Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90 results about "Printed circuit board" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A printed circuit board (PCB) mechanically supports and electrically connects electronic components or electrical components using conductive tracks, pads and other features etched from one or more sheet layers of copper laminated onto and/or between sheet layers of a non-conductive substrate. Components are generally soldered onto the PCB to both electrically connect and mechanically fasten them to it.

Methods for upgrading, diagnosing, and maintaining replaceable non-volatile memory

In one embodiment of the invention, a replaceable memory apparatus is disclosed. The replaceable memory apparatus includes a first rectangular multilayer printed circuit board having a first side and a second side opposite the first side; a first male pluggable electrical connector mounted to the first side near a first edge; a first female pluggable electrical connector mounted to the second side; and first non-volatile memory mounted to the first side and the second side. The first female pluggable electrical connector is coupled to the first male pluggable electrical connector to feed through first signals. The first non-volatile memory is coupled to the first female pluggable electrical connector and the first male pluggable electrical connector to receive the first signals.

Owner:WESTERN DIGITAL TECH INC

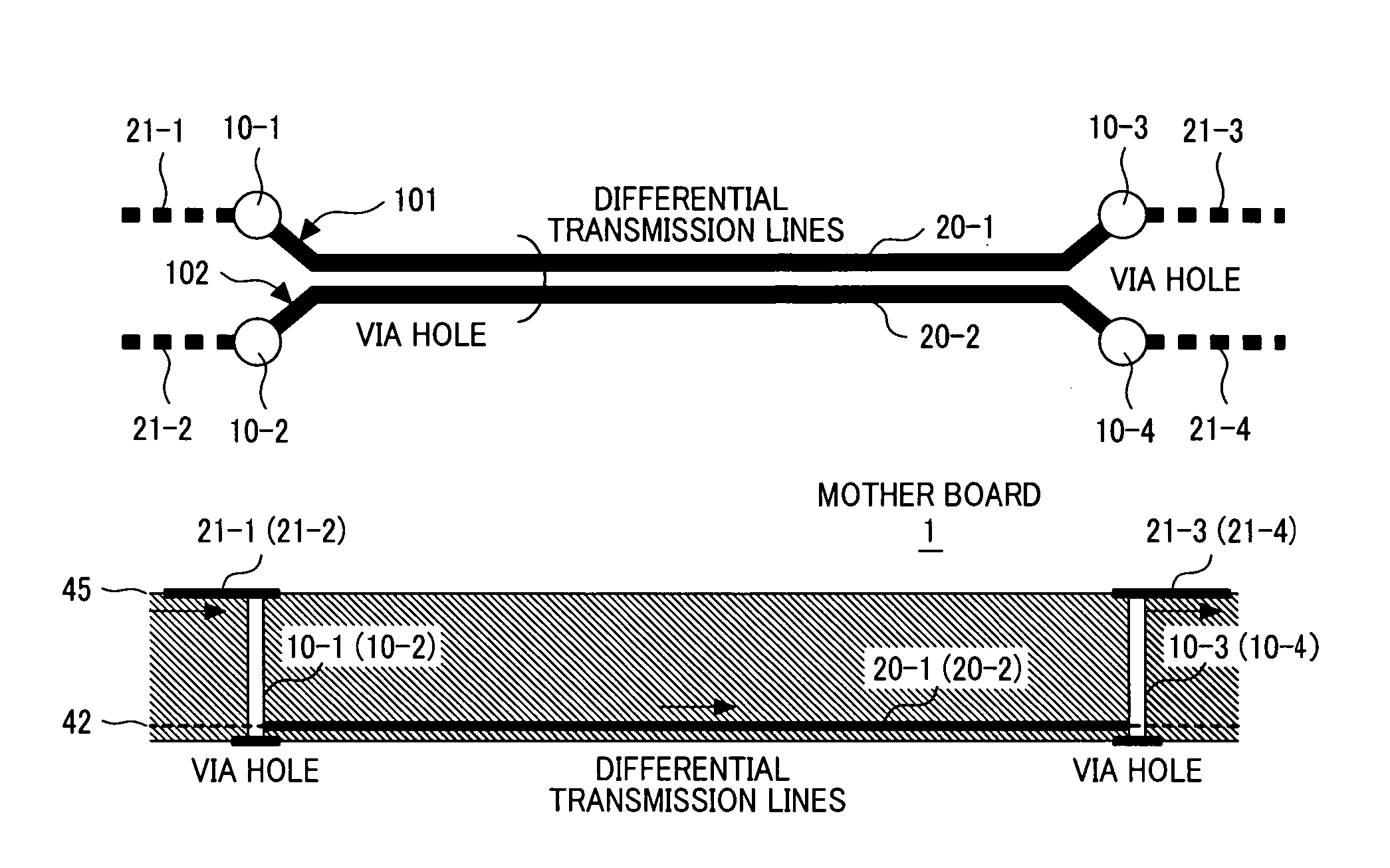

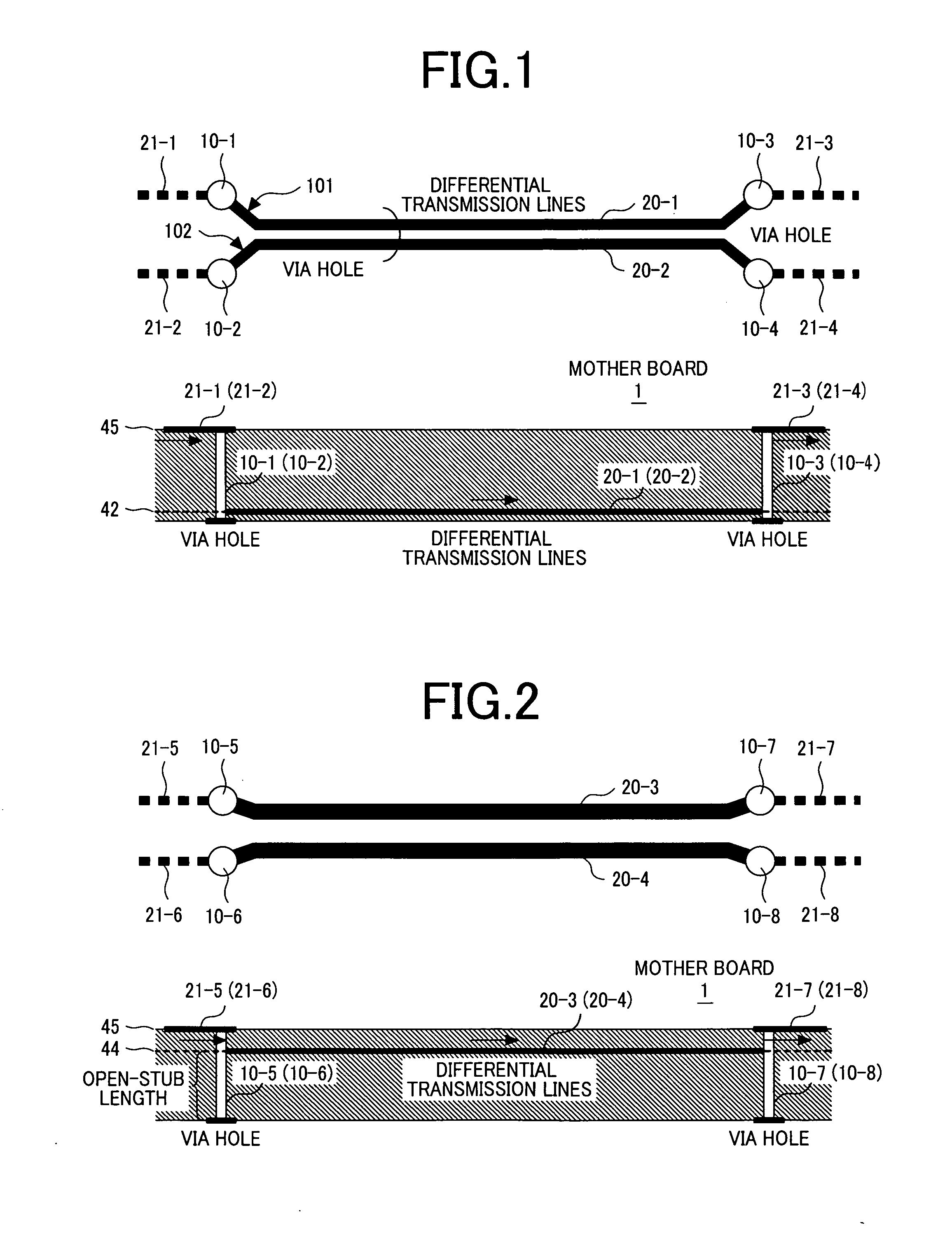

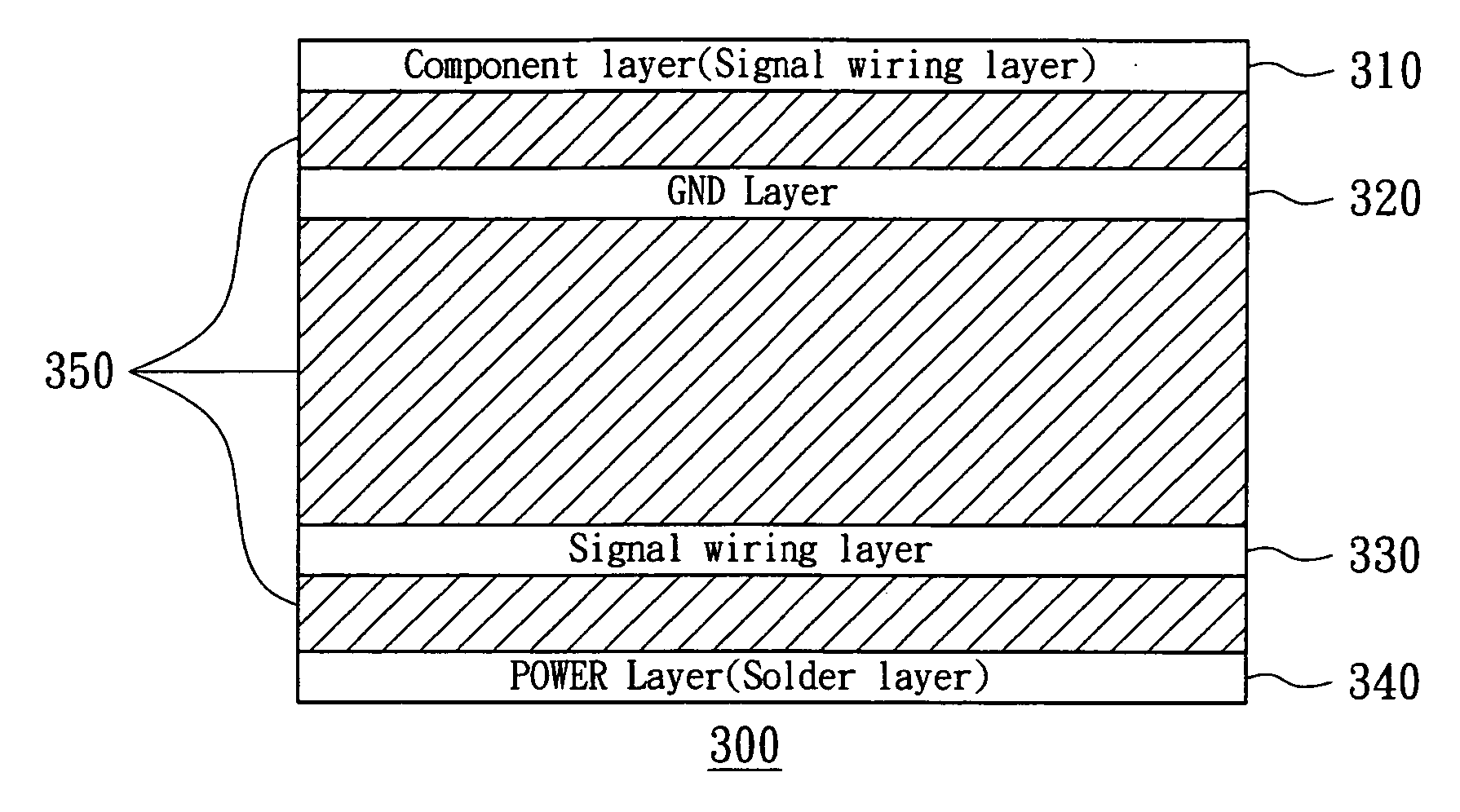

Multilayer printed circuit board for high-speed differential signal, communication apparatus, and data storage apparatus

InactiveUS20070130555A1Decreasing reflection of backwardReduce jitterRotary current collectorSemiconductor/solid-state device detailsCouplingDifferential transmission

Owner:HITACHI LTD

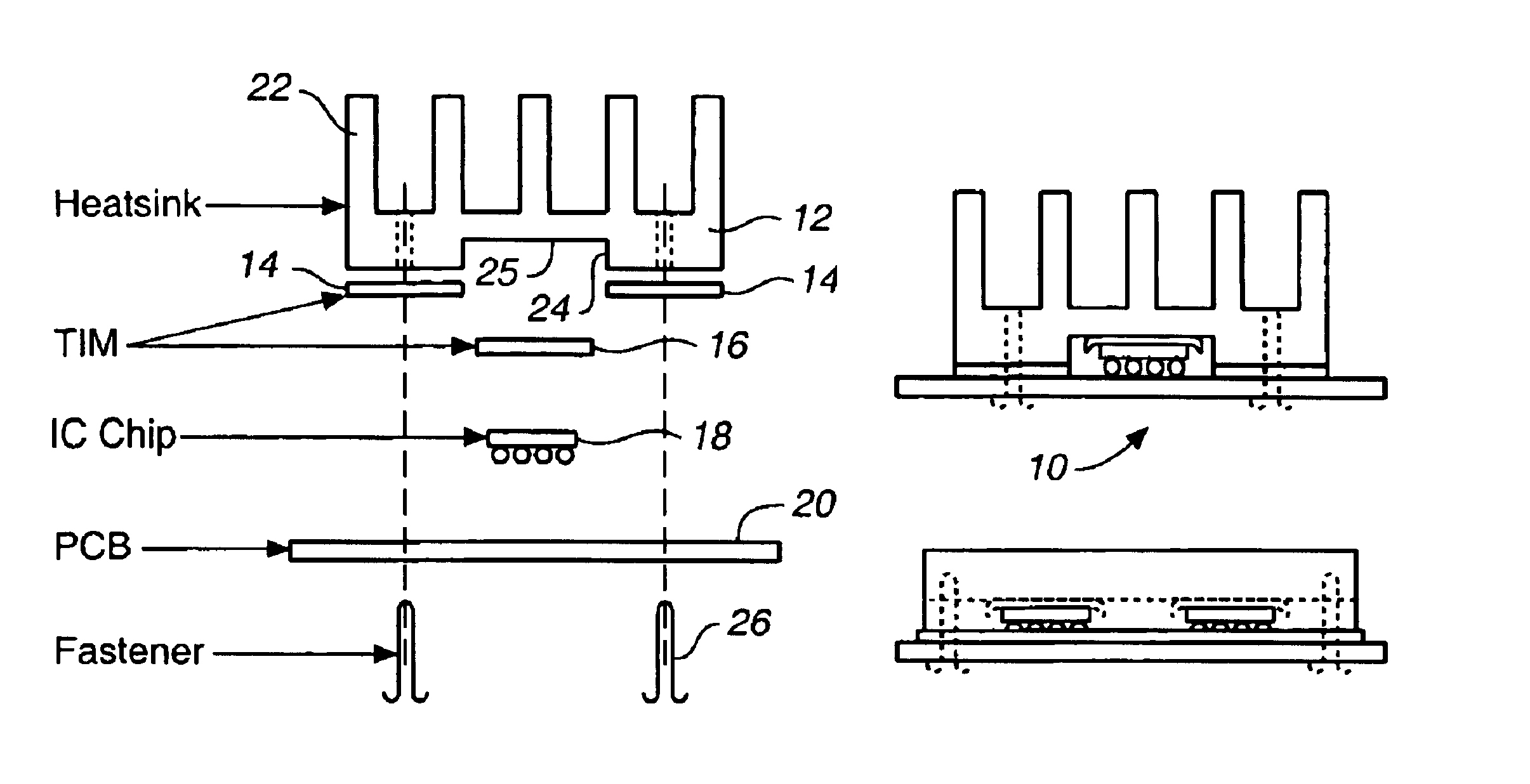

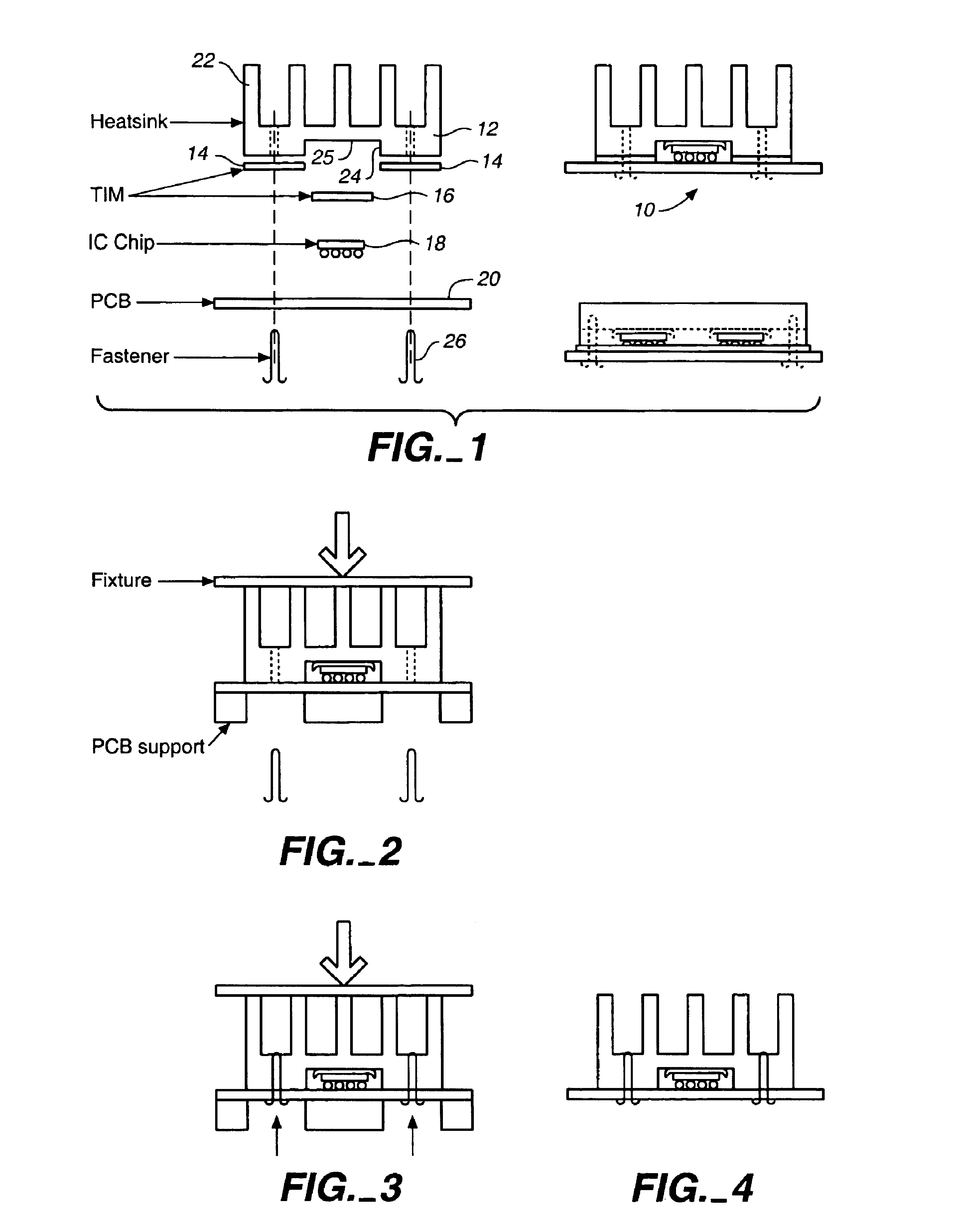

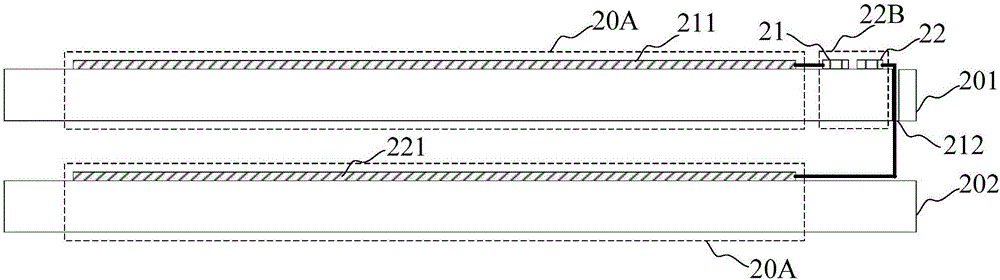

Heatsinking and packaging of integrated circuit chips

InactiveUS6853068B1Semiconductor/solid-state device detailsSolid-state devicesIntegrated circuitPrinted circuit board

Owner:VOLTERRA SEMICONDUCTOR

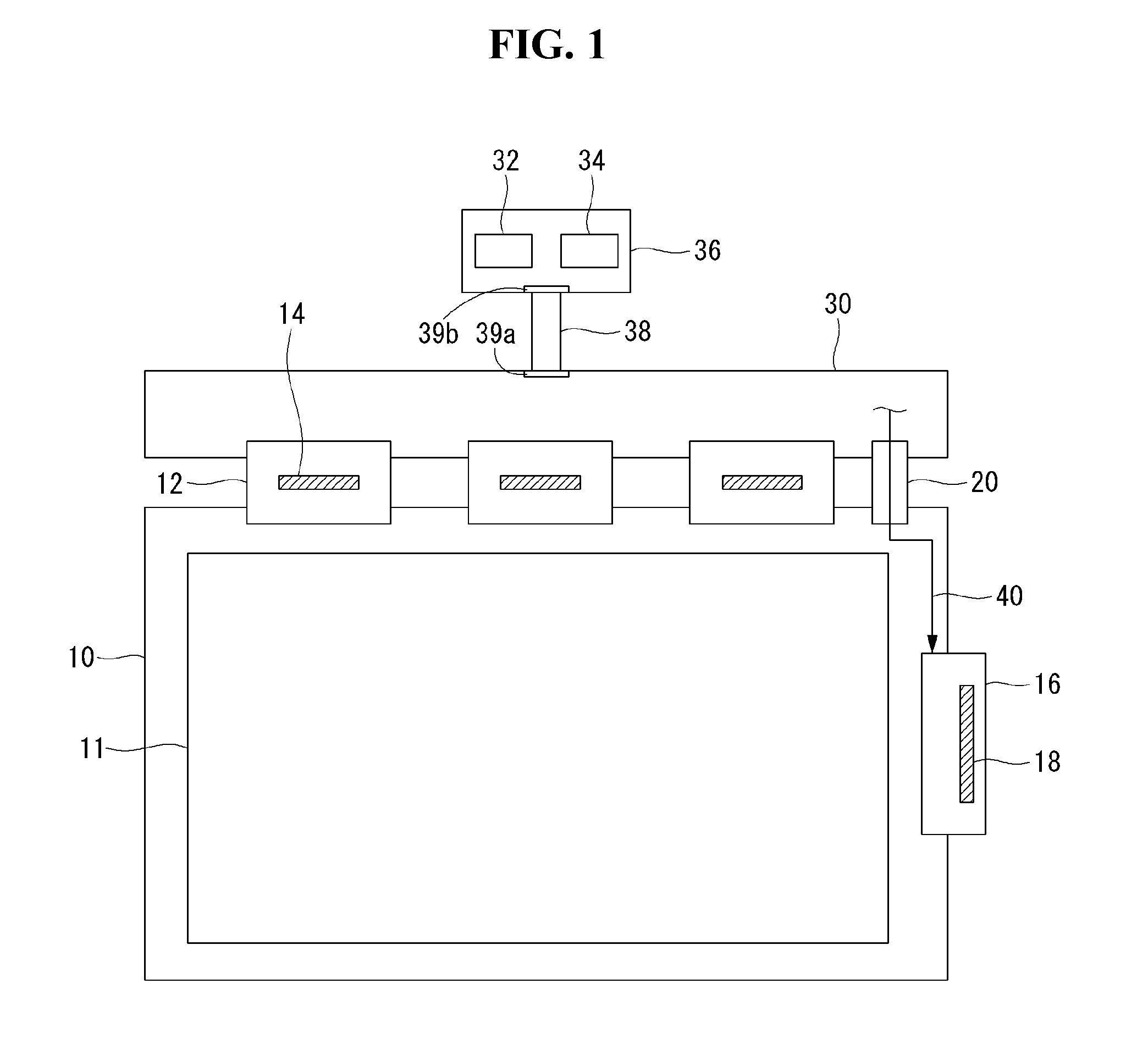

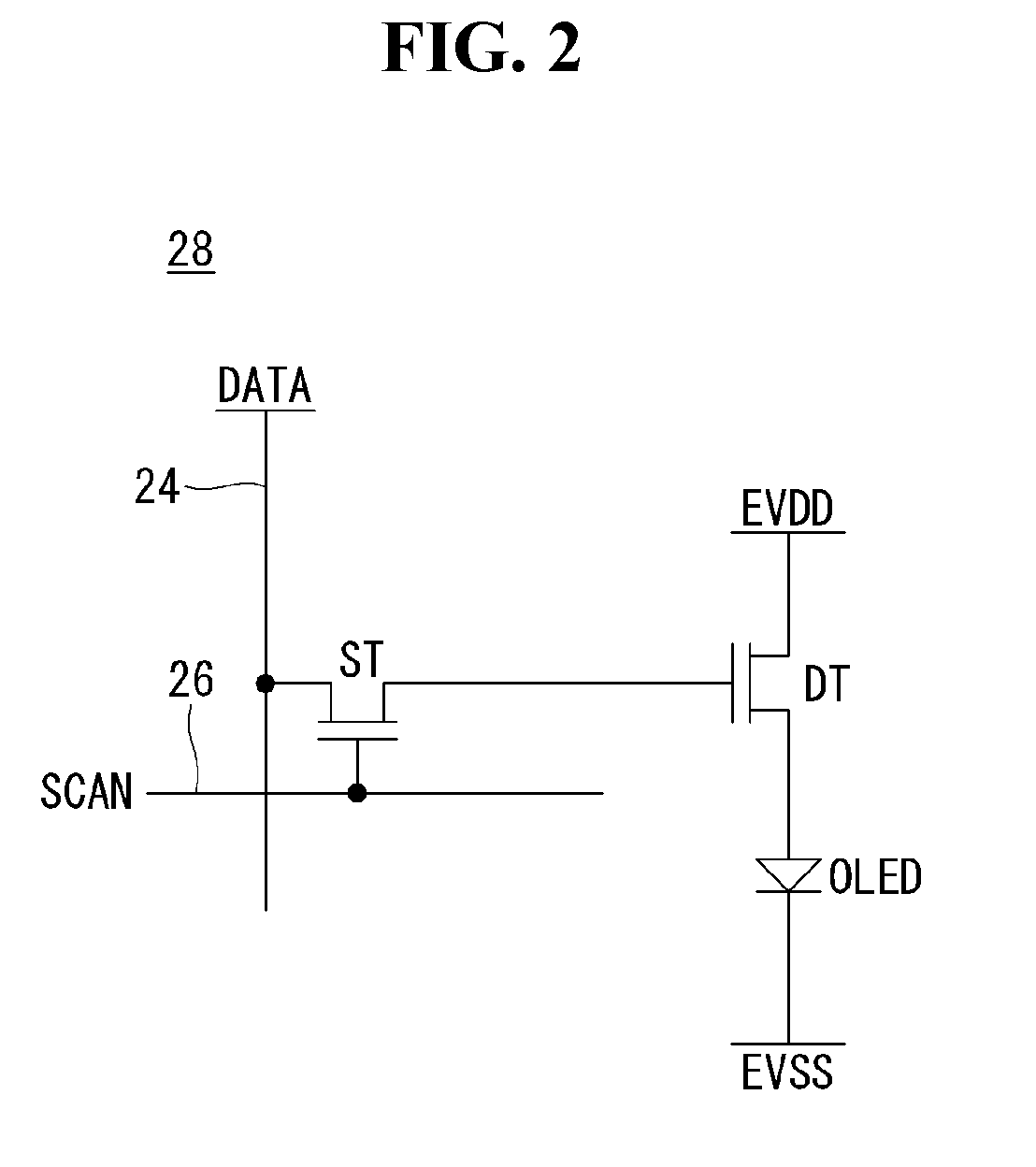

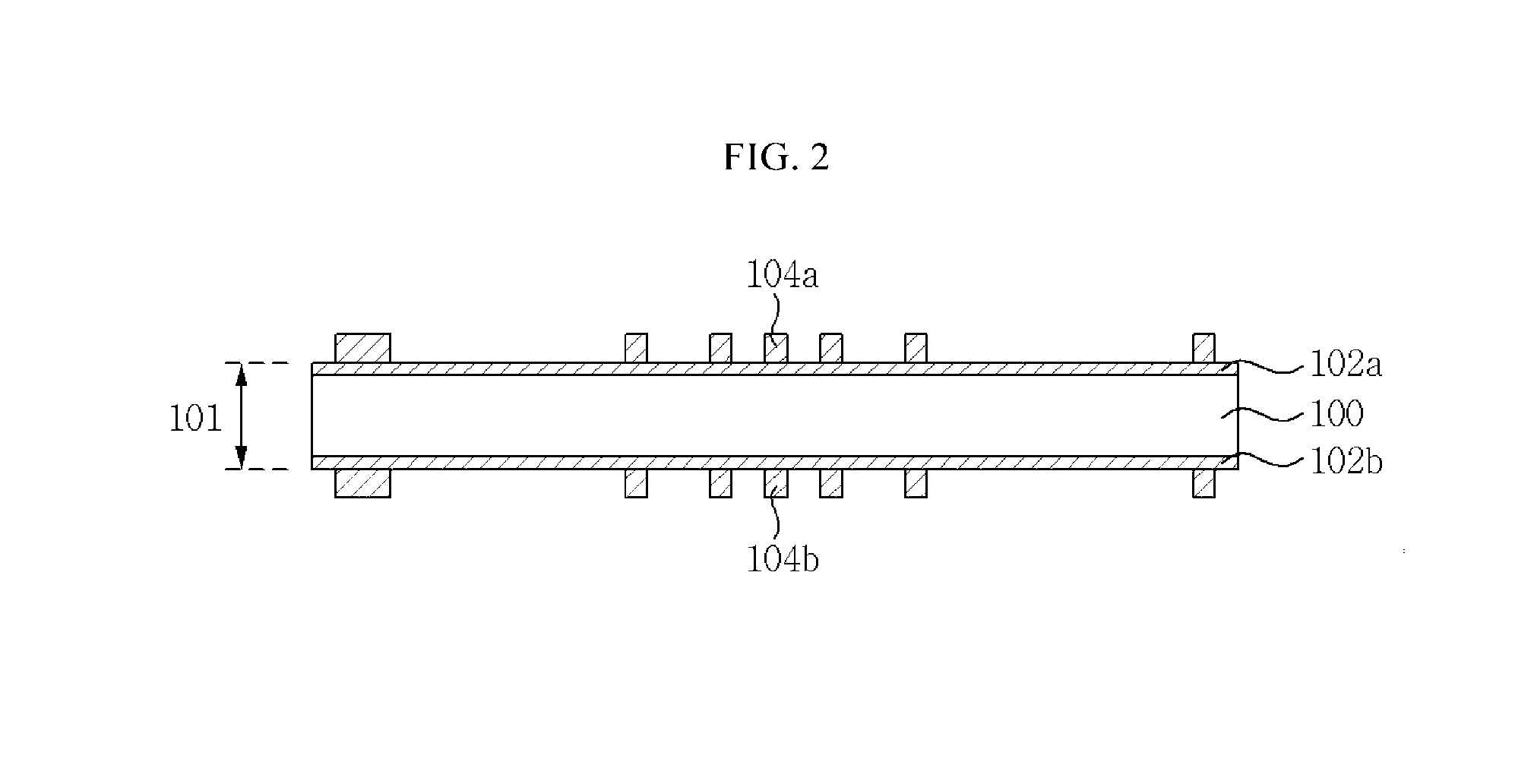

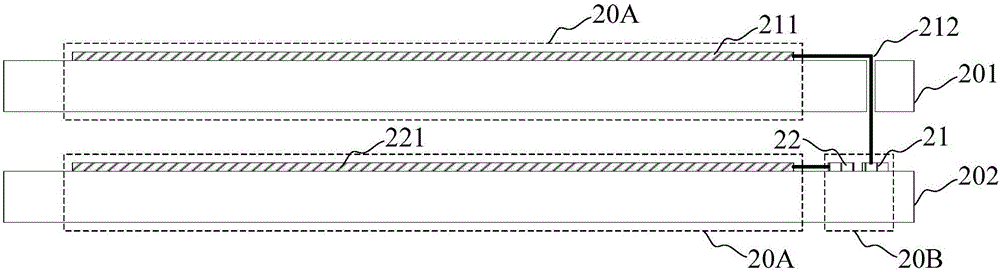

Display device having flexible film cable

ActiveUS20140085281A1Avoid crackingBlock display panelCathode-ray tube indicatorsInput/output processes for data processingDisplay deviceEngineering

Owner:LG DISPLAY CO LTD

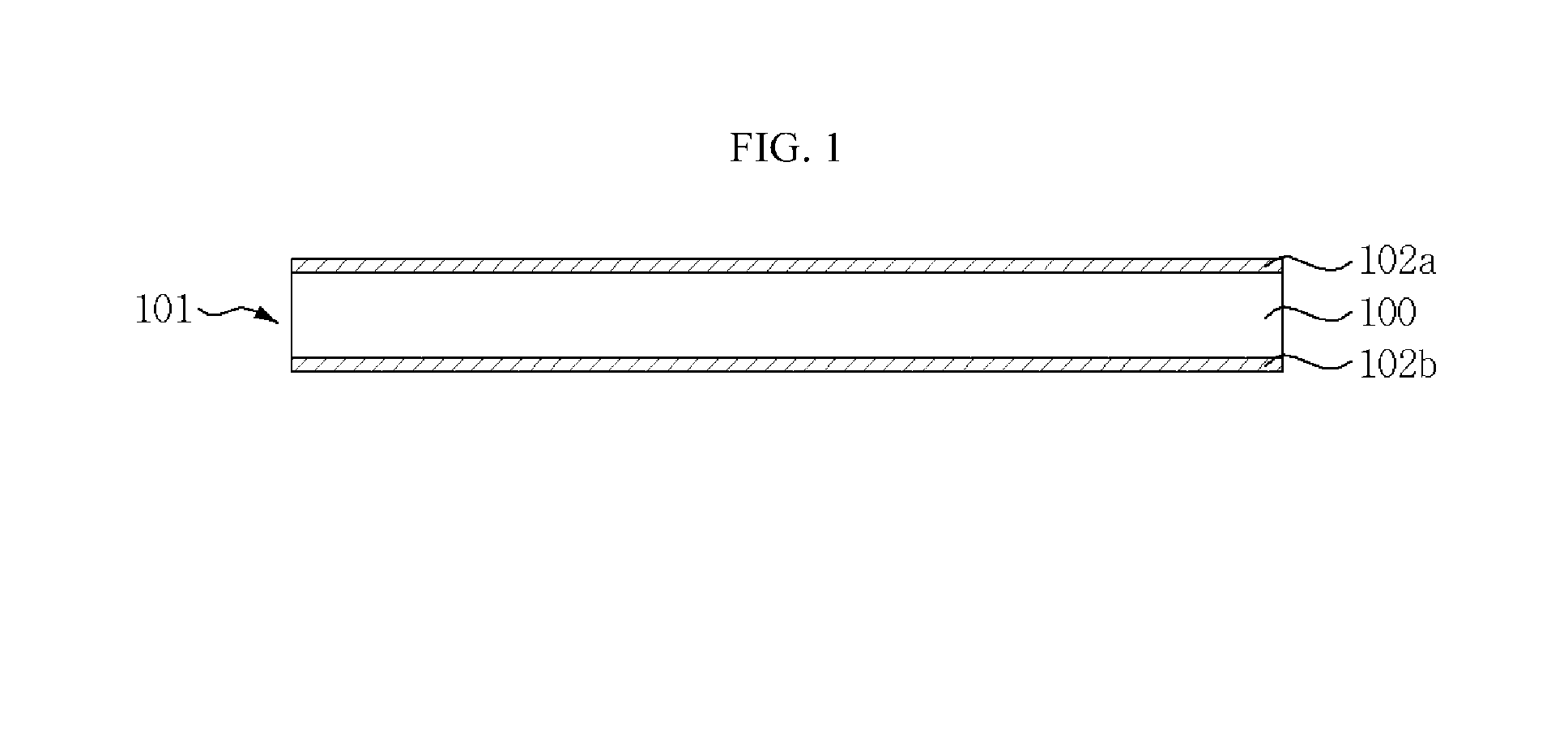

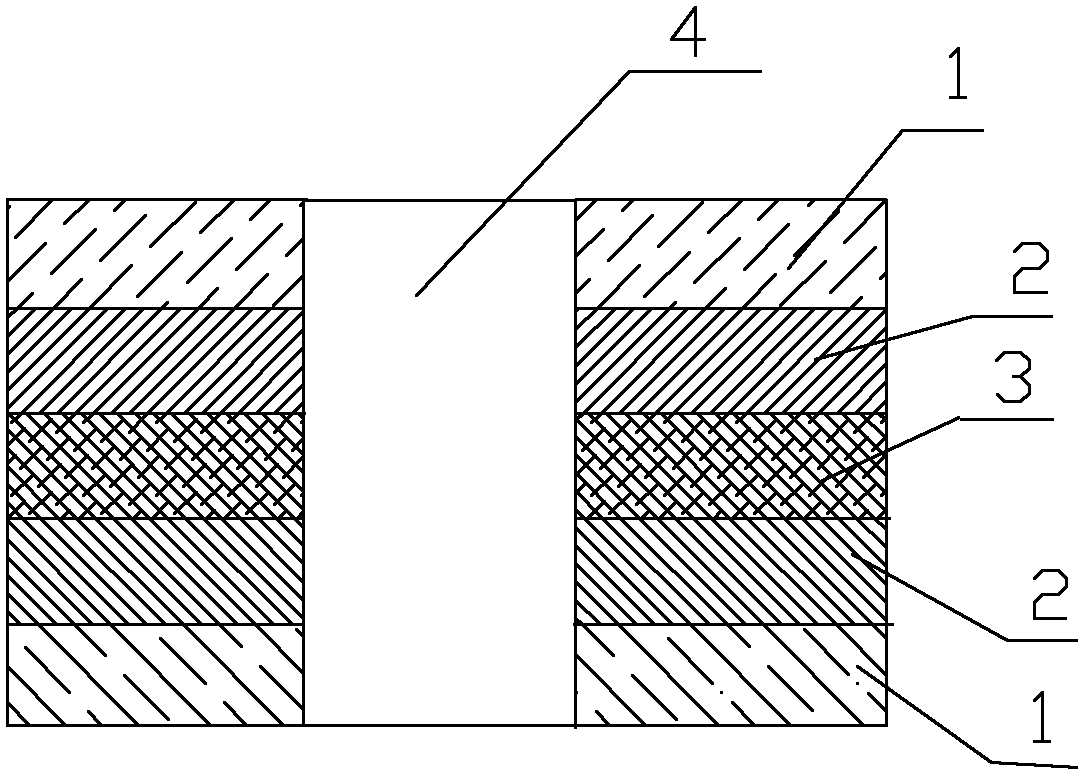

Embedded printed circuit board and method of manufacturing the same

InactiveUS20160174381A1Well formedSolid-state devicesElectrical connection printed elementsInsulation layerElectronic component

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

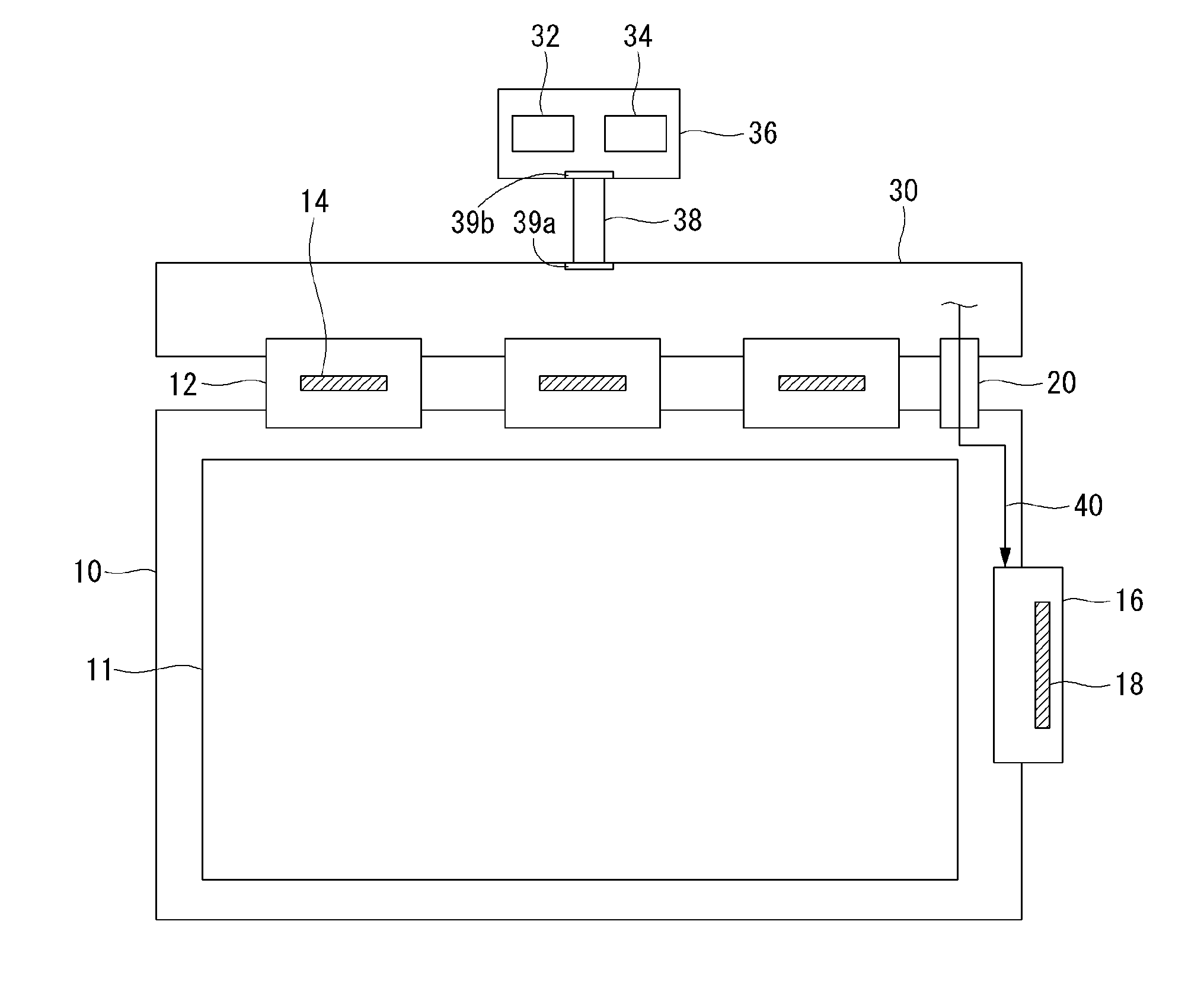

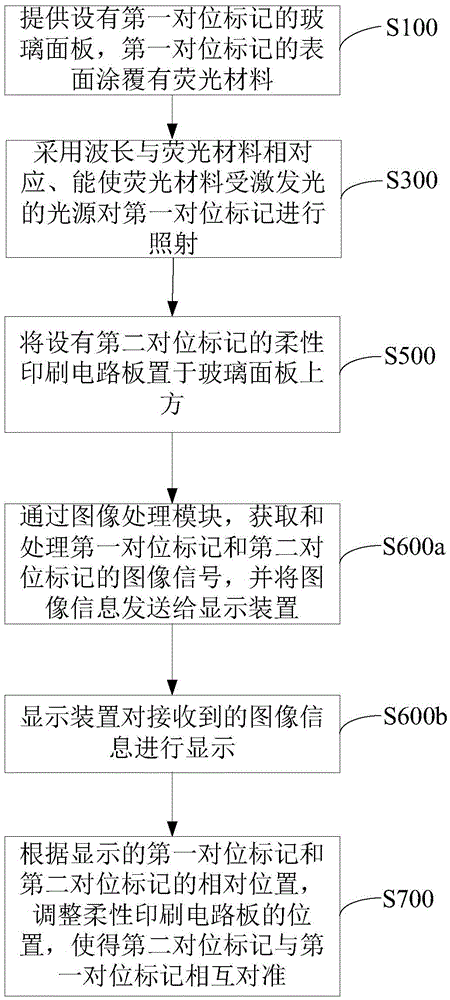

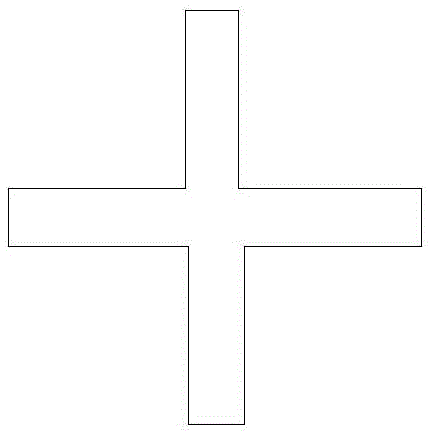

Alignment method and system of FOG technology

InactiveCN105652492ADisplay clearAlignment is normalInput/output processes for data processingNon-linear opticsEngineeringFlexible electronics

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

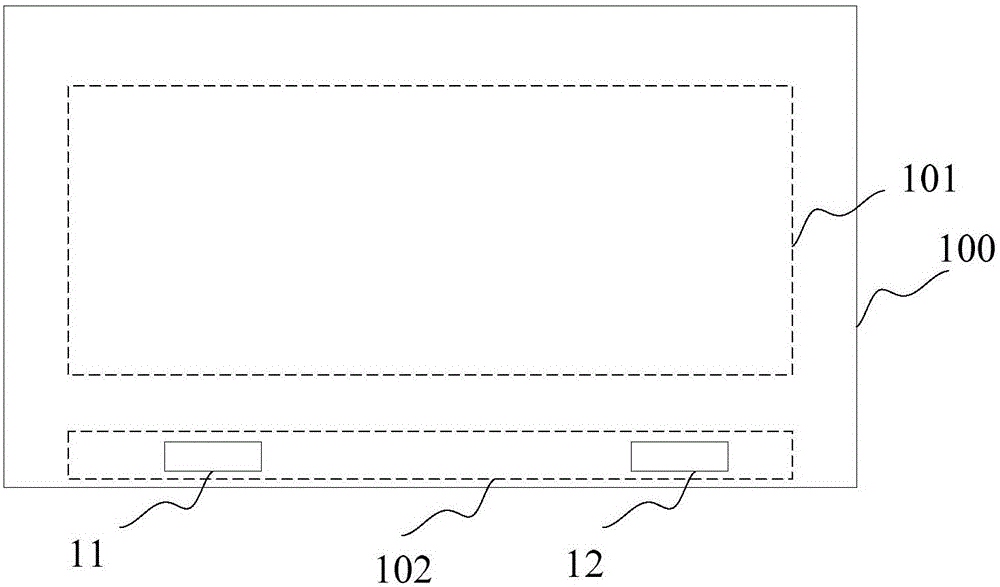

Display substrate, display panel, display device and binding method

InactiveCN106847827AReduce bonding timesSolve the low yield rate of mass productionDigital data processing detailsFinal product manufactureBinding numberPrinted circuit board

The invention discloses a display substrate, a display panel, a display device and a binding method, and belongs to the field of display devices. The display substrate includes a transparent substrate body which includes a display region and a binding region located on the periphery of the display region; the binding region is provided with a first binding terminal connected with a touch control electrode, and a second binding terminal connected with a display electrode; one of the touch control electrode and the display electrode is located in the display region, the other of the touch control electrode and the display electrode is located on another transparent substrate body, and the another transparent substrate body is opposite to the transparent substrate body. The first binding terminal and the second binding terminal are both located on the transparent substrate body of the display substrate and therefore can be bound to a flexible printed circuit board at the same time, no secondary binding is needed, the binding number is reduced, time is saved, labor is saved, and the low production yield problem is solved at the same time.

Owner:BOE TECH GRP CO LTD +1

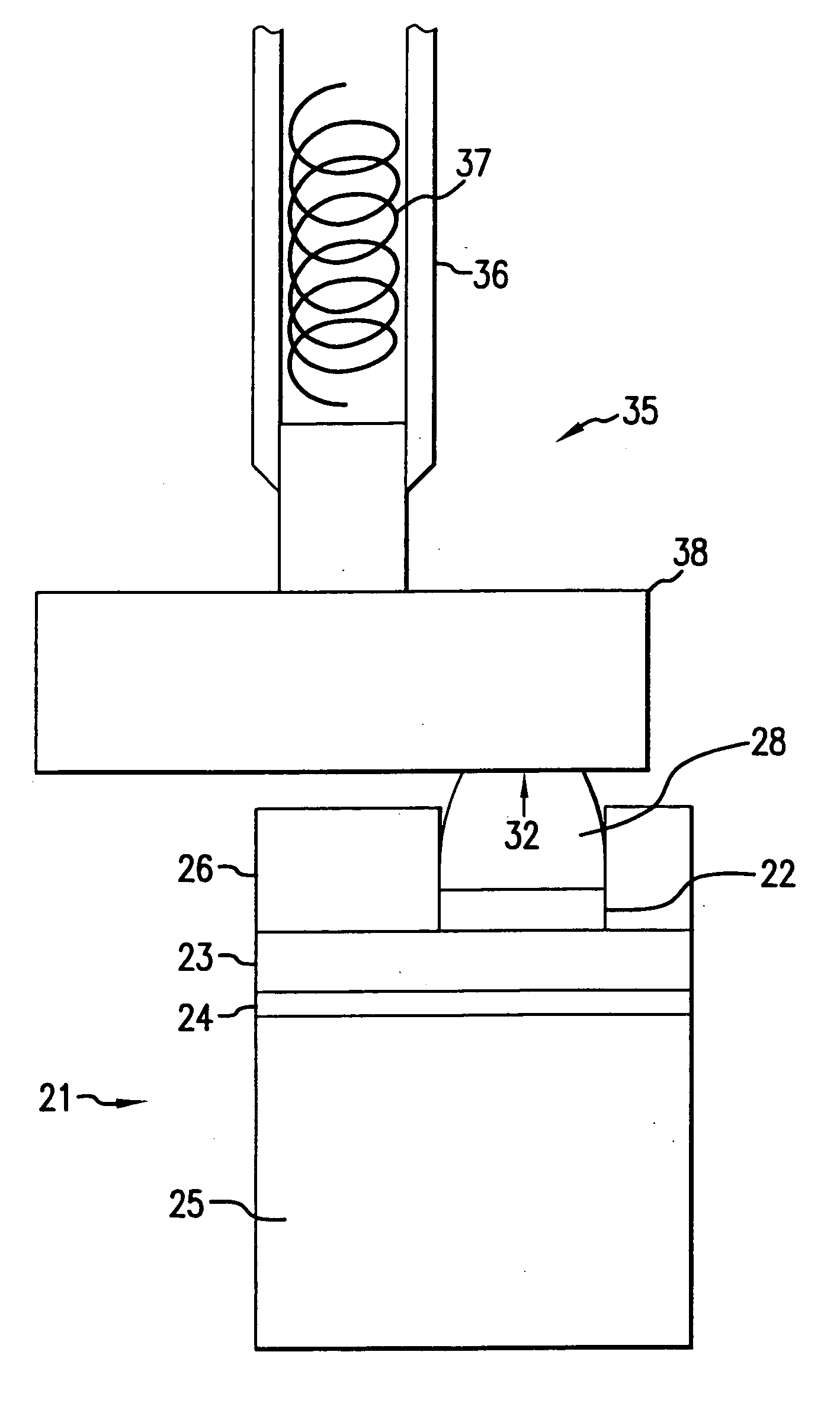

Method and apparatus for manufacturing and probing printed circuit board test access point structures

ActiveUS20060097737A1Minimize perturbationElectrical testingInspection/indentification of circuitsElectricityPrinted circuit board

Owner:KEYSIGHT TECH

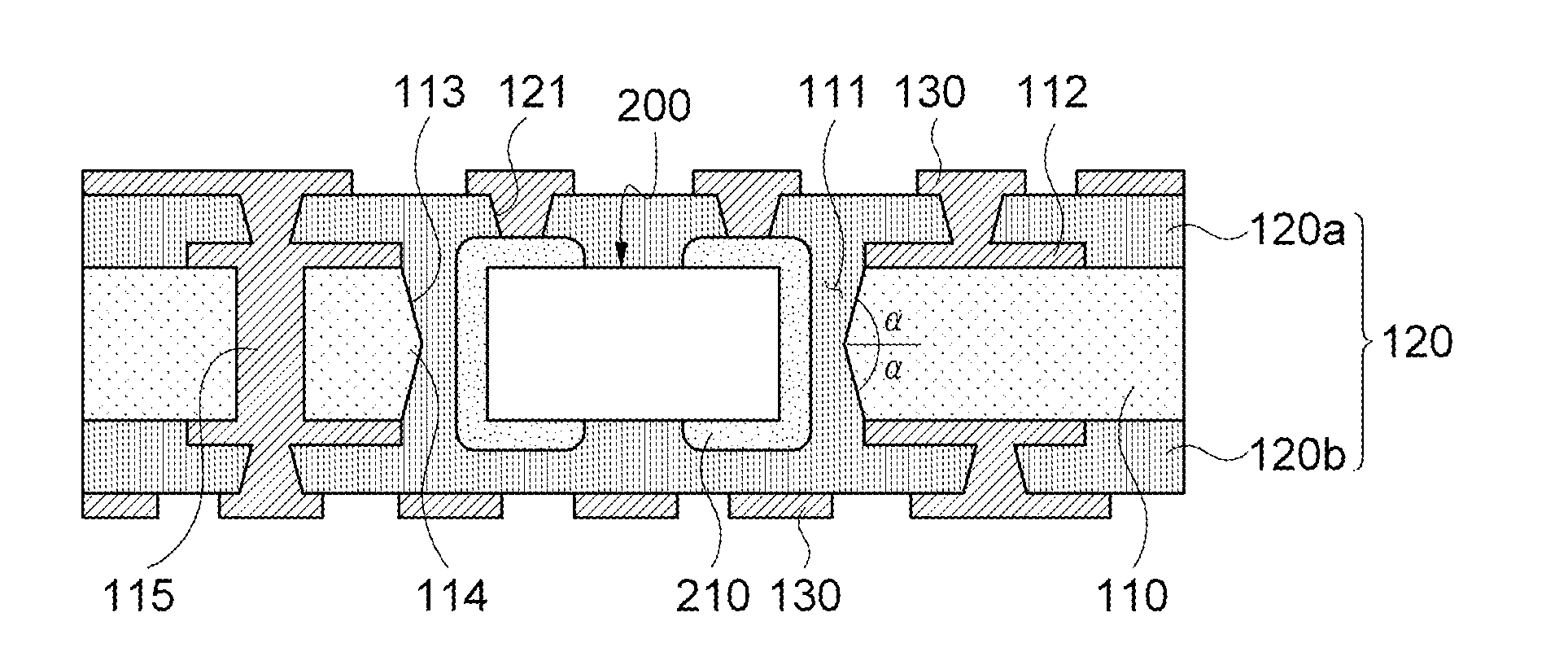

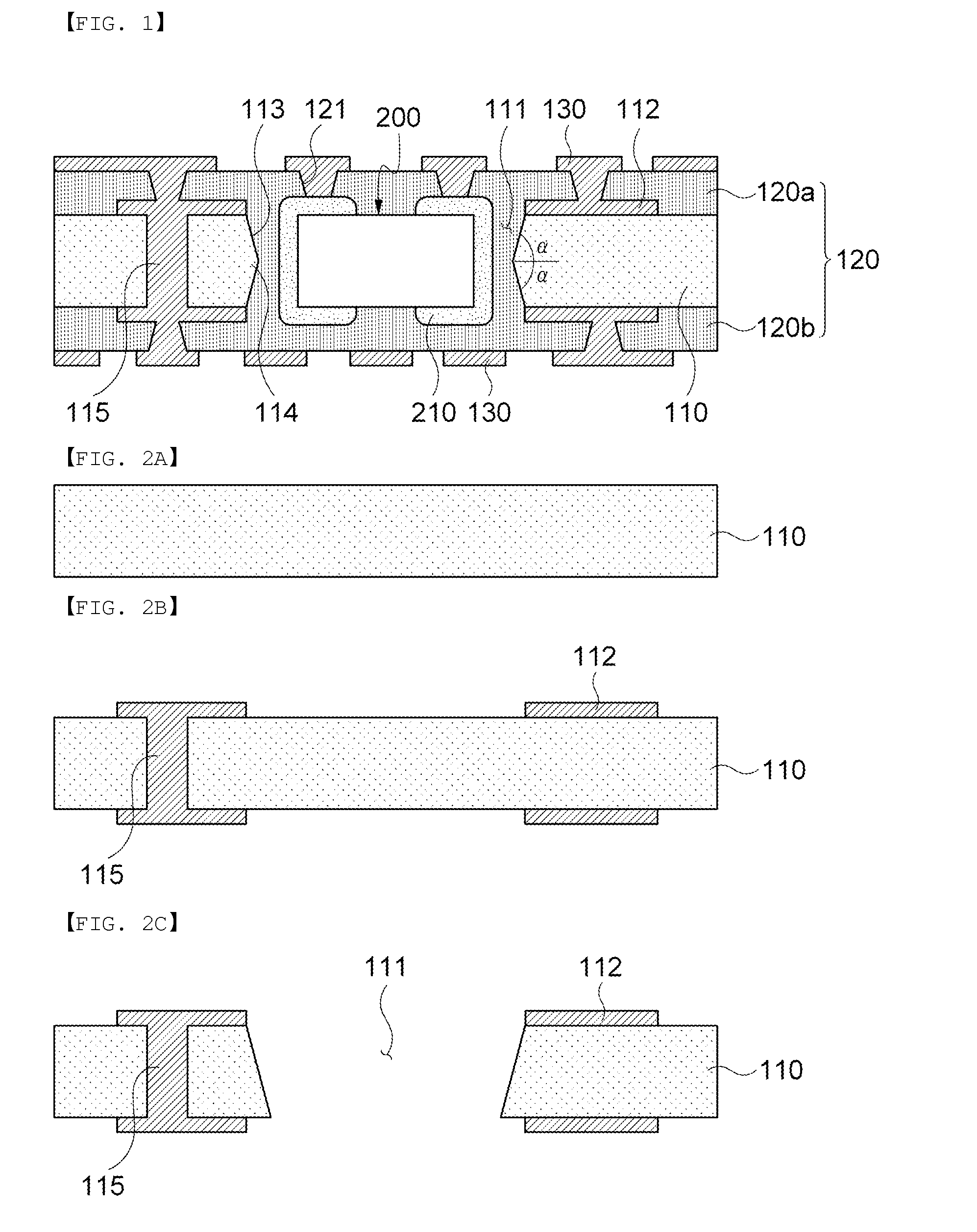

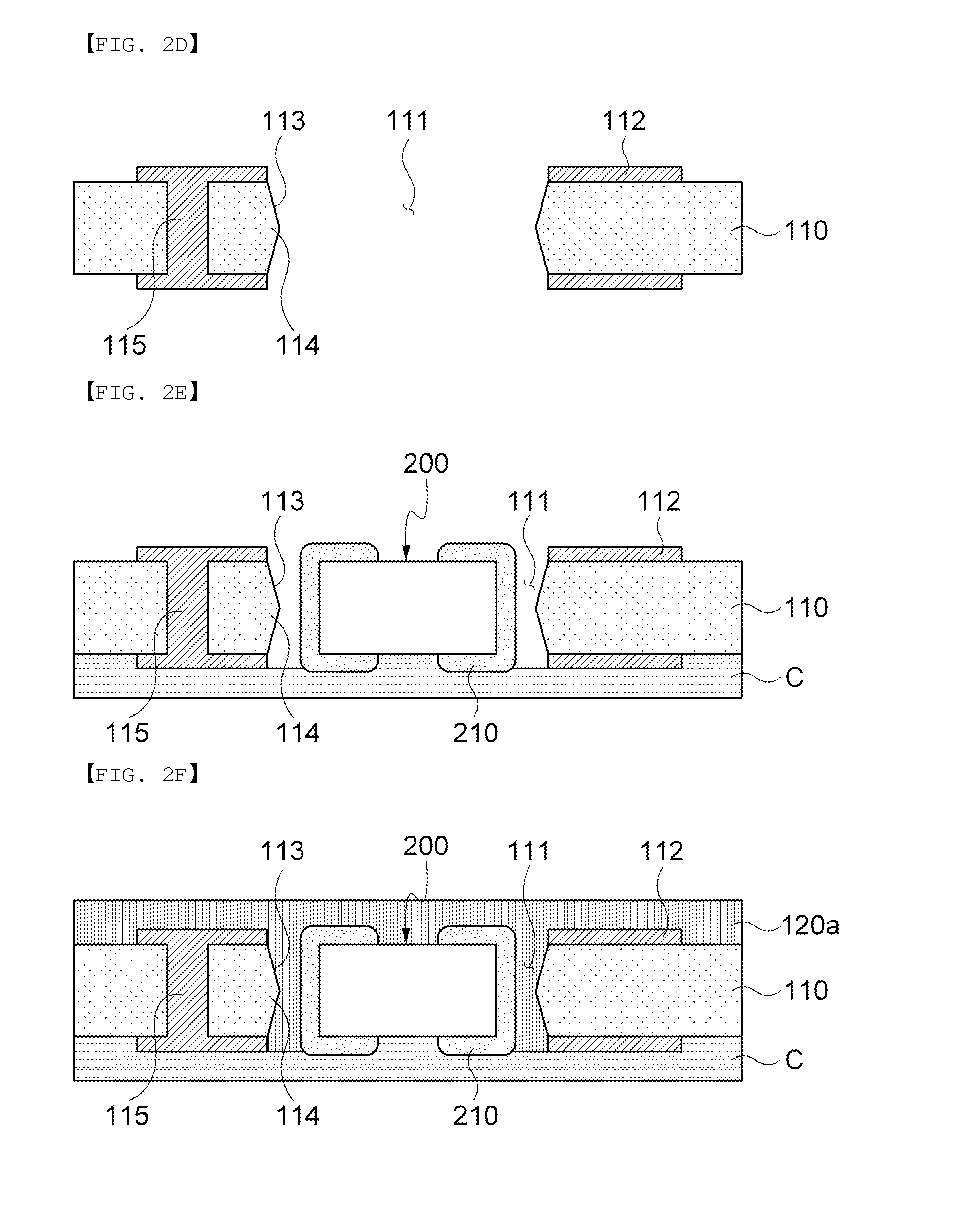

Printed circuit board including electronic component embedded therein and method for manufacturing the same

ActiveUS20140321084A1Improve reliabilityHigh yieldPrinted circuit assemblingPrinted electric component incorporationEngineeringElectronic component

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

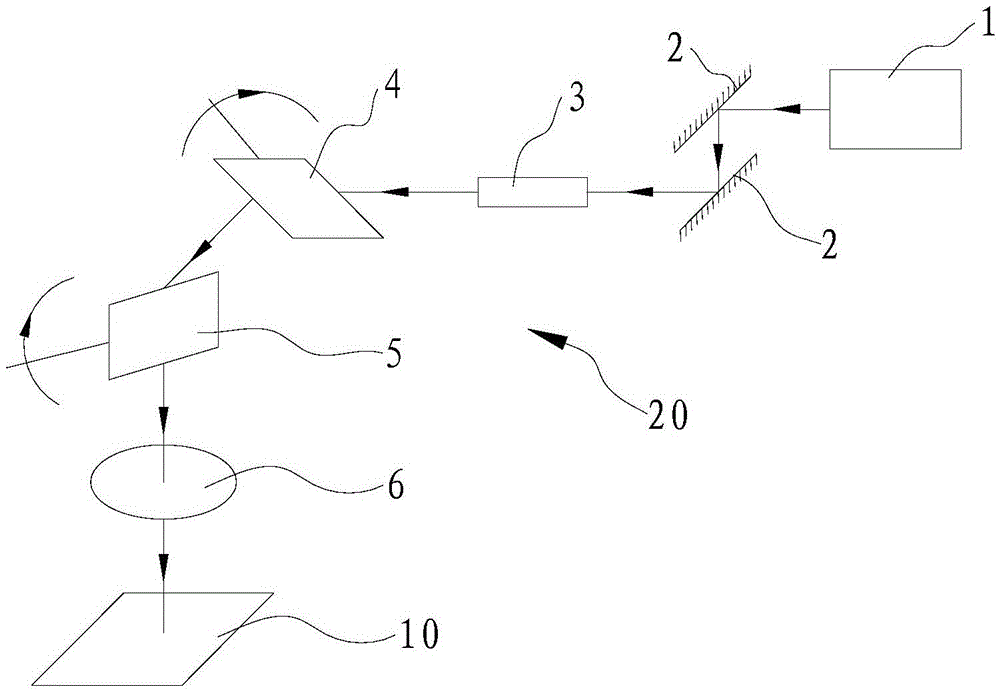

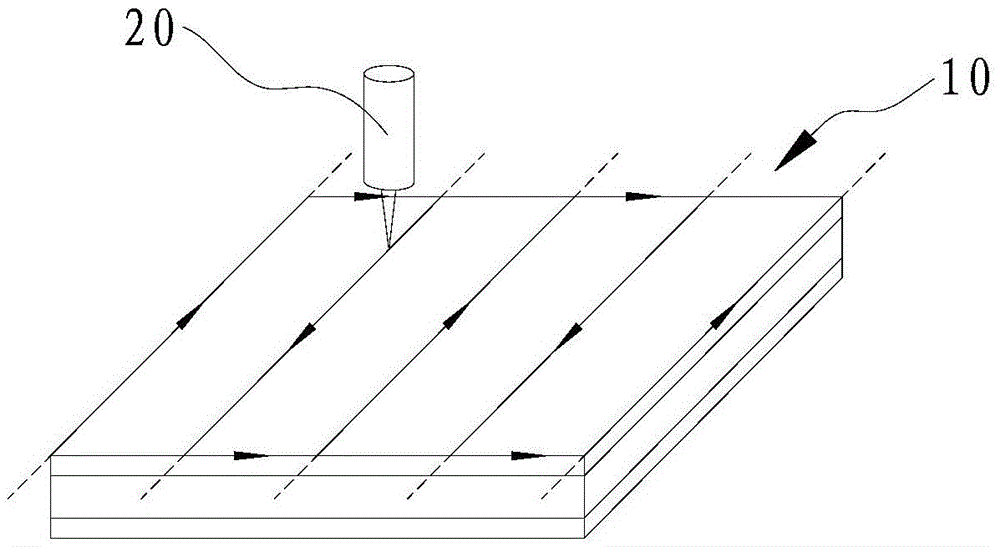

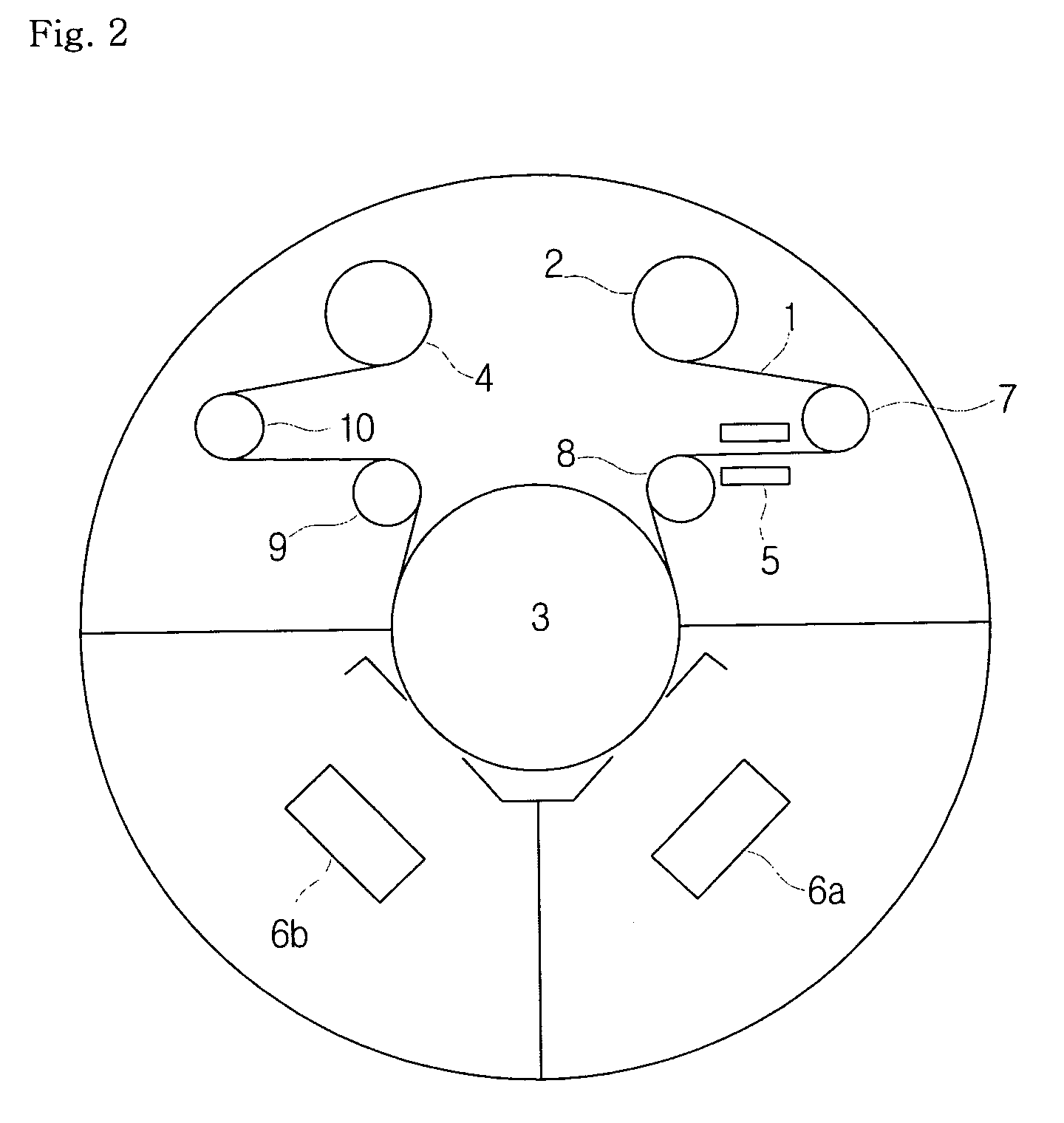

Multi-wavelength femtosecond laser scanning type etching method for printed circuit board

InactiveCN105562939AEasy to processImprove machining accuracyPrinted circuitsMetal working apparatusEtchingLine width

Owner:SUZHOU UNIV

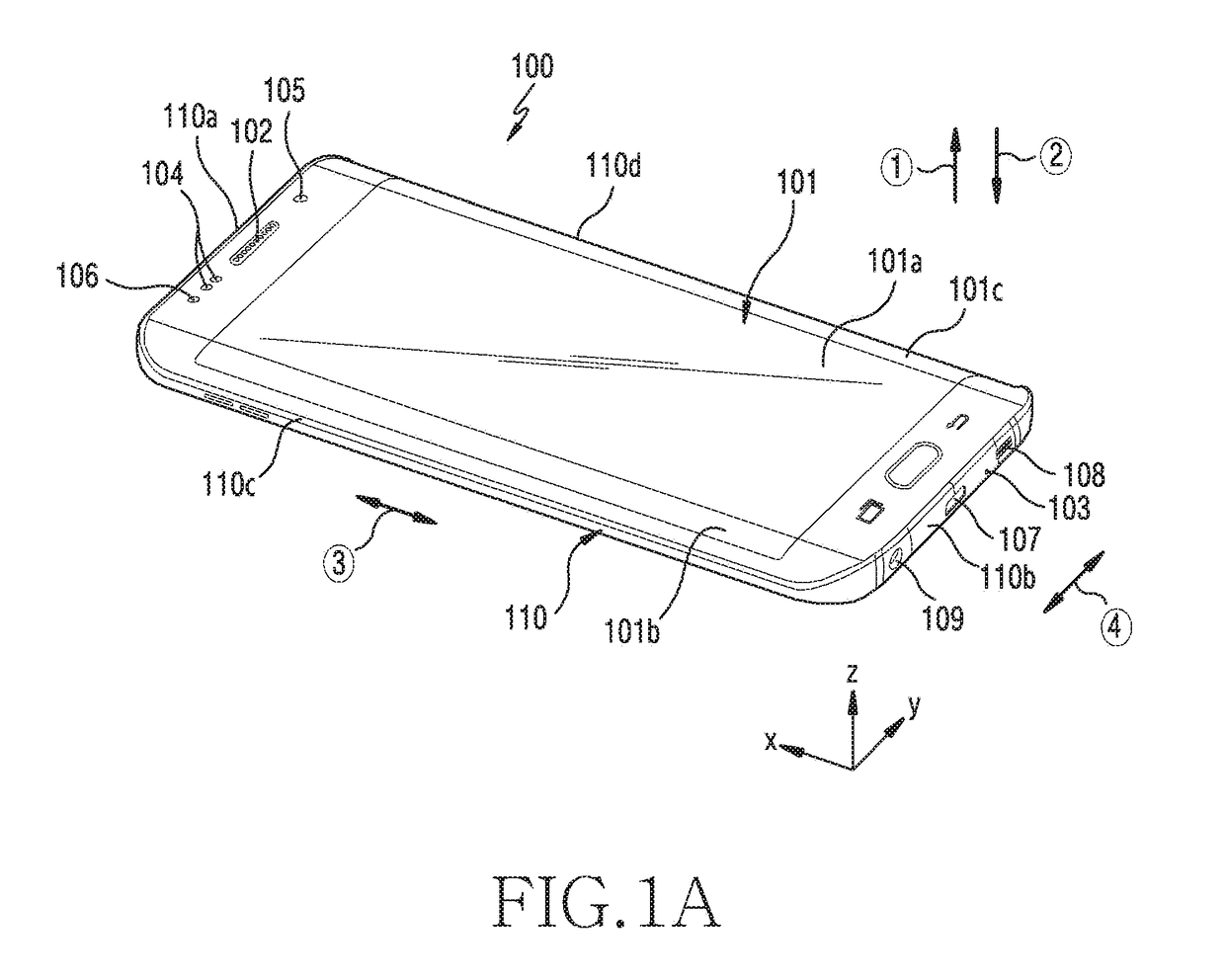

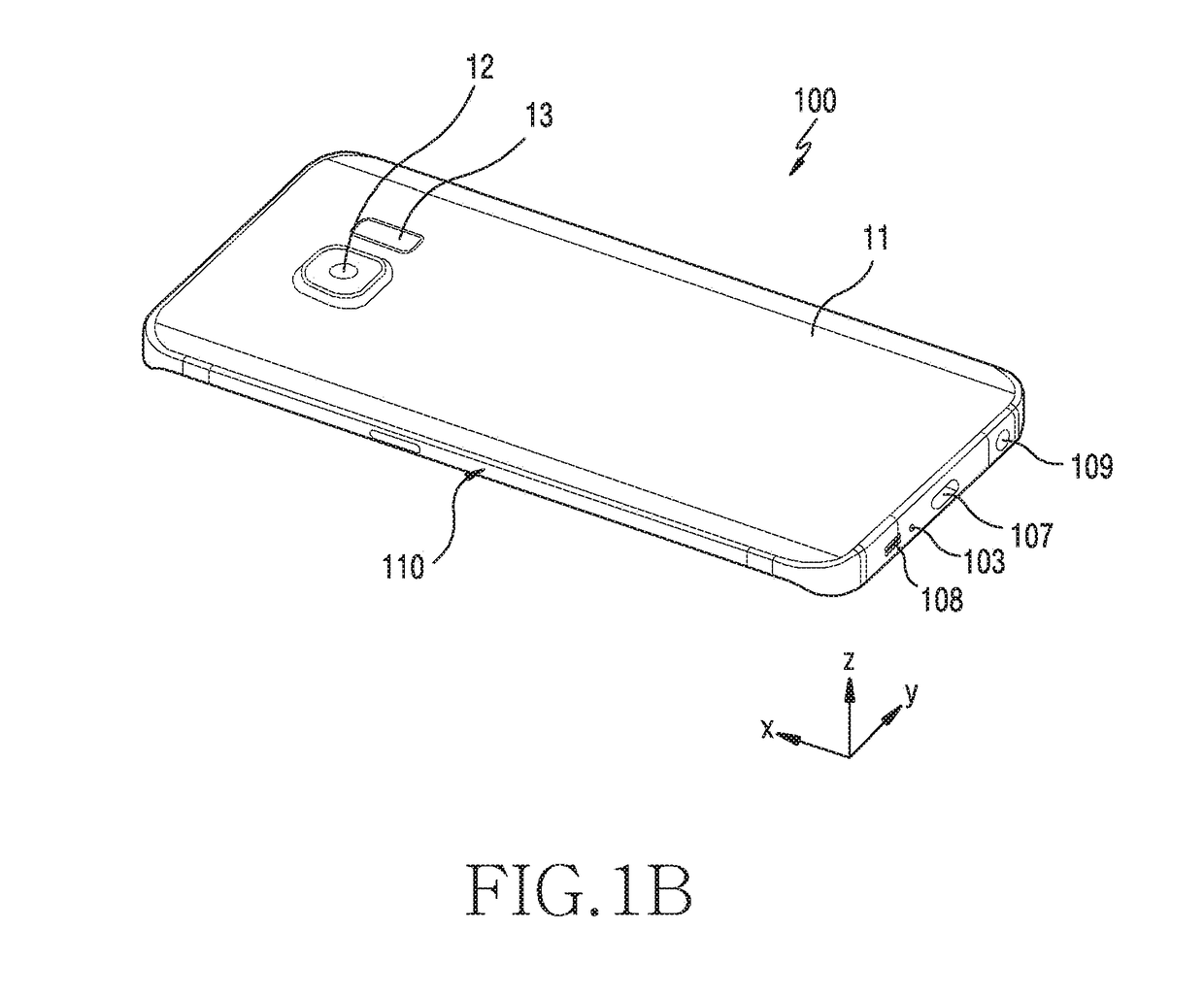

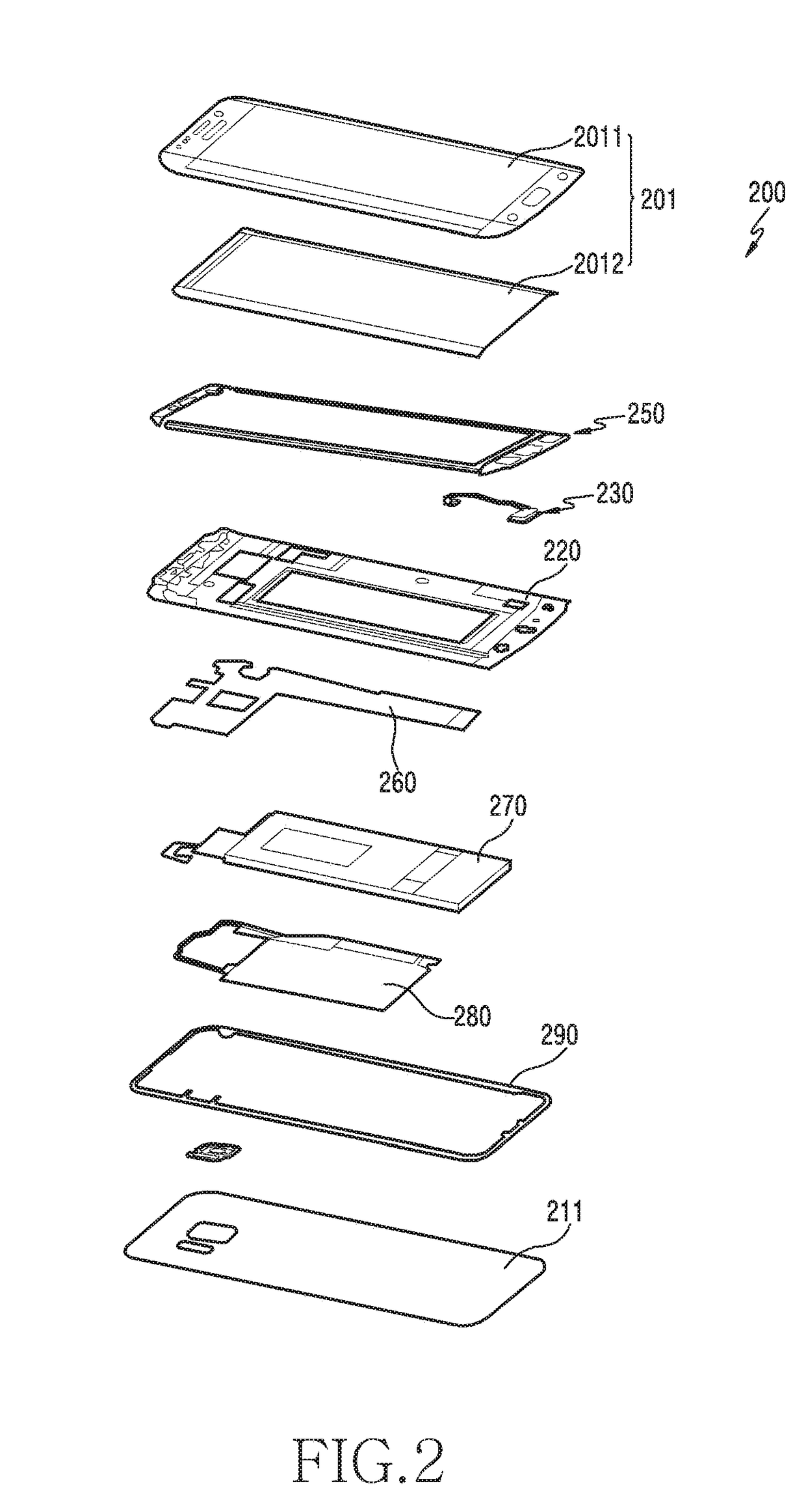

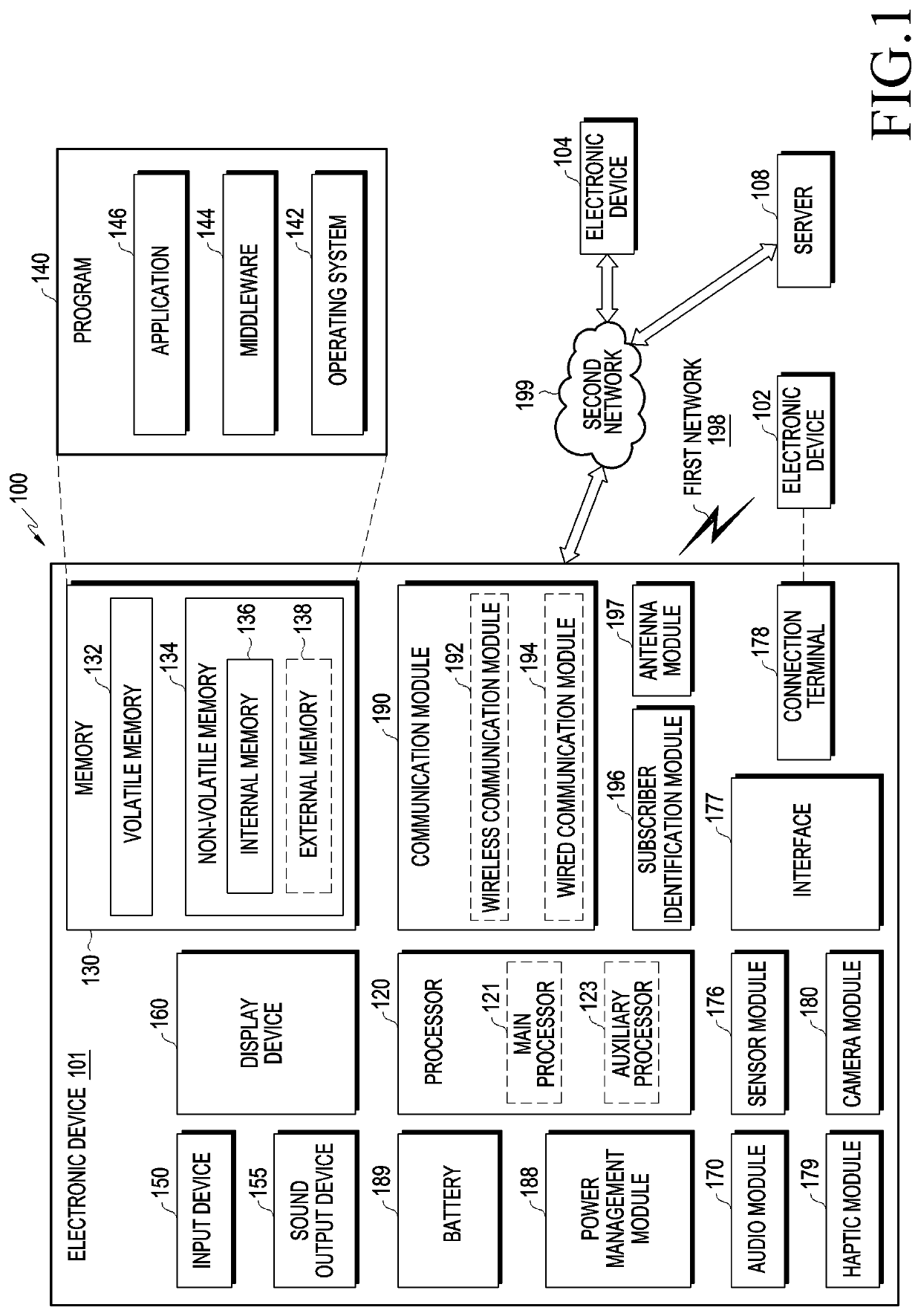

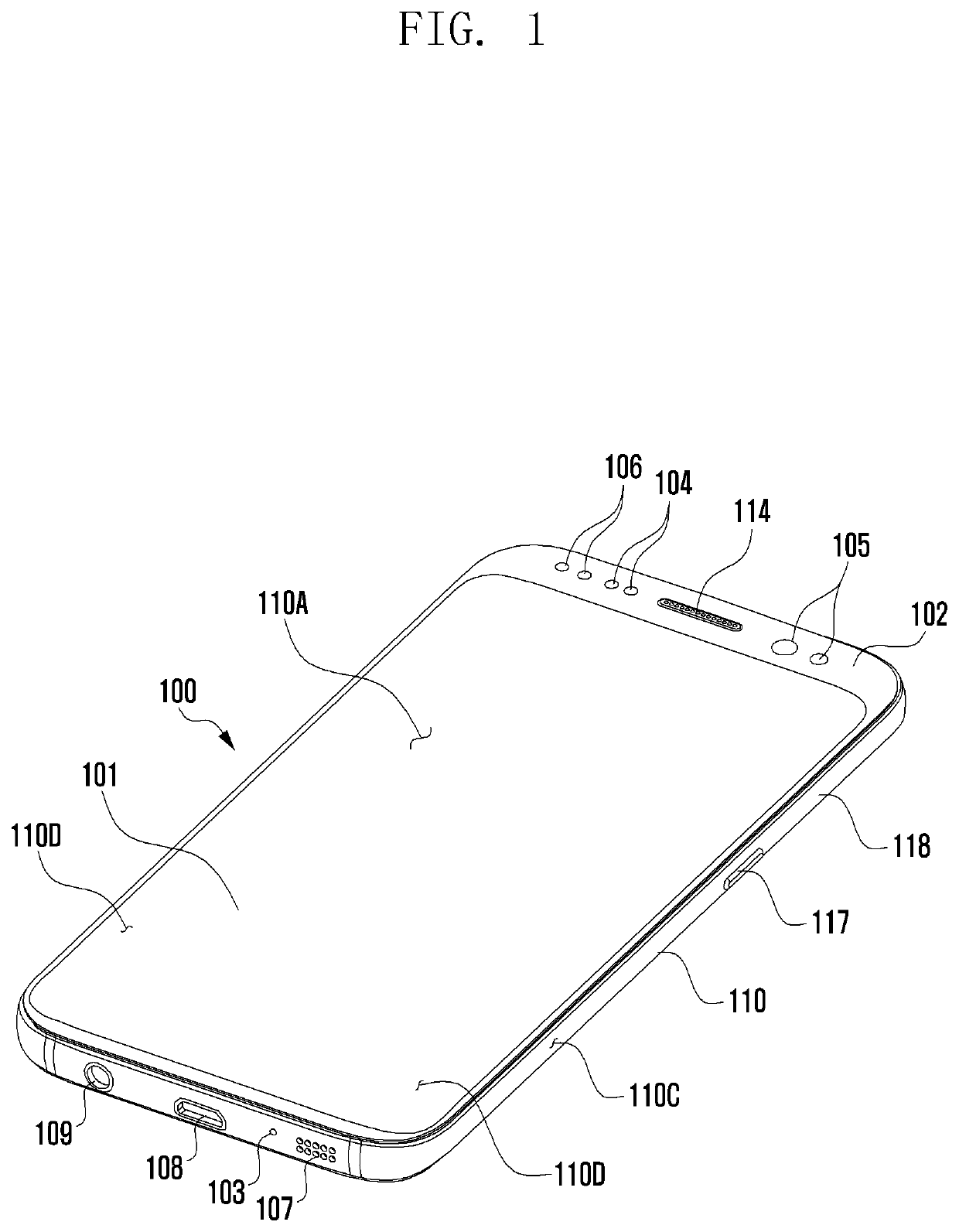

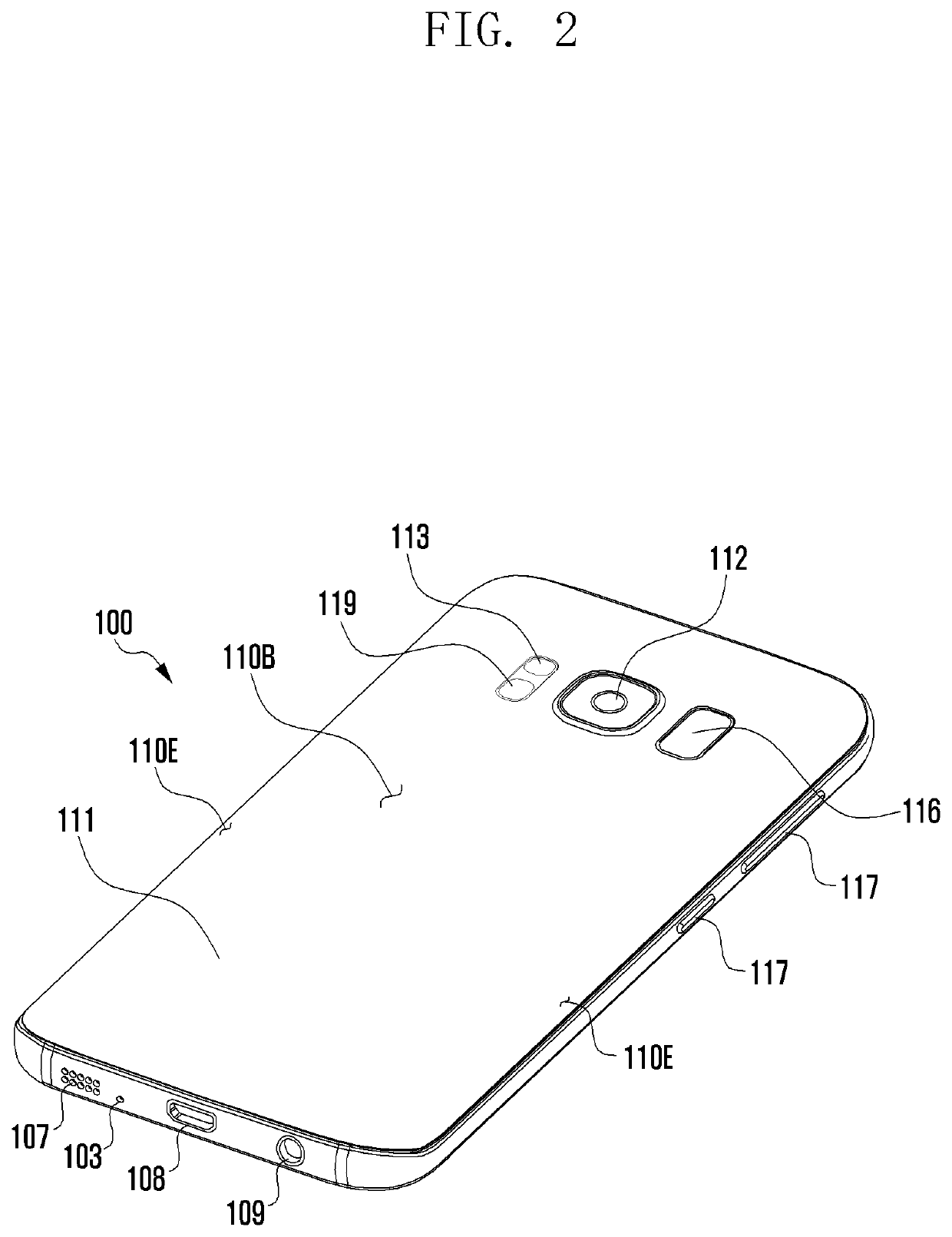

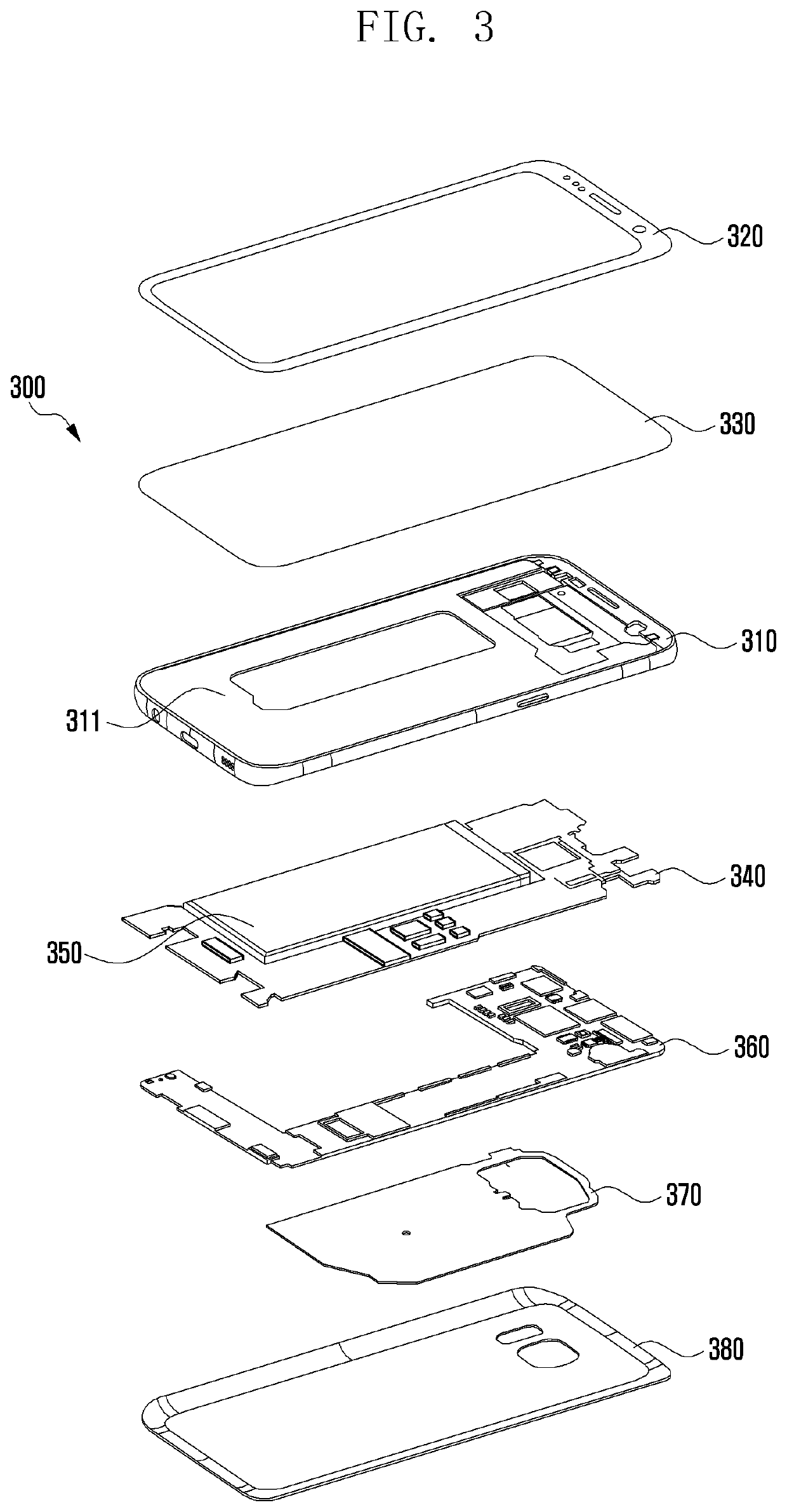

Electronic device with display

ActiveUS20190012007A1Improve placement efficiencyInput/output for user-computer interactionStatic indicating devicesIntegrated circuitPrinted circuit board

Owner:SAMSUNG ELECTRONICS CO LTD

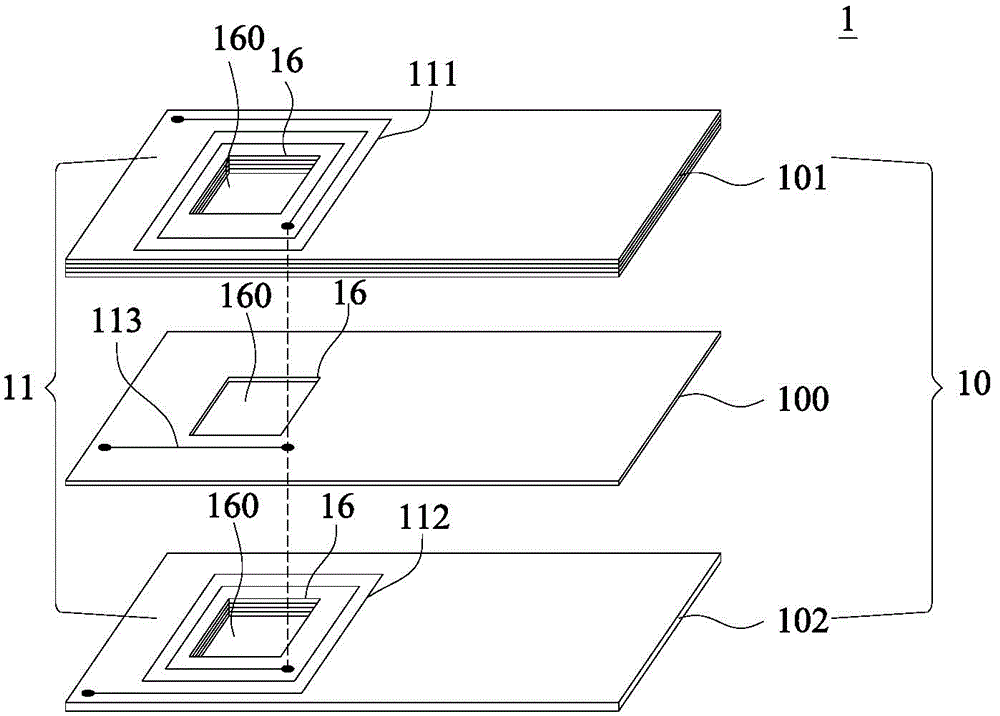

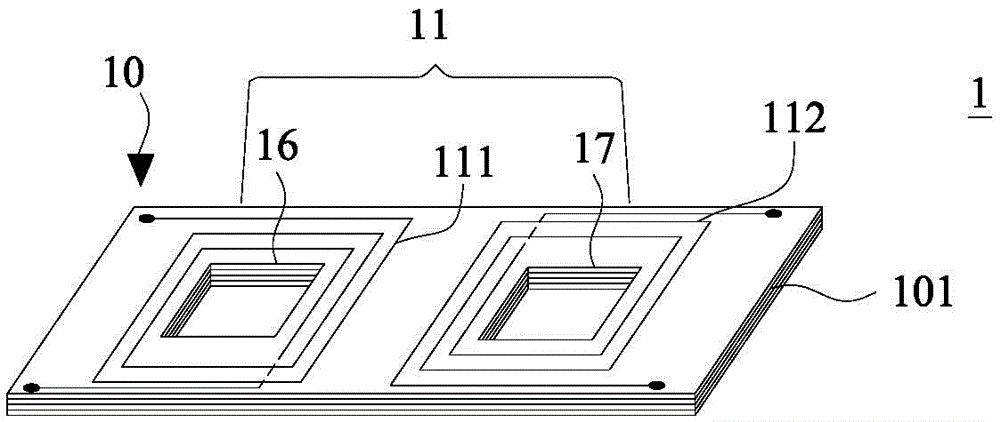

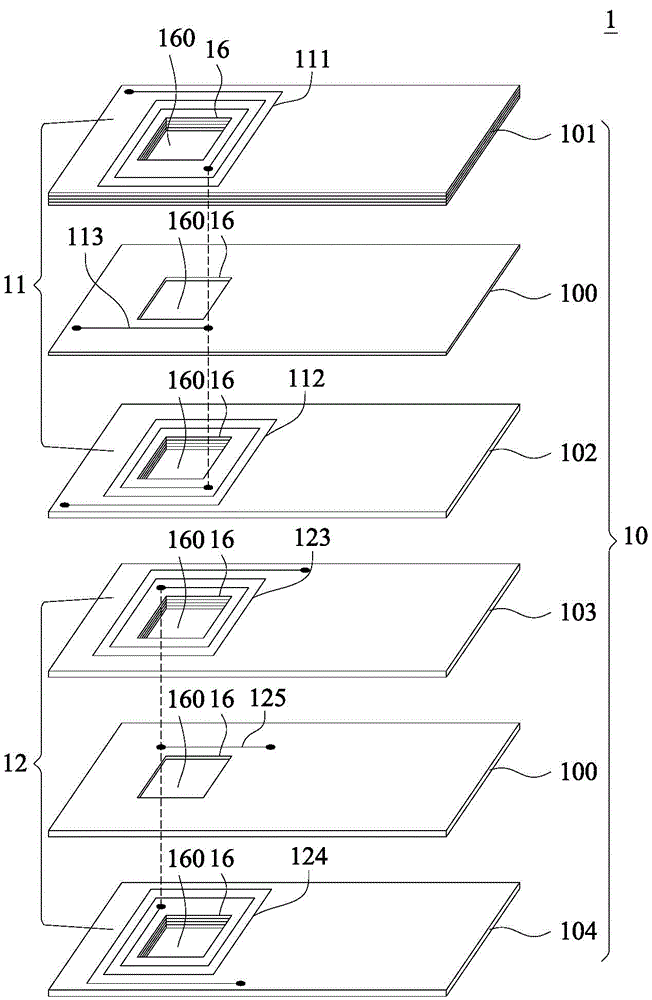

Induction coil assembly

InactiveCN105163489AValid settingsRealize the structurePrinted circuit non-printed electric components associationCoilsPlanar inductorEngineering

Owner:XULI ELECTRONICS CO LTD

Epoxy resin composition and prepreg and printed circuit board made therefrom

ActiveCN102260402AImprove heat resistanceGood chemical resistanceCircuit susbtrate materialsMetal layered productsEpoxyManganese oxide

The invention relates to an epoxy resin composition which comprises (a) epoxy resin; (b) a hardening agent; and (c) manganese oxide used as inorganic filler.

Owner:TAIWAN POWDER TECH CO LTD

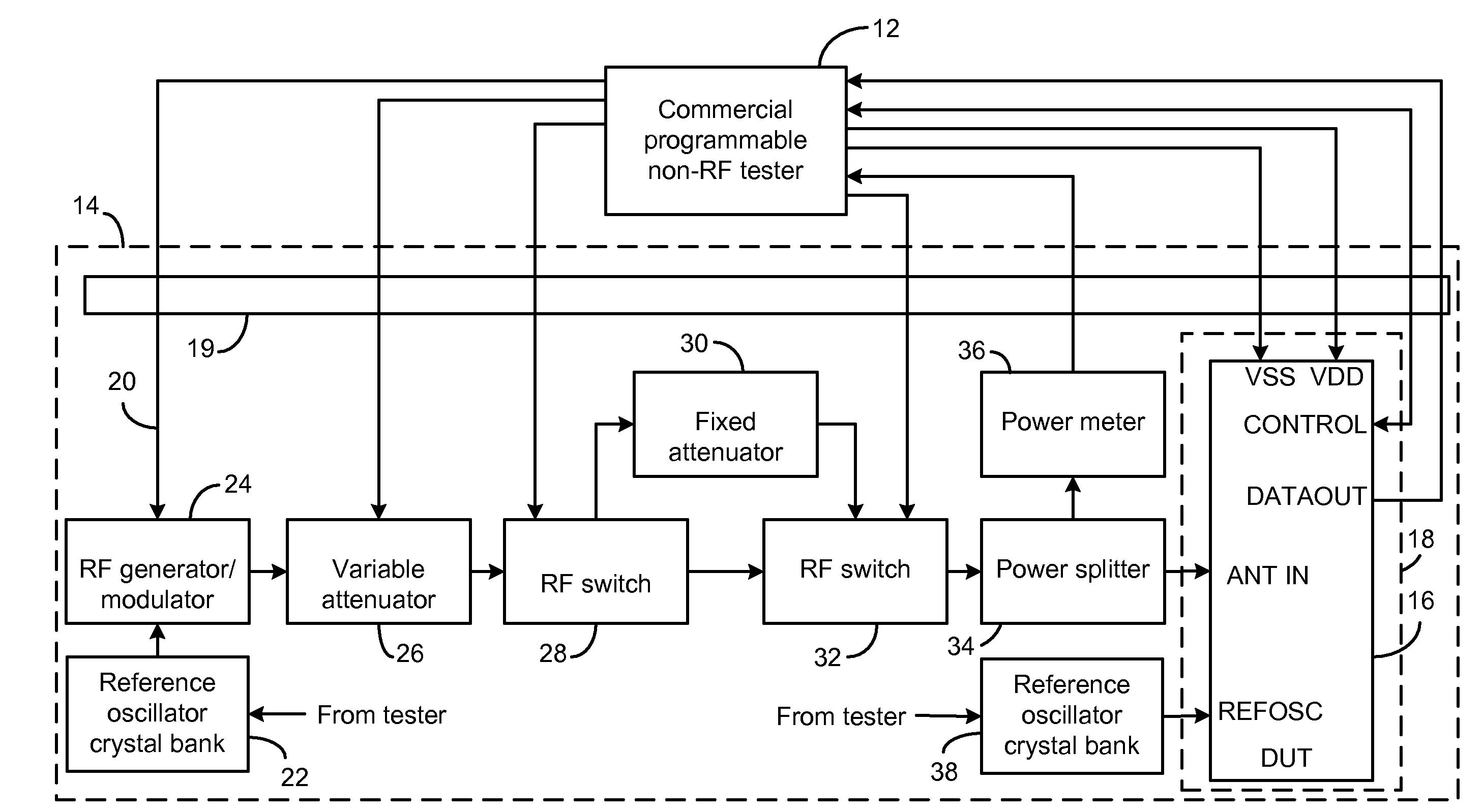

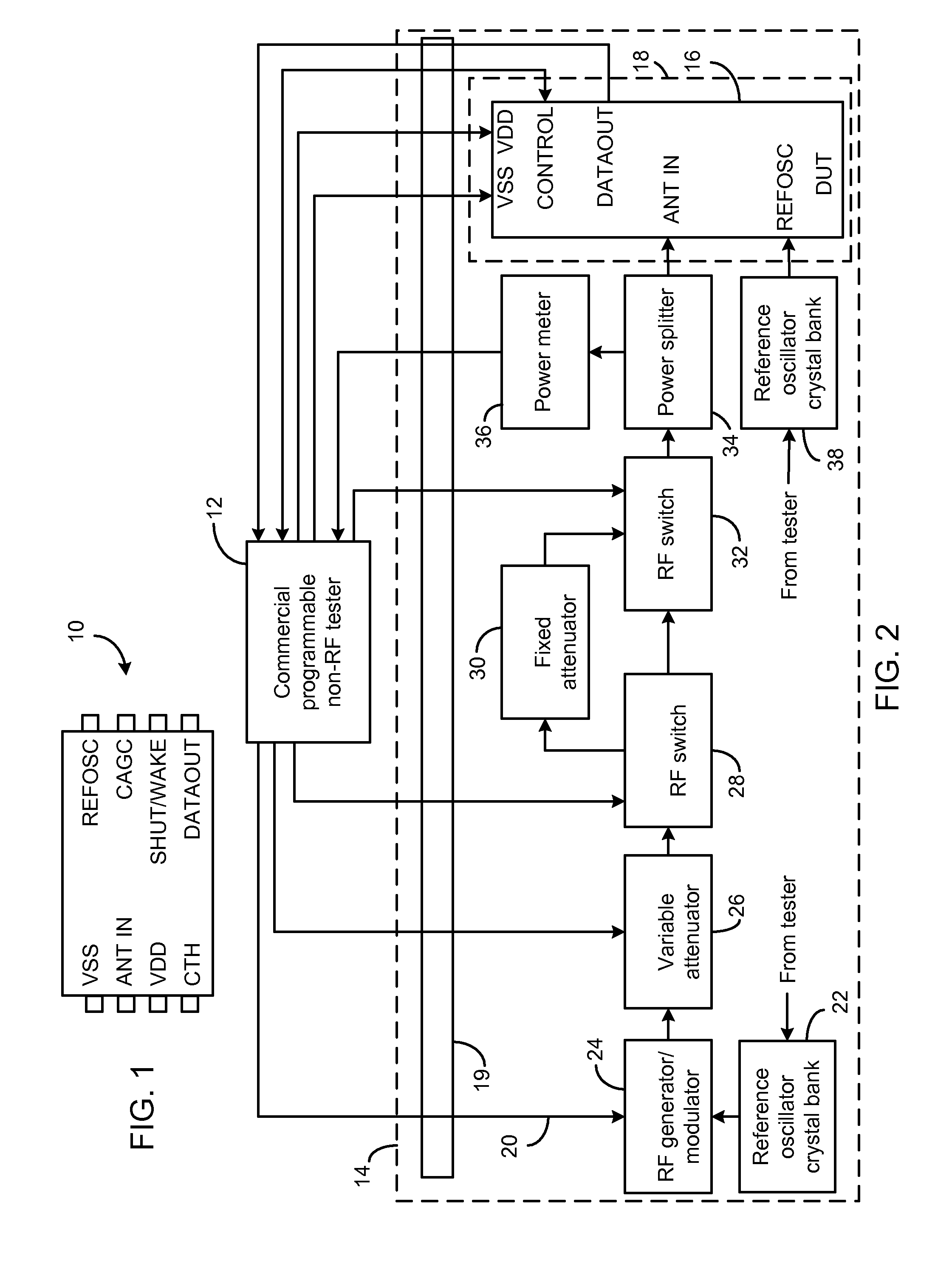

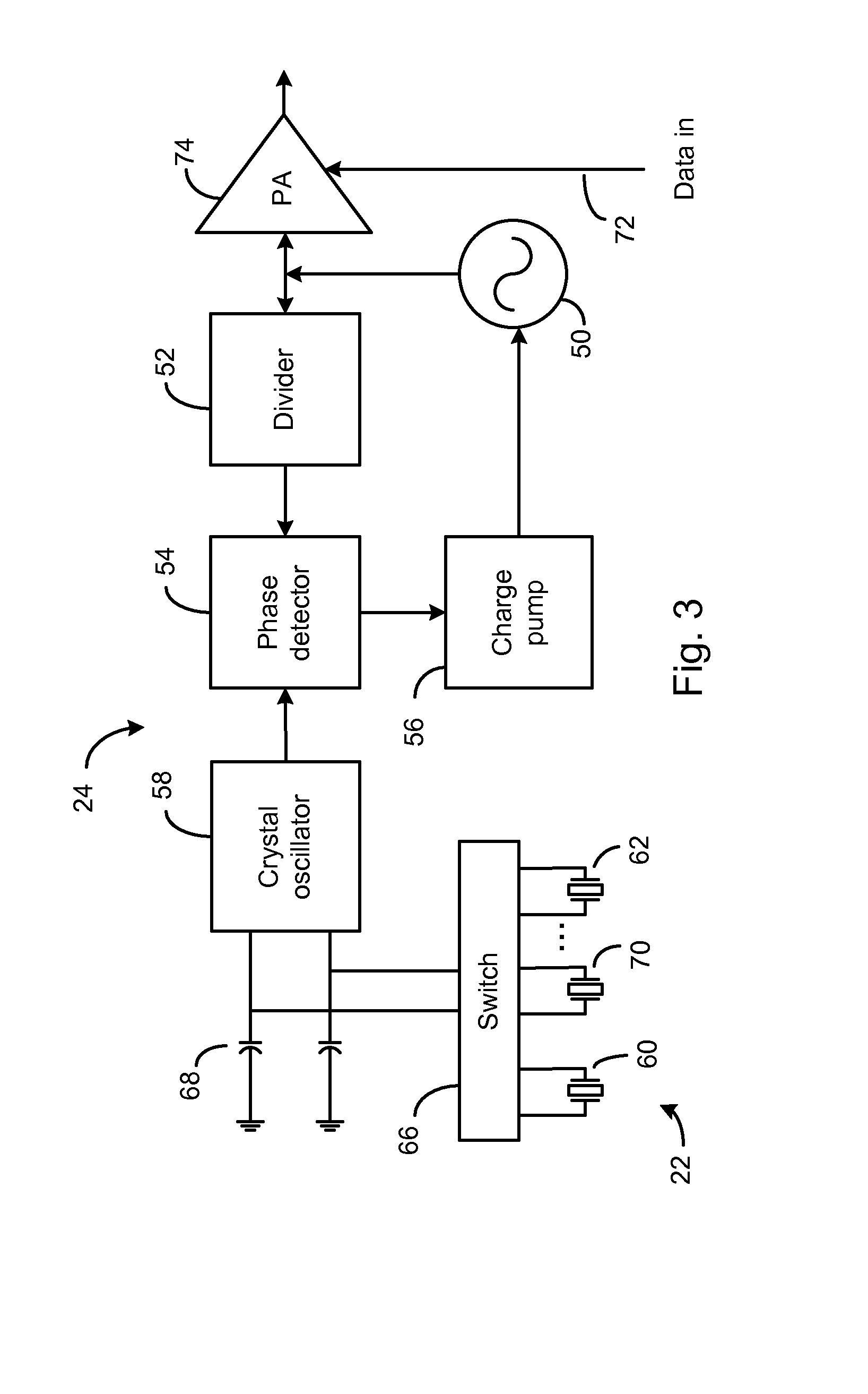

Tester for RF Devices

InactiveUS20100052708A1Easy to set upLimited setResistance/reactance/impedenceVoltage-current phase angleTester deviceEngineering

Owner:MICREL

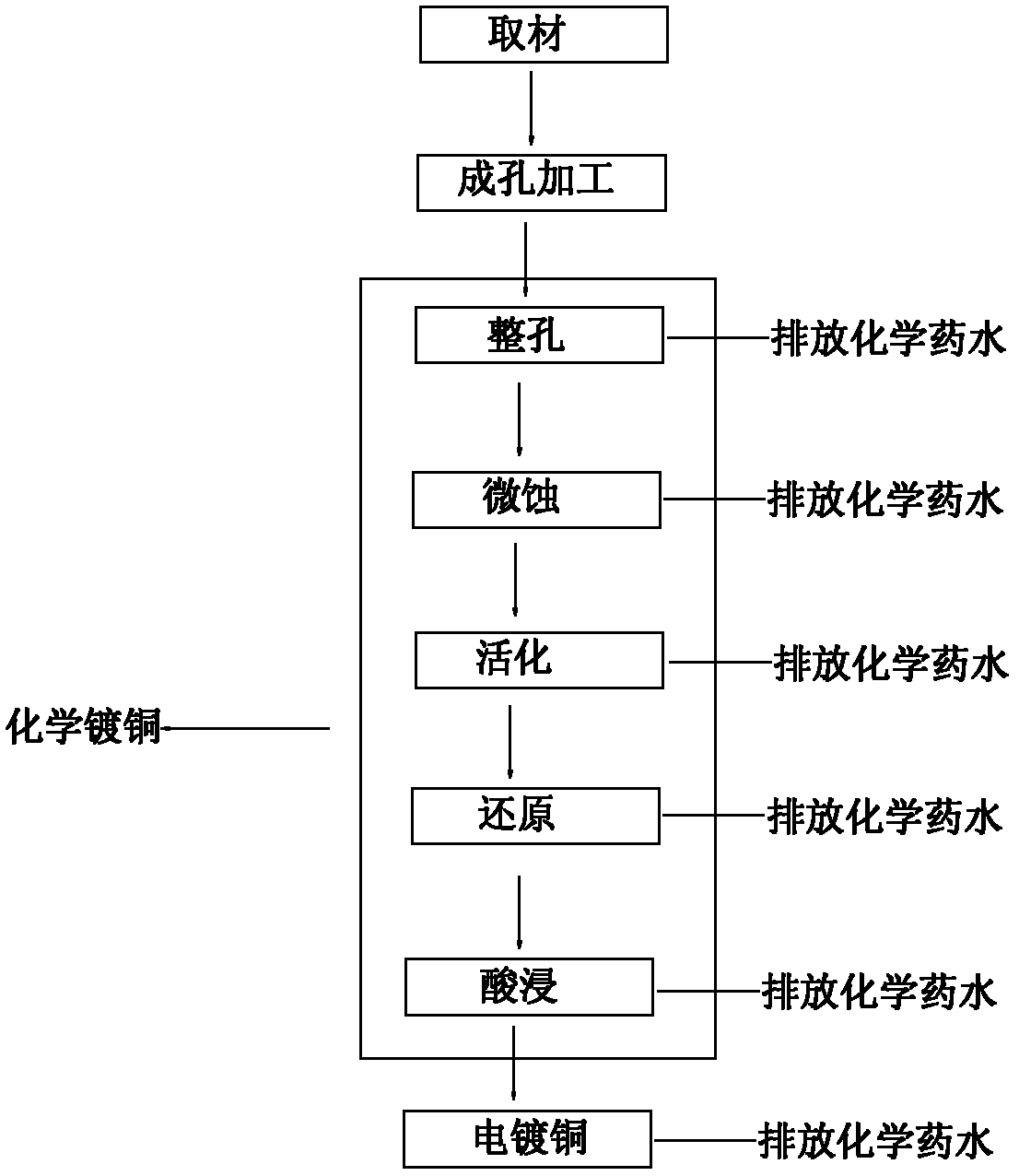

Manufacturing process of interlayer copper connector of printed circuit board

InactiveCN102638946AReduce investmentReduce investment riskPrinted element electric connection formationScreen printingInsulation layer

Owner:SHENZHEN HONGHAI ELECTRON MATERIAL TECH CO LTD

Conductive film and touch screen

In the present invention, the base material in the conductive film includes an integrally formed first part and a second part, the first part includes a touch sensing area and a frame area, and the second part extends outward from at least one side of the first part At least one flexible connection part is formed, and the sensing electrode leads and the driving electrode leads are respectively extended to the ends of each flexible connection part to form a first plug-in structure and a second plug-in structure containing electrode leads, so as to form a plug-in type structure, so that it is not necessary to bind an additional flexible printed circuit board on the touch sensing layer when it is connected with the main board or other components through a connector, so it is unnecessary to use expensive flexible printed circuit boards and avoid flexible printed circuit boards. Poor contact and poor reliability of subsequent samples are likely to occur during the bonding process between the circuit board and the touch sensing layer.

Owner:NANCHANG O FILM DISPLAY TECH CO LTD

Printed circuit board and method for manufacturing thereof

InactiveUS20080121414A1Improve thermal conductivityPrinted circuit aspectsConductive pattern formationInter layerEngineering

A printed circuit board and a method of manufacturing thereof are disclosed. With a printed circuit board comprising an insulating layer; a circuit pattern formed on one side of the insulating layer; an inter-layer conductive part joining with the insulating layer by passing through the insulating layer, and electrically connected to the circuit pattern; a heat dissipating layer laminated on the other side of the insulating layer; and a heat dissipating coating layer interposed between the insulating layer and the heat dissipating layer, and connected with the inter-layer conductive part, the heat contained in the insulating layer may be delivered to the heat dissipating layer effectively and the efficiency of heat dissipation may be improved.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

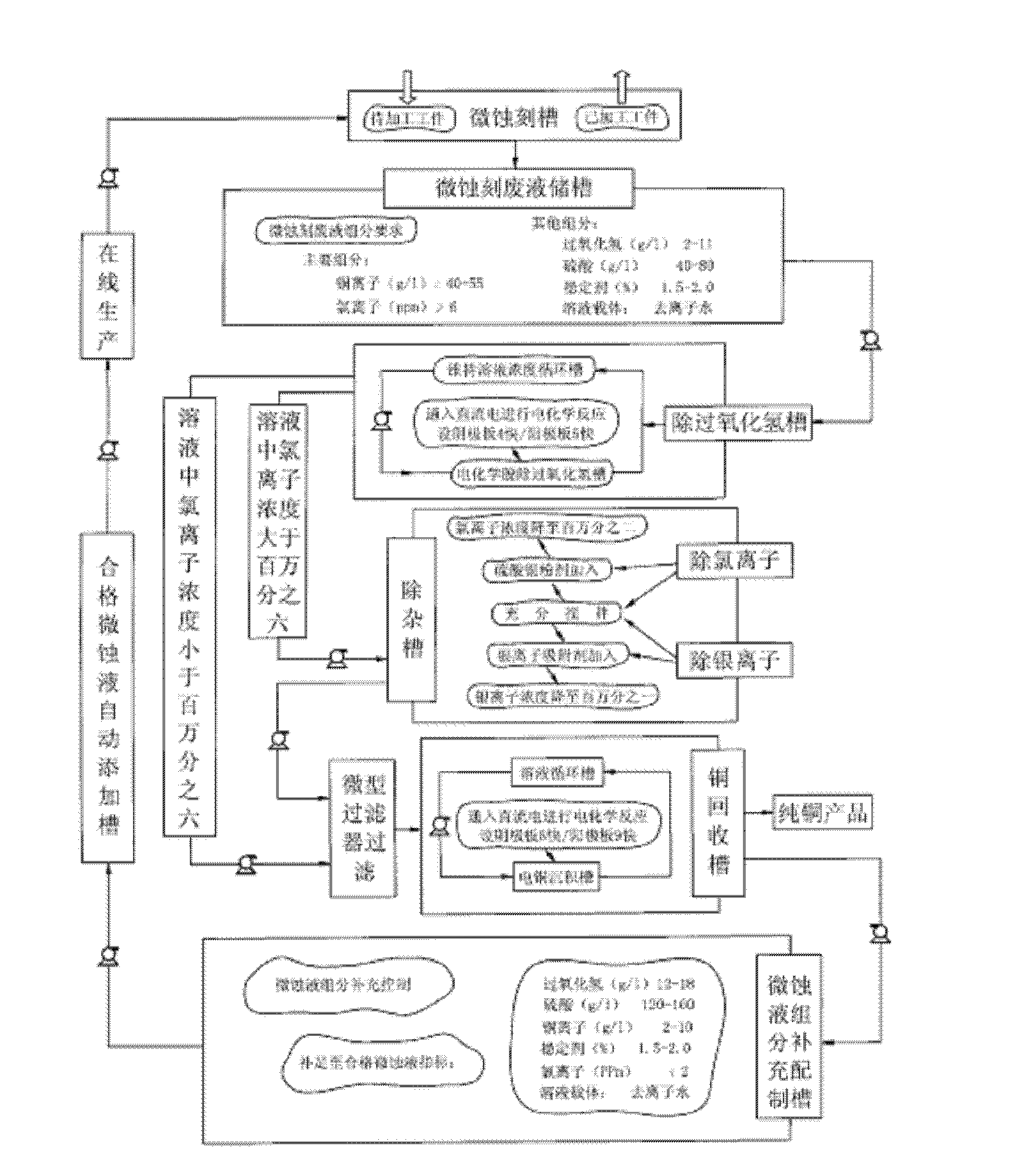

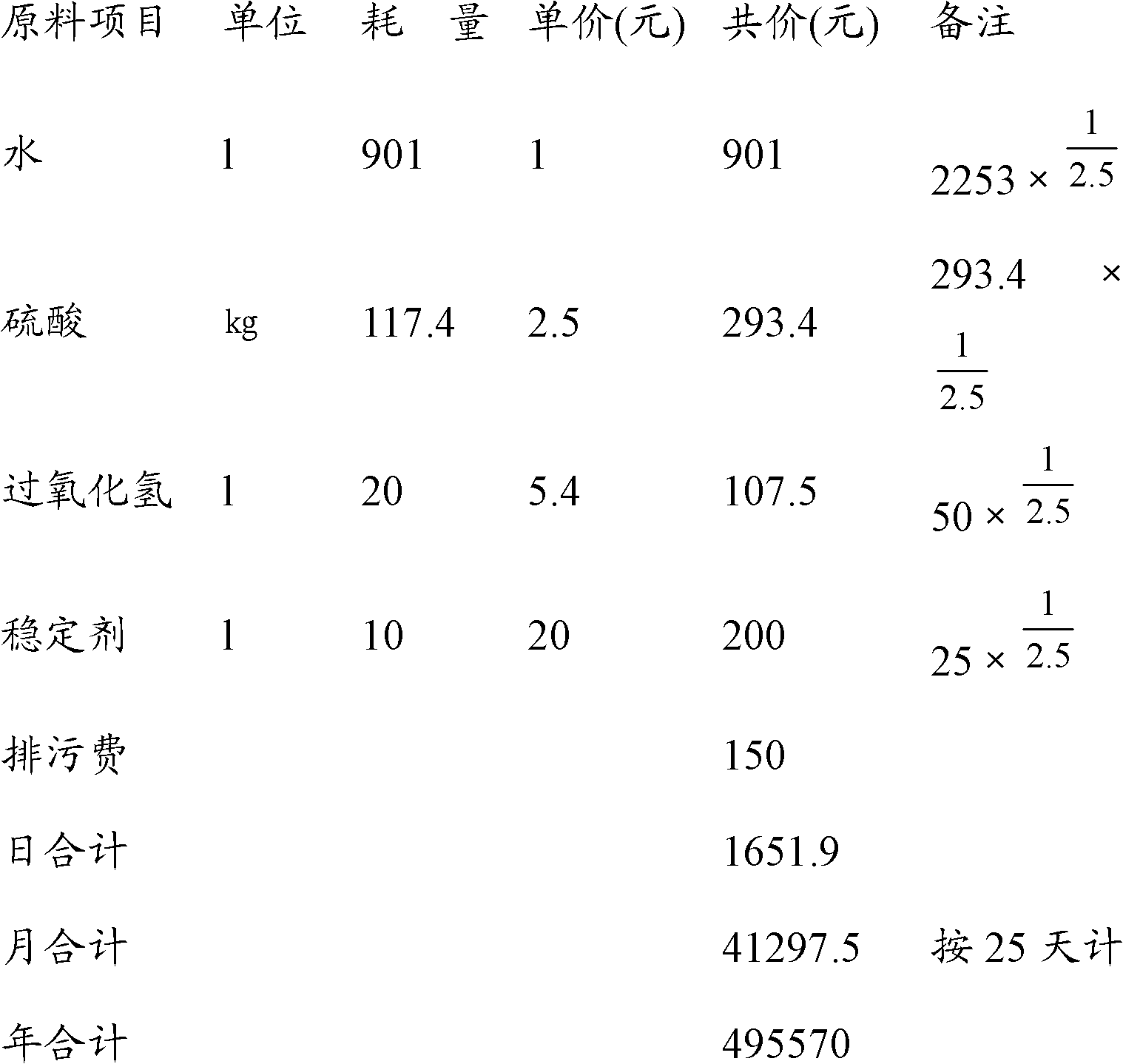

Process for recycling circuit board micro-etching waste liquid

InactiveCN102127766AHigh degree of automation controlEasy maintenancePrinted circuit boardHydrogen peroxide

The embodiment of the invention provides a process for recycling circuit board micro-etching waste liquid. The process for recycling the circuit board micro-etching waste liquid comprises the following steps of: a, pumping the micro-etching waste liquid into a hydrogen peroxide removing tank; b, removing the hydrogen peroxide, and pumping the micro-etching waste liquid into a copper recovery tank; c, pumping the micro-etching waste liquid into a micro-etching liquid component supplementing and preparing tank; and d, returning qualified micro-etching waste liquid to a production line automatically. The embodiment of the invention also provides a device for recycling the circuit board micro-etching waste liquid. By the process for recycling the circuit board micro-etching waste liquid in the embodiment of the invention, the defects that the micro-etching waste liquid in the conventional process for micro-etching circuit boards in printed circuit board (PCB) enterprises is only simply treated to be discharged, and waste is large and resources are severely lost in the treatment process are overcome.

Owner:深圳市惠尔能科技有限公司

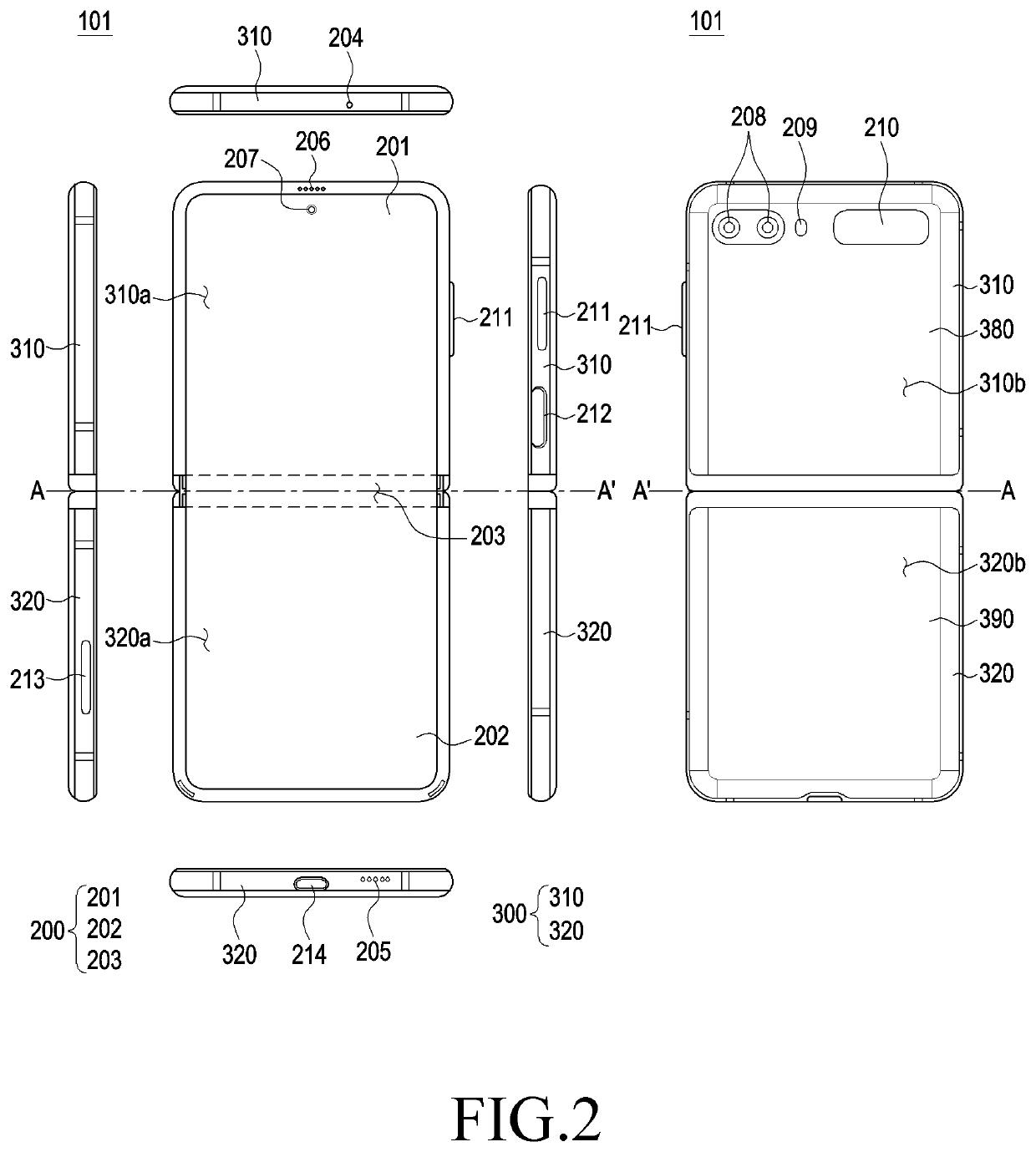

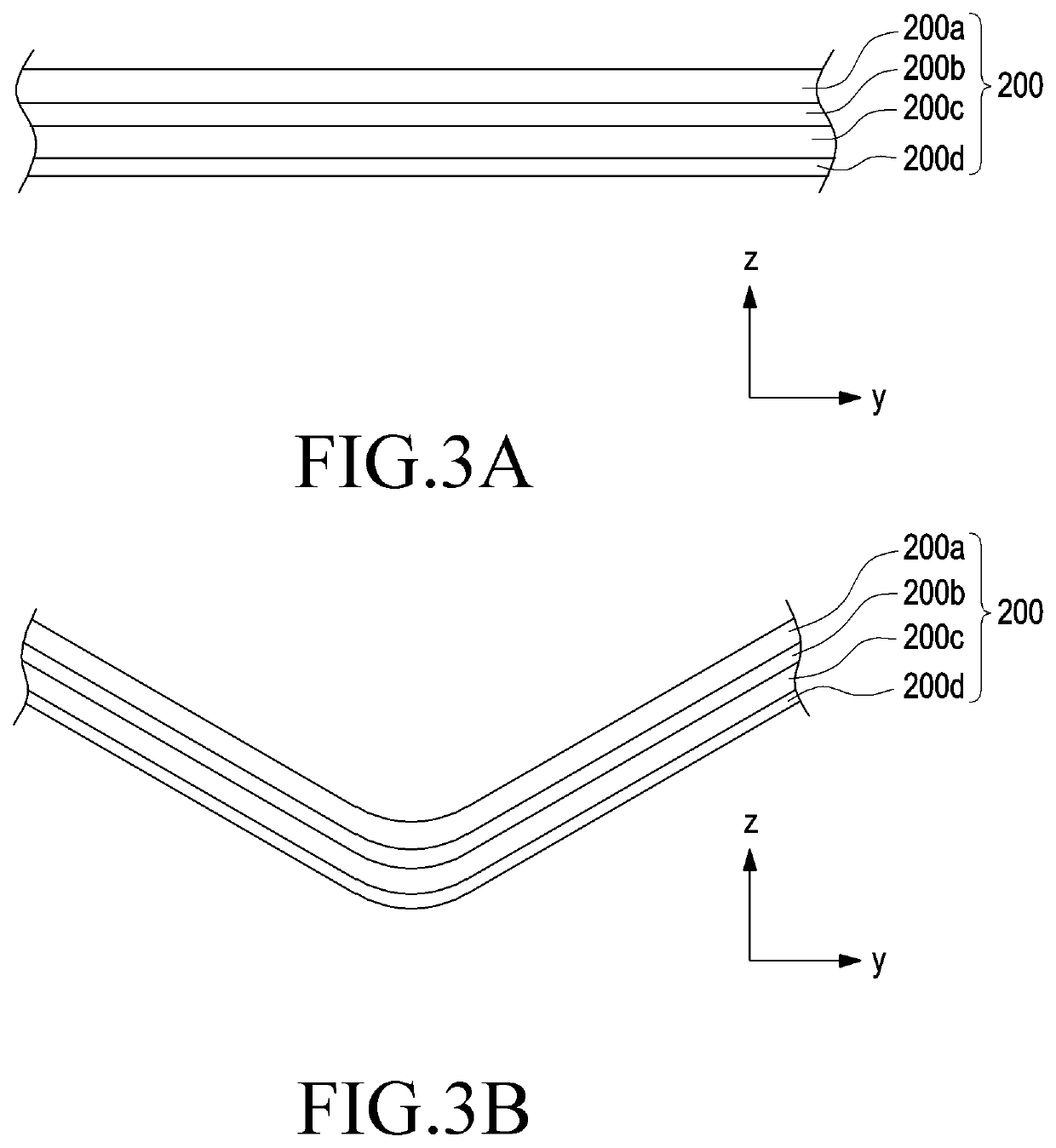

Foldable electronic device

ActiveUS20210247806A1Details for portable computersSubstation equipmentPrinted circuit boardEngineering

Owner:SAMSUNG ELECTRONICS CO LTD

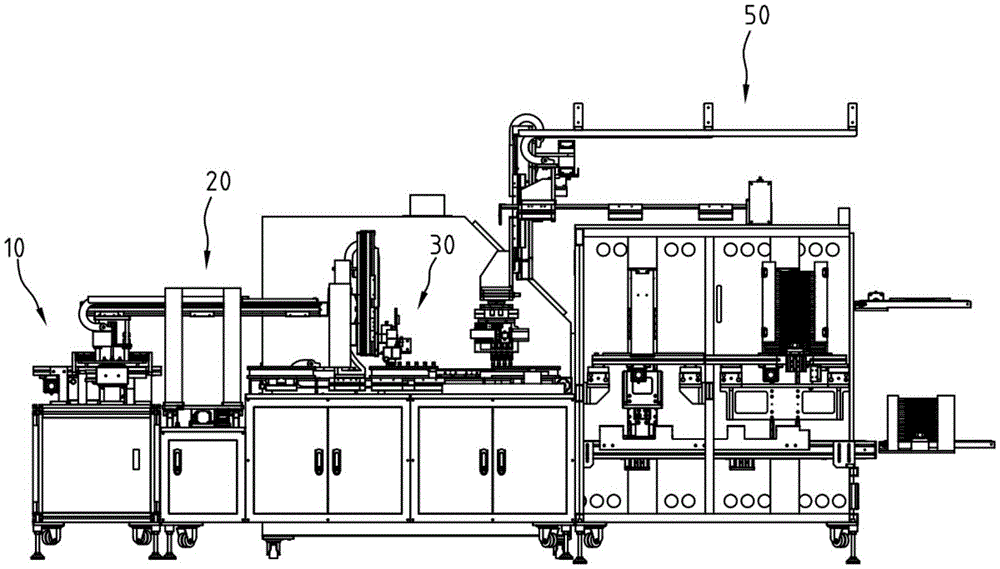

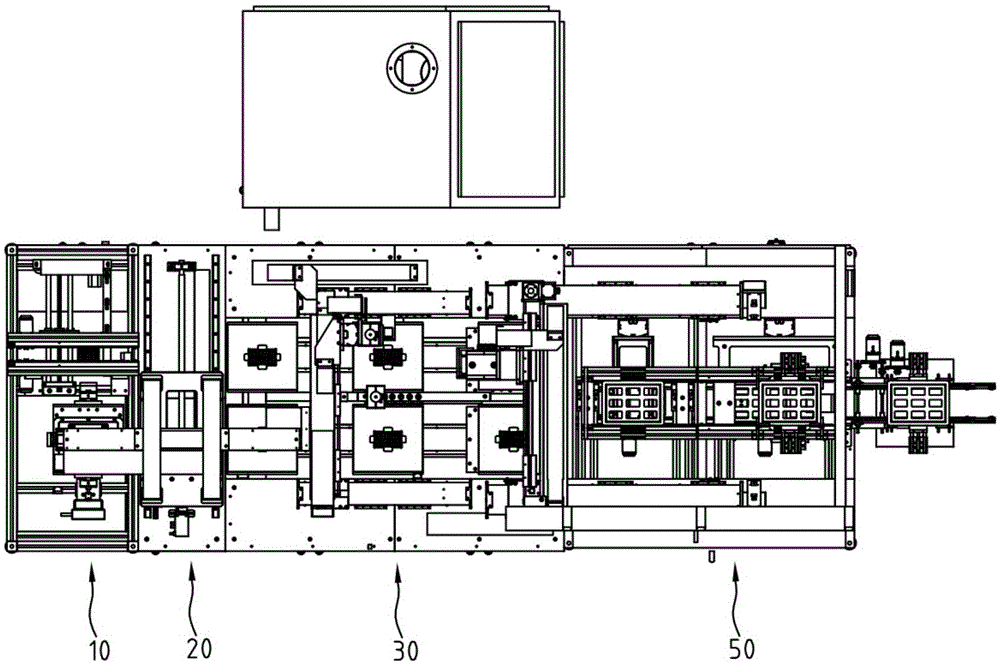

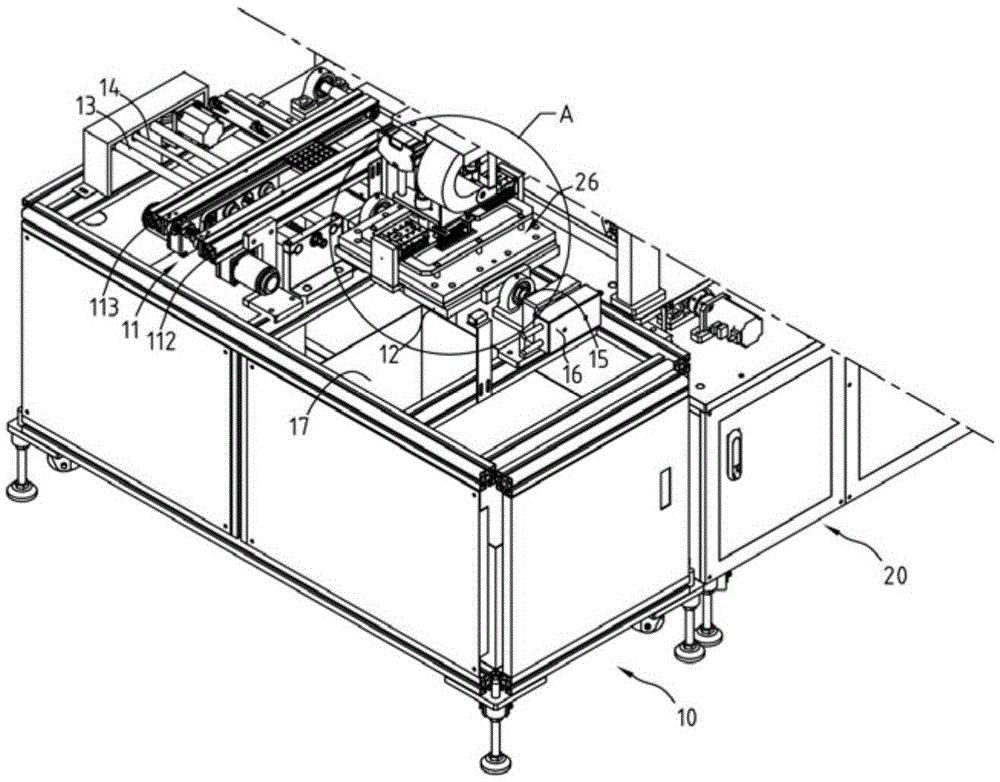

Slot-type circuit board applied to motor and assembly process thereof

InactiveCN103259371AAvoid breakingAvoid problems such as exposed leakageAssociation with control/drive circuitsManufacturing dynamo-electric machinesMaterial consumptionElectronic component

Owner:DONGGUAN GAOCHUANG MOTOR TECH

PCB (Printed Circuit Board) connection sheet dividing machine provided with jig returning lifting platform

InactiveCN105458364AMeasurement/indication equipmentsMilling equipment detailsTelescopic cylinderPrinted circuit board

Owner:SUZHOU HEROIC AUTOMATION TECH

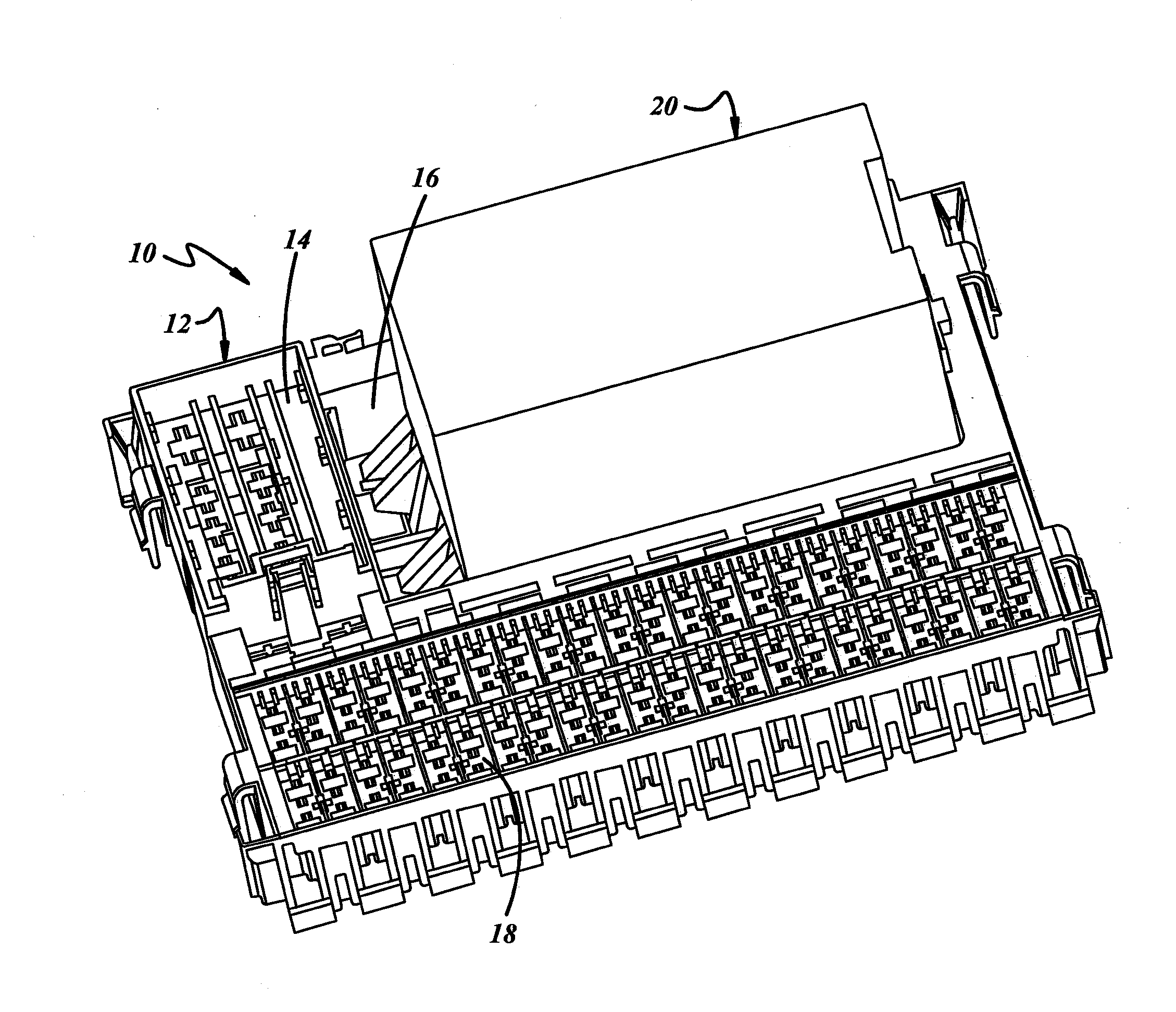

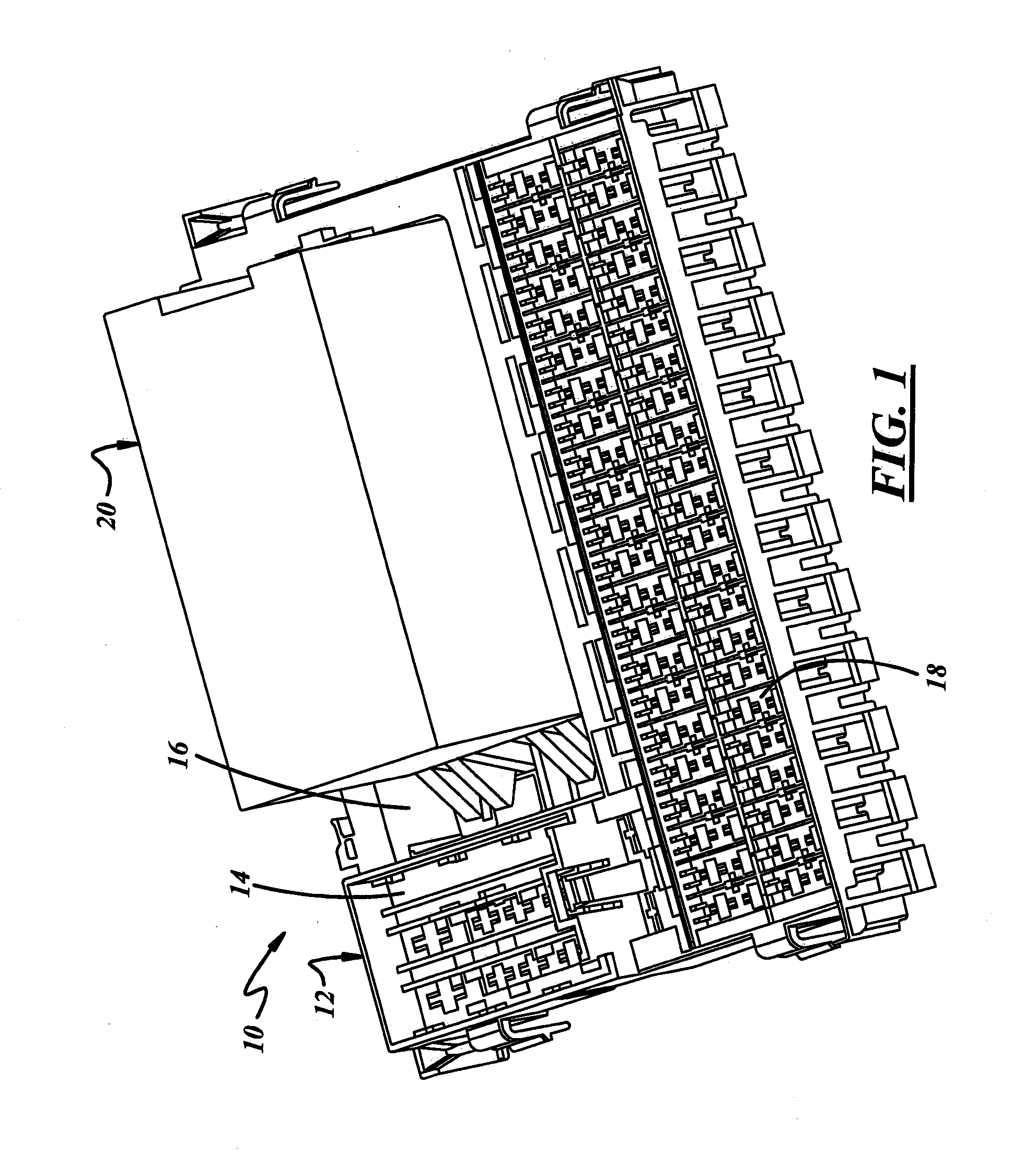

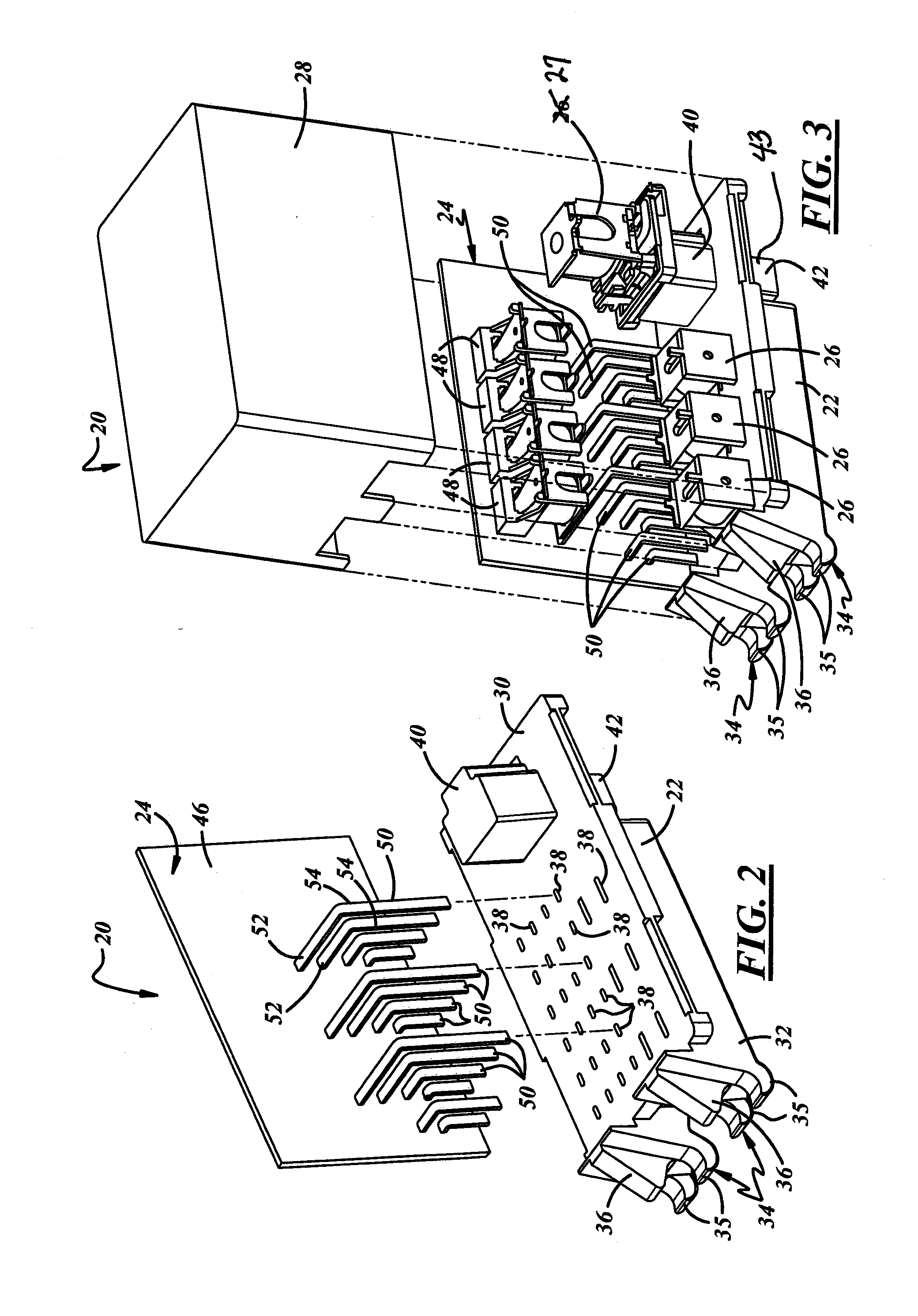

Relay module, electrical center having a relay module and method of assemblying the same

Owner:APTIV TECH LTD

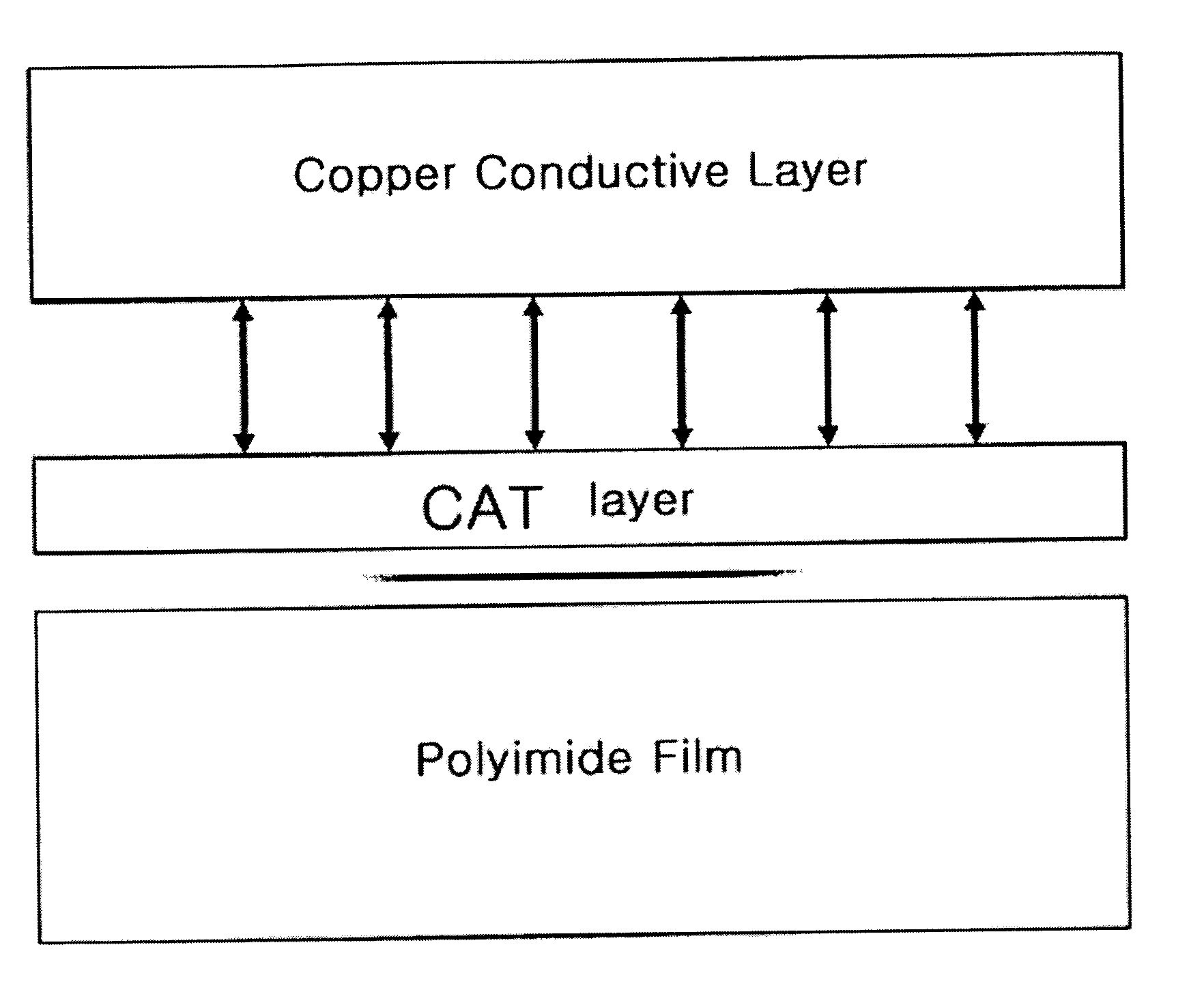

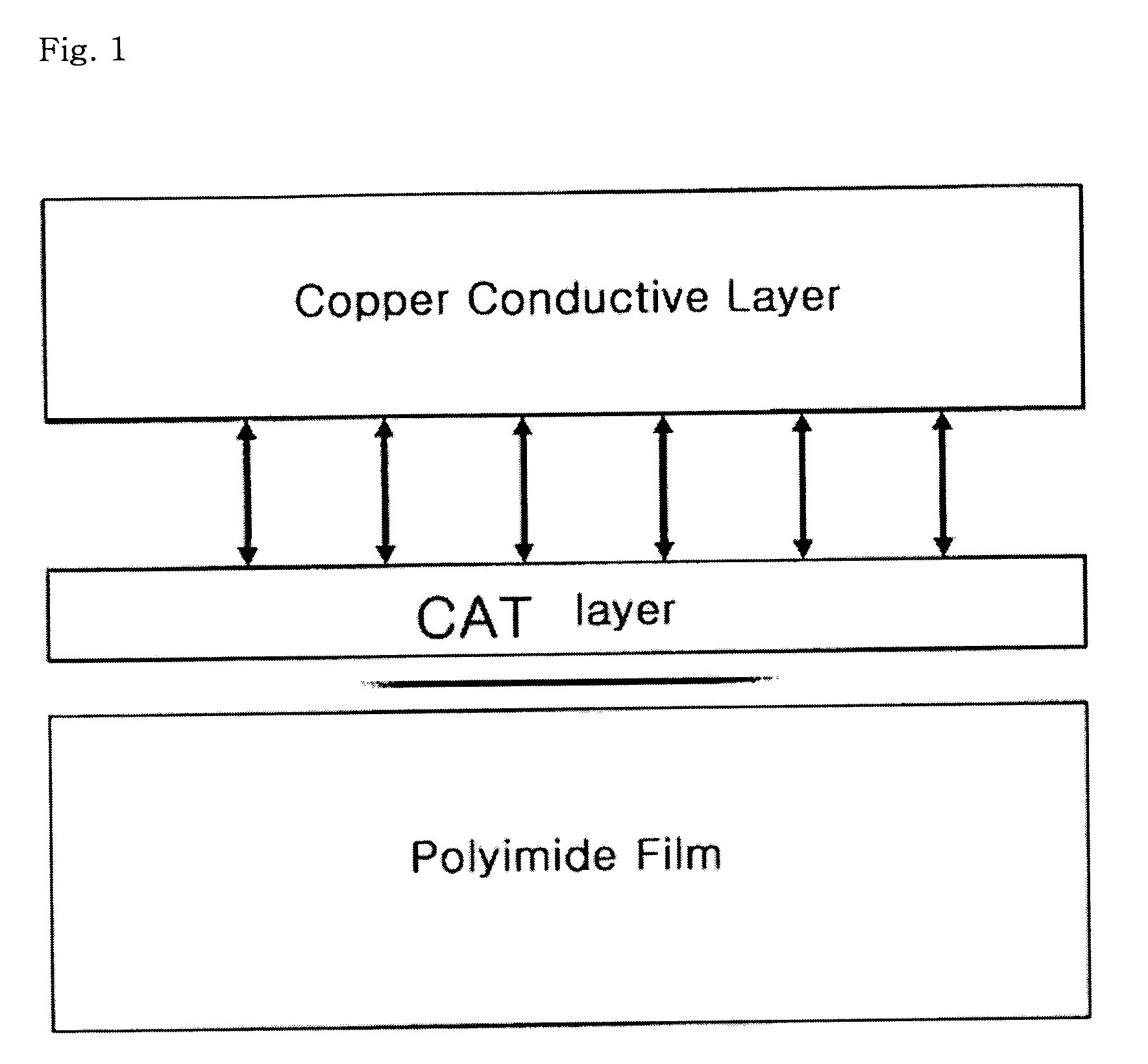

Laminate for flexible printed circuit board comprising tie layer of ternary copper alloy

InactiveUS20060029819A1Improve adhesion strengthGood chemical resistanceInsulating substrate metal adhesion improvementCircuit susbtrate materialsMetallurgyFlexible electronics

Owner:TORAY SAEHAN

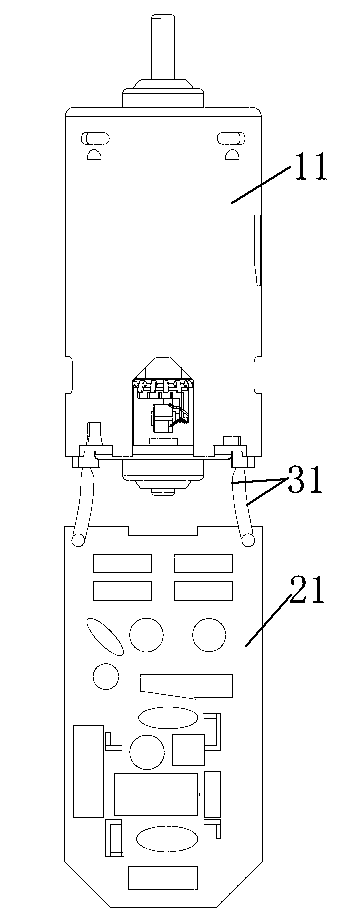

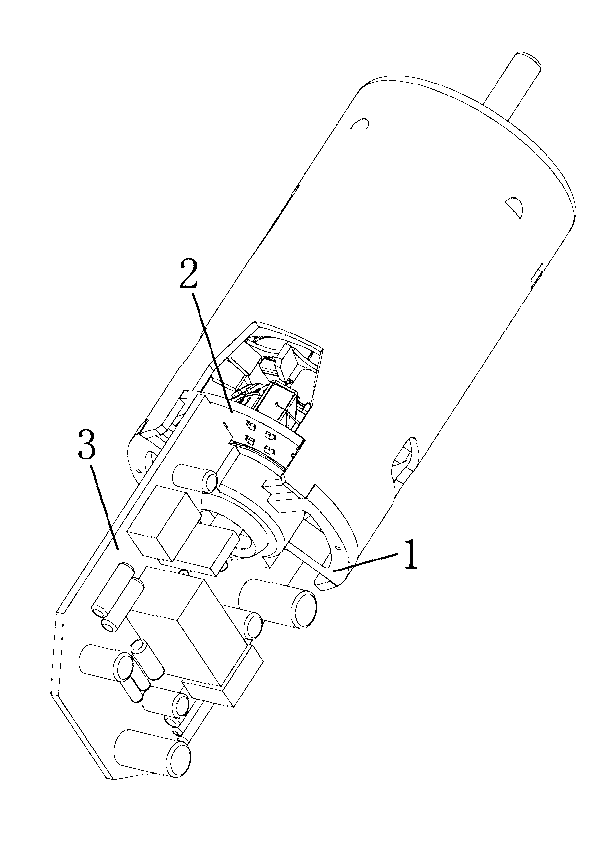

Compensating pyroelectric infrared unit detector

InactiveCN103474502AImprove performanceIncrease productivityFinal product manufactureSemiconductor devicesField-effect transistorPrinted circuit board

The invention discloses a compensating pyroelectric infrared unit detector belonging to the technical field of infrared detectors. The compensating pyroelectric infrared unit detector comprises a shell (1), and a window which is arranged at the head end of the shell, wherein an infrared filter (2), a base (3), pins (4), a double-sided circuit board (5), a field effect transistor (6), a pyroelectric infrared sensitive element (7), a pyroelectric compensation sensitive element (8) and a resistor (9) are arranged on the window; a through hole is formed in the center of the double-sided circuit board (5); the field effect transistor (6) is embedded in the through hole, and the bottom of the field effect transistor (6) is flush with the lower surface of the double-sided circuit board (5); the thickness of the field effect transistor (6) is smaller than the thickness of the double-sided circuit board (5); the pyroelectric infrared sensitive element (7) and the pyroelectric compensation sensitive element (8) are arranged above the through hole. The compensating pyroelectric infrared unit detector has the advantages of excellent performance, easiness in manufacturing, low production cost, high production efficiency and wide application range.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

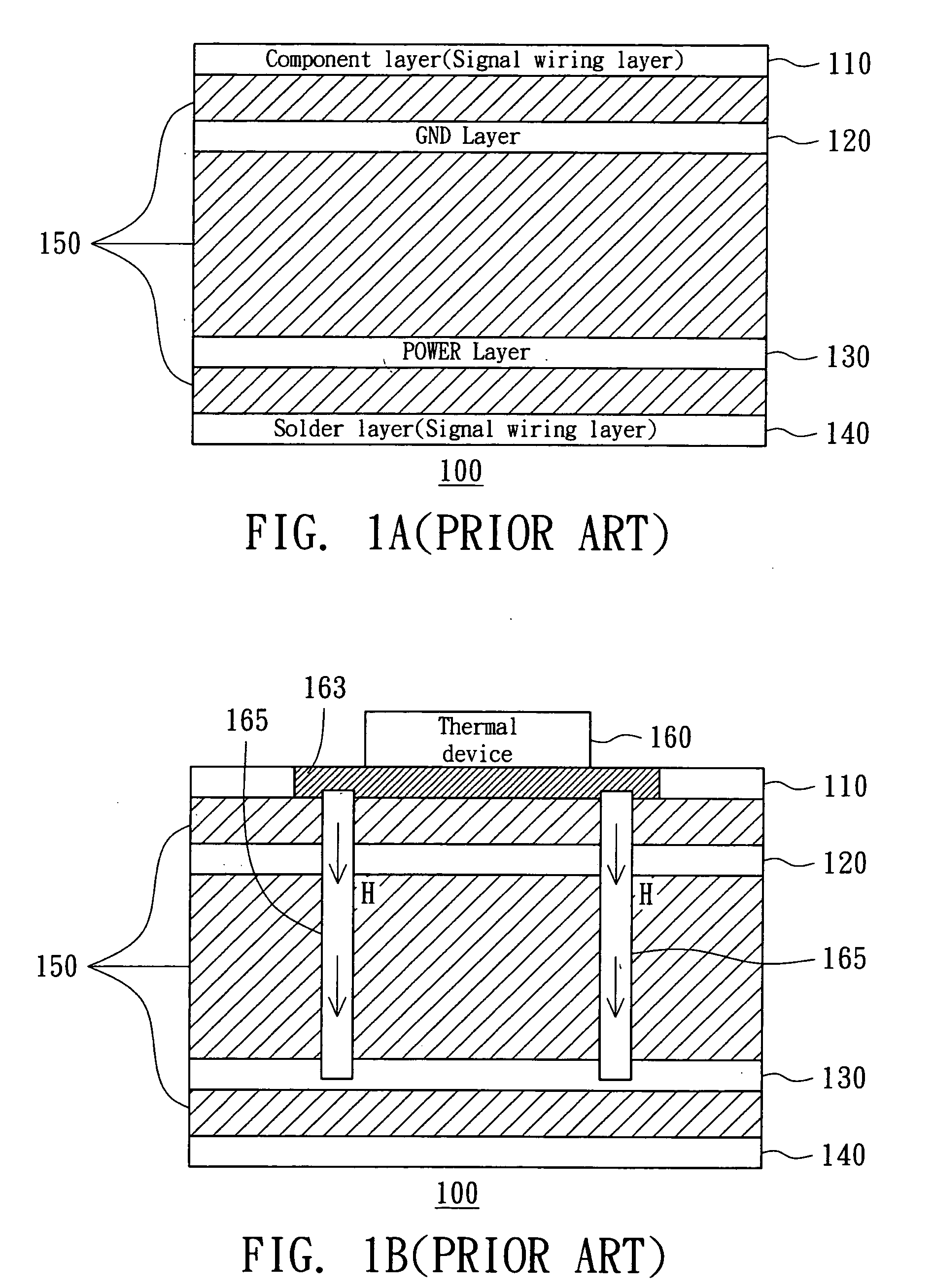

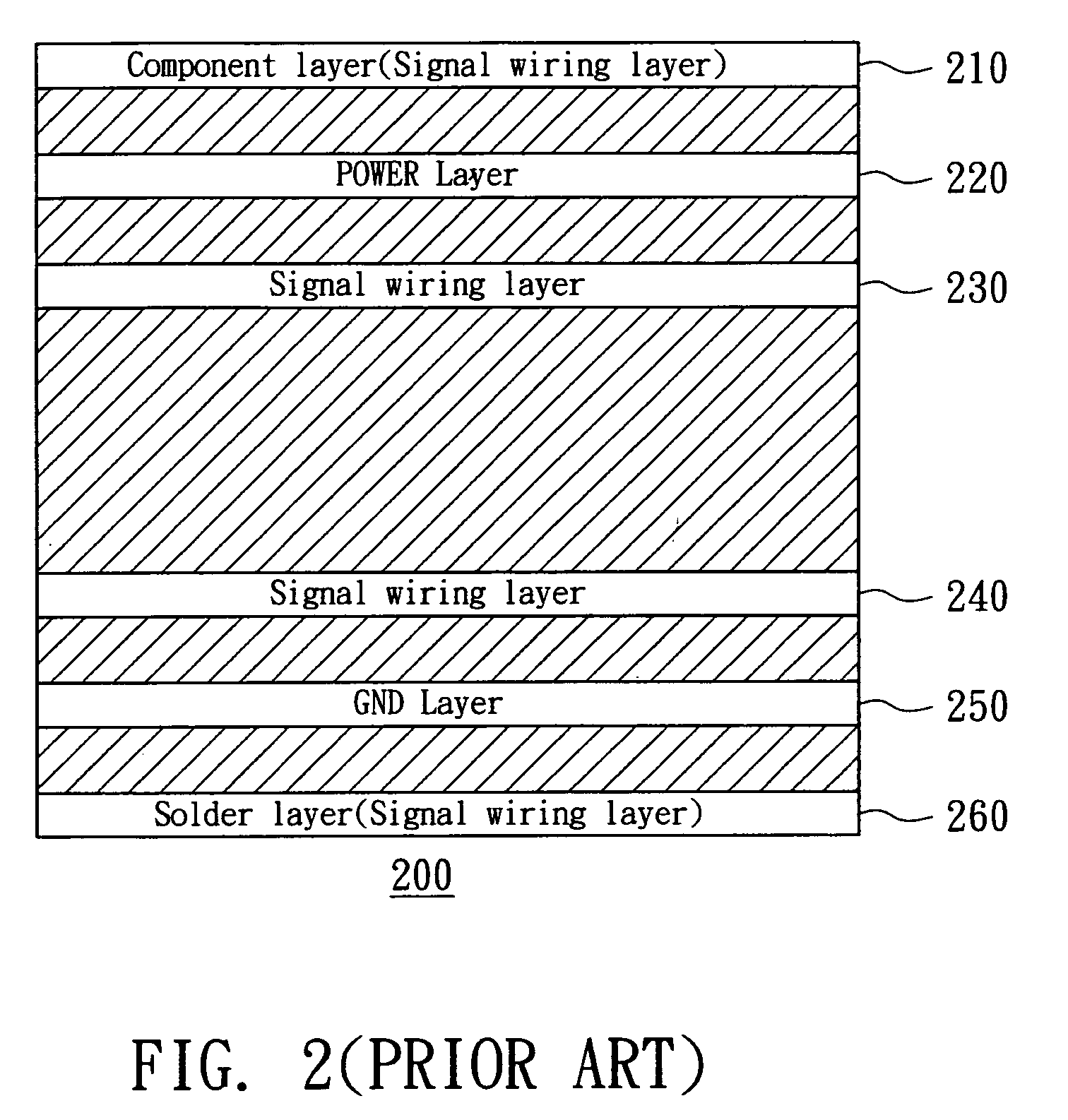

Printed circuit board structure

InactiveUS20060231289A1Increase manufacturing costHeat dissipationPrinted circuit aspectsElectrical connection printed elementsPrinted circuit boardBoard structure

Owner:ASUSTEK COMPUTER INC

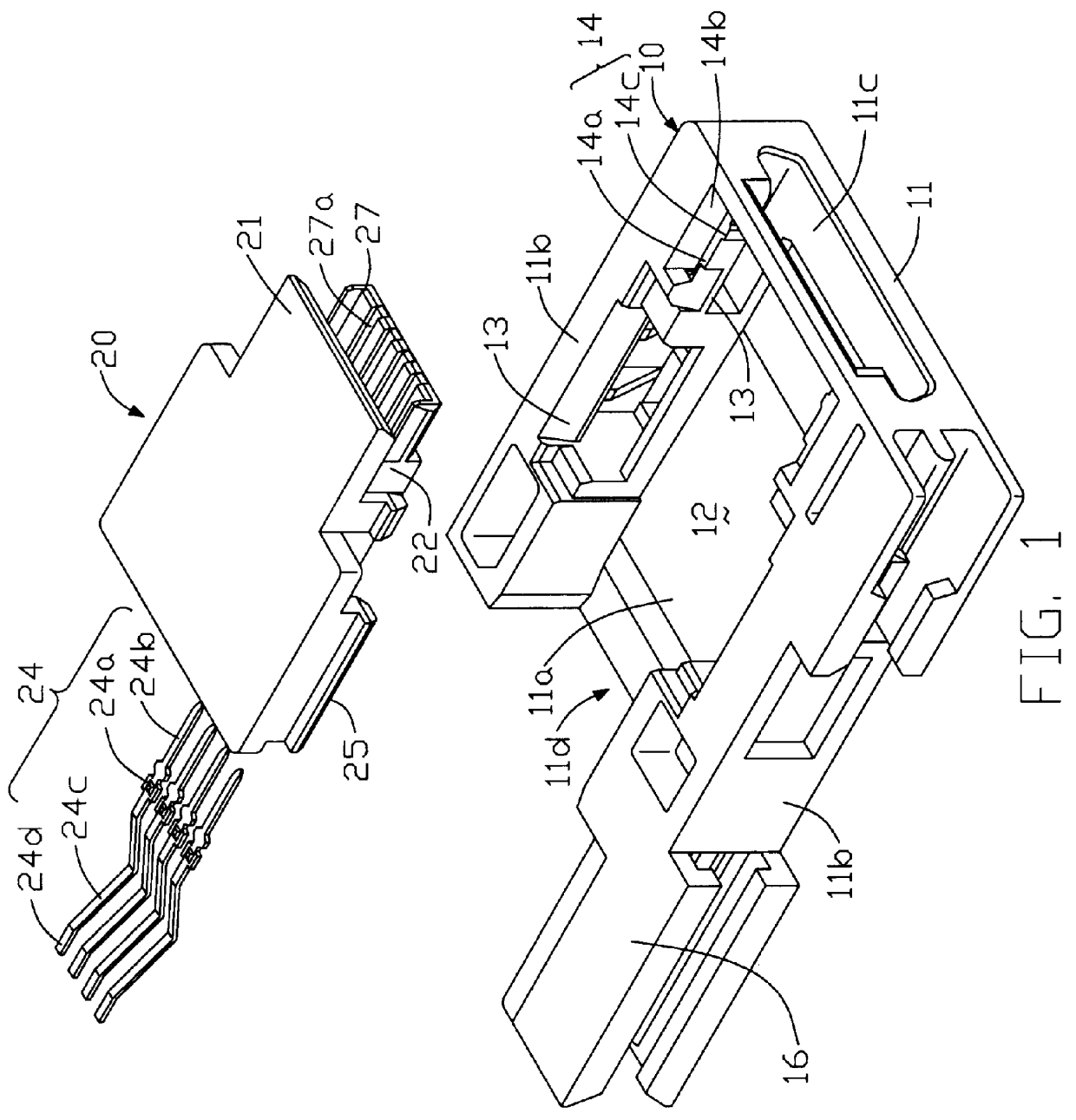

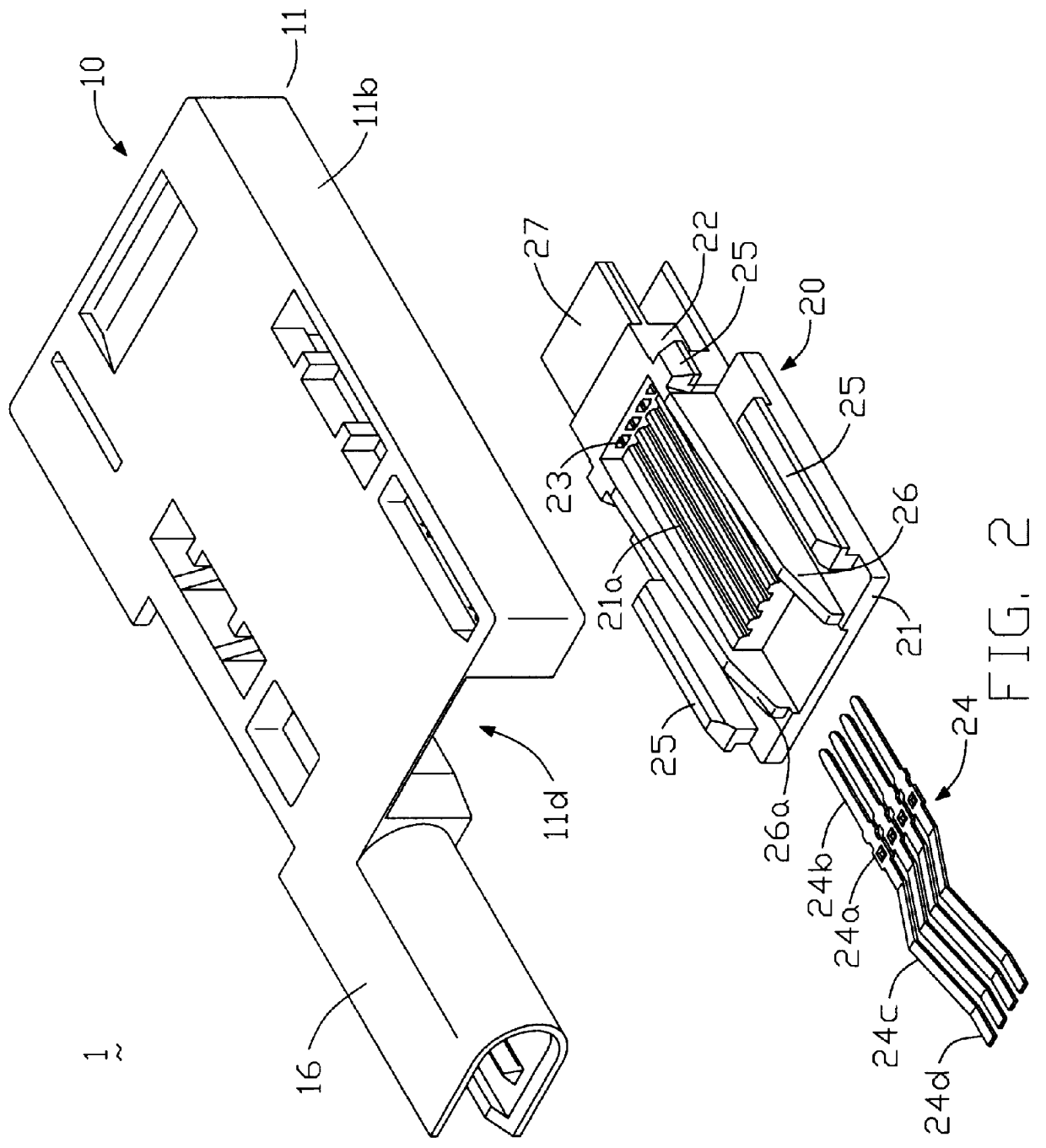

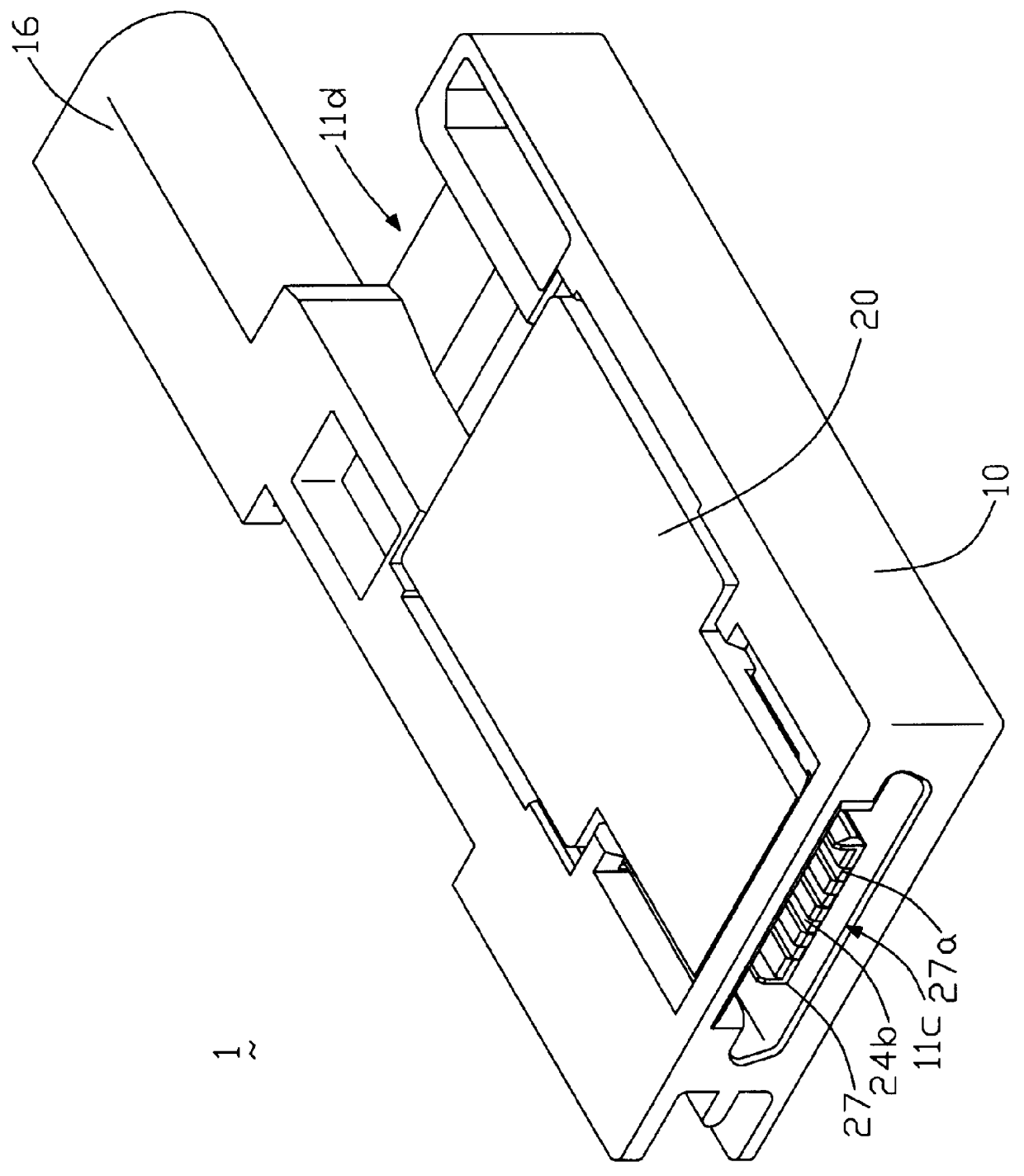

Connector assembly

Owner:HON HAI PRECISION IND CO LTD

Stack structure of printed circuit boards using interposer and electronic device including the same

ActiveUS20200266562A1Configuration highClosed casingsCasings with display/control unitsElectrical connectionStructural engineering

Owner:SAMSUNG ELECTRONICS CO LTD

Electronic Device Used In A Health Care Setting

ActiveUS20100195295A1Avoid the needCasings with display/control unitsSupport structure mountingCare settingEngineering

An electronic device for use in a health care setting has a rigid enclosure assembly formed by a rigid shell and a rigid printed circuit board carrying circuitry for operating the device. A switch dome layer and an overlay are independently attached to the device but not to each other, whereby the overlay may be removed without disturbing the dome layer and a better tactile response is achieved.

Owner:CURBELL MEDICAL PRODS

Fixture for assembling automobile dashboard PCB (printed circuit board) and radiating fins

InactiveCN103909485AEasy to operateImprove work efficiencyWork holdersDashboardStructural engineering

The invention discloses a fixture for assembling an automobile dashboard PCB (printed circuit board) and radiating fins. The fixture comprises a bottom plate, wherein a support for placing the radiating fins is fixed in the center of the bottom plate; a lifting mechanism for supporting and lifting the automobile dashboard PCB is fixed on the bottom plate; guiding blocks are fixed on the outer circle of the bottom plate; the lifting mechanism is arranged between the adjacent guiding blocks; the bottom plate is connected with a cover plate; two positioning holes are formed in the cover plate; a screw positioning mechanism is fixed above the positioning holes; and the positioning holes are coaxial with the automobile dashboard PCB and screw holes in the radiating fins. The fixture for assembling the automobile dashboard PCB and the radiating fins has the advantages that by using the fixture, the automobile dashboard PCB and the radiating fins can be accurately connected to each other through screws in a fastened manner; and the fixture is convenient to operate and high in operating efficiency.

Owner:SCHEUGENPFLUG RESIN METERING TECH (SIP) CO LTD

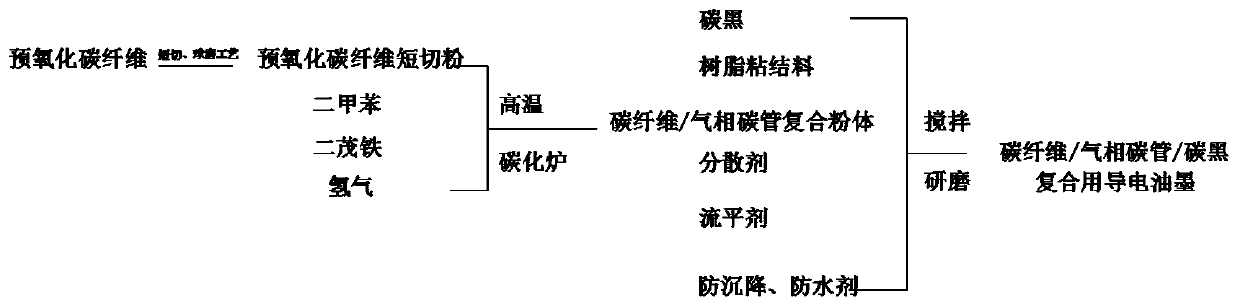

Carbon fiber/gaseous carbon tube/carbon black compound conductive ink and preparation method thereof

Owner:HANGZHOU CHAOTAN NEW MATERIAL TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap