Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45 results about "Insulation layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Display device

InactiveUS7180677B2Improve utilization efficiencyStatic indicating devicesNon-linear opticsInsulation layerDisplay device

Owner:FUJIFILM CORP +1

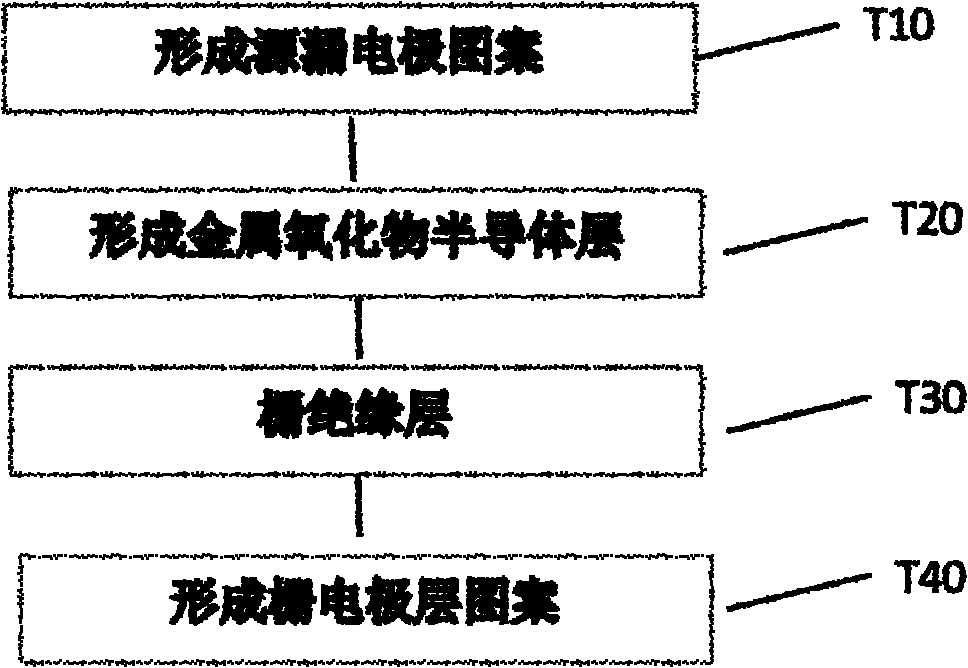

Preparation method of top gate metal oxide thin film transistor (TFT)

InactiveCN102157564ASolve the technical problem of insufficient chargingIncrease the on-state currentTransistorSemiconductor/solid-state device manufacturingEtchingElectrical conductor

Owner:SHANGHAI JIAO TONG UNIV

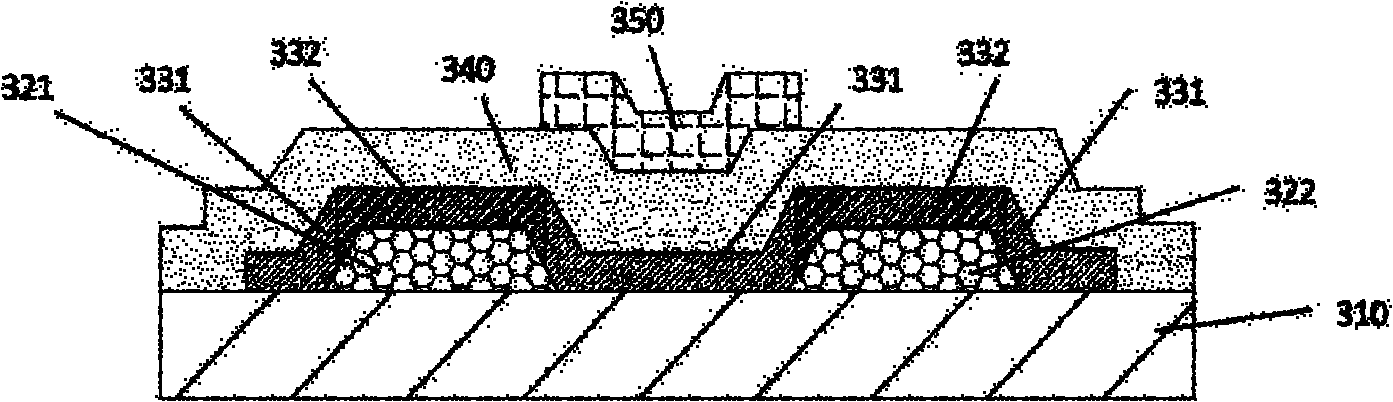

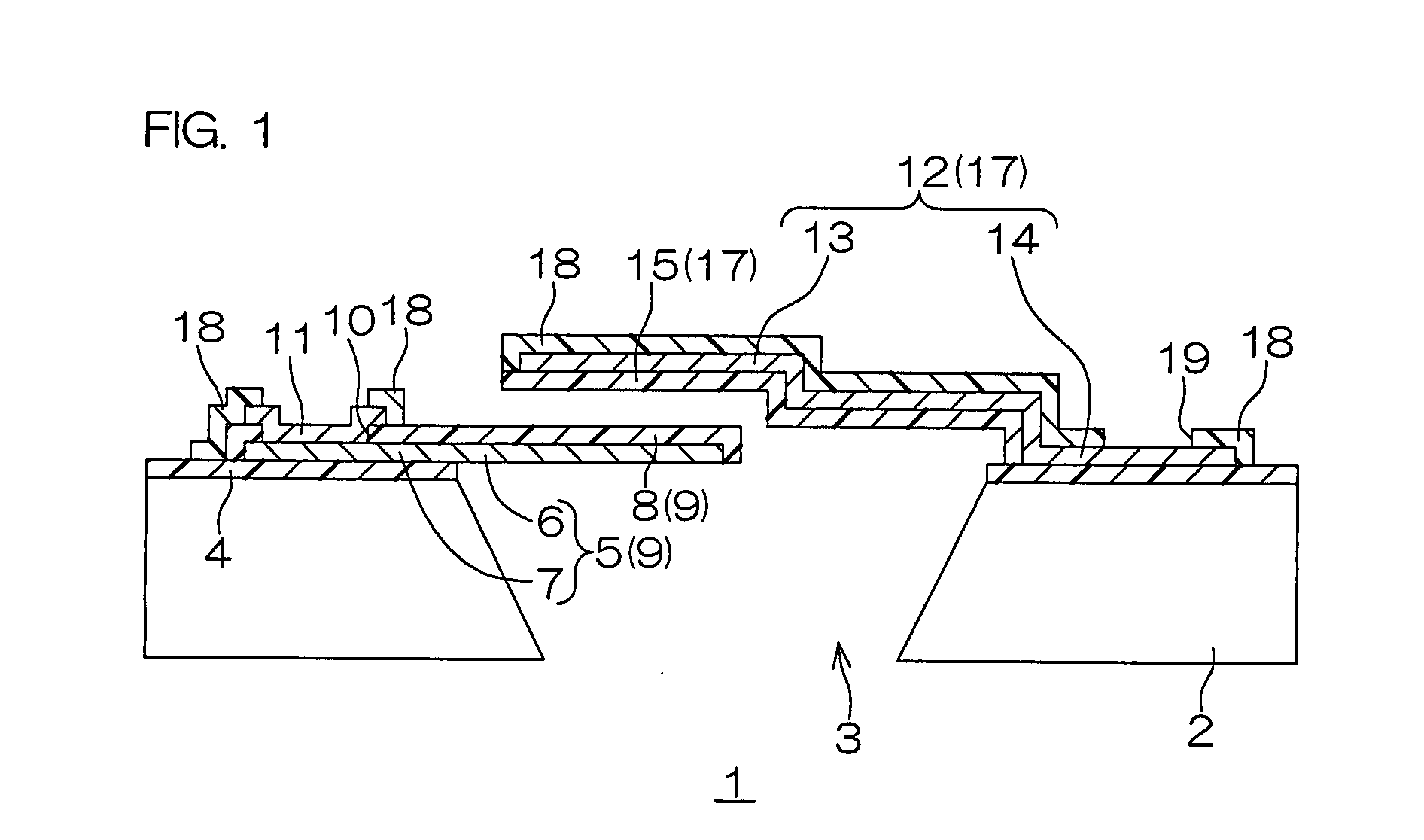

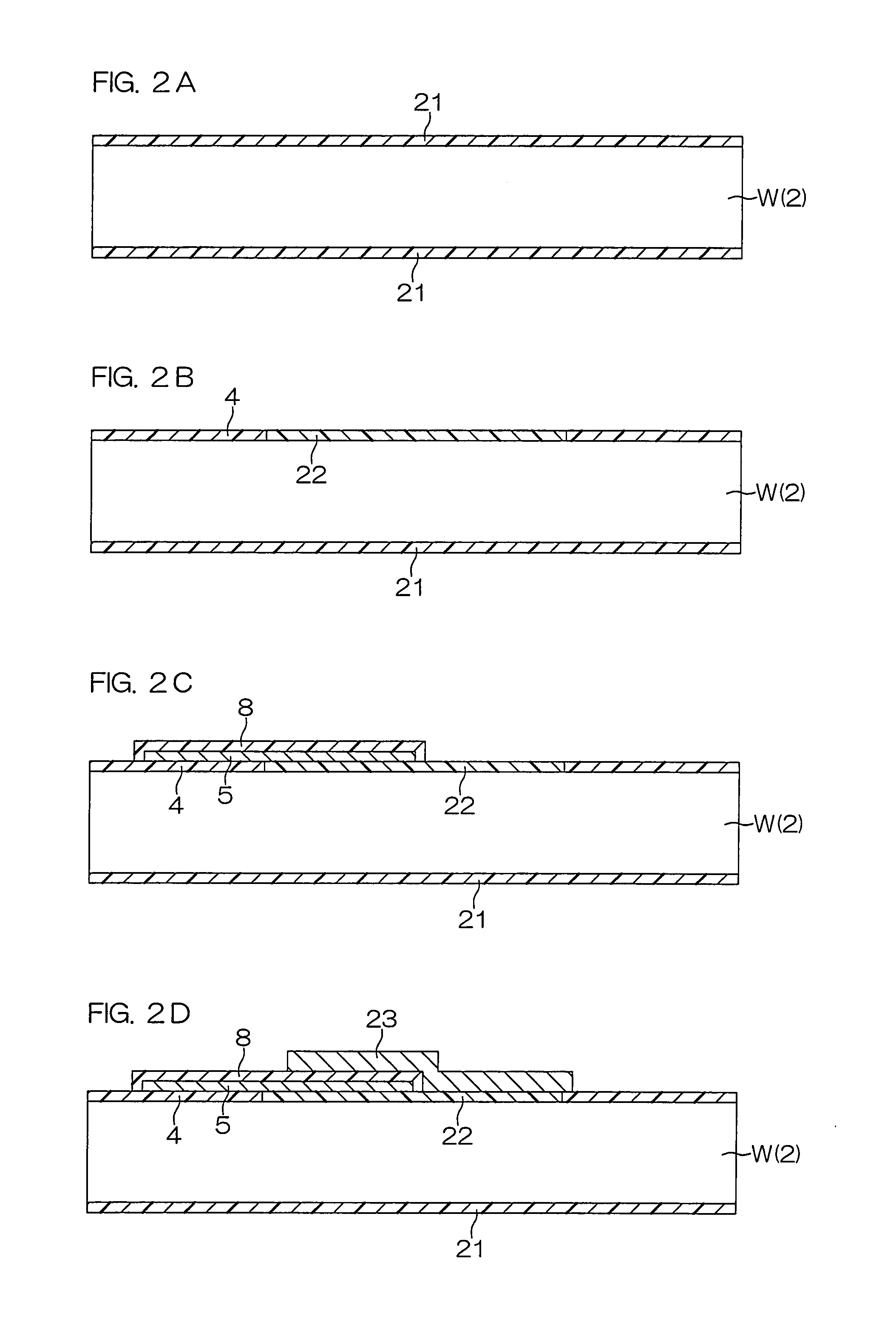

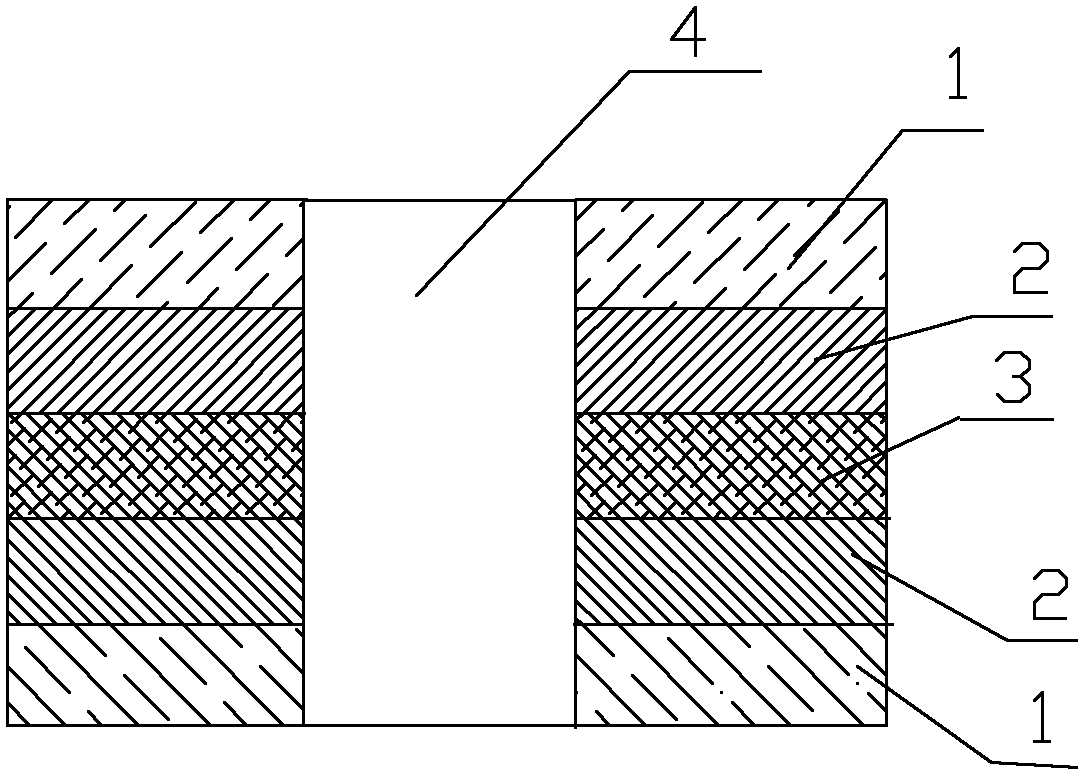

Embedded printed circuit board and method of manufacturing the same

InactiveUS20160174381A1Well formedSolid-state devicesElectrical connection printed elementsInsulation layerElectronic component

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

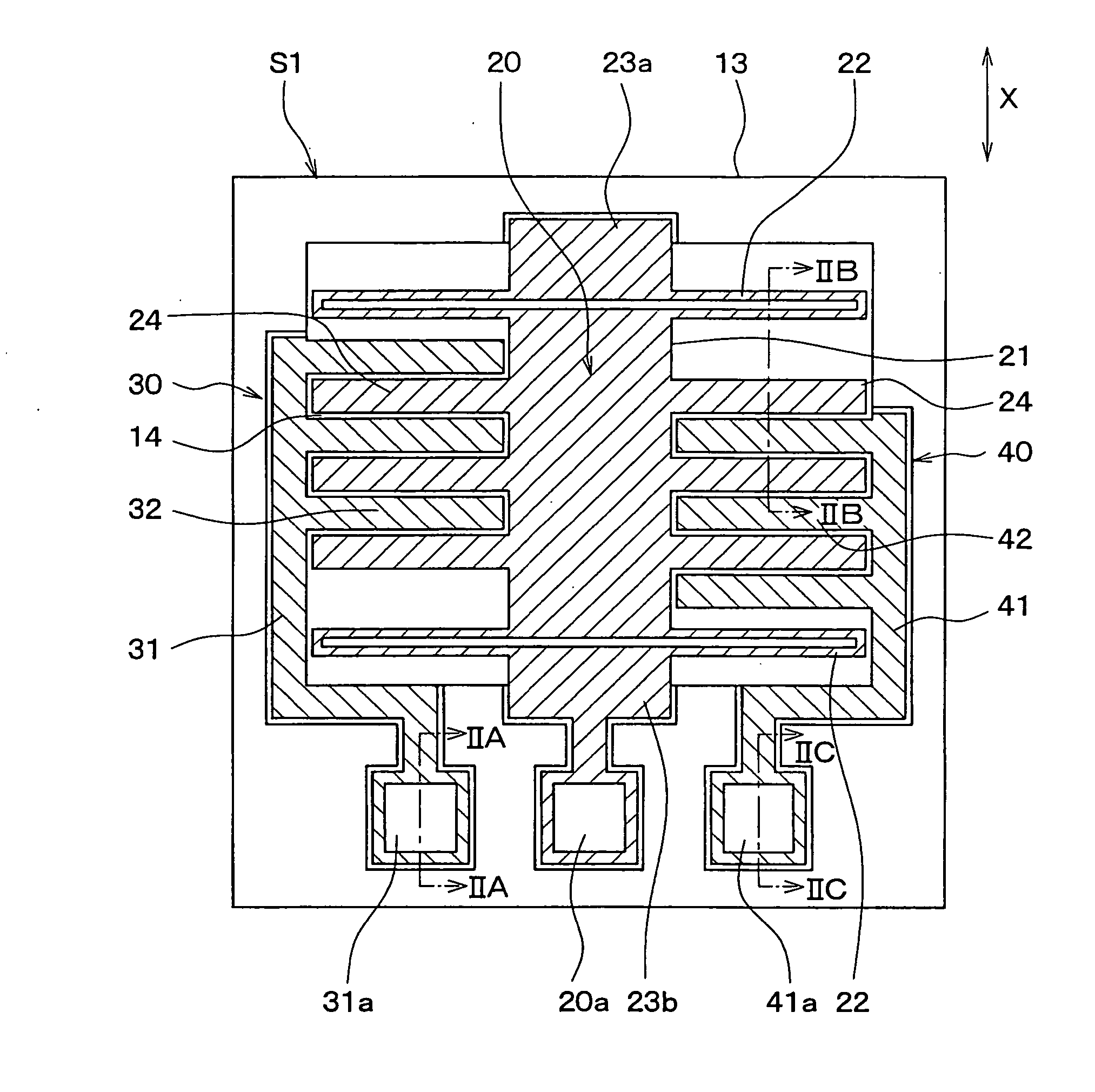

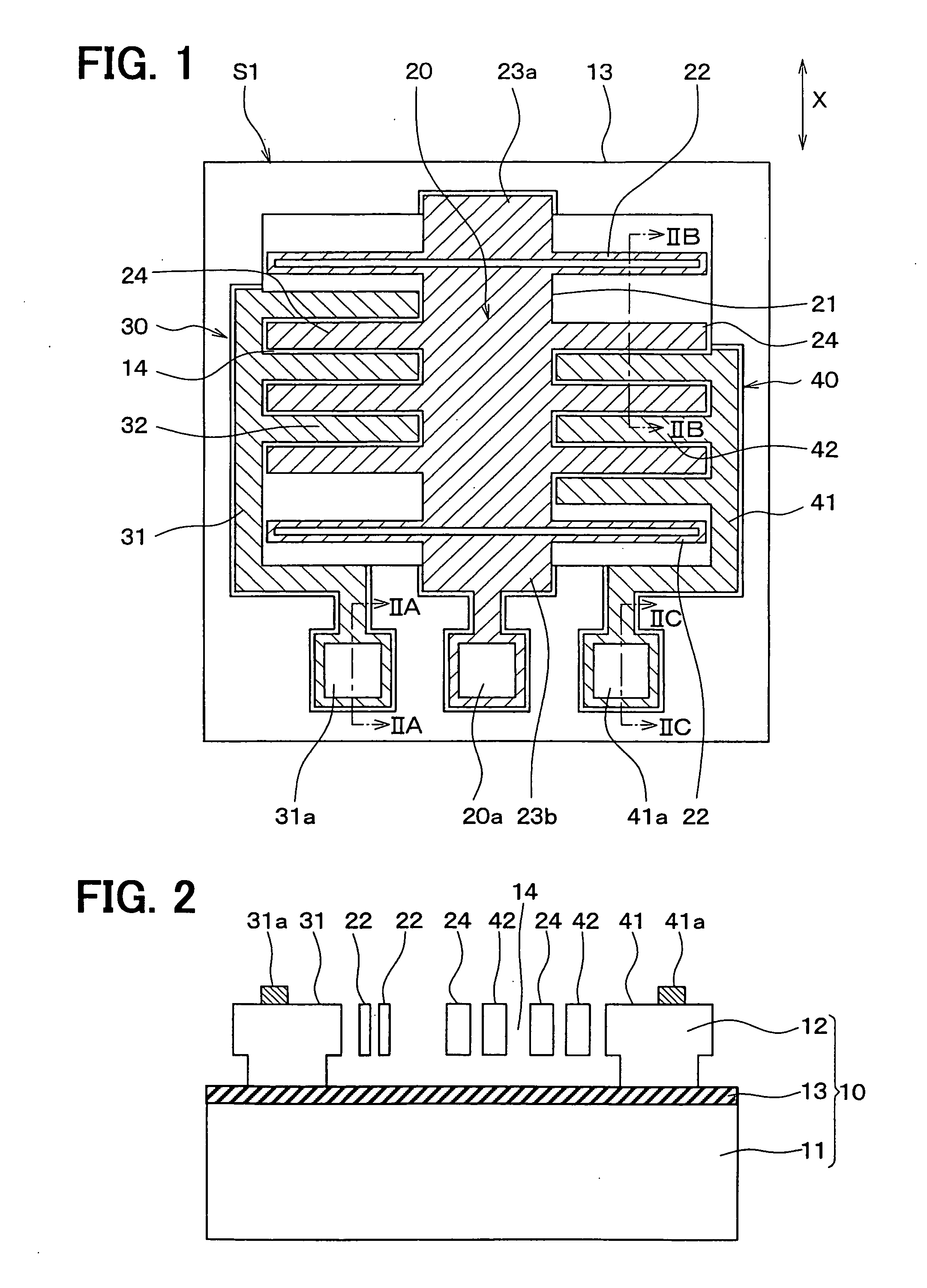

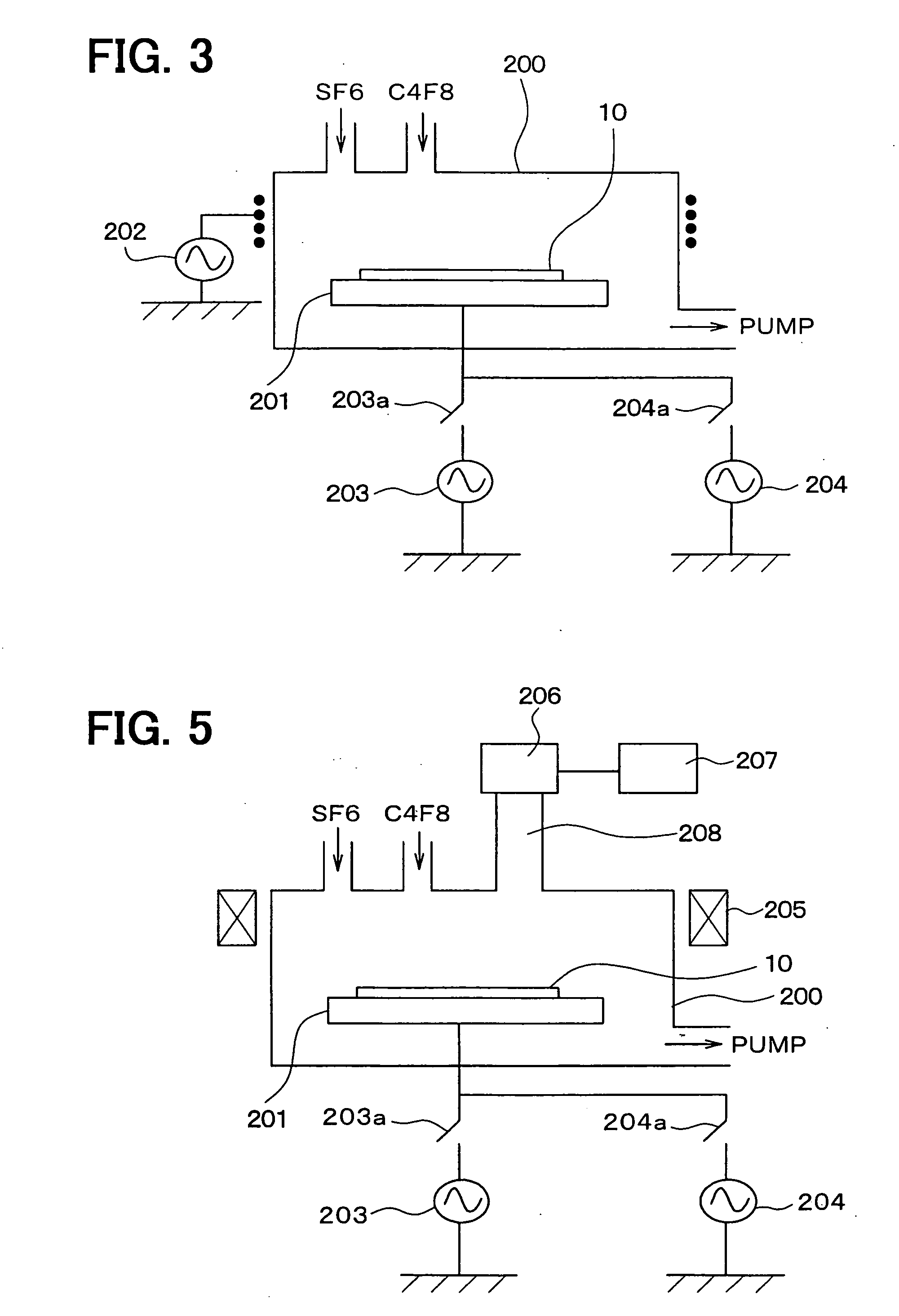

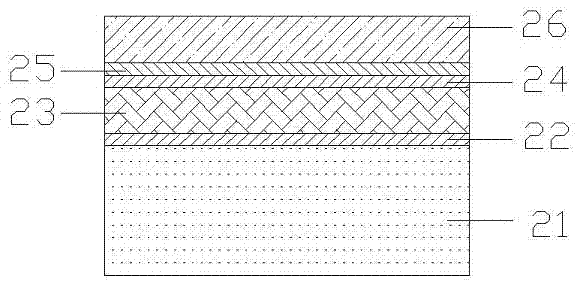

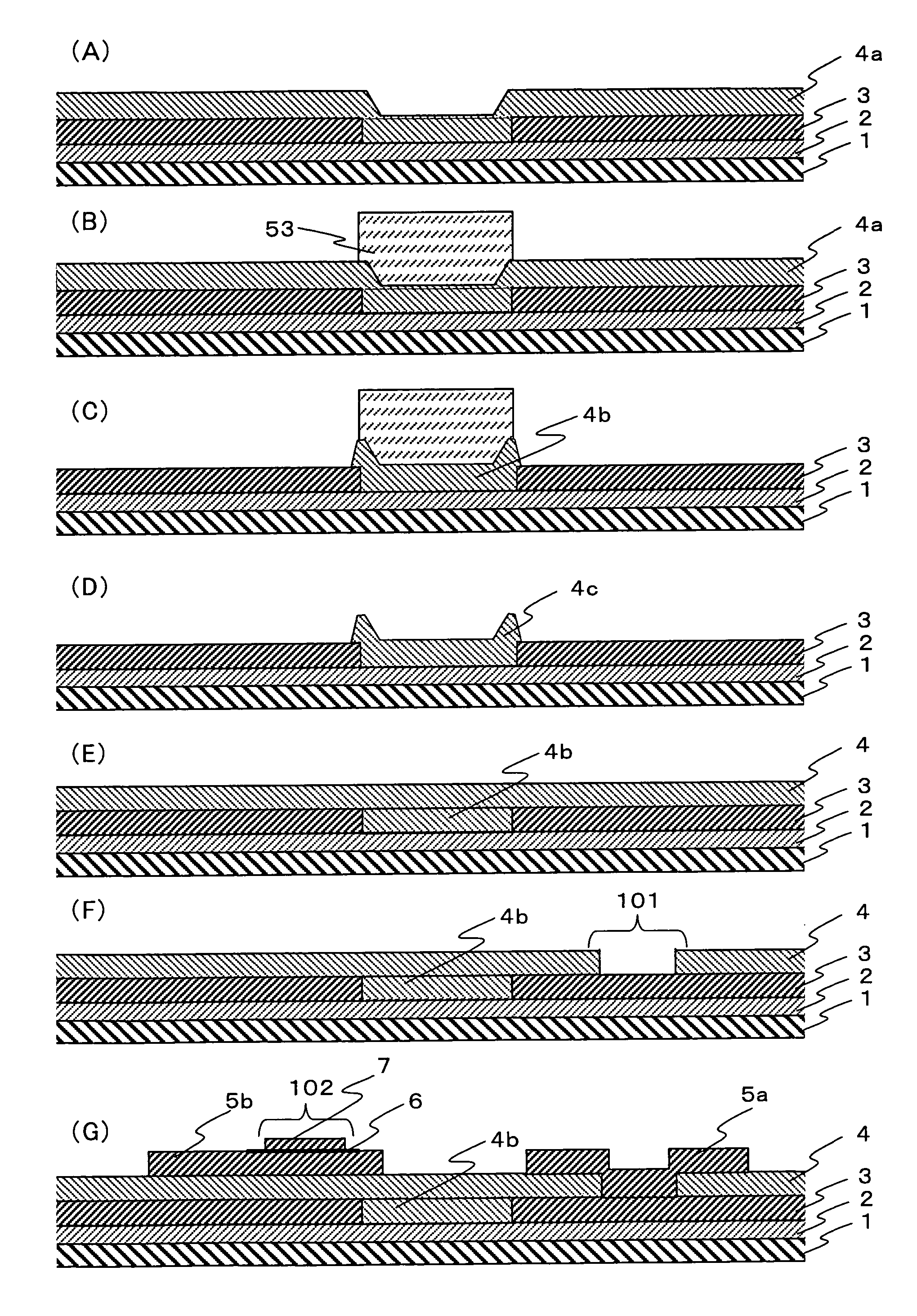

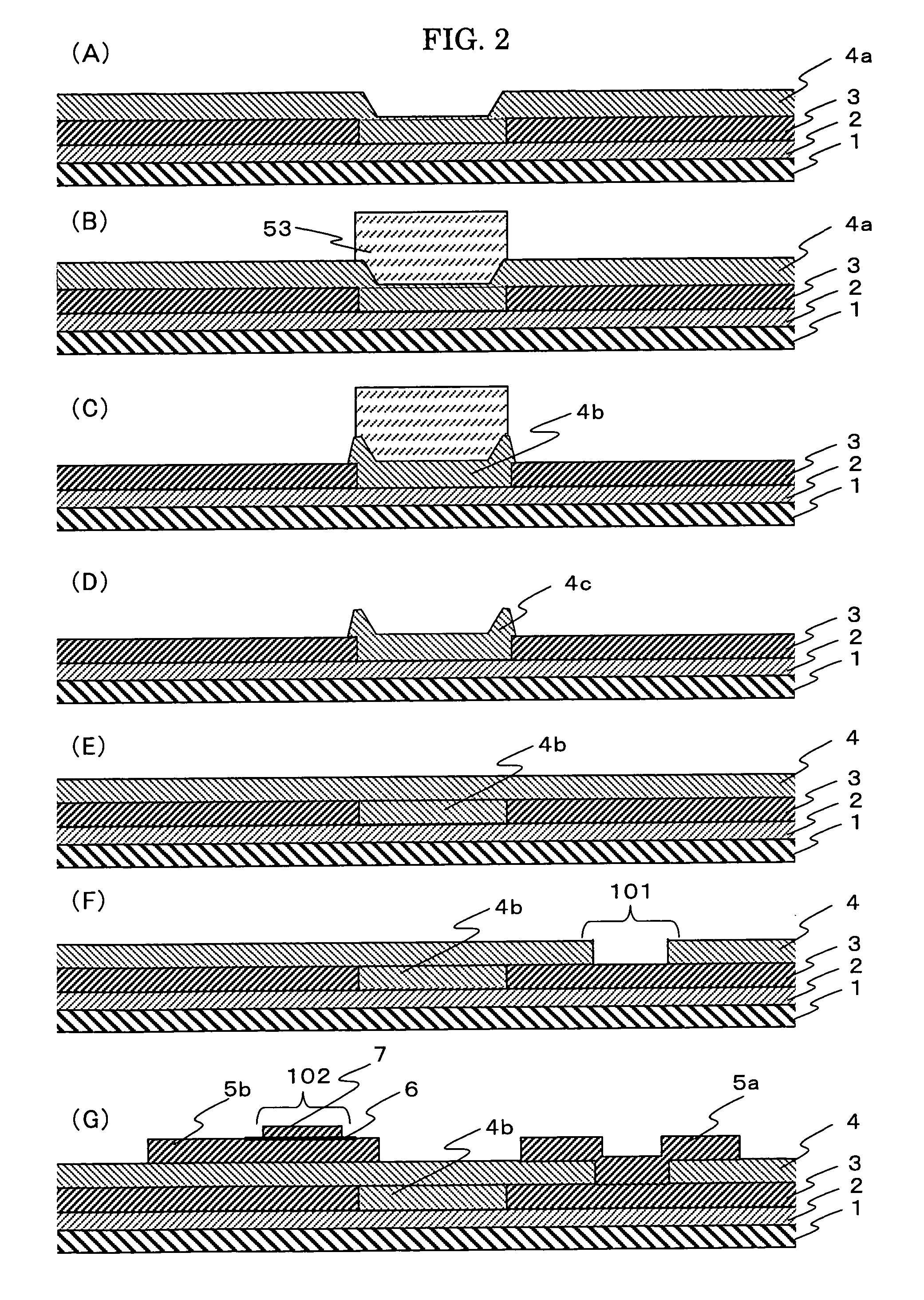

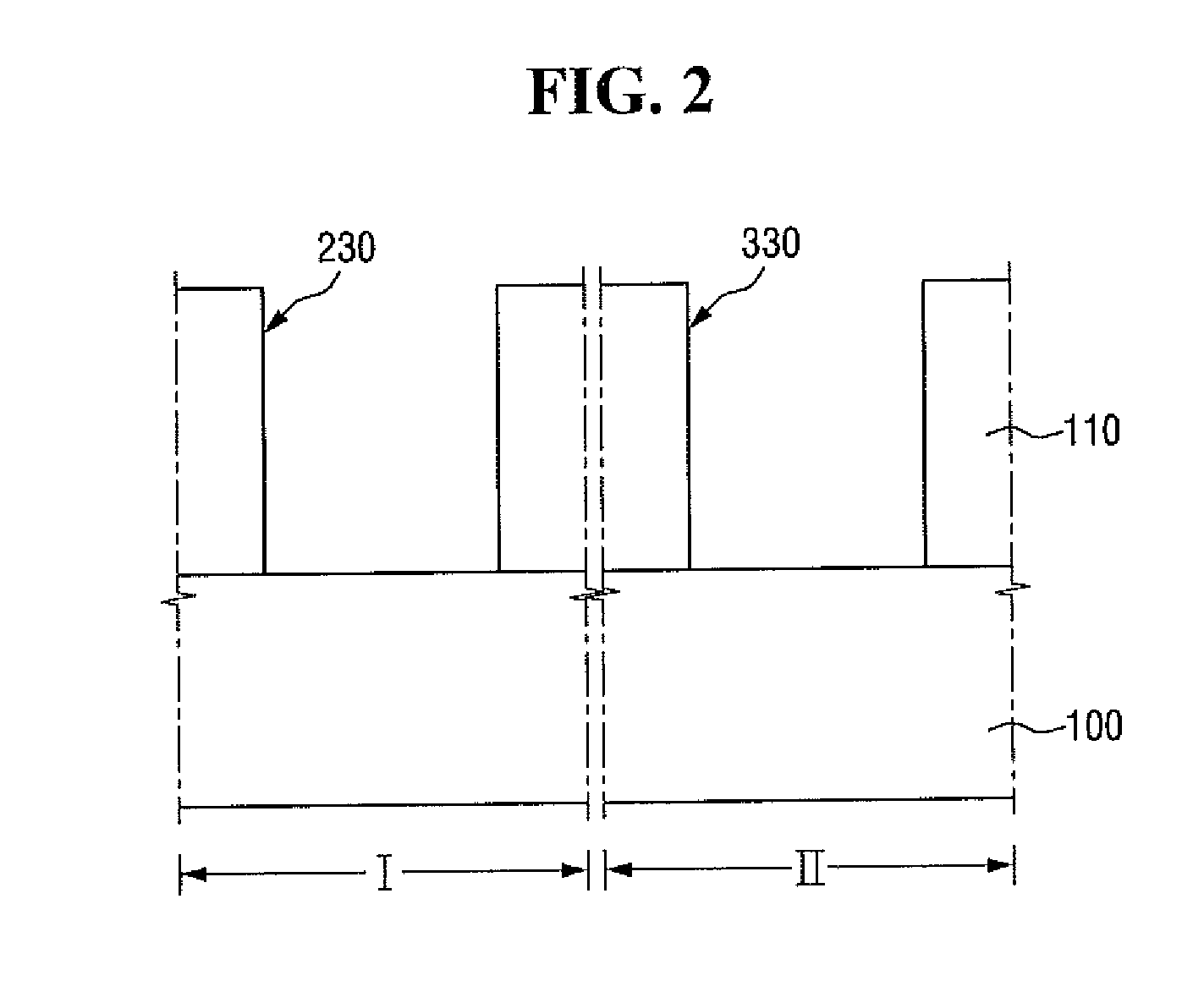

Method for manufacturing movable portion of semiconductor device

ActiveUS20050054153A1Short processing timeEasy to disassembleTransistorDecorative surface effectsInsulation layerDevice material

Owner:DENSO CORP

Low Dielectric Loss Power Cable Sheaths Comprising High Pressure Polyolefins Free of Silane Functionality

Power cables that comprise a sheath layer, e.g., an insulation layer, are produced from a mixture of a high pressure polyolefin free of silane functionality, e.g., high pressure low density polyethylene, and a polyether polyol of which at least 50 percent of its molecules comprise no more than a single hydroxyl functionality. Preferably, the power cable is a medium or high voltage power cable, and the polyolefin is crosslinked as the sheath layer is fabricated and / or subsequent to the fabrication of the sheath layer.

Owner:DOW GLOBAL TECH LLC

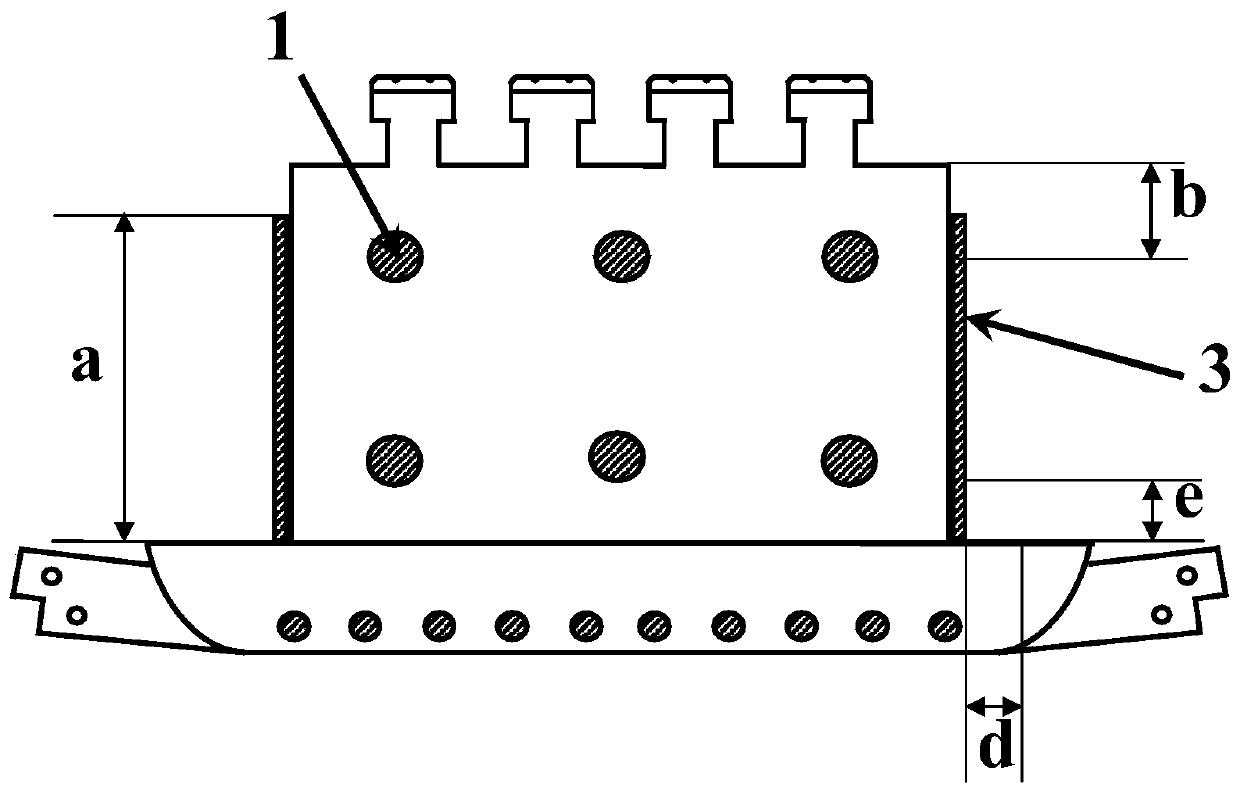

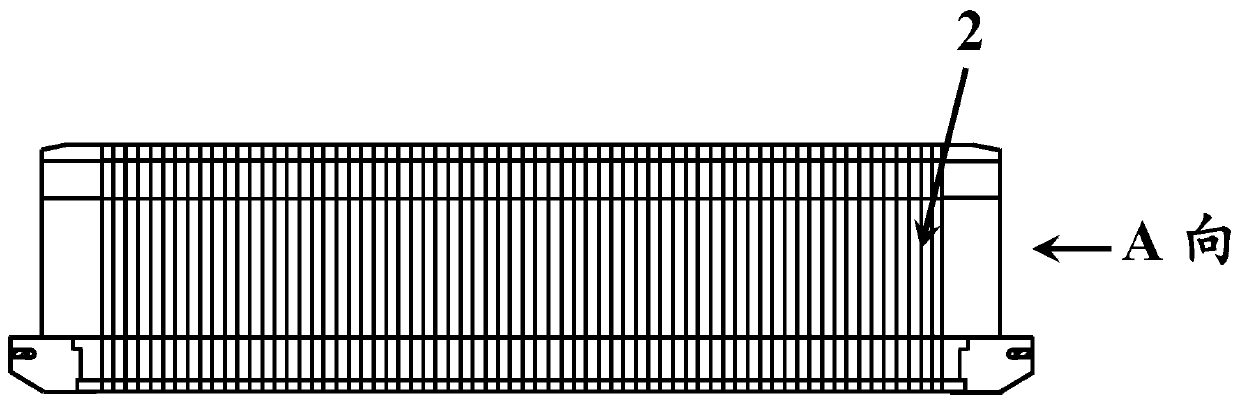

Double-sided aluminum base circuit board with super-high thermal conductivity and preparation method thereof

InactiveCN102740591ASimple processImprove yieldPrinted circuit detailsPrinted element electric connection formationDlc coatingInsulation layer

Owner:苏州热驰光电科技有限公司

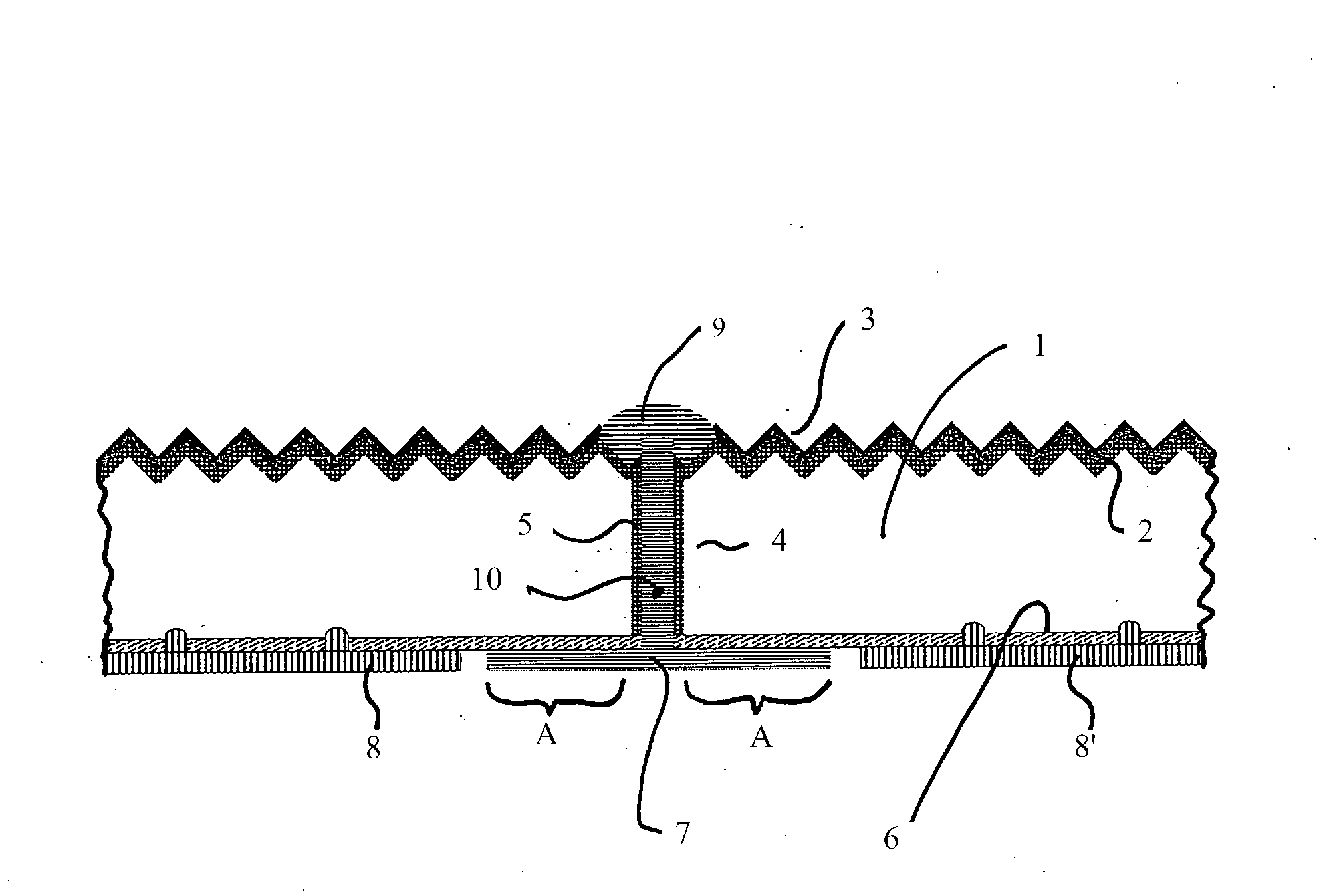

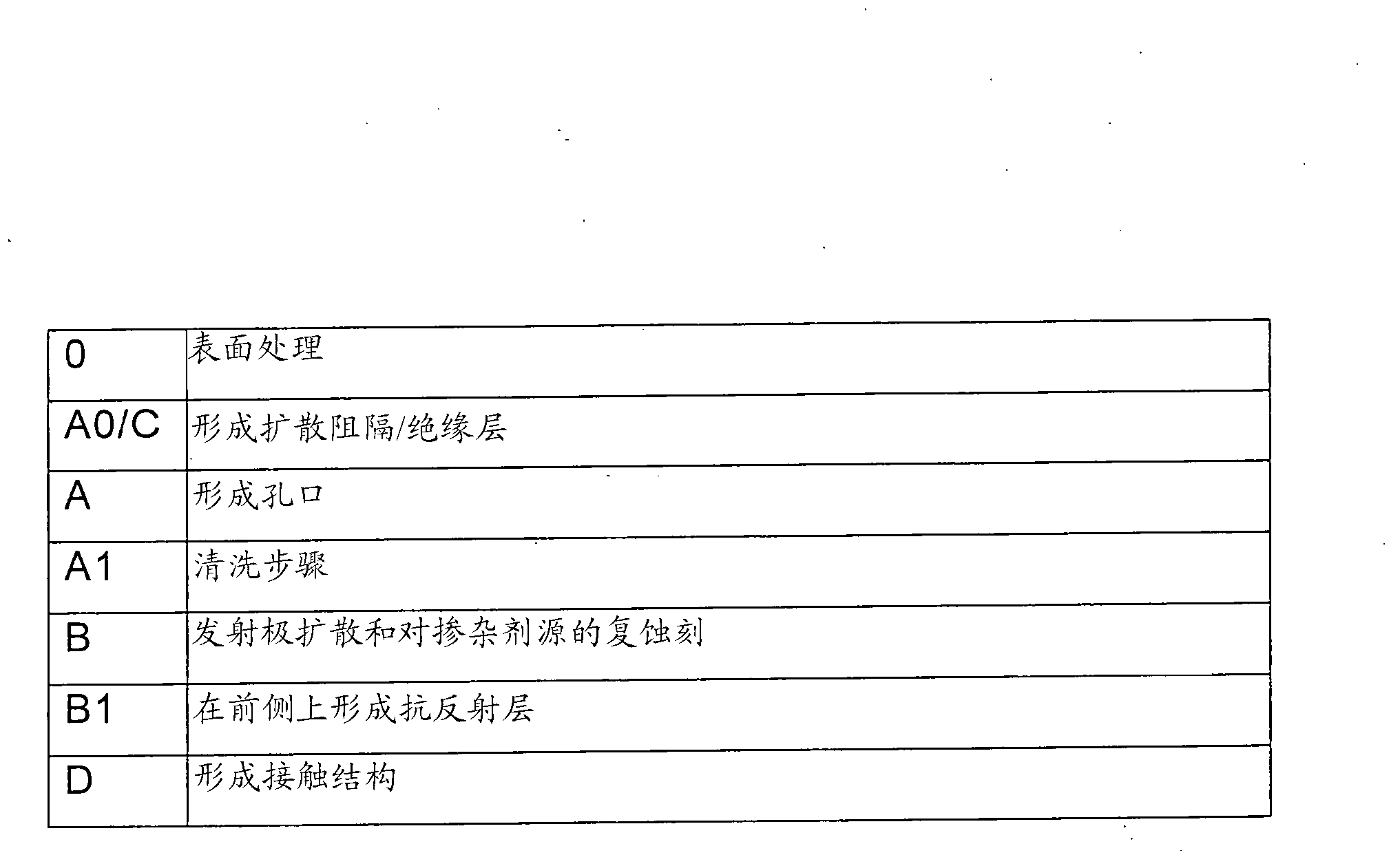

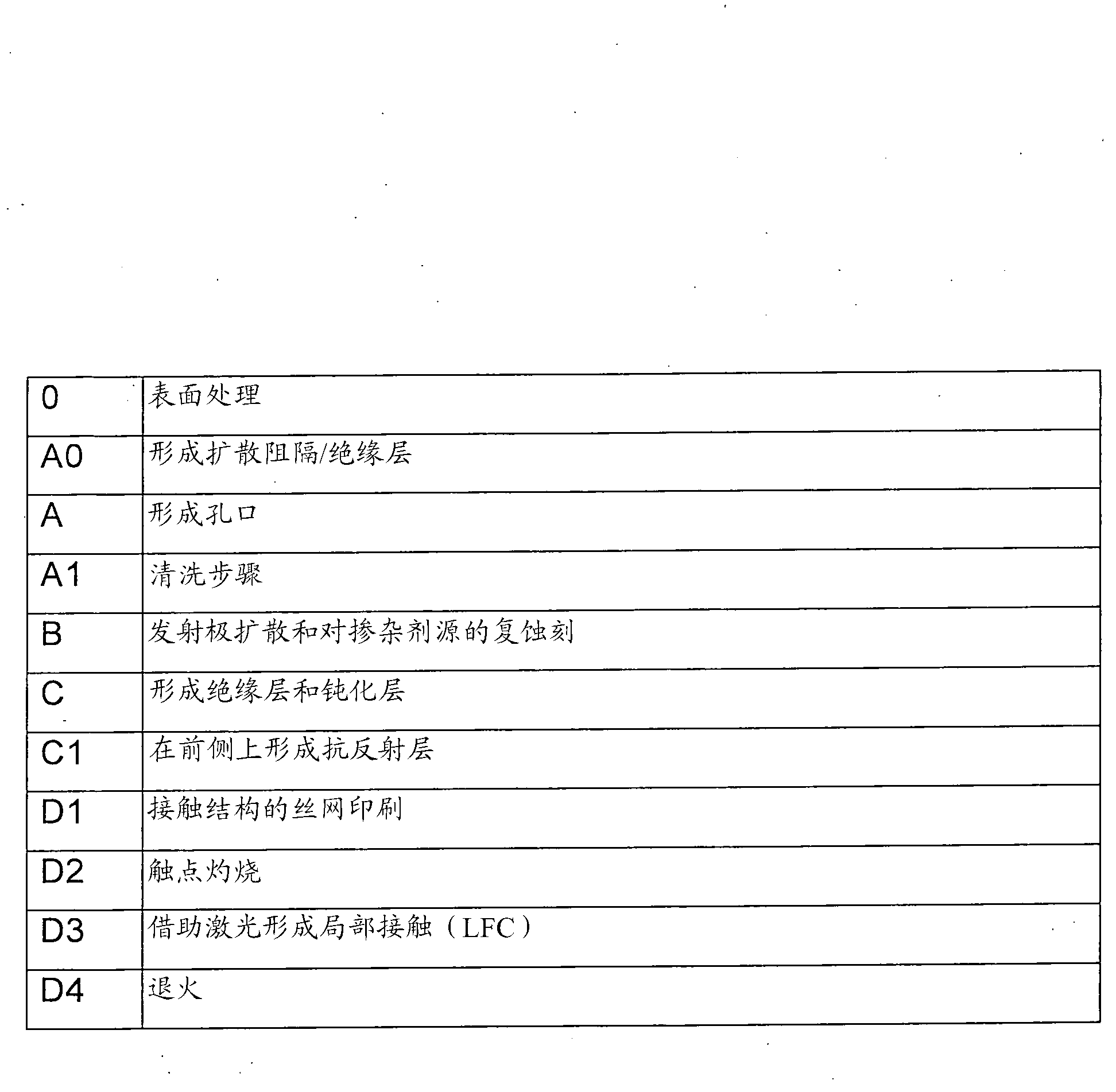

Photovoltaic solar cell and method for producing a photovoltaic solar cell

InactiveCN103003951AFinal product manufacturePhotovoltaic energy generationElectrically conductiveInsulation layer

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Method for manufacturing capacitive sensor, and capacitive sensor

InactiveUS20080087971A1Simple structureFirmly connectedSemiconductor/solid-state device manufacturingMicrostructural device manufactureInsulation layerCapacitive sensing

Owner:ROHM CO LTD

Crack-self-healed dismounting-free insulation system and preparation method thereof

InactiveCN104234245AStop sheddingImprove liquidityClimate change adaptationHeat proofingInsulation layerArchitectural engineering

Owner:盐城市长达建材科技有限公司

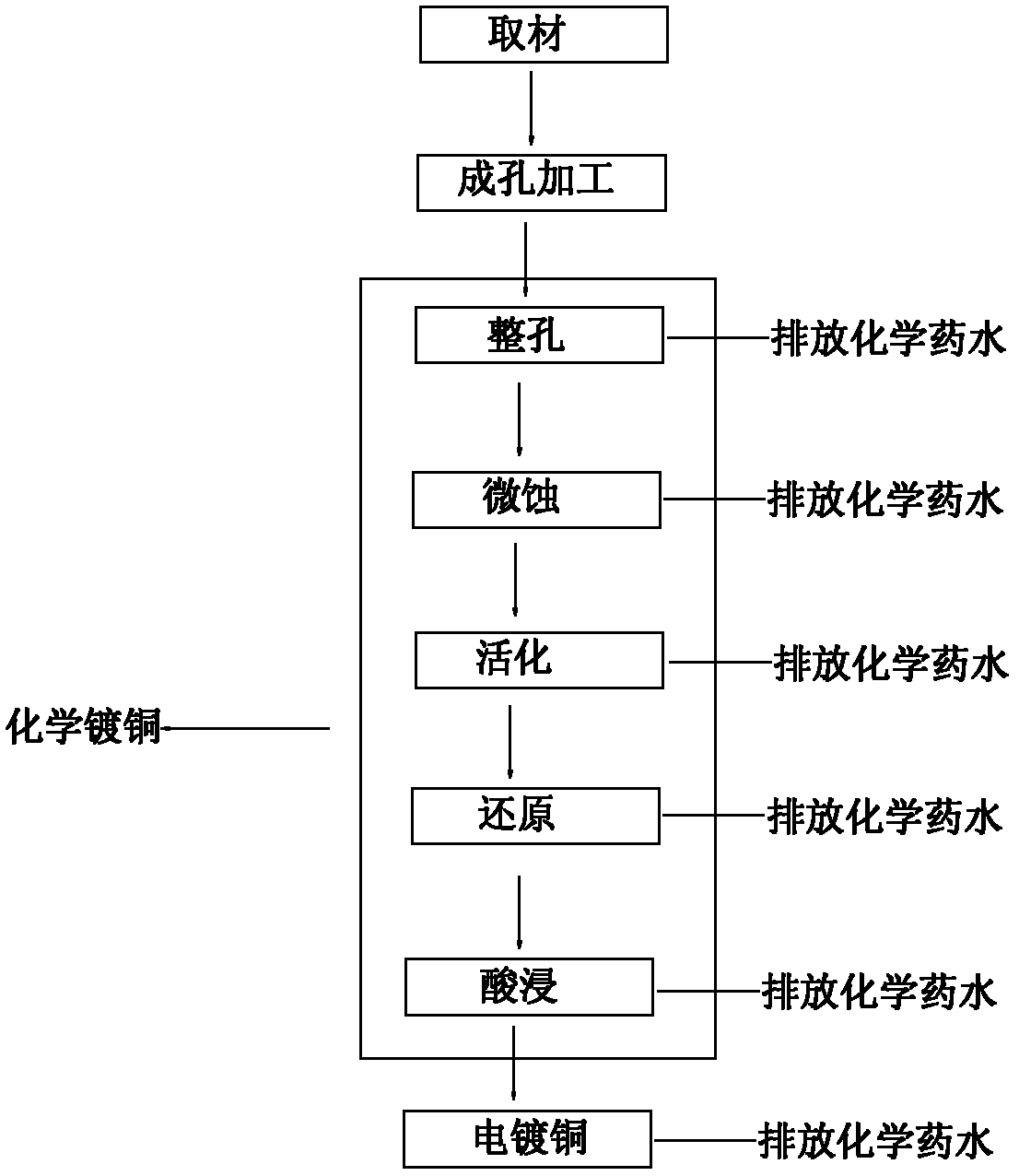

Manufacturing process of interlayer copper connector of printed circuit board

InactiveCN102638946AReduce investmentReduce investment riskPrinted element electric connection formationScreen printingInsulation layer

Owner:SHENZHEN HONGHAI ELECTRON MATERIAL TECH CO LTD

Manufacturing method for electronic device and multiple layer circuits thereof

InactiveUS7081417B2Large process marginRemarkable effectDecorative surface effectsSolid-state devicesInsulation layerMultiple layer

Owner:HITACHI LTD +2

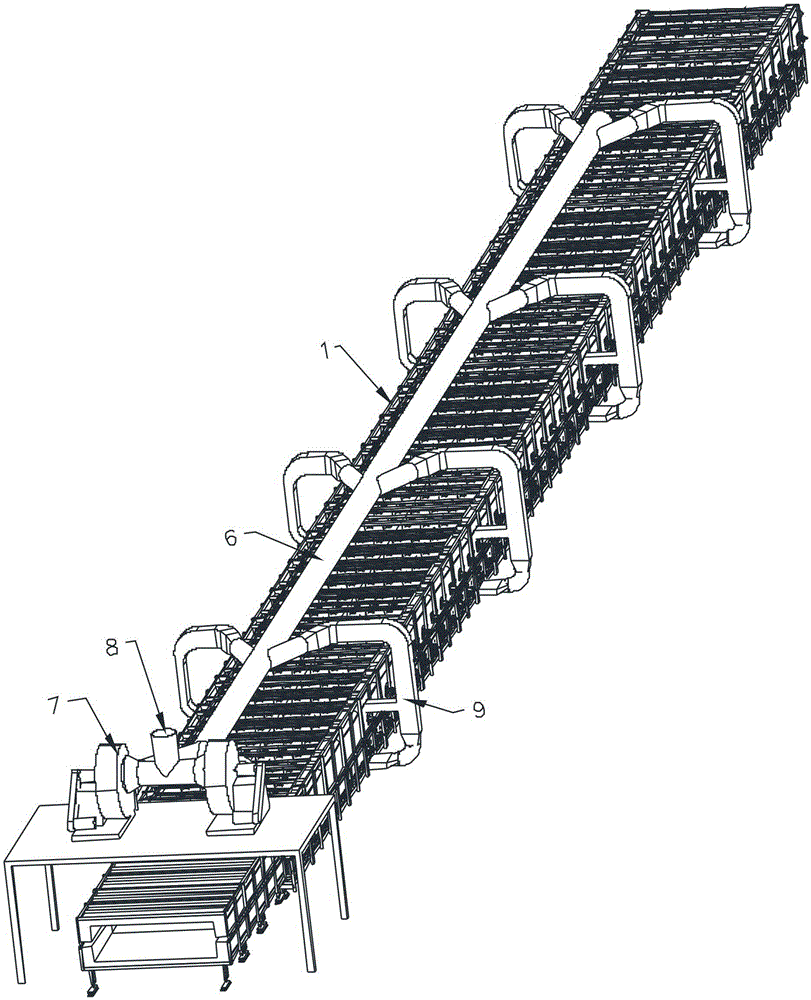

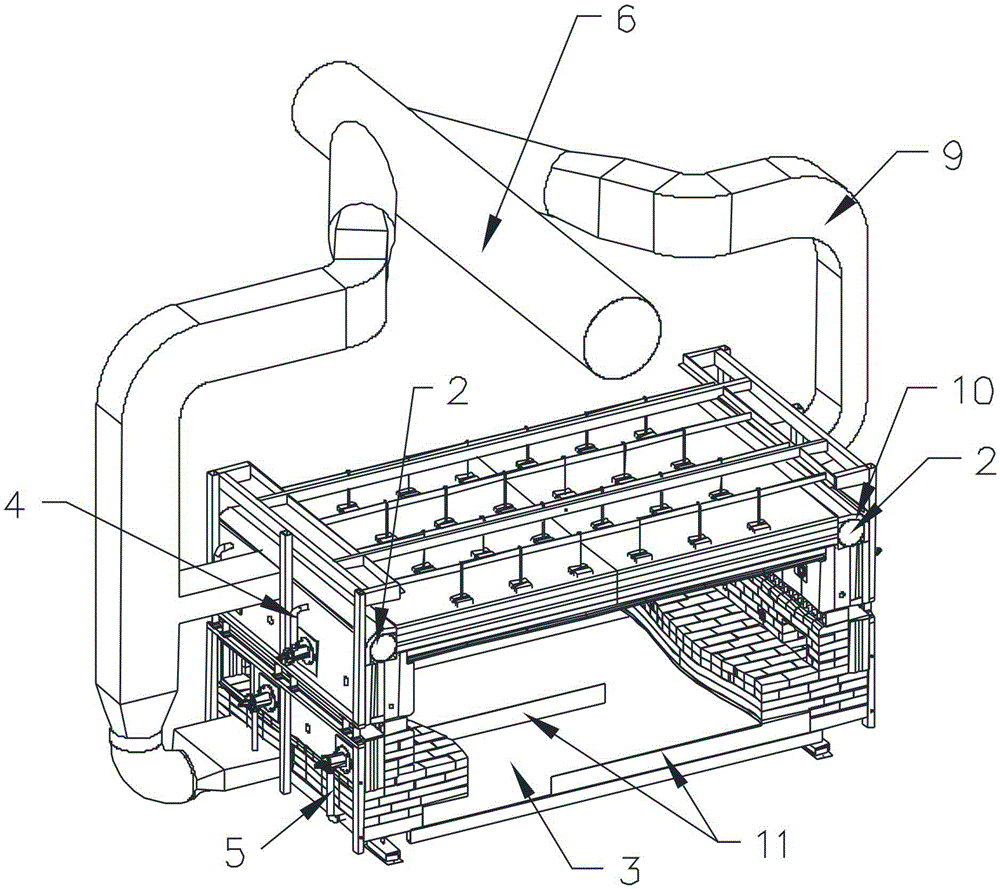

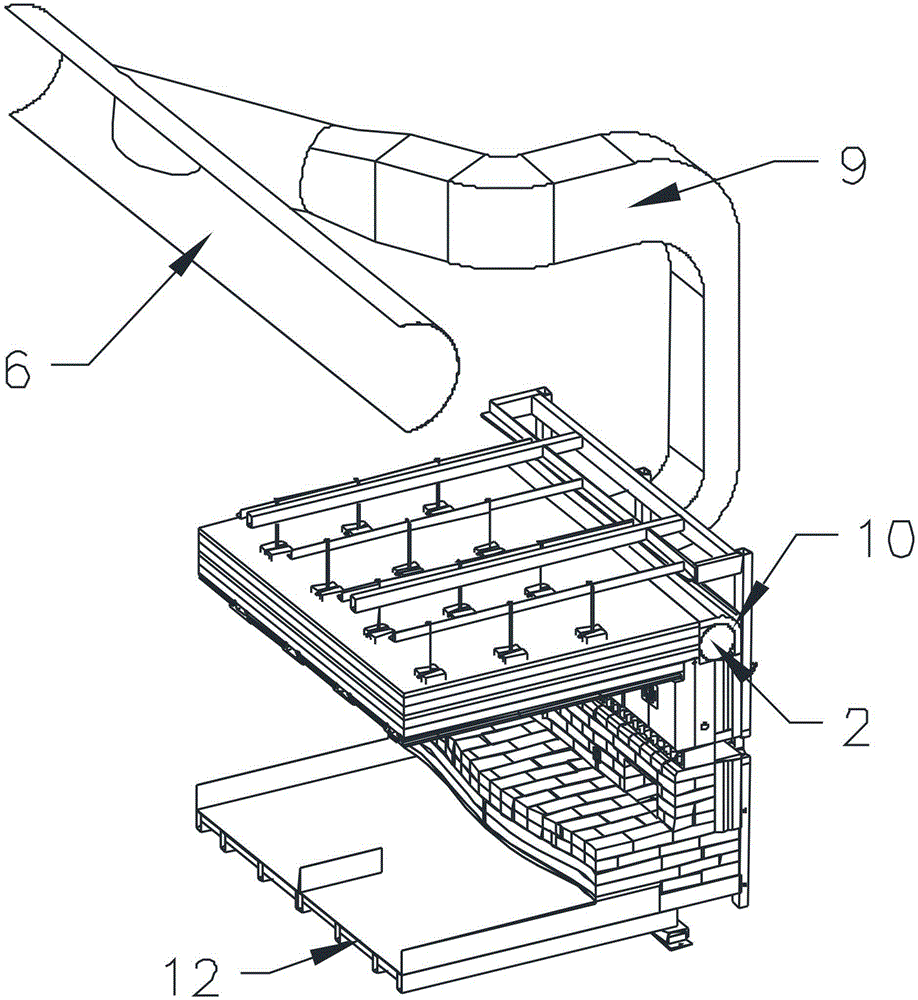

Combustion supporting air heating and energy storing energy-saving roller kiln

InactiveCN105403037AReduce lossReduce energy consumptionFurnace typesWaste heat treatmentCombustionInsulation layer

Owner:MODENA TECH LTD

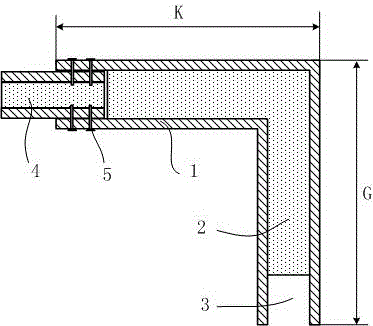

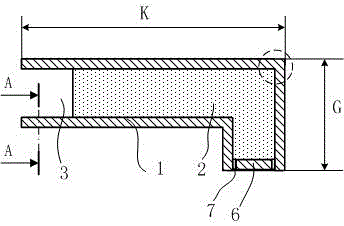

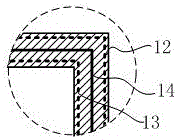

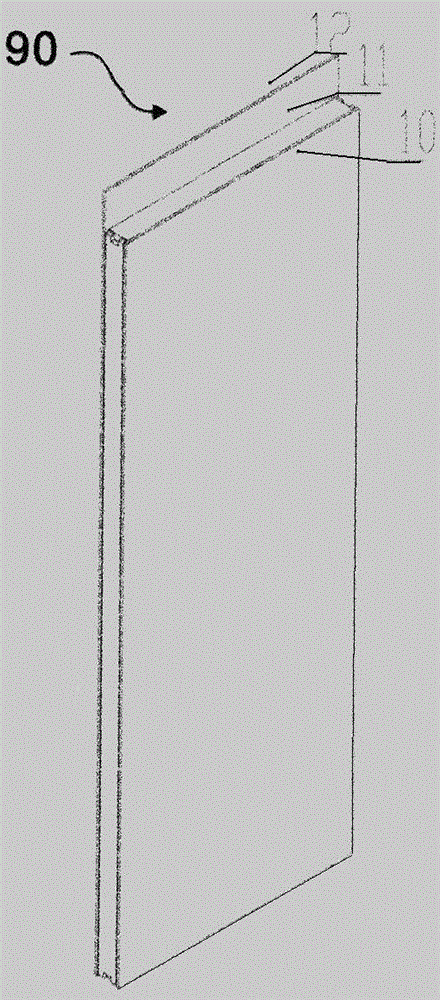

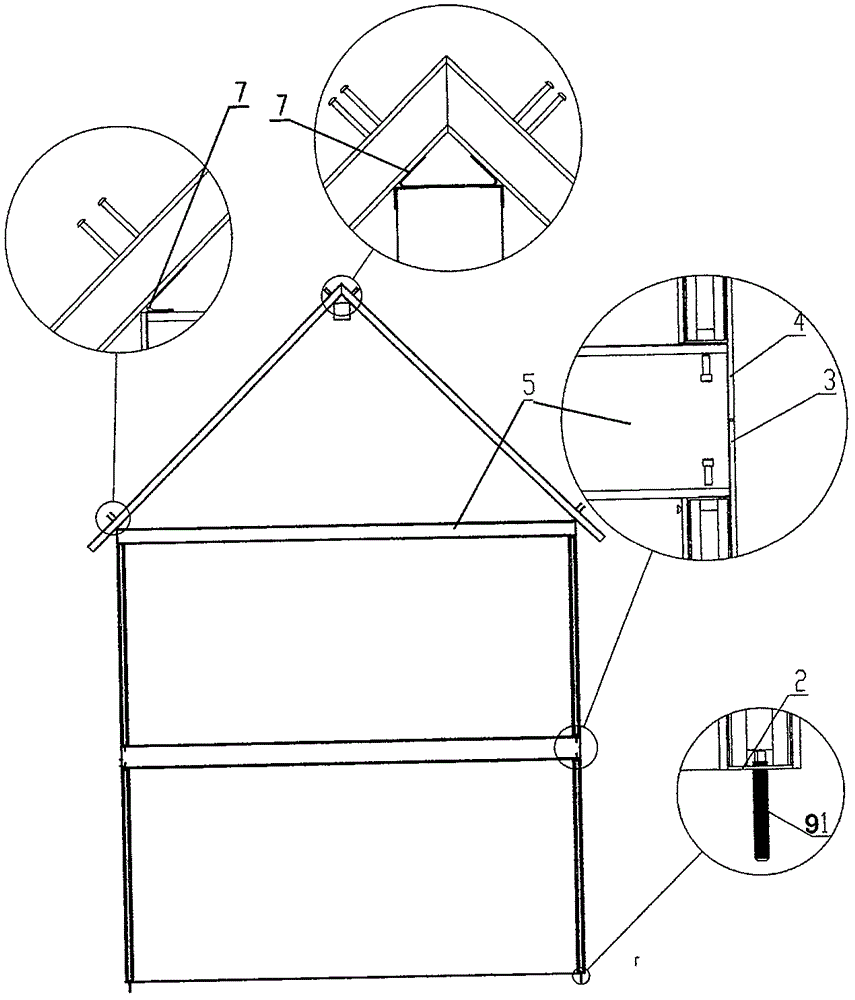

Assembling type composite inner wall corner

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

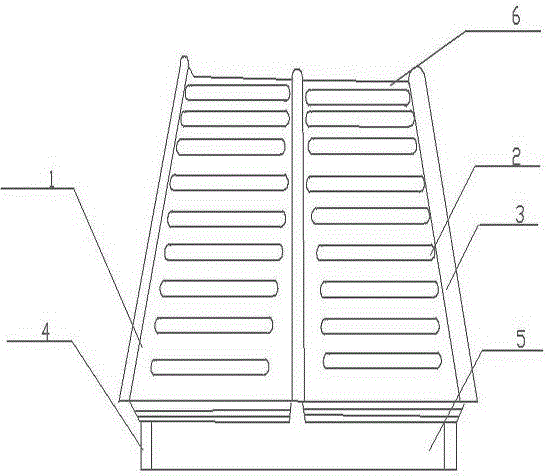

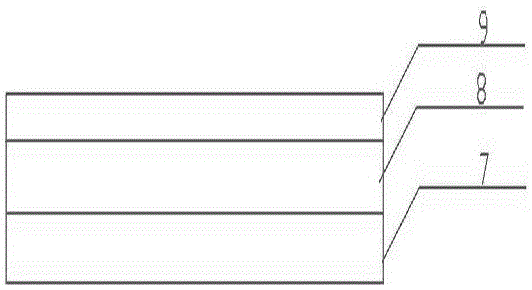

Polyurethane heat insulation roof board

InactiveCN106555462ARoof covering using slabs/sheetsSynthetic resin layered productsEngineeringInsulation layer

Owner:TAIZHOU DONGSHENG STEEL STRUCTURE ENG

Magnetic sensor and method for producing the same

ActiveUS20100283457A1Easy to produceSimple processNanomagnetismWave amplification devicesInsulation layerMagnetic reluctance

A magnetoresistive element includes, in plan view, an element section and an extension region extending from an end portion of the element section; and an insulation layer is formed on the element section and the extension region. A contact hole having a recessed shape, penetrating through the insulation layer, and extending at least to the extension region is formed; an electrode pad is formed in the contact hole; a surface of the electrode pad is exposed to outside; and the electrode pad is electrically connected to the extension region. The element section and the extension region are integrally formed so as to have an identical layer configuration employing a magnetoresistive effect in which electrical resistance varies in response to external magnetic fields.

Owner:ALPS ALPINE CO LTD

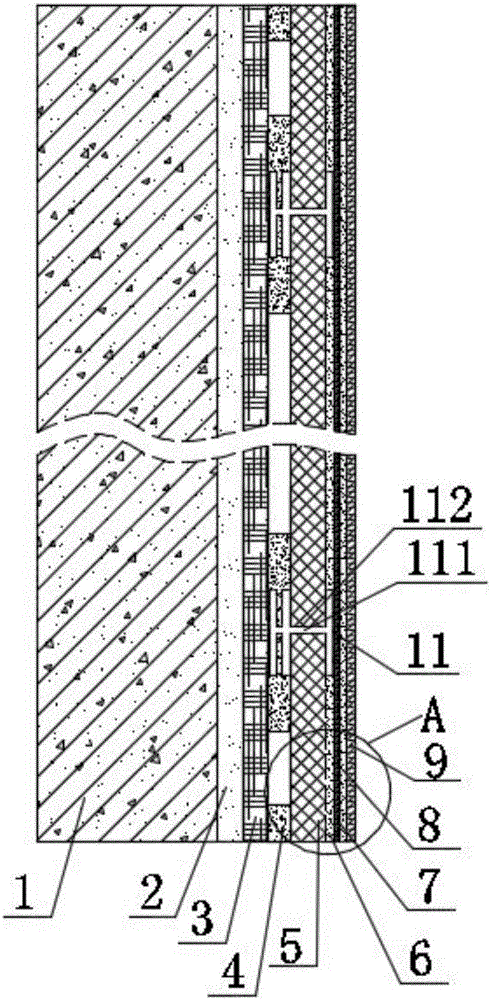

Waterproof type external wall insulation structure and production method thereof

Owner:JIANGSU WONIUSHAN THERMAL INSULATION & WATERPROOF TEHNOLOGY

Wafer-level packaging method of semiconductor device

ActiveCN104465973ASmall sizeIn line with the trend of miniaturizationSolid-state devicesSemiconductor devicesInsulation layerDevice material

Owner:JIANGYIN CHANGDIAN ADVANCED PACKAGING CO LTD

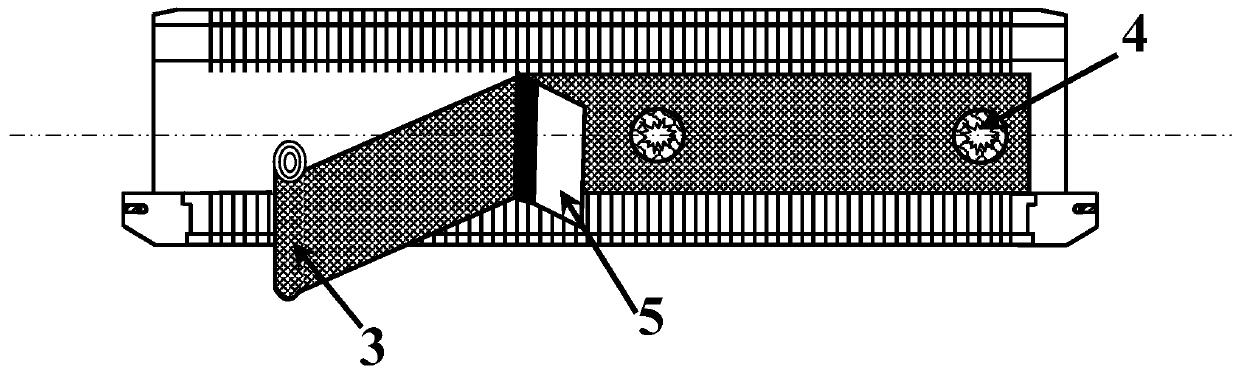

Quick heat-radiation light emitting diode (LED) garden lamp

InactiveCN102367928AFast heat dissipationImprove cooling effectPoint-like light sourceLighting heating/cooling arrangementsInterference fitInsulation layer

The invention relates to the field of an illumination lamp, in particular to a quick heat-radiation light emitting diode (LED) garden lamp having a good heat radiation effect, which aims to solve the heat radiation difficulty of the present LED lamp, and has fast heat radiation speed and large amount of heat radiation. The invention adopts a technical scheme that: the quick heat radiation LED garden lamp consists of a lamp holder, a heat radiator and a lamp adapter, which are sequentially connected with each other from top to bottom, wherein an axial through hole is arranged in the middle of the heat radiator, the periphery of the through hole is provided with heat radiation sheets, the upper end of a heat conducting bar is embedded inside the through hole, the lower end surface of the heat conducting bar is sequentially provided with a binding layer, an insulation layer substrate, a copper-clad layer and an insulation layer, and LED lamp beads are welded on the heat conducting bar through a tin soldering layer. 95 percent of the heat is radiated from the inside of each lamp bead through a central point of the LED lamp beads, and good heat conduction performance of the heat conducting bar and a mechanical-connection-free interference fit way between the heat conducting bar and the heat radiator are utilized to quickly transfer the heat received by the heat conducting bar to the heat radiator.

Owner:张向阳

High-temperature alloy coating for gas turbine hot parts

InactiveCN101037552ADurable resistance to high temperature oxidationPersistent corrosionFireproof paintsInsulation layerCombustion

Owner:郑效慈

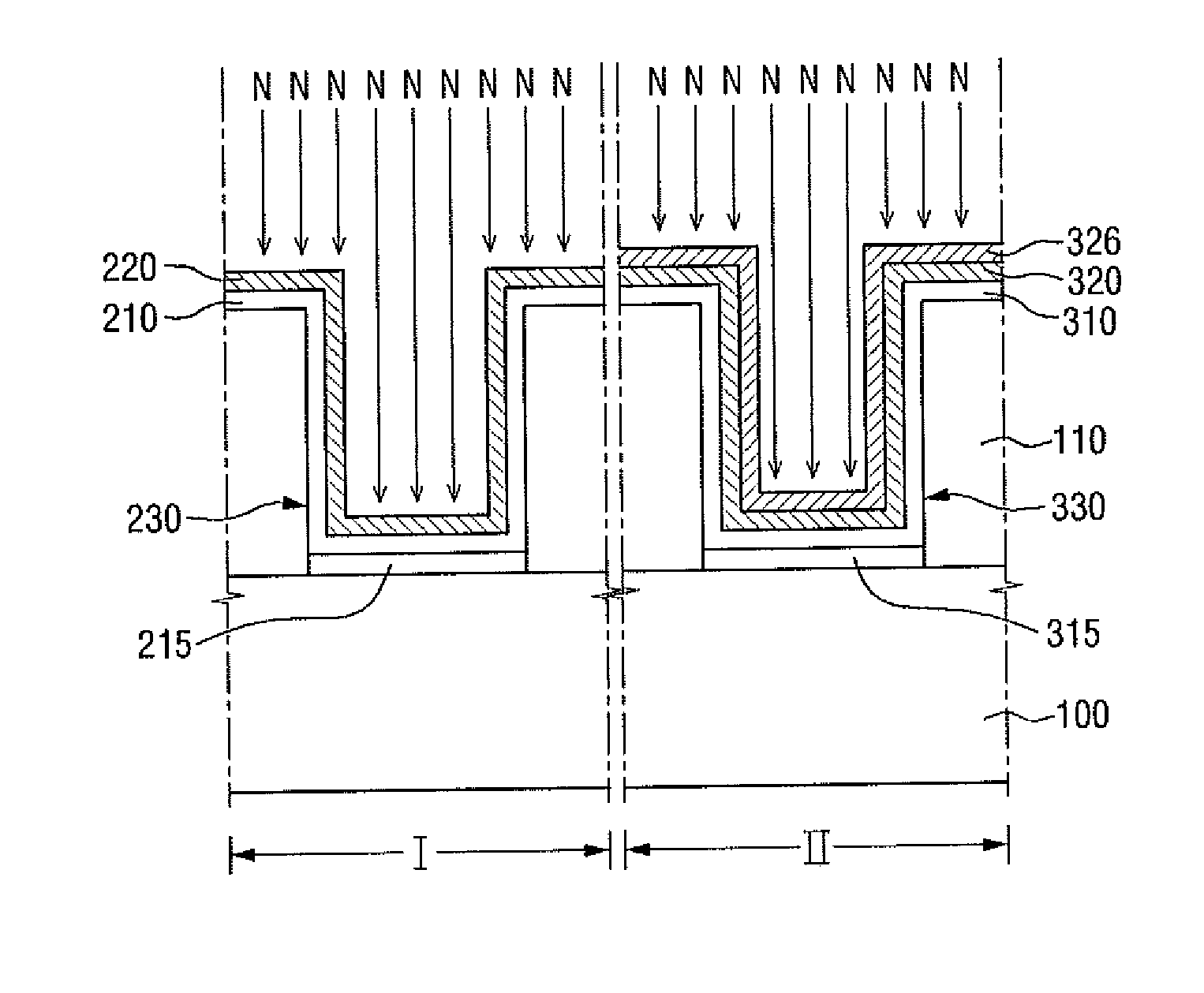

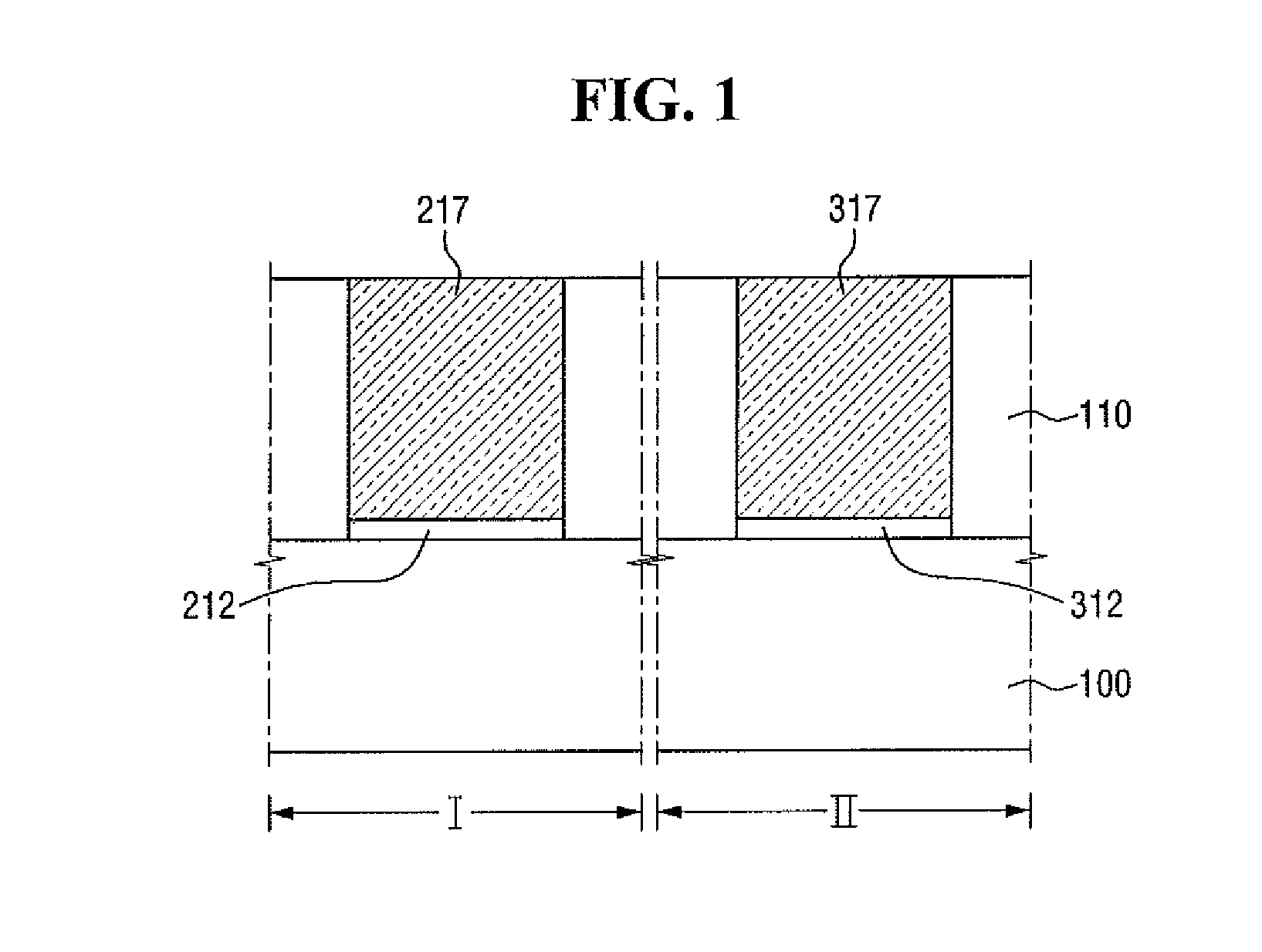

Semiconductor device and method for fabricating the same

InactiveUS20160049478A1Semiconductor/solid-state device manufacturingSemiconductor devicesInsulation layerSemiconductor

Owner:SAMSUNG ELECTRONICS CO LTD

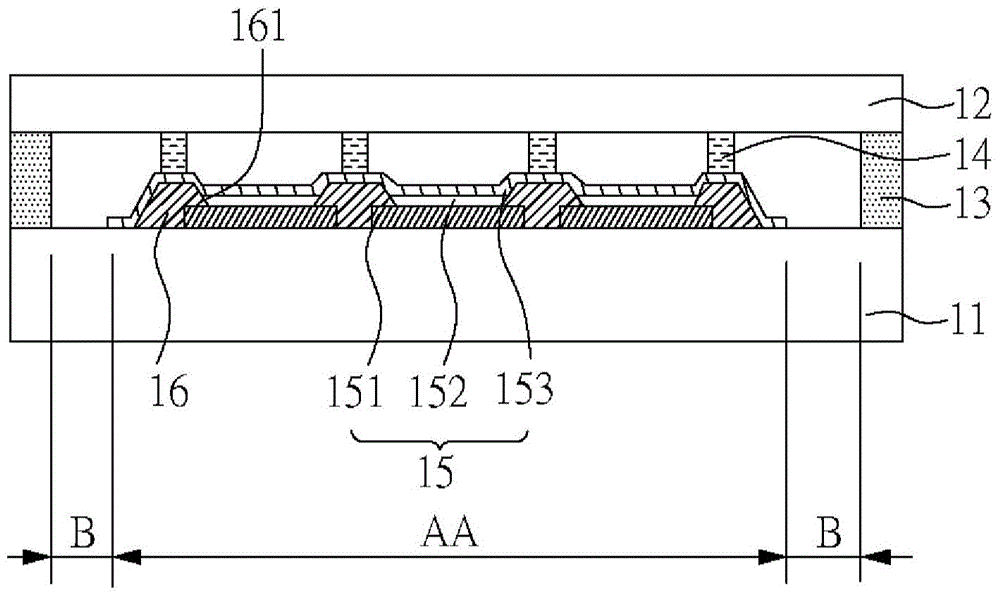

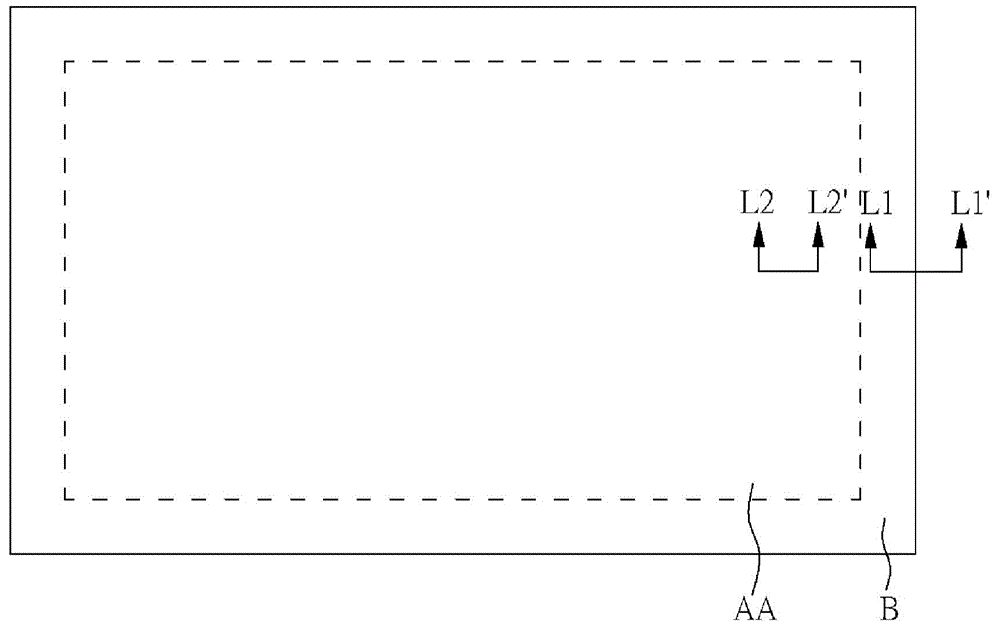

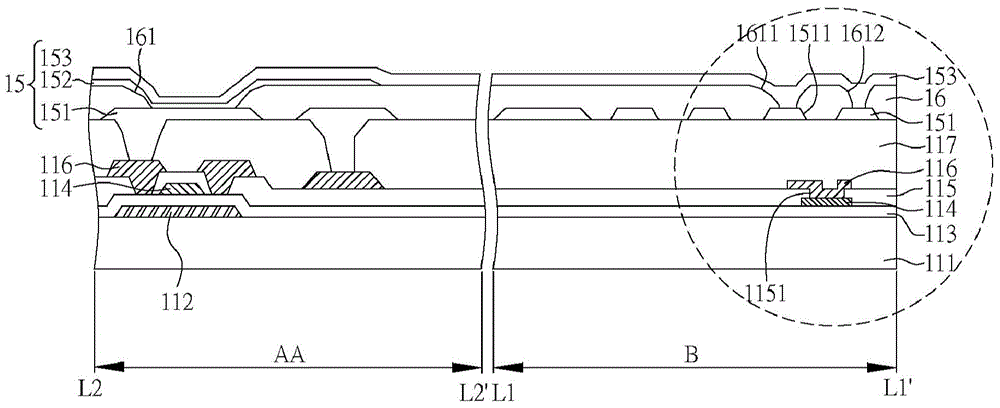

Display device

ActiveCN106298840ASolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsInsulation layer

Owner:INNOLUX CORP

Composite wall and splicing structure of house composed of composite walls

InactiveCN107178161ALow costShorten the construction periodBuilding roofsWallsInsulation layerEngineering

Owner:时靖

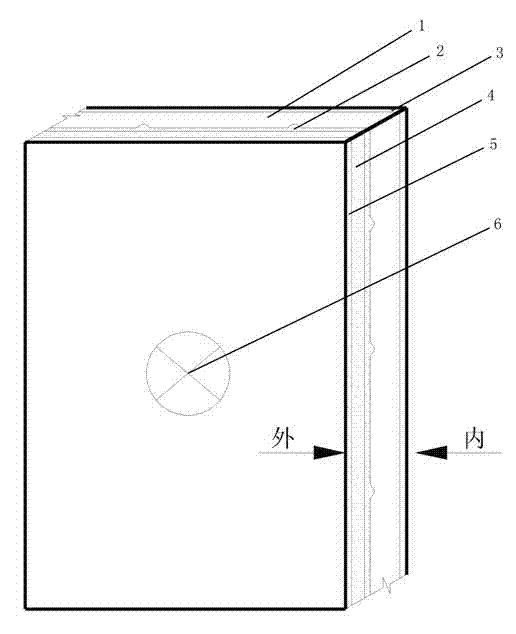

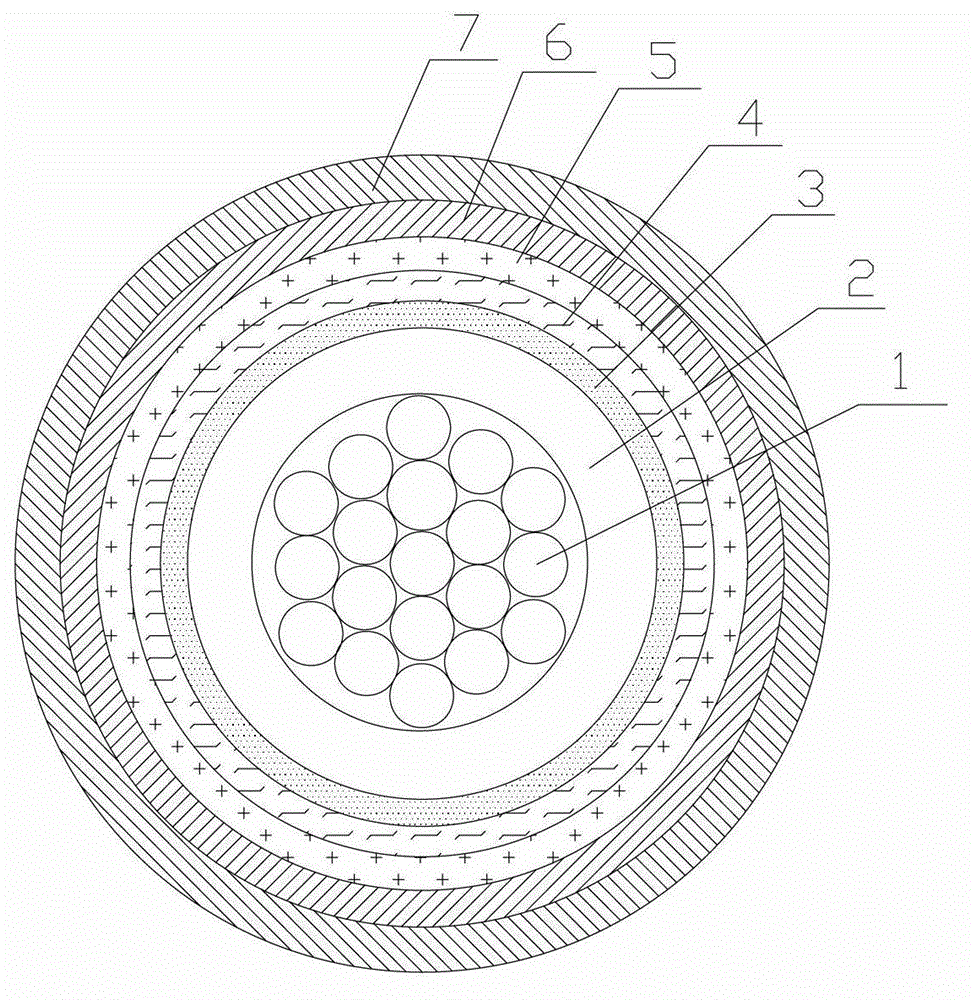

Method for producing high-voltage generator and stator with stator winding in circular cross section

InactiveCN101212155AReduce lossImprove availabilityWindings insulation materialWindings insulation shape/form/constructionElectrical conductorInsulation layer

The invention discloses a high-voltage generator with a circular section stator winding and a stator manufacture method, which relates to a filed of a motor. The invention solves the problems of small rating output voltage, large eddy current loss and complex devices which exist in the current generators. The stator winding section of the generator is circular; the generator comprises a conductor, an internal semiconductor layer, an insulation layer and an external semiconductor layer from the internal to the external in sequence; the conductors is one or a plurality of hinged wires; a wave winding groove is opened along a radial direction of an iron core; the stator winding is arranged in the wave winding groove of the iron core to cooperate at the interval; at least four circular dissipation grooves are evenly opened in a circumferential direction of an iron core yoke, in which dissipation water pipes are arranged. The stator manufacture method includes the processes as follows: firstly, the iron core is arranged on a generator base; secondly, one end of the stator winding is penetrated from one end of the wave winding groove of the iron core to the other end of the wave winding groove of the iron core; according to the requirements of a pitch, the end of the stator winding is penetrated back and the penetration is carried out repeatedly; thirdly, the dissipation water pipes are introduced into the circular dissipation groove; lastly, the pipes are enlaced in order. The invention has the advantages of simple structure, high stability and simple cooling system.

Owner:HARBIN UNIV OF SCI & TECH

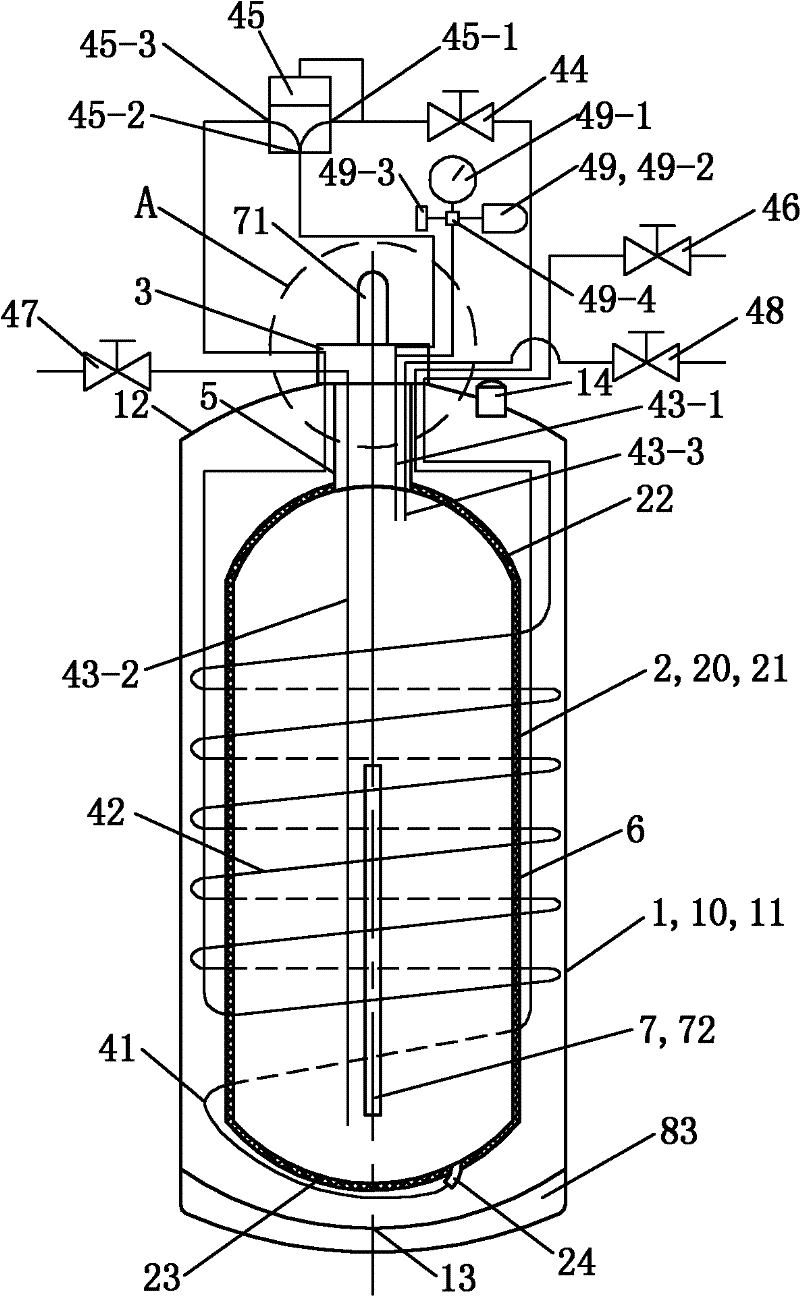

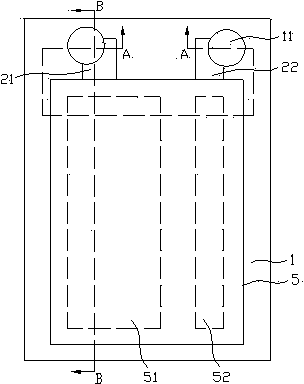

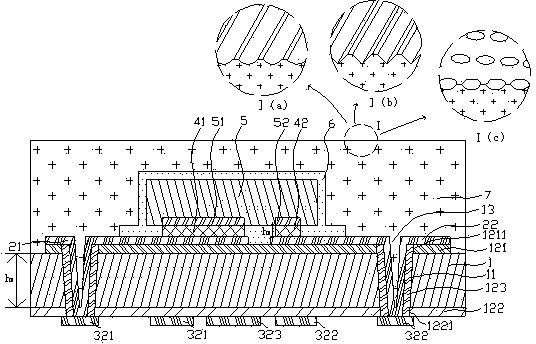

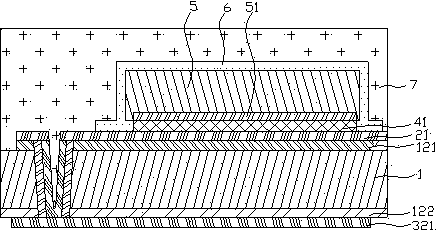

Chip-level ultra-miniature refrigerator for uncooled infrared detector

ActiveCN108493271ASimple structureHighly integratedThermoelectric device with peltier/seeback effectSolid-state devicesInsulation layerEngineering

The present invention provides a chip-level ultra-miniature refrigerator for an uncooled infrared detector. The chip-level ultra-miniature refrigerator comprises an outer-layer package layer structureand an inner-layer refrigerator structure; the outer-layer package layer structure comprises a vacuum package housing, an anti-radiation layer and a radiation layer, and the top portion of the vacuumpackage housing is provided with an infrared sensitive window; the inner-layer refrigerator structure comprises an upper-layer structure, a middle-layer structure and a lower-layer structure. The chip-level ultra-miniature refrigerator performs heating and cooling of a nano-film thermoelectric layer to maintain a constant temperature so as to effectively block the heat exchange between a supportstructure and an external environment through a substrate, and a heat insulation layer is laid at the bottom portion of the substrate to further inhibit the heat conduction of the external environment. An annular cantilever beam and the support structure further avoid heat conduction, the heat insulation layer is arranged to further inhibit the internal heat conduction and exchange so as to achieve heat insulation between the infrared detector and the external environment. The anti-radiation layer is deposited and grown to inhibit heat radiation, and a vacuum package method is employed to avoid heat convection and exchange of the internal portion and the external portion.

Owner:SOUTHEAST UNIV

Process method for insulation attaching type bonding of large-scale motor rotor magnetic pole body

Owner:HARBIN ELECTRIC MASCH CO LTD

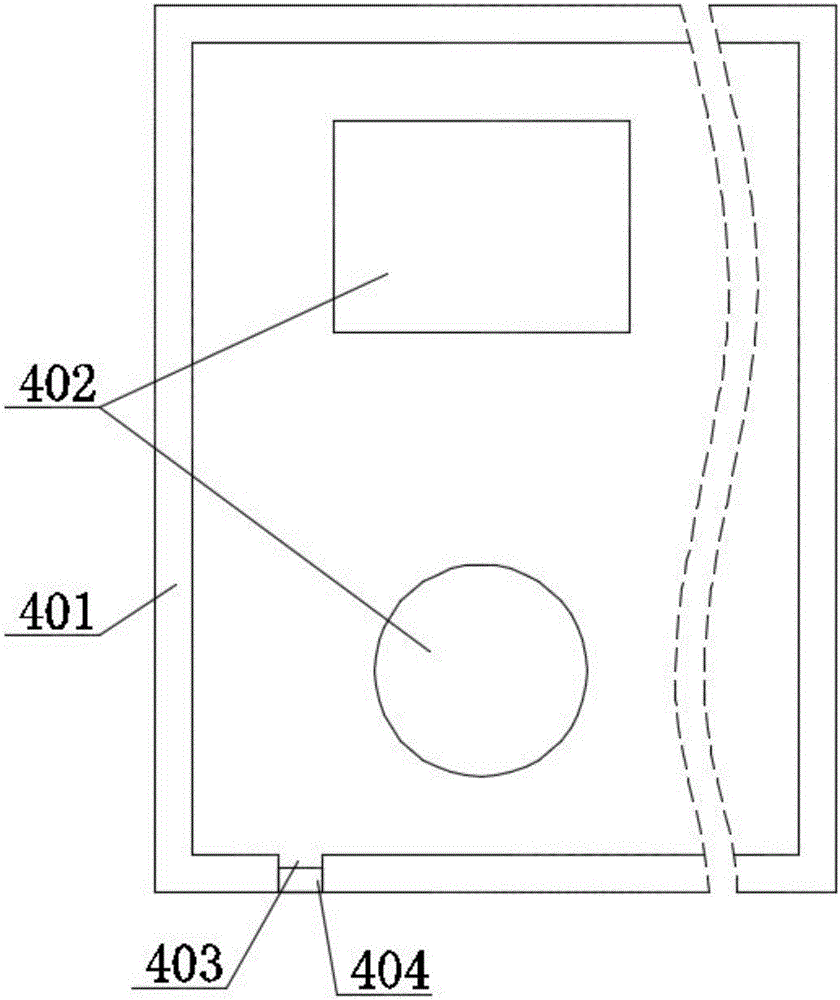

Switch socket apparatus

InactiveCN101350503AAvoid breakingSimple structureSubstation/switching arrangement casingsSubstation/switching arrangement boards/panels/desksInsulation layerEngineering

The invention discloses a switch socket device, comprising a base, functional parts on the base, a mounting box, etc. A bolt hole is arranged at the circle-center of the base, and the functional parts are arranged on the base. Locating teeth are arranged on the circumferential side-wall of the base, and tooth slots mating with the teeth are arranged on the inner wall of the mounting box; and a spacing member is arranged at the central part of the mounting box. A thread segment is arranged in the internal hole of the spacing member. The functional parts may be a power supply switch or various receptacles, and special elastic connection mechanisms are arranged on the functional parts and the base. The invention is easy to install, adjust and use, and is capable to avoid the accidents incurred by damage to the insulation layer of the wire.

Owner:吴侃武

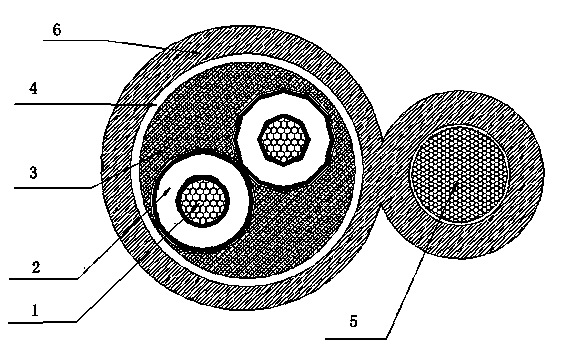

Semi-conductive waterproof cable

InactiveCN102982878AAvoid enteringImprove waterproof performanceClimate change adaptationInsulated cablesElectrical conductorInsulation layer

Owner:JING FENG GRP

Electromagnetic shielding method and product

InactiveCN102950828ANo pollution in the processElectromagnetic shielding method is simple and fastVacuum evaporation coatingSputtering coatingInsulation layerSilicon oxygen

The invention provides an electromagnetic shielding method comprising the steps that: a substrate is provided; a vacuum plating method is adopted, wherein an aluminum-silicon alloy target is adopted as a target material, oxygen is adopted as a reaction gas, and an insulation layer is formed on the substrate, wherein the insulation layer is an aluminum-silicon-oxygen layer; and a vacuum plating method is adopted, wherein a nickel-copper alloy target is adopted as a target material, and a conductive layer is formed on the insulation layer, wherein the conductive layer is a nickel-copper alloy layer. The invention also provides a product obtained with the provided electromagnetic shielding method.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Reinforced control cable

InactiveCN103440912AImprove flexibilityImprove recoverabilityCommunication cablesFlexible cablesInformatizationElectrical conductor

Owner:JIANGSU XINFENG CABLE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap