Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about "Electrically conductive connections" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

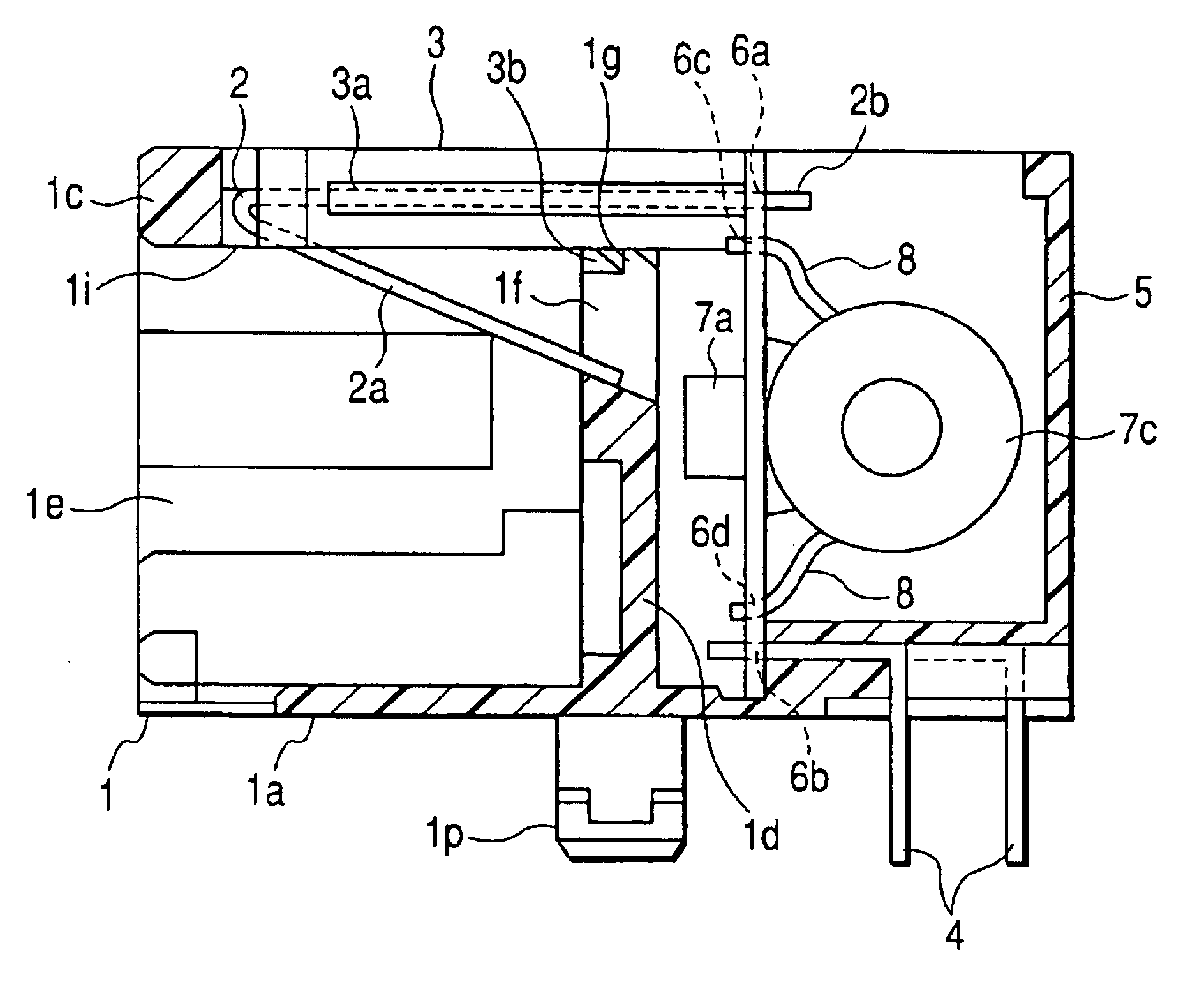

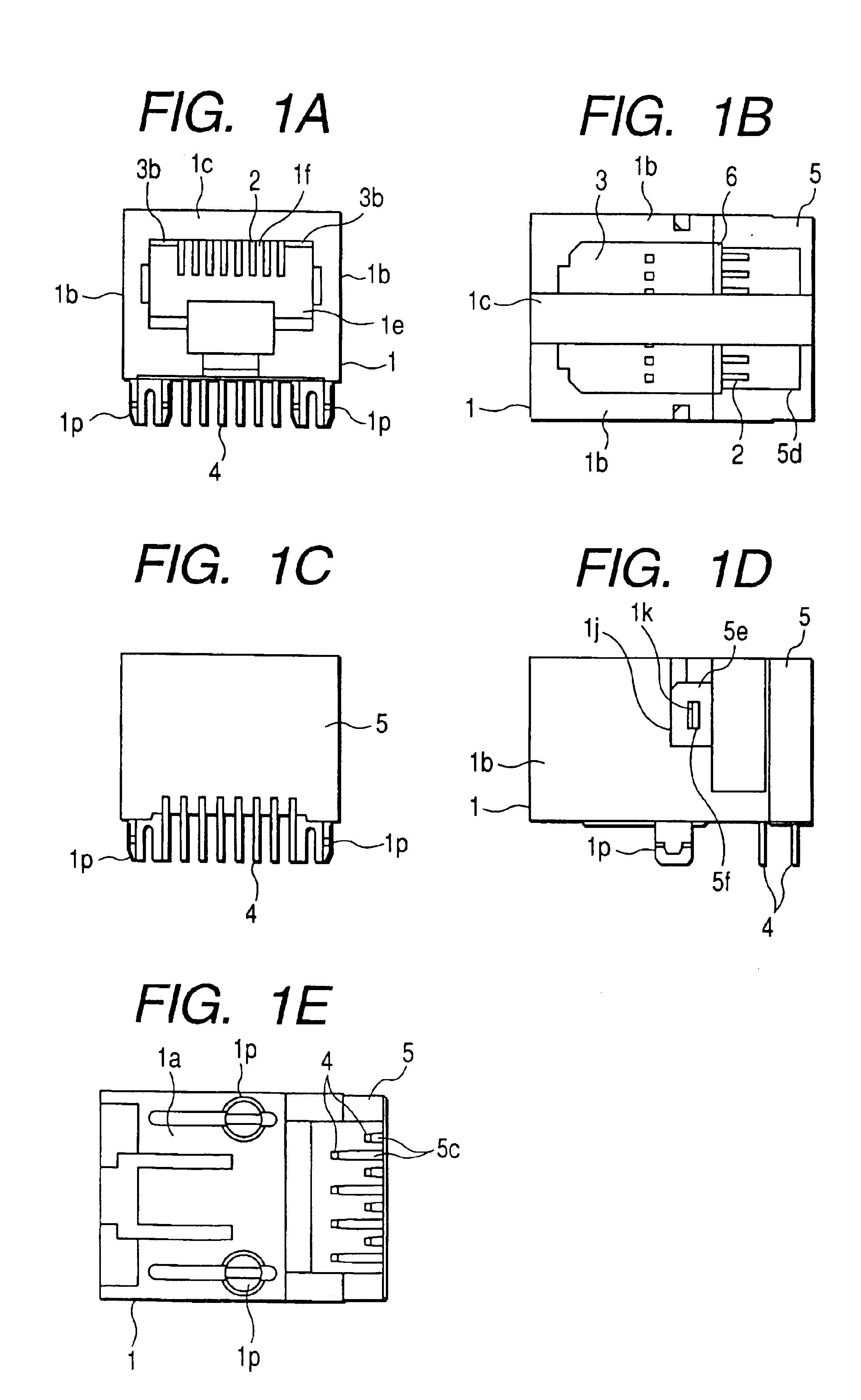

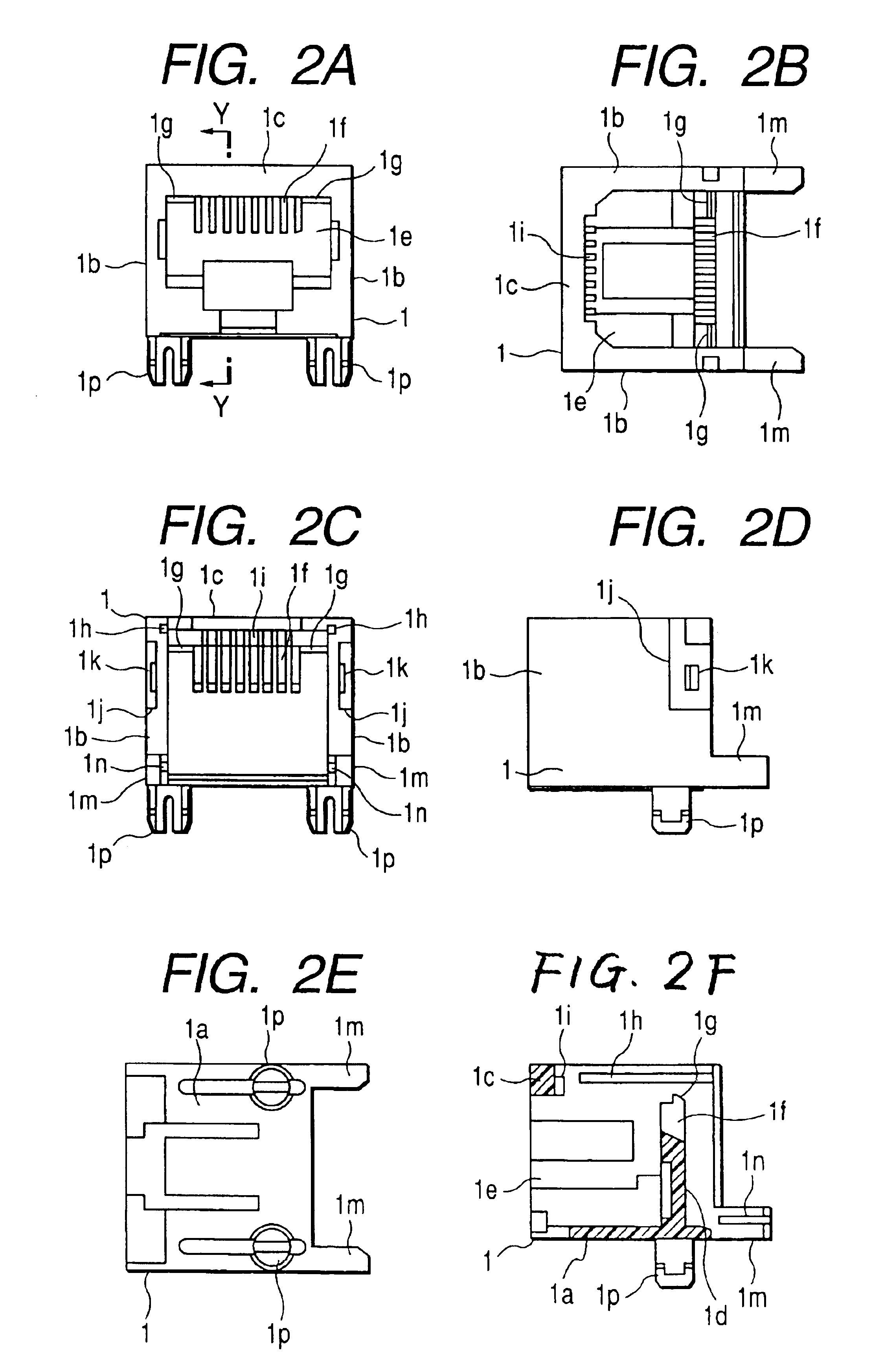

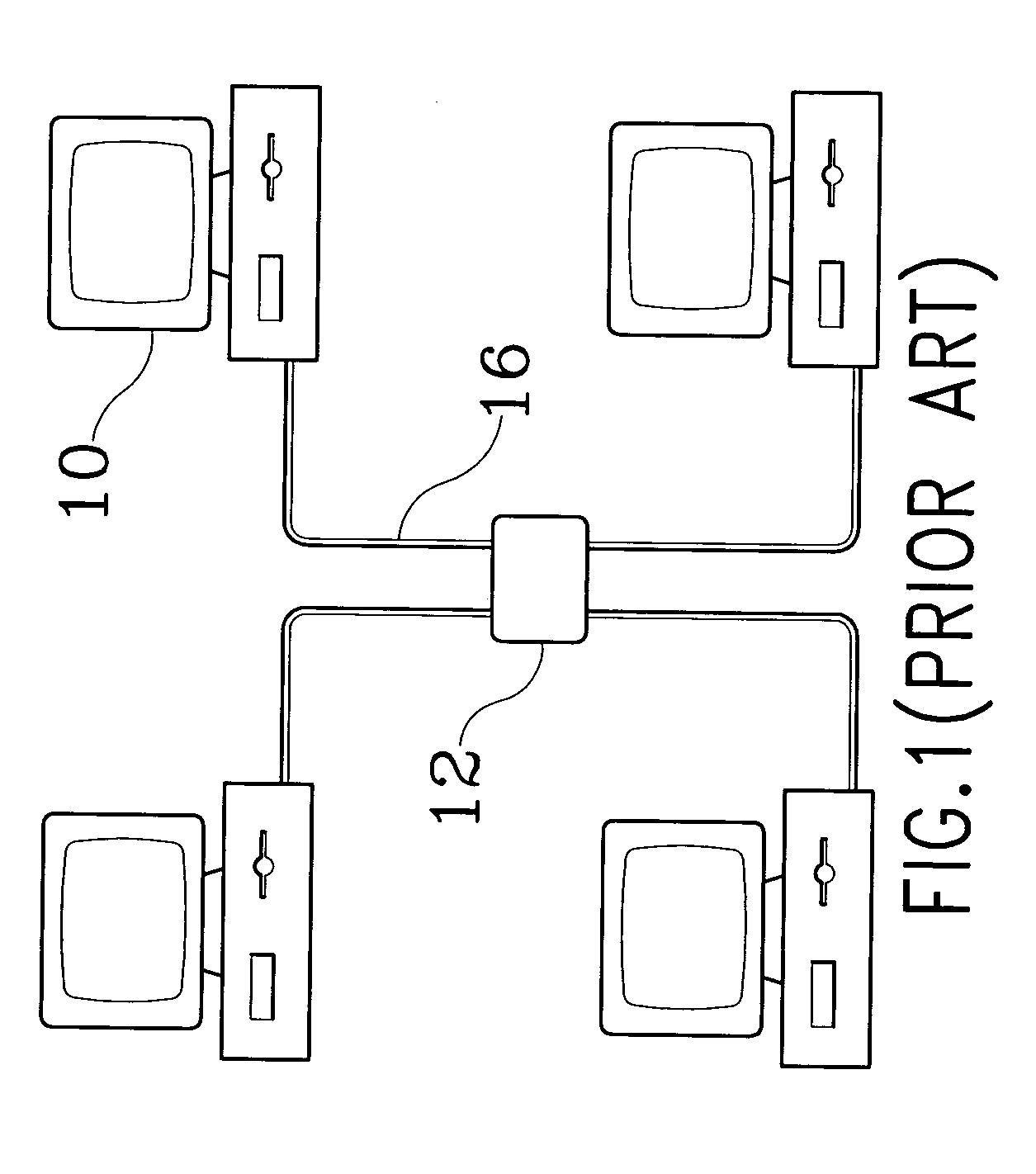

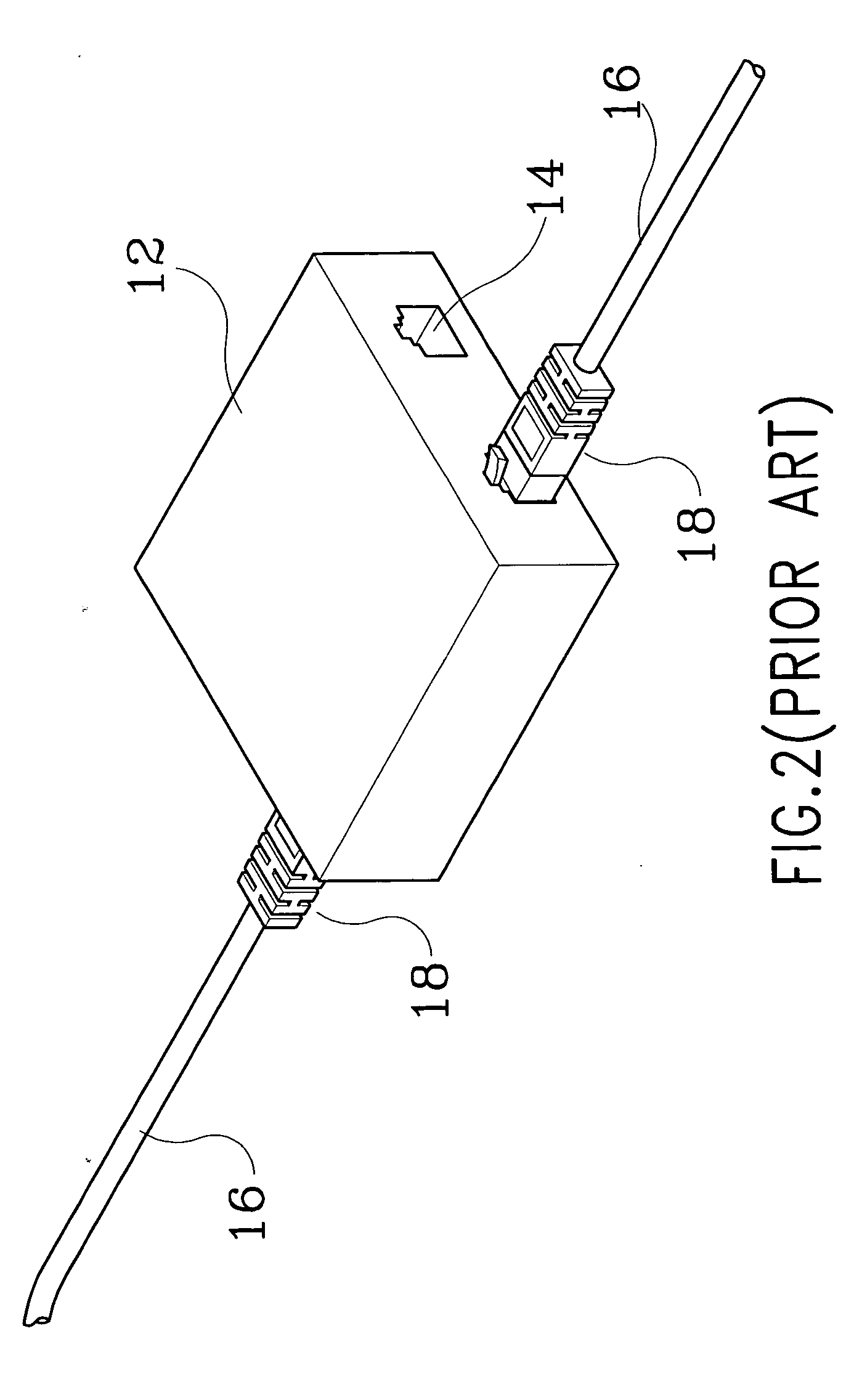

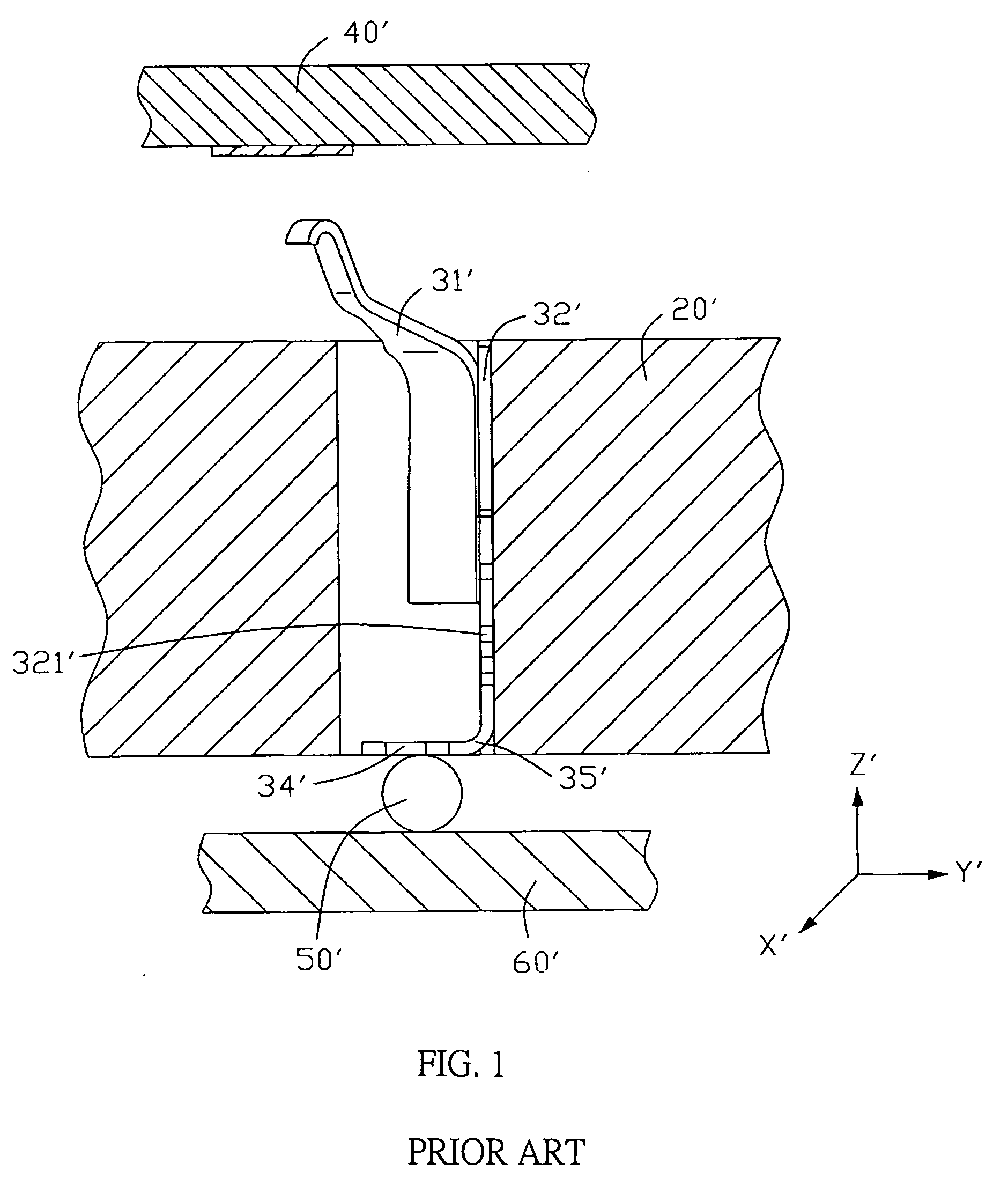

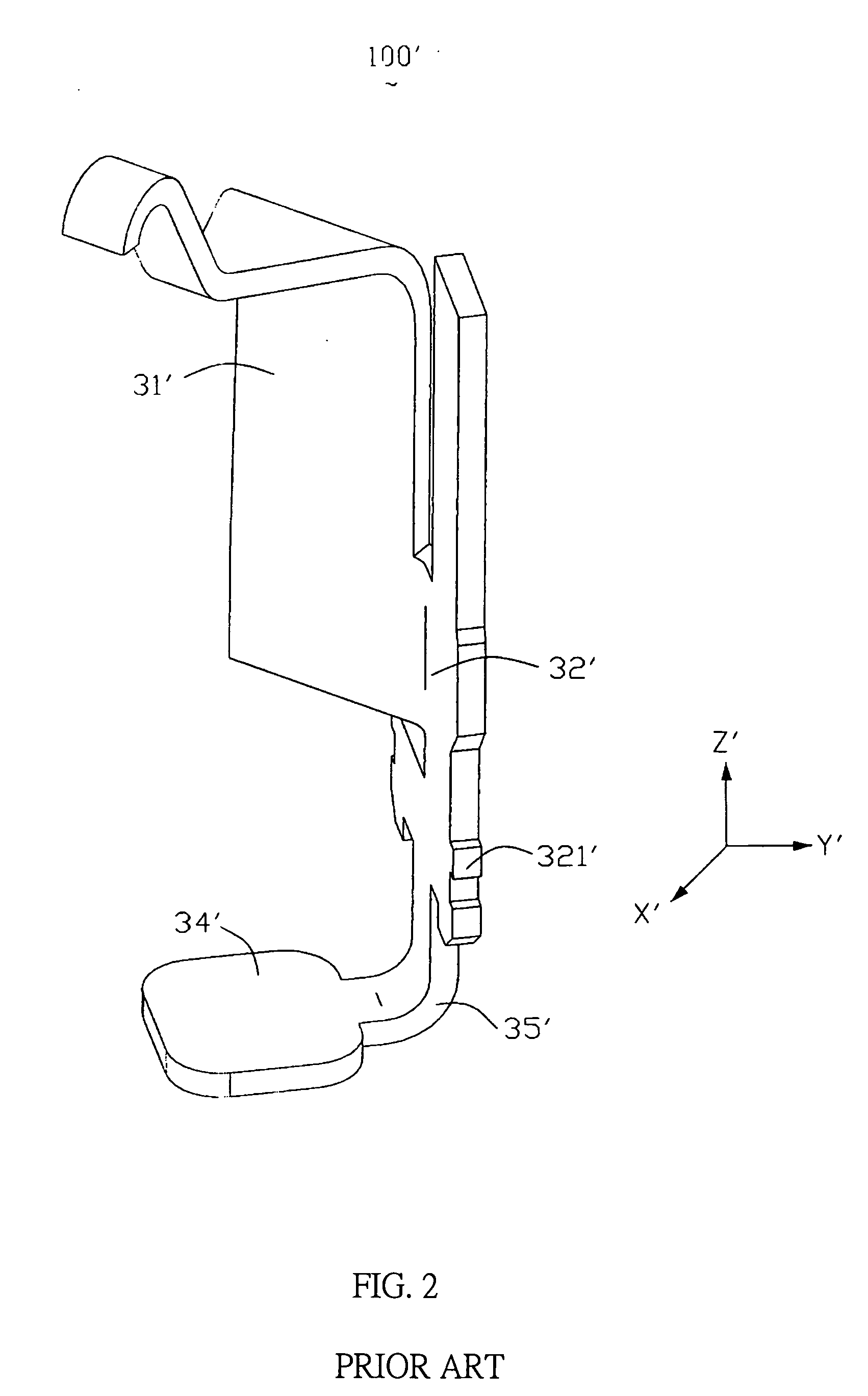

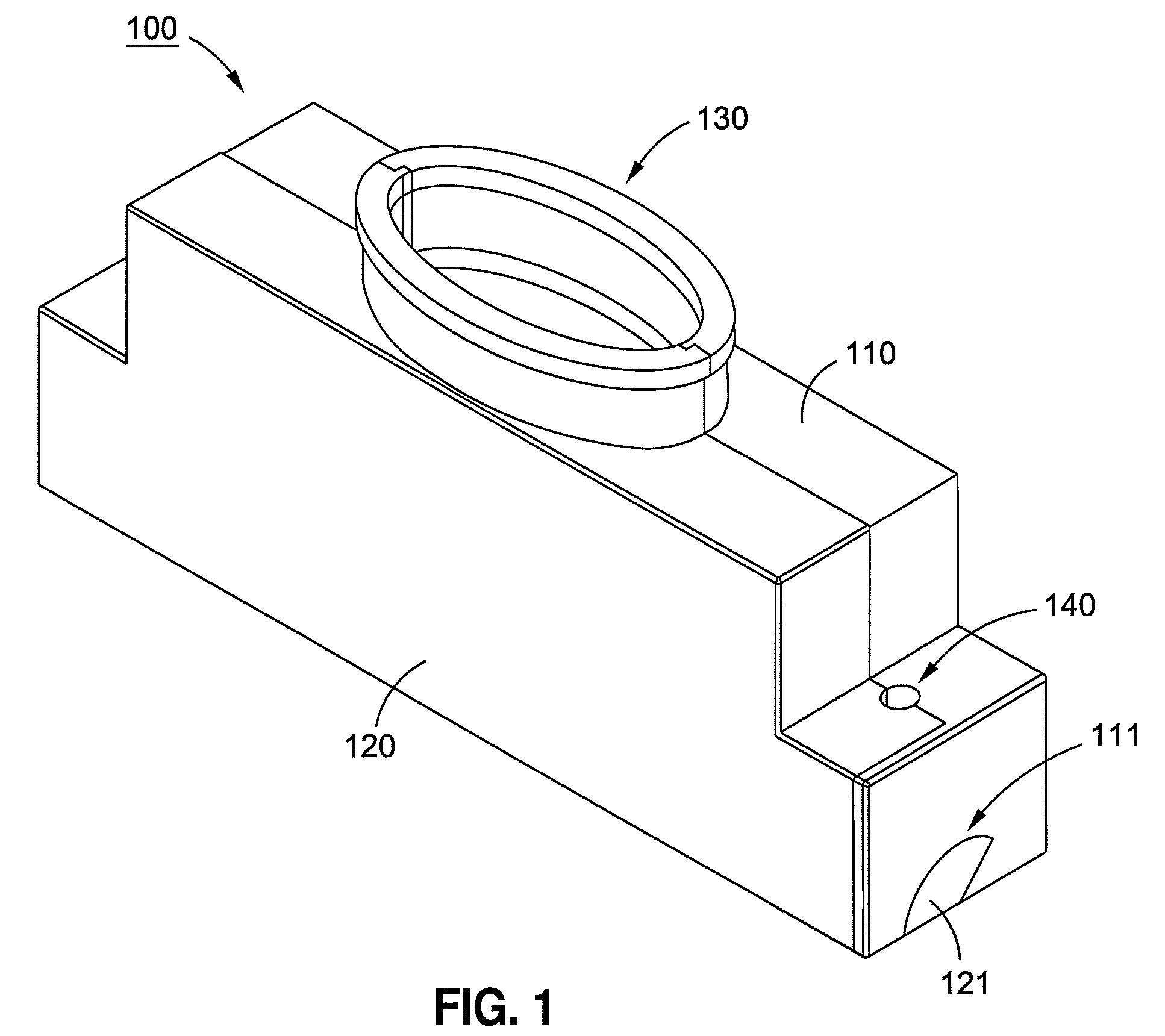

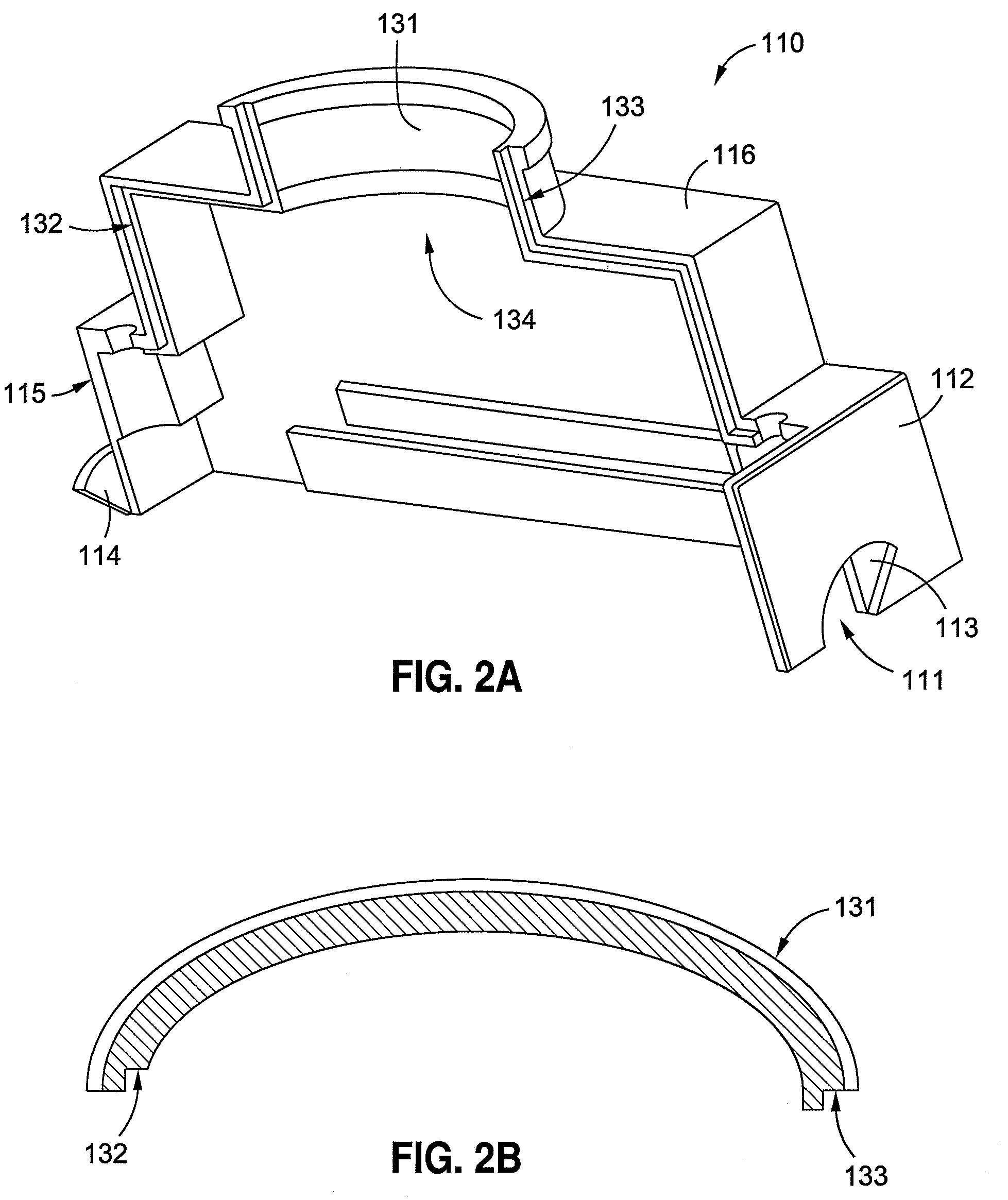

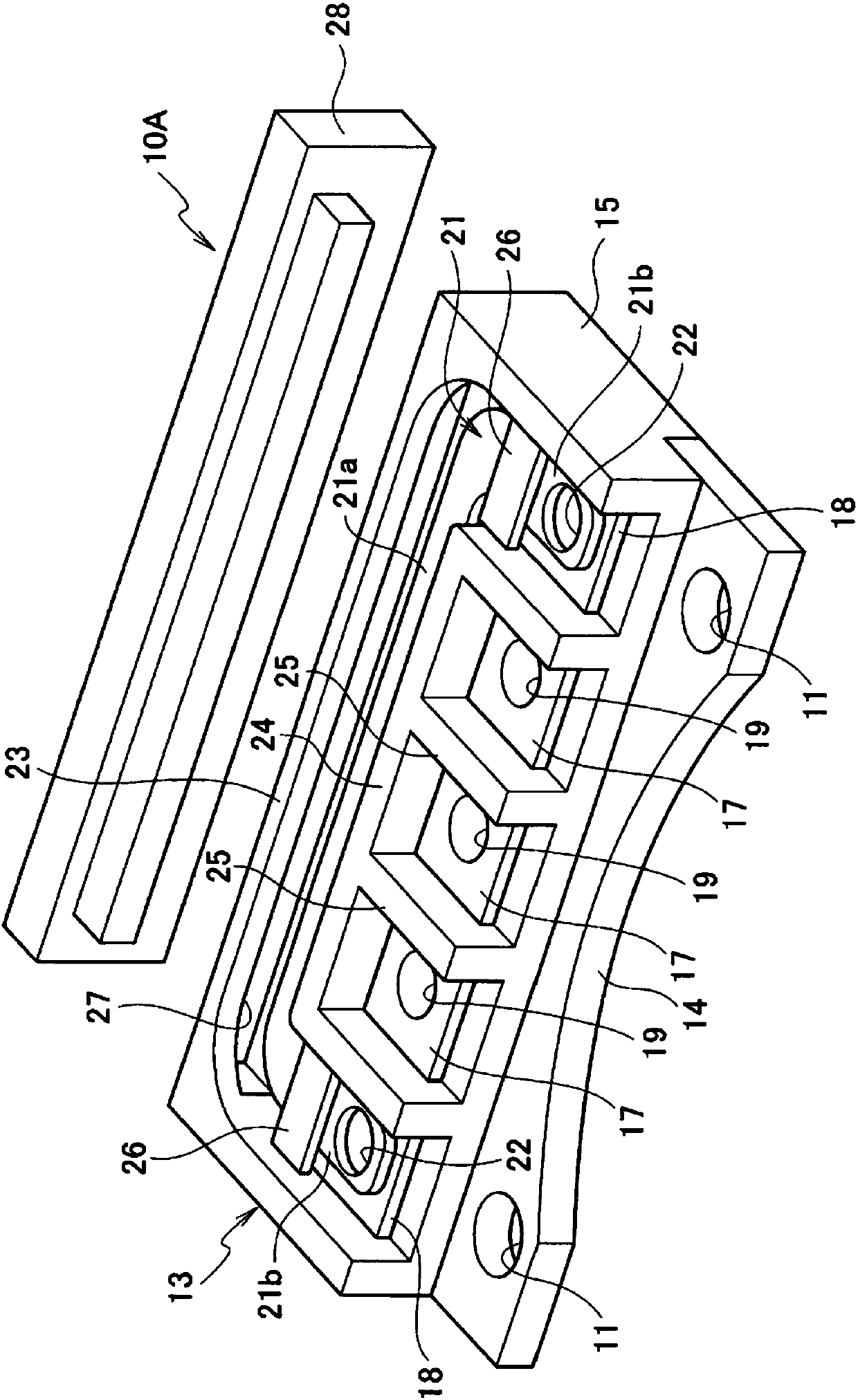

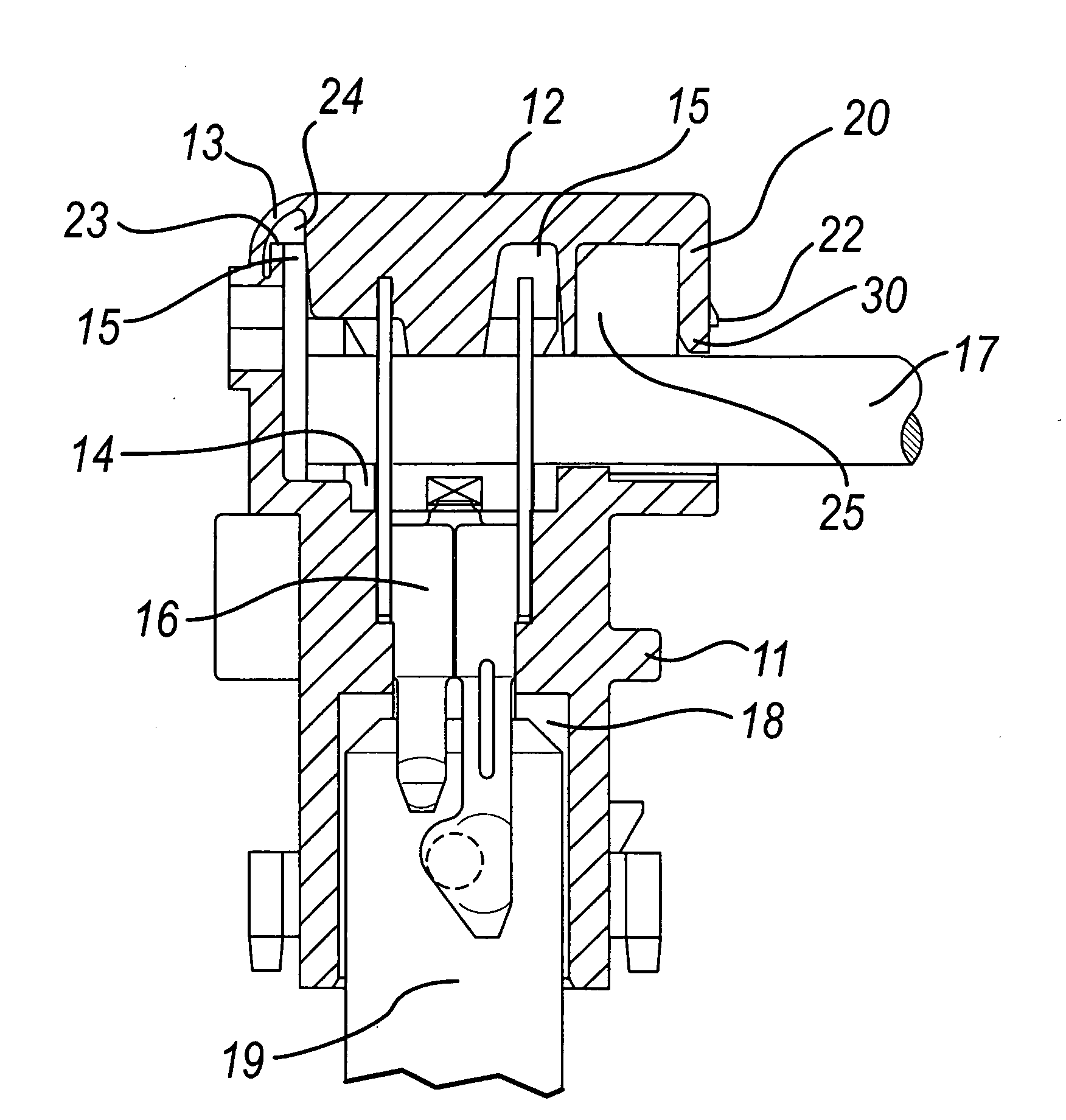

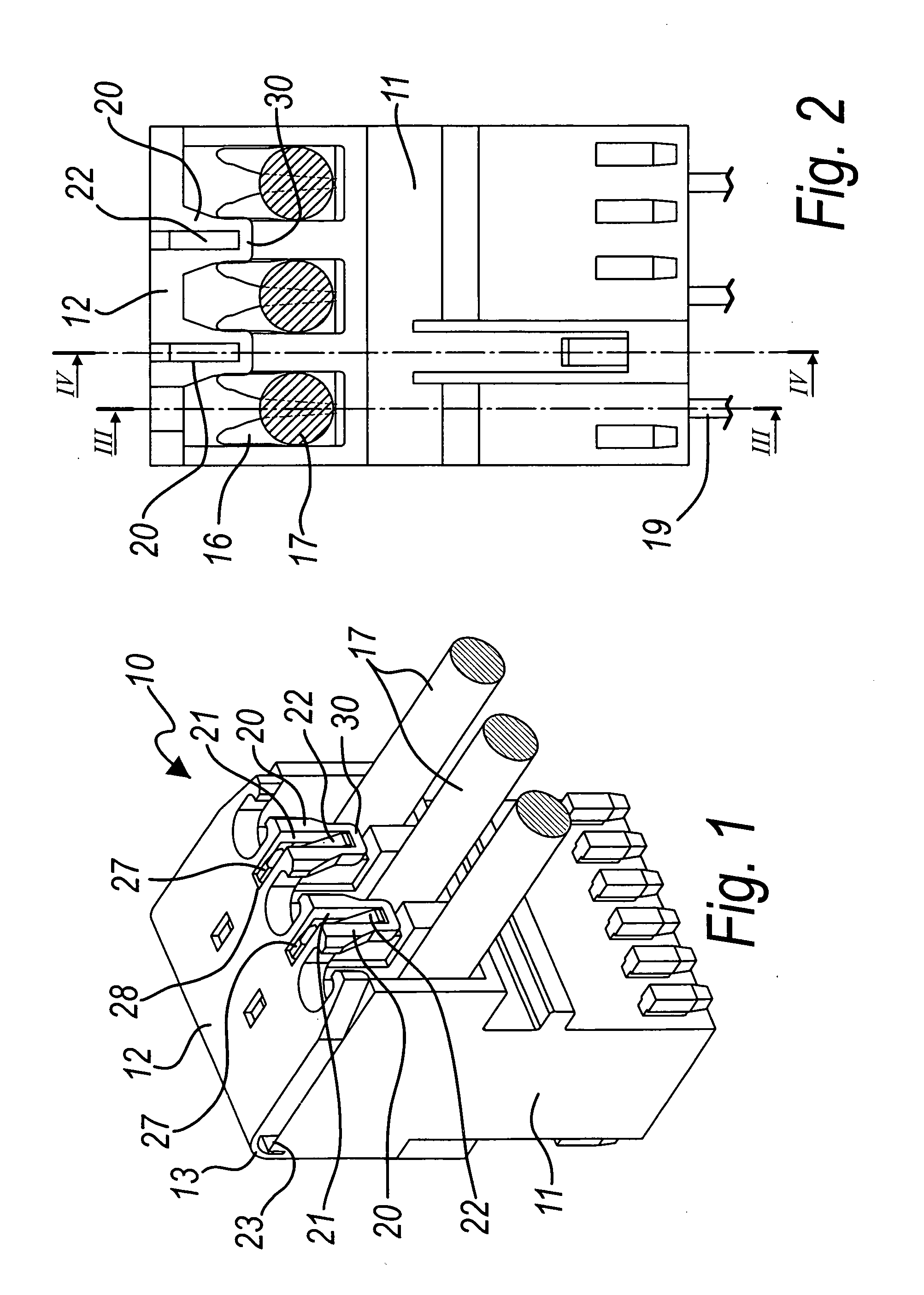

Modular jack

ActiveUS6926558B2Easy to assembleSmall sizeElectrically conductive connectionsCoupling for high frequencyModularityEngineering

Owner:TDK CORPARATION

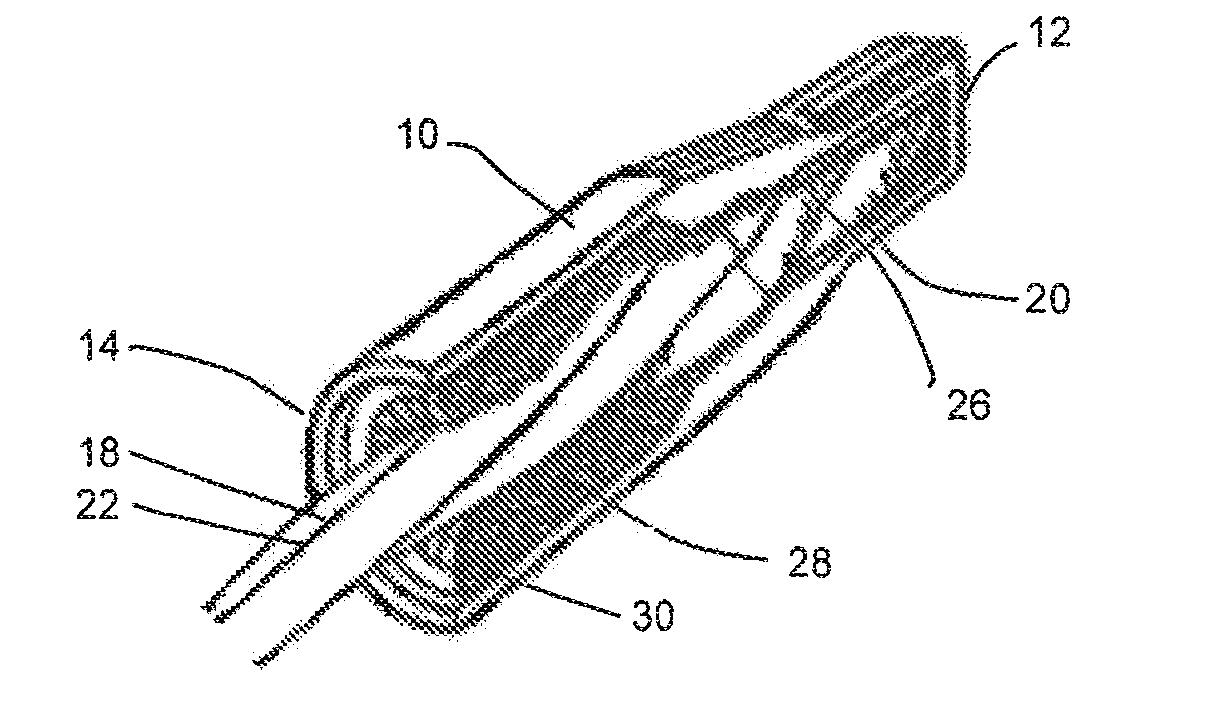

Compliant Electrical Contact and Assembly

ActiveUS20090111289A1Sufficient complianceReduce manufacturing costElectrically conductive connectionsCoupling device detailsShunt DeviceSkew angle

A compliant electrical contact and an assembly employing a plurality of the contacts that provides an interface between two electrical devices. The contact has a convoluted spring with convolutions and a contact point at each end. In one contact embodiment, the convolutions have appendages which electrically short adjacent convolutions throughout a significant portion of the compression range of the contact. An appendage may be a single finger that extends from one convolution toward the adjacent convolution, a pair of opposed fingers that extend toward each other from adjacent convolutions, or machined edges on adjacent convolutions. In some configurations, the fingers or a surface on the appendage or fingers are at a skew angle to the direction of compression. In another contact embodiment, a shunt attached at one contact point and parallel to the spring spans most or all of the convolutions longitudinally. The shunt electrically shorts adjacent convolutions by wiping on the abutting surface of the shunt or by a wiper extending from the convolution to the shunt. Alternatively, the shunt electrically shorts the two contact points, bypassing the convolutions. The contact is placed within a through aperture in a dielectric panel that has openings at each end through which the contact points protrude.

Owner:ARDENT CONCEPTS INC

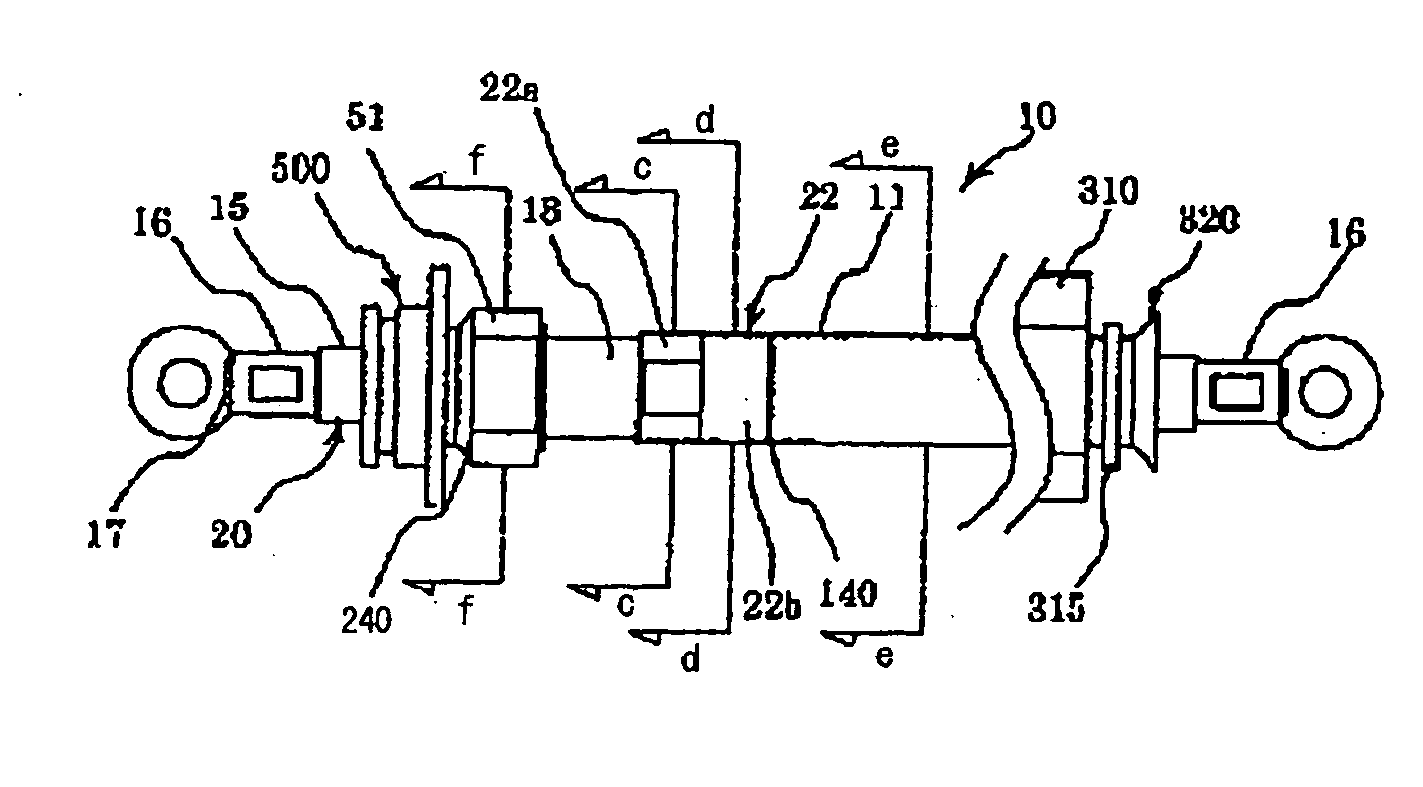

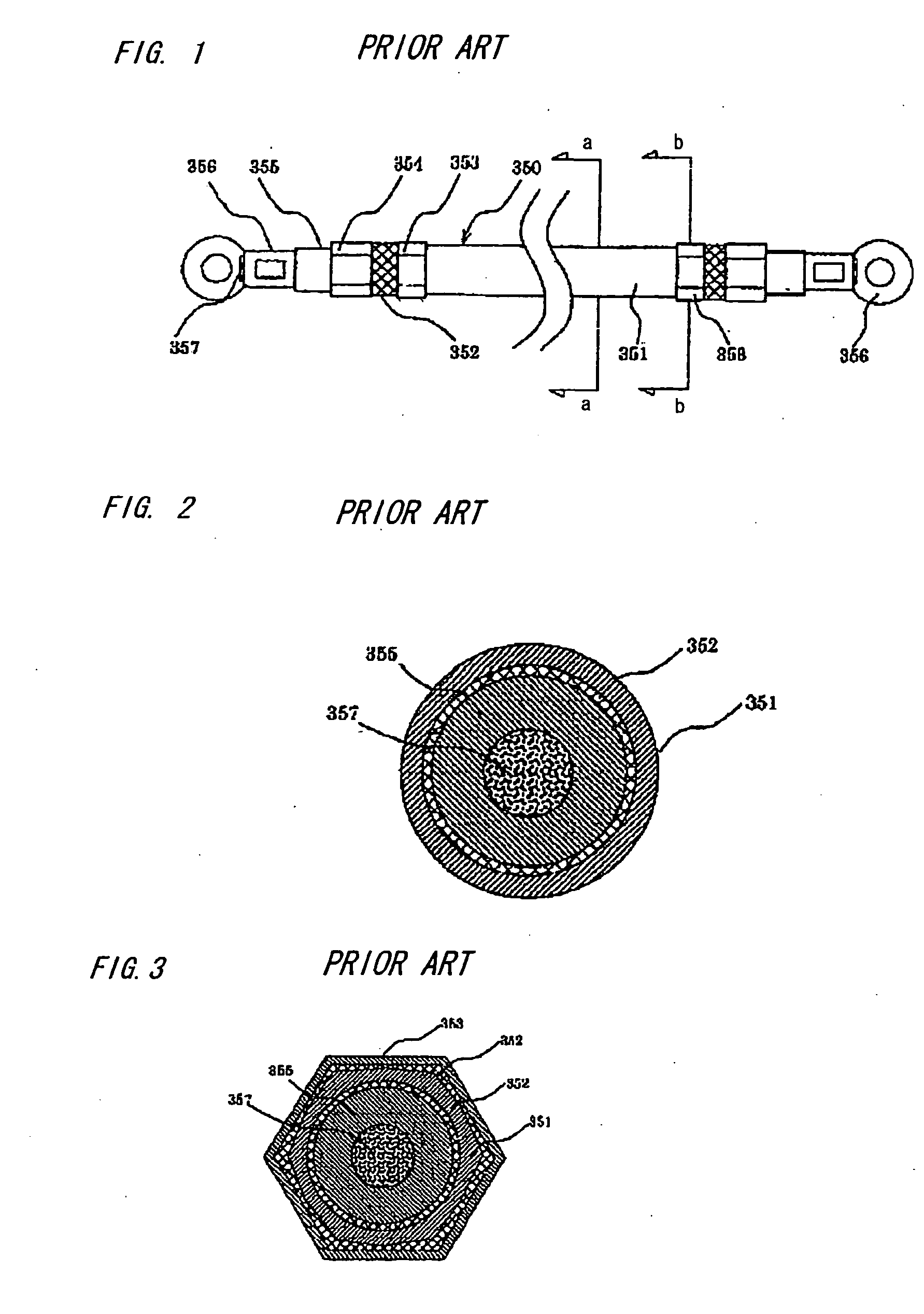

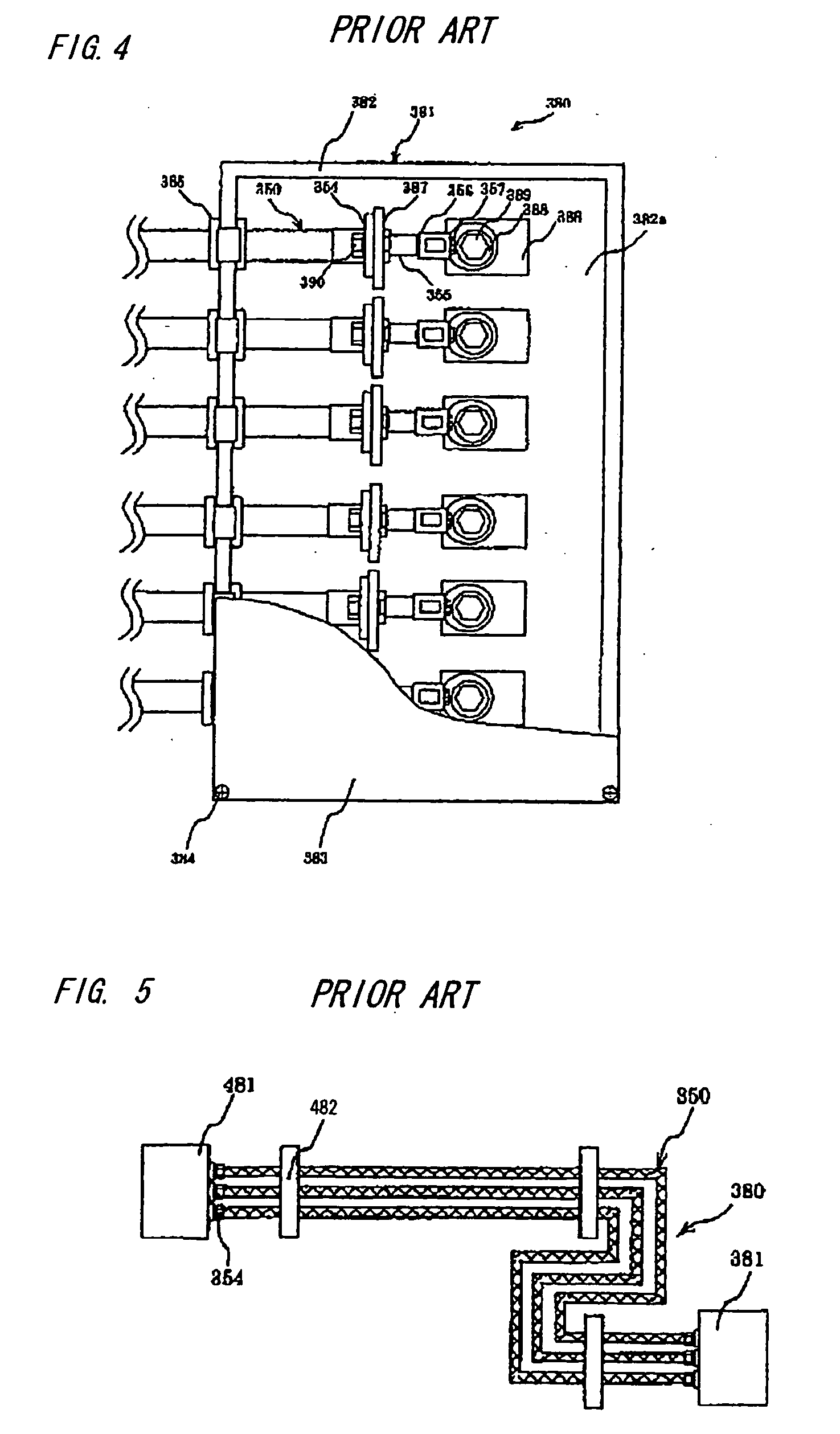

Shield wire, housing connected with same, connecting method thereof and shield wire unit

InactiveUS20060137893A1Good bending propertiesImprove seismic performanceVehicle connectorsLine/current collector detailsElectrical conductorEngineering

Owner:HITACHI METALS LTD

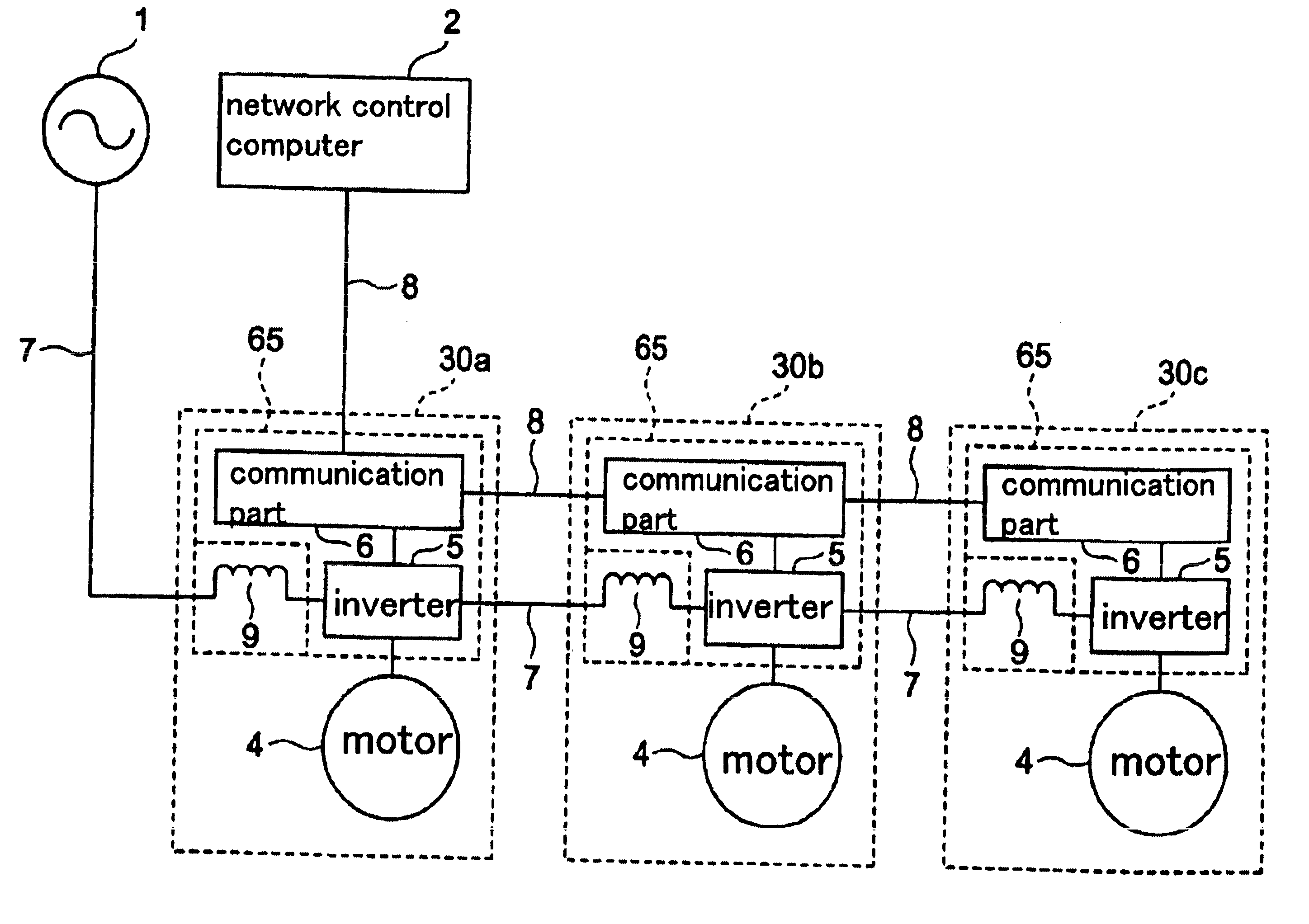

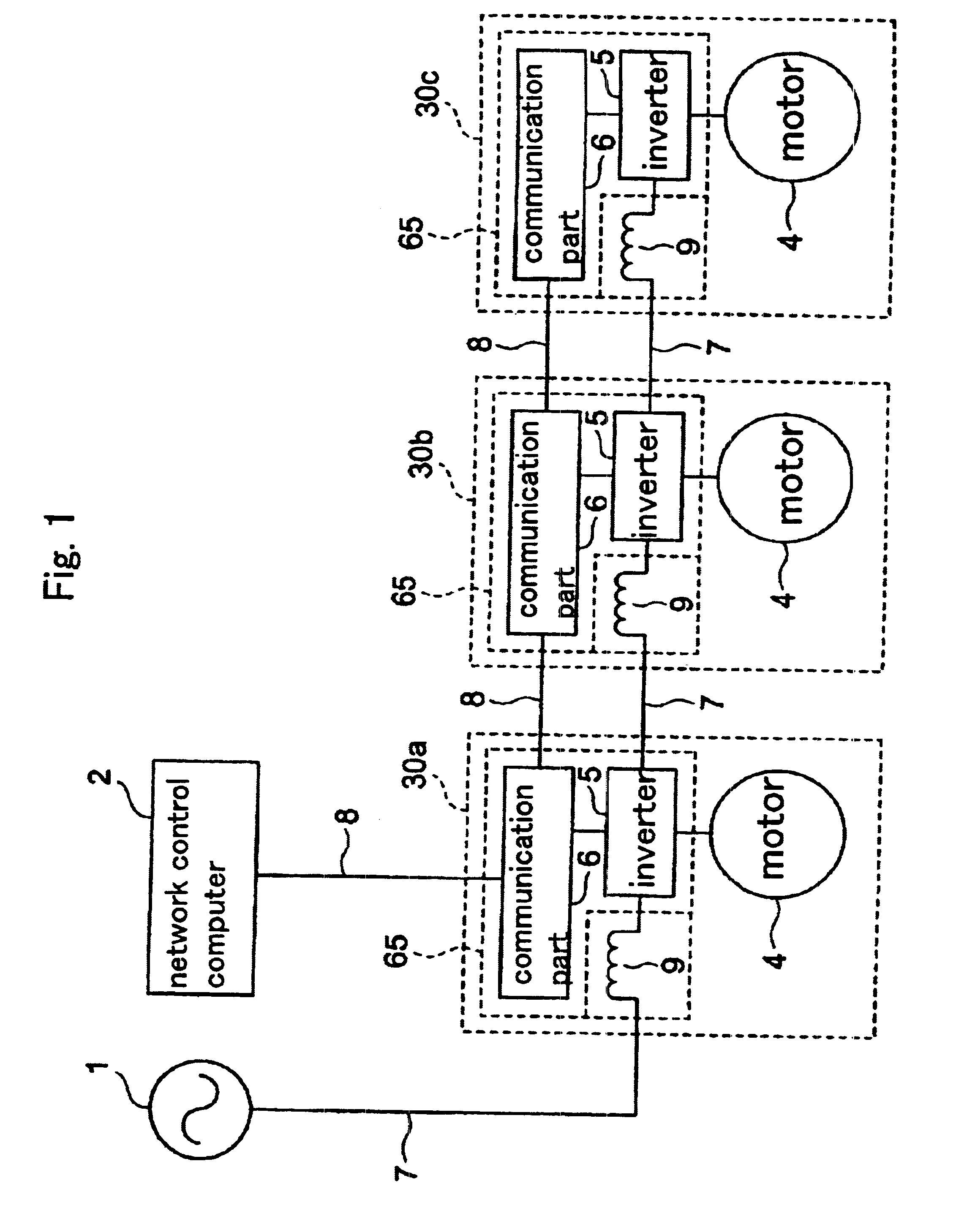

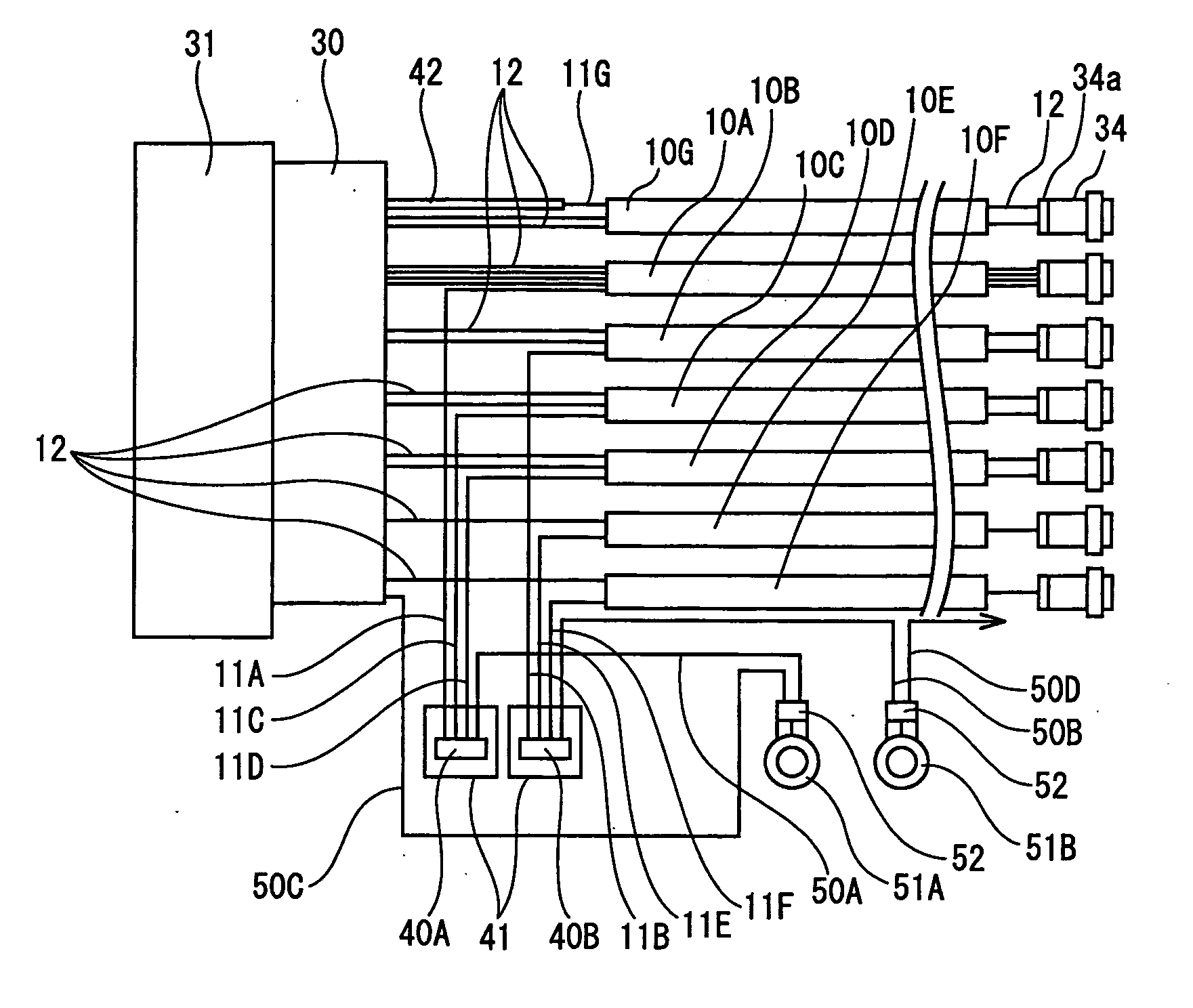

Motor network control system

InactiveUS6686712B2Shorten the line lengthEasy to carryElectrically conductive connectionsMultiple dynamo-motor startersPower cableControl system

Owner:MITSUBISHI ELECTRIC CORP

Shielded Wire-Grounding construction

InactiveUS20090314511A1Decrease lead-out lengthImprove shielding effectVehicle connectorsElectrically conductive connectionsEngineeringElectrical conductor

Owner:AUTONETWORKS TECH LTD +2

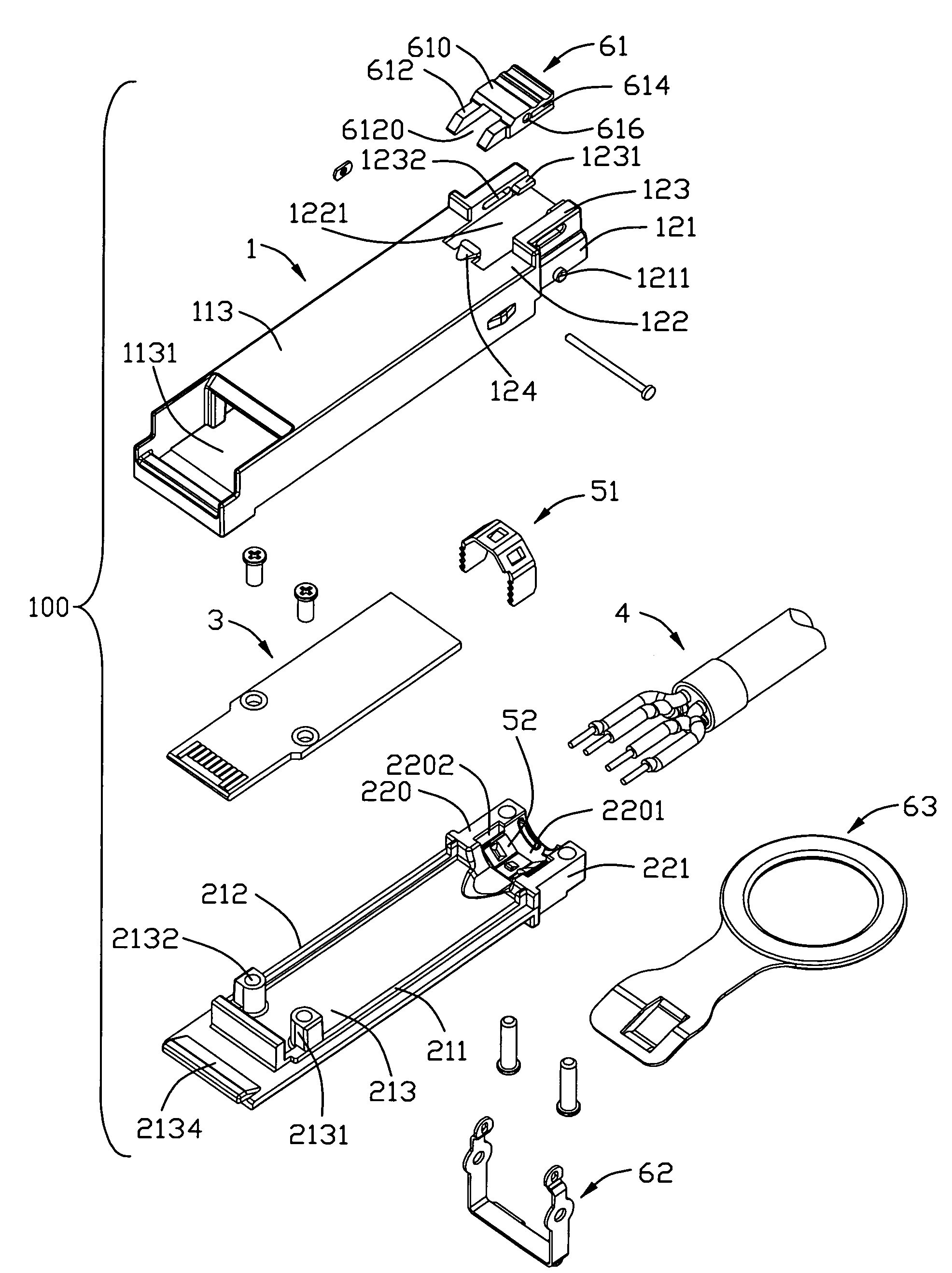

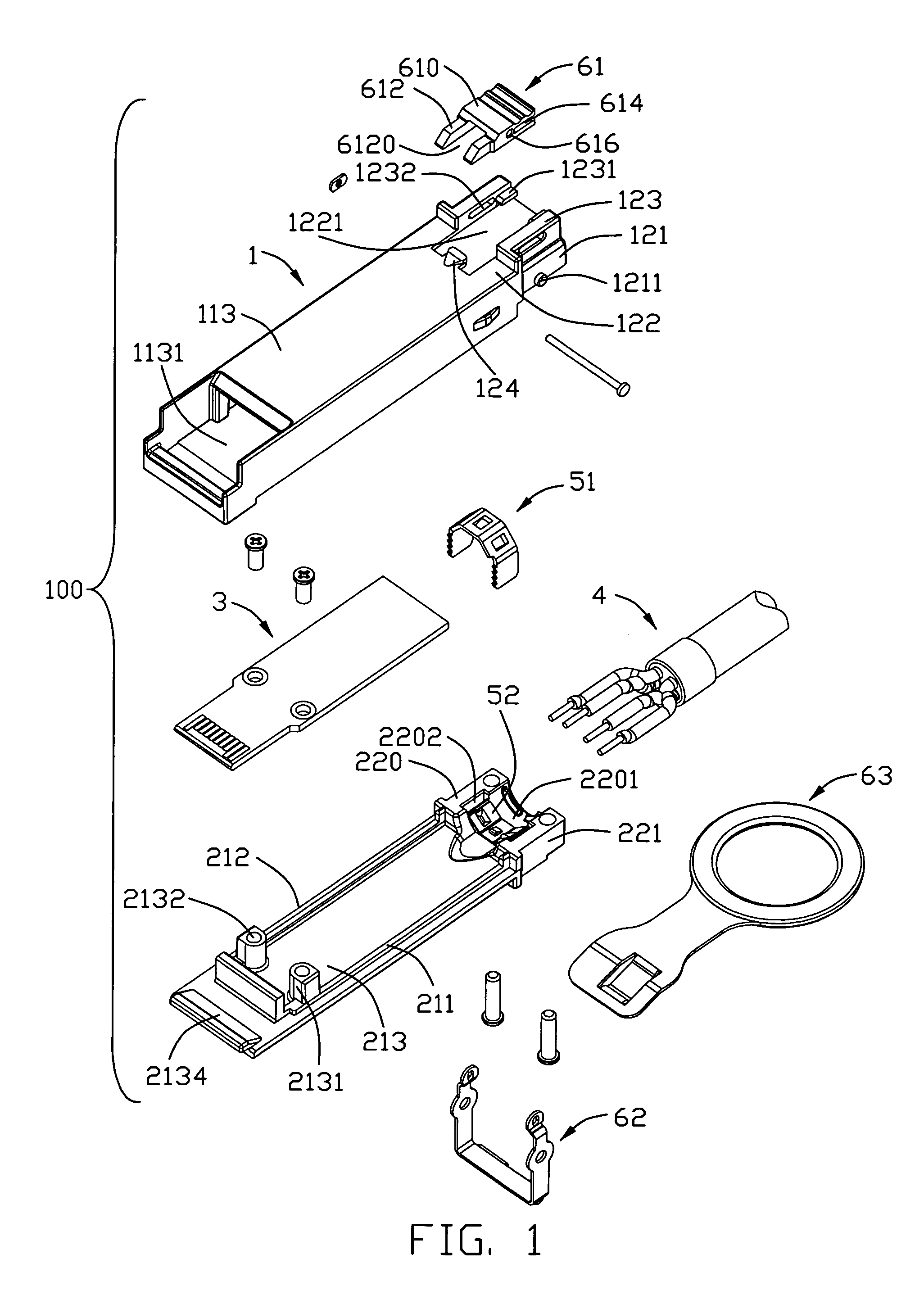

Electronic module with easily operated latch mechanism

InactiveUS20090291578A1Easily released latchEngagement/disengagement of coupling partsElectrically conductive connectionsMechanical engineeringElectronic modules

Owner:HON HAI PRECISION IND CO LTD

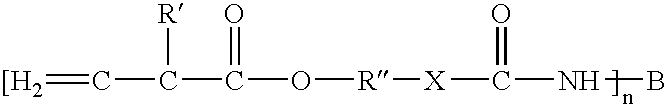

Anaerobic wire connector sealant and moisture resistant wire connector containing the same

InactiveUS7368663B1Easy maintenanceElectrically conductive connectionsCable junctionsElectrical connectionEngineering

Owner:HENKEL IP & HOLDING GMBH

Crimped solder on a flexible circuit board

InactiveUS20100186997A1Electrically conductive connectionsPrinted circuit aspectsFlexible circuitsElectrical connection

Owner:SAMTEC

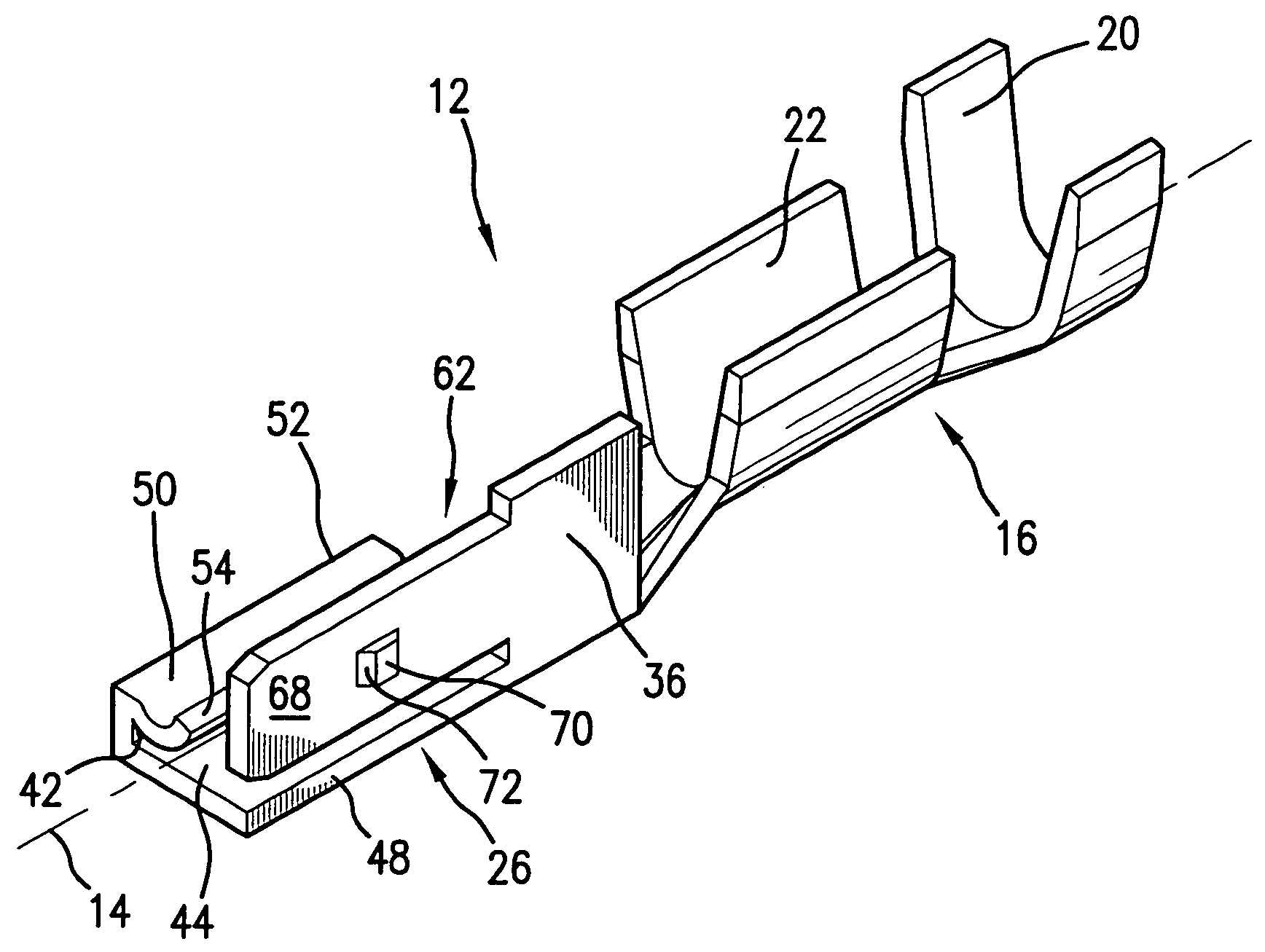

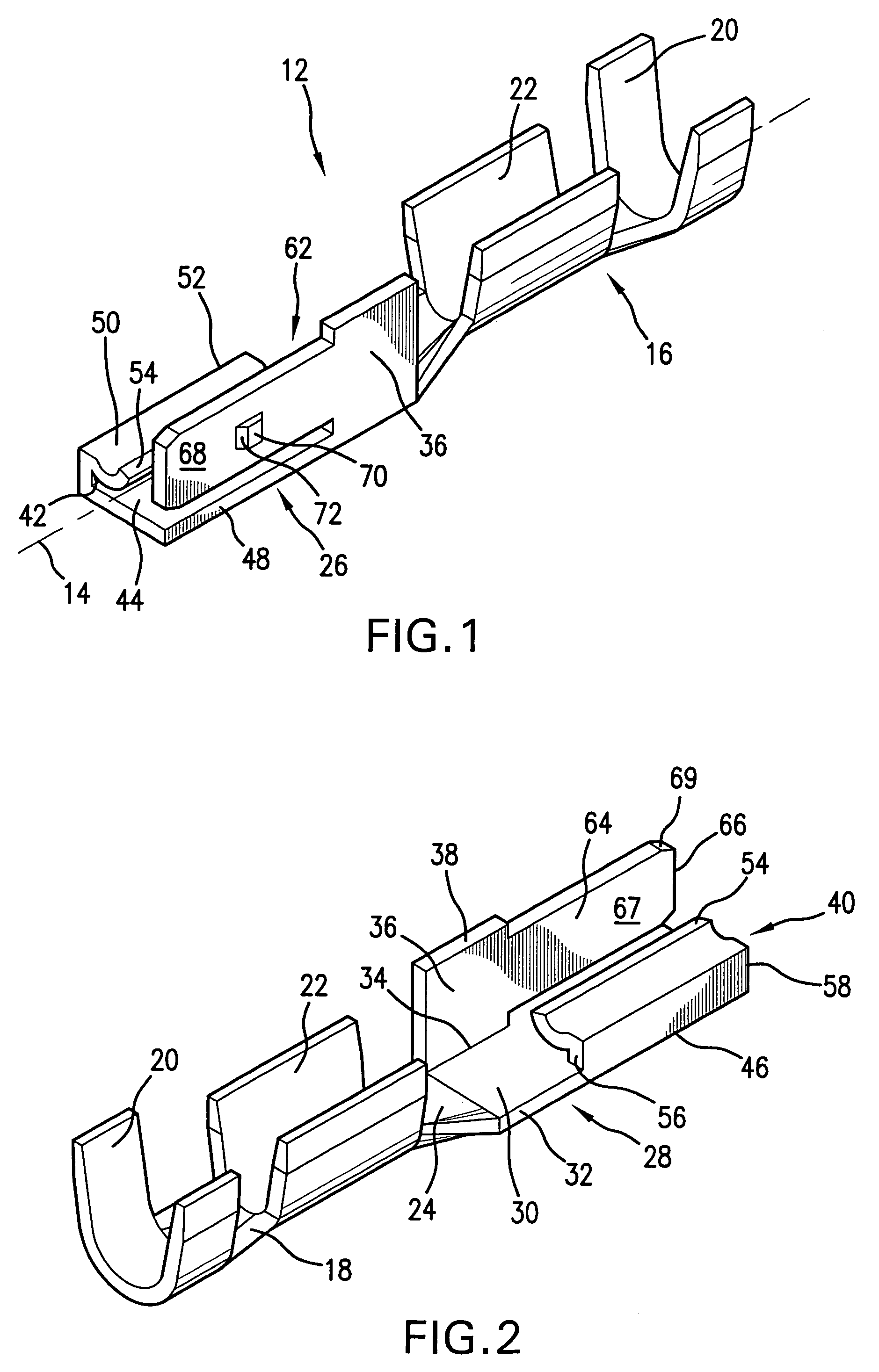

Standardized electrical terminal

InactiveUS7033194B1Maintain electrical connectionLess toolingElectrically conductive connectionsCoupling contact membersElectric wireCircular segment

Owner:YAZAKI NORTH AMERICA

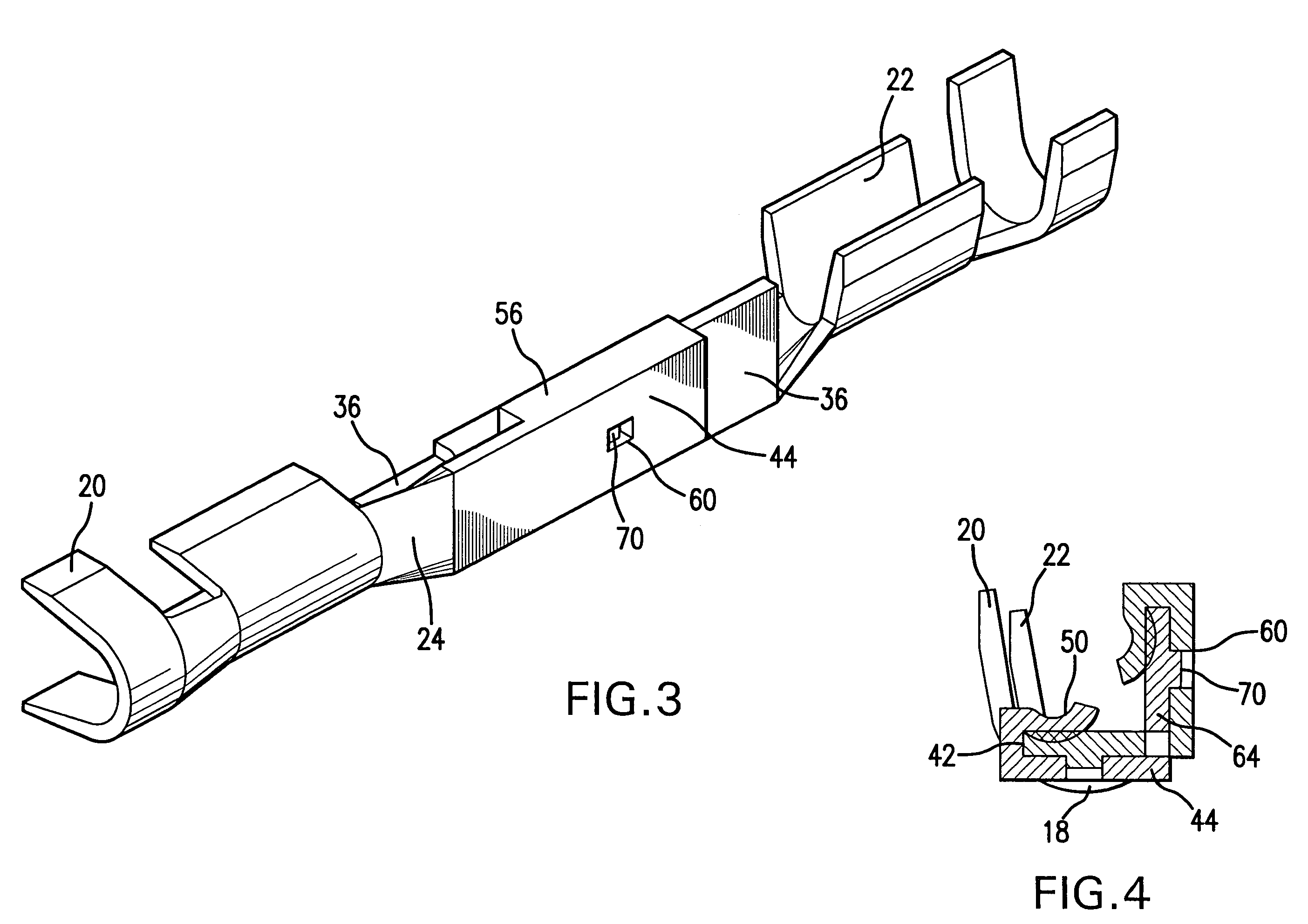

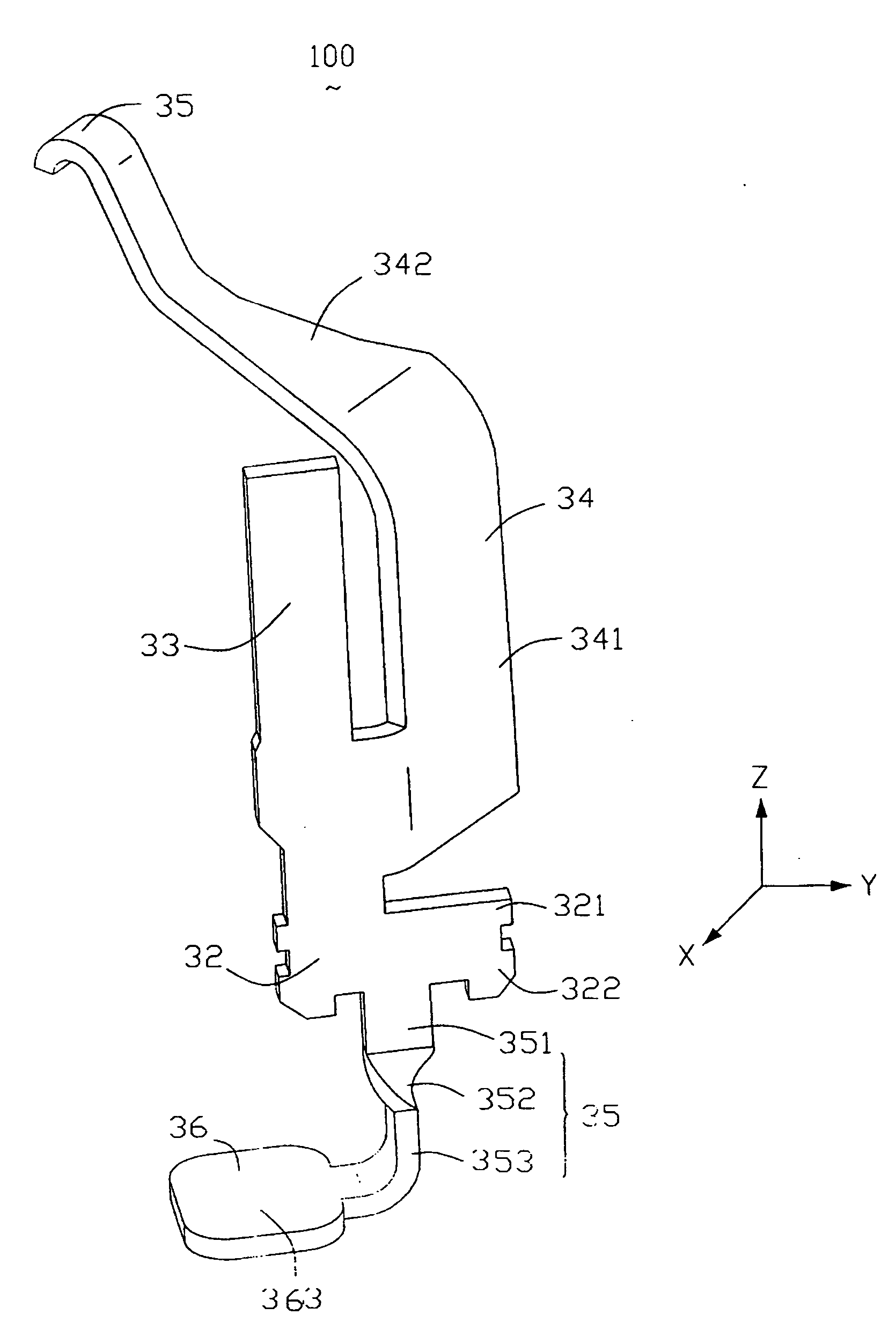

Electrical terminal

ActiveUS20130273790A1Bending process easyReduce internal stressContact member manufacturingElectrically conductive connectionsContact elementMetal

Owner:YAZAKI EURO

Network cable

InactiveUS20050023026A1Easy to findPractical to useElectrically conductive connectionsIncorrect coupling preventionEngineeringControl circuit

Owner:CHEN WILSON

Method for conductively connecting a component on a transparent substrate

InactiveUS20120266461A1Avoid cleaningFast solderingPrinted circuit assemblingLight absorption dielectricsEnergy supplyLength wave

The invention relates to a method to conductively connect an electrical component with at least one conductive layer, whereby the conductive layer is applied to a substrate which is essentially transparent in the visible wavelength zone of light, comprising the following steps: the electrical component or the conductive layer is provided with a soldering material in the area where the component is to be connected to the conductive layer; the soldering material is provided with energy supplied by an energy source, such that the soldering material melts and a non-detachable, material-bonded conductive connection between the electrical component and the conductive layer is established.

Owner:SCHOTT AG

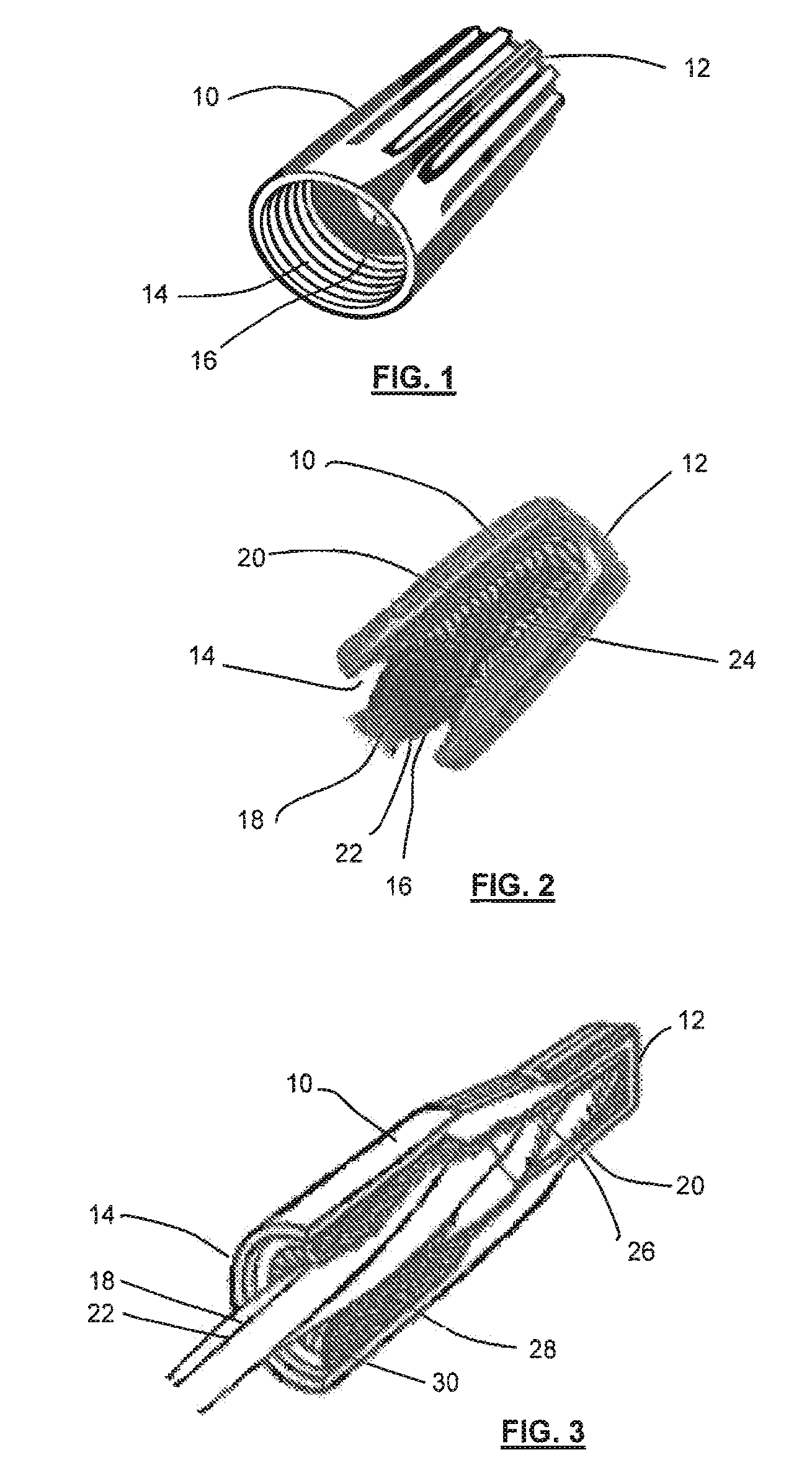

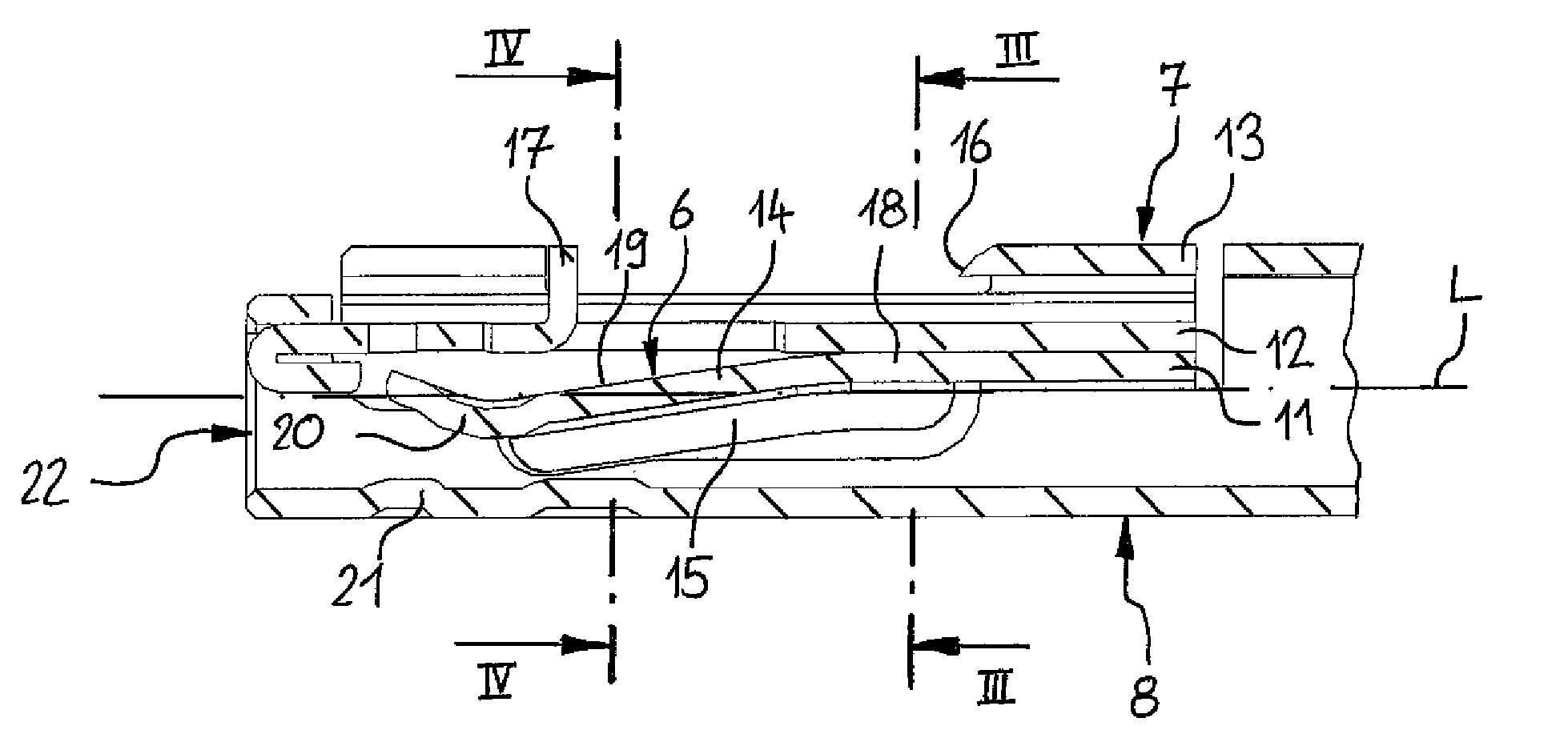

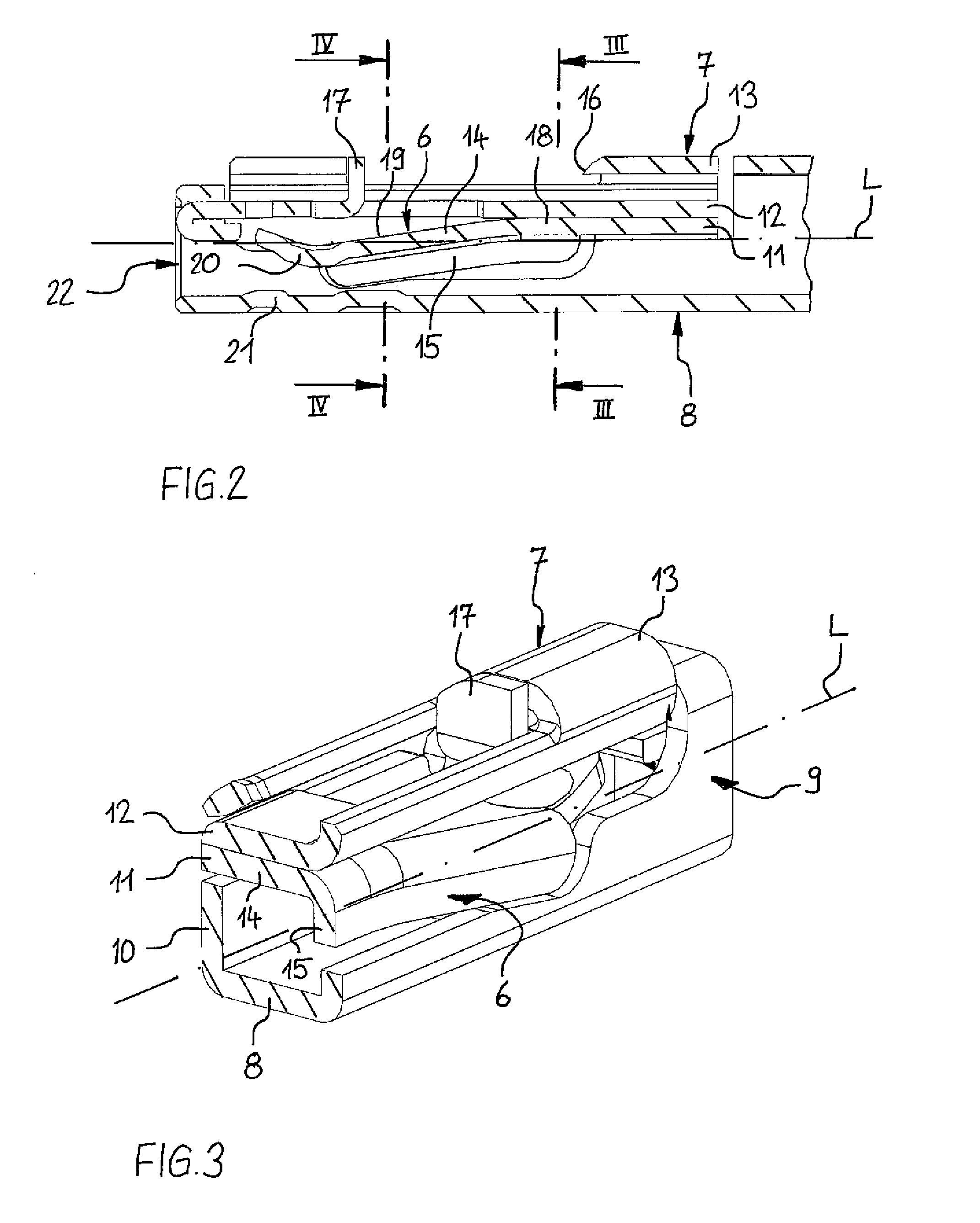

Radio frequency coxial connector

ActiveUS20100311272A1Sufficient forceElectrically conductive connectionsTwo pole connectionsElectrical conductorRadio frequency

A RF coaxial connector has an insulative housing, an internal terminal and an external terminal. The insulative housing has a cavity. The internal terminal is mounted in the cavity and has a mounting section, two resilient arms protruding from the mounting section, a free section formed between the resilient arms and a contacting section protruding from the free section. The external terminal is mounted on the insulative housing. The internal terminal provides sufficient resistance force against a pin conductor of a corresponding connector engaged with the RF coaxial connector for stable signal transmission.

Owner:ADVANCED CONNECTEK INC

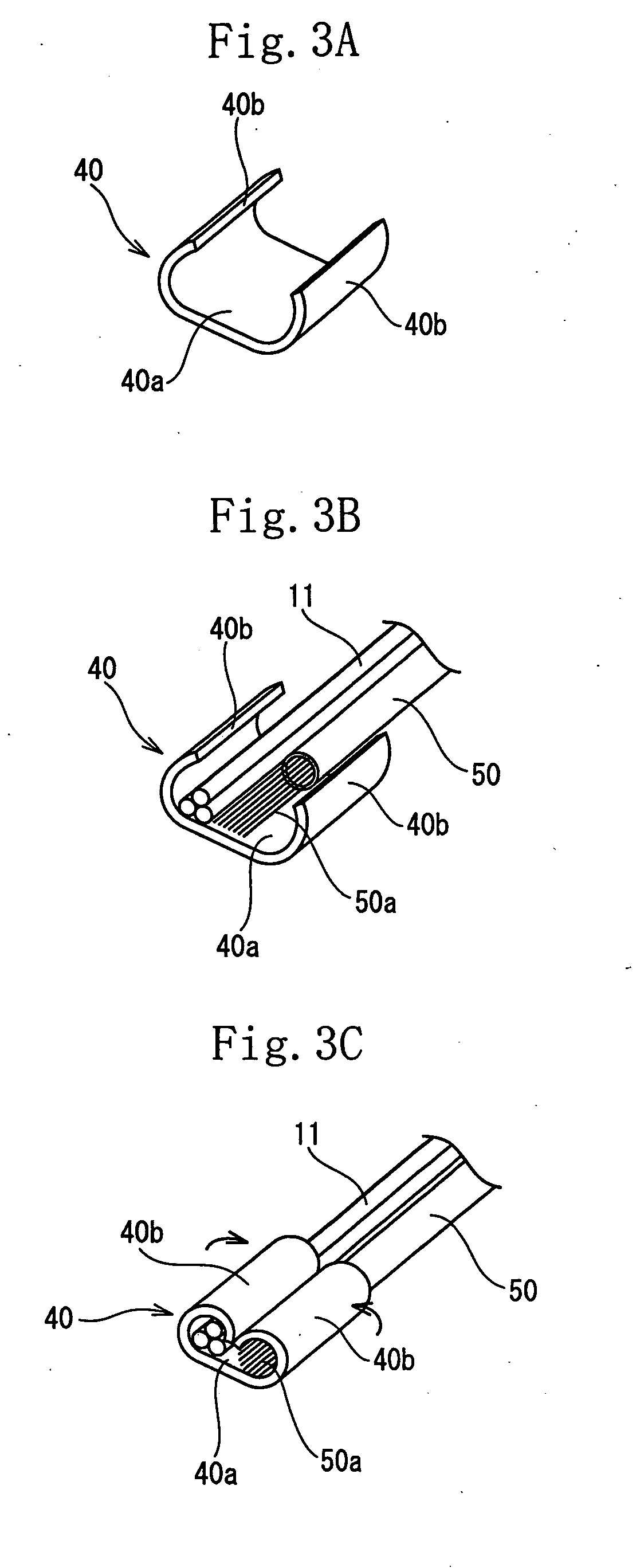

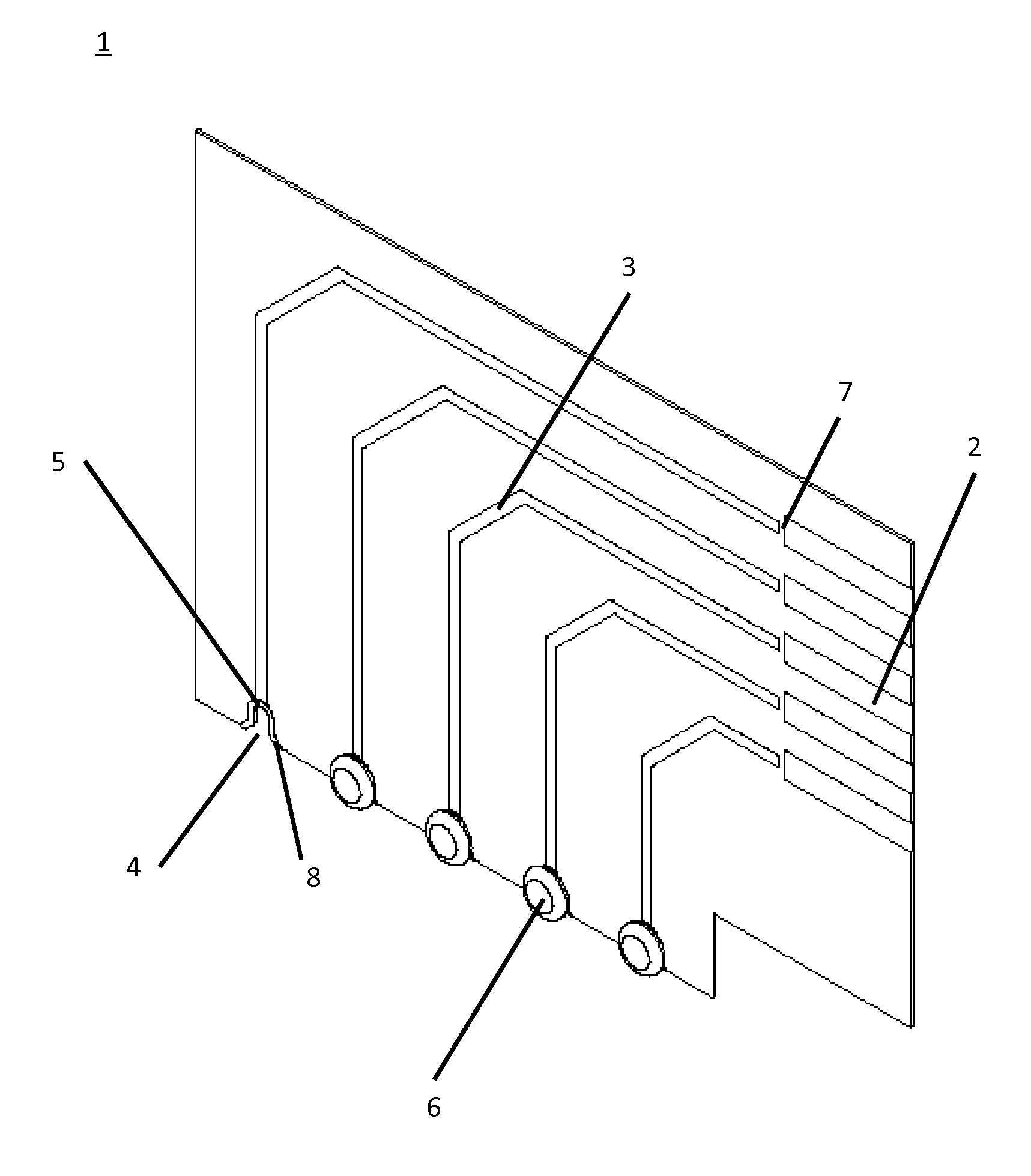

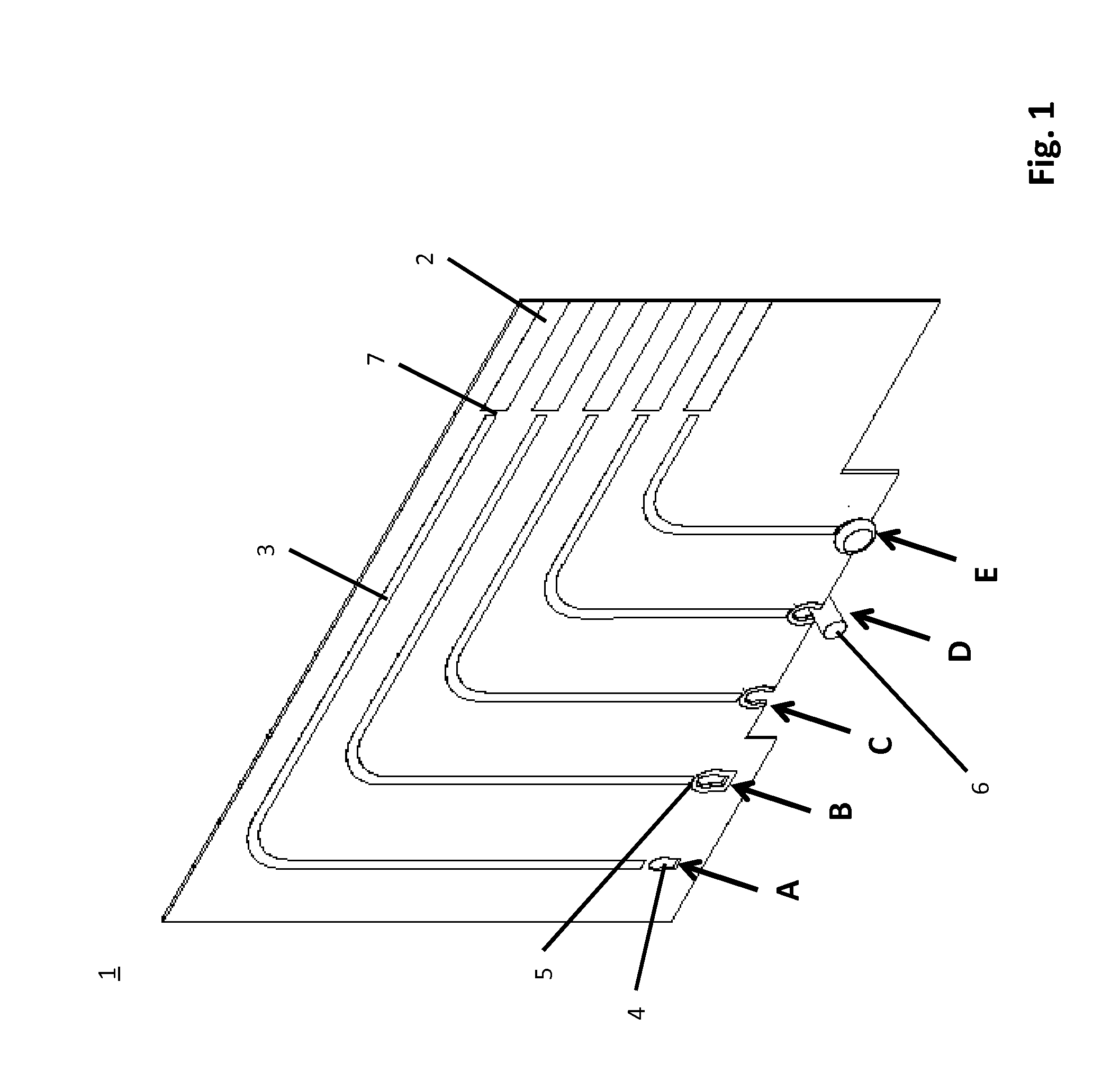

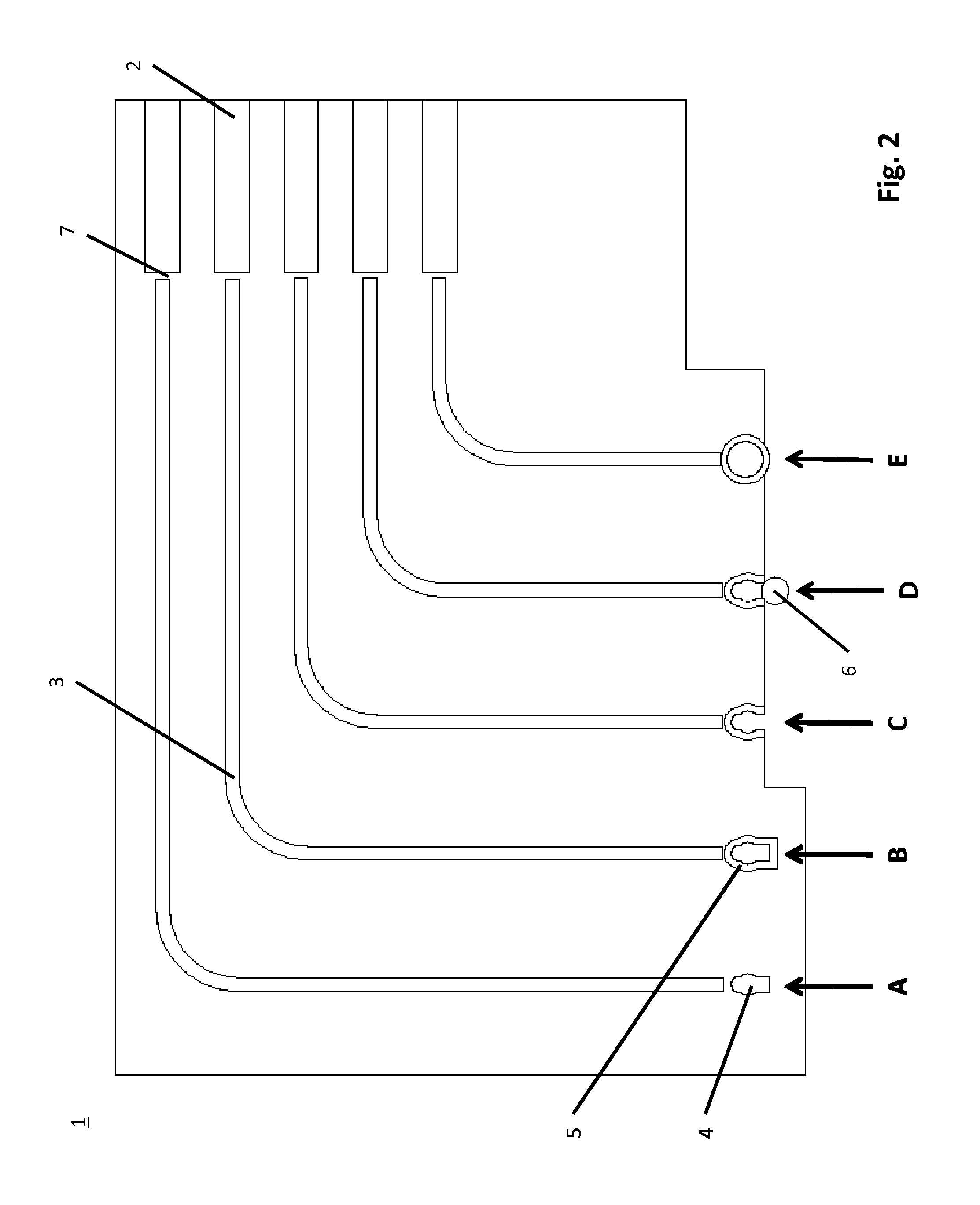

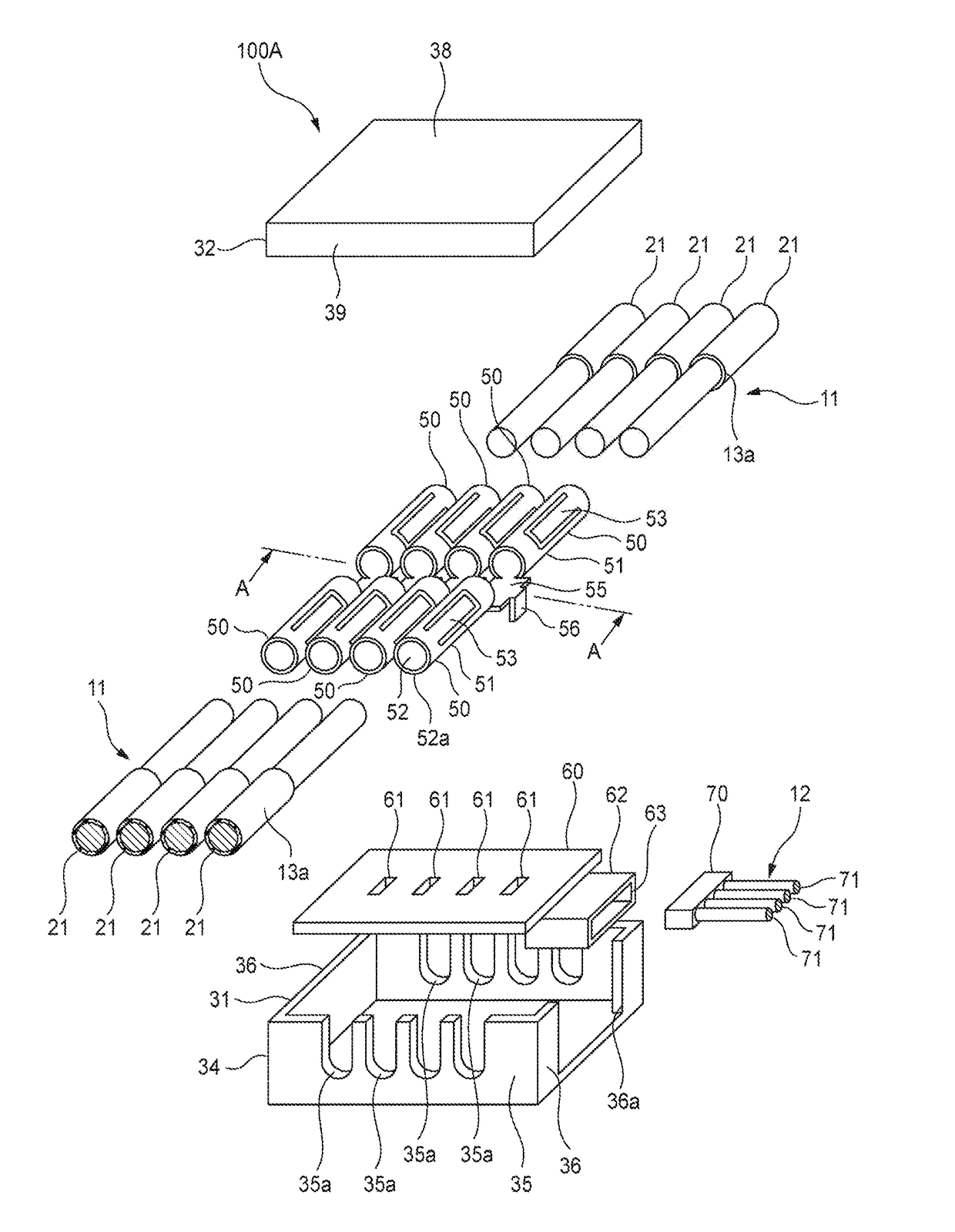

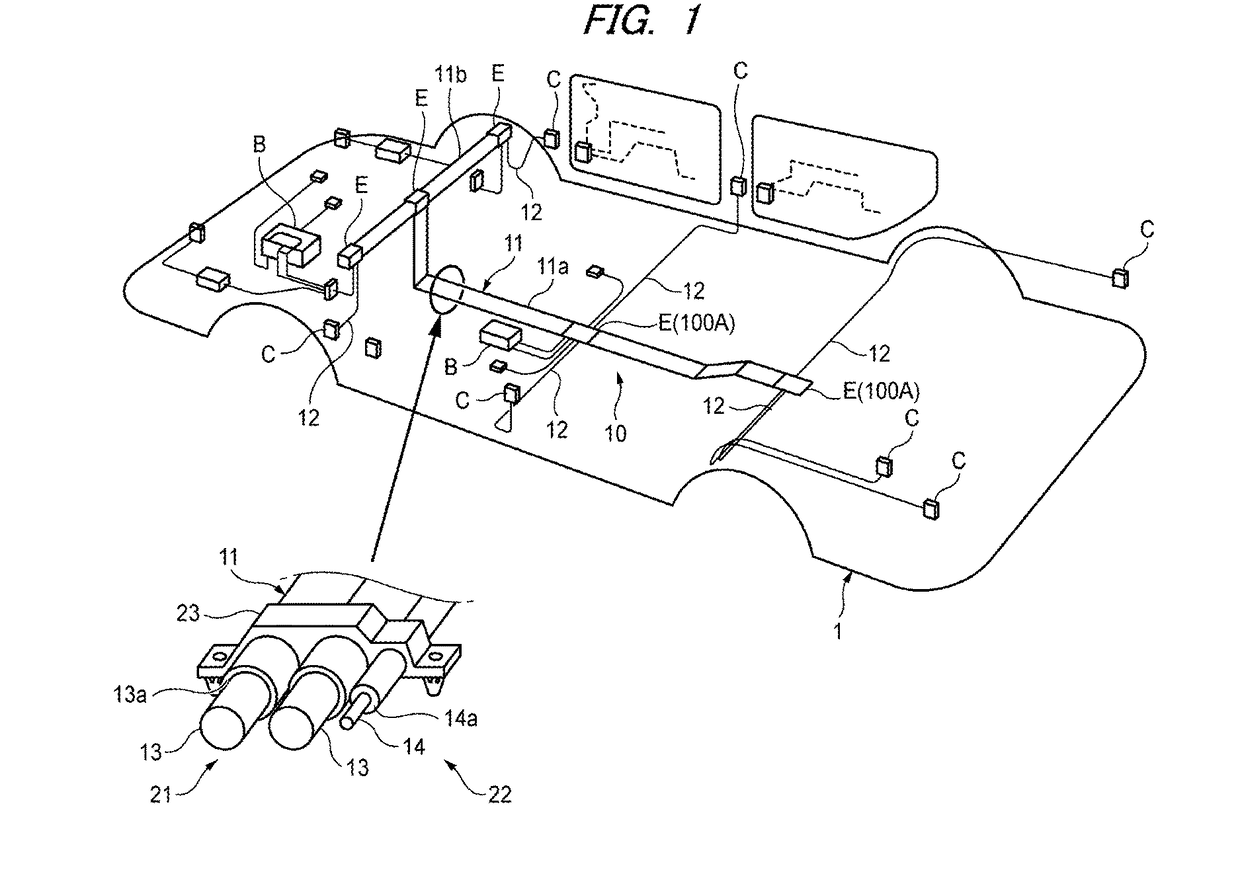

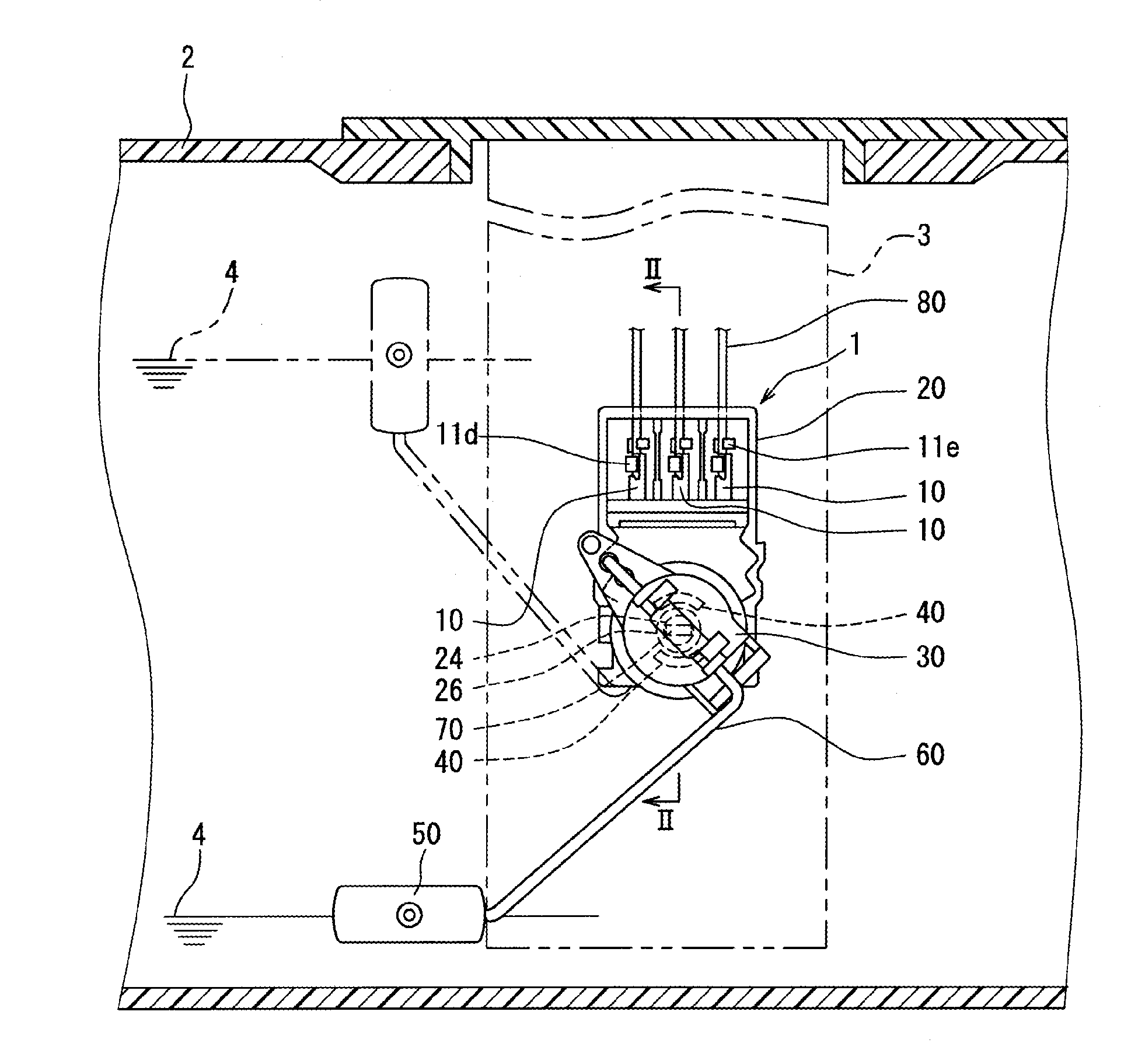

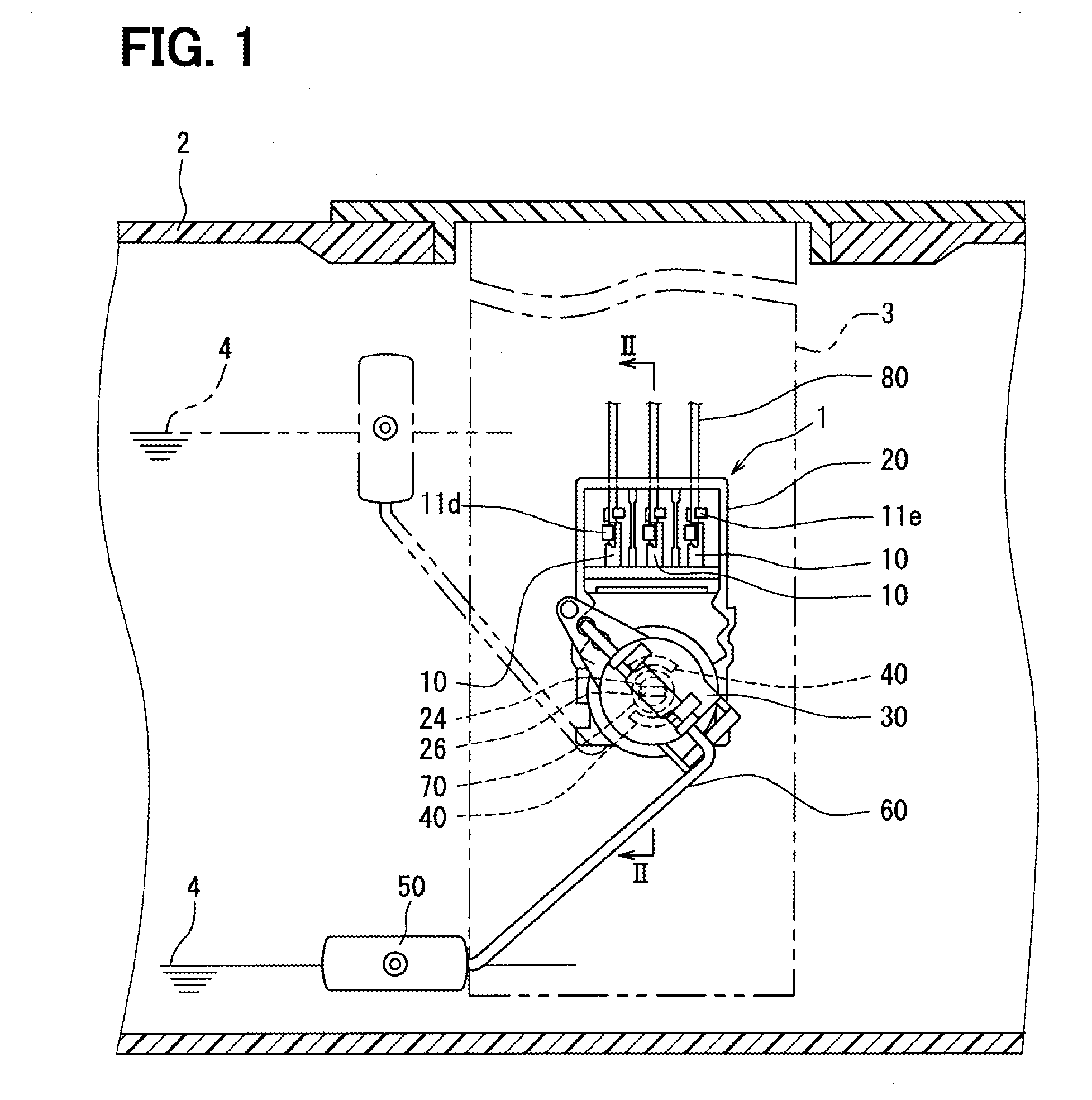

Branching structure and wire harness

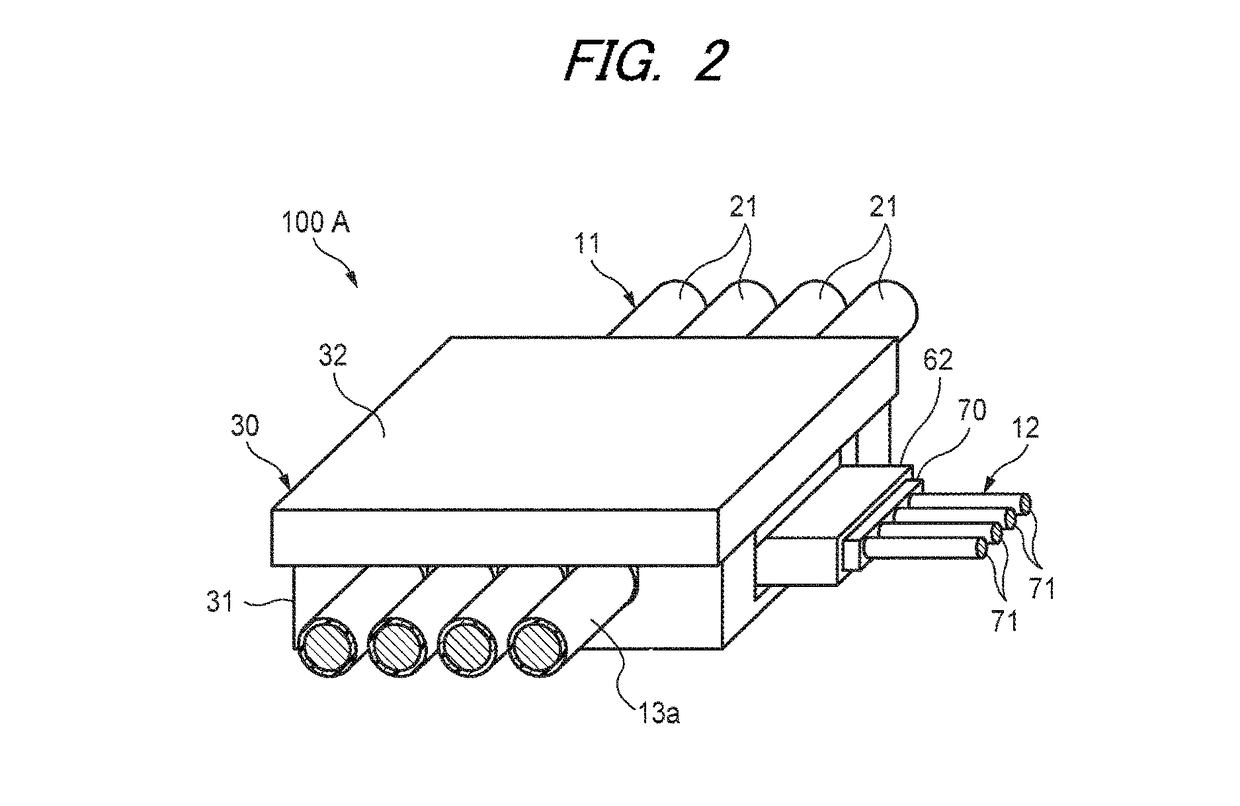

ActiveUS20180123301A1Reduce extra spaceImprove electrical connection reliabilityVehicle connectorsElectrically conductive connectionsElectrical conductorEngineering

Owner:YAZAKI CORP

Method for temporary repair of the overbraid for metal overbraided wiring harnesses

InactiveUS20050198820A1Line/current collector detailsElectrically conductive connectionsBiomedical engineeringMetal

A method for the repair of the overbraid for metal overbraided wiring harness is provided. The method requires no special wiring harness design, uses readily available materials and can be accomplished without removing the wiring harness. The method involves trimming around the damaged area, spreading the braid to expose a repair area, covering the repair area with a metal cover and then covering the repair area with wire screen mesh. Finally, the mesh is secured onto the wiring harness. Also provided is a metal overbraid wiring harness having been repaired with the method of the present invention.

Owner:HONEYWELL INT INC

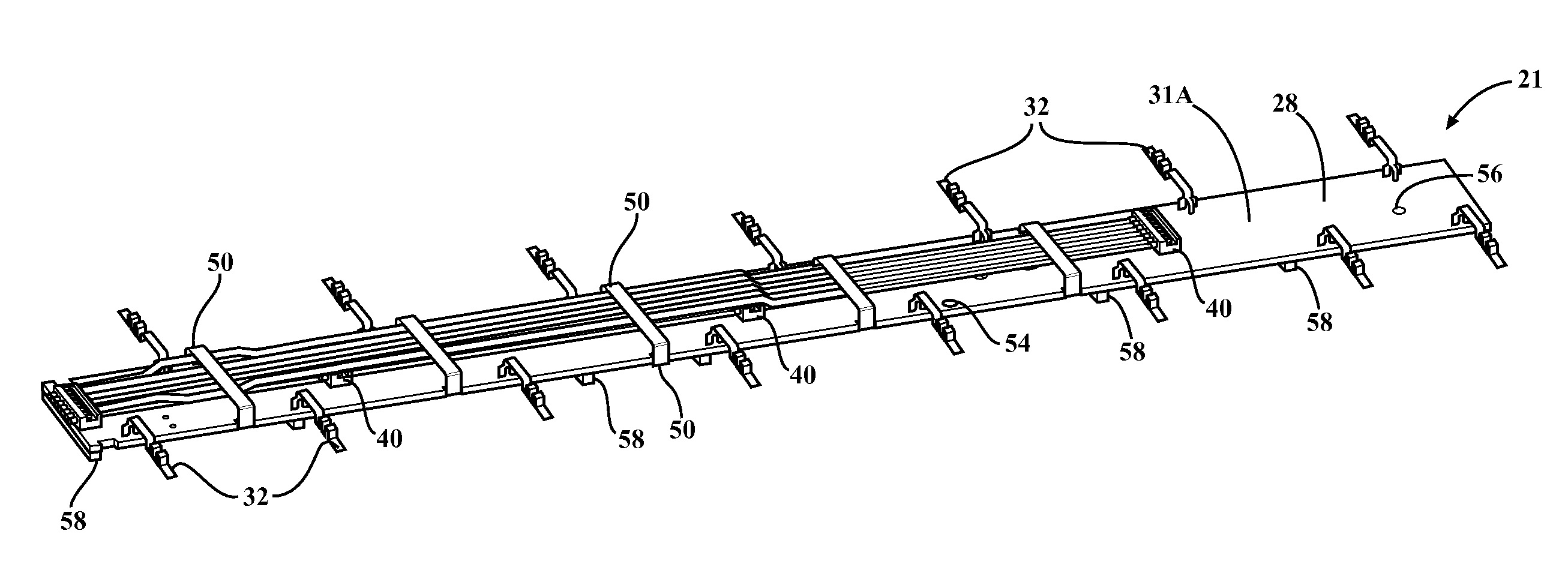

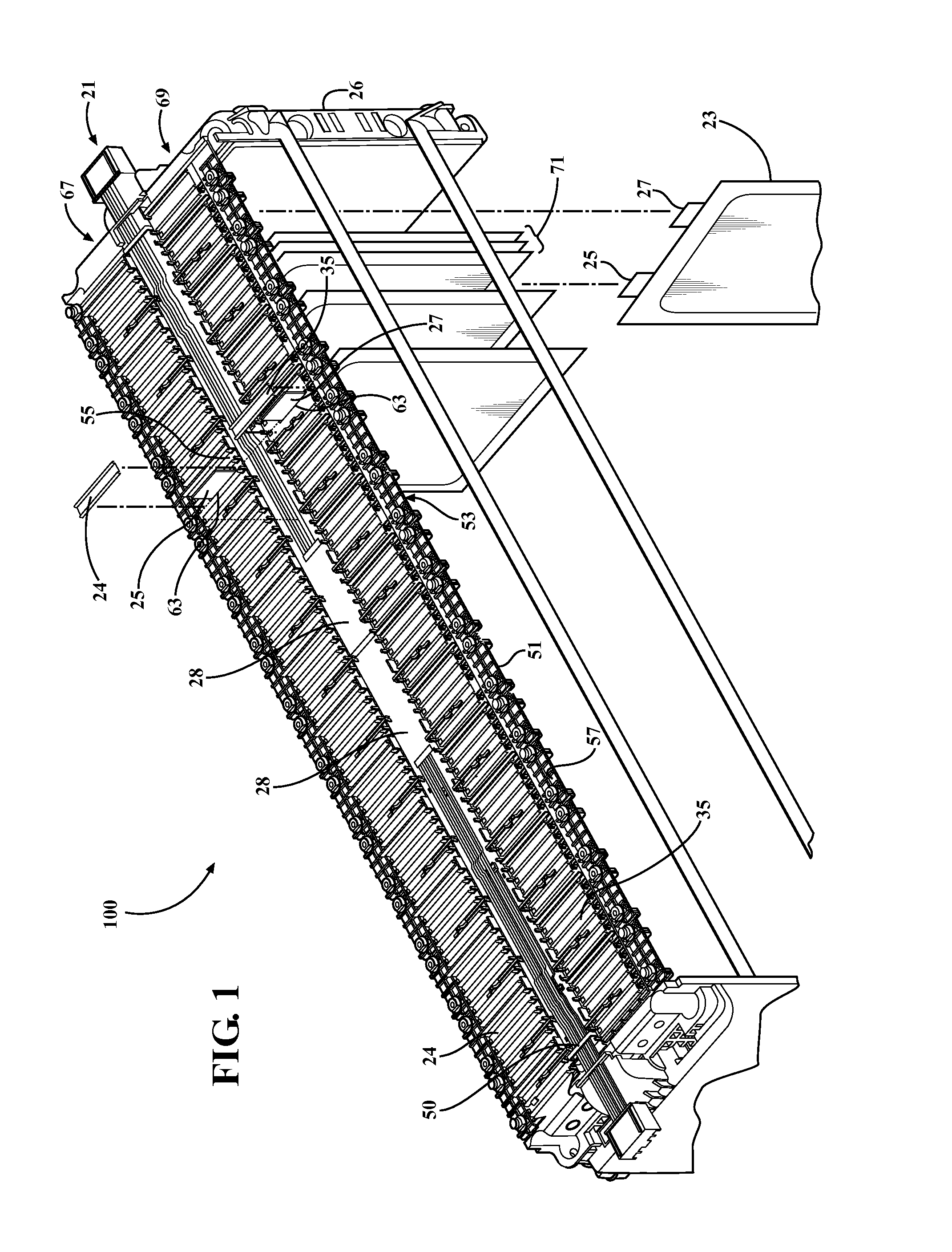

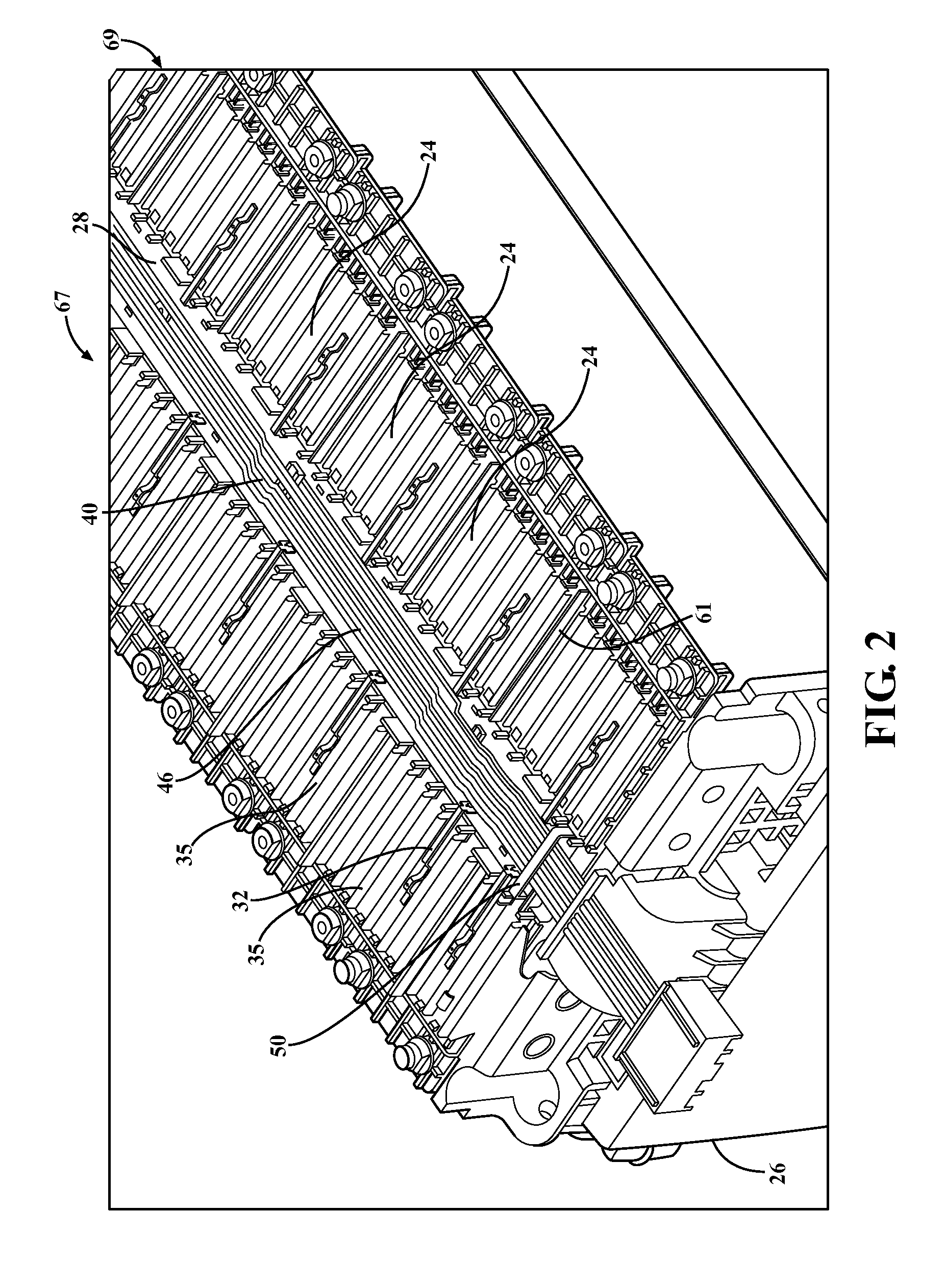

Battery monitoring system

InactiveUS20140003016A1Simple and inexpensive to manufactureEasy to installElectrically conductive connectionsBatteries circuit arrangementsElectricityElectrical battery

Owner:AEES INC

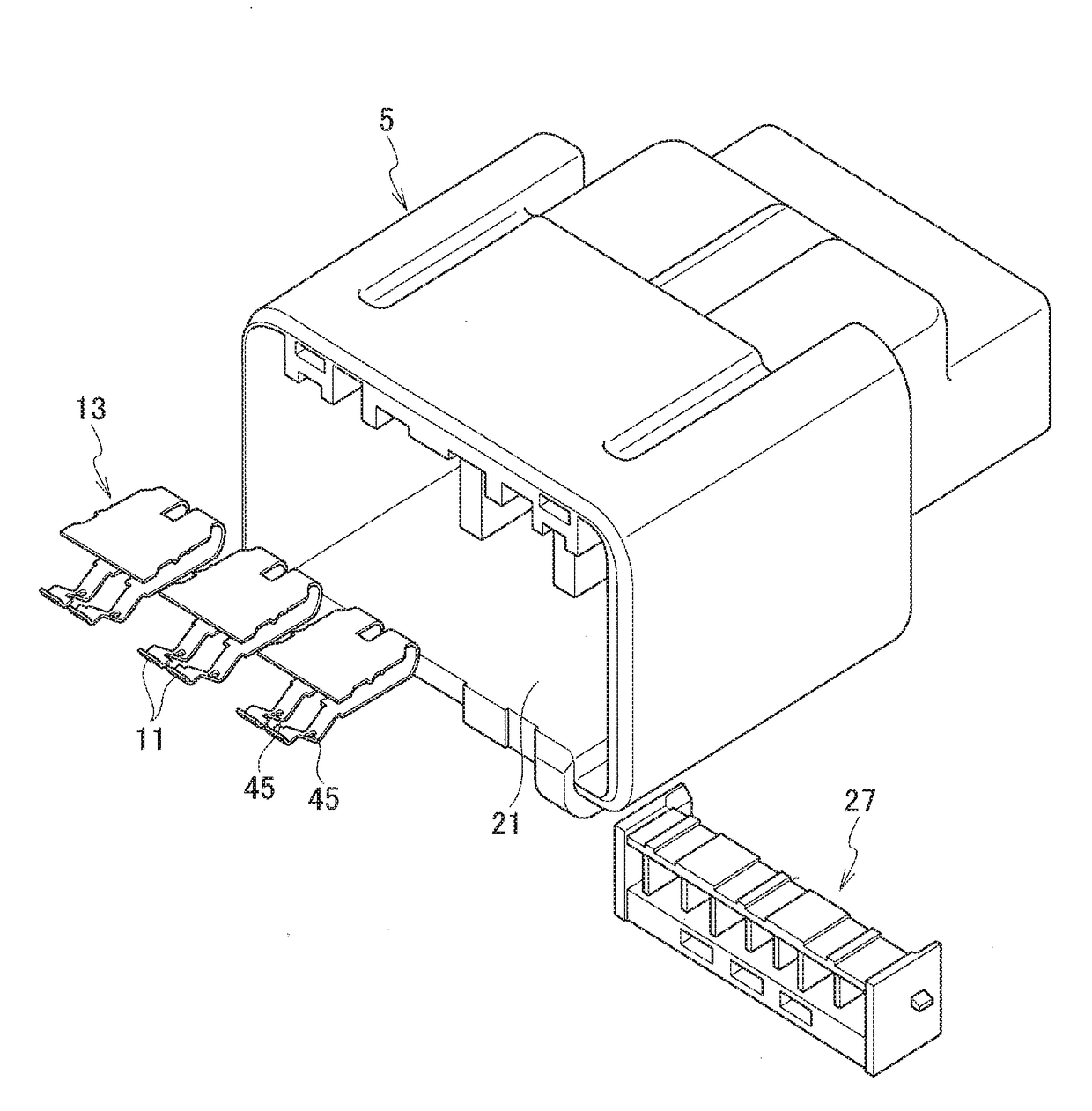

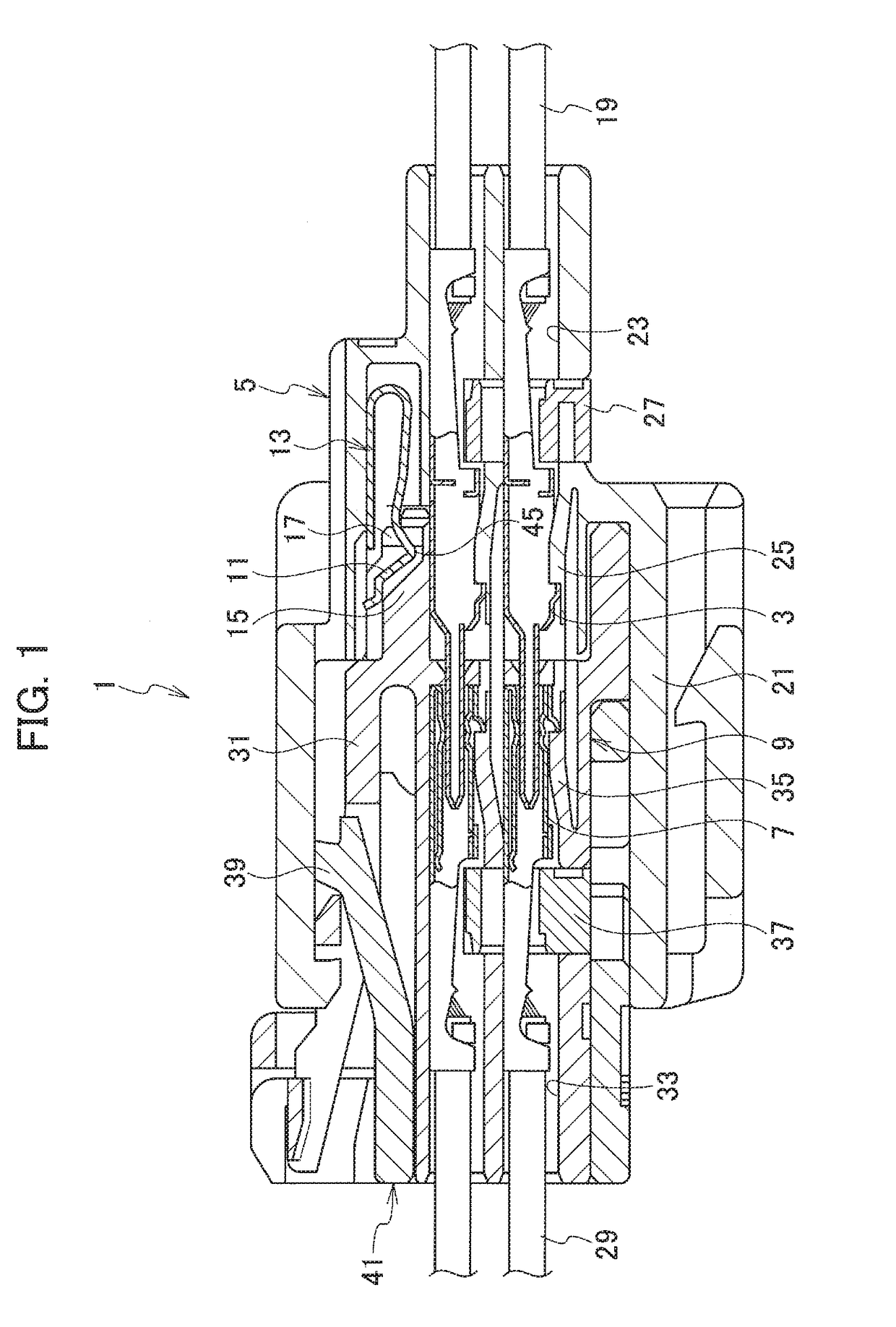

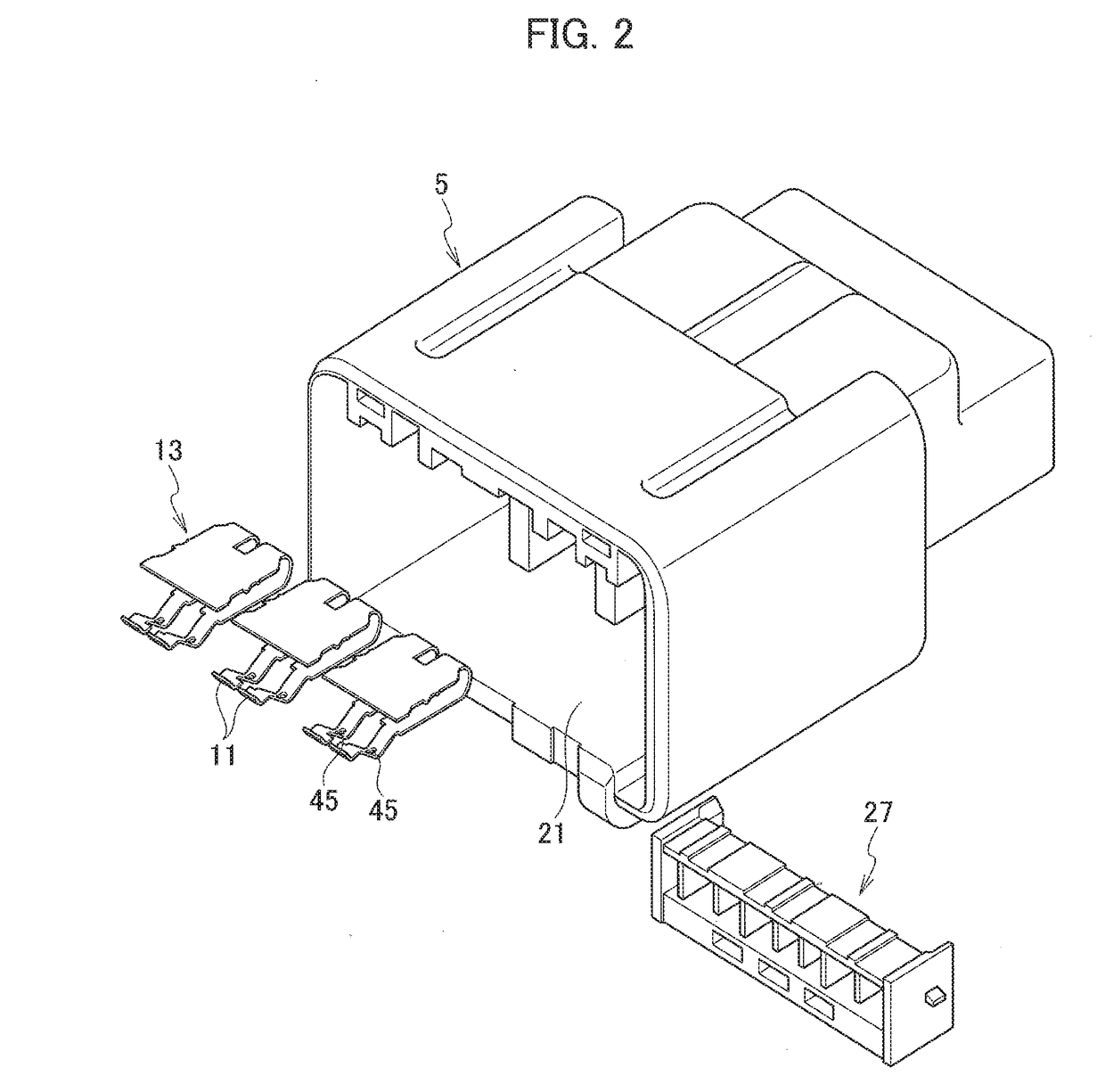

Connector

ActiveUS20180034180A1Suppress enlargingReduce manufacturing costElectrically conductive connectionsCoupling contact membersShort circuit

Owner:YAZAKI CORP

Contact used in an electrical connector

InactiveUS20070173138A1Additional flawResistance capabilityElectrically conductive connectionsCoupling contact membersEngineeringElectrical connector

Owner:HON HAI PRECISION IND CO LTD

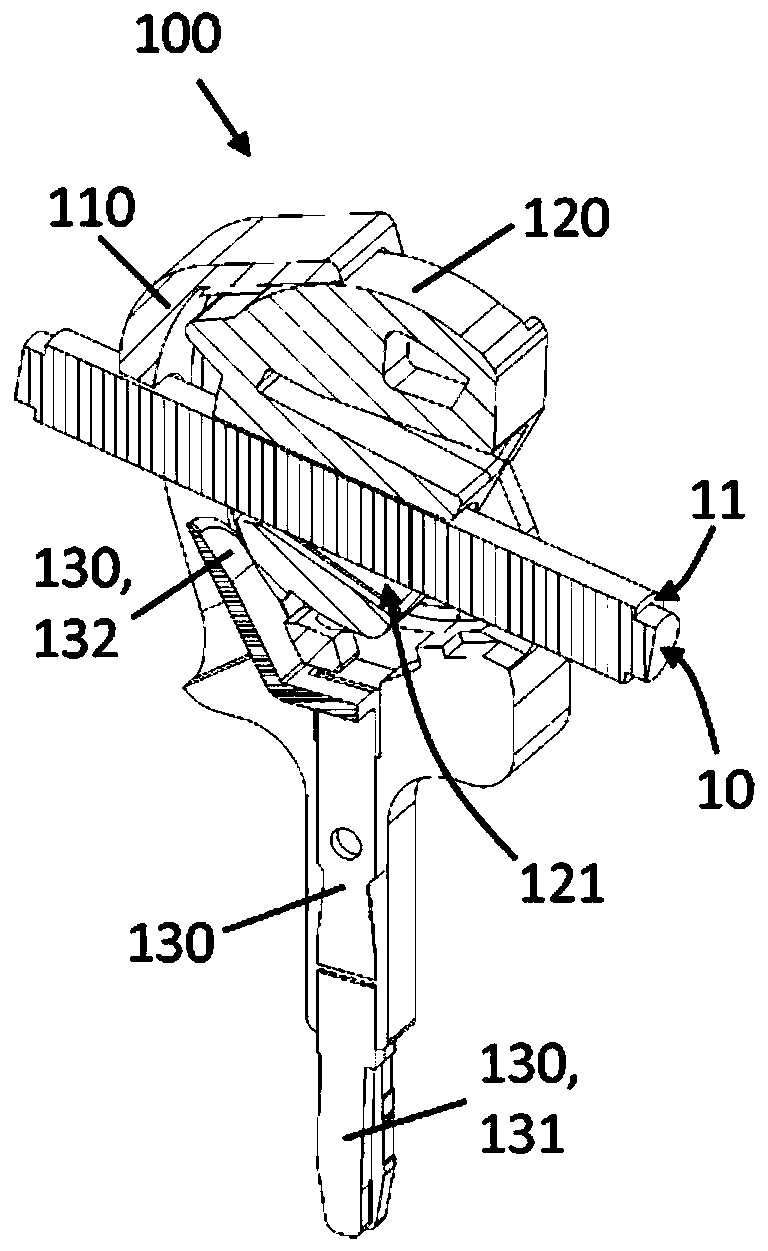

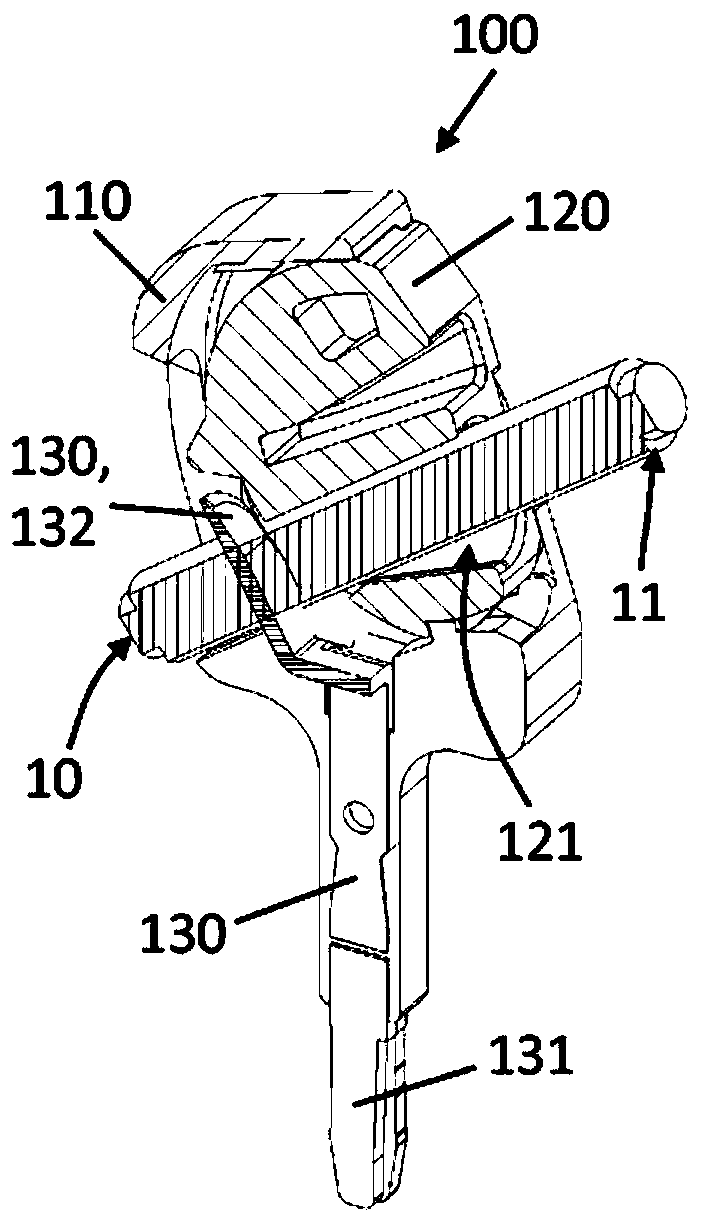

Gripper assembly for battery charging and discharging

ActiveUS20150061596A1Electrically conductive connectionsBatteries circuit arrangementsBattery electrodeBattery charge

Owner:LG ENERGY SOLUTION LTD

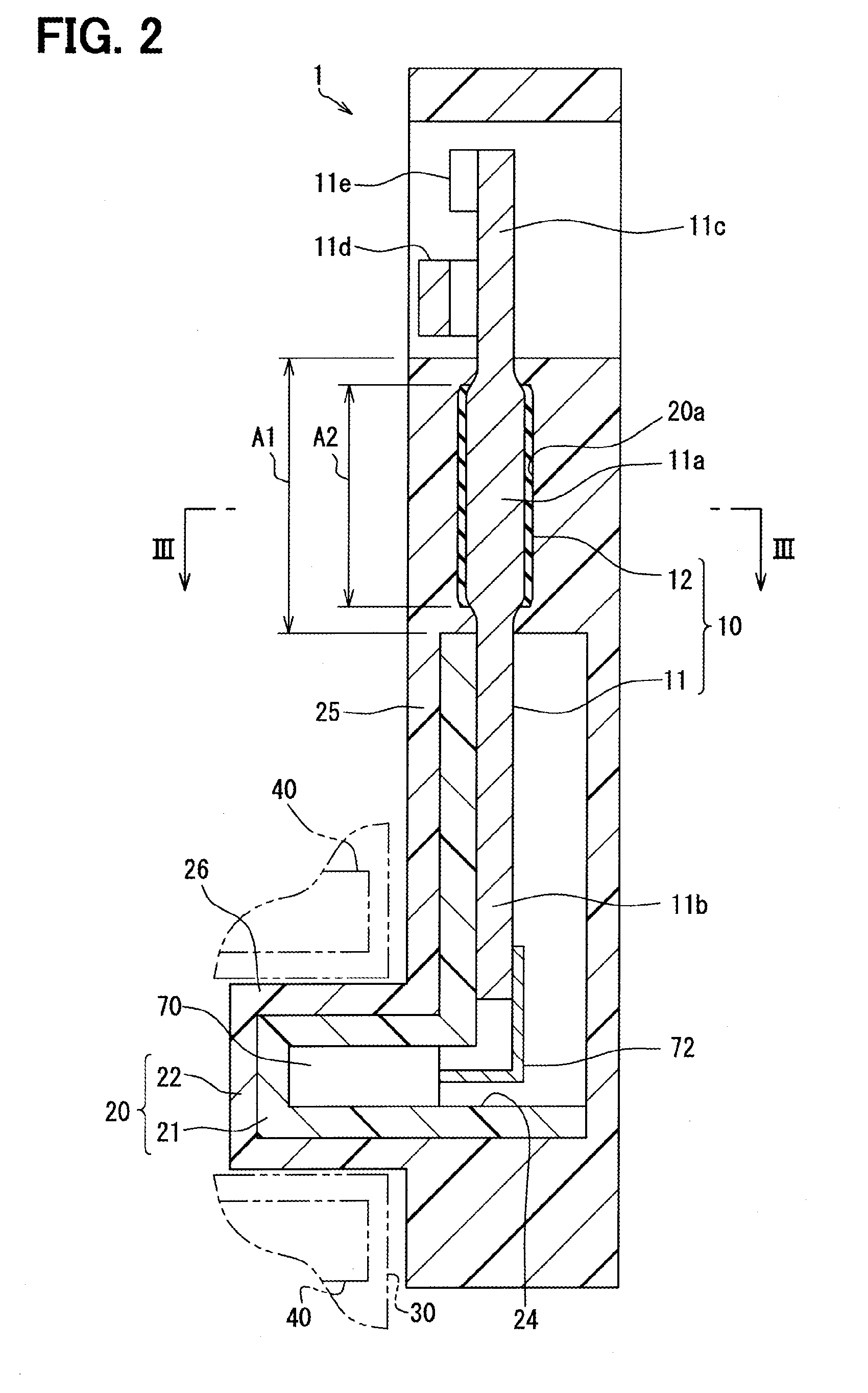

Method for manufacturing terminal, and terminal

ActiveUS20150207253A1Reduce thinningEasy electrical connectionContact member manufacturingElectrically conductive connectionsElectrically conductiveElectrical connection

A method for manufacturing a terminal includes: an electrically conductive member that has an electrical connection, which is formed at an end portion of the electrically conductive member; and a seal film that is formed in a surface of a predetermined portion of the electrically conductive member, which is other than the electrical connection. In the method for manufacturing, the electrically conductive member is formed by processing an end portion of a rounded rod, which has a cross section having an arcuate shape, into a planar shape to form the electrical connection. Furthermore, a liquid seal agent is coated on a predetermined portion of the rounded rod, which is other than the end portion. Then, the coated liquid seal agent is solidified to form the seal film.

Owner:DENSO CORP

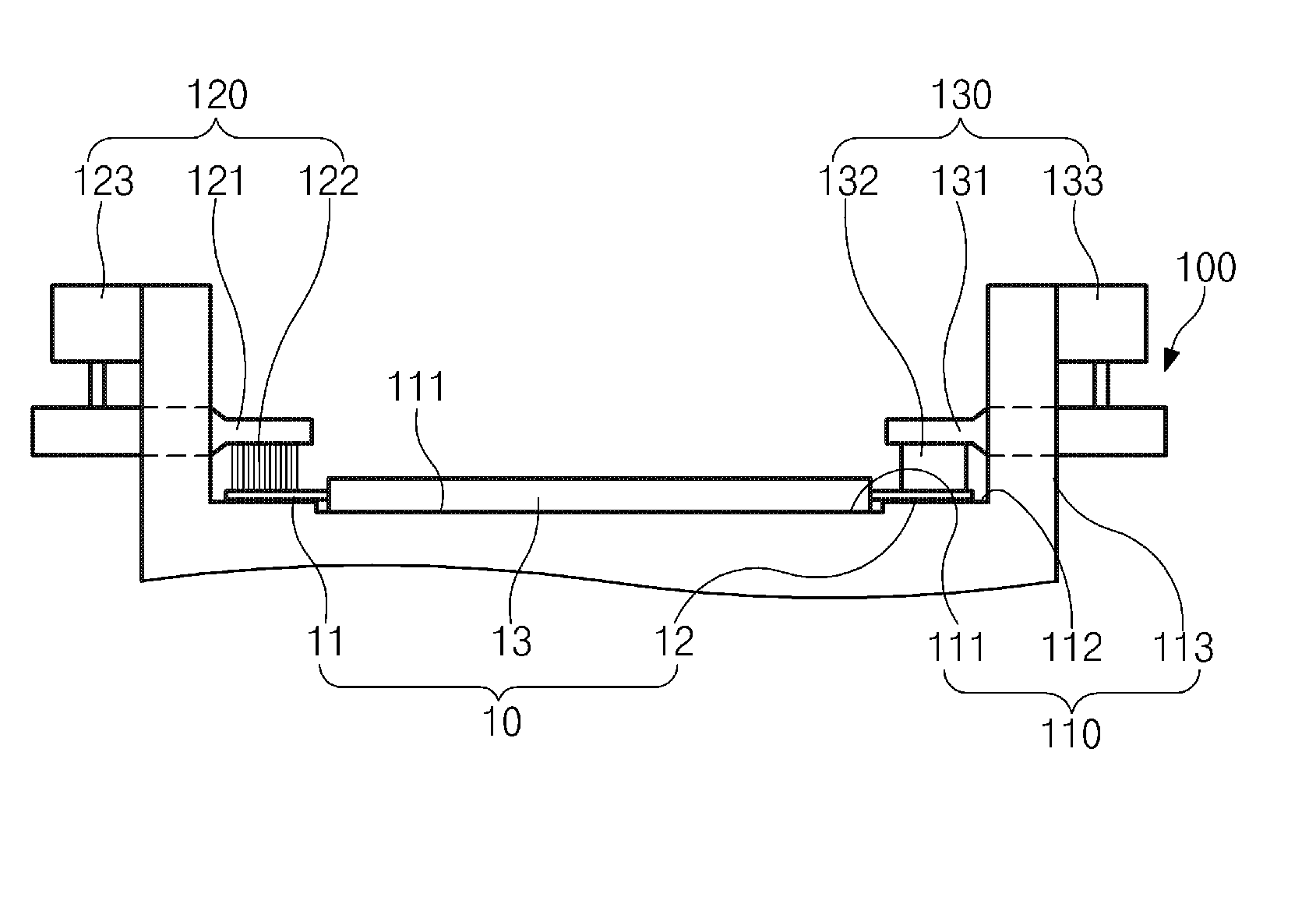

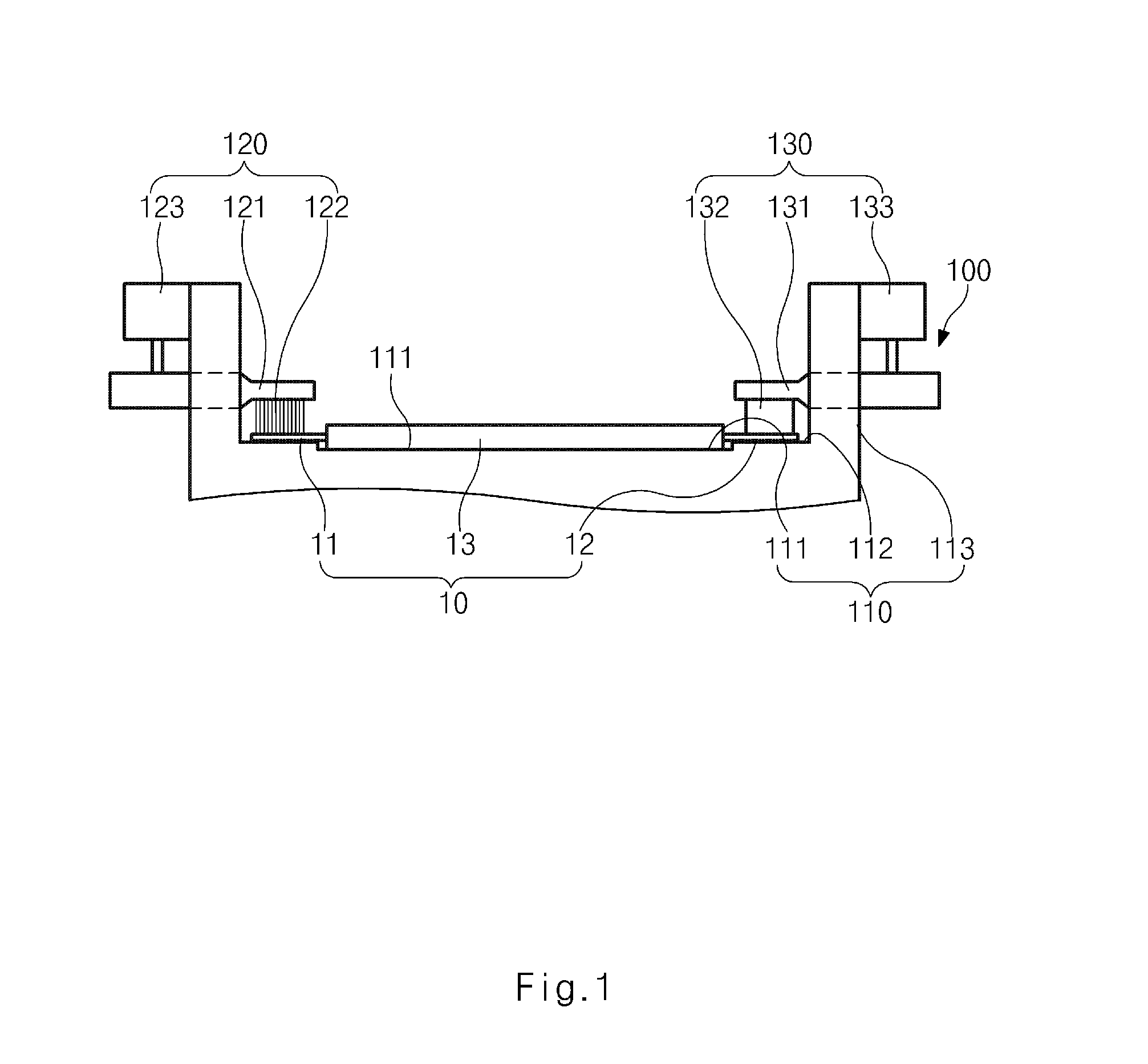

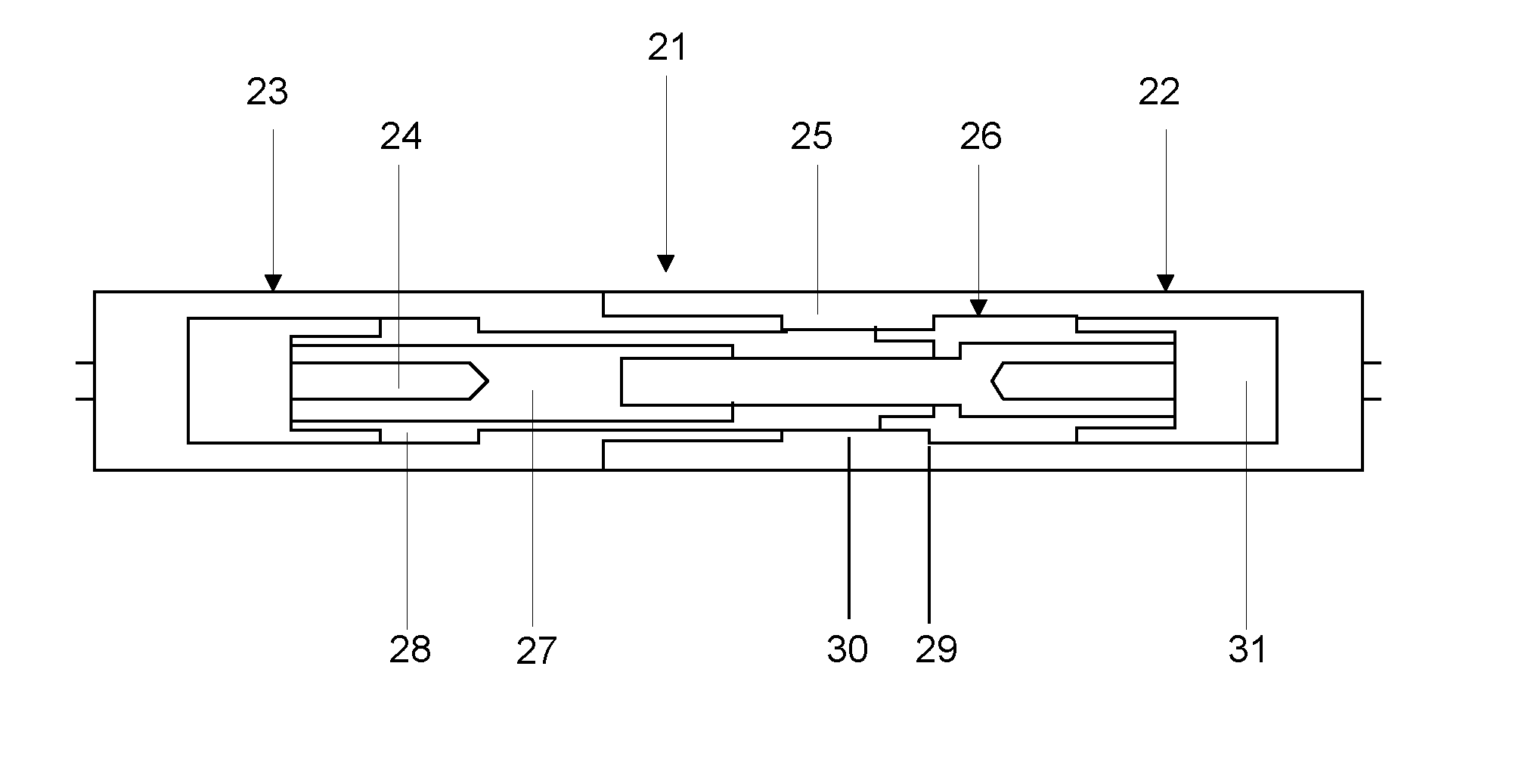

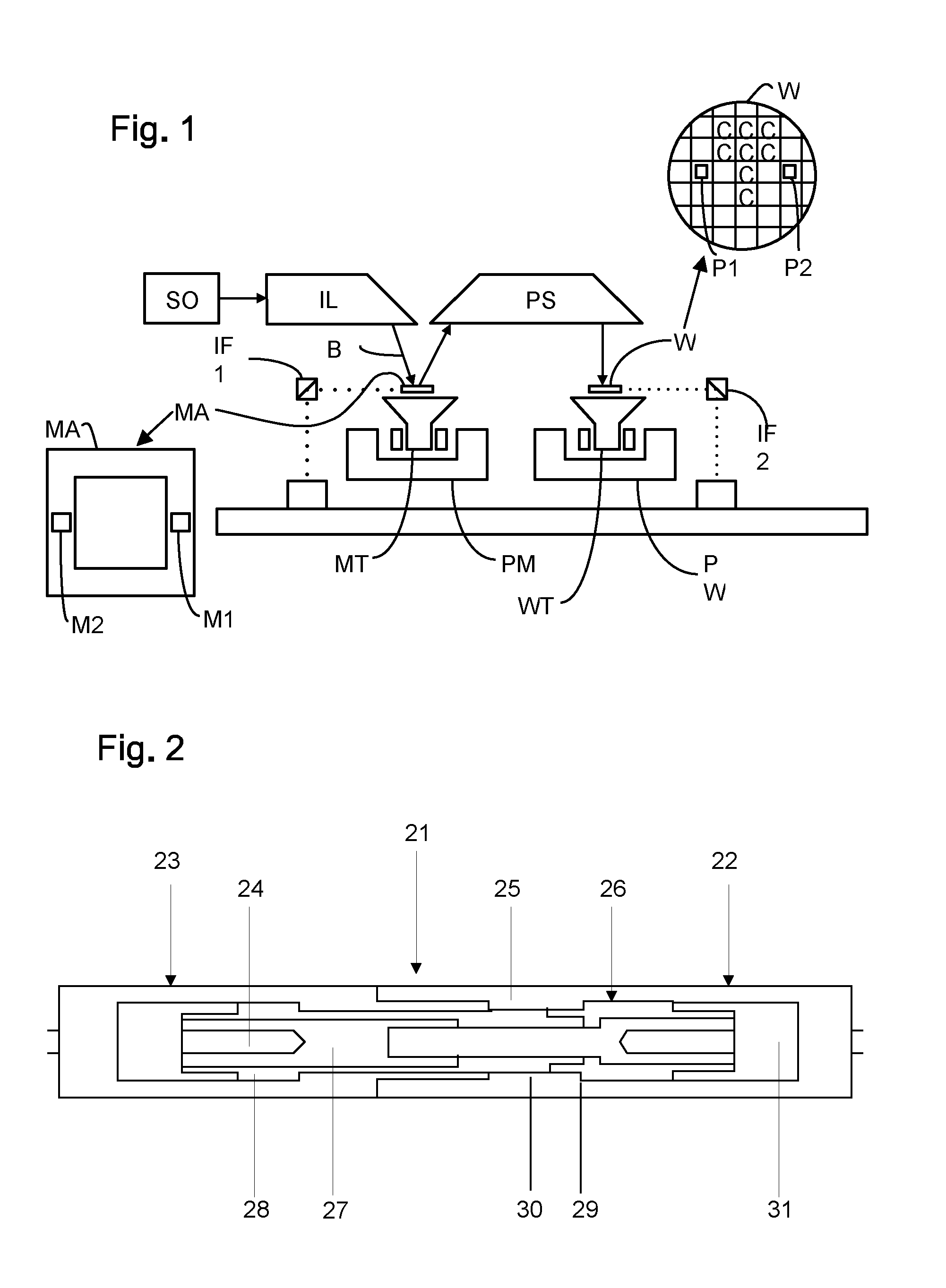

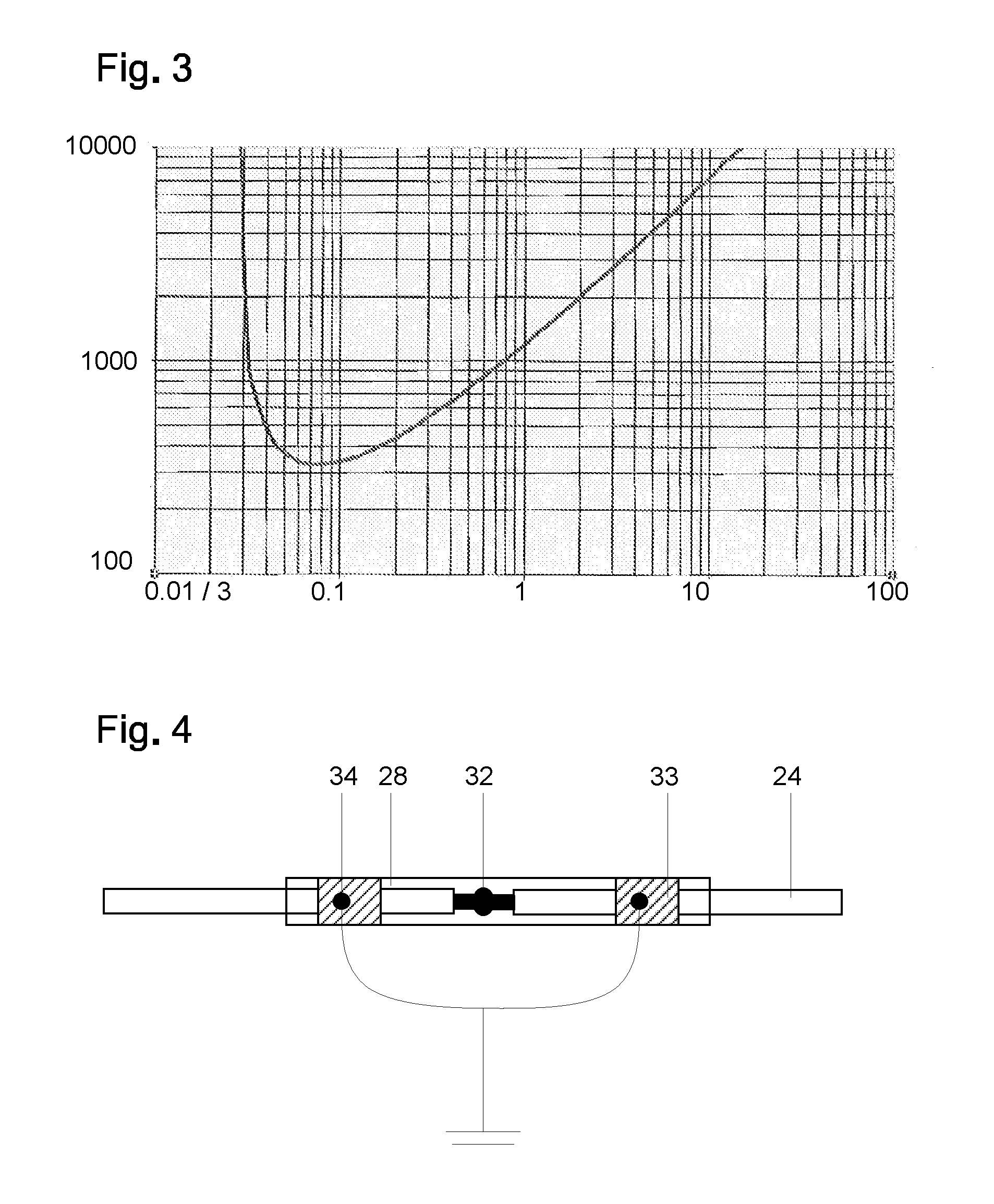

Lithographic Projection Apparatus and Device Manufacturing Method

ActiveUS20120154776A1Electrically conductive connectionsPhotomechanical apparatusElectricityElectrical conductor

Owner:ASML NETHERLANDS BV

Remote control device with improved shielding and grounding performance

InactiveUS20070247325A1Sufficient shielding and grounding propertyElectric signal transmission systemsElectrically conductive connectionsElectricityRemote control

A remote control device (100) includes an insulated housing (2, 3) including an outer surface (20, 30) plated with a conductive material for providing a suppression of EMI, an inner surface (21, 31), and a receiving space (4) defined by the outer surface and the inner surface, a printed circuit board (51) received in the receiving space, and including at least a first conductive pad (511), and a second conductive pad electrically connected to the first conductive pad by conductive trace, a cable including at least one grounding conductor electrically connected to the second conductive pad, grounding means (22) electrically connected to the conductive material and the first conductive pad for providing a sheath for ESD generated on the remote control device.

Owner:HON HAI PRECISION IND CO LTD

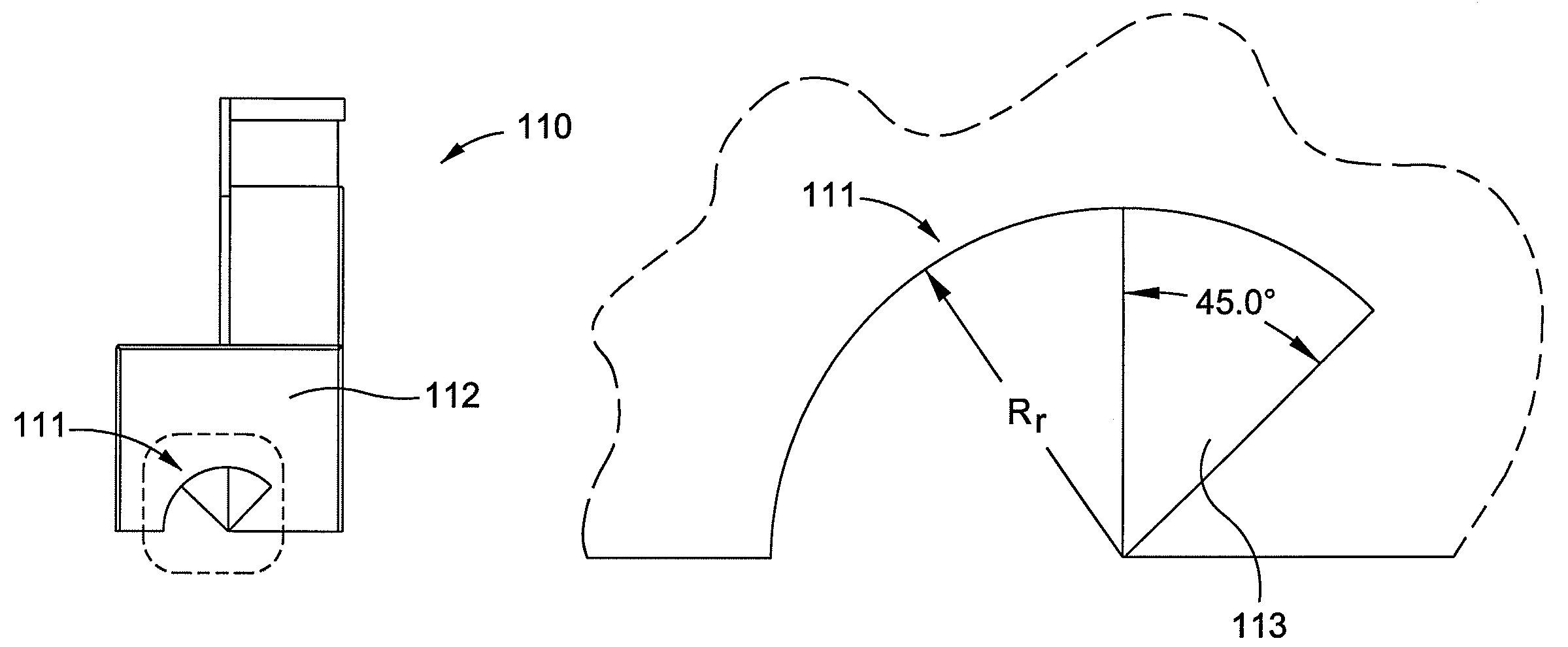

Lightweight electrical connector split backshell

InactiveUS7513799B1Reduce manufacturing costLow costElectrically conductive connectionsCoupling device detailsAngular distanceElectrical connector

Owner:LOCKHEED MARTIN CORP

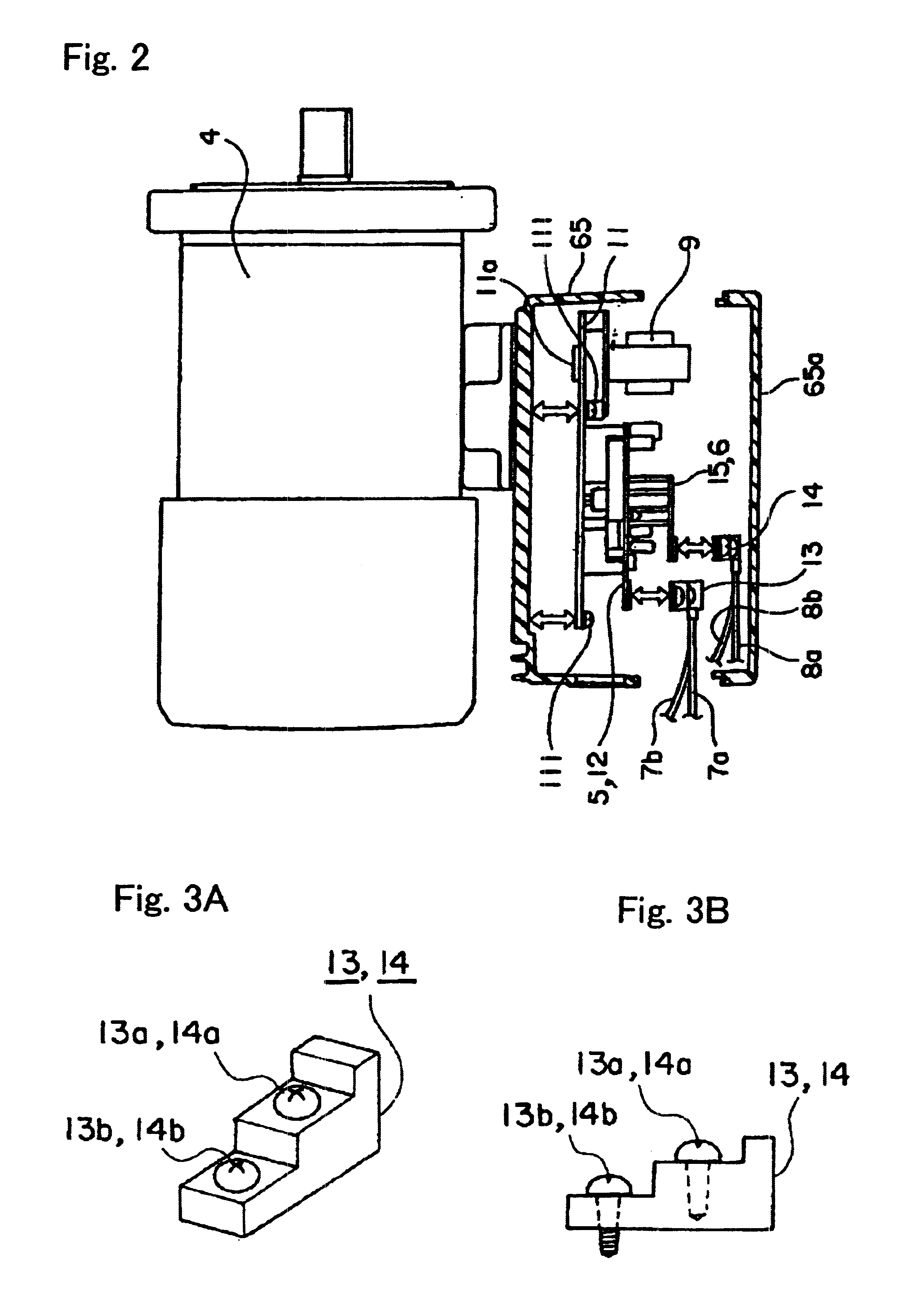

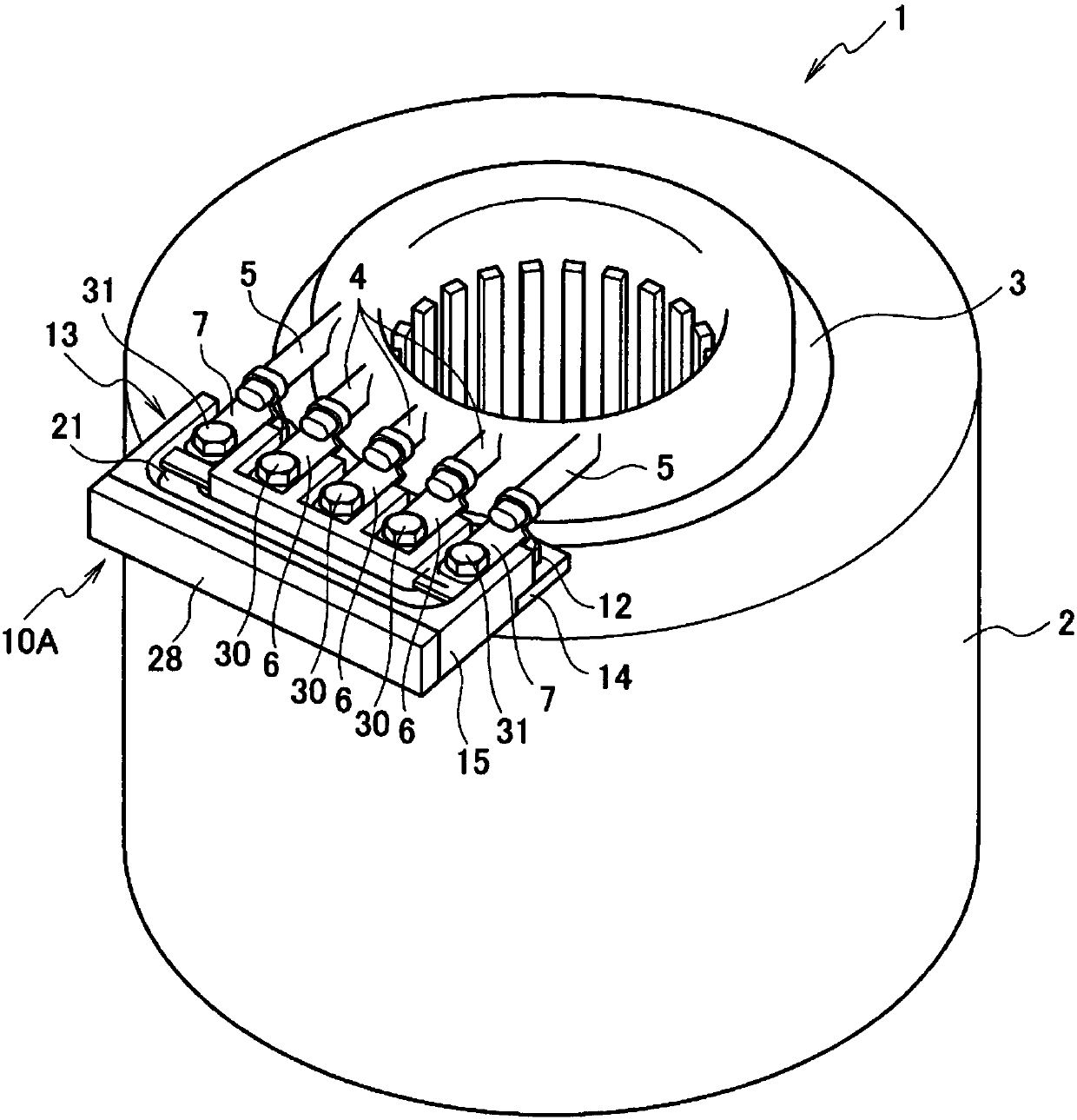

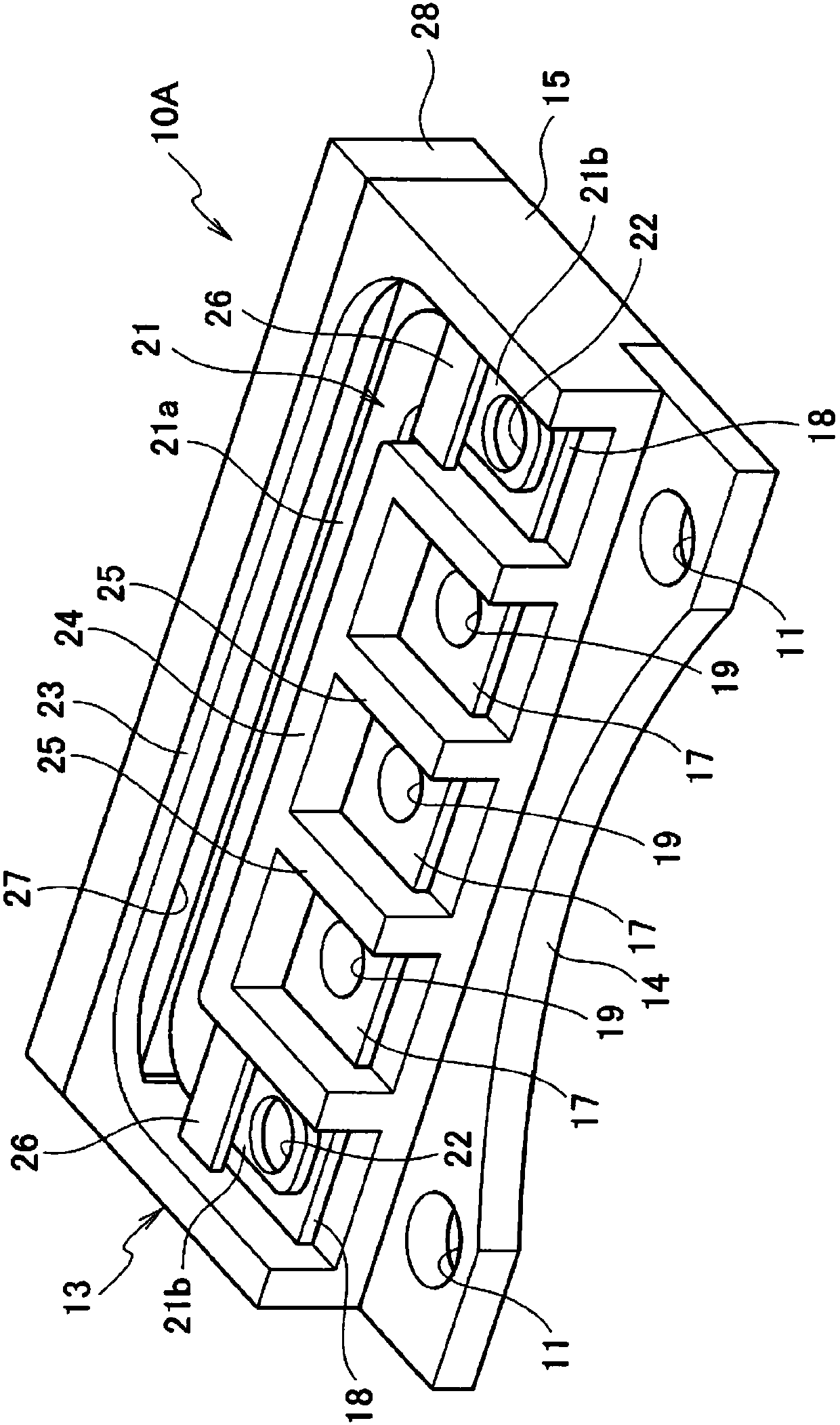

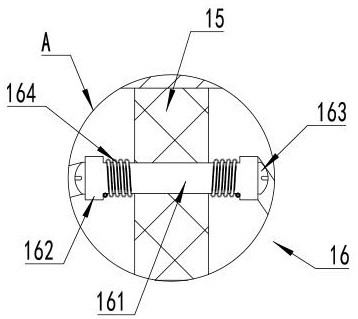

Terminal block of rotating electric machine

ActiveCN107925307AElectrically conductive connectionsSupports/enclosures/casingsHigh currentElectric machine

Owner:NISSAN MOTOR CO LTD

Electrical connector

InactiveUS20080287006A1Drawback can be obviatedElectrically conductive connectionsSecuring/insulating coupling contact membersElectrical connectionElectrical connector

Owner:INARCA

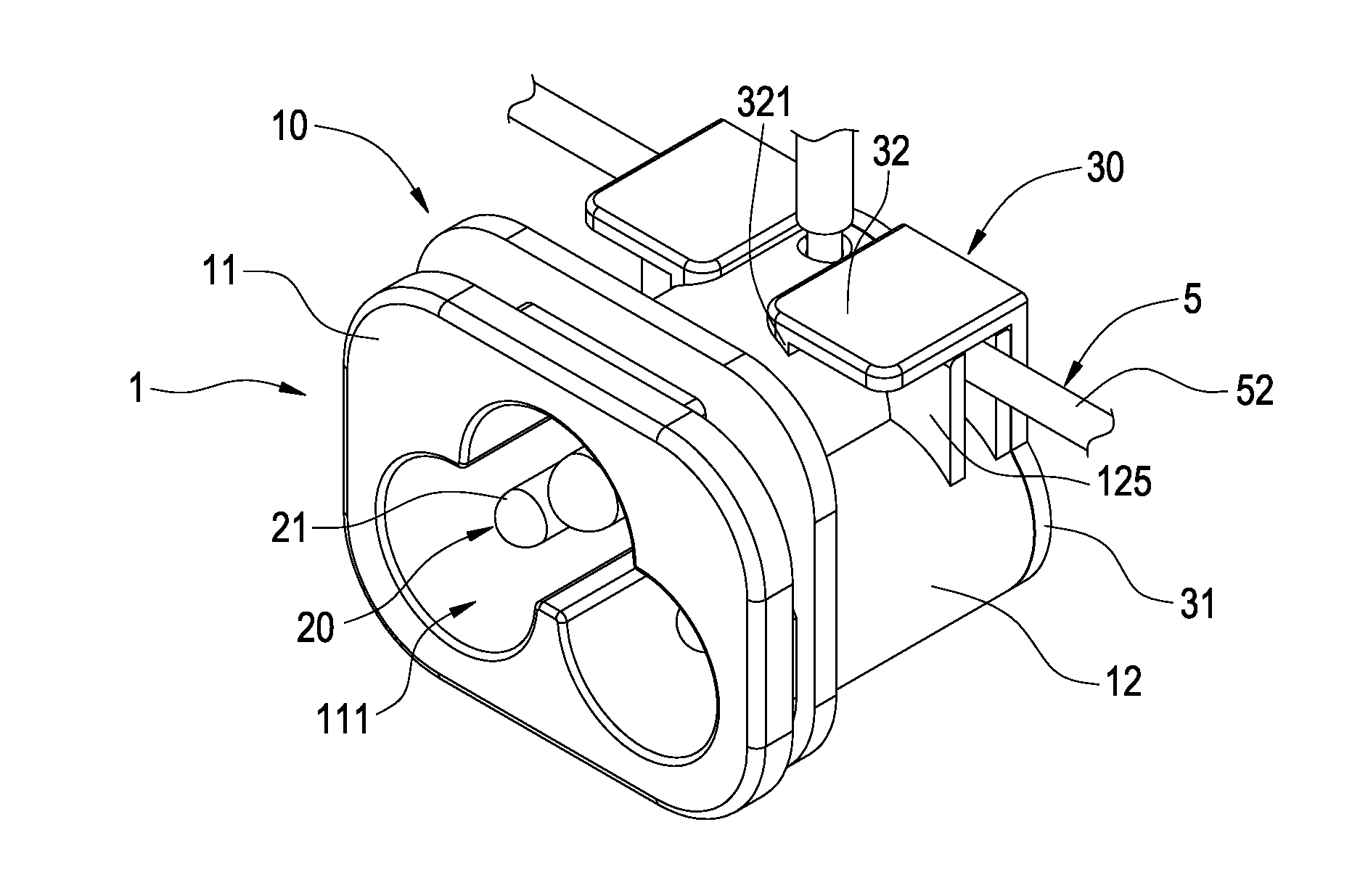

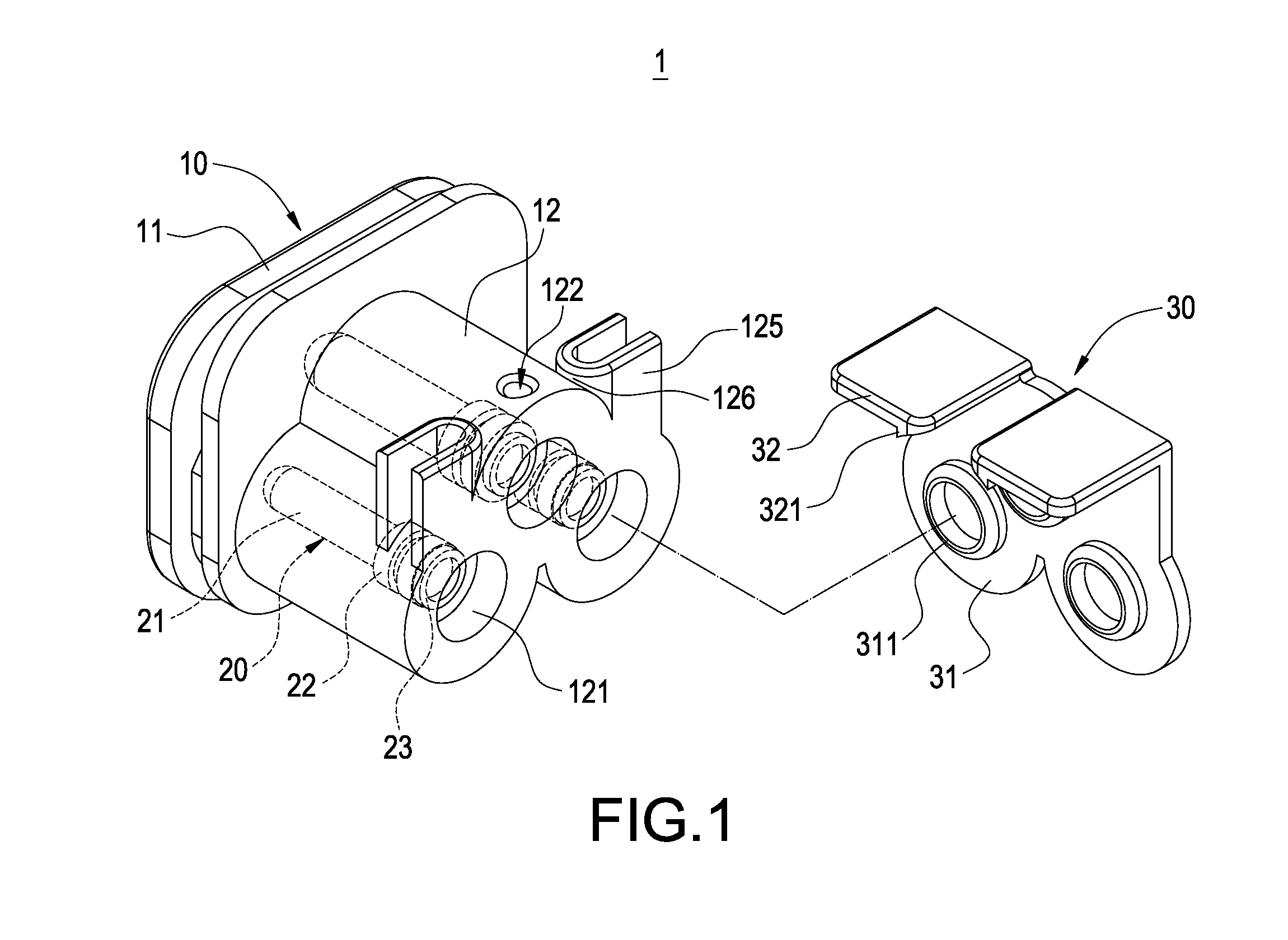

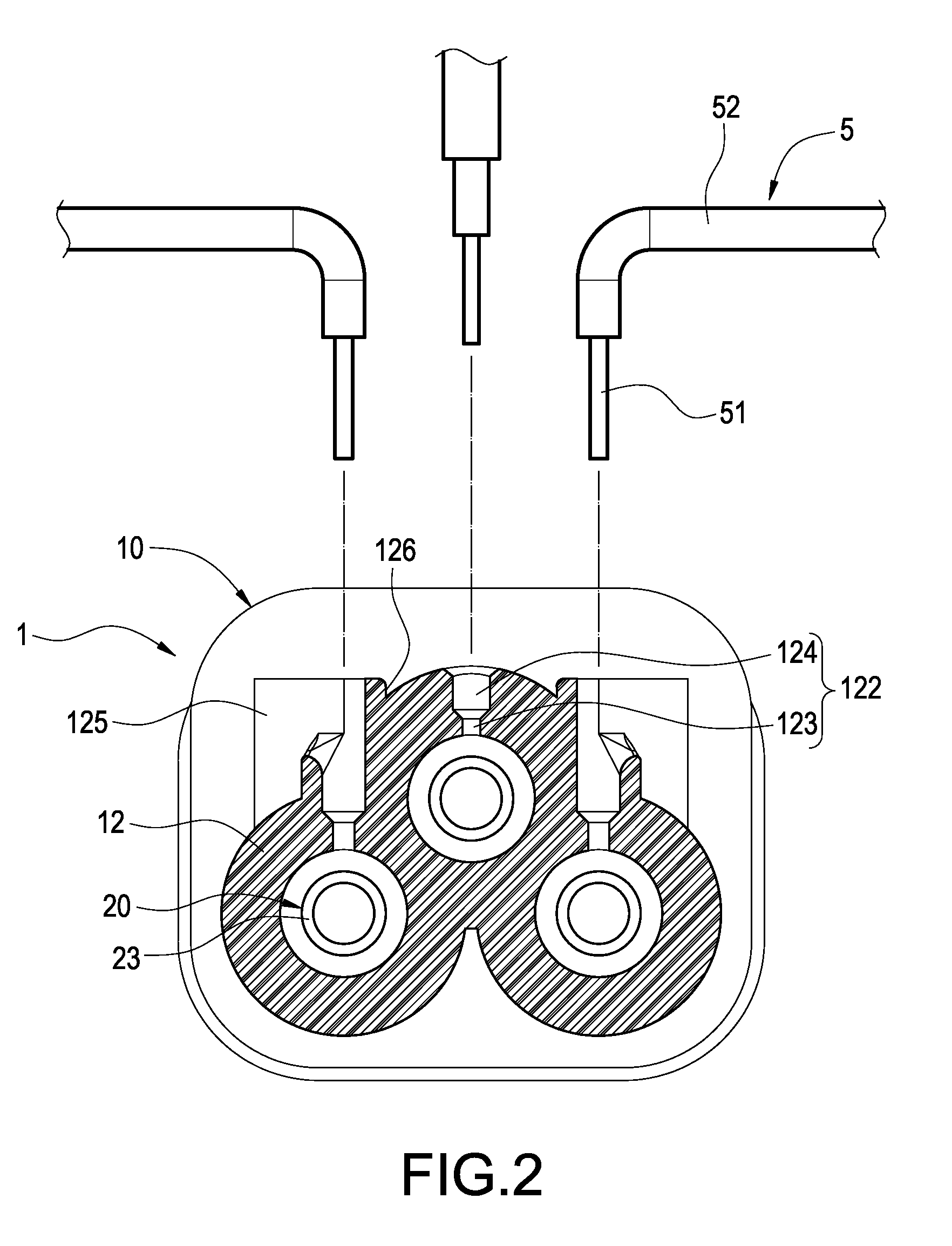

Power socket and adaptor having the same

ActiveUS20150288112A1Avoid conductionAvoid separationElectrically conductive connectionsTwo pole connectionsManufacturing cost reductionBiomedical engineering

Owner:CHICONY POWER TECH CO LTD

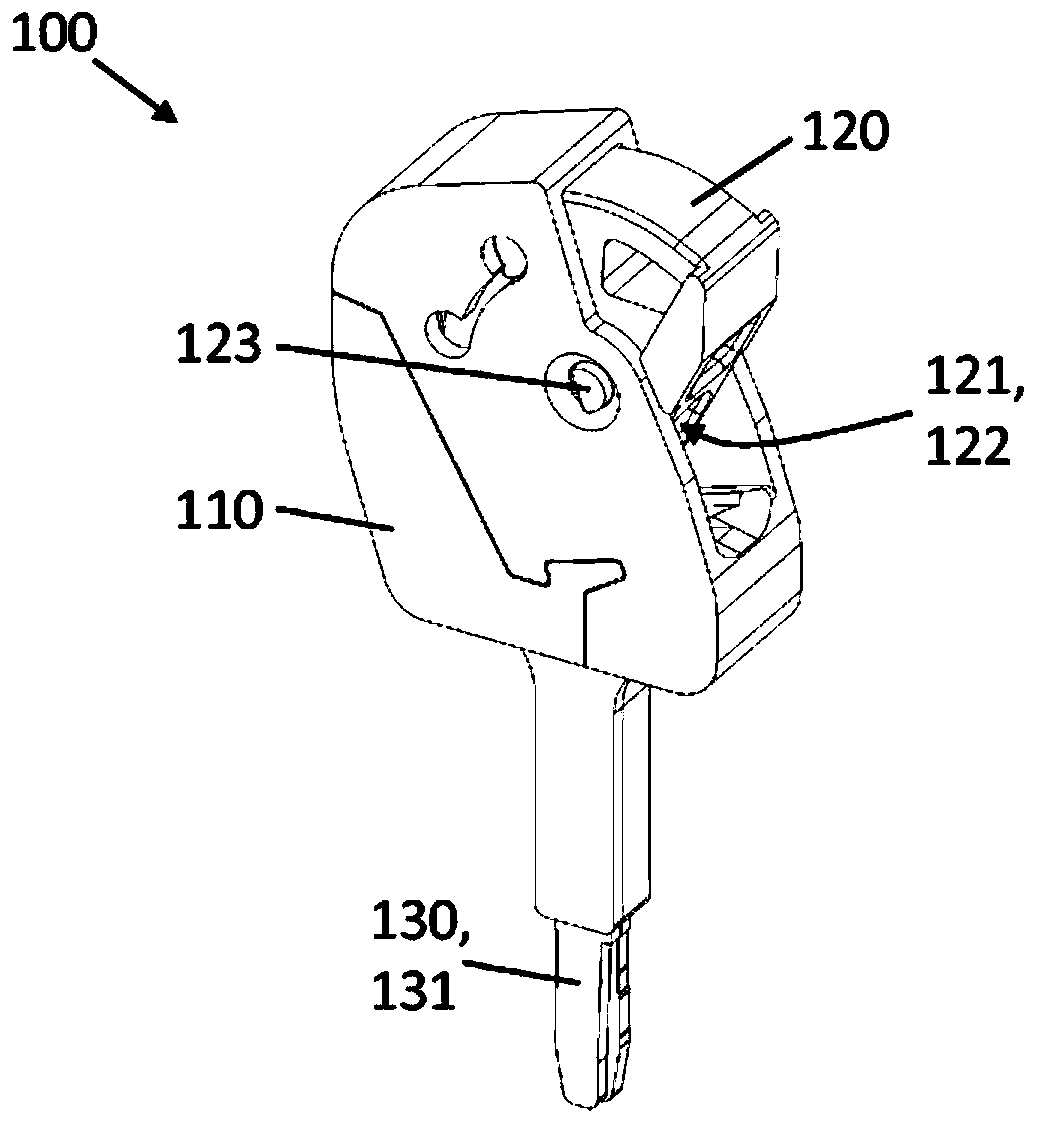

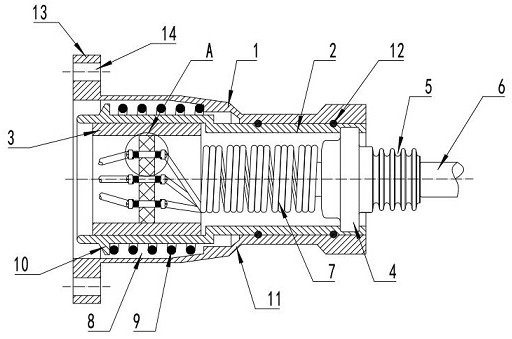

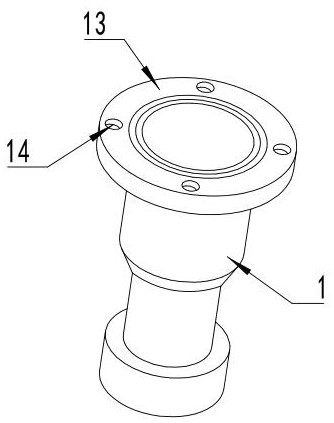

Battery-end electrical connector

ActiveCN109119775AImprove reliabilityImprove connection reliabilityElectrically conductive connectionsCoupling contact membersEngineeringElectrical connector

The invention discloses a battery-end electrical connector comprising conductive pole columns and a pole column mounting base. The conductive pole columns are arranged on the pole column mounting base. The pole column mounting base is provided with mounting holes. The conductive pole columns are clamped into the mounting holes. There is a positioning part on the outer wall of each conductive polecolumn, and the positioning parts are used to limit the movement of the conductive pole columns along the axial direction of the mounting holes relative to the pole column mounting base. Each conductive pole column has a head end and a tail end. The head ends of the conductive pole columns are parallel to the surface on one side of the pole column mounting base, and the tail ends protrude from thesurface on the other side of the pole column mounting base. The conductive pole columns in the battery-end electrical connector will not move along the axial direction of the mounting holes relativeto the pole column mounting base. The reliability of connection between the conductive pole columns and the pole column mounting base is improved, and the reliability of the battery-end electrical connector is improved.

Owner:SHANGHAI DIANBA NEW ENERGY RESOURCES SCI & TECH +1

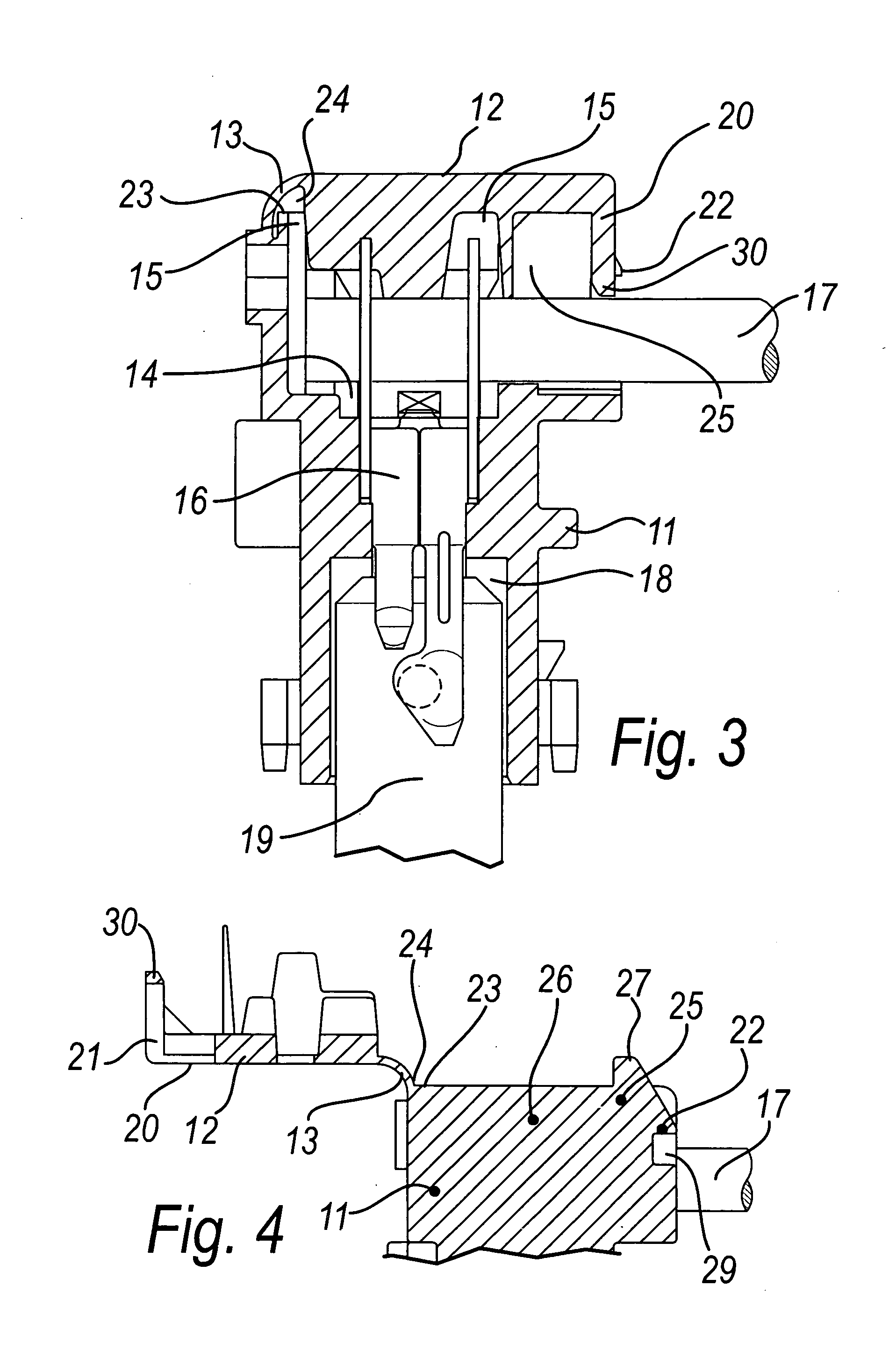

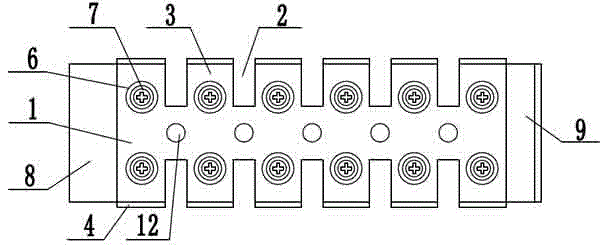

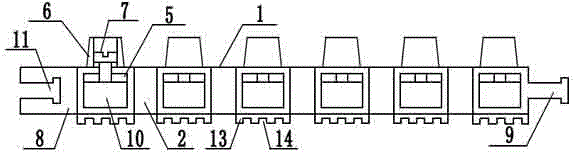

Cable bridge module for flexibly linking connection terminals

ActiveCN110366798ACoupling device connectionsElectrically conductive connectionsElectricityElectrical connection

Owner:PHOENIX CONTACT GMBH & CO KG

Communication cable joint structure and installation method thereof

ActiveCN112769090ALine/current collector detailsElectrically conductive connectionsControl theoryElectric cables

Owner:天津七一二移动通信有限公司

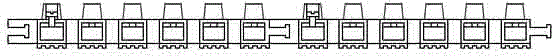

Wiring terminal with multiple segments capable of being in lap joint

InactiveCN104466451AGuarantee the number of connection holesSimple structureElectrically conductive connectionsLap jointEngineering

Owner:潘阿海

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap