism with the rack in a sliding mode, and a power transmission mechanism driving the supporting base, the machining forming mechanism comprises a fixed plate and a sliding plate, a cutter is arranged under the sliding plate, the machining forming mechanism further comprises a rope arranging device, a flanging device, a heat sealing device, a hot pressing device, a clamping device, amoving device and a cutting device, the sliding plate slides on the fixed plate through a driving device, and the machining forming mechanism further comprises a length control device, a controller and a detecting element. The production line is high in automatic integration degree, the quality of finished products is guaranteed, automatic continuous production can be effectively achieved, manpower is saved, the occupied space is small, and the production line can adapt to dotting of tarpaulins of different sizes, and meet different production requirements.

Owner:青岛铭宇智能设备有限公司

Automobile electric control unit calibration system and method based on ASAP standard

InactiveCN101334662AGuarantee product qualityResolve interface mismatchProgramme total factory controlTotal factory controlCAN busCommunication interface

Owner:CHONGQING UNIV OF POSTS & TELECOMM

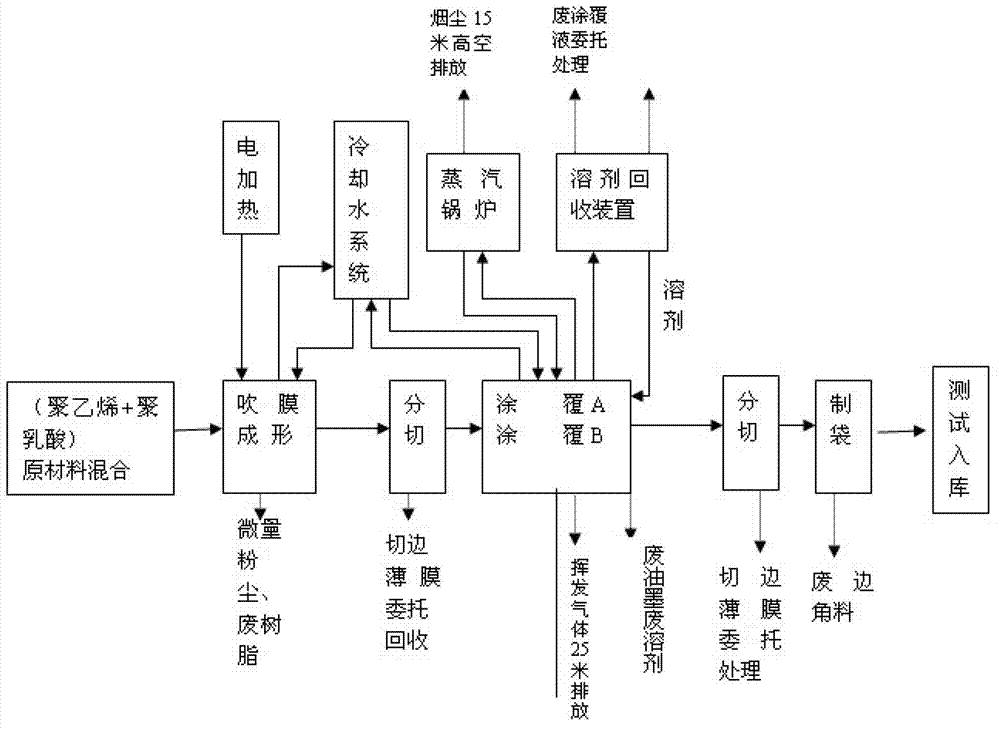

Preparation method of polyethylene flexible printing environment-friendly thin film

Owner:SHANGHAI FUKUSUKE IND

Flat ceramic membrane formulation carrying nano copper oxide and preparation method thereof

The invention a flat ceramic membrane formulation carrying nano copper oxide and a preparation method thereof. The flat ceramic membrane comprises a carrier and a separation membrane layer; the carrier incudes a main materials and auxiliary materials; the main materials of the carrier include one or more of alumina, mullite, dolomite, and bauxite; the auxiliary materials of the carrier include a sintering aid, a plasticizer, a pore-forming agent and a binder; the separation membrane layer is made with adhesive, nano copper oxide particles, a dispersing agent and a plasticizer. The flat ceramicmembrane carrying nano copper oxide has the advantages that the materials of the carrier are simple and easily accessible, the materials have antibacterial and catalytic functions, the pore size is flexibly controllable, and the materials have good features, such as excellent mechanical properties and low thermal expansion coefficient.

Owner:CHANGZHOU SUNAN WATER ENVIRONMENT RES INST CO LTD

A manufacturing assembly technology for egg white and yolk separation spoon

A manufacturing assembly technology for an egg white and yolk separation spoon includes forming four long strip-shaped holes, four connection ribs, N circular holes and two symmetrical pin holes in a spoon head; forming two symmetrical shaft holes in an overturning circular base; arranging the overturning base on the center of a spoon head; arranging shafts and springs in the symmetrical shaft holes; and inserting the other ends of the shafts into the symmetrical shaft holes so as to allow the symmetrical pin holes to be connected to the symmetrical shaft holes. The manufacturing assembly technology for the egg white and yolk separation spoon can orderly perform production and installation according to a specification so as to ensure the manufacturing quality and demand of products, can reduce unrelated and unnecessary steps, can save raw materials, can reduce the cost, and is safe in production process.

Owner:QINGDAO CENTURY YUNFAN IND

Hydraulic turnover machine for heavy workpieces

PendingCN113618321AFlipAvoid deformationWelding/cutting auxillary devicesWork holdersHydraulic cylinderEngineering

The invention relates to a turnover machine for heavy workpieces. The turnover machine comprises at least two turnover mechanisms, each turnover mechanism comprises a machine frame and a turnover frame, the turnover frame comprises two turnover arms which form an angle, the connecting position of the two turnover arms is hinged to the machine frame, a hydraulic cylinder is hinged to the bottom of the turnover frame, the hydraulic cylinder stretches out and draws back to drive the turnover frame to overturn by a certain angle, the number of the turnover mechanisms can be adjusted according to the lengths of the workpieces, the overturning requirements of more heavy workpieces are met, the machine frame is horizontally arranged, the two turnover arms are perpendicular to each other, the hydraulic cylinder stretches out and draws back to drive the turnover frame to rotate by 0-90 degrees, and overturning of the heavy workpieces is achieved.

Owner:HENAN DADAO IND EQUIP CO LTD

Installation device of printing mesh for solar cell

The invention provides an installation device of a printing mesh for a solar cell. The installation device is used for the connection of a printing mesh (7) and a mesh frame (9) and comprises an operation platform (1) and a location supporting piece (2) which is arranged on a platform surface of the operation platform (1) and is in contact with the edge of the printing mesh (7), wherein the printing mesh (7) is arranged on the location supporting piece (2), and a gap is arranged between the inner side of the edge of the printing mesh (7) and the location supporting piece (2). According to the installation device of the printing mesh for the solar cell, provided by the invention, the printing mesh (7) is prevented from being polluted as the printing mesh (7) is in contact with other objects during a combination and installation process and is prevented from being damaged during an operation process, the production quality of the solar cell of a solar cell assembly is ensured, the operation difficulty of installation and connection of the printing mesh (7) and the mesh frame (8) is reduced simultaneously, and the working efficiency is greatly increased.

Owner:YINGLI ENERGY CHINA

Thin sealing ring split part machining device

InactiveCN109746704AEasy clampingSimple structurePositioning apparatusMetal-working holdersNatural stateEngineering

The invention relates to a thin sealing ring split part machining device. The device comprises a clamp used for positioning the sealing ring, the sealing ring and the clamp are connected through a locking bolt and are positioned through a locking nut, the clamp comprises a convex ring penetrating through the center hole of the sealing ring and a base body extending backwards to the back side of the sealing ring, the base body is used for supporting the rear surface of the sealing ring, and the size of the convex ring is smaller than that of the center hole of the sealing ring, the convex ringand the central hole are coaxially arranged, a gap exists between the convex ring and the center hole of the sealing ring, the gap is used for allowing the locking bolt to penetrate into and is arranged on the clamp, and the locking bolts on the front surface and the rear surface of the sealing ring are used for realizing fastening connection of the clamp and the sealing ring. The device solves the problems that due to the fact that the thickness is too thin, clamping is not easy, the self-manufacturing clamp is easy to manufacture, the structure is simple, the clamping is convenient, the partis made to be processed in a natural state, the direct clamping force of the product is dispersed, and the deformation is reduced.

Owner:CHINA DESIGN PRECISION MFG JIANGSU CO LTD

Method for purification of taxifolin

InactiveCN106065011AGuarantee product qualityHigh utilization rate of raw materialsOrganic chemistryAlcoholChemistry

Owner:南京泽朗医药技术有限公司

Method for evaluating malt lipid oxidation degree

ActiveCN106405024AAnticipate freshness in advanceGuaranteed qualityComponent separationTesting beveragesLipid formation2-Nonenal

The invention relates to a method for evaluating malt lipid oxidation degree, and lipoxygenase enzymatic reaction promotion substance content, lipoxygenase enzymatic reaction inhibition substance content, trans-2-nonenal content, nonenal precursor content and lipoxygenase activity are selected as evaluation factors for establishment of a malt lipid oxidation comprehensive evaluation system. According to the method, multiple factors influencing the malt lipid oxidation degree are selected for establishment of the comprehensive evaluation system for the evaluation of the malt lipid oxidation degree, so that freshness of beer can be predicted in advance, and the method is essential to ensure the quality of the beer. The method not only can be used to evaluate the lipid oxidation degree of a single malt sample, but also can be used for macroscopic analysis of different malt varieties and research of difference of the varieties.

Owner:TSINGTAO BREWERY

Detection device for tensioning of motor rotor guide bar

PendingCN114295337AGuarantee product qualityLow production costMachine part testingMaterial strength using tensile/compressive forcesClassical mechanicsElectric machine

Owner:YONGJI XINSHISU ELECTRIC EQUIP

Enrofloxacin injection and production method thereof

ActiveCN107362132ARaise quality standardsIncrease dosageOrganic active ingredientsPharmaceutical delivery mechanismSulfite saltSodium sulfite

The present invention relates to an enrofloxacin injection and a production method thereof. The enrofloxacin injection comprises enrofloxacin with a concentration of 48-52 g / L, sodium hydroxide with a concentration of 5.5-6.5 g / L, propylene glycol with a concentration of 180-220 g / L, sodium sulfite with a concentration of 1.9-2.1 g / L, and a solvent, wherein the solvent is water for injection. According to the present invention, the use amount of the propylene glycol is increased in the formula or the production process of the enrofloxacin injection, such that the product is stable, and the quality of the product is ensured; specifically various detected indexes are qualified and especially the crystallization problem is effectively solved after the product is stored for more than 2 years; and the product meet the quality standard of the enrofloxacin injection in the new Veterinary Pharmacopoeia of the People's Republic of China, the storage time is prolonged, and it is ensured that various indexes are qualified within the validity period.

Owner:BEIJING LISHIDA PHARMA

Novel film monitoring device

InactiveCN109540849AGuarantee product qualityIncrease productivityTransmissivity measurementsUsing optical meansEngineeringLaser transmitter

Owner:NINGBO CHENYU ENERGY TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap