Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about "Line/current collector details" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

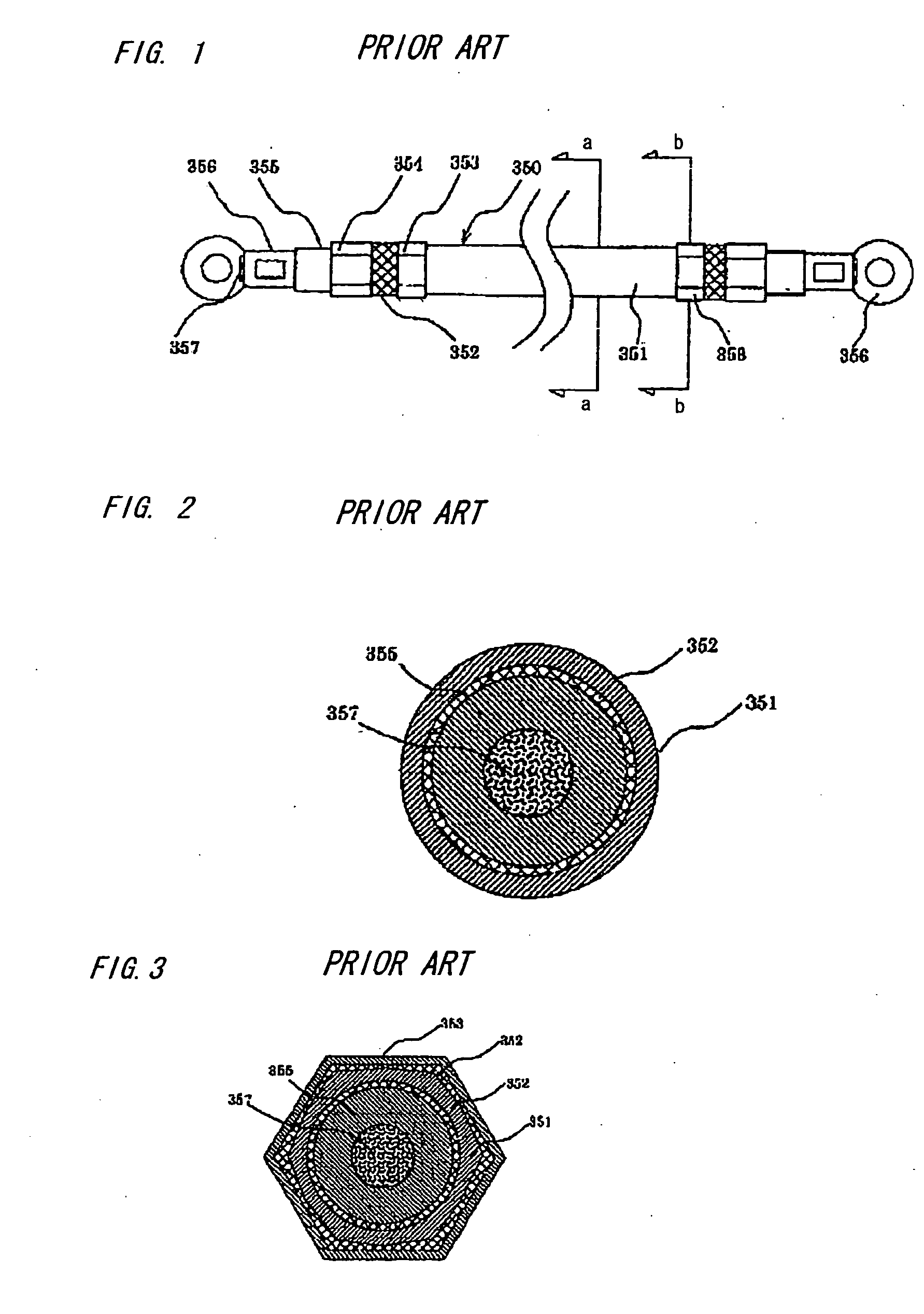

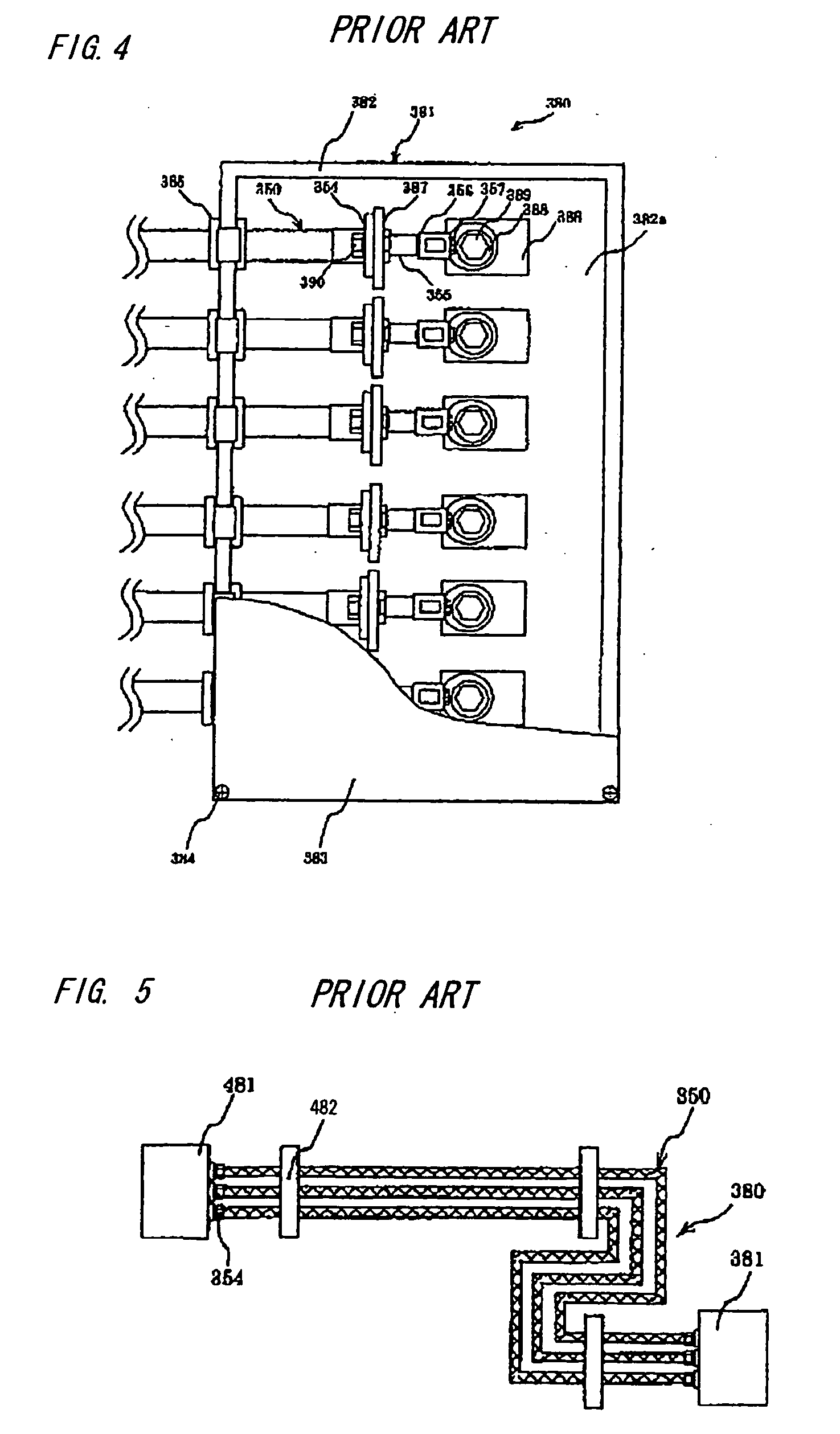

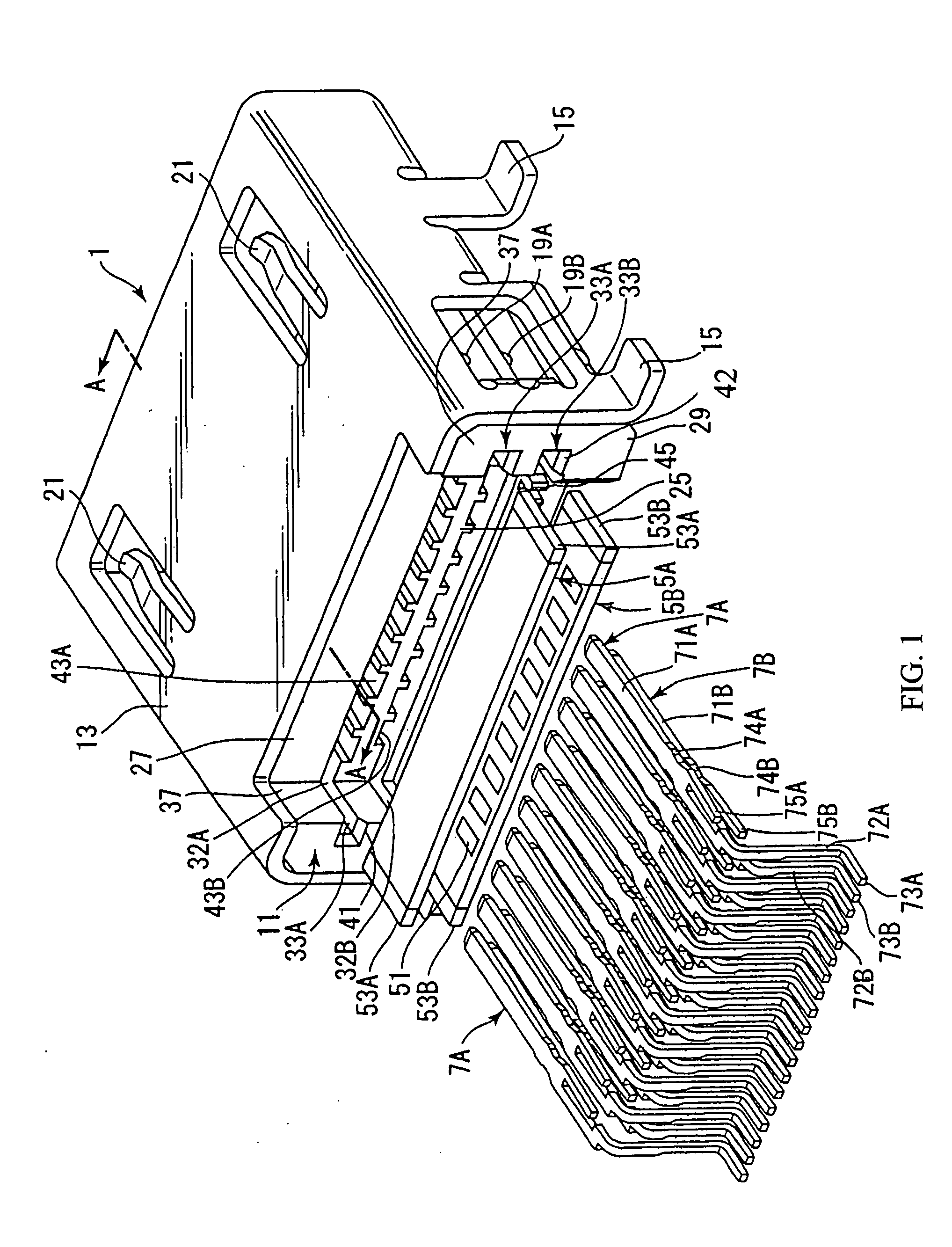

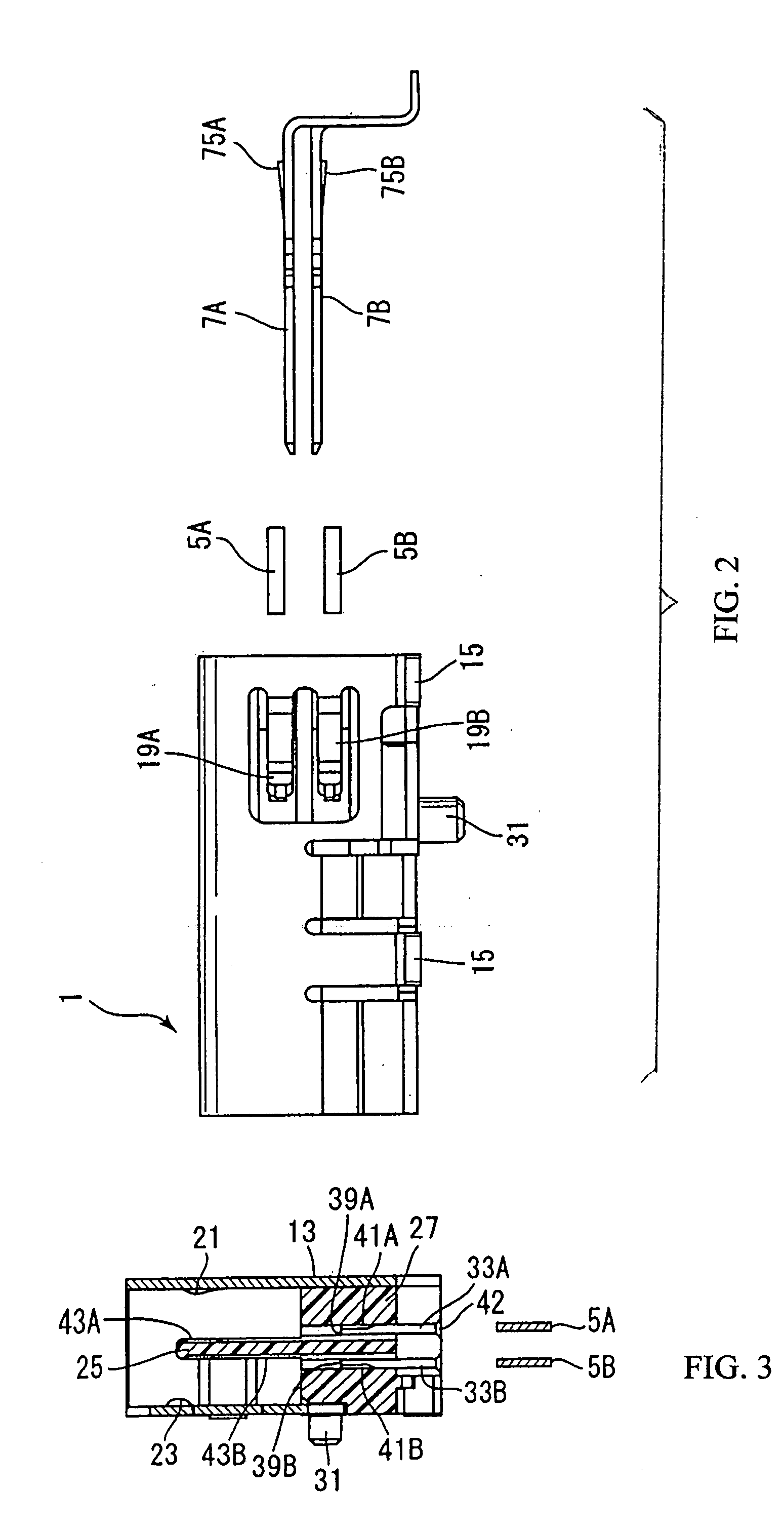

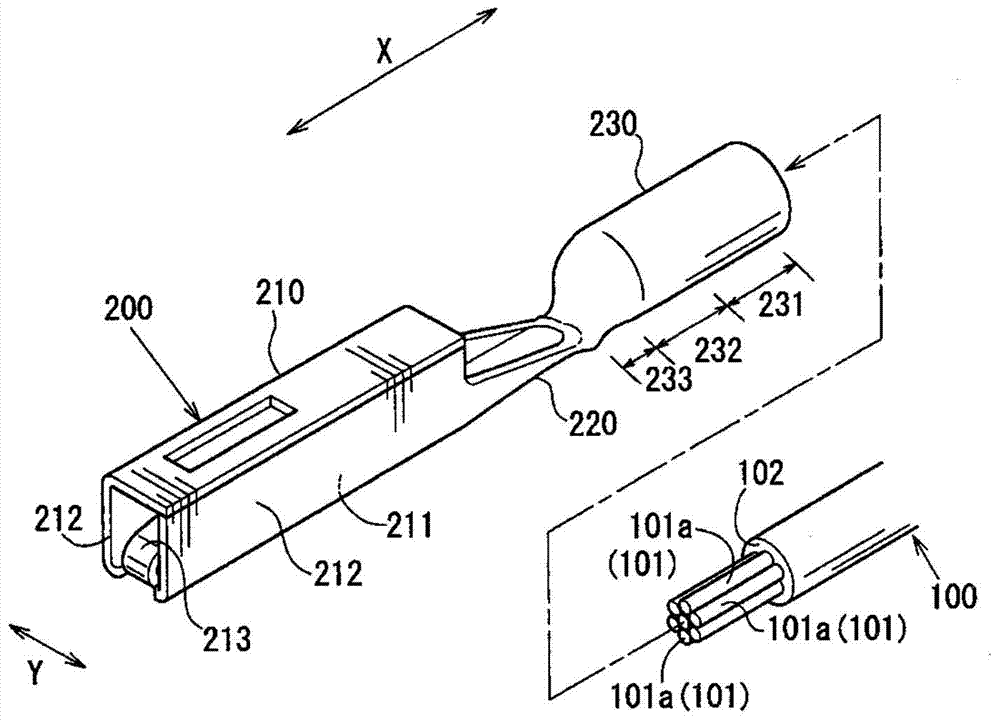

Shield wire, housing connected with same, connecting method thereof and shield wire unit

InactiveUS20060137893A1Good bending propertiesImprove seismic performanceVehicle connectorsLine/current collector detailsElectrical conductorEngineering

Owner:HITACHI METALS LTD

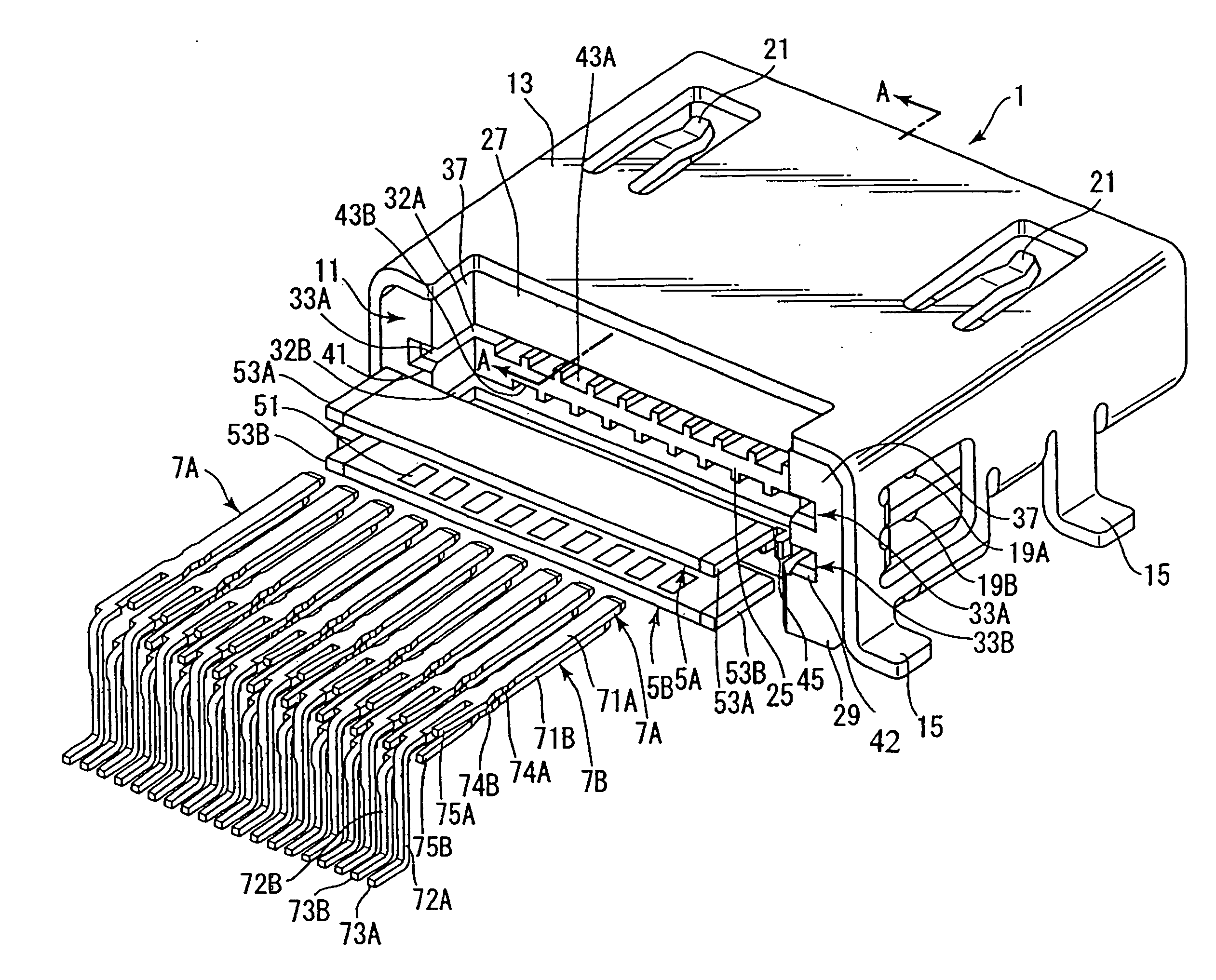

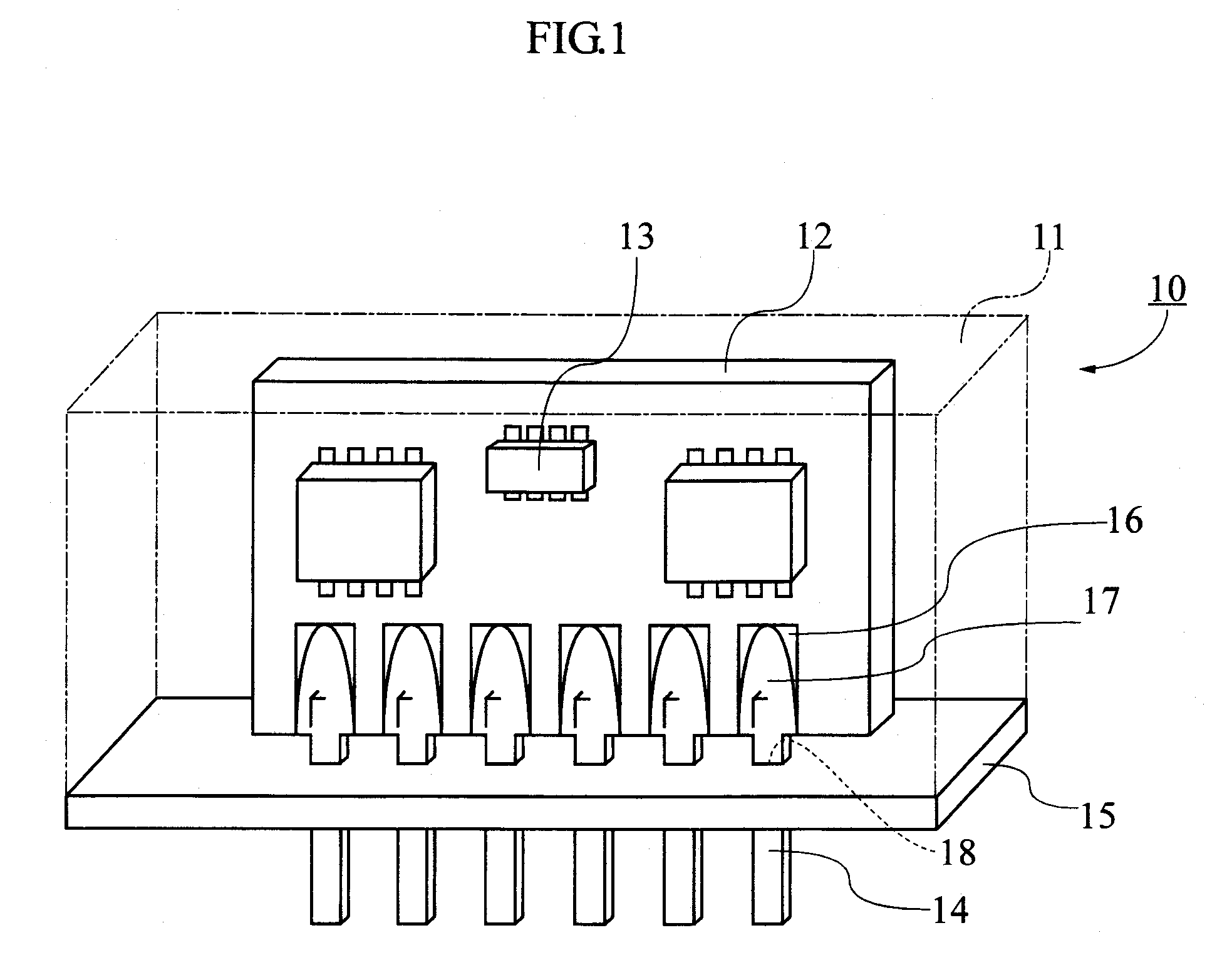

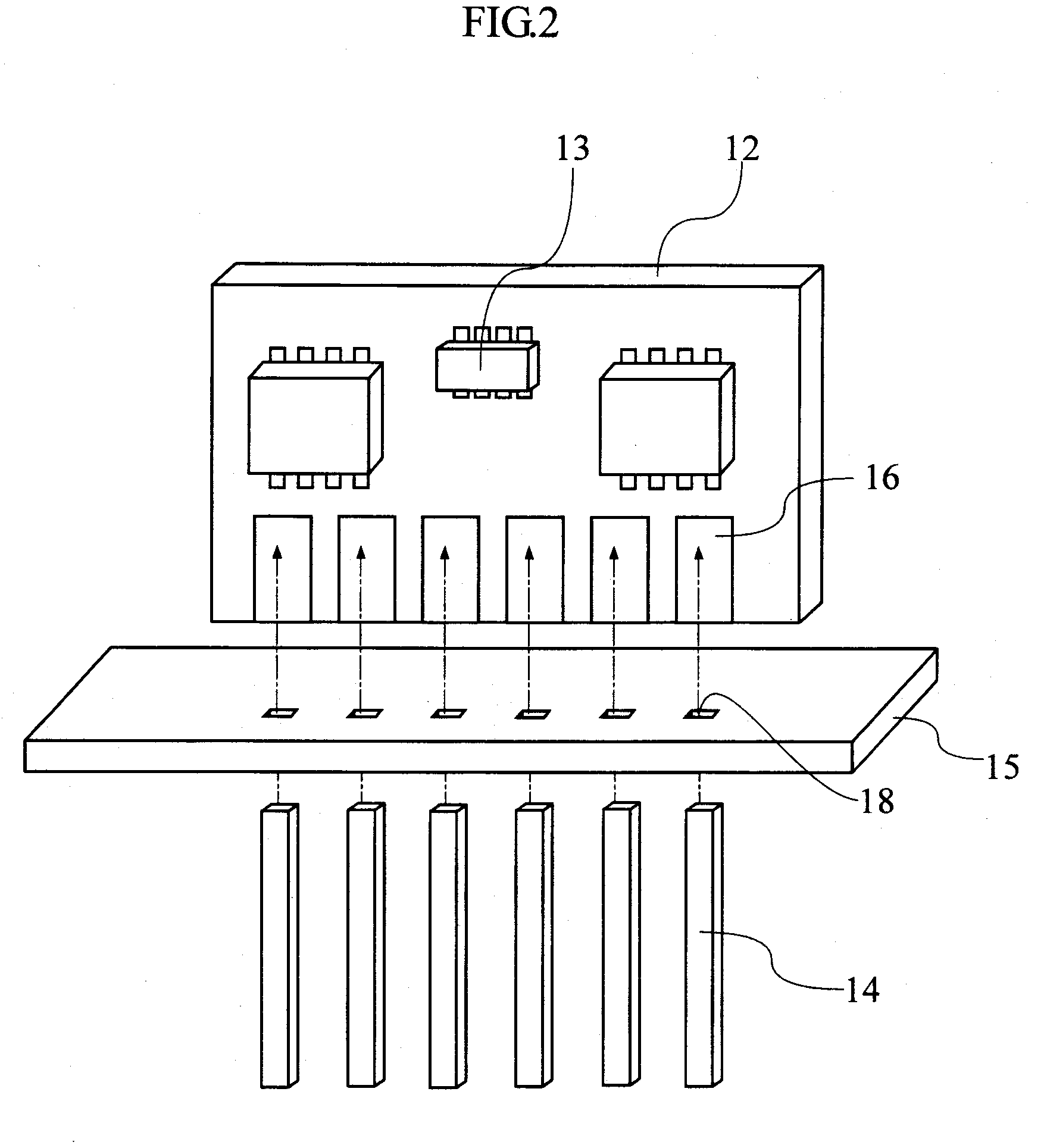

Connector with built-in substrate and its assembling method

InactiveUS20060040562A1Easy to assembleLess numberLine/current collector detailsElectric discharge tubesEngineeringElectrical and Electronics engineering

Owner:HIROSE ELECTRIC GROUP

Multilayer Printed Wiring Board And Manufacturing Method For Same

InactiveUS20080121416A1Prevented from short circuitingLine/current collector detailsPrinted circuit detailsConductive pasteAdhesive

In a case of multilayer circuit boards where a plurality of conventional films are used as insulating layers, the films are connected with each other using an adhesive, and therefore, the adhesive sometimes negatively affects reduction in thickness. Therefore, a plurality of two-sided boards with films used therein are pasted together with a paste connection layer interposed therebetween, the paste connection layer being configured such that through holes formed in a prepreg are filled in with a conductive paste which is then cured, and second wires are electrically connected with each other through the conductive paste with which the through holes formed in the paste connection layer in advance are filled in, and thus, a multilayer board can be provided without using an adhesive, and the entirety of the multilayer circuit board can be reduced in thickness.

Owner:PANASONIC CORP

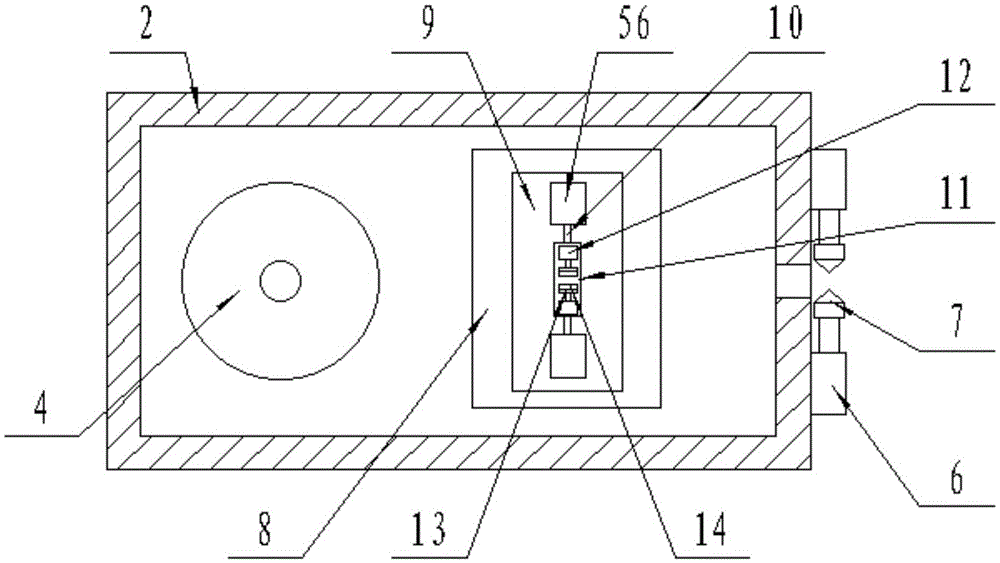

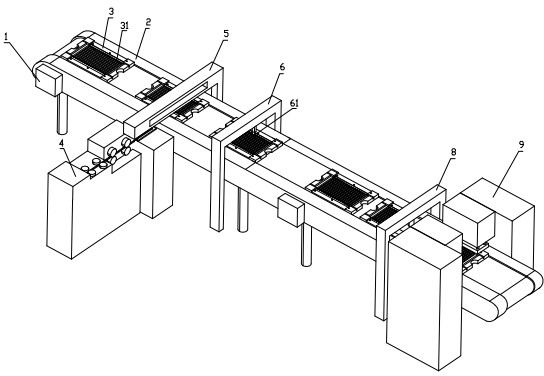

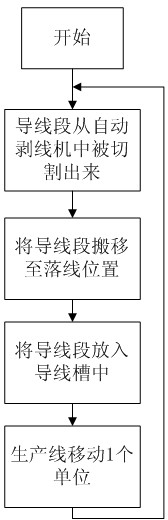

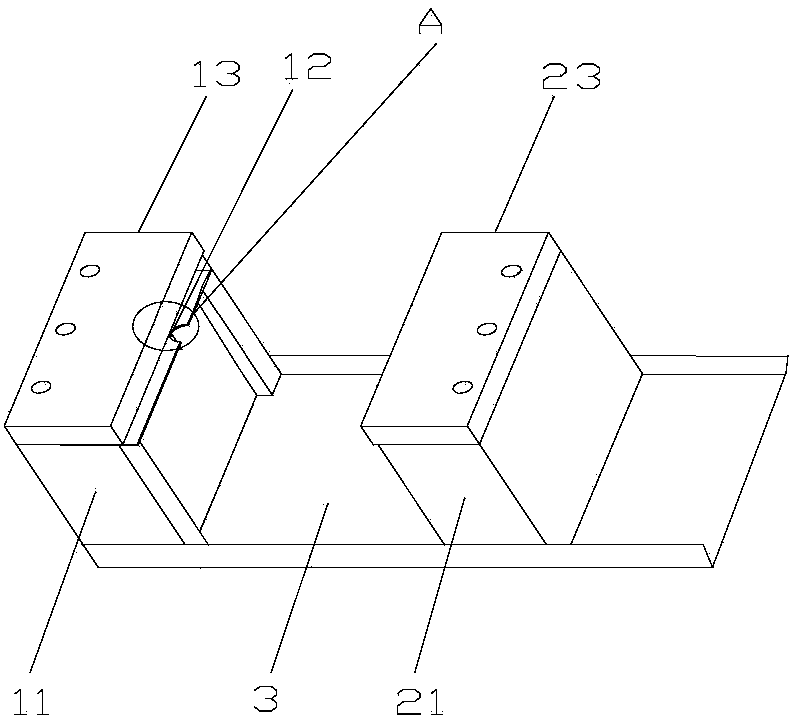

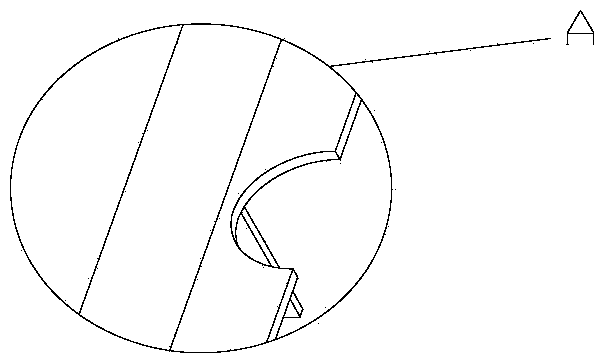

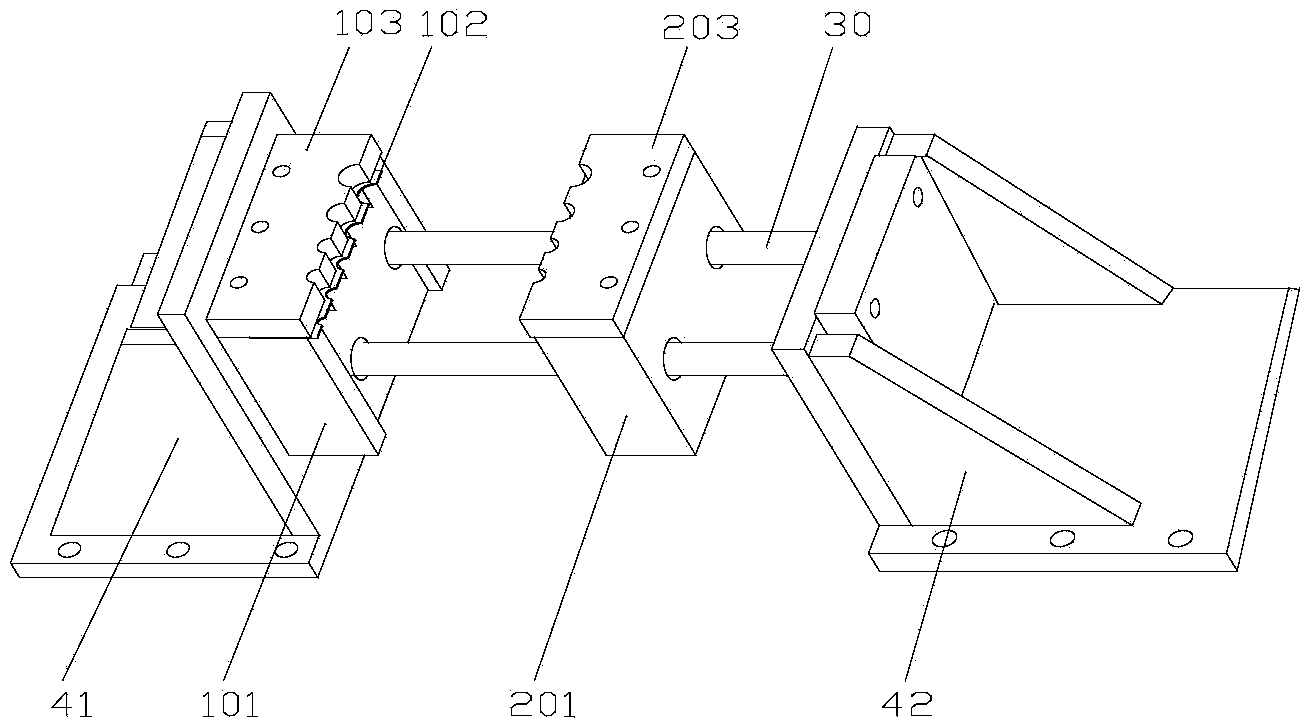

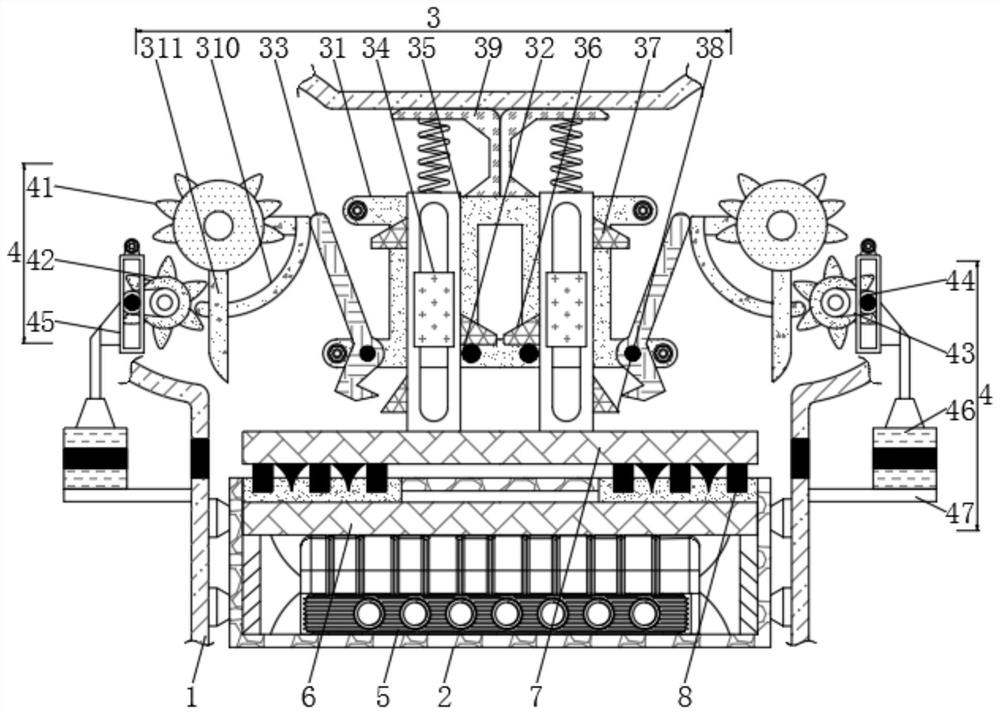

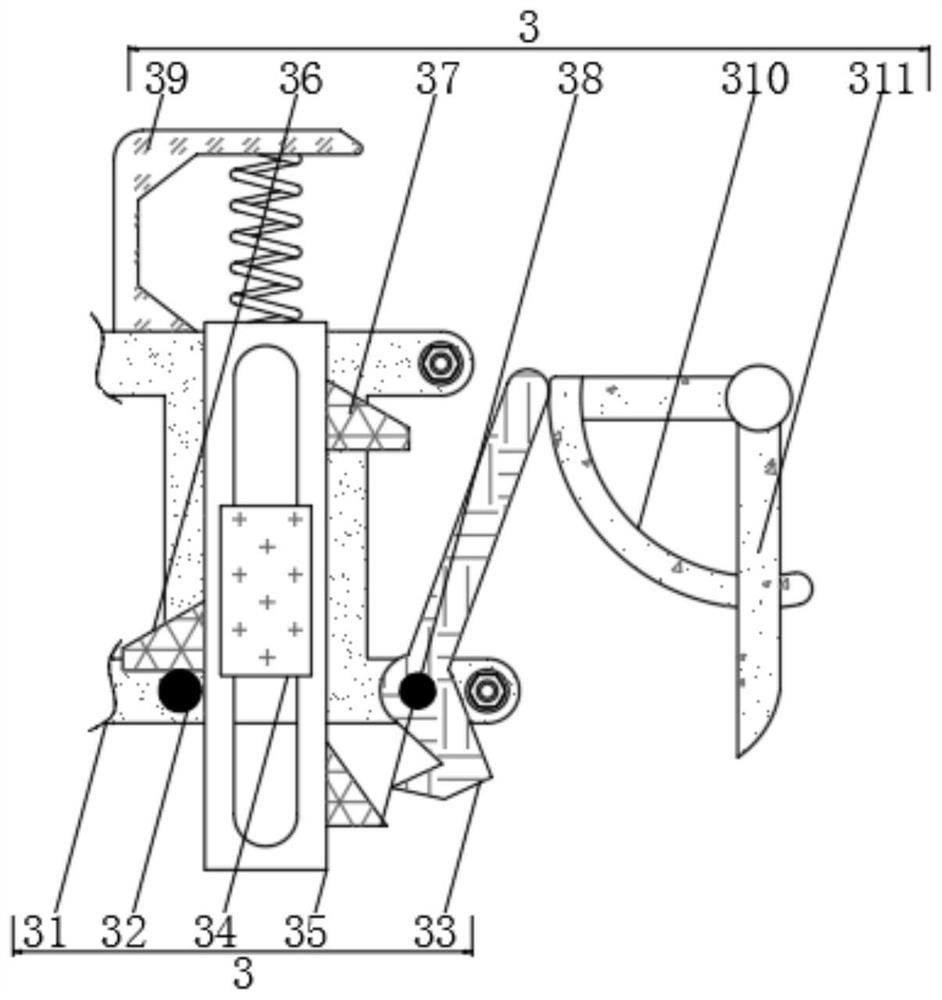

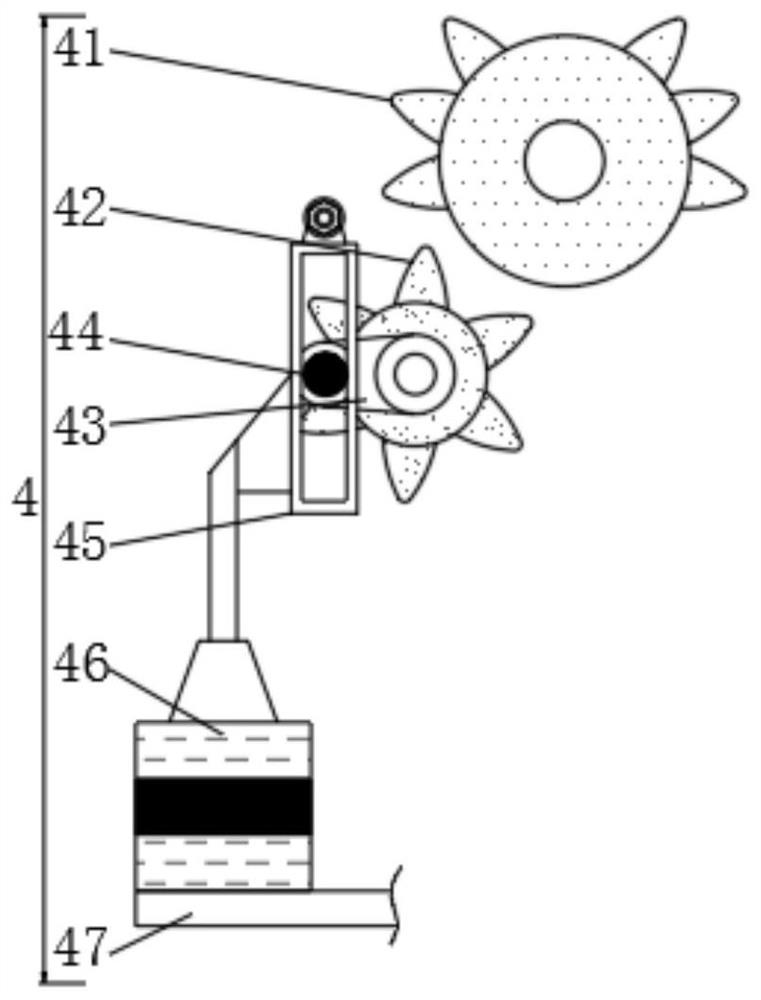

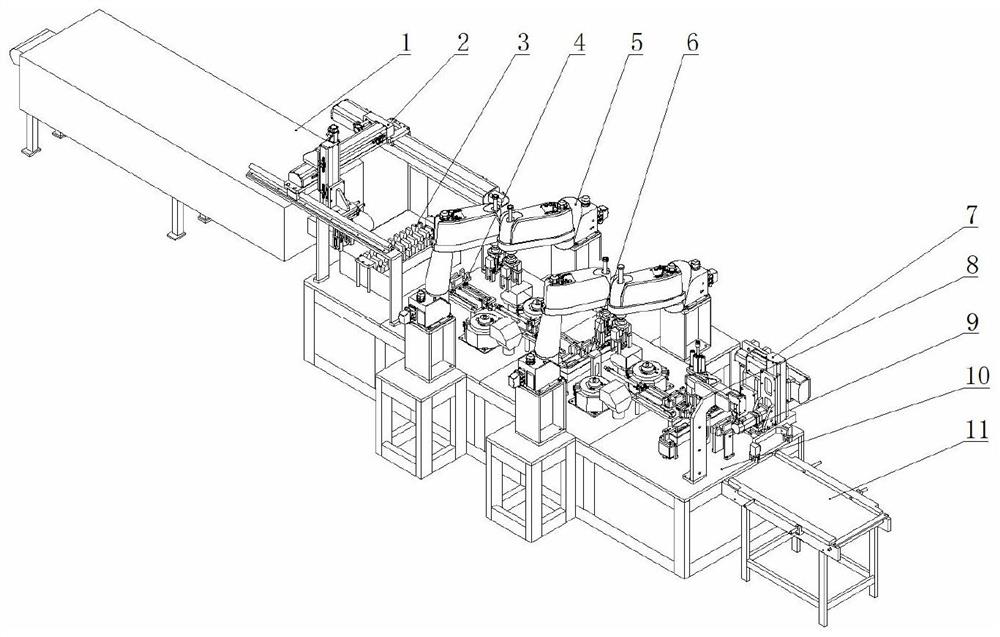

Swing type clamping one-way fuse tube electric wire welding production line

InactiveCN105618637AControllable distanceIncrease productivityLine/current collector detailsProduction lineElectric wire

Owner:徐海慧

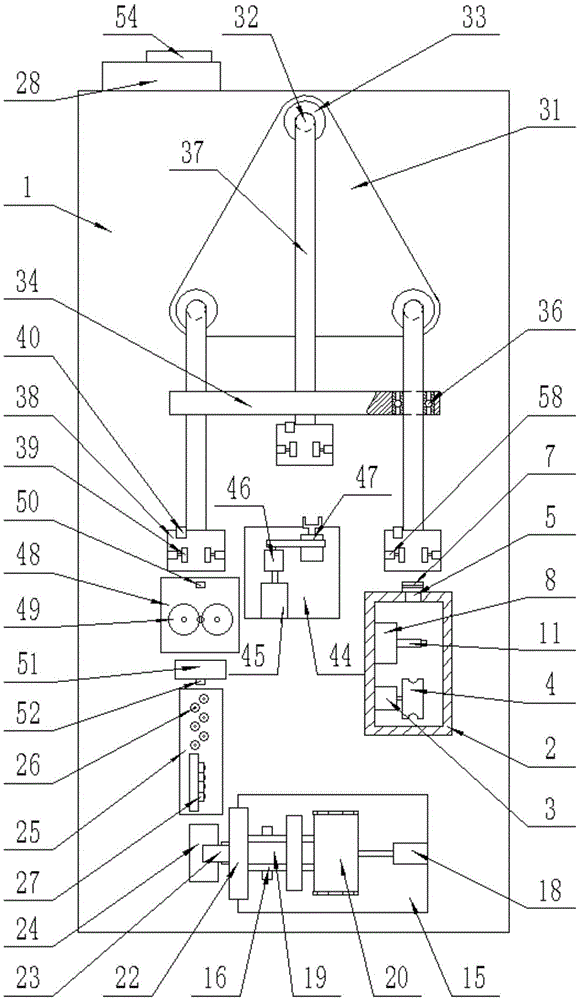

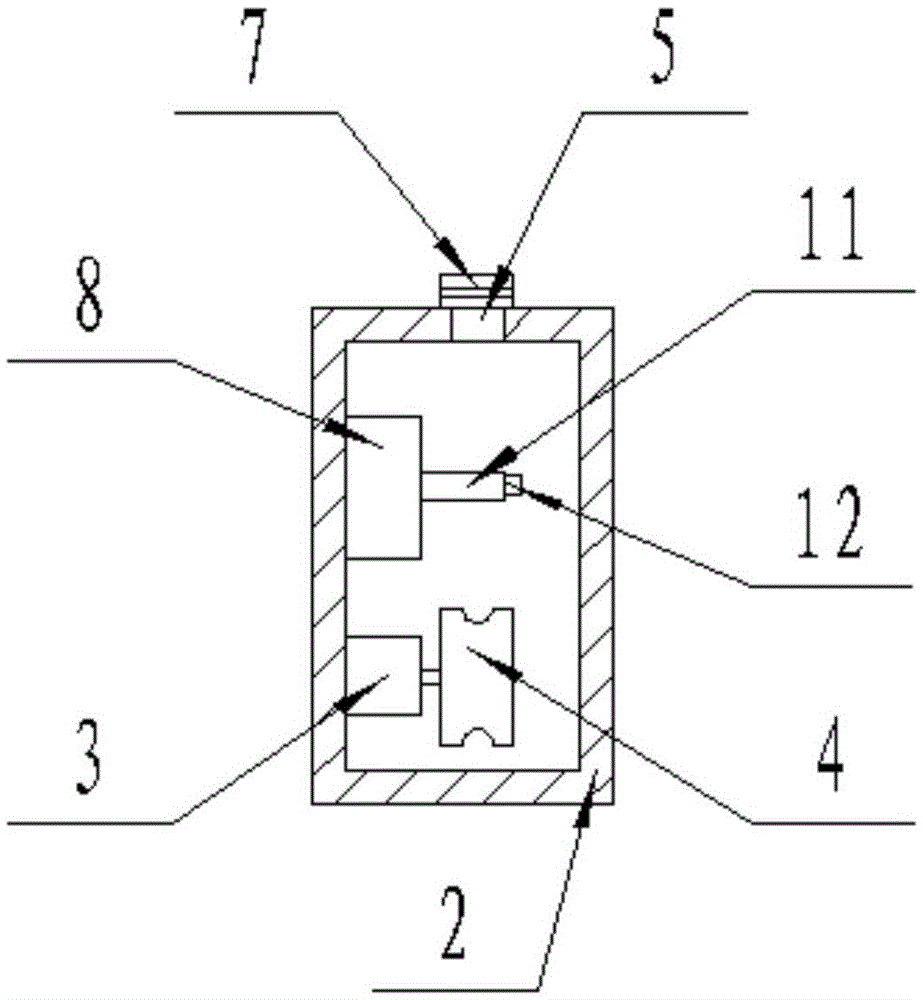

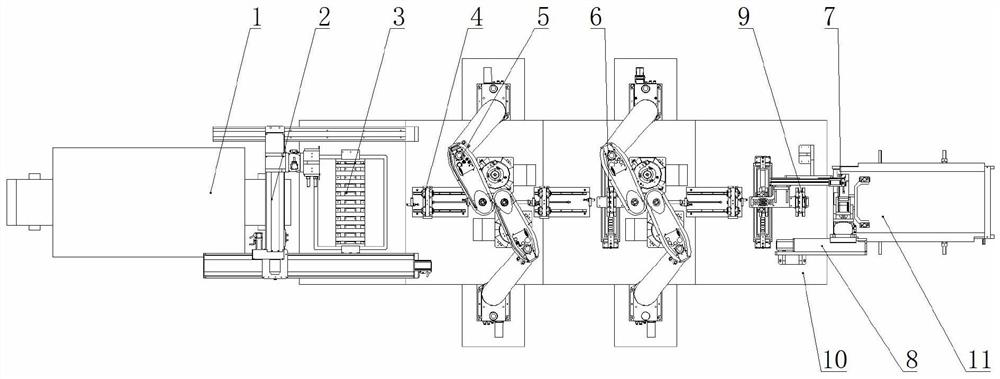

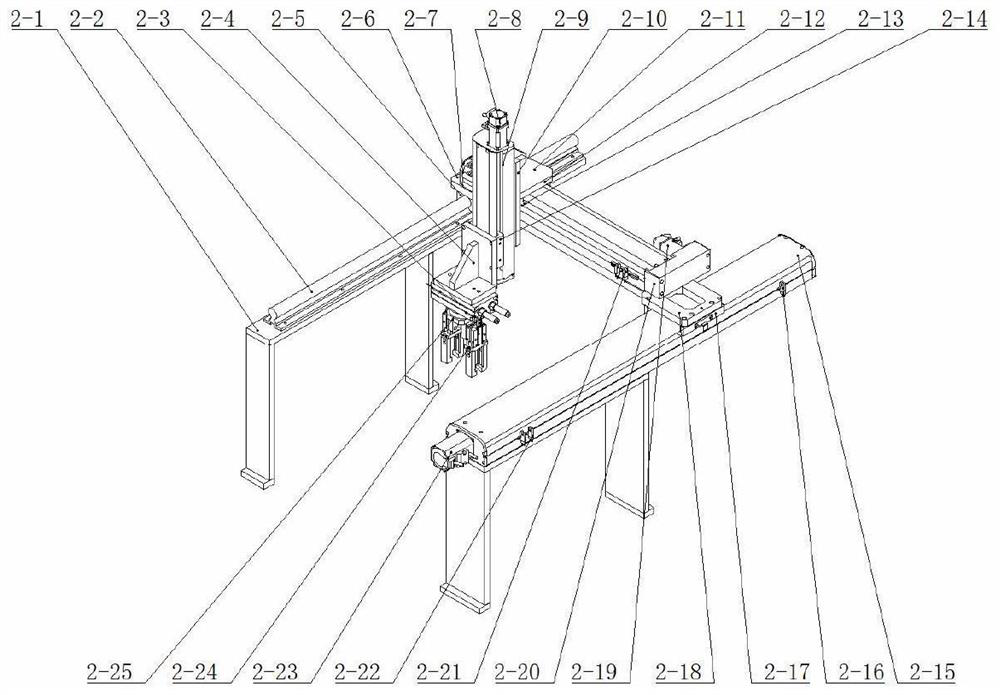

Full-automatic wire bundle machining and assembling equipment

ActiveCN108666841AAutomate operationsReduce manual operationsLine/current collector detailsRubber ringEngineering

Full-automatic wire bundle machining and assembling equipment is characterized in that a wire bundle feeding and cutting mechanism comprises a wire bundle cutting mechanism, a first wire bundle transferring mechanism, a wire bundle coil mechanism, a second wire bundle transferring mechanism, a wire bundle binding mechanism, a wire bundle end positioning mechanism and a third wire bundle transferring mechanism which are sequentially arranged from left to right. A wire bundle end machining and assembling system comprises a plurality of machining stations and a synchronous positioning and transferring mechanism. Each machining station is sequentially provided with a rubber ring sleeving mechanism, a copper ring sleeving mechanism, a peeling mechanism, a pin welding mechanism and a connector riveting and pressing mechanism. The equipment has the advantages that feeding, cutting, winding, binding, rubber ring sleeving, copper ring sleeving, peeling, pin welding, connector riveting and pressing and discharging are completed automatically, automation of the whole process is achieved, manual operation is reduced, the working efficiency is improved, the labor cost is reduced, the working precision is high, and the qualified rate of products is guaranteed.

Owner:ZHEJIANG XIAOYU TECH CO LTD

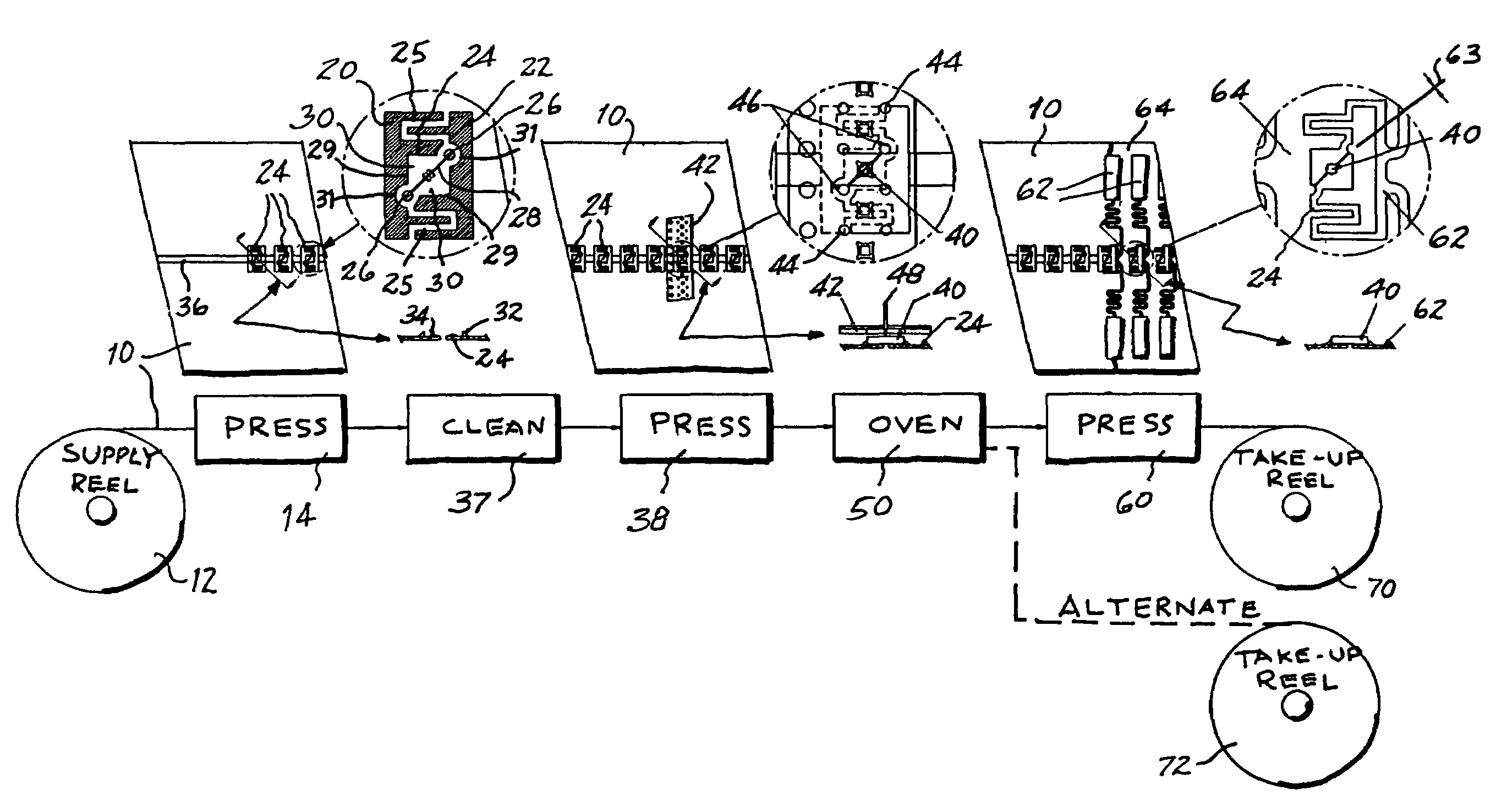

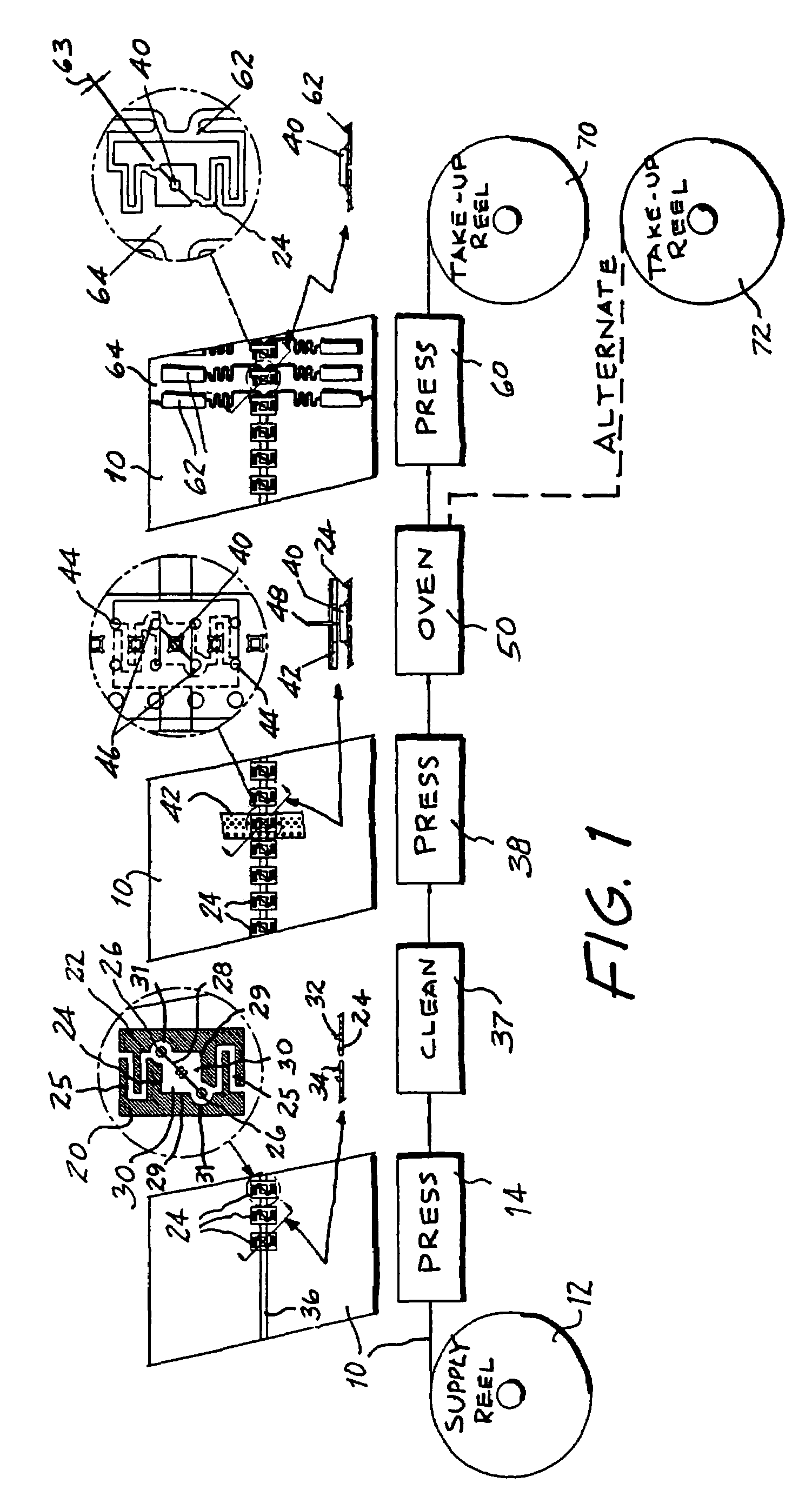

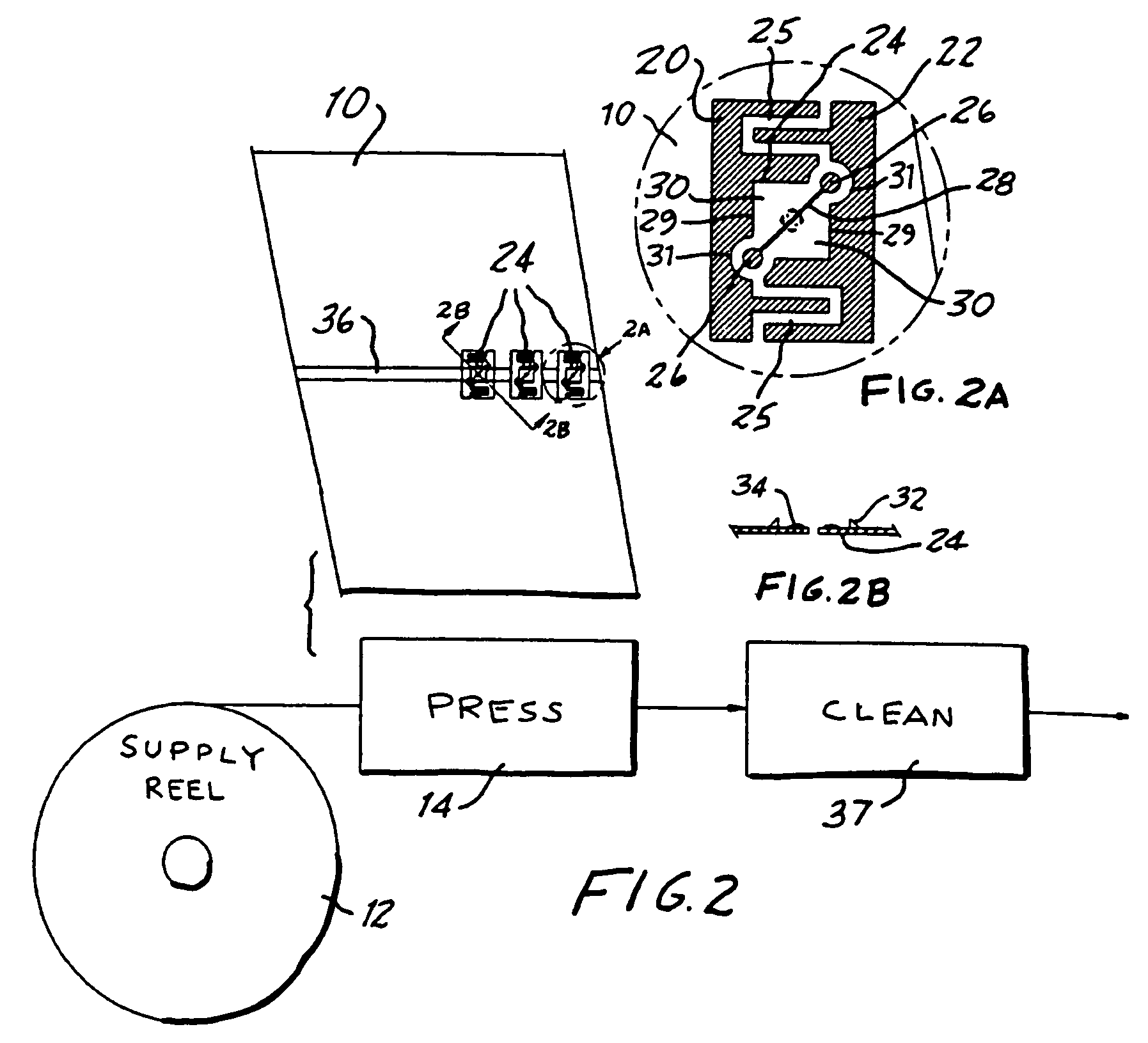

Manufacture of RFID tags and intermediate products therefor

InactiveUS7229018B2Easy to manufactureHighly effectiveLine/current collector detailsElectronic circuit testingCouplingEngineering

Owner:A K STAMPING

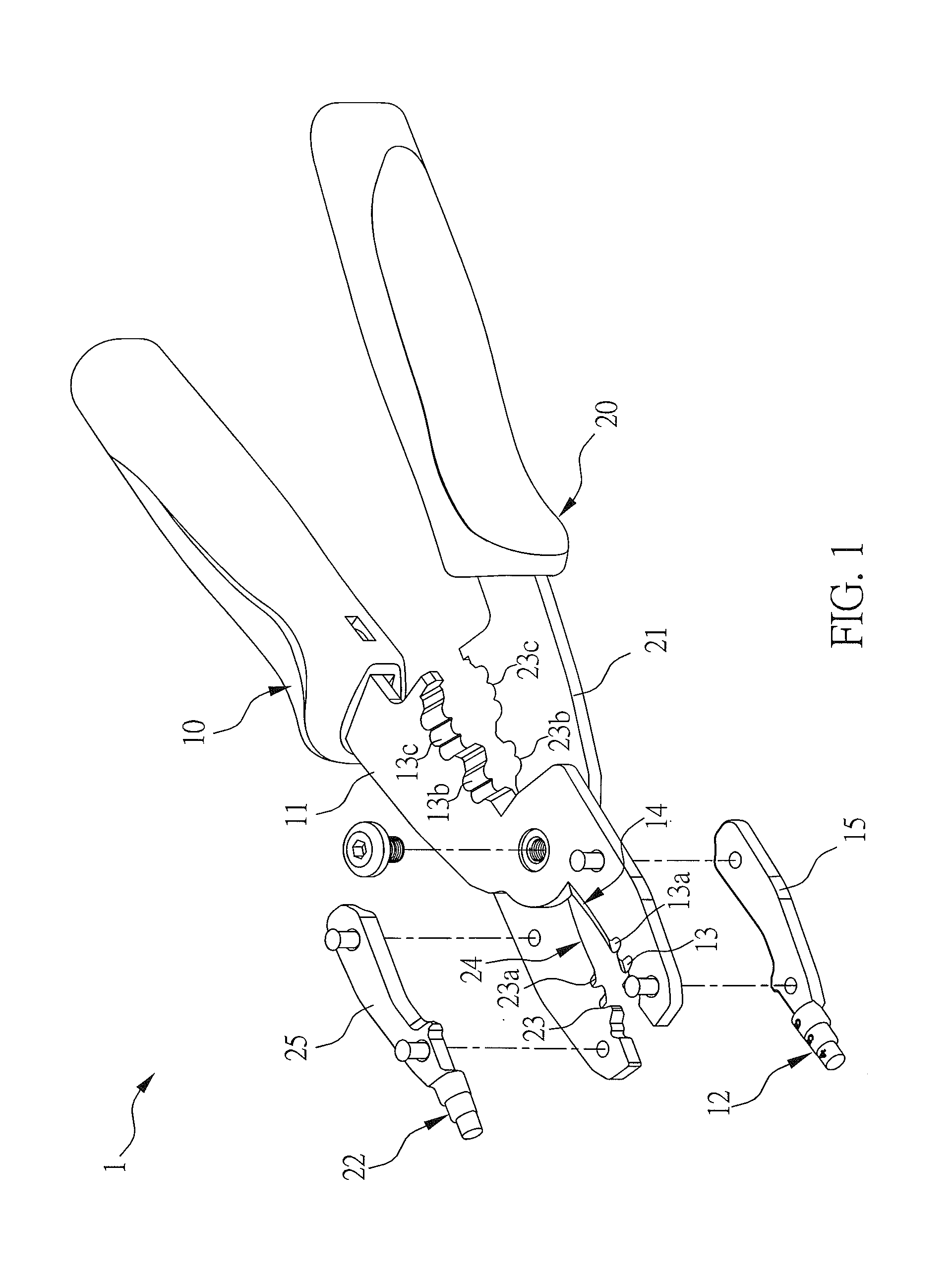

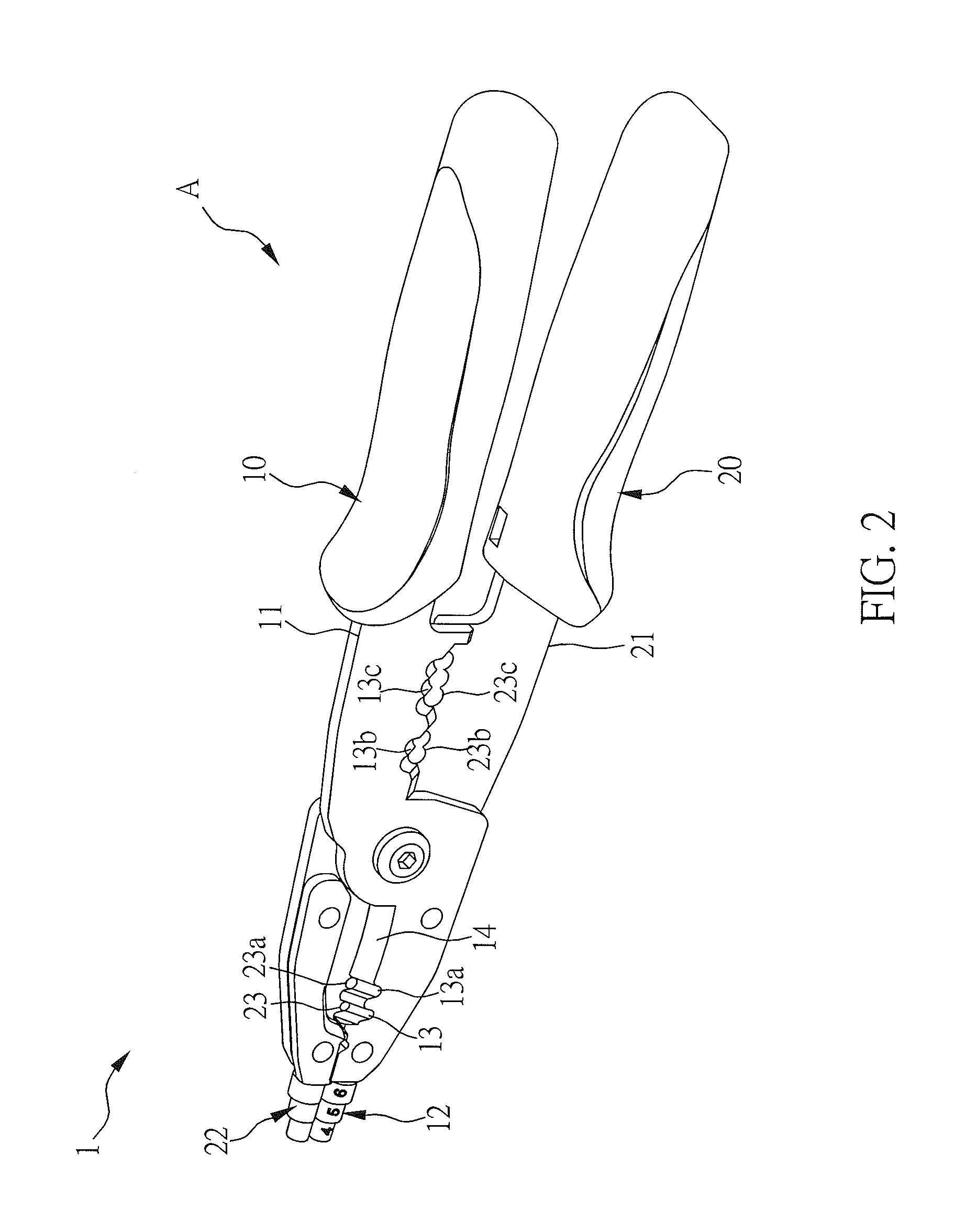

Wire Treatment Pliers Set

InactiveUS20160181772A1Line/current collector detailsApparatus for cutting/splicing cablesEngineering

Owner:HANLONG INDAL

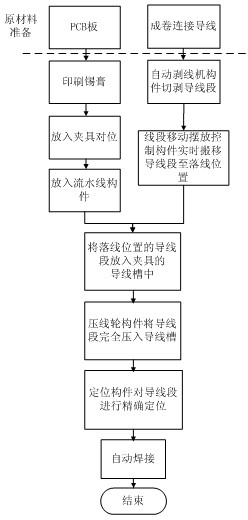

Automatic welding method and system for LED module connecting lead

InactiveCN102570237AFacilitate automatic weldingImprove qualityLine/current collector detailsProduction lineEngineering

Owner:黎明

Device for stripping insulating layer of cable

InactiveCN103594907AFacilitate strippingExcellent peelabilityLine/current collector detailsElectrical and Electronics engineering

Owner:ANHUI LEOCH BATTERY TECH

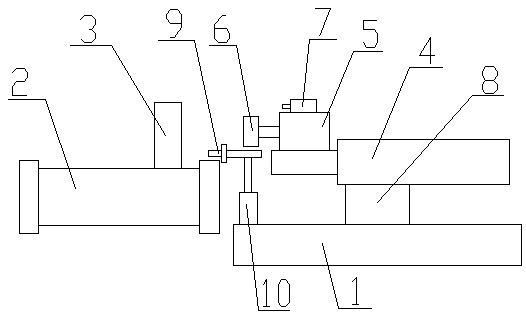

Metal cable connector welding machine

InactiveCN104779508AMeet welding requirementsReasonable designLine/current collector detailsCable/conductor manufactureCopper conductorEngineering

A metal cable connector welding machine comprises a fixed copper conductor (1), a sliding copper conductor (2), bolts (3), push rods (4), slide rods (5), a cable slot I (6), a handle (7), a connecting rod (8), a power regulator (9) and a work bench (10), and is characterized in that the other ends of the slide rods (5) are connected with the handle (7) through the connecting rod (8); ends of two metal cables requiring welding are placed in the cable slot I (6) and a cable slot II (11) respectively and tightened by bolts (3), the handle (7) pushes the slide rods (5) on the push rods (4) through the connecting rod (8), two ends of each cable are contacted and powered on, the cables are molten, and welding is completed. The metal cable connector welding machine is reasonable in design, simple in structure, reliable in action and convenient to operate and can feasibly meet the cable welding requirement, and the product quality is ensured.

Owner:JIANGSU GANGHONG WIRE & CABLE CO LTD

Method for temporary repair of the overbraid for metal overbraided wiring harnesses

InactiveUS20050198820A1Line/current collector detailsElectrically conductive connectionsBiomedical engineeringMetal

A method for the repair of the overbraid for metal overbraided wiring harness is provided. The method requires no special wiring harness design, uses readily available materials and can be accomplished without removing the wiring harness. The method involves trimming around the damaged area, spreading the braid to expose a repair area, covering the repair area with a metal cover and then covering the repair area with wire screen mesh. Finally, the mesh is secured onto the wiring harness. Also provided is a metal overbraid wiring harness having been repaired with the method of the present invention.

Owner:HONEYWELL INT INC

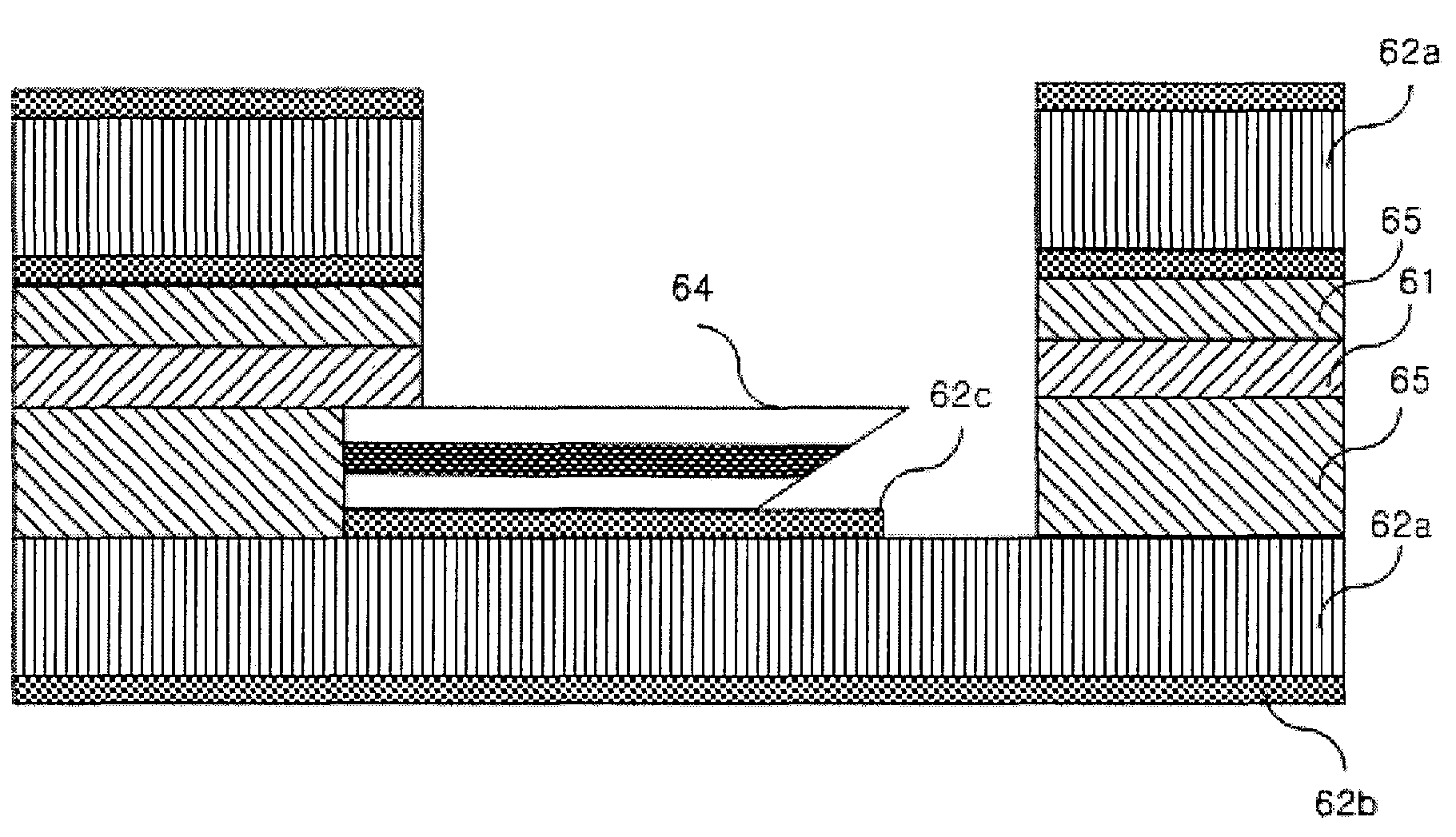

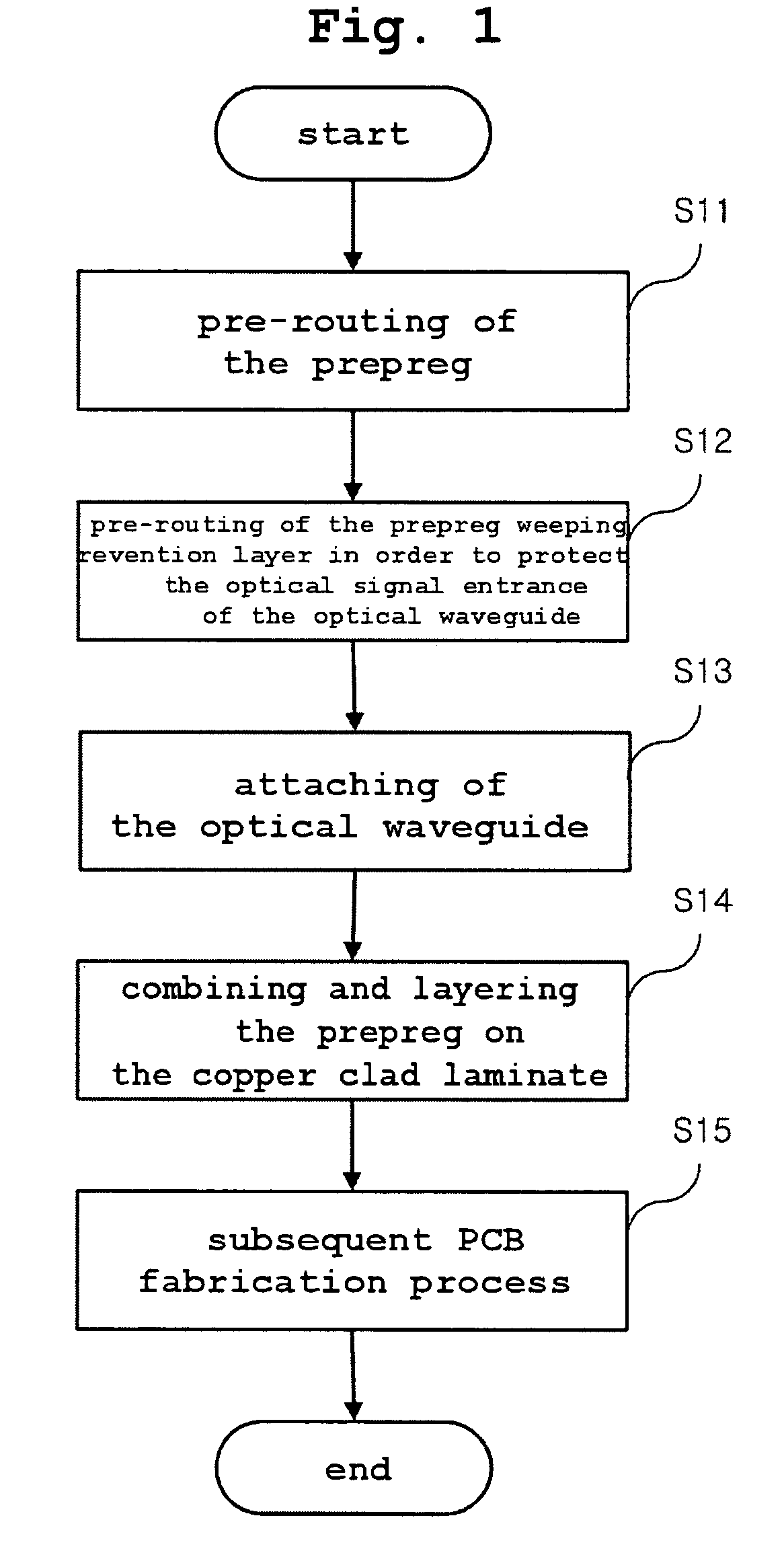

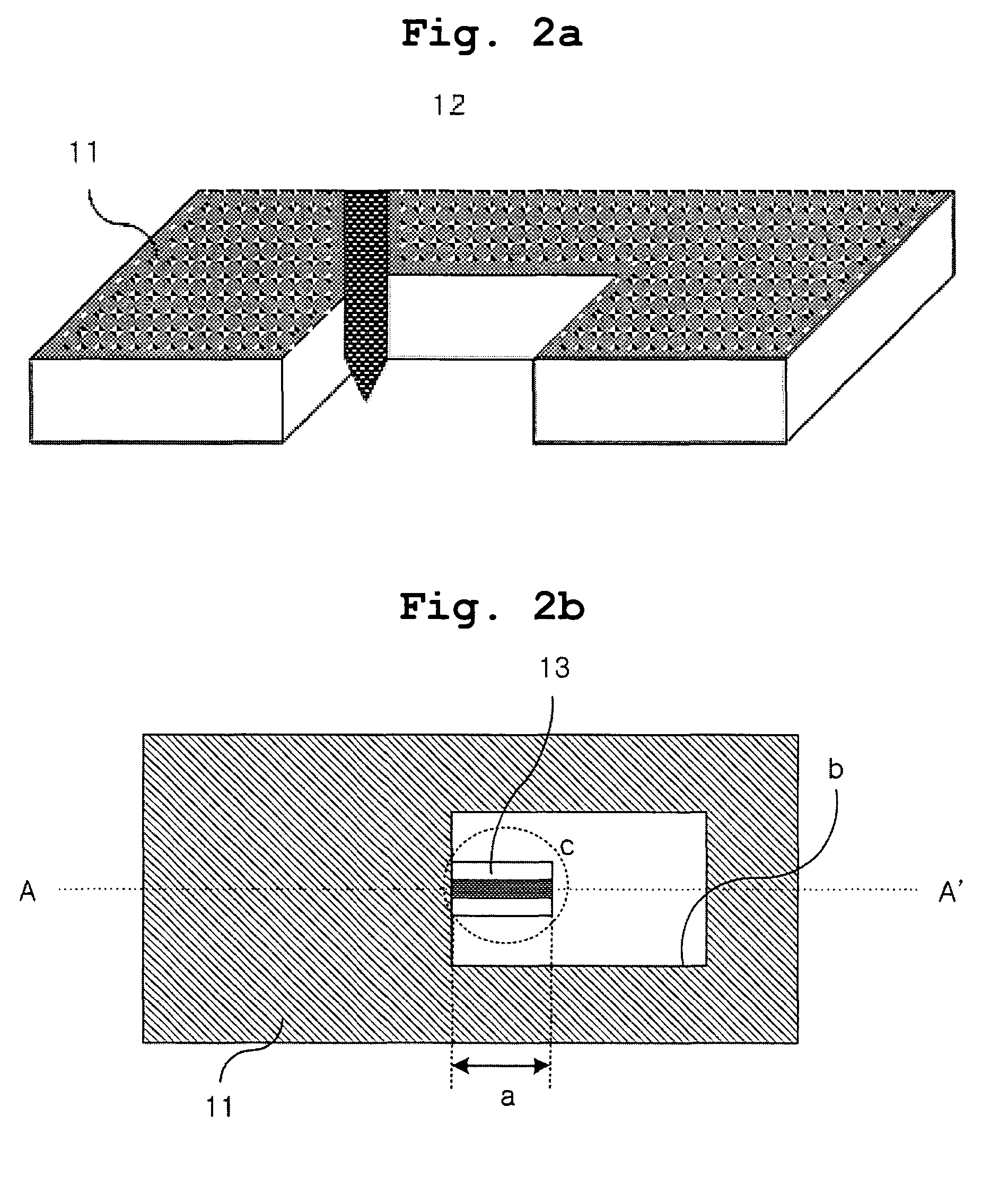

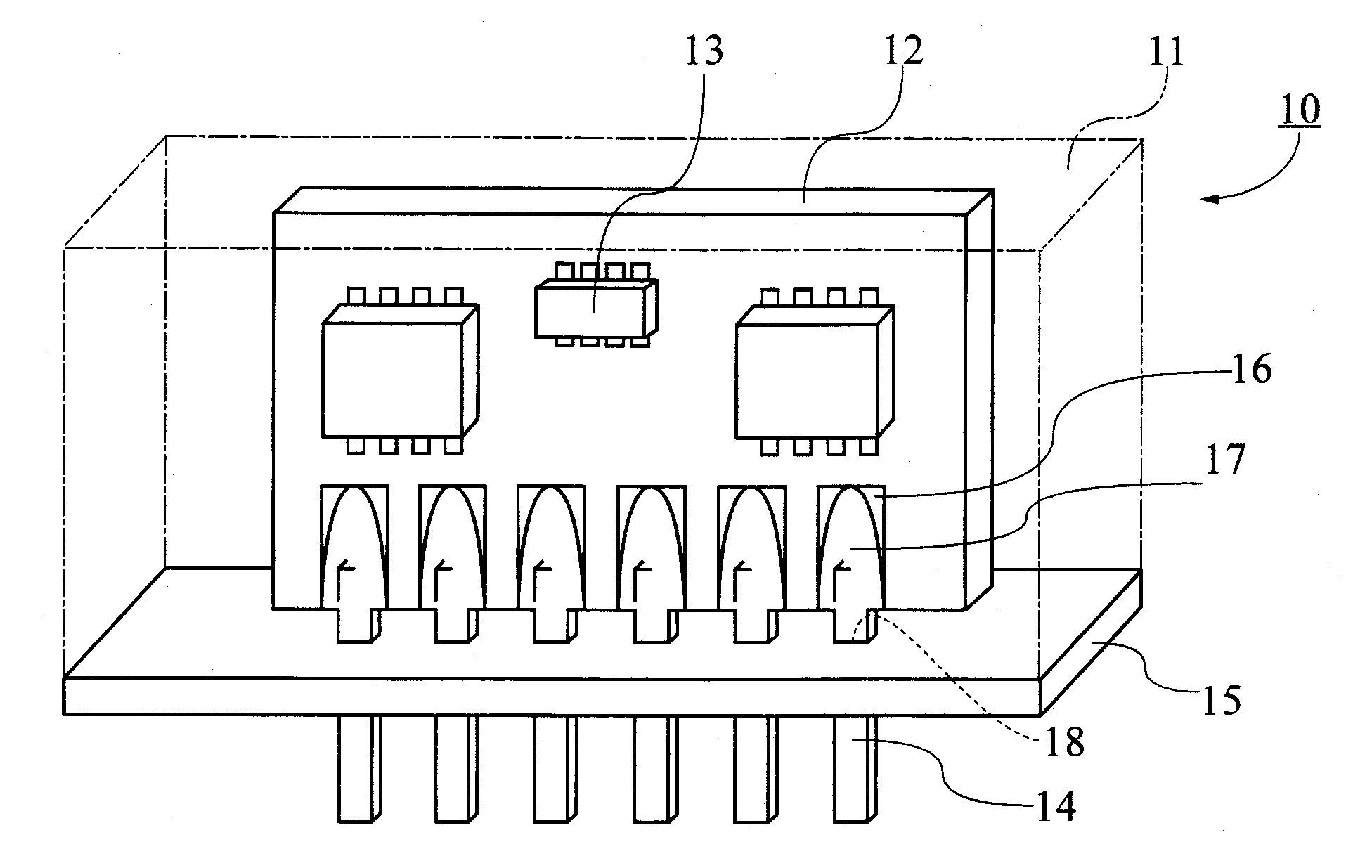

Method of fabricating multi-layered printed circuit board for optical waveguides

InactiveUS7046870B2Facilitating precise interfacing of optical signalPrinted circuit assemblingLine/current collector detailsAdhesiveCopper foil

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Cable joint connecting structure and connecting method

ActiveCN109786987AEasy to operateImprove connection reliabilityLine/current collector detailsSoldered/welded conductive connectionsStructural engineeringSoldering

The invention discloses a cable joint connecting structure and a connecting method. The disadvantages that a cable joint and a cable conductor are inconvenient for connecting operation, the connectionreliability is bad, and the loose risk is existent are solved. The connecting structure comprises the joint body and the cable conductor; a large-diameter cylinder, a small-diameter cylinder and lugplates are arranged on the joint body; a soldering frame is arranged in the small-diameter cylinder, the soldering frame comprises a base, a plurality of support strips connected to the base; a plurality of axially arranged slots are correspondingly arranged on the inner wall of the small-diameter cylinder and the support strips one by one; the support strips are inserted into the slots in an adapting manner; a plurality of small-diameter soldering slots communicating with the slots are arranged on the outer wall of the small-diameter cylinder, and small-diameter soldering blocks are arrangedin the small-diameter soldering slots; a plurality of inward arched clamping shrapnel is uniformly arranged on the inner wall of the large-diameter cylinder, one end of each inward arched clamping shrapnel is tightly connected with the inner wall of the large-diameter cylinder, the other end movably fits with the inner wall of the large-diameter cylinder; the plurality of large-diameter solderingslots are arranged on an outer wall of the large-diameter cylinder, the large-diameter soldering blocks are arranged in the large-diameter soldering slots, and the cable conductors are inserted into the large-diameter cylinder and the small-diameter cylinder.

Owner:HANGZHOU SHIBANG ELECTRIC TECH CO LTD

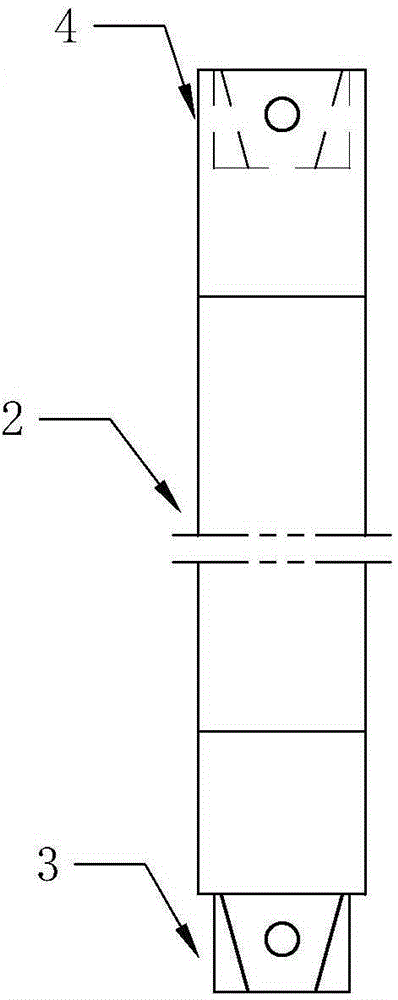

Device and method for butting single-phase single-sheet transition conductor of bus duct connector

ActiveCN102820560ALarge carrying capacityReduce temperature riseLine/current collector detailsElectric connection structural associationsElectrical conductorEngineering

The invention relates to a device and method for butting a single-phase single-sheet transition conductor of a bus duct connector. The device comprises double-insertion-sheet type bus duct connectors (2) and single-insertion-sheet type bus duct connectors (3) which are arrayed in sequence, and when the power supply is of a three-phase four-wire system, one single-insertion-sheet type bus duct connector (3), the double-insertion-sheet type bus duct connector (2) and another single-insertion-sheet type bus duct connector (3) are arrayed in sequence. Each double-insertion-sheet type bus duct connector (2) comprises a two-phase insulating sheet (21) and a transition conductor (22). The connection method is as follows: dividing the end of a bus duct into branches with prestress, inserting the B-phase branch and C-phase branch of the power supply into the double-insertion-sheet type bus duct connectors (2) respectively, and inserting the single-insertion-sheet type bus duct connectors (3) between the A-phase branch and the B-phase branch, between the C-phase branch and the N-phase branch and between the N-phase branch and the PE-phase branch respectively. Due to the clamping function of the prestressed branches of a bus duct conductor bar (1), the conductor of the connector can be matched tightly before being fastened by insulating bolts (7).

Owner:JIANGSU ONEQ ELECTRICAL APPLIANCE GRP

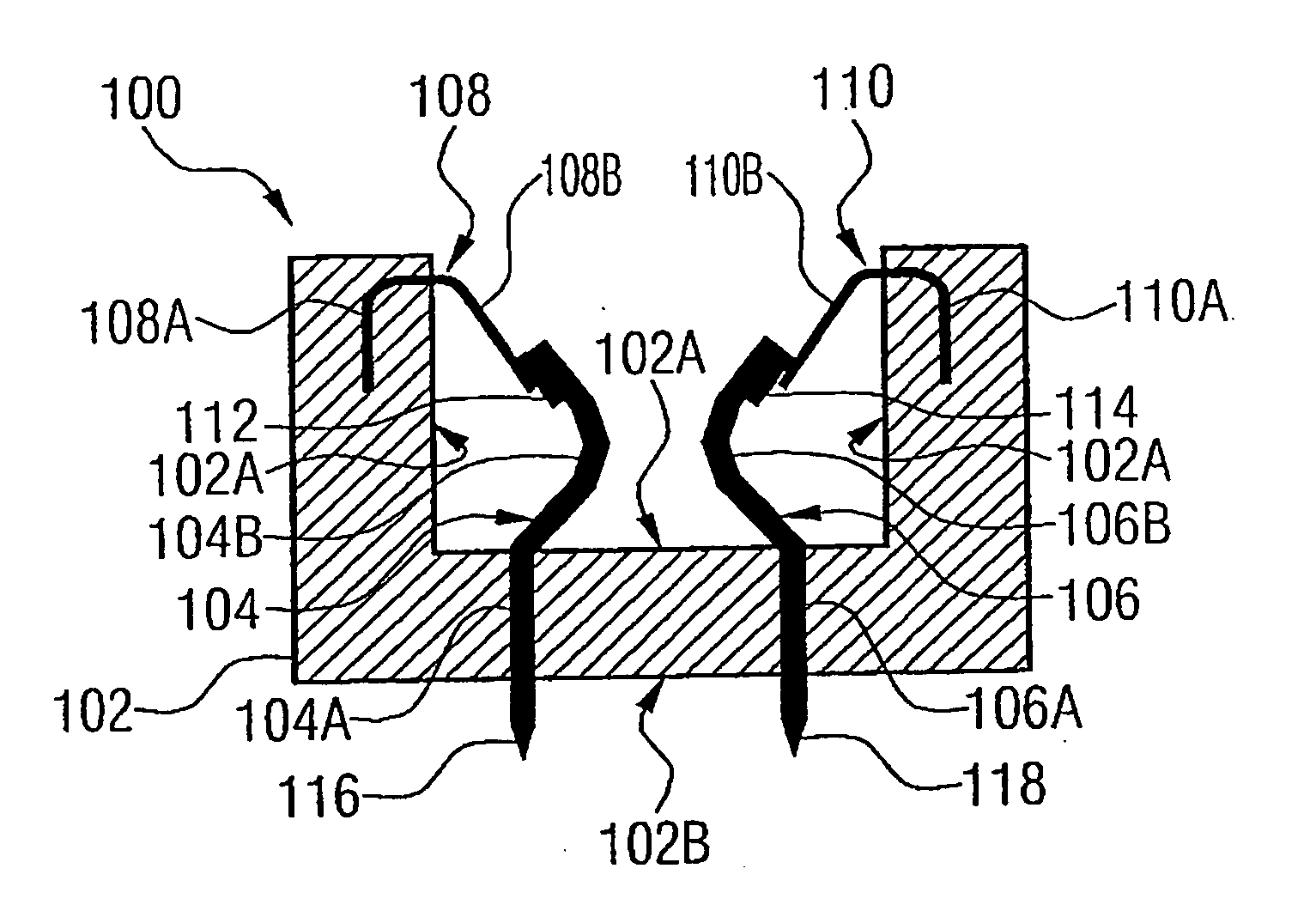

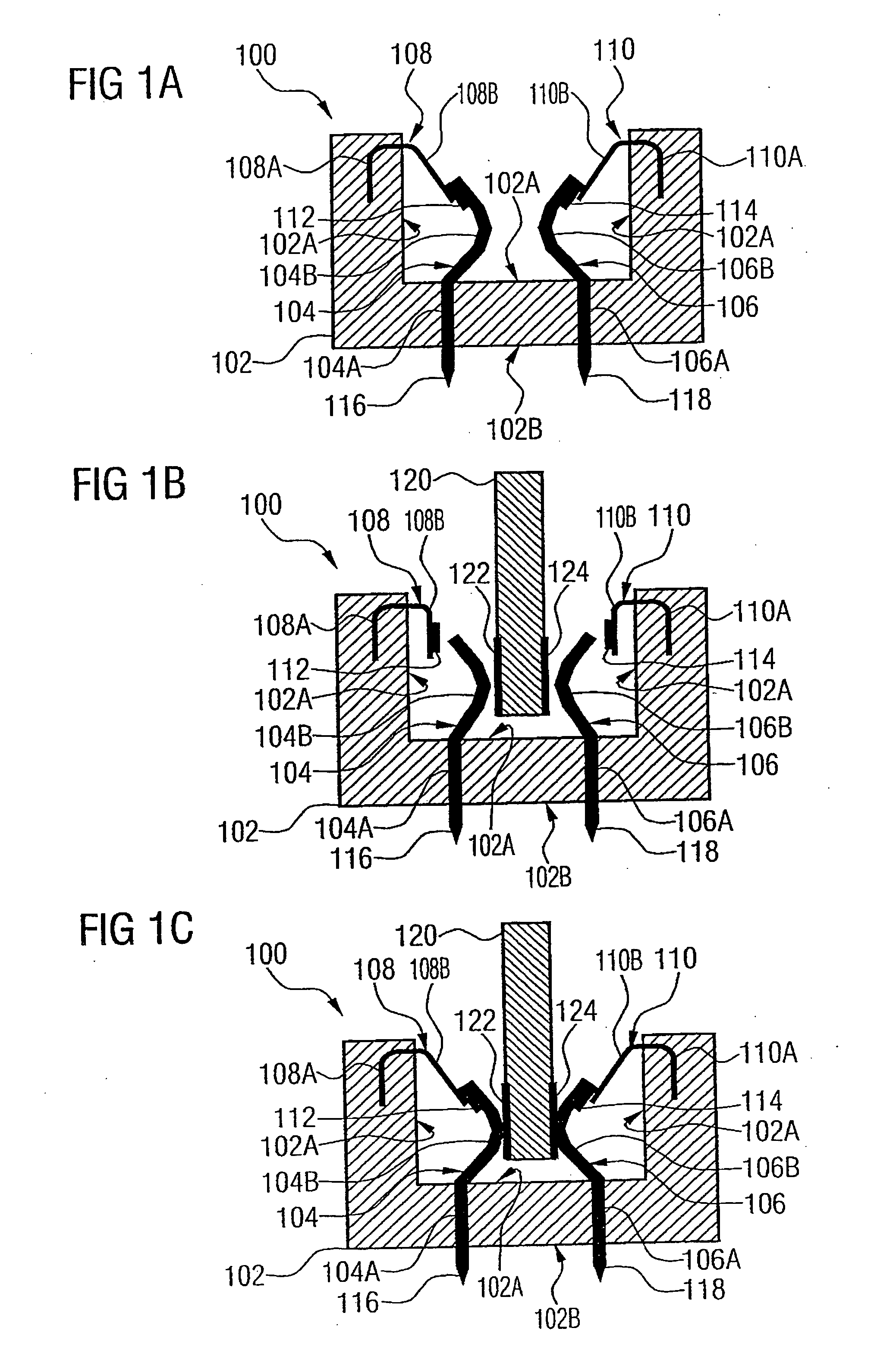

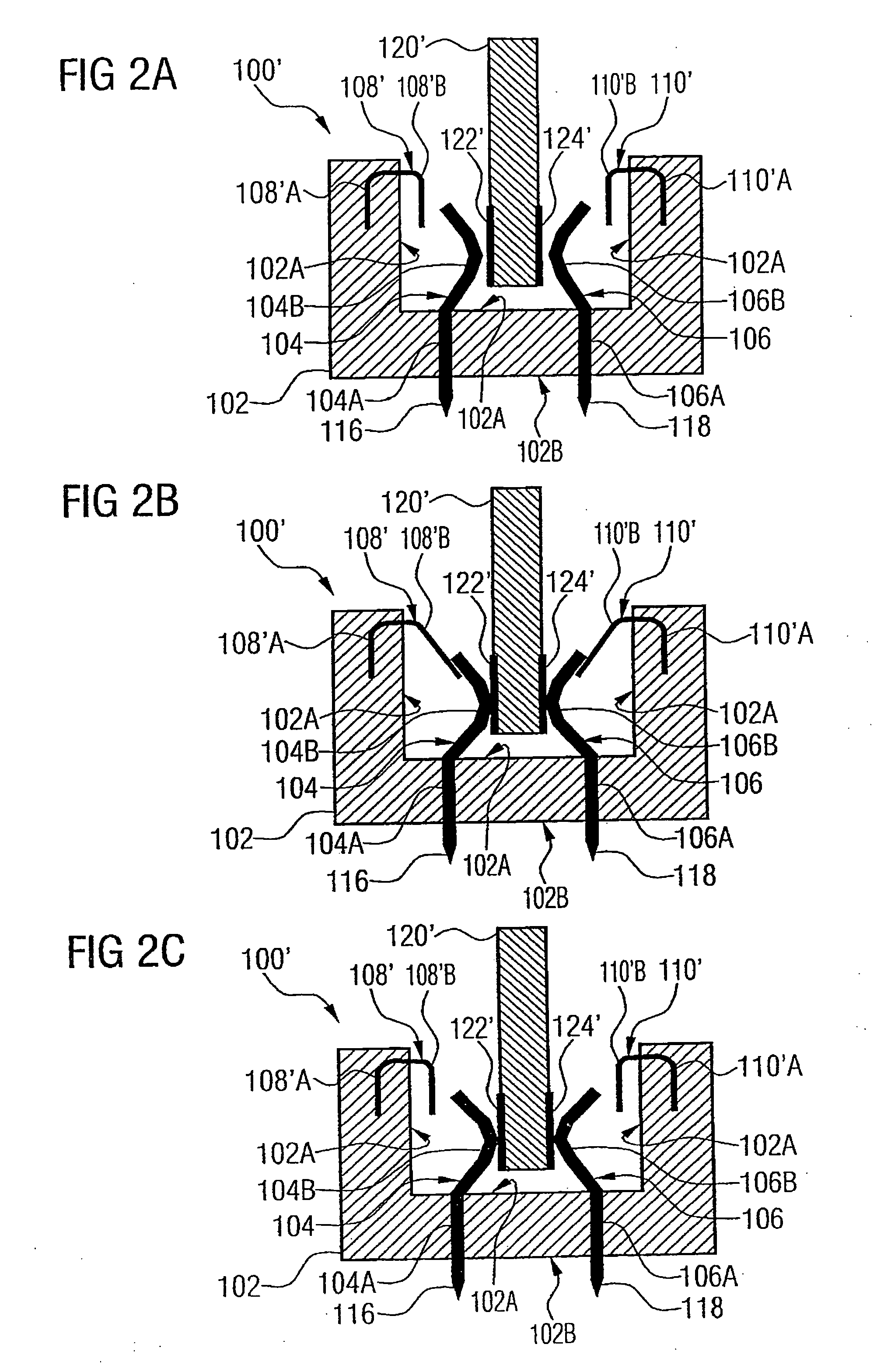

IC device and method of manufacturing the same

ActiveUS20090016040A1Line/current collector detailsWave amplification devicesPrinted circuit boardEngineering

Owner:ROHM CO LTD

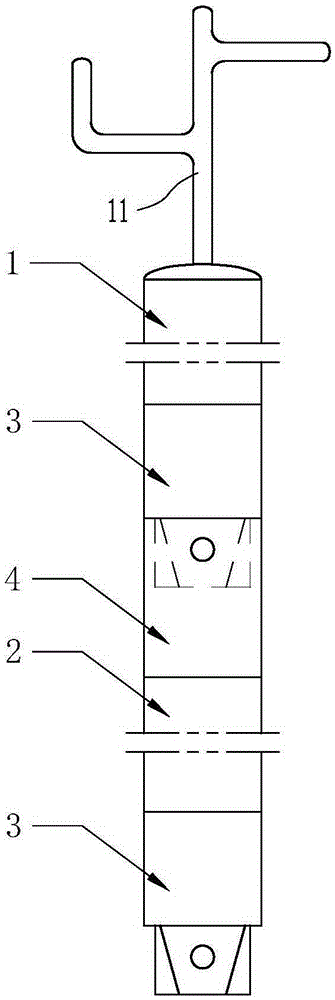

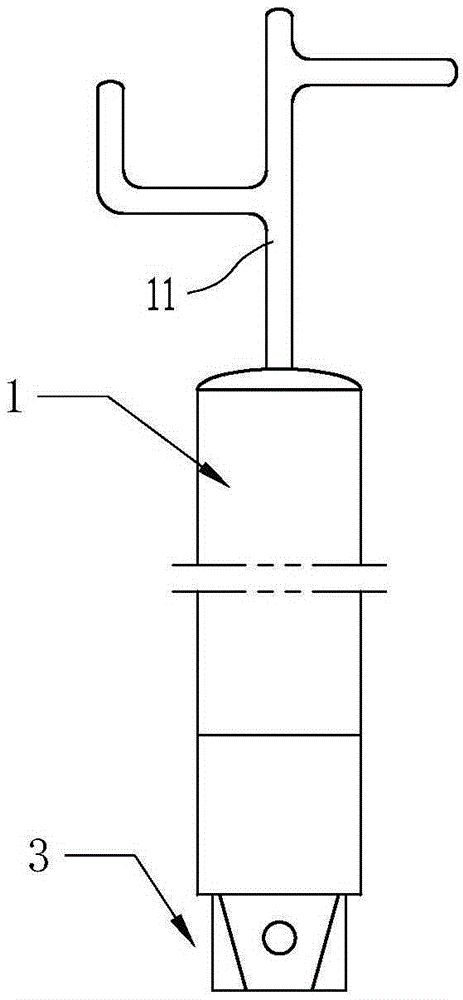

Insulating rod

InactiveCN105356190AEasy structure and operationEasy to disassembleLine/current collector detailsCable installation apparatusBiochemical engineering

Owner:国网山东潍坊市寒亭区供电公司 +1

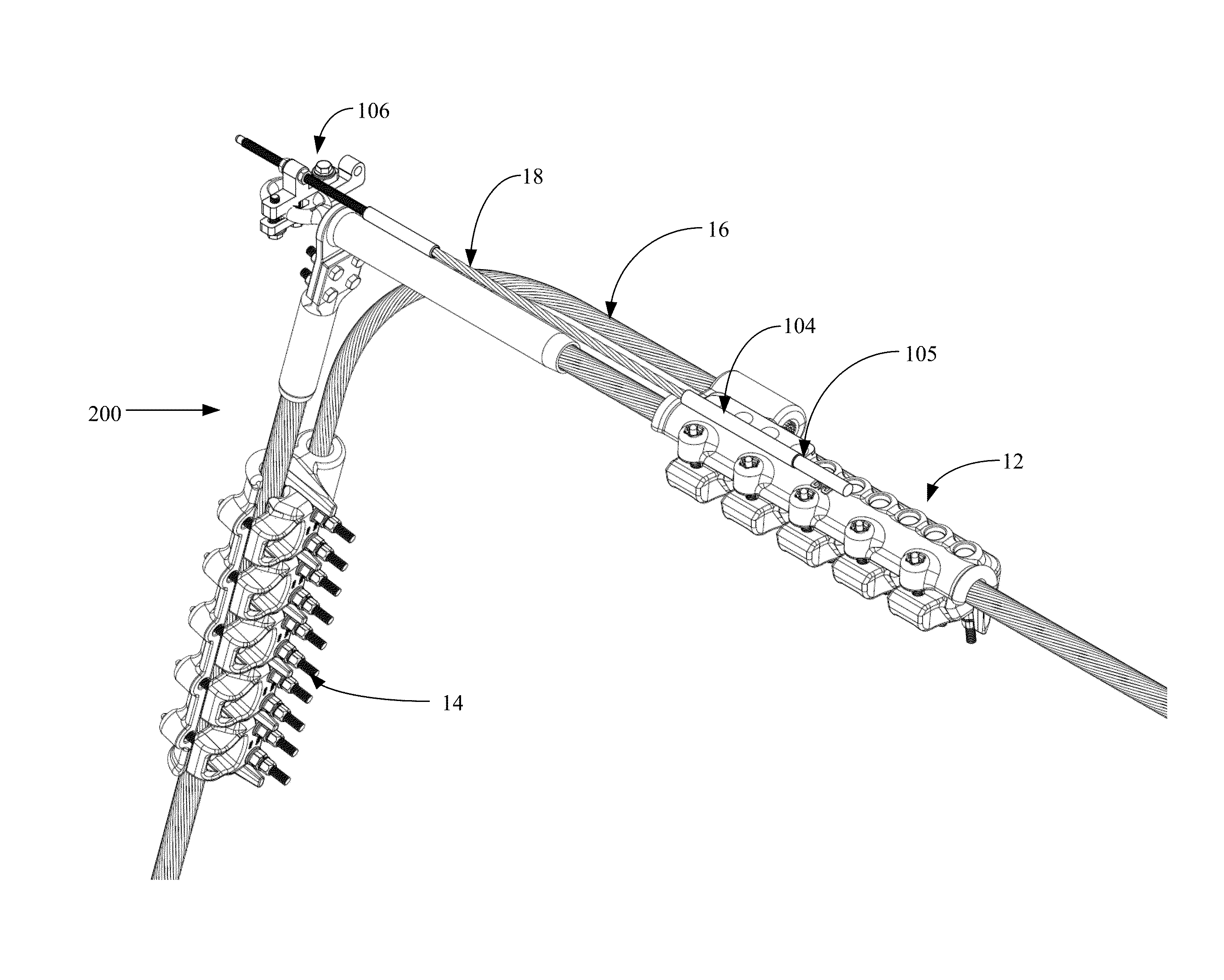

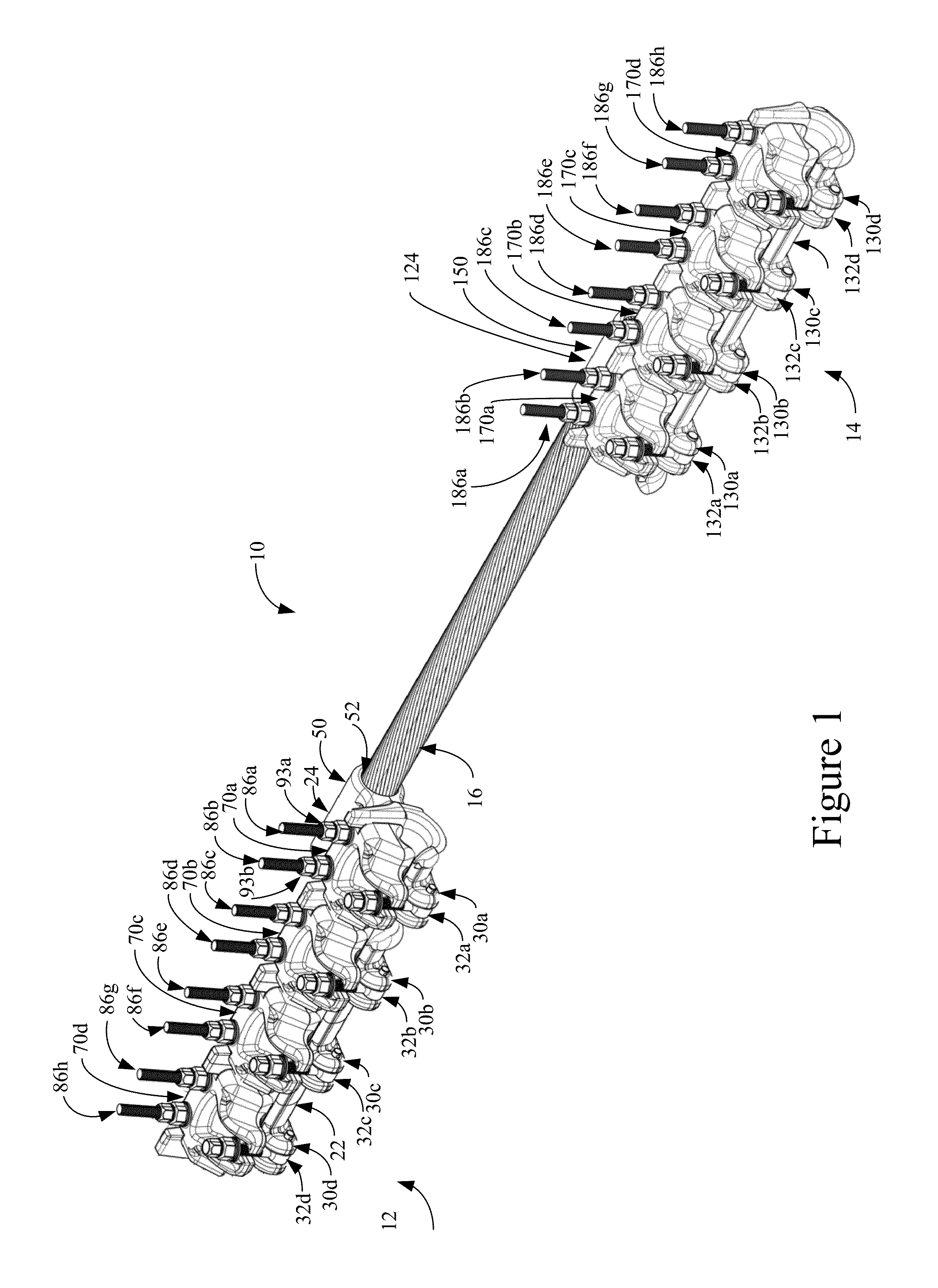

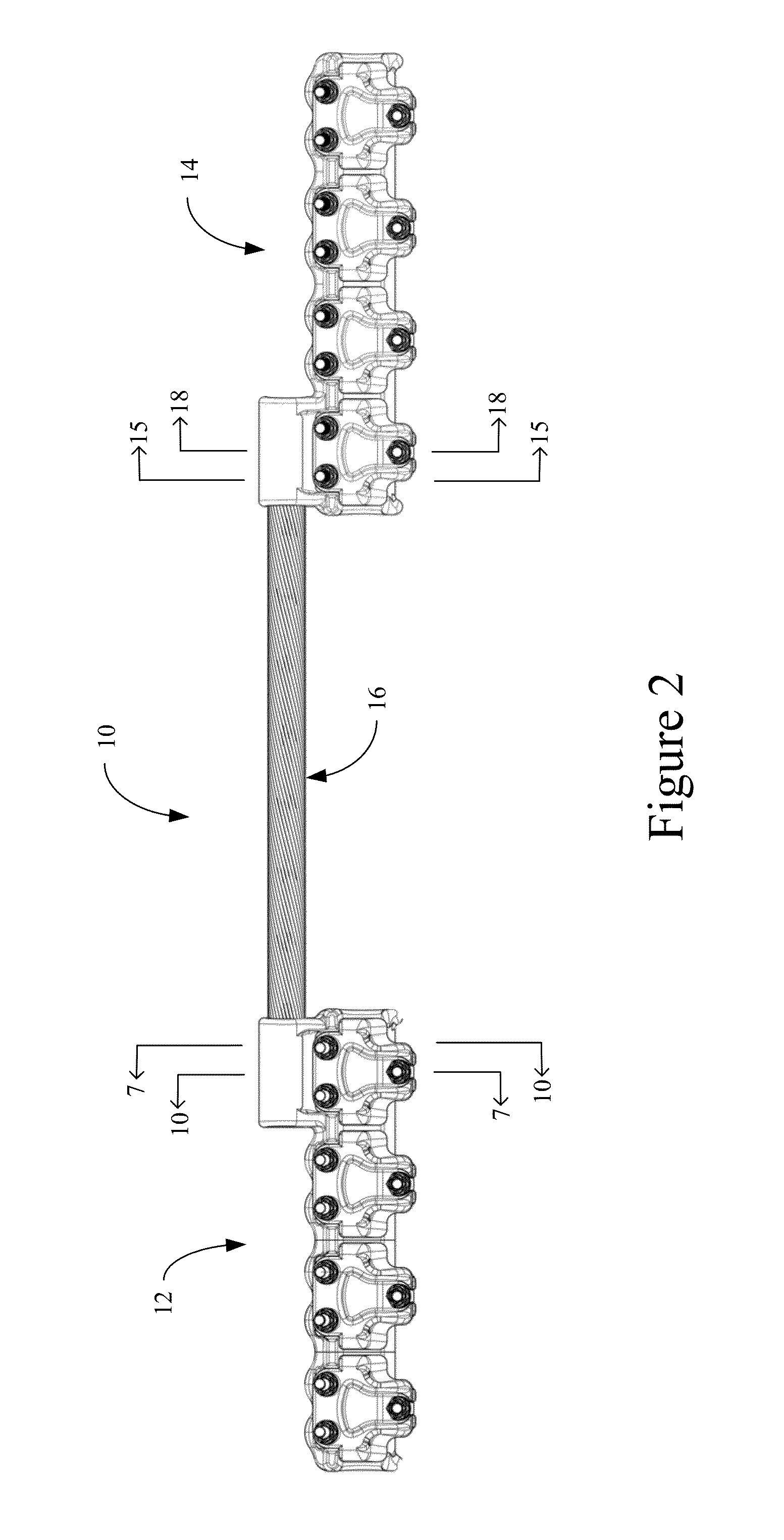

Electrical Transmission Line Repair Apparatus

ActiveUS20150255888A1Line/current collector detailsClamped/spring connectionsElectric power transmissionElectrical conductor

Owner:CLASSIC CONNECTORS

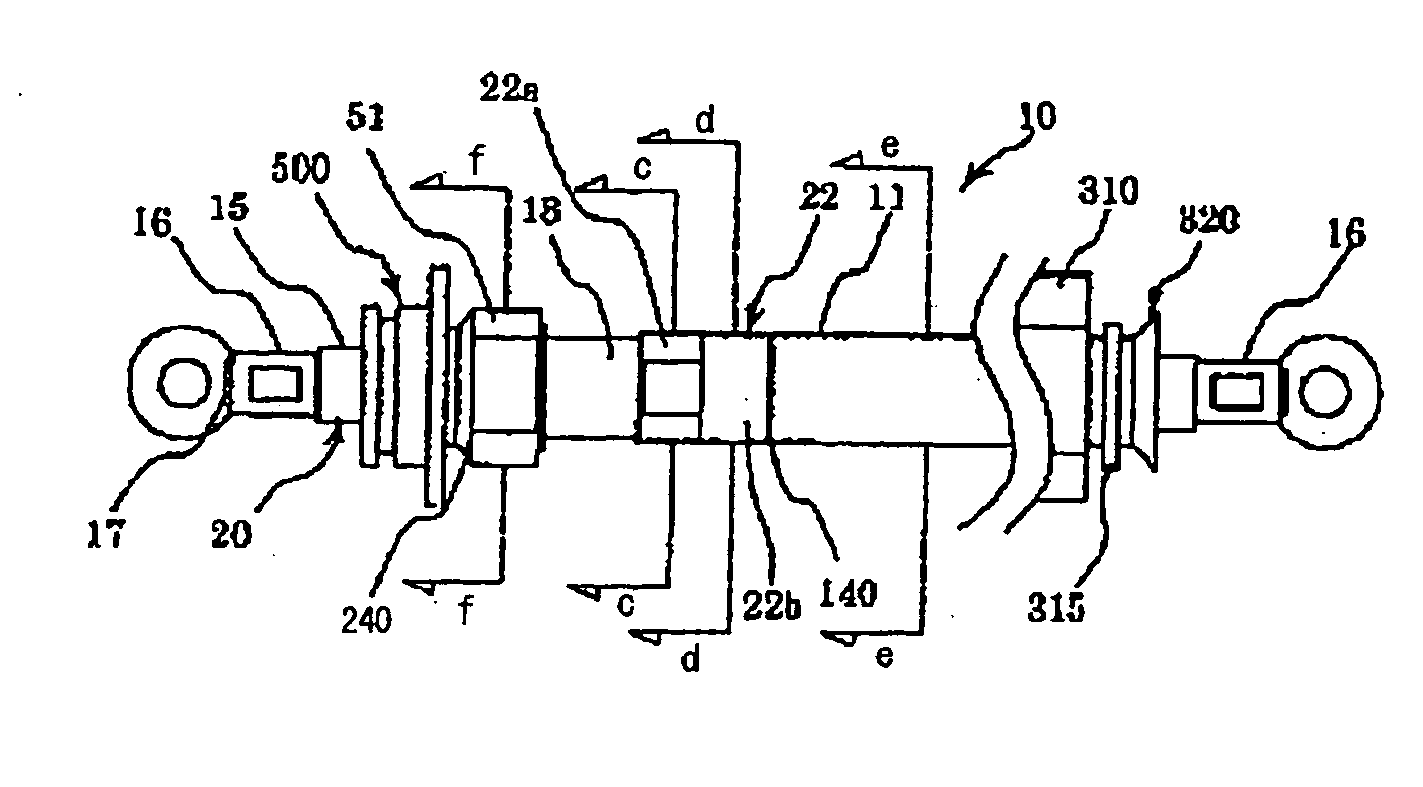

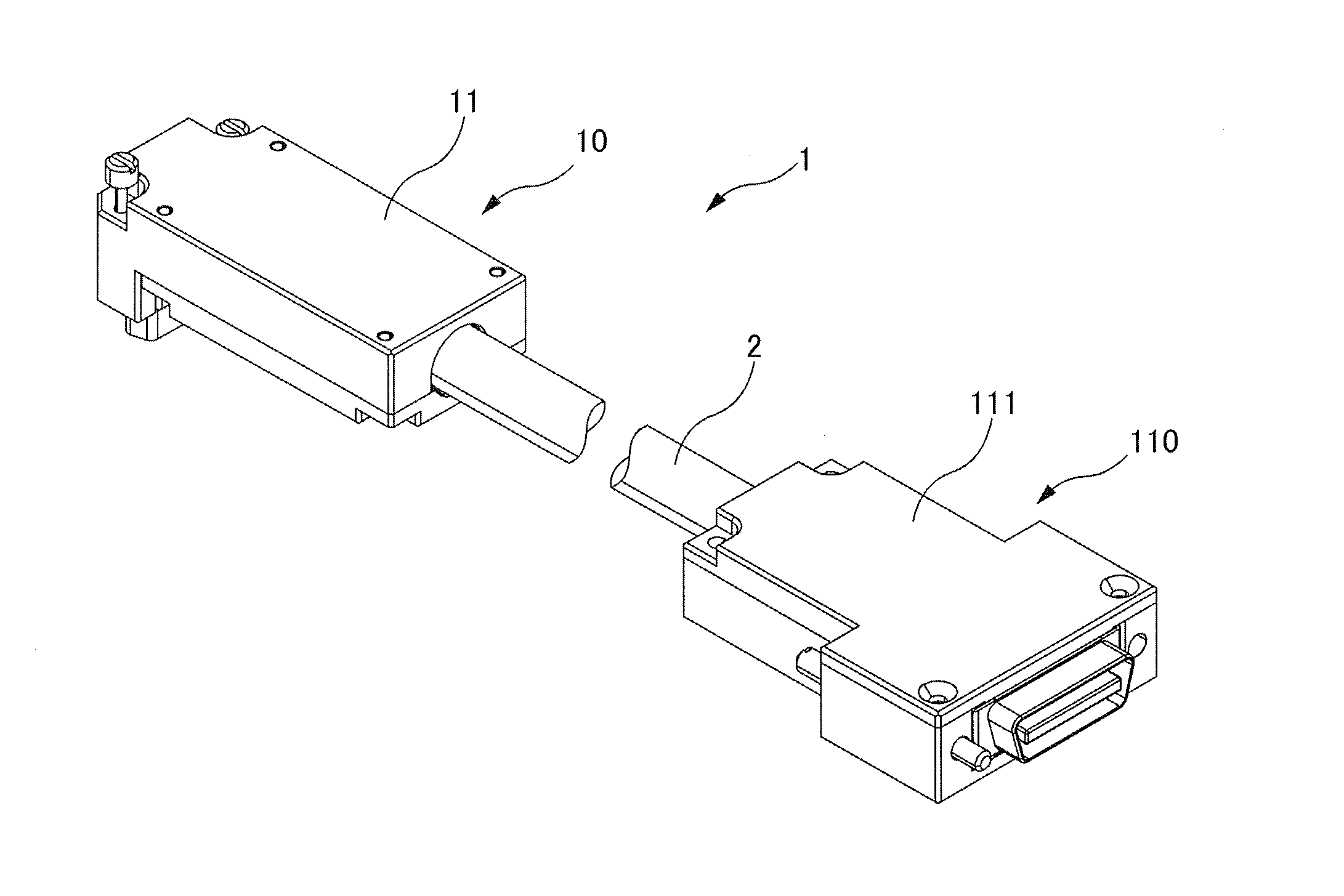

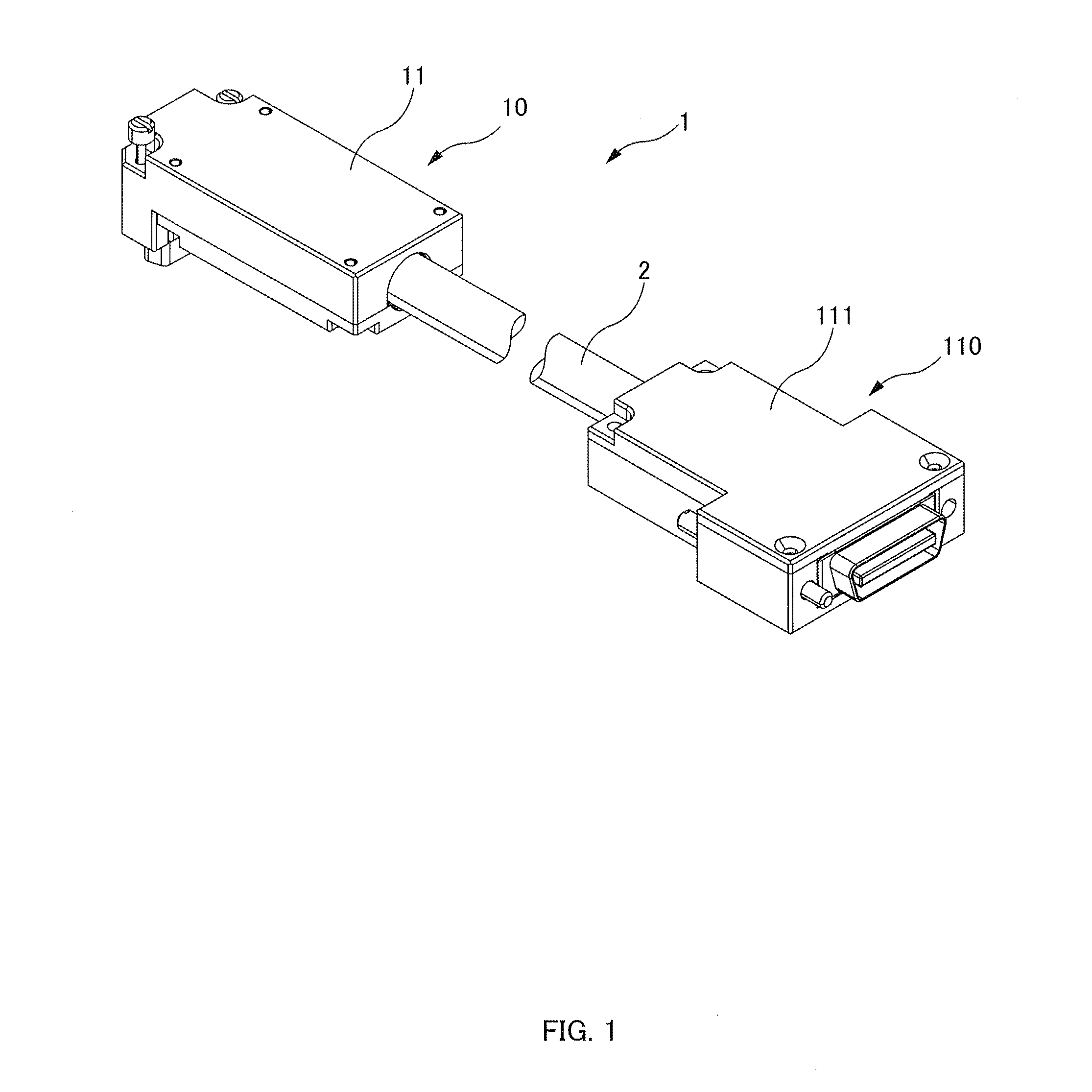

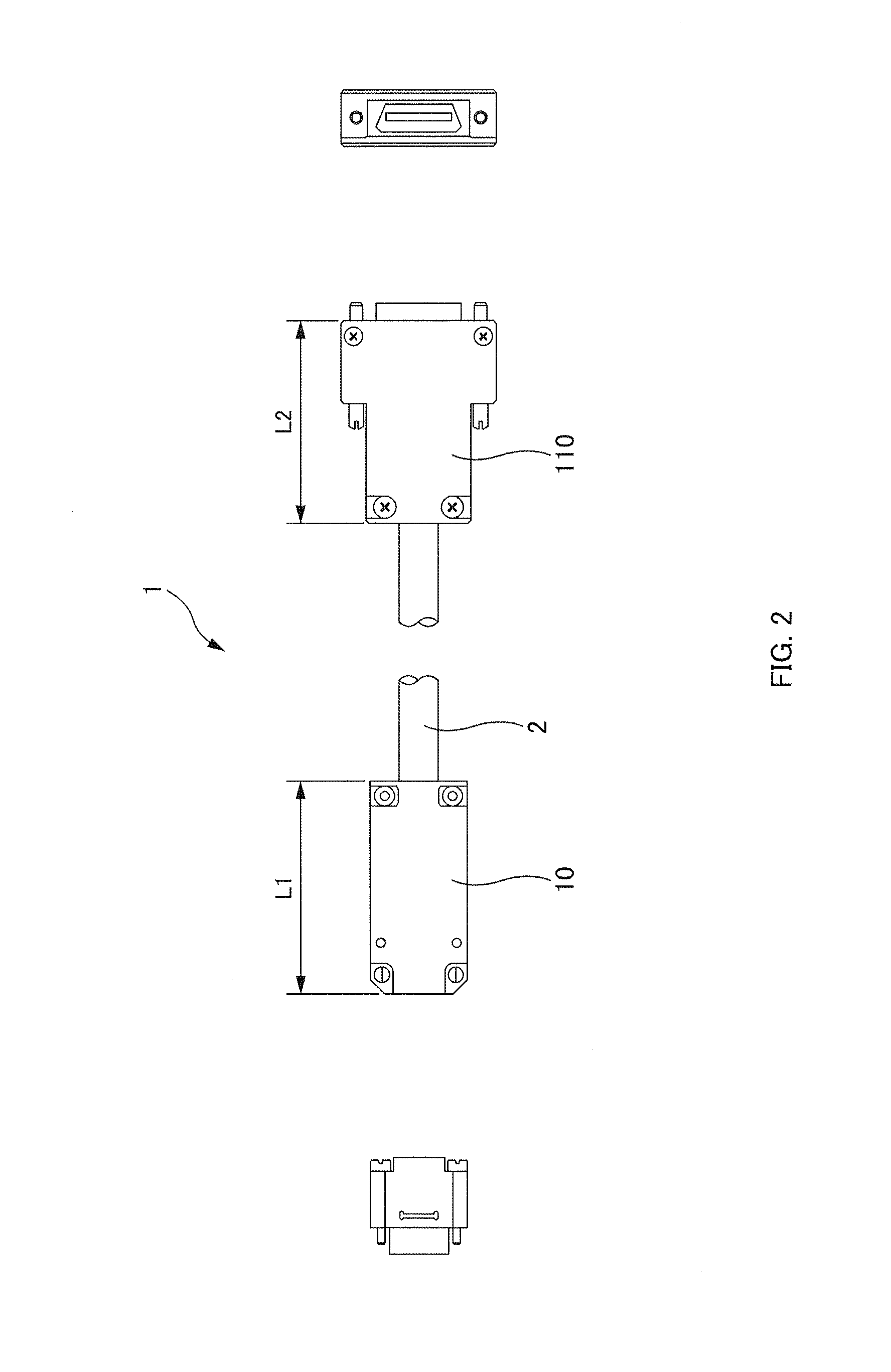

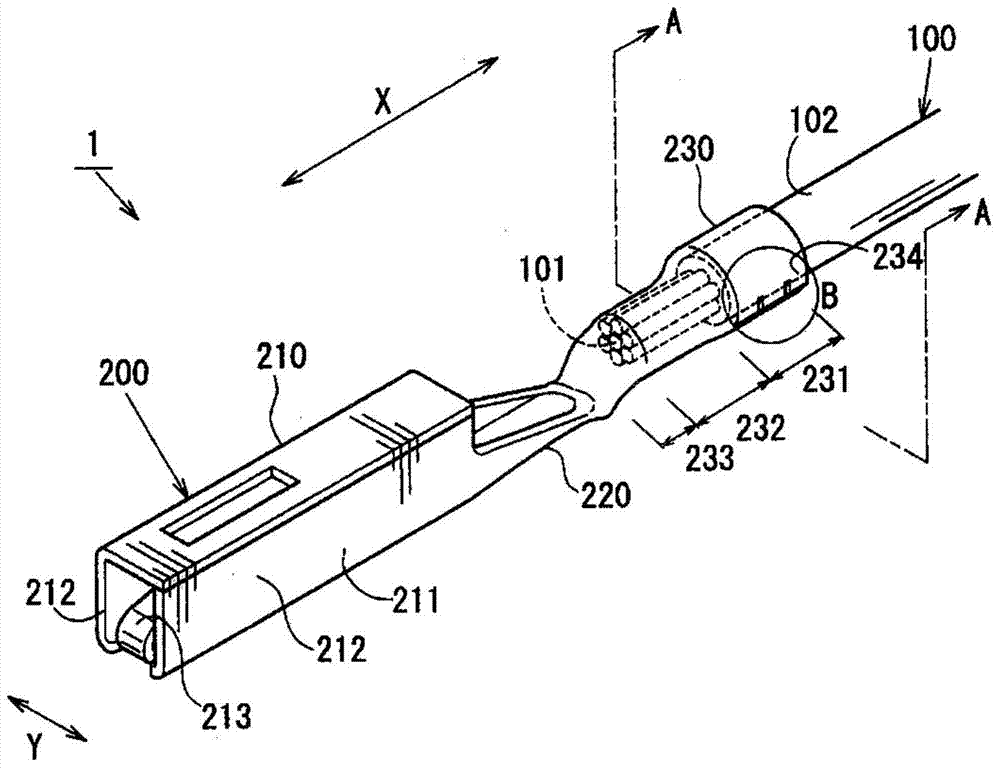

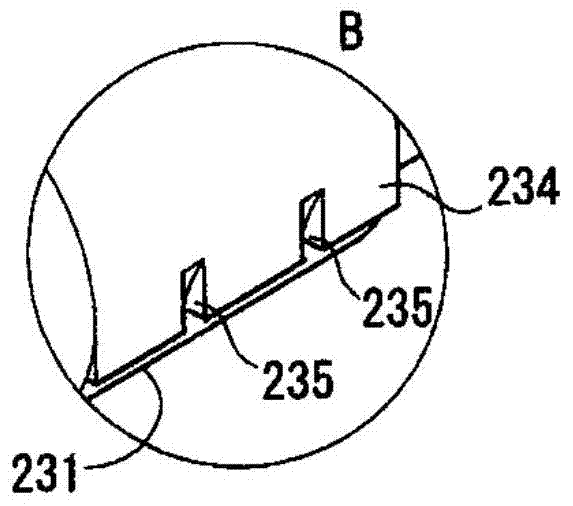

Connectored cable and method for manufacturing connectored cable

InactiveUS20130272662A1Damage suppressionLess likely to moveLine/current collector detailsCoupling light guidesEngineeringPhotoelectric conversion

Owner:THE FUJIKURA CABLE WORKS LTD

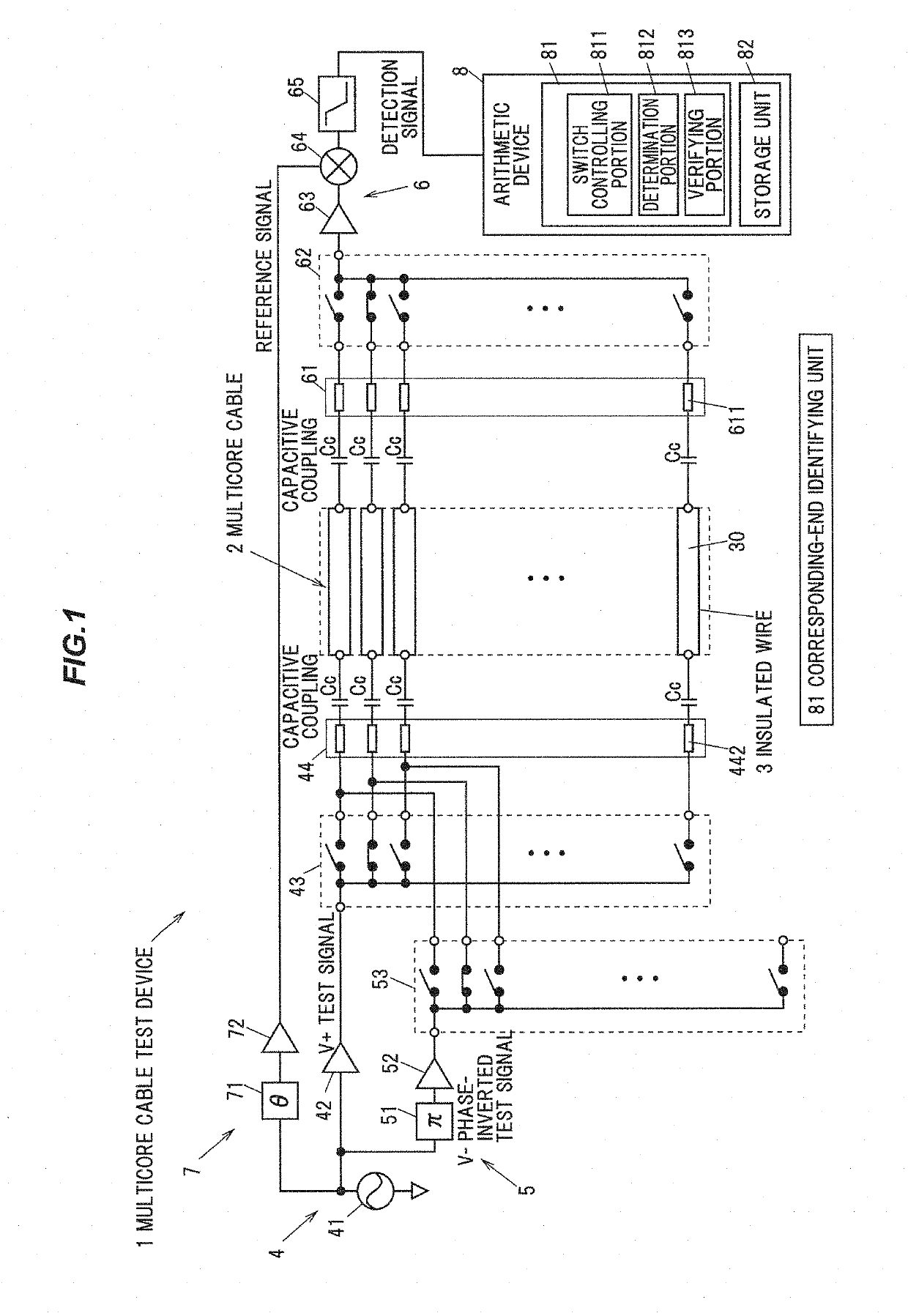

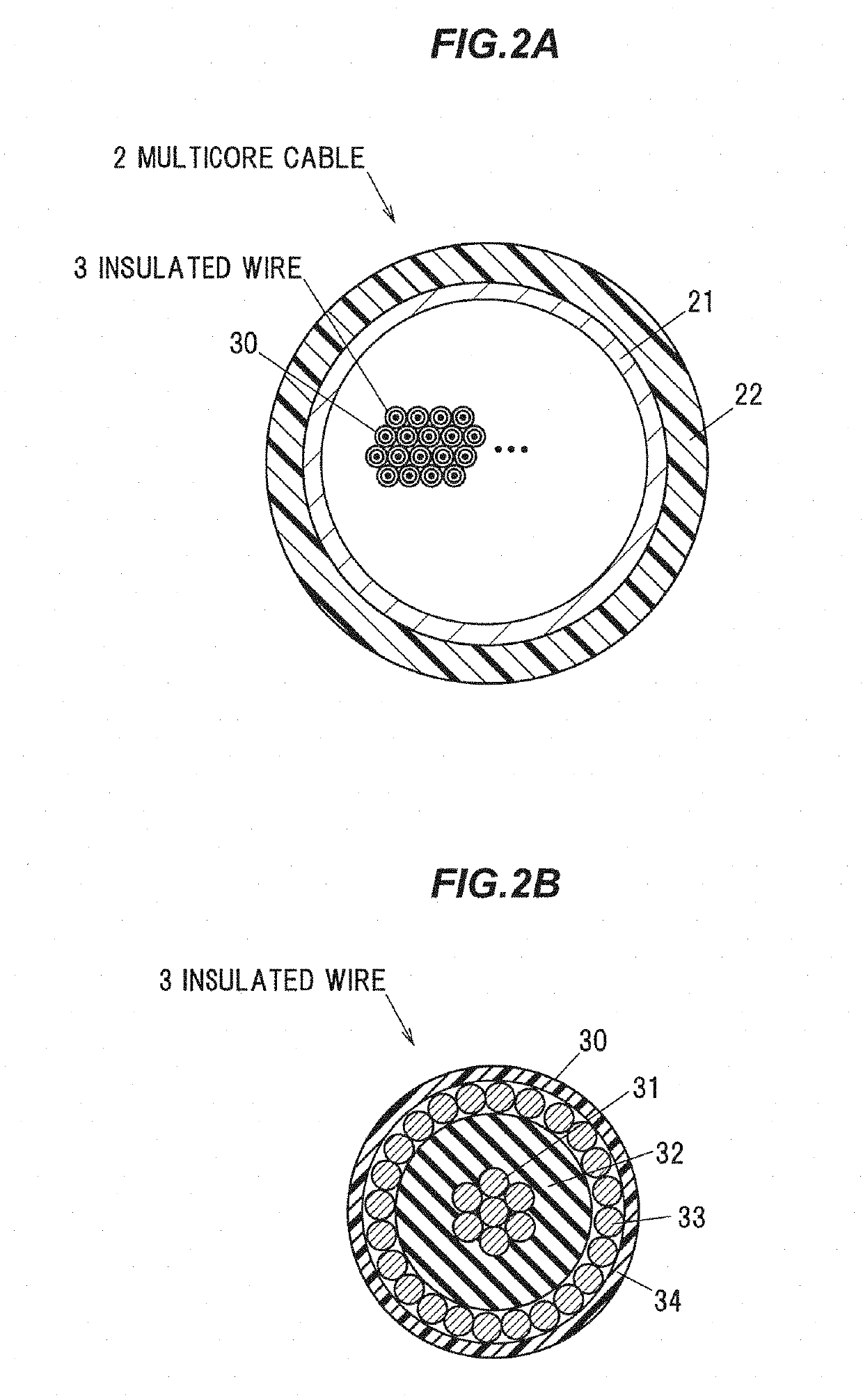

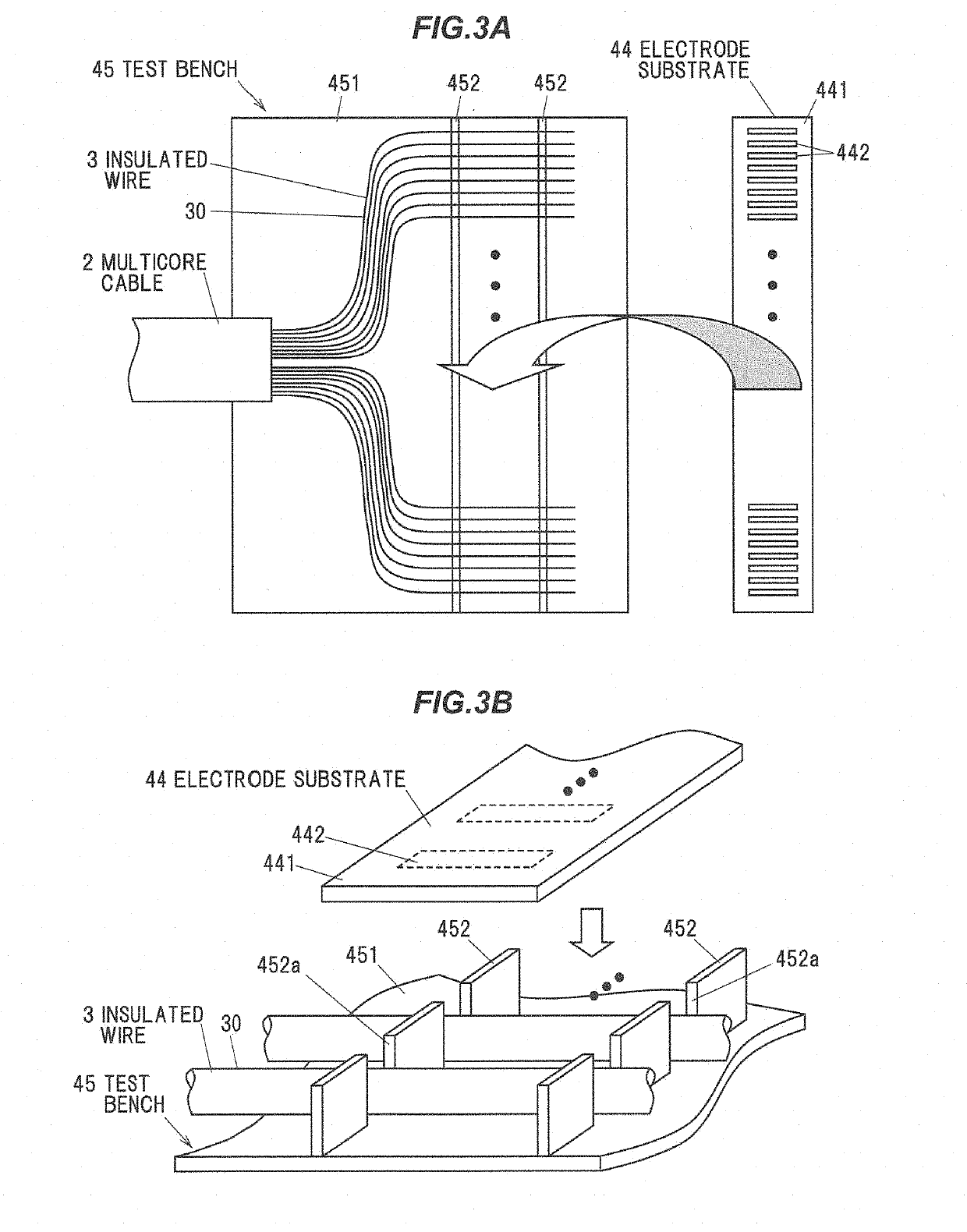

Method for testing multicore cable, method for manufacturing multicore cable assembly, and multicore cable test device

ActiveUS20190212379A1Reduce the impactLine/current collector detailsCurrent/voltage measurementCapacitive couplingCapacitance

Owner:HITACHI METALS LTD

Electric wire connection structure, method for manufacturing said electric wire connection structure, connector provided with said electric wire connection structure, and crimping die

ActiveCN104126252ASmall tightImprove water barrier effectLine/current collector detailsConnections effected by permanent deformationElectric wireElectrical wiring

Owner:FURUKAWA ELECTRIC CO LTD +1

Cable assembly

InactiveCN109449831ALine/current collector detailsApparatus for removing/armouring cablesEngineeringElectrical conductor

Owner:JIANGSU HENGHUI ELECTRICAL

Remote data acquisition device for informatization improvement of offshore oil production platform

InactiveCN113594726ARealize automatic dockingEliminates screwing operationsLine/current collector detailsElectric connection structural associationsInformatizationGear drive

Owner:深圳市云帆自动化技术有限公司

Connector

InactiveUS20050059300A1Increase resistanceEasy to operateLine/current collector detailsCoupling contact membersEngineeringMechanical engineering

Owner:POLARIS INNOVATIONS

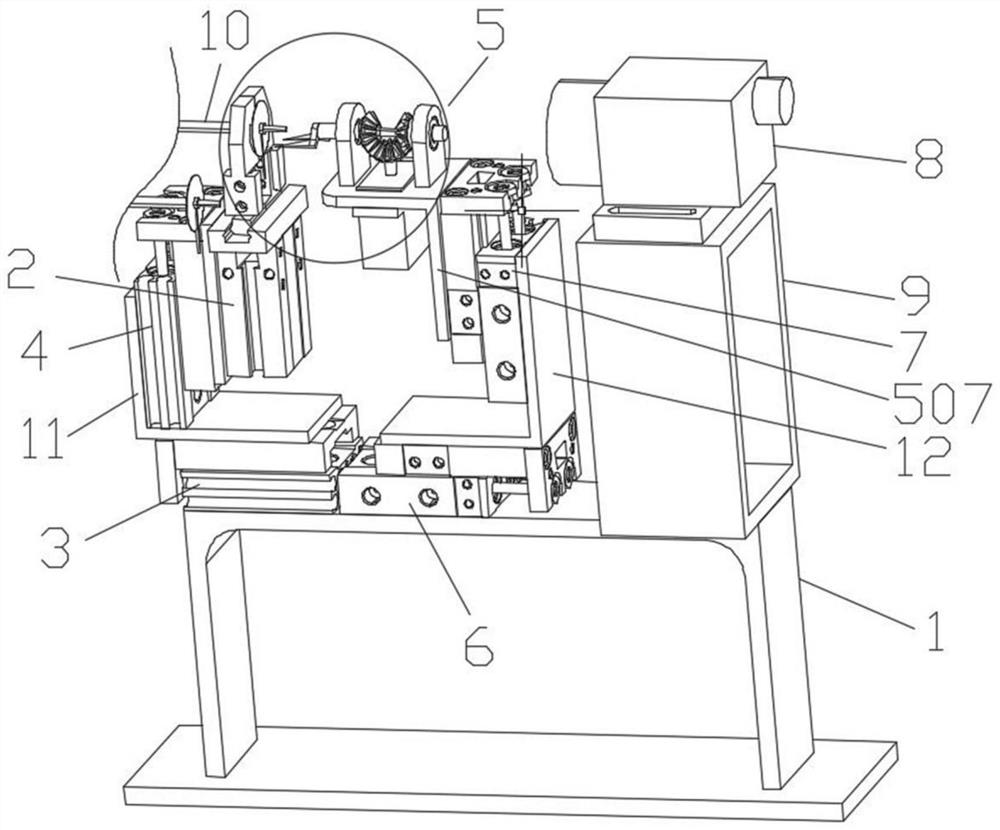

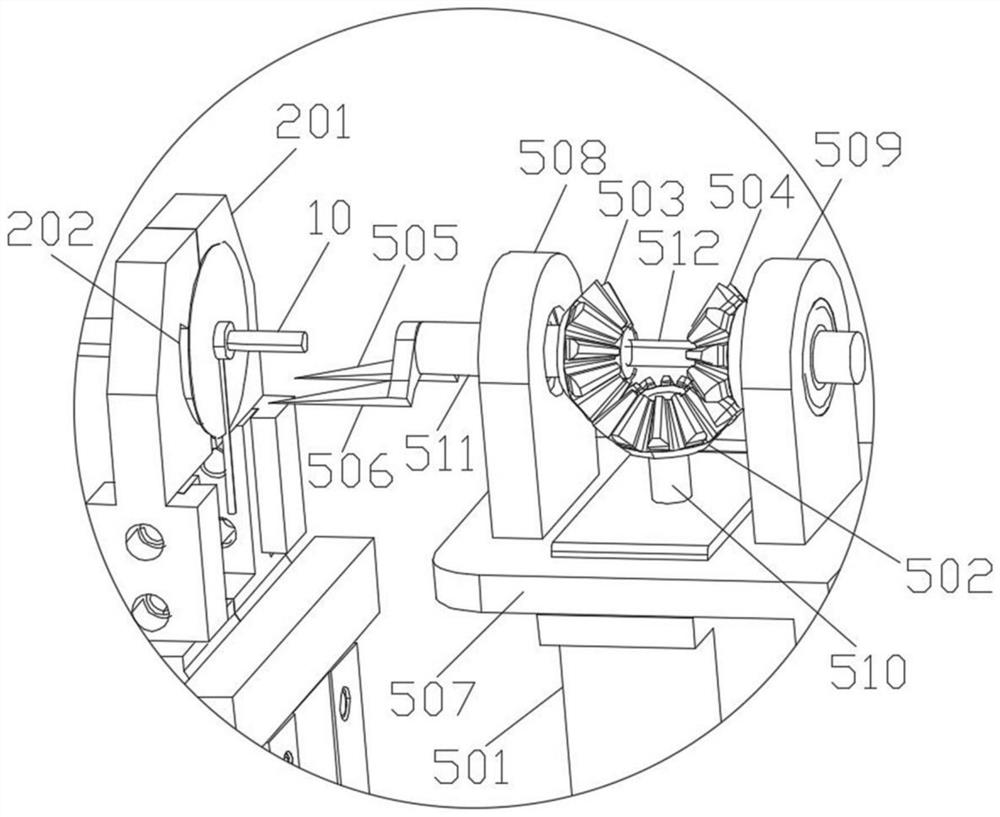

Tin soldering equipment for wiring terminal and enameled aluminum wire on straight stator

PendingCN113708179AIncrease productivityDip fully and evenlyLine/current collector detailsMegasonic cleaningStructural engineering

Owner:浙江理工大学上虞工业技术研究院有限公司 +2

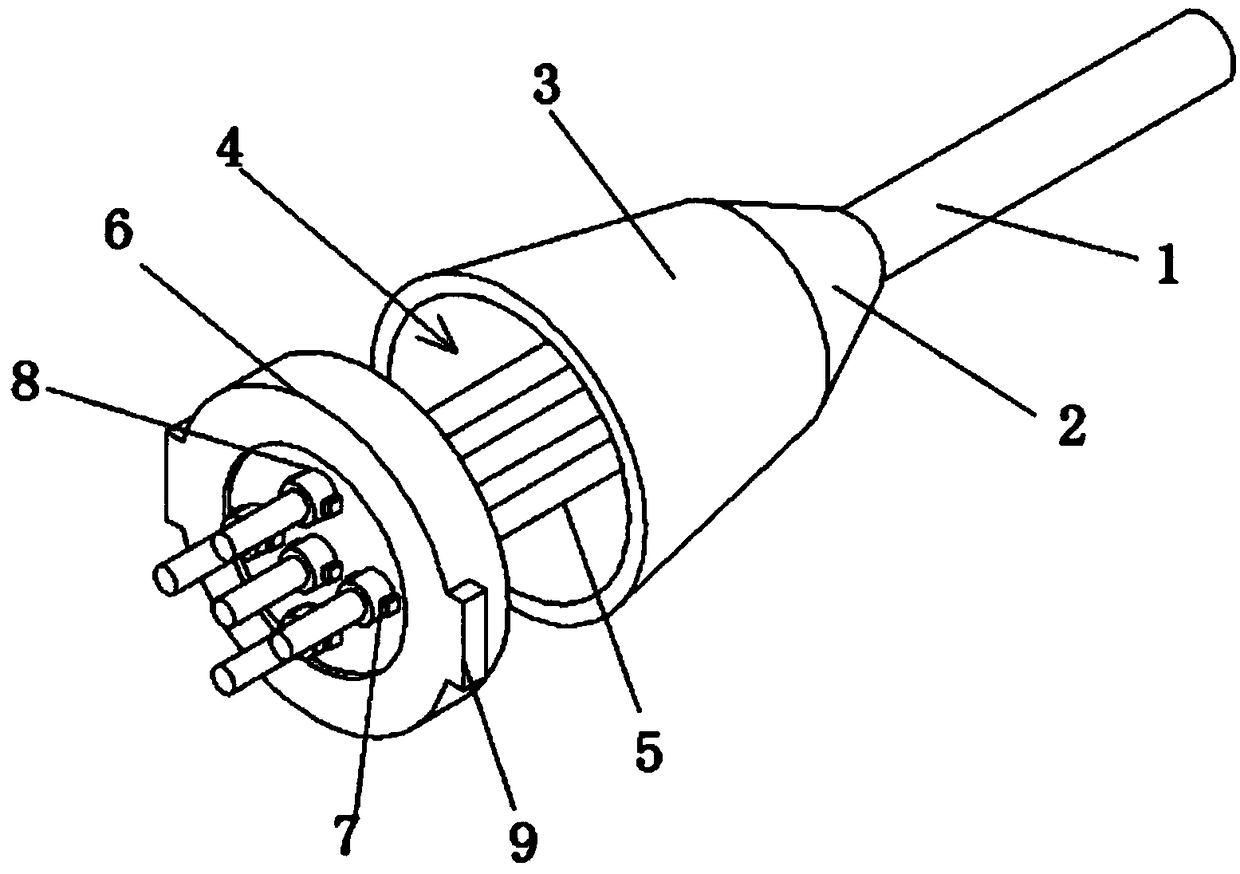

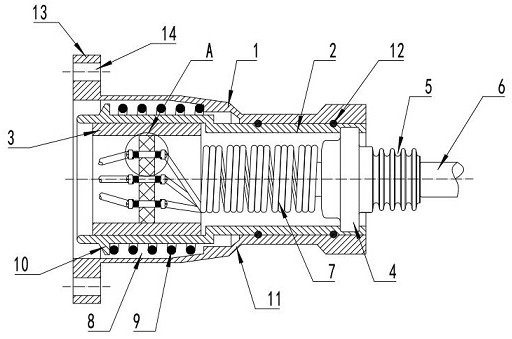

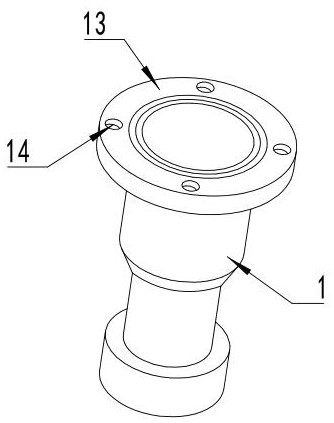

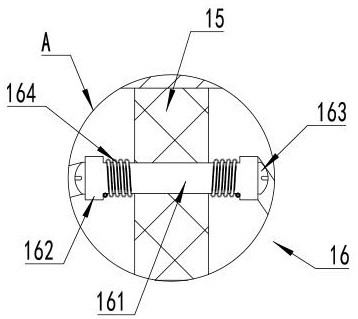

Radio frequency (RF) connector pin assembly

ActiveCN110622362ALine/current collector detailsTwo-part coupling devicesDielectricMechanical engineering

A radio frequency (RF) connector pin assembly is disclosed herein. In one embodiment, the RF connector pin assembly includes a first dielectric, a second dielectric, and a contact pin positioned in ahousing. The contact pin has a first pin section, a second pin section, and an annular collar. Axial movement of the contact pin is limited by the annular collar moving in a gap between the first andsecond dielectrics. The first pin section is adapted to provide electrical continuity with an external component, for example, a connector, and the second pin section terminates distally in a connection feature, which may be connected to an external structure, for example, a printed circuit board (PCB). The contact pin axially moves, or floats, in response to movement of the connection feature byengagement with the external structure. Multiple housings may be independently removably mounted in a block with independently movable contact pins.

Owner:CORNING OPTICAL COMM LLC

Communication cable joint structure and installation method thereof

ActiveCN112769090ALine/current collector detailsElectrically conductive connectionsControl theoryElectric cables

Owner:天津七一二移动通信有限公司

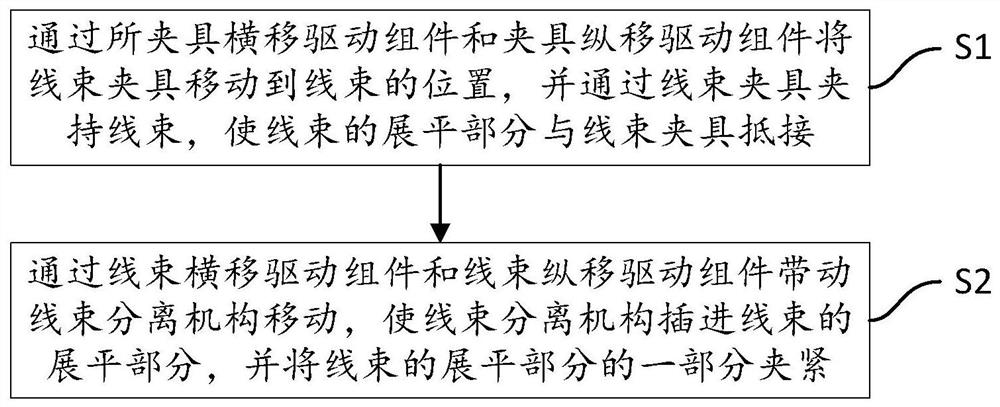

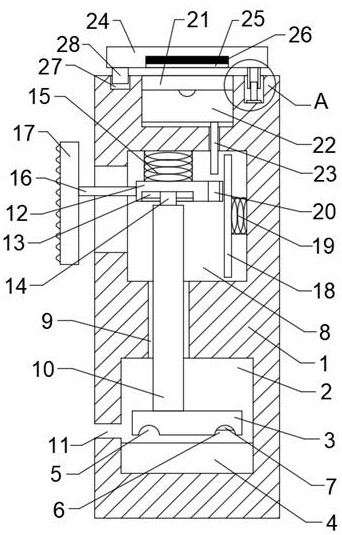

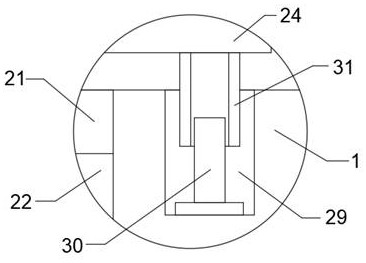

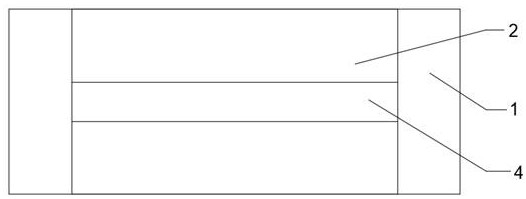

Wire harness separation system and separation method thereof

Owner:长光(滁州)高端智能装备研究院

Process for manufacturing plug-in type cable head

Owner:ZHANGJIAGANG JINHAIGANG WIRE & CABLE

Electric power wiring tool capable of preventing electric wire from being damaged

Owner:国网河南省电力公司温县供电公司

Wire end copper wire tightening apparatus for electric wire plug

PendingCN107800022AImprove securityPrevent leakageLine/current collector detailsSafety wireFly-by-wire

Owner:WUHU SHUNCHENG ELECTRONICS

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap