Shield wire, housing connected with same, connecting method thereof and shield wire unit

a shield wire and shield wire technology, applied in the field of shield wire, can solve the problems of vibration and heat, poor bending property of conventional shield wire 350, and poor handing property when subjected to vibration and heat, and achieve good bending property, shock resistance, and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

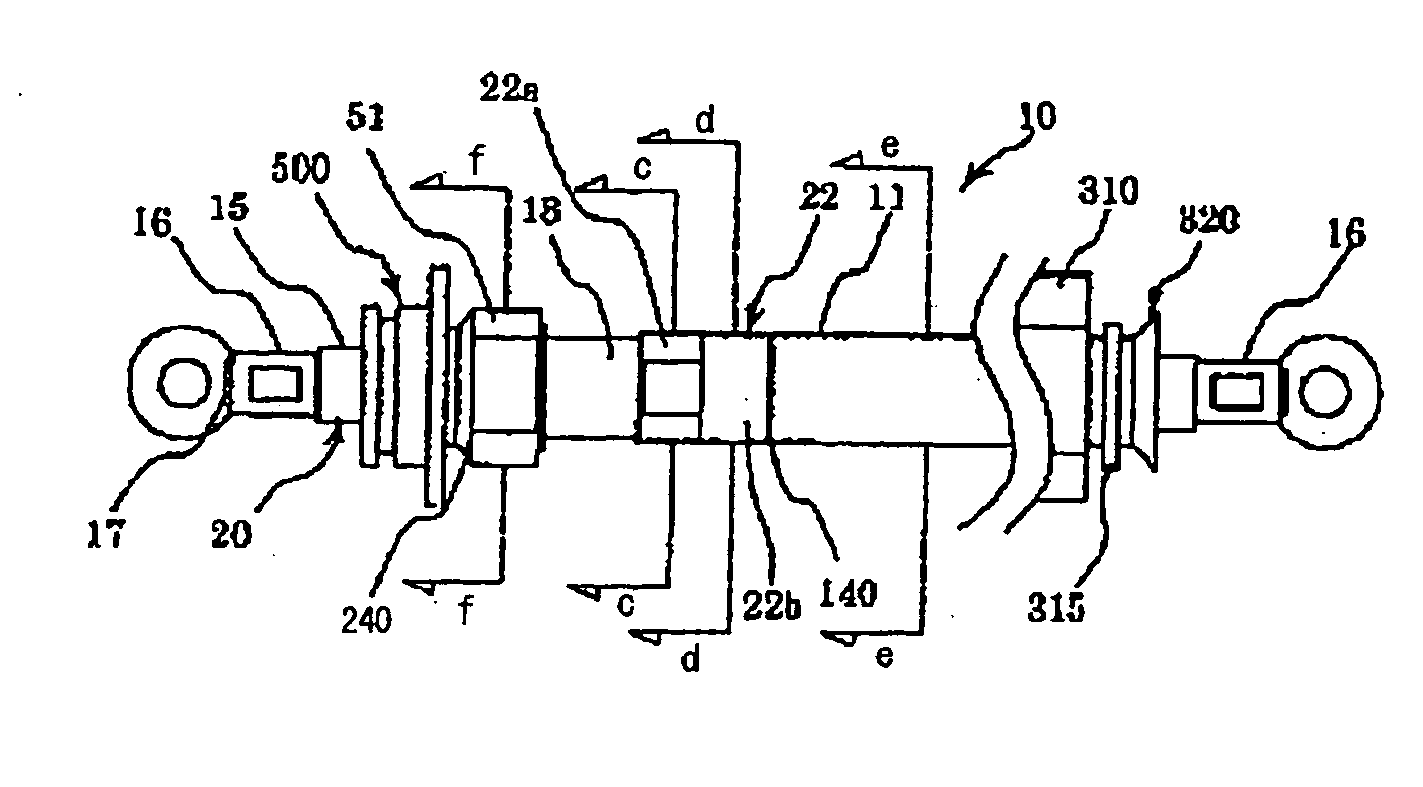

[0111]FIG. 6 is a plain view showing a shield wire in the preferred embodiment of the invention.

Composition of Shield Wire

[0112] As shown, the shield wire of this embodiment is composed such that a shield member is disposed around a wire main body 20 that a conductor 17 formed of single wire or stranded wire is covered with an insulation 15. The shield wire is provided with connection terminals 16, 16 at its both ends. One of the connection terminals 16, 16 (on the left side in FIG. 6) is connected to an inverter side as described later, and the other (on the right side in FIG. 6) is connected to a transmission side as described later.

Shield Member

[0113] The shield member is composed of a tubular body 50 as shown in FIG. 10 and a metal pipe 11 as shown in FIG. 16. The shield member is formed by abutting the tubular body 50 to the metal pipe 11 and then electrically connecting the tubular body 50 through a weld portion to the metal pipe 11. As shown in FIGS. 10 and 11, the tubular

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap